Seat gate cast-in-place pile construction device and construction method

A construction device and cast-in-place pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in ensuring the verticality of the casing, impact on the quality of cast-in-place piles, easy occurrence of shrinkage holes, oblique holes, etc. Achieve the effect of improving pile quality, improving stability and avoiding installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

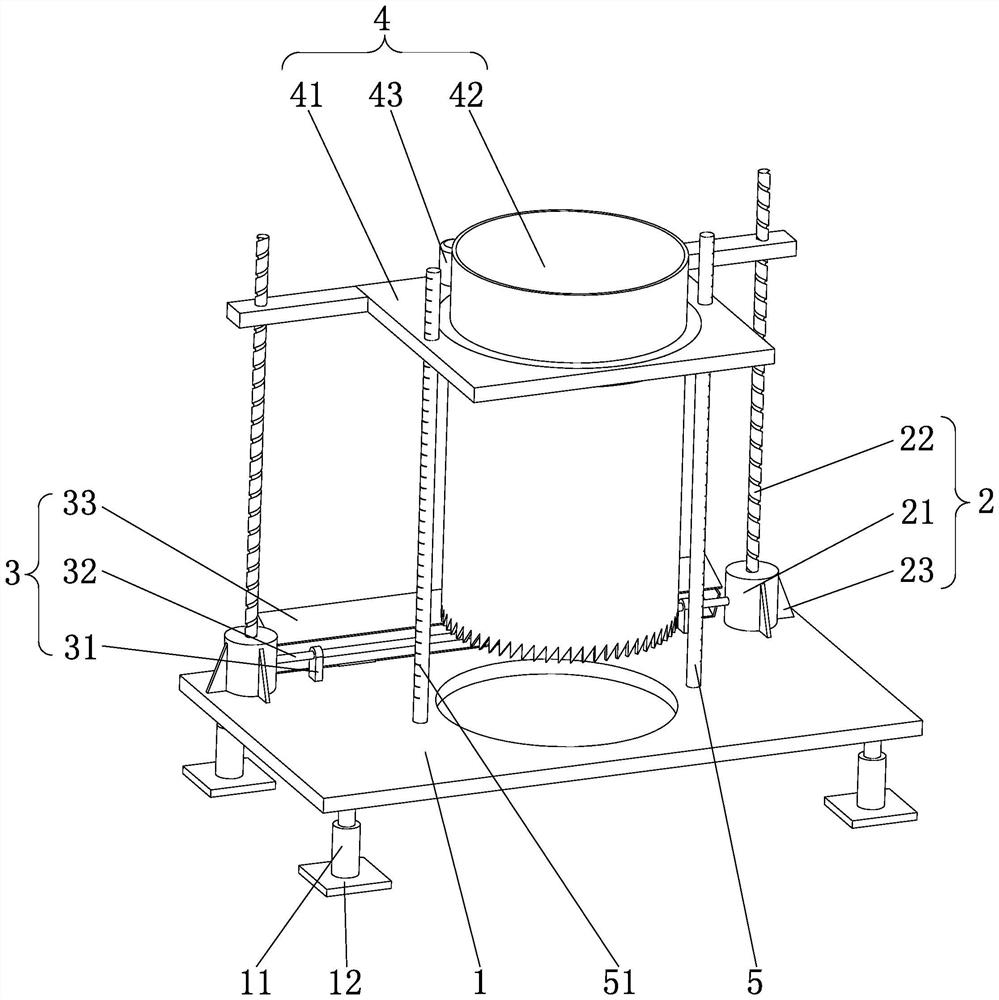

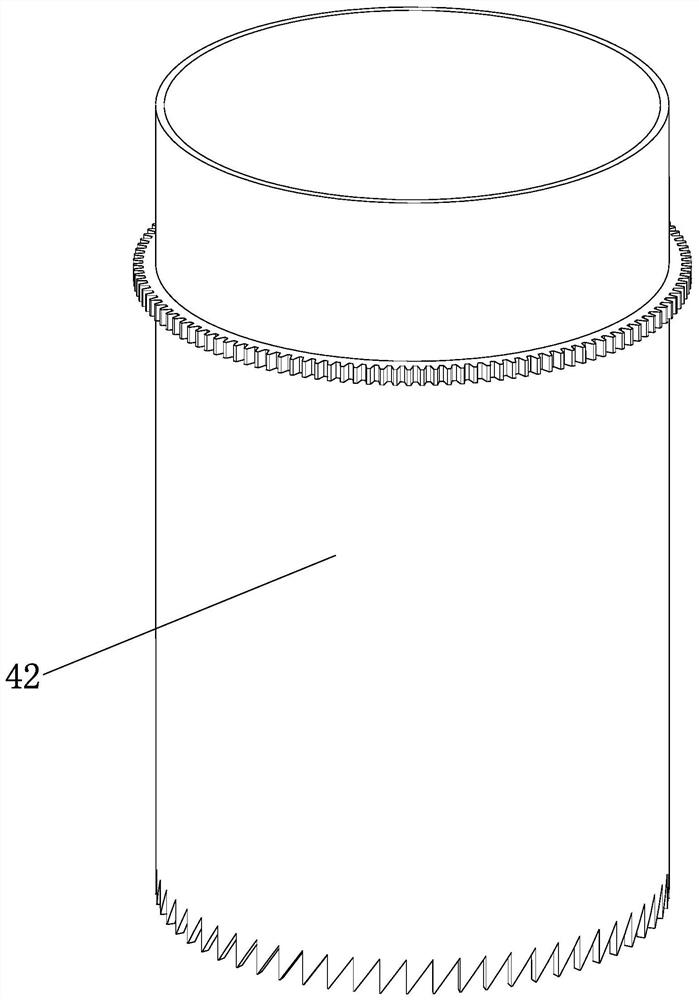

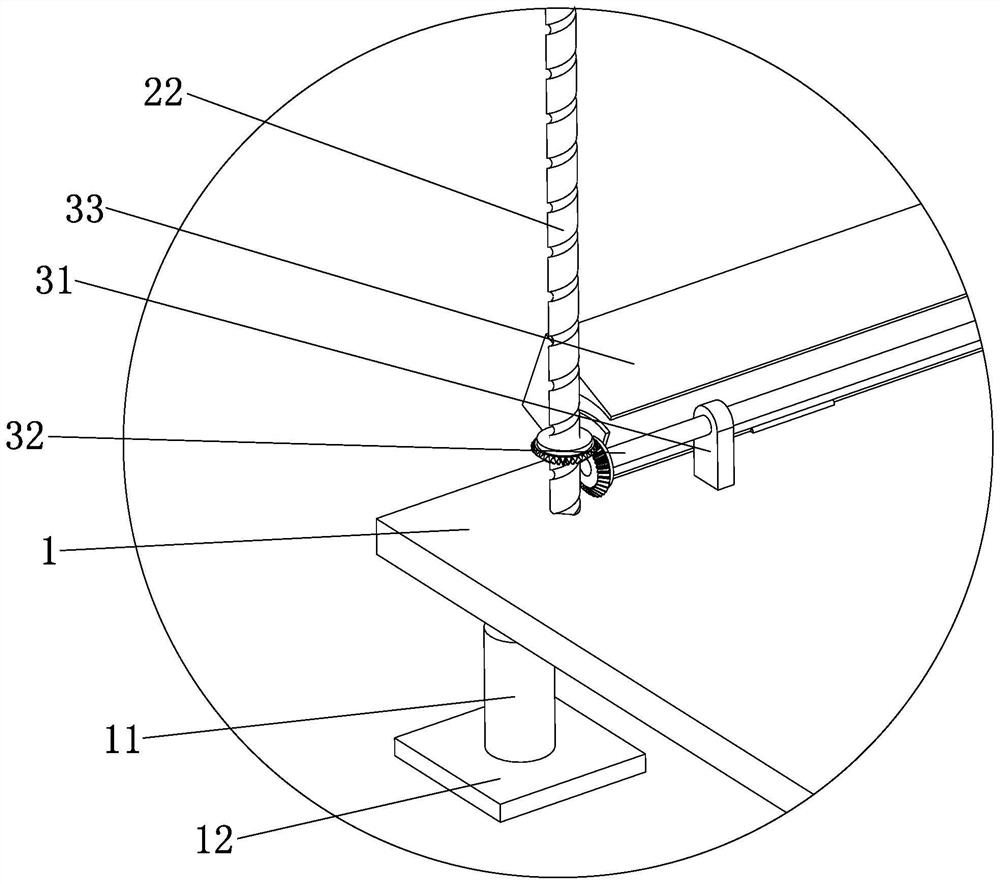

[0031] Attached to the following Figure 1-3 This application provides further details.

[0032] Concrete cast-in-place piles are a common type of building foundation support structure. The installation accuracy of the casing will directly affect the pile quality of the cast-in-place pile. The existing casing installation methods include the press-in method and the landfill method. The press-in method is easy to deform the top of the casing, which in turn affects the measurement accuracy of the pile top elevation; the landfill method is not suitable for construction sites with soft soil because the hutongs are easily loosened after backfilling. . In order to improve the piling quality of the seat gate cast-in-place pile and improve the installation accuracy of the casing, the present application provides a seat gate cast-in-place pile construction device and a construction method.

[0033] In a first aspect, an embodiment of the present application discloses a construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com