Patents

Literature

82results about How to "Efficient descaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

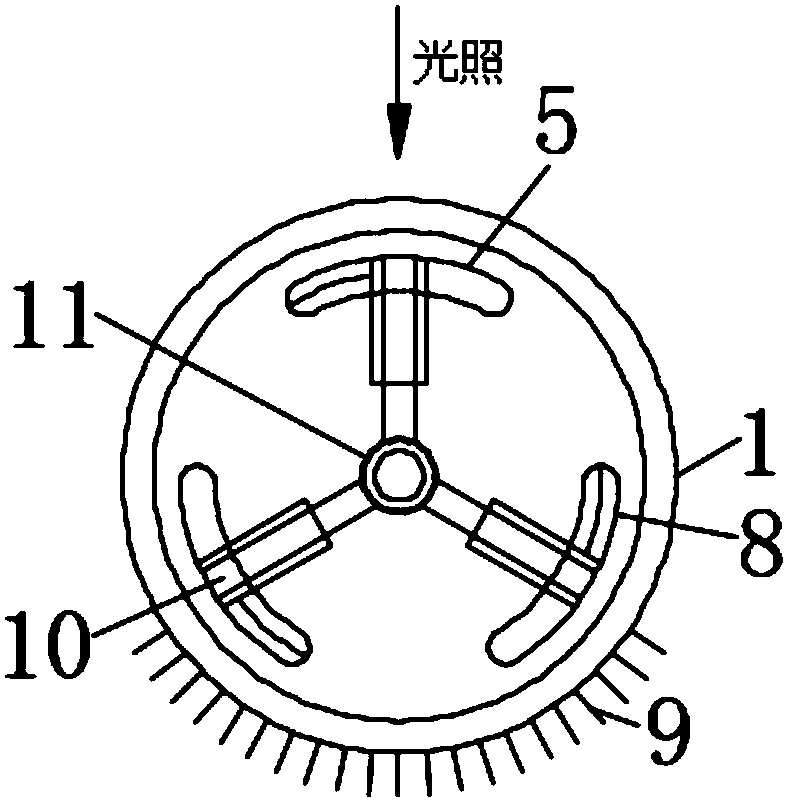

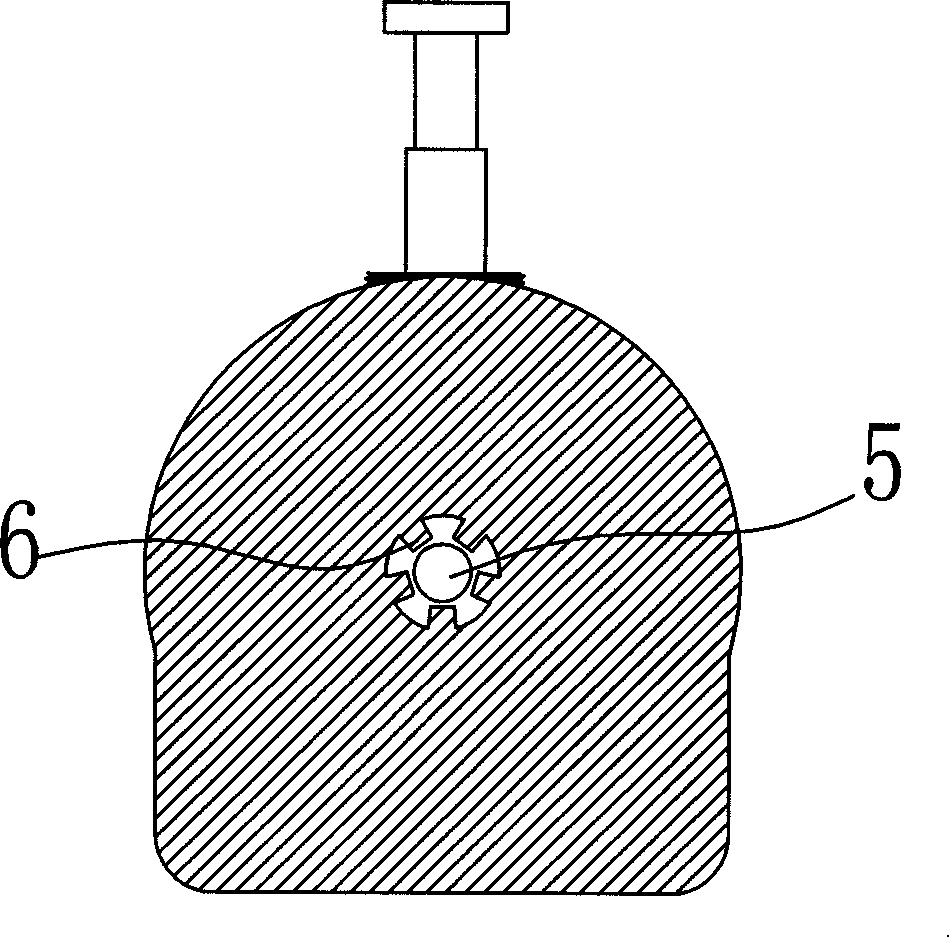

Self-cleaning solar vacuum pipe

ActiveCN109269123AEfficient descalingReduce the level of complexitySolar heating energySolar heat collectors with working fluidsBoiling pointEngineering

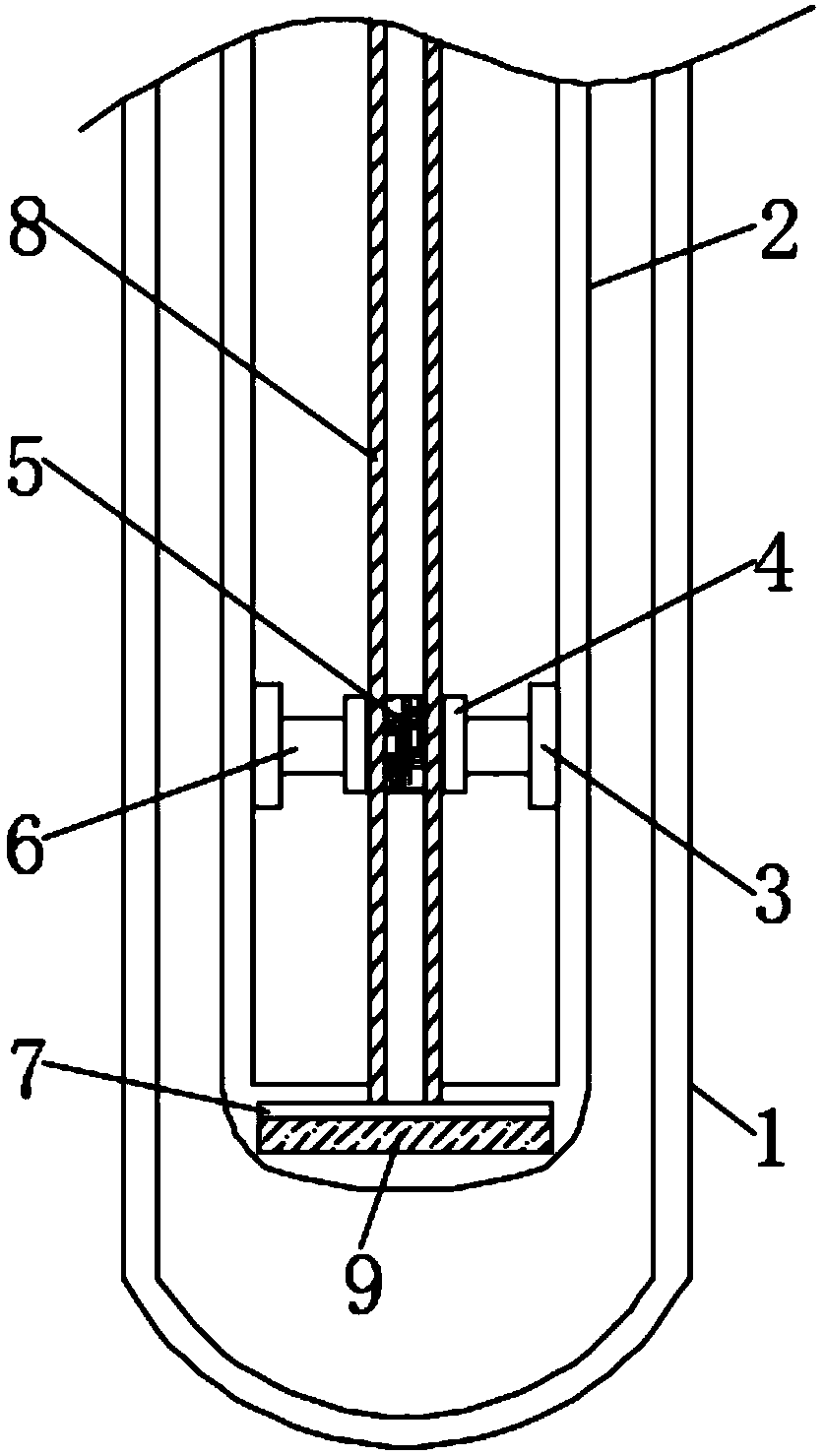

The invention discloses a self-cleaning solar vacuum pipe. The solar vacuum pipe is composed of an inner pipe body and an outer pipe body, a liquid storage cavity is formed in the inner bottom of theinner pipe body and contains an evaporating liquid with a low boiling point, and a metal scraping ring which is always in contact with the inner wall of the inner pipe body is slidably connected intothe inner pipe body; a moving device used for pushing the metal scraping ring to move is installed in the inner pipe body and can axially move along the inner pipe body, and the metal scraping ring isfixedly connected to the moving device through a connector. The self-cleaning solar vacuum pipe is novel in concept, incrustation scale on the inner wall of the solar vacuum pipe can be removed, andthe heating efficiency and service life of the solar vacuum pipe are ensured.

Owner:夏进秋

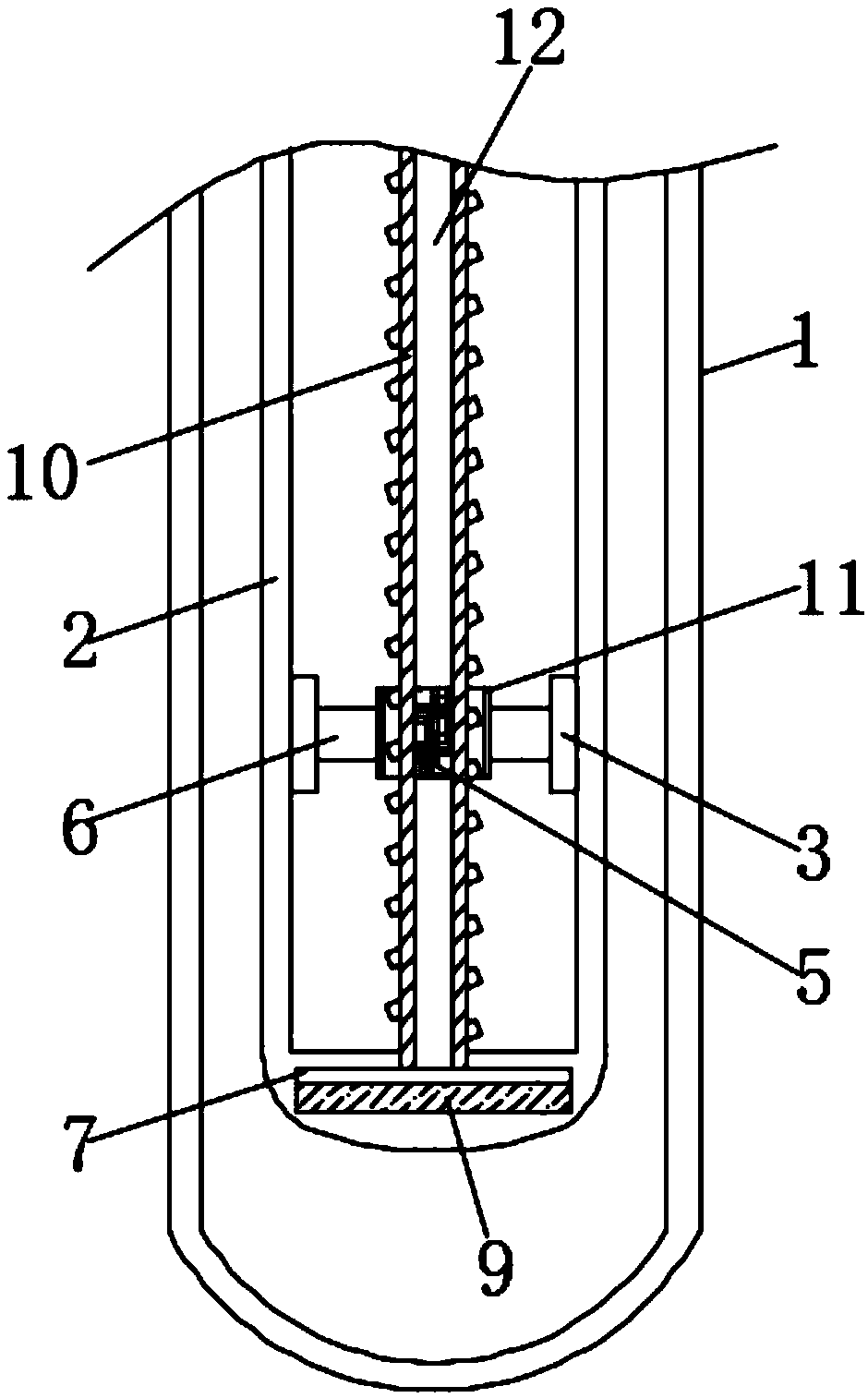

Itaconic acid copolymer, and preparing method and use thereof

InactiveCN1454909AEfficient formationEfficient descalingScale removal and water softeningPolymer sciencePotassium

The present invention discloses an itaconic acid copolymer, its preparation, its preparation method and its application. Said invention provides the general formula of its chain unit structure which is obtained by utilizing itaconic acid, (methyl) propene sulfosalt, (methyl) hydroxyl acrylate monomer and initiating agent through the polymerization in aqueous solution, said polymer colour is brown-red or caramel, and its pH value is less than or equal to 3.0. Said polymer can be used as scale inhibitor and cleaning agent in water treatment.

Owner:QINGDAO LANGYATAI GRP

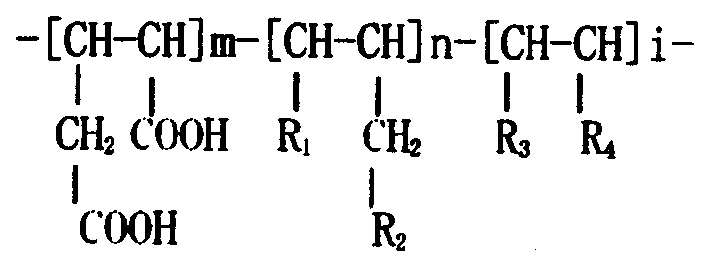

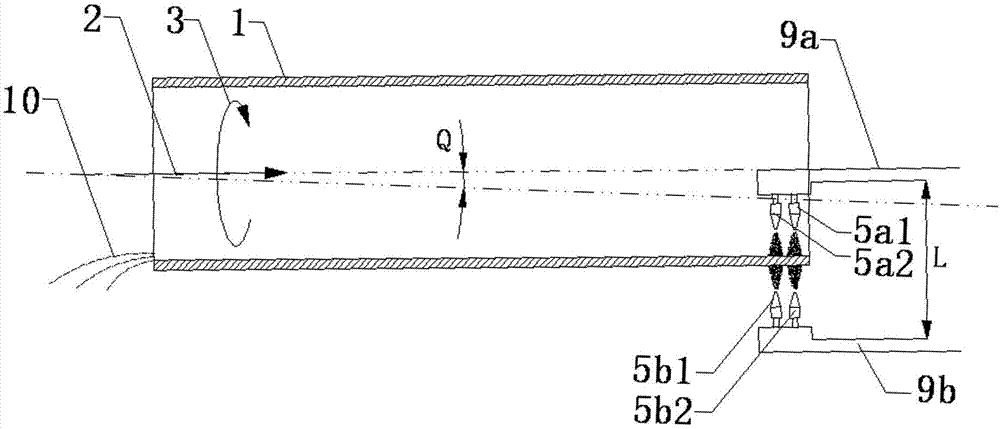

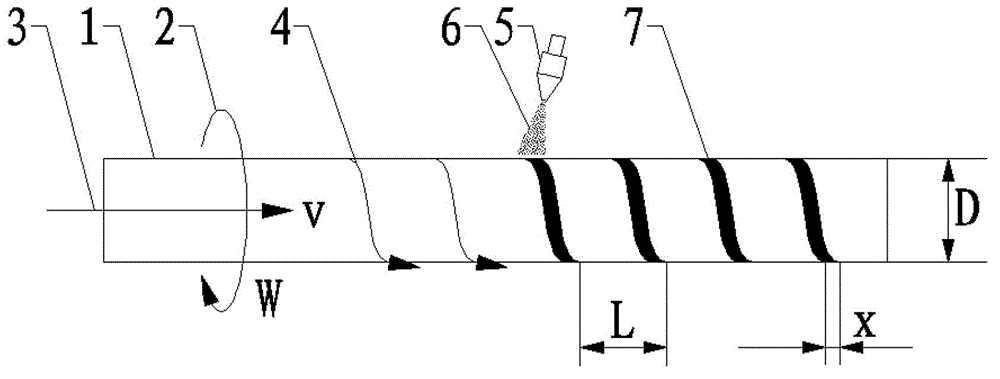

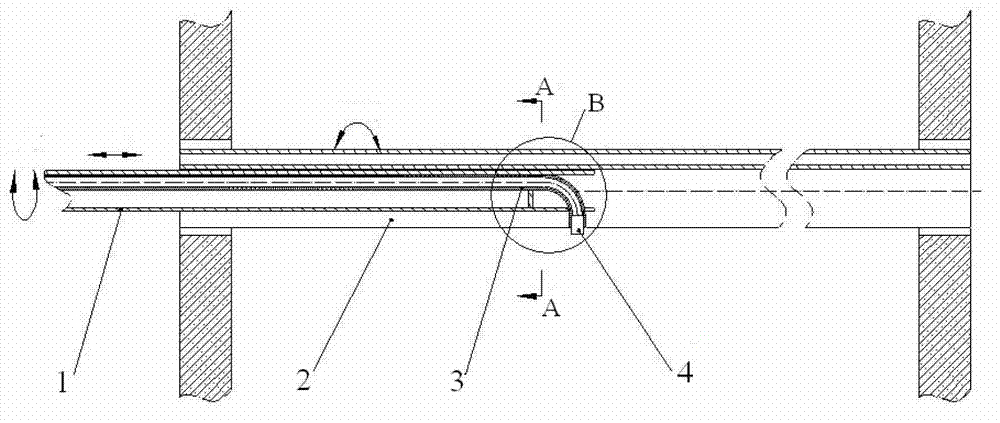

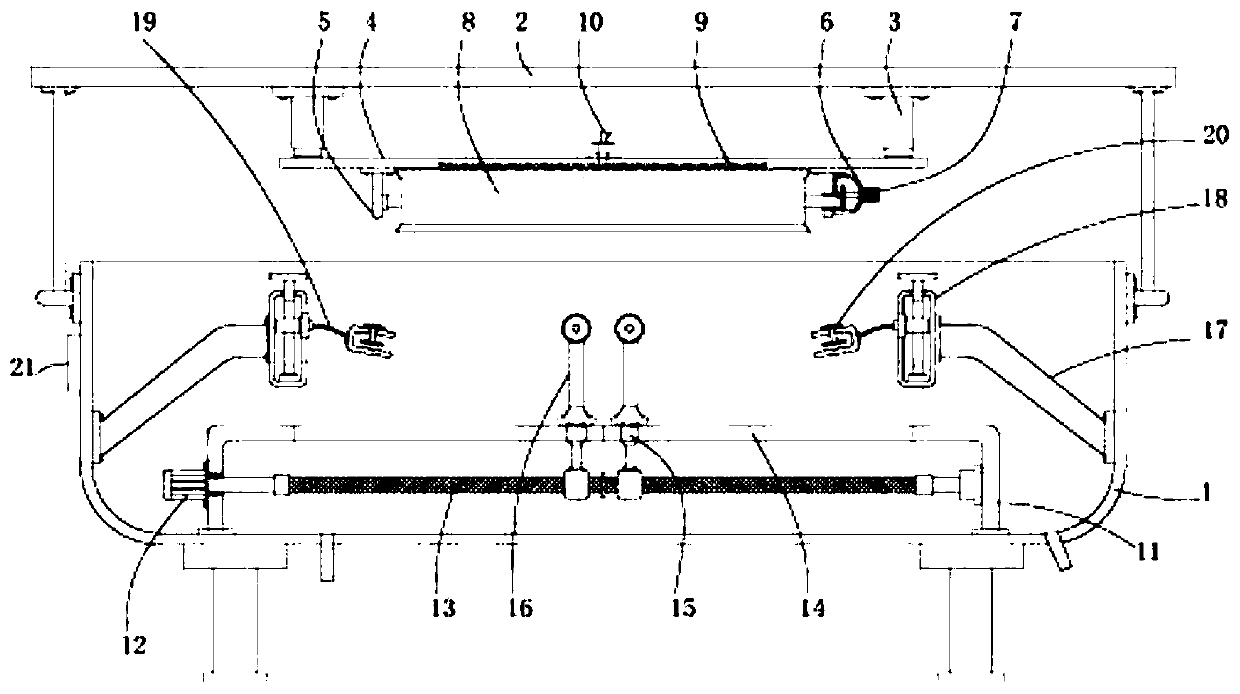

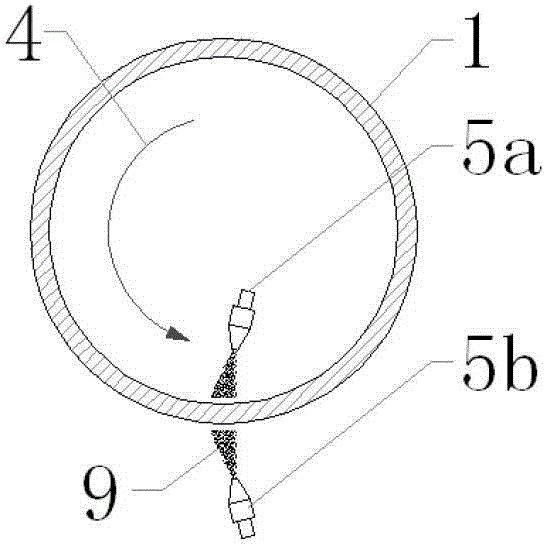

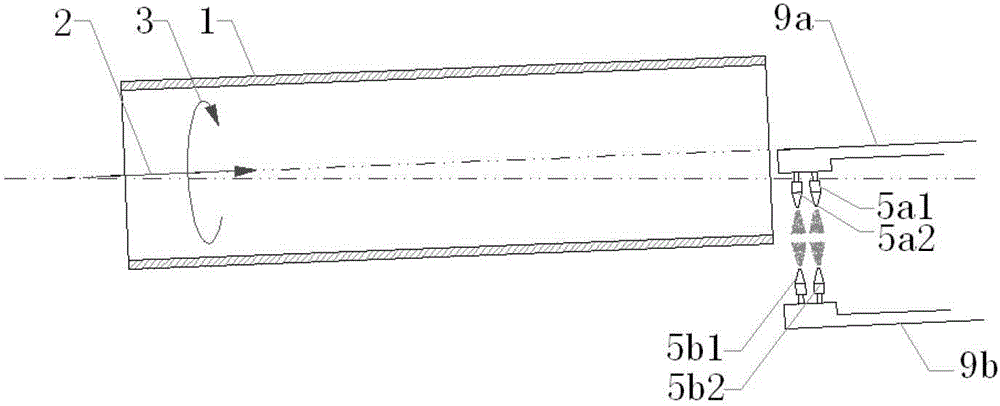

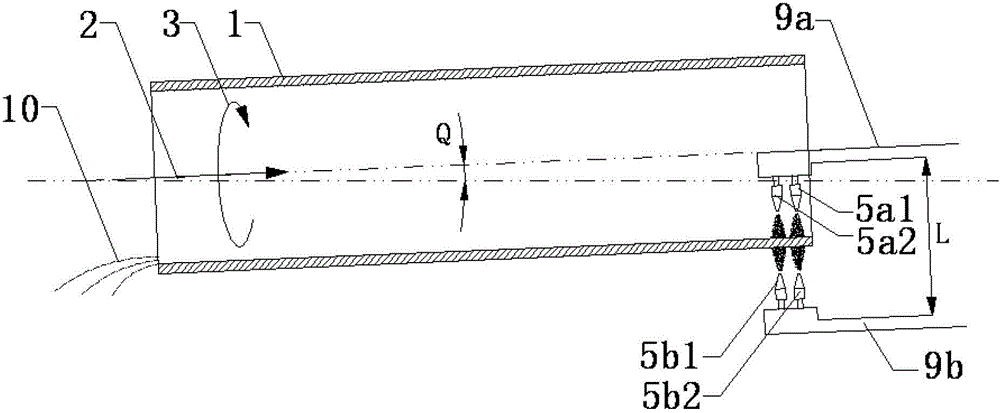

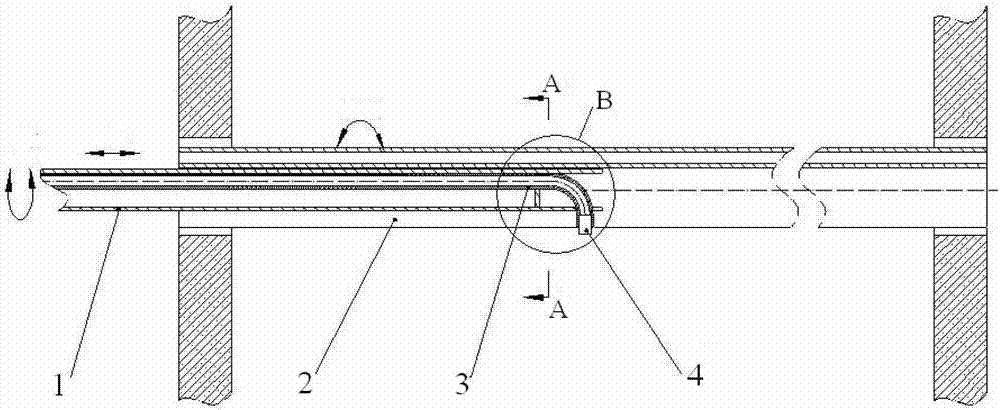

Inner surface and outer surface jet flow descaling system and method for big-diameter metal pipe wall

ActiveCN102764778AEnvironmentally friendly descaling processGreen descaling processWork treatment devicesMetal rolling arrangementsEngineeringMotion Mode

The invention discloses an inner surface and outer surface jet flow descaling system for a big-diameter metal pipe wall, which is characterized by comprising at least one spraying unit, wherein the spraying unit is used for simultaneously spraying mixed jet flow to the inner surface and the outer surface of the metal pipe wall and carrying out descaling; the inner surface and outer surface jet flow descaling system at least comprises two groups of spraying units, wherein one group is an inner spraying subunit used for descaling the inner surface of the metal pipe wall, and the other group is an outer spraying subunit used for descaling the outer surface of the metal pipe wall; the descaling system also comprises an actuating mechanism used for realizing a purpose that the big-diameter metal pipe wall carries out spiral motion; and therefore, the big-diameter metal pipe wall realizes the rotating motion around the self axis while axially moving. According to a special arrangement mode of mixed jet flow nozzles and a special motion mode of the big-diameter cold-state metal pipe wall, a continuous efficient mode that roll scales on the inner surface and the outer surface of the big-diameter cold-state metal pipe wall are synchronously removed can be realized so as to satisfy the processing requirement of the post-process.

Owner:BAOSHAN IRON & STEEL CO LTD

Solid descaling acid rod for oil well

InactiveCN102358834AMeet pressure deliveryMaintain strong solubilityDrilling compositionSolubilitySolid acid

The present invention discloses a solid descaling acid rod for an oil well. The rod comprises a main acid, a cementing agent, a weighting agent and a water-absorbent resistant agent. The main acid comprises: a solid acid, a penetrant, a corrosion inhibitor and a cleaning agent. In the prior art, the scale remover for the oil well has the following defects that: the strong acid in the scale remover has strong corrosion and strong irritation, the scale remover is inconvenient to produce and use, and the like. With the acid rod provided by the present invention, the defects in the prior art are solved. Compared to the conventional scale removers, the solid descaling acid rod provided by the present invention has advantages of strong solubility, weak acidity and the like, can effectively removing the scale, and does not cause corrosion to the pipe string and packer rubber.

Owner:NORTHEAST GASOLINEEUM UNIV

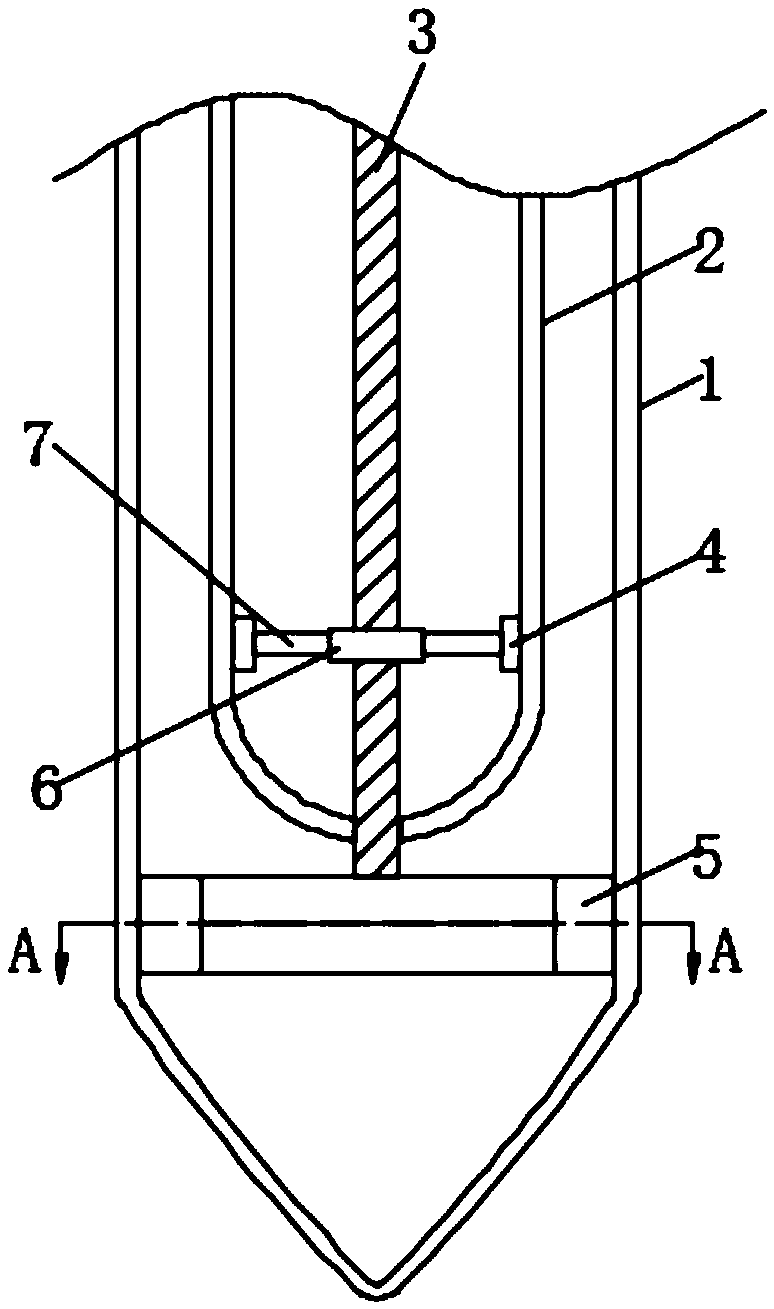

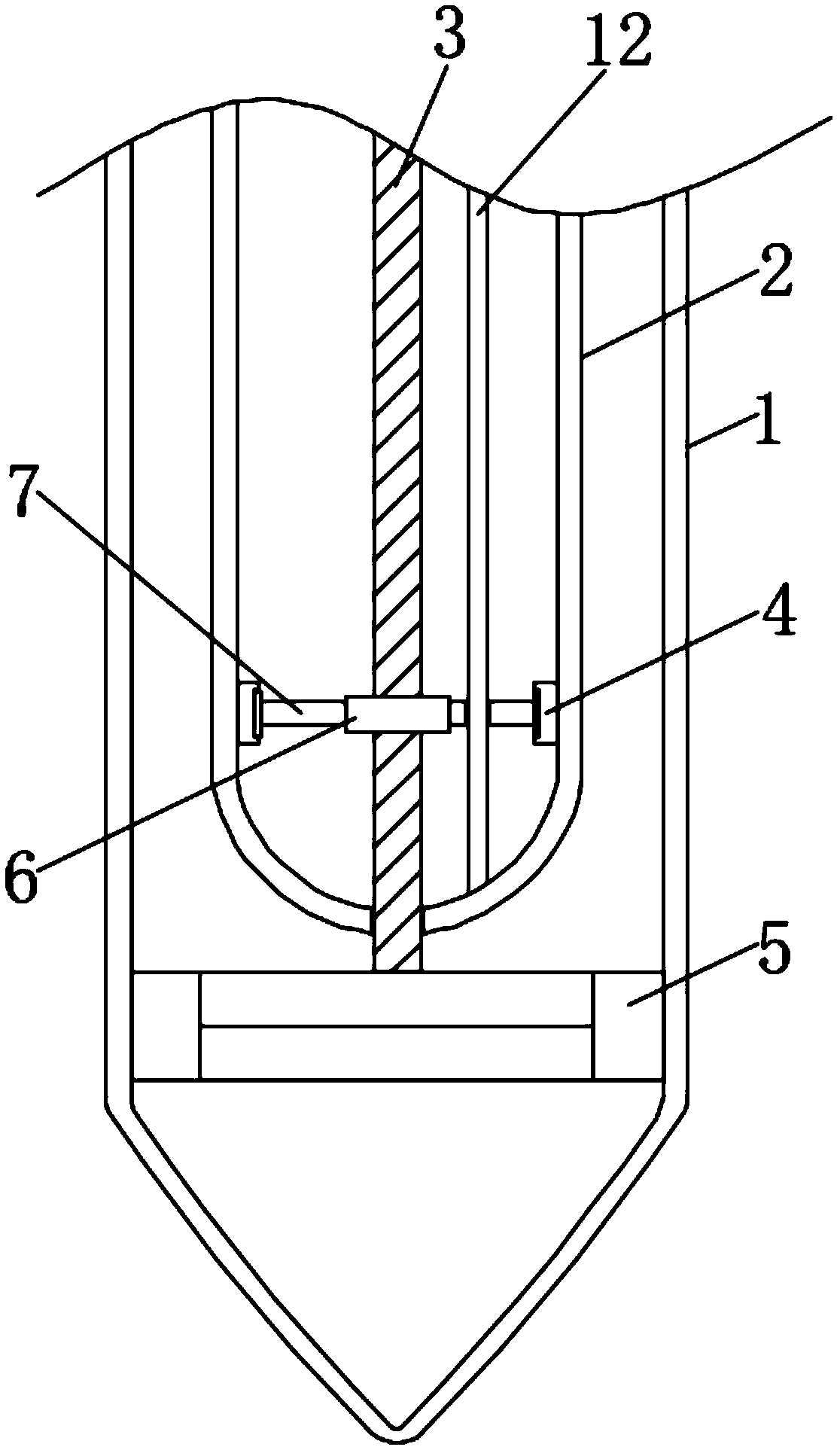

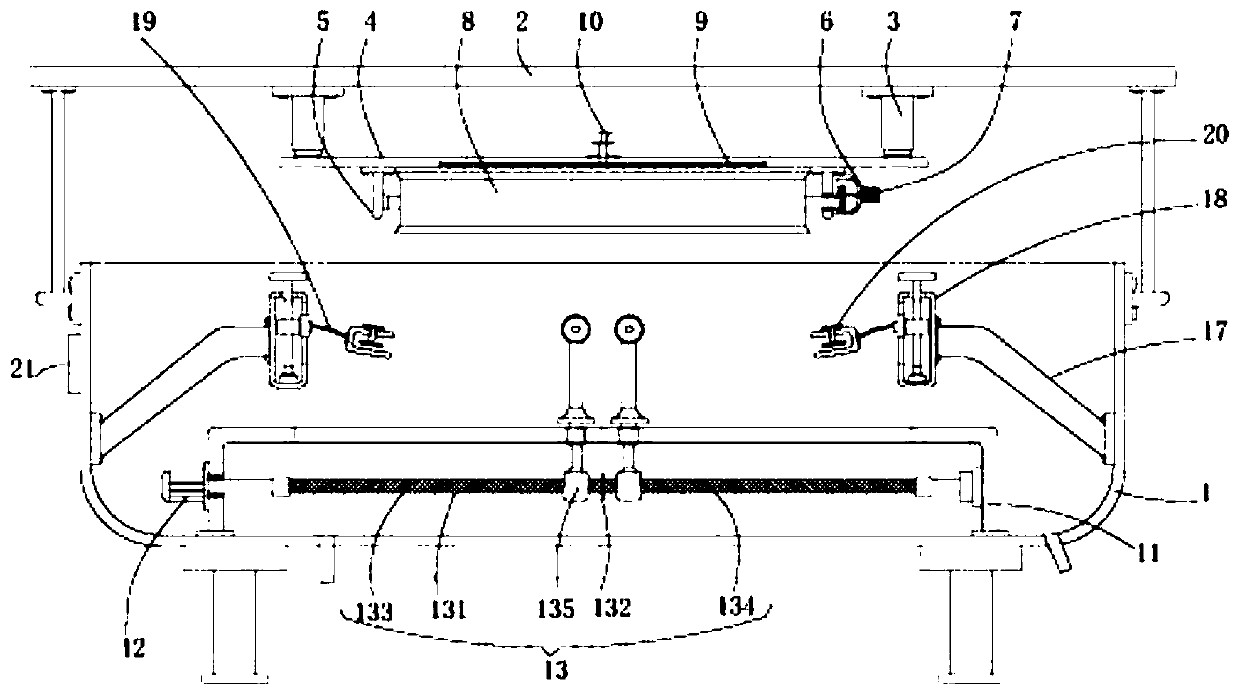

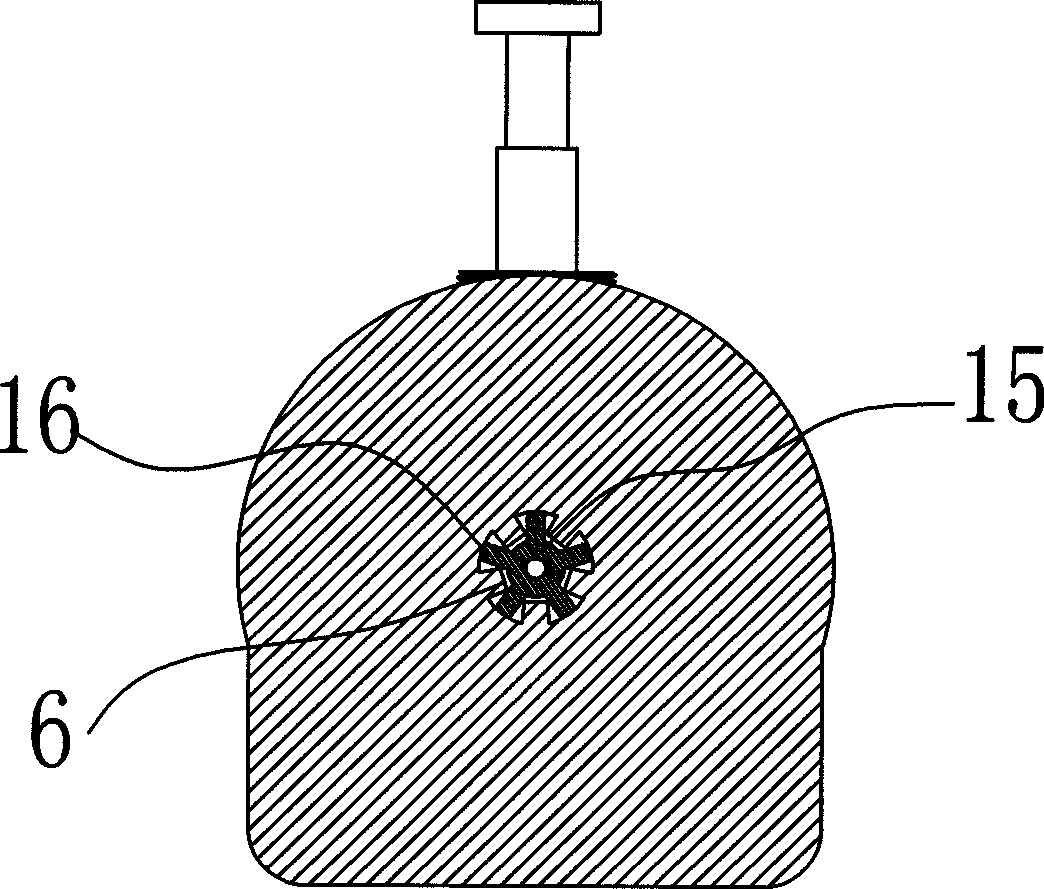

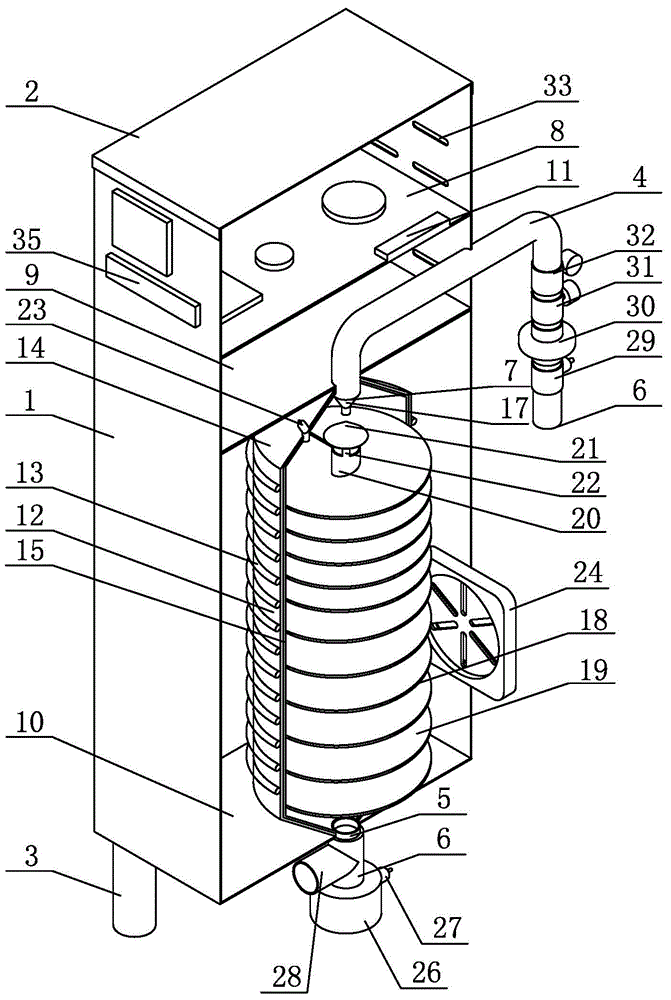

Solar vacuum tube with inner tube water scale self-clearing function

ActiveCN109579317AReduce the level of complexityReduce consumptionSolar heating energySolar heat collectors with working fluidsEngineeringMagnetic line

The invention discloses a solar vacuum tube with an inner tube water scale self-clearing function. The solar vacuum tube comprises a solar vacuum tube body composed of an inner tube and an outer tube,a ball screw is arranged at the inner bottom of the inner tube in a penetrating mode, the ball screw is rotatably connected with the inner bottom of the inner tube in a sealing mode, a rotating cylinder is fixedly arranged on the part, located at the lower end, of the ball screw in a sleeving mode, a plurality of electromagnet brush sheets are arranged on the side wall of the rotating cylinder atequal intervals in the circumferential direction of the rotating cylinder, and the direction of the magnetic line of each of the electromagnet brush sheets is along the radial direction of the rotating cylinder. Heat dissipating tiles matched with the inner wall of the outer tube are fixedly installed at the outer ends of the electromagnet brush sheets, and the side surfaces of the heat dissipating tiles sweep the arc surface of the outer tube as the heat dissipating tiles rotate along the rotating cylinder. The solar vacuum tube has a novel concept, can remove water scales of the inner wallof the solar vacuum tube, and the heating efficiency and the service life of the solar vacuum tube are ensured.

Owner:ZHEJIANG YAUNN NEW ENERGY CO LTD

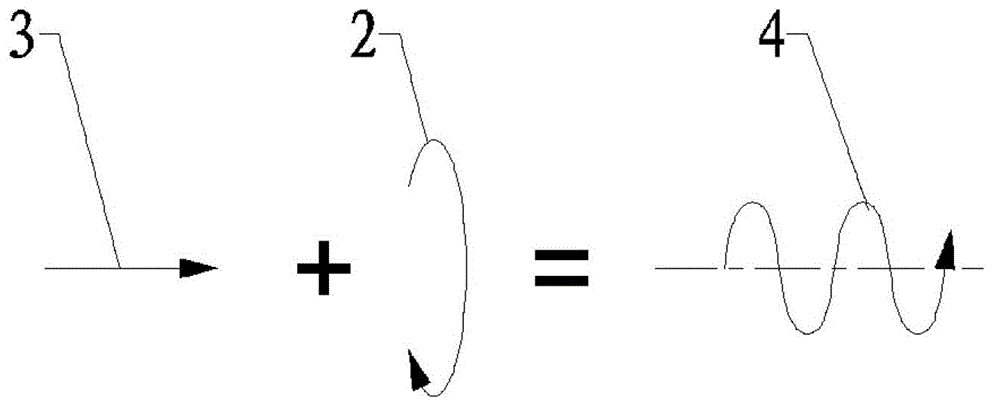

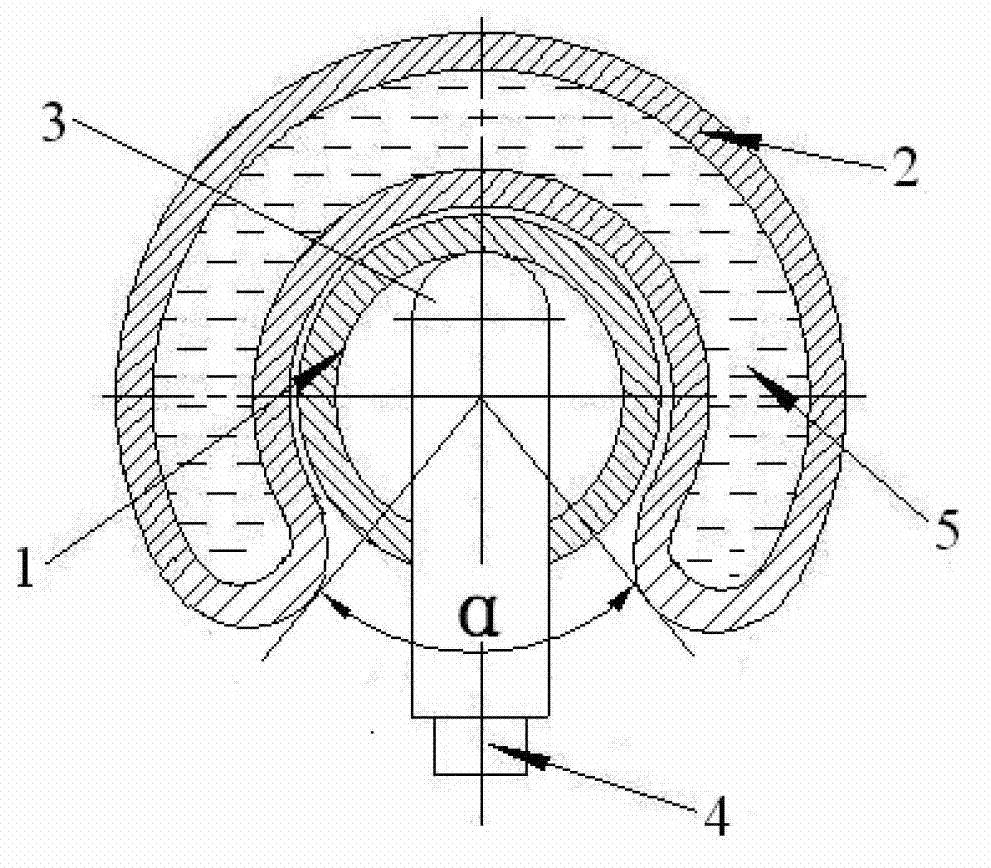

Large-diameter metal bar surface jet flow descaling system and method

ActiveCN102716922AThe descaling process is environmentally friendlyEnvironmentally friendly descaling processWork treatment devicesMetal rolling arrangementsJet flowSpray nozzle

The invention relates to a large-diameter metal bar surface jet flow descaling system and method; the large-diameter metal bar surface jet flow descaling system comprises at least one nozzle unit used for spraying mixed jet flow, and an actuating mechanism used for realizing helical motion of a large-diameter metal bar; and the large-diameter metal bar can performs rotary motion around the self axis while performing axial movement. The invention has the advantages that cold state surface descaling of the large-diameter metal bar is realized in a way of mixed jet flow; compared with the traditional descaling technology, the method provided by the invention the advantages that a more environmentally-friendly descaling technology is adopted, the production cost is low and stronger competitive advantages are achieved; due to the special arrangement way of nozzles and the special composite motion law of the bar, high-efficiency bar descaling can be realized in the state of fewer nozzles.

Owner:BAOSHAN IRON & STEEL CO LTD

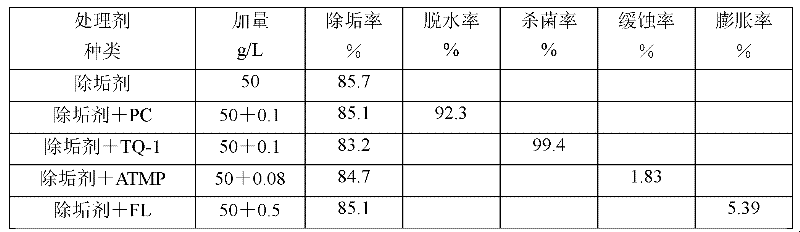

Scale remover used for cleaning hot-blast stove and boiler and accessories thereof, and cleaning method thereof

InactiveCN104293531ANo pollution in the processSolve corrosiveInorganic non-surface-active detergent compositionsCleaning using liquidsCleaning methodsSodium fluoride

The invention belongs to the technical field of a chemical descaling cleaning compound, and concretely relates to a scale remover used for cleaning a hot-blast stove and a boiler and accessories thereof, and a cleaning method thereof. The scale remover solves the technical problems that severe metal corrosion is generated when the current scale removers are used for cleaning the hot-blast stove and the boilers, secondary oxidation is easily generated, and metal surface fineness is poor. For solving the above technical problems, the invention provides the scale remover used for cleaning hot-blast stove and boiler and accessories thereof, the scale remover comprises the following raw materials by weight: 8-10% of hydrochloric acid, 1-6% of sodium fluoride, 1.5-3% of trisodium phosphate, 0.6% of corrosion inhibitor, 1.5-3% of osmotic agent and the balance of water. The scale remover has the advantages that descaling efficiency is high, no toxic and side effect is generated, no environmental pollution is generated on the waste after descaling, and a protection film is formed on the metal surface to prolong the equipment usage life.

Owner:范国臣

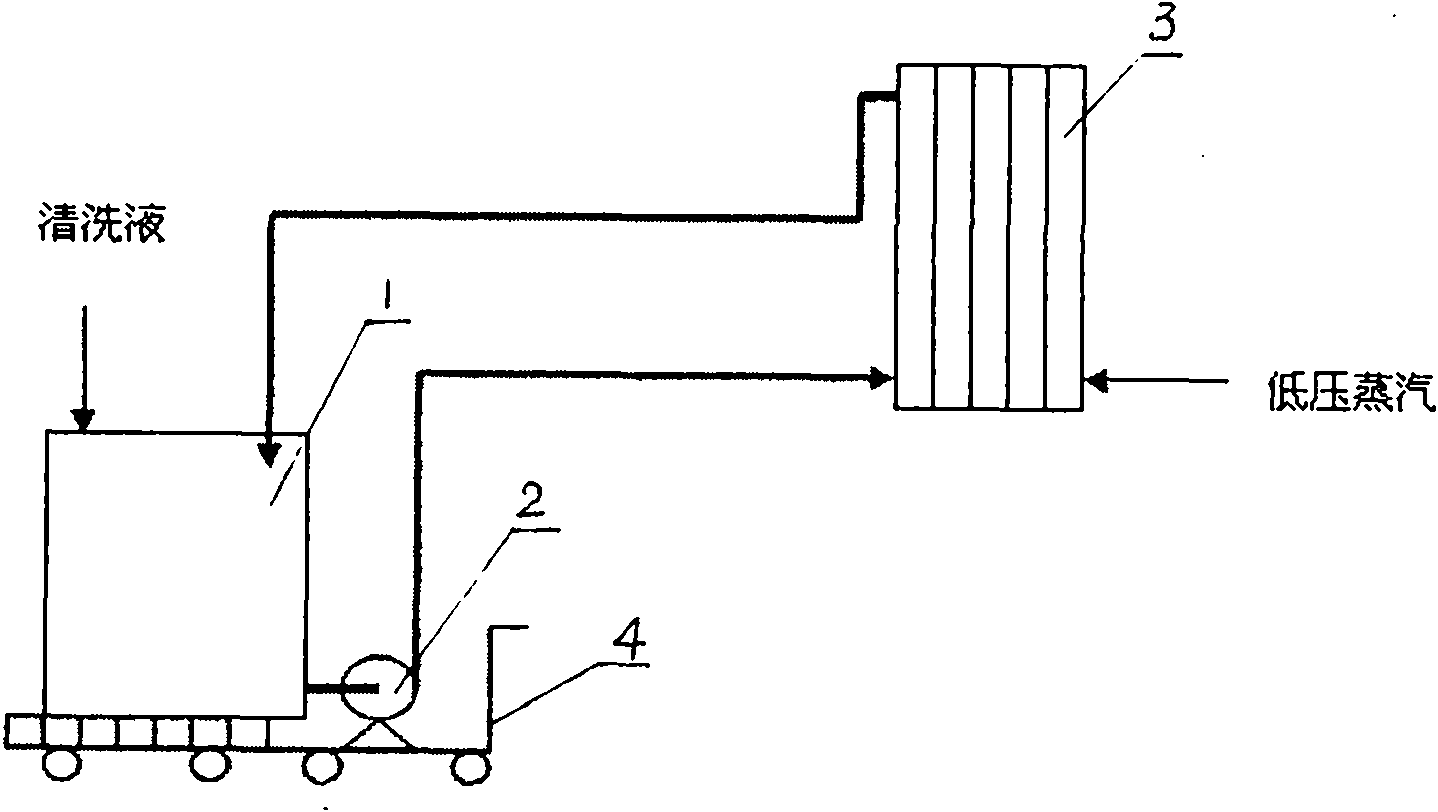

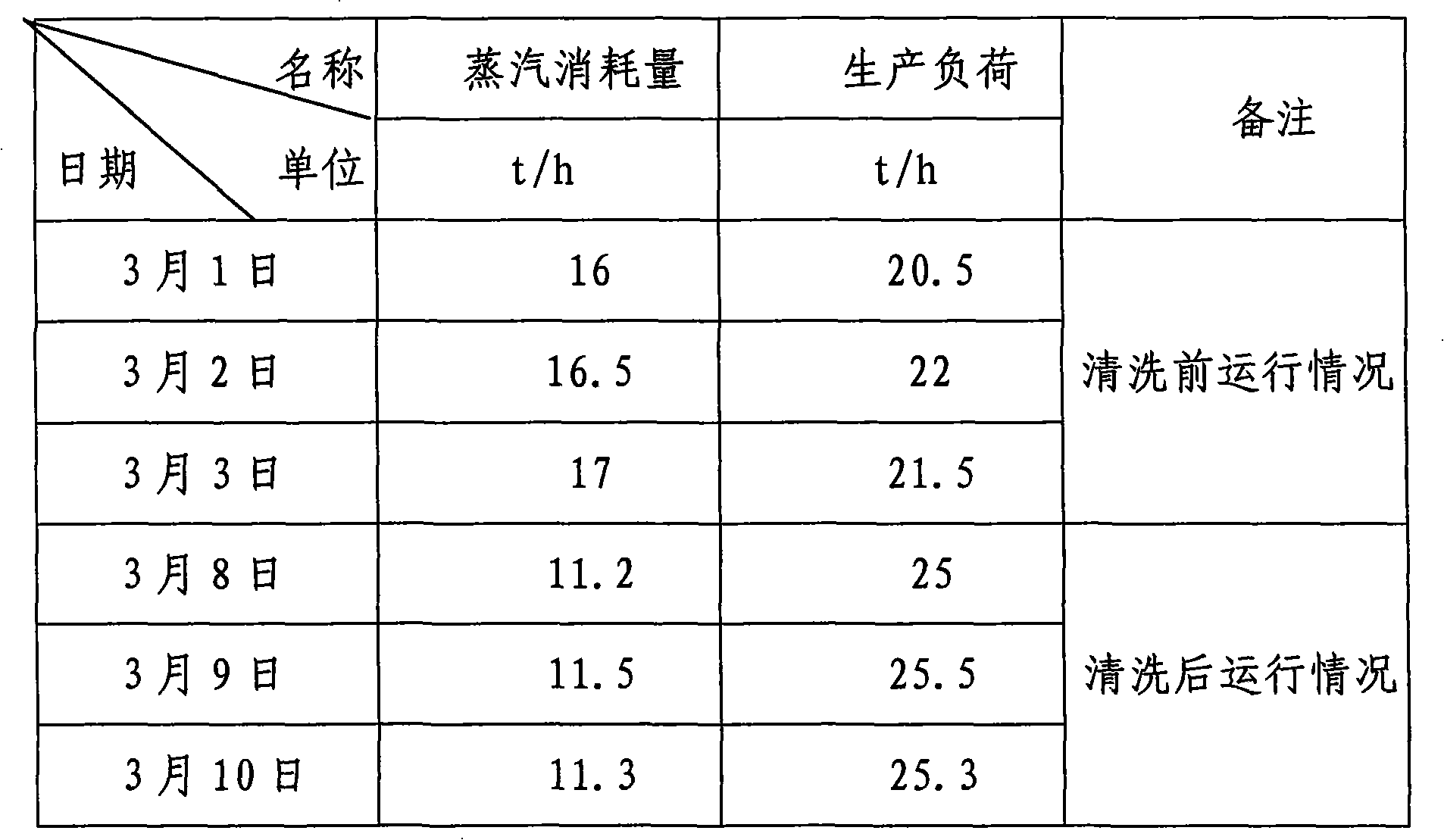

Method for clearing shell side scale of shell and tube heater in monoammonium phosphate production on line

The invention discloses a method for clearing shell side scale of a shell and tube heater in monoammonium phosphate production on line, which comprises: (1) preparing cleaning solution consisting of 20 to 40 percent of phosphoric acid (in form of P2O5), 30 to 40 percent of nitric acid, 60 to 98 percent of sulfuric acid and 10 to 15 percent of fluosilicic acid in a mass ratio of 5:3:1:1; (2) placing a container serving as a cleaning circulating tank and a conveying pump connected with a cleaning solution outlet pipe on a mobile cart, moving the mobile cart toward the shell and tube heater of which the scale is to be cleared, connecting the conveying pump with an acid inlet at the lower part of the shell side of the heater and connecting the acid outlet on the upper part of the shell side of the heater with the container by a conduit; and (3) starting the conveying pump during the periodical stop of the device, feeding the cleaning solution the shell side of the heater to clean the shell side of the heater circularly, and introducing low-pressure steam from the bottom of the heater for heating. In the method, the online scale clearing can be realized flexibly without detaching the heater and with small investment; the equipment configuration is simple; the scale are cleared obviously; and cleaning is performed once a year. The method is applicable for monoammonium phosphate manufacturers.

Owner:WENGFU (GRP) CO LTD

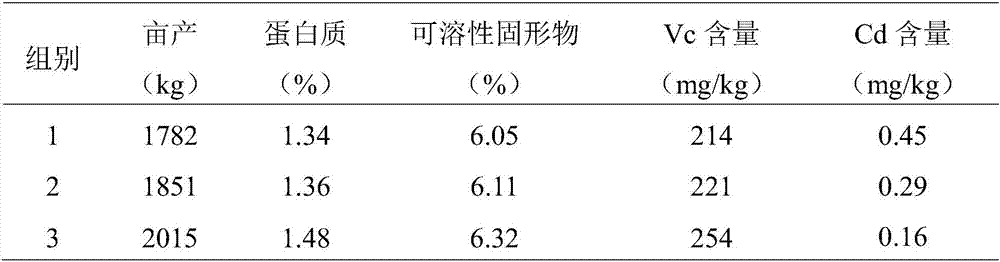

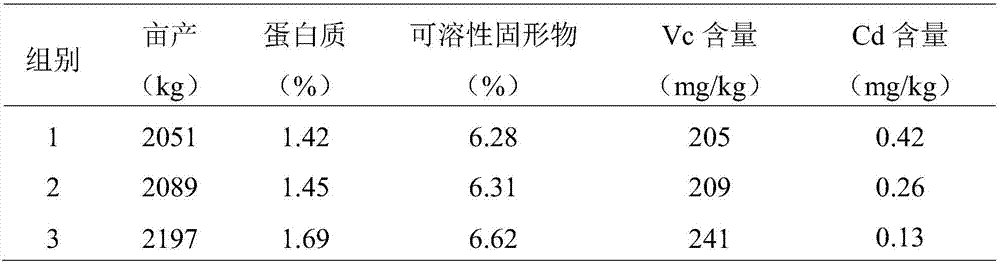

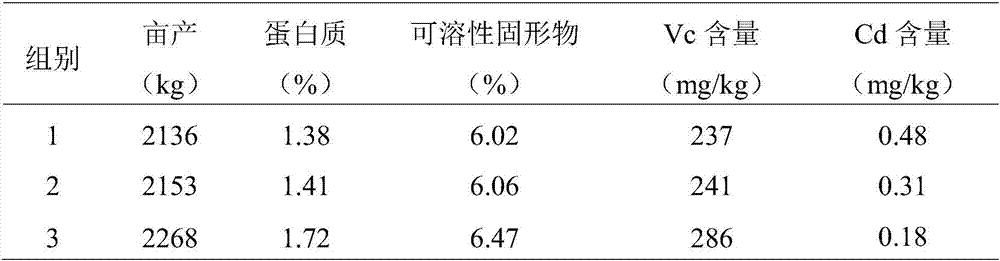

Soil heavy metal deactivator

ActiveCN107384433AReduced effectivenessReduced portabilityAgriculture tools and machinesOrganic fertilisersSodium metasilicateSoil heavy metals

The invention relates to a soil heavy metal pollution treatment technology, and concretely relates to a soil heavy metal deactivator, and a method using the soil heavy metal deactivator to deactivate and repair soil heavy metal pollution. The soil heavy metal deactivator comprises, by weight, 30 parts of peanut shells, 15 parts of red pine needles, 10 parts of sepiolite, 10 parts of fly ash, 5 parts of chitin, 3 parts of sodium metasilicate pentahydrate, 0.4 part of sodium tripolyphosphate, 0.1 part of choline chloride, 1.2 parts of a microbial inoculum and 0.05 part of quicklime. The soil heavy metal deactivator can effectively reduce the heavy metal content of plants to achieve the deactivation and repairing purposes.

Owner:南京宁粮生物工程有限公司

Cleaning agent of automobile cooling system and preparation method thereof

The invention belongs to the technical field of cleaning an automobile cooling system, and particularly discloses a cleaning agent of the automobile cooling system and a preparation method thereof. The cleaning agent of the automobile cooling system mainly comprises the following components in percentage by weight: 10 to 12 percent of glycollic acid, 5 to 8 percent of sulfonic acid, 3 to 6 percent of acid cleaning inhibitor and the balance of water. The preparation method comprises the following steps of: (1) taking water, adding the sulfonic acid and the glycollic acid into the water, and then uniformly stirring the mixture; and (2) adding the acid cleaning inhibitor into the mixture obtained in the step (1), and then uniformly stirring the latter mixture to obtain a finished product. The cleaning agent is subjected to a large number of scientific experiments and internal practical application for years to prove that the cleaning agent not only has high cleaning and pollutant removal effects, but also overcomes the defect of corrosion.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

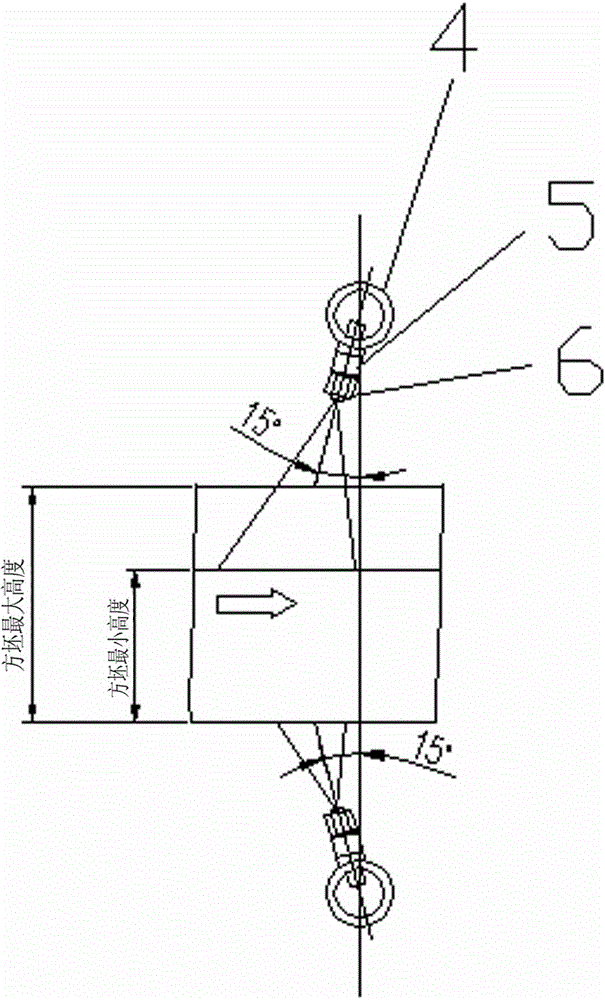

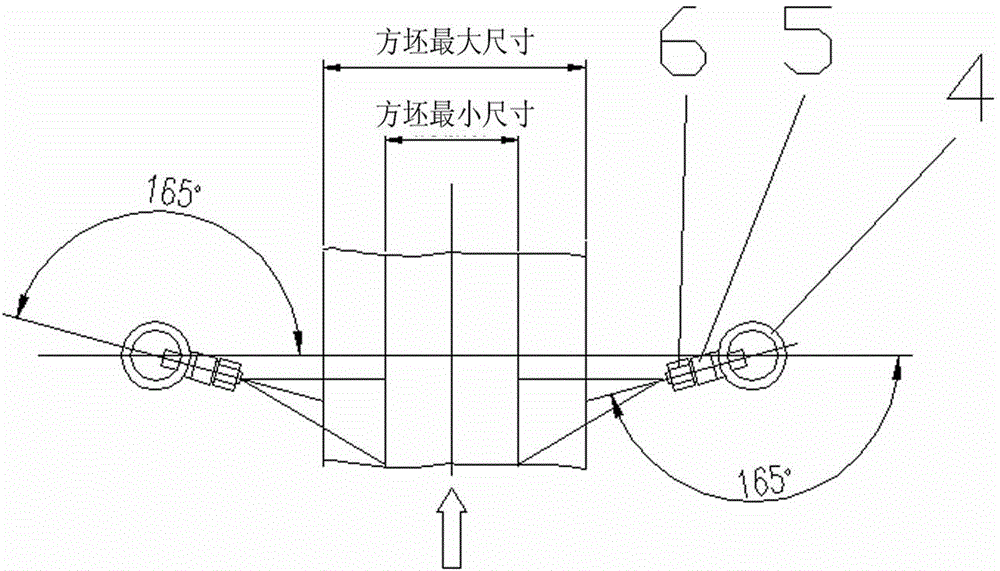

Efficient descaling method for square billets

InactiveCN104801555AEfficient descalingFast descalingWork treatment devicesMetal rolling arrangementsRing deviceWater source

The invention relates to an efficient descaling method for square billets. The efficient descaling method comprises a descaling ring device selective adaptability method and a descaling nozzle selective adaptability method. According to the efficient descaling method, the problem that the conventional square billet scaling ring is incapable of descaling thoroughly can be solved; meanwhile, the problems that nozzles on two sides idly spray water and the water source is wasted can also be avoided; efficient descaling can be conducted on all different-sized billets. The efficient descaling method is convenient to use, thorough in descaling, energy-saving, environmental-friendly and the like.

Owner:SGIS SONGSHAN CO LTD

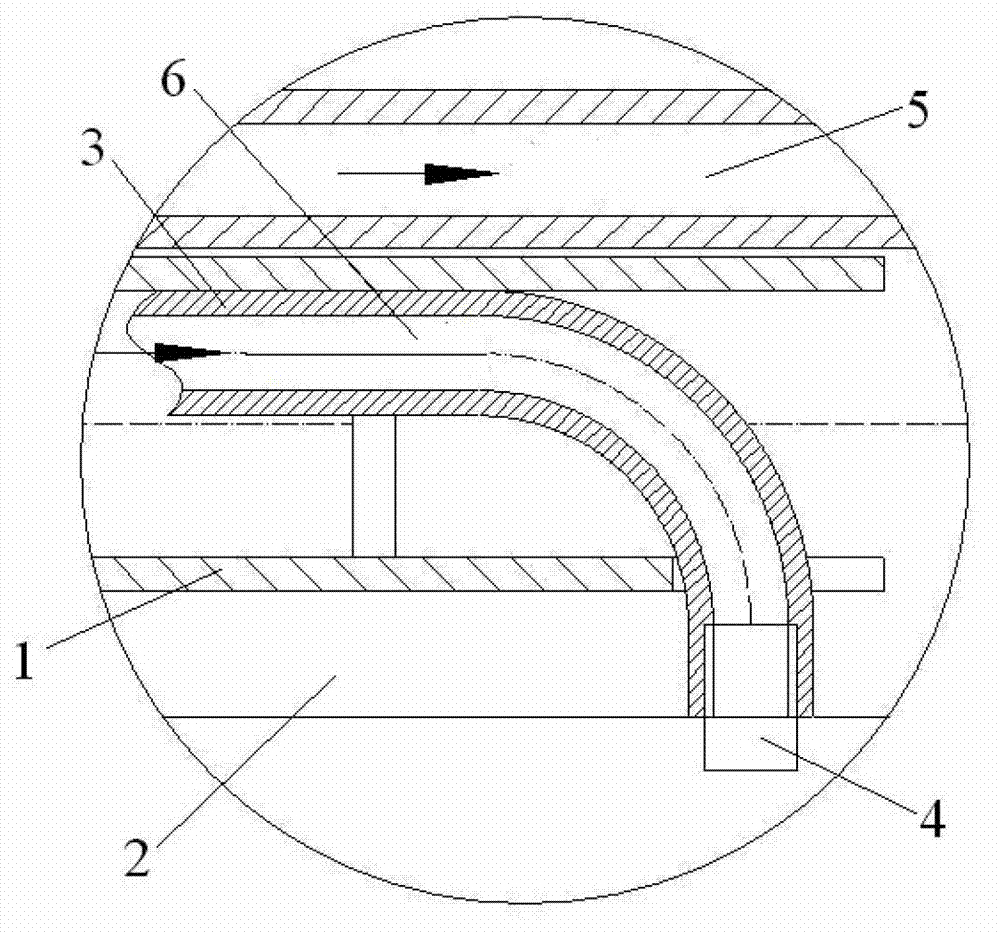

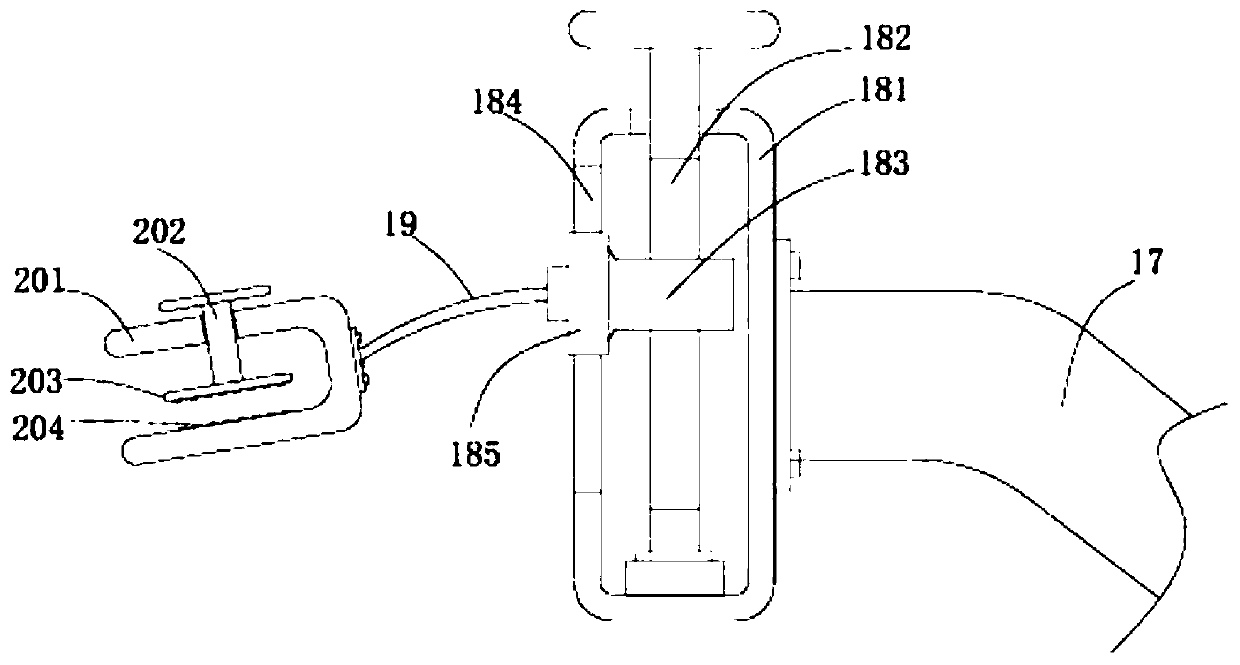

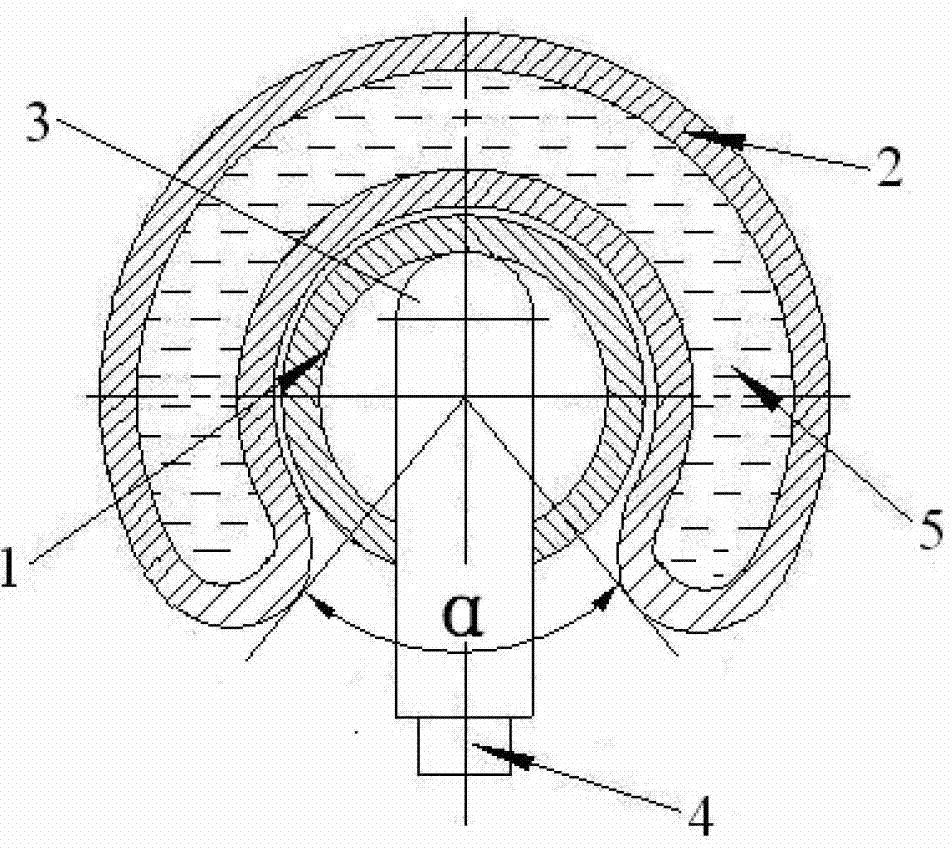

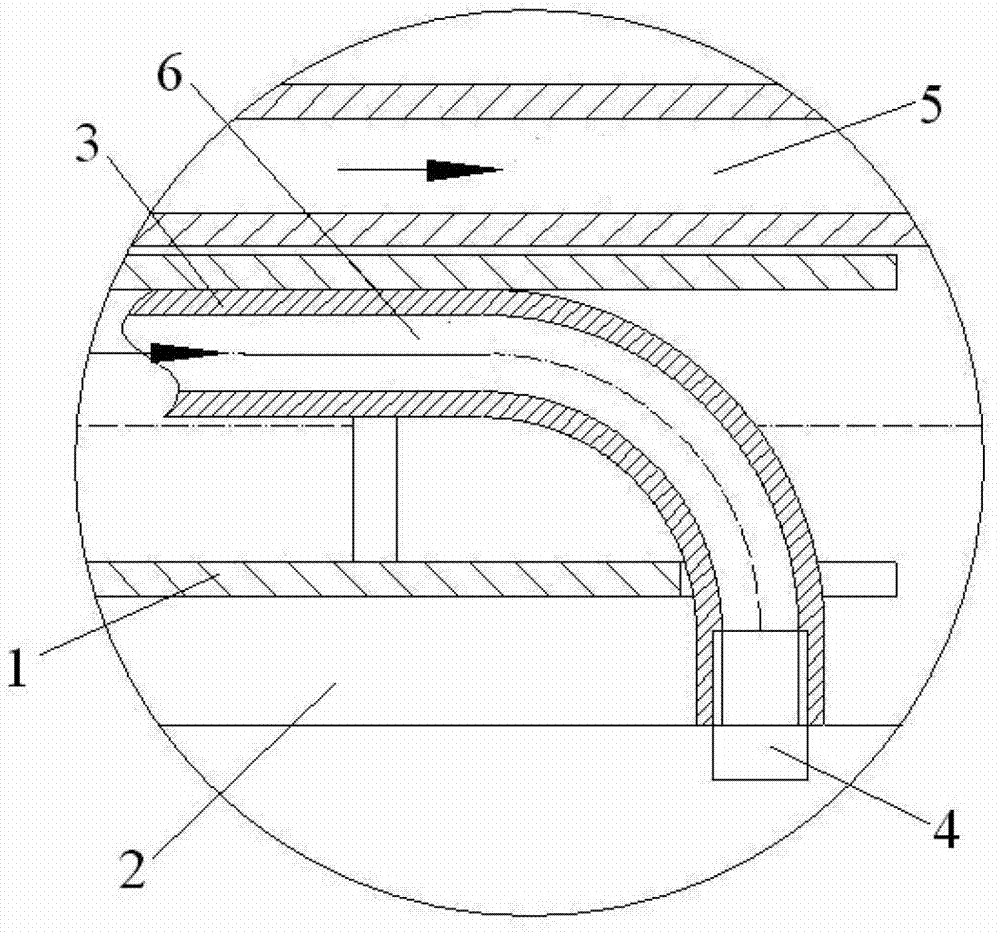

Scale removing device for heat exchange pipe

ActiveCN102814309AImprove work efficiencyIncrease the heat exchange areaHollow article cleaningSpray nozzleEngineering

The invention discloses a scale removing device for a heat exchange pipe. The scale removing device comprises a cooling beam (2), a spray gun (3) and a spray nozzle (4), wherein the cross section of the cooling beam (2) is of a C-shaped tubular structure; the spray gun (3) is arranged in an internal chamber of the cooling beam (2) through a spray gun sleeve (1); and the spray nozzle (4) extends out of the cooling beam (2) through a C-shaped gap. According to the technical scheme, the spray gun can rotate in the cooling beam, and also can be moved by stepping; spraying particular mediums are sprayed on a heat exchanger full of dirt through the spray gun at a high speed for removing the scale, so as to achieve the purpose of efficiently removing the scale and improving the working efficiency of the heat exchanger, and as a result, the purpose of saving energy and reducing the consumption can be achieved; the spray gun is cooled through cooling water in the cooling beam, therefore, the problem that the spray gun cannot work with high efficiency due to excessive heat during running in a high temperature condition can be avoided.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

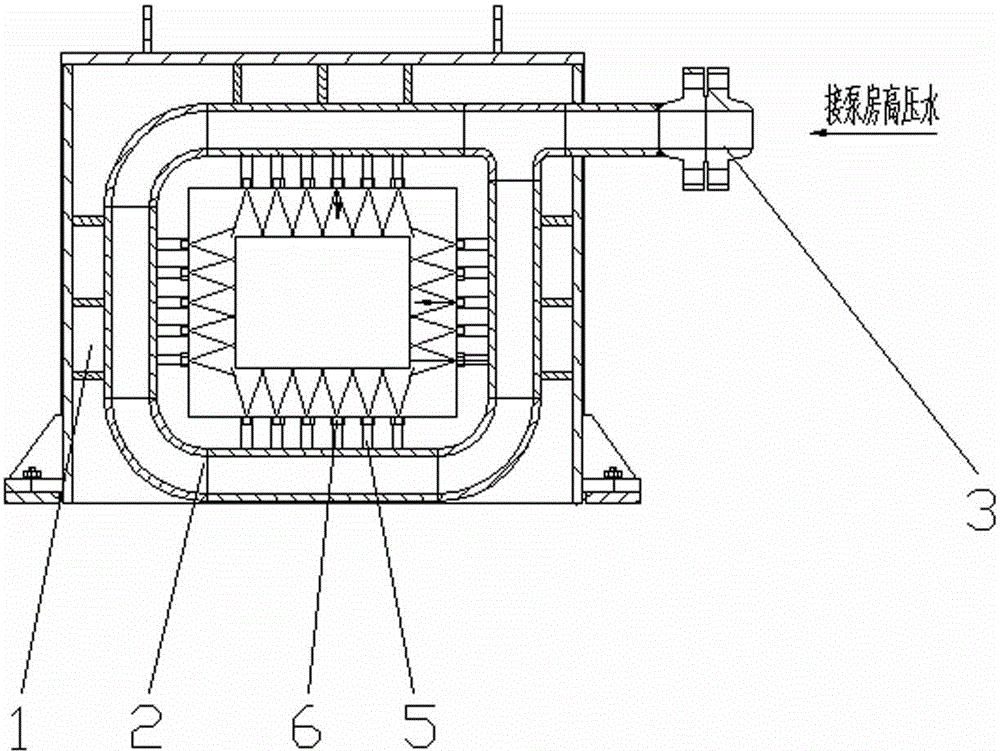

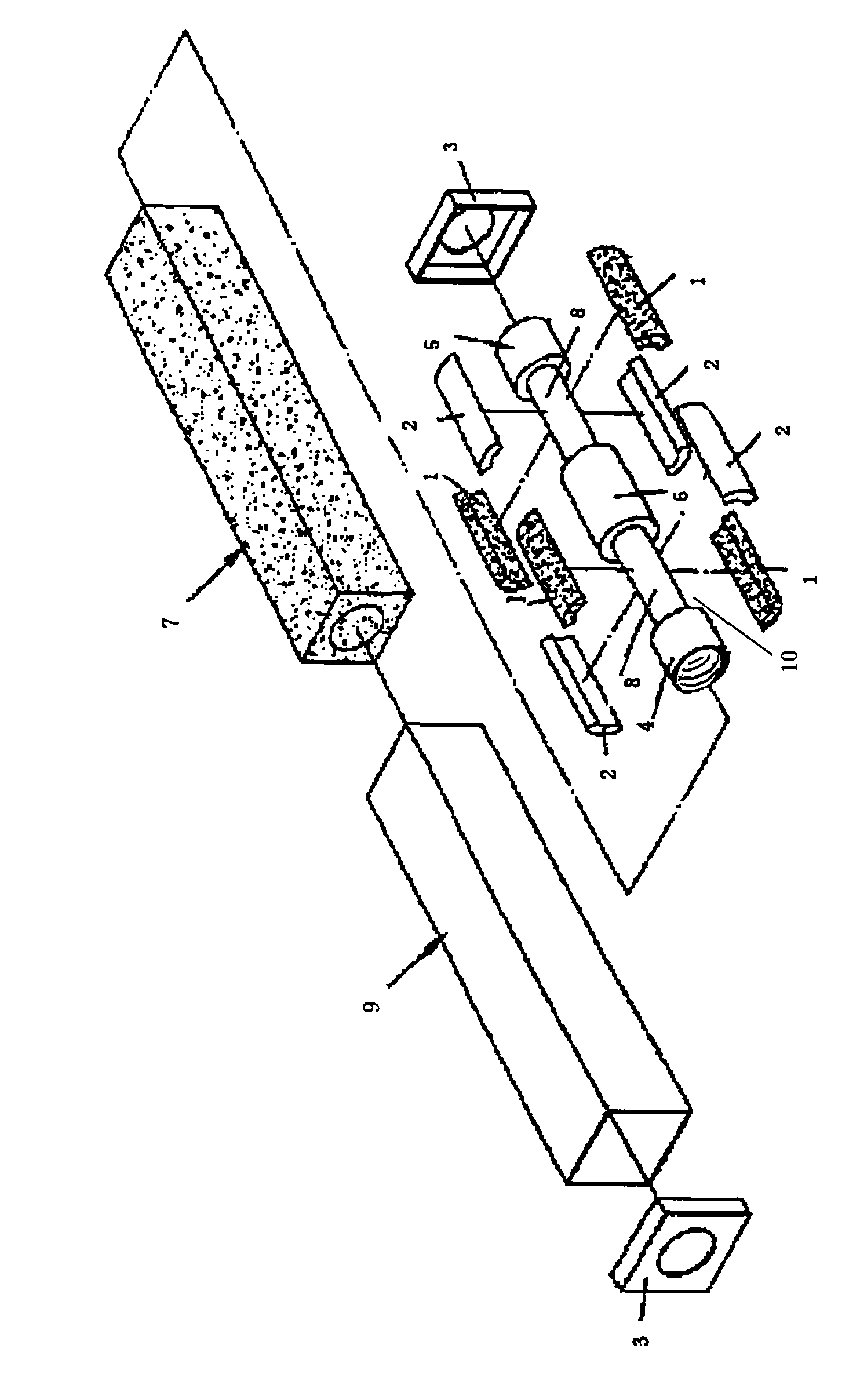

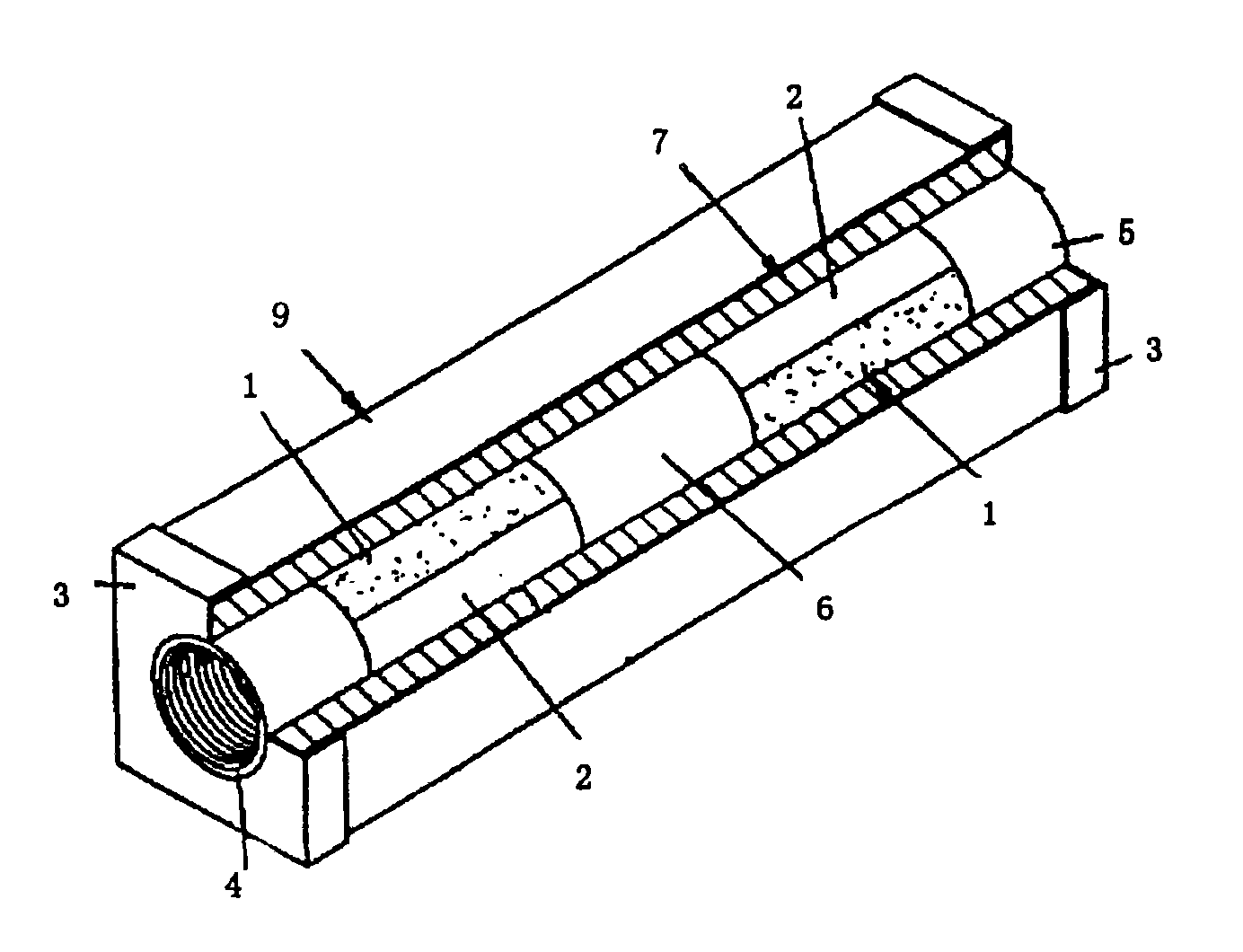

Strong magnetic and high-efficiency antiscaling and descaling device

InactiveCN101638271AGuaranteed uptimeImprove heat exchange efficiencyScale removal and water softeningMagnetic tension forceCooling tower

The invention provides a strong magnetic and high-efficiency antiscaling and descaling device and relates to an environment-friendly, energy-saving and safe device for antiscaling and descaling by using super-strong magnetic force. The device is applicable to heat exchange equipment, such as boilers, cooling towers, evaporators and condensers for matching use, and has advantages of being capable of avoiding formation of scale deposit and removing the original scale deposit, greatly improving heat exchange efficiency of the heat exchange equipment, saving energy and ensuring safe operation of boilers. The device comprises an outer shell and an inner tube, wherein, the inner tube is arranged inside the outer shell, internally provided with at least one plunger tube to form at least two magnetized descaling part tubes, and the plunger tube is intercommunicated with the magnetized descaling part tubes; and at least two magnetized units which are attached and arranged at outer edges of themagnetized descaling part tubes and each one consists of two strong-magnetic force permanent magnets with the N poles opposite to the S poles, wherein, a non-magnetic metallic body is arranged betweenthe two strong-magnetic force permanent magnets to form magnetized descaling parts, and the strong-magnetic force permanent magnets of the two magnetized descaling parts of two adjacent plunger tubesare arranged in a vertical and interlacing mode.

Owner:JIANGSU NENGRUI ENVIRONMENTAL ENERGY SAVING TECH CO LTD

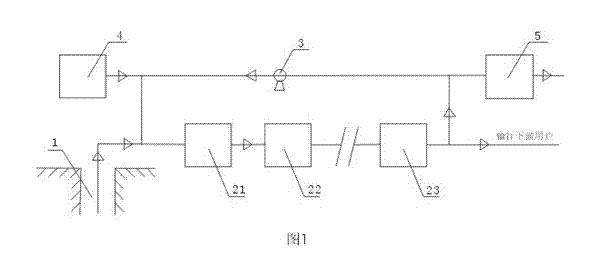

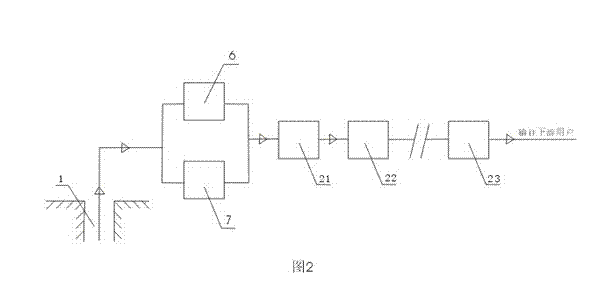

Methods for processing and preventing water scales in geothermal system

InactiveCN103159332AHigh in mineralsForward-lookingWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentChemical treatmentIon exchange

The invention relates to methods for processing and preventing water scales in a geothermal system. The methods for processing and preventing the water scales in the geothermal system are characterized by aiming at solving the problems that in the geothermal system, mineral content is high and water scales are easily formed. The methods for processing and preventing the water scales in the geothermal system are capable of comprehensively solving the problem of the water scales in the geothermal system. The method for processing the water scales in the geothermal system comprises a mechanical method and a chemical method. In the chemical method for processing the water scales, not only are the water scales removed, but also a chemical compound obtained by reaction of an anti-scaling agent and the water scales is further recovered and processed. The water scales are changed into a product. The number of product chains of the system is increased. Full utilization of the materials is achieved. The method for preventing the water scales in the geothermal system comprises addition of water softener and an ion-exchange resin method. In the ion-exchange resin method, adsorbed ions in resin can be eluted through low-price regeneration liquid, and regeneration and repeated utilization of ion-exchange resin are achieved, wherein the adsorbed ions are low in price. Therefore, cost is reduced, and environment is protected. The methods for processing and preventing the water scales in the geothermal system are simple in process, economical in reagent, multiple in alternative scheme, capable of effectively solving and preventing the problem of the water scales in the geothermal system.

Owner:徐毅

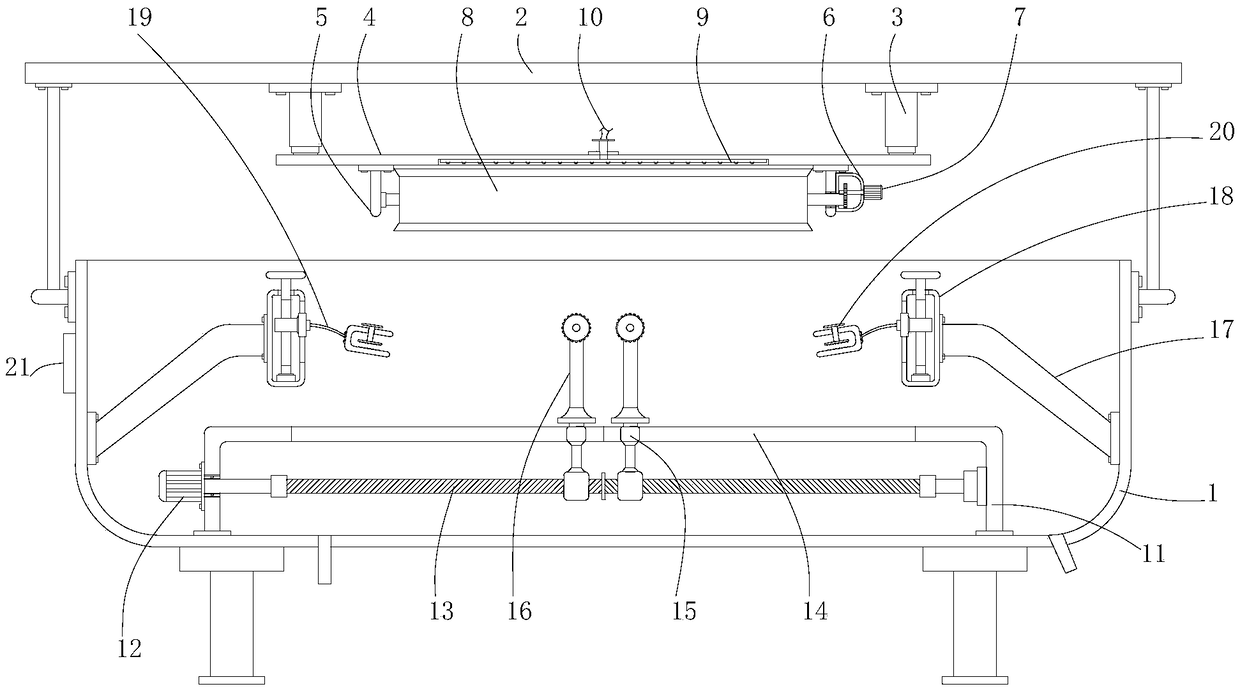

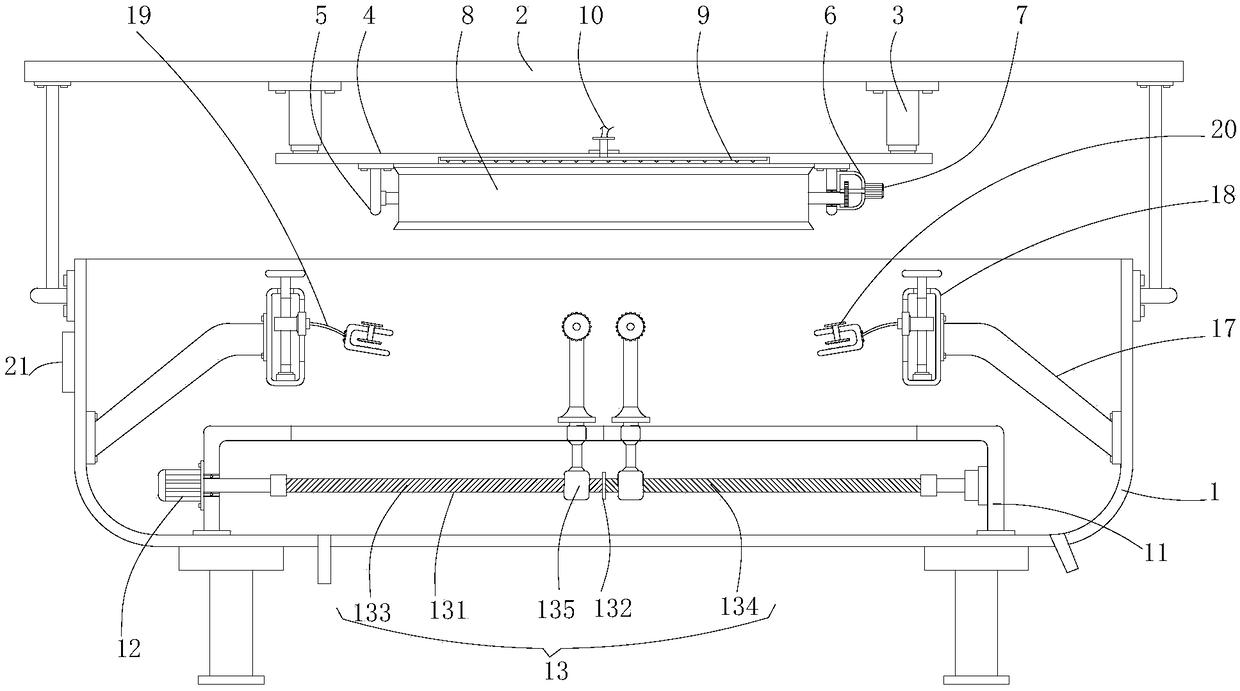

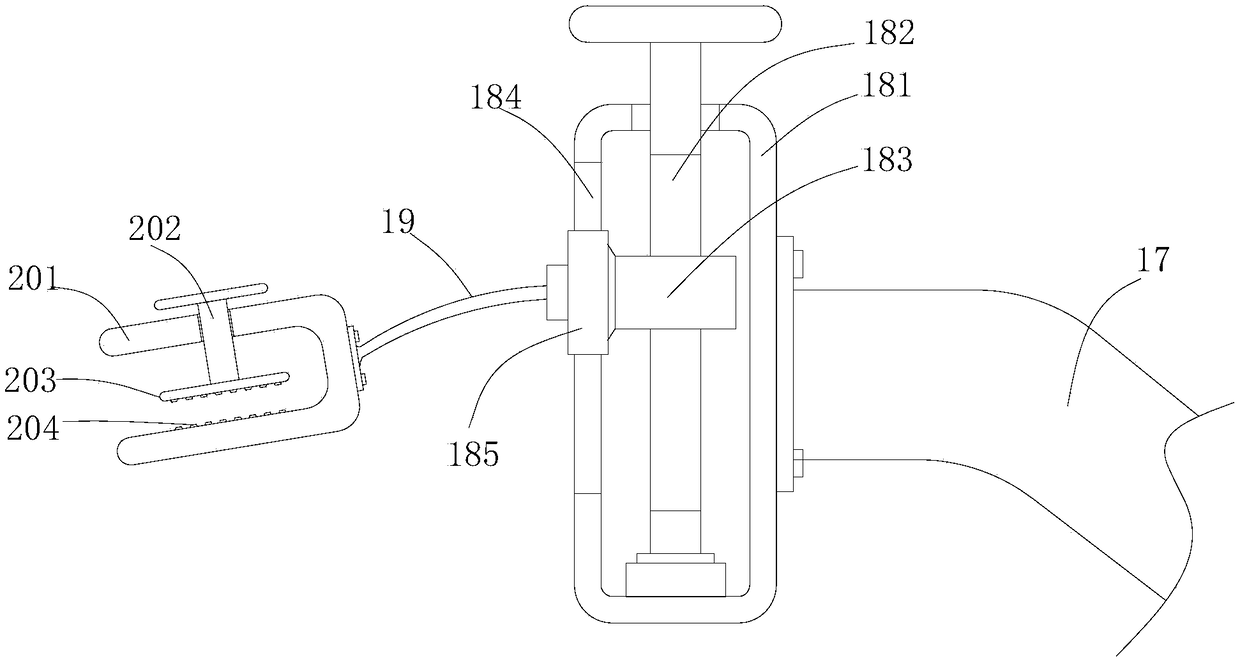

Descaling device and method for square mahjong mat

InactiveCN111468448AAvoid damageIncreased frictional contactCleaning using toolsCleaning using liquidsElectric machineDrive motor

The invention relates to the technical field of treatment of household articles, and discloses a descaling device and method for a square mahjong mat. The descaling device comprises a machine body, asupport frame, two electric lifting rods, a bearing plate, a fixing frame, a transmission set, a driving motor, a brushing roller set, a multi-way spray pipe, a water guide joint, an inner case, a low-speed motor, a transverse adjusting mechanism, a transverse chute, two transverse connecting blocks, two contact mechanisms, four fixing pieces, four vertical adjusting mechanisms, four connecting elastic sheets, four clamping mechanisms, a control panel, two auxiliary sliding chutes and four sliding balls, wherein the support frame is arranged right above the machine body, the two electric lifting rods are symmetrically arranged at the top of the inner side of the support frame, and the bearing plate is fixedly connected to the tail ends of the two electric lifting rods. According to the descaling device for the square mahjong mat, the gaps between mahjong mat blocks are effectively descaled, so that the problem that a traditional mat cleaning device cannot effectively remove the dirt inthe gaps between the mat blocks is solved.

Owner:桂兆林

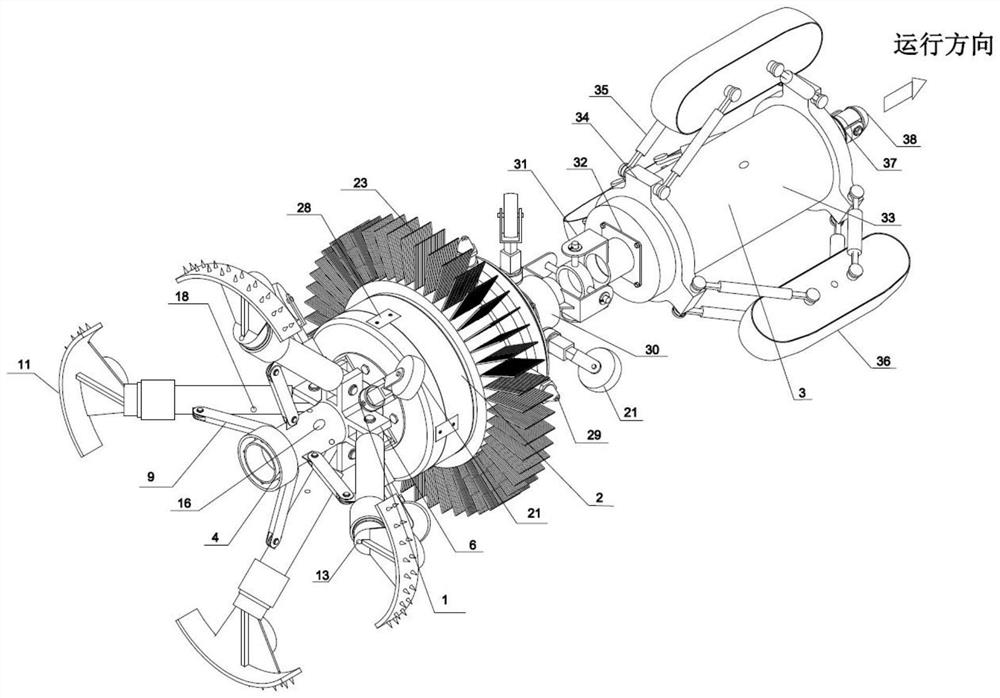

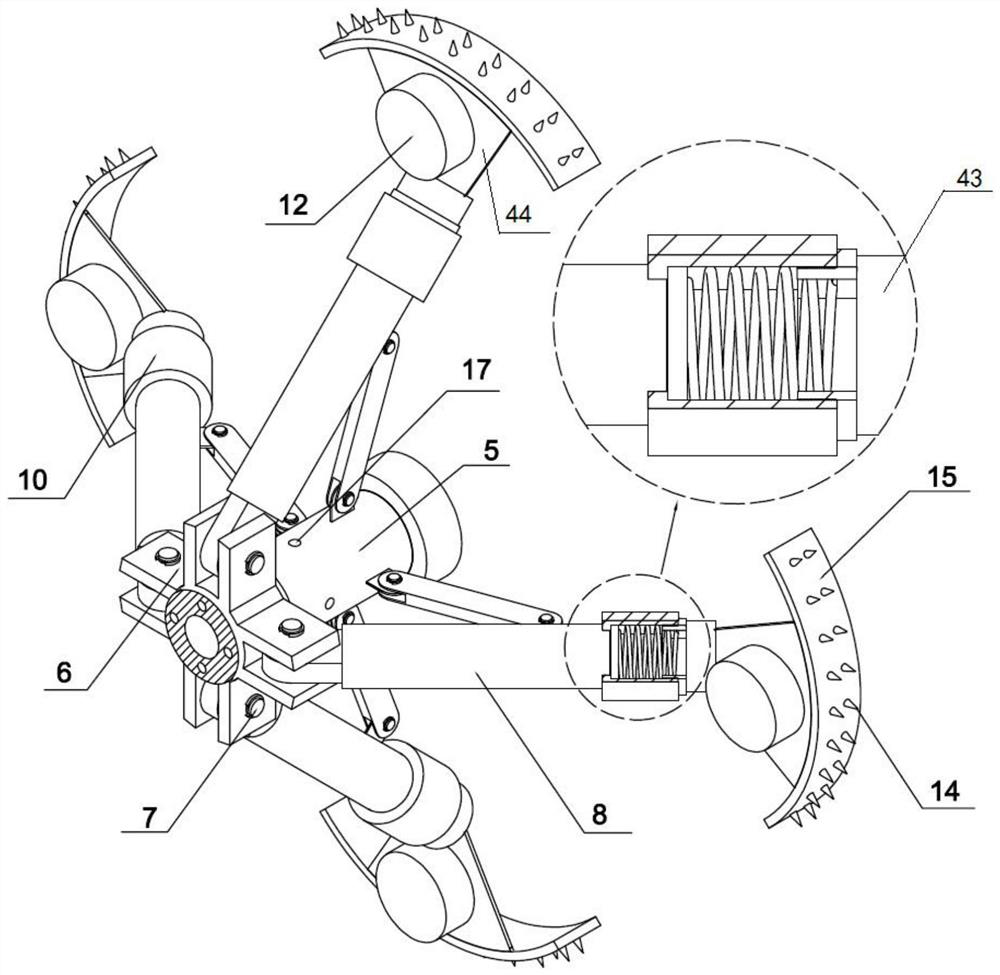

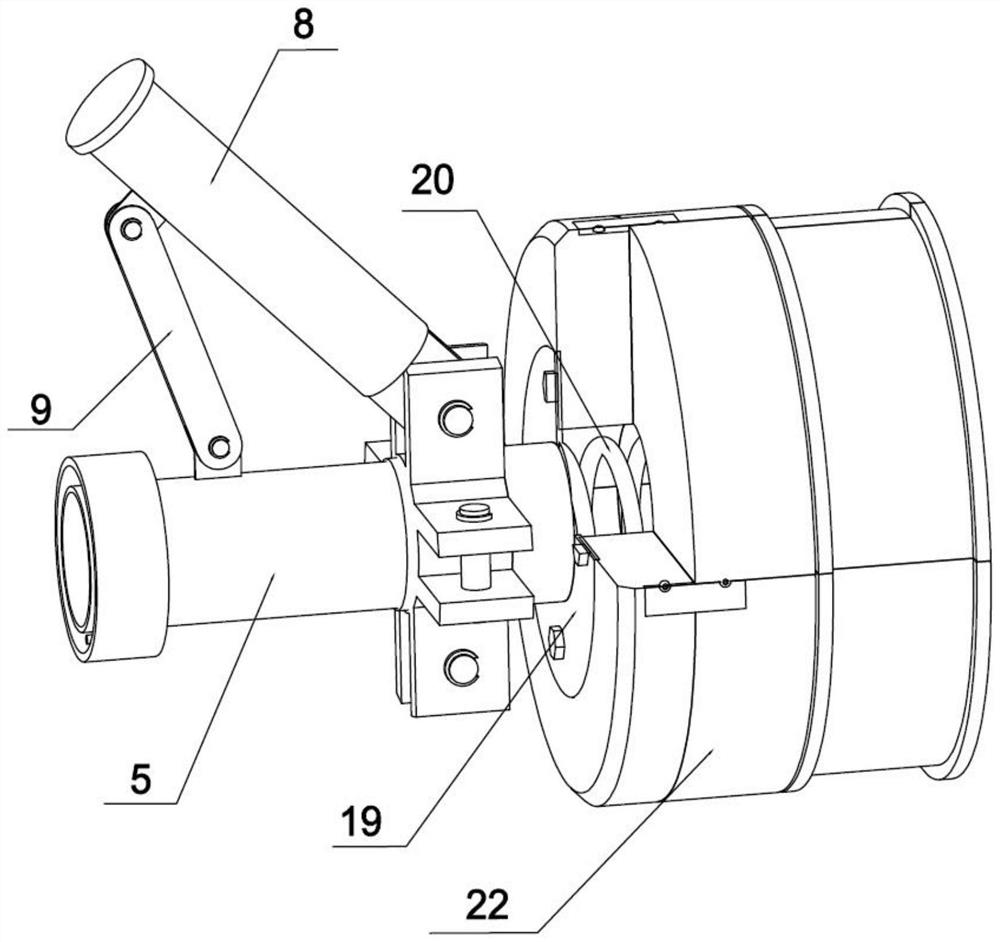

In-pipe combined type visual automatic descaling device and descaling method

ActiveCN112893346AChanges in scale structureGuaranteed efficiencyHollow article cleaningCleaning using liquidsElectric machineryJet flow

The invention discloses an in-pipe combined type visual automatic descaling device which comprises an ultrasonic descaling assembly, a mechanical descaling assembly and a power assembly. The ultrasonic descaling assembly comprises an inner shaft, a four-way connector, a claw head arm rod, an arm rod supporting rod and an ultrasonic descaling claw head. The mechanical descaling assembly comprises a connecting ring, a supporting wheel, a device cavity, a wheel brush, an outer rotor motor, a jet flow component and a connecting disc. The power assembly is fixedly installed at the side, away from the jet flow component, of the connecting disc, and an infrared camera is installed at the other end of the power assembly. The invention further discloses an in-pipe combined type visual automatic descaling method. According to the in-pipe combined type visual automatic descaling device and the descaling method provided by the invention, pipelines with different sizes and in various scaling forms can be cleaned stably and efficiently on the premise that the pipelines are not damaged, and the descaling effect is visualized.

Owner:SOUTHWEST PETROLEUM UNIV +2

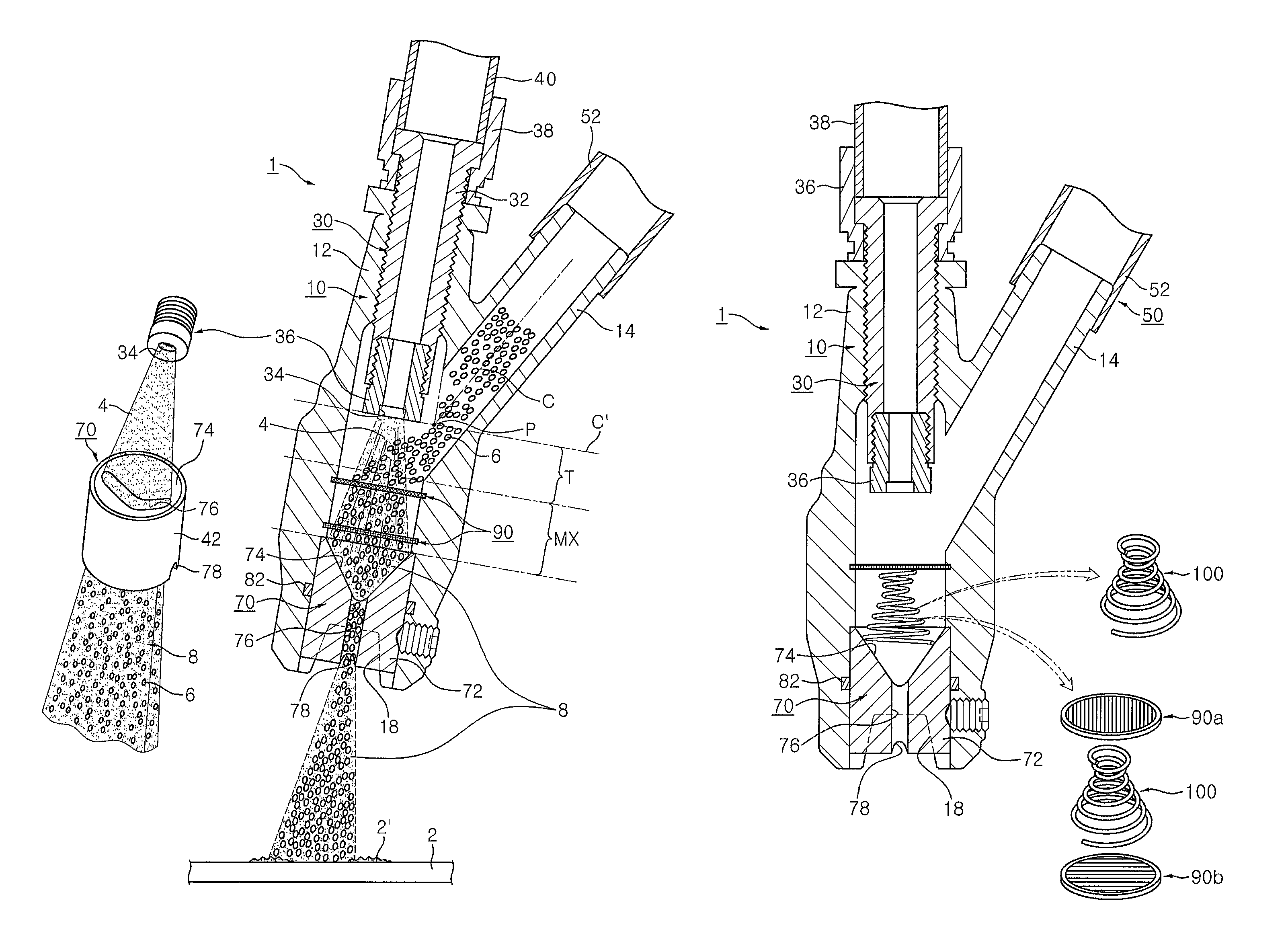

Descaling apparatus

ActiveUS9321147B2Environmental efficiencyMore environmentally friendlyBlast gunsWork treatment devicesSlurryEngineering

Provided is a descaling device for effectively removing scale formed on a surface of a hot-rolled steel strip (steel sheet). The descaling device, for example, may be configured to include: a device housing disposed in a feed path of a hot-rolled steel strip, a high-pressure fluid supply unit provided to supply a high-pressure fluid to the device housing, an abrasive input unit provided to introduce an abrasive to the device housing, and an abrasive slurry spraying unit provided in the device housing to spray an abrasive slurry of the high-pressure fluid and the abrasive mixed inside the device housing on the steel strip.

Owner:POHANG IRON & STEEL CO LTD

Pure natural incense nutritious liquid shampoo of dahurian angelica

InactiveCN1732892ACause some damagesIncrease aromaCosmetic preparationsHair cosmeticsMonkshoodsVitamin b6

The invention discloses a pure natural incense nutritious liquid shampoo of dahurian angelica, which comprises the following constituents (by weight proportions), Chinese honey locust powder 30-50 parts, root of Dahurain angelica 10-15 parts, peppermint 6-12 parts, monkshood 10-15 parts, Chinese dittany bark 10-15 parts, bisabolol 6-12 parts, and olive oil 20-30 parts, phosphatidy lcholine 3-5 parts, vitamin B6 0.5-0.8 part, potassium sorbate 3-5 part, vegetation emulsifying agent 20-50 parts, perfume compound 0.1-0.8 part, and humectant 0.3-0.5 part.

Owner:宋秀华

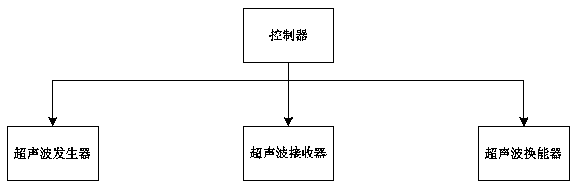

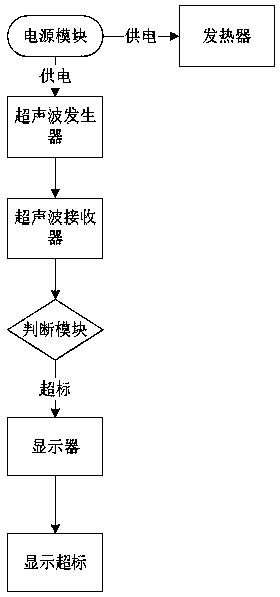

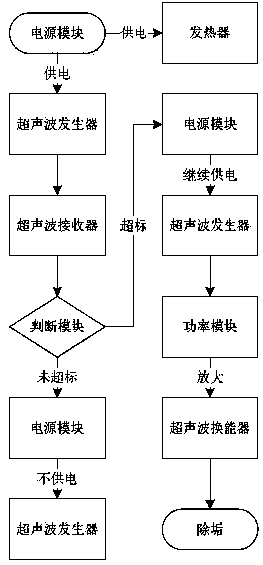

Ultrasonic electric kettle

InactiveCN108030389AEasy to operateImprove work efficiencyWater-boiling vesselsElectricityWater quality

The invention provides an ultrasonic electric kettle. The ultrasonic electric kettle includes a kettle lid, a kettle body, a base and a heating device; the electric kettle is also provided with an ultrasonic water quality detection and descaling device, and the ultrasonic water quality detection and descaling device includes an ultrasonic wave generator, an ultrasonic wave receiver, an ultrasonictransducer and a controller. The controller is connected with the ultrasonic wave generator, the ultrasonic wave receiver and the ultrasonic transducer. The ultrasonic electric kettle is easy to operate, the work efficiency of the ultrasonic transducer is improved, the electric energy is saved, the descaling effect is more effective, harmful substances in water are volatilized, and the improvementof the water quality is facilitated.

Owner:东莞市极酷机电科技有限公司

Descaling and corrosion inhibiting composition

ActiveUS20060142170A1Efficient descalingHighly effectiveSpecific water treatment objectivesHollow article cleaningProcess equipmentAcridine orange

The present invention is directed to a composition, and a process employing same, for descaling, cleaning and inhibiting the corrosion of process equipment made of steel by including an inhibitory effective amount of acridine orange in the composition.

Owner:SAUDI ARABIAN OIL CO

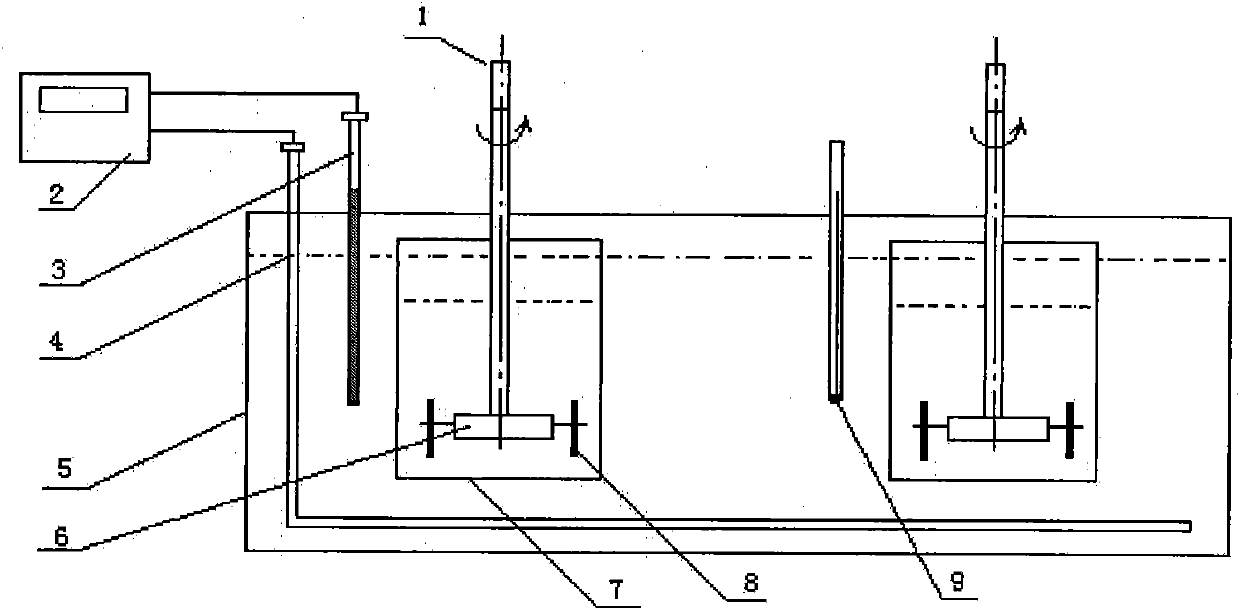

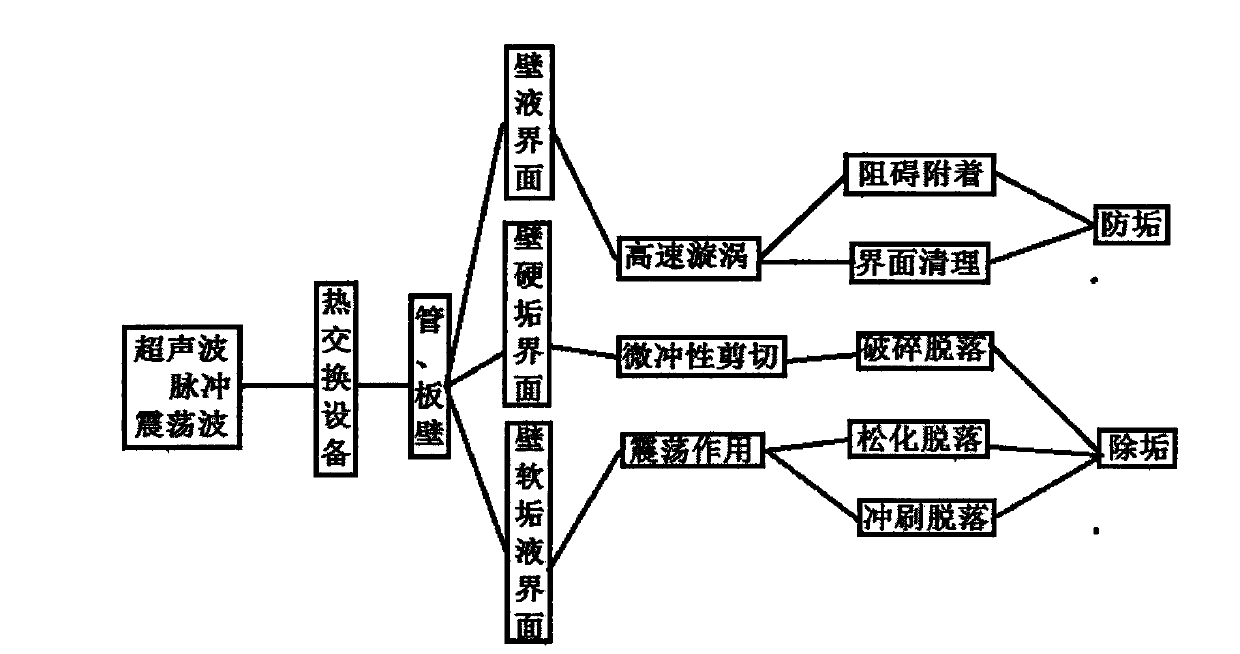

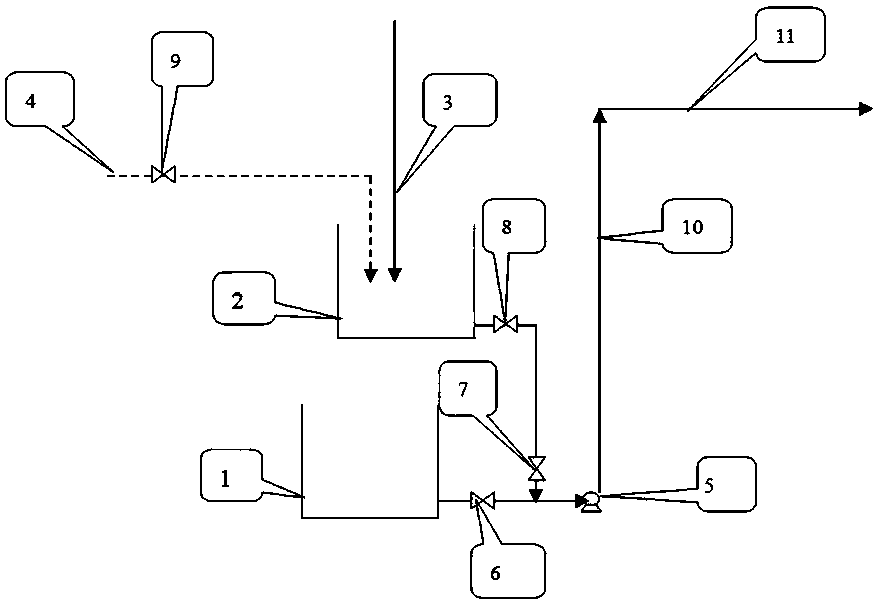

Ultrasonic on-line anti-scaling and descaling system for heat-exchange device

InactiveCN102814299AEffective anti-foulingEfficient descalingCleaning using liquidsElectricityUltrasonic attenuation

The invention relates to an ultrasonic on-line anti-scaling and descaling system for a heat-exchange device. The ultrasonic on-line anti-scaling and descaling system for the heat-exchange device comprises an ultrasonic sounding unit and an energy converter electrically connected with the ultrasonic sounding unit. The ultrasonic sounding unit comprises an adjusting and controlling unit. The adjusting and controlling unit performs directional design and adjusting on ultrasonic acoustic parameters according to ultrasonic attenuation information inside a pipeline which is fed back through an ultrasonic signal feedback unit. Compared with the prior art, the ultrasonic on-line anti-scaling and descaling system can perform adaptive adjustment on the ultrasonic acoustic parameters according to different application environments, so that effective and sufficient antiscale and descaling can be performed under different pipeline environments of the heat-exchange devices of different types.

Owner:安徽省科捷能源科技有限公司

Safe and efficient boiler

InactiveCN103727515AEfficient descalingIncrease the heating areaSteam generation heating methodsBoiler cleaning apparatusPush and pullVaporization

The invention relates to a safe and efficient boiler which comprises a boiler body and a water inlet nozzle, a steam outlet pipe. A boiler heating wire is arranged in the boiler body, a water steam channel is further arranged in the boiler body, and a protrusion is arranged on the lateral wall of the water steam channel; a water dividing sheet is further arranged in the water steam channel and located below the water inlet nozzle; a containing cavity is formed in the lower portion of the water steam channel, a water steam separating pipe is arranged in the containing cavity, a bottom ring is arranged at the bottom end of the water steam separating pipe, and a water containing cavity is defined by the bottom ring, the lateral wall of the containing cavity and the lateral wall of the water steam separating pipe; a radial inserting cavity intersecting with the water steam channel is formed below the containing cavity, the inserting cavity is located above a steam outlet pipe, a switching steam rod is inserted into the inserting cavity, and the bottom ring of the water steam separating pipe is erected on the switching steam rod; a radial through steam hole is formed in the switching steam rod, and the switching steam rod can be pushed and pulled to enable the steam hole to be communicated with the water steam separating pipe. When the safe and efficient boiler is used, the vaporization amount is large, and the safe and efficient boiler can be safely used.

Owner:陈春曦

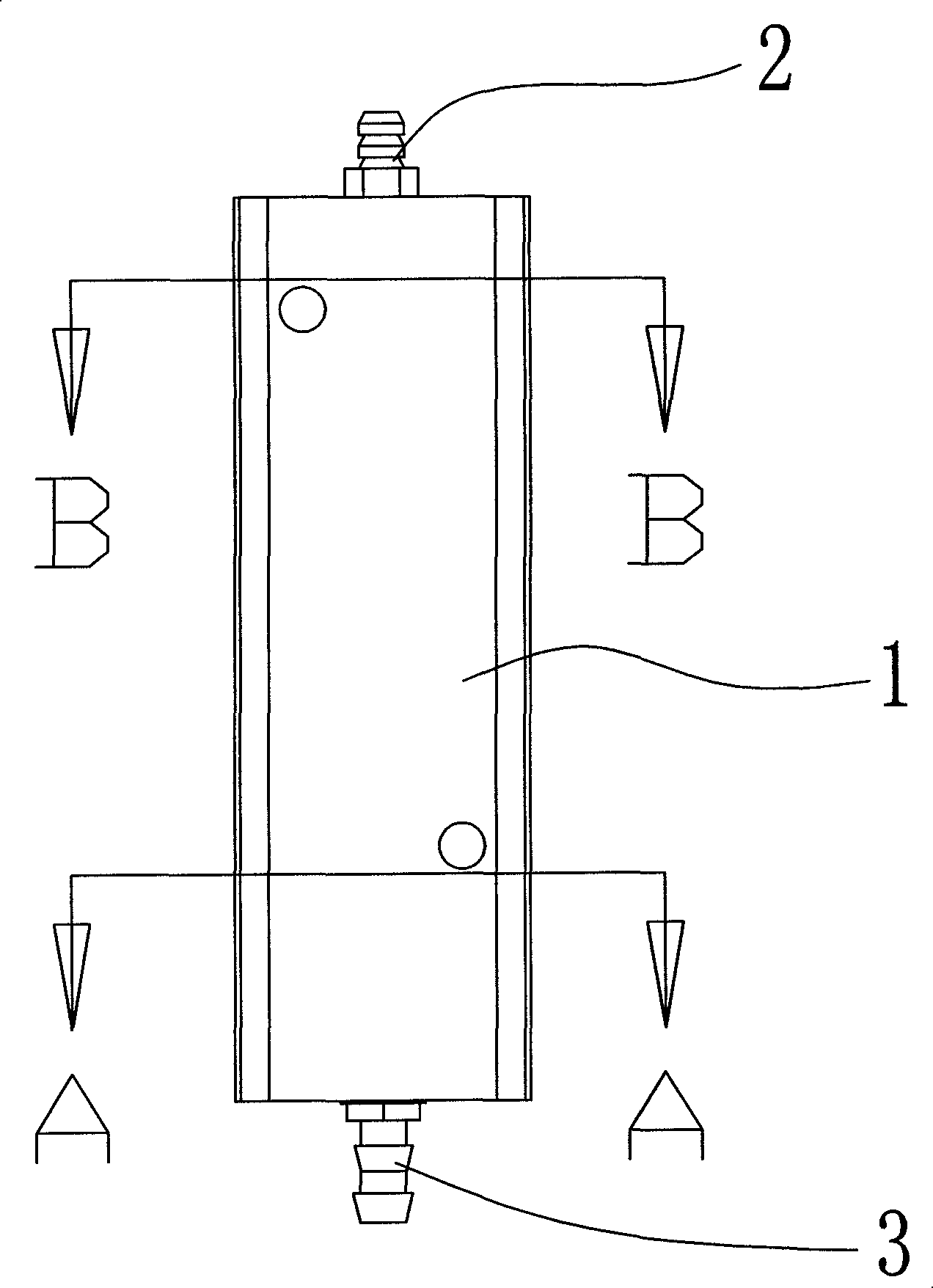

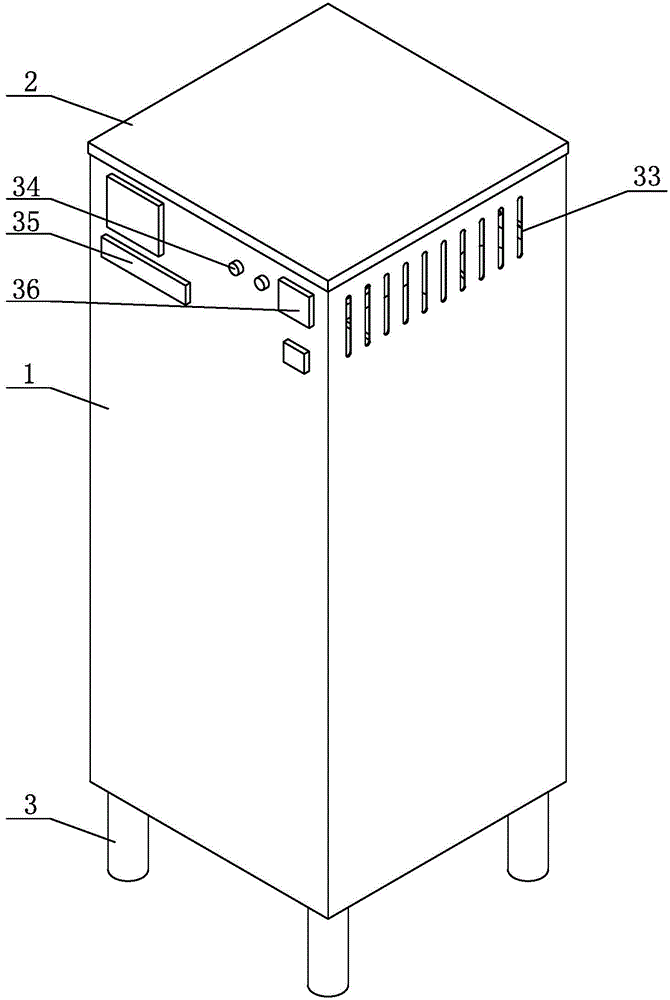

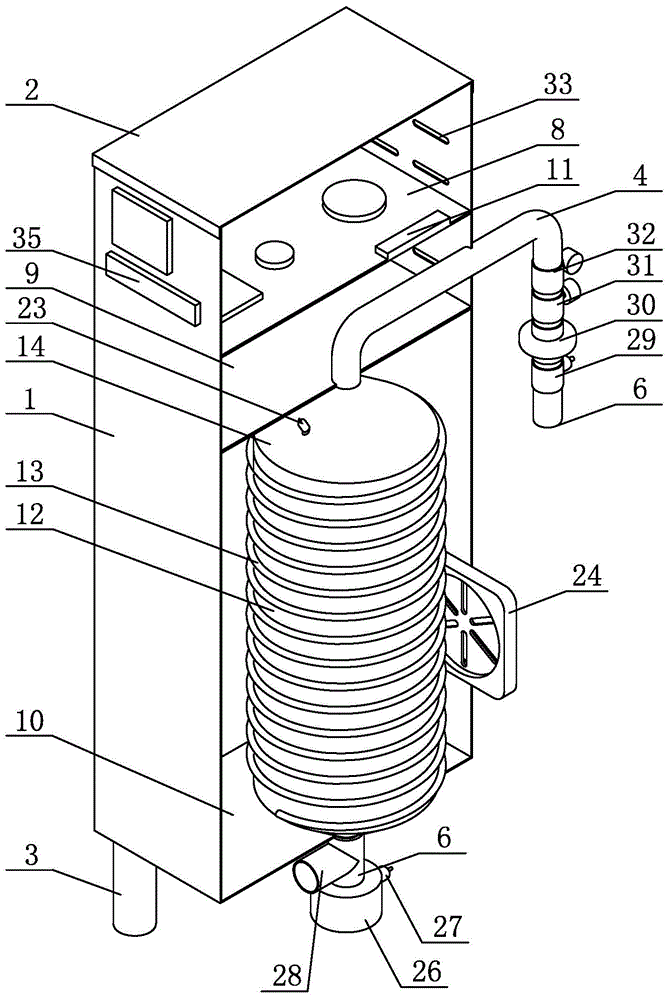

Column-shaped energy-saving steam generator

ActiveCN105987367AEfficient descalingExtended service lifeSteam generation heating methodsBoiling processEngineering

The invention discloses a column-shaped energy-saving steam generator. The column-shaped energy-saving steam generator comprises a shell, a water inlet pipe, a steam outlet and a control circuit. The column-shaped energy-saving steam generator is characterized in that a steam inner container is arranged inside the shell, an inner cavity of the steam inner container is provided with a spiral steam guide plate, a spiral steam channel is formed between the spiral steam guide plate and the side wall of the inner cavity of the steam inner container, the upper end of the steam inner container is connected with the water inlet pipe, and the lower end of the steam inner container is connected with the steam outlet; and a heat preservation layer is wrapped outside the steam inner container, and an inductance coil is wound on the heat preservation layer and connected with the control circuit. The column-shaped energy-saving steam generator is small in size, occupies small space, does not need a water boiling process, and is high in efficiency and low in energy consumption. Through path heating, high-temperature steam at the temperature of 180 DEG C or above can be generated under normal pressure, descaling can be conducted efficiently, and thus market requirements are greatly met, and the column-shaped energy-saving steam generator is suitable for being widely used and popularized.

Owner:深圳宝联智汇科技有限公司

Dirt removing device for square mahjong mattress

InactiveCN109465219AEffectively fixedAvoid damageCleaning using toolsCleaning using liquidsLow speedFixed frame

The invention relates to the technical field of household article processing, and discloses a dirt removing device for a square mahjong mattress. The device includes a body, a support frame, two electric lift bars, a bearing plate, a fixing frame, a transmission group, a drive motor, a brush roller group, a multi-pass nozzle, a water guide joint, an inner case, a low speed motor, a lateral adjusting mechanism, a transverse chute, two transverse connecting blocks, two contact mechanisms, four fixing members, four vertical adjusting mechanisms, four connecting spring plates, four clamping mechanisms, a control panel, two auxiliary sliding grooves and four sliding balls, the support frame are mounted directly above the body, the two electric lift bars are symmetrically mounted on the inner top of the support frame, and the bearing plate is fixedly connected to the ends of the two electric lift bars. The dirt-removing device of the square mahjong mattress effectively removes dirt in the gap between the mattress blocks of the mahjong mattress, thereby solving the problem that the traditional mattress cleaning device cannot effectively remove the dirt in the gap between the mattress blocks of the mahjong mattress.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

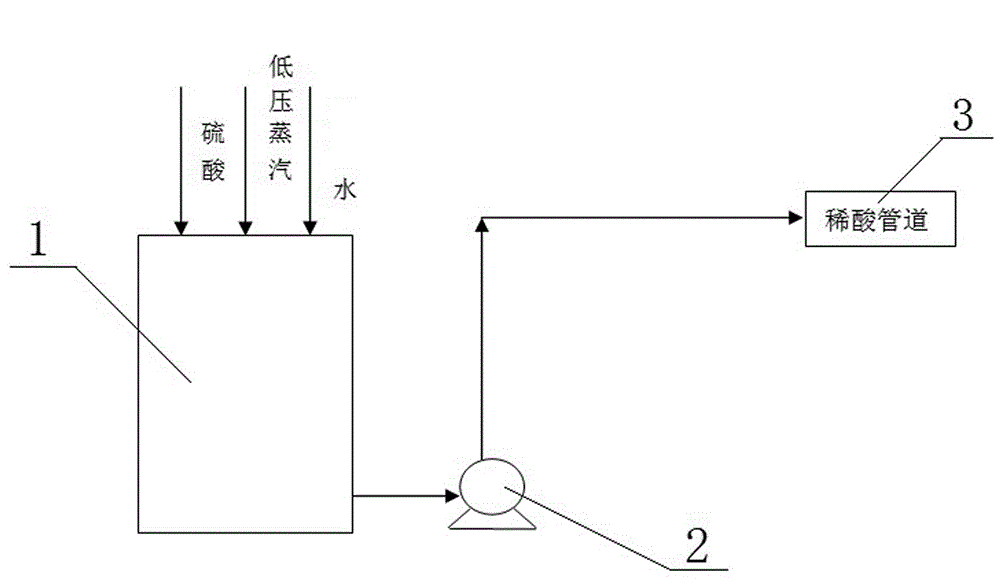

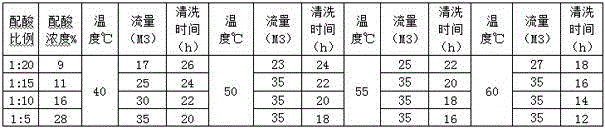

On-line clearing method of dilute acid pipe scales in phosphate ore magnesium-removing and ore-dressing production

InactiveCN104307814ARealize on-line descalingNo investment requiredHollow article cleaningCleaning using liquidsPhosphateTime-Consuming

The invention aims to provide an on-line clearing method of dilute acid pipe scales in phosphate ore magnesium-removing and ore-dressing production and solves the problem in the prior art that the manual cleaning of a dilute acid pipe is time-consuming and labor-consuming in the phosphate ore magnesium-removing and ore-dressing production. The on-line clearing method comprises the following steps: configuring cleaning liquid composed of sulfuric acid and water in a dilute acid configuration tank, wherein the volume ratio of the sulfuric acid to the water is 1:(5-20); then introducing low-pressure steam in the dilute acid configuration tank to heat; conveying the heated cleaning liquid into a dilute acid pipe by using a conveying pump to clean under the situation of no parking. The on-line clearing method has the benefits that the on-line clearing of the scales is realized, no pipe needs to be disassembled, no investment is required, the maneuverability is realized, and no extra equipment needs to be arranged; the scale removal is more obvious, the cleaning is required once a month, and time and labor are saved.

Owner:GANSU WENGFU CHEM

Inner surface and outer surface jet flow descaling system and method for big-diameter metal pipe wall

ActiveCN102764778BEnvironmentally friendly descaling processGreen descaling processWork treatment devicesMetal rolling arrangementsSpray nozzleEngineering

The invention discloses an inner surface and outer surface jet flow descaling system for a big-diameter metal pipe wall, which is characterized by comprising at least one spraying unit, wherein the spraying unit is used for simultaneously spraying mixed jet flow to the inner surface and the outer surface of the metal pipe wall and carrying out descaling; the inner surface and outer surface jet flow descaling system at least comprises two groups of spraying units, wherein one group is an inner spraying subunit used for descaling the inner surface of the metal pipe wall, and the other group is an outer spraying subunit used for descaling the outer surface of the metal pipe wall; the descaling system also comprises an actuating mechanism used for realizing a purpose that the big-diameter metal pipe wall carries out spiral motion; and therefore, the big-diameter metal pipe wall realizes the rotating motion around the self axis while axially moving. According to a special arrangement mode of mixed jet flow nozzles and a special motion mode of the big-diameter cold-state metal pipe wall, a continuous efficient mode that roll scales on the inner surface and the outer surface of the big-diameter cold-state metal pipe wall are synchronously removed can be realized so as to satisfy the processing requirement of the post-process.

Owner:BAOSHAN IRON & STEEL CO LTD

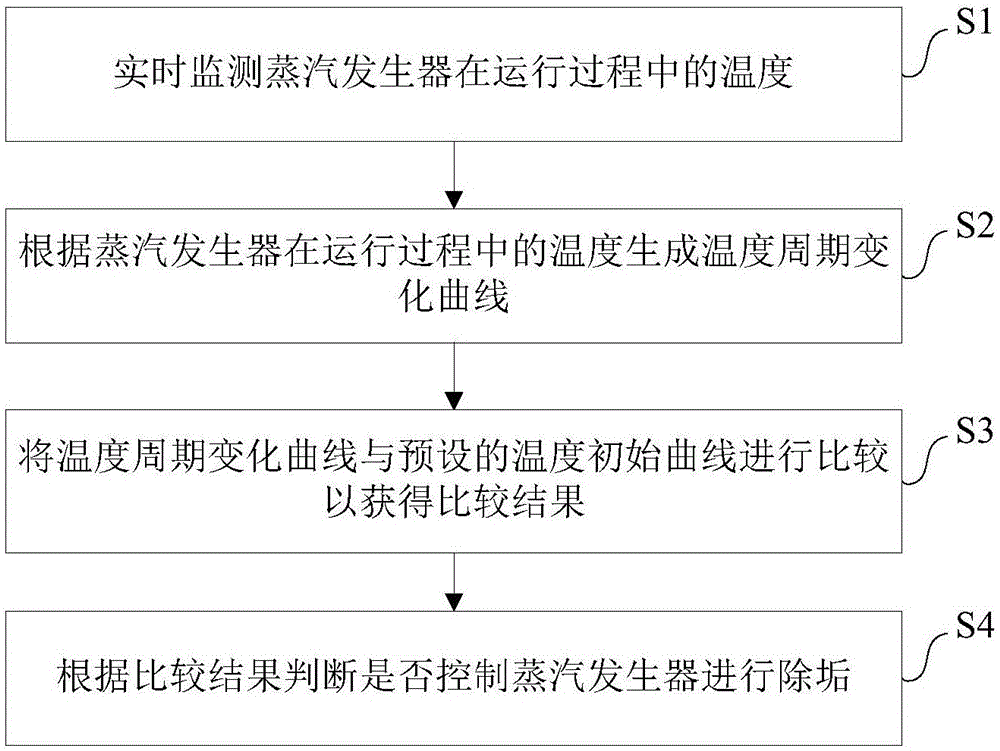

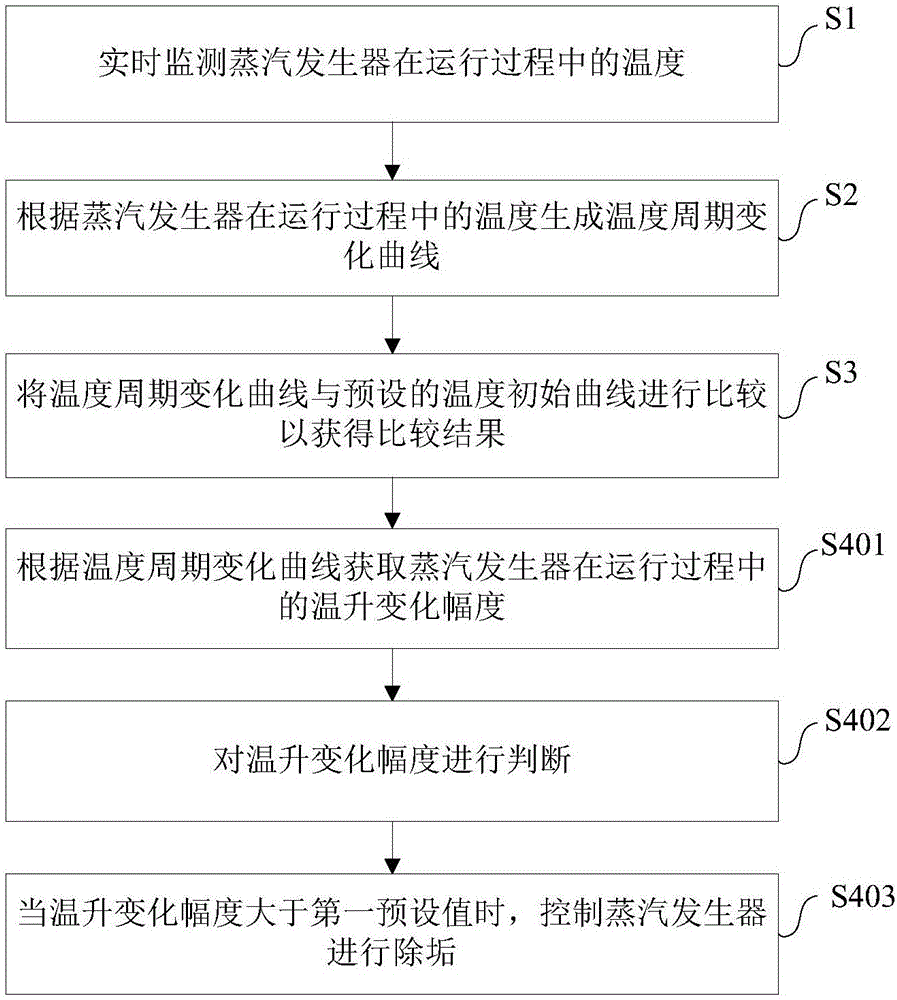

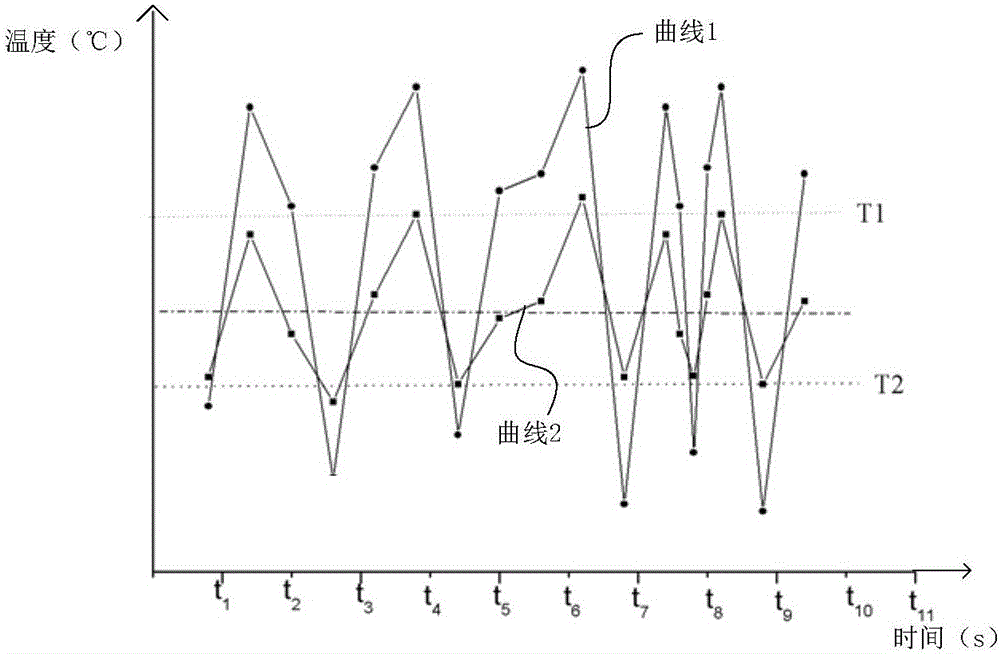

Vapor generator, descaling control method and descaling control device thereof, and electric appliance

InactiveCN106524125AEfficient descalingMonitor temperature in real timeBoiler cleaning apparatusWater qualityEngineering

The invention discloses a vapor generator, a descaling control method and a descaling control device thereof, and an electric appliance. The descaling control method comprises the following steps of real-time monitoring the temperature of the vapor generator during an operation process; generating a temperature cycling curve according to the temperature of the vapor generator during the operation process; comparing the temperature cycling curve and a preset temperature initial curve so as to obtain a comparative result; and judging whether the vapor generator needs to be controlled to be descaled or not according to the comparative result. According to the method, the temperature of the vapor generator during the operation process is real-time monitored, and whether the vapor generator needs to be descaled or not is accurately judged, so that the effectively intelligent descaling of the vapor generator can be realized.

Owner:MIDEA GRP CO LTD

Scale removing device for heat exchange pipe

ActiveCN102814309BImprove work efficiencyIncrease the heat exchange areaHollow article cleaningSpray nozzleEngineering

The invention discloses a scale removing device for a heat exchange pipe. The scale removing device comprises a cooling beam (2), a spray gun (3) and a spray nozzle (4), wherein the cross section of the cooling beam (2) is of a C-shaped tubular structure; the spray gun (3) is arranged in an internal chamber of the cooling beam (2) through a spray gun sleeve (1); and the spray nozzle (4) extends out of the cooling beam (2) through a C-shaped gap. According to the technical scheme, the spray gun can rotate in the cooling beam, and also can be moved by stepping; spraying particular mediums are sprayed on a heat exchanger full of dirt through the spray gun at a high speed for removing the scale, so as to achieve the purpose of efficiently removing the scale and improving the working efficiency of the heat exchanger, and as a result, the purpose of saving energy and reducing the consumption can be achieved; the spray gun is cooled through cooling water in the cooling beam, therefore, the problem that the spray gun cannot work with high efficiency due to excessive heat during running in a high temperature condition can be avoided.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

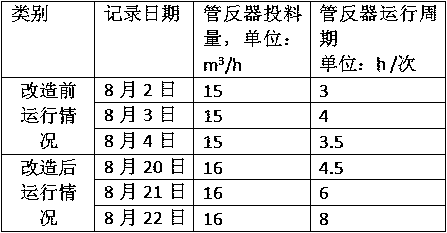

Online cleaning method of tubular reactor fouling in ammonium phosphate production

InactiveCN108212995AReduce labor intensityLess investmentPhosphatesAlkali orthophosphate fertiliserControl valvesAmmonia

The invention discloses an online cleaning method of tubular reactor fouling in ammonium phosphate production. The method comprises the steps that firstly, cleaning liquid is prepared, the cleaning liquid is formed by mixing sulfuric acid with the mass fraction being 60 to 98% and water, and the mass ratio of the sulfuric acid to the water is 1:25-30; secondly, an outlet pipe of a cleaning liquidstorage groove is connected with an inlet of a tubular reactor conveying pump; thirdly, when fouling appears in a tubular reactor, a tubular reactor acid blending groove bottom valve is closed, a cleaning liquid storage groove control valve is opened, the cleaning liquid is fed into the tubular reactor through the tubular reactor conveying pump, through an ammonia blowing pie of the tubular reactor, the steam is heated, and fouling cleaning of the tubular reactor and related pipelines can be accelerated. The method has the beneficial effects that the tubular reactor does not need to be detached, online running for fouling cleaning is achieved, investment is small, equipment configuration is simple, fouling is quite obvious, device running efficiency is improved, and enterprise benefits areimproved.

Owner:GANSU WENGFU CHEM

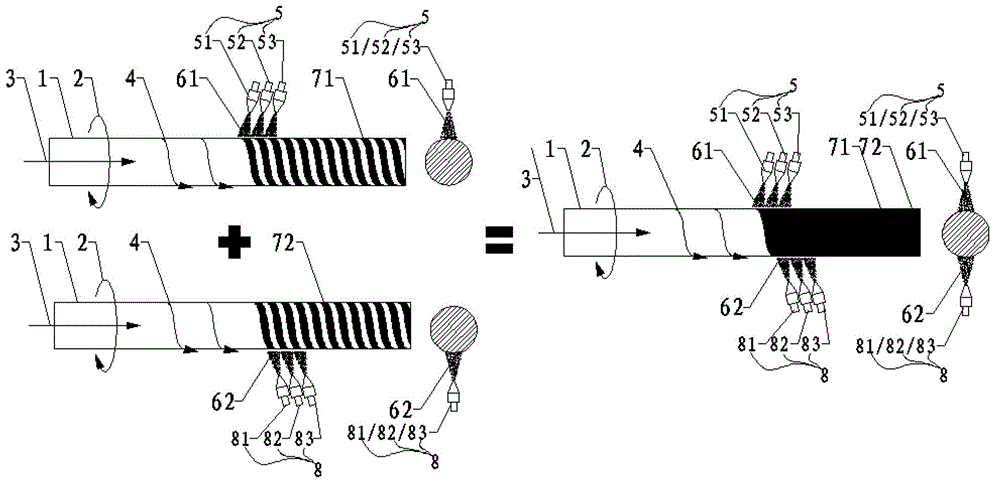

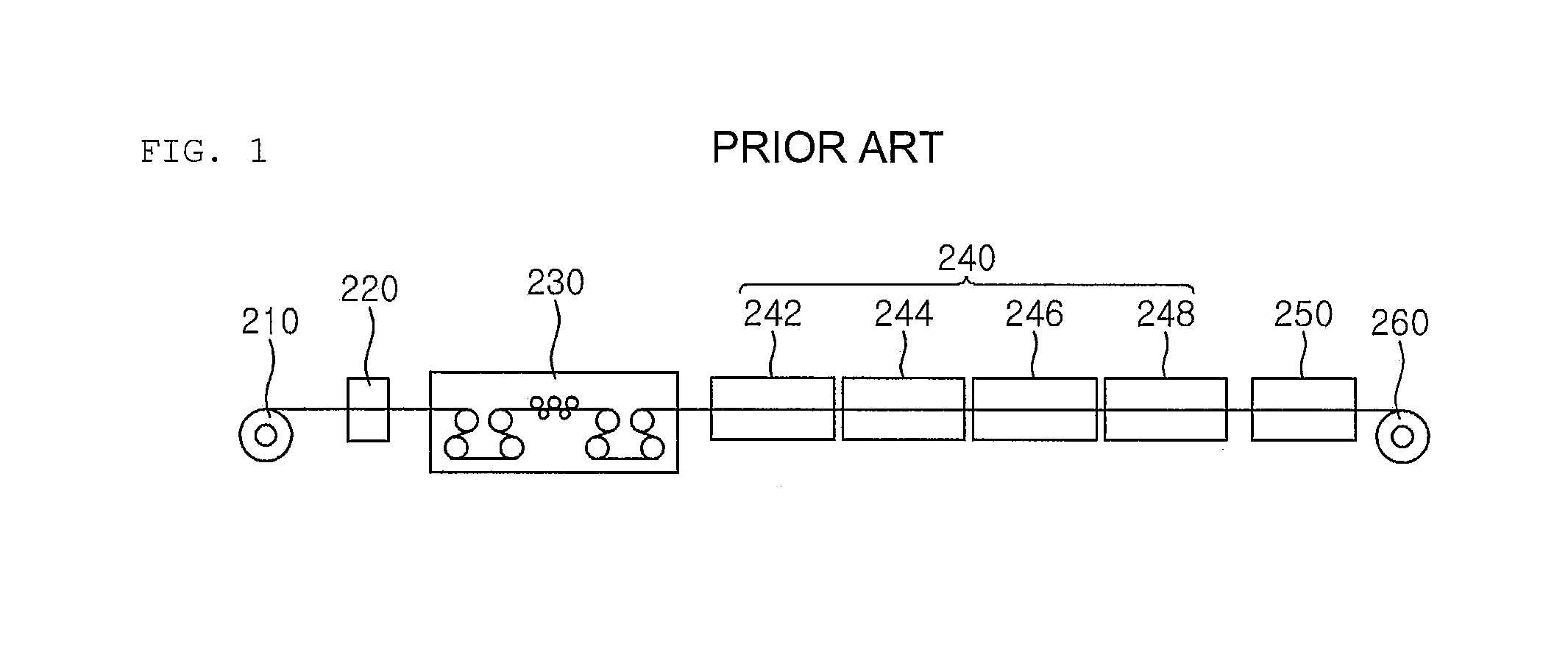

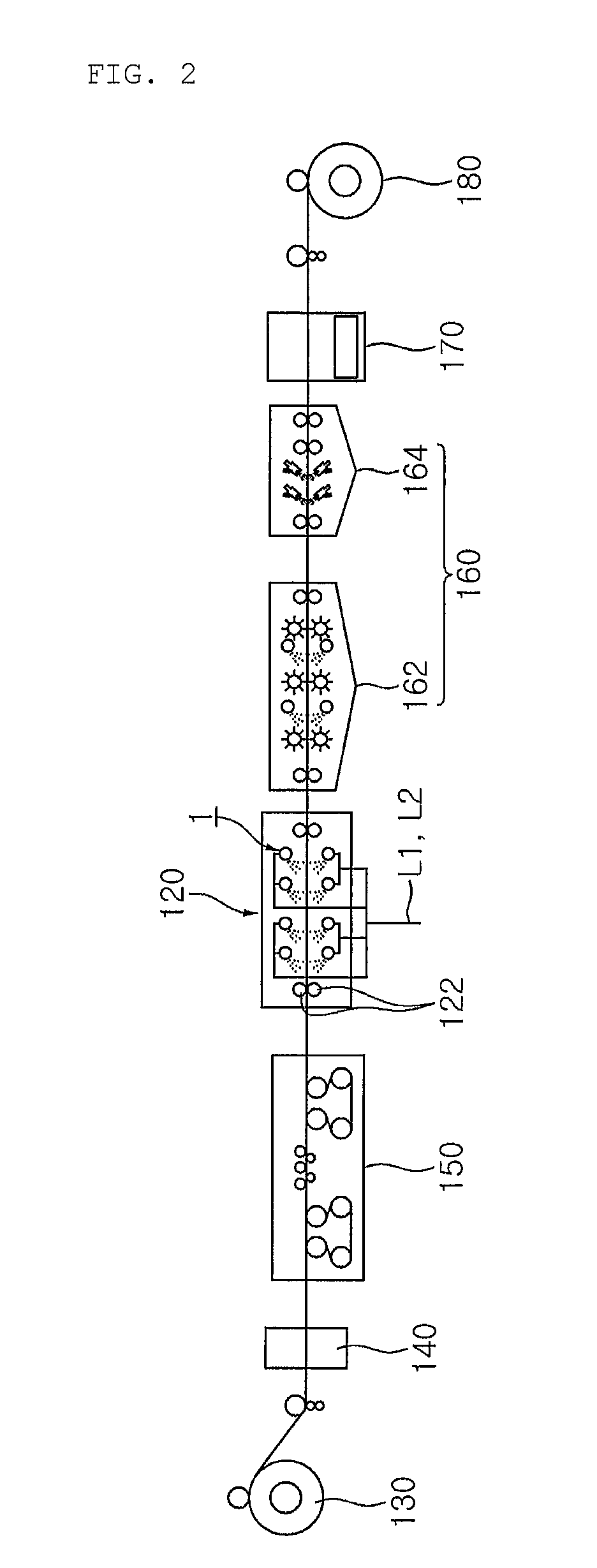

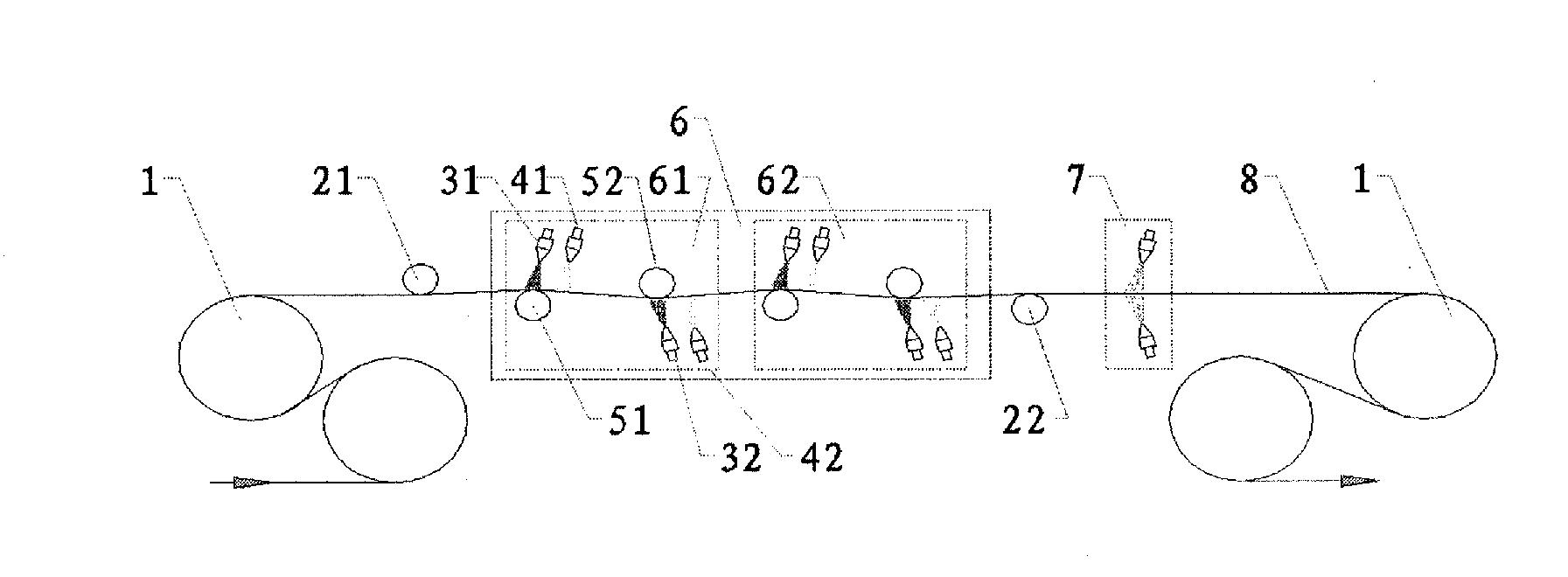

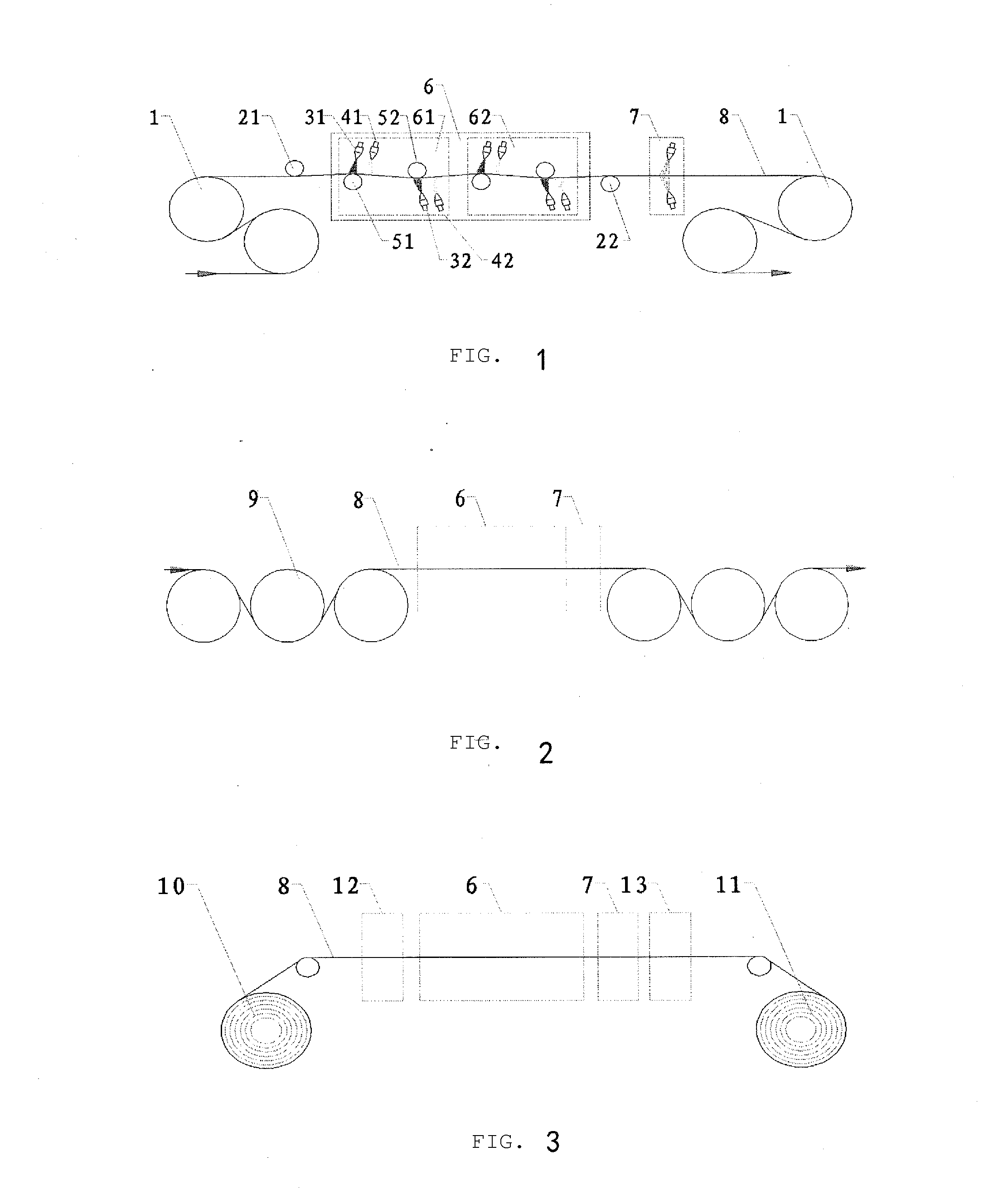

Cold state metal plate strip surface treatment system and treatment method of the same

ActiveUS20150143862A1Rapidly descale the obverse and reverse surfacesEfficient descalingWork treatment devicesExtrusion cleaning devicesProduction rateProduction line

A cold state metal plate strip surface treatment system and a treatment method thereof, used for high-pressure jet-flow descaling and rinsing metal plate strips, includes a high-pressure jet-flow descaling section 6. A tension unit and a stabilizing roller 21 are provided in front of the high-pressure jet-flow descaling section 6, and a stabilizing roller 22, a compressed air drying device 7 and a tension unit are provided after the high-pressure jet-flow descaling section 6; at least one descaling unit is provided in the high-pressure jet-flow descaling section 6, wherein the descaling unit includes first and second bending rollers 51, 52 used for bending a metal plate strip 8, and correspondingly first and second jet-flow descaling nozzles 31, 32, and first and second rinsing nozzle sets 41, 42. The present invention can be used for replacing the prior cold state continuous descaling pickling sets for metal plate strip, to meet the requirements of the rapidness and continuousness of modern cold-state metal plate strip, without affecting the original productivity of the production line. The present invention not only performs the synchronous and continuous descaling for both obverse and reverse surfaces of the metal plate strips, but also meets the requirements for the plate surfaces in the following procedure.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com