Rotation shear stress relaxation test device for asphalt mixture and method

A technique of asphalt mixture, stress relaxation, applied in the direction of testing the strength of the material using a steady shear force applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

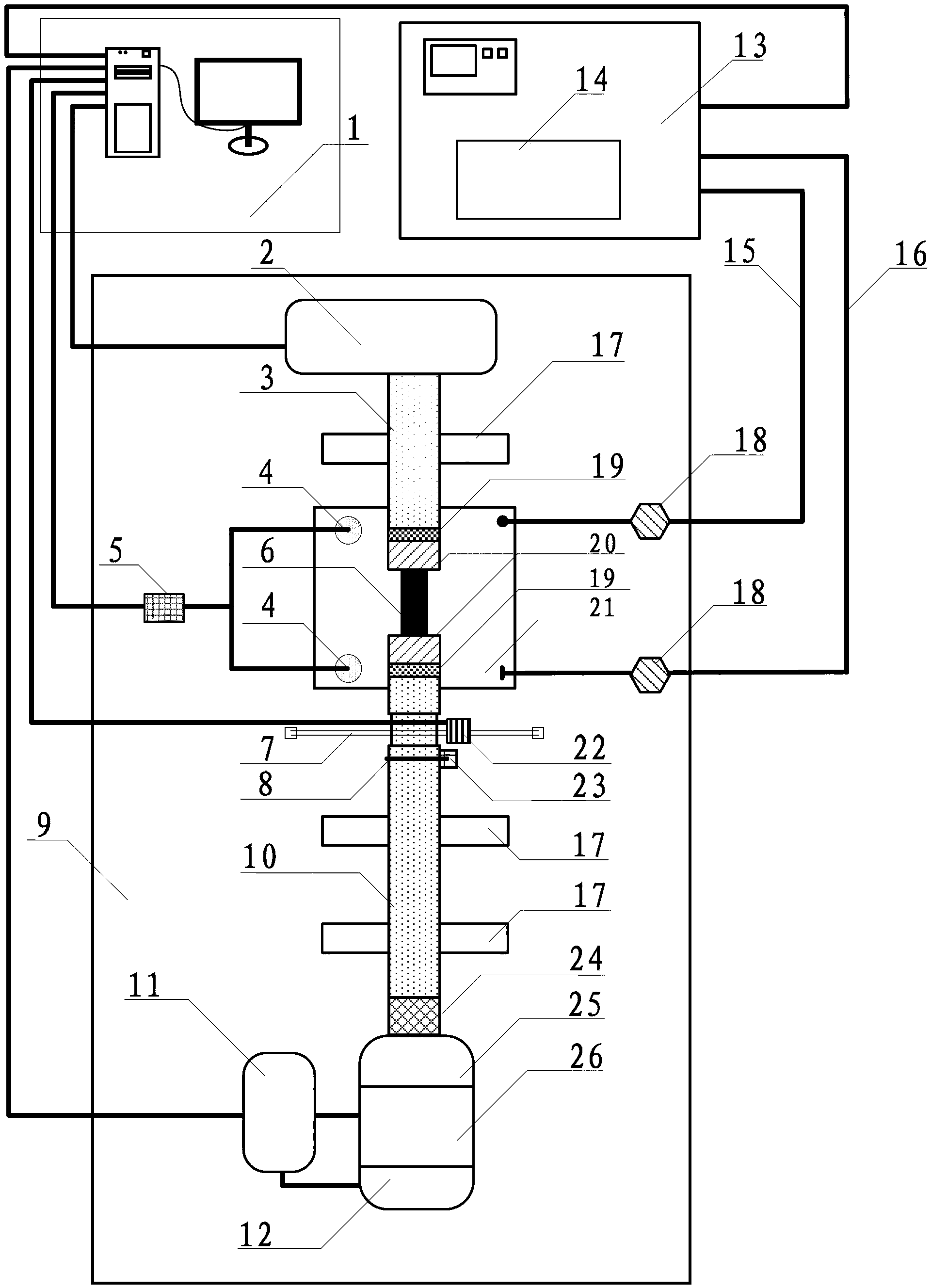

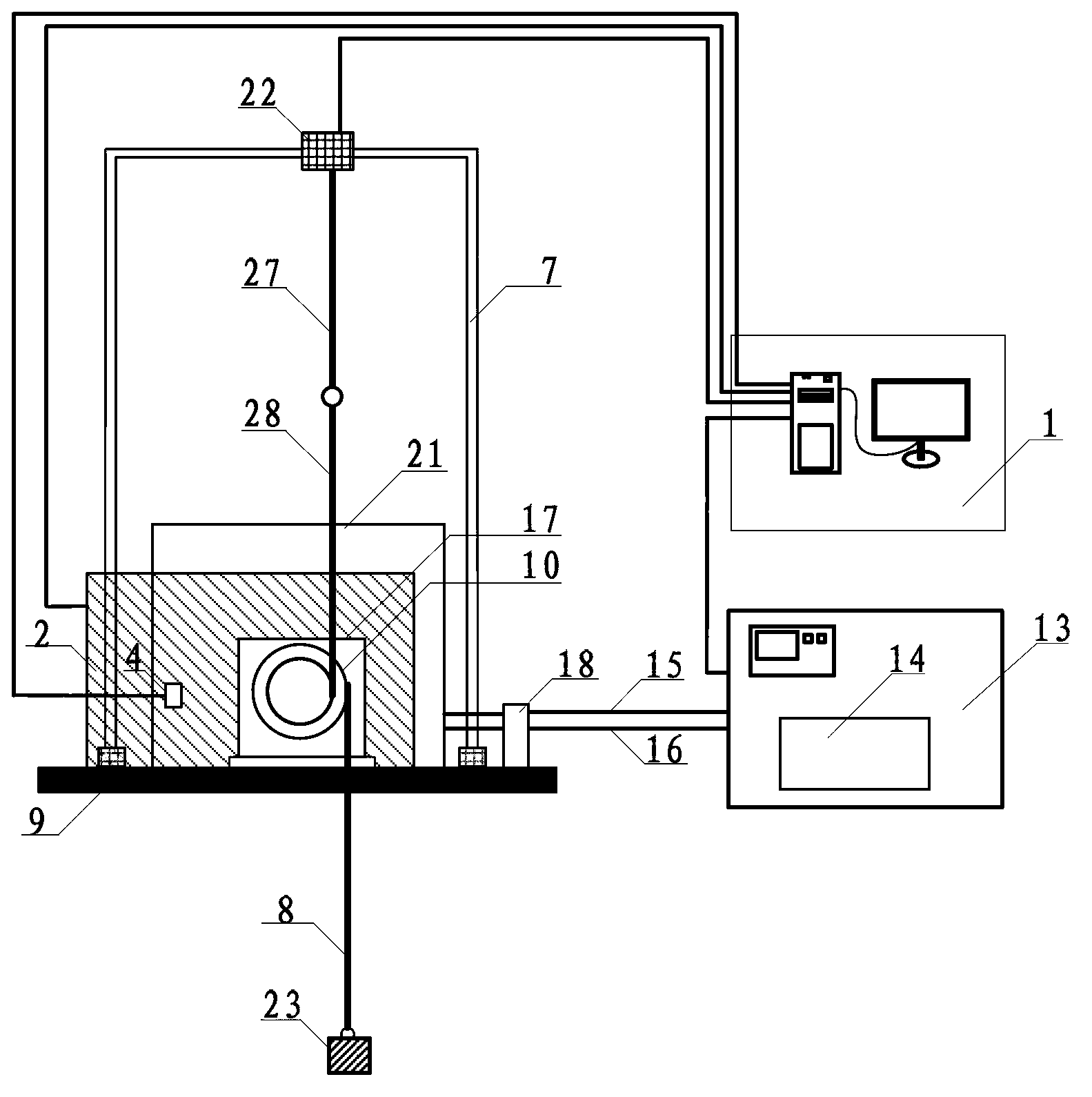

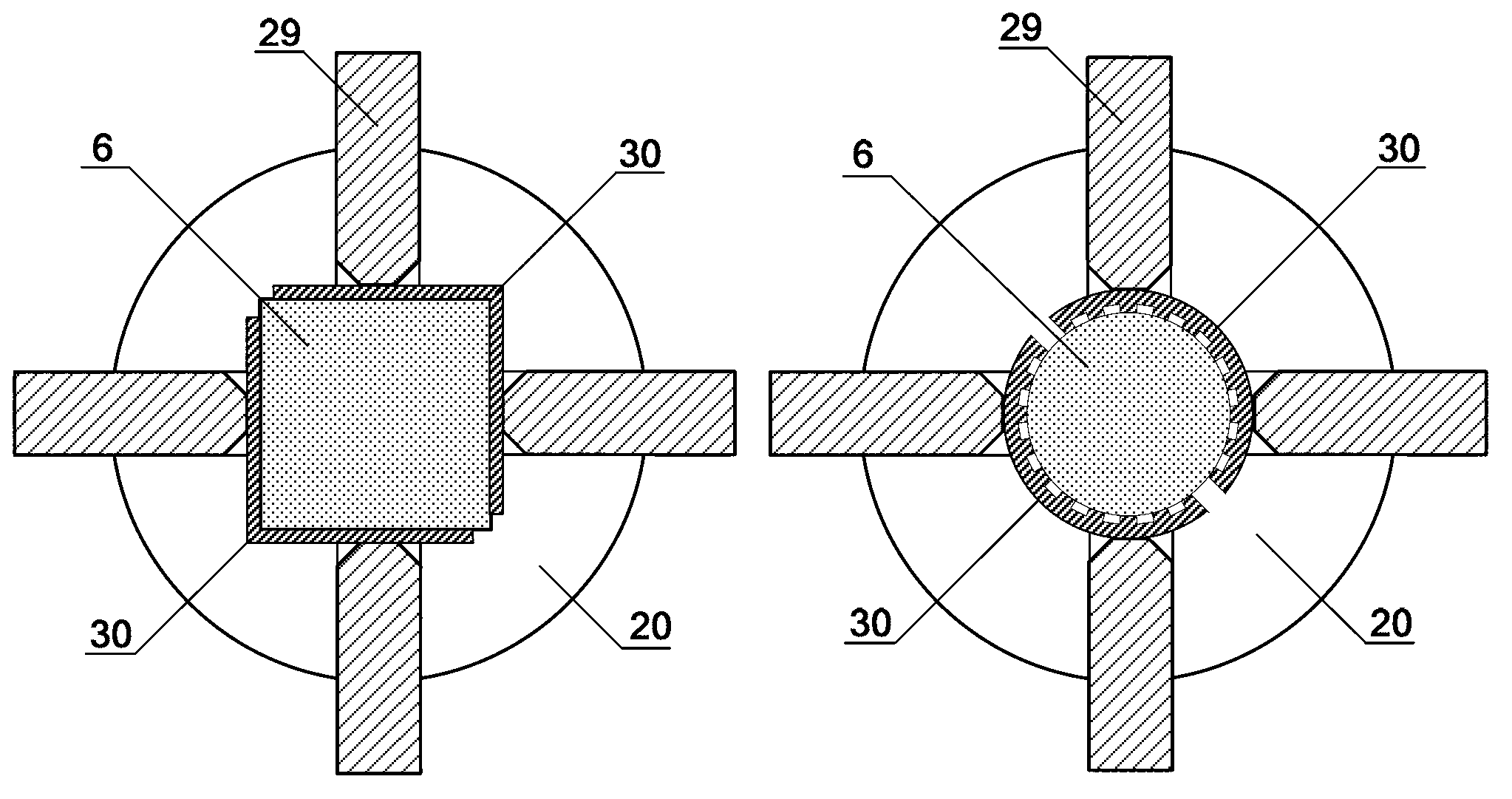

[0020] Rotary shear stress relaxation test device for asphalt mixture, consisting of test platform, loading system, temperature control system and computer control system;

[0021] The test platform consists of a test piece, a micro motor 26 for loading, a platform steel plate 9, a bearing seat 17, a torque sensor and an encoder 2, a fixed shaft 3, a rotating shaft 10, a door bracket 7, a pull-type displacement sensor and an encoder 22. Displacement measurement stay wire 28 and balance weight 23 are composed; the torque sensor and encoder 2 and three bearing seats 17 are fixed in parallel on the platform steel plate 9 in order, and a bearing seat 17 close to the torque sensor and encoder 2 is used for Support the fixed shaft 3; the other two bearing seats 17 are used to support the rotating shaft 10; one end of the fixed shaft 3 is detachably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com