Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

A technology of aluminum alloy formwork and construction method, which is applied in the direction of pipes, pipe laying and maintenance, pipes/pipe joints/pipe fittings, etc., and can solve problems such as difficult control of position and size, disturbance or loss of casing, inaccurate reservation of casing, etc. , to achieve good overall aesthetics, reduce the possibility of water leakage, and achieve remarkable results in energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

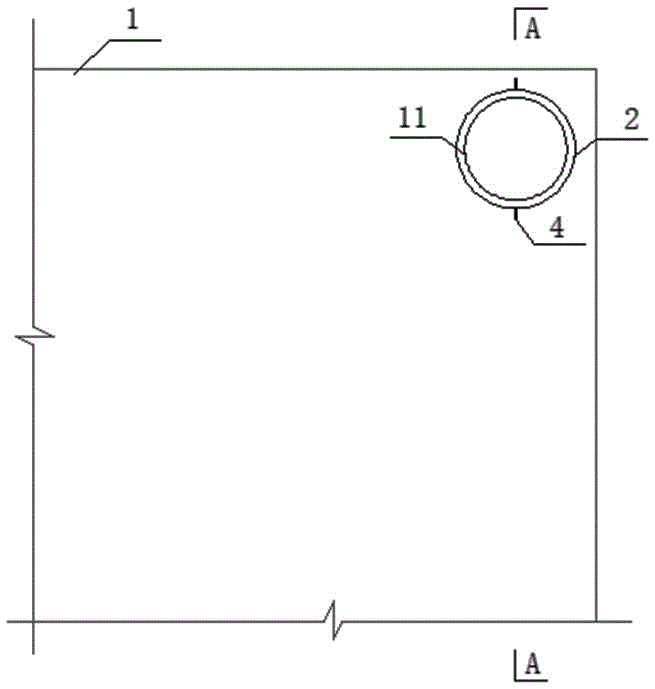

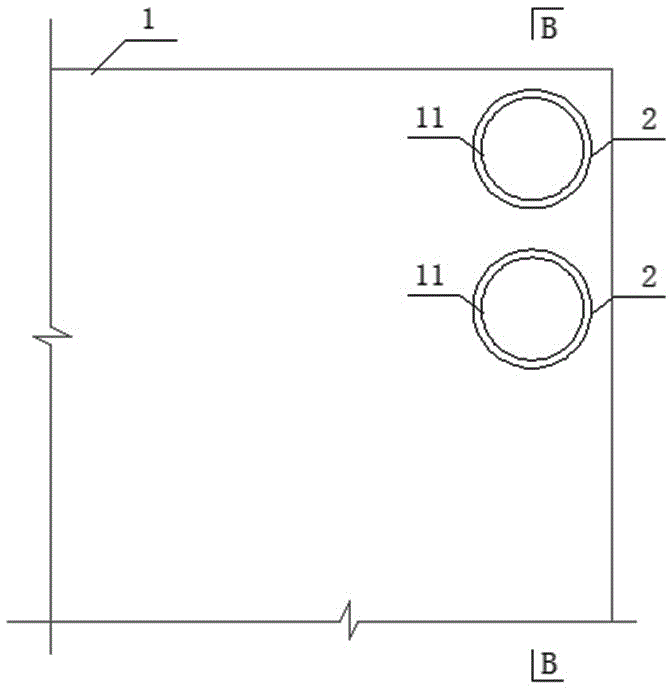

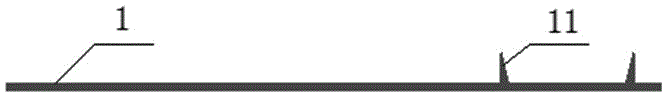

[0060] see figure 1 and figure 2 The aluminum alloy formwork with accurate pre-embedded water supply and drainage casings includes more than two aluminum alloy formworks 1 and water supply casings or drainage casings 2 on the floor bottom.

[0061] see image 3 and Figure 4 , the inner surface of the aluminum alloy formwork 1 on the bottom of the floor is fixed with a positioning snap ring 11 at the position of the set water supply pipe or drain pipe, and the positioning snap ring 11 is perpendicular to the aluminum alloy formwork 1 on the bottom of the floor.

[0062] When constructing concrete floors, the operation steps are as follows:

[0063] (1). Use BIM technology to build models, simulate the installation of water supply and drainage pipelines, conduct collision checks on the location of water supply and drainage pipelines, and deeply optimize the design of water supply and drainage pipeline construction drawings.

[0064] (2). Use BIM technology to design the al...

Embodiment 2

[0071] see Figure 11 , the aluminum alloy formwork with accurate pre-buried water supply and drainage casing includes two sets of wall aluminum alloy formwork 1 corresponding to each other, each group of wall aluminum alloy formwork 1 is composed of more than three wall aluminum alloy formwork 1; water supply is also included Casing or drain casing2.

[0072] Wherein the inner sides of the wall aluminum alloy formwork 3 corresponding to each other are respectively fixed with positioning snap rings 11, the positioning snap rings 11 are perpendicular to the wall aluminum alloy formwork 3, and the positioning snap rings 11 on the wall aluminum alloy formwork 3 on both sides correspond to each other.

[0073] When constructing concrete walls, the operation steps are as follows:

[0074] Steps (1) to (3) are the same as in Example 1.

[0075] Step (4), see Figure 12 and Figure 13 C-C sectional view, after the reinforcement binding of the concrete wall is completed, the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com