Method for aligning perpendicularity of installation tank body by using cross-shaped bridge frame

A technology of cross bridge and verticality, applied in the direction of application, plumb line, household container, etc., can solve the problems of consuming a lot of manpower, material resources, accumulation of verticality out of tolerance, increasing construction and installation costs, etc., to achieve simple operation, Reduce cumulative errors and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] Figure 1-Figure 7 It is a specific embodiment of the present invention. The specific implementation is as follows:

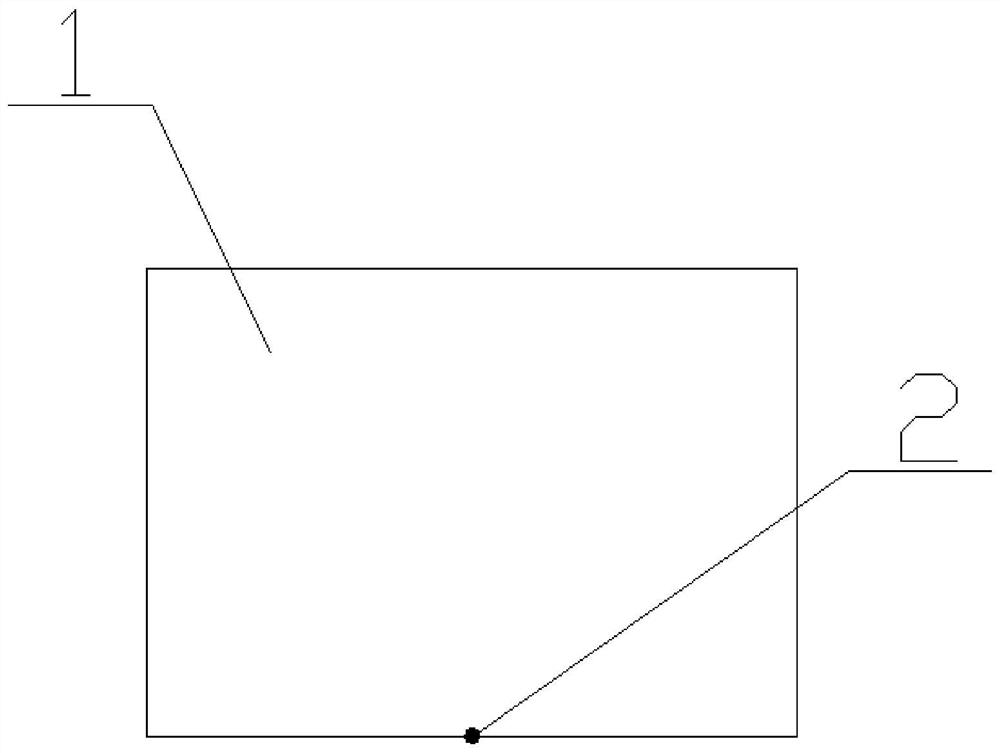

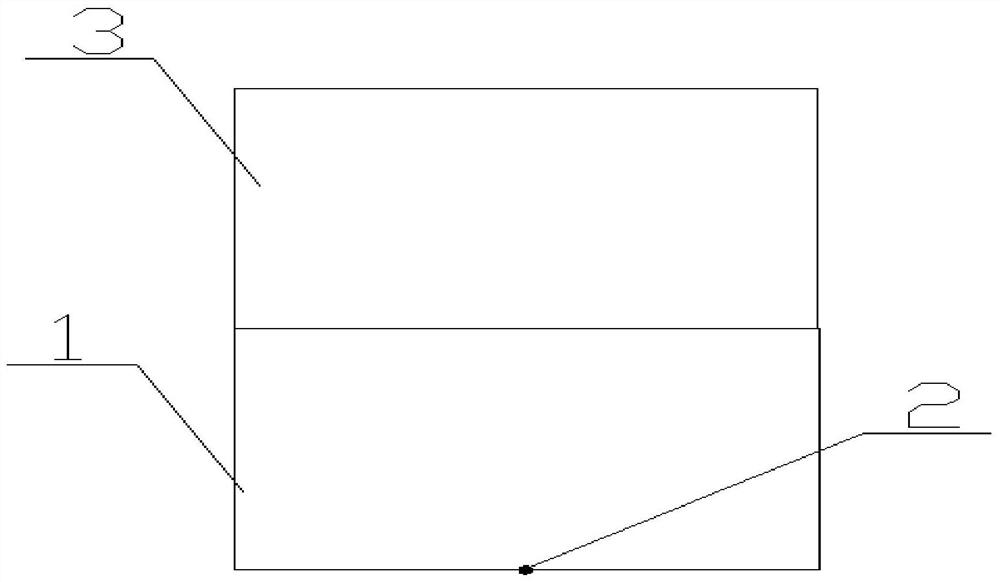

[0021] The first step is to install the first section of the tank body 1, and set a fixed sphere 2 on the center bottom plate of the first section of the tank body 1;

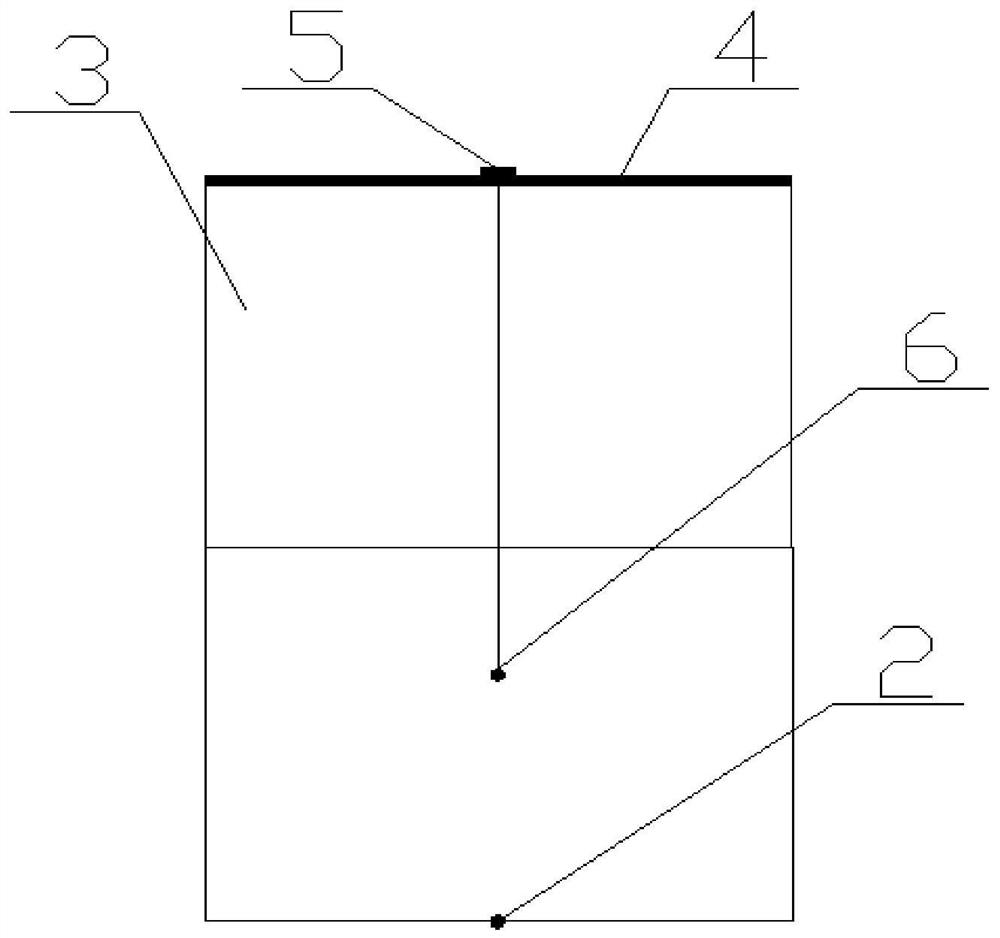

[0022] In the second step, the second section of the tank body 3 is installed on the first section of the tank body 1;

[0023] The third step is to use section steel to make the cross bridge 4. The inner diameter of the cross bridge 4 is consistent with the inner diameter of the installation tank. At the same time, a round hole 5 is opened in the middle of the bridge 4, and a pendant 6 is set, and then the cross bridge 4 is placed in the second section. on the tank body 3, and release the pendant 6 to fall vertically;

[0024] The fourth step is to adjust the position of the second tank body 3 according to the position of the pendant 6 and the fixed sphere 2 on the center bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com