Patents

Literature

24120results about "Material strength using tensile/compressive forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

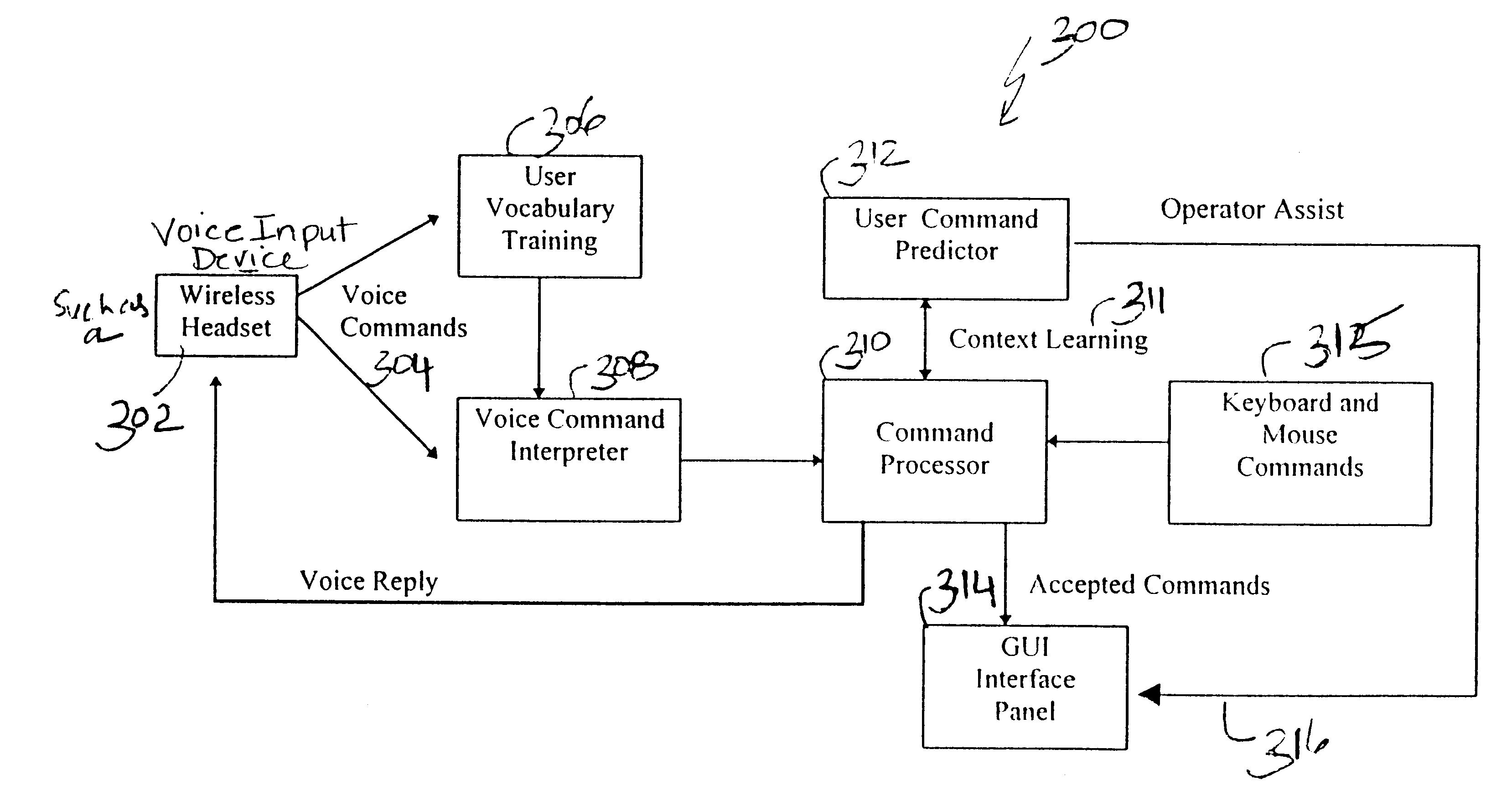

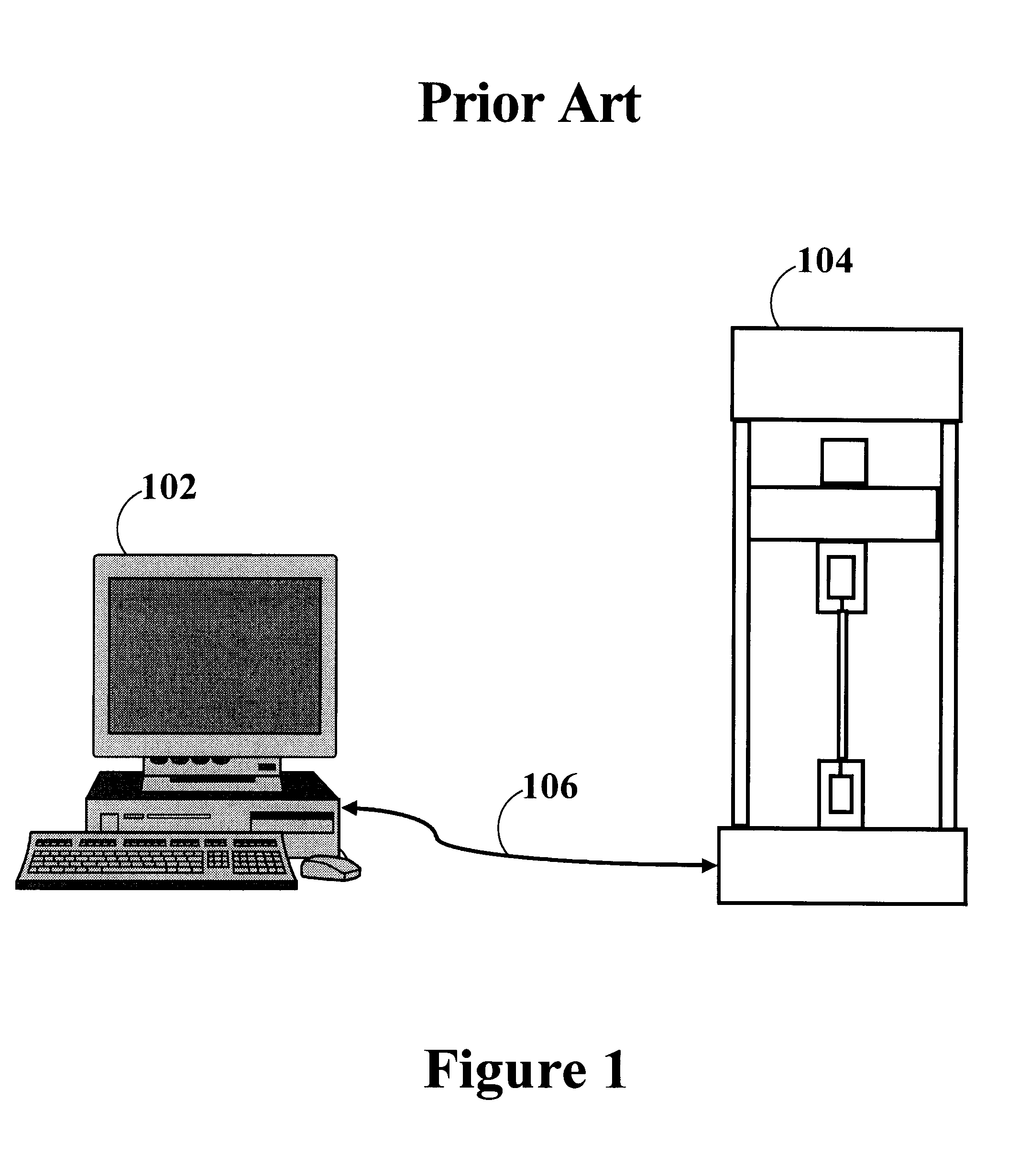

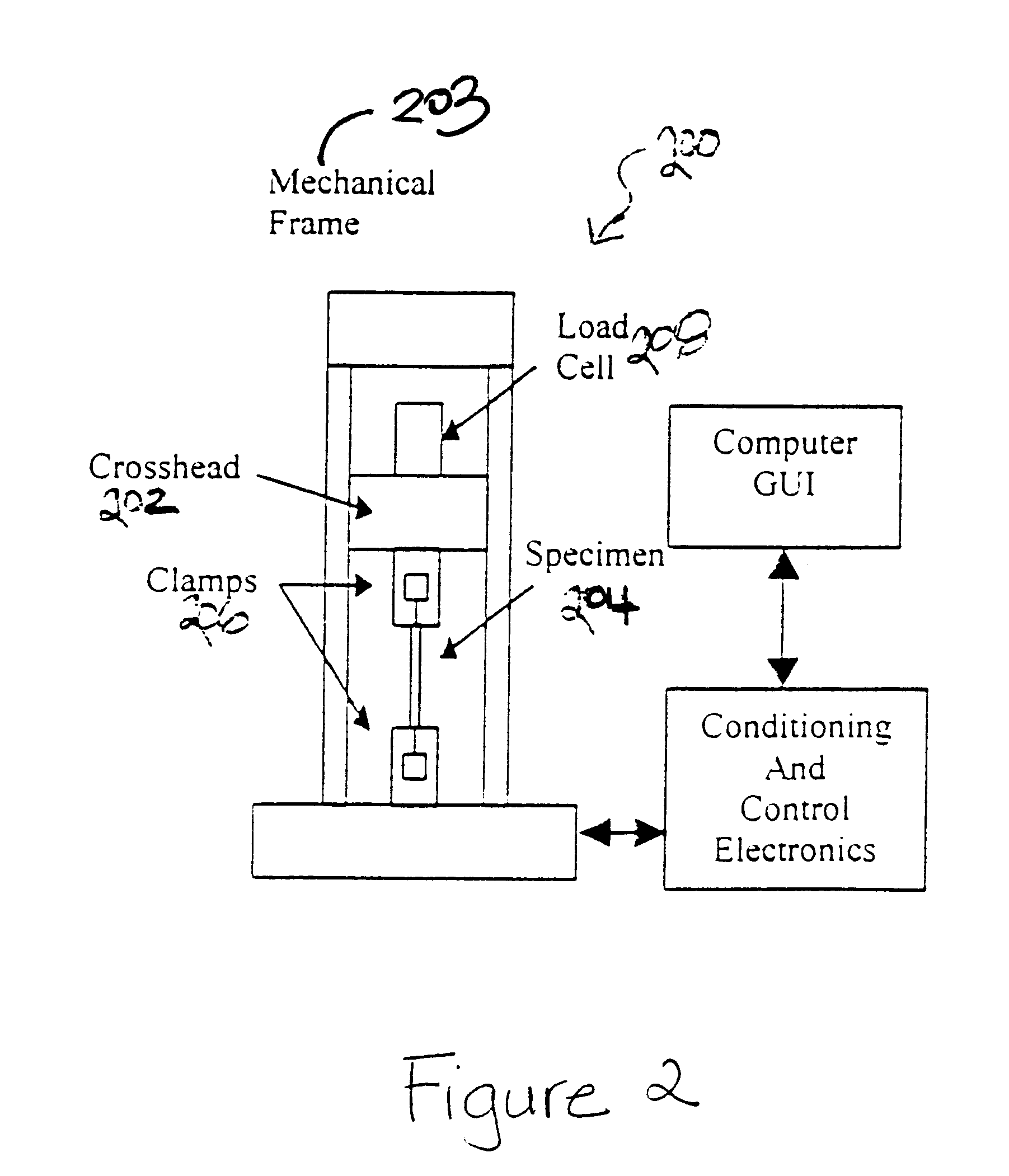

Voice actuation with contextual learning for intelligent machine control

InactiveUS6895380B2Reduce probabilityImprove robustnessFlow propertiesMeasurement arrangements for variableHuman–computer interactionTensile testing

An interactive voice actuated control system for a testing machine such as a tensile testing machine is described. Voice commands are passed through a user-command predictor and integrated with a graphical user interface control panel to allow hands-free operation. The user-command predictor learns operator command patterns on-line and predicts the most likely next action. It assists less experienced operators by recommending the next command, and it adds robustness to the voice command interpreter by verbally asking the operator to repeat unlikely commanded actions. The voice actuated control system applies to industrial machines whose normal operation is characterized by a nonrandom series of commands.

Owner:ELECTRO STANDARDS LAB

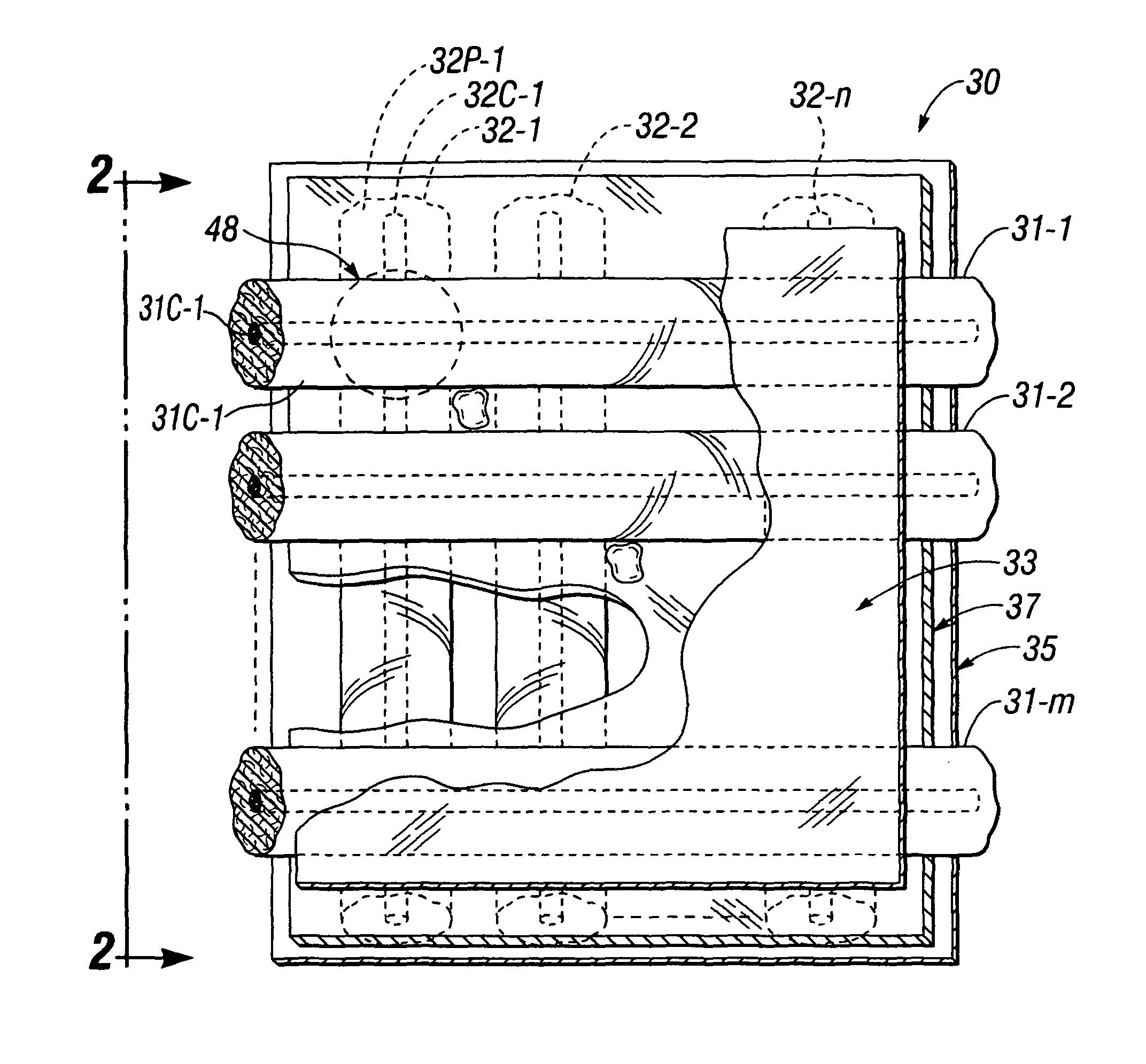

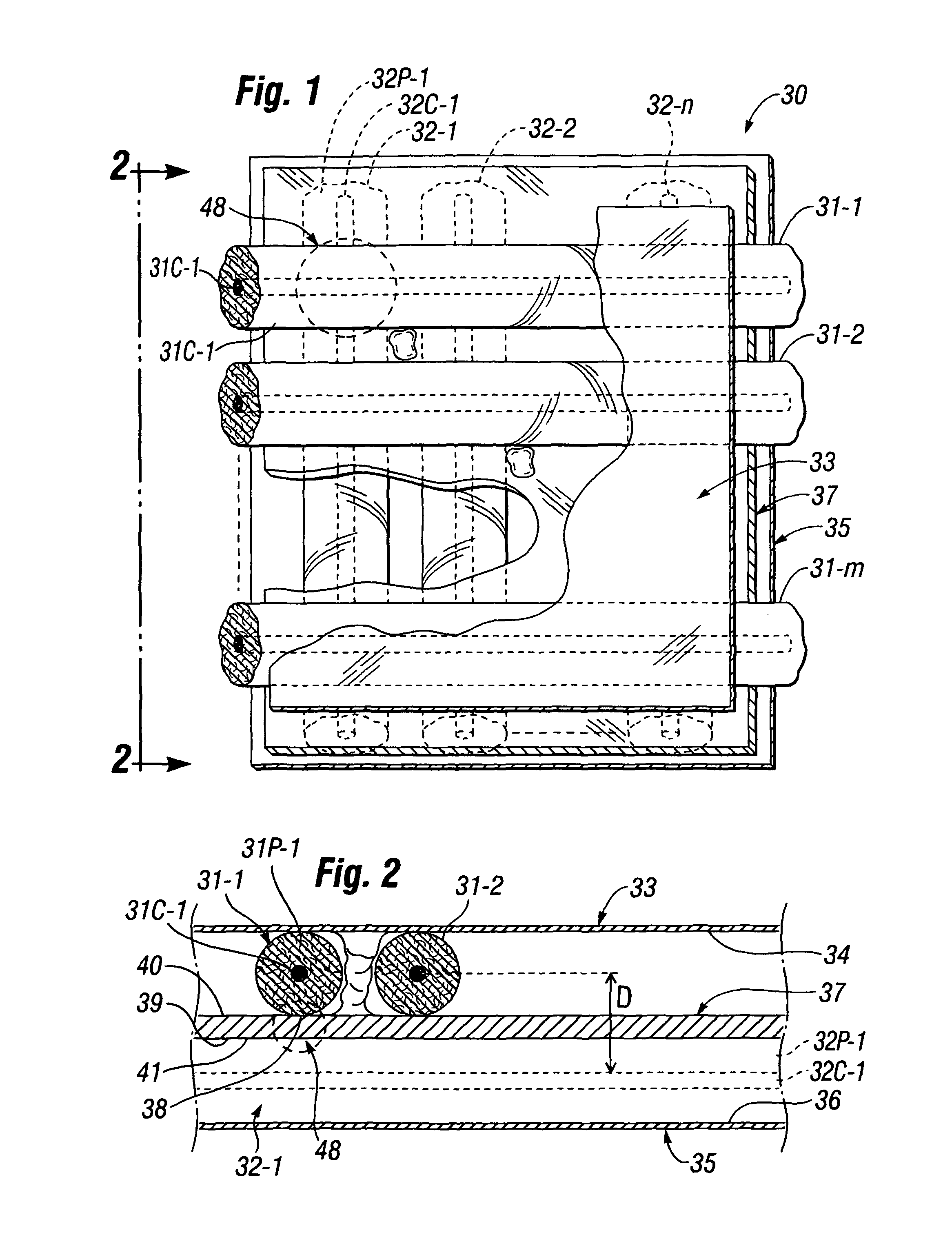

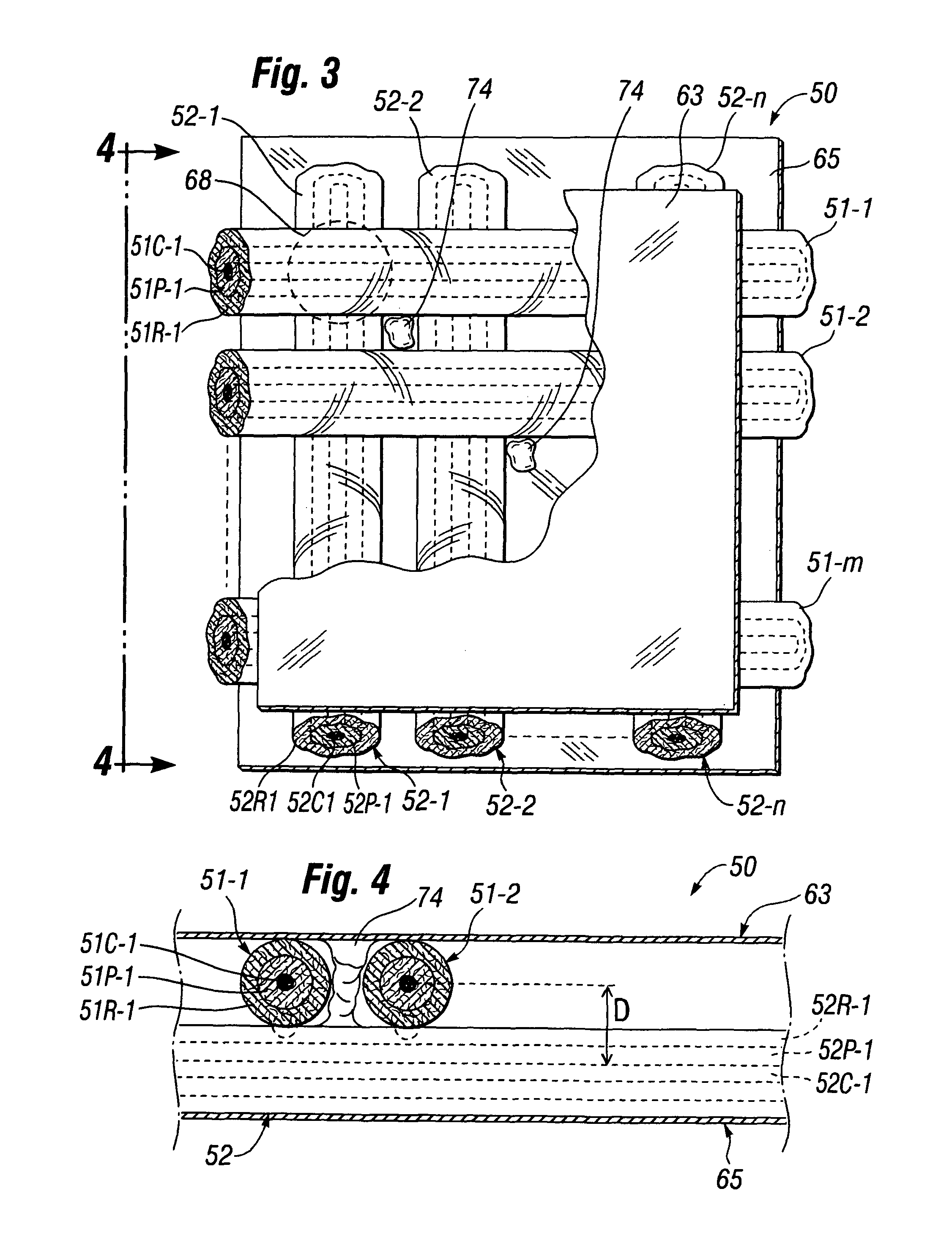

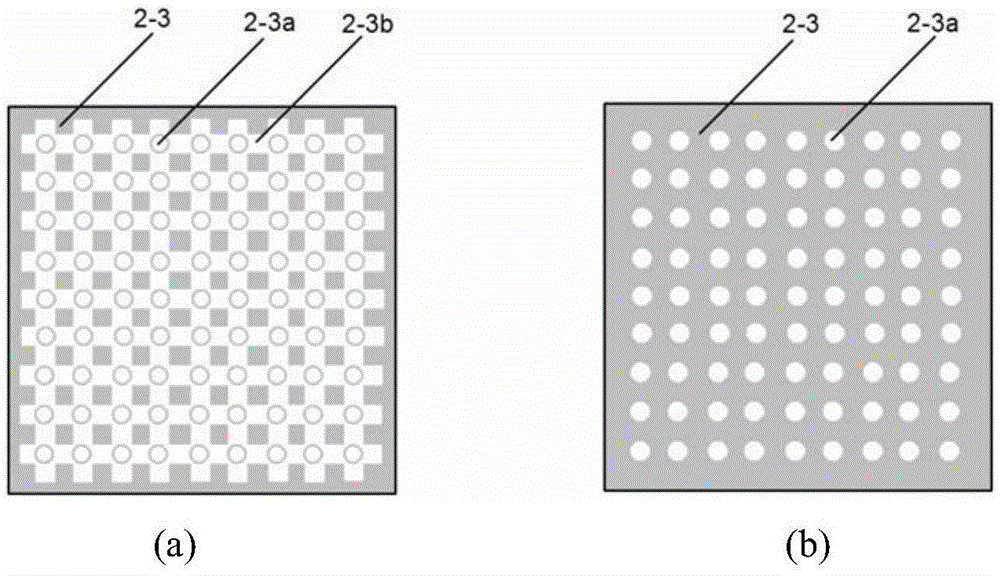

Elastically stretchable fabric force sensor arrays and methods of making

ActiveUS8161826B1Facilitate measuring and mapping forcesWork measurementMaterial strength using tensile/compressive forcesSensor arrayConductive polymer

Force or pressure transducer arrays have elastically stretchable electrically conductive polymer threads disposed in parallel rows and columns that contact at intersections thereof a piezoresistive material which has an electrical resistivity which varies inversely with pressure or force exerted thereon to form a matrix array of force or pressure sensor elements. The threads are fixed to a single one or pair of flexible elastically stretchable substrate sheets made of thin sheets of an insulating polymer such as PVC, or for greater elasticity and conformability to irregularly-shaped objects such as human body parts, an elastically stretchable fabric such as LYCRA or SPANDEX. Elastic stretchability of the sensor arrays is optionally enhanced by disposing either or both row and column conductive threads in sinuously curved, serpentine paths rather than straight lines.

Owner:PATIENTECH LLC

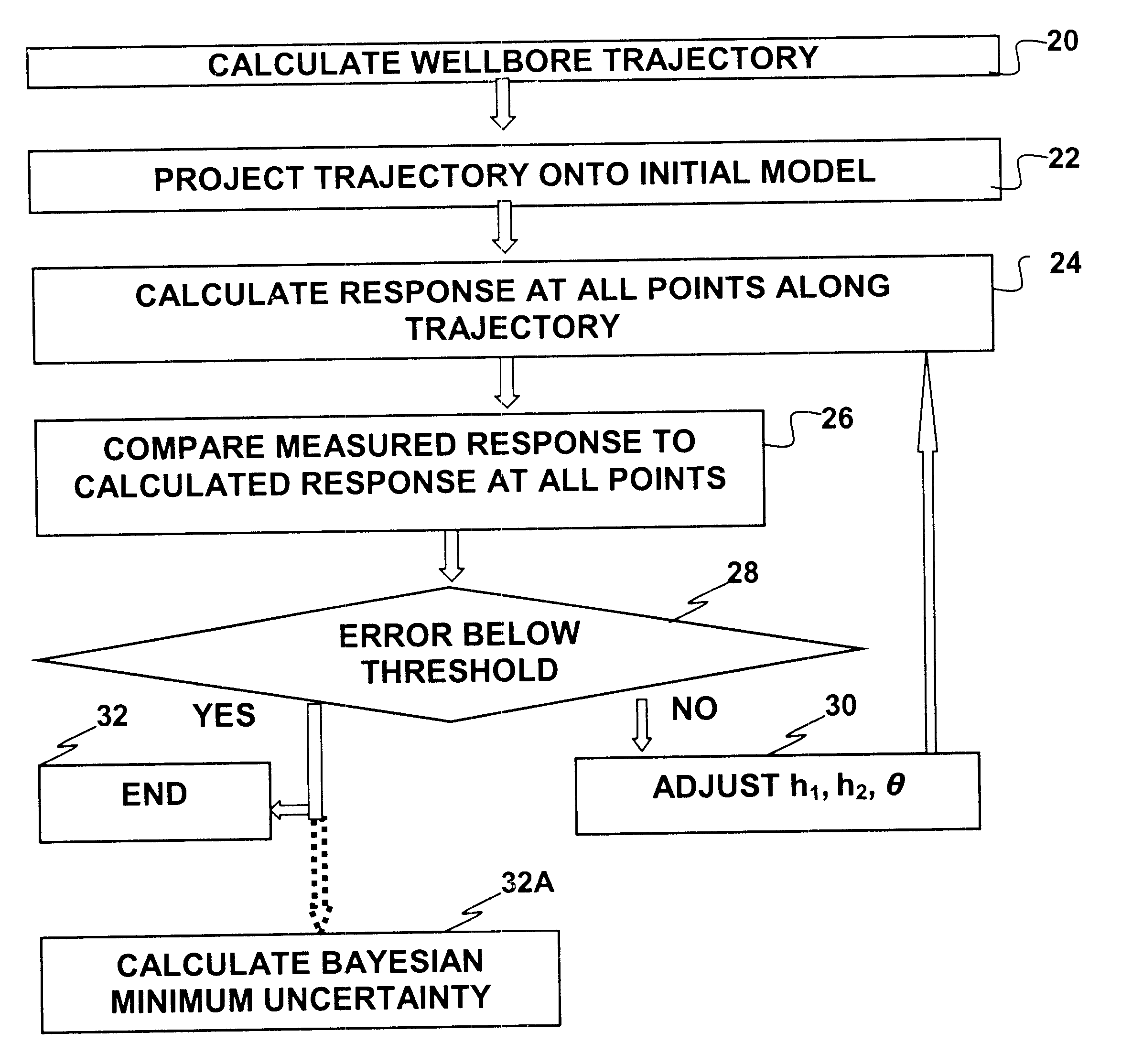

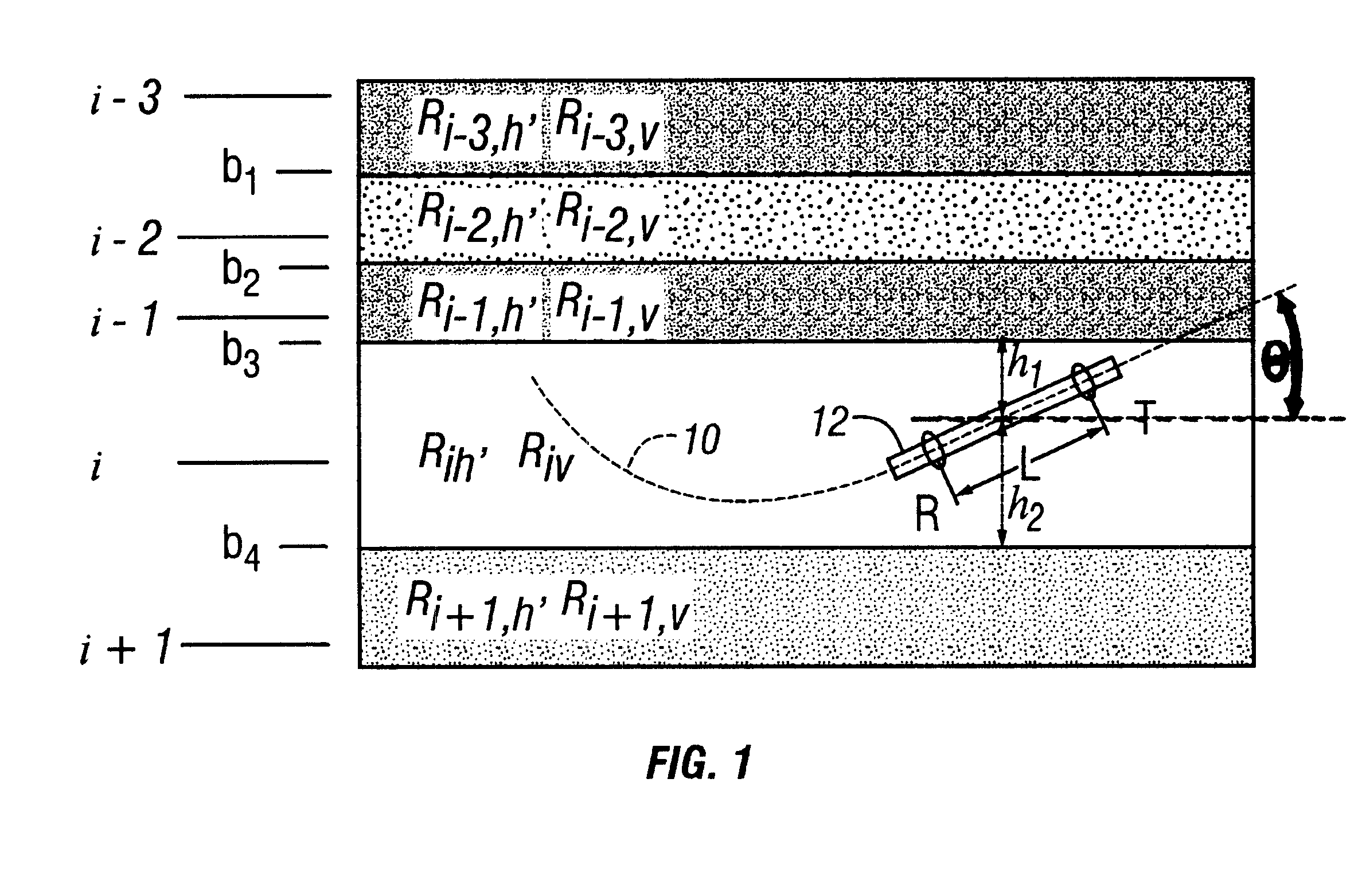

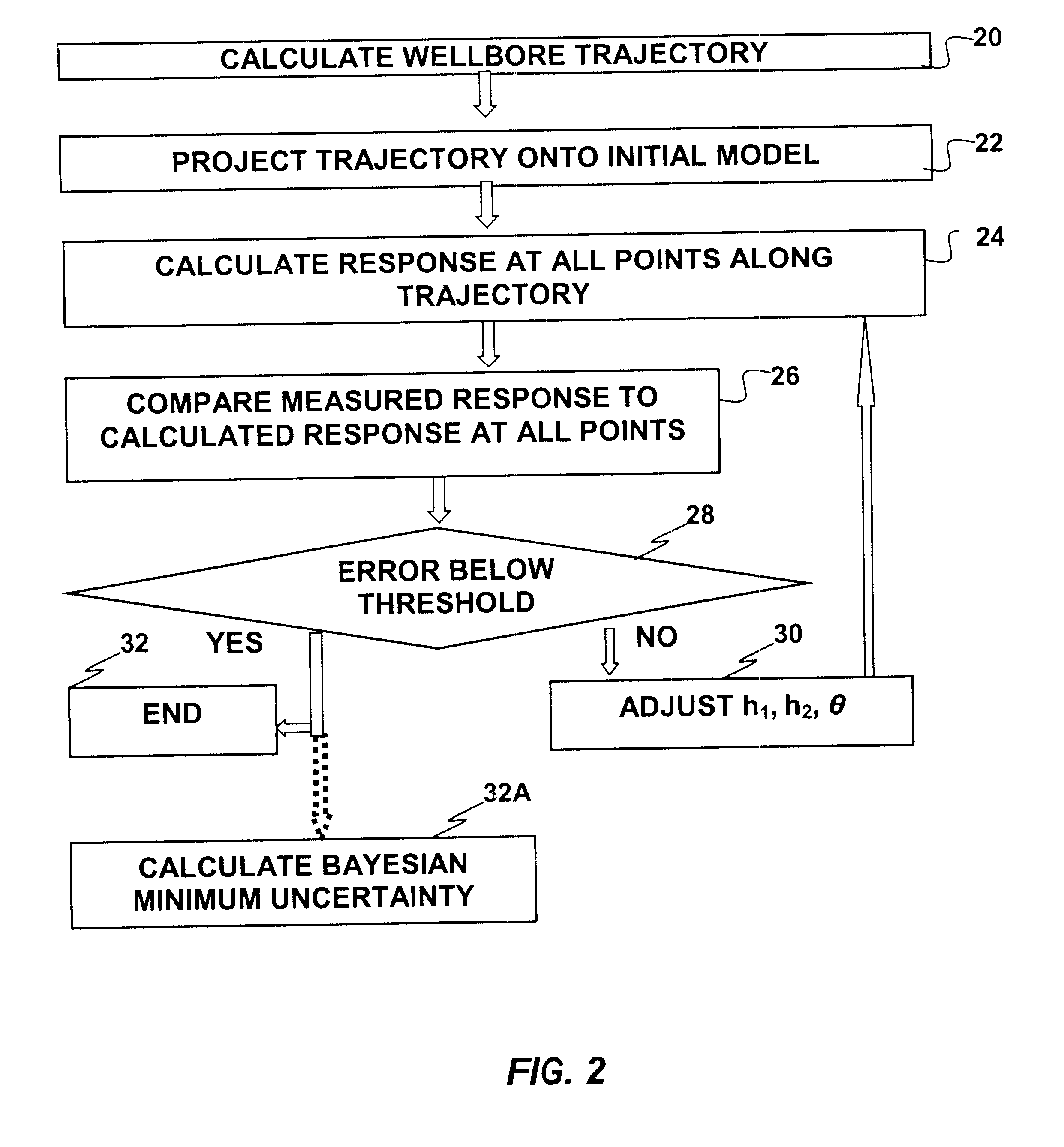

Method for calculating a distance between a well logging instrument and a formation boundary by inversion processing measurements from the logging instrument

InactiveUS6594584B1Improve inversion accuracyElectric/magnetic detection for well-loggingSurveyWell loggingInstrumentation

A method is disclosed for determining a position of a wellbore with respect to layer boundaries in earth formations. The method includes projecting a trajectory of the wellbore onto an initial model of the earth formations, selecting a segment of the trajectory and calculating along the segment expected responses of a well logging instrument. Differences between the expected responses and responses measured by the instrument along the segment are determined. The model is adjusted, the expected responses are recalculated and the differences are again determined. These are repeated until the differences fall below a selected threshold. In one embodiment, the trajectory of the wellbore can be adjusted to remain within a selected distance of a selected one of the layer boundaries.

Owner:SCHLUMBERGER TECH CORP

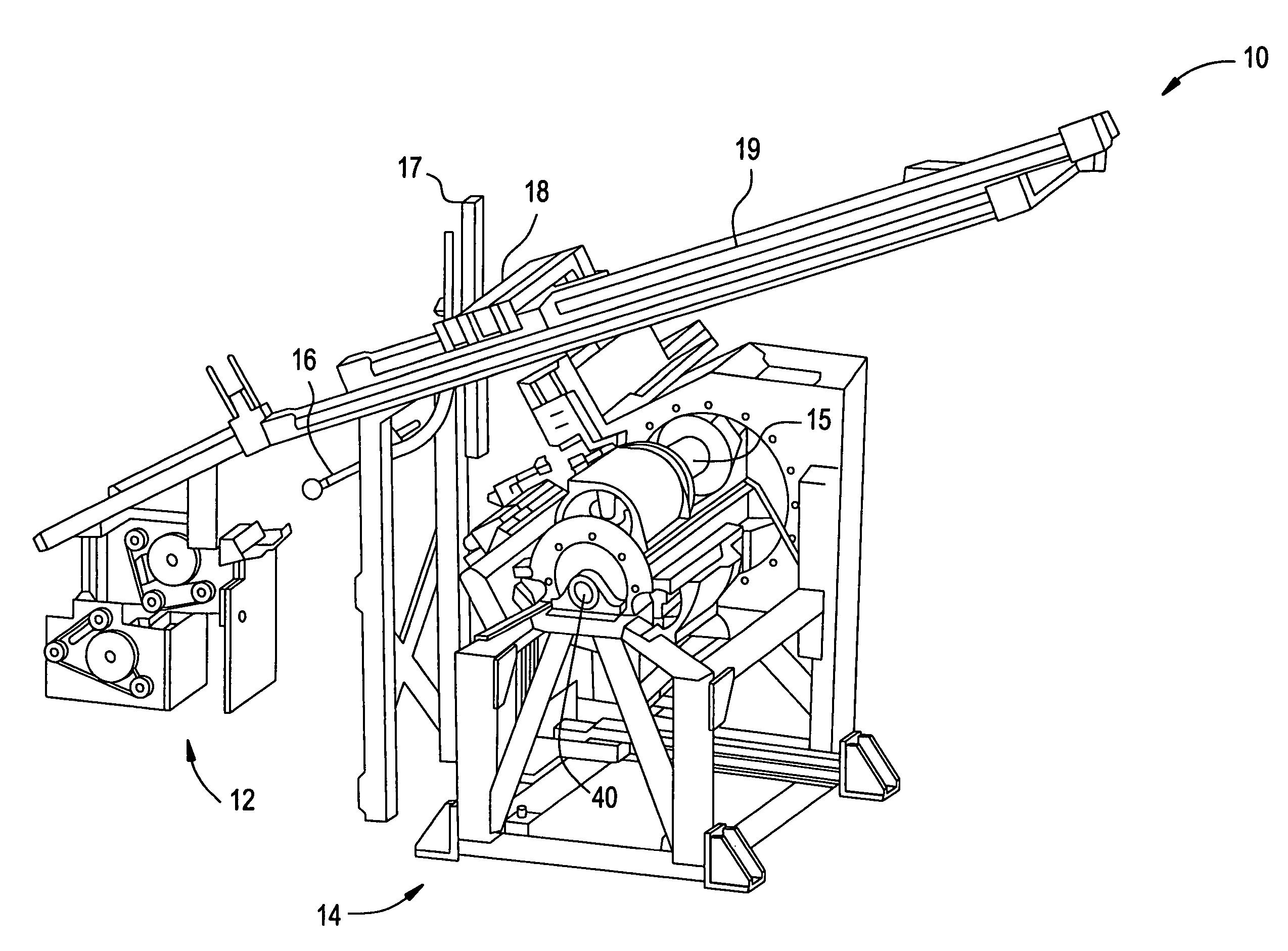

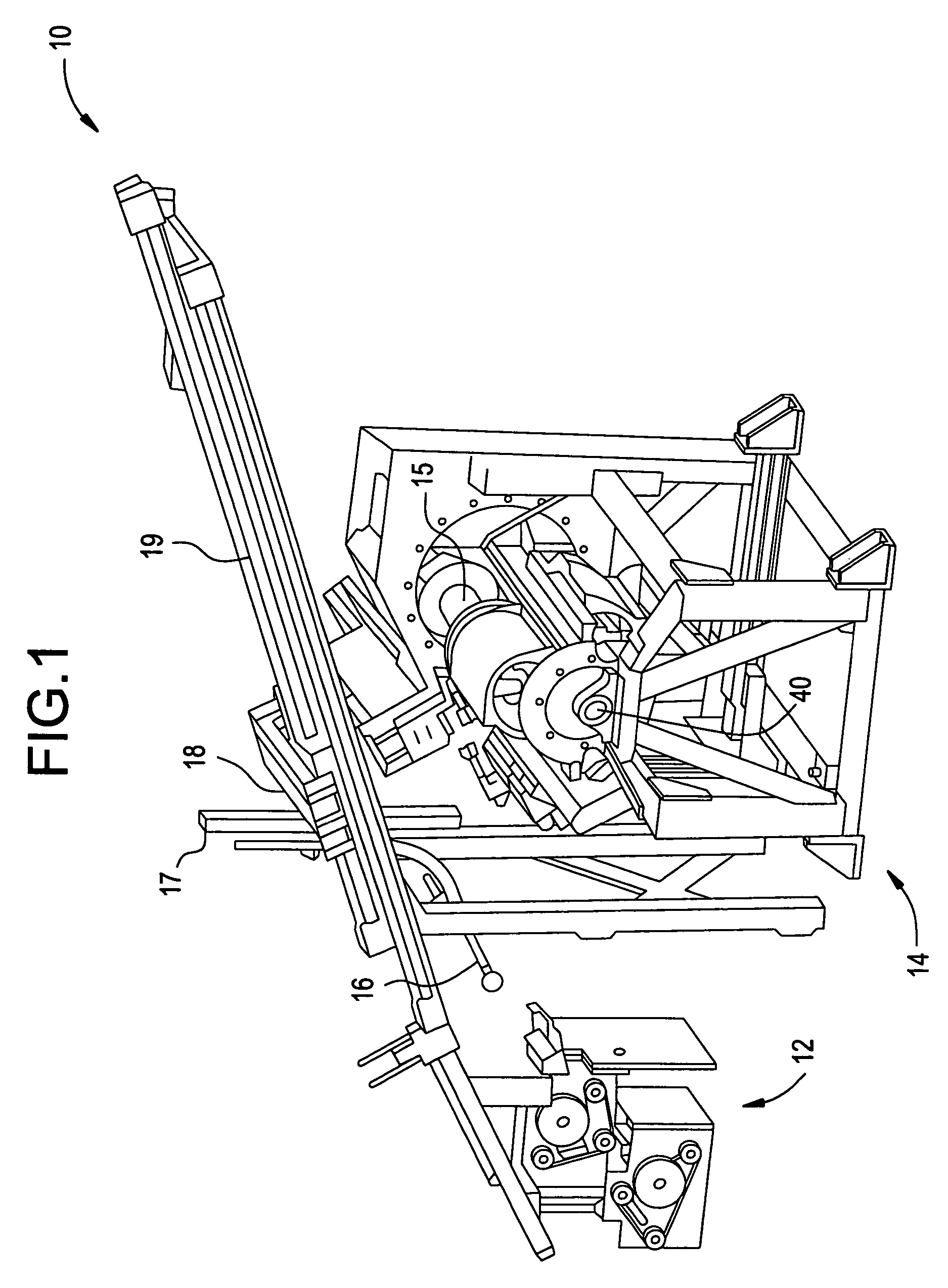

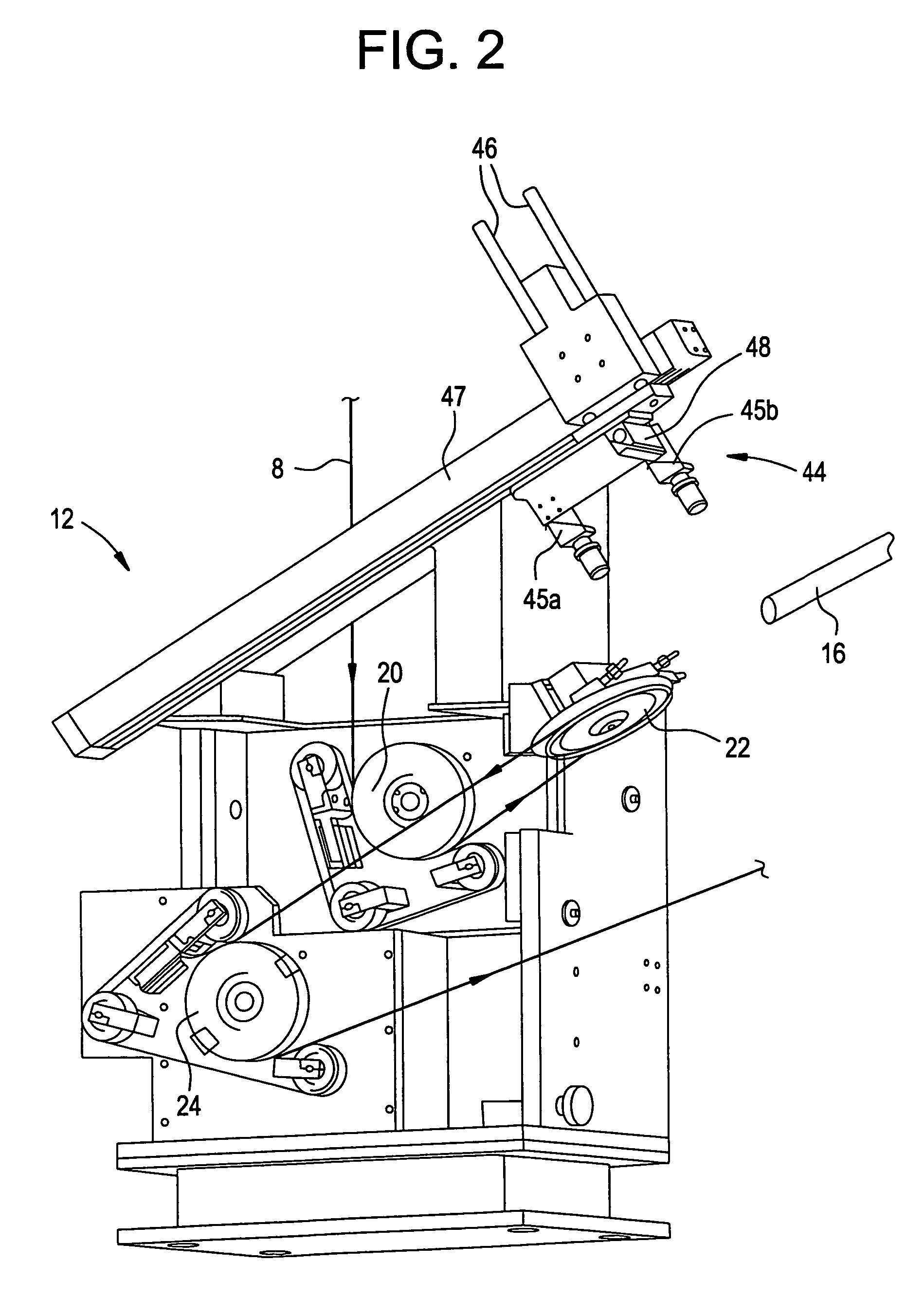

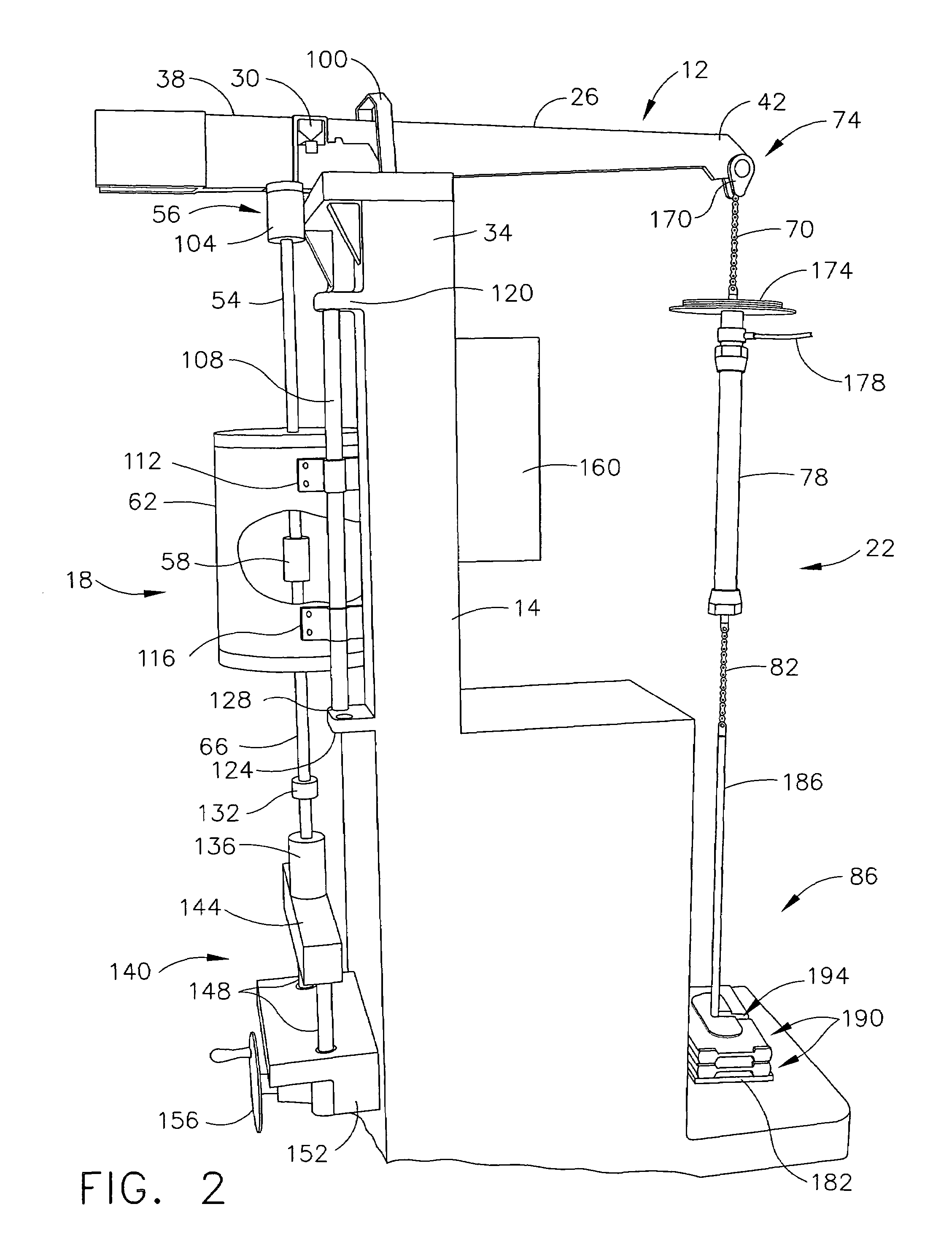

Method and apparatus for tensile testing and rethreading optical fiber during fiber draw

InactiveUS7832675B2Processing speedGlass fibre drawing apparatusFilament handlingFiber drawingTensile testing

A method and apparatus for automatic threading and winding of optical fiber onto various components in a fiber draw system, as well as methods and apparatus for conducting online tensile screening of optical fiber at high speeds. In a preferred embodiment, the fiber is tensile tested during fiber draw and wound directly onto a shipping spool to be shipped to a customer. The tensile stress can be imparted to the fiber during the draw process by feeding the fiber through a screener capstan, which works in conjunction with another capstan to impart the desired tensile stress to the fiber during the draw process. Another aspect is a method and apparatus for threading or rethreading of a moving length of fiber through a fiber draw or fiber testing process, in which fiber is wound onto a spool, comprising activating an aspirator to obtain the fiber at a first location and moving said aspirator in at least two dimensions to thereby move the fiber to a second location and thread the fiber through or onto at least one component in the fiber draw or testing process.

Owner:CORNING INC

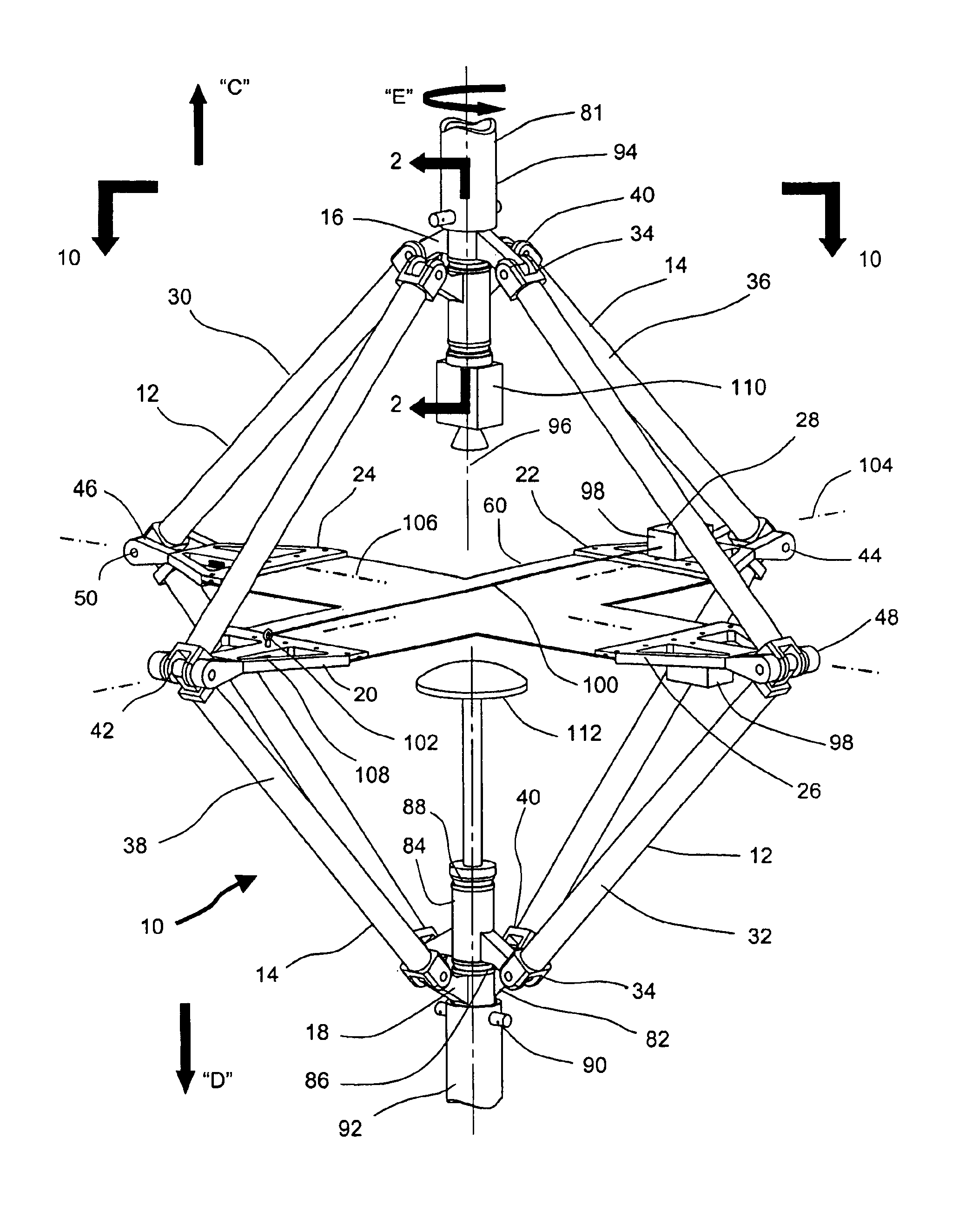

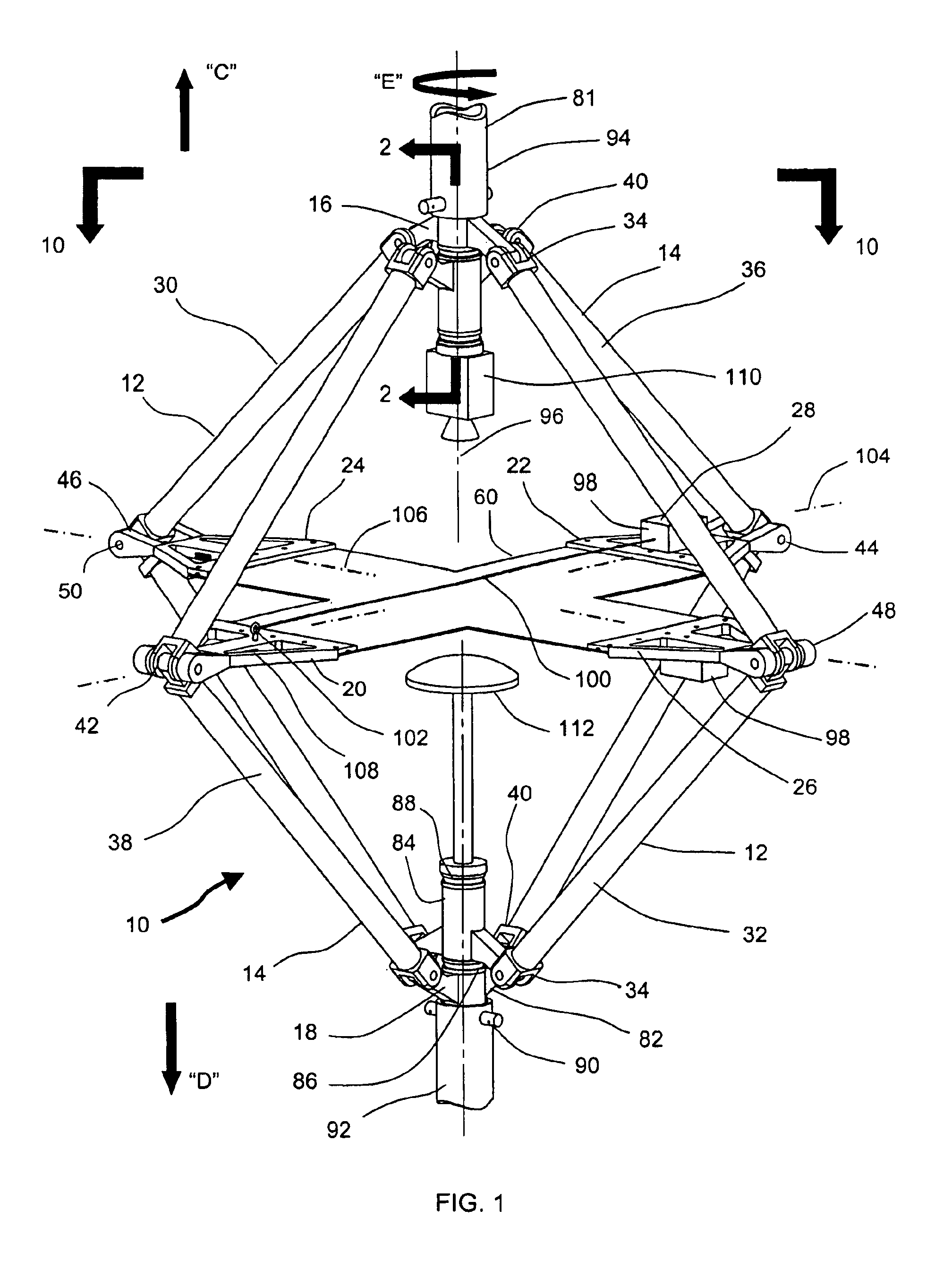

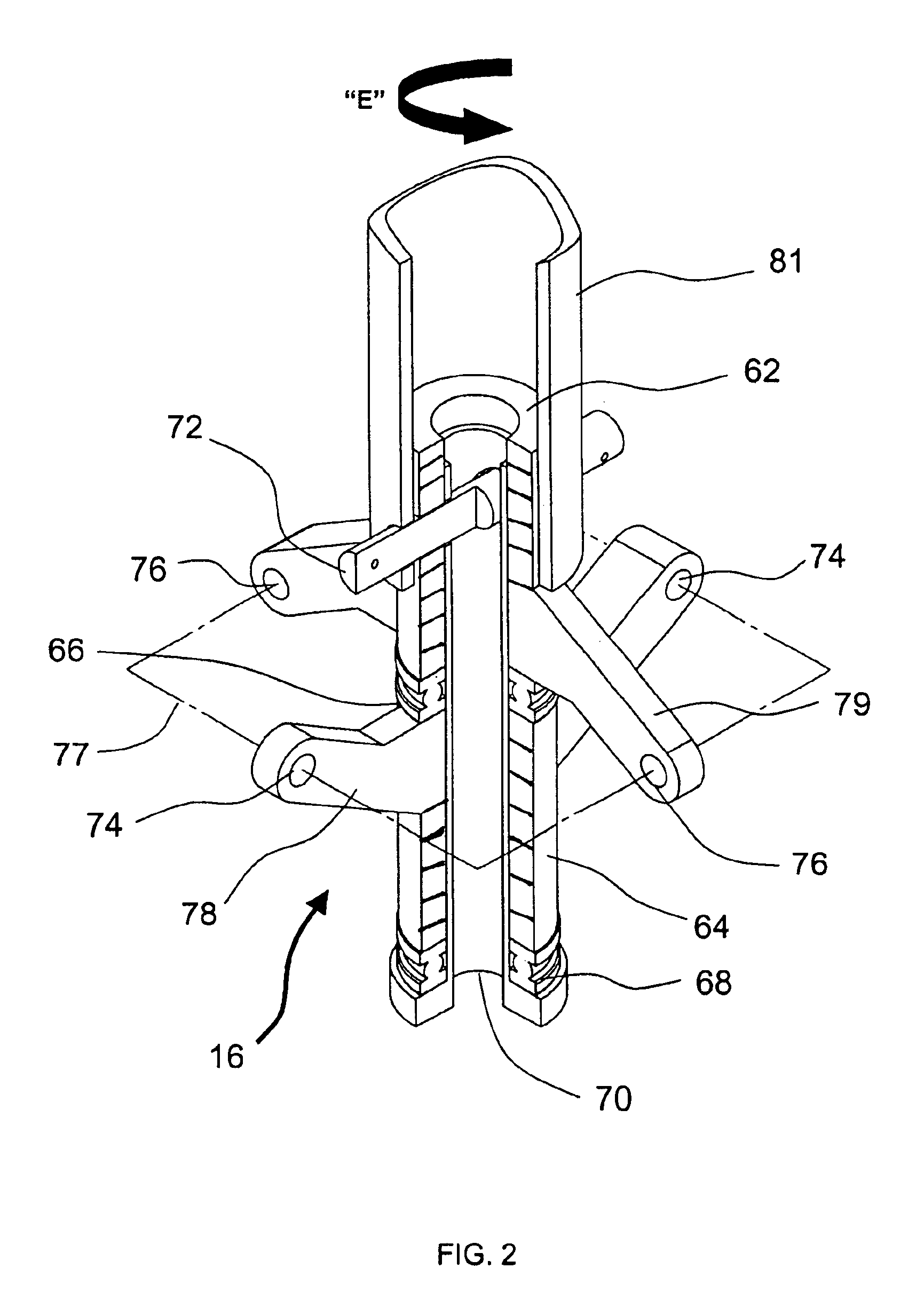

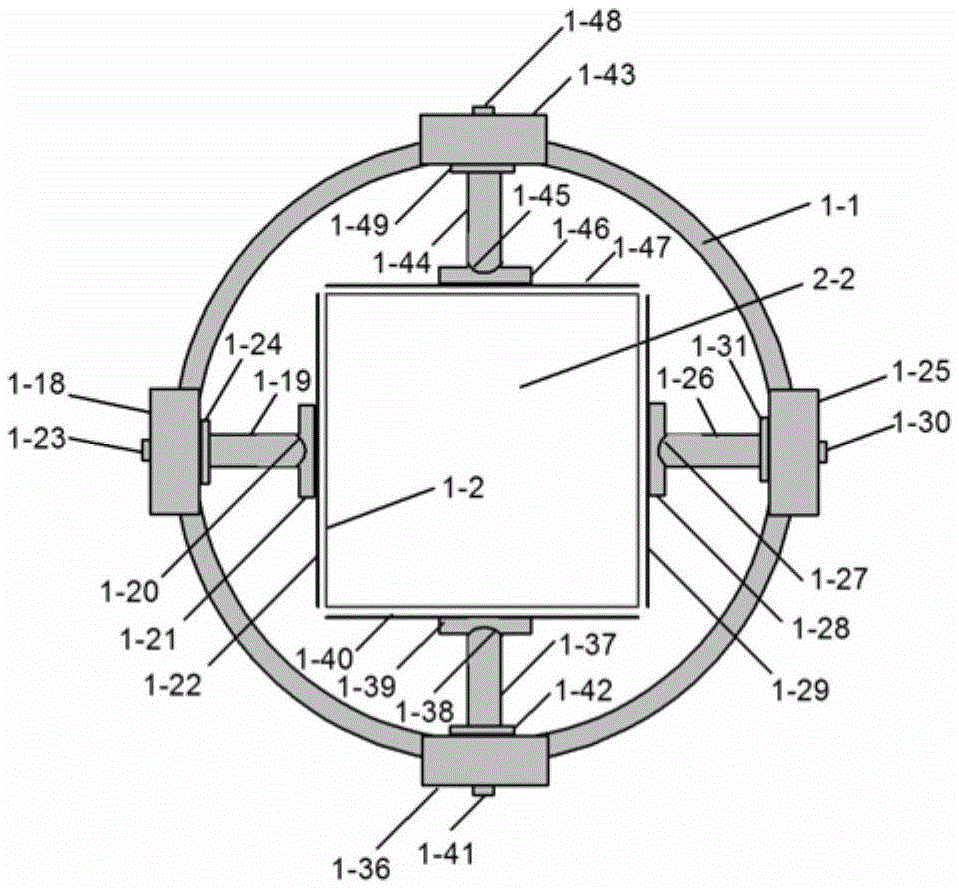

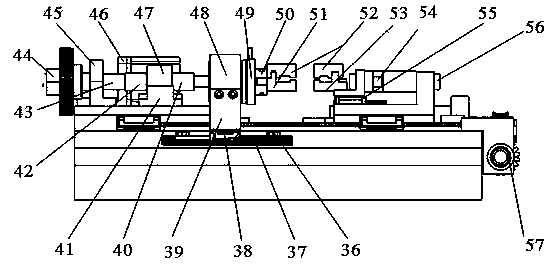

Combined in-plane shear and multi-axial tension or compression testing apparatus

ActiveUS6860156B1Provide flexibilityIncrease distanceMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringTorsional load

An in-plane shear and multi-axial tension or compression testing apparatus having four-bar linkages pivotable to two sleeves on an opposite vertices with the sleeves of each vertex rotationally attached to each other. Lateral links of each linkage are pivotally attached to load transfer plates in which the plates secure a test specimen. Each linkage is rotatable to the other linkages while the vertices are subjected to a compression or tensile load. The vertices are also capable of rotation by a testing machine for shear testing. During compression or tension of the vertices of the apparatus, the plates respectfully move toward or away from each other thereby applying compression or tension to the specimen. The bars of one linkage can be rotated with respect to the other, thereby applying torsional loading to the specimen.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

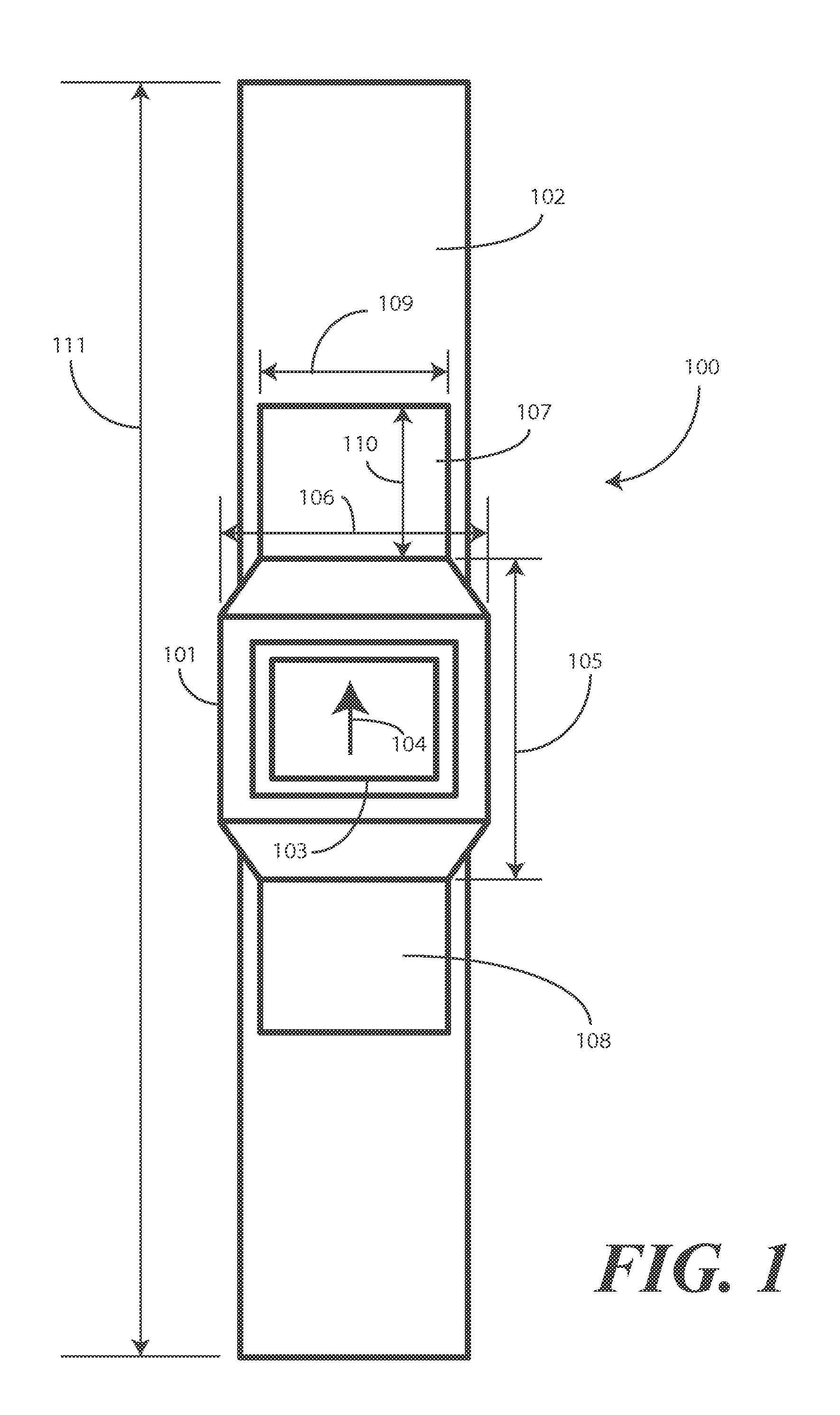

Methods and Devices for Clothing Detection about a Wearable Electronic Device

ActiveUS20130119255A1Radiation pyrometryMaterial strength using tensile/compressive forcesEngineeringWearable Electronic Device

A method in a wearable electronic device of detecting clothing includes: detecting whether the wearable electronic device is coupled to a user, determining whether the wearable electronic device is covered, and adjusting one or more device settings of the wearable electronic device. A secondary check can perform an additional determination of whether the wearable electronic device is covered with clothing. One or more sensors, such as a skin sensor, a tension sensor, an infrared sensor, or microphones, can be used to execute the steps in the wearable electronic device.

Owner:GOOGLE TECH HLDG LLC

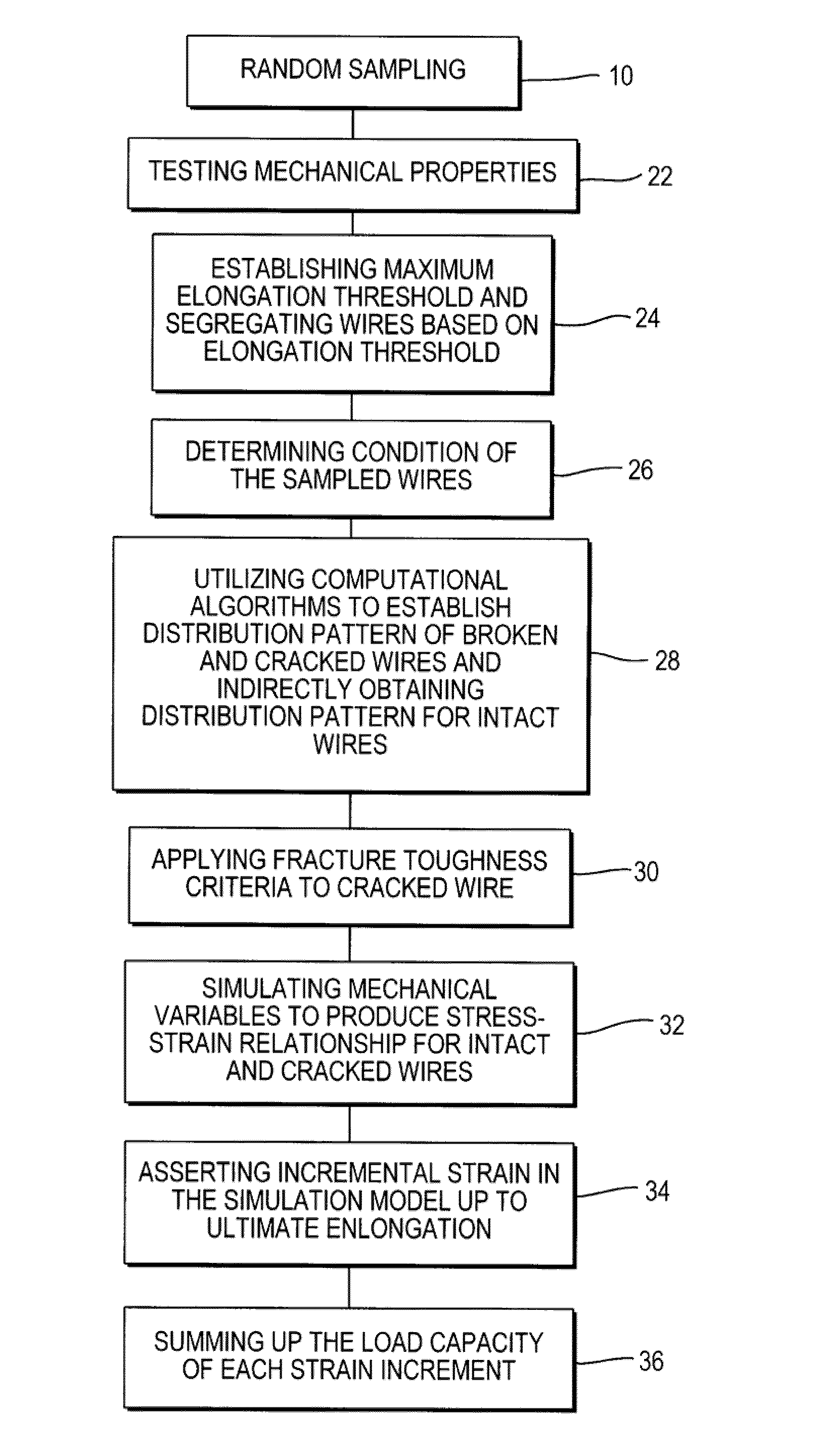

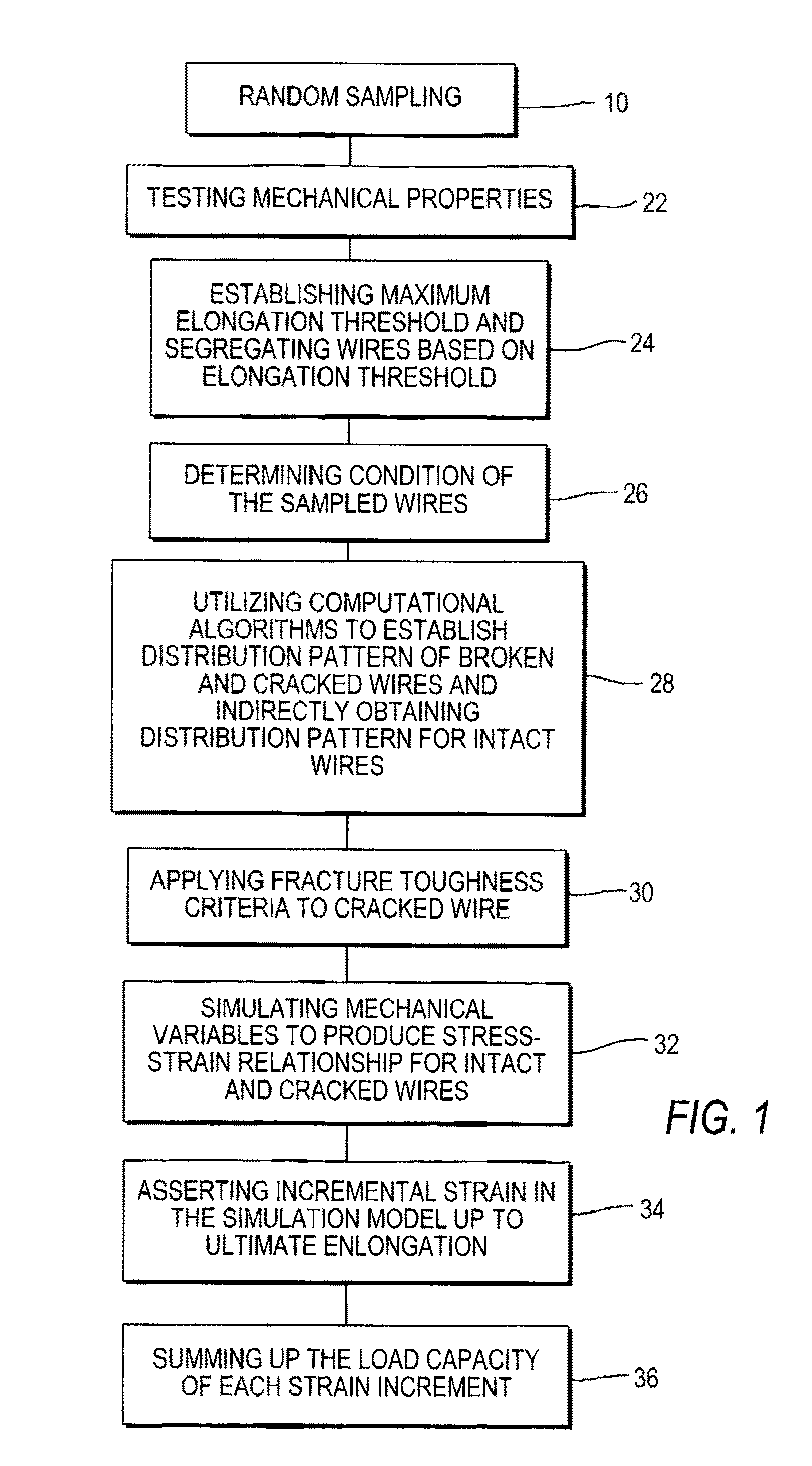

Method for assessment of cable strength and residual life

ActiveUS7992449B1Minimizes vulnerabilityMaterial strength using tensile/compressive forcesStress–strain curveEngineering

A method for determining the condition assessment and residual life span of bridge cables based on a parametric statistical model. The method includes random sampling of individual cable wires, mechanically testing the sampled wires, determining the probability of broken and cracked wires and the ultimate strength of cracked wires using fracture toughness and imputing the above data to simulate stress-strain curves for each wire in the cable, applying strain increments until reaching ultimate elongation. Assessing remaining service life of the cable by determining the rate of change of broken wires detected over a time frame, measuring the rate of change of fracture toughness over said time frame, and applying the rates of change to a time-dependent degradation prediction model.

Owner:MAHMOUD KHALED M

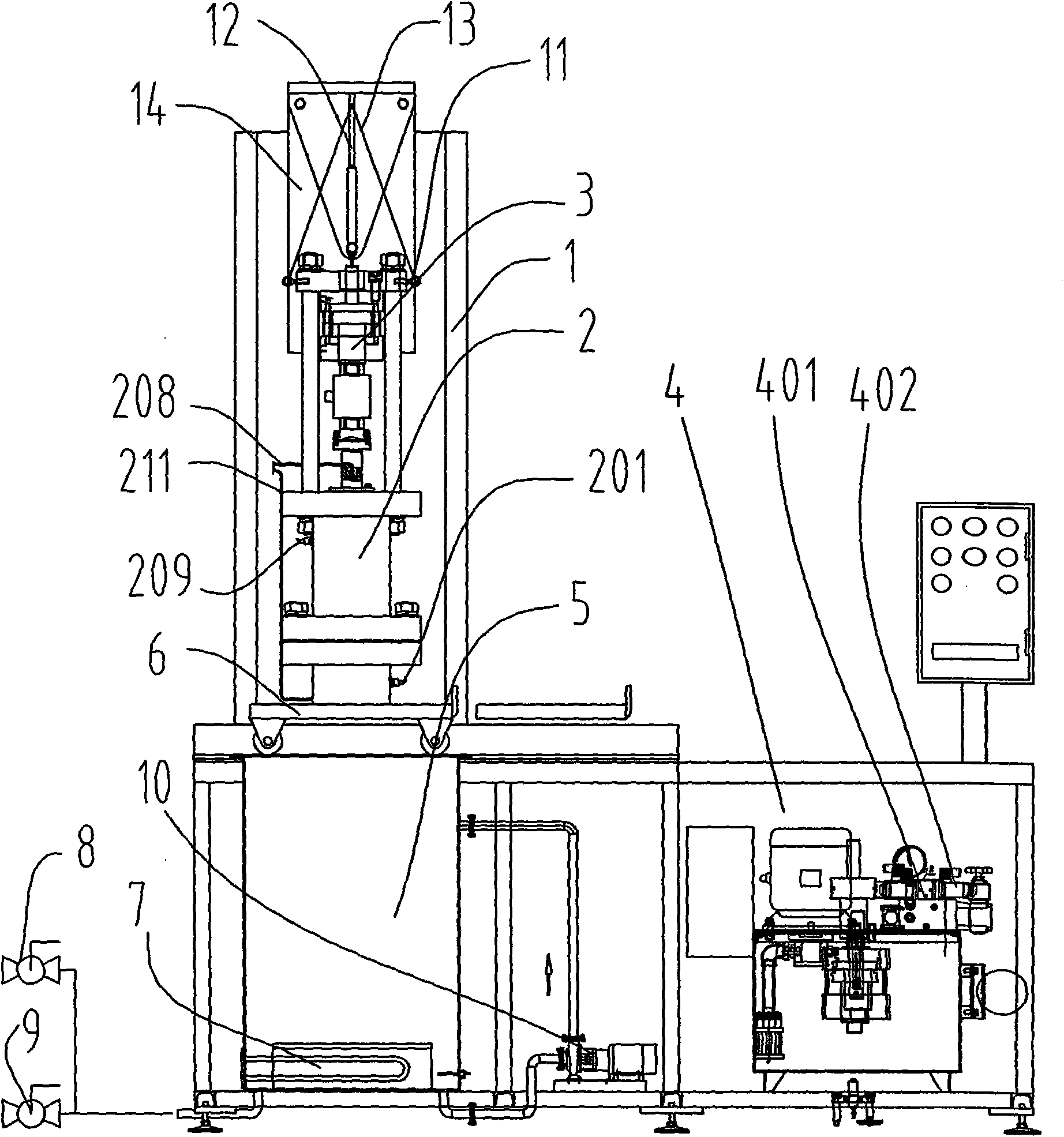

Coal-rock hydraulic fracturing testing method under true triaxial state

ActiveCN102735547AReveal deformationRevealing intensityMaterial strength using tensile/compressive forcesPermeability/surface area analysisFracture testingHydraulic fracturing

The invention discloses a coal-rock hydraulic fracturing testing method under a true triaxial state. The coal-rock hydraulic fracturing testing method under the true triaxial state comprises the following steps: 1) preparing a test piece; 2) installing the test piece; 3) pre-loading; 4) loading; 5) hydraulically fracturing; 6) unloading; 7) storing all data recorded by a data collection system, taking out the test piece and observing the shape of the test piece. According to the coal-rock hydraulic fracturing testing method, the real work condition can be more really simulated, and a theoretical basis is provided for solving on-site problems.

Owner:CHONGQING UNIV

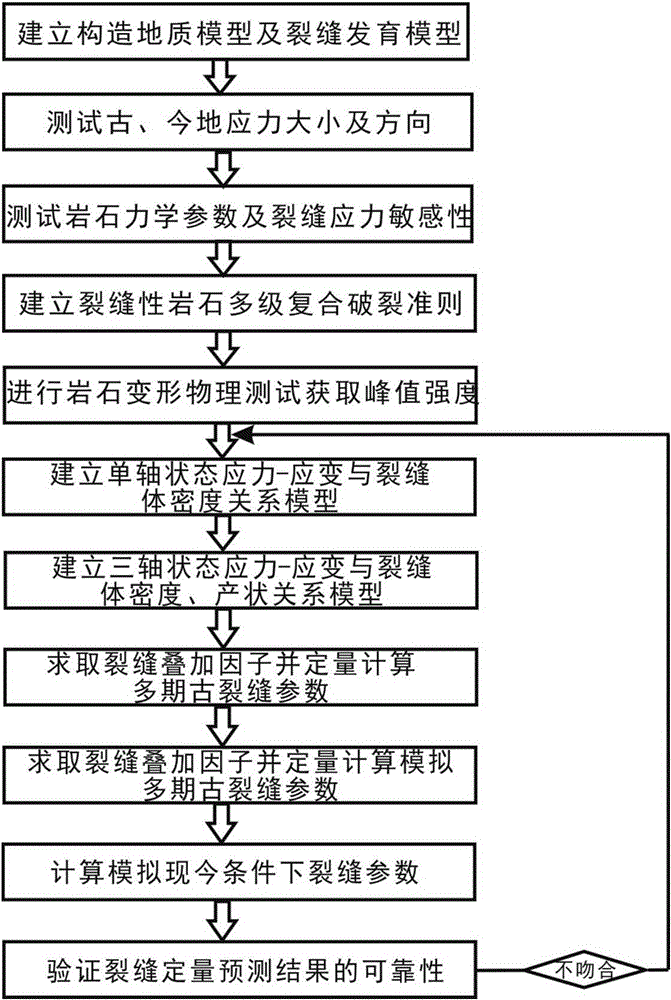

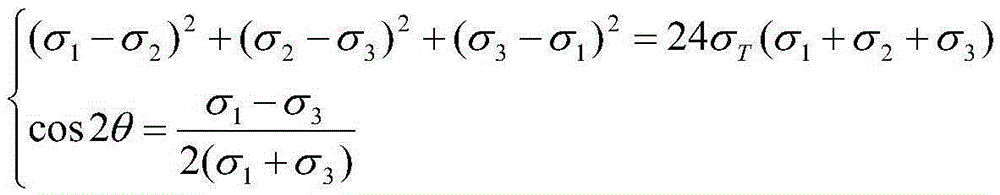

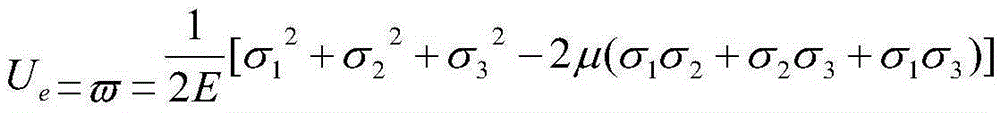

Compact sandstone reservoir complex netted fracture prediction method

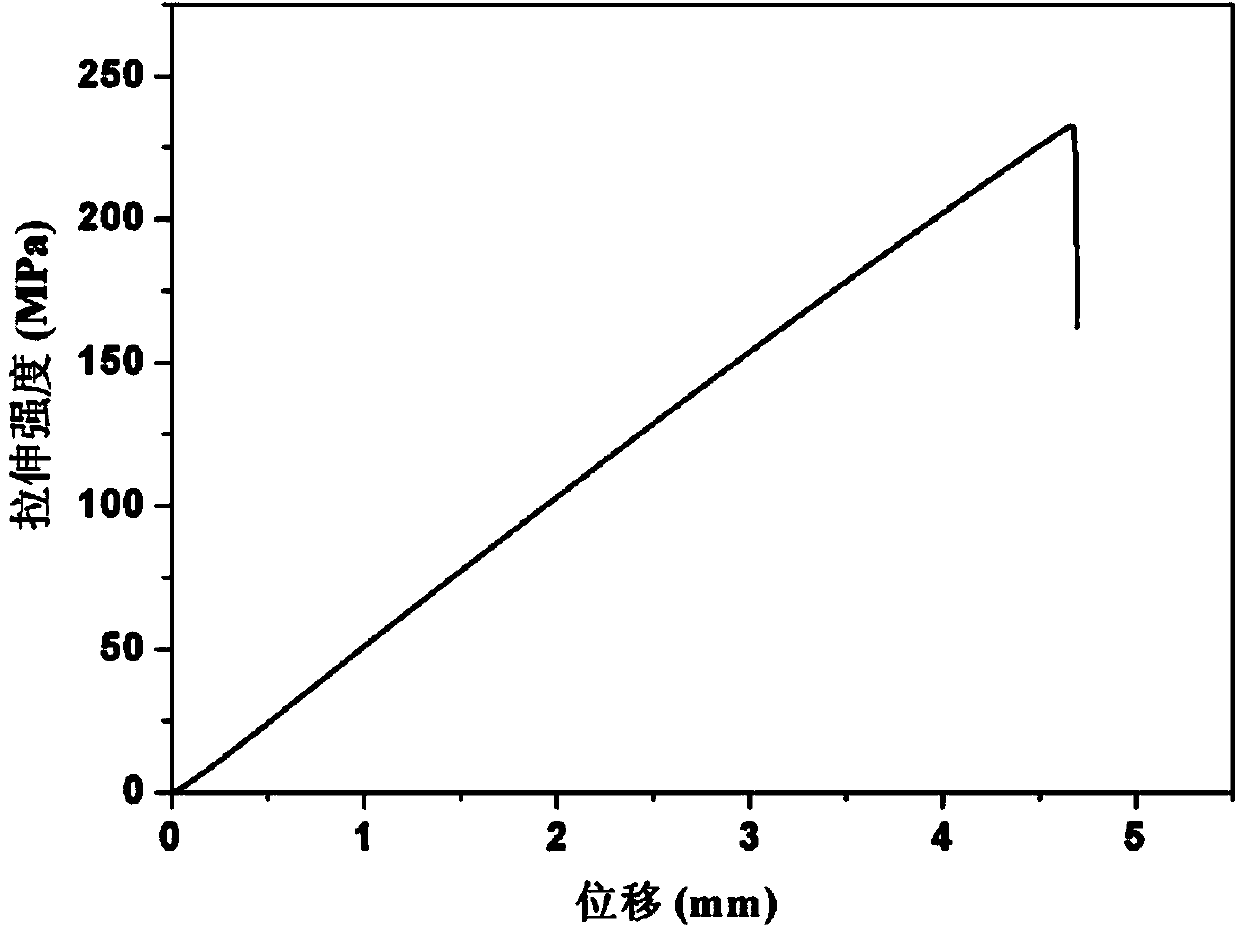

ActiveCN105319603AEffectively predict occurrenceEffective predictive densityMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesRelational modelPeak value

The invention belongs to the petroleum exploration field, and concretely relates to a compact sandstone reservoir complex netted fracture prediction method. The method comprises the steps of: building a geological structure model and a fracture growth model; testing magnitudes and directions of ancient and modern crustal stresses; completing a rock mechanic parameter experiment; testing rock mechanic parameters and fracture stress sensitivities; developing a fracture rock multistage composite rupture criterion; performing a rock deformation physical test to obtain a peak value intensity; building a relation model between single axle state stress-strain and fracture bulk density; building a relation model between triaxial state stress-strain and fracture bulk density and occurrence; building a relation model between single axle state stress-strain and fracture bulk density; calculating and stimulating fracture parameters under modern conditions; and verifying the reliability of a fracture quantitative prediction result. The method can accurately obtain compact sandstone reservoir complex netted fracture parameters, and perform quantitative characterization, is suitable for quantitative prediction of any fracture mainly with a brittle reservoir, and reduces exploitation risks and costs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

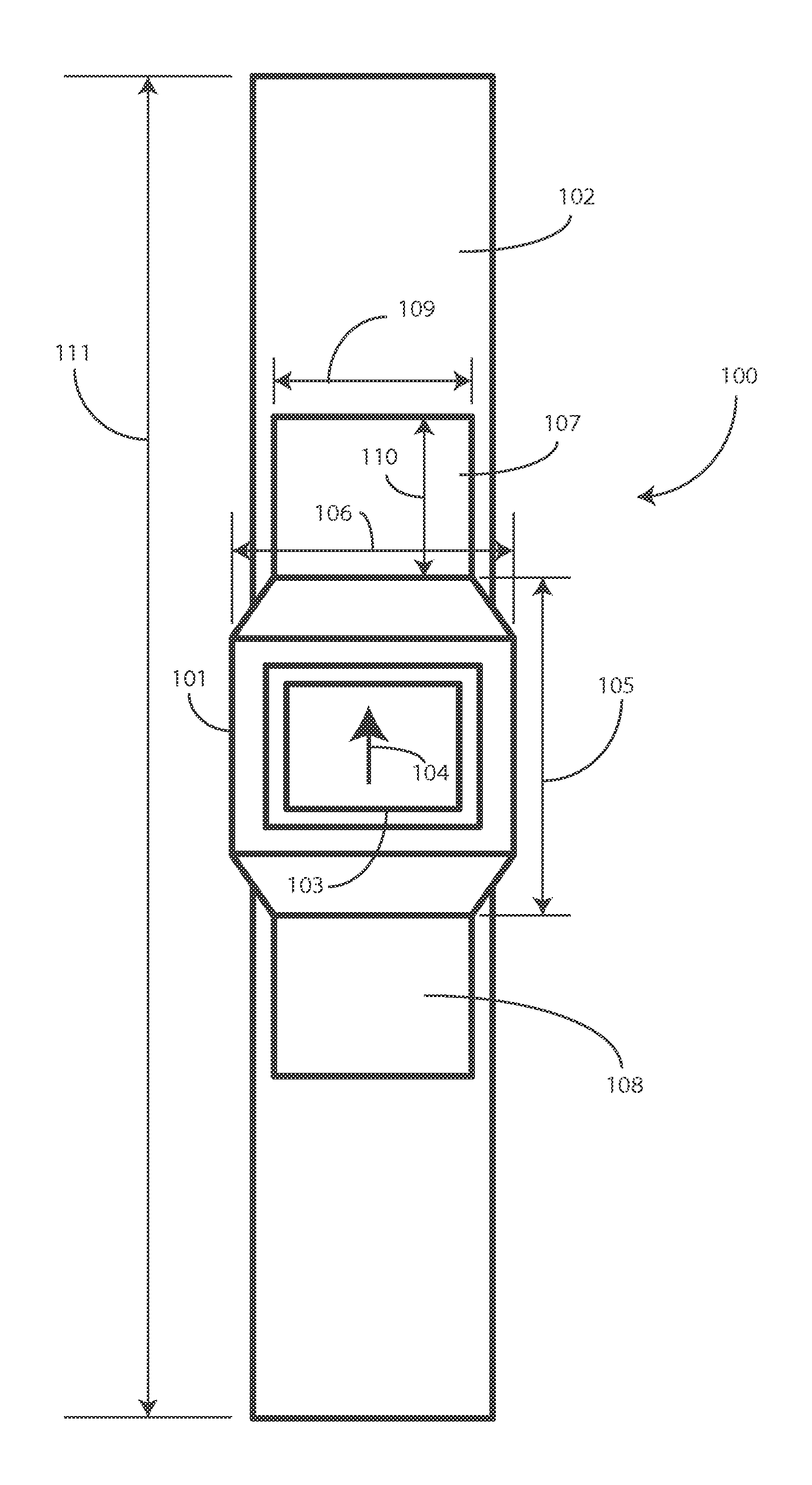

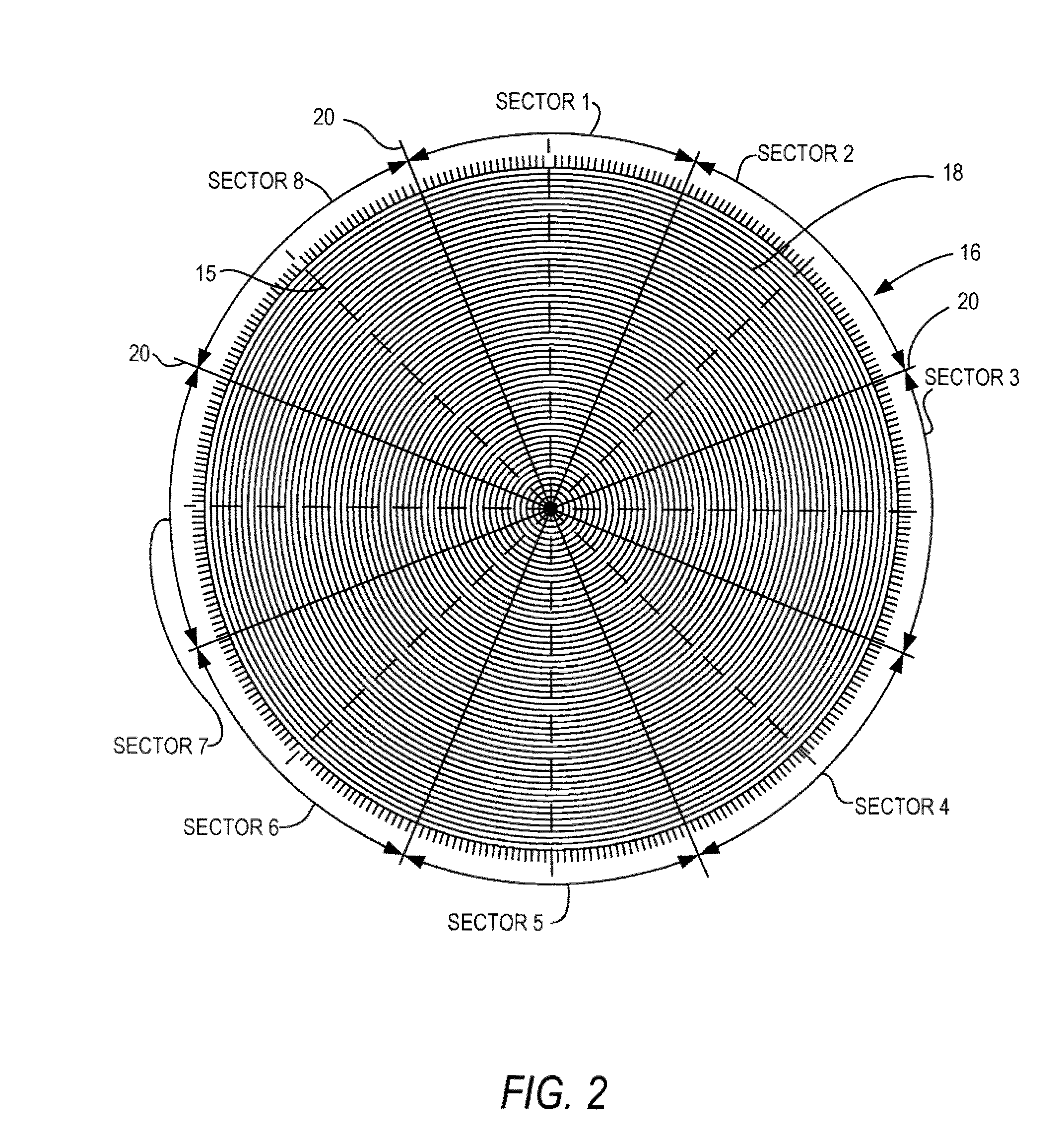

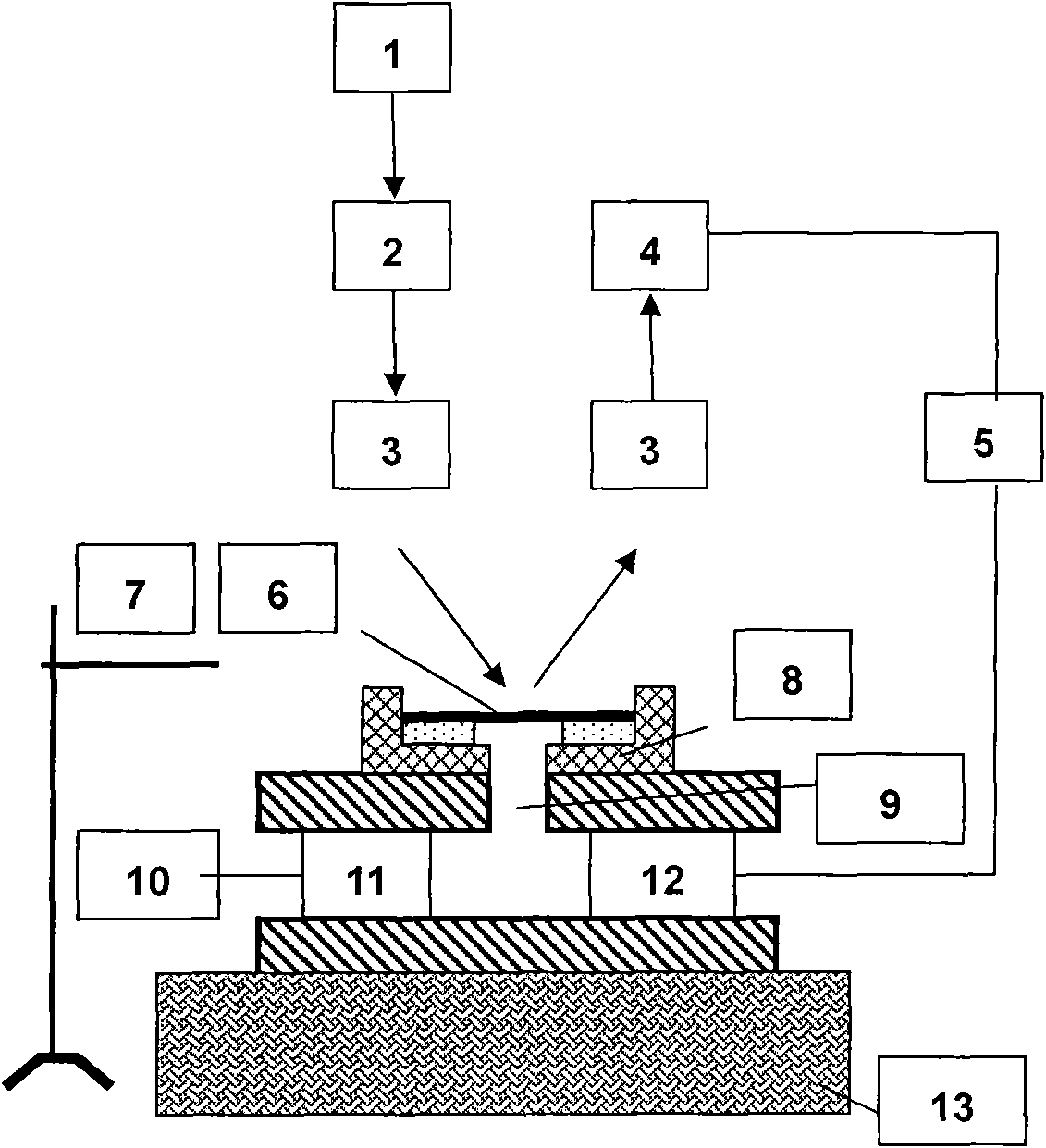

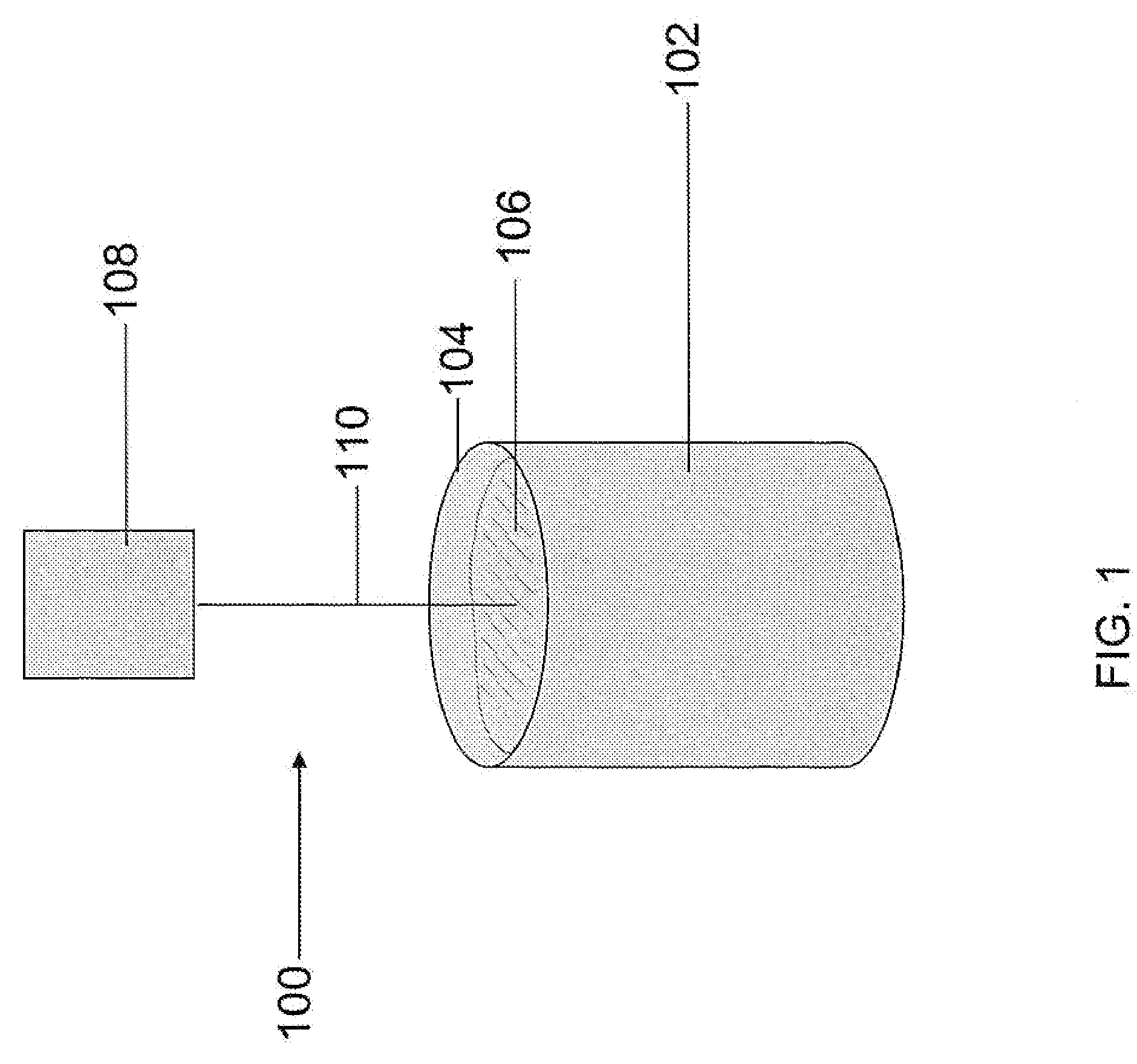

Method and apparatus for determining the angle of gyration and/or the pressure in a gyratory compactor

InactiveUS6868738B2Preparing sample for investigationMaterial strength using tensile/compressive forcesEngineering

An apparatus adapted to interact with a cylindrical mold for a gyratory compactor so as to determine a property of the gyratory compactor is provided, wherein the mold is adapted to contain a sample therein. Such an apparatus comprises a rigid disk-shaped plate defining an axis and a periphery, with the plate being adapted to be disposed within the mold. At least one sensing device is operably engaged with the plate, wherein the at least one sensing device is configured to measure a proximity of the at least one sensing device with respect to a reference member and to produce a corresponding signal indicative of the property of the gyratory compactor. In one embodiment, the apparatus is configured to determine the gyration angle of the mold, while in another embodiment, the apparatus is configured to determine the pressure exerted on the sample within the mold. The property of the mold may be determined either statically or dynamically. Associated apparatuses, devices, systems, and methods are also provided.

Owner:TROXLER ELECTRONICS LAB INC

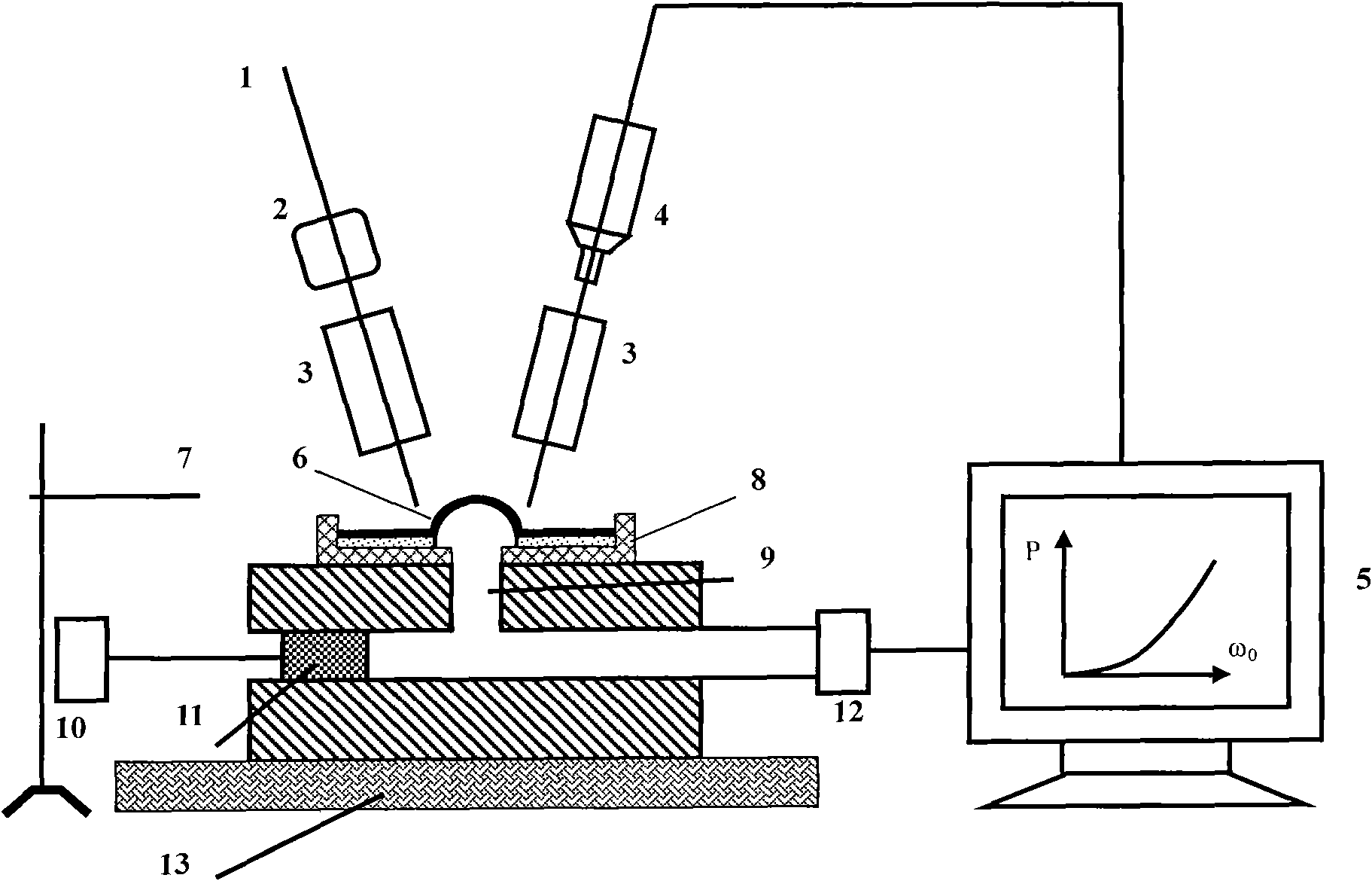

Device for detecting mechanical property of multifunctional film

ActiveCN101788427AHigh measurement accuracyMeasuring field of view can be adjustedMaterial strength using tensile/compressive forcesUsing optical meansElastic plasticSpeckle correlation

The invention discloses a device for detecting the mechanical property of a multifunctional film, comprising a sample stage, a loading mechanism for applying pressure on a film sample, a measuring mechanism for detecting the pressure applied on the film sample and deformation and a computer. The invention uses a digital speckle correlation method (DSCM) to measure film deformation, and combines two mechanical test methods of a bubbling method and a modified layer removal method, thus conveniently, rapidly and accurately measuring a pressure-deformation curve or a corrosion thickness-deformation curve; and mechanical properties of a film and a coating are extracted in terms of a corresponding theoretical model, thus being suitable for detecting the mechanical properties of tool films, decorative films, polymeric films and films of other types in various elastic-plastic systems.

Owner:XIANGTAN UNIV

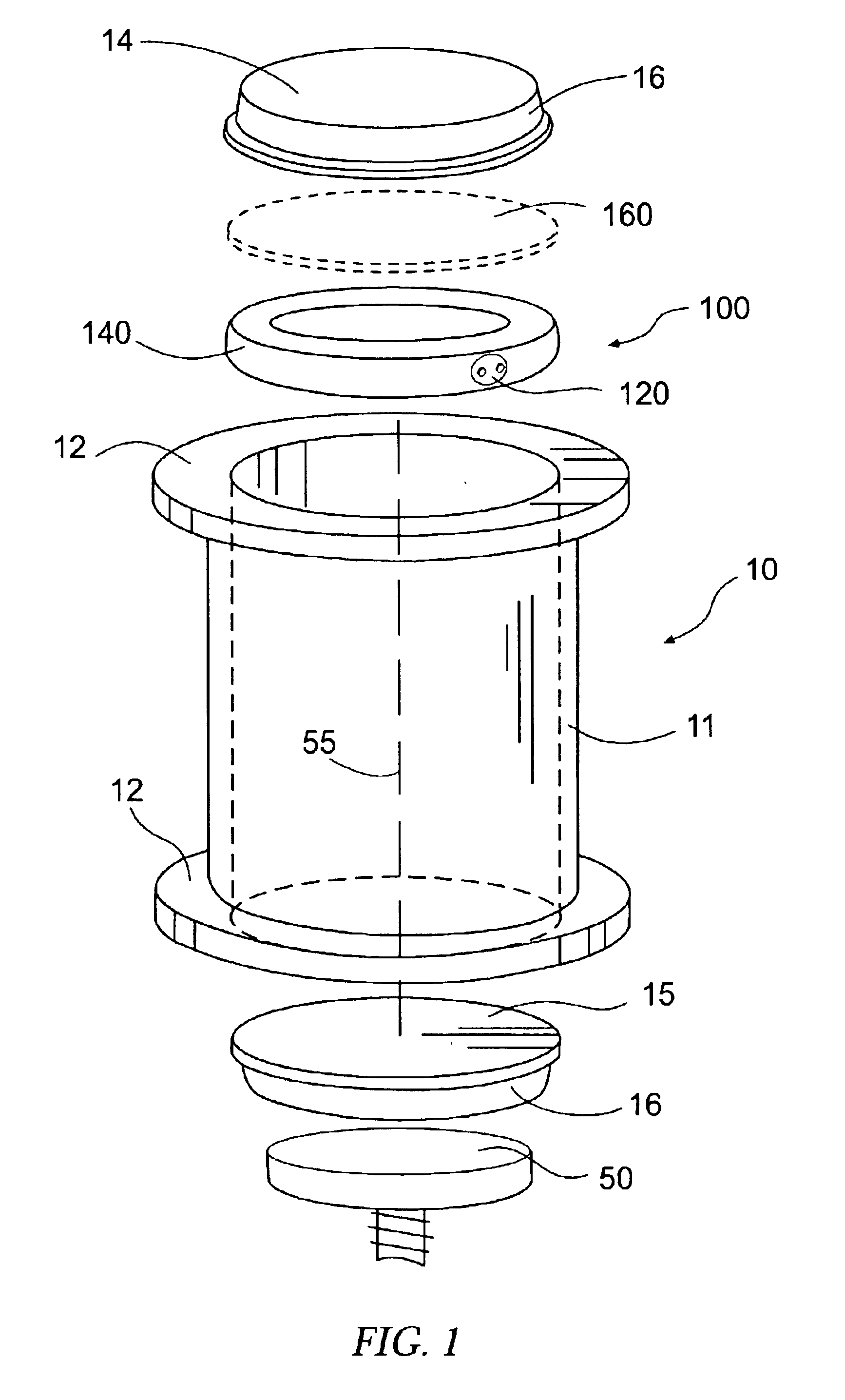

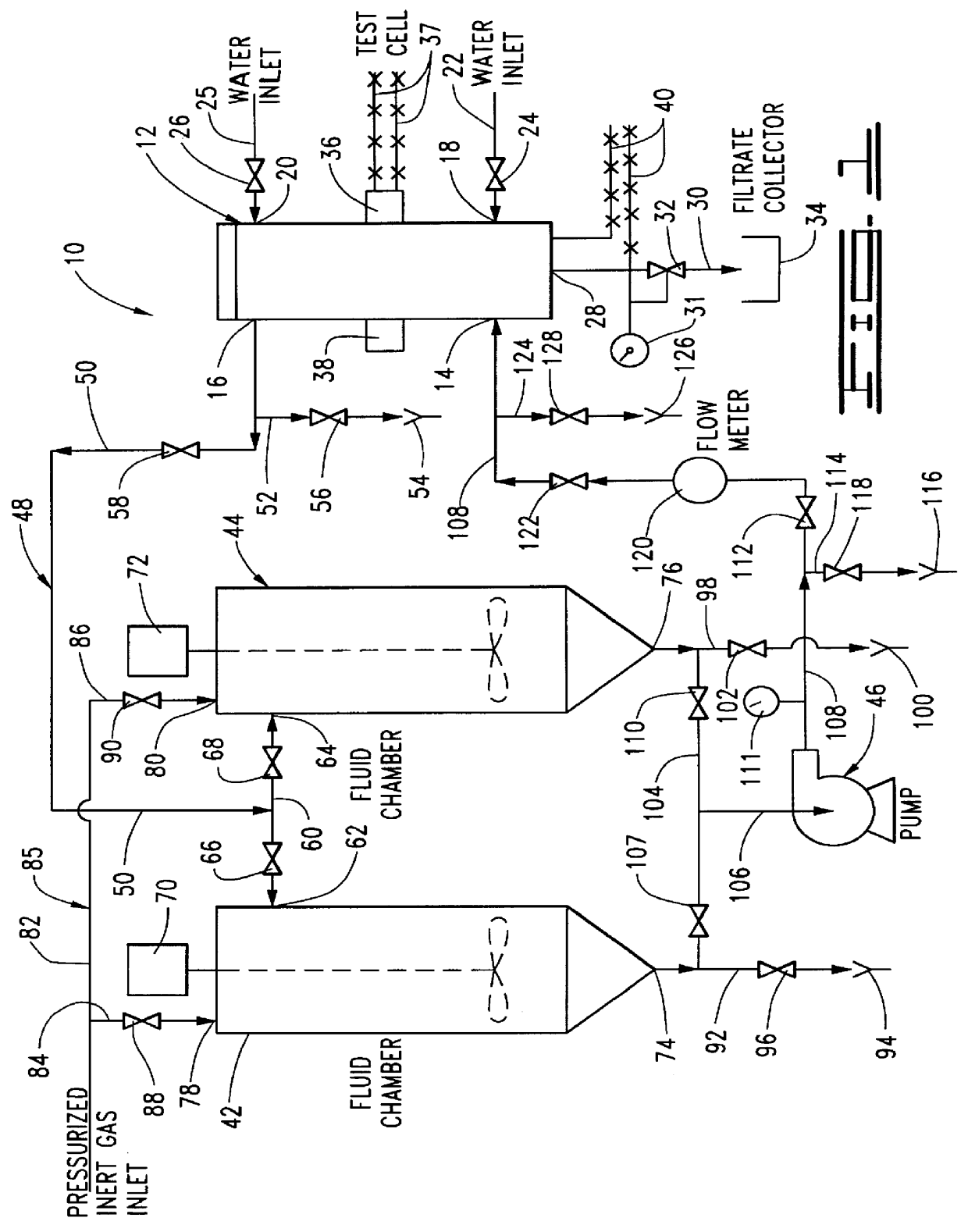

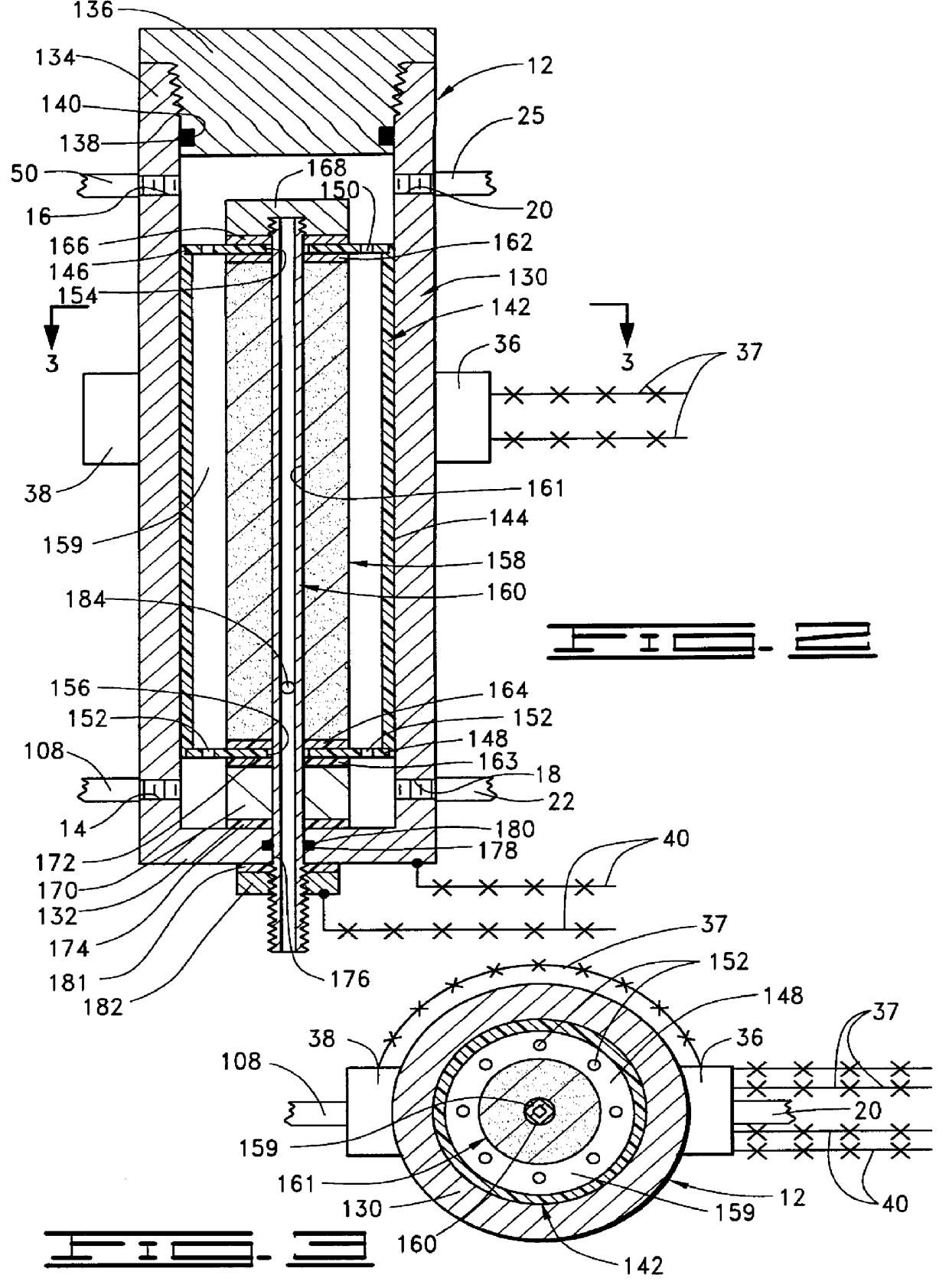

Apparatus and method for simulating well bore conditions

InactiveUS6055874AMaterial analysis using sonic/ultrasonic/infrasonic wavesSamplingRock coreWell drilling

The present invention provides methods and apparatus for simulating well bore conditions before and after cementing therein. The methods of the invention are basically comprised of the steps of circulating a drilling fluid through a closed test cell containing a permeable rock core while maintaining a selected pressure differential across the rock core to form a layer of filter cake thereon, circulating a filter cake removal fluid through the test cell to simulate the clean-up of the well bore and then determining the condition of the rock core with respect to the effectiveness of the filter cake removal fluid thereon.

Owner:HALLIBURTON ENERGY SERVICES INC

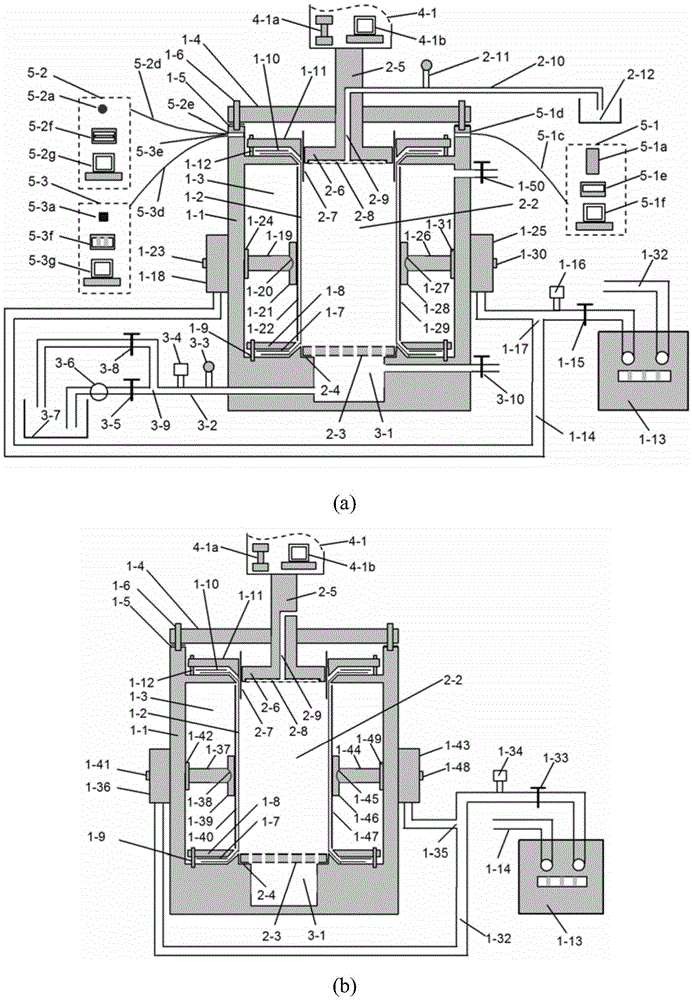

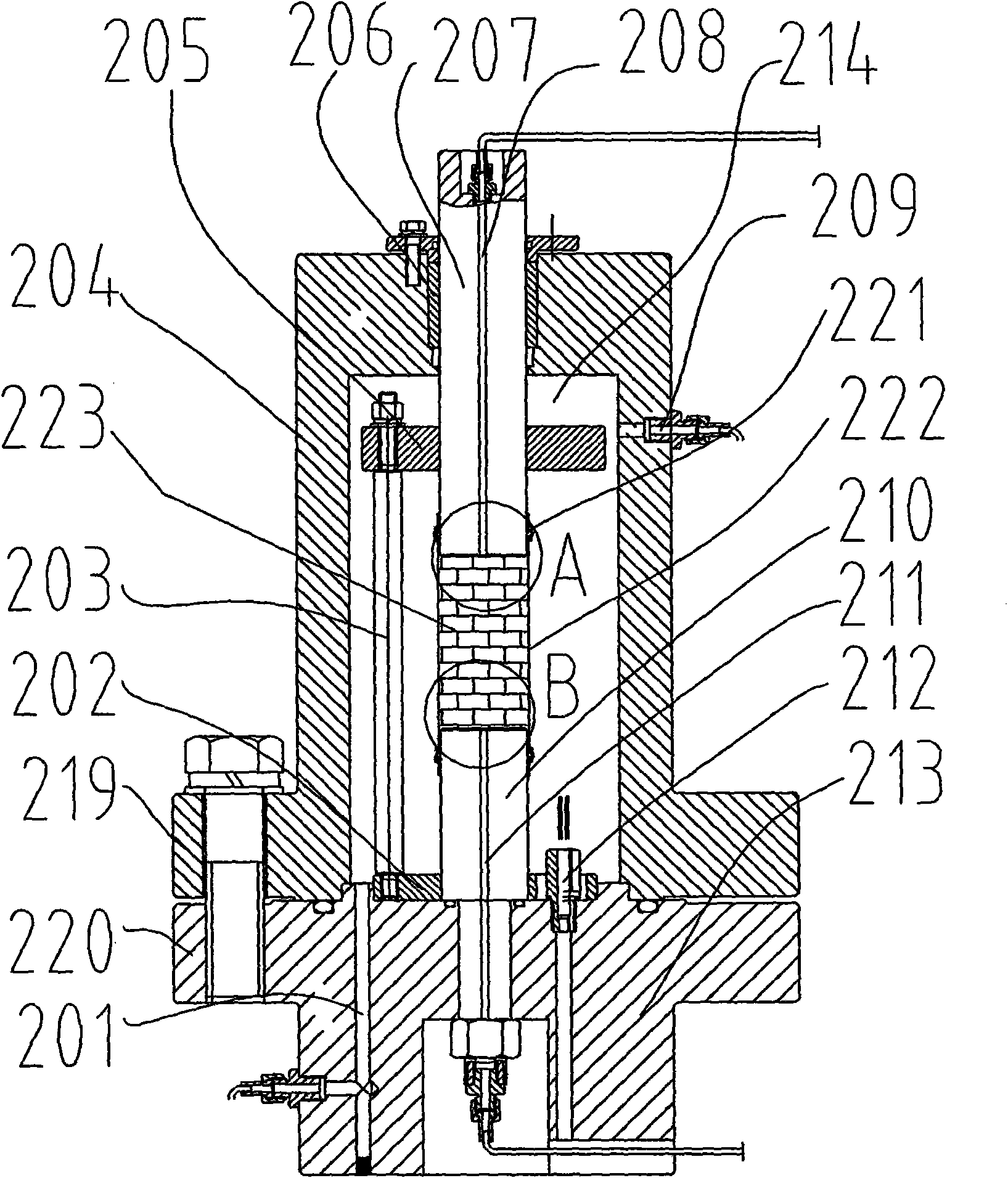

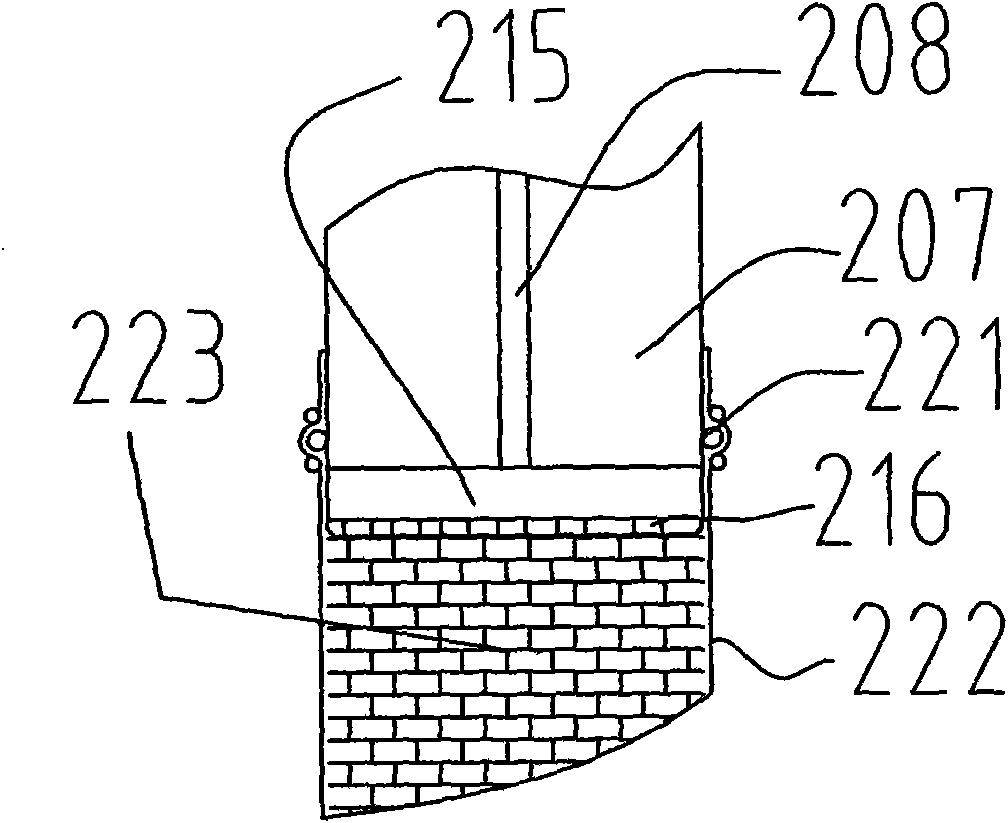

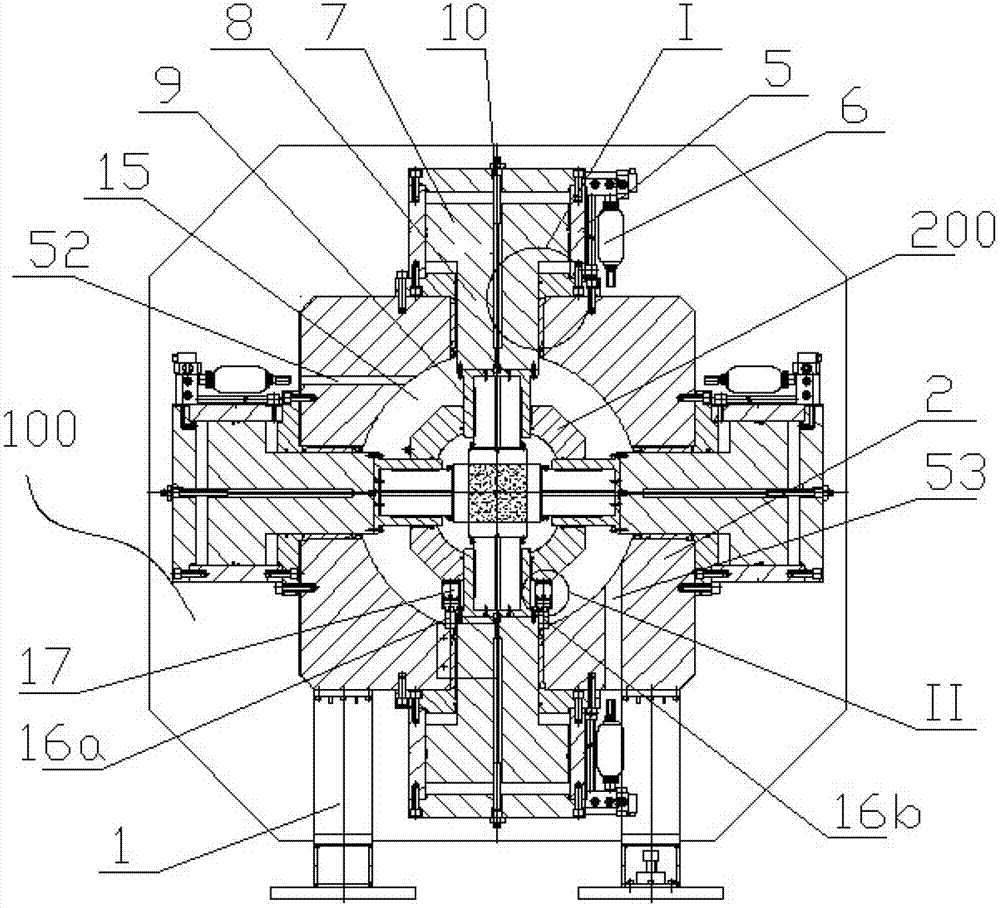

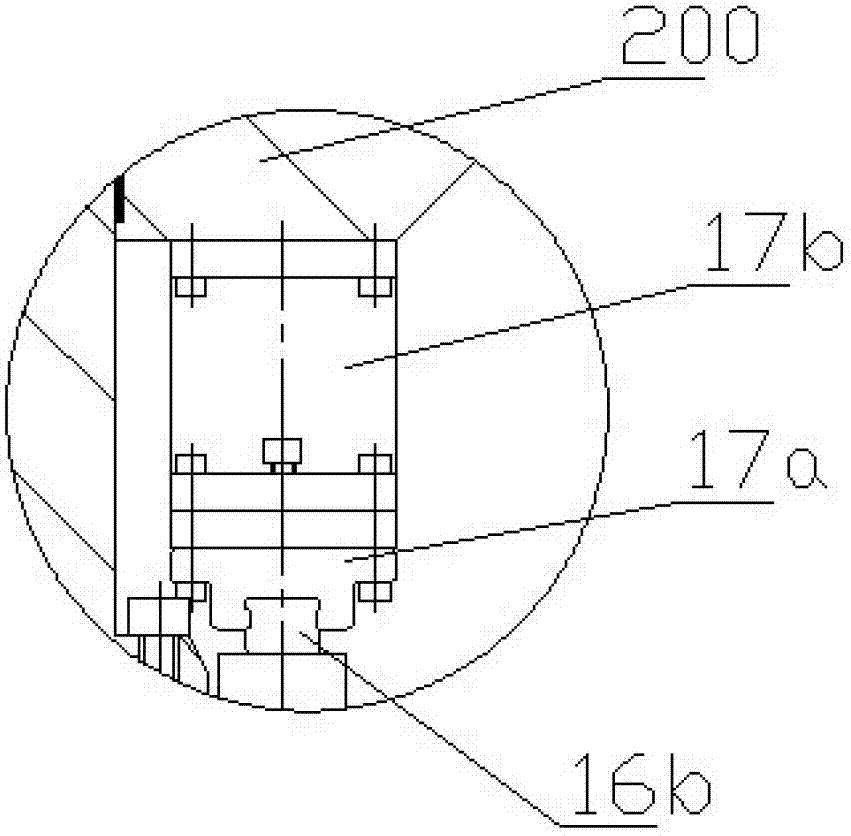

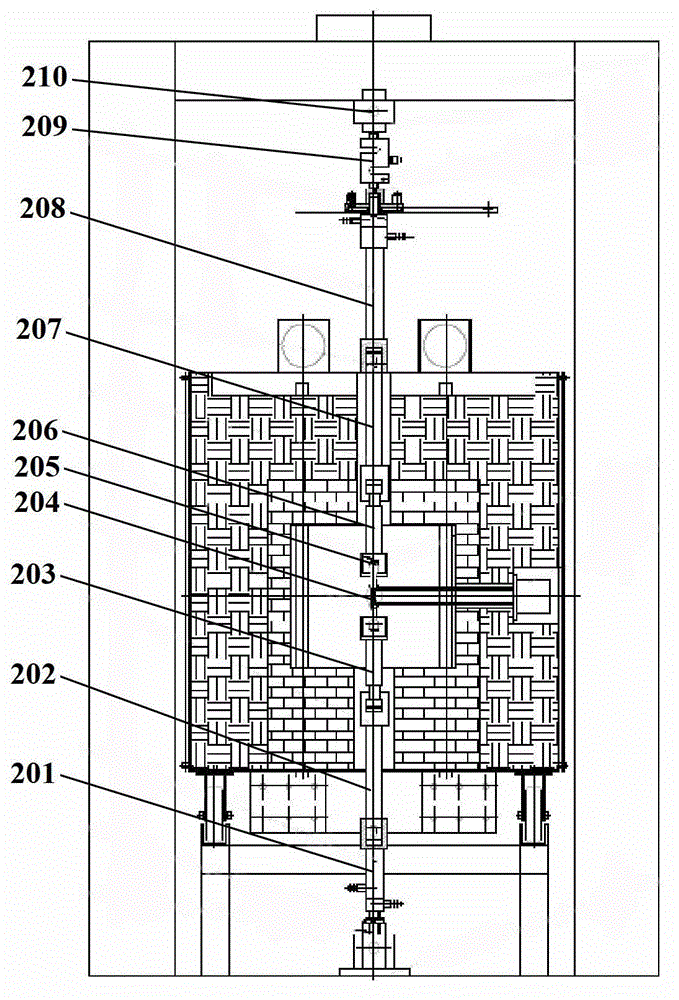

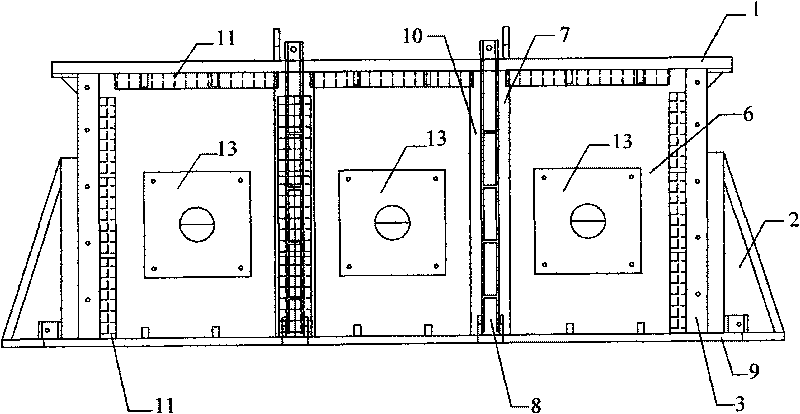

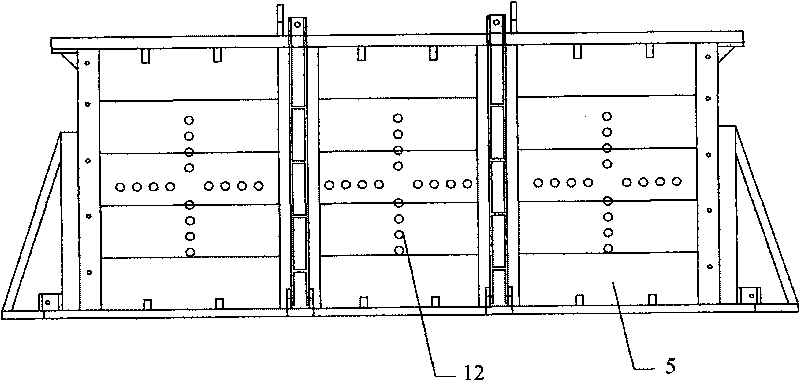

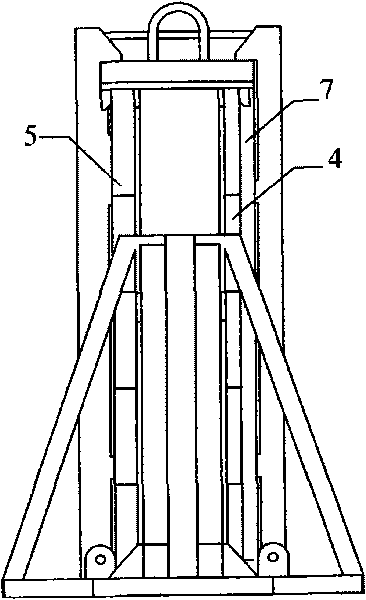

True triaxial loading and unloading test device for large-size bedded pressure-bearing rock and testing method

ActiveCN105547849AEasy to replaceAvoid damageMaterial strength using tensile/compressive forcesPermeability/surface area analysisTriaxial shear testConfined water

The invention discloses a true triaxial loading and unloading test device for large-size bedded pressure-bearing rock and a testing method. The device comprises a confining pressure loading module, a sample storage and water outlet module, a confined water loading module, a load loading module and a signal collecting and processing system, wherein the confining pressure loading module comprises two horizontal loading and unloading systems which are independent and perpendicular to each other and is used for performing horizontal load loading and unloading on the wrapped sample storage and water outlet module; the confined water loading module is located at the bottom of the sample storage and water outlet module and is used for performing confined water loading and unloading on the bottom of the bedded rock; the load loading module is located at the top of the sample storage and water outlet module and is used for performing vertical load loading and unloading on the top of the bedded rock; the signal collecting and processing system is used for collecting and analyzing signals in a test process. The test device realizes the true triaxial test of the bedded rock through four independent loading and unloading systems, truly simulates three-way anisobaric stress state of the coal-series bedded pressure-bearing rock and is more true and more reliable than a conventional triaxial test.

Owner:ANHUI UNIV OF SCI & TECH

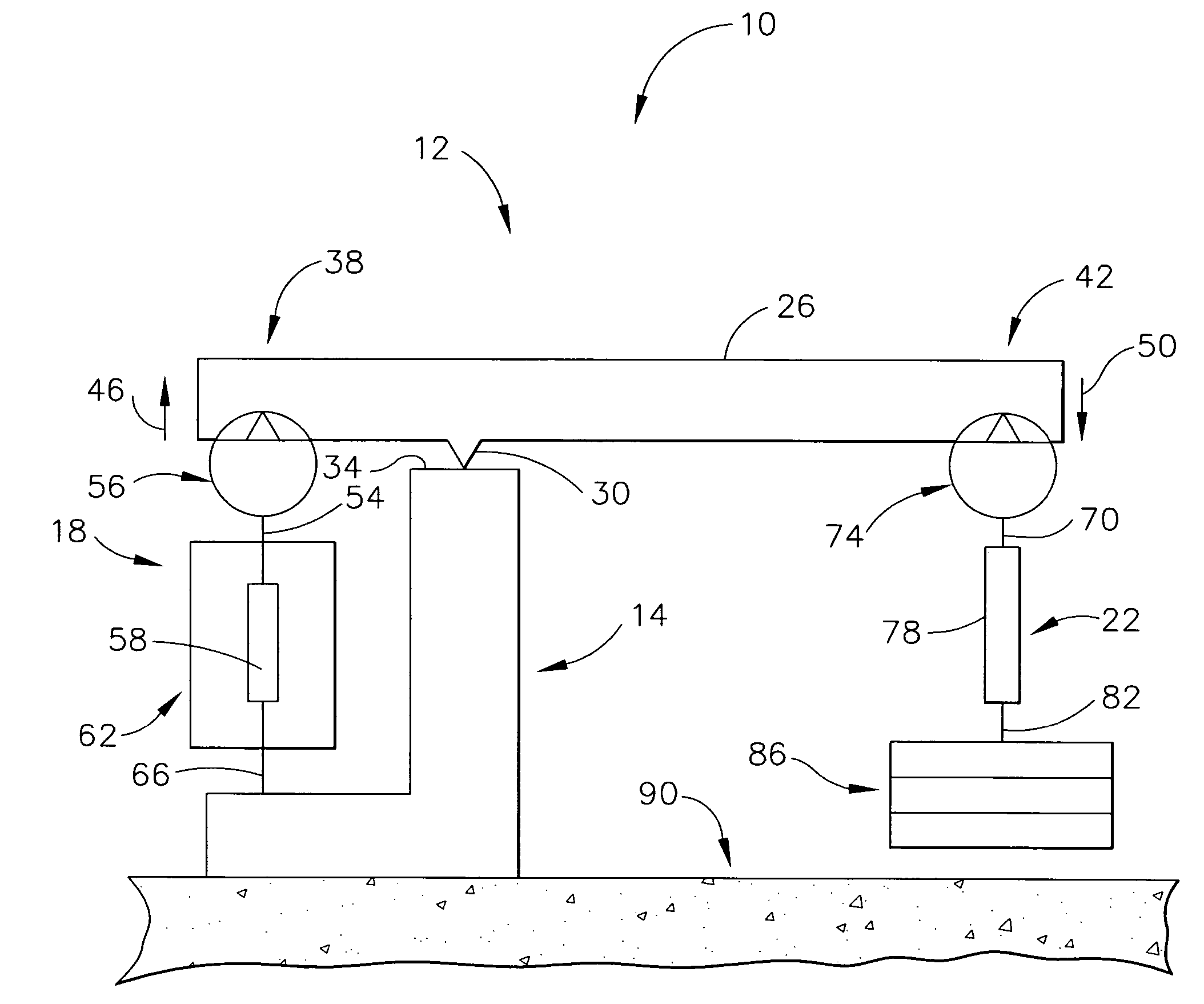

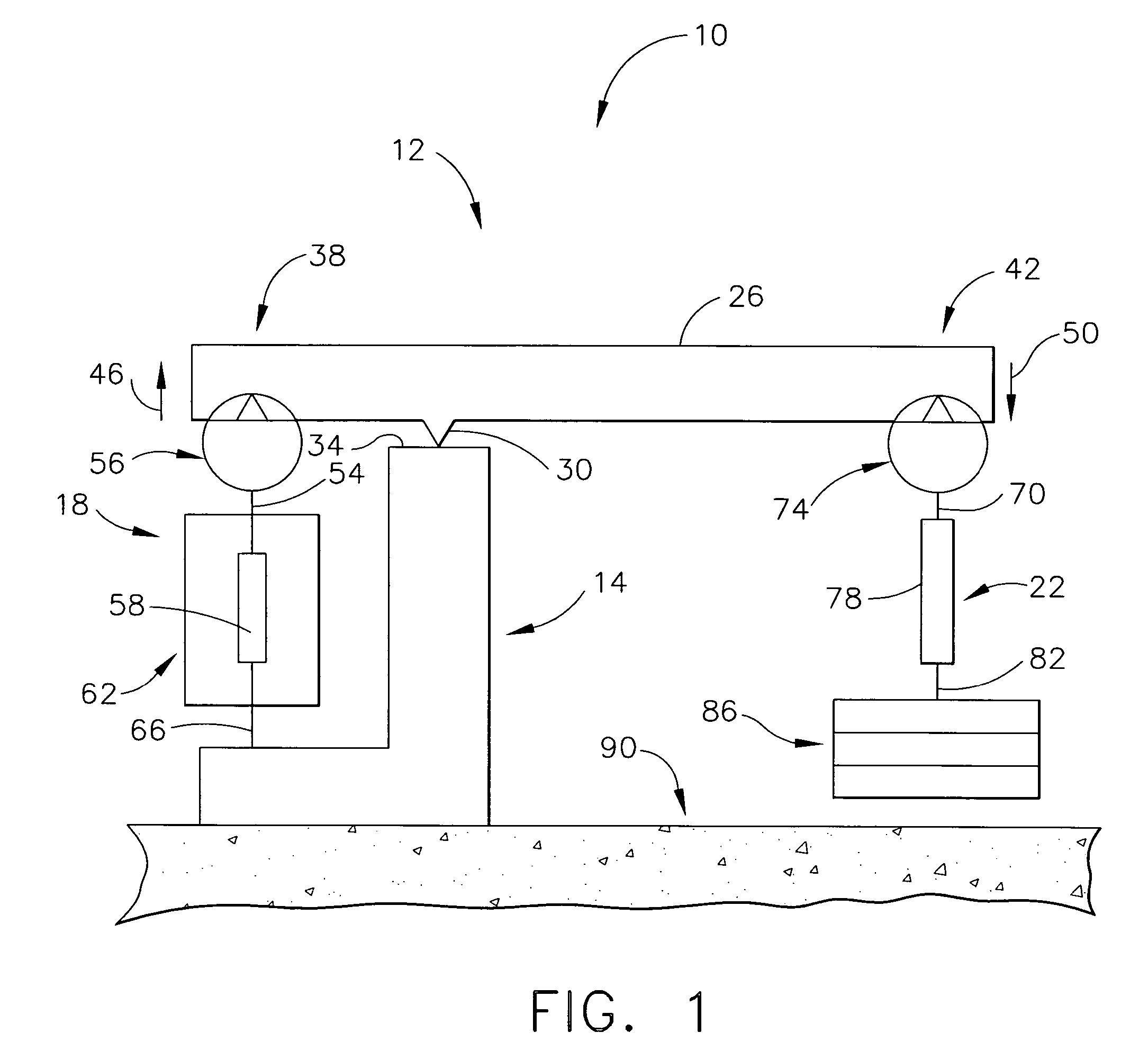

System, apparatus and method for testing under applied and reduced loads

InactiveUS7353715B2Easy maintenanceApply evenlyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringLoad regulation

A system which cyclically applies and reduces a load on a test specimen and which can use an apparatus comprising: (a) a frame; (b) a load adjusting section having a fluidic mechanical muscle that contracts and extends in length to cyclically apply and reduce a load; (c) a load train section frame for subjecting a test specimen to the load; and (d) a lever arm configured to apply and reduce the load from the loading adjusting section to the load train section. The system and apparatus can be used in a method for cyclically applying and reducing a load on a test specimen to thereby subject the test specimen to tensile testing and can also comprise a mechanism for decoupling at least a portion of the load from the test specimen when the load is reduced.

Owner:GENERAL ELECTRIC CO

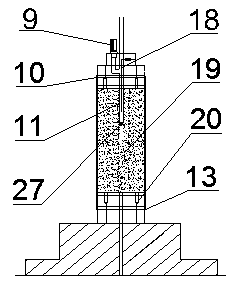

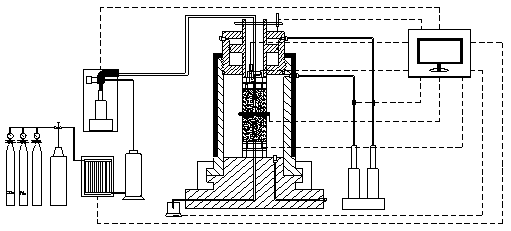

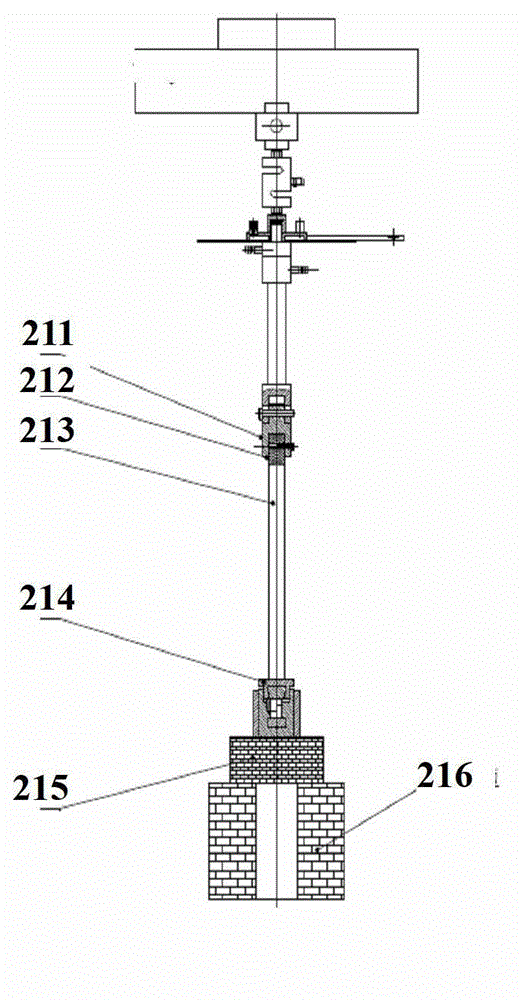

Fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal

InactiveCN101634621APrecise permeability measurementImprove breathabilitySurface/boundary effectMaterial strength using tensile/compressive forcesWater bathsAxial compression

The invention discloses a fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal, comprising a lifting stand, a hydraulic servo control system, an axial loading device mounted at the top of the lifting stand and a triaxial pressure chamber connected with the lower end of the axial loading device. A thermostatic water tank is arranged below the triaxial pressure chamber; a movable worktable is arranged above the thermostatic water tank; the lower end of the triaxial pressure chamber is arranged on the movable worktable; heating tubes are arranged in the thermostatic water tank; and a water inlet valve, a water drain valve and a water-bath circulating water pump are arranged outside the thermostatic water tank and are communicated with the thermostatic water tank. In the hydraulic servo control system, an axial compression loading oil pump is communicated with an oil inlet and an oil outlet by a pipeline, and a peripheral compression loading oil pump is communicated with an oil intake / drain hole by a pipeline. The fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal can carry out the research of gas-contained coal percolation tests in states, such as different terrestrial stresses, different gas pressures, different temperatures, and the like and the distortion and failure characteristics of the gas-contained coal in a percolation process.

Owner:CHONGQING UNIV

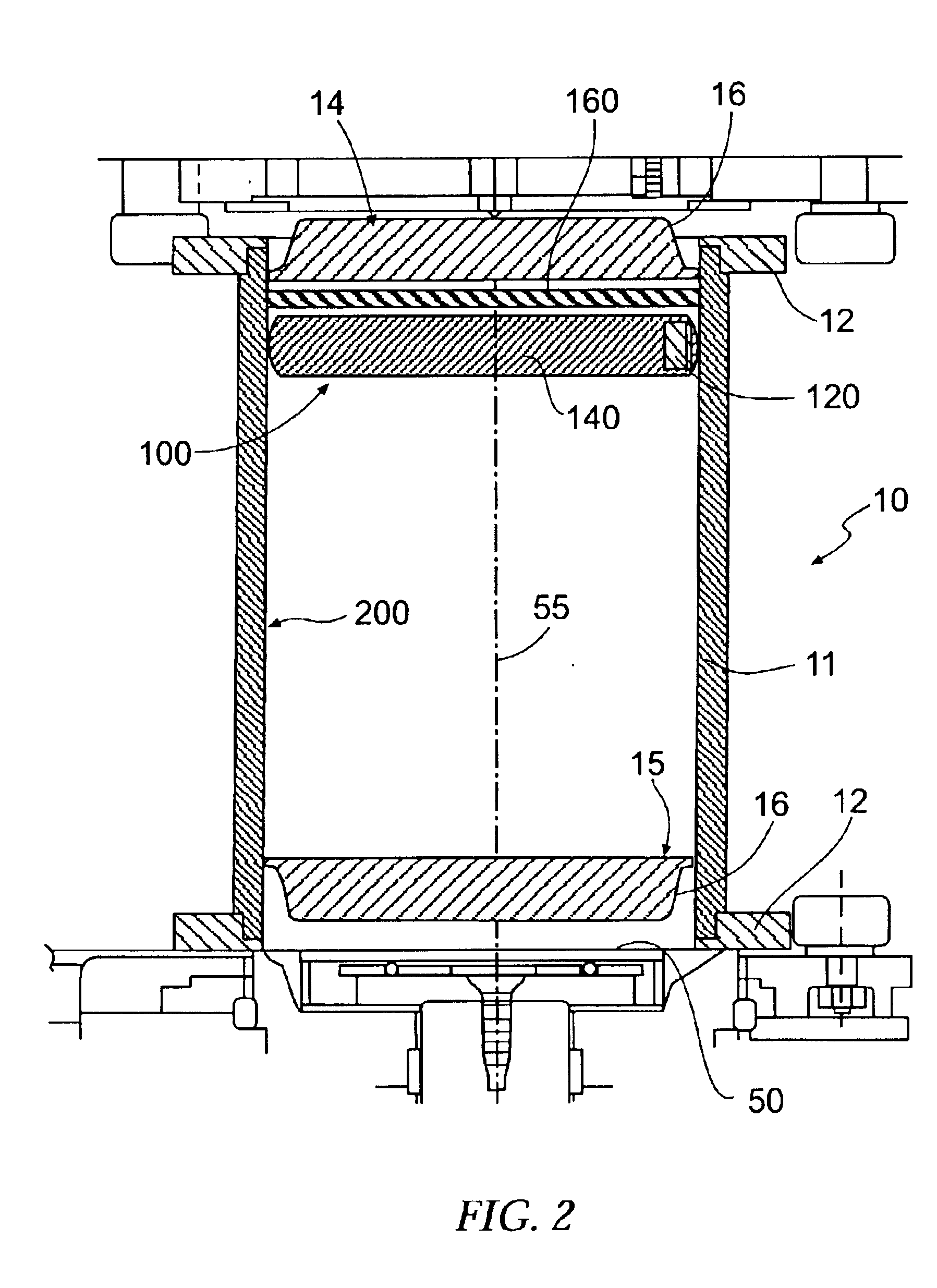

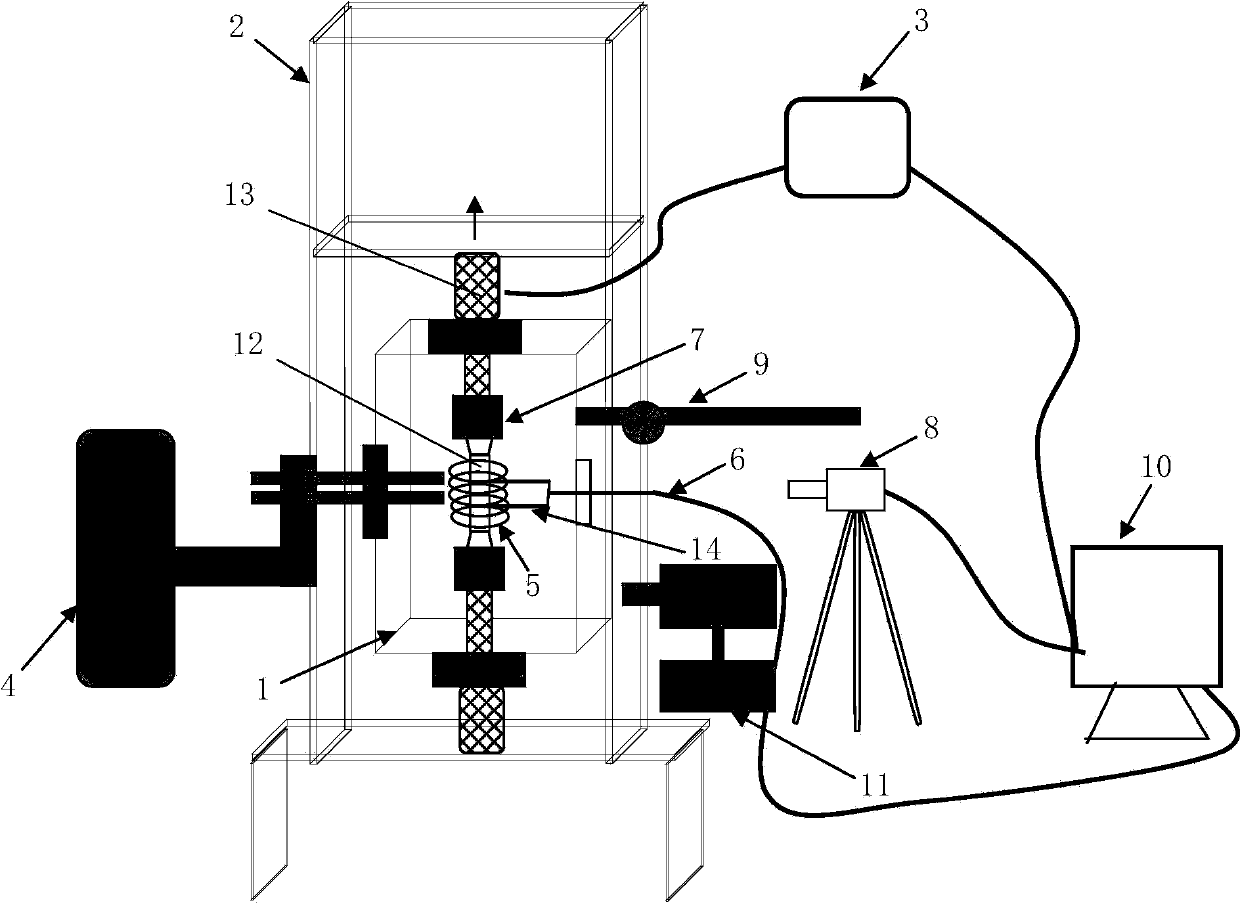

Experimental method of simulating dynamic and static load and device thereof

InactiveCN101532931AOvercome gradationOvercome sizeFluid pressure measurement by electric/magnetic elementsMaterial strength using tensile/compressive forcesExperimental methodsData acquisition

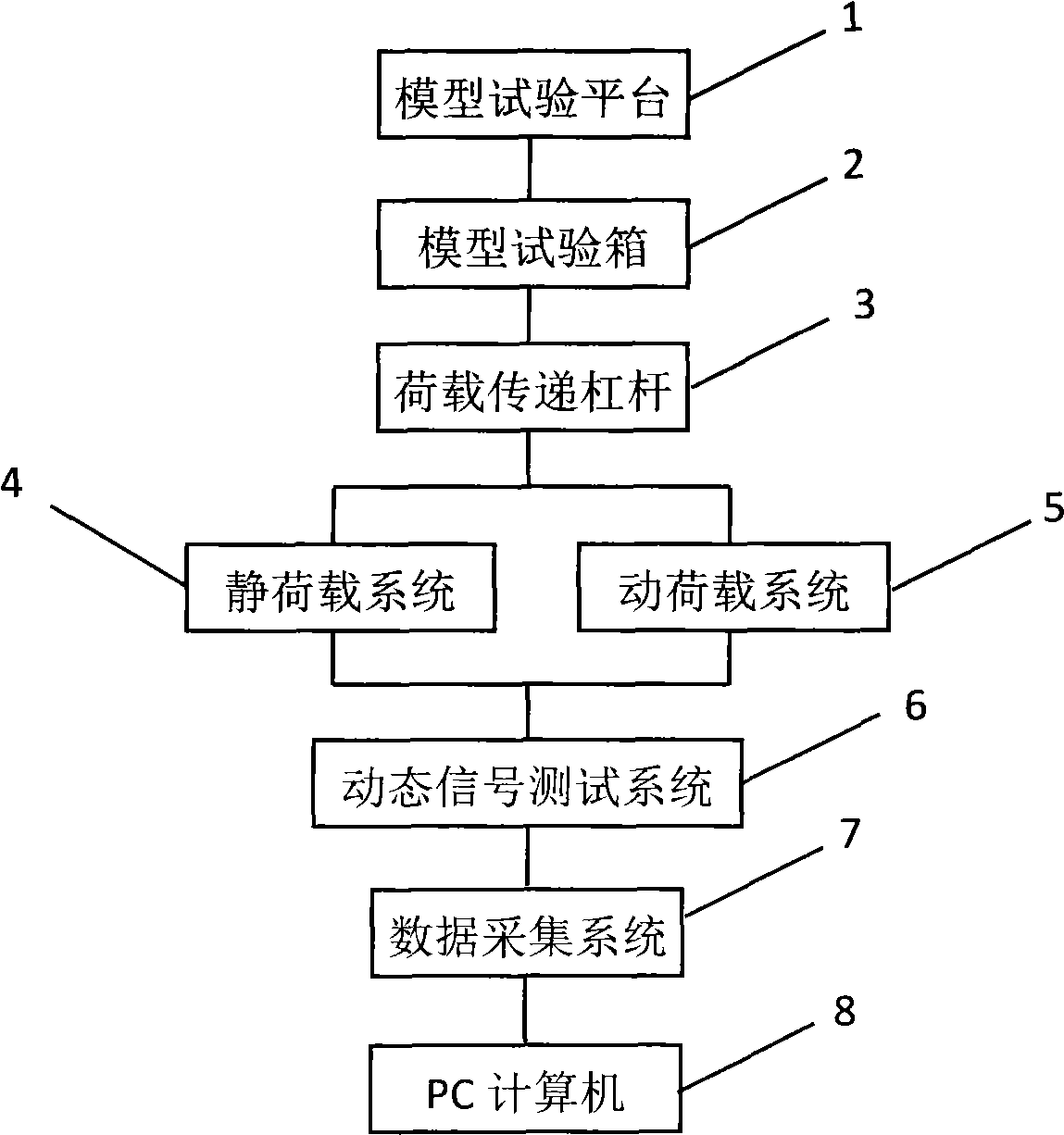

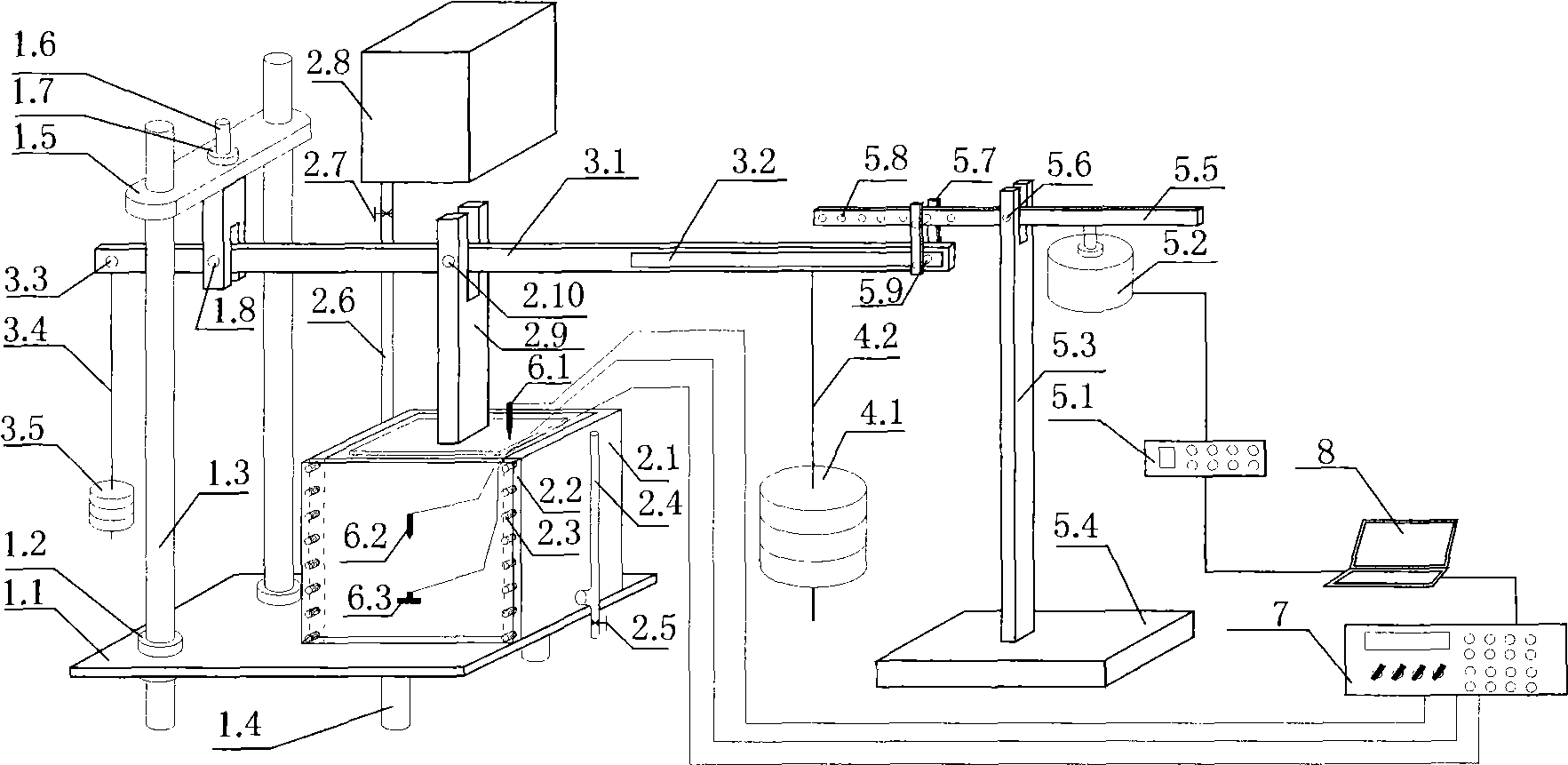

The invention discloses an experimental method of simulating dynamic and static load and a device thereof, relating to indoor model experimental technique of geotechnical engineering. The structure of the device is as follows: a model experimental platform (1), a model experimental box (2) and a load transmitting lever (3) are sequentially connected; the load transmitting lever (3) is respectively connected with a static load system (4) and a dynamic load system (5) which are respectively connected with a dynamic signal testing system (6); the dynamic signal testing system (6), a data acquisition system (7) and a computer (8) are sequentially connected. The device caries out dynamic and static load experiments on different structure models, and can monitor and collect non-linear properties of deformation and stress of gneiss under complex load condition in real time. The device has intuitional testing principle, simple structure, high precision, good stability, easy operation, convenient detachment and no high technical requirement to mounting and testing workers.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

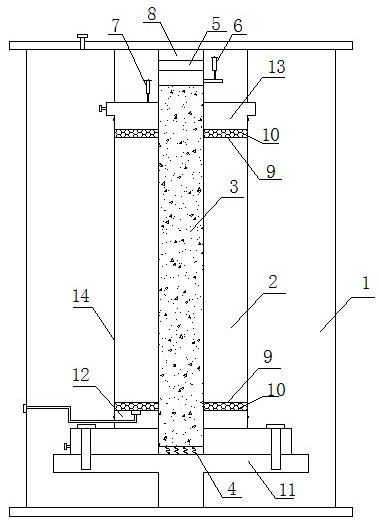

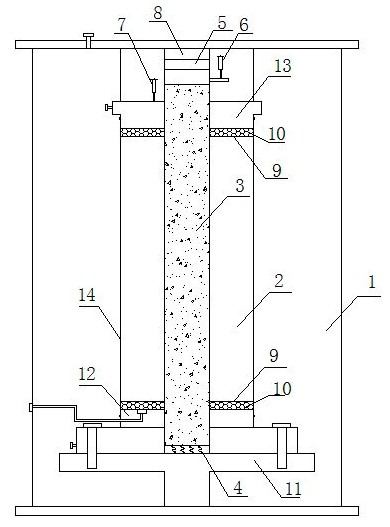

Device and method for testing mechanical properties of pile-soil contact surface

ActiveCN102628767ARealize moving up and downSimple structureMaterial strength using tensile/compressive forcesEngineeringFilter paper

The invention discloses a device for testing the mechanical properties of a pile-soil contact surface. The device is composed of a sealed pressure chamber, a hollow cylindrical soil sample, a solid cylindrical concrete pile sample and the like. The pile sample is prefabricated, and its diameter is equal to the internal diameter of the hollow cylindrical soil sample, and the two samples joint together closely. The lower end of the concrete pile sample is disposed on a pedestal through a spring assembly, and the upper end is connected to a stress loading system through a dowel bar, which is provided with a stress sensor and a displacement sensor I. The outside of the concrete pile sample is the hollow cylindrical soil sample. Filter paper and permeable stones are disposed at the lower end of the soil sample, and the lower end is positioned on the pedestal, while the upper end of the soil sample is provided with filter paper, permeable stones, a top cover and a displacement sensor II in order. During test, a confining pressure is exerted first for consolidating, and then a static (dynamic) load is exerted on the pile sample for measuring the axial deformation, pore water stress and the like of the pile and the soil. The device provided in the invention has a simple structure, is easy to realize, and can be used to measure the mechanical properties of a pile-soil contact surface under the action of a static (dynamic) load.

Owner:HOHAI UNIV

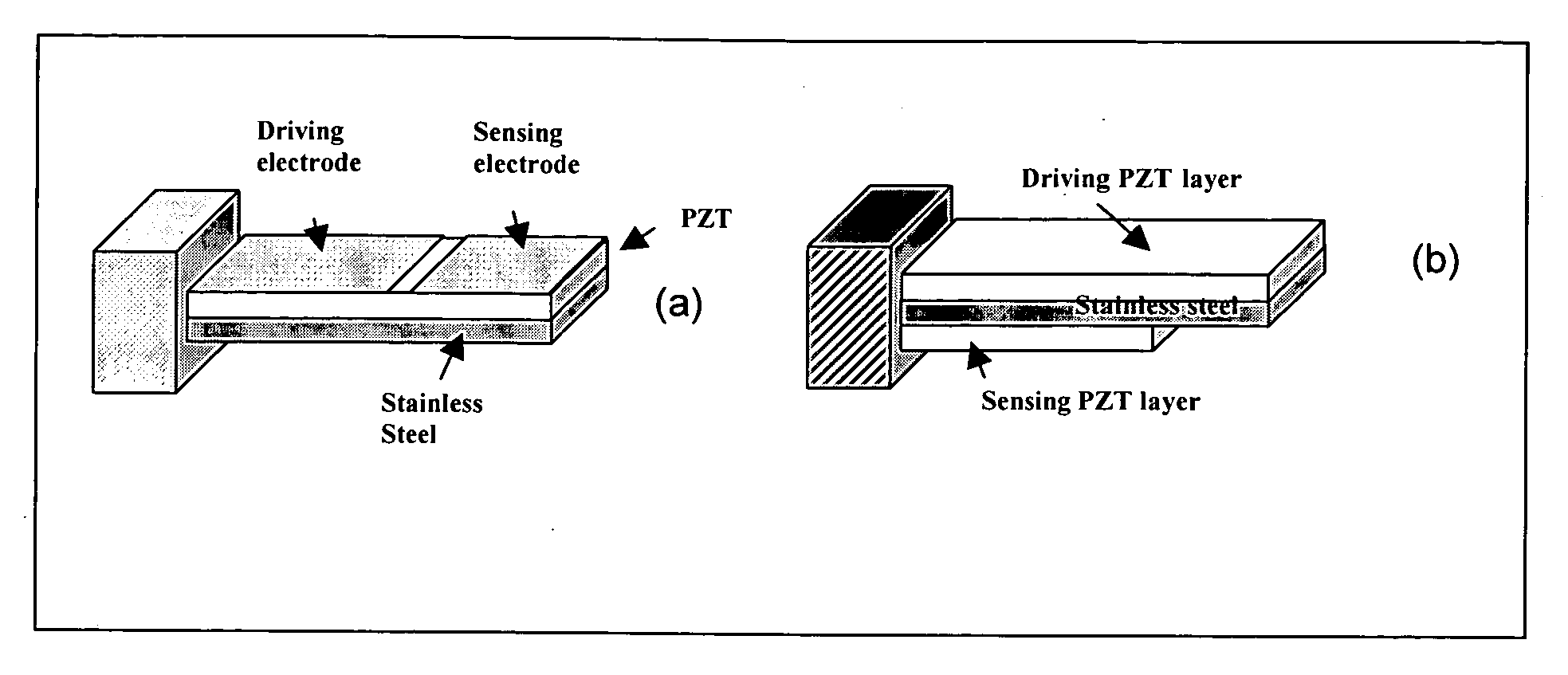

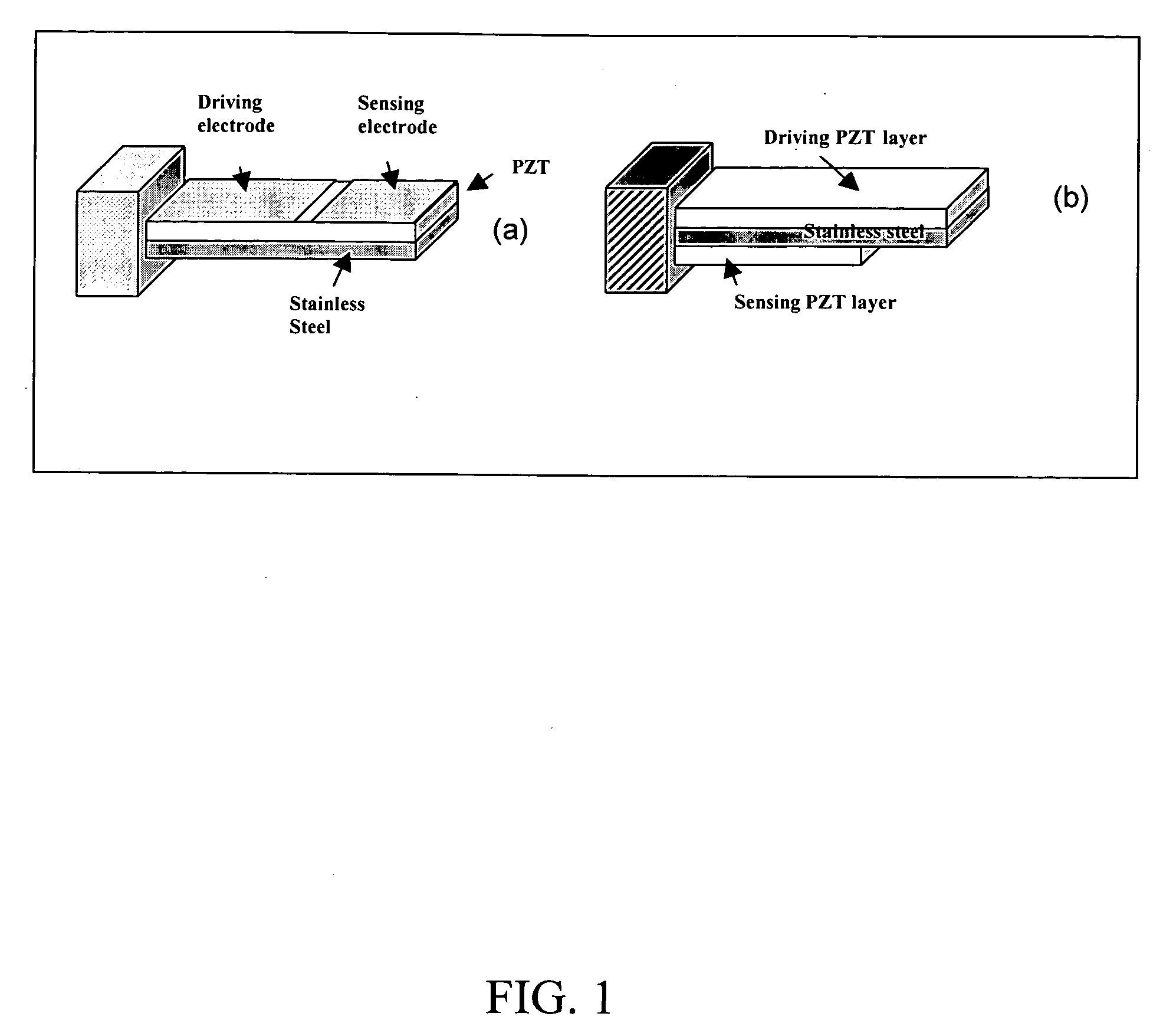

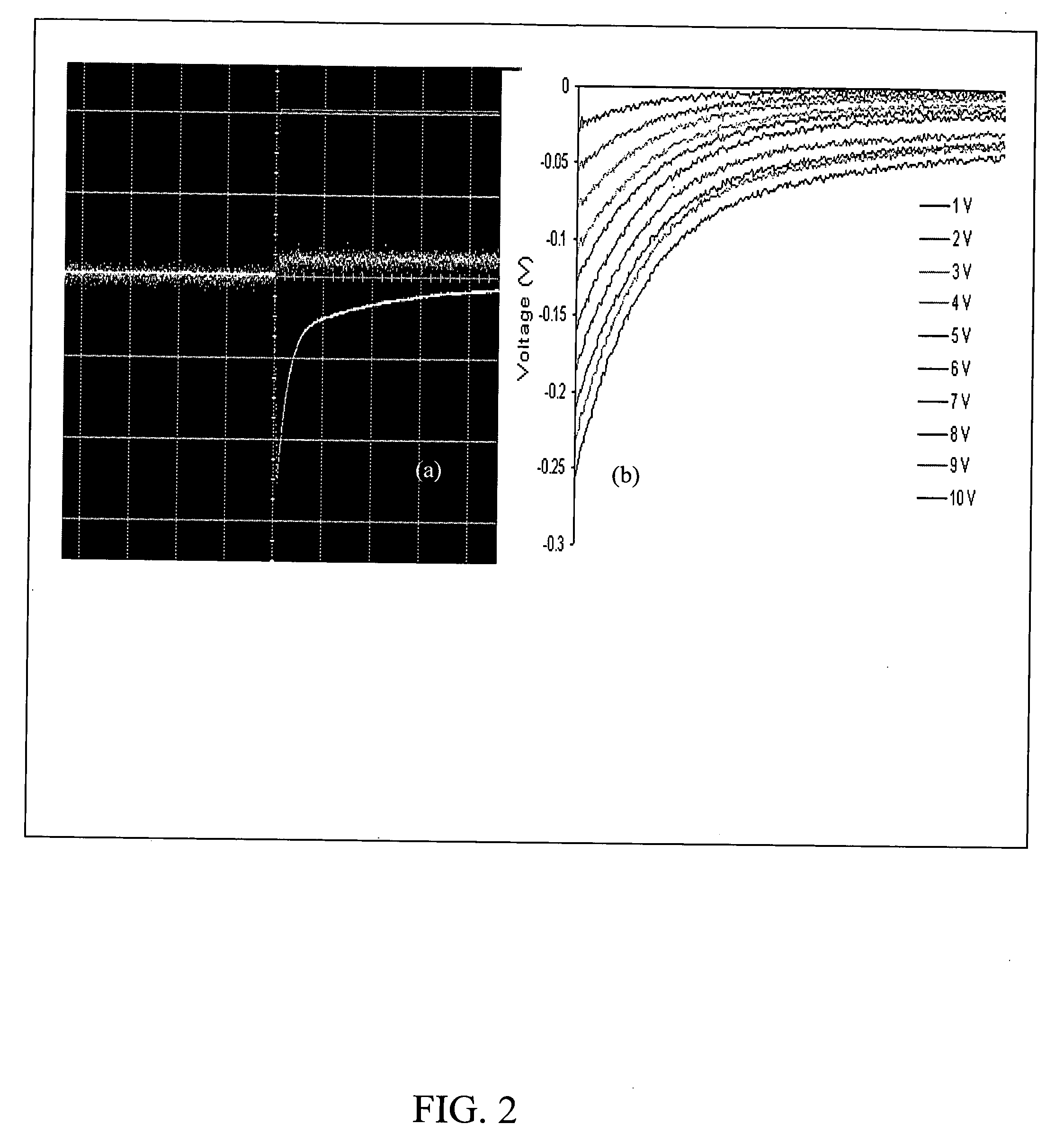

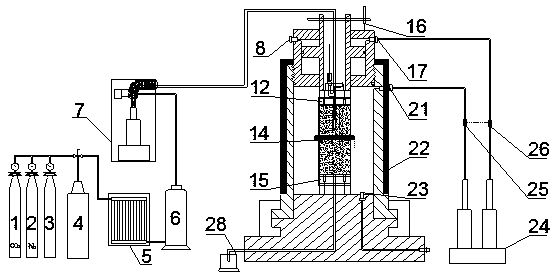

All electric piezoelectric finger sensor (PEFS) for soft material stiffness measurement

A PEFS (Piezoelectric Finger Sensor) acts as an “electronic finger” capable of accurately and non-destructively measuring both the Young's compression modulus and shear modulus of tissues with gentle touches to the surface. The PEFS measures both the Young's compression modulus and shear modulus variations in tissue generating a less than one-millimeter spatial resolution up to a depth of several centimeters. This offers great potential for in-vivo early detection of diseases. A portable hand-held device is also disclosed. The PEF offers superior sensitivity.

Owner:DREXEL UNIV

Coal petrography multiphase different fluid three-axis crushing test unit and method

ActiveCN105510142ARealize the effects of fracturingEnables research on the effects of fracturingMaterial strength using tensile/compressive forcesTest comparisonData acquisition

The invention discloses a coal petrography multiphase different fluid three-axis crushing test unit and method and belongs to the technical field of rock and rock mass mechanics and engineering. The unit is composed of a three-axis stress real-time loading system, a multiphase different fluid crushing system, a sealing system, a temperature control system, an acoustic emission monitoring system and a data acquisition system. Different fluid and multiphase crushing test comparison can be conducted on a coal petrography test piece, sensibility of parameters, such as fluid pressurization rate, fluid viscosity, fluid isothermal compressibility and fluid temperature, affecting crushing of the coal petrography test piece can be analyzed under multiple conditions, the change rule of the pressure and temperature of a crushing medium can be precisely recorded in a crushing experiment, acoustic emission events during test piece crushing can be recorded in real time through an assembled micro acoustic emission sensor, and multi-phase fluid seepage tests before and after crushing can also be conducted on the coal petrography test piece.

Owner:TAIYUAN UNIV OF TECH

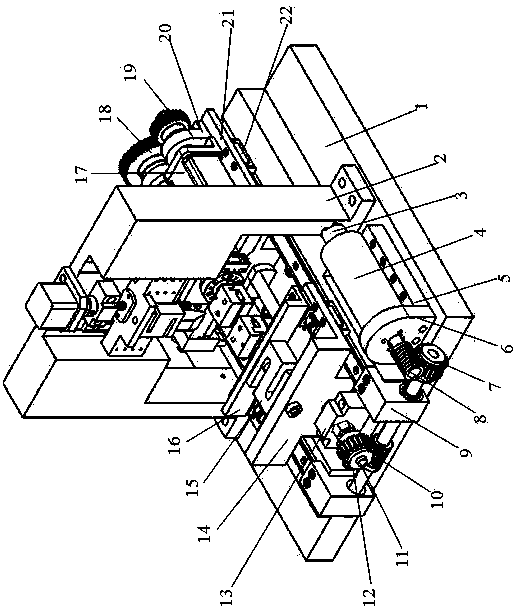

Micro material mechanical performance testing platform under stretching-bending-twisting multi-loads

ActiveCN103389243ANovel ideaCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectromechanicsStress level

The invention relates to a micro material mechanical performance testing platform under stretching-bending-twisting multi-loads, and belongs to the field of electromechanics. The micro material mechanical performance testing platform comprises a tension and compression module, a bending module, a twisting module, a detection control module and a test-piece clamping module, wherein the testing platform takes the tension and compression module as a basic function module; the twisting module is arranged at one end of the tension and compression module; the test-piece clamping module is arranged on the tension and compression module; the bending module is independently arranged at one side of a portal frame. The micro material mechanical performance testing platform can be taken as a material mechanical performance test device with an independent stretching / compressing mode or an independent bending mode or independent twisting mode, namely a single load testing mode, and can be applied to a material mechanical performance test of a twisting load under the given stretching / compressing stress level or a material mechanical performance test of a bending load under the given stretching / compressing stress level, namely a composite load testing mode. The stress strain process of a material under the effect of a composite load can be detected by the collection of a load / displacement signal by using the detection control module.

Owner:JILIN UNIV

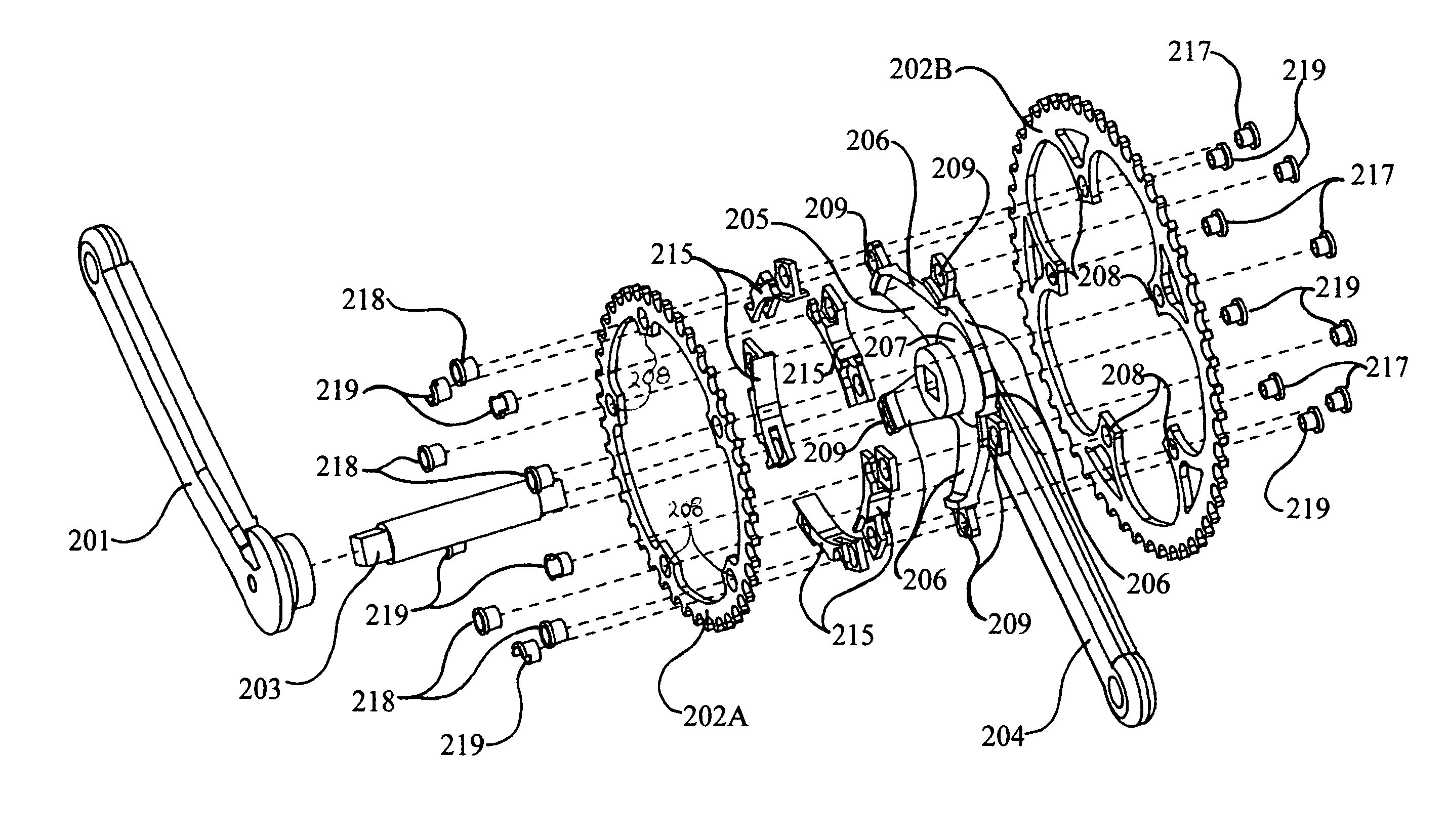

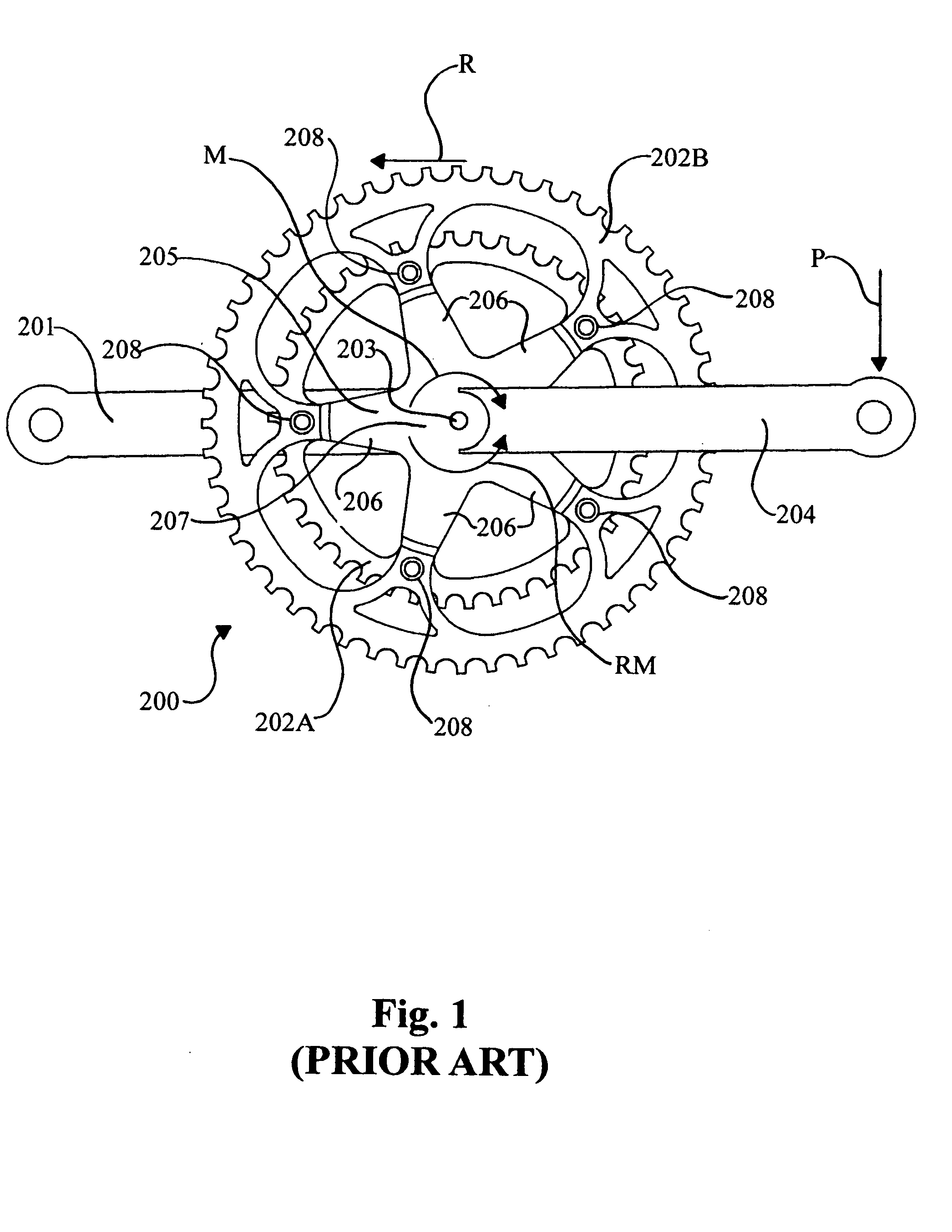

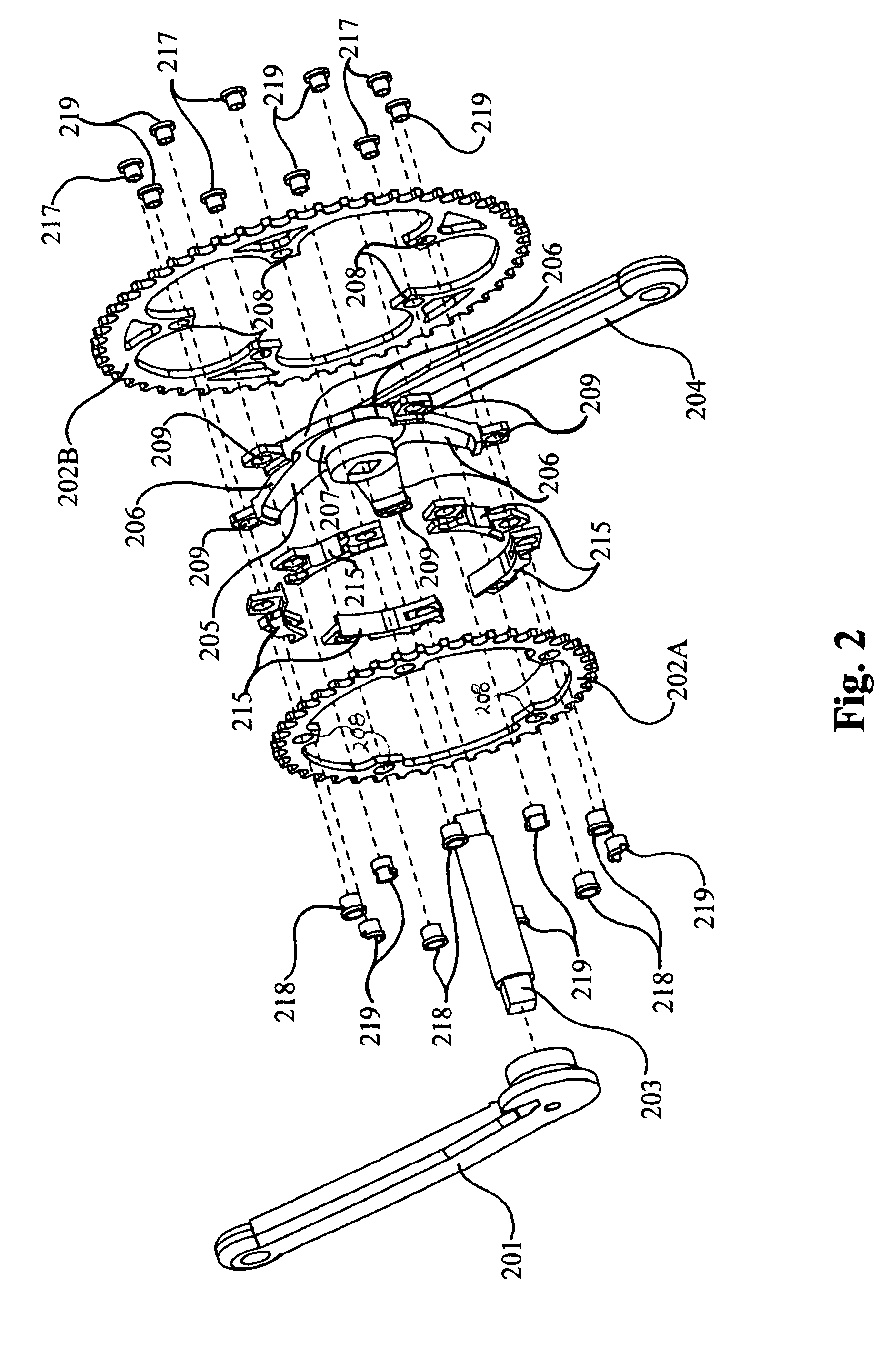

Load measurement apparatus and methods utilizing torque sensitive link for pedal powered devices

InactiveUS20050178210A1Easy to installEasy maintenanceChain/belt transmissionForce measurementEngineeringSprocket

Apparatus and methods for use in measurement of applied load at a chainring assemblage of a pedal powered device are provided. The apparatus includes a link adapted for interposition between a chainring attachment site located on a conventional chainring mount, or spider, and a corresponding chainring attachment locale at a conventional chainring. The link has a geometry and / or material composition selected to accommodate measurement of load exhibited between the attachment site and the corresponding chainring attachment locale. Means for measuring the load exhibited thereby is associated with the link.

Owner:FORZA

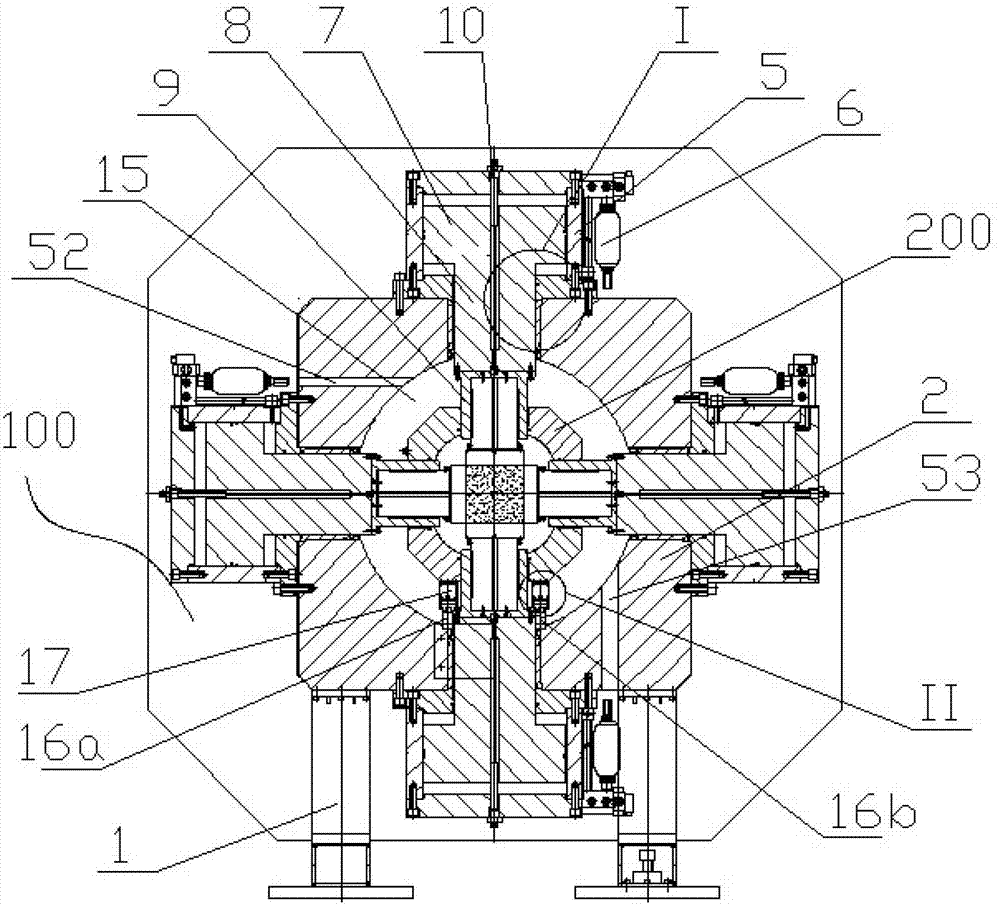

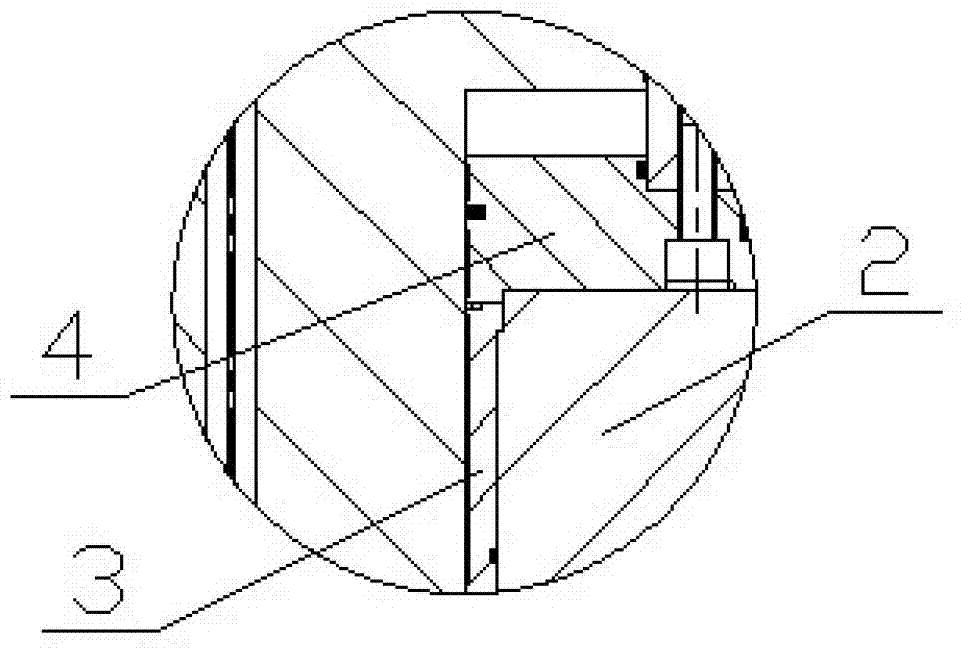

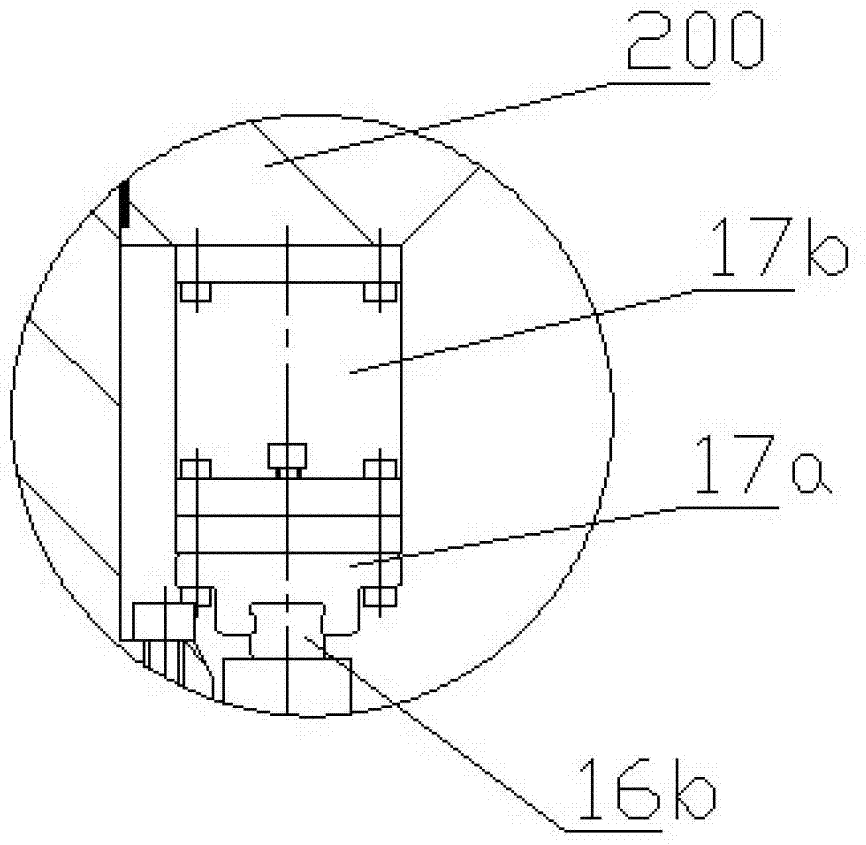

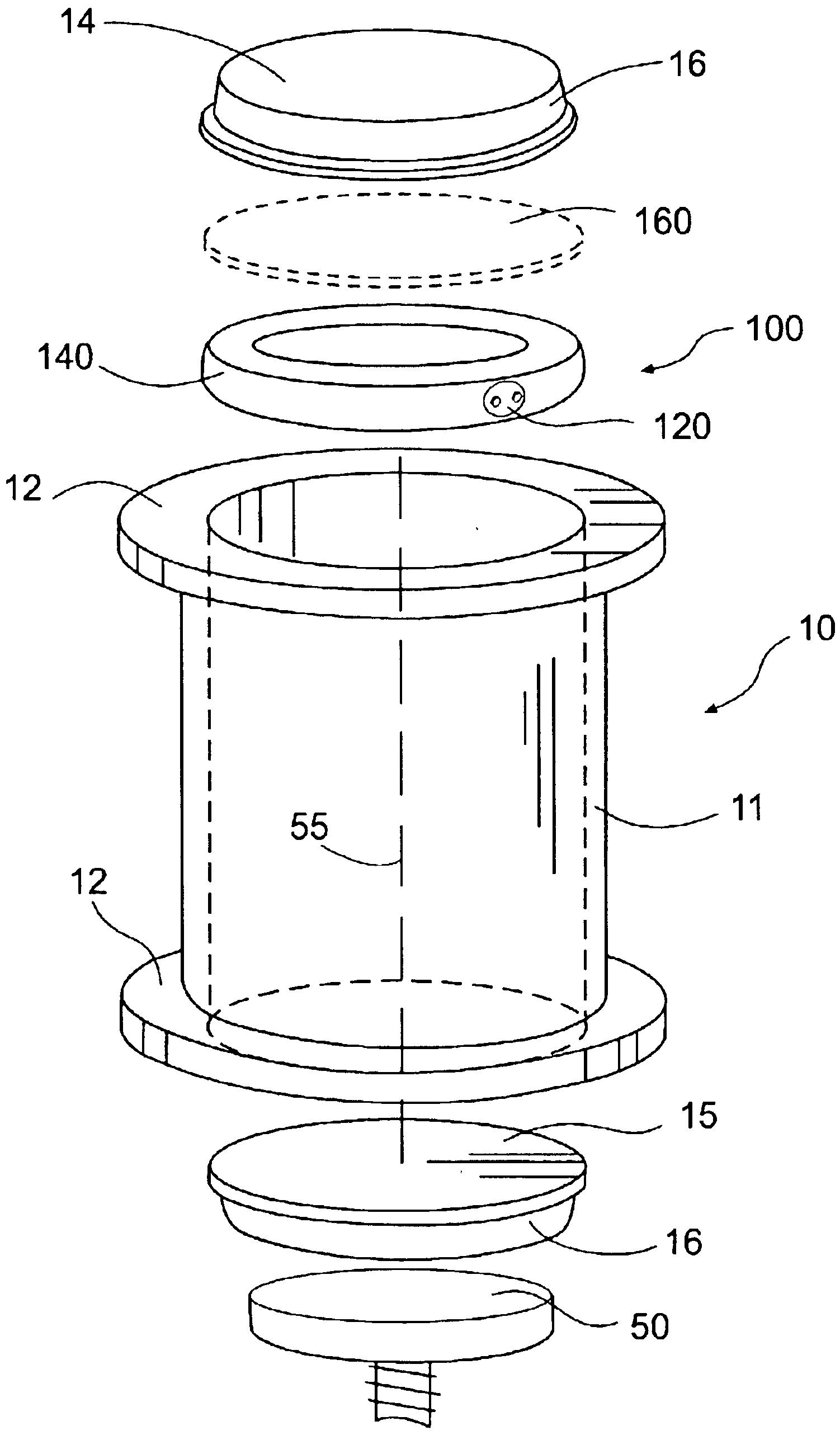

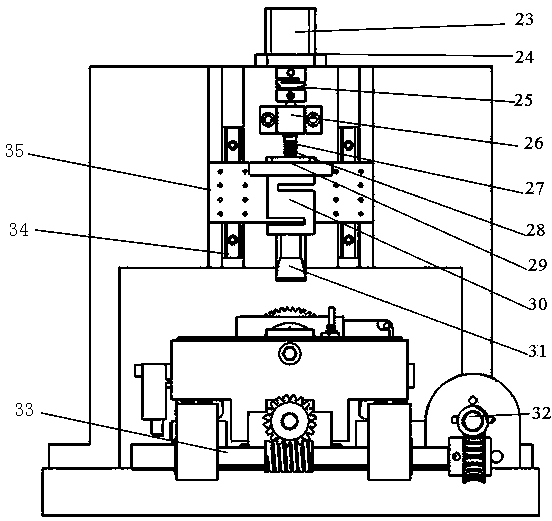

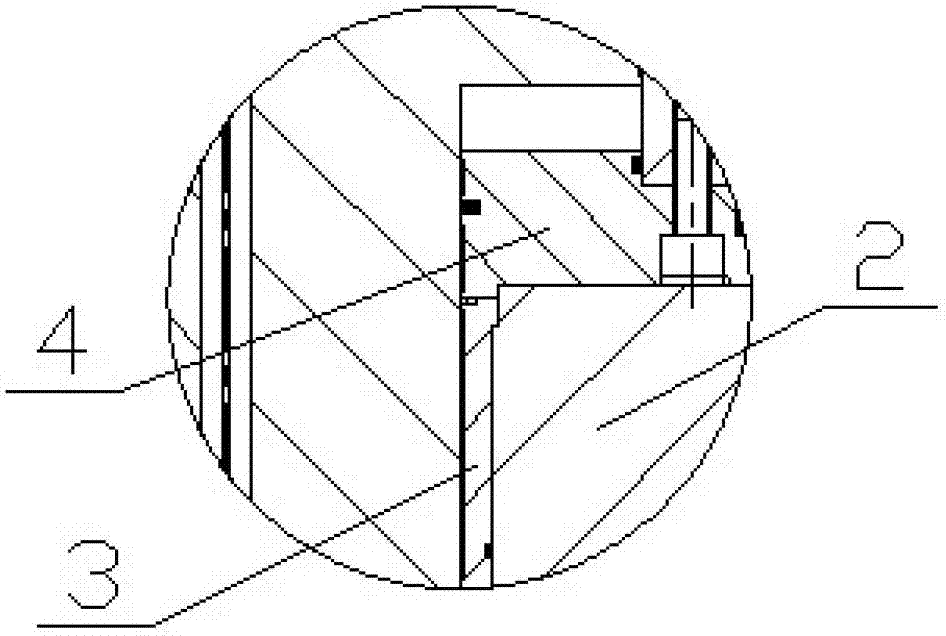

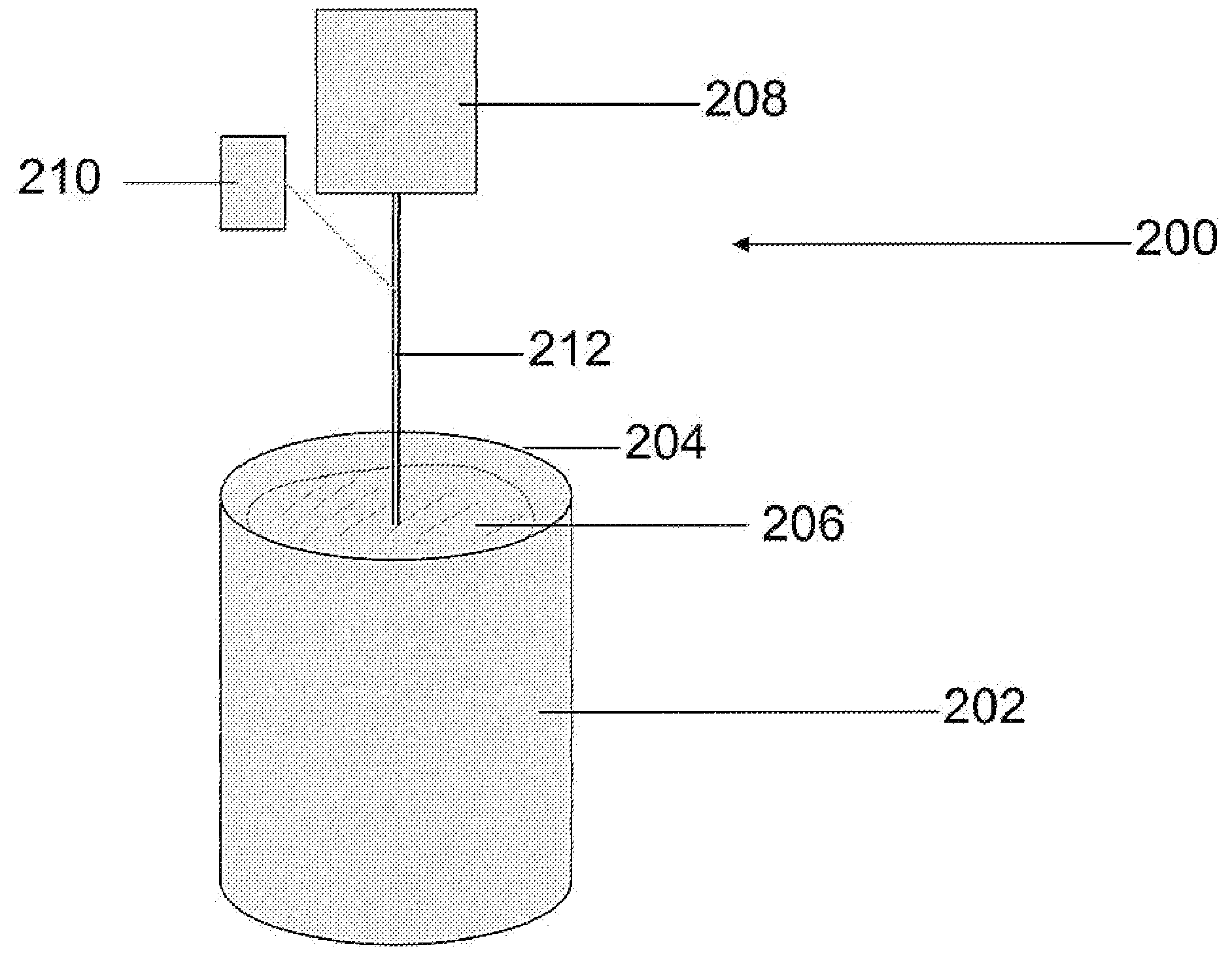

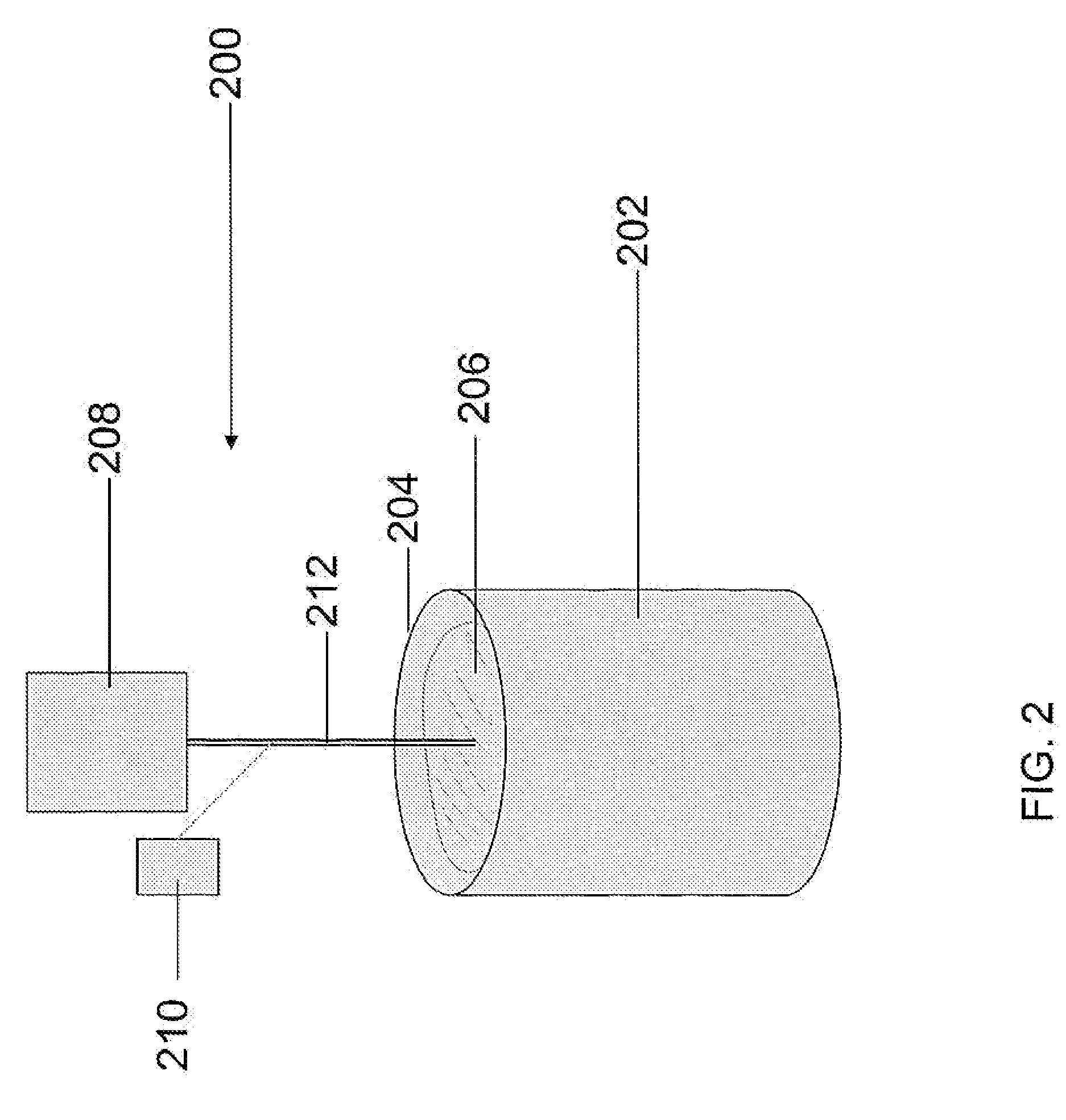

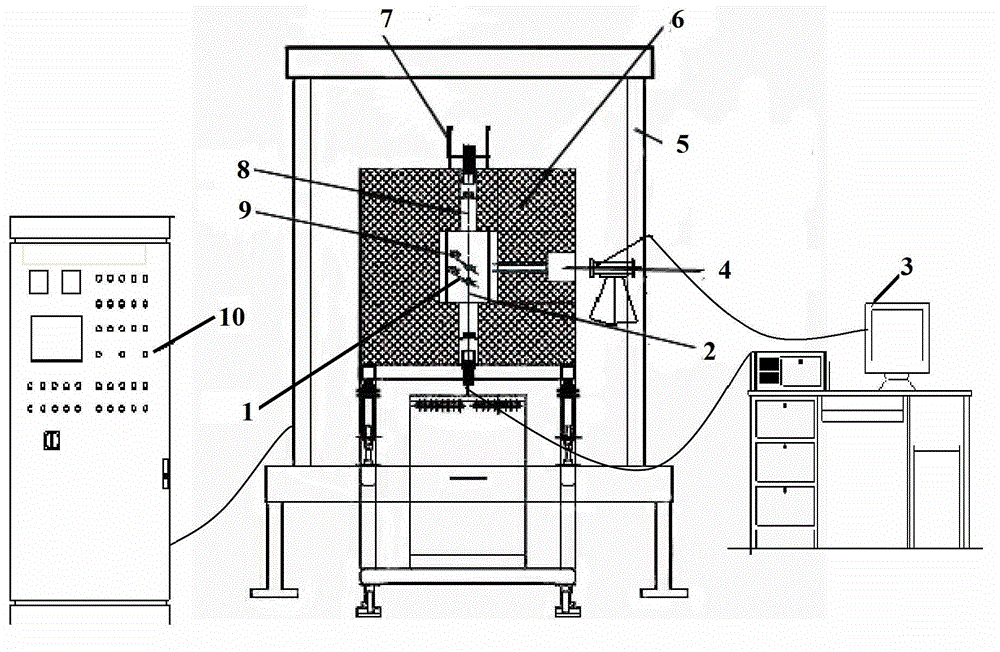

Multifunctional true triaxial flow solid coupling test system

ActiveCN102735548AReveal deformationRevealing intensityMaterial strength using tensile/compressive forcesPermeability/surface area analysisCouplingEngineering

The invention discloses a multifunctional true triaxial flow solid coupling test system which comprises a frame (100) and a pressure chamber (200) capable of arranging a coal rock sample, wherein the frame (100) comprises a support (1); the support (1) is fixedly connected with a frame (2), and a pressurizing system and a sensing system which are independent are arranged in each of X, Y and Z directions of the pressure chamber. Therefore, according to the multifunctional true triaxial flow solid coupling test system, a real work condition can be really simulated, and a theoretical basis is provided for solving on-site problems.

Owner:CHONGQING UNIV

Method of manufacturing and testing monofilament and multi-filaments self-retaining sutures

The present invention relates to self-retaining (“barbed”) systems for surgical procedures, methods of manufacturing self-retaining systems for surgical procedures, included their uses and testing. In various embodiments of the invention, a device and method for barbing sutures uses a laser to cut the suture under appropriate temperature and tensile strength conditions. In various embodiments of the invention, a device and method tests the tensile strength and elasticity of a barbed monofilament or multifilament suture. In various embodiments of the invention, a potting material can be used to retain one end of the suture for manufacture or testing.

Owner:ETHICON INC

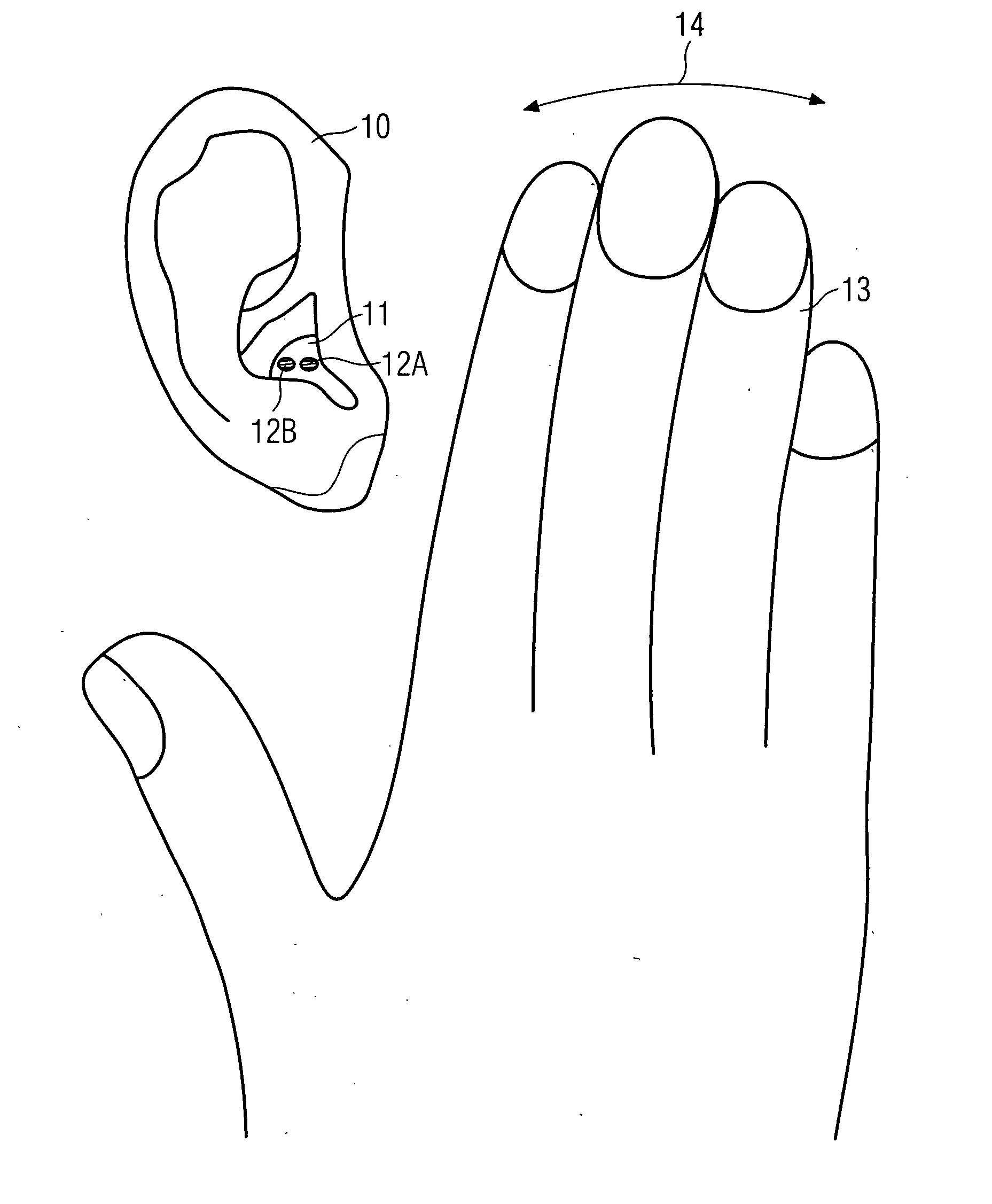

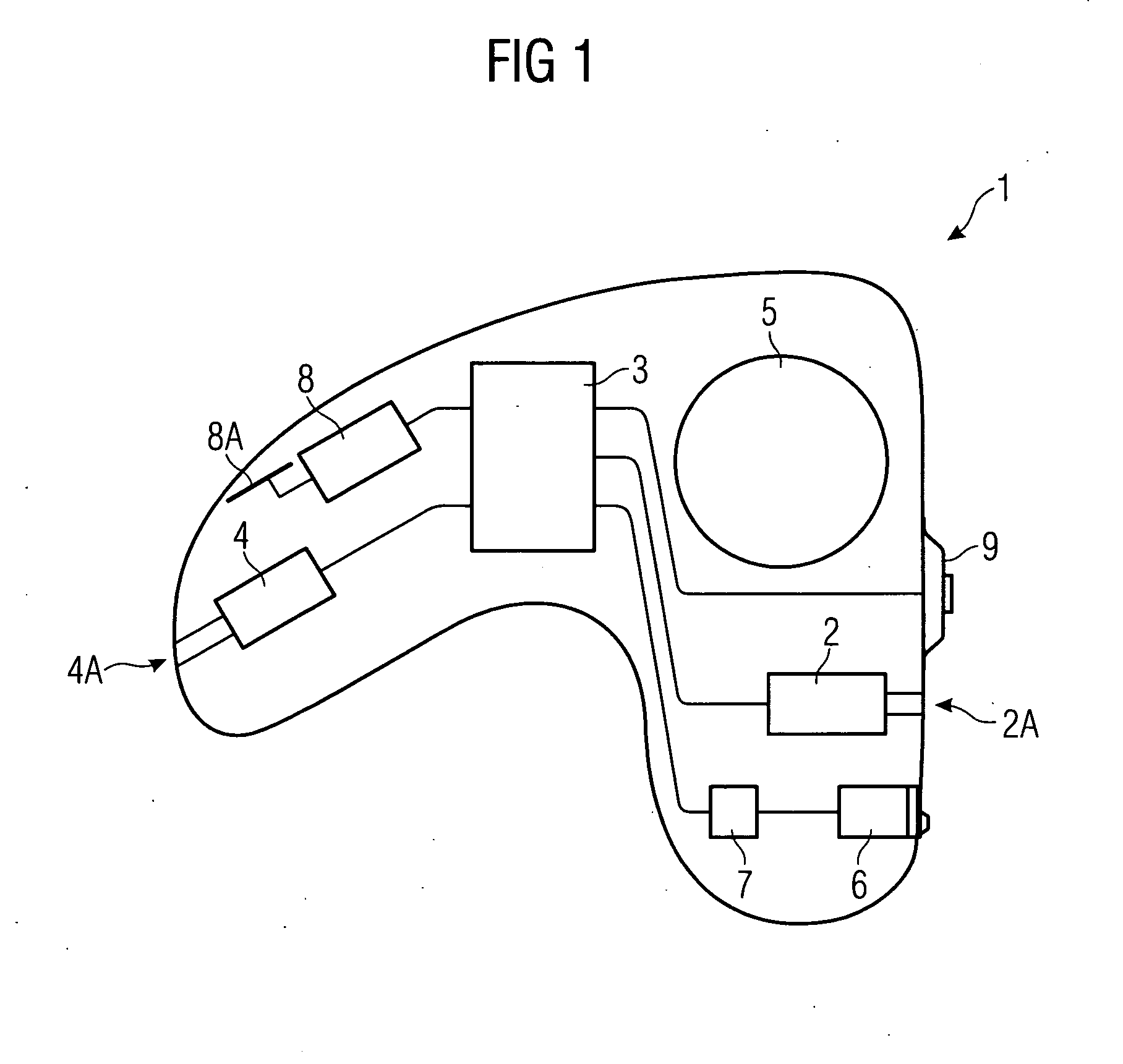

Hearing aid

ActiveUS20050238190A1Avoid failureAvoid switchingManually-operated gain controlEar supported setsProximity sensorRemote control

The increasing miniaturization of hearing aids means that less and less space is available for accommodating controls (9). It is thus proposed that, at least one proximity sensor (6; 12A, 12B) be provided on a hearing aid (1; 11) so as to enable an operating function to be performed even without touching a control directly. For operation of a hearing aid (1; 11) in accordance with the invention, in addition to the hearing aid (1; 11) itself, no further technical aids such as remote control, magnets etc. have to be worn as well.

Owner:SIVANTOS PTE LTD

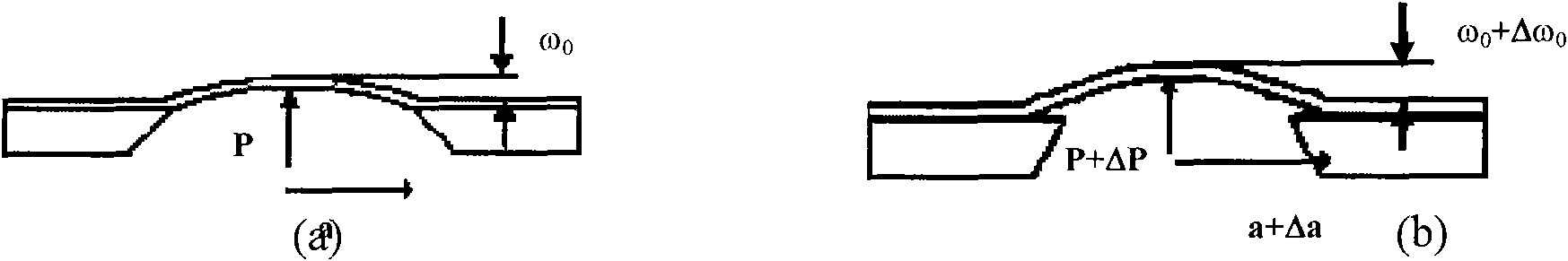

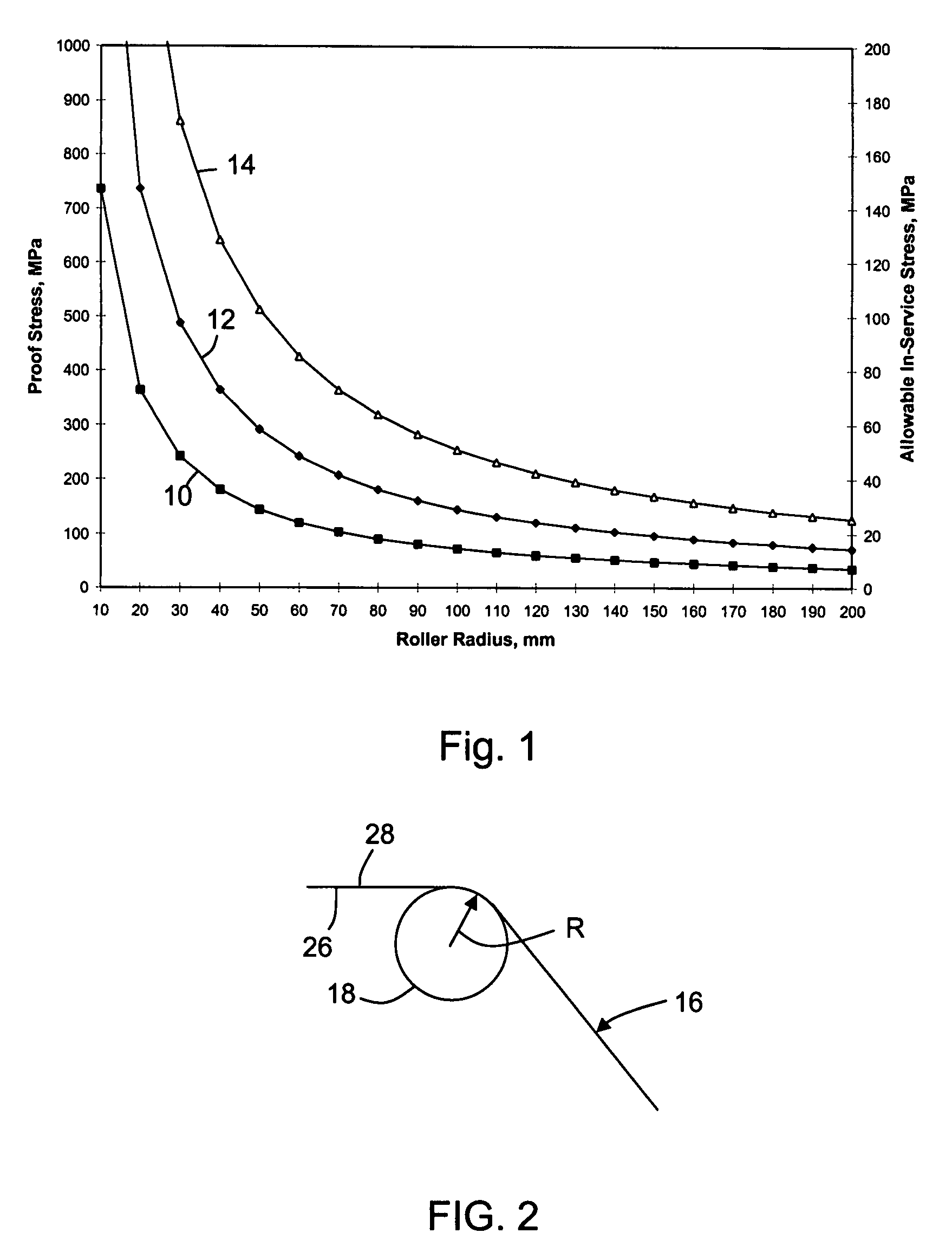

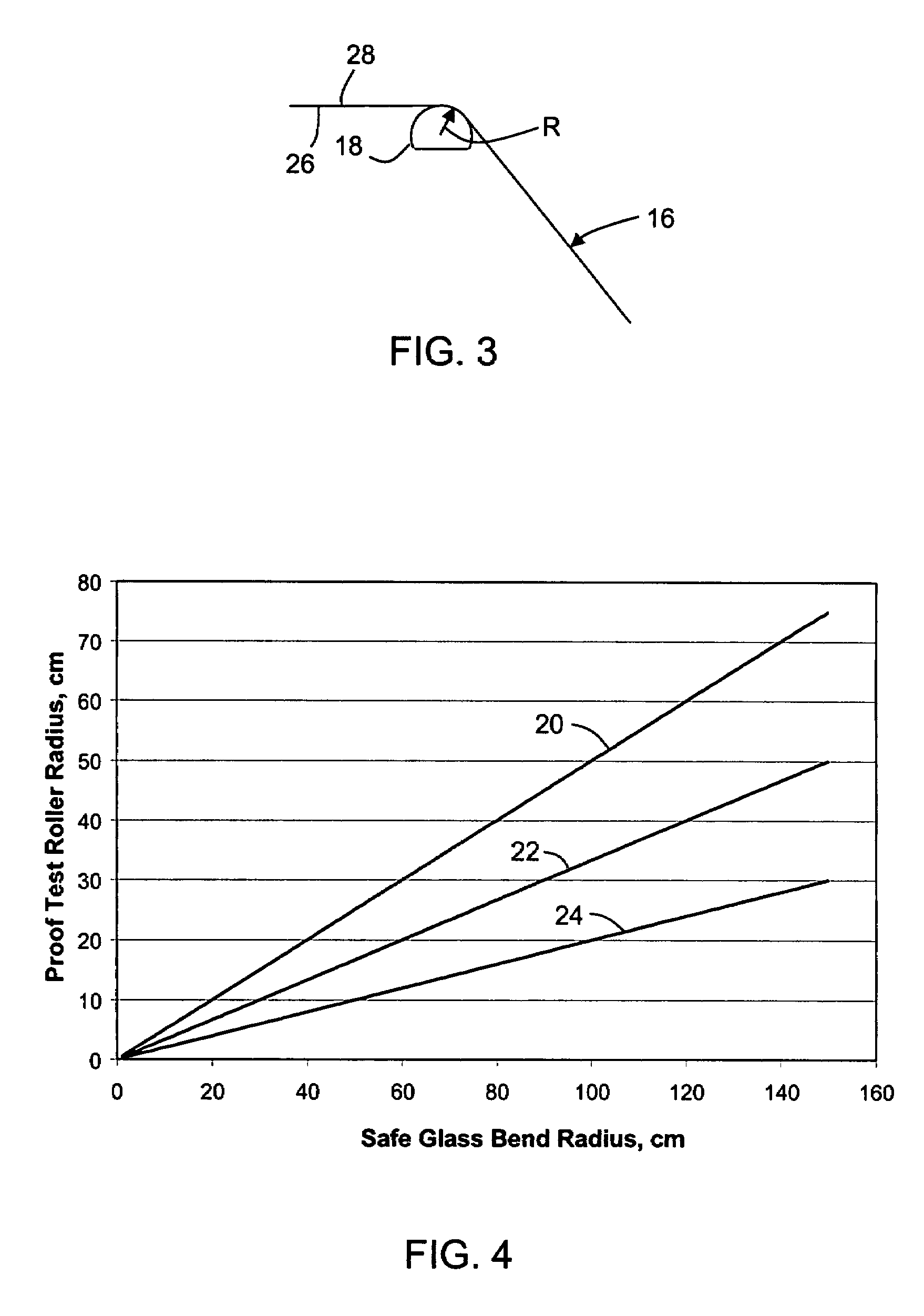

Method and apparatus for proof testing a sheet of brittle material

InactiveUS7461564B2Force measurementMaterial strength using tensile/compressive forcesStress inducedRelative motion

Disclosed is a method of proof testing a sheet of brittle material such as a glass or glass-ceramic based material. The method comprises bending the glass sheet over at least one arcuate member to detect sheets having a strength greater than a predetermined value. The method includes imparting a bend to the sheet and producing relative motion between the sheet and the bend such that the bend traverses the sheet, and wherein tensile stress induced in a surface of the sheet by the bend corresponds to the predetermined strength value. An apparatus for performing the proof testing is also disclosed.

Owner:CORNING INC

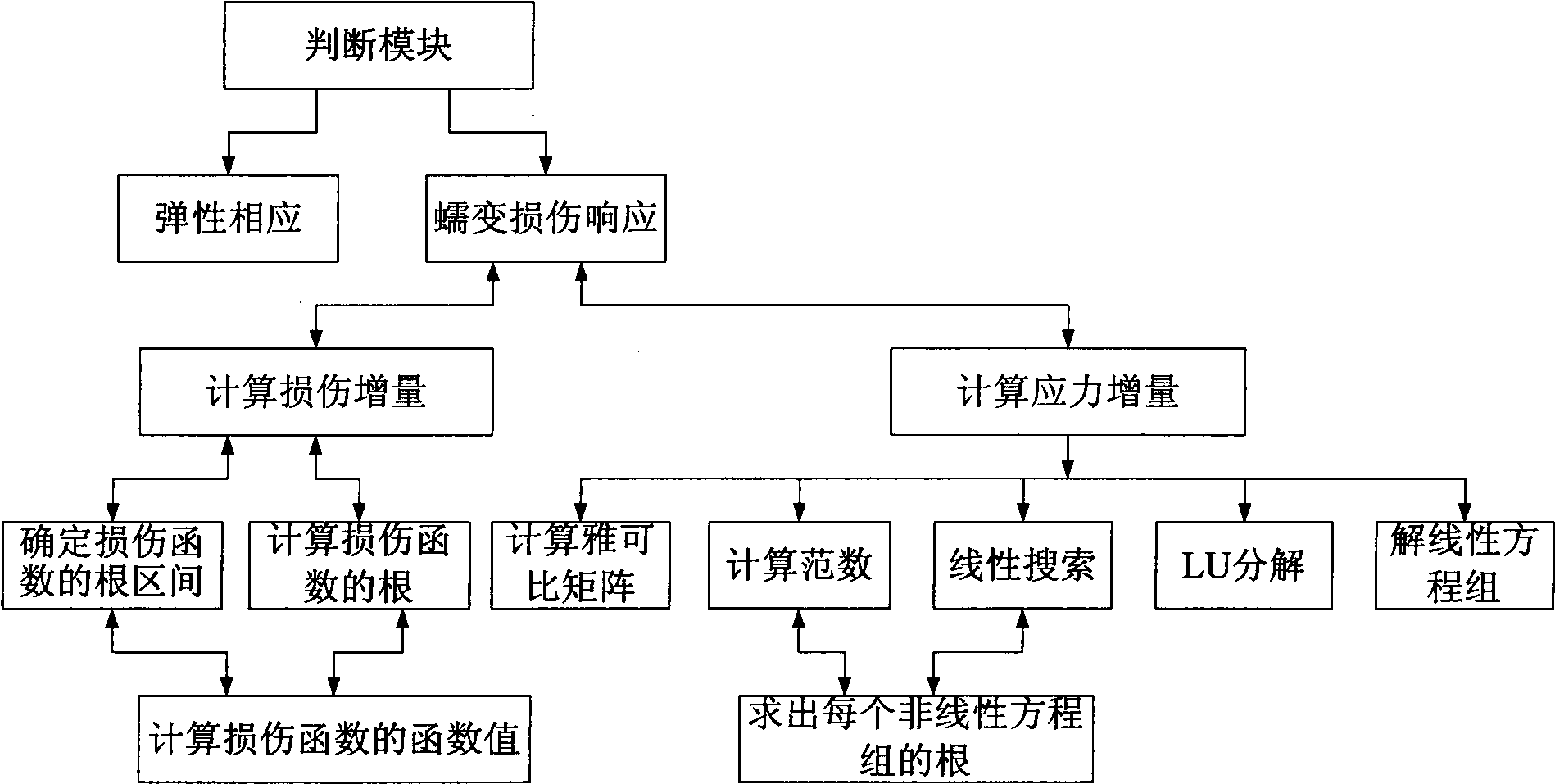

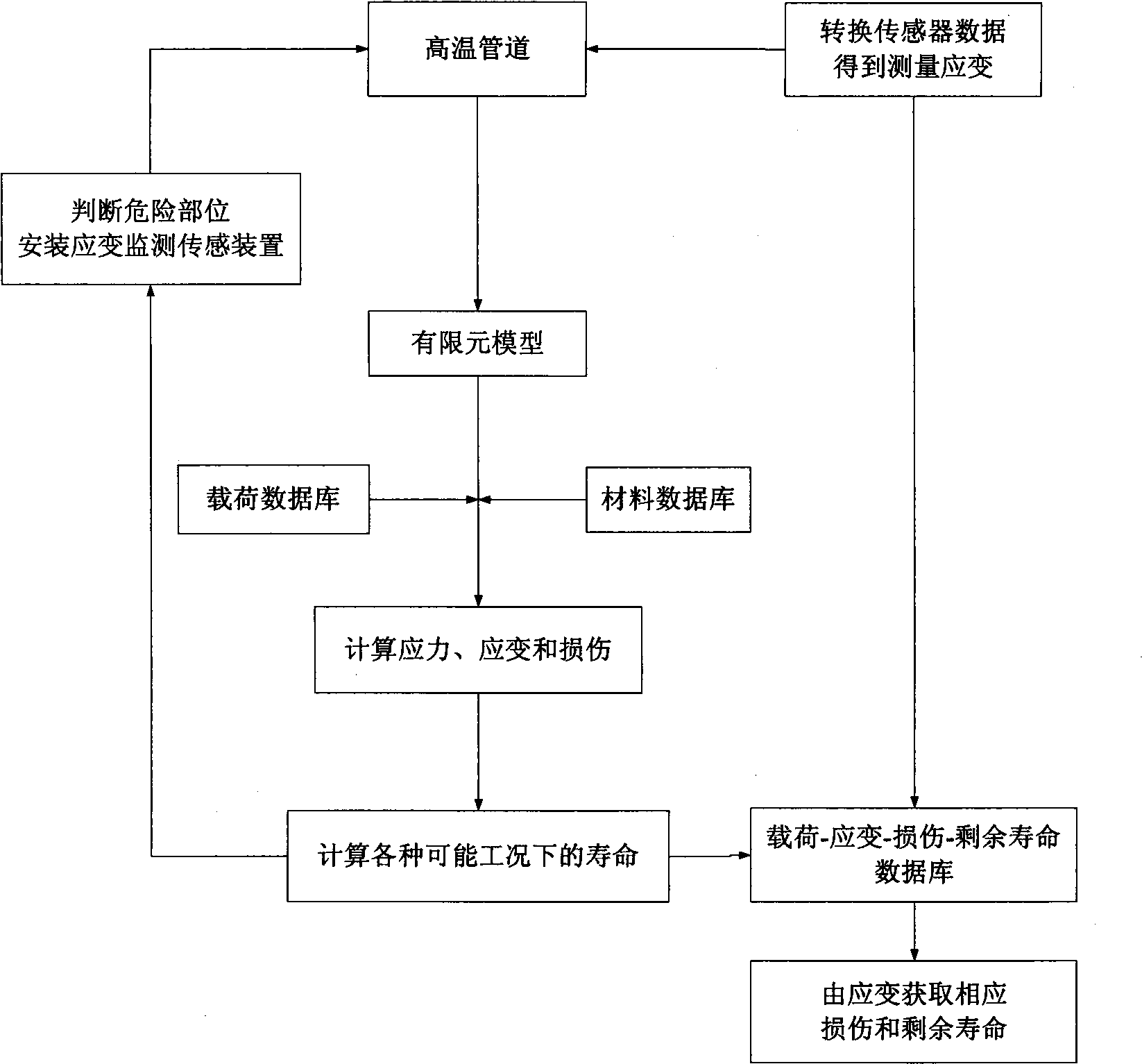

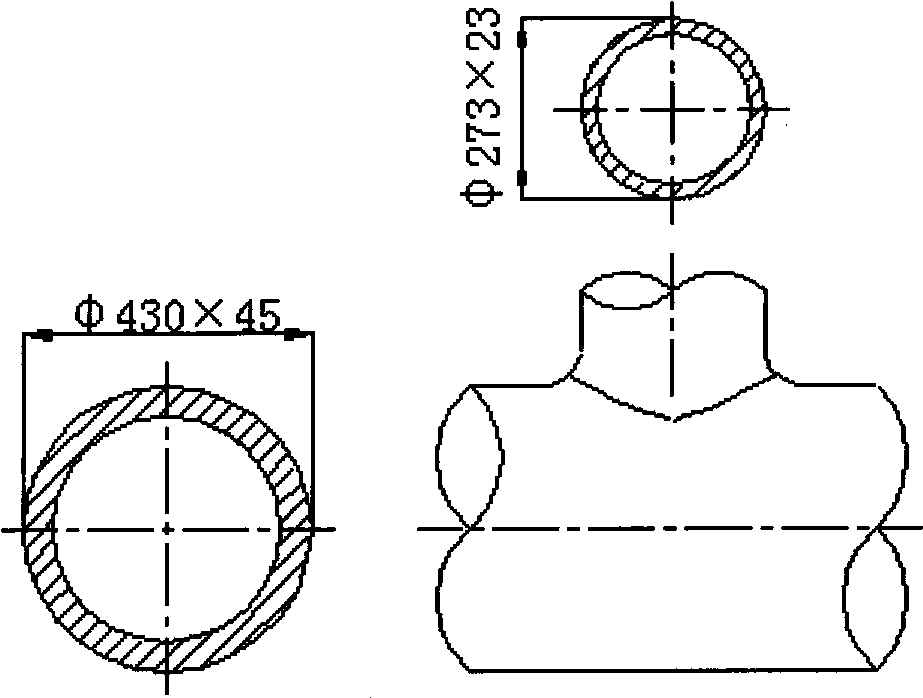

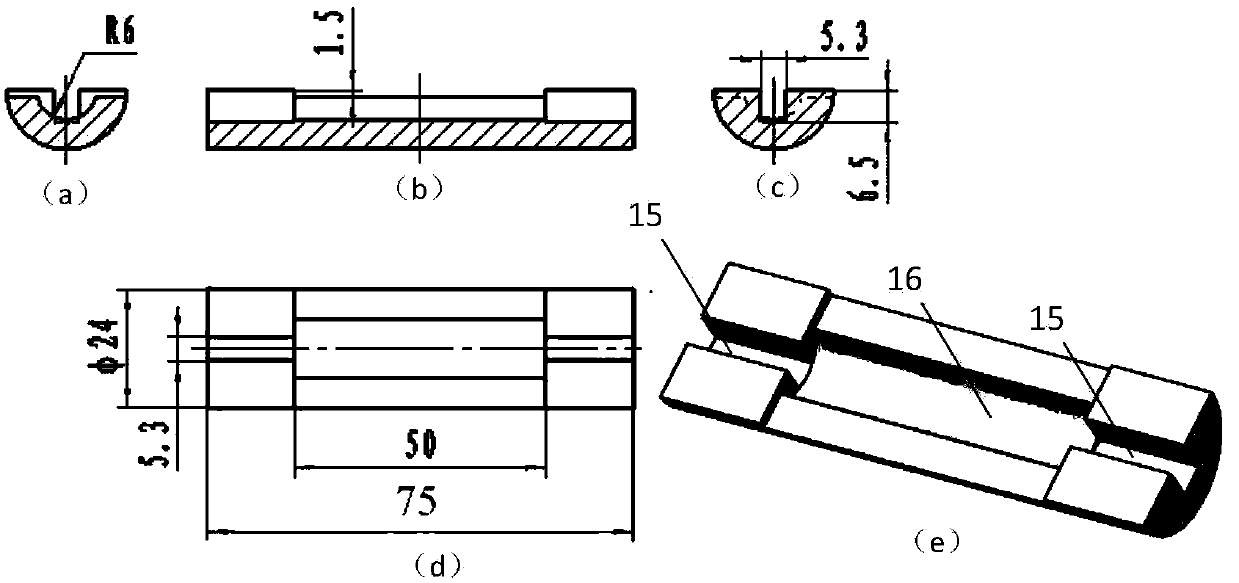

On-line prediction method for high-temperature pipe damage and longevity

InactiveCN101509855AGuaranteed real-time monitoringExtend your lifeMaterial strength using tensile/compressive forcesSpecial data processing applicationsElement analysisPredictive methods

The invention relates to an online predicting method of damage and service life of a high temperature pipeline. The method comprises the following implementing steps of: (1) carrying out finite element simulation analysis of damage and coupling to the high temperature pipeline; (2) finding out important monitoring parts according to the analysis results, arranging a sensor and monitoring the strain of the sensor; (3) carrying out finite element analysis (including analytical subprogram of a constitutive equation) for different working conditions and establishing database with damage, strain and residual life and strain; and (4) carrying out online inquiry and comparison to strain values detected online and the value of the load working condition and the data in the database so as to obtain the assessment value of corresponding damage and residual life. The online predicting method has the advantages of being capable of carrying out real-time monitoring to the high temperature pipeline in operation while production is carried out normally, reflecting the deformation and damage of the important parts and key parts in time, making correct estimation to the use life and residual life of the pipeline, being beneficial to guaranteeing safe production, adjusting the production load, planning maintenance reasonably and effectively prolonging the service life of production equipment.

Owner:EAST CHINA UNIV OF SCI & TECH

Soil one-dimensional consolidation, penetration and stress looseness comprehensive test apparatus and method of use thereof

InactiveCN1699997AEliminate the effects of excessive errorEarth material testingMaterial strength using tensile/compressive forcesCombined testSoil science

The invention discloses a soil one-dimensional consolidation, penetration, stressing relaxation combined test instrument and usage, which posits punch inside a punch cavity at the bottom of pressure container. It can do consolidation and compression to the same soil sample K0, it also can do soil sample penetration test and stressing relaxation test directly and simultaneously. It can test the soil sample's value of coefficient of static lateral pressure K0 and the process of pore water pressure followed by time. The test instrument and method can arrange soil's consolidation characteristic parameter by test outcome and using theoretical formula penetration method. It can do soil's theological behavior analysis by the outcome of stressing relaxation test.

Owner:CHANGAN UNIV

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

Tunnel construction simulation plane strain model test device

InactiveCN101738331ATransmission systemsMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention discloses a tunnel construction simulation plane strain model test device, which comprises a model rack, a loading system and a data acquisition system, wherein the model rack is used for providing a space for accommodating test models and providing a counter force for the loading system; the loading system comprises a plurality of load bodies and is used for synchronously controlling different load bodies to perform a test for loading at least one set of load body on the test models; and the data acquisition system is used for testing the real-time displacement and pressure stress of the test models in the process of the loading test. The tunnel construction simulation plane strain model test device which is based on a 'loading-first and hole digging-second' test method can synchronously perform similar model tests of three test models with different parameters and loading conditions, adopts an air bag loading mode, solves the problems of nondurable stability of loading in the traditional tests and can regulate lateral pressure flexibly.

Owner:BEIJING JIAOTONG UNIV

Popular searches

Simultaneous indication of multiple variables Tension measurement Speech recognition Vehicle position/course/altitude control Distance measurement Position/direction control Force measurement using piezo-electric devices Fluid mattresses Force measurement using piezo-resistive materials Diagnostic recording/measuring

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com