Patents

Literature

691 results about "Materials design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

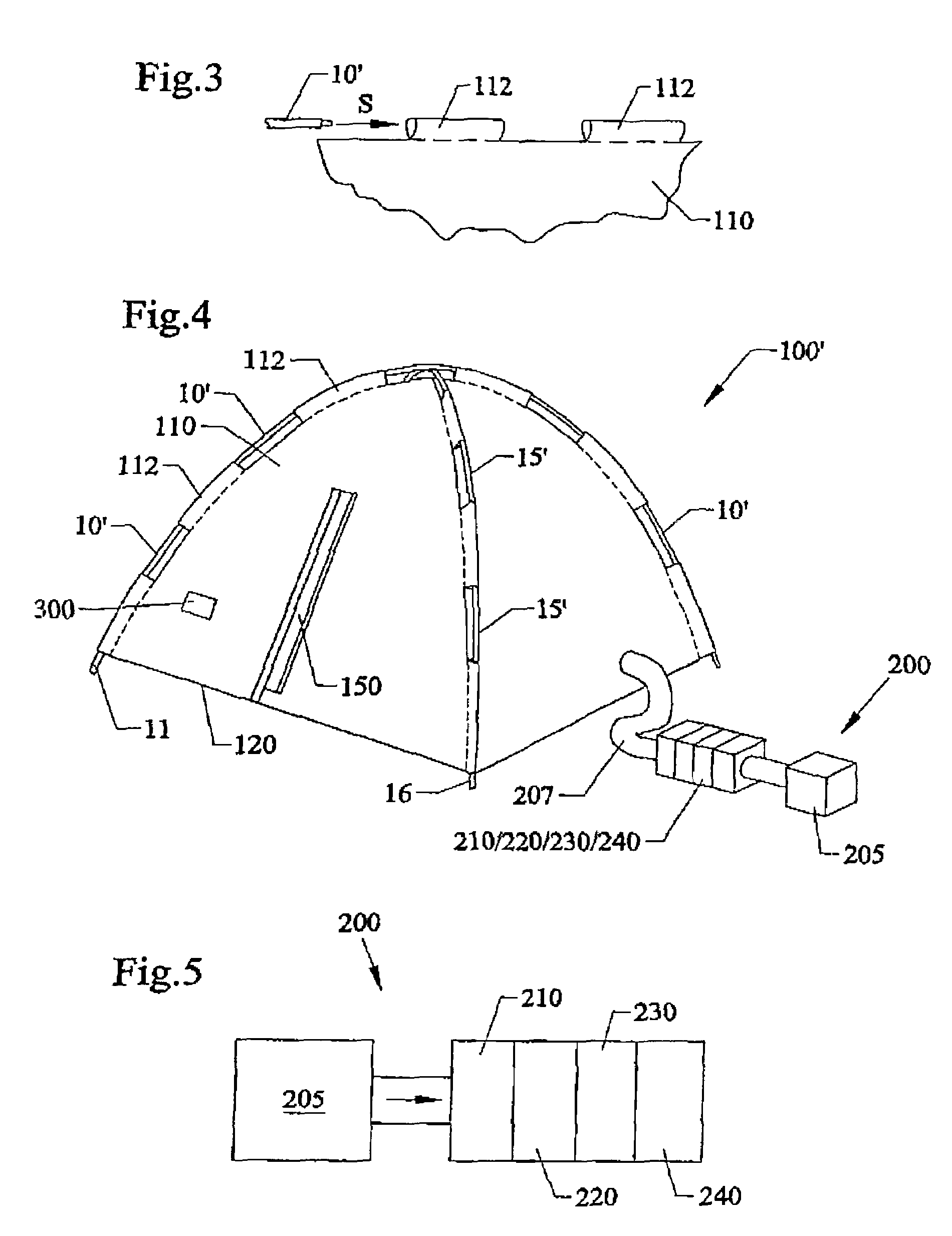

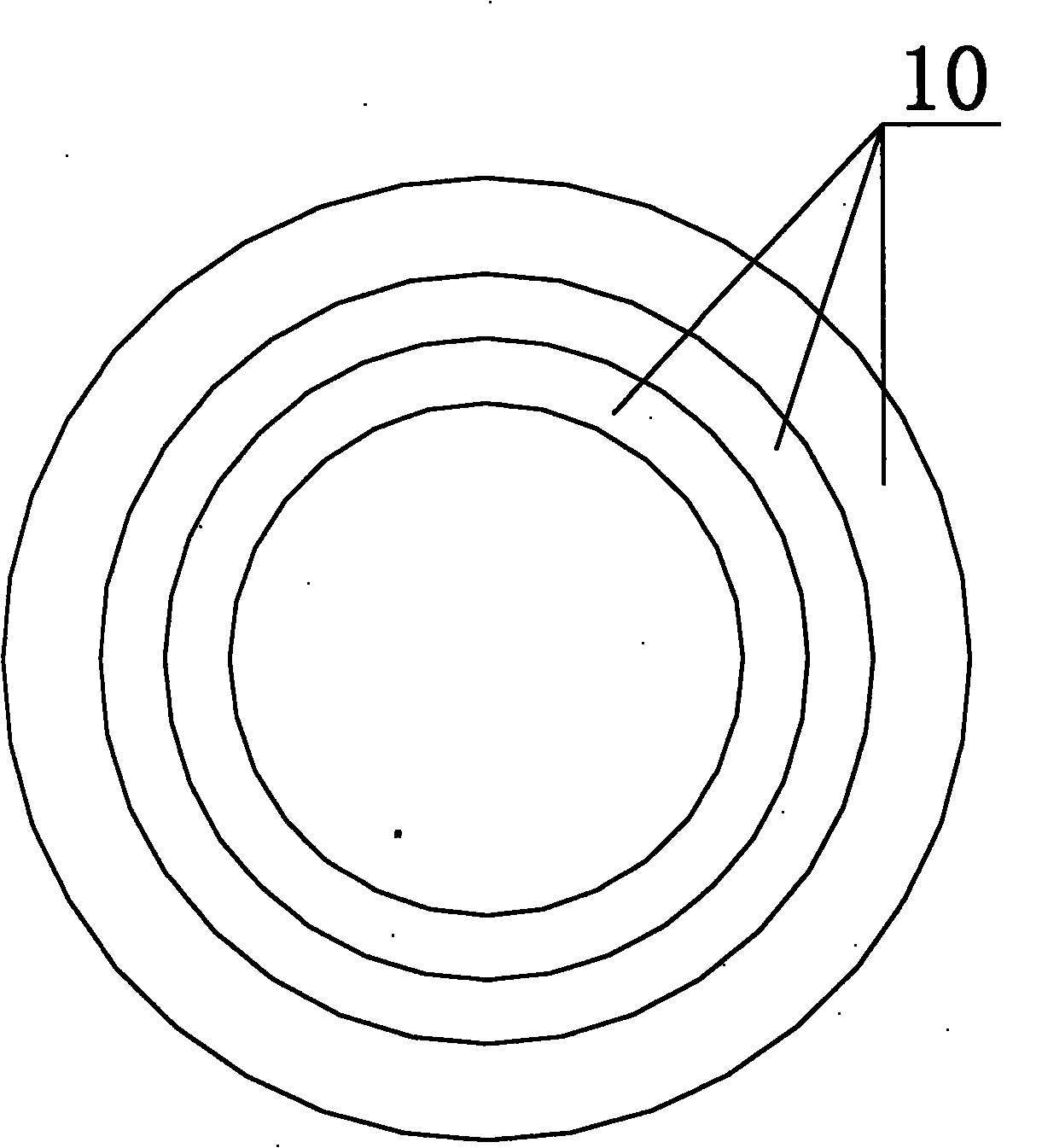

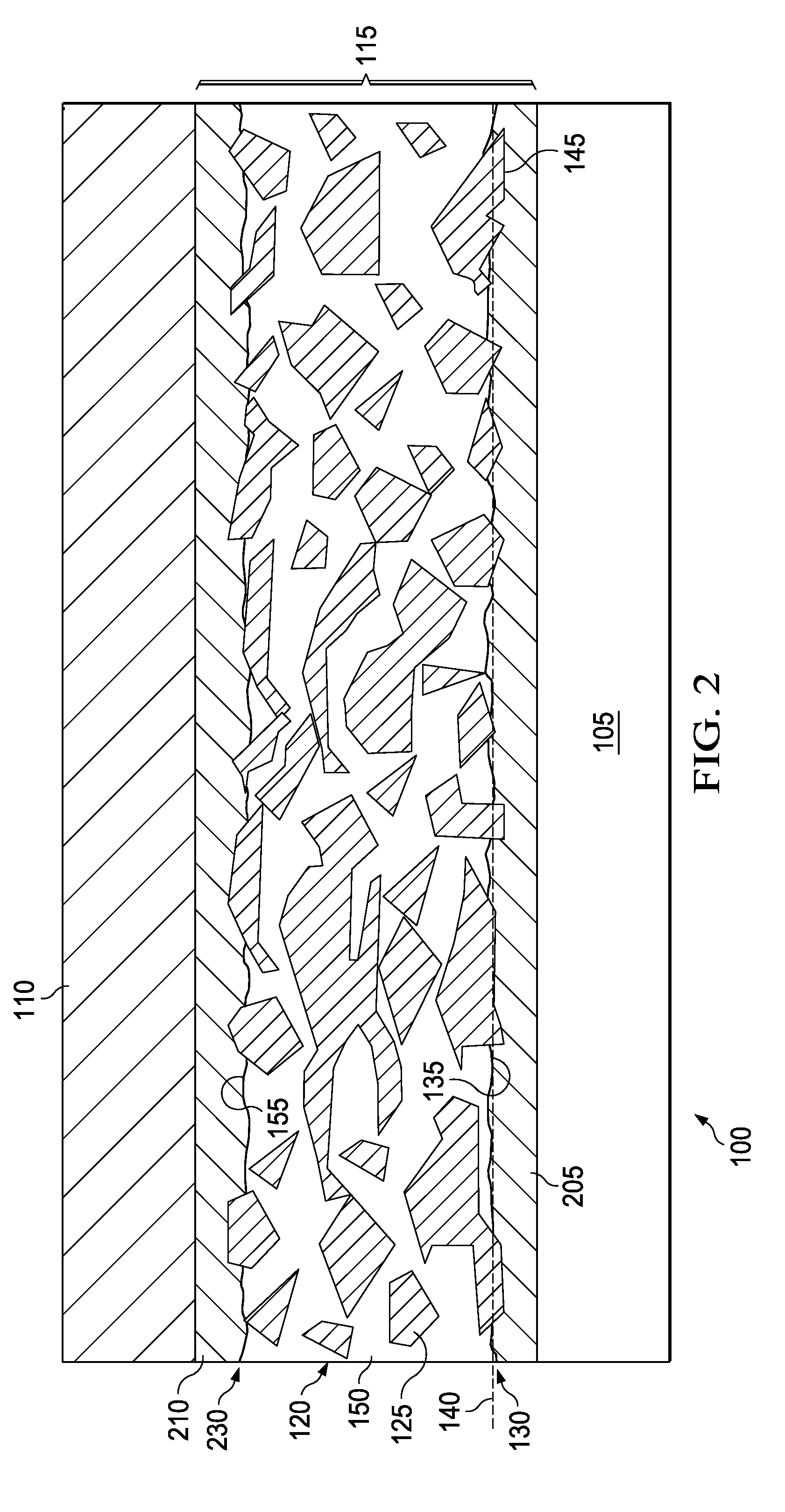

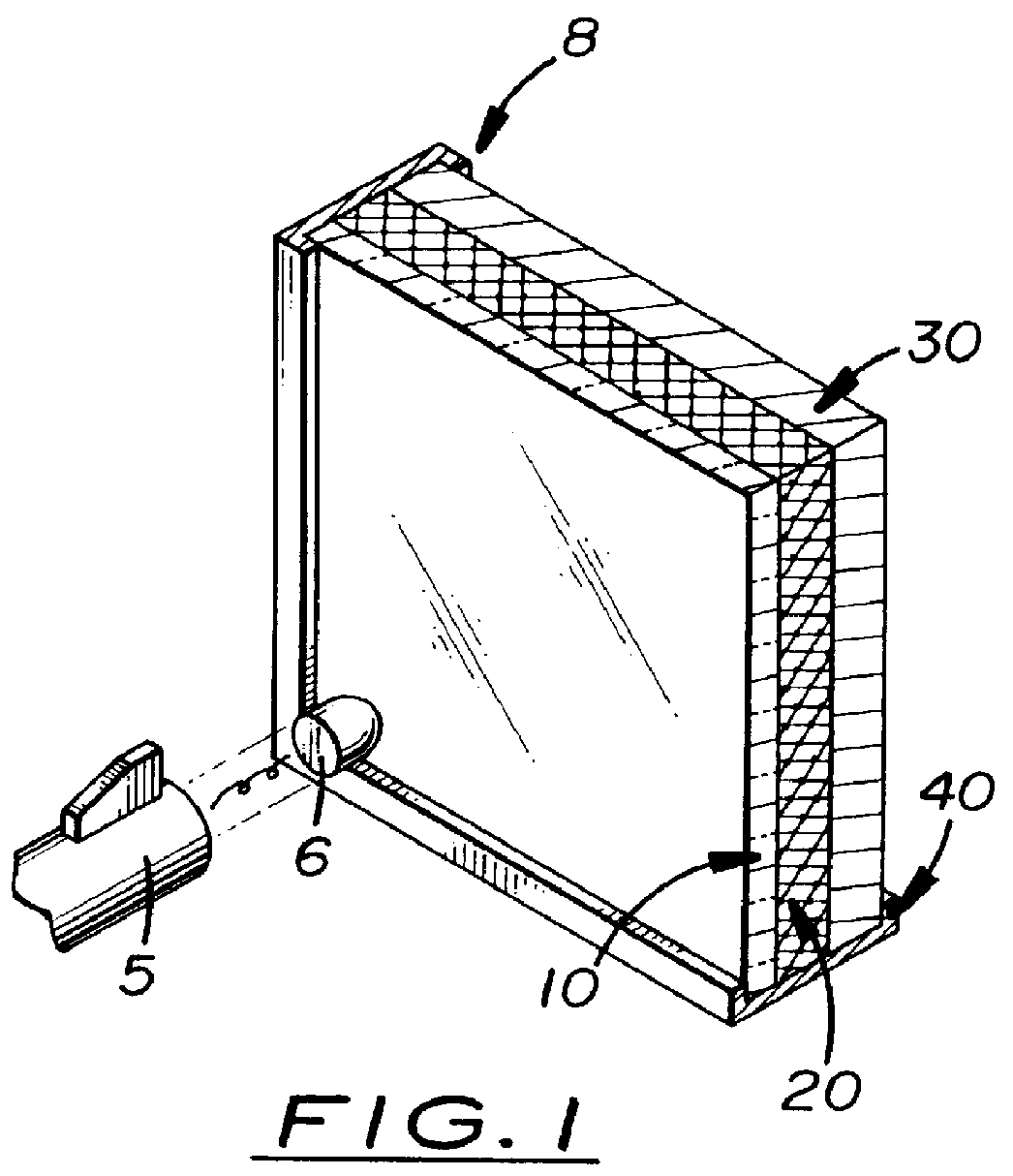

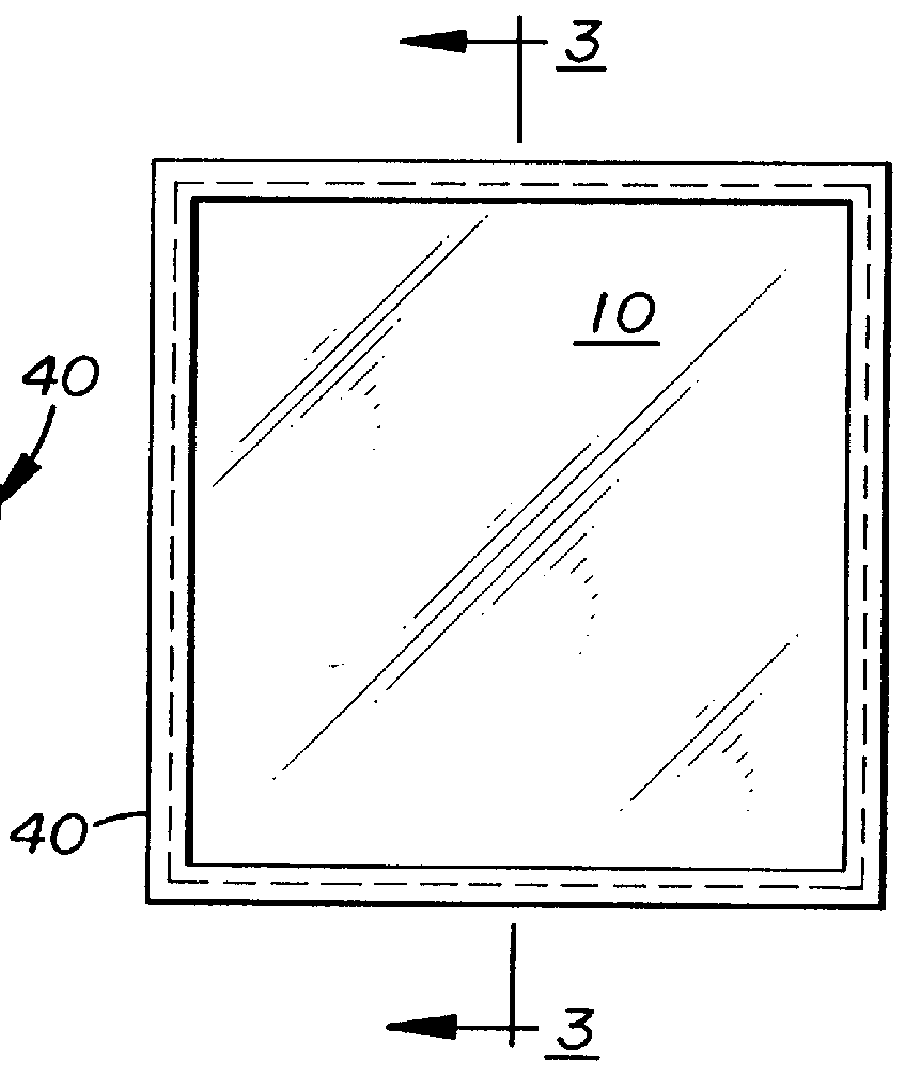

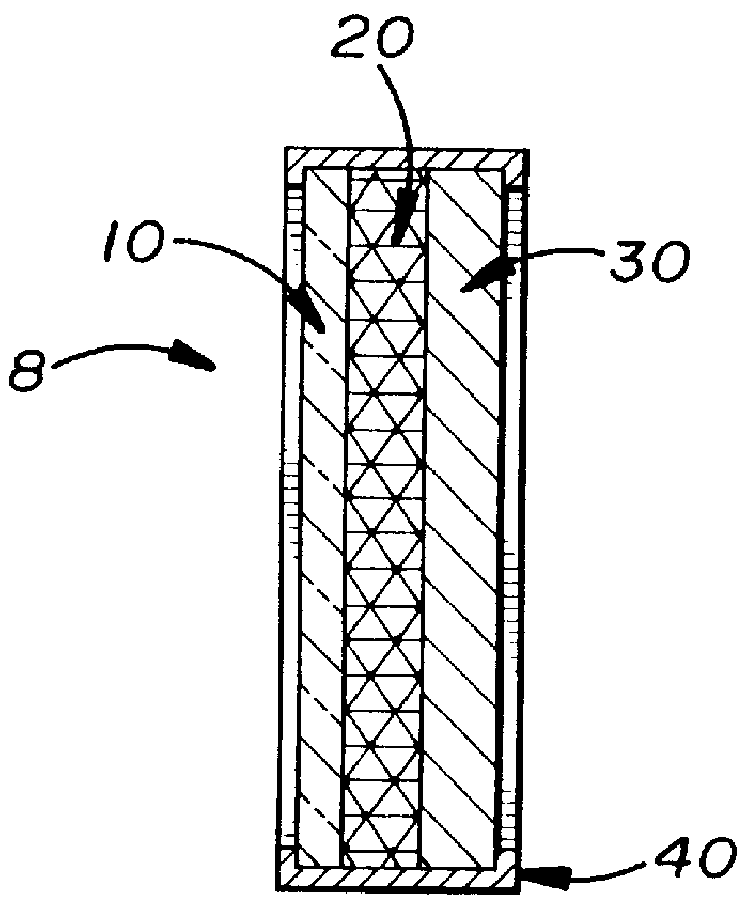

Vented, layered-wall deepwater conduit and method

A flexible conduit constructed of overlapping layers of sealing and strengthening materials designed to resist tensile, compressive, and axial forces is employed as a submerged flow line carrying pressurized fluid. Sealing material layers disposed radially on either side of the strengthening layers isolate the strengthening layers from the liquids that contact the internal and external conduit walls. The innermost seal layer is positioned within a burst layer that protects the external strengthening layers from pressure-induced damage. The annular area between the strengthening layers is continuously vented to the atmosphere to prevent pressure damage to the strengthening layers caused by gases leaking or permeating into the annular area through the seal layers. End connectors join sections of the conduit together and connect the vents of the sections to each other to form a continuous vent passage that vents the annulus gas at the water surface.

Owner:GE OIL & GAS UK LTD

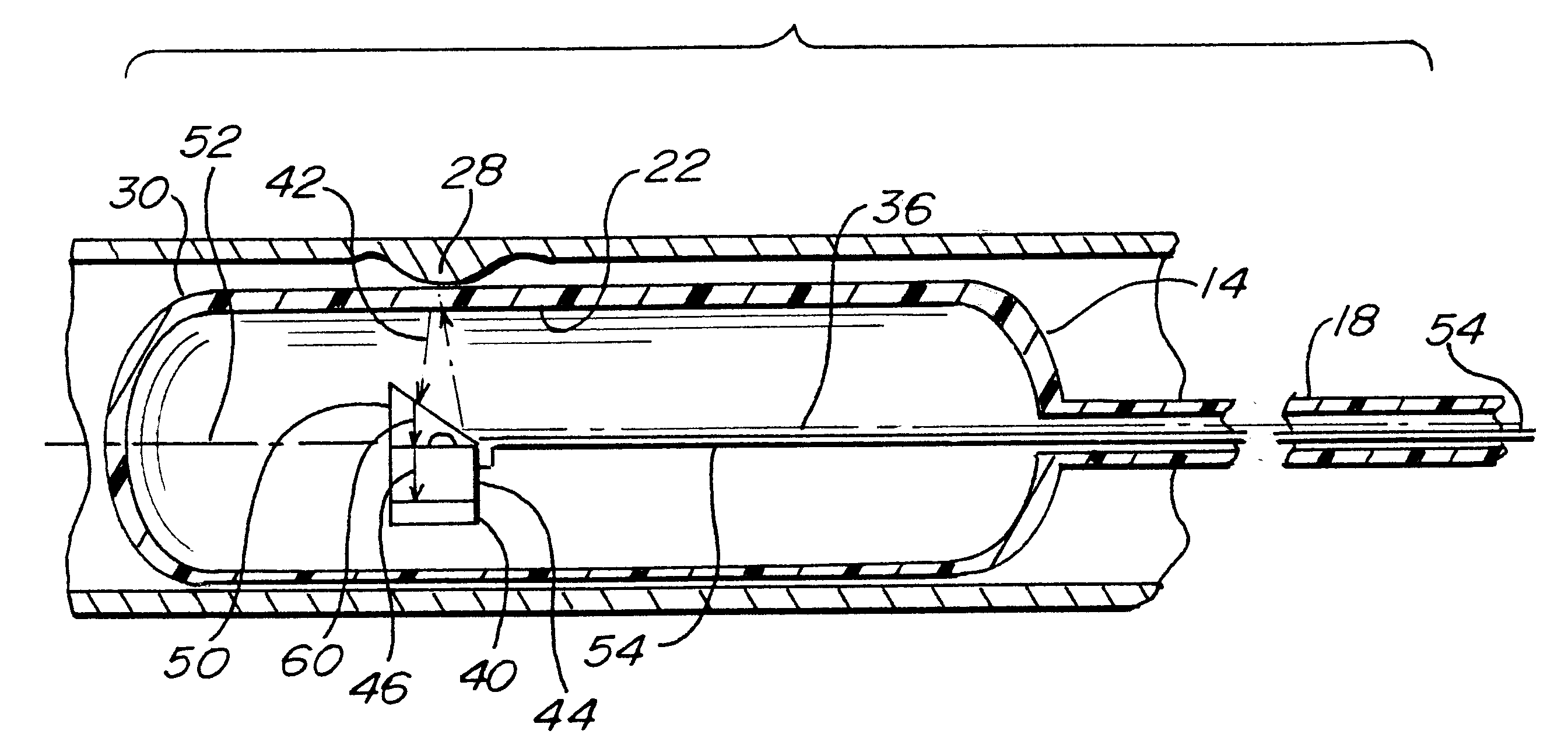

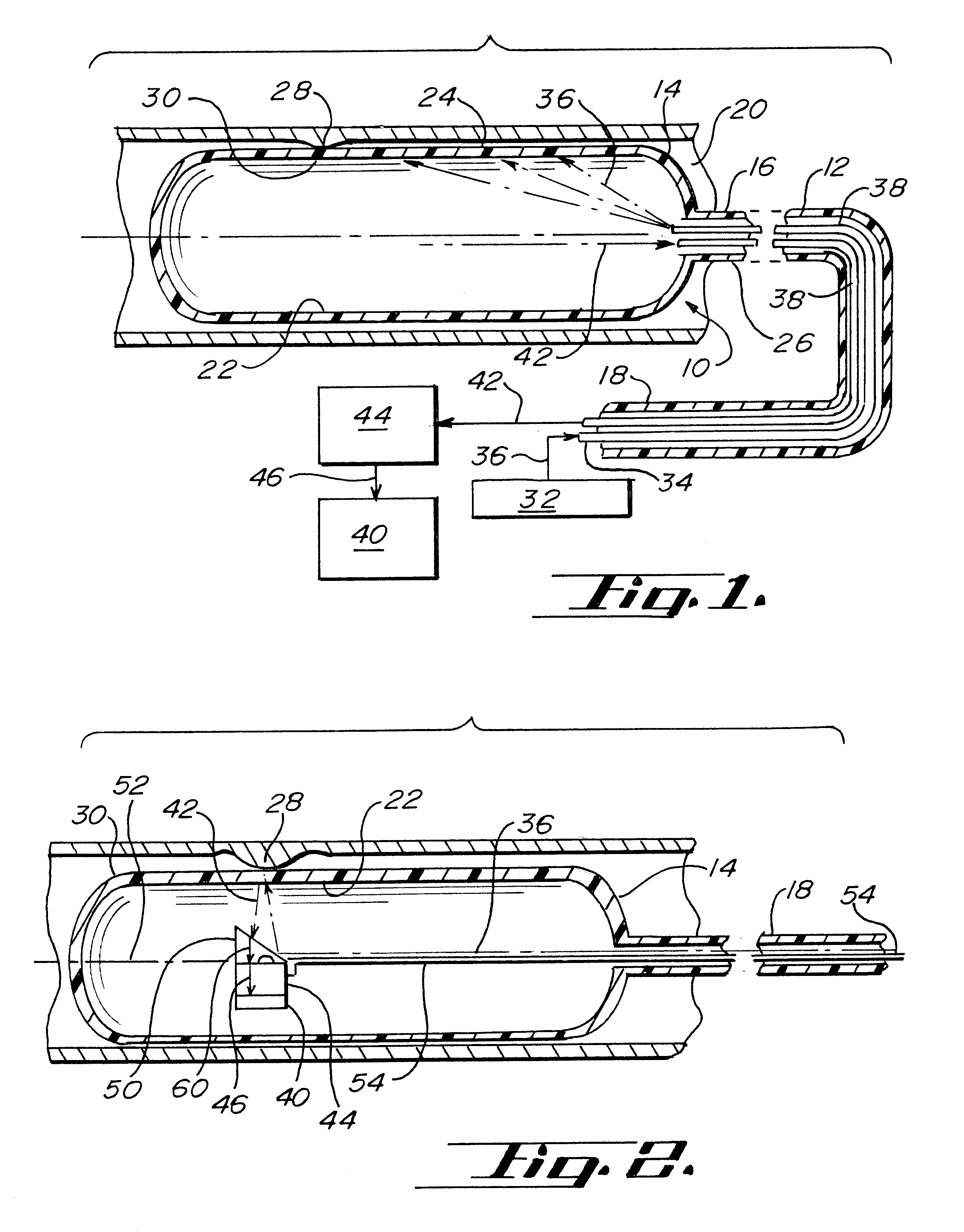

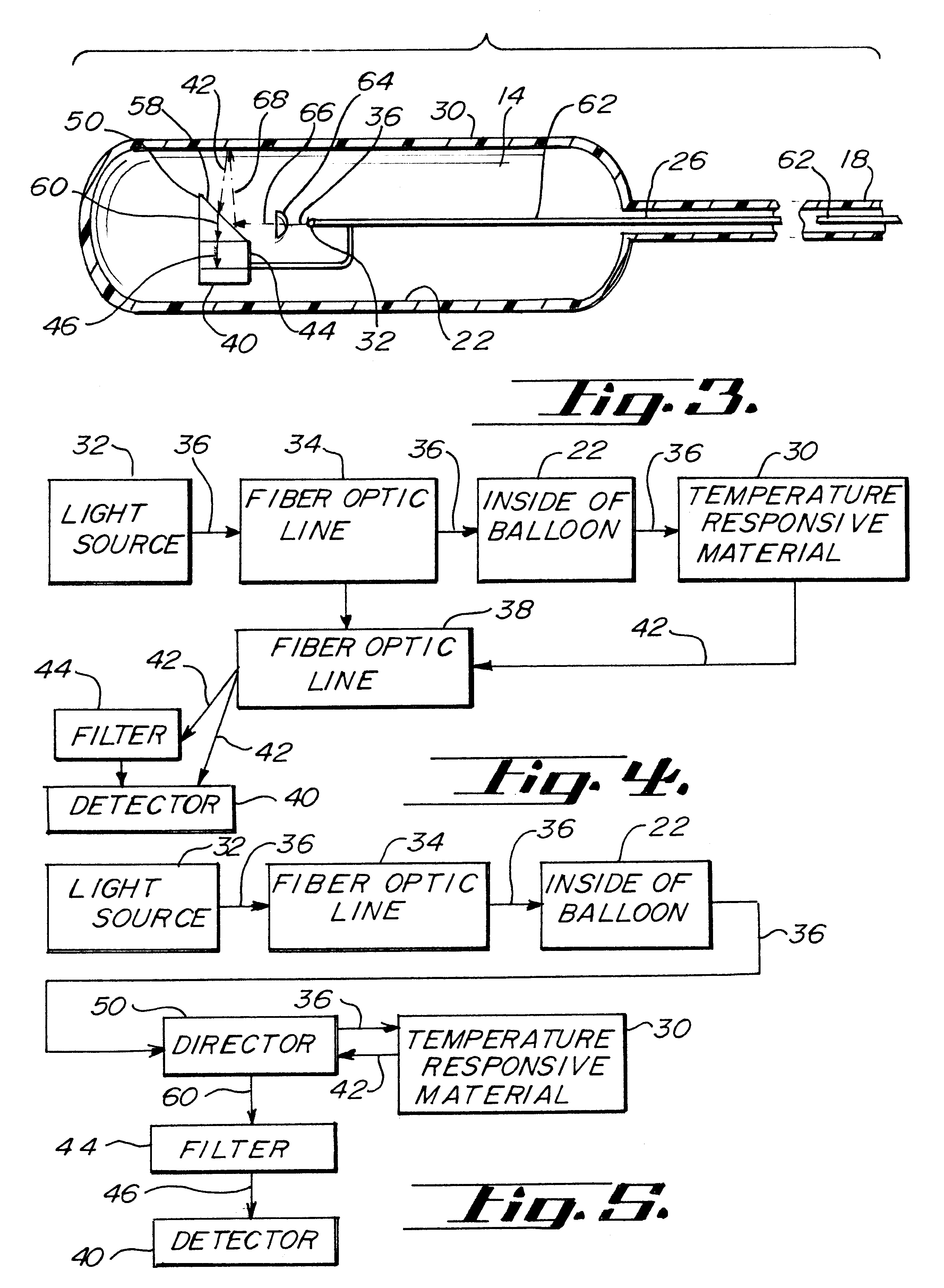

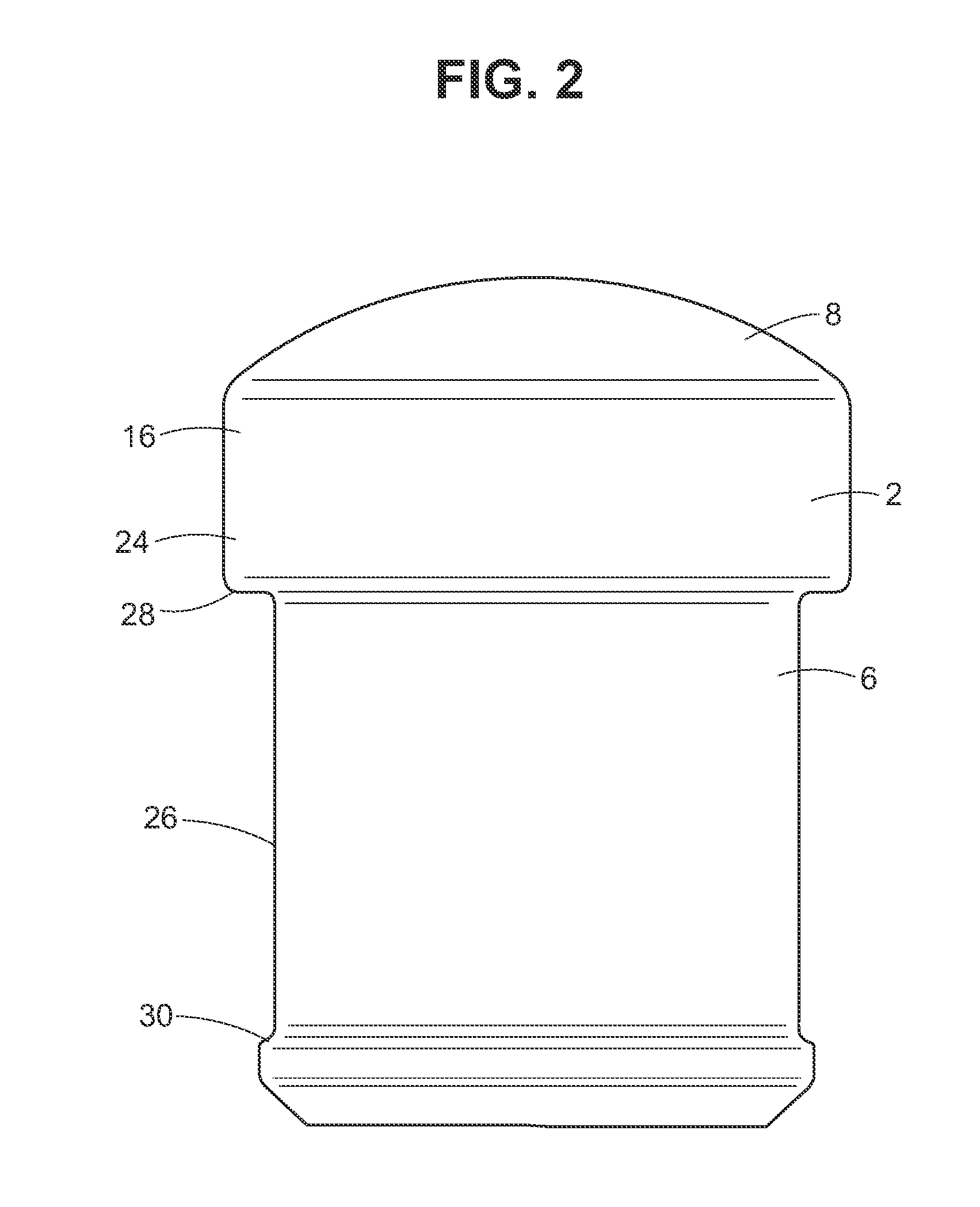

Temperature measuring balloon

A balloon catheter for locating vulnerable plaque lesions within a body lumen comprising a unique balloon mounted on a catheter shaft. The balloon having an uninflated state and being expandable to an inflated state, the balloon further having an inside and an outside, the balloon being made at least partially of at least one temperature responsive material. The at least one temperature responsive material designed to exhibit at least one predetermined color when the material is in contact with an object having an elevated temperature, such as a vulnerable plaque lesion. The catheter having a lumen which allows a light source to transmit light into the inside of the balloon. The light directed to illuminate at least a portion of the temperature responsive material. A light detector positioned to detect the light reflected off of the portion of the temperature responsive material to provide indicate the presence of the suspected lesion based on one or more characteristic changes to the light reflected from the temperature responsive material.

Owner:BOSTON SCI SCIMED INC

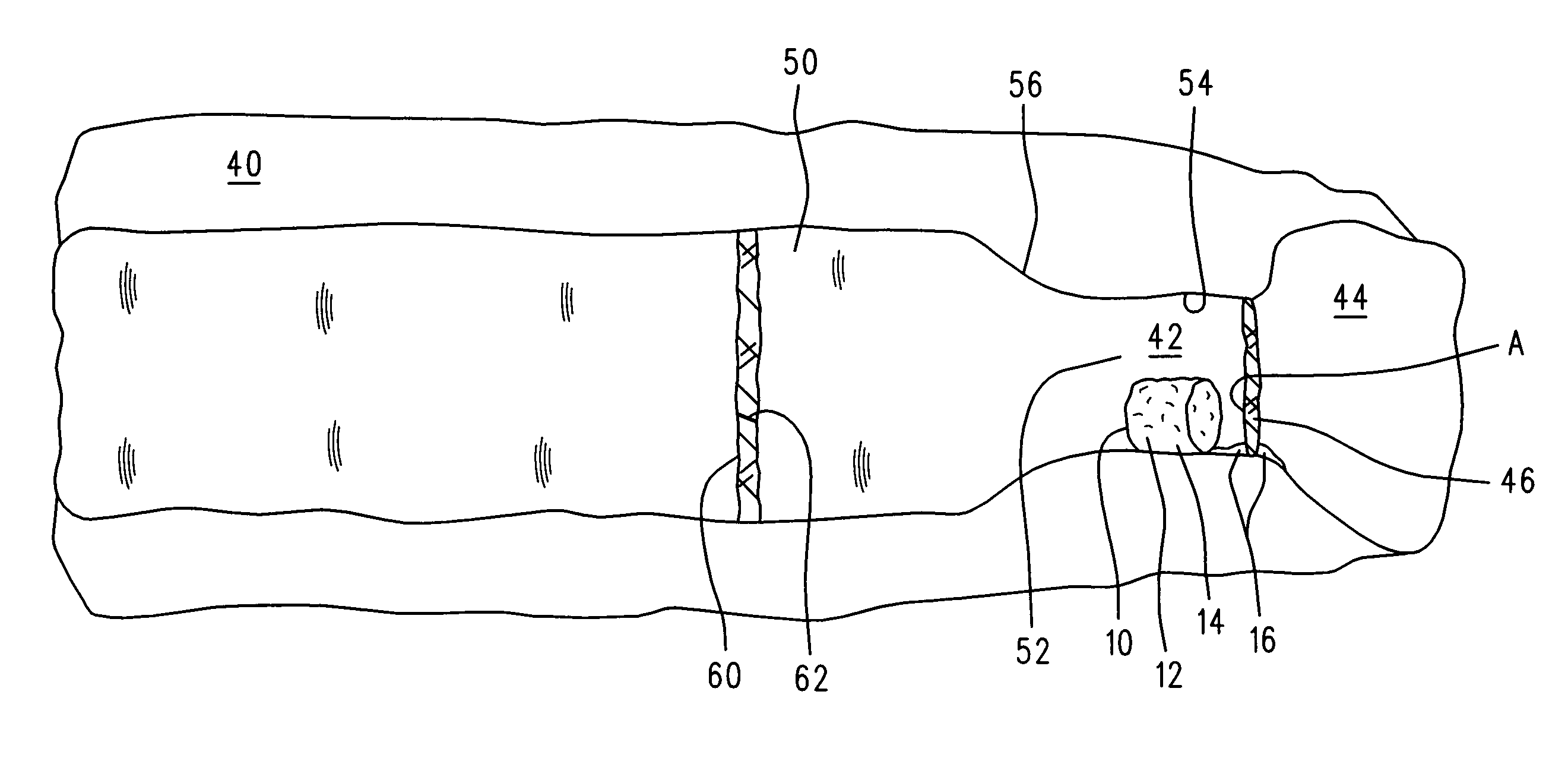

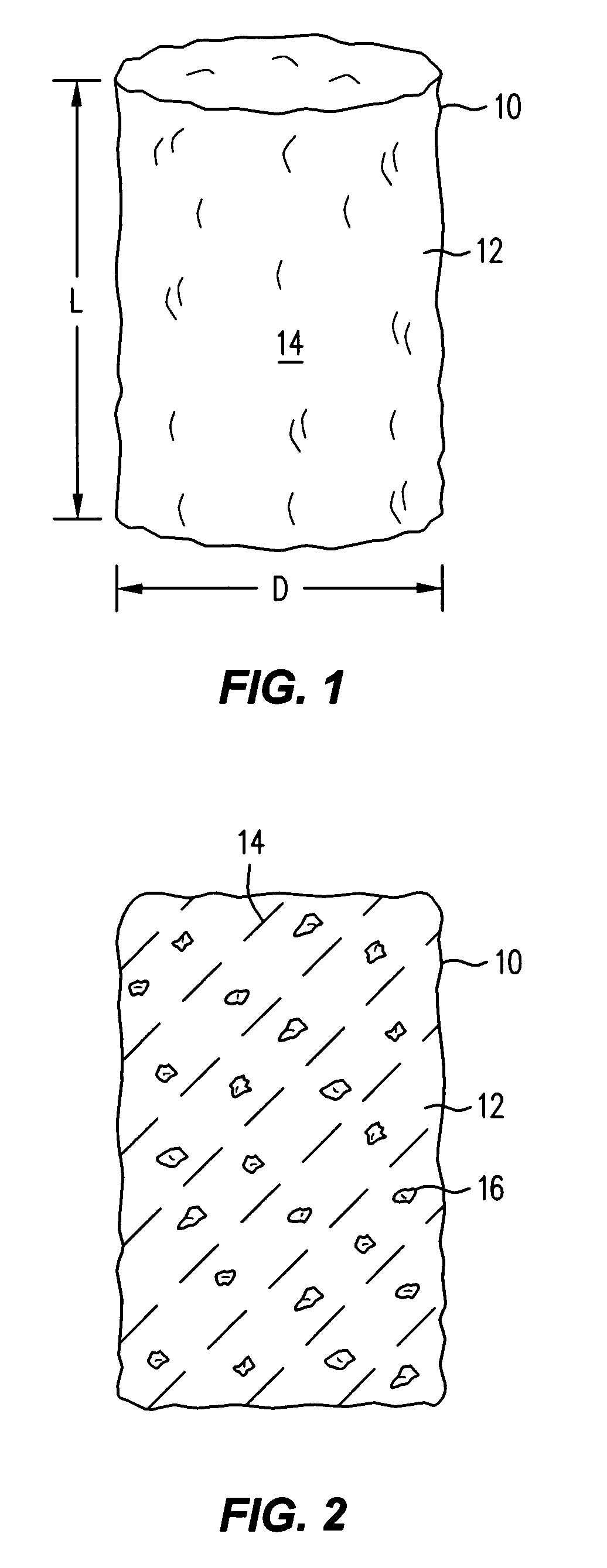

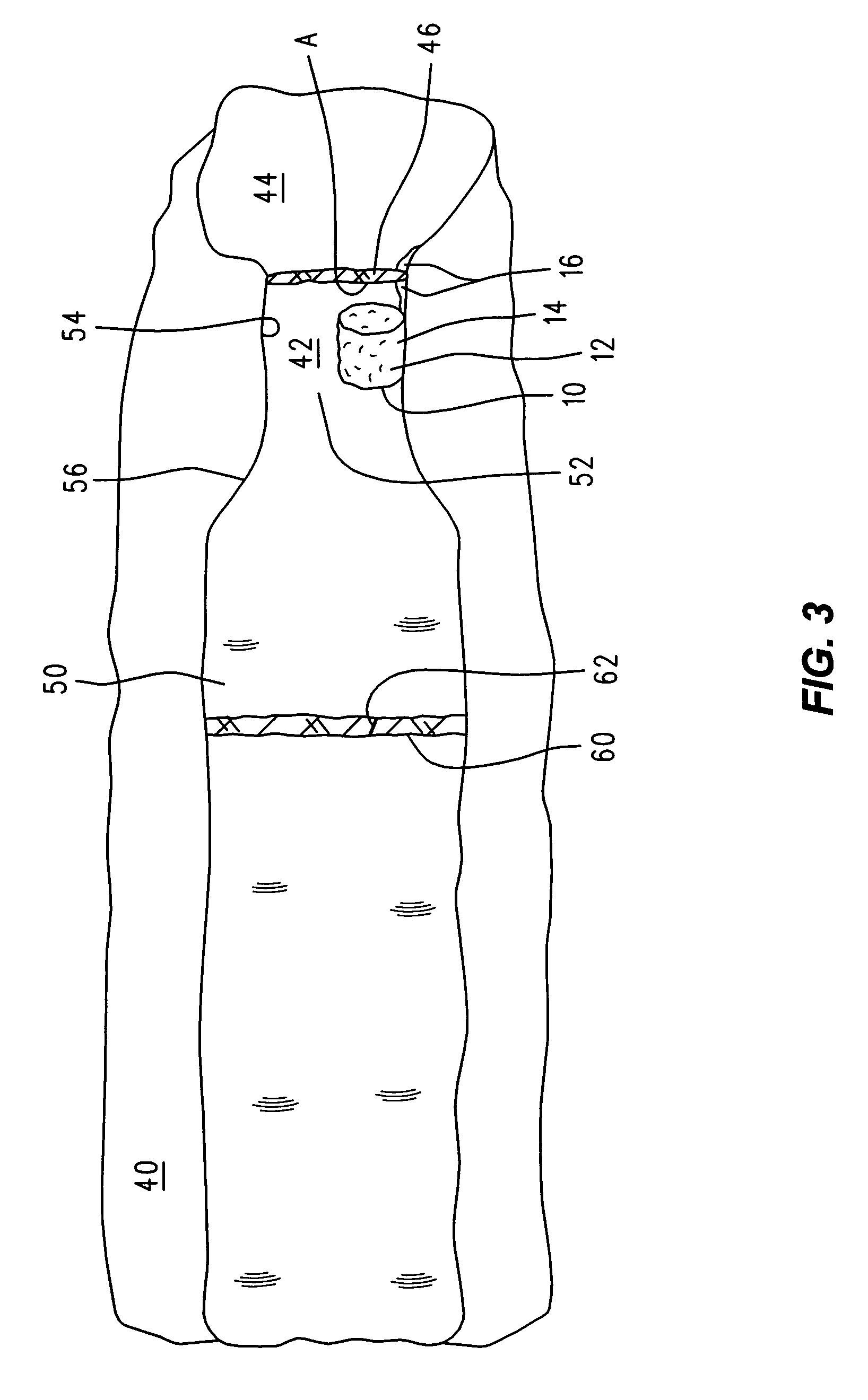

Controlled release system for delivering therapeutic agents into the inner ear

InactiveUS8197461B1Effective drug deliveryEfficient mannerEar treatmentMedical devicesControlled releaseControl manner

A specialized drug delivery unit for inner ear treatment which employs a portion of carrier media material containing one or more therapeutic agents therein. The carrier media material is designed to release the therapeutic agents in a controlled manner over time. The drug delivery unit is sized for placement in the round window niche of a patient. The released therapeutic agents come in contact with the round window membrane and pass therethrough into the inner ear for treatment purposes. This system provides many benefits ranging from the ability to deliver drugs in a site specific, highly controlled manner to the transfer of such materials with minimal patient discomfort and monitoring requirements.

Owner:DURECT CORP

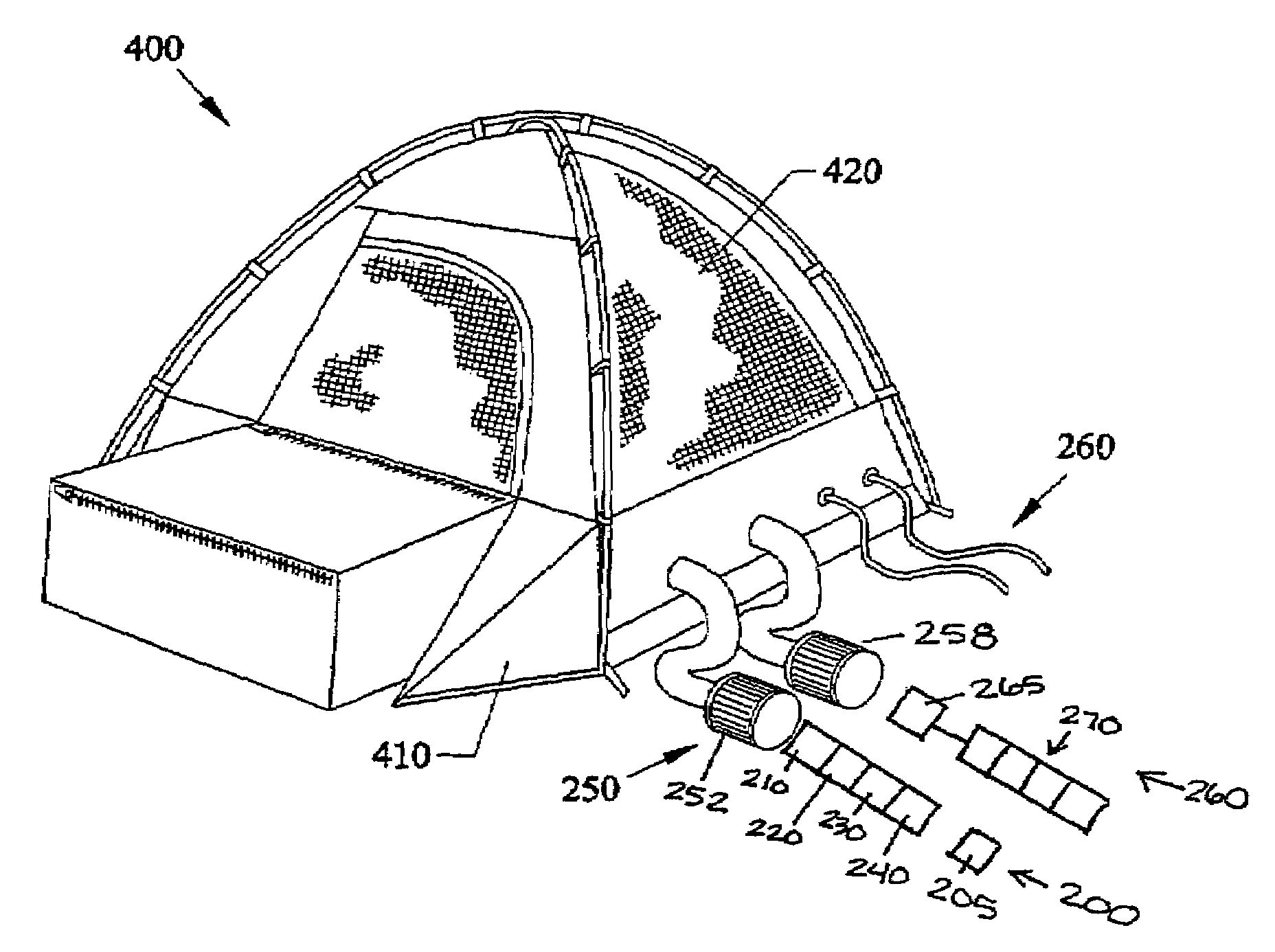

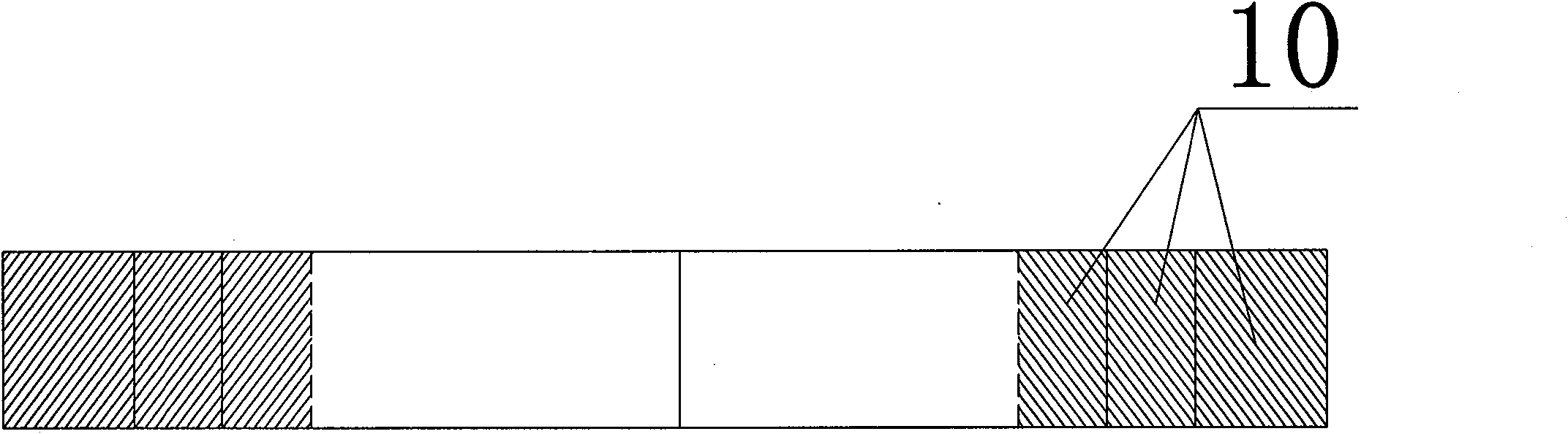

Bio-hazard attack family survival dome

A family protective shelter which can be erected quickly inside in a home living room, family room, patio, or on an outside lawn area. This dome tent enclosure is designed of clear plastic sheet material which is impervious to gases used to conduct chemical warfare (such as nerve gas, mustard gas, serin, cyanide, and the like) dispersed biohazard aerosol compounds (such as anthrax, smallpox, polio, bacteria, viruses, or fungi), or other atmospheric toxins, such as those from a nuclear fallout. This protective “pop-up”, external frame enclosure will be sized to house at least two adults comfortably (6×9×7 high inside, up to about 10×18′×7′ high), will incorporate a zip-lock entrance / egress isolation portal chamber, and will communicate to the outside world through combat gas mask filters, plus phone, computer and electrical outlet feed-through, and perhaps a water trap coupling. The invention can keep a family of 1 to 10 (with a larger size) relatively isolated and safe from the harmful effects of a chemical biohazard, or nuclear fallout enemy attack for a matter of hours up to several days. The portal chamber can also connect together additional modules.

Owner:BIODOME GRP

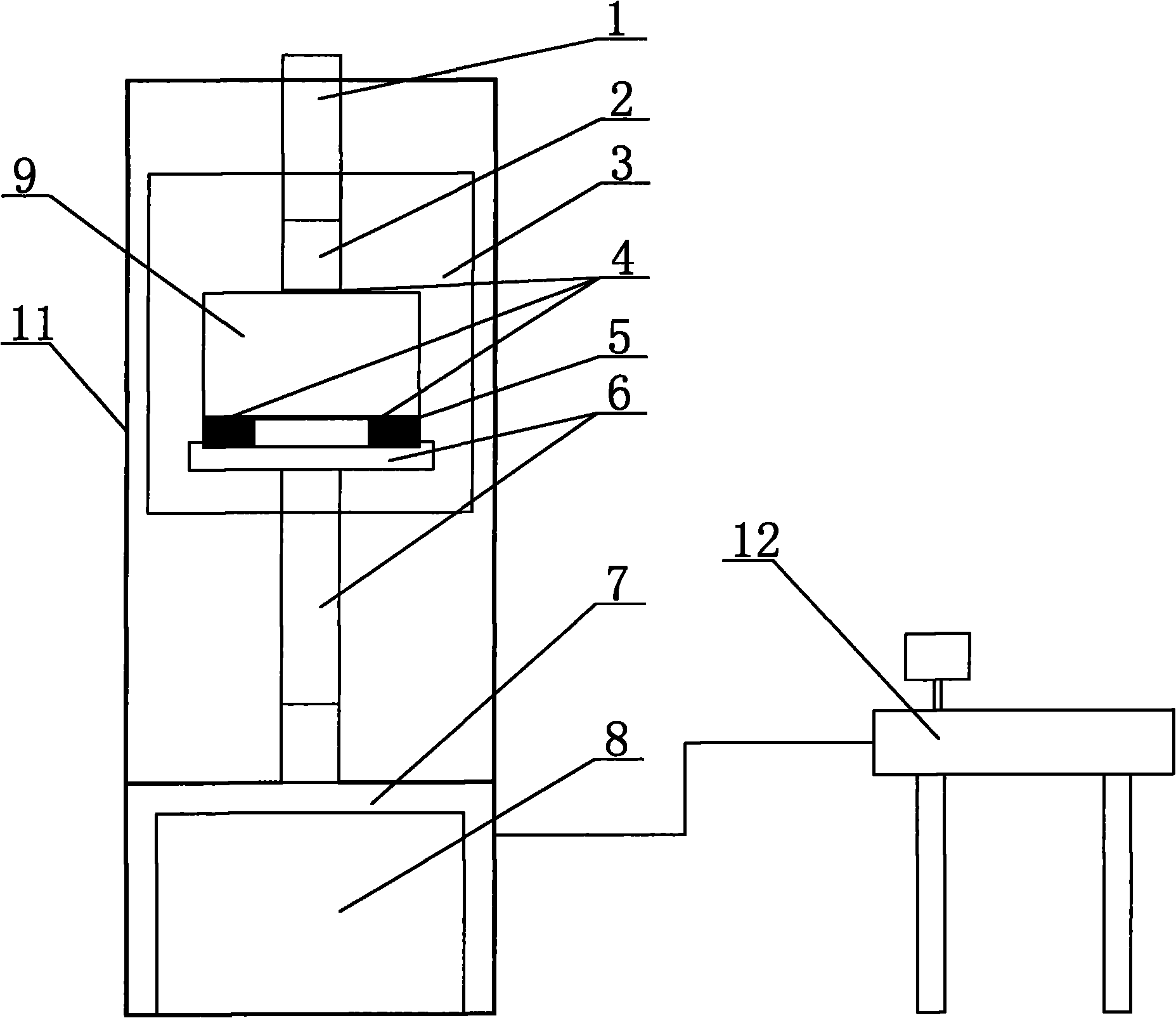

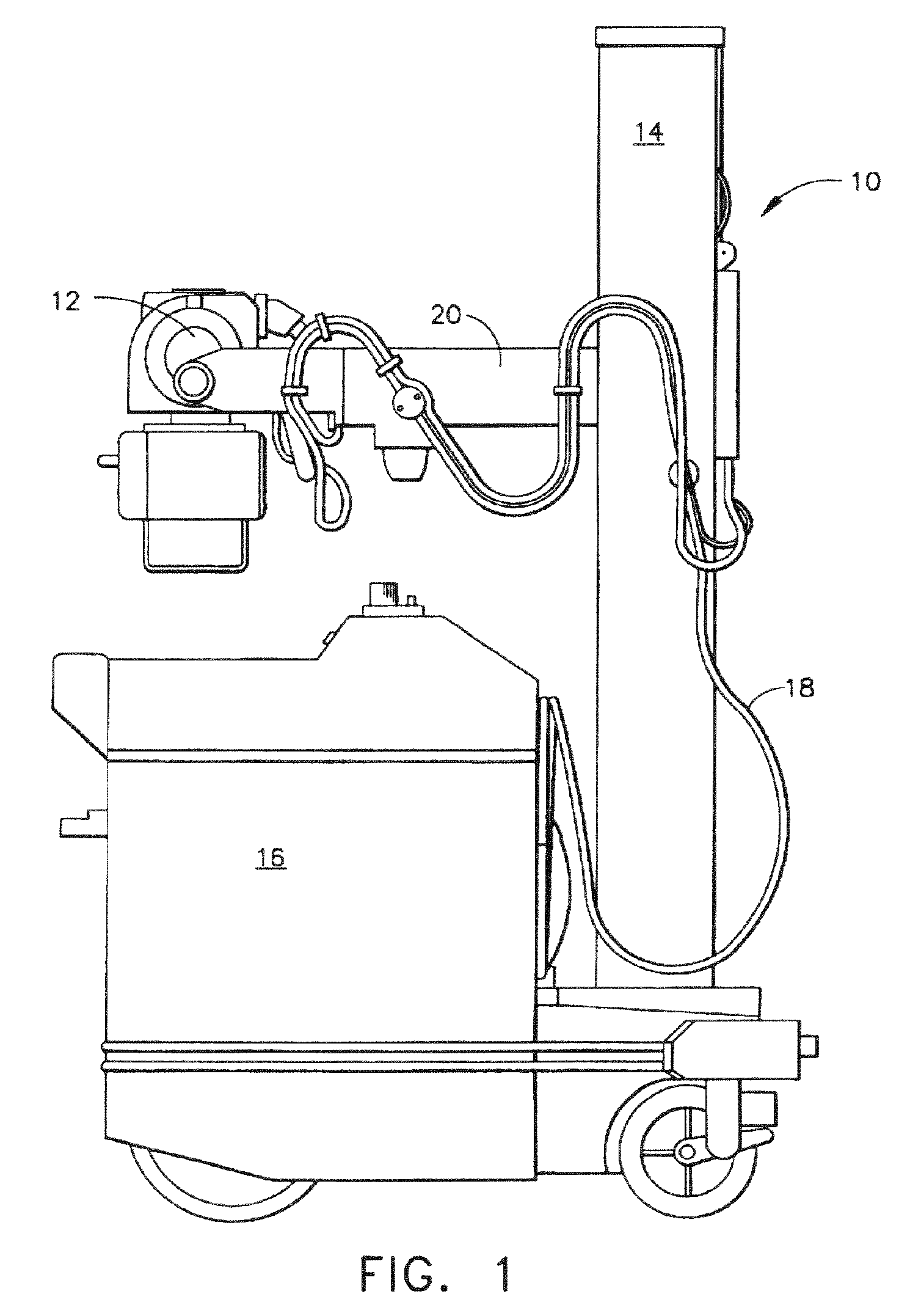

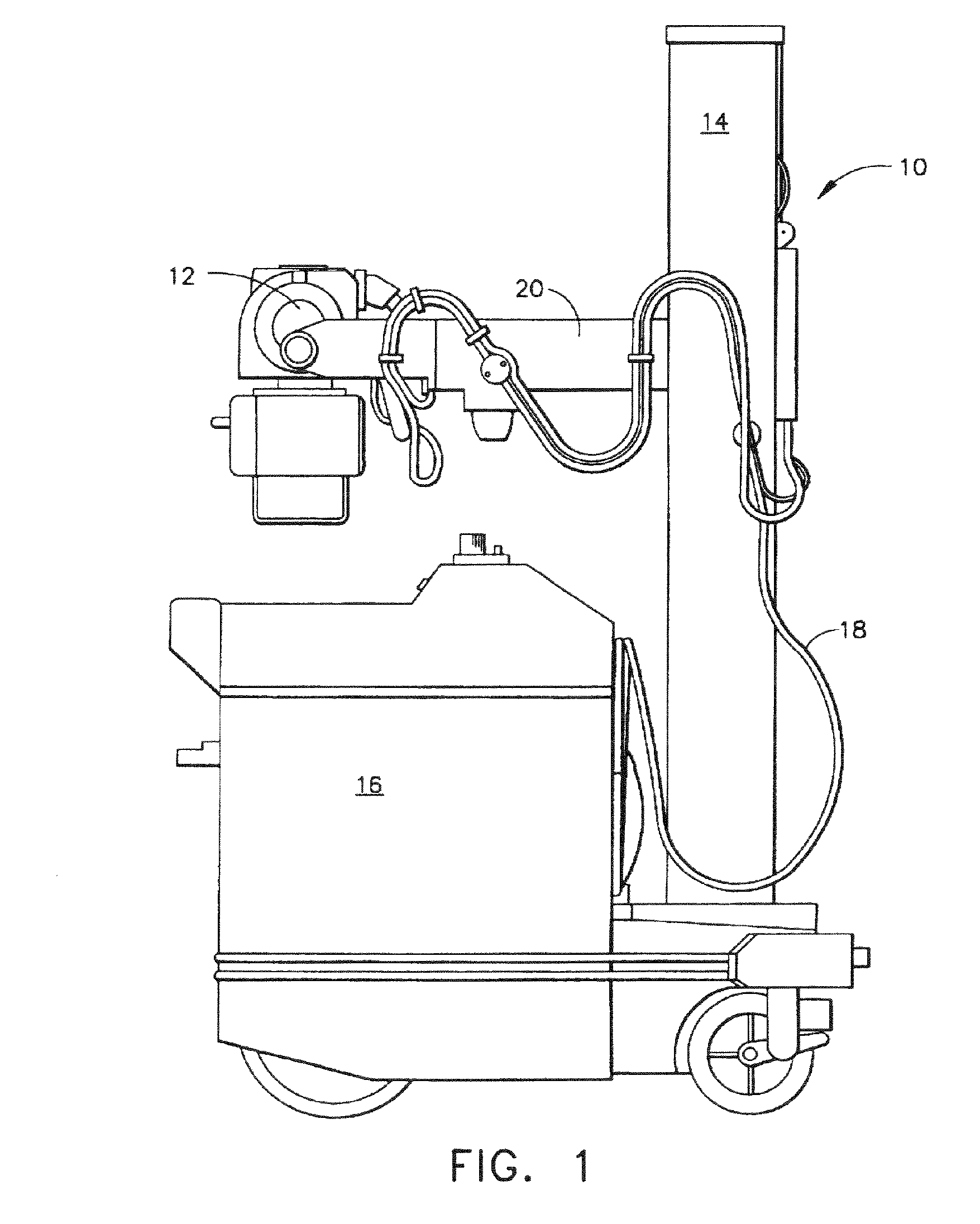

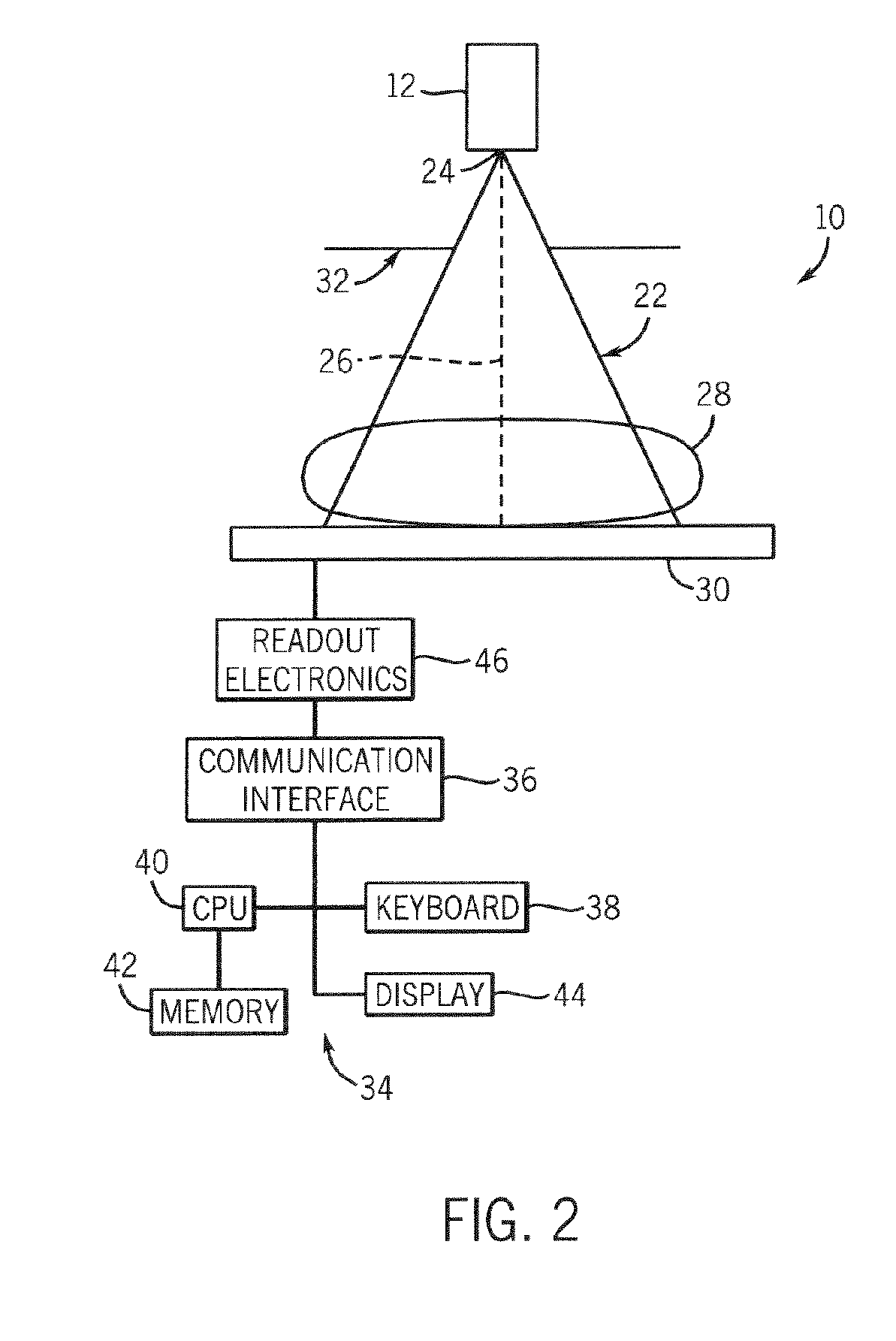

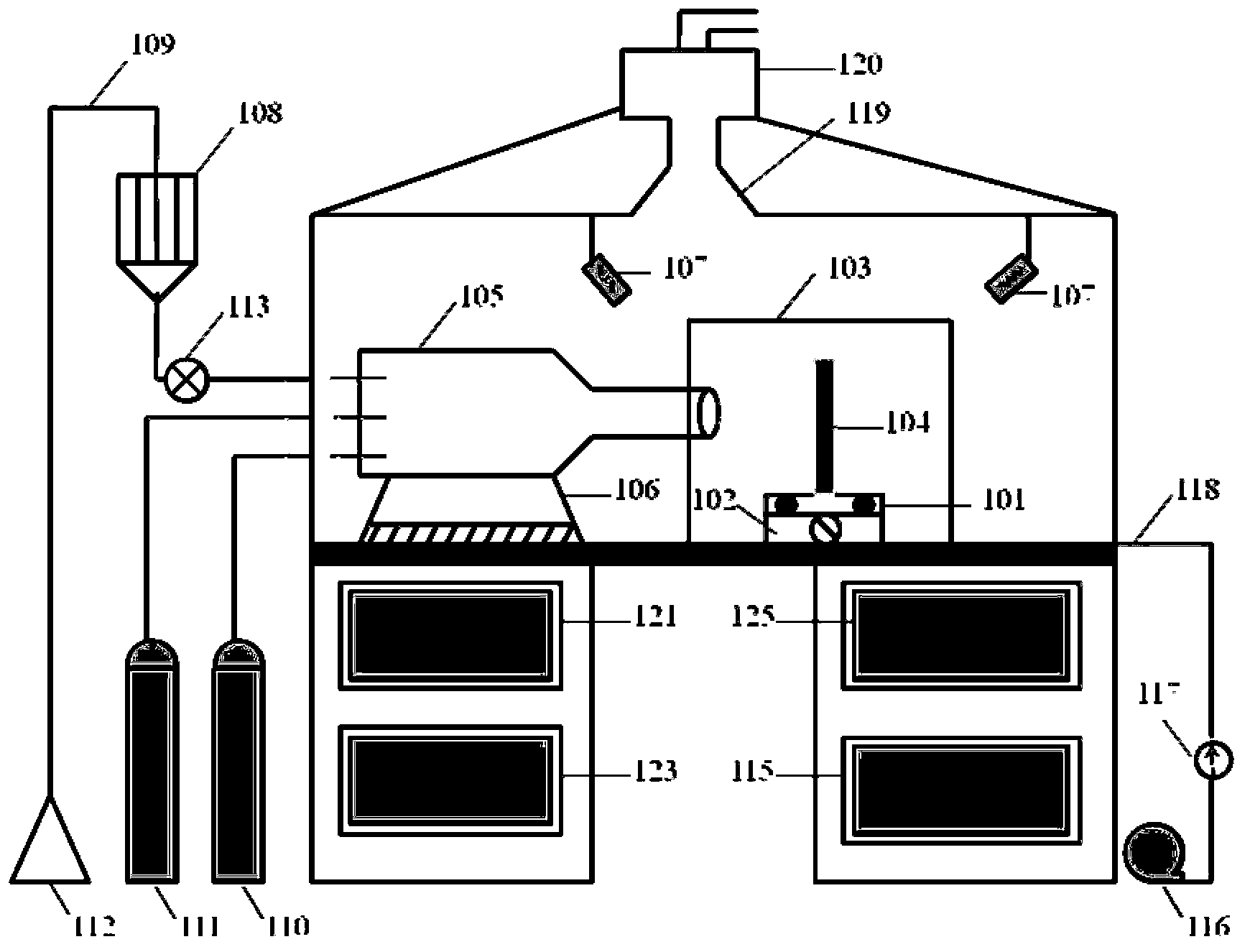

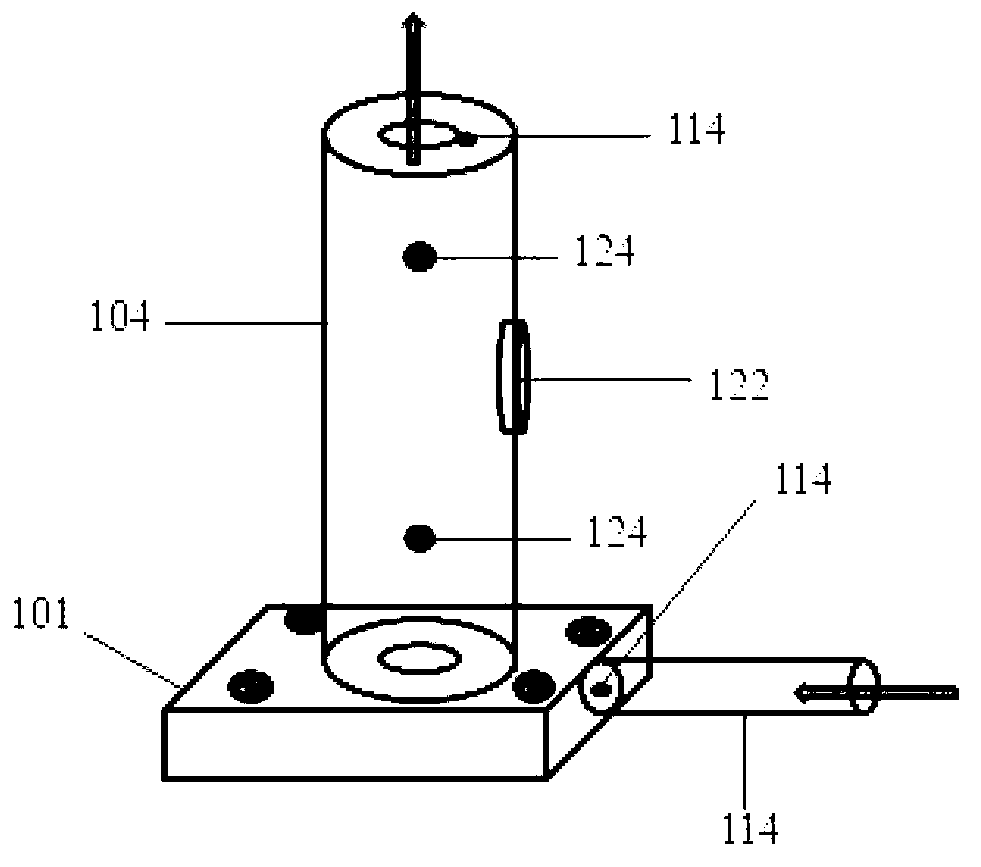

Device and method for testing shear performance of asphalt mixture

InactiveCN101788431AFree disassemblyThe testing process is simplePreparing sample for investigationMaterial strength using steady shearing forcesTemperature controlStress ratio

The invention discloses a device and a method for testing shear performance of an asphalt mixture. The shear strength and shear fatigue life of the asphalt mixture under different temperature conditions are tested by adopting a circular ring shearing test. The method comprises that: before the test, an asphalt mixture test-piece is subjected to heat preservation in a temperature control box at a preset test temperature for over 6 hours; in the test, the asphalt mixture test-piece is arranged on a circular ring, and is loaded through a pressure head to cause shear failure so as to form a conical shear failure surface, and the shear strength of the asphalt mixture is calculated; and according to requirements, a specific load in a range of 0.1 to 0.9 time of failure load is selected to perform a repeated loading fatigue test on parallel test-pieces, the loading waveform is sine waves, the frequency is 10Hz, and the shear fatigue life of the asphalt mixture at different stress ratios is read out. The test method has important significance for studying the shear performance of the asphalt mixture and designing and evaluating the material of the asphalt mixture.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

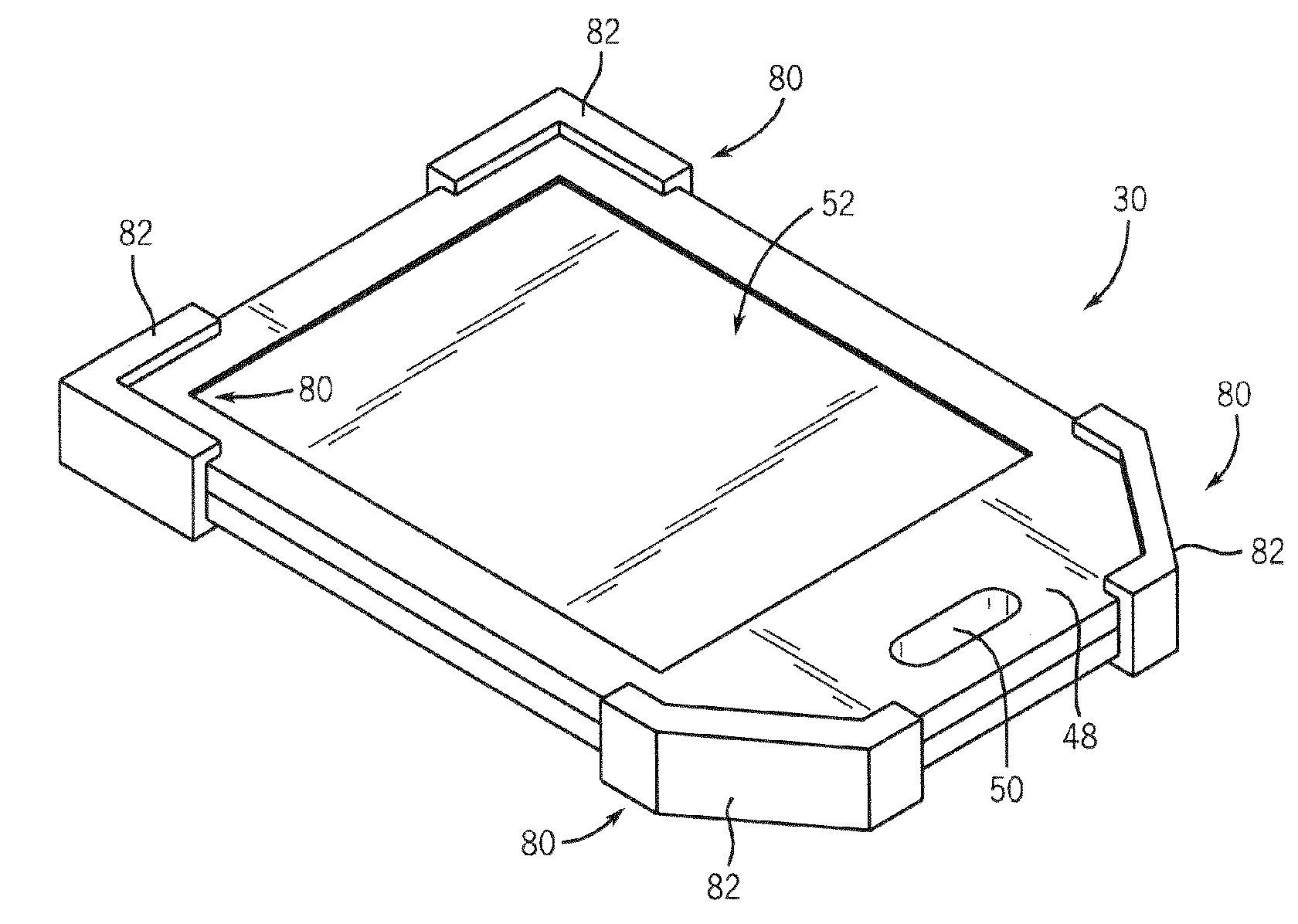

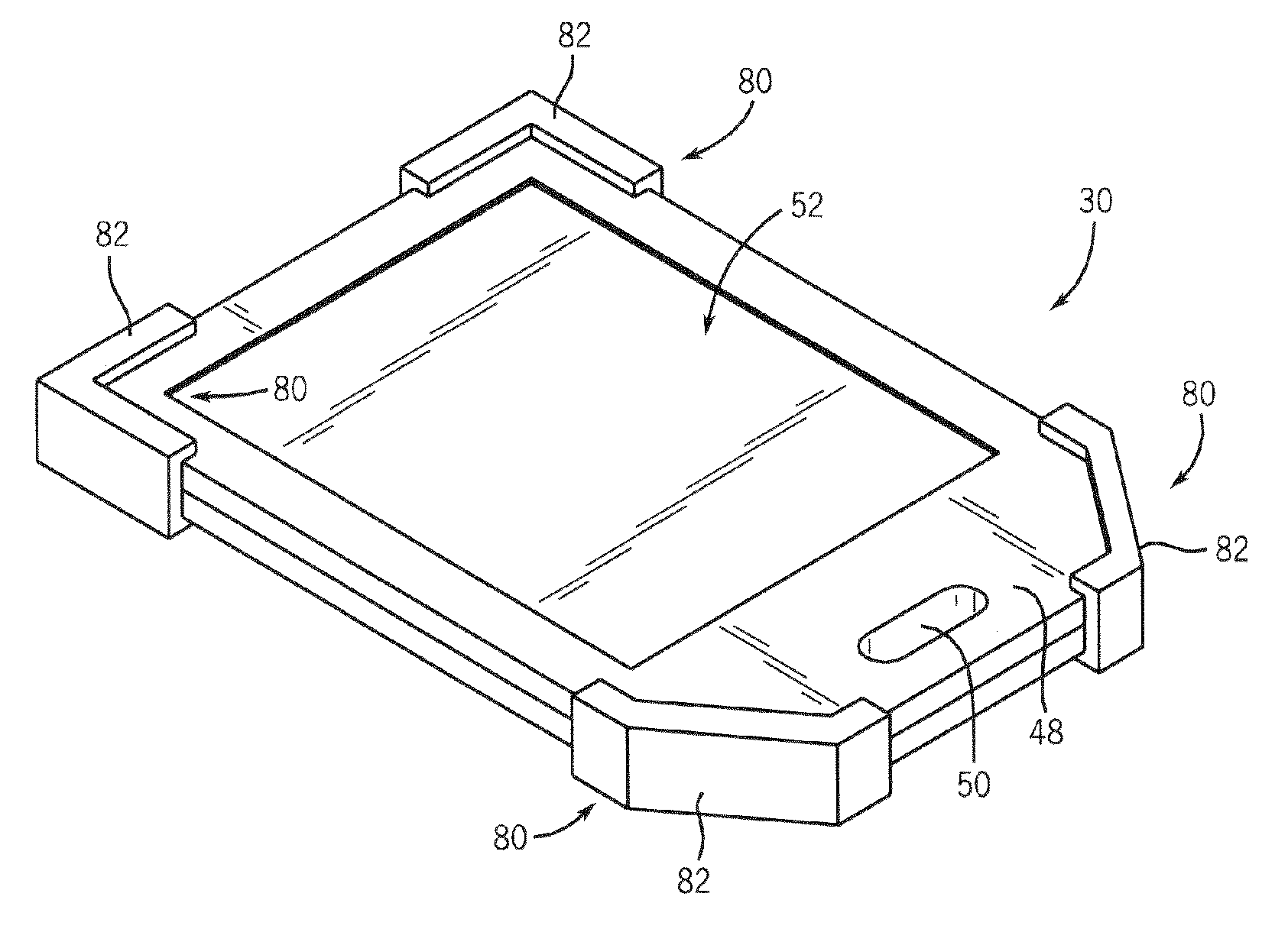

X-ray detector with impact absorbing cover

ActiveUS7189972B2Solid-state devicesMaterial analysis by optical meansMaterial DesignMaterials design

The present invention is a directed to a cover assembly for an x-ray detector that incorporates impact-absorbing material designed to absorb the shock, vibration, stress, and strain placed on the detector when dropped or subjected to a load. The cover assembly may include a layer or inserts of impact-absorbing material. Bumpers of impact-absorbing material may also be secured to the x-ray detector cover. Viscoelastic foam or other plastics may be used as the impact-absorbing material.

Owner:GENERAL ELECTRIC CO

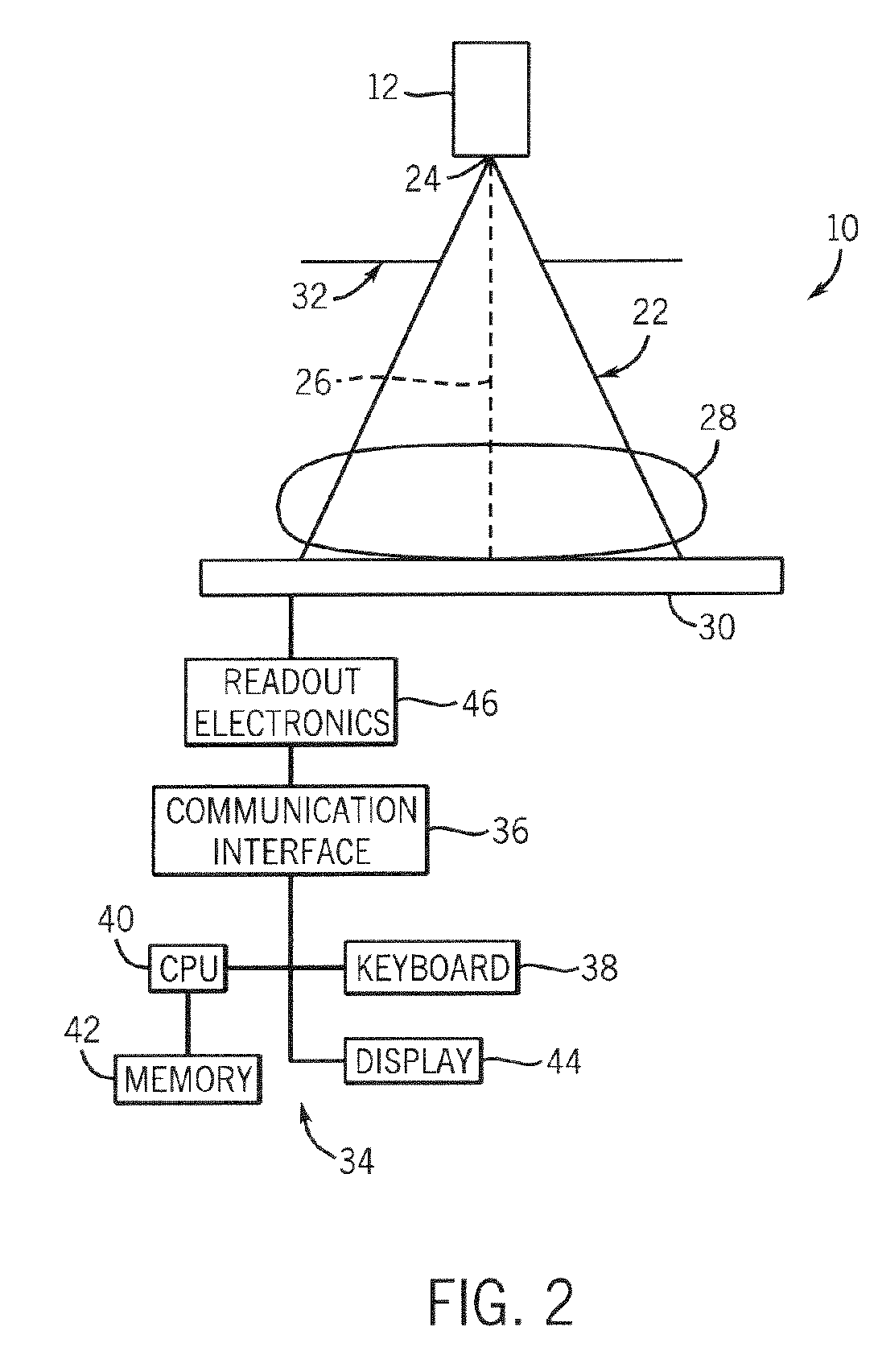

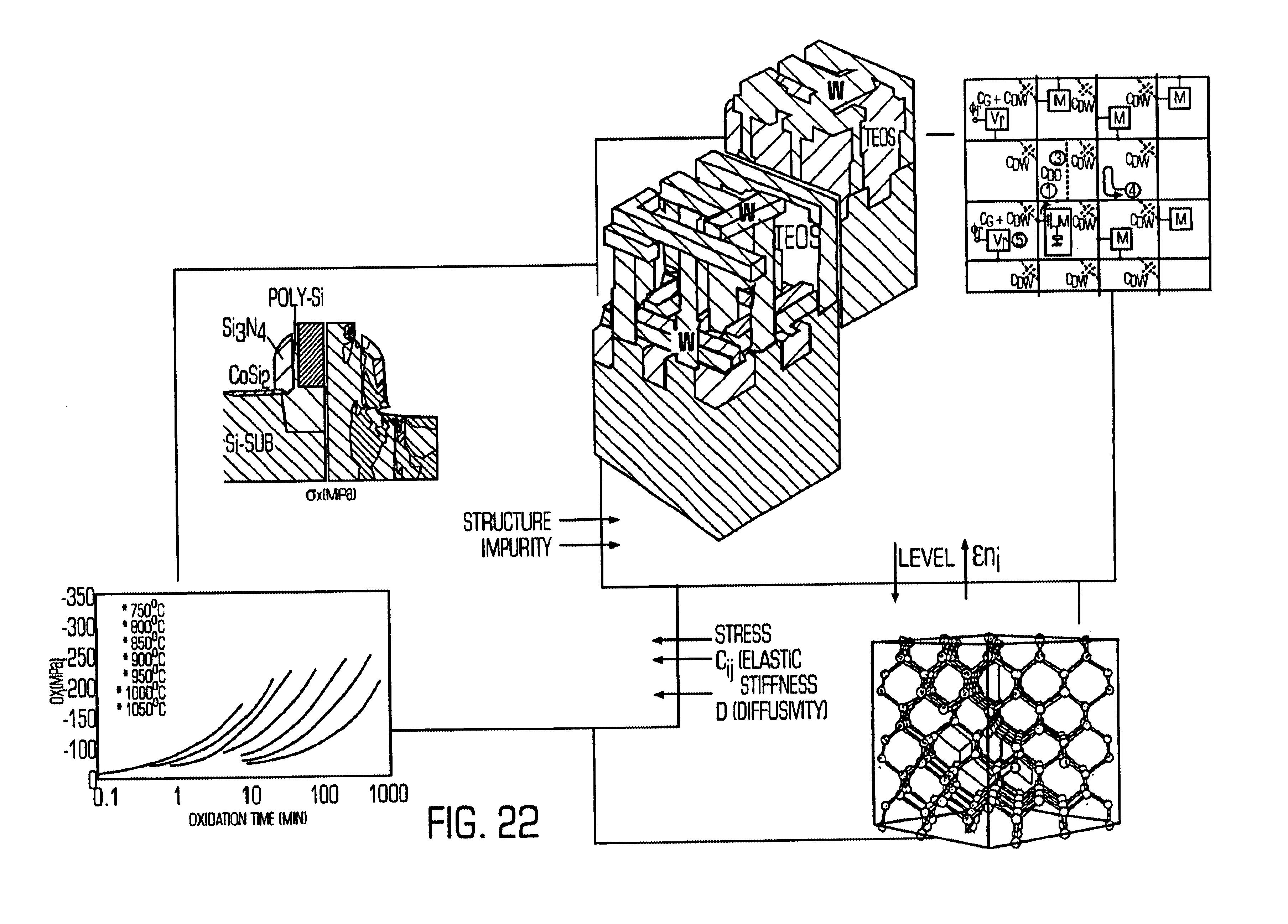

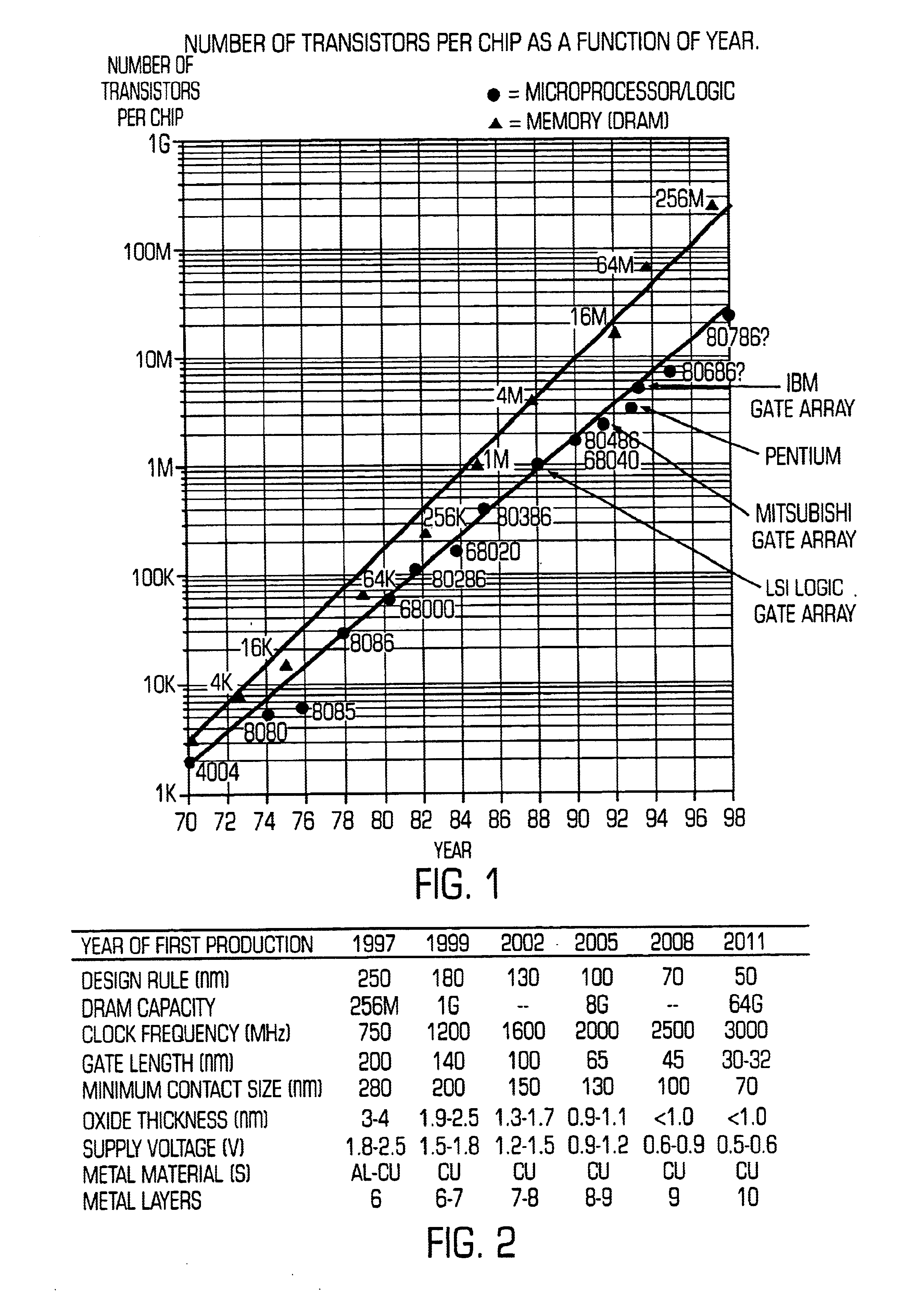

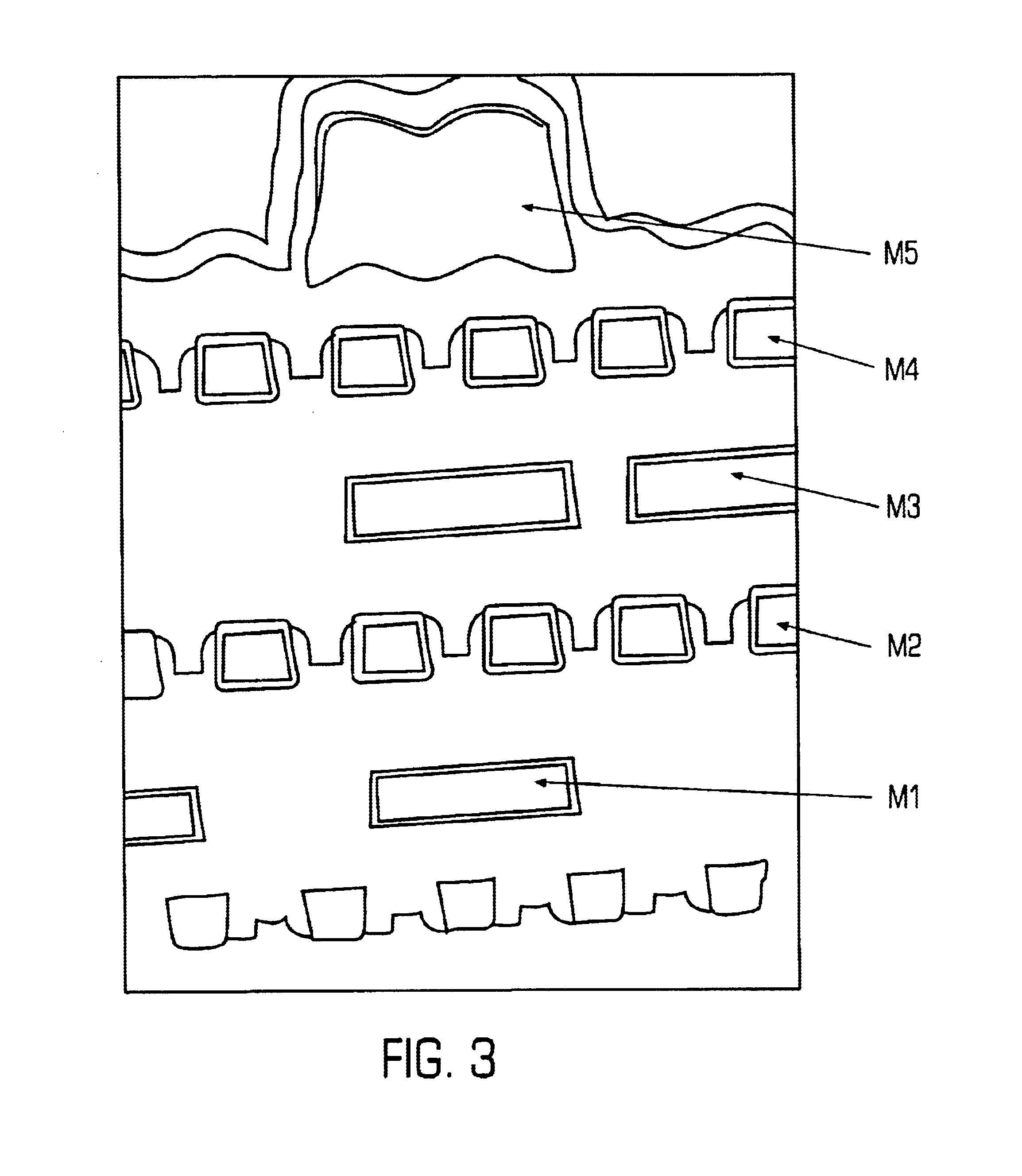

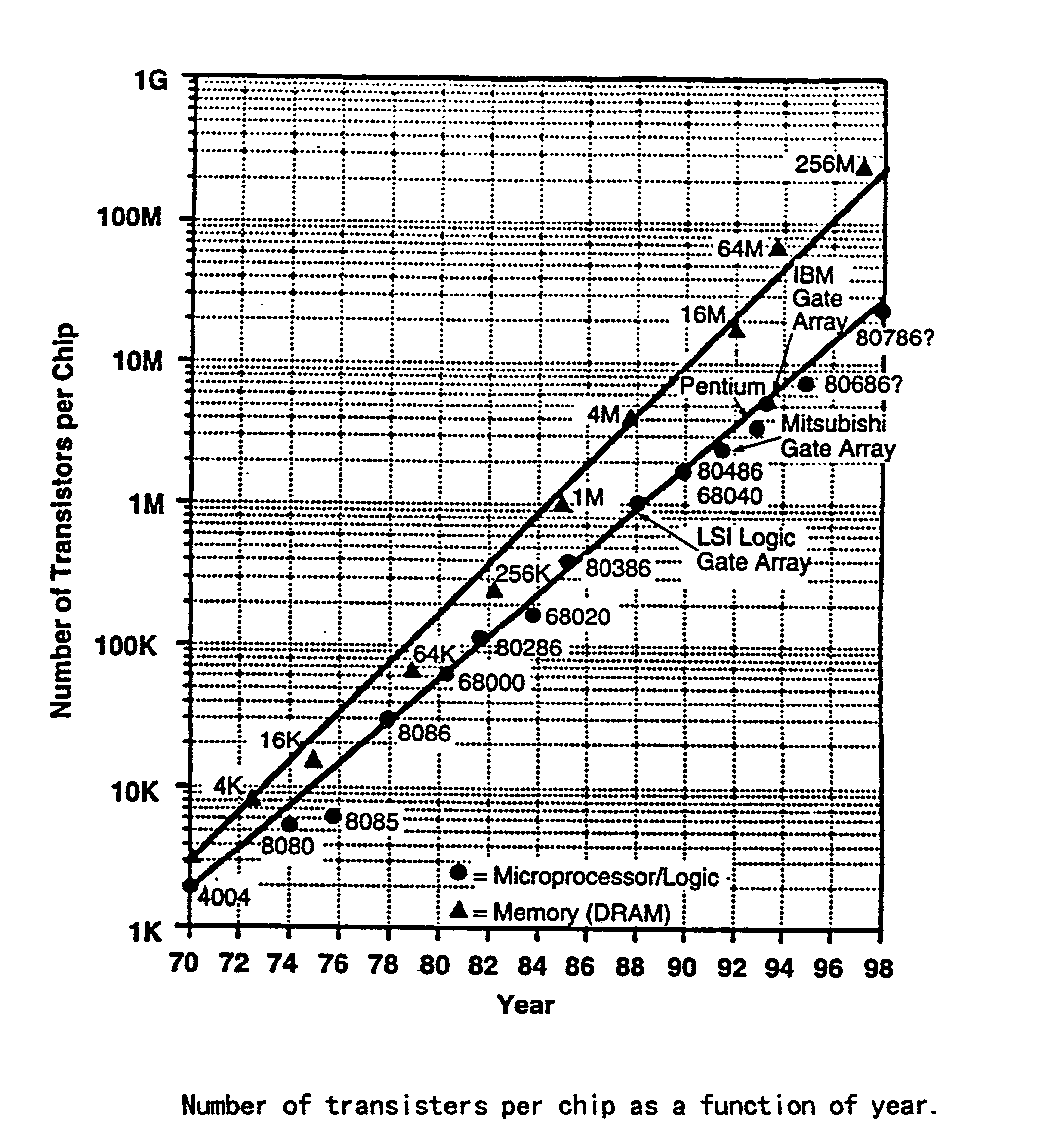

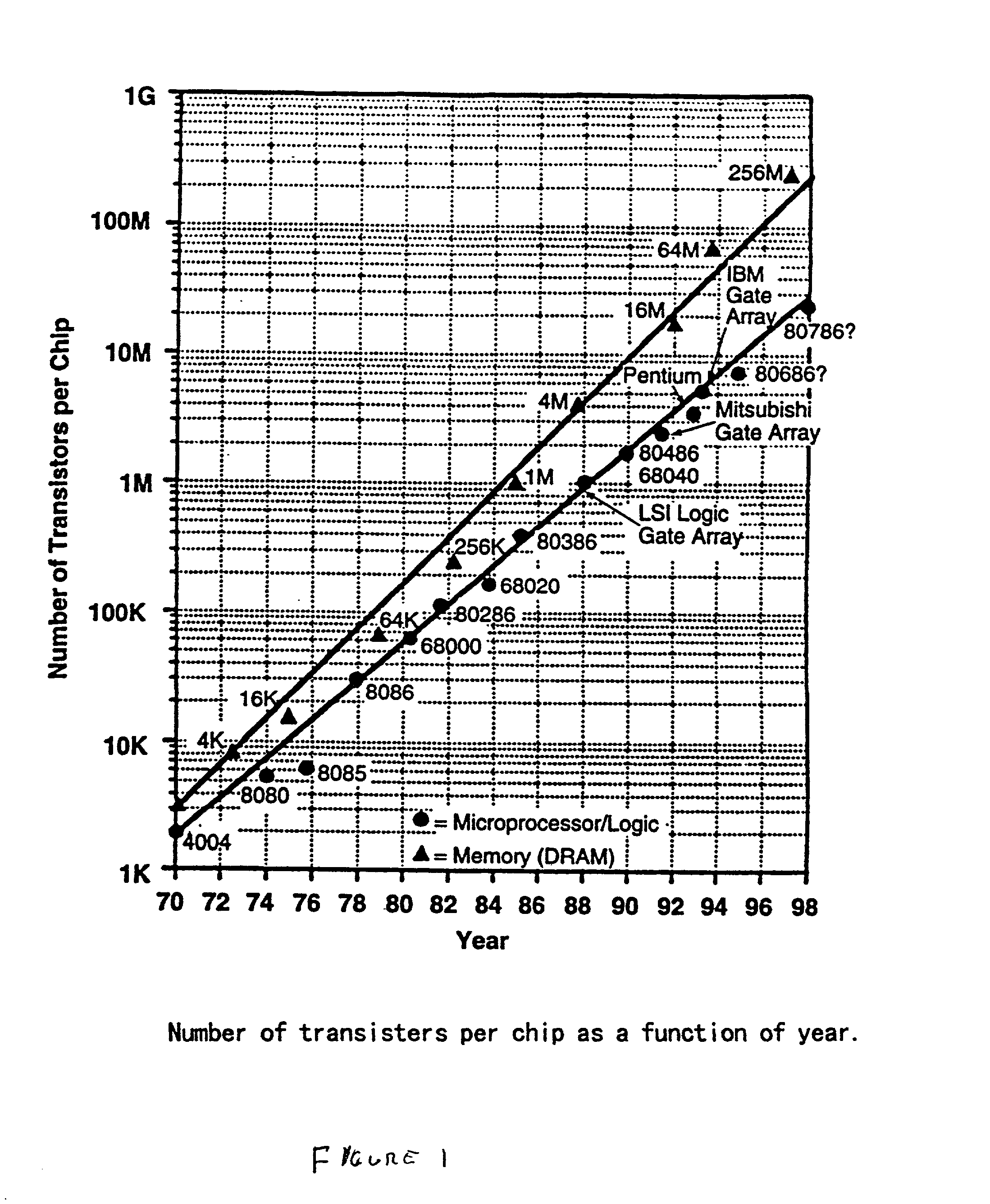

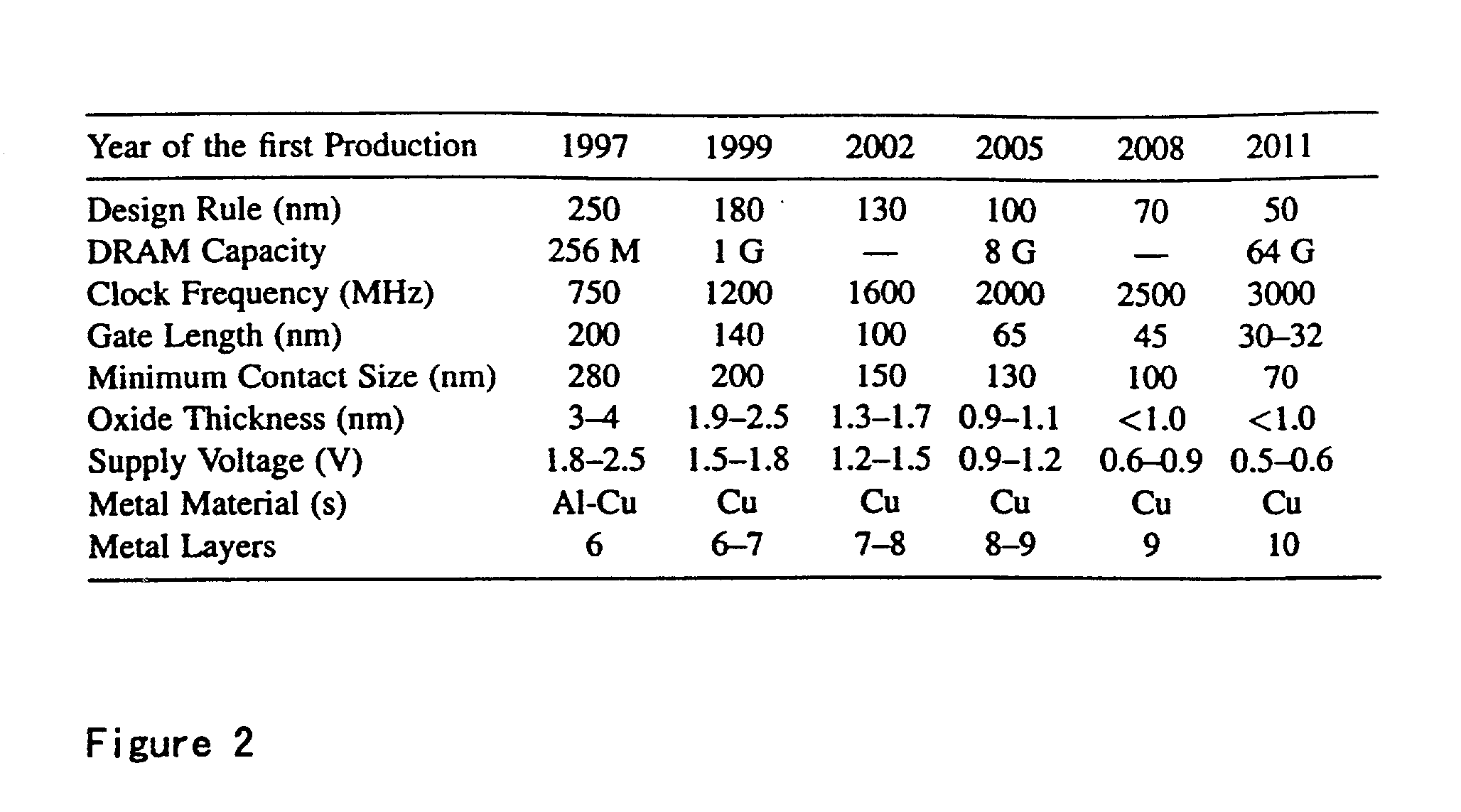

Method and apparatus for simulating manufacturing, electrical and physical characteristics of a semiconductor device

InactiveUS6826517B2Semiconductor/solid-state device detailsDetecting faulty computer hardwareElement modelMaterial Design

An electronic device simulator includes a three-dimensional lumped device model, a three-dimensional visco-elastic process simulation model and a material design model that are interlinked with each other. The three-dimensional lumped device element model comprises a Poisson's equation model, an electron continuity equation model, a hole continuity equation model, a Maxwell's equations model, an eddy current equation model, and an Ohm's law equation model. The simulator accounts for the three dimensional characteristics of the circuit to determine circuit performance.

Owner:KK TOSHIBA

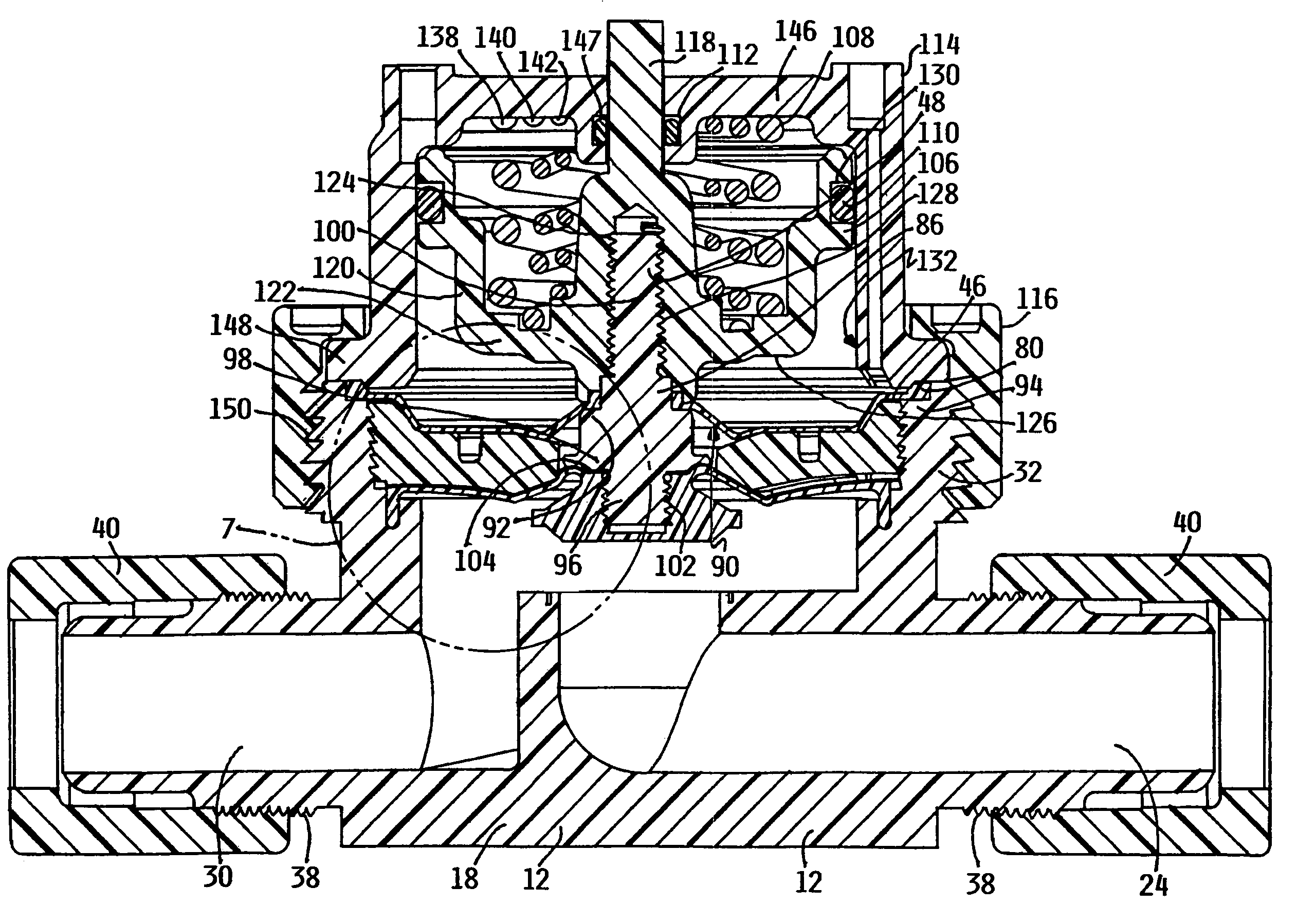

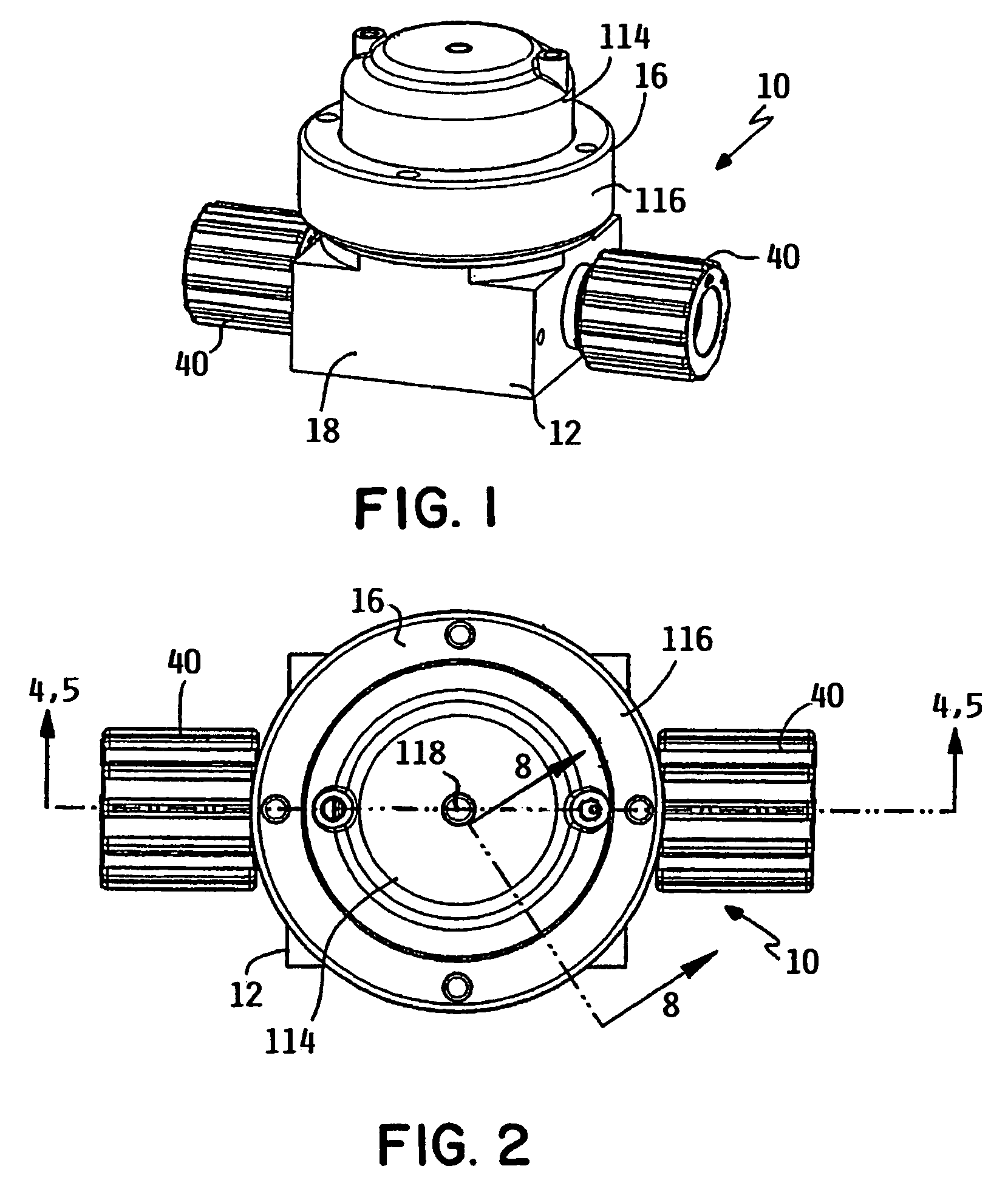

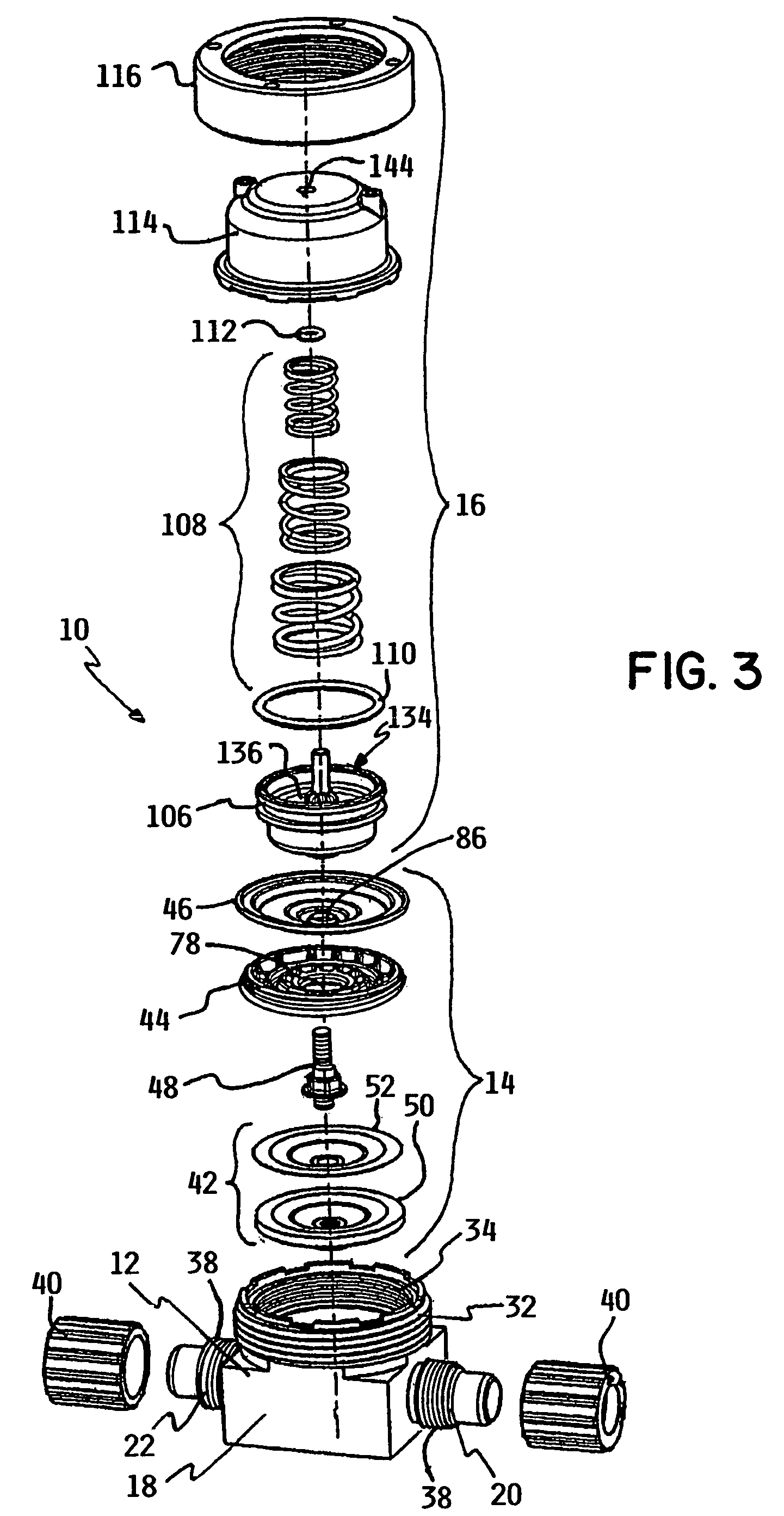

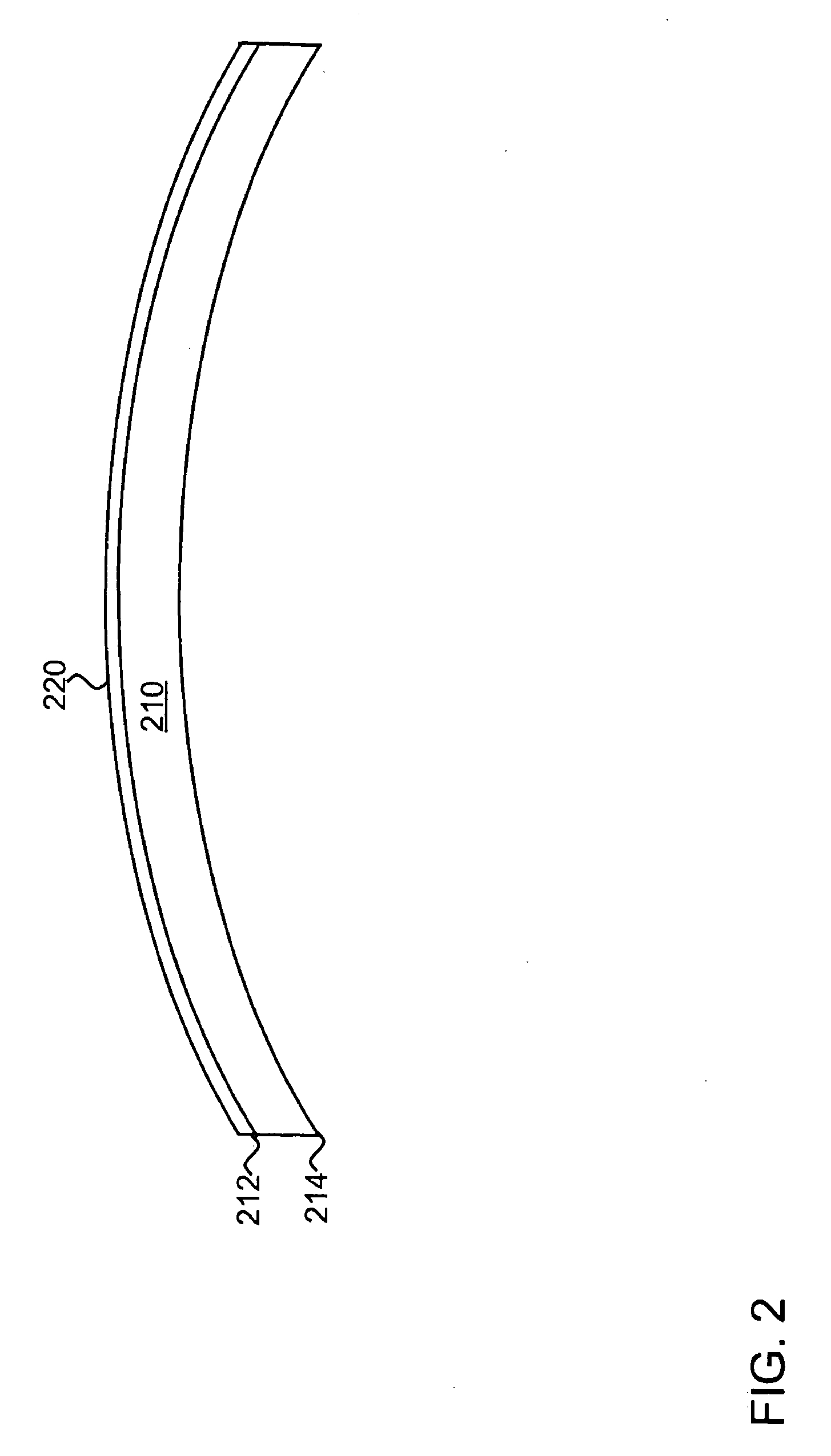

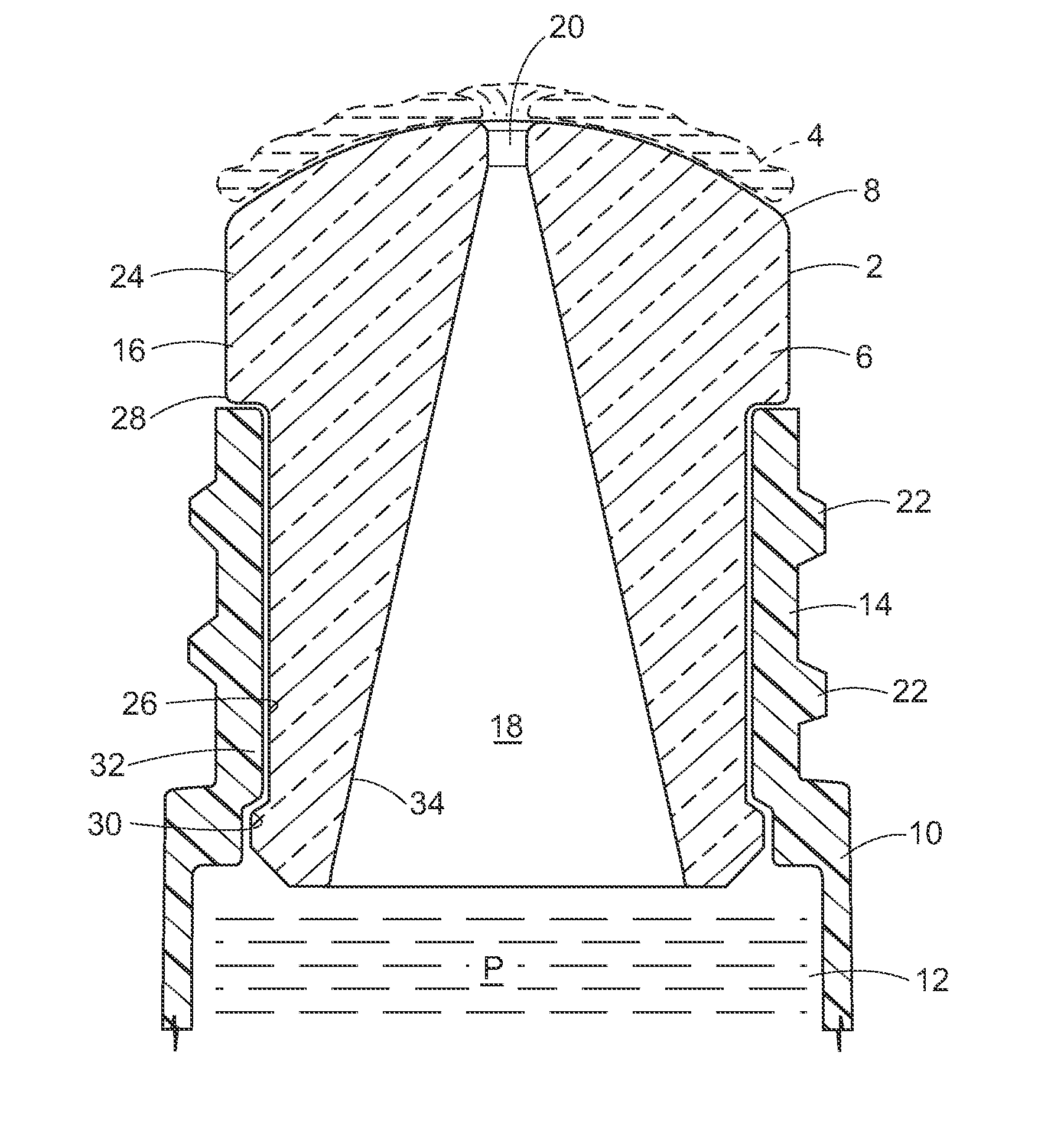

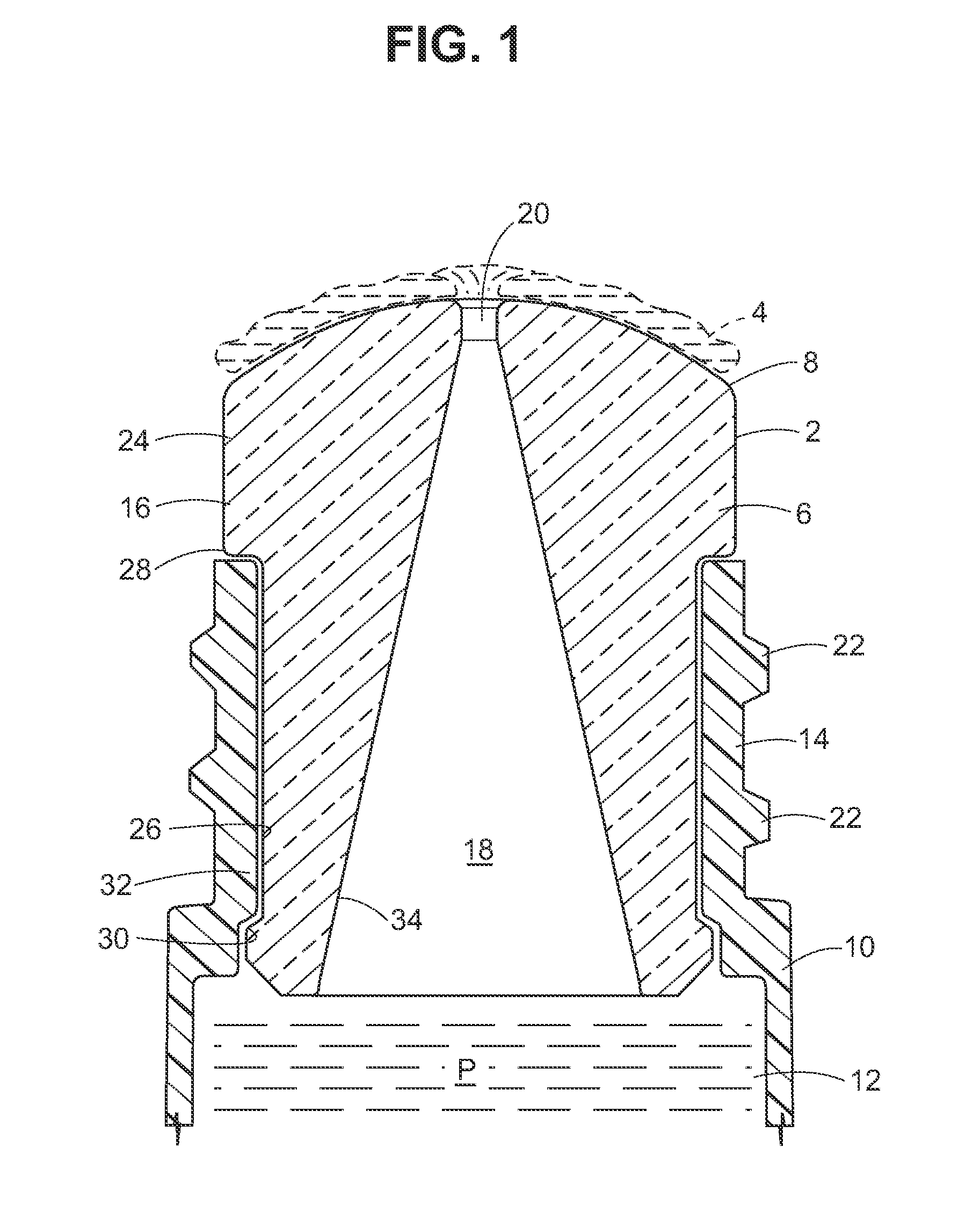

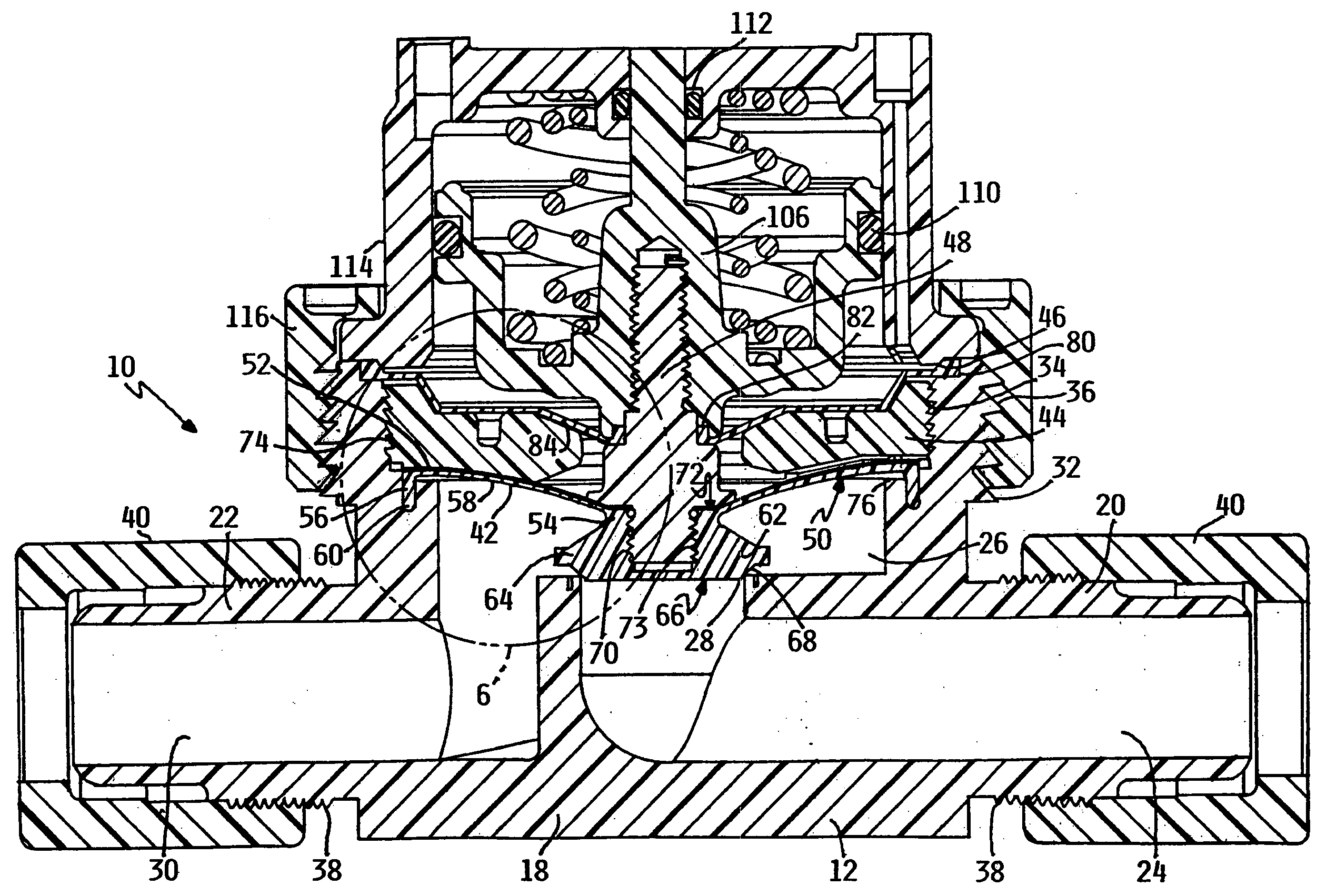

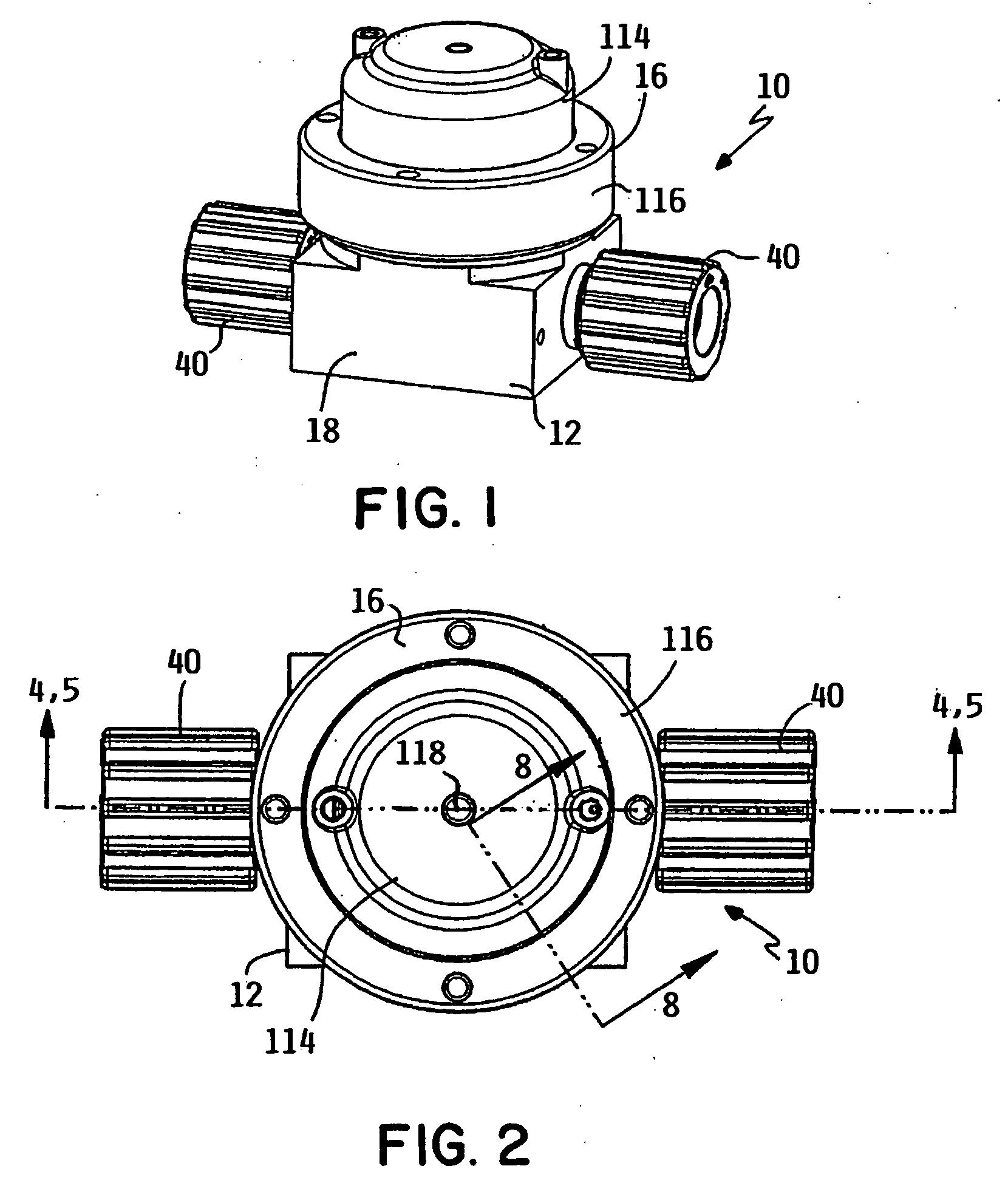

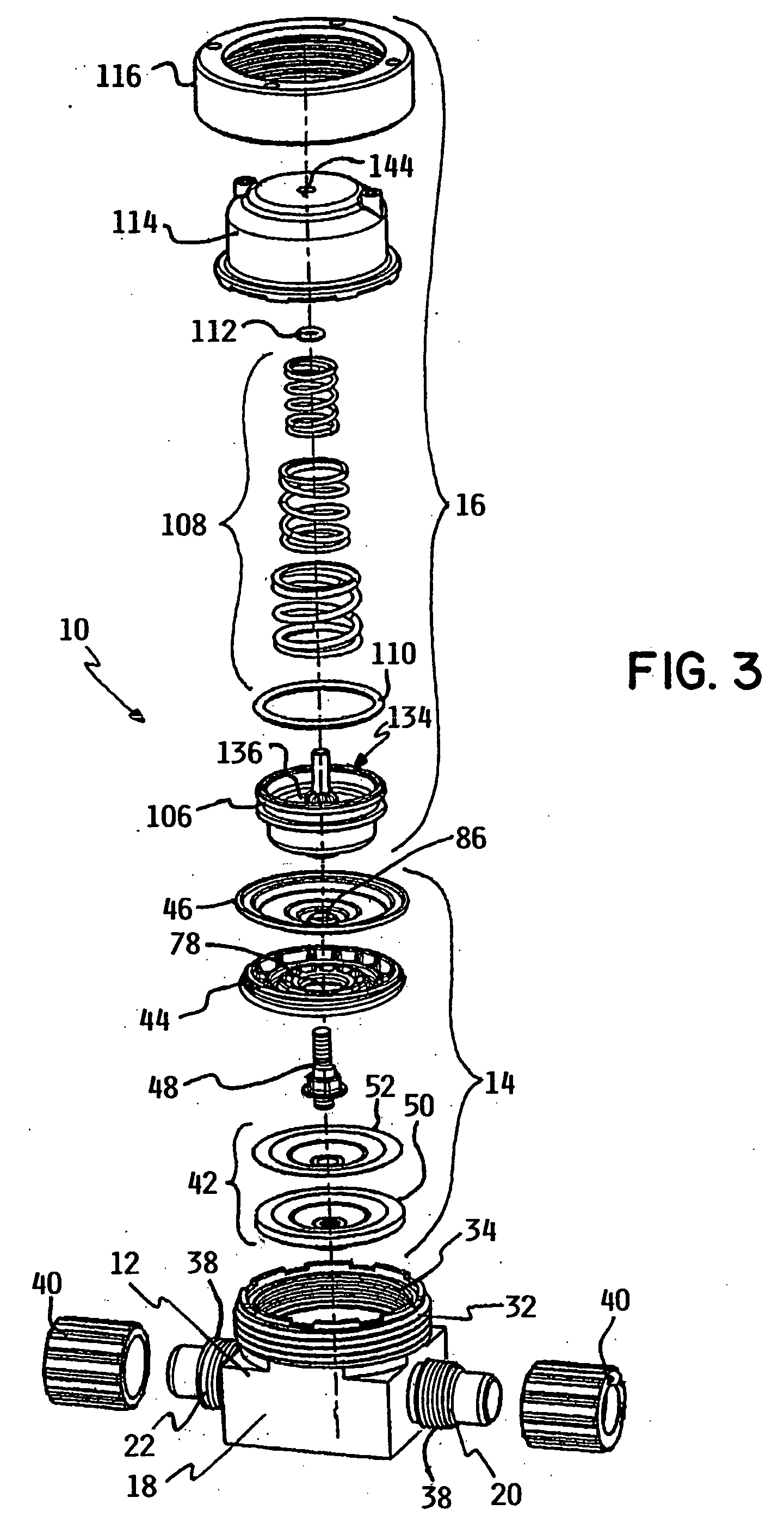

Extended stroke valve and diaphragm

ActiveUS7063304B2Extended service lifeHigh strengthDiaphragm valvesOperating means/releasing devices for valvesMaterial DesignEngineering

An extended stroke poppet valve particularly suited for handling caustic fluids and having features enabling an extended service life for the valve. The valve includes a two part primary diaphragm assembly with a wetted diaphragm made from highly fatigue resistant fluoropolymer material, and a diaphragm backer made from high strength fluoropolymer material designed to withstand the high stress loads imposed by an extended valve stroke. The combination of these two layers in a single primary diaphragm assembly yields a highly durable, caustic chemical resistant, diaphragm capable of use in a long stroke poppet valve and having a relatively long service life.

Owner:ENTEGRIS INC

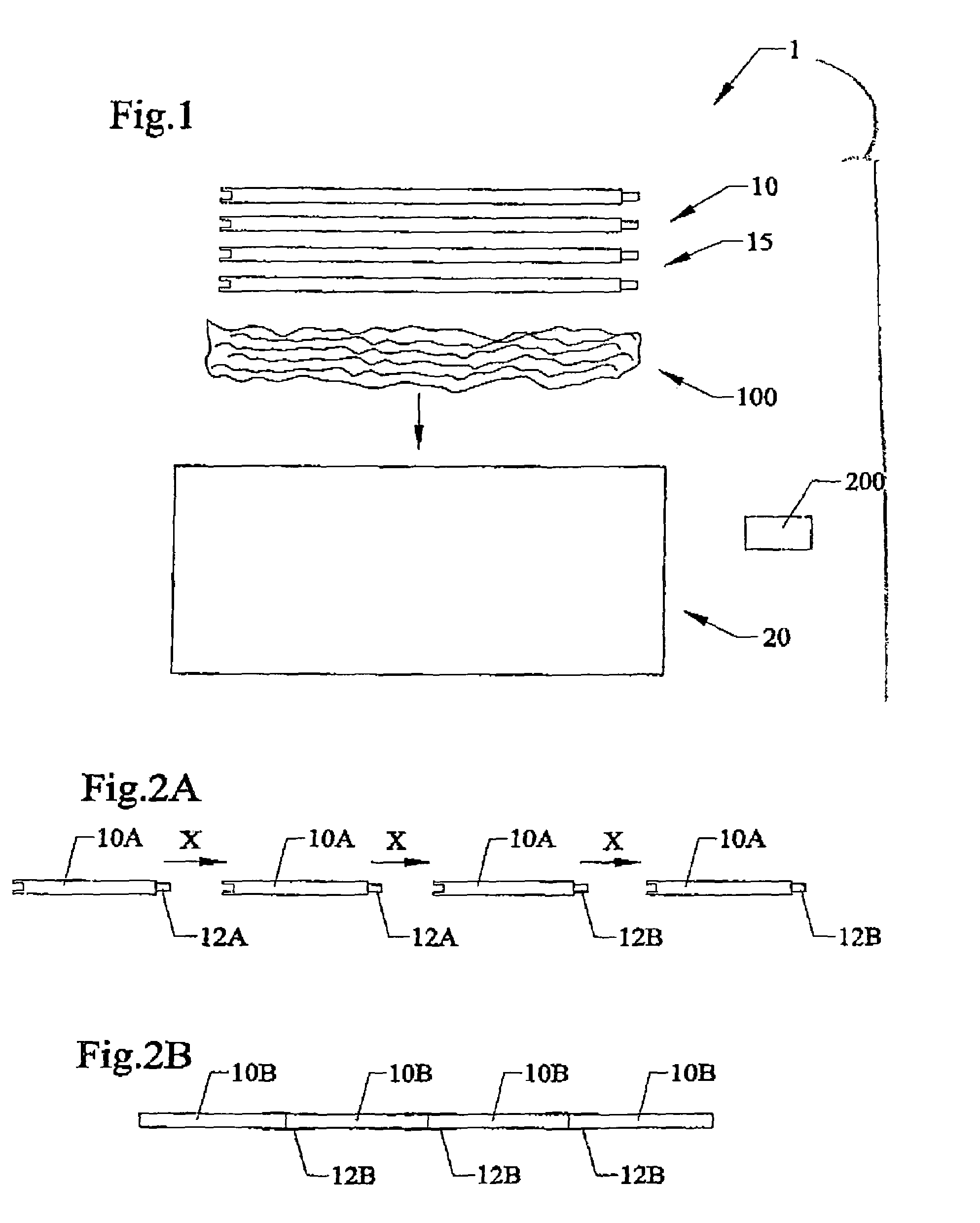

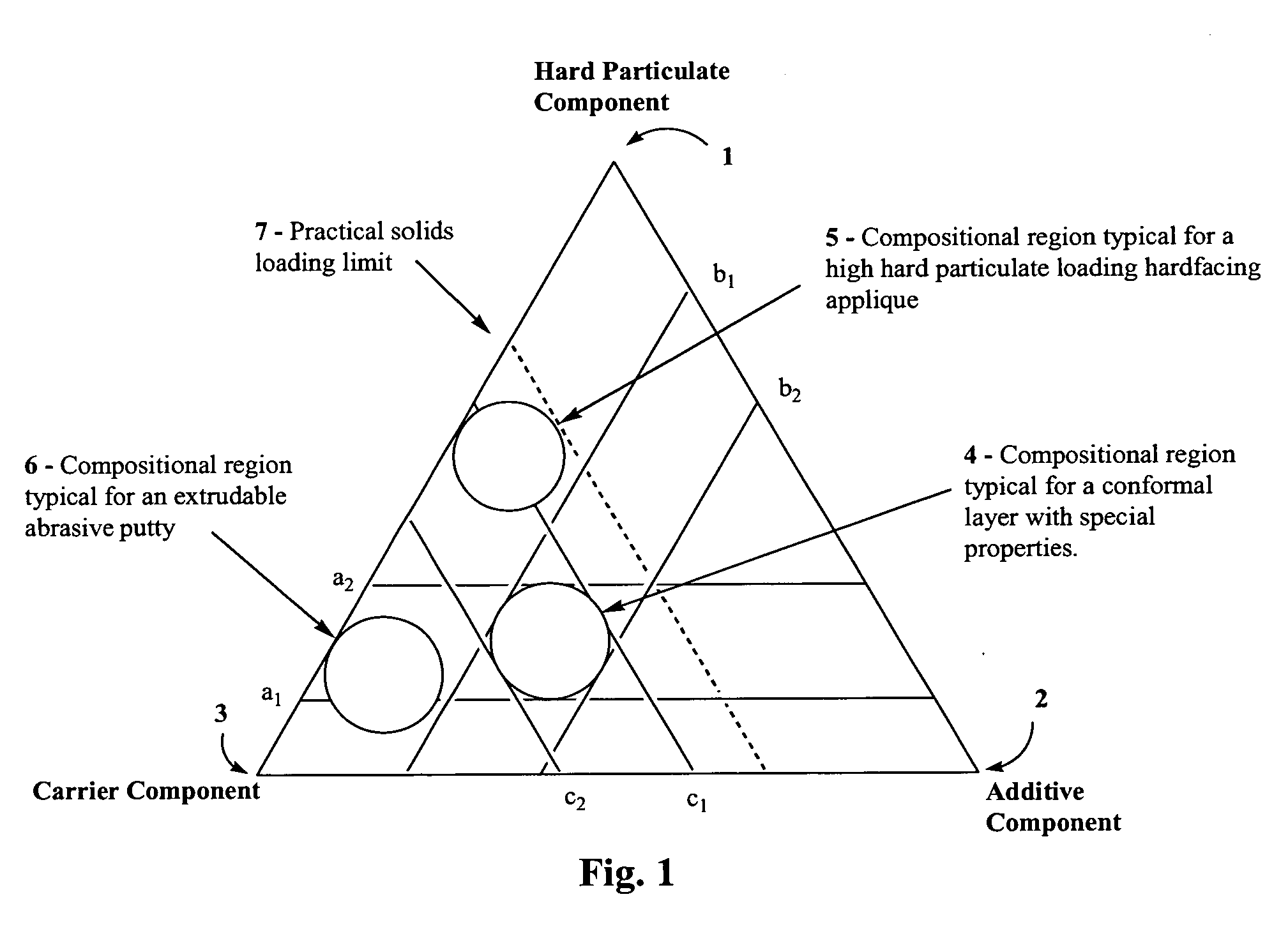

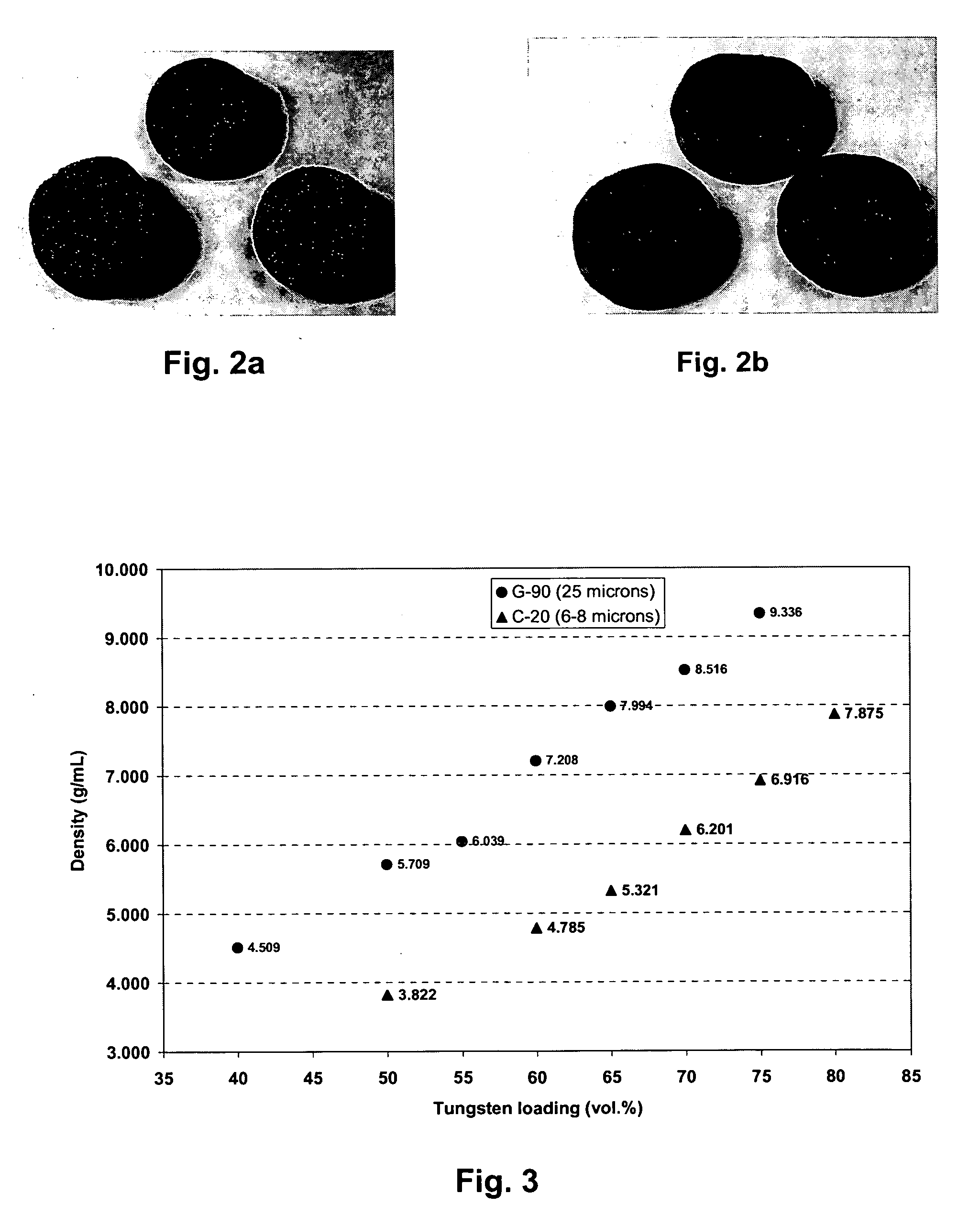

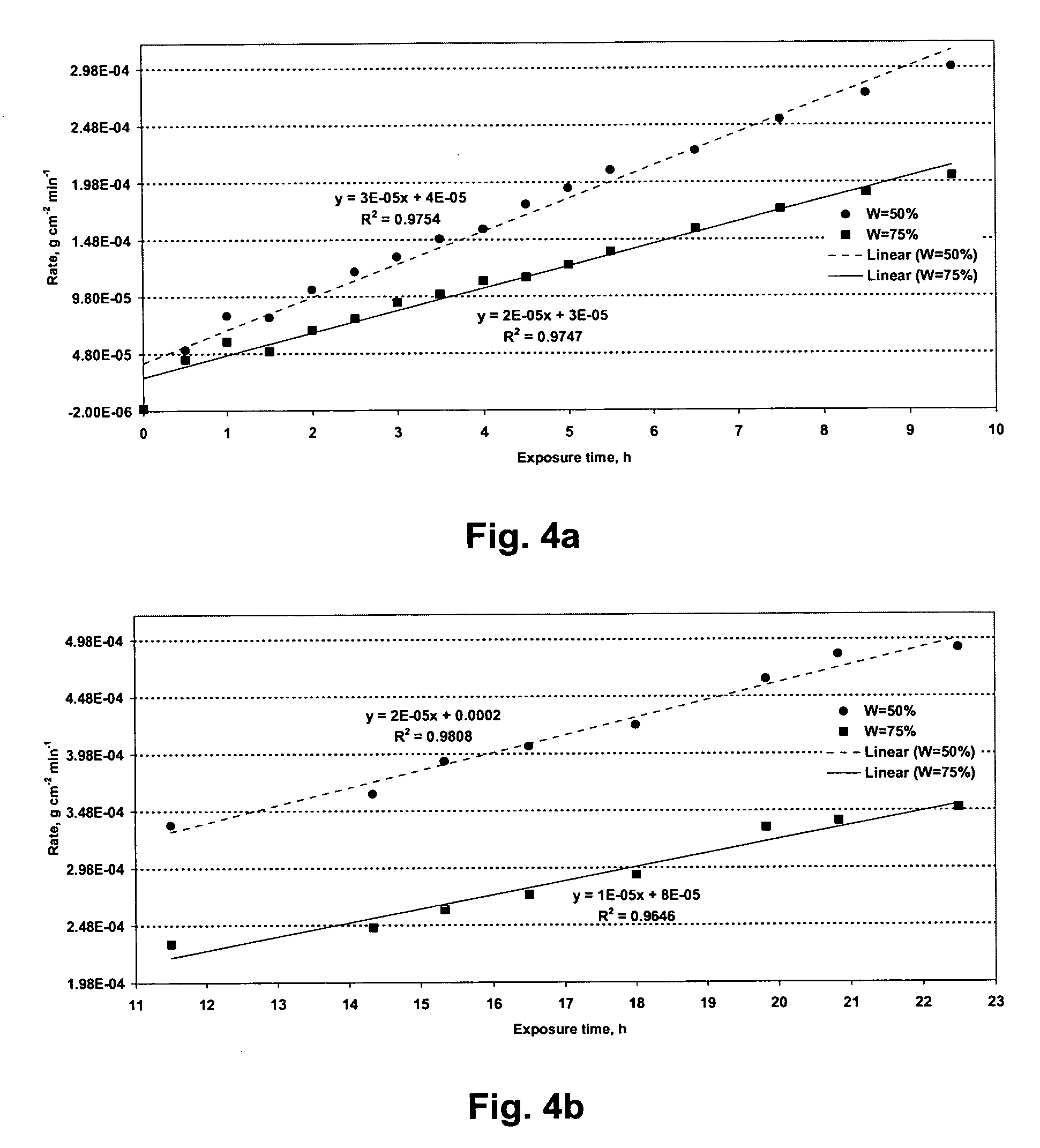

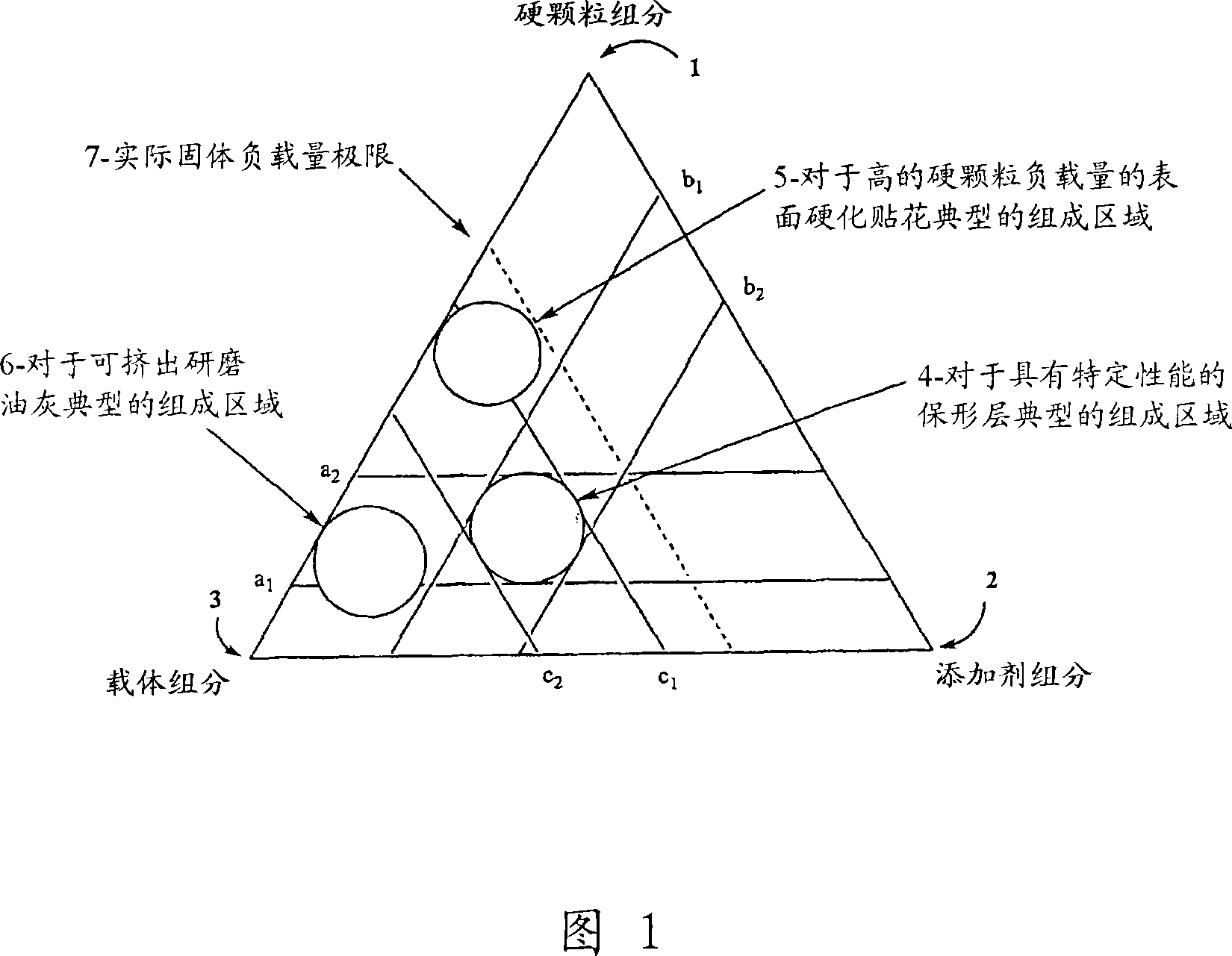

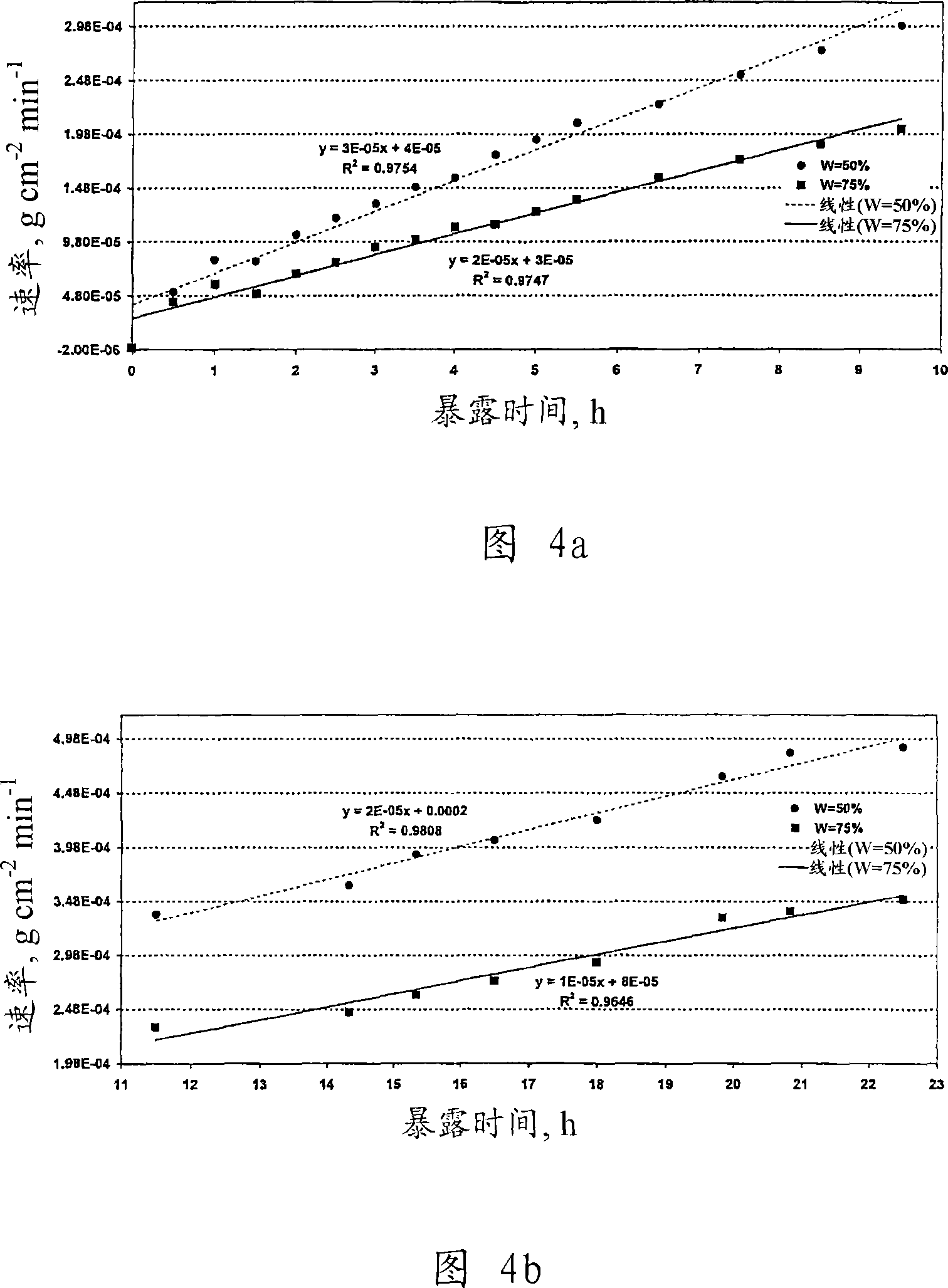

Composite materials and method for making same

Certain non-limiting embodiments of the present disclosure comprise a family of composite materials targeting specific applications through a materials design approach involving; 1) a hard particulate; 2) a carrier or binder phase; and 3) one or more additives for property enhancement and / or hardness adjustment. According to certain embodiments, the composite material may be one of flexible conformal sheet; a rigid machinable molded preform; and an extrudable putty. Methods of manufacture of the composite materials are also disclosed.

Owner:ATI PROPERTIES

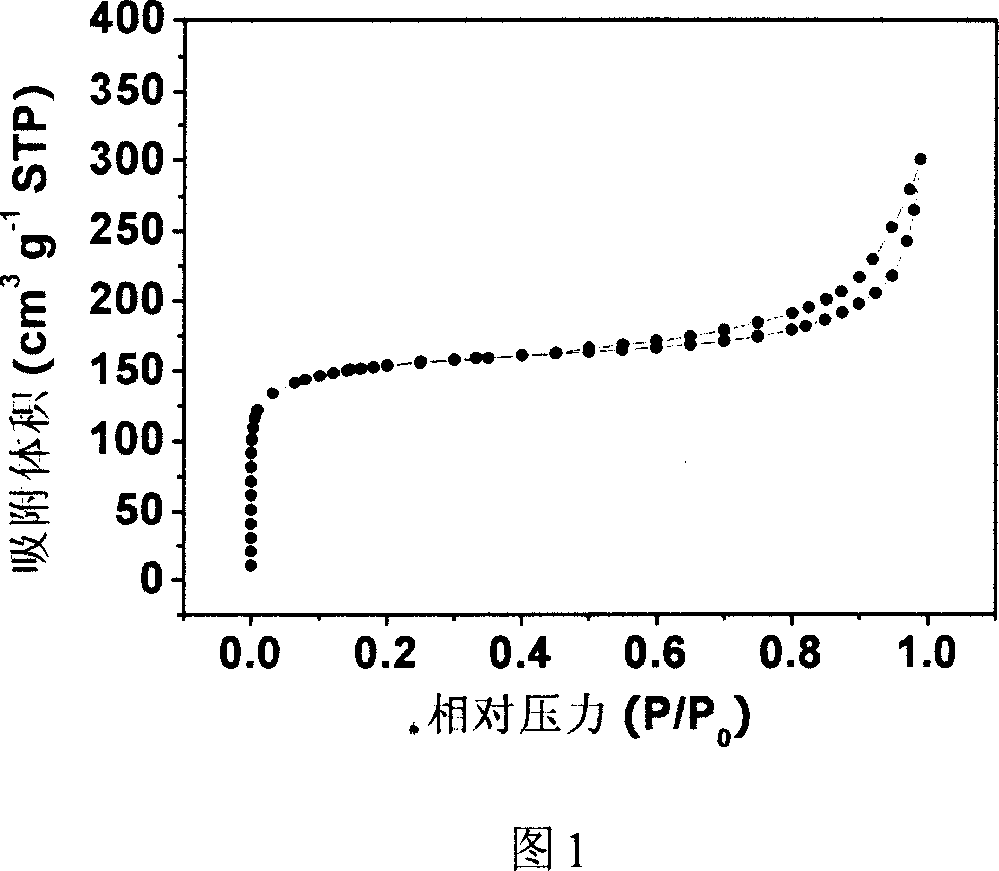

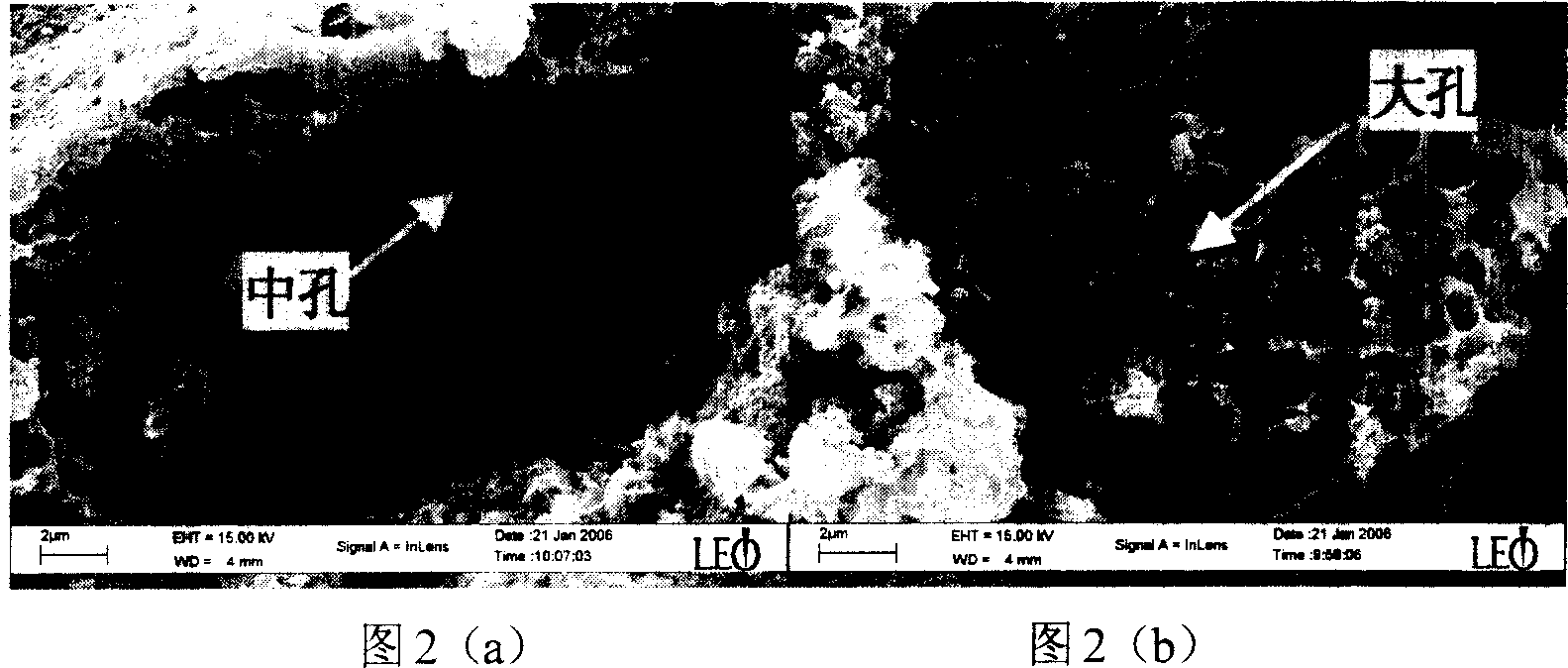

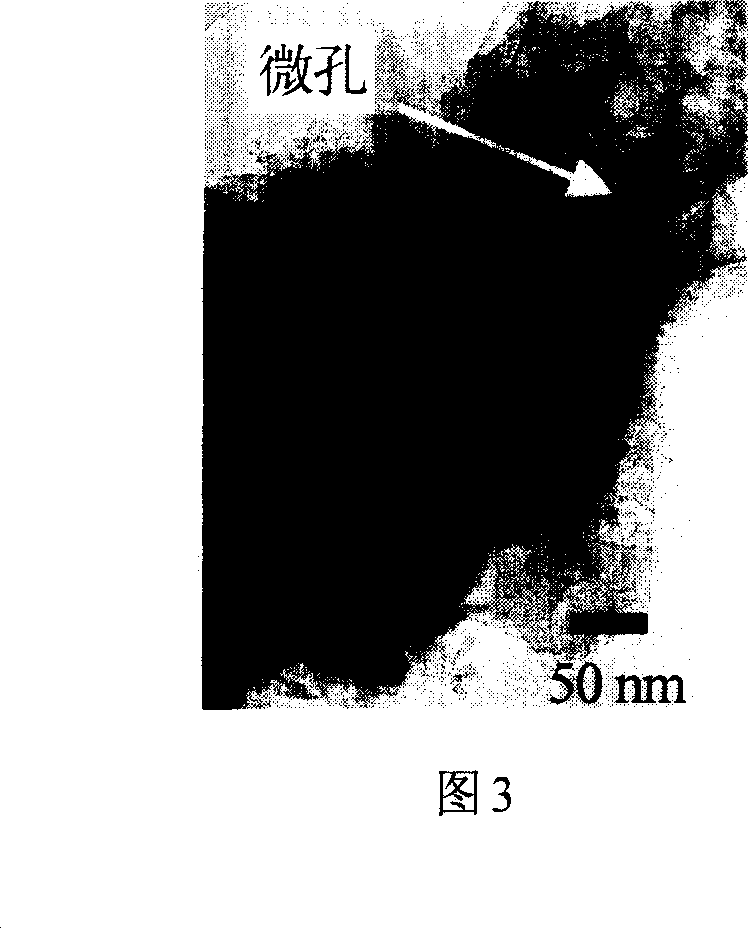

Layer combination controllable carbon material with nano pole of different scale, preparation method and application

The invention relates to a method for design advanced materials with nano-scaled structure and techniques for preparing same. In particular, the invention relates to a carbon material capable of controllable laminated combination with the nano-holes of variable sizes and preparation and application thereof. The method comprises the steps of: preparing metal oxide sol in the alkali solution system, which is then mixed with an alcohol solution of an alcohol-soluble resin; the oxide sol being used as the template and water being the resin precipitation agent during the process to directly prepare resin / oxide sol composite system. After solvent removal, carbonization, activation and template removal processes, the carbon material with laminated nano-holes combination is prepared which is of controllable micro-holes proportion, controllable medium-holes aperture and proportion, controllable big-holes aperture and propotion and concentrated distribution of medium-holes and big-holes apertures. The carbon material capable of controllable laminated combination with the nano-holes of variable sizes prepared in the invention is characterized in laminated holes structure, excellent ion transfer performances and high electrochemical active specific surface area and the material is expected to be used as high energy density high power density electrochemical capacitor used electrode material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

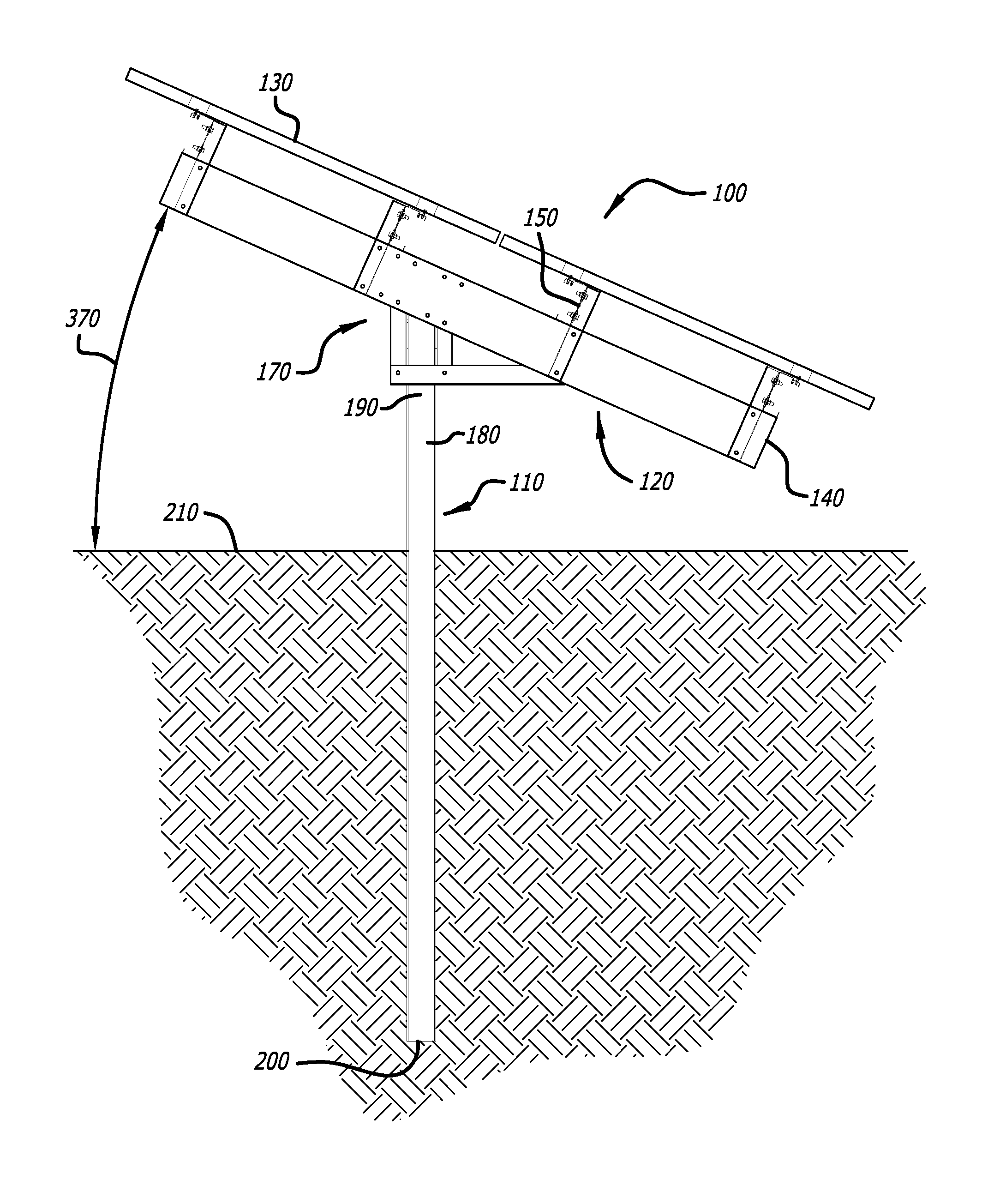

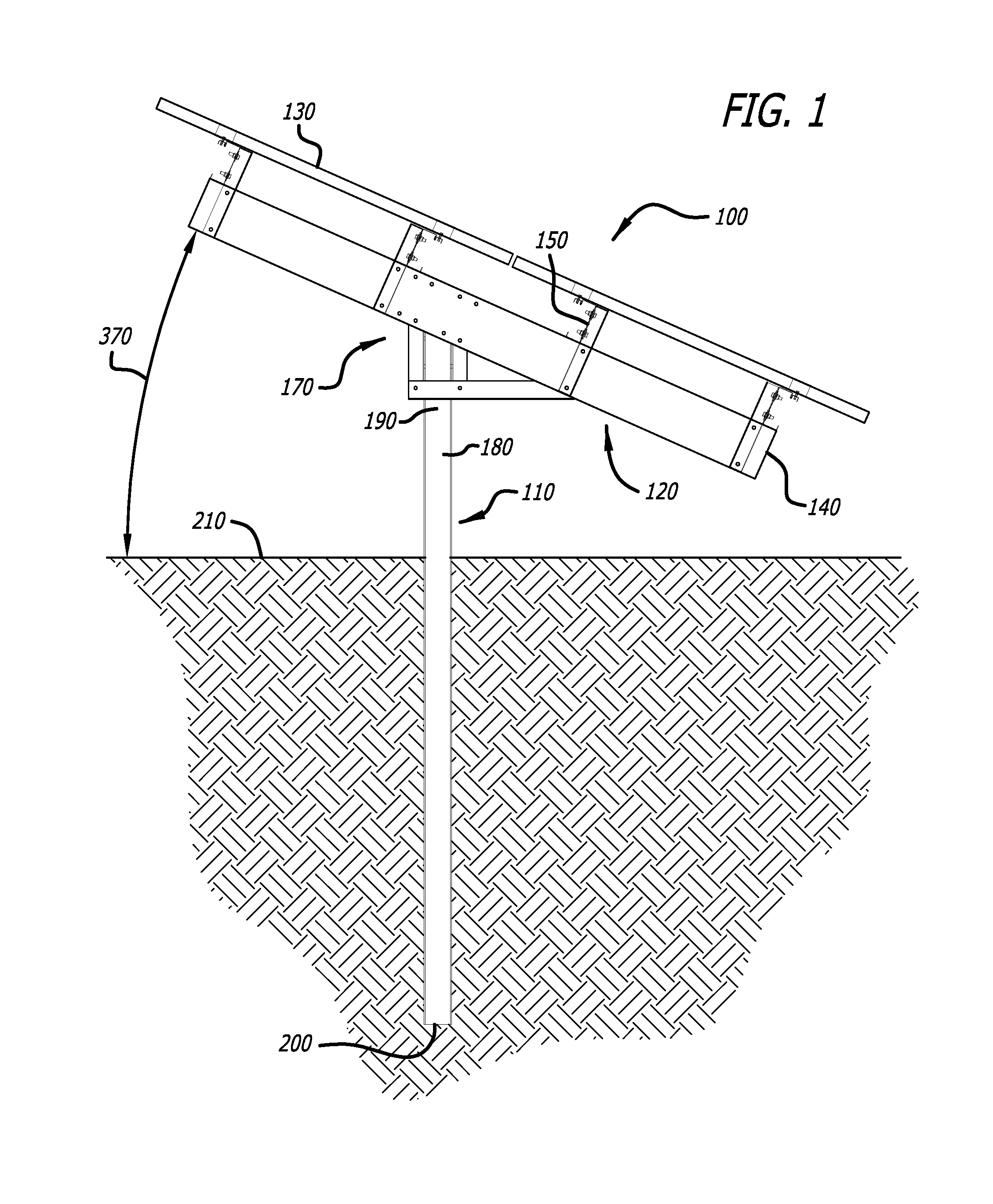

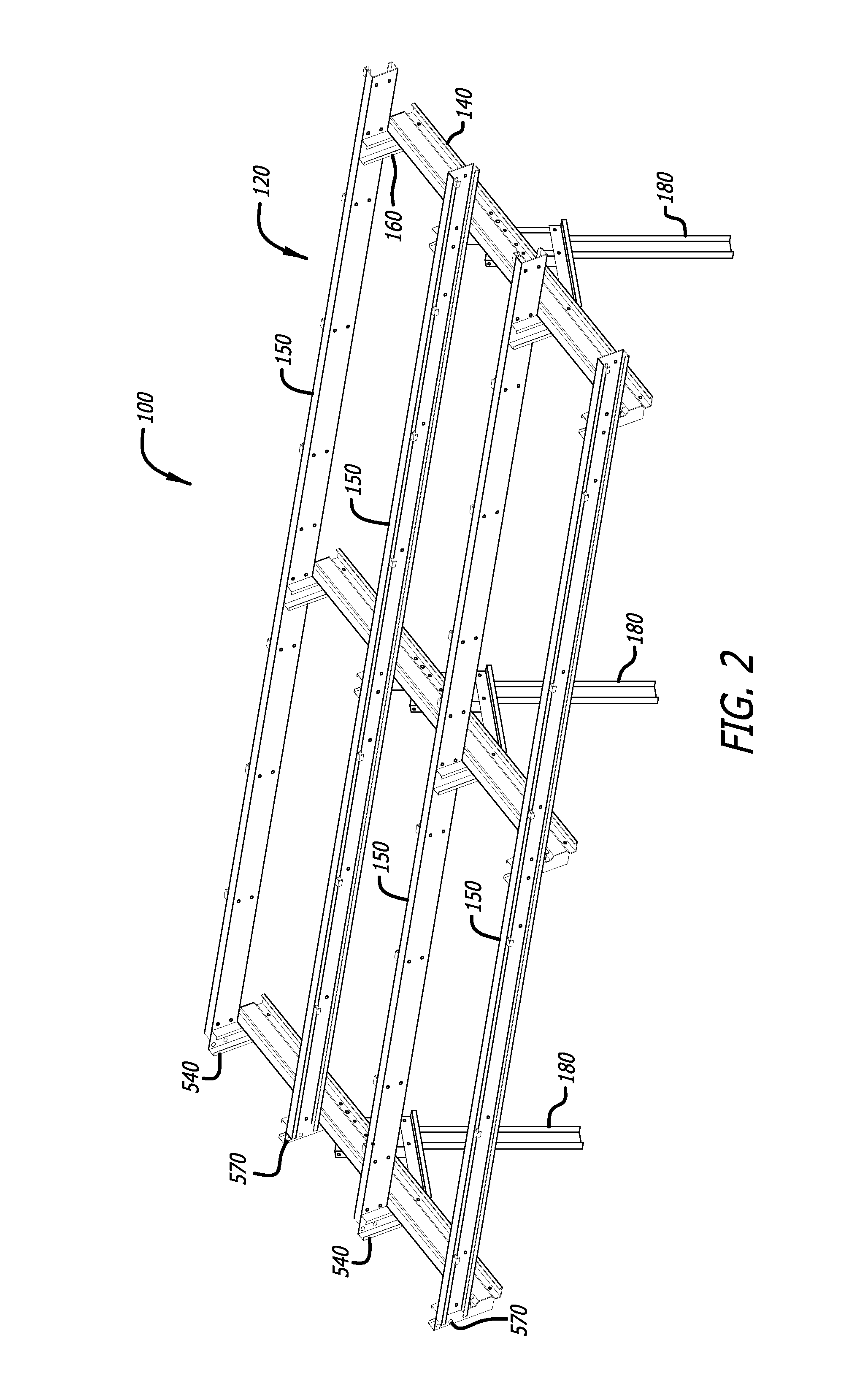

Photovoltaic Mounting Apparatus and Method of Installation

InactiveUS20130167907A1Reduce weightQuick and easy deploymentPhotovoltaic supportsSolar heating energyTerrainComputer module

A photovoltaic mounting apparatus includes a mounting frame coupled to a pile capable of being anchored in numerous terrain and slope conditions, universal clamping for mounting any type of solar panel thereto, and components enabling customized angles of inclination of photovoltaic modules mounted onto the frame. Optimized testing and preparation for installation are part of a process ensuring that design of materials and installation of a photovoltaic mounting apparatus is customizable to reduce time and expense in a method of installation.

Owner:SOLAR CUBE

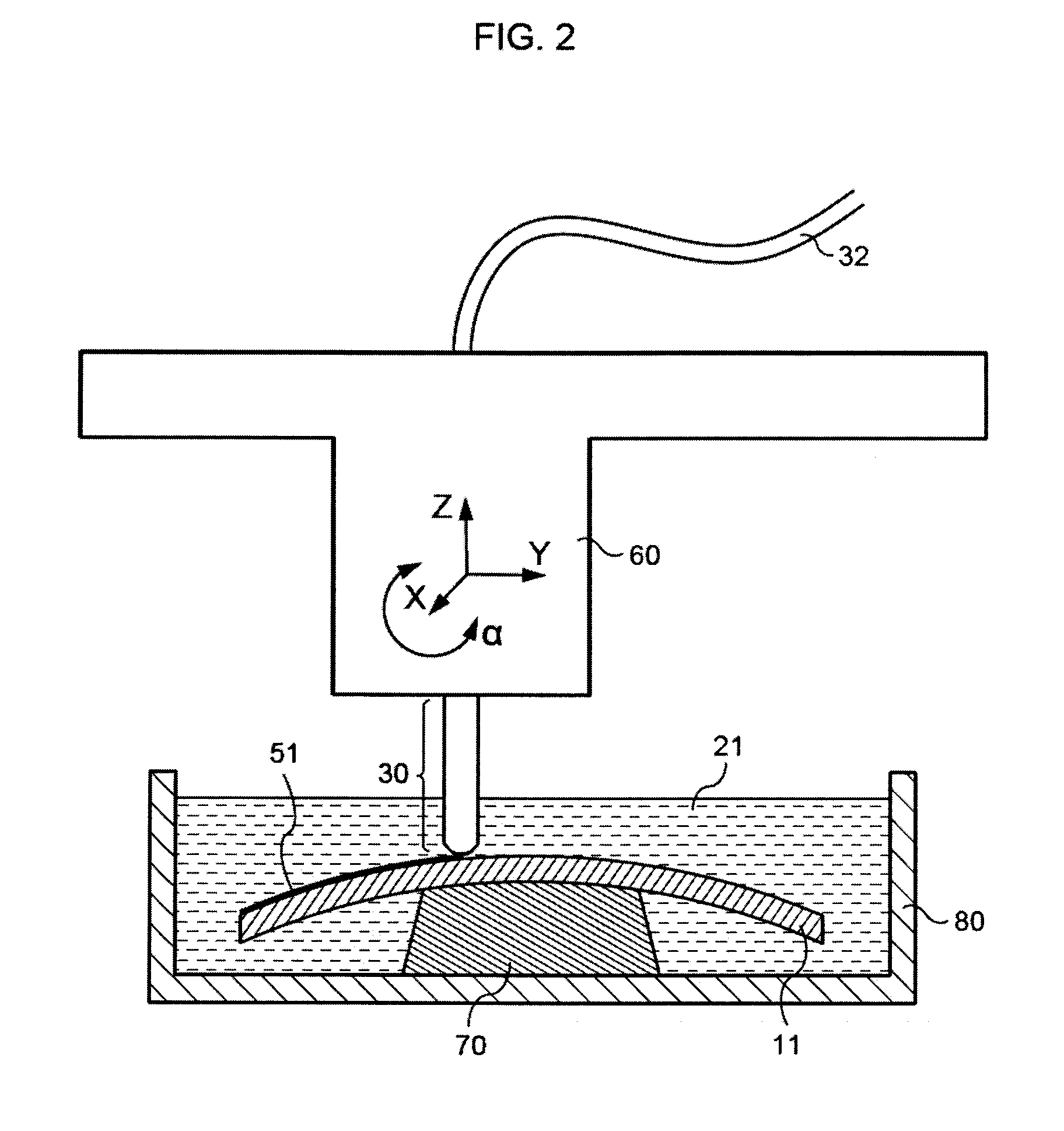

Eyewear lens production by additive techniques

ActiveUS20150277146A1Different optical propertyDifferent physical propertyAdditive manufacturing apparatusOptical articlesMaterial DesignEyewear

A method that adds material selectively to a lens substrate and is used to produce a customized eyewear lens with optical power that is discernibly different from the optical power of the lens substrate. The method involves obtaining the lens substrate, calculating and generating an added material design to convert the lens substrate's optical power to a desired optical power for the customized eyewear lens, contacting the lens substrate with a bulk source of flowable radiation-polymerizable material, and irradiating the material with radiation that is controlled for wavelength range, energy and spatial distribution to polymerize the radiation-polymerizable material only in a selected area according to the added material design. The method does not require the use of external shaping structures to form the customized lens on the lens substrate, and the added material is integrally bonded to the substrate.

Owner:INDIZEN OPTICAL TECH

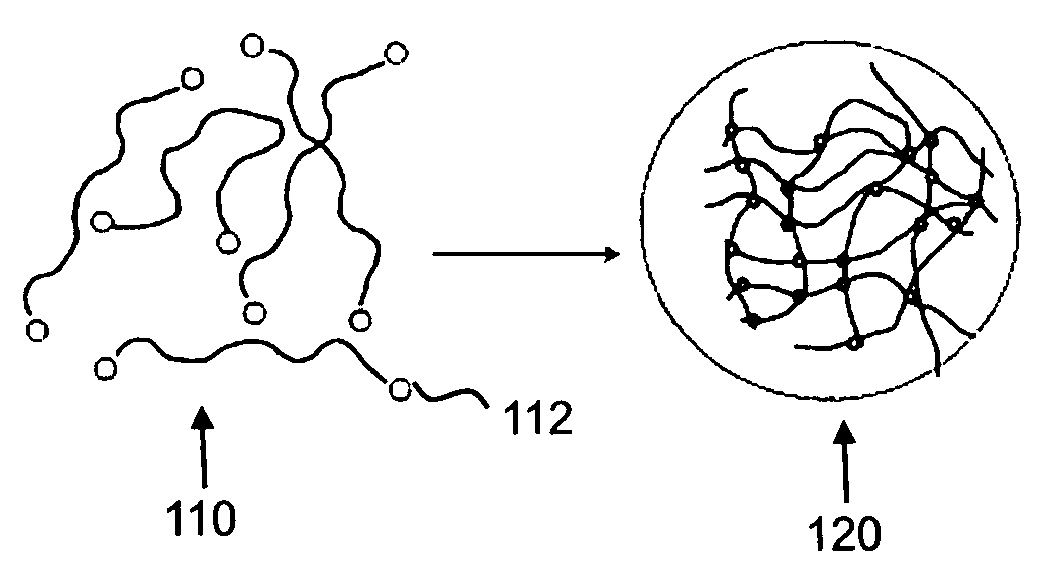

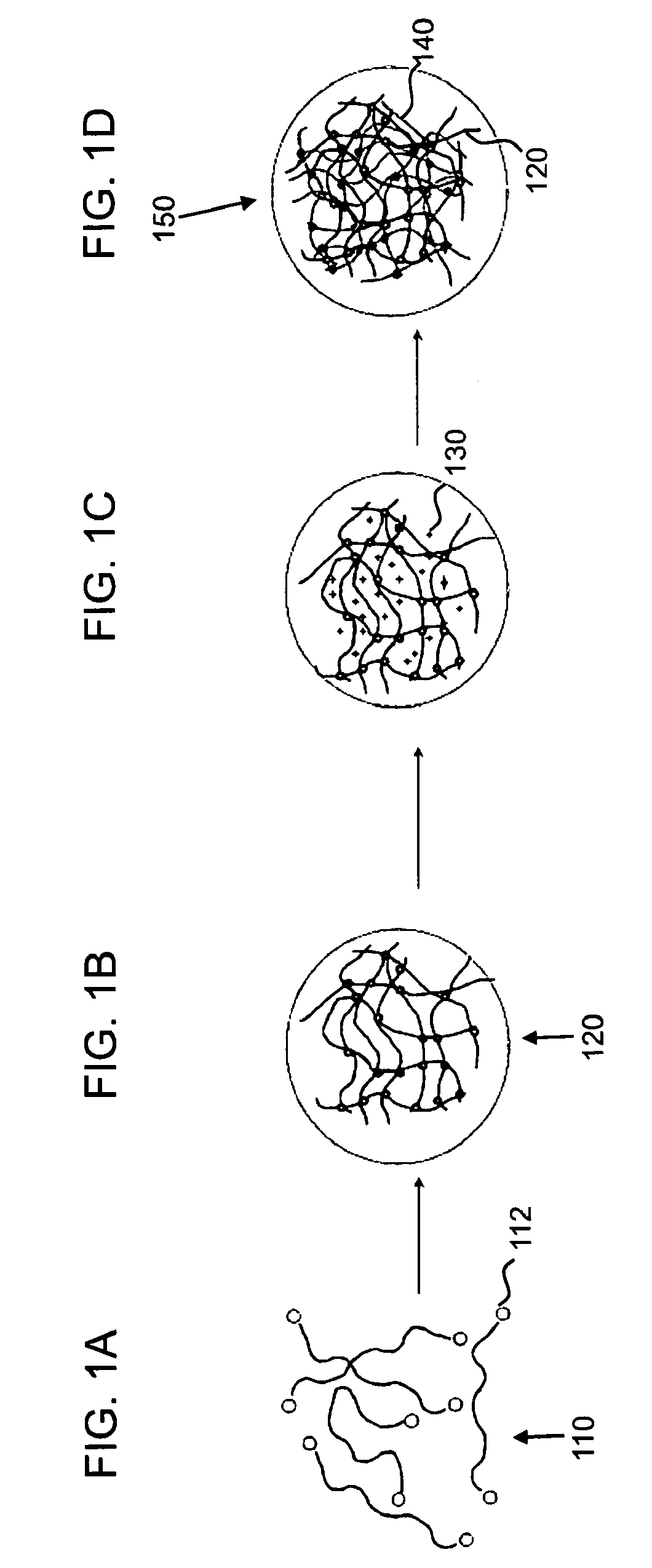

Interpenetrating polymer network hydrogel contact lenses

InactiveUS7857447B2High tensile strengthHigh oxygen permeabilityIntraocular lensOptical partsCross-linkHydrophilic monomer

The present invention provides interpenetrating polymer network hydrogels that have high oxygen permeability, strength, water content, and resistance to protein adsorption. The hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. The telechelic macromonomer preferably has a molecular weight of between about 575 Da and about 20,000 Da. Mixtures of molecular weights may also be used. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. The material is designed to serve as a contact lens.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

X-ray detector with impact absorbing cover

ActiveUS20060071172A1Material analysis by optical meansRadiation intensity measurementMaterial DesignPhysics

The present invention is a directed to a cover assembly for an x-ray detector that incorporates impact-absorbing material designed to absorb the shock, vibration, stress, and strain placed on the detector when dropped or subjected to a load. The cover assembly may include a layer or inserts of impact-absorbing material. Bumpers of impact-absorbing material may also be secured to the x-ray detector cover. Viscoelastic foam or other plastics may be used as the impact-absorbing material.

Owner:GENERAL ELECTRIC CO

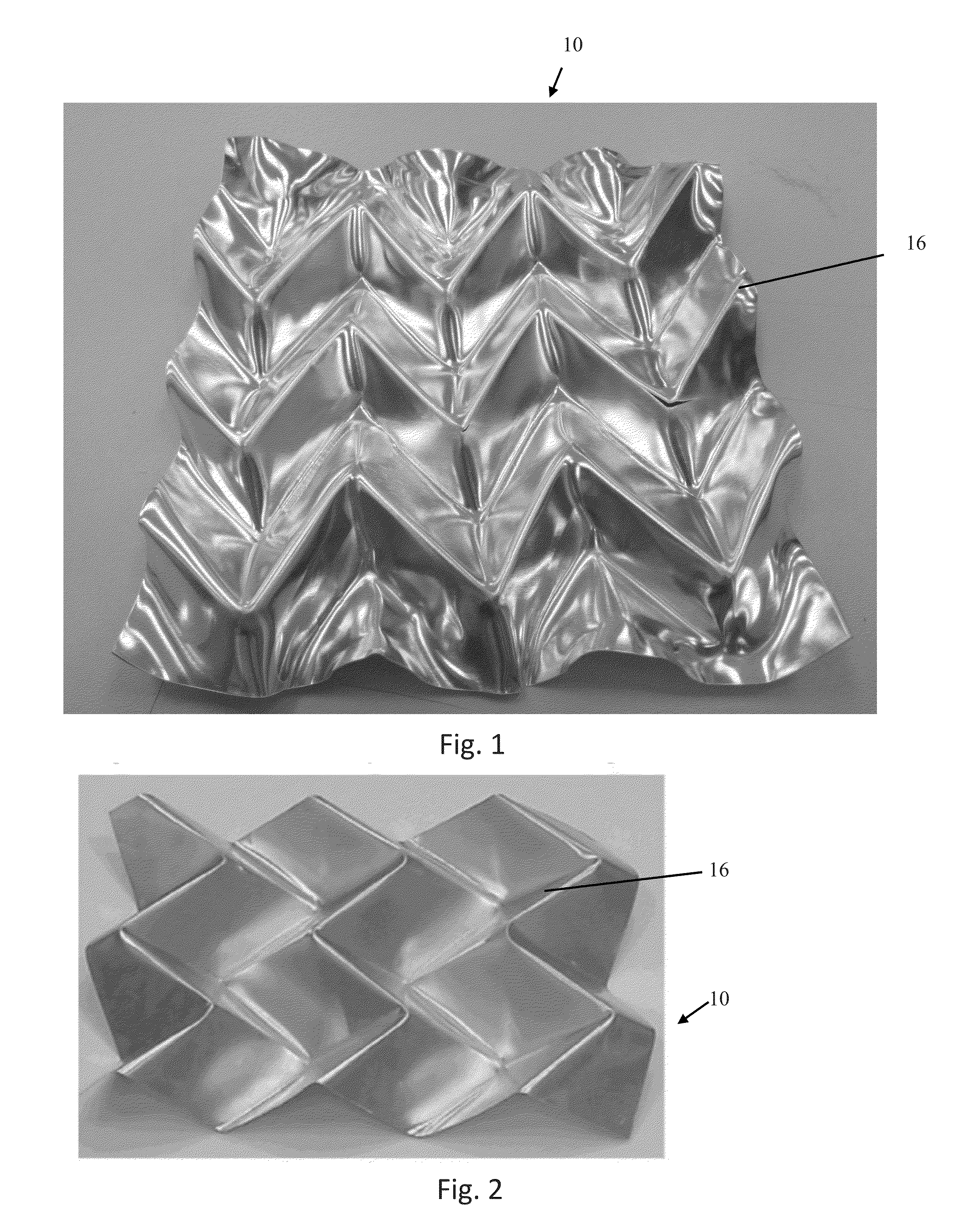

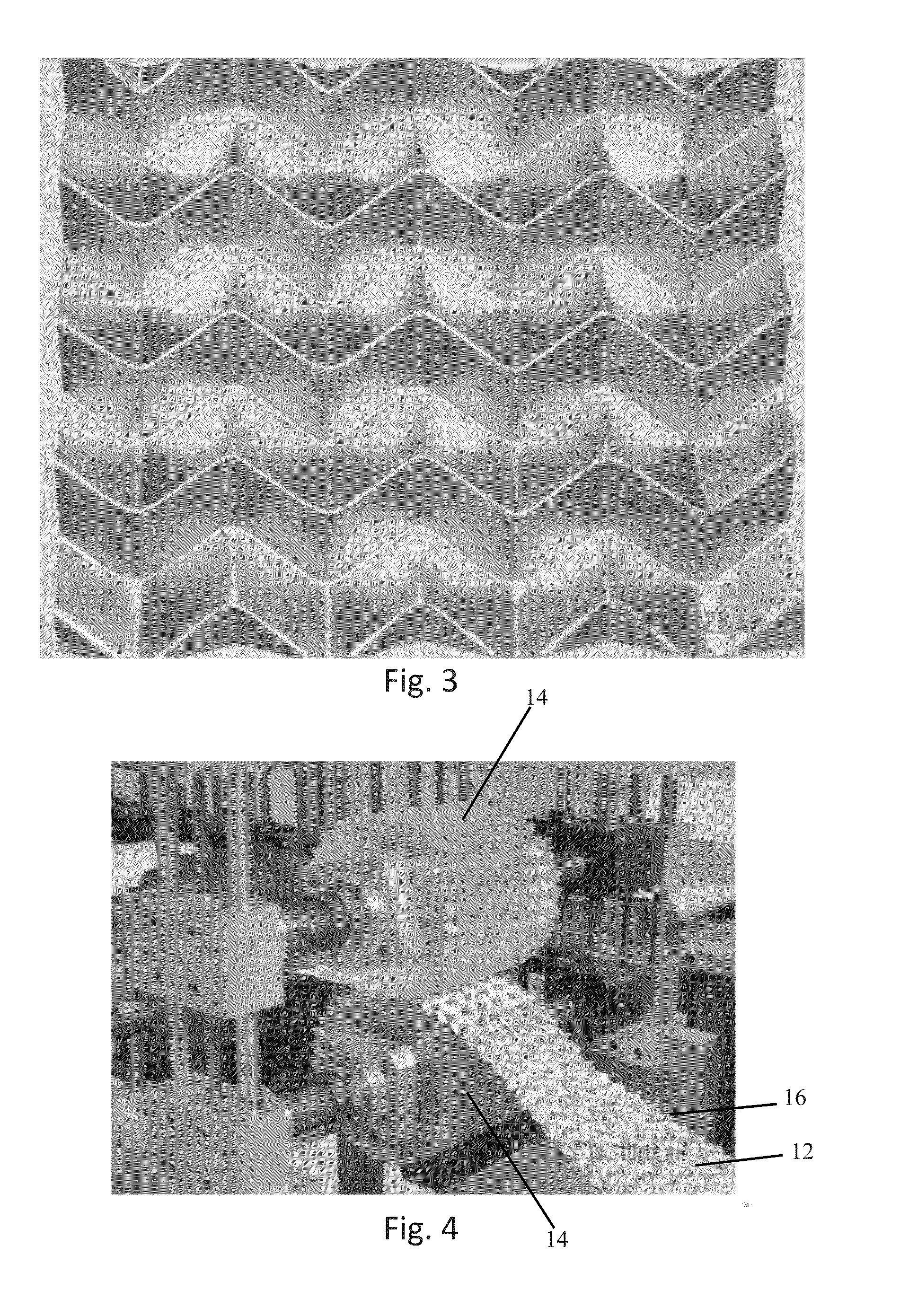

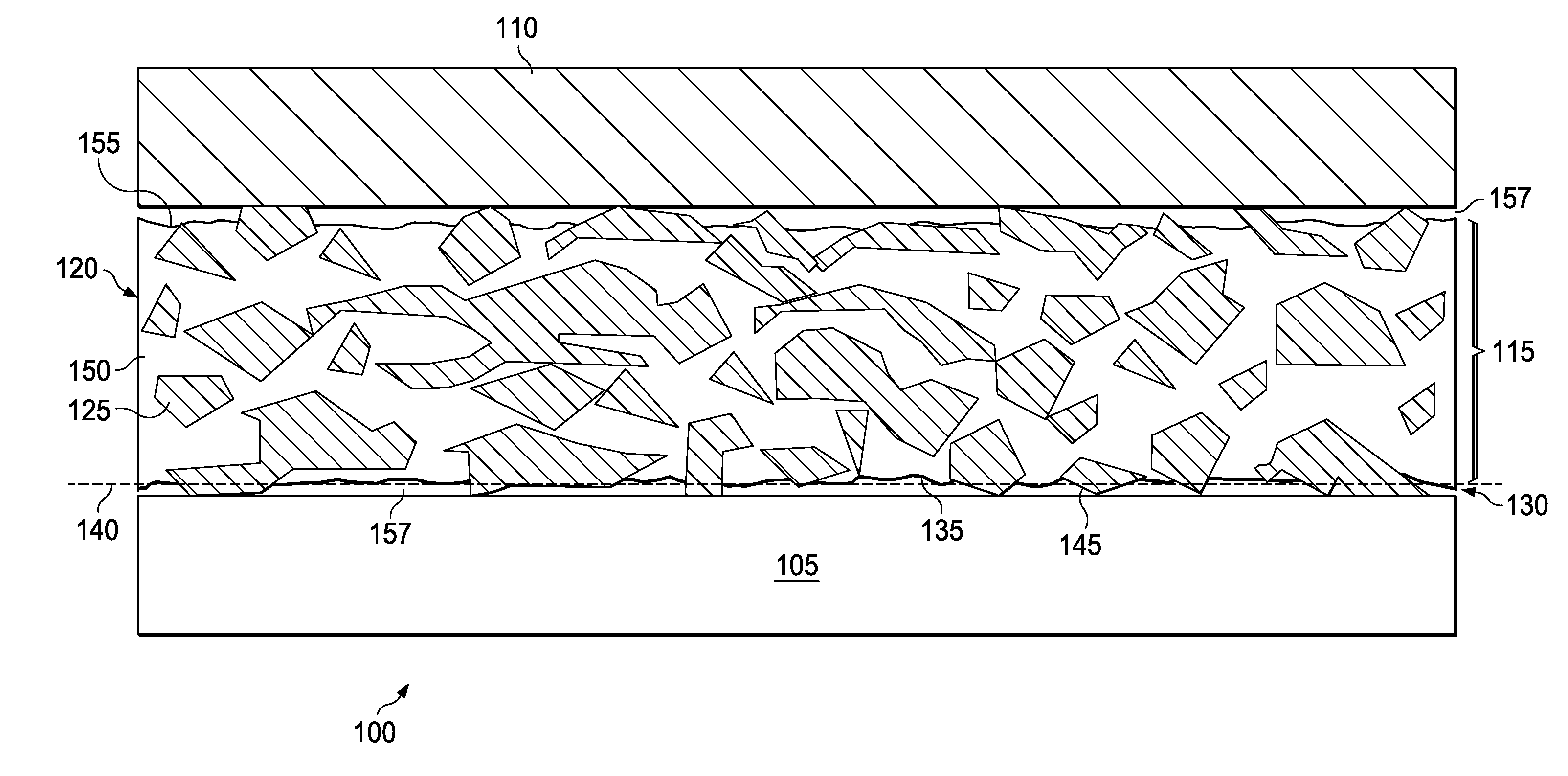

Macro-patterned materials and structures for vehicle arresting systems

Embodiments of the present disclosure relate generally to macro-patterned materials and methods of their use in connection with vehicle arresting systems. Certain embodiments provide 3-D folded materials, honeycombs, lattice structures, and other periodic cellular material structures, that can be used for arresting vehicles. The materials can be engineered to have properties that allow them to reliably crush in a predictable manner under pressure from a vehicle. The materials can be formed into various shapes and combined in various ways in order to provide the desired properties.

Owner:ENGINEERED ARRESTING SYST CORP

Thermal interface material design for enhanced thermal performance and improved package structural integrity

An electronic package comprising a semiconductor device, a heat spreader layer, and a thermal interface material layer located between the semiconductor device and the heat spreader layer. The thermal interface material layer includes a resin layer having heat conductive particles suspended therein. A portion of the particles are exposed on at least one non-planar surface of the resin layer such that the portion of exposed particles occupies a majority of a total area of a horizontal plane of the non-planar surface.

Owner:TEXAS INSTR INC

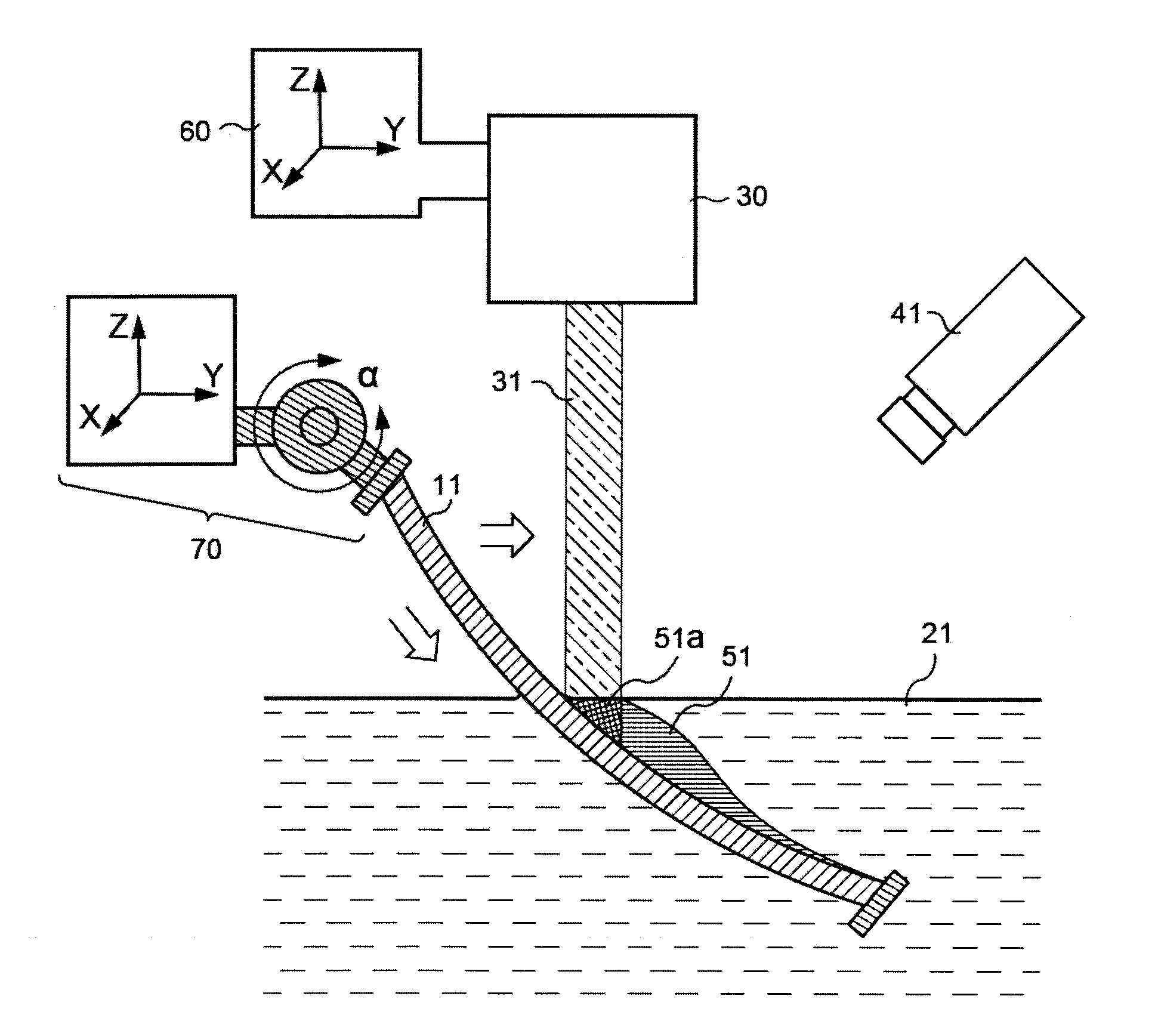

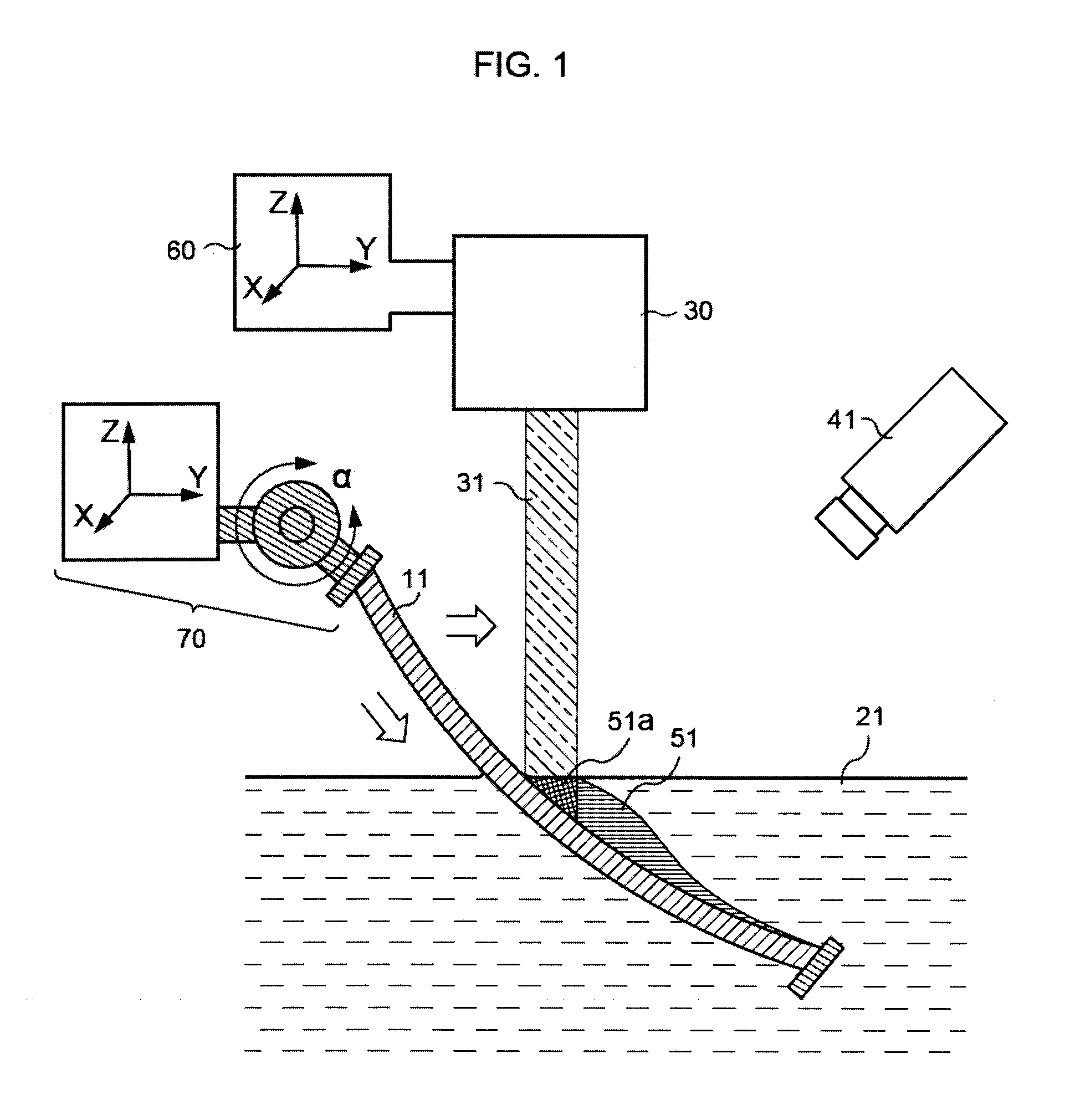

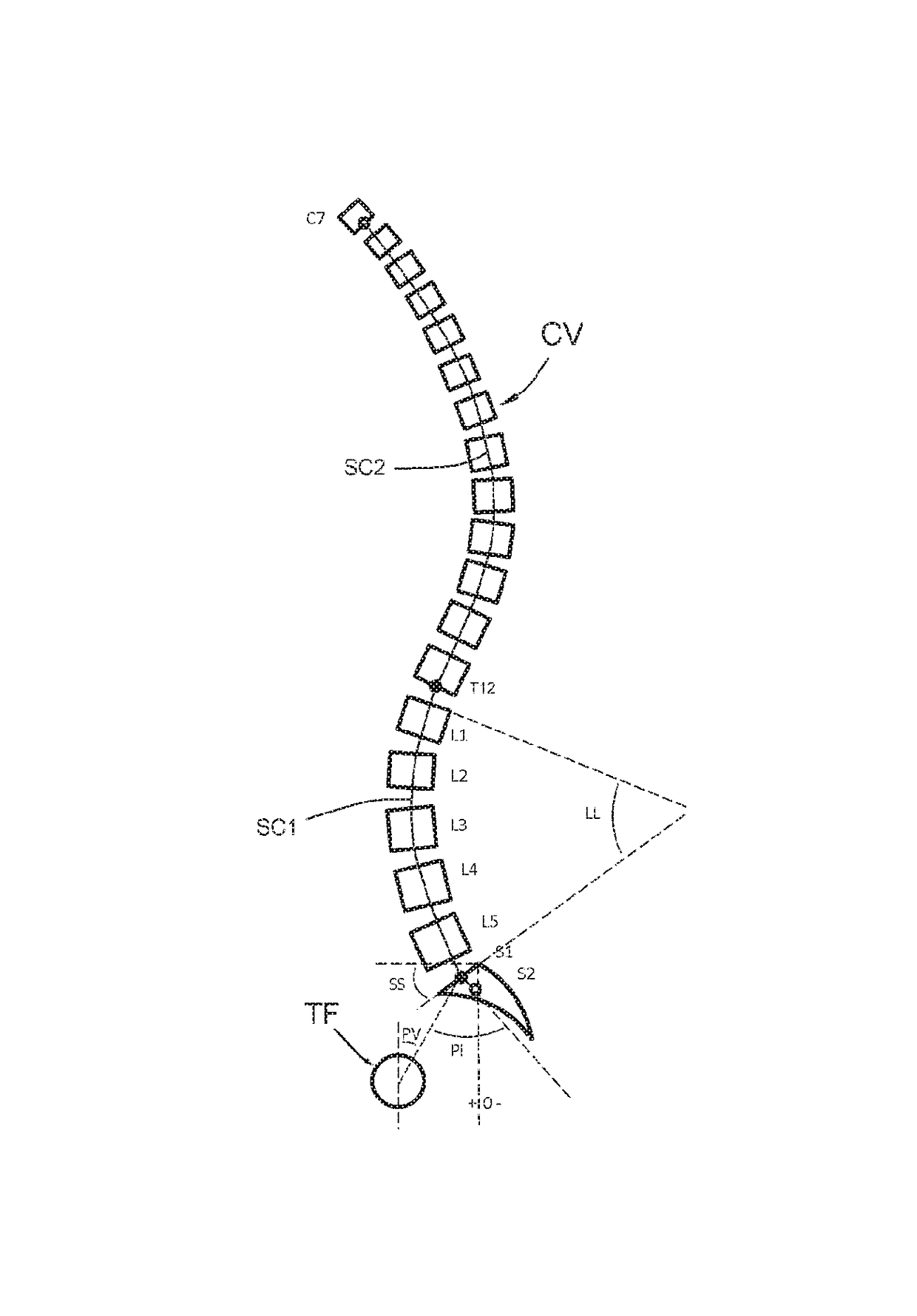

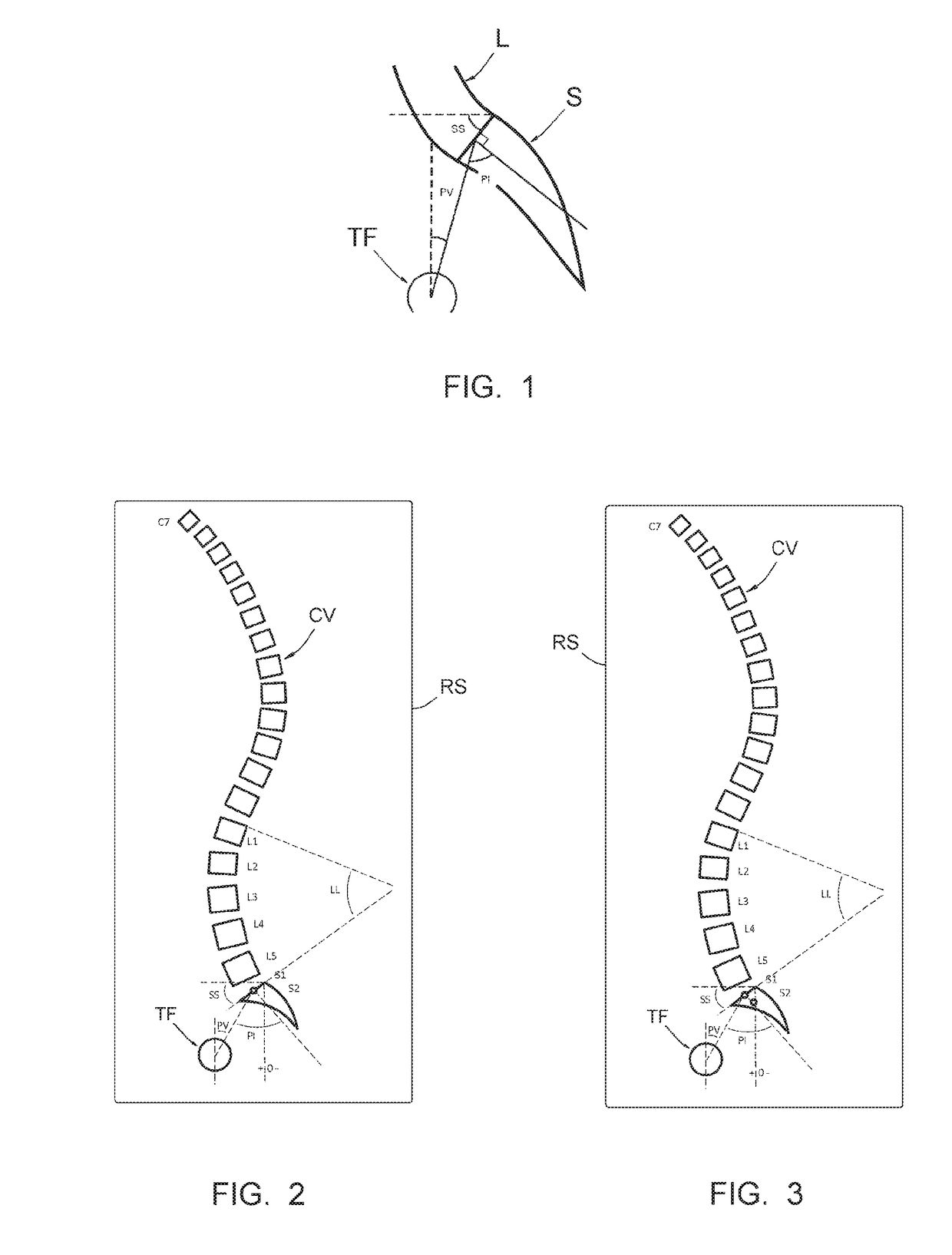

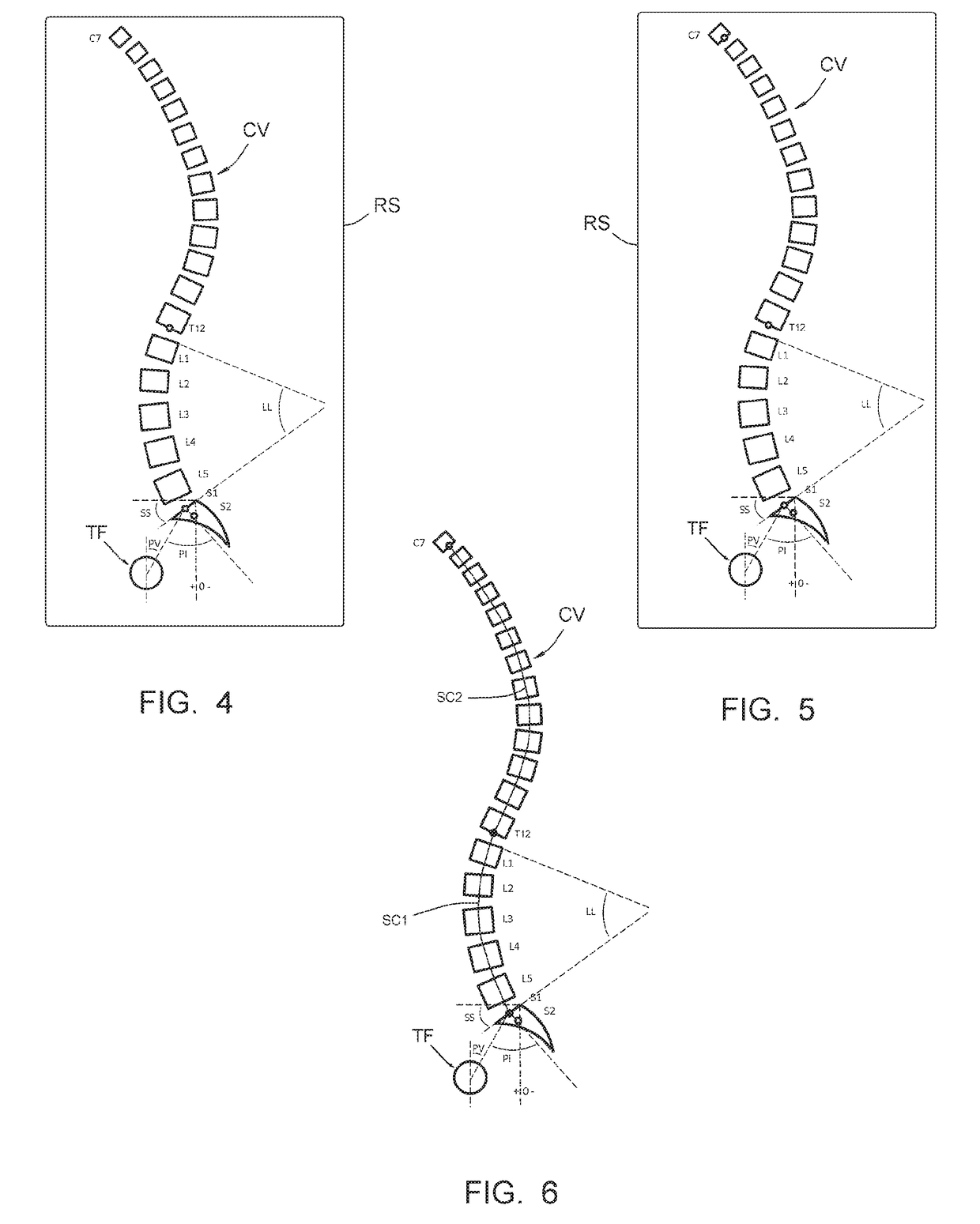

Method making it possible to produce the ideal curvature of a rod of vertebral osteosynthesis material designed to support a patient vertebral column

ActiveUS9693831B2Impart the appropriate curvature to a straight rod easilyEasily impartedImage enhancementImage analysisSpinal columnMedicine

According to the invention, the process includes the steps of: a) taking a sagittal preoperative x-ray of the vertebral column of the patient to be treated, extending from the cervical vertebrae to the femoral heads; b) on that x-ray, identifying points on S1, S2, T12 et C7; c) depicting, on the said x-ray, curved segments beginning at the center of the plate of S1 et going to the center of the plate of C7; e) identifying, on that x-ray, the correction(s) to be made to the vertebral column, including the identification of posterior osteotomies to make; f) pivoting portions of said x-ray relative to other portions of that x-ray, according to osteotomies to be made; g) performing, on said x-ray, a displacement of the sagittal curvature segment extending over the vertebral segment to be corrected; h) from a straight vertebral rod (TV), producing the curvature of that rod according to the shape of said sagittal curvature segment in said displacement position.

Owner:MEDICREA INT SA

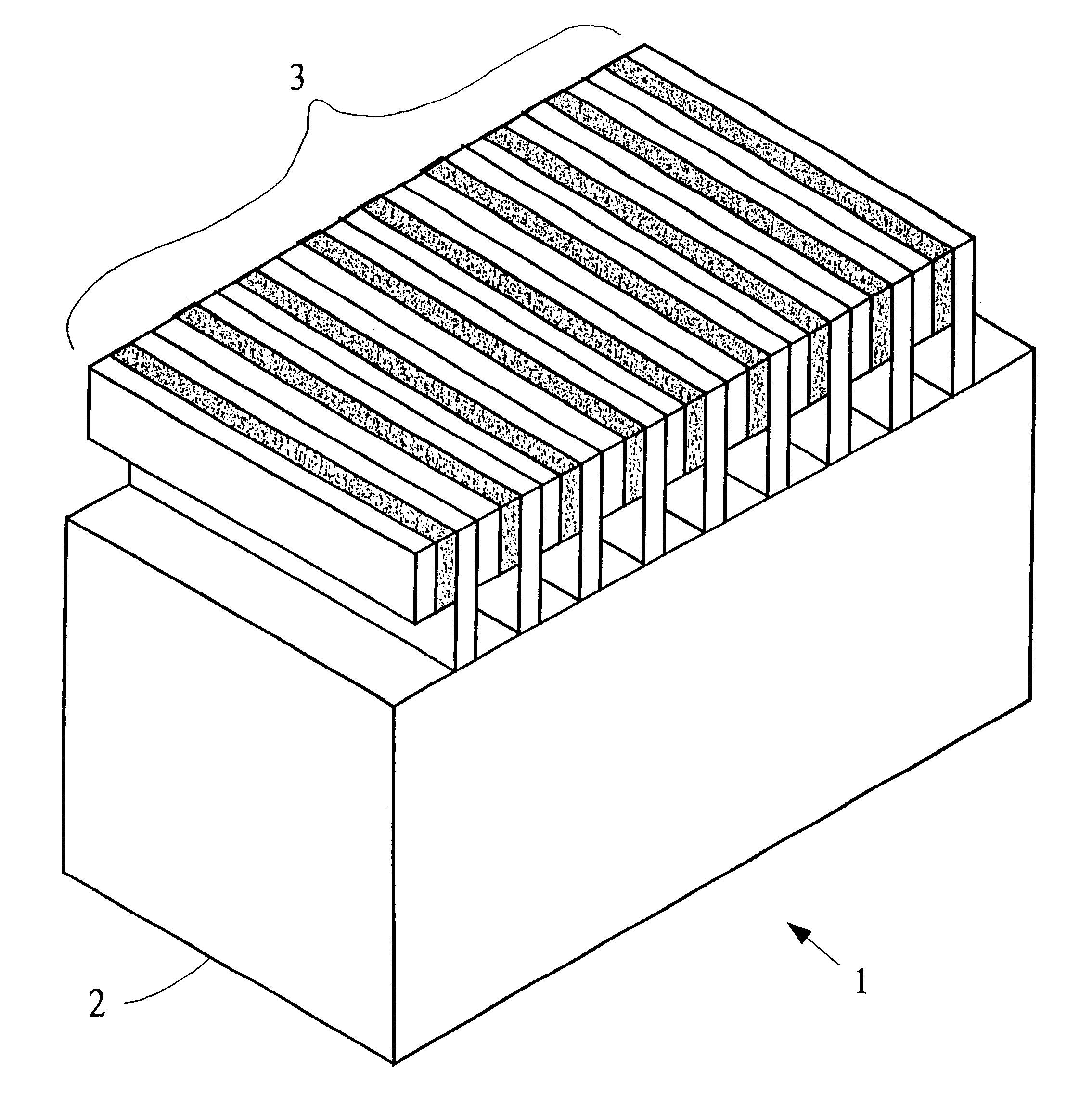

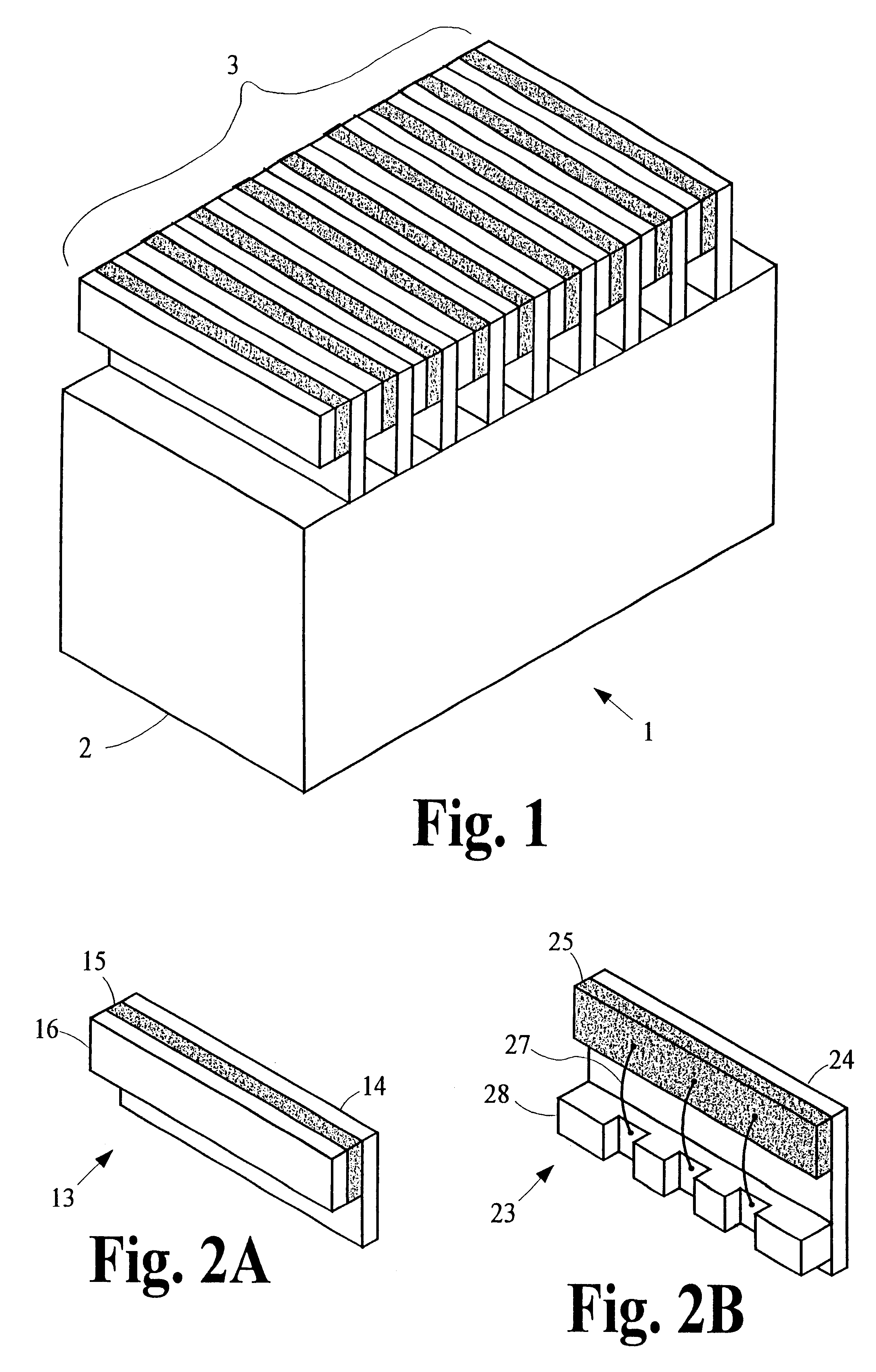

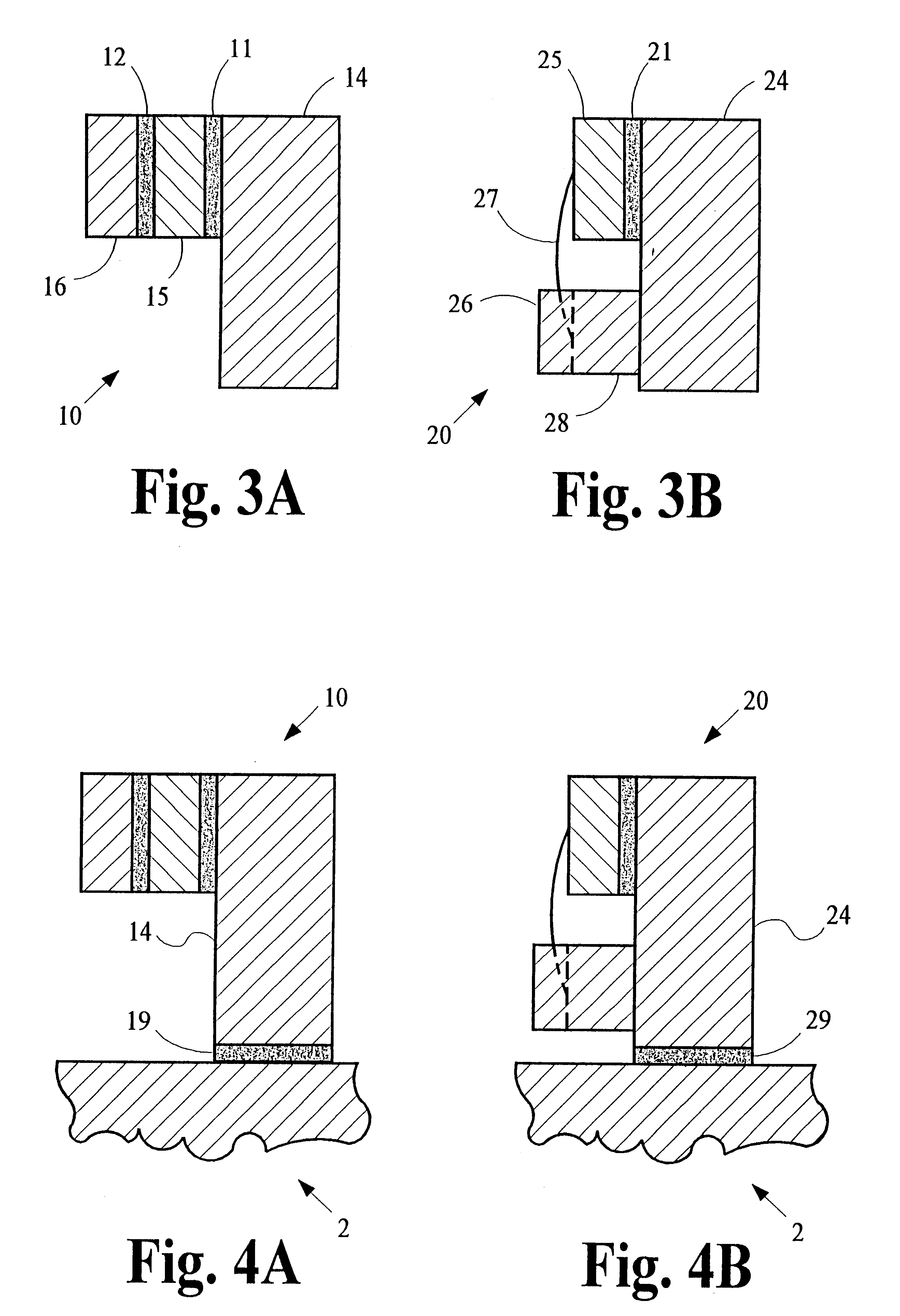

Solder and material designs to improve resistance to cycling fatigue in laser diode stacks

InactiveUS6424667B1Improve resistance to cycling fatigueReduce mechanical strainOptical wave guidanceSemiconductor laser arrangementsMaterial DesignThermal expansion

Laser modules that are operated intermittently are prone to stop operating after only a few thousand cycles or less. The laser modules sometimes experience a significant increase in operating temperature before they stop operating and, in some cases, manifest an opening of the electrical circuit that connects the laser diodes in the stack of laser subassemblies. In extreme cases, the laser module disintegrates into component subassemblies. These problems arise from structural failures in affixing agents like solder that are used to affix component parts to each other. The structural failures are caused by cyclical thermal expansion and contraction of component parts that exceed the elastic limit of the solder. Resistance to global plastic deformation (creep) and to local plastic deformation (fatigue) is improved by selecting materials to reduce mechanical strain and increase resistance to creep and fatigue, by altering the structural design of the laser module to reduce mechanical strain induced into the affixing agents, and by altering operational practices to reduce the range of temperatures imposed on laser module components. One design method improves resistance to creep and fatigue by controlling the thickness of the affixing agents used to affix component parts to each other.

Owner:JDS UNIPHASE CORP

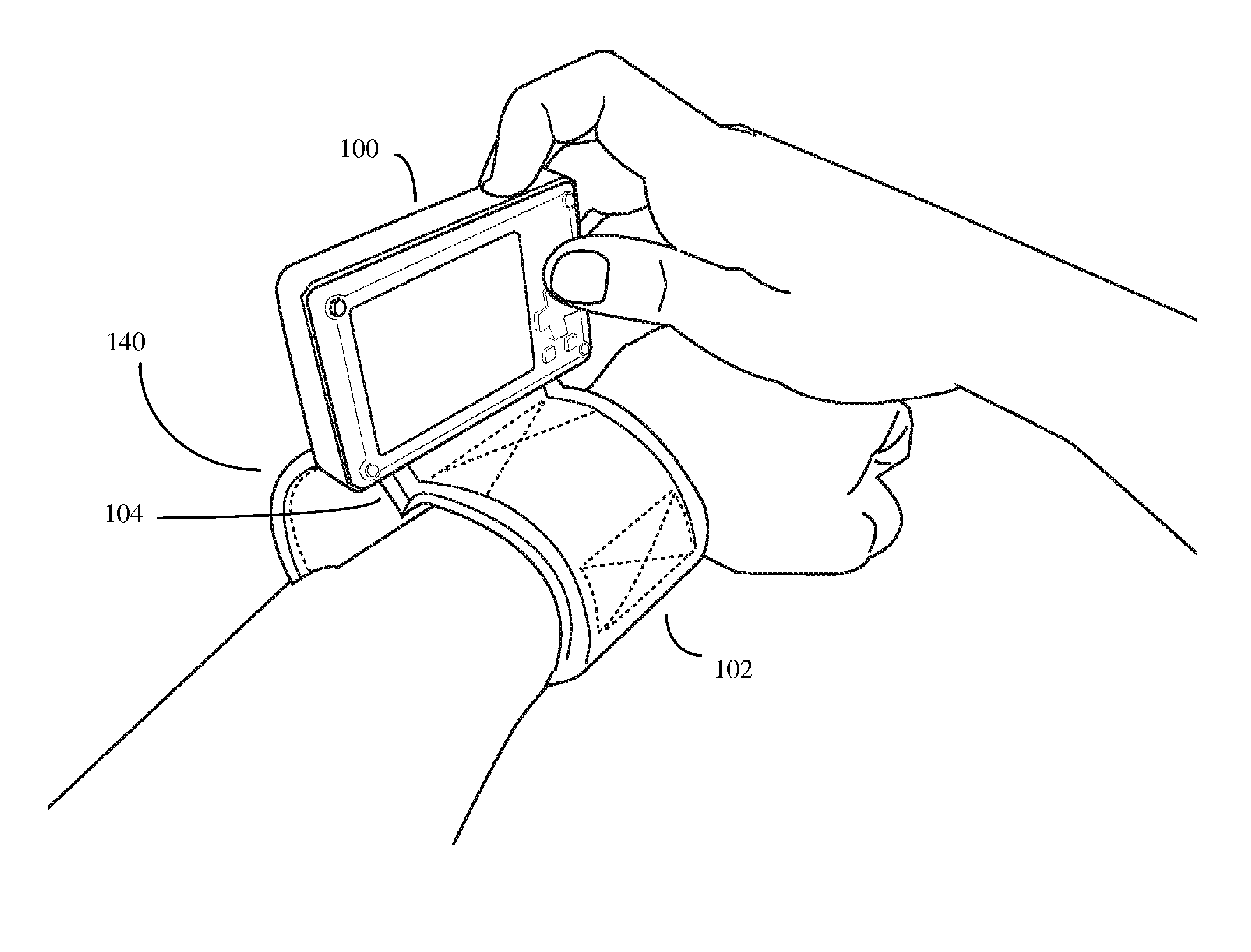

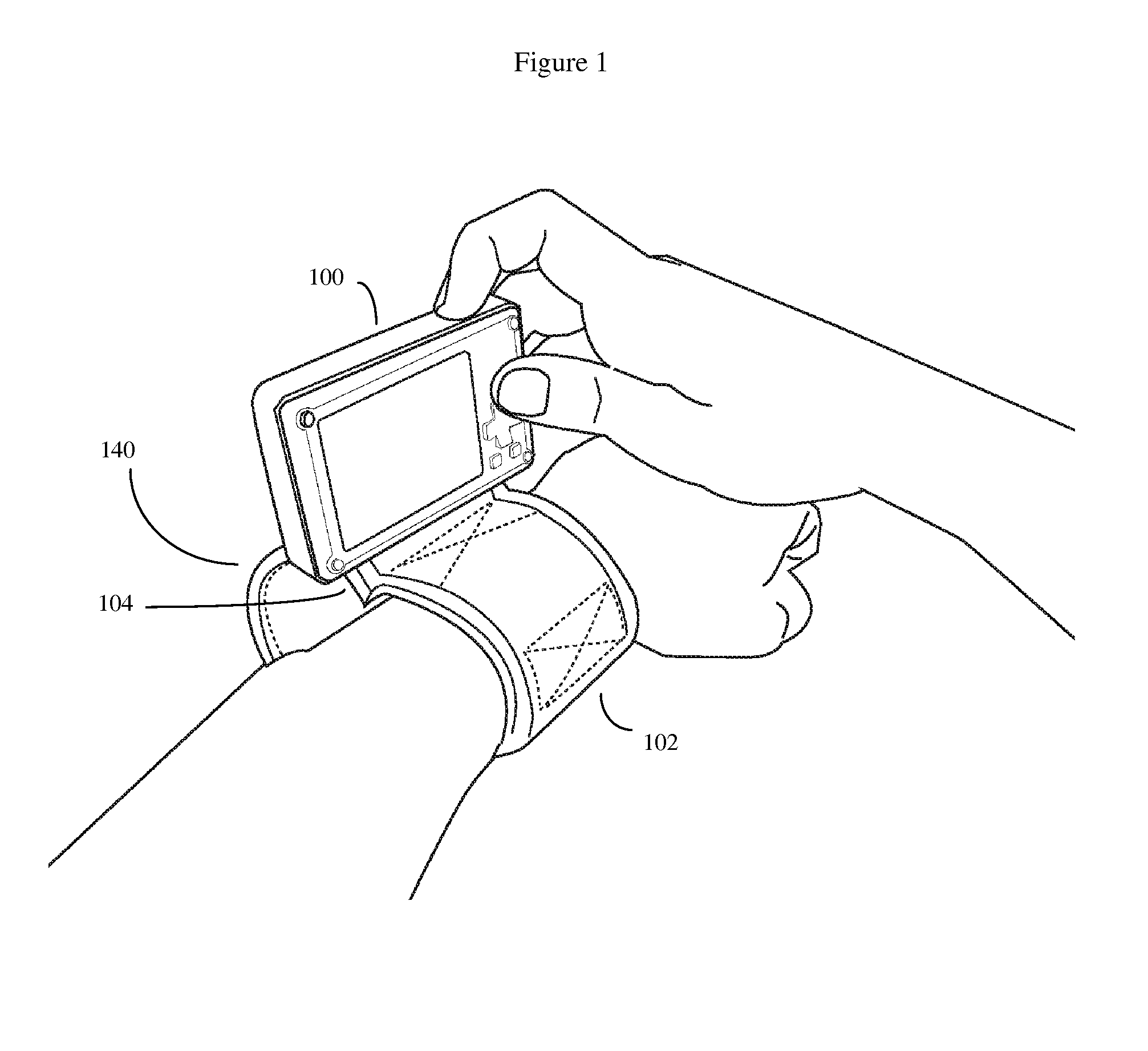

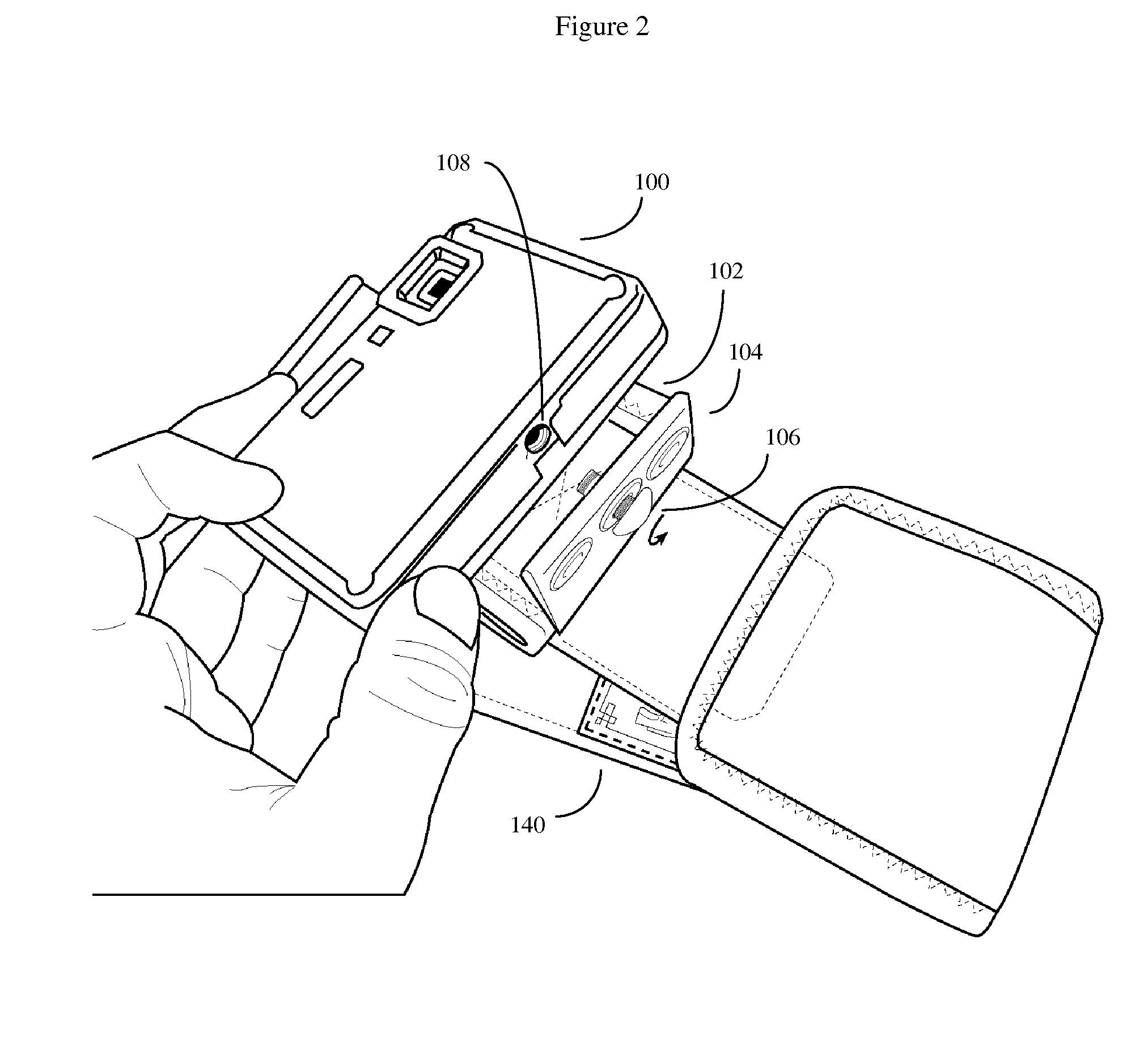

Wrist or arm strap with hinged mount for camera

InactiveUS20100316369A1Easy to controlAvoid accidental damageTravelling sacksOther accessoriesMaterial DesignHand arm

A device capable of attaching a portable handheld camera to the wrist or arm of a human user is disclosed. The device is a multi-component detachable band of fabric or other material designed to encircle a user's wrist or arm, and hold a small handheld camera to the user's arm by way a camera mounting screw that attaches, by way of a rigid or semi-rigid hinged camera mounting bracket affixed to the band, to the camera's tripod socket. The device will often additionally contain a built-in second band of fabric or other material that can be positioned over the majority of the camera's front, and both hold the camera tightly to the user's wrist or arm when photography is not desired, as well as help protect the camera from accidental damage. The device is particularly useful for action sports photography.

Owner:PYLE COLIN JAMES

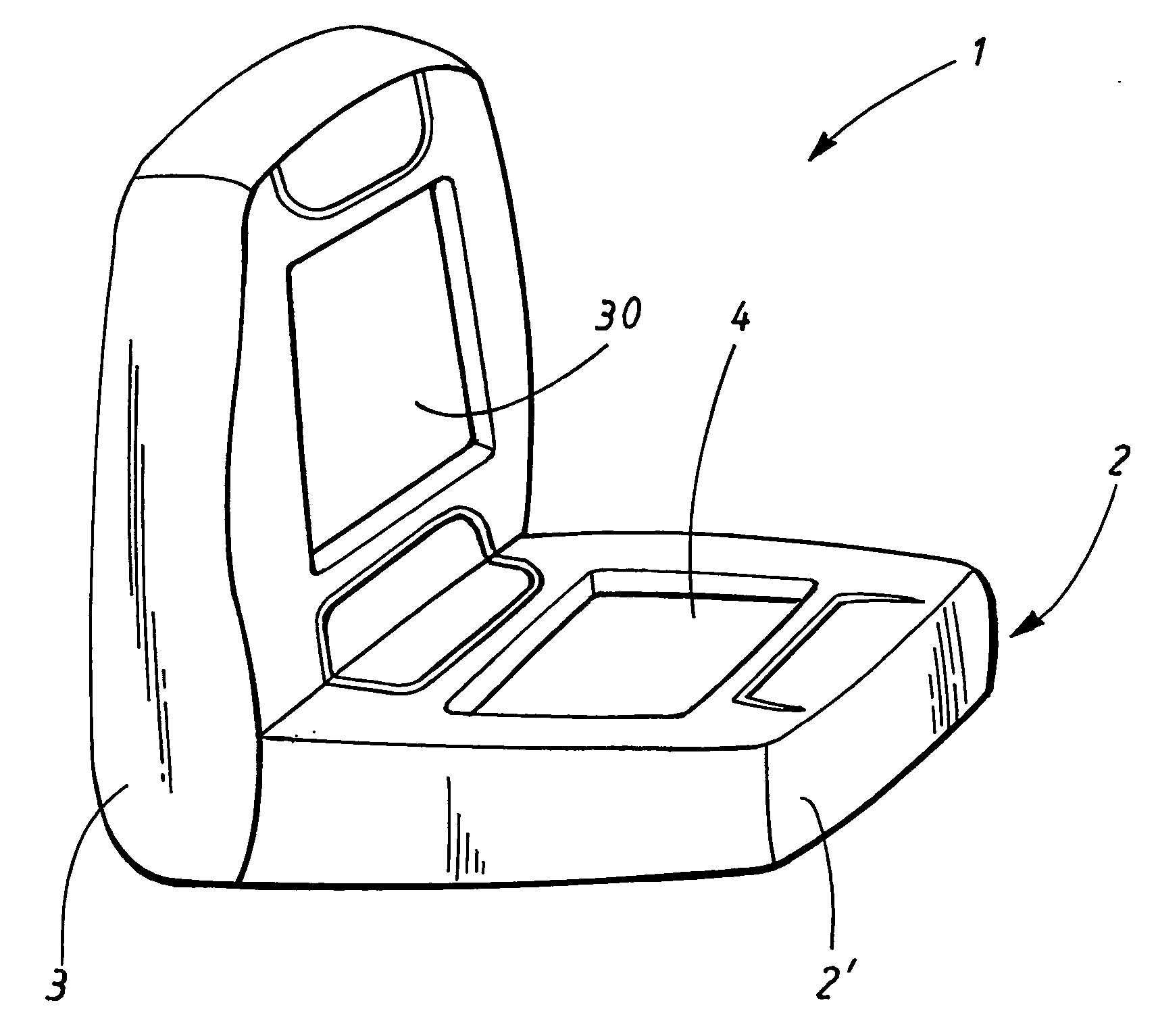

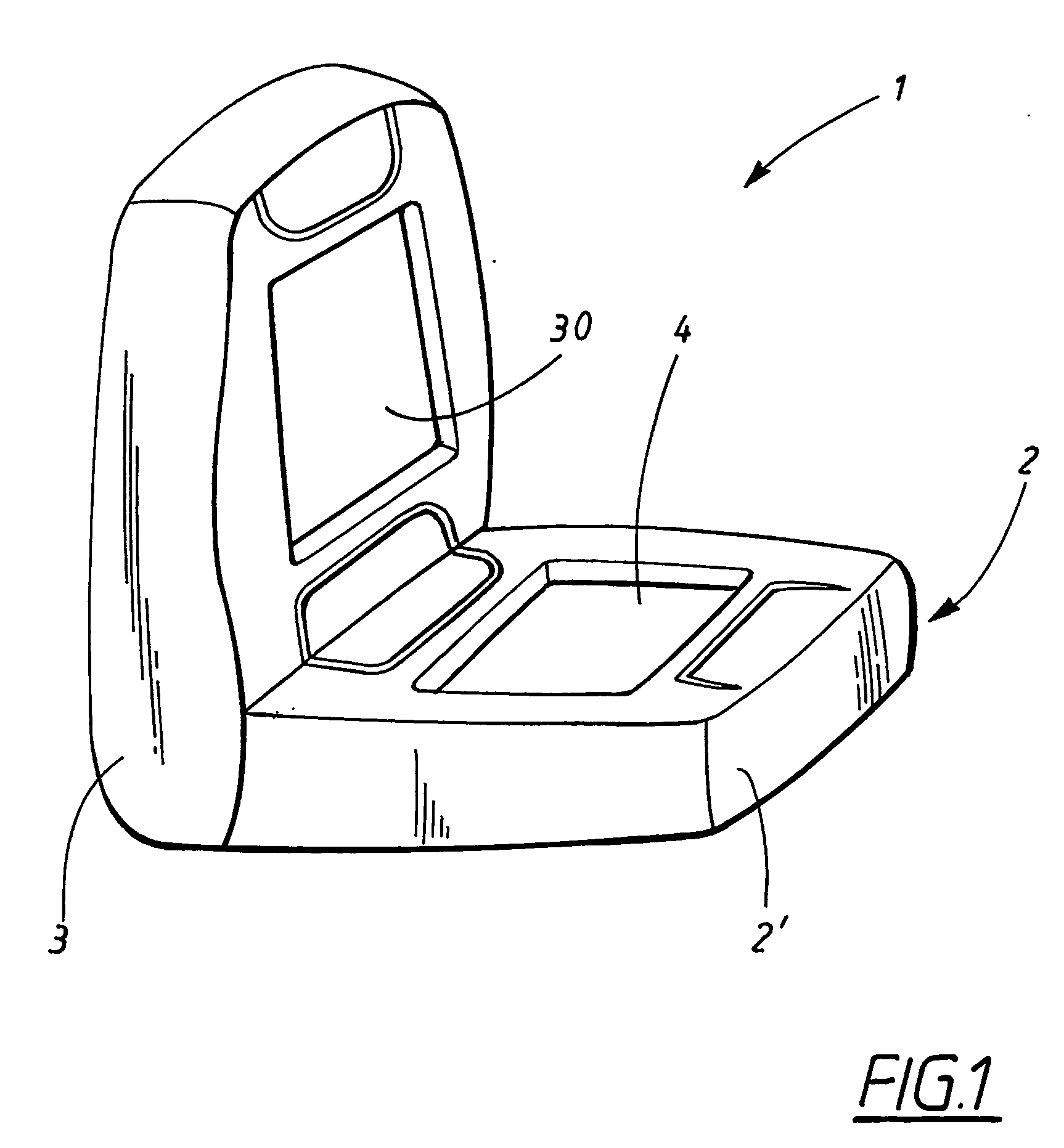

Arrangement for ventilation of a vehicle seat

InactiveUS20070063551A1Cost-effective manufacturingEasy constructionSeat heating/ventillating devicesStoolsMaterials designElectrically conductive

The invention relates to an arrangement for ventilation of a vehicle seat, which arrangement comprises an air-distributing material and an electric heating element comprising at least one electrically conductive component arranged in a pattern in conjunction with at least one support, where the vehicle seat comprises a bottom part which is adapted for ventilation by blowing air in or sucking air out via at least one passage through the bottom part and on through the said air-distributing material. According to the invention, the said support, heating element and air-distributing material are manufactured as an integrated arrangement adapted for mounting in conjunction with the said vehicle seat, the said air-distributing material being designed as at least one unit which is dimensioned for mounting in a correspondingly designed cutout in the vehicle seat. By means of the invention, an improved arrangement for heating and ventilation of a seat in a vehicle is obtained.

Owner:KONGSBERG AUTOMOTIVE AB (SE)

Method and apparatus for simulating manufacturing, electrical and physical characteristics of a semiconductor device

InactiveUS20020123872A1Semiconductor/solid-state device detailsSolid-state devicesElement modelMaterial Design

An electronic device simulator includes a three-dimensional lumped device model, a three-dimensional visco-elastic process simulation model and a material design model that are interlinked with each other. The three-dimensional lumped device element model comprises a Poisson's equation model, an electron continuity equation model, a hole continuity equation model, a Maxwell's equations model, an eddy current equation model, and an Ohm's law equation model. The simulator accounts for the three dimensional characteristics of the circuit to determine circuit performance.

Owner:KK TOSHIBA

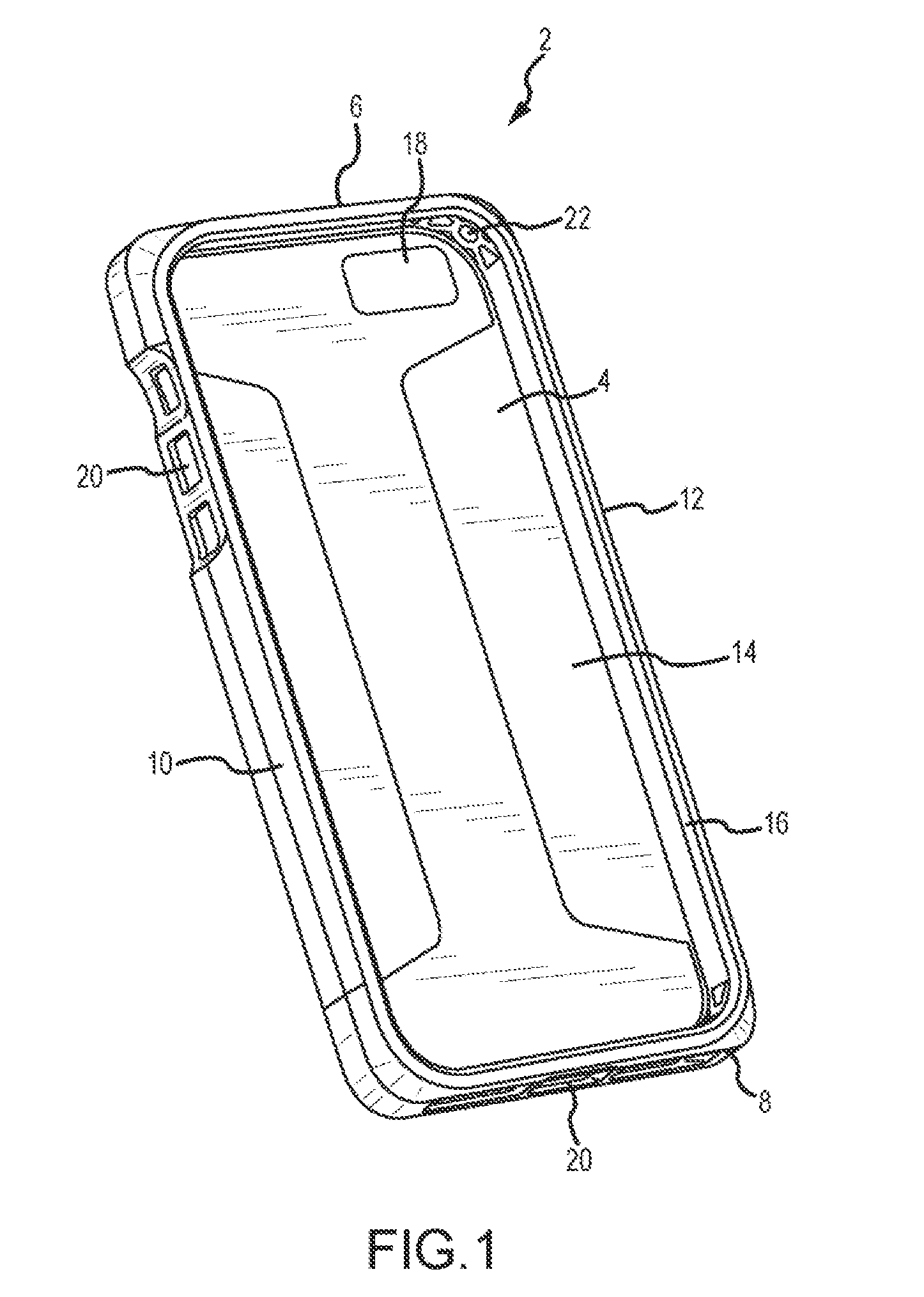

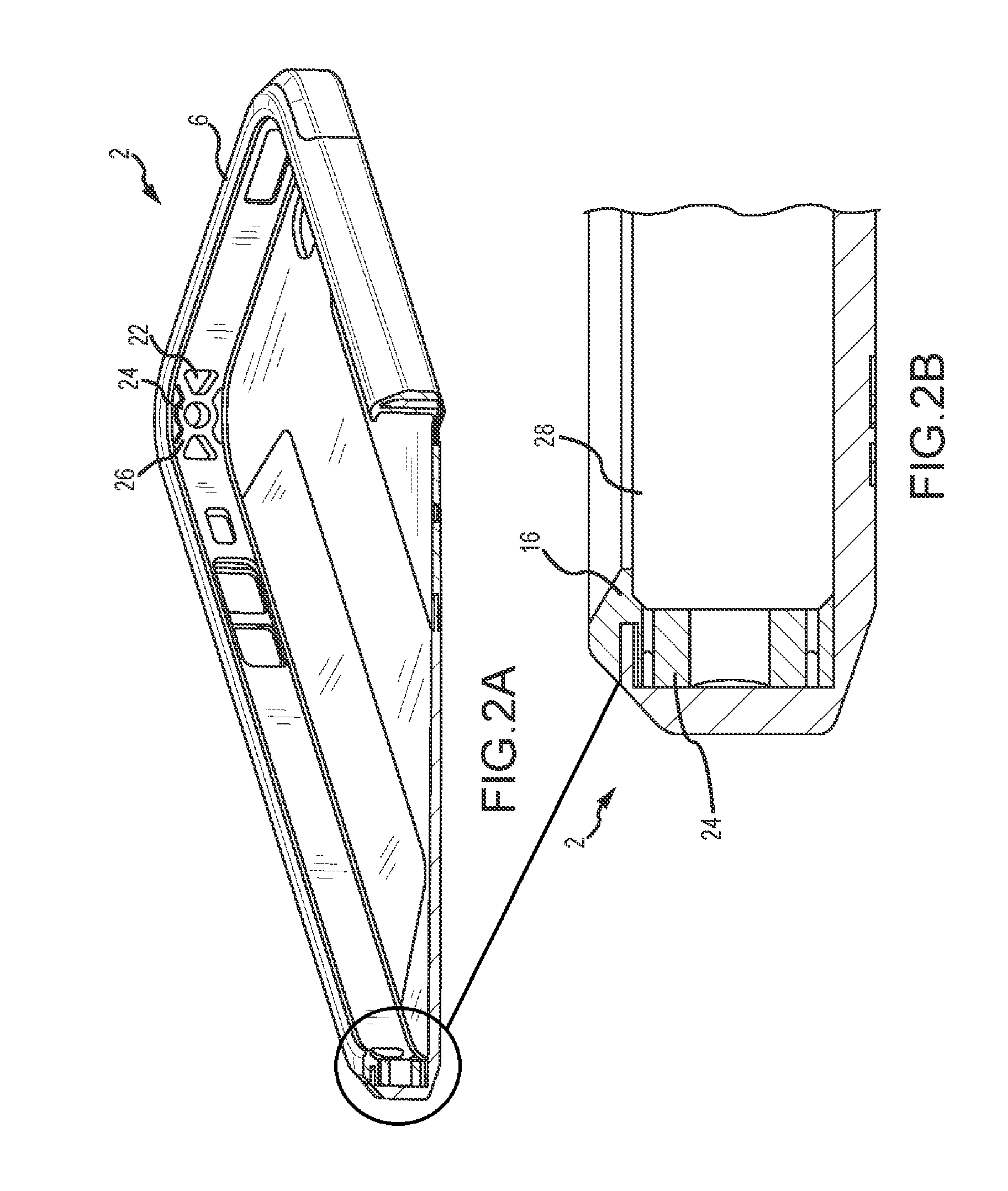

Protective case for an electronic device

InactiveUS20150097009A1Reduce impactImprove the protective effectTravelling carriersHoldersMulti materialElectric equipment

A protective case for receiving and retaining a portable electronic device is provided. The case comprises dampening features disposed in at least two corners of the case to protect the electronic device from inadvertent impact and the resultant forces. Various embodiments of the case comprise multi-materials designs and features that allow utilize of various controls and features of the electronic device.

Owner:THULE ORG SOLUTIONS

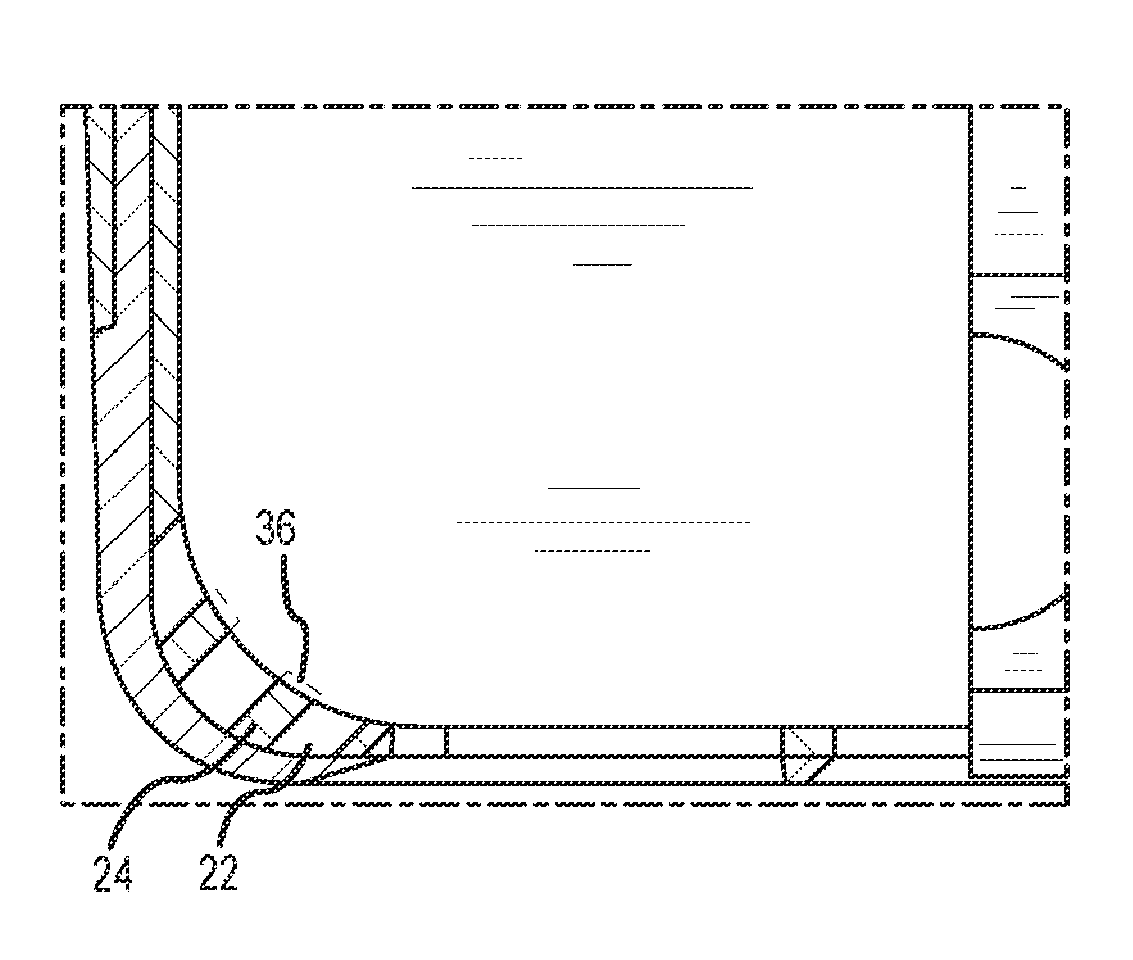

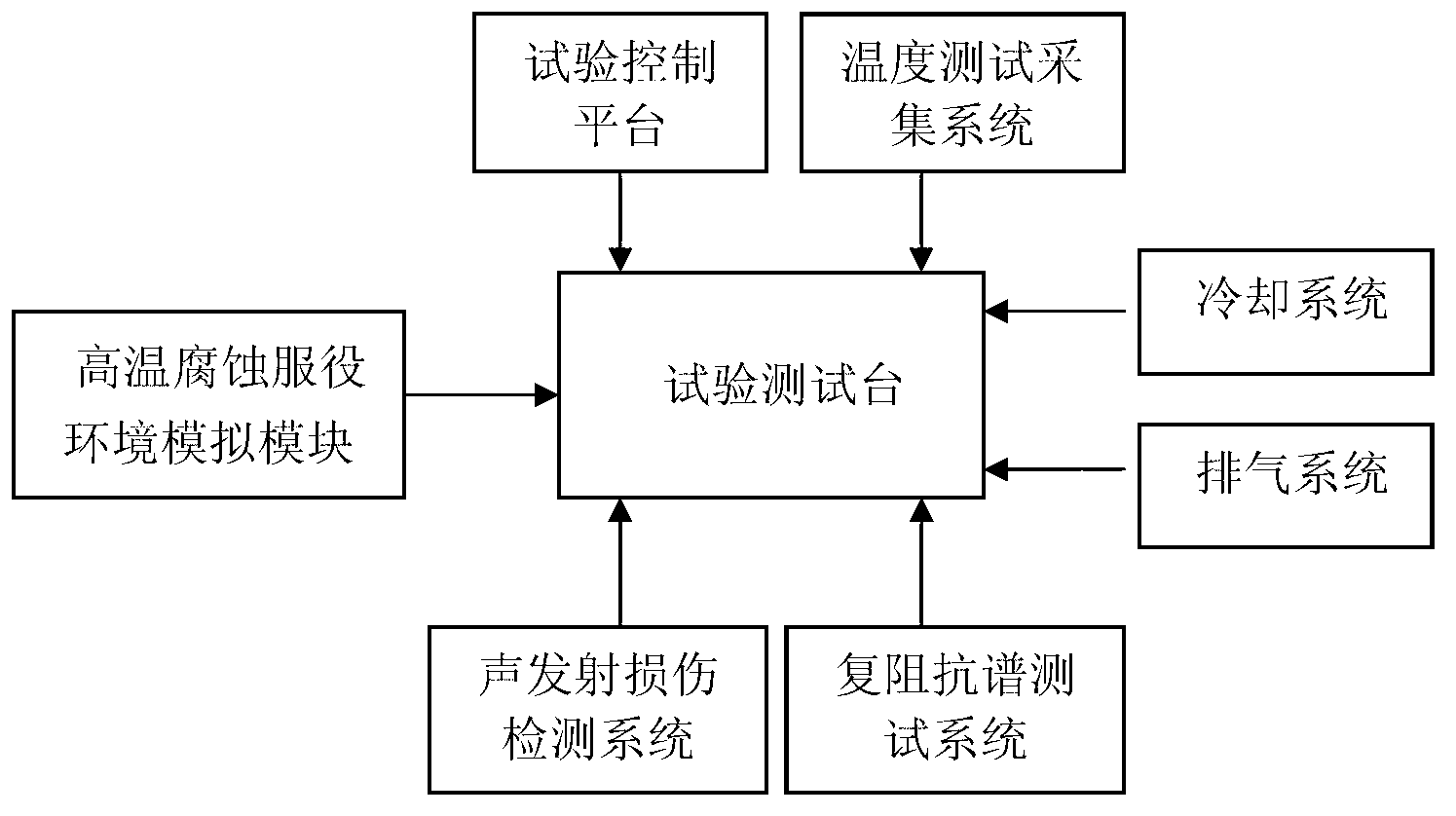

Testing device for simulation and real-time detection of high-temperature deposition corrosion of thermal barrier coatings

ActiveCN103063563AConcentration adjustableIngredients adjustableWeather/light/corrosion resistanceComplex impedance spectraMaterial Design

The invention discloses a testing device for simulation and real-time detection of high-temperature deposition corrosion of thermal barrier coatings, belonging to the field of simulation devices in a special service environment. The testing device comprises a test board which is equipped with a sample fixture and a fixture fixing device, a cooling system, a high-temperature corrosion service environment simulation module, an exhaust system, a complex impedance spectroscopy measuring system, an acoustic emission testing system and a test control and display platform, wherein the complex impedance spectroscopy measuring system and the acoustic emission testing system are integrated together. The device can be used for adjusting the parameters such as variety, concentration, corrosive temperature of corrosive medium. The change of coating impedance and damaged acoustic emission signals when a sample is corroded can be periodically detected by the complex impedance spectroscopy measuring system and the acoustic emission testing system, the high-temperature corrosion of various impurity particles, such as Ca, Mg, Al, Si and Na of thermal barrier coatings of aero-engine turbine blades in actual service temperature environment is actually simulated; in addition, the corrosion failure process is periodically detected; and an important test platform is provided for correctly understanding the high-temperature corrosion mechanism of thermal barrier coatings and optimizing the material design thereof.

Owner:XIANGTAN UNIV

Ceramic Cosmetic Applicator

InactiveUS20110103878A1Remarkable effectLower skin temperatureLiquid surface applicatorsBall-point pensAbsorption capacityMaterial Design

A cosmetic applicator formed from ceramic material designed to provide a product chilling effect when applying creams, lotions, treatment products, etc. The applicator is provided with a relatively substantial mass so that it has a greater thermal capacity than the dose of cosmetic and the application area combined. The applicator is in the form of a molded-ceramic applicator head or applicator tip designed to provide a relatively larger product-chilling effect to both the dose of cosmetic applied and to the user's skin in the application area when applying creams, lotions, treatment products, etc. The applicator provides an application device which will deliver the creams, lotions, treatment products, etc. such that the temperature of the product being delivered is lower than the temperature of the skin, and to provide a means of lowering the temperature of the skin by virtue of the thermal absorption capacity of the applicator head or tip, and to provide a vehicle by which formulations may be activated or enhanced by specific compounds in the ceramic material from which the applicator tip is comprised.

Owner:ELC MANAGEMENT LLC

Method for establishing composite pavement temperature field model of underground road

ActiveCN103031801ARoads maintainenceSpecial data processing applicationsTemperature stressMaterial Design

The invention relates to composite pavement temperature measurement of an underground road. The purposes of the invention are to make a research on a method for predicating the temperature of a pavement at any time and in any position and preferably instruct pavement structural and material design of the underground road. In order to achieve the purposes, a technical scheme adopted in the invention is as follows: a method for establishing a composite pavement temperature field model of the underground road is characterized by comprising the following steps: actually measuring a composite pavement temperature field of the underground road; carrying out heat transfer theoretical analysis, air convection heat exchange and air radiation heat exchange on the composite pavement temperature field of the underground road; from basic principles of climatology and heat transfer theory, analyzing the temperature field and temperature stress of the underground road pavement by using a two-dimensional elastic layer theory system according to actual situations of a pavement structure; and making the following basic assumptions. The method is mainly applied to the temperature measurement of the composite pavement of the underground road.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Single-use, bullet-proof shield

InactiveUS6009790AReduce manufacturing costEasy to useArmour platesBullet catchersMaterial DesignMetallic materials

Owner:TEKORIUS PAUL

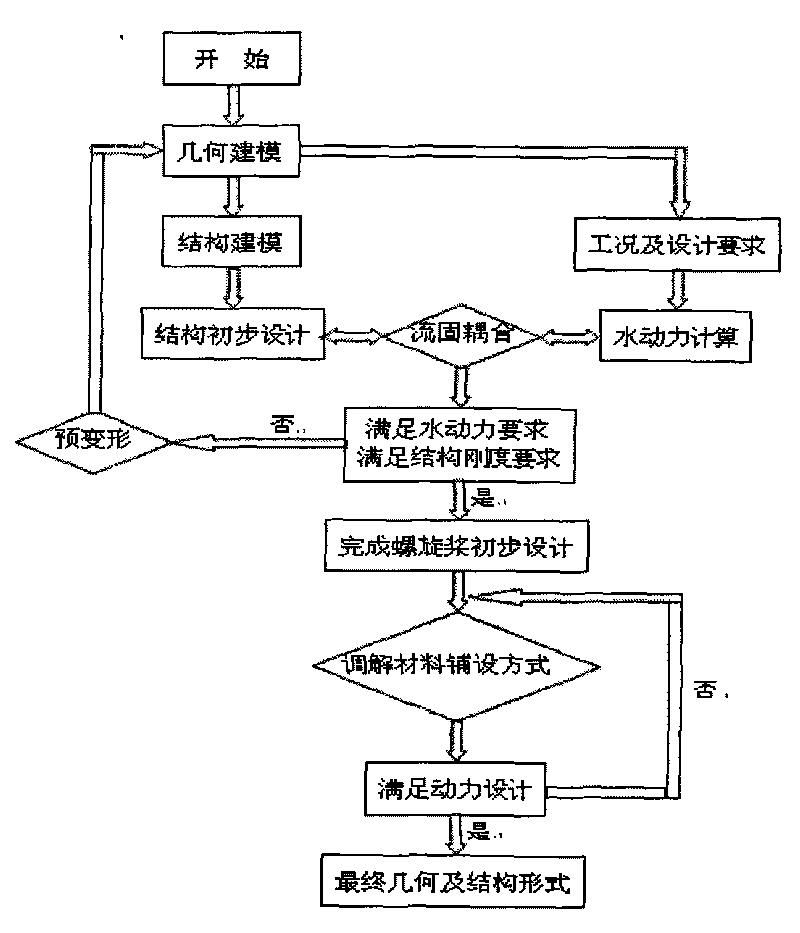

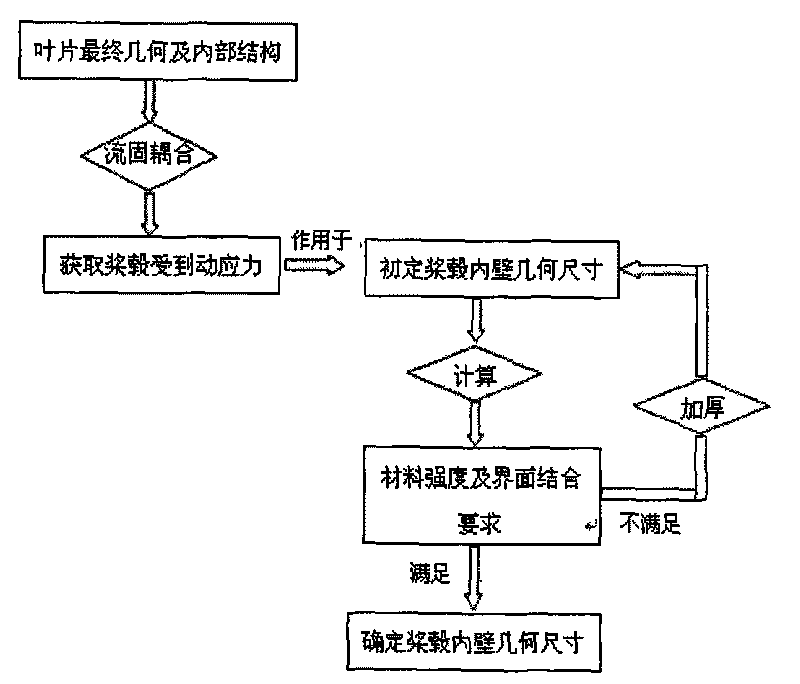

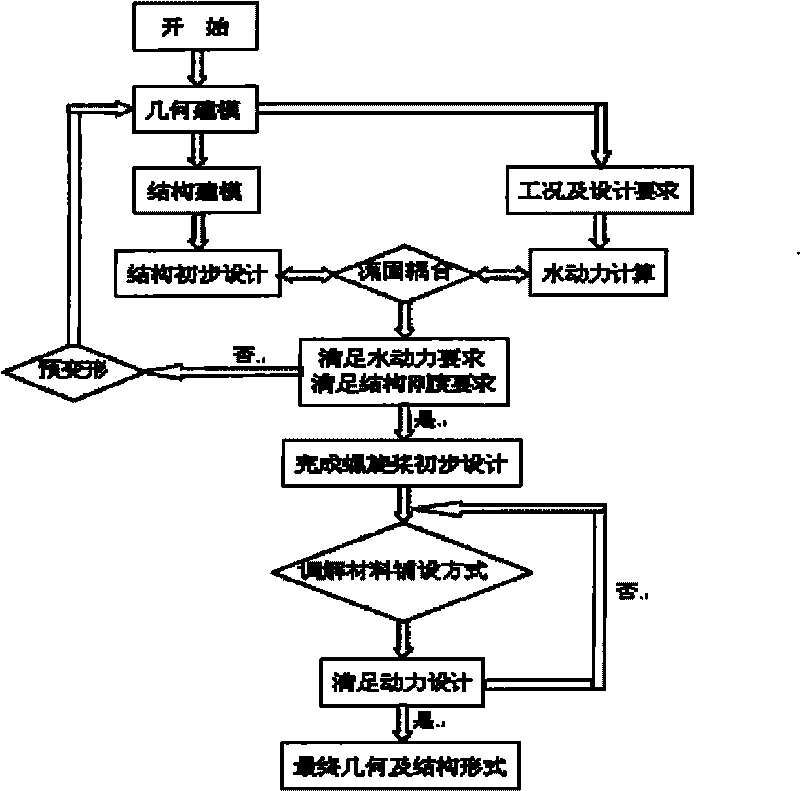

Design method for marine propeller made of carbon fiber composite material

InactiveCN101706833AImprove flow elasticityMeet propulsion performance requirementsRotary propellersSpecial data processing applicationsMaterial DesignPre deformation

A design method for marine propeller made of carbon fiber composite material relates to a design method for a propeller. The invention solves the problem that the current design method for the marine propeller made of carbon fiber composite material is imperfect. The geometrical appearance of the blade by the design method for marine propeller made of carbon fiber composite material is calculated by fully using the flexibility and designable performance of the composite material on the basis of the value data of the original MAU metal propeller blade and combining the fluid-structure coupling method with the implementation of the pre-deformation tactics; and the outside of the propeller hub is wrapped by the carbon fiber composite material. The marine propeller made of carbon fiber composite material designed by the method has the geometrical appearance and the internal structure more suitable for the propeller made of carbon fiber composite material, thereby being capable of effectively improving the fluid elasticity of the propeller and improving the propulsive efficiency.

Owner:HARBIN INST OF TECH

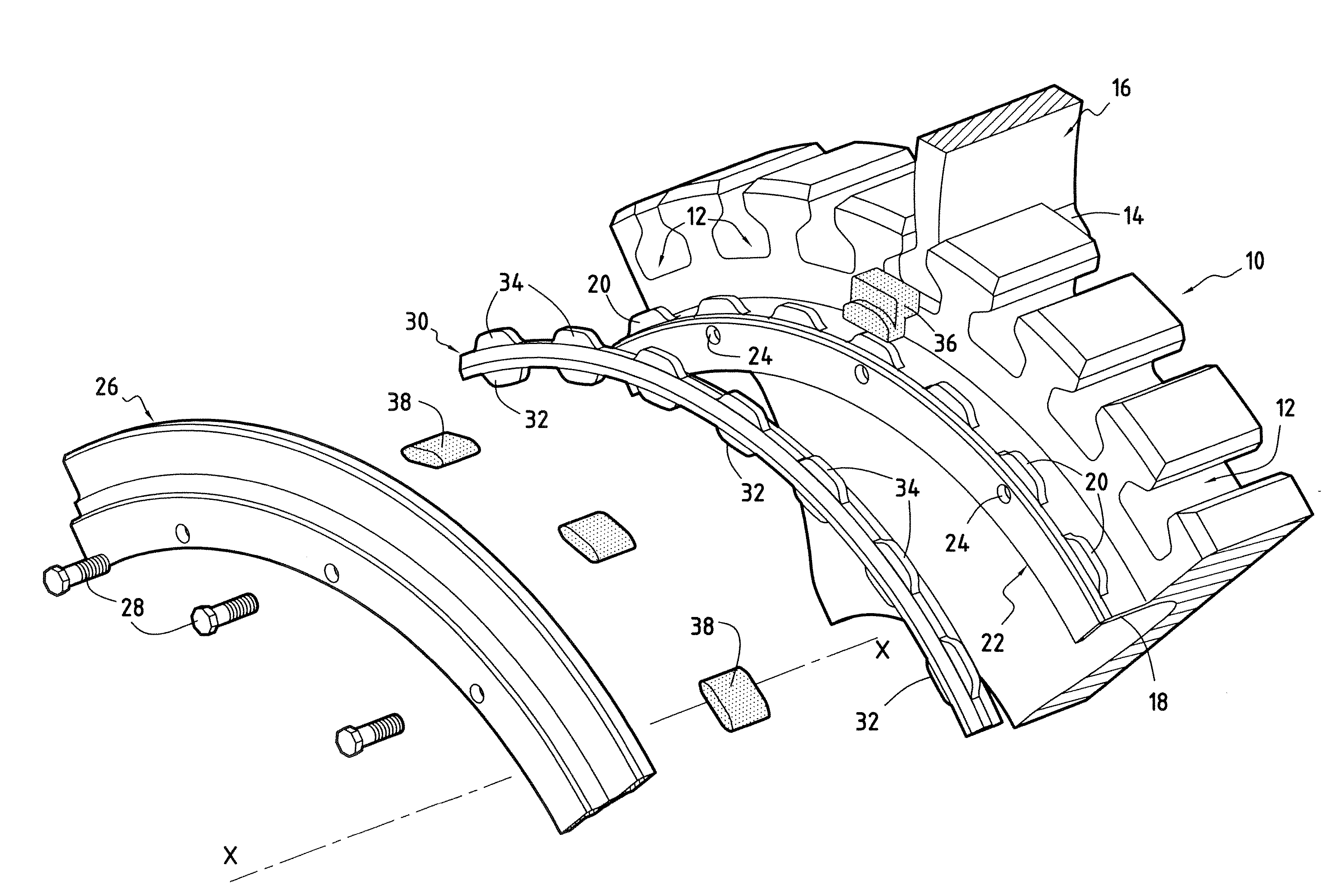

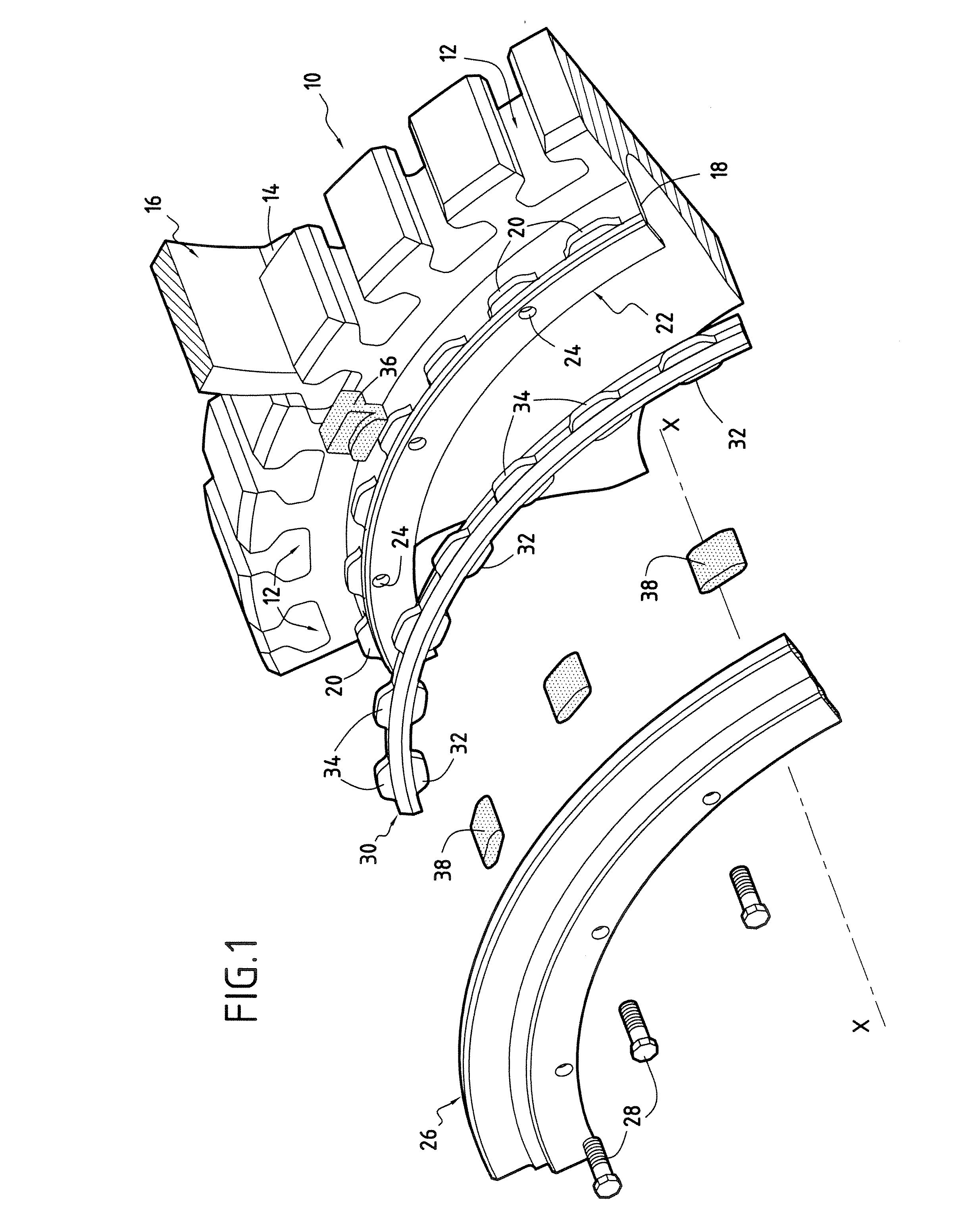

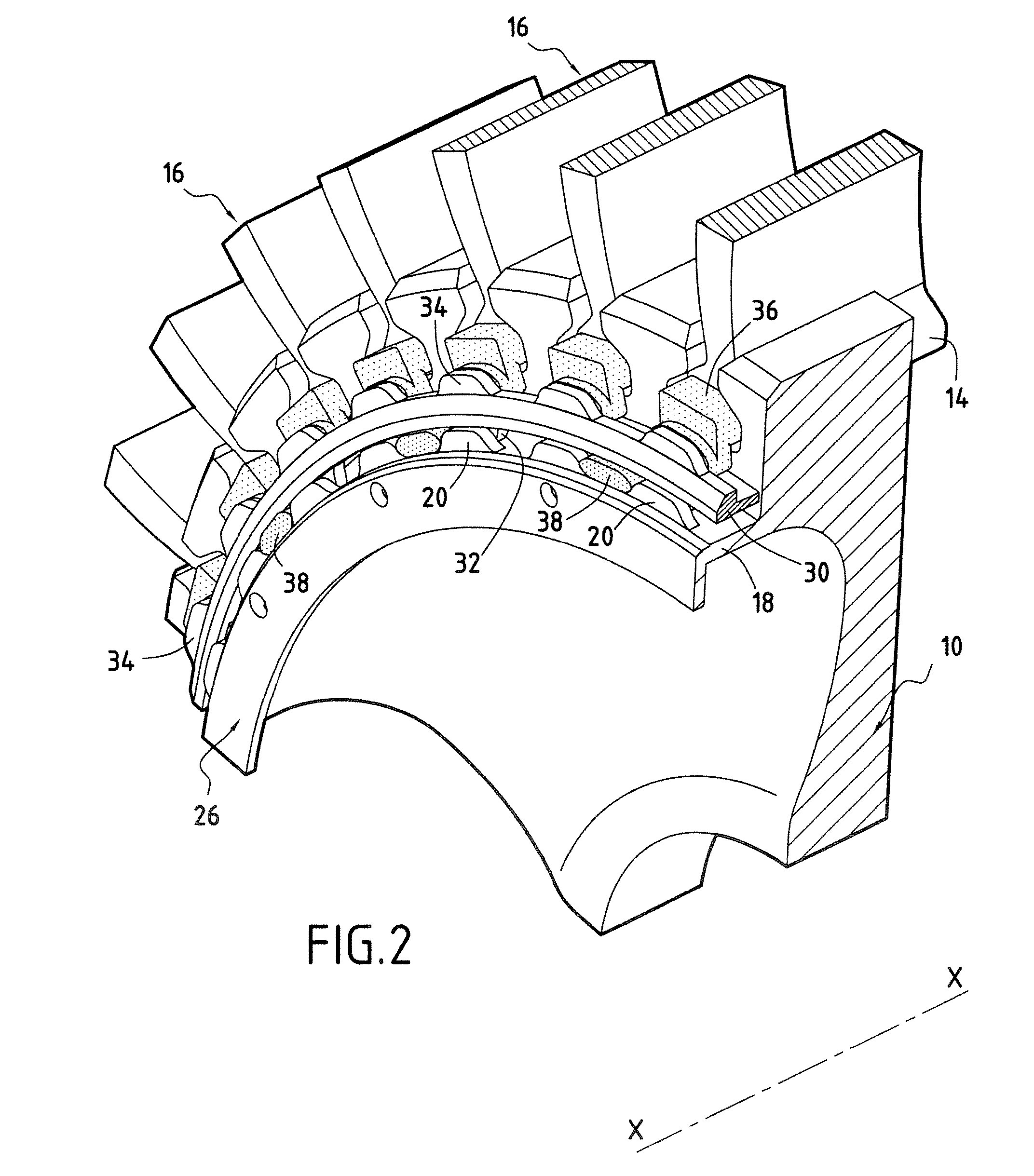

A device for damping vibration of a ring for axially retaining turbomachine fan blades

ActiveUS20070020089A1Mitigate such drawbackReduce riskEngine manufacturePump componentsElastomerMaterial Design

A device for damping vibration of a retention ring for axially retaining turbomachine fan blades, the blades being designed to be mounted via their roots on a rotary disk having an annular flange extending axially and provided with a plurality of radial crenellations for coming into contact with a plurality of complementary radial crenellations of a retention ring designed to be mounted around the disk flange, the device comprising an abutment element of elastomer material designed to be received axially between two adjacent crenellations of the flange and two adjacent complementary crenellations of the retention ring, and radially between the flange of the rotary disk and the retention ring, said abutment element presenting contact surfaces for coming into contact with the adjacent crenellations, with the retention ring, and with the flange of the rotary disk.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Extended stroke valve and diaphragm

ActiveUS20050006617A1Low costExtended service lifeDiaphragm valvesOperating means/releasing devices for valvesMaterial DesignCompound (substance)

An extended stroke poppet valve particularly suited for handling caustic fluids and having features enabling an extended service life for the valve. The valve includes a two part primary diaphragm assembly with a wetted diaphragm made from highly fatigue resistant fluoropolymer material, and a diaphragm backer made from high strength fluoropolymer material designed to withstand the high stress loads imposed by an extended valve stroke. The combination of these two layers in a single primary diaphragm assembly yields a highly durable, caustic chemical resistant, diaphragm capable of use in a long stroke poppet valve and having a relatively long service life.

Owner:ENTEGRIS INC

Composite materials

Certain non-limiting embodiments of the present disclosure comprise a family of composite materials targeting specific applications through a materials design approach involving; 1 ) a hard particulate; 2) a carrier or binder phase; and 3) one or more additives for property enhancement and / or hardness adjustment. According to certain embodiments, the composite material may be one of flexible conformal sheet; a rigid machinable molded preform; and an extrudable putty. Methods of manufacture of the composite materials are also disclosed.

Owner:ATI PROPERTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com