Patents

Literature

67 results about "Relaxation test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relaxation test. A creep test in which the decrease of stress with time is measured while the total strain (elastic and plastic) is maintained constant.

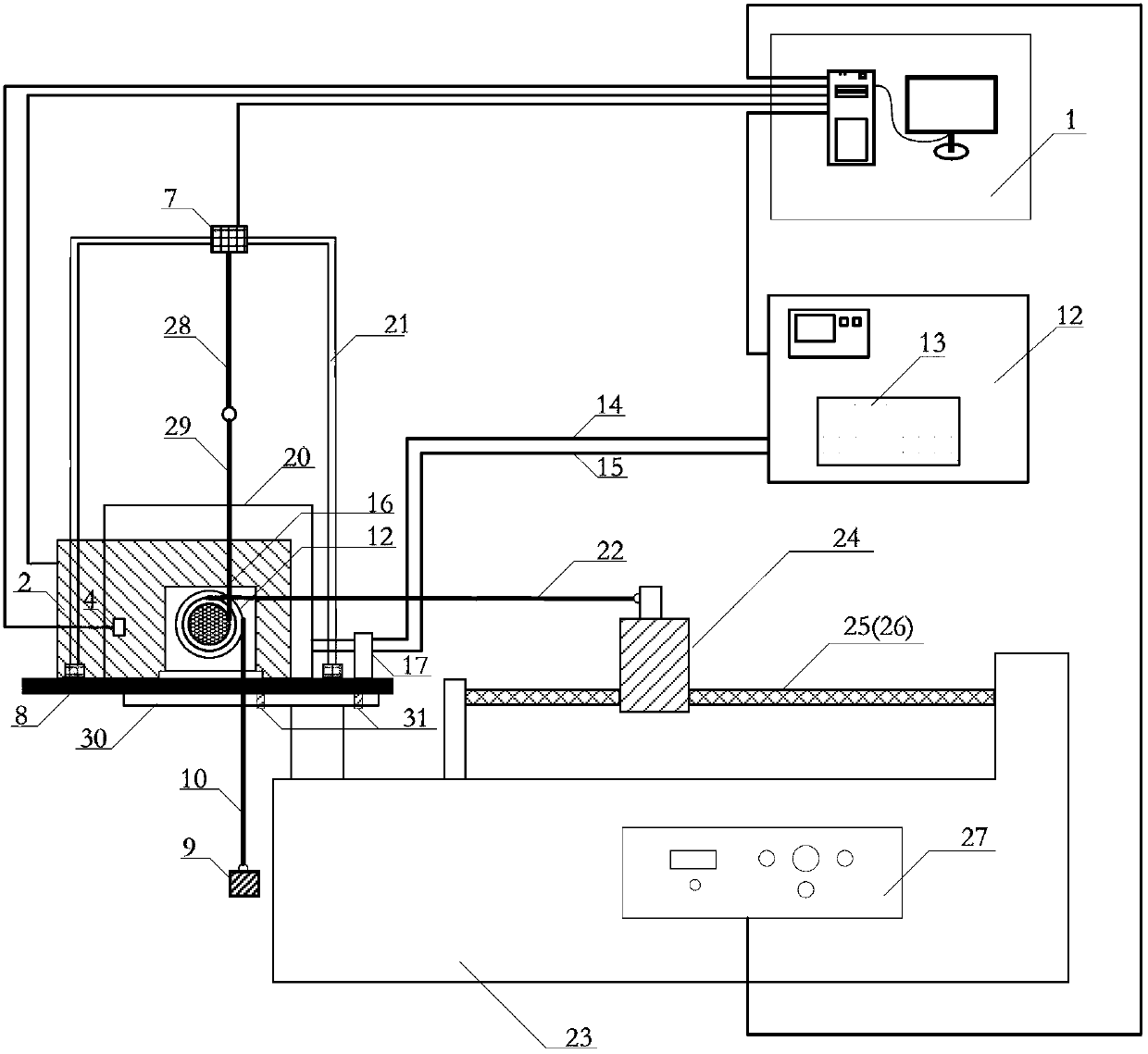

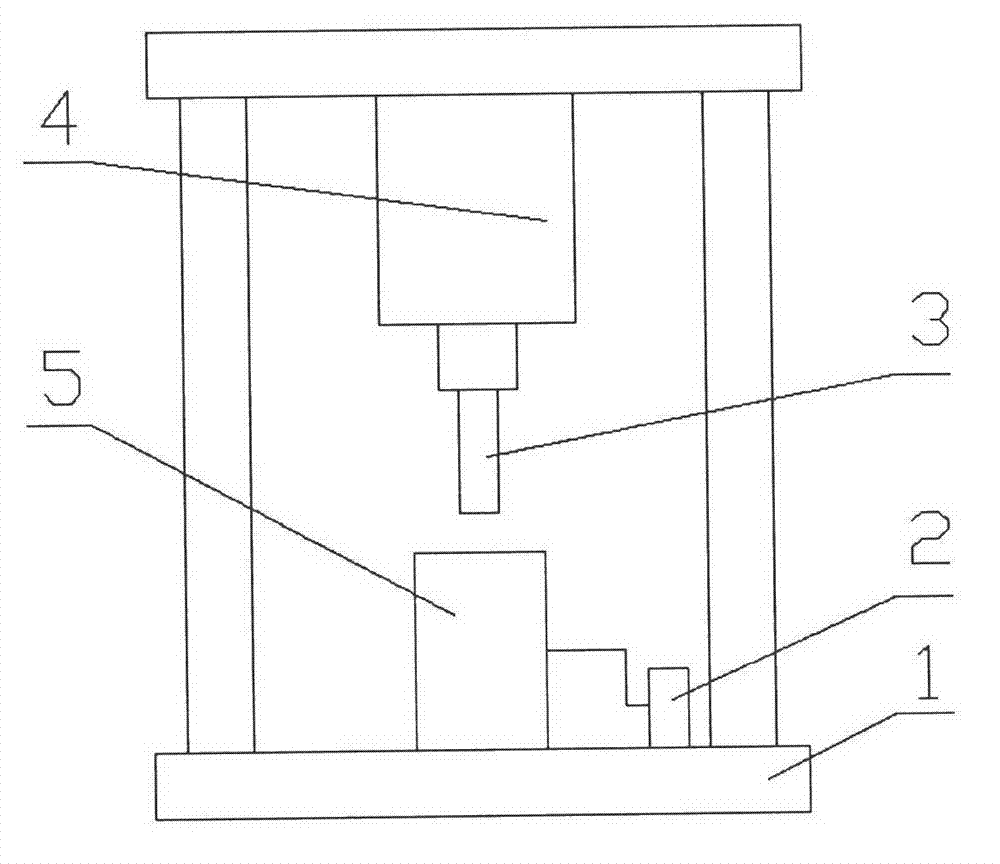

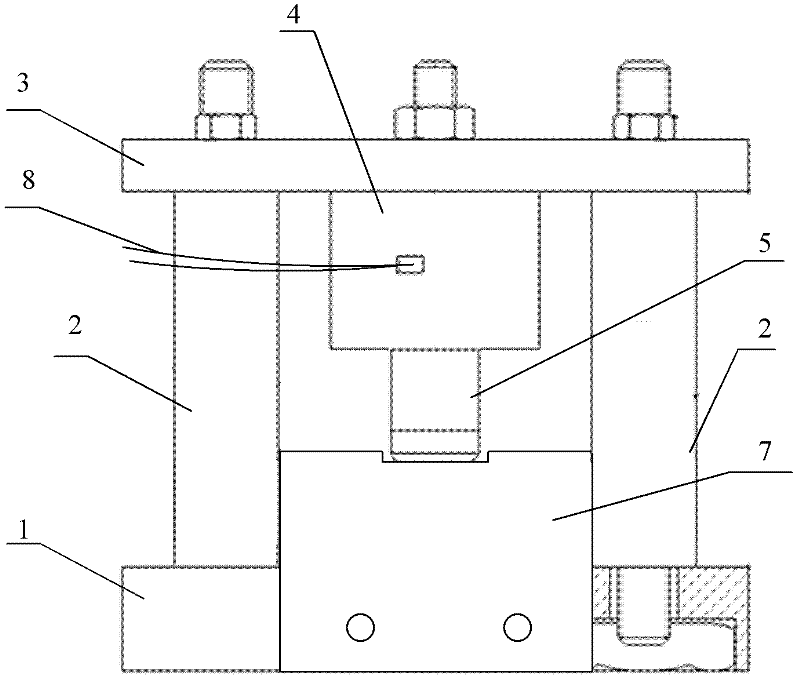

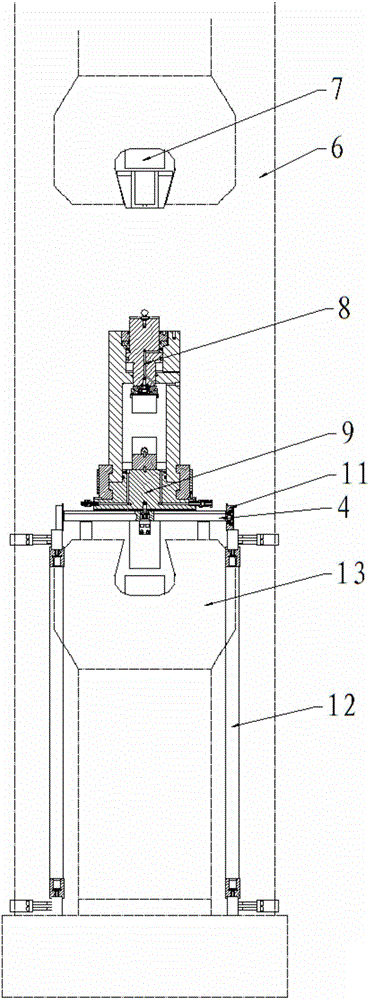

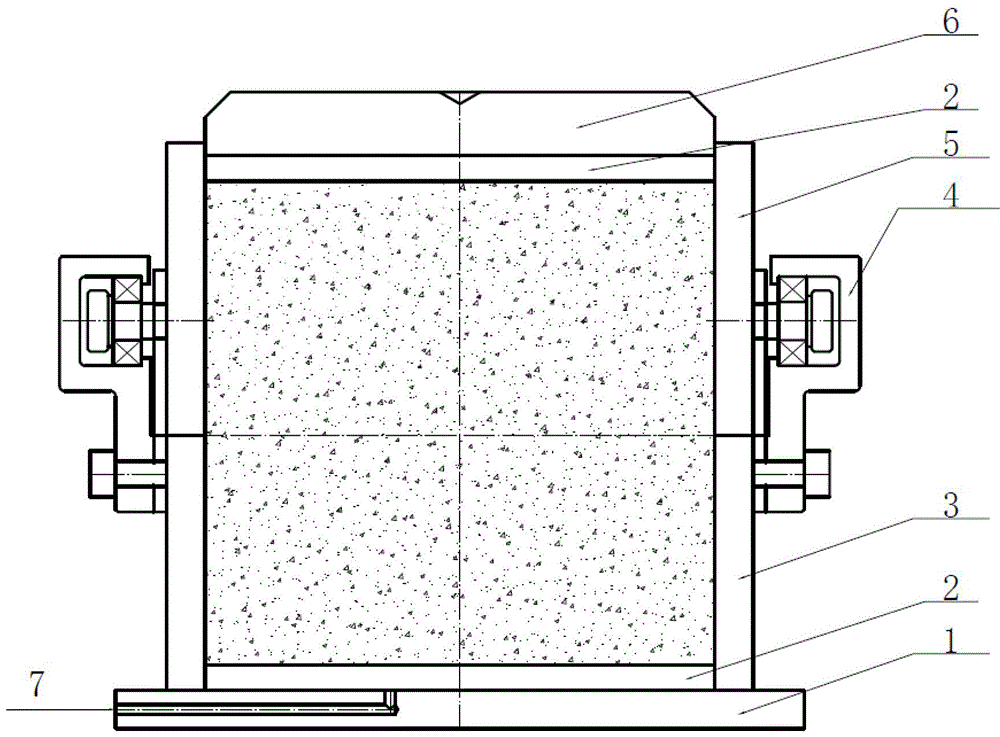

Soil one-dimensional consolidation, penetration and stress looseness comprehensive test apparatus and method of use thereof

InactiveCN1699997AEliminate the effects of excessive errorEarth material testingMaterial strength using tensile/compressive forcesCombined testSoil science

The invention discloses a soil one-dimensional consolidation, penetration, stressing relaxation combined test instrument and usage, which posits punch inside a punch cavity at the bottom of pressure container. It can do consolidation and compression to the same soil sample K0, it also can do soil sample penetration test and stressing relaxation test directly and simultaneously. It can test the soil sample's value of coefficient of static lateral pressure K0 and the process of pore water pressure followed by time. The test instrument and method can arrange soil's consolidation characteristic parameter by test outcome and using theoretical formula penetration method. It can do soil's theological behavior analysis by the outcome of stressing relaxation test.

Owner:CHANGAN UNIV

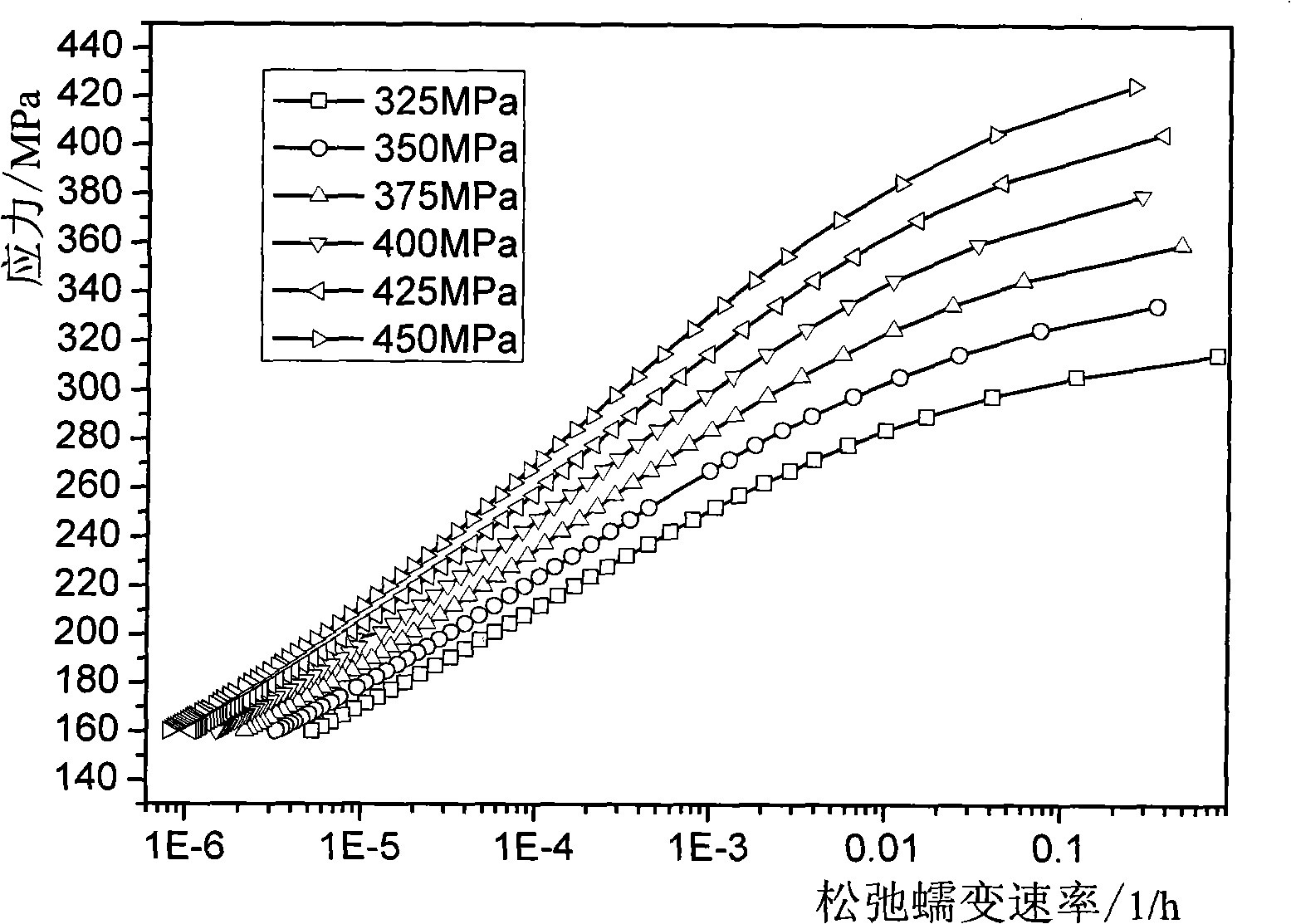

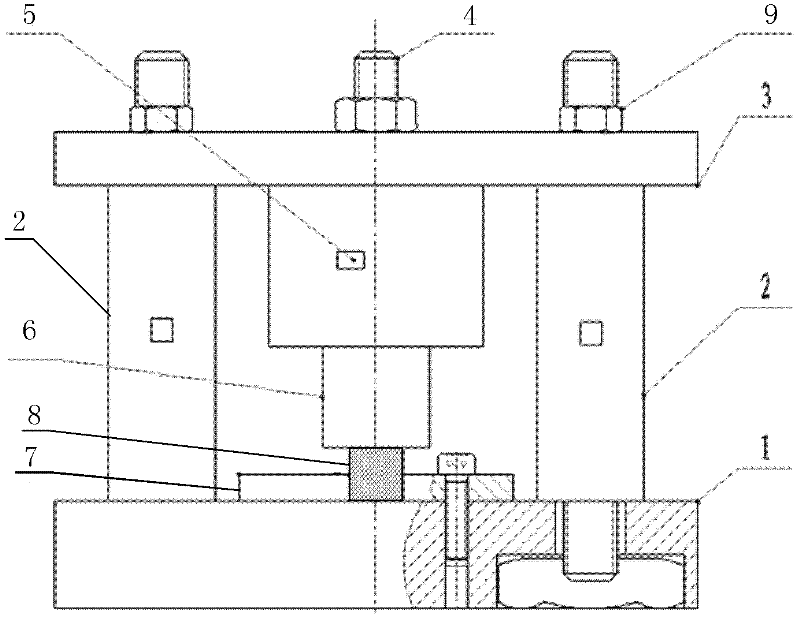

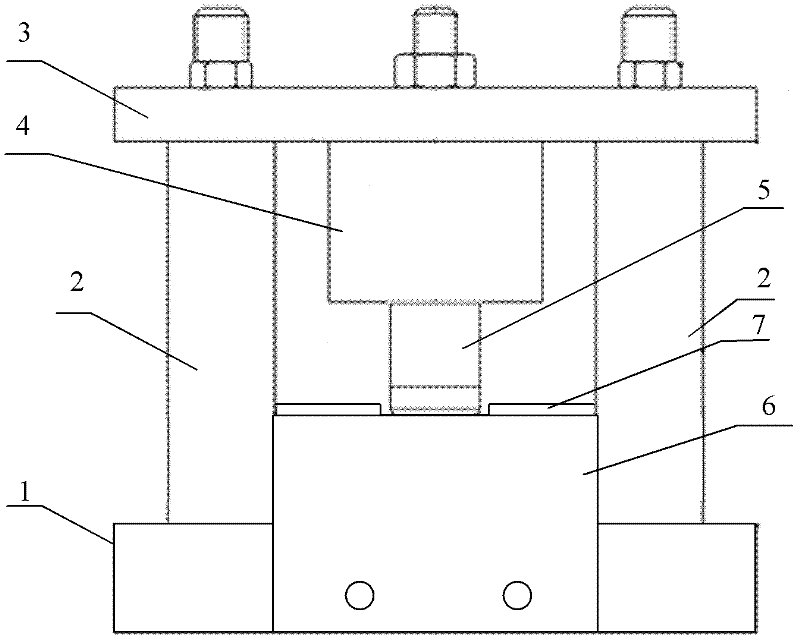

Device and method for testing normal-temperature and high-temperature compression stress relaxation of rubber

InactiveCN102353588AGuaranteed accuracyGuaranteed repeatabilityMaterial strength using tensile/compressive forcesRoom temperatureRelaxation test

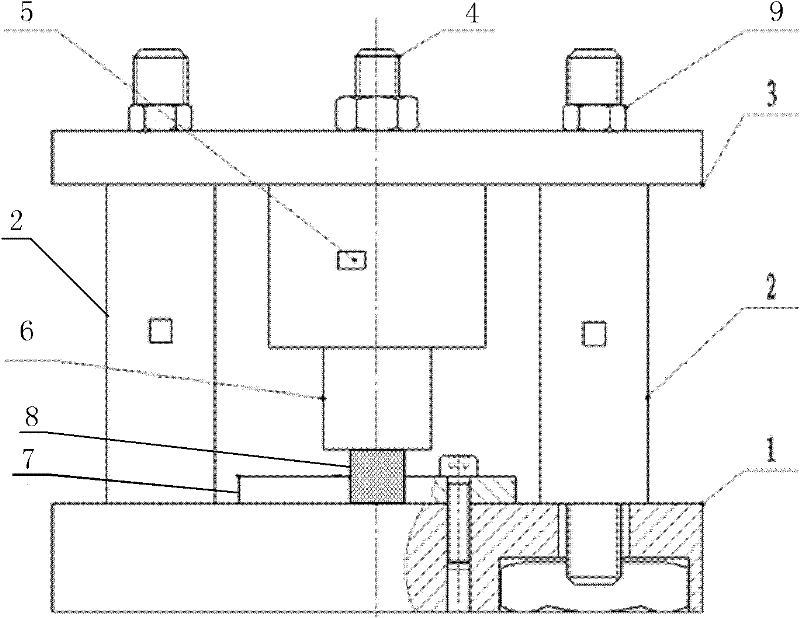

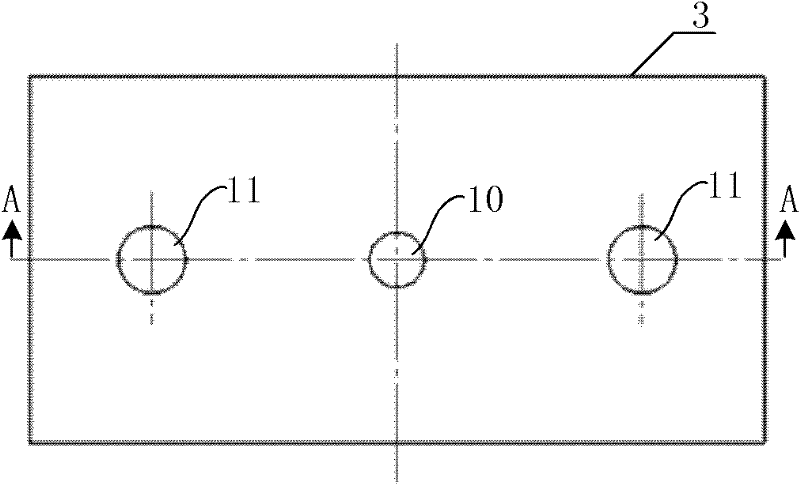

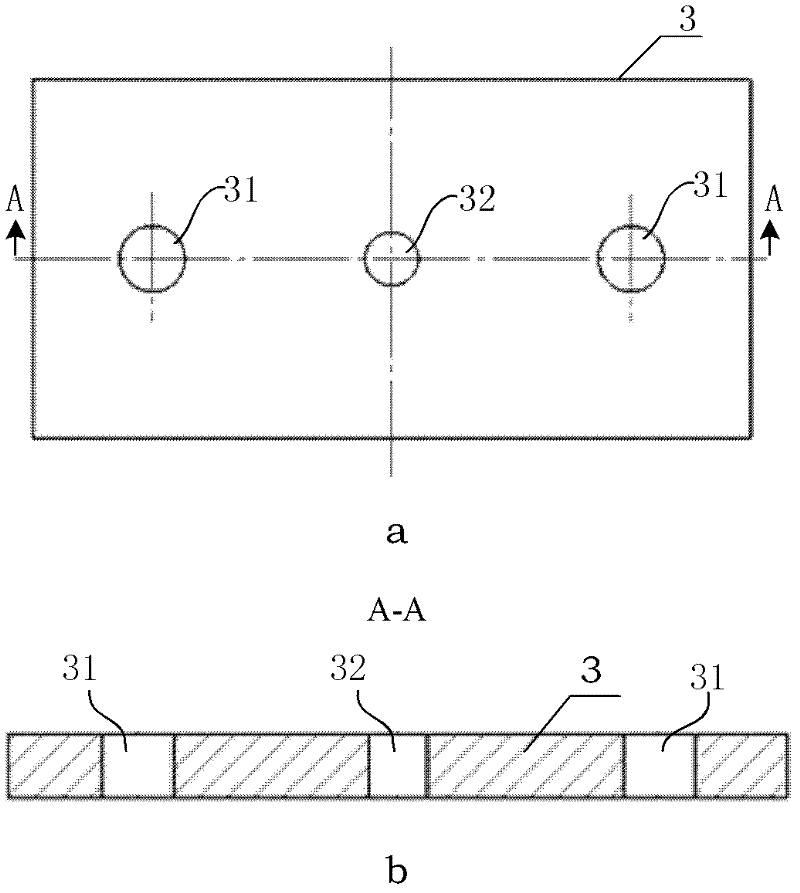

The invention provides a device and a method for testing normal-temperature and high-temperature compression stress relaxation of rubber. The device mainly comprises an upper plate, a lower plate, a limiter, a pressure sensor, a pressure head and a flange. The upper plate is fixed to the lower plate through the limiter. The pressure sensor is fixed at a center position of the upper plate and is located between the upper plate and the lower plate. The pressure head is fixed at another end of the pressure sensor. A rubber sample is fixed at a center position of the lower plate by the flange and contacts with the pressure head. The method comprises the following steps of preparing an appropriate rubber sample, assembling the device, fixing exactly the appropriate rubber sample at the center of the lower plate, contacting the appropriate rubber sample with the pressure head, removing the flange, putting the device into an aging test box for an experiment, and after the experiment is finished, determining compression stress relaxation coefficients of the appropriate rubber sample. Through the device and the method, normal-temperature and high-temperature compression stress relaxation tests are realized; real-time monitoring of compression stress variation is realized; and the accuracy, the repeatability and the reproducibility of a life prediction result are guaranteed.

Owner:BEIHANG UNIV

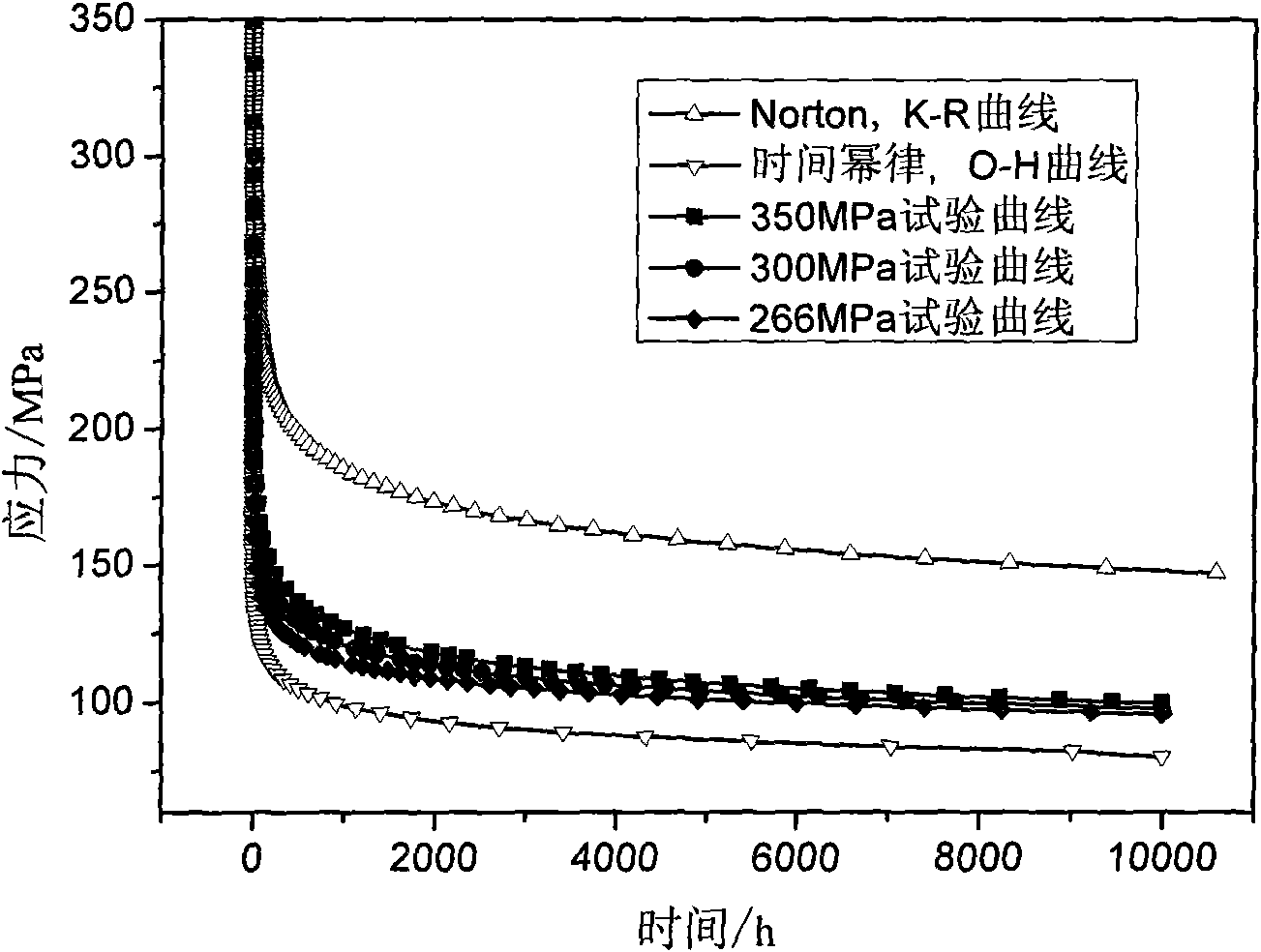

Material high-temperature creep life-span accelerated test method

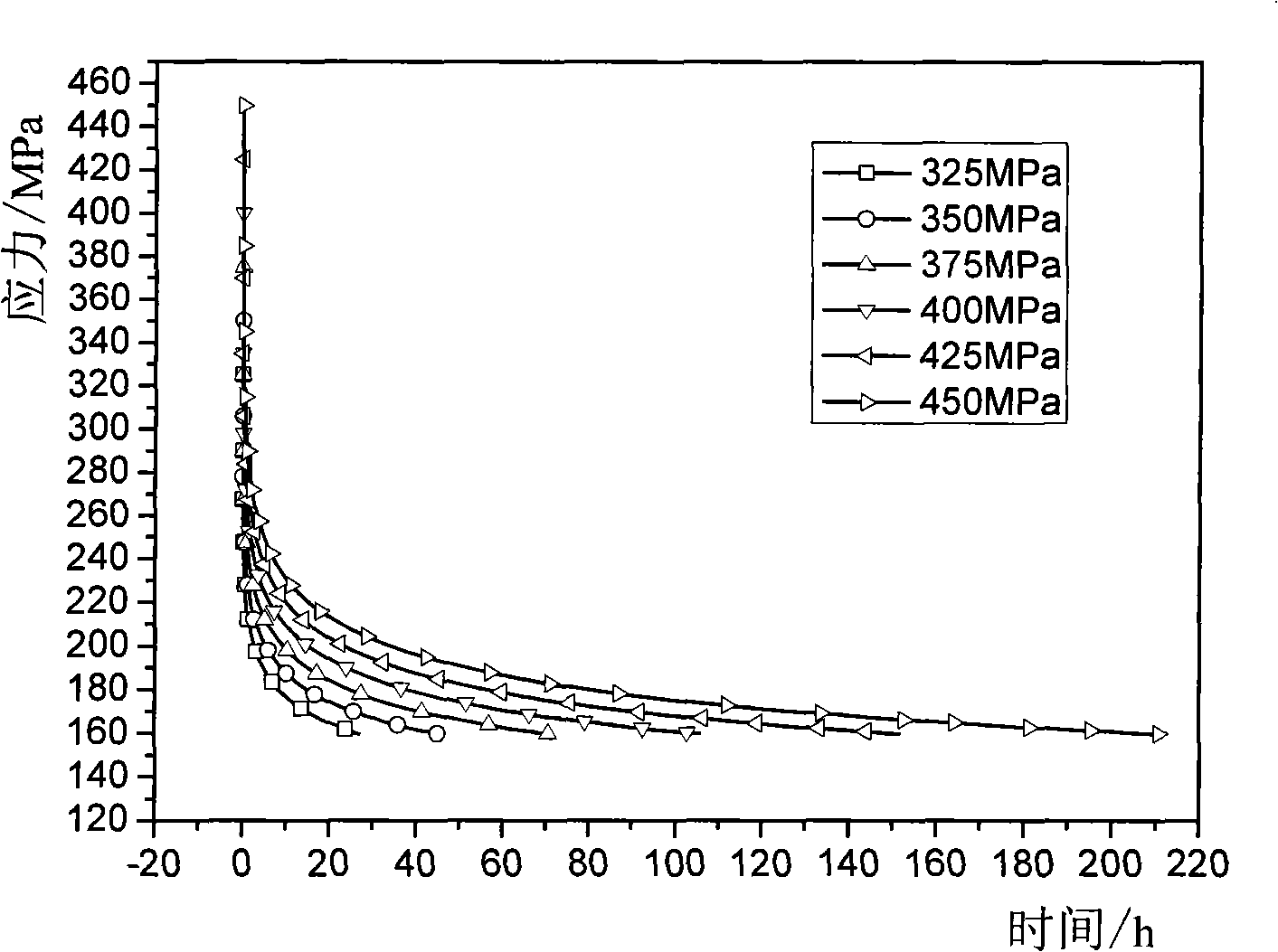

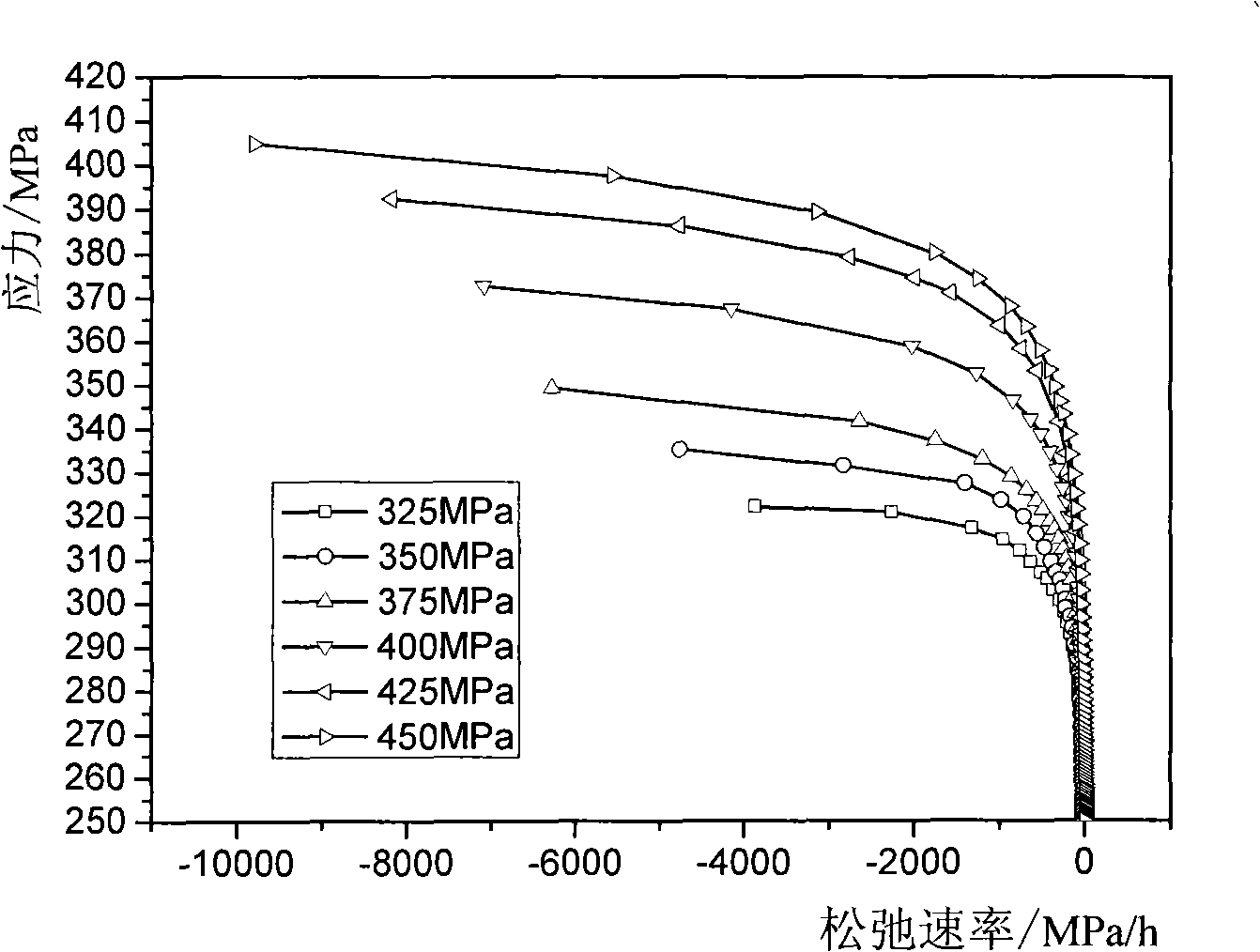

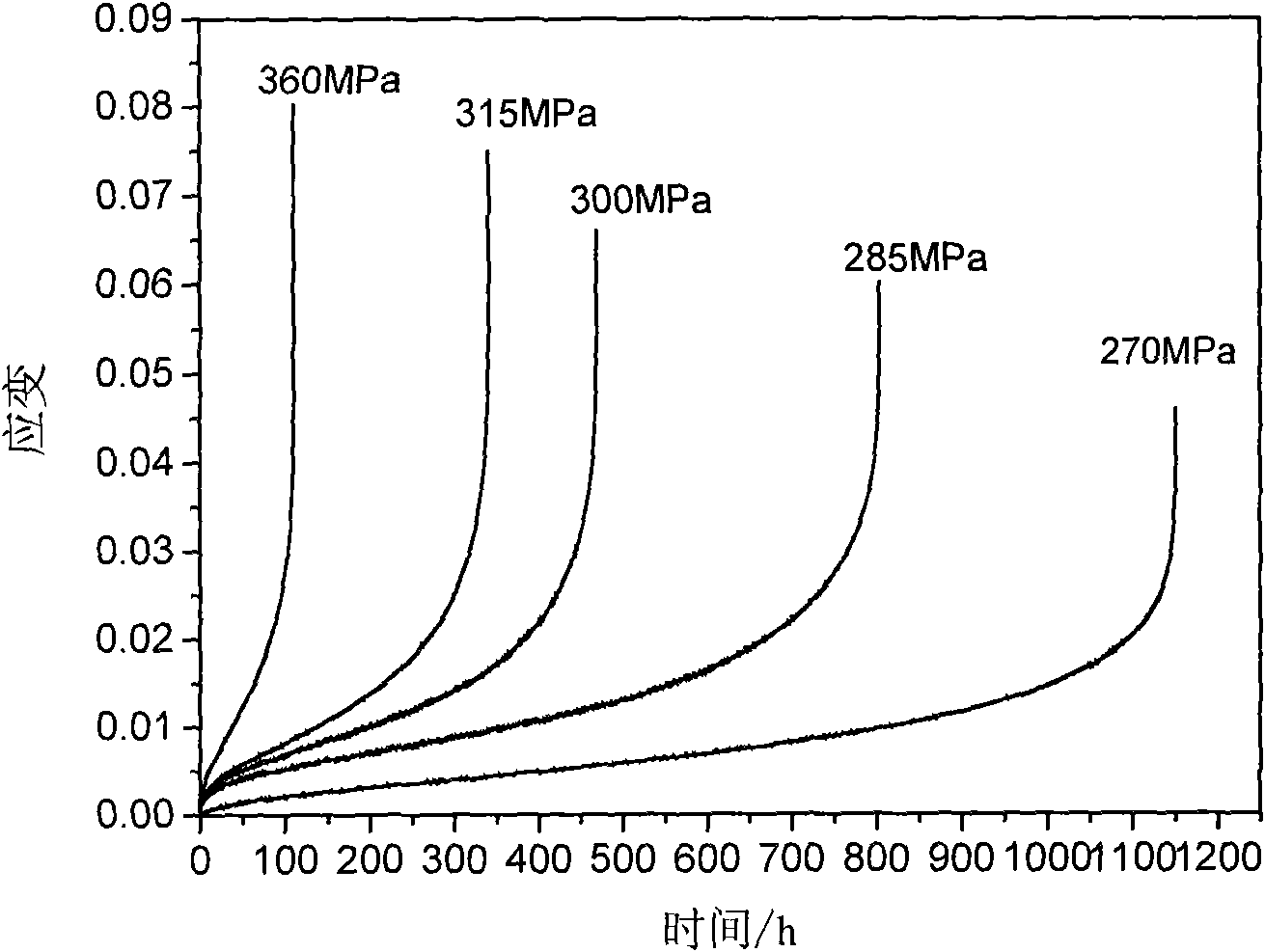

InactiveCN101308127AAccelerated Creep DesignMethod scienceSpecial data processing applicationsStrength propertiesRelaxation equationCreep rate

The invention relates to a high temperature creep life accelerated test method of a material, which comprises: a plurality of groups of short time stress relaxation tests of the material at the same temperature, acquiring a relaxation rate-stress curve based on the numerical differentiation principle, forming a relaxation creep rate-stress curve by utilizing a relaxation equation, calculating creep data to build a creep curve, and building a steady state creep rate curve and a Norton creep equation. The method starts from the physical relation between relaxation and creep, covers rather broad properties of creep strain rate by utilizing the short time relaxation process, and educes broader creep data than that educed from general creep tests by above ten times, thereby effectively reducing the amount of high temperature creep tests and time of tests and providing basic data for development of new material and engineering application.

Owner:EAST CHINA UNIV OF SCI & TECH

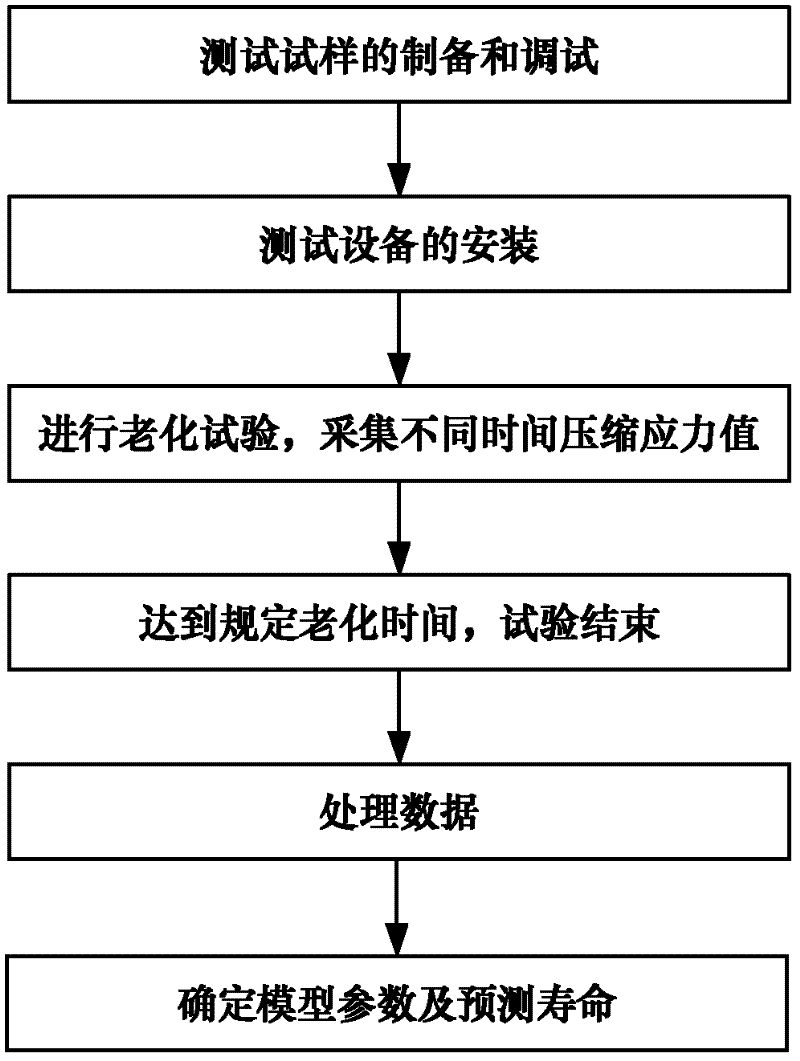

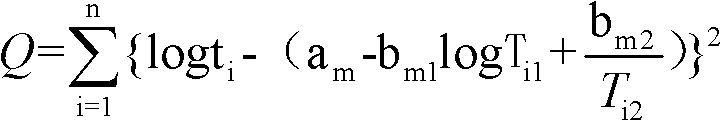

Method for predicting rubber storage life on basis of compression stress relaxation test equipment

InactiveCN102589977AReduced service lifeImprove accuracyMaterial strength using tensile/compressive forcesEngineeringModel parameters

The invention provides a method for predicting the rubber storage life on the basis of compression stress relaxation test equipment, which belongs to the technical field of rubber life prediction. Firstly, a test sample is prepared and debugged, the test equipment is installed, the test is prepared, and the ageing test is carried out, so different compression stress values are acquired; then the data is processed, MATLAB (Matrix Laboratory) software is utilized to plot the logarithm logt of ageing time through utilizing compression permanent deformation retention rate or stress relaxation retention rate, so scatter diagrams under different ageing temperatures are obtained, and the data in the diagrams is fitted by adopting the Boltzmann mathematical function; and finally, model parameters are determined, and the life is predicted. The method utilizes a pressure sensor and an external data display instrument to monitor the compression stress variation in real time, the sample does not needed to be taken out for the test and does not need to be replaced during the test process, so the temperature fluctuation is avoided, the data fluctuation factor is reduced, and the accuracy and repeatability of the life prediction result are ensured.

Owner:BEIHANG UNIV

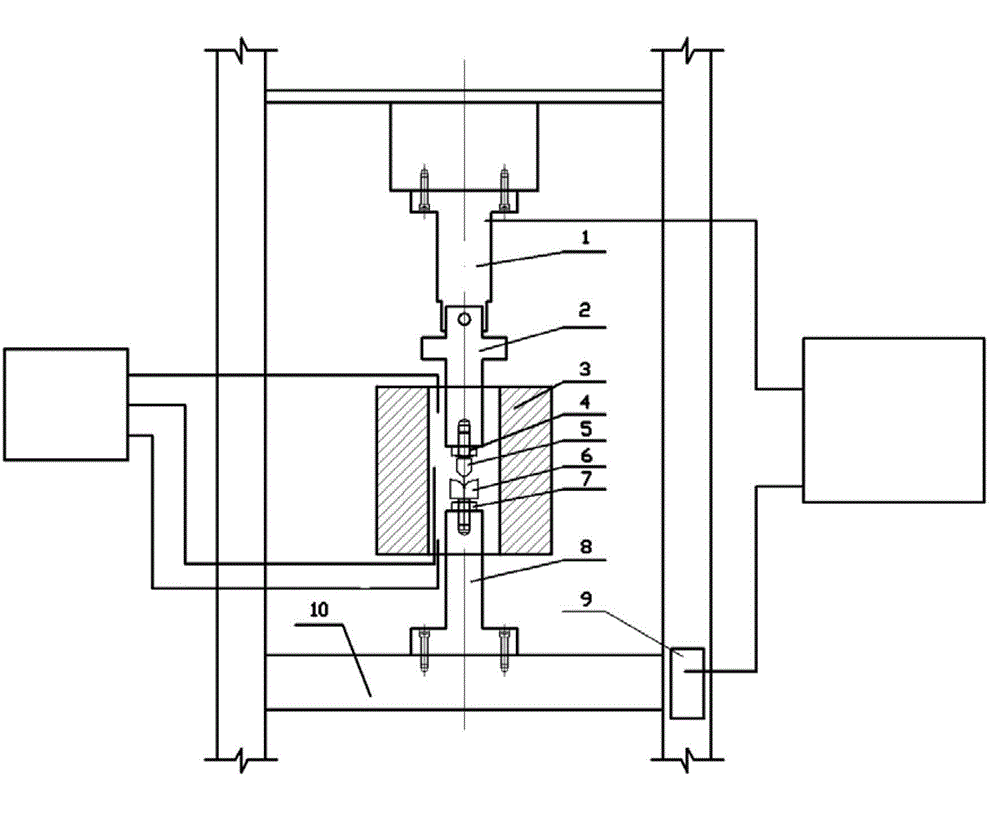

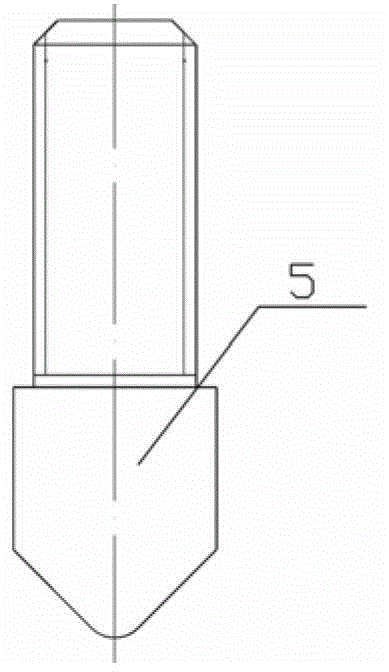

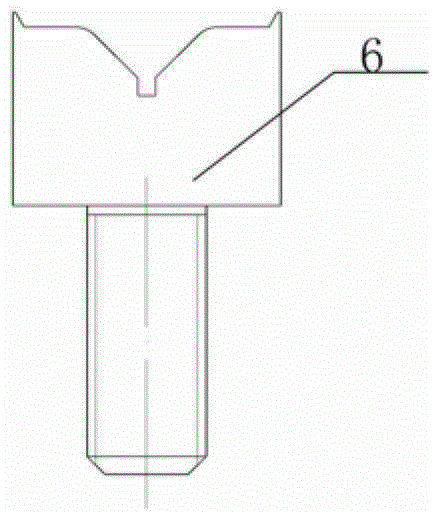

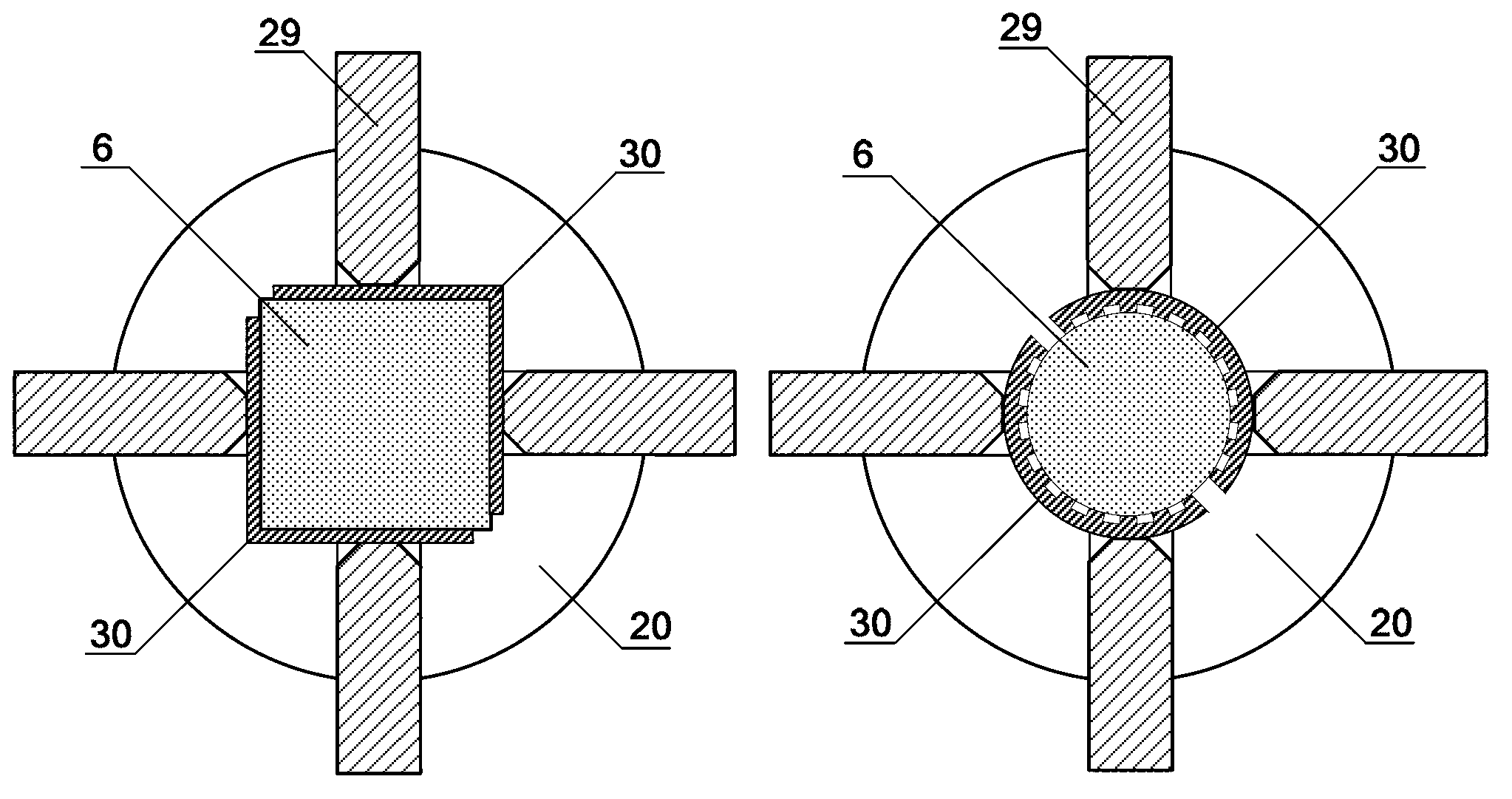

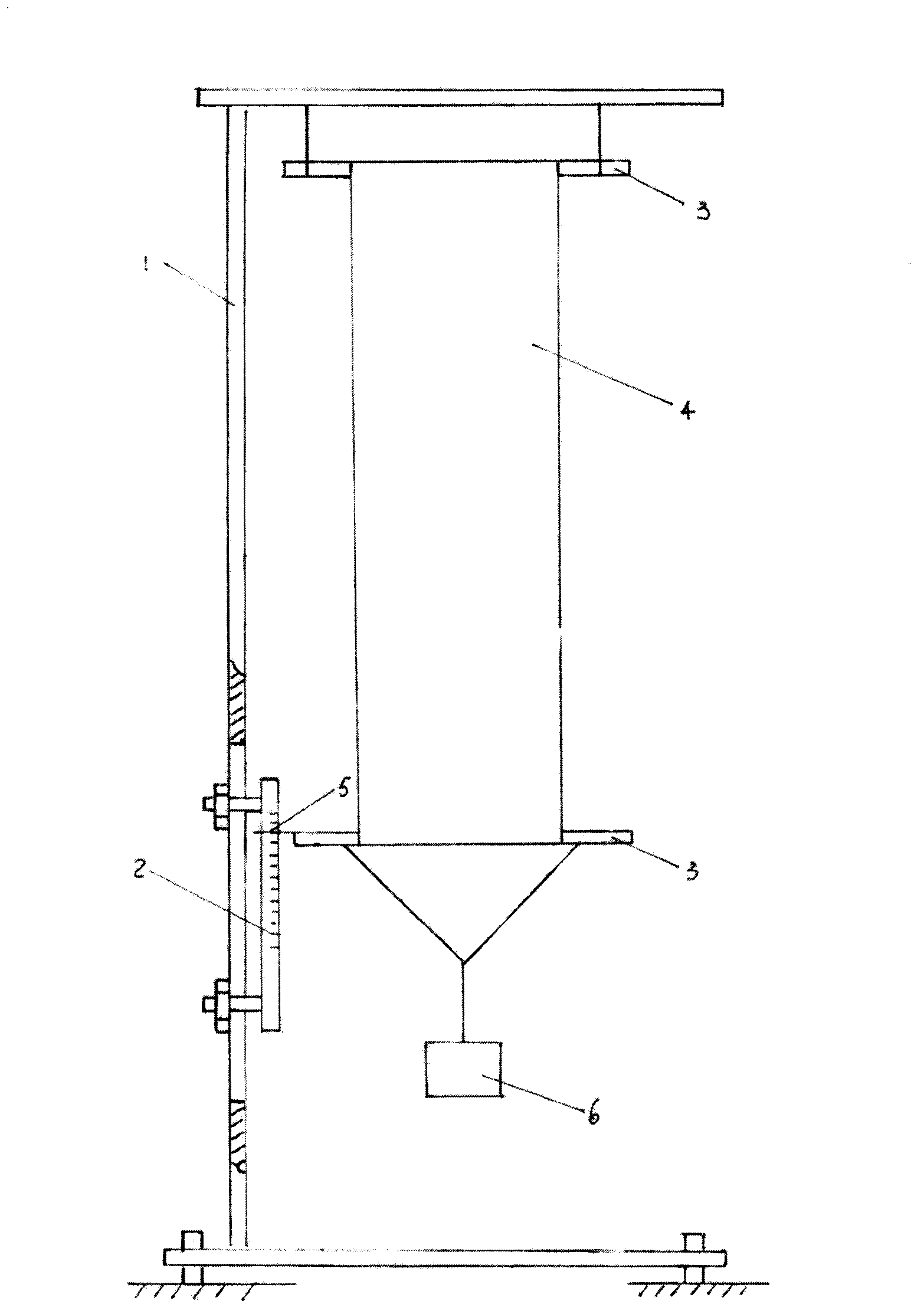

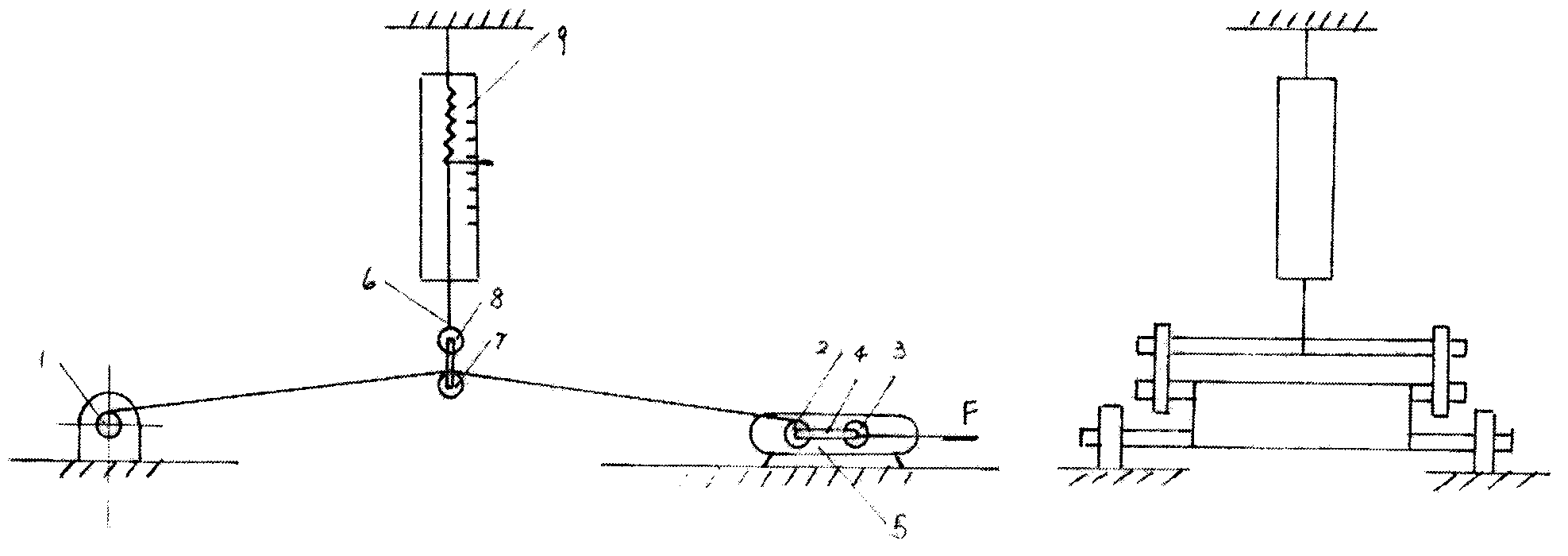

Titanium alloy stress relaxation test device and method based on V-type hot bending

The invention discloses a titanium alloy stress relaxation test device and a titanium alloy stress relaxation test method based on V-type hot bending, belonging to the field of hot working of metals. The invention provides a load relaxation test device and a load relaxation test method based on V-type bending. A V-type bending loading test implemented in an electronic test machine can realize stress relaxation; the loading of a bending load for a sample placed between a bending convex die (5) and a bending concave die (6) is realized by use of the displacement provided by a beam (10), and a load sensor continuously records the bending load and the change of the load along with time in a shaping process; and in the condition of different shaping durations, different sample bending springback angles are obtained. The device and the method disclosed by the invention can test the change of the bending load along with time during hot shaping, can determine the rule of the load relaxing along with time under the condition with different shaping durations for a titanium alloy sample with the bending load while deriving the linear relation between load and sample stress, and can be widely applied to the field of hot working of metals.

Owner:HARBIN INST OF TECH

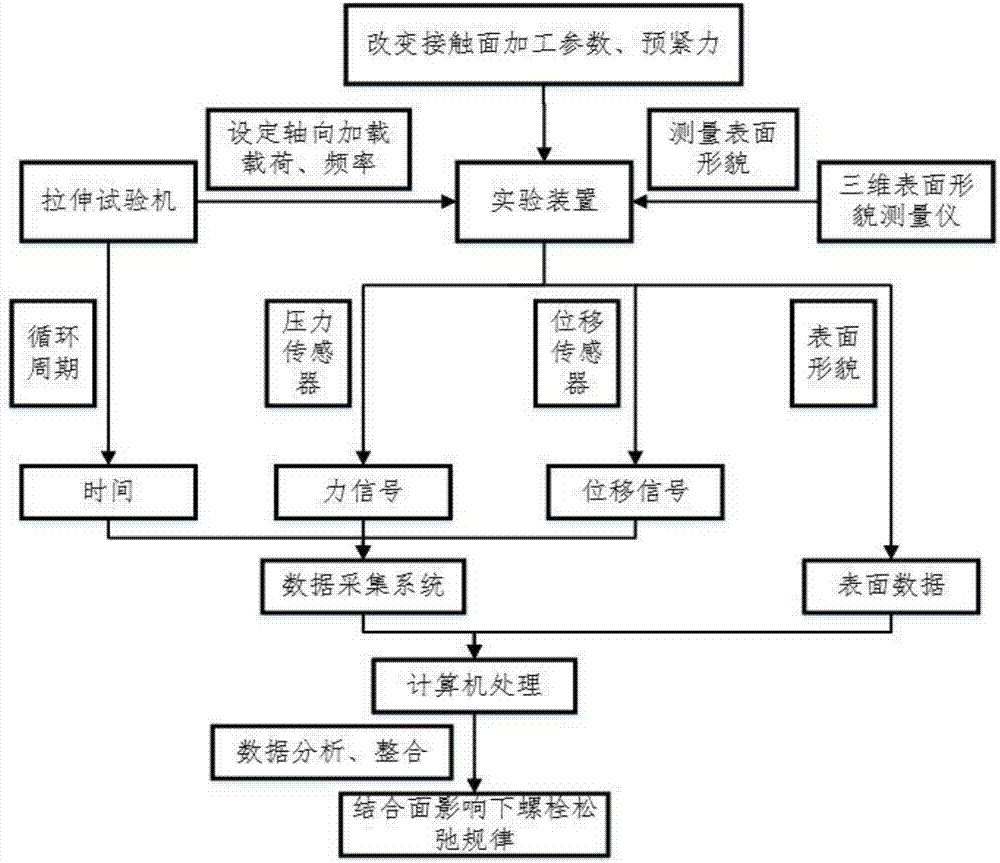

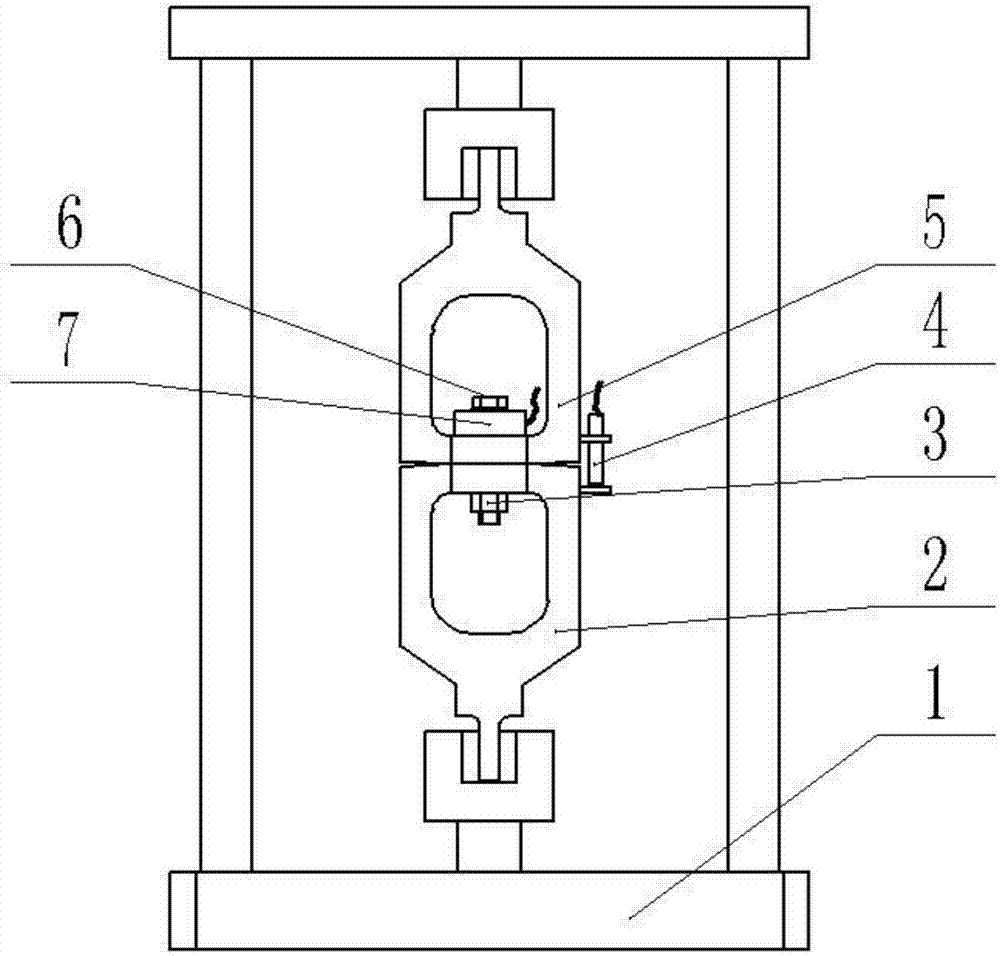

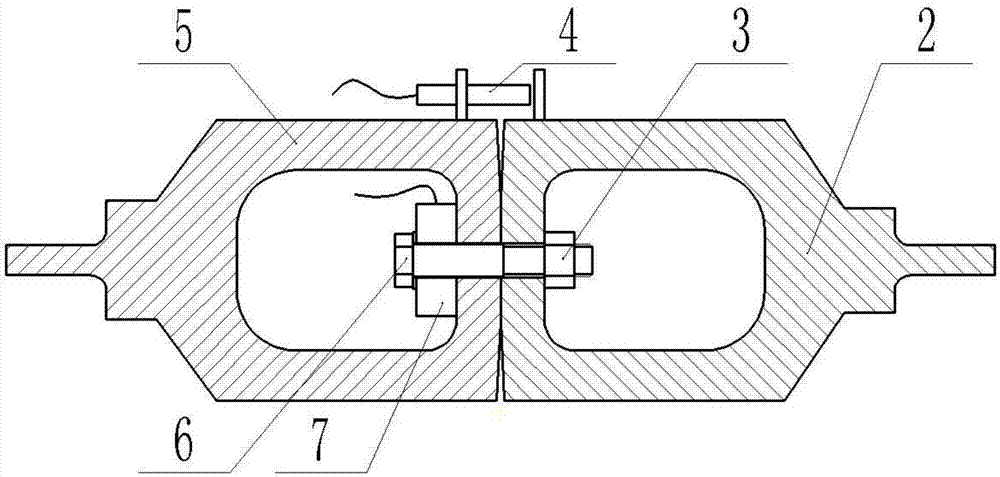

Device and method used for measuring axial bolt relaxation in consideration of joint surface characteristics

InactiveCN107192494AMeet the rigidity requirementsGuaranteed accuracyMeasurement of torque/twisting force while tighteningAxial displacementData acquisition

The invention discloses a device and method used for measuring axial bolt relaxation in consideration of joint surface characteristics, which belongs to the field of mechanical manufacturing and structural mechanics. A bolt bar passes through upper and lower connectors, and contact surfaces have specific size and surface data. A pressure sensor is used to measure the attenuation of the bolt clamping force. An eddy current displacement sensor is used to measure displacement between the contact surfaces. Three-dimensional topography scanning is used to measure the surface three-dimensional data. A tensile testing machine is used to carry out cyclic tensile test and simulate the bolt conditions. The axial clamping force and axial displacement are transmitted to a computer for recording and processing through a data acquisition system. Axial bolt relaxation characteristics are acquired by analysis and processing several kinds of data. According to the invention, the connection characteristic of an axial part is ensured; the influence of a fixed joint surface on bolt relaxation is considered; and the bolt relaxation test precision is improved.

Owner:BEIJING UNIV OF TECH

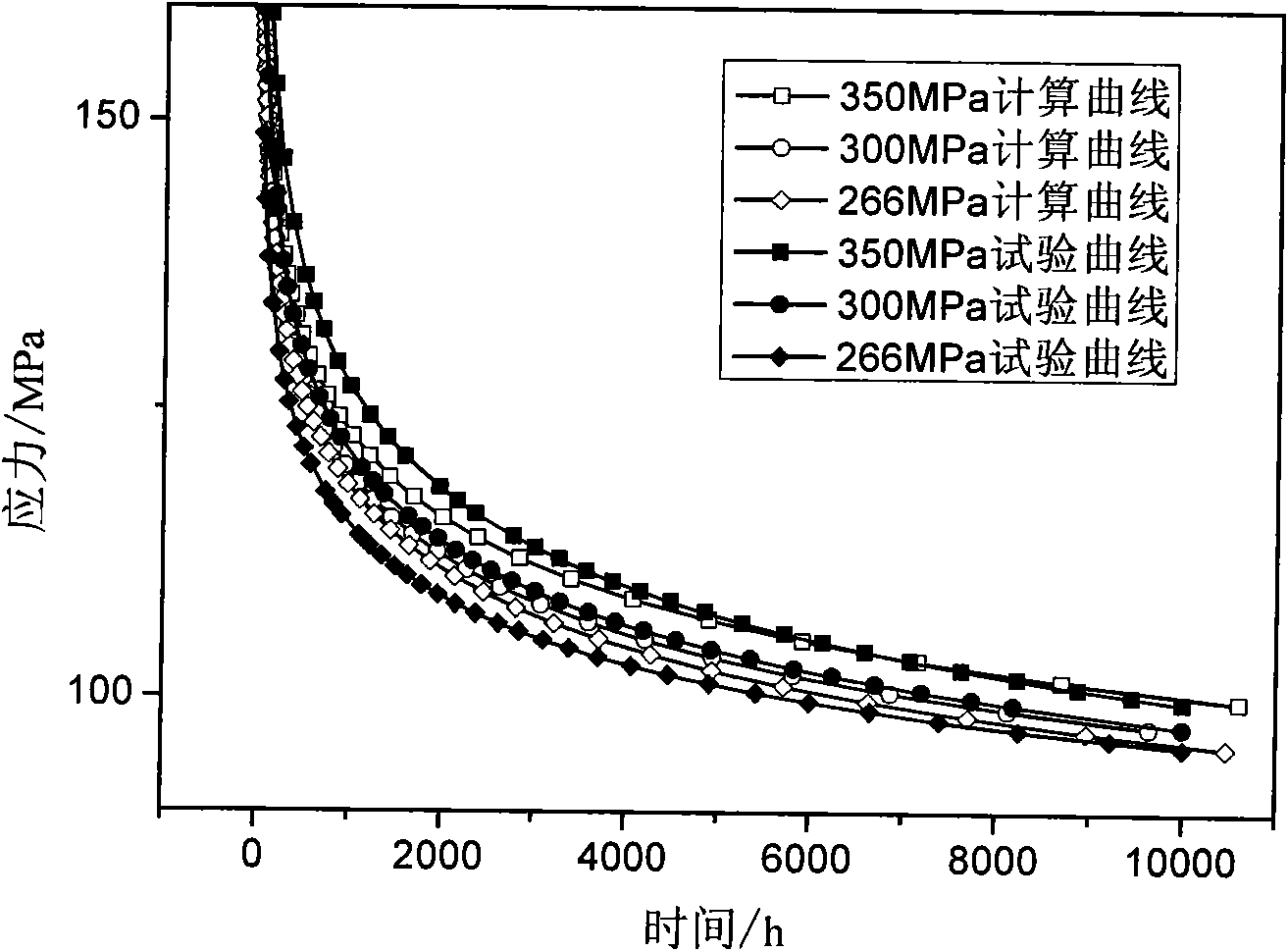

Method for converting creep data into material high-temperature stress relaxation data

InactiveCN101625351ALow professional knowledge requirementImprove conversion accuracySpecial data processing applicationsStrength propertiesTemperature stressRelaxation test

The invention relates to a method for converting creep data into material high-temperature stress relaxation data, which comprises the following steps: a method and a step for acquiring the material creep property data of a high-temperature component material at certain temperature and performing normalization processing on the material creep property data, a method for dividing the process of relaxation, and a process of creep-relaxation conversion. The method comprehensively considers the influences at different creep stages, improves the precision of data conversion from creep to relaxation, can acquire the relaxation property data satisfying the design requirements on engineering structures, and can be expected to replace relaxation tests having high requirements on experimental installations.

Owner:EAST CHINA UNIV OF SCI & TECH

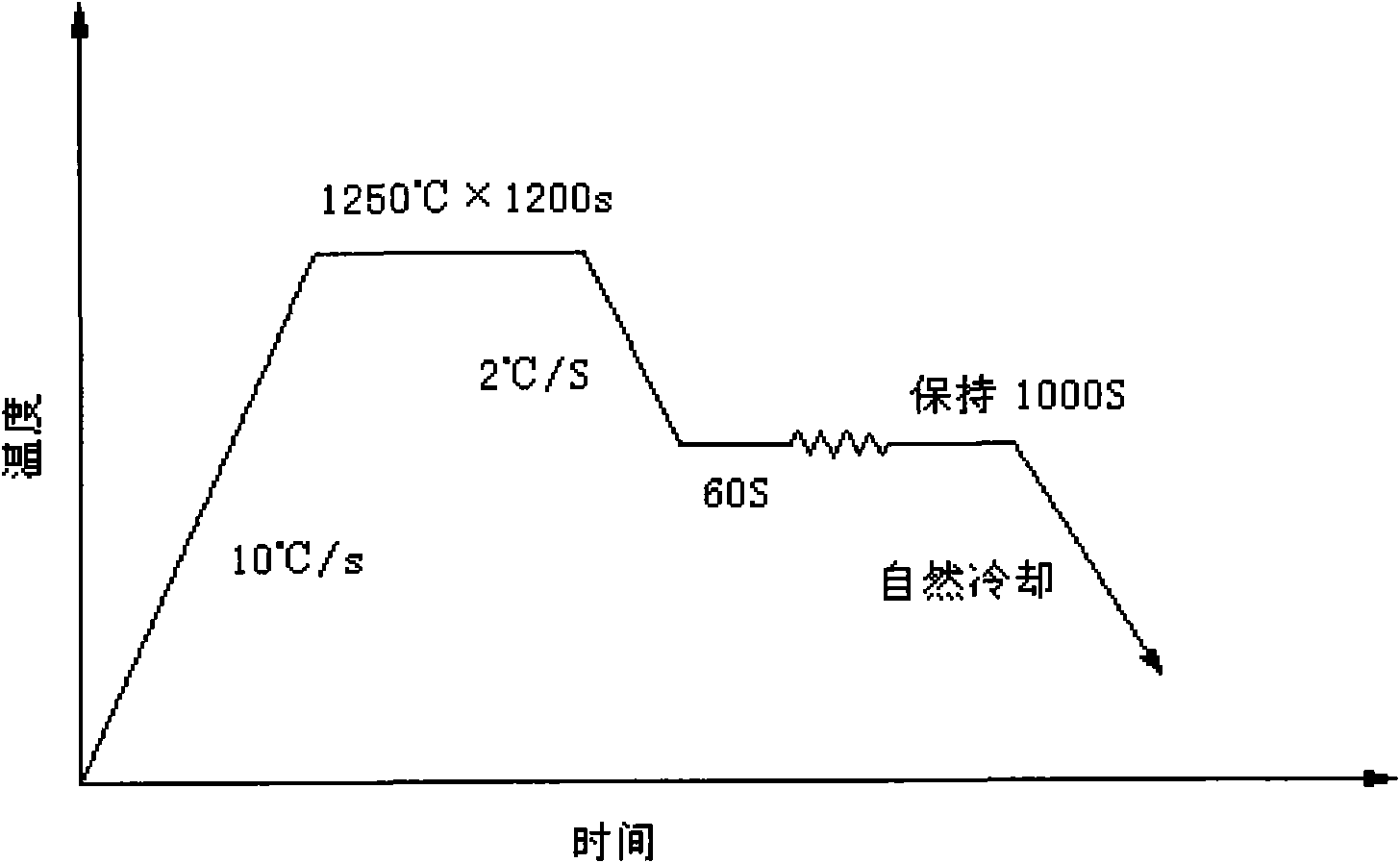

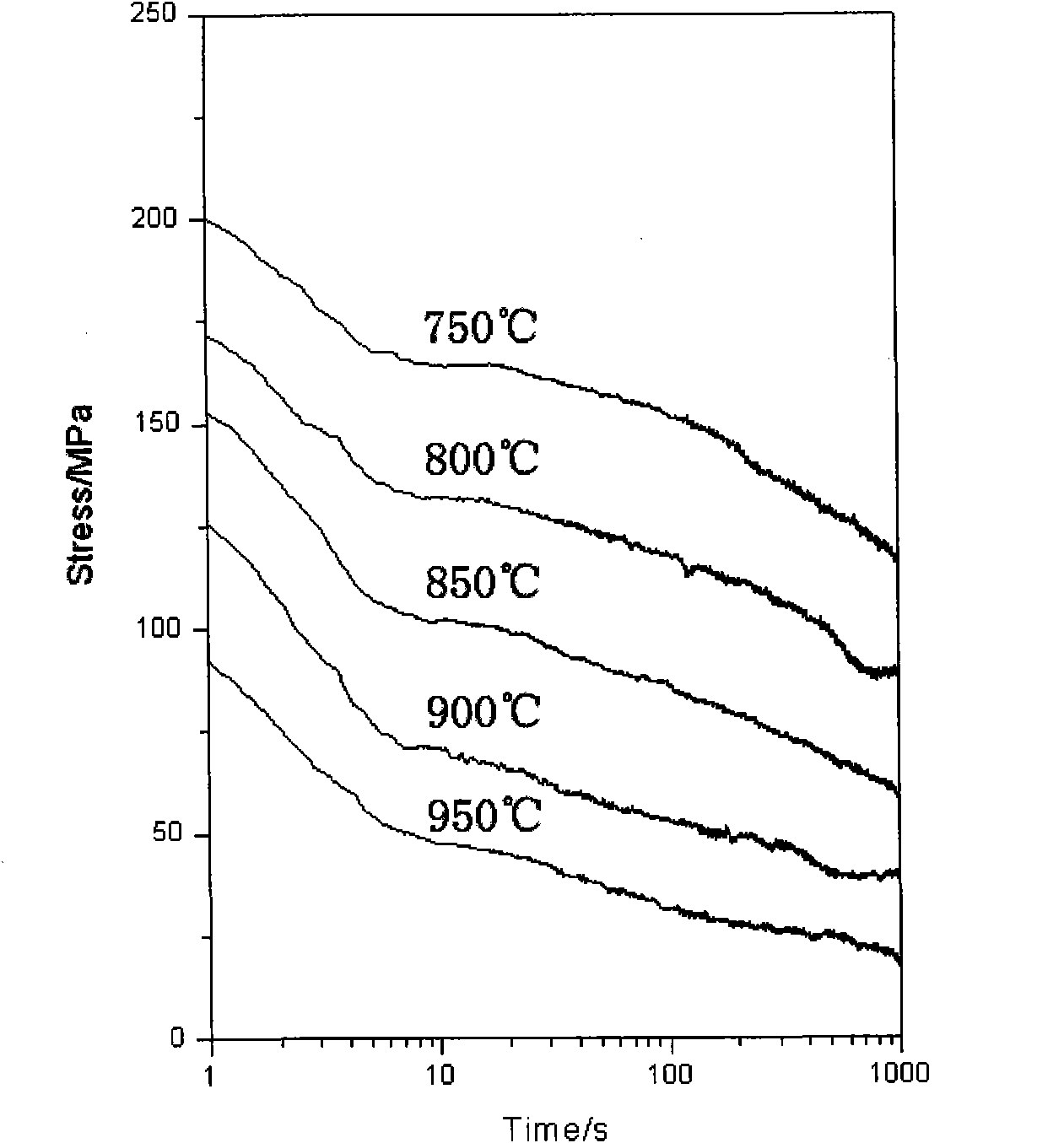

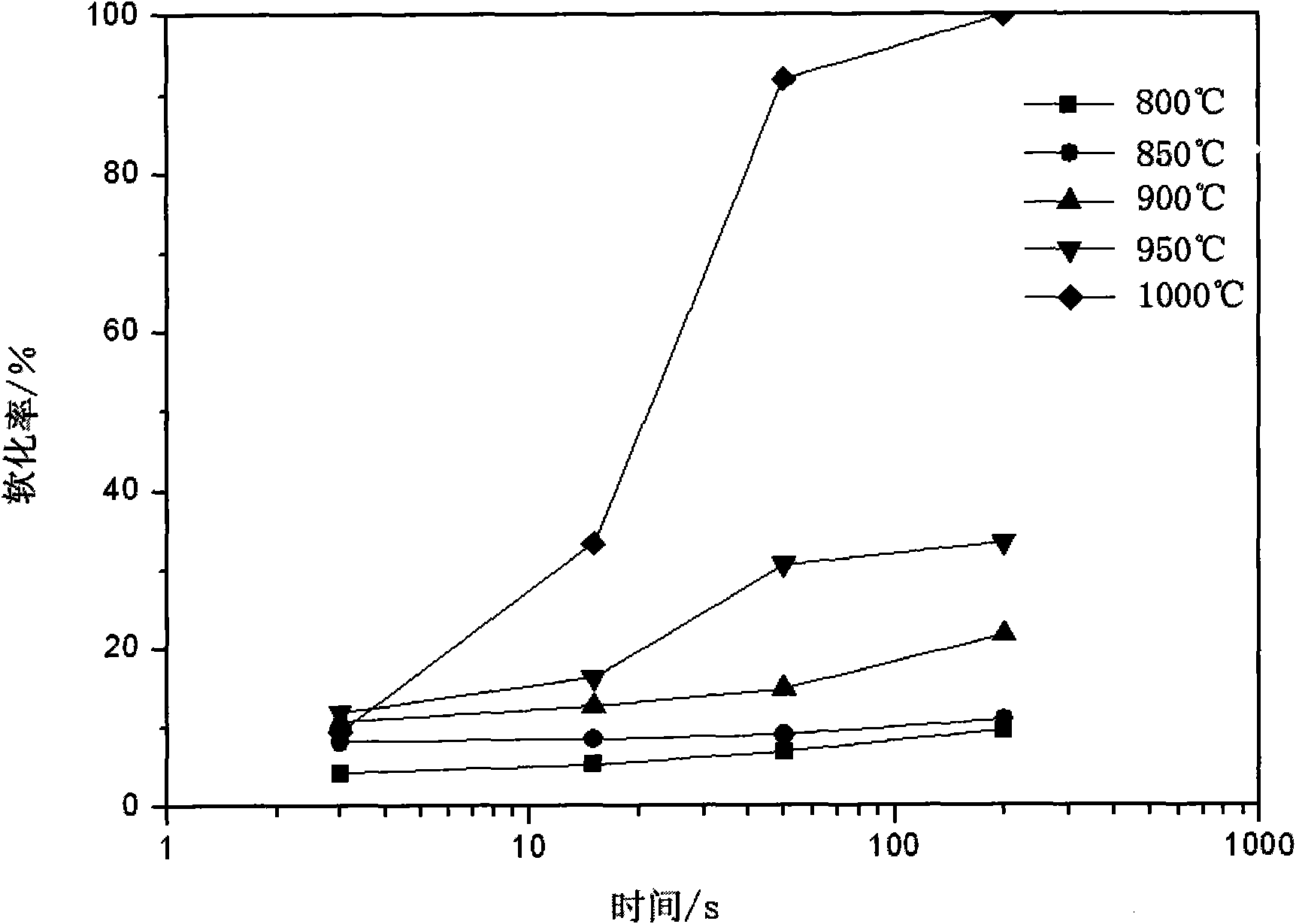

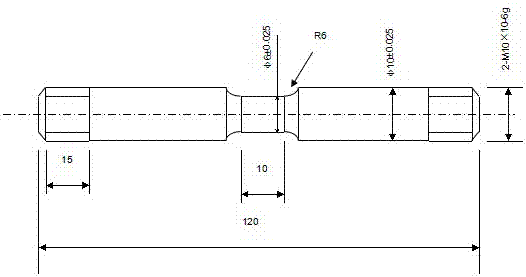

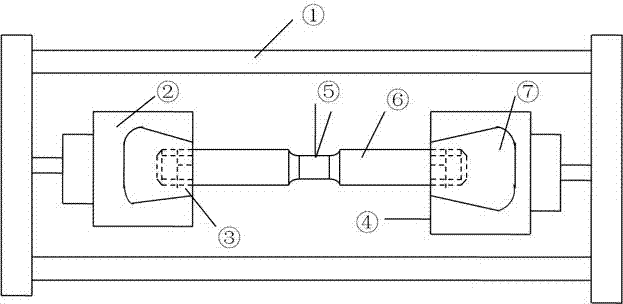

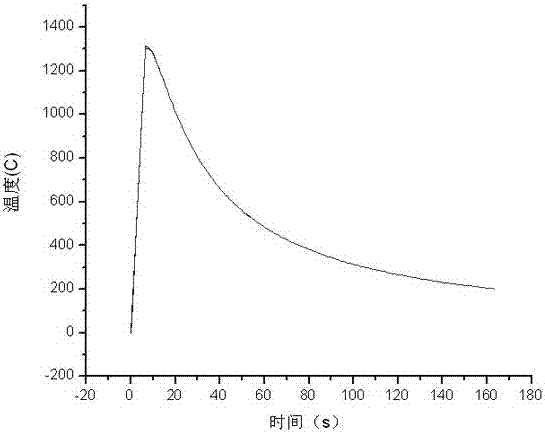

Method for carrying out stress relaxation test on Gleeble3800 hydraulic wedge unit in Jaw control mode

InactiveCN101793644ALow costHigh precisionMaterial strength using tensile/compressive forcesEngineeringFriction force

The invention discloses a method for carrying out a stress relaxation test on a Gleeble3800 hydraulic wedge unit in a Jaw control mode, which comprises the following steps: welding a thermocouple onto a sample, adopting a K-shaped thermocouple when the heating temperature of the sample is below 1200 DEG C, and adopting an S-shaped thermocouple when the heating temperature of the sample is above 1250 DEG C; respectively spreading a lubricant on a pressure head and the sample to reduce the friction force in compression, and isolating the pressure head and the sample through a tantalum sheet to prevent the pressure head and the sample to react in a high temperature state; opening an air hammer, compacting the sample, controlling the pressure to be about 100Kg, then opening a Gleeble3800 thermal simulation tester and leftwards moving the pressure head to a proper position; carrying out vacuum pumping, and charging Ar gas for protection when the vacuum degree is up to 2.4*10 to 1tau; carrying out compression by adopting the Jaw control mode; and after equipment operation is finished, reserving a high temperature organization state by adopting a direct quenching method, verifying precipitation and recrystallization conditions, and finishing the stress relaxation test. The invention has low cost and high precision and can be used for researching the precipitation behavior of various strain induced precipitates.

Owner:NANJING IRON & STEEL CO LTD

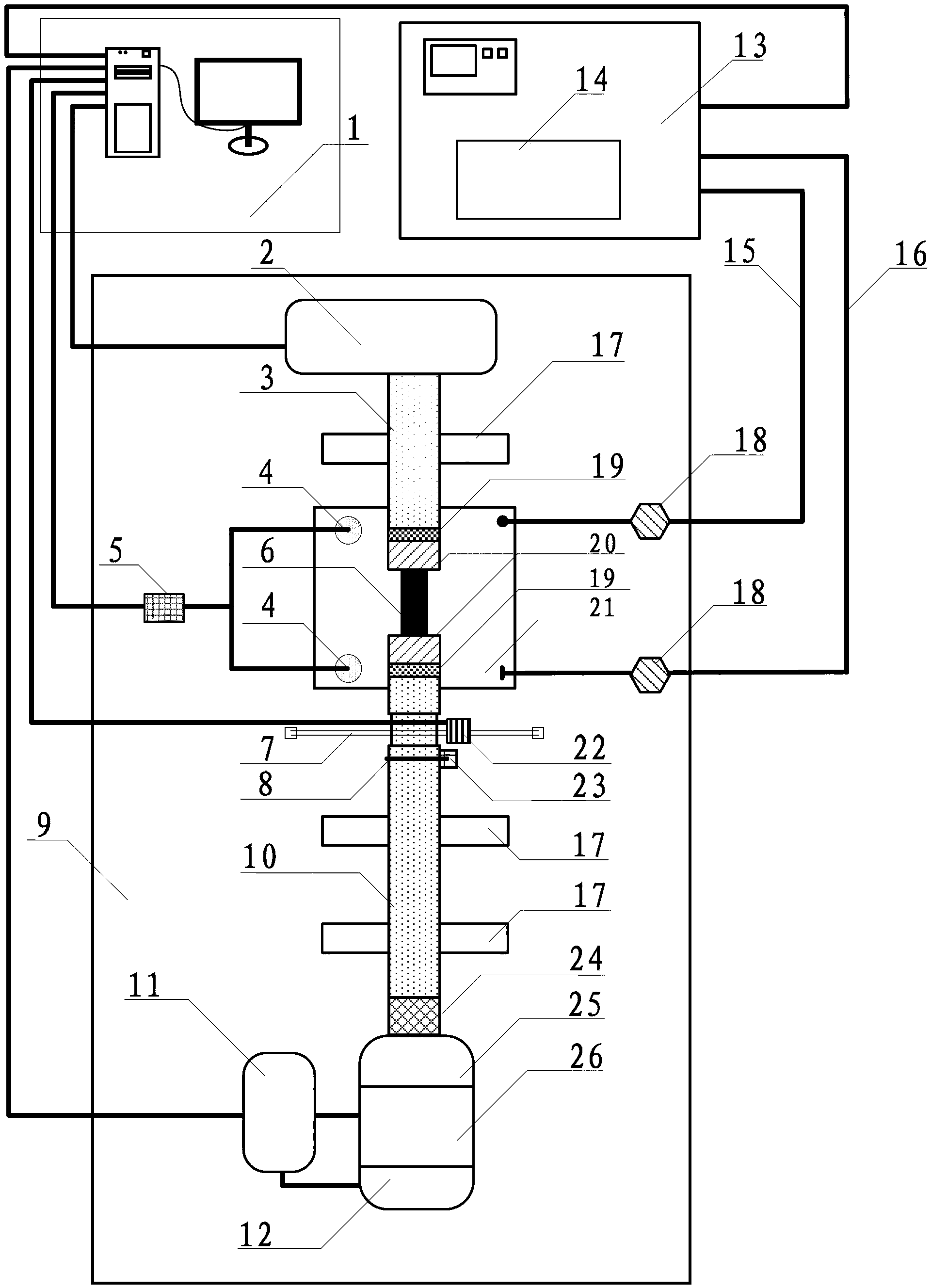

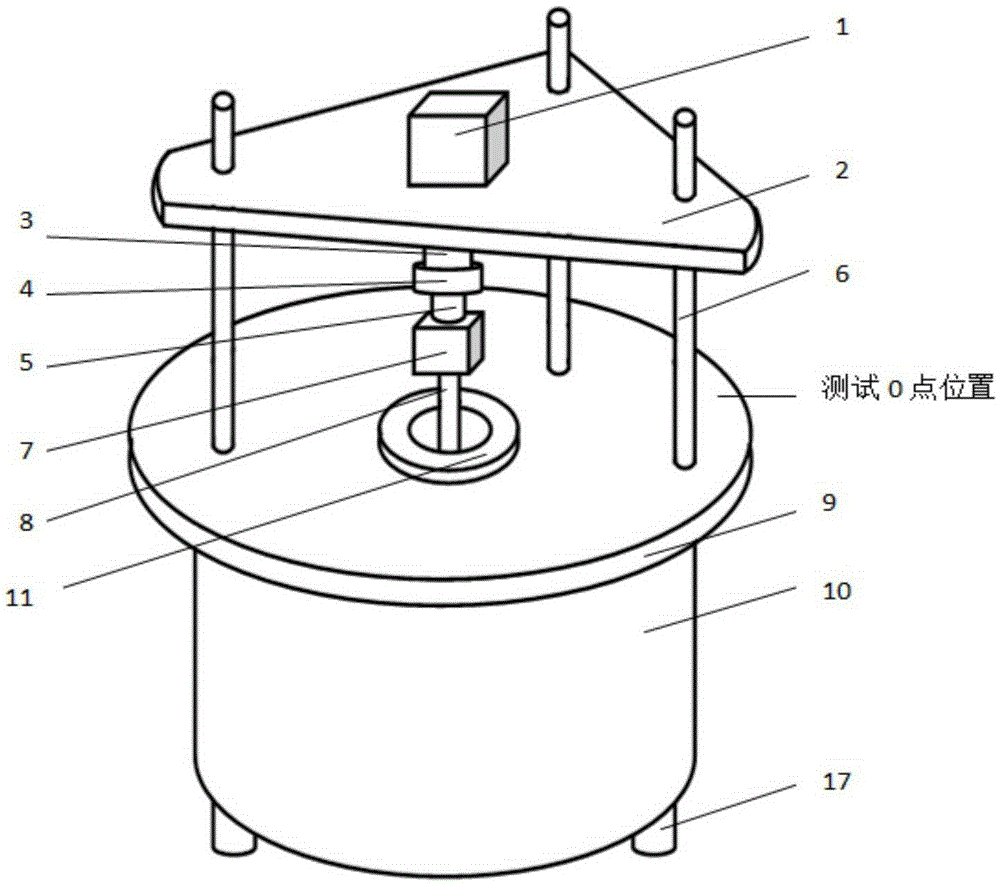

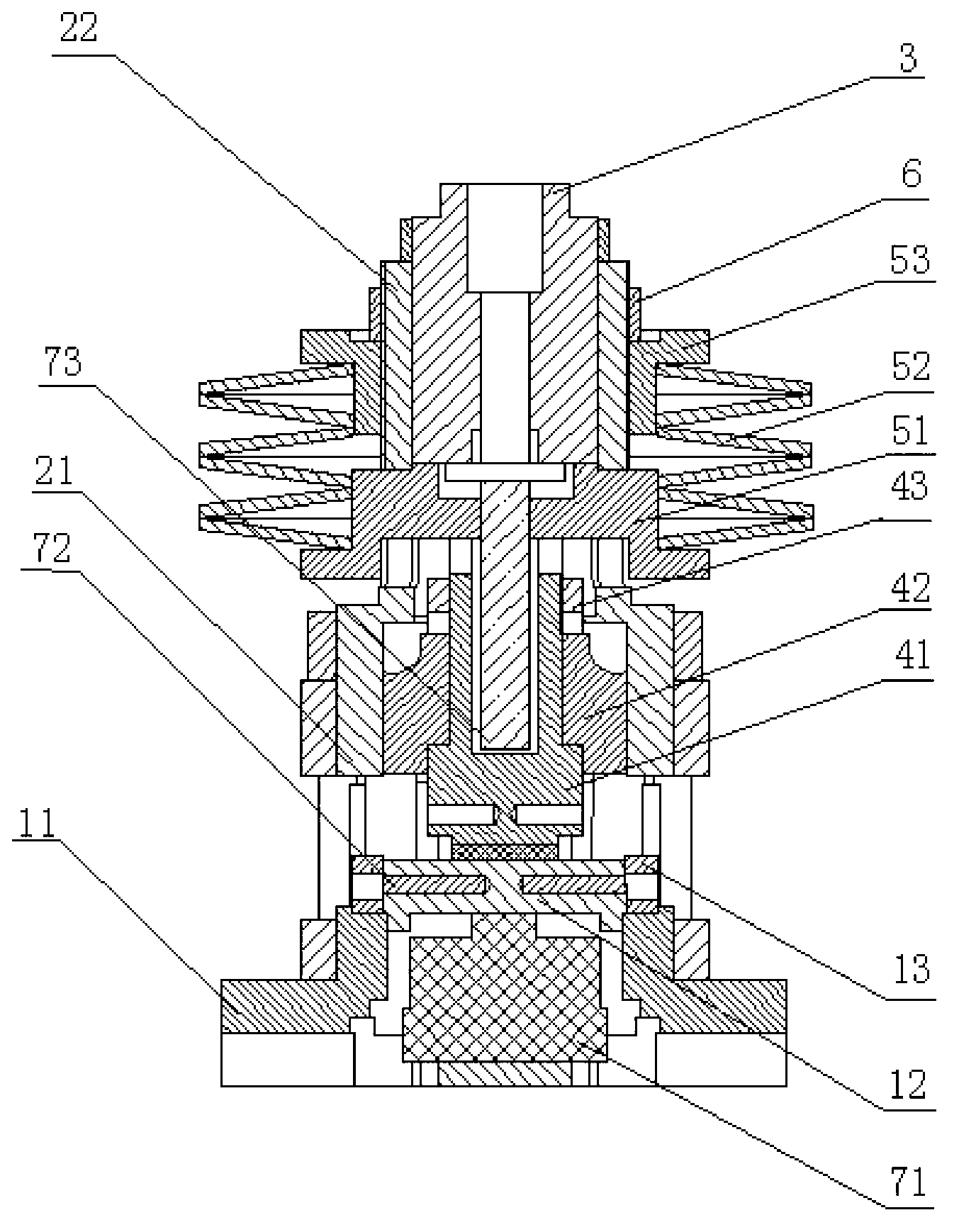

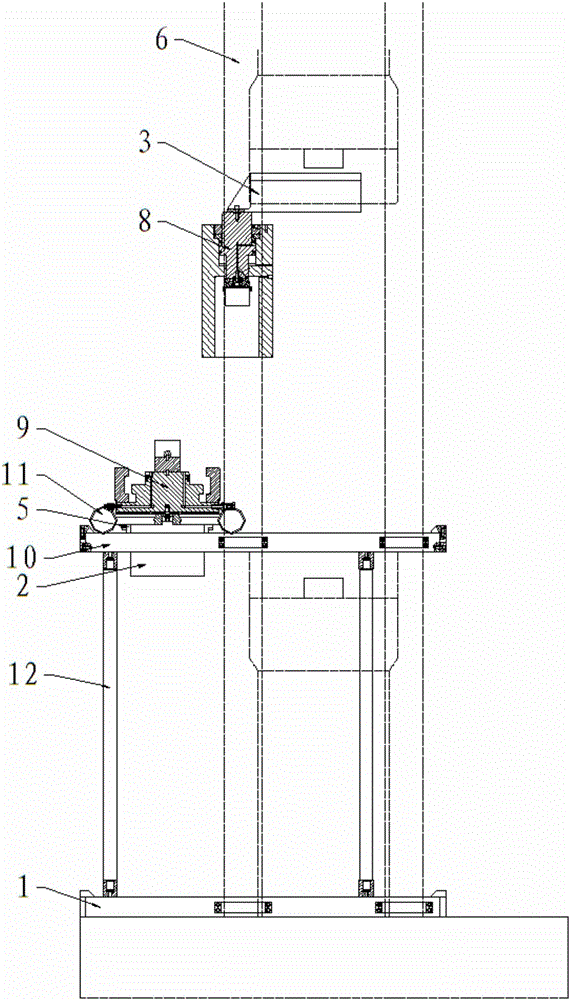

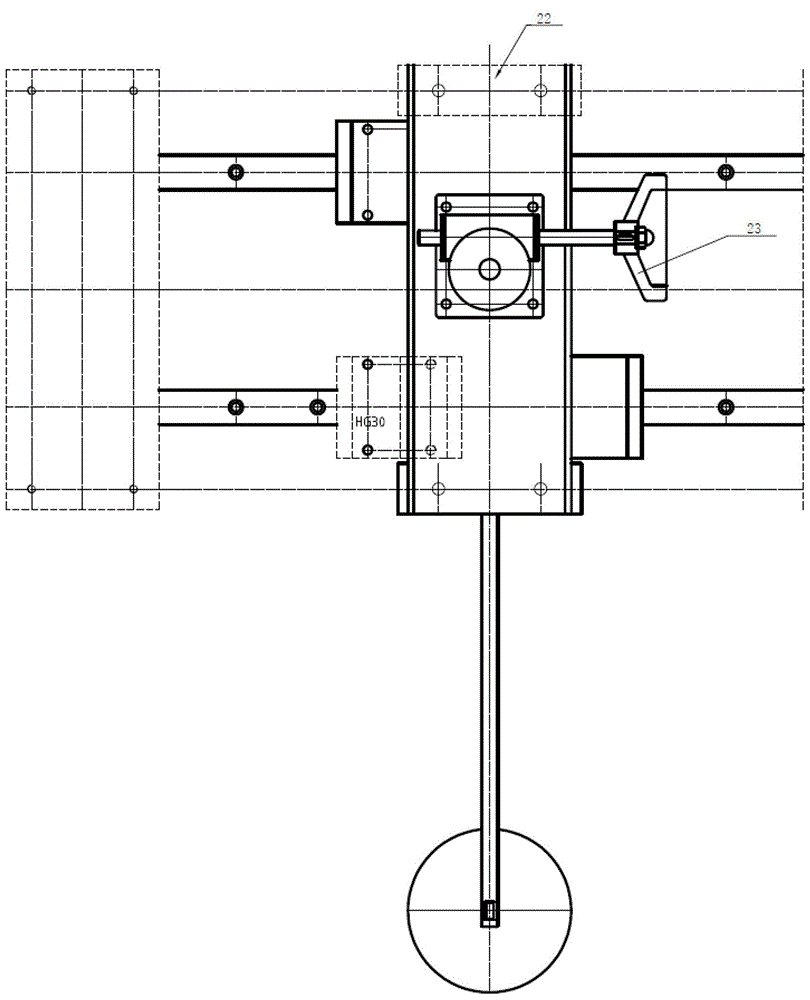

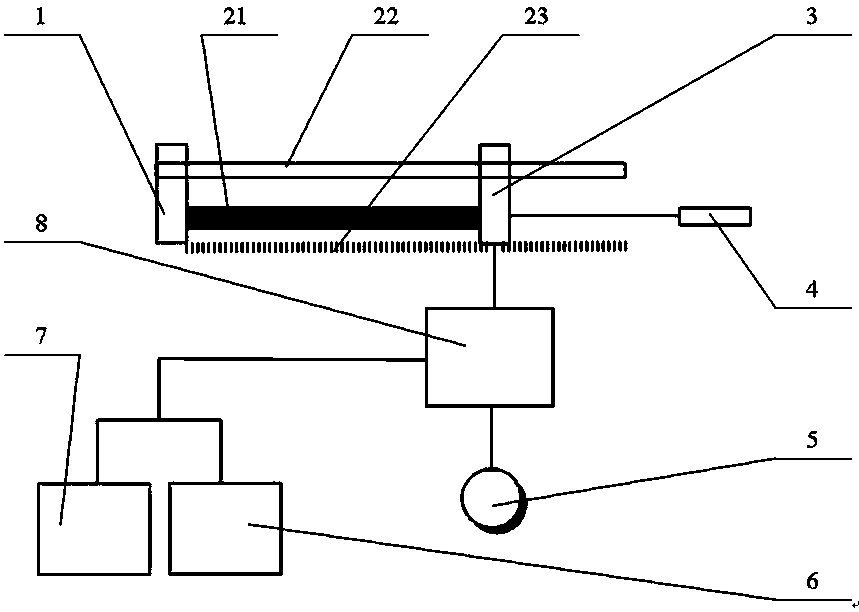

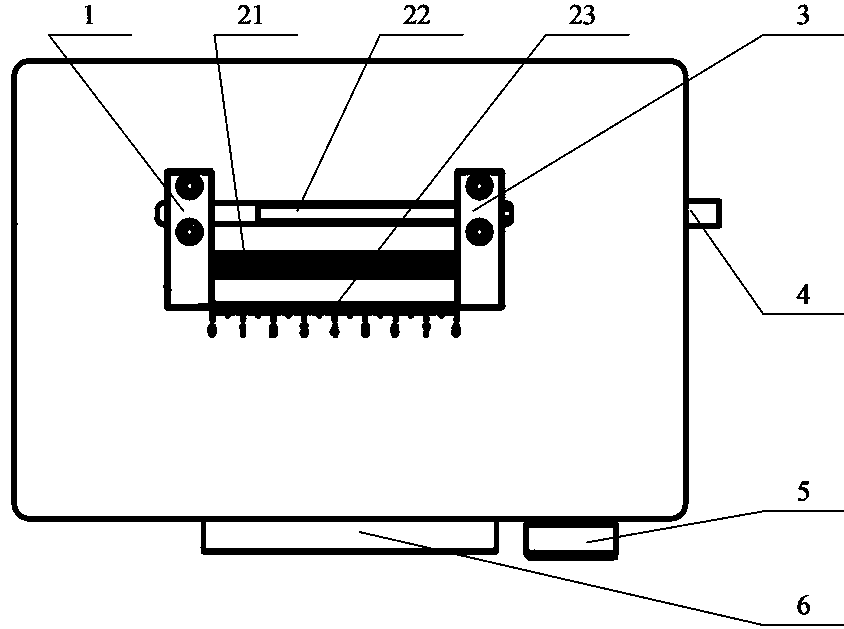

Rotation shear stress relaxation test device for asphalt mixture and method

A rotation shear stress relaxation test device for an asphalt mixture and a method, belong to a mechanical property test technology field of the asphalt mixture. The device is composed of a test platform, a loading system, a temperature control system and a computer control system, wherein the loading system comprises a frequency converter (11), an electronic brake (12), a reduction box (25) and a micro motor (26), which can be controlled by a computer. The computer control system (1) can control the electronic brake (12) by the frequency converter (11) to implement rotation shearing loading, load holding and unloading that are stress relaxation test on an asphalt mixture test piece (6). The device and the method are suitable for determining stress relaxation performances of a common asphalt mixture, an SMA asphalt mixture, a regeneration asphalt mixture and other asphalt mixtures under different parameters, such as different temperatures, different strain levels, different loading, and different load holding time. When repetition frequency is set to be multitimes, and other test parameters such as unloading, load holding and stay time, are set, repeat stress relaxation test can be completed.

Owner:DALIAN UNIV OF TECH

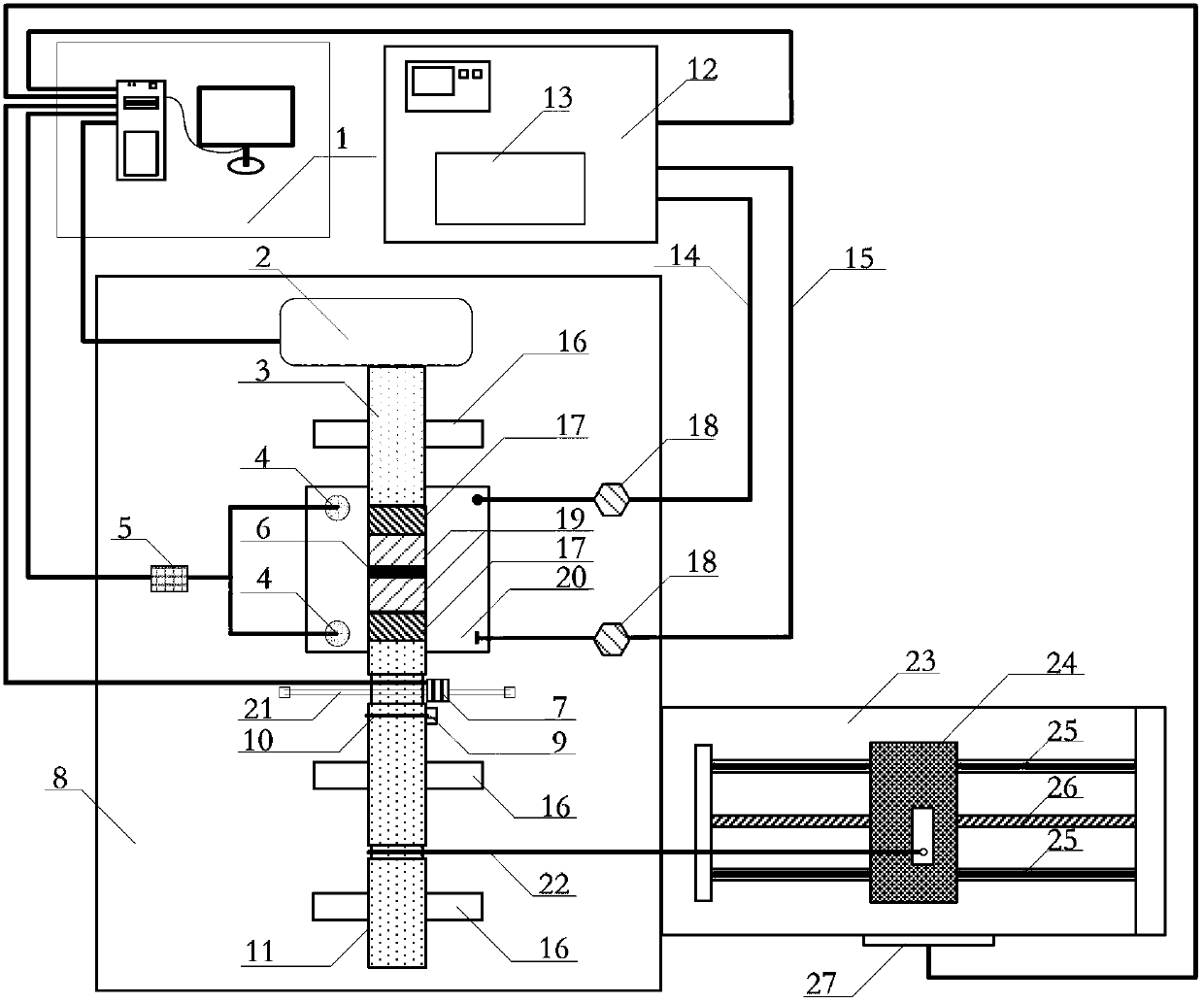

Method for evaluating material reheating crack sensitivity through stress relaxation test

ActiveCN107389445AReduce lossShort test cycleMaterial strength using tensile/compressive forcesRelaxation testStress relaxation test

The invention relates to a method for evaluating material reheating crack sensitivity through a stress relaxation test. The method comprises the following steps: integrating welding thermal simulation and stress simulation, simulating a welded HAZ coarse-grain region microstructure by simulating different welding process parameters, and simulating a residual stress state of a sample by taking certain measures; performing destressed heat-treatment simulation until the sample is fractured or the set heat insulation stage is ended so as to obtain a change relationship between the temperature, the stress and the like along with time; characterizing the material reheating crack sensitivity by using a fracture temperature-fracture time curve. According to the method disclosed by the invention, the material reheating crack sensitivity is directly evaluated on a thermal simulated testing machine through weld simulation and stress relaxation testing. The whole testing process is very close to the actual situation, the testing cycle is very short, high-efficiency and accurate, and the material loss is less during the test. The method disclosed by the invention can be used for various weld and stress simulation process parameters. The method has great significance in the actual material reheating crack sensitivity prediction and has progressiveness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

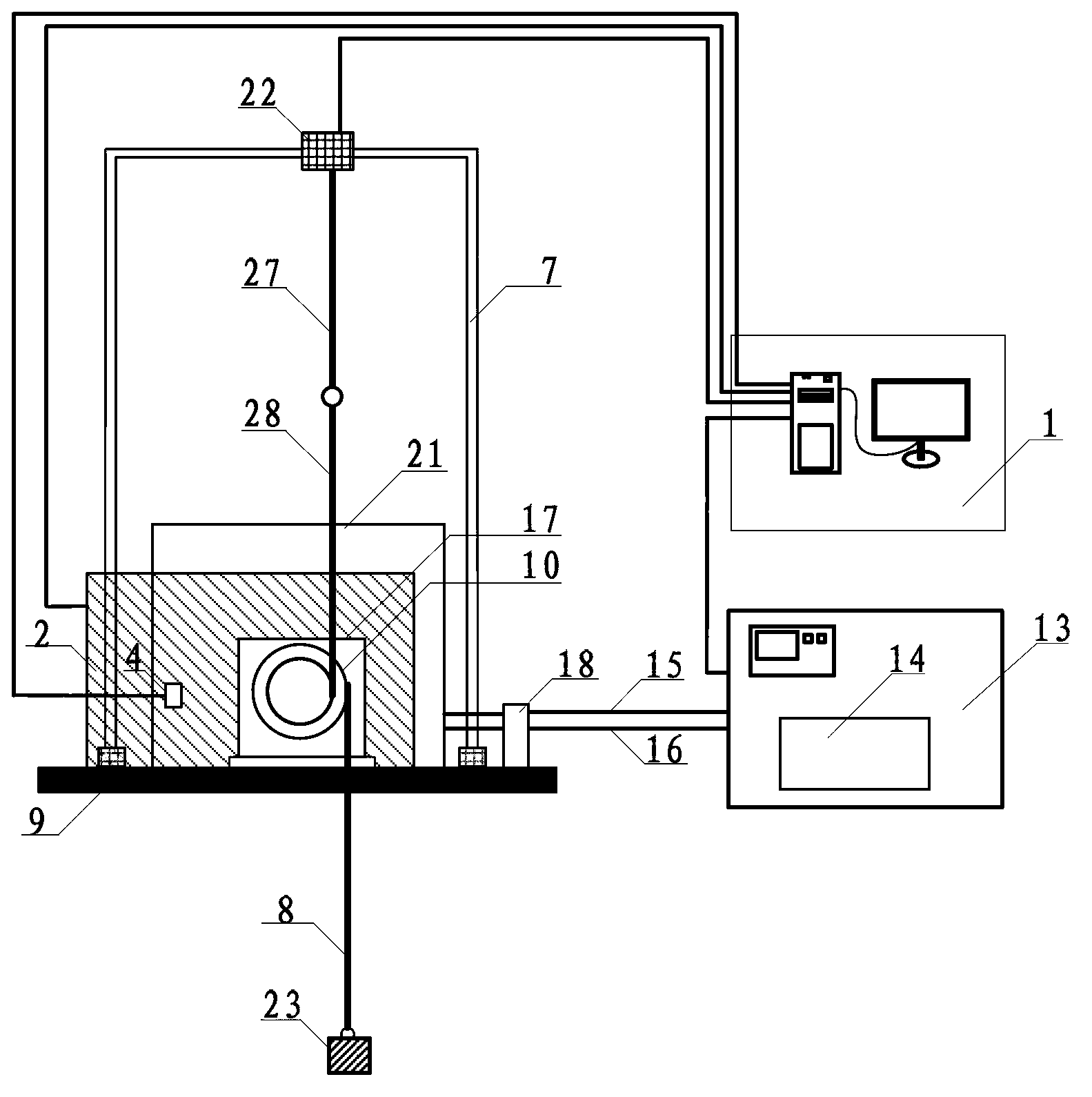

Asphalt rotation shear stress relaxation test apparatus

InactiveCN103217343AMaterial strength using steady shearing forcesComputer control systemTemperature control

The invention discloses an asphalt rotation shear stress relaxation test apparatus, which belongs to the field of asphalt mechanical property test, and the apparatus is composed of a test platform, a loading system, a temperature control system and a computer control system. The computer control system controls the loading system for rotating and loading an asphalt test piece on the test platform and holding stress and automatically unloading under the constant shearing strain state, and controls the temperature control system for temperature control of the test process. The invention is suitable for determining relaxation performance of common asphalt, SBS modified asphalt, rubber asphalt and other polymer modified asphalts and asphalt cementation materials under the rotation shearing effect; When the repeating frequency is set to multitime, and loading, stress holding, unloading and stay time and rest test parameters are set, the repeat stress relaxation test can be completed.

Owner:DALIAN UNIV OF TECH

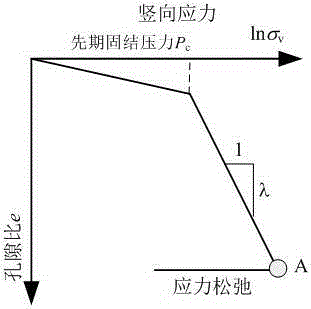

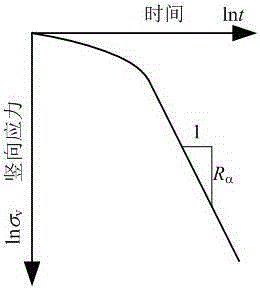

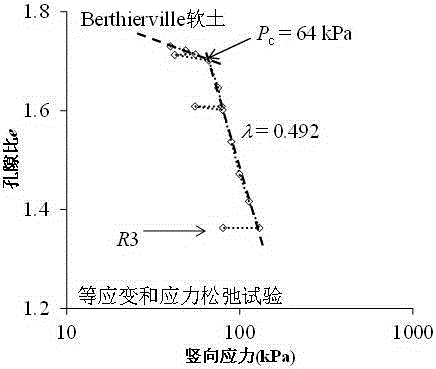

Method for estimating soft soil consolidation coefficient based on one-dimensional equal strain and stress relaxation tests

InactiveCN105181934ASave time and costSimple methodEarth material testingTest efficiencySoil science

The invention discloses a method for estimating the soft soil consolidation coefficient based on one-dimensional equal strain and stress relaxation tests, and is applied to water and soil conservation and administration. The method comprises the following steps of firstly, carrying out a one-dimensional equal strain rate test until the target load is reached, thus obtaining the compression index of soil; then carrying out a stress relaxation test to obtain the stress relaxation coefficient of soil; and calculating the consolidation coefficient through the relation between the consolidation coefficient, compression index and stress relaxation coefficient. The method disclosed by the invention has the advantages of being simple and consuming short time, saving test cost and time cost, improving the test efficiency and parameter determination.

Owner:CHINA UNIV OF MINING & TECH

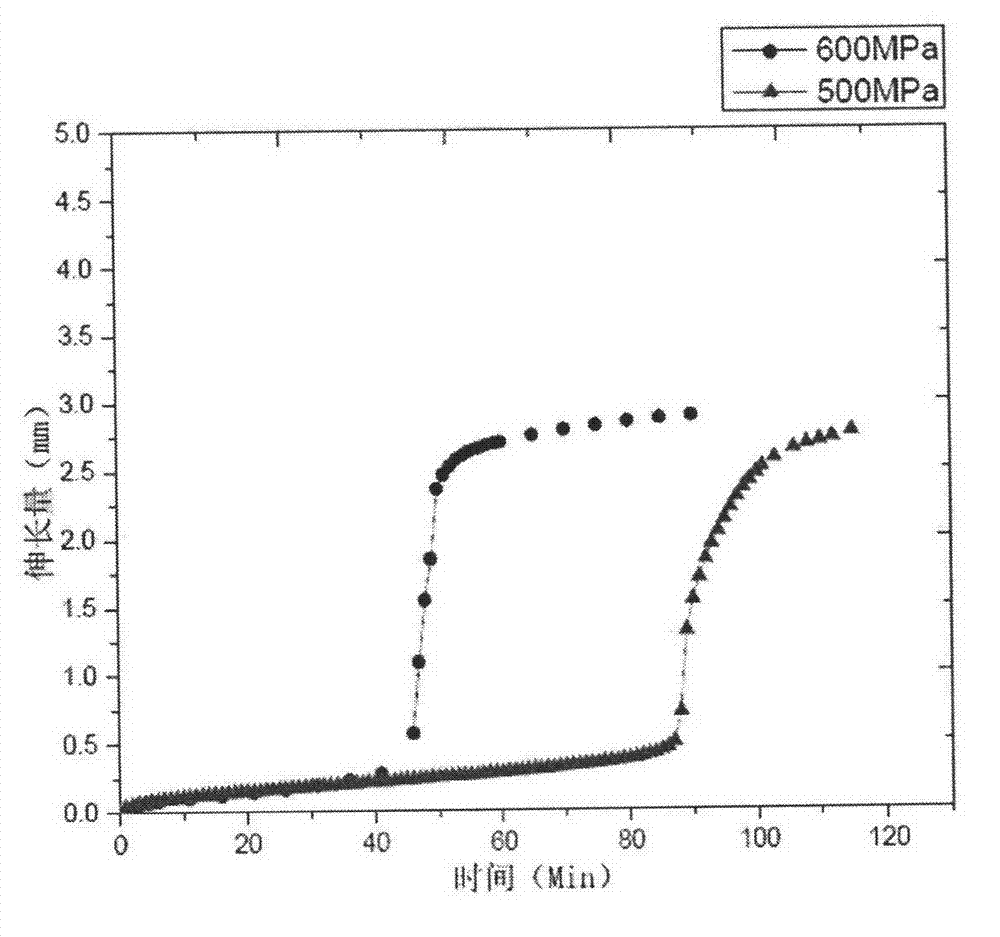

Test method for researching transformation mechanism of martensite in austenitic stainless steel

ActiveCN102901672AThe testing process is simpleValid testMaterial strength using tensile/compressive forcesMetallurgyRelaxation test

The invention discloses a method for researching the transformation characteristic of martensite in deformation strengthening austenitic stainless steel in a low-temperature environment. The method comprises the following steps of: performing a stress-applied creep test and a constant-strain relaxation test on an austenitic stainless steel material in the low-temperature environment; and acquiring the transformation mechanism of the martensite in the deformation strengthening austenitic stainless steel in the low-temperature environment by a stress relaxation curve and a sample deformation curve. The problem that research on the transformation mechanism of the martensite by applied stress or strain under the condition of sufficient degree of supercooling does not exist in the prior art is solved; and the method is simple and effective and is used for testing the transformation mechanism of the martensite under the condition of stress or strain in the low-temperature environment, provides technical support for manufacture of the austenitic stainless steel for a deformation strengthening pressure vessel in the low-temperature environment, and has quite important value and significance on research of the transformation mechanism of the martensite in the austenitic stainless steel in the low-temperature environment.

Owner:EAST CHINA UNIV OF SCI & TECH

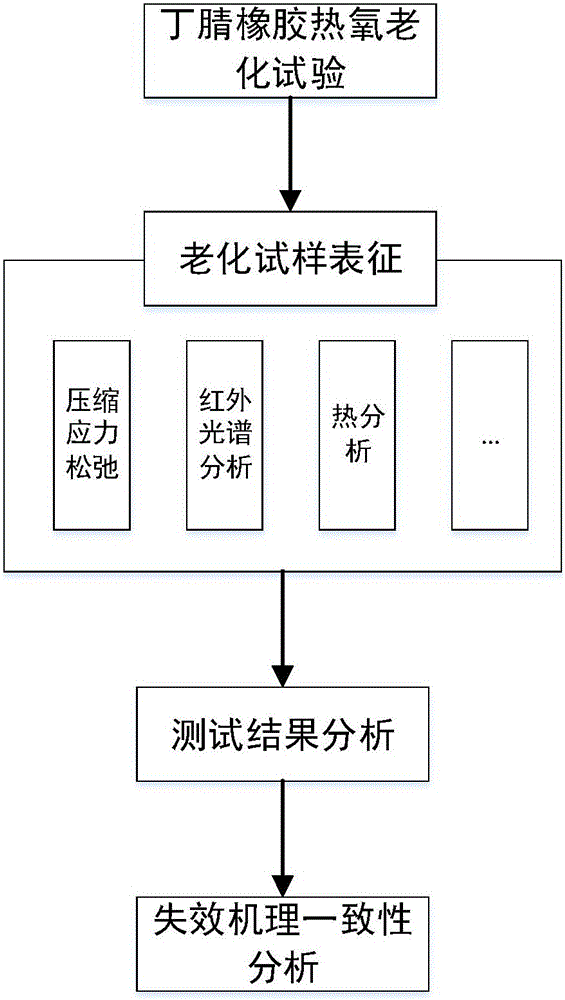

Method for verifying consistency of mechanisms involved in accelerated testing of butadiene-acrylonitrile rubber based on failure physics

InactiveCN106404643AGuaranteed validityVerify consistencyWeather/light/corrosion resistanceRelaxation testHigh acceleration

The invention provides a method for verifying the consistency of mechanisms involved in accelerated testing of butadiene-acrylonitrile rubber based on failure physics. The method comprises the following steps: 1, carrying out a thermo-oxidative aging experiment on the butadiene-acrylonitrile rubber; 2, subjecting an aged sample to a compression stress relaxation test, an infrared spectroscopic test and a thermal analysis test; 3, analyzing the test results of the compression stress relaxation, infrared spectroscopy and thermal analysis of the aged sample; and 4, verifying the consistency of mechanisms involved in accelerated testing of the butadiene-acrylonitrile rubber by using analysis results. According to the invention, the method analyzes and verifies the consistency of mechanisms involved in accelerated testing of the butadiene-acrylonitrile rubber by combining related experimental data of the compression stress relaxation test, infrared spectroscopic test and thermal analysis test, overcomes the problem of how to determine whether degradation mechanisms have abruptly changed due to too high acceleration stress during designing of an accelerated test, guarantees the consistency of failure mechanisms during accelerated testing and is of great practical significance to designing of accelerated tests of the butadiene-acrylonitrile rubber and guaranteeing of validity of experimental data in the future.

Owner:BEIHANG UNIV

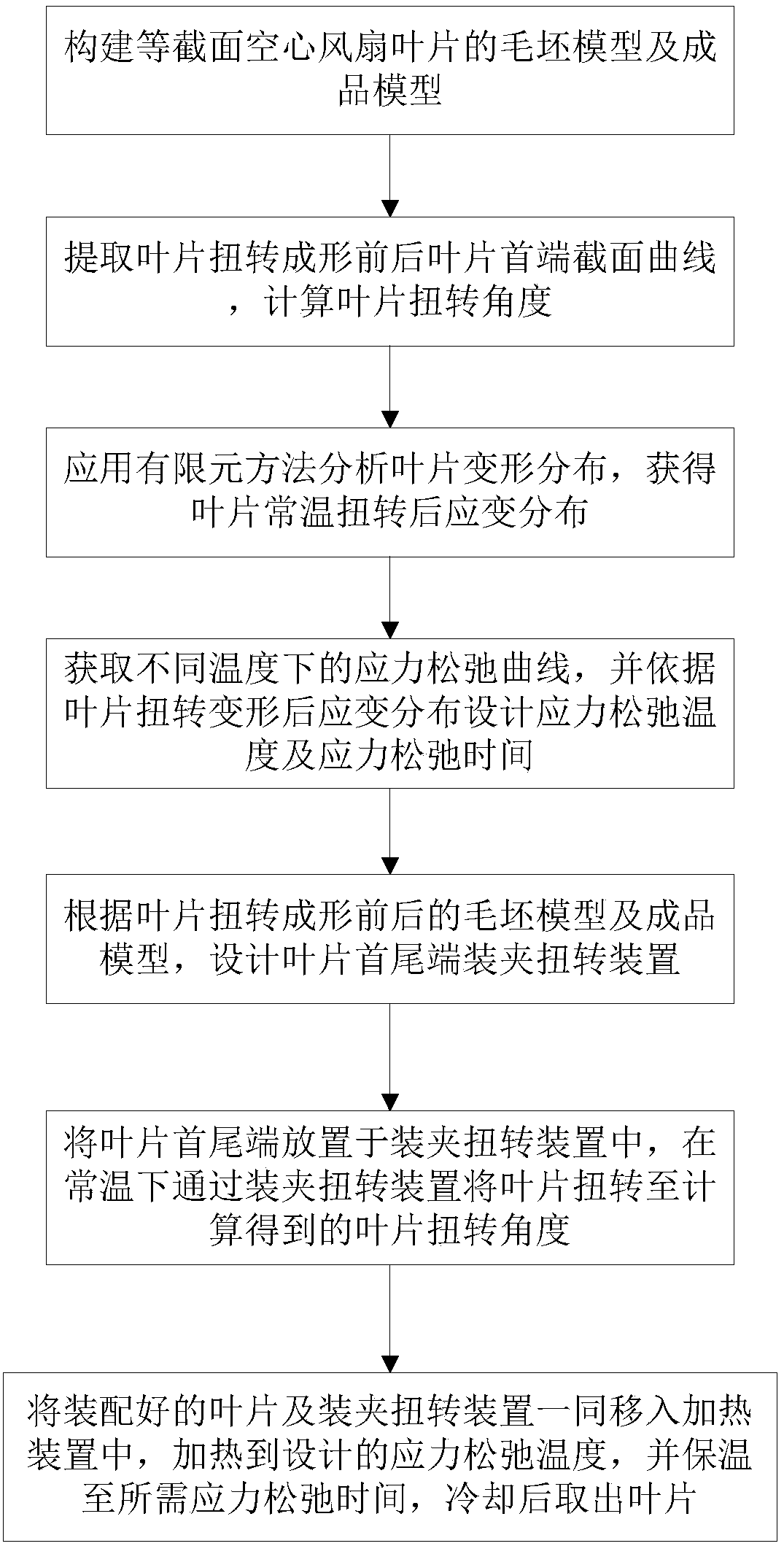

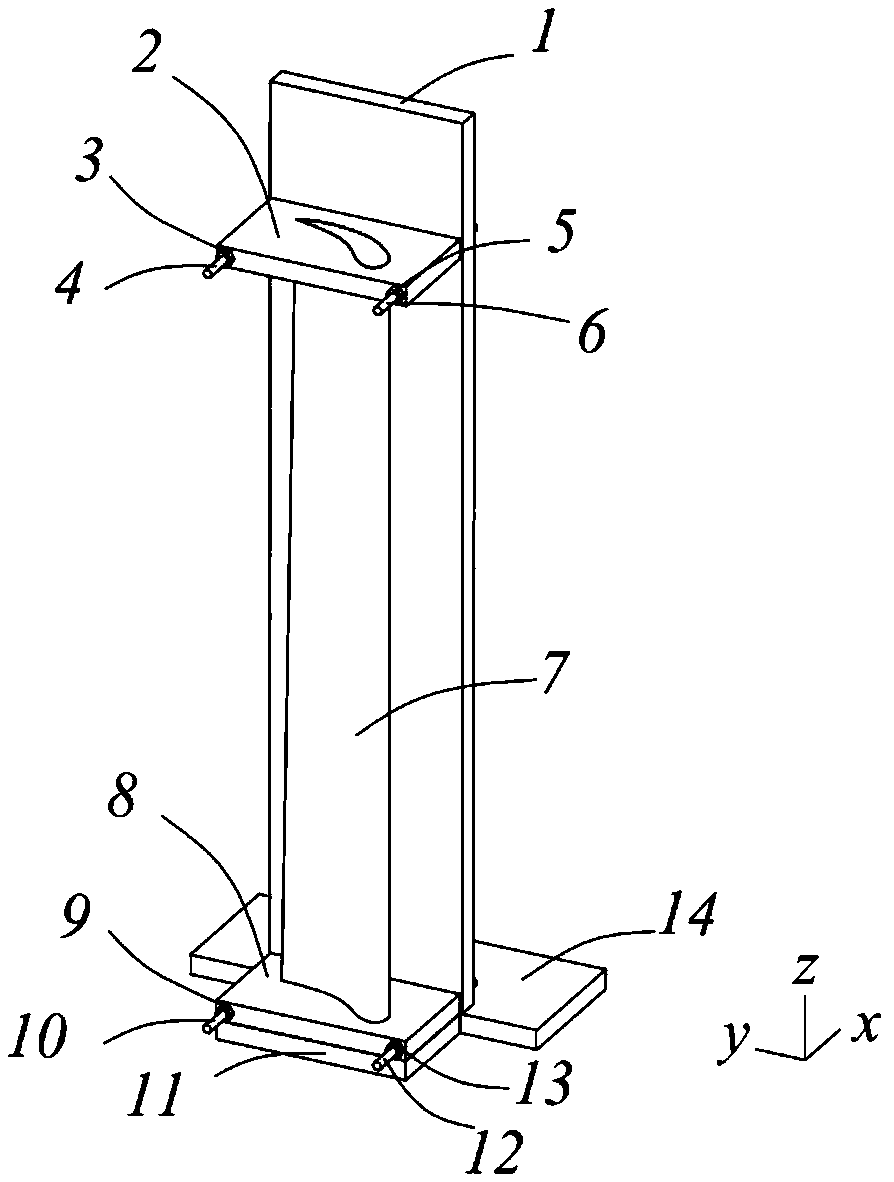

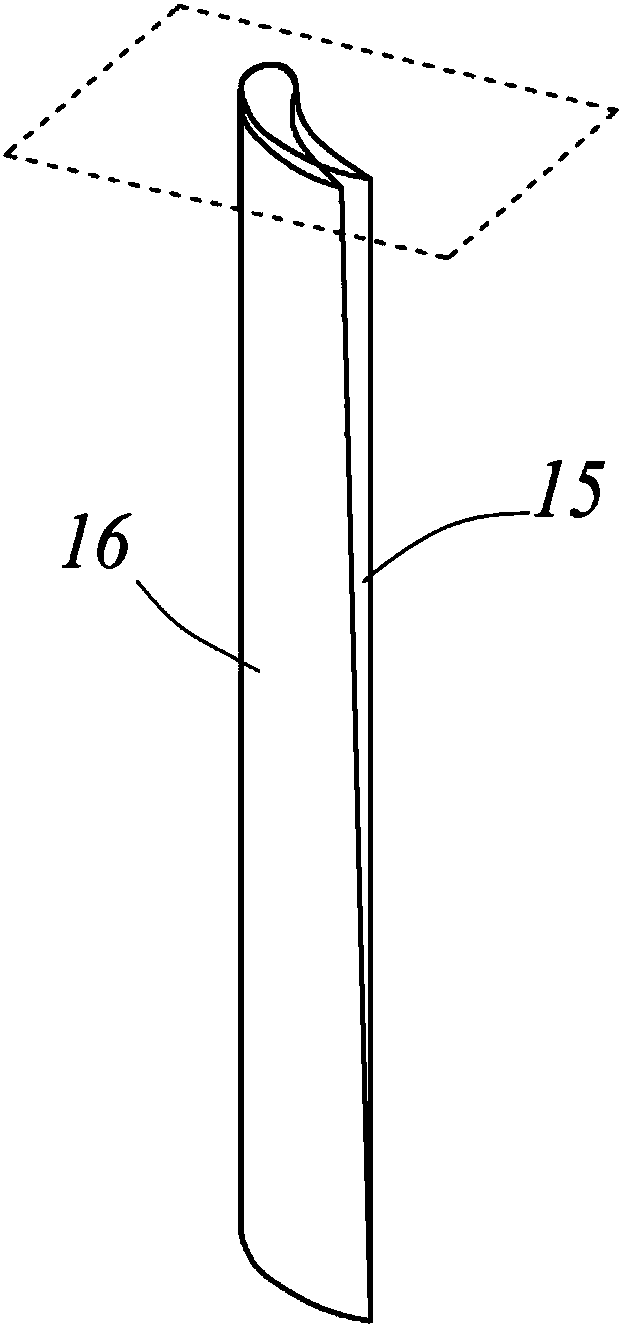

Uniform section hollow fan blade small-angle turning-around method based on stress relaxation

ActiveCN107671152APrevent movementPrecise control of twist angleShaping toolsTemperature stressRelaxation test

The invention discloses a uniform section hollow fan blade small-angle turning-around method based on stress relaxation. The uniform section hollow fan blade small-angle turning-around method based onstress relaxation comprises the steps that a high-temperature stress relaxation test method is adopted to acquire a stress relaxation curve of a blade material at the different temperatures and different initial strain conditions, and the forming temperature and the stress relaxation time are determined according to the deformation amount of a blade after the blade is turned around; a clamping and turning-around device is designed according to the cross-section shape of the blade and the turning-around angle of the blade; at the room temperature, the blade is turned around to the final forming angle through the clamping and turning-around device cooperating with the two ends of the hollow blade; the clamped blade and the clamping and turning-around device are moved into a heating device,the blade is heated to the designed stress relaxation temperature, and the designed stress relaxation temperature is kept for designed relaxation time; and heating is stopped, the blade is taken out after cooling, and the clamping and turning-around device is dismounted. By means of the uniform section hollow fan blade small-angle turning-around method based on stress relaxation, an existing high-temperature turning-around forming device and process are simplified, and turning-around forming is carried out on the hollow fan blade through a high-temperature stress relaxation method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fabric creep and relaxation measurement method and device

The invention discloses a fabric creep and relaxation testing method and a special device thereof. A tested fabric can be subjected to long-duration and constant stretching, a heavy punch hanging method is adopted in the process of testing the fabric creep, and creep elongation of the fabric is measured. When relaxation of the fabric is tested, one end of a fabric sample is fixed, constant tension is applied to the fabric by using a lifting screw at the other end, the center of the fabric is tensioned by using a tensioning rack, and a force measuring device is suspended on the tensioning rack and is used for measuring relaxation change of the fabric. The method is suitable for creep and relaxation test of embroidery blank fabrics.

Owner:SUZHOU VOCATIONAL UNIV +1

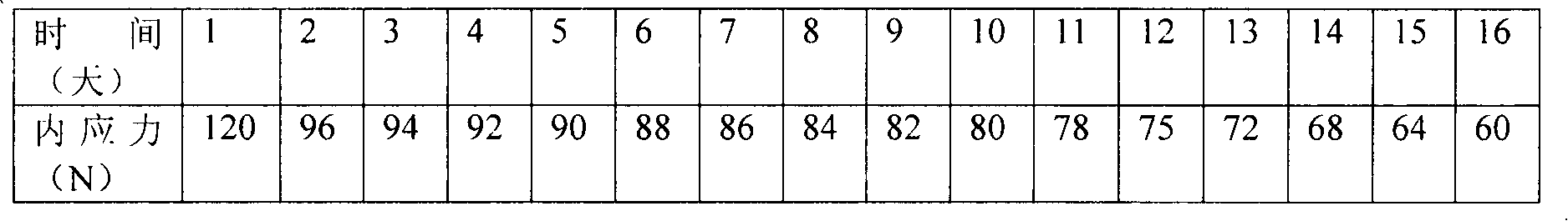

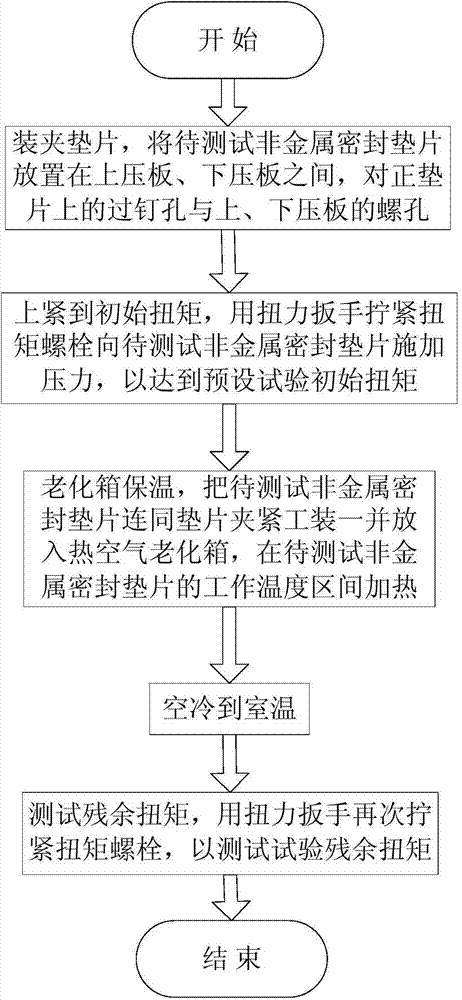

Testing method for creep relaxation of non-metal sealing gasket

InactiveCN103575602AImprove test efficiencyInvestigating material ductilityTest efficiencyRoom temperature

The invention discloses a testing method for creep relaxation of a non-metal sealing gasket. The testing method comprises the following steps of (1) clamping the gasket; (2) tightening to an initial torque; (3) insulating by an aging box; (4) carrying out air cooling to room temperature; and (5) testing the residual torque, and screwing a torque bolt again by using a torque wrench so as to test the residual torque. Compared with the similar products, the testing method for creep relaxation of the non-metal sealing gasket, disclosed by the invention, has the advantages that under the same control condition, the capability of given compression stress is maintained along with the passage of time, and the creep relaxation of the gasket is evaluated by the degree of bolt torque loss; and a testing device is simple, a finished gasket can be directly tested on a production site, and the testing efficiency is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

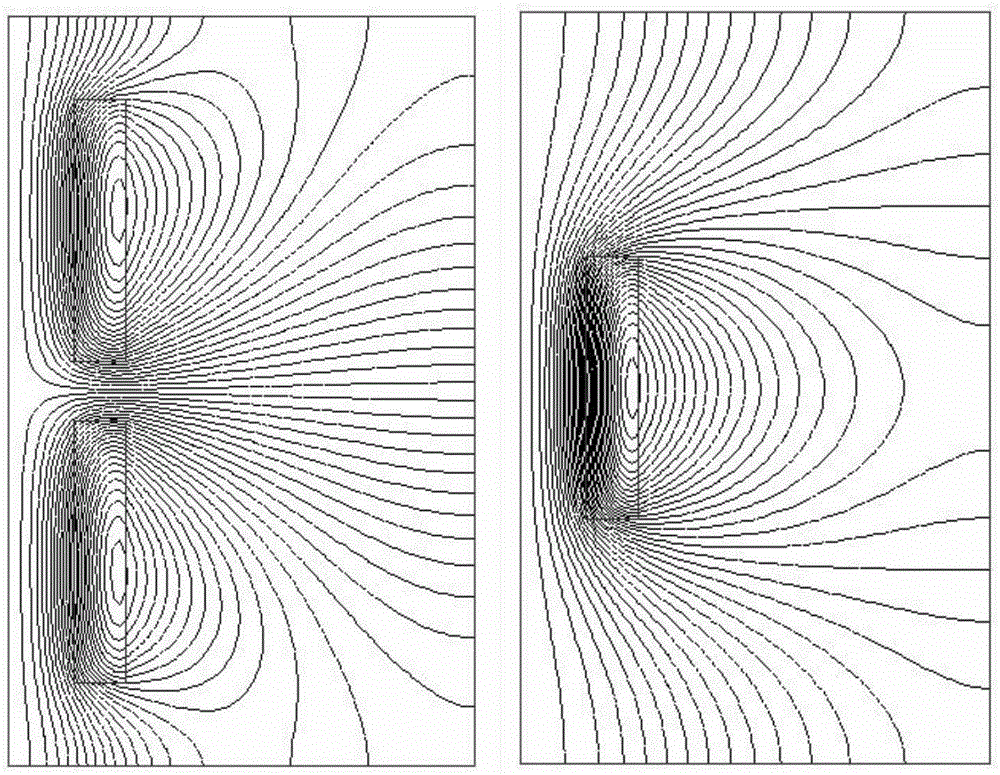

High-gradient high-intensity magnetic field magnetic suspension characteristic test technology

InactiveCN105300567AVarious structural testsSimple structureMagnetic measurementsForce measurementMagnetic disturbanceTest platform

The invention discloses a high-gradient high-intensity magnetic field magnetic suspension characteristic test technology. A test platform is provided for suspension characteristics in multiple aspects of a high-gradient high-intensity magnetic field to a superconducting block. A test device is mainly composed of an external magnetic field formed by a superconducting magnet (10) and a test support arranged above the superconducting magnet. The superconducting magnet (10) is internally provided with a coaxial superconducting magnet excitation coil A (12) and a superconducting magnet excitation coil B (13) which are completely identical in structure. When excitation currents with different sizes and directions are piped in the two superconducting excitation coils, a low-intensity magnetic field, a high-intensity magnetic field and magnetic field configurations of which gradient and intensity are variable are generated. Suspension force and suspension force relaxation tests of the high-temperature superconducting block material in the high-gradient magnetic field, the high-intensity magnetic field and the variable magnetic fields can be realized on the same device, and AC loss of the high-temperature superconducting block under AC magnetic disturbance can be tested so that the structure is relatively simple and operation is convenient, and the defects in the certain existing technologies that the test content is single, the structure is complex and operation is complicated can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

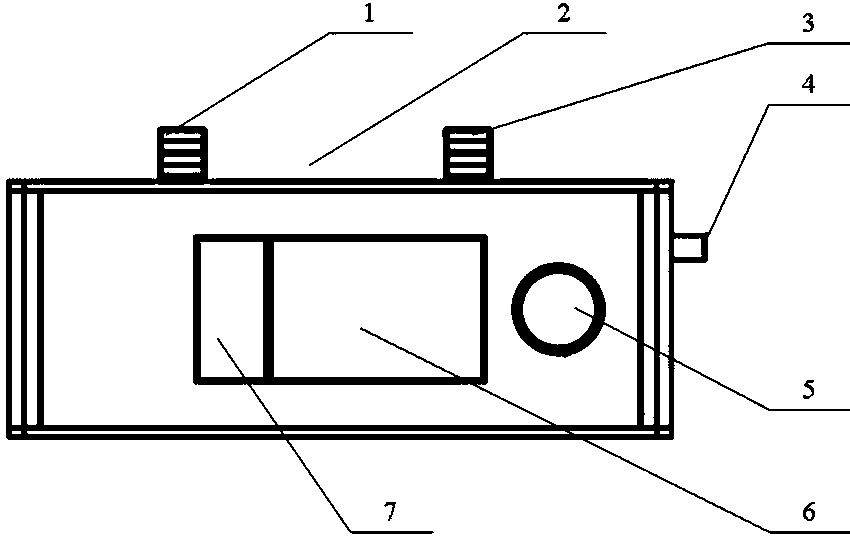

Online testing system of polymer cushion stress loading and testing method

InactiveCN103076228ASolving Load Coordination ChallengesEasy to controlMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention discloses an online testing system of polymer cushion stress loading for testing the compressive stress strain of polymer materials including a cushion and the like. The online testing system comprises a stress loading device and an online detecting system, wherein the stress loading device comprises a base component, a test piece sleeve, a compression column component, a force application component and a limiting rod; and the online detecting system comprises a pressure sensor, a temperature sensor, a displacement sensor, an online detecting collector, a database server and online detecting data analysis software. According to the invention, the functions of testing the fixed compression amount stress relaxation and the fixed compression stress strain can be realized. The independent stress loading can be realized in the two test states; the compression amount of the cushion can be controlled precisely in the quantitative compression stress relaxation test; meanwhile, the online detection, automatic data acquisition, storage and analysis of the stress, displacement and temperature indexes are realized; the automation technology level of the system is improved integrally; and the data detection is accurate and reliable.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

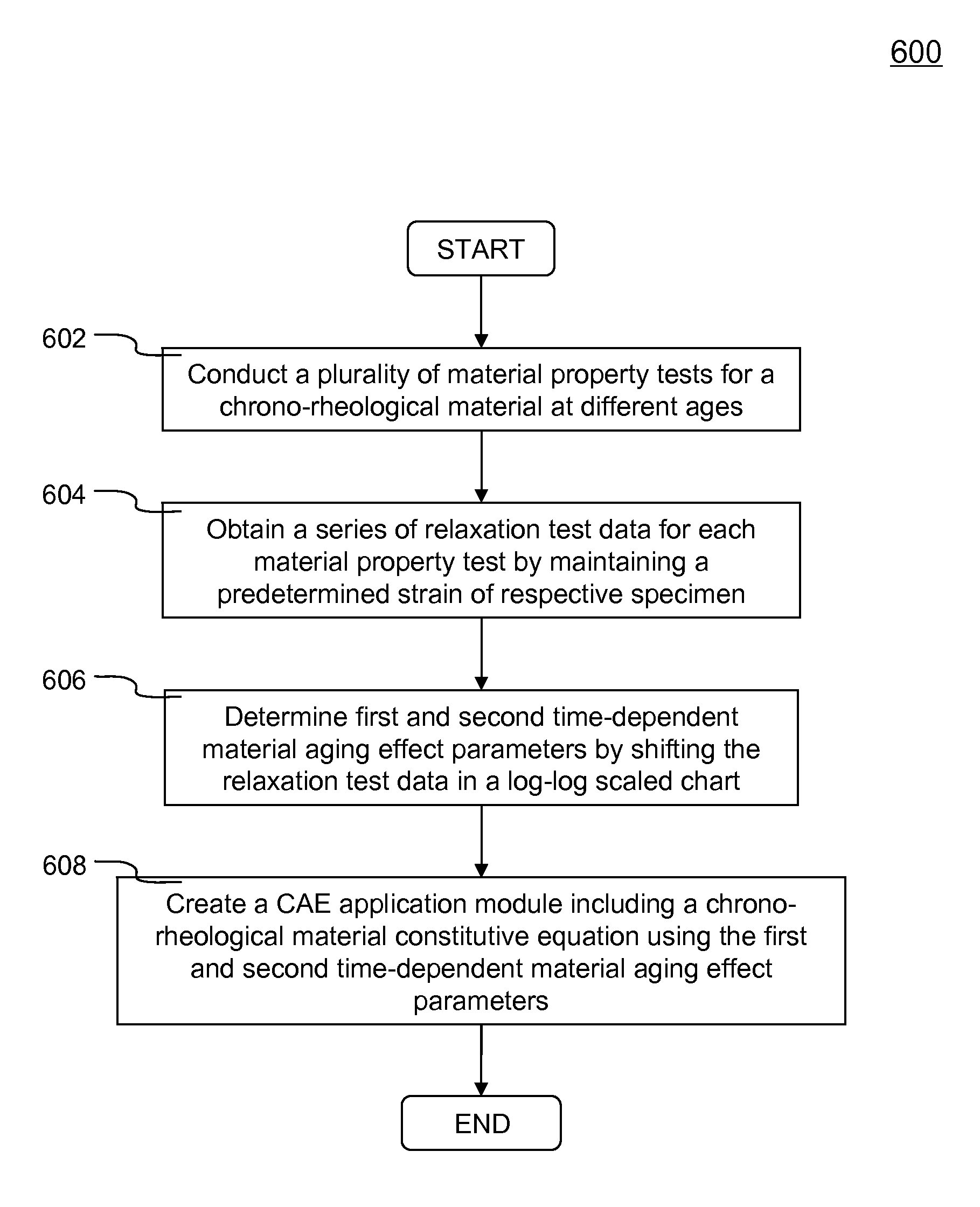

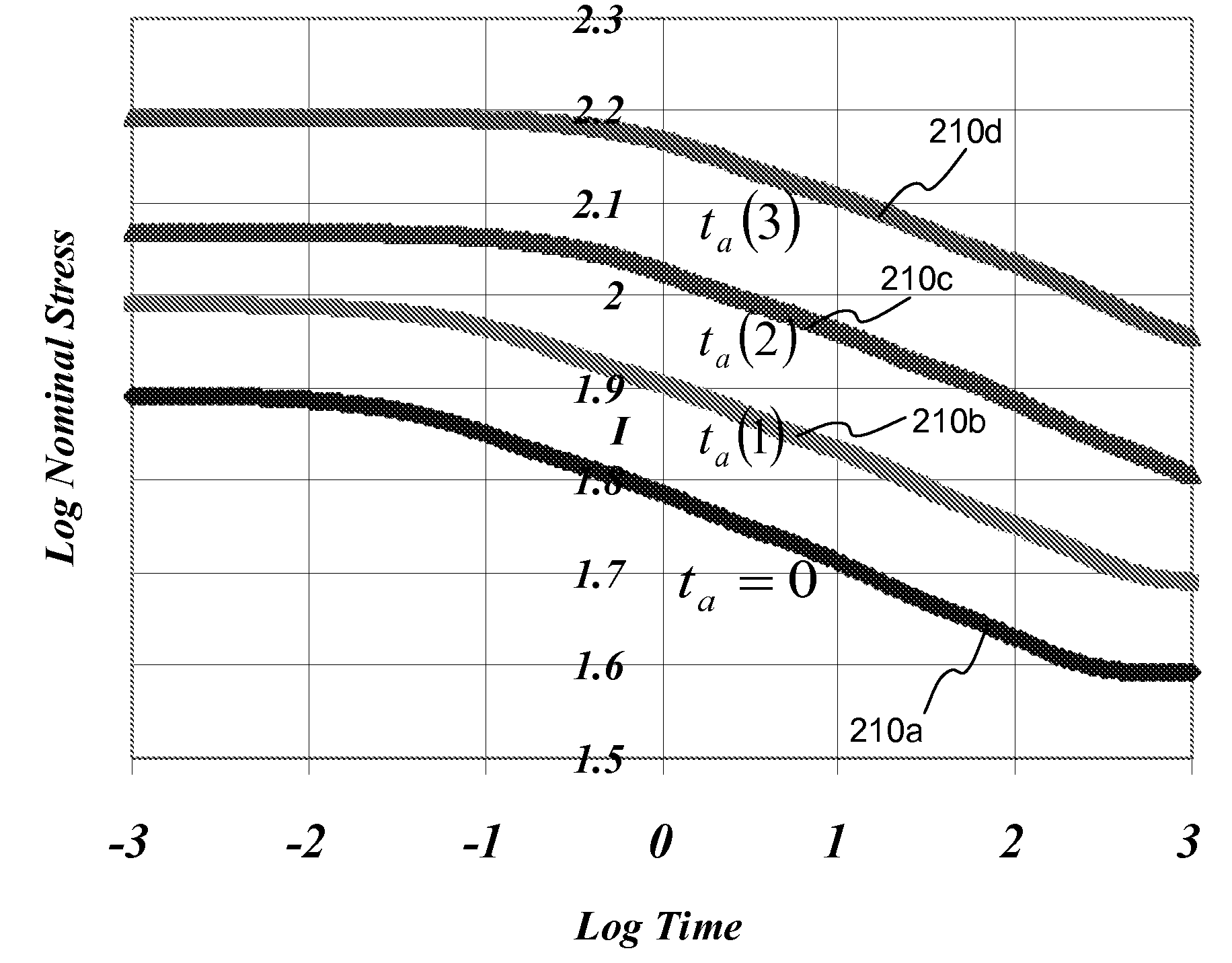

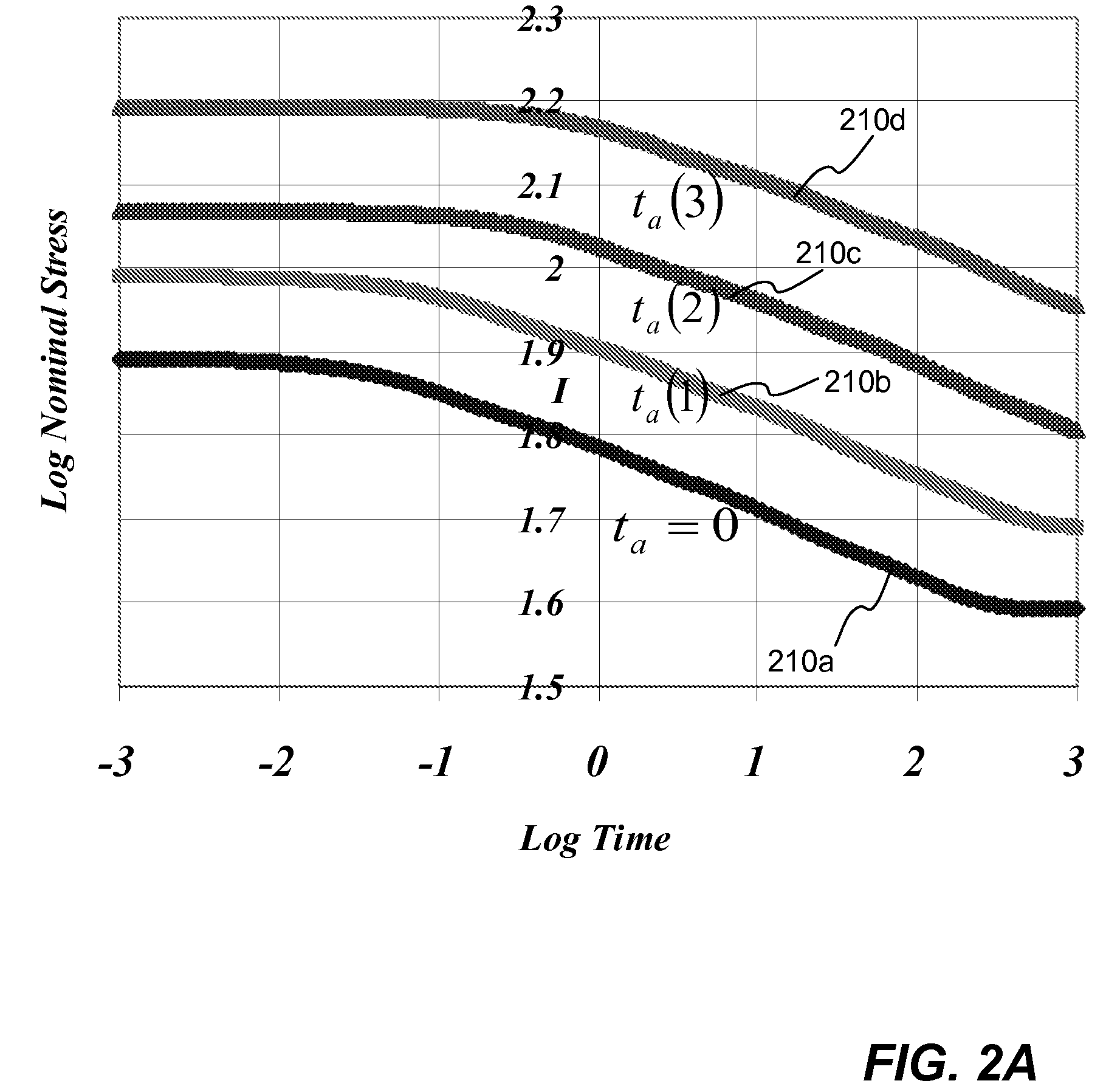

Methods and systems for enabling simulation of aging effect of a chrono-rheological material in computer aided engineering analysis

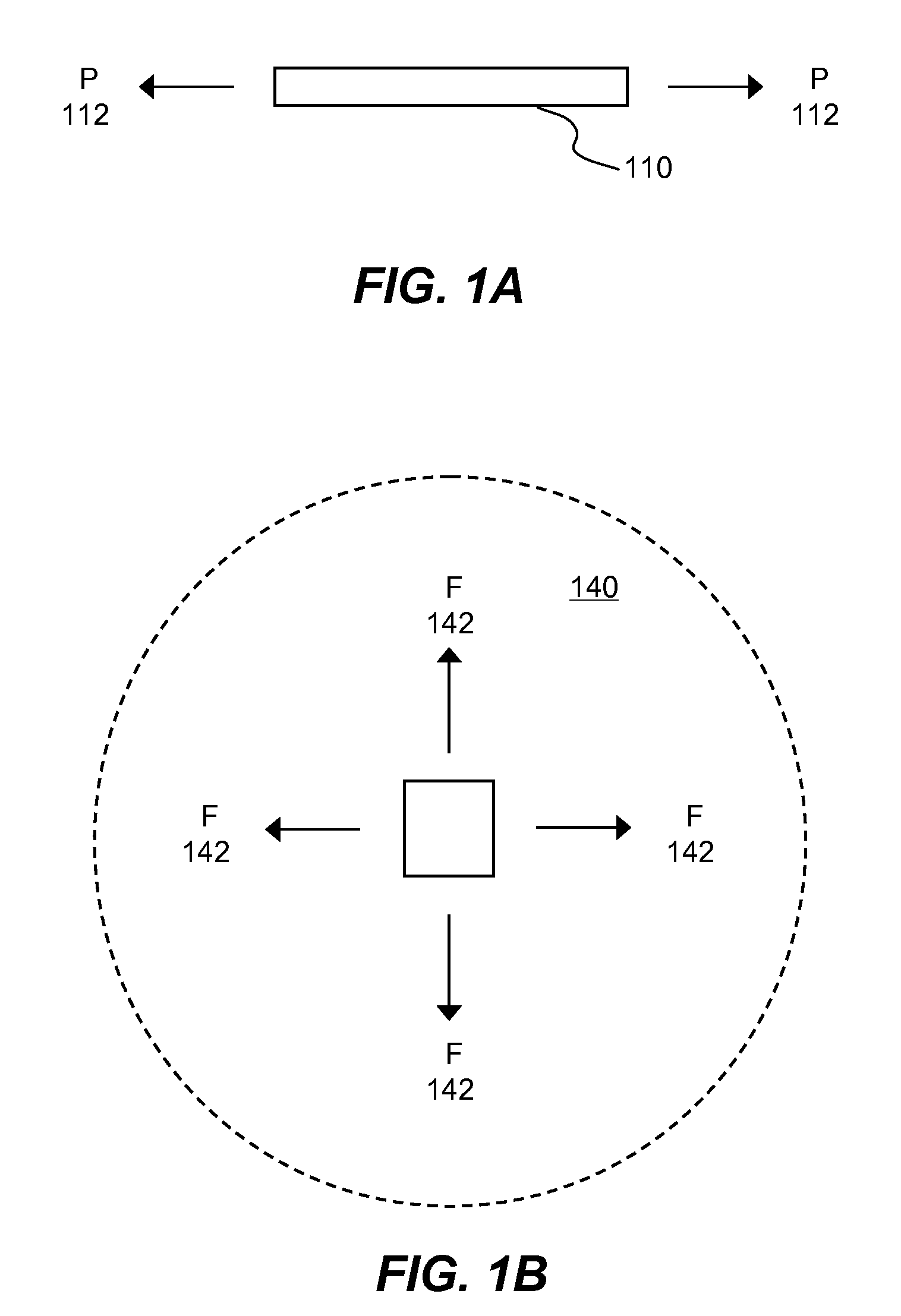

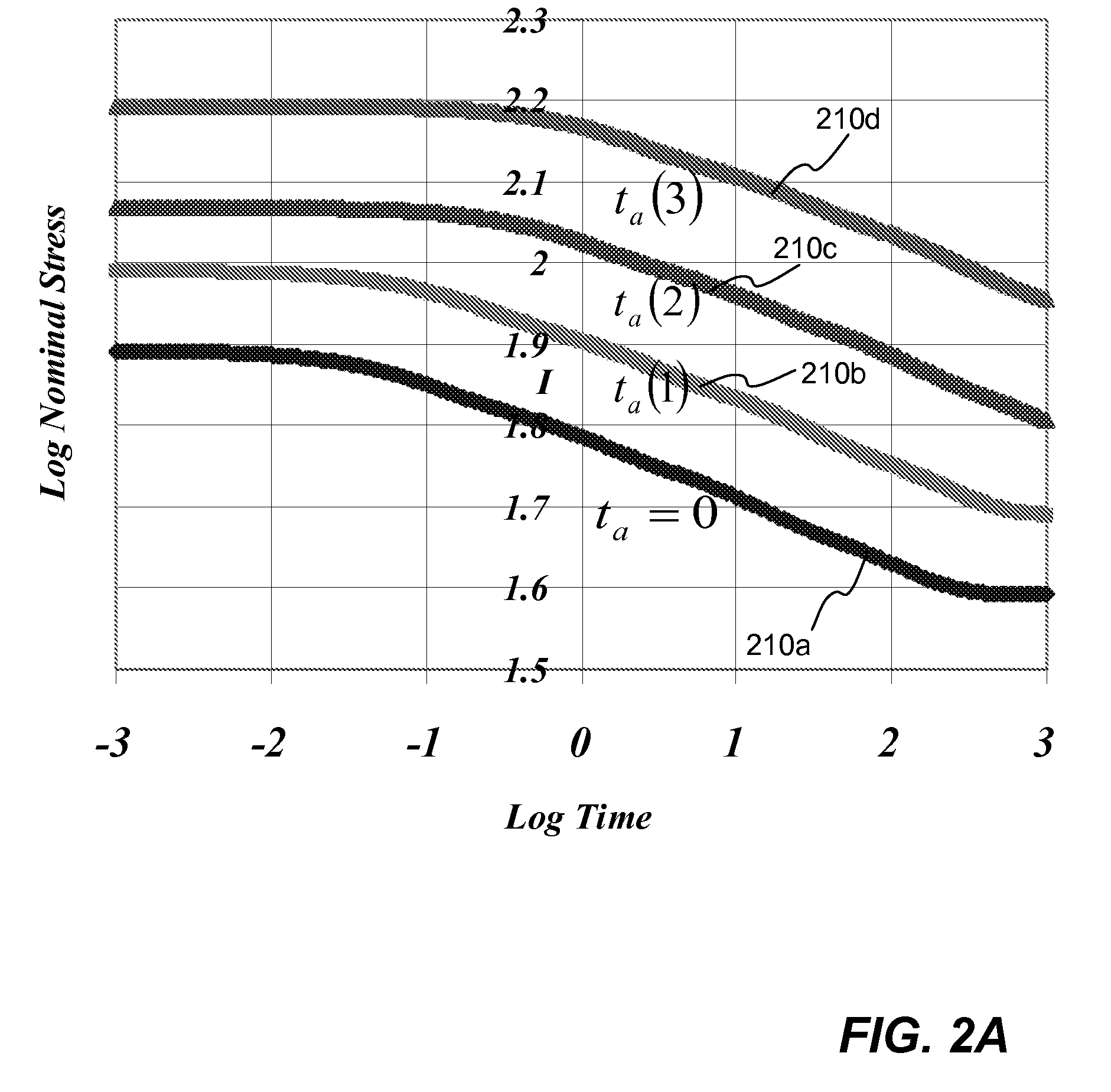

Methods and systems for enabling simulation of material aging effect of chrono-rheological materials in computer aided engineering (CAE) analysis are disclosed. According to one aspect, a set of material property tests is conducted for a chrono-rheological material of interest. Each test obtains a series of material properties such as relaxation test data at different age. The relaxation test data are measured by maintaining a specimen of the chrono-rheological material at a predetermined strain. A set of first and second time-dependent material aging effect parameters is determined by shifting and matching the series of relaxation test data between each pair of the tests. The set of first and second time-dependent material aging effect parameters in conjunction with a CAE analysis application module with a chrono-rheological material constitutive equation configured therein are then used for simulating material aging effect by performing a CAE analysis of an engineering structure containing at least in part the chrono-rheological material.

Owner:ANSYS

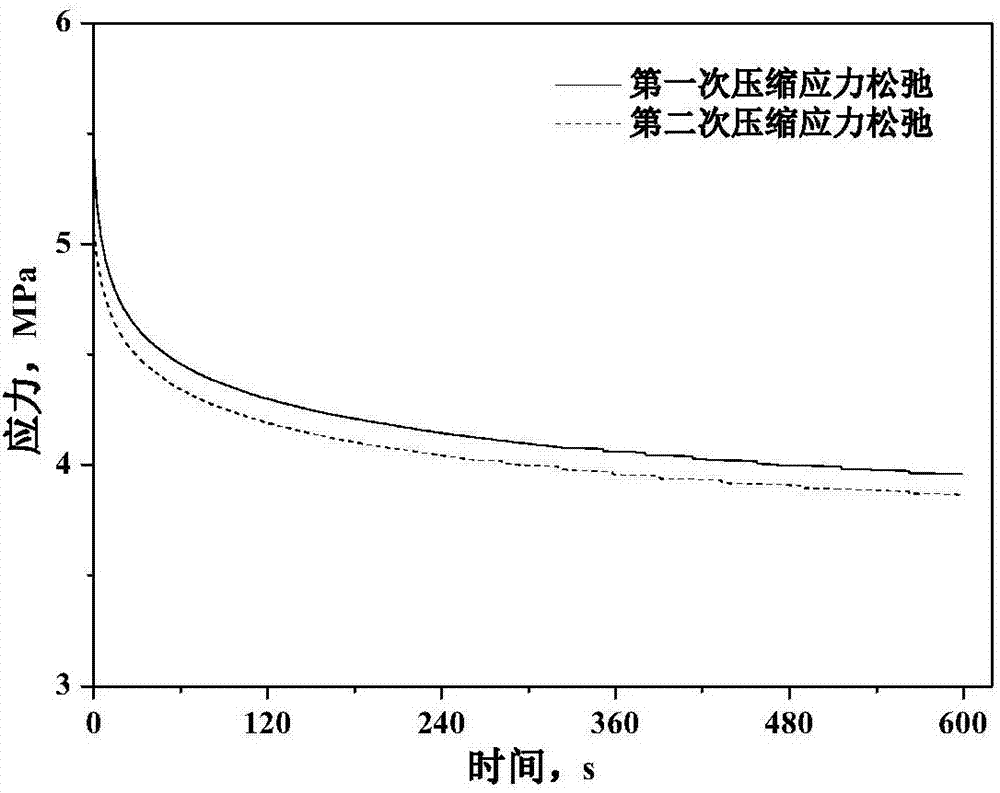

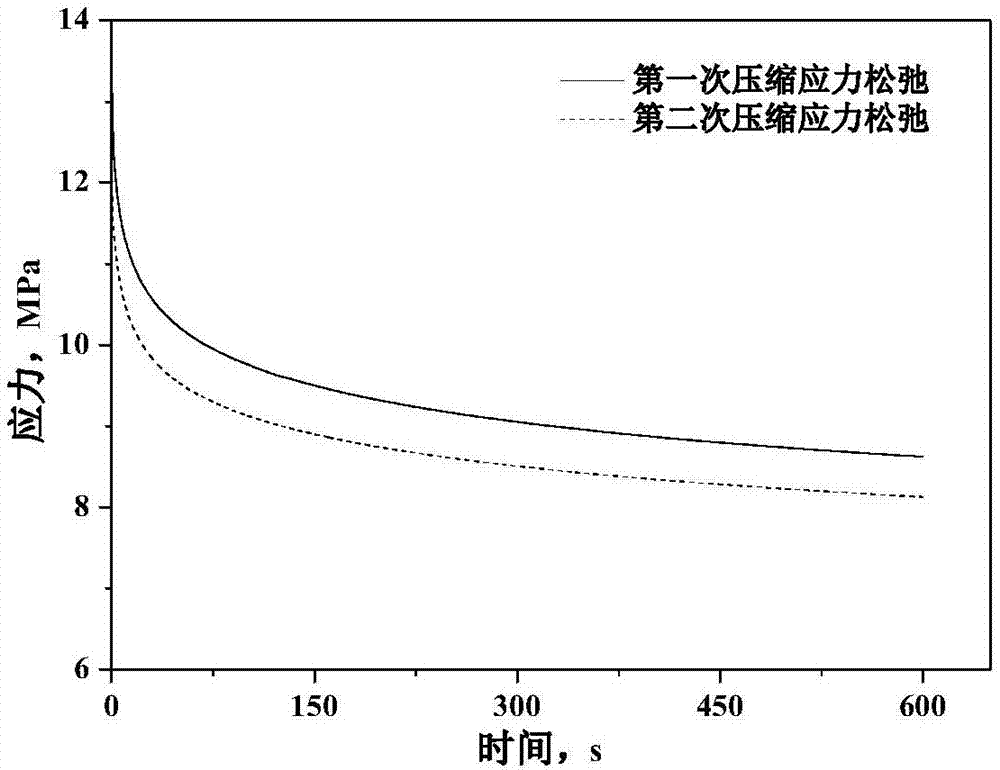

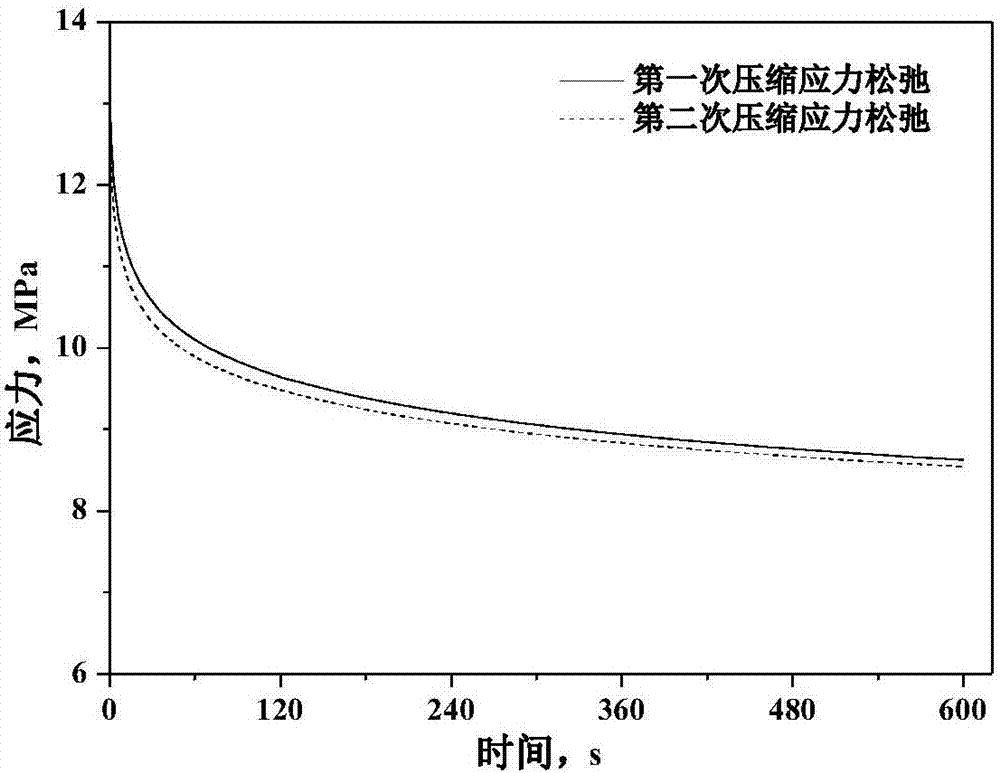

Thermoplastic vulcanizate compression stress relaxation reversible recovery behavior characterization method

The invention relates to a thermoplastic vulcanizate compression stress relaxation reversible recovery behavior characterization method, which provides an effective method for qualitative and quantitive characterization of reversible recovery. The characterization method comprises the steps of a, applying a compression strain on a sample, measuring a primary stress relaxation behavior, wherein the initial height of the sample is h0, and the height becomes hs when the sample is compressed to the stipulated strain; b, after finishing the primary test, carrying out heat treatment on the sample, and then cooling to the room temperature, wherein the height is h1, and the compression set is recorded as shown in the below figure; c, carrying out secondary compression stress relaxation test on the heat-treated sample, and by adopting the h1 as a baseline, applying the same strain of the primary test; d, reading the maximum stress in a stress relaxation curve, wherein the maximum stress recovery rate is equal to (the secondary stress relaxation maximum stress / the primary stress relaxation maximum stress) x 100 percent; e, qualitatively judging a reversible recovery degree according to a close degree of two-time stress relaxation behavior curves; and quantitatively judging the reversible recovery degree according to the compression set and the maximum stress recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

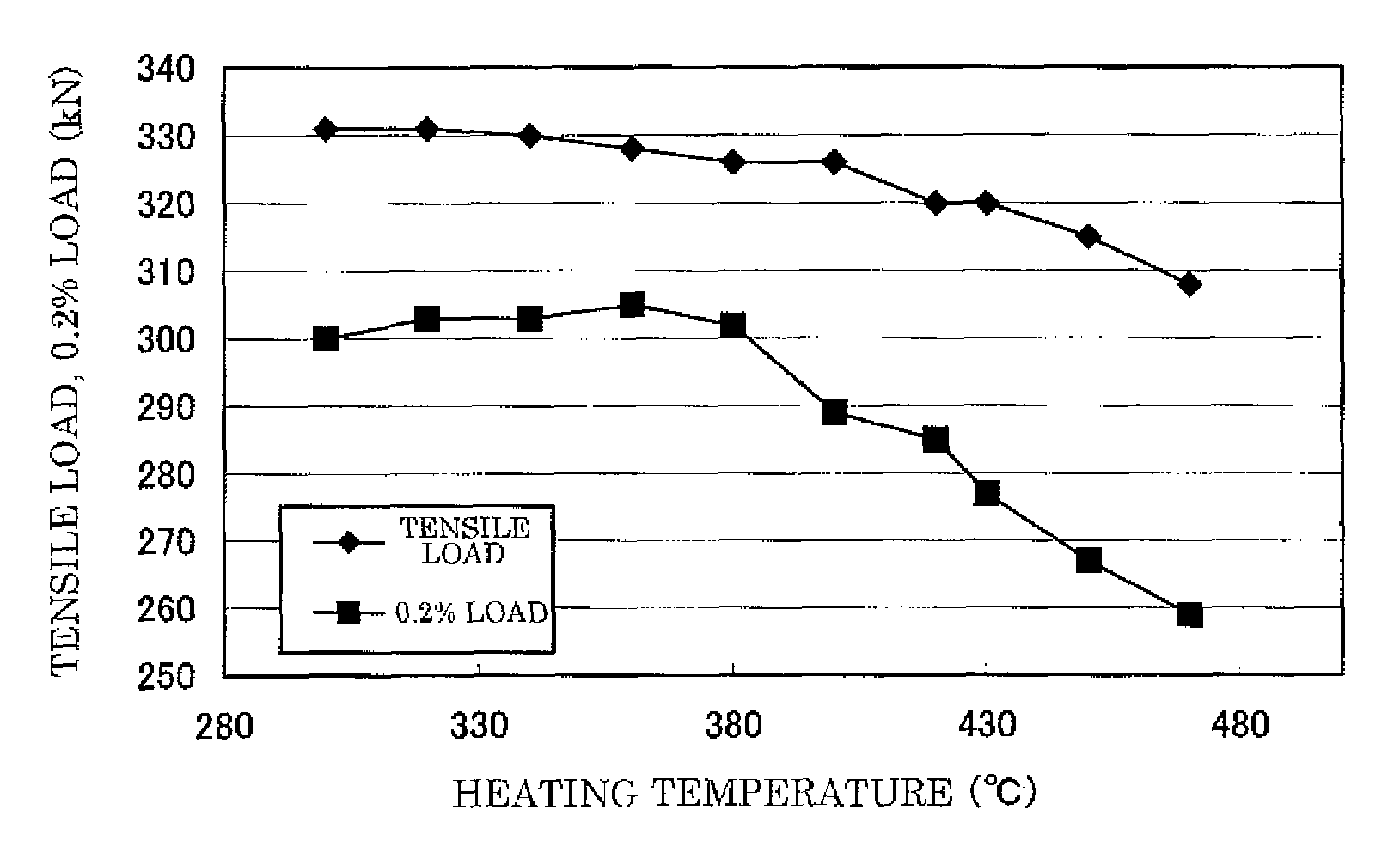

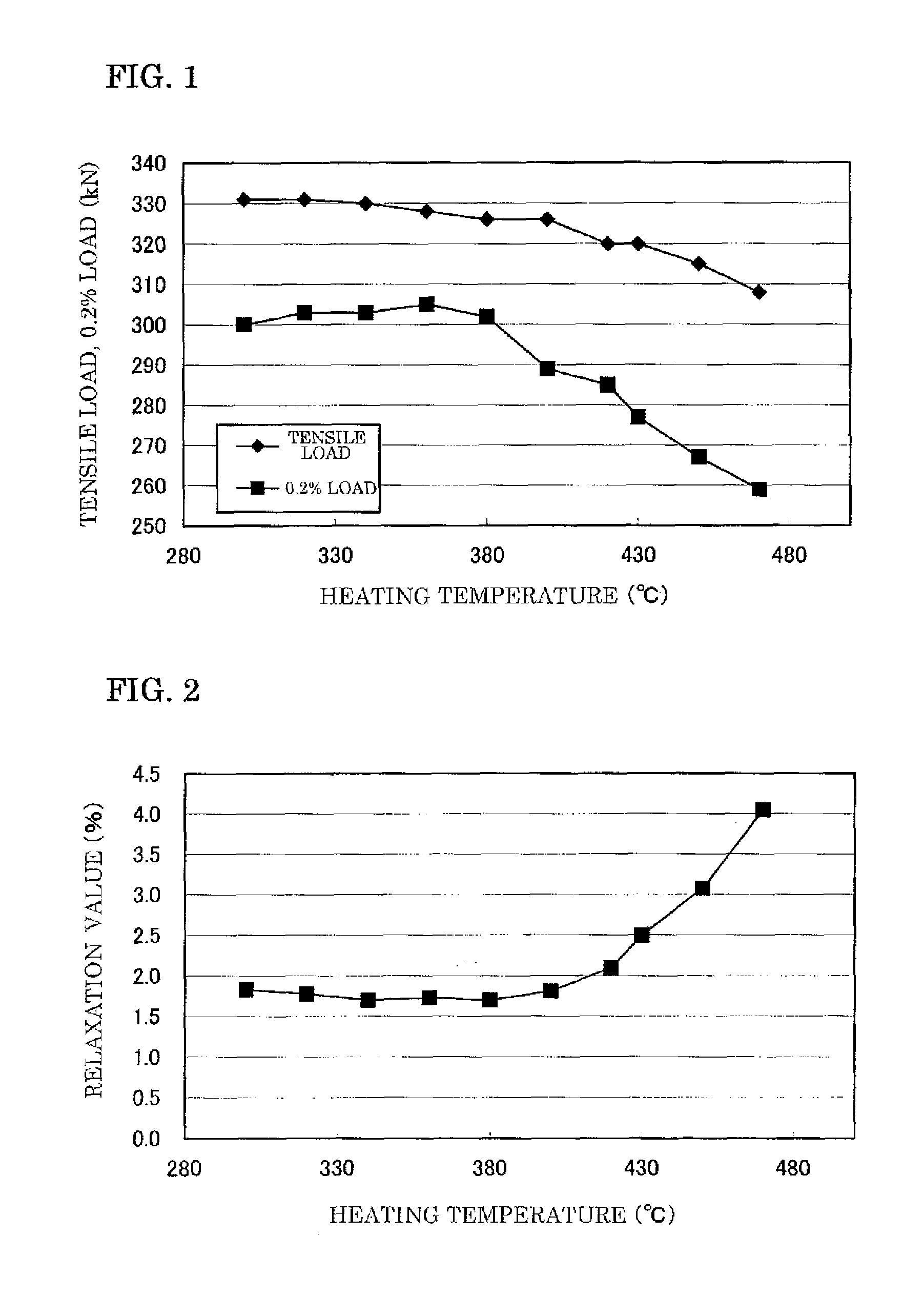

High-strength prestressing strand, method for manufacturing the same, and concrete construction using the same

ActiveUS7861507B2High strengthPractical to useSolid state diffusion coatingBuilding reinforcementsPre stressRelaxation test

Owner:SUMITOMO ELECTRIC IND LTD

Testing equipment for normal temperature and high temperature stress relaxation of flat spring

InactiveCN102650581AEasy accessAccurate acquisitionInvestigating material hardnessTesting equipmentRelaxation test

The invention provides testing equipment for normal temperature and high temperature stress relaxation of a flat spring. The testing equipment mainly comprises a base, limiters, an upper plate, a pressure sensor, a pressure head, a front lateral plate and a rear lateral plate, wherein the front lateral plate and the rear lateral plate are respectively fixed on the front and the rear sides of the base, the pressure head is fixed at the lower end of the pressure sensor, the upper end of the pressure sensor is fixed on the upper plate, the upper plate is positioned right above the base, the upper plate and the base are fixed together through two limiters, one end of a flat spring to be tested is fixed on the upper side of the front lateral plate through a bolt, the other end of the flat spring extends into a groove formed in the upper side of the rear lateral plate, bottom surfaces of the grooves in the upper lateral surface and the rear lateral surface of the front lateral plate are positioned on the same horizontal plane, and the pressure head is in line contact with the sample. The equipment provided by the invention is simple and convenient to design, is easy to process, requires no determination of the relationship between the stress and the deflexion, is simple to measure and obtain the testing data, ensures the accuracy, the repeatability and the reproducibility of the stress testing results, and improves the accuracy of the measured data.

Owner:BEIHANG UNIV

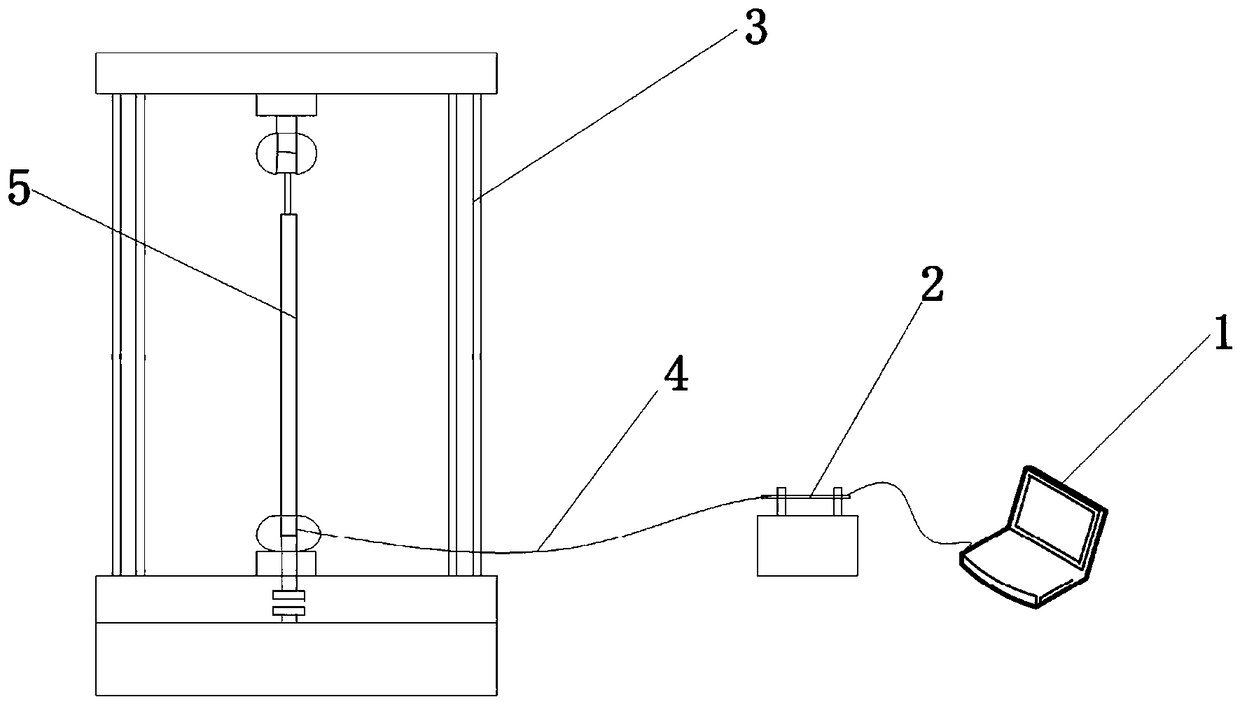

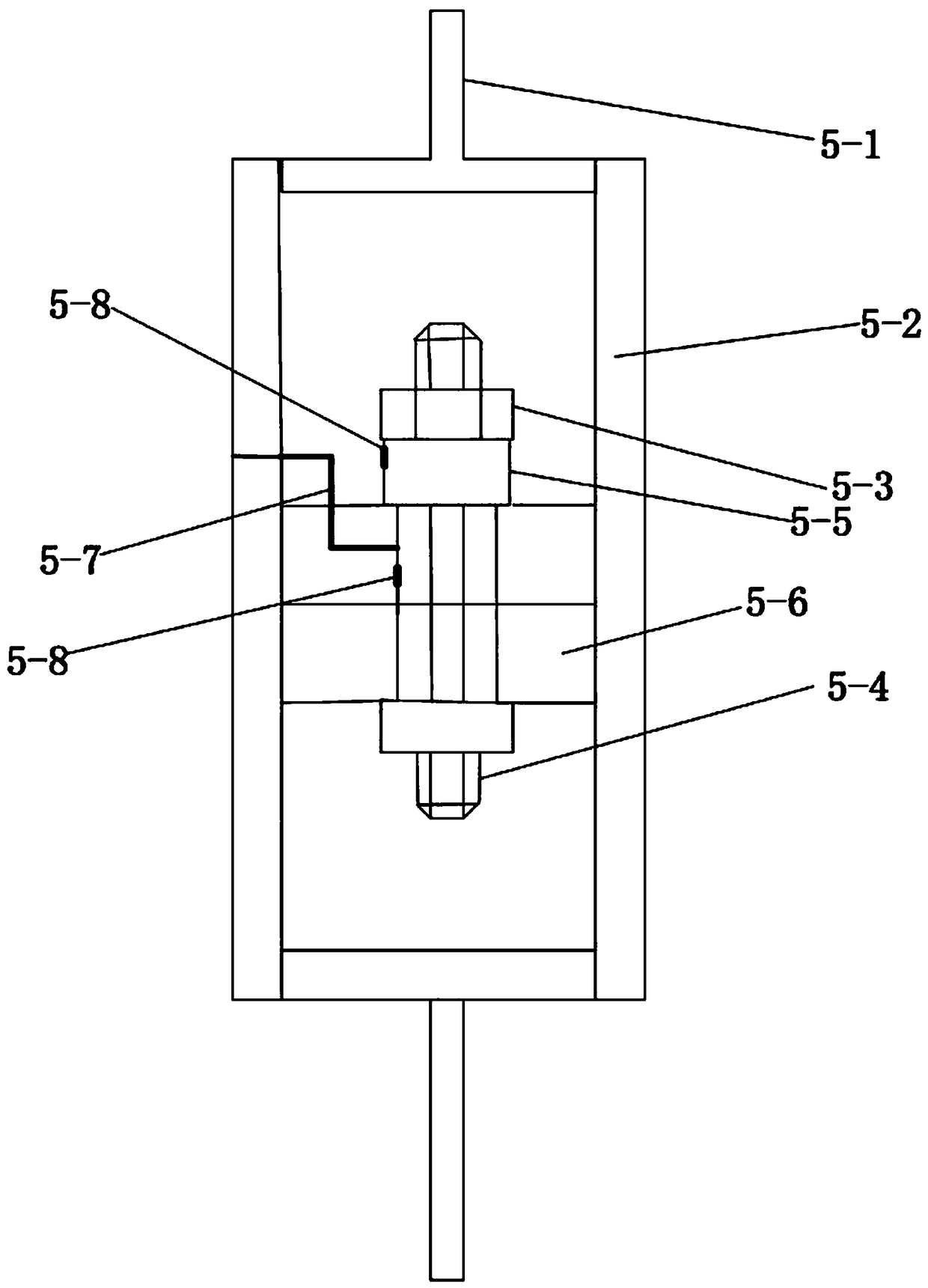

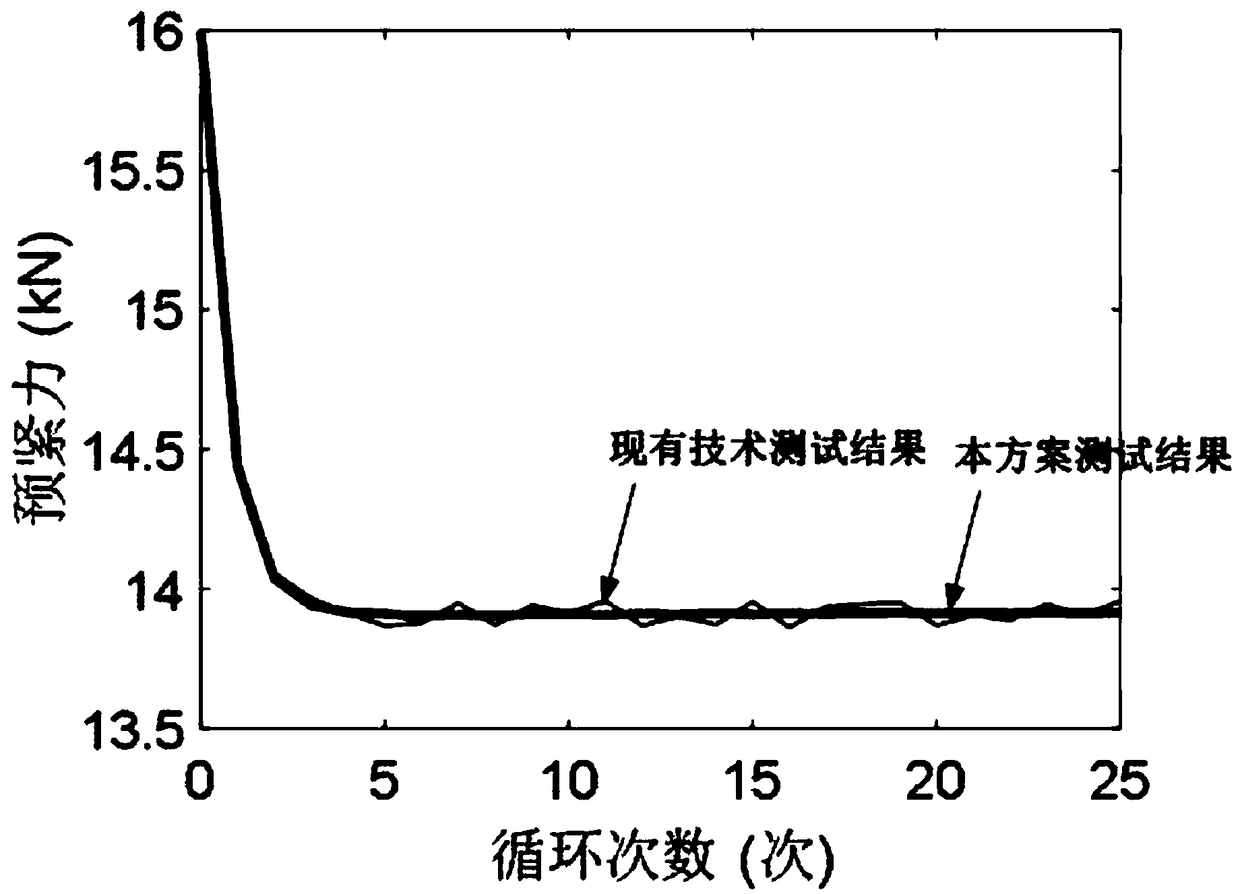

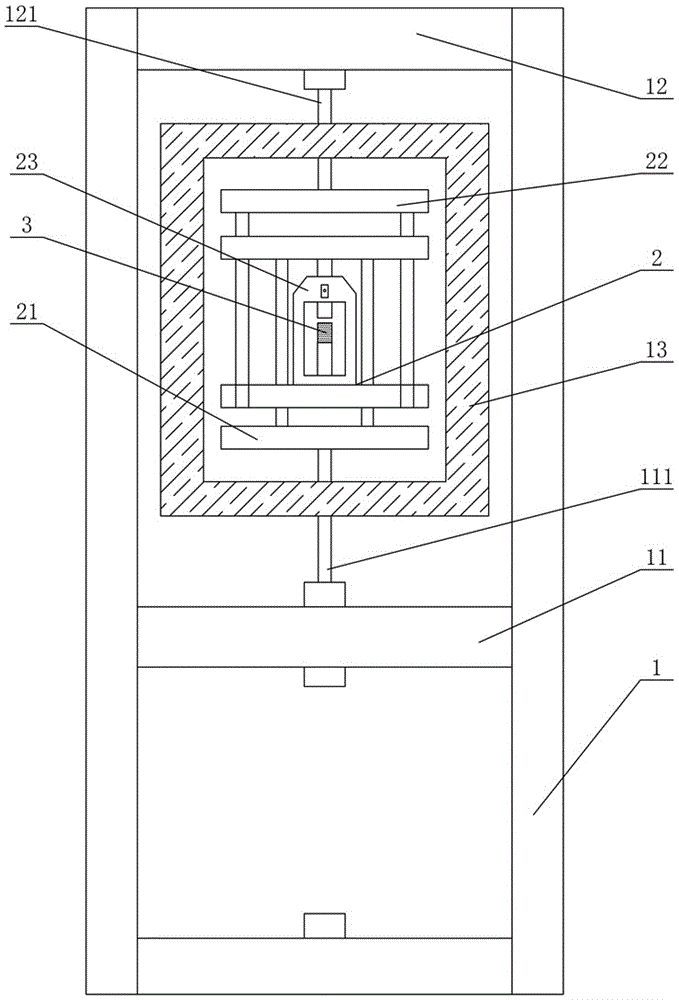

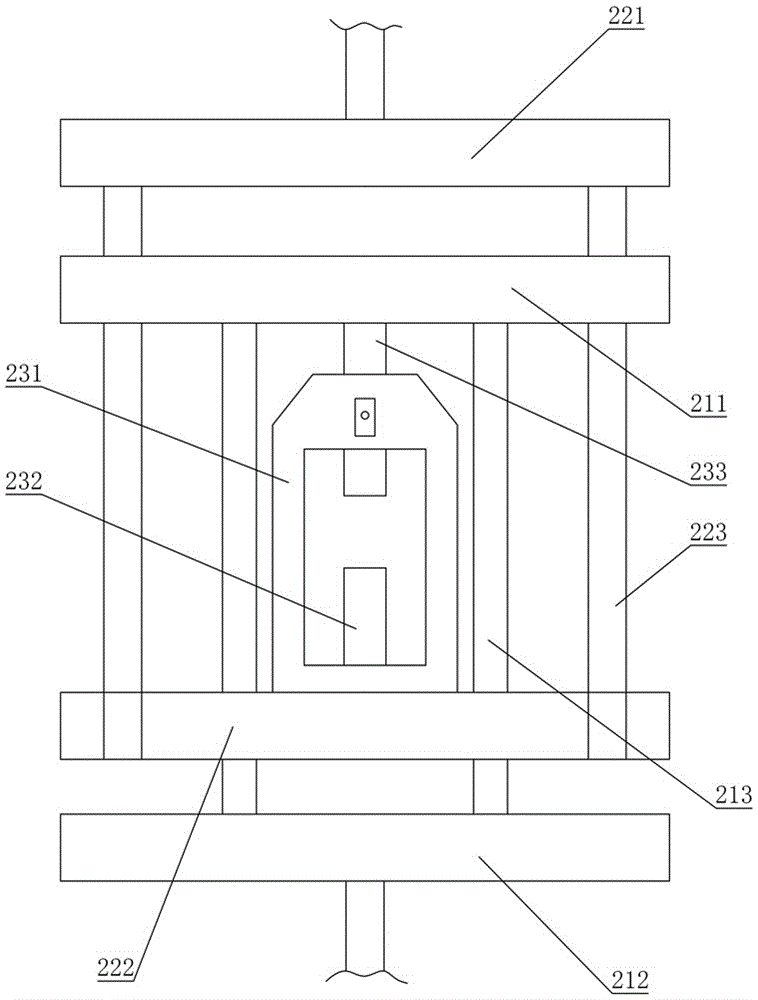

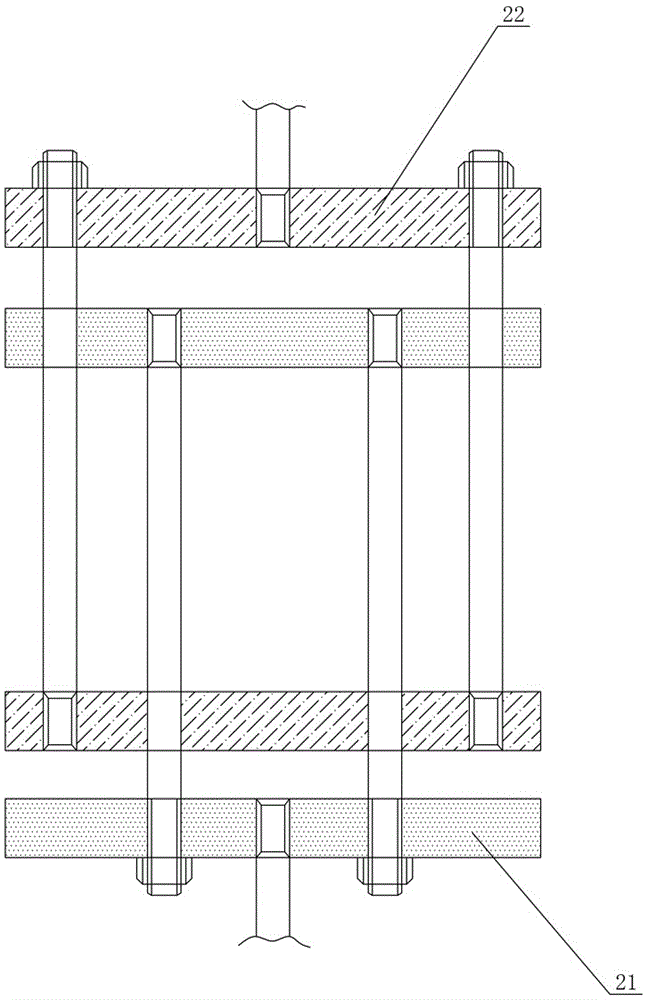

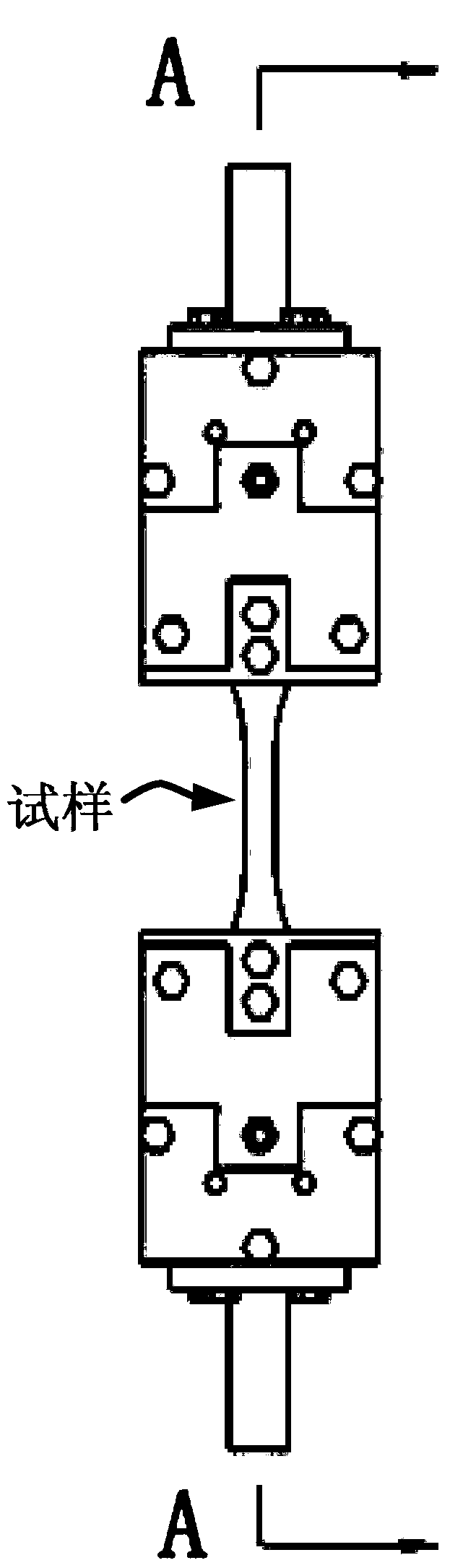

NiTi memory alloy bolt connector self-relaxation test device and method

PendingCN108387468ASolve the problem of accurate slackImprove test accuracyMaterial strength using repeated/pulsating forcesRelaxation testData acquisition

The invention discloses a NiTi memory alloy bolt connector self-relaxation test device and method. The device is connected with a strain data acquisition instrument by utilizing a data acquisition unit; the strain data acquisition instrument is connected with a cyclic stretching tooling through a strain data leading-out line; the cyclic stretching tooling is mounted on electronic stretching equipment. The method is that a stretching rod is connected with a stretching sleeve through threads, a bolt is tightened on two connected parts through nuts, a strain gauge conductor is led out from holesin the connected parts, the stretching sleeve is connected with the connected parts through threads, and a strain gauge is bonded to a test gasket. The NiTi memory alloy bolt connector self-relaxationtest device and method disclosed by the invention have the beneficial effects that the cyclic tensile loading test of bolt connection is performed by utilizing a bolt axial cyclic tensile test device, the self-relaxation quantity of the bolt can be accurately measured, and a new way and a scheme are provided for accurate measurement on bolt self-relaxation.

Owner:GUILIN UNIV OF AEROSPACE TECH

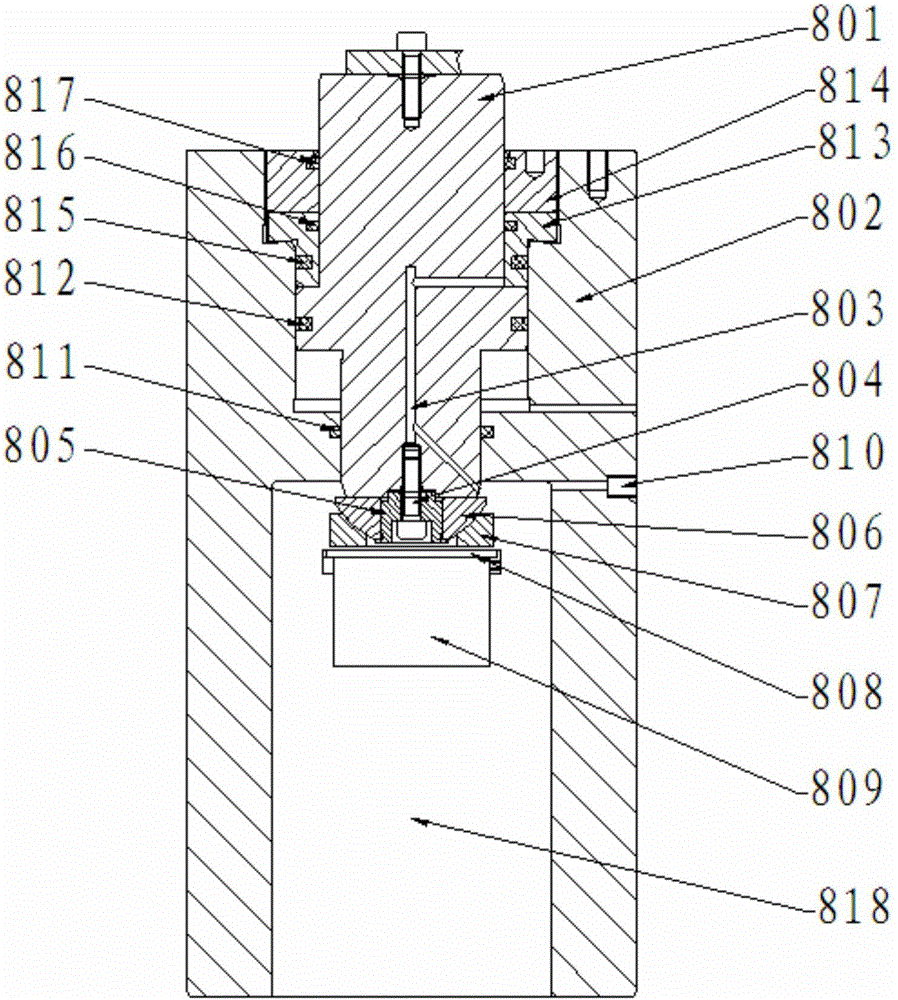

Compression stress relaxation test apparatus for rubber test specimens

InactiveCN105910901AGuaranteed control accuracyGuaranteed measurement accuracyMaterial strength using tensile/compressive forcesRelaxation testTest chamber

The invention discloses a compression stress relaxation test apparatus for rubber test specimens. The compression stress relaxation test apparatus comprises an electronic universal testing machine and a test specimen loading component. The electronic universal testing machine comprises a movable transverse beam and a static transverse beam, a test chamber is arranged between the movable transverse beam and the static transverse beam, a connecting rod which extends from the top of the test chamber to an inner cavity of the test chamber is arranged on the static transverse beam, a draw bar which extends from the bottom of the test chamber to the inner cavity of the test chamber is arranged on the movable transverse beam, the test specimen loading component is positioned in the test chamber, the top of the test specimen loading component is connected with the connecting rod, the bottom of the test specimen loading component is connected with the draw bar, and the test specimen loading component can be driven by the draw bar to apply compression load on a rubber test specimen in the test specimen loading component. The compression stress relaxation test apparatus has the advantages that the compression stress relaxation test apparatus is simple in structure, easy to mount, convenient to operate and high in accuracy class, and the rubber test specimens, particularly small rubber test specimens, can be tested by the aid of the compression stress relaxation test apparatus at various temperatures.

Owner:NAT UNIV OF DEFENSE TECH

Methods and systems for enabling simulation of aging effect of a chrono-rheological material in computer aided engineering analysis

Methods and systems for enabling simulation of material aging effect of chrono-rheological materials in computer aided engineering (CAE) analysis are disclosed. According to one aspect, a set of material property tests is conducted for a chrono-rheological material of interest. Each test obtains a series of material properties such as relaxation test data at different age. The relaxation test data are measured by maintaining a specimen of the chrono-rheological material at a predetermined strain. A set of first and second time-dependent material aging effect parameters is determined by shifting and matching the series of relaxation test data between each pair of the tests. The set of first and second time-dependent material aging effect parameters in conjunction with a CAE analysis application module with a chrono-rheological material constitutive equation configured therein are then used for simulating material aging effect by performing a CAE analysis of an engineering structure containing at least in part the chrono-rheological material.

Owner:ANSYS

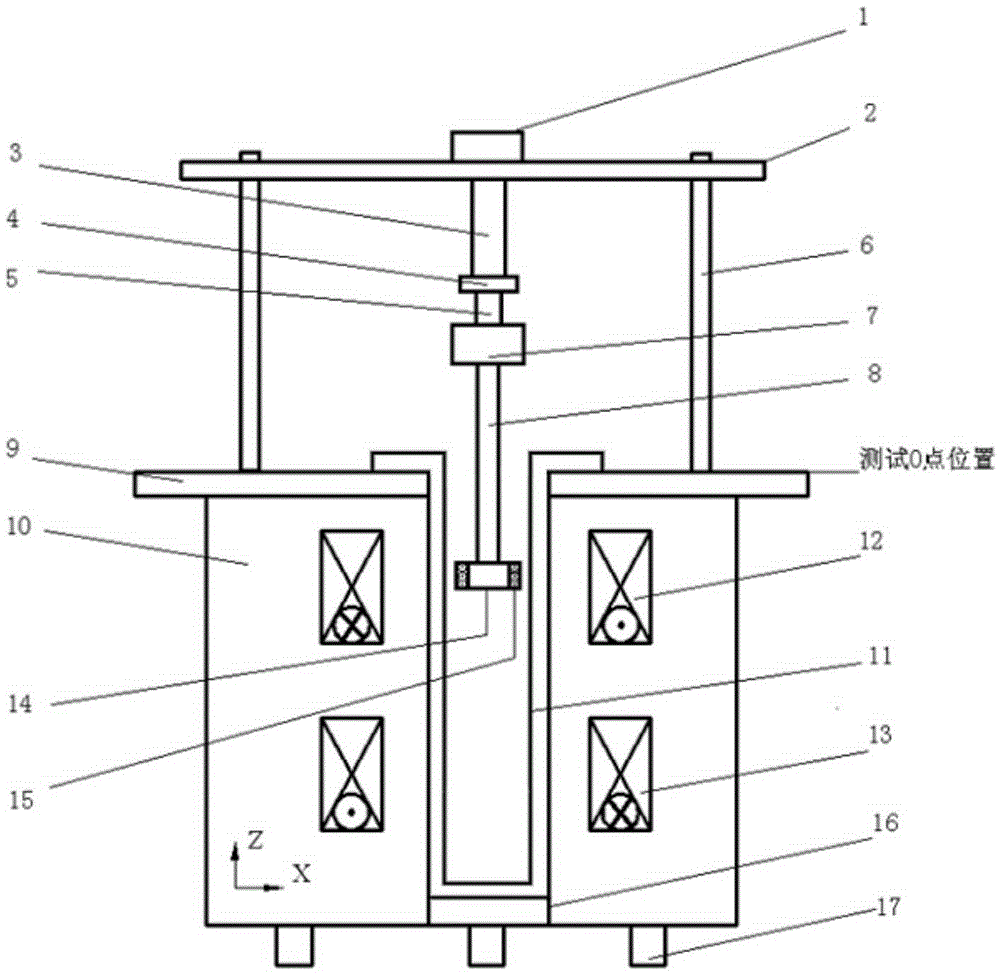

Pseudo-triaxial test device based on dynamic fatigue testing machine

ActiveCN106769493AHigh control precisionComplete protection functionsNuclear energy generationMaterial strength using tensile/compressive forcesRelaxation testEngineering

The invention discloses a pseudo-triaxial test device based on a dynamic fatiguetesting machine. The device comprises a stand column, wherein an upper hydraulic chuck and a lower hydraulic chuck are correspondingly arranged on the upper end and the lower end of the stand column; the upper hydraulic chuck is connected to the upper end of an upper pressure-transmitting column; the lower end of the upper pressure-transmitting column is connected with an upper connecting block; a pressure chamber main body is fixedly arranged on the lower end of the upper connecting block; a pressure chamber base is correspondingly arranged under the pressure chamber main body, and is fixedly arranged on a trolley; a lower connecting block is arranged under the trolley, is fixedly arranged on the trolley through a connecting plate, and is connected with the lower hydraulic chuck. According to the device designed by the invention, equipment is refitted on the basis of the dynamic fatigue testing machine, so that an elastic parameter of a rock can be measured, and a strain test, a creep test and a relaxation test are finished at different confining pressures, and a flow parameter of a stratum is tested, and the breaking tenacity of the rock and the in-situ stress of the stratum are tested under a simulated in-situ stress level.

Owner:PLA UNIV OF SCI & TECH

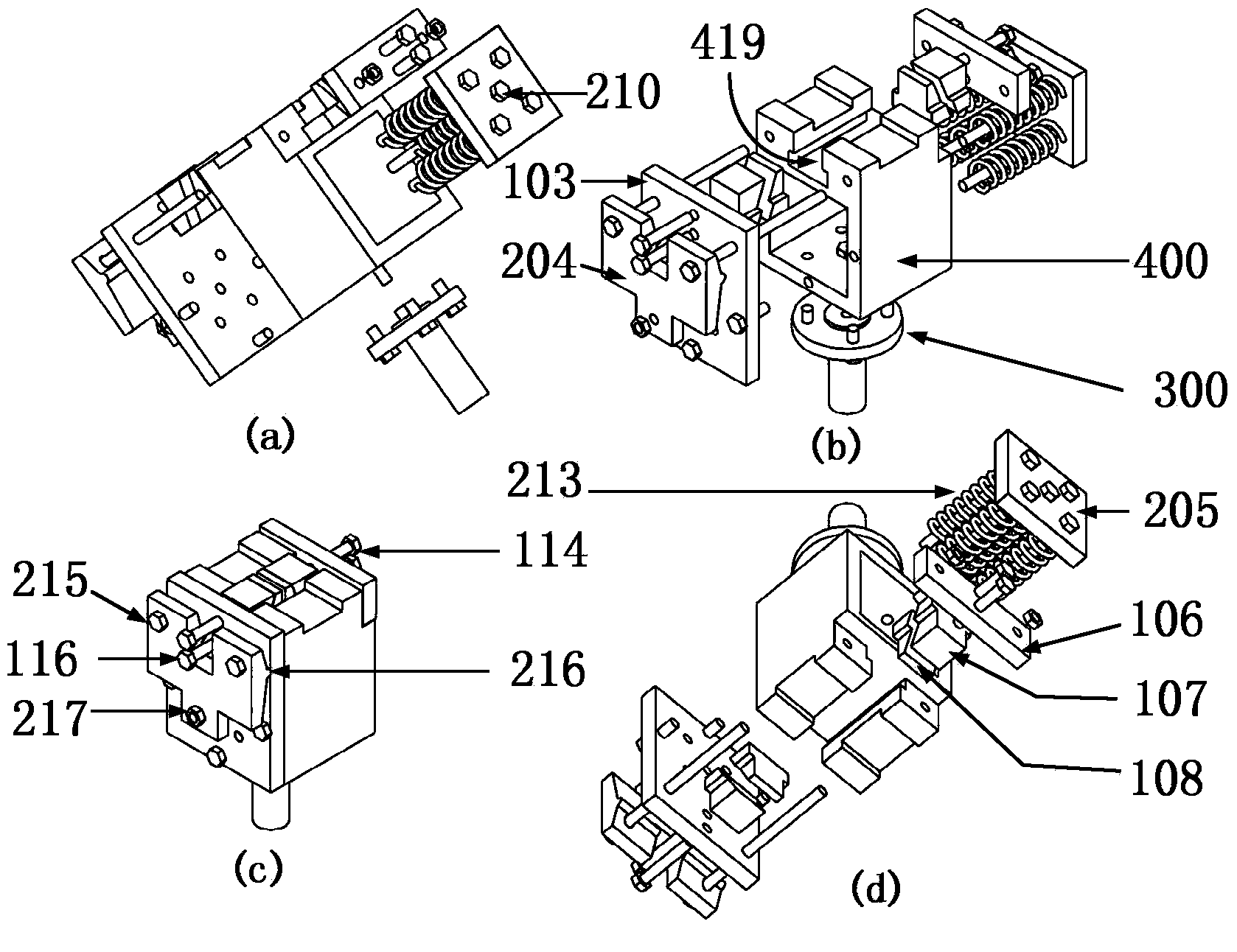

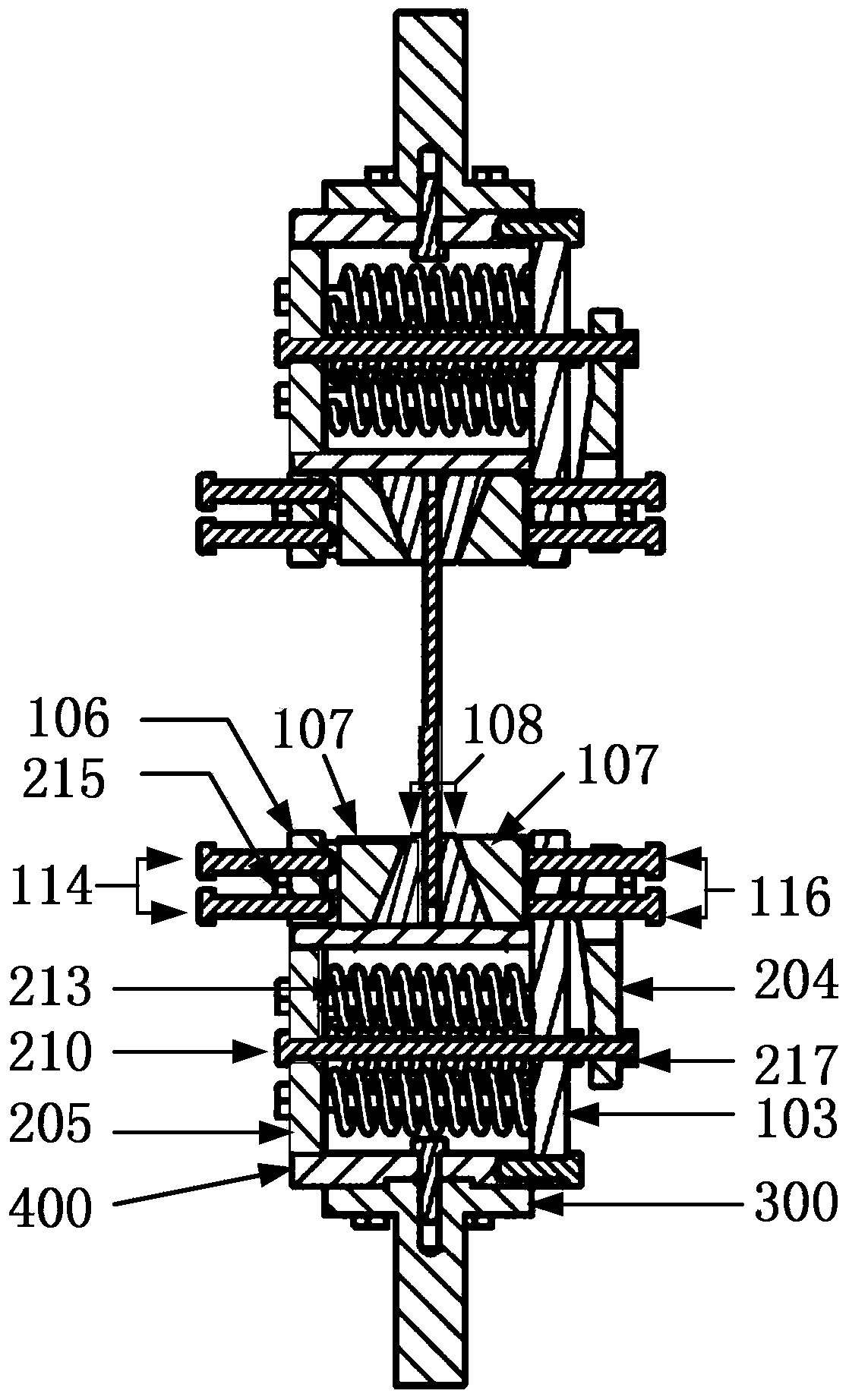

Multifunctional material test clamp based on lever principle

The invention relates to a multifunctional material test clamp based on a lever principle. The multifunctional material test clamp comprises a main box (400), a sample clamping mechanism (100), a clamping force adjustment mechanism (200) and a switching flange (300), wherein the sample clamping mechanism (100) and the clamping force adjustment mechanism (200) are arranged on two inner sides of the main box (400) separately; the switching flange (300) is connected to the main box to be linked with a main shaft of a tester; the clamping force adjustment mechanism transfers force on a spring to a clamping block through a lever warping plate (204). The multifunctional material test clamp can be used for discriminating the magnitude of clamping force, is suitable for clamping of different types of materials by virtue of an enough clamping force adjusting range, and can be conveniently used in a warm humid environment box. The clamping force of the test clamp cannot be quickly decreased due to micro-deformation of a sample, and thus the phenomenon of slippage of the sample in the test process can be effectively prevented. The multifunctional material test clamp is applied to different types of samples, is used for single-axis or multi-axis pulling-pressing circulation tests, torsion tests and relaxation tests, and has the advantages of simple structure, complete functions, convenience in processing, economy, practicality and the like.

Owner:SOUTHWEST JIAOTONG UNIV

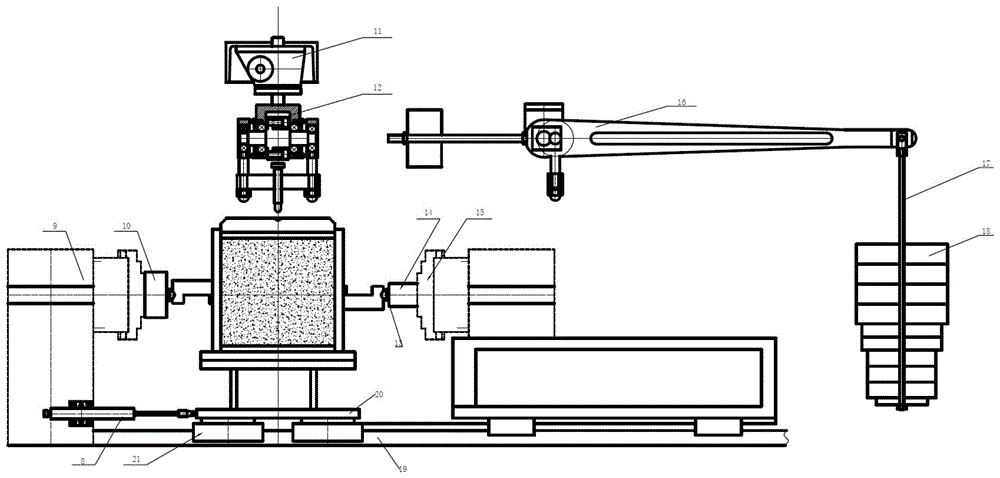

Earth-rock aggregate direct shear relaxation test device and test method

ActiveCN106556542AAccurate measurementHigh degree of automationMaterial strength using steady shearing forcesElectric machineryRelaxation test

The invention discloses an earth-rock aggregate direct shear relaxation test device and test method. The device comprises a direct shearing box seat, a direct shearing box, a displacement sensor, a first force sensor, a second force sensor, a strain stress control pushing device, a heading seat, a separator plate, a base plate, a linear slide rail, a rectangular motor and a normal loading device. The method comprises sample pressing, stress change acquisition and strain constant maintenance processes. The device and the method have the advantages of high measurement precision, meeting of constant strain requirements of direct shear relaxation test through strain-controlled loading, convenience in test, and high result accuracy.

Owner:NANJING UNIV

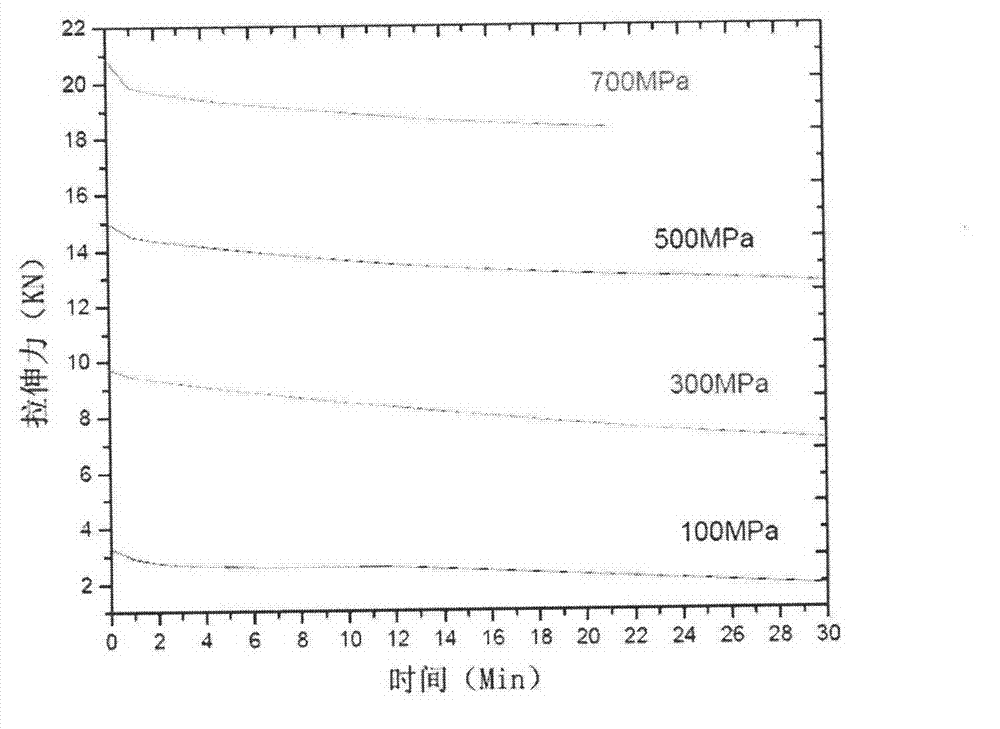

Tensile stress relaxation testing device and method of rubber material

PendingCN108827780ASimple structural designEasy to operateMaterial strength using tensile/compressive forcesRubber materialData acquisition

The invention discloses a tensile stress relaxation testing device and method of a rubber material. The tensile stress relaxation testing device comprises a sample clamping module and a data acquisition module, wherein the sample clamping module is a functional unit for fixing a sample and adjusting and stretching the sample to predetermined elongation, and the data acquisition module is a functional unit for acquiring a tensile stress value corresponding to time. The tensile stress relaxation testing method comprises the steps that firstly, the sample is clamped and fixed to a sample clamp fixing and moving end, the sample is stretched to the predetermined elongation through a rotary clamp movement adjusting knob, the tensile stress value corresponding to testing time is acquired, and then data processing is performed to obtain a tensile stress relaxation curve of the sample and stress relaxation rates corresponding to different service times. The device is simple in structural designand convenient to control actually. The method is a real-time monitoring method, testing results are accurate, the judgment on stress relaxation degree and evolutionary trend is quick, convenient andeffective by adopting the method, and the device and the method are especially suitable for assessment of materials for long-term service.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com