Patents

Literature

396results about How to "Improve placement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

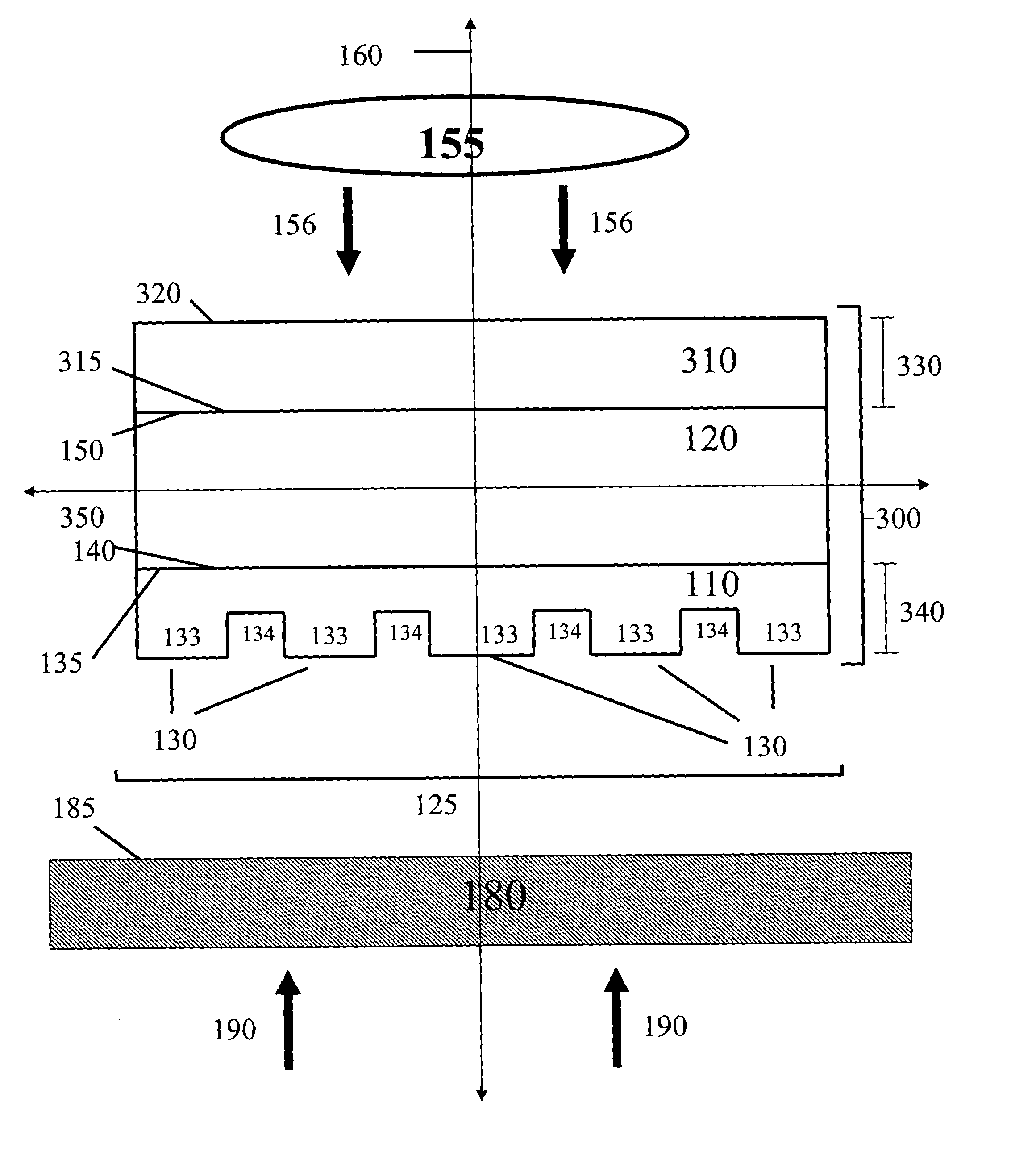

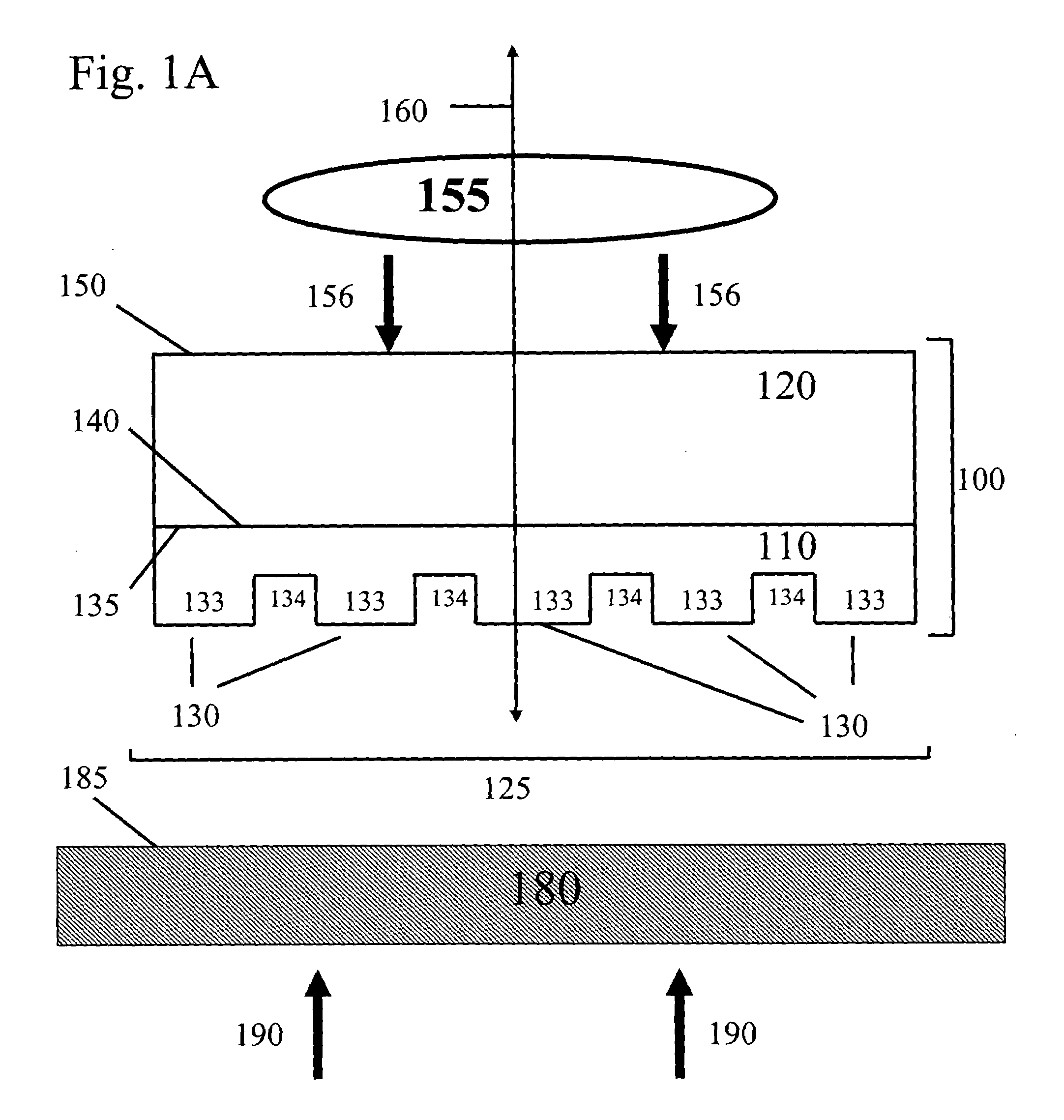

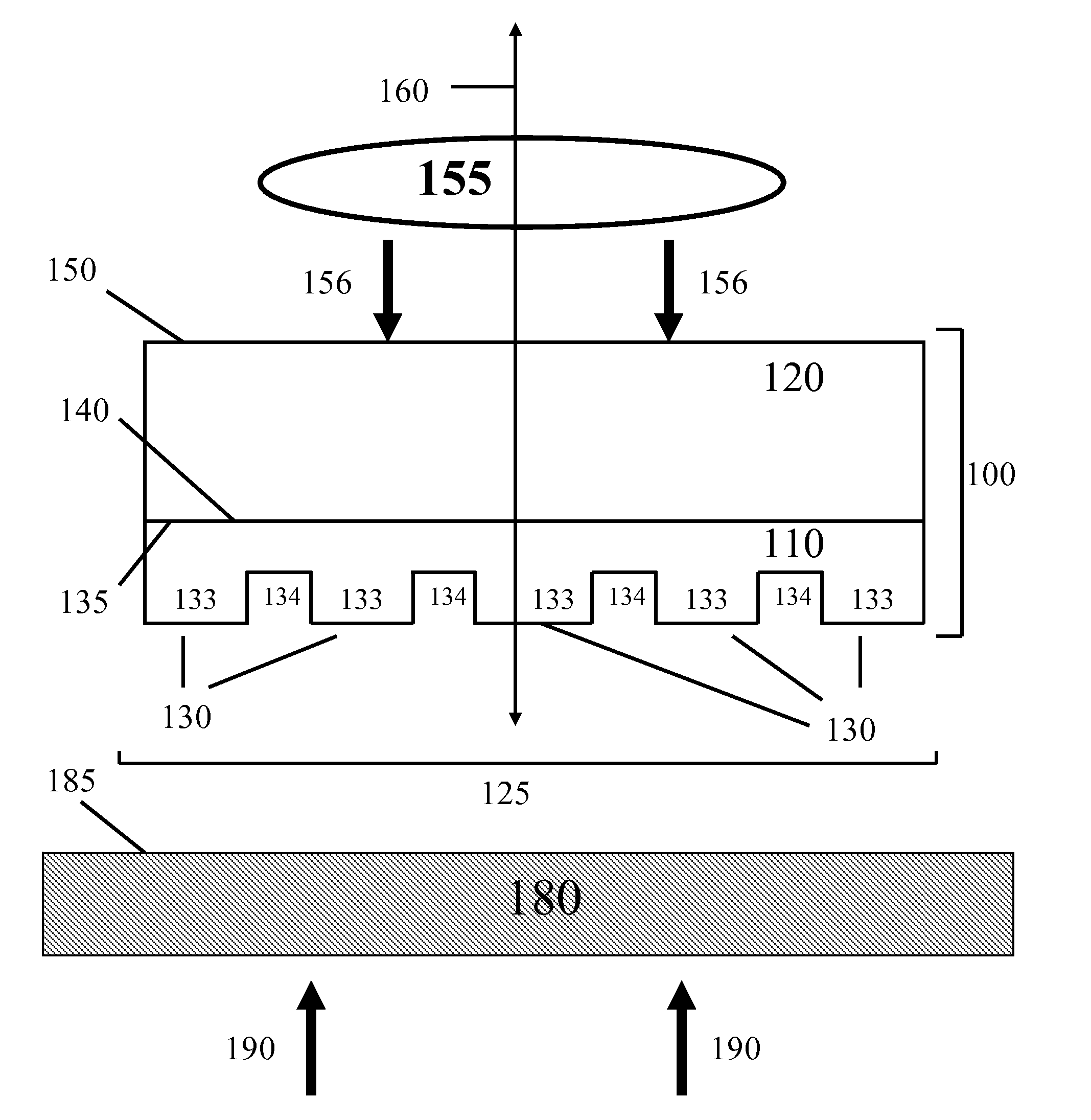

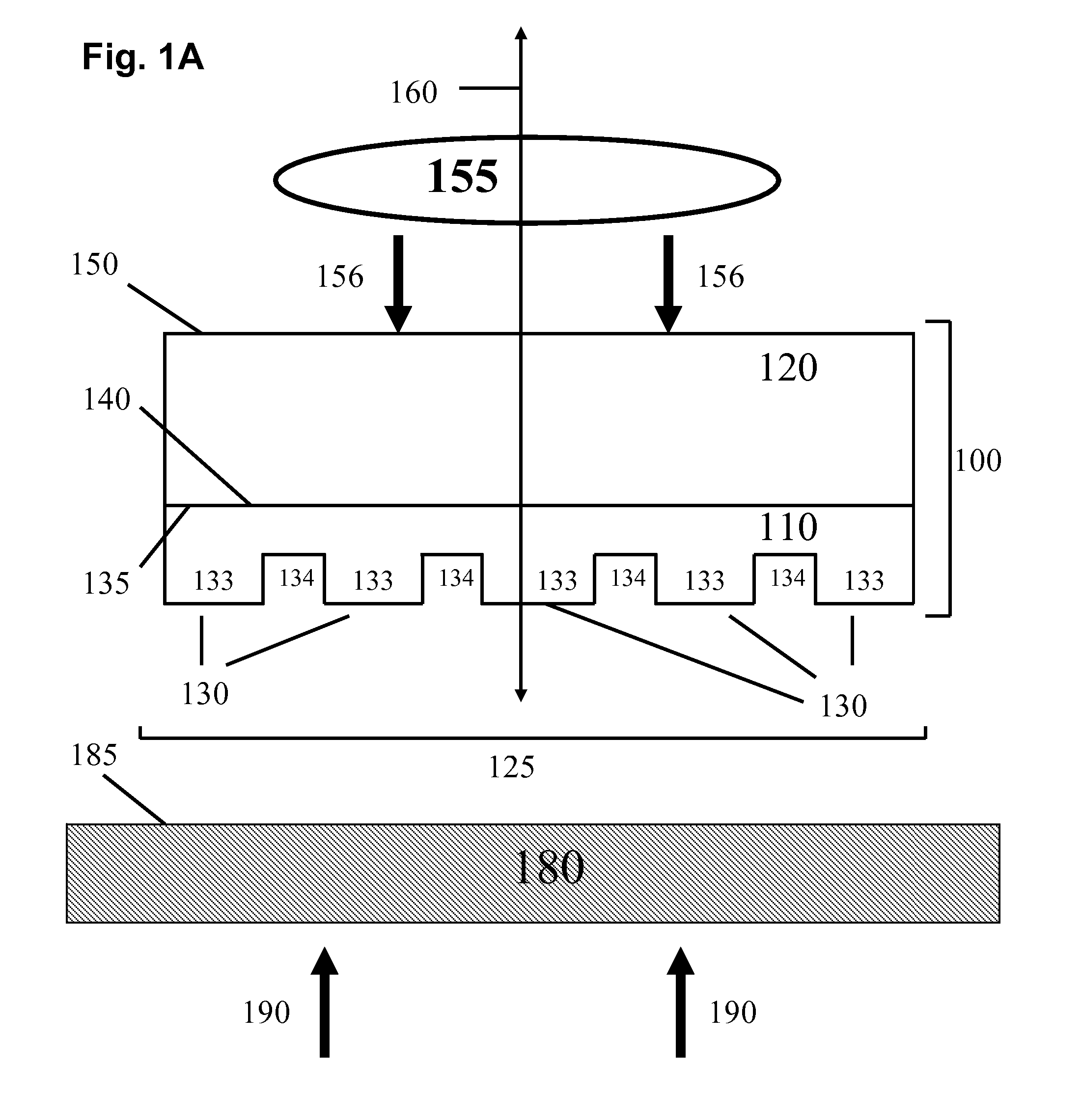

Composite patterning devices for soft lithography

ActiveUS7195733B2Improve fidelityIncrease resistanceMaterial nanotechnologyNanoinformaticsNano sizeYoung's modulus

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

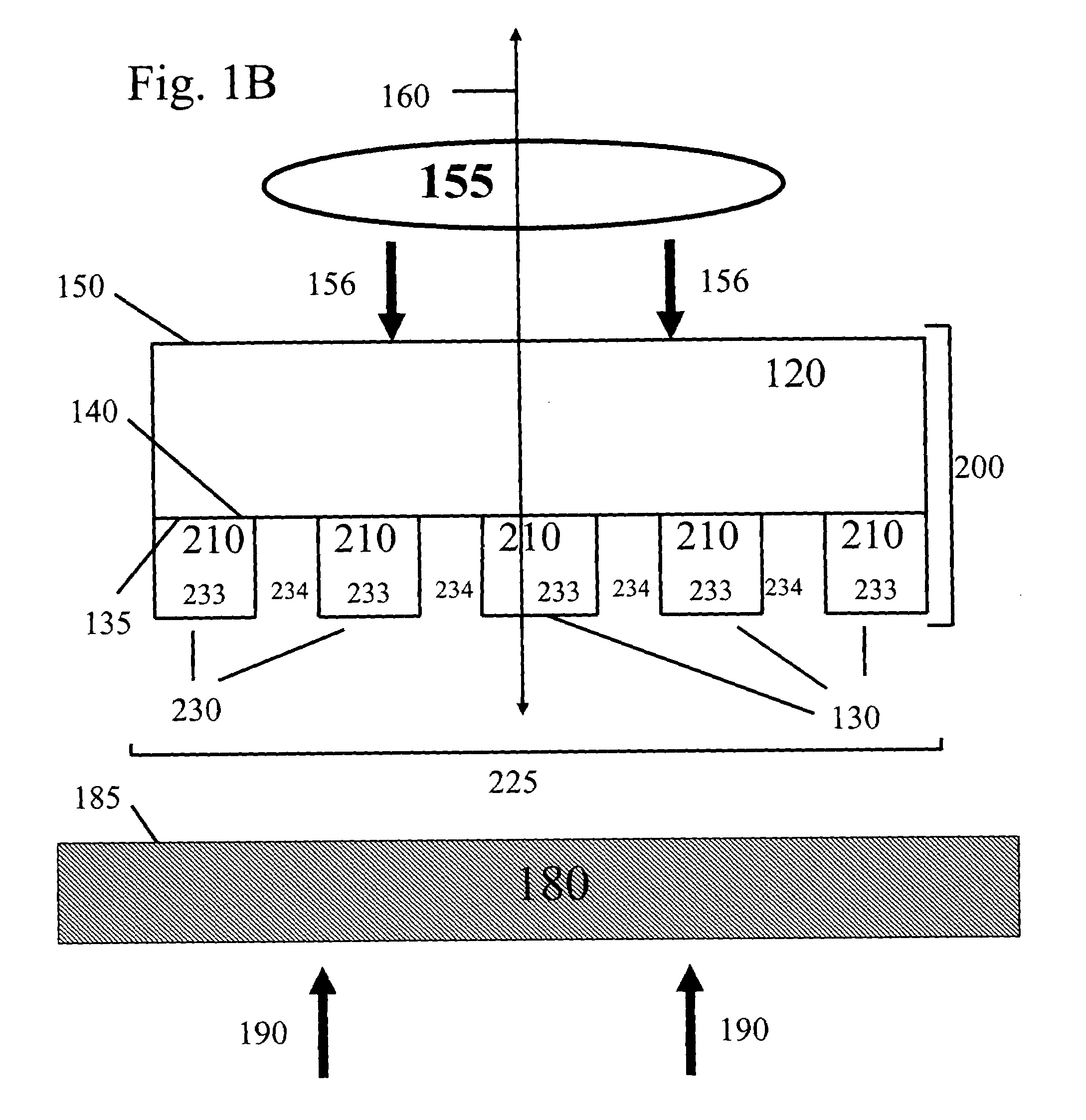

Devices and methods for pattern generation by ink lithography

InactiveUS20080055581A1Improve fidelityIncrease resistanceNanostructure manufactureNanoinformaticsElastomerLithographic artist

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions and including relief and recess features with variable height, depth or height and depth. Composite patterning devices comprising a plurality of polymer layers each having selected mechanical and thermal properties and physical dimensions provide high resolution patterning on a variety of substrate surfaces and surface morphologies. Gray-scale ink lithography photomasks for gray-scale pattern generation or molds for generating embossed relief features on a substrate surface are provided. The particular shape of the fabricated patterned can be manipulated by varying the three-dimensional recess pattern on an elastomeric patterning device which is brought into conformal contact with a substrate to localize patterning agent to the recess portion of the pattern.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

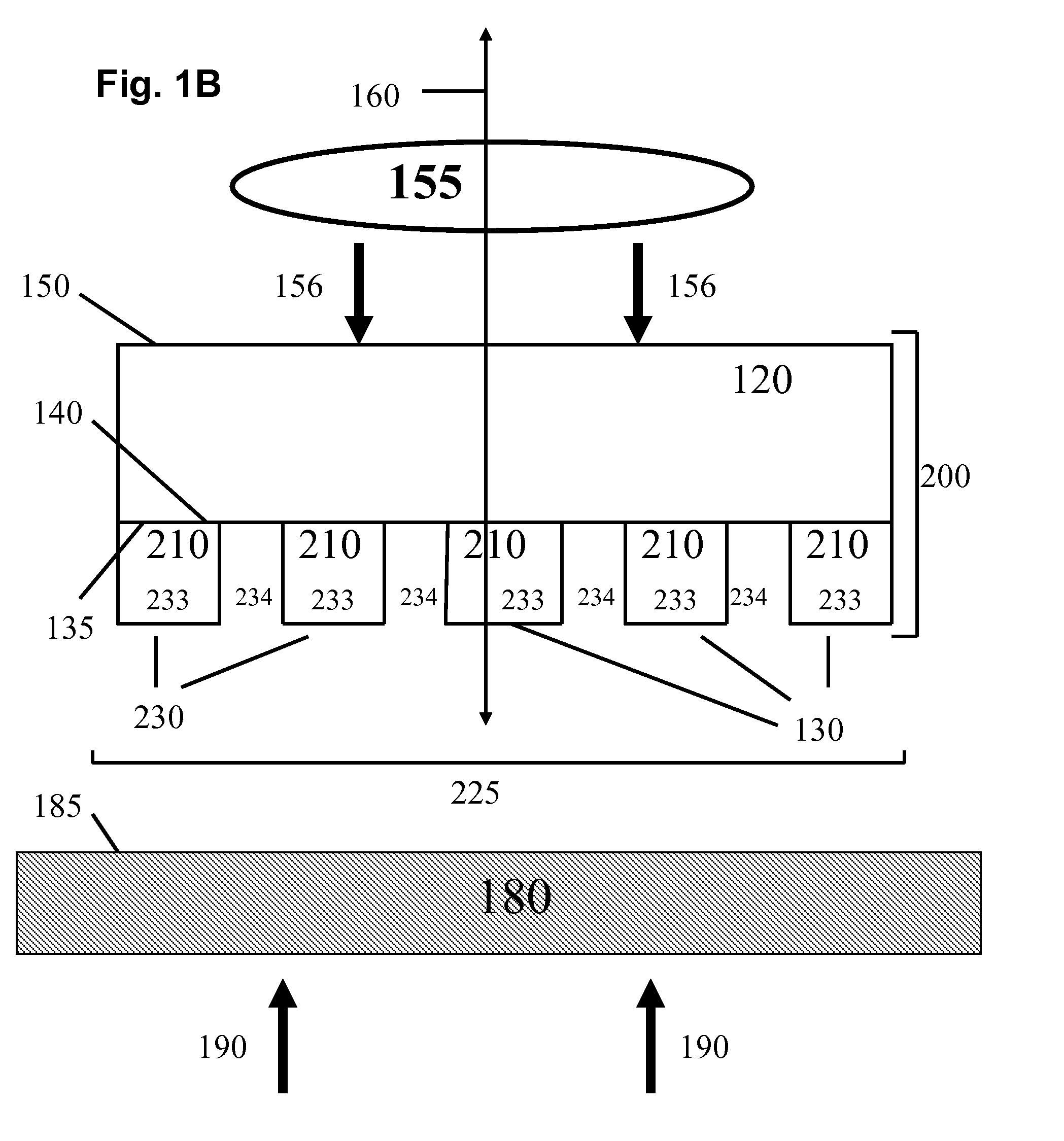

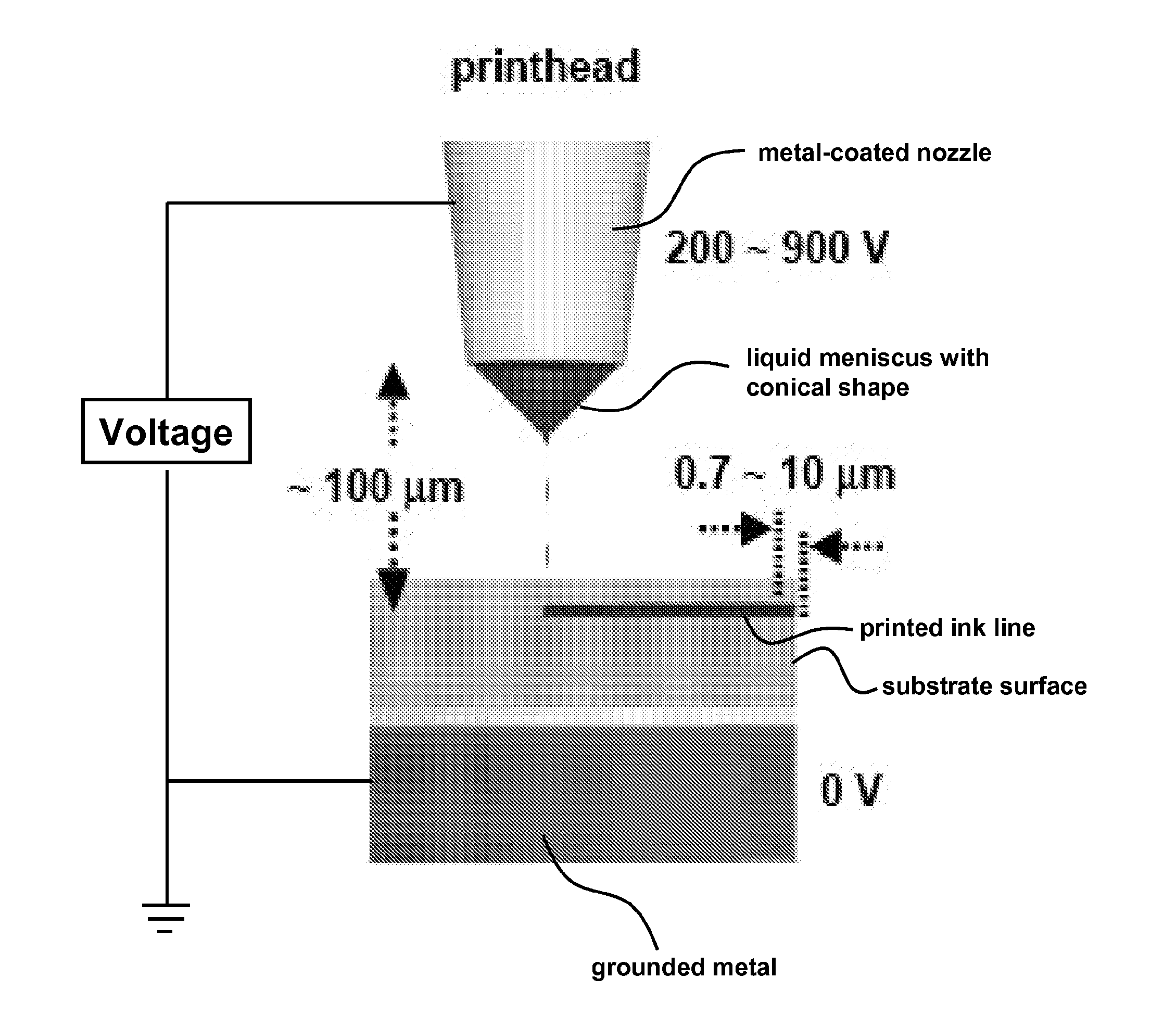

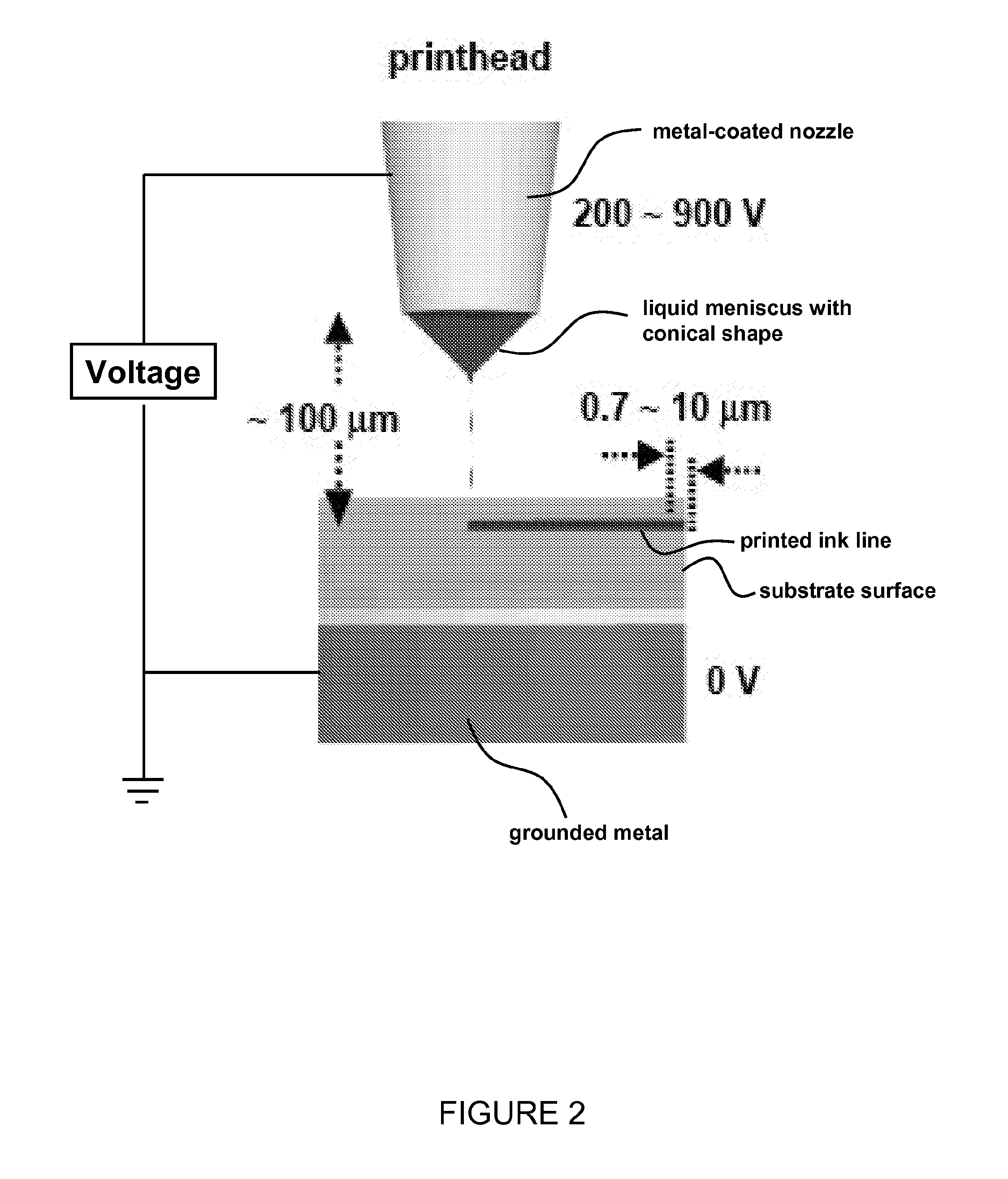

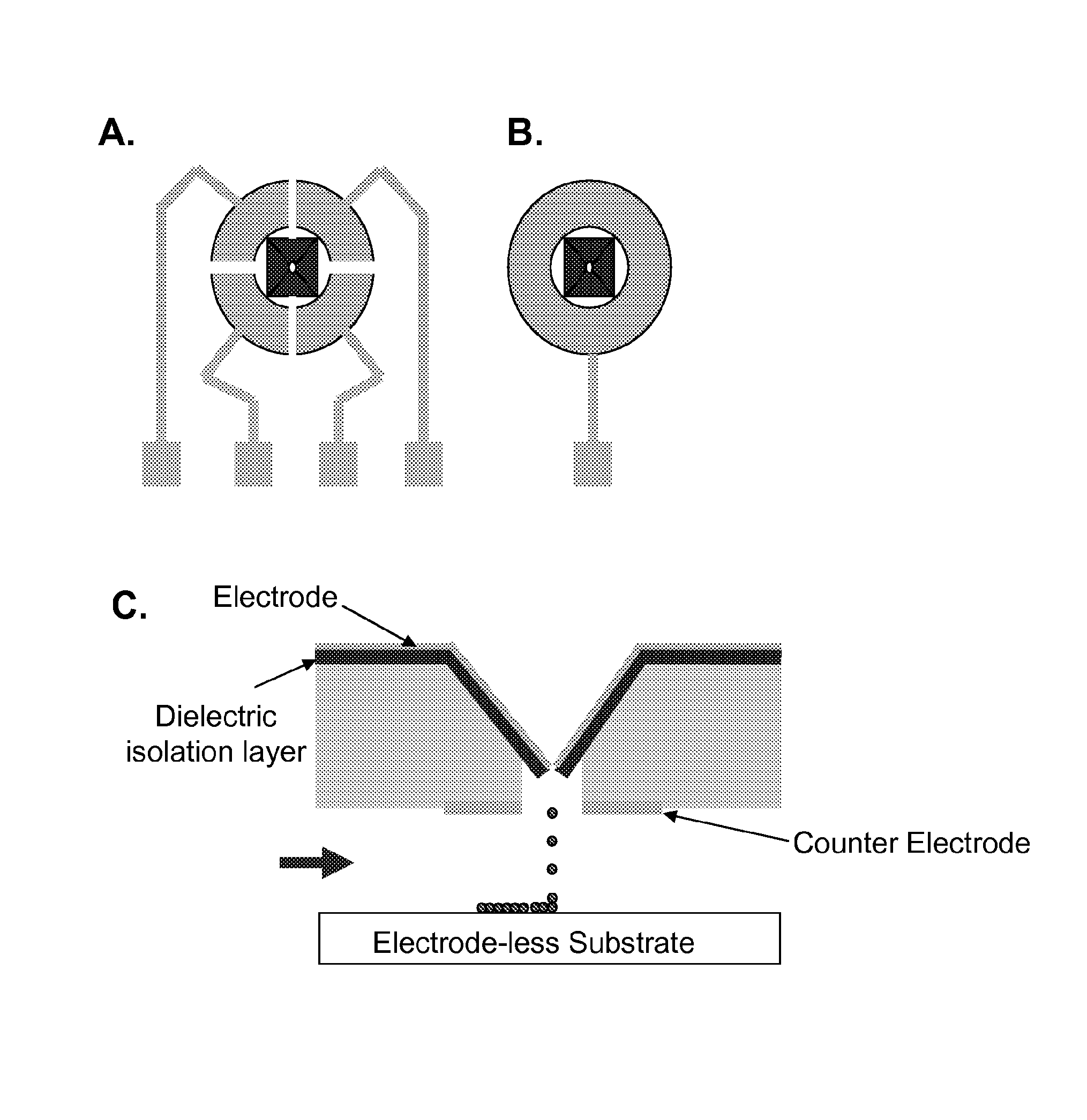

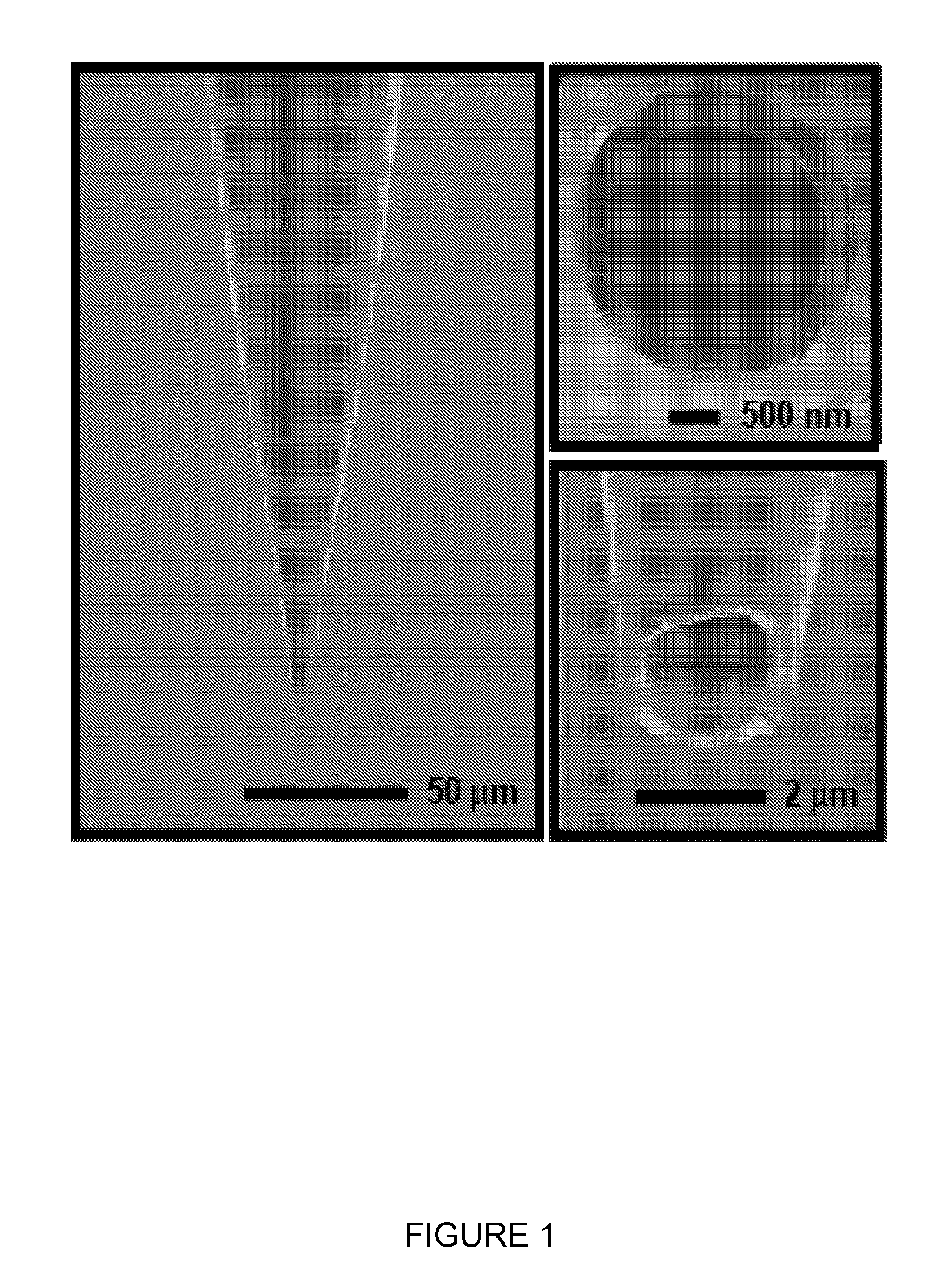

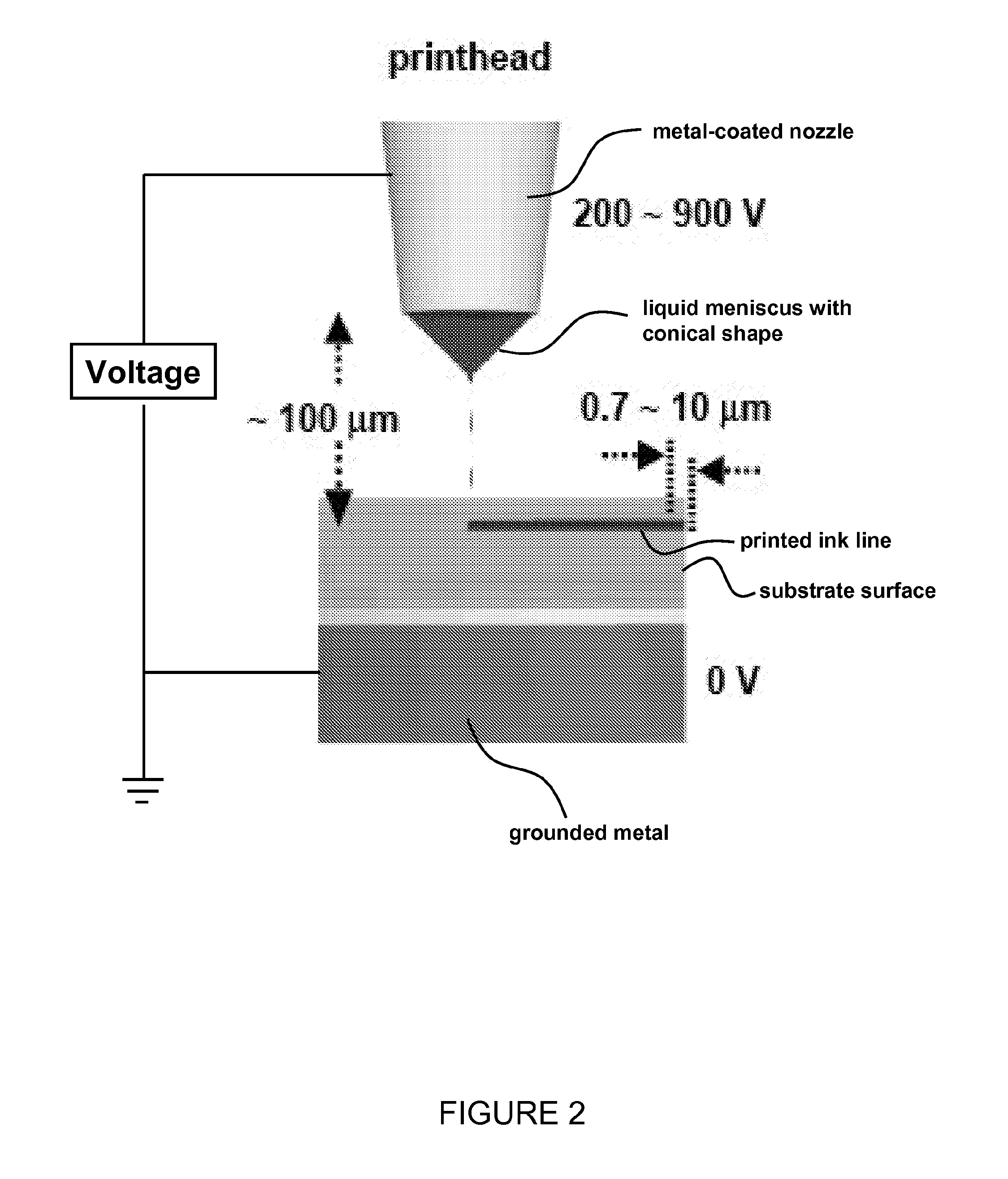

High Resolution Electrohydrodynamic Jet Printing for Manufacturing Systems

ActiveUS20110187798A1Improve placement accuracyBetter confinedPrintingImage resolutionVoltage source

Provided are high-resolution electrohydrodynamic inkjet (e-jet) printing systems and related methods for printing functional materials on a substrate surface. In an embodiment, a nozzle with an ejection orifice that dispenses a printing fluid faces a surface that is to be printed. The nozzle is electrically connected to a voltage source that applies an electric charge to the fluid in the nozzle to controllably deposit the printing fluid on the surface. In an aspect, a nozzle that dispenses printing fluid has a small ejection orifice, such as an orifice with an area less than 700 μm2 and is capable of printing nanofeatures or microfeatures. In an embodiment the nozzle is an integrated-electrode nozzle system that is directly connected to an electrode and a counter-electrode. The systems and methods provide printing resolutions that can encompass the sub-micron range.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

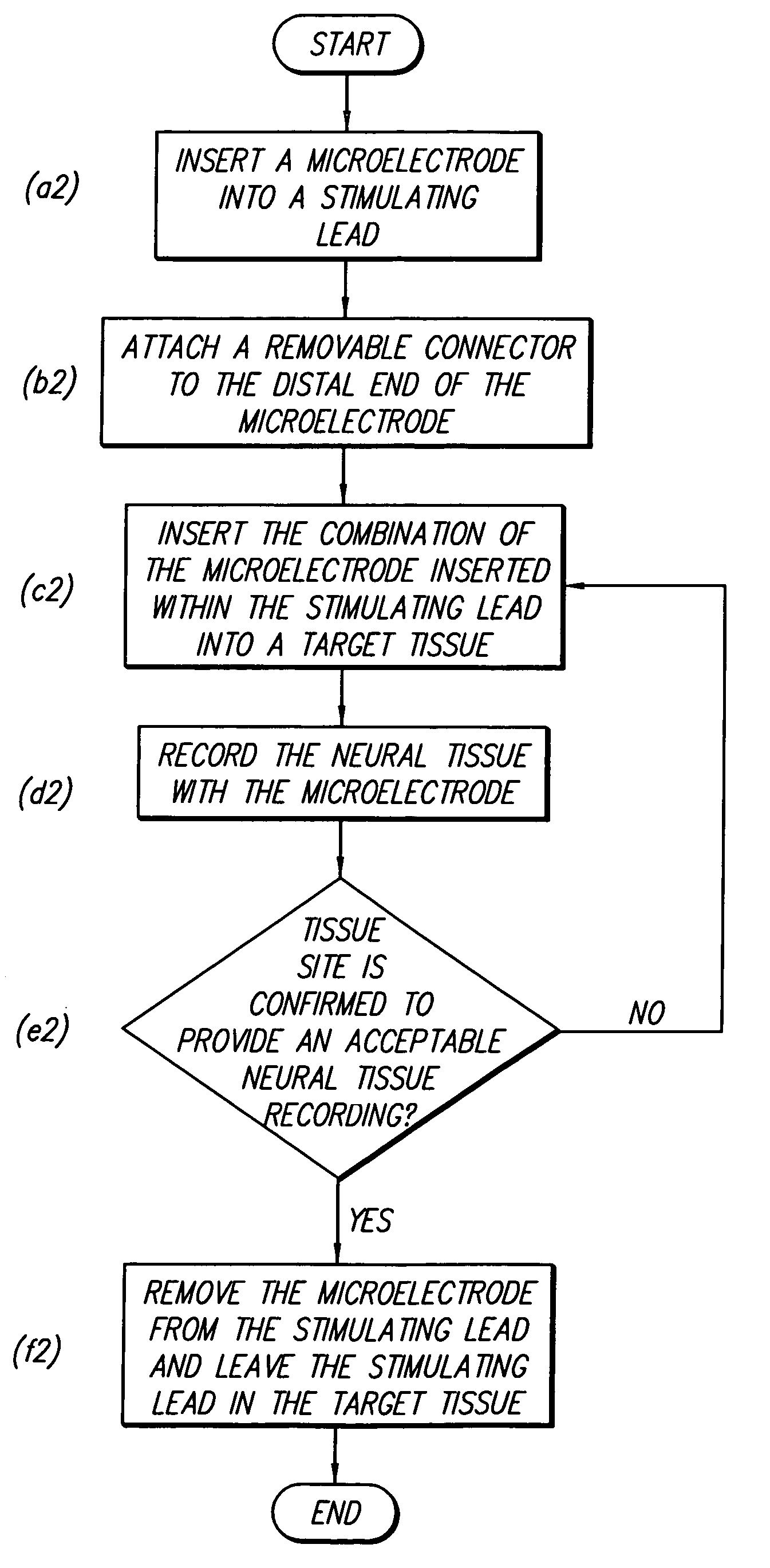

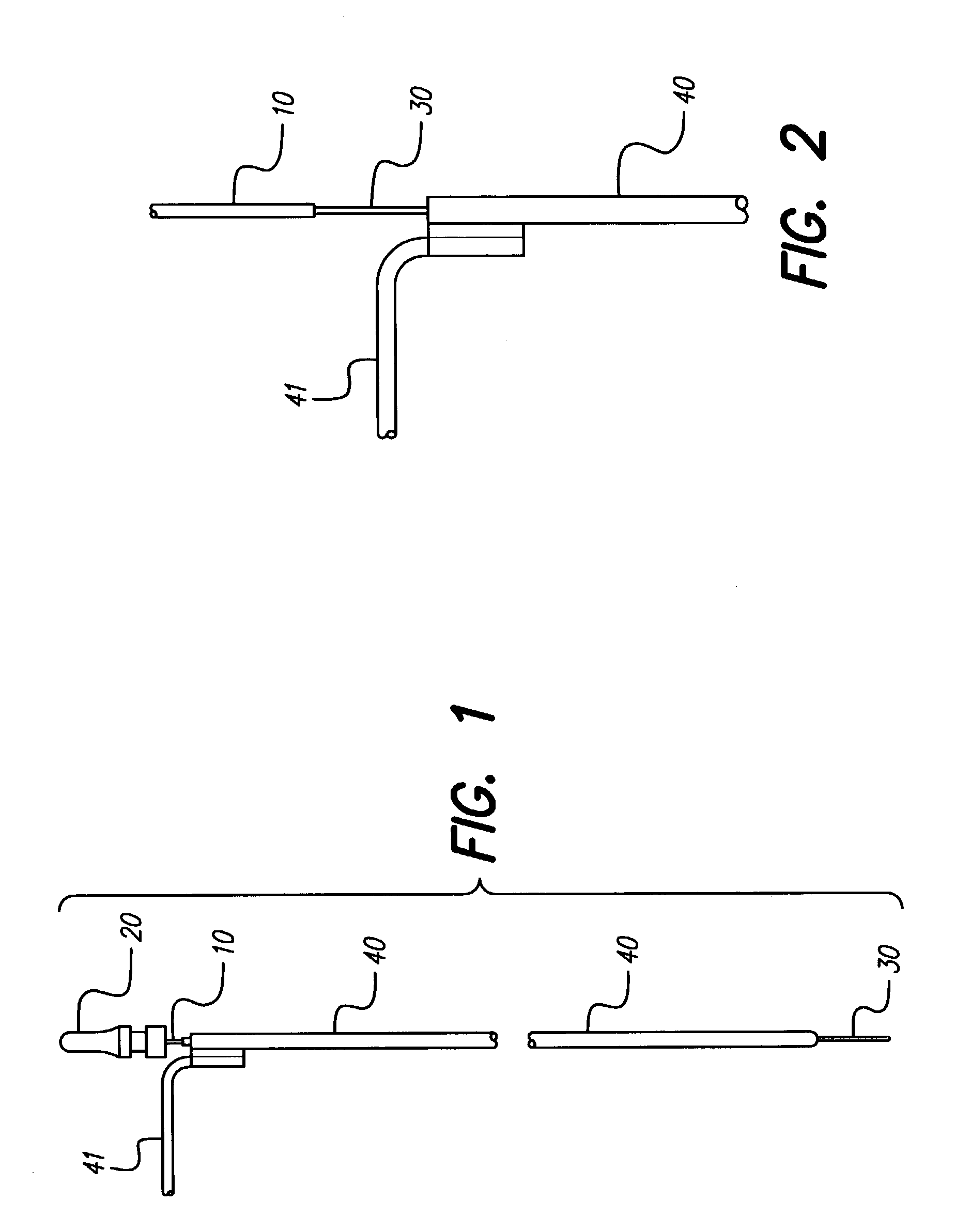

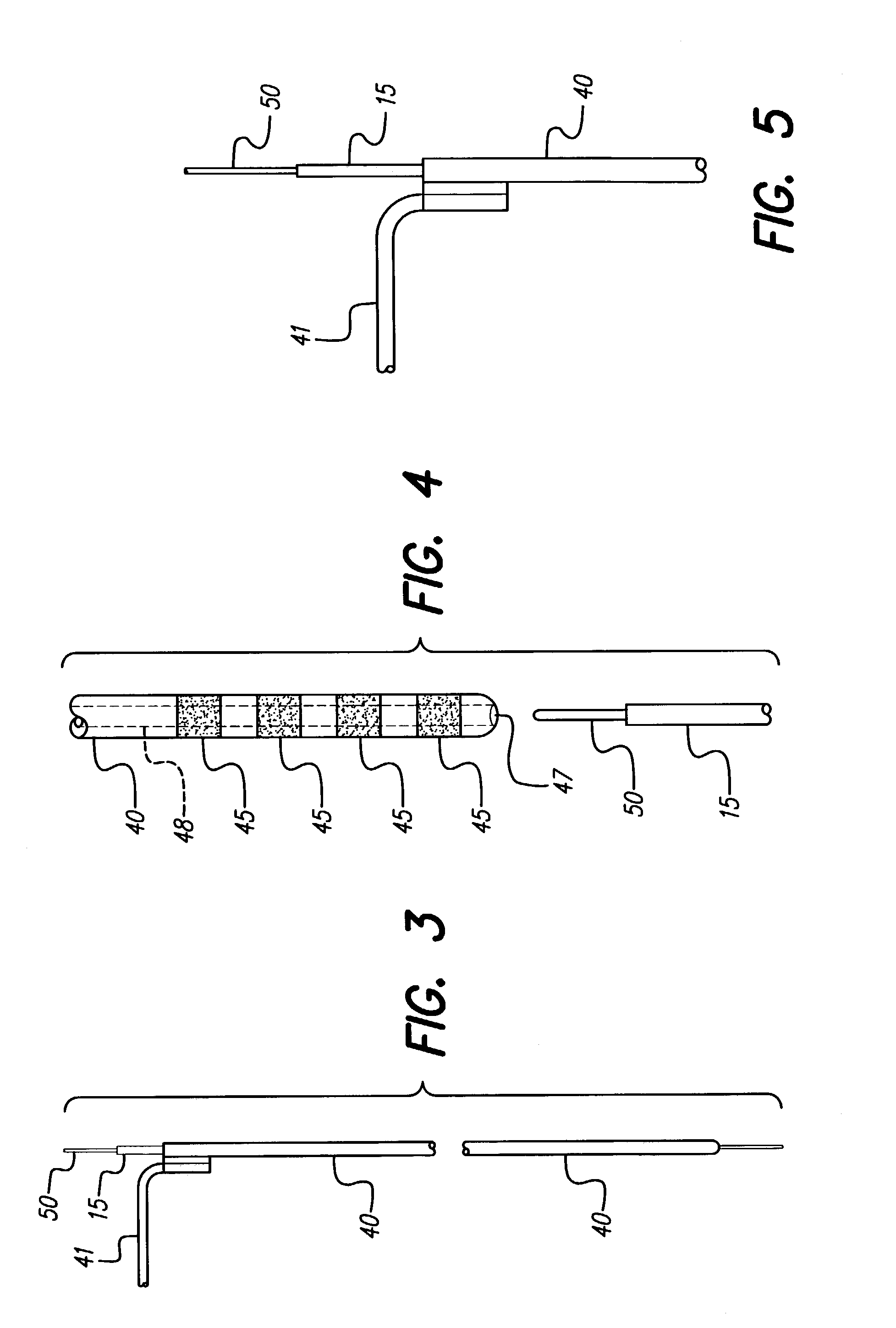

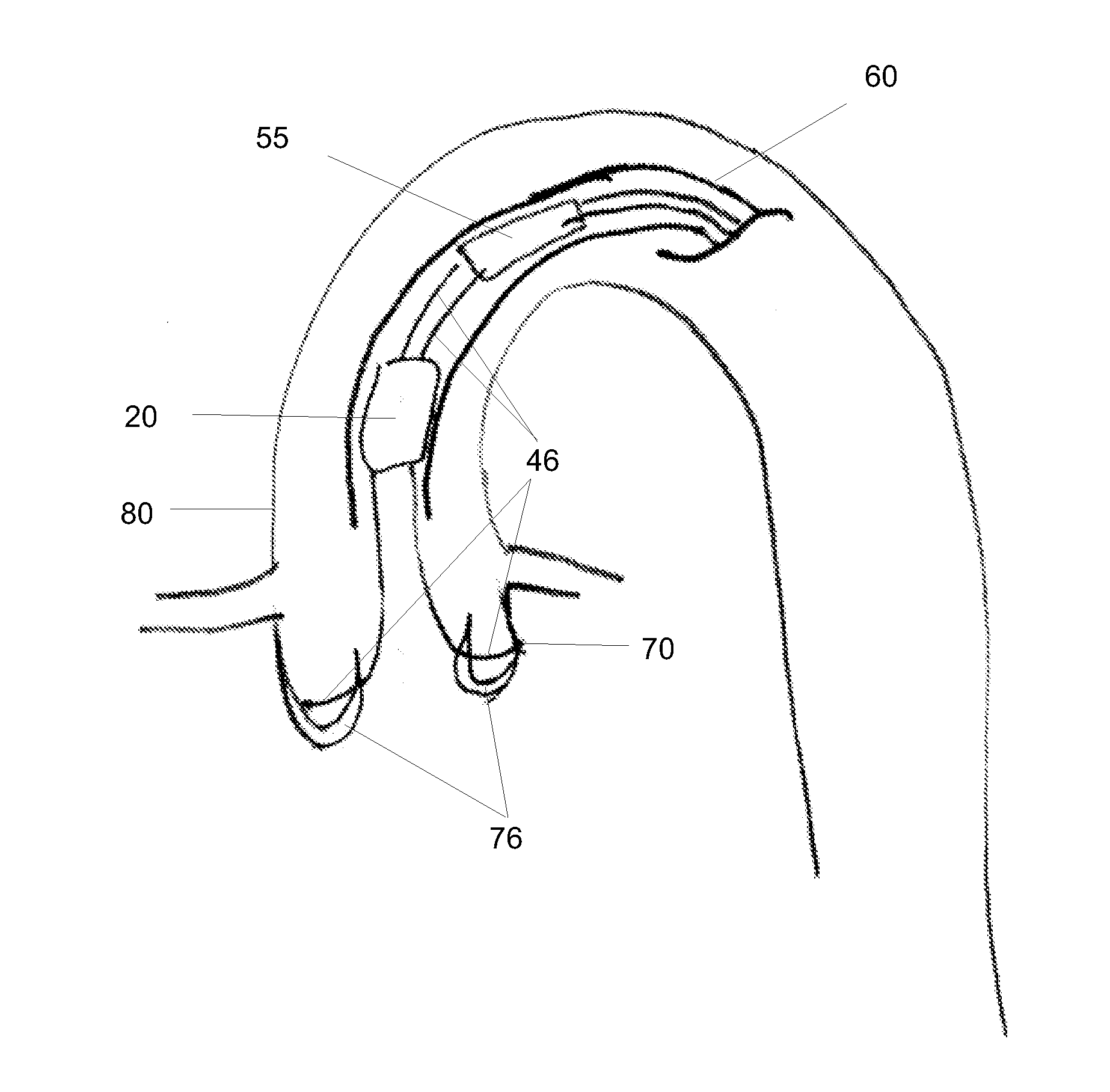

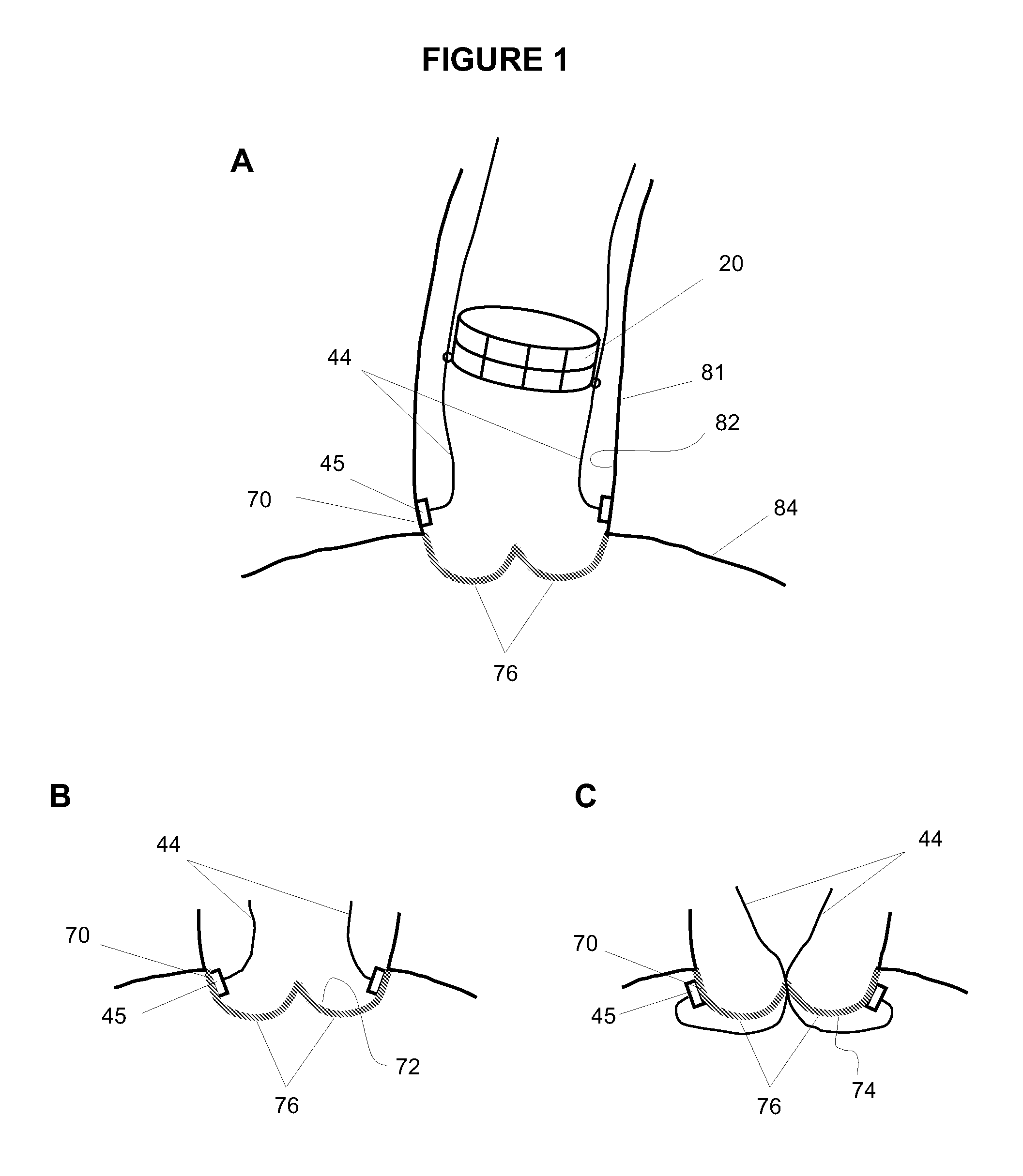

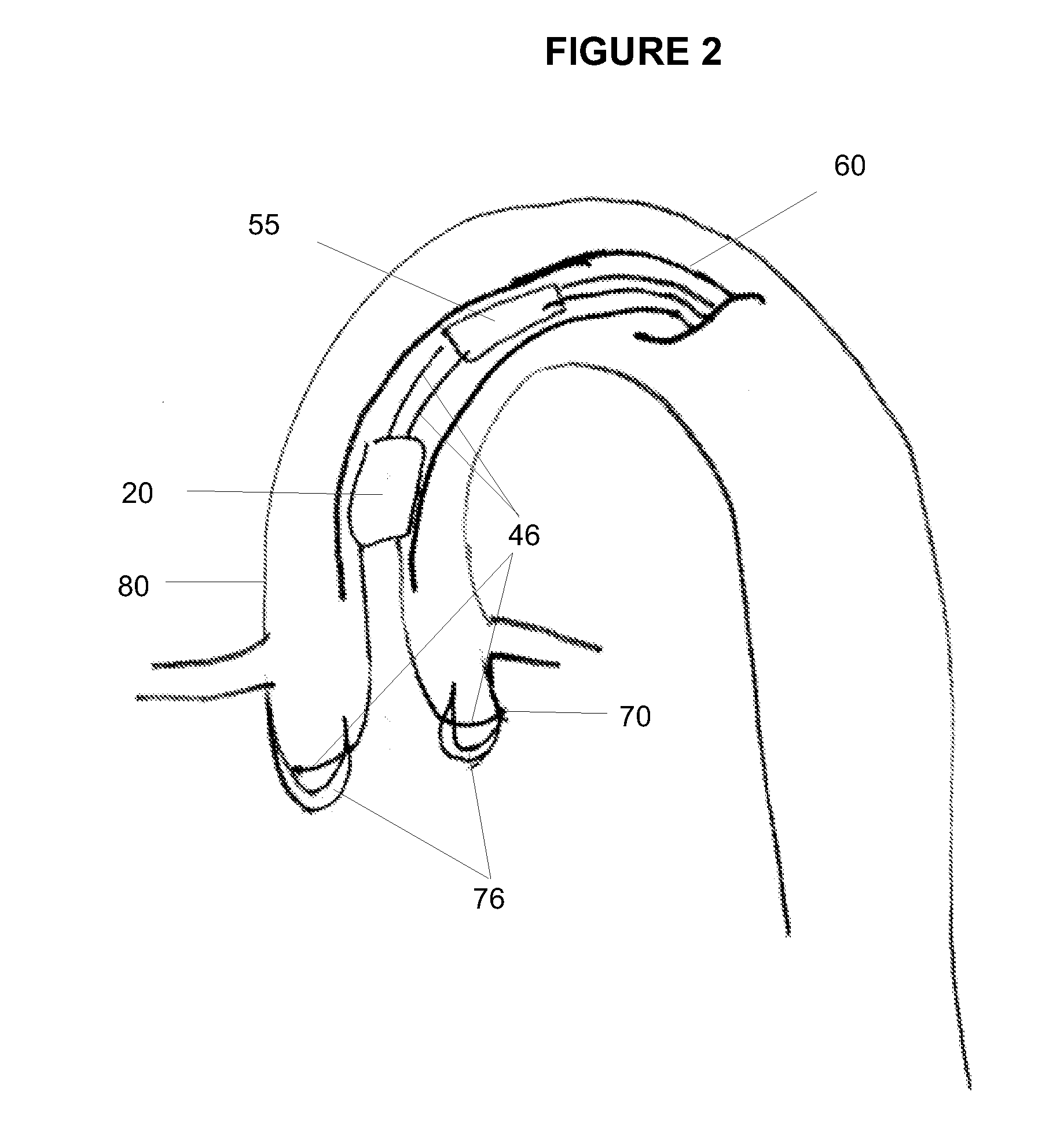

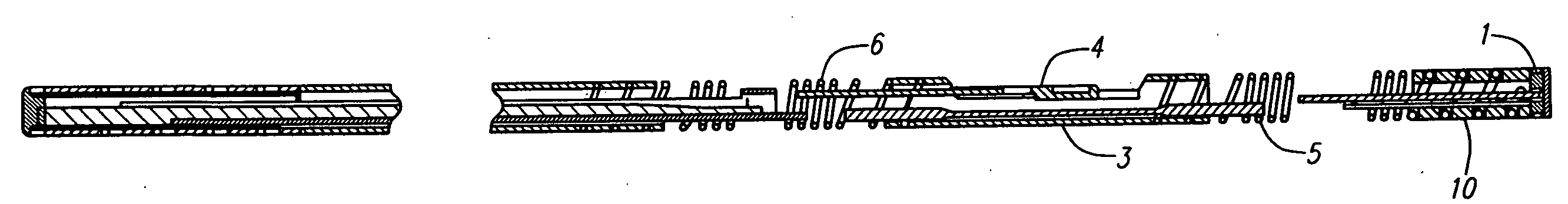

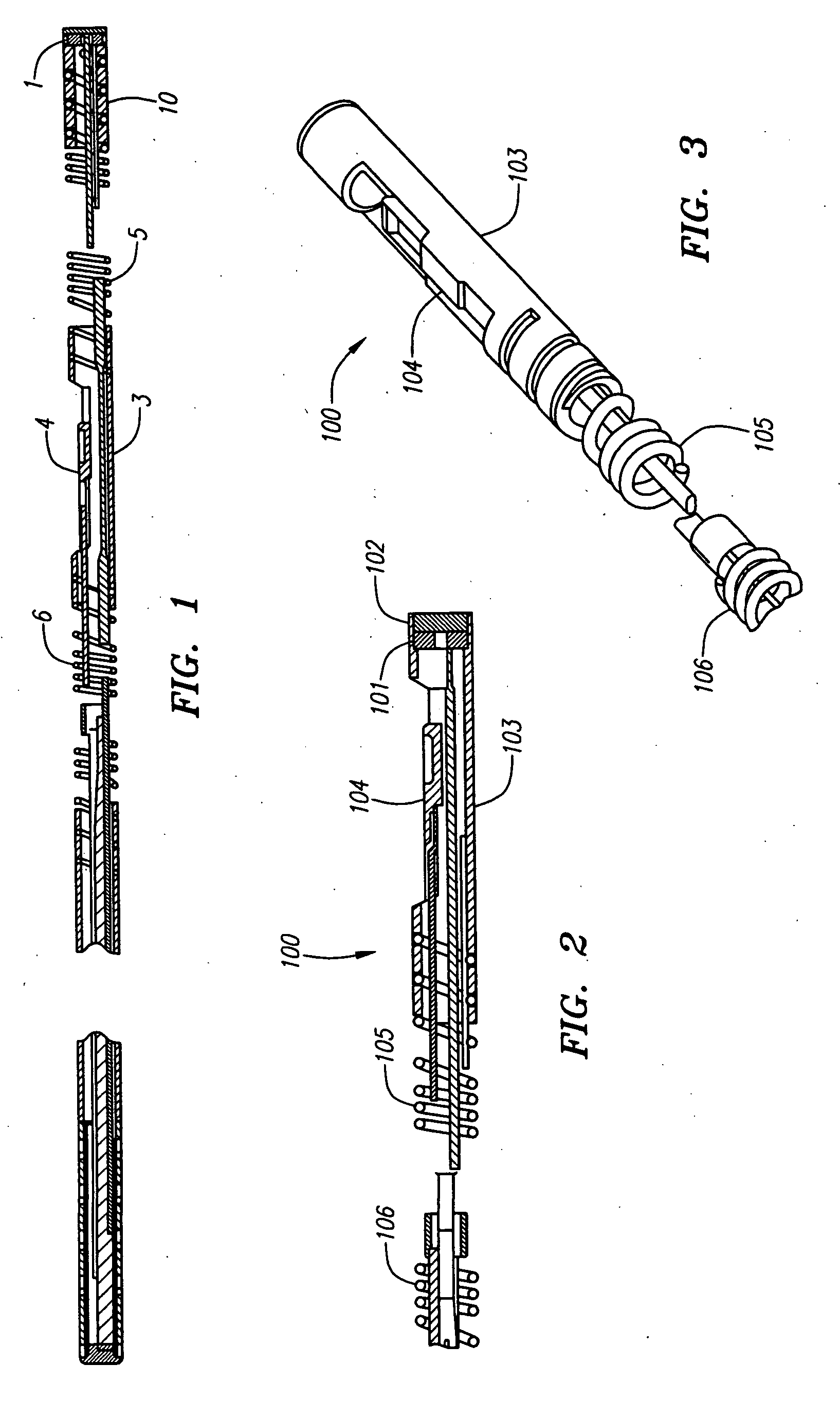

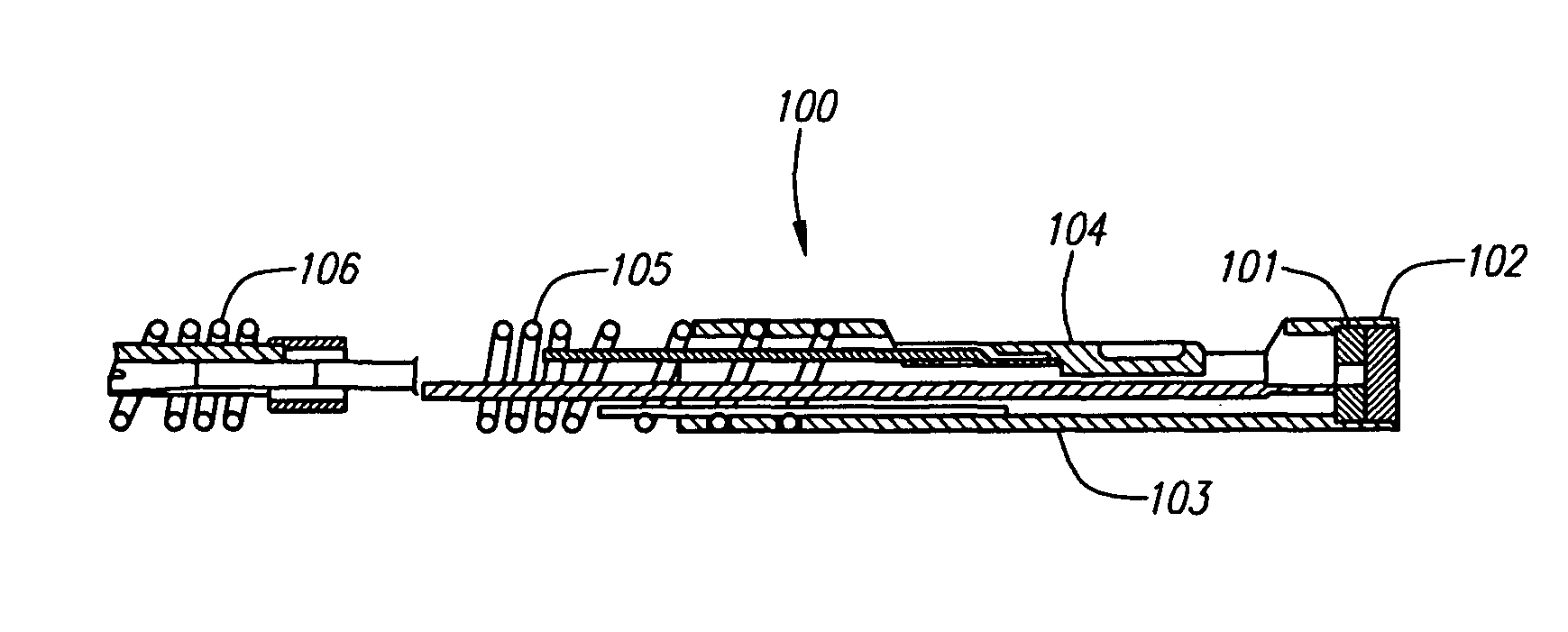

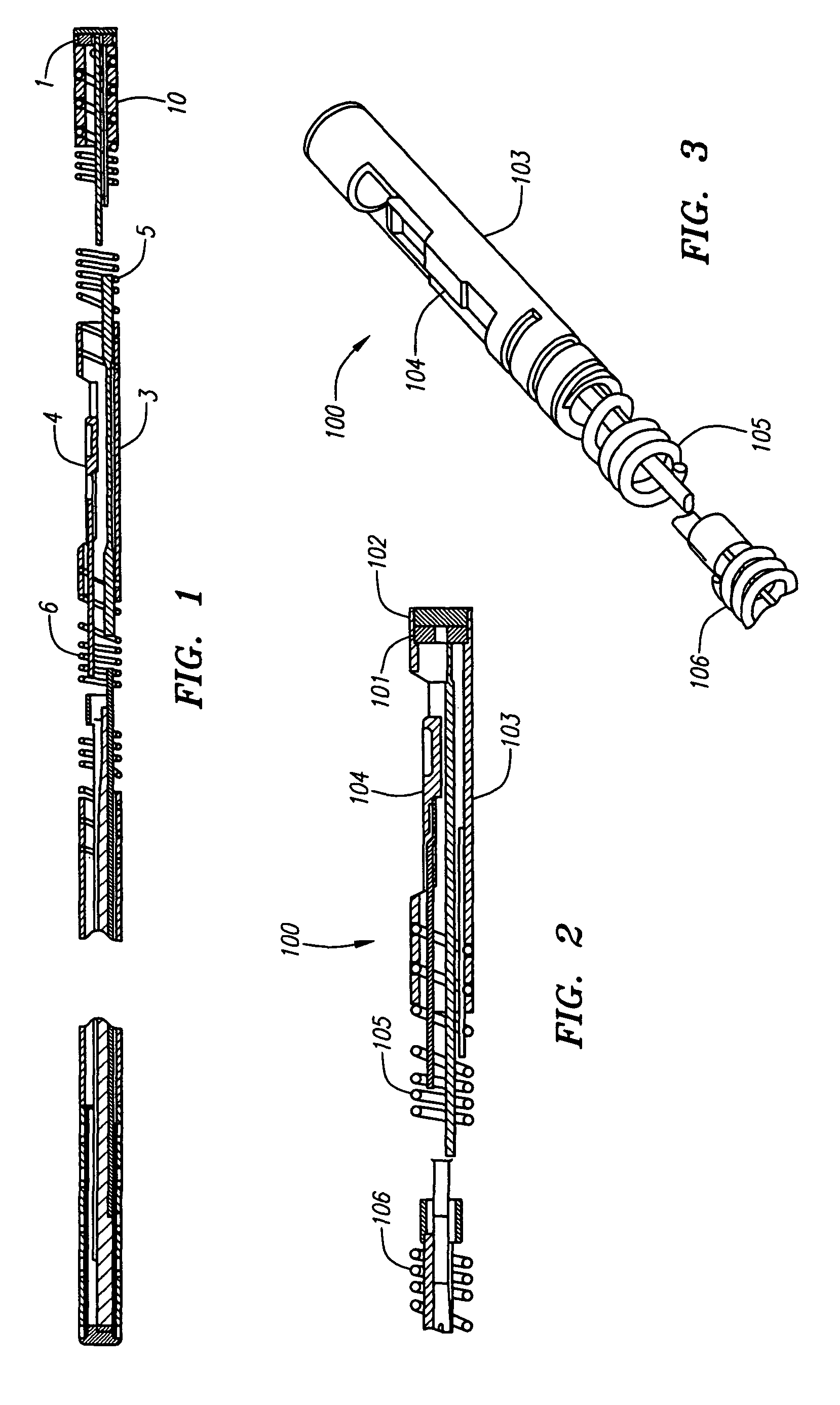

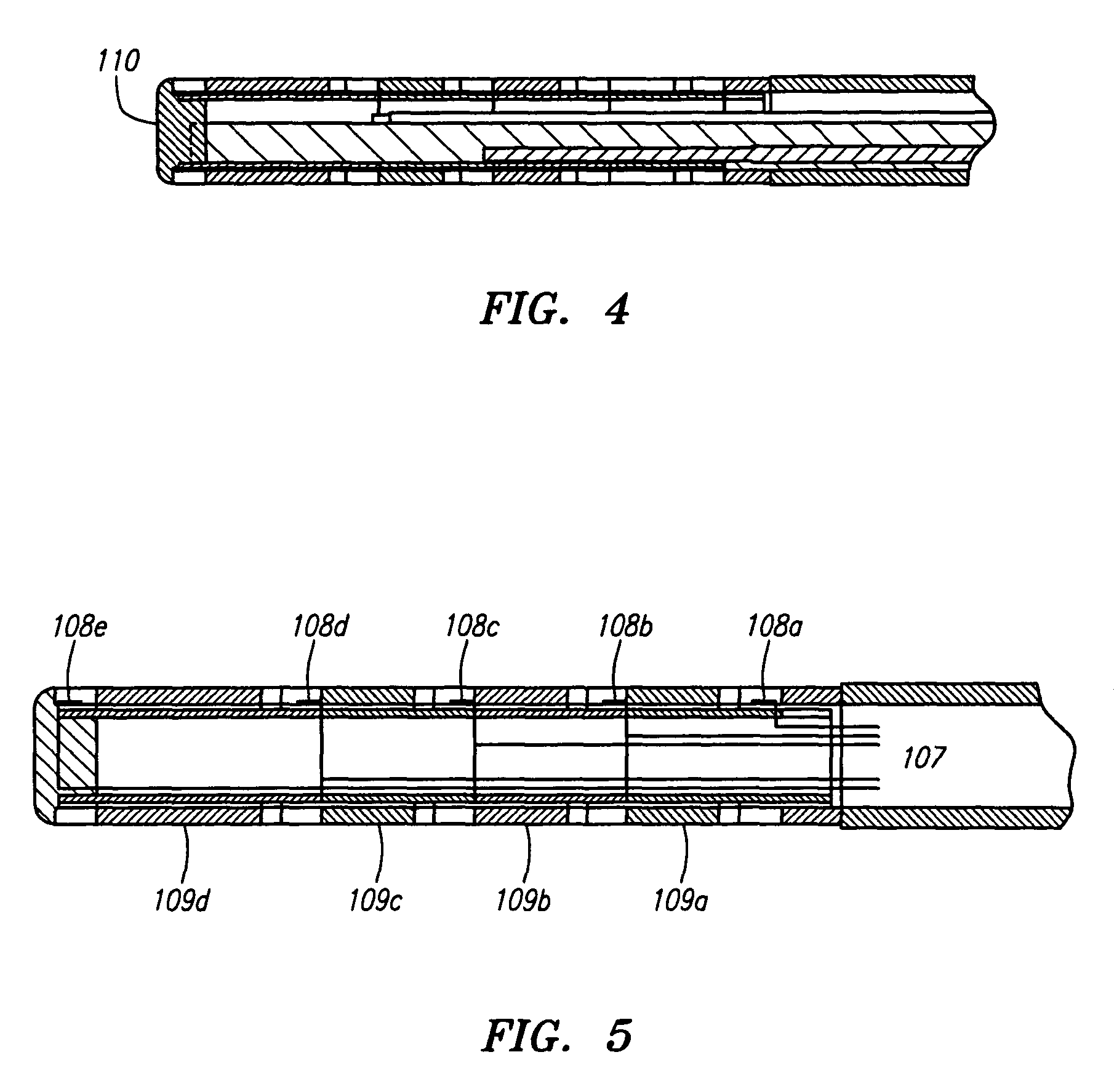

System for permanent electrode placement utilizing microelectrode recording methods

InactiveUS7177701B1Avoid tanglesReduces critical operating timeHead electrodesSurgeryElectrode placementMicroelectrode

A lead stimulation / recording system is provided, which is a combination of a permanent DBS stimulating lead and a recording microelectrode. The DBS lead has a lumen extending from the proximal to the distal end of the lead, the lumen having an opening on each end of the lead. The microelectrode is configured and dimensioned to be insertable into the DBS lead from either the distal or proximal opening of the DBS lead, thereby permitting the microelectrode to be placed before, concurrently with, or after placement of the DBS lead. In addition, the system may be used with known microelectrode recording systems and methods of inserting the electrodes, such as the five-at-a-time method, the dual-microdrive method, or the single microdrive method.

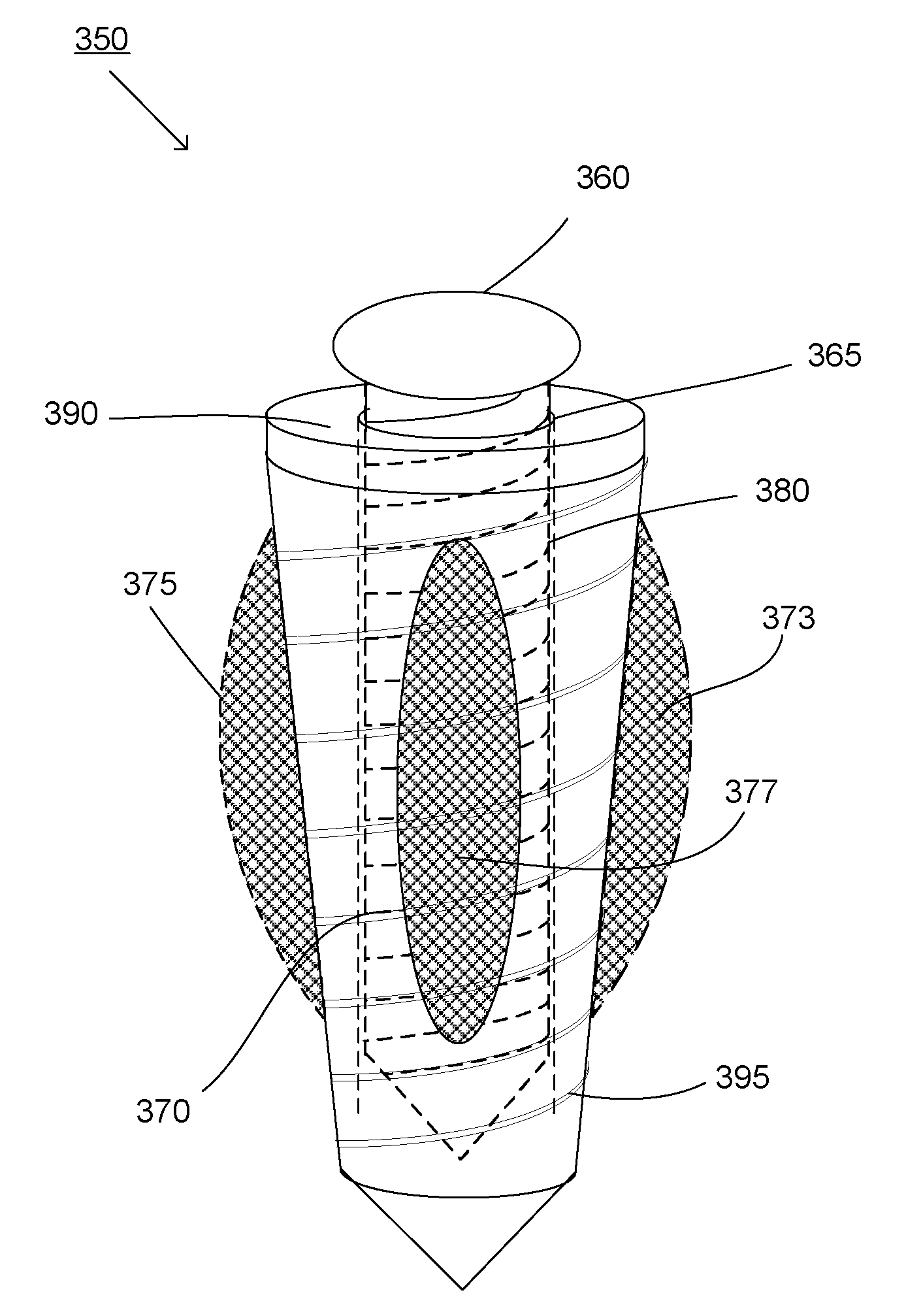

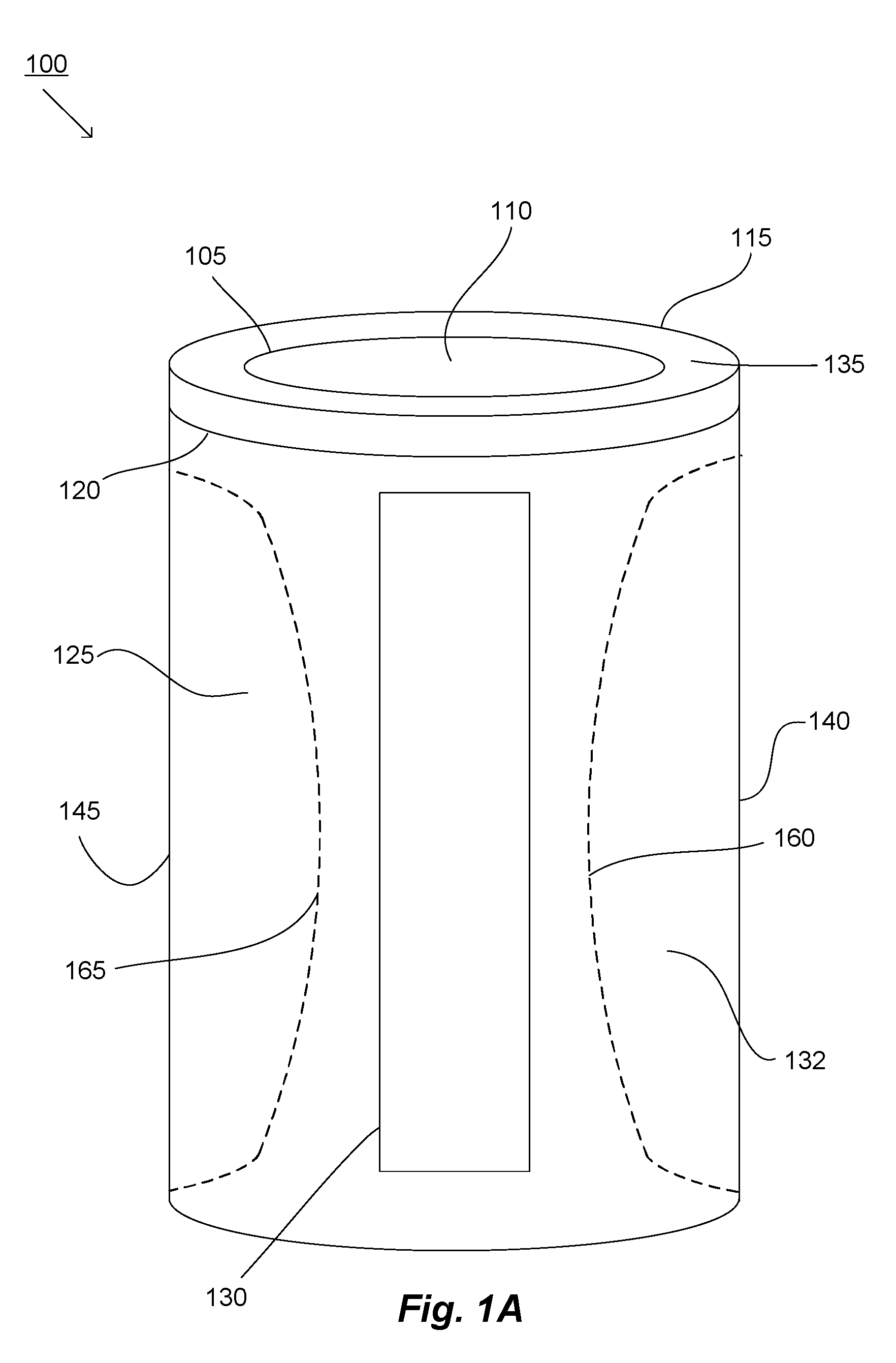

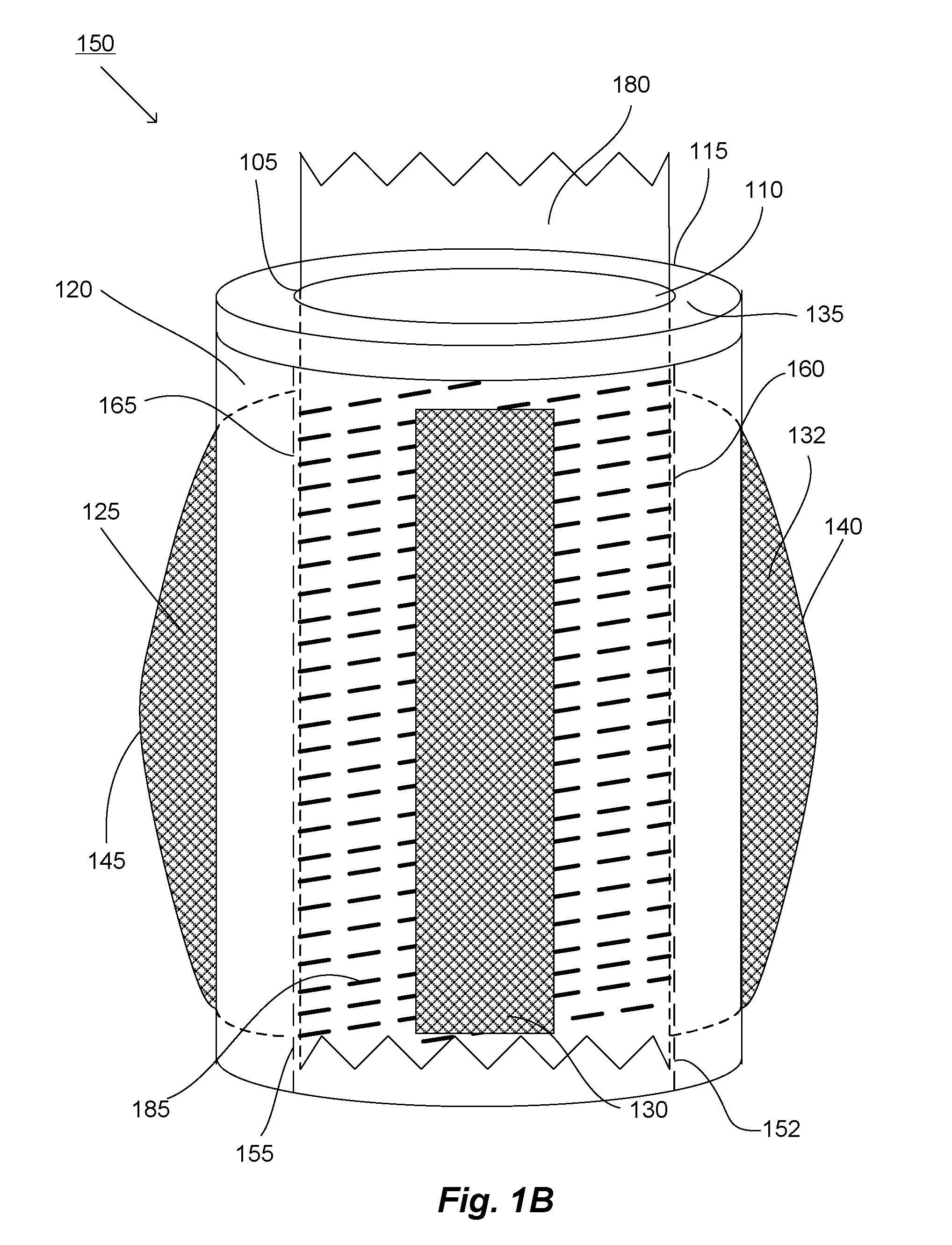

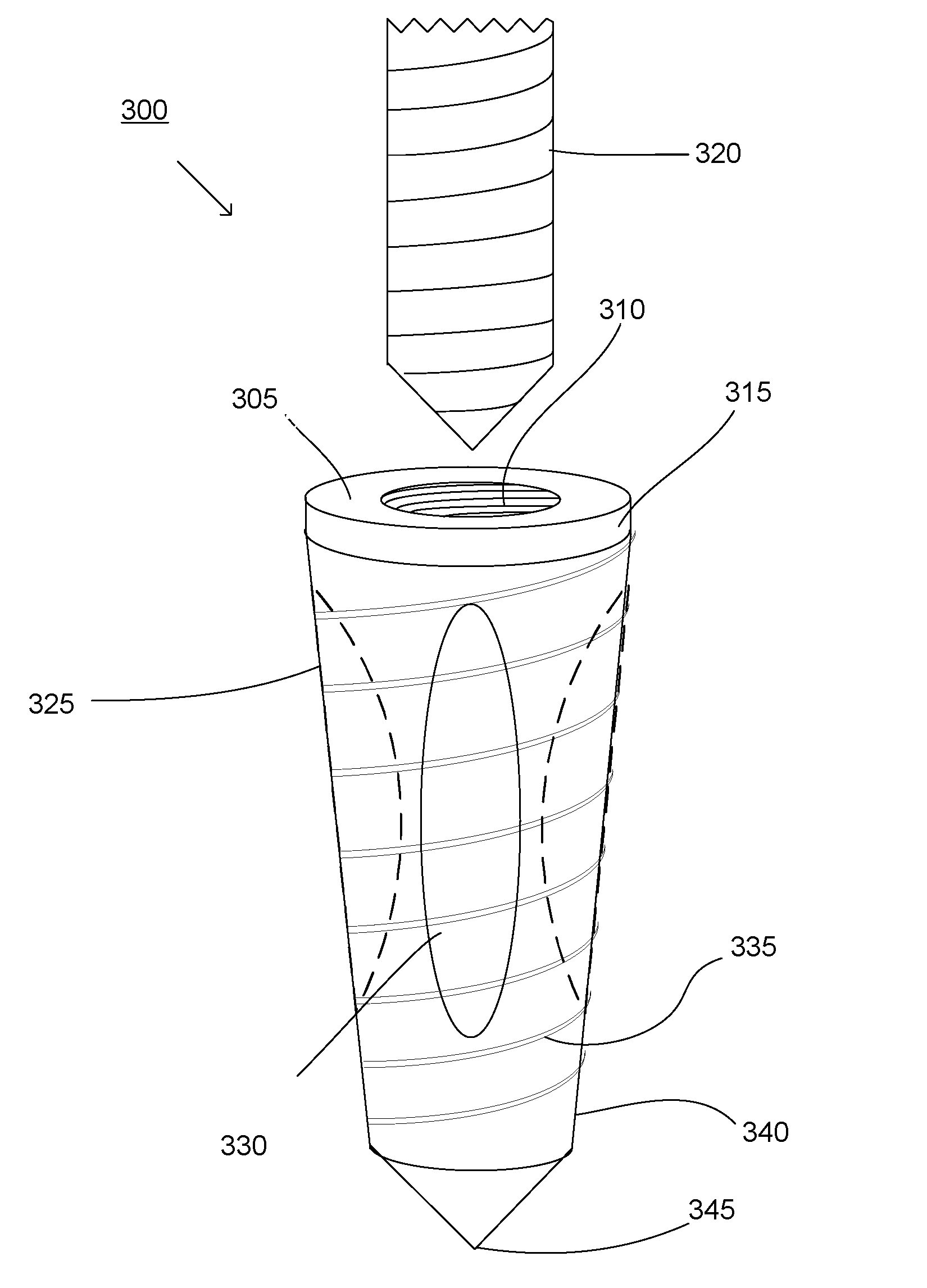

System and method for placing a percutaneous valve device

InactiveUS20100179648A1Improve accuracyImprove placement accuracyHeart valvesProsthetic valveImplantation Site

A system and process for placing a percutaneous valve device in a body lumen at the location of implantation is provided. The placement system and method are simple and enhance the accuracy of the placement of the valve device. Anchors and placement wires or sutures are used to fix the implantation target and guide the device to the implantation site. The system and method are applicable to pre-assembled percutaneous valve devices as well as a modular prosthetic valve device, which modular device is also provided. The modular valve device comprises two or more device modules and is designed to be delivered unassembled and then assembled in the body lumen at or near the site where implantation occurs. The device modules may be assembled before or after the implantation target is fixed with the anchor, and then placed using the placement system in a manner similar to how a pre-assembled percutaneous valve device may be placed in accordance with the invention.

Owner:VALVE MEDICAL

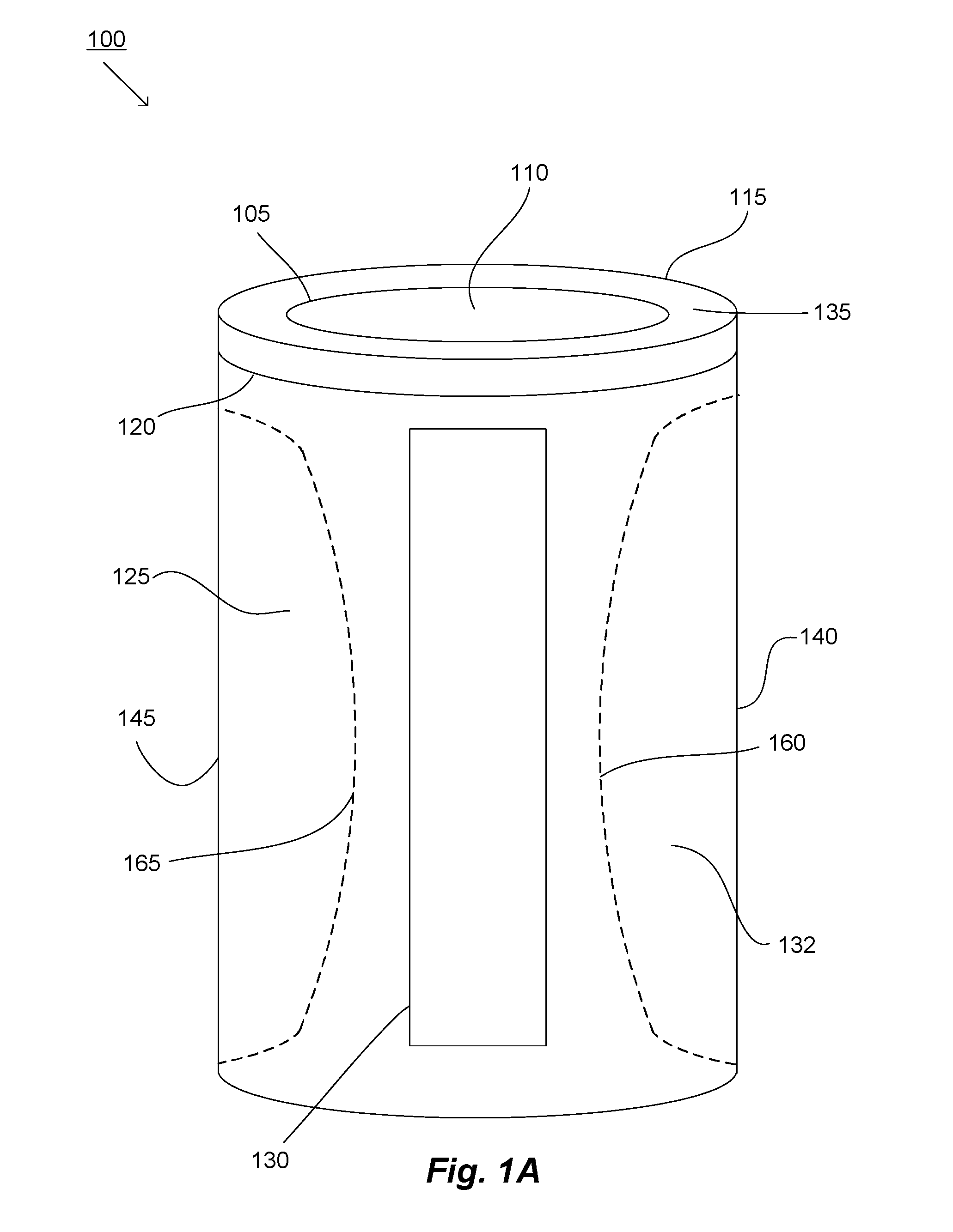

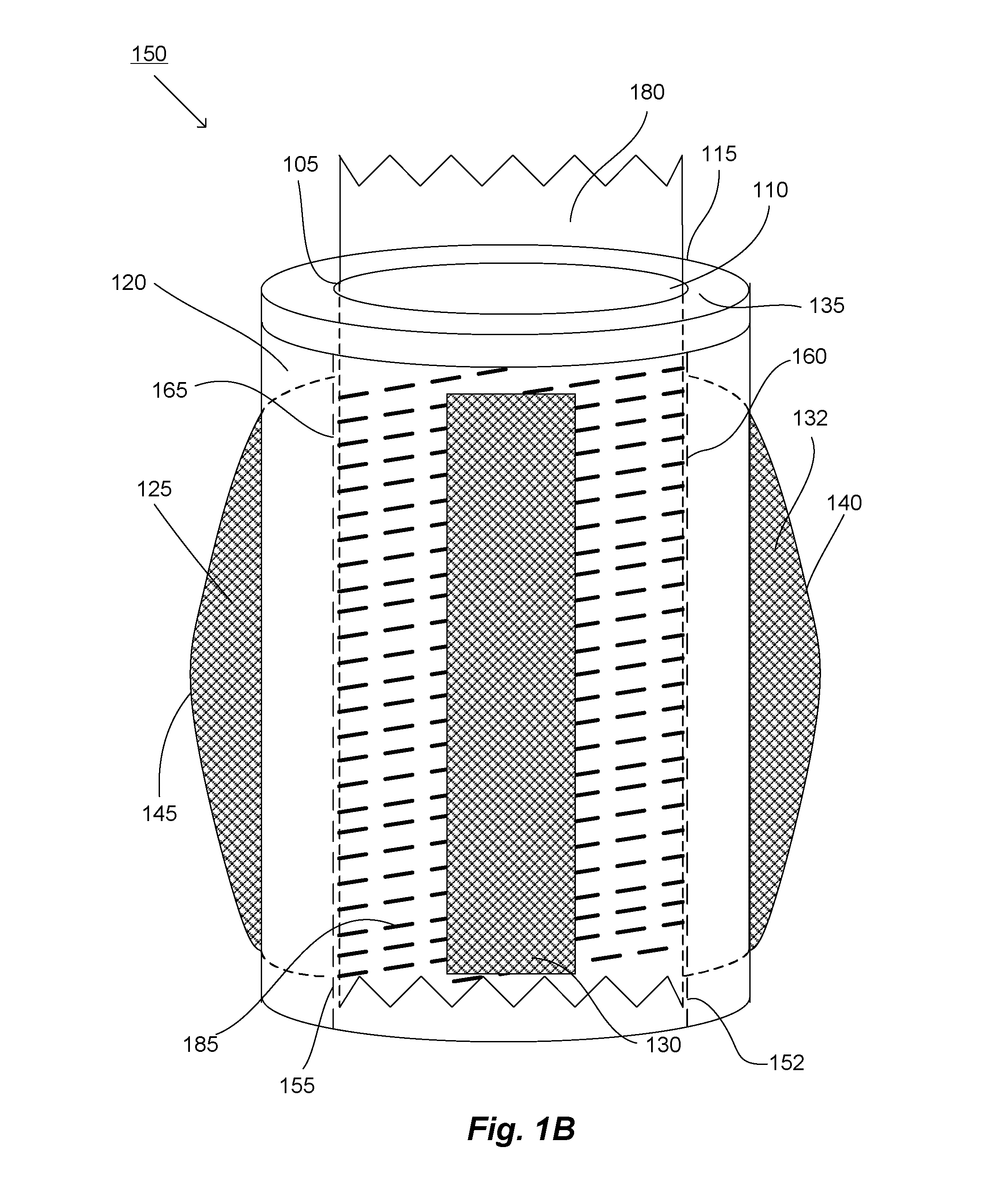

Systems and Methods for the Medical Treatment of Structural Tissue

InactiveUS20080221623A1Easy to insertEasy to attachSuture equipmentsInternal osteosythesisOrthopedic ProceduresEngineering

The present invention is directed generally to a biomedical system(s) and method(s). More specifically, some embodiments may include system(s) and method(s) used in medical treatment(s). Various embodiments may include medical system(s) and method(s) that may use an anchoring mechanism and screw (bolt, etc.) arrangement that increases the strength of attachment. Some embodiments may further include, for example, an anchoring mechanism that expands upon insertion of a screw (bolt, etc.) into an opening. Some embodiments may include, for example, a system(s) and method(s) for improvement of structural tissue (e.g., bone, cartilage) fixation and safety. Further, some embodiments may also include, for example, an anchoring mechanism and screw (bolt, etc.) system that may be utilized in orthopedic procedures. Still some embodiments may further include system(s) and method(s) providing improved screw fixation and enhanced stabilization in structural tissue or fracture repair. Various embodiments may include multiple anchor mechanisms and anchor mechanism holding means.

Owner:GOOCH HUBERT L

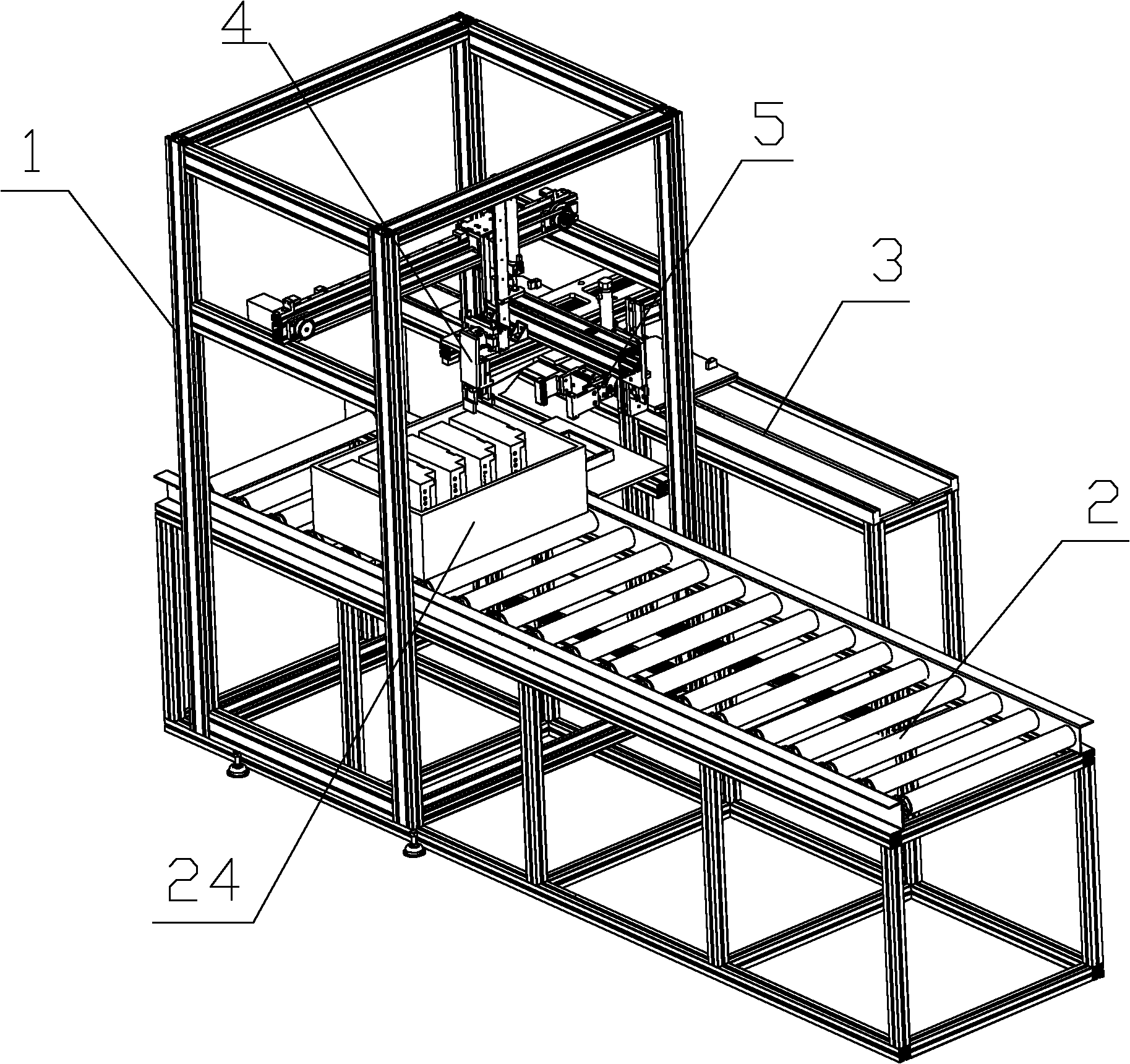

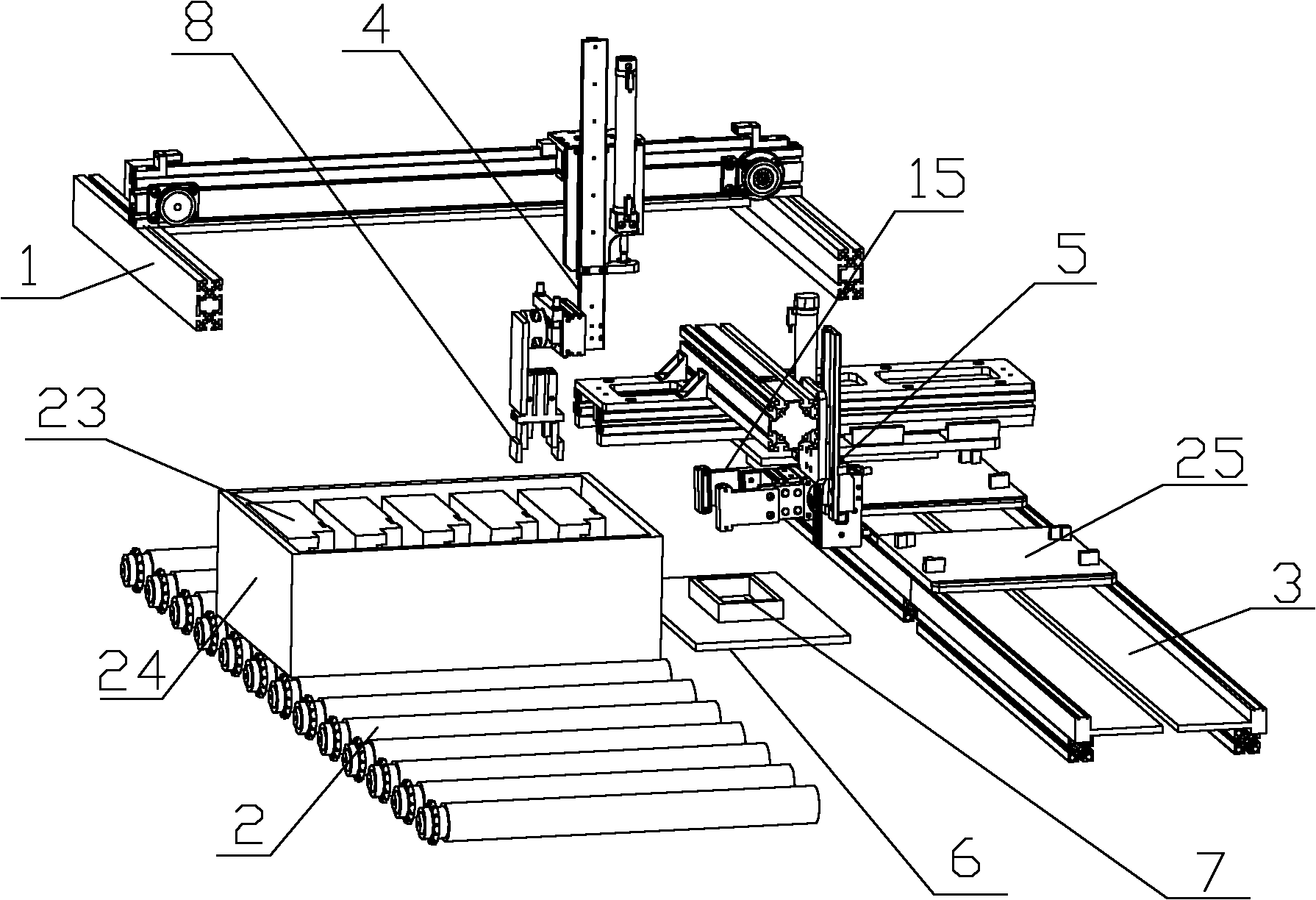

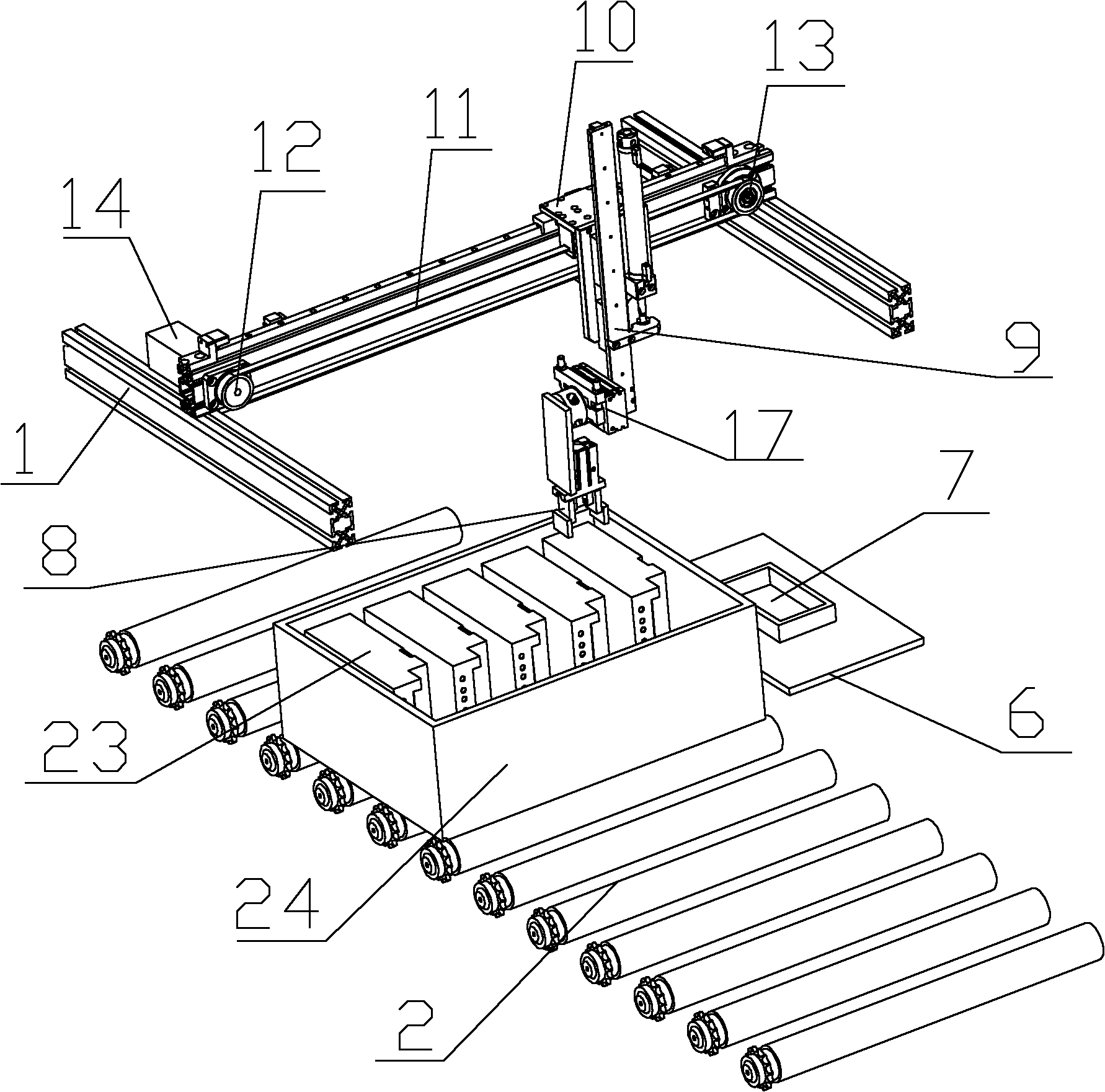

Device for shifting electric energy meter between meter box and single-epitope tooling plate

ActiveCN102126615AImprove placement accuracyEliminate Tolerance EffectsConveyor partsTransfer mechanismManipulator

The invention designs a device for shifting an electric energy meter between a meter box and a single-epitope tooling plate, relates to electric energy meter shifting equipment and solves the technical problem of poor efficiency due to manual operation in majorities. The device comprises a rack and is characterized in that the rack is provided with a transferring platform, a first manipulator anda second manipulator which both can move horizontally and vertically, the transferring platform is provided with an accommodating groove arranged between the first manipulator and the second manipulator, the first manipulator of the rack is laterally provided with meter box conveying chains, the second manipulator of the rack is laterally provided with a single-epitope tooling plate conveying chains, a rotating mechanism is installed on the first manipulator, and a turnover mechanism is installed on the second manipulator. The device operates automatically and improves the production efficiency; and the tolerance influence on an inner module of the meter box is eliminated by arranging the transferring mechanism and the two manipulators are used for reducing moving errors to improve the accuracy of placing the electric energy meter on the single-epitope tooling plate. Moreover, the device has low cost and is suitable for popularization and application on a large scale.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

Systems and Methods for the Medical Treatment of Structural Tissue

InactiveUS20080221624A1Easy to insertEasy to attachSuture equipmentsInternal osteosythesisOrthopedic ProceduresPlastic surgery

The present invention is directed generally to a biomedical system(s) and method(s). More specifically, some embodiments may include system(s) and method(s) used in medical treatment(s). Various embodiments may include medical system(s) and method(s) that may use an anchoring mechanism and screw (bolt, etc.) arrangement that increases the strength of attachment. Some embodiments may further include, for example, an anchoring mechanism that expands upon insertion of a screw (bolt, etc.) into an opening. Some embodiments may include, for example, a system(s) and method(s) for improvement of structural tissue (e.g., bone, cartilage) fixation and safety. Further, some embodiments may also include, for example, an anchoring mechanism and screw (bolt, etc.) system that may be utilized in orthopedic procedures. Still some embodiments may further include system(s) and method(s) providing improved screw fixation and enhanced stabilization in structural tissue or fracture repair. Various embodiments may include multiple anchor mechanisms and anchor mechanism holding means.

Owner:GOOCH HUBERT L

Combination sensor guidewire and methods of use

ActiveUS20060241505A1Good accuracy and consistencyMinimize impactBlood flow measurement devicesCatheterEngineeringGuide wires

The present invention provides for an improved combination sensor tip that includes a pressure sensor and a second sensor other than a pressure sensor, both disposed at or in close proximity to the distal end of the combination sensor tip. The present invention also provides for an improved connector to couple a guide wire to a physiology monitor that reduces torsional resistance when maneuvering the guide wire.

Owner:VOLCANO CORP

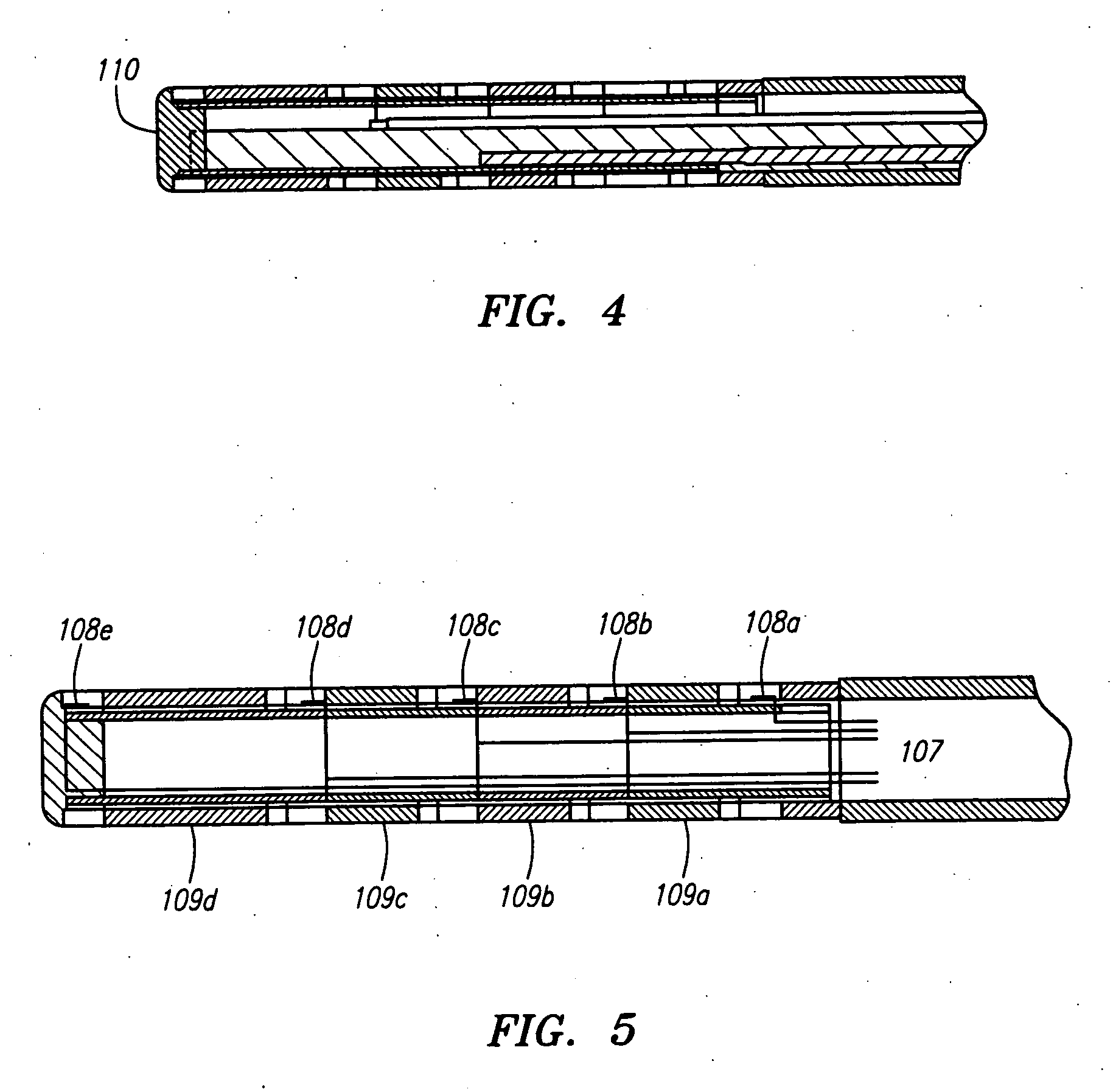

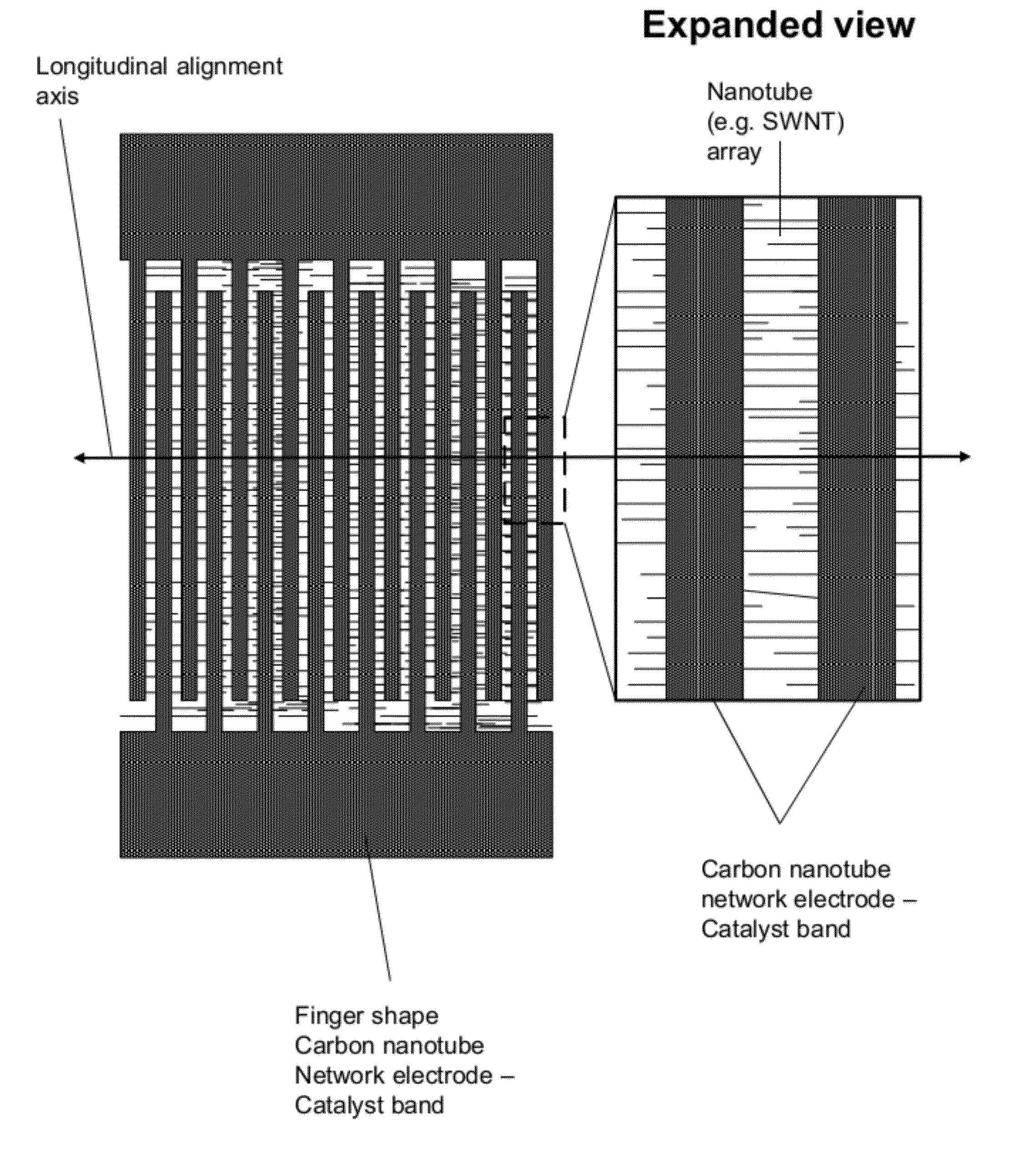

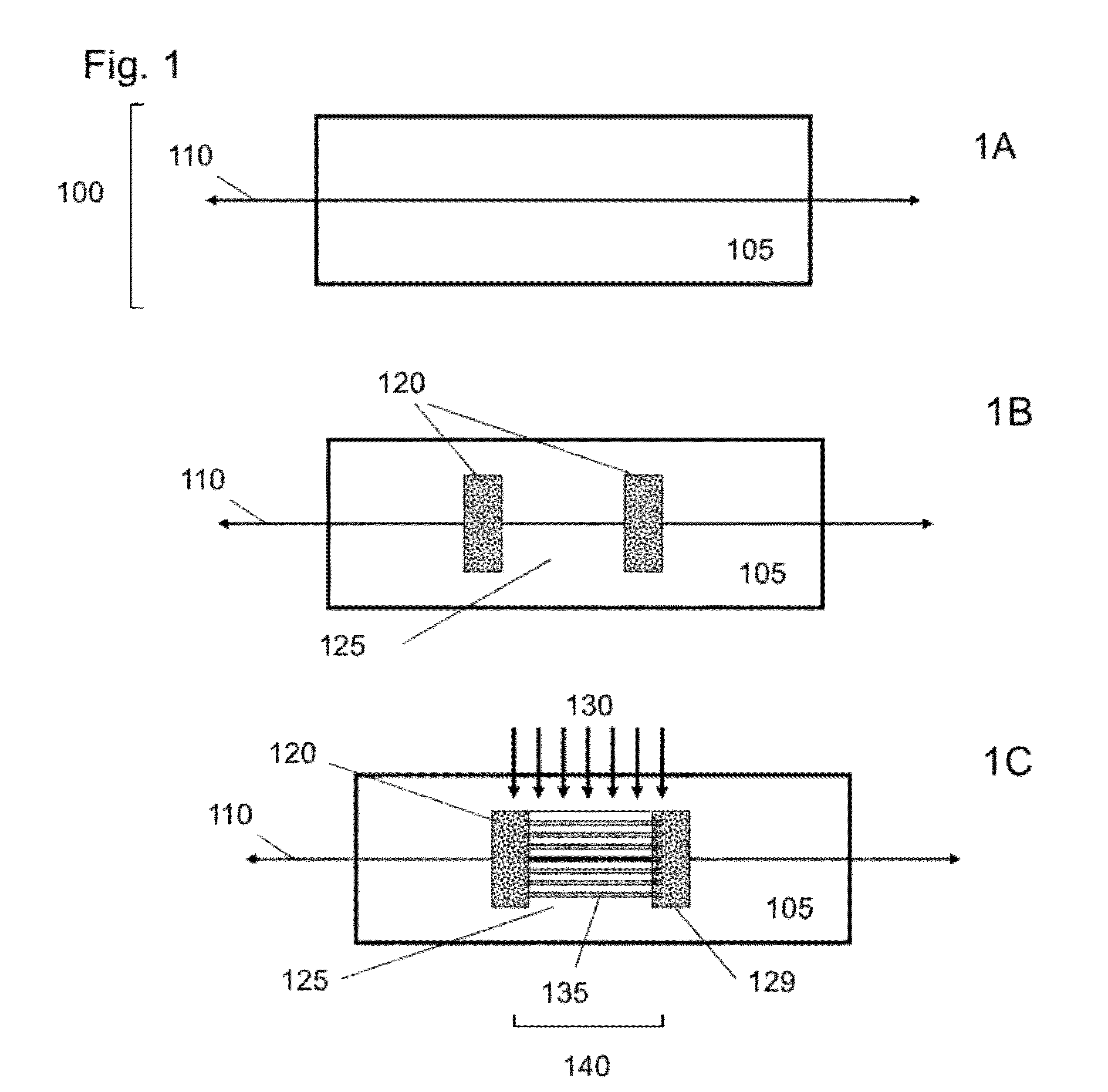

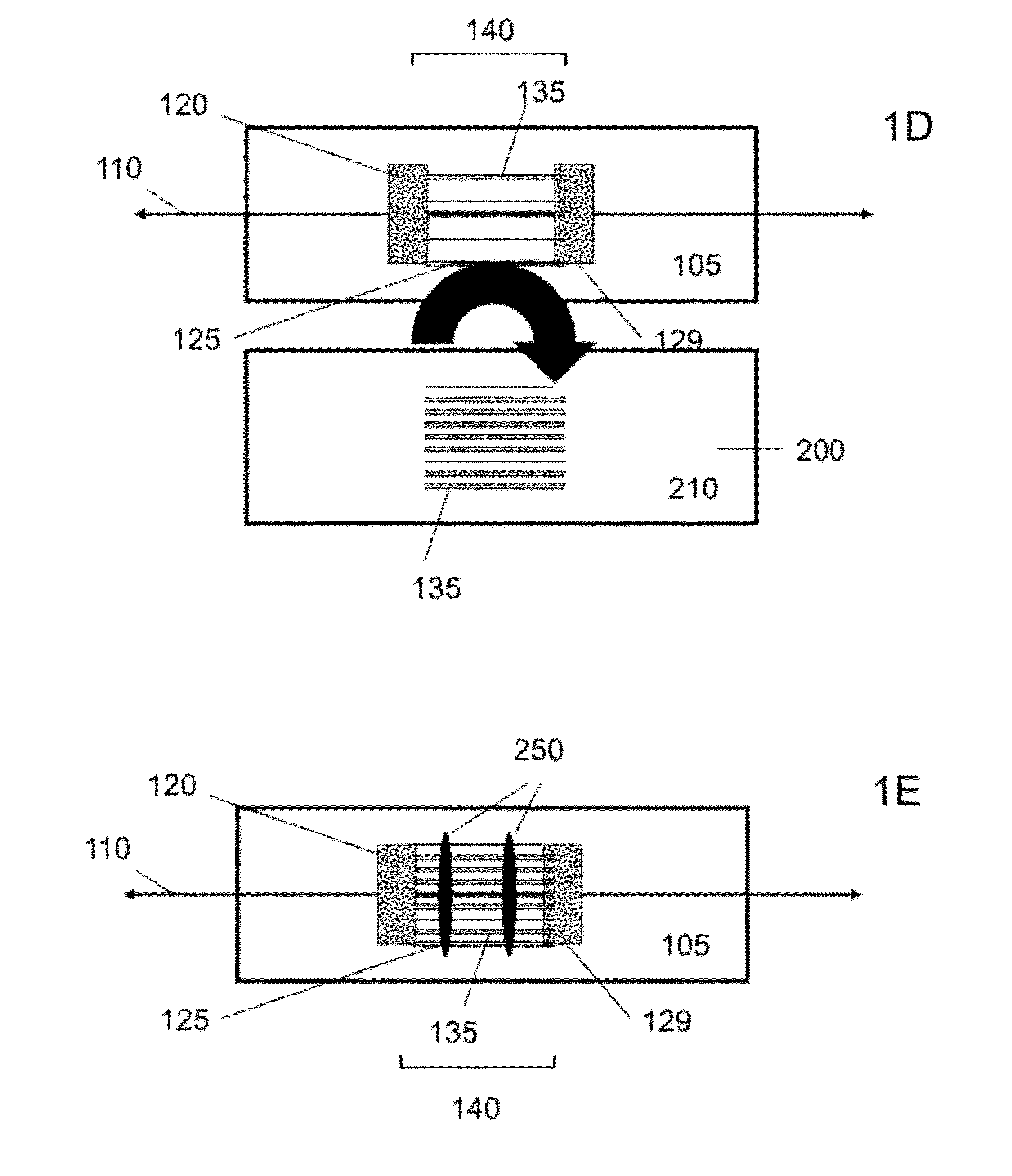

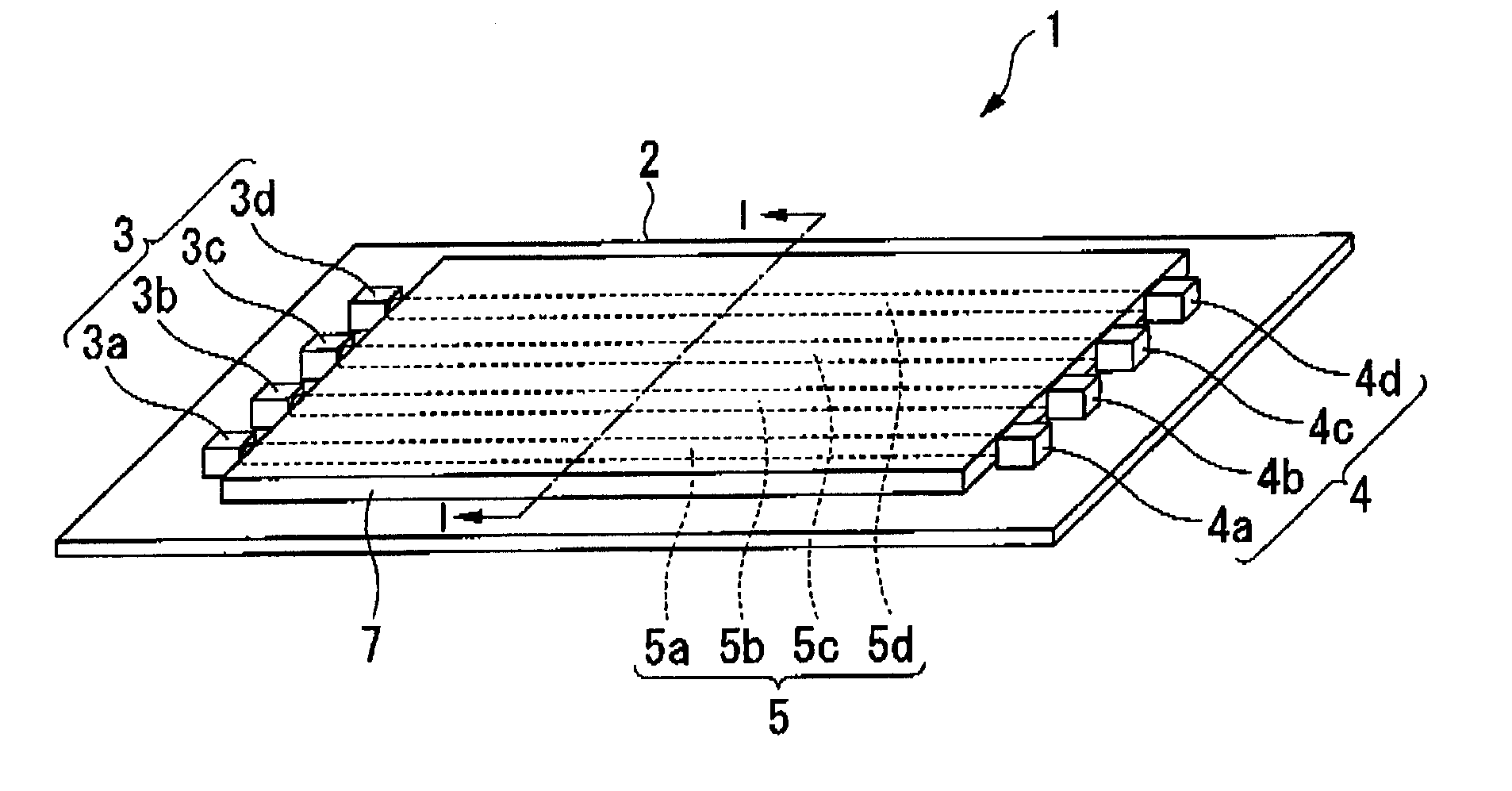

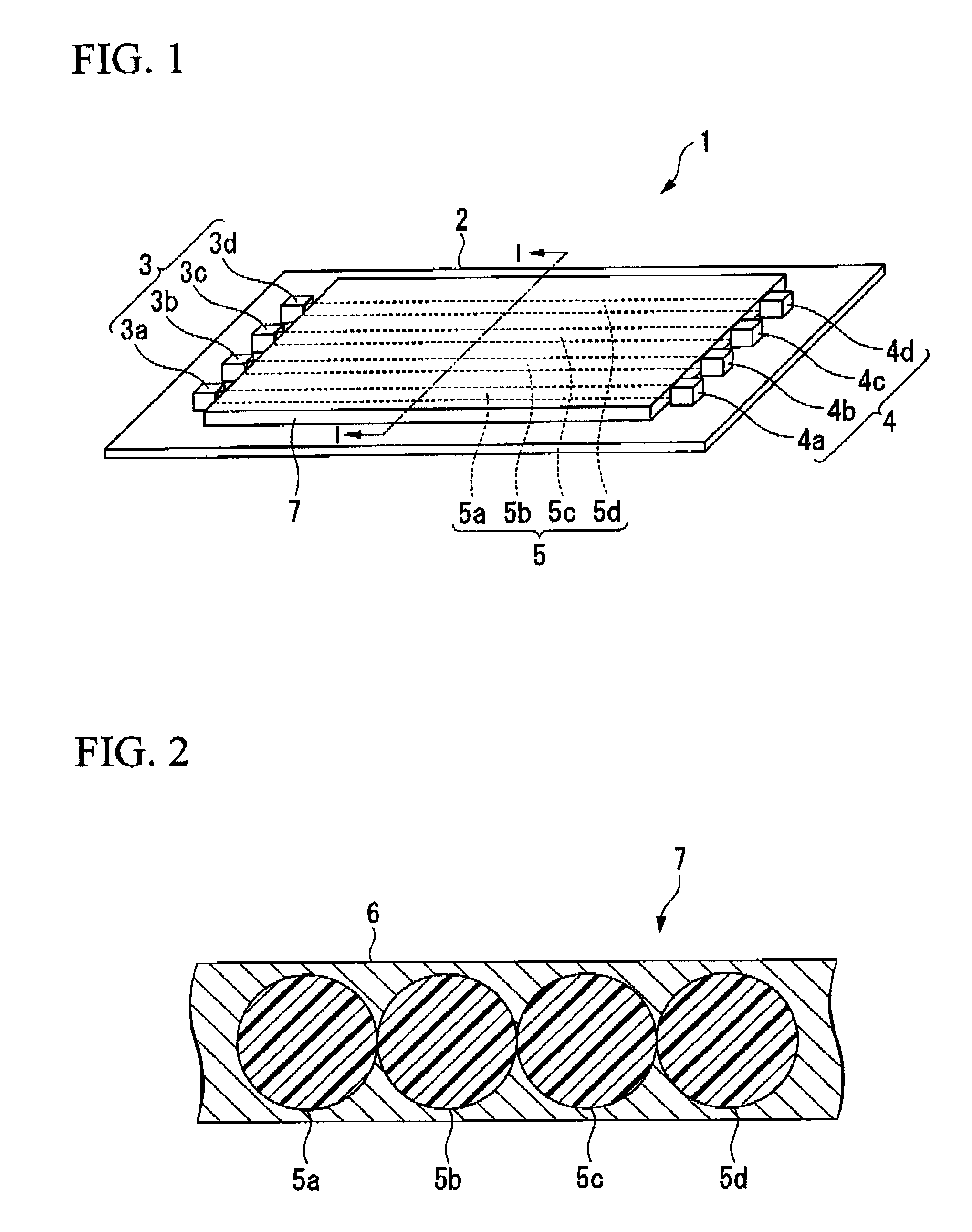

Methods of Making Spatially Aligned Nanotubes and Nanotube Arrays

ActiveUS20120321785A1Improve placement accuracyImprove fidelityMaterial nanotechnologyNanoinformaticsElectronNanotube array

The present invention provides arrays of longitudinally aligned carbon nanotubes having specified positions, nanotube densities and orientations, and corresponding methods of making nanotube arrays using guided growth and guided deposition methods. Also provided are electronic devices and device arrays comprising one or more arrays of longitudinally aligned carbon nanotubes including multilayer nanotube array structures and devices.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

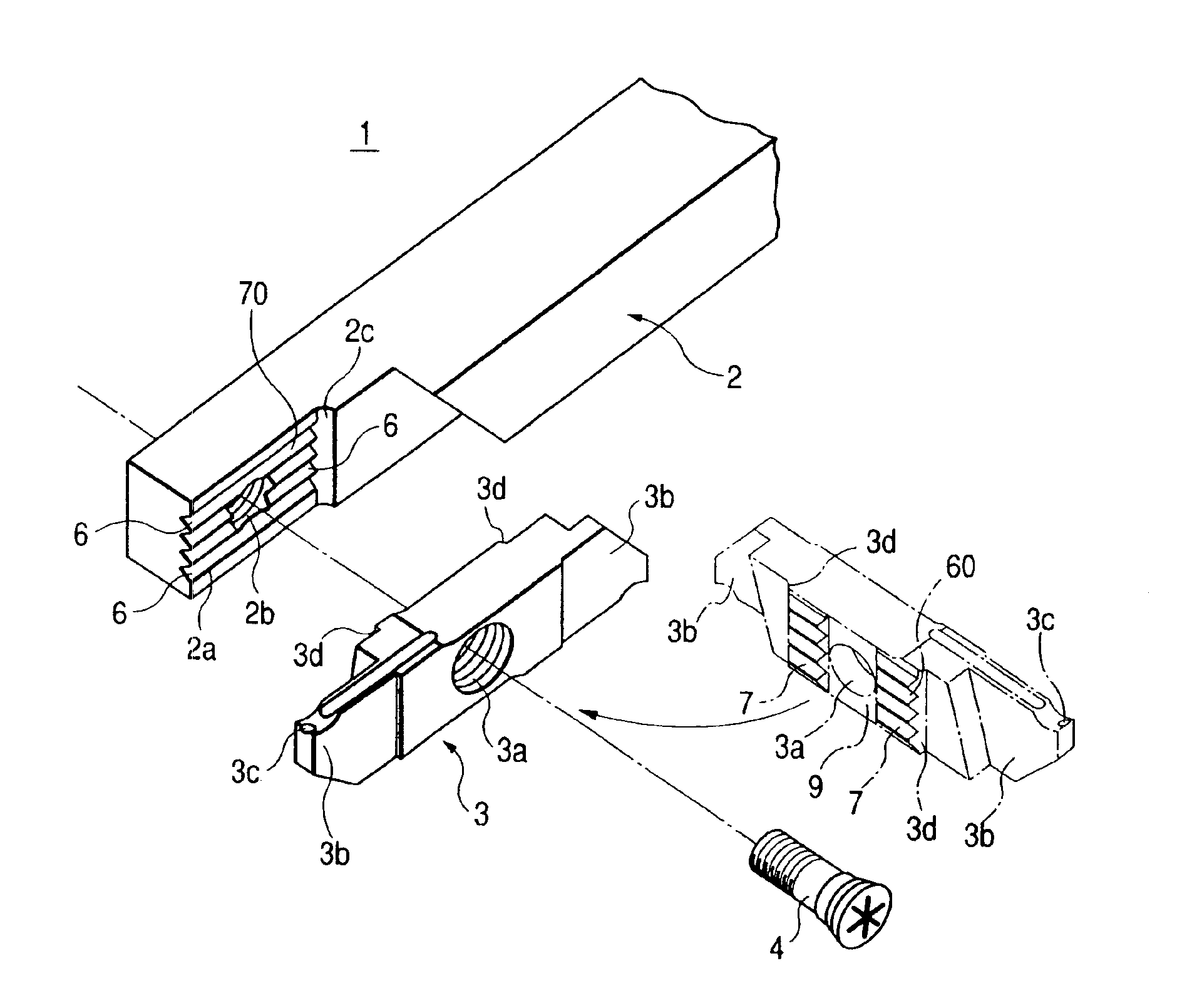

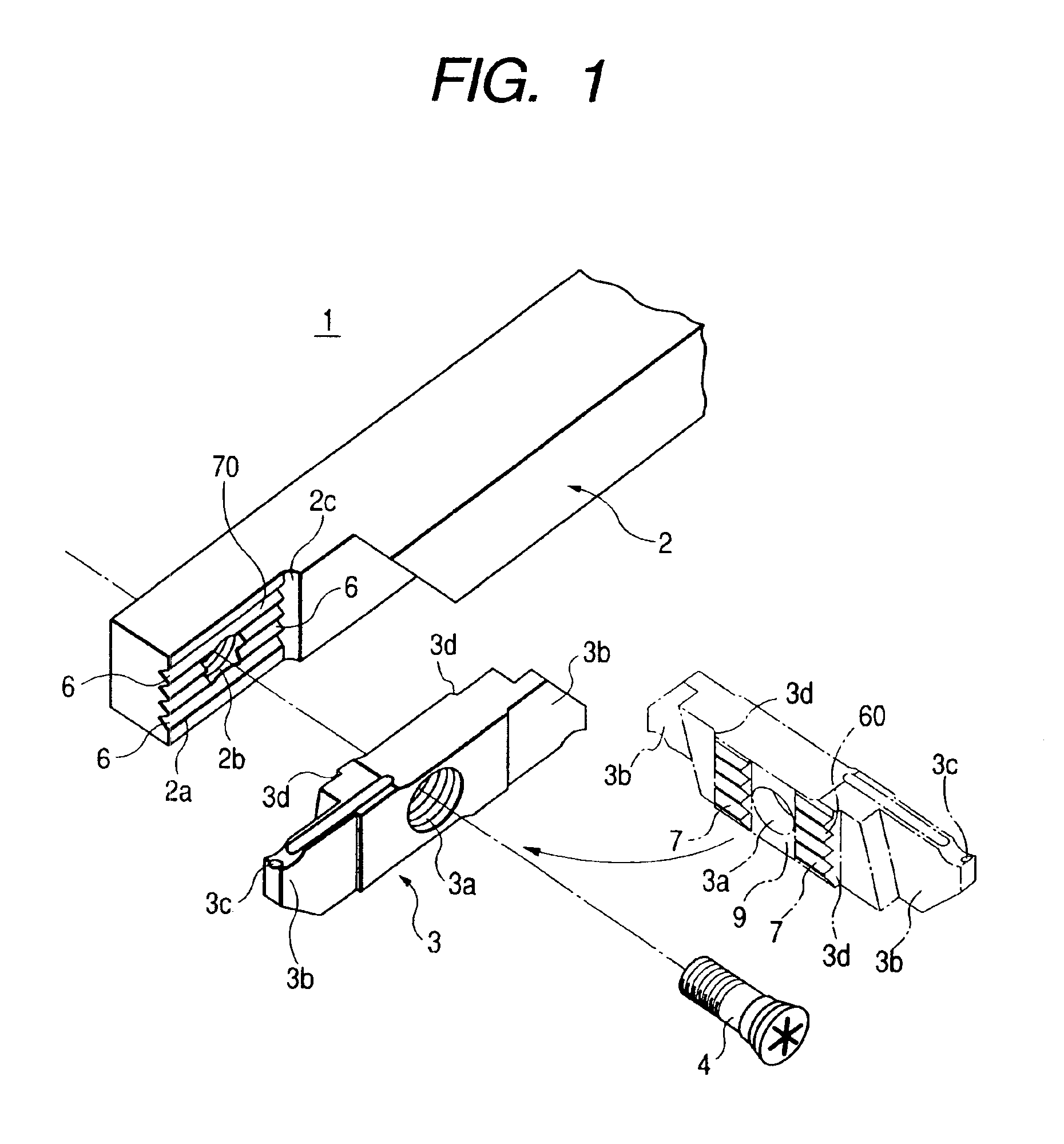

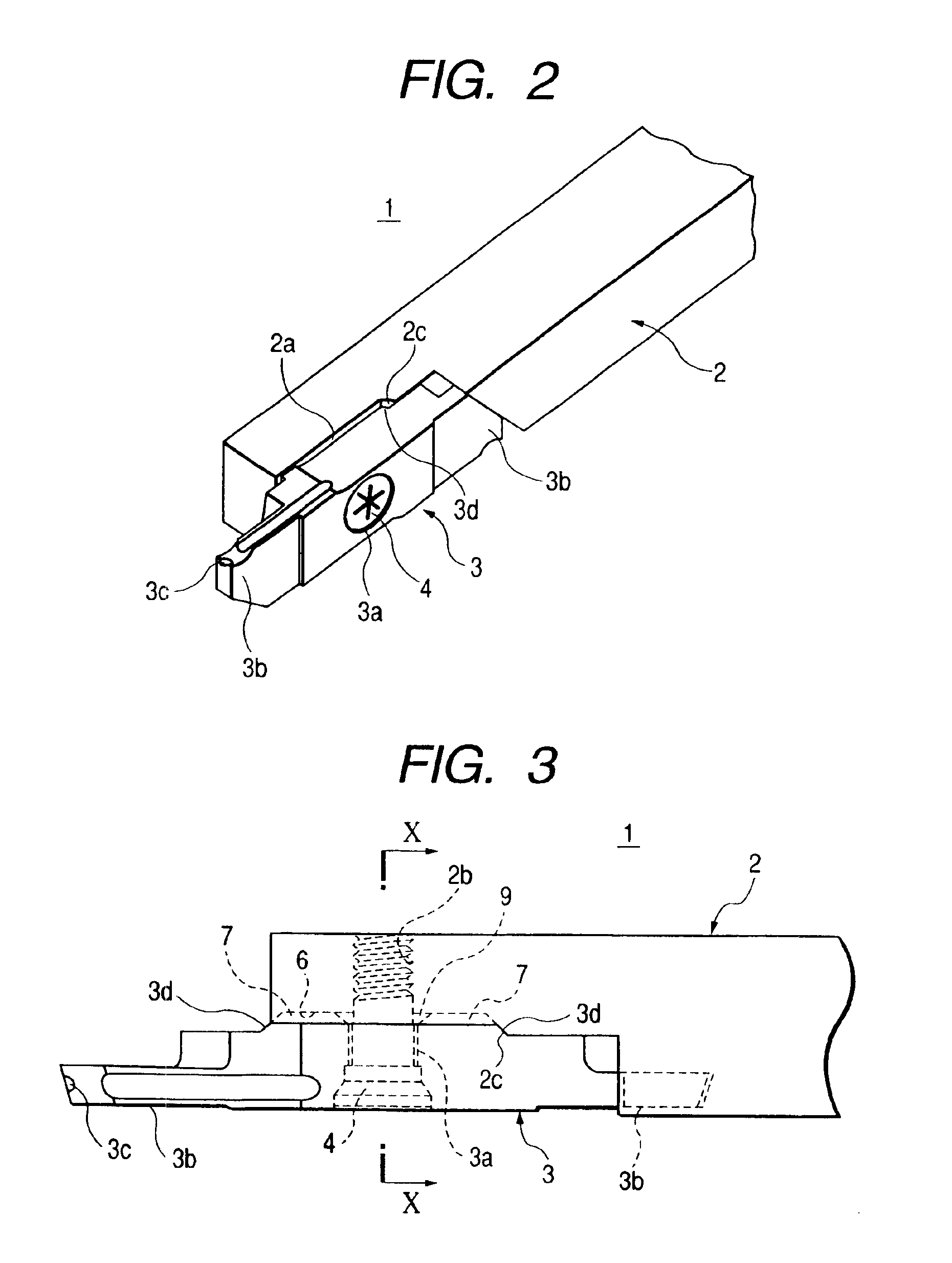

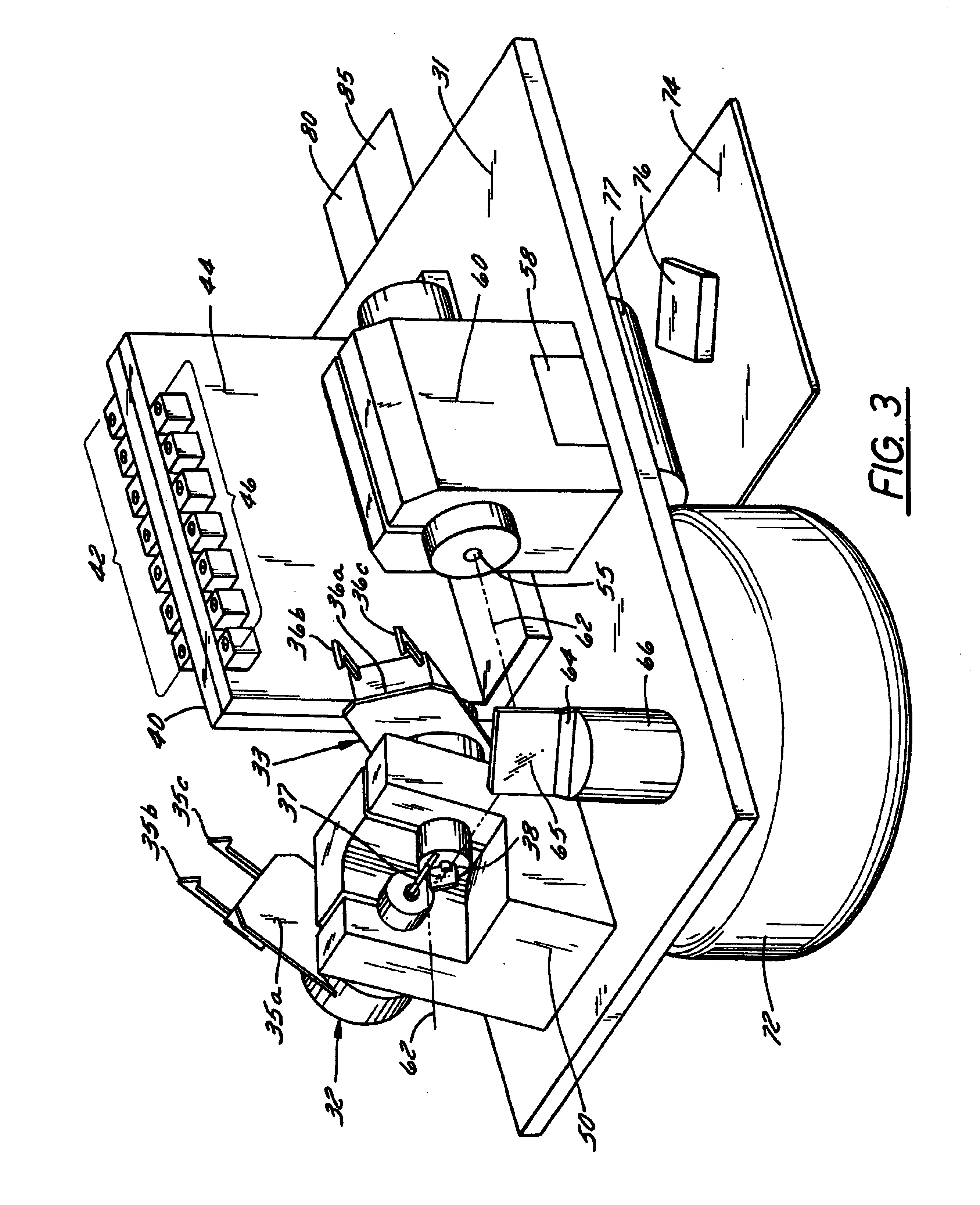

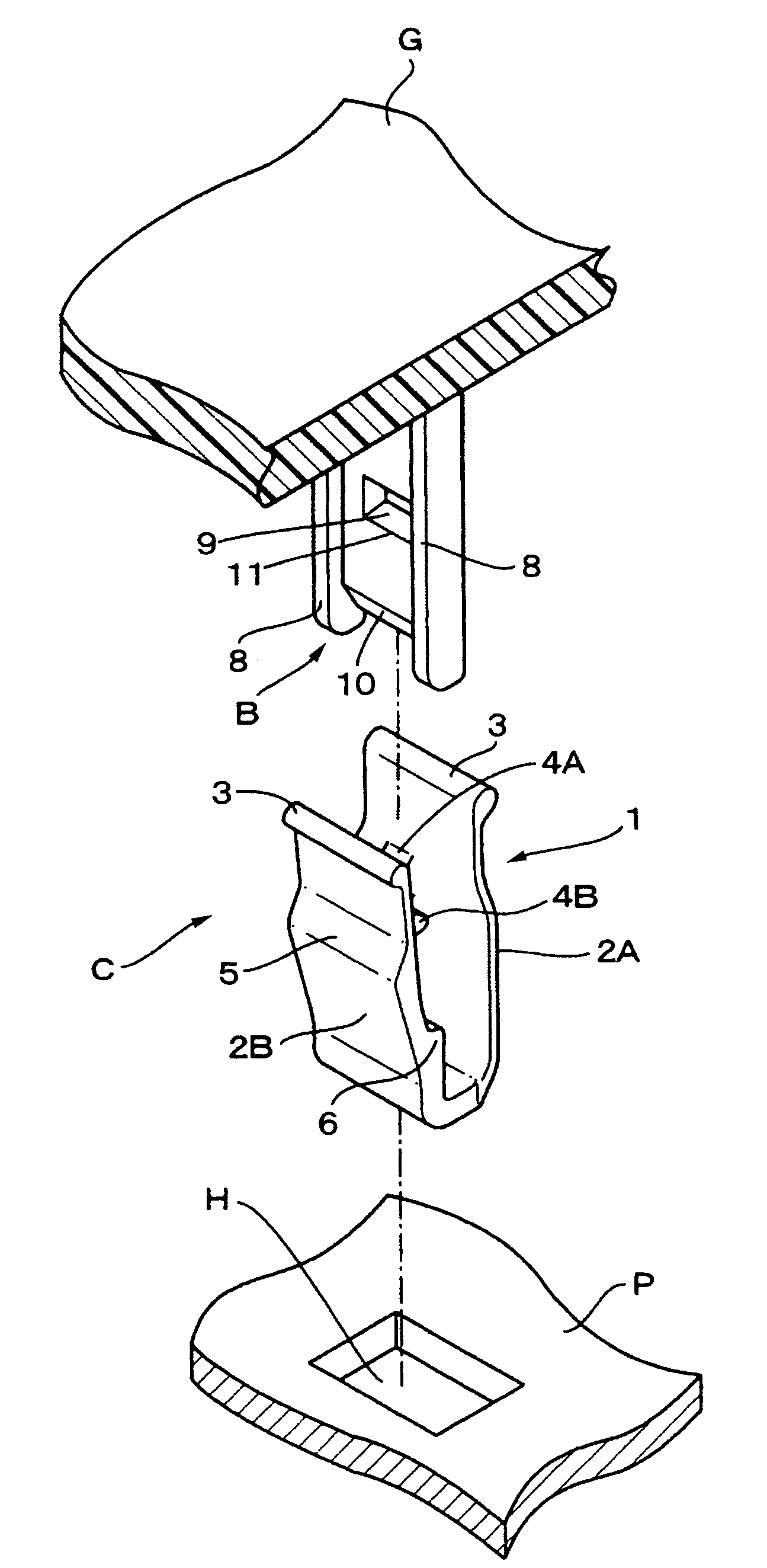

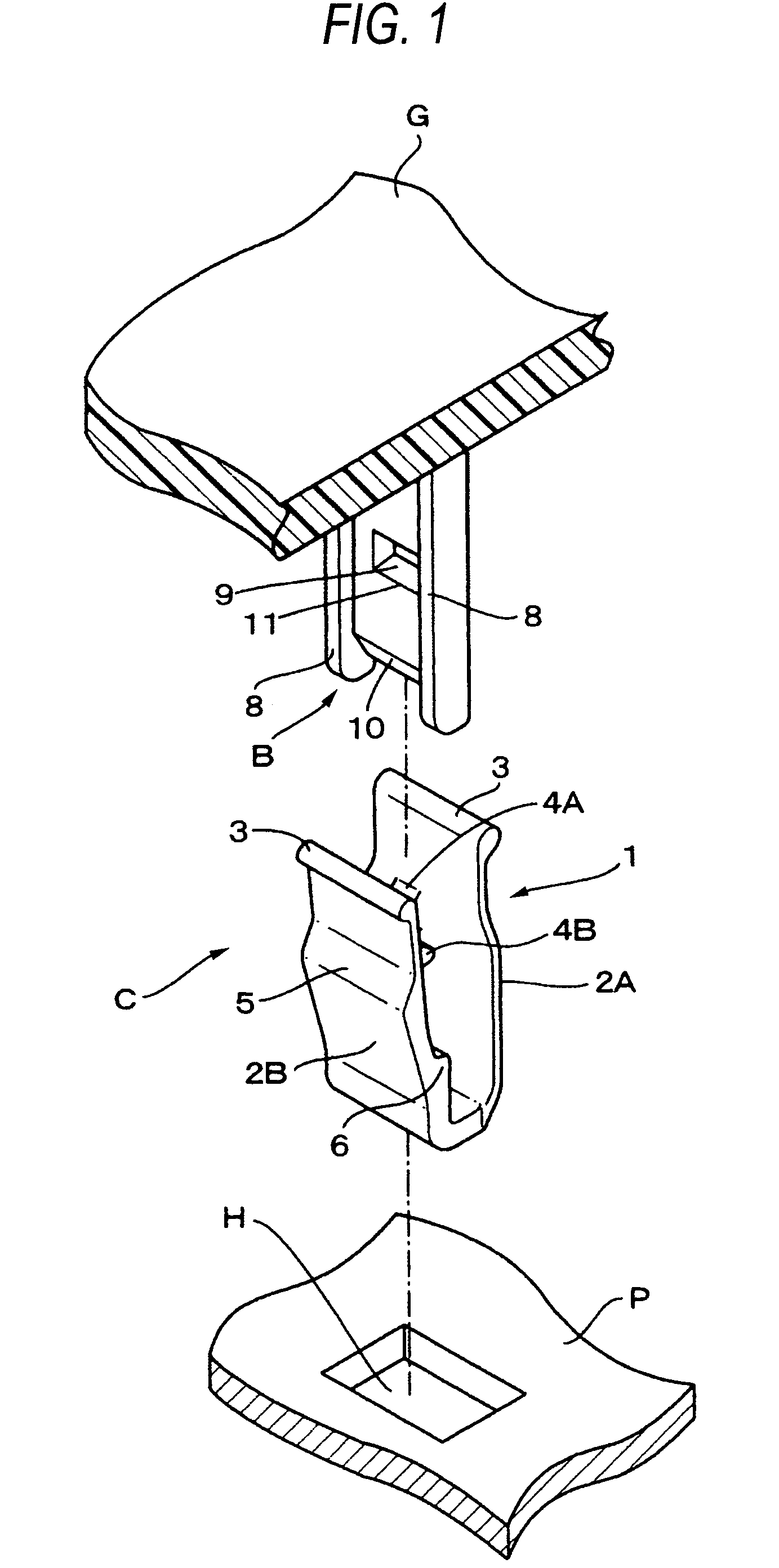

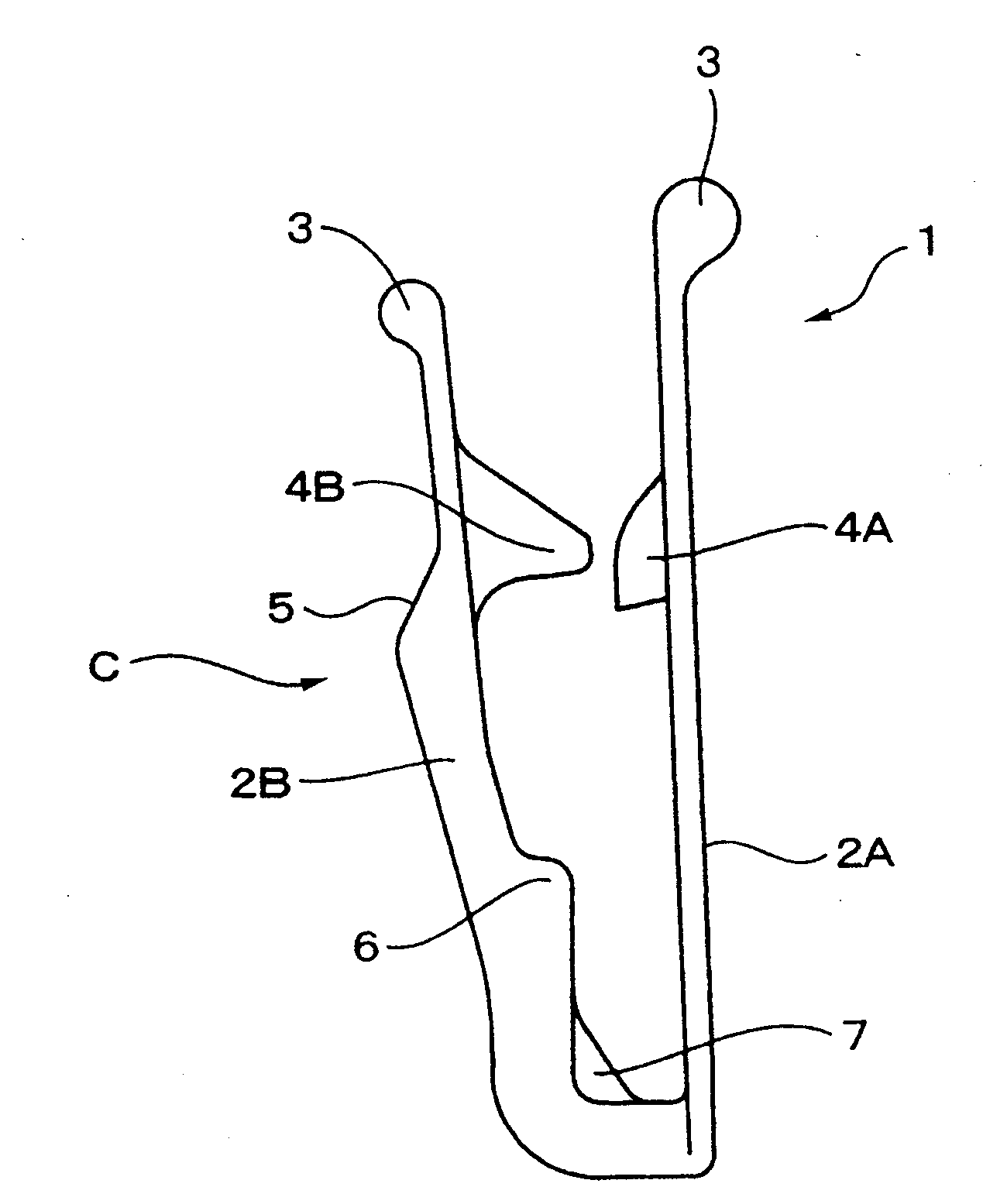

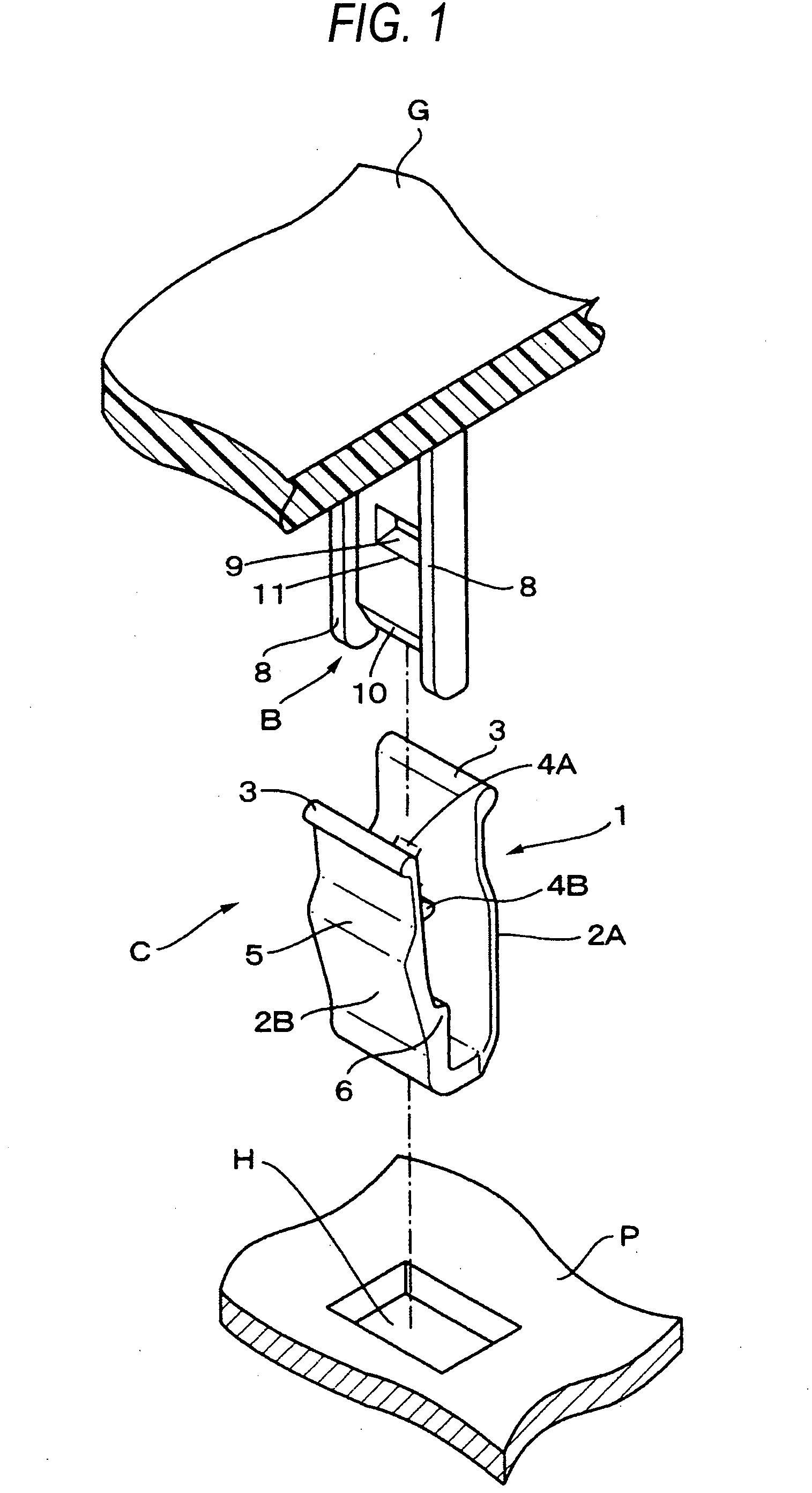

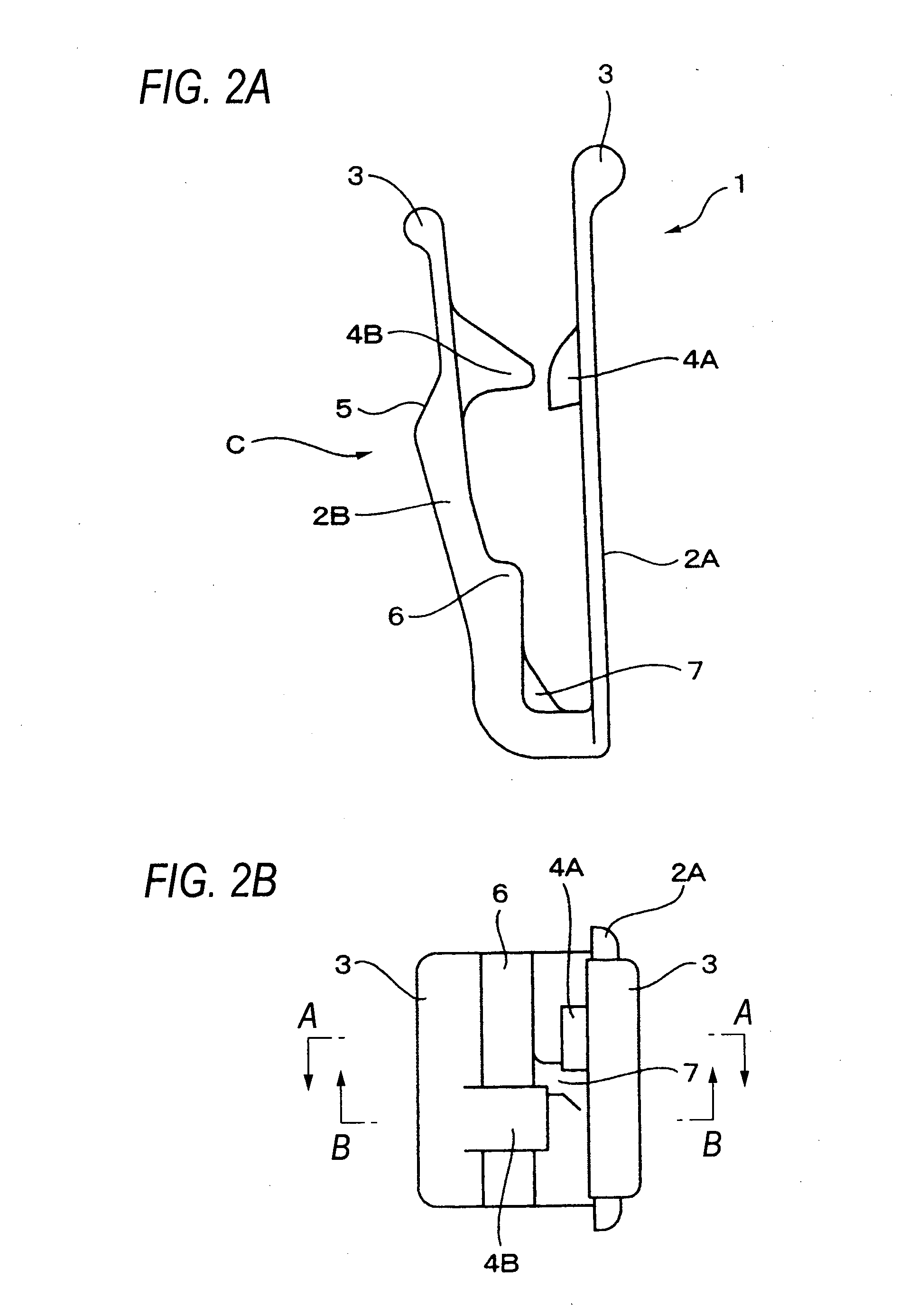

Insert, holder and cutting tool

InactiveUS6960049B2Improve placement accuracyMilling machinesTurning toolsEngineeringMechanical engineering

A cutting tool has an insert shaped as a parallelogram that is detachably mounted by a clamp screw 4 on a tip mounting face of a holder. Concave grooves are formed like parallel stripes on the tip mounting face of the holder, and convex lines are formed on the abdominal face of the insert to be fitted in the concave grooves, so that the insert is clamped by the clamp screw to the holder in a state where the convex lines are fitted in the concave grooves on the tip mounting face.

Owner:NGK SPARK PLUG CO LTD

High resolution electrohydrodynamic jet printing for manufacturing systems

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

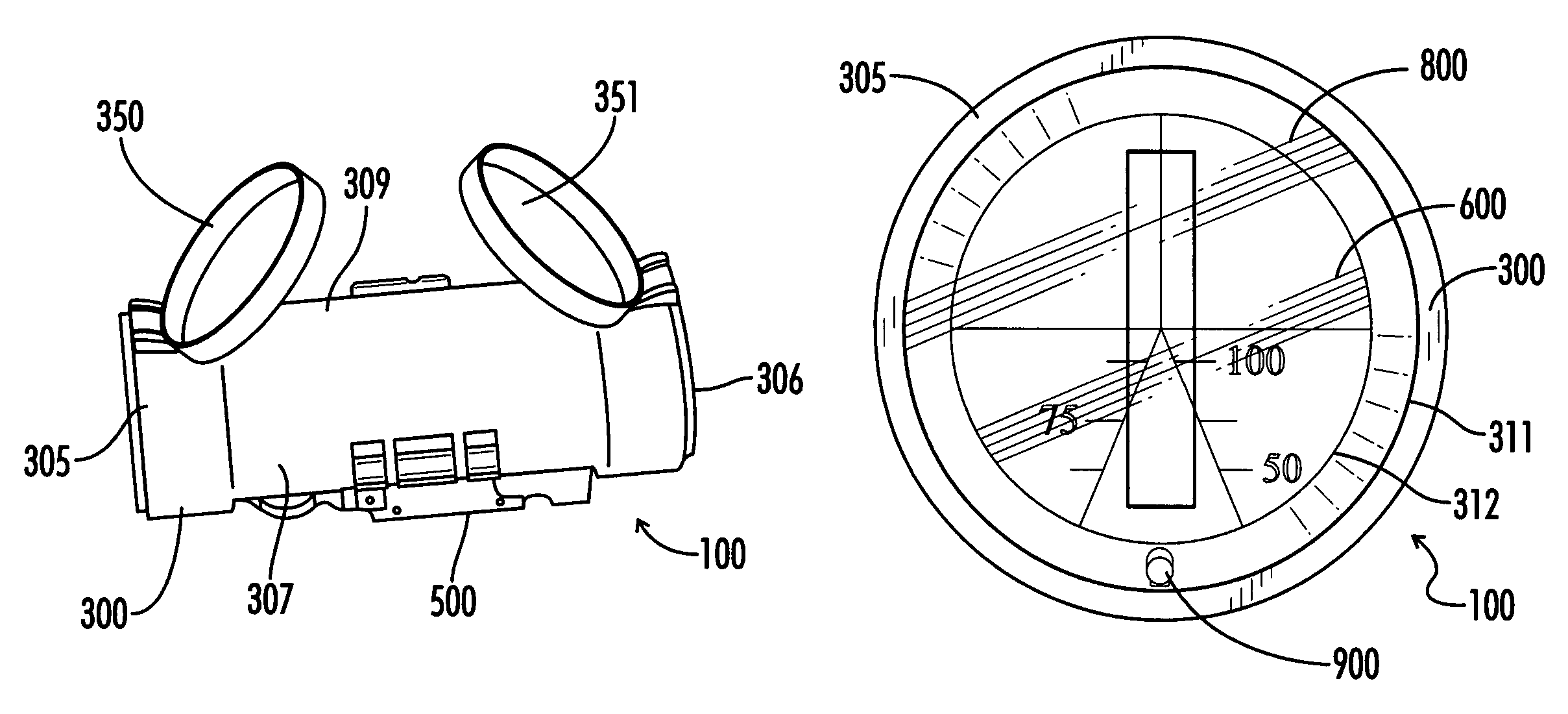

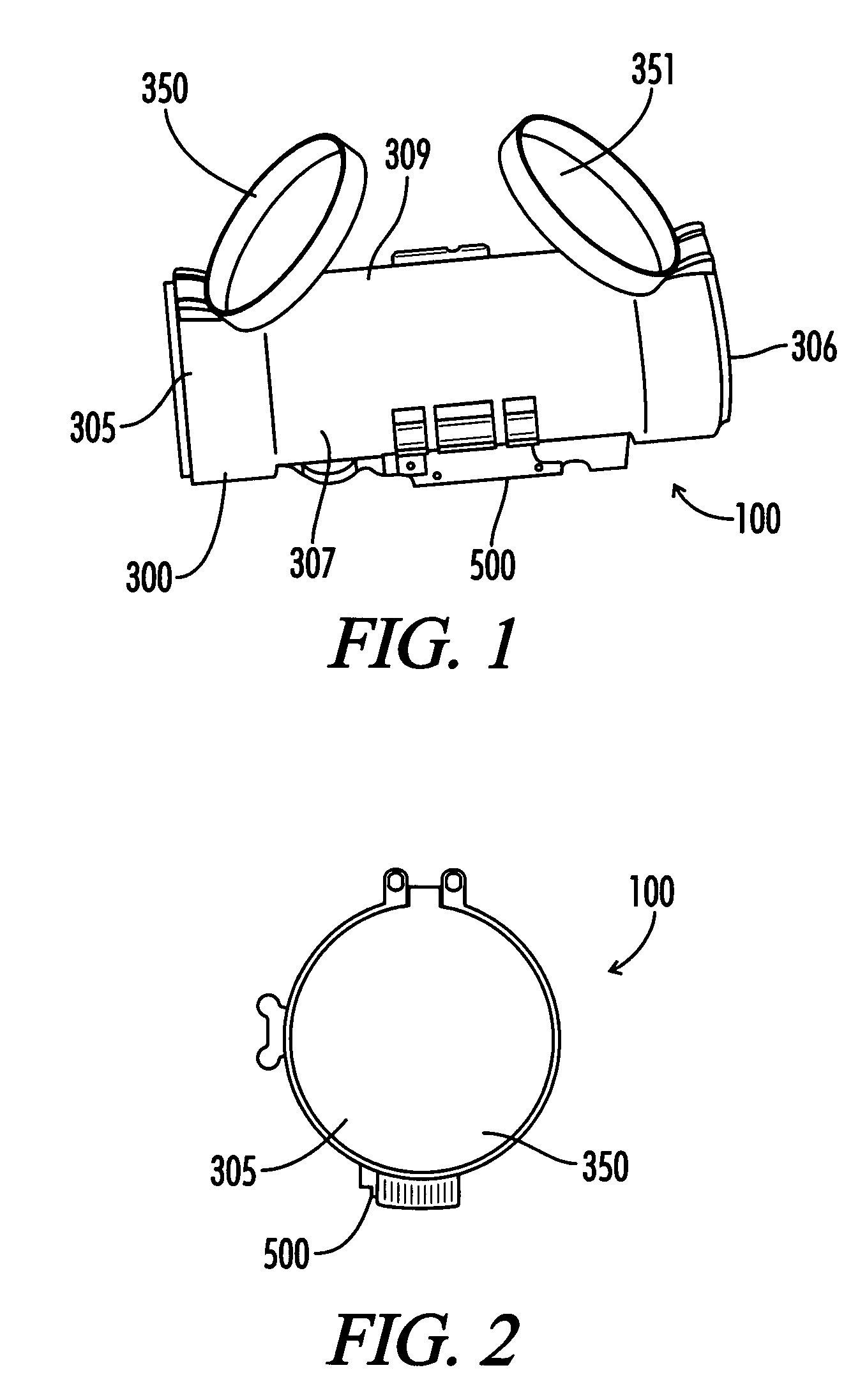

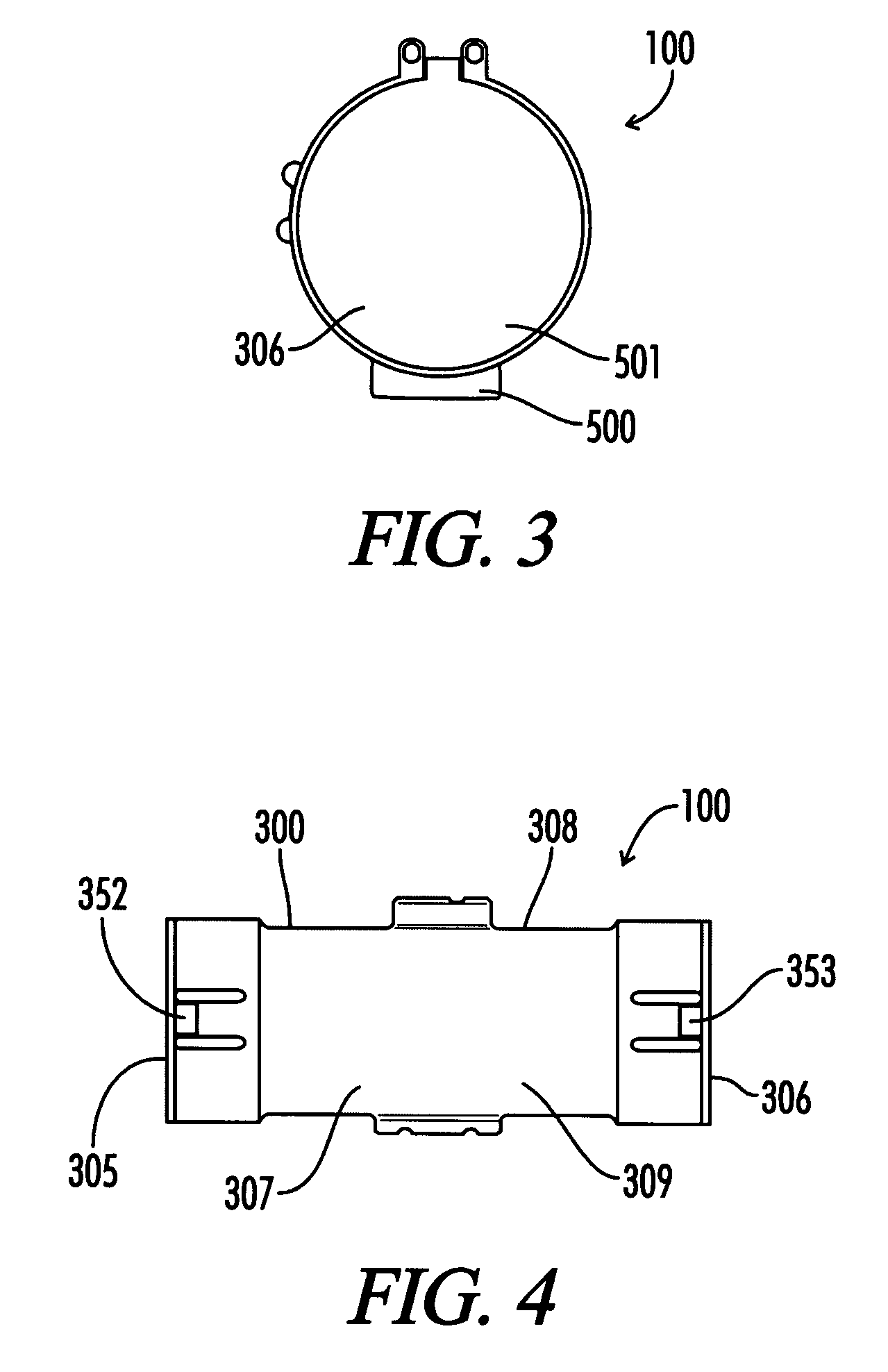

Paintball marker sight apparatus

InactiveUS7685760B1Improve placement accuracyImprove accuracySighting devicesEngineeringElectrical and Electronics engineering

A sight apparatus for attachment to a paintball marker having two distinct reticles to assist with the placement accuracy of paintballs. The sight apparatus comprises a body, a first reticle and a second reticle. The first reticle is substantially transparent and includes a diameter line, at least two radius lines, and at least three segment lines extending from each of at least two radius lines. The second reticle is substantially transparent and has a rectangular outline.

Owner:KEE ACTION SPORTS I

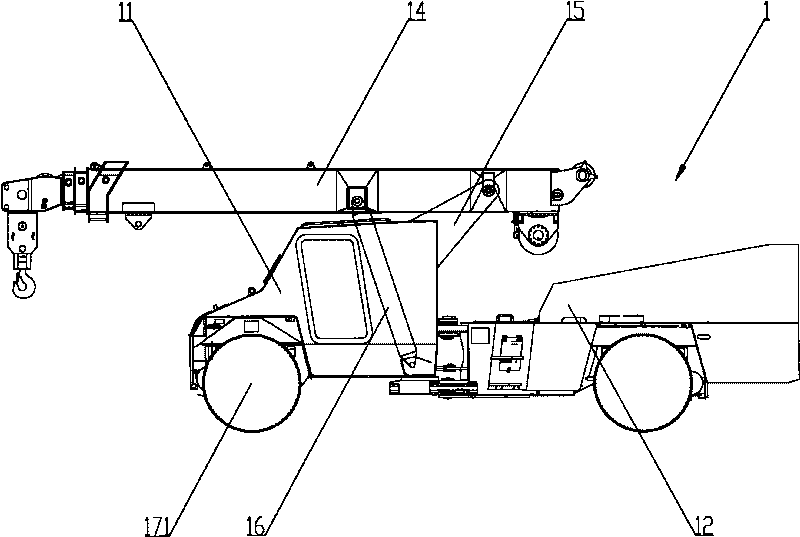

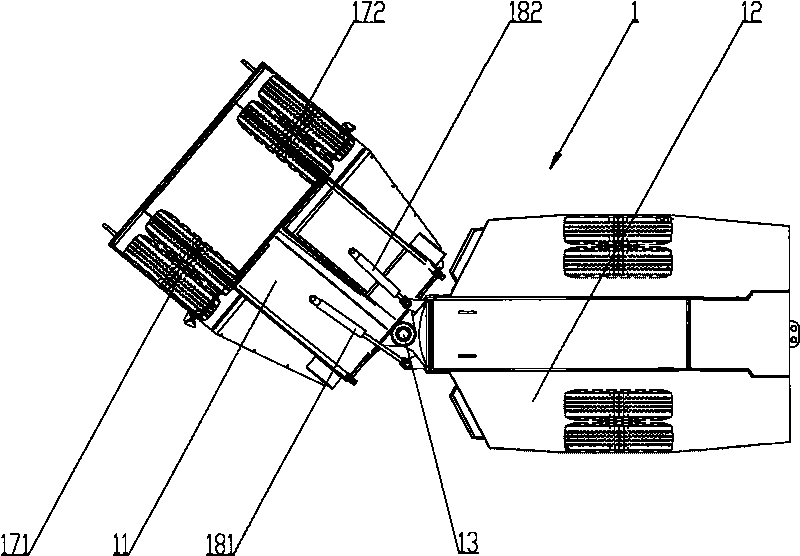

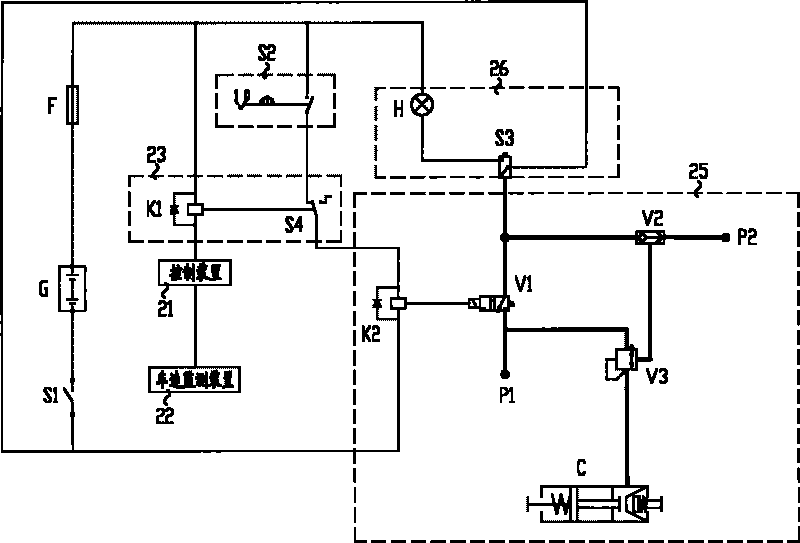

Articulated front-handling mobile crane and operation control system thereof

InactiveCN101723256AAccurate placementImprove placement accuracyLoad-engaging elementsCranesControl systemSpace activity

The invention discloses an articulated front-handling mobile crane. The crane comprises at least one braking device, wherein at least one of a front-left wheel or a front-right wheel of the articulated front-handling mobile crane can be independently braked by the braking device. The invention also provides an operation control system for the articulated front-handling mobile crane, which comprises at least one braking device, an independent brake switch, a safety device, a vehicle speed monitoring device and a control device. The articulated front-handling mobile crane can take a front wheel on any side thereof as the center for steering, so the articulated front-handling mobile crane can remarkably reduce steering radius and improve placing accuracy and small-space activity ability of heavy objects. At the same time, the articulated front-handling mobile crane can also ensure that the braking device cannot be started during high-speed operation further to improve safety performance and ensure the safety of personnel, equipment and loads.

Owner:XUZHOU HEAVY MASCH CO LTD

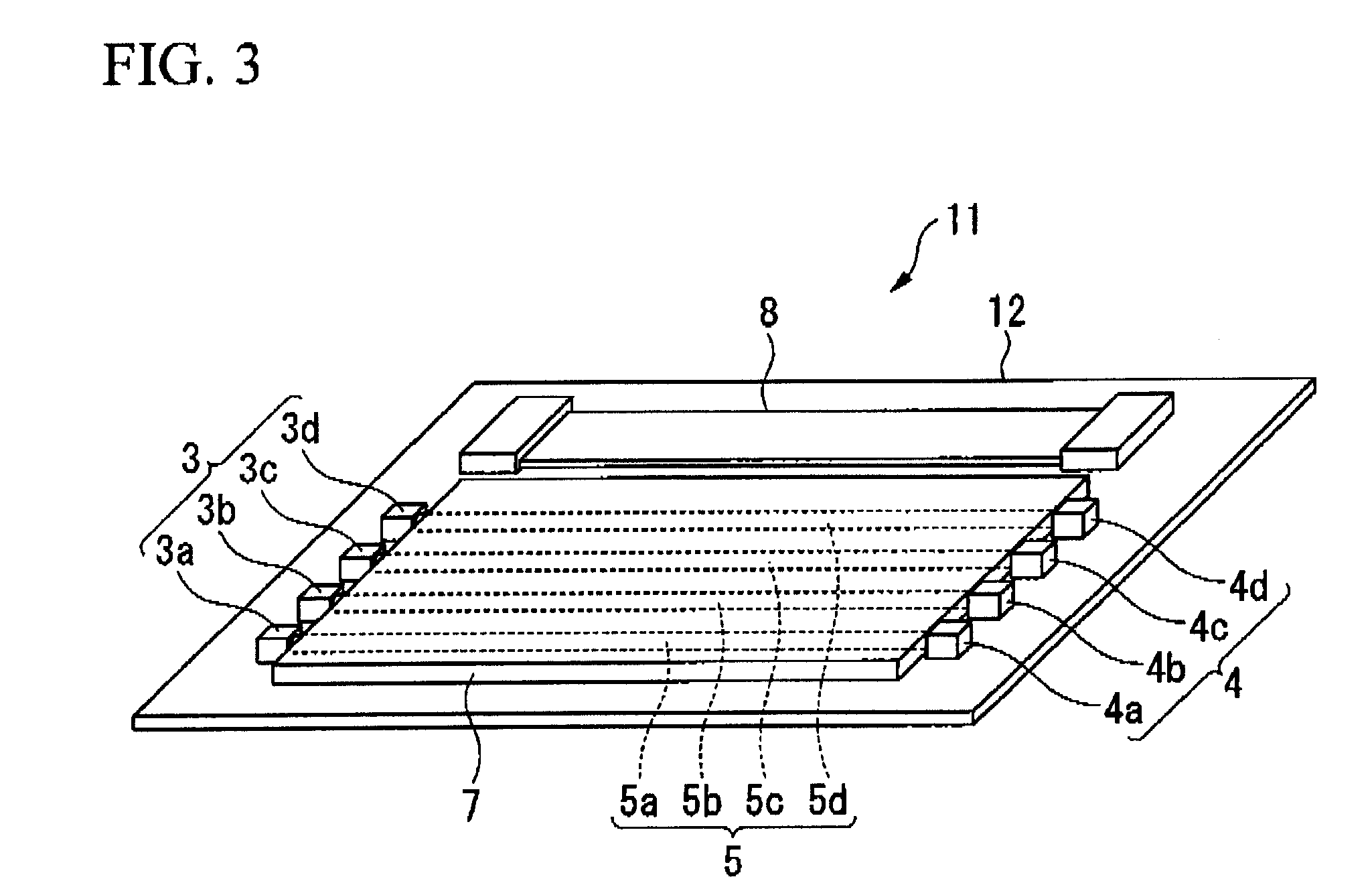

Optical/electrical circuit interconnect board and evaluation method therefor

InactiveUS20070230863A1Easy to installImprove alignment accuracyCoupling light guidesFibre mechanical structuresEngineeringOpto electronic

An optical / electrical interconnect board includes a base material composing an electrical circuit; a plurality of light receiving / emitting units, each of the units being constituted by a light emitting element and a light receiving element packaged on the base material; and an optical fiber tape that connects the light emitting element to the light receiving element for each of the light receiving / emitting units, the optical fiber tape being formed by bringing together optical wires for the units in a side-by-side manner and coating with a first coating material.

Owner:THE FUJIKURA CABLE WORKS LTD +1

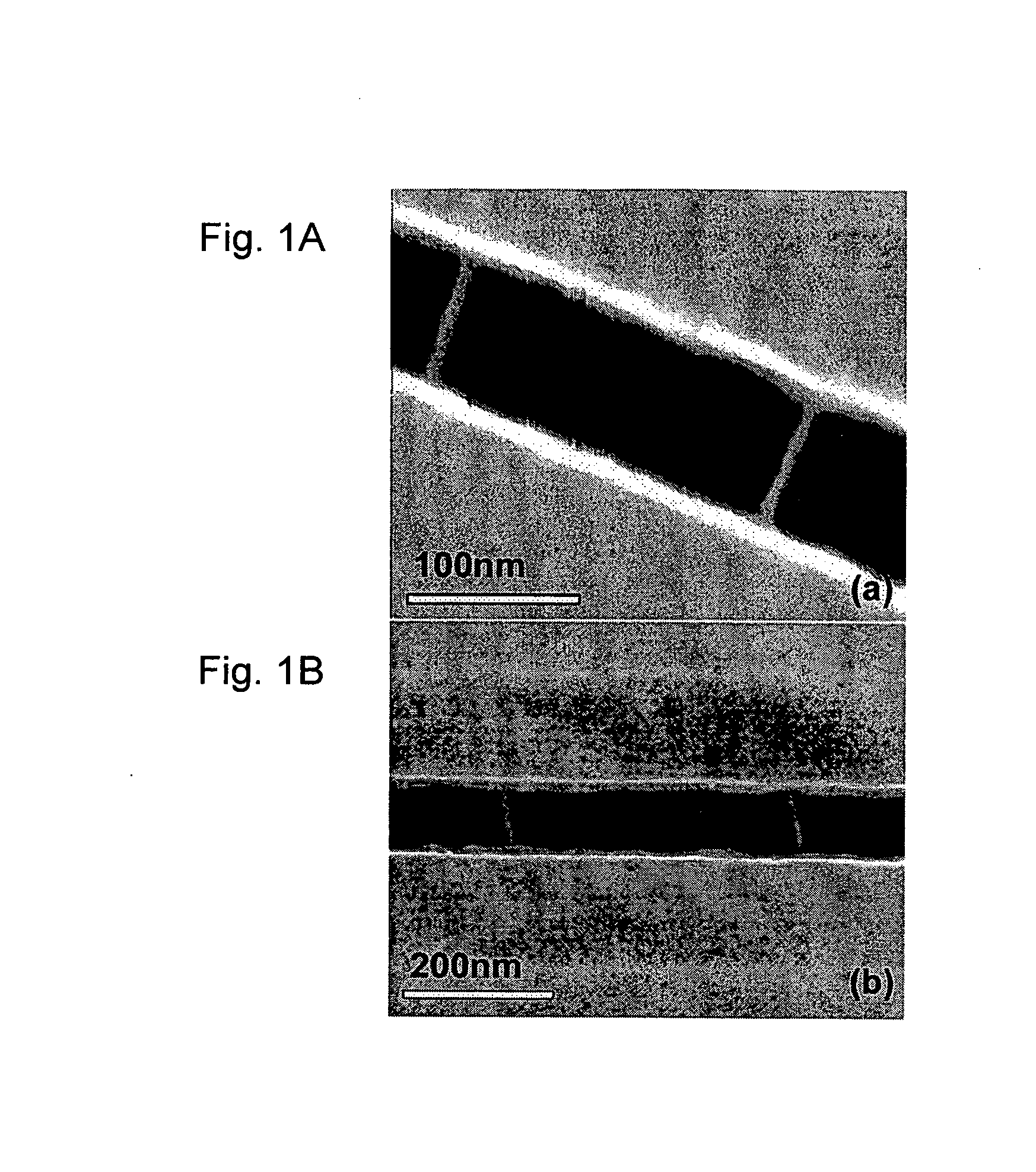

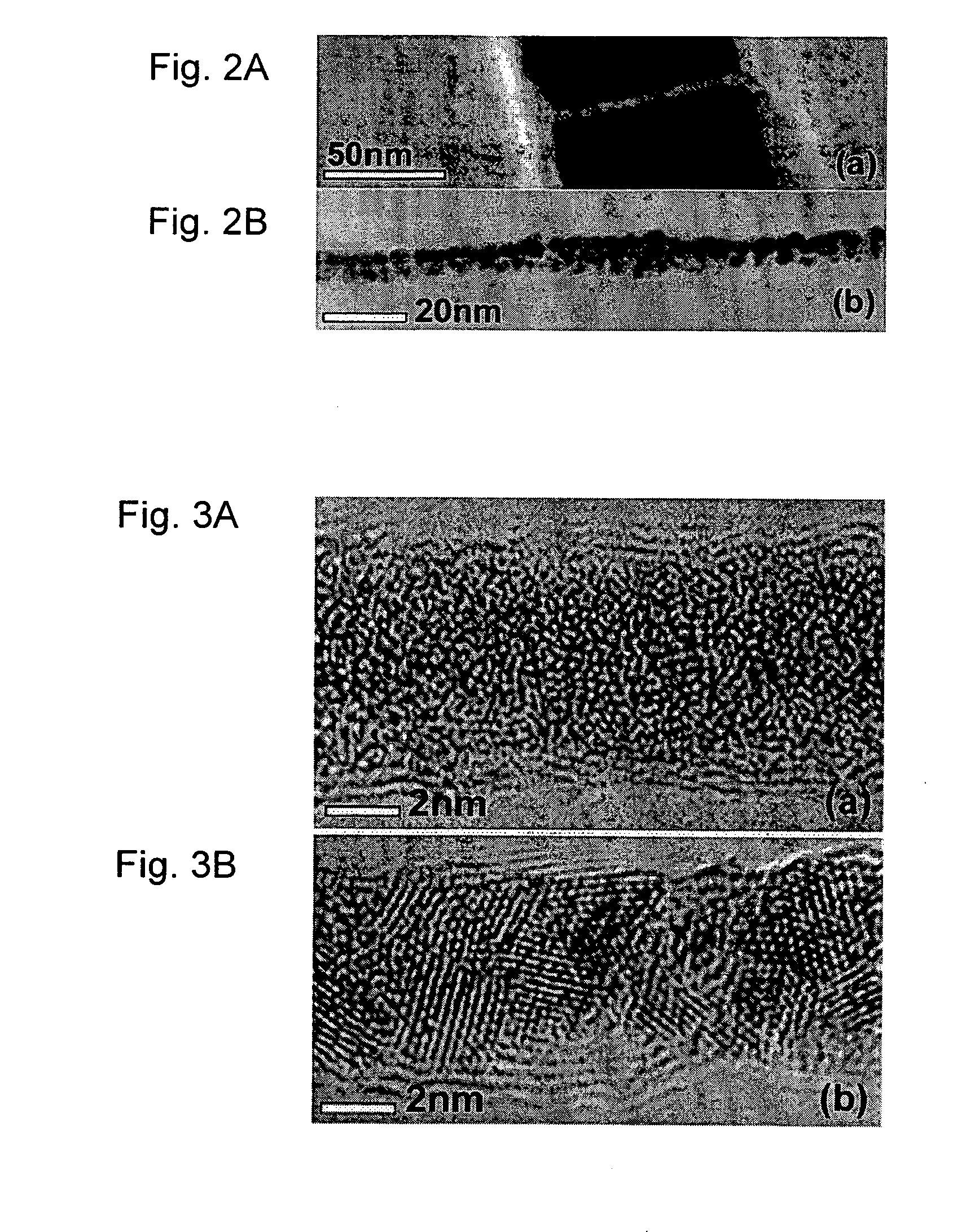

Nanowire structures and electrical devices

InactiveUS20070040191A1Improve placement accuracyReduced cross-sectional dimensionNanoinformaticsSolid-state devicesNanowireElectrical devices

The present invention provides structures and devices comprising conductive segments and conductance constricting segments of a nanowire, such as metallic, superconducting or semiconducting nanowire. The present invention provides structures and devices comprising conductive nanowire segments and conductance constricting nanowire segments having accurately selected phases including crystalline and amorphous states, compositions, morphologies and physical dimensions, including selected cross sectional dimensions, shapes and lengths along the length of a nanowire. Further, the present invention provides methods of processing nanowires capable of patterning a nanowire to form a plurality of conductance constricting segments having selected positions along the length of a nanowire, including conductance constricting segments having reduced cross sectional dimensions and conductance constricting segments comprising one or more insulating materials such as metal oxides.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

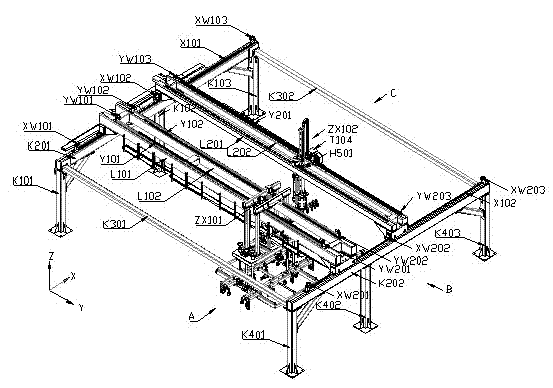

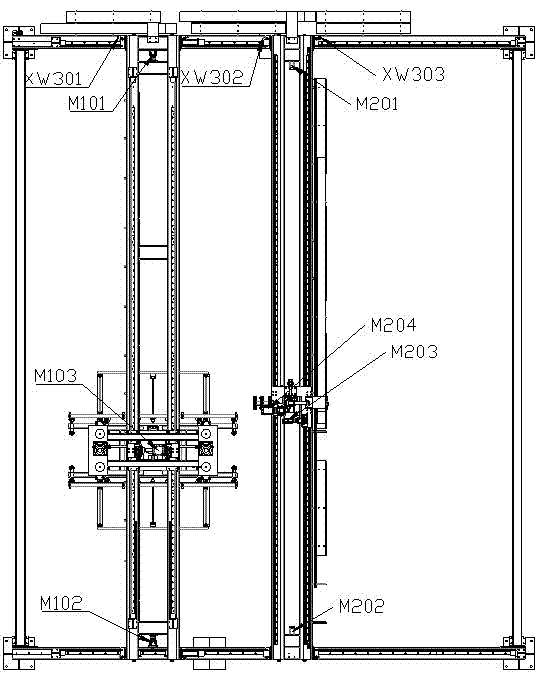

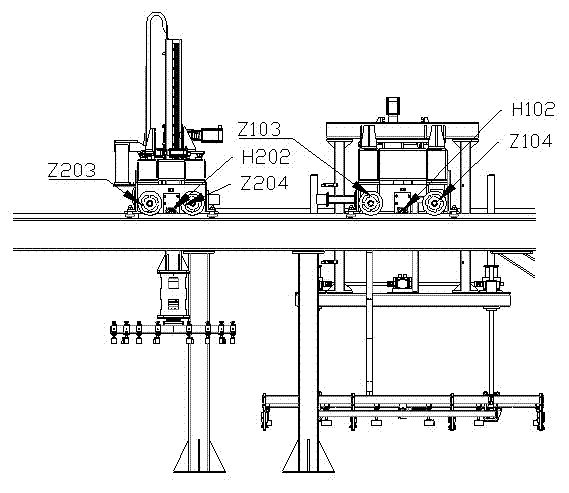

Overloaded manipulator of ten-shaft double-gantry

ActiveCN102962841ARun smoothlyReduce noiseProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention discloses an overloaded manipulator of a ten-shaft double-gantry. The overloaded manipulator comprises a rack, a first gantry and a second gantry, wherein the rack consists of supporting legs, supports, racks and limit components, wherein first, second, third and fourth supports are connected end to end to form a four-sided frame, and the supporting legs are connected with the four-sided frame in a supporting way; a first rack and first and second mechanical limit devices in an X-axis direction are arranged on the first support, and a second rack and third and fourth mechanical limit devices in the X-axis direction are arranged on the third support; the third and fourth mechanical limit devices are positioned at the two ends of the second rack, and the first and second gantries are respectively arranged on the first and third supports; the first gantry is parallel to the second gantry, and the first gantry moves in X, Y and Z-axis directions to complete the moving of overloaded plates; and the second gantry moves in X, Y and Z-axis directions to complete the moving of small plates. The overloaded manipulator provided by the invention has the advantages of smooth running, low noise, high reliability and long service life, and provides a strong guarantee for the performance of the entire overloaded manipulator.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Combination sensor guidewire and methods of use

ActiveUS8231537B2Good accuracy and consistencyMinimize impactBlood flow measurement devicesCatheterEngineeringGuide wires

The present invention provides for an improved combination sensor tip that includes a pressure sensor and a second sensor other than a pressure sensor, both disposed at or in close proximity to the distal end of the combination sensor tip. The present invention also provides for an improved connector to couple a guide wire to a physiology monitor that reduces torsional resistance when maneuvering the guide wire.

Owner:VOLCANO CORP

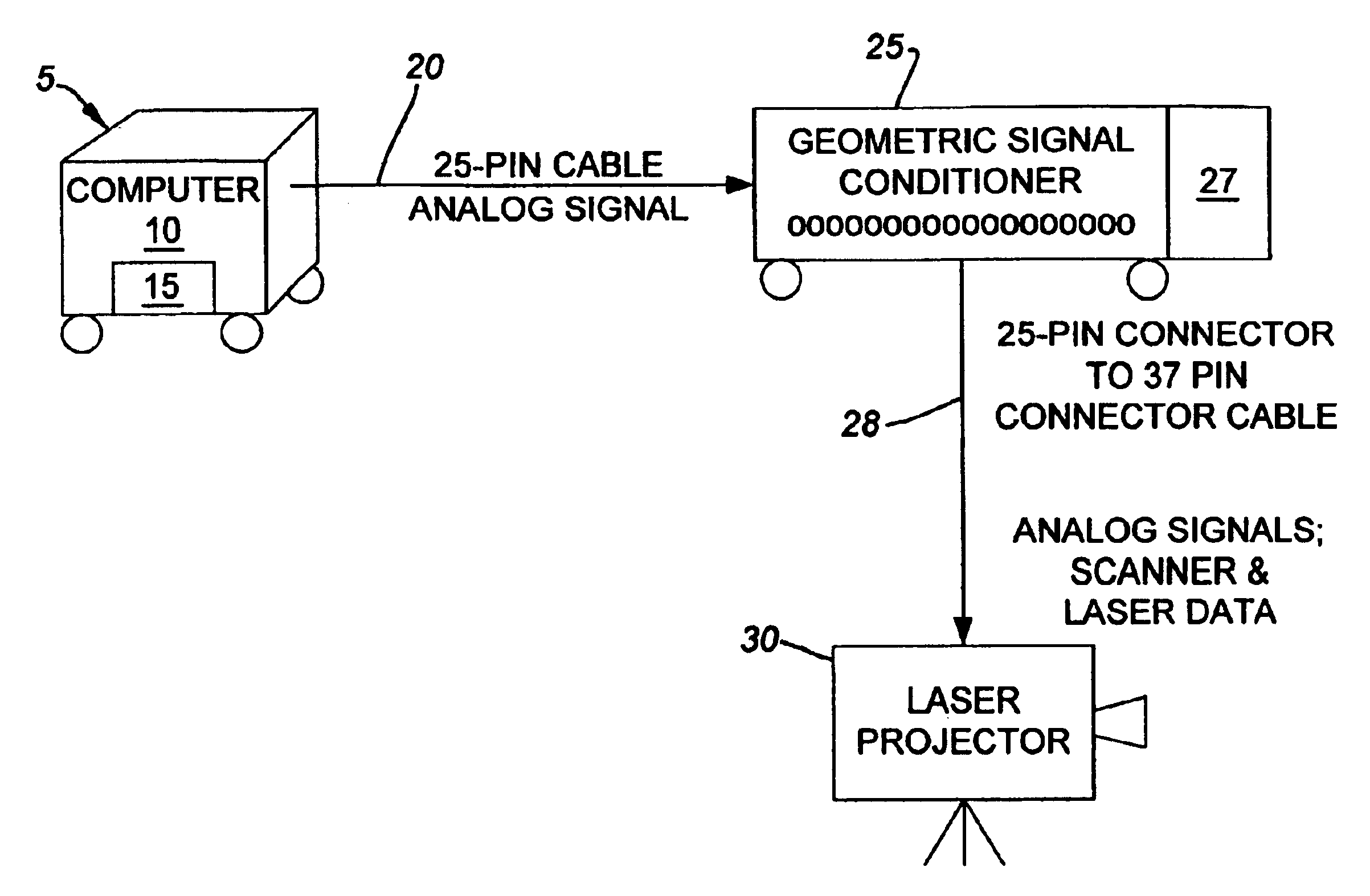

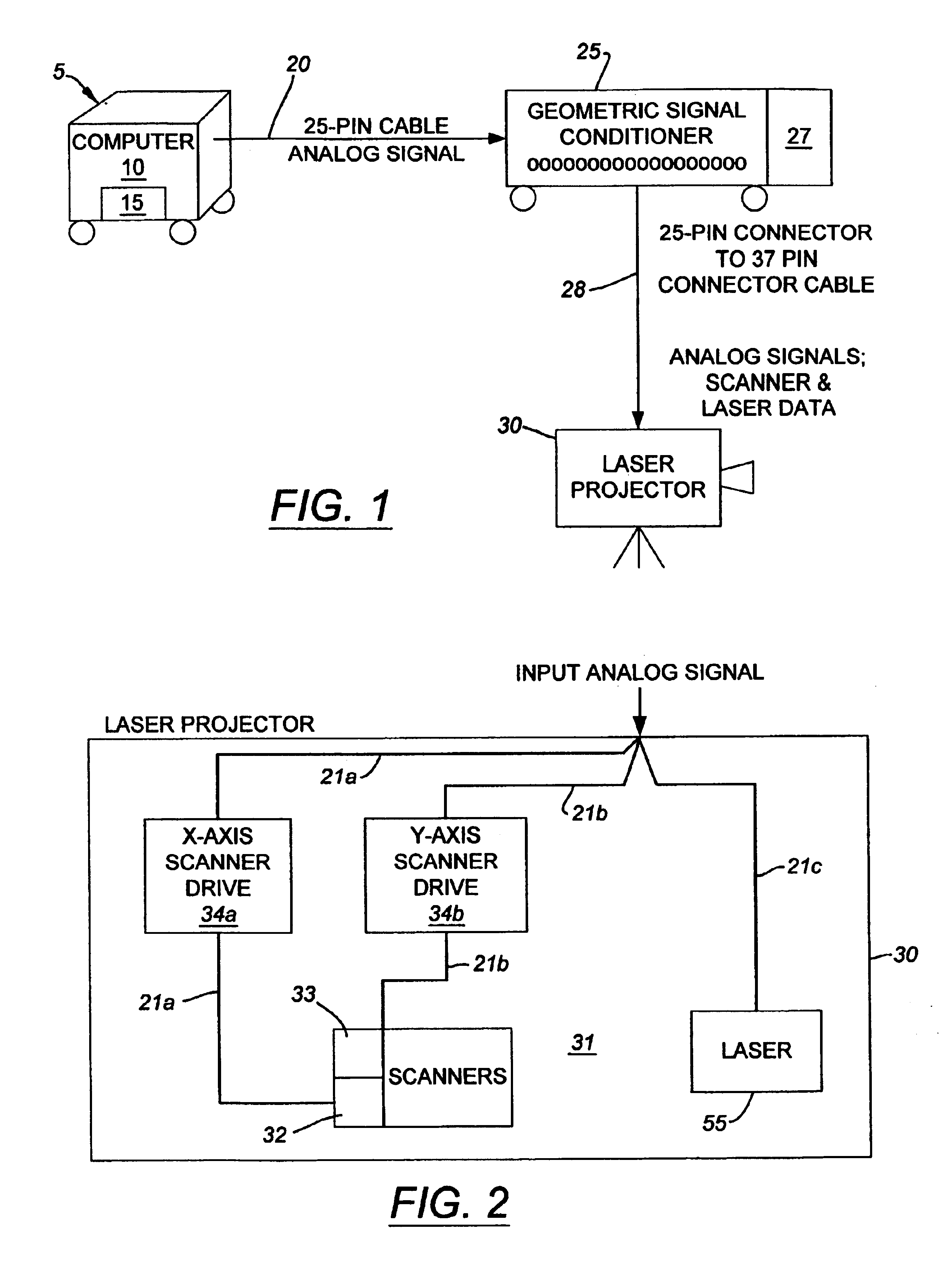

System for projecting light on a work surface to produce an image for tracing

InactiveUS6731991B1Shorten the timeSmall and portablePicture changing apparatusComputer controlComputer graphics (images)Signal Conditioner

A method and system of projecting light on a planar surface to produce an image for tracing is disclosed. The system includes a projector that has a light source and a signal conditioner that is operably connected to the projector. A computer is operably connected to the signal conditioner. A scanner is connected to the projector. A test pattern from the computer is projected from the projector through the scanners to visually align an image to a sector on a work surface. A grid is operably aligned with the work surface. A geometric pattern from the computer is then projected by the projector on the planar work surface for tracing. The method comprises the steps of creating a pattern, tracing lines along the pattern on the planar work surface, cutting the pattern along the traced lines, discarding pieces of the planar surface outside the pattern, and placing edging along an outer edge of the pattern.

Owner:STUART CHRISTOPHER J +1

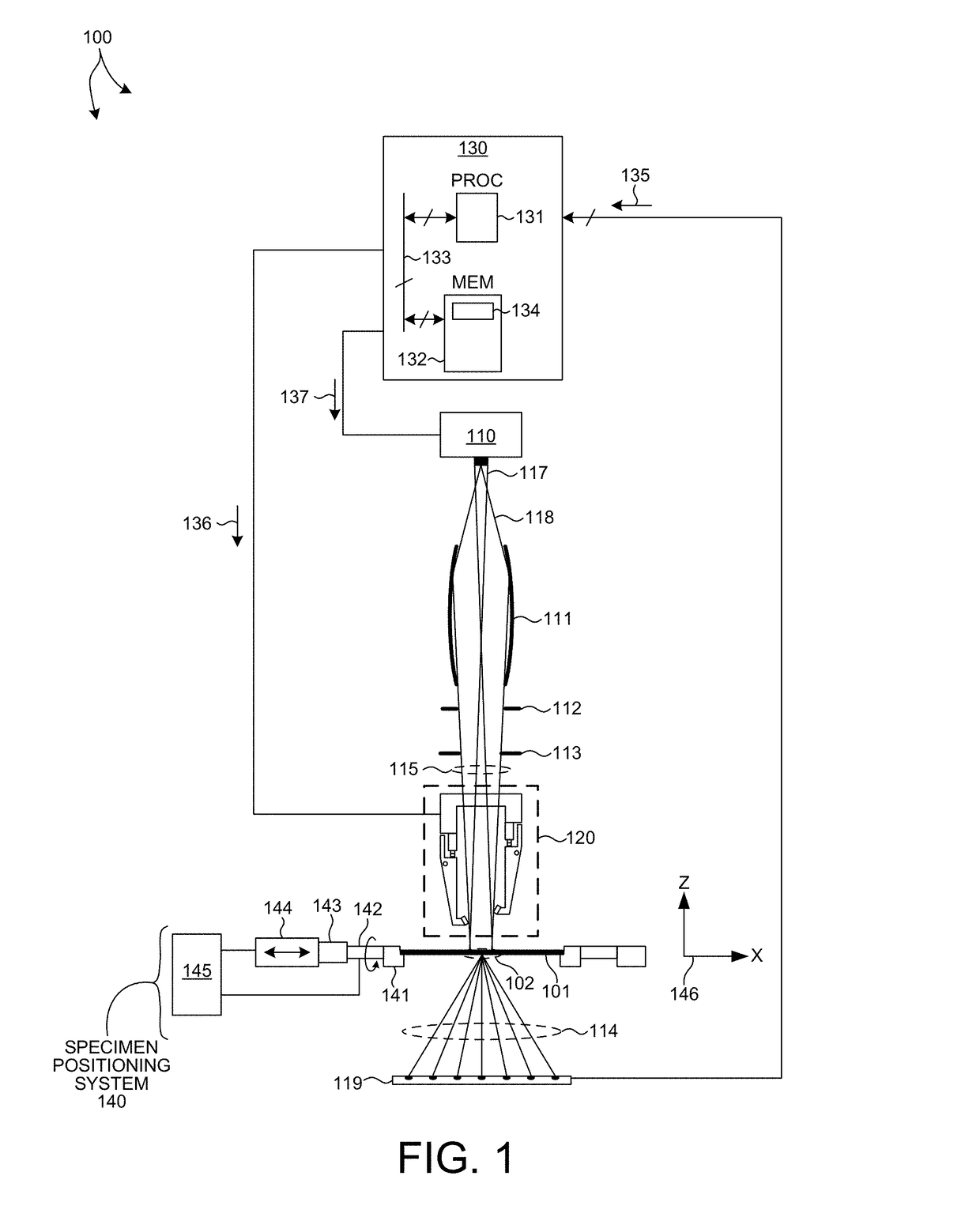

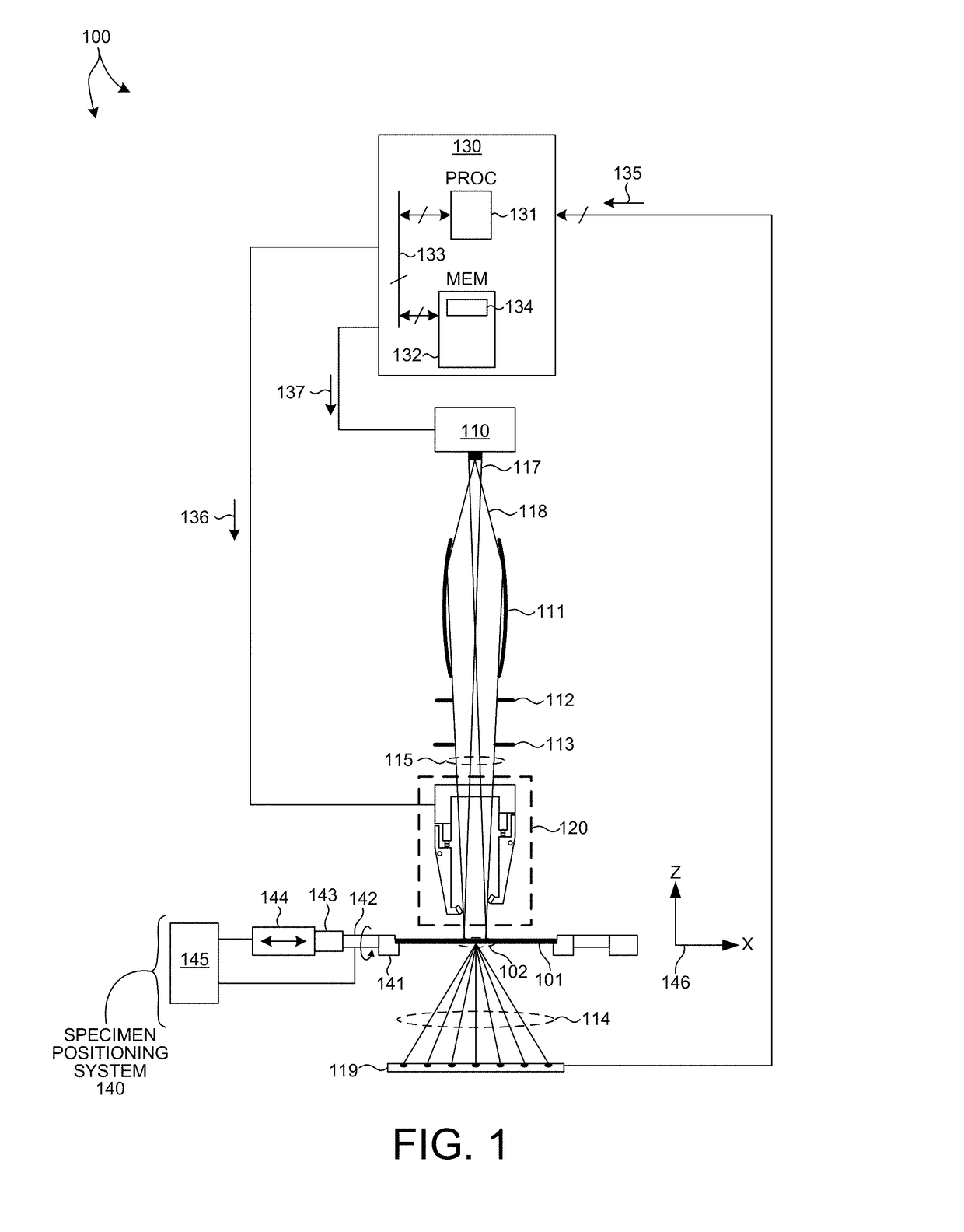

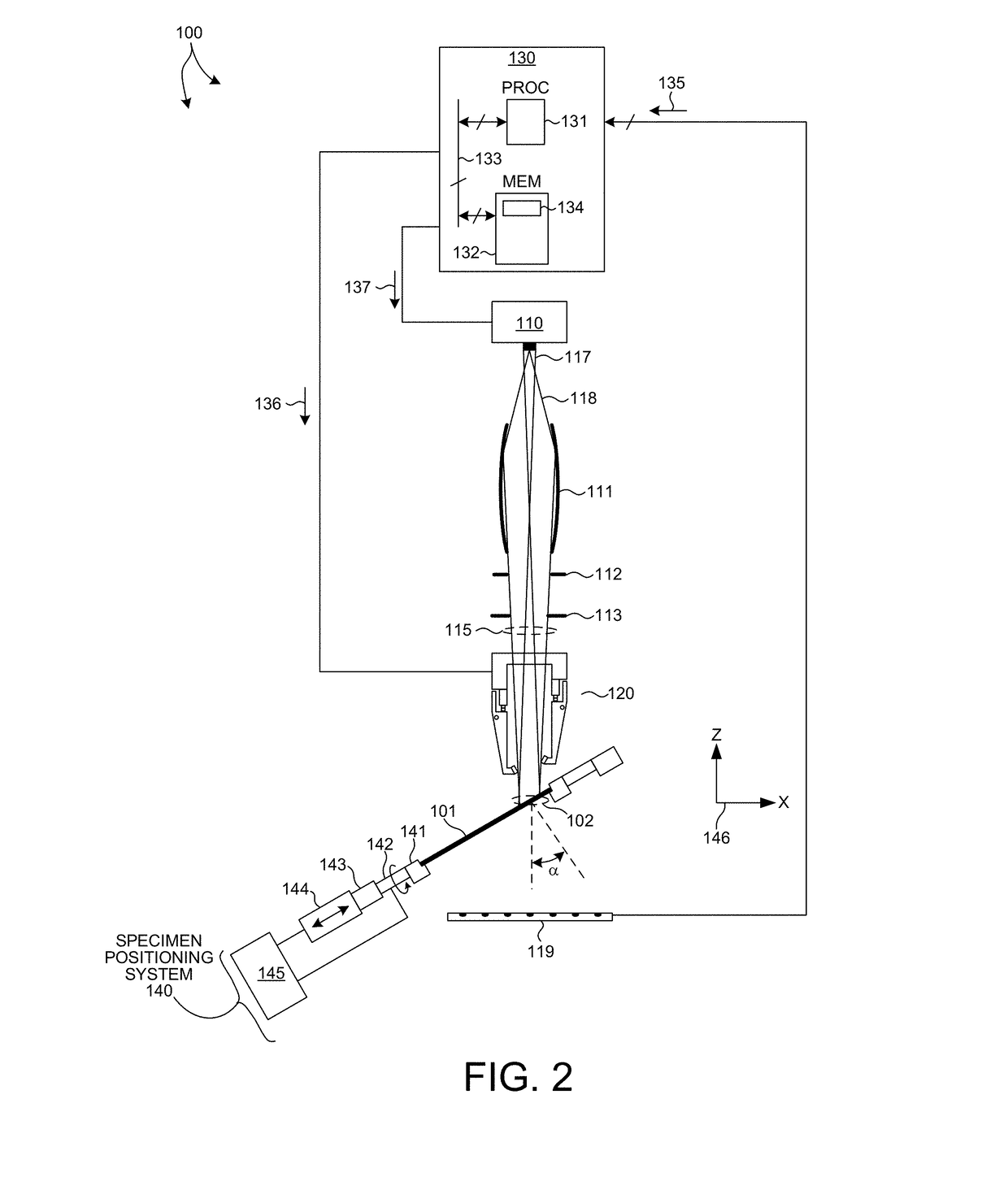

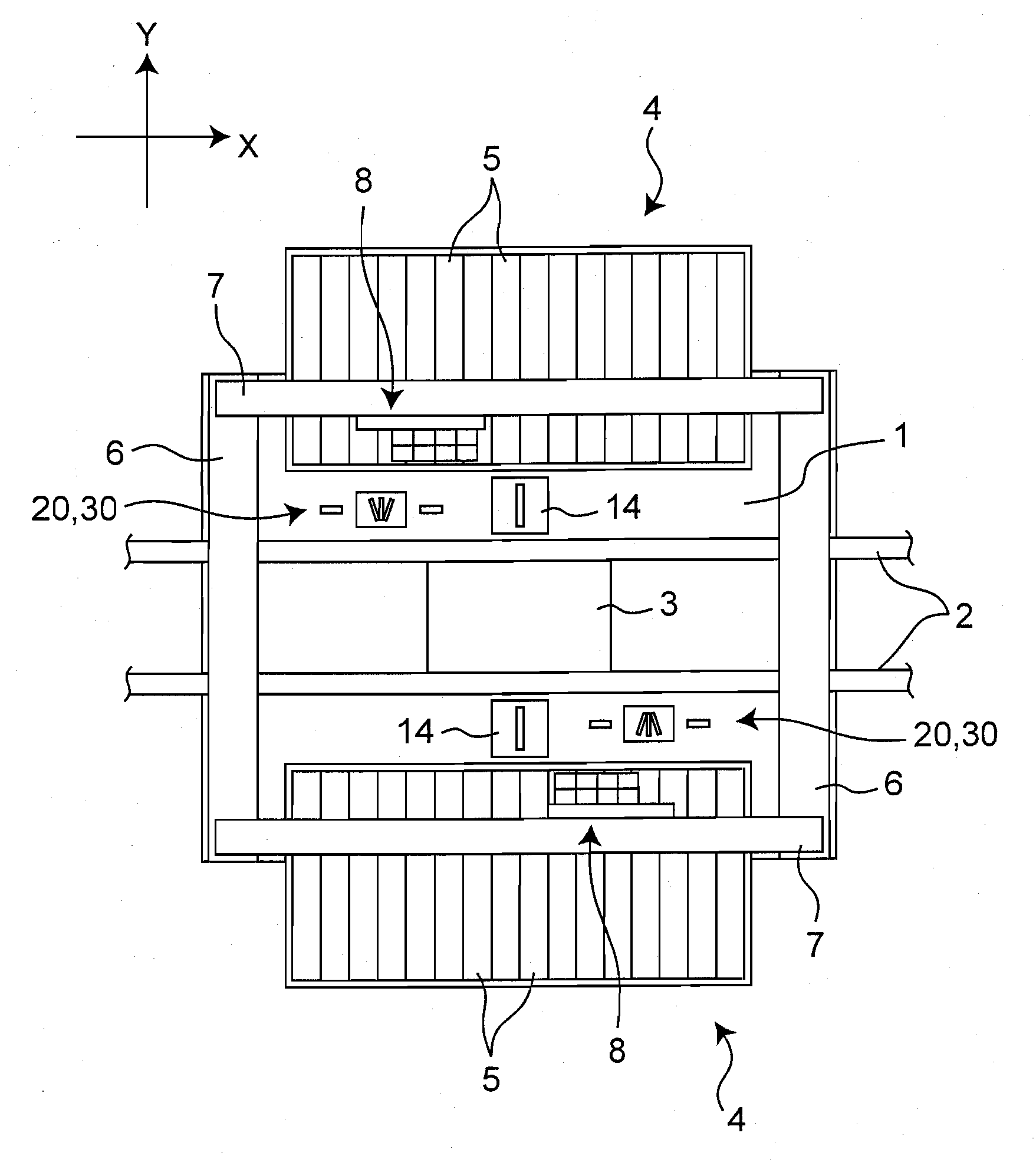

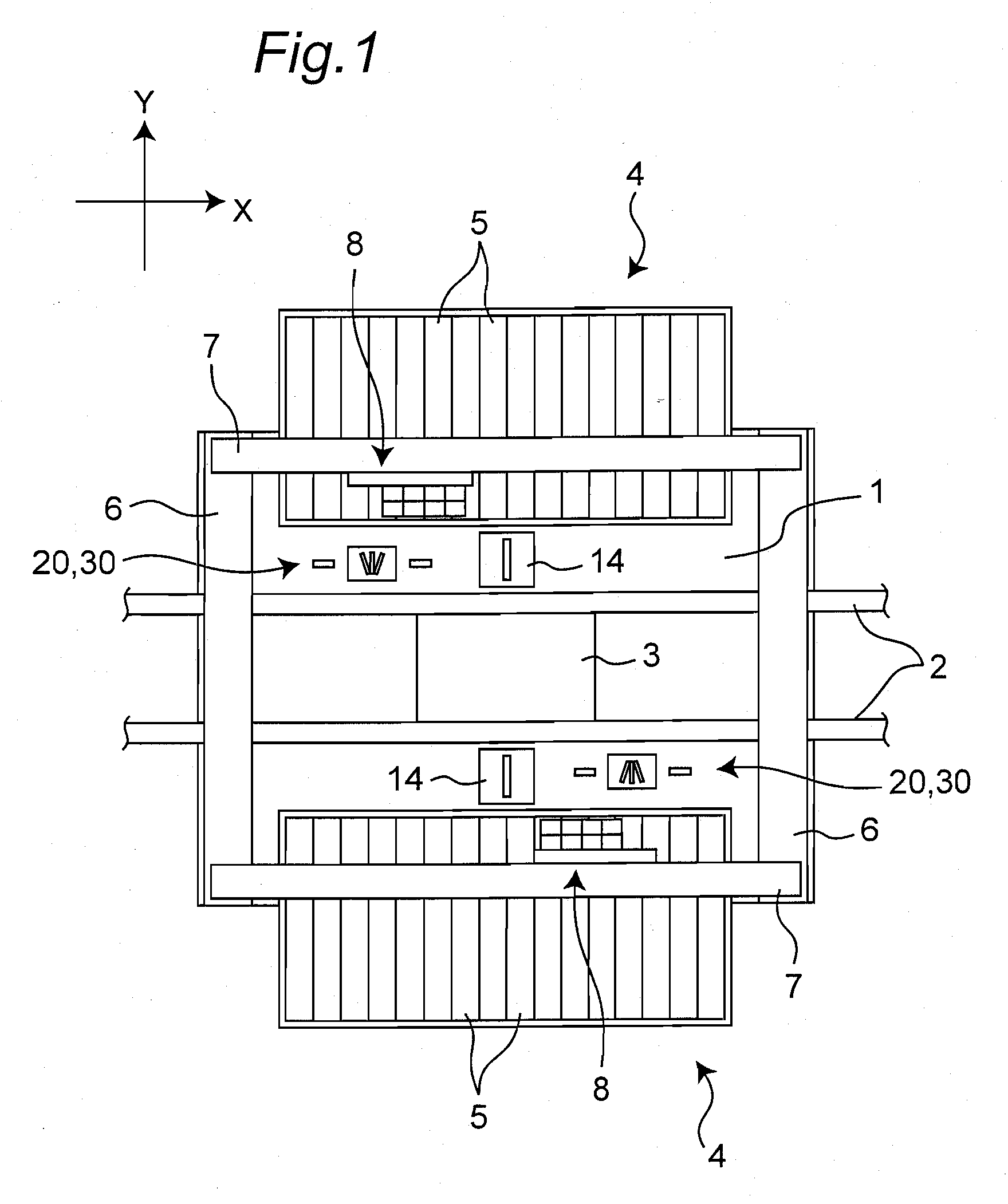

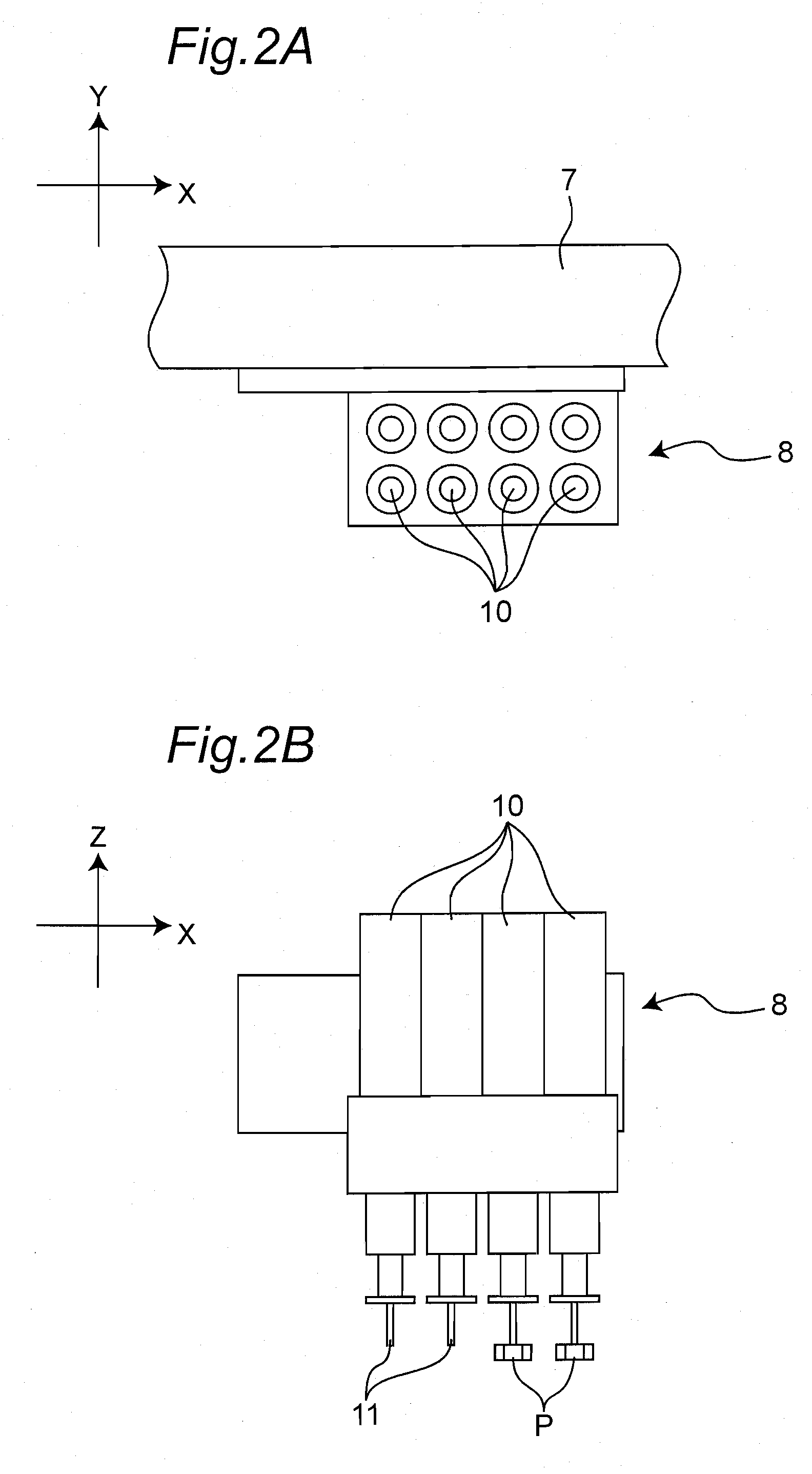

Beam Shaping Slit For Small Spot Size Transmission Small Angle X-Ray Scatterometry

ActiveUS20170307548A1Reduce the impactEffect of beam divergence on beam spot size is minimizedHandling using diaphragms/collimetersMaterial analysis using radiation diffractionSmall-angle X-ray scatteringLight beam

Methods and systems for reducing the effect of finite source size on illumination beam spot size for Transmission, Small-Angle X-ray Scatterometry (T-SAXS) measurements are described herein. A beam shaping slit having a slender profile is located in close proximity to the specimen under measurement and does not interfere with wafer stage components over the full range of angles of beam incidence. In one embodiment, four independently actuated beam shaping slits are employed to effectively block a portion of an incoming x-ray beam and generate an output beam having a box shaped illumination cross-section. In one aspect, each of the beam shaping slits is located at a different distance from the specimen in a direction aligned with the beam axis. In another aspect, the beam shaping slits are configured to rotate about the beam axis in coordination with the orientation of the specimen.

Owner:KLA TENCOR TECH CORP

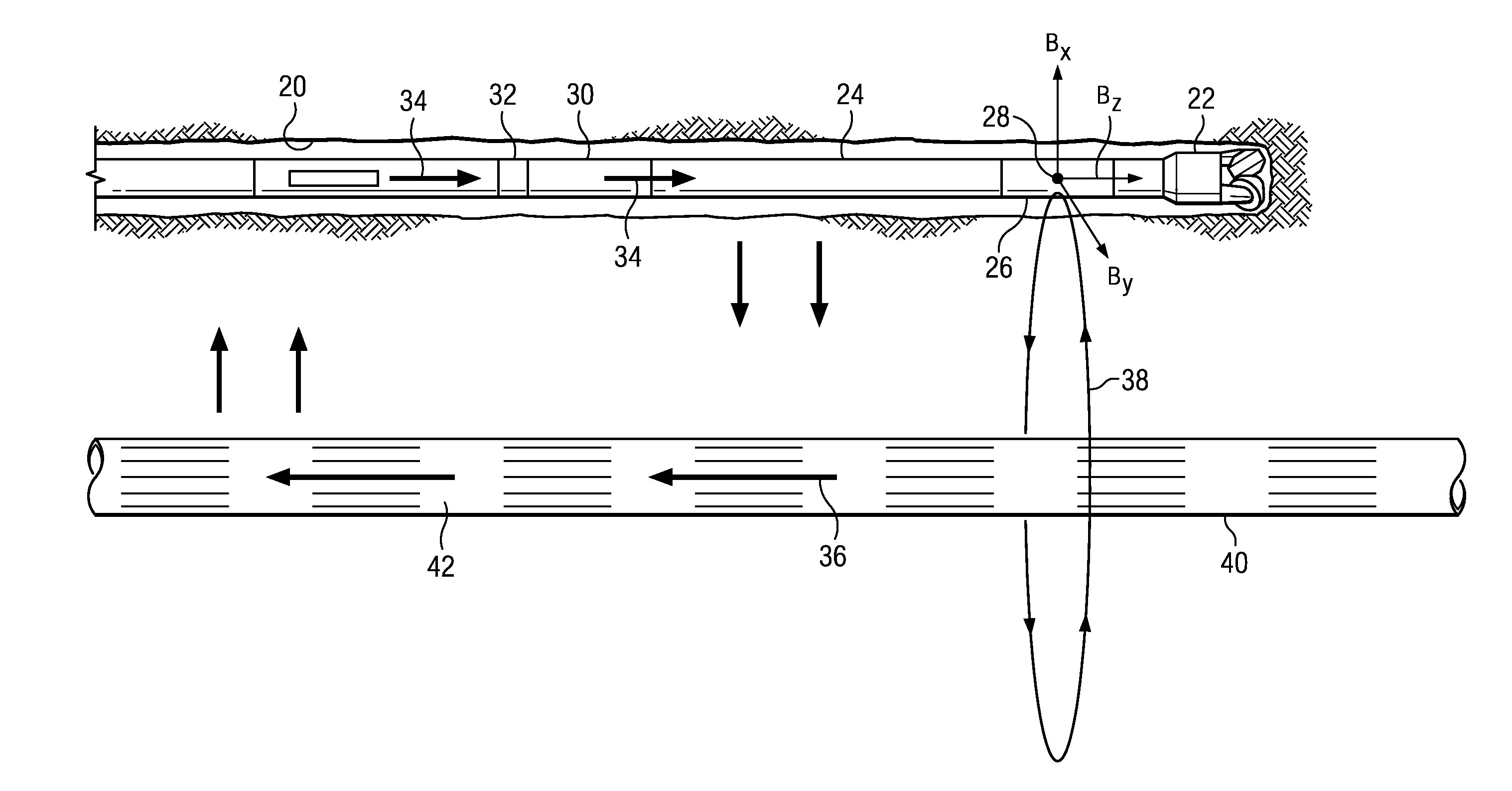

Mounting structure of vehicle interior material

InactiveUS7461436B2Reliably prevent the clip from being disengaged from the boss partImprove placement accuracySnap fastenersSheet joiningEngineeringMechanical engineering

Owner:PIOLAX CO LTD

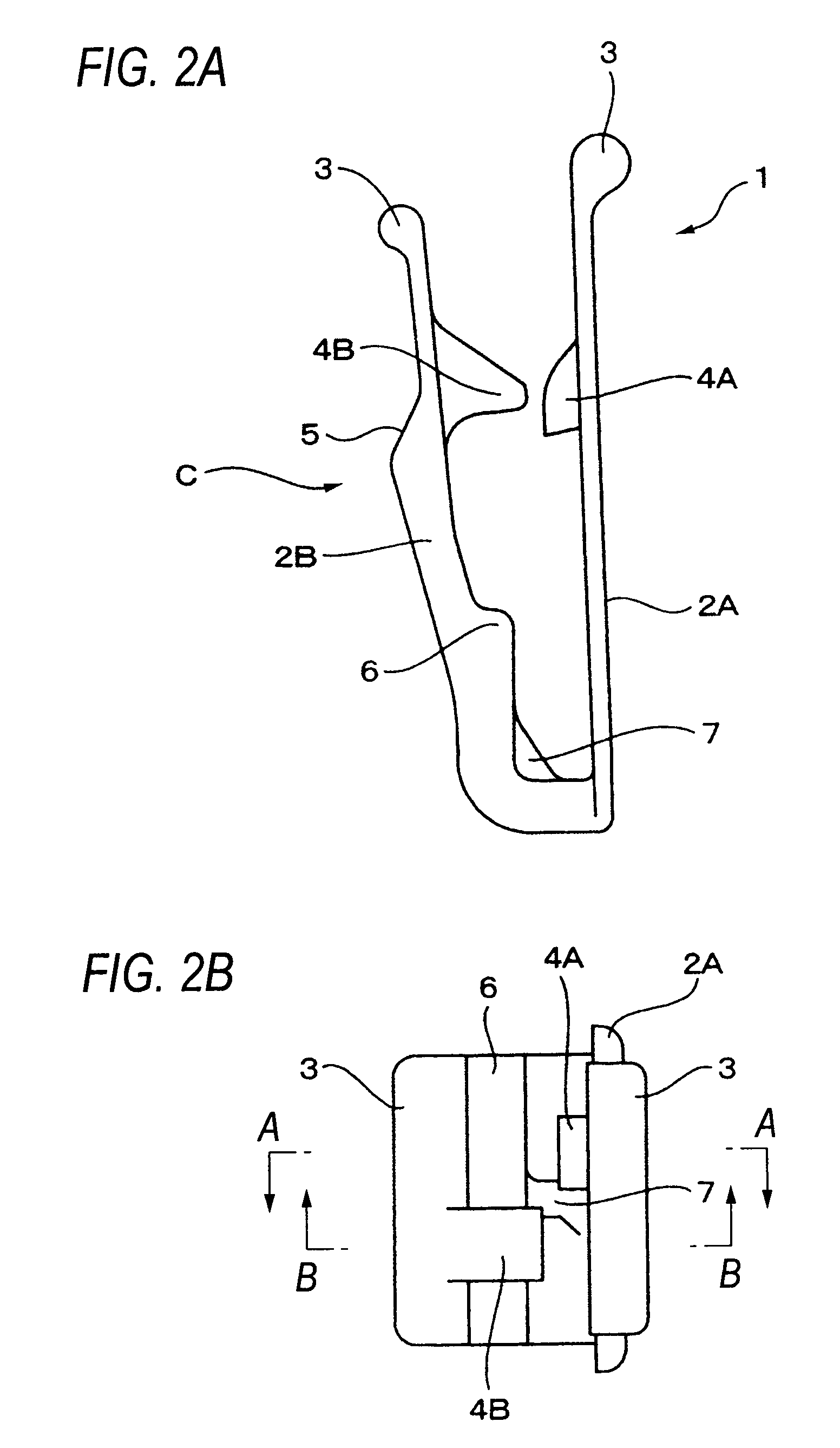

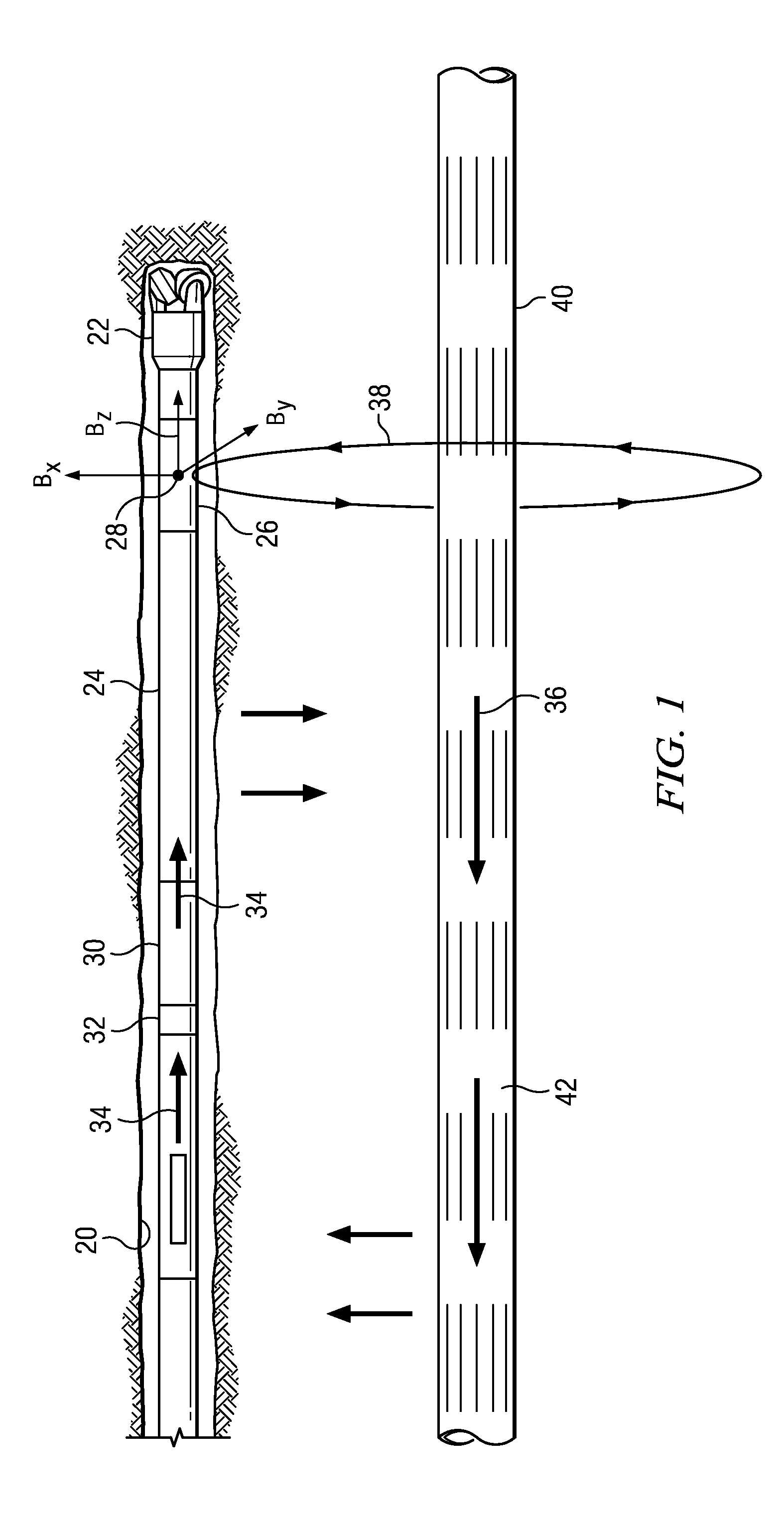

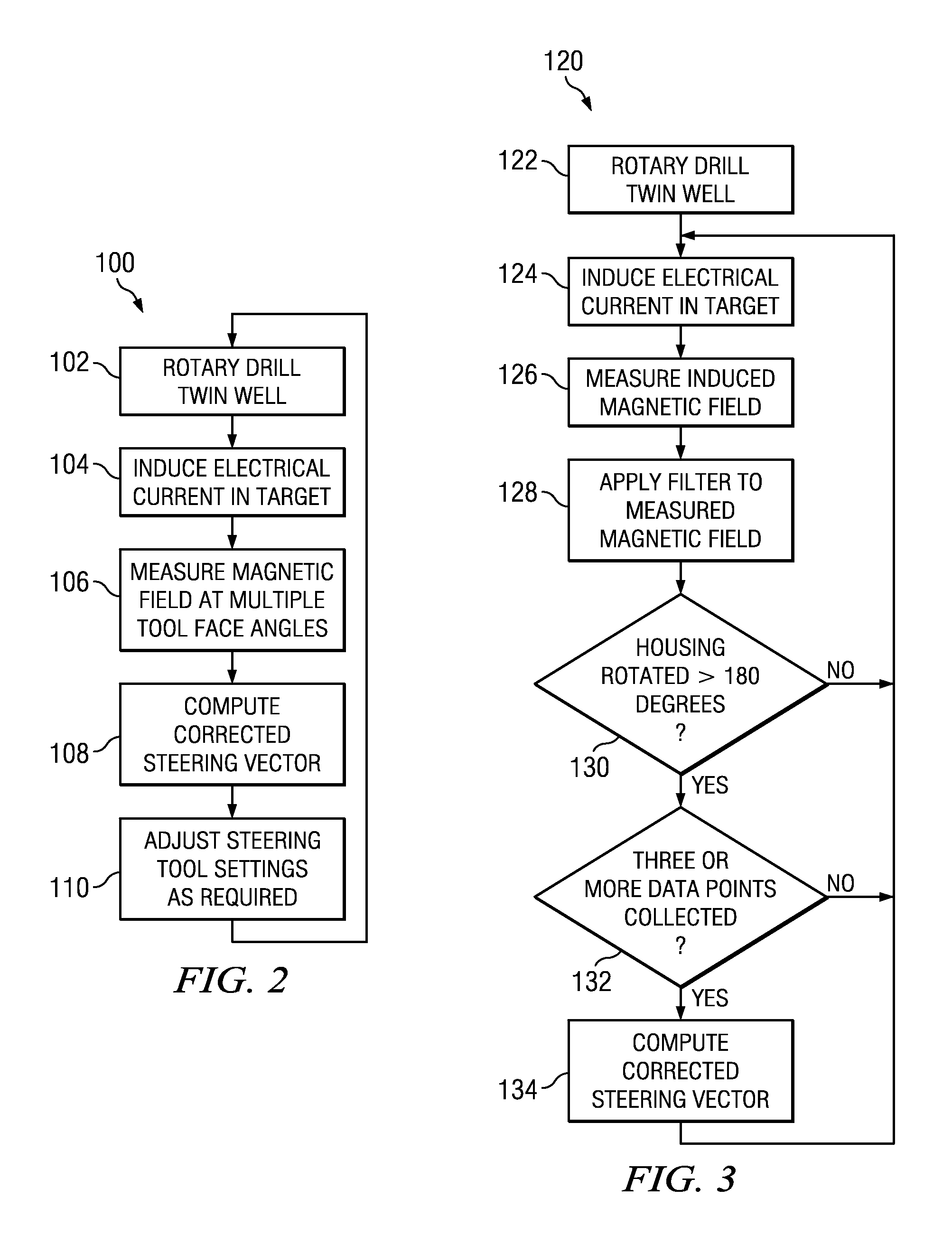

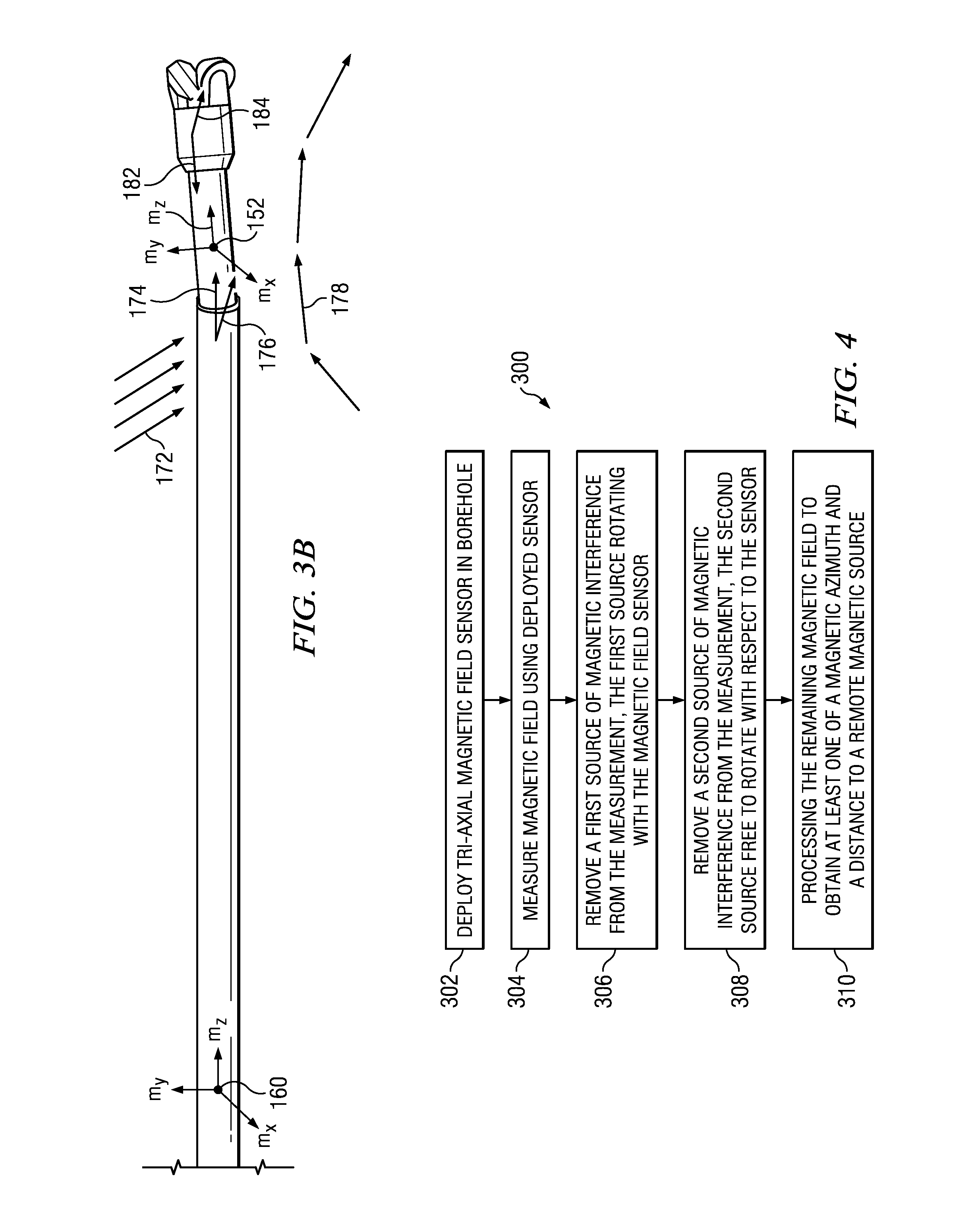

Closed loop well twinning methods

Closed loop methods for drilling twin wells are disclosed. The disclosed method make use of a bottom hole assembly including a rotary steerable tool. An electrical current is induced in the target well. The corresponding magnetic field about the target well is measured in the twin well and used to guide drilling of the twin well.

Owner:PATHFINDER ENERGY SERVICES LLC +1

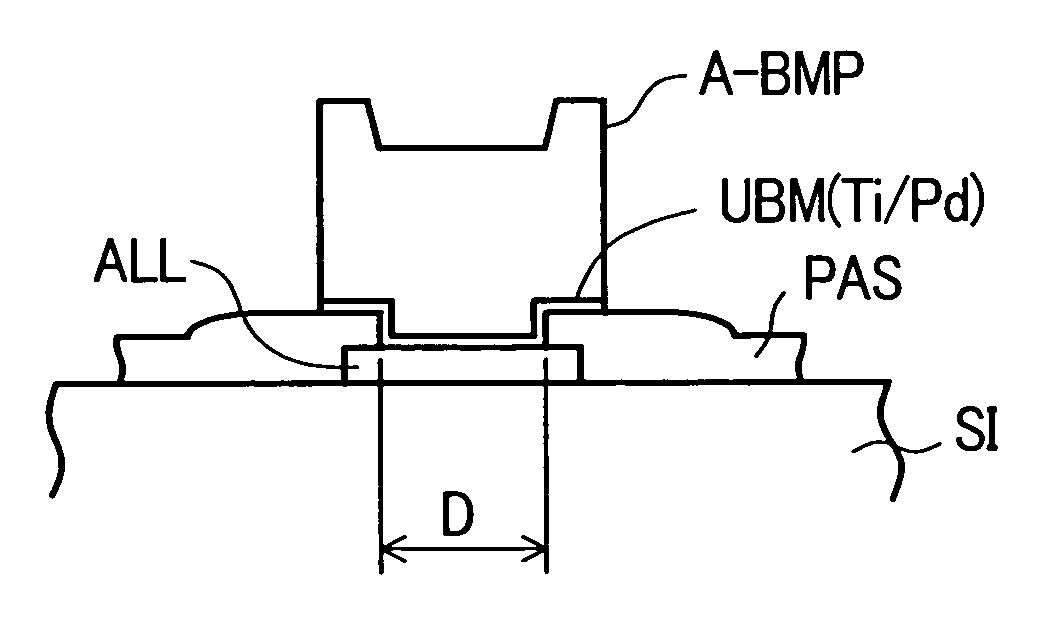

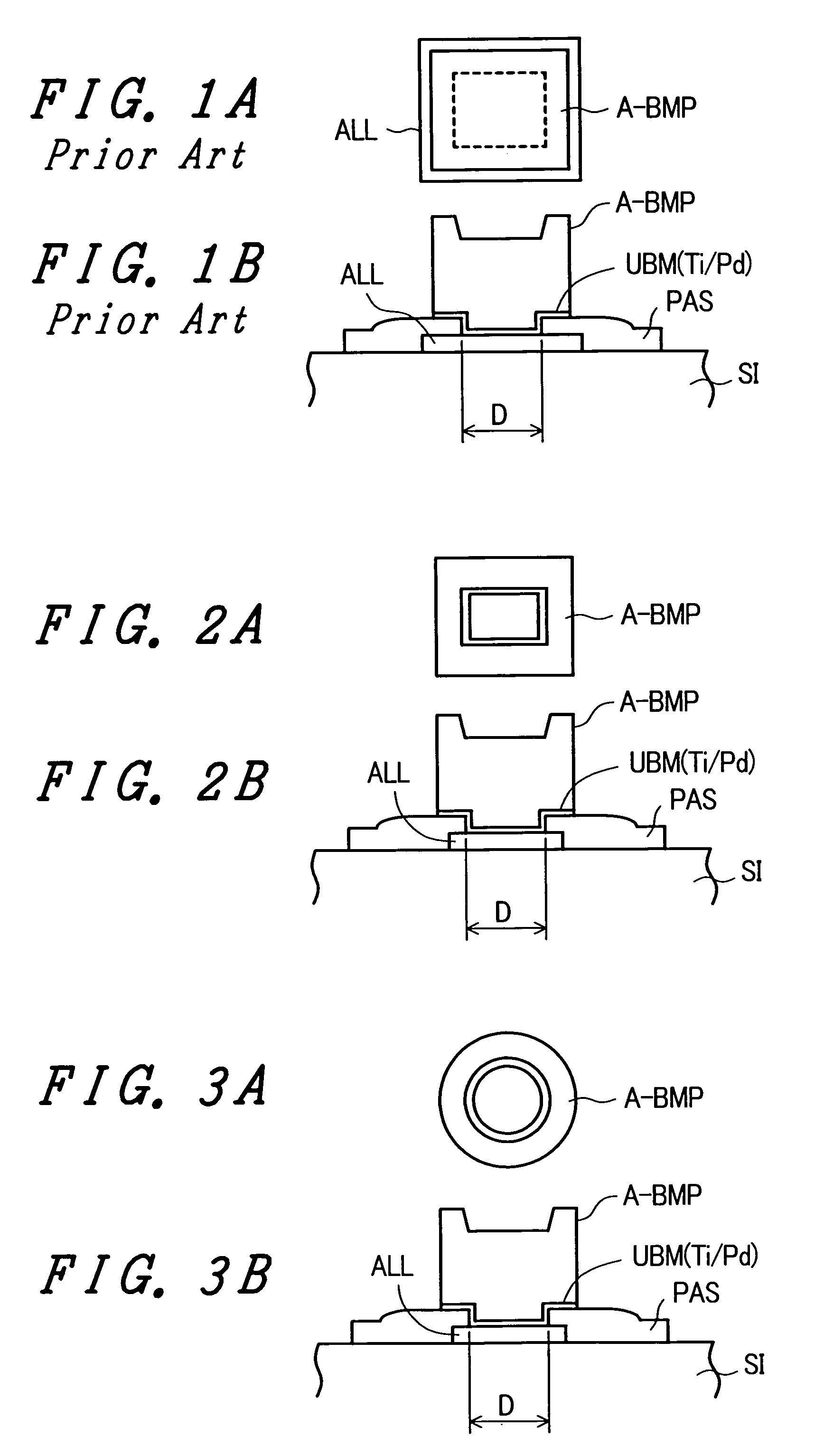

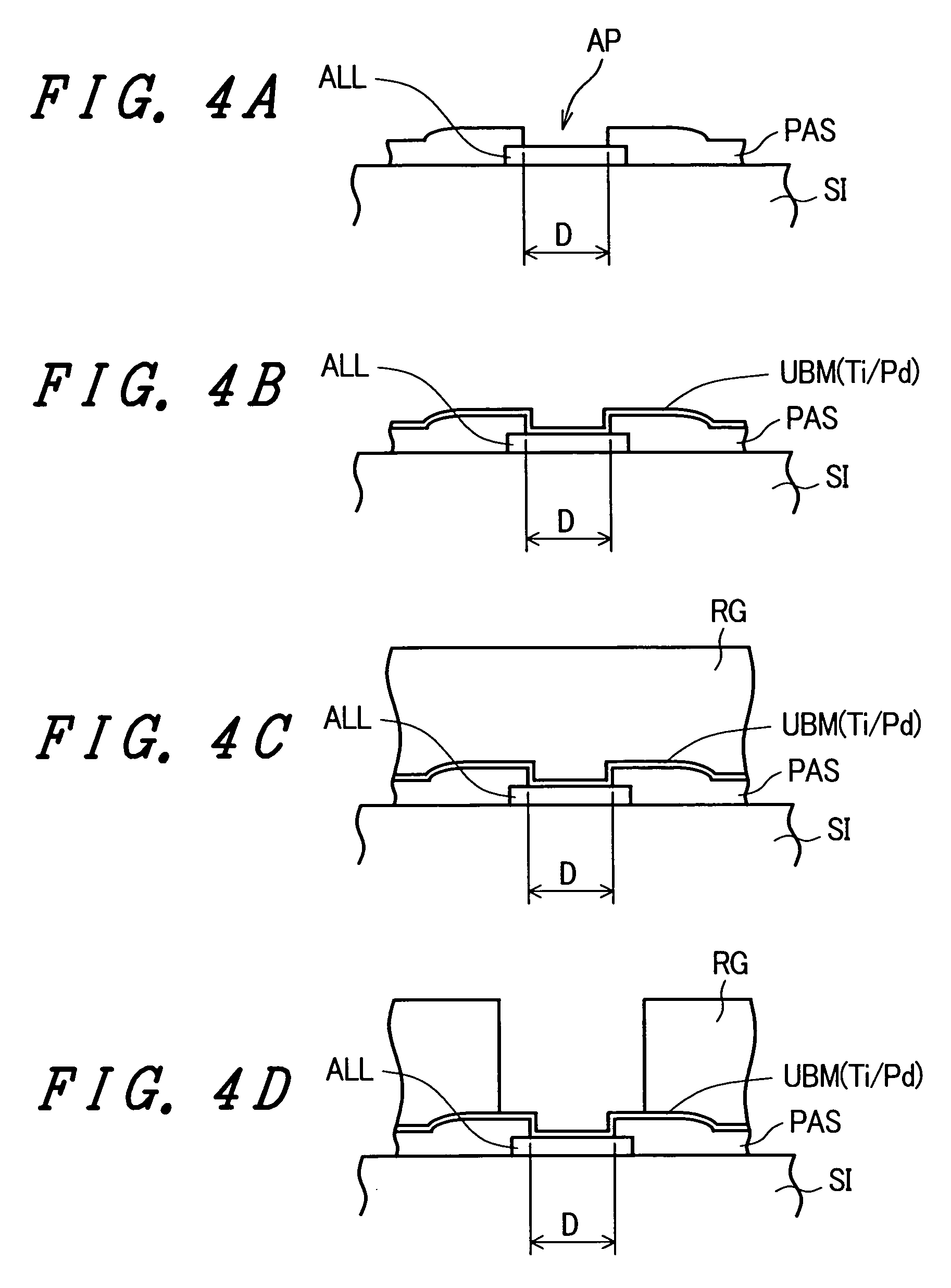

Display device and manufacturing method of the same

ActiveUS20050242436A1Precise alignmentPrevent display quality degradationStatic indicating devicesSemiconductor/solid-state device detailsDisplay deviceSemiconductor

The present invention enhances the mounting accuracy of a drive circuit chip on a substrate thus realizing a display of high quality. Bumps (for example, gold bumps) on the drive circuit chip are used for alignment. Here, to enhance the recognition property of the alignment bumps, a plane shape of a conductive layer which is formed between a semiconductor substrate (Si substrate) of the drive circuit chip and the alignment bump is set to be included within a profile of a plane shape of the alignment bump. That is, by preventing the conductive layer from being observed in a periphery of the alignment bump, it is possible to prevent a photographed pattern of the bump taken by a camera or the like from be influenced by the conductive layer.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

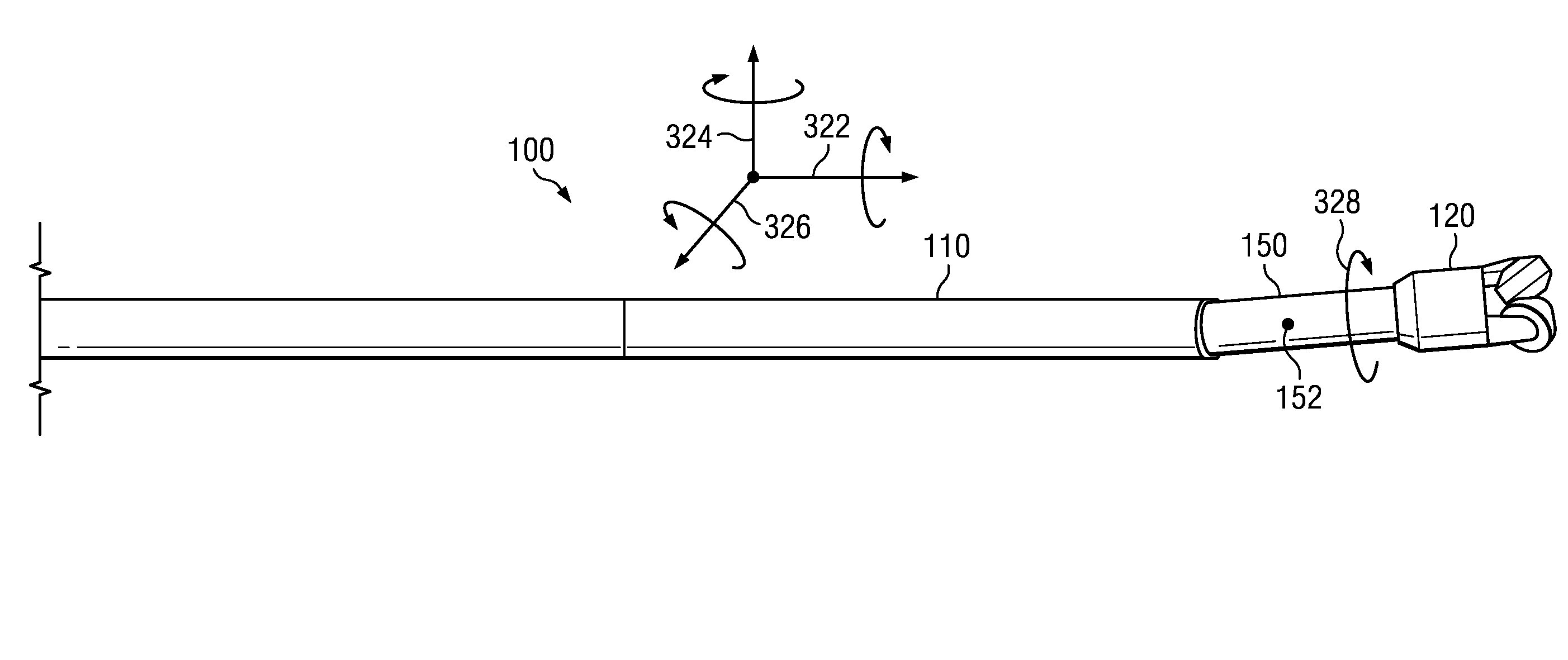

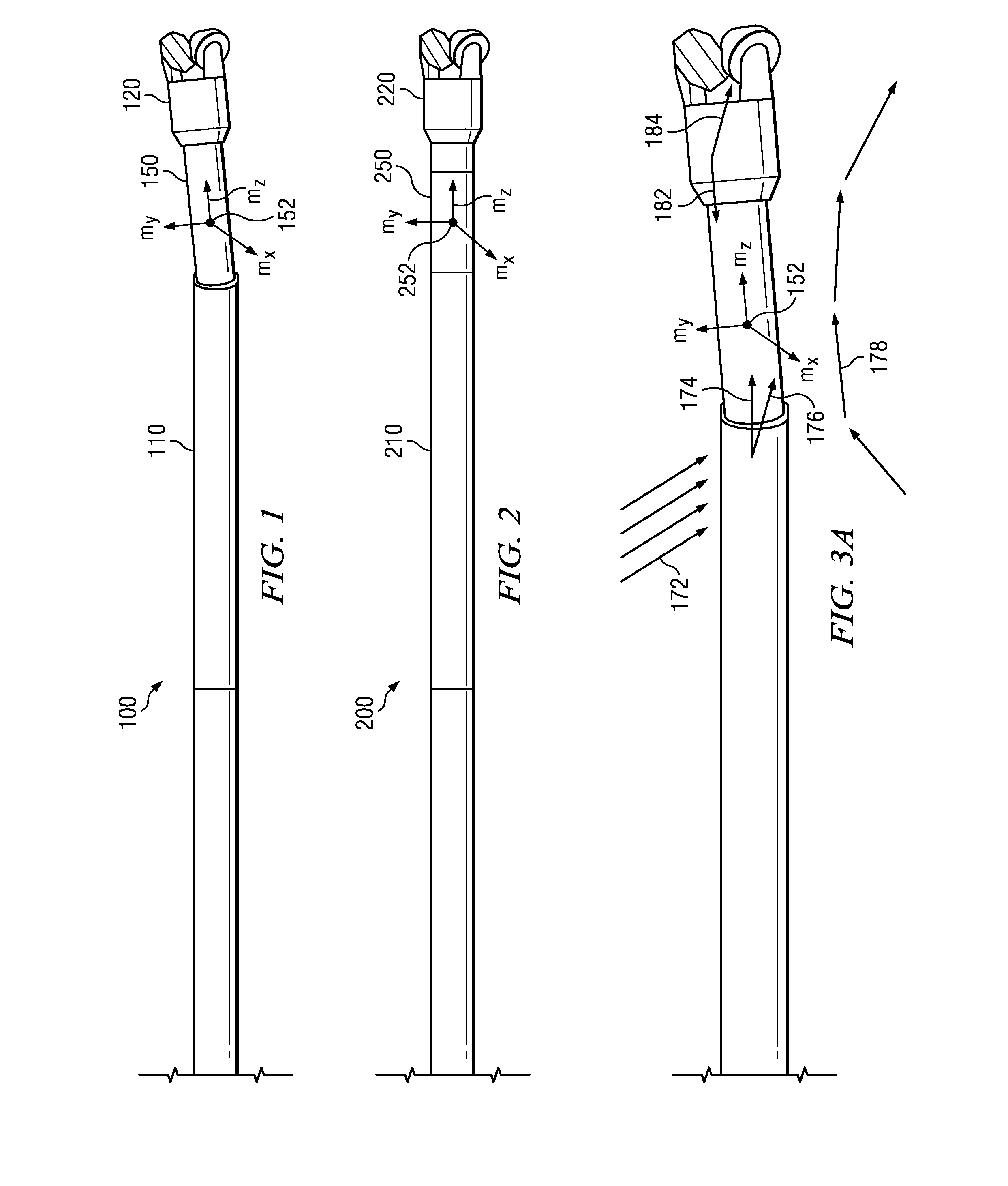

At-bit magnetic ranging and surveying

ActiveUS20130069655A1Lower latencyEasy to controlElectric/magnetic detection for well-loggingSurveySurveyorBottom hole assembly

A bottom hole assembly configured for a subterranean drilling operation having a drill bit; a downhole tool deployed above the drill bit, at least a portion of the downhole tool free to rotate with respect to the drill bit about a longitudinal axis of the bottom hole assembly a sensor sub deployed axially between the drill bit and the downhole tool, the sensor sub configured to rotate with the drill bit about the longitudinal axis of the bottom hole assembly and free to rotate with respect to the downhole tool about the longitudinal axis and a tri-axial magnetic field sensor deployed in the sensor sub.

Owner:SCHLUMBERGER TECH CORP

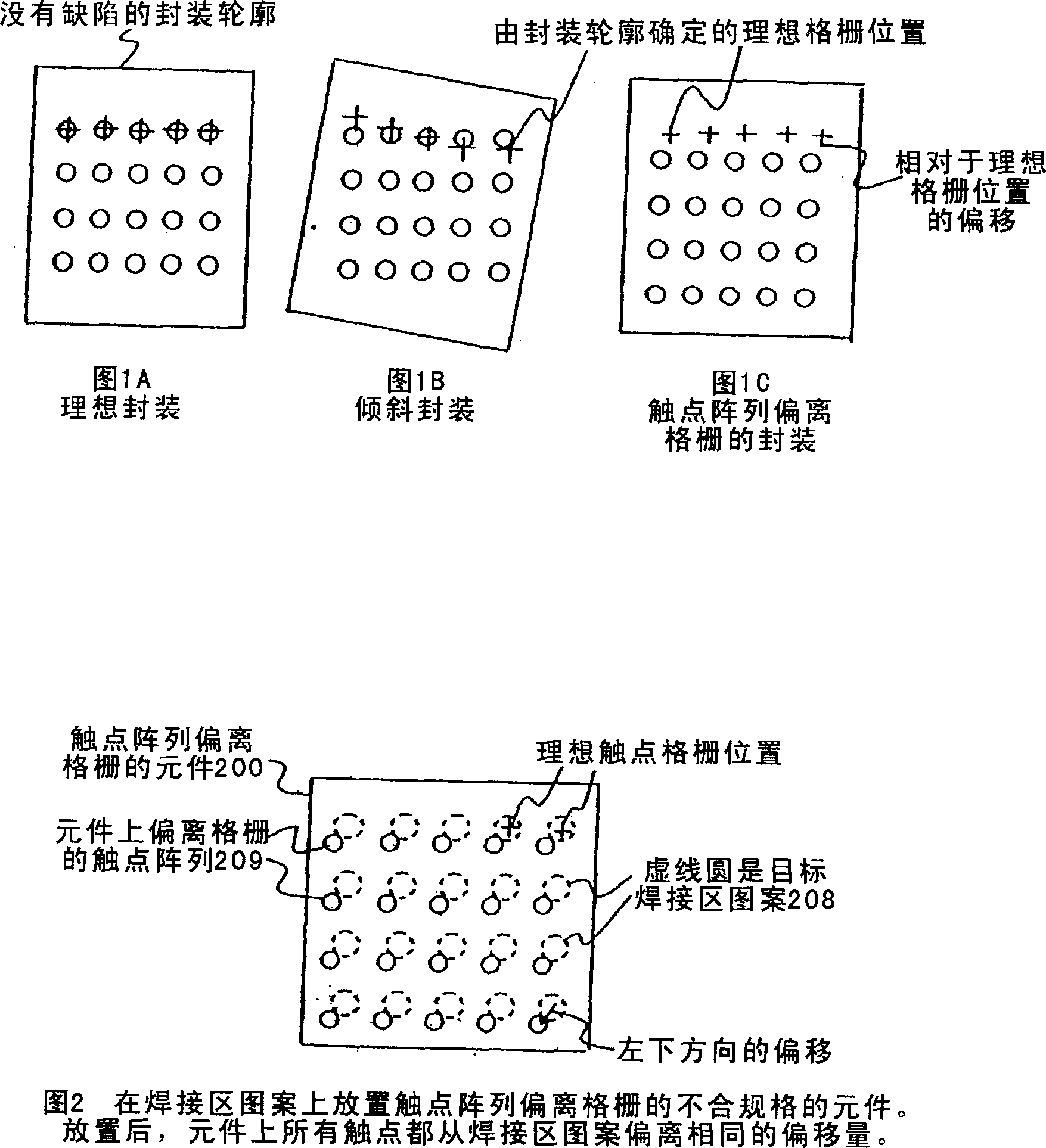

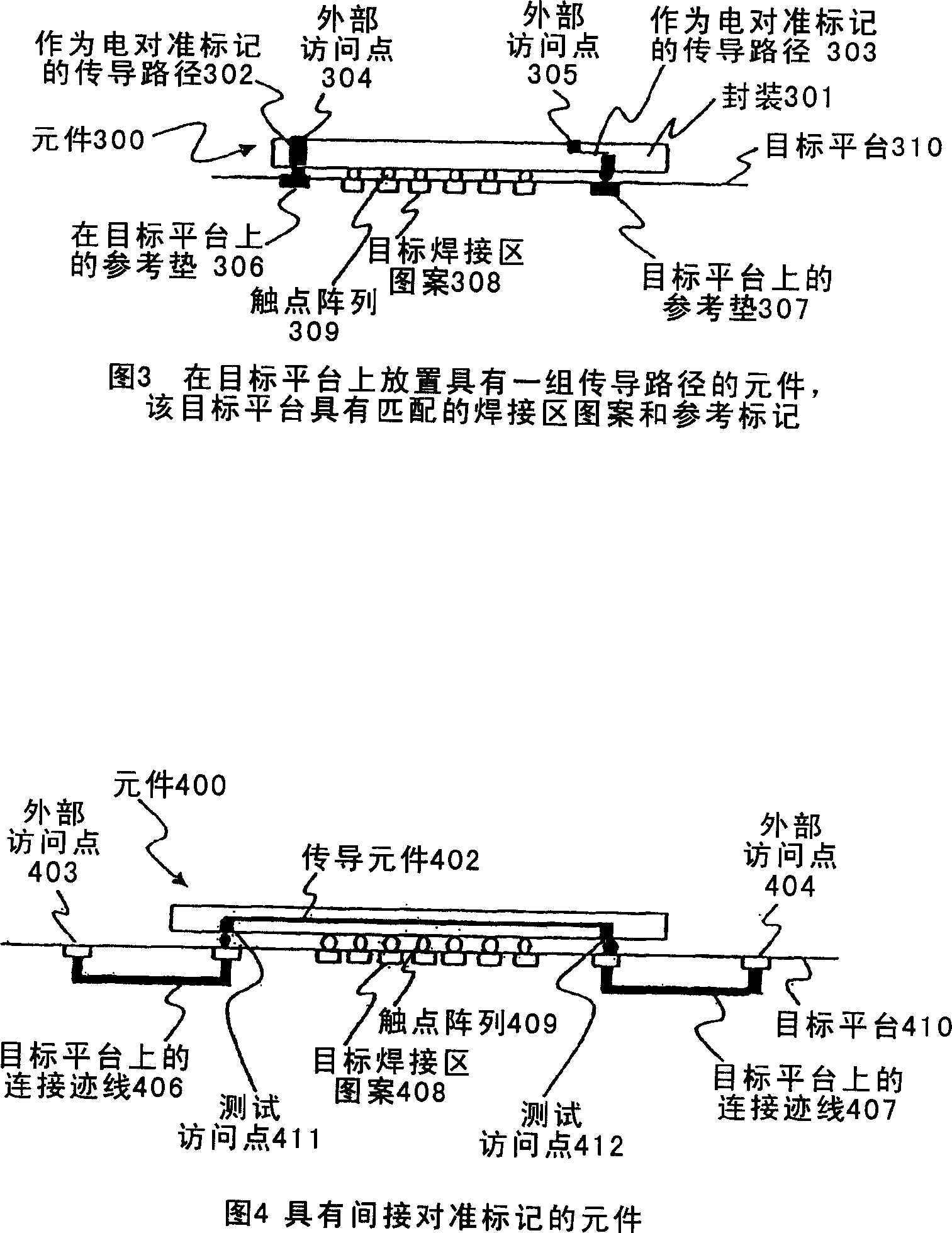

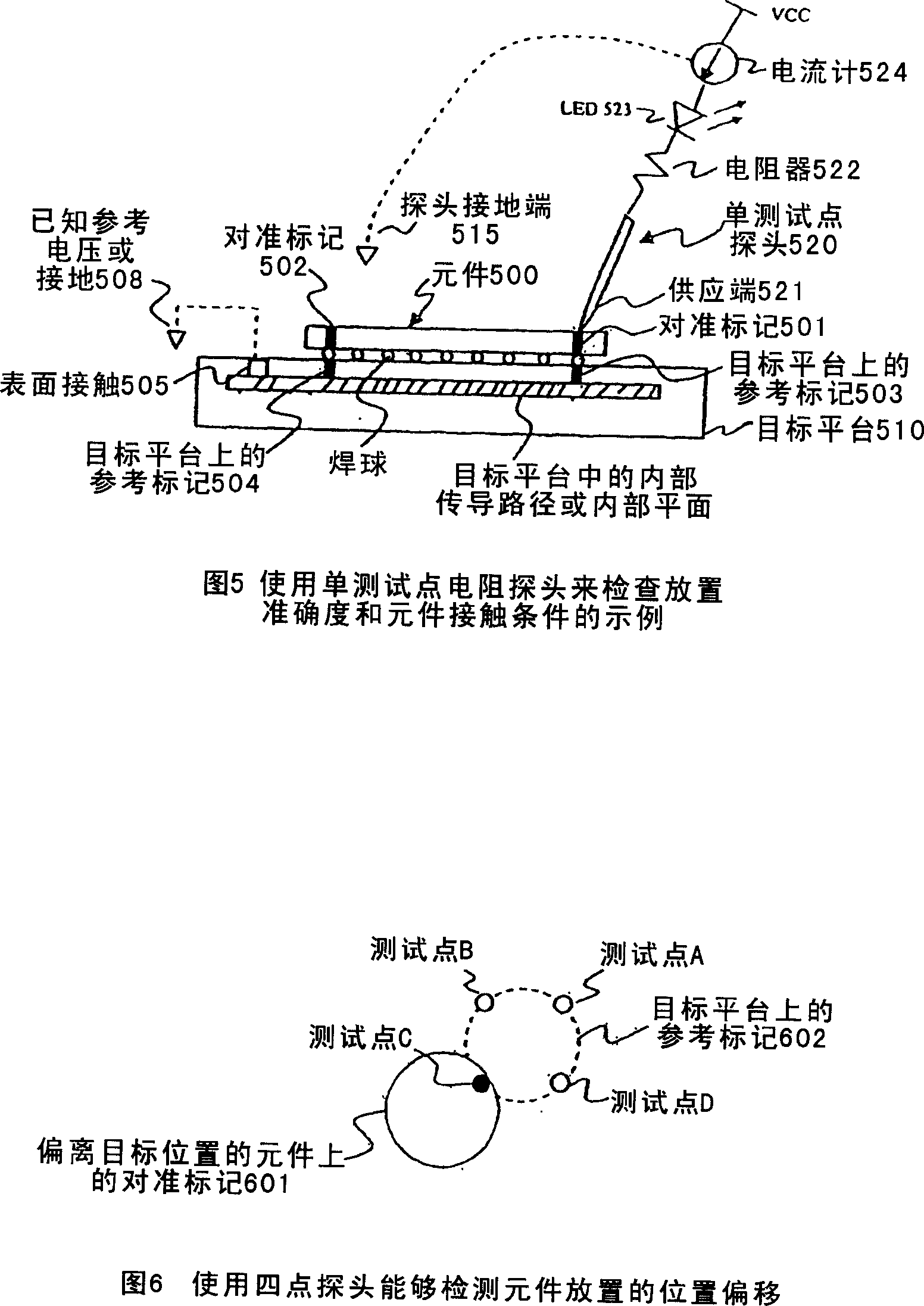

Apparatus and method for arranging predetermined element on target platform

ActiveCN101118899AHigh yieldReduce reworkSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineering

Owner:温泰克工业有限公司

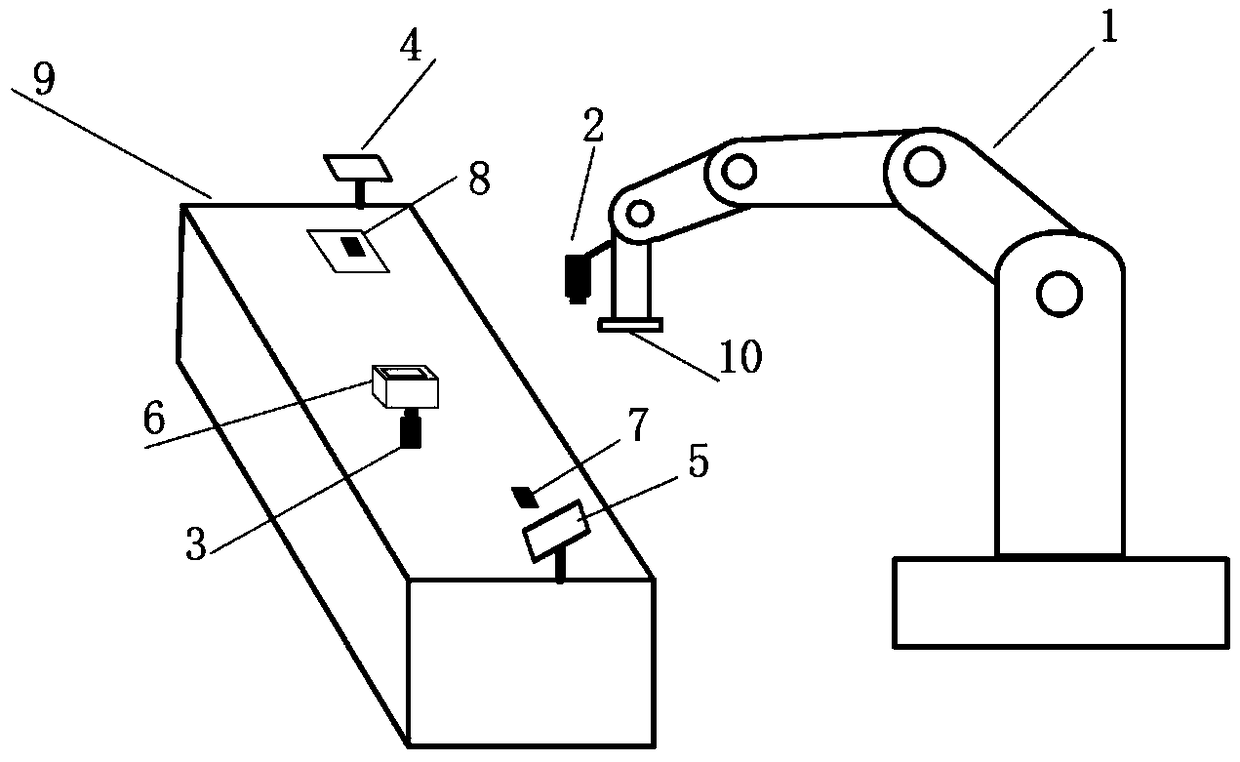

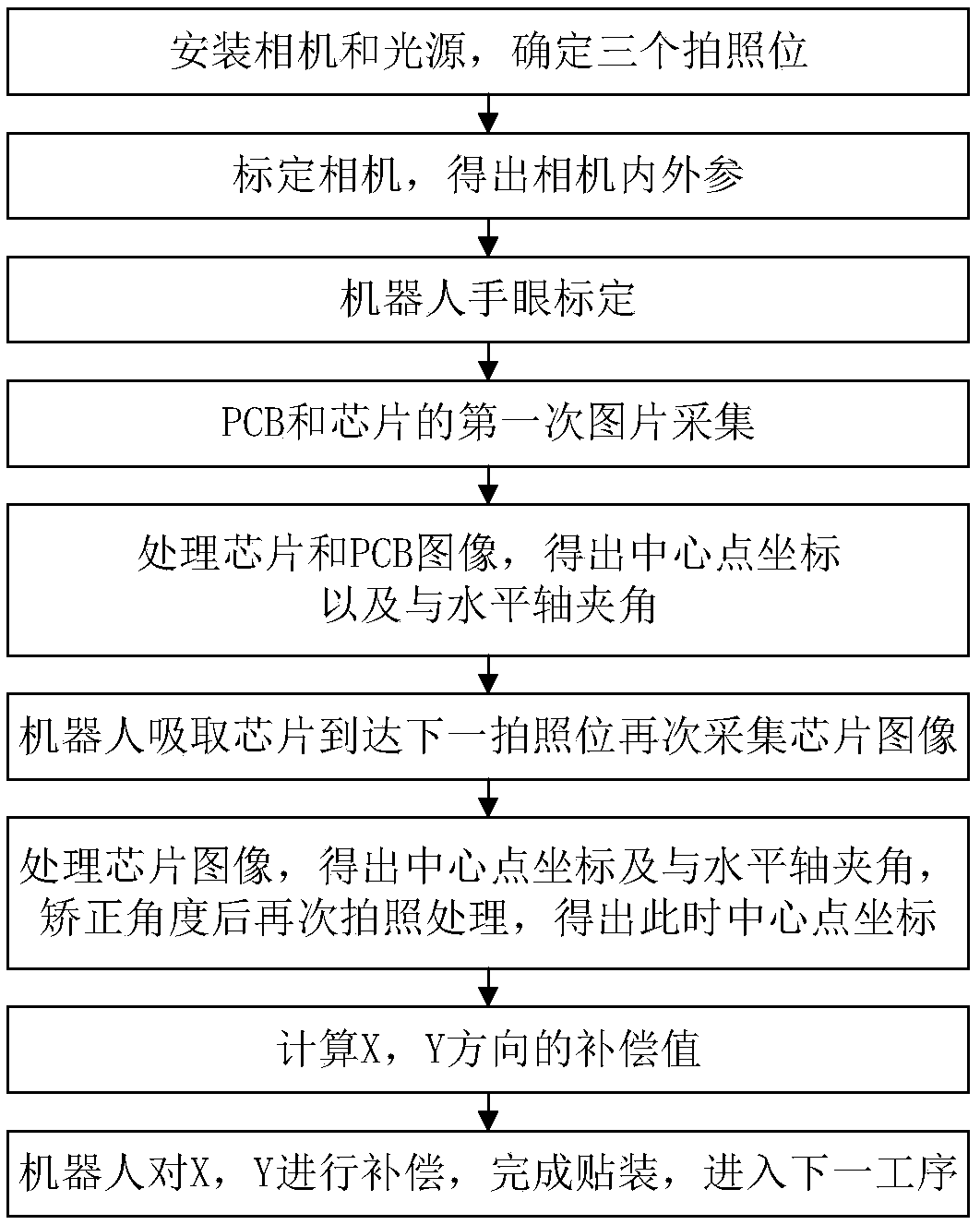

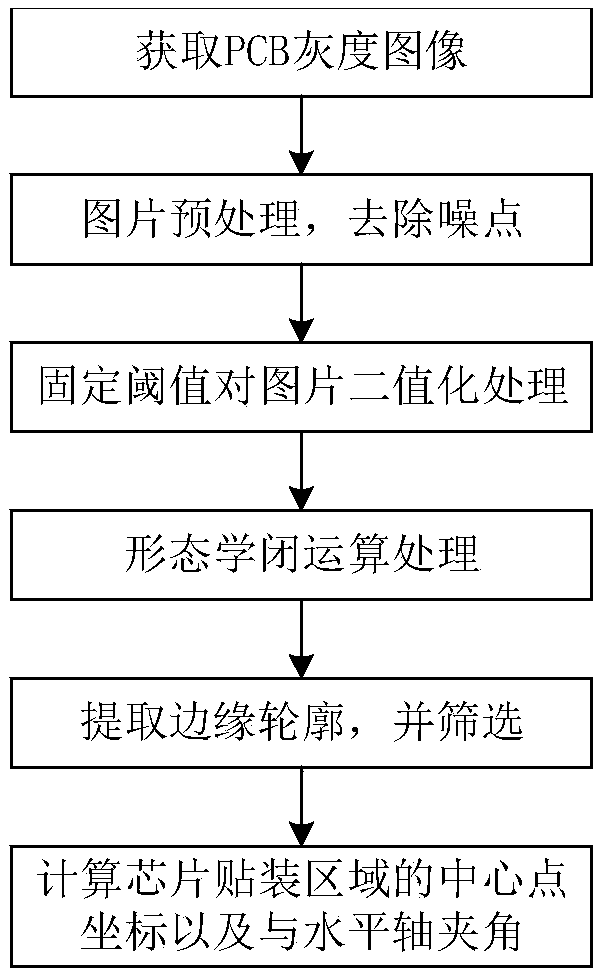

Chip mounting method and system for guiding robot vision

ActiveCN108766894AIncrease freedomIncrease flexibilitySemiconductor/solid-state device manufacturingAngular degreesHorizontal axis

The invention discloses a chip mounting method and system for guiding robot vision. A second industrial camera is additionally arranged in each of a PCB placing area and a chip placing area; a robot is used for absorbing chips to be moved to the positions of the second industrial cameras, the images of the absorbed chips are shot, and angular difference between the included angle of the chip mounting area and a horizontal axis and the included angle of the chips after the chips are absorbed and the horizontal axis is compared so that an end actuator rotates at the position of P3 in the angulardifference, angular compensation is carried out, compensation is carried out on X axis and Y axis, the sliding error generated when the chips are absorbed or in the moving process after the chips areabsorbed is improved, and the mounting precision is improved; moreover, a six-axis robot is adopted, due to the fact that the six-axis robot has higher degree of freedom and flexibility, the chip mounting inside workpieces such as cavities is realized, and flexible production is achieved; and then, first industrial cameras are arranged on the hands of the robot, and the robot is easier to move, so that the visual control method based on position is higher in flexibility and wider in range of application.

Owner:HUNAN UNIV

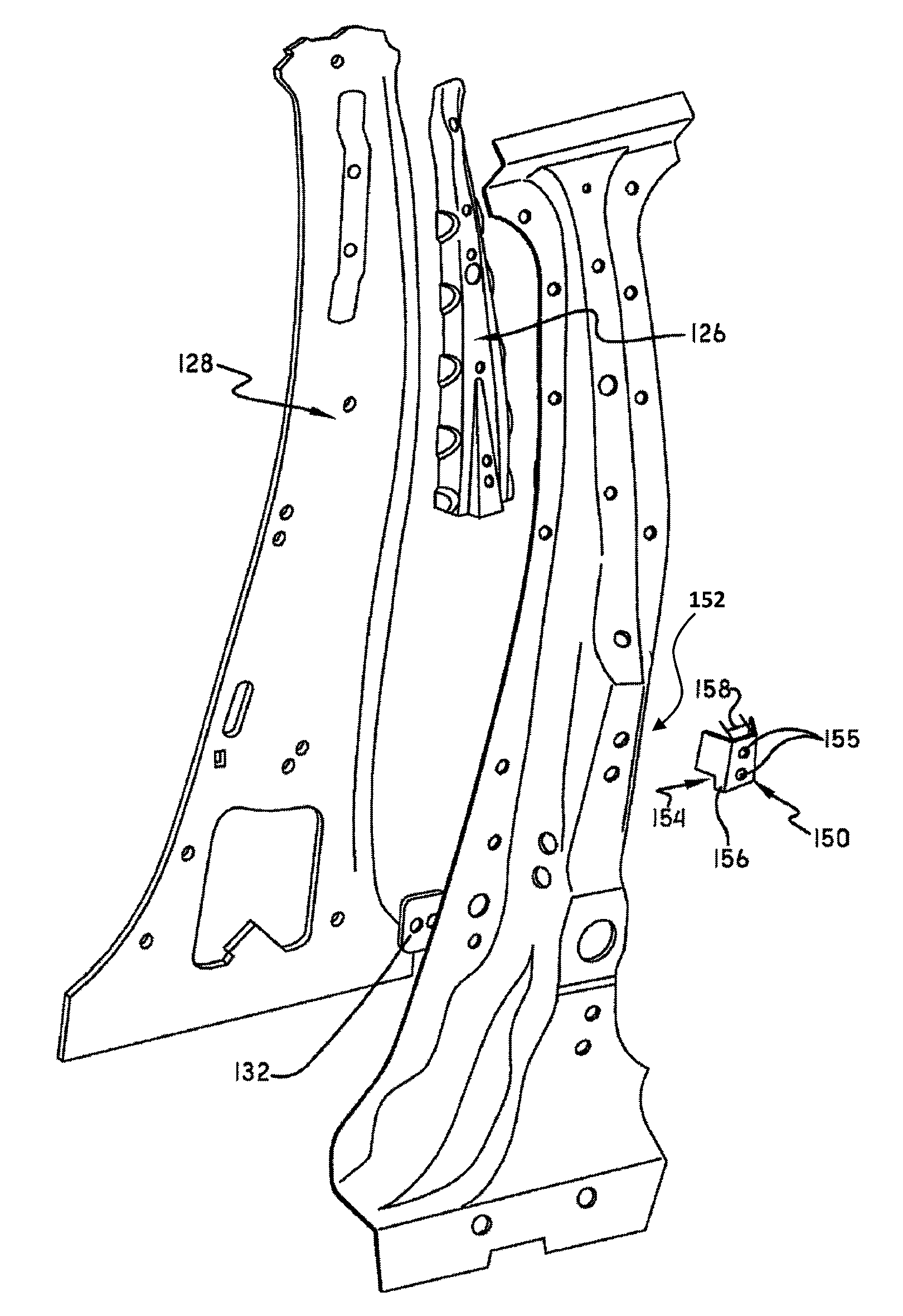

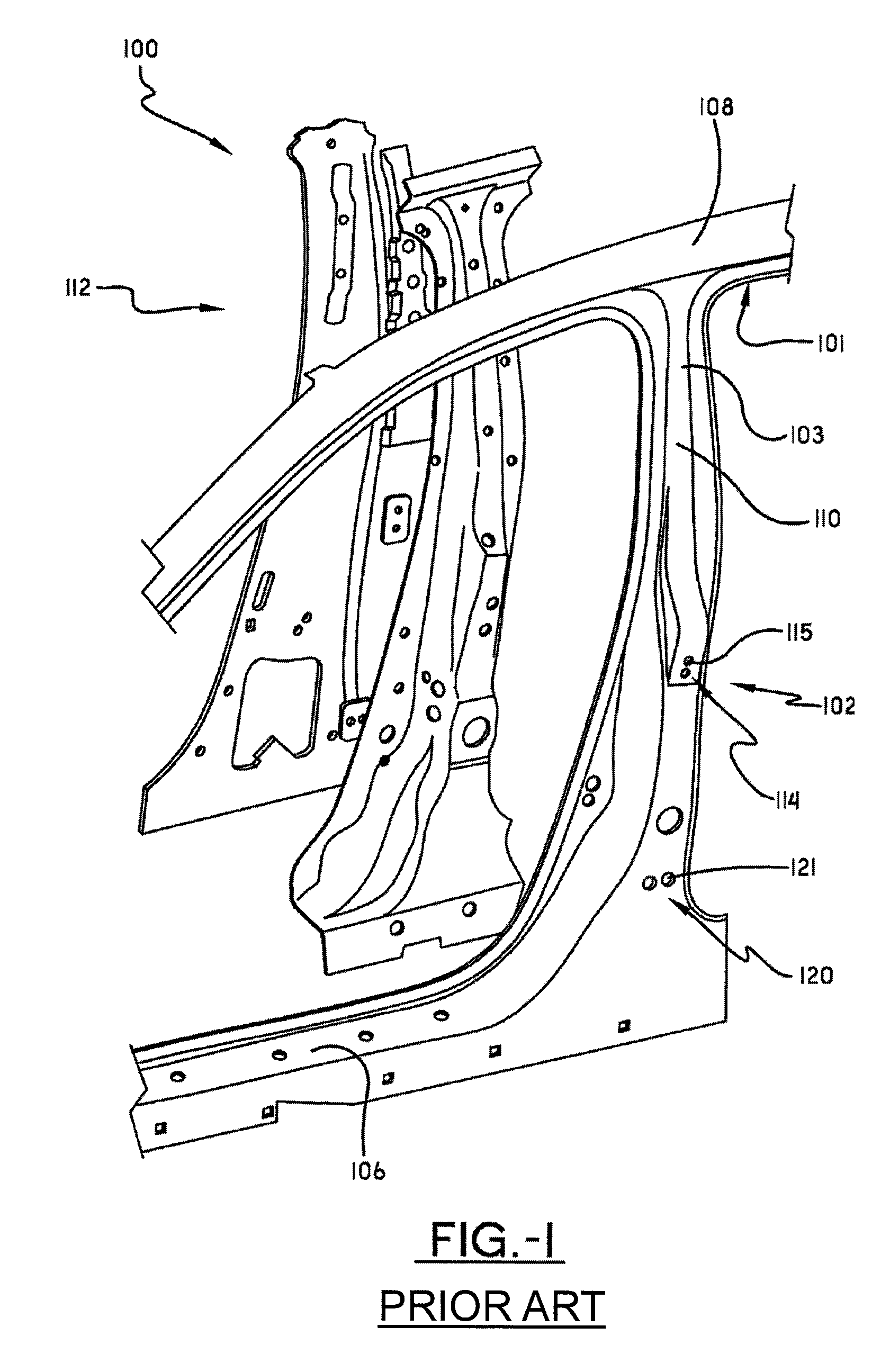

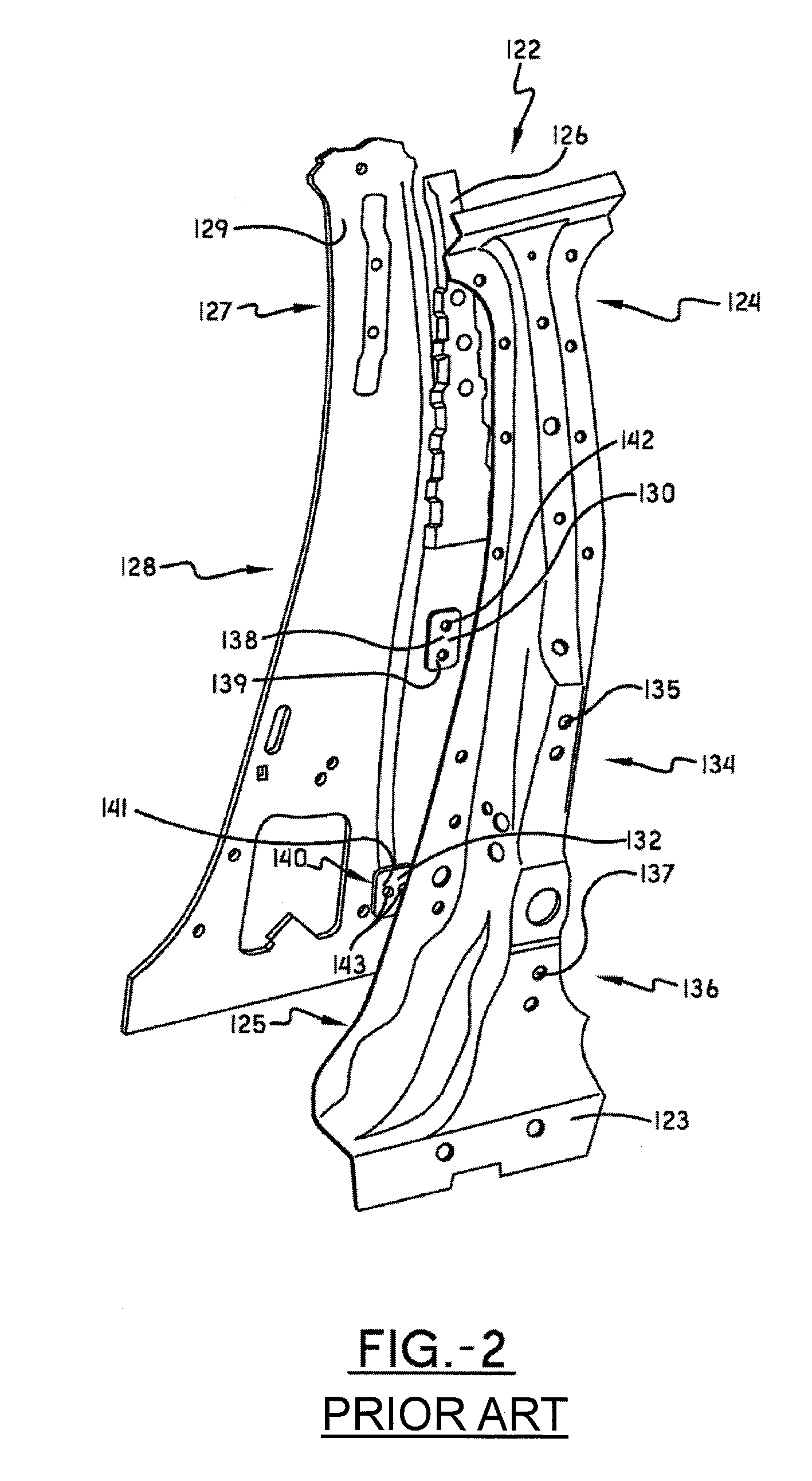

Modified upper rear door hinge patch

InactiveUS7959217B2Good molding effectReduce depthVehicle seatsSuperstructure subunitsEnergy absorptionSide impact

Owner:HONDA MOTOR CO LTD

Electronic component mounting apparatus, height detection method for electronic component, and optical-axis adjustment method for component height detection unit

InactiveUS20090225304A1Accurate detectionImprove placement accuracyMechanical depth measurementsDigital computer detailsOptical axisLight beam

An electronic component mounting apparatus includes a beam projector for projecting a laser beam, a beam receiver which is placed in opposition to the beam projector and which receives a laser beam projected from the beam projector, a light-reception-sensitivity setting unit for adjusting light-reception sensitivity of the beam receiver, a projection-side orifice provided in the beam projector to narrow a projection spot diameter of the laser beam, and a reception-side orifice provided in the beam receiver to narrow a light-reception spot diameter, where the light-reception sensitivity of the beam receiver is improved. As a result, an electronic component mounting apparatus capable of accurately detecting height size of small components by using a relatively inexpensive photoelectric sensor can be provided.

Owner:PANASONIC CORP

Mounting structure of vehicle interior material

InactiveUS20060085955A1Small insertion forceReliably prevent the clip from being disengaged from the boss partSnap fastenersSheet joiningEngineeringMechanical engineering

Owner:PIOLAX CO LTD

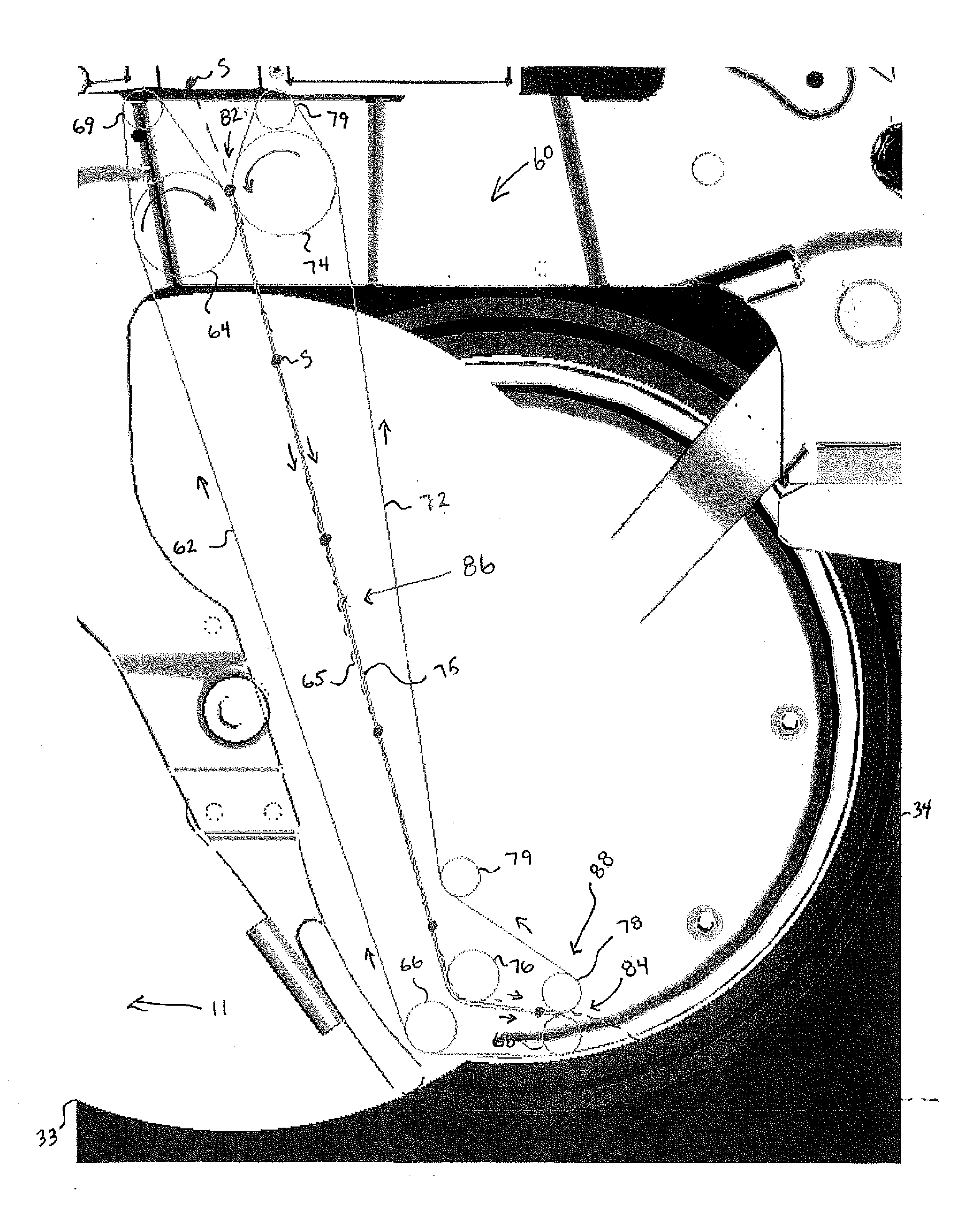

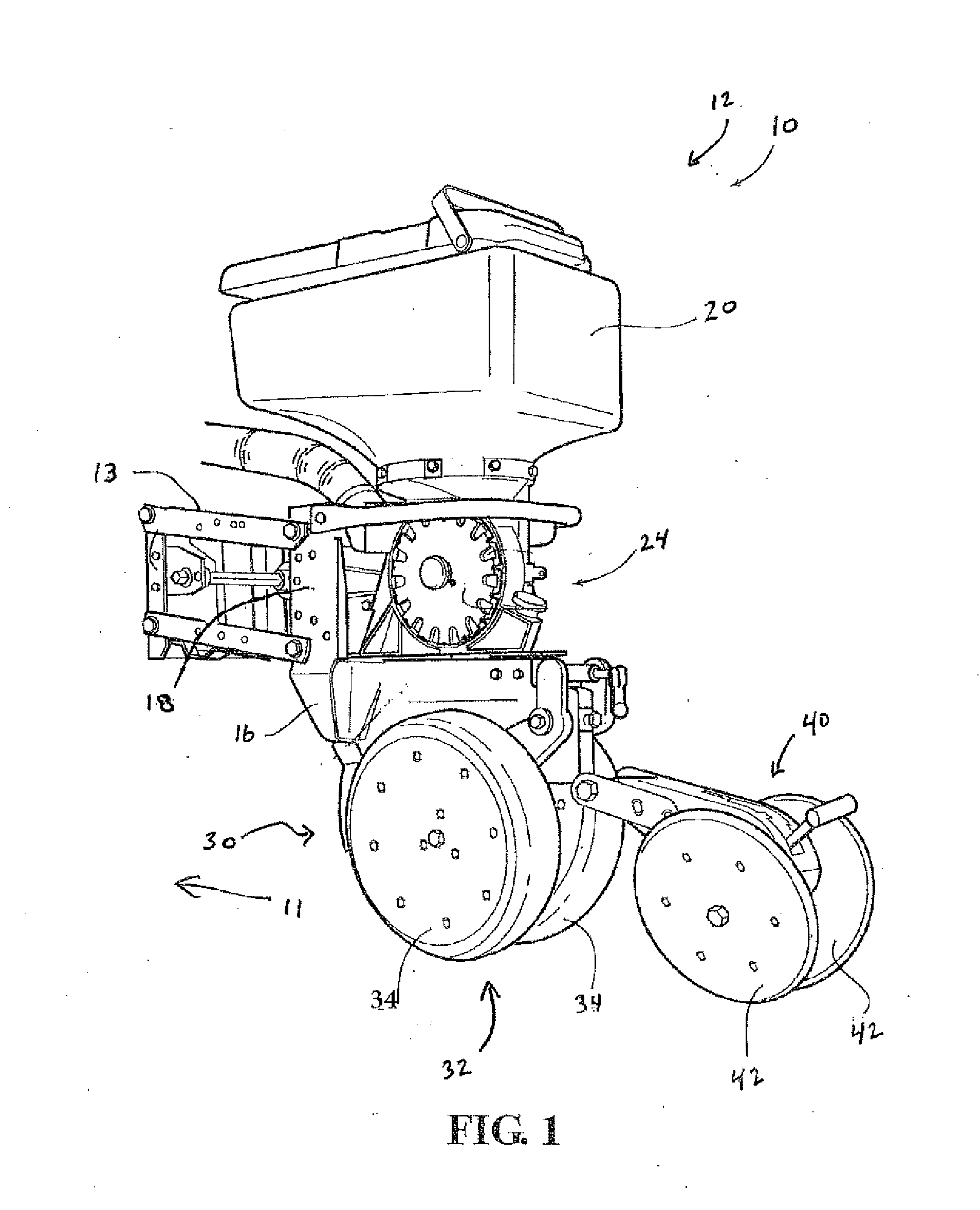

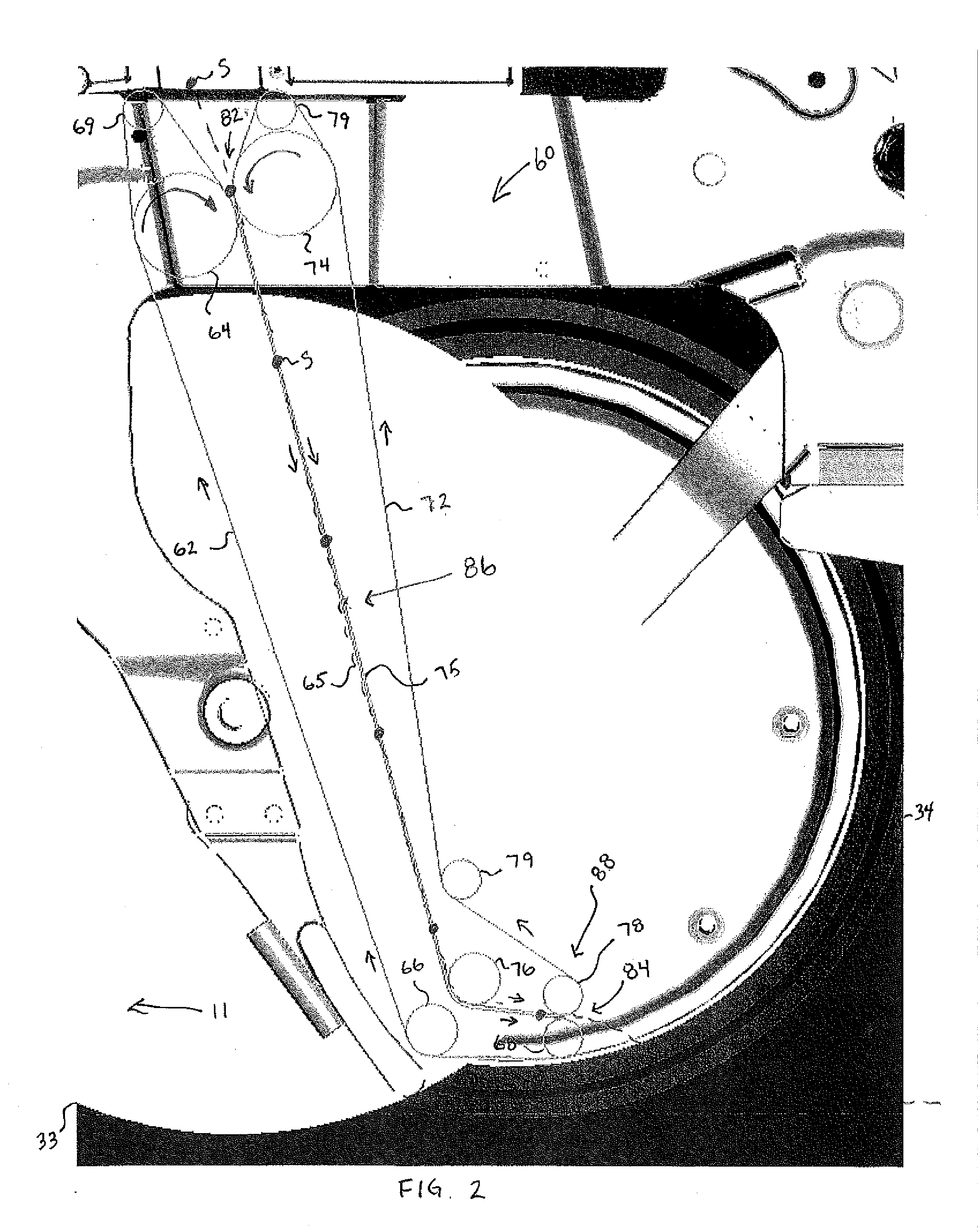

Dual belt seed delivery mechanism

ActiveUS20150237793A1Improve placement accuracyImprove crop yield and efficiency and profitabilityPotato plantersFurrow making/coveringAdemetionineRelease point

A seed delivery mechanism for an agricultural planter that receives seeds from a seed meter of the planter and delivers the seeds to a seed trench as the planter moves in a planting direction has a first endless belt trained about a first drive pulley and a second endless belt trained about a second drive pulley. The first and second drive pulleys rotate the first and second endless belts to provide confronting belt segments that form a seed delivery path between a conveyor entry point and a release point. The first and second endless belts are configured with a downward reach oriented to move seeds predominantly downward and a rearward reach oriented to move the seed predominantly rearward. The rearward reach provides a rearward velocity component to seeds at the release point that offsets a forward velocity of the planter as the planter moves in the planting direction.

Owner:AGCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com