Patents

Literature

1091 results about "Process simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants, chemical processes, environmental systems, power stations, complex manufacturing operations, biological processes, and similar technical functions.

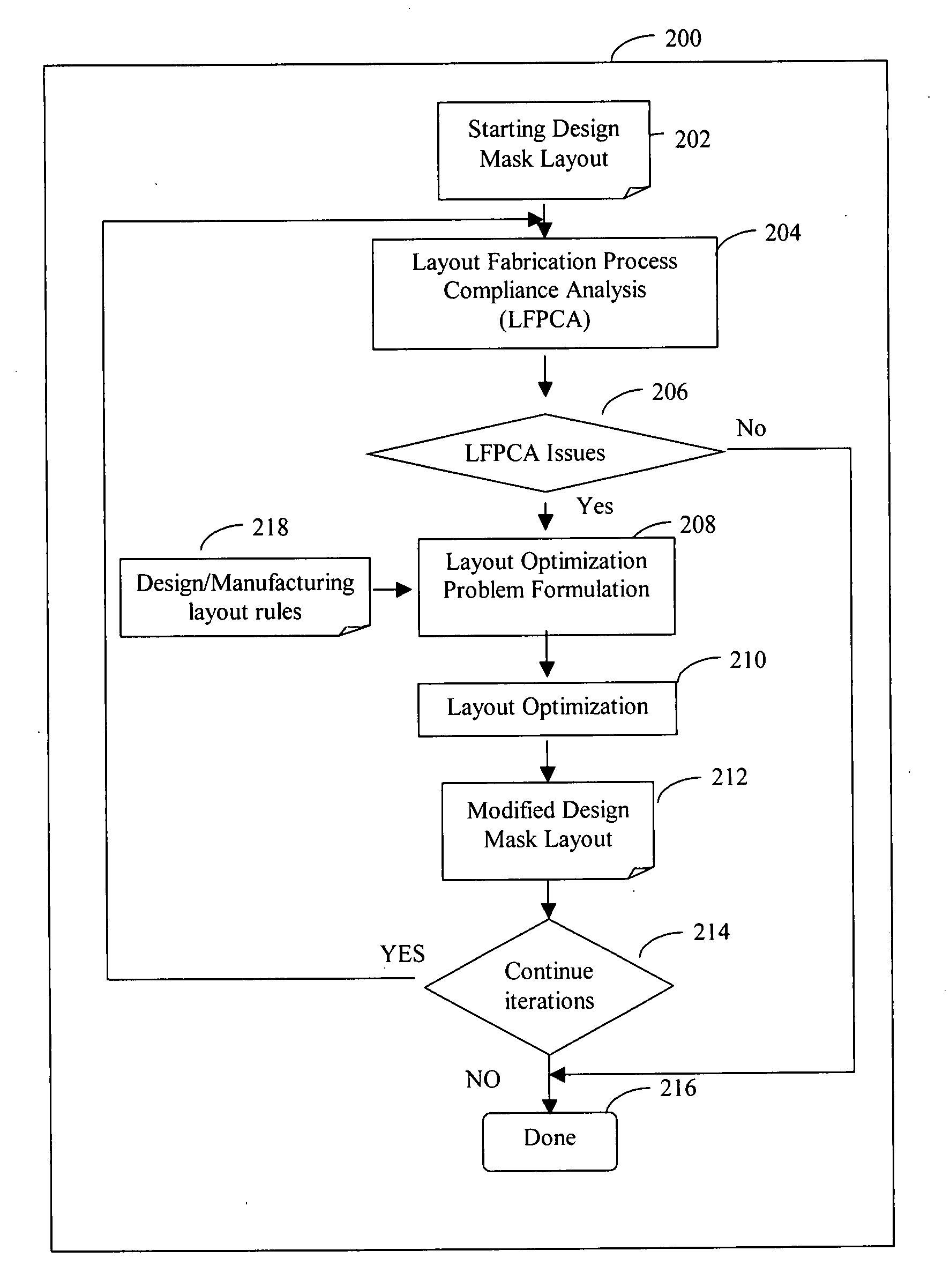

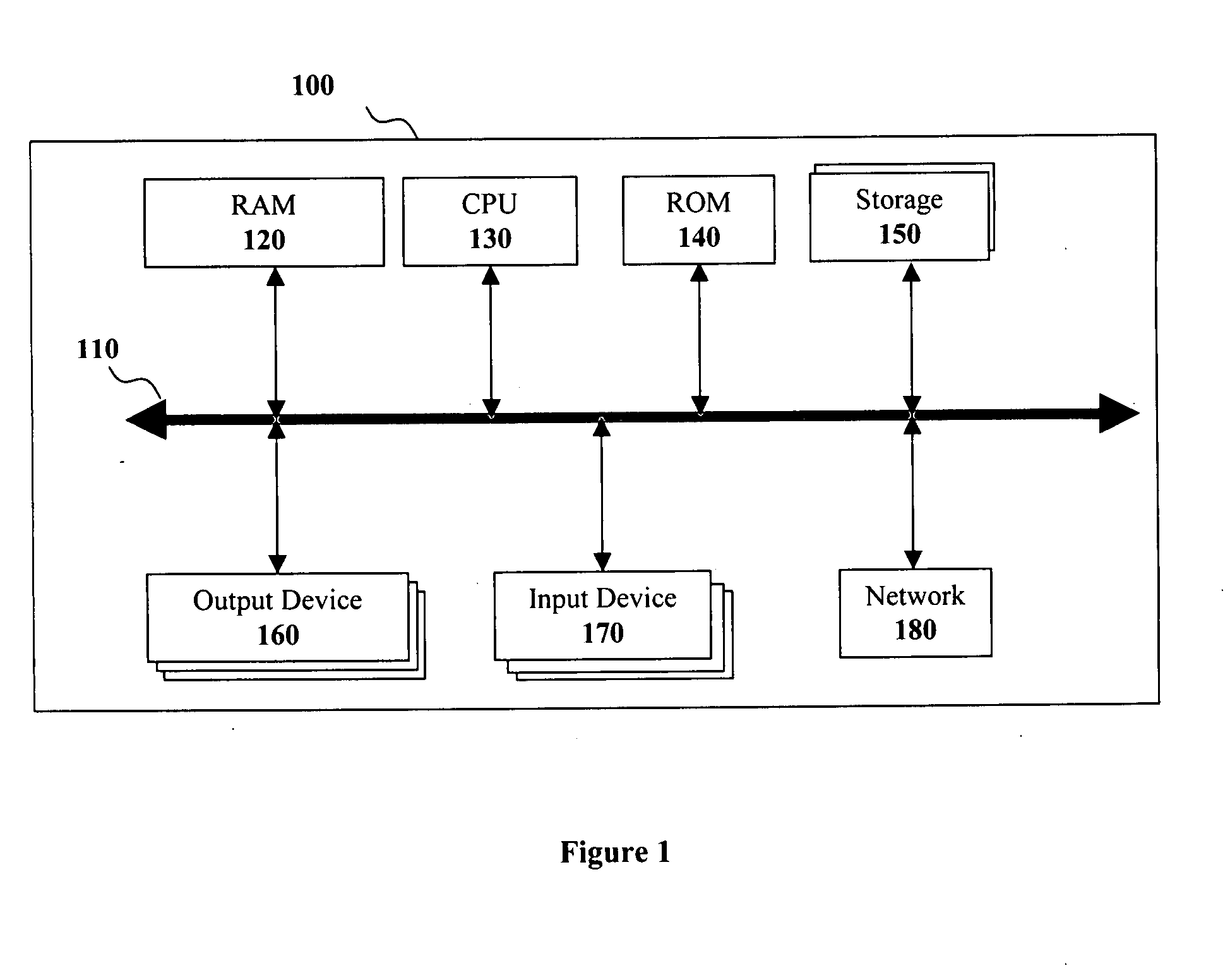

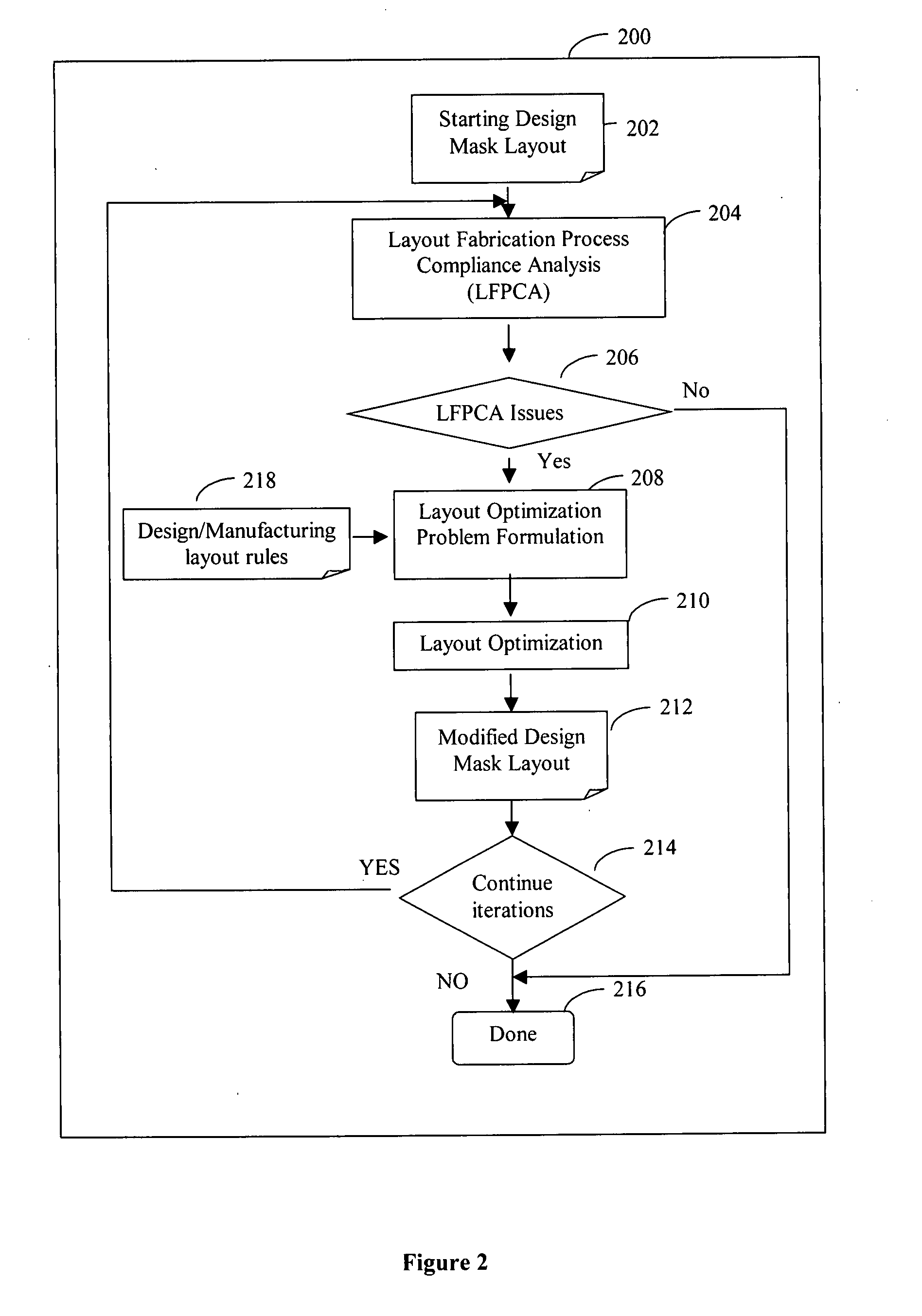

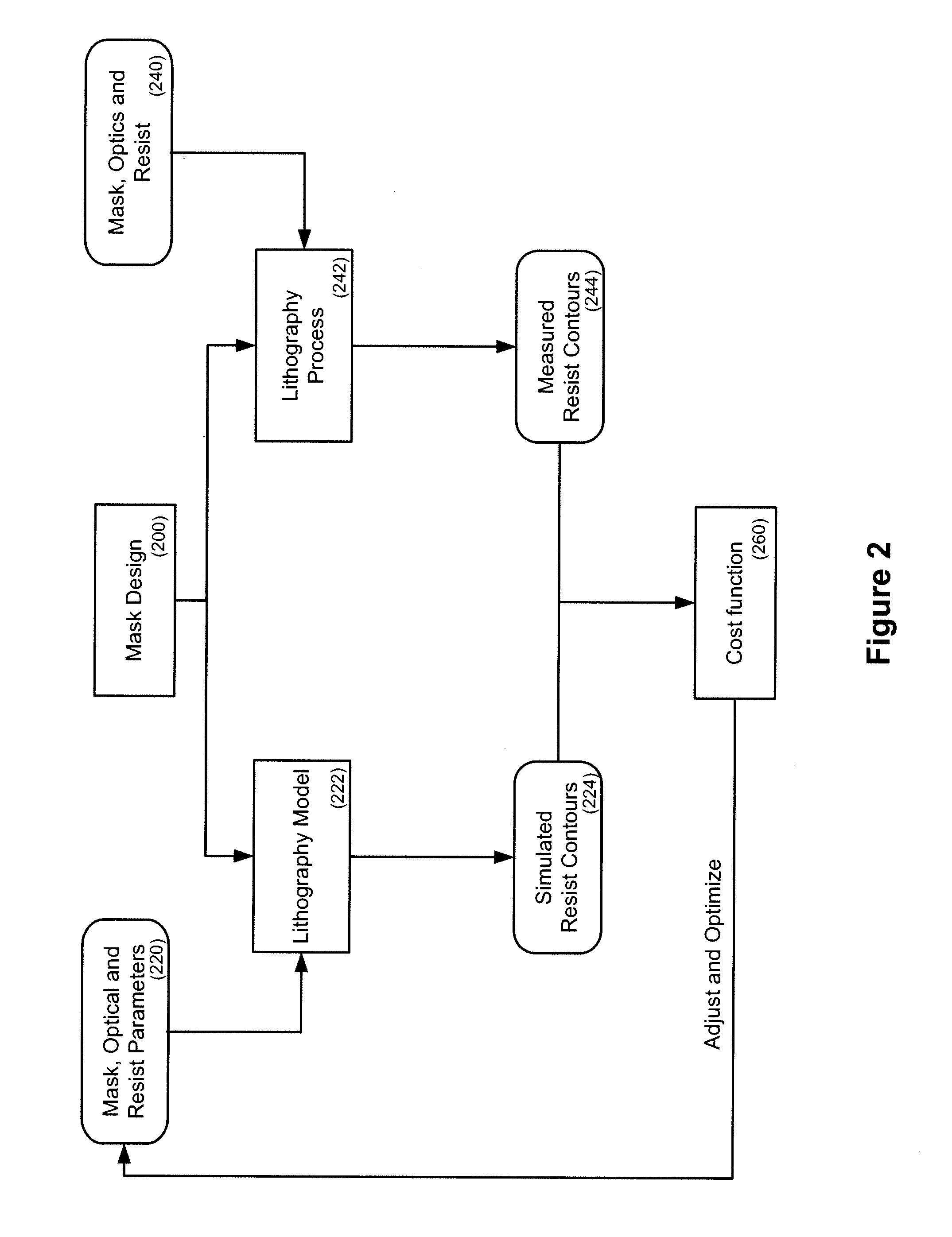

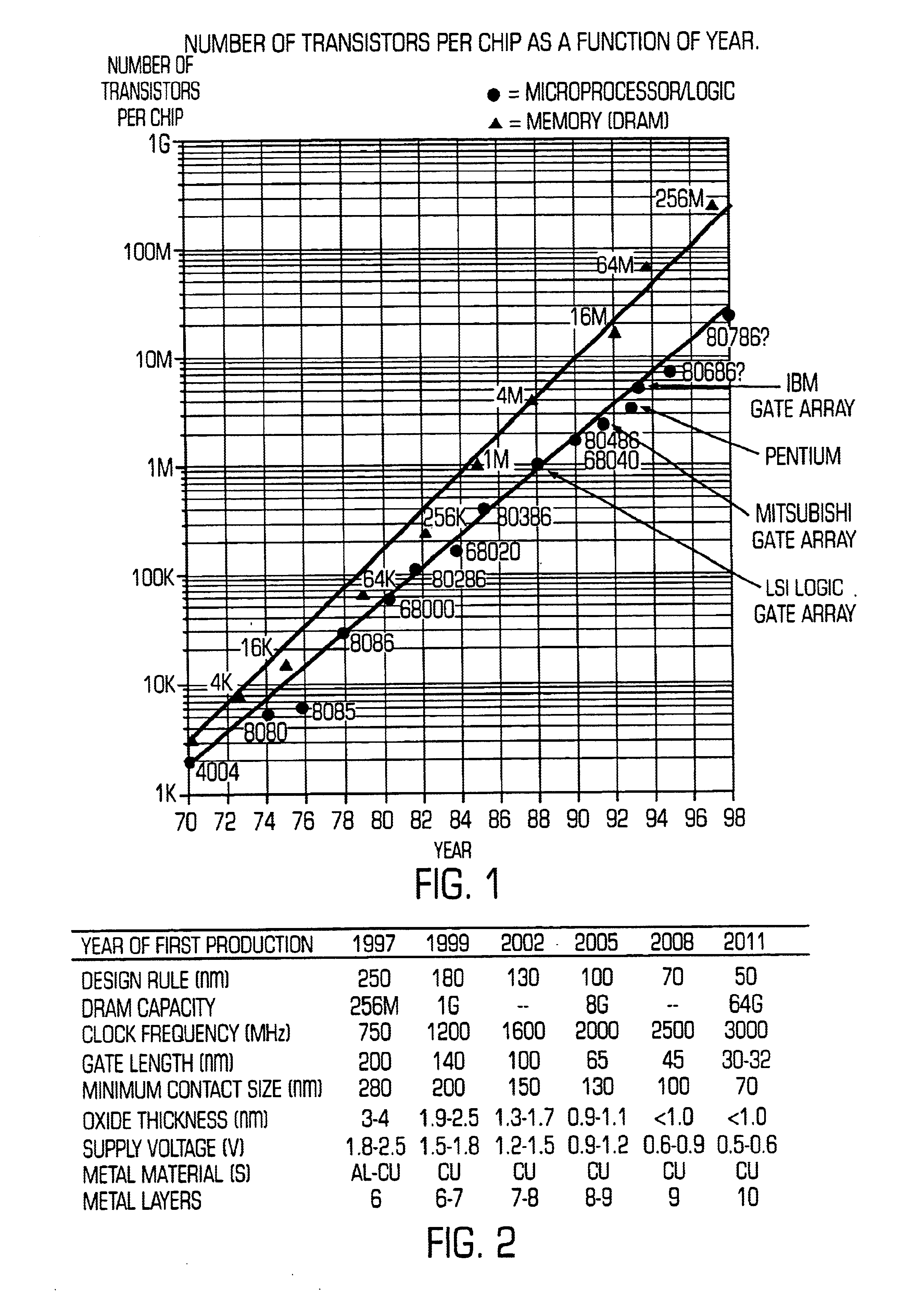

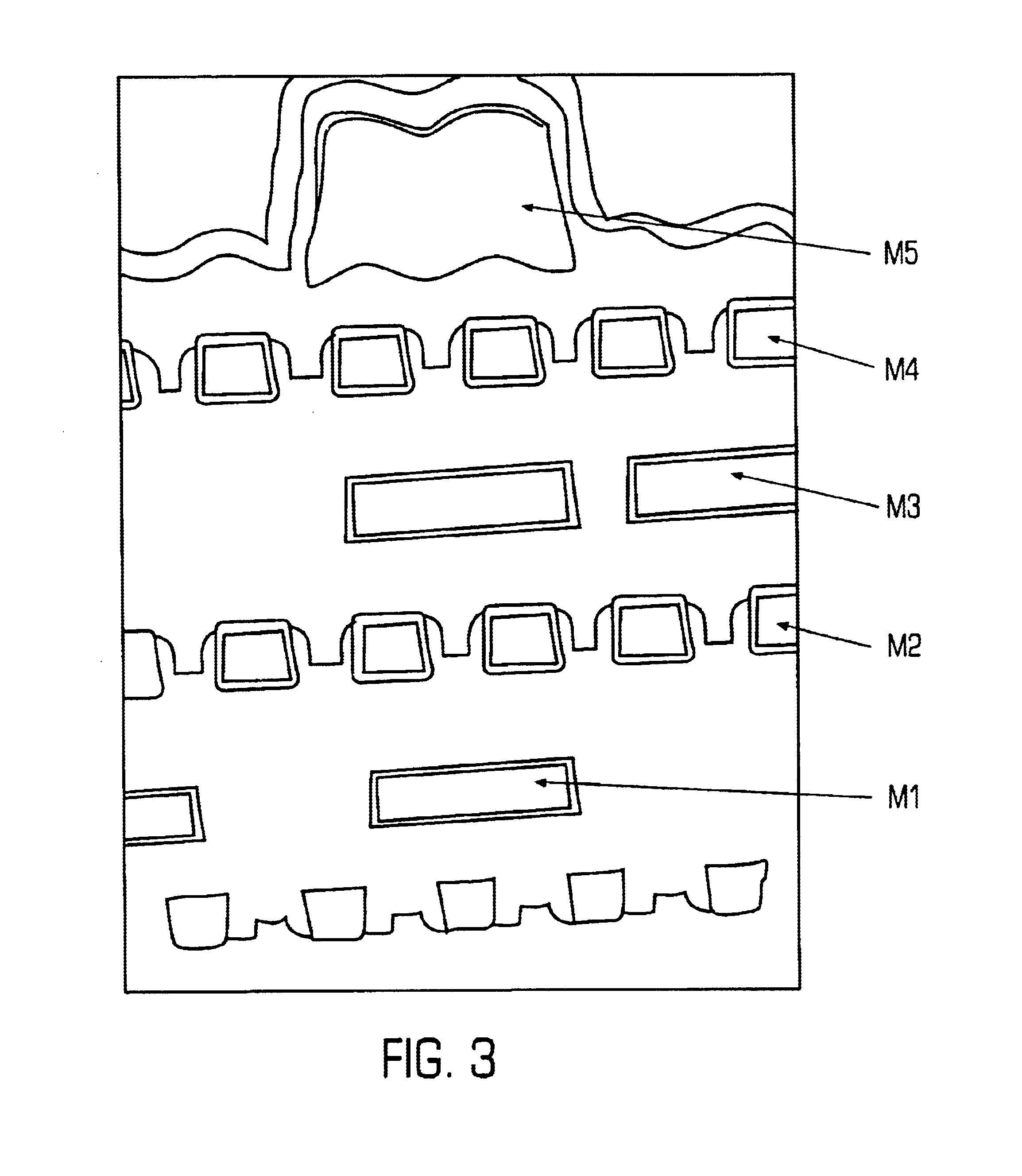

System and method of maximizing integrated circuit manufacturing yield with fabrication process simulation driven layout optimization

InactiveUS20080046846A1Maximizing manufacturing yieldYield maximizationCAD circuit designSoftware simulation/interpretation/emulationIntegrated circuit manufacturingEngineering

A system and a method of maximizing the manufacturing yield of integrated circuit (“IC”) design using IC fabrication process simulation driven layout optimization is described. An IC design layout is automatically modified through formulation of a layout optimization problem utilizing the results of layout fabrication process compliance analysis tools. The modification of layout is performed adaptively and iteratively to make an IC layout less susceptible to yield issues while maintaining design rule correctness and minimal circuit performance impact.

Owner:CHEW MARKO P +1

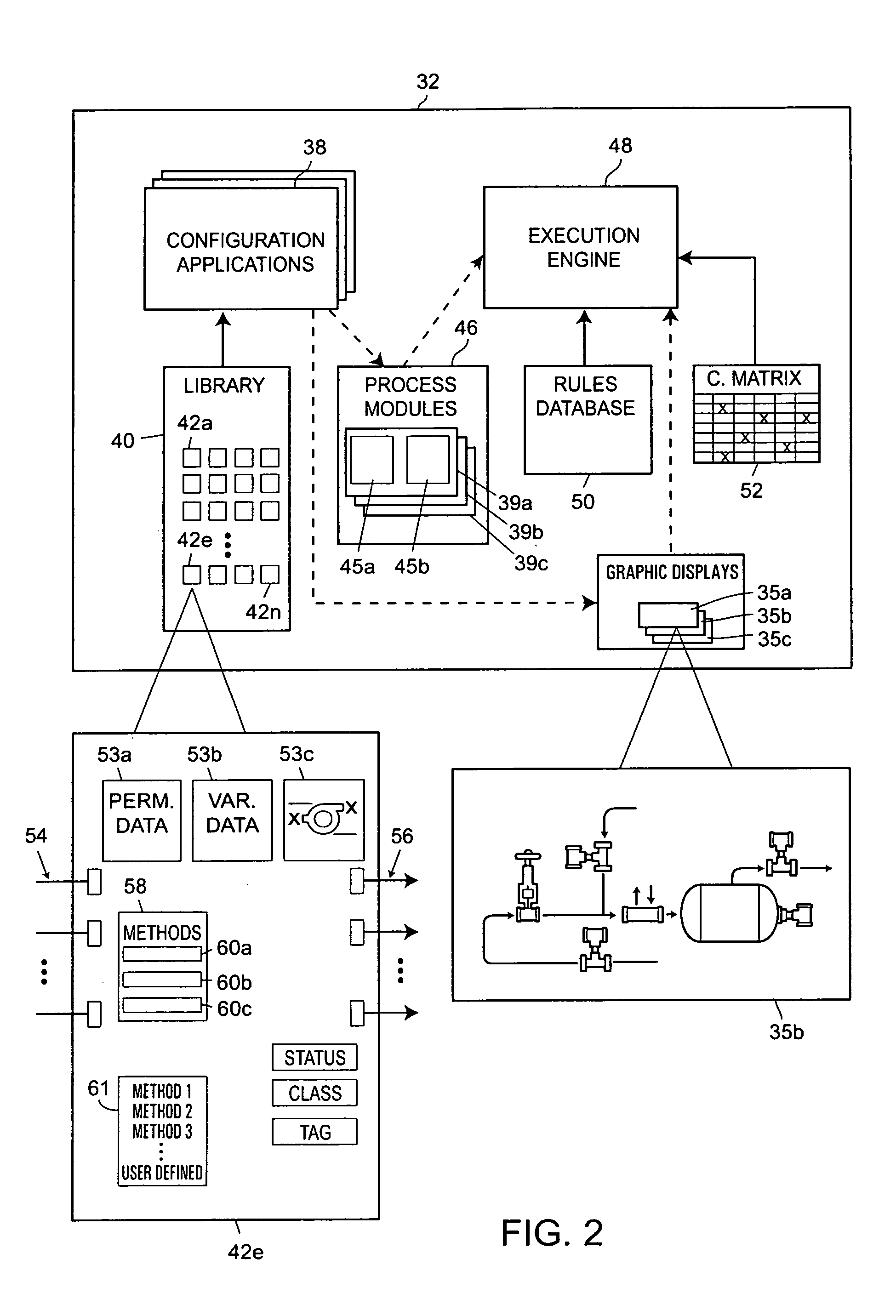

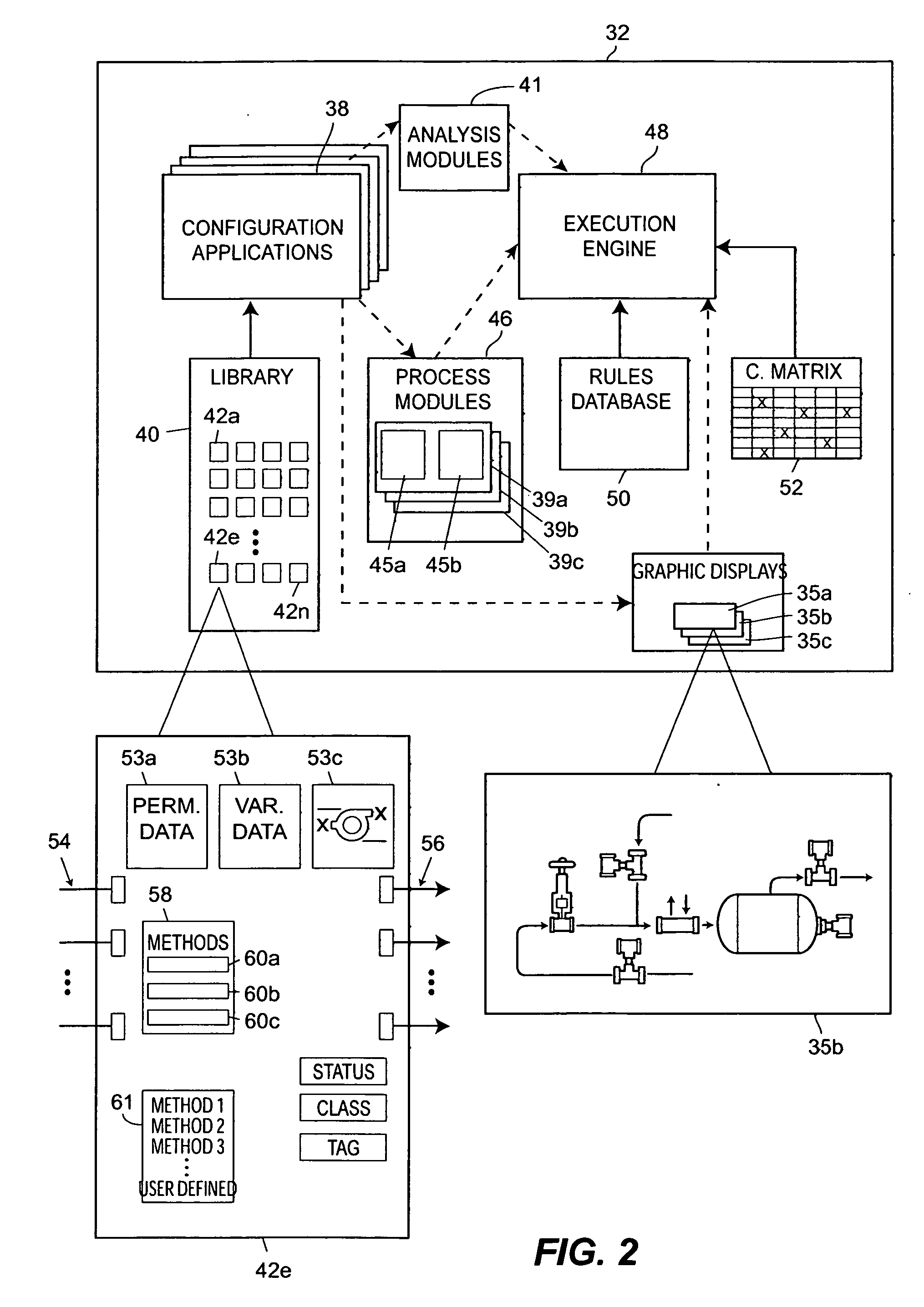

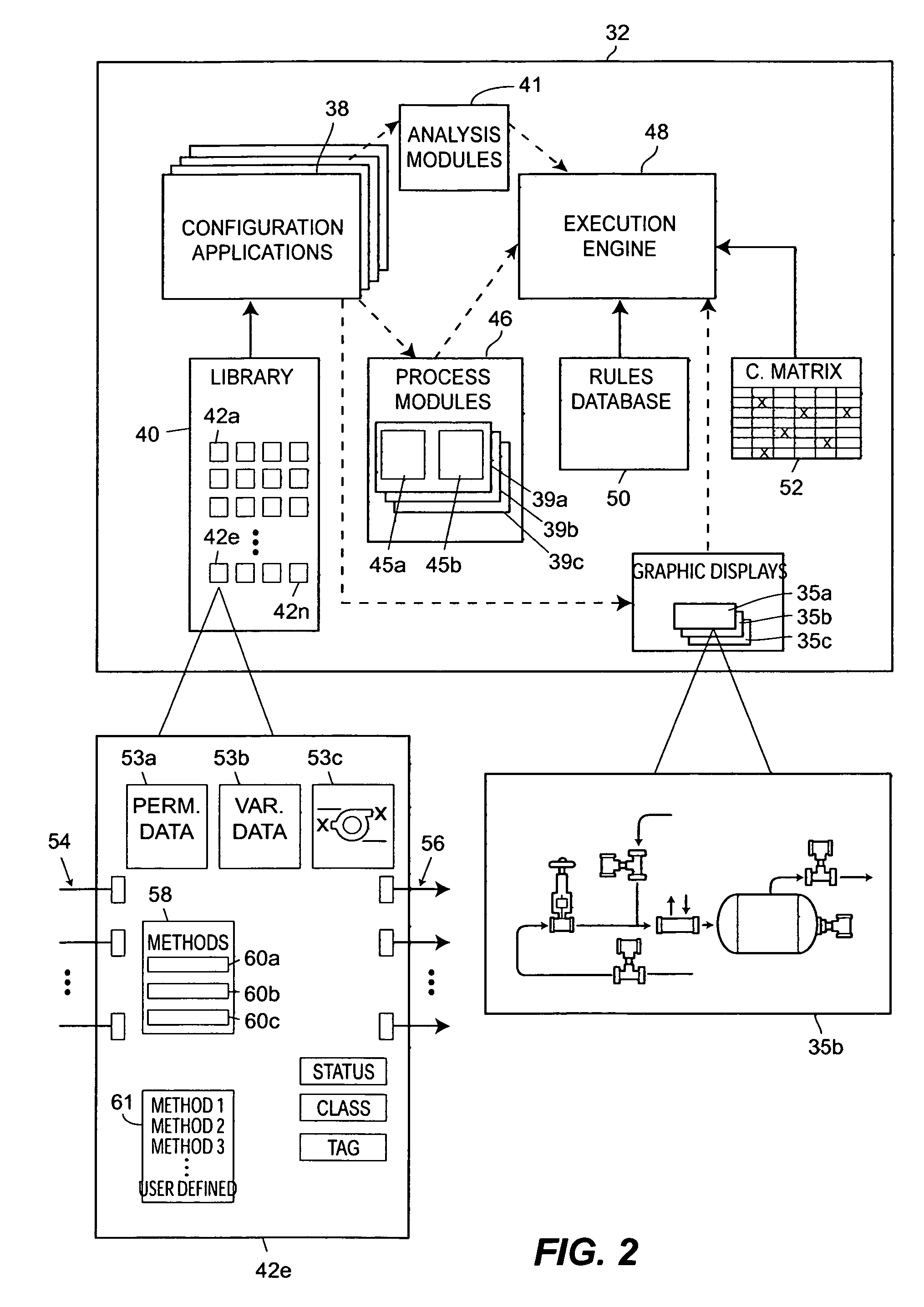

Smart process objects used in a process plant modeling system

ActiveUS20050096872A1Advanced and accurate simulationModel is usedProgramme controlComputer controlElectricityGraphics

Smart process objects, which have both graphical and simulation elements, may be used to create one or more graphic displays and one or more process simulation modules, each having elements which may communicate with one another and with devices within a process plant to model and depict the operation of a process plant. The smart process objects may include one or more device objects, which represent physical devices within the process plant, and may include one or more smart connection objects which represent and model the flow of a material, such as a gas, a liquid, a composition of solid, electricity, etc., through a connection between entities within the process plant. The smart process objects may also include one or more smart stream objects, which also may represent and model the flow of a material at a particular point in the process plant. The smart device, connection, and stream objects may be interconnected to model the flow of material through the actual physical devices within the process plant thereby enabling enhanced simulation and modeling capabilities with the smart connection and stream objects providing a convenient manner of enabling different entities and sections of a process model to be tied to one another.

Owner:FISHER-ROSEMOUNT SYST INC

Process plant monitoring based on multivariate statistical analysis and on-line process simulation

ActiveUS20070005266A1Electric testing/monitoringTechnology managementMultivariate statisticalProcess measurement

Disclosed are systems and methods for on-line monitoring of operation of a process in connection with process measurements indicative of the operation of the process. In some cases, the operation of the process is simulated to generate model data indicative of a simulated representation of the operation of the process and based on the process measurements. A multivariate statistical analysis of the operation of the process is implemented based on the model data and the process measurements. The output data from the multivariate statistical analysis may then be evaluated during the operation of the process to enable the on-line monitoring of the process involving, for instance, fault detection via classification analysis of the output data.

Owner:FISHER-ROSEMOUNT SYST INC

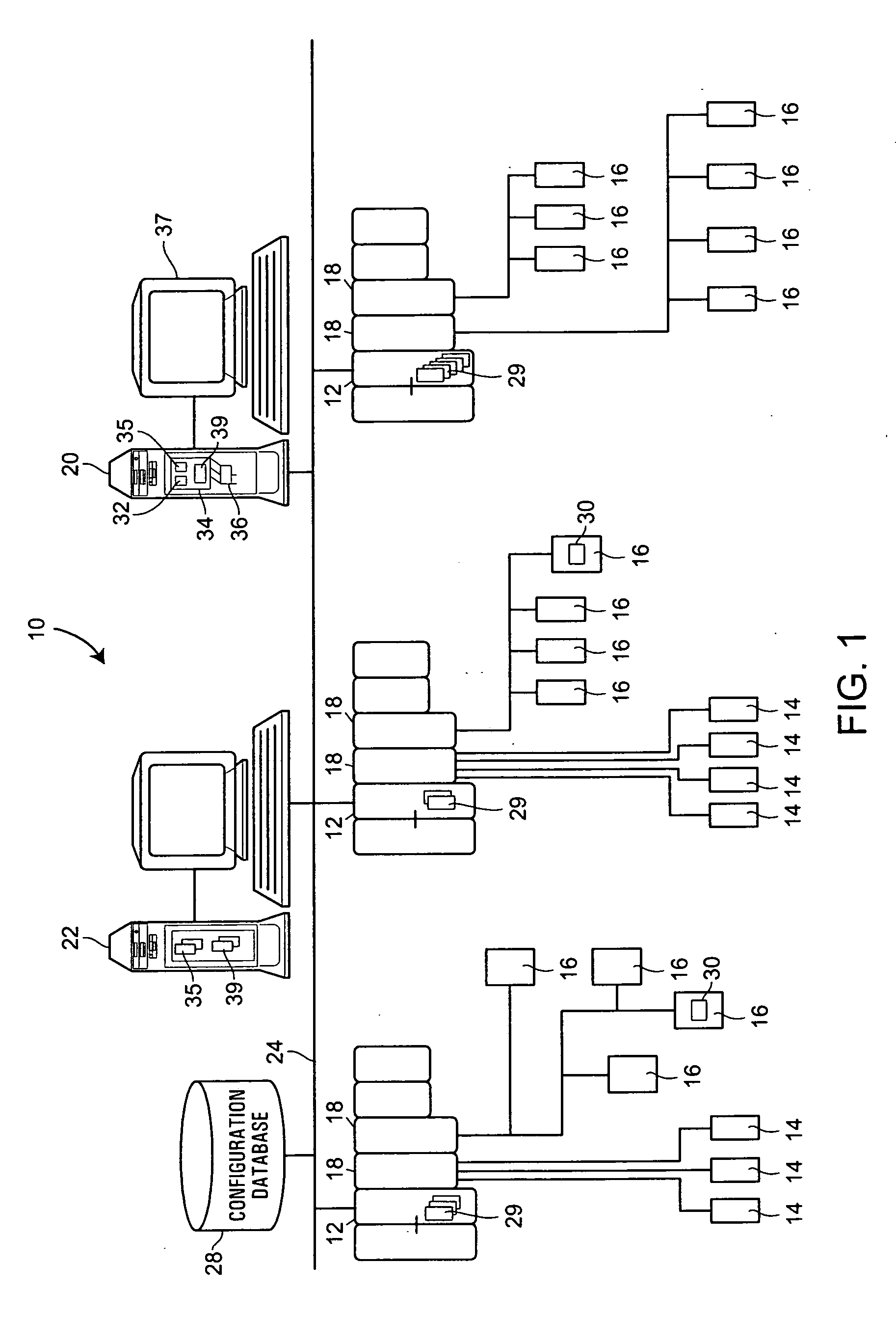

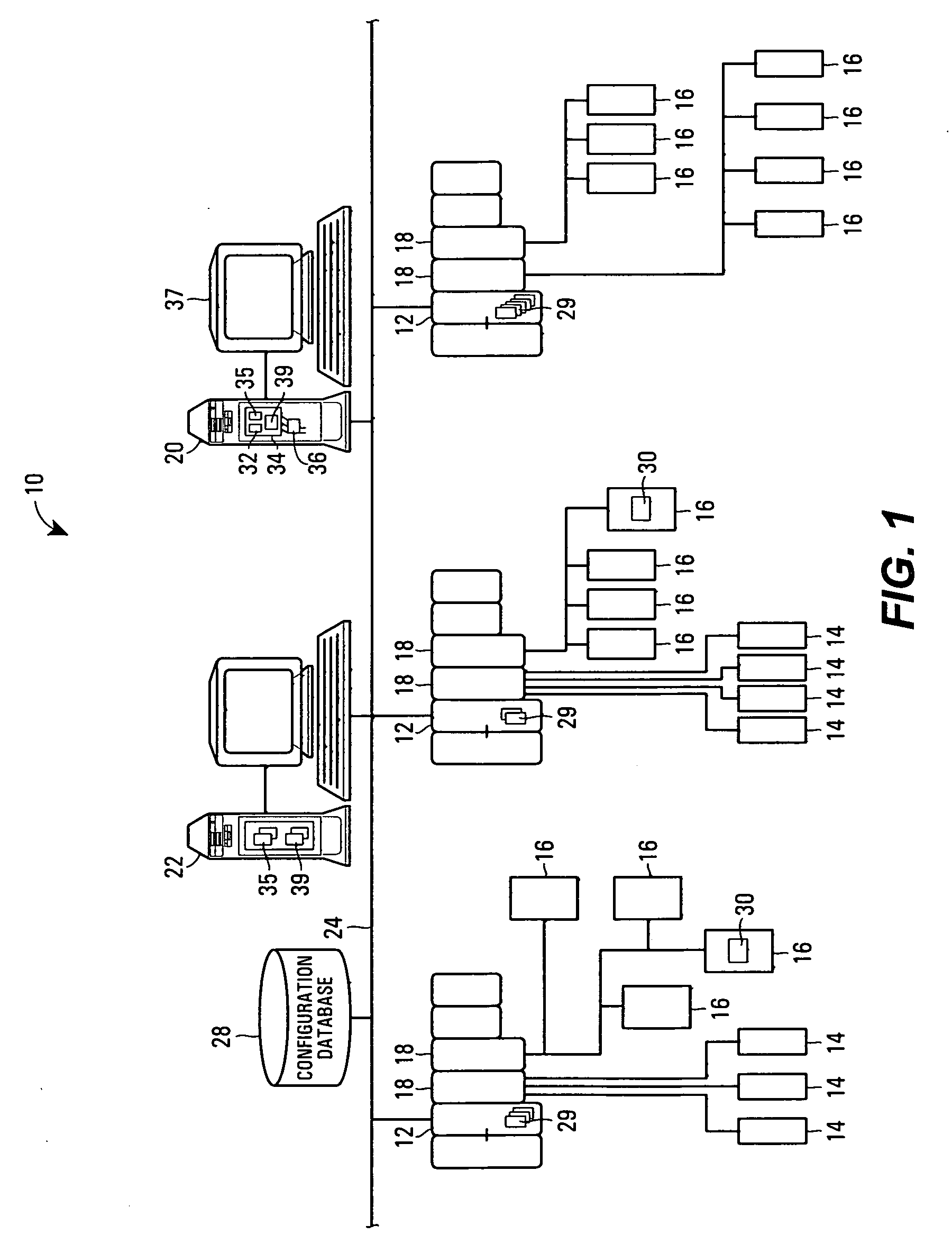

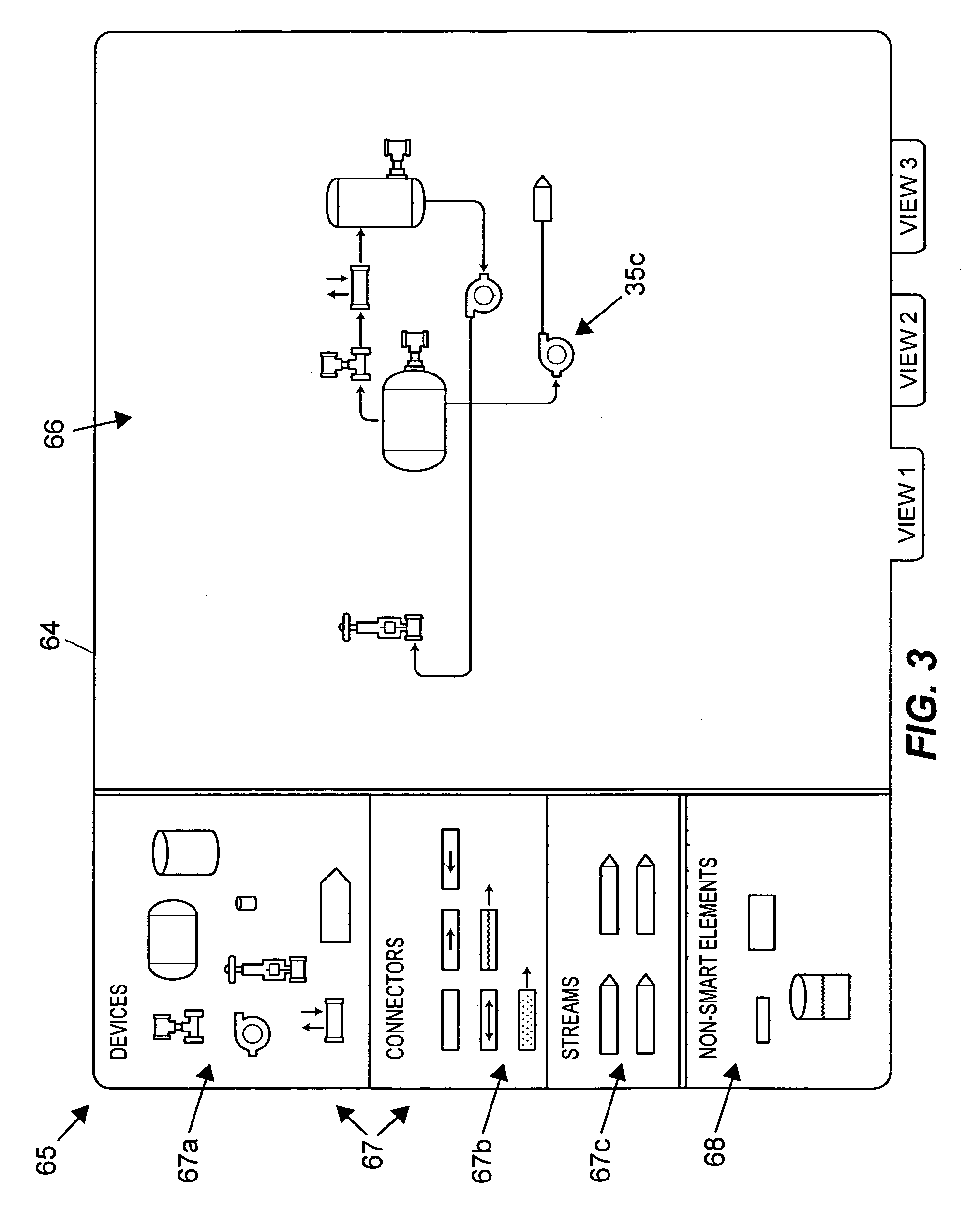

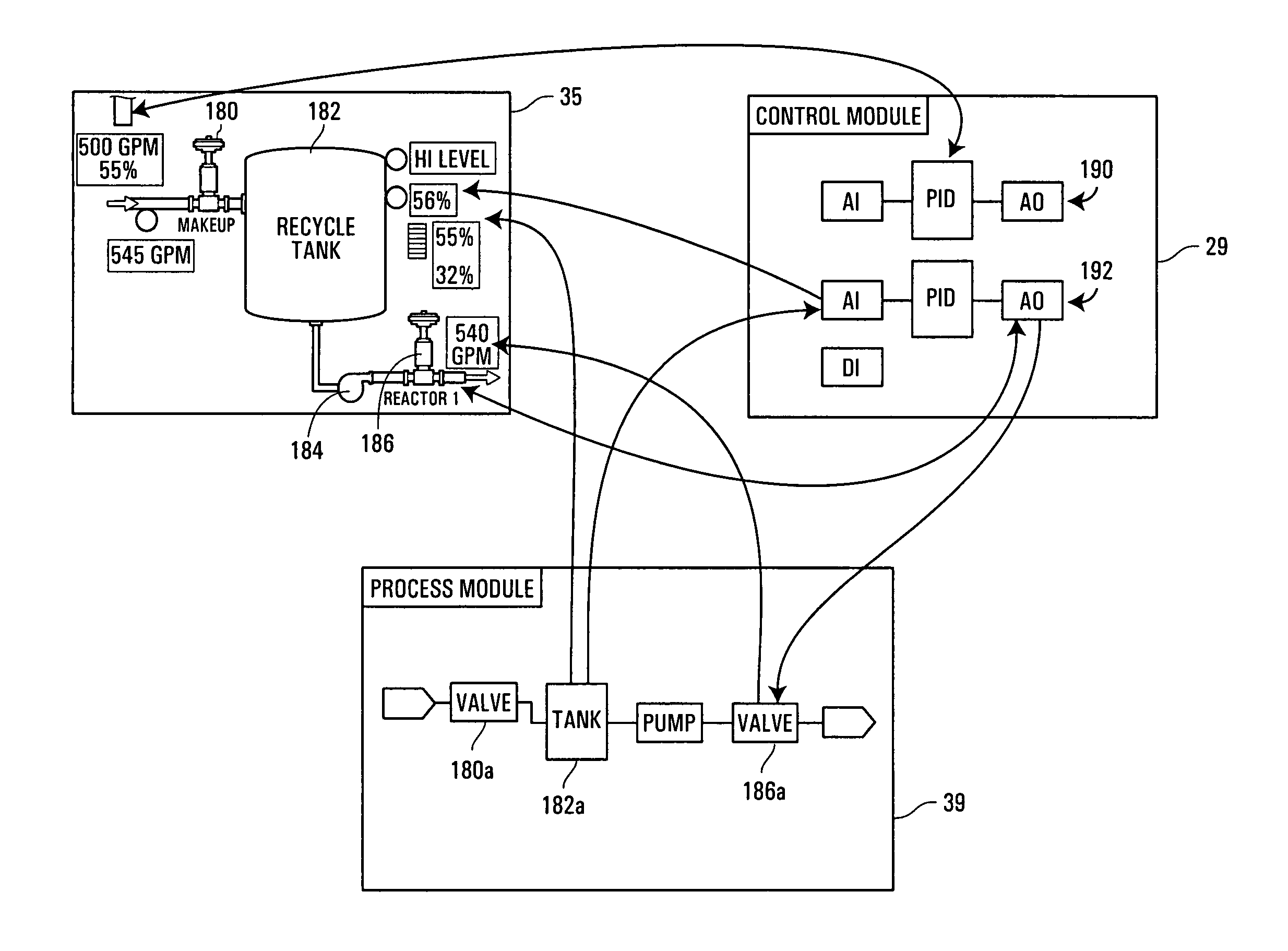

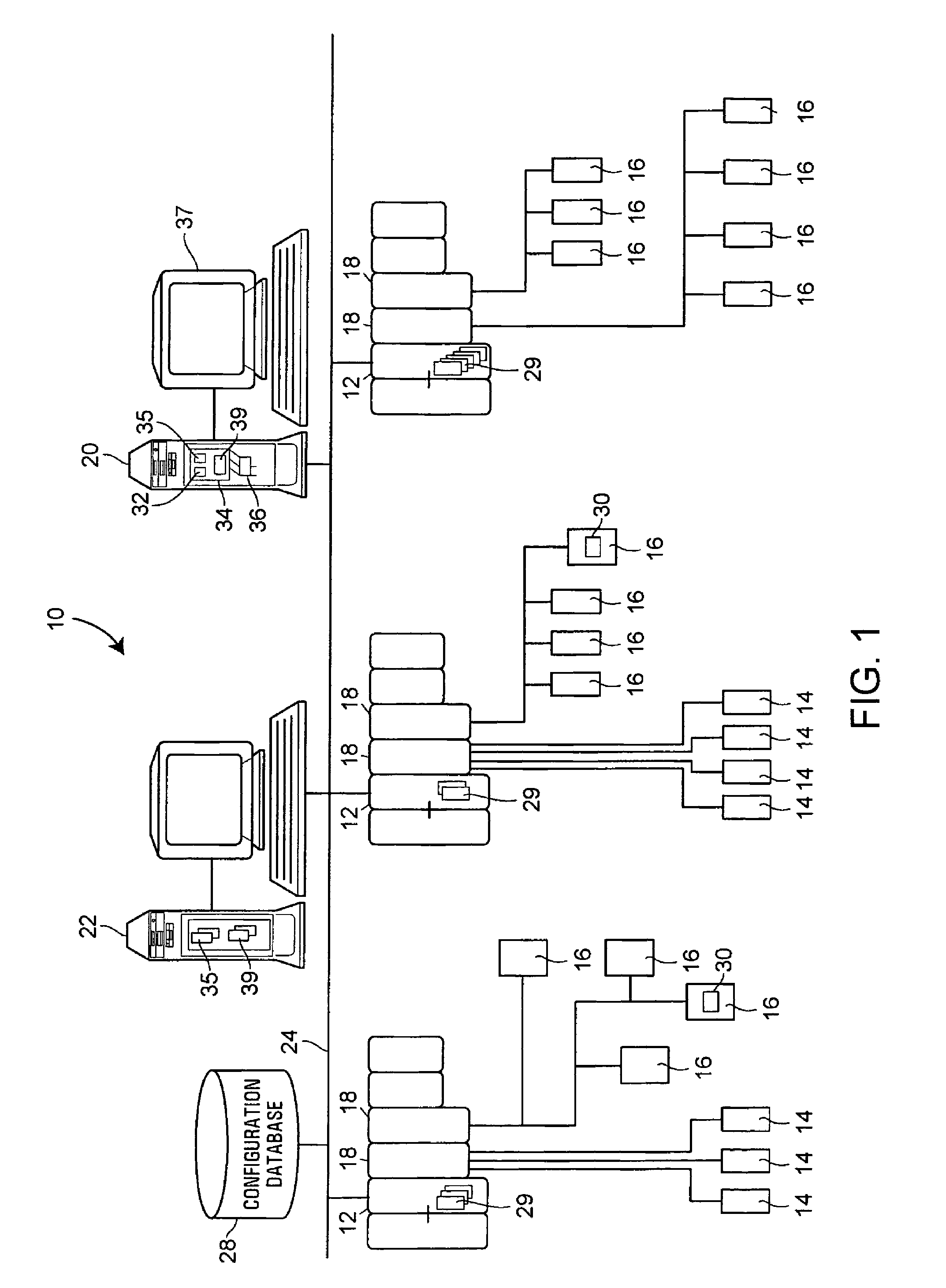

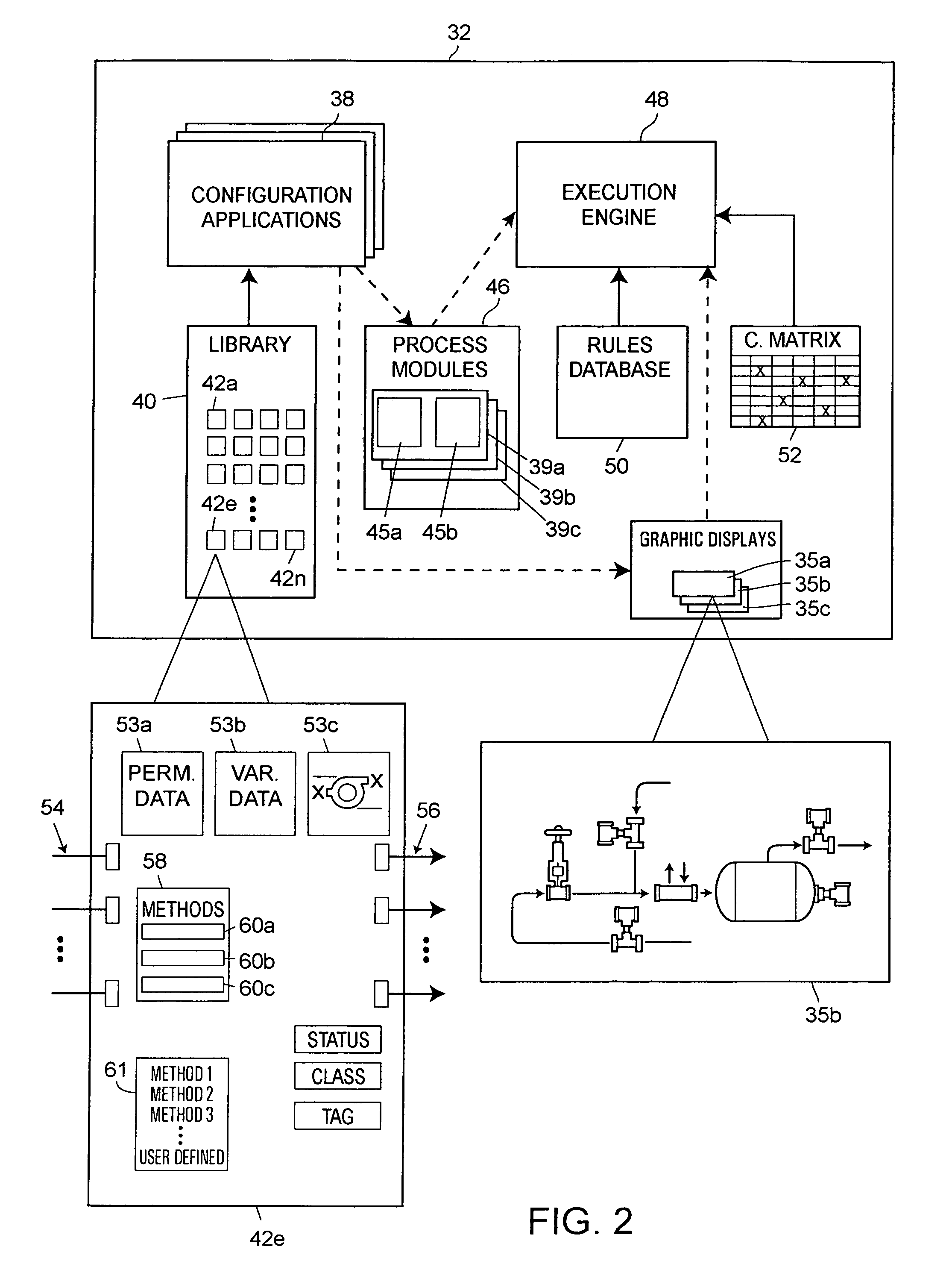

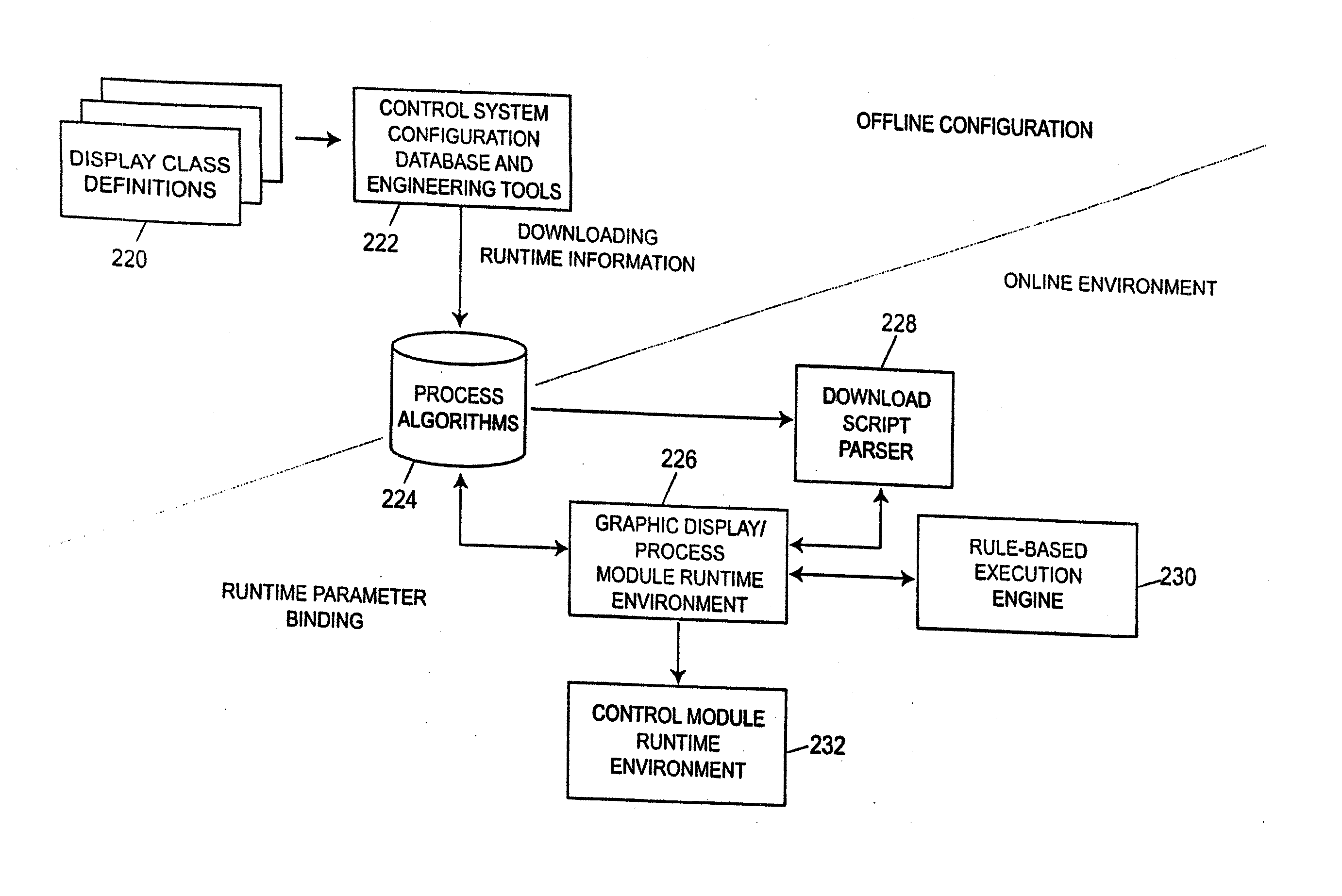

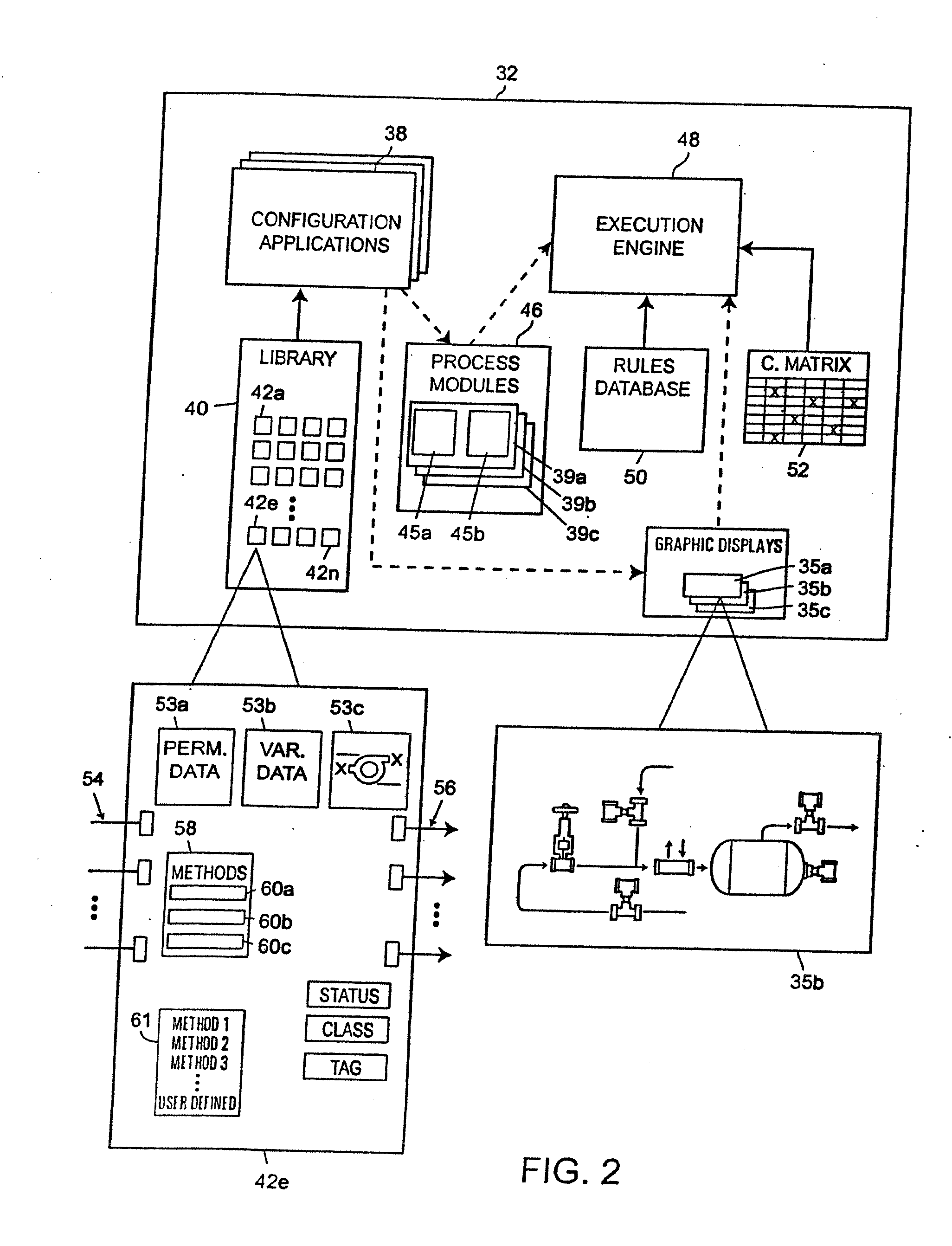

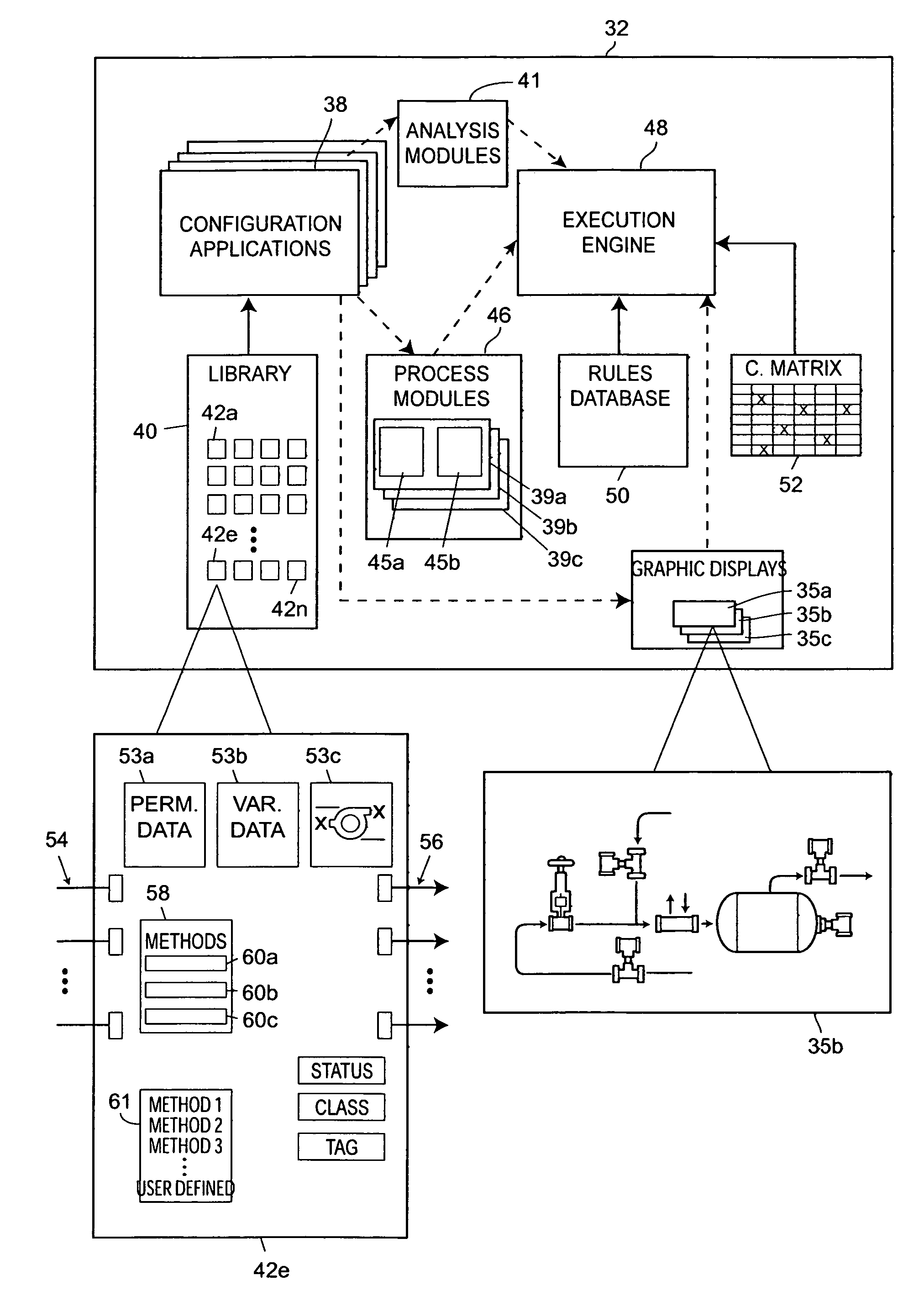

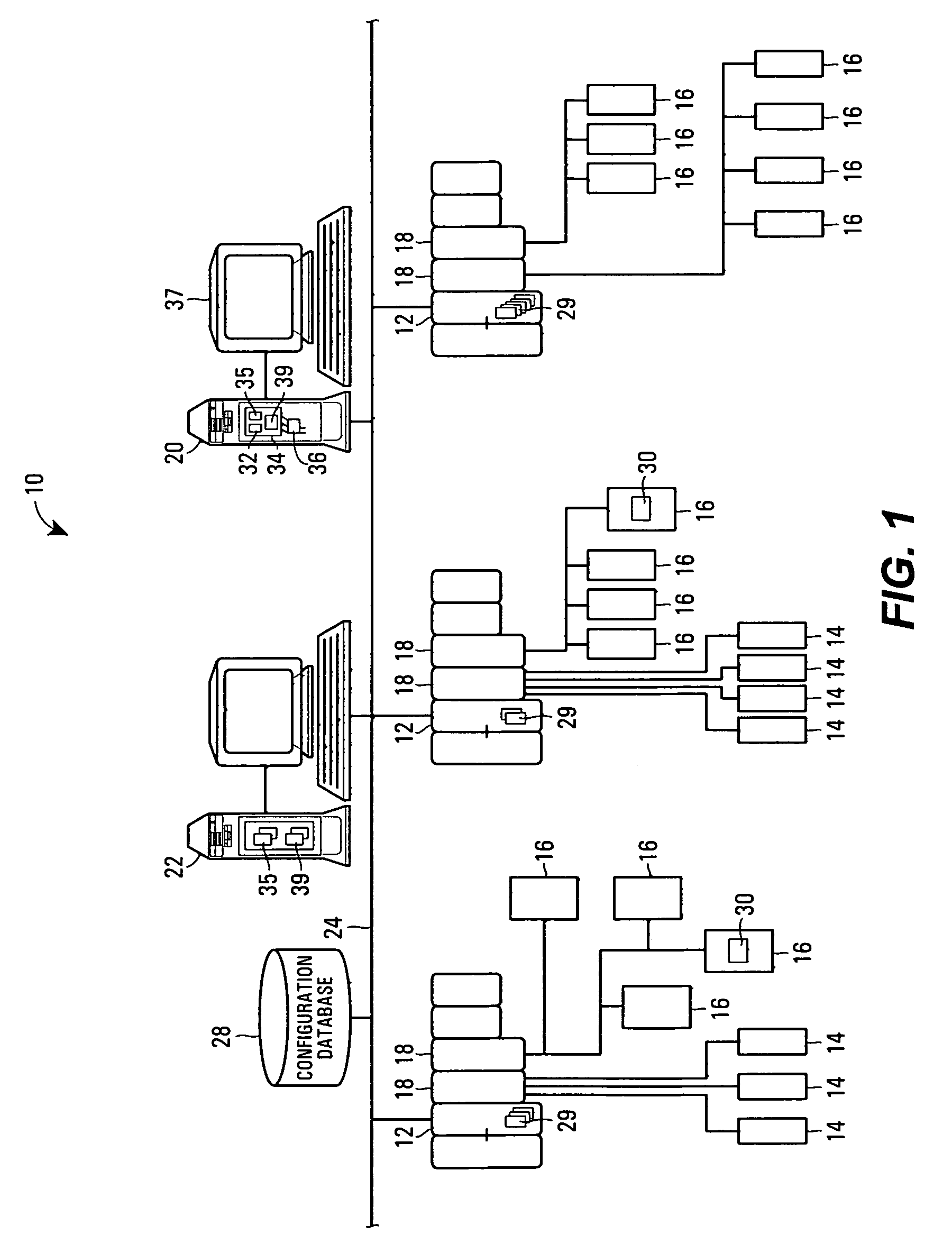

Integration of graphic display elements, process modules and control modules in process plants

InactiveUS7110835B2Easy to useEasy to implementSpace heating and ventilationDomestic heating detailsGraphicsProcess module

Graphic displays, which display information about process elements and the manner in which these elements are connected within a process, process modules, which simulate the operation of the elements depicted within the graphic displays and control modules, which perform on-line control activities within a process, may be communicatively connected together to provide a combined control, simulation and display environment that enables enhanced control, simulation and display activities. Smart process objects, which have both graphical and simulation elements, may used to create one or more graphic displays and one or more process simulation modules, each having elements which may communicate with one another to share data between the graphic displays and the process modules. Additionally, function blocks within control modules executed in the process plant may reference the elements within the graphic displays and the process modules (and vice versa) so that control modules may use simulated data developed by the process modules to perform better control, so that process modules may perform better simulation using actual pant data from the control modules, and so that the graphic displays may be used to illustrate actual process data and / or simulated process data as developed by the control modules and the process modules.

Owner:FISHER-ROSEMOUNT SYST INC

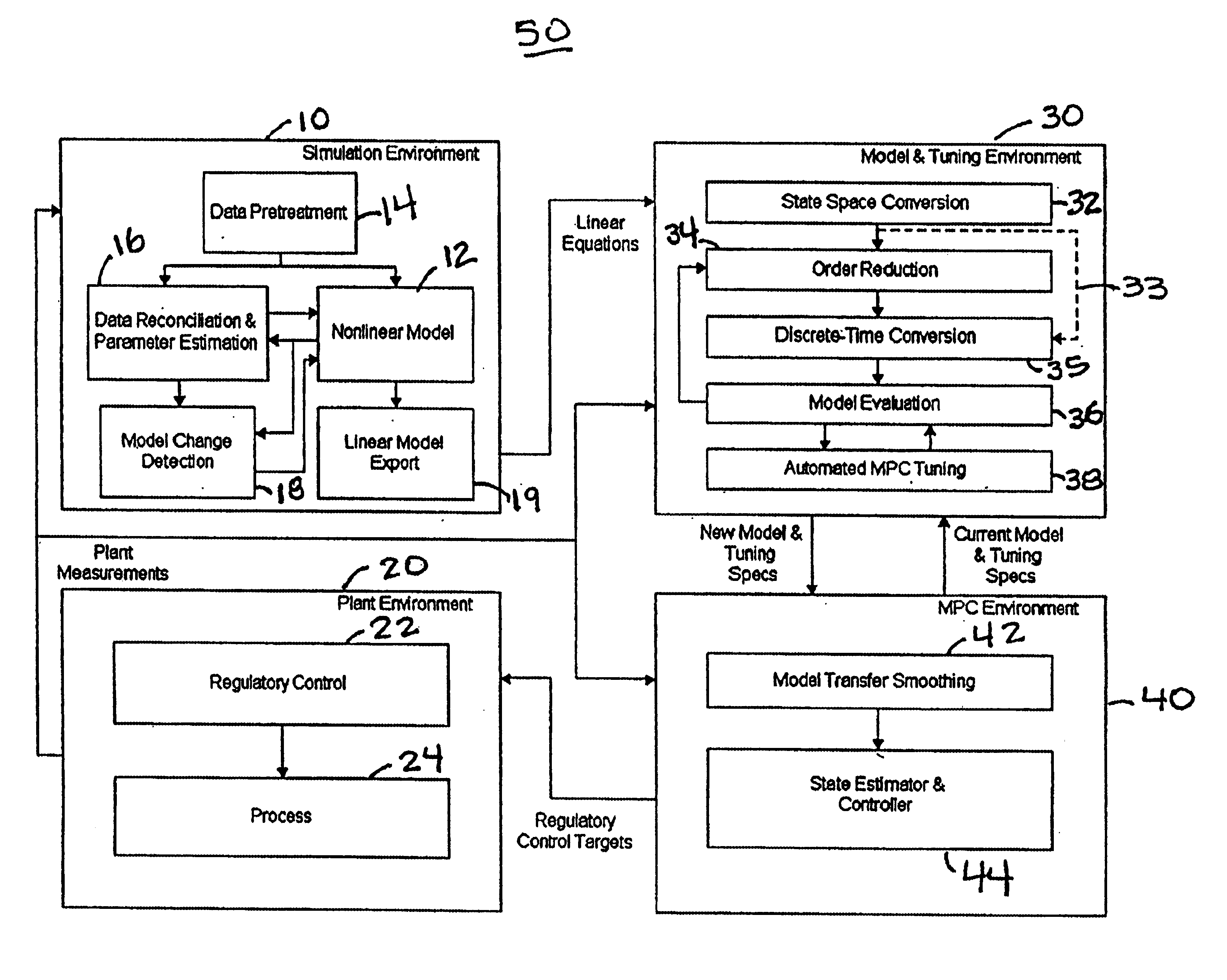

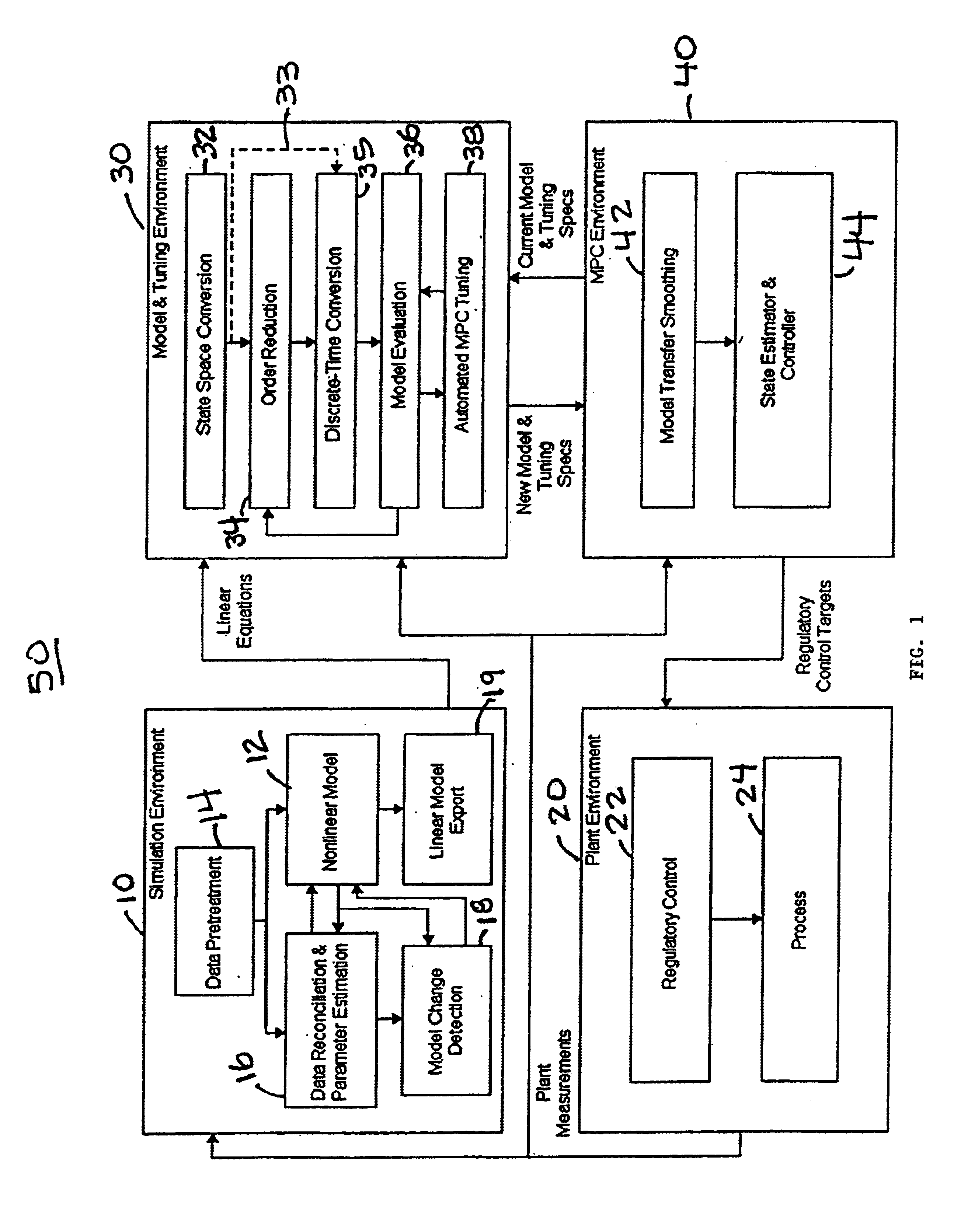

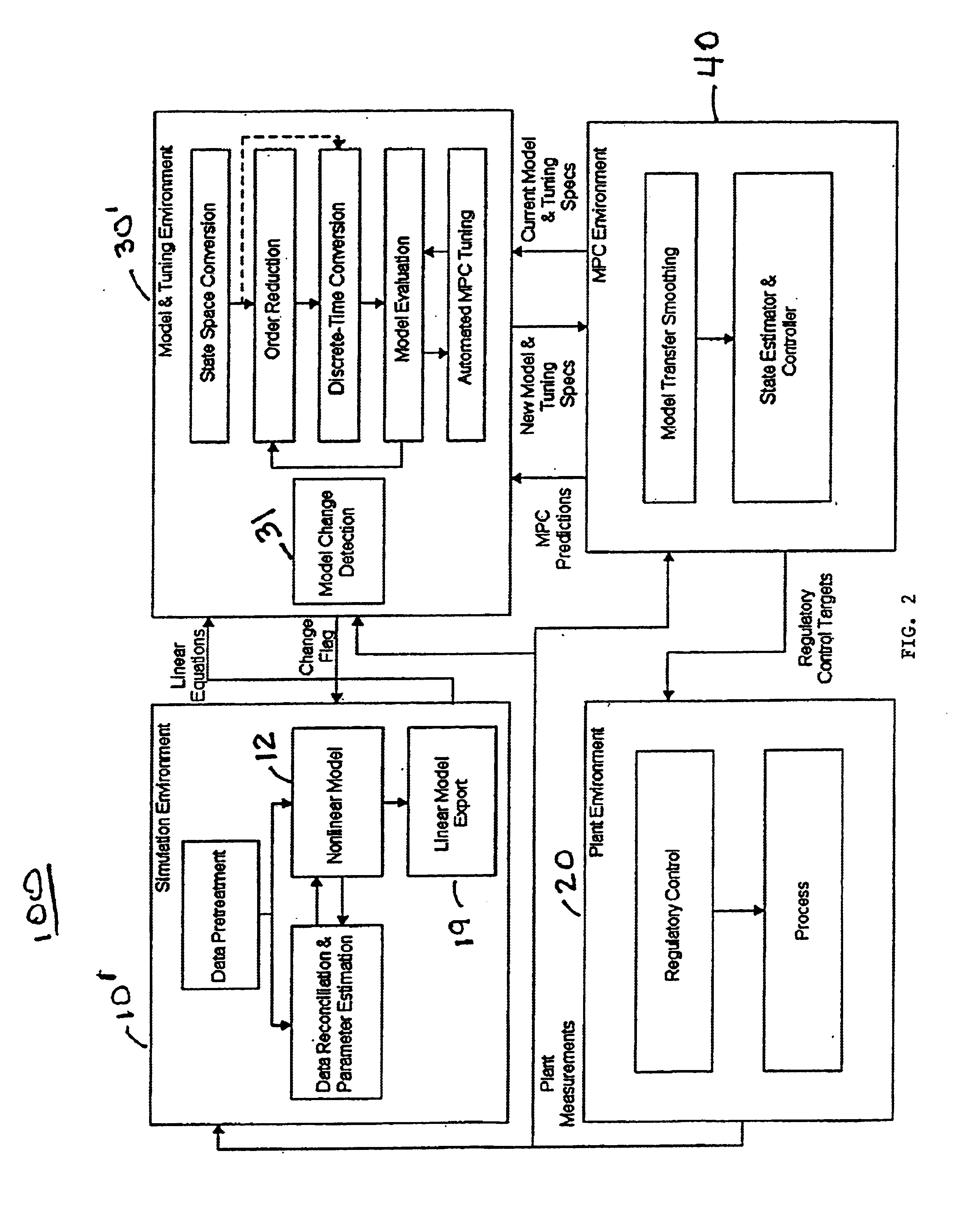

System and methodology and adaptive, linear model predictive control based on rigorous, nonlinear process model

InactiveUS6826521B1Analogue computers for chemical processesAdaptive controlSoftware systemPredictive controller

A methodology for process modeling and control and the software system implementation of this methodology, which includes a rigorous, nonlinear process simulation model, the generation of appropriate linear models derived from the rigorous model, and an adaptive, linear model predictive controller (MPC) that utilizes the derived linear models. A state space, multivariable, model predictive controller (MPC) is the preferred choice for the MPC since the nonlinear simulation model is analytically translated into a set of linear state equations and thus simplifies the translation of the linearized simulation equations to the modeling format required by the controller. Various other MPC modeling forms such as transfer functions, impulse response coefficients, and step response coefficients may also be used. The methodology is very general in that any model predictive controller using one of the above modeling forms can be used as the controller. The methodology also includes various modules that improve reliability and performance. For example, there is a data pretreatment module used to pre-process the plant measurements for gross error detection. A data reconciliation and parameter estimation module is then used to correct for instrumentation errors and to adjust model parameters based on current operating conditions. The full-order state space model can be reduced by the order reduction module to obtain fewer states for the controller model. Automated MPC tuning is also provided to improve control performance.

Owner:ABB AUTOMATION INC

Updating and Utilizing Dynamic Process Simulation in an Operating Process Environment

InactiveUS20070208549A1Easy to useAdvanced and accurate simulationProgramme controlSimulator controlEngineeringProcess simulation

A simulation system that includes interconnected simulation blocks which use process models to perform simulation activities for a process plant is integrated into a process control environment for the process plant in a manner that makes the simulation system easy to use and easily updated for on-line process simulation. The disclosed simulation system enables future predicted values as well as the current predicted values of process parameters produced by the simulation system to be made available for performance evaluation as well as to guide plant operations. Additionally, the simulation system is connected to the operating process plant to receive various on-line process plant measurements, and uses these measurements to automatically update the process models used in the simulation system, to thereby keep the simulation system coordinated with the actual operating conditions of the process plant.

Owner:FISHER-ROSEMOUNT SYST INC

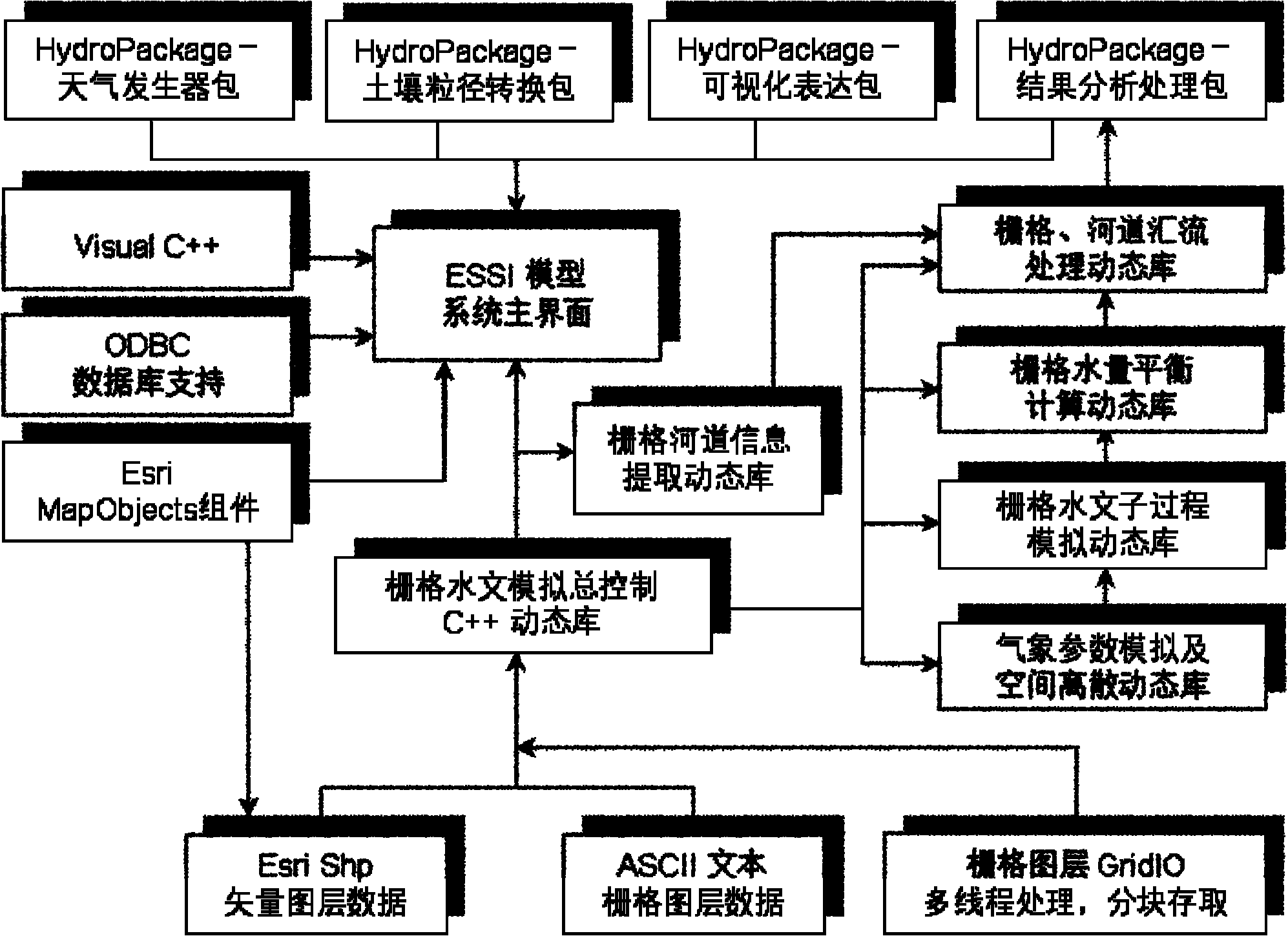

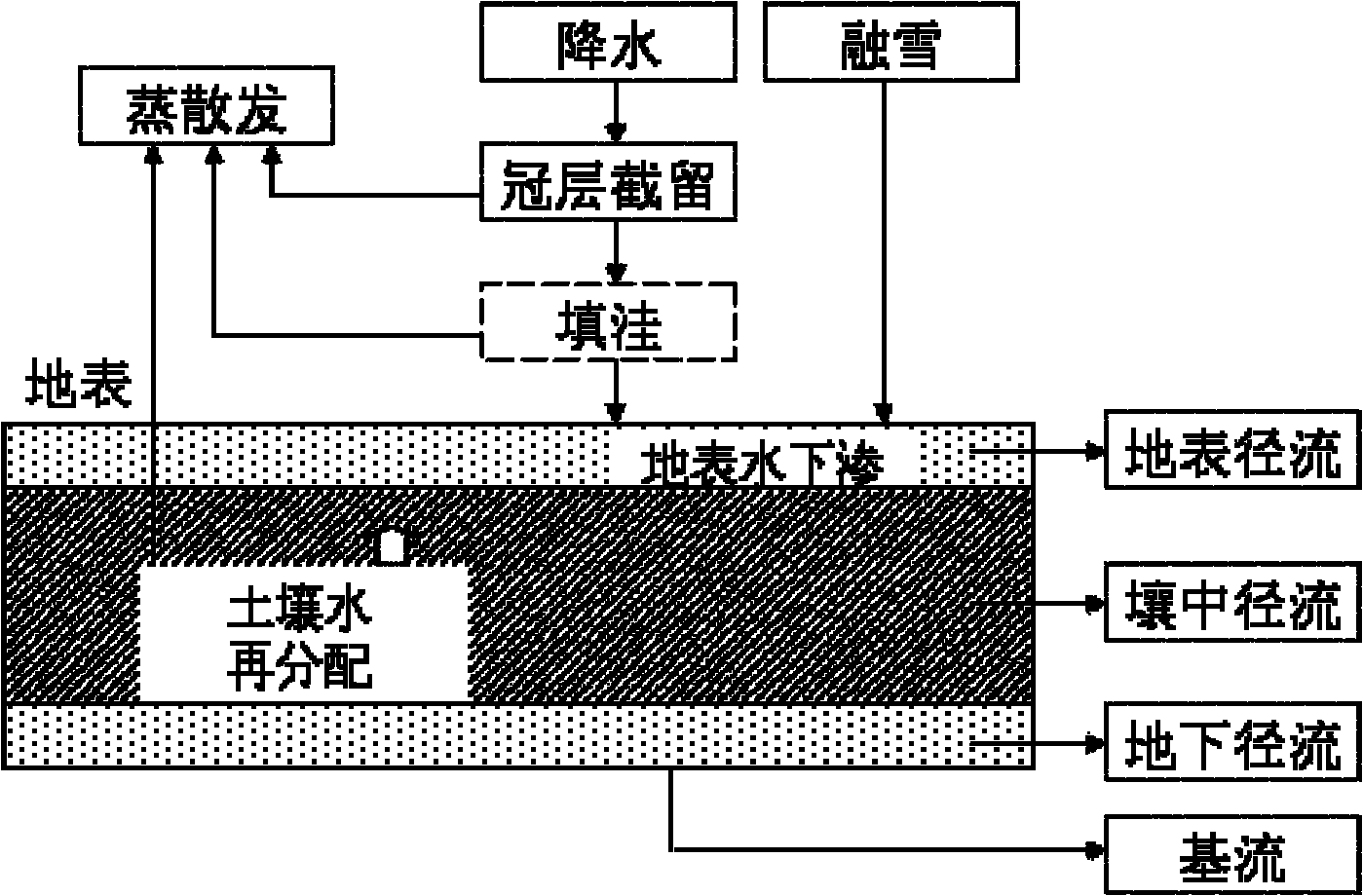

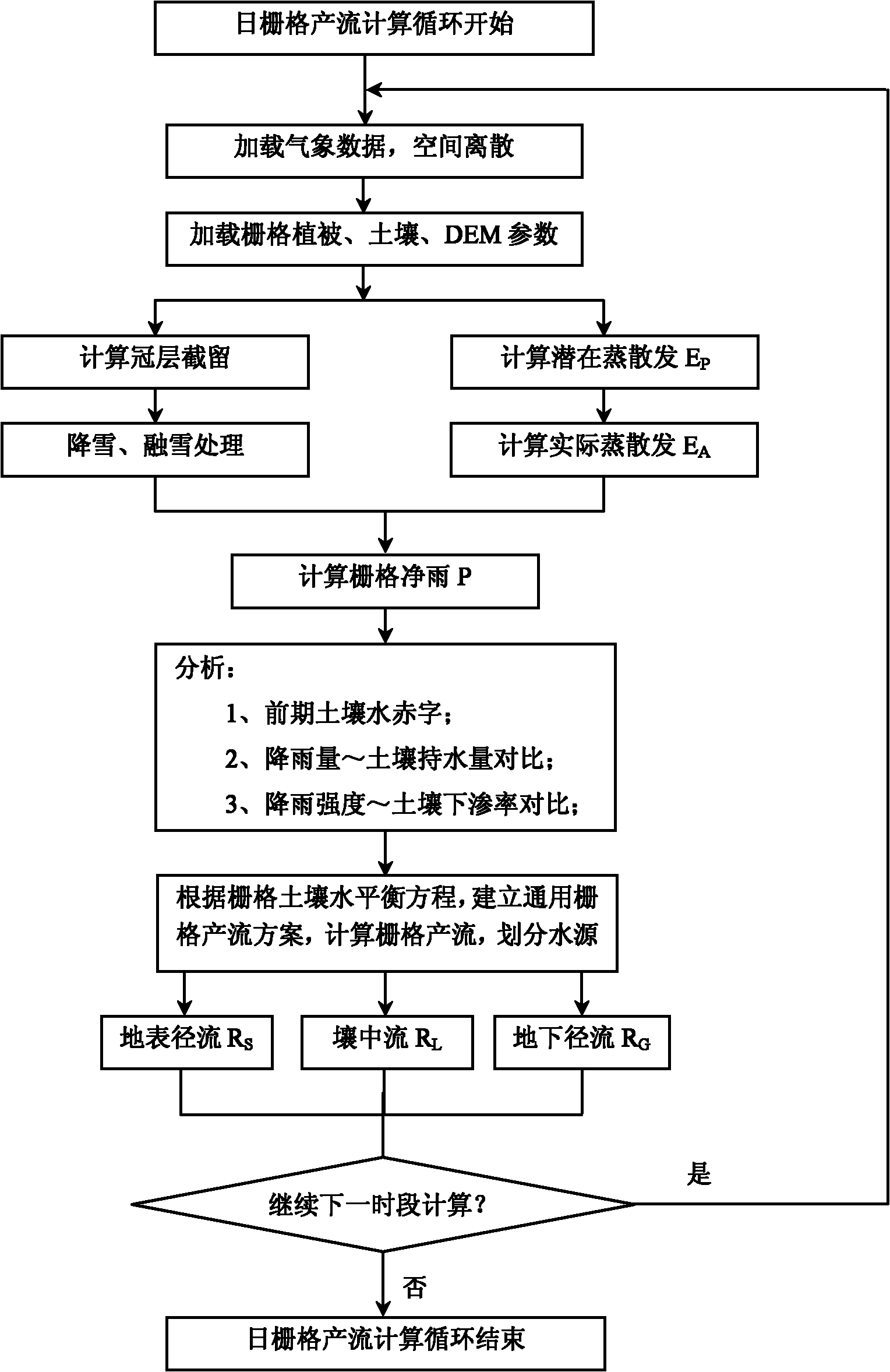

Design method for distributed hydrological model by using grid as analog unit

InactiveCN102034001AImprove scalabilityImprove execution efficiencyClimate change adaptationSpecial data processing applicationsAridRainfall runoff

The invention discloses a design method for a distributed hydrological model by using a grid as an analog unit, which is called as ESSI for short. The design method comprises the following steps of: obtainment of a distributed parameter: converting vector data into grid data; generalization of a watershed hydrological process: establishing a universal runoff generating type for the grid; design of a runoff generating process: respectively computing the water-quantity distributing condition of each part according to different prior-period soil water conditions; design of a flow collecting process: respectively designing a Muskingum-Cunge method, a delay algorithm and a riverway segmentation Muskingum method for the flow collecting process computation of the model under different conditions; and model development and integration. The invention not only can finish the watershed hydrological process simulation at an arid region and a humid region, but also can realize the short-term flood forecast and the long-term rainfall-runoff process simulation and prediction of a watershed by using modularization and integration ideas as means, thereby providing scientific reference bases for deeply learning about the physical mechanism of water circulation by people, reducing the drought and water-logging disasters and reasonably developing and utilizing water resources.

Owner:NANJING UNIV

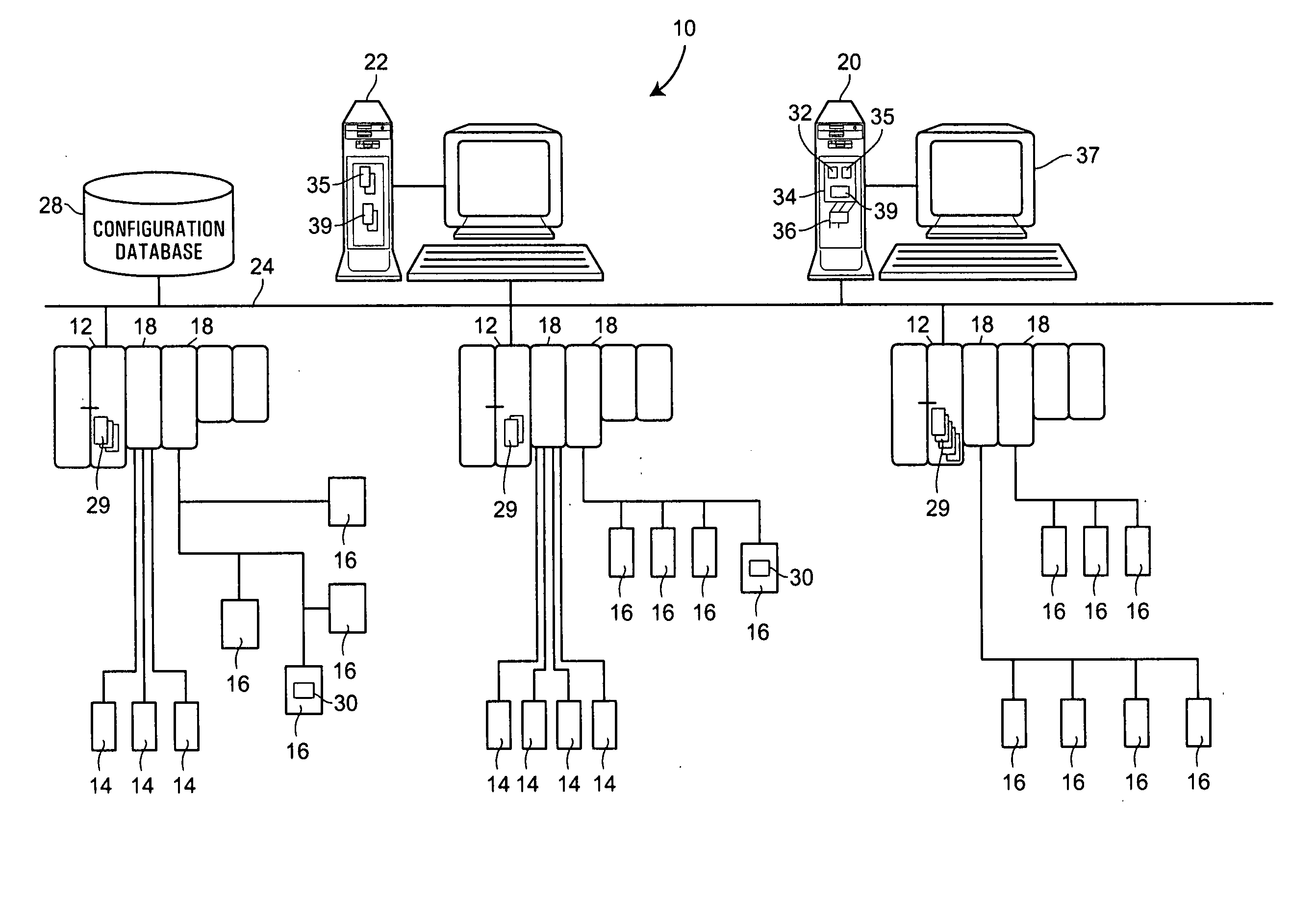

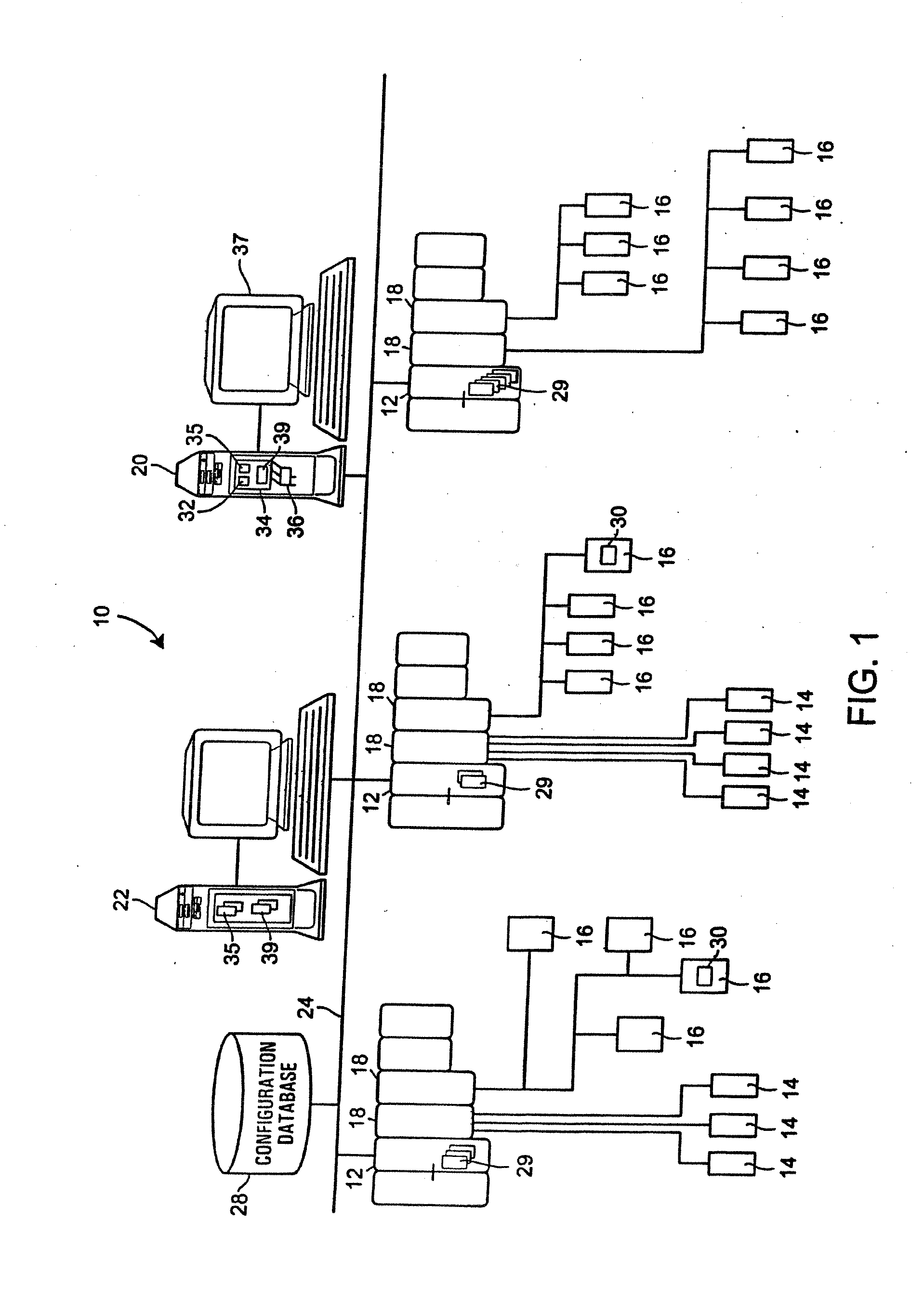

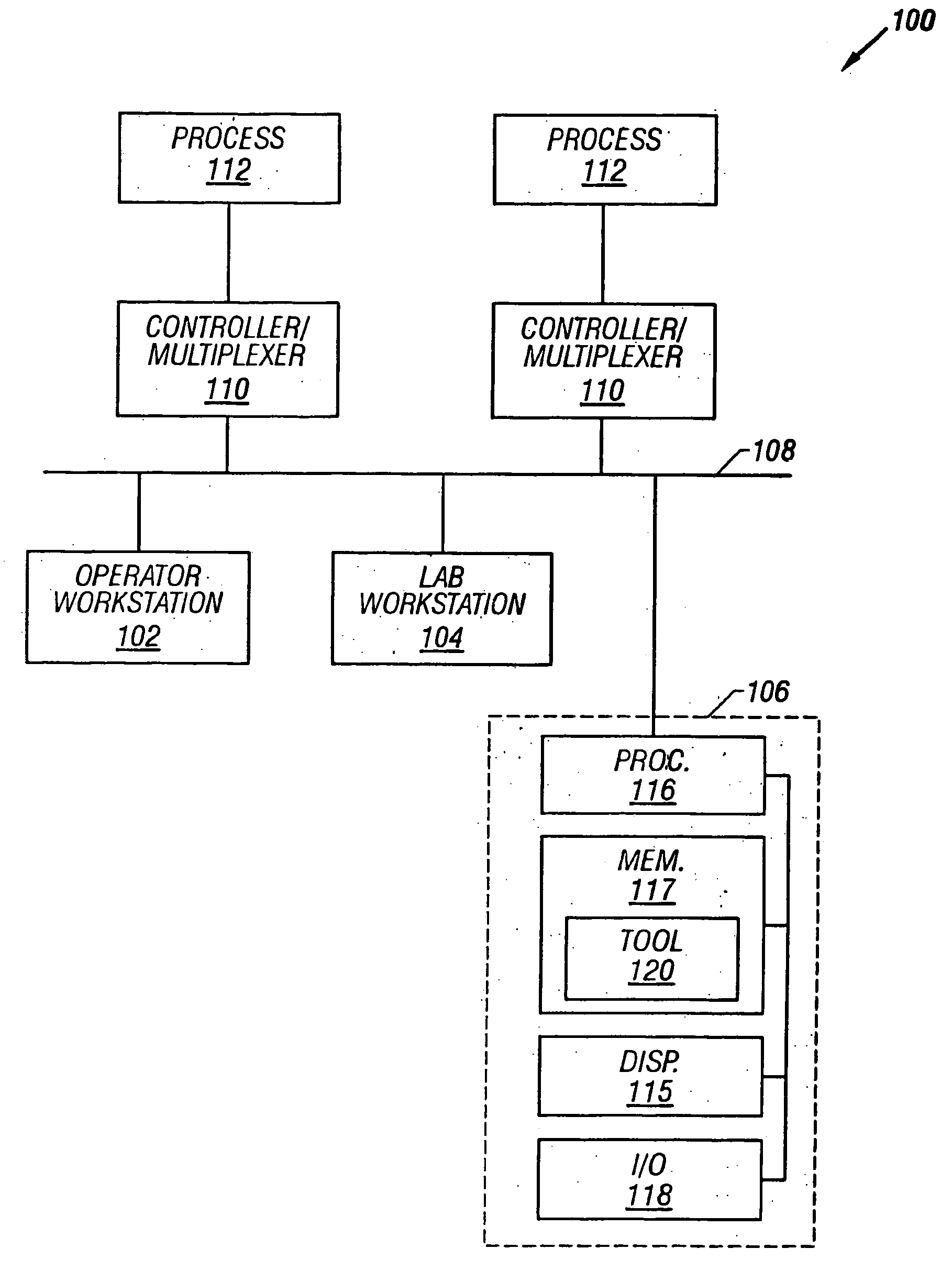

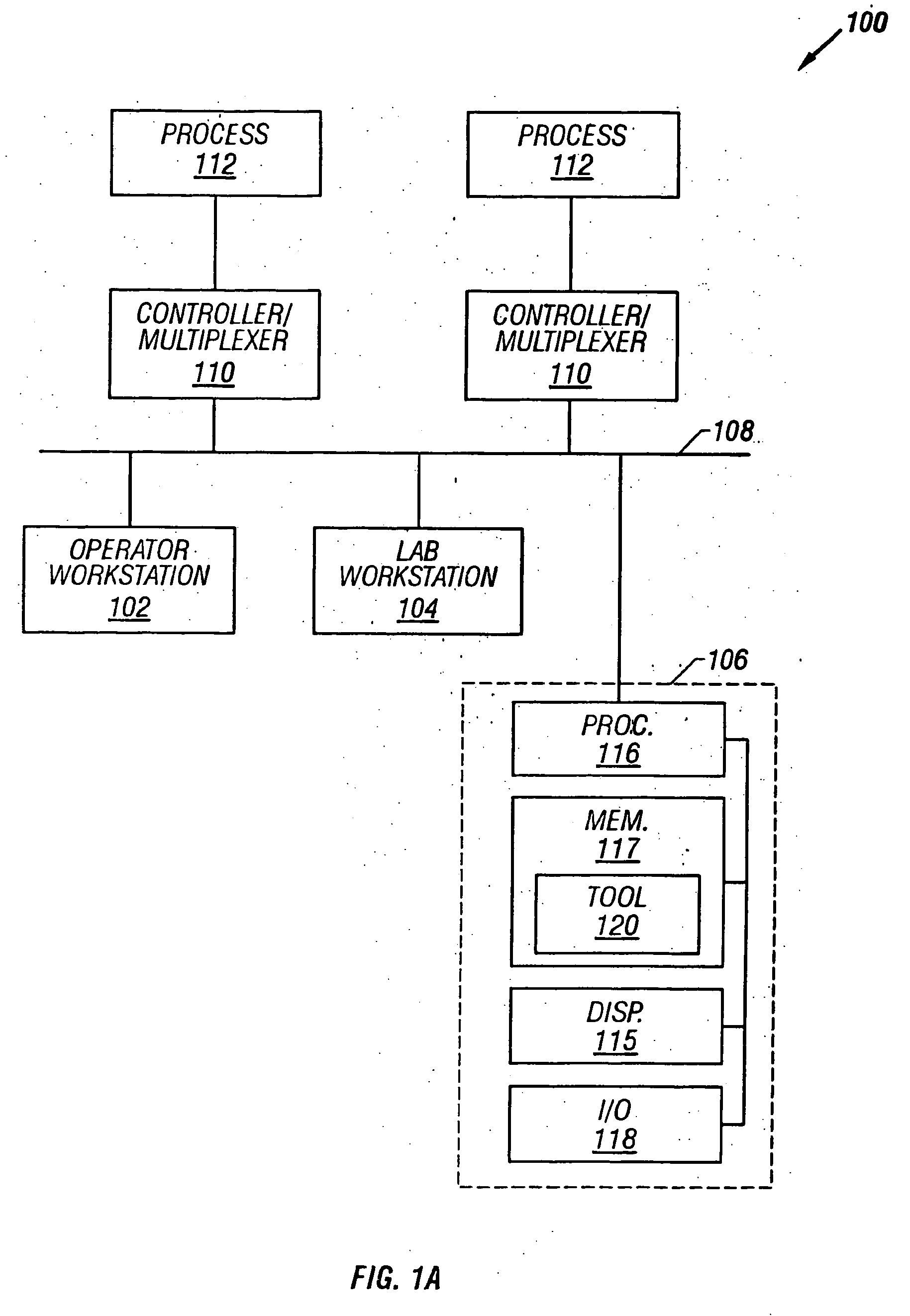

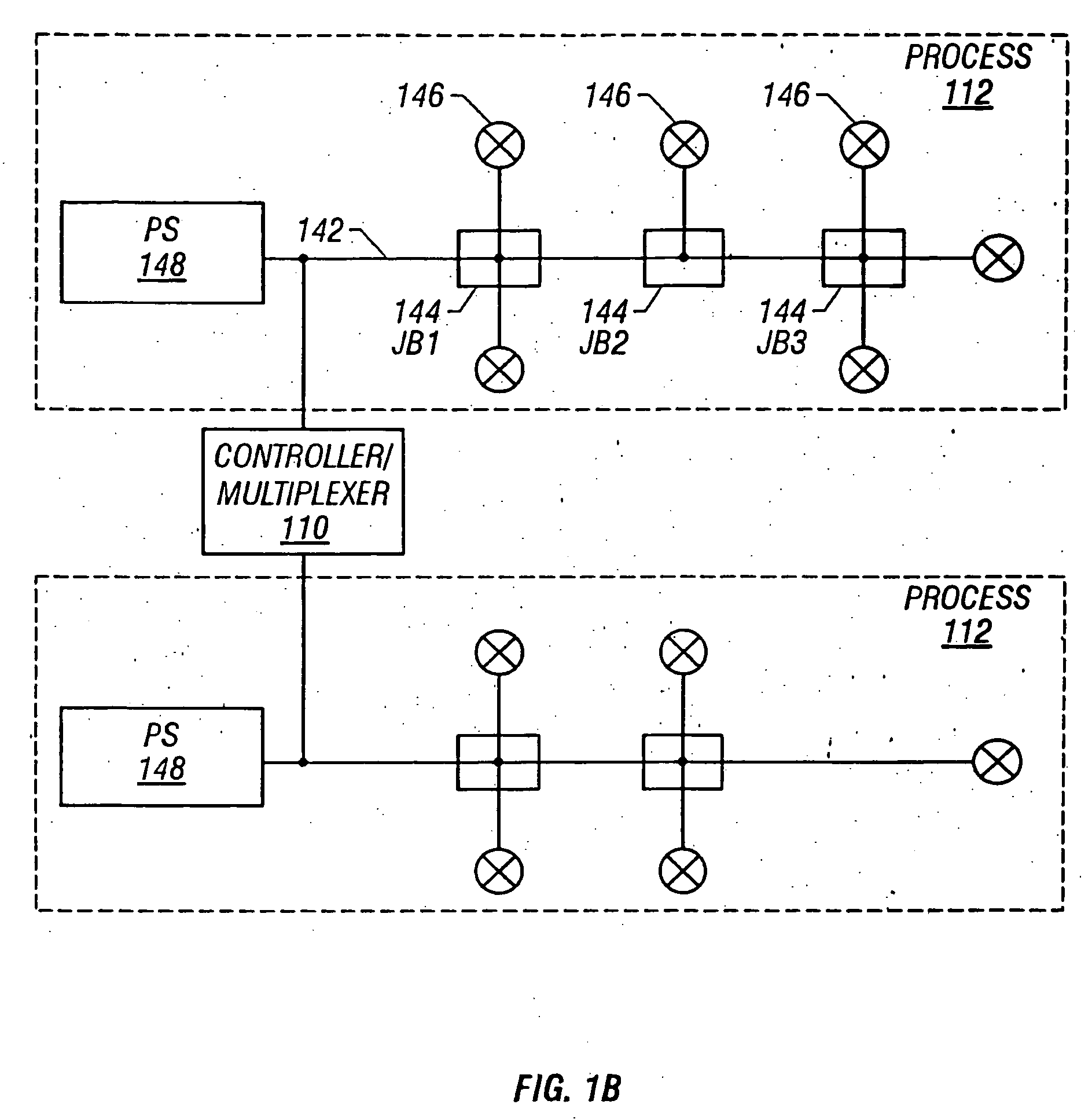

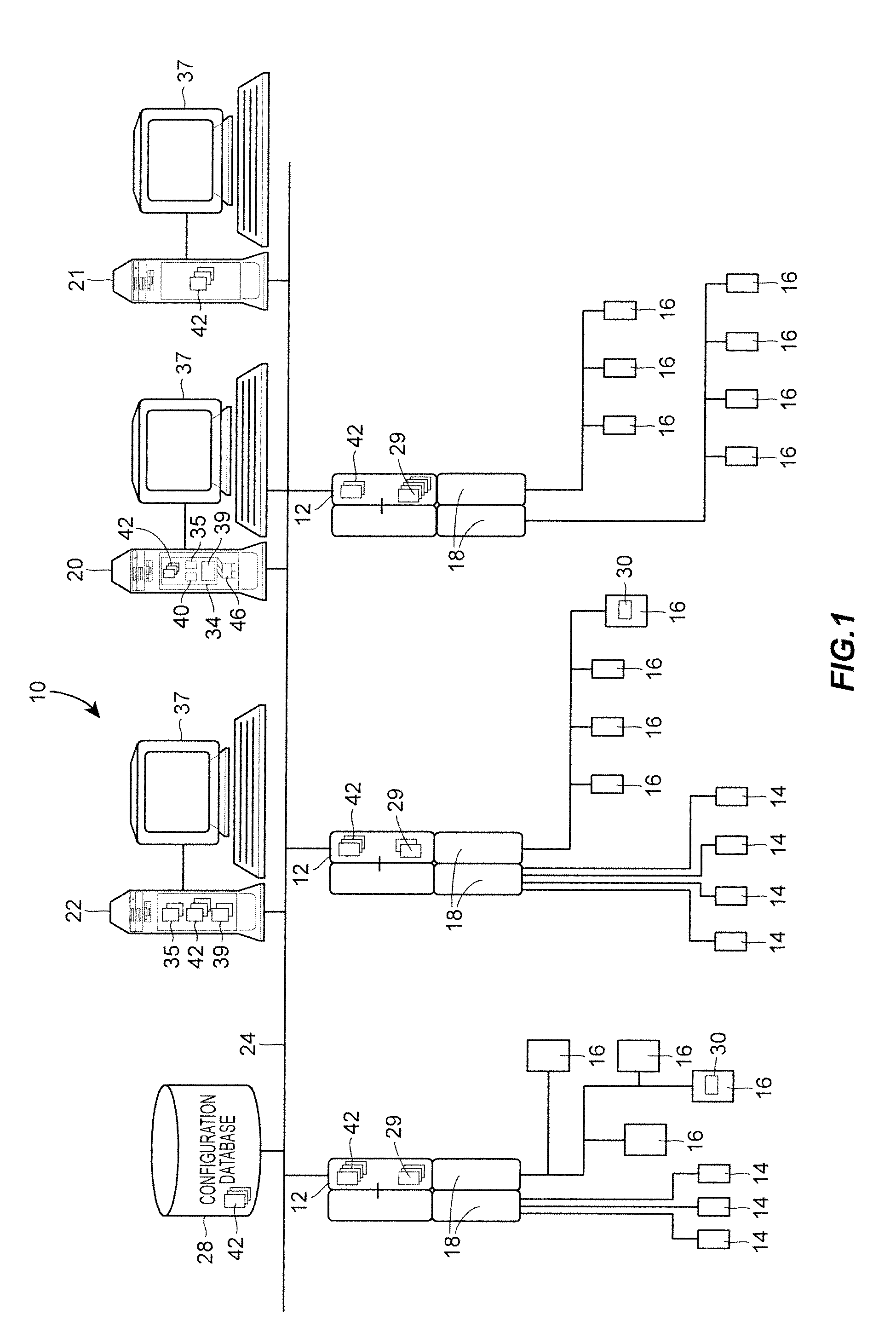

Enhanced tool for managing a process control network

InactiveUS20070179645A1Efficient designEfficient use ofSampled-variable control systemsComputer controlProcess control networkControl system

A process control configuration and management system provides a plurality of function blocks representing a plurality of devices in relation to a spatial layout of a facility in which the process control system is implemented. The configuration and management system also provides process control information and process simulation information related to each of the plurality of devices in relation to the spatial layout of the facility. The configuration and management system may be implemented on a handheld device and it may include a geographic positioning system providing geographic positioning data related to the handheld device and various devices in relation to the spatial layout of the facility.

Owner:FISHER-ROSEMOUNT SYST INC

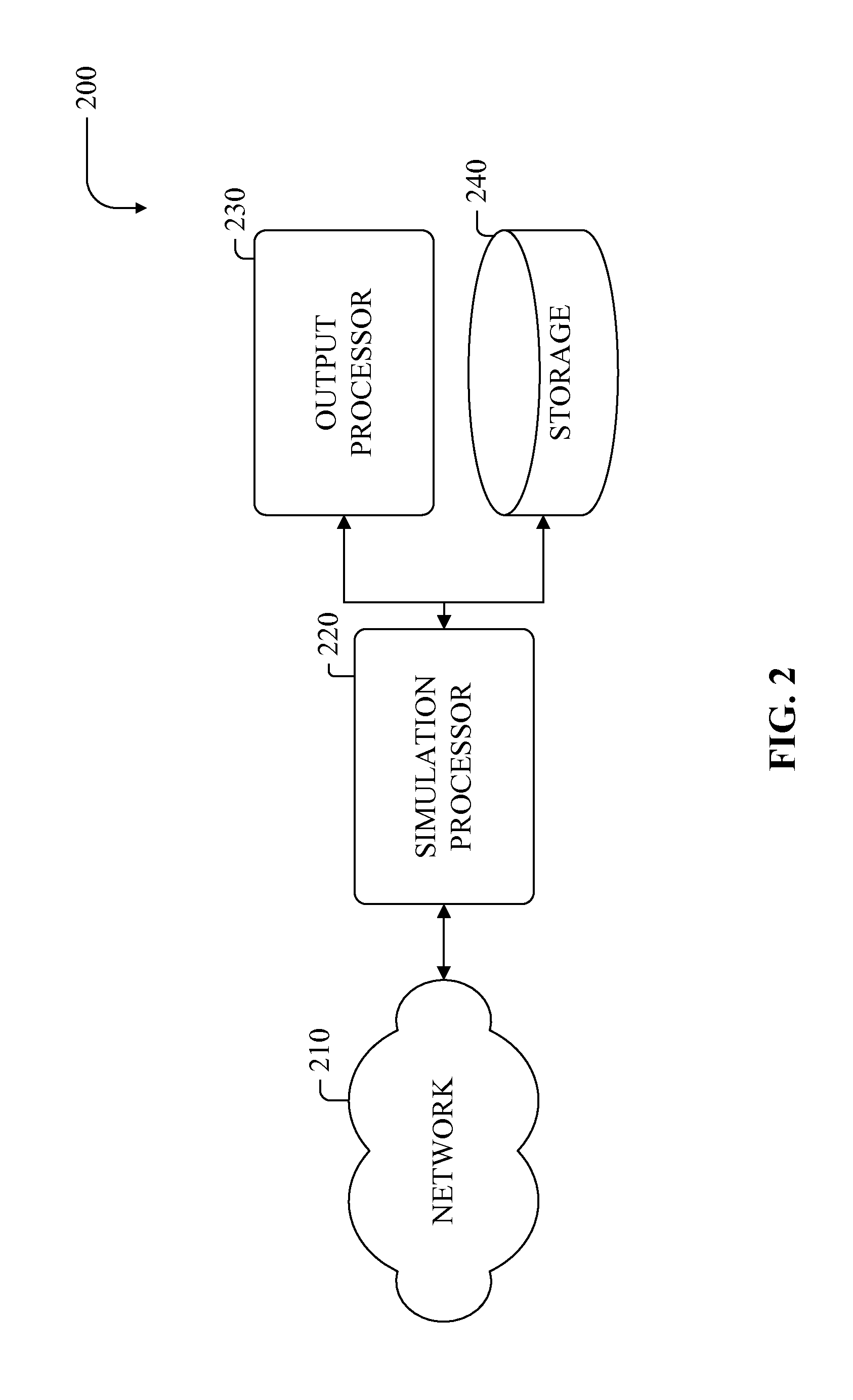

Decentralized industrial process simulation system

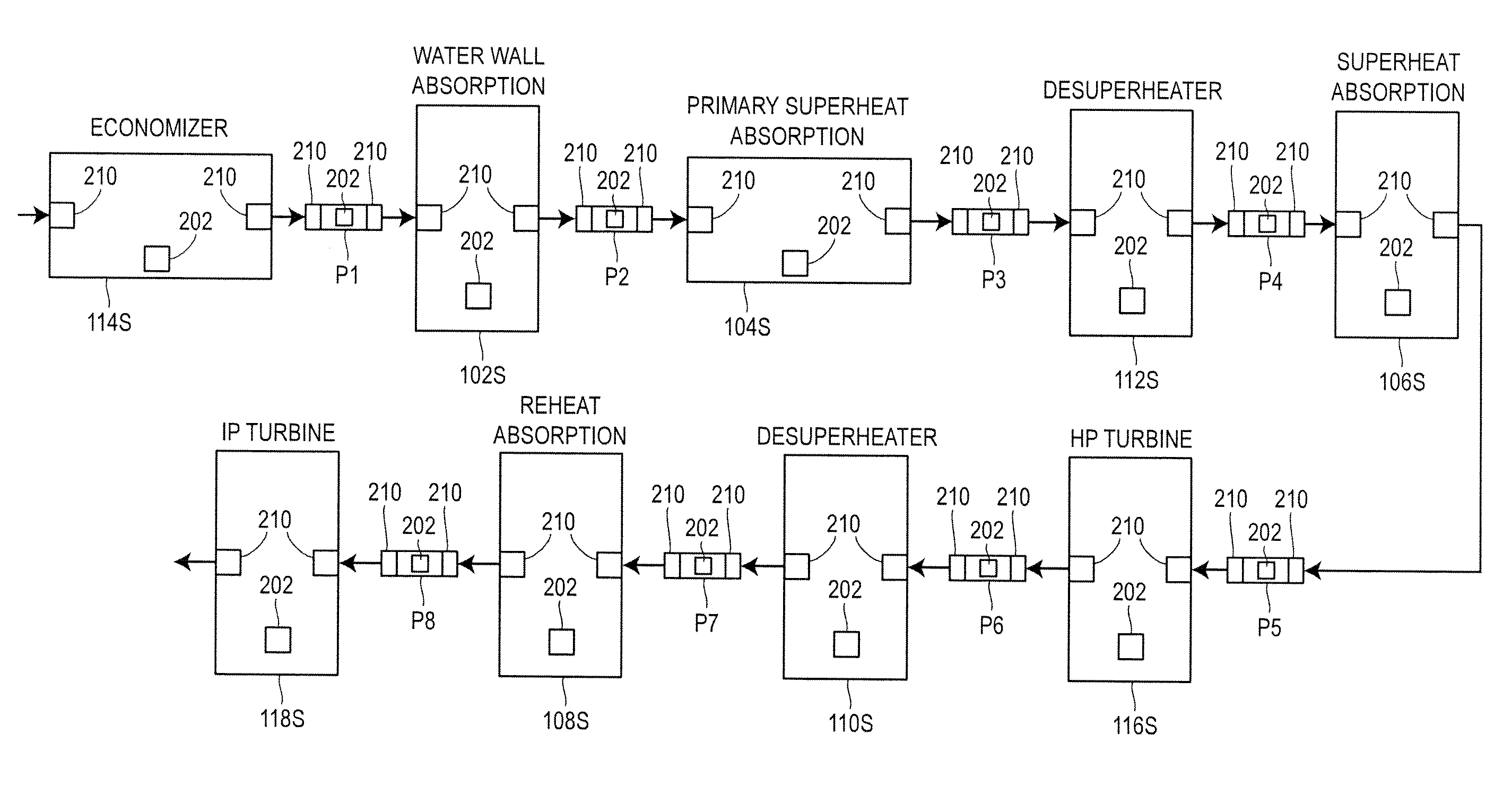

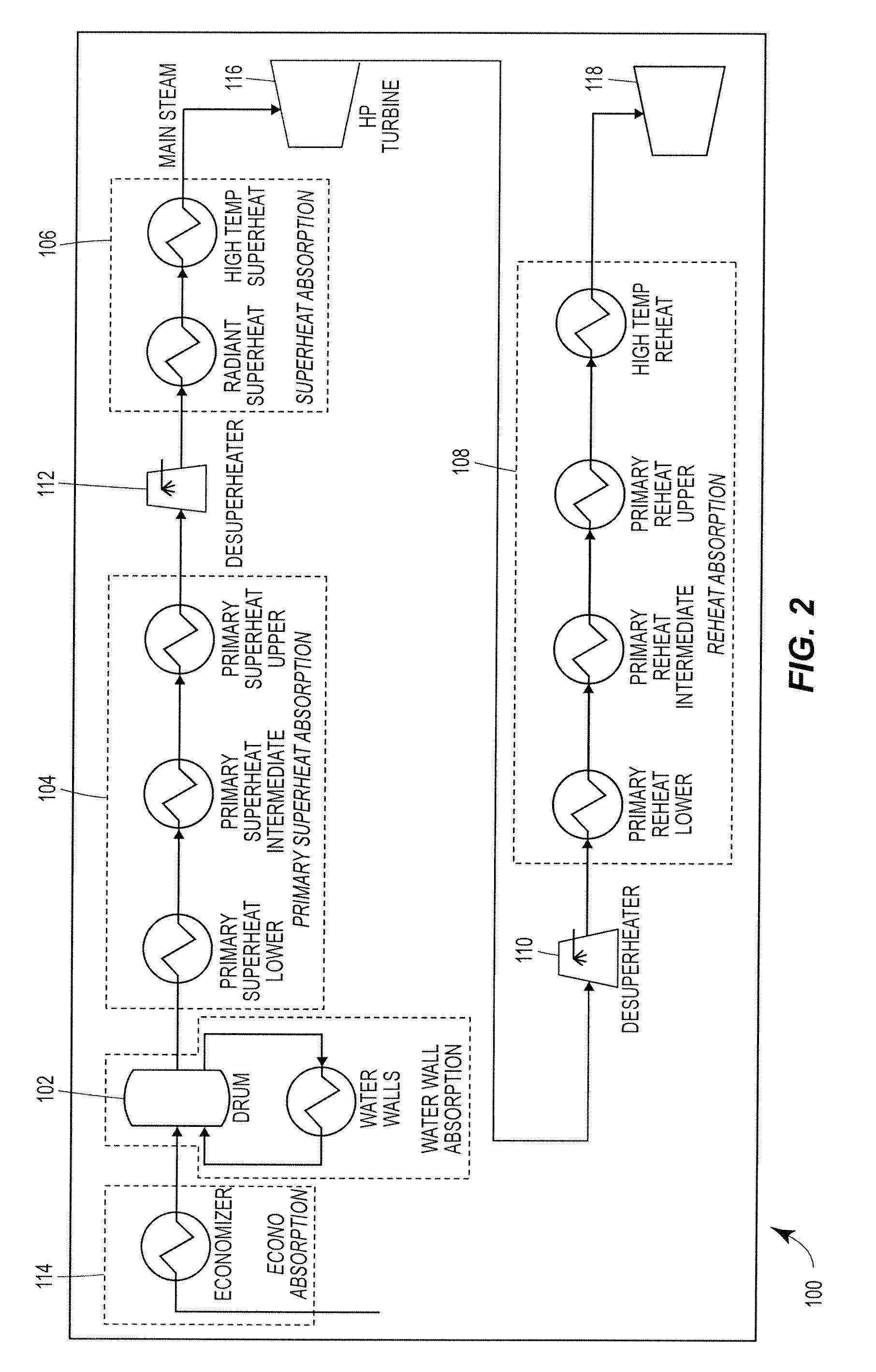

ActiveUS20110131017A1Accurately solves massAccurately flow balanceProgramme controlAnalogue computers for control systemsMass storageParallel computing

A high fidelity distributed plant simulation technique includes a plurality of separate simulation modules that may be stored and executed separately in different drops or computing devices. The simulation modules communicate directly with one another to perform accurate simulation of a plant, without requiring a centralized coordinator to coordinate the operation of the simulation system. In particular, numerous simulation modules are created, with each simulation module including a model of an associated plant element and these simulation modules are stored in different drops of a computer network to perform distributed simulation of a plant or a portion of a plant. At least some of the simulation modules, when executing, perform mass flow balances taking into account process variables associated with adjacent simulation modules to thereby assure pressure, temperature and flow balancing (i.e., conservation of mass flow) through the entire simulation system. In a dynamic situation, a transient mass storage relay technique is used to account for transient changes in mass flow through any non-storage devices being simulated by the simulation modules. Moreover, adjacent simulation modules located in different drops communicate directly with one another using a background processing task, which simplifies communications between adjacent simulation modules without the need for a central coordinator.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

Process simulation utilizing component-specific consumption data

ActiveUS20100274367A1Low costStable supportLevel controlVolume/mass flow measurementGranularityParallel computing

Methods and apparatuses are provided for simulating components and processes using discrete, variable-granularity, component-specific data relating to energy consumption or other sustainability factors. Simulations can be analyzed and optimized to facilitate forecasting of sustainability factors and determine advantageous modifications to the components or processes.

Owner:ROCKWELL AUTOMATION TECH

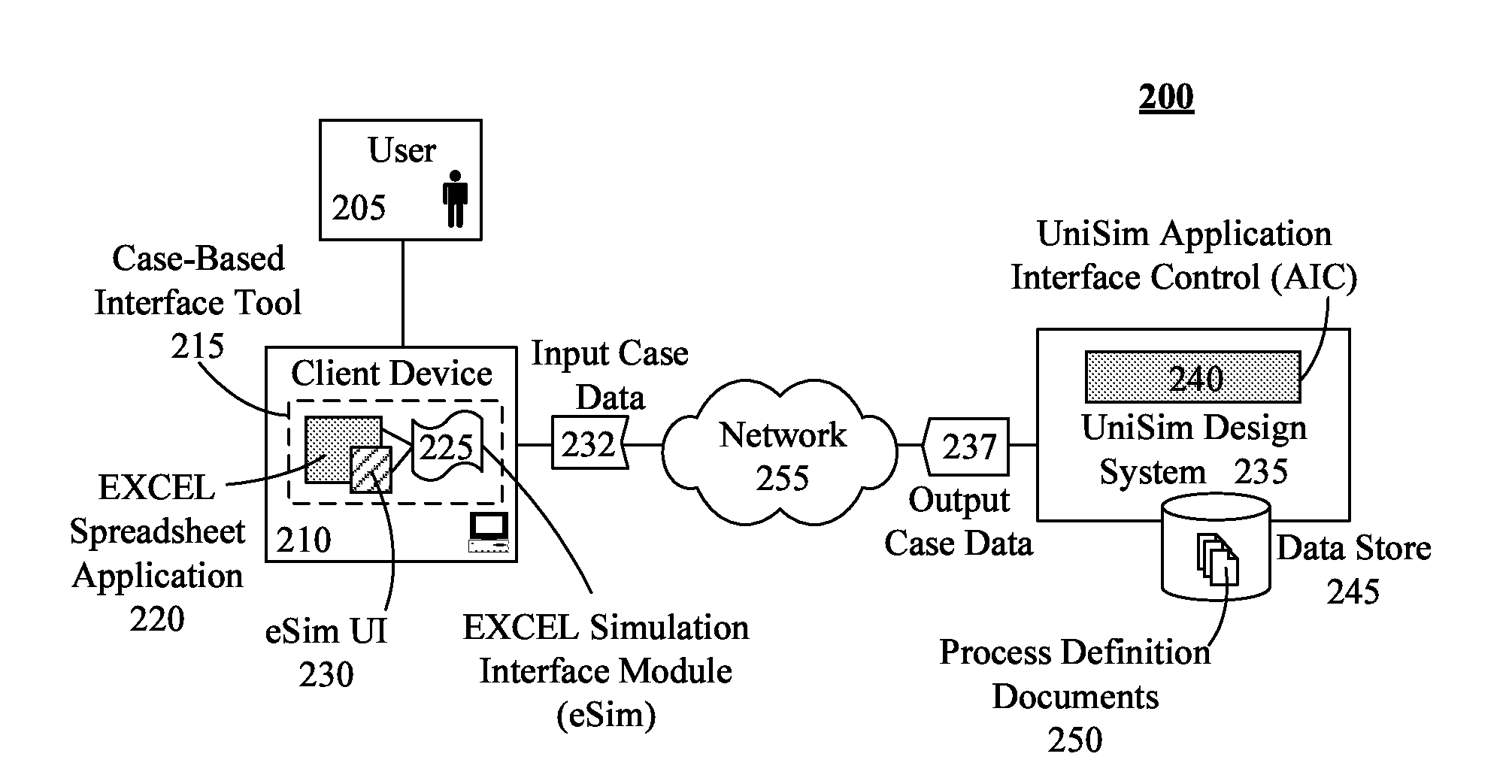

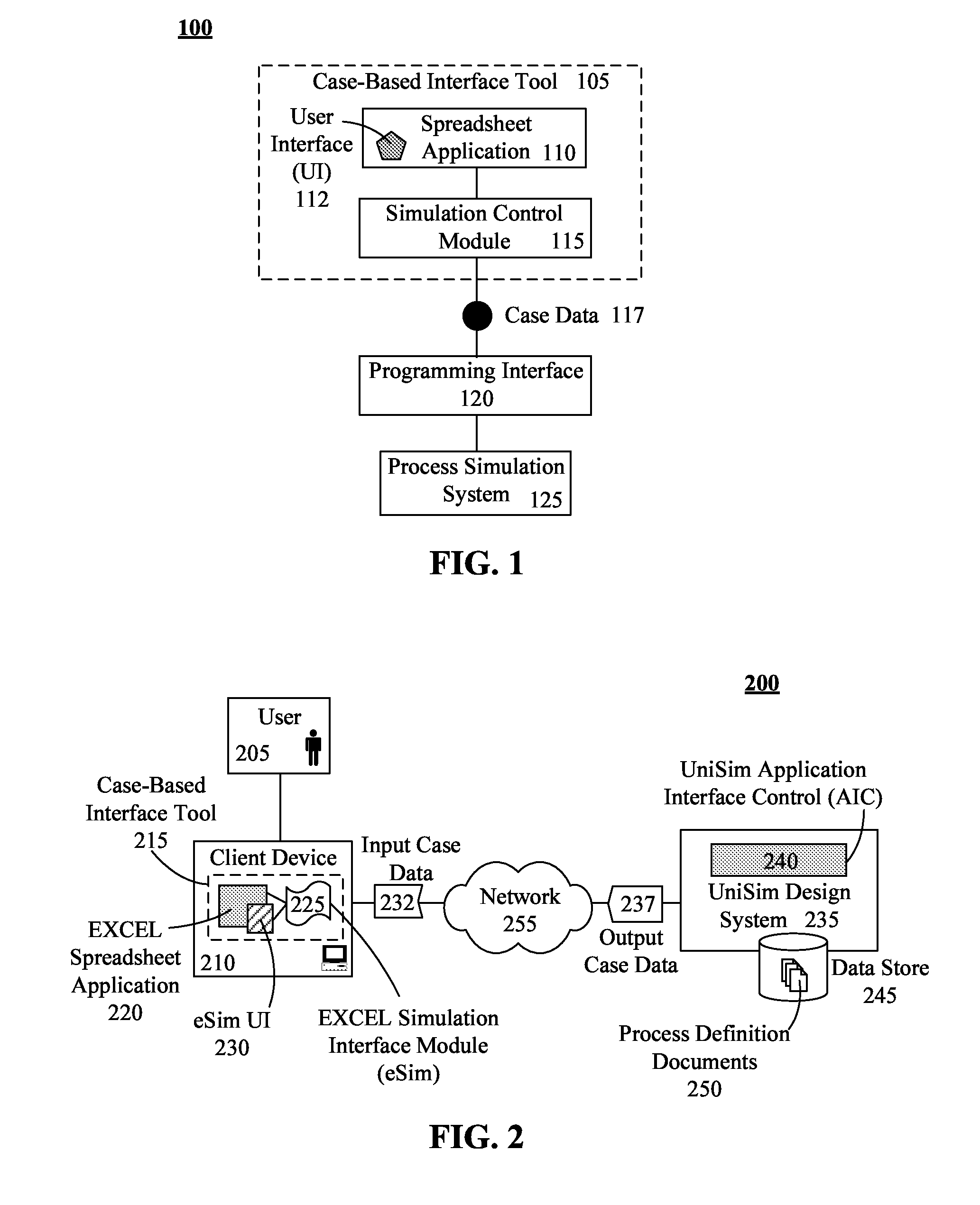

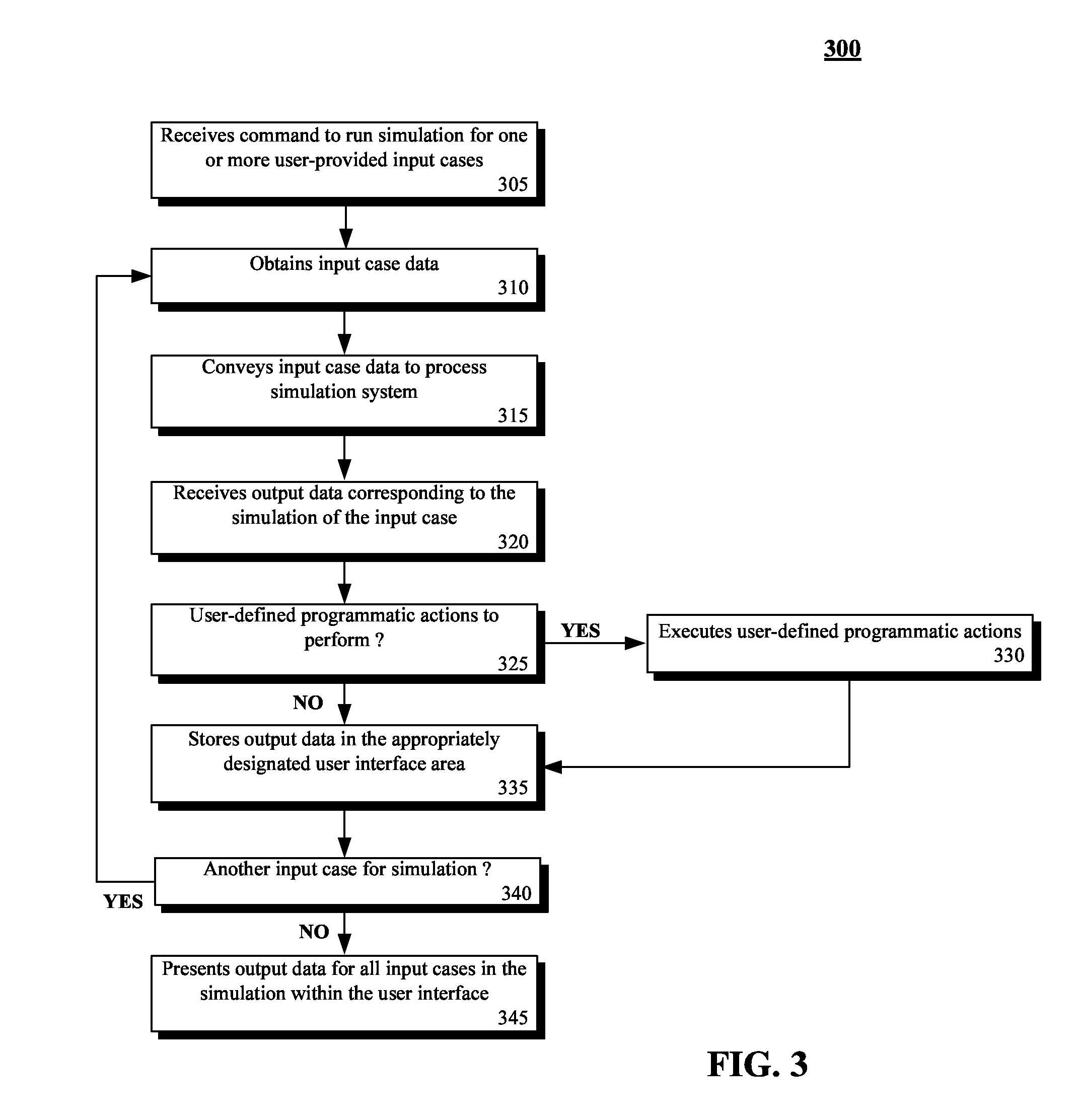

Utilizing spreadsheet user interfaces with flowsheets of a cpi simulation system

InactiveUS20100262900A1Shorten the timeSimulator controlAnalogue computers for chemical processesElectronic formParallel computing

A simulation system includes at least one processor configured to execute a computer program product, stored upon a storage medium. The computer program product includes a spreadsheet application, a process simulation application, and an integration tool (e.g., eSim), where the spreadsheet application and the process simulation application are discrete, stand alone products. The process simulation application can simulate chemical processes using at least one flowsheet, which models a general flow of chemical plant processes and equipment. The integration tool can map process simulation application objects and properties to spreadsheet application objects, can convey information between mapped objects, can perform case management functions, and can perform orchestrated calculation functions.

Owner:HONEYWELL INT INC

Process plant monitoring based on multivariate statistical analysis and on-line process simulation

Disclosed are systems and methods for on-line monitoring of operation of a process in connection with process measurements indicative of the operation of the process. In some cases, the operation of the process is simulated to generate model data indicative of a simulated representation of the operation of the process and based on the process measurements. A multivariate statistical analysis of the operation of the process is implemented based on the model data and the process measurements. The output data from the multivariate statistical analysis may then be evaluated during the operation of the process to enable the on-line monitoring of the process involving, for instance, fault detection via classification analysis of the output data.

Owner:FISHER-ROSEMOUNT SYST INC

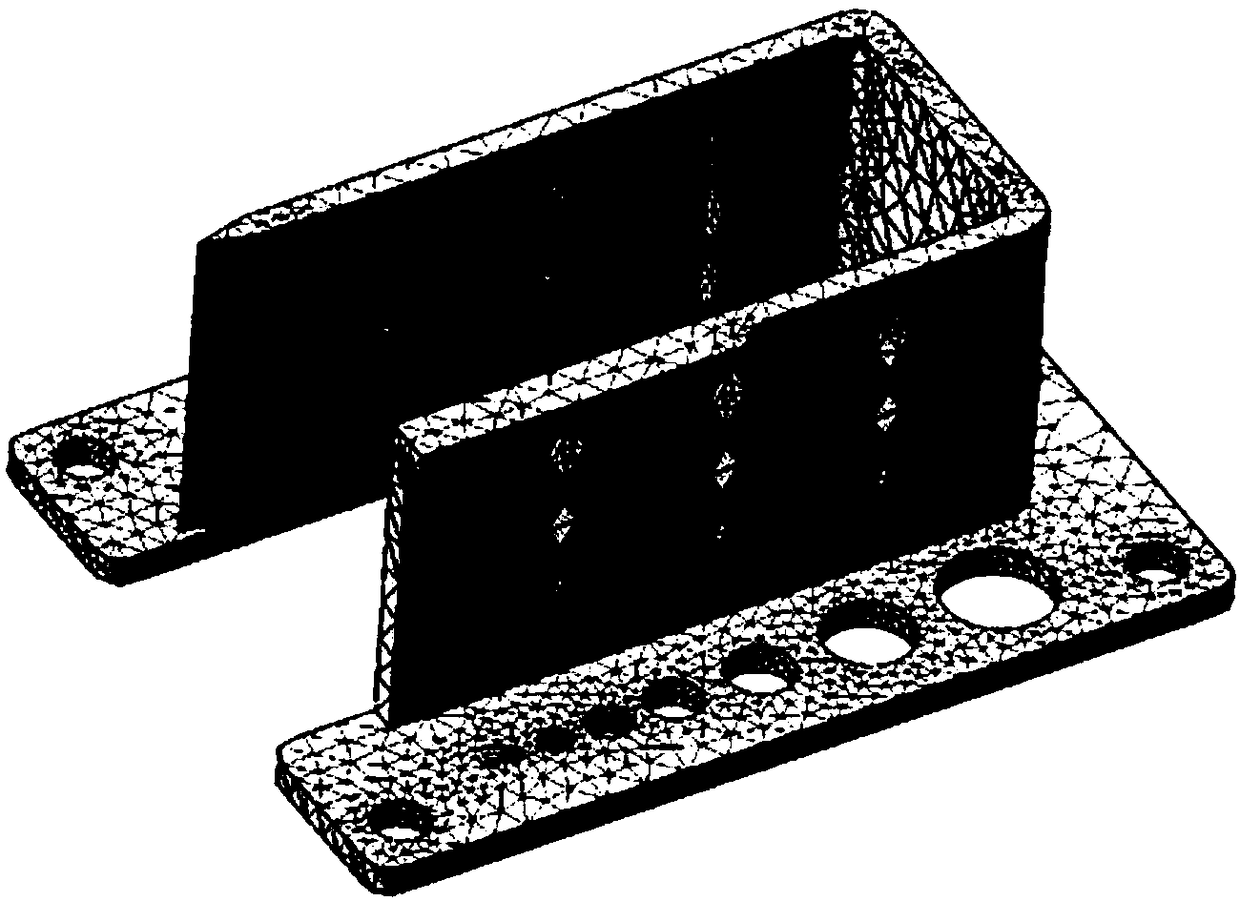

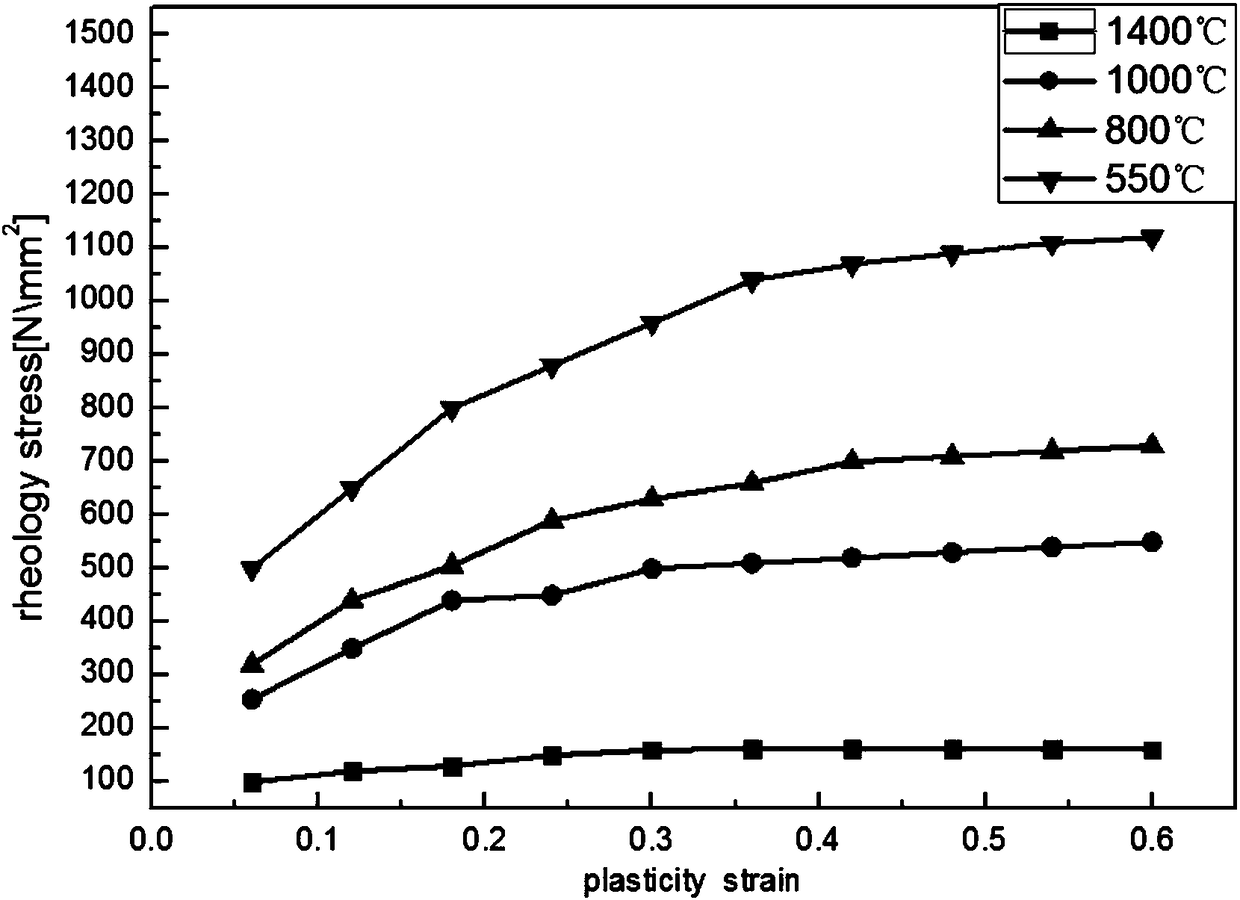

Numerical simulation method for selective laser melting process

InactiveCN108062432APrevent cracks and other phenomenaOptimize printing parametersDesign optimisation/simulationSpecial data processing applicationsSelective laser meltingElement model

The invention discloses a numerical simulation method for a selective laser melting process. The method comprises a first step of establishment of a finite element model of additive manufacturing process simulation; a second step of meshing on the finite element model of the additive manufacturing process, wherein full-hexahedron meshing is adopted; a third step of definition of printing powder material properties and thermal physical performance parameters which must be determined for temperature field analysis in the additive manufacturing process; a fourth step of loading of a control equation of a mobile heat source; and a fifth step of analysis of thermal stress field and total deformation changes in the additive manufacturing process and after sintering is finished. Through the numerical simulation method for the selective laser melting process, printing parameters can be optimized, and warping and deformation of parts can be prevented; and the method provides effective guidancefor supporting structural design and a printing strategy (speed and direction), lowering the rejection rate and realizing ''success at a time''.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

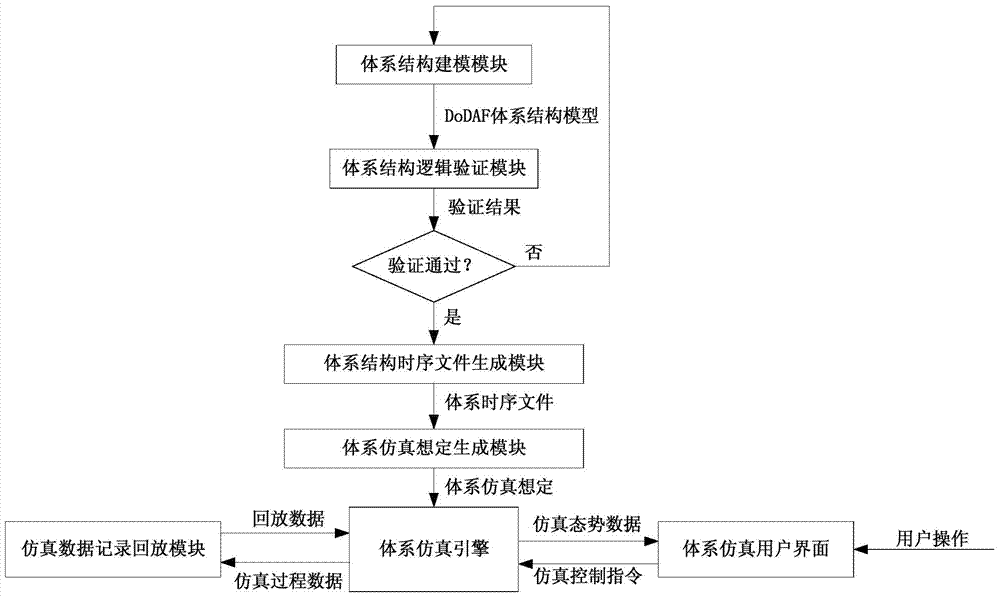

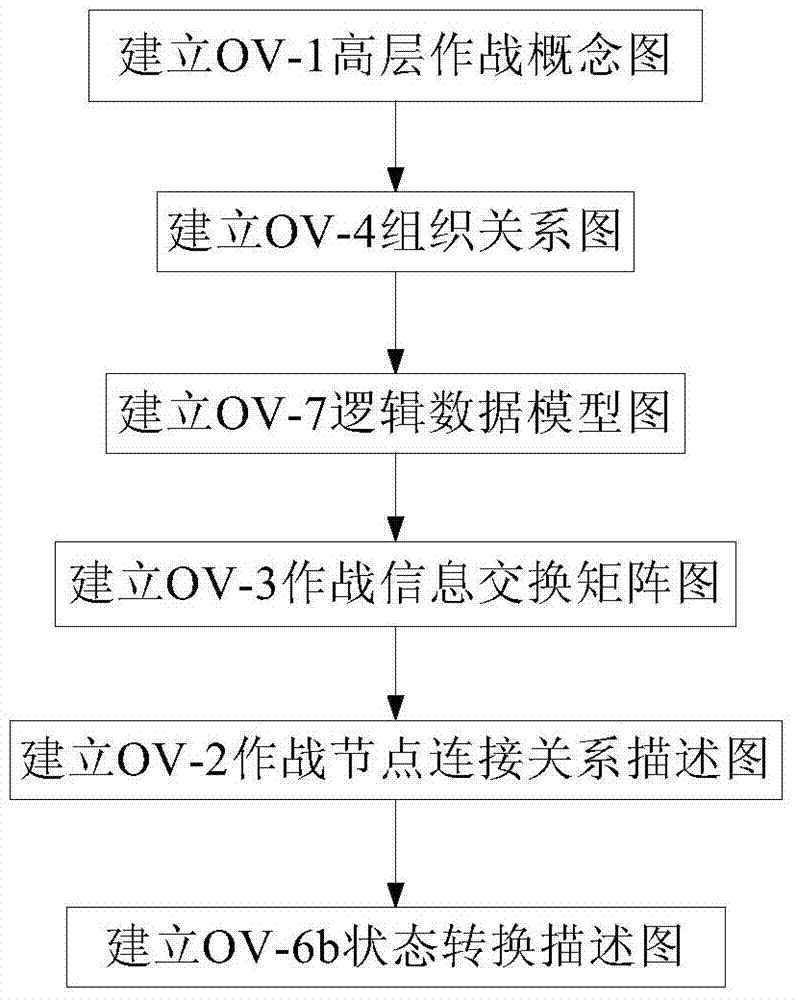

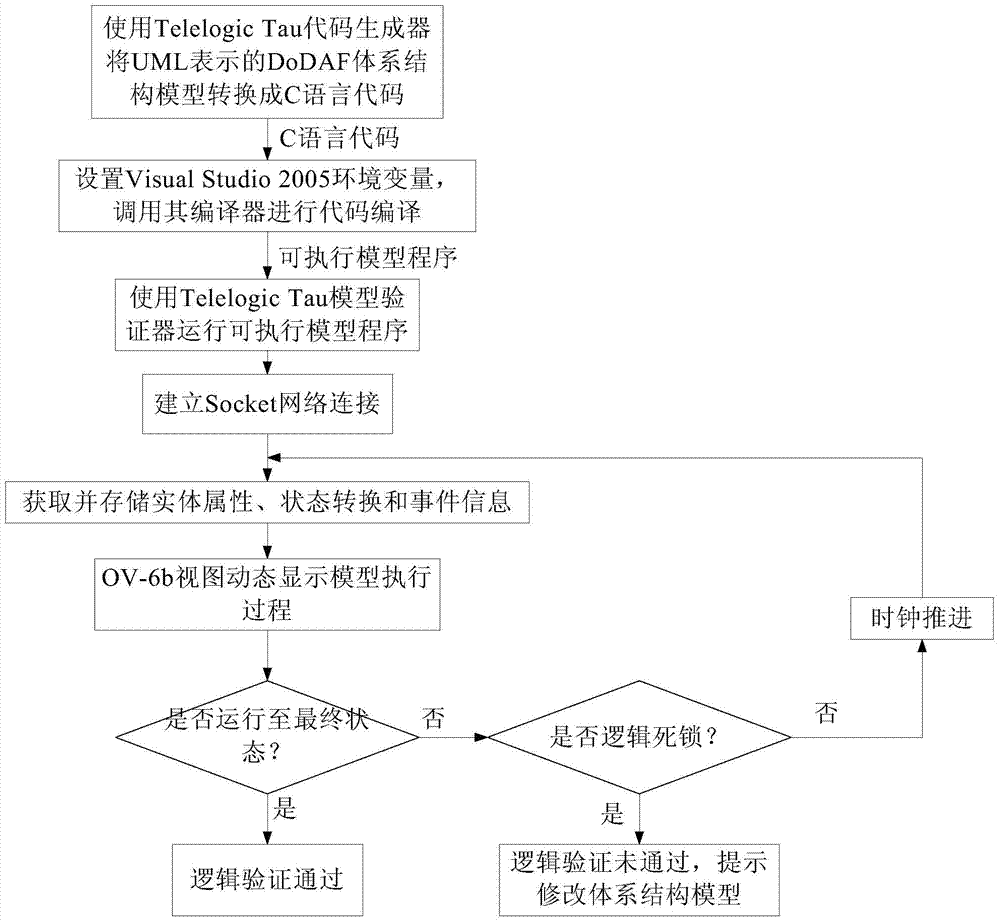

Combat system modeling and simulation system

ActiveCN103593516AImprove versatilityIncrease flexibilitySpecial data processing applicationsModeling and simulationData recording

The invention relates to a combat system modeling and simulation system which is composed of a system structure modeling module, a system structure logic verification module, a system structure timing sequence file generation module, a system simulation scenario generation module, a system simulation user interface, a system simulation engine and a simulation data recording playback module. The system structure modeling module is used for building a system structure model meeting the DoDAF standard at first, then the system structure logic verification module is used for verifying whether a logic flow of the system structure model is correct, the system structure timing sequence file generation module generates corresponding timing sequence description files after verification is passed, the system simulation scenario generation module imports and analyzes system structure timing sequence files, and a simulation scenario is automatically generated; according to the simulation scenario, the system simulation engine uploads a needed simulation solid model to conduct combat process simulation, a battlefield situation map is displayed through the system simulation user interface, and the simulation data recording playback module is used for recording simulation process data and conducting playback on the simulation process.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

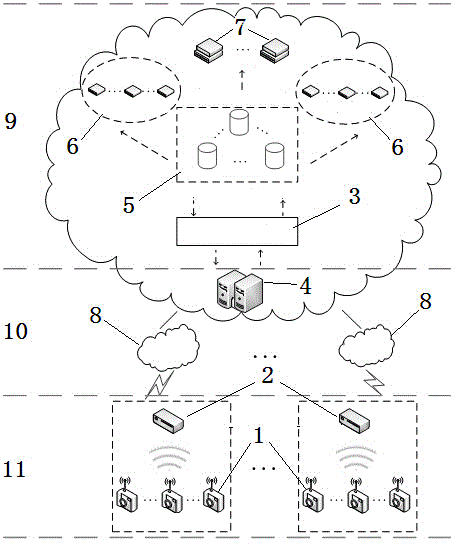

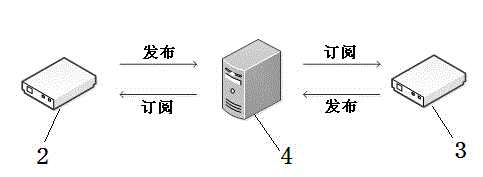

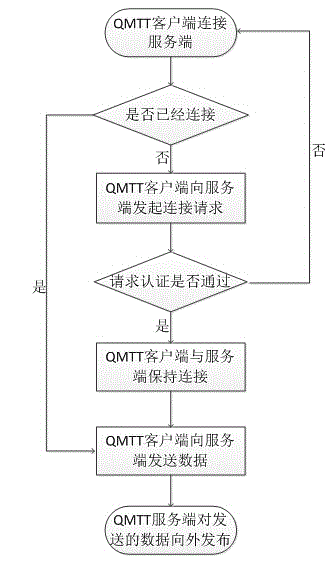

System and method for real-time cloud simulation on Internet of things sensing device

The invention discloses a system and a method for real-time cloud simulation on an Internet of things sensing device. The system comprises the Internet of things sensing device, an Internet of things gateway device, a cloud device simulation center and an MQTT (Message Queuing Telemetry Transport) server; the Internet of things sensing device is an intelligent sensing device which is accessed to a sensing network; the Internet of things gateway device is used for providing the access for a heterogeneous sensing network; the cloud device simulation center comprises a simulation data processing module and a simulation node module, wherein the simulation data processing module is used for receiving, pushing and processing simulation data, the simulation node module is used for establishing cloud simulation nodes, and the cloud simulation nodes and the Internet of things sensing device are maintained to be synchronized; the MQTT server is an interaction intermediary of the Internet of things sensing device and the cloud simulation node which is corresponding to the Internet of things sensing device. According to the system and the method for the real-time cloud simulation on the Internet of things sensing device, the cloud simulation node which is corresponding to the Internet of things sensing device is established at the position of a cloud according to real-time data sent from the Internet of things sensing device to enable the functions of the cloud simulation node to be as same as the functions of the Internet of things entity sensing device and accordingly the access of the cloud application service to the entity sensing device and the operation of the cloud application service on the entity sensing device are convenient.

Owner:河南金路网络科技股份有限公司

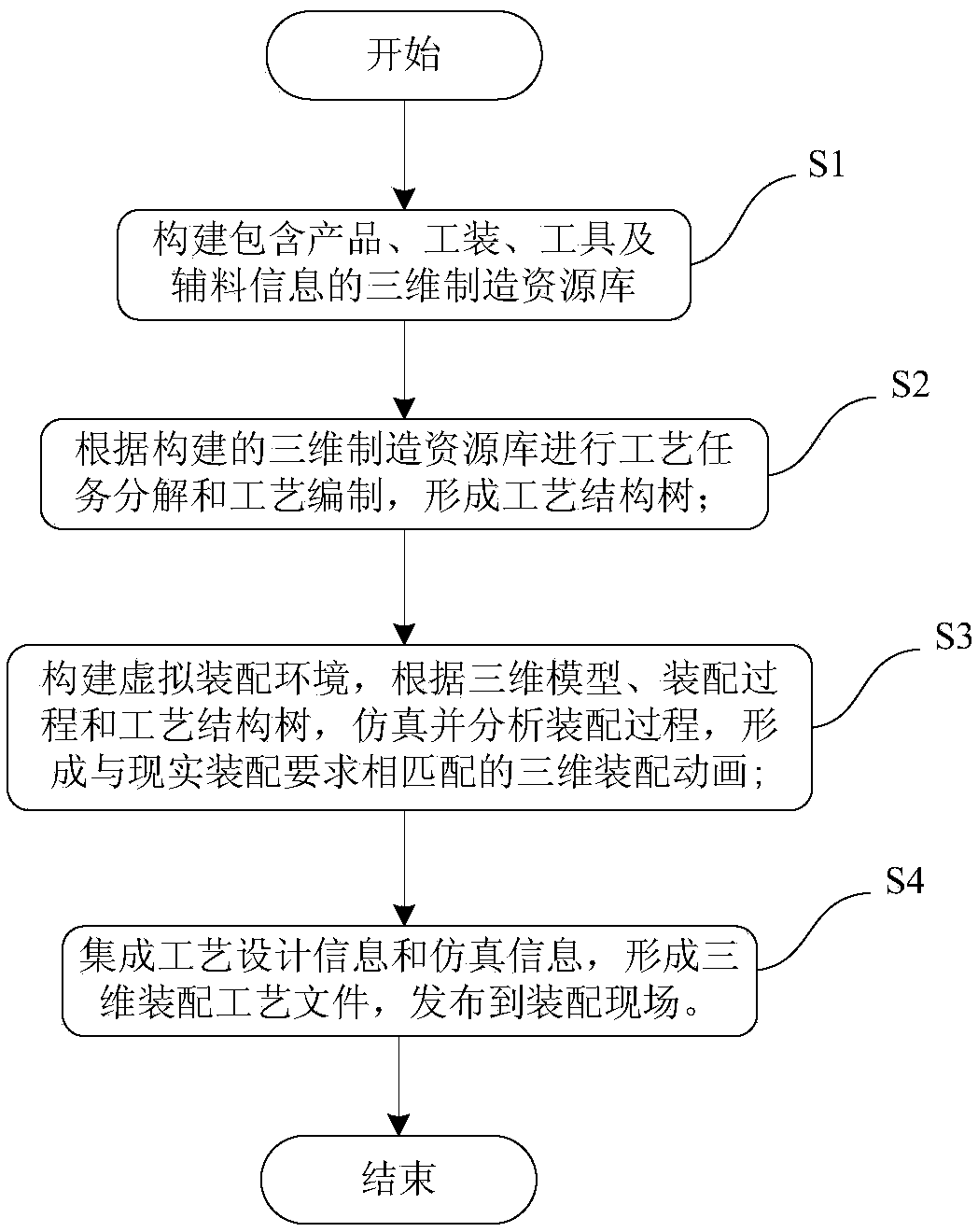

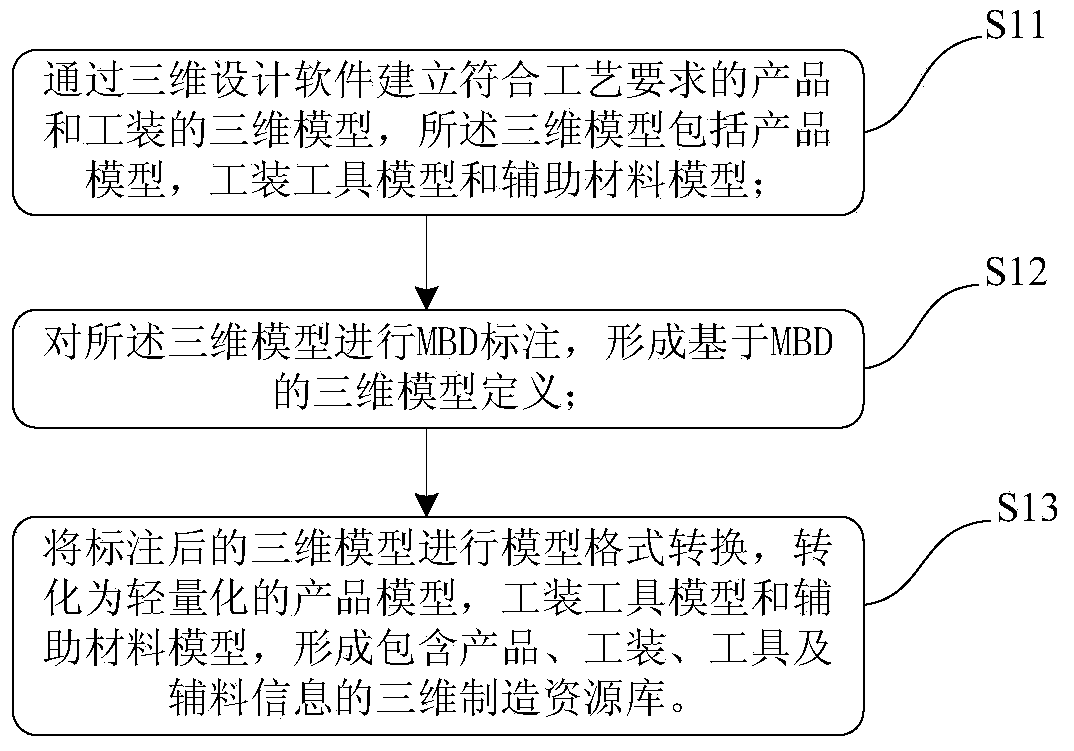

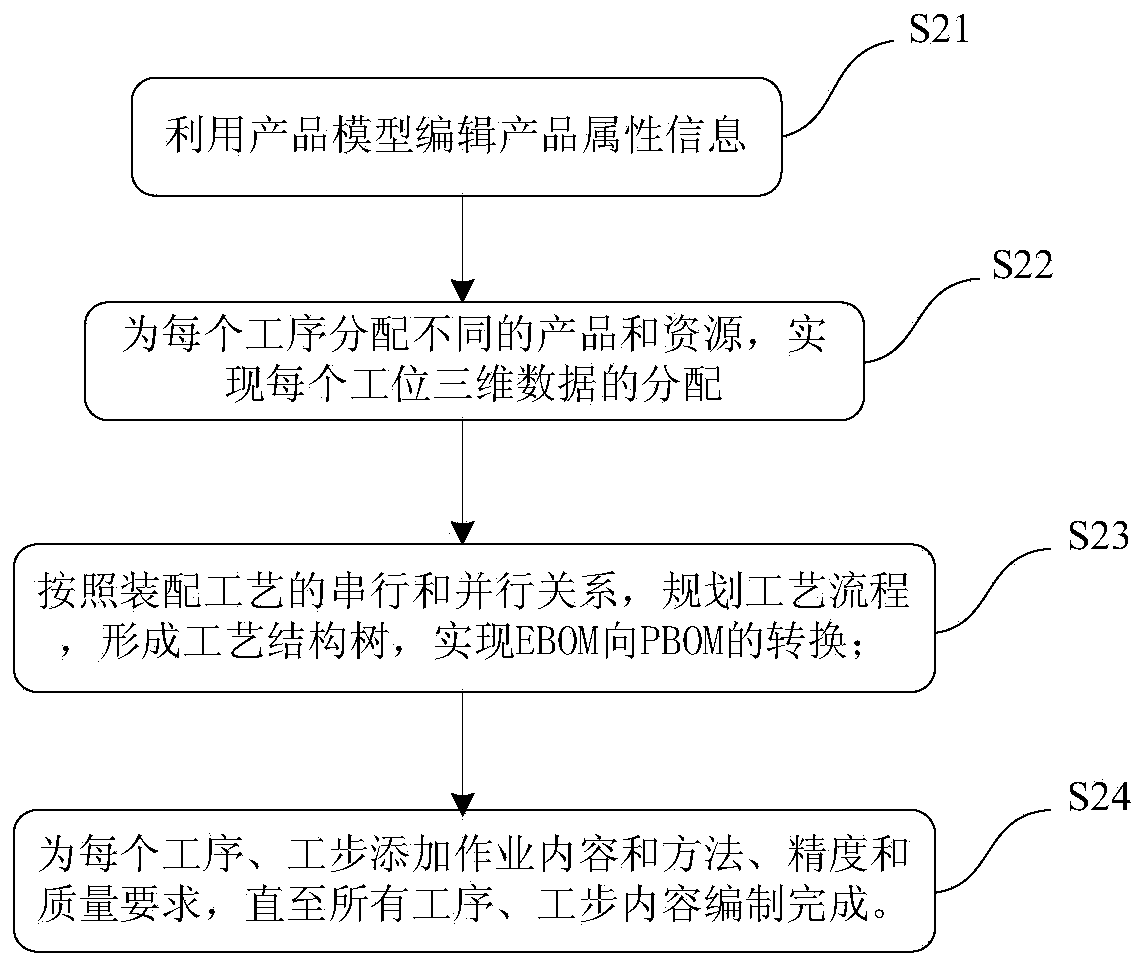

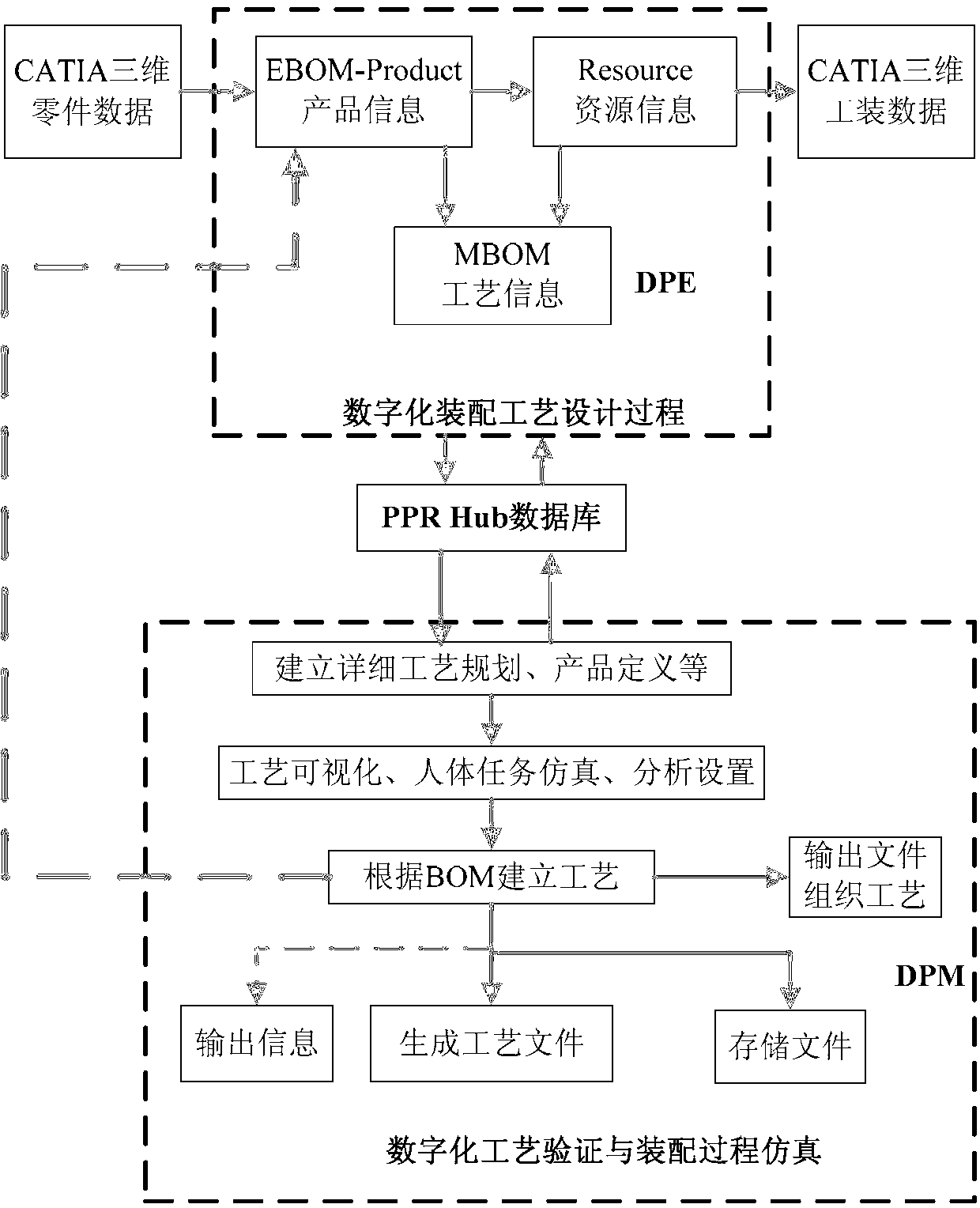

Three-dimensional assembly process generation method and system for aerospace product

InactiveCN103413004AAddressing the information gapAccurate visualizationAnimationSpecial data processing applicationsAnimationInformation gap

The invention provides a three-dimensional assembly process generation method and system for an aerospace product. The system comprises a three-dimensional manufacturing resource library building module, a three-dimensional assembly process design module, a three-dimensional assembly process simulation module and a three-dimensional assembly process release module, the three-dimensional manufacturing resource library building module is used for building a three-dimensional manufacturing resource library containing product, fixture, tool and auxiliary material information, the three-dimensional assembly process design module is used for decomposing process tasks and planning a process according to the built three-dimensional manufacturing resource library to form a process structure tree, the three-dimensional assembly process simulation module is used for building a virtual assembly environment and simulating and analyzing the assembly process according to a three-dimensional model, the assembly process and the process structure tree to form a three-dimensional assembly animation meeting actual assembly requirements, and the three-dimensional assembly process release module is used for integrating process design information and simulation information, forming a three-dimensional assembly process file and releasing the three-dimensional assembly process file to an assembly site. Accurate and visual three-dimensional visual means are provided for aerospace product assembly, so that the problem of information gaps among three-dimensional product design, three-dimensional process design and three-dimensional assembly site implementation in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

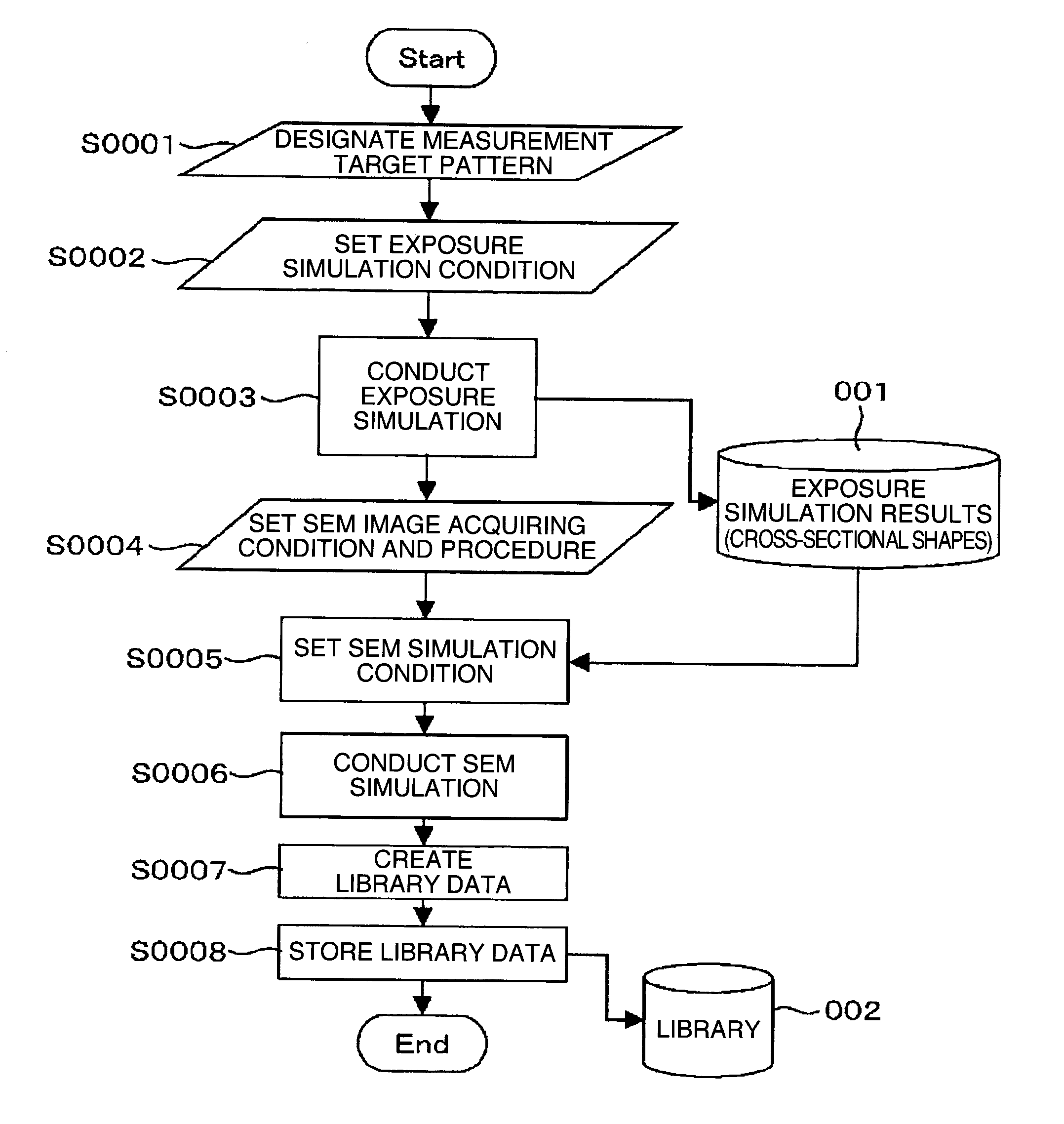

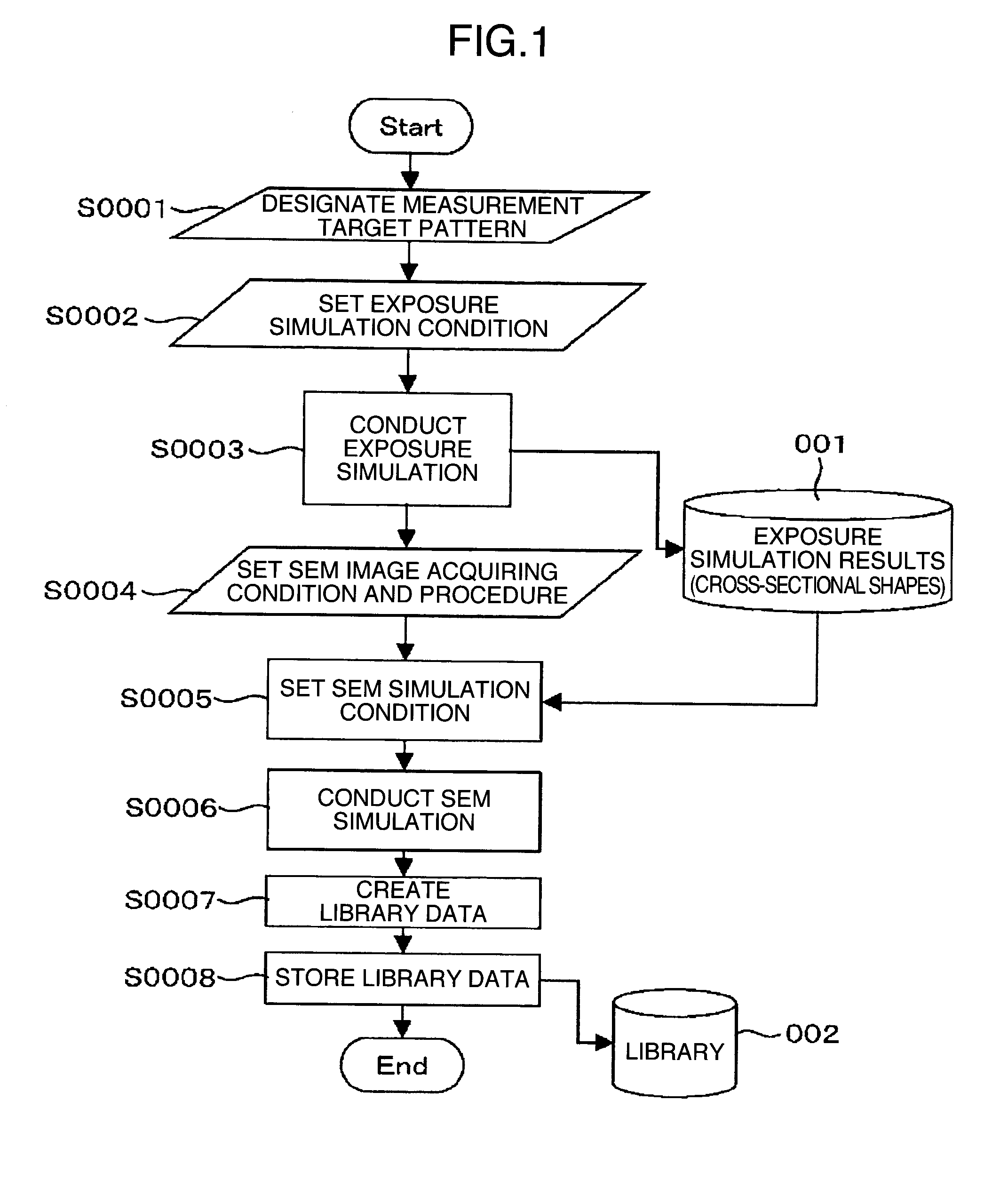

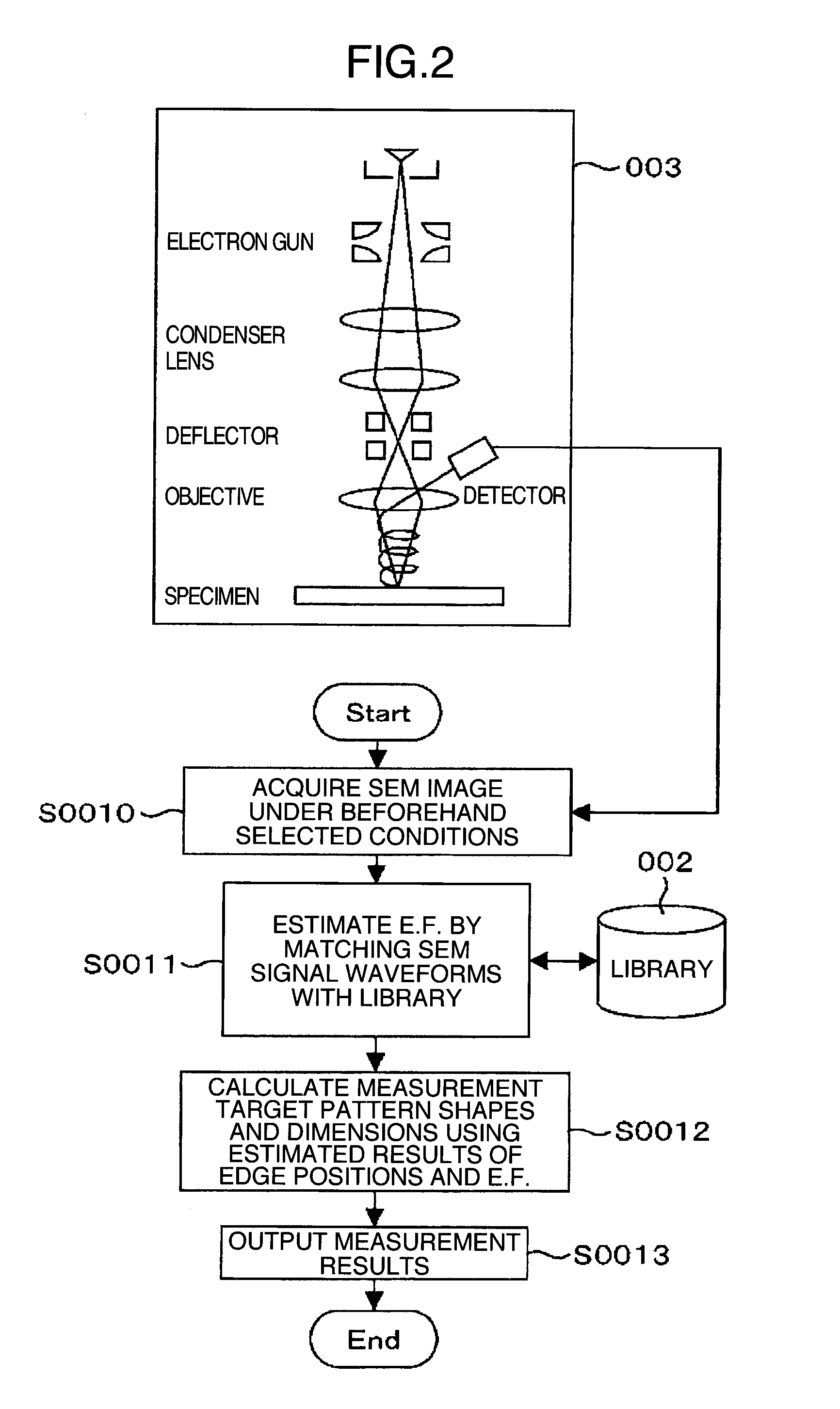

Pattern Shape Estimation Method and Pattern Measuring Device

InactiveUS20120151428A1Stable and high-precision pattern shape selectionImprove accuracySemiconductor/solid-state device testing/measurementSolid-state devicesPattern recognitionEstimation methods

The present invention aims at proposing a library creation method and a pattern shape estimation method in which it is possible, when estimating a shape based on comparison between an actual waveform and a library, to appropriately estimate the shape.As an illustrative embodiment to achieve the object, there are proposed a method of selecting a pattern by referring to a library, a method of creating a library by use of pattern cross-sectional shapes calculated through an exposure process simulation in advance, and a method for selecting a pattern shape stored in the library.

Owner:HITACHI HIGH-TECH CORP

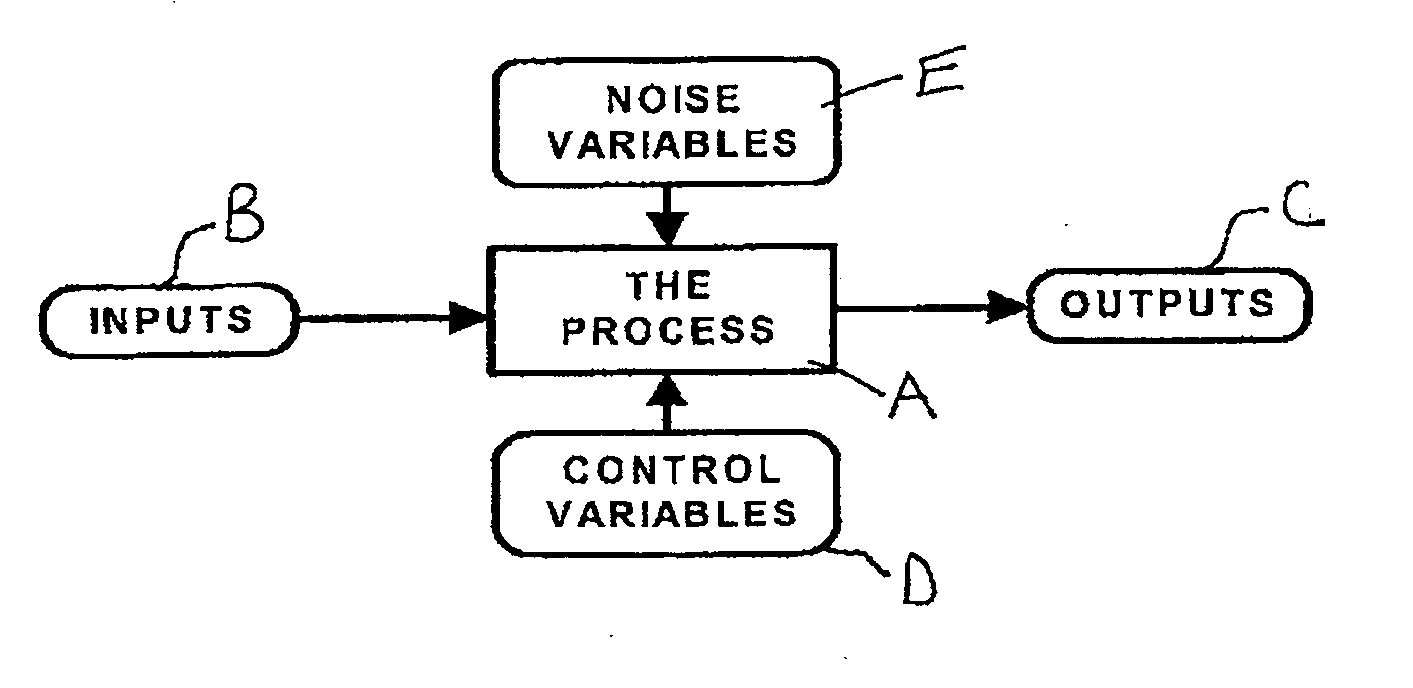

Manufacturing design and process analysis and simulation system

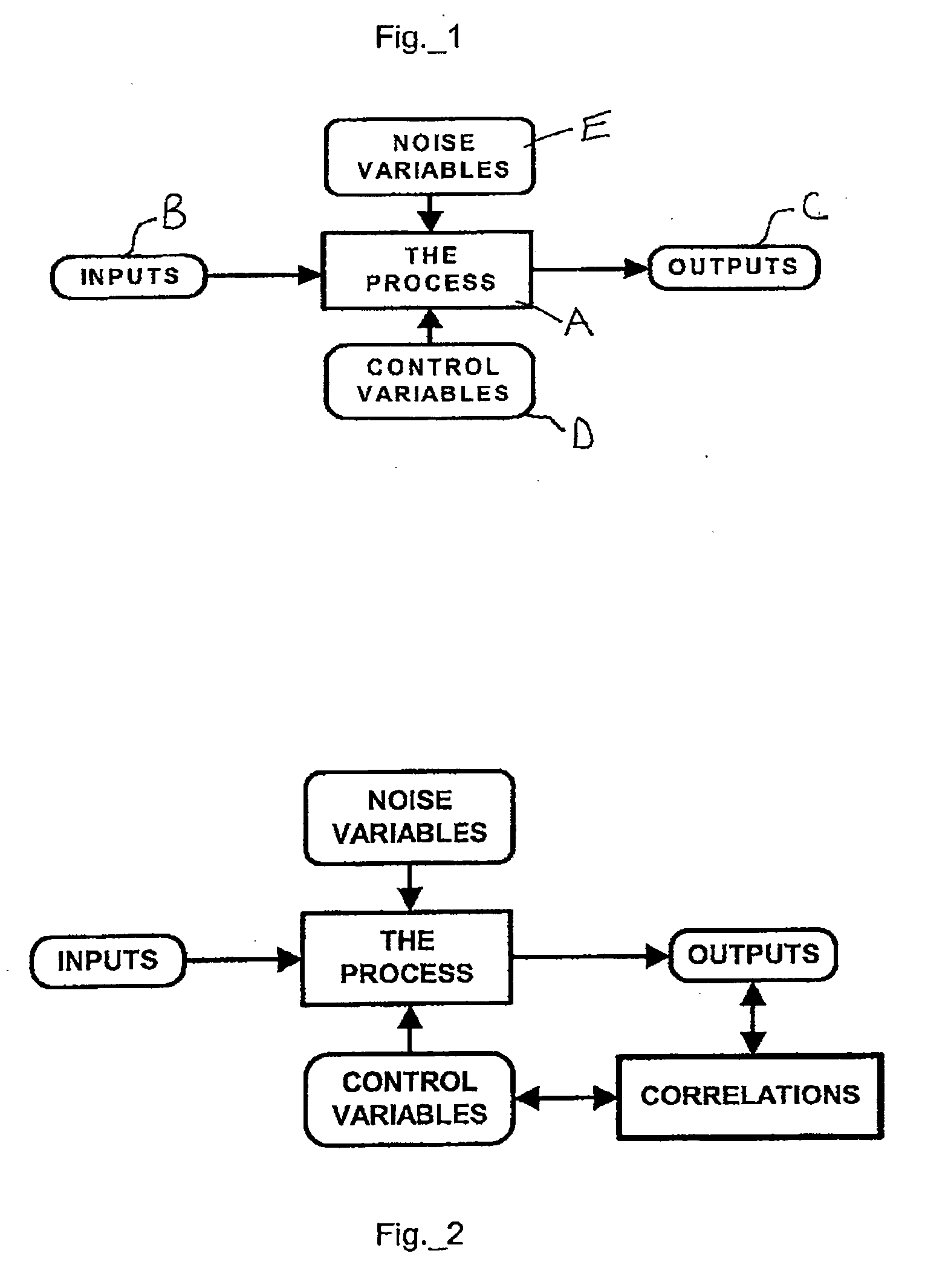

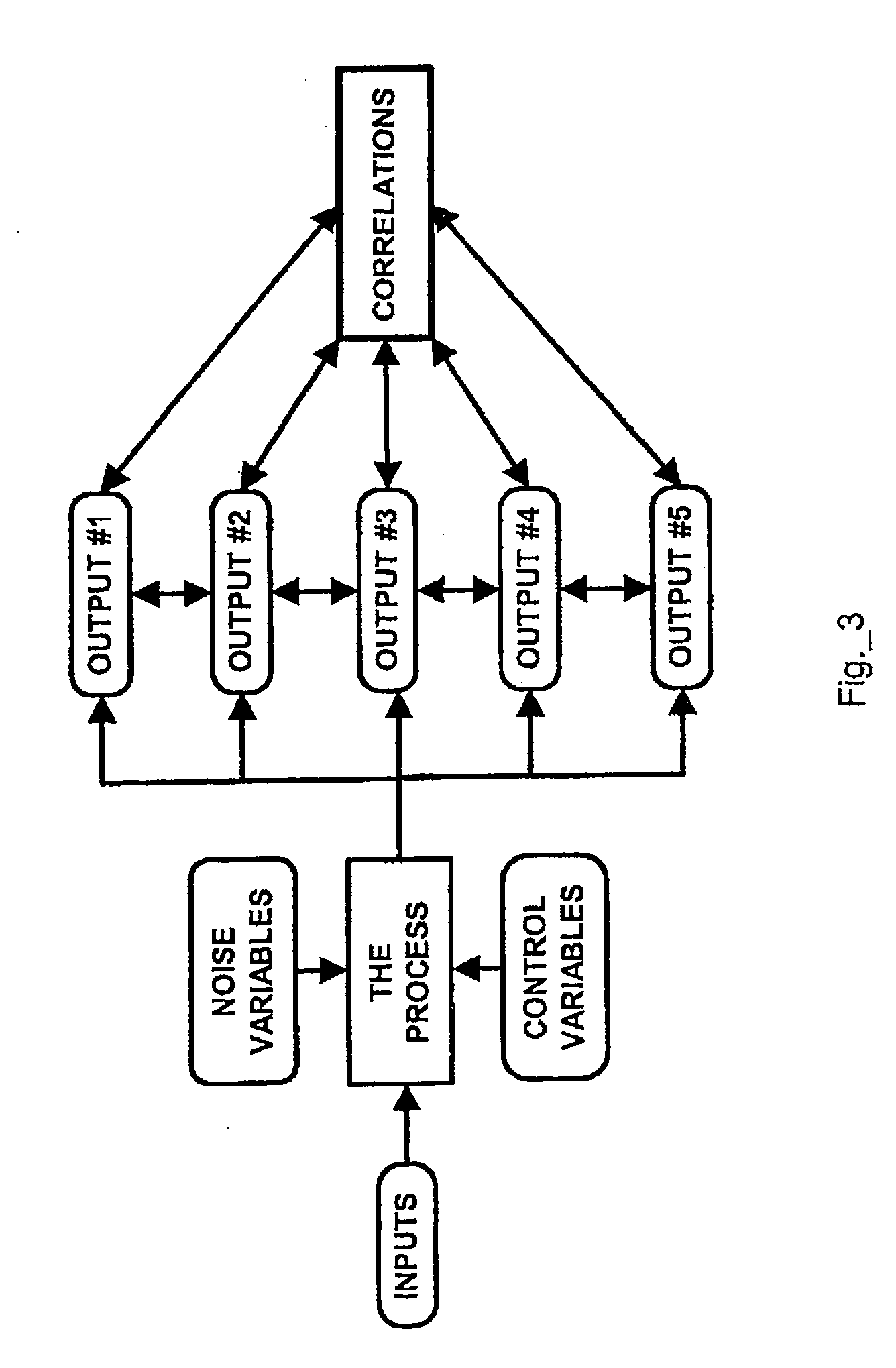

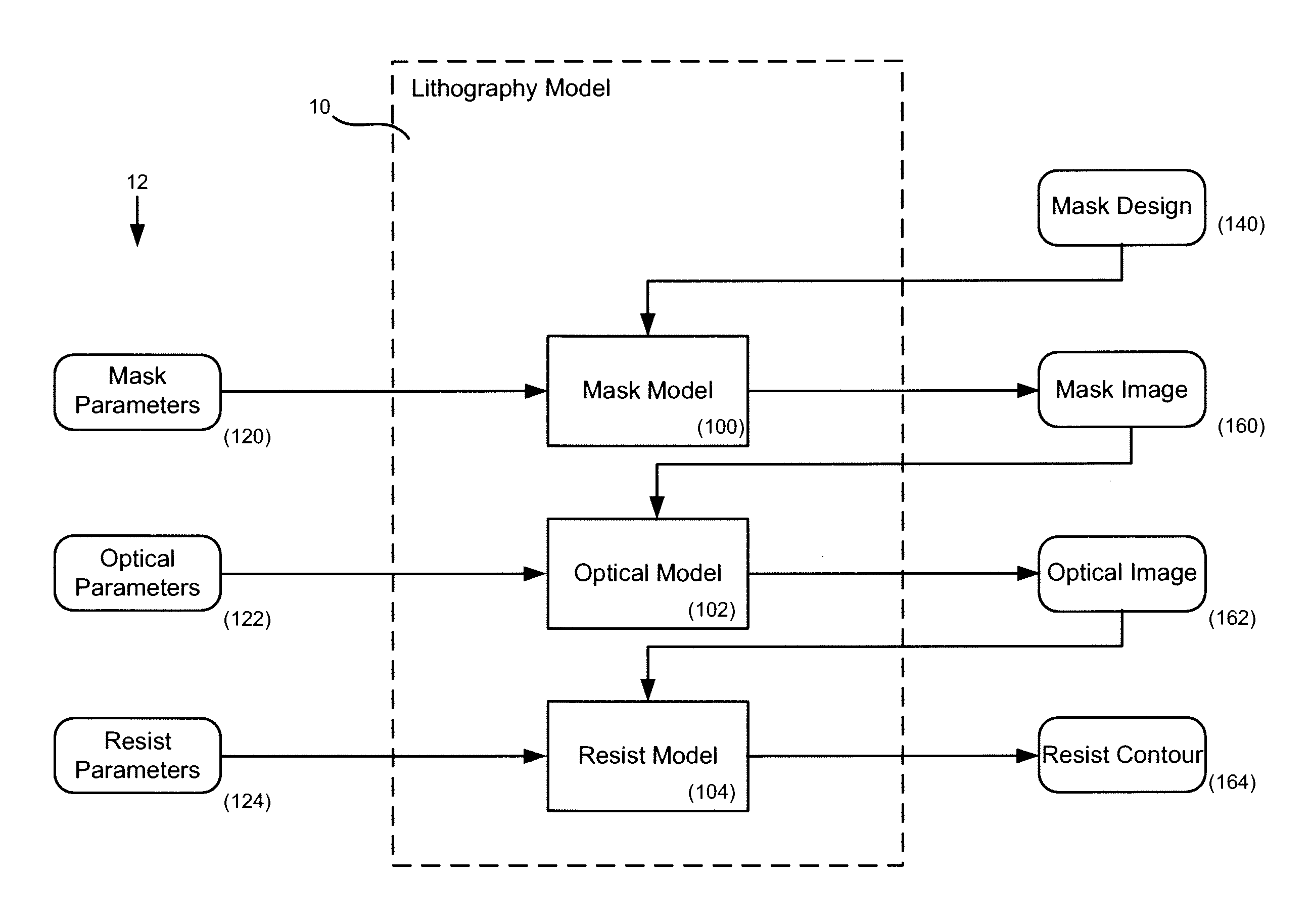

InactiveUS20050055110A1Simple designPromote productionSimulator controlElectric controllersProcess dimensionProcess simulation

A process simulation system that simulates the operation of the manufacturing and measurement systems used to produce and measure the articles being analyzed relative to engineering design targets, engineering design tolerances, producibility and / or quality. In one embodiment, the user is able to assess, without risk or production cost while accelerating speed-to-market, the effect of contemplated changes (i.) to engineering design targets, (ii.) to engineering design tolerances, (iii.) to tooling, (iv.) to part pre-process dimensions and (v.) to the measurement system—on manufactured part dimensions, producibility and quality (i.) without modifying tooling, (ii.) without changing part pre-process dimensions, (iii.) without producing new parts, (iv.) without measuring article characteristics on the new parts and (v.) without changing the measurement system. The simulation functionalities, according to embodiments of the present invention, enable the user to verify whether or not the contemplated changes will have the desired effect without incurring the time and expense involved in actually making the changes, producing parts, measuring part characteristics, changing the measurement system and then determining whether the changes accomplished the desired objectives.

Owner:TUSZYNSKI STEVE W

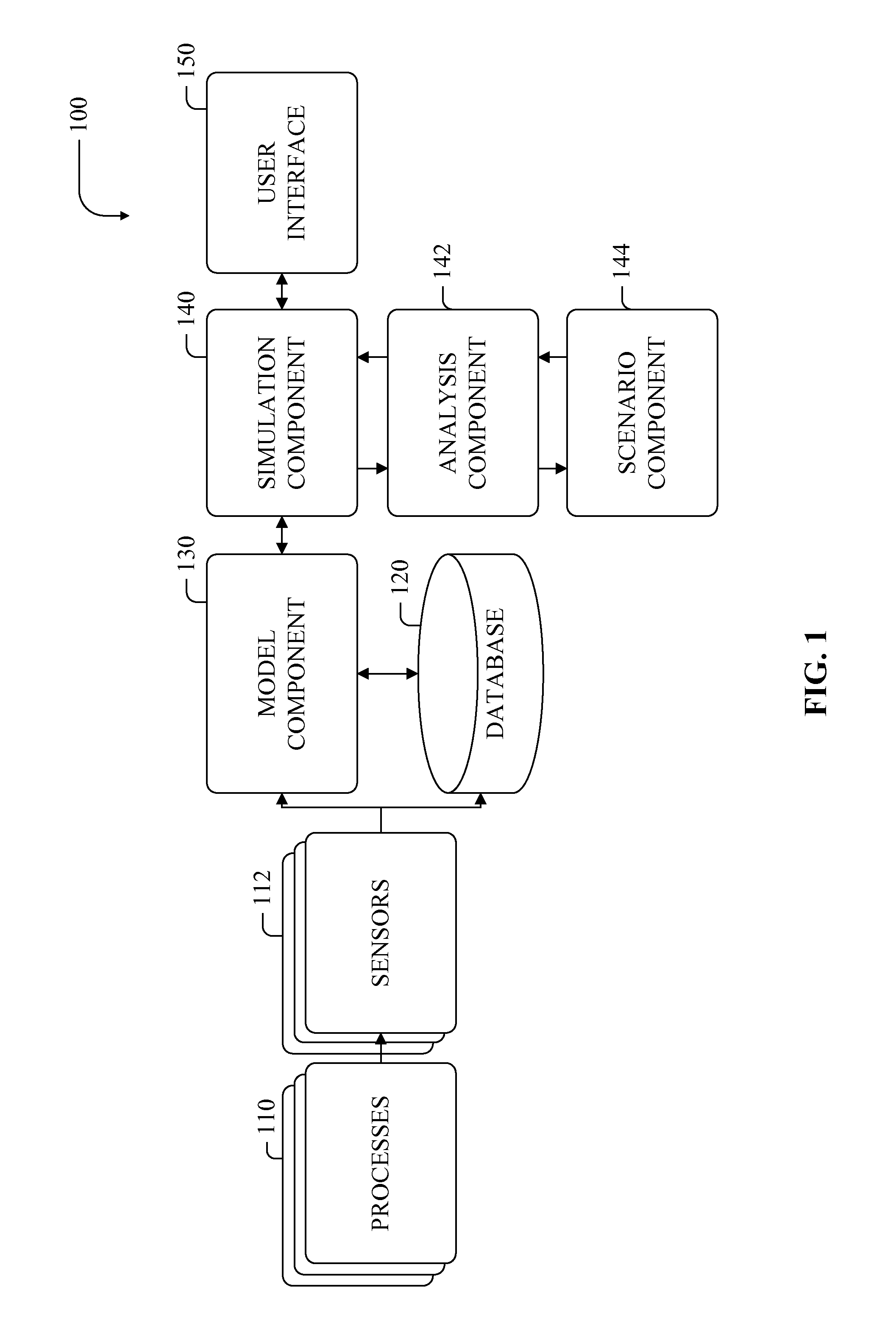

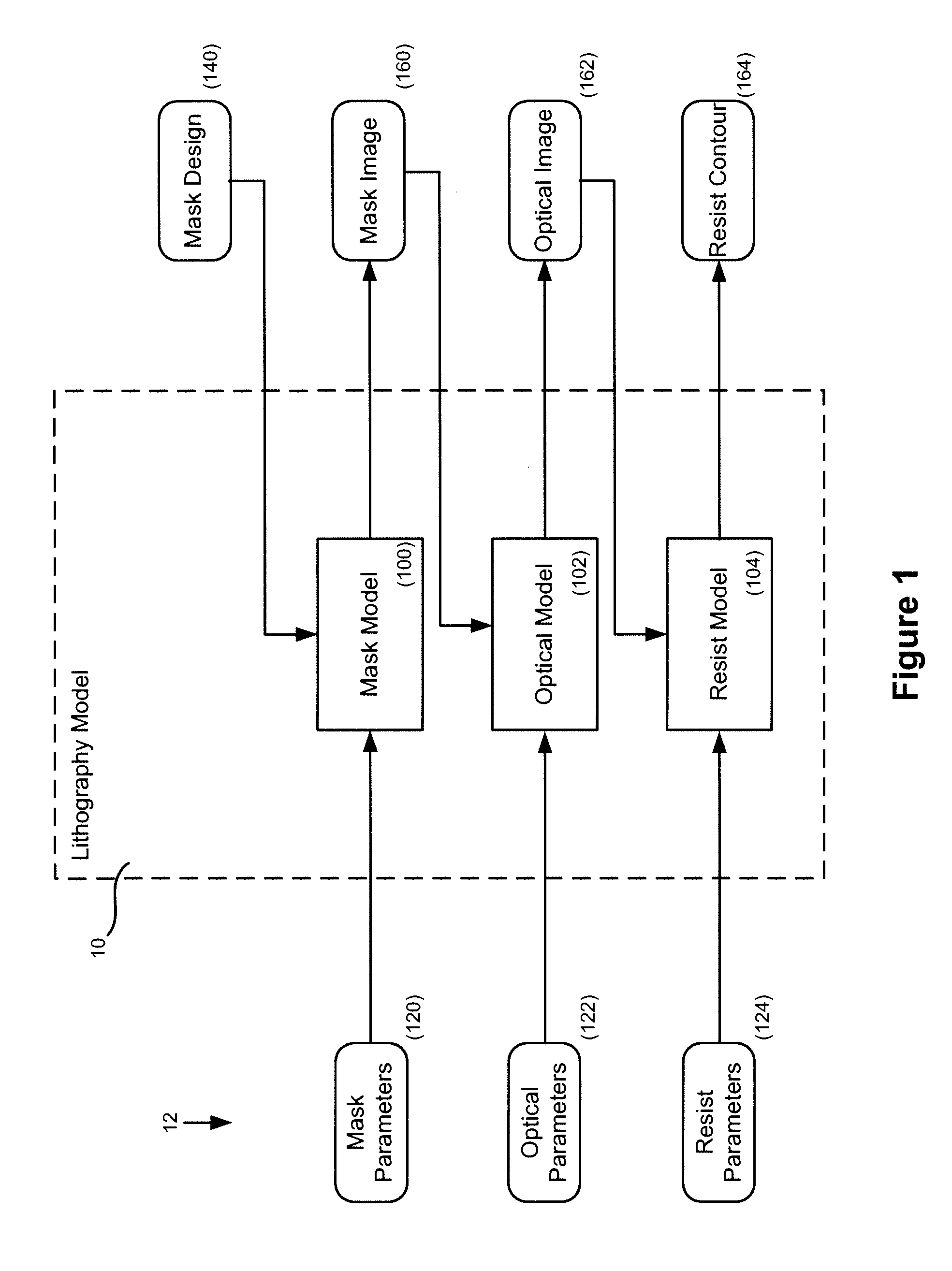

Model-based process simulation systems and methods

ActiveUS20090300573A1Semiconductor/solid-state device manufacturingDesign optimisation/simulationReference modelCritical dimension

Owner:ASML NETHERLANDS BV

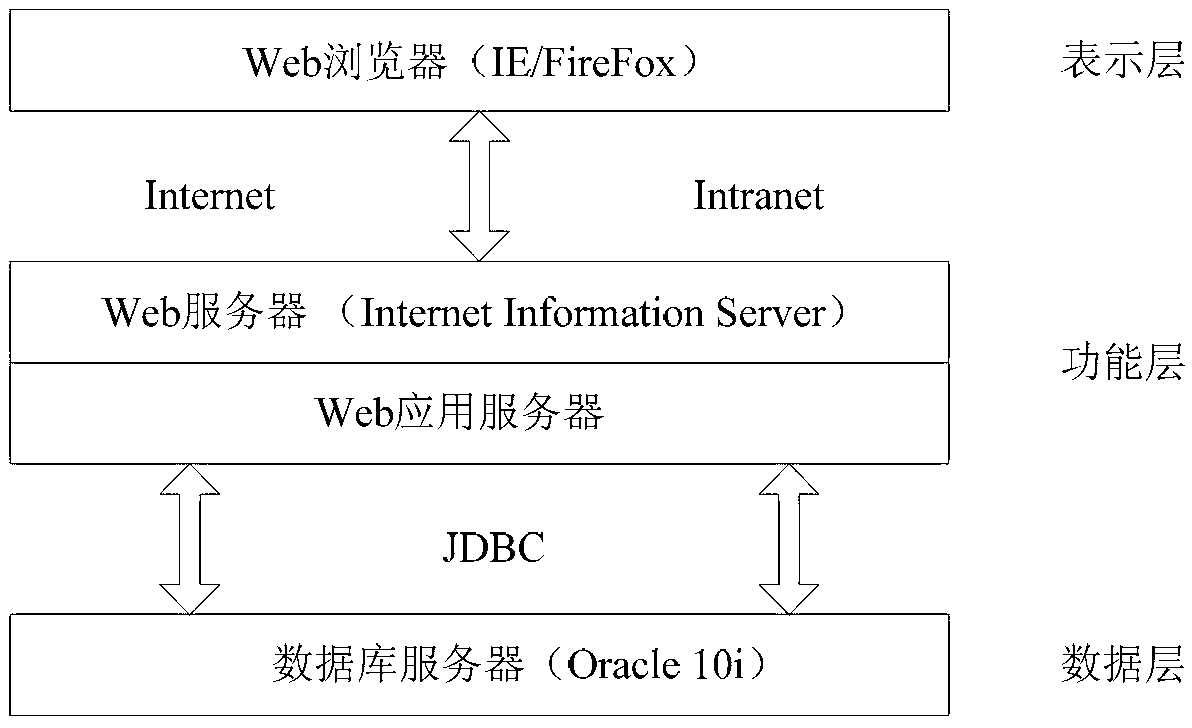

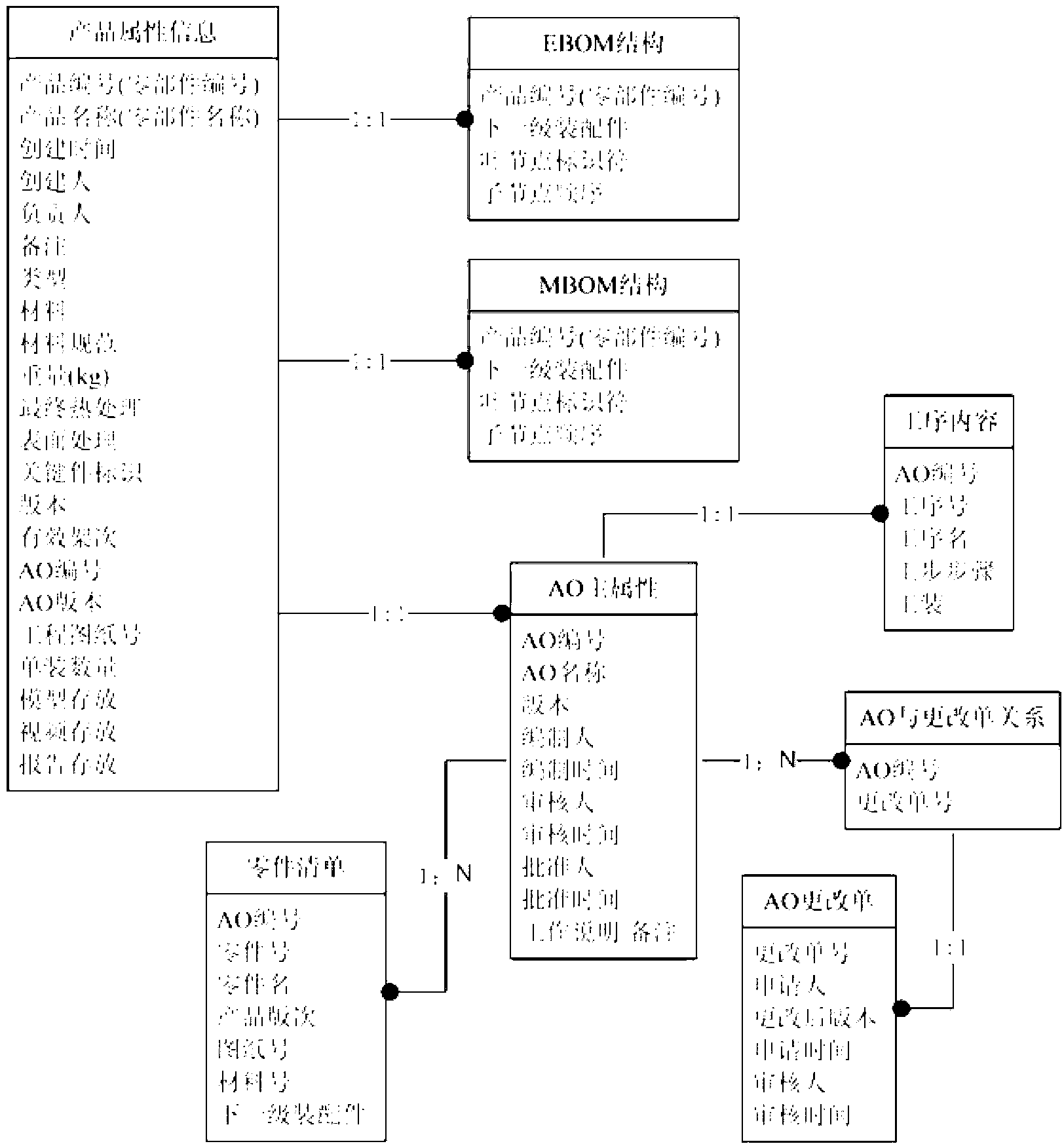

Aircraft assembly data visualization method based on Web

ActiveCN103020393ARealize online browsingReduce redundancySpecial data processing applicationsBill of materialsSimulation

The invention relates to an aircraft assembly data visualization method based on Web. The method comprises four steps as follows: step 1, setting up system architecture and development environment; step 2, visualization AO (Assembly Order) designing; step 3, assembling process simulation; and step 4, using in an assembly site. The method is used for realizing visual online browse of data such as BOM (Bill of Material), AO, product information and the like, and the assembly quality and the working efficiency of aircrafts are increased. The method has a better practical value and a wide application prospect in the aircraft industry.

Owner:BEIHANG UNIV

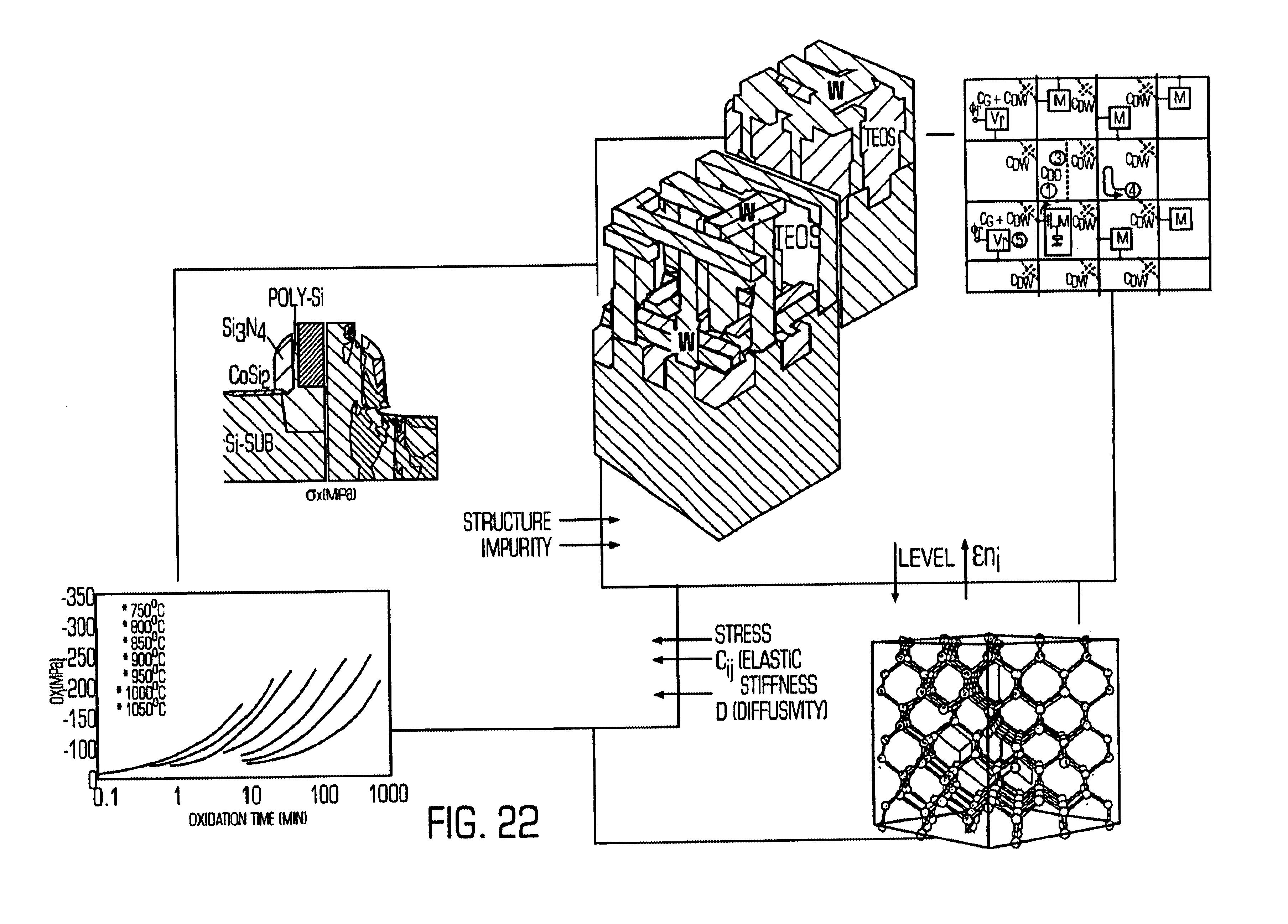

Method and apparatus for simulating manufacturing, electrical and physical characteristics of a semiconductor device

InactiveUS6826517B2Semiconductor/solid-state device detailsDetecting faulty computer hardwareElement modelMaterial Design

An electronic device simulator includes a three-dimensional lumped device model, a three-dimensional visco-elastic process simulation model and a material design model that are interlinked with each other. The three-dimensional lumped device element model comprises a Poisson's equation model, an electron continuity equation model, a hole continuity equation model, a Maxwell's equations model, an eddy current equation model, and an Ohm's law equation model. The simulator accounts for the three dimensional characteristics of the circuit to determine circuit performance.

Owner:KK TOSHIBA

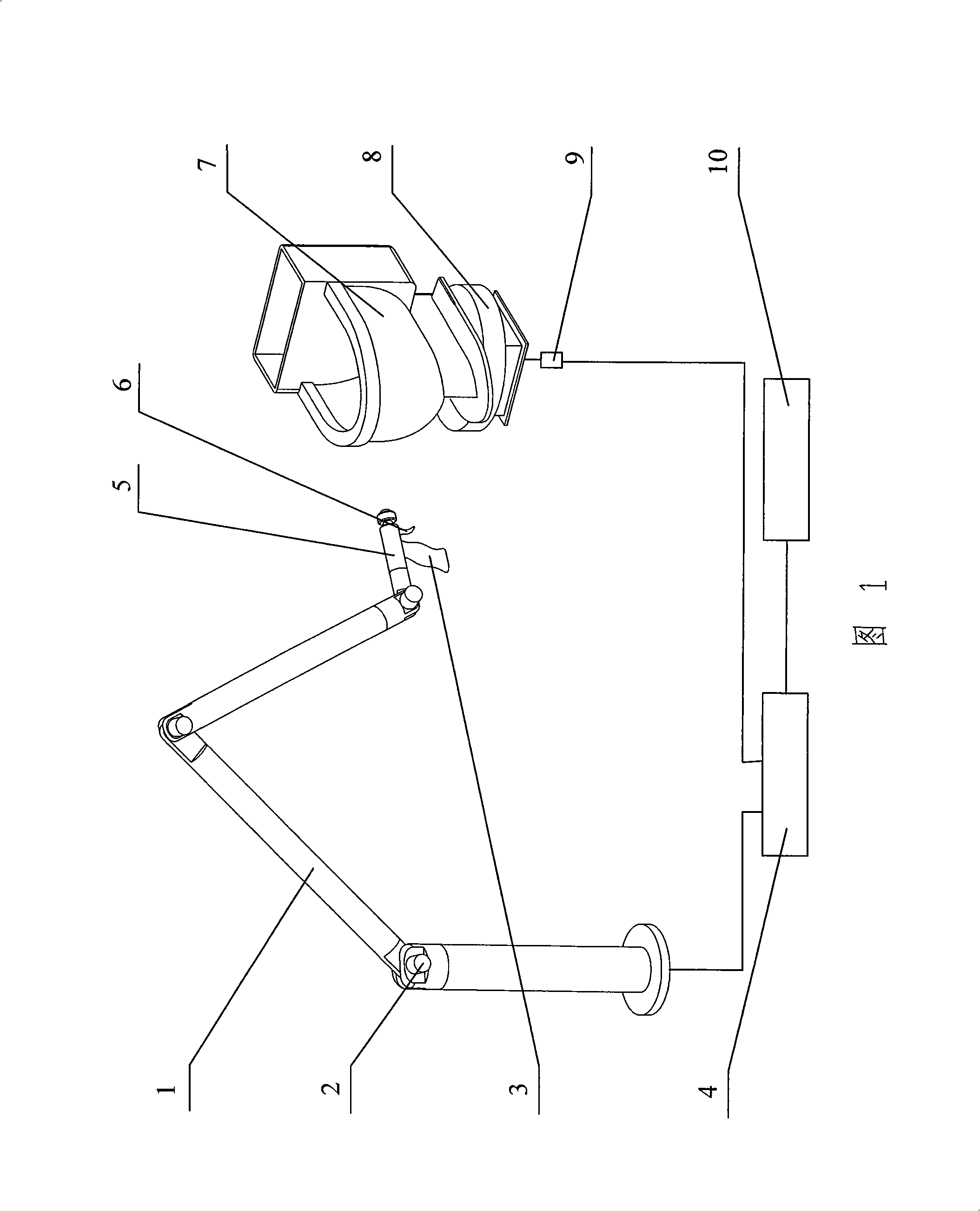

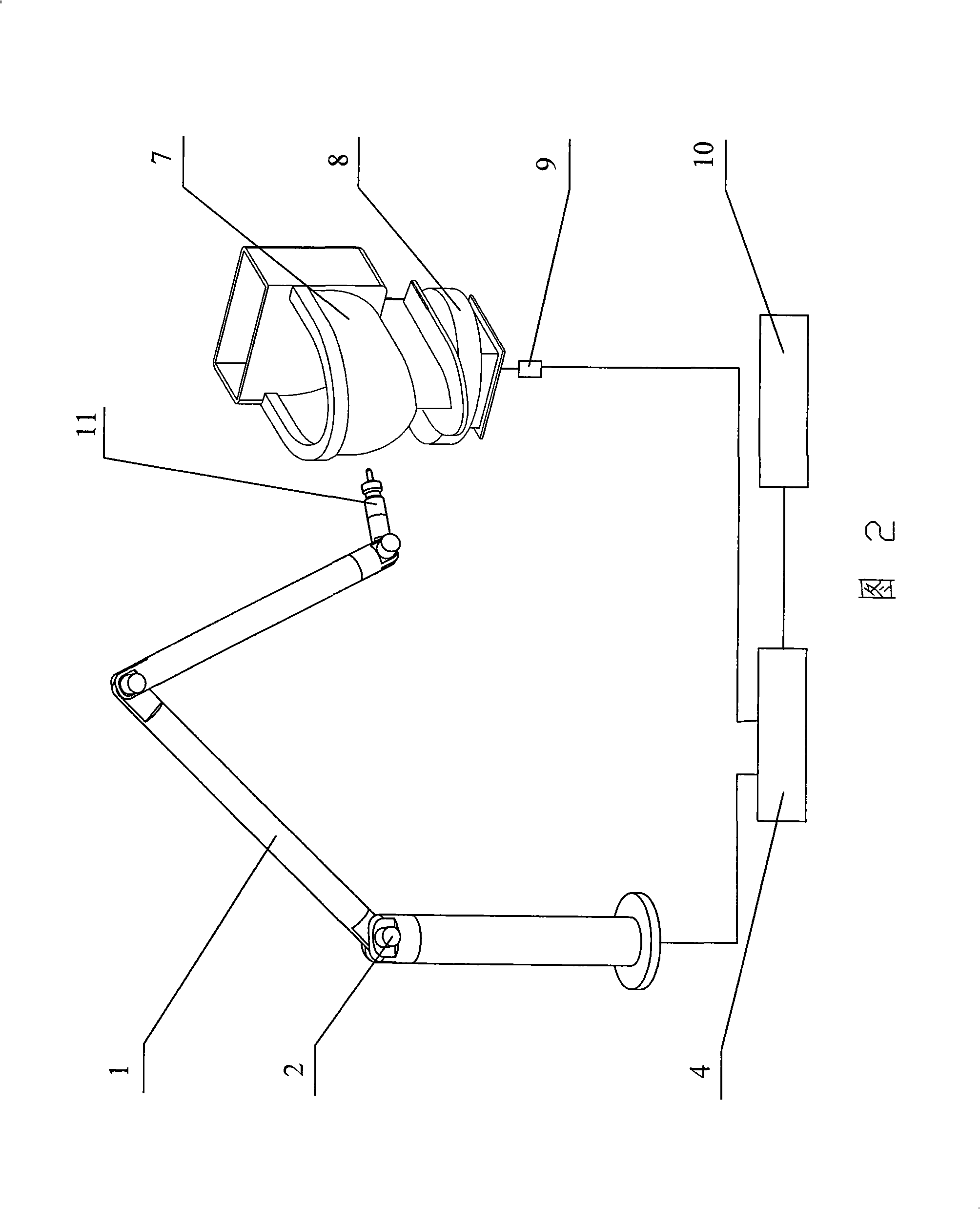

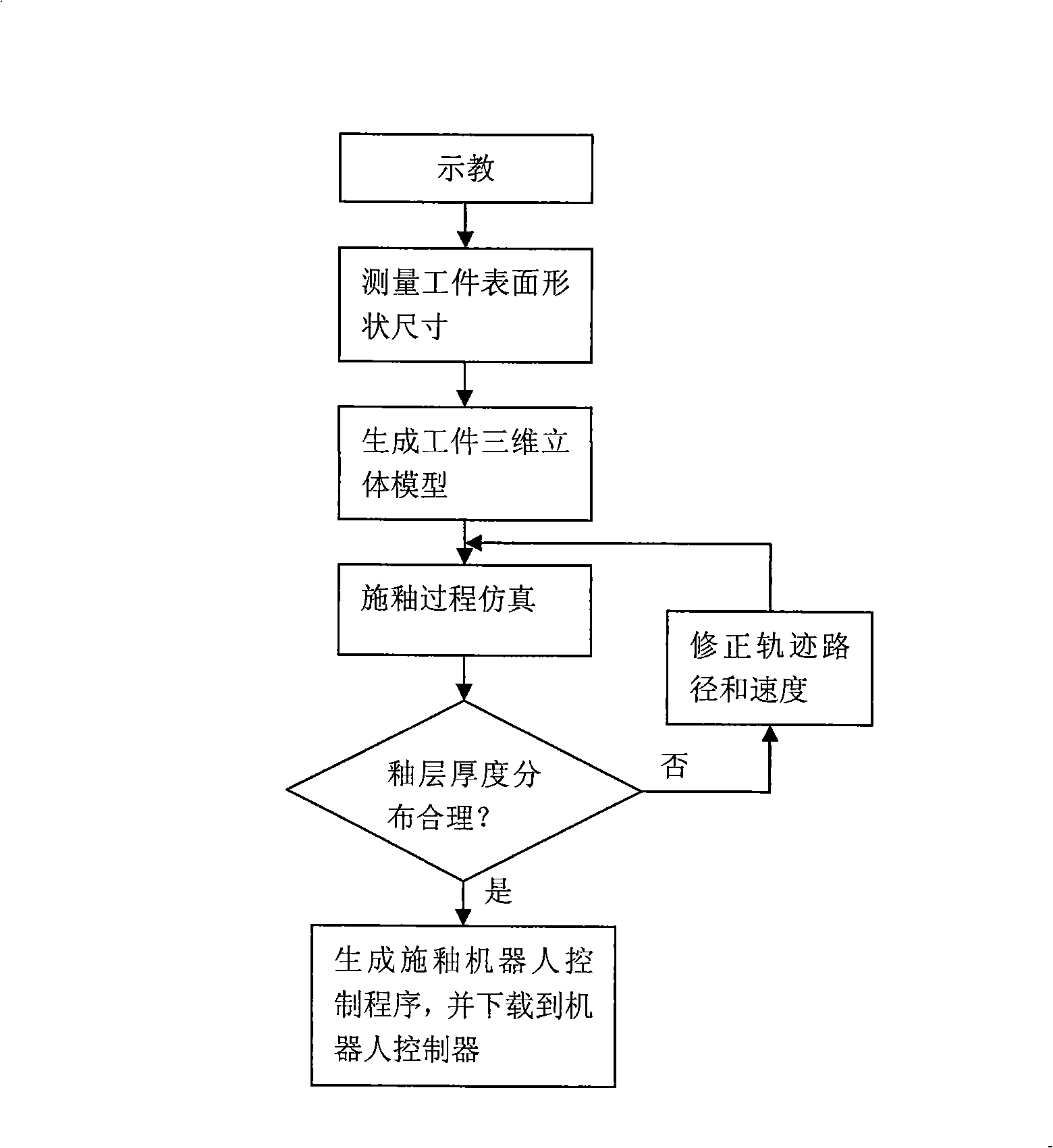

Glazing robot off-line teaching device and teaching method

InactiveCN101327590AEasy to programEasy to operateProgramme-controlled manipulatorSimulationProcess simulation

The present invention relates to an off-line glazing robot-demonstrating device, which belongs to the field of industrial robots. The demonstrating mechanism of the off-line glazing robot-demonstrating device has the same degree of freedom, the same type and number of hinges, the same mechanism size and the same operating space as the actual glazing robot does, joints are connected together by link rods, and the rotary shafts of the joints are respectively connected with an encoder. A demonstrating ejection gun is assembled on the end of the demonstrating mechanism and held by a hand in order to demonstrate, and a data-acquiring unit acquires and records the position and the speed of each joint and the on-off state of the ejection gun. A touch switch is assembled on the end of the demonstrating mechanism, the shape and the size of the surface of a workpiece are measured, and then the three-dimensional model of the workpiece is built in a computer. A glazing process simulation software simulates the piling process and the thickness distribution of glaze on the surface of the workpiece in the process of glazing. A data transmission unit converts the acquired data into a control program for the glazing robot, and then the glazing robot conducts a glazing action according to a data sequence. The off-line glazing robot-demonstrating device has the advantages of light weight, flexibility, high demonstration efficiency and convenient operation, and the glazing process simulation can forecast the thickness distribution of the glazed layer of the surface of the workpiece.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

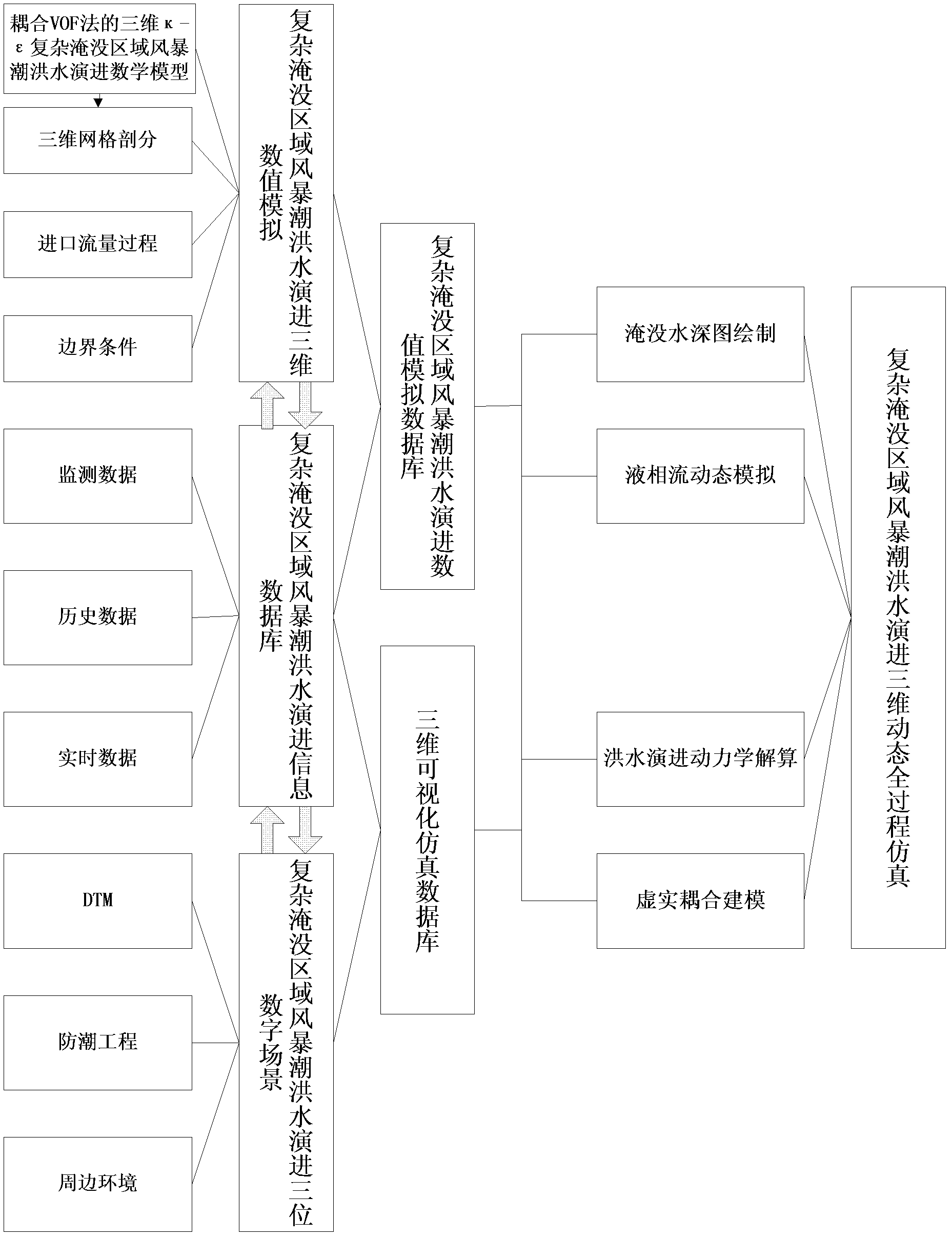

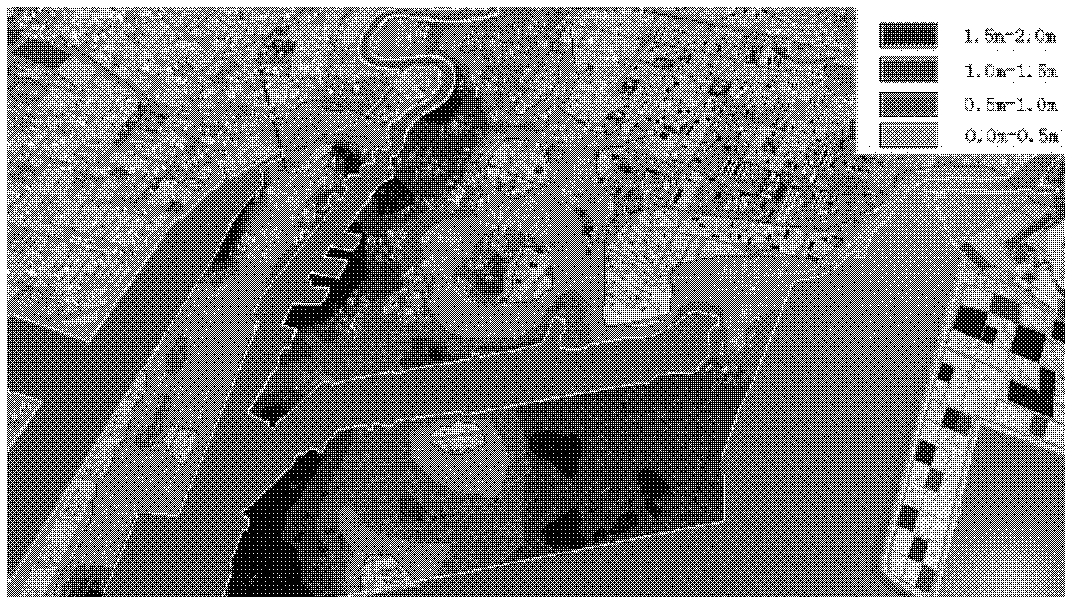

Three-dimensional dynamic whole-process simulation method for storm surge and flood routing in complex flooding areas

InactiveCN102663827AIn line with the law of flowAchieve drawing3D modellingMathematical modelProcess simulation

Owner:TIANJIN UNIV

Real environment-based concrete cracking whole process test apparatus and method

ActiveCN105352876ARigid enoughImprove stabilityWeather/light/corrosion resistanceThermal isolationTemperature control

The present invention provides a real environment-based concrete cracking whole process test apparatus and test method, a main testing machine includes an environmental tank and a concrete specimen containing device arranged in the environmental tank, a specimen is placed in the concrete specimen containing device, a load system is connected with a movable clamp head on the concrete specimen containing device, and simulated real environment is provided in the environmental tank. The method comprises restraining stress, free variables, elastic modulus, deformation separation, and creep and other tests. In the whole process from pouring to hardening of test concrete, under a variety of temperature control conditions, the self temperature stress development process includes adiabatic temperature rise, thermal expansion coefficient, elastic modulus and creep and other parameter development process over time, a real meteorological environment can also be simulated, and temperature stress and cracking mechanism affected by natural factors are simulated. The device can set, according to the needs, different temperature and constraint conditions including thermal isolation, constant temperature, setting of the temperature rise and drop processes, and the like. Through the concrete cracking whole process simulation, concrete crack resistance can be evaluated.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

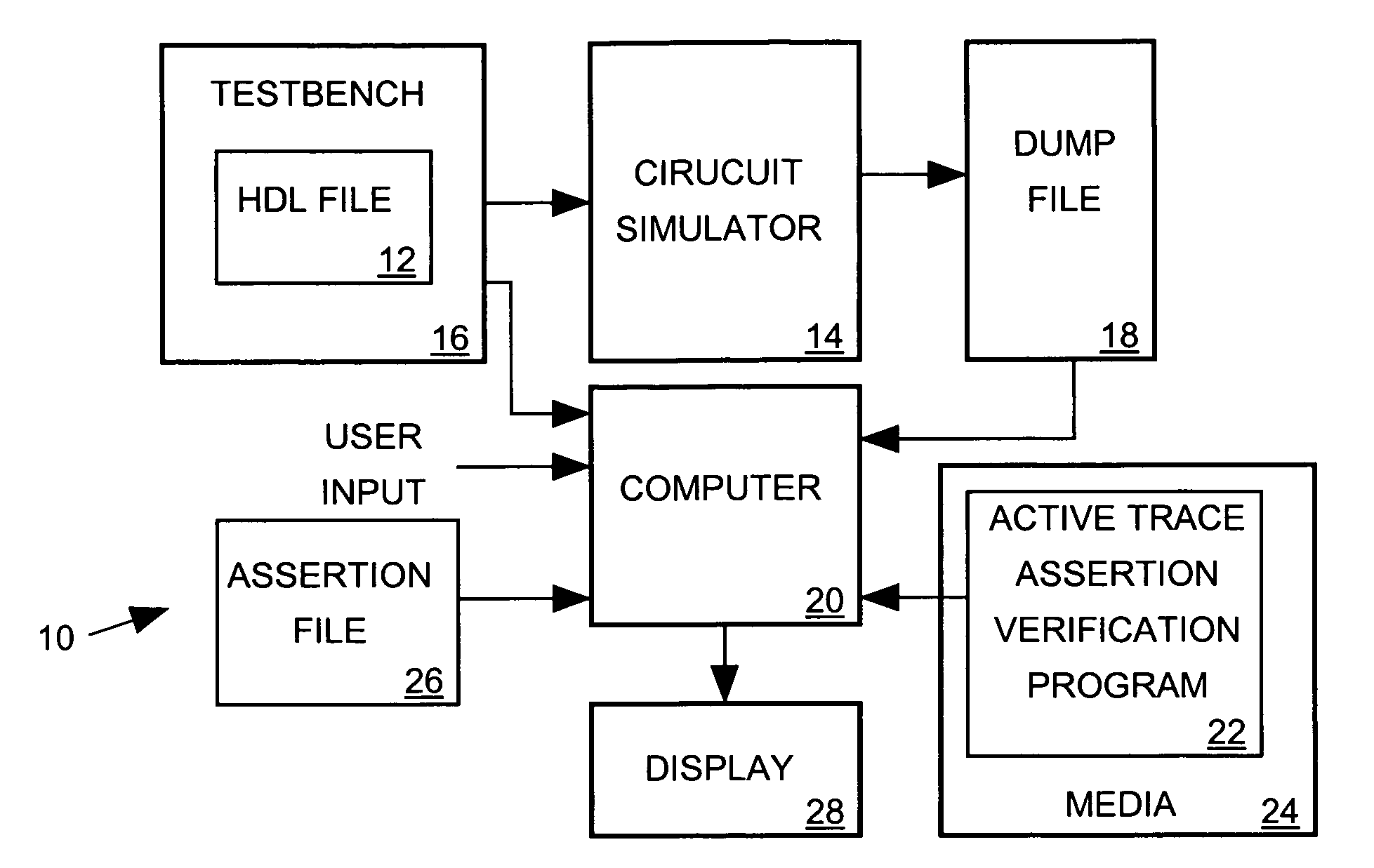

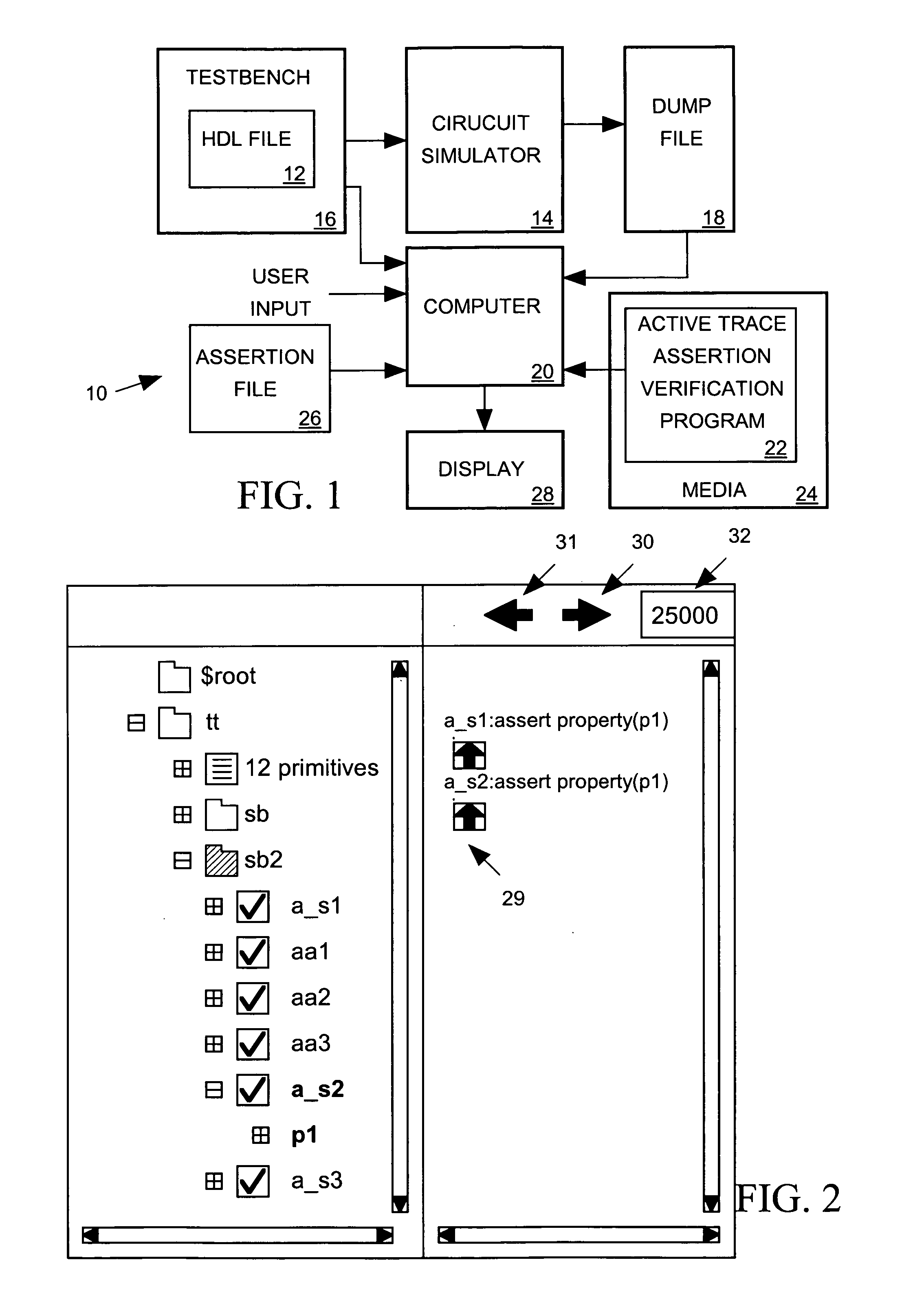

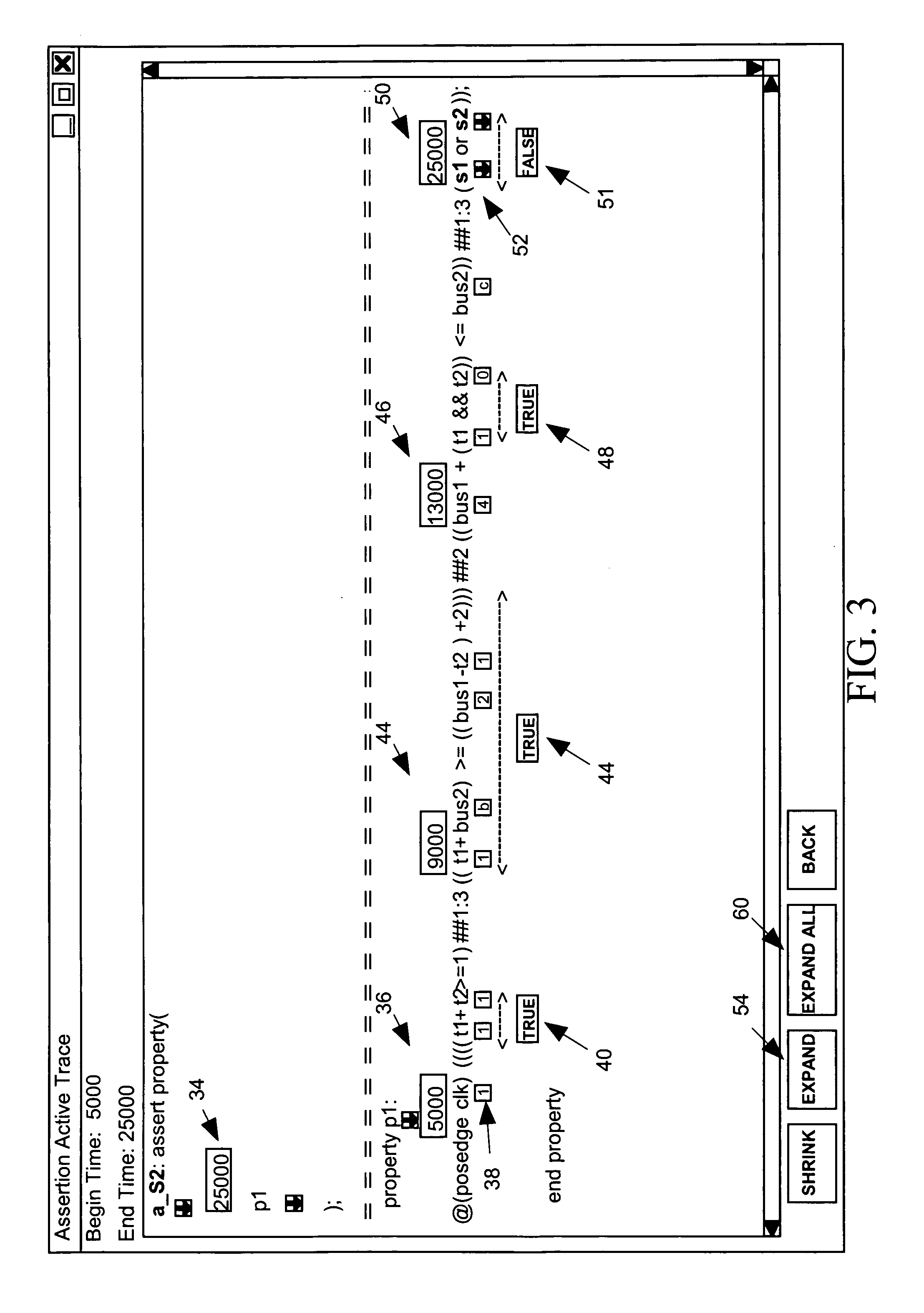

Active trace assertion based verification system

ActiveUS20070294651A1CAD circuit designSoftware simulation/interpretation/emulationTheoretical computer scienceVerification system

A computer processes simulation data indicating values of circuit signals as functions of simulation time to determine whether a circuit exhibits a property defined by an assertion. The assertion expresses the property as a sequence of expressions, each a function of one or more variables, where each variable represents a value of one or more signals or a value of another sequence of expressions. The assertion statement separately defines an evaluation time for each expression, a particular simulation time at which the expression is to be evaluated. Each expression must evaluate true if the circuit has the property. The computer produces a display including a representation of each expression of the property including a separate variable symbol for each of its variables. For each expression that evaluated false, the computer identifies each variable that caused that expression to evaluate false and distinctively marks that variable's symbol relative to other variable symbols within the display. For each expression that evaluated true, the computer identifies the evaluation time contributing the fulfillment of assertion property. The computer also annotates the representation of each expression with its corresponding evaluation time and annotates each displayed variable symbol with a value of the variable it represents.

Owner:SYNOPSYS INC

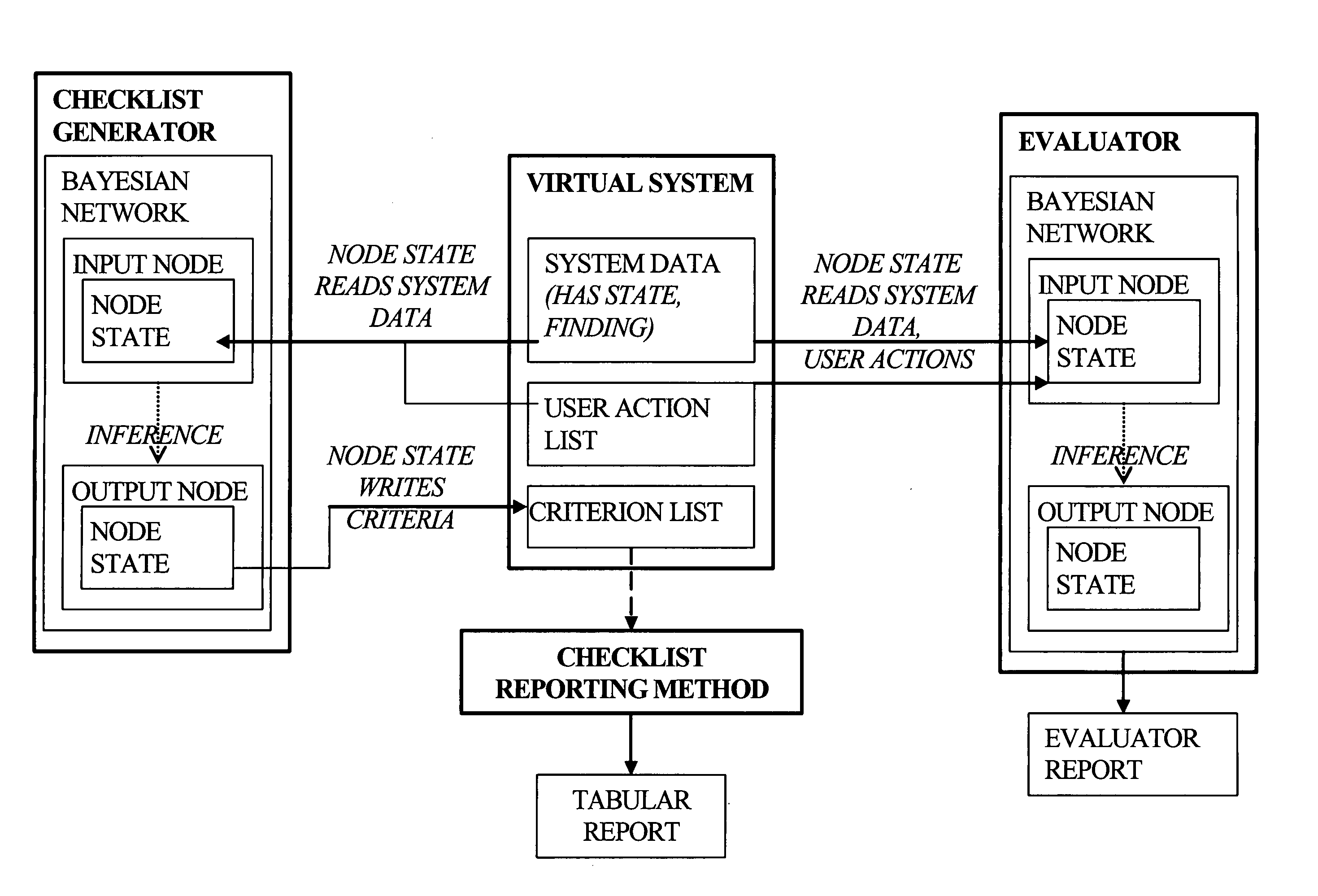

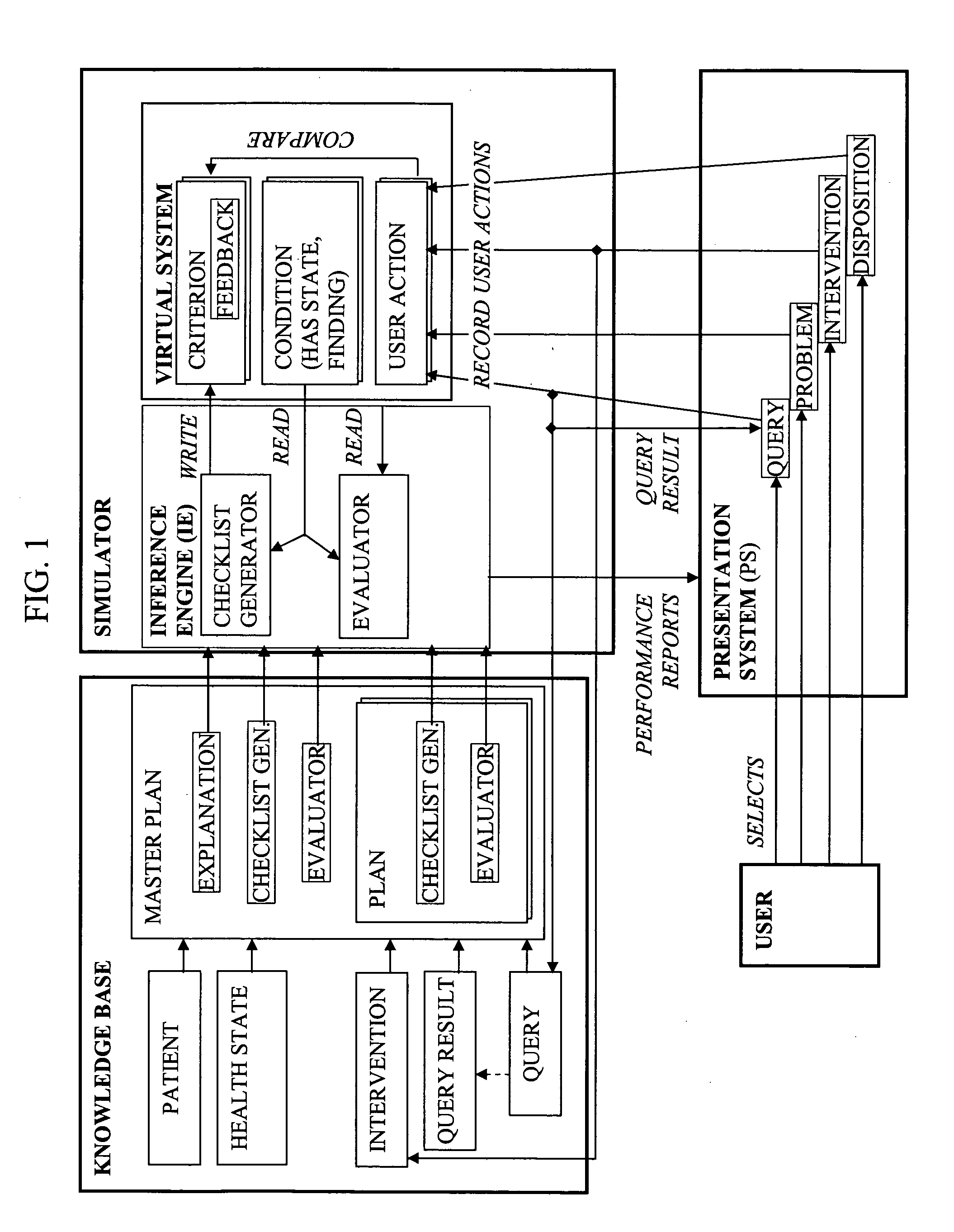

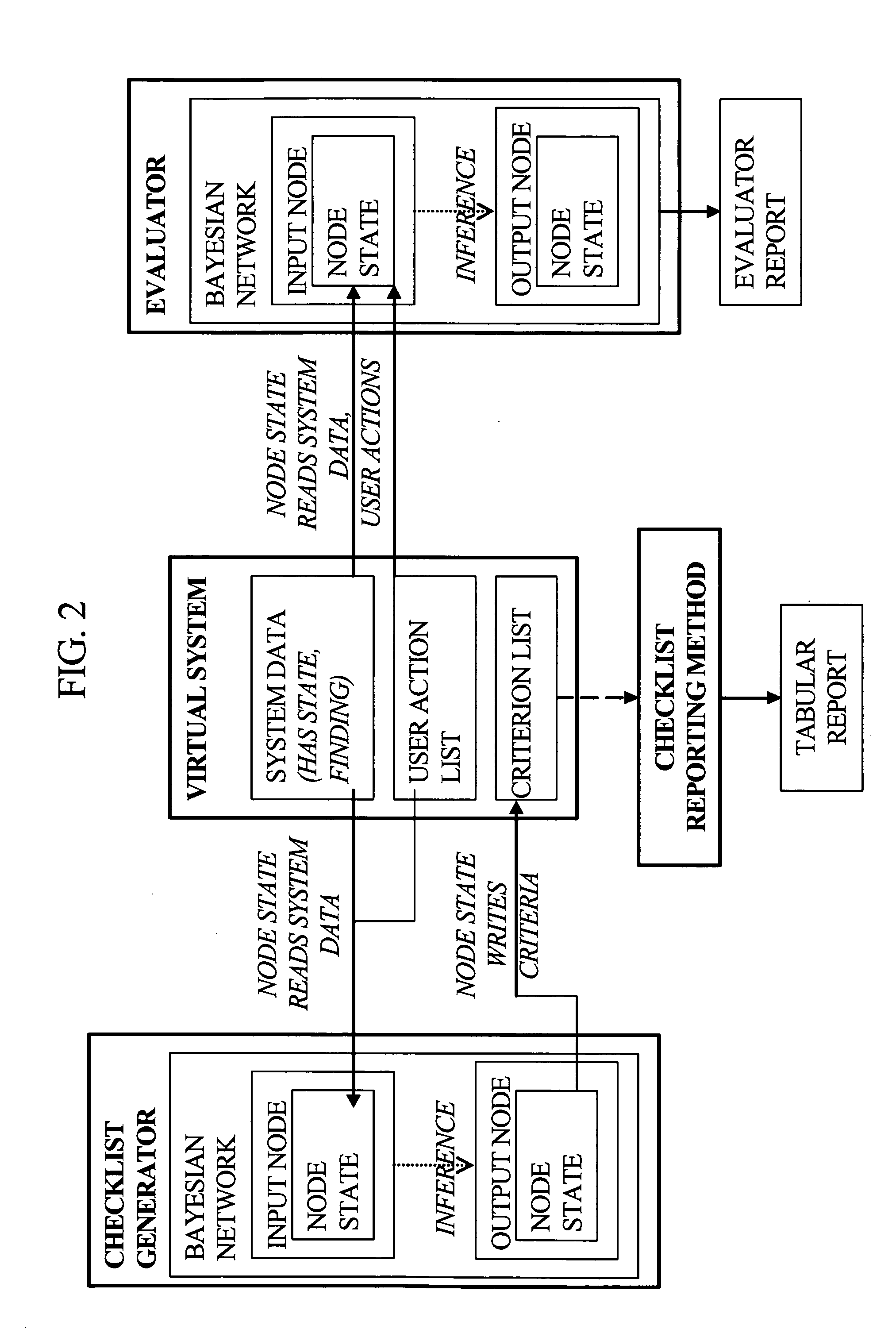

Computer architecture and process of user evaluation

ActiveUS20050118557A1Easy to reconfigureDigital computer detailsBiological neural network modelsPrimitive stateComplex system

The present invention is generally related to a computer architecture and process for evaluating and reporting on a user's competence in managing a simulation of a complex system modeled in a computer based testing and training system. The simulation may be called a “virtual system.” The method generates evaluation criteria responsive to a user profile, user choices in managing the virtual system, and events that occur during a simulation, in addition to the original state of the system. The method produces summary evaluations responsive to a plurality of characteristics of the simulated system. The implementation may be advantageously employed to evaluate a medical clinician's management of computer-simulated human patients, hereinafter called “virtual patients”. The present invention is also suitable for evaluation of user management of a plurality of complex systems including but not limited to animals, plants, cells, machines, and populations.

Owner:AMERICAN BOARD OF FAMILY MEDICINE

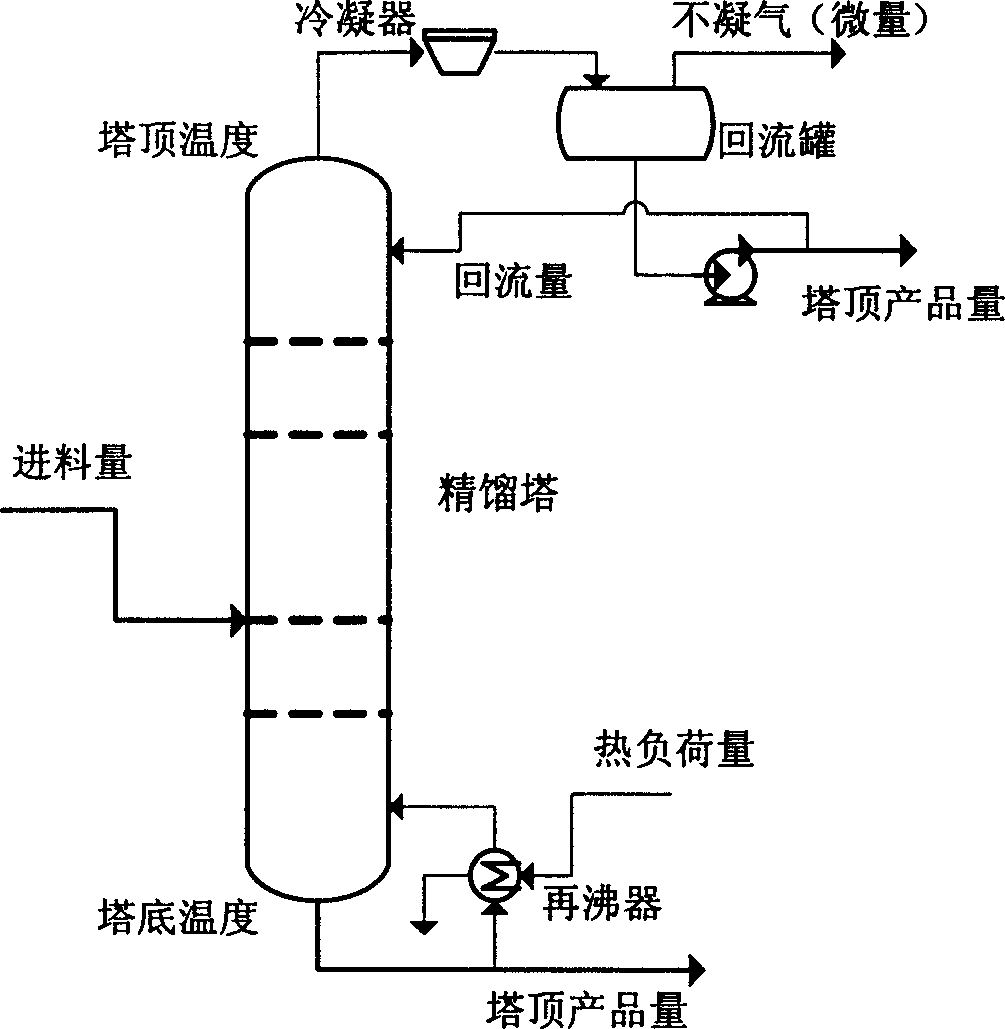

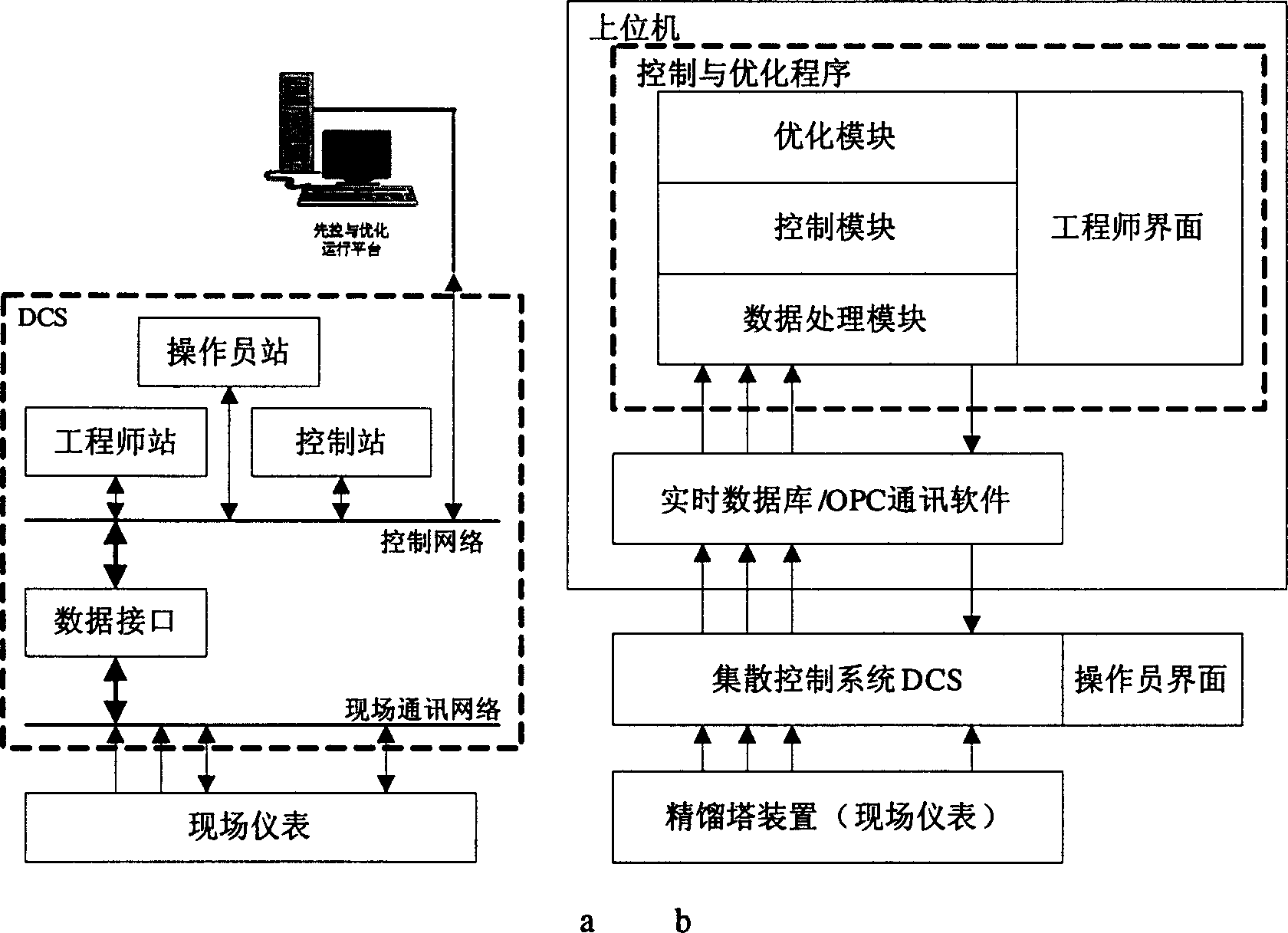

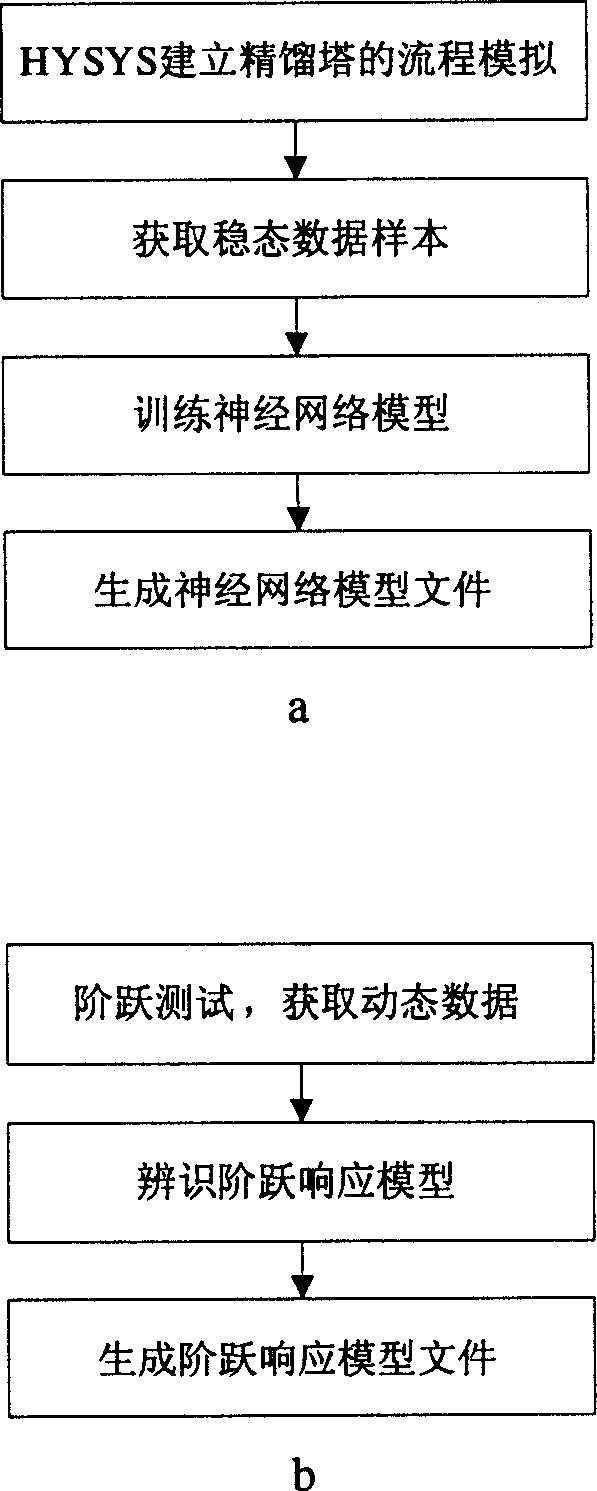

Rectification tower automatic control and optimization method

InactiveCN1762525AEasy to operateLess impuritiesDistillation regulation/controlAutomatic controlMaterial balance

The invention relates to a method for controlling and optimizing the distillation tower. It controls the distillation tower in dependence on the material balance relation and component balance relation, optimizes the distillation tower by using representative model. Employing the abstraction proportion between the light product on the top of the tower and heavy product in the bottom of the tower (in following, taking the proportion between light and heavy product for abbreviation) as main controlled variable depending on the distillation principle, the material balance and component balance in the distillation tower, controlling the proportion between the light and heavy product, temperature, reflux ratio to realize stable operation by regulating the quantity of reflux and heat load of re-boiler. Simulating the practical course through the technological process simulation software, and training the nerve net model to become the representative model for the course optimization. Optimizing the operation with the representative model by using the analytical data for the raw material and product to realize the product Ka bian optimization, increasing the productivity of product with high value on the condition of guaranteeing the product quality and realizing the device energy saving and consumption reduction.

Owner:TSINGHUA UNIV

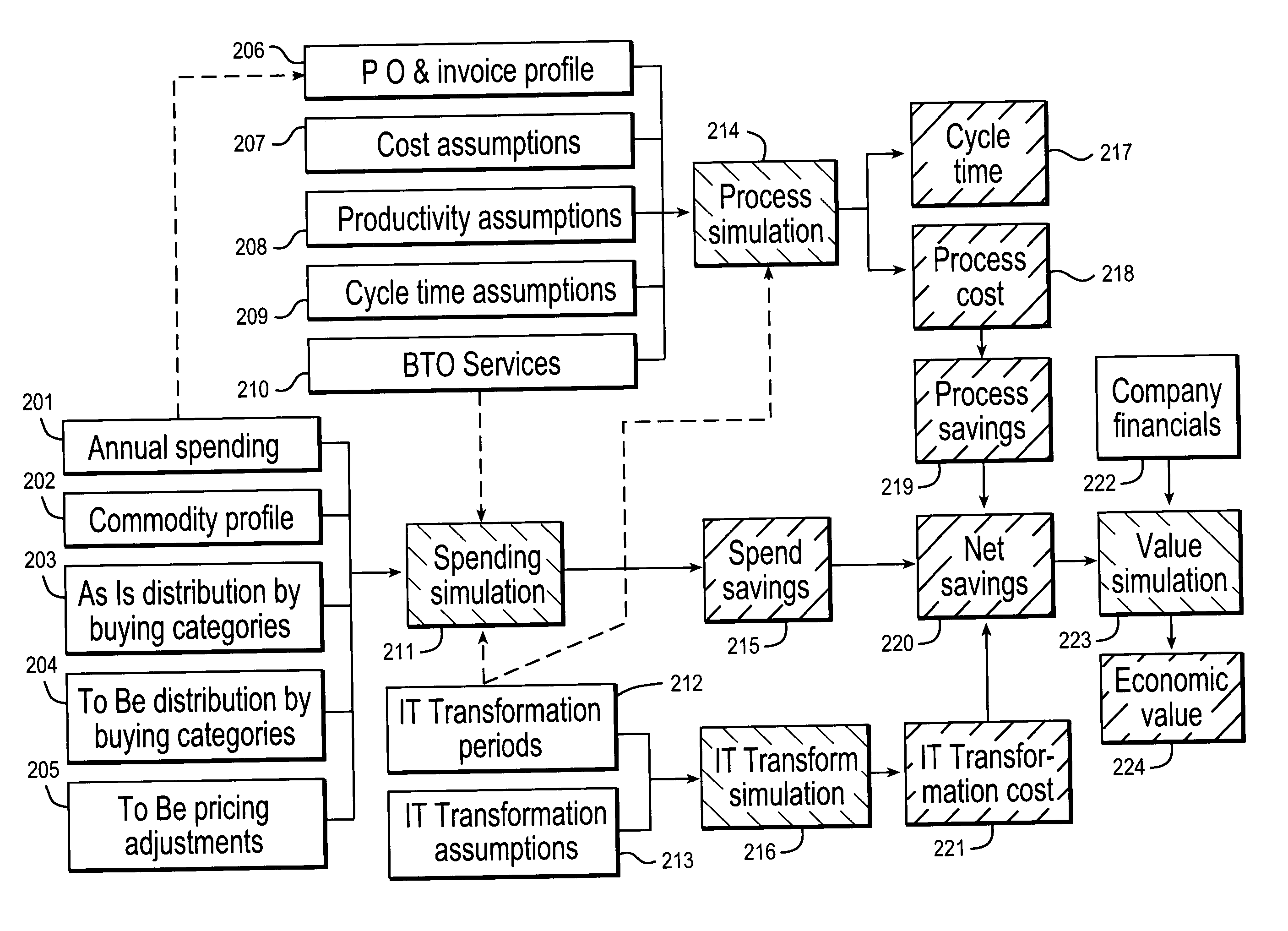

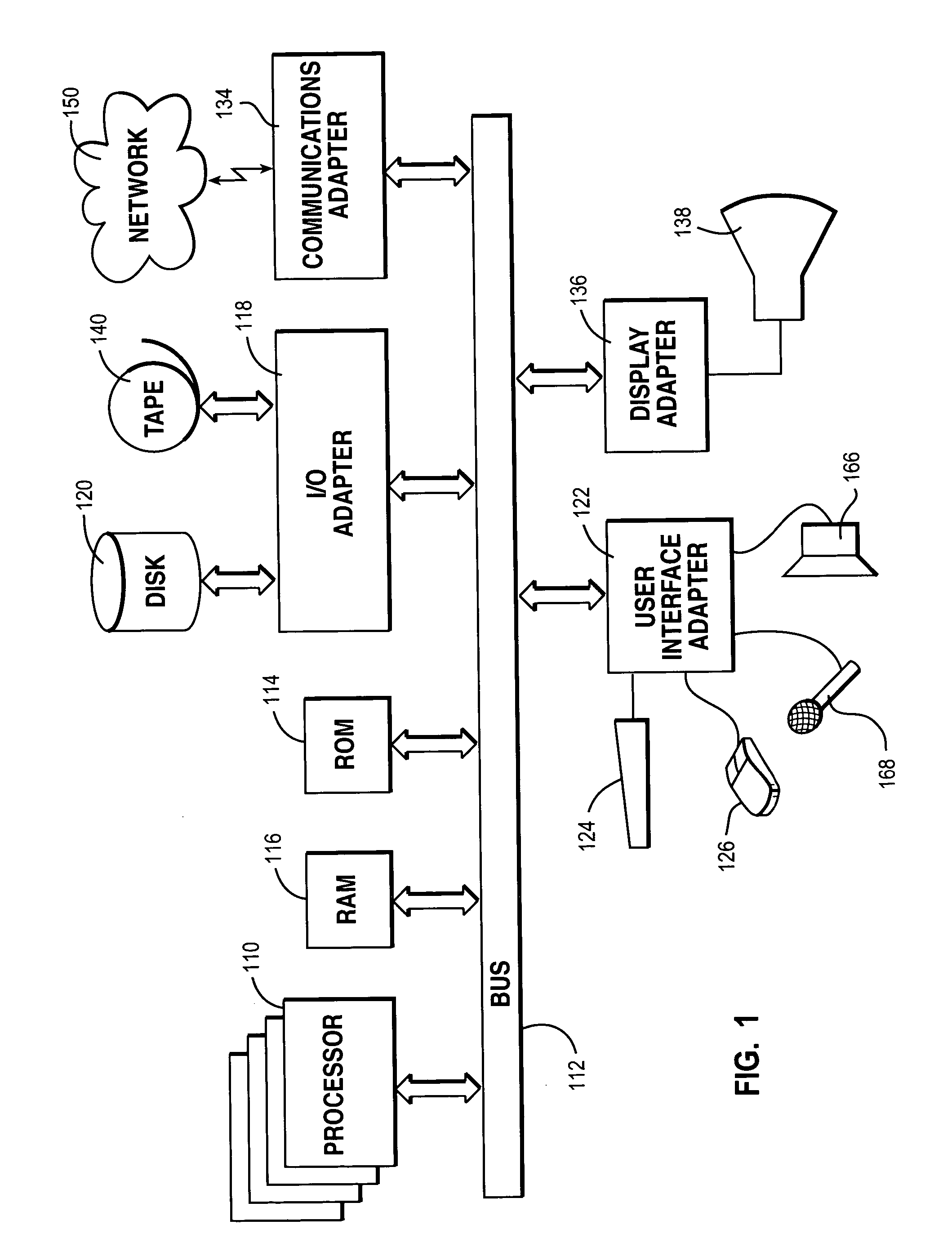

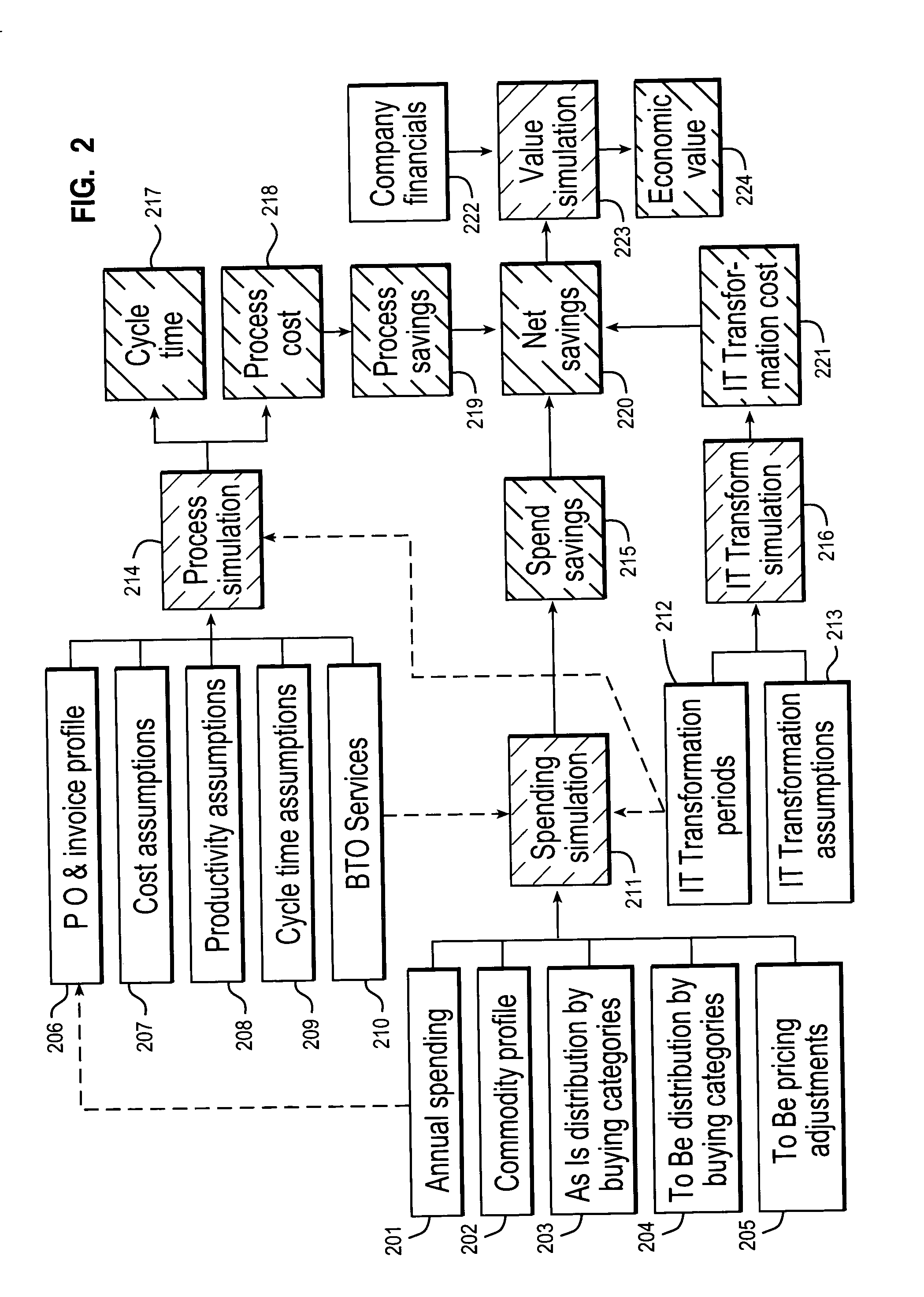

Simulation of business transformation outsourcing of sourcing, procurement and payables

InactiveUS20050065831A1Data processing applicationsSpecial data processing applicationsAccounts payableClient organization

An example of a solution provided here comprises: performing a spending simulation, process simulation, information technology simulation, and value simulation, providing interactions among the simulations, and representing with the simulations the use by a client organization of one or more business transformation outsourcing services, such as sourcing, procurement, and payables.

Owner:IBM CORP

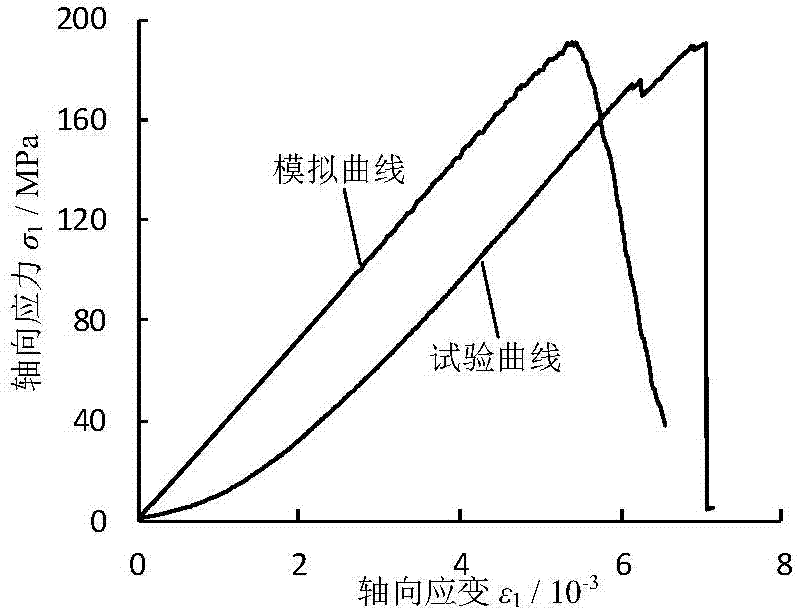

Determination method for mesoscopic parameters simulating mechanical properties of intermittent crack rock

InactiveCN103940666AVerify accuracyDeepen understandingMaterial strength using tensile/compressive forcesParticle flowAxial pressure

Belonging to a rock mechanical determination method, the invention provides a determination method for mesoscopic parameters simulating mechanical properties of an intermittent crack rock. The method includes: firstly sampling an engineering rock mass to be tested, and making a complete and intermittent crack cuboid sample; placing the made sample in a sealed pressure cylinder of a servo test machine, firstly bringing a testing machine pressure head into close contact with the upper end and lower end of the rock sample; applying an axial pressure on the sample according to displacement loading, and conducting loading on the sample till fracture, thus obtaining a sample compression process stress-strain overall process curve, a crack propagation process and a final fracture mode; employing particle flow code in 2 dimensions (PFC2D) to establish a complete sample numerical model, and debugging the mesoscopic parameters continuously to acquire a set of mesoscopic parameters able to reflect complete rock sample test results; establishing an intermittent crack numerical model based on the mesoscopic parameters, carrying out compression process simulation, comparing the simulation results with the intermittent crack rock test results so as to further verify the accuracy of the mesoscopic parameters.

Owner:CHINA UNIV OF MINING & TECH

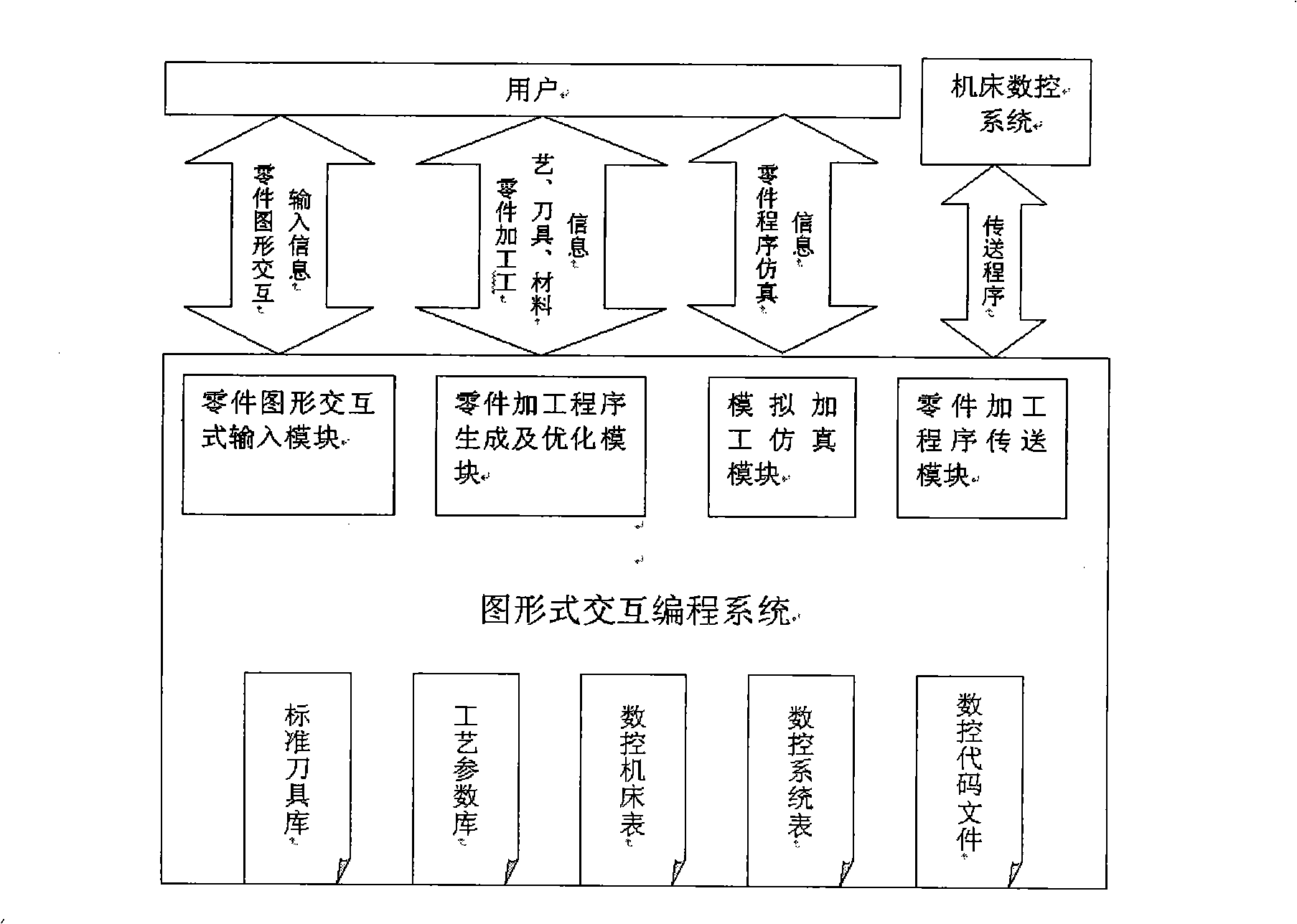

Numerical control longitudinal cutting machine tool machining program simulated realization method and its system

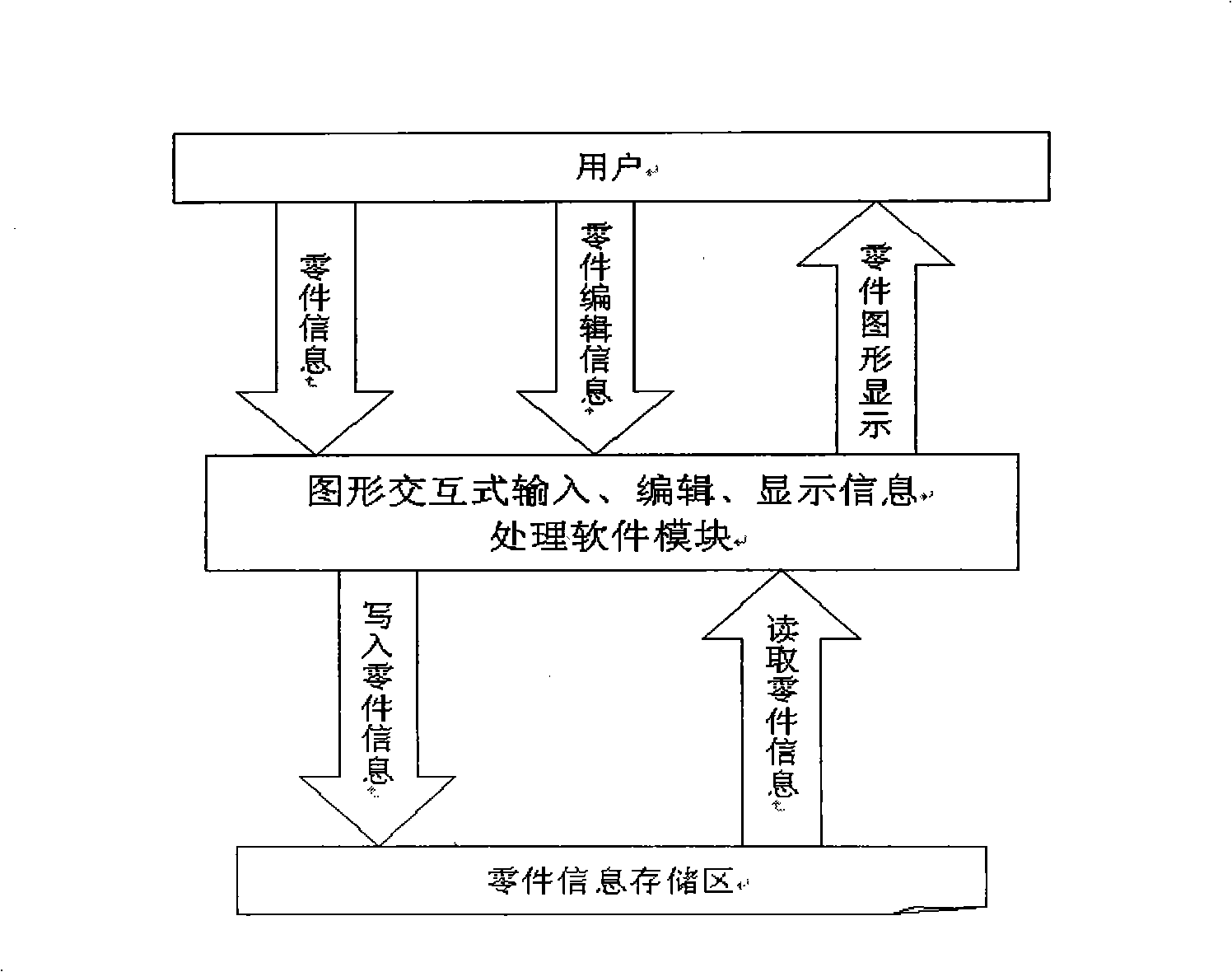

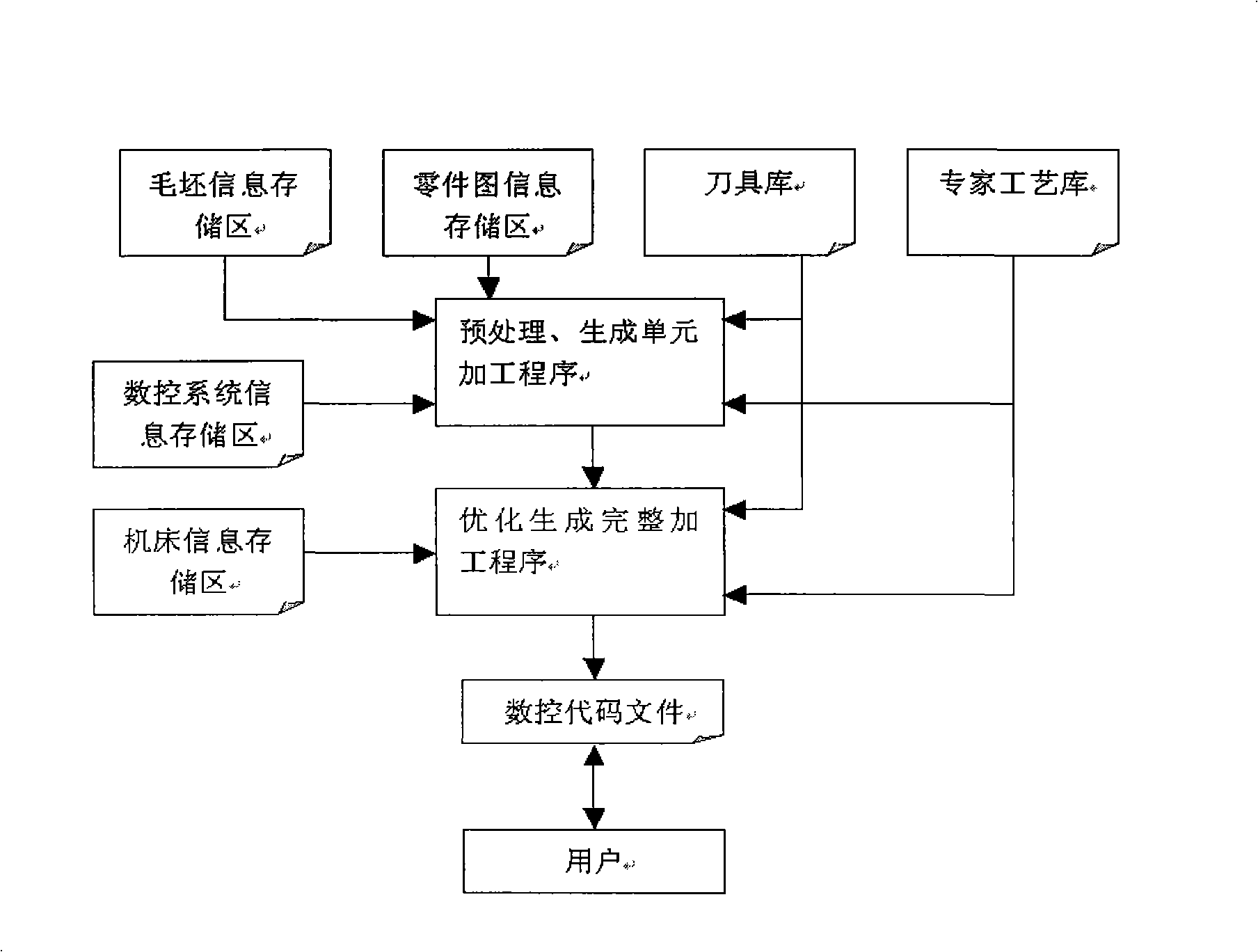

The invention relates to a PC-based numerical control sliver automatic lathe part processing automatic programming and simulation realization method and a system. The method comprises the following steps: A. entering the simulator part graphic interactive input interface, and inputting the geometric figure and the related information of the parts to be processed; B. entering the part processing generation interface, and generating the part processing program and the related processing parameters; C. entering the simulation interface of the part processing program to make simulation inspection to the generated part processing program through the system, and the user can simulate the part processing course on a PC screen; D. transmitting the part processing program to the corresponding numerical control machine, and completing the programming and input of the part processing program. The system comprises processing program interactive generation and simulation, and relates to numerical control machines to realize the generation and simulation of PC-NC machine processing programs. The method and system of the invention can effectively increase the work efficiency of productivity of numerical control sliver automatic lathes.

Owner:四川普什宁江机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com