Patents

Literature

424results about How to "Short cleaning time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

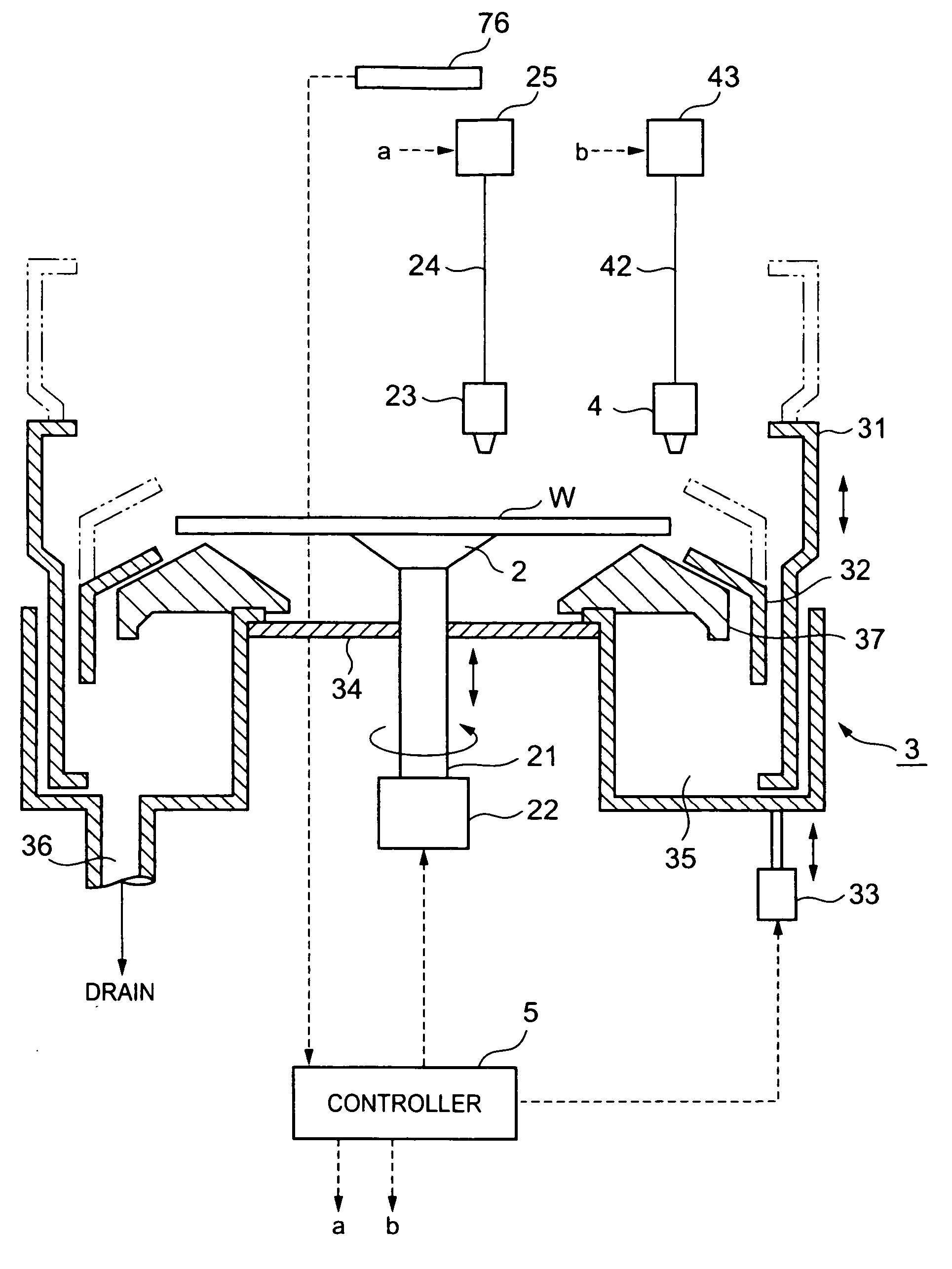

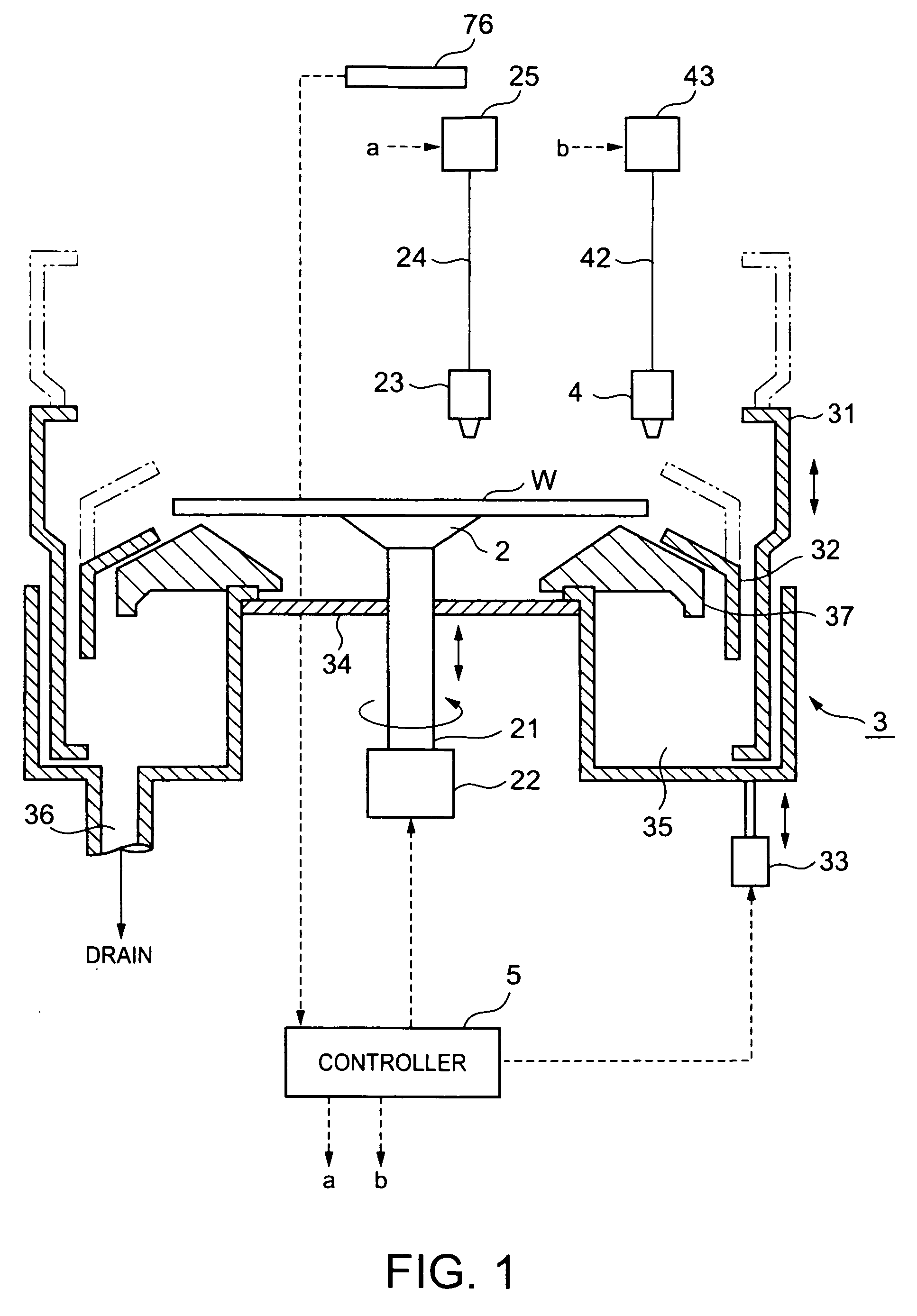

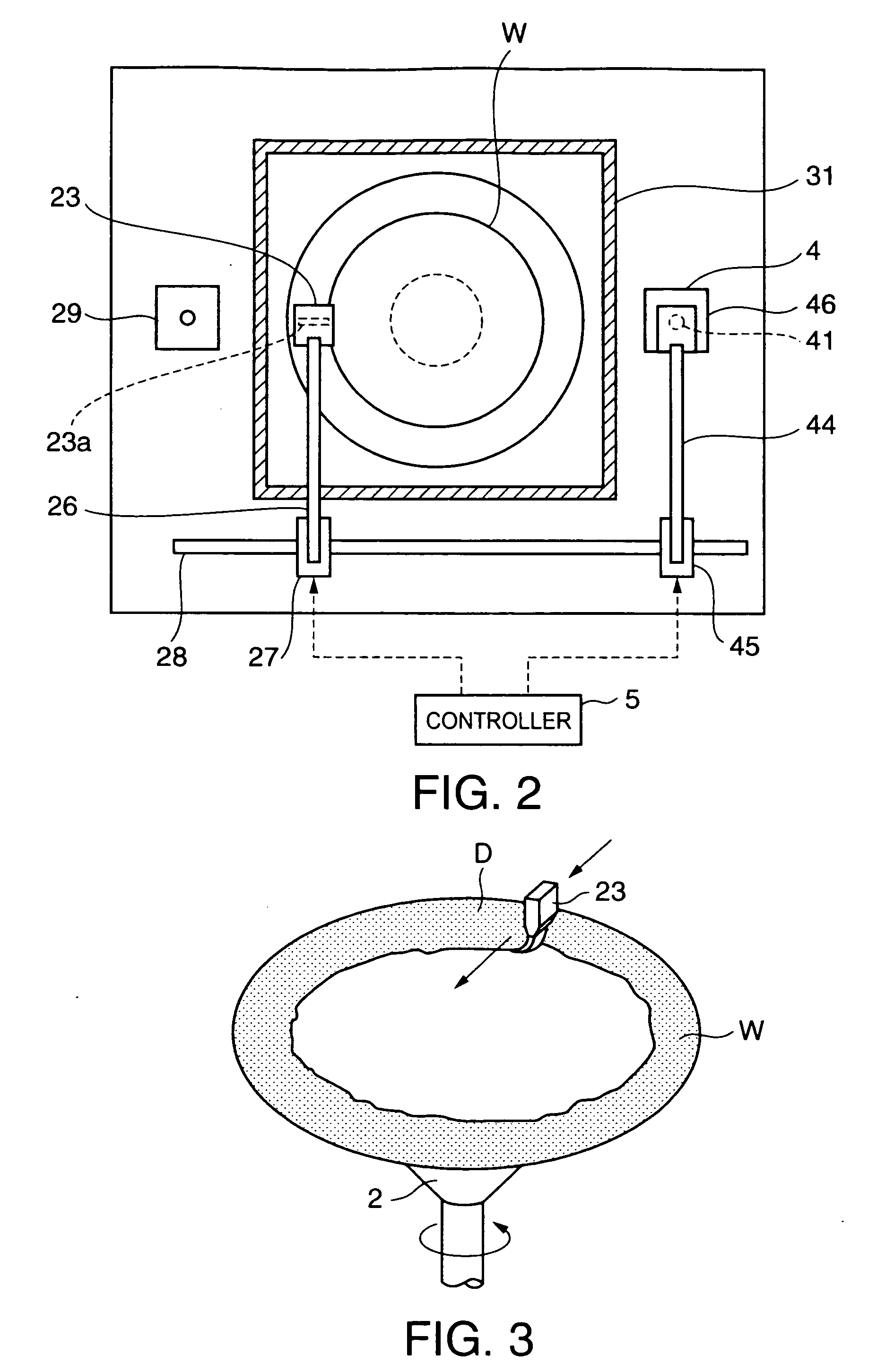

Substrate cleaning method and developing apparatus

ActiveUS20060048792A1Easy to cleanShort cleaning timePhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A cleaning method highly effectively cleans a surface of a semiconductor wafer by removing a dissolution product, produced when a surface of a semiconductor wafer is processed by a developing process that develops an exposed film formed on the semiconductor wafer by wetting the exposed film with a developer, from the surface of the semiconductor wafer. A cleaning liquid is poured through a cleaning liquid pouring nozzle onto a central part of a rotating wafer processed by a developing process to spread the cleaning liquid in a film over the surface of the wafer. Then, the cleaning liquid pouring nozzle is shifted to create a dry area in a central part of the wafer and the wafer is rotated at 1500 rpm to expand the dry area. The cleaning liquid pouring nozzle is moved at a nozzle moving speed high enough to keep the cleaning liquid pouring position ahead of the margin of the dry area and pouring the cleaning liquid is stopped upon the arrival of the cleaning liquid pouring nozzle at a predetermined position at 80 mm from the center of the wafer or at 5 mm above toward the center of the wafer from the peripheral edge of the wafer. The cleaning liquid may be poured through another cleaning liquid pouring nozzle disposed beforehand at the predetermined position and pouring the cleaning liquid through the cleaning liquid pouring nozzle may be stopped immediately before the margin of the dry area reaches a part onto which the cleaning liquid is poured through the cleaning liquid pouring nozzle. Preferably, a gas is blown instantaneously against the central part of the wafer to form a core fore the dry area.

Owner:TOKYO ELECTRON LTD

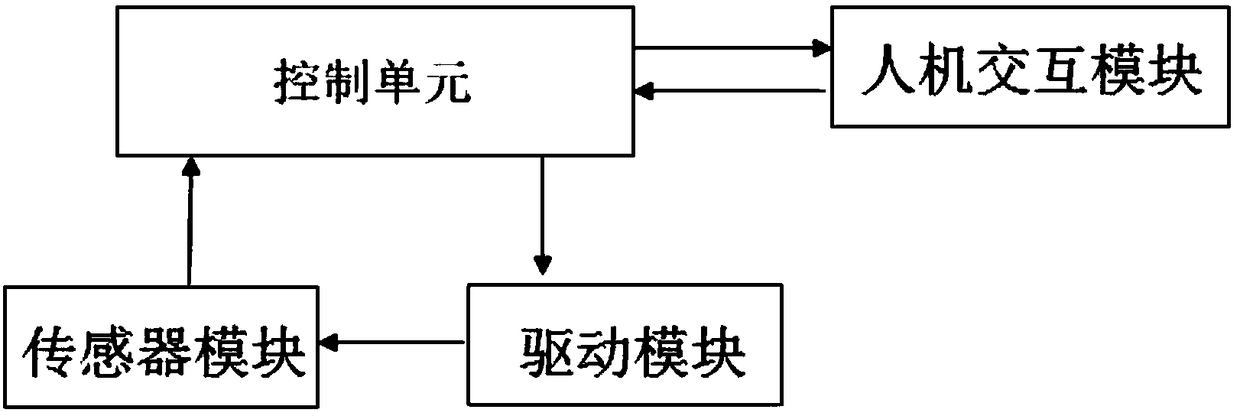

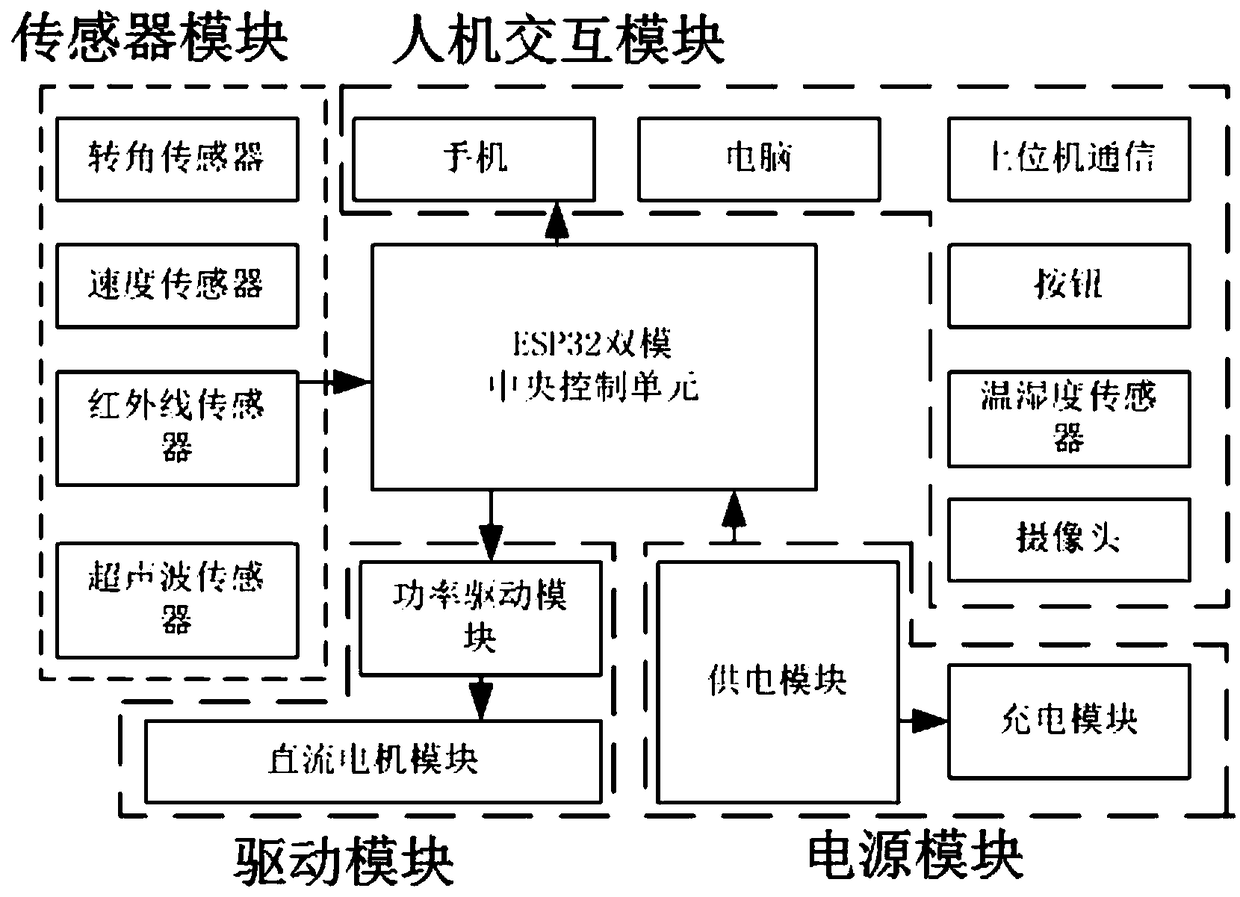

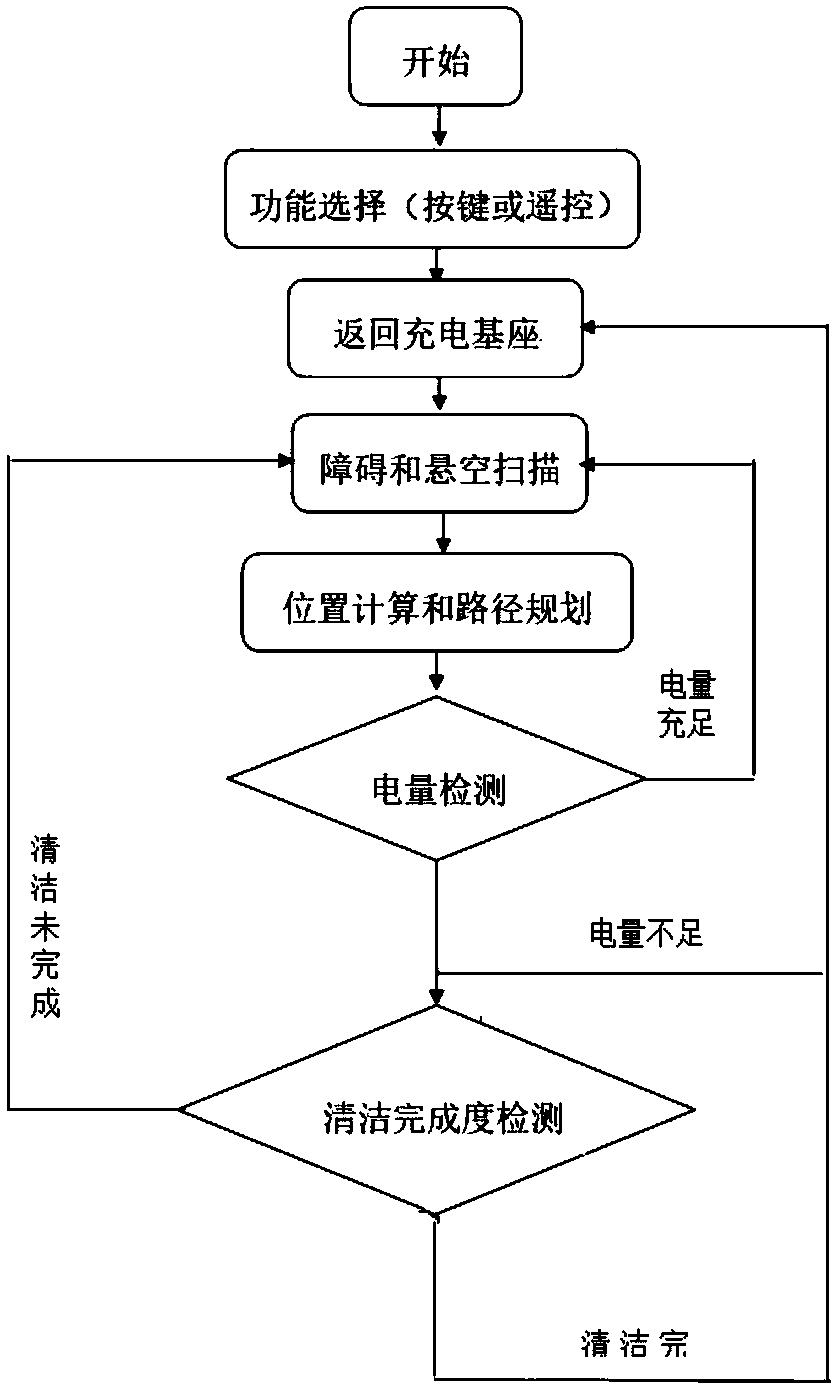

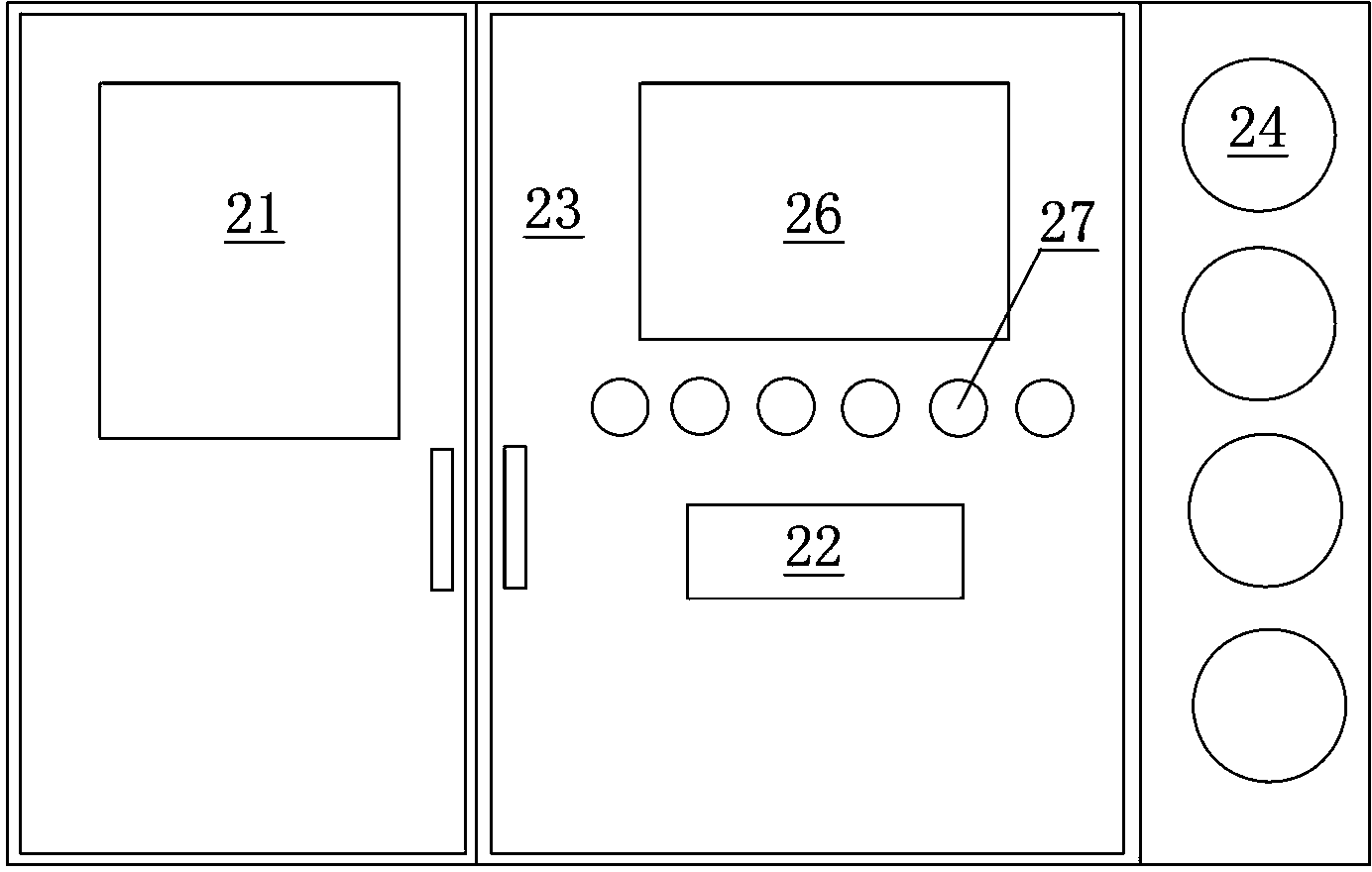

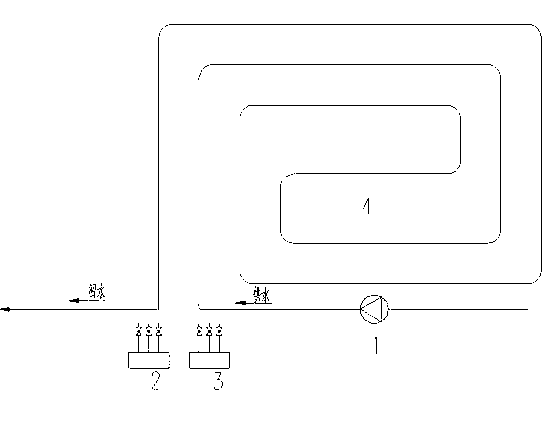

Intelligent cleaning robot and path planning method thereof

ActiveCN109144067AAchieve maximum coverageAchieving cleanlinessPosition/course control in two dimensionsVehiclesReal time analysisRemote control

The invention discloses an intelligent cleaning robot and a path planning method thereof. A sensor module is used for analyzing and feeding back real-time cleaning environment information; an accuratepositioning module is used for acquiring the position of the current intelligent cleaning robot on the environment map which is established through a geometric-topological hybrid map technology, andthe environment map and the real-time position are combined, the optimal sweeping path is planned by using an advanced path planning algorithm, and the data is uploaded to a cloud platform for realizing the real-time analysis, recording, and control; a driving module is used for driving the intelligent cleaning robot to run according to the planned optimal path and carrying out cleaning operation;a man-machine interaction module can be used for displaying the working state and performance of the intelligent cleaning robot by combining the temperature and humidity sensor with the camera, and the remote control and reservation functions of the intelligent cleaning robot can be completed through wifi / Bluetooth technology. According to the invention, the labor intensity is reduced, the laborefficiency is improved, and the robot is suitable for hotels, libraries, office places and public families.

Owner:CHECC DATA CO LTD +1

Cleaning machine with brine electrolysis device and cleaning method thereof

ActiveCN103801530AEasy to cleanImprove antivirusWashing processesSpecific water treatment objectivesAlkaline waterElectricity

The invention discloses a cleaning machine with a brine electrolysis device and a cleaning method thereof. The cleaning machine comprises a container. A water inlet is formed in the circumferential face of the container, a rotary gushing arm is arranged above the bottom face of the container, and the outer side of the water inlet is provided with a movable water inlet pipe which can be inserted in or stretch out of the water inlet and is communicated with the rotary gushing arm. The cleaning machine further comprises the brine electrolysis device. The water inlet pipe of the outside enters a first three-way electromagnetic valve, the other two ends of the first three-way electromagnetic valve are connected with a water channel and a circulating water pump of the brine electrolysis device respectively, and a water outlet of the circulating water pump is connected to a second three-way electromagnetic valve. A water outlet pipe of an acidic water tank and a water outlet pipe of an alkaline water tank are both communicated with the circulating water pump. The second end of the second three-way electromagnetic valve is connected to a movable water inlet pipe. According to the cleaning machine with the brine electrolysis device and the cleaning method thereof, electrolyzed alkaline water and acidic water are used for conducting circulation cleaning and sterilizing, and thus pollution of waste water to the environment is reduced; moreover, the design process is reasonable and compact, cleaning time is short, the quantity of electricity is greatly saved, and the efficiency of labor is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

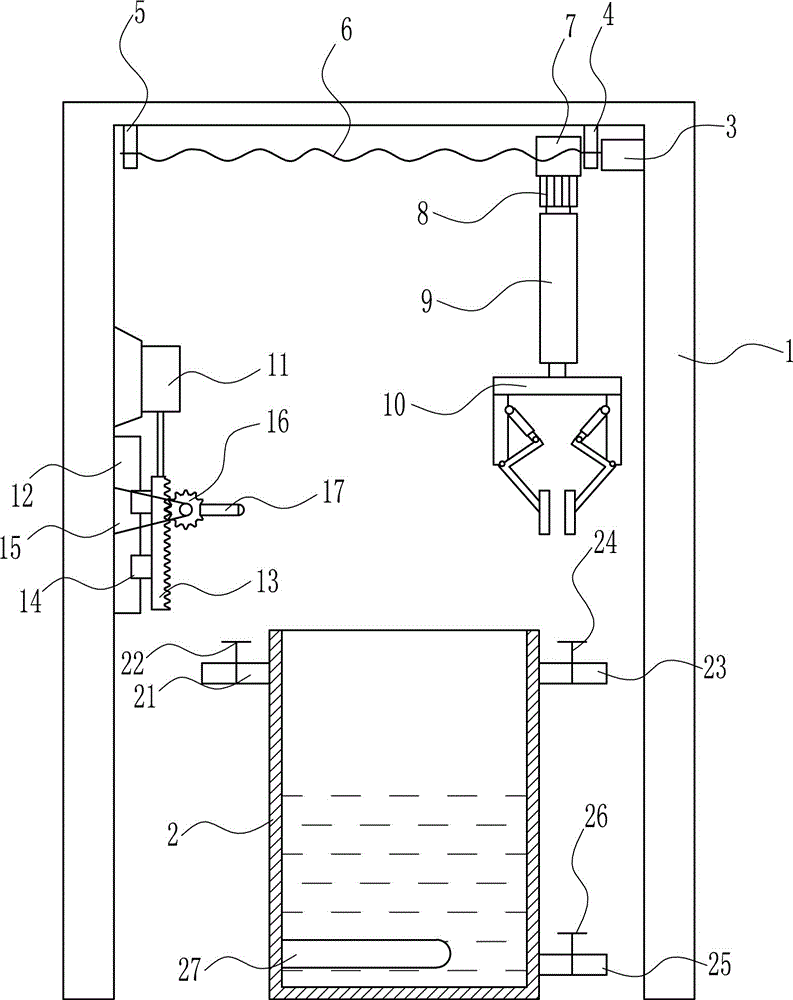

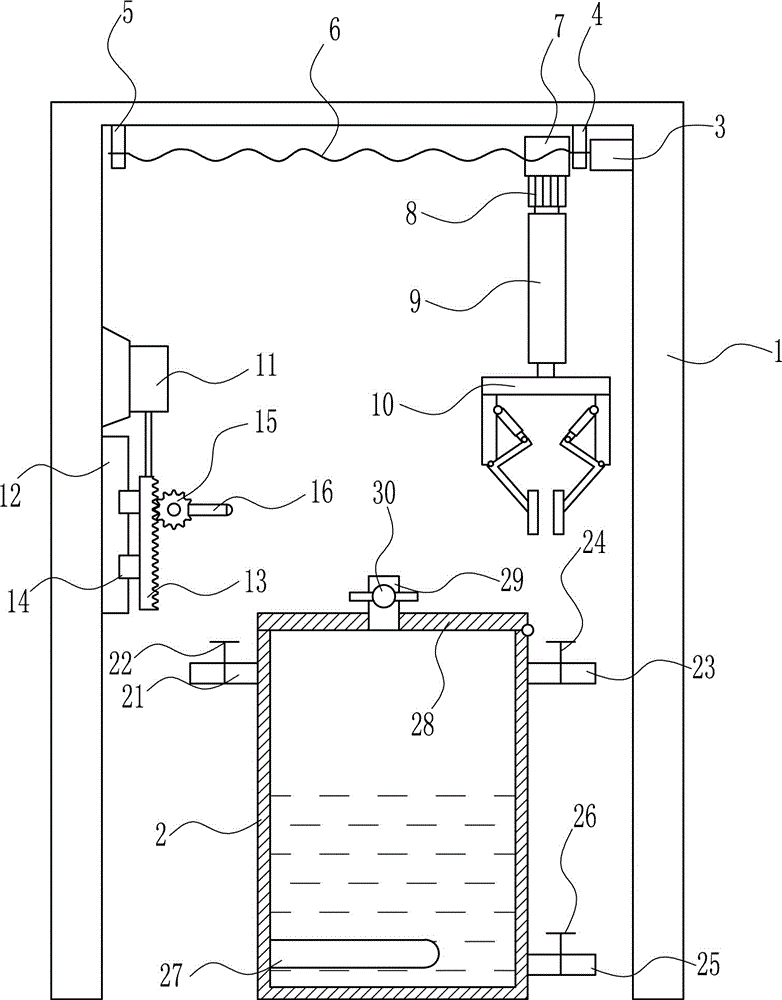

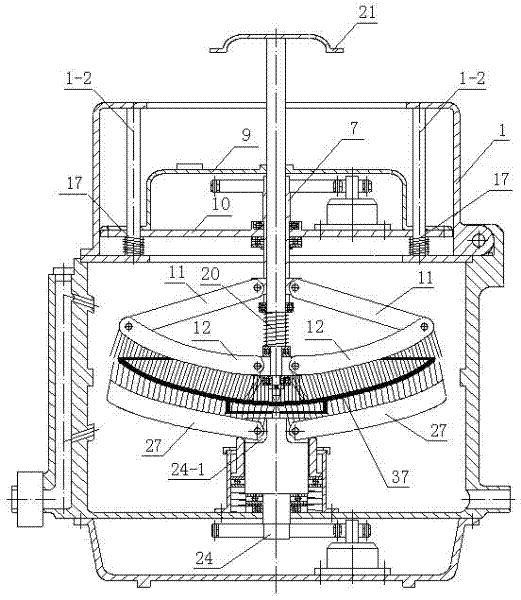

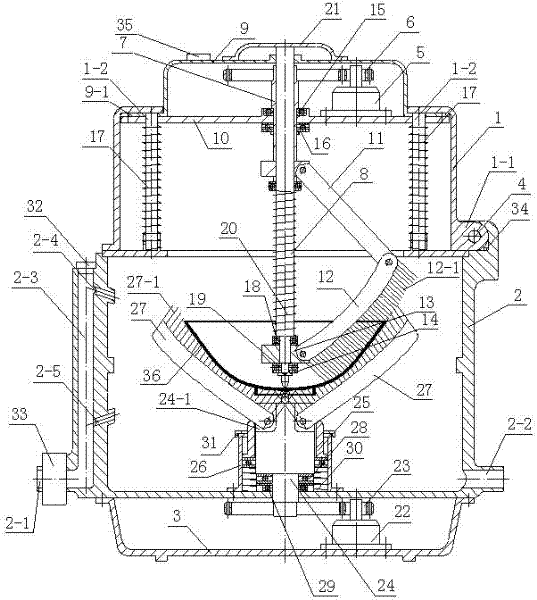

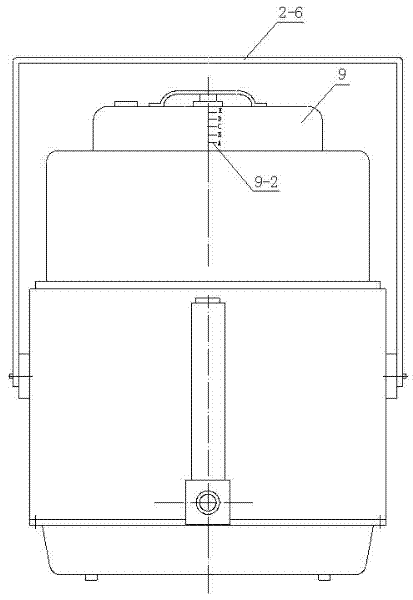

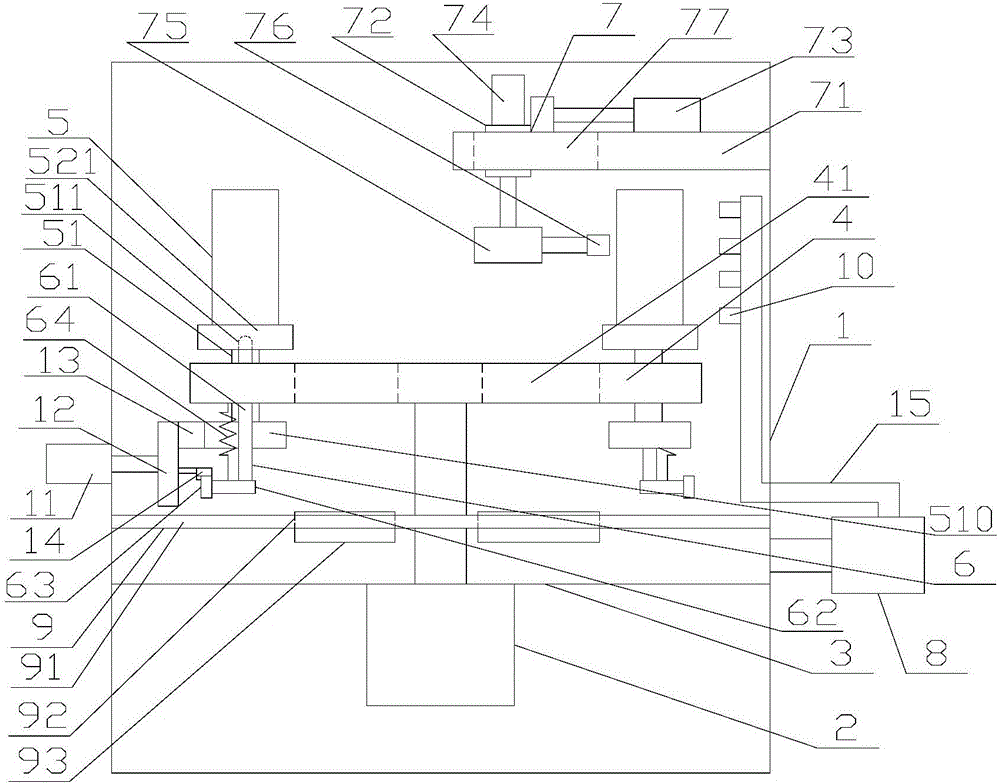

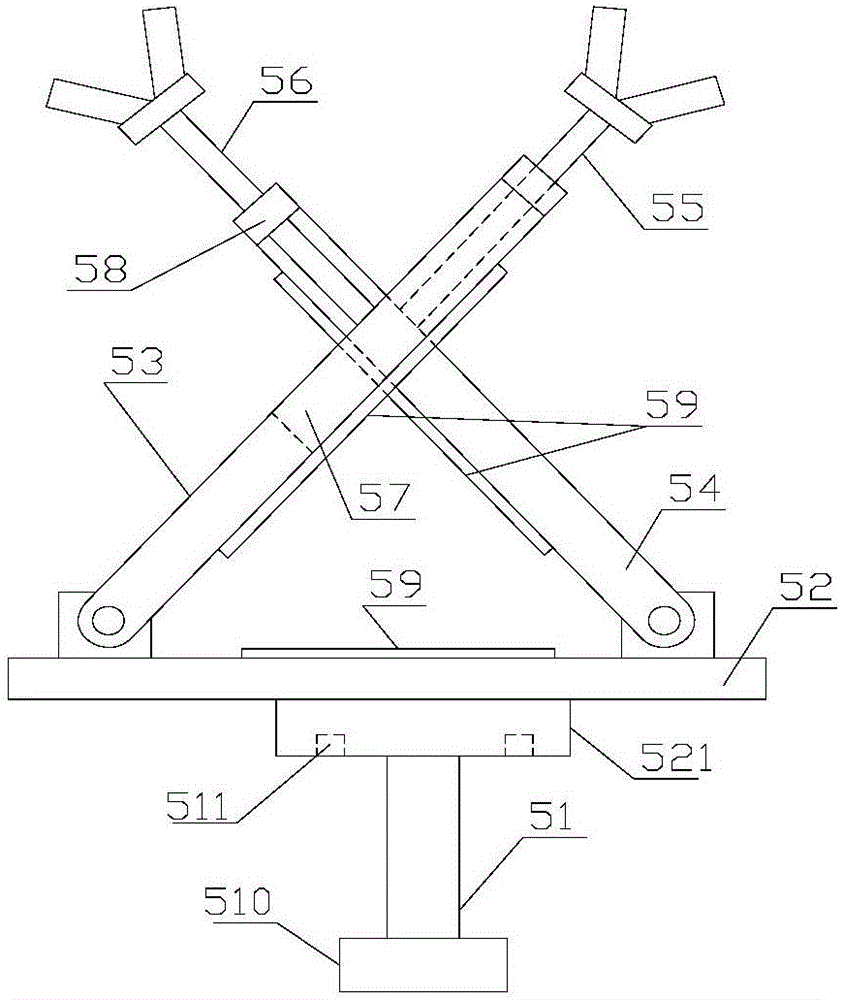

Automatic cleaning device for gauze mask

InactiveCN105689319AShort cleaning timeEasy to cleanDrying machines with progressive movementsCleaning using liquidsGear wheelElectric machinery

The invention relates to a cleaning device, particularly to an automatic cleaning device for a gauze mask which is aimed at solving the technical problem. The automatic gauze mask cleaning device which is capable of achieving automatic cleaning, short in cleaning time and good in cleaning effect, and can achieve sterilization and disinfection. The automatic gauze mask cleaning device provided by the invention comprises a bracket I, a cleaning jar, a horizontal motor, a right bearing seat, a left bearing seat, a screw, a nut, a vertical motor, a cleaning cylinder, a clamping device, a swinging cylinder, a slide rail, a rack, a sliding block, a bracket II, a sector gear, a nozzle, a clean water pipe, a valve I, a disinfectant pipe, a valve II, a draining pipe, a bottom valve and a heating wire, wherein the swinging cylinder, the slide rail and the bracket II are mounted at the left end of the bracket I; and the sliding block matched with the slide rail is arranged on the slide rail. According to the automatic gauze mask cleaning device, the automatic cleaning can be achieved, the cleaning time is short, the cleaning effect is good, and the sterilization and disinfection effects can be realized.

Owner:郭承干

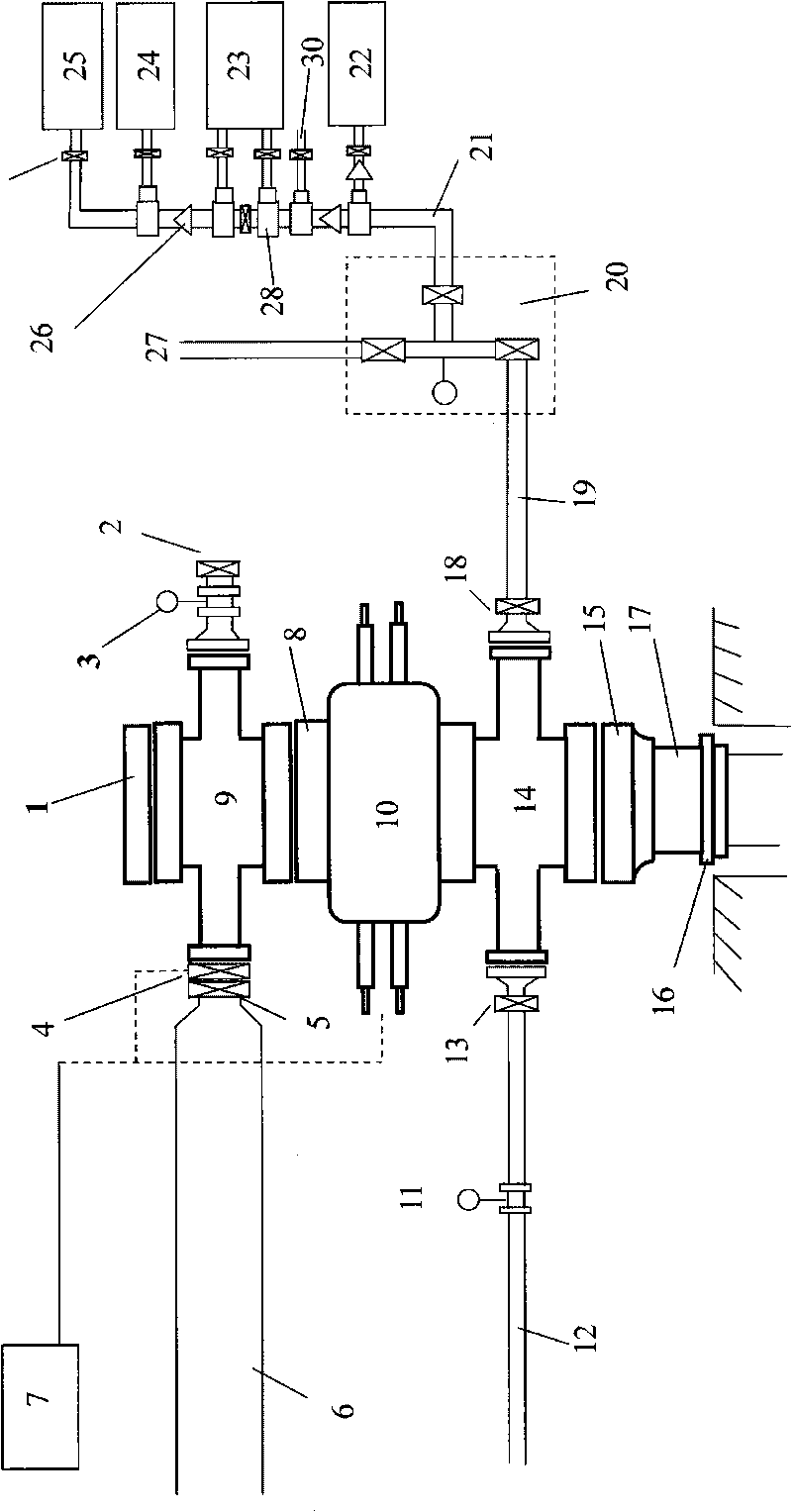

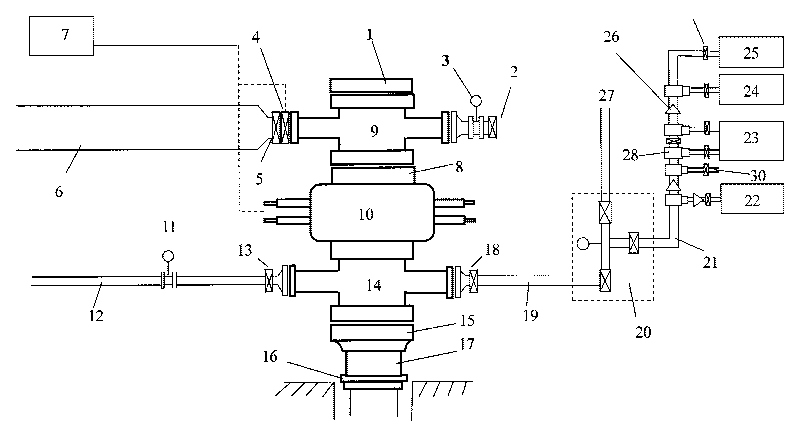

Reverse circulation aerodynamic cavitation method for coalbed methane well and equipment

The invention discloses a reverse circulation aerodynamic cavitation method for a coalbed methane well and equipment. The reverse circulation aerodynamic cavitation method comprises the following steps of: arranging wellhead equipment on a wellhead and sinking a working pipe to a bottom hole; clearly eliminating rock coal dust and water inside the well by using an air compressor in a circulating way; then lifting the working pipe upwards and injecting air / foam by using the air compressor and a supercharger, wherein the air injecting pressure is 3-15 MPa; meanwhile continuously injecting atomized water into the well with the water injecting amount of 3.0-5.0 m<3> each time; opening a hydraulic flat plate gate valve for discharging; after discharging, sinking the working pipe to a coalbed part; injecting the air simultaneously by the air compressor and the supercharger; meanwhile injecting water / foam with the amount of 3.0-10.0 m<3> by using an injection pump for washing the well to thebottom hole; after completing one cycle of discharging and well washing, detecting initial data; closing the air compressor, the supercharger, the injection pump and the hydraulic flat plate gate valve to enable gas inside the well to return freely; measuring the change of gas output of coalbed gas in one hour by using a flow meter; and placing a torch at a discharge port to ignite the gas. The invention improves the construction safety, improves the yield of single well coalbed gas, and saves the construction cost.

Owner:河南省资源环境调查二院

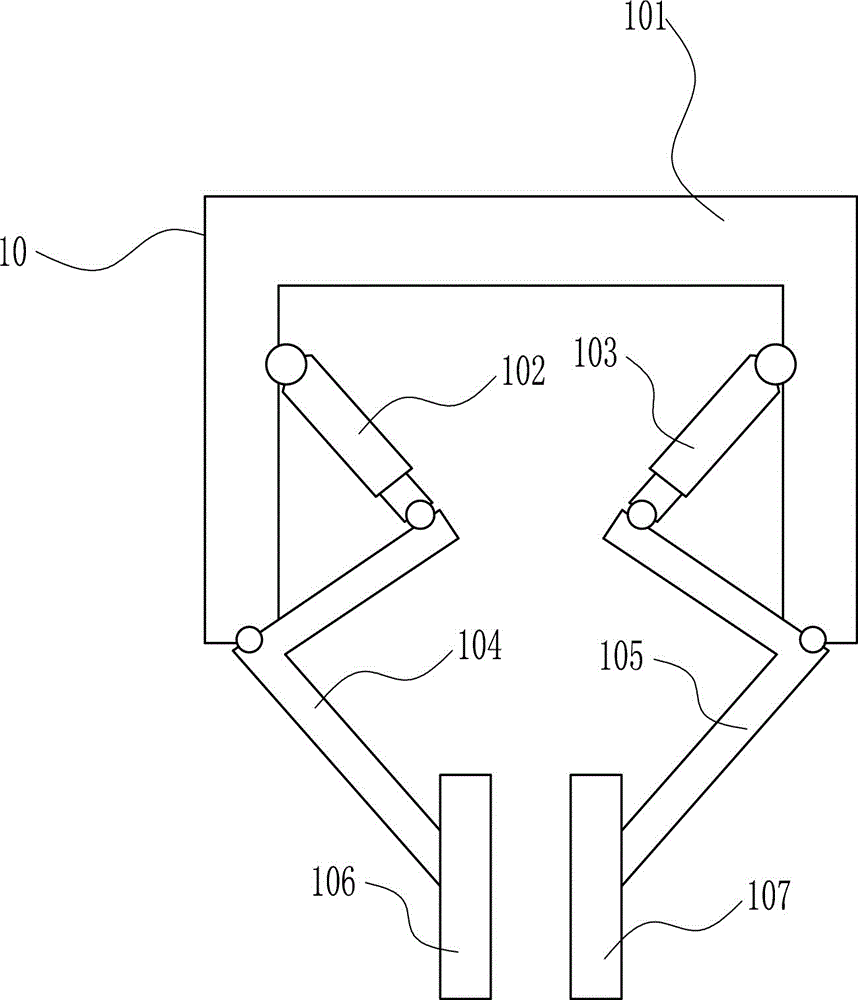

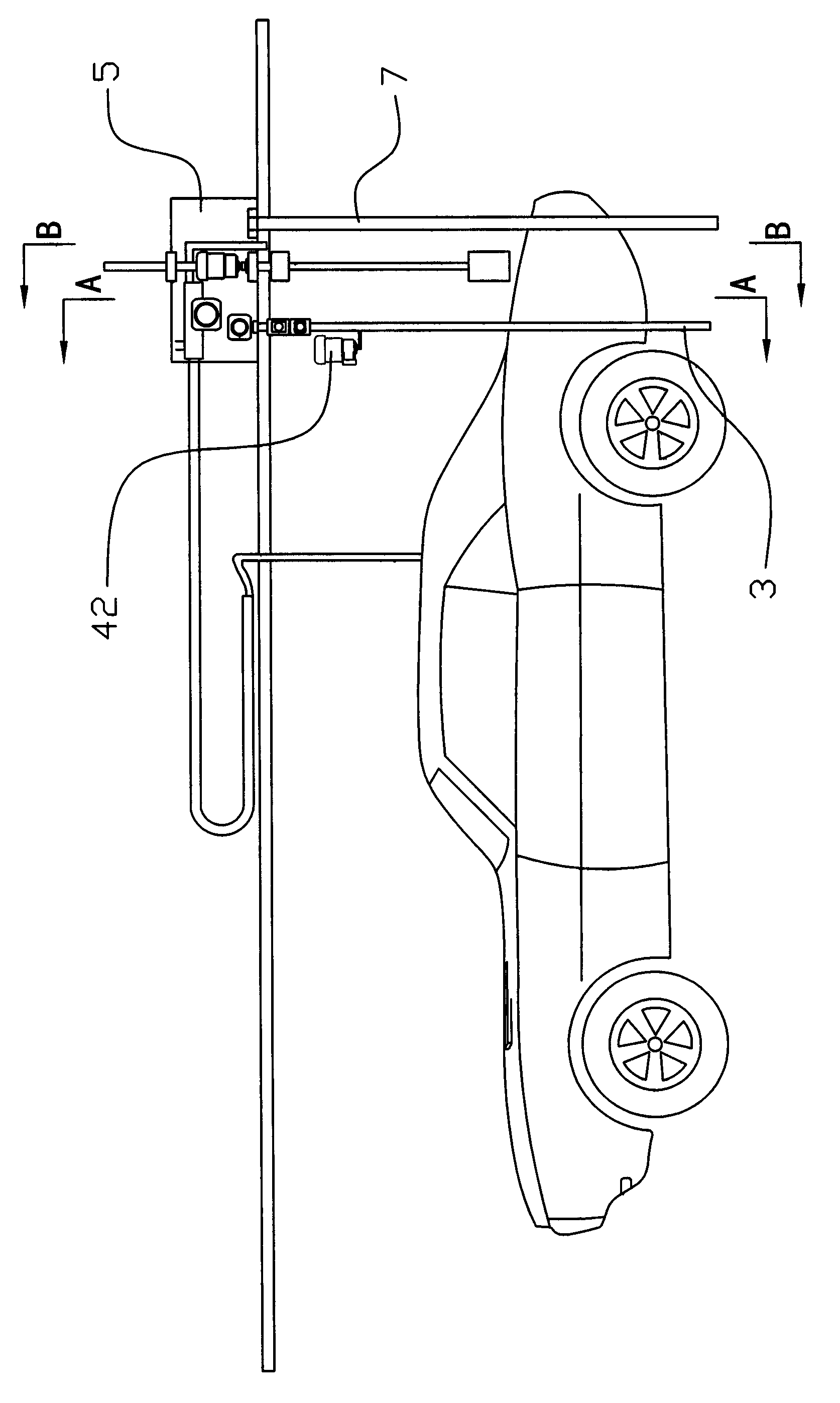

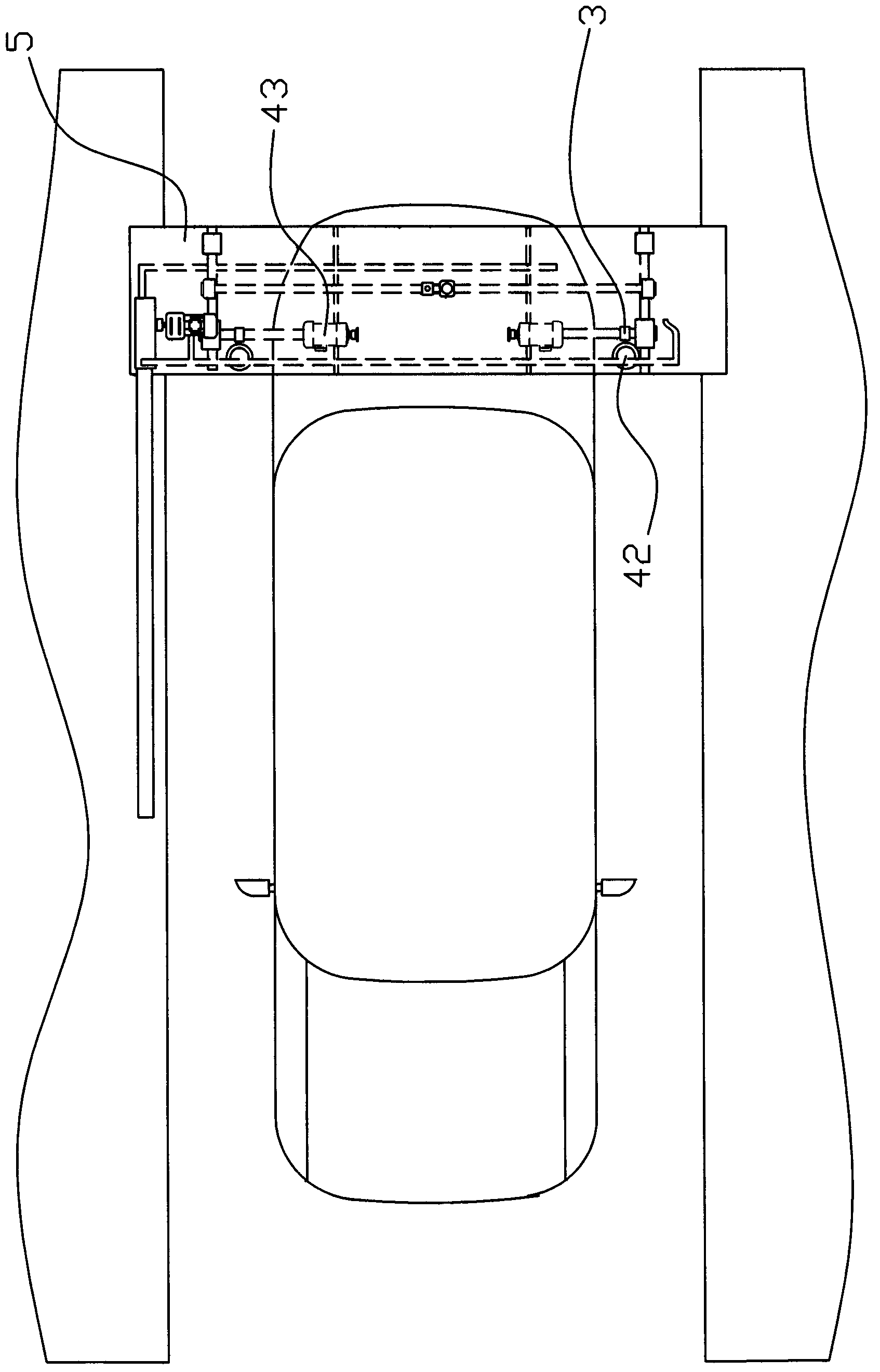

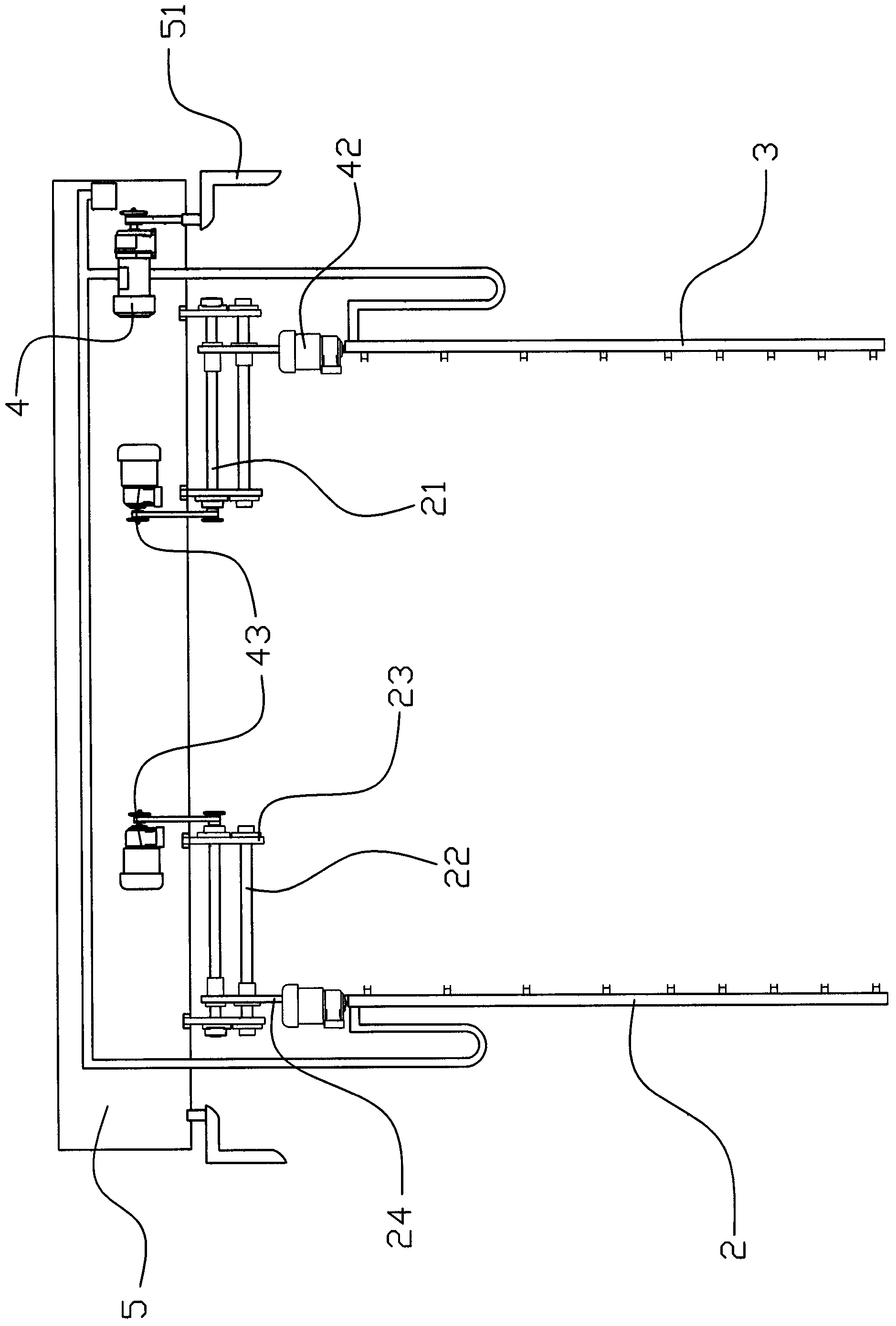

Full-automatic automobile washing device

ActiveCN104290718AShorten cleaning timeCar wash cleanCleaning apparatus for vehicle exteriorsElectric machineryDrive motor

A full-automatic automobile washing device comprises a spraying device. The spraying device comprises a top spraying rod and vertical spraying rods. The left vertical spraying rod and the right vertical spraying rod are each provided with a plurality of shower nozzles in the vertical direction, and the nozzles of the left vertical spraying rod are opposite to the nozzles of the right vertical spraying rod. Shower nozzles with nozzles facing downwards are distributed on the top spraying rod. The spraying rods are each provided with a switching mechanism, and the shower nozzles can be connected with a high-pressure water source and a high-pressure air source. The switching mechanisms can be in linkage with an output shaft of a switching motor. The top spraying rod, the left vertical spraying rod and the right vertical spraying rod are connected with a beam which is arranged on a guide rail in the manner of sliding forwards and backwards through a driving motor, the top spraying rod can be arranged on the beam in an ascending and descending mode through a lifting motor, the left vertical spraying rod and the right vertical spraying rod can be connected with the beam in the manner of moving left and right through respective motors, and the beam is provided with a detecting device which can detect the size of an automobile body. The full-automatic automobile washing device is ingenious and reasonable in structure, high in automation degree and more complete in function, effectively solves the problems of an existing automobile washing machine, and is a very practical automobile washing device.

Owner:绍兴市中令汽车服务有限公司

Water-based type environment protection cleaning agent and preparation method thereof

ActiveCN101225346AThe formula is scientific and reasonableSimple production processSurface-active detergent compositionsDetergent compounding agentsWater basedMan-hour

The invention relates to a water based environment-friendly cleaning agent and the preparation method, which is characterized in that the agent comprises natural plant extract, degradable surface active agent, inhibiter and de-ionized water. The preparation method is as follows: (1) preparing materials according to the weight ratio, (2) adding the raw material orderly in series, (3) stirring at even pace and (4) evenly mixing to make the finished cleaning agent ultimately. The preparation method for the water based environment-friendly cleaning agent has the advantages of scientific prescription, simple production technique, strong cleaning ability, short cleaning time, low labor and man-hour, high work efficiency, low causticity to the equipment, good safety and low equipment cost. The water based environment-friendly cleaning agent is degradable liquid and can be biologically degraded into harmless material in nature completely. The waste liquid after be cleaned cab be directly discharged without polluting the environment and reach the sewage discharge standard. The water based environment-friendly cleaning agent is provided with the surface active agent and the inhibiter which can form a rustproof protecting film on the metal surface after cleaning, and ensures that the part after cleaning has an advantage of good rust protection.

Owner:北京凯兰航空技术有限公司

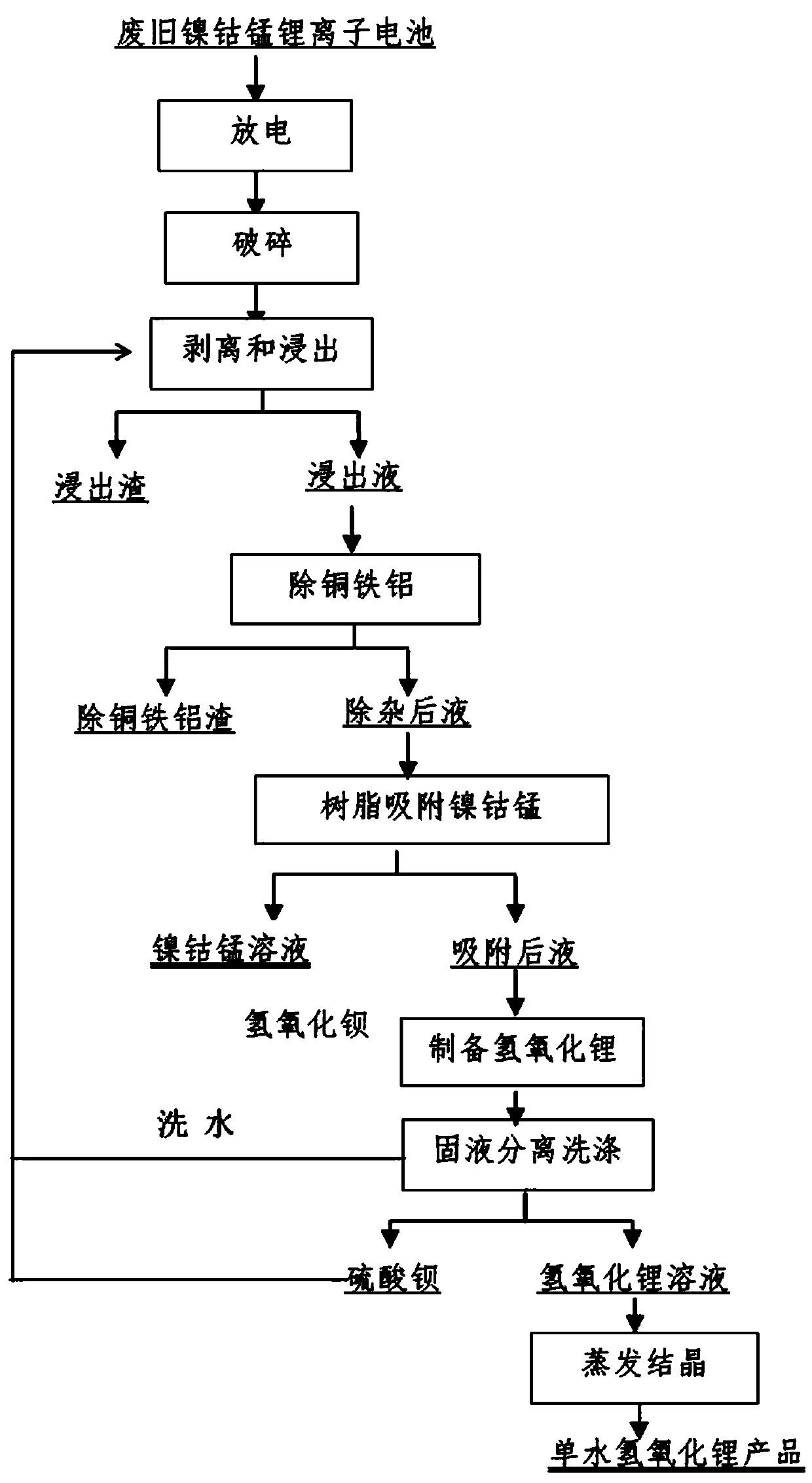

Method for recovering valuable metals in waste nickel-cobalt-manganese lithium ion battery by ion exchange method

InactiveCN110527836AAvoid introducingEliminate the evaporation crystallization processIon-exchange process apparatusIon-exchanger regenerationHigh sodiumIon content

The invention relates to a method for recovering the valuable metals in a waste nickel-cobalt-manganese-lithium ion battery by an ion exchange method, which comprises the following steps of disassembling, discharging and crushing the waste nickel-cobalt-manganese-lithium ion battery, leaching, replacing the leachate with nickel powder or cobalt powder to remove the copper, and hydrolyzing with a valuable metal alkali solution as a neutralizer to remove the iron and aluminum; regenerating the chelating resin with a lithium hydroxide solution, adsorbing the nickel, cobalt and manganese in the impurity-removed solution, and backwashing with sulfuric acid to obtain a nickel-cobalt-manganese mixed solution; and recovering the lithium in the liquid after resin adsorption in the form of lithium hydroxide. According to the method, the stripping and leaching of the waste nickel cobalt lithium manganate ion battery are completed in one step, the impurity elements are not introduced during the leachate impurity removal and valuable metal separation and extraction process, the lithium hydroxide used for ion exchange resin is regenerated via the lithium hydroxide, at the same time, the nickel-cobalt-manganese is absorbed, so that the lithium is prevented from being adsorbed and entering a nickel, cobalt and manganese solution to be lost, and the lithium recovery is prevented from being influenced due to the high sodium ion content in the solution with the sodium hydroxide. According to the present invention, the recovery rate of nickel, cobalt and manganese reaches 98% or above, the recovery rate of lithium reaches 90% or above, the technological process is short, the equipment is few, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

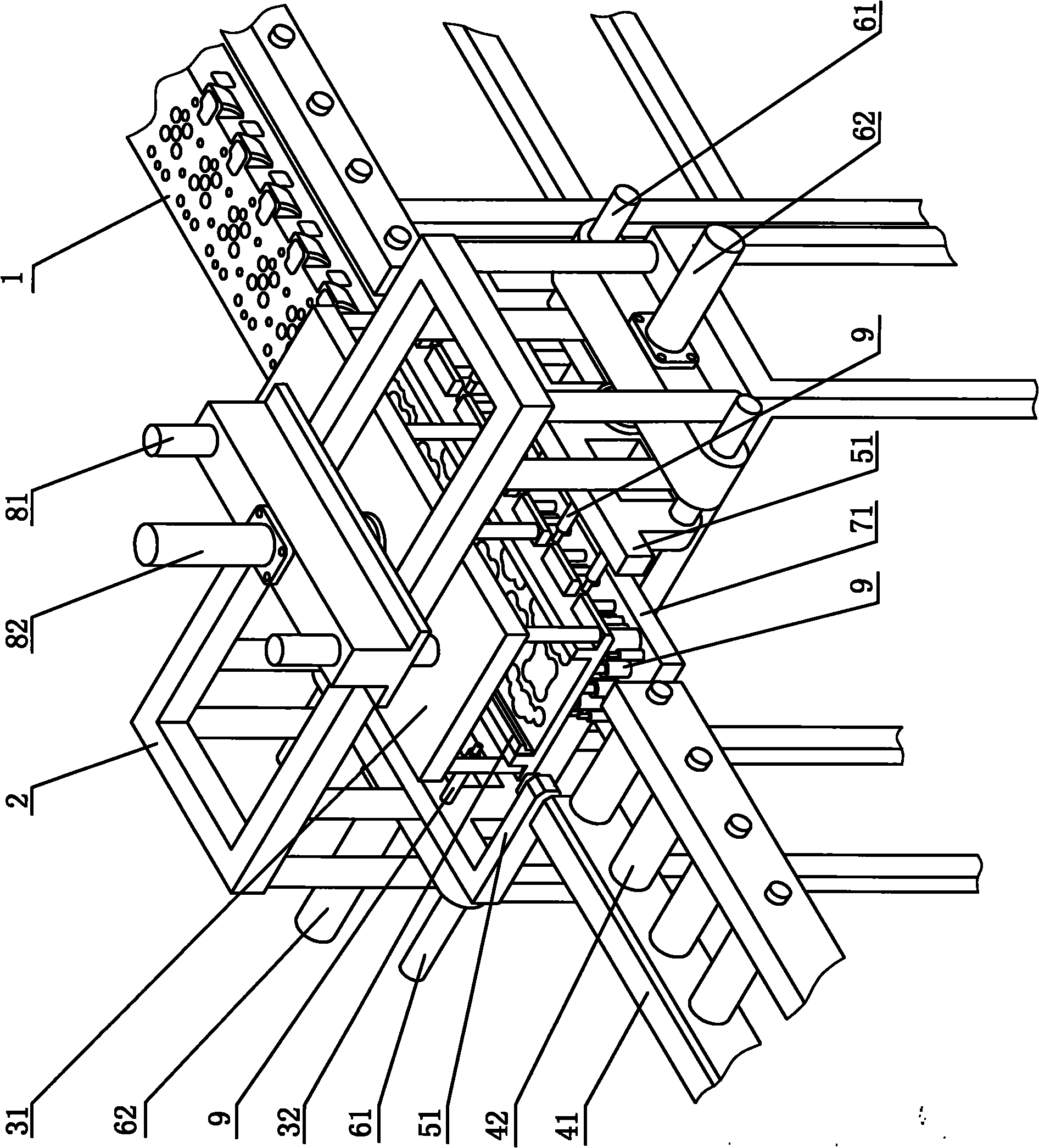

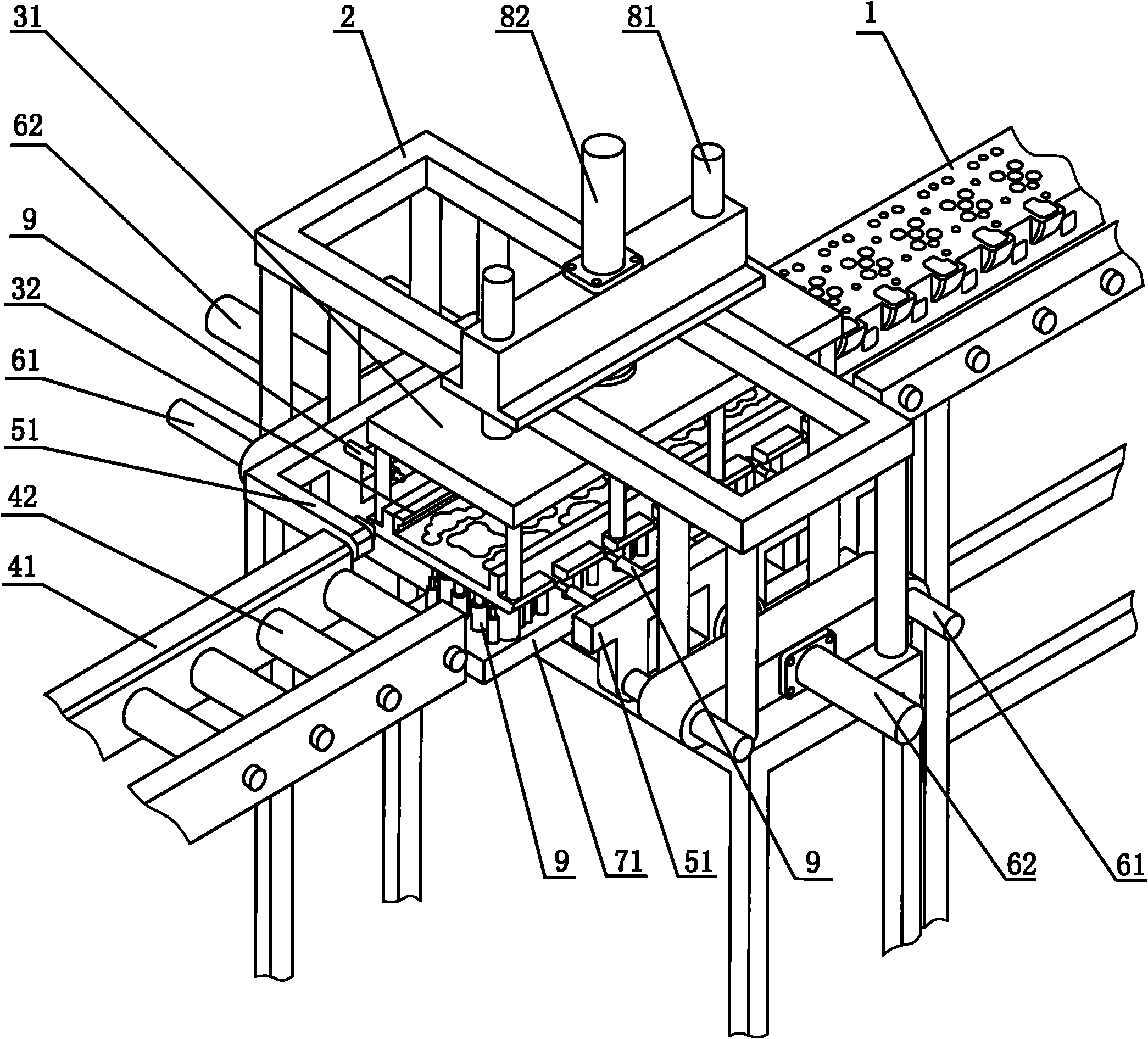

Automatic cleaning device for inner hole of cylinder cover

InactiveCN101982651ASuitable for mass productionSmall pressure lossMachines/enginesEngine componentsBatch productionEngineering

The invention discloses an automatic cleaning device for an inner hole of a cylinder cover, which is used for cleaning the inner hole of the cylinder cover. The automatic cleaning device comprises a rack; a cylinder cover cleaning bracket is arranged on the rack; the cylinder cover cleaning bracket is provided with a cylinder cover feeding end and a cylinder cover discharge end; the cylinder cover feeding end and the cylinder cover discharge end are connected with a cylinder cover conveying device respectively; at least one telescopic cleaning device capable of extending to the inner hole of the cylinder cover for cleaning is arranged on the rack; and a telescopic driving device is arranged between the telescopic cleaning device and the rack. The cylinder cover enters the cylinder cover cleaning bracket through the cylinder cover conveying device, and the spray head part of each cleaning device enters the inner hole of the cylinder cover to perform spraying and cleaning, so the cleaning time is short and the cleaning efficiency is high; the cleaning solution is directly sprayed onto the hole wall in the inner hole of the cylinder cover, so the pressure loss of the cleaning solution is extremely low, and the cleaning effect is good; and the whole cleaning process does not need manual operation and has high automation degree. The automatic cleaning device has the advantages of high automation degree, good cleaning effect, high cleaning efficiency and suitability for large-batch production.

Owner:潍坊浩泰机械有限责任公司

Stripping and cleaning compositions for microelectronics

InactiveUS7928046B2No metal corrosion of the metal elementsShort cleaning timeCationic surface-active compoundsOrganic detergent compounding agentsOrganic solventQuaternary ammonium ions

Aqueous, silicate free, cleaning compositions of about pH 9 or below and method of using the cleaning compositions for cleaning microelectronic substrates, which compositions are able to essentially completely clean such substrates and produce essentially no metal corrosion of the metal elements of such substrates. The aqueous cleaning compositions of this invention have (a) water, (b) at least one of ammonium and quaternary ammonium ions and (c) at least one of hypophosphite (H2PO2−) and / or phosphite (HPO32−) ions. The cleaning compositions also may contain fluoride ions. Optionally, the composition may contain other components such as organic solvents, oxidizing agent, surfactants, corrosion inhibitors and metal complexing agents.

Owner:AVANTOR PERFORMANCE MATERIALS LLC

Method for refining lipid

InactiveCN101485365ALow viscosityImprove hydrophilic abilityEdible oils/fatsUltrafiltrationProteolytic enzymes

The invention provides a method for refining fat. The raw material fat is subjected to degumming treatment at pressure of between 0.1 and 1.0MPa at a temperature of between 25 and 55 DEG C through an ultrafiltration membrane (aperture of between 5 and 10nm) for 10 to 30 hours, is subjected to deacidifying treatment at pressure of between 0.1 and 1.0MPa at a temperature of between 25 and 55 DEG C through a nanofiltration membrane (aperture of between 0.1 and 1.0nm) for 40 to 70 hours, and is subjected to deodorization at a temperature of between 220 and 250 DEG C at pressure of between 50 and 200Pa so as to produce the refined fat. The degumming membrane is cleaned by an aqueous solution containing 0.1 to 5.0 weight percent of enzyme preparation (mixture of lipase, phosphatidase A and proteolytic enzyme), and is cleaned by water to be reused; and the deacidifying membrane is cleaned by an aqueous solution containing 0.1 to 5.0 weight percent of lipase, and is cleaned by water to be reused. The membrane permeability is less attenuated, the membranes have long service life, the process is stable, and the refined fat product has good quality.

Owner:DALIAN UNIV OF TECH

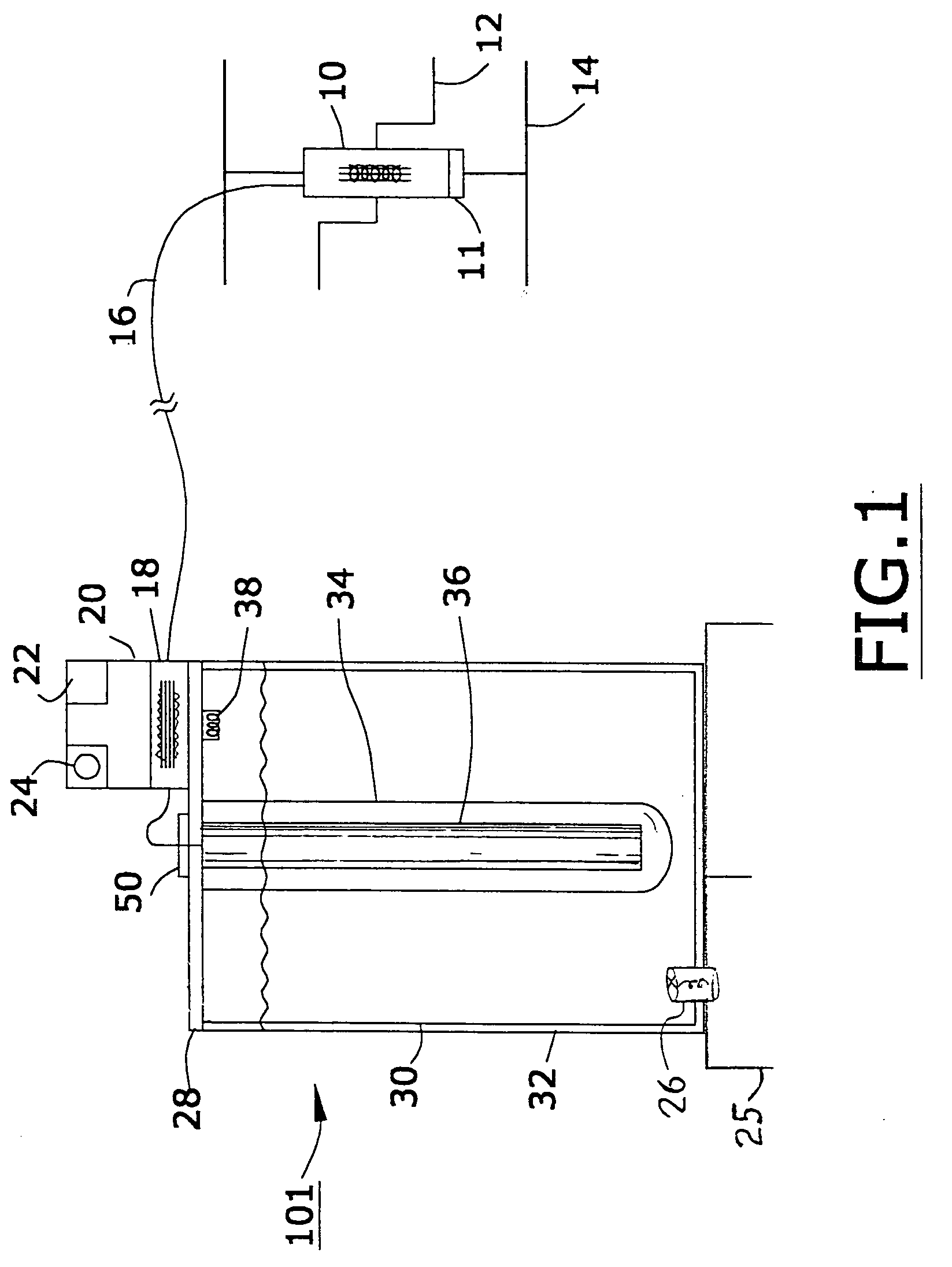

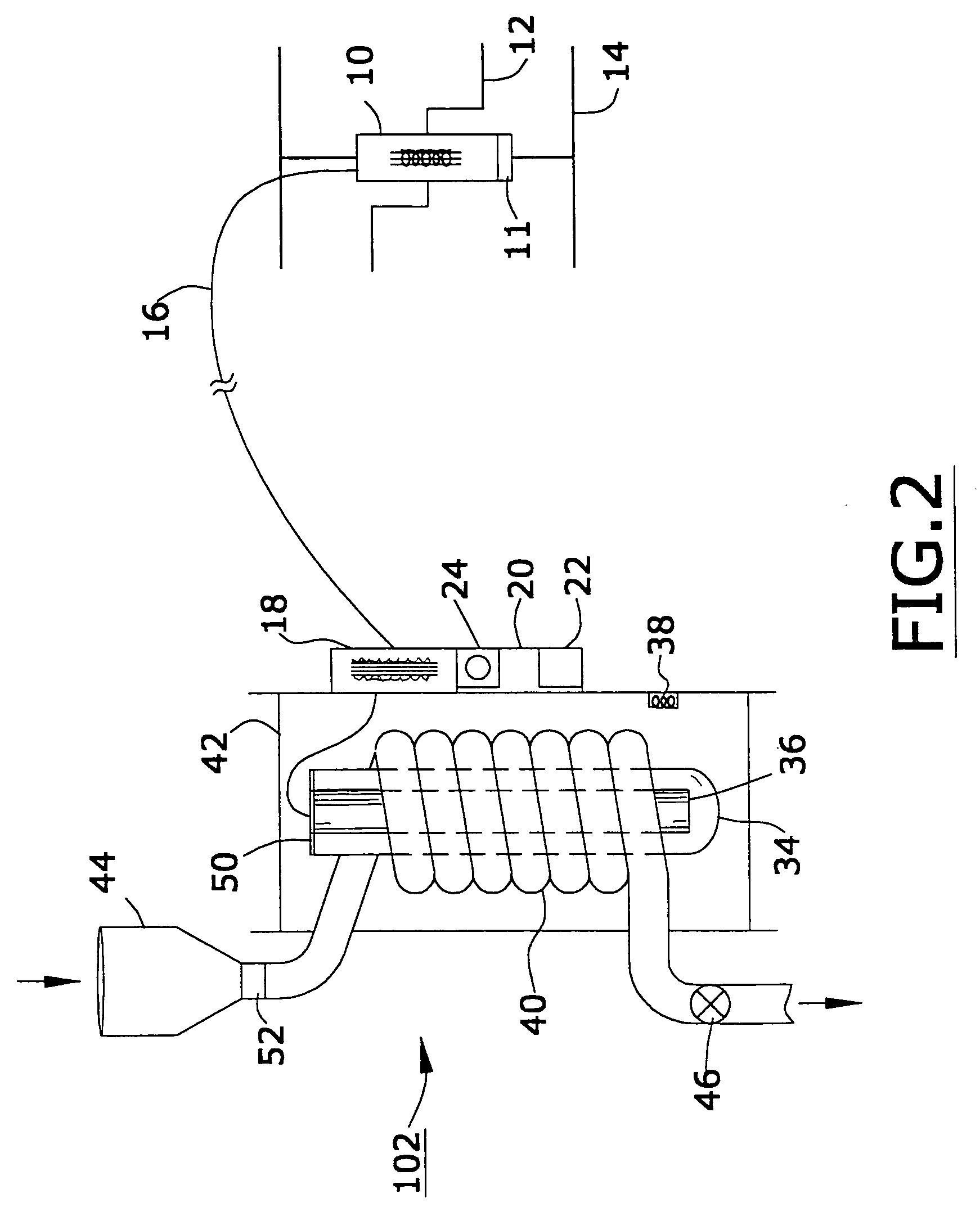

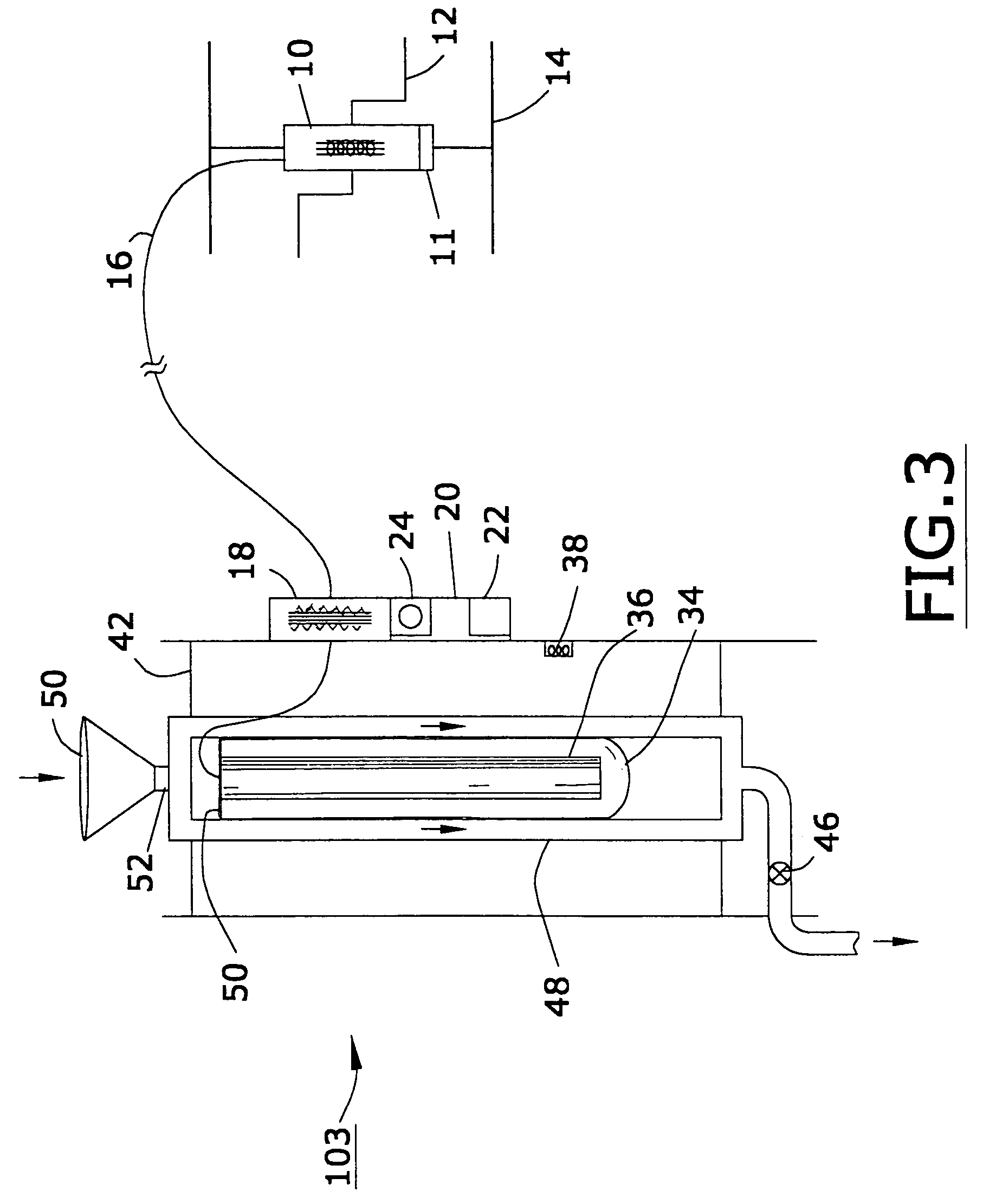

System and method for purifying water with human power

InactiveUS20050109690A1Short timeReduce transmissionWater/sewage treatment by irradiationGeneral water supply conservationUltravioletEngineering

An ultraviolet water disinfection system in which the power source to operate the system is human motion. The human power source is any form of repetitive motion such as pedaling, stepping, cranking, winding, shaking, etc. This repetitive motion is converted to electrical energy of sufficient magnitude to power a small water disinfection system using ultraviolet irradiation principles.

Owner:BECHTOLD ROBERT M

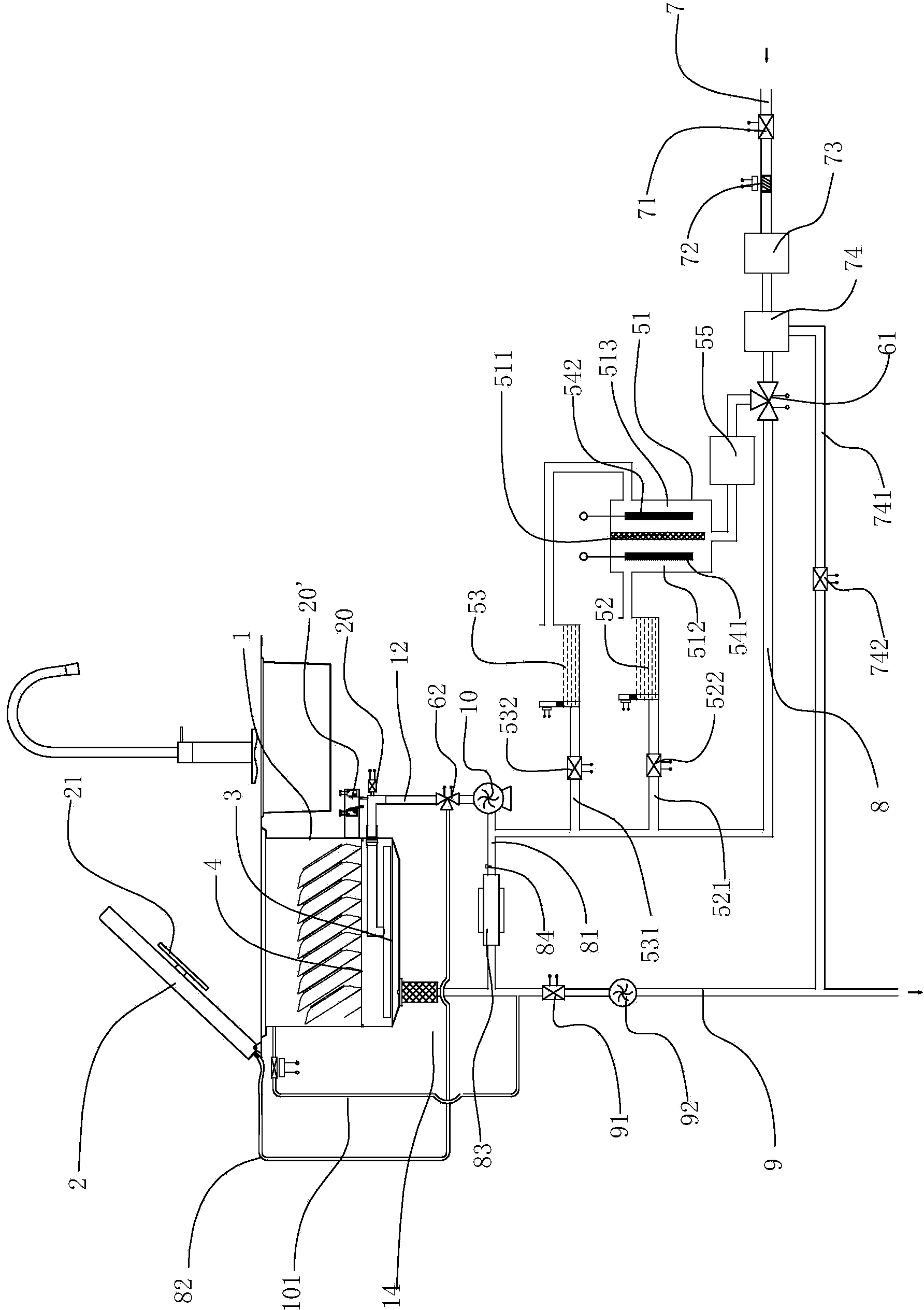

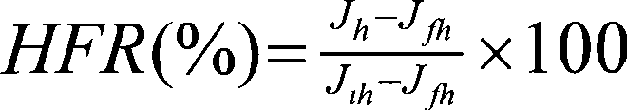

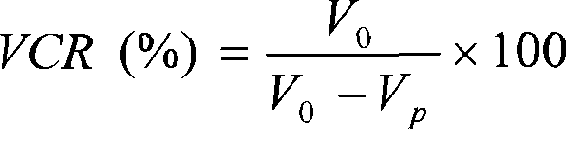

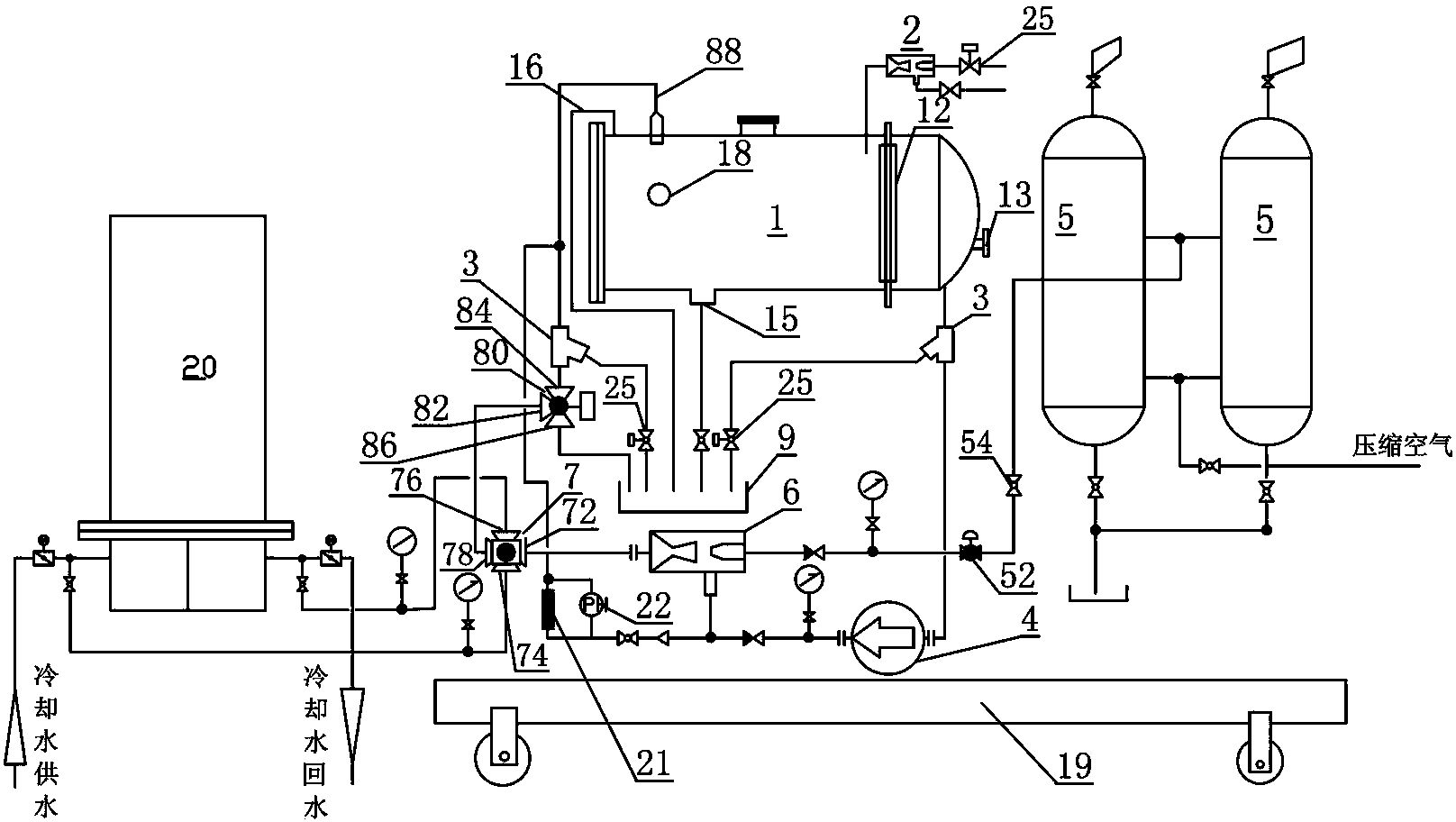

Pulse circulation cleaning device for heat exchanger and using method thereof

ActiveCN104048556AImprove heat transfer efficiencyClean up thoroughlyFlush cleaningFluid phaseBuffer tank

The invention provides a pulse circulation cleaning device for a heat exchanger and a using method thereof. The pulse circulation cleaning device for the heat exchanger is characterized by comprising a gas buffering tank, a pulse generator, a gas and liquid mixer and a switching valve. The gas buffering tank is used for providing compressed air. An air inlet of the pulse generator is connected with an air outlet of the gas buffering tank. The gas and liquid mixer is provided with a gas phase inlet, a liquid phase inlet and a gas and liquid outlet. The liquid phase inlet is connected with an outlet of a cleaning pump. The switching valve is provided with a water inlet, a drainage opening, a circulating water supply opening and a circulating water return opening. The water inlet is connected with the gas and liquid outlet. The invention further provides a method for using the cleaning device for cleaning the heat exchanger. According to the cleaning device, the gas-liquid pulse cleaning technology, the chemical circulation cleaning technology and the circulation cleaning technology are combined, and therefore the pulse circulation cleaning device has the advantages of being high in cleaning efficiency, good in adaptability, low in cleaning cost, easy and convenient to use and operate and the like, and various heat exchangers can be cleaned without shutting down a unit.

Owner:郑州赛为机电设备有限公司

Method for cleaning heat exchangers

InactiveCN106032966AShort cleaning timeGood effectNon-surface-active detergent compositionsMetallic material coating processesAcetic acidGlycollic acid

The invention provides a method for cleaning heat exchangers. The method comprises a step of alkali wash: alkaline degreaser and antifoam agent are added and cyclic cleaning is performed for a first preset duration under 40 to 50 DEG C; a step of acid wash: an acid wash solution comprising nitric acid with mass fraction of 2% - 4%, citric acid with mass fraction of 0.5%-1%, glycollic acid with mass fraction of 1%-2.5%, HEDP with mass fraction of 0.5%-1%, sulfated oil with mass fraction of 0.3%-0.5% and balance of water is prepared; the acid wash solution is added after the alkali wash waste solution is discharged and cyclic cleaning is performed for a second preset duration under 50 to 60 DEG C. The provided method has good cleaning effect and short cleaning time.

Owner:SAE TECH DELEVOPMENT DONGGUAN

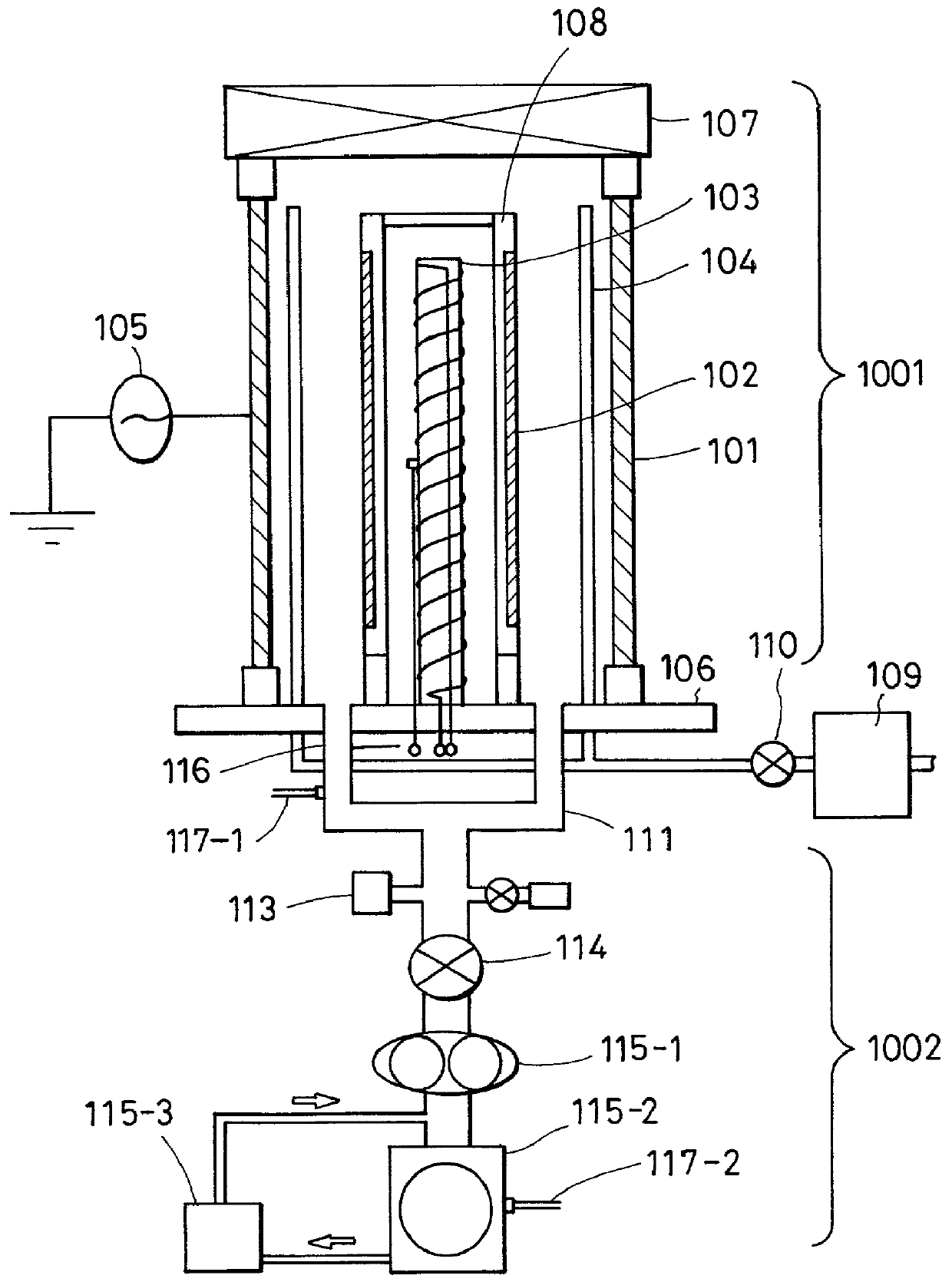

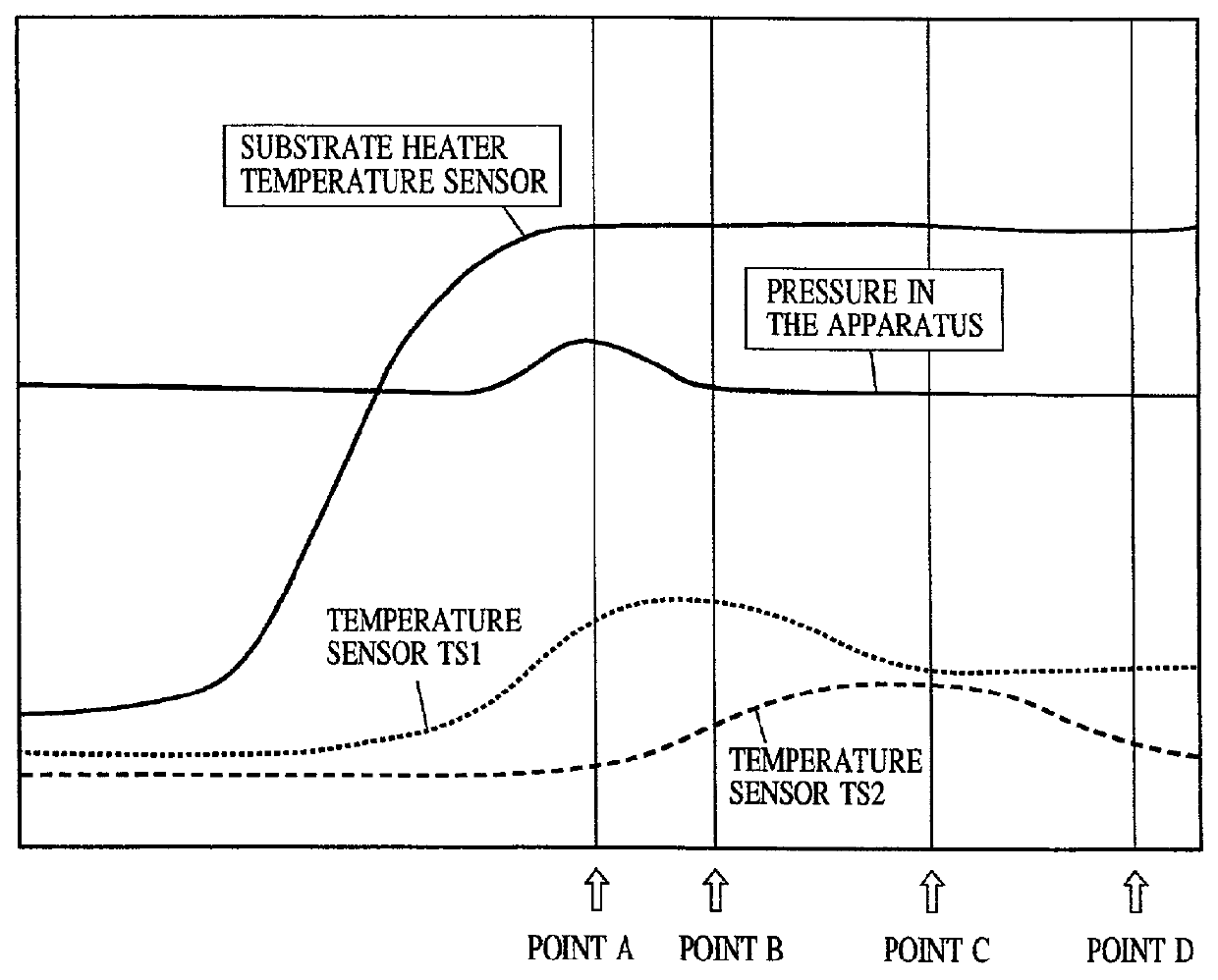

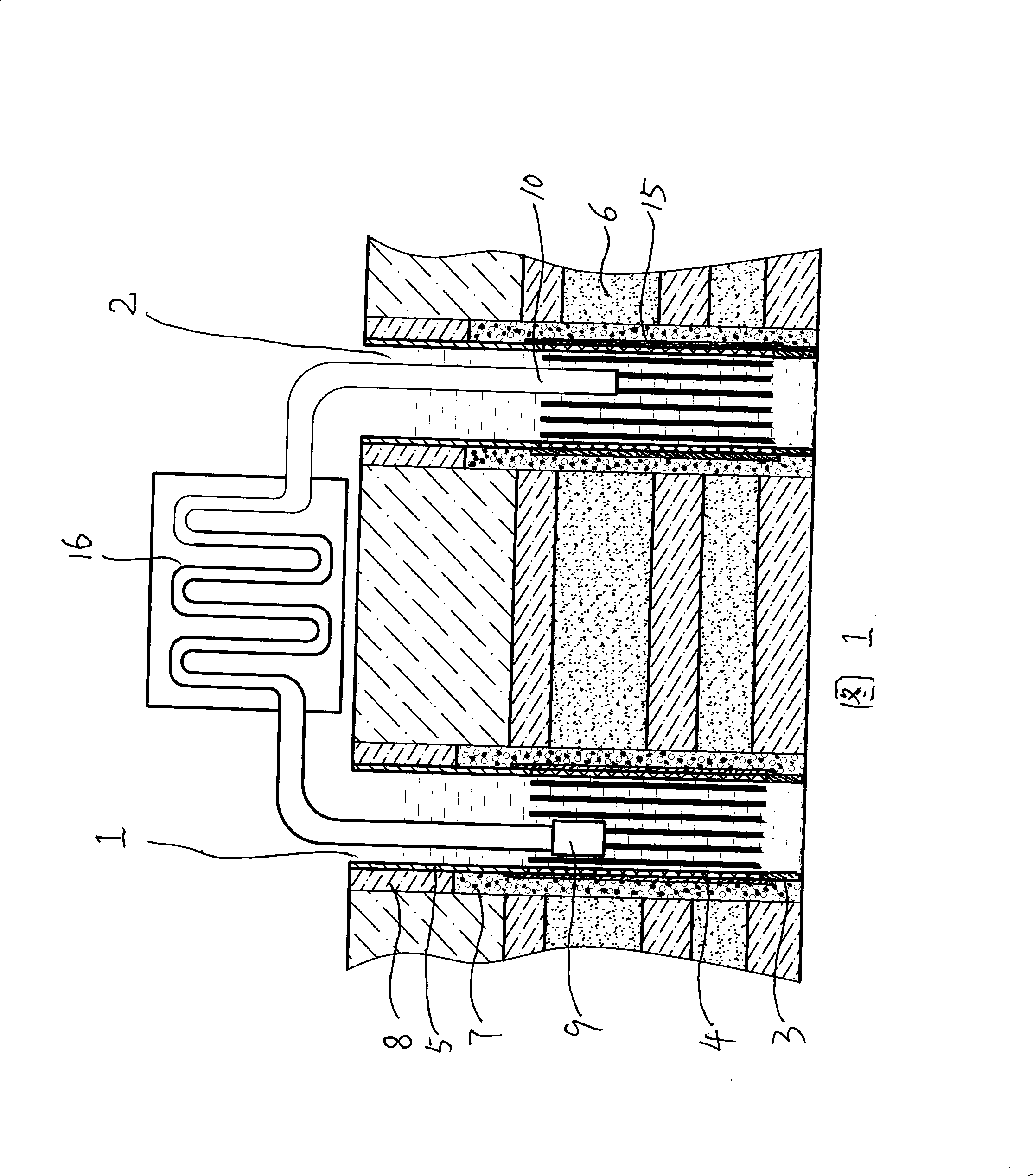

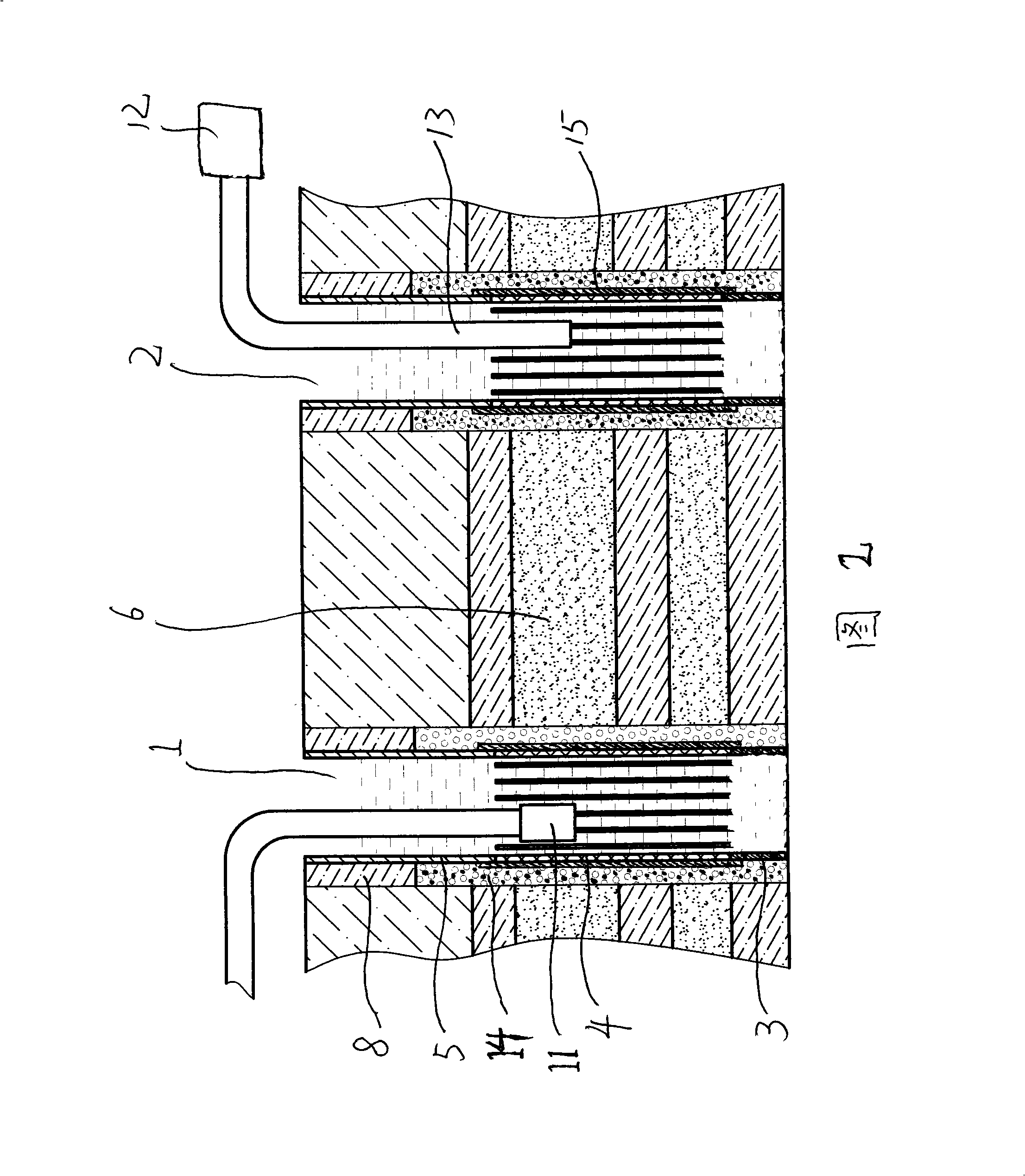

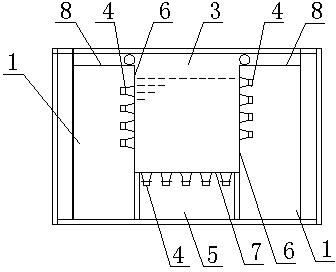

Method of cleaning a film deposition apparatus, method of dry etching a film deposition apparatus, and an article production method including a process based on the cleaning or dry etching method

InactiveUS20010054430A1Good repeatabilityImprove responseLighting and heating apparatusVacuum gauge using ionisation effectsHigh frequency powerEngineering

Owner:CANON KK

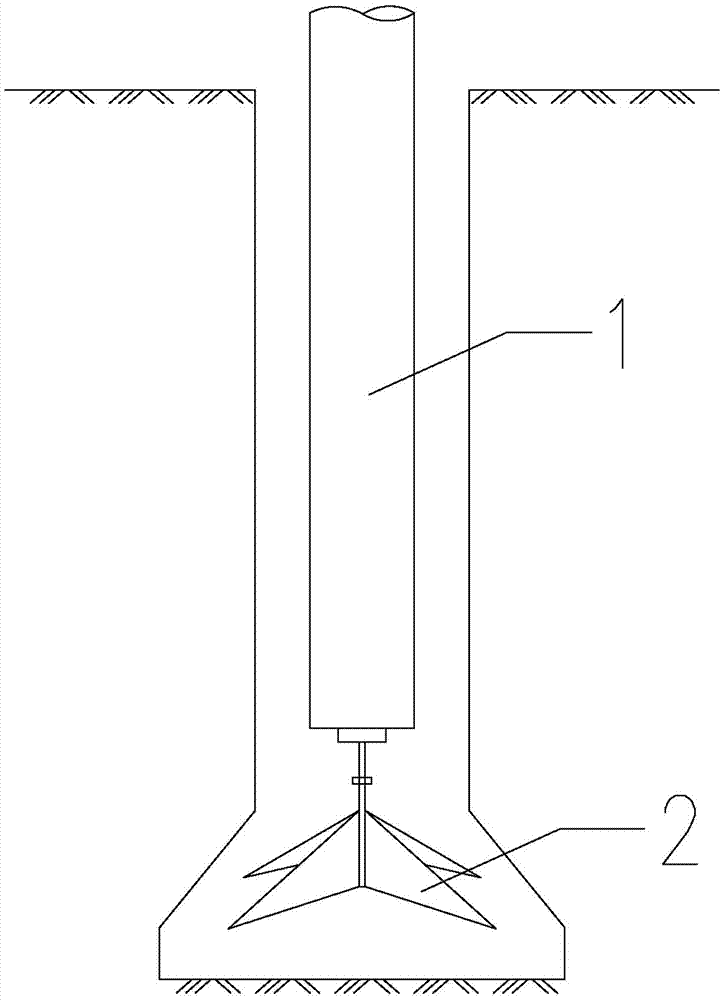

Ground water back pouring cyclic utilization method

InactiveCN101298945ACreate pollutionIncrease pressureOther heat production devicesGeothermal energy generationFlushing timeGroundwater recharge

The invention belongs to the technical field of the groundwater recharge cyclic utilization method, particularly discloses a groundwater recharge cyclic utilization method, which is characterized by determining the depth of the pumping well and drilling a recharge well borehole having the same depth with the pumping well in the precipitation action radius of the pumping well, according to the local hydrogeology. The well pipe is fixed in the borehole according to the sequence of a sedimentation pipe, a strainer and a case pipe, then filter material, the killing well and the flushing are filled in turn, finally a pumping device and a recharging device are arranged, which forms a circular loop in the water pumping and recharging process. In the flow process of the groundwater, the temperature rises or lowers; and flushing is performed again after killing well, the flushing time is short and complete, and the groundwater does contact with the outside, which does not pollute the groundwater after recharging. The invention not only is suitable for the puaternary system stratal configuration, also suitable for the tertiary stratal configuration of the pottery and the Minghua town.

Owner:刘娇娜

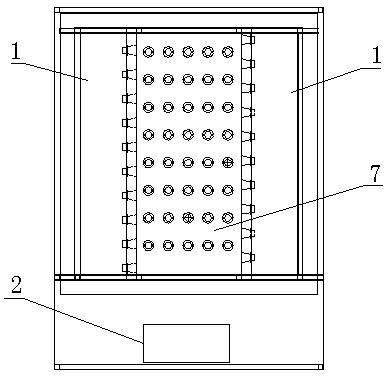

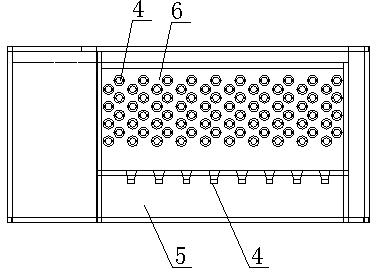

ultrasonic cleaner

InactiveCN102274838AReduce noiseImprove cleaning rateCleaning using liquidsElectrolysisMegasonic cleaning

The invention discloses an ultrasonic cleaning machine, which comprises a cleaning tank, vibrator chambers are respectively arranged on both sides of the cleaning tank, the cleaning tank and the vibrator chamber are separated by side partitions, several vibrators are respectively arranged on the outer walls of the partitions on both sides, the cleaning tank A bottom vibrator chamber is arranged under the bottom partition, and several vibrators are arranged on the bottom surface of the bottom partition; all the vibrators are connected to the ultrasonic generator. The invention overcomes the defects of high labor intensity and low work efficiency of the existing manual and semi-mechanized cleaning of electrolysis cathode plates, and is suitable for batch cleaning of electrolysis cathode plates and other similar items.

Owner:湘潭大众整流器制造有限公司

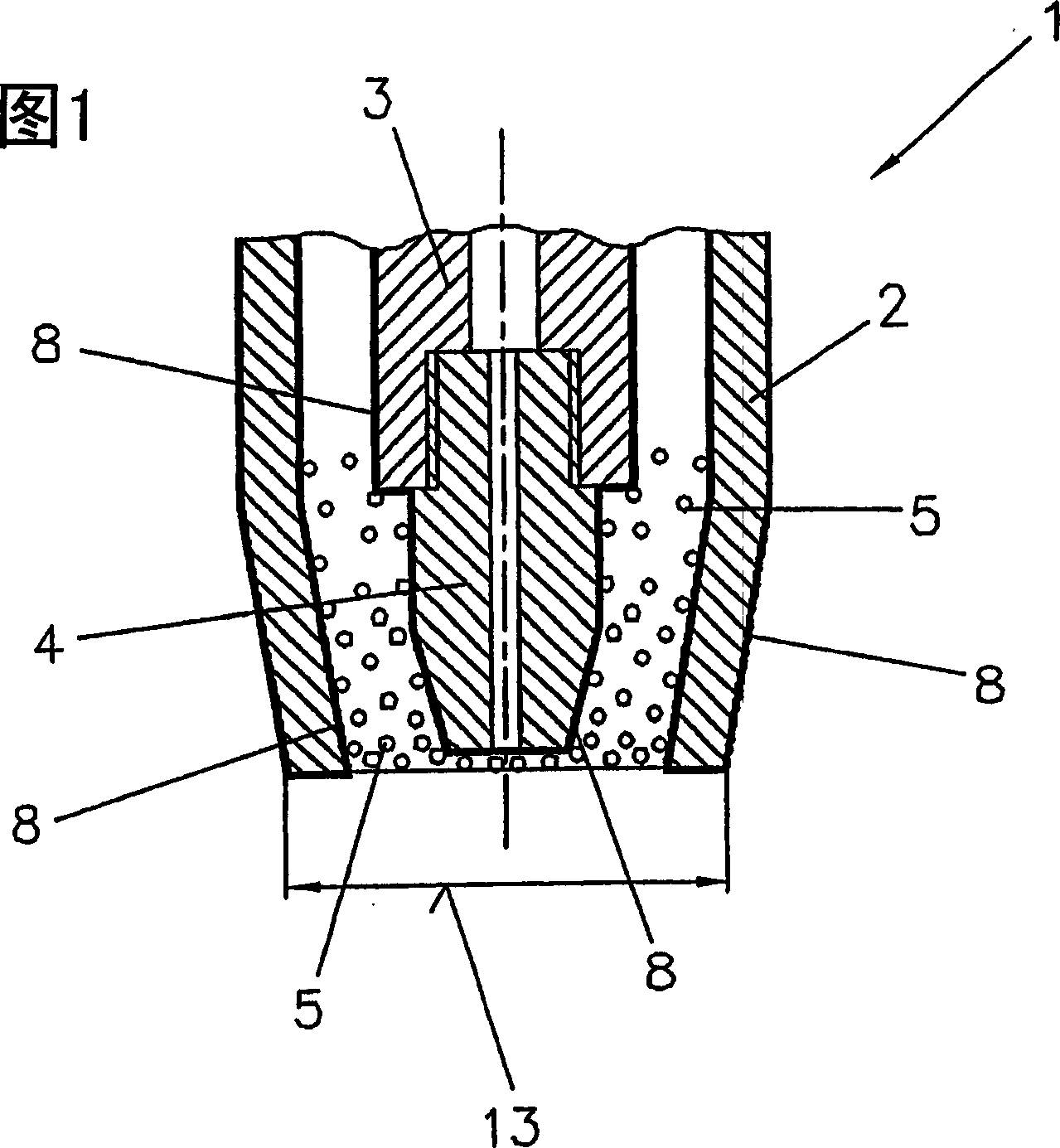

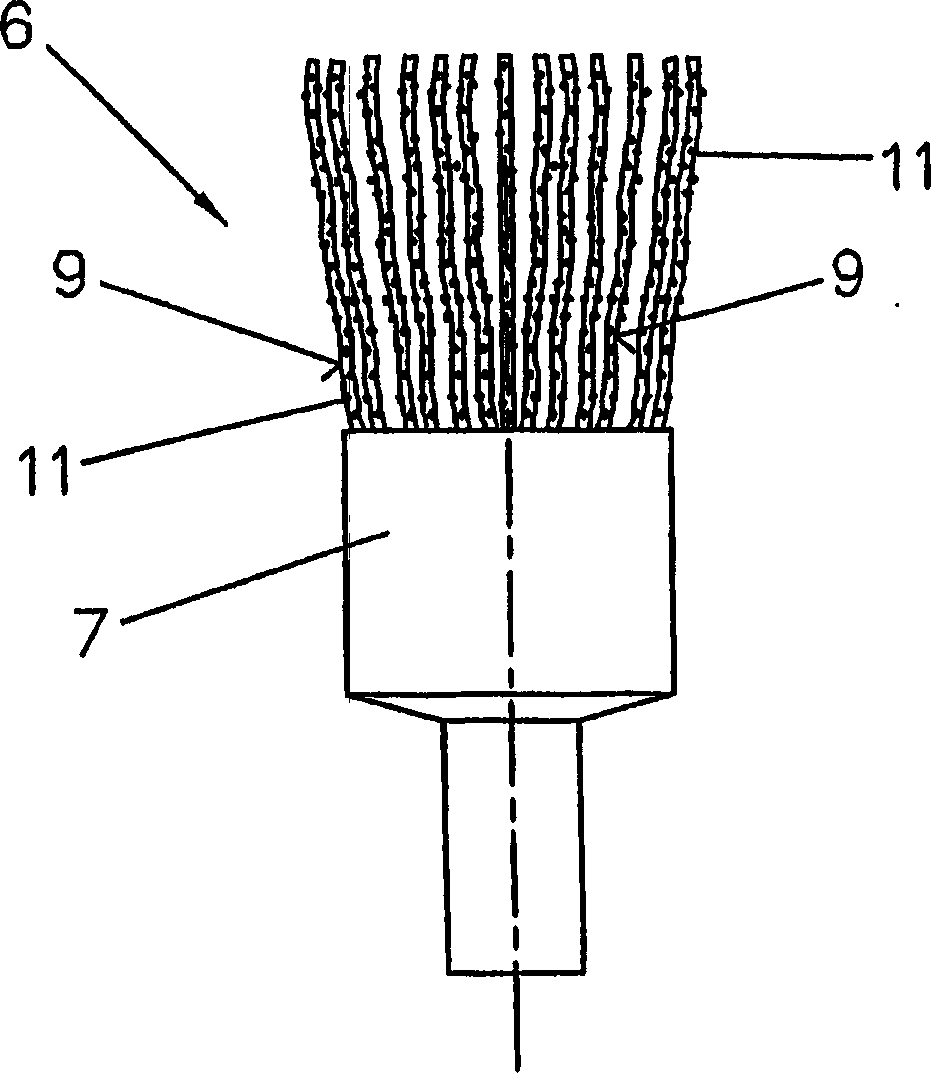

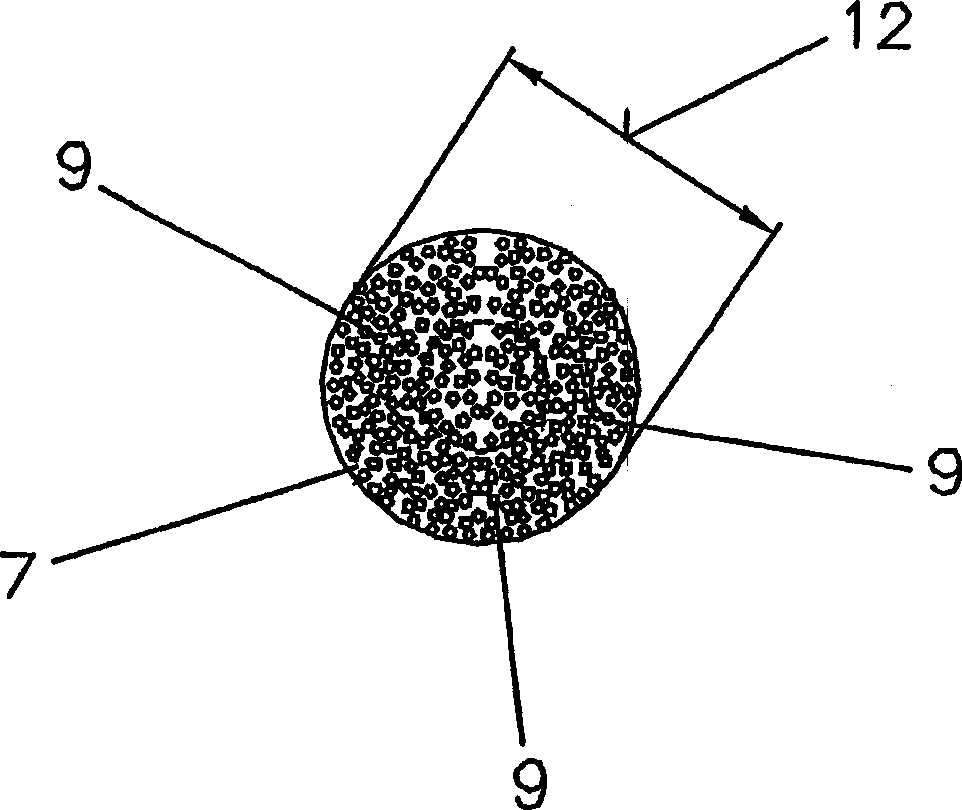

Gas nozzle for a welding torch, welding torch having a produced patina layer; cleaning device for a welding torch having bristles made of a soft elastic material and abrasive grains embedded in these

The invention relates to a gas nozzle (2) and a welding torch (1) equipped with said gas nozzle (2), a nozzle assembly (3) and a conductive tube (4), said gas nozzle (2), nozzle The component ( 3 ) and the conductive tube ( 4 ) have an artificially produced patina ( 8 ) on at least a partial area of their surface for the purpose of reducing the adhesion of welding spatter. The invention also relates to a cleaning device for a welding torch (1) having a brush with bristles. These bristles are made of a very soft elastic material, preferably plastic, and abrasive particles are embedded in said bristles.

Owner:FRONIUS INTERNATIONAL GMBH

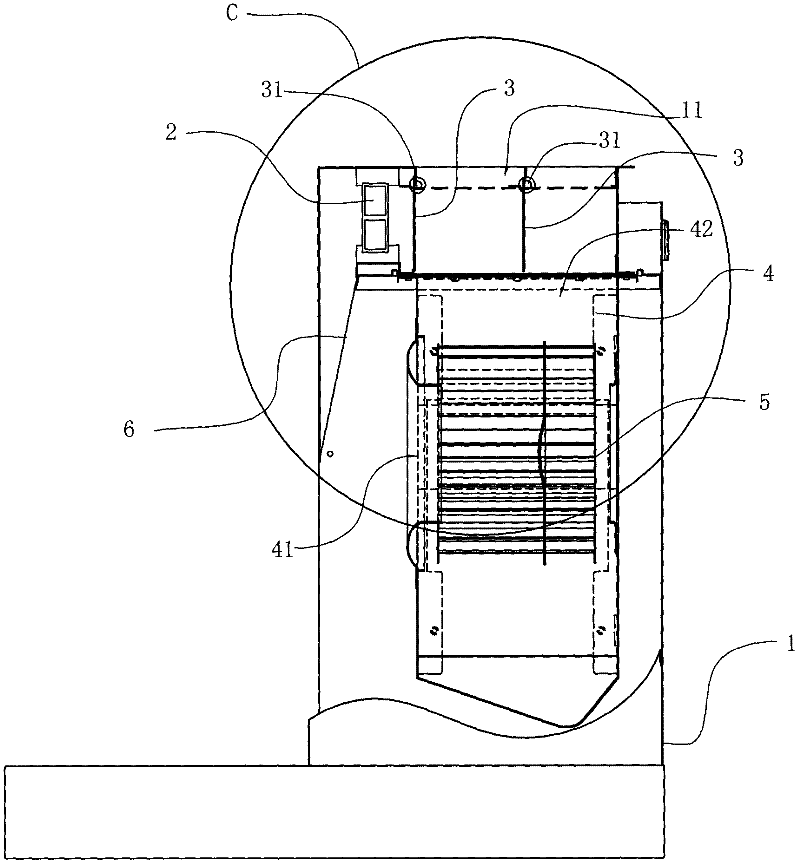

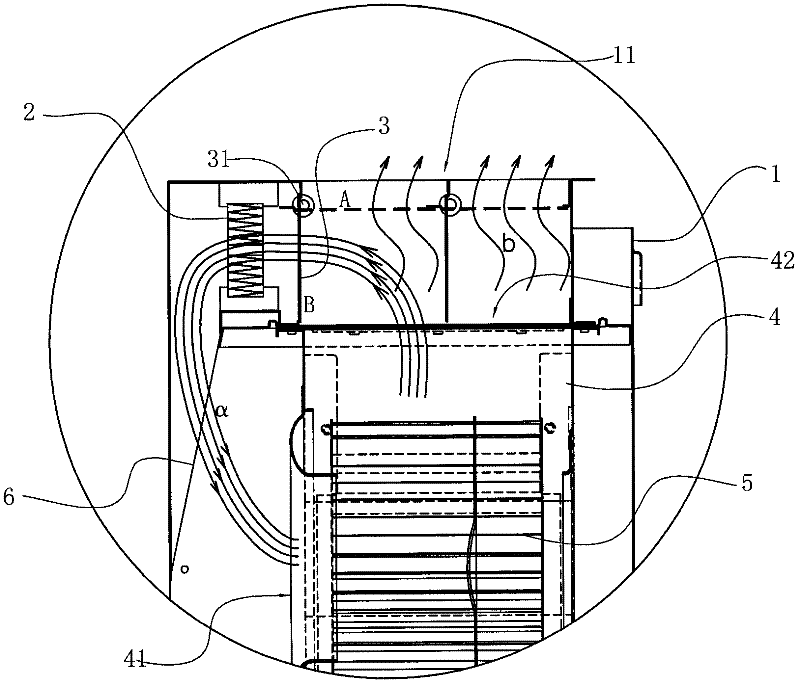

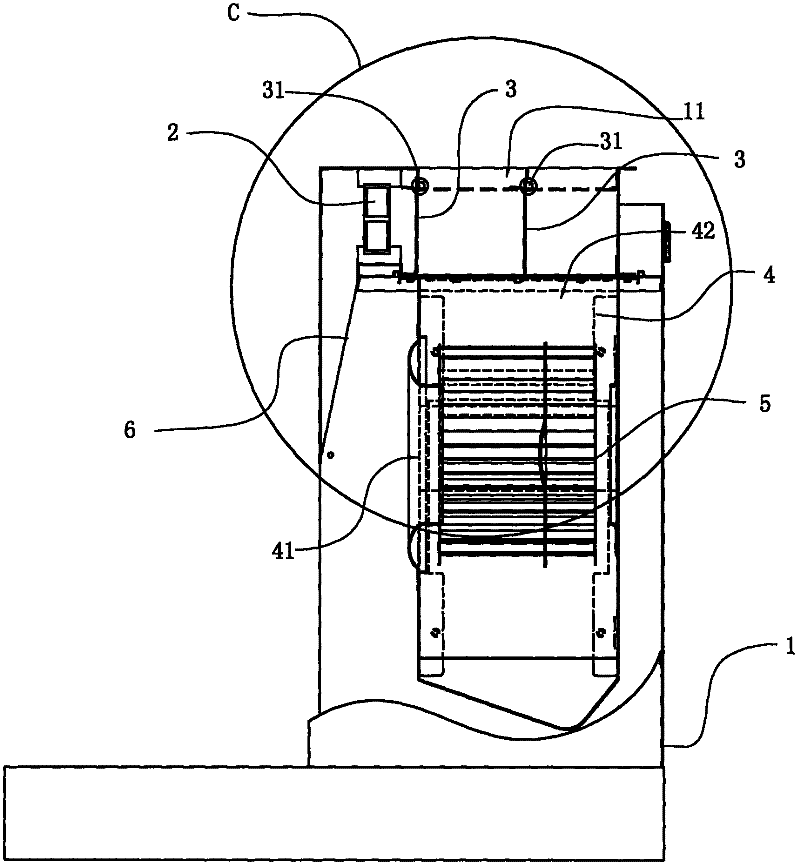

Range hood self-cleaning device

ActiveCN102287858ASimple structureLow costDomestic stoves or rangesLighting and heating apparatusImpellerInner loop

The invention discloses a self-cleaning device of a range hood. The device comprises a heating device which is positioned in a shell of the range hood, and is characterized in that the heating device is positioned at the outer side of a volute of the range hood; an internal recycle channel is formed between the heating device and the volute of the range hood; and the internal recycle channel and a smoke discharge channel of the range hood are separated mutually and are not smooth simultaneously. The self-cleaning device of the range hood provided by the invention not only has a simple structure and low cost, but also the heating device is far away from the volute, the device can be heated efficiently and rapidly, and the cleaning time is shorter; the volute and an impellor can be heated together through the internal recycle wind in the range hood, the self-cleaning effect is improved, and the self-cleaning time is improved; and only when the heating device is cleaned, greasy dirt passes, the accumulation of the greasy dirty on the surface of the heating device is prevented, the safety problem of greasy dirt ignition caused by the overheating of the heating device is prevented, and the safety performance of the self-cleaning device is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

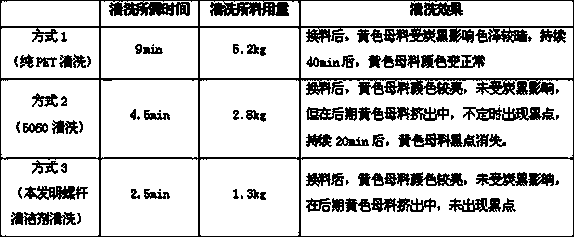

Cleaning agent for screw extruder and preparation method thereof

InactiveCN103555471AShort cleaning timeLess cleaning materialsSurface-active non-soap compounds and soap mixture detergentsComposite materialPolymer chemistry

The invention provides a cleaning agent for a screw extruder. The cleaning agent is characterized in that the cleaning agent mainly containing an inorganic mineral micro fiber powder body comprises the following ingredients in parts by weight: 50-60 parts of micro fiber powder body, 20-30 parts of inorganic adsorbent, 5-10 parts of activator, 3-5 parts of lubricant and 1-2 parts of dispersant. The invention further provides a preparation method of the cleaning agent for the screw extruder; the method comprises the following steps of micro-dispersing the micro fiber powder body by a vertical jet micro-pulverizer and activating and modifying the by using the activator to obtain a micro fiber brush; and the method is characterized in that the micro fiber brush obtained due to the activation and the modification by using the activator can promote the activator to permeate into the stubborn carbon deposit and dust deposit so as to activate the carbon deposit and the dust deposit, and the inorganic absorbent slightly expands to absorb various activated granular impurities and rapidly remove the impurities out of the screw by adhesion. The cleaning agent has the characteristics of good cleaning effect, high cleaning speed, and no new resin residues, can be applied to the cleaning of the screw extruders in the industries of plastic, rubber, food and the like, and is especially suitable for the cleaning of various types of resin.

Owner:东莞市振大塑胶科技有限公司

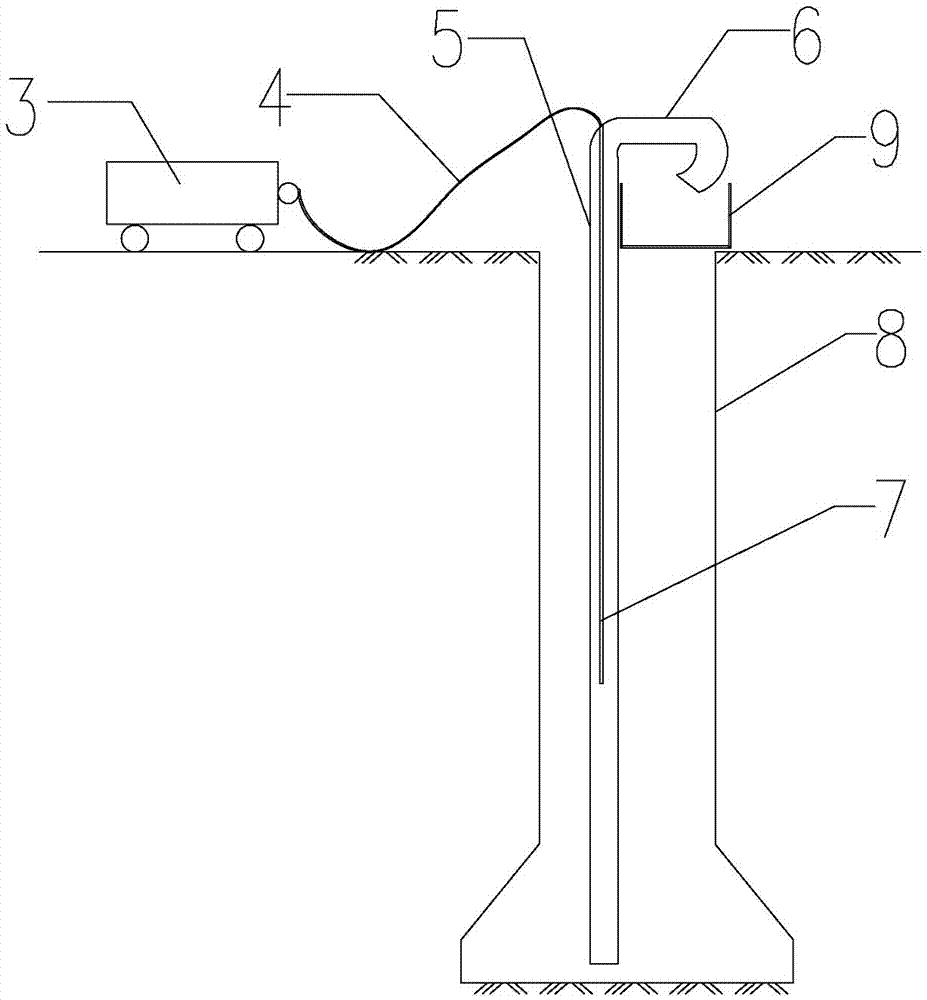

Rotary-drilling and bottom-expanding construction process for cast-in-place pile

The invention discloses a rotary-drilling and bottom-expanding construction process for a cast-in-place pile. A rotary drilling rig is adopted to conduct rotary drilling to form a hole, helix pieces in the middle of a drill bit of the rotary drilling rig are equal in diameter, and the diameters of helix pieces on the upper portion and the lower portion of the drill bit are gradually reduced. The construction process includes the steps of setting-out positioning, in-place arrangement of the rotary drilling rig, primary drilling, burying of a steel casting, rotary drilling and hole forming, bottom expanding, hole clearing, hoisting and arranging of a reinforcement cage, installation of a guiding pipe, concrete pouring and the like. According to the rotary-drilling and bottom-expanding construction process for the cast-in-place pile, construction is convenient, the dimension is accurate, and the quality is good.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Cleaning agent for flue dust scale on surface of gas heat exchanger of gas desulfurization system and preparation method thereof

InactiveCN101892489AThorough cleaning and descalingShort cleaning timeCleansing AgentsHydroxyethylidene Diphosphonic Acid

The invention discloses a cleaning agent for flue dust scale on the surface of a gas heat exchanger of a gas desulfurization system and a preparation method thereof. The cleaning agent is characterized by comprising the following components in percentage by mass: 5 to 25 percent of main cleaning agent, 3 to 15 percent of auxiliary cleaning agent, 2 to 10 percent of release agent, 2 to 8 percent of corrosion inhibitor, and the balance water, wherein the main cleaning agent is one or two of nitric acid, hydrochloric acid and sulfuric acid; the auxiliary cleaning agent is more than one of methanoic acid, acetic acid, ethylene diamine tetraacetic acid, sulfamic acid, glycollic acid, oxalic acid and hydroxyethylidene diphosphonic acid; the release agent is one of dodecyl dimethyl benzyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride and distearyl dimethyl ammonium chloride; and the corrosion inhibitor is pickling inhibitor. The cleaning agent can realize online cleaning at normal temperature, complete scale removal, short cleaning time, lower cleaning cost and no corrosion to enamel on the surface of a heat exchange element.

Owner:广州普凯热伏微能源科技有限公司

Chemical cleaning method of heat exchanger

The invention provides a chemical cleaning method of a heat exchanger, which is short in cleaning time and low in corrosive property. The chemical cleaning method comprises the following steps: (1) configuring a pipe for the heat exchanger in the shutdown state of a cooling system, and connecting a liquid preparation tank and a cleaning pump to the outside of the configured pipe to form a closed system for pump circulation cleaning; (2) adding soaking liquid obtained by mixing a dispersion chelating agent with a stripping agent into the closed system in the step (1), and soaking the heat exchanger for 1 hour; (3) selecting corresponding acid and corrosion inhibitor according to the material of the heat exchanger, adding the acid and the corrosion inhibitor into the soaking liquid of the closed system in the step (1) to form cleaning liquid, performing pump circulation acid-washing for 2-3 hours, and properly prolonging or shortening the acid-washing time according to the scale formation thickness; and (4) adjusting the pH value of the cleaning liquid in the step (3) to be about 7 by using sodium hydroxide, discharging, and flushing to finish the cleaning process.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

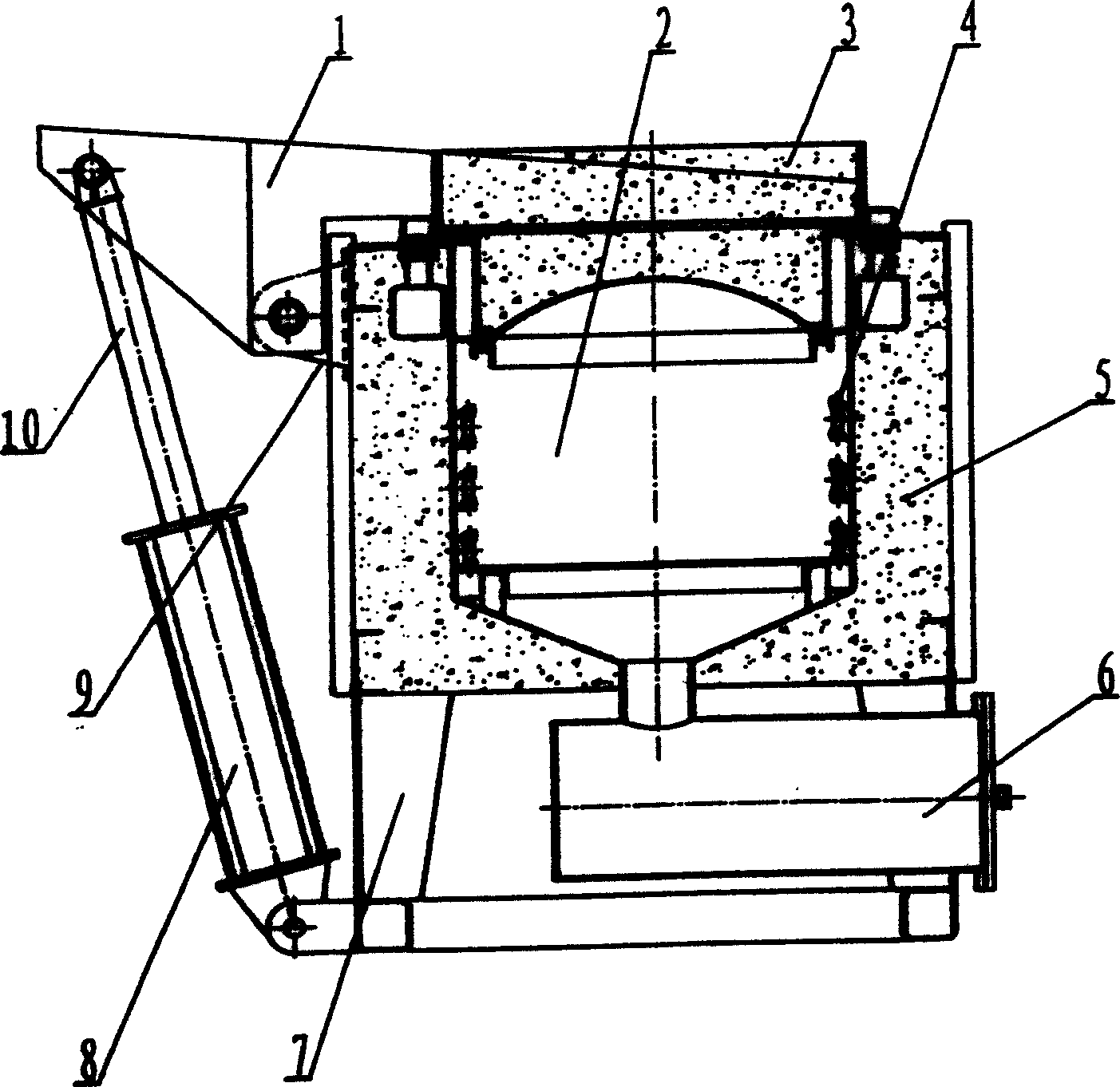

Rectangular vacuum cracking washing furnace with conveniently opening and closing lid

InactiveCN1752297AShort cleaning timeEasy to cleanFurnace componentsSpinnerette packsReciprocating motionEngineering

The invented rectangular vacuum cracking cleaning furnace contains vertical furnace cavity, furnace body, furnace cover, heating element, waste material collecting tank, in which the vertical furnace cavity is communicated with waste material collecting tank, on the furnace body a lever is movably mounted, one end of the lever is fixed on the furnace cover, another end of said lever is movably connected with piston rod, the cylinder body is movably matched with piston rod, one end of said cylinder body is movably connected with furnace body support, and the heating element is placed on the inner wall of vertical furnace cavity.

Owner:盐城化纤机械有限公司

A household dishwasher

InactiveCN102293618AShort cleaning timeImprove efficiencyTableware washing/rinsing machine detailsDish washer applicanceElectricityEngineering

The invention relates to a domestic bowl washing machine, which comprises an upper cover, a tube body, a bottom case, an internal cleaning device and an external cleaning device, wherein the upper cover is overlapped on the upper end surface of the tube body, the lower edge of the upper cover is provided with a convex lug, the convex lug is rotatablely connected with the tube body, the bottom case is fixedly connected with the lower end of the tube body, the internal cleaning device is in contact with the upper cover, the external cleaning device is fixedly connected with the tube body and the bottom case, the internal cleaning device and the external cleaning device are coaxially arranged and are in contact with each other, and at least two symmetrically distributed guide posts are arranged in the upper cover. The domestic bowl washing machine has the advantages that the speed is high, the efficiency is high, the cleaning is clean, the effect is good, the function is complete, the electricity, the water and the time are saved, the structure is compact, the appearance is attractive, the operation is easy, the carrying and the placement are convenient, and the manufacturing cost islow.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

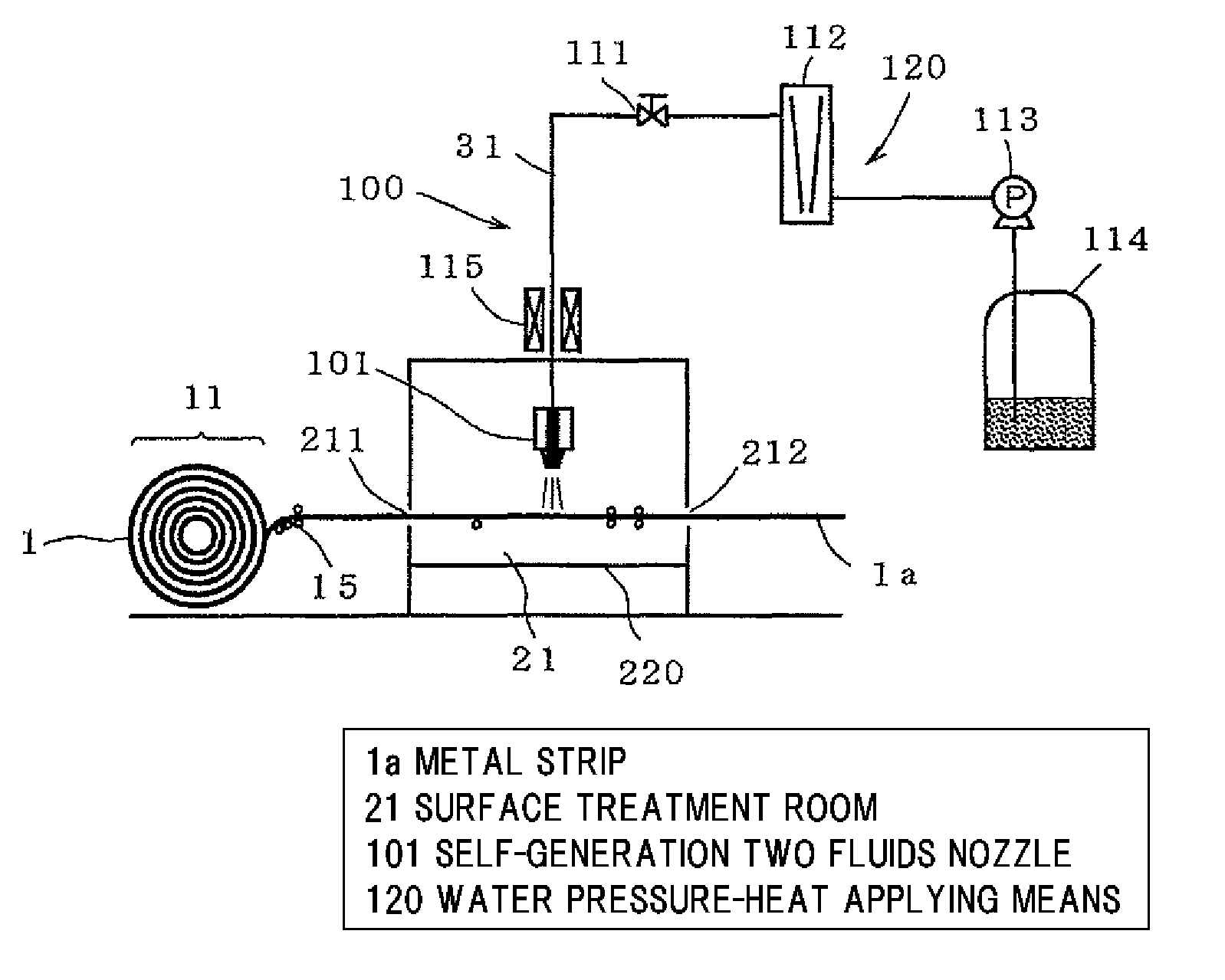

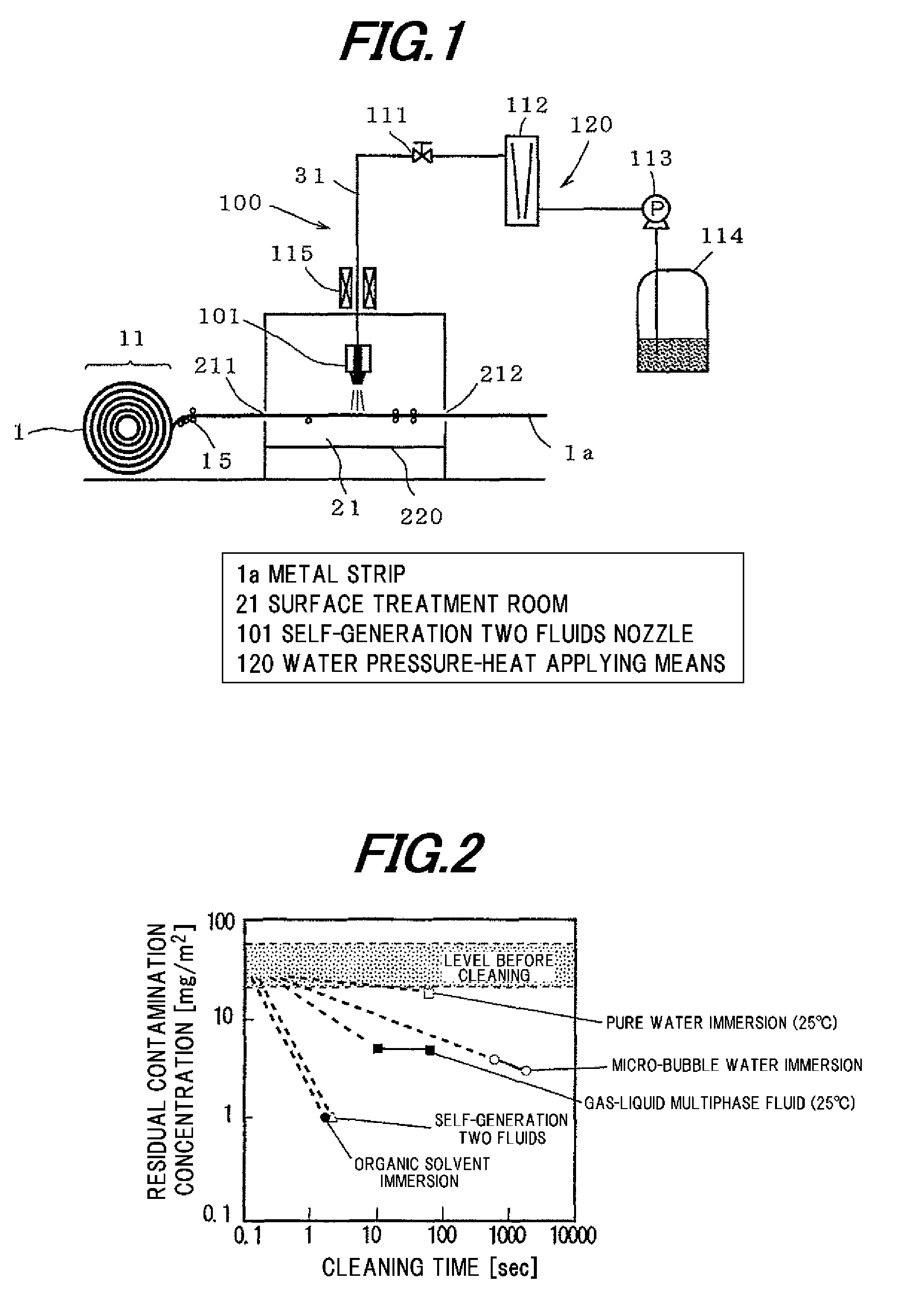

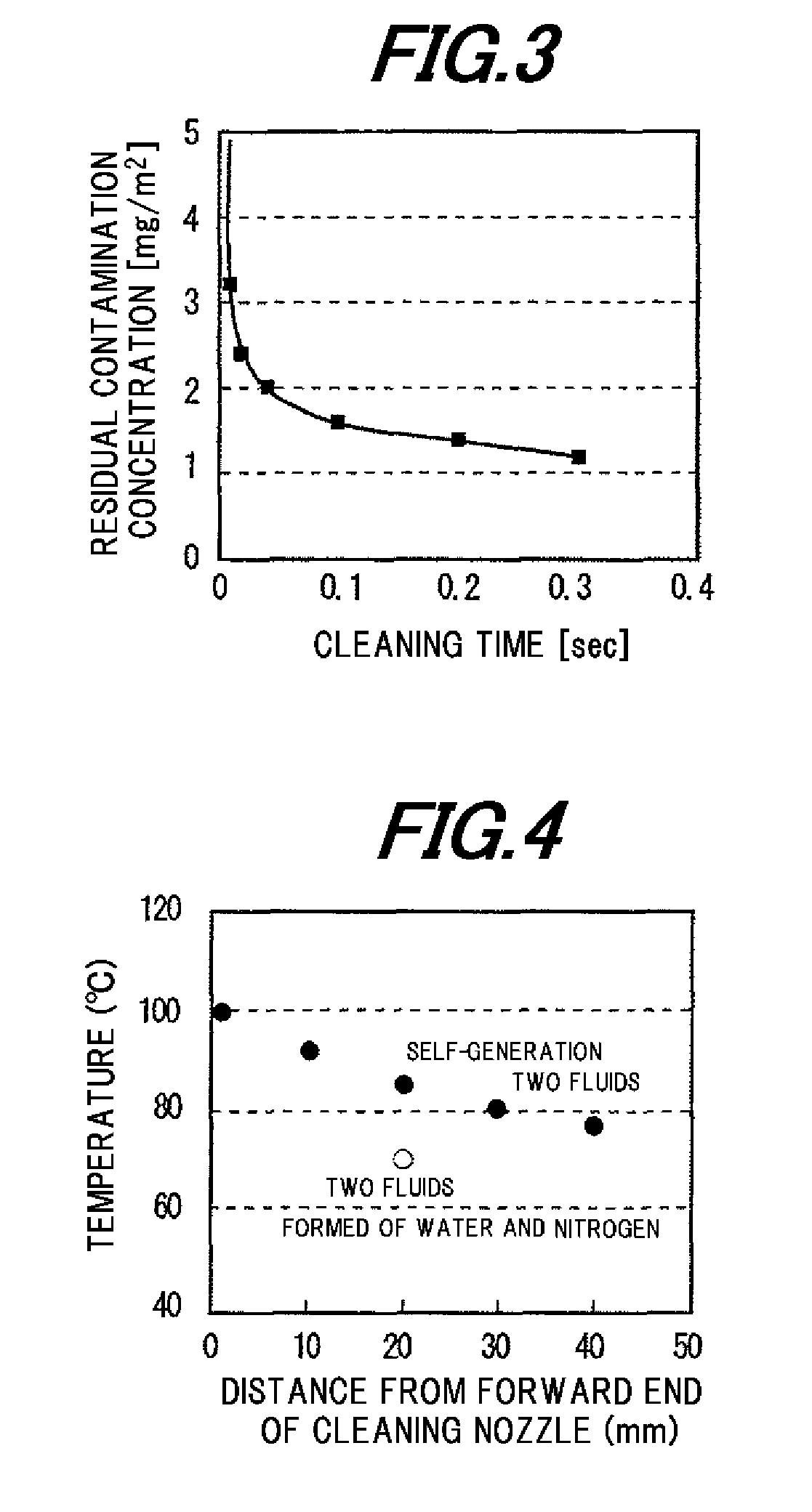

Surface treatment method of metal member and cleaning nozzle

InactiveUS20110048454A1High cleaning powerShort cleaning timeCleaning using toolsCleaning using gasesNozzleMetal

A surface treatment method of a metal member according to an embodiment of the invention includes removing an oily substance on the metal member by using gas-liquid two fluids that are obtained by boiling heated and pressured water under ordinary pressure. A surface treatment device of a metal member for removing an oily substance on the metal member includes self-generation two fluids production means for producing gas-liquid two fluids by boiling heated and pressured water under ordinary pressure, and a surface treatment room carrying out a surface treatment by bringing the self-generation two fluids into contact with the metal member.

Owner:HITACHI CABLE

Derusting and cleaning agent for non-ferro metal

The invention provides non ferrous metal derusting cleaning agent which includes phosphate, surface active agent, pH value regulator and de-ionized water. The weight percentage of each component is as follows: 5 to 10 percent of phosphate, 5 to 10 percent of surface active agent, 1 to 6 percent of pH value regulator and the rest is the de-ionized water. The pH value of the mixed liquid is ranged from 11 to 12; the non ferrous metal derusting cleaning agent has the effects of high efficiency and easy cleaning to non ferrous metals to lead the rusty spots on the surfaces of the non ferrous metals to be completely cleaned, can prevent the surfaces of the non ferrous metals from forming rusty spots again, can also shorten the cleaning time and improve the working efficiency; the non ferrous metal derusting cleaning agent is water-soluble cleaning agent, convenient for the processing and drainage of the wasted liquid after cleaning and accords with the requirements for environment protection; besides, the corrosion property to device is low; the production cost is effectively reduced; besides, the non ferrous metal derusting cleaning agent is safely and reliably used.

Owner:JIANGSU HAIXUN IND GROUP SHARE

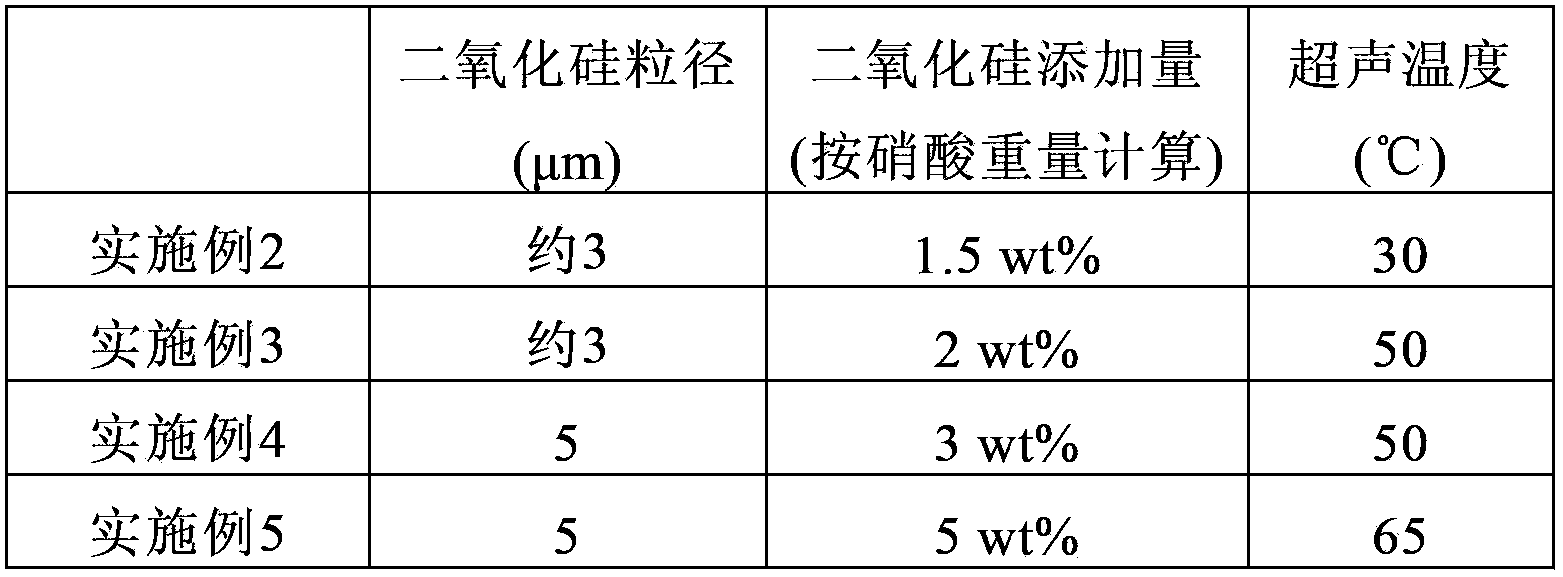

Cleaning method for polyacrylonitrile precursor spinning spinneret

ActiveCN103451748AShorten cleaning timeClean up thoroughlySpinnerette packsInorganic particleCleaning methods

The invention discloses a cleaning method for a polyacrylonitrile precursor spinning spinneret. The cleaning method comprises the step of performing ultrasonic cleaning treatment on the spinneret by nitric acid added with inorganic particles. The invention further discloses a multi-step cleaning method for the polyacrylonitrile precursor spinning spinneret in combination with the cleaning method. The method is short in cleaning time and good in cleaning effect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for cleaning floor heating pipes

The invention provides a method for cleaning floor heating pipes. The method is characterized by comprising the following steps of: firstly flushing, removing loams in the pipes, then soaking the pipes by cleaning fluid, dissolving rust and scale in the pipe, and finally Secondarily flushing the pipe. Through the method, the cleaning is safe and convenient, the cleaning time is short, the cleaning effect is excellent, the cleaning cost is low, the excellent radiation function of the pipe after cleaning can be kept, the service life of the floor heating pipe can be prolonged, no harm to human body is generated in the cleaning process, the equipment is not corroded, and the environment is not affected.

Owner:山西省第二建筑工程公司

Improved bearing cleaning machine allowing inner rings of cleaned bearings to be rotatable

The invention discloses an improved bearing cleaning machine allowing inner rings of cleaned bearings to be rotatable. The improved bearing cleaning machine comprises a barrel, a motor, a partition plate, a rotary plate, a plurality of fixing frames, a plurality of fixing mechanisms, a driving mechanism driving the inner rings of the cleaned bearings to rotate, a pump set, a plurality of sprayers, a third air cylinder, a mounting plate, an upper guide rail, a lower guide rail and a water pipe. The partition plate and the driving mechanism are arranged inside the barrel. The motor is arranged at the bottom of the partition plate. The rotary plate is arranged on a rotary shaft of the motor and located above the partition plate. The fixing frames and the fixing mechanisms for fixing the fixing frames are arranged on the rotary plate. The input end of the pump set communicates with the part, above the partition plate, of the barrel. The output end of the pump set communicates with the water pipe. The sprayers are arranged on the part, inside the barrel, of the water pipe. The third air cylinder is arranged on the front side face of the barrel. The mounting plate is arranged on the part, inside the barrel, of a piston rod of the third air cylinder. The upper guide rail and the lower guide rail are arranged on the mounting plate. Compared with the prior art, the improved bearing cleaning machine is good in cleaning effect, short in cleaning time and convenient to use.

Owner:XINCHANG JIANGBEI BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com