Patents

Literature

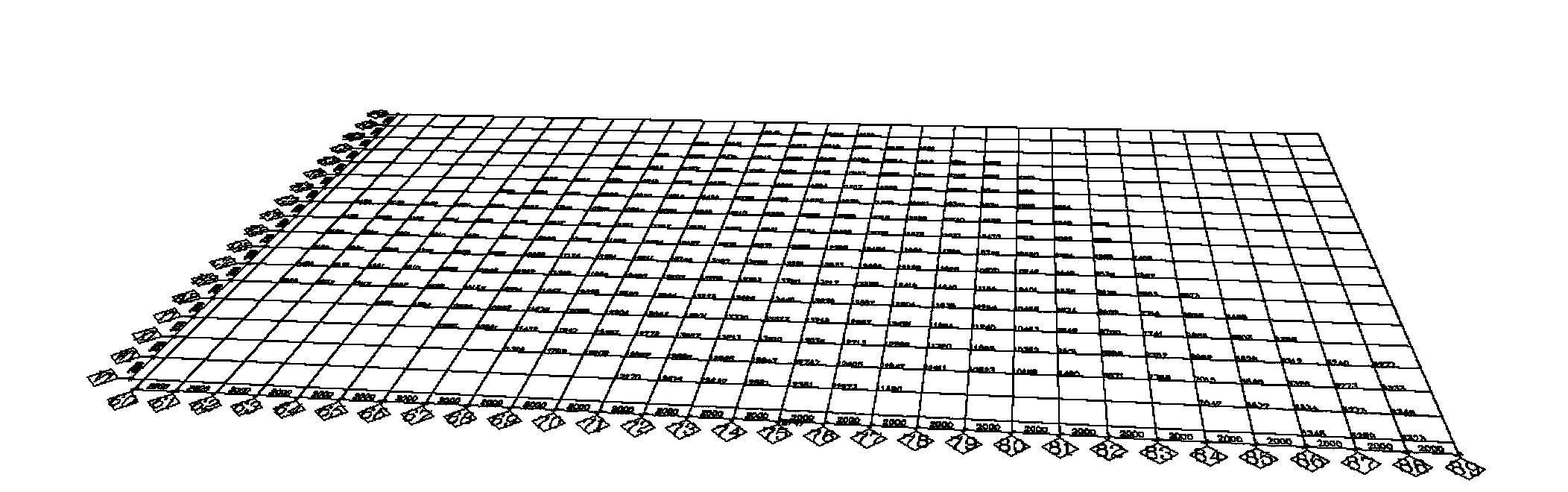

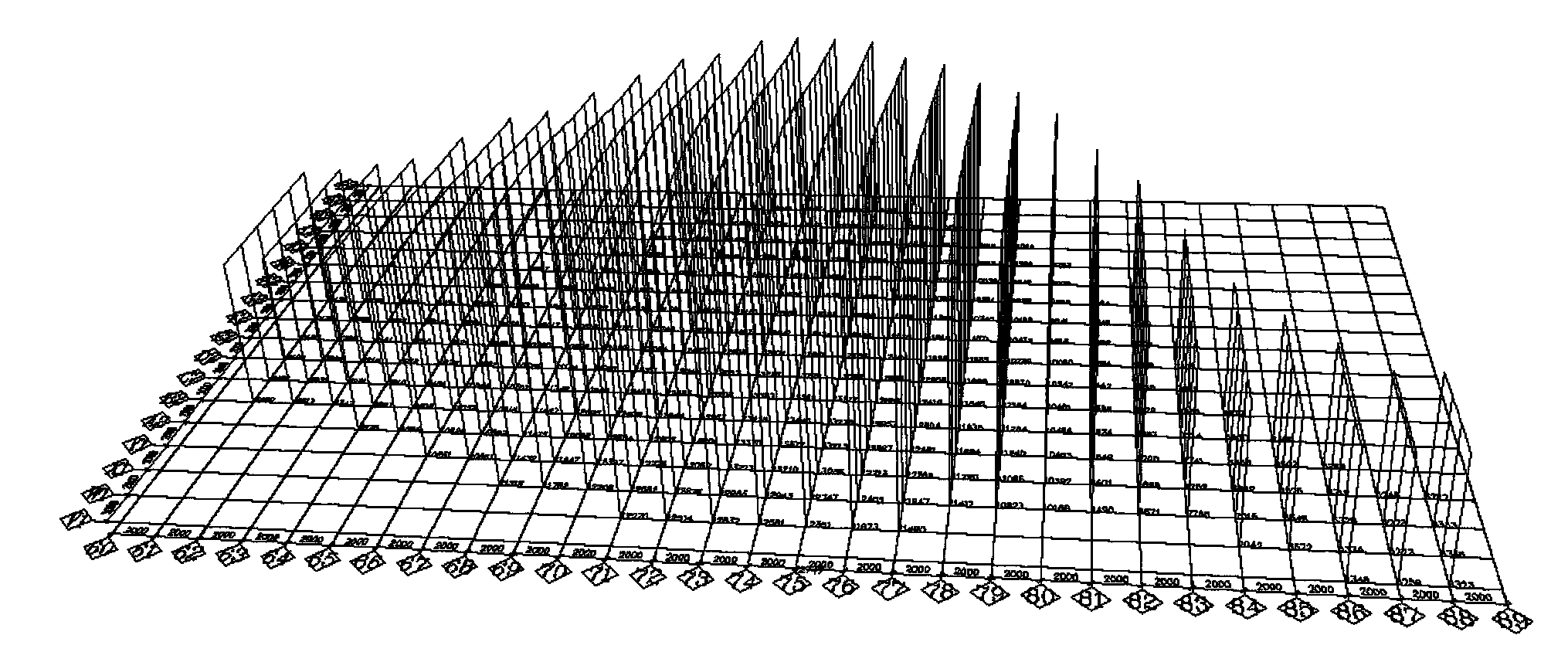

818results about How to "Reduce rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

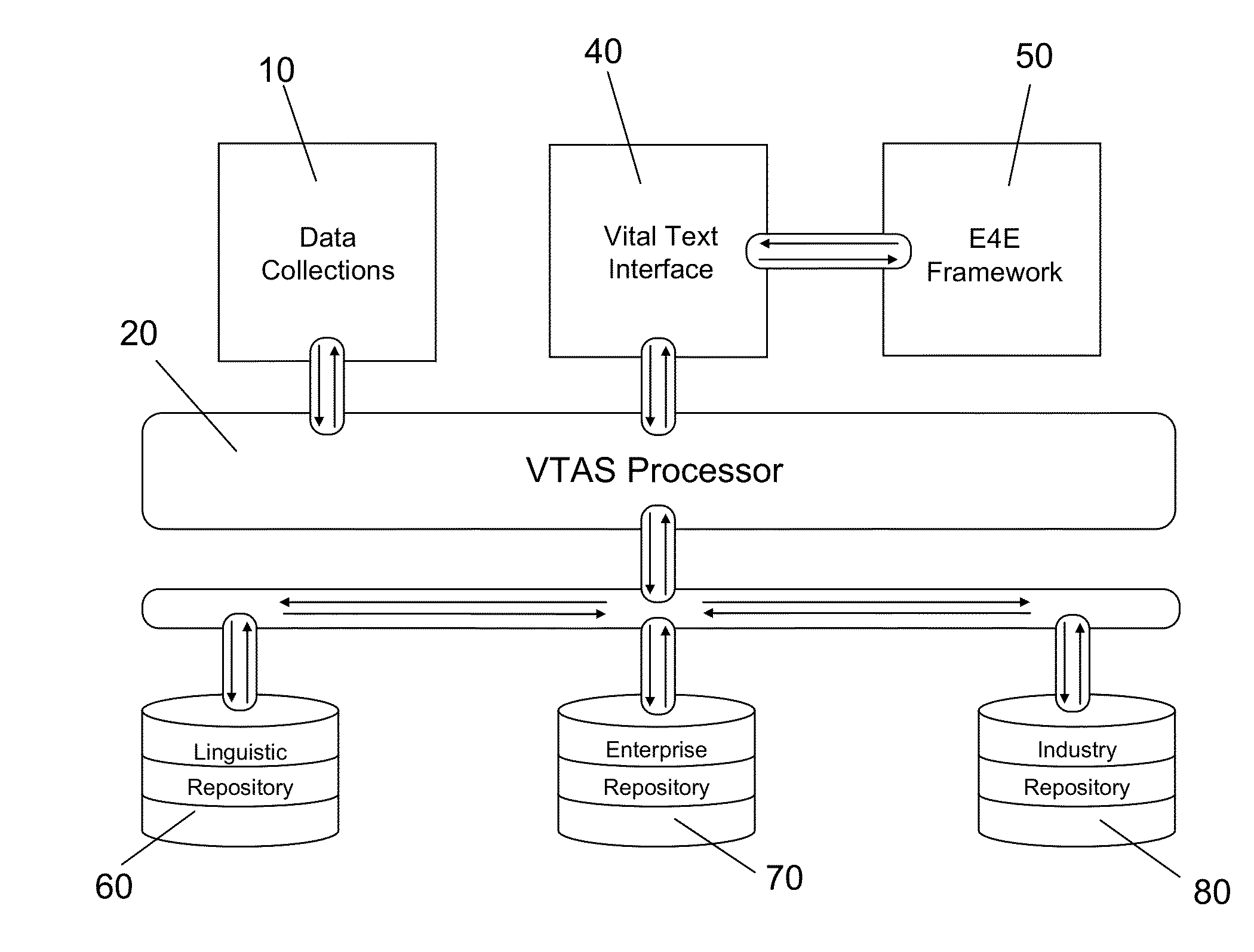

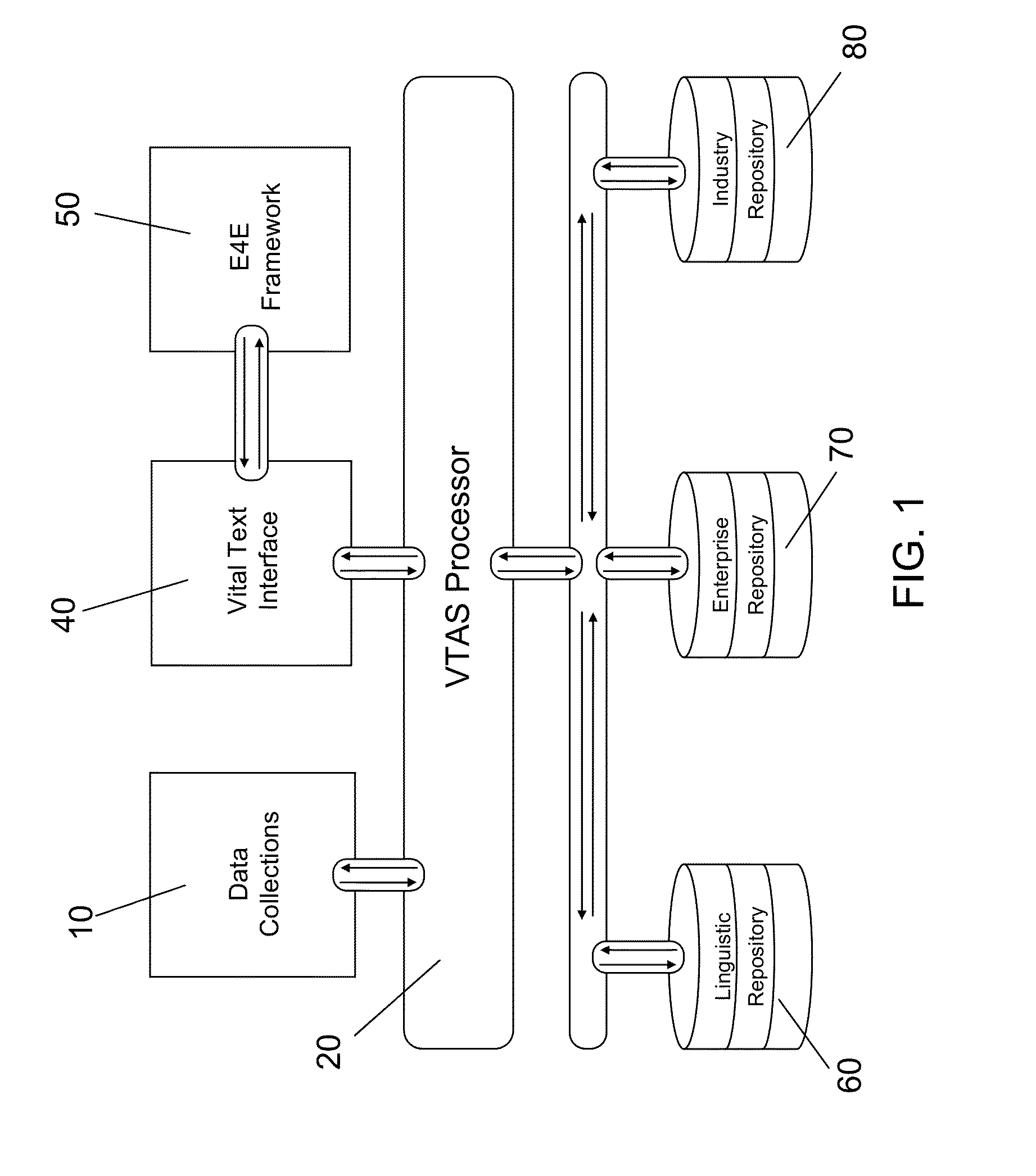

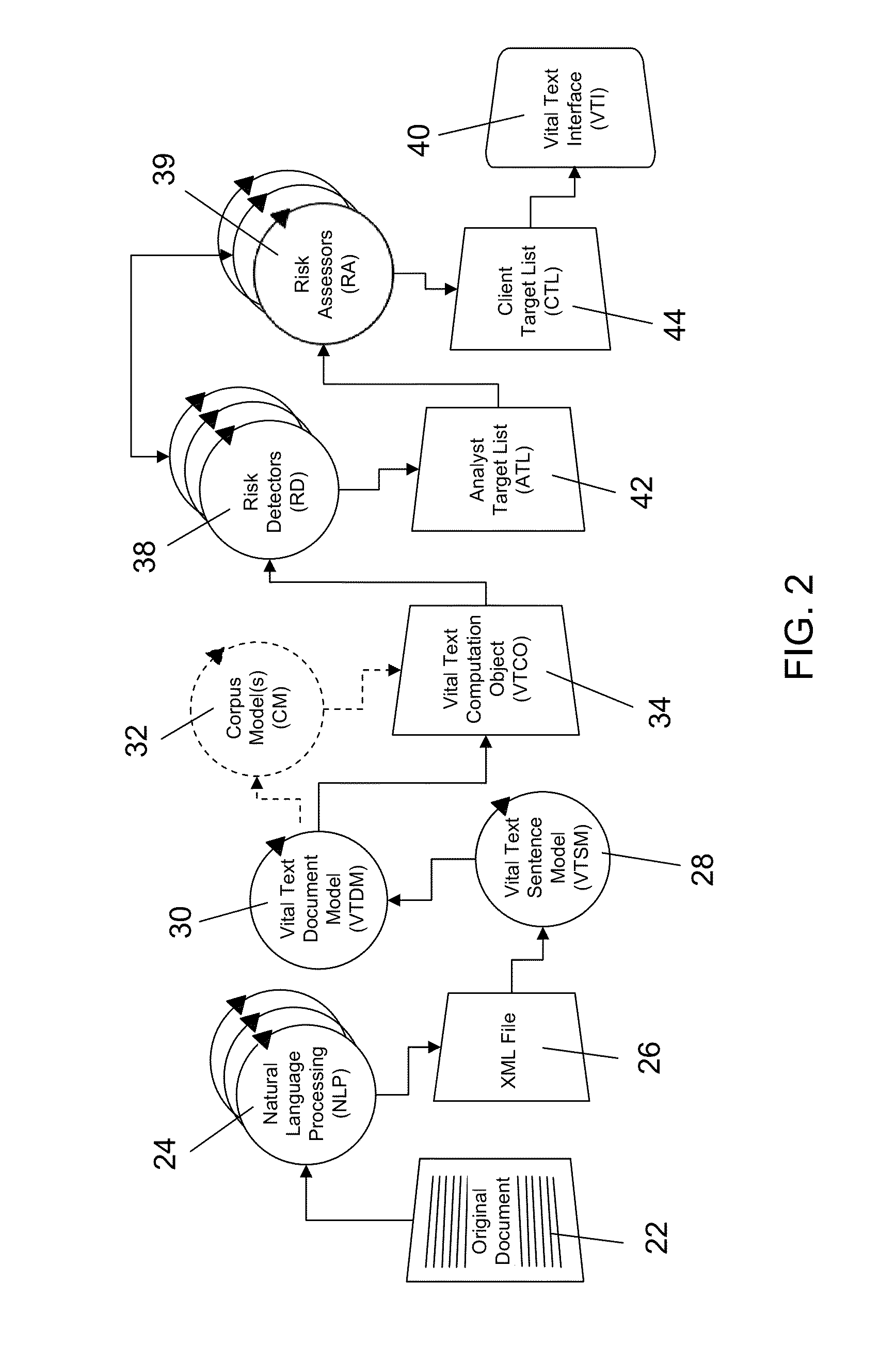

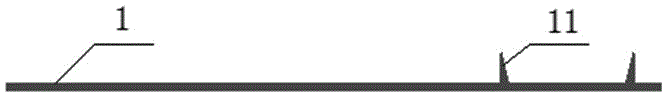

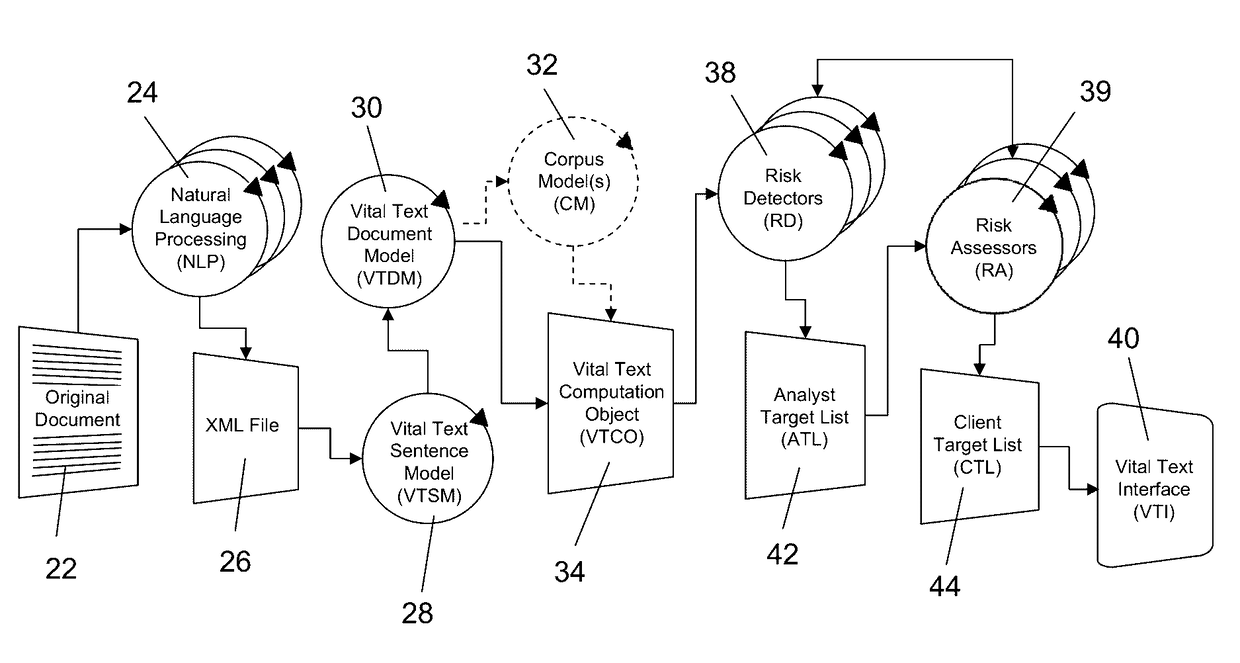

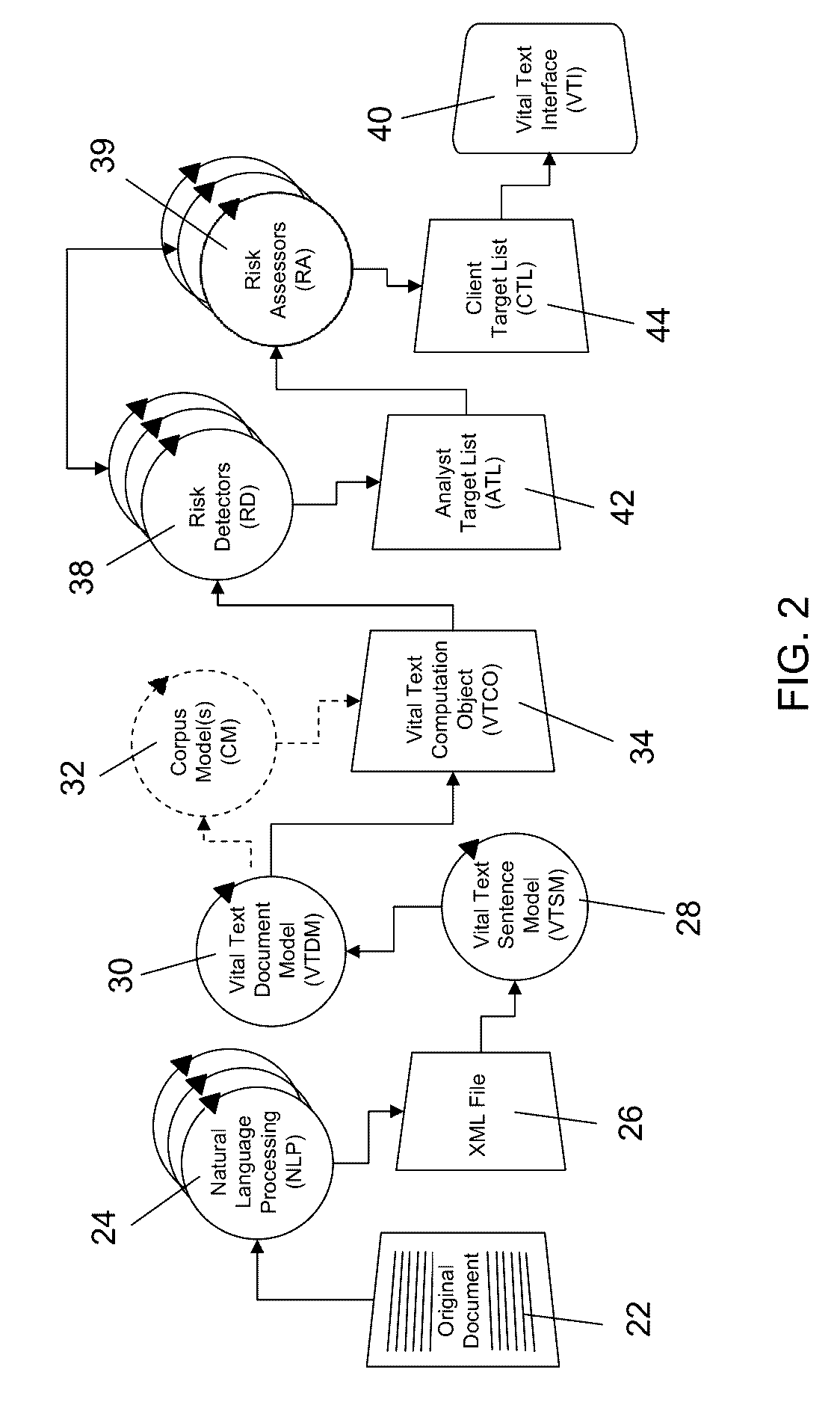

Vital text analytics system for the enhancement of requirements engineering documents and other documents

ActiveUS20140172417A1Improve efficiencyReduce defectsSemantic analysisSpecial data processing applicationsDocumentation procedureTechnical specifications

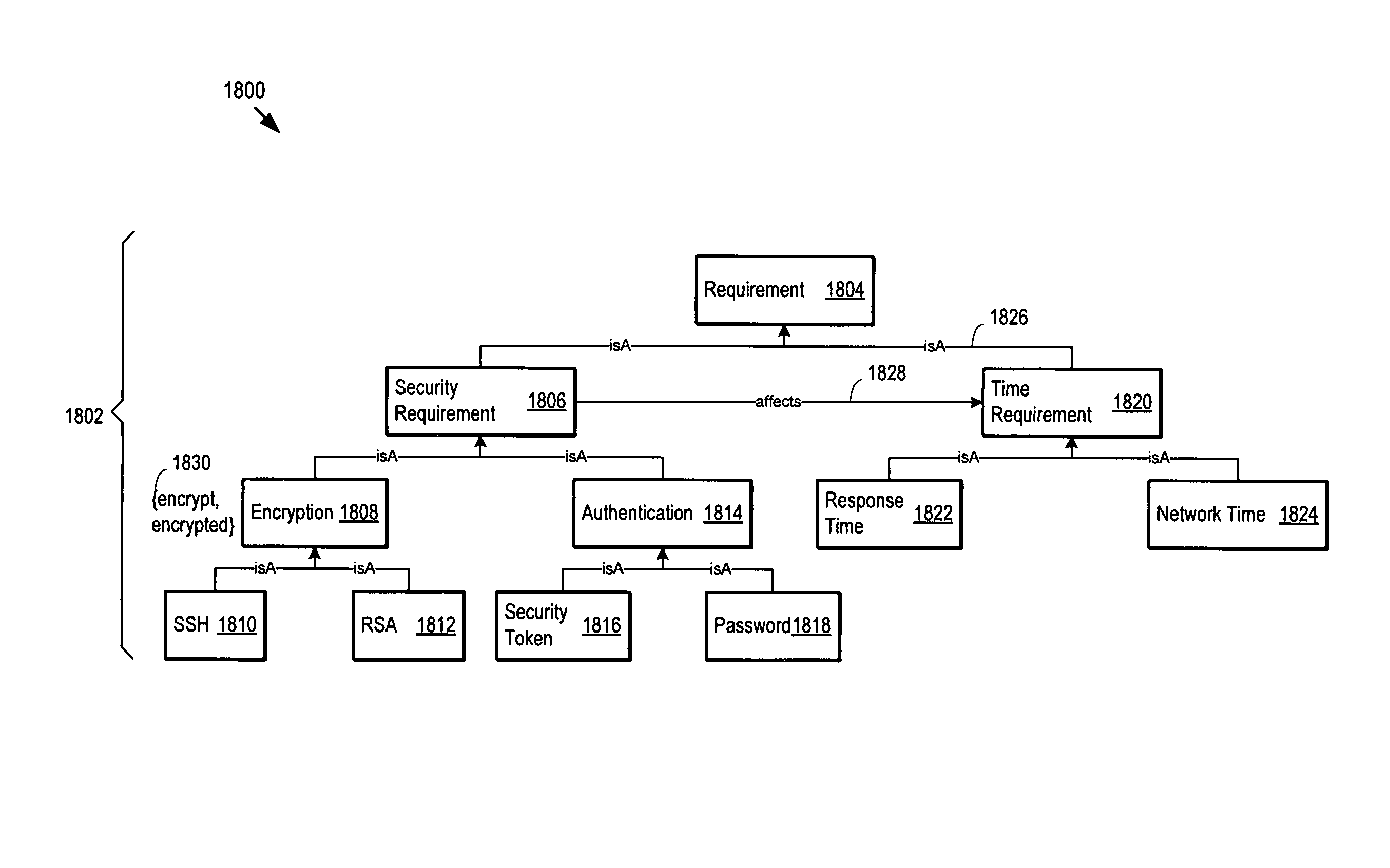

A Vital Text Analytics System (VTAS), incorporating a repository of enterprise terms or concepts, is one that improves the readability and fidelity of technical specifications, instructions, training manuals requirements engineering documents and other related engineering documents, typically from a single organization or workgroup. The system stresses ontological analysis of a corpus of related documents, and applies a suite of computational tools that supports the identification and assessment of risk in evaluating the content of the documents, as well as providing statistical measures reflecting the frequency and severity of document features that threaten comprehension.

Owner:CLOUD 9 LLC DBA VITAL TEXT SYST

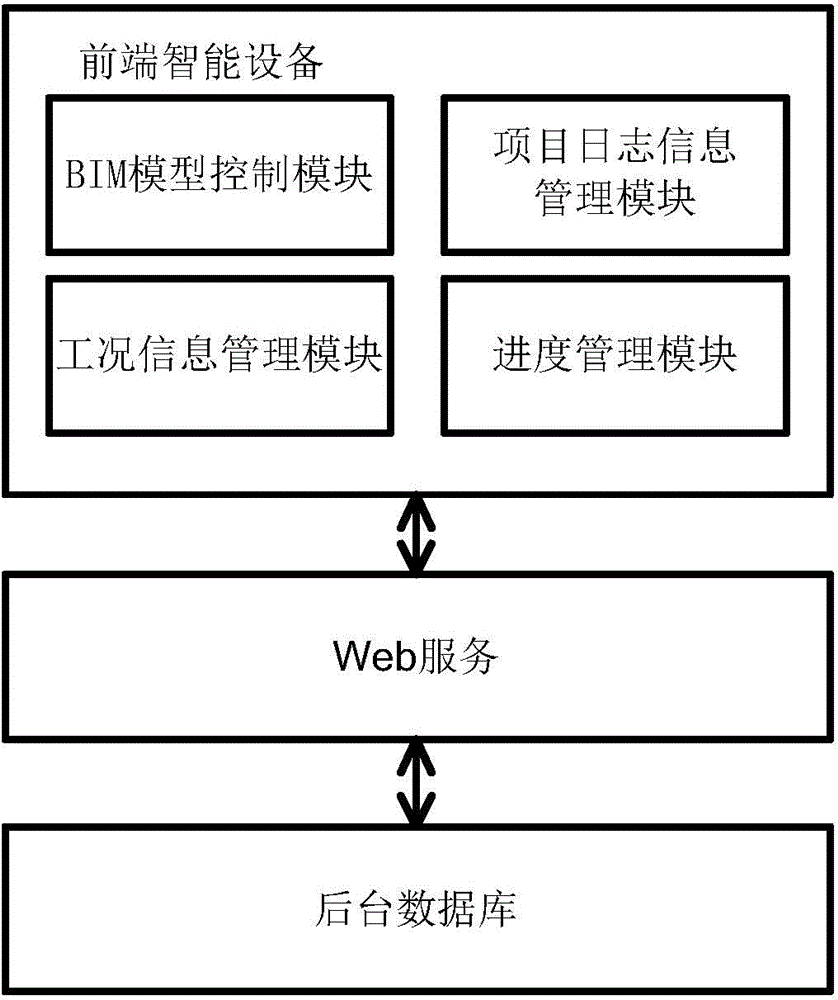

BIM-based project management system and method

InactiveCN104680320ARealize real-time upload and downloadAccurate descriptionResourcesSpecial data processing applicationsData synchronizationWeb service

The invention provides a BIM (Building Information Modeling)-based project management system and method. The BIM-based project management system comprises a front-end intelligent device for transmitting a user command to a WEB server, the WEB server for synchronously updating data between the front-end intelligent device and a background database end, and the background database end for controlling a BIM and managing the data of BIM, working conditions and log. The invention has the following advantages: 1, the site problems can be found and corrected effectively, so as to reduce the rework possibility; 2, the site management personnel has no need to take a large number of drawings and other information, can complete all the work through one mobile device; 3, the handling progress of the site problems can be tracked effectively; 4, the constructability of the project can be understood intuitively; 5, the receiving, transmitting and processing of all the data can be performed in real time and can be completed within seconds according to the network status, and the response speed is high.

Owner:SHANGHAI TONGZHU INFORMATION TECH +1

Method for repairing leaked coiled-material water-proof roof

ActiveCN101994399ALeak effectiveEffective leak repairRoof covering using flexible materialsBuilding repairsEavesConstruction engineering

The invention relates to a method for repairing a leaked coiled-material water-proof roof. The method comprises the steps of basic layer processing, detail repairing, large-area repairing, and the like. The step of detail repairing comprises: repairing cracked gutters and eaves gutter coiled-materials, repairing flashing parts and repairing deformed joints. The step of large-area repairing comprises: paving water-proof coiled materials, repairing cracks on a coiled-material water-proof layer, repairing the raised edges of a joint opening, repairing a raised part, and the like. The whole repairing scheme of the invention has the advantages of scientific design, reasonable system, overall prospection, rigorous analysis, practicability and good construction effect, and ensures that leaked houses can be effectively repaired. In the method, the materials, construction manner, construction environment, and the like, are all comprehensively considered. The construction cost performance is high and the use range is wide. The construction method is safe and environment-friendly, can meet the demands of building use and safety, can ensure that the manpower, material resources and financial resources are saved, and is suitable for various repairing for the leaked coiled-material water-proof roof. The application and practice show that the construction condition of the method is in good condition.

Owner:HENAN GUOJI CONSTR GRP

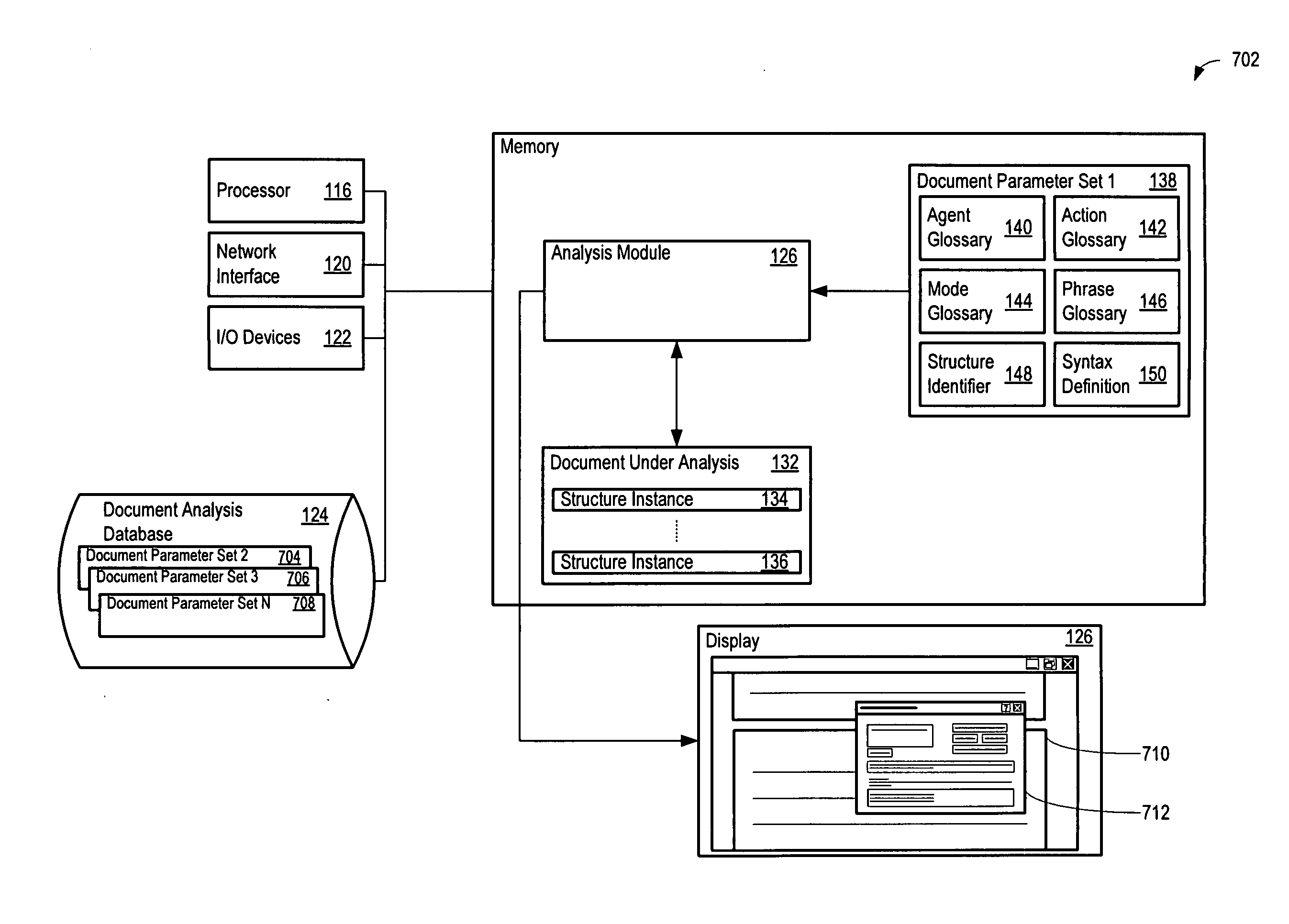

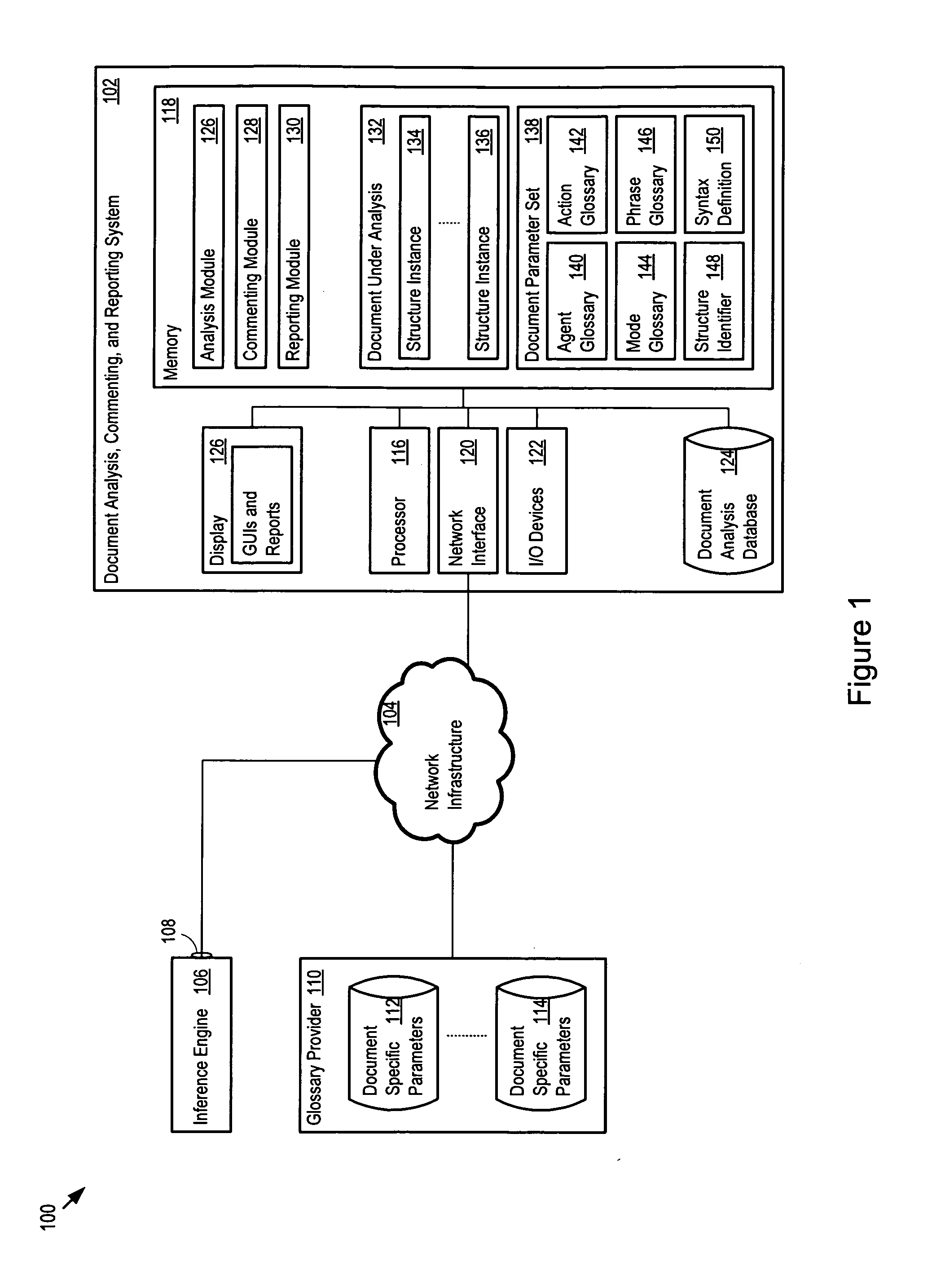

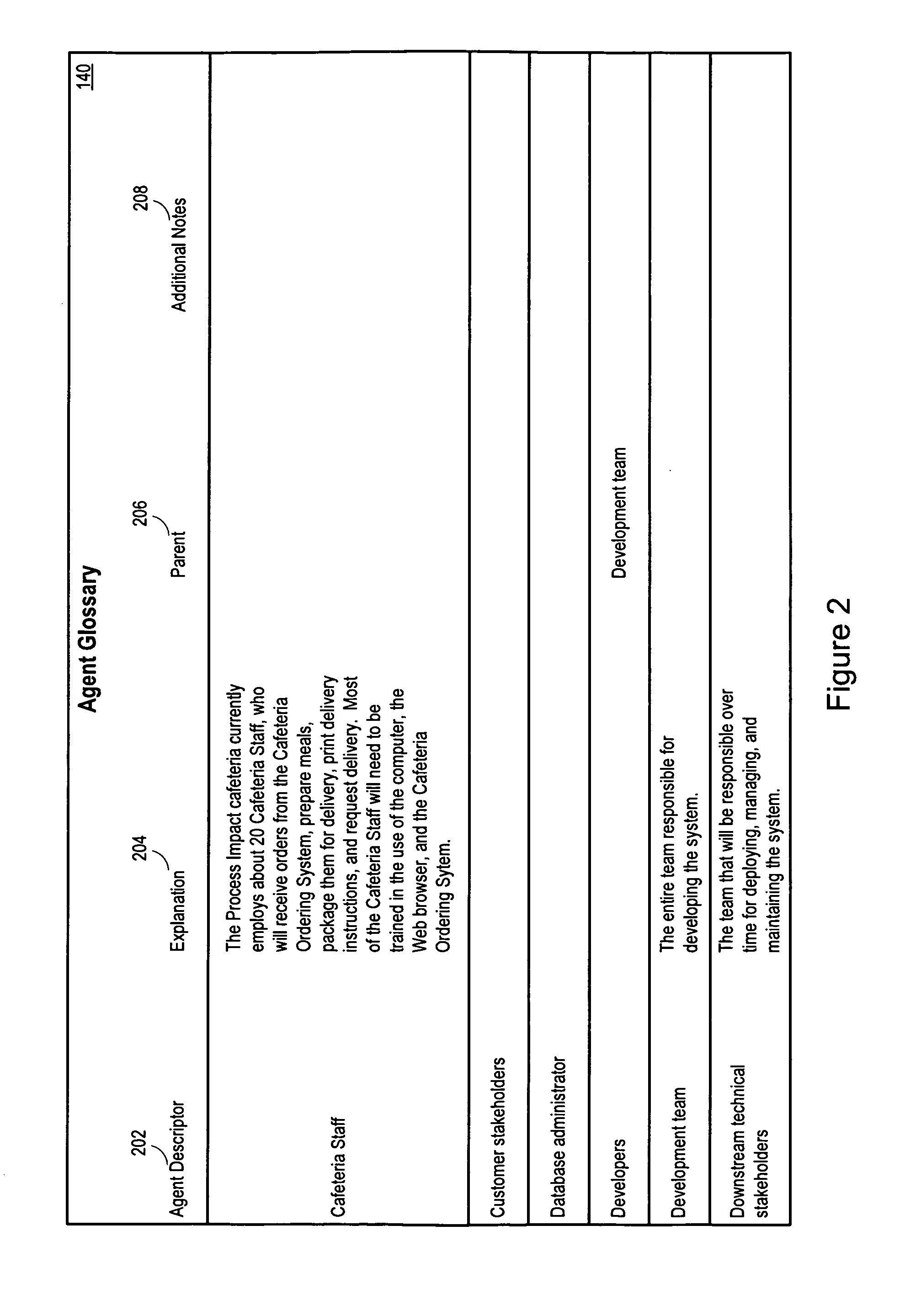

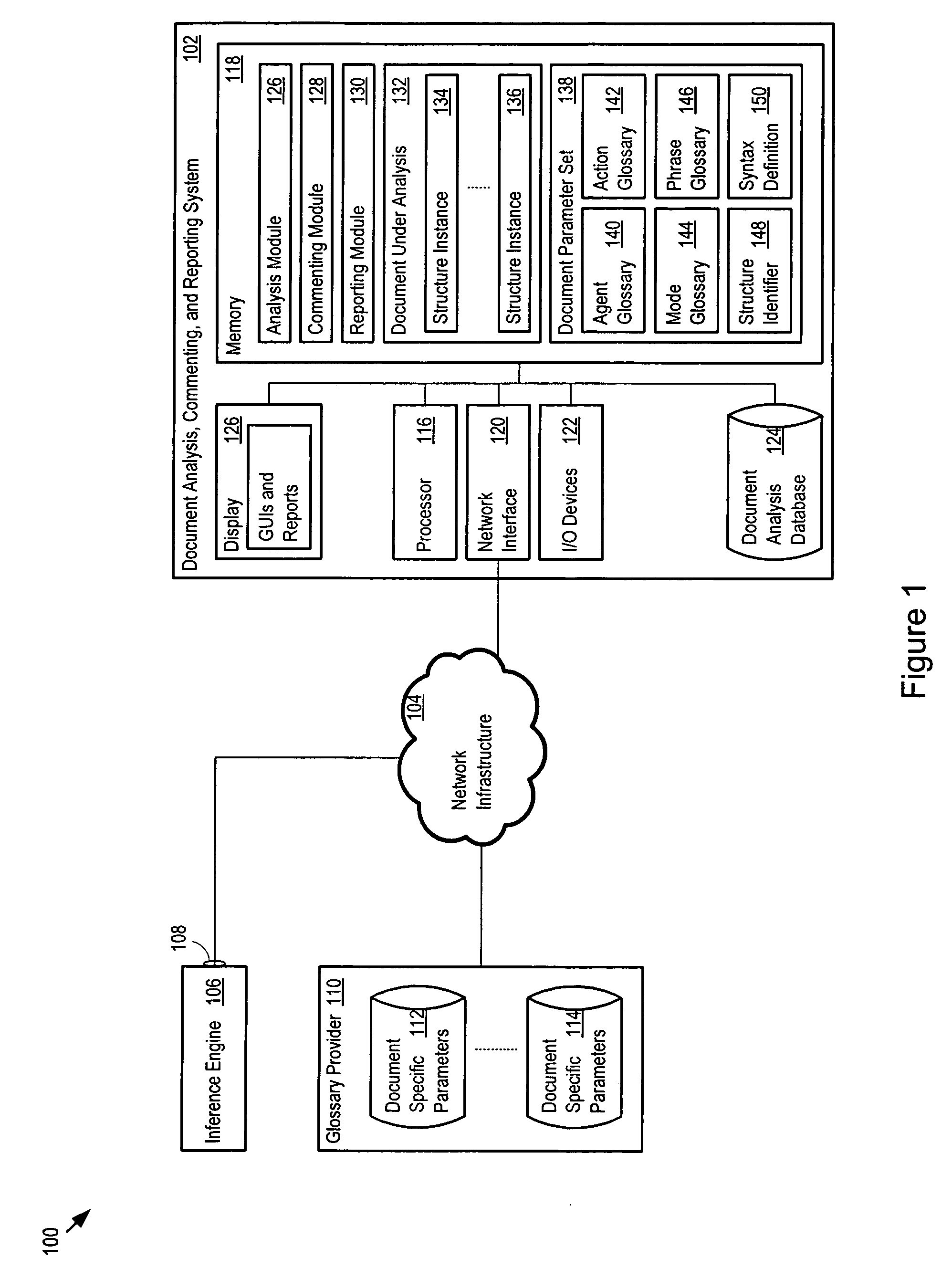

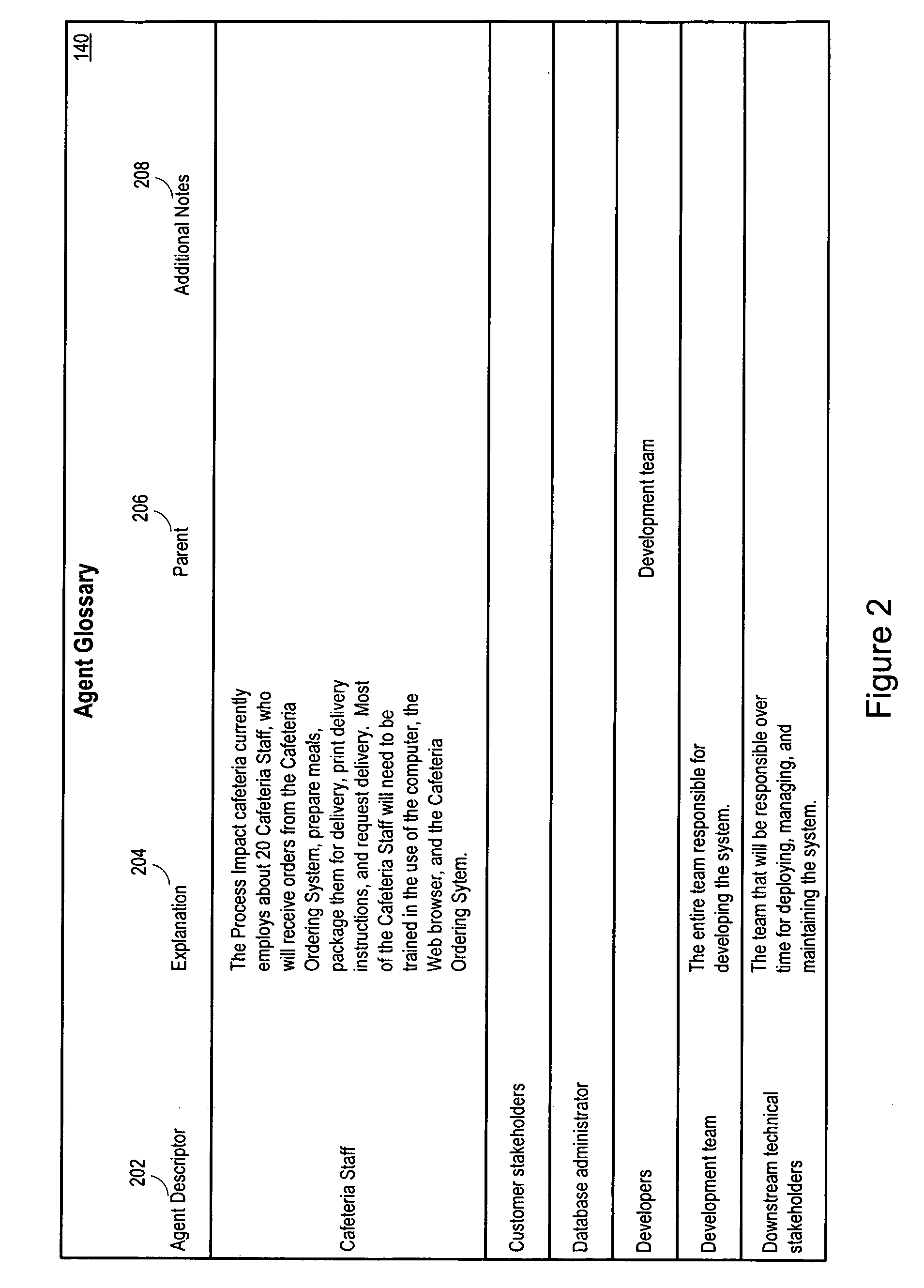

Document Analysis, Commenting, and Reporting System

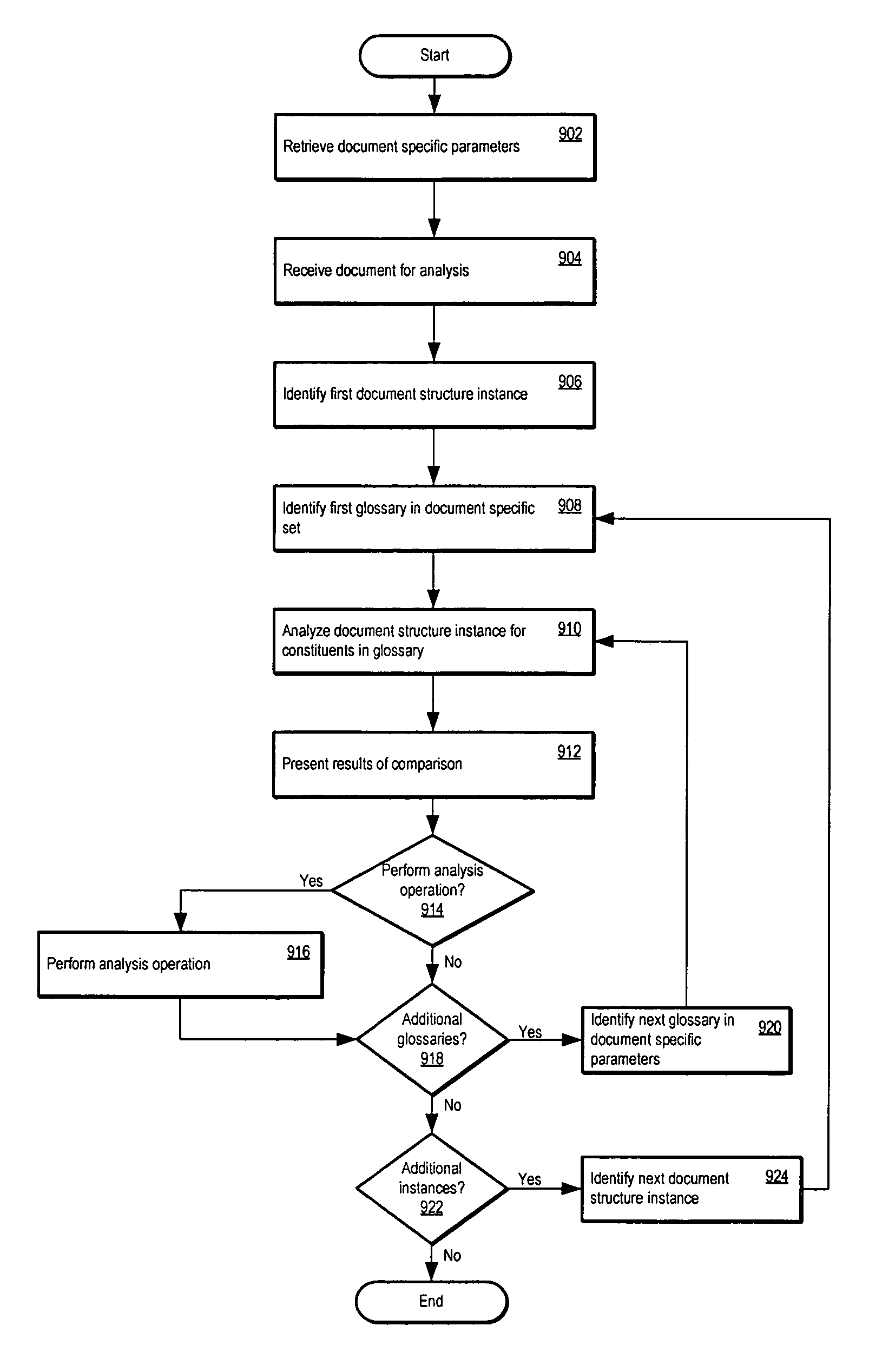

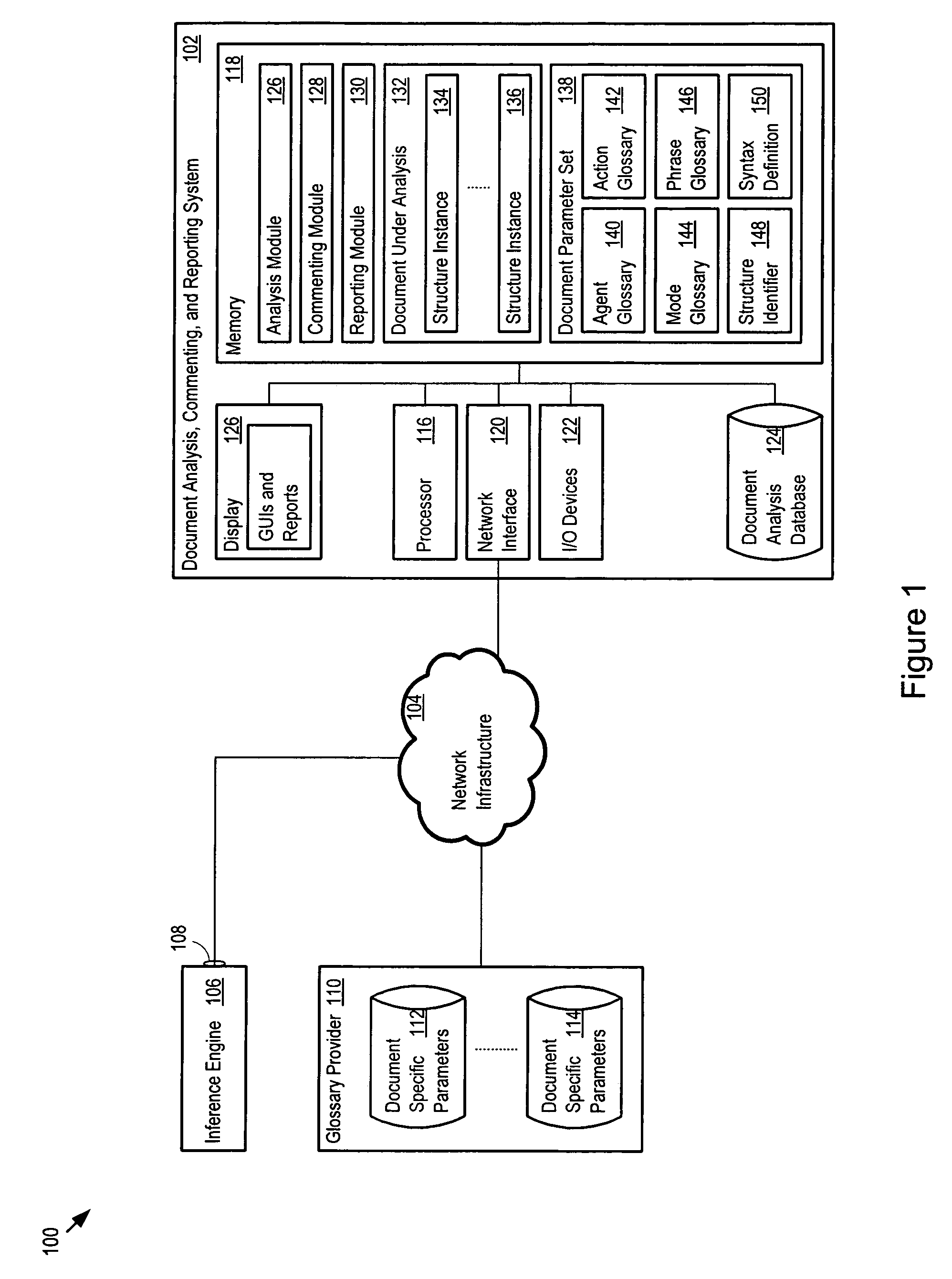

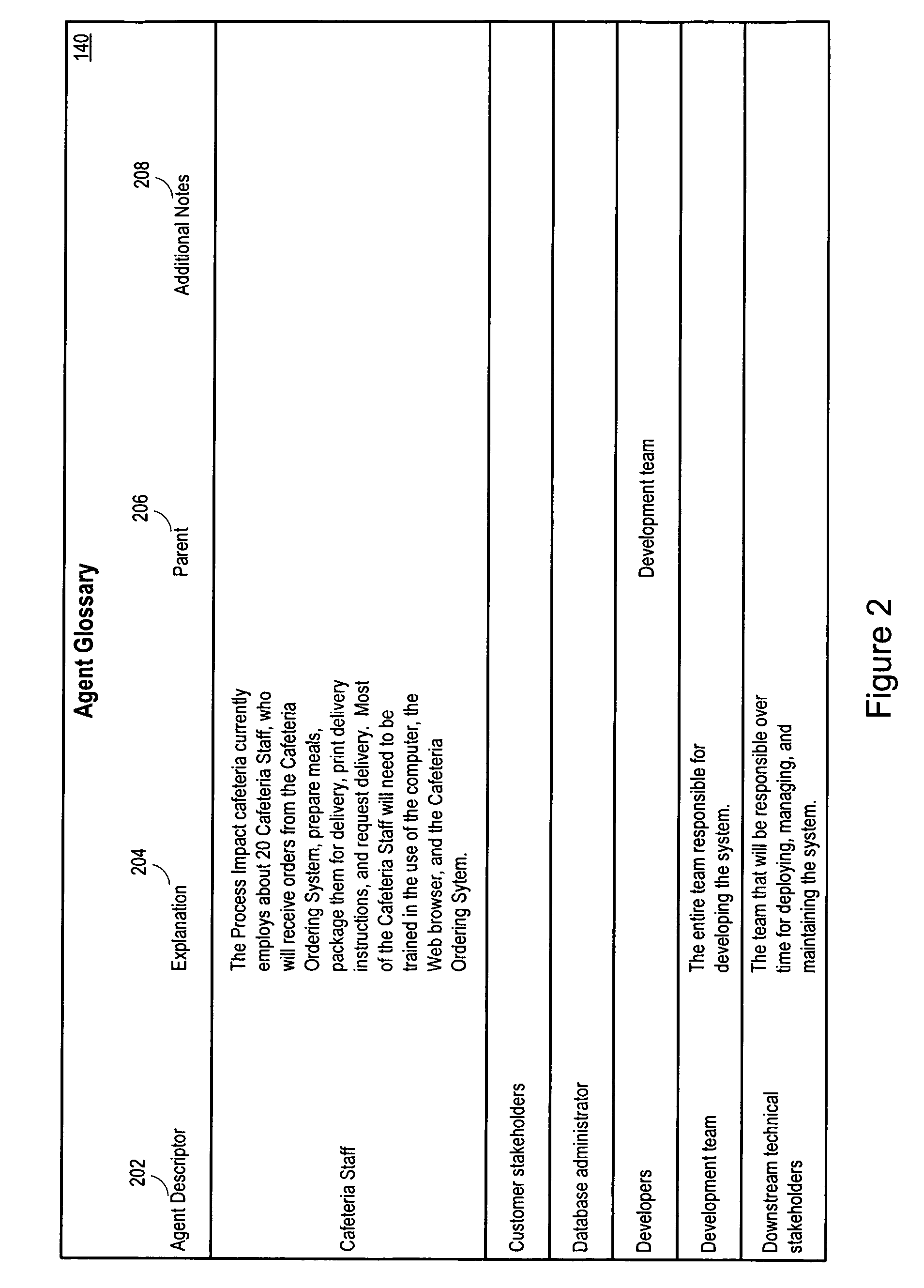

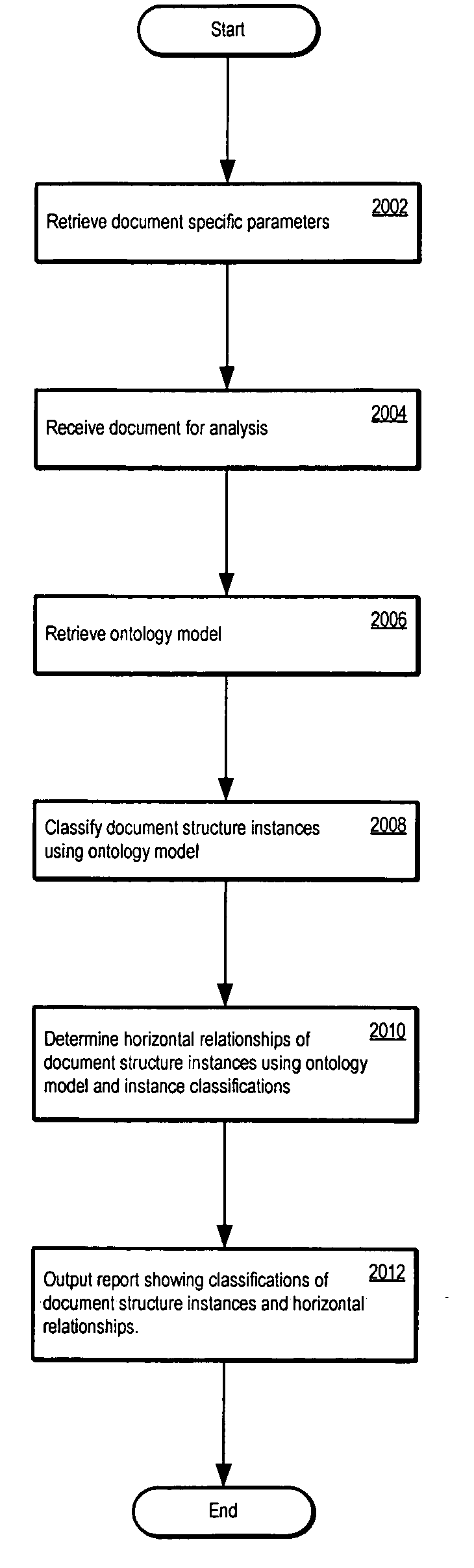

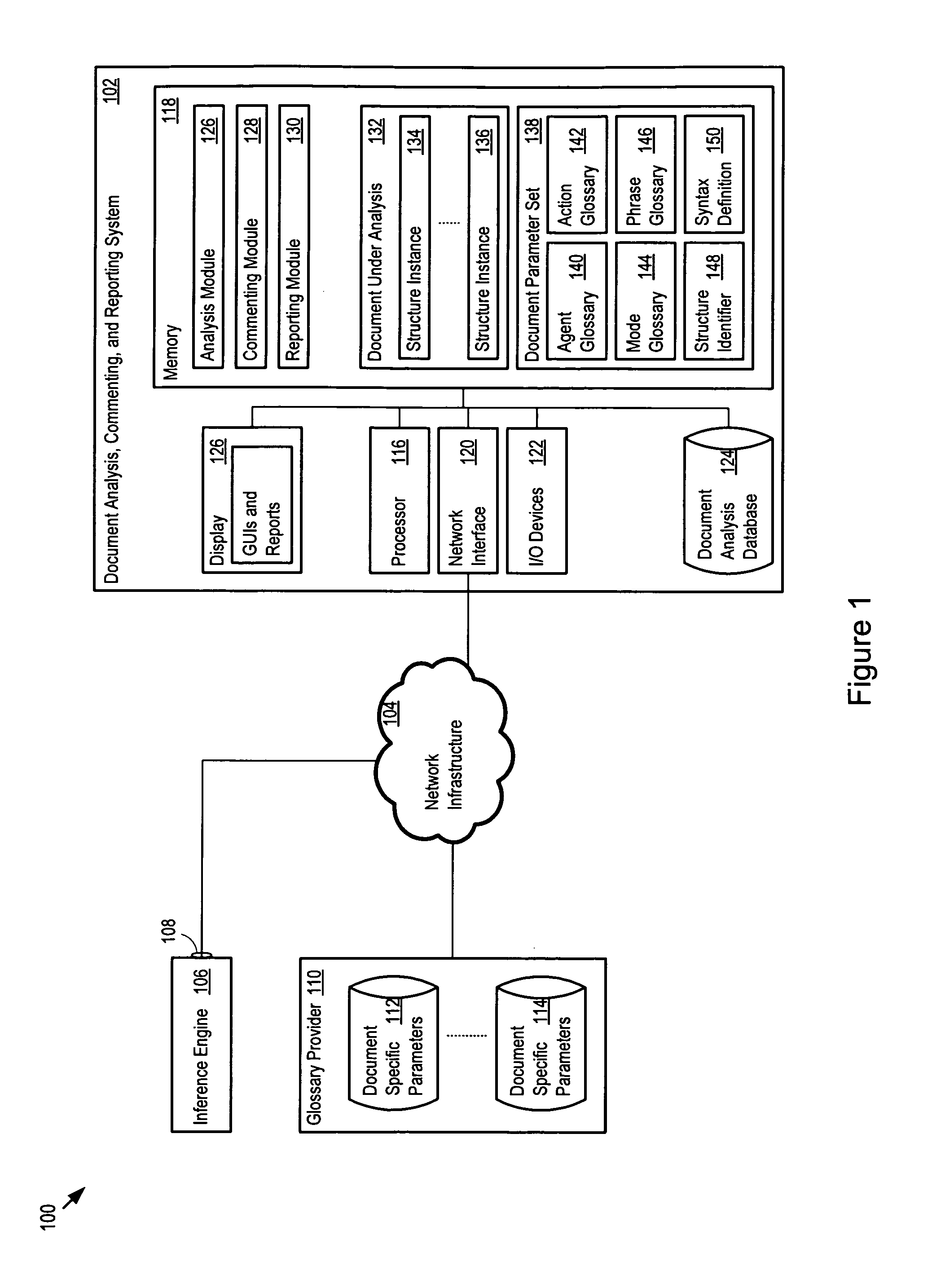

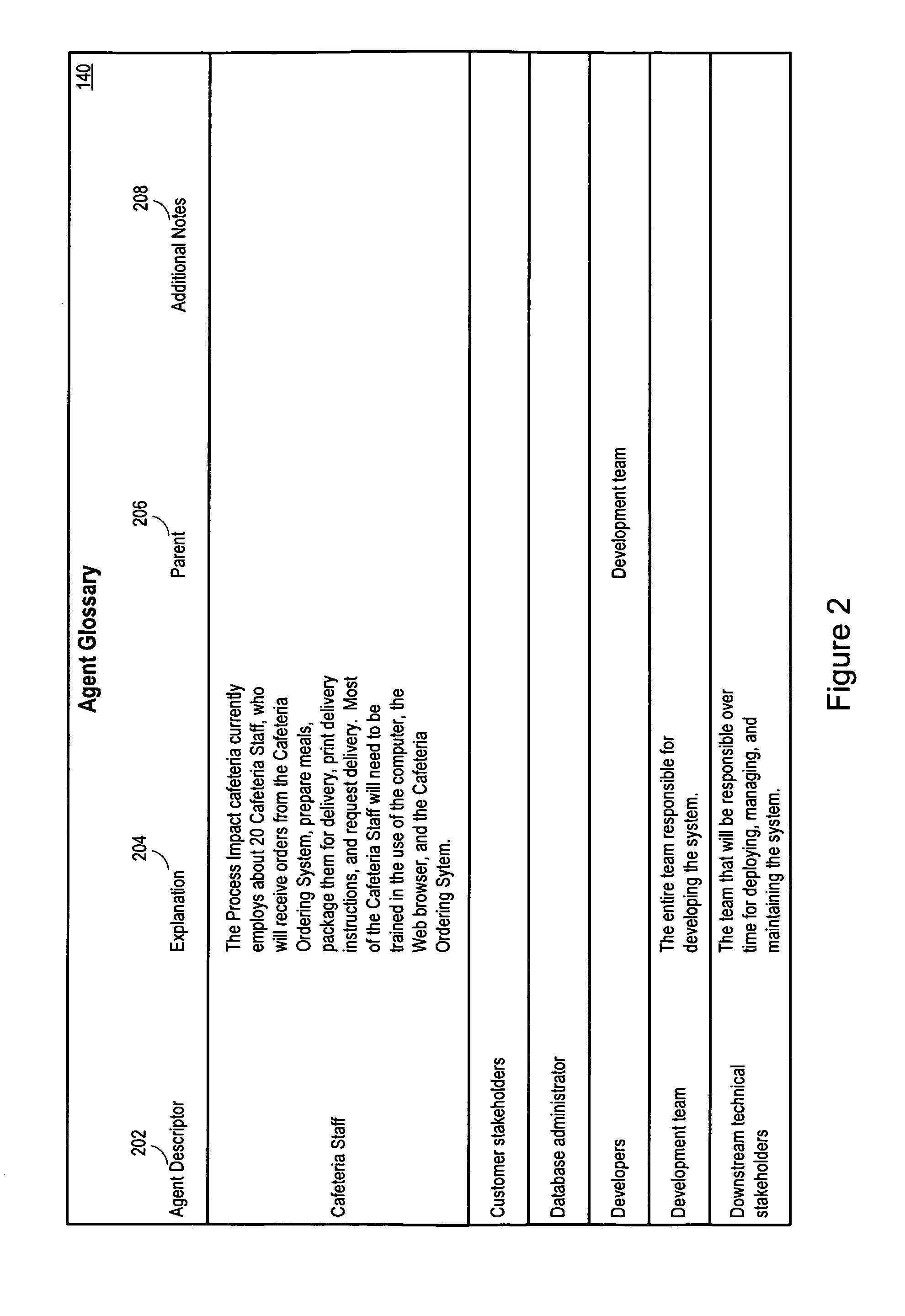

ActiveUS20090138793A1Avoid confusionPromote resultsNatural language data processingRequirement analysisDocument analysisDocumentation procedure

A document analysis, commenting, and reporting system provides tools that automate quality assurance analysis tailored to specific document types. As one example, the specific document type may be a requirements specification and the system may tag different parts of requirements, including actors, entities, modes, and a remainder. However, the flexibility of the system permits analysis of any other document type, such as instruction manuals and best practices guides. The system helps avoid confusion over the document when it is delivered because of non-standard terms, ambiguous language, conflicts between document sections, incomplete or inaccurate descriptions, size and complexity of the document, and other issues.

Owner:ACCENTURE GLOBAL SERVICES LTD

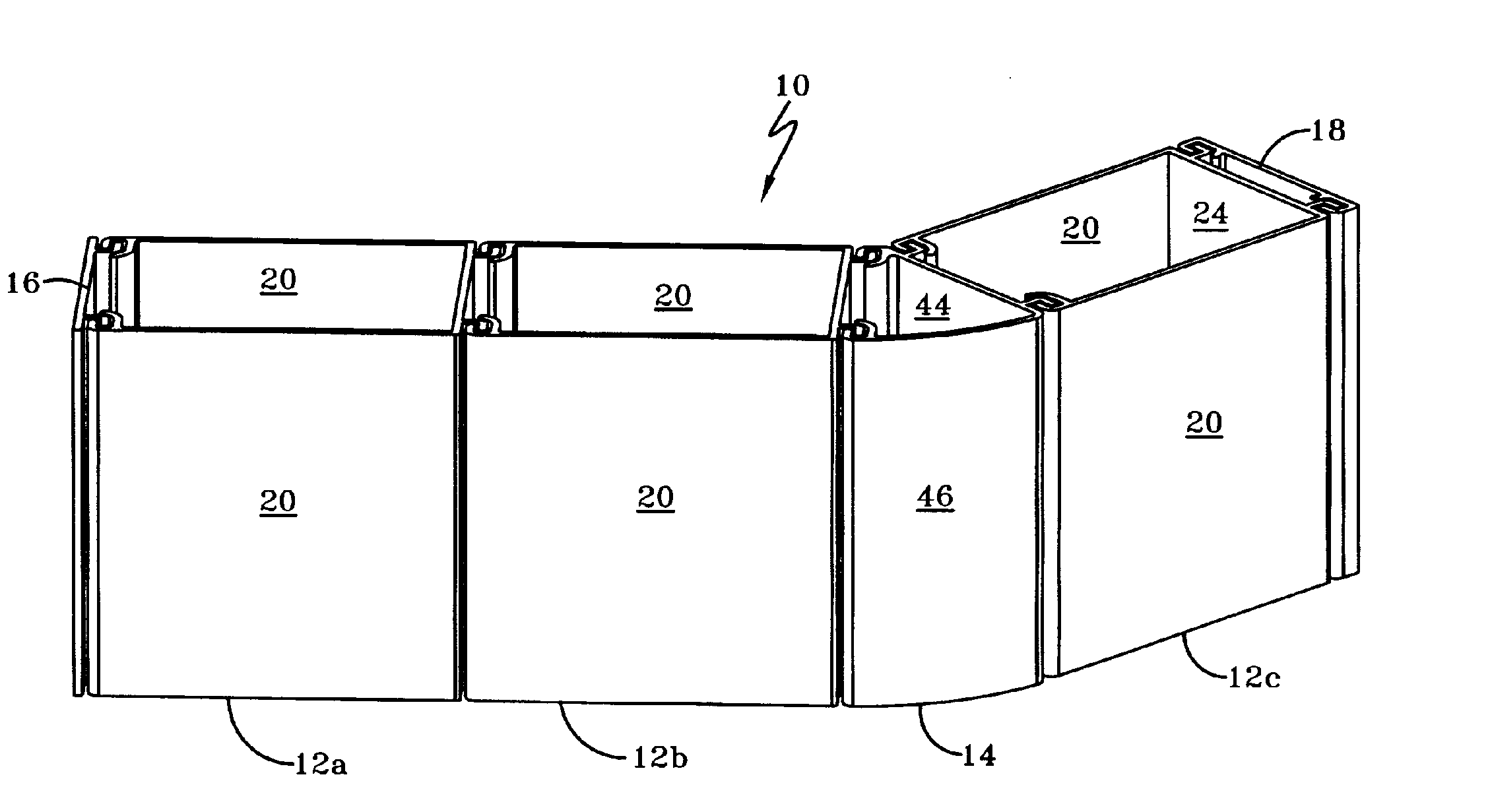

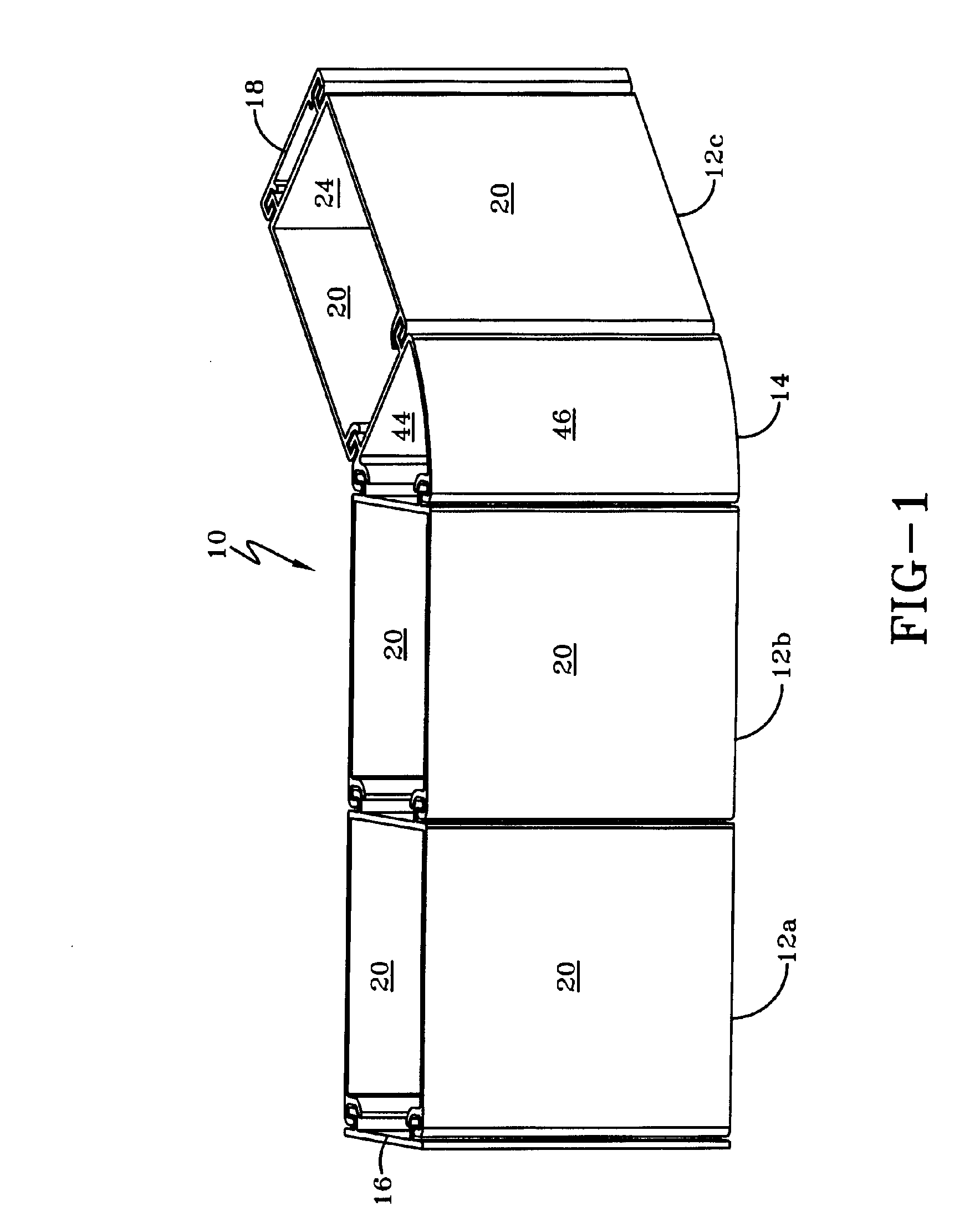

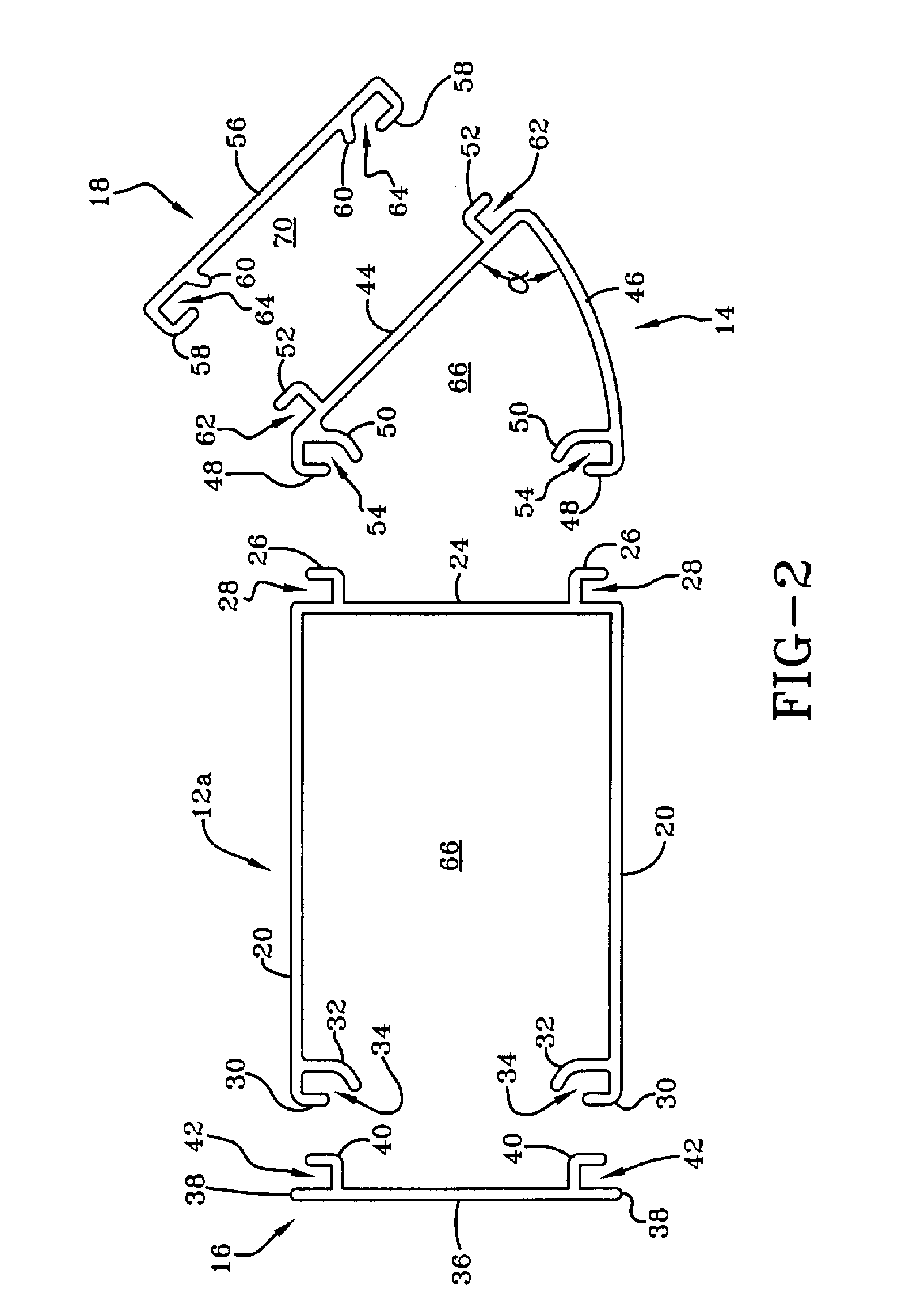

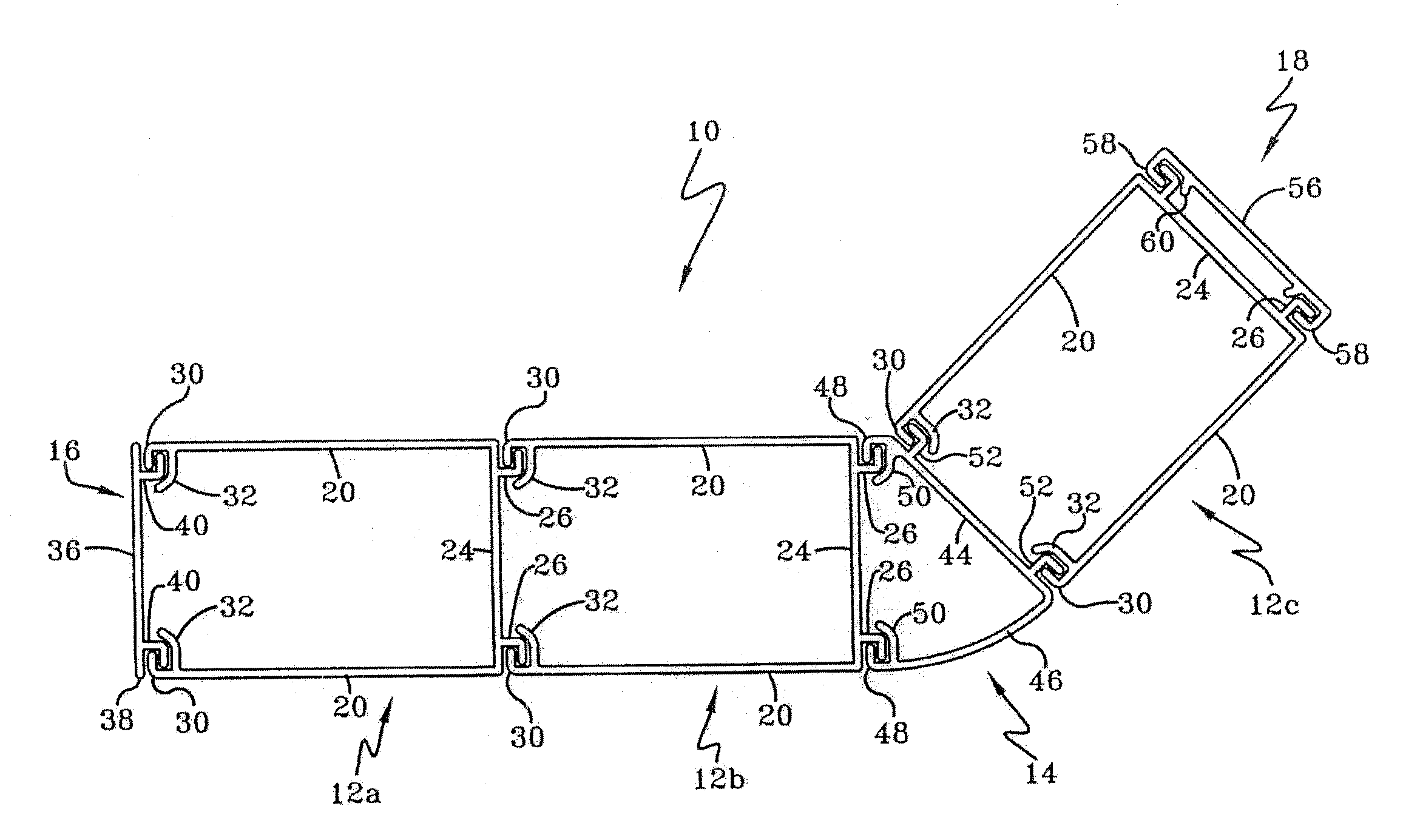

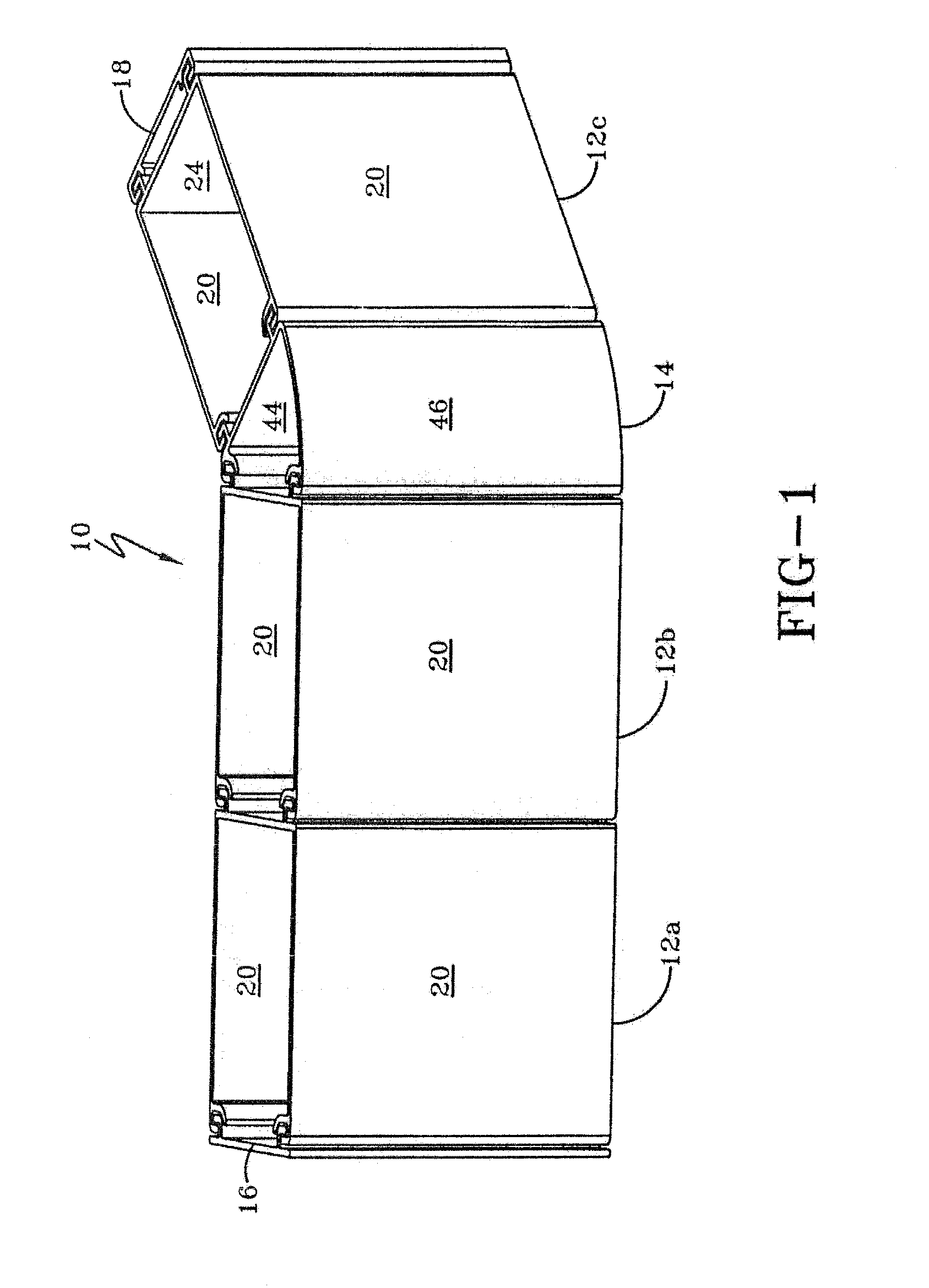

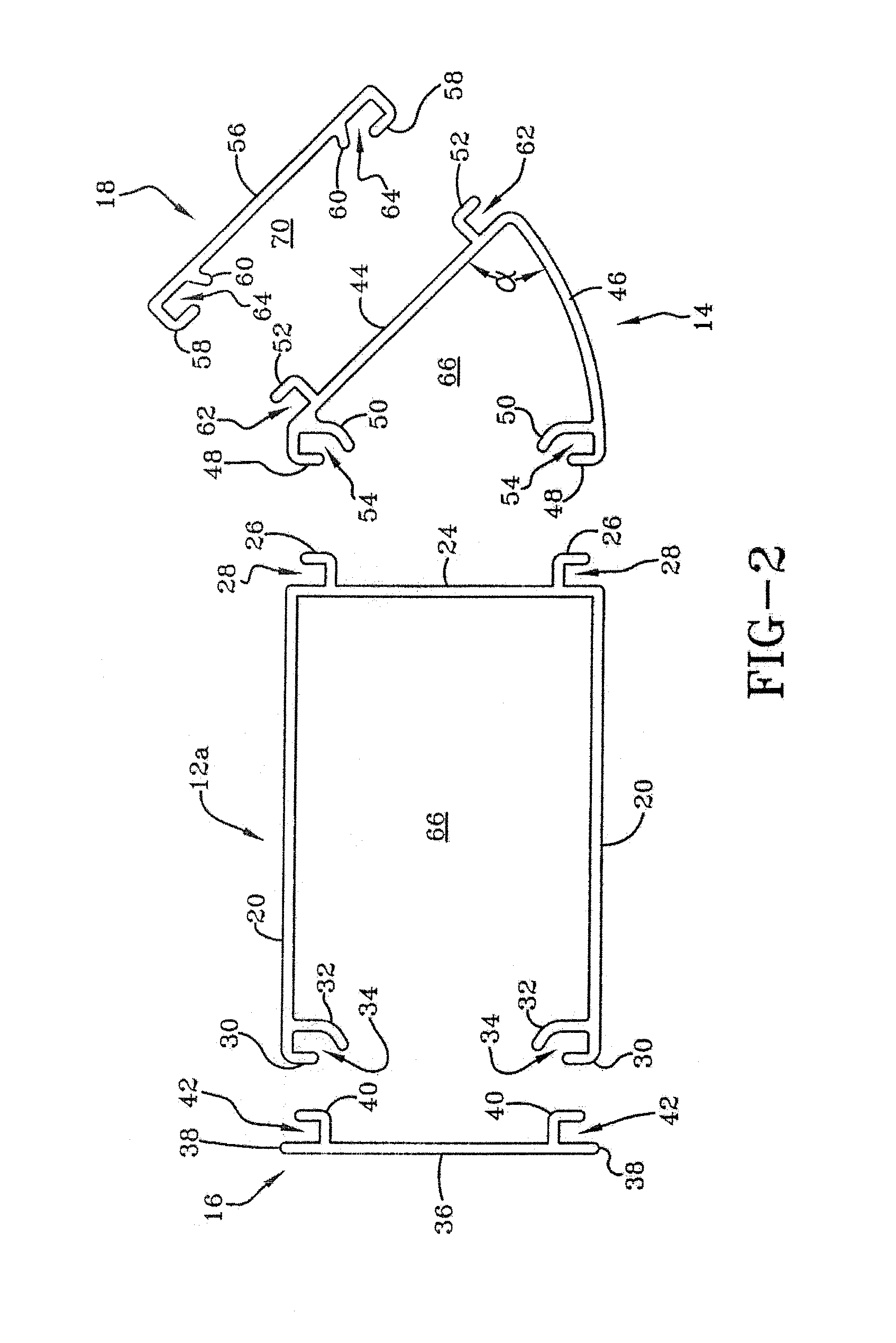

Modular retaining wall

A modular retaining wall with improved features is illustrated and described. Open or closed polygonal modules having channels disposed therein are set at least partially below a surface, said surface either being land-based or aqueous-based, and interfaces therebetween, e.g., shoreline, and attached to each other by respective fastening means which provide engaging connectivity between the modules.

Owner:FORMTECH ENTERPRISES

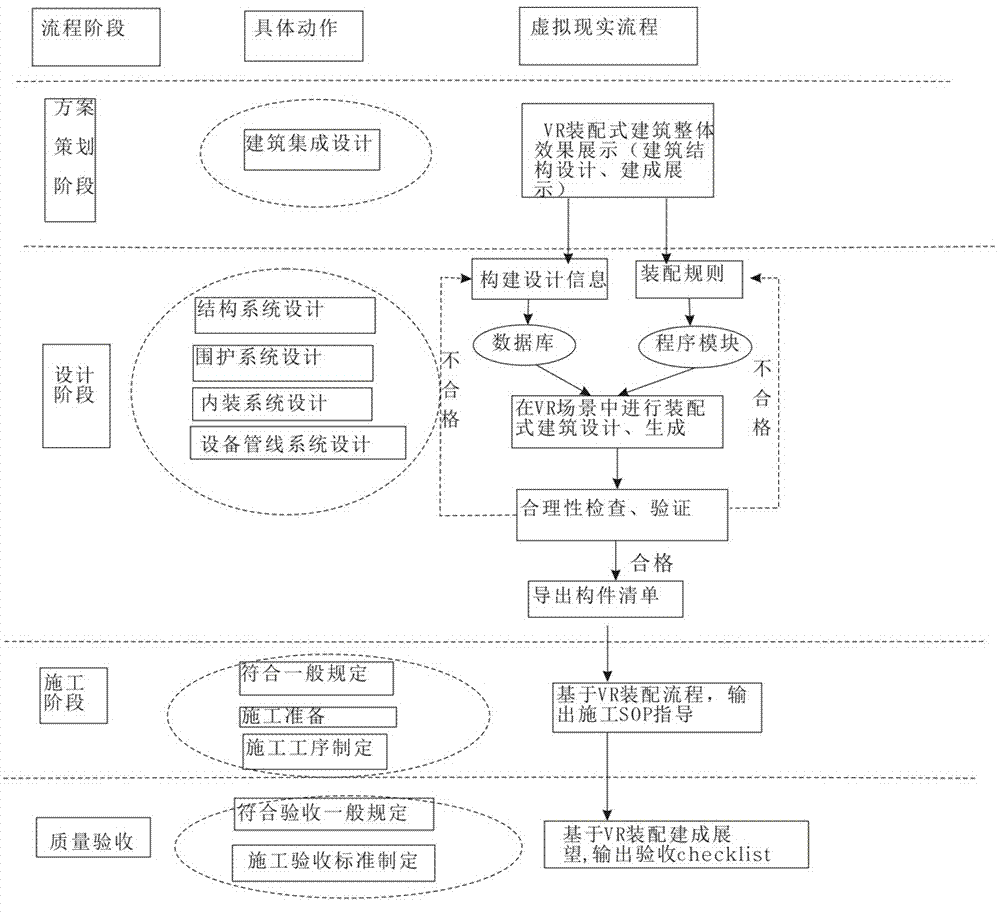

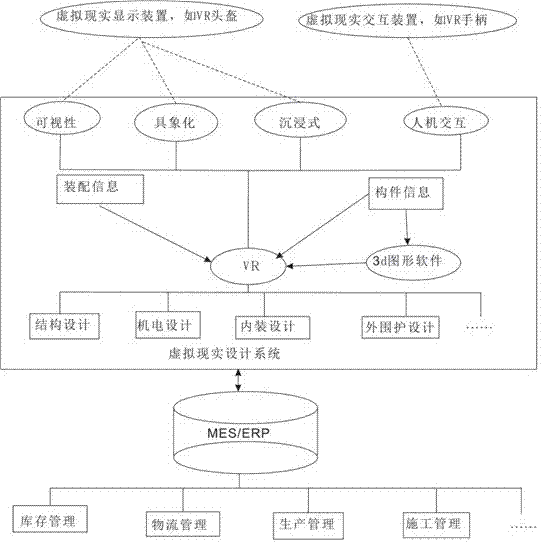

Method for applying virtual reality technology to fabricated building industry

ActiveCN106971028AImprove presentationReduce communication costsGeometric CADData processing applicationsBuilding designCommunication effects

The invention relates to a method for applying a virtual reality technology to a fabricated building industry. The method comprises the steps of firstly, building 3D models of fabricated building members, and endowing the fabricated building members with attribute information; secondly, establishing fabrication rules of the fabricated building members through a virtual reality system; thirdly, performing splicing construction of the fabricated building members based on the fabrication rules of the fabricated building members in a VR scene by a designer through wearing a VR device to generate a fabricated building; and finally, performing rationality verification on the generated fabricated building, and if the verification succeeds, exporting a fabricated building member list and calculating total mass of the fabricated building based on member list information. According to the method, the immersive experience of a fabricated building design process is realized based on the VR technology; a design concept of the fabricated building is accurately passed on; the communication cost is reduced; and the communication effect is improved.

Owner:福州众衡时代信息科技有限公司

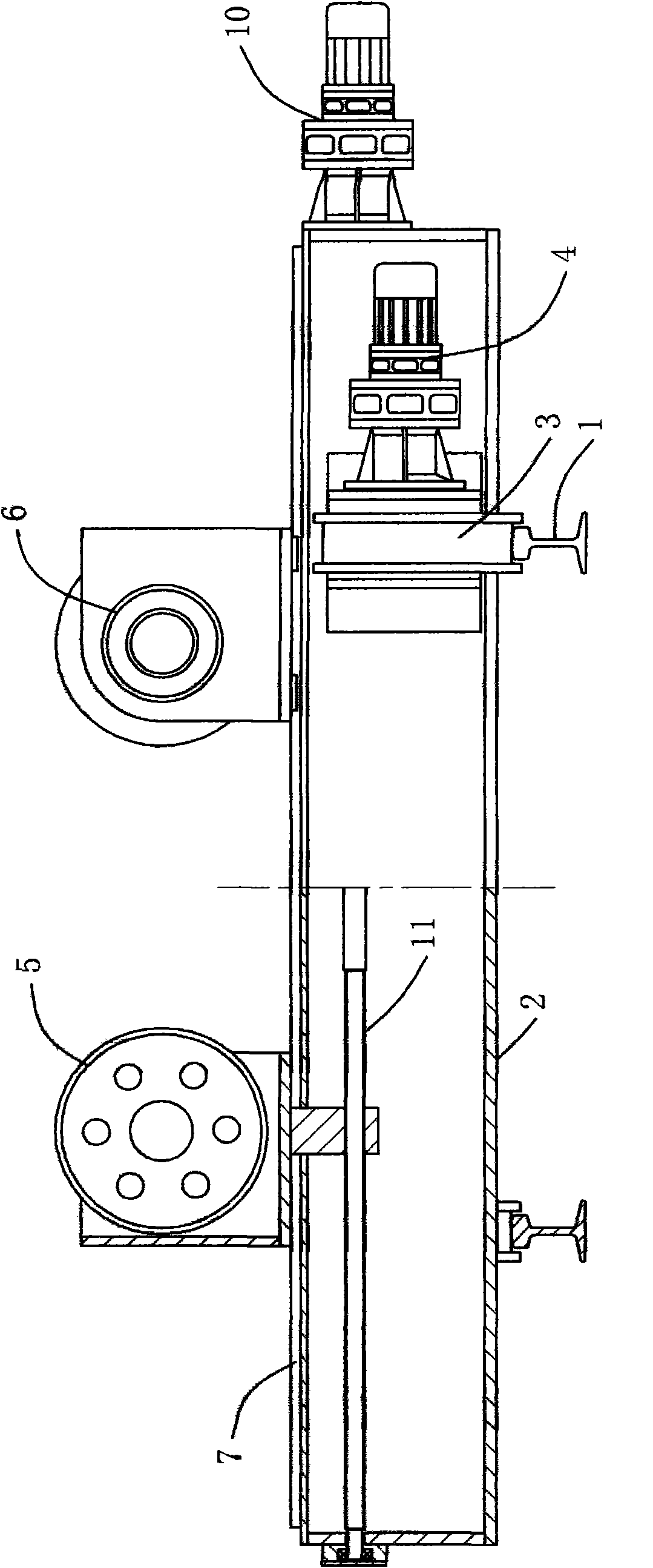

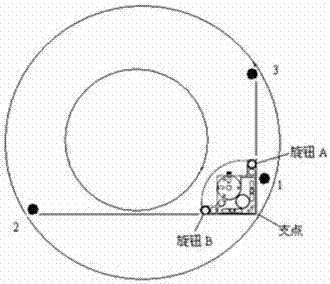

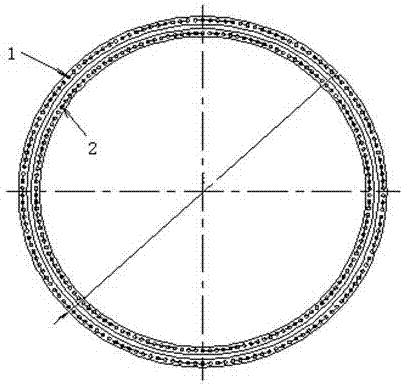

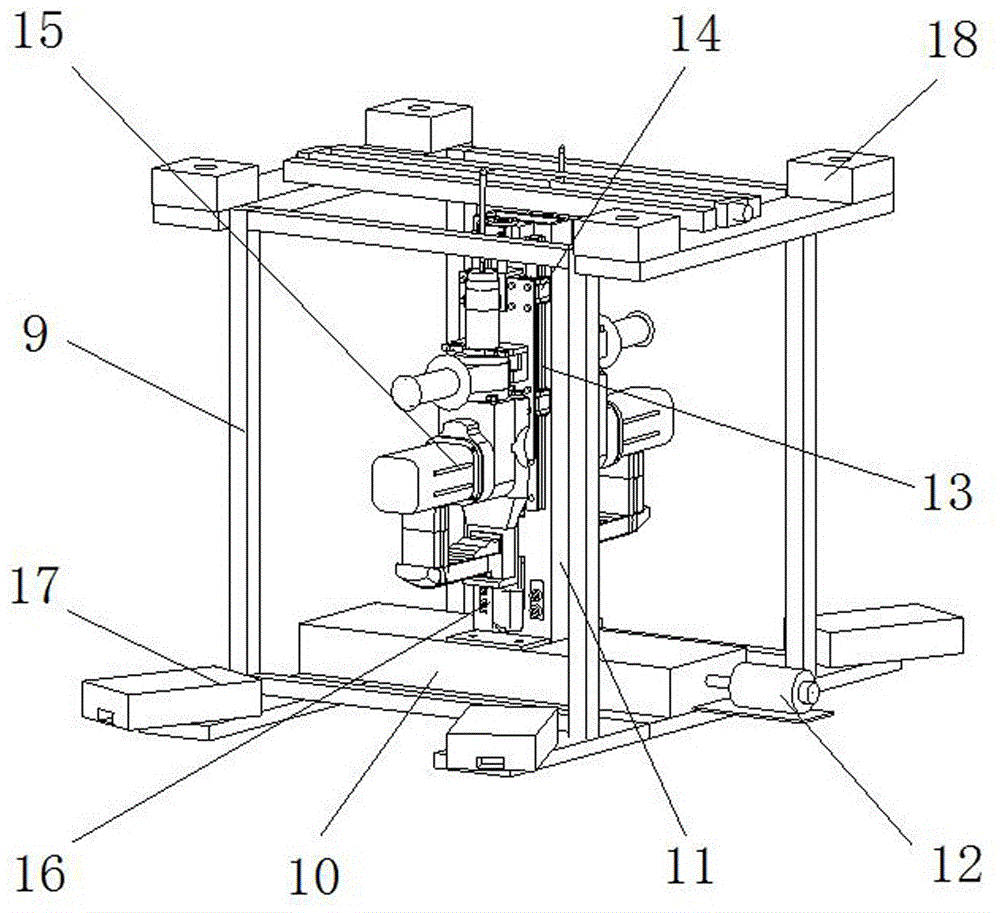

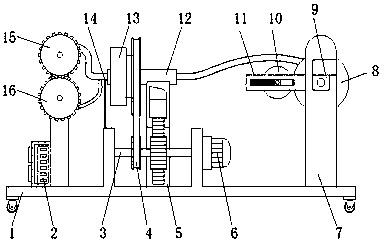

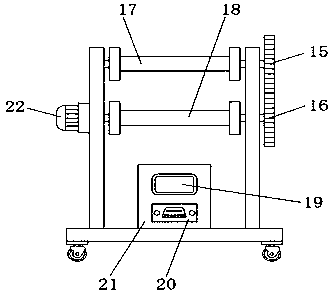

Shell ring assembly device for assembly of tower body of wind power generation iron tower

InactiveCN101885129AIncrease productivityEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower

The invention discloses a shell ring assembly device for the assembly of a tower body of a wind power generation iron tower, which belongs to the technical field of wind power generation iron tower machining equipment. The shell ring assembly device comprises at least two groups of assembly units which are arranged on horizontal rails in a sliding way, and two rotating wheels for bearing shell rings, wherein each assembly unit comprises a roller frame arranged on the horizontal rails; the roller frame is provided with a roller matched with the corresponding horizontal rails; the upper end face of the roller frame is provided with a sliding rail which is vertical to the extension direction of the horizontal rails; and the two rotating wheels are oppositely arranged on the corresponding sliding rails in the sliding way. The shell ring assembly device solves the technical problems, in the assembly of the tower body of the wind power generation iron tower, that the coaxiality of a plurality of groups of shell rings is difficult to regulate, that the labor intensity of operators is high and that the working efficiency is low, has a rational structure and is widely applied to the machining process of the wind power generation iron tower.

Owner:WEIFANG WUZHOU WIND POWER EQUIP

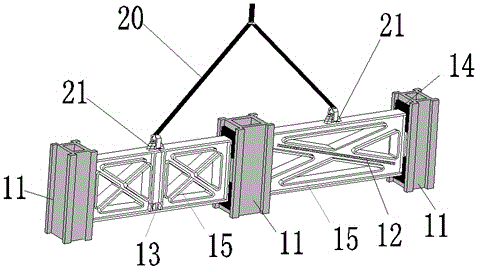

Steel structure integral hoisting method based on BIM

ActiveCN104866659AHigh precisionImprove securityBuilding material handlingSpecial data processing applicationsCompletion timePre stress

According to the present invention, a steel structure integral hoisting method based on BIM comprises: calculating member deflection by using BIM software, determining an arching degree of a single truss, checking member deflection in construction, comparing the member deflection in construction with a pre-arching degree, and comparing a deflection degree after loading that follows completion of construction with designed control deflection degree requirements; using an MIDAS finite element analysis plug-in to set hoisting points at intersection of an upper chord and a diagonal web member on the truss and on each truss, performing design calculations of lifting lugs, and analyzing displacement of structurally critical nodes; performing manual or automatic layout on the integral steel truss, steel tubes and steel cables in a venue model, performing integral analysis on the steel truss of the steel structure, calculating pre-stress of each node of the integral structure by using the BIM software; finally, virtually adding an environment and roads of a construction site by using the BIM software, completing stimulation of a whole erection process, determining the installation time and the situation of occupying construction roads of each steel truss, and estimating construction completion time. The present invention solves the construction problem of limited space, reduces the construction cost and shorten the construction period.

Owner:JIANGSU NEW BLUE SKY STEEL STRUCTURE

Construction process of wind power tower tube

InactiveCN107876943AGuaranteed accuracyReduce reworkFinal product manufactureWelding accessoriesNumerical controlElectricity

The invention relates to a construction process of a wind power tower tube. The construction process comprises the procedures of sectioned tube section manufacturing, tower tube flange installation, and tower tube assembly; sectioned tube section manufacturing comprises the procedures of factory inspection of raw materials, material reinspection, pretreatment of a steel plate, numerical control cutting blanking, dimensional inspection, groove machining, circle rolling, group-welding of longitudinal joints, circle rectifying, measuring of tube section ovality, 100%UT detection and T-shaped seam100%MT detection; tower tube flange installation is achieved through the procedures of flange detection, tower tube detection, flange fixing, tube body installation, welding measuring, bottom flangeassembly, tube body connection, bolt connection, tube body positioning welding and detection after welding jointly; and tower tube assembly comprises the procedures of grouping of tube sections and flange nipples, inspection, welding, 100% UT detection, inspection, drawing of position lines of inner parts, inspection, group-welding of the inner parts, anticorrosion treatment, assembly of the innerparts, packing and forwarding. The construction process has the advantage of being high in precision.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

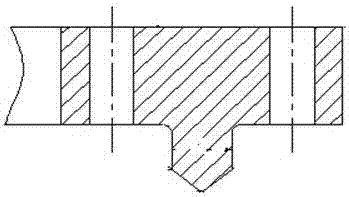

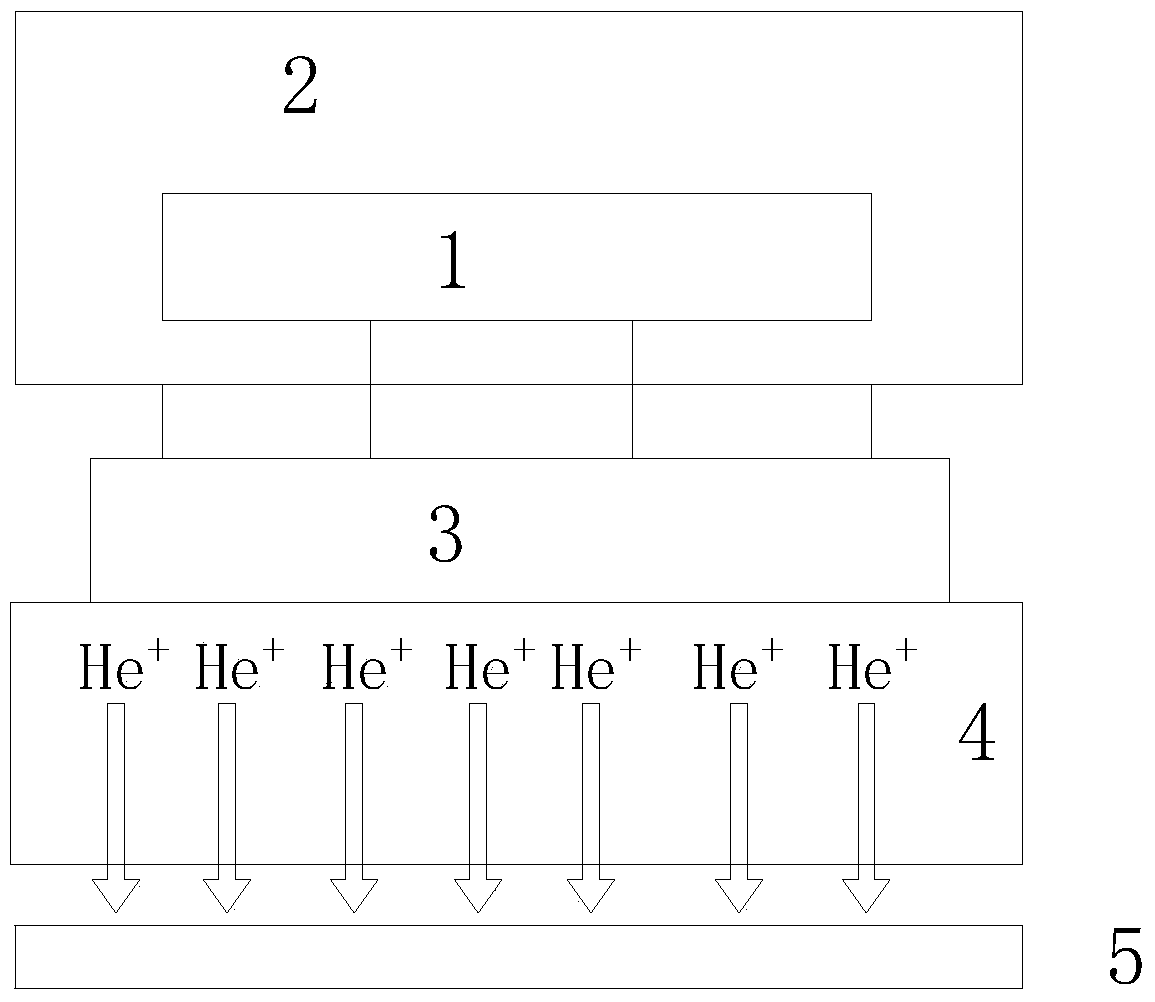

Preparation method of sapphire-glass laminated sheet

ActiveCN103707578AReduce reworkAvoid microcracksGlass/slag layered productsMaterials preparationSapphire

The invention discloses a preparation method of a sapphire-glass laminated sheet. The preparation method comprises the following steps: (1) injecting a He<+> ion layer on the surface of a sapphire material; (2) peeling the He<+> ion layer to obtain an ultrathin sapphire material with at least one damage-free and ultra-smooth face; (3) roasting and welding to obtain a laminated sheet with one damage-free face and the other glass face; and (4) processing. The preparation method disclosed by the invention has the beneficial effects that (1) the processing speed is relatively fast, a lot of re-work in the sapphire material preparation and loading process is saved, and the production cost is lowered; (2) the ultra-smooth laminated sheet with characteristics of glass material and sapphire material is obtained, microcracks in the conventional sapphire processing process are avoided, and the application range of sapphire is expanded, so that the preparation method can be widely applied to the fields of optics, display and substrates.

Owner:贵阳嘉瑜光电科技咨询中心

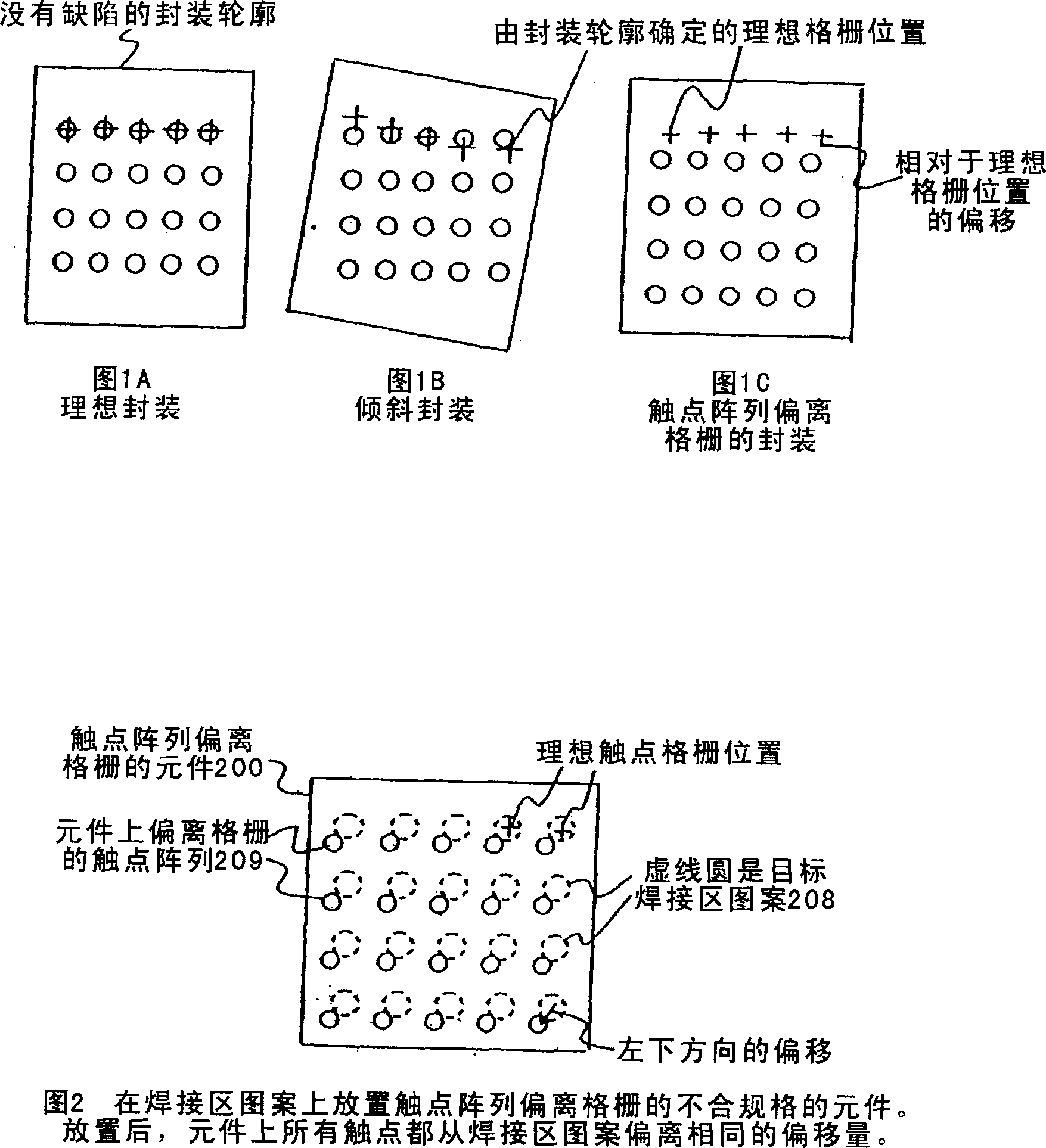

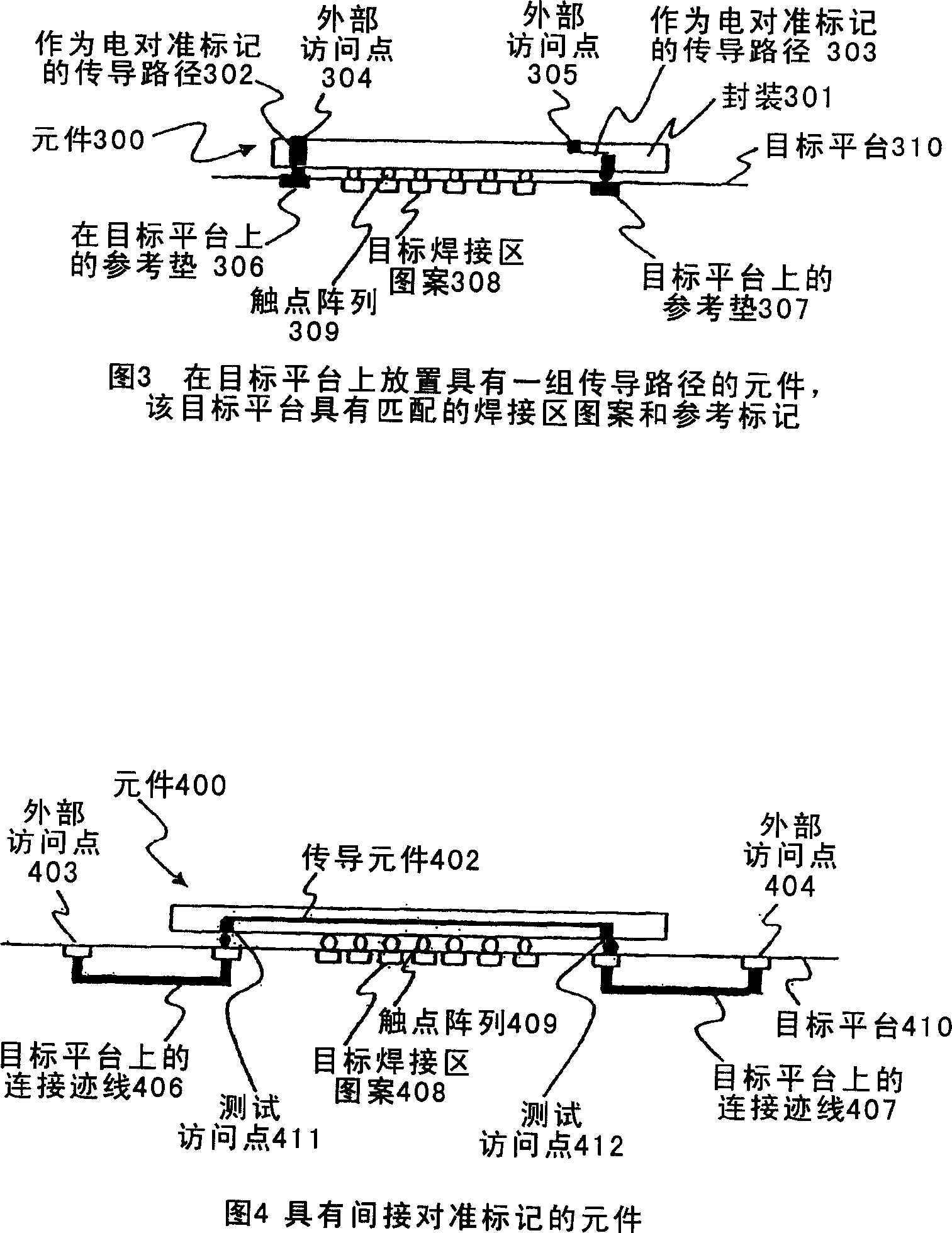

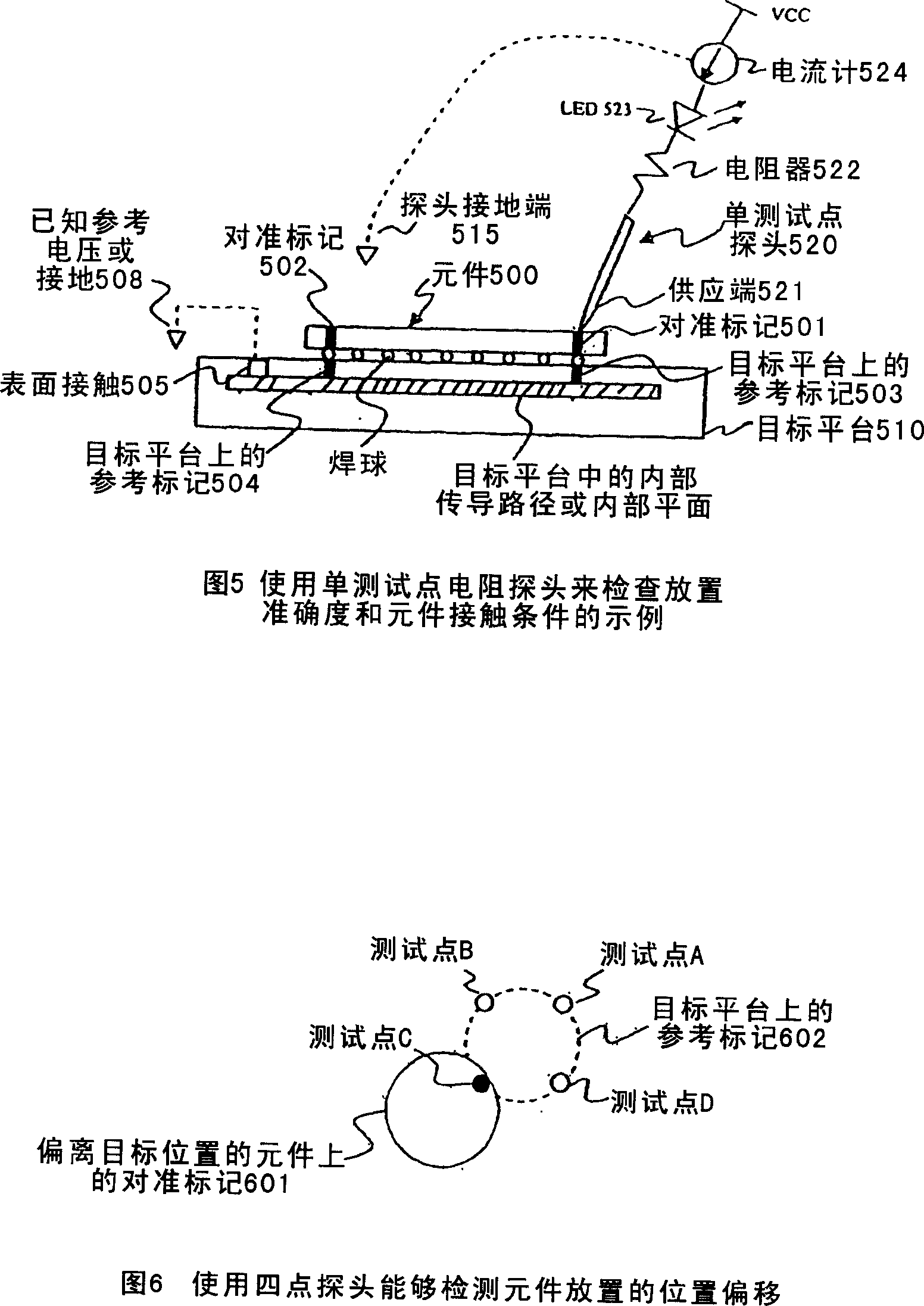

Apparatus and method for arranging predetermined element on target platform

ActiveCN101118899AHigh yieldReduce reworkSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineering

Owner:温泰克工业有限公司

Modular retaining wall

A modular retaining wall is illustrated and described having open or closed polygonal modules with channels disposed therein. The wall is set at least partially below a surface, the surface either being land-based or aqueous-based, and interfaces therebetween, e.g., shoreline. The modules of the wall are fastened to each other by respective fastening means such that engaging connectivity is provided between the modules, yet retains the ability for fluid to pass through.

Owner:TRULINE

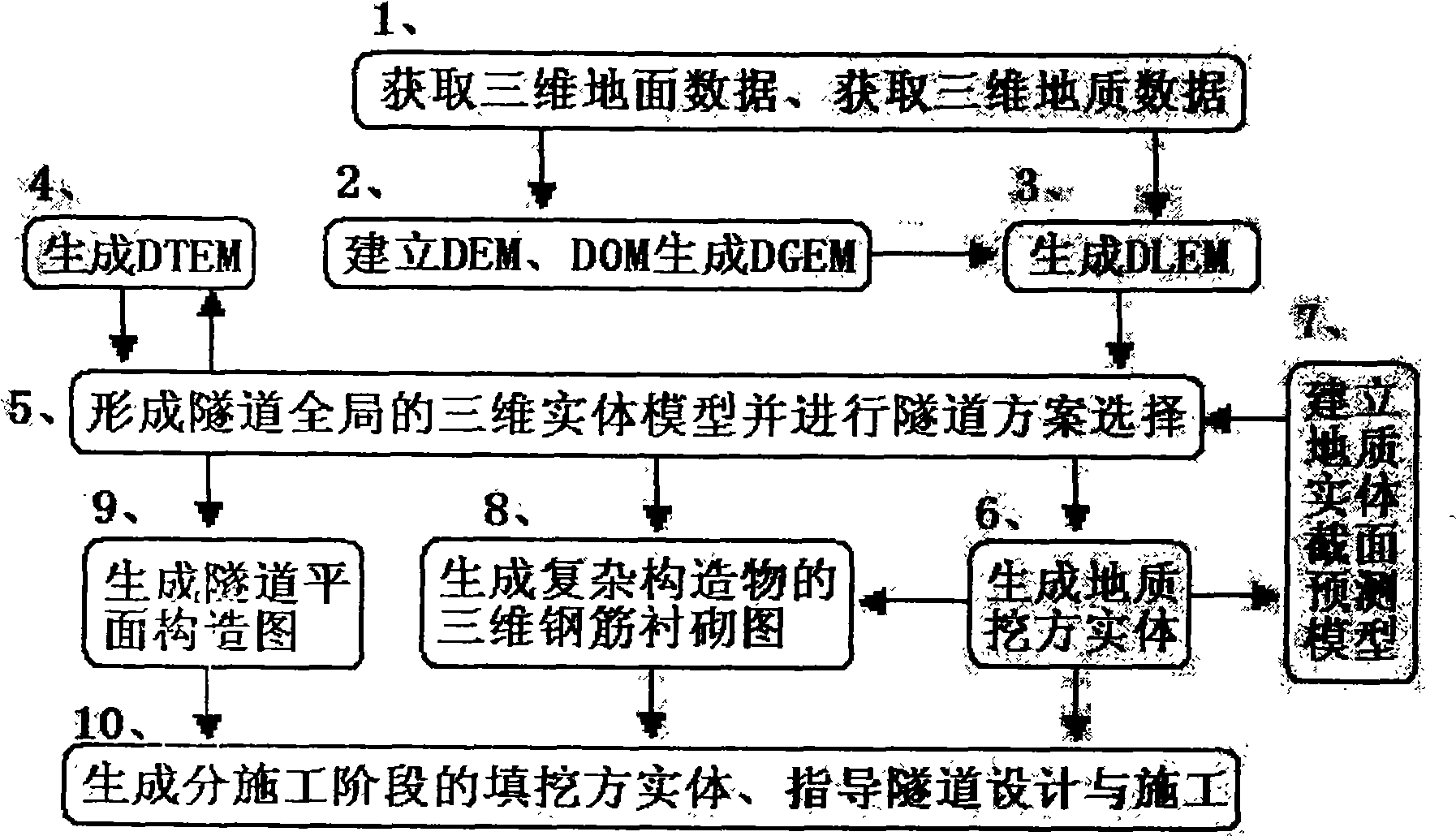

Tunnel surveying method

The invention relates to a method for investigating a tunnel, comprising the following steps: 1) obtaining 3-dimensional data on ground and geology; 2) generating DGME; 3) generating DLEM; 4) generating DTEM; 5) forming an overall 3-dimensional hardware model of the tunnel and selecting a tunneling solution; 6) generating a geological excavation entity; 7) establishing a forecasting model for geological entity section; 8) generating a 3-dimensional steel bar lining diagram of a complex structure; 9) generating a tunnel plane structure diagram: 10) generating a cut and fill entity with different construction stages, guiding tunnel design and construction. By the method of the invention, 3-dimensional effect and geological conditions of the tunnel can be directly obtained for exact, intuitive and convenient selection of the tunneling solution, thus effectively reducing rework, improve investigating quality, construction safety and tunnel stability, coordinating the tunnel mouth with the environment, remarkably improving design effects of a tunnel portal, a tunnel face and a tunnel trunk. As a result, the method of the invention can be widely applied to tunnel investigation, and in terms of engineering application, related softwares can be configured according to actual needs.

Owner:COMM DESIGN INST CO LTD OF JIANGXI PROV

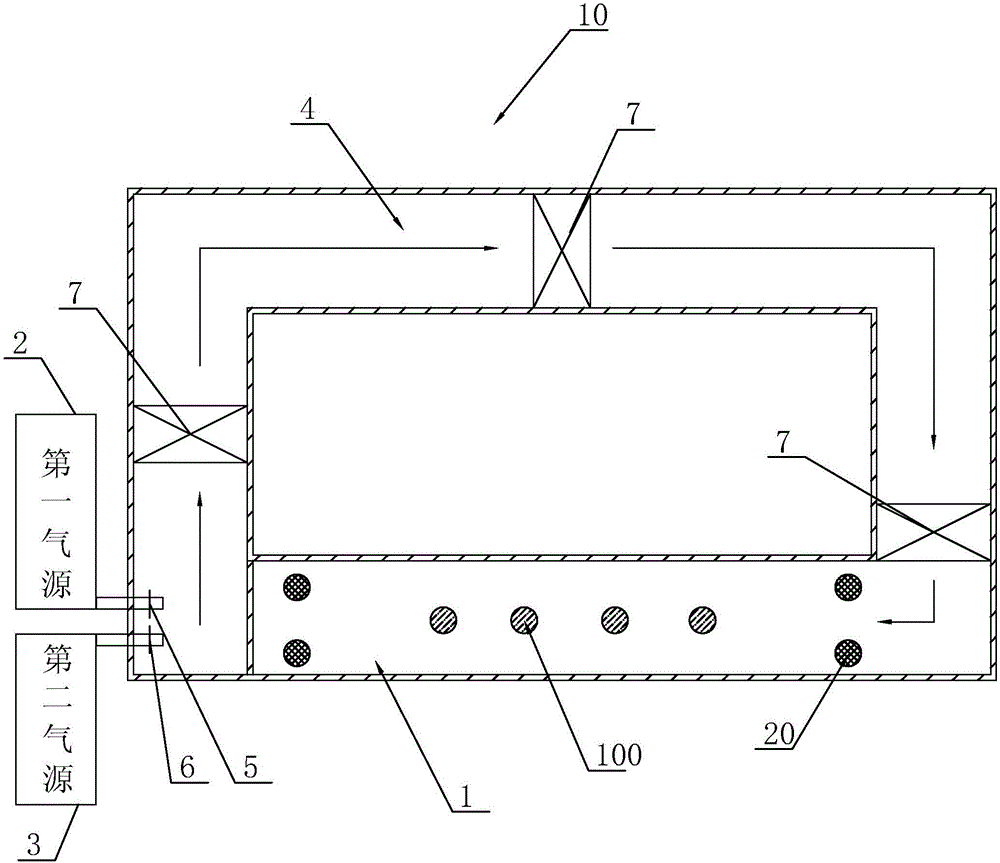

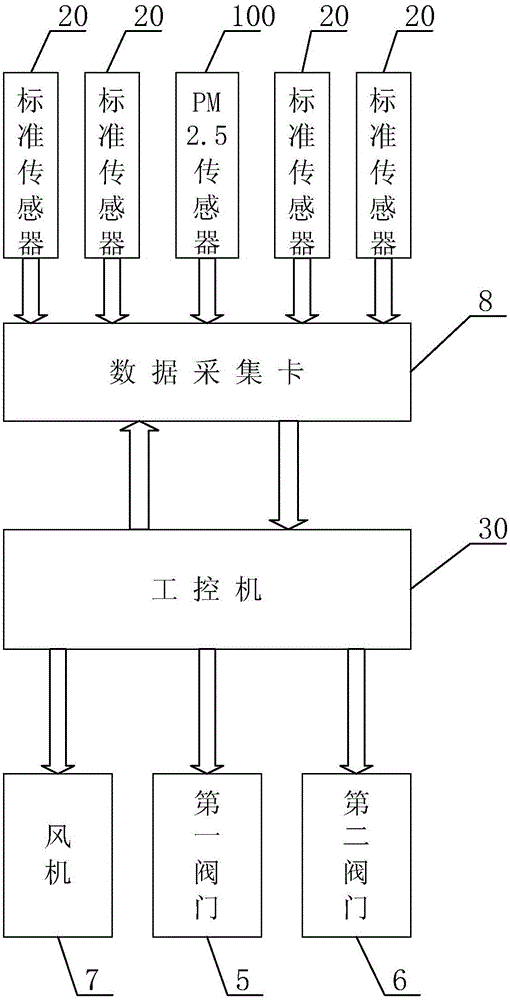

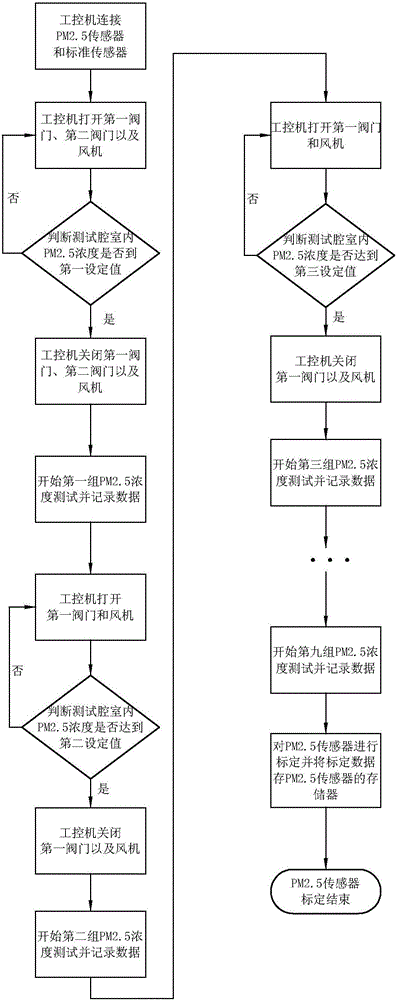

Calibration device for PM2.5 sensors and calibrating method thereof

ActiveCN105865994AGuaranteed measurement accuracyHigh measurement accuracyParticle suspension analysisParticulatesProcess engineering

The invention relates to a calibration device for PM2.5 sensors. The calibration device for the PM2.5 sensors comprises a PM2.5 gas generation device, a plurality of standard sensors and an industrial personal computer, wherein the PM2.5 gas generation device comprises a testing cavity for accommodating a gas mixture; in the gas mixture,PM2.5 particulates are uniformly mixed; the standard sensors are distributed in the testing cavity; the industrial personal computer is connected with the PM2.5 gas generation device, the standard sensors and the PM2.5 sensors; the industrial personal computer can control the PM2.5 concentration of the gas mixture inside the testing cavity of the PM2.5 gas generation device; the standard sensors can detect the PM2.5 concentration of the gas mixture; the industrial personal computer can collect PM2.5 concentration values of the gas mixture measured by the standard sensors and the PM2.5 sensors, and the PM2.5 sensors are calibrated according to errors between measured values of the PM2.5 sensors and the standard sensors. According to the calibration device, independent detection and calibration for the batched PM2.5 sensors can be realized, the measurement accuracy of the PM2.5 sensors is guaranteed, the qualification rate is improved, the rework amount is reduced, and the production cost is reduced.

Owner:SUZHOU HANLIN AUTOMOBILE TECH CO LTD

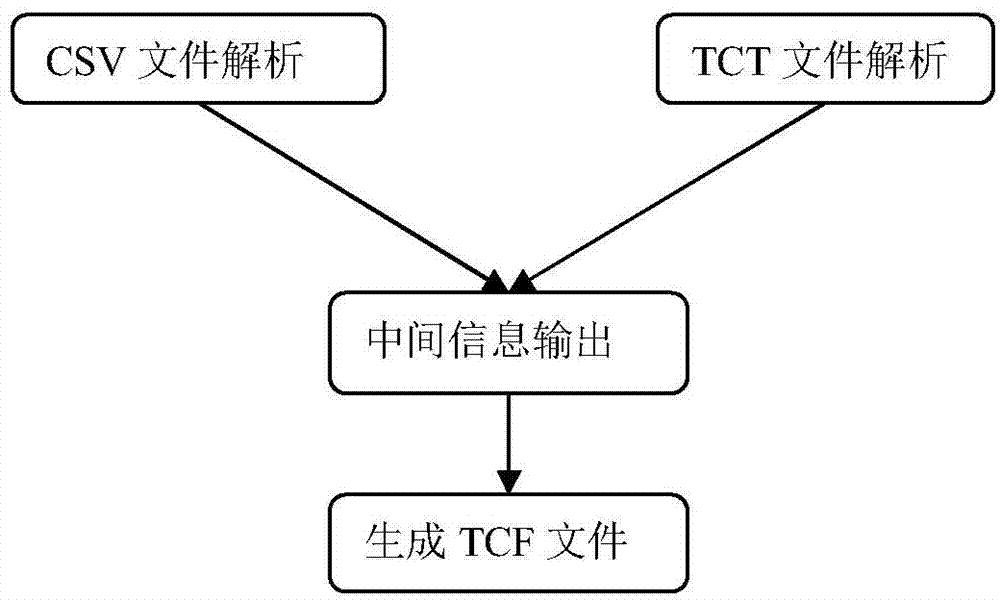

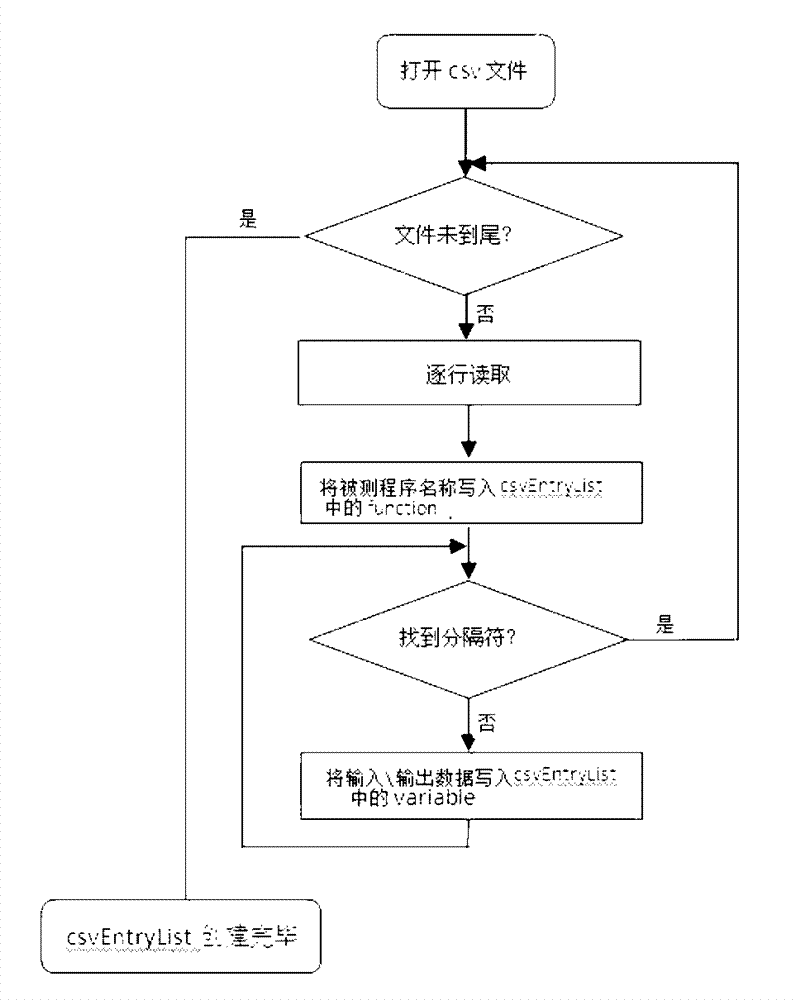

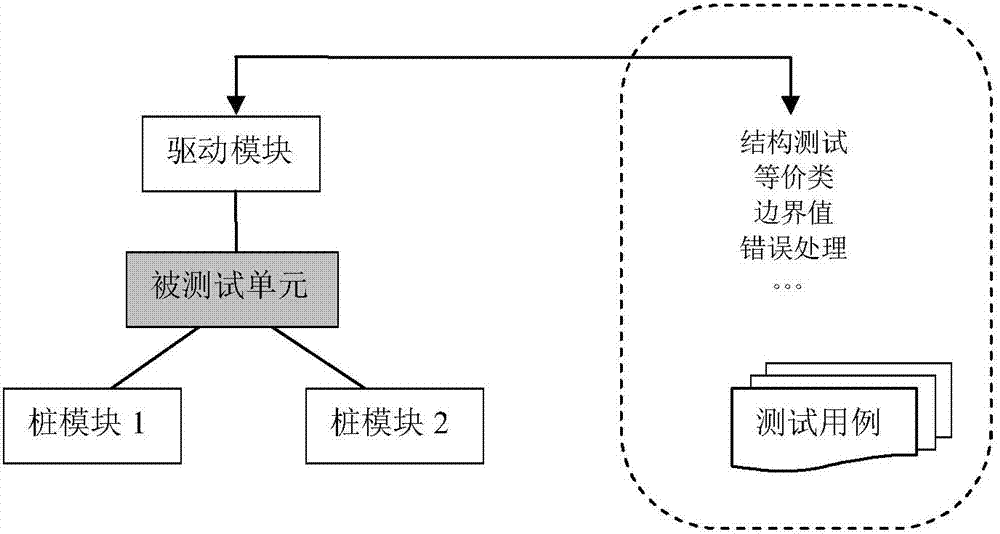

Method for generating test cases in batch mode

InactiveCN104268073APortfolio diversificationBig amount of dataSoftware testing/debuggingProgramming languageTest case

The invention provides a method for generating test cases in a batch mode. The method comprises the steps that a parameter file which is only used for storing test data is analyzed, a group of keywords defined by a test tool based on one test case are applied mechanically to constitute a file capable of storing a batch of test cases, the file for the test cases can be led in the test tool and is carried out. When the method for generating the test cases in the batch mode is used, under the conditions that parameter combinations of a tested function are multiple and the data size is big, the labor cost can be obvious saved, and meanwhile omission occurring in the process of the test cases are established one by one manually can be avoided.

Owner:CHINA TECHENERGY +1

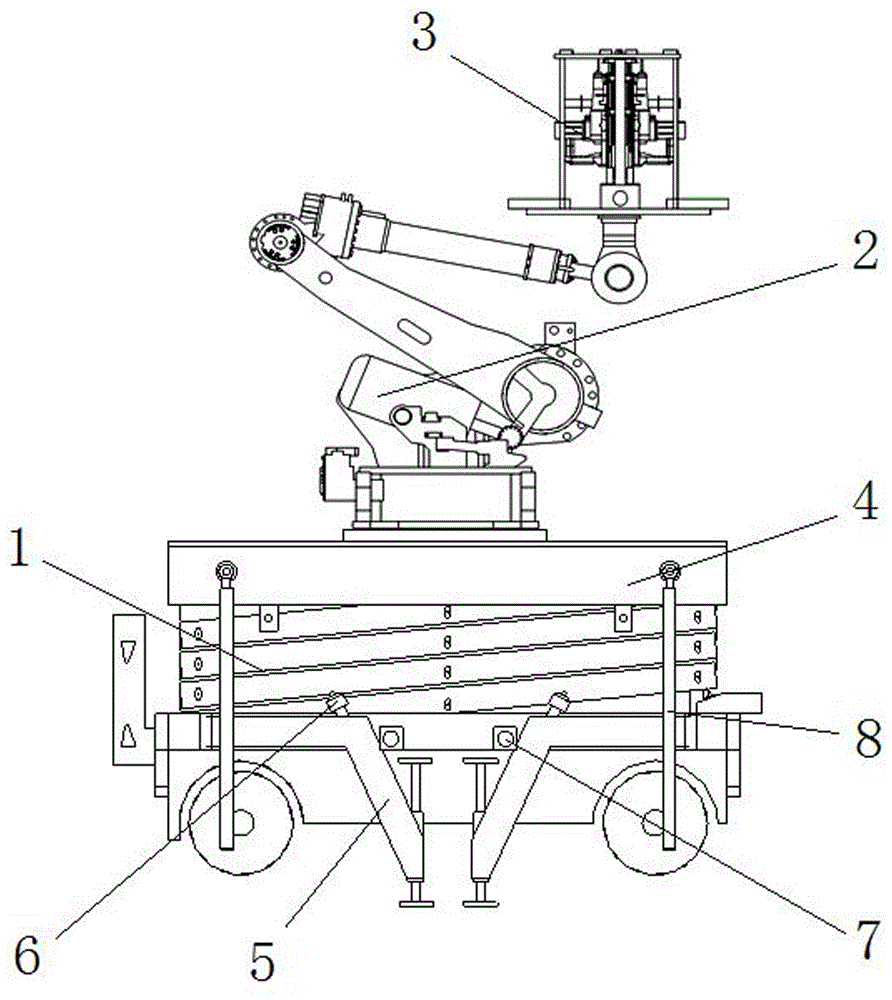

Automatic punching device and method for high-speed railway tunnel anchor implantation

InactiveCN106703689APrevent health damageEliminate human errorLifting devicesAnchoring boltsRailway tunnelLaser ranging

The invention discloses an automatic punching device and method for high-speed railway tunnel anchor implantation and solves problem that health of construction staff is damaged, punching accuracy is poor in anchor implantation, construction efficiency is low and security of the construction staff cannot be guaranteed in existing tunnel anchor implantation. Each of the front end and the rear end of a hydraulic life truck is provided with a support leg, each support leg is provided with a support ball head and a winch, each of the front end face and the rear end face of a lift platform is provided with a hydraulic telescopic rod, each of the upper and lower ends of a frame-type housing is provided with a horizontal chute, a fixing pillar is vertically arranged in the two horizontal chutes, a horizontal servo motor and vertical chutes are arranged in the fixing pillar, each of the vertical chutes is provided with an electric hammer, vertical servo motors are arranged under the electric hammers, a gravity sensor and a laser range finder are arranged at the lower end of the frame-type shell, and a radar range instrument is arranged at the upper end of the frame-type shell. By the arrangement, working accuracy is greatly improved, and danger coefficient in construction is reduced.

Owner:NORTH ENG OF THE ELECTRIFICATION BUREAU GROUP CRCC

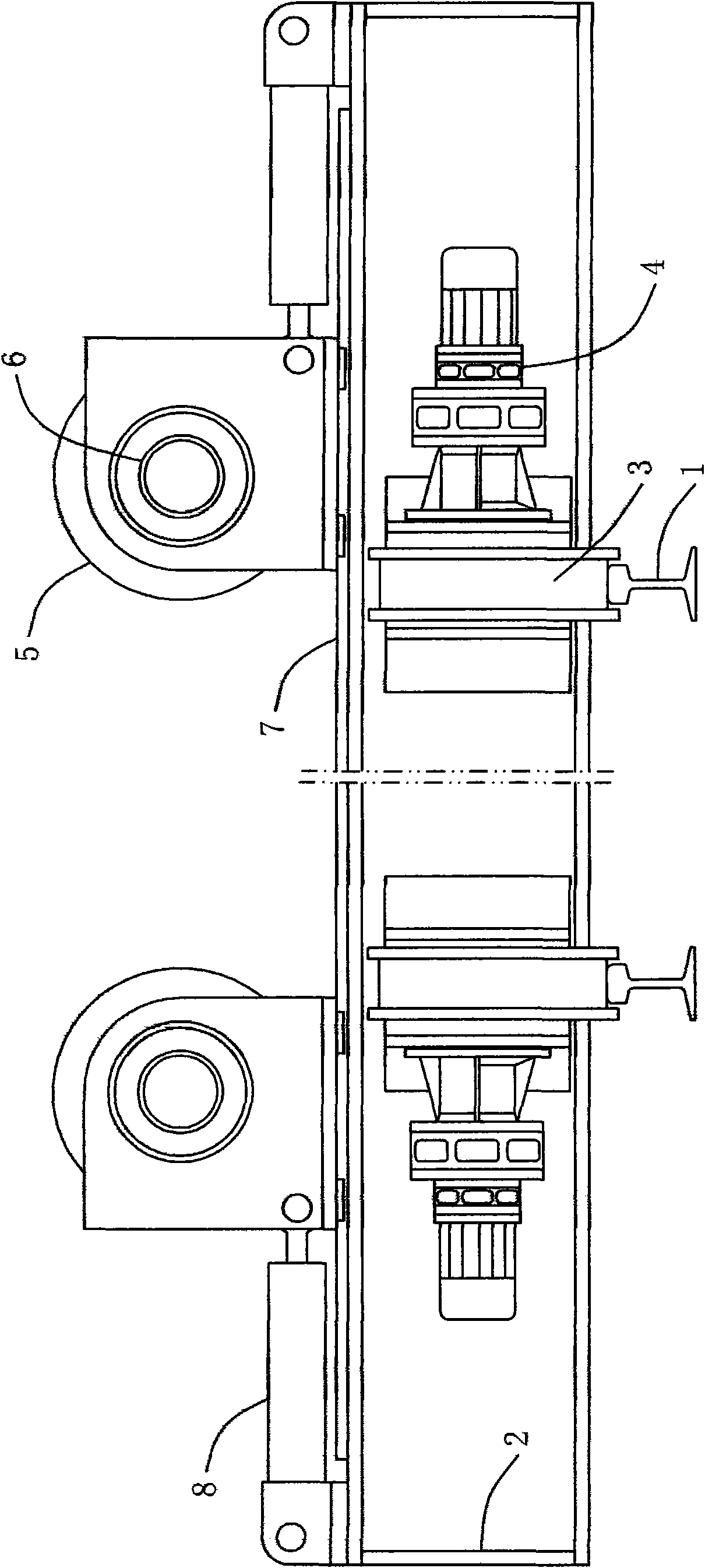

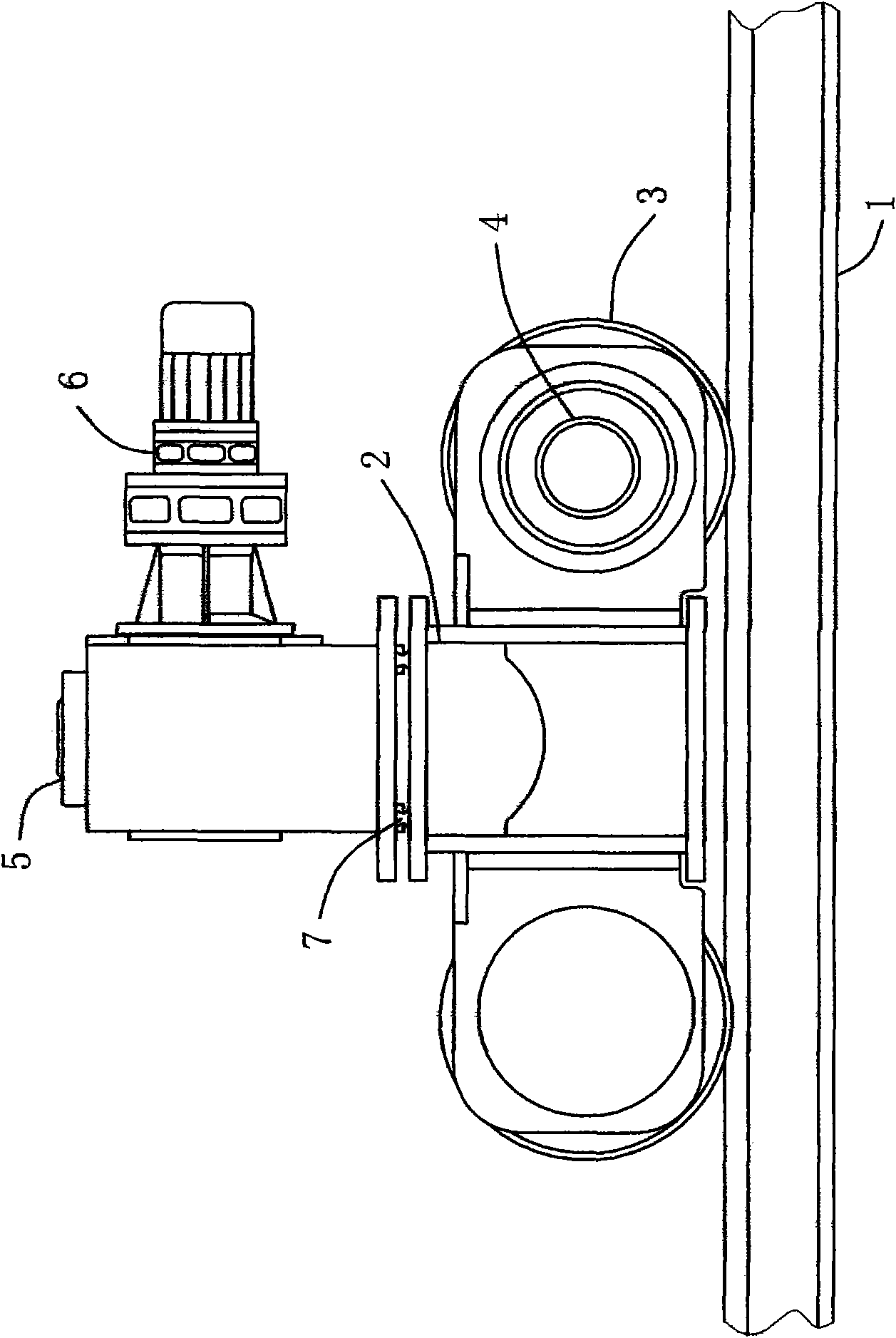

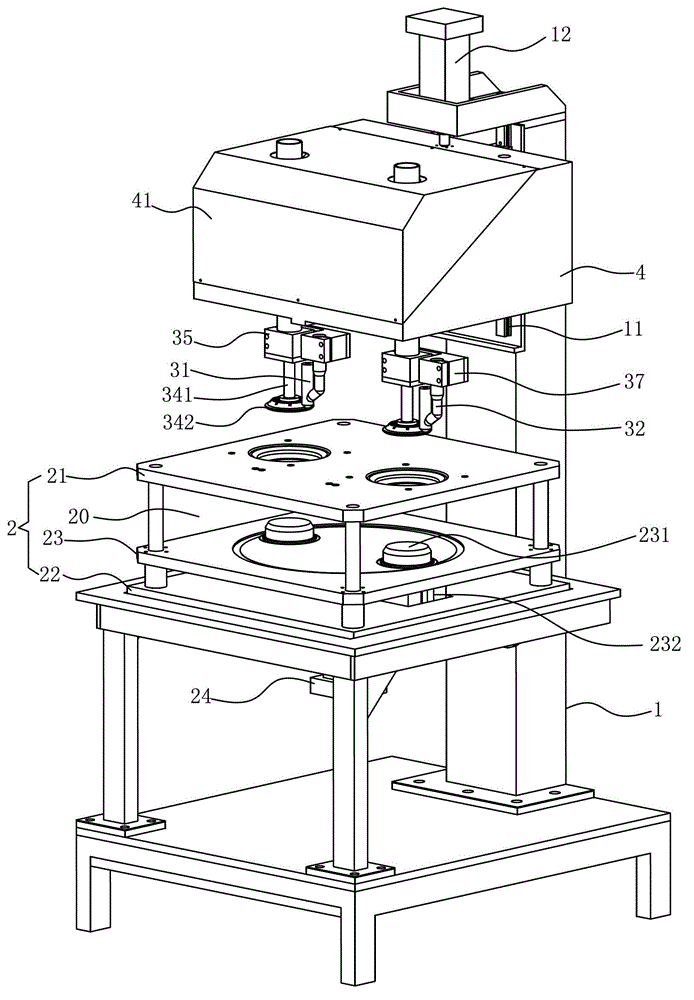

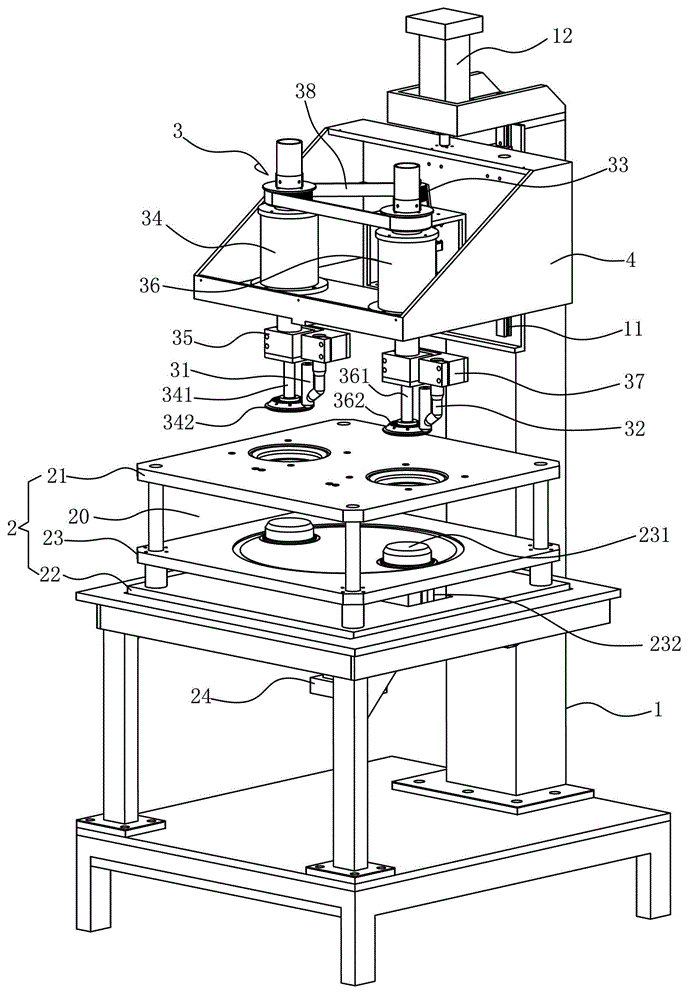

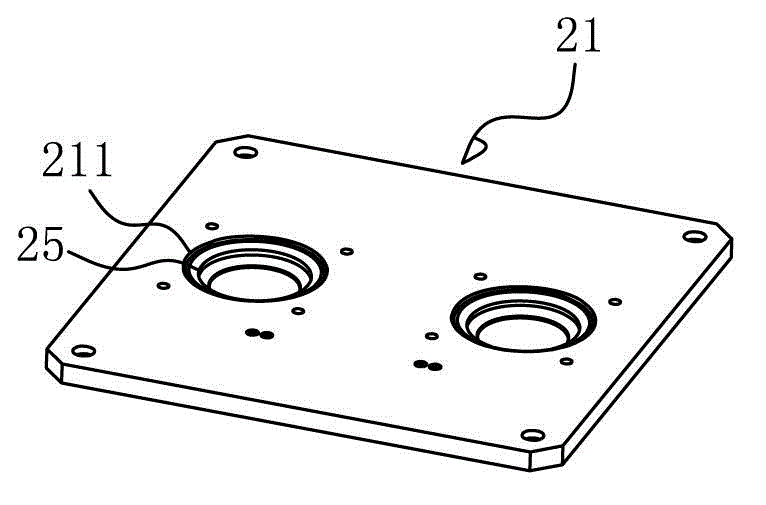

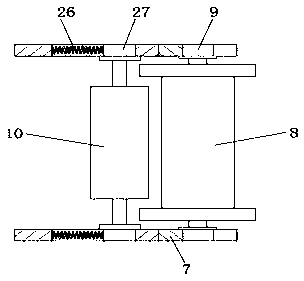

Double-station circumferential stitch welding device for heat exchanger

ActiveCN103056499AReduce human errorReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive motor

The invention discloses a double-station circumferential stitch welding device for a heat exchanger. The stitch welding device comprises a rack, a jig and a welding device for welding, wherein the jig is arranged on the rack and used for positioning sheets of the heat exchanger; the welding device comprises a first welding gun and a second welding gun which are capable of welding inner circles of the sheets of the heat exchanger synchronously and a drive motor for driving the first welding gun and the second welding gun to weld according to circular tracks; the jig comprises upper and lower clamping dies fixedly installed on the rack and a movable clamping plate movably installed between the upper and lower clamping dies, the bearing position for accommodating the sheets of the heat exchanger is formed between the upper clamping die and the movable clamping plate, and two scalable top blocks for limiting the sheets of the heat exchanger are arranged in the movable clamping plate. The stitch welding device which is an automatic welding device is accurate in positioning, capable of welding two inner circles of the sheets of the heat exchanger simultaneously, obvious in welding quality and effects, high in working efficiency and low in production cost.

Owner:东莞埃欧热能技术有限公司

Tube induced deformity elimination proccess

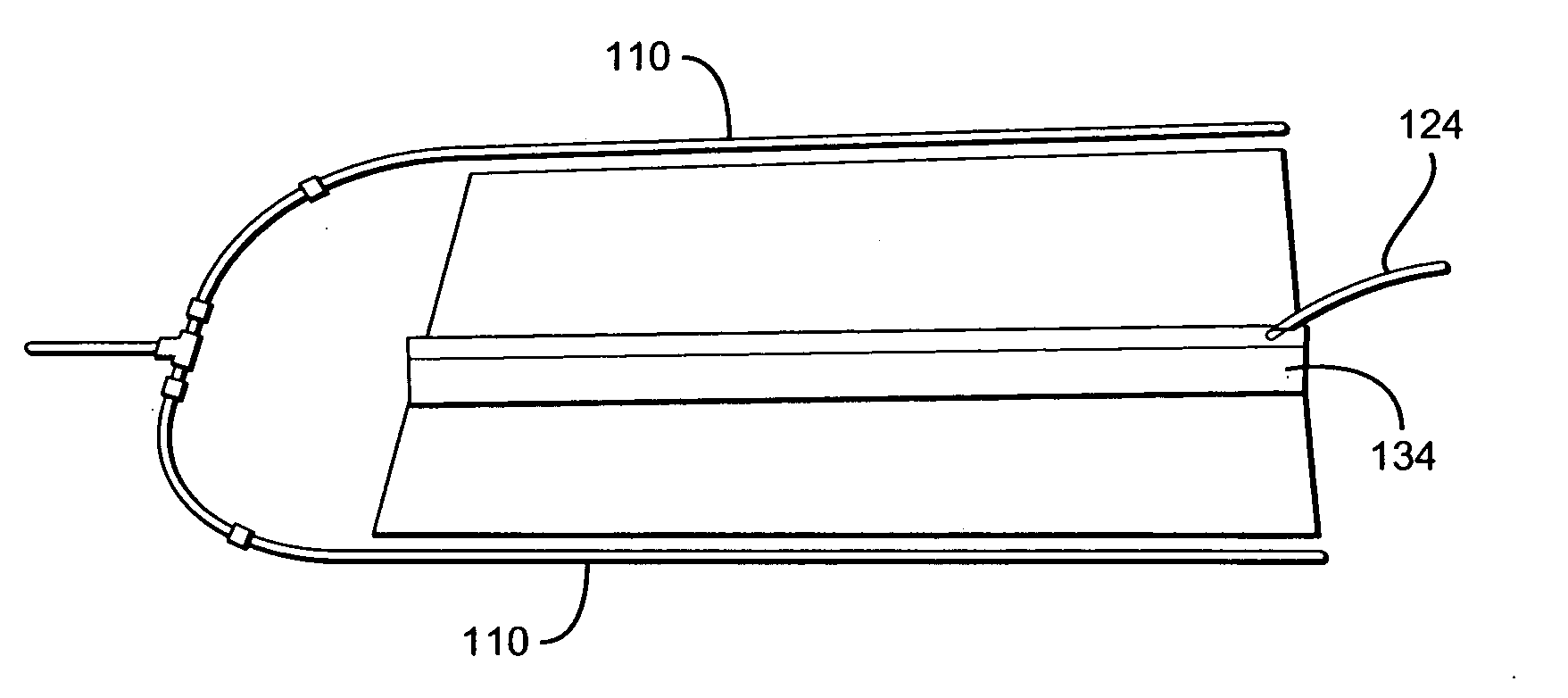

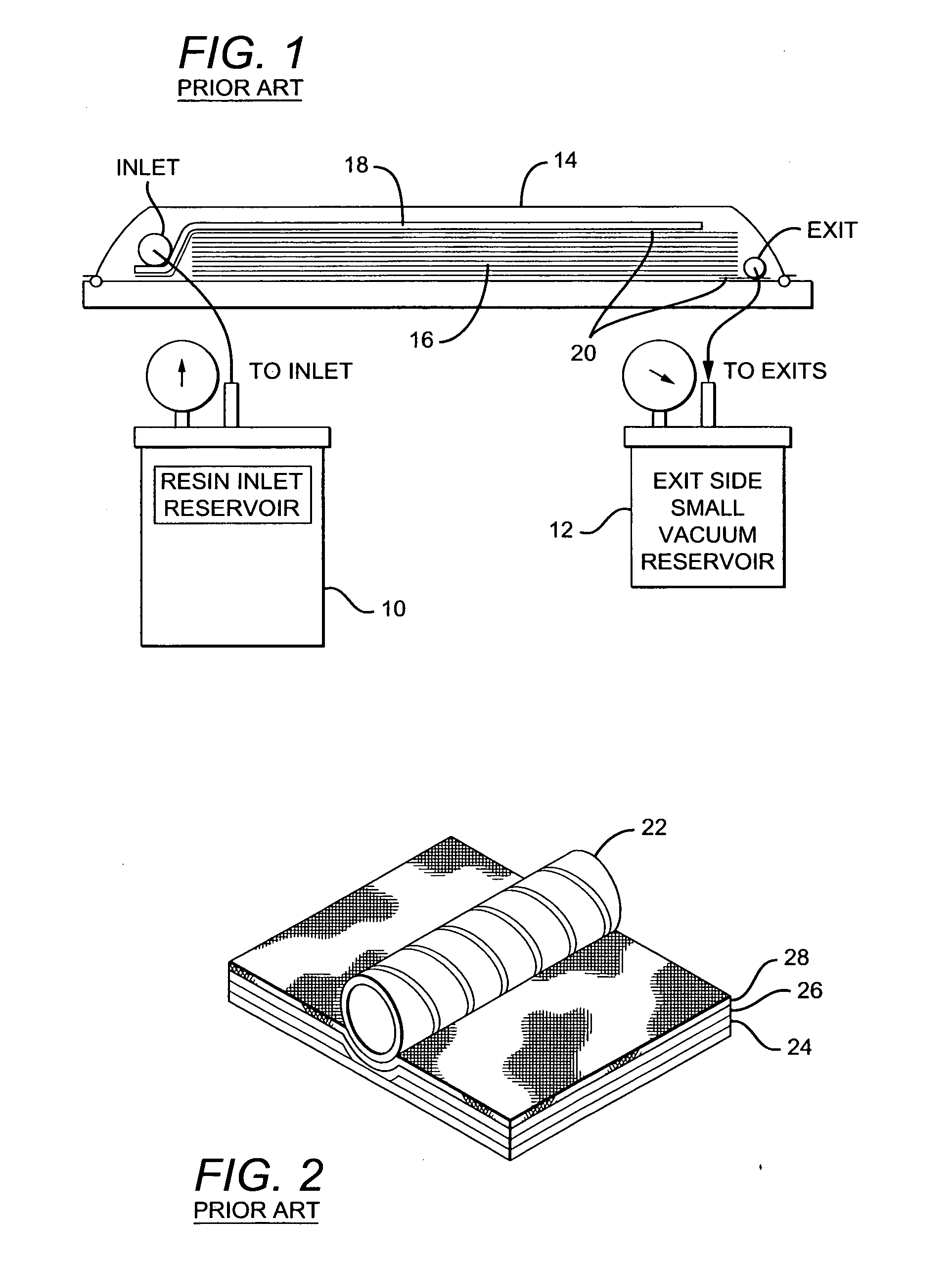

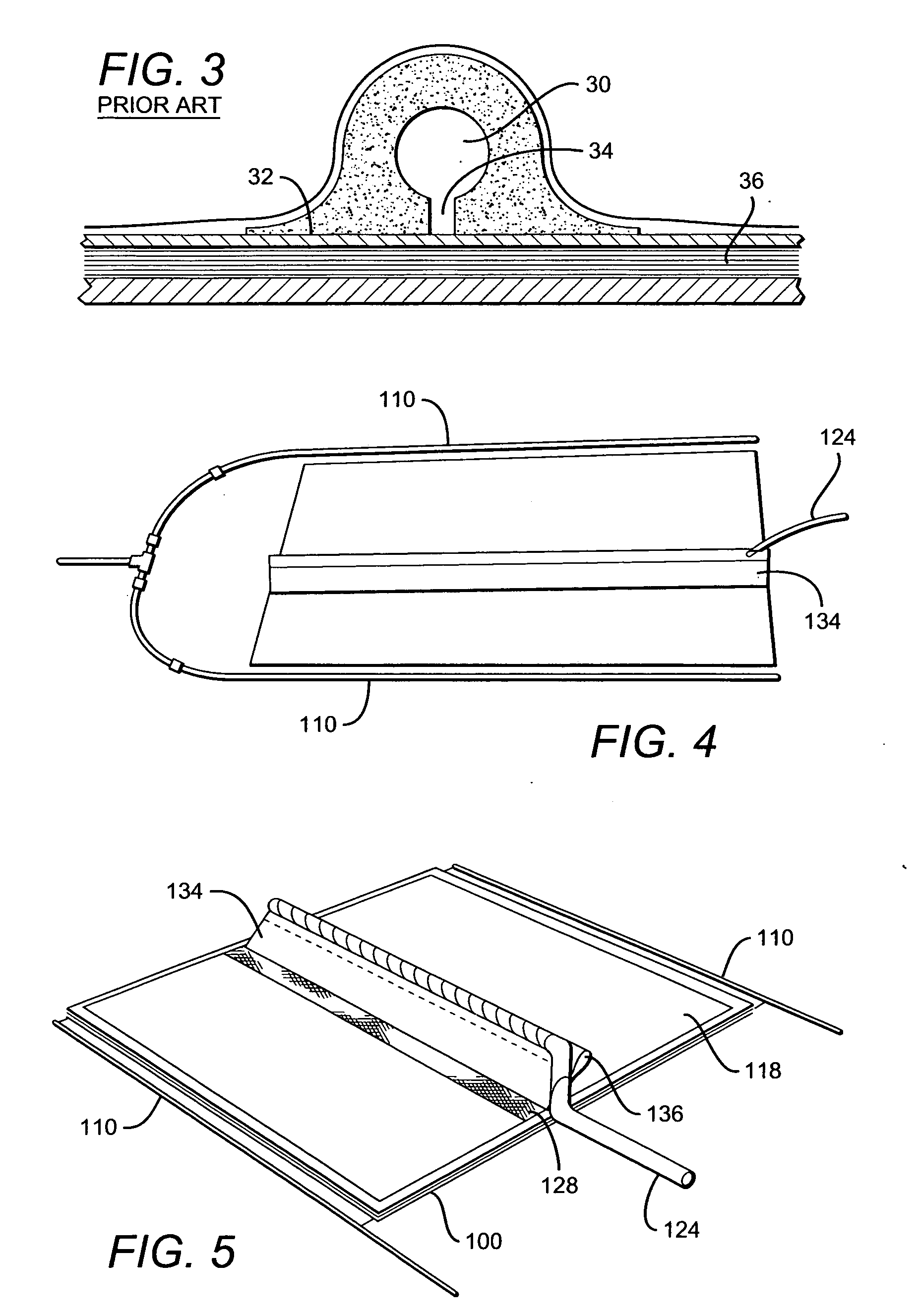

ActiveUS20080079193A1Reduces and eliminates deformationEliminate deformationLaminationWood working apparatusResin dispensingEngineering

The invention is directed to a process for elimination of deformations on resin infused composite parts in which the resin distribution tube used in a resin vacuum infusion process is positioned above the surface of a preform and is not in contact with the preform. Flow media indirectly connects the resin distribution tube to the preform which allows for free movement of resin without direct contact of the resin distribution tube to the perform, and thus, this eliminates deformations that are caused by direct contact of the resin distribution tube to the preform.

Owner:THE BOEING CO

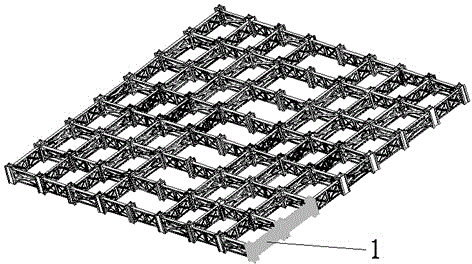

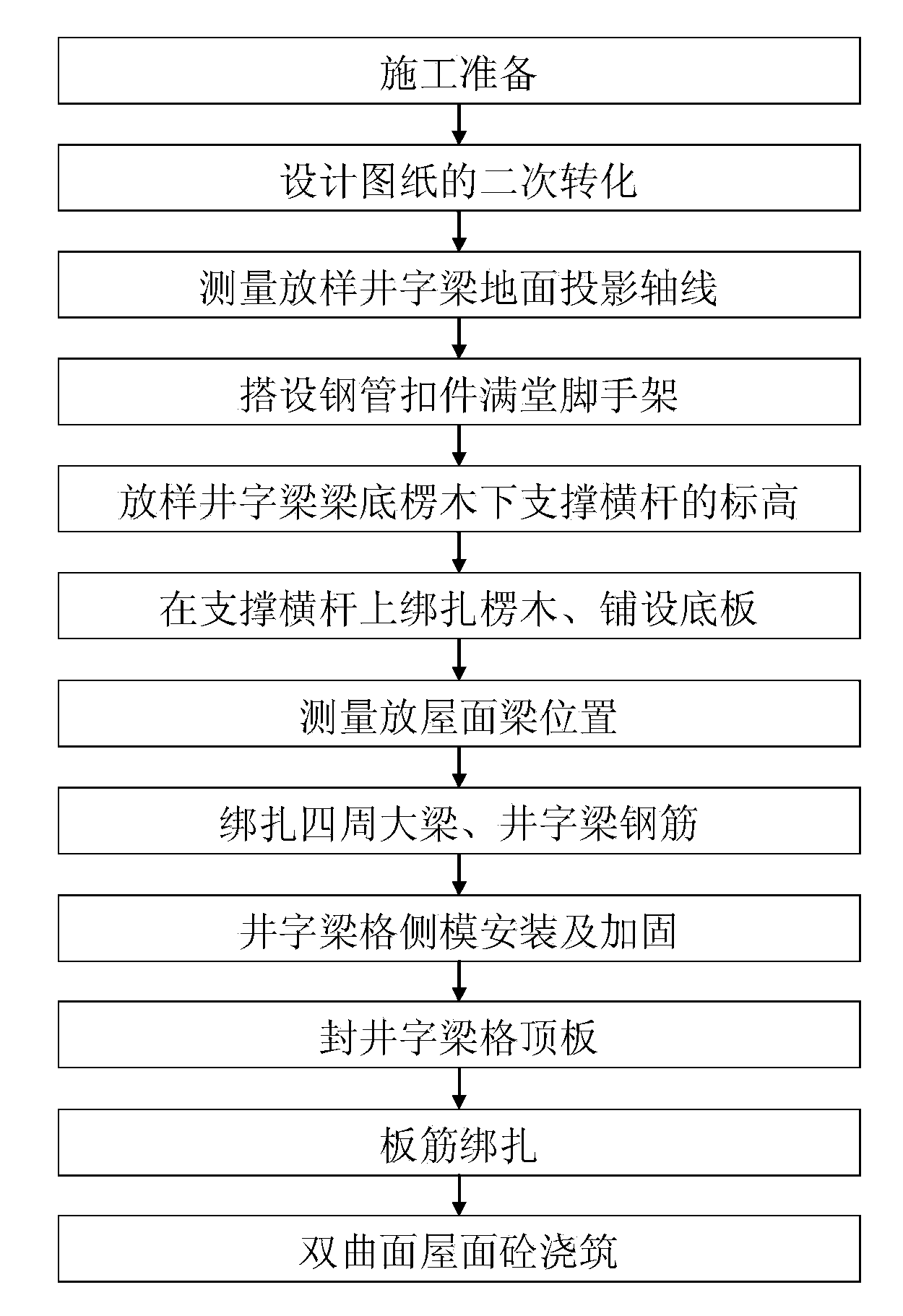

Irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method

ActiveCN103615110AImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

Method for sticking cakes in plastering engineering by using laser

InactiveCN102071792AEasy to operateLow skill level requiredSurveying instrumentsBuilding constructionsControl lineLaser

The invention discloses a method for sticking cakes in plastering engineering by using laser. The method comprises the step that: the cakes are stuck by taking a crossed vertical laser surface output by a laser marking gauge as a reference surface for sticking the mud cakes, namely, a control line is set on a floor of a building which is required to be subjected to plastering construction in a conventional mode, and the laser marking gauge is placed on the control line to keep a straight line projected to laser cross on the floor coincided or parallel with the control line; thus the mud cakes can be stuck by taking the laser surface which is coincided or parallel with the control line as the reference surface for sticking the cakes, the distance from the end face of each mud cake to the laser surface serving as the reference surface is measured by using an angle steel ruler, and the distance from the end face of each stuck mud cake to the laser surface serving as the reference surface is kept same. The method has the advantages of high construction efficiency, good quality, low construction cost, low requirement on the technical level of the construction personnel and the like, and is easy and convenient to operate, and the raw materials are saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Waste power cable recycling device convenient for peeling

InactiveCN109473915AQuick changeReduce frictionBasic electric elementsApparatus for removing/armouring cablesPower cableDrive shaft

The invention belongs to the technical field of electric power tools, in particular to a waste power cable recycling device convenient for peeling. For the problem that a cable is inconvenient for being clamped and fixed when the existing cable recycling device is used, and the splicing knife is easy to slip, the following solution is proposed that the waste power cable recycling device comprisesa base, wherein the top and bottom of the outer wall at one side of the base are respectively provided with a driven shaft mounting hole and a driving shaft mounting hole, the inner wall of the drivenshaft mounting hole and the inner wall of the driving shaft mounting hole are respectively connected with a driven shaft and a driving shaft through the bearings, and a push rod screw on the outer wall at one side of the base is fixed with a recovery motor. The device facilitates quick replacement of the pay-off roller, helps to improve the separation speed of the wire and the jacket, helps to improve the working efficiency, can effectively improve the phenomenon that the cable roller is loosened by the rotation of the pay-off roller, can clamp and fix cables of different sizes, and helps toreduce the probability that the cutting is not complete as the splicing knife slides, resulting in rework.

Owner:六安市匠心信息科技有限公司

Document analysis, commenting, and reporting system

ActiveUS8412516B2Avoid confusionPromote resultsDigital data processing detailsNatural language data processingDocument analysisDocumentation procedure

A document analysis, commenting, and reporting system provides tools that automate quality assurance analysis tailored to specific document types. As one example, the specific document type may be a requirements specification and the system may tag different parts of requirements, including actors, entities, modes, and a remainder. However, the flexibility of the system permits analysis of any other document type, such as instruction manuals and best practices guides. The system helps avoid confusion over the document when it is delivered because of non-standard terms, ambiguous language, conflicts between document sections, incomplete or inaccurate descriptions, size and complexity of the document, and other issues.

Owner:ACCENTURE GLOBAL SERVICES LTD

Document analysis, commenting, and reporting system

ActiveUS20090138257A1Avoid confusionPromote resultsDigital data processing detailsNatural language data processingDocumentation procedureDocument analysis

A document analysis, commenting, and reporting system provides tools that automate quality assurance analysis tailored to specific document types. As one example, the specific document type may be a requirements specification and the system may tag different parts of requirements, including actors, entities, modes, and a remainder. However, the flexibility of the system permits analysis of any other document type, such as instruction manuals and best practices guides. The system helps avoid confusion over the document when it is delivered because of non-standard terms, ambiguous language, conflicts between document sections, incomplete or inaccurate descriptions, size and complexity of the document, and other issues.

Owner:ACCENTURE GLOBAL SERVICES LTD

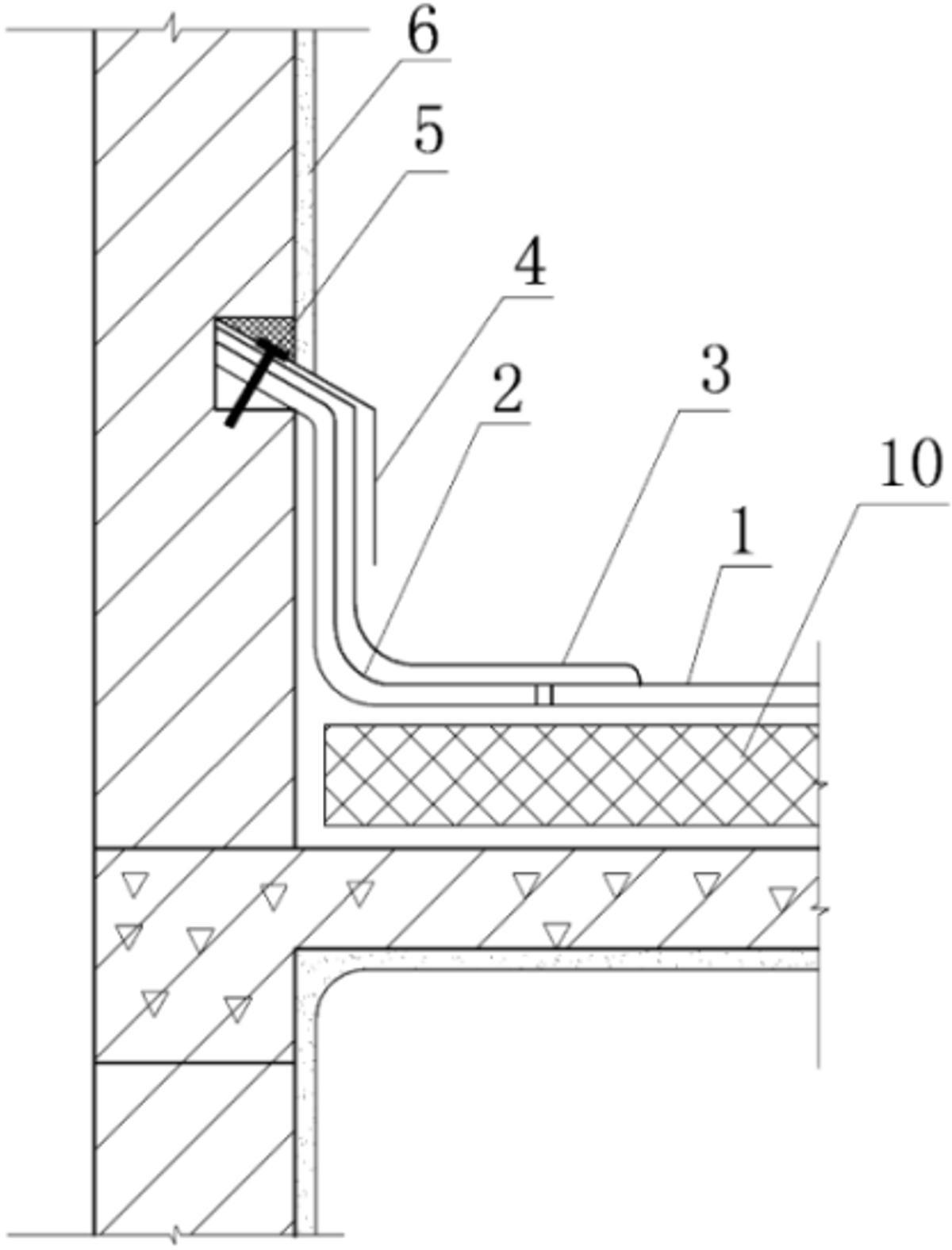

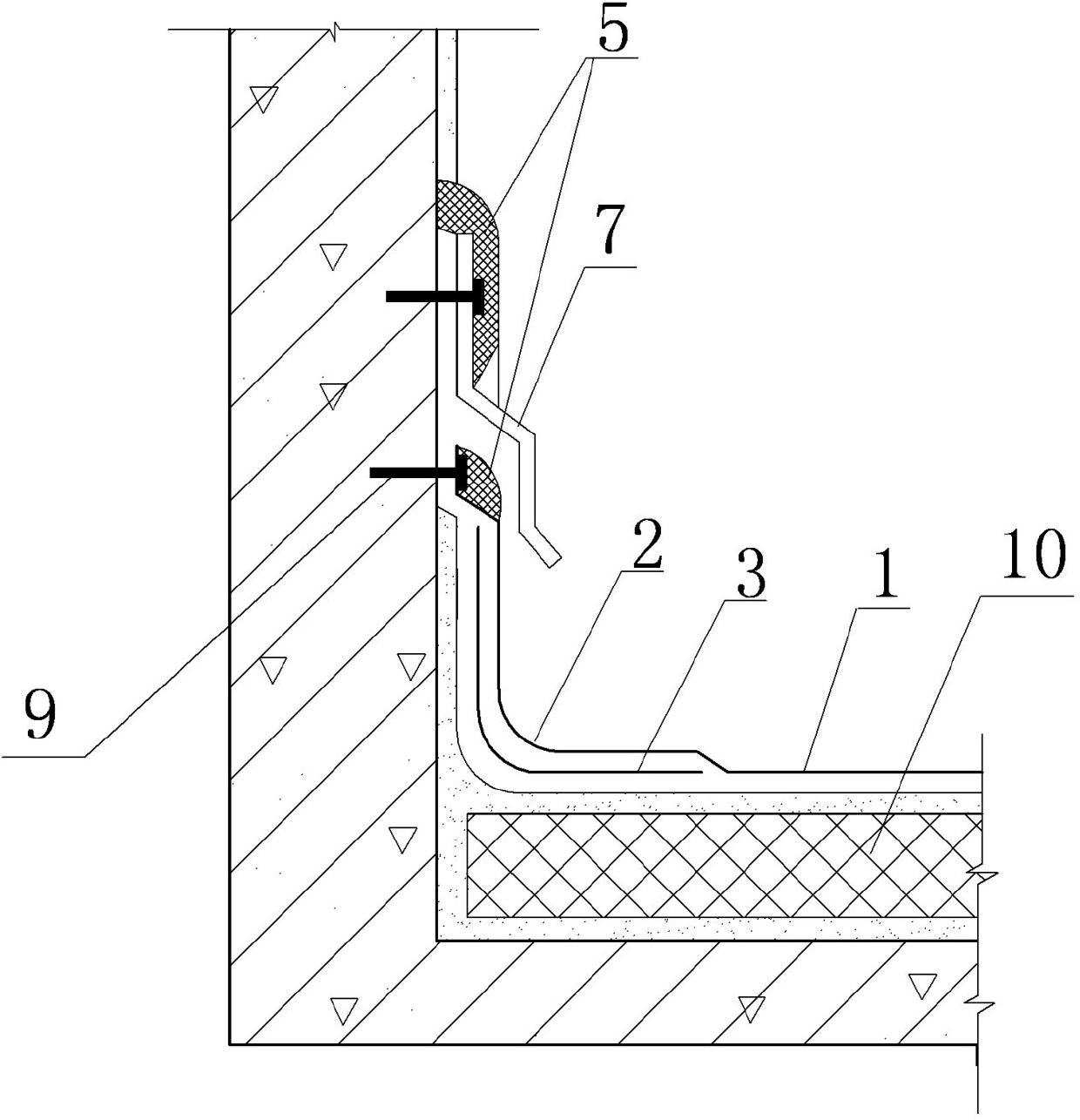

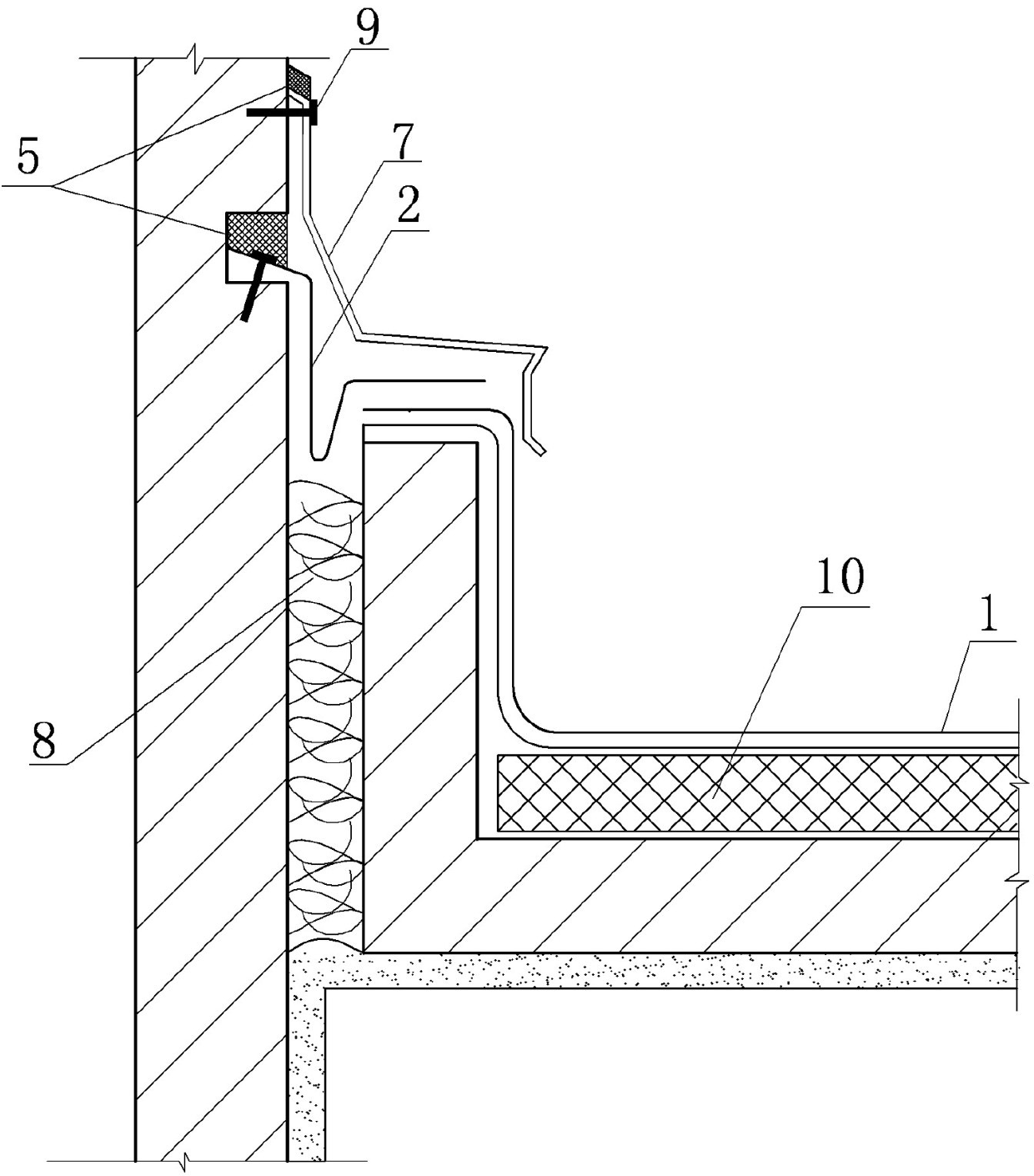

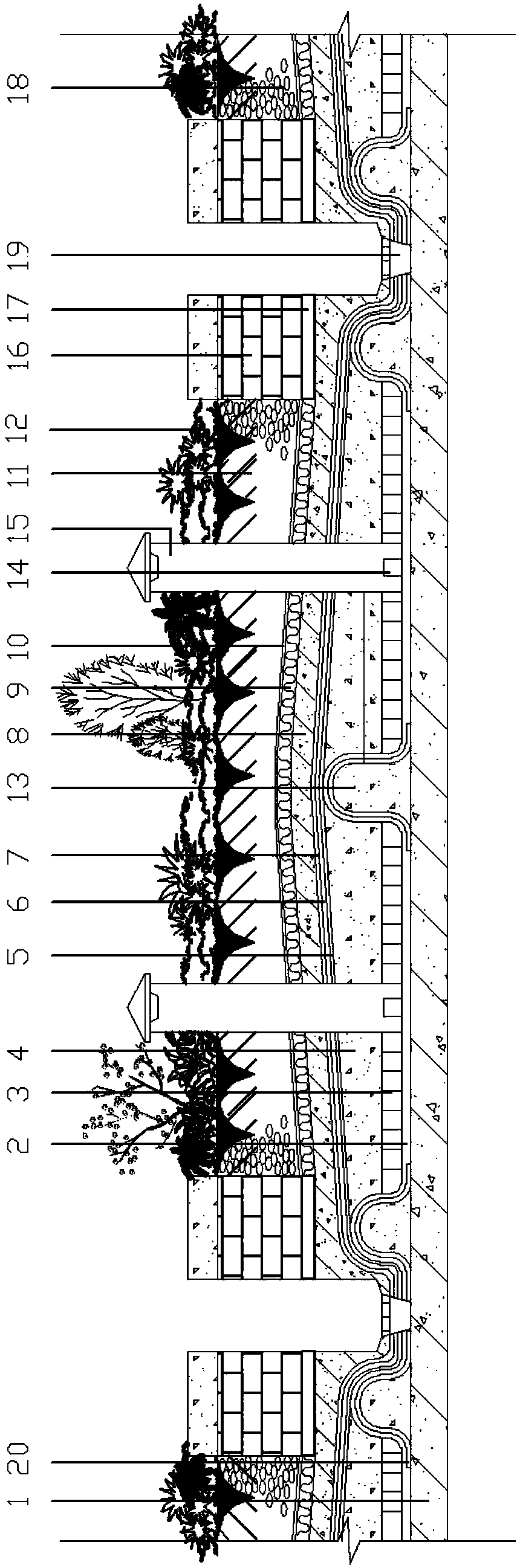

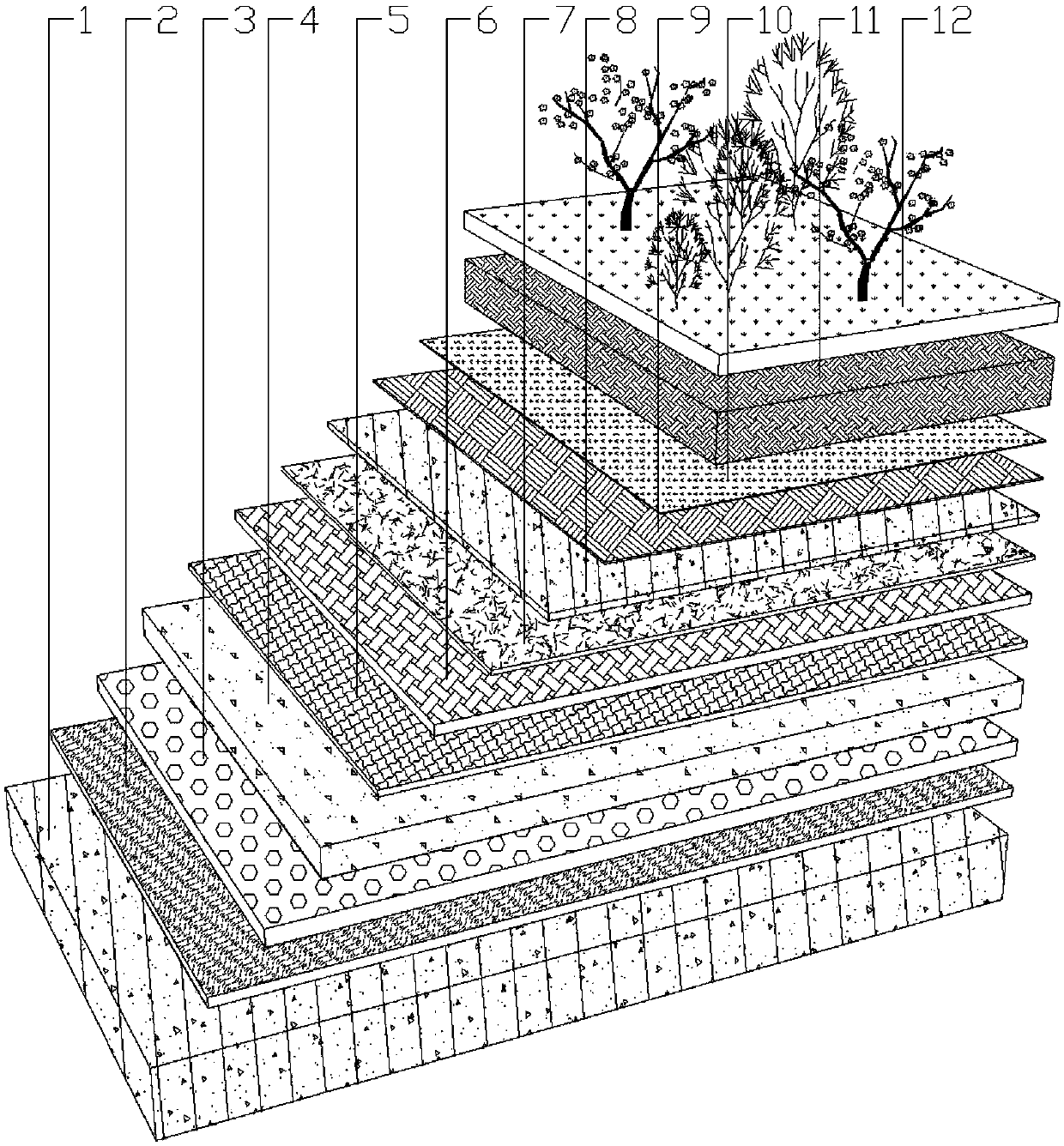

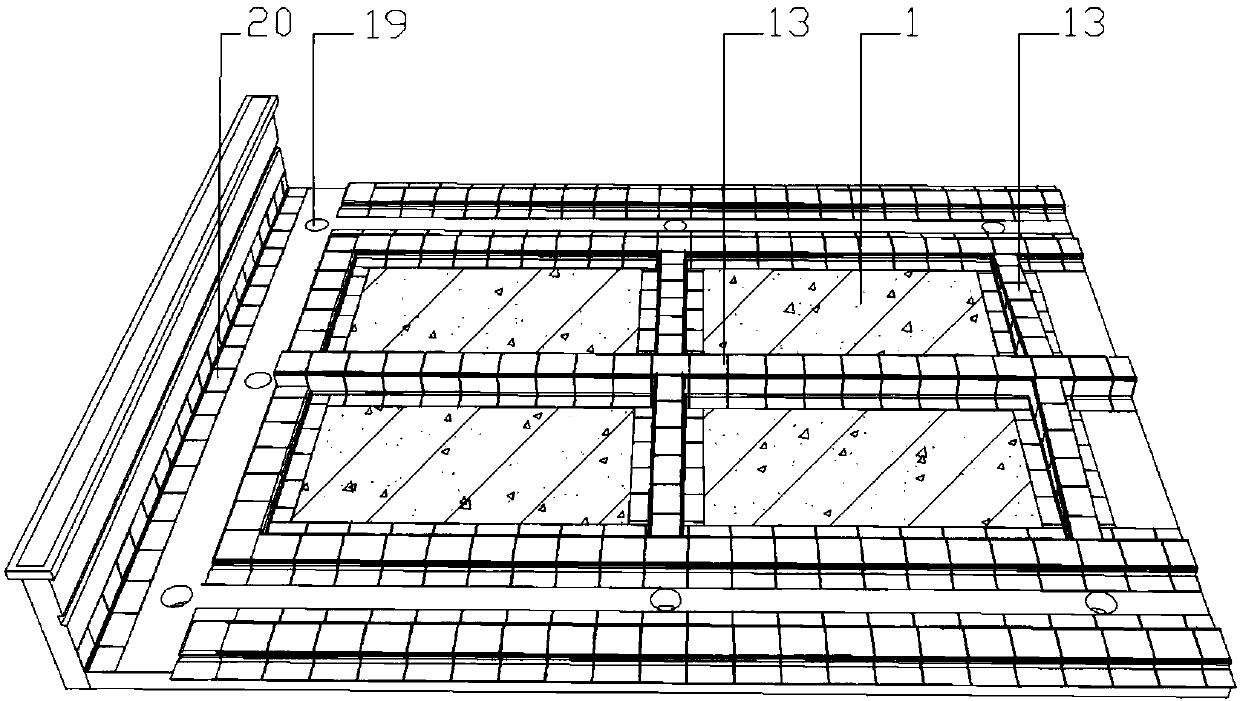

Construction method for planting roof structure

ActiveCN107060226AReduce loadGuaranteed waterproof reliabilityRoof improvementHops/wine cultivationSocial benefitsVegetation

The invention discloses a super large area planting roof structure and a construction method thereof. The construction method includes the following steps of (1) roof structure layer processing, (2) roof structure separate warehouse and additional layer construction, (3) composite waterproof layer construction, (4) insulating layer construction, (5) roof structure exhaust system construction, (6) slope asking layer construction, (7) ordinary coiled material waterproof layer construction, (8) root resistance puncturing separating root waterproof layer construction, (9) asphalt felt isolating layer construction, (10) rigidity protecting layer construction, (11) drainage ditch barricade construction, (12) water drainage and impounding layer construction, (13) drainage system construction, (14) filtering layer construction, (15) planting dielectric layer construction, and (16) vegetation layer construction. The great effects on the heat preservation, heat insulation, water proof and virescence of the super large area planting roof structure are achieved, the technology is simple, the operation is easy, the construction quality is great, and the economic benefits and the social benefits are huge.

Owner:WUHAN CONSTR ENG

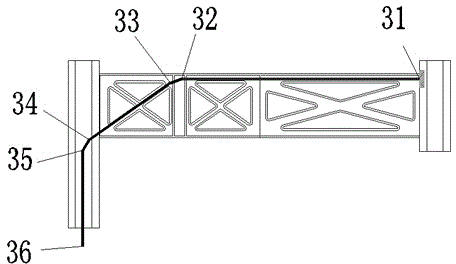

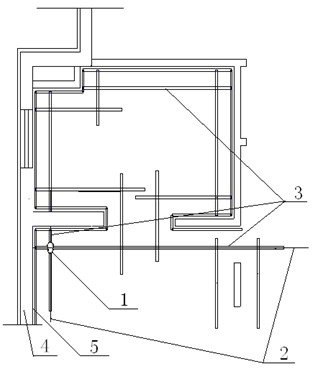

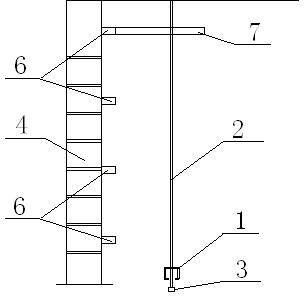

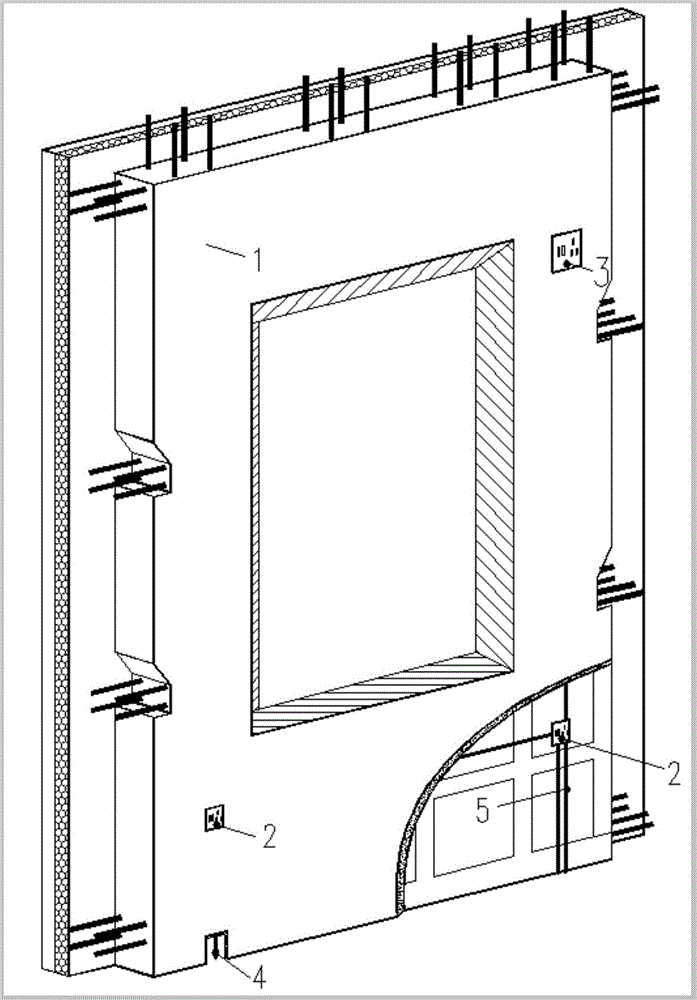

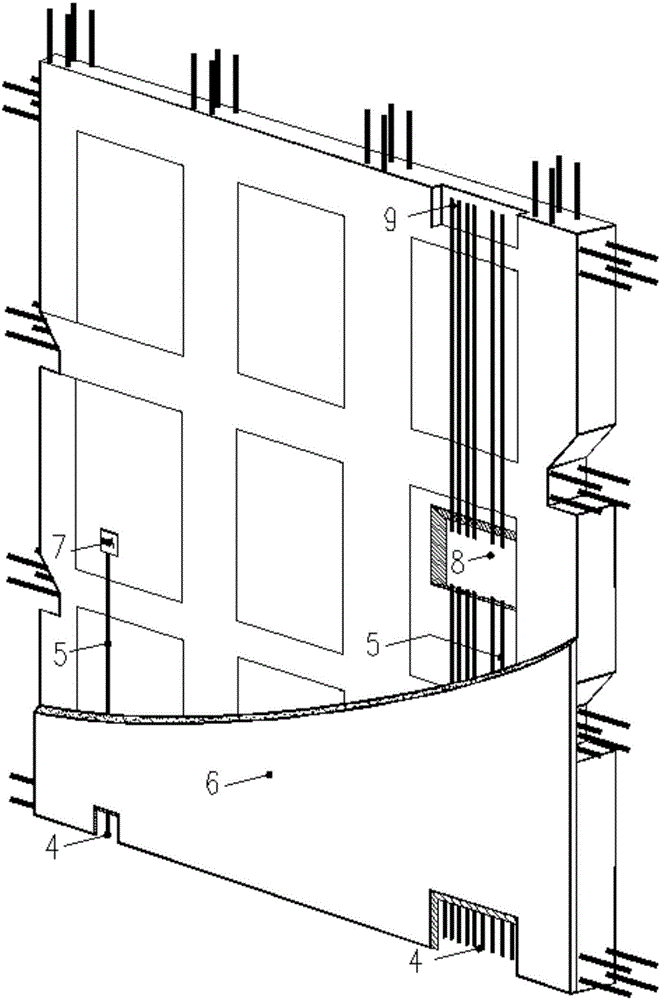

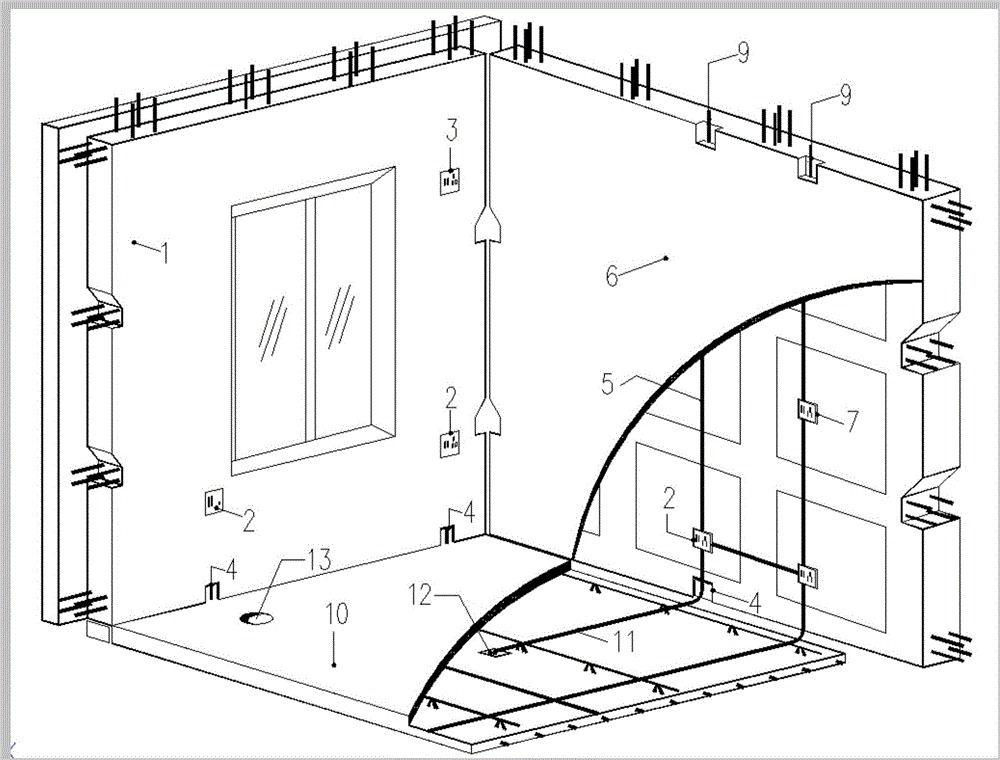

Integrated construction equipment pipeline structure based on inverted trapezoid slot type composite wallboard and design and construction process of integrated construction equipment pipeline structure

InactiveCN106499046AImprove qualityAvoid the hassle of installing plumbingBuilding componentsThermal insulationArchitectural engineering

The invention discloses a construction equipment pipeline structure based on an inverted trapezoid slot type composite wallboard. The construction equipment pipeline structure comprises a sandwiched thermal insulation composite external wallboard, a composite internal wallboard and a truss steel bar laminated floor, wherein edge rib columns of the composite external wallboard and the composite internal wallboard are in the shape of an inverted trapezoid slot at a steel bar outlet; the lower bottom of the inverted trapezoid slot is an open end, and the waists, on the upper side, of the are inclined; electric pipelines and device installation positions are embedded in the sandwiched thermal insulation composite external wallboard, the composite internal wallboard and the truss steel bar laminated floor. The invention further provides a design and construction process of the structure. The construction equipment pipelines are embedded to realize integrated design and construction of the inverted trapezoid slot type composite wall construction equipment pipelines in the process of producing the inverted trapezoid slot type composite wallboard. The trouble of performing later secondary grooving and slotting construction is saved, pipeline collision occurring during site construction is effectively avoided, the problems of losses and rework caused by the errors at the construction stage are greatly reduced, and the effects of optimizing the space and bring convenience to use and maintenance are achieved.

Owner:西咸新区矩阵实业有限公司

Document analysis, commenting, and reporting system

ActiveUS8266519B2Avoid confusionPromote resultsNatural language data processingRequirement analysisDocument analysisQuality assurance

A document analysis, commenting, and reporting system provides tools that automate quality assurance analysis tailored to specific document types. As one example, the specific document type may be a requirements specification and the system may tag different parts of requirements, including actors, entities, modes, and a remainder. However, the flexibility of the system permits analysis of any other document type, such as instruction manuals and best practices guides. The system helps avoid confusion over the document when it is delivered because of non-standard terms, ambiguous language, conflicts between document sections, incomplete or inaccurate descriptions, size and complexity of the document, and other issues.

Owner:ACCENTURE GLOBAL SERVICES LTD

Case deep hole processing method and application thereof

InactiveCN110497152AGuaranteed positionPrevent deviationBoring/drilling machinesCyclic processPilot hole

The invention discloses a case deep hole processing method and application thereof in aluminum-magnesium case deep hole processing. The case deep hole processing method comprises the steps of (S1) processing a pilot hole; and (S2) peck drilling and cycling. The peck drilling and cycling step comprises the steps of firstly controlling a long drill bit to enter the pilot hole at low rotary speed; when at a predetermined safety distance away from the working allowance, increasing the rotary speed to the processing rotary speed, then carrying out peck drilling processing, pausing for the predetermined time after drilling for the depth which is 1 to 2 times of the diameter of the drill bit every time in the peck drilling process every time, breaking a produced continuous chip and discharging out of a hole port through the feeding pause of the long drill bit, and retreating the long drill bit to the position at the predetermined drilling depth far away from a drill hole port after peck drilling for the predetermined depth every time so as to remove chips and cool; and repetitively circulating until processing to the target depth. According to the method, in the deep hole peck drilling circulating process, pause and chip breaking is adopted, the position of drill bit retraction is controlled, and the pilot hole is used for guiding and supporting the long drill bit, so that the problems of deflection and unsmoothness in chip removal are effectively avoided, and the processing quality and the stability are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Vital text analytics system for the enhancement of requirements engineering documents and other documents

ActiveUS9678949B2Reduce defectsAccelerated trainingSemantic analysisSpecial data processing applicationsTechnical specificationsDocumentation procedure

A Vital Text Analytics System (VTAS), incorporating a repository of enterprise terms or concepts, is one that improves the readability and fidelity of technical specifications, instructions, training manuals requirements engineering documents and other related engineering documents, typically from a single organization or workgroup. The system stresses ontological analysis of a corpus of related documents, and applies a suite of computational tools that supports the identification and assessment of risk in evaluating the content of the documents, as well as providing statistical measures reflecting the frequency and severity of document features that threaten comprehension.

Owner:CLOUD 9 LLC DBA VITAL TEXT SYST

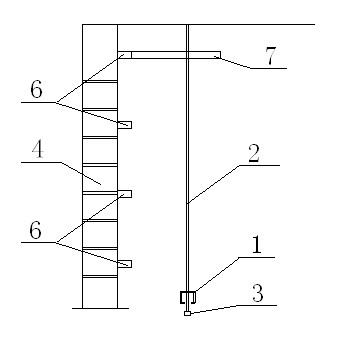

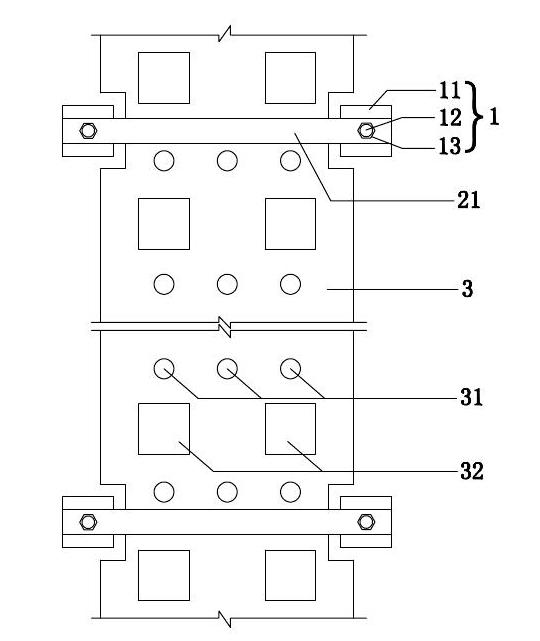

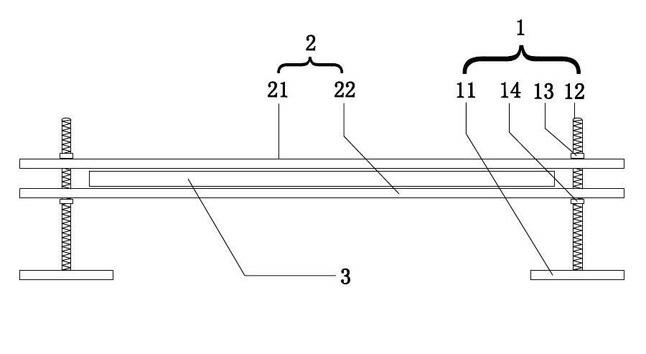

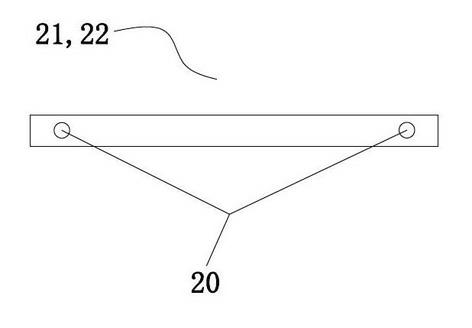

Concrete foundation embedded bolt bracket and embedding method for concrete foundation embedded bolts

InactiveCN102619235ARealize up and down adjustmentEliminate displacementFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a concrete foundation embedded bolt bracket and an embedding method for concrete foundation embedded bolts. The embedded bolt bracket of a concrete foundation comprises at least four groups of support assemblies, at least two groups of clamping piece steel plates, steel templates, wherein every two groups of support assemblies correspond to a group of clamping piece steel plates; the support assemblies are arranged at the side parts of the steel templates; two ends of the clamping piece steel plates are movably connected with the support assemblies; the clamping piece steel plates comprise upper clamping piece steel plates and lower clamping piece steel plates; the steel templates are respectively clamped between every two clamping piece steel plates; and a plurality of bolt holes for allowing the embedded bolts to pass through are formed in the steel templates. According to the concrete foundation embedded bolt bracket and the embedding method for the concrete foundation embedded bolts, which are disclosed by the invention, the embedded bolts can be adjusted from six directions, the displacement and settlement of the embedded bolts caused by concrete construction are eliminated and high-precision embedding is realized, so that the embedding of the bolts is finished at one time and further the work efficiency is increased.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com