Method for carrying out stress relaxation test on Gleeble3800 hydraulic wedge unit in Jaw control mode

A stress relaxation and control mode technology, applied in the field of thermal simulation test, can solve the problems of difficult to observe the precipitation platform, high price, poor accuracy, etc., to achieve the effect of low cost, cost saving and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

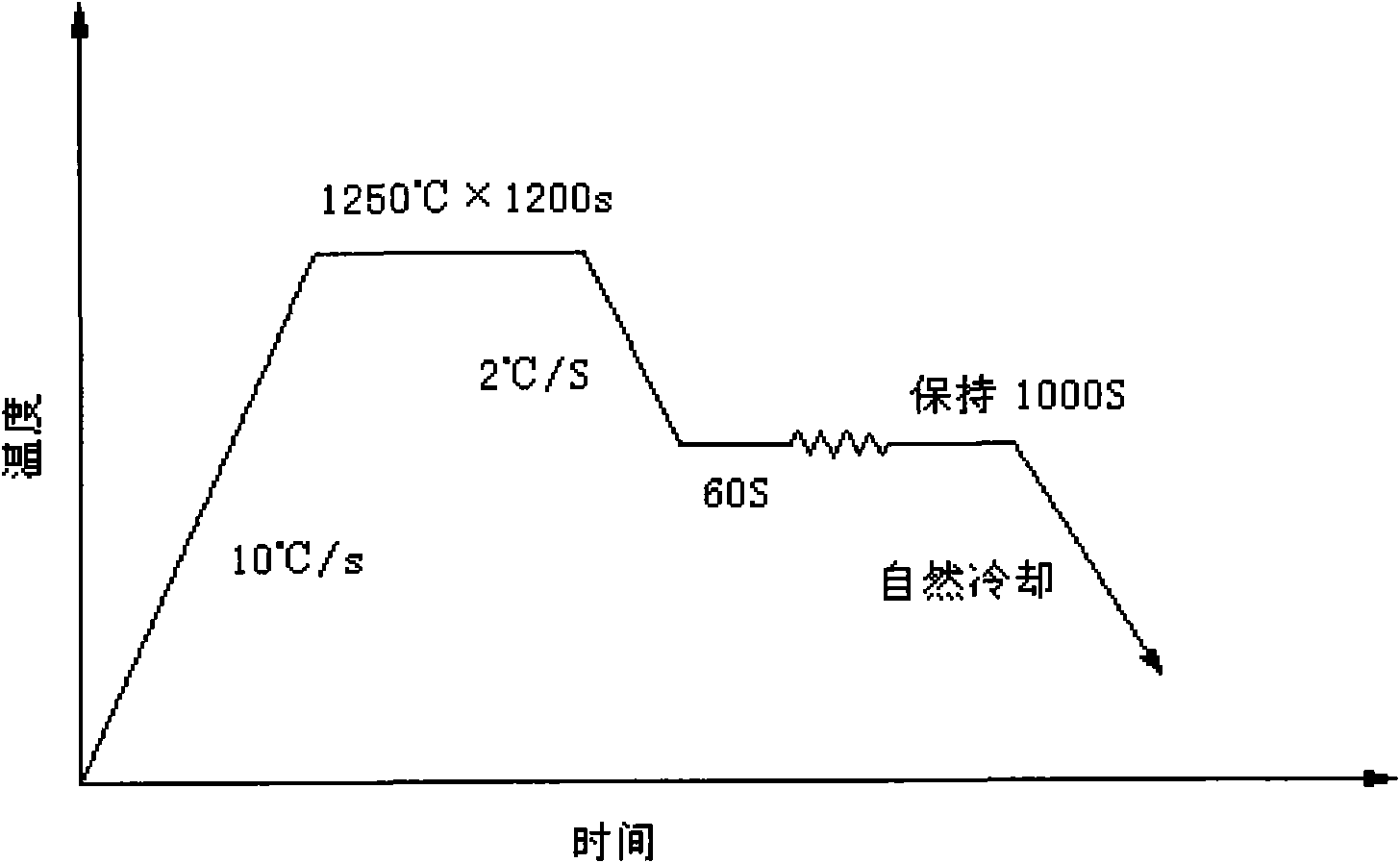

[0024] A method for performing stress relaxation tests on a Gleeble 3800 hydraulic wedge unit using the Jaw control mode, where the stress relaxation test is performed directly on the hydraulic wedge unit. The material selected in this embodiment is Q550D, the deformation amount is 0.2e, and the deformation speed is 0.1e / s. Specifically include the following steps:

[0025] 1) Weld the thermocouple to the sample, use the K-type thermocouple when the sample heating temperature is below 1200°C, and use the S-type thermocouple above 1250°C;

[0026] 2) Apply lubricant to the indenter and the sample to reduce the friction during compression, and use tantalum sheets to isolate the indenter and the sample to prevent the reaction between the indenter and the sample under high temperature conditions;

[0027] 3) Turn on the air hammer, compress the sample, and control the stress at about 100Kg, then turn on the Gleeble3800 thermal simulation testing machine, and move the indenter to ...

Embodiment 2

[0037] Yet another method of performing stress relaxation test on Gleeble3800 hydraulic wedge unit with Jaw control mode, the stress relaxation test is directly performed on the hydraulic wedge unit. The material selected in this embodiment is E36-T, the deformation amount is 0.2e, and the deformation speed is 0.1e / s. Concrete steps are identical with embodiment 1.

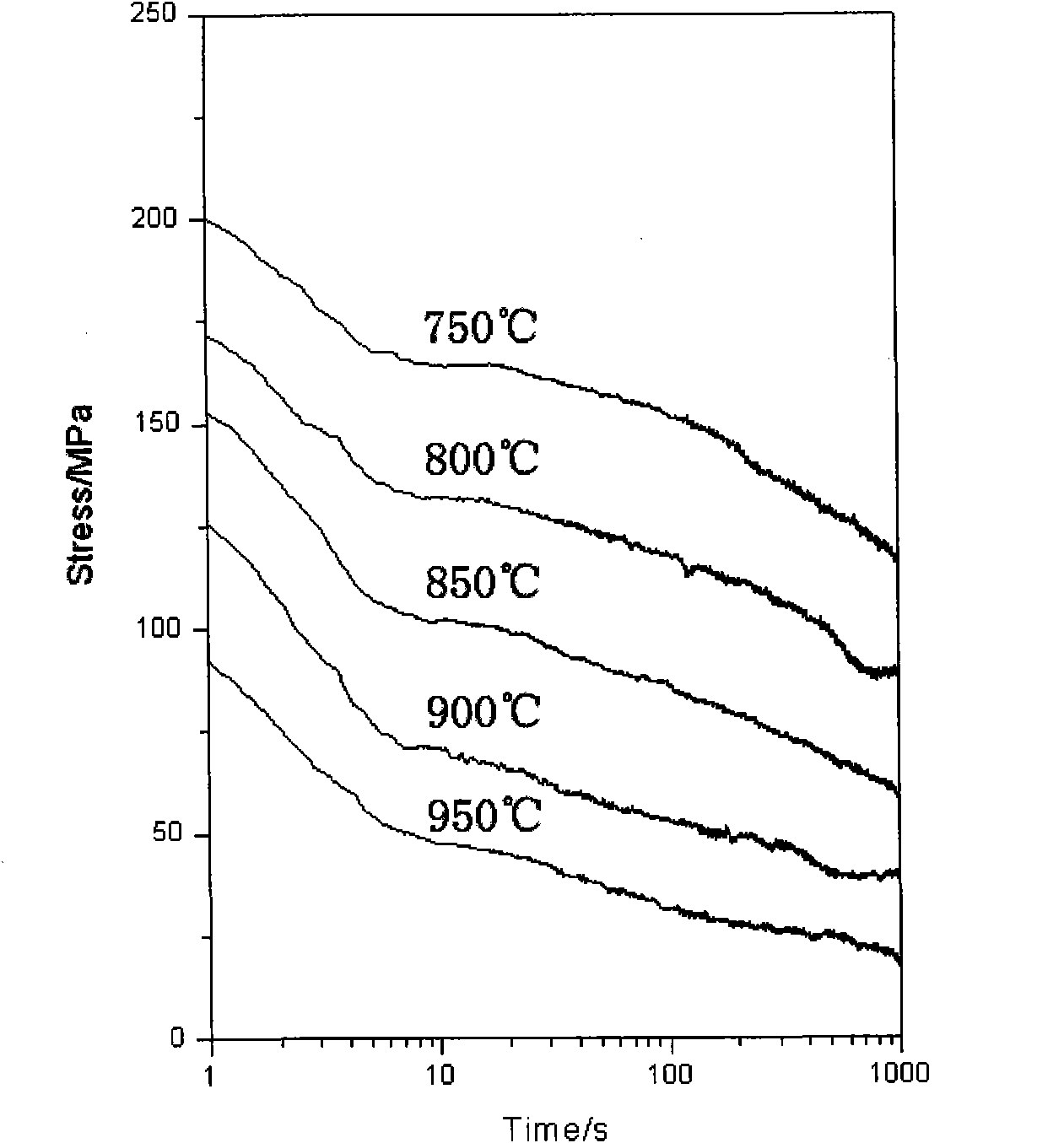

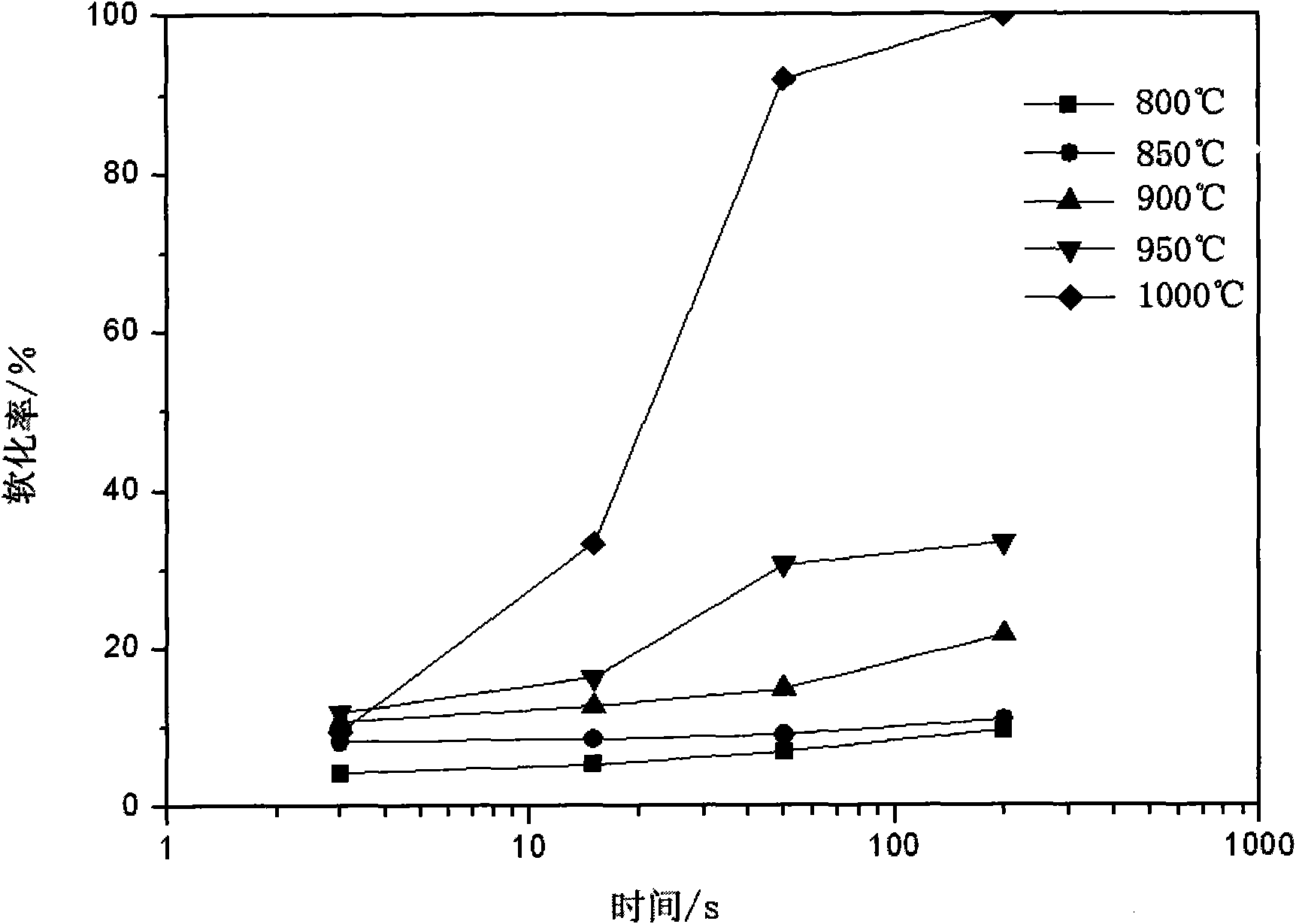

[0038] The measured stress relaxation is as Figure 5 shown. Through the stress relaxation test, it can be seen that the start time of precipitation at 800-900°C is within 10s, and the end time is also within 100s. 20s, the precipitation can play a very good role in inhibiting recrystallization, but as time goes by, the insufficient precipitation leads to the weakening of the effect of inhibiting recrystallization, which completely corresponds to the results of the softening fraction of the double-pass compression test, again It is entirely possible to illustrate the curves for this test stress relaxation. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com