Cleaning agent of automobile cooling system and preparation method thereof

A technology for automobile cooling and cleaning agent, applied in the field of automobile cooling system cleaning agent and its preparation, can solve the problems of easy corrosion of automobile cooling system, time-consuming, inability to remove scale, etc. The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

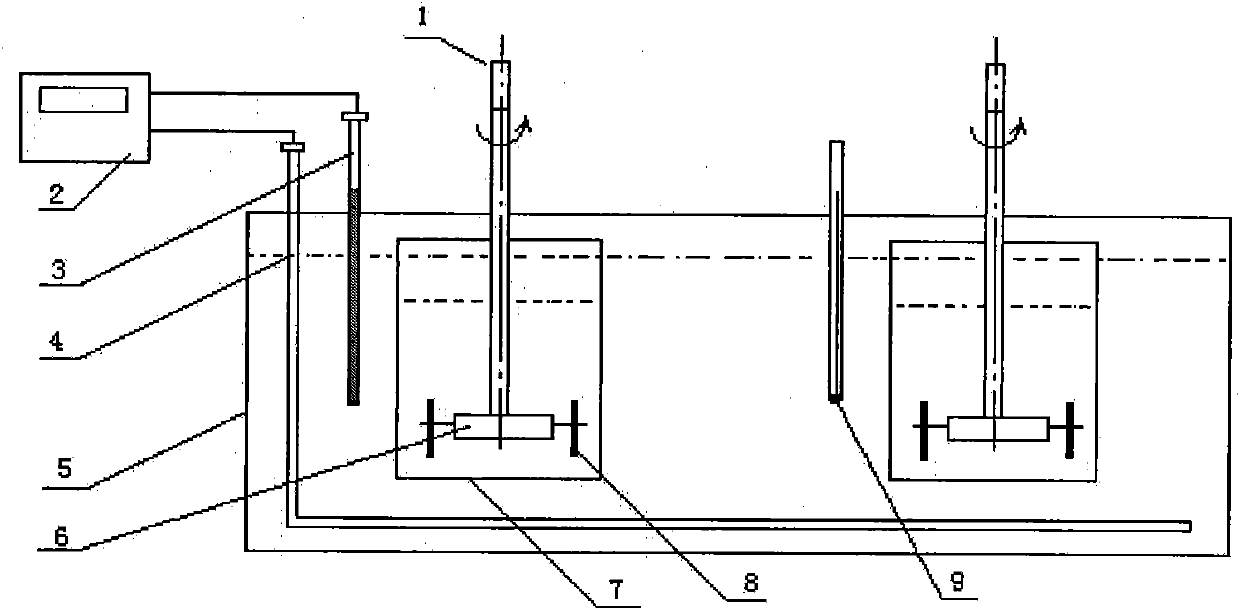

Image

Examples

Embodiment 1

[0038] 100kg of automobile cooling system cleaning agent is composed of the following components by weight: glycolic acid 10kg, sulfonic acid 5kg, Lan-8263kg, and the balance is water.

[0039] The preparation steps are as follows:

[0040] (1) Take water, add sulfonic acid and glycolic acid in turn while stirring at room temperature, and stir evenly after adding (8min);

[0041] (2) In (1), add Lan-826 while stirring at room temperature, and then stir evenly (8 minutes) after adding, to obtain the finished product.

Embodiment 2

[0043] 100kg of automobile cooling system cleaning agent is made up of each component of following weight: glycolic acid 11kg, sulfonic acid 7kg, Lan-55kg, surplus is water.

[0044] The preparation steps are as follows:

[0045] (1) Take water, add sulfonic acid and glycolic acid in turn while stirring at room temperature, and stir evenly after adding (9min);

[0046] (2) In (1), add Lan-5 while stirring at room temperature, and then stir evenly (9 minutes) after the addition, to obtain the finished product.

Embodiment 3

[0048] 100kg of automobile cooling system cleaning agent is made up of each component of following weight: glycolic acid 12kg, sulfonic acid 8kg, urotropine 6kg, surplus is water.

[0049] The preparation steps are as follows:

[0050] (1) Take water, add sulfonic acid and glycolic acid in turn while stirring at room temperature, and stir evenly after adding (10min);

[0051] (2) In (1), add urotropine while stirring at room temperature, and then stir evenly (10min) after adding, to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com