Patents

Literature

64141 results about "Mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of mechanical property. : a property that involves a relationship between stress and strain or a reaction to an applied force.

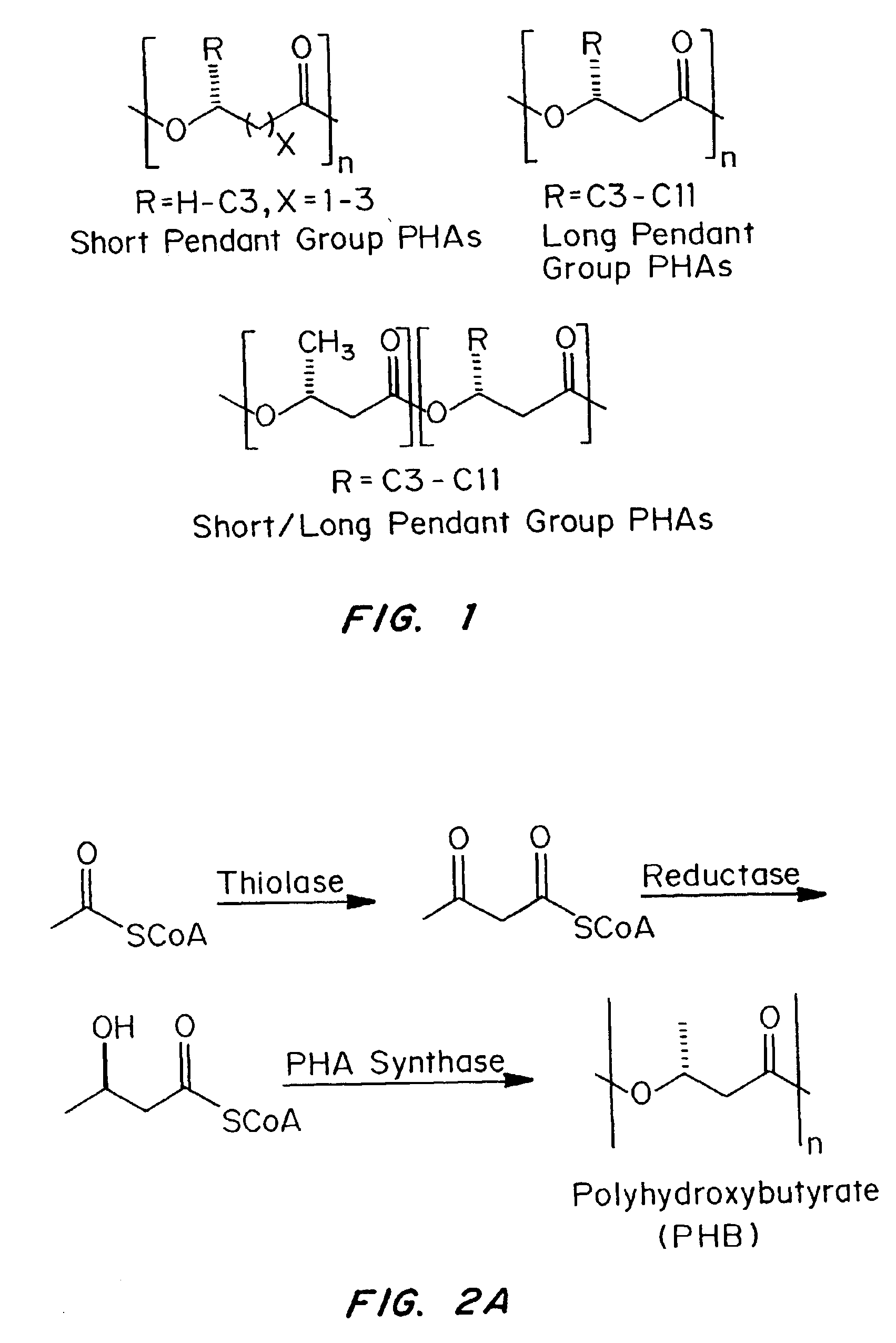

Medical devices and applications of polyhydroxyalkanoate polymers

InactiveUS6838493B2High porosityReduce probabilitySuture equipmentsOrganic active ingredientsTissue repairBiocompatibility Testing

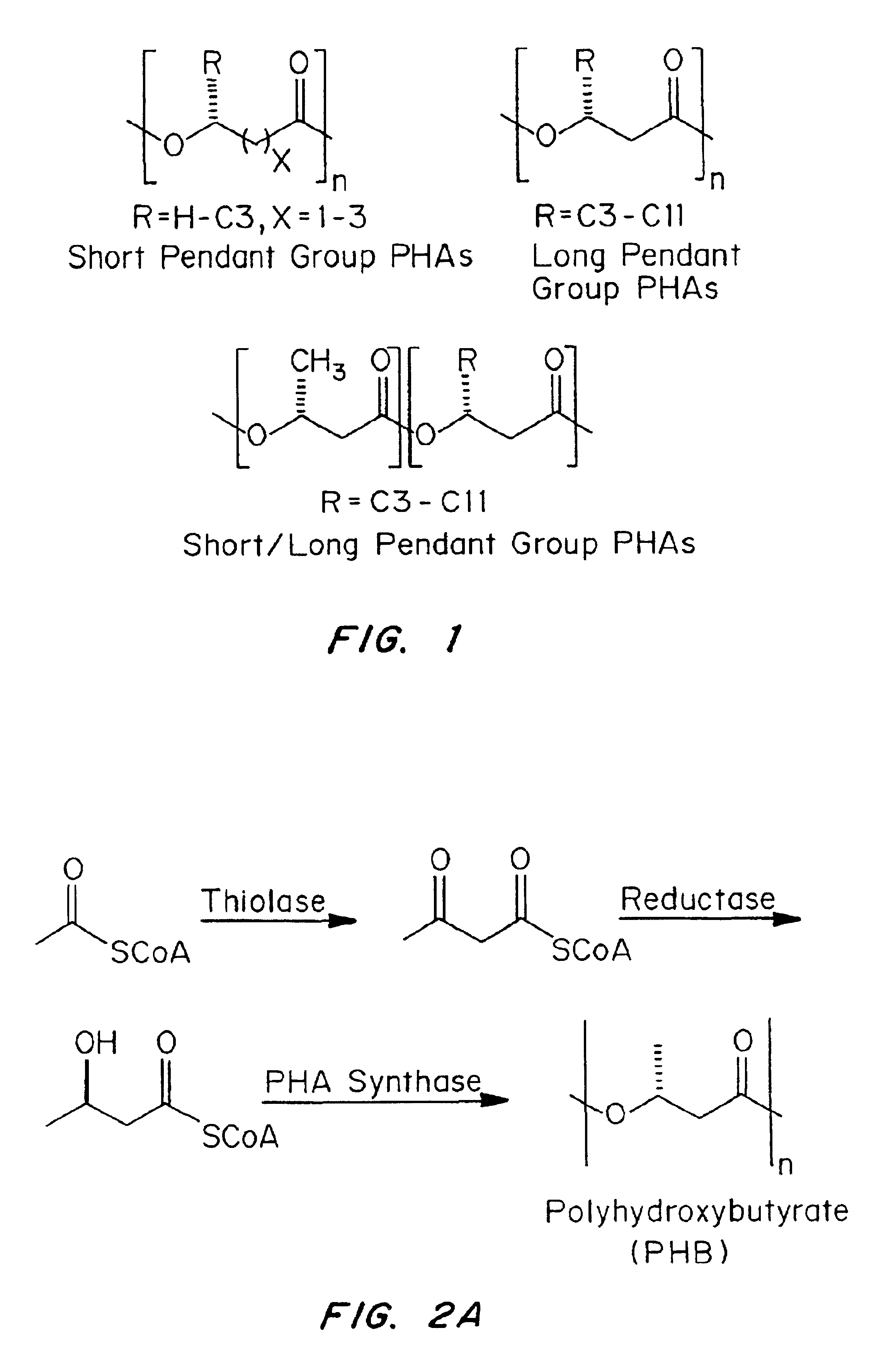

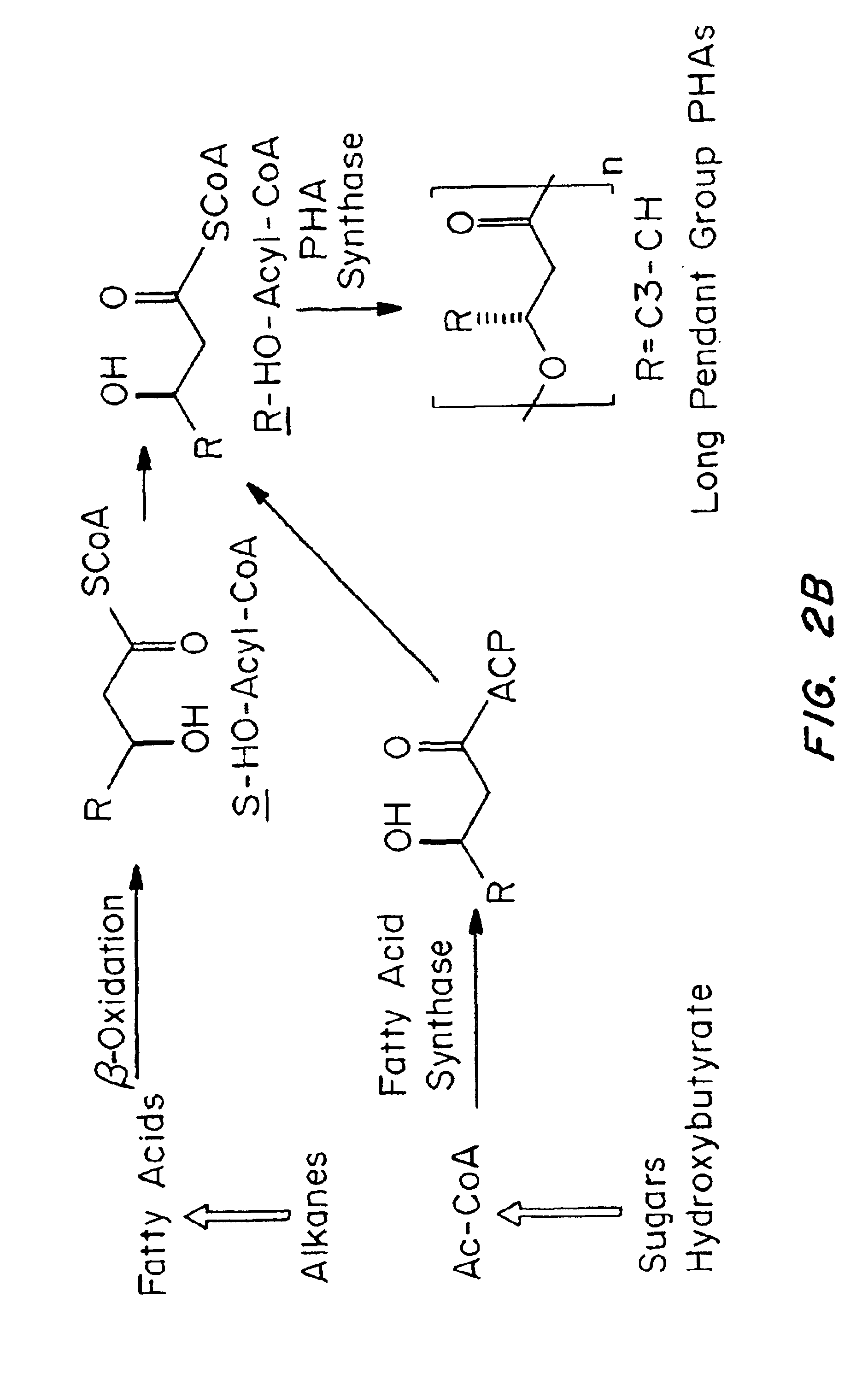

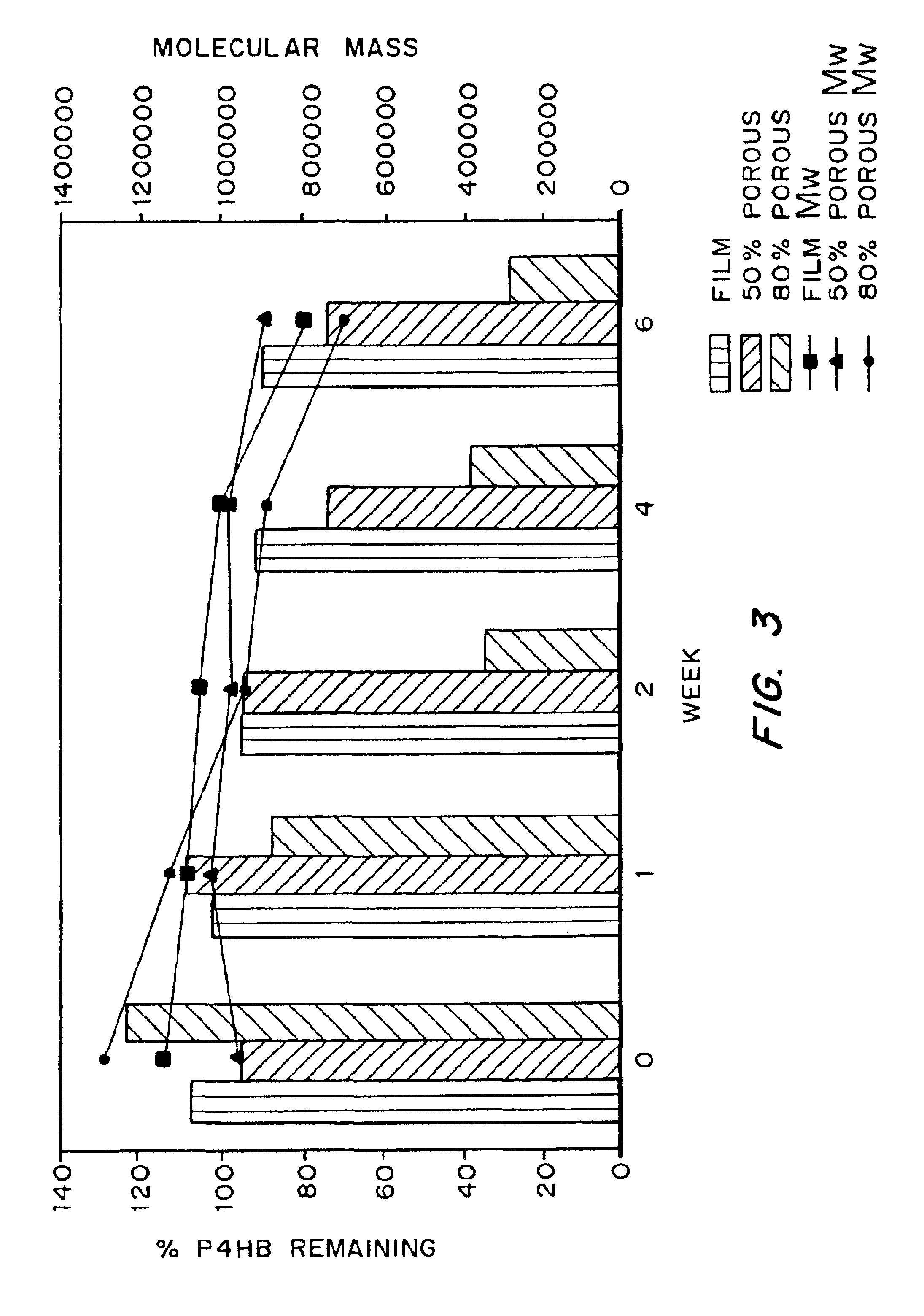

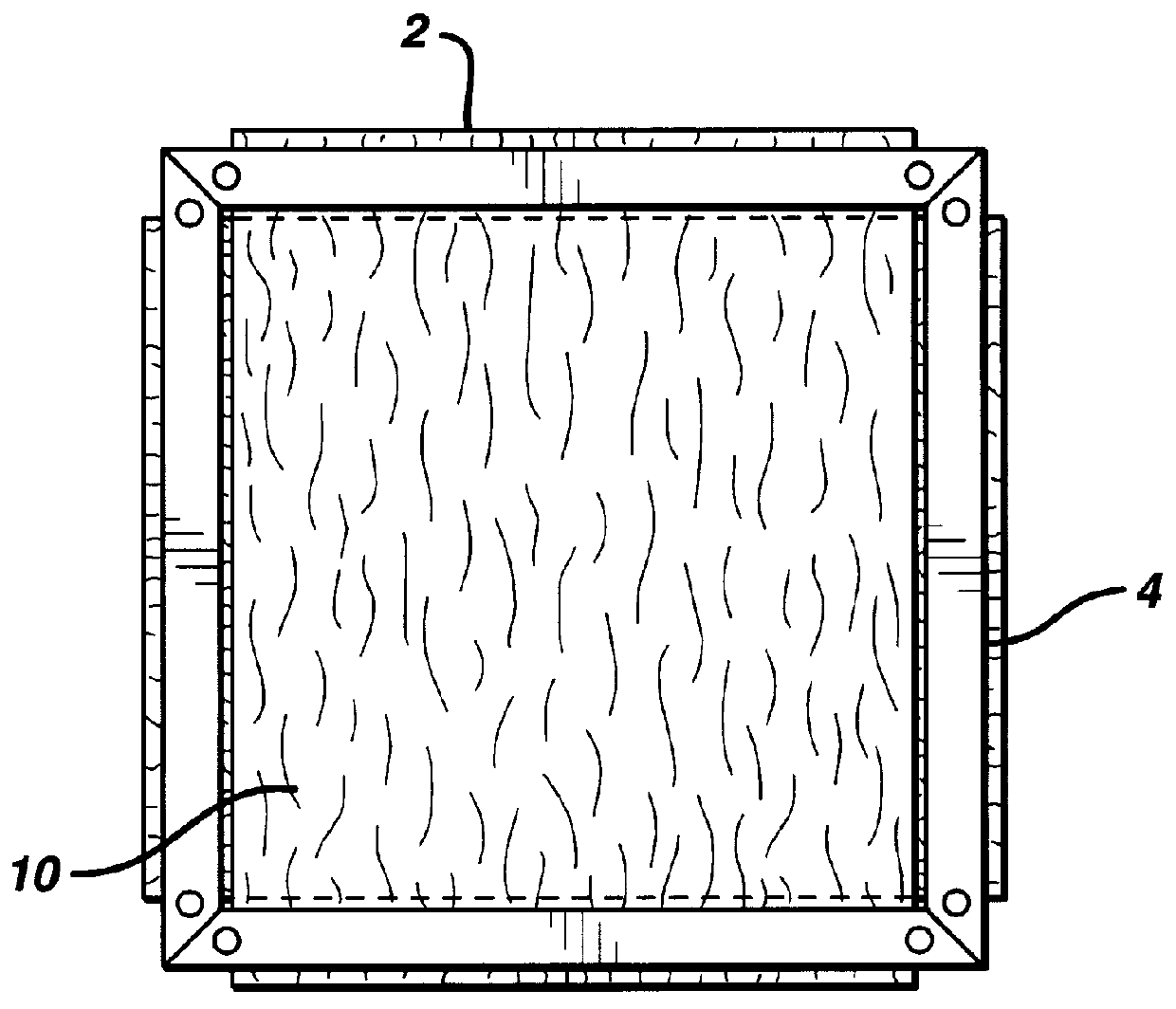

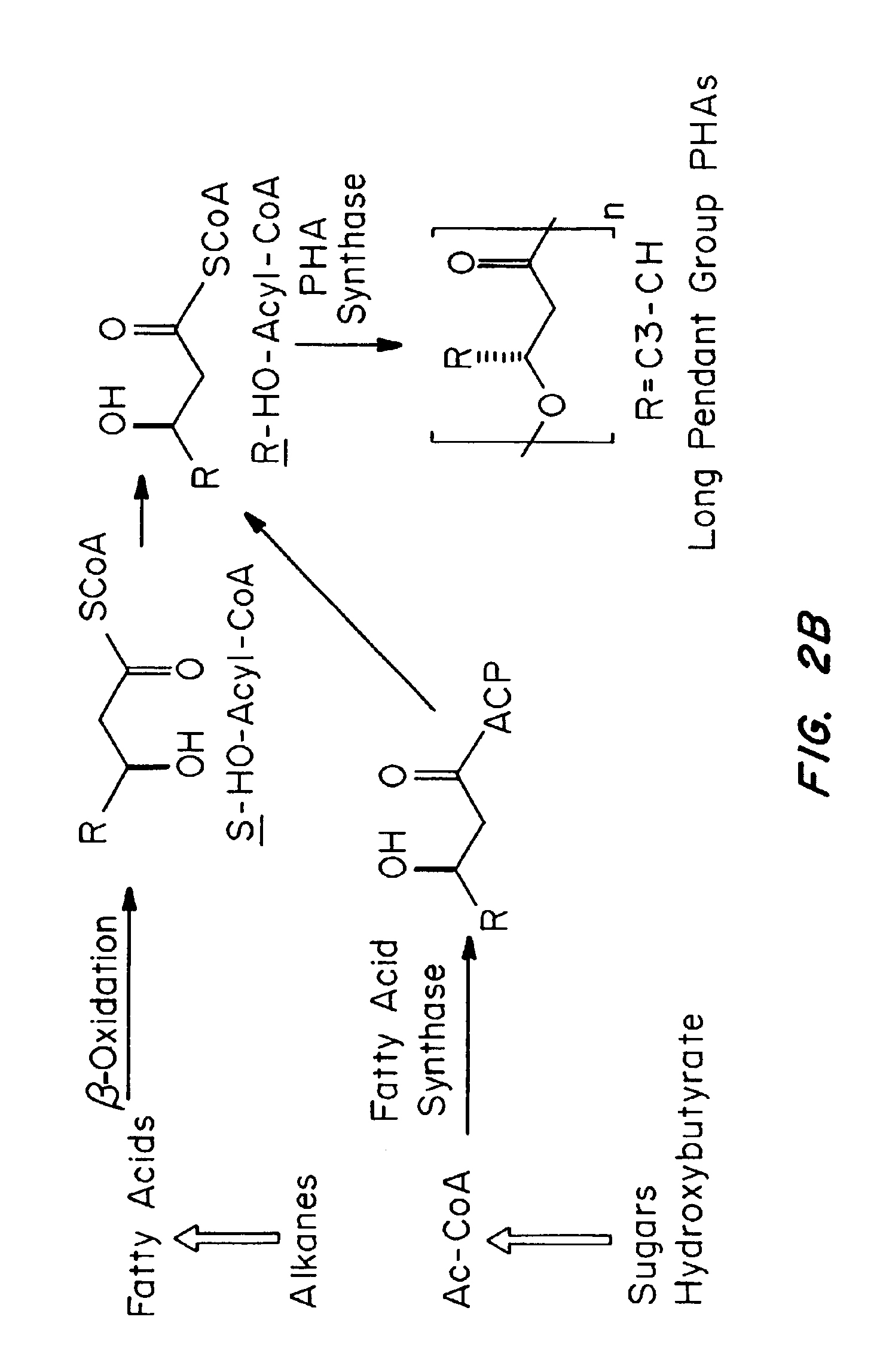

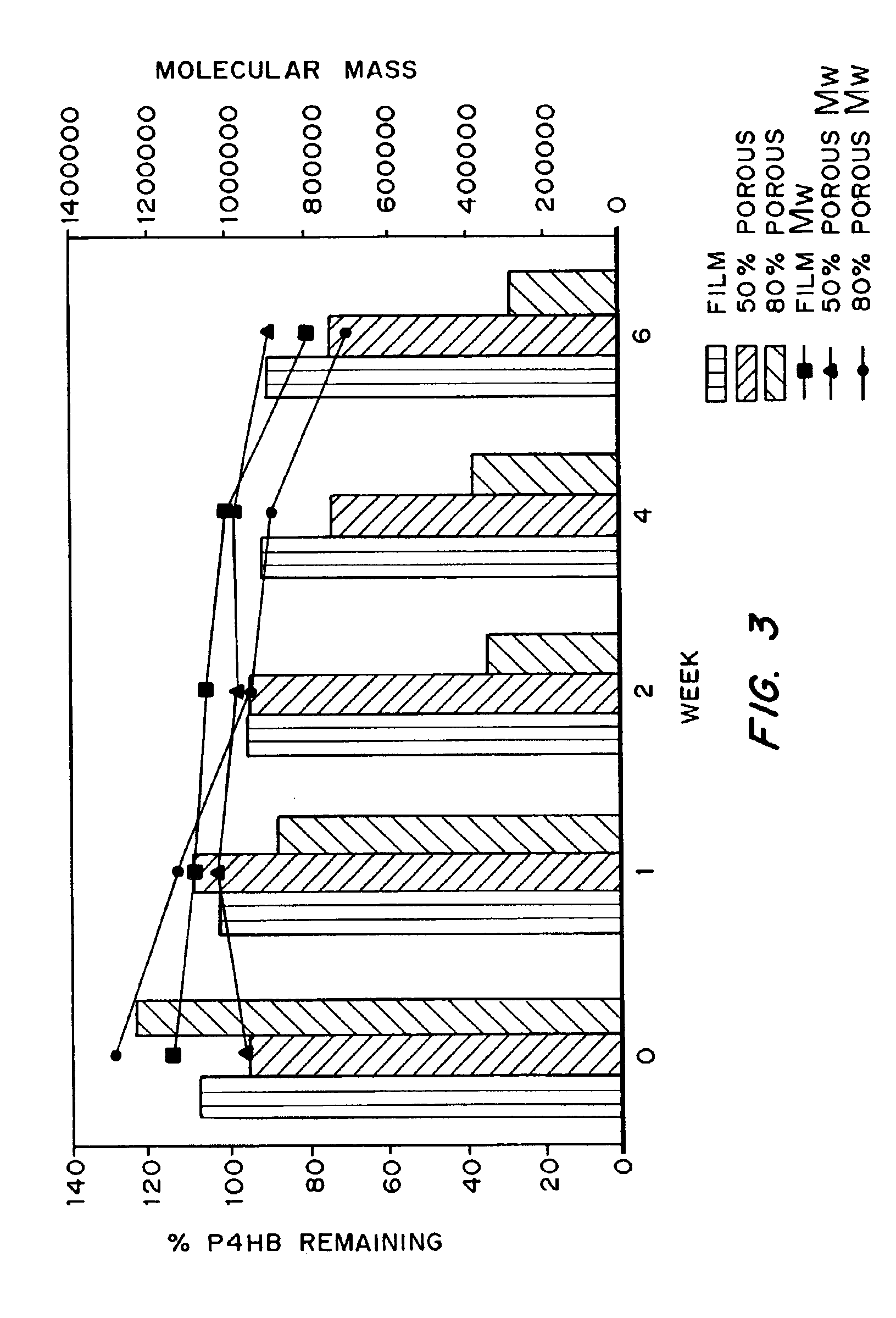

Devices formed of or including biocompatible polyhydroxyalkanoates are provided with controlled degradation rates, preferably less than one year under physiological conditions. Preferred devices include sutures, suture fasteners, meniscus repair devices, rivets, tacks, staples, screws (including interference screws), bone plates and bone plating systems, surgical mesh, repair patches, slings, cardiovascular patches, orthopedic pins (including bone filling augmentation material), adhesion barriers, stents, guided tissue repair / regeneration devices, articular cartilage repair devices, nerve guides, tendon repair devices, atrial septal defect repair devices, pericardial patches, bulking and filling agents, vein valves, bone marrow scaffolds, meniscus regeneration devices, ligament and tendon grafts, ocular cell implants, spinal fusion cages, skin substitutes, dural substitutes, bone graft substitutes, bone dowels, wound dressings, and hemostats. The polyhydroxyalkanoates can contain additives, be formed of mixtures of monomers or include pendant groups or modifications in their backbones, or can be chemically modified, all to alter the degradation rates. The polyhydroxyalkanoate compositions also provide favorable mechanical properties, biocompatibility, and degradation times within desirable time frames under physiological conditions.

Owner:TEPHA INC

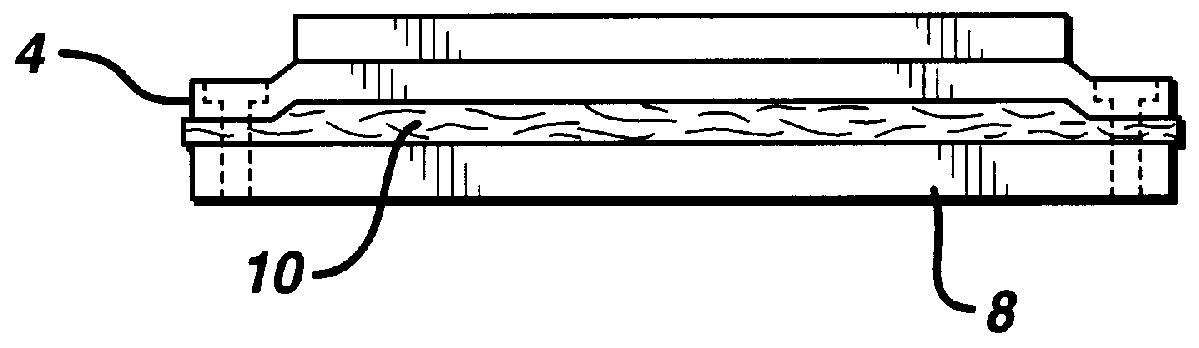

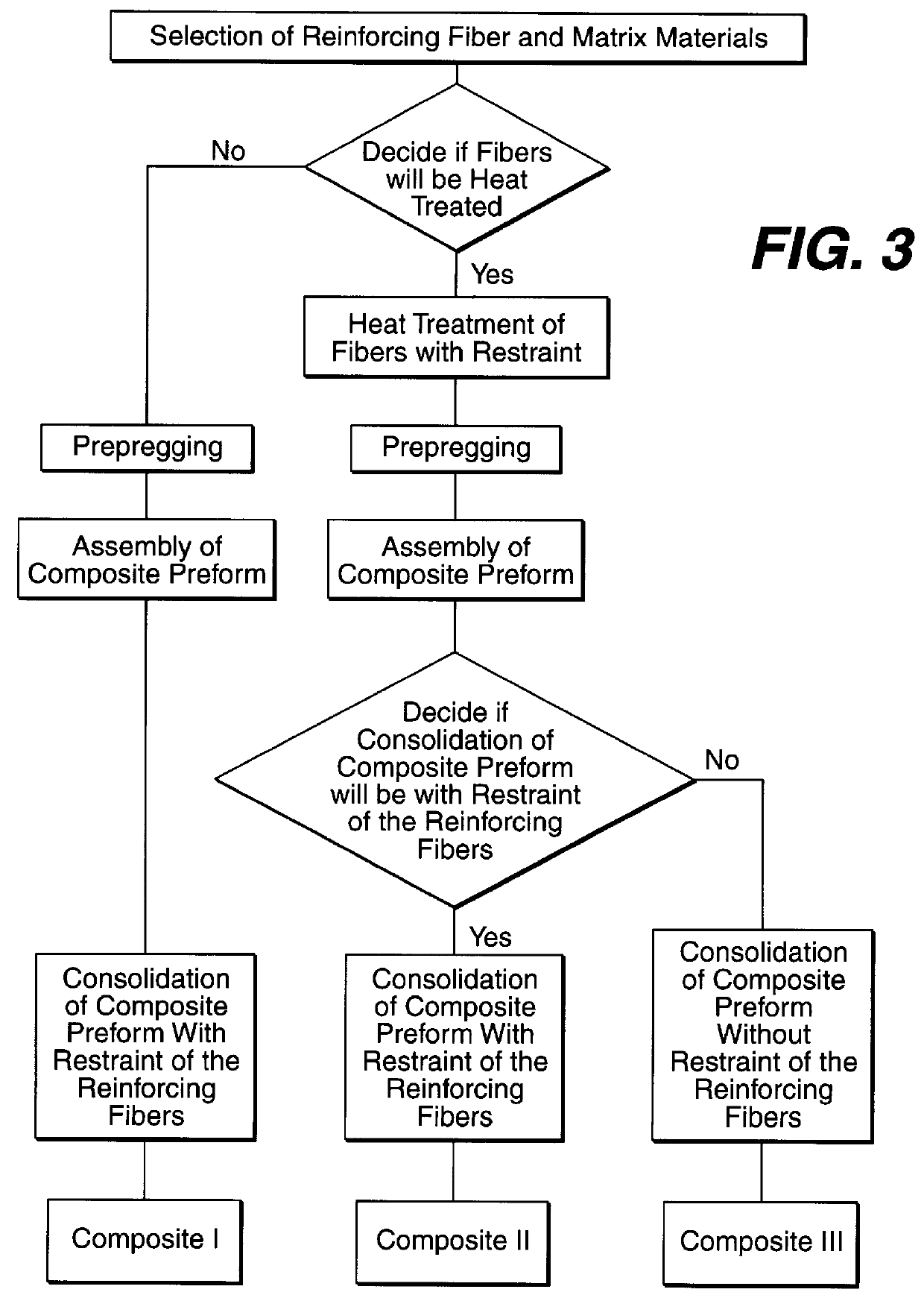

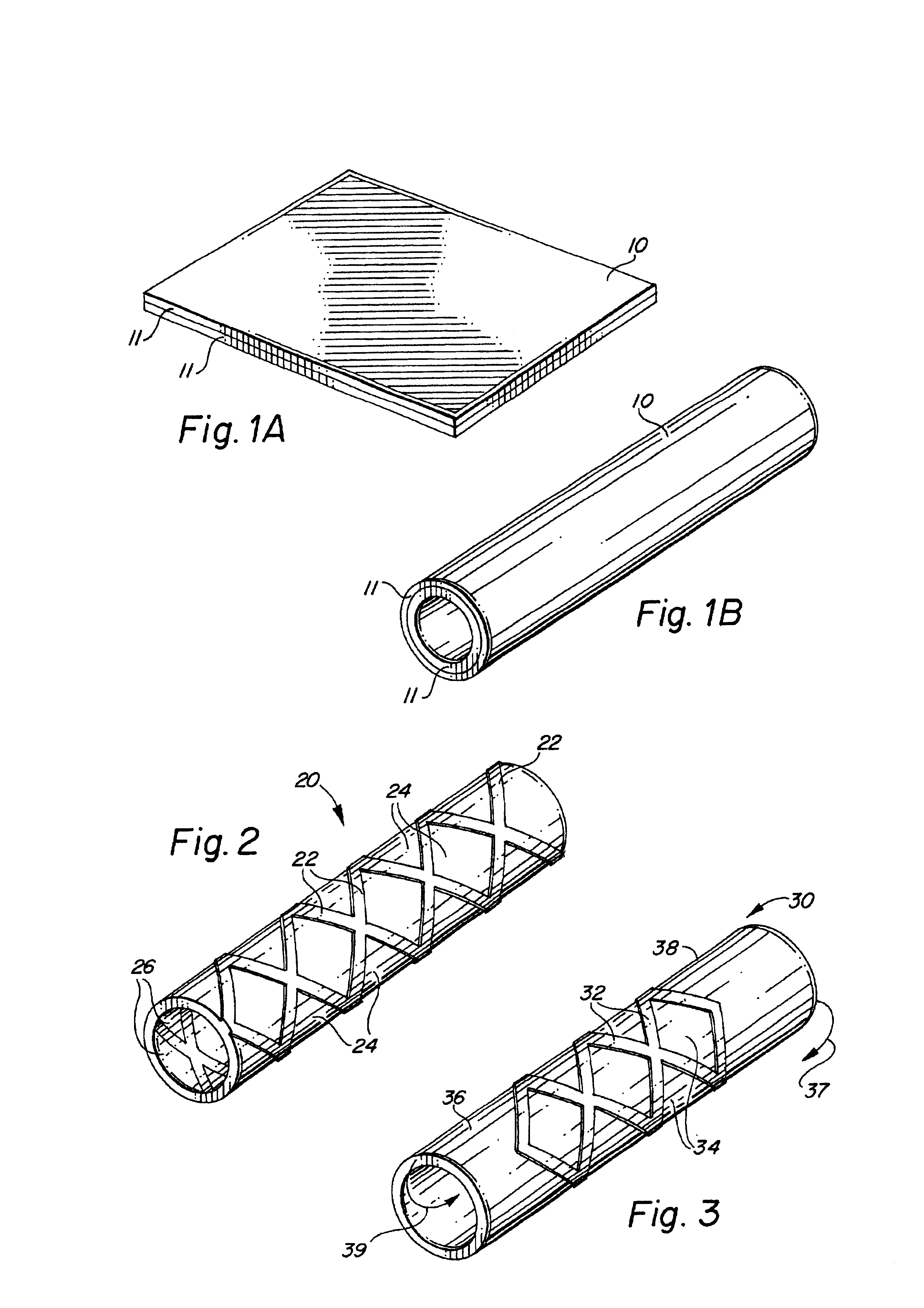

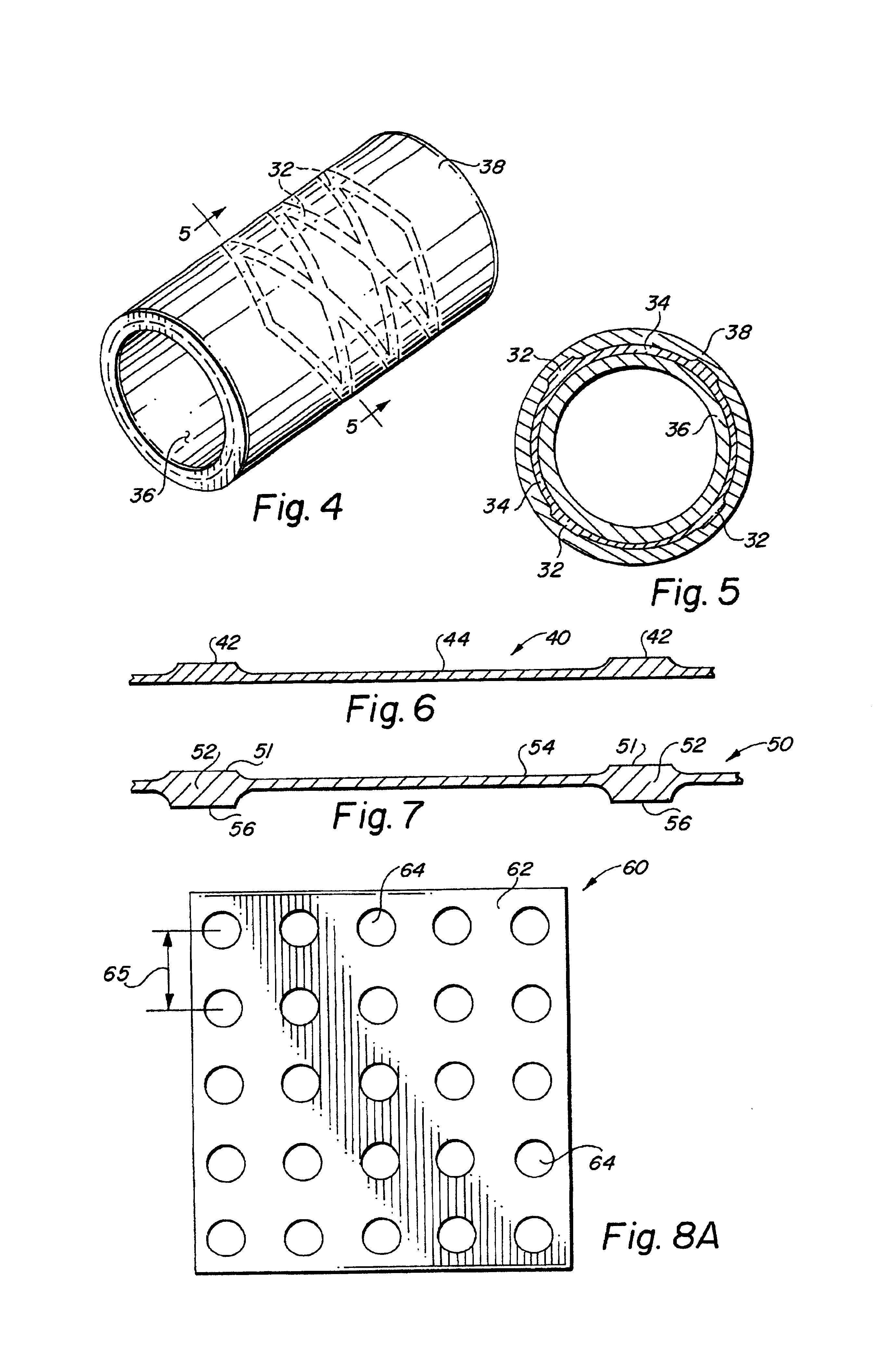

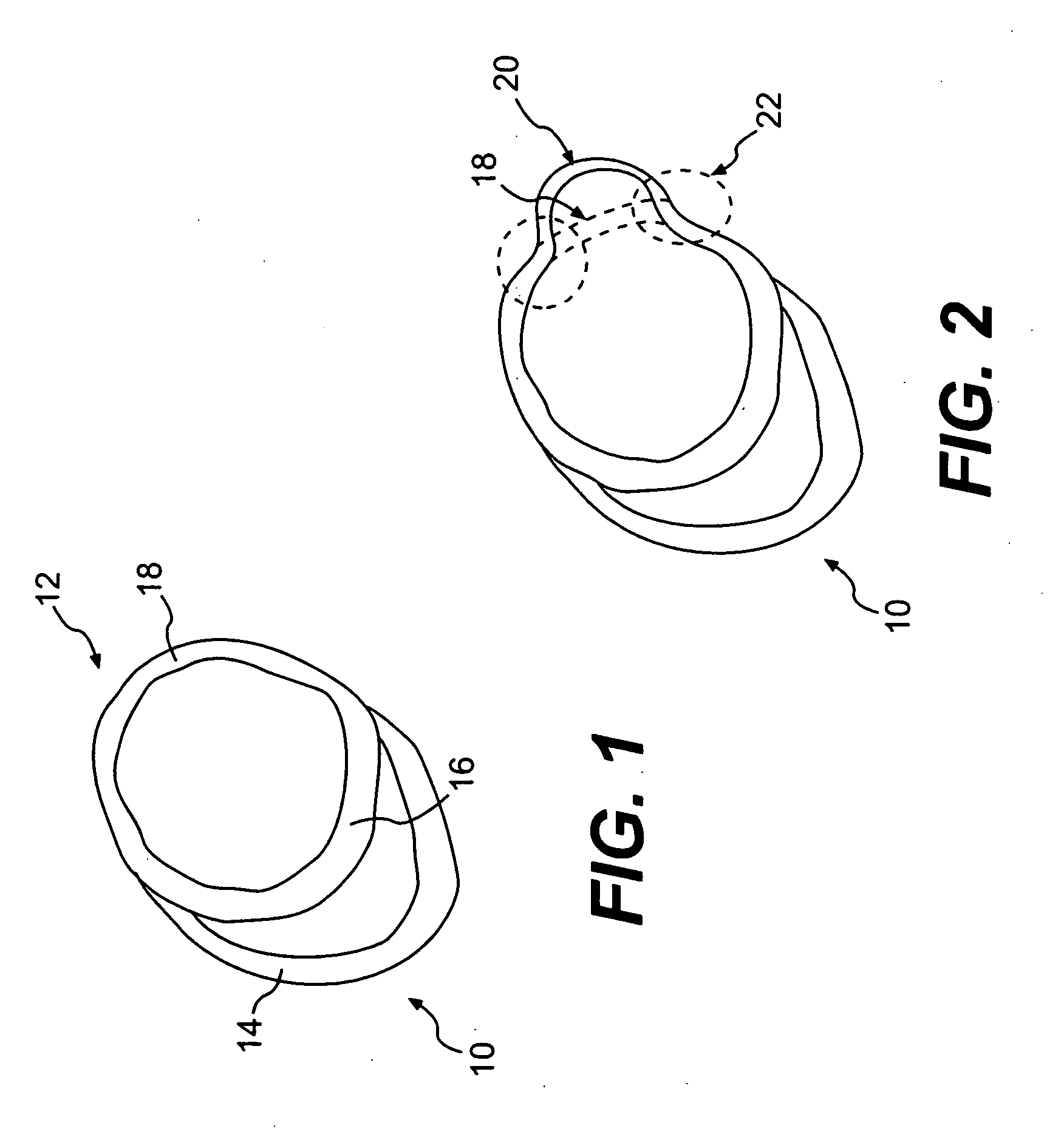

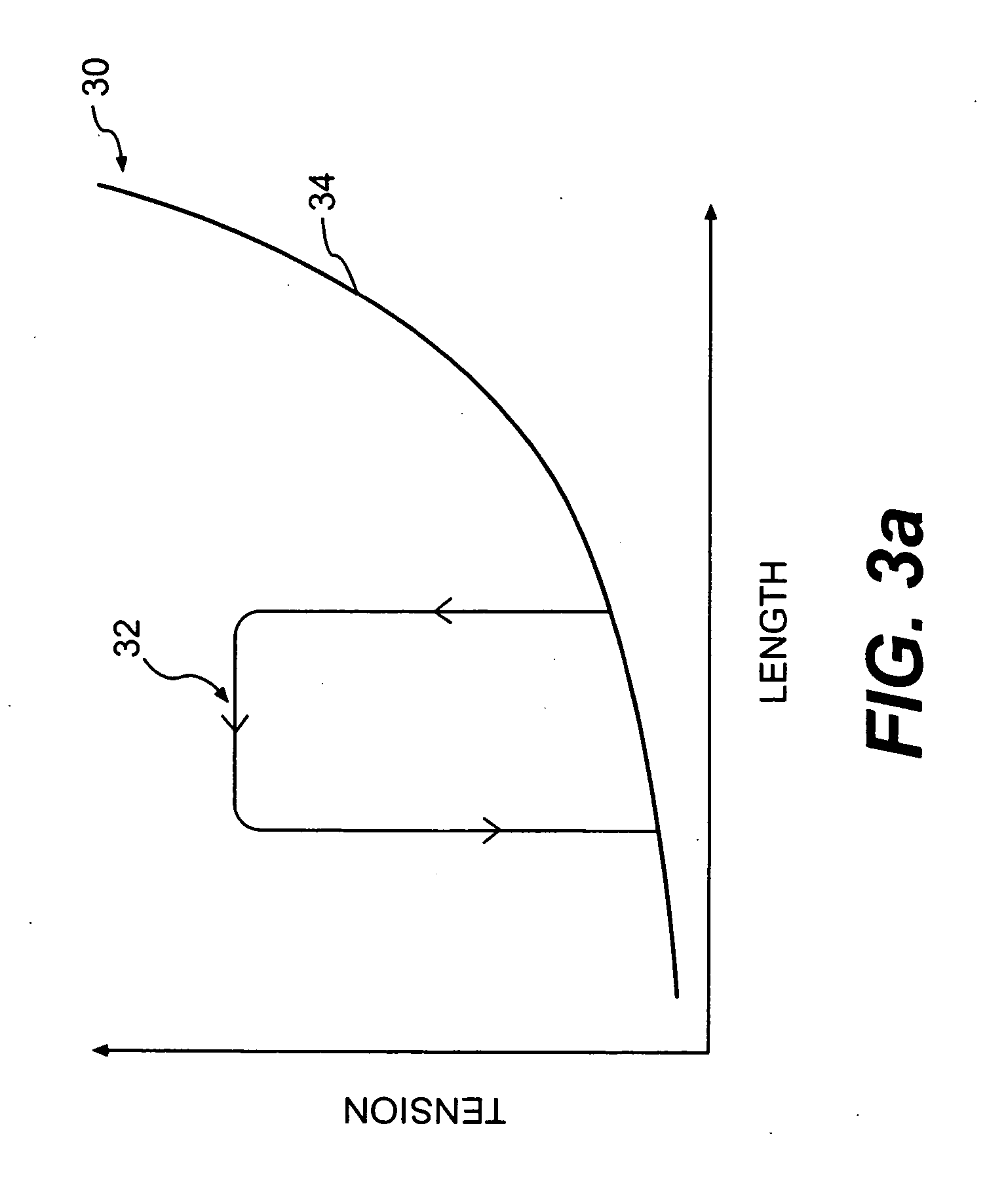

Fabrication of biocompatible polymeric composites

InactiveUS6147135ASure easyImprove performanceSuture equipmentsCosmetic preparationsFiberPolymer science

Composite materials formed from biocompatible polymer fibers and biodegradable polymers are disclosed. The heat treatment conditions for the reinforcing fibers are described so that the mechanical properties of the fibers can be retained during composite consolidation process. The processing conditions and set-ups to consolidations are constrained to the temperatures lower than fiber heat treatment temperatures. The reinforcing fibers are restrained under tension so that the minimum relaxation occurs during consolidation process.

Owner:ETHICON INC

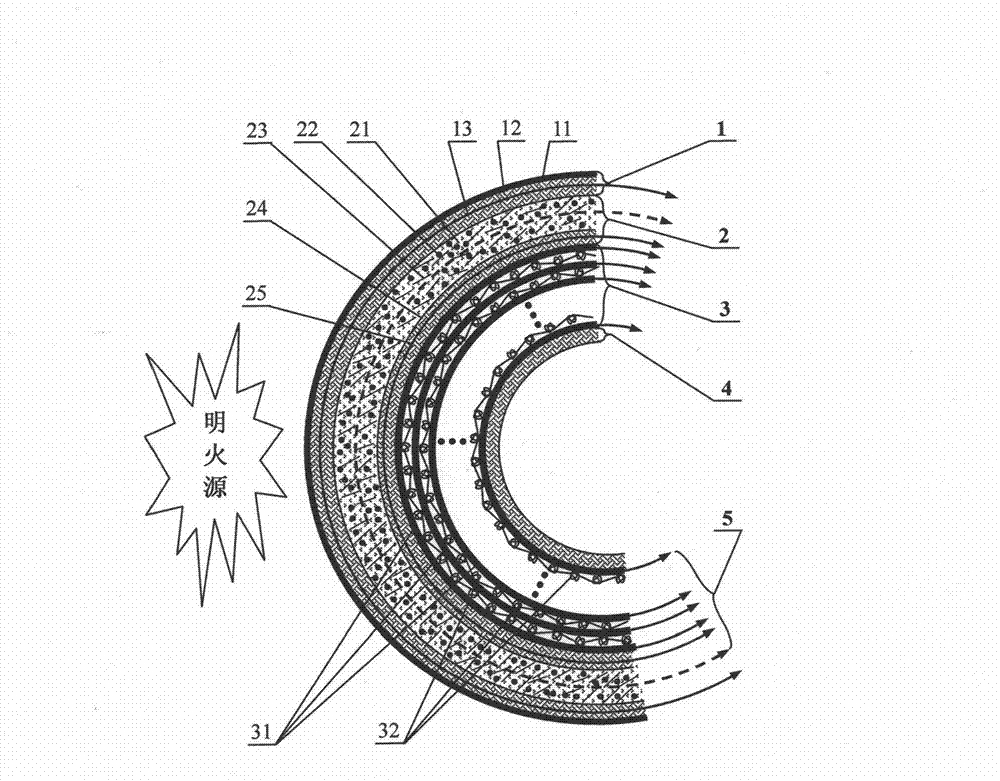

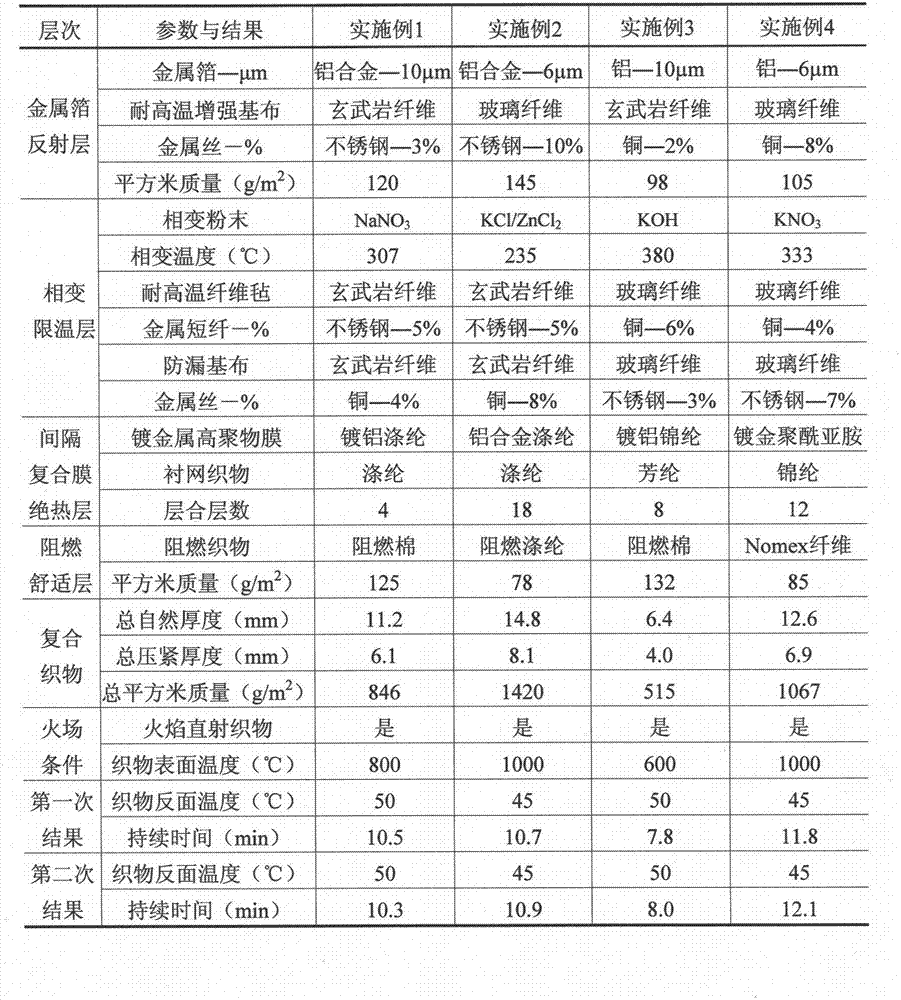

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

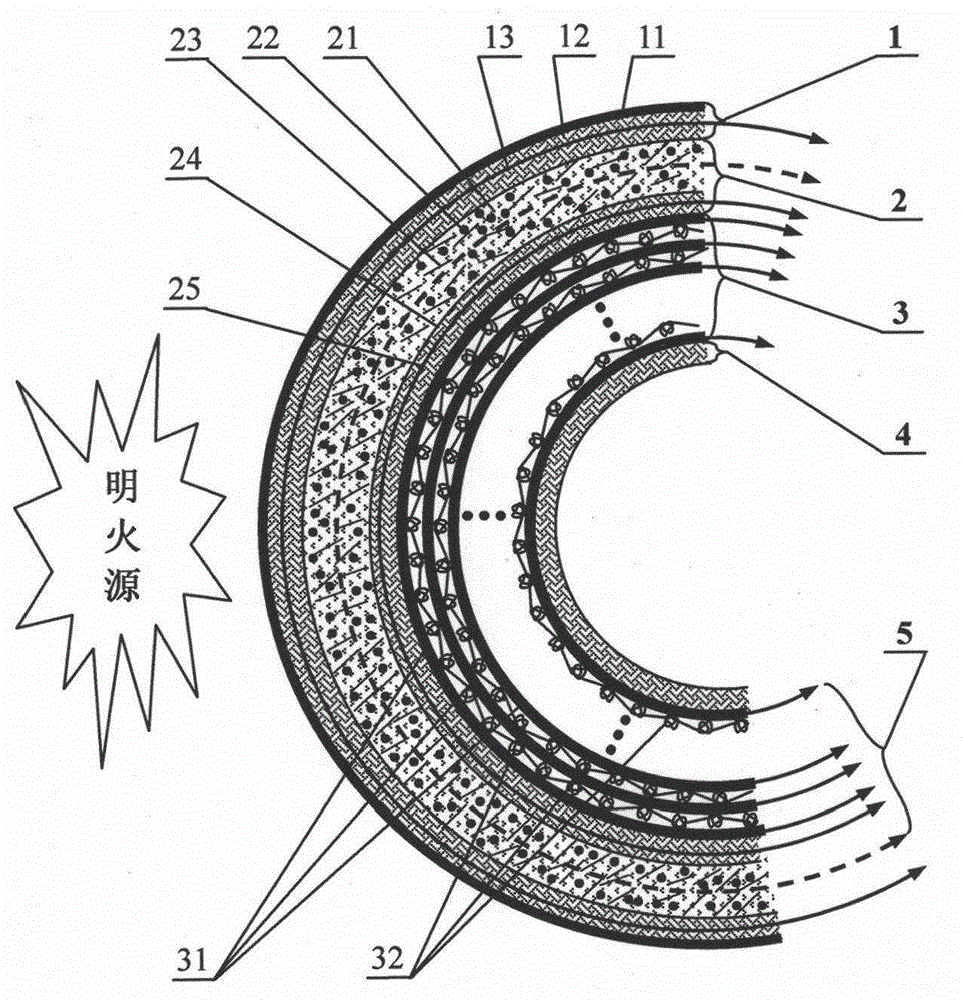

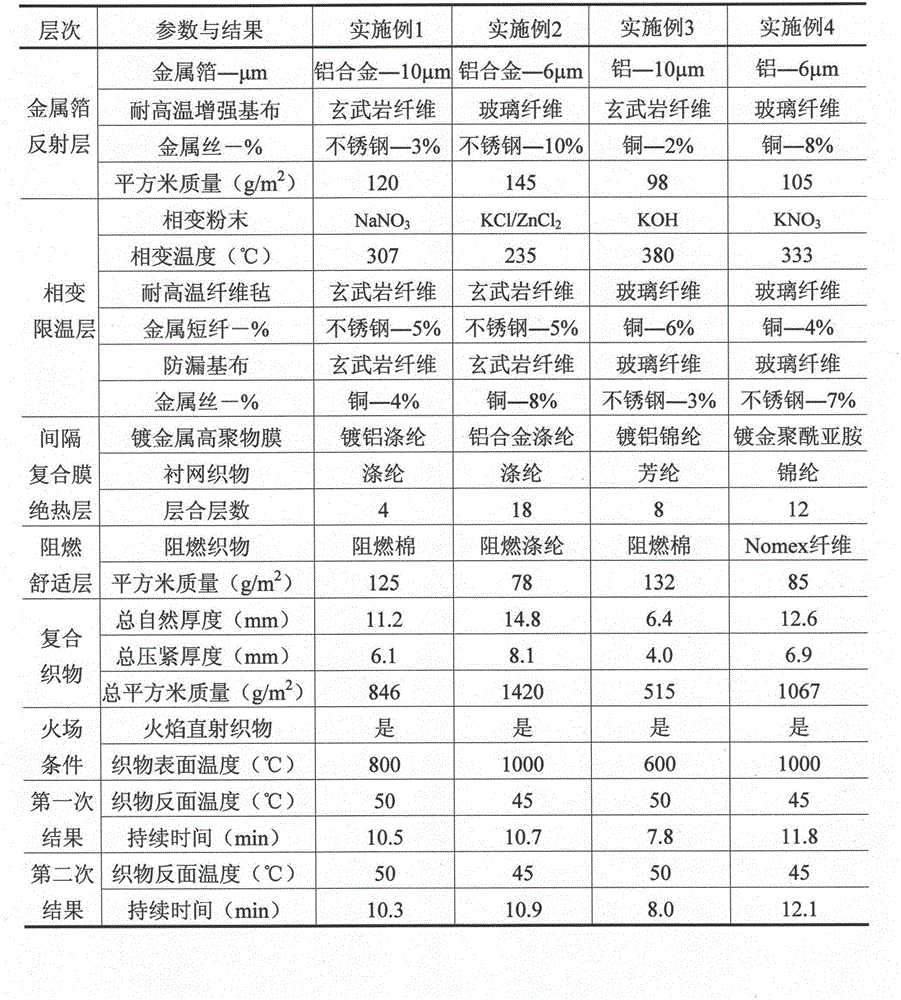

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Optical systems fabricated by printing-based assembly

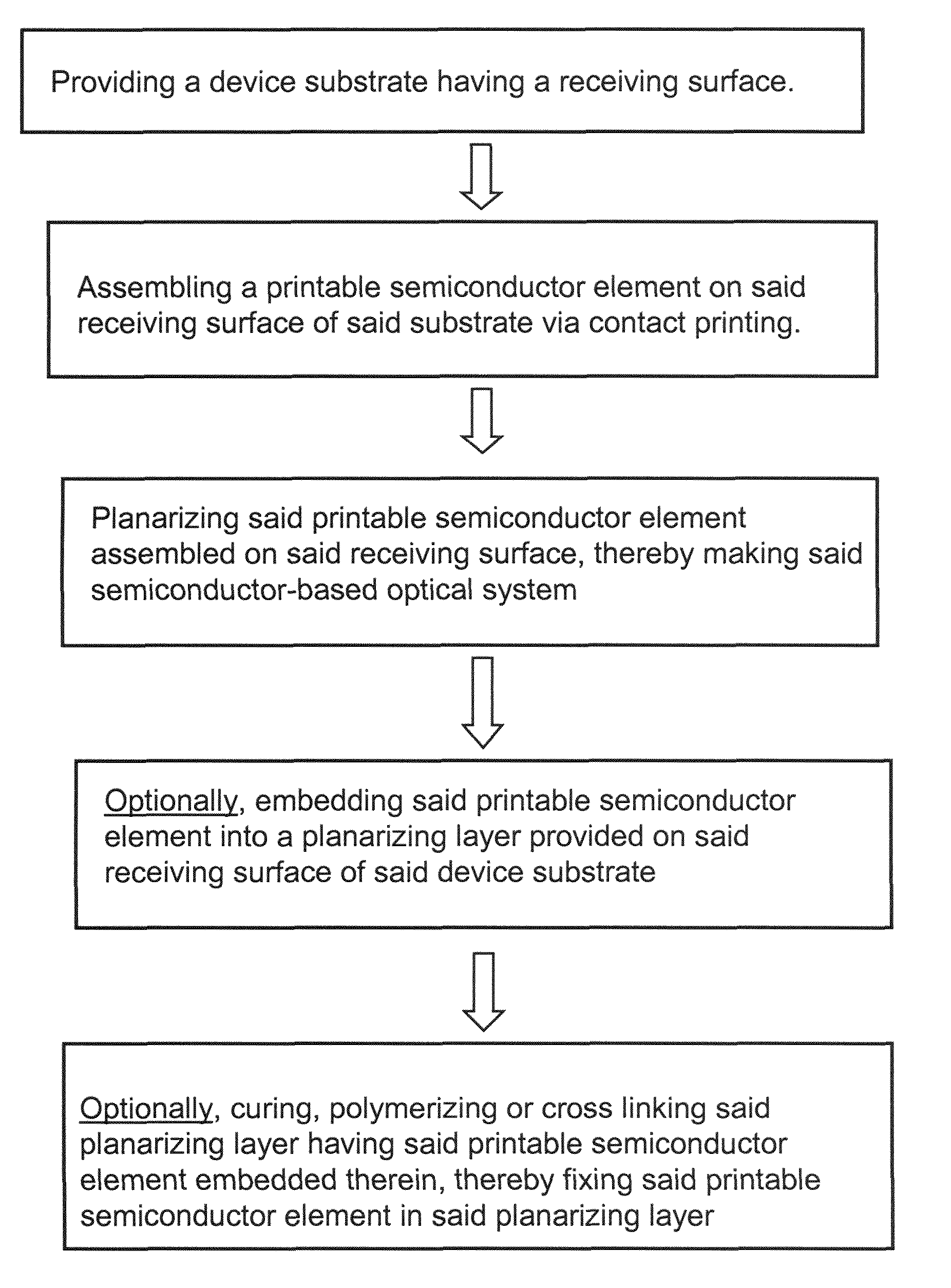

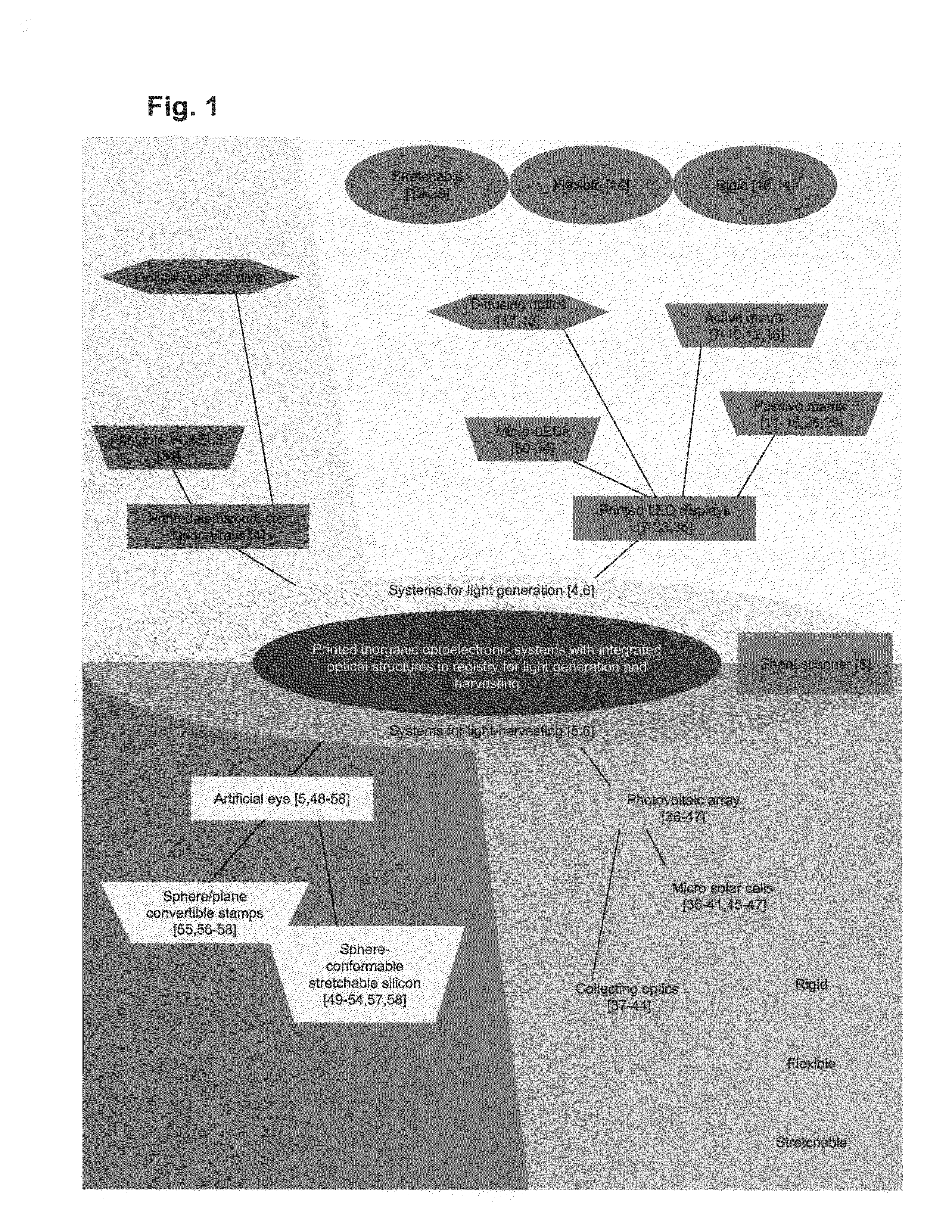

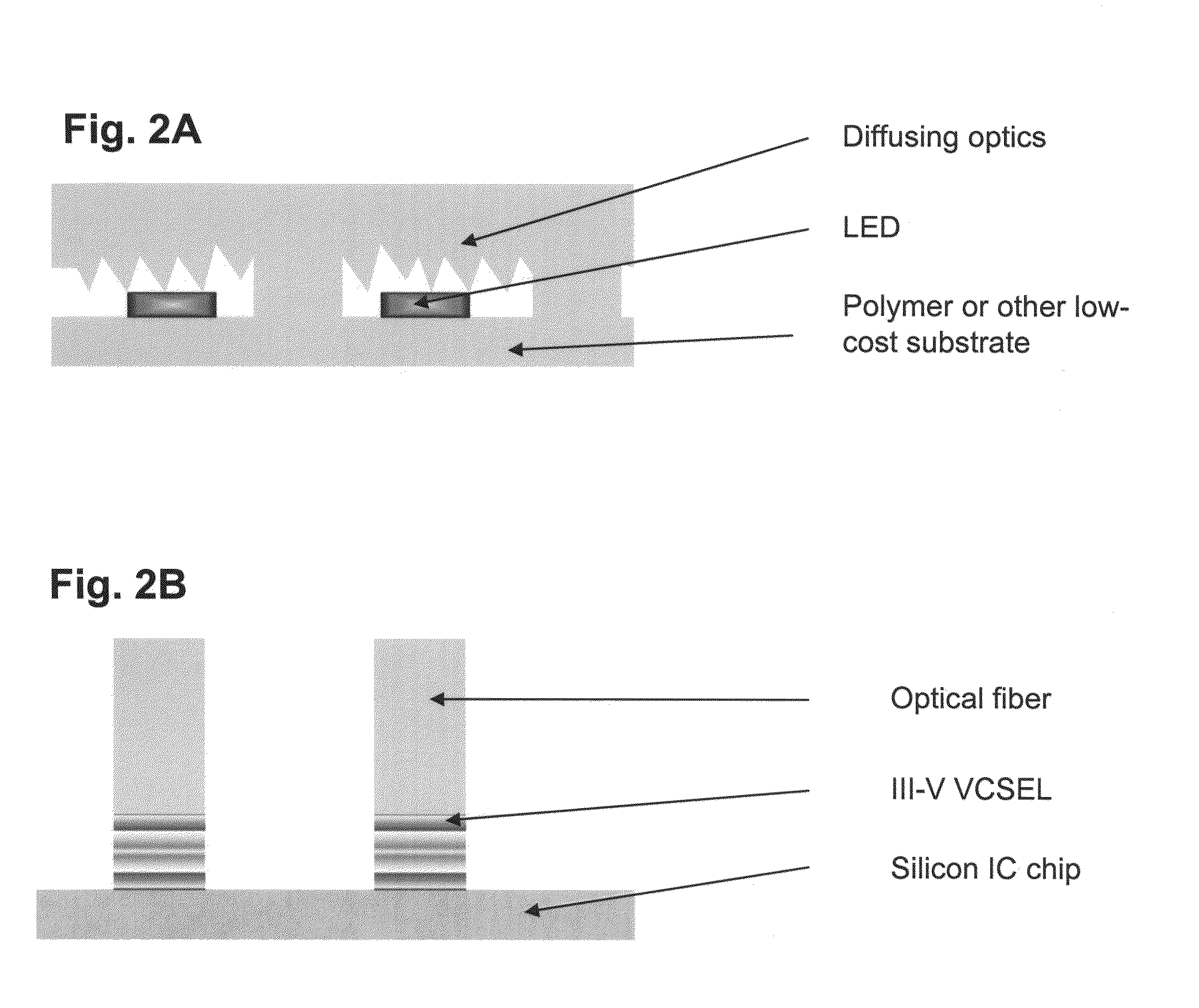

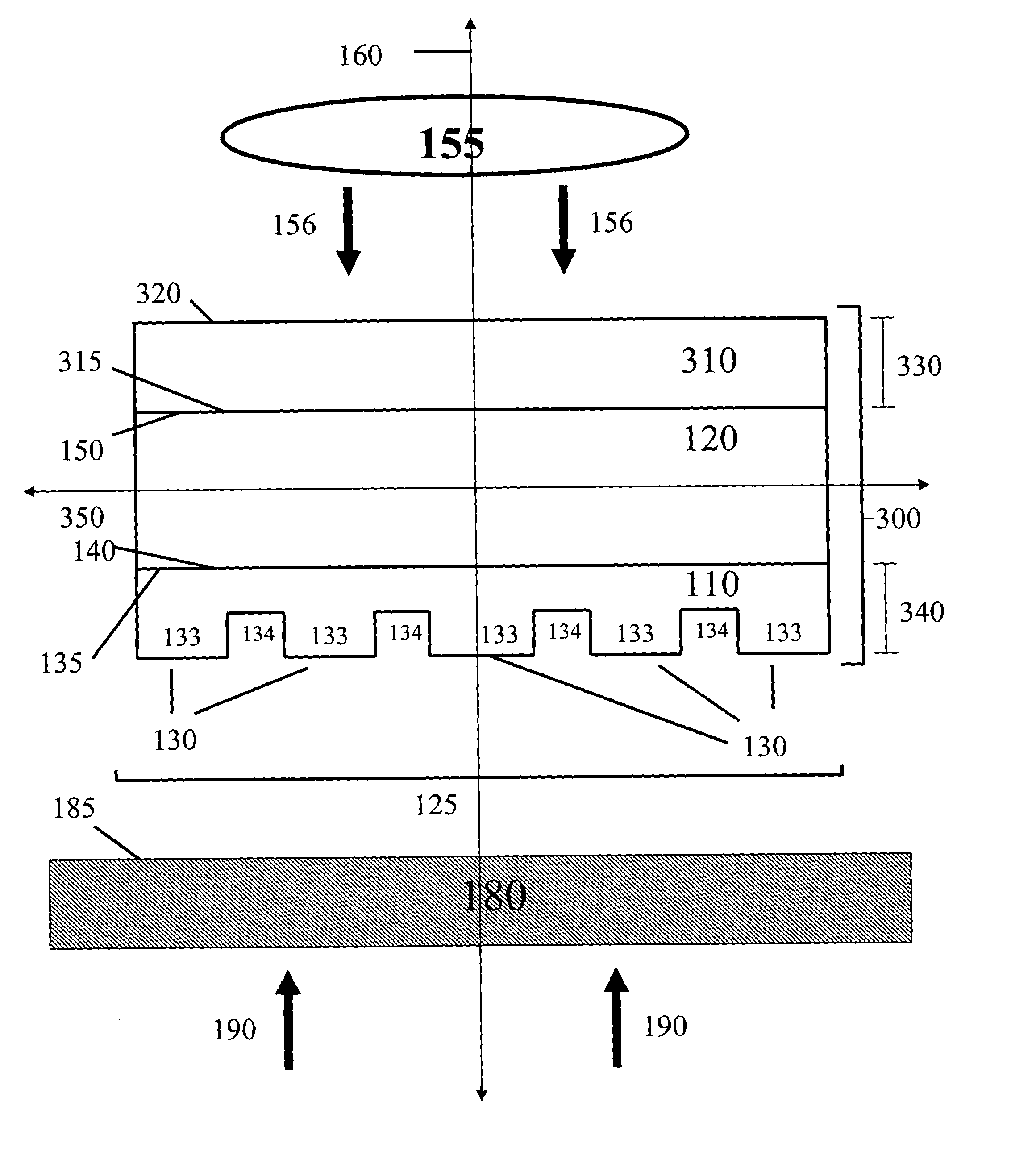

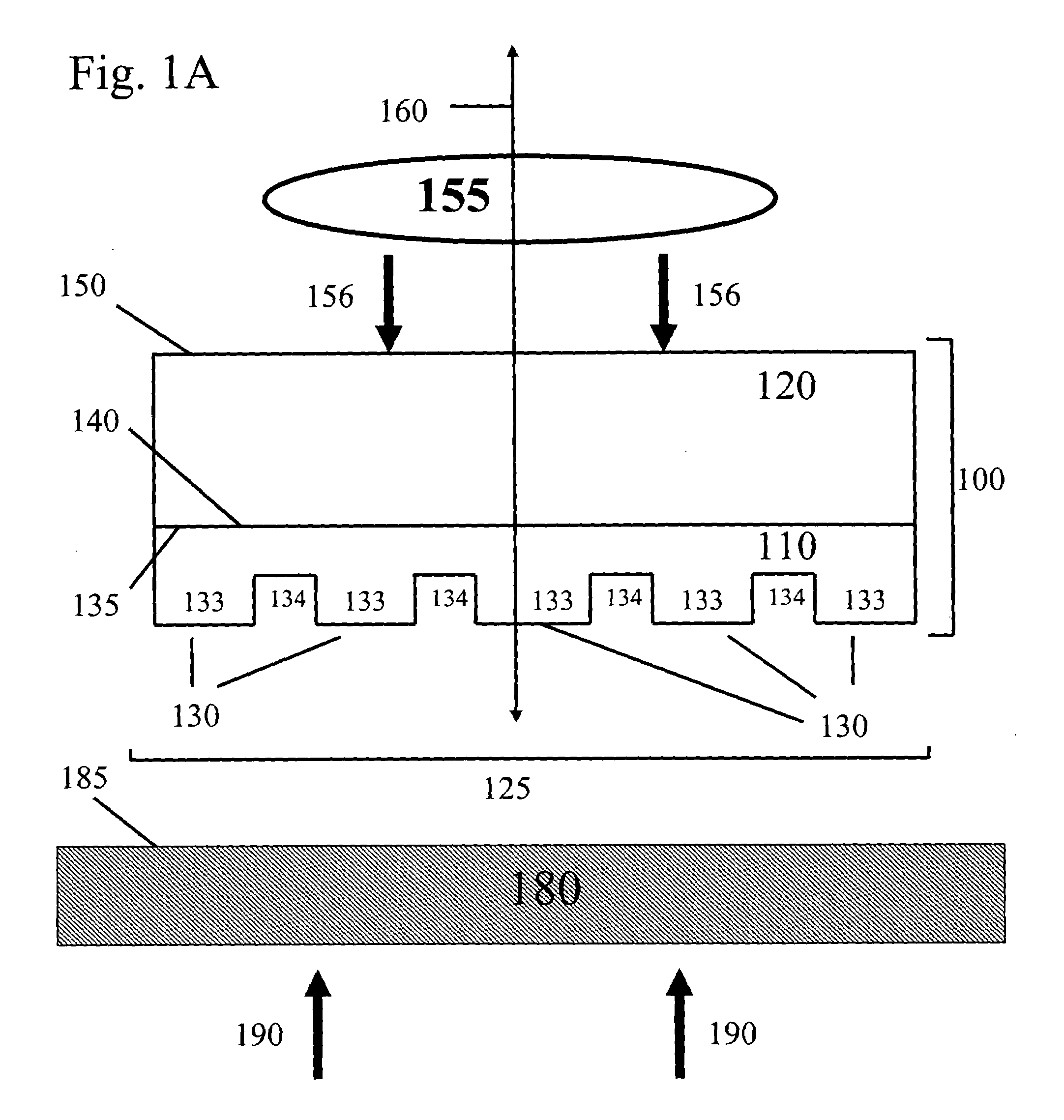

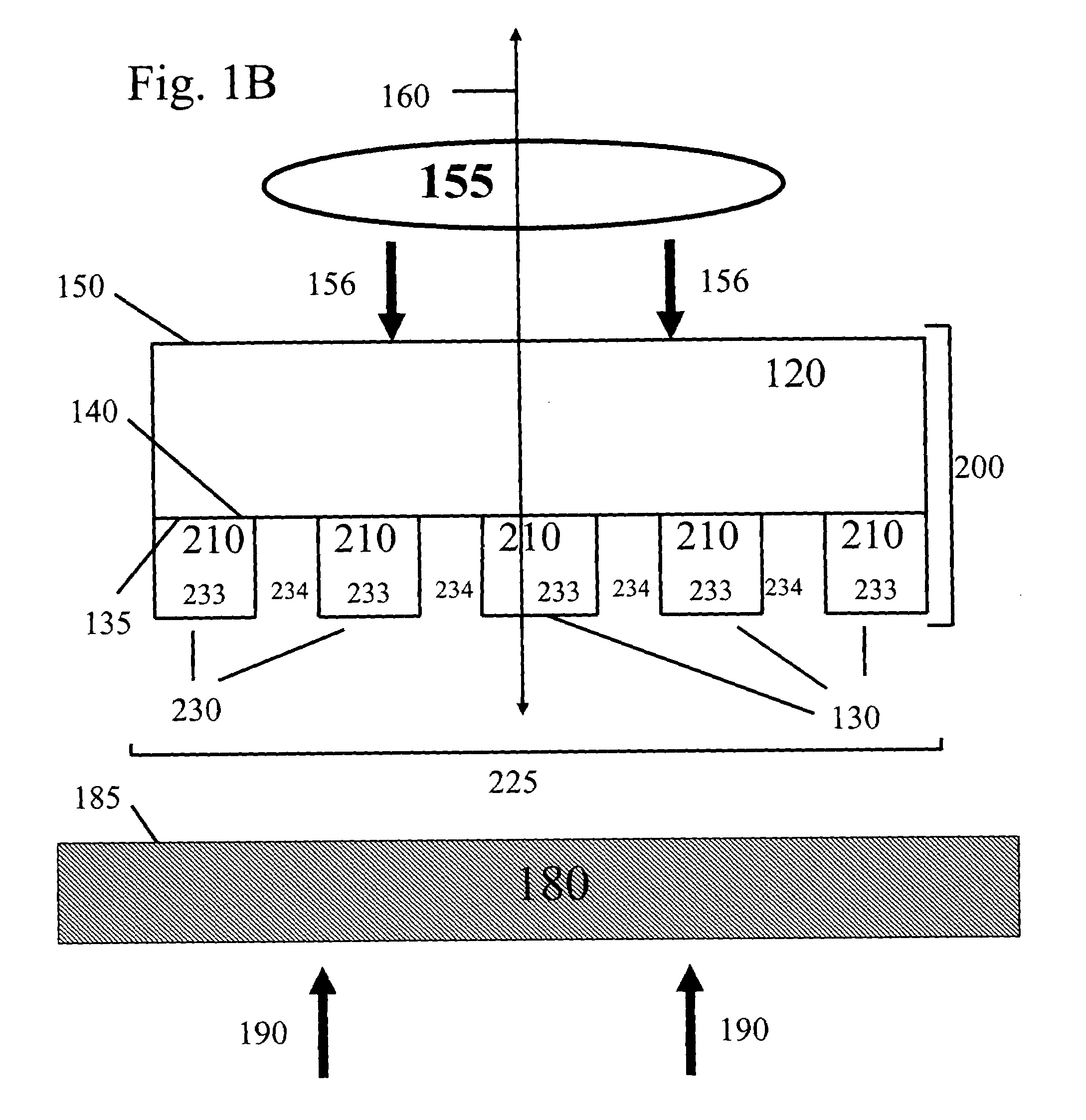

ActiveUS7972875B2Low costImprove performanceFinal product manufactureNanoinformaticsLight sensingSingle crystal

Provided are optical devices and systems fabricated, at least in part, via printing-based assembly and integration of device components. In specific embodiments the present invention provides light emitting systems, light collecting systems, light sensing systems and photovoltaic systems comprising printable semiconductor elements, including large area, high performance macroelectronic devices. Optical systems of the present invention comprise semiconductor elements assembled, organized and / or integrated with other device components via printing techniques that exhibit performance characteristics and functionality comparable to single crystalline semiconductor based devices fabricated using conventional high temperature processing methods. Optical systems of the present invention have device geometries and configurations, such as form factors, component densities, and component positions, accessed by printing that provide a range of useful device functionalities. Optical systems of the present invention include devices and device arrays exhibiting a range of useful physical and mechanical properties including flexibility, shapeability, conformability and stretchablity.

Owner:X DISPLAY CO TECH LTD +1

Composite patterning devices for soft lithography

ActiveUS7195733B2Improve fidelityIncrease resistanceMaterial nanotechnologyNanoinformaticsNano sizeYoung's modulus

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

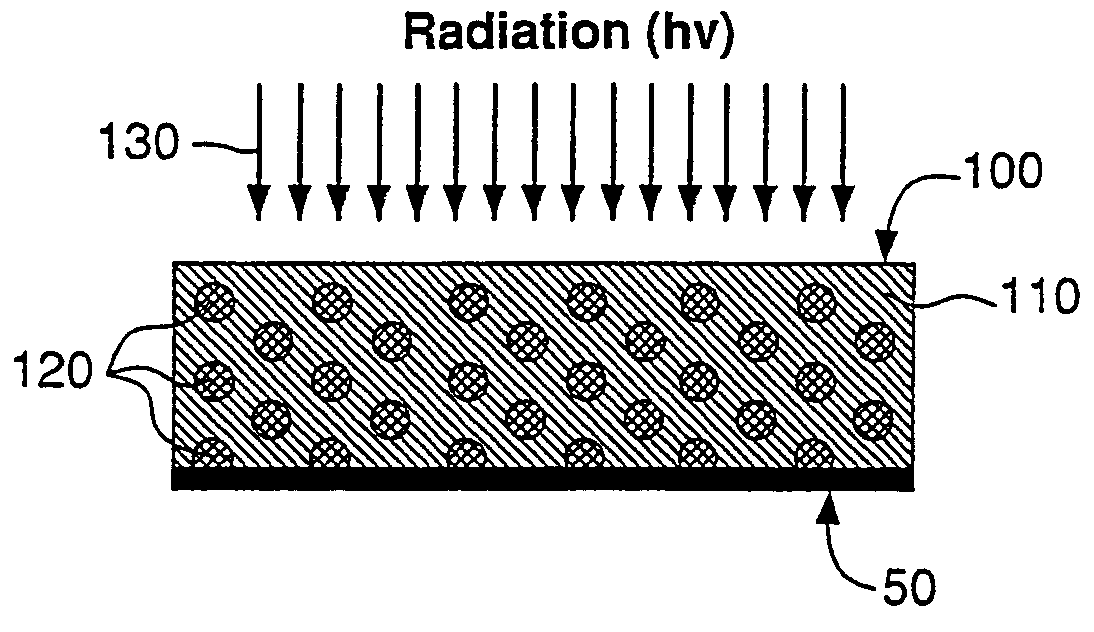

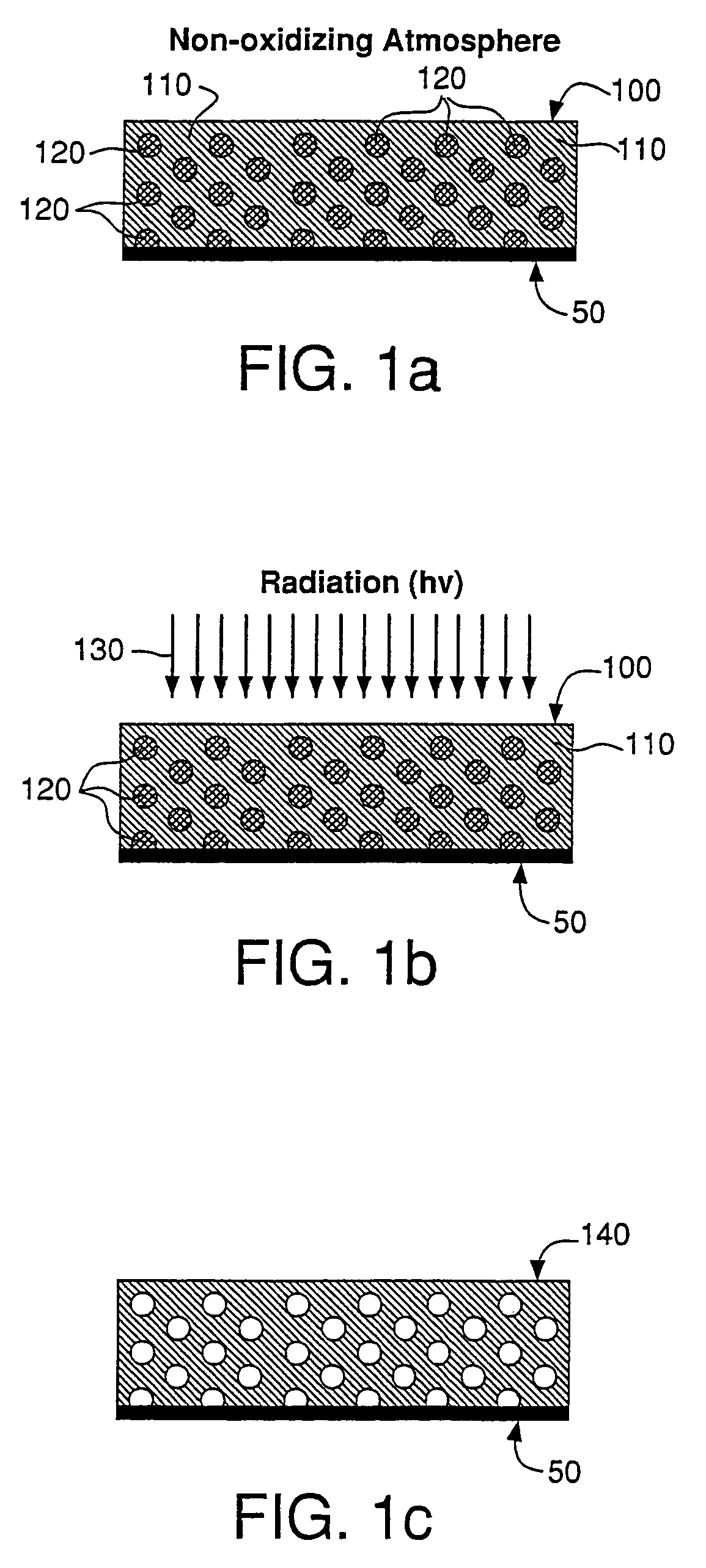

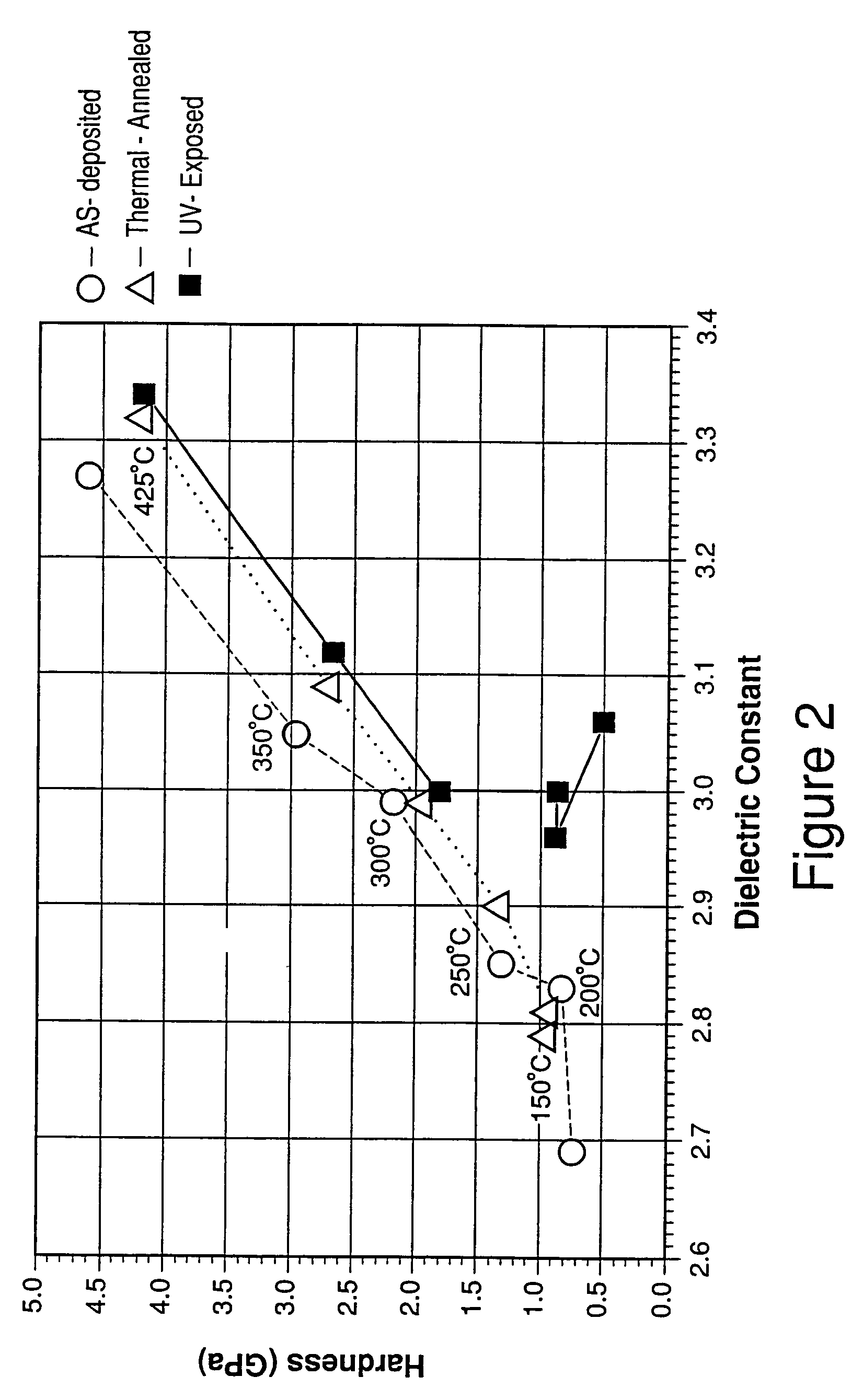

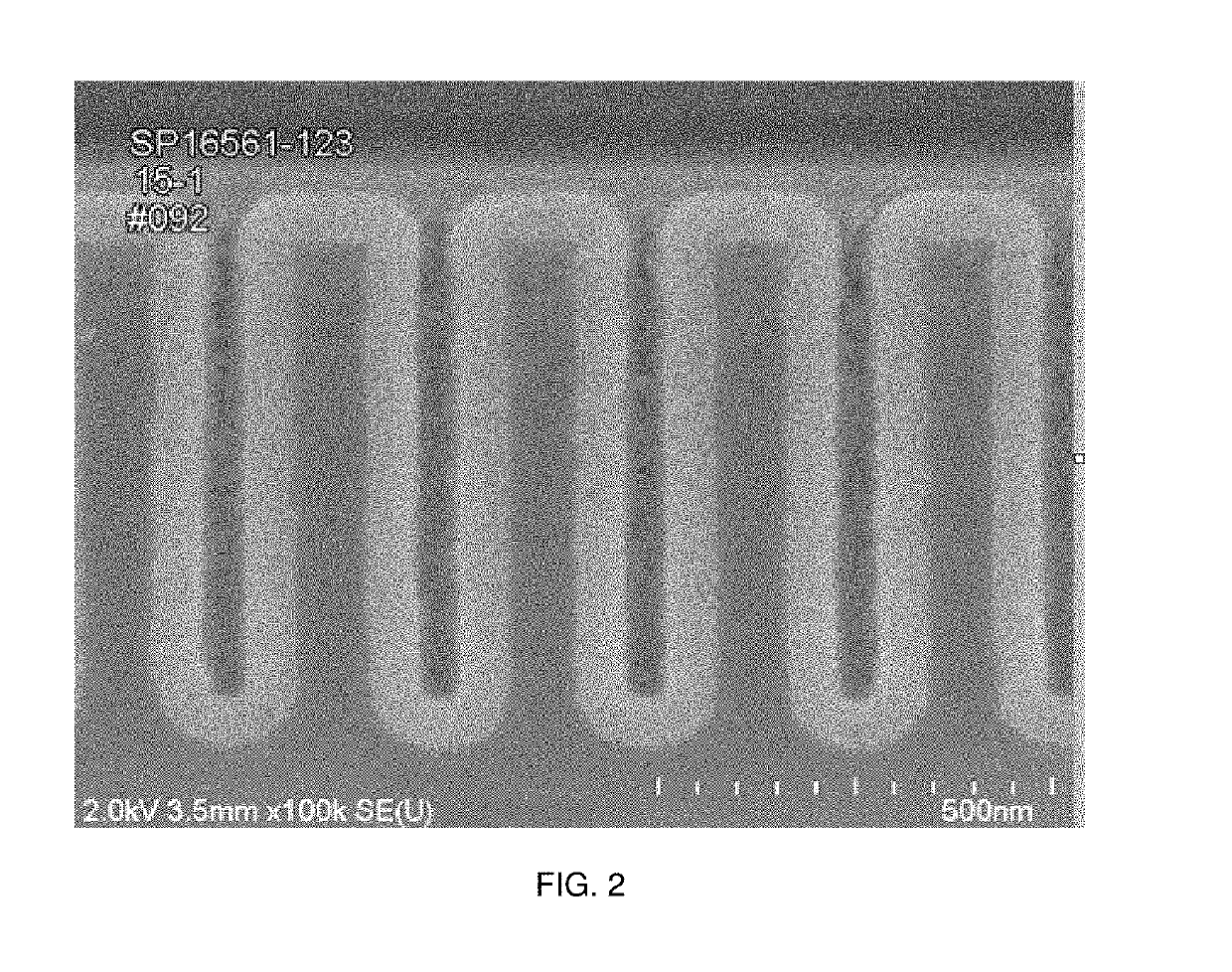

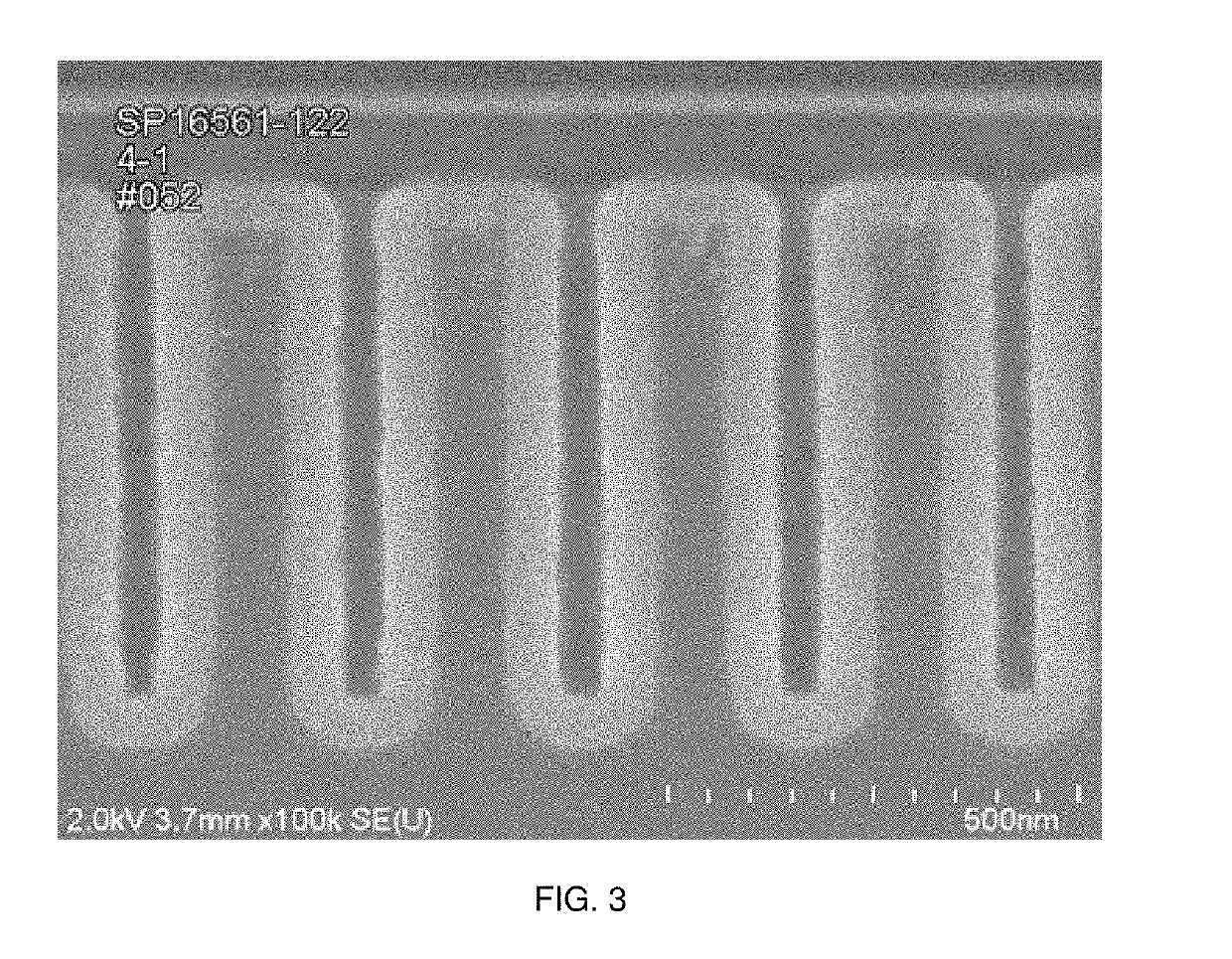

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7098149B2Low dielectric constantIncrease modulusSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricUltraviolet lights

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

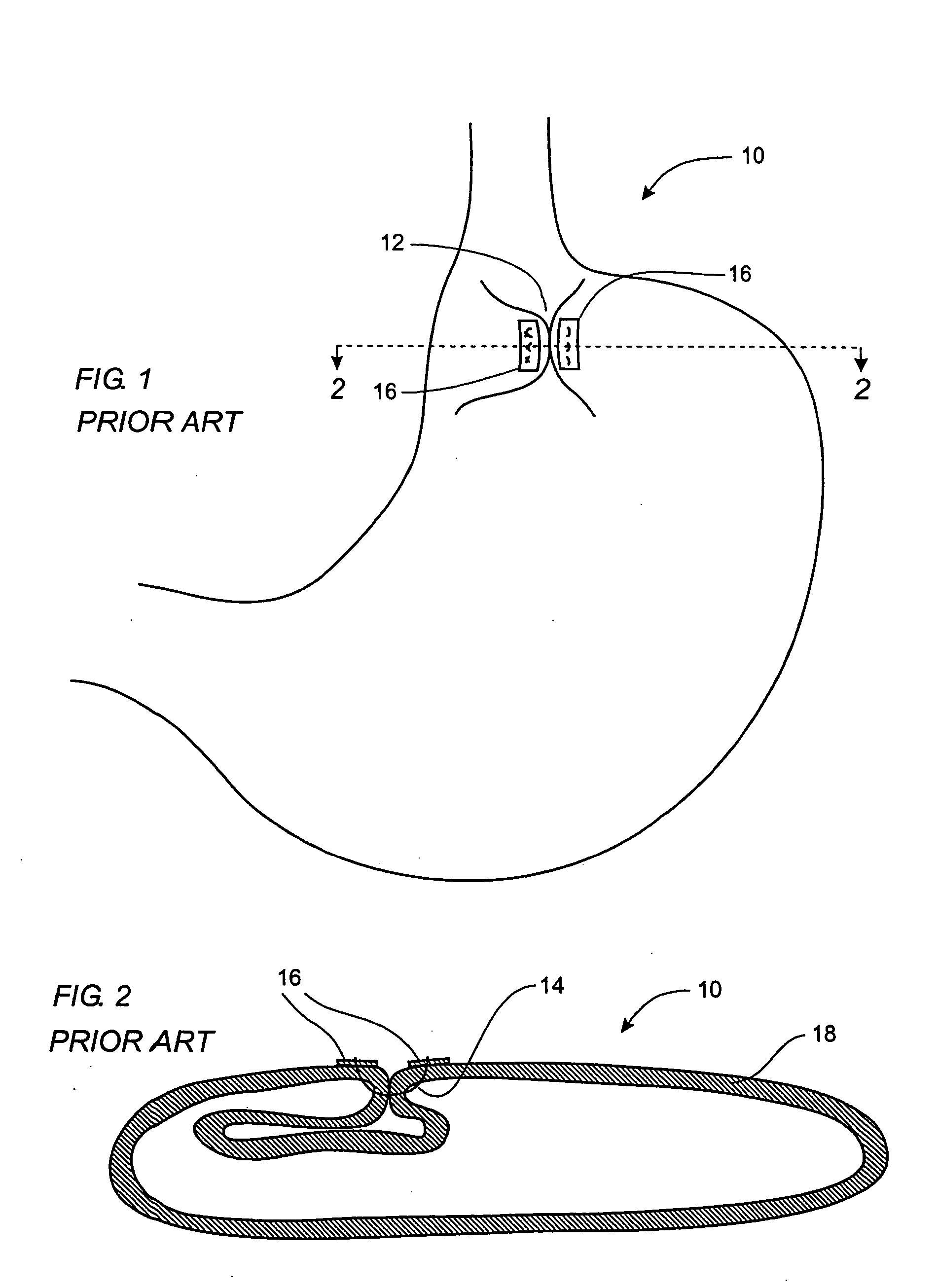

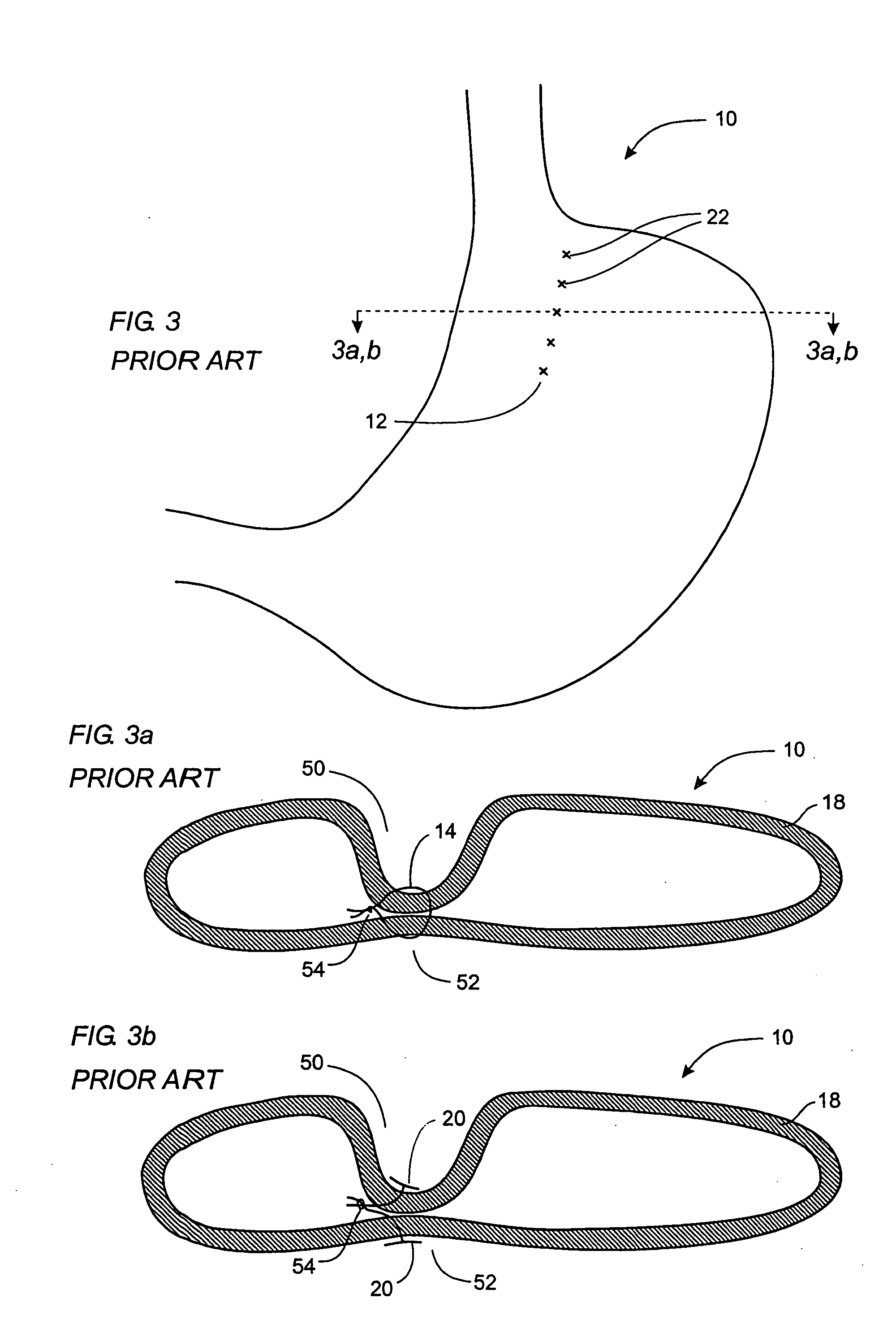

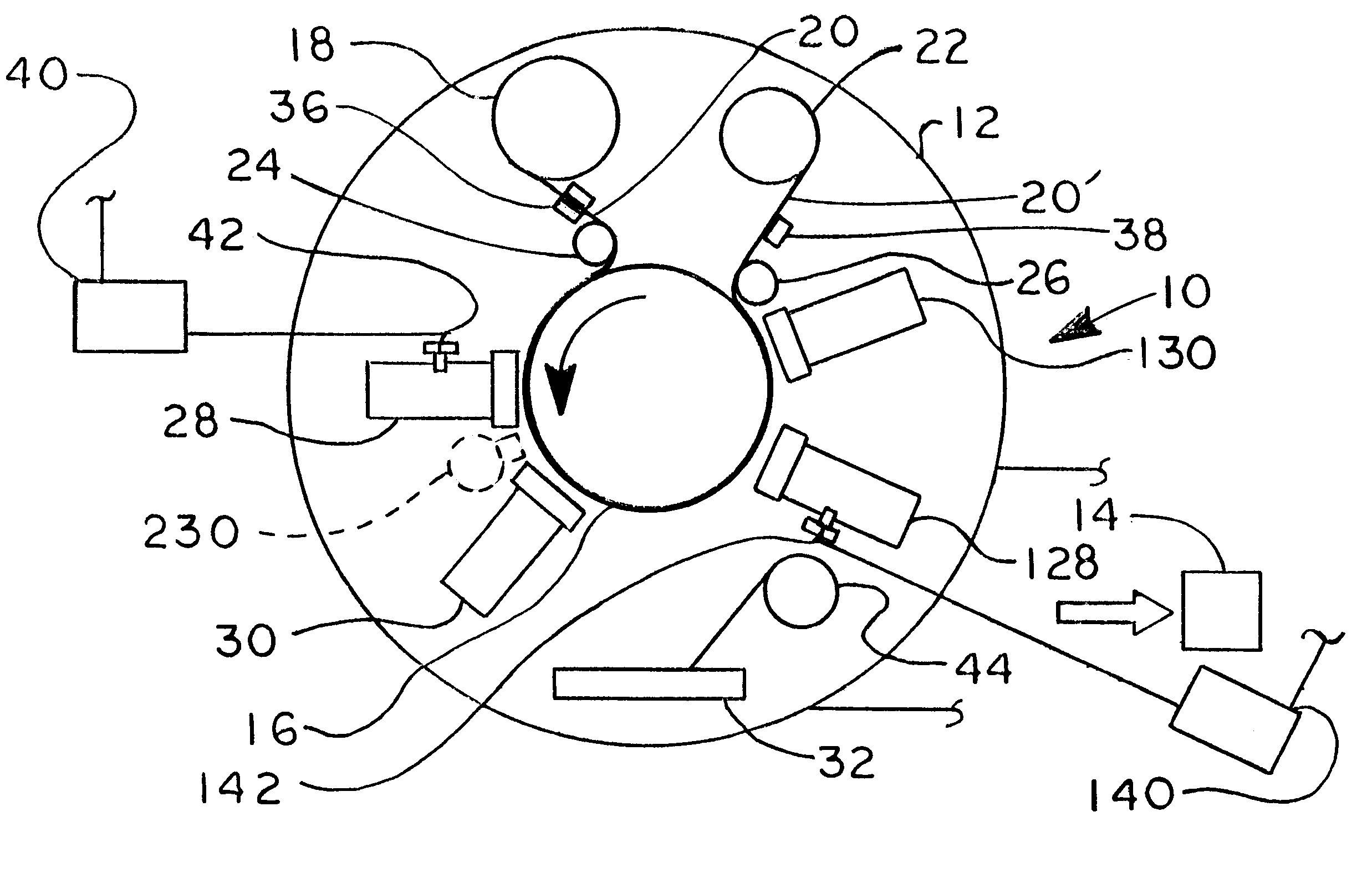

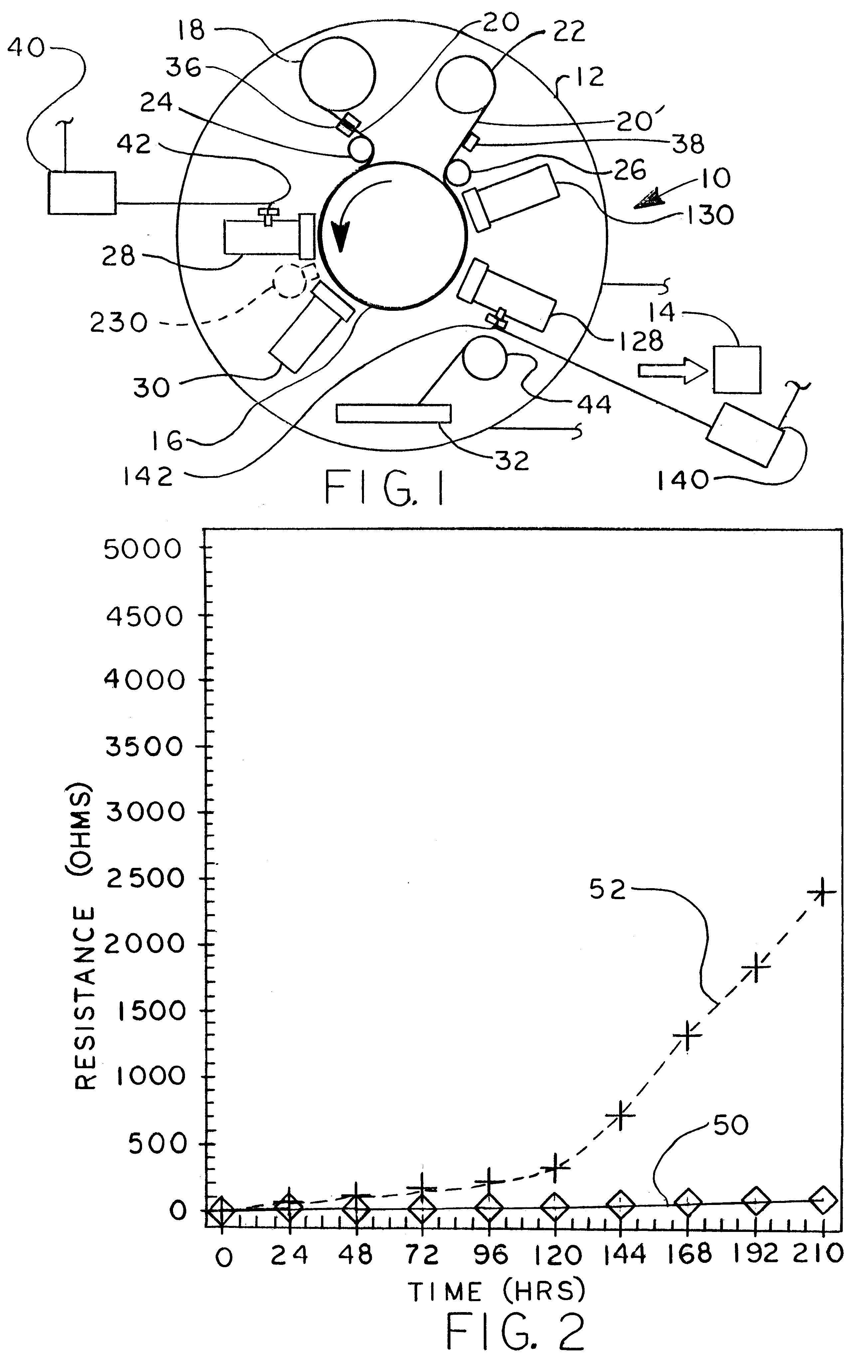

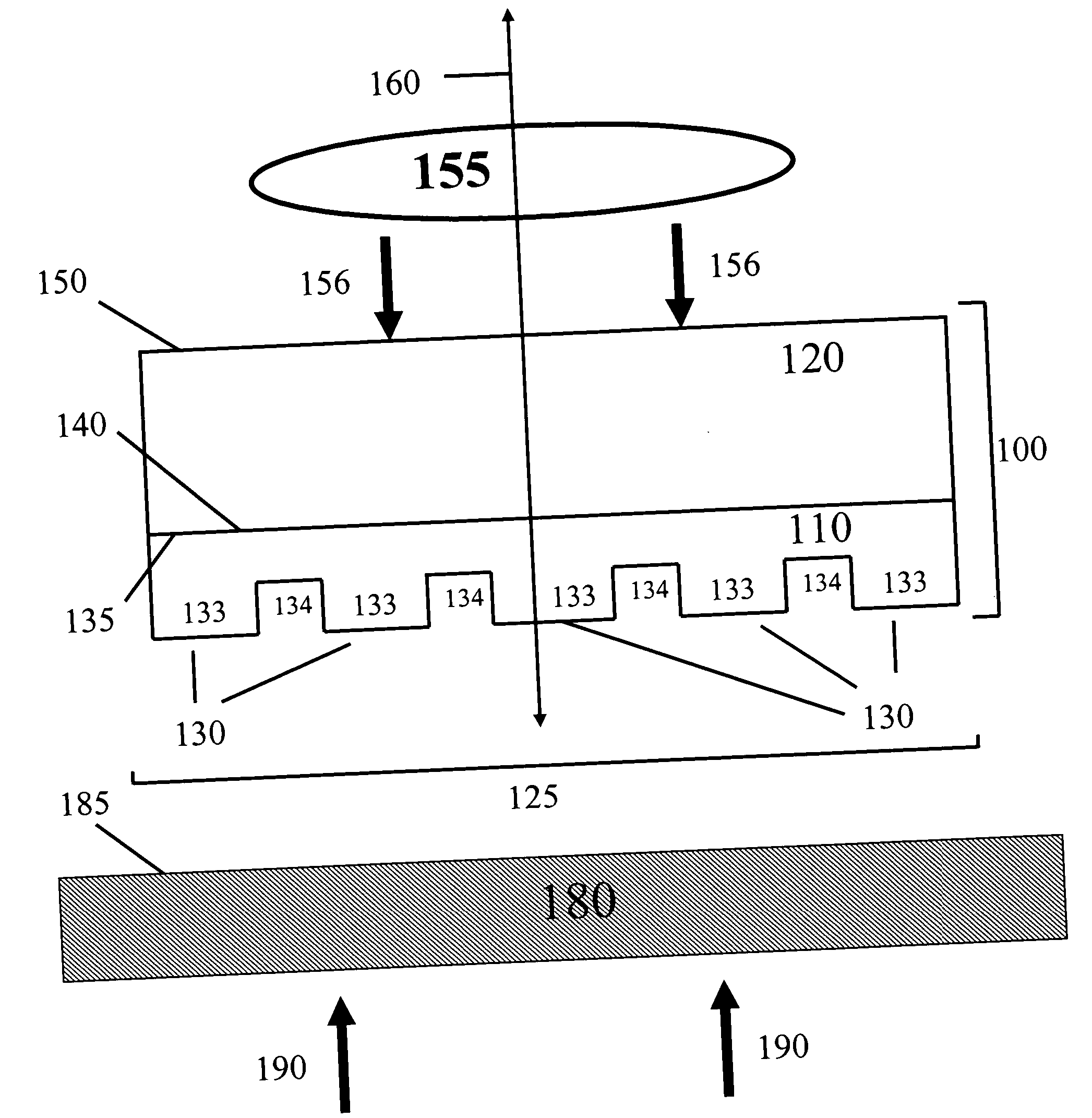

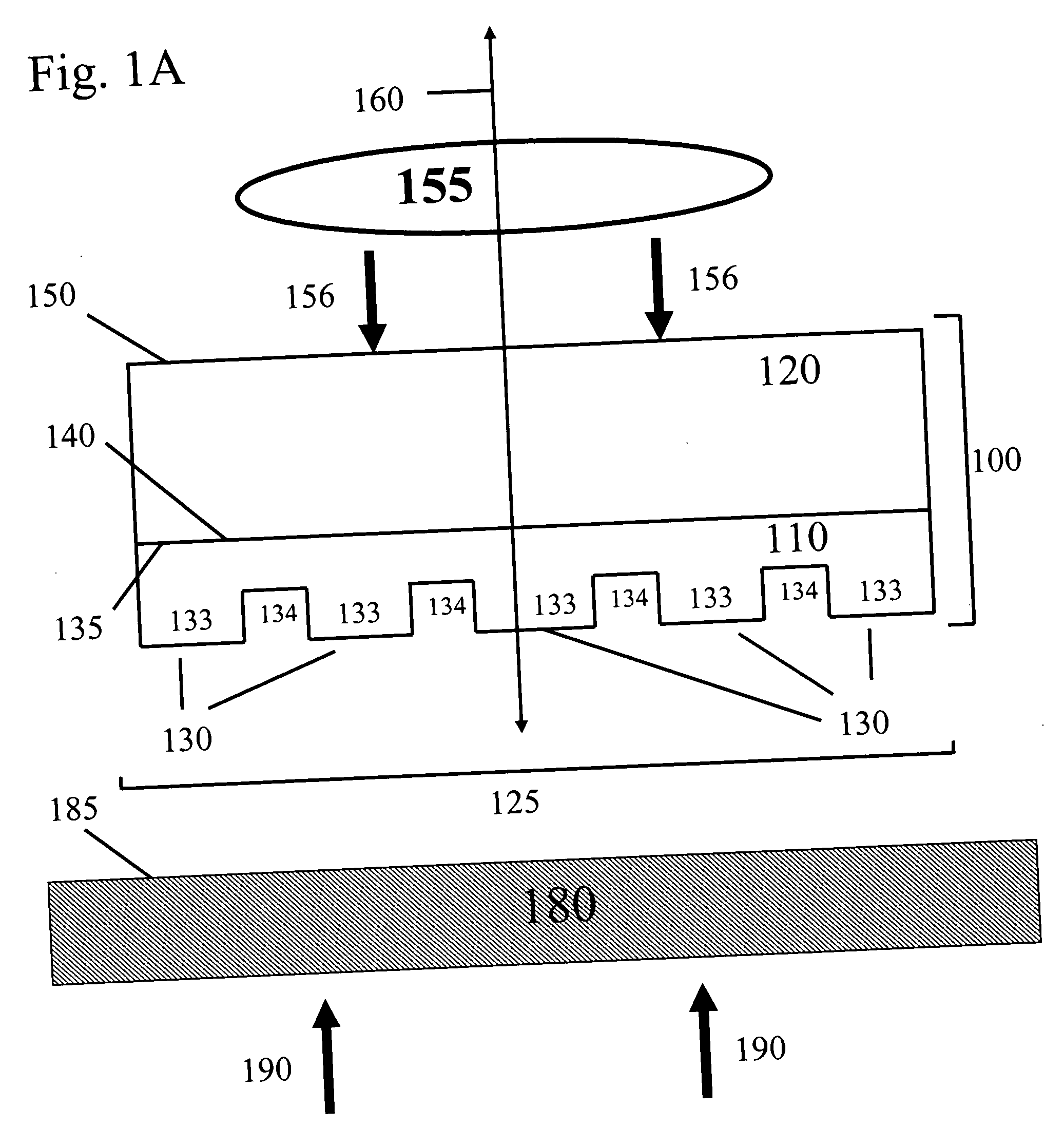

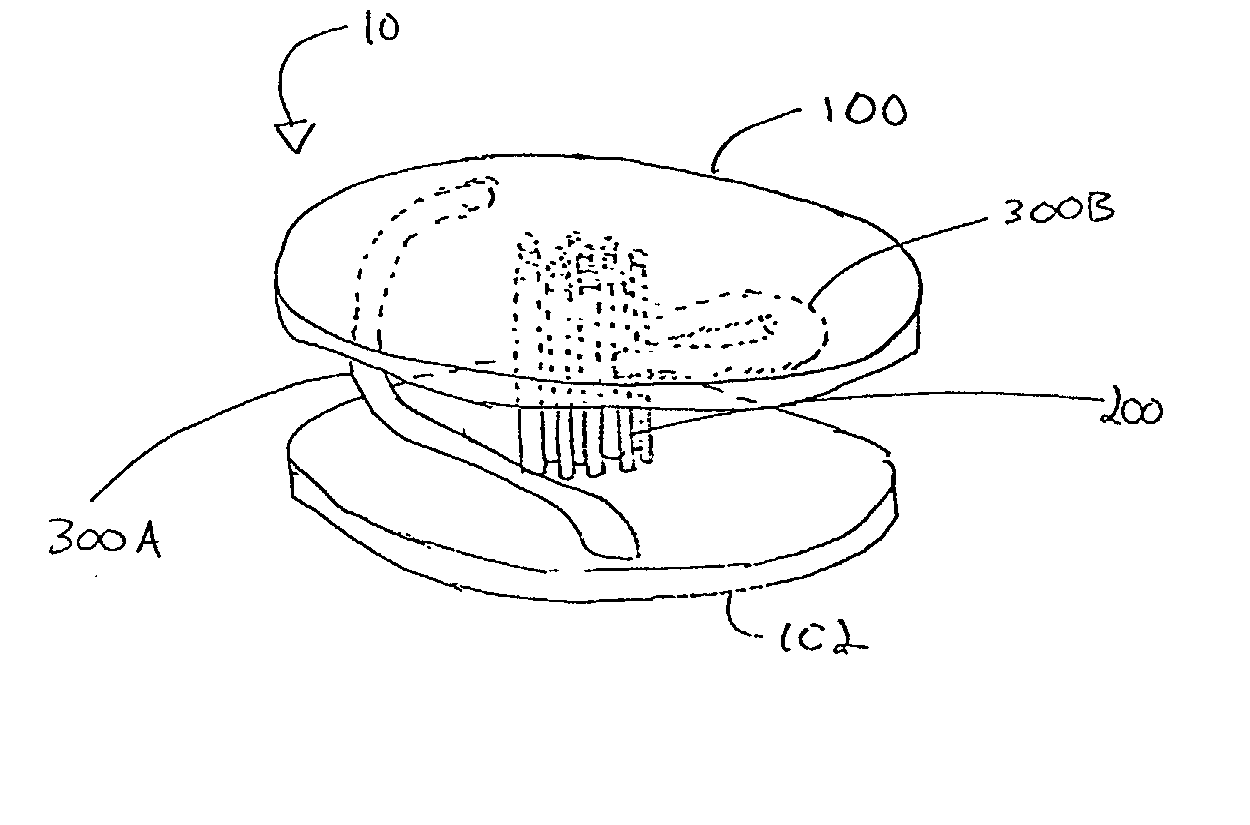

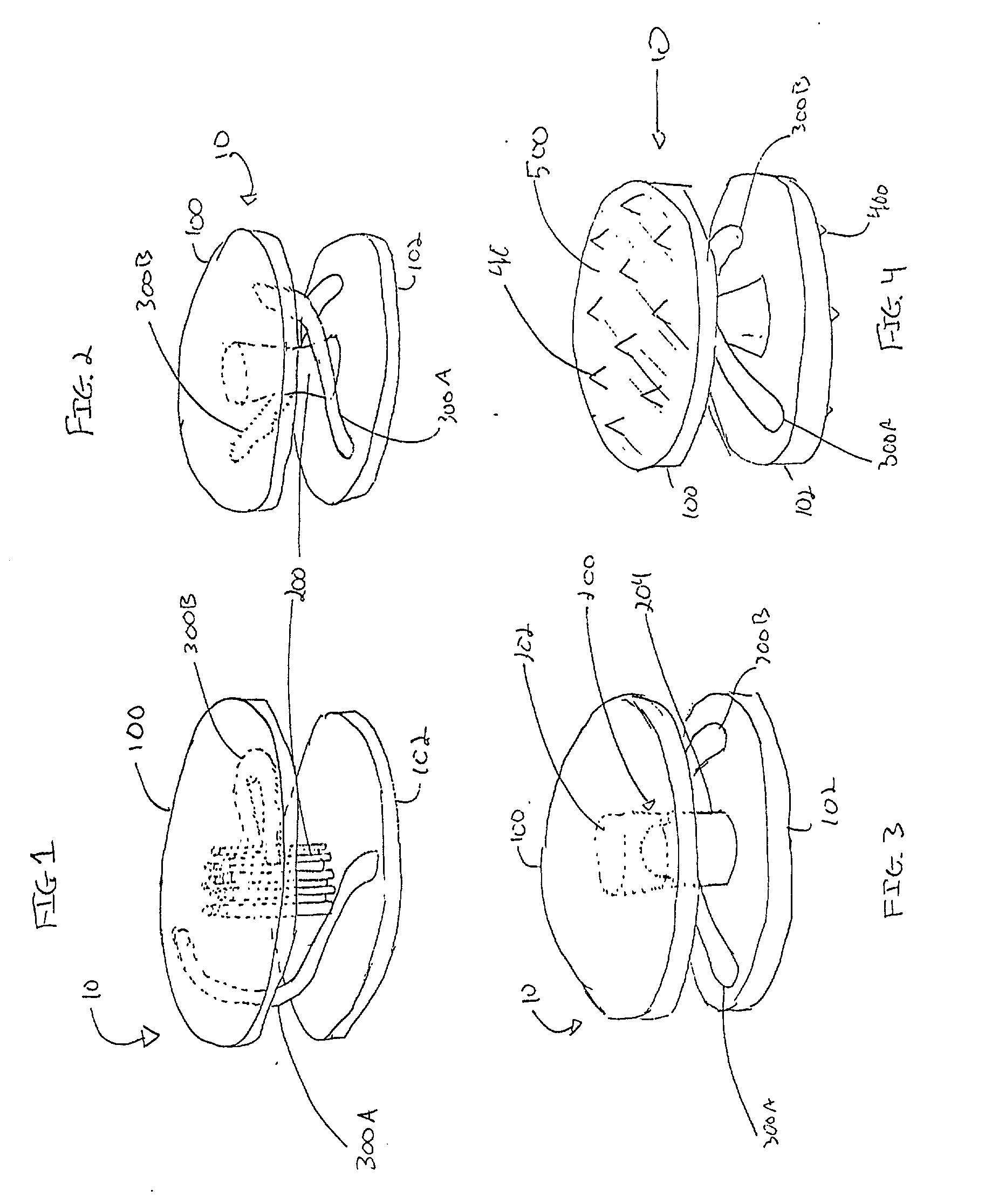

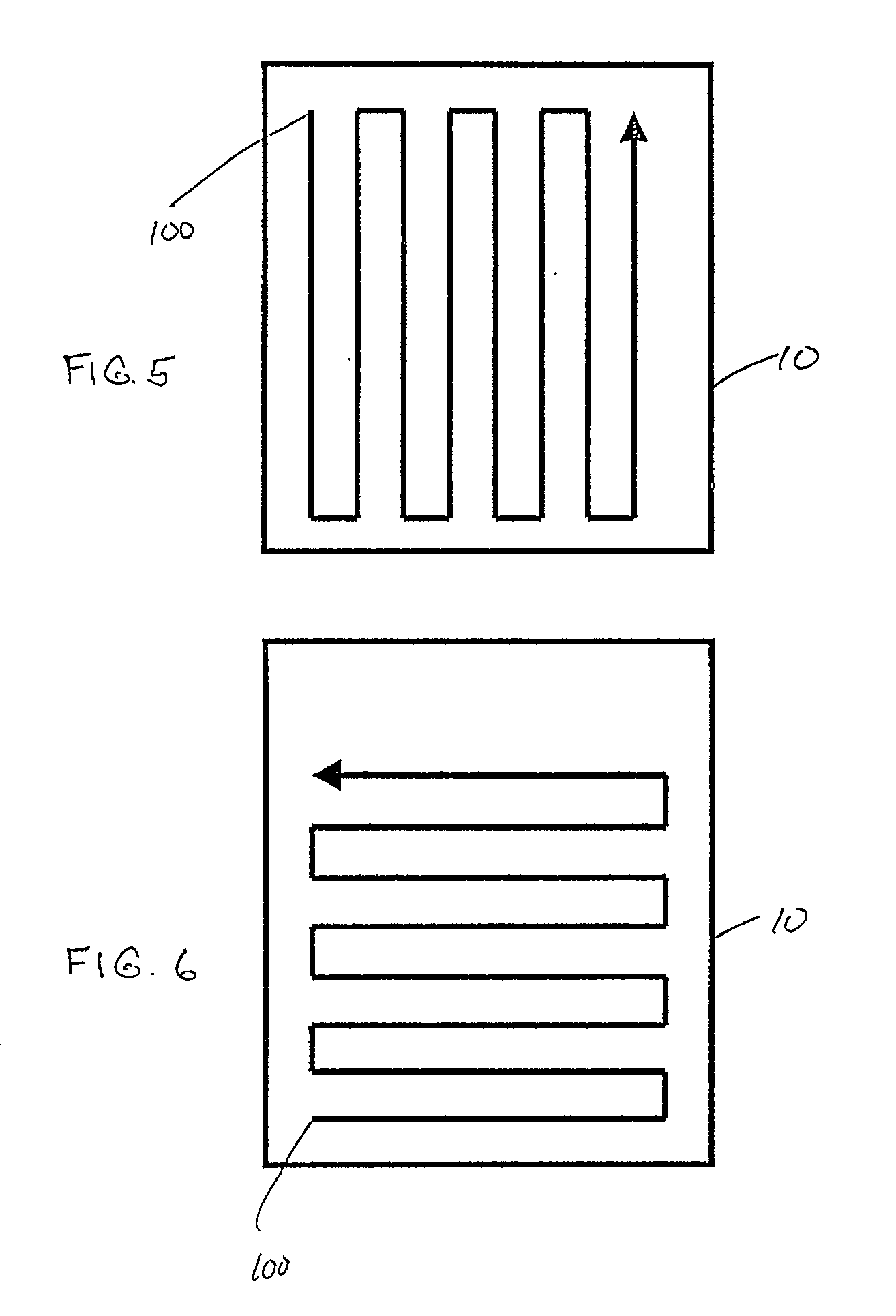

Methods and devices for soft tissue securement

Devices and methods for improved soft tissue securement are disclosed, and, in particular, to tissue anchoring elements and deployment thereof. Such tissue anchoring elements may comprise a linkage element and an array of spreading elements. Endoscopic devices and methods are disclosed for deploying multiple anchoring elements to multiple sites and manipulating at least some of the associated linkage elements to approximate selected sites. Applications of such endoscopic devices and methods may include endoluminal therapy such as gastroplasty, which may be used for the treatment of obesity and gastroesophageal disease. Such devices and methods may also include the attachment of a foreign body to a tissue mass. Further aspects of the invention include devices and methods for the modification of mechanical properties of the anchoring sites so as to decrease the likelihood that anchoring elements will pull out. Such modification may include irritating or injuring the tissue within the anchoring sites, thereby causing a healing or scarification response, or may alternatively include deploying a solidifying agent within the anchoring sites.

Owner:KELLEHER BRIAN

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

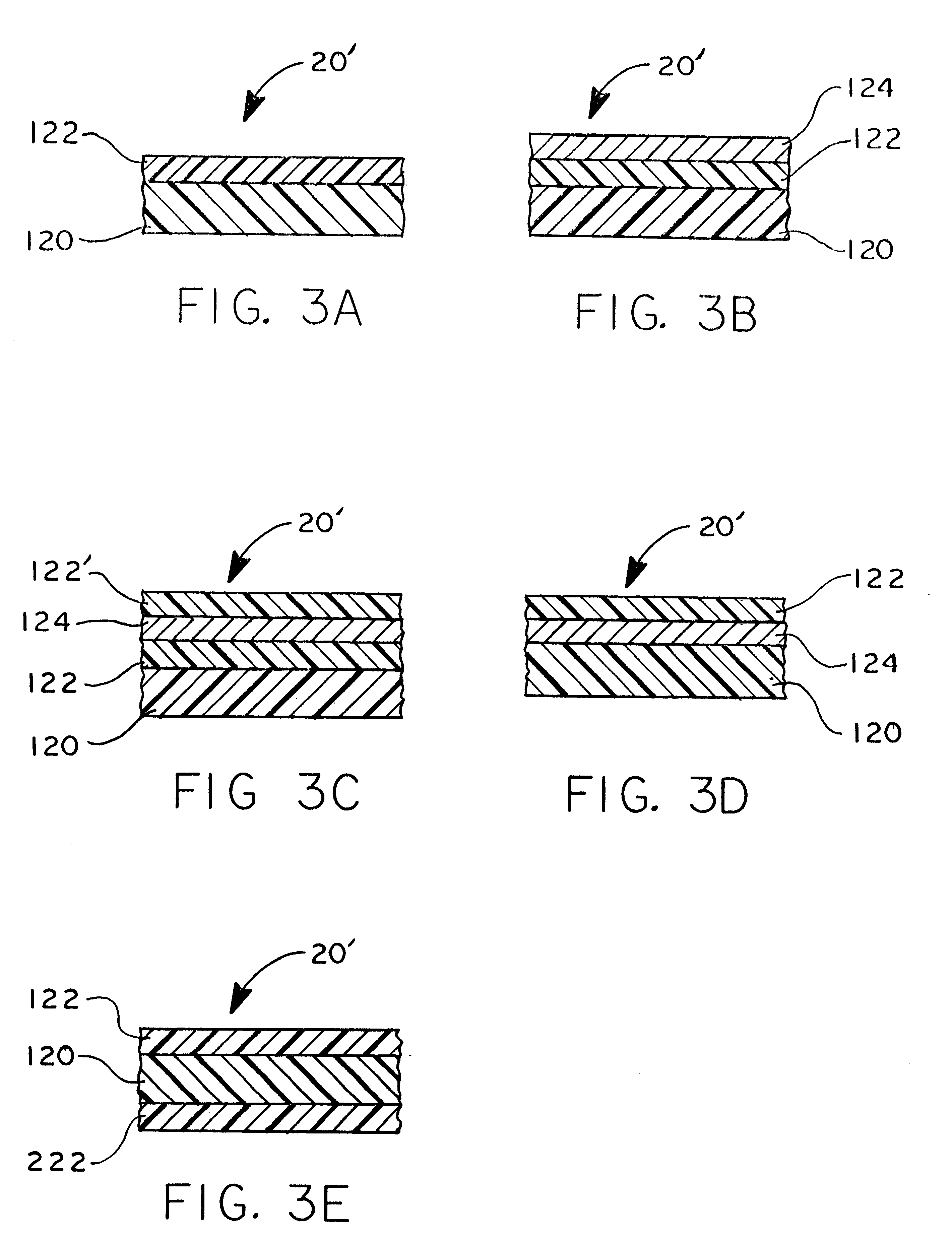

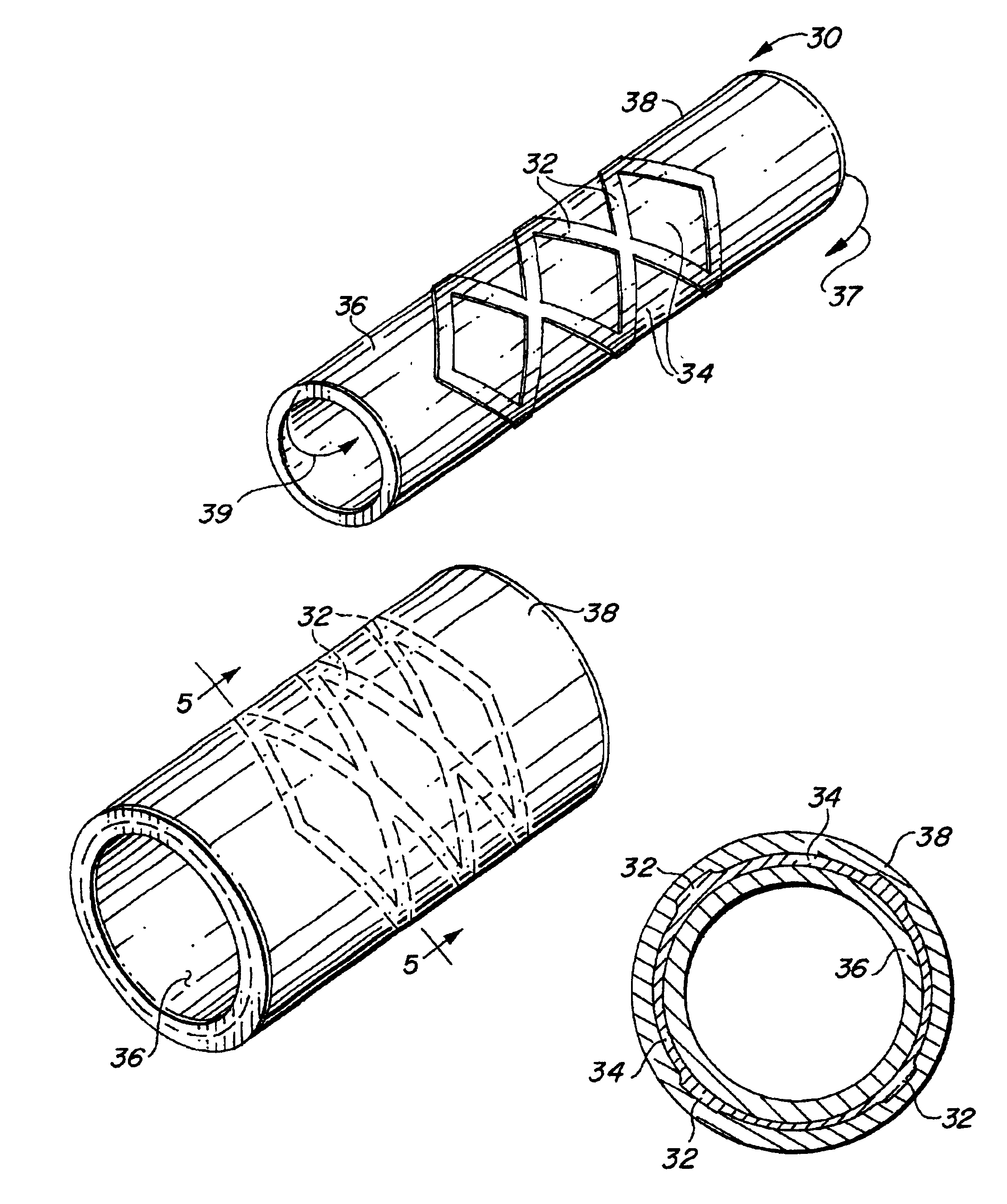

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

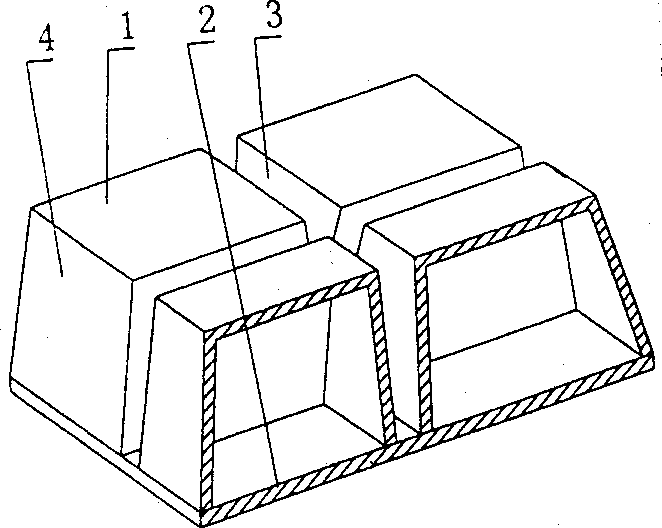

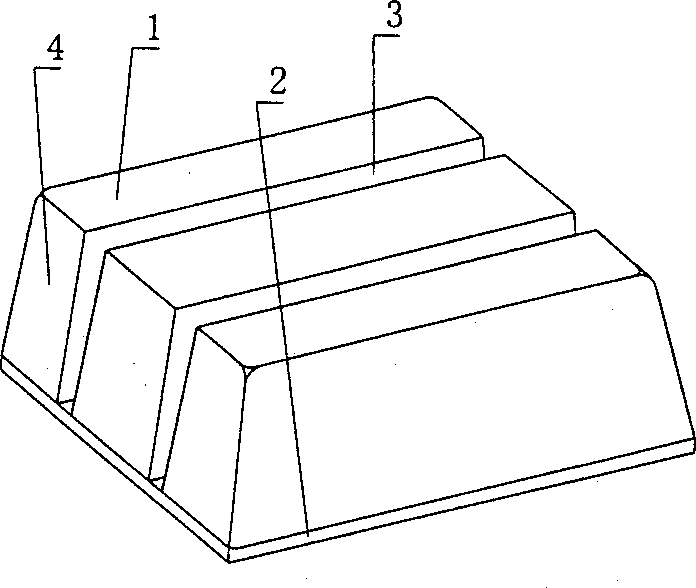

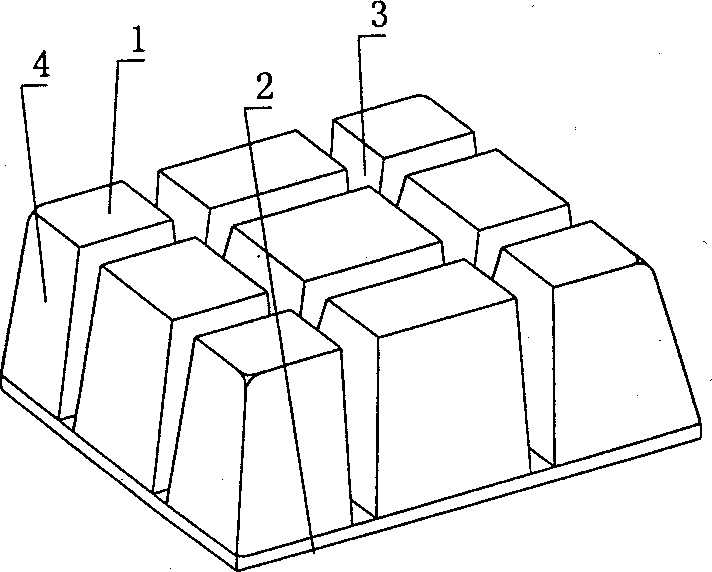

Comobined ribbed cavity member for spatial structure roof

A combined-rib cavity member for space-structure flooring includes cavity form and structure bottom plate, which are connected into one integral whole. It is characterized by that there are at least two cavity forms arranged alternate with each other on the structure bottom plate, its side forms with the structure bottle plate at least one subrit form cavity of casti-in-situ structure, and other other sides of the cavity form forms the side fromboard of main rib or beam or wall for cast-in-situ structure. By this, the subrib of cast-in-situ structure can be formed in the sub-rib form cavity on the structure battom plate, the sub-rib participates in load bearing of structural bottom slat, cast-in-situ main rib, cast-in-sita upper slab so to a load-bearing space structure, improved mechanical property, raise integrity and anti-shock property, decrease structural wt. lower cost and make construction be convenient.

Owner:湖南邱则有专利战略策划有限公司

Medical devices and applications of polyhydroxyalkanoate polymers

InactiveUS6867247B2Reduce probabilityHigh porositySuture equipmentsStentsTissue repairBiocompatibility Testing

Devices formed of or including biocompatible polyhydroxyalkanoates are provided with controlled degradation rates, preferably less than one year under physiological conditions. Preferred devices include sutures, suture fasteners, meniscus repair devices, rivets, tacks, staples, screws (including interference screws), bone plates and bone plating systems, surgical mesh, repair patches, slings, cardiovascular patches, orthopedic pins (including bone filling augmentation material), adhesion barriers, stents, guided tissue repair / regeneration devices, articular cartilage repair devices, nerve guides, tendon repair devices, atrial septal defect repair devices, pericardial patches, bulking and filling agents, vein valves, bone marrow scaffolds, meniscus regeneration devices, ligament and tendon grafts, ocular cell implants, spinal fusion cages, skin substitutes, dural substitutes, bone graft substitutes, bone dowels, wound dressings, and hemostats. The polyhydroxyalkanoates can contain additives, be formed of mixtures of monomers or include pendant groups or modifications in their backbones, or can be chemically modified, all to alter the degradation rates. The polyhydroxyalkanoate compositions also provide favorable mechanical properties, biocompatibility, and degradation times within desirable time frames under physiological conditions.

Owner:TEPHA INC

Composite patterning devices for soft lithography

ActiveUS20050238967A1High resolutionImprove placement accuracyMaterial nanotechnologyNanoinformaticsEngineeringThermal expansion

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

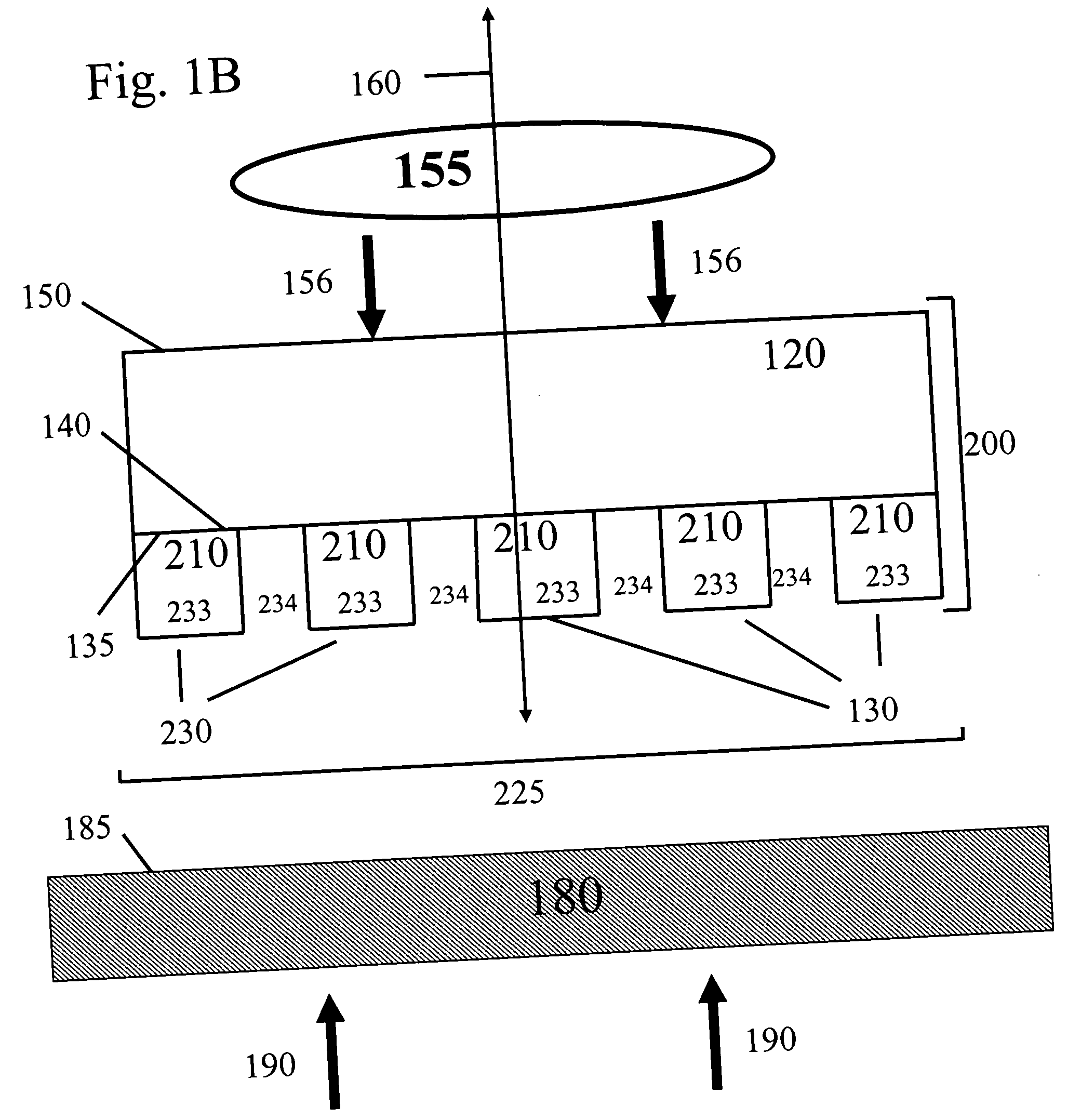

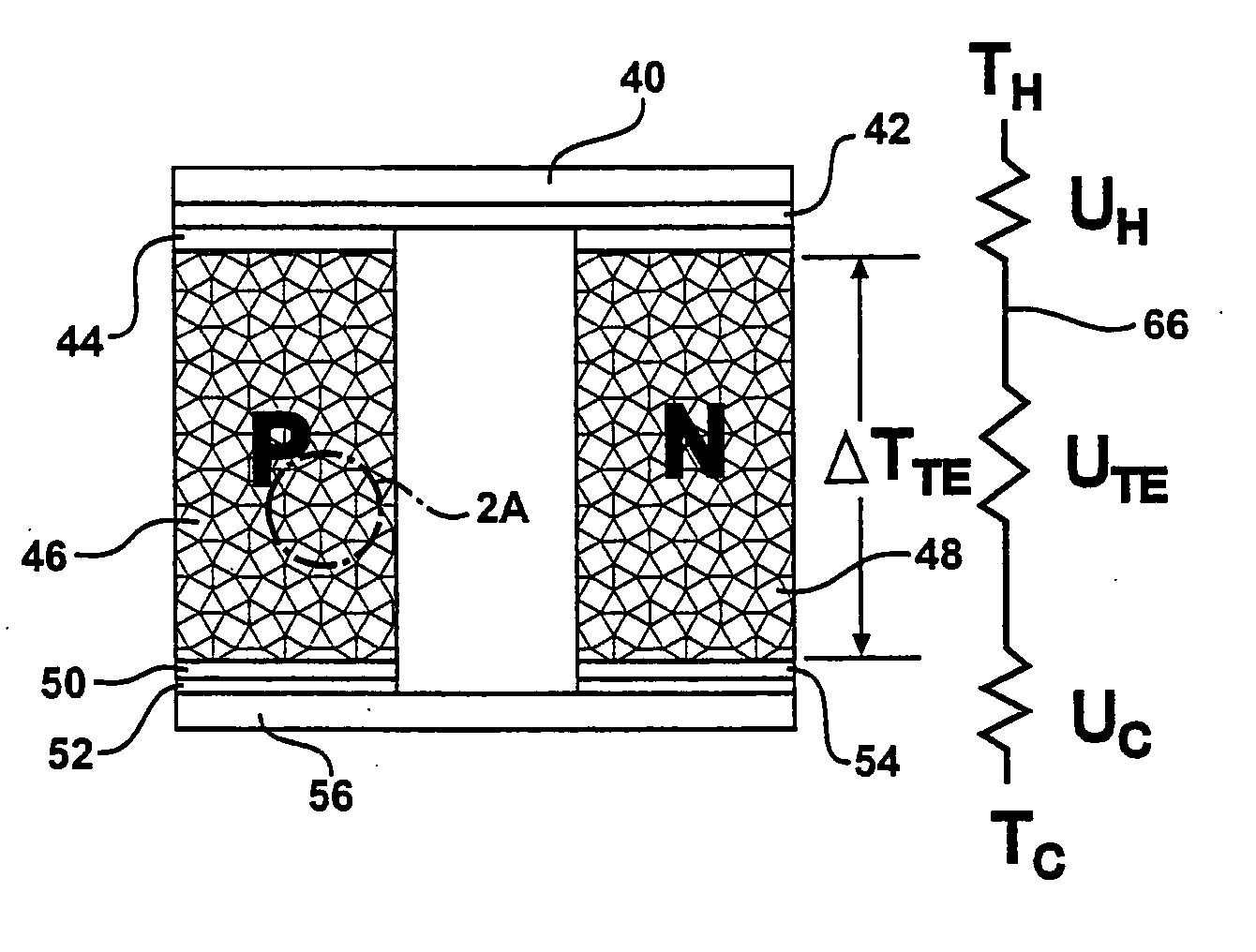

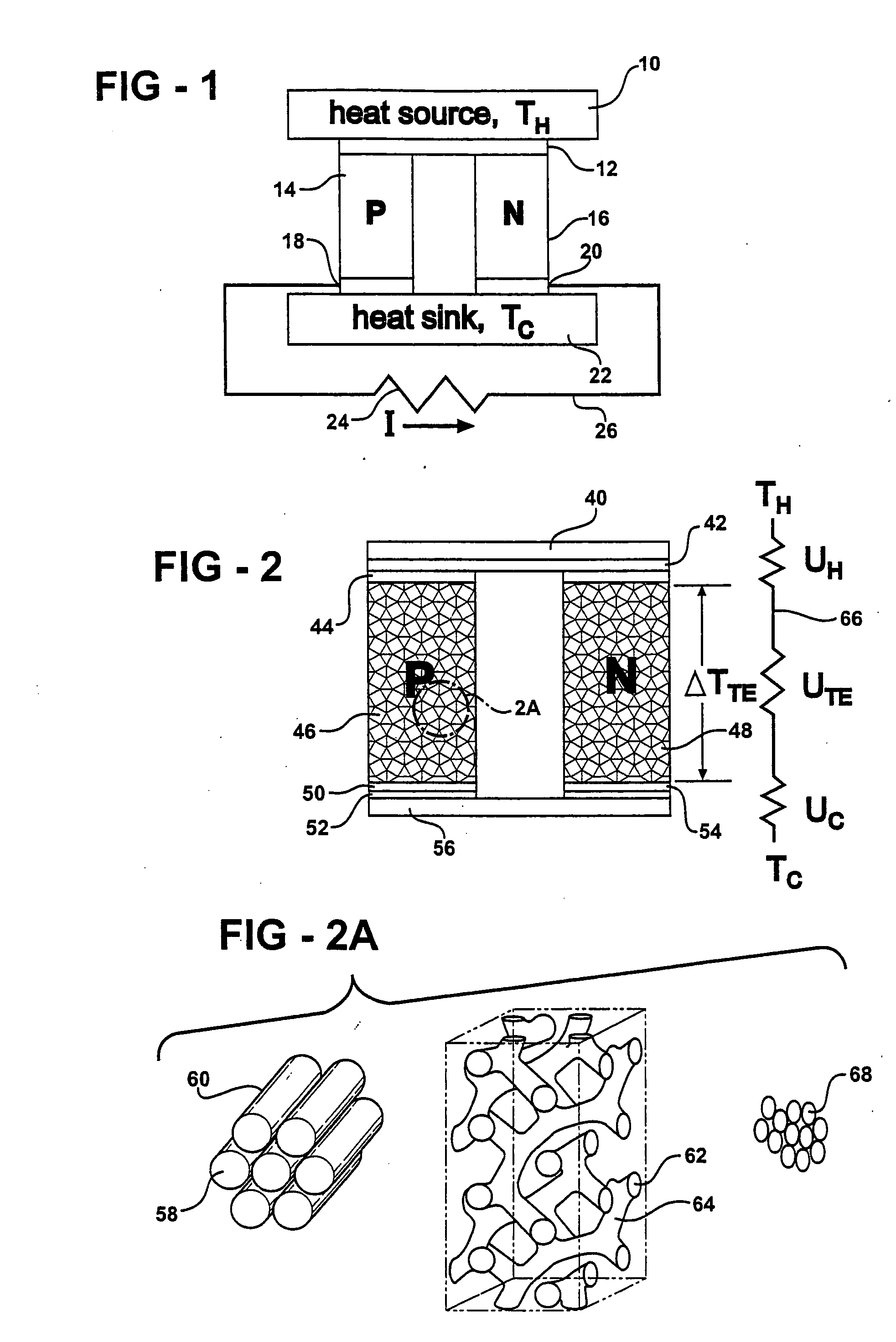

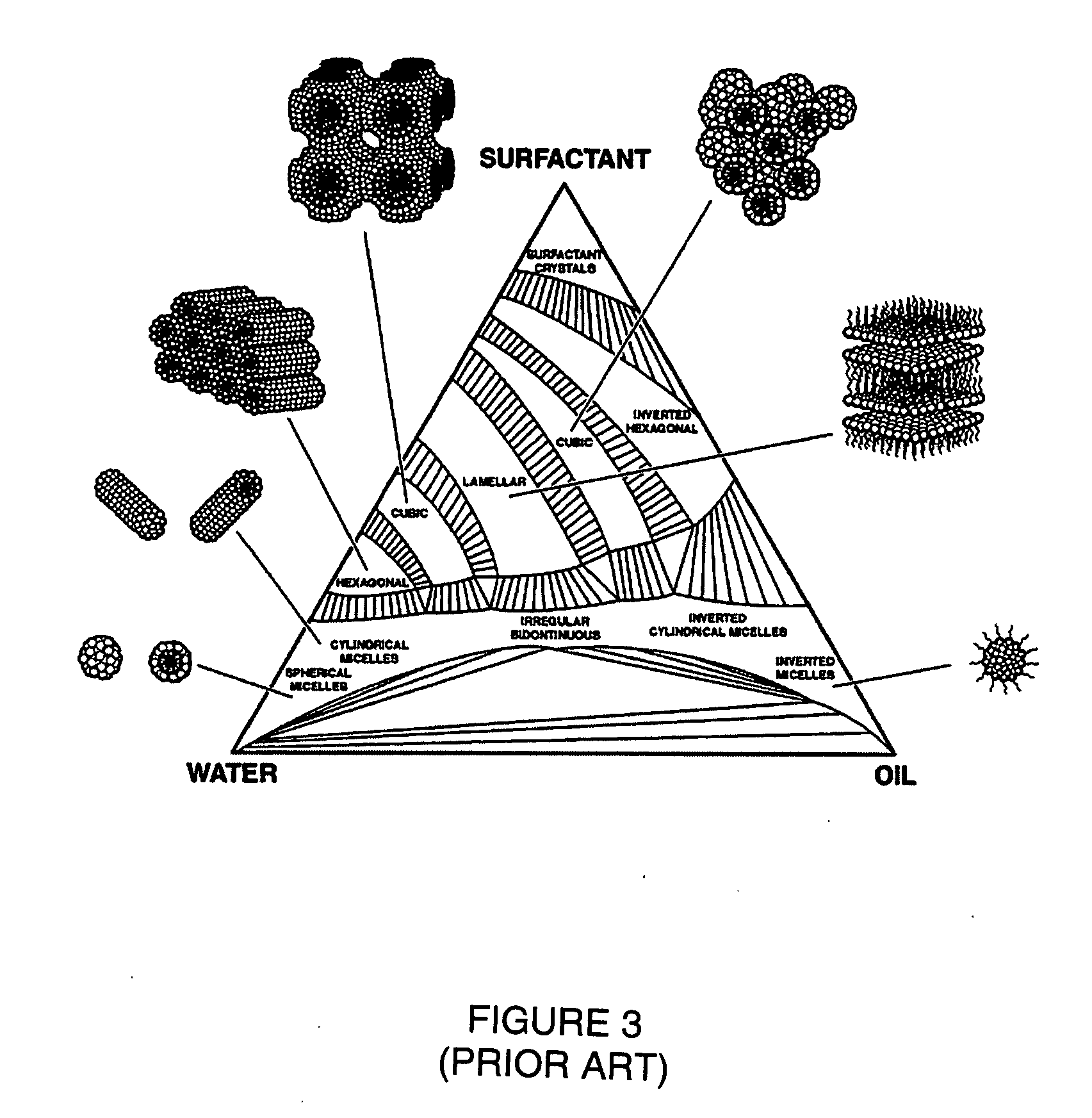

Nanostructured bulk thermoelectric material

ActiveUS20060118158A1High quality factorImprove mechanical propertiesThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsNanowire

A thermoelectric material comprises two or more components, at least one of which is a thermoelectric material. The first component is nanostructured, for example as an electrically conducting nanostructured network, and can include nanowires, nanoparticles, or other nanostructures of the first component. The second component may comprise an electrical insulator, such as an inorganic oxide, other electrical insulator, other low thermal conductivity material, voids, air-filled gaps, and the like. Additional components may be included, for example to improve mechanical properties. Quantum size effects within the nanostructured first component can advantageously modify the thermoelectric properties of the first component. In other examples, the second component may be a thermoelectric material, and additional components may be included.

Owner:TOYOTA MOTOR CO LTD +1

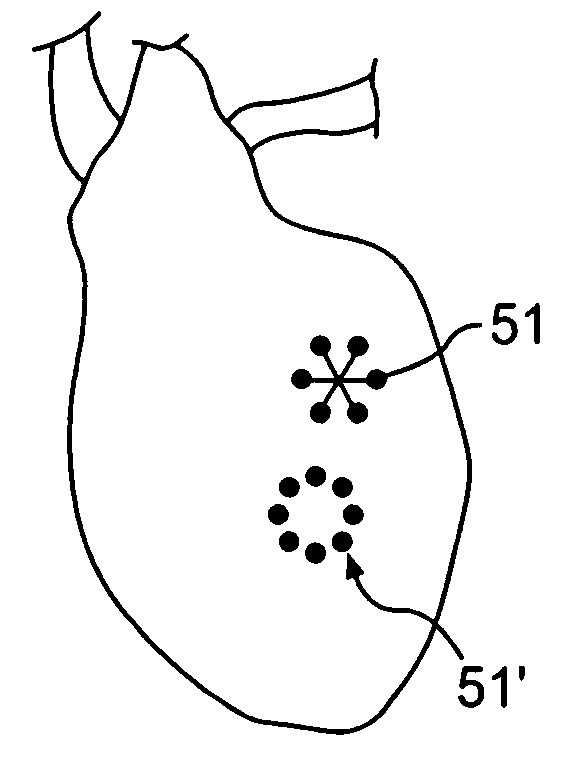

Prevention of myocardial infarction induced ventricular expansion and remodeling

ActiveUS20050080402A1Prevent further deteriorationInhibit swellingSuture equipmentsPowder deliveryCardiac muscleTherapeutic treatment

A method for direct therapeutic treatment of myocardial tissue in a localized region of a heart having a pathological condition. The method includes identifying a target region of the myocardium and applying material directly and substantially only to at least a portion of the myocardial tissue of the target region. The material applied results in a physically modification the mechanical properties, including stiffness, of said tissue. Various devices and modes of practicing the method are disclosed for stiffening, restraining and constraining myocardial tissue for the treatment of conditions including myocardial infarction or mitral valve regurgitation.

Owner:MYOMEND

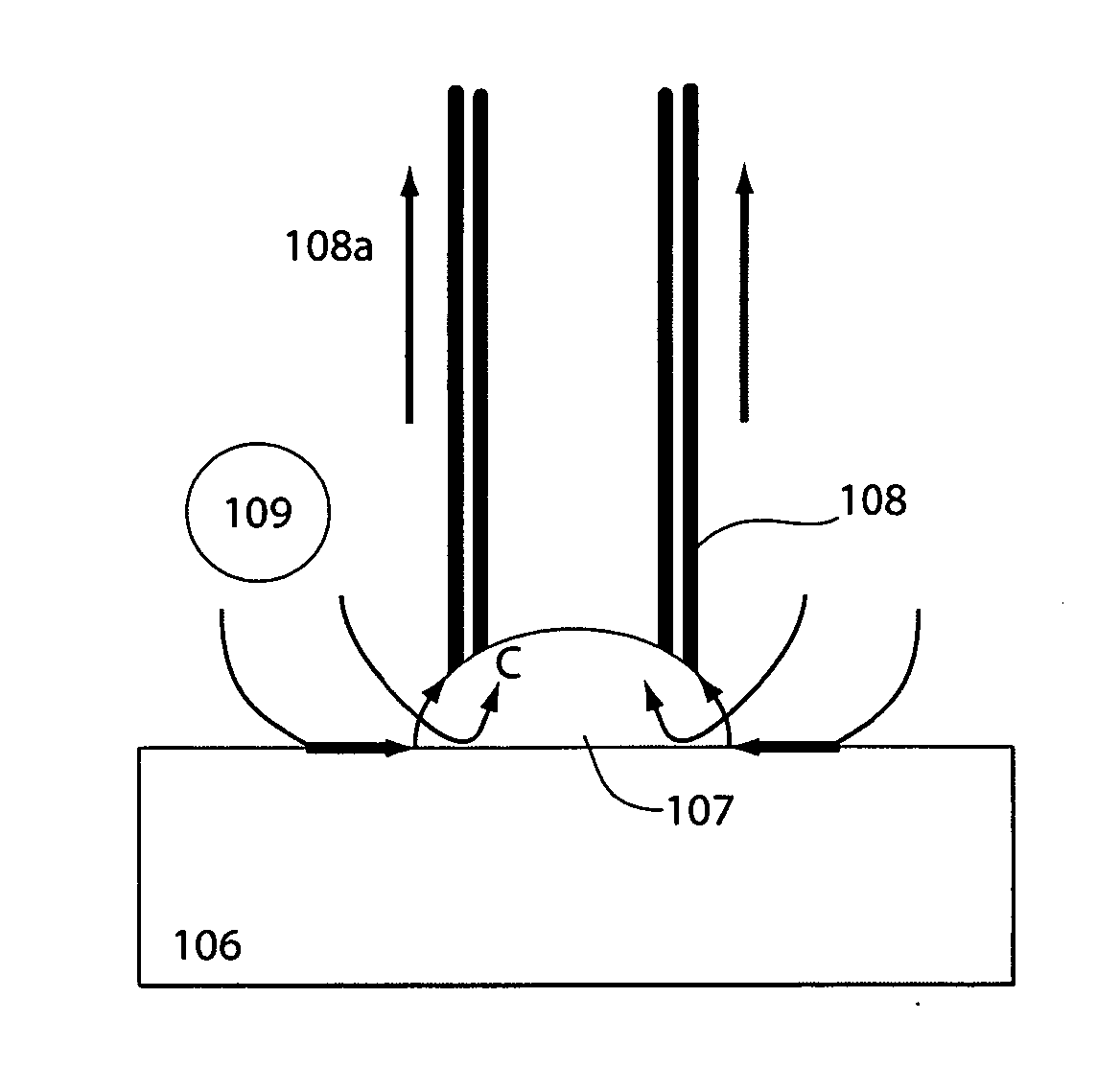

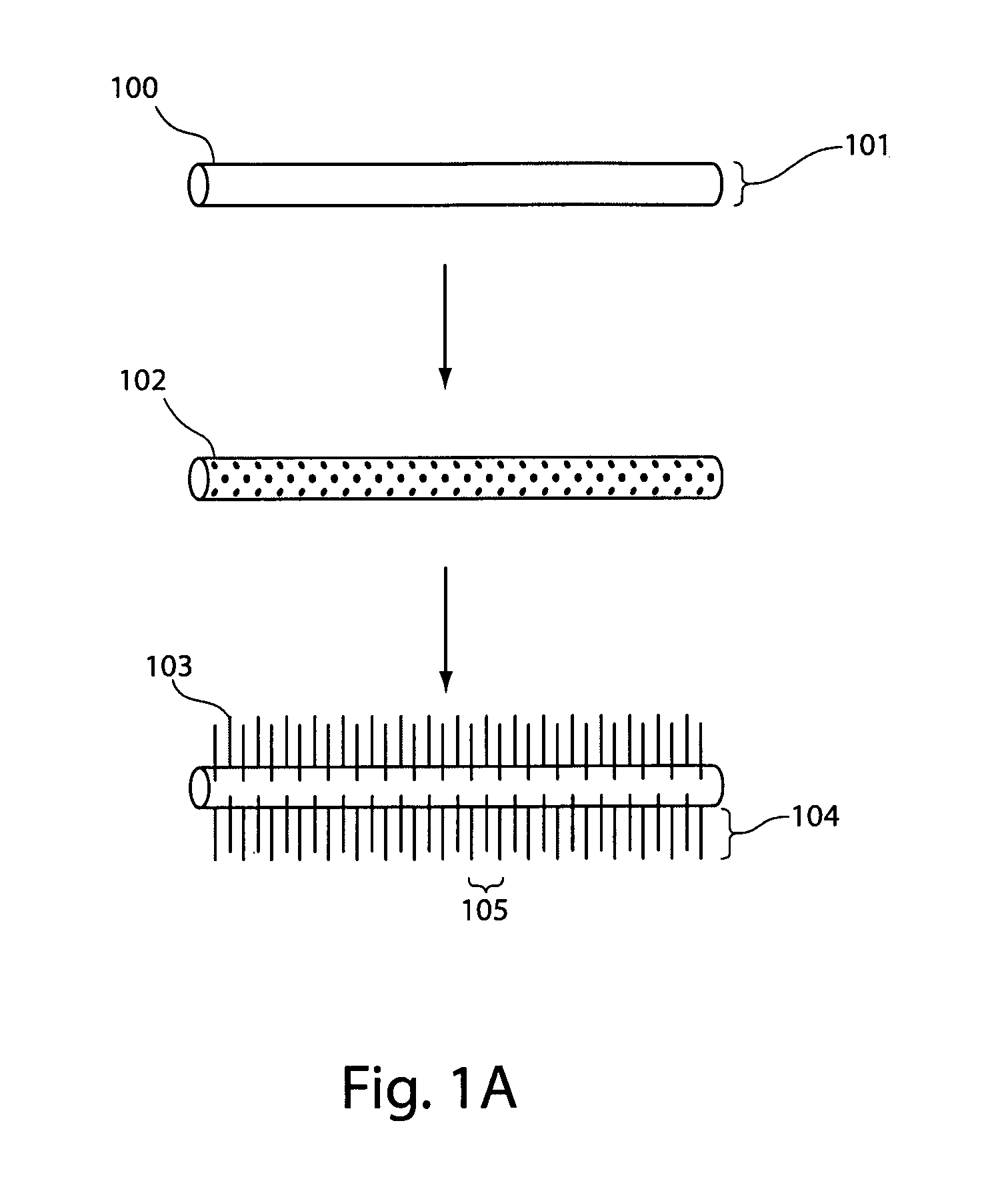

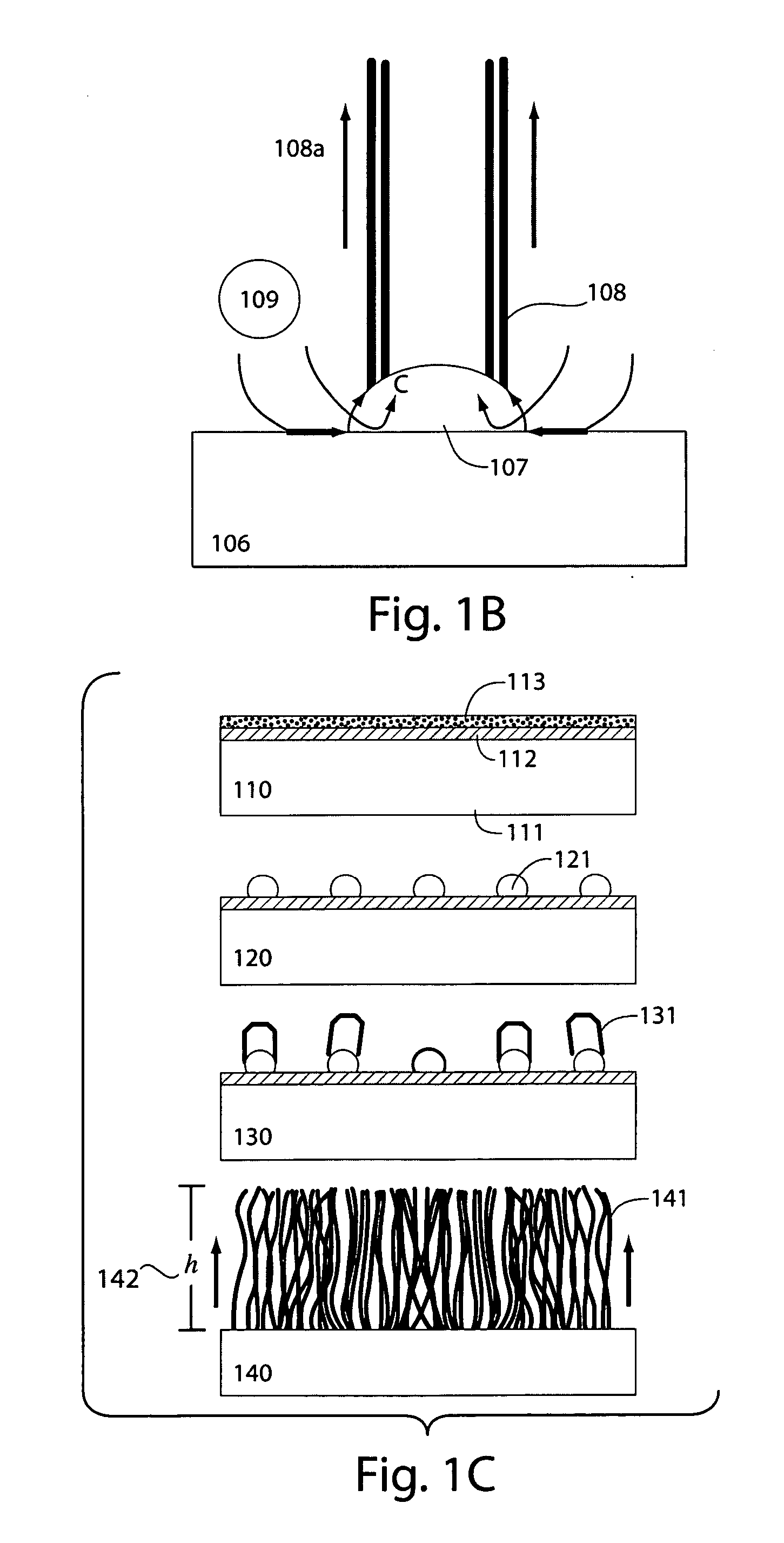

Nanostructure-reinforced composite articles and methods

ActiveUS20080075954A1Material nanotechnologyIndividual molecule manipulationElectronic propertiesNanostructure

The present invention provides methods for uniform growth of nanostructures such as nanotubes (e.g., carbon nanotubes) on the surface of a substrate, wherein the long axes of the nanostructures may be substantially aligned. The nanostructures may be further processed for use in various applications, such as composite materials. For example, a set of aligned nanostructures may be formed and transferred, either in bulk or to another surface, to another material to enhance the properties of the material. In some cases, the nanostructures may enhance the mechanical properties of a material, for example, providing mechanical reinforcement at an interface between two materials or plies. In some cases, the nanostructures may enhance thermal and / or electronic properties of a material. The present invention also provides systems and methods for growth of nanostructures, including batch processes and continuous processes.

Owner:MASSACHUSETTS INST OF TECH

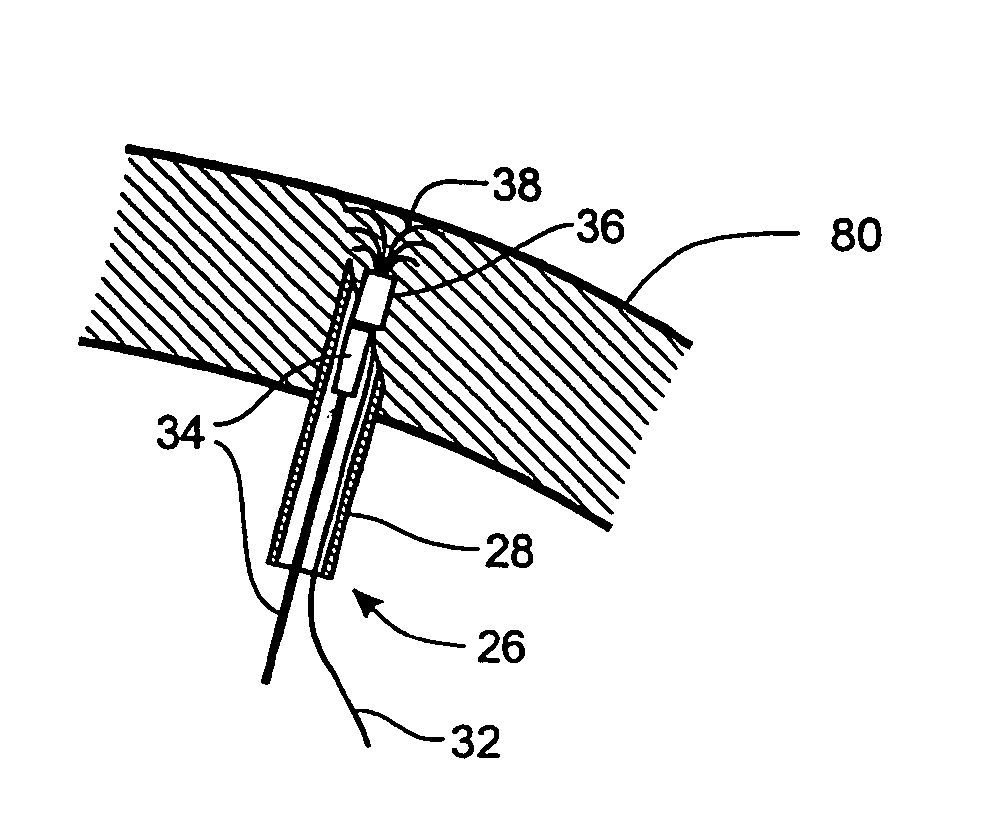

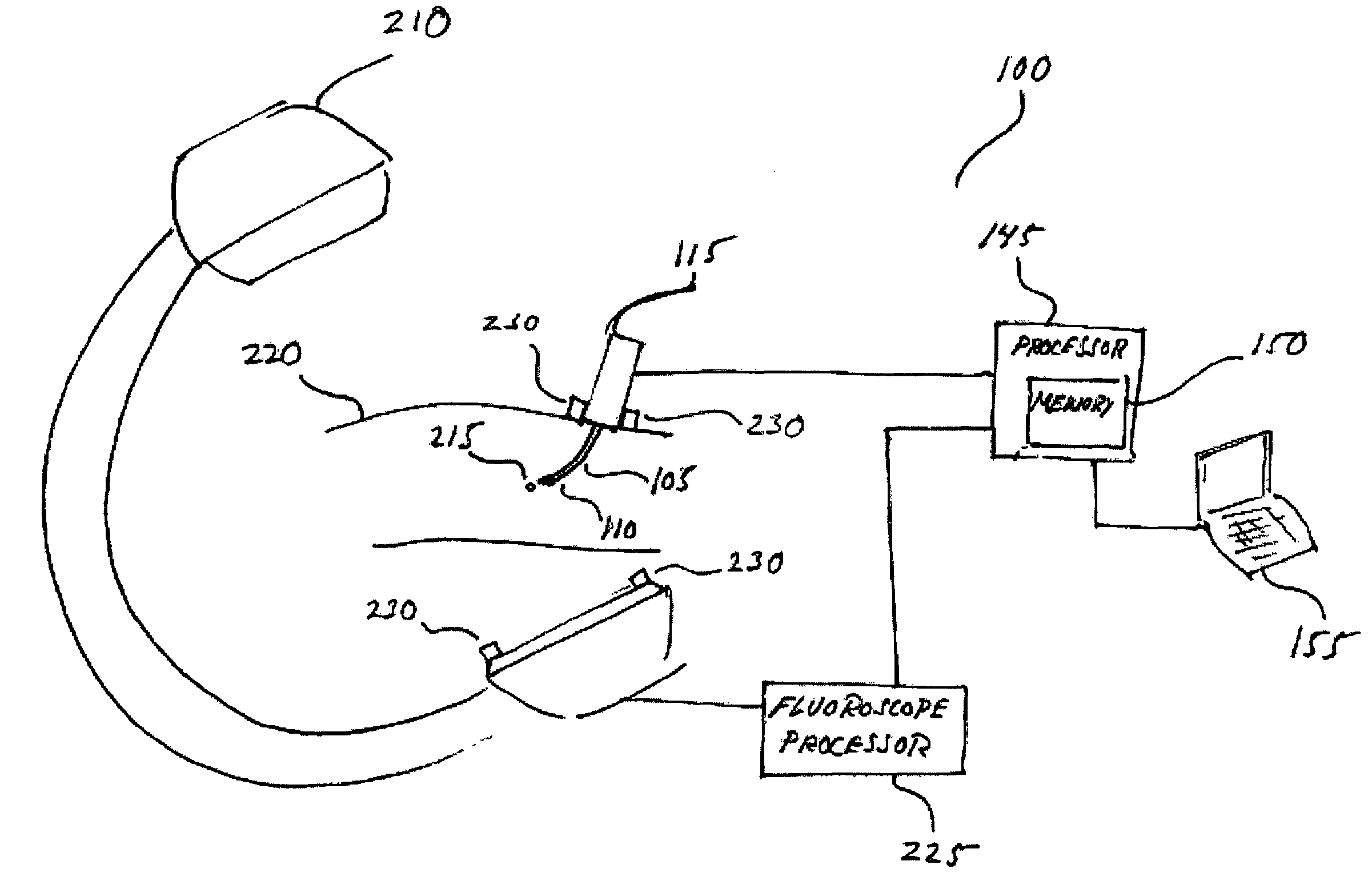

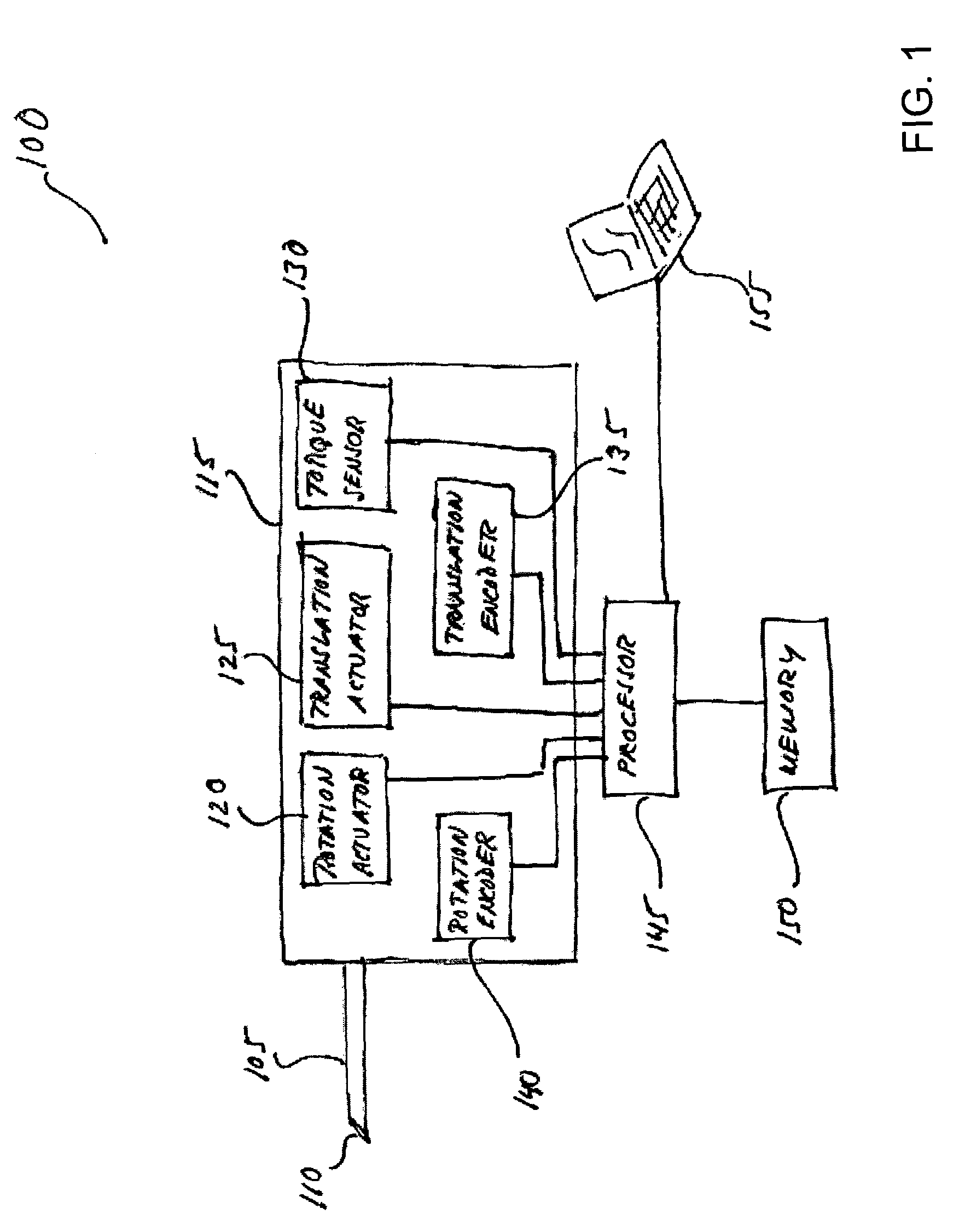

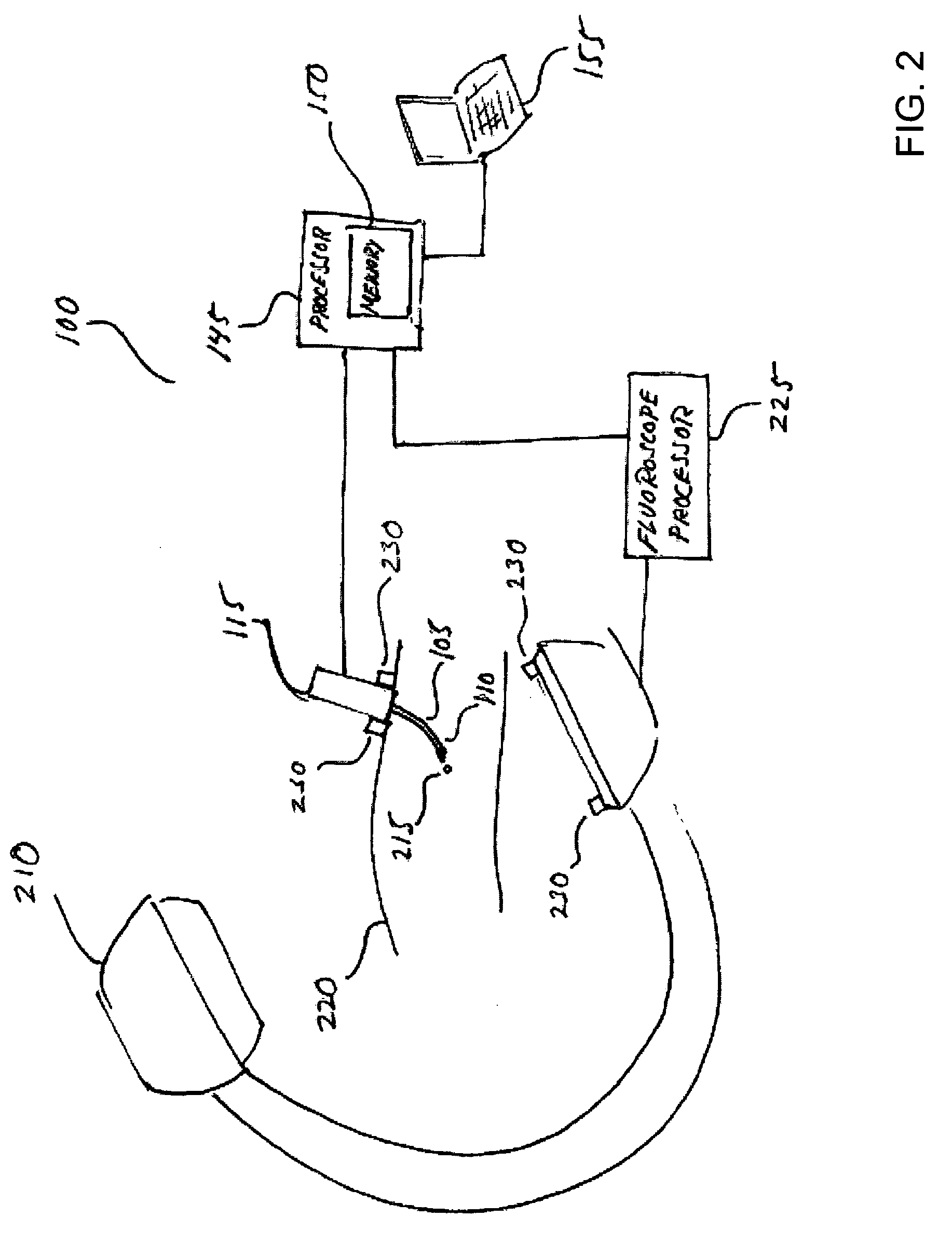

Distal bevel-tip needle control device and algorithm

ActiveUS7822458B2Improve accuracy and precisionReduce complicationsUltrasonic/sonic/infrasonic diagnosticsSurgical needlesNeedle steeringMechanical property

Disclosed is a system for percutaneously steering a surgical needle. Needle steering is accomplished by taking advantage of a deflection force imparted on the bevel tip of the needle by the tissue medium as the needle is pushed through the tissue. By controlling the translation speed and rotation angle of the bevel, a flexible needle may be steered substantially without deflecting or distorting the tissue. The control inputs (translation speed and rotation angle) are computed based on a “bicycle” non-holonomic kinematic model that is a function of mechanical properties of the tissue medium. The system may be used with image-based feedback, which may provide for feedback-based refinement of the model as the needle propagates through the tissue.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Orthopedic implant and method of making metal articles

The present application is directed to an orthopedic implant. More specifically, the orthopedic implant is suitable for arthroplasty procedures where optimized multifunctional behavior of the implant is desired. In some embodiments the implant is suitable for the replacement of a spinal disc. In one embodiment, the present application is directed to an orthopedic implant including a first plate a second plate and a flexible support. The flexible support may have a single connection to the first plate and a single connection to the second plate and may vary in cross section. The first plate, the second plate and the flexible support may be unitarily formed. This application is also directed to methods of producing metal articles having microstructure for improved mechanical properties. Such methods may be suitable for the production of medical devices. In one embodiment, the method includes directing a stream including a particulate material in a pattern corresponding to at least a portion of a structure of an orthopedic implant and fusing at least a portion of the particulate material with a laser.

Owner:DEPUY ACROMED INC

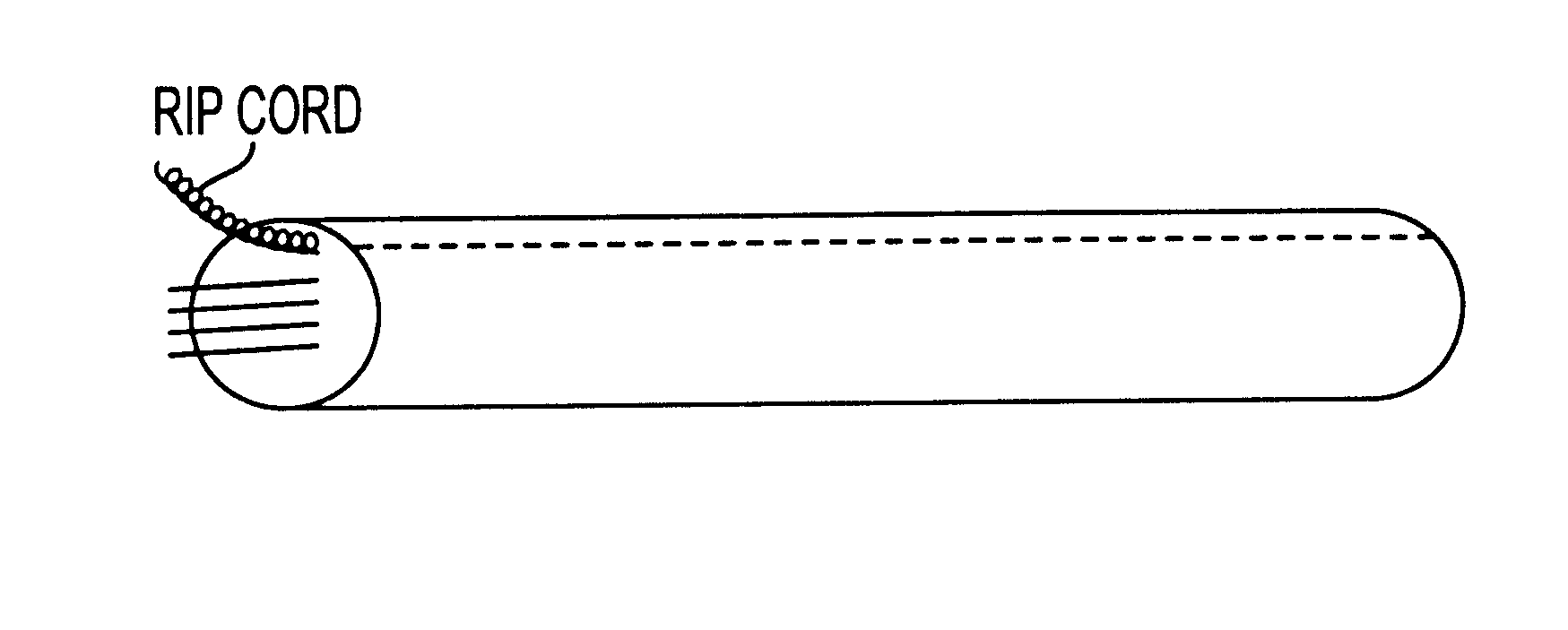

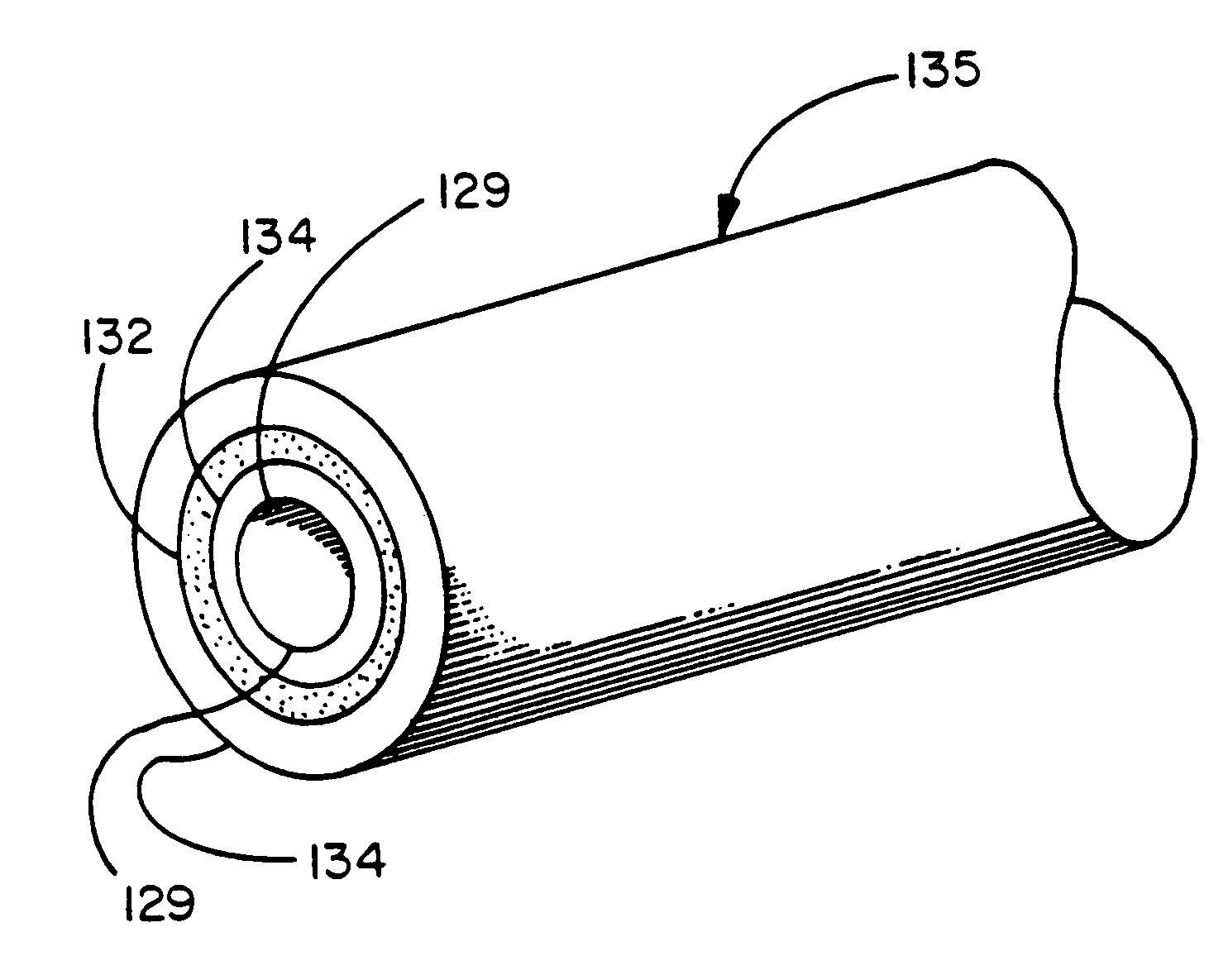

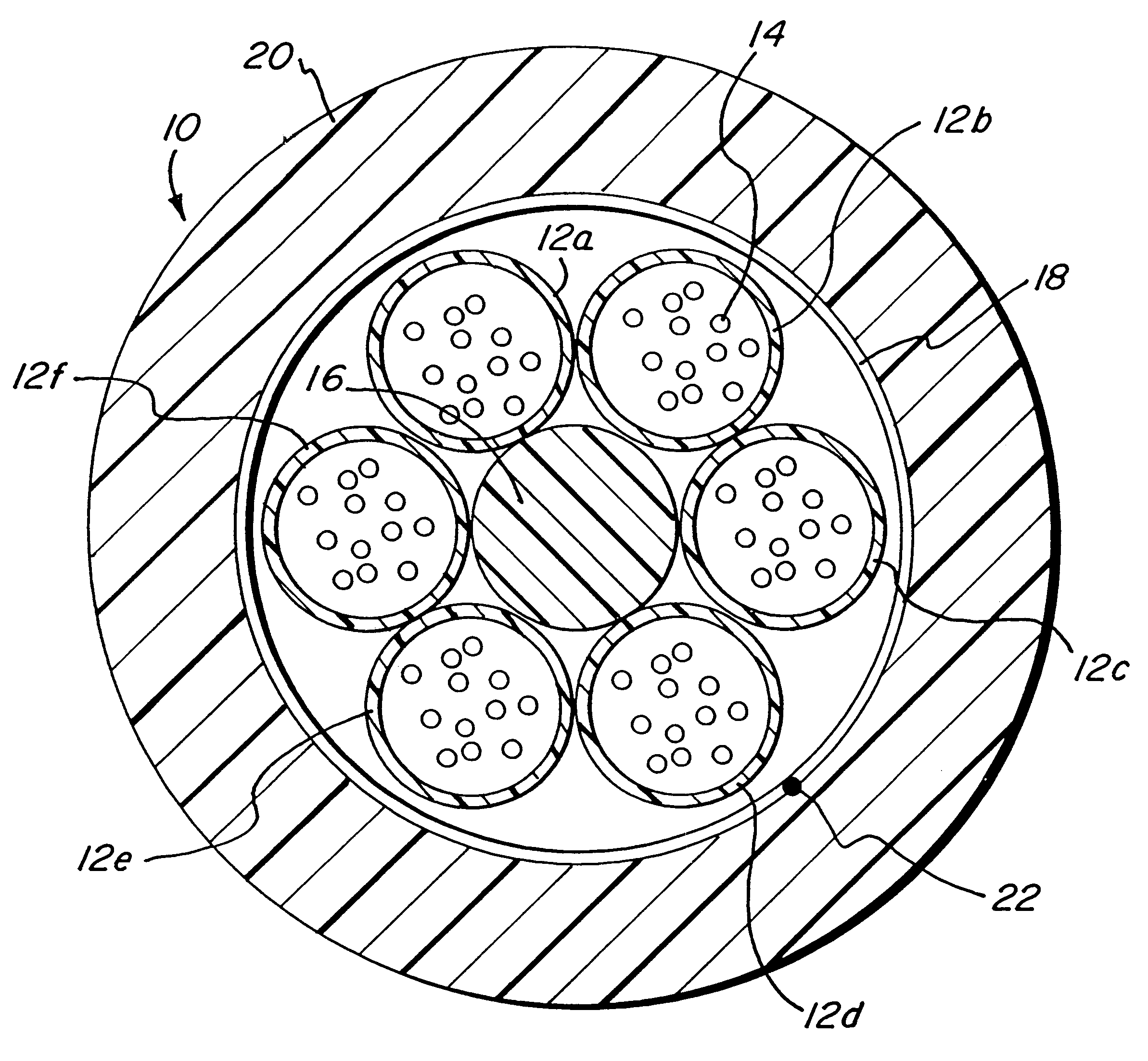

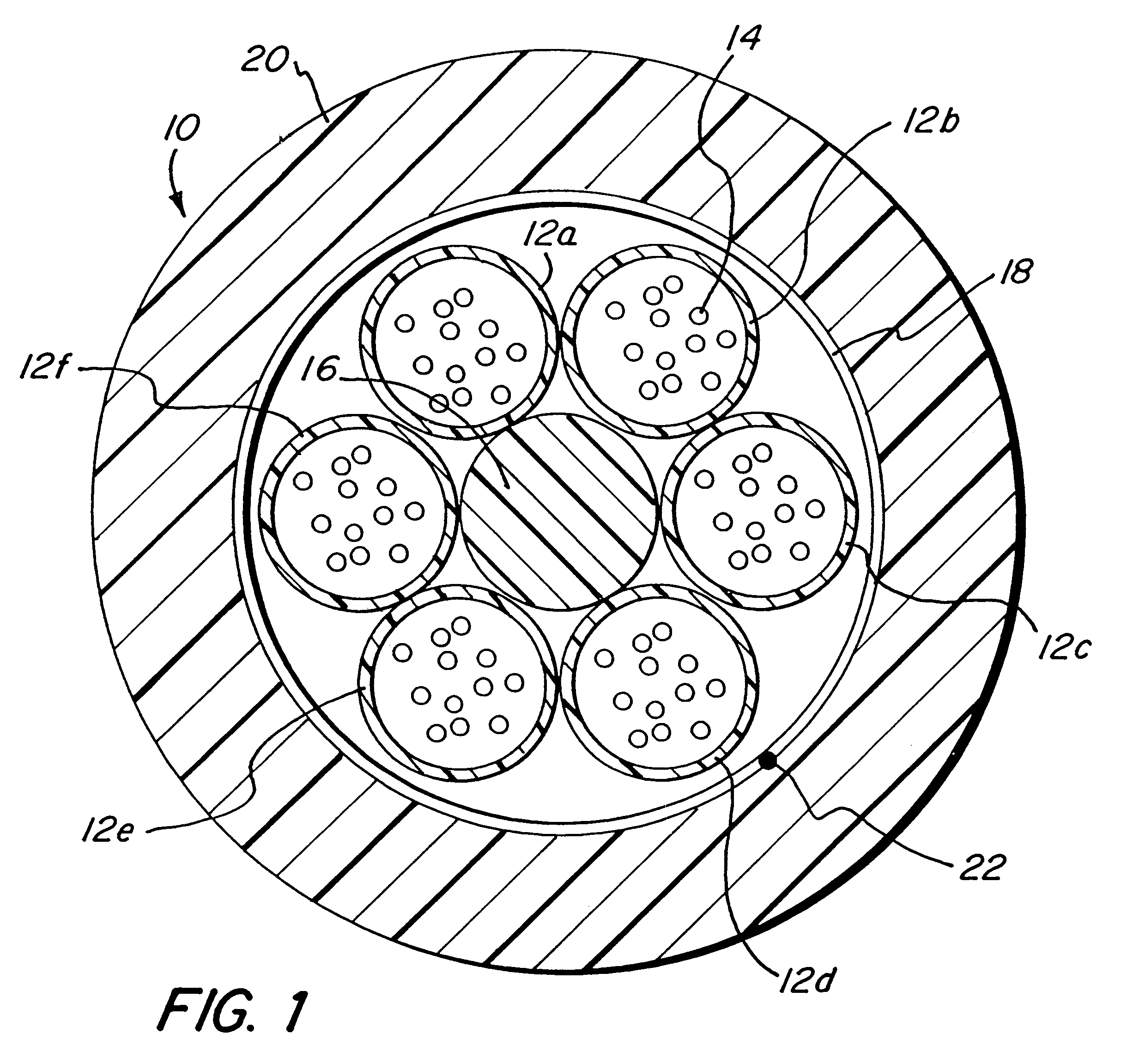

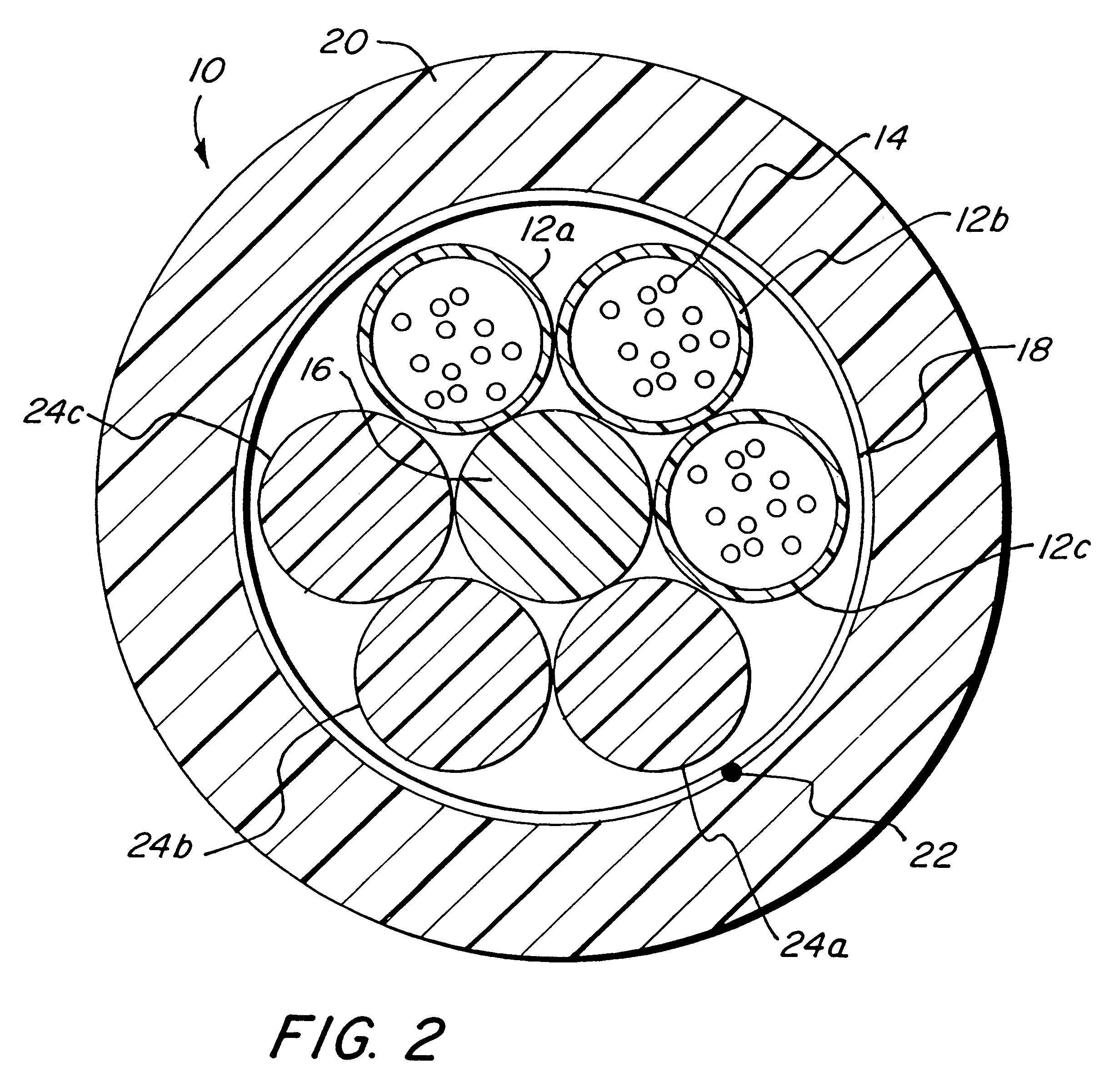

Buffer tube that results in easy access to and low attenuation of fibers disposed within buffer tube

A buffer tube design that allows easy access to signal carrying fibers disposed within the buffer tube with risk of damaging the signal carrying fibers. The buffer tube can be made with a ripcord disposed within. Additionally, the buffer tube has the mechanical properties that allow the ripcord to be pulled through the tube wall with less energy than is required to bend the signal carrying fibers within. The buffer tube can also be designed without a ripcord in such a way that the mechanical properties allow the tube to be hand torn using a lower amount of energy than required to bend the signal carrying fibers within.

Owner:ALCATEL LUCENT SAS

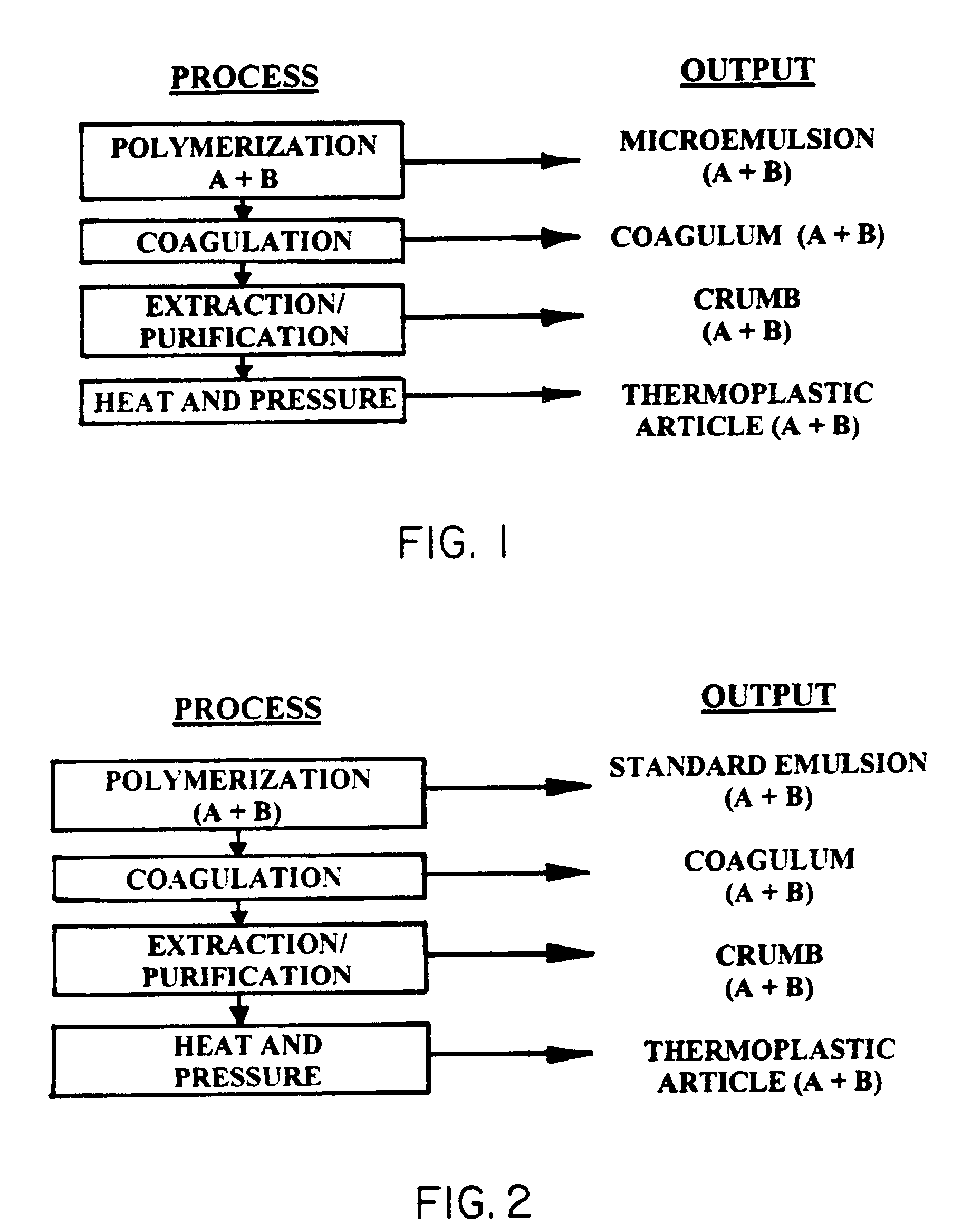

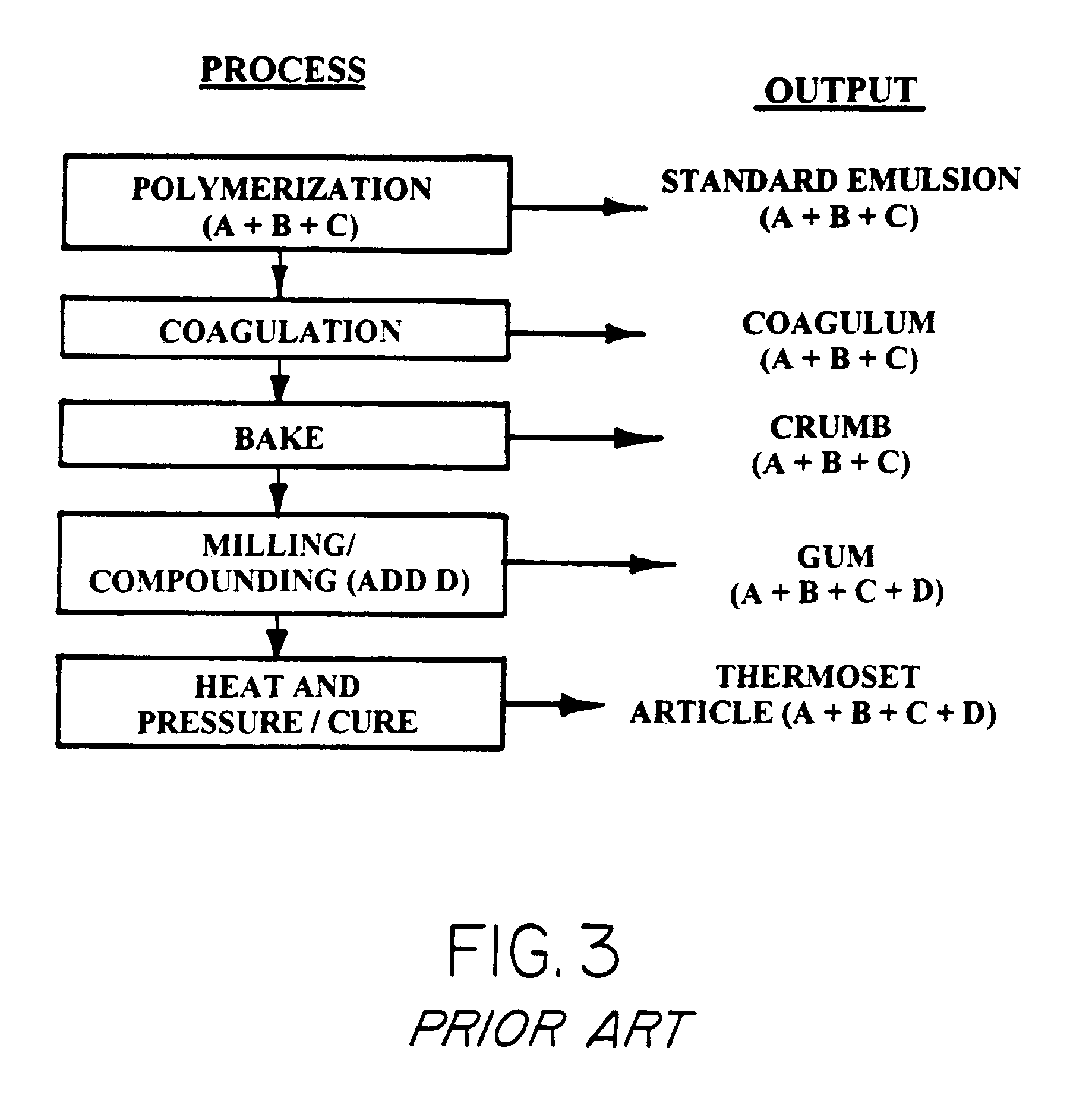

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

Thermoplastic Elastomer Composition, Method for Producing Same and Formed Article

The invention provides a thermoplastic elastomer composition having mechanical properties equivalent or superior to those of conventional thermoplastic elastomer compositions and having excellent heat resistance and oil resistance and a preparation process thereof, and molded or formed products making use of this thermoplastic elastomer composition. The thermoplastic elastomer composition according to the present invention contains a thermoplastic resin having a polar group and an ethylene•α-olefin elastomer having a functional group. The ethylene•α-olefin elastomer having the functional group is preferably a random copolymer obtained by copolymerizing ethylene, an α-olefin having 3 to 10 carbon atoms, an unsaturated monomer having the functional group and an optional non-conjugated diene.

Owner:JSR CORPORATIOON

Precursors and flowable CVD methods for making low-K films to fill surface features

A method for depositing a silicon-containing film, the method comprising: placing a substrate comprising at least one surface feature into a flowable CVD reactor which is at a temperature of from about −20° C. to about 400° C.; introducing into the reactor at least one silicon-containing compound having at least one acetoxy group to at least partially react the at least one silicon-containing compound to form a flowable liquid oligomer wherein the flowable liquid oligomer forms a silicon oxide coating on the substrate and at least partially fills at least a portion of the at least one surface feature. Once cured, the silicon oxide coating has a low k and excellent mechanical properties.

Owner:VERSUM MATERIALS US LLC

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

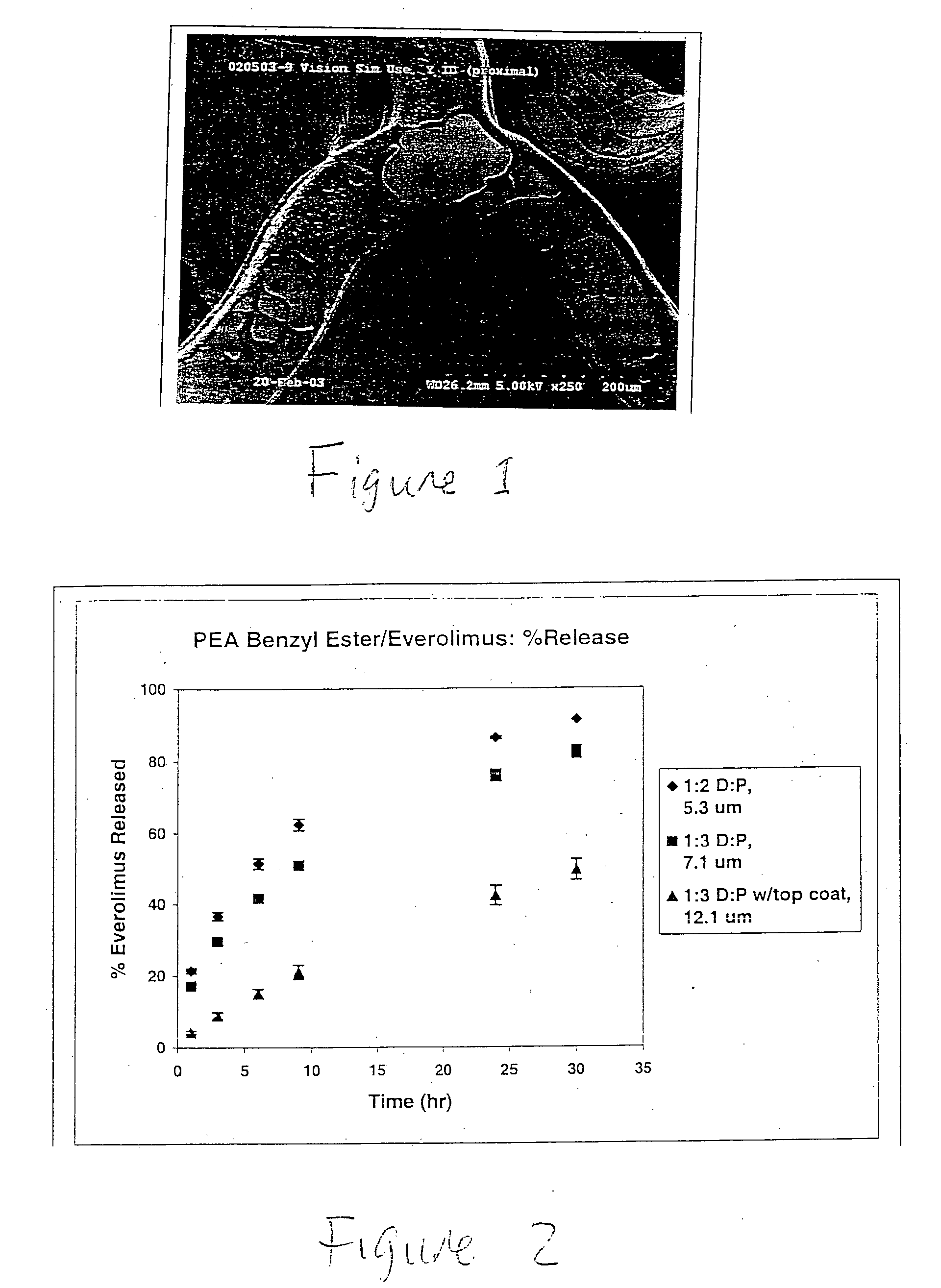

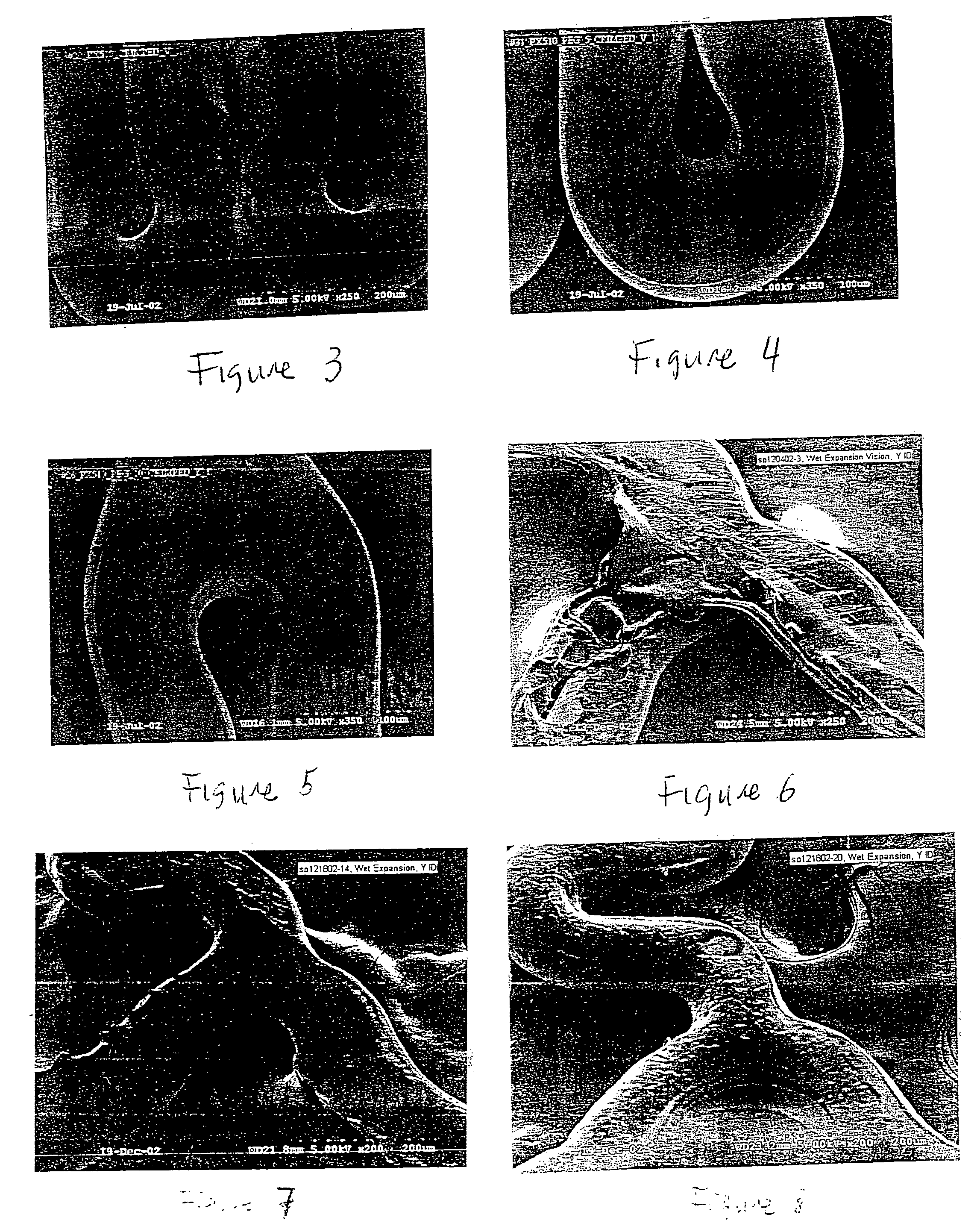

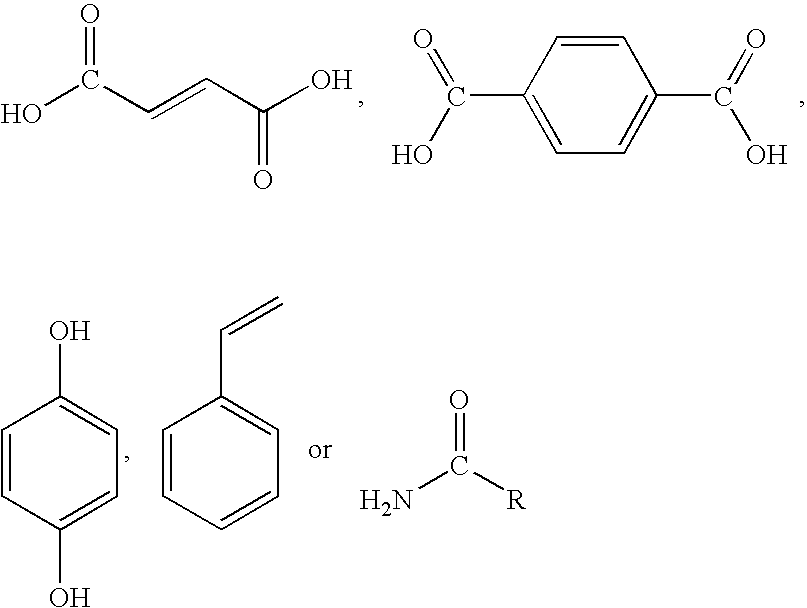

Methods for modulating thermal and mechanical properties of coatings on implantable devices

InactiveUS20050245637A1Narrow molecular weight distributionHigh molecular weightStentsSurgical adhesivesVulnerable plaquePercent Diameter Stenosis

Methods for modulating and enhancing thermal and mechanical properties and biocompatibilities of coatings on implantable devices are disclosed. Implantable devices containing the enhanced thermal and mechanical properties and biocompatibilities are also described. The implantable devices can be used to treat a medical condition such as vulnerable plaque or restenosis.

Owner:ABBOTT CARDIOVASCULAR

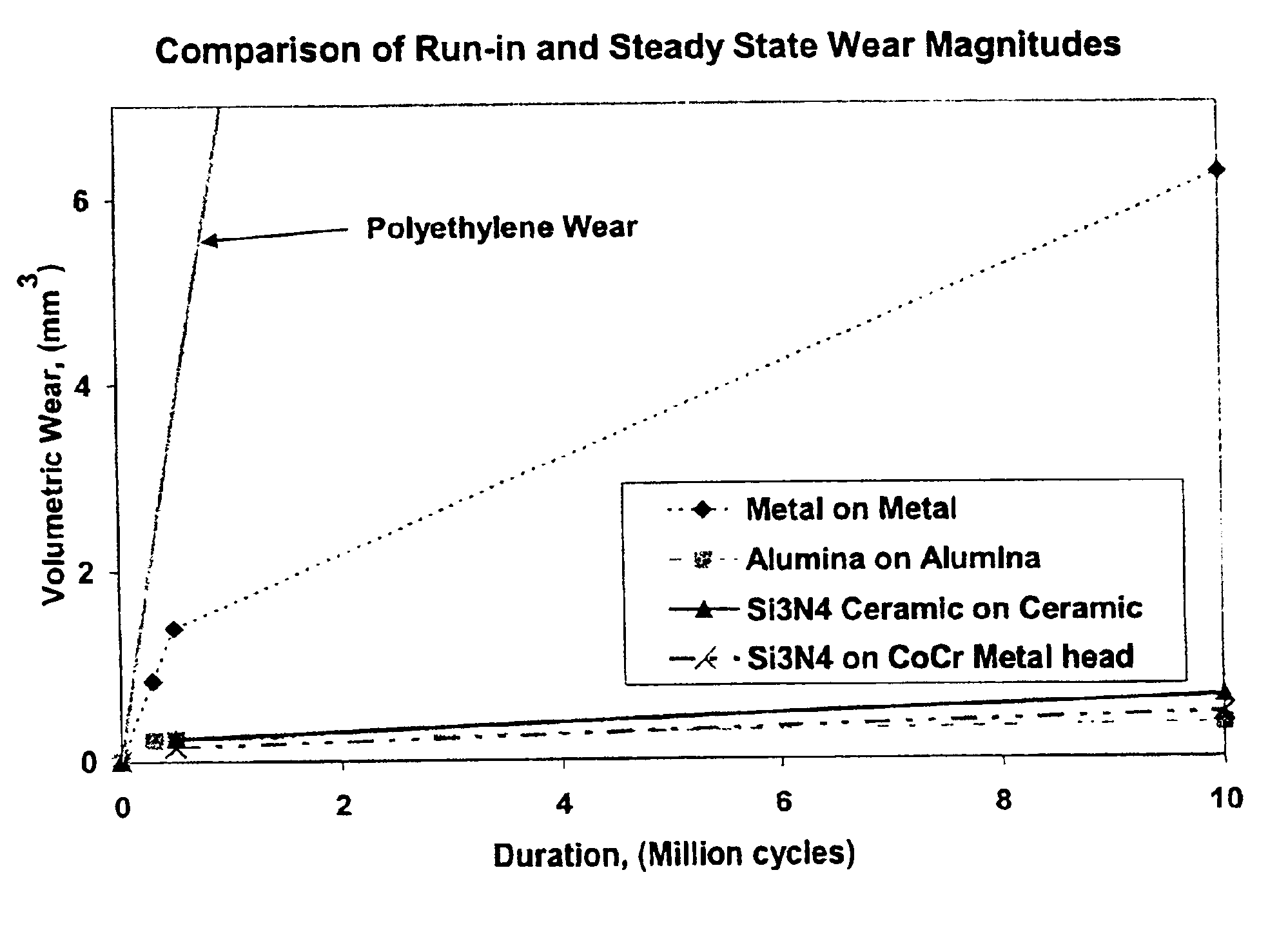

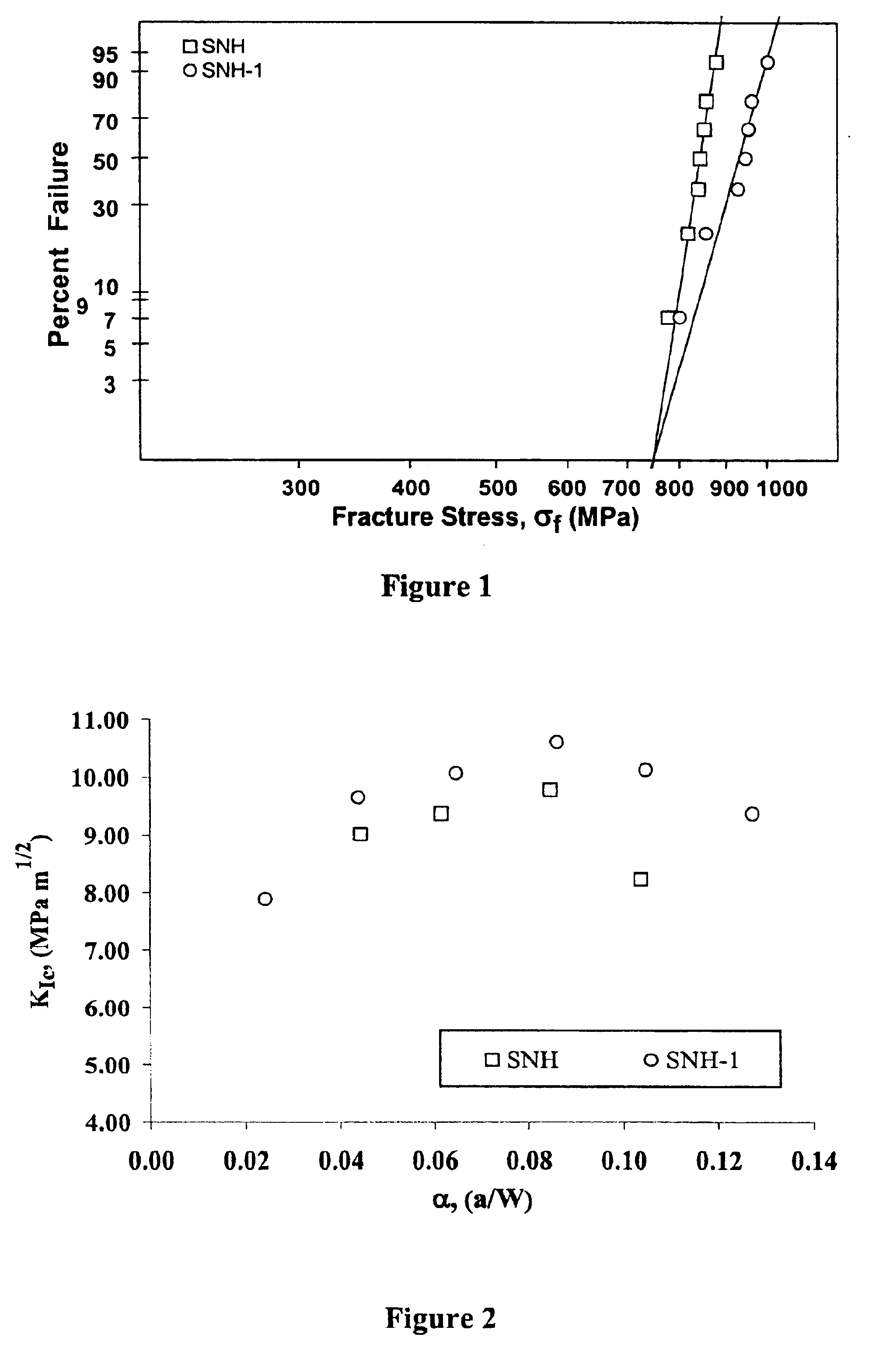

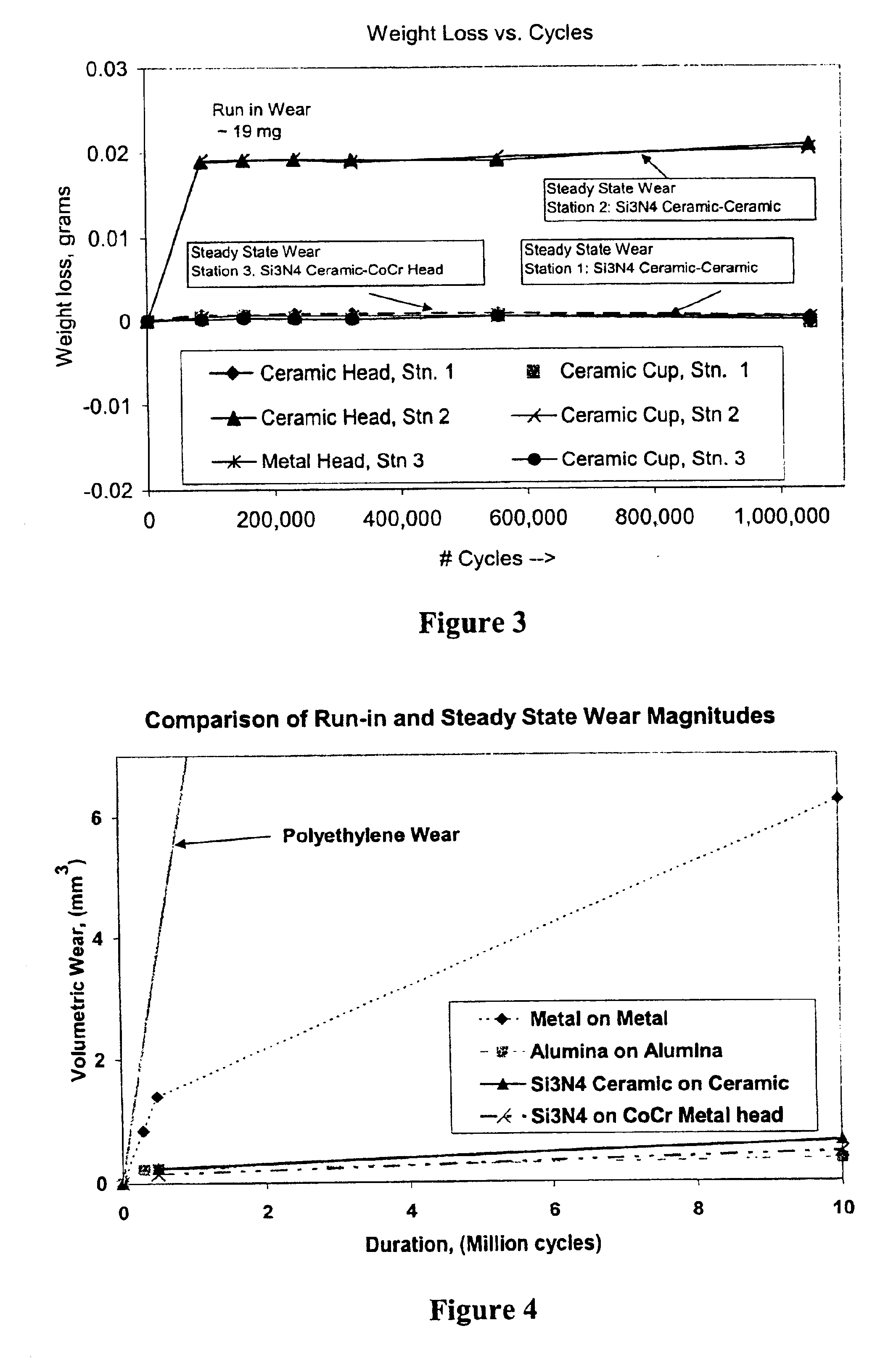

Metal-ceramic composite articulation

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

Flame retardant laser direct structuring materials

Flame retardant thermoplastic compositions that are capable of being used in a laser direct structuring process. The compositions include a thermoplastic resin, a laser direct structuring additive, and a flame retardant. The compositions offer flame retardant characteristics while also substantially maintaining the mechanical properties of the base thermoplastic resin, such as the impact strength and / or HDT of the composition. The compositions can be used in a variety of applications such as personal computers, notebook and portable computers, cell phone and other such communications equipment.

Owner:SHPP GLOBAL TECH BV

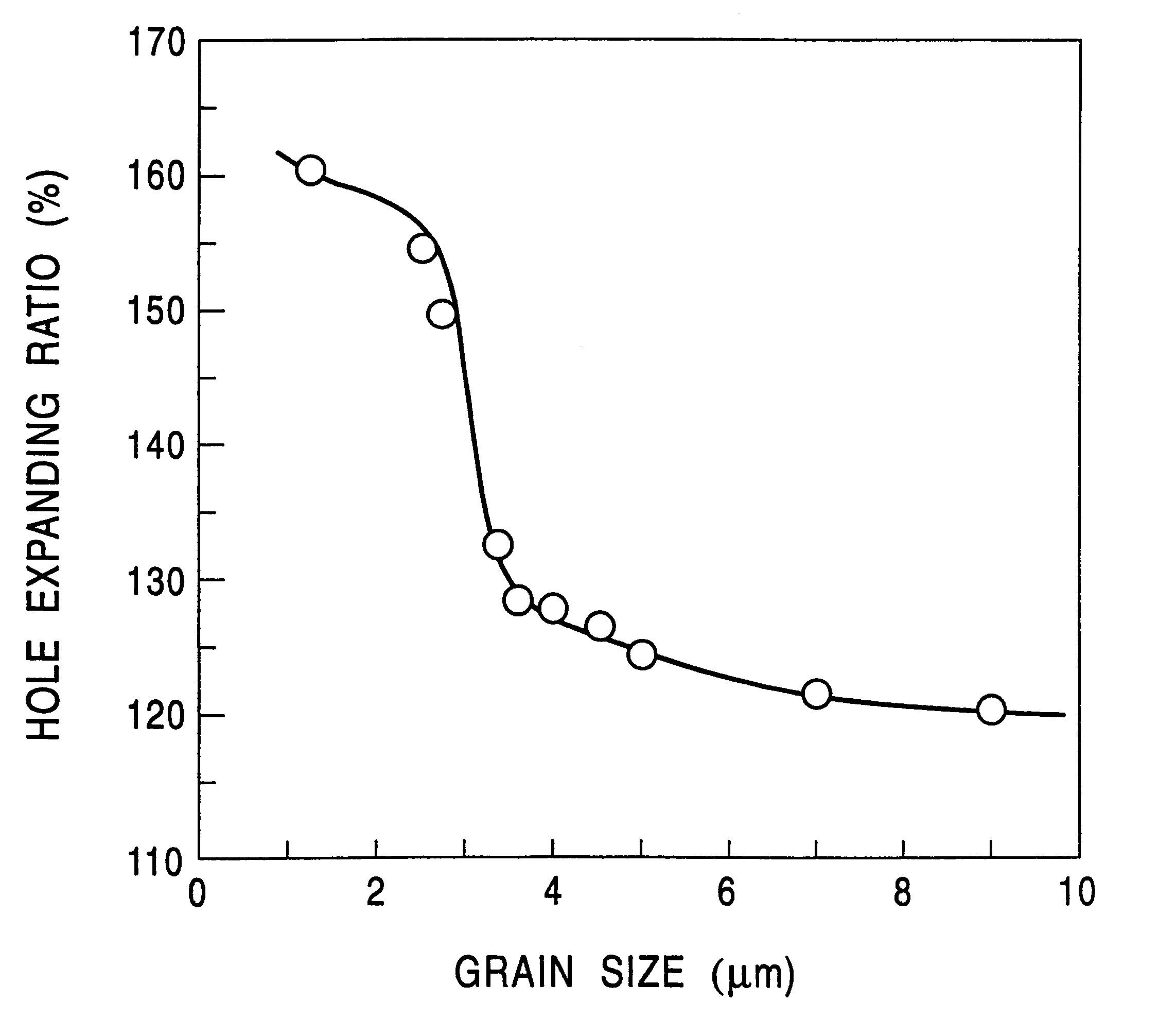

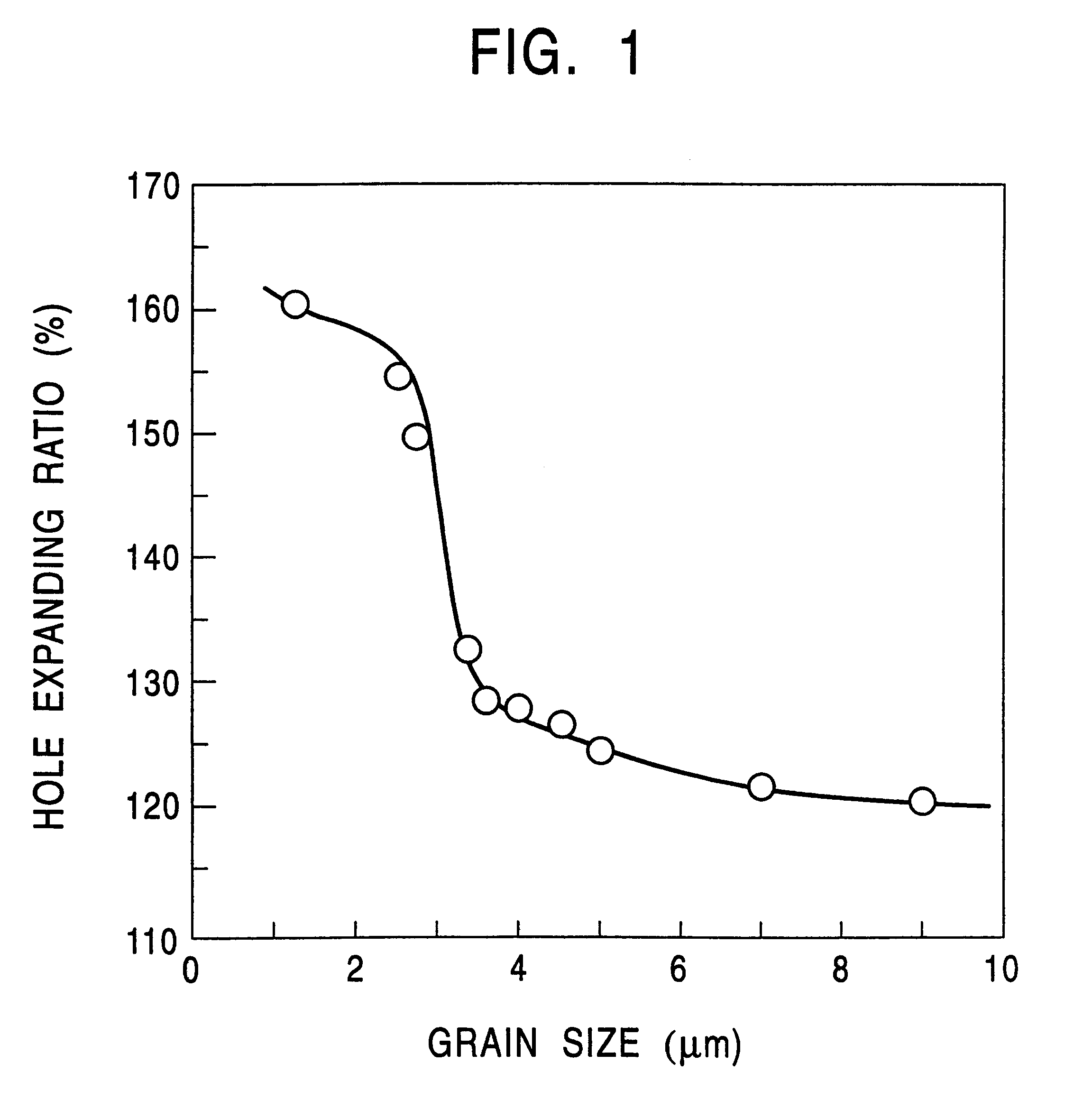

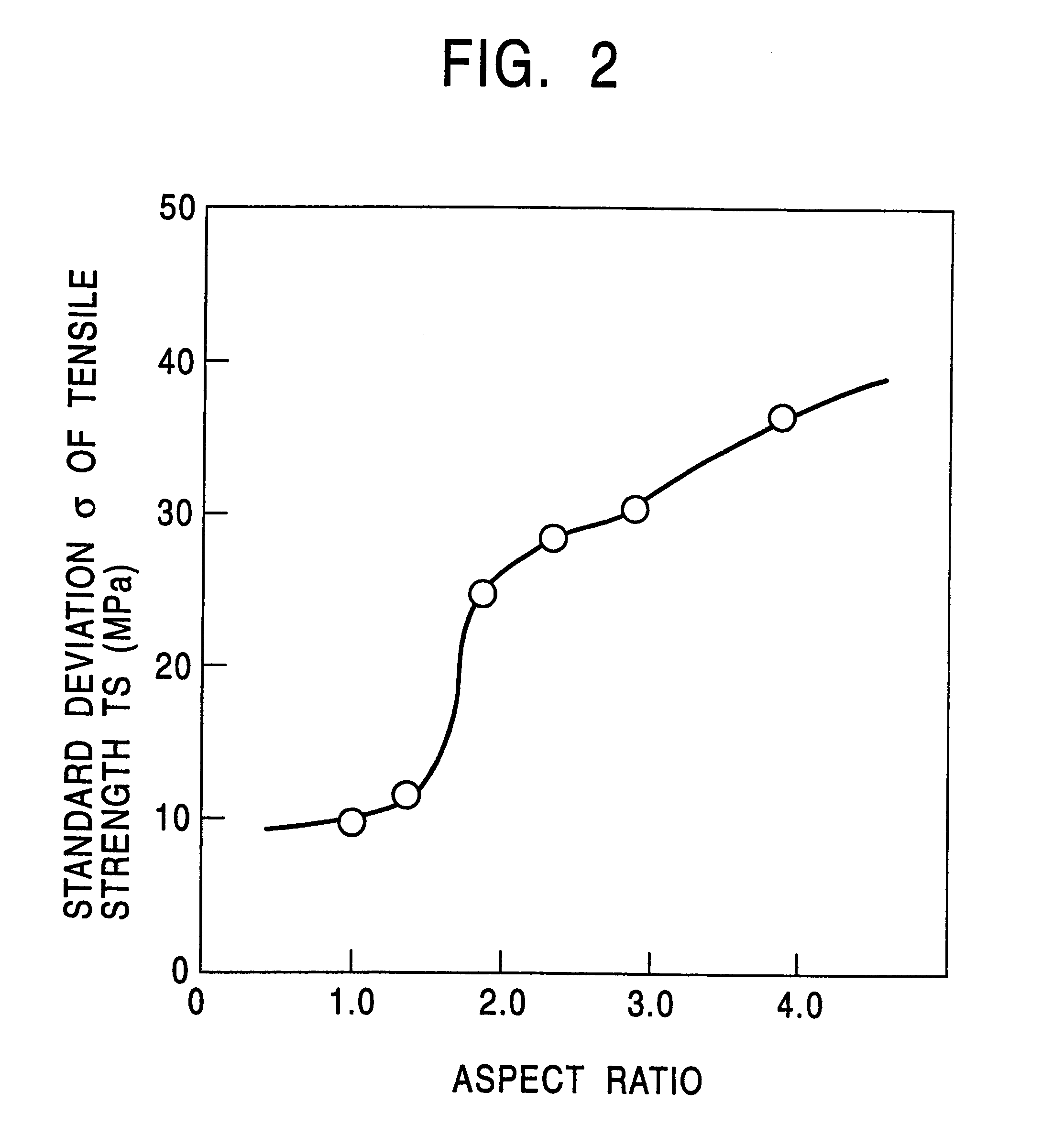

High-strength hot-rolled steel sheet having excellent stretch flangeability, and method of producing the same

InactiveUS6364968B1Easy to stretchImprove uniformityFurnace typesHeat treatment furnacesHigh intensityMechanical property

The invention provides a thin high-strength hot-rolled steel sheet with a thickness of not more than 3.5 mm which has excellent stretch flangeability and high uniformity in both shape and mechanical properties of the steel sheet, as well as a method of producing the hot-rolled steel sheet. A slab containing C: 0.05-0.30 wt %, Si: 0.03-1.0 wt %, Mn: 1.5-3.5 wt %, P: not more than 0.02 wt %, S: not more than 0.005 wt %, Al: not more than 0.150 wt %, N: not more than 0.0200 wt %, and one or two of Nb: 0.003-0.20 wt % and Ti: 0.005-0.20 wt % is heated at a temperature of not higher than 1200° C. The slab is hot-rolled at a finish rolling end temperature of not lower than 800° C., preferably at a finish rolling start temperature of 950-1050° C. A hot-rolled sheet is started to be cooled within two seconds after the end of the rolling, and then continuously cooled down to a coiling temperature at a cooling rate of 20-150° C. / sec. The hot-rolled sheet is coiled at a temperature of 300-550° C., preferably in excess of 400° C. A fine bainite structure is obtained in which the mean grain size is not greater than 3.0 mum, the aspect ratio is not more than 1.5, and preferably the maximum size of the major axis is not greater than 10 mum.

Owner:KAWASAKI STEEL CORP

Biodegradable resin compositions

InactiveUS6669771B2Increase resistanceHigh strengthCosmetic preparationsAntifouling/underwater paintsBiodegradable productDigestion

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com