Patents

Literature

74 results about "Stress relaxation test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress relaxation tests are very effective for conducting ageing tests, as substantial amounts of information result with little effort, especially when using the continuous measurement system.

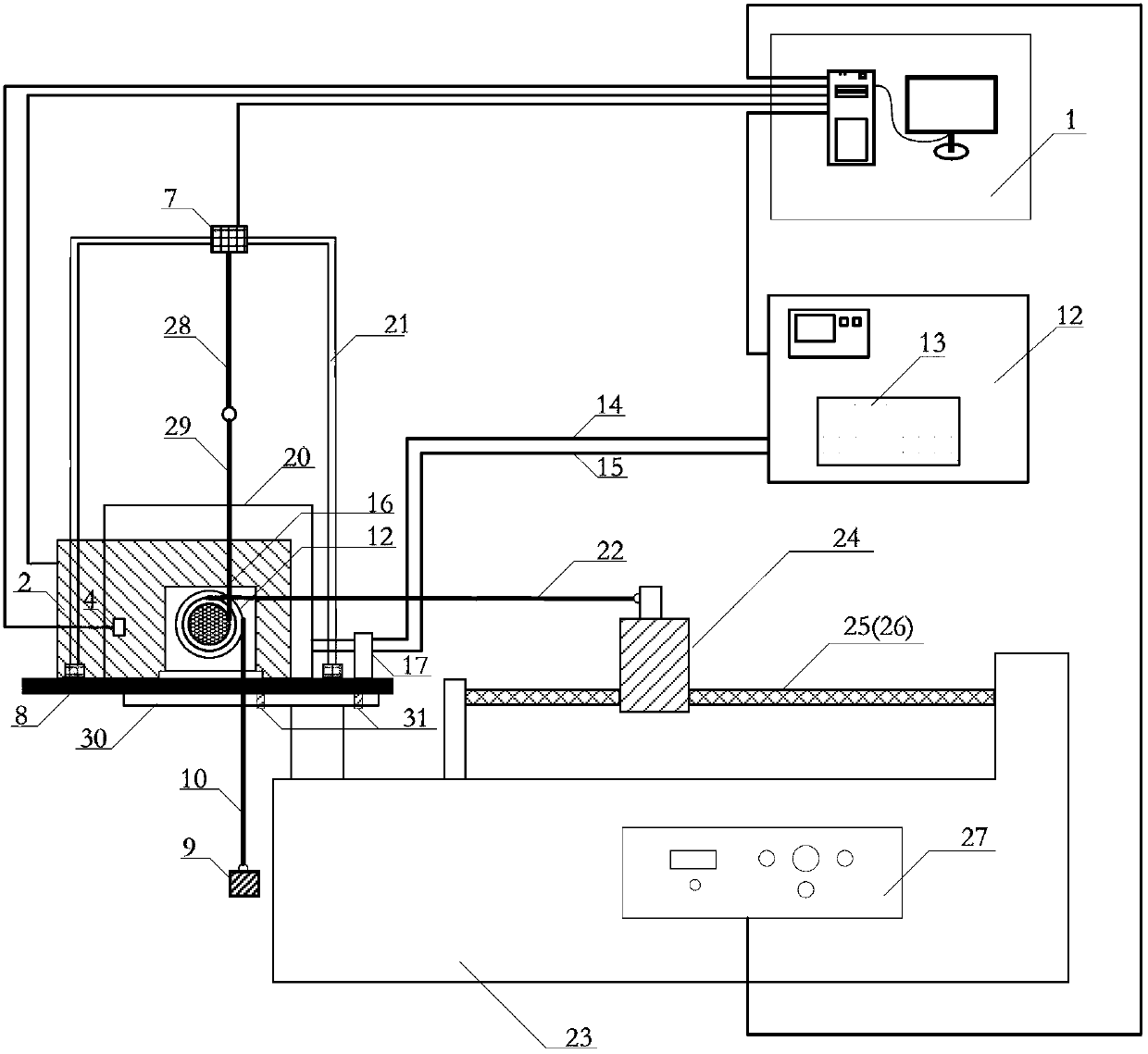

Soil one-dimensional consolidation, penetration and stress looseness comprehensive test apparatus and method of use thereof

InactiveCN1699997AEliminate the effects of excessive errorEarth material testingMaterial strength using tensile/compressive forcesCombined testSoil science

The invention discloses a soil one-dimensional consolidation, penetration, stressing relaxation combined test instrument and usage, which posits punch inside a punch cavity at the bottom of pressure container. It can do consolidation and compression to the same soil sample K0, it also can do soil sample penetration test and stressing relaxation test directly and simultaneously. It can test the soil sample's value of coefficient of static lateral pressure K0 and the process of pore water pressure followed by time. The test instrument and method can arrange soil's consolidation characteristic parameter by test outcome and using theoretical formula penetration method. It can do soil's theological behavior analysis by the outcome of stressing relaxation test.

Owner:CHANGAN UNIV

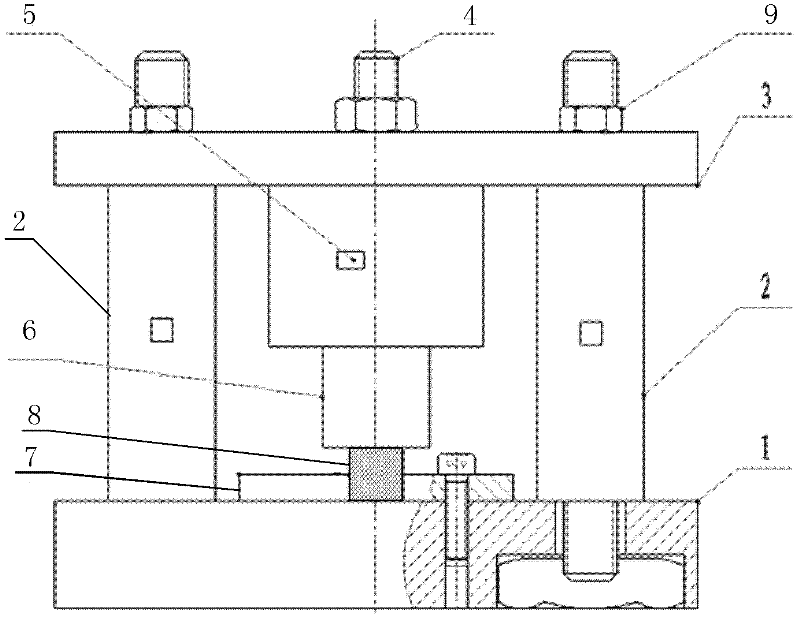

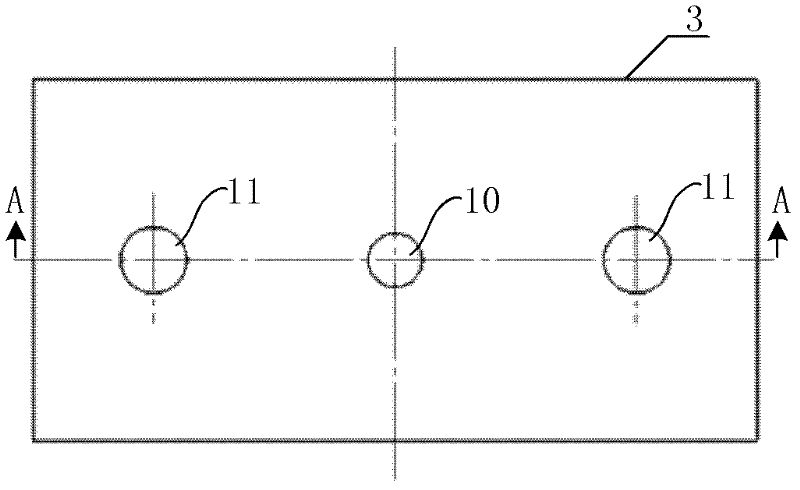

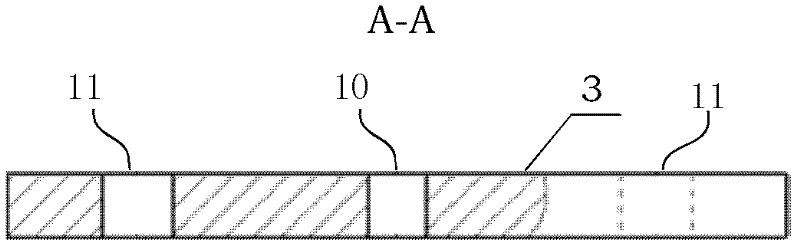

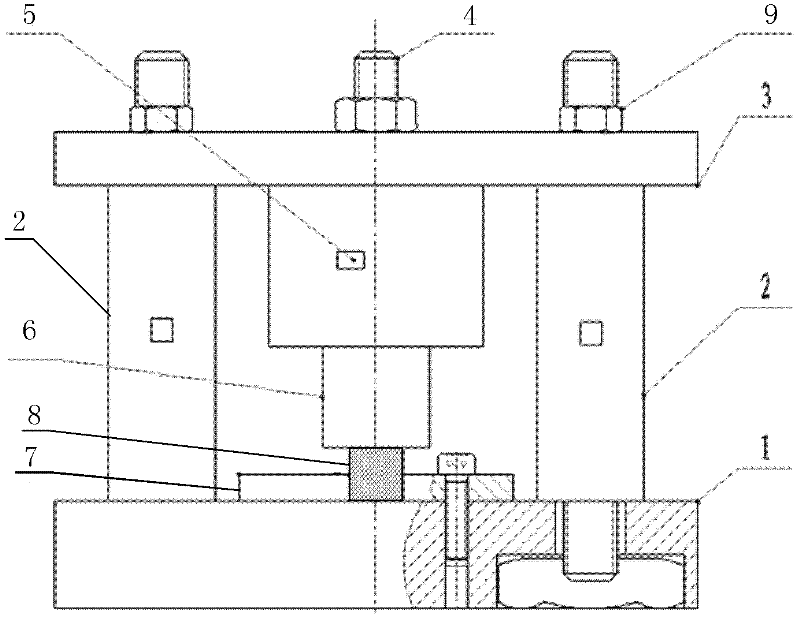

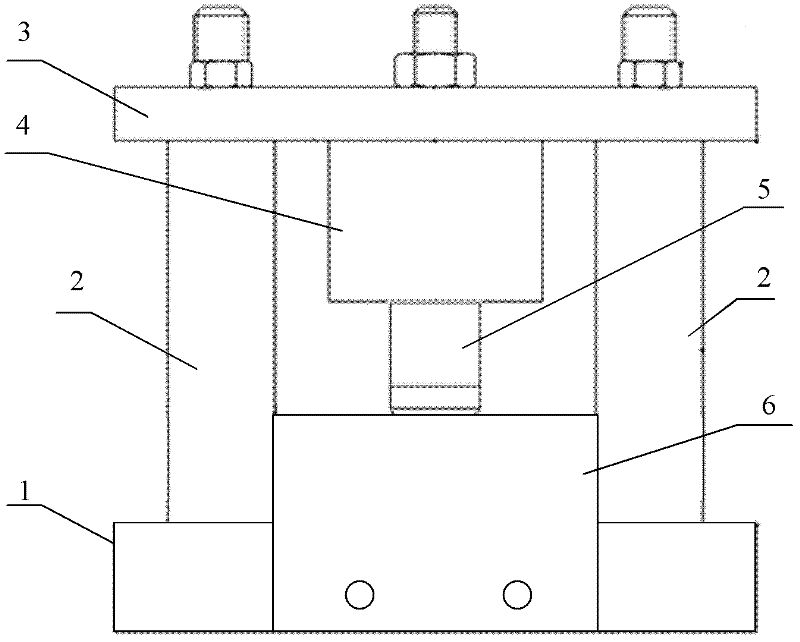

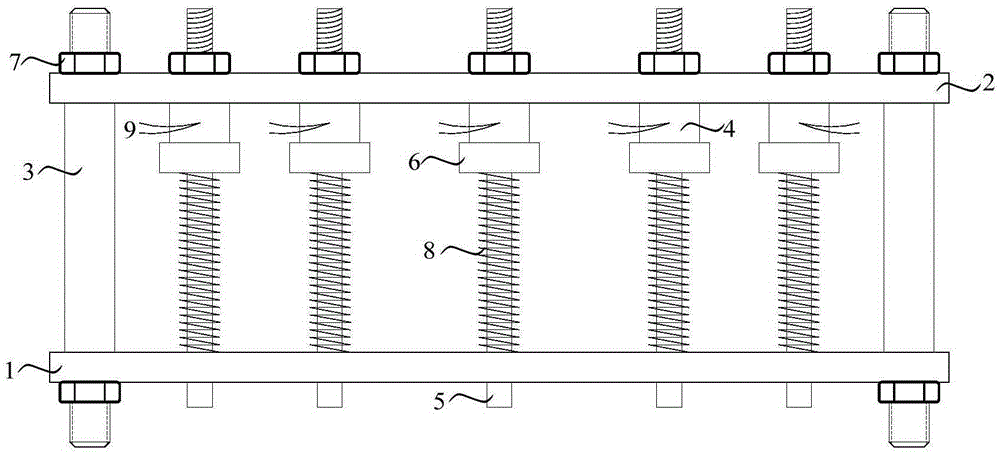

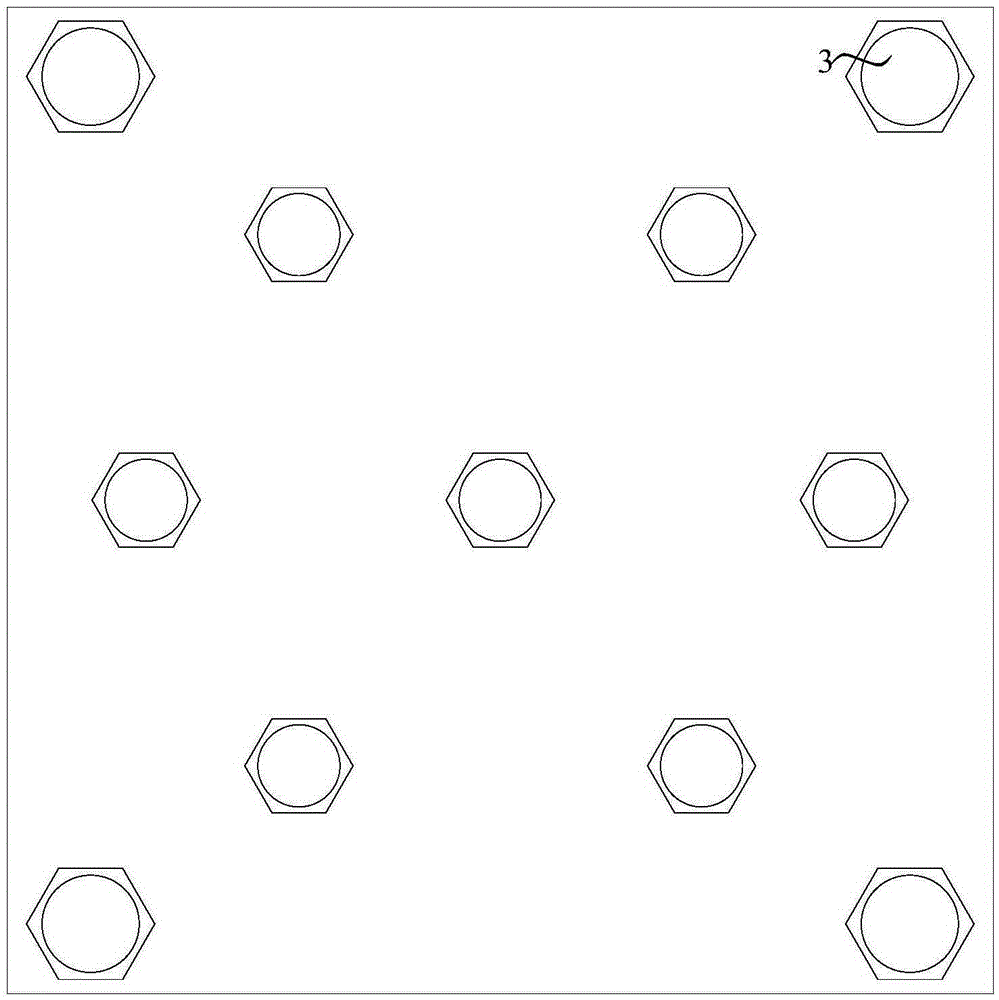

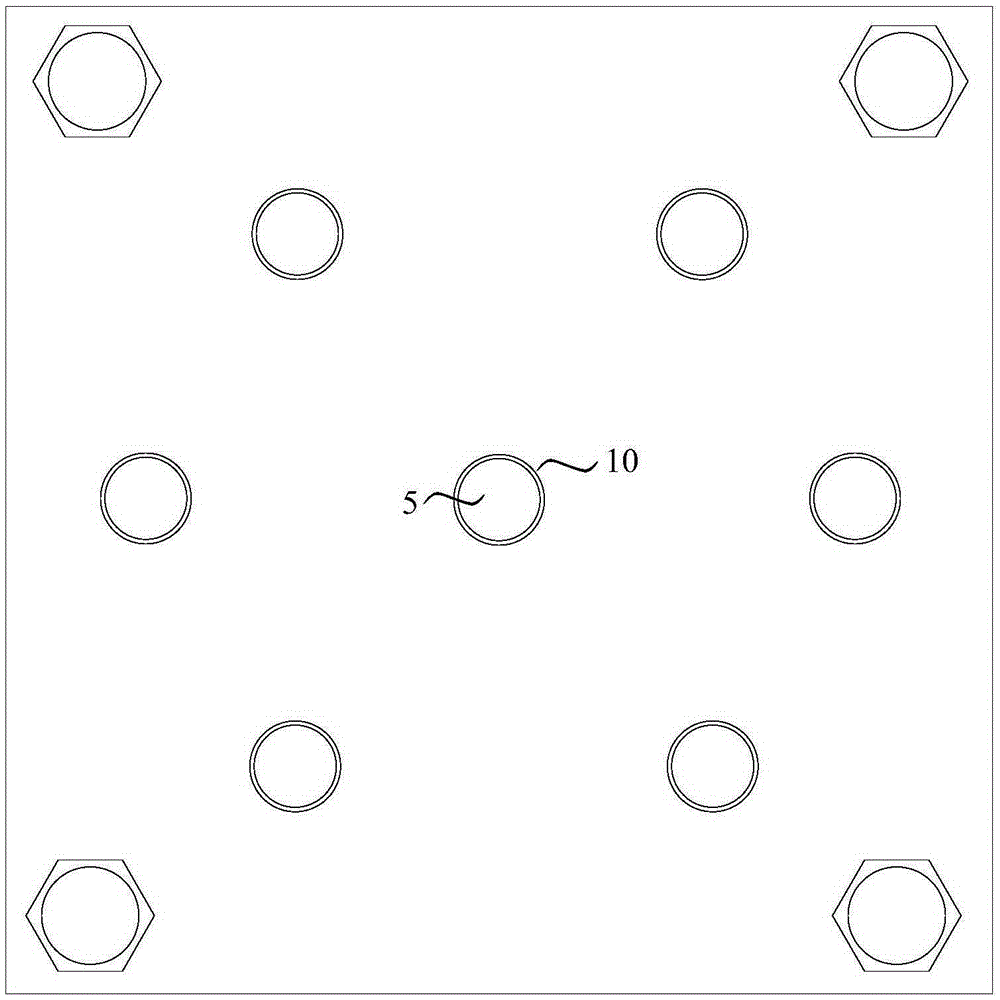

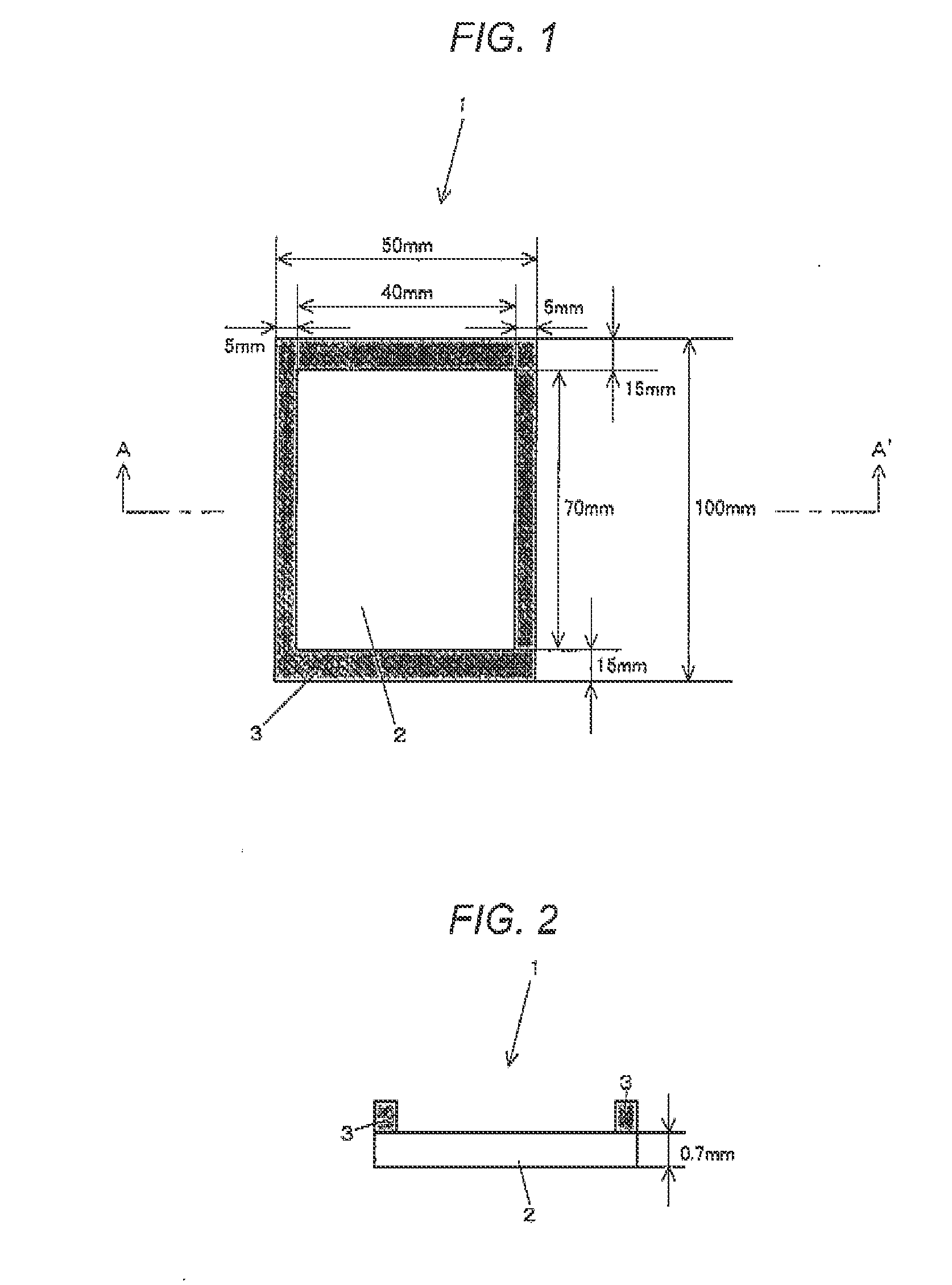

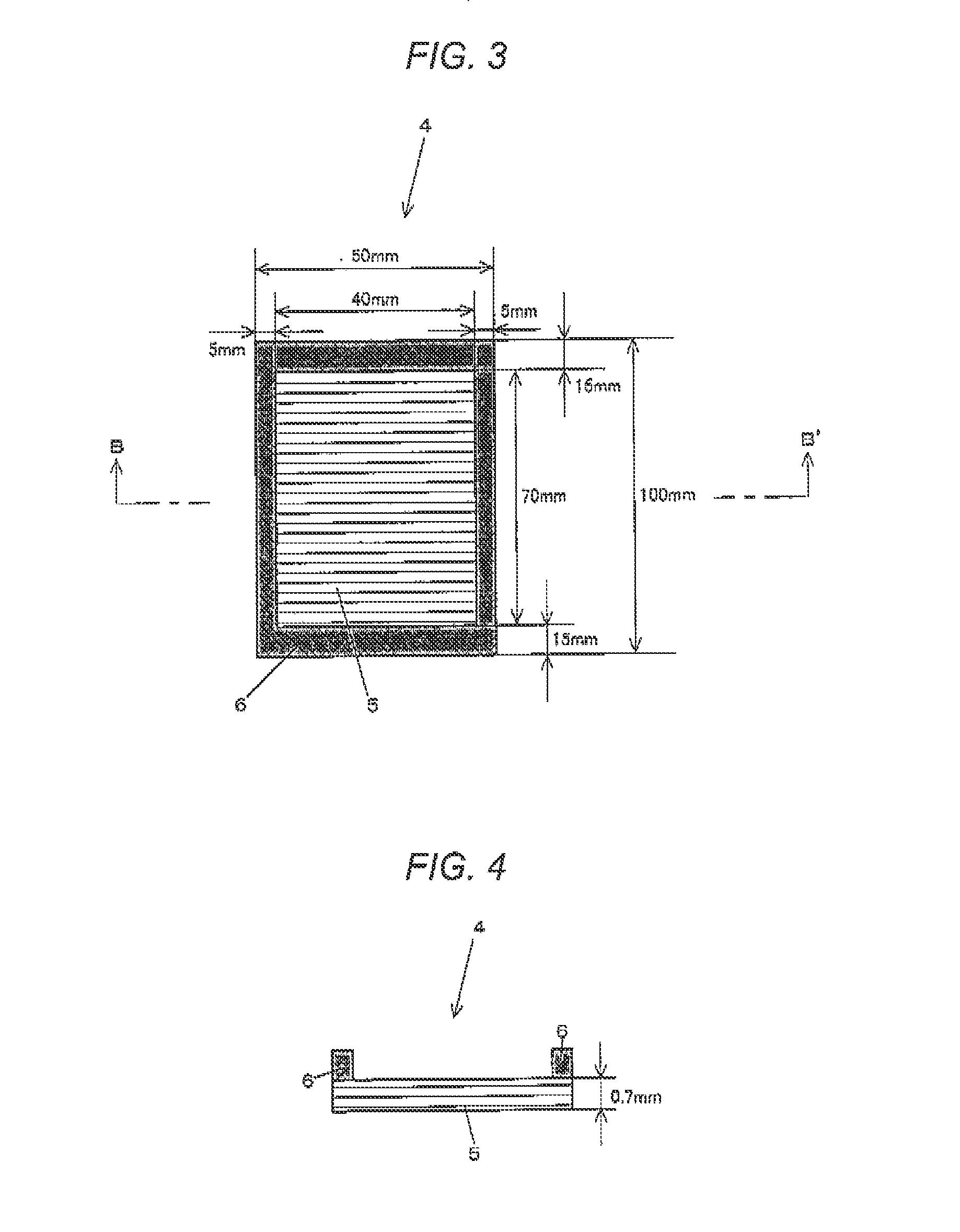

Device and method for testing normal-temperature and high-temperature compression stress relaxation of rubber

InactiveCN102353588AGuaranteed accuracyGuaranteed repeatabilityMaterial strength using tensile/compressive forcesRoom temperatureRelaxation test

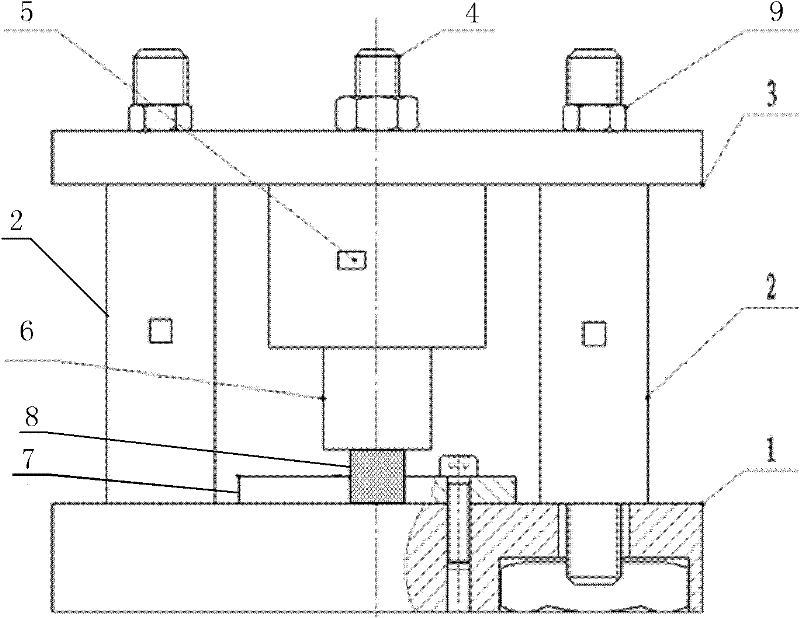

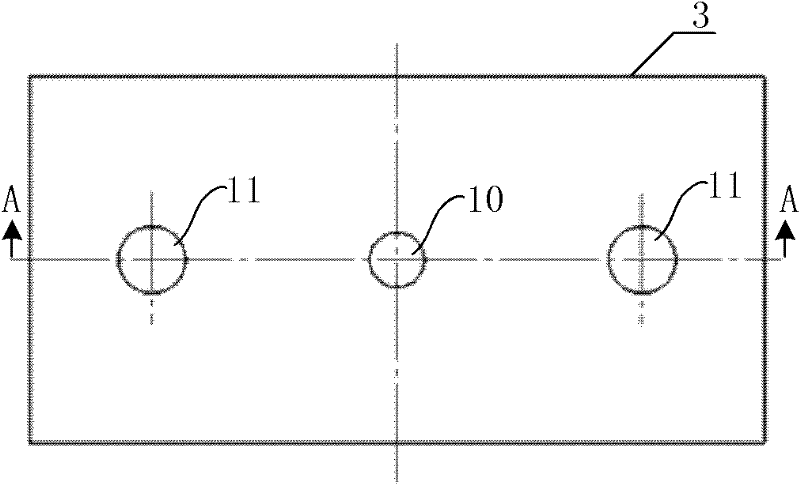

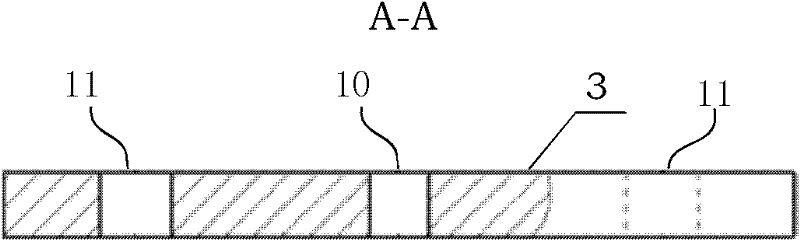

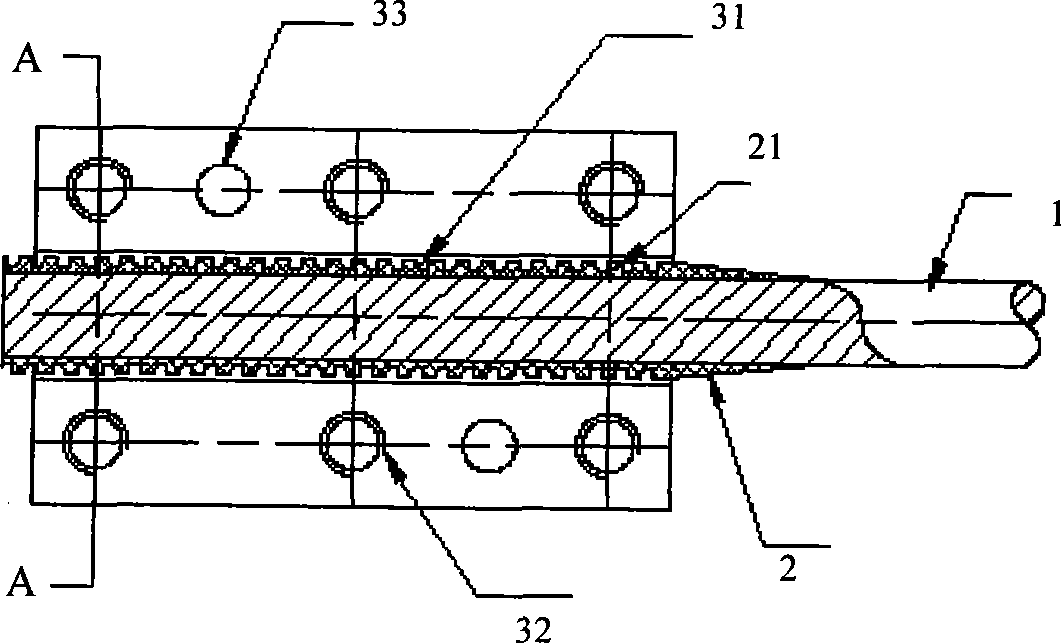

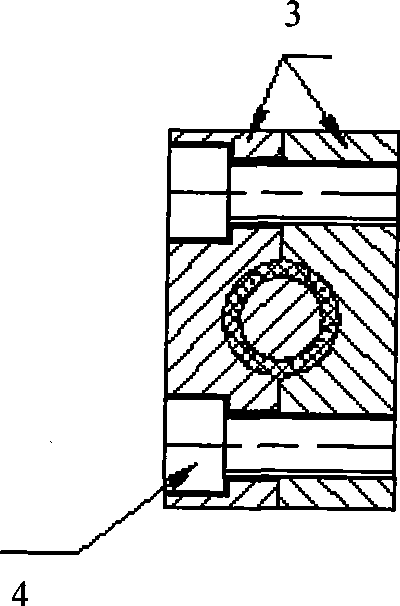

The invention provides a device and a method for testing normal-temperature and high-temperature compression stress relaxation of rubber. The device mainly comprises an upper plate, a lower plate, a limiter, a pressure sensor, a pressure head and a flange. The upper plate is fixed to the lower plate through the limiter. The pressure sensor is fixed at a center position of the upper plate and is located between the upper plate and the lower plate. The pressure head is fixed at another end of the pressure sensor. A rubber sample is fixed at a center position of the lower plate by the flange and contacts with the pressure head. The method comprises the following steps of preparing an appropriate rubber sample, assembling the device, fixing exactly the appropriate rubber sample at the center of the lower plate, contacting the appropriate rubber sample with the pressure head, removing the flange, putting the device into an aging test box for an experiment, and after the experiment is finished, determining compression stress relaxation coefficients of the appropriate rubber sample. Through the device and the method, normal-temperature and high-temperature compression stress relaxation tests are realized; real-time monitoring of compression stress variation is realized; and the accuracy, the repeatability and the reproducibility of a life prediction result are guaranteed.

Owner:BEIHANG UNIV

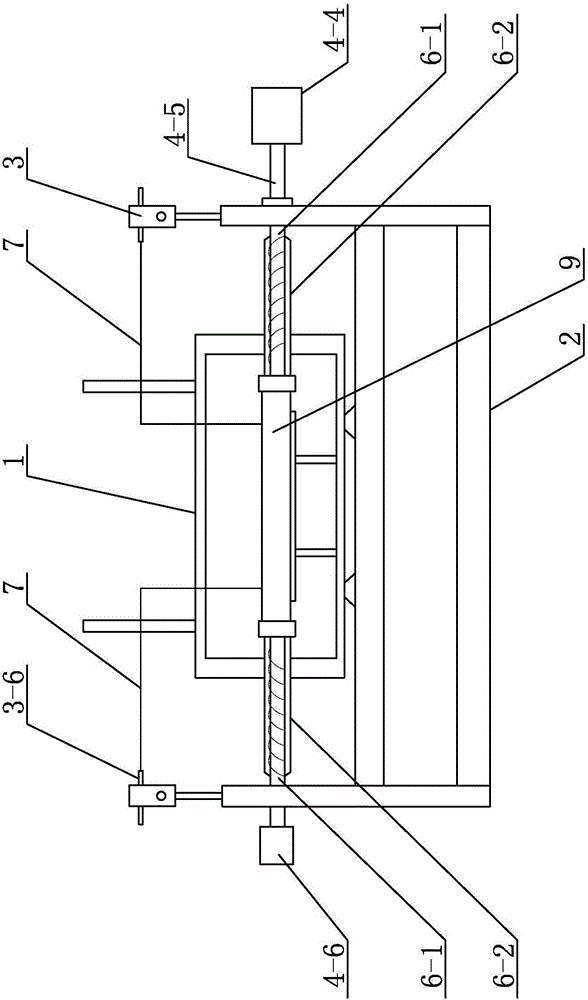

Apparatus for high-temperature creep test and stress relaxation test of rubber elastomer

ActiveCN106124337ALess volatilityThe data result is accurateMaterial strength using tensile/compressive forcesElastomerTemperature control

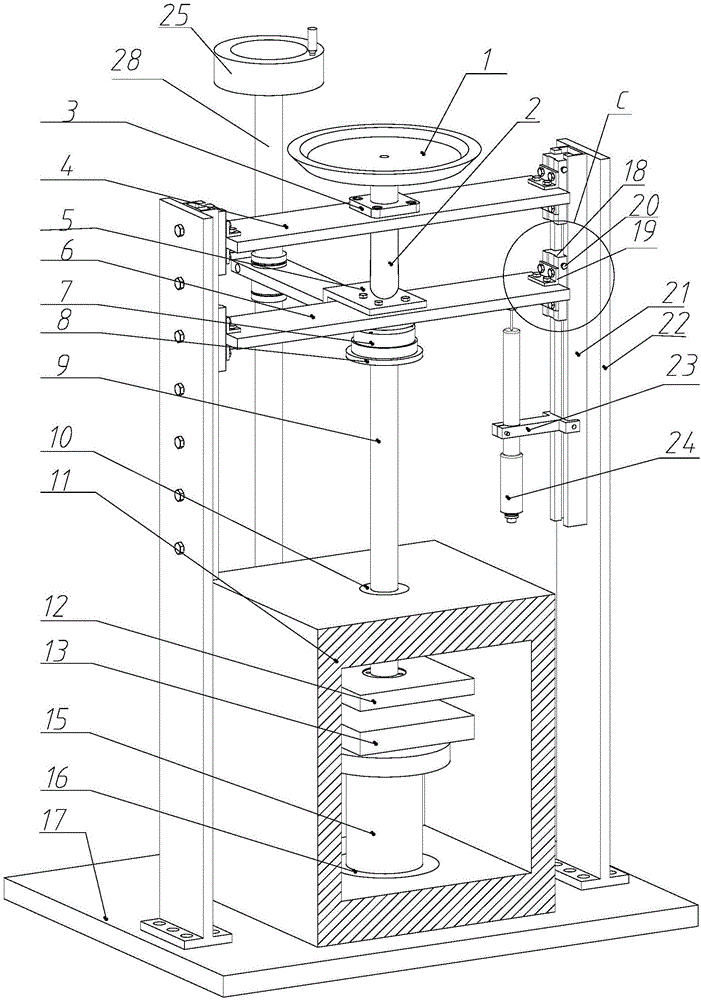

The invention relates to an apparatus for a high-temperature creep test and a stress relaxation test of a rubber elastomer. A stress loading part is positioned right above a temperature control part; a clamp comprises an upper pressing plate and a lower pressing plate which correspond to each other in the vertical direction, wherein the upper pressing plate is horizontally suspended in a high-temperature test box by virtue of a connecting rod, and the lower pressing plate is movably installed in the high-temperature test box; an upper crossbeam is positioned above a lower crossbeam; two ends of the upper crossbeam are fixed on a side plate, and two ends of the lower crossbeam are fixed on the side plate by virtue of a slide apparatus which can slide up and down along the side plate and can be positioned; a straight shaft vertically penetrates through the upper crossbeam, the upper end of the straight shaft is fixedly provided with a weight disc, and the lower end of the straight shaft pushes against the upper surface of the lower crossbeam; a pressure sensor is connected with a connecting rod penetrating through the top of the high-temperature test box; a displacement sensor is fixed on the side plate; and a drive part comprises a ball screw pair consisting of a ball screw and a bearing, the bearing is installed on a base, the ball screw is engaged with the bearing, and the ball screw is detachably connected with the lower crossbeam by virtue of a fixed bracket.

Owner:ZHEJIANG UNIV OF TECH

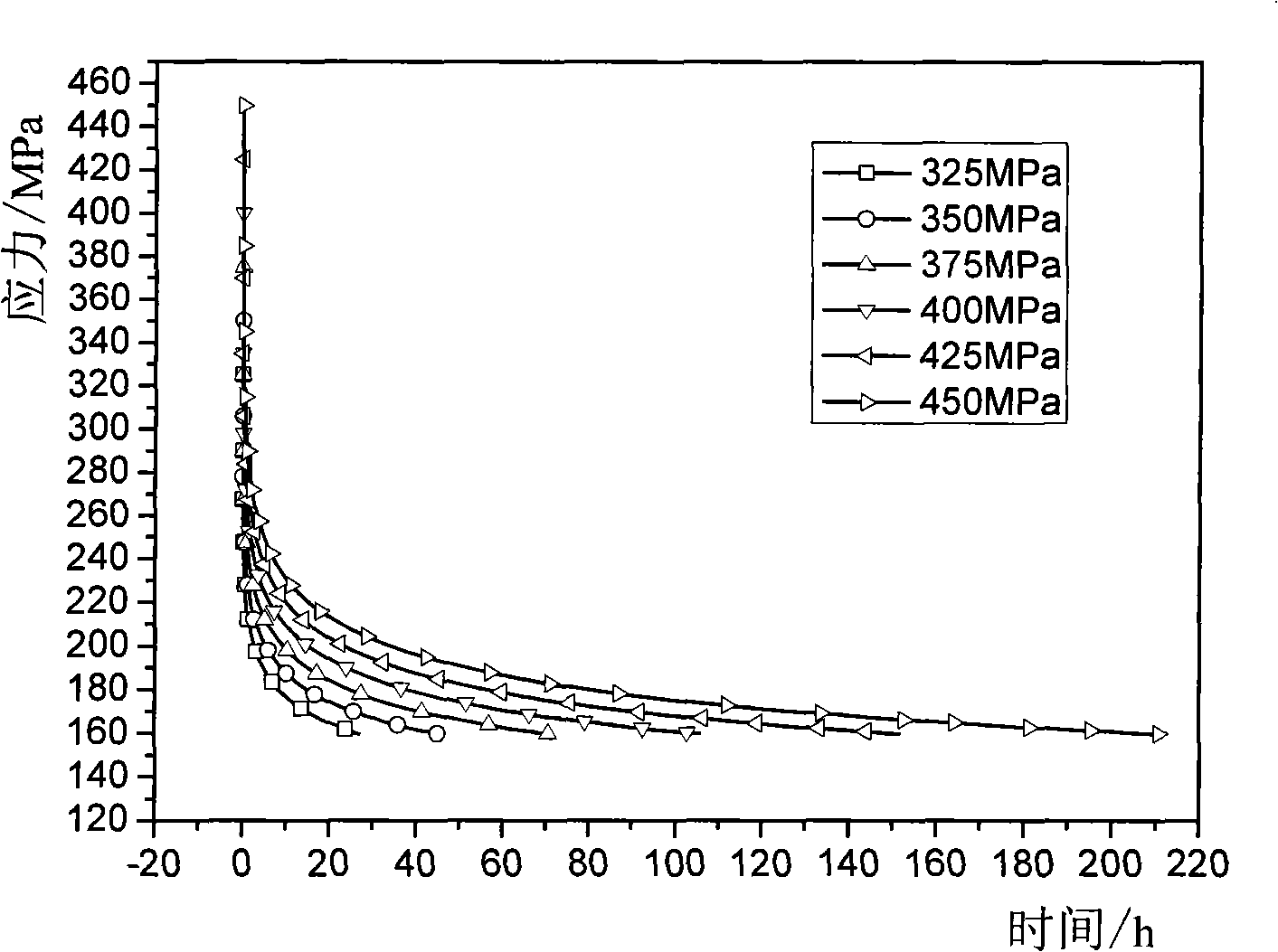

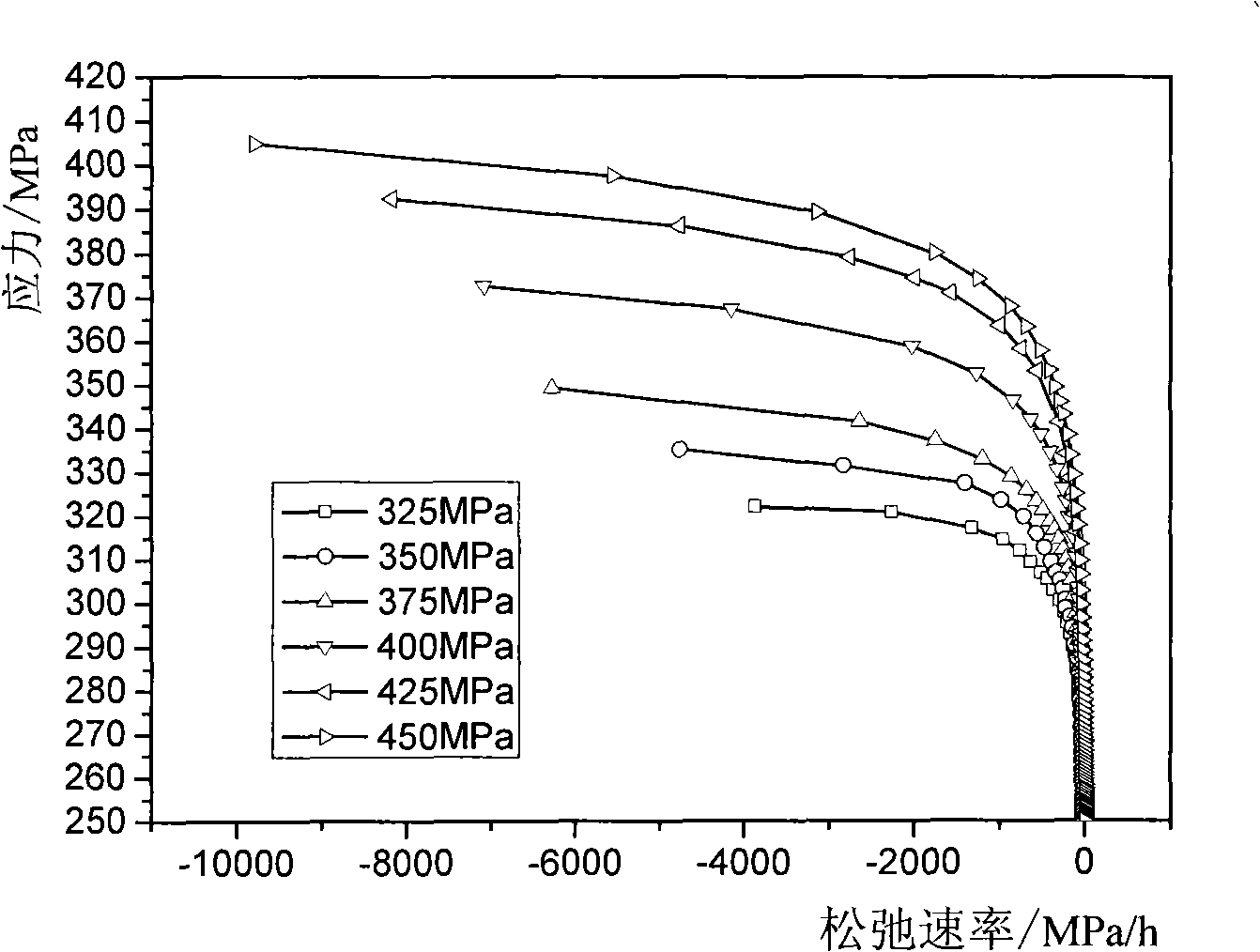

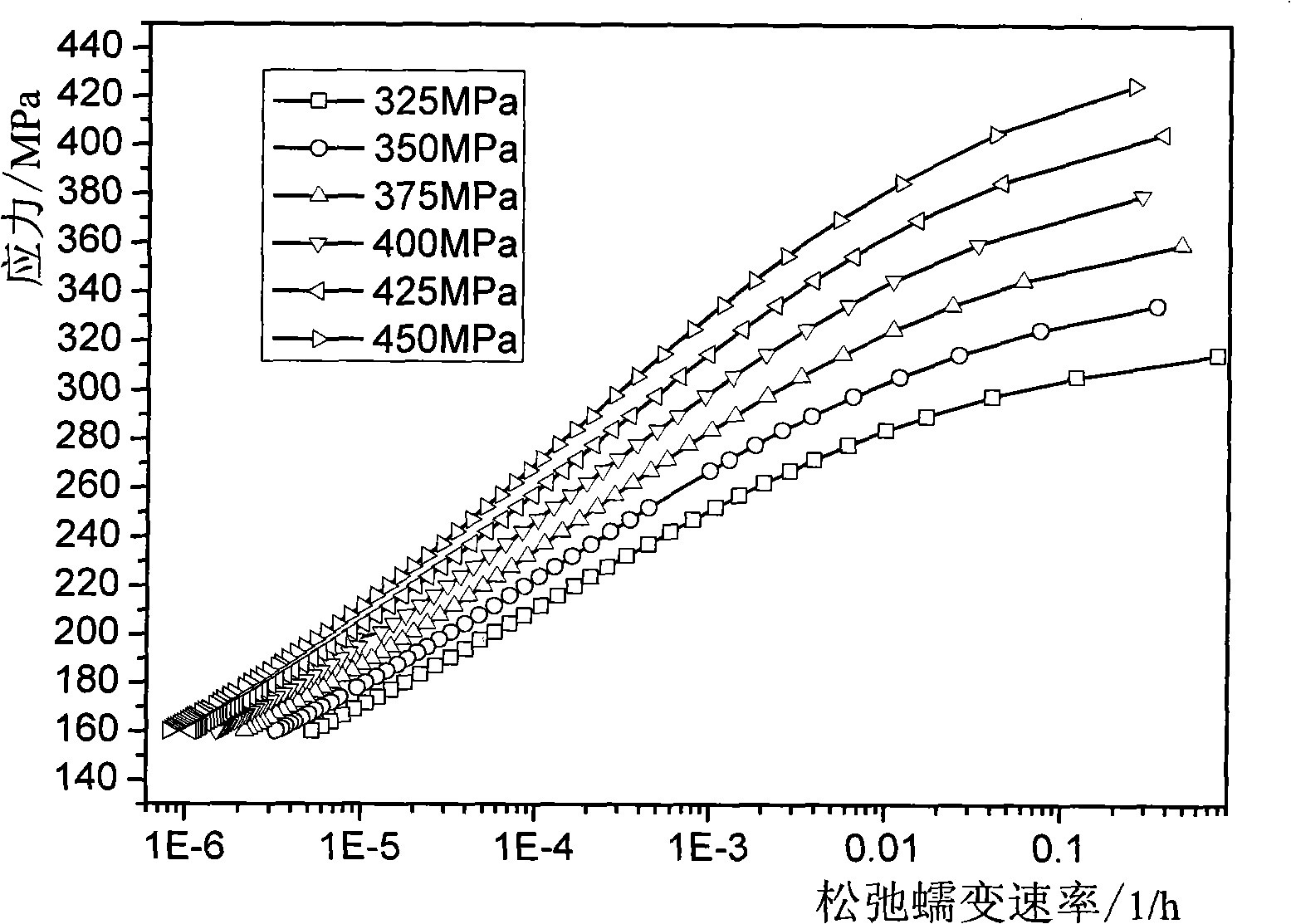

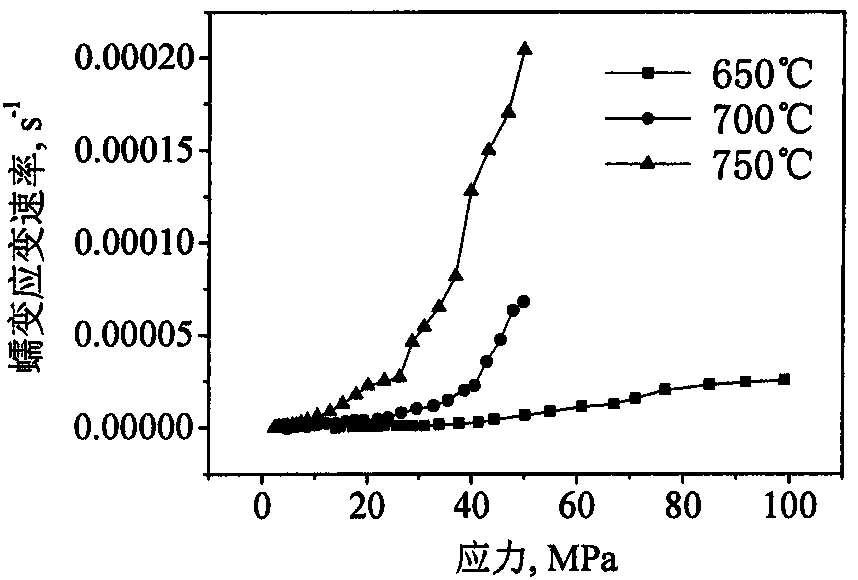

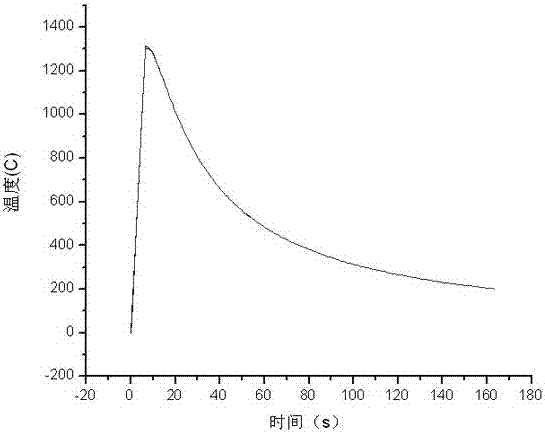

Material high-temperature creep life-span accelerated test method

InactiveCN101308127AAccelerated Creep DesignMethod scienceSpecial data processing applicationsStrength propertiesRelaxation equationCreep rate

The invention relates to a high temperature creep life accelerated test method of a material, which comprises: a plurality of groups of short time stress relaxation tests of the material at the same temperature, acquiring a relaxation rate-stress curve based on the numerical differentiation principle, forming a relaxation creep rate-stress curve by utilizing a relaxation equation, calculating creep data to build a creep curve, and building a steady state creep rate curve and a Norton creep equation. The method starts from the physical relation between relaxation and creep, covers rather broad properties of creep strain rate by utilizing the short time relaxation process, and educes broader creep data than that educed from general creep tests by above ten times, thereby effectively reducing the amount of high temperature creep tests and time of tests and providing basic data for development of new material and engineering application.

Owner:EAST CHINA UNIV OF SCI & TECH

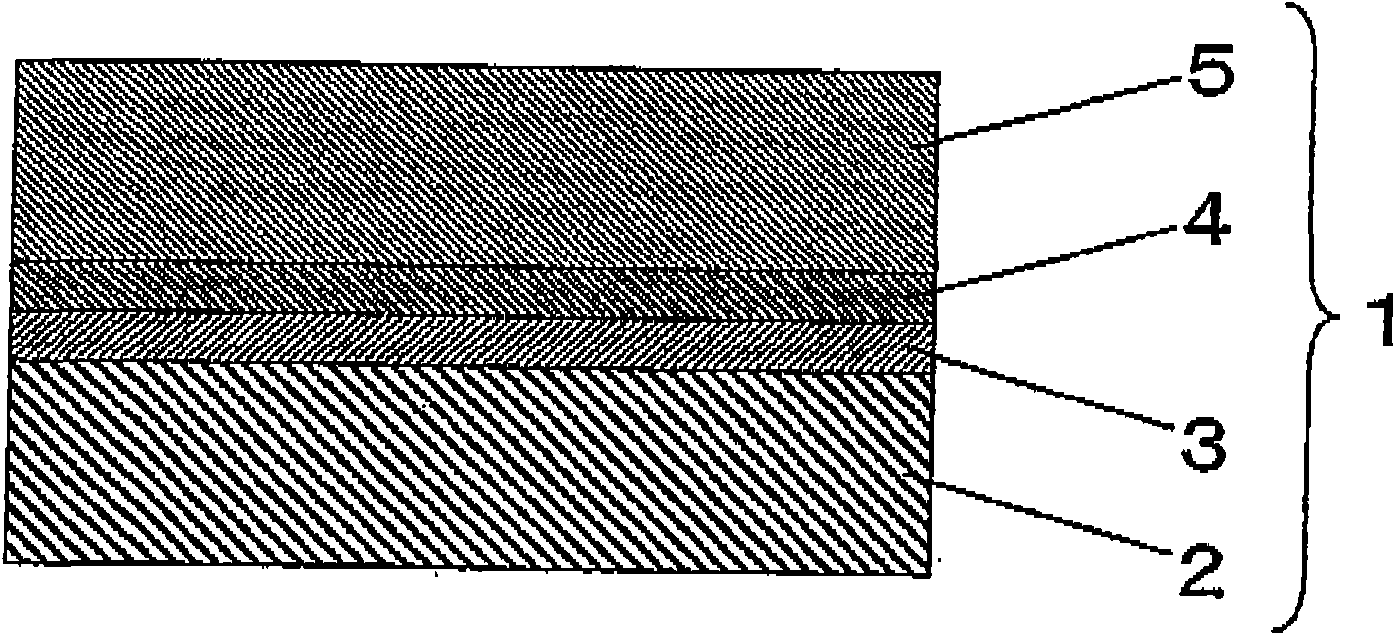

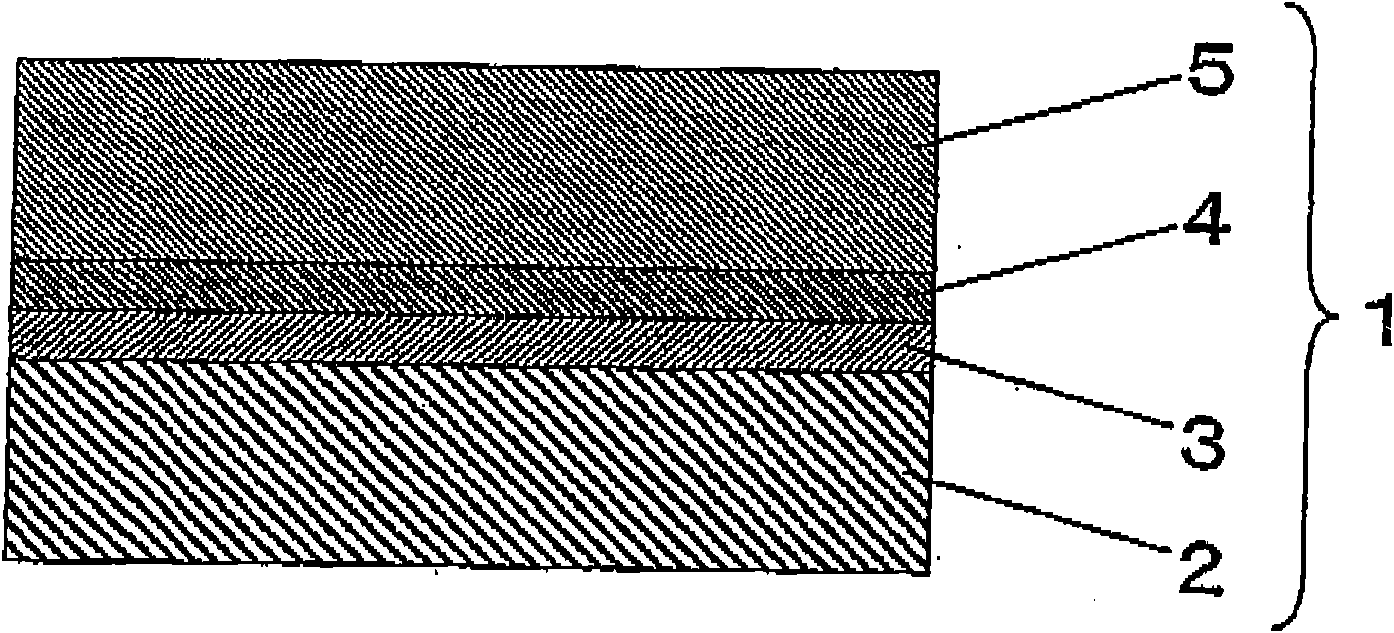

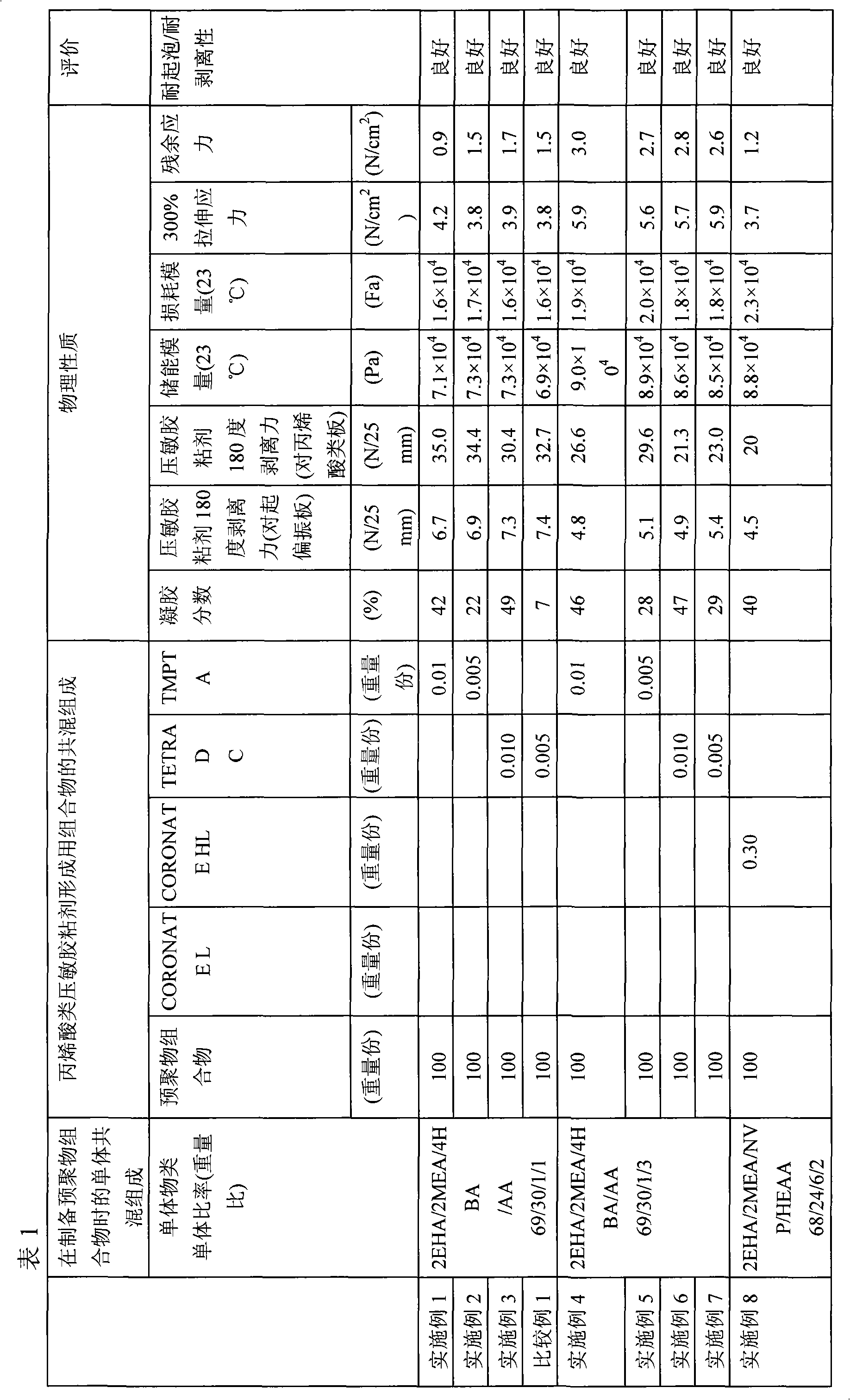

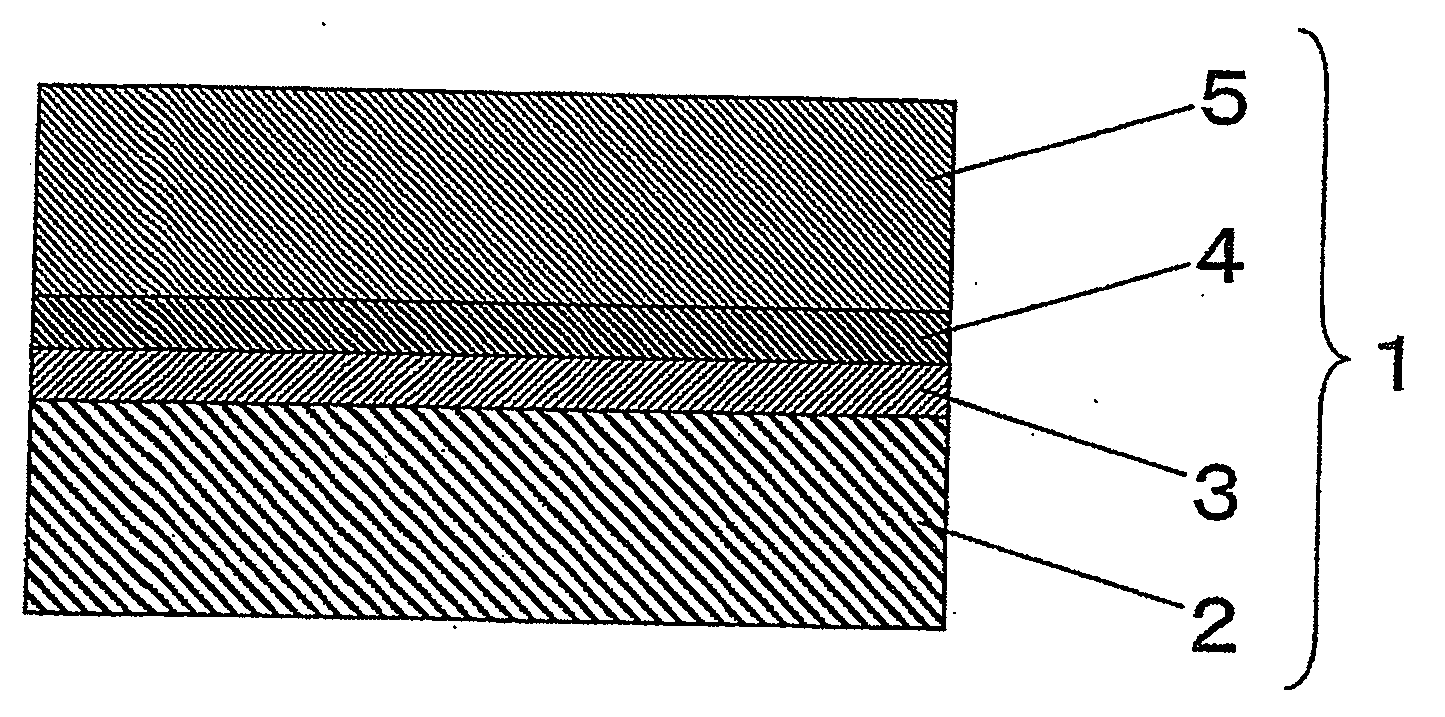

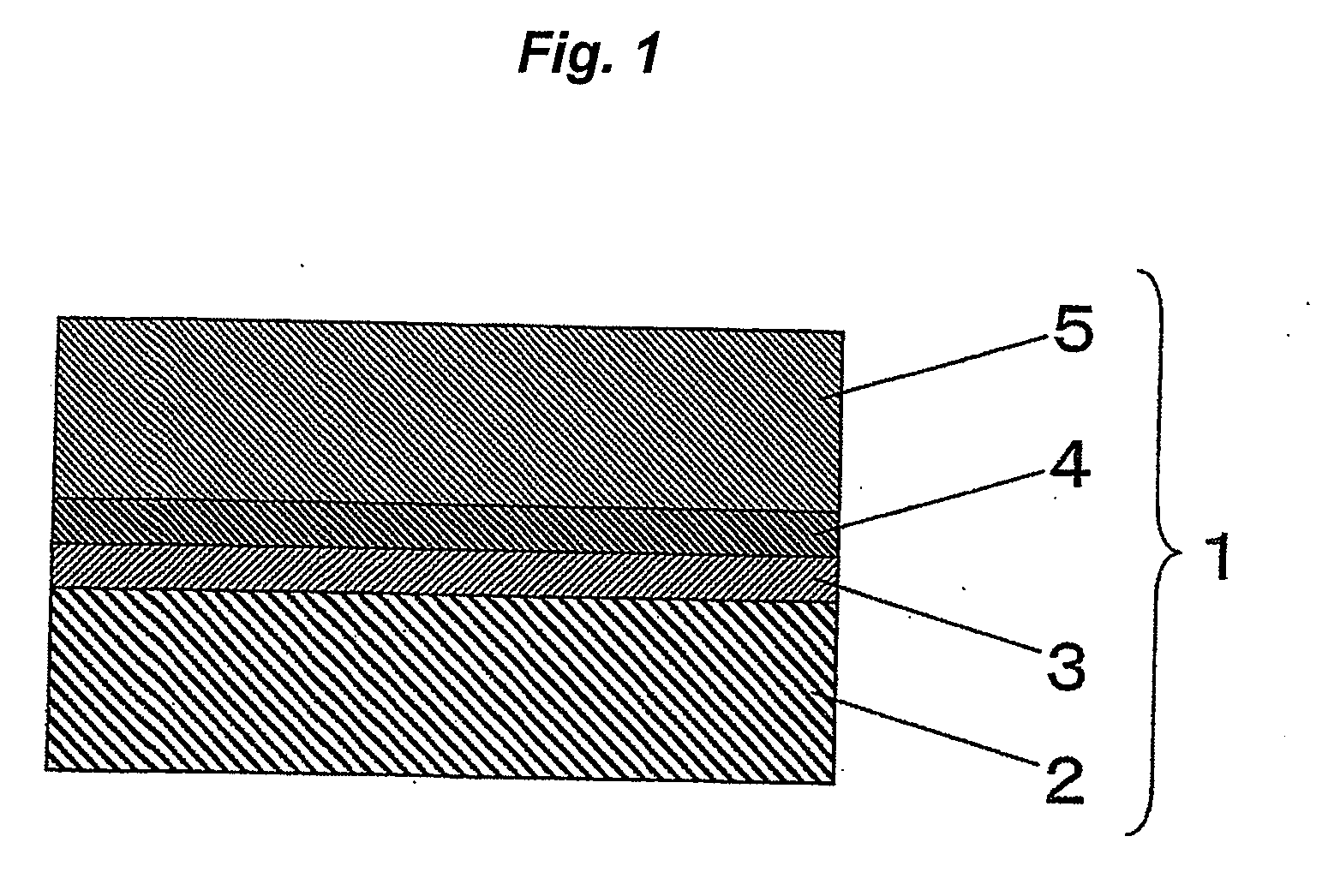

Double-sided pressure-sensitive adhesive sheet and pressure-sensitive adhesive type optical member

InactiveCN101805566AImproved blister/peel resistanceFilm/foil adhesivesEster polymer adhesivesDynamic viscoelasticityStress relaxation test

The present invention provides a double-sided pressure-sensitive adhesive sheet, including at least one pressure-sensitive adhesive layer which has a gel fraction of 10 to 70%, has a storage modulus at 23 DEG C. of 1105 Pa or less, and has a residual stress after 180 seconds of 3.5 N / cm2 or less, the storage modulus at 23 DEG C. being measured in accordance with a dynamic viscoelasticity measurement and the residual stress after 180 seconds being measured in accordance with a tensile stress relaxation test under conditions of a temperature of 23 DEG C. and a strain of 300%.

Owner:NITTO DENKO CORP

Rubber-storage-life predicting model based on test equipment for room-temperature and high-pressure compression stress relaxation of rubber

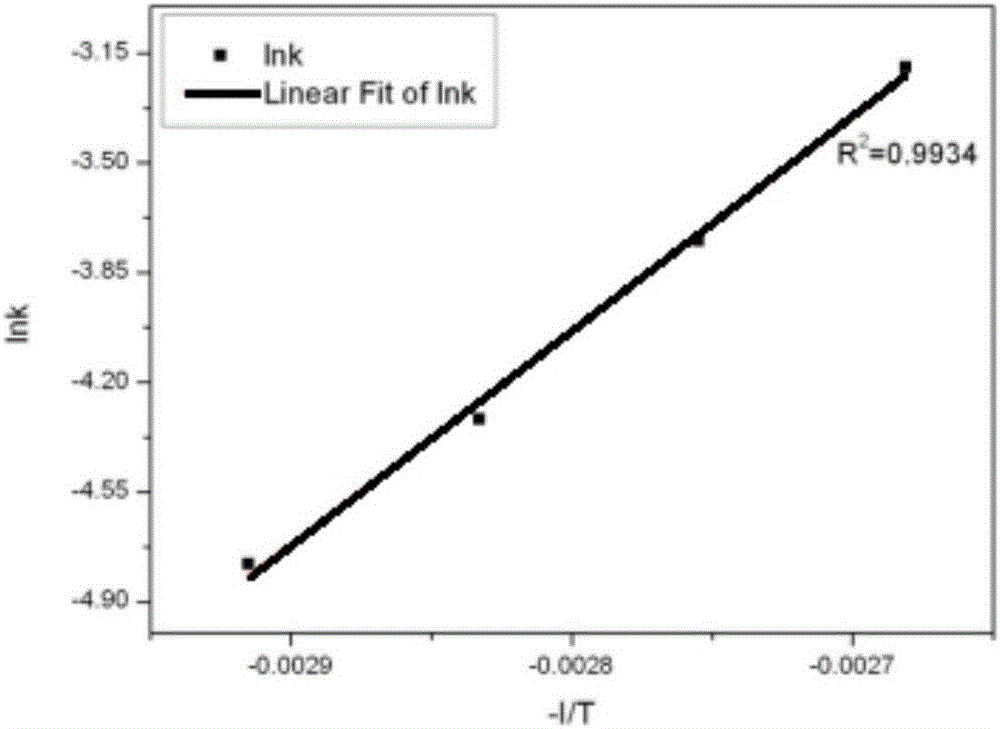

InactiveCN102589976AGuaranteed accuracyGuaranteed repeatabilityMaterial strength using tensile/compressive forcesEngineeringLinear regression

The utility model provides a life predicting model based on test equipment for room-temperature and high-pressure compression stress relaxation of rubber. The life predicting model comprises the following steps of: firstly, drawing stress relaxation change data acquired by the device into a diagram to obtain the relation between the stress relaxation condition and the ageing time and the relation between the speed constant and the ageing temperature; secondly, obtaining all coefficients in the equation by utilizing an approximation method, a linear regression method and MATLAB programming software, and judging the linear regression effect according to the related method; and finally, determining a rubber life predicting value after giving critical values of temperature and stress relaxation. The life predicting model has the advantages that the device for testing the compression stress relaxation of high-temperature rubber can be utilized for monitoring the change of the compression stress, so as to establish the life predicting model, and the accuracy, the repeatability and the reproducibility of a life predicting result are guaranteed.

Owner:BEIHANG UNIV

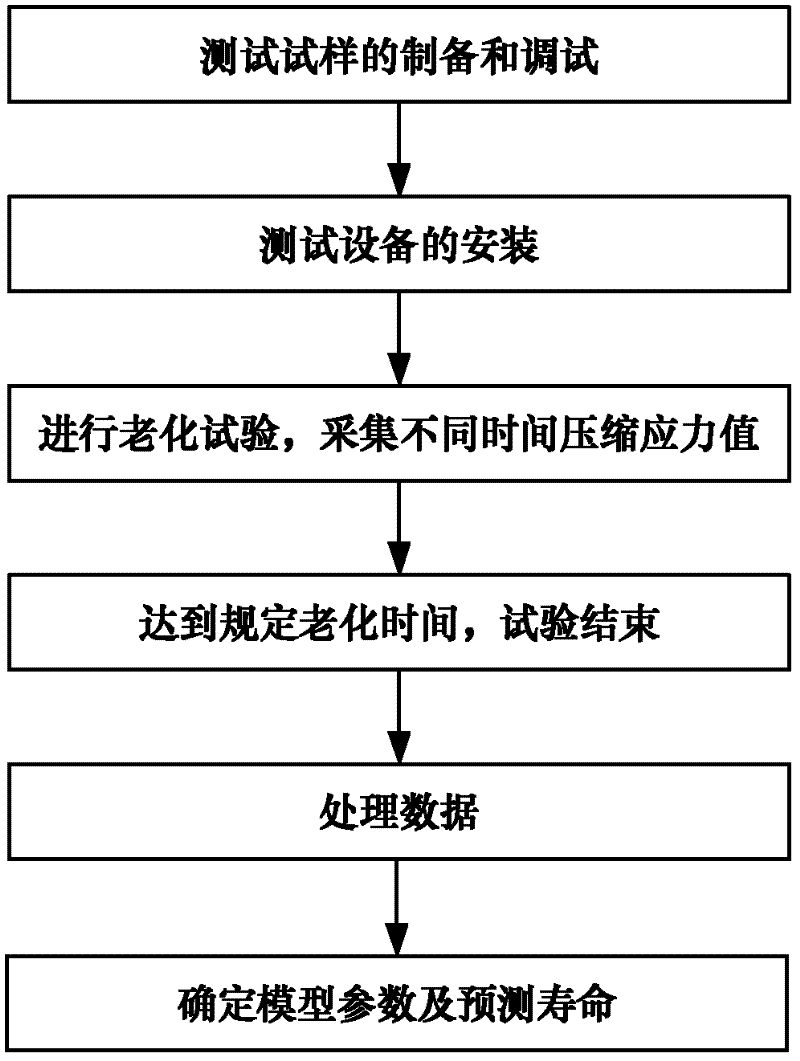

Method for predicting rubber storage life on basis of compression stress relaxation test equipment

InactiveCN102589977AReduced service lifeImprove accuracyMaterial strength using tensile/compressive forcesEngineeringModel parameters

The invention provides a method for predicting the rubber storage life on the basis of compression stress relaxation test equipment, which belongs to the technical field of rubber life prediction. Firstly, a test sample is prepared and debugged, the test equipment is installed, the test is prepared, and the ageing test is carried out, so different compression stress values are acquired; then the data is processed, MATLAB (Matrix Laboratory) software is utilized to plot the logarithm logt of ageing time through utilizing compression permanent deformation retention rate or stress relaxation retention rate, so scatter diagrams under different ageing temperatures are obtained, and the data in the diagrams is fitted by adopting the Boltzmann mathematical function; and finally, model parameters are determined, and the life is predicted. The method utilizes a pressure sensor and an external data display instrument to monitor the compression stress variation in real time, the sample does not needed to be taken out for the test and does not need to be replaced during the test process, so the temperature fluctuation is avoided, the data fluctuation factor is reduced, and the accuracy and repeatability of the life prediction result are ensured.

Owner:BEIHANG UNIV

Double-sided pressure-sensitive adhesive sheet and pressure-sensitive adhesive type optical member

InactiveUS20100209703A1Excellent stress relaxationImprove the immunityOpticsAdhesivesDynamic viscoelasticityStress relaxation test

The present invention provides a double-sided pressure-sensitive adhesive sheet, including at least one pressure-sensitive adhesive layer which has a gel fraction of 10 to 70%, has a storage modulus at 23° C. of 1×105 Pa or less, and has a residual stress after 180 seconds of 3.5 N / cm2 or less, the storage modulus at 23° C. being measured in accordance with a dynamic viscoelasticity measurement and the residual stress after 180 seconds being measured in accordance with a tensile stress relaxation test under conditions of a temperature of 23° C. and a strain of 300%.

Owner:NITTO DENKO CORP

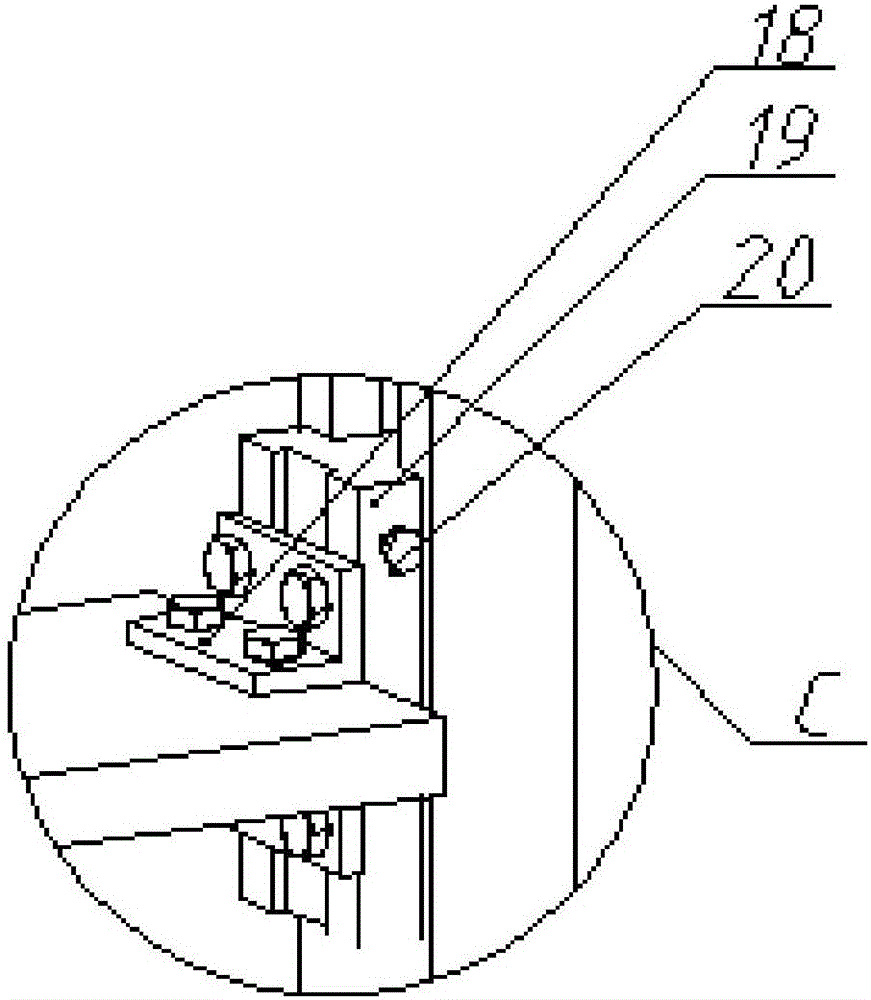

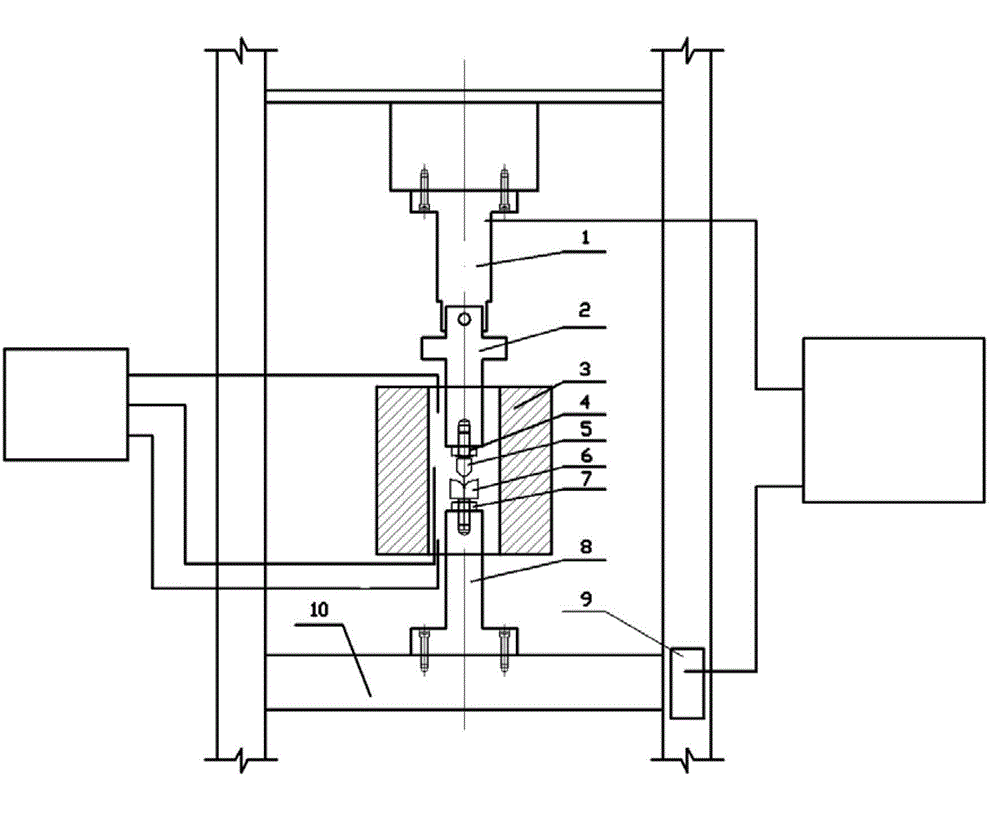

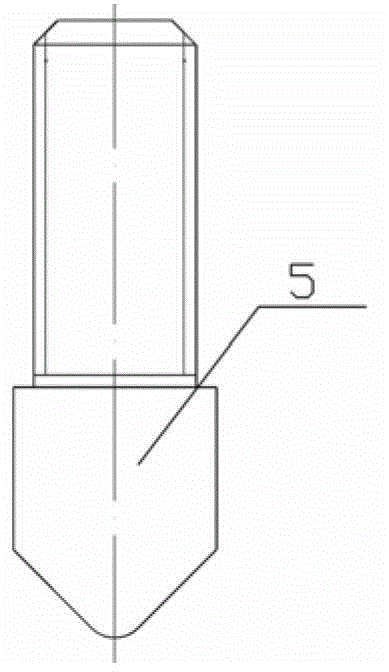

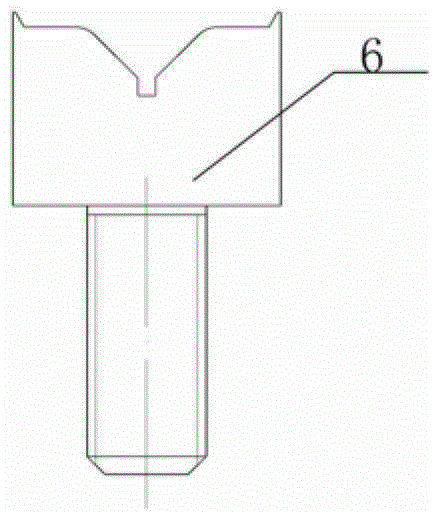

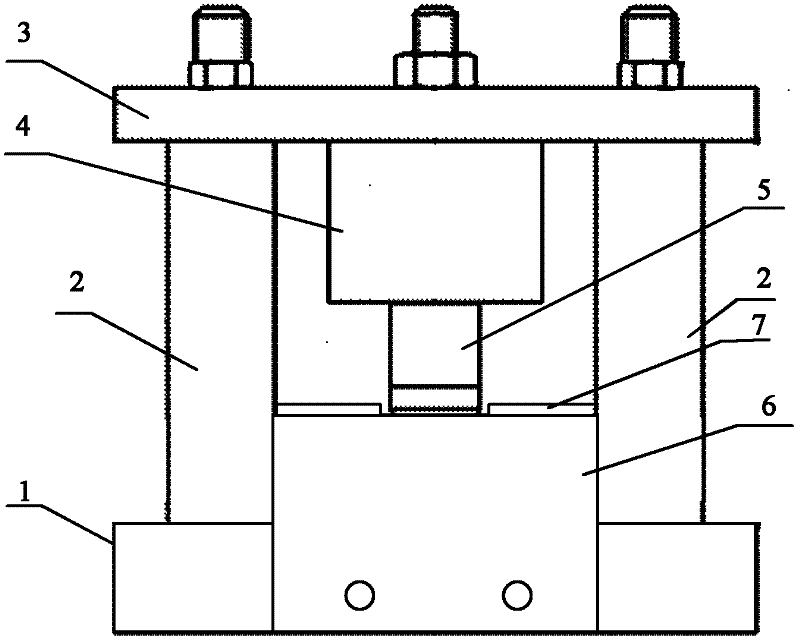

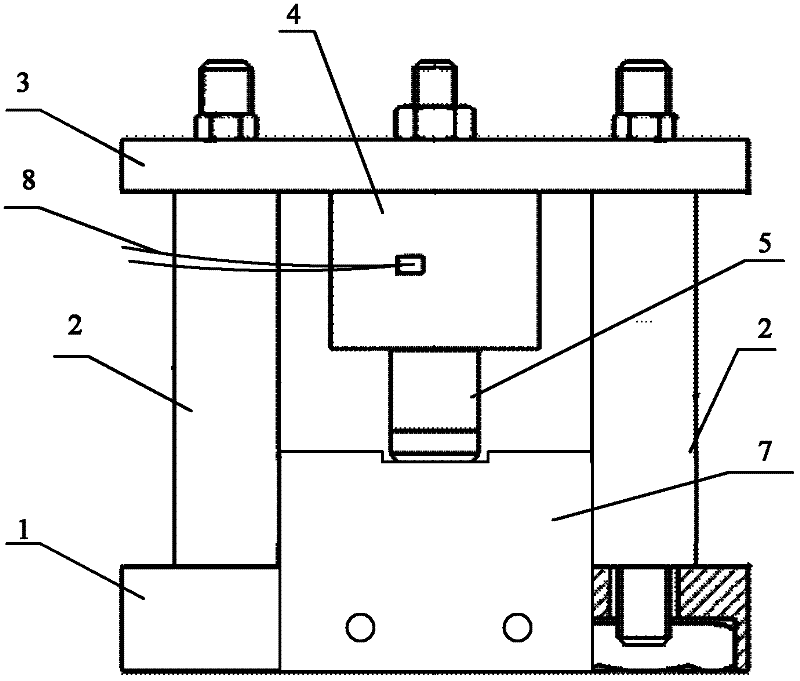

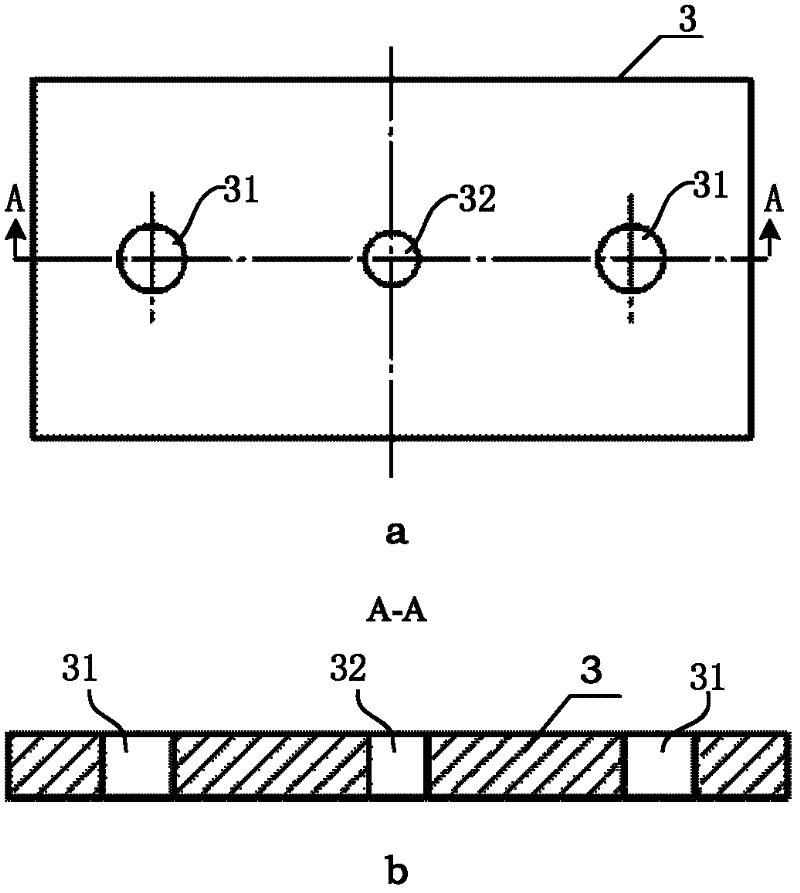

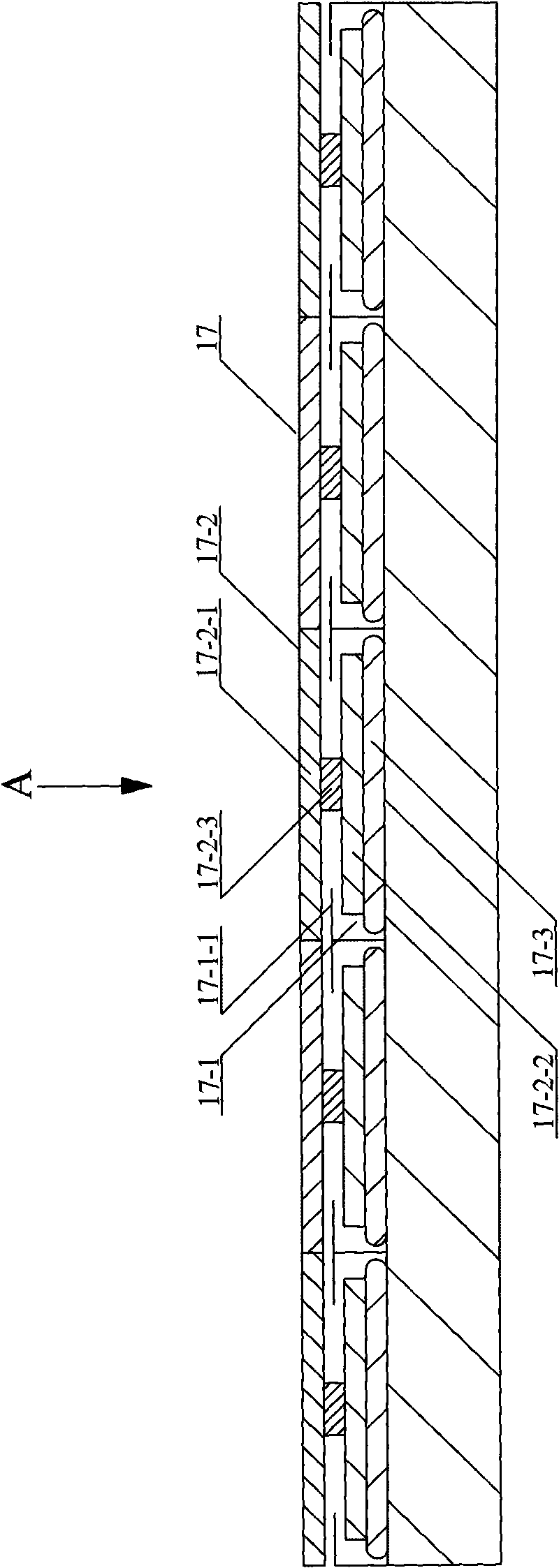

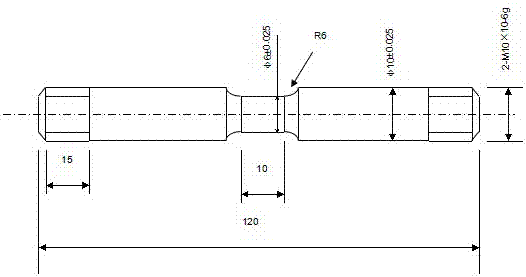

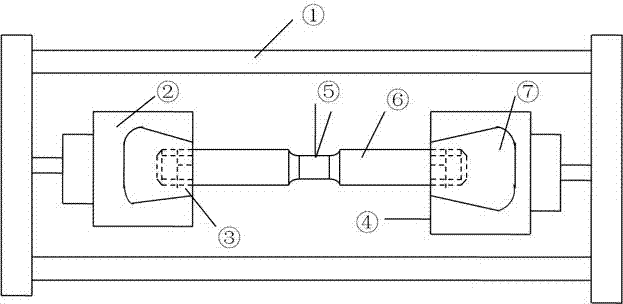

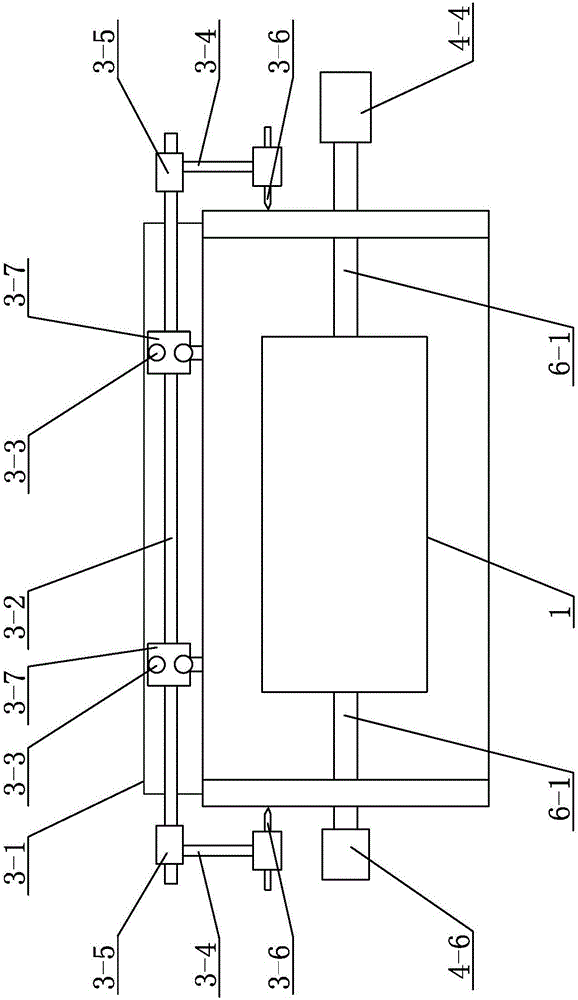

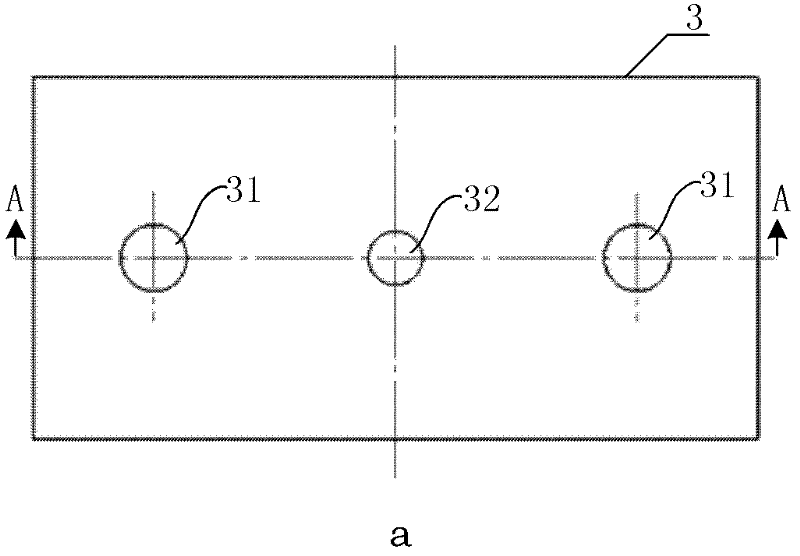

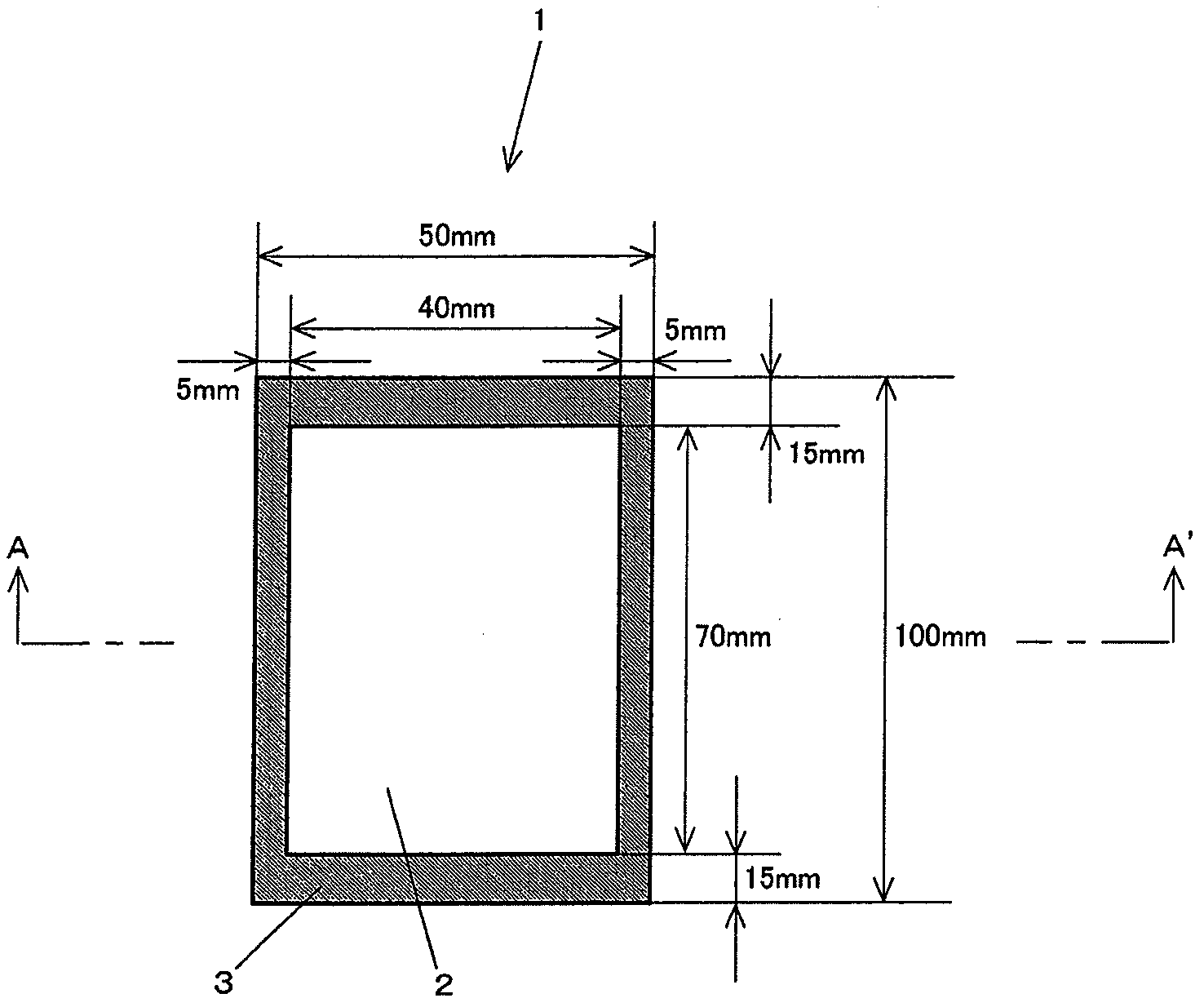

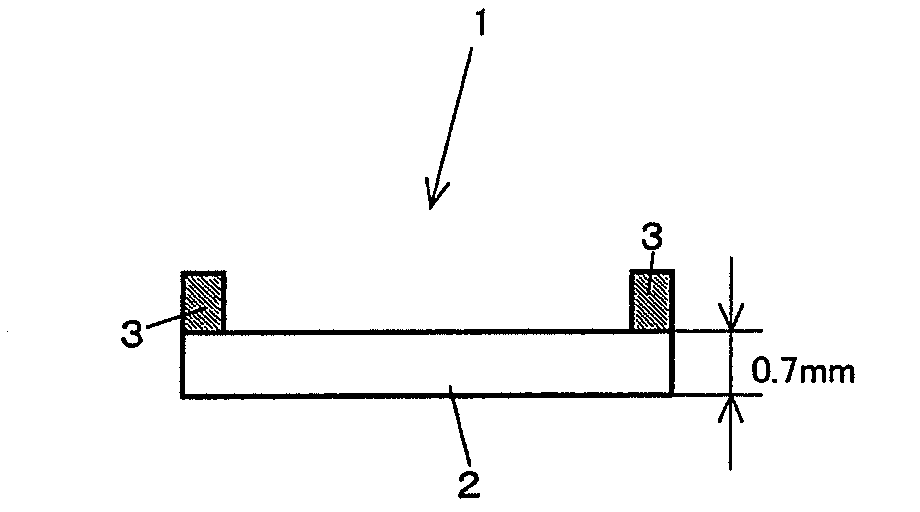

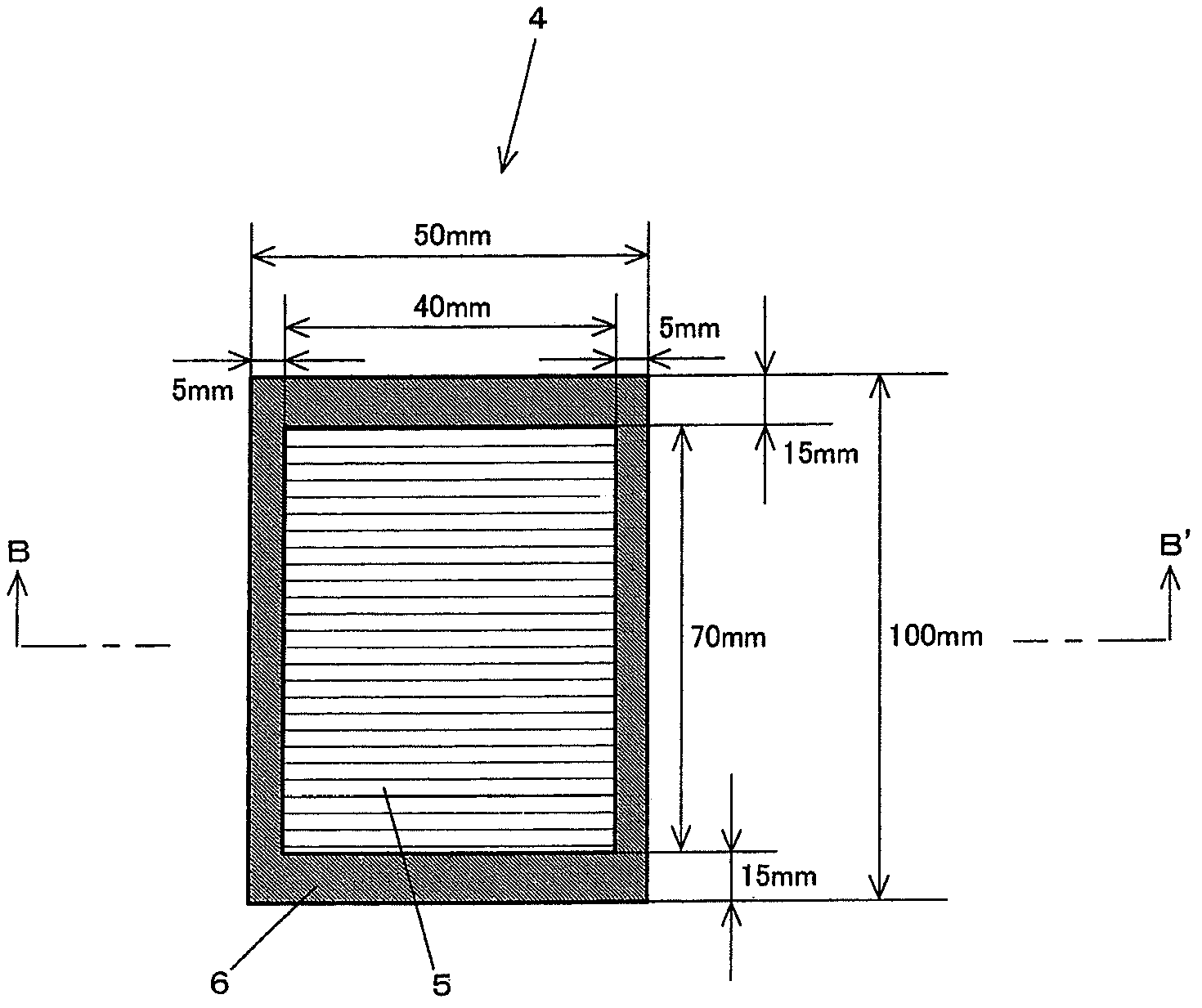

Titanium alloy stress relaxation test device and method based on V-type hot bending

The invention discloses a titanium alloy stress relaxation test device and a titanium alloy stress relaxation test method based on V-type hot bending, belonging to the field of hot working of metals. The invention provides a load relaxation test device and a load relaxation test method based on V-type bending. A V-type bending loading test implemented in an electronic test machine can realize stress relaxation; the loading of a bending load for a sample placed between a bending convex die (5) and a bending concave die (6) is realized by use of the displacement provided by a beam (10), and a load sensor continuously records the bending load and the change of the load along with time in a shaping process; and in the condition of different shaping durations, different sample bending springback angles are obtained. The device and the method disclosed by the invention can test the change of the bending load along with time during hot shaping, can determine the rule of the load relaxing along with time under the condition with different shaping durations for a titanium alloy sample with the bending load while deriving the linear relation between load and sample stress, and can be widely applied to the field of hot working of metals.

Owner:HARBIN INST OF TECH

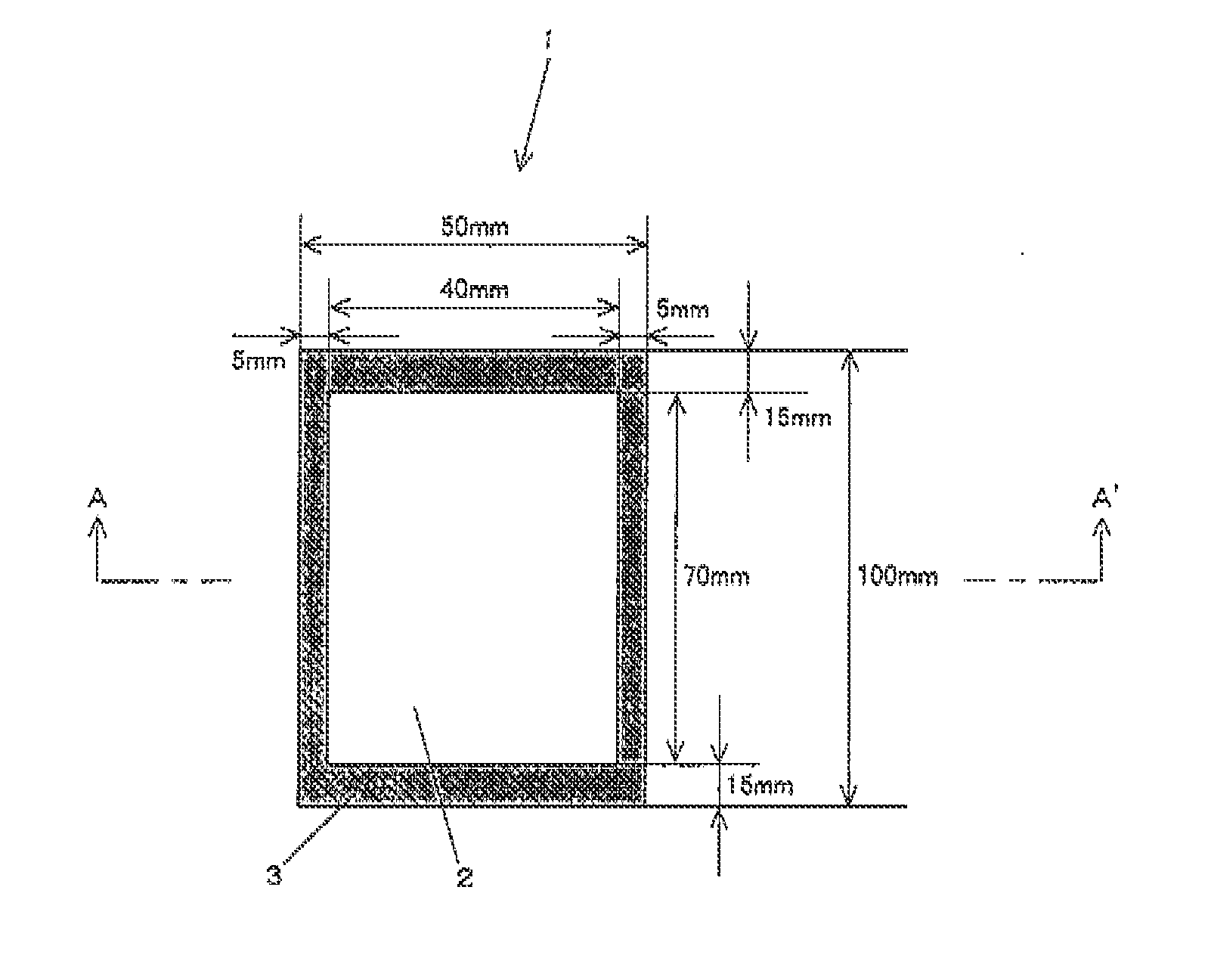

Testing method for normal temperature and high temperature stress relaxation of flat spring

InactiveCN102650578AEasy to useGuaranteed accuracyMachine part testingMaterial strength using tensile/compressive forcesTemperature stressRoom temperature

The invention provides a testing method for normal temperature and high temperature stress relaxation of a flat spring. Firstly, a to-be-tested spring sample is prepared, the prepared to-be-tested spring sample is an equal stress sample and has a symmetrical-shaped flat structure; secondly, installation and test preparation of testing equipment are performed, the testing equipment is provided with a base, lateral plates are fixed on the front and the rear sides of the base, the two ends of the to-be-tested spring sample are respectively placed on the lateral plates, the base and an upper plate are fixed together through a limiter, a pressure sensor is mounted on the upper plate, and a pressure head mounted at the lower end of the pressure sensor exerts pressure force onto the sample; then a spring stress relaxation test is performed, and the stress values at different time can be collected; and finally, the condition of stress relaxation loss of the material of the sample is determined. Through the method provided by the invention, the bending deflection of the sample, which is difficult to measure, is converted into electrical signals easy to measure, the work efficiency is improved, the method is simple, and the testing data is accurate.

Owner:BEIHANG UNIV

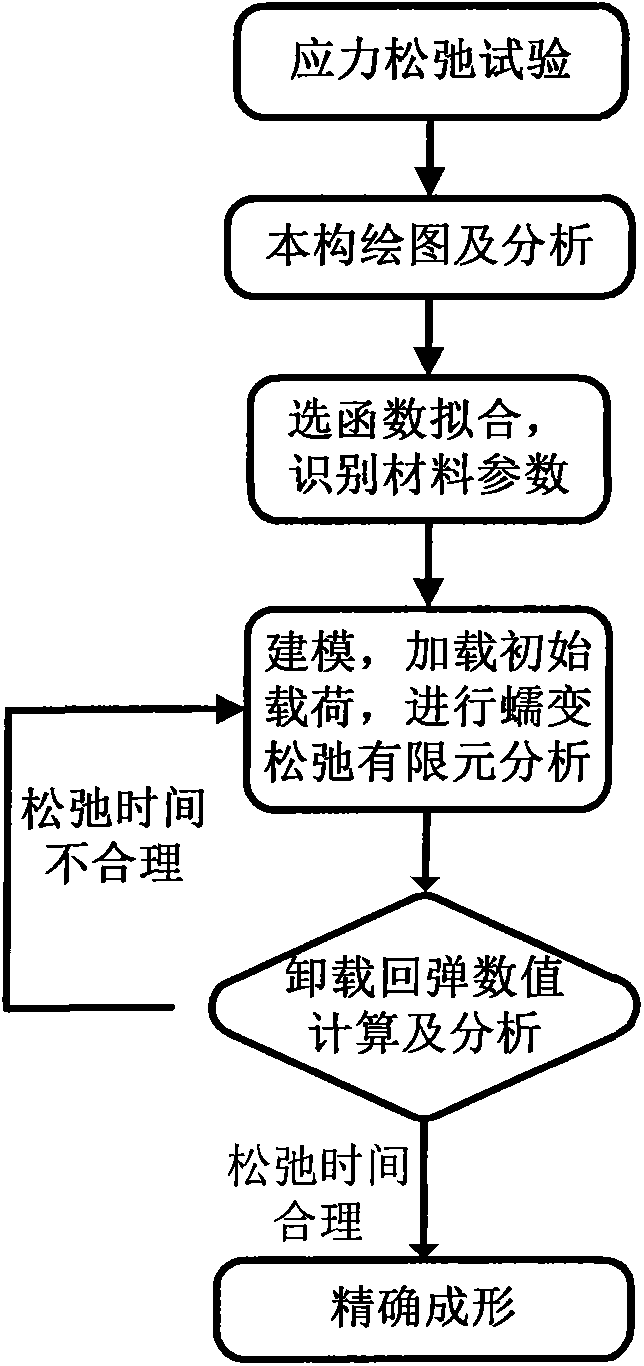

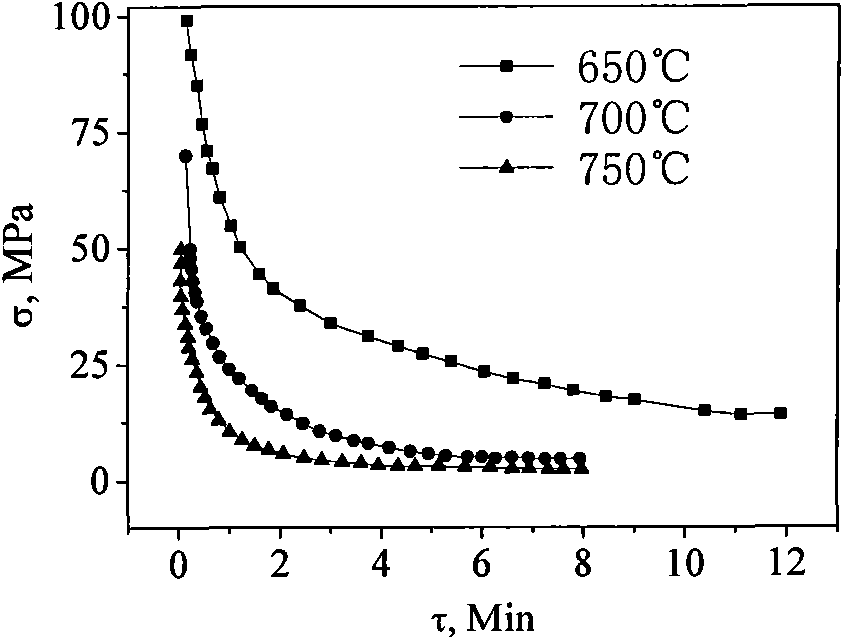

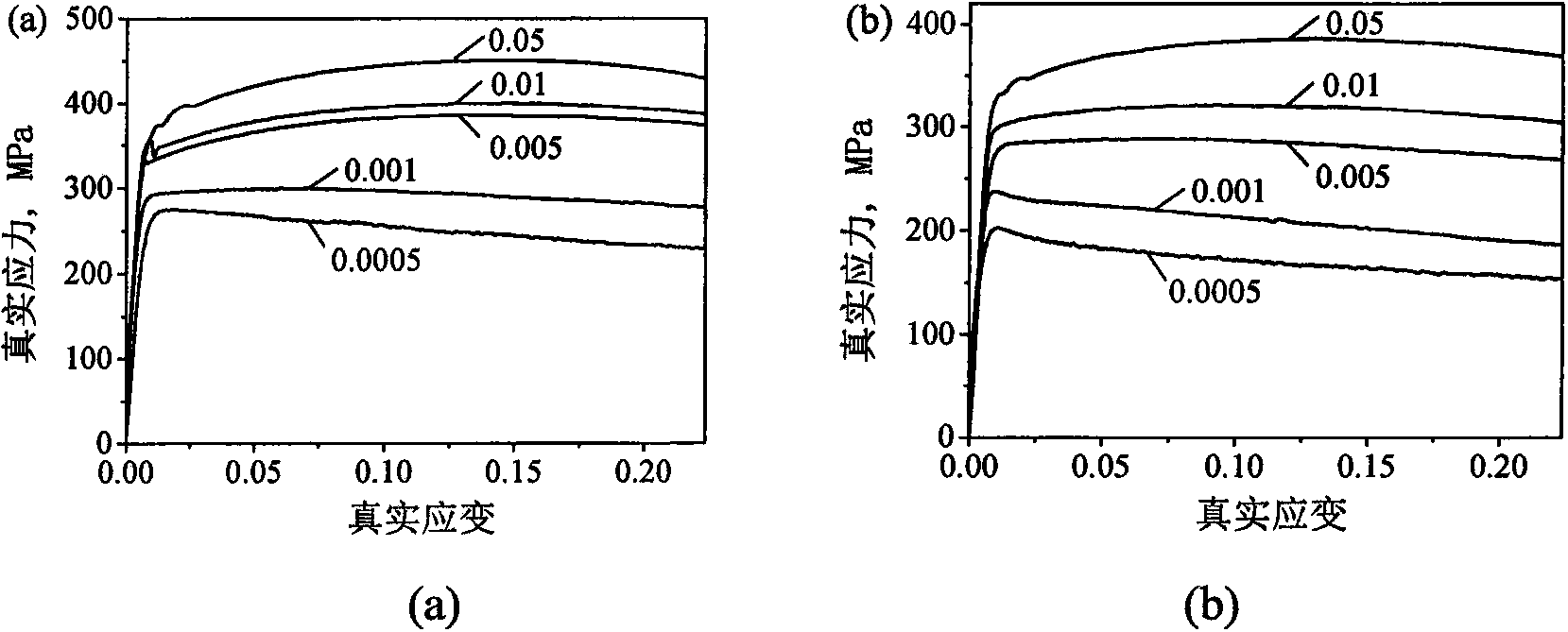

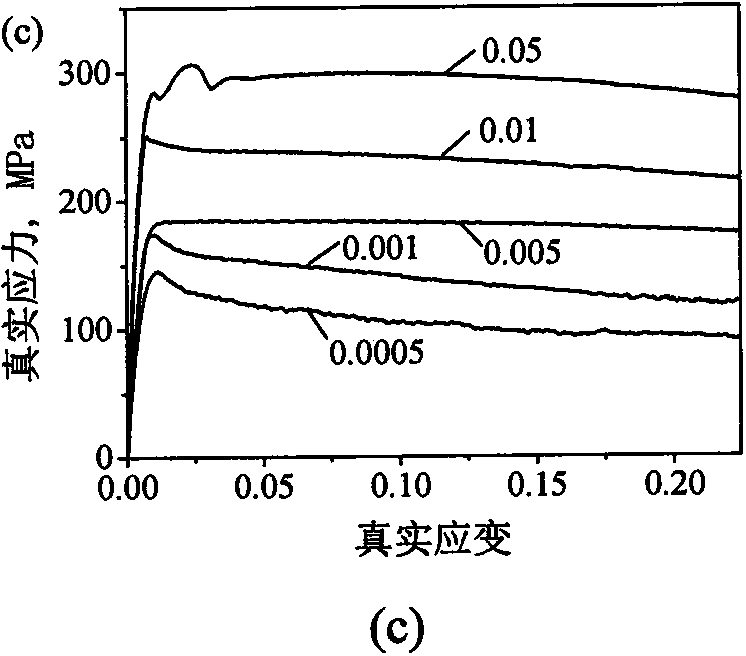

Method for computing stress relaxation numerical values and resilience of titanium alloy

ActiveCN103745114ALow costAccurate calculationSpecial data processing applicationsMetallurgyFinite element software

The invention provides a method for computing stress relaxation numerical values and resilience of titanium alloy. The method includes steps of (1), performing thermal stress relaxation tests on titanium alloy materials on material testing machines; (2), drawing stress relaxation curves of the titanium alloy and analyzing features of the curves; (3), selecting proper creep constitutive functions according to a principle that stress relaxation is essentially creep, and determining material parameters of the titanium alloy by a trial and error process; (4), substituting the parameters determined in the step (3) into creep analysis modules on the basis of finite element software ABAQUS and analyzing creep relaxation of workpieces by a static implicit algorithm; (5), determining resilience unloading initial states according to creep relaxation data, analyzing resilience of the workpieces and determining the magnitude of resilience of the workpieces after the workpieces resile from creep. The method has the advantages that as shown by analysis results, the resilience of components is greatly reduced after the titanium alloy is relaxed from stress, and the forming precision can be improved; proper relaxation time is selected, so that the titanium alloy components can be precisely formed.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

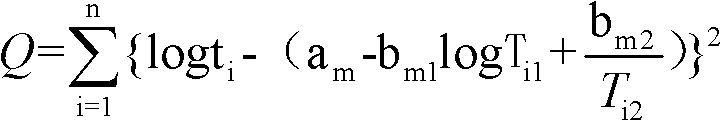

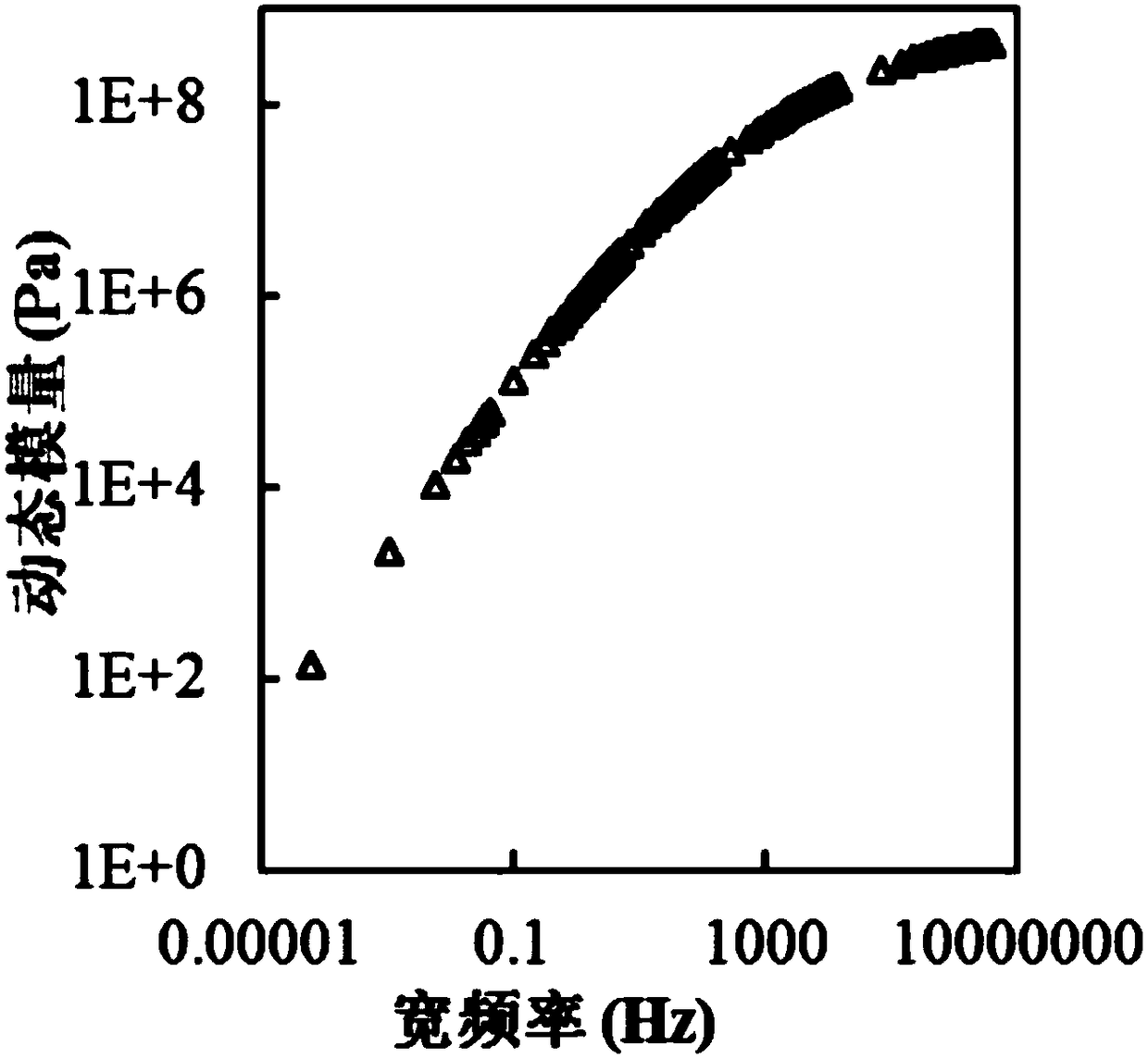

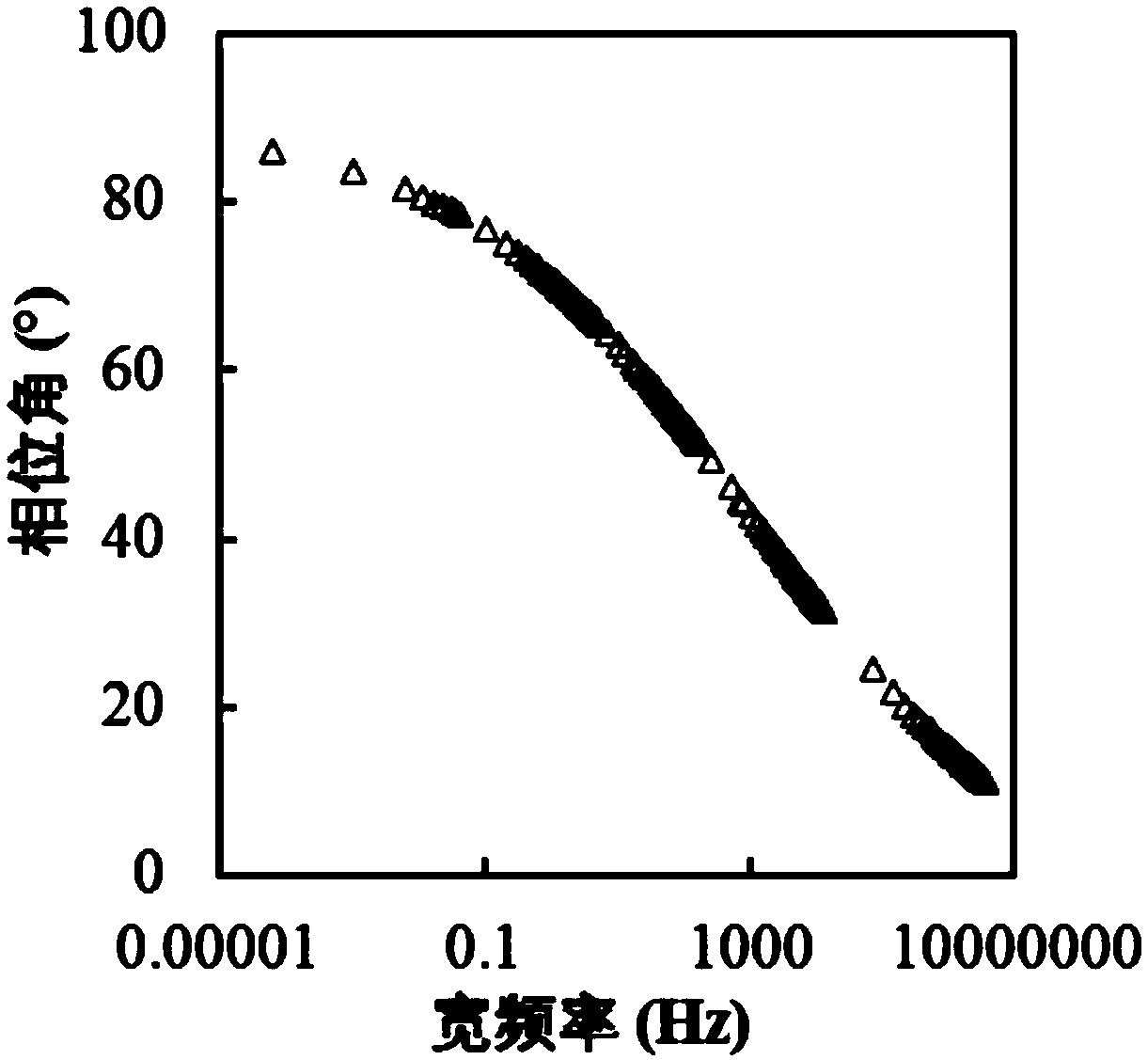

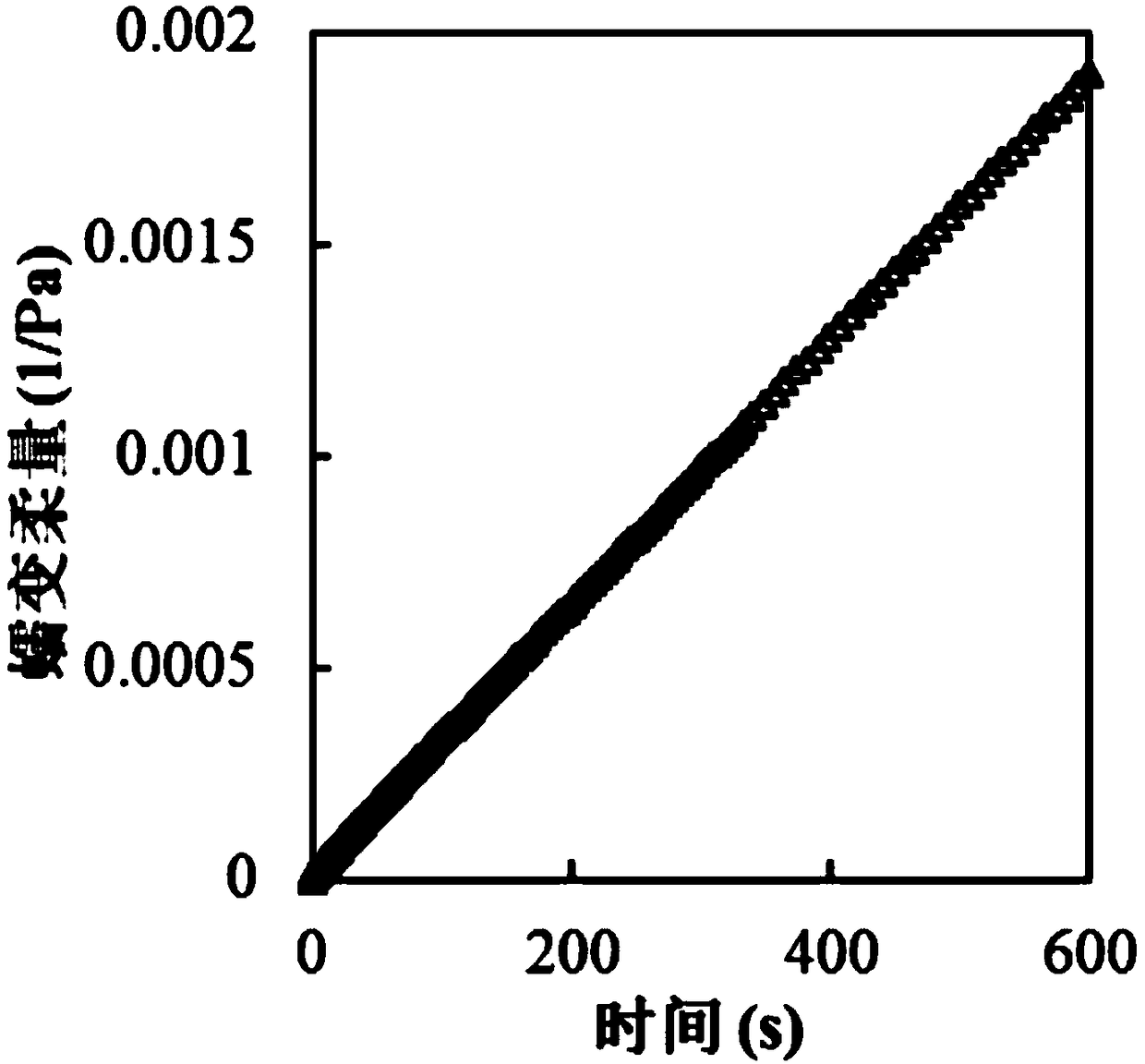

Parameter identification method of asphalt viscoelastic model based on comprehensive data optimization criterion

InactiveCN108846143AReflect viscoelastic propertiesDesign optimisation/simulationSpecial data processing applicationsDynamic shear rheometerSynthetic data

The invention provides a parameter identification method of an asphalt viscoelastic model based on a comprehensive data optimization criterion and belongs to the technical field of a parameter identification method of an asphalt viscoelastic model. The method comprises a step of carrying out a dynamic frequency scanning test, a static creep test and a stress relaxation test on asphalt by using a dynamic shear rheometer, establishing a dynamic modulus main curve and a phase angle main curve based on the test data, and drawing a creep compliance-time curve and a relaxation modulus-time curve, astep of establishing the asphalt viscoelastic model and deriving an expression of each viscoelastic parameter, which is a fitting value of the model, and a step of identifying model parameters according to the comprehensive data optimization criterion, thus modifying the model parameters, and taking a set of parameters corresponding to a smallest sum-of-squared differences to be parameter values in a final model. According to the method, the dynamic and static viscoelastic properties of the asphalt are comprehensively considered, and the method has important significance for the comprehensivecharacterization of the viscoelastic performance of an asphalt material by the model and the design and maintenance of an asphalt pavement.

Owner:HARBIN INST OF TECH

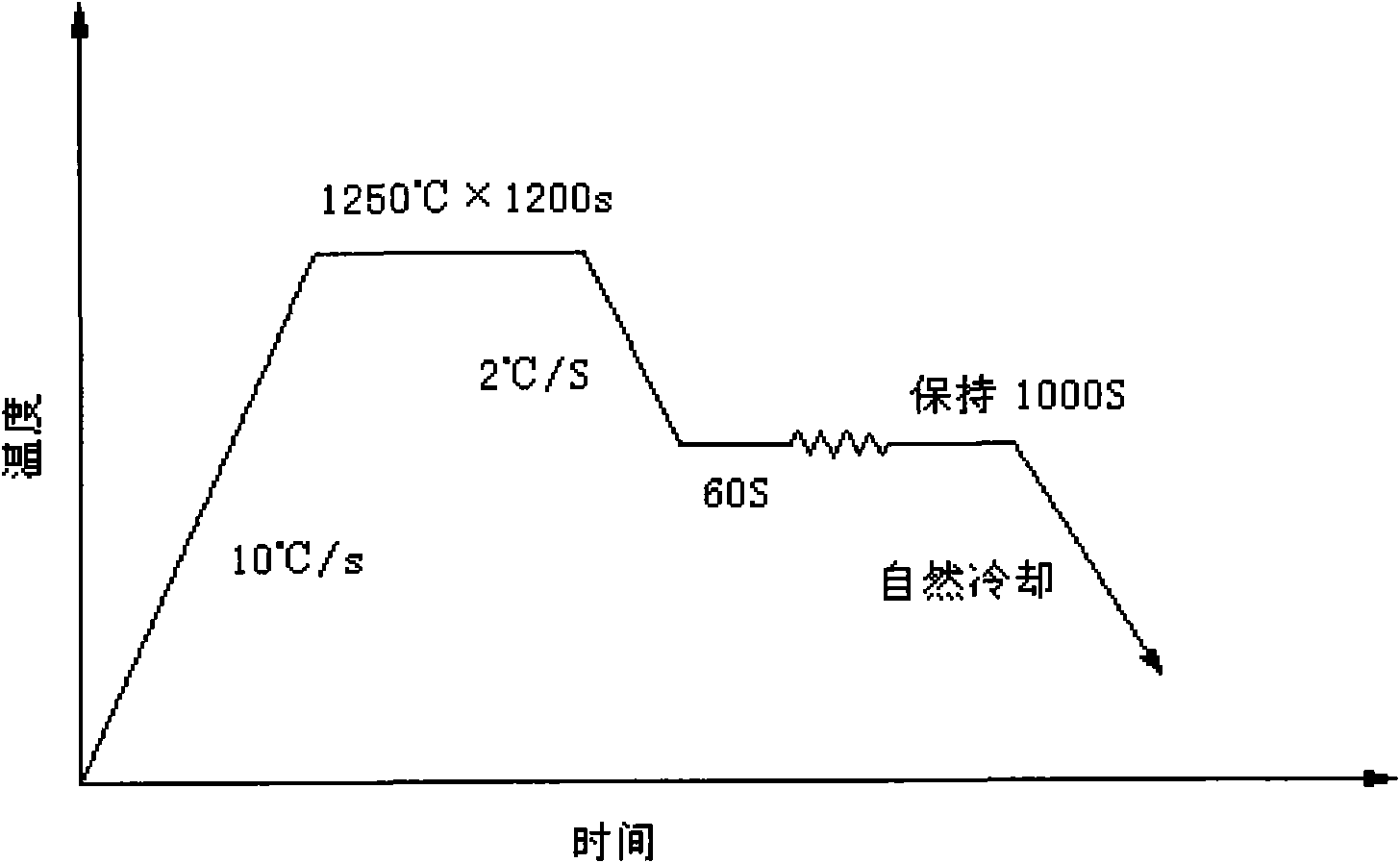

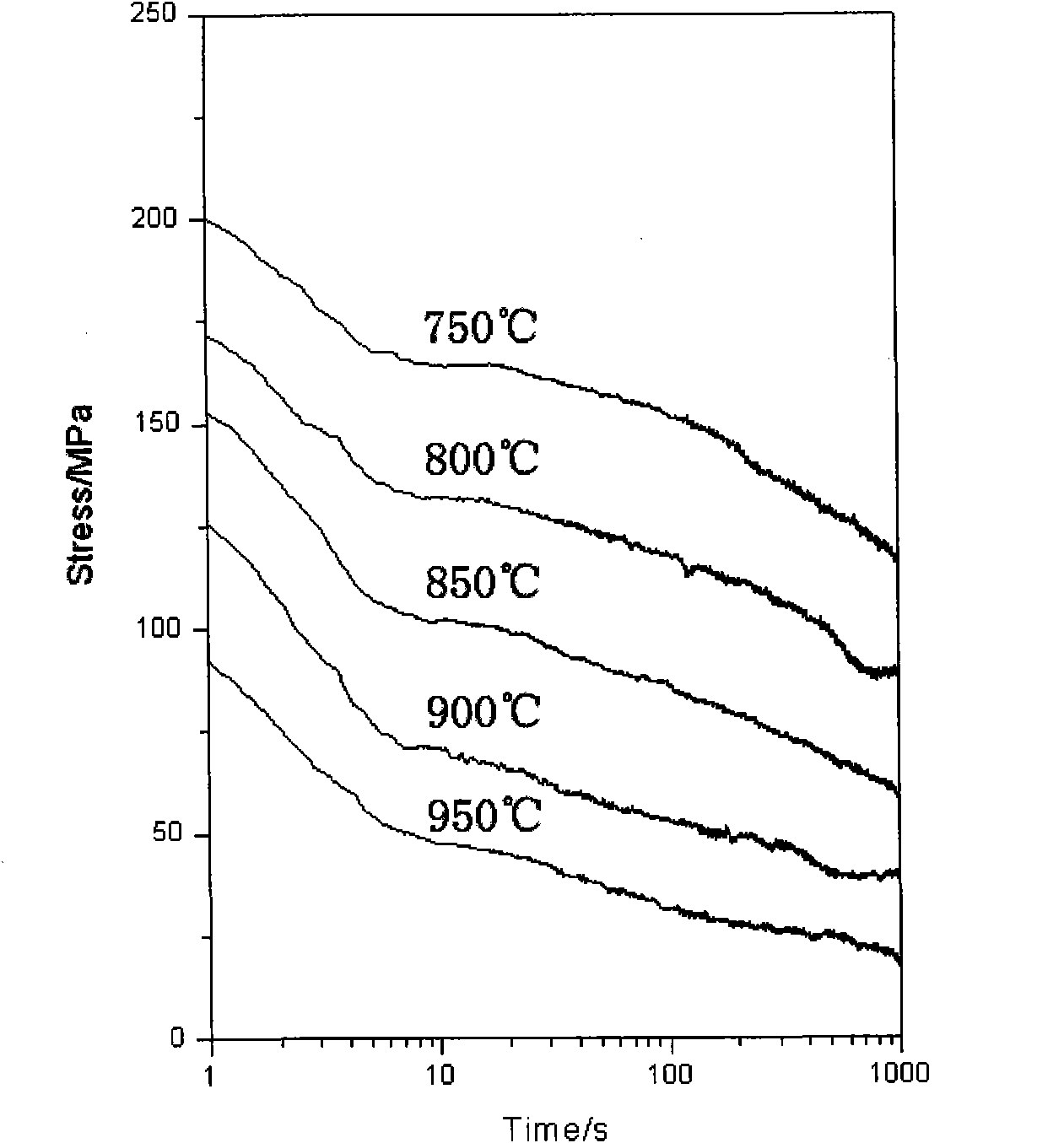

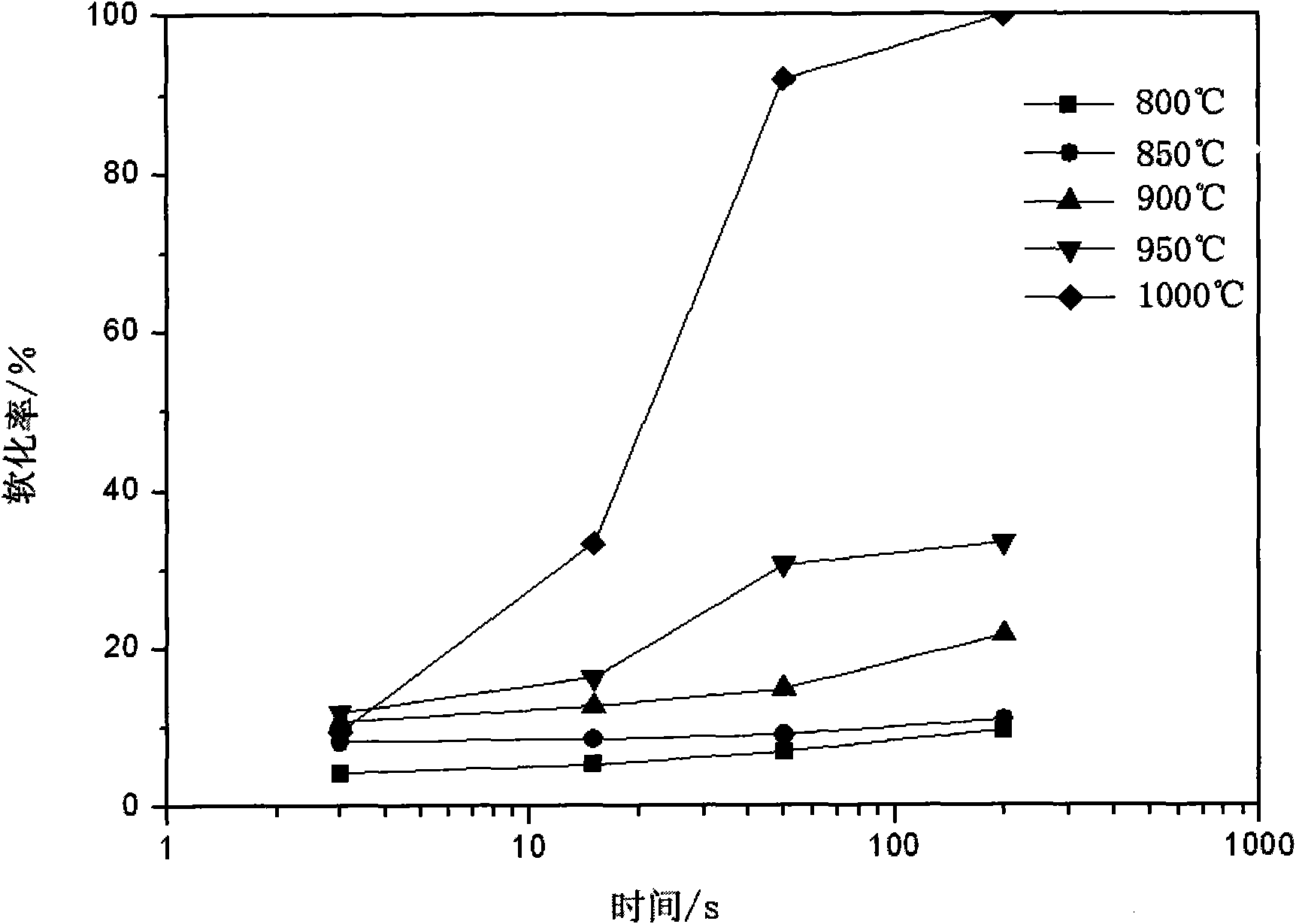

Method for carrying out stress relaxation test on Gleeble3800 hydraulic wedge unit in Jaw control mode

InactiveCN101793644ALow costHigh precisionMaterial strength using tensile/compressive forcesEngineeringFriction force

The invention discloses a method for carrying out a stress relaxation test on a Gleeble3800 hydraulic wedge unit in a Jaw control mode, which comprises the following steps: welding a thermocouple onto a sample, adopting a K-shaped thermocouple when the heating temperature of the sample is below 1200 DEG C, and adopting an S-shaped thermocouple when the heating temperature of the sample is above 1250 DEG C; respectively spreading a lubricant on a pressure head and the sample to reduce the friction force in compression, and isolating the pressure head and the sample through a tantalum sheet to prevent the pressure head and the sample to react in a high temperature state; opening an air hammer, compacting the sample, controlling the pressure to be about 100Kg, then opening a Gleeble3800 thermal simulation tester and leftwards moving the pressure head to a proper position; carrying out vacuum pumping, and charging Ar gas for protection when the vacuum degree is up to 2.4*10 to 1tau; carrying out compression by adopting the Jaw control mode; and after equipment operation is finished, reserving a high temperature organization state by adopting a direct quenching method, verifying precipitation and recrystallization conditions, and finishing the stress relaxation test. The invention has low cost and high precision and can be used for researching the precipitation behavior of various strain induced precipitates.

Owner:NANJING IRON & STEEL CO LTD

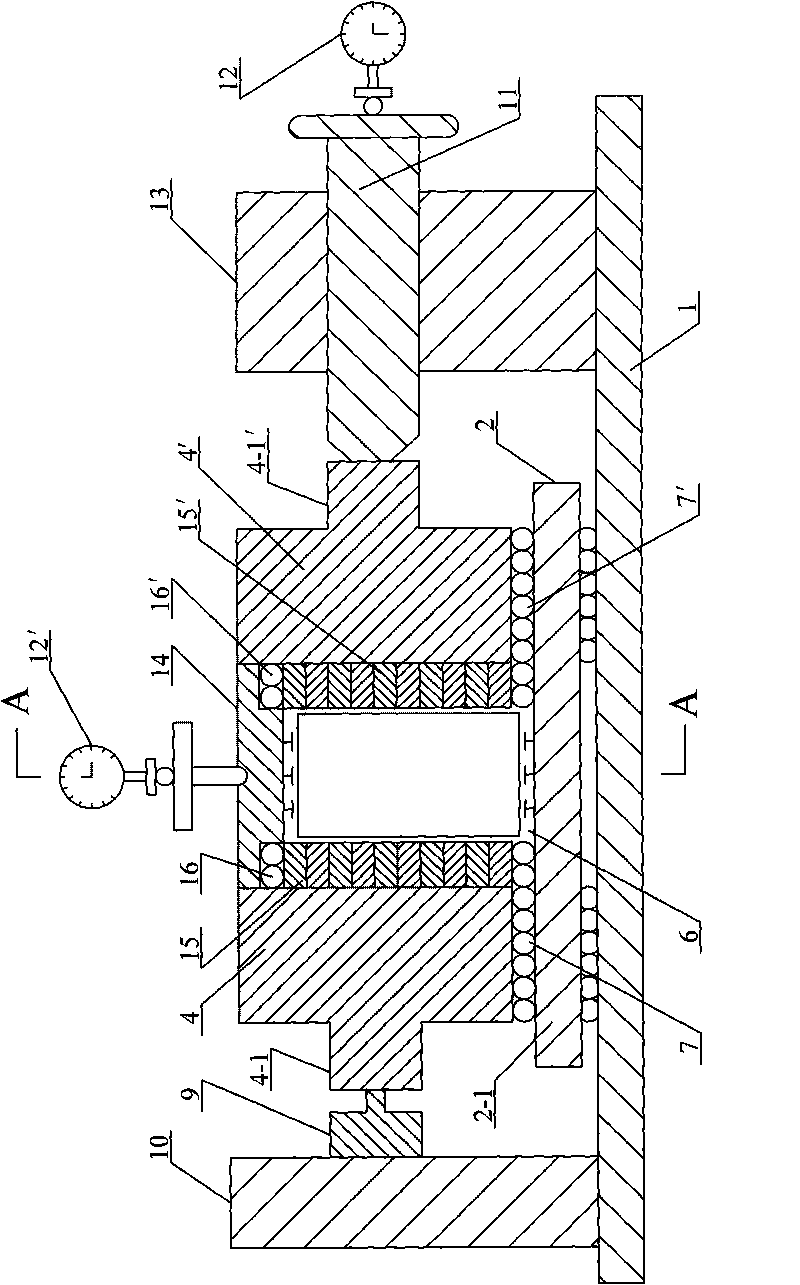

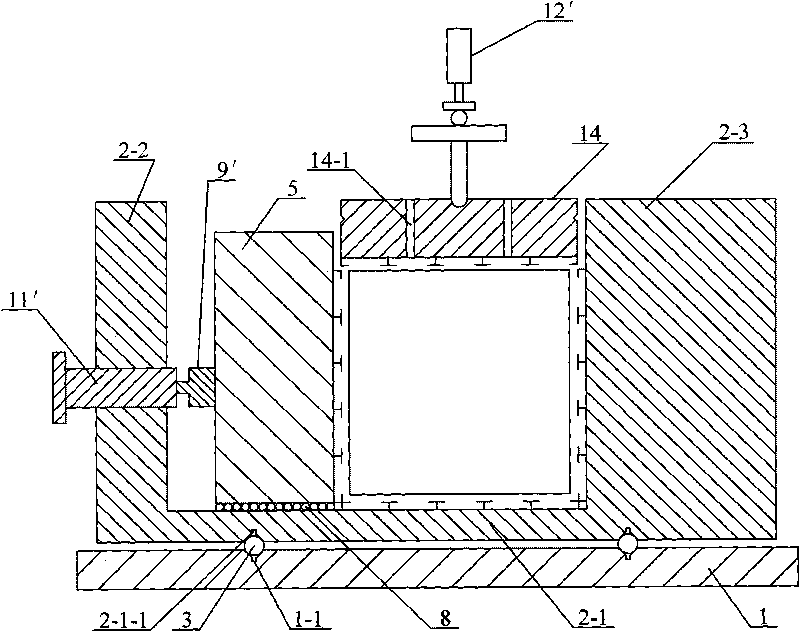

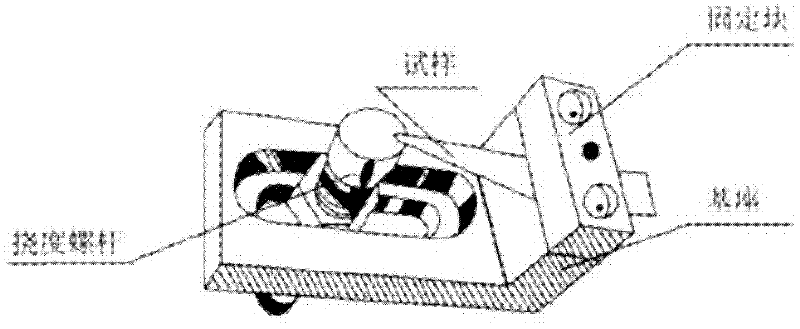

Planar and lateral strain controlled triaxial apparatus

InactiveCN101699257AMaterial strength using tensile/compressive forcesEngineeringStress relaxation test

The invention discloses a planar and lateral strain controlled triaxial apparatus. The triaxial apparatus can perform a lateral unloading test or a lateral confined stress relaxation test for a soil sample under a planar strain condition and acquire precise test data. A trolley of the triaxial apparatus comprises a bottom plate and first and second lateral plates which are parallel with each other and vertical to the bottom plate. The trolley is in rolling connection with a chassis; a first lateral plug, a second lateral plug and a lateral baffle are in rolling connection with the chassis of the trolley respectively and form a soil sample accommodating chamber together with the second lateral plate; a first pressure sensor is contacted with the outer side face of the first lateral plug; two ends of a first rotary screw are contacted with the second lateral plug and a first dial indicator respectively; a second pressure sensor is connected with the later baffle and is contacted with the first later plate; a cover plate is arranged on the top of the soil sample accommodating chamber; and a second dial indicator is contacted with the upper side face of the cover plate.

Owner:HOHAI UNIV

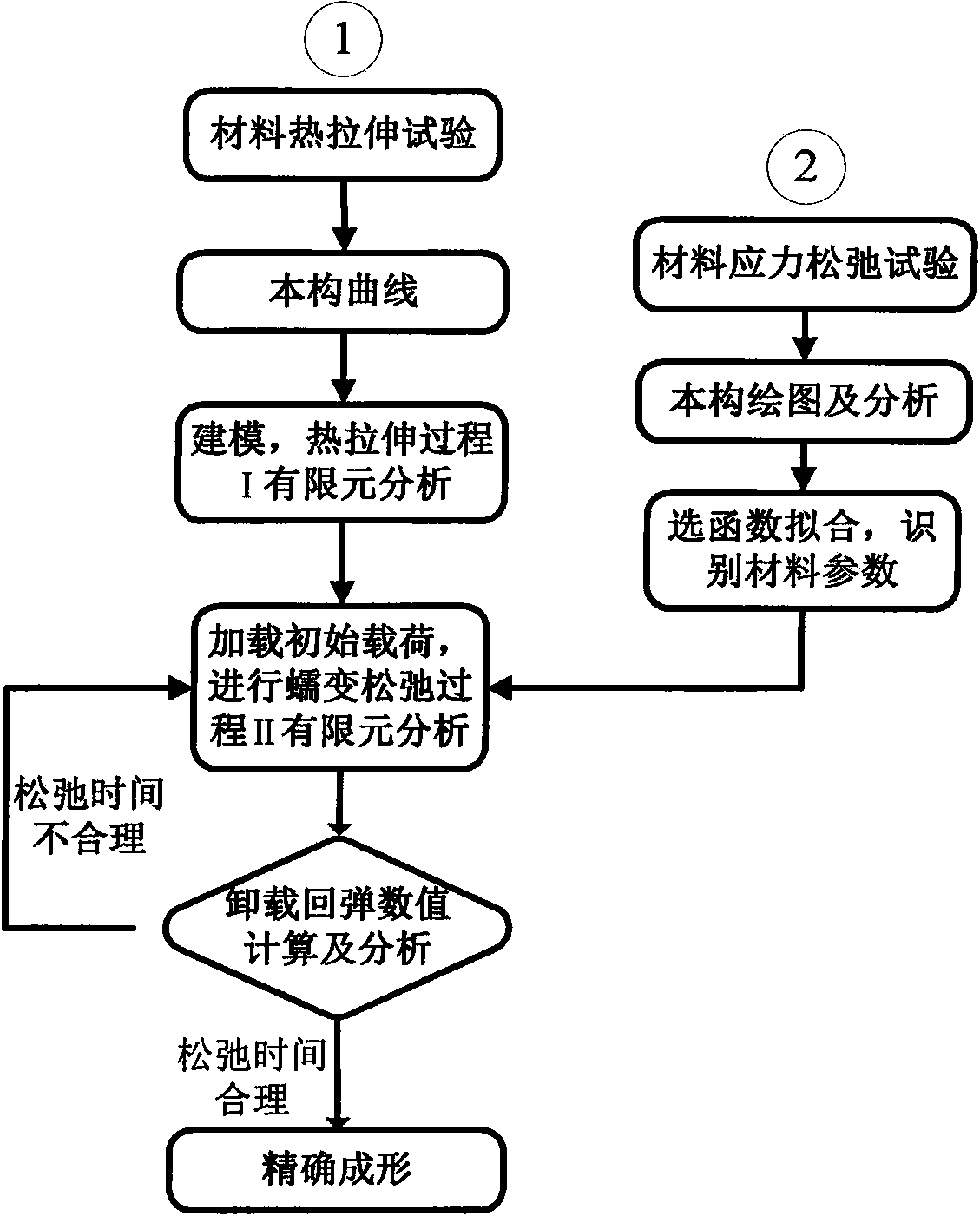

Numerical simulation method for thermal composite forming of titanium alloy

The invention provides a numerical simulation method for thermal composite forming of titanium alloy. The numerical simulation method includes the steps of 1), subjecting the titanium alloy to a thermal unidirectional tensile test in a material testing machine; 2), drawing titanium alloy constitutive curves and identifying material parameters; 3), inputting the parameters determined in the step 2) into an analysis module on the basis of finite element software and analyzing the thermal tensile deformation process I; 4), performing material thermal stress relaxation test on the material testing machine; 5), drawing titanium alloy stress relaxation curves; 6), selecting proper creep deformation constitutive function and determining relaxation parameters of materials; 7), substituting the relaxation parameters determined in the step 6) into a creep deformation analysis module on the basis of taking simulation results in the step 3) as an initial state of the relaxation process II; 8), performing springback analysis by taking relaxation simulation data as the initial state of springback unloading. The results show that the titanium alloy subjected to stress relaxation is lowered in stress and reduced in springback, and parts are high in forming accuracy.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Specimen end clipping reinforcement method during FRP rib stress relaxation characteristics test

The invention provides a method for reinforcing and gripping at an end part of a test piece during stress relaxation test of an FRP rib. A gradient transition section is arranged at a reinforcing section at the end part of the test piece, and an external thread arranged at the reinforcing section is matched with a screw thread of a metal splint with an internal thread to eliminate sliding and creeping of a gripping area at the end part during experiment. The method is specifically realized by the following steps: intertwining a section of fiber cloth soaked by resin and being capable of realizing gradient transition at the end part of the test piece, winding the external thread at the glass fabric intertwined section by a thin fiber strand according to a predetermined thread pitch before resin solidification, matching the external thread with the internal thread of the metal splint, and buckling two prefabricated metal splints coated with release agent to the wound screw thread to be fixed. The method solves the problem that sliding, creeping and the like in the gripping area at the end part of the test piece influence the test results when the FRP rib is subjected to stress relaxation test, and the metal splints can be repeatedly utilized.

Owner:TONGJI UNIV +1

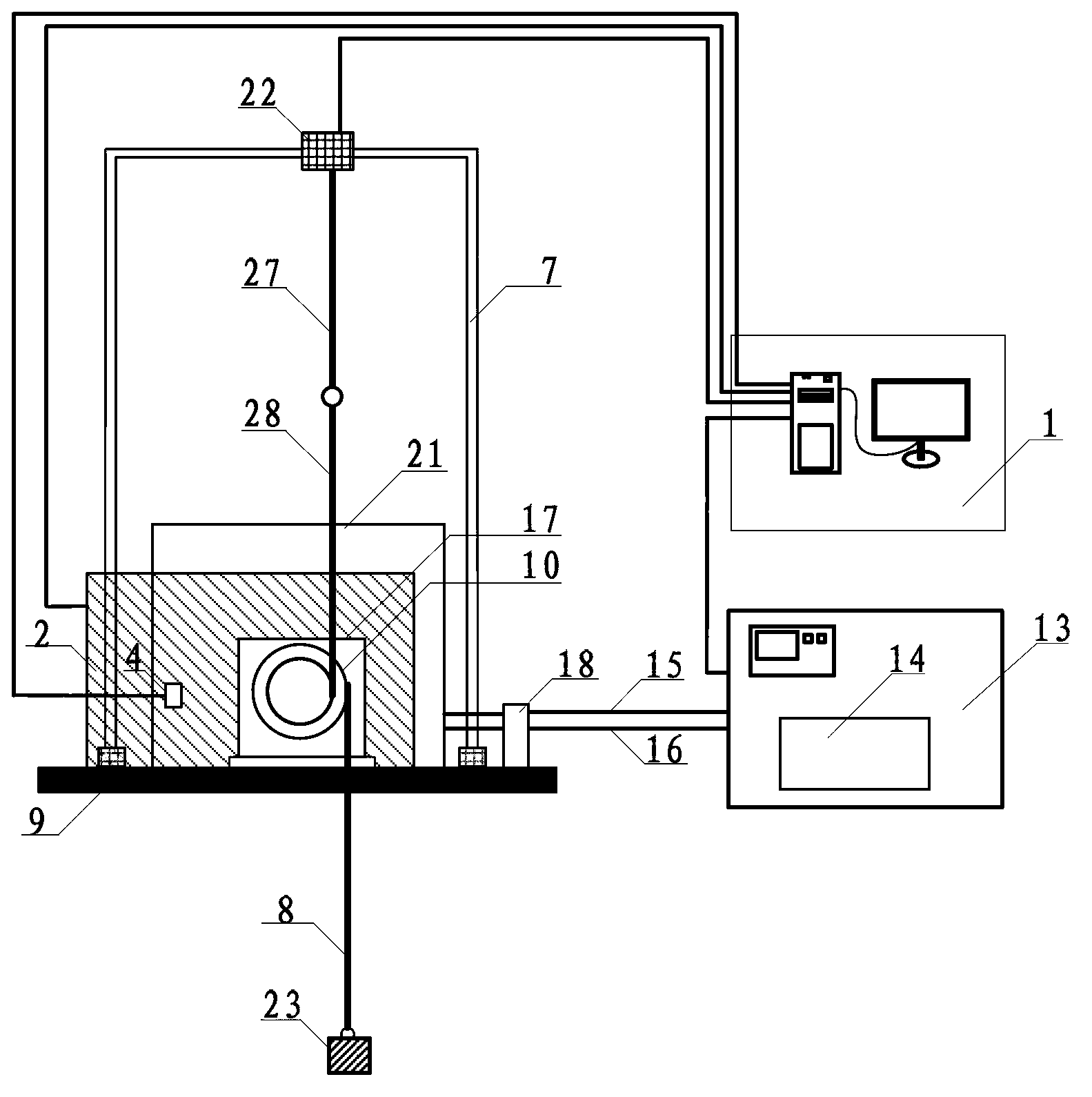

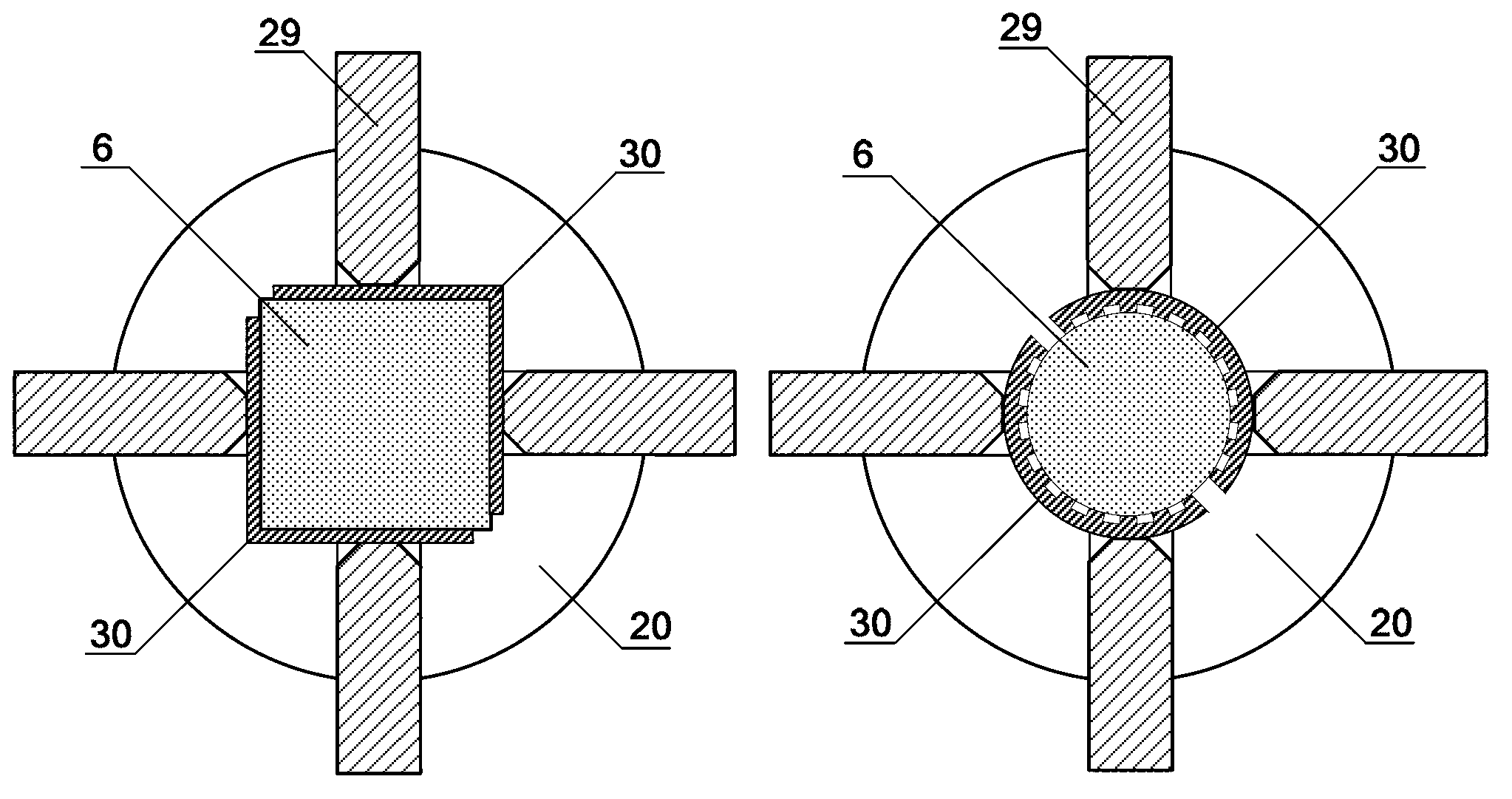

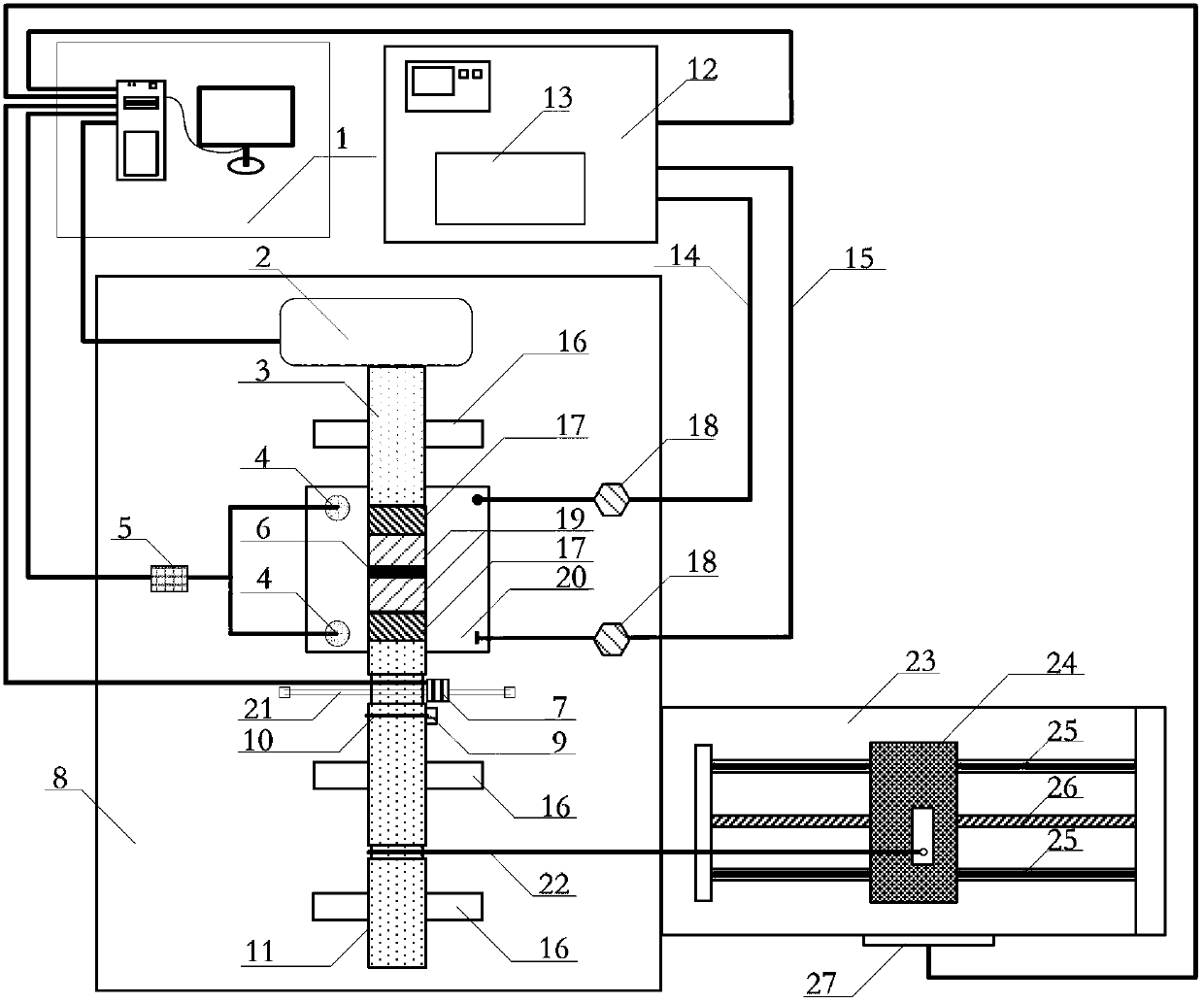

Rotation shear stress relaxation test device for asphalt mixture and method

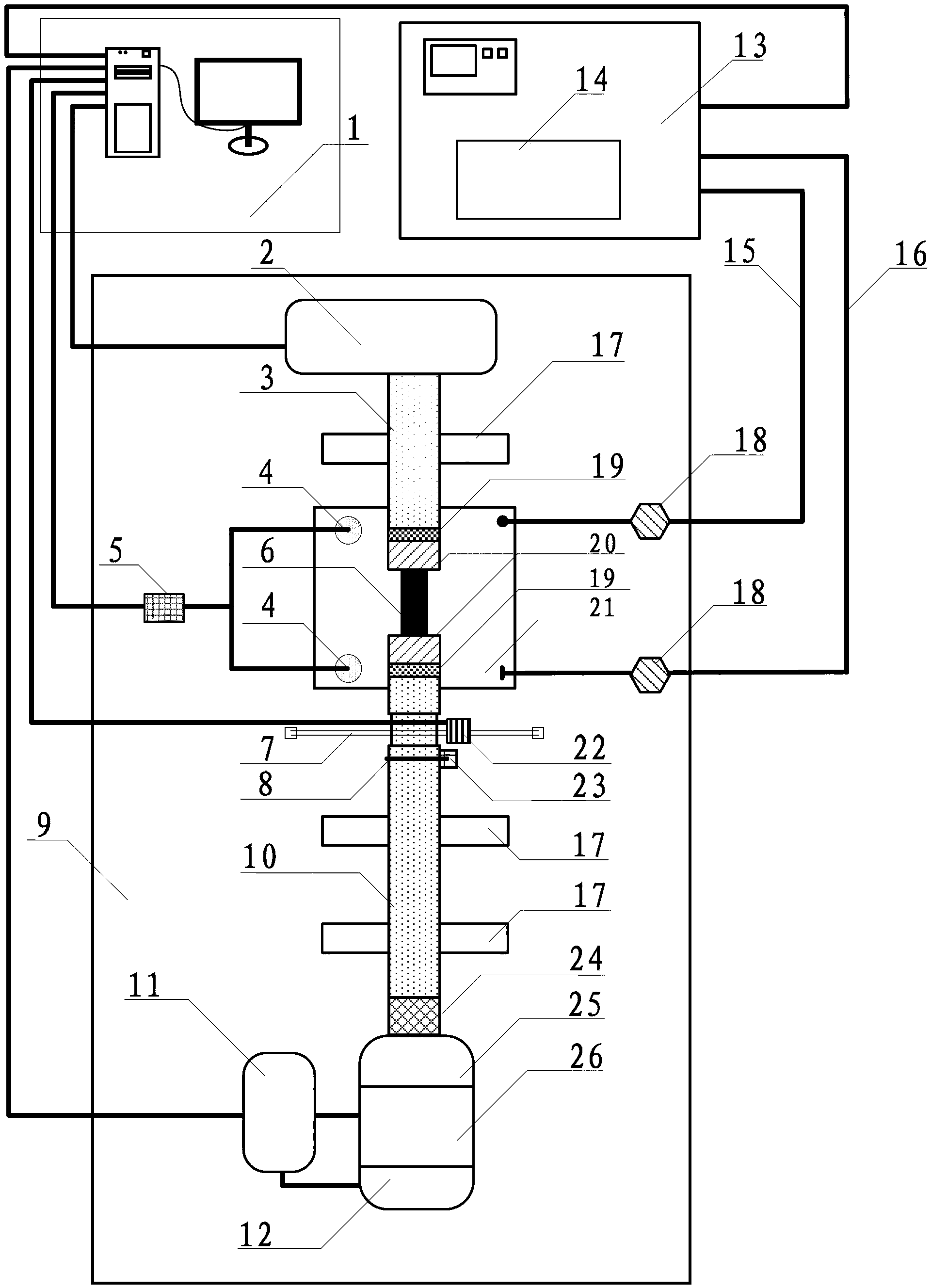

A rotation shear stress relaxation test device for an asphalt mixture and a method, belong to a mechanical property test technology field of the asphalt mixture. The device is composed of a test platform, a loading system, a temperature control system and a computer control system, wherein the loading system comprises a frequency converter (11), an electronic brake (12), a reduction box (25) and a micro motor (26), which can be controlled by a computer. The computer control system (1) can control the electronic brake (12) by the frequency converter (11) to implement rotation shearing loading, load holding and unloading that are stress relaxation test on an asphalt mixture test piece (6). The device and the method are suitable for determining stress relaxation performances of a common asphalt mixture, an SMA asphalt mixture, a regeneration asphalt mixture and other asphalt mixtures under different parameters, such as different temperatures, different strain levels, different loading, and different load holding time. When repetition frequency is set to be multitimes, and other test parameters such as unloading, load holding and stay time, are set, repeat stress relaxation test can be completed.

Owner:DALIAN UNIV OF TECH

Method for evaluating material reheating crack sensitivity through stress relaxation test

ActiveCN107389445AReduce lossShort test cycleMaterial strength using tensile/compressive forcesRelaxation testStress relaxation test

The invention relates to a method for evaluating material reheating crack sensitivity through a stress relaxation test. The method comprises the following steps: integrating welding thermal simulation and stress simulation, simulating a welded HAZ coarse-grain region microstructure by simulating different welding process parameters, and simulating a residual stress state of a sample by taking certain measures; performing destressed heat-treatment simulation until the sample is fractured or the set heat insulation stage is ended so as to obtain a change relationship between the temperature, the stress and the like along with time; characterizing the material reheating crack sensitivity by using a fracture temperature-fracture time curve. According to the method disclosed by the invention, the material reheating crack sensitivity is directly evaluated on a thermal simulated testing machine through weld simulation and stress relaxation testing. The whole testing process is very close to the actual situation, the testing cycle is very short, high-efficiency and accurate, and the material loss is less during the test. The method disclosed by the invention can be used for various weld and stress simulation process parameters. The method has great significance in the actual material reheating crack sensitivity prediction and has progressiveness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Comprehensive bituminous-mixture low-temperature-performance detection device

ActiveCN105973717AExclude the effect of coolingAddress stressMaterial strength using tensile/compressive forcesMaterial thermal analysisControl systemEngineering

The invention discloses a comprehensive bituminous-mixture low-temperature-performance detection device, and relates to a comprehensive detection device. A low-temperature shrinkage test, a low-temperature stress relaxation test and a freezing breaking test need to be carried out through different devices, the problems that as the universality of the devices is poor, test cost is high, and meanwhile the accuracy of the detection result of a bituminous-mixture testing piece is low exist. The comprehensive bituminous-mixture low-temperature-performance detection device comprises an environmental box, a counterforce frame, a displacement measuring system, a data collecting control system, a micro-data collecting system and a heating system. The environmental box is arranged in the counterforce frame, a digital speckle camera faces to a visible window of the environmental box, a bituminous-mixture testing piece is arranged in the environmental box, one end of the bituminous-mixture testing piece is connected with a motor sequentially through a dowel steel and a transmission device, the other end of the bituminous-mixture testing piece is connected with a stress sensor through the other dowel steel, and the displacement measuring system is arranged outside the environmental box and connected with the counterforce frame. The comprehensive bituminous-mixture low-temperature-performance detection device is used for detecting the low-temperature performance of bitumen.

Owner:黑龙江省工研院资产经营管理有限公司

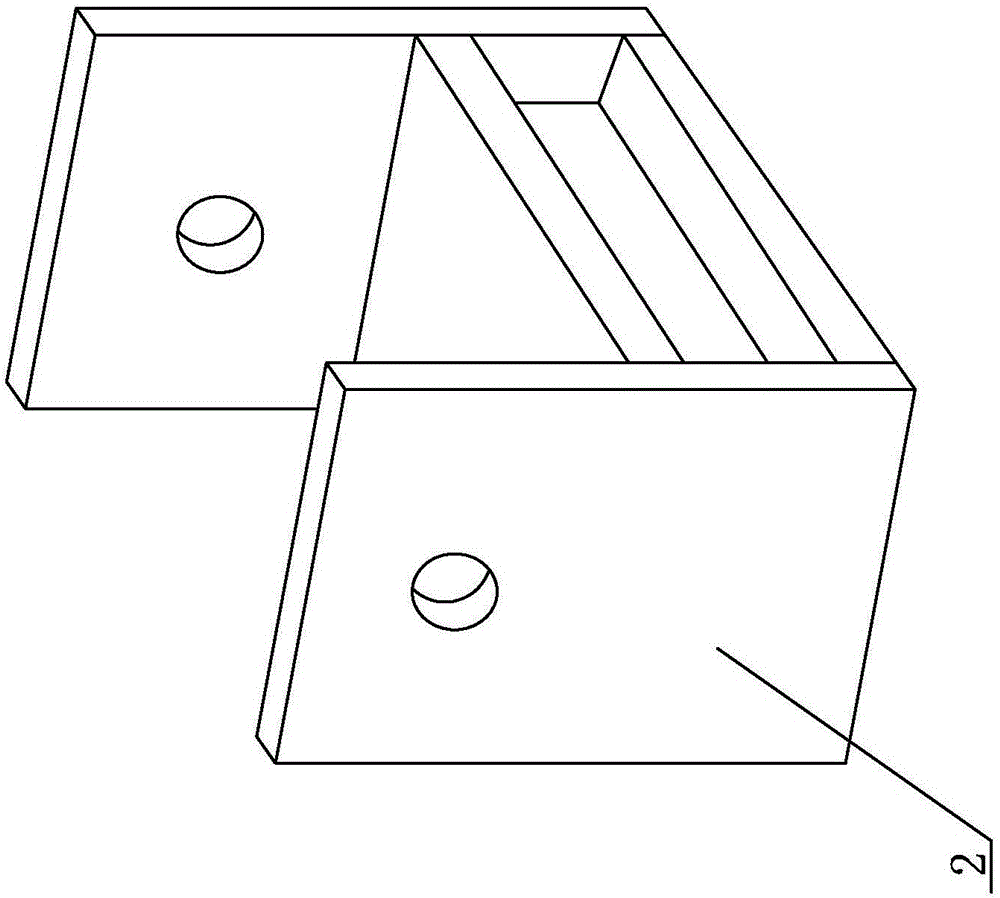

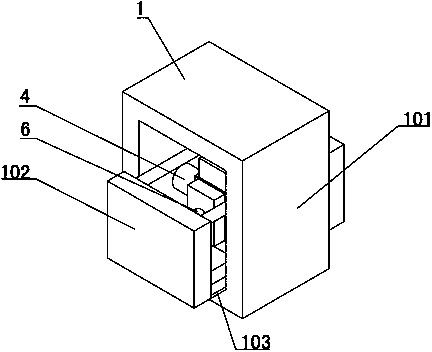

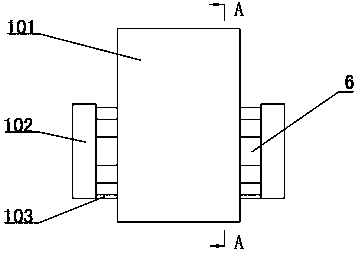

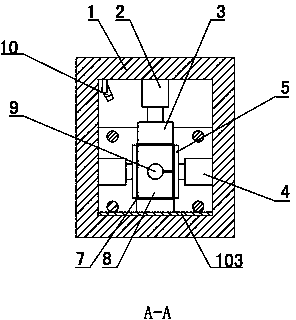

True-triaxial loading and unloading rock stress relaxation test device and test method

InactiveCN104897467ATightly boundIn line with the site conditionsMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a true-triaxial loading and unloading rock stress relaxation test device and a test method, and belongs to the technical field of test detection and monitoring of mining industry and geotechnical engineering. The true-triaxial loading and unloading rock stress relaxation test device is characterized in that supercharging devices comprise a vertical supercharging device, a horizontally-lateral supercharging device and a horizontal longitudinal supercharging device, wherein the supercharging devices are connected with an upper computer by a wireless pressure transmitter respectively for uploading a pressure signal to the upper computer in real time; an ultrasonic monitoring device and a camera device which are connected with the upper computer are further arranged; the ultrasonic monitoring device comprises an ultrasonic monitoring probe (9) and a nonmetal ultrasonic detector; and the ultrasonic monitoring probe (9) is arranged in an opening in the middle of a loading board and is pressed by springs supported on the supercharging devices. According to the true-triaxial loading and unloading rock stress relaxation test device disclosed by the invention, a test sample can be kept unchanged for a long term, and the supercharging devices are independently loaded in three directions respectively; and the test method agrees with the actual situation better, so that theoretical basis is provided for roadway (tunnel) stability and control research.

Owner:SHANDONG UNIV OF TECH

Asphalt rotation shear stress relaxation test apparatus

InactiveCN103217343AMaterial strength using steady shearing forcesComputer control systemTemperature control

The invention discloses an asphalt rotation shear stress relaxation test apparatus, which belongs to the field of asphalt mechanical property test, and the apparatus is composed of a test platform, a loading system, a temperature control system and a computer control system. The computer control system controls the loading system for rotating and loading an asphalt test piece on the test platform and holding stress and automatically unloading under the constant shearing strain state, and controls the temperature control system for temperature control of the test process. The invention is suitable for determining relaxation performance of common asphalt, SBS modified asphalt, rubber asphalt and other polymer modified asphalts and asphalt cementation materials under the rotation shearing effect; When the repeating frequency is set to multitime, and loading, stress holding, unloading and stay time and rest test parameters are set, the repeat stress relaxation test can be completed.

Owner:DALIAN UNIV OF TECH

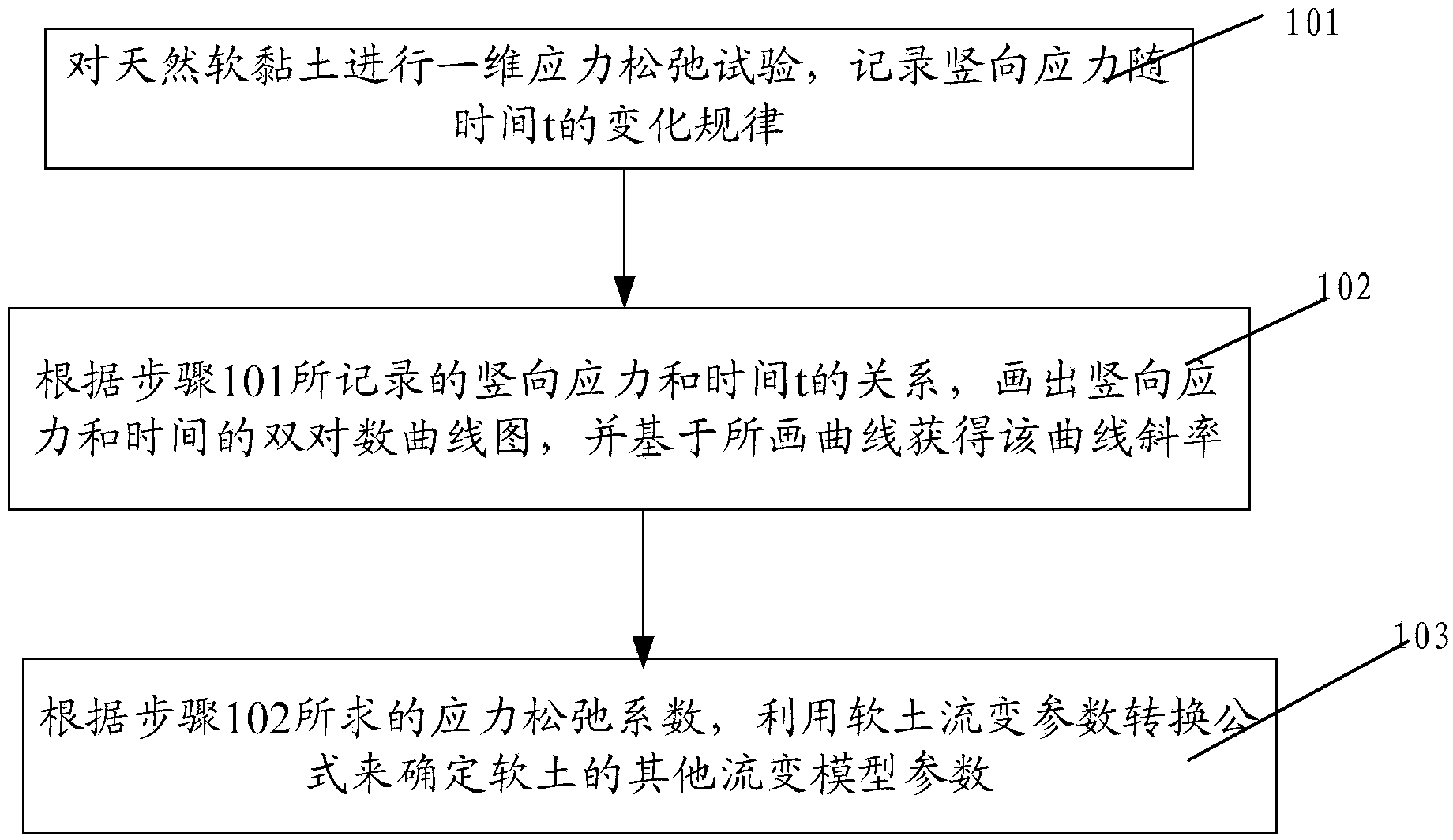

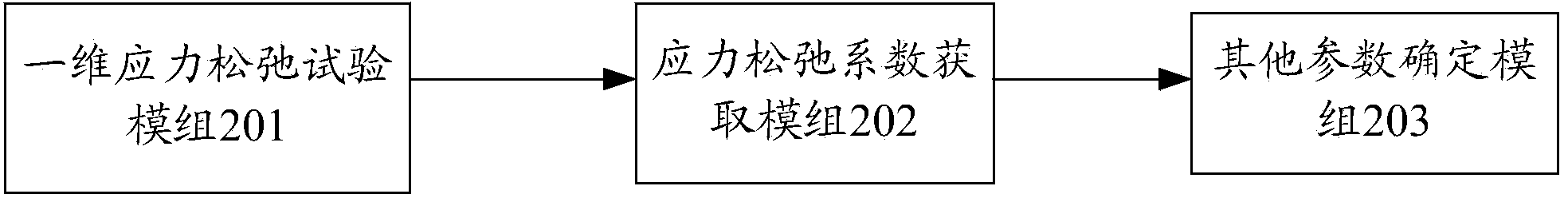

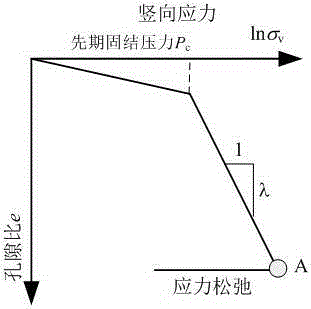

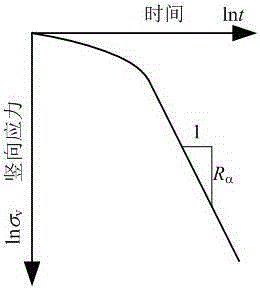

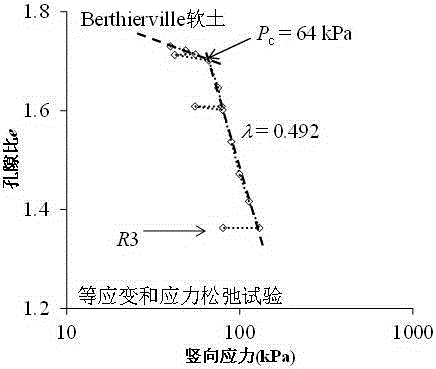

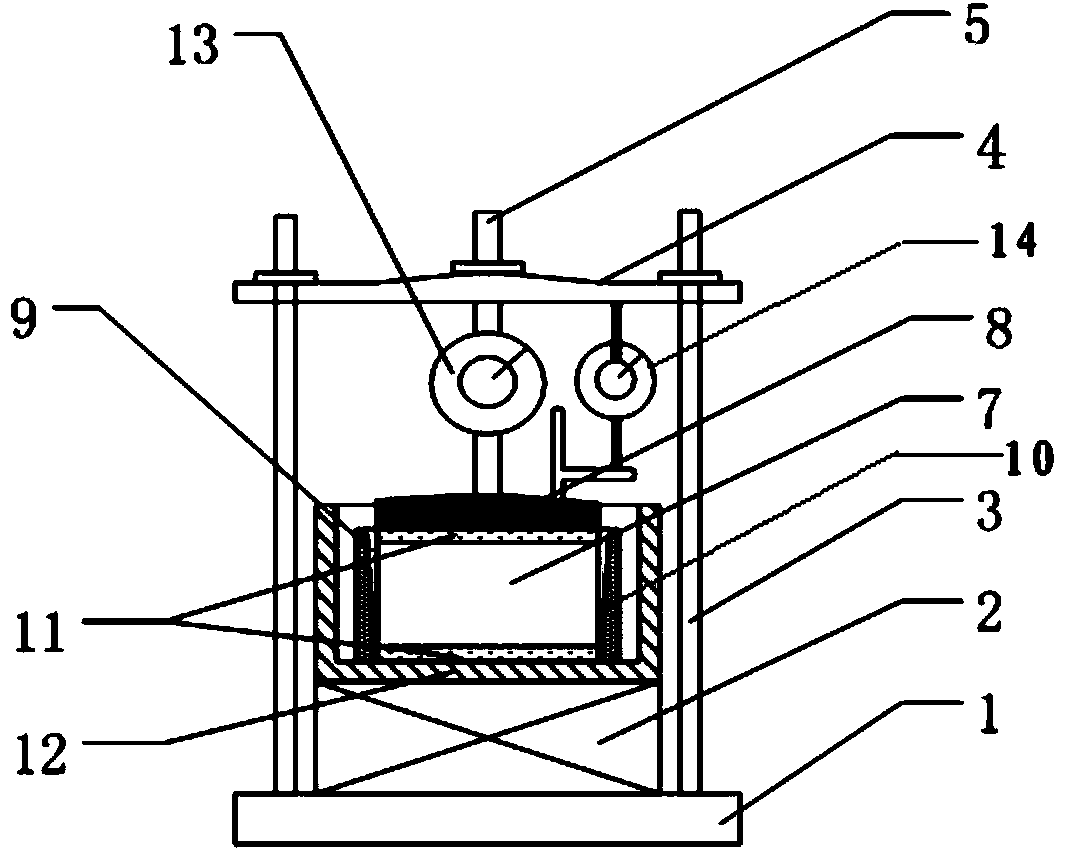

Soft soil rheological parameter determination method and soft soil rheological parameter determination device based on one-dimensional stress relaxation test

InactiveCN103471920AAccurately determineEasy to operateMaterial strength using tensile/compressive forcesSoil scienceSoft clay

The invention discloses a soft soil rheological parameter determination method and a soft soil rheological parameter determination device based on a one-dimensional stress relaxation test. The method comprises the following steps: carrying out one-dimensional stress relaxation test on natural soft clay and recording a change rule of a vertical stress sigmav along with time t; drawing an lnsigmav-lnt double logarithmic curve graph according to a relation between the recorded vertical stress sigmav and the time t; obtaining the slope of a curve based on the drawn curve, wherein the slope of the curve is a stress relaxation coefficient Ralpha; and determining other rheological model parameters of soft soil by utilizing a soft soil rheological parameter conversion formula according to the solved stress relaxation coefficient Ralpha. The soft soil rheological parameter determination method has the advantages of convenience in operation, short consumed time, testing cost saving and time cost saving, the improvement of the testing efficiency and accurate determination of the parameters.

Owner:SHANGHAI JIAO TONG UNIV

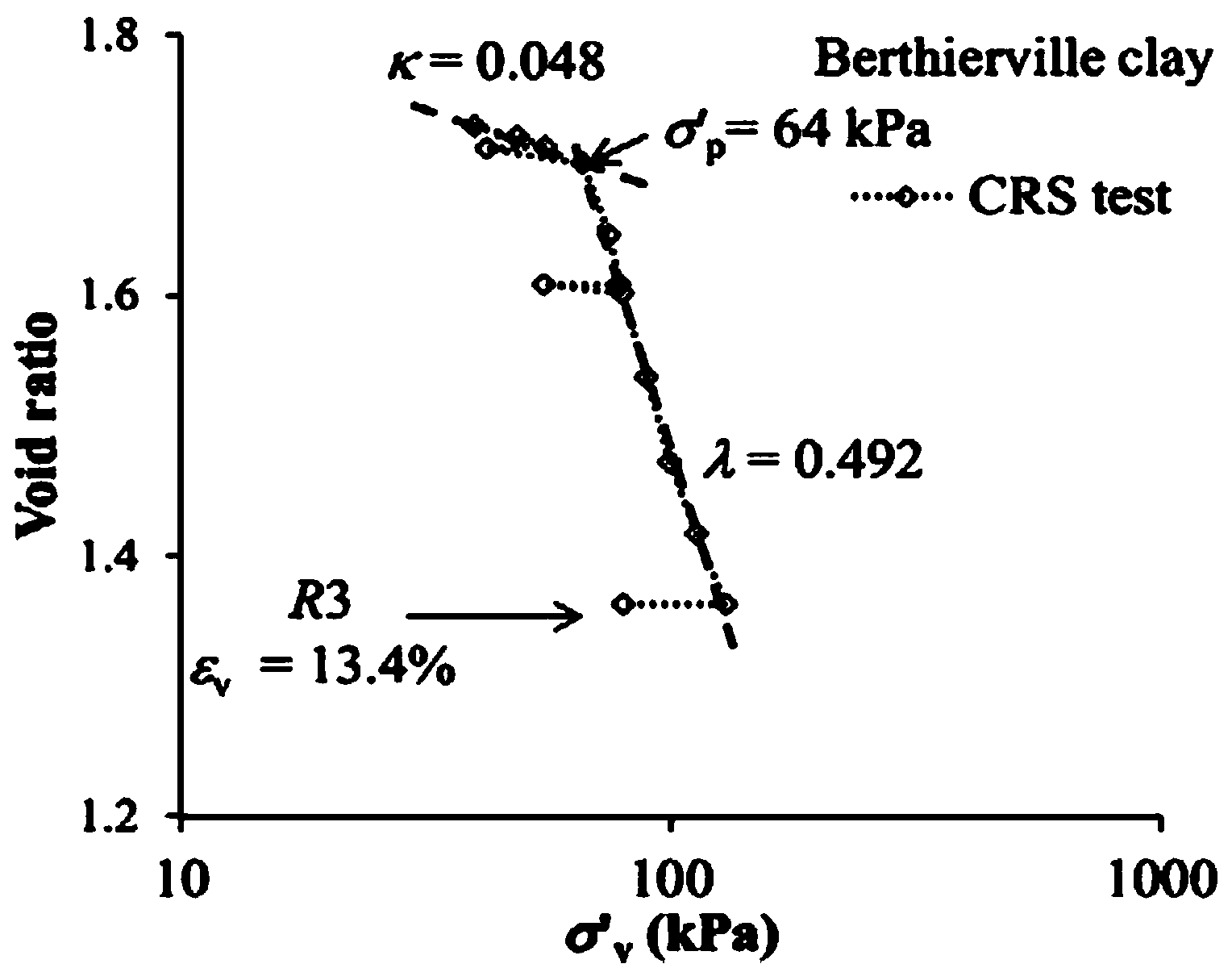

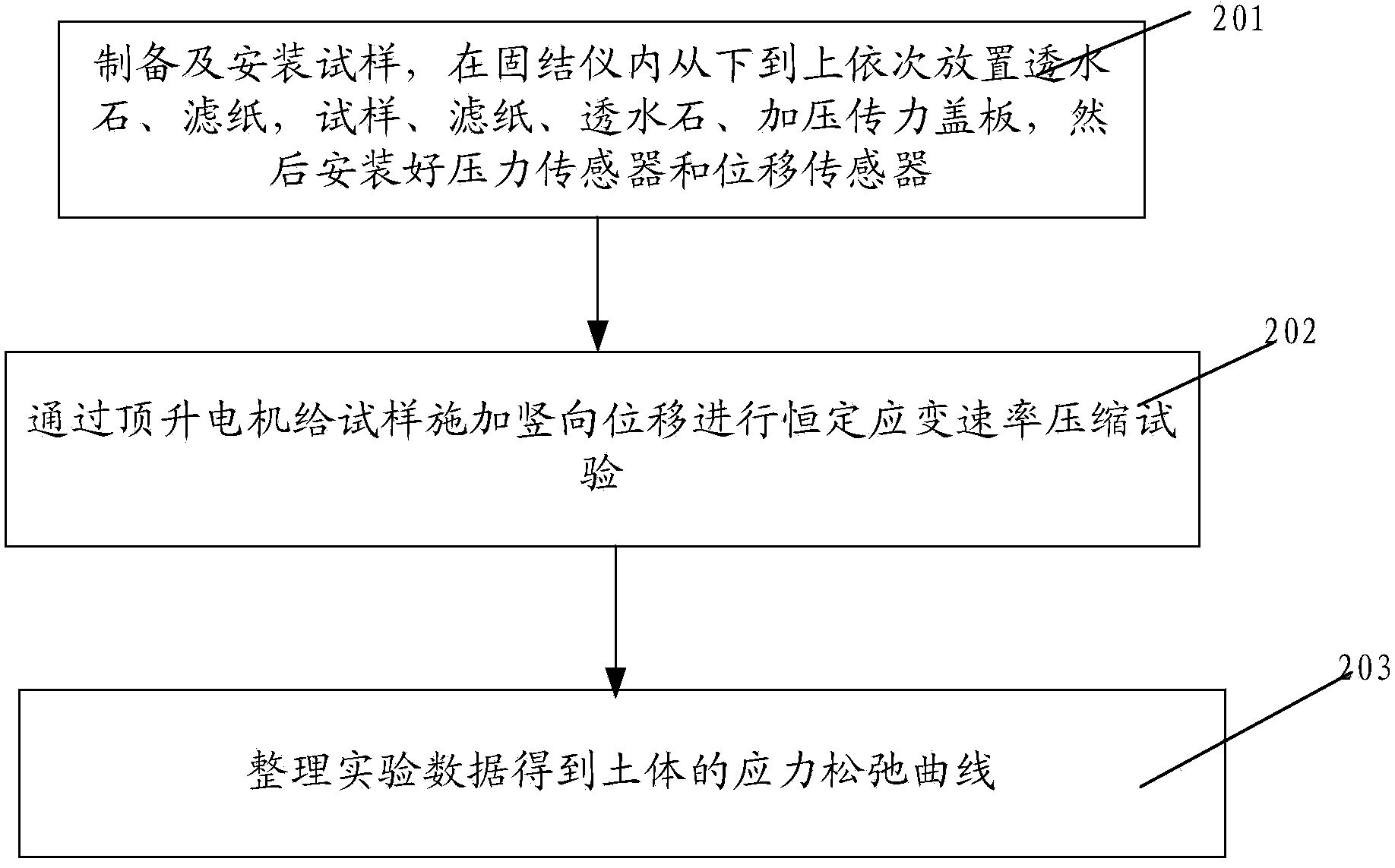

Method for estimating soft soil consolidation coefficient based on one-dimensional equal strain and stress relaxation tests

InactiveCN105181934ASave time and costSimple methodEarth material testingTest efficiencySoil science

The invention discloses a method for estimating the soft soil consolidation coefficient based on one-dimensional equal strain and stress relaxation tests, and is applied to water and soil conservation and administration. The method comprises the following steps of firstly, carrying out a one-dimensional equal strain rate test until the target load is reached, thus obtaining the compression index of soil; then carrying out a stress relaxation test to obtain the stress relaxation coefficient of soil; and calculating the consolidation coefficient through the relation between the consolidation coefficient, compression index and stress relaxation coefficient. The method disclosed by the invention has the advantages of being simple and consuming short time, saving test cost and time cost, improving the test efficiency and parameter determination.

Owner:CHINA UNIV OF MINING & TECH

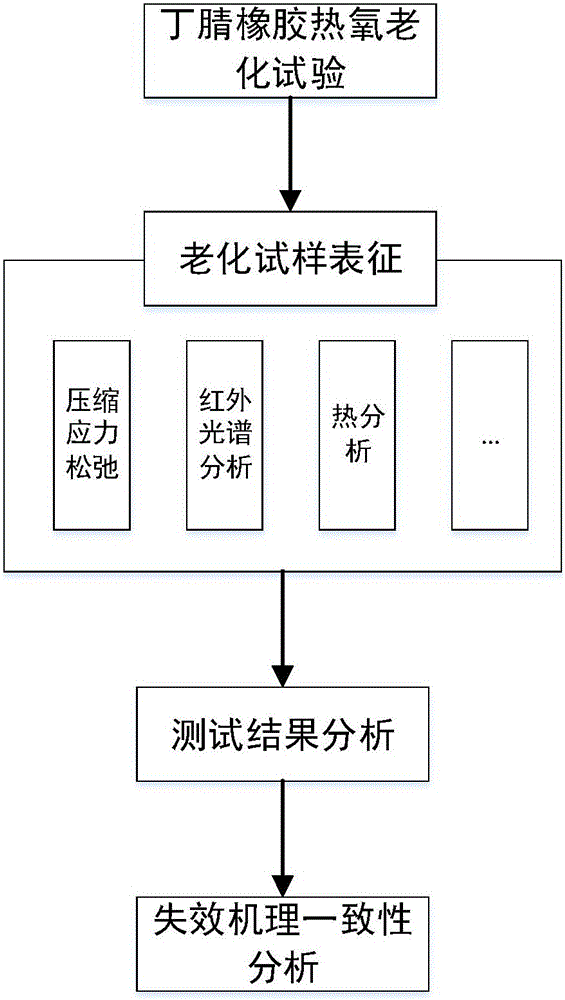

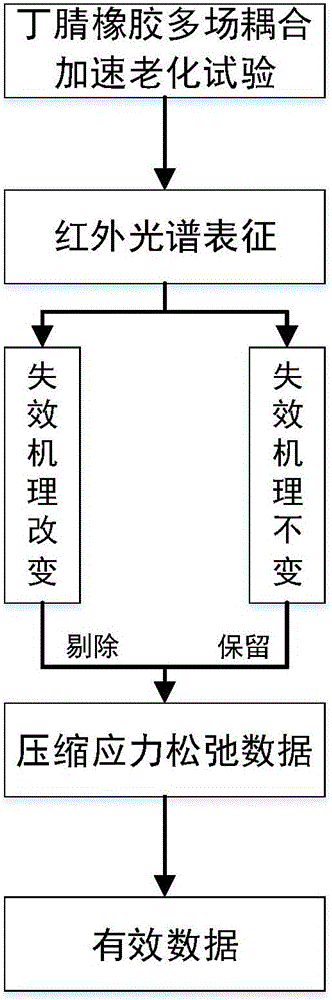

Method for verifying consistency of mechanisms involved in accelerated testing of butadiene-acrylonitrile rubber based on failure physics

InactiveCN106404643AGuaranteed validityVerify consistencyWeather/light/corrosion resistanceRelaxation testHigh acceleration

The invention provides a method for verifying the consistency of mechanisms involved in accelerated testing of butadiene-acrylonitrile rubber based on failure physics. The method comprises the following steps: 1, carrying out a thermo-oxidative aging experiment on the butadiene-acrylonitrile rubber; 2, subjecting an aged sample to a compression stress relaxation test, an infrared spectroscopic test and a thermal analysis test; 3, analyzing the test results of the compression stress relaxation, infrared spectroscopy and thermal analysis of the aged sample; and 4, verifying the consistency of mechanisms involved in accelerated testing of the butadiene-acrylonitrile rubber by using analysis results. According to the invention, the method analyzes and verifies the consistency of mechanisms involved in accelerated testing of the butadiene-acrylonitrile rubber by combining related experimental data of the compression stress relaxation test, infrared spectroscopic test and thermal analysis test, overcomes the problem of how to determine whether degradation mechanisms have abruptly changed due to too high acceleration stress during designing of an accelerated test, guarantees the consistency of failure mechanisms during accelerated testing and is of great practical significance to designing of accelerated tests of the butadiene-acrylonitrile rubber and guaranteeing of validity of experimental data in the future.

Owner:BEIHANG UNIV

Portable one-dimensional stress relaxation testing device and testing method thereof

InactiveCN103471919AEasy to manufactureEasy to carryMaterial strength using tensile/compressive forcesTest efficiencyElectric machine

Owner:SHANGHAI JIAO TONG UNIV

Beryllium bronze leaf spring normal-temperature and high-temperature stress relaxation testing device and testing method thereof

InactiveCN102650583ASimple designHigh precisionInvestigating material hardnessStress measurementEngineering

The invention provides a beryllium bronze leaf spring normal-temperature and high-temperature stress relaxation testing device and a testing method thereof. A side plate is fixed at the front side of a base of the testing device, a sample is an equal stress sample, which is provided with an opening at one end and is fixed on the upper side of the side plate, the base and the upper plate are fixed together through two limiters, a pressure sensor and a pressure head are fixed under the upper plate, and the pressure head is in line contact with the sample. Based on the testing device, the testing method comprises the following steps of: firstly preparing the equal stress sample, then determining the vertical distance difference between the limiters and the side plate, and arranging the testing device and the sample according to the distance difference; and then carrying out a spring stress relaxation test and acquiring stress values at different time, and determining the stress relaxation loss condition of a beryllium bronze leaf spring sample to be tested after the regulated test time is up. The device disclosed by the invention is simple in design, is not deformed at high temperature, is easy to process and has high measuring precision, the test data is accurate, continuous stress measurement of the beryllium bronze leaf spring test is realized, personal errors are reduced, and the work efficiency is improved.

Owner:BEIHANG UNIV

Optical double-sided pressure-sensitive adhesive sheet

InactiveCN102838941AExcellent anti-foaming peeling performanceExcellent step absorptionEster polymer adhesivesFilm/foil adhesives without carriersStress relaxation testAcrylic polymer

The present invention provides an optical double-sided pressure-sensitive adhesive sheet excellent in step absorbability and anti-foaming release property. The invention relates to an optical double-sided pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer which contains an acrylic polymer A and an acrylic polymer B having a weight average molecular weight of from 1,000 to 30,000, and has a residual stress after 180 seconds of 3.0 N / cm 2 or less, the residual stress after 180 seconds being measured in accordance with a tensile stress relaxation test under the conditions of a temperature of 23 DEG C and a strain of 300 %.

Owner:NITTO DENKO CORP

Reliability determination method based on compression spring stress relaxation testing data

ActiveCN105300673AImprove consistencyEasy to implementMachine part testingData sourceAssessment data

A reliability determination method based on compression spring stress relaxation testing data comprises the steps of 1) mounting test equipment and performing test preparation; 2) determining test temperatures, performing compression spring stress relaxation tests at different temperatures, acquiring bearing forces at different test times and drawing a stress relaxation curve; 3) respectively drawing a semi logarithmic curve between compression spring load loss rate and time at each testing temperature according to the bearing force and the test time acquired in the step 2) in a manner than the compression spring load loss rate is used as an ordinate and the logarithm of the corresponding test time is used as an abscissa, furthermore obtaining a stress relation equation of a spring sample at an actual operation temperature, and calculating the load loss rate and residual load of the spring sample at the actual operation temperature in the late period of the service life of the spring sample; and 4) acquiring the reliability of the spring sample (8) in the late period of the service life. The reliability determination method effectively settles the problems of high data discreteness, long test time and relatively low data source evaluation precision in reliability evaluation of the compression spring.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Optical double-sided pressure-sensitive adhesive sheet

InactiveUS20120328864A1Good release effectPromote absorptionSynthetic resin layered productsEster polymer adhesivesStress relaxation testAcrylic polymer

The present invention provides an optical double-sided pressure-sensitive adhesive sheet excellent in step absorbability and anti-foaming release property. The invention relates to en optical double-sided pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer which contains an acrylic polymer A and an acrylic polymer B having a weight average molecular weight of from 1,000 to 30,000, and has a residual stress after 180 seconds of 3.0 N / cm2 or less, the residual stress after 180 seconds being measured in accordance with a tensile stress relaxation test under the conditions of a temperature of 23° C. and a strain of 300%.

Owner:NITTO DENKO CORP

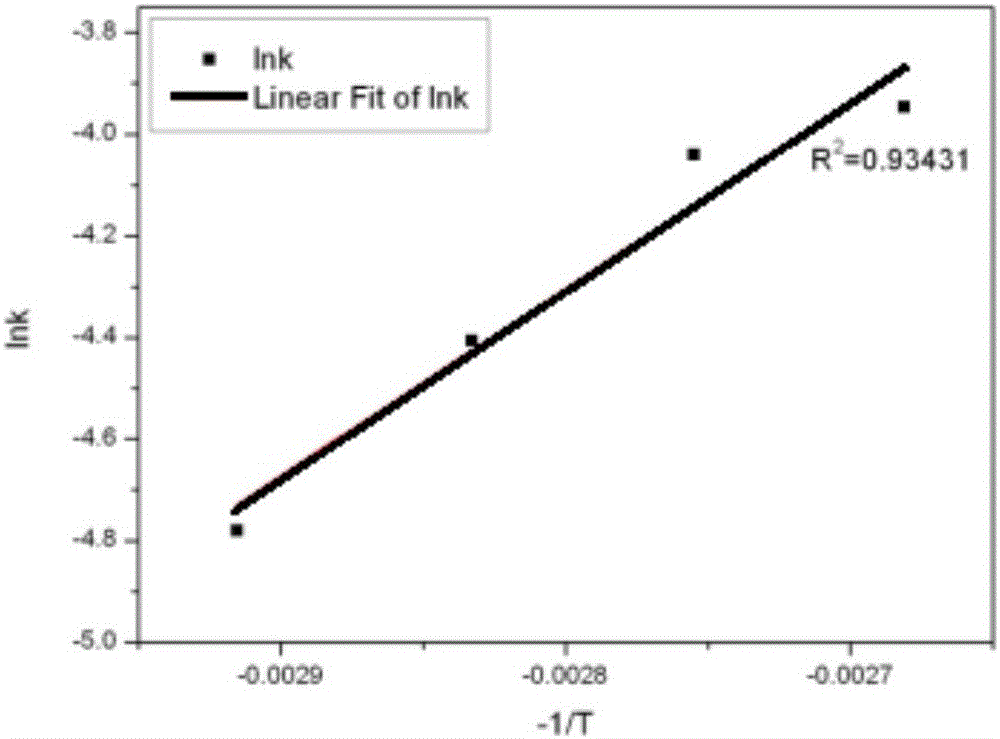

Method for analyzing validity of degradation data on basis of failure physics

The invention discloses a method for analyzing validity of degradation data on the basis of failure physics. The method comprises steps as follows: 1, a thermo-oxidative aging test is performed on nitrile rubber; 2, a compressive stress relaxation test and a Fourier transform infrared spectrum test are performed on an aged sample; 3, infrared spectrum and compressive stress relaxation test results of the aged sample are analyzed; 4, inspection is performed with a method based on data consistency. By means of the steps, whether a failure mechanism of the sample in the aging accelerating process changes is judged through analysis of related experimental data of the infrared spectrum test performed on the accelerated aging nitrile rubber sample, so that whether experimental data in the compressive stress relaxation test are valid is determined; invalid data are eliminated, and the fitting degree of valid data reaches 0.99 through data fitting and is far higher than original 0.93. By means of the method, the blank about analysis of validity of the degradation data of the nitrile rubber before is filled up, and the method has great significance for accuracy and precision of follow-up life prediction.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com