Patents

Literature

1378results about How to "Shorten cleaning time" patented technology

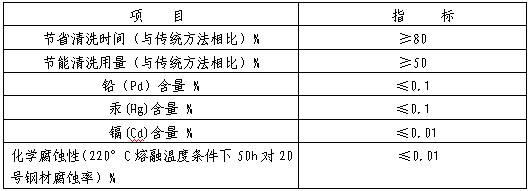

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid energy saving screw cleaning agent

The invention provides a solid energy saving screw cleaning agent which can prepare non-corrosive and non-abrasive energy saving screw cleaning material. The raw material formula of the cleaning agent is as follows by weight percentage: 40-60% of matrix resin, 30%-40% of modified powder and 10-20% of auxiliary agent, and the sum of the weight percentage of all the components is 100%; the auxiliary agent is a cleaning surface, a surface active agent, a lubricating agent, a forming agent and a blowing activator; the raw material formula of the modified powder is as follows by weight percentage: 83-97% of inorganic powder, 2.0-8.0% of dispersing agent and 1.0-5.0% of coupling agent. According to the proportion of the formula, the matrix resin, the prepared modified powder, the cleaning agent, the surface active agent, the lubricating agent, the forming agent and the blowing activator are added into a high-speed mixer, and then are extruded and formed by an extruder to obtain the solid screen cleaning agent.

Owner:彭超

Cleaning agent

InactiveCN104403813AShorten cleaning timeReduce processing costsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryForeign matter

The invention belongs to the technical field of chemical products, and particularly relates to a cleaning agent. The cleaning agent comprises components as follows: 25%-40% of a stabilizer, 3%-10% of a chelating agent, 2%-10% of a penetrating agent, 1%-4% of a surfactant, 1%-5% of a dispersing agent and the balance of water. Compared with the prior art, the cleaning agent can thoroughly clean up foreign matters such as solid powder, organic matters, greasy dirt, fingerprints, various greases, abrasives, dust, dirt and the like on optical glass, plate glass, plexiglass, a mobile phone lens, a camera lens, glass lenses, sapphire glass, a ceramic wafer and a quartz optical product once, doesn't corrode surfaces of the optical glass, the plate glass, the plexiglass, the mobile phone lens, the camera lens, the glass lenses, the sapphire glass, the ceramic wafer, the quartz optical product and the like, and is not left over the surfaces.

Owner:DONGGUAN FUXING DETERGENT TECH

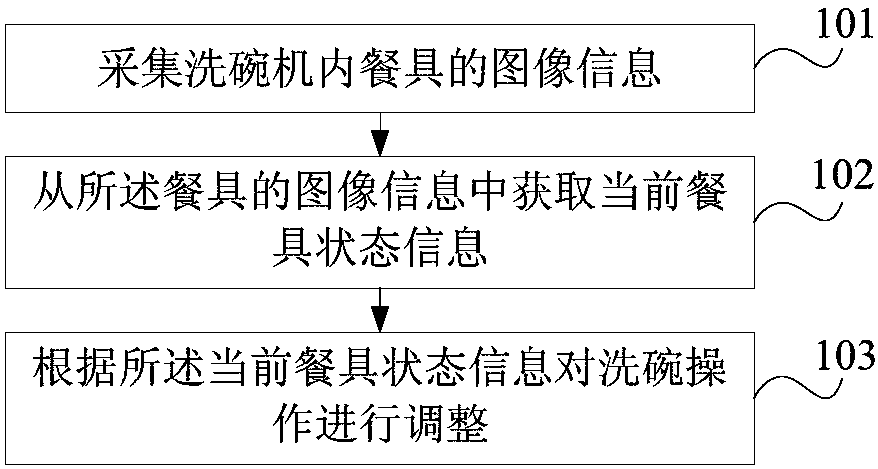

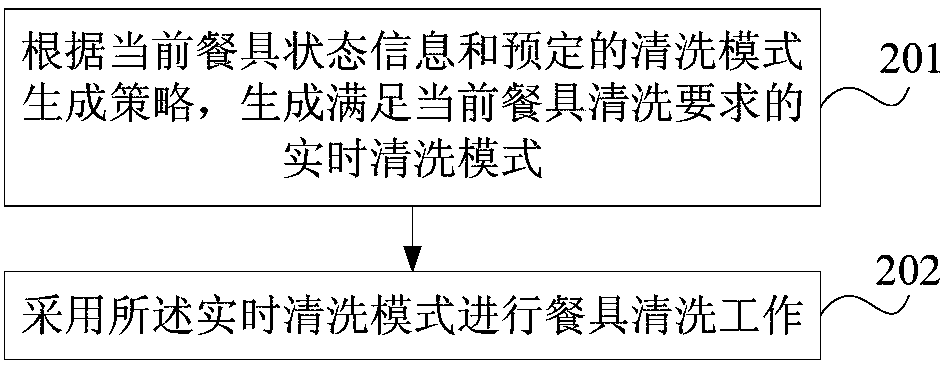

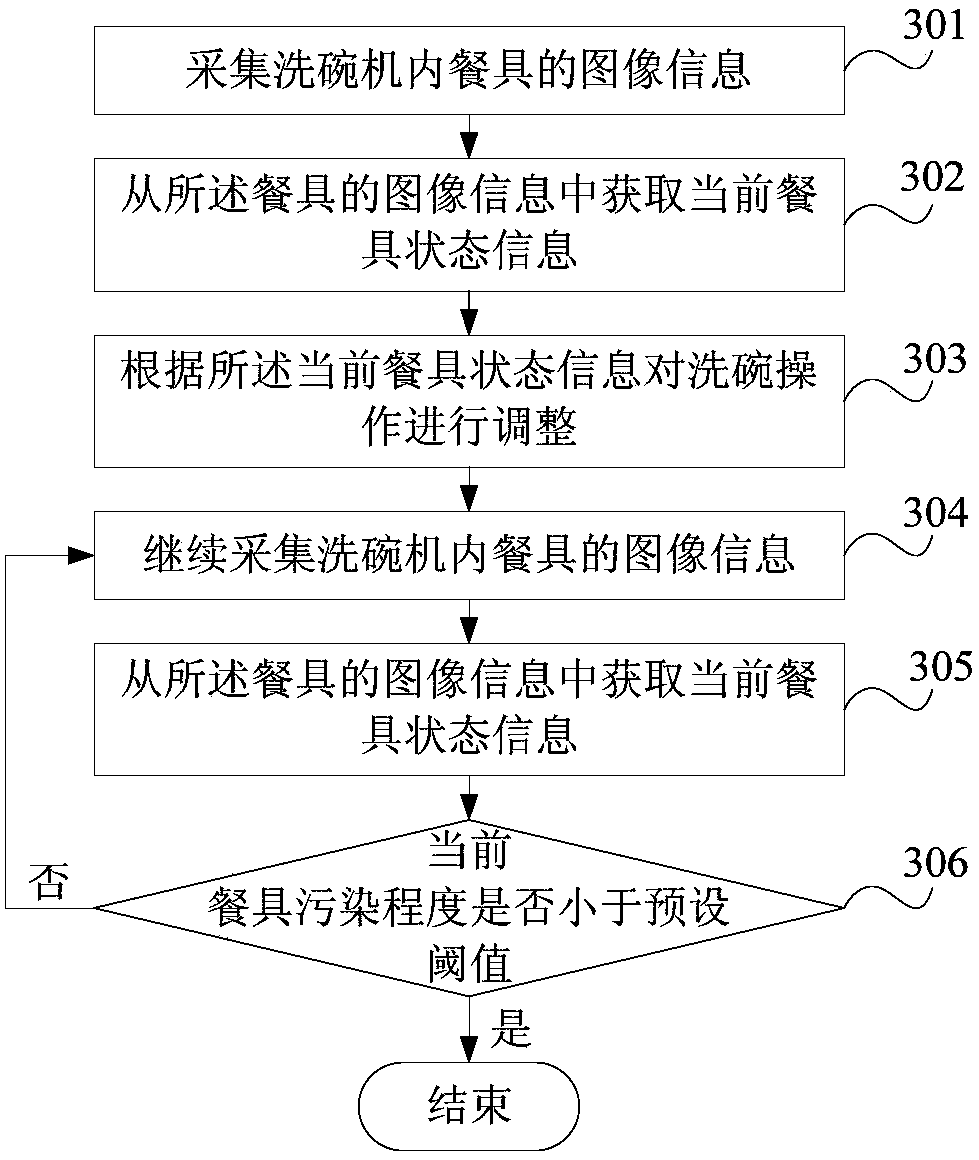

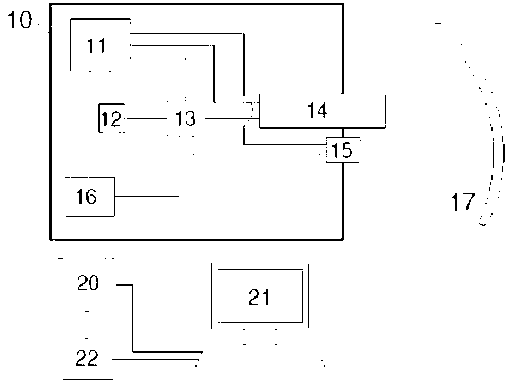

Dish-washing machine control method and device, dish-washing machine and computer readable storage medium

InactiveCN108577730ASolve the cleaning rateSolve efficiency problemsWashing controlling processesHome appliance efficiency improvementMachine controlEnergy consumption

An embodiment of the invention discloses a dish-washing machine control method and device, a dish-washing machine and a computer readable storage medium, relates to the field of intelligent householdelectrical appliances and can solve the problems of low washing rate and working efficiency of existing dish-washing machines. The dish-washing machine control method comprises steps as follows: acquiring image information of tableware in the dish-washing machine; acquiring current tableware state information from the image information of the tableware; adjusting dish-washing operation according to the current tableware state information. The washing rate and washing efficiency of the dish-washing machine can be improved, the cleaning time is saved, energy consumption and water consumption arereduced, and the dish-washing machine control method and device are applicable to various dish-washing machines.

Owner:KINGSOFT

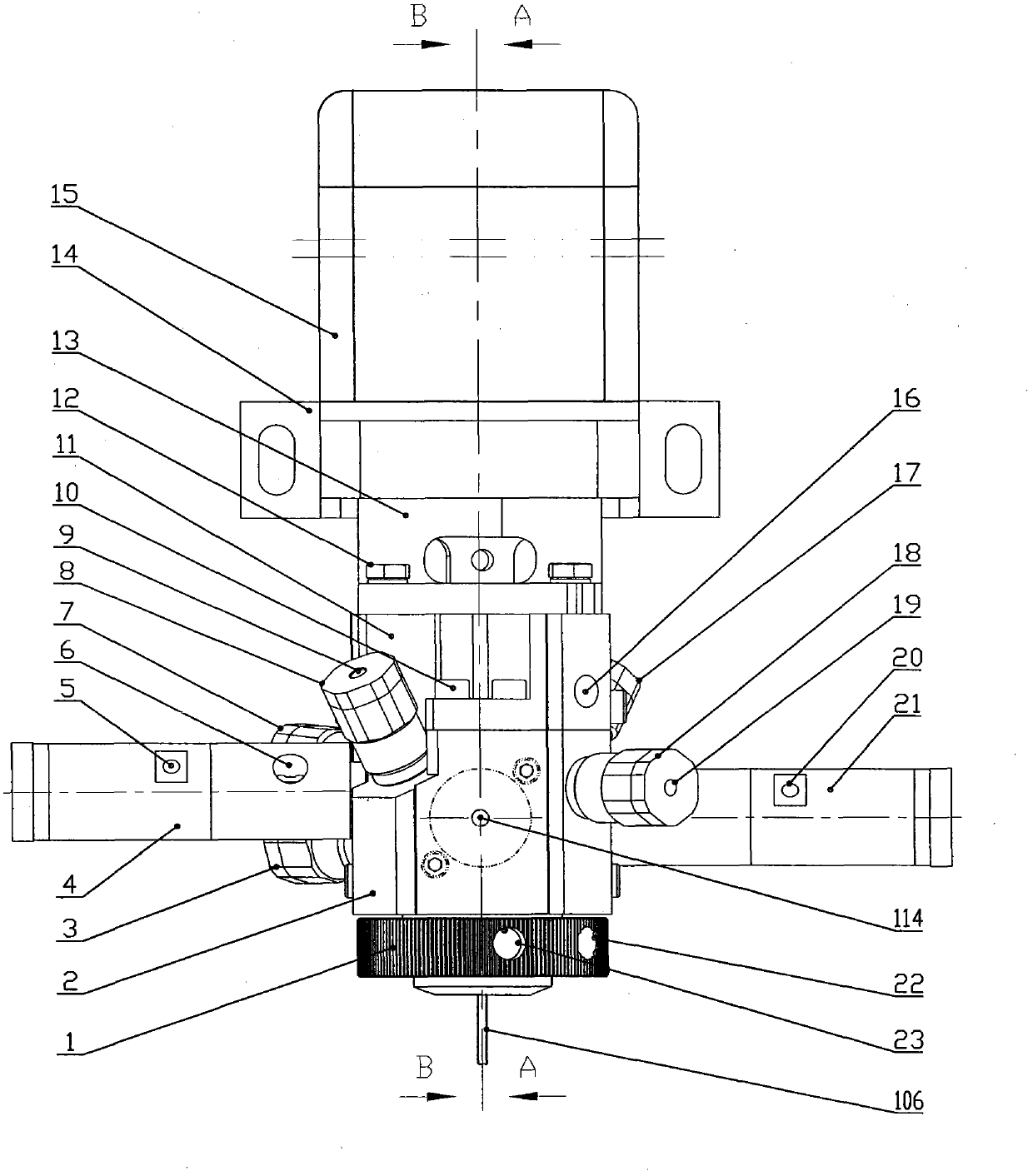

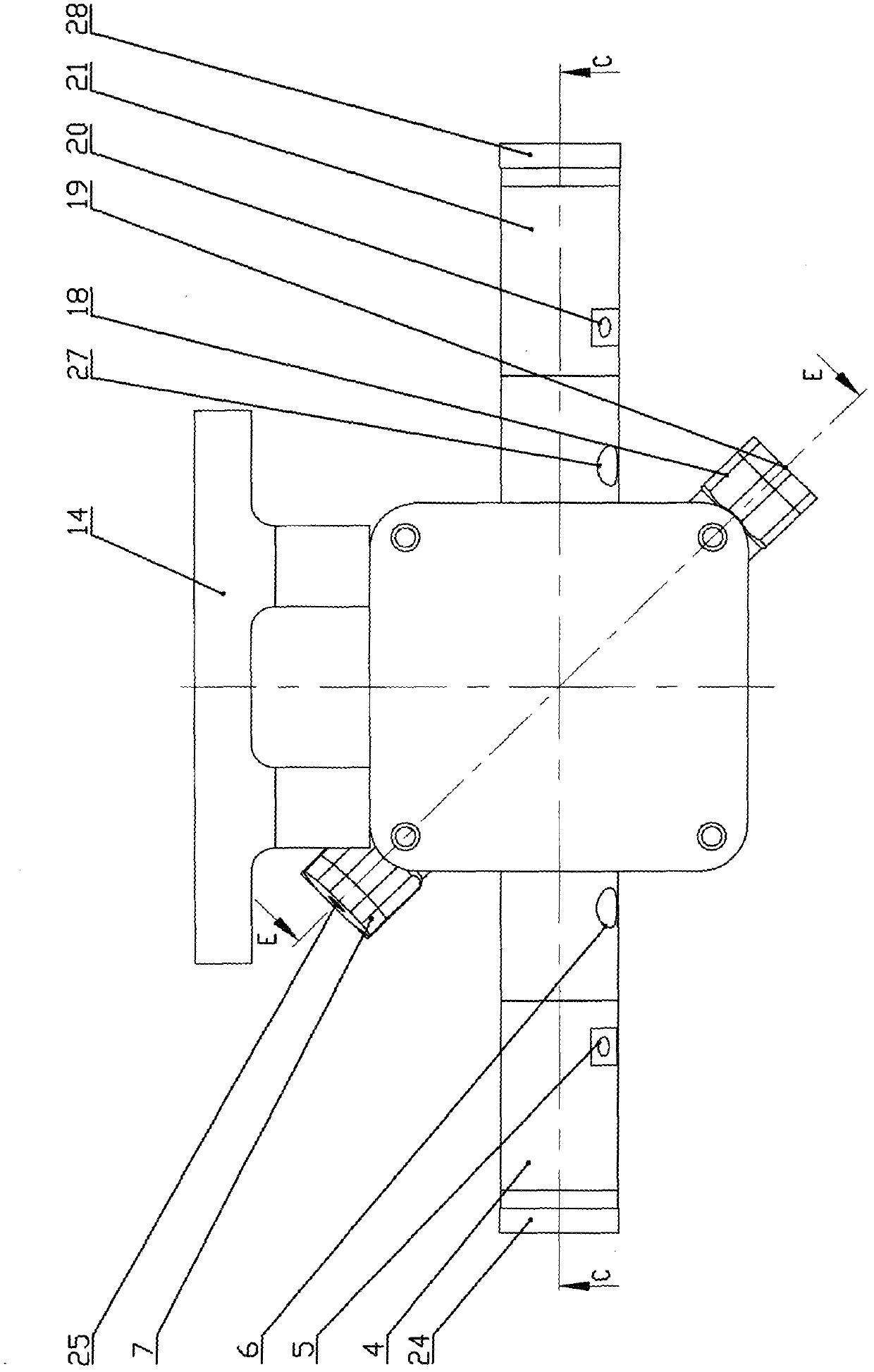

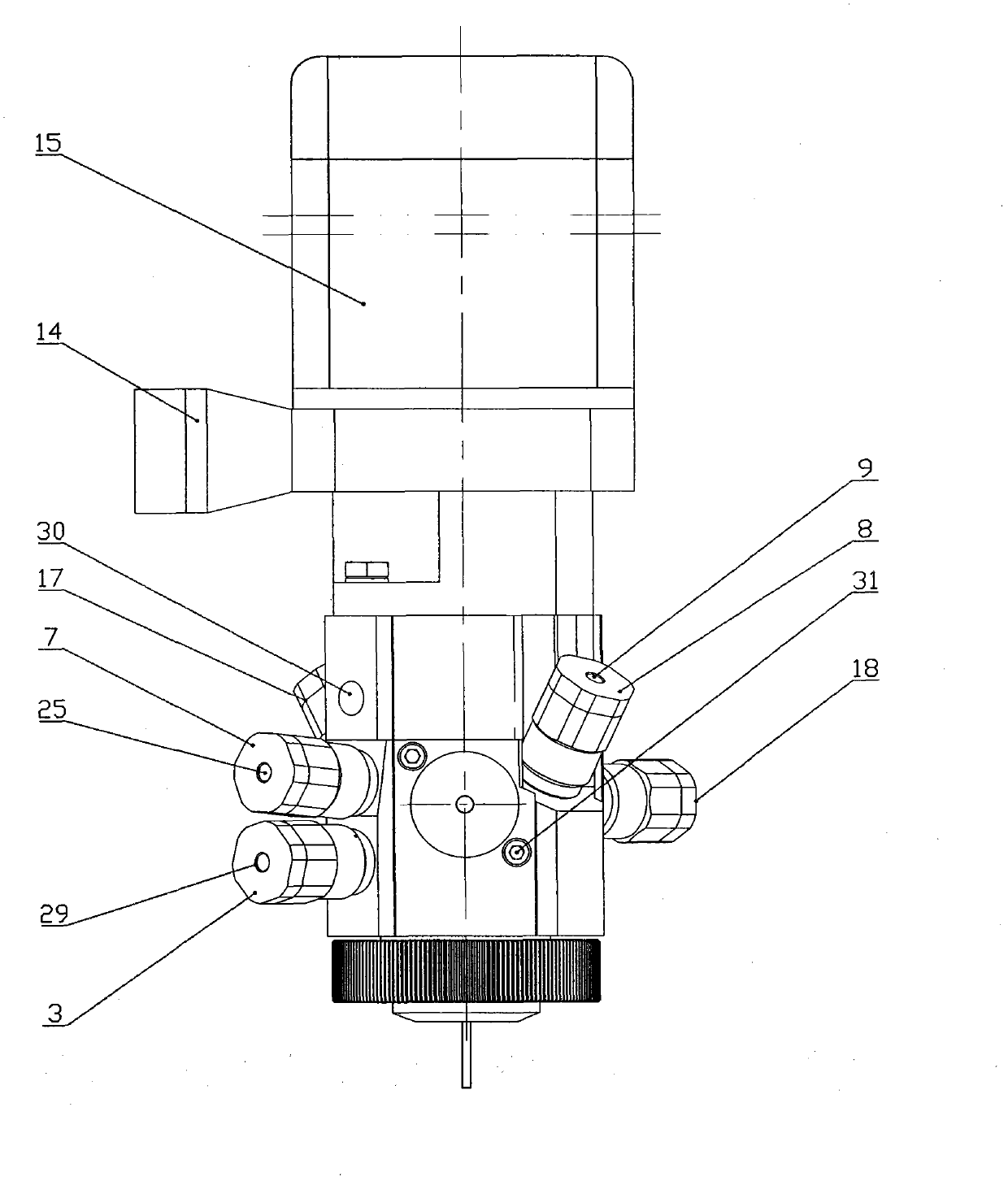

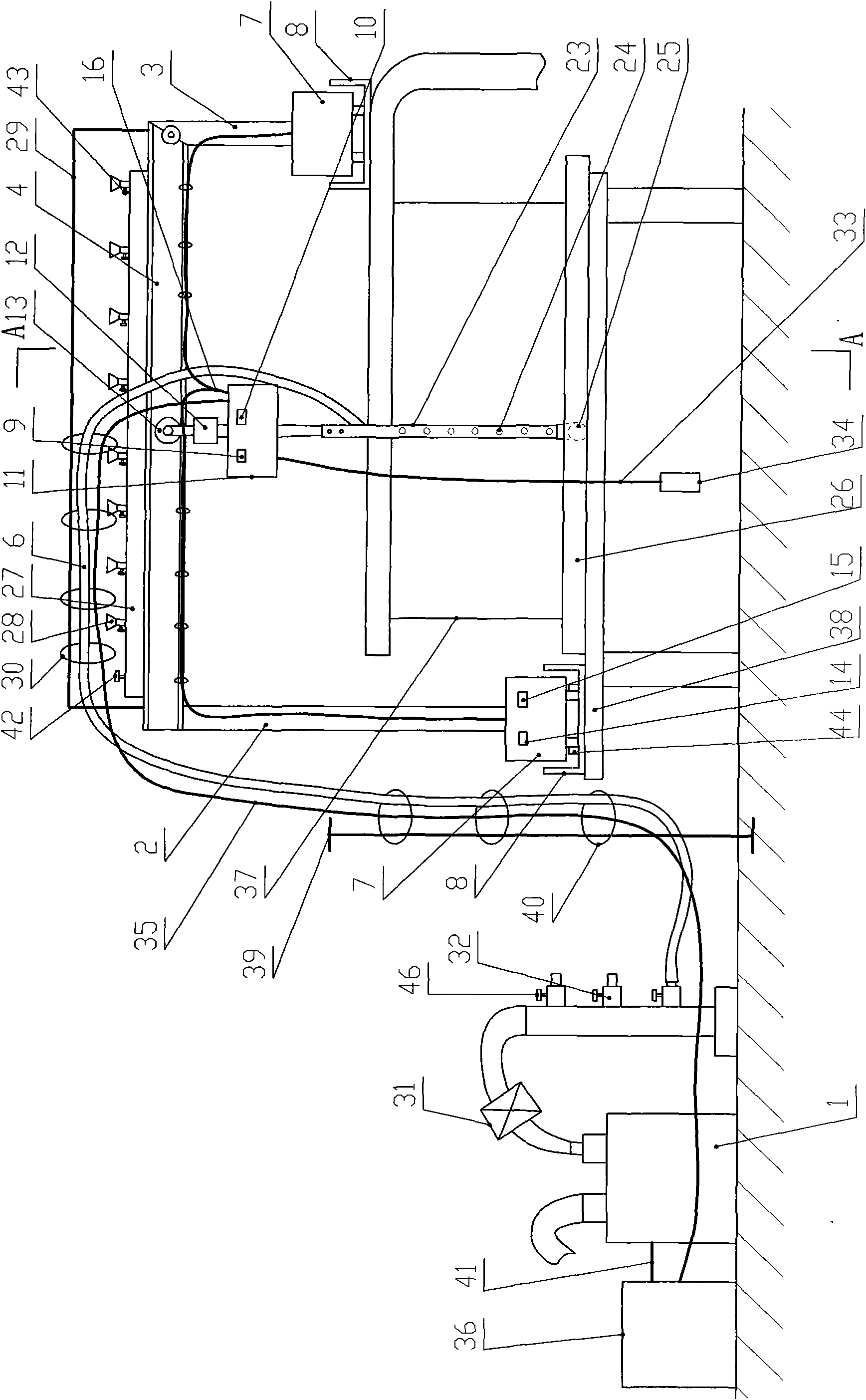

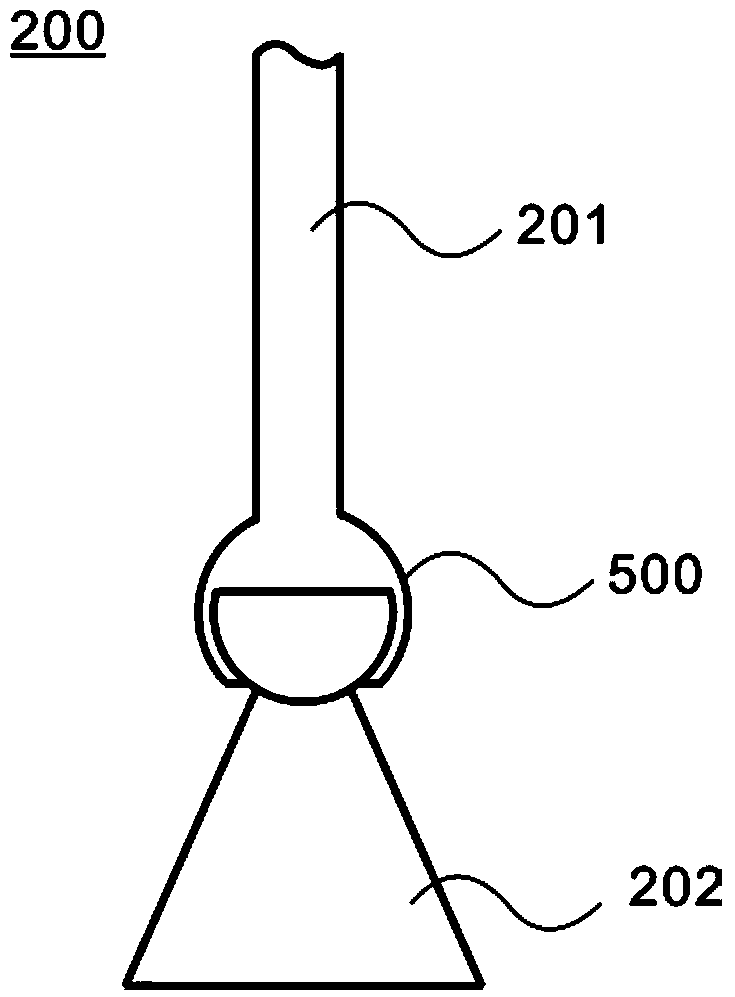

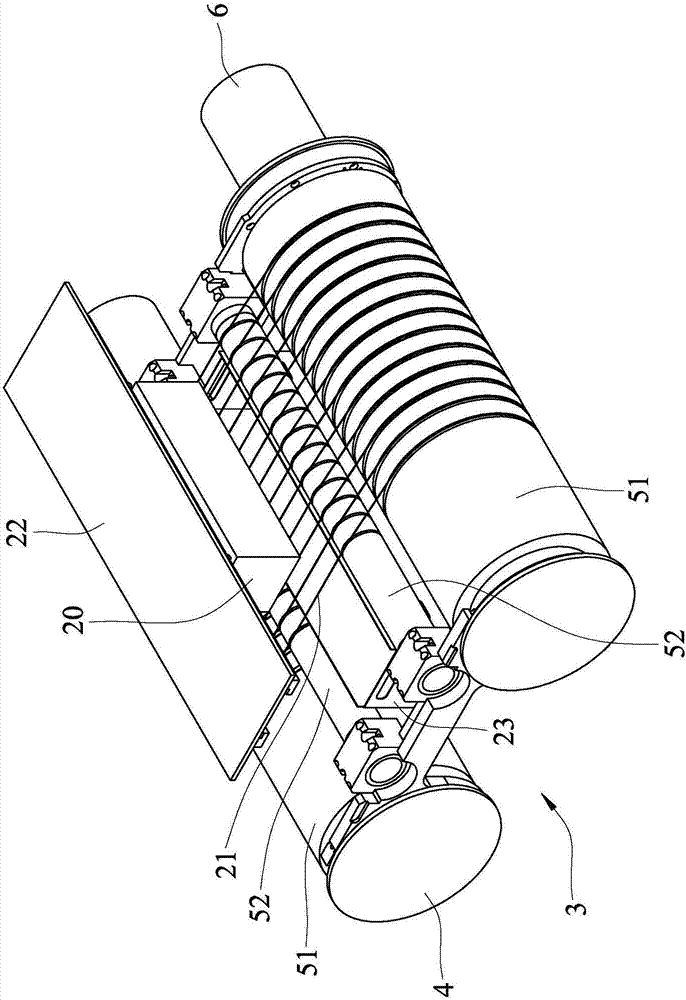

Water-cleaning gluing head for multi-component polyurethane needle valve

ActiveCN102601018ARemove threatEliminate pollutionLiquid surface applicatorsHollow article cleaningPhysical well beingEngineering

The invention relates to a water-cleaning gluing head for a multi-component polyurethane needle valve, in order to solve the problem that the traditional double-component polyurethane gluing head must be cleaned with a solvent and cannot be cleaned with water. The multi-component polyurethane water-cleaning gluing head comprises a motor, a transmission shaft, a stirring blade, a cup moving part, a valve base, a middle valve body, an upper valve body, a valve fixing plate, an component needle valve A, a component needle valve B, a water valve A, a water valve B, a water valve C, a water valve D and an air valve, wherein a cup base is connected with the valve base; a sealing ring A, a sealing ring B and a sealing ring C are mounted on an outer ring of a moving cup body; a check ring, a sealing circle and a sealing ring are mounted on an inner ring of the moving cup body; and a fixing sleeve is mounted between an ending opening on the cup base and the valve base. The manner of cleaning with water and then cleaning with compressed air is realized; the cleaning time is shortened; the threat to the health of operators and the environmental pollution caused by the solvent are eliminated; the structure is simple and compact; the mounting is convenient; the repairing is quick; and the stability is increased.

Owner:DALIAN HUAGONG INNOVATION TECH

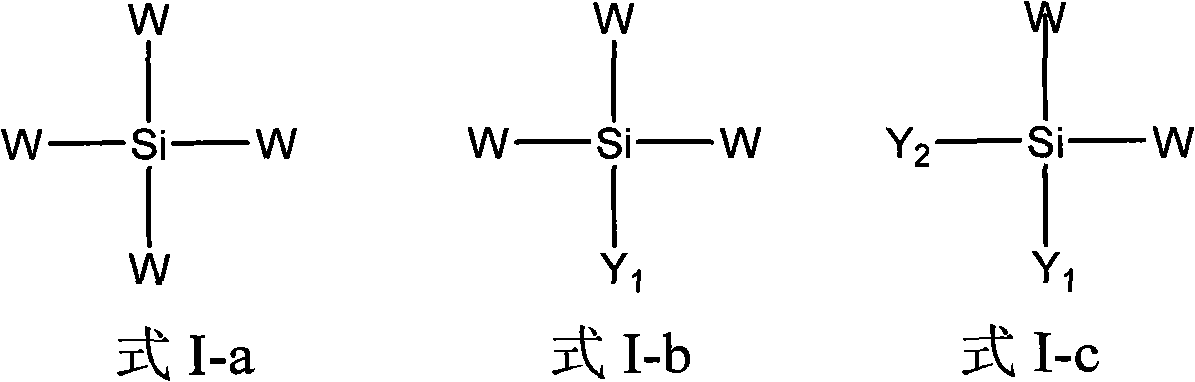

Mold release agent and preparation method and application thereof

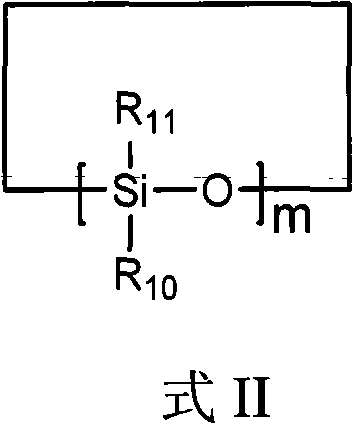

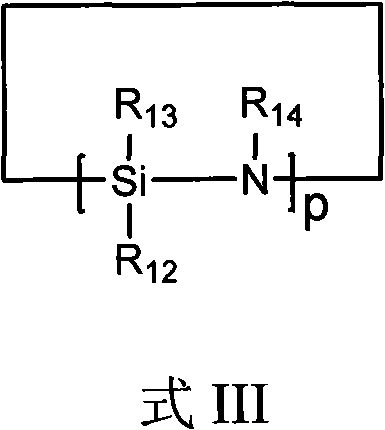

The invention provides a mold release agent, which contains the following components: a silicon-hydrogen bond-containing polysiloxane compound, a cross-linking agent, a catalyst and a solvent, wherein the cross-linking agent is a silicon compound containing Si-OH groups and / or a silicon compound which can form the Si-OH groups through hydrolyzation. The mold release agent is a semi-permanent mold release agent, and has the advantages of rapid low-temperature solidification, less mold release agent transfer, less wax deposition, convenient construction, low cost and the like; the produced product has uniform openings; and the mold release agent particularly achieves major breakthrough in the field of producing polyurethane foam products. The invention also provides a method for preparing the mold release agent, and application of the mold release agent in producing polyurethane foam products, epoxy resin products, glass fiber reinforced epoxy resin products, rubber products, unsaturated polyester products and other polyurethane products.

Owner:HENKEL CORP

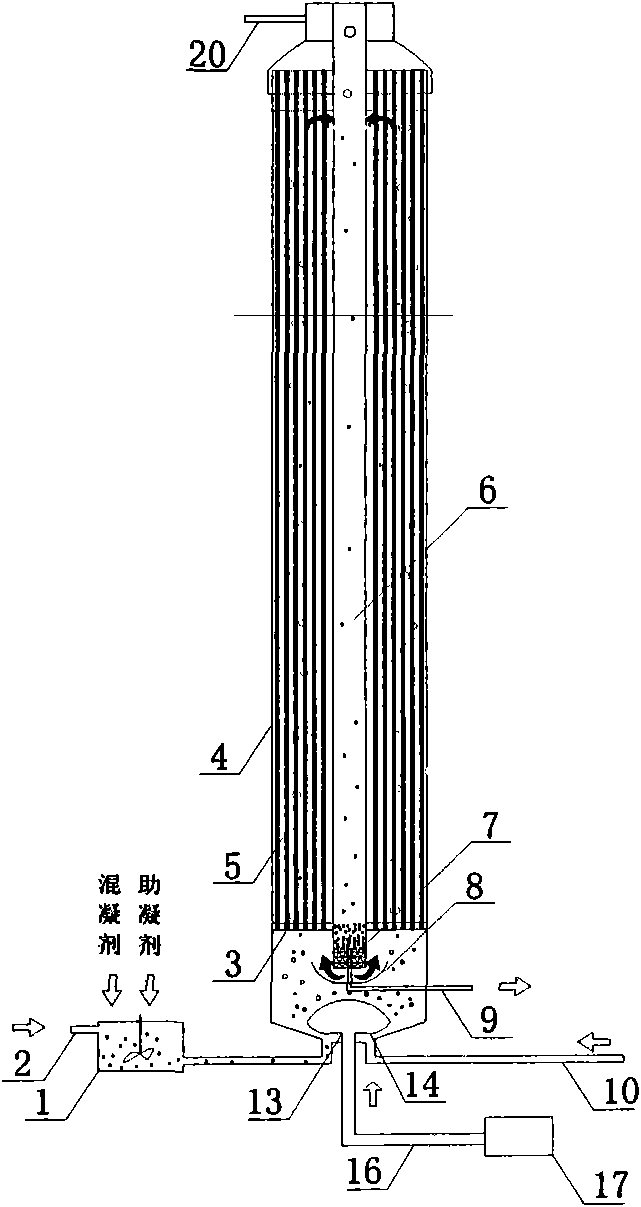

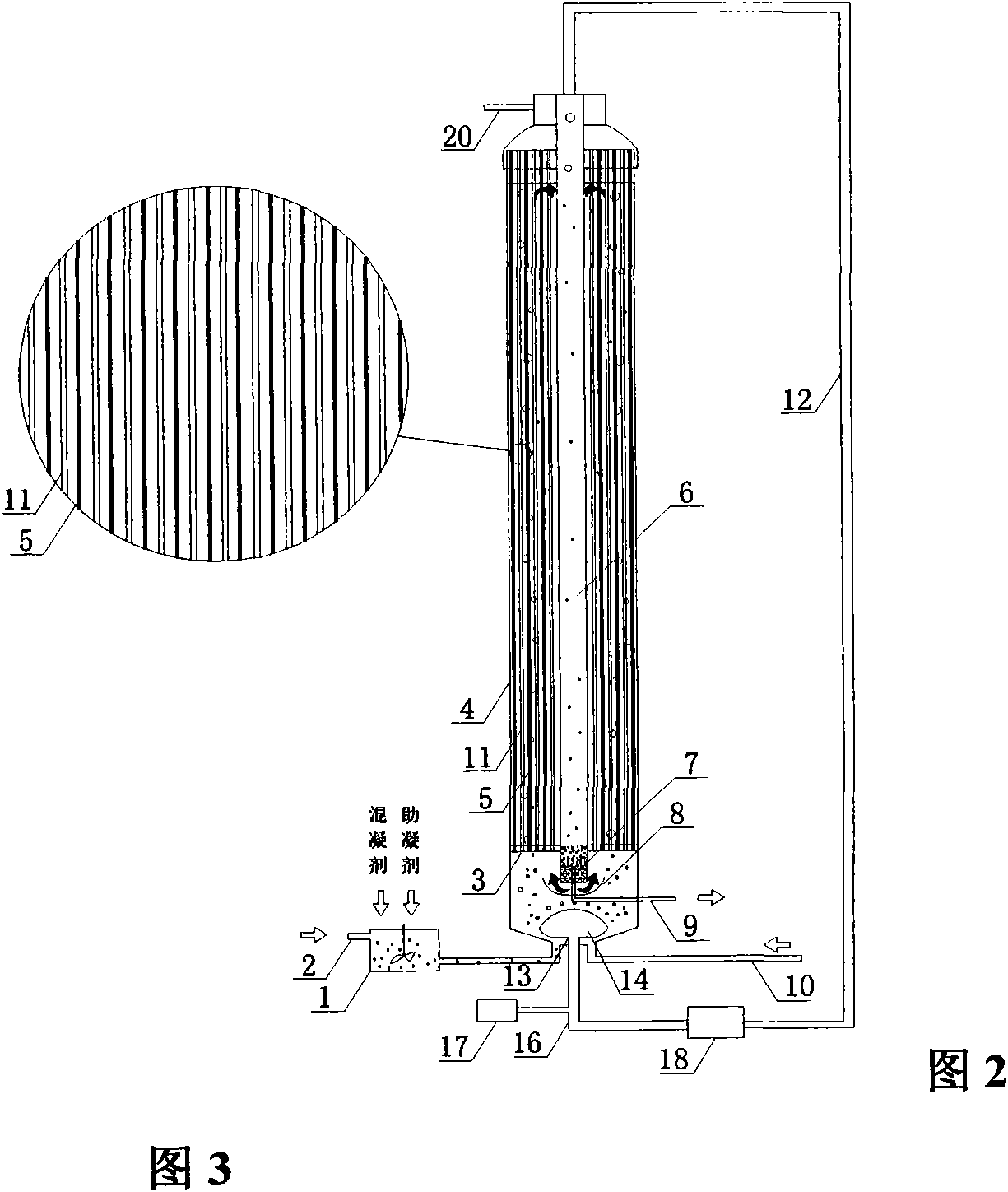

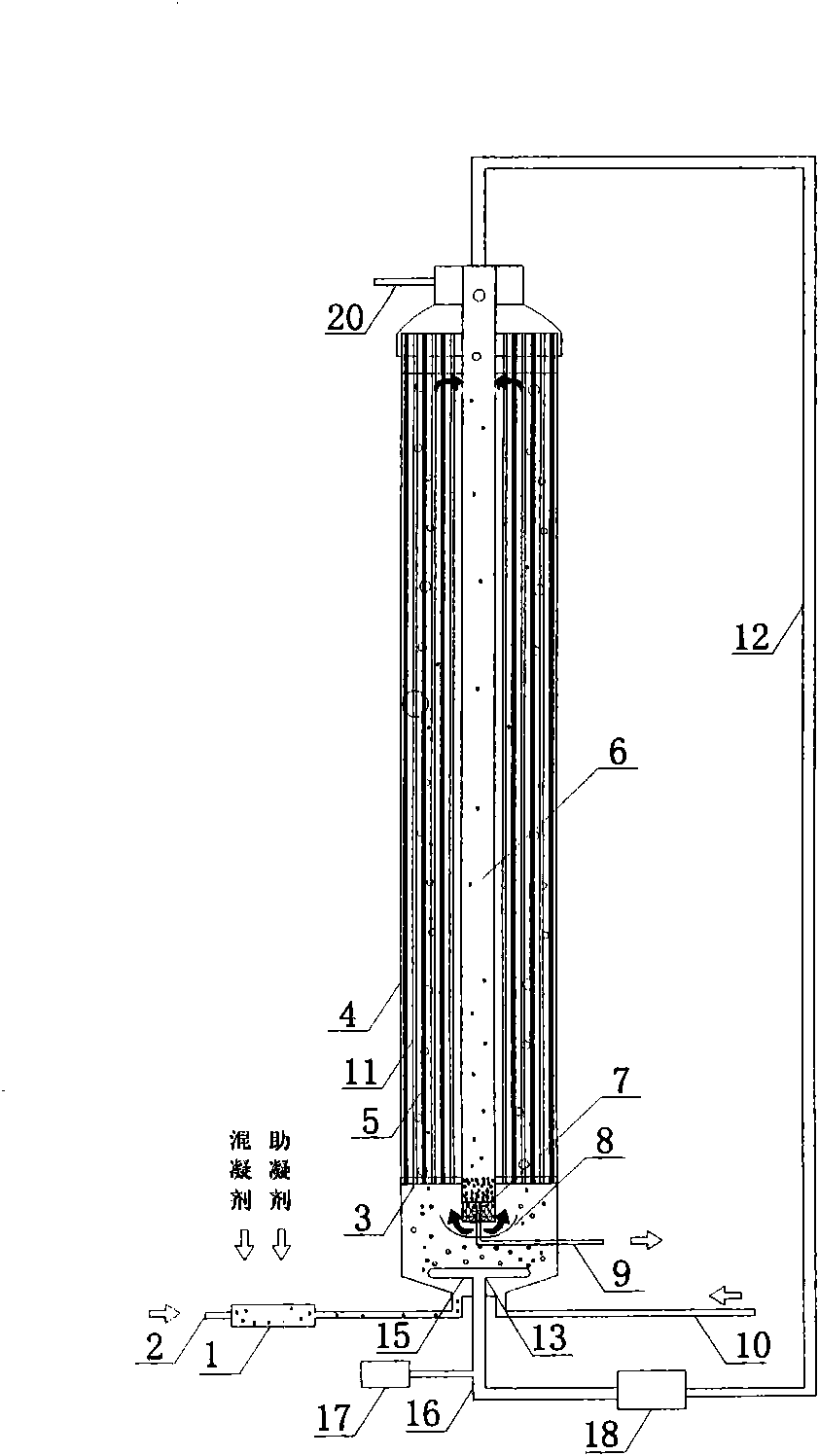

Enhanced coagulation-gas stripping-membrane integration method and device for lightening membrane pollution

InactiveCN101774731AReduce cloggingImprove processing efficiencyTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationEngineering

The invention discloses an enhanced coagulation-gas stripping-membrane integration method for lightening membrane pollution. In the method, a coagulating agent and a coagulant aid are added into raw water and undergo enhanced coagulation reaction by applying hydraulic condition, and airflow circulation and lift treatment is performed while an external pressure hollow fiber membrane component is used for filtration. The invention also discloses an integration device designed according to the method. Through the technical measures of throwing the coagulating agent and the coagulant aid into the raw water, positioning gas stripping type aeration treatment under the filtering of the external pressure hollow fiber membrane component and the like, the method improves the pollutant removal rate and the water treatment effect, greatly lightens the membrane pollution, saves energy consumption of membrane component operation, prolongs the operating cycle of the membrane component, shortens the cleaning time, reduces the back washing cost, has small occupied area, low investment cost and simple and flexible implementation, is applicable to water treatment for large cities, and is also applicable to vast cities and towns and rural regions with imperfect water treatment process and small treatment scale.

Owner:SICHUAN UNIV

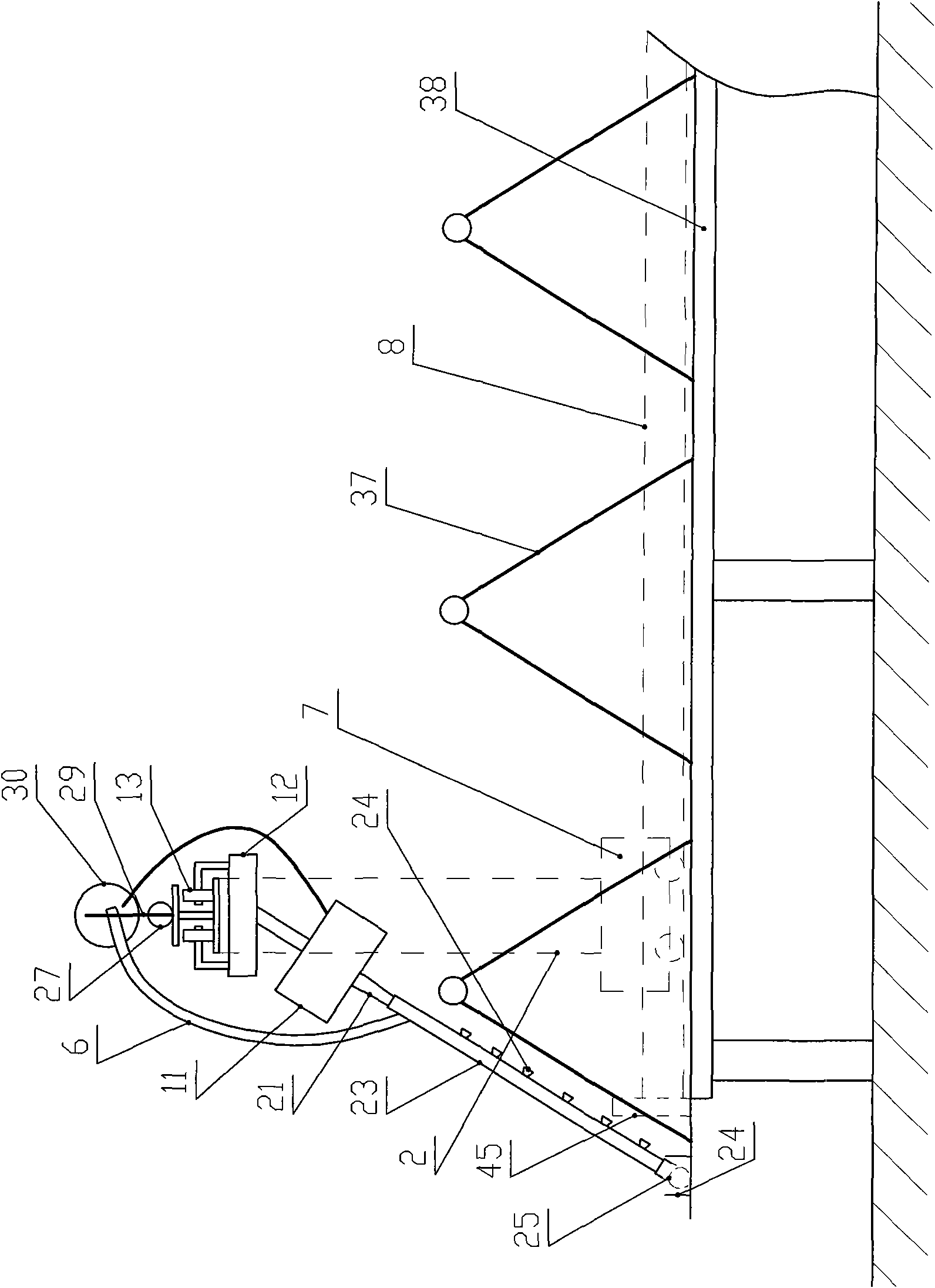

Winebottle cleaning device

ActiveCN105149307AShorten cleaning timeExtend cleaning timeHollow article cleaningCleaning using liquidsEngineeringMechanical engineering

The invention provides a winebottle cleaning device. The winebottle cleaning device comprises a rack, two rotary conveying belts and a picking device, a cleaning tank, a water draining tank, an evaporating box, a drying box, a sterilizing chamber, a winebottle pushing device and a driving device which are sequentially arranged on the rack; the picking device comprises a picking air cylinder, suction cups, a vacuumizing device and multiple fixing blocks, the rear sides of all the fixing blocks are arranged on the rotary conveying belts in a pivoted mode along the two transverse ends of the fixing blocks, each fixing block is provided with three to five clamping heads used for tightly clamping winebottles, and a suction cup abdication hole is formed in the portion, corresponding to the middle of each clamping head, of the corresponding fixing block; the picking air cylinder is arranged on the rack, the suction cups of which the number corresponds to that of the clamping heads are arranged on a piston rod of the picking air cylinder side by side, the vacuumizing device is arranged on the rack, and all the suction cups are communicated with the vacuumizing device.

Owner:迁安市贯头山酒业有限公司

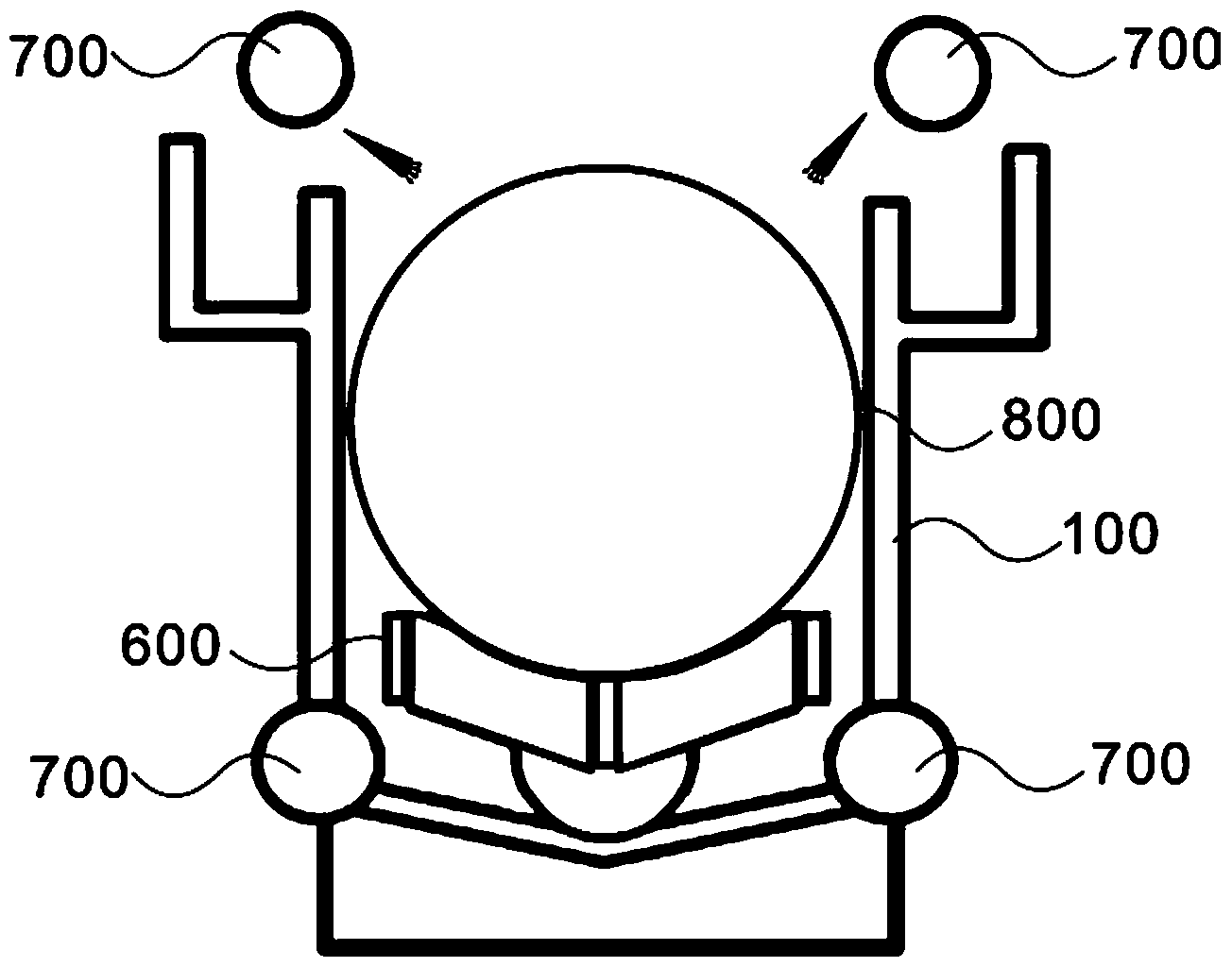

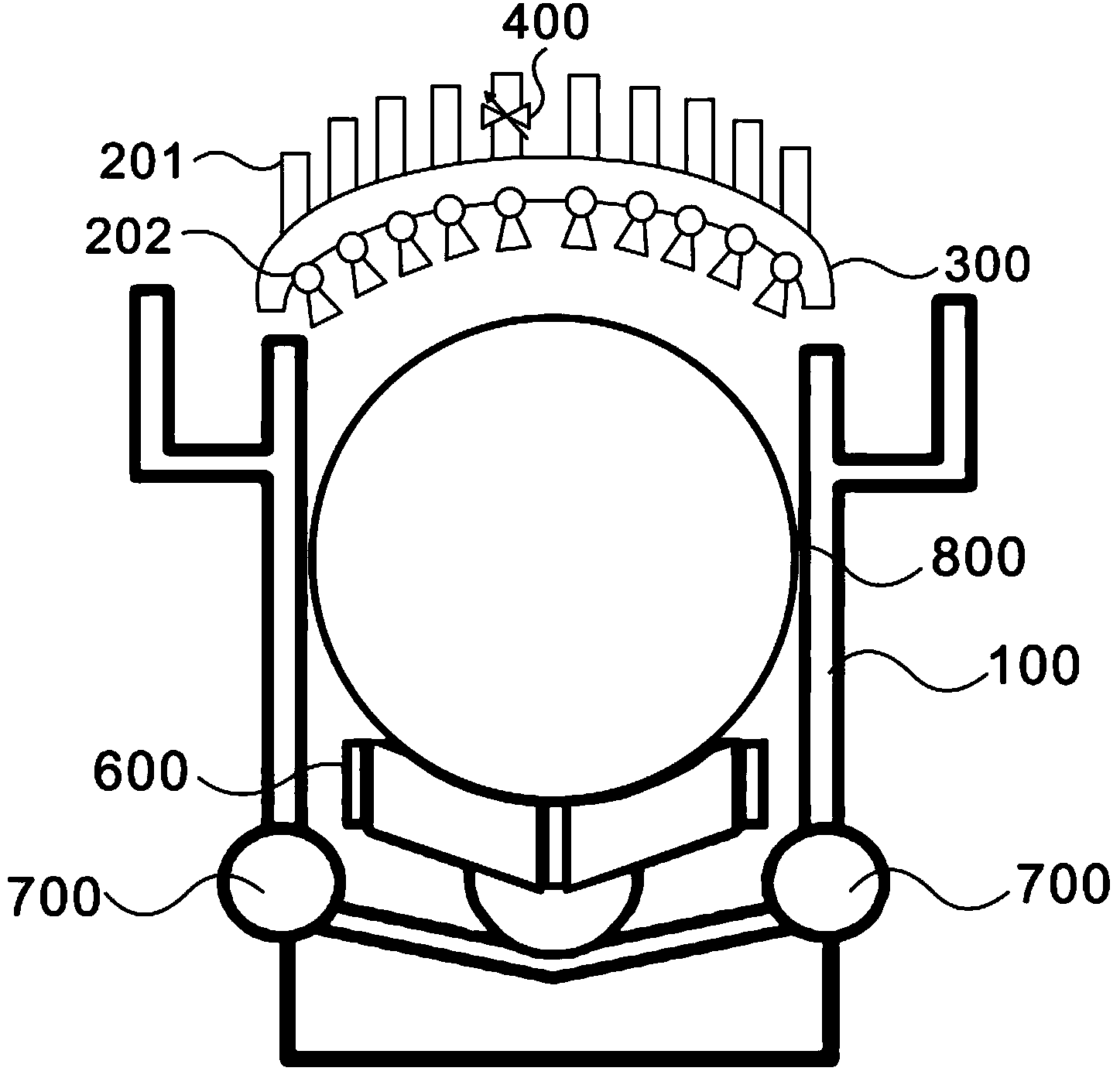

Multifunctional rotary spraying-type washing device and method

ActiveCN103658091AOvercome the defect that the dead corner cannot be cleanedHigh degree of automationCleaning using liquidsEngineeringAutomation

The invention discloses a multifunctional rotary spraying-type washing device and method. The multifunctional rotary spraying-type washing device comprises a washing box and a washing mechanism, wherein the washing mechanism is arranged inside the washing box and comprises a washing basket, a filtering layer, a washing basket rotation driving assembly, an upper spray pipe with a nozzle, and a lower spray pipe with a nozzle; the filtering layer is fixed into the washing basket located on the filtering layer; the bottom of the washing basket is connected with the washing basket rotation driving assembly; the upper spray pipe is arranged on the washing basket; the lower spray pipe is arranged between the washing basket and the filtering layer; the upper spray pipe and the lower spray pipe are externally connected with a washing liquid supply mechanism. According to the multifunctional rotary spraying-type washing method, a work piece is clamped in the washing basket through a clamp, washing liquid is sprayed on the work piece through rotation of the washing basket and combination of the upper spray pipe and the lower spray pipe, and then the work piece is washed. The multifunctional rotary spraying-type washing device and method are provided for complex work pieces of the small and medium sizes, existing manual washing can be replaced, the degree of automation is improved, the washing efficiency is high, and the washing effect is better.

Owner:广东四会实力连杆有限公司

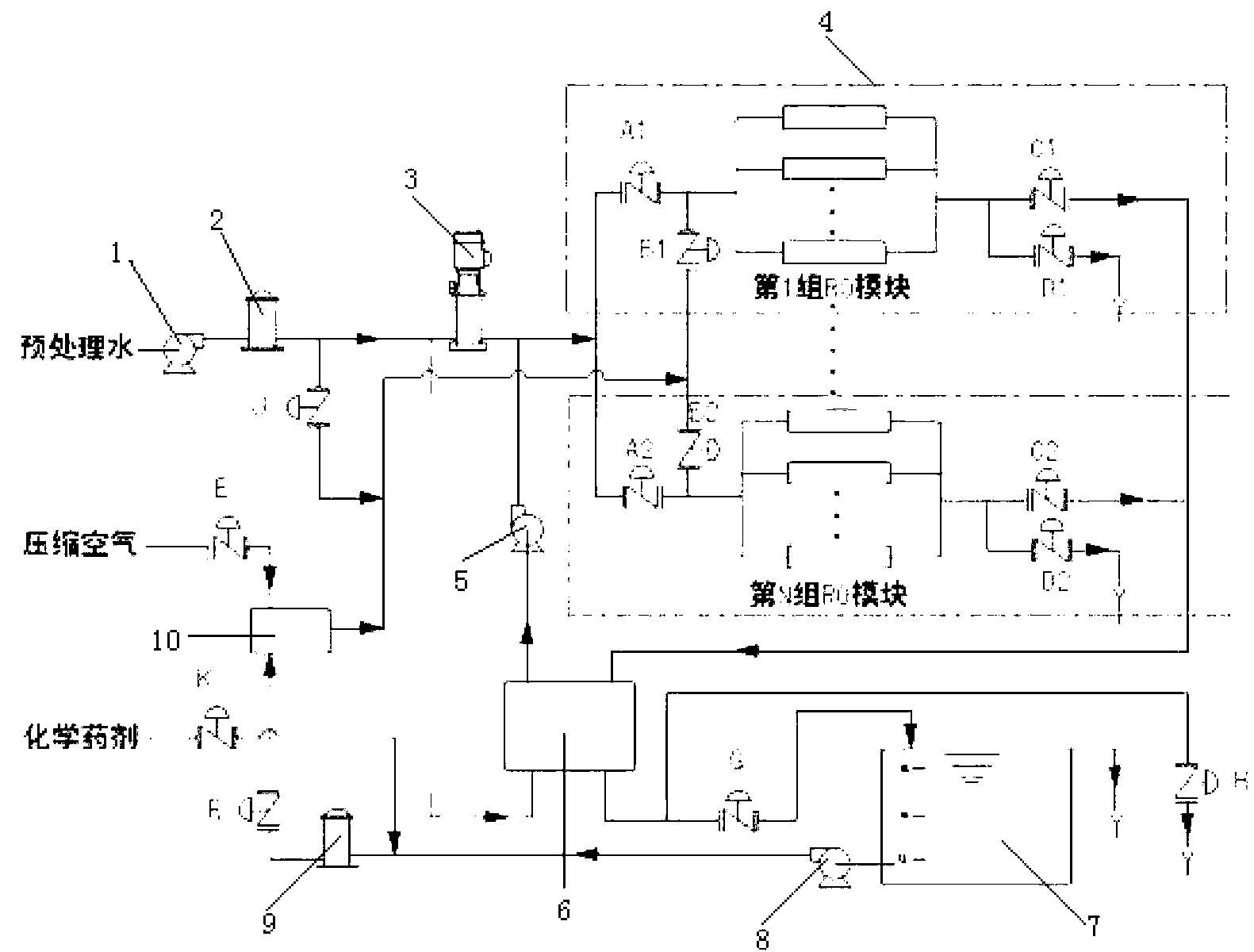

Washing method for preventing reverse osmosis membrane or nano-filtration membrane from being polluted

ActiveCN103301753ALarge water supplyReduce operating pressureSemi-permeable membranesGeneral water supply conservationSocial benefitsWater desalination

The invention belongs to the technical field of seawater desalting and water treatment and relates to a washing method for preventing a reverse osmosis membrane or a nano-filtration membrane from being polluted. The washing method comprises the following steps of: firstly carrying out gas-water two-phase flow washing or simultaneous chemical washing; then extracting reverse osmosis concentrated water to wash the surface of the reverse osmosis membrane; discharging the reverse osmosis concentrated water through a concentrated water discharging valve; then, conveying pretreated water to a reverse osmosis module and displacing and discharging washing concentrated water on a reverse osmosis concentrated water side until the conductivity is recovered to 98% of the conductivity of the pretreated water; finally, closing a washing water discharging valve and opening the concentrated water discharging valve to recover normal operation of the reverse osmosis module; and sequentially washing other sets of reverse osmosis modules. The washing method disclosed by the invention is reliable in process, simple and convenient to operate, lower in energy consumption, good in economic benefits and social benefits, and environment-friendly.

Owner:OCEAN UNIV OF CHINA

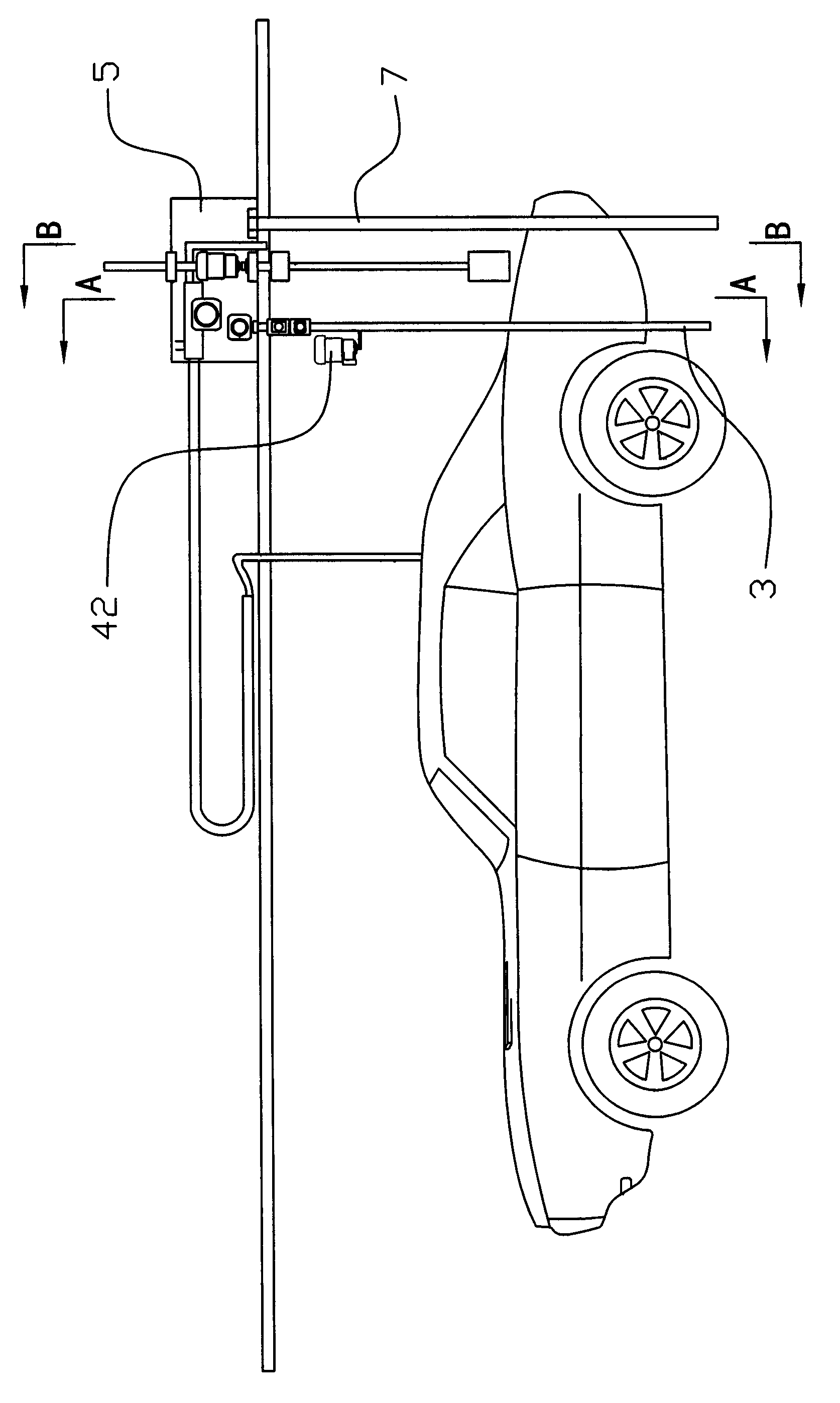

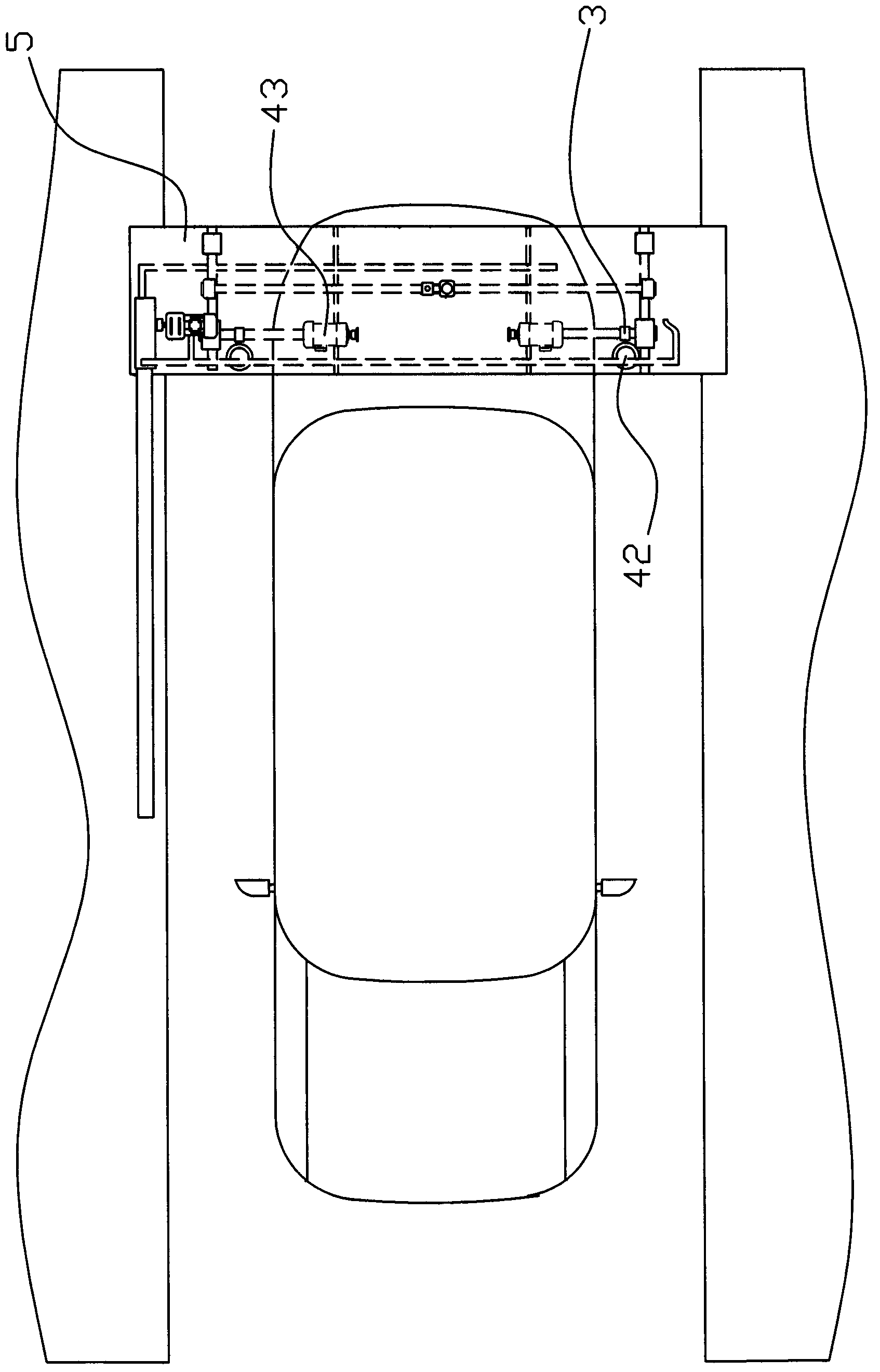

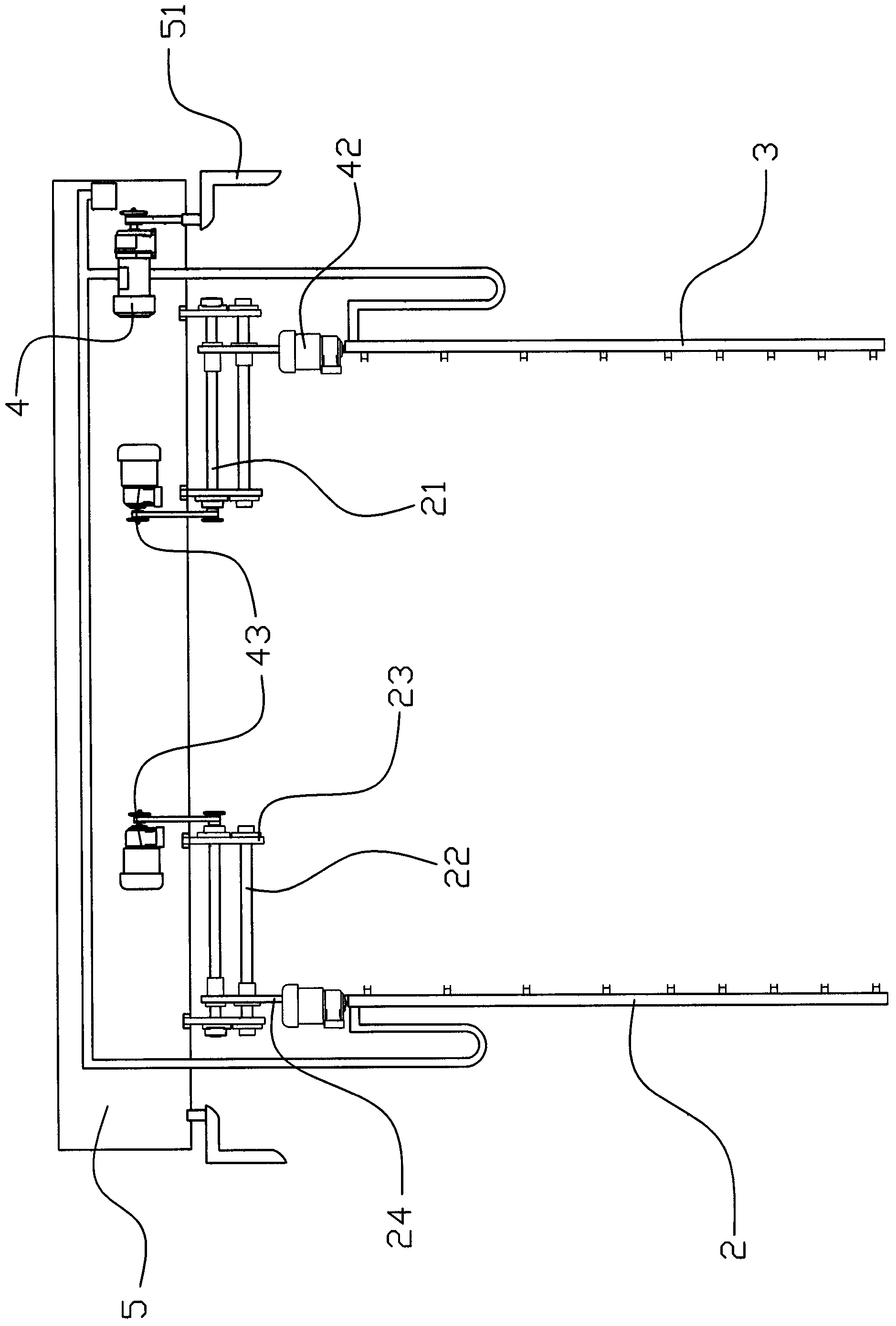

Full-automatic automobile washing device

ActiveCN104290718AShorten cleaning timeCar wash cleanCleaning apparatus for vehicle exteriorsElectric machineryDrive motor

A full-automatic automobile washing device comprises a spraying device. The spraying device comprises a top spraying rod and vertical spraying rods. The left vertical spraying rod and the right vertical spraying rod are each provided with a plurality of shower nozzles in the vertical direction, and the nozzles of the left vertical spraying rod are opposite to the nozzles of the right vertical spraying rod. Shower nozzles with nozzles facing downwards are distributed on the top spraying rod. The spraying rods are each provided with a switching mechanism, and the shower nozzles can be connected with a high-pressure water source and a high-pressure air source. The switching mechanisms can be in linkage with an output shaft of a switching motor. The top spraying rod, the left vertical spraying rod and the right vertical spraying rod are connected with a beam which is arranged on a guide rail in the manner of sliding forwards and backwards through a driving motor, the top spraying rod can be arranged on the beam in an ascending and descending mode through a lifting motor, the left vertical spraying rod and the right vertical spraying rod can be connected with the beam in the manner of moving left and right through respective motors, and the beam is provided with a detecting device which can detect the size of an automobile body. The full-automatic automobile washing device is ingenious and reasonable in structure, high in automation degree and more complete in function, effectively solves the problems of an existing automobile washing machine, and is a very practical automobile washing device.

Owner:绍兴市中令汽车服务有限公司

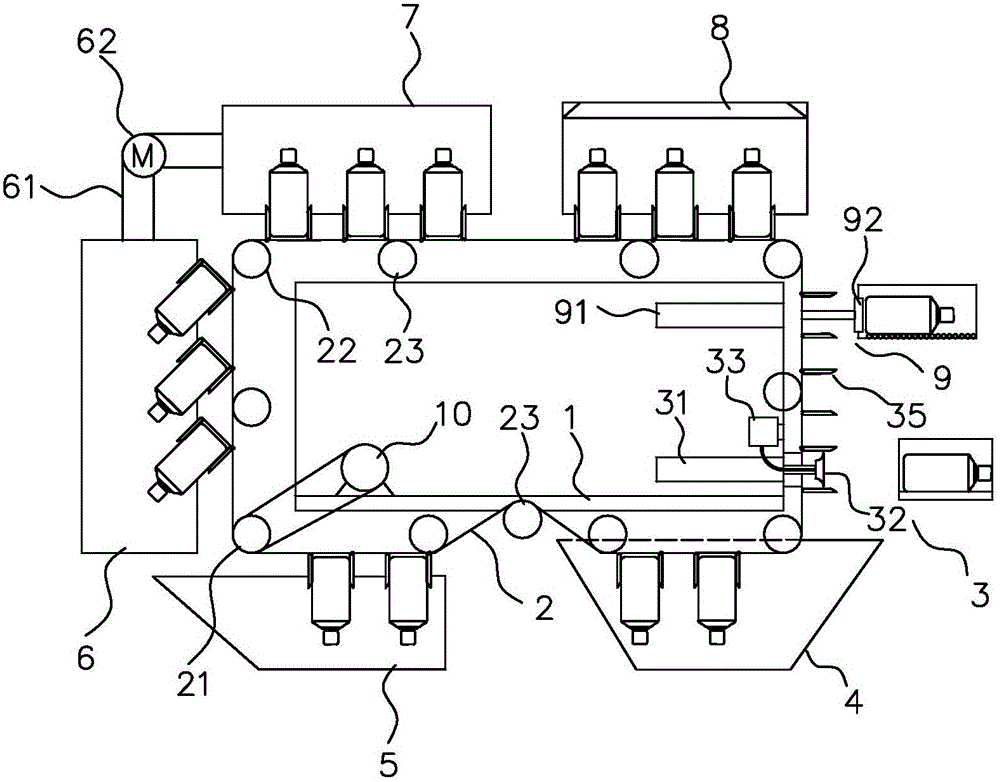

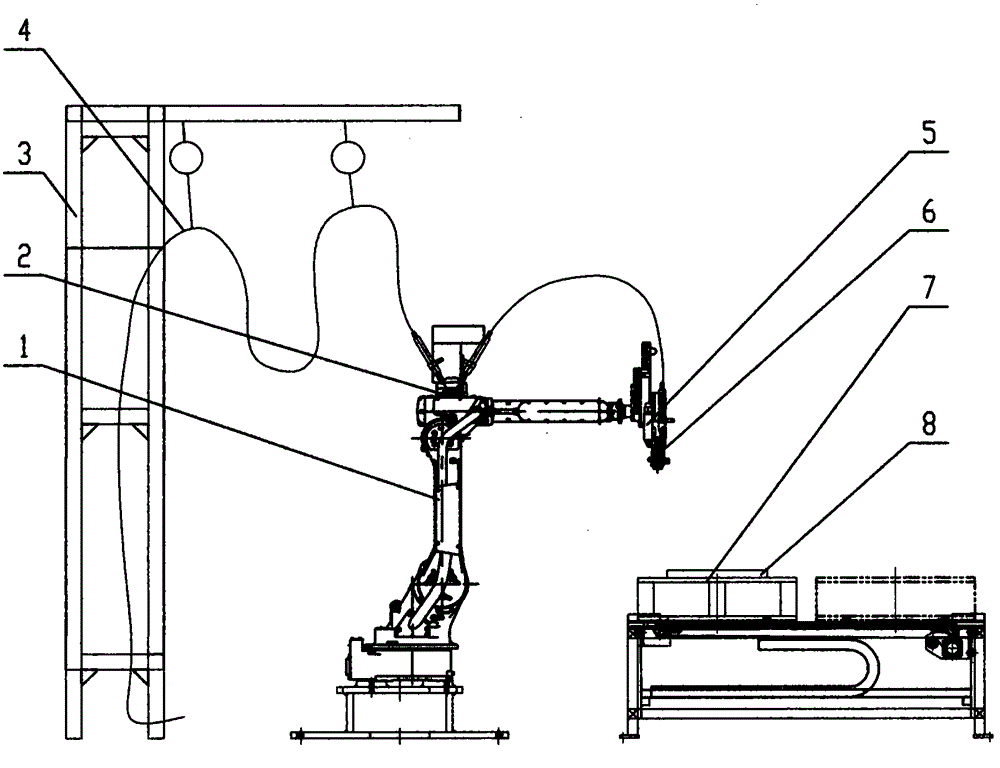

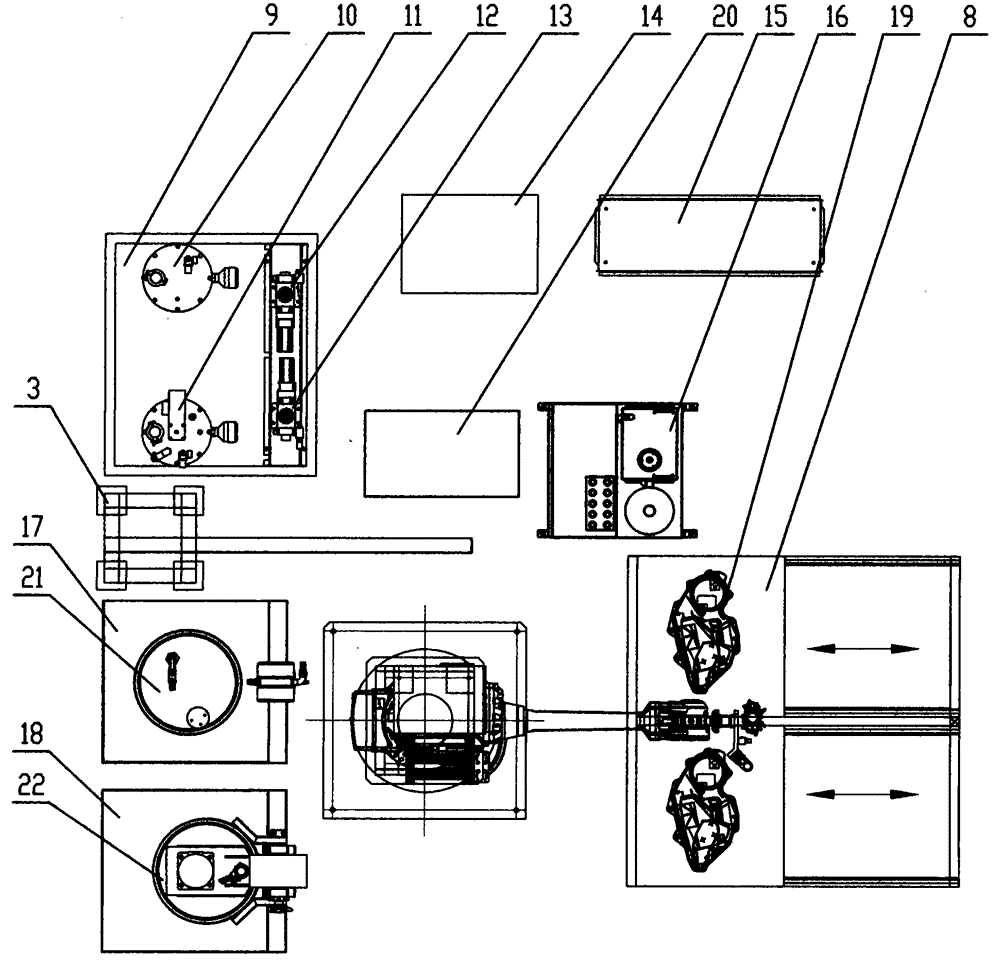

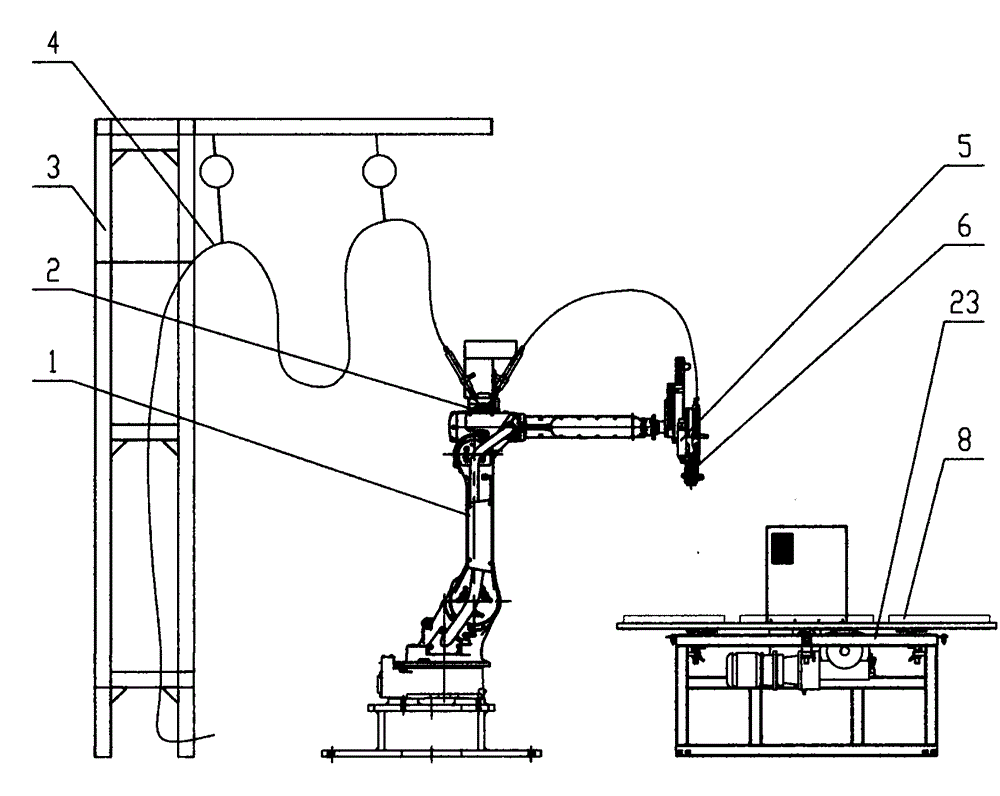

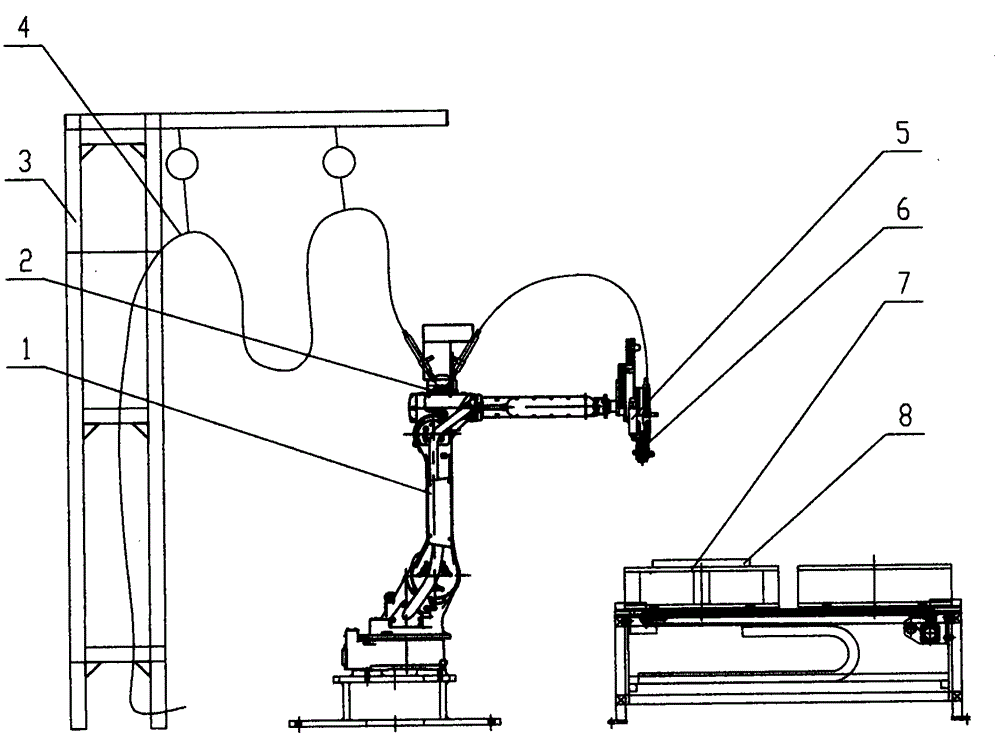

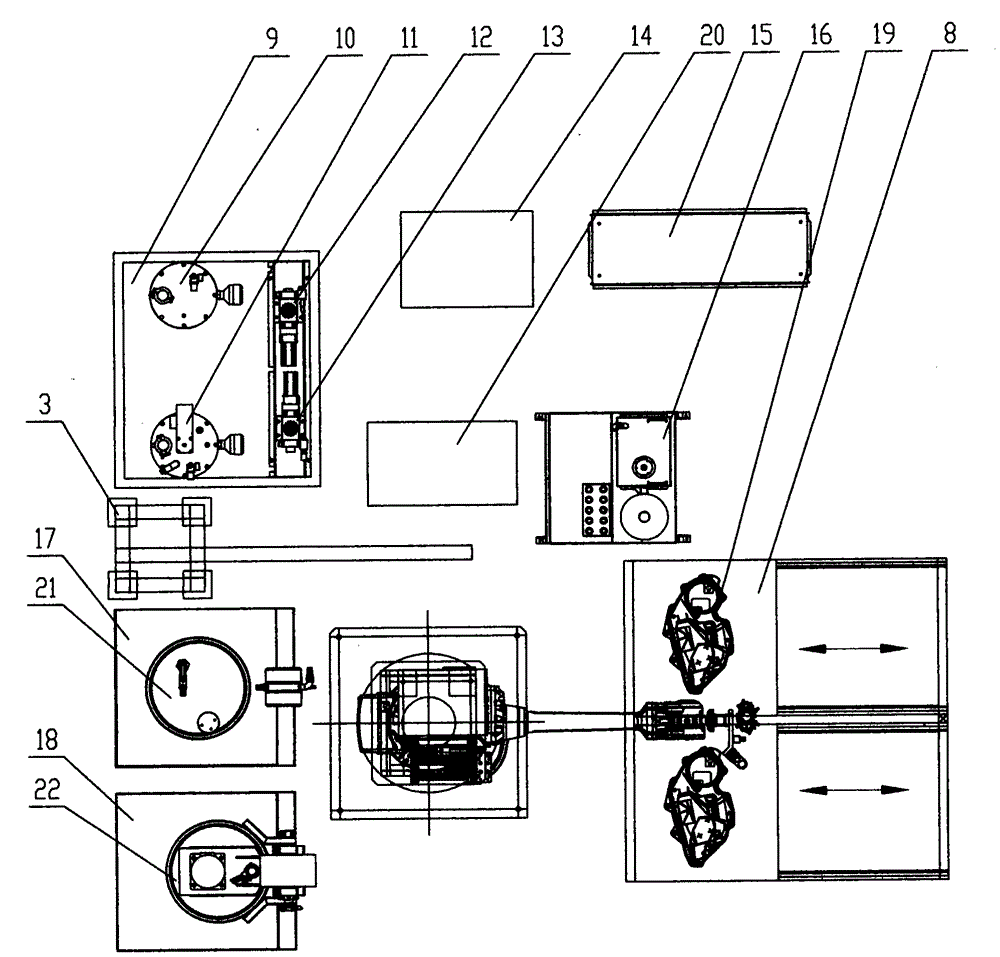

Full-automatic robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

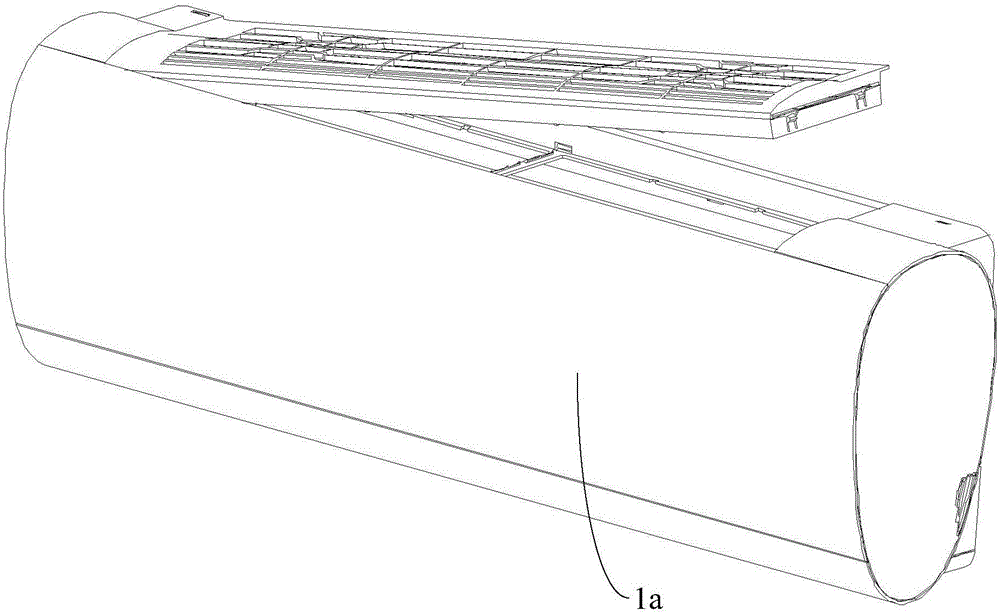

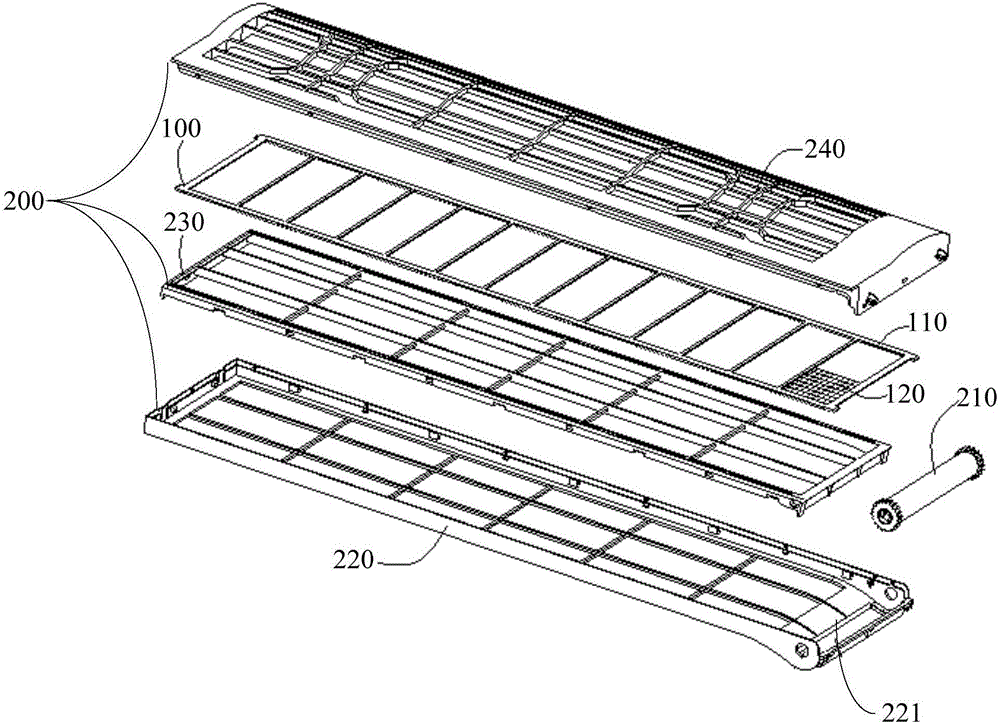

Air-conditioner and clean control method thereof

InactiveCN105953326AAutomatic cleaningEasy to useMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigeration

The invention discloses an air-conditioner and a clean control method thereof. When the air-conditioner needs to be cleaned, the air-conditioner is controlled to carry out refrigeration so that an indoor heat exchanger can be cleaned; and a controller is further used for controlling a dust removal device to clean a filter screen while the indoor heat exchanger is cleaned. According to the air-conditioner and the clean control method thereof, the filter screen does not need to be disassembled when being cleaned, and the filter screen can be cleaned automatically; moreover, the indoor heat exchanger is further cleaned while the filter screen is cleaned; and the cleaning time is shortened, the cleaning efficiency is improved, and a user can use the air-conditioner more conveniently.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

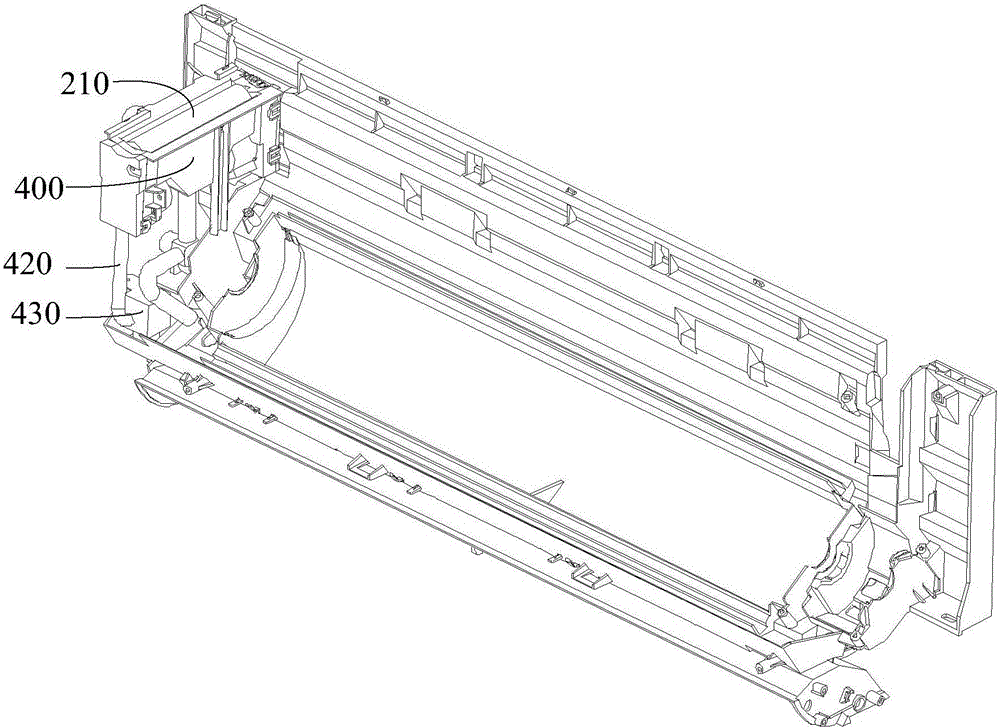

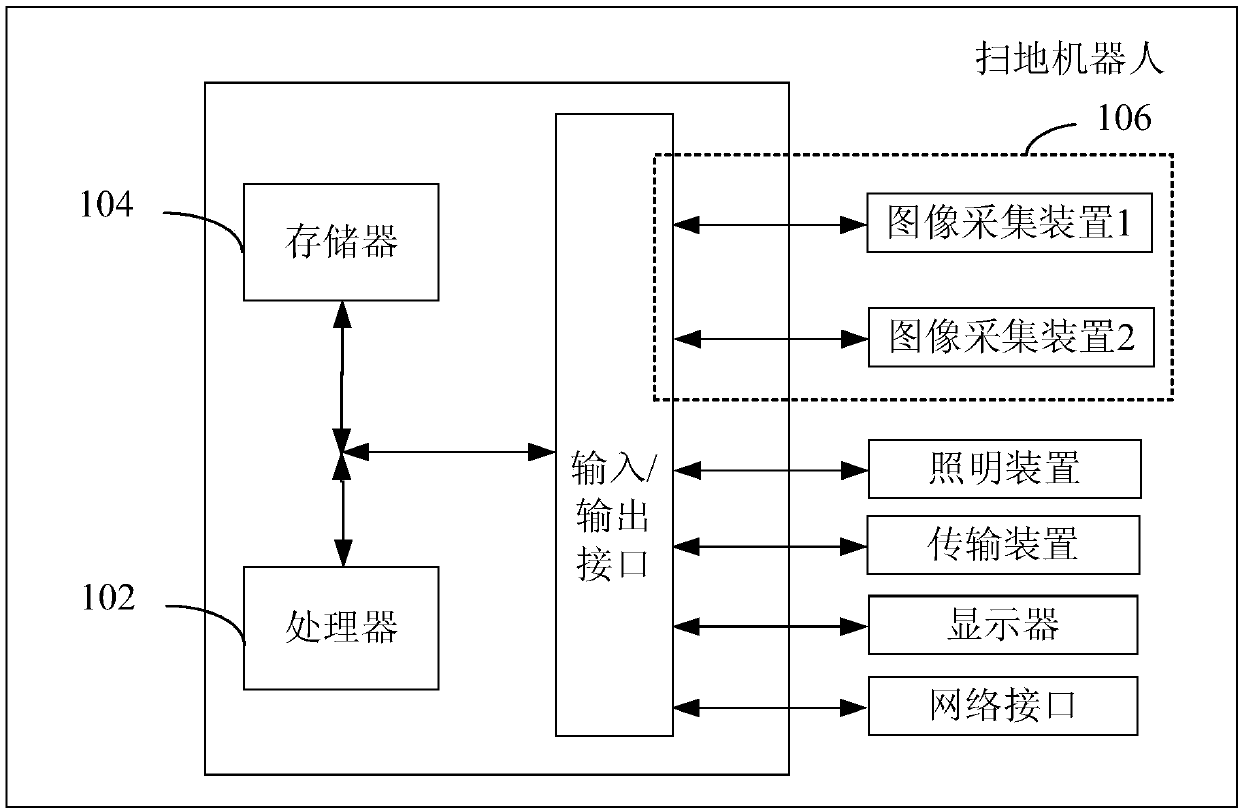

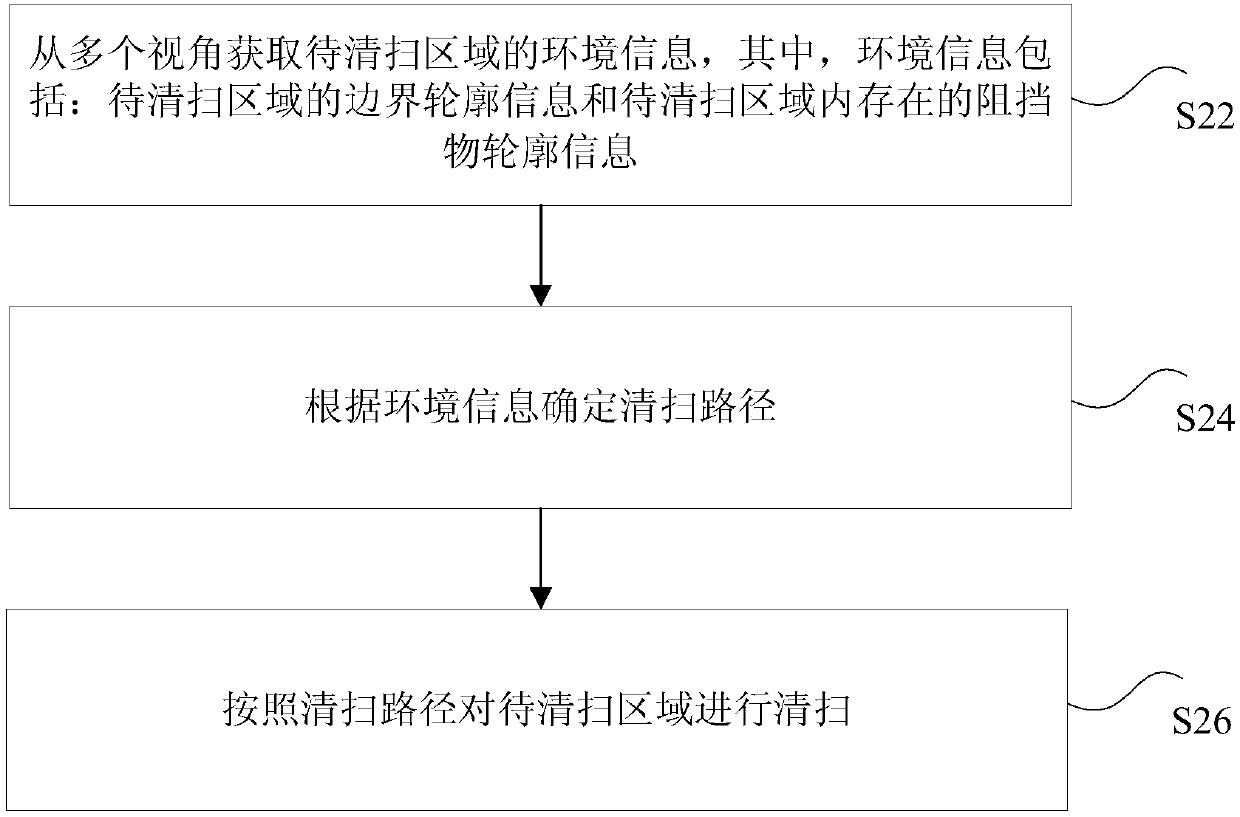

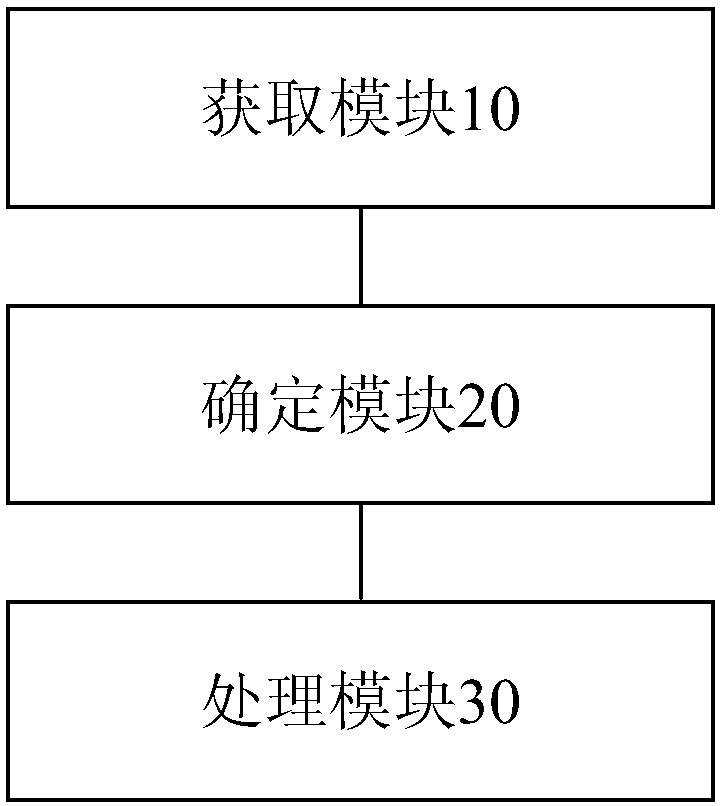

Area sweeping method and device, storage medium, processor and floor sweeping robot

InactiveCN107752910AReduce cleaning timeImprove cleaning efficiencyAutomatic obstacle detectionTravelling automatic controlMultiple viewMultiple perspective

The invention discloses an area sweeping method and device, a storage medium, a processor and a floor sweeping robot. The method comprises the steps that environment information of an area to be sweptis obtained from multiple view angles, wherein the environment information comprises the information of the boundary contour of the area to be swept and the information of the contours of obstacles which exist in the area to be swept; according to the environment information, a sweeping path is determined; according to the sweeping path, the area to be swept is swept. By means of the area sweeping method and device, the storage medium, the processor and the floor sweeping robot, the technical problems are solved that in the related technologies, all-round sweeping with a low repetition rate cannot be achieved when the floor sweeping robot needs to avoid the obstacles.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

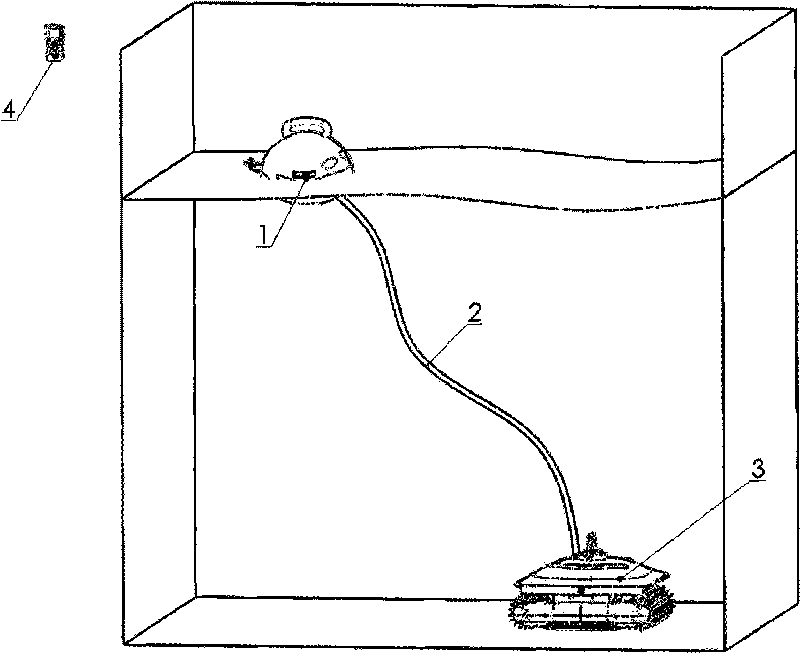

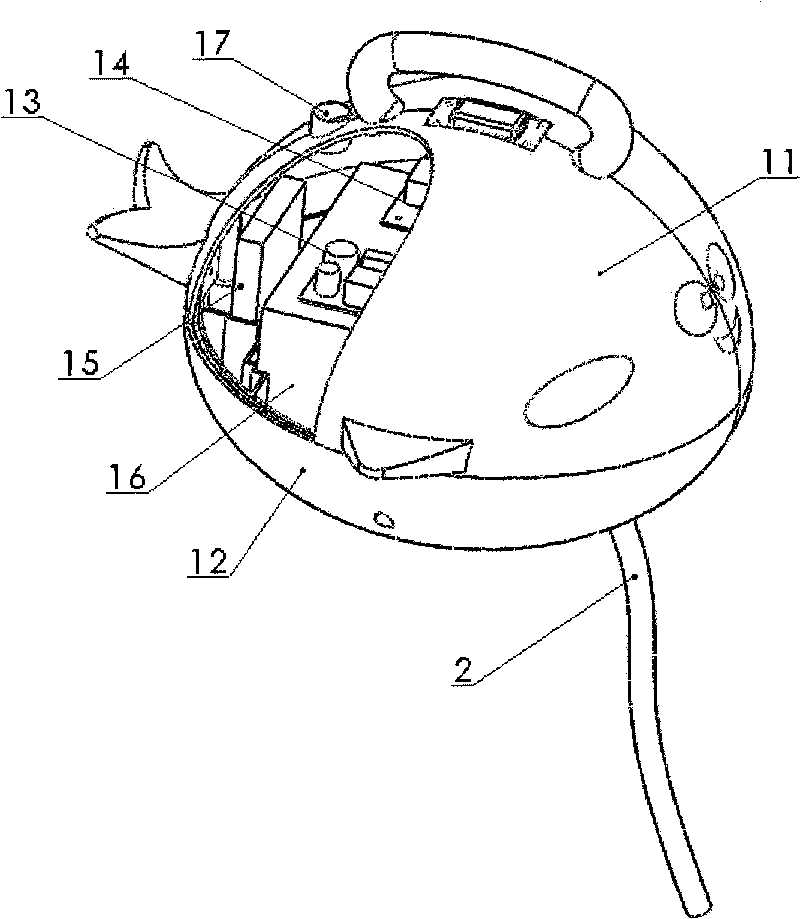

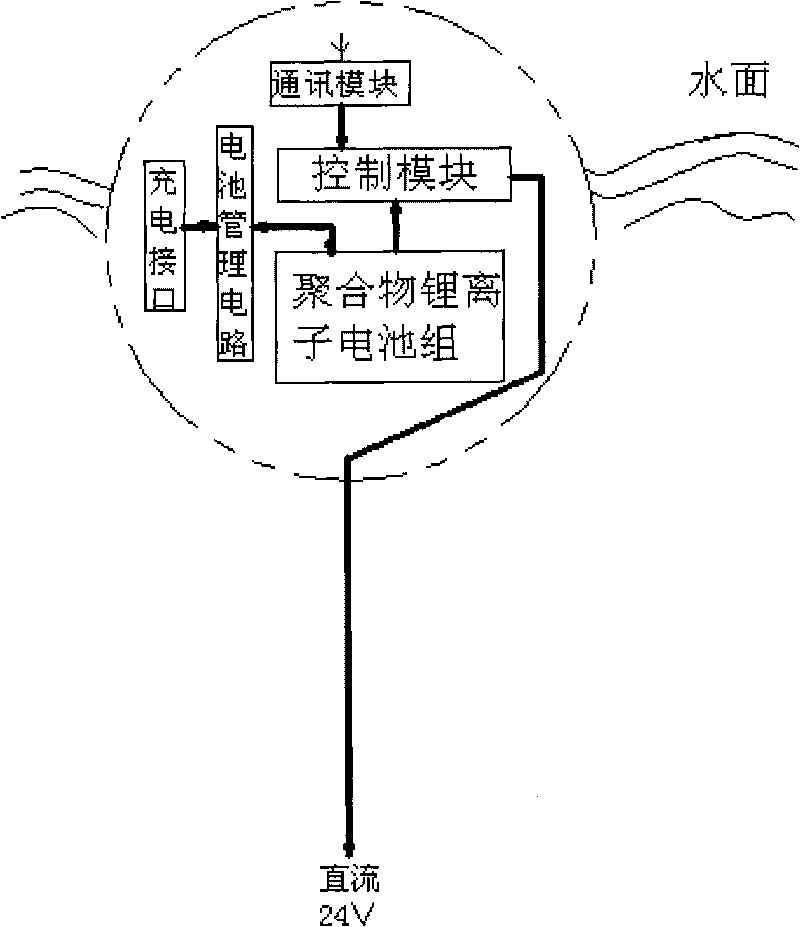

Automatic cleaner with cableless remote control floating power supply for swimming pool

ActiveCN101725263AEliminate windingEliminate the disadvantages of hanging cardsBatteries circuit arrangementsElectric powerMarine engineeringRemote control

The invention relates to an automatic cleaner with a cableless remote control floating power supply for a swimming pool, comprising a rechargeable floating power supply, an umbilical cable, an underwater automatic cleaner of the swimming pool and a remote controller. The rechargeable floating power supply floats on the water surface with the upper part exposing out of the water surface and receives signals sent by the remoter controller to control the underwater automatic cleaner to work; the underwater auto-cleaner uses a direct current (DC) motor, can automatically clean the swimming pool in accordance with a predetermined program and further performs the cleaning work in accordance with the signals sent by the remote controller. In the automatic cleaner with the cableless remote control floating power supply for the swimming pool, a longer power supply cable is cancelled, therefore, the automatic cleaner is not limited by length of the cable and can reach all places of the swimming pool to perform the cleaning work, and the defects of winding and locking cables, and the like are eliminated simultaneously.

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

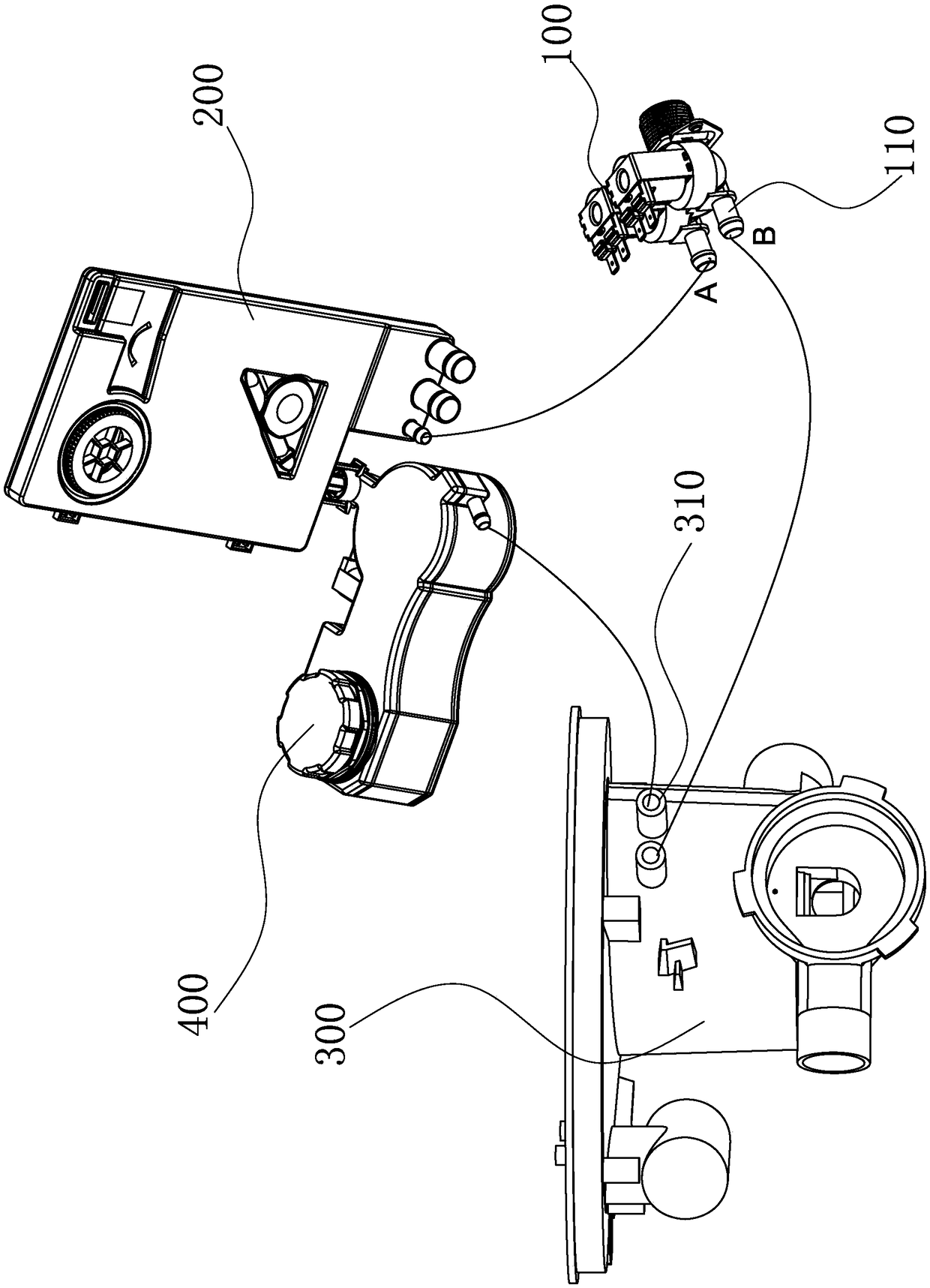

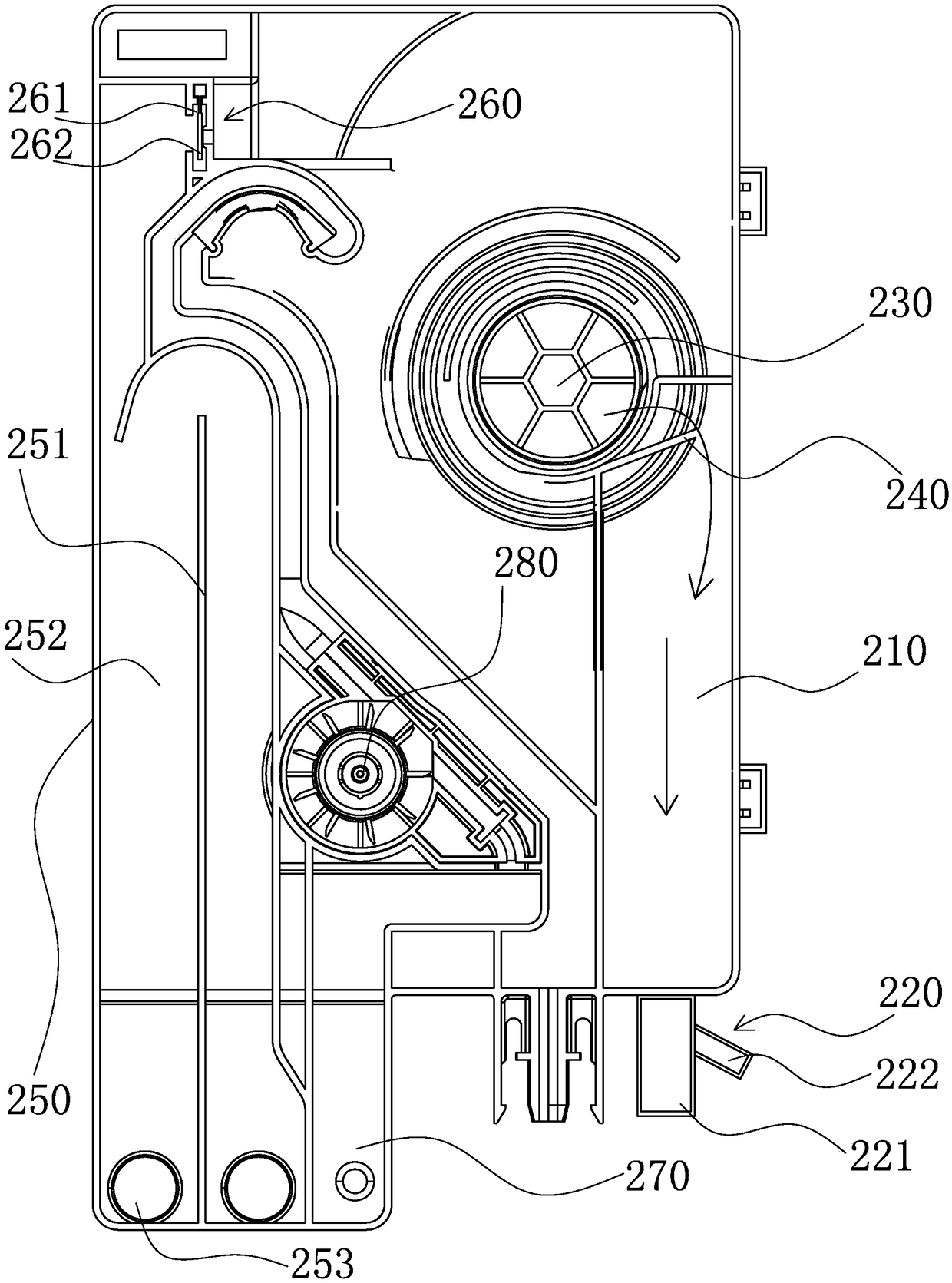

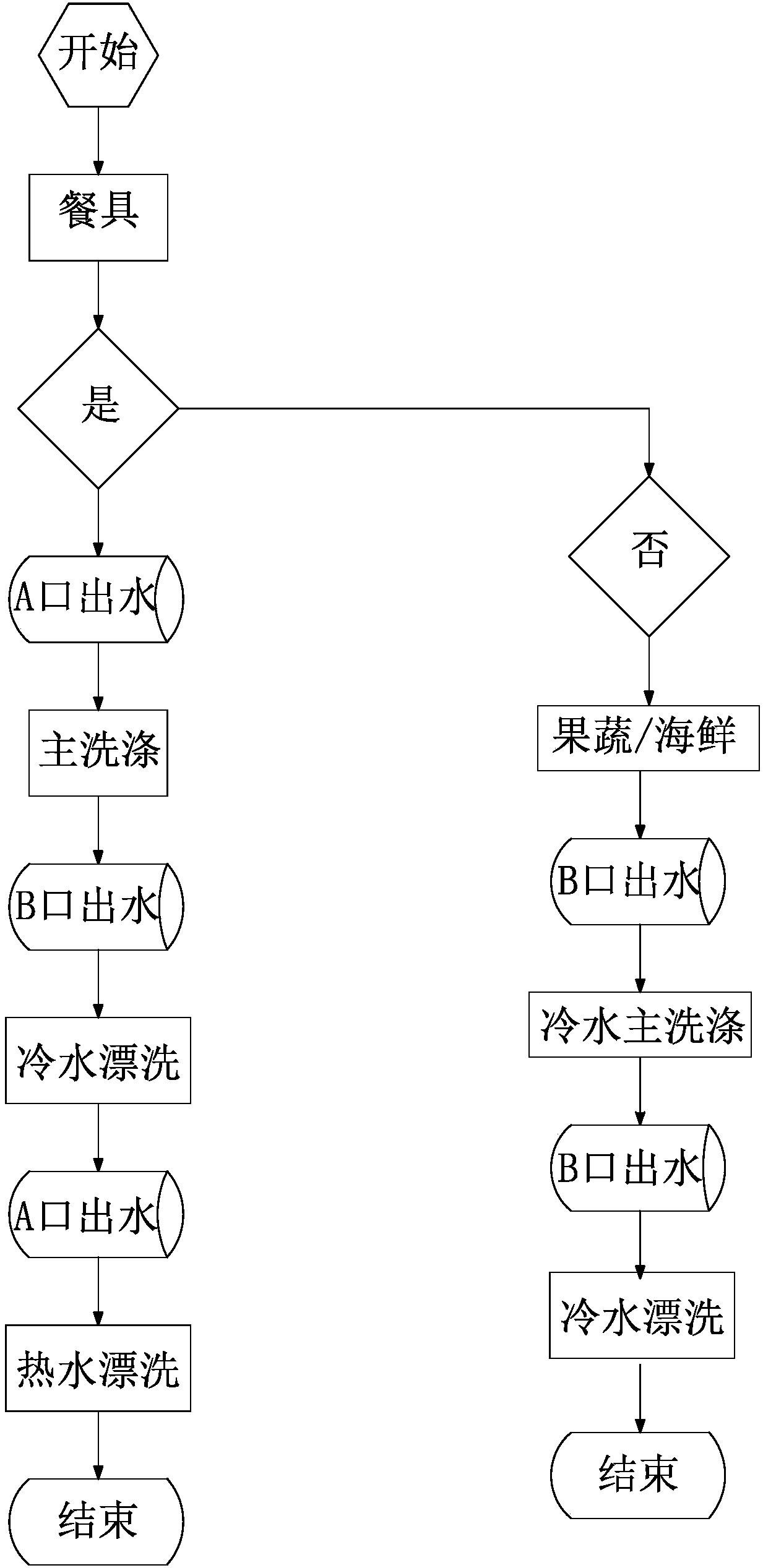

Dish washing machine water inlet device and water inlet method

PendingCN108065884AImprove regenerative abilityAvoid frequent regenerationTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionEngineeringFruits and vegetables

The invention provides a dish washing machine water inlet device and a water inlet method, the device comprises a water inlet dual valve and a water softening apparatus, wherein the water inlet dual valve is connected with an outside municipal water route, two water outlet ports are formed in the water inlet dual valve, one water outlet port is connected with a respirator, and the other water outlet port is connected with a dish washing machine water cup; two ends of the water softening apparatus are connected with the respirator and the dish washing machine water cup respectively. According to the dish washing machine water inlet device and the water inlet method, two water inlet routes which are mutually independent and not interfere are realized by the aid of the water inlet dual valve,different water inlet routes are selected according to cleaning objects, the resource of the water softening apparatus is saved while the fruit and vegetable / seafood washing time is saved, the watersoftening regeneration capacity with same specifications is improved by 30% or above, besides, the phenomenon that the use cost is increased due to the fact that the water softening apparatus is usedrepeatedly is avoided.

Owner:NINGBO OULIN IND CO LTD

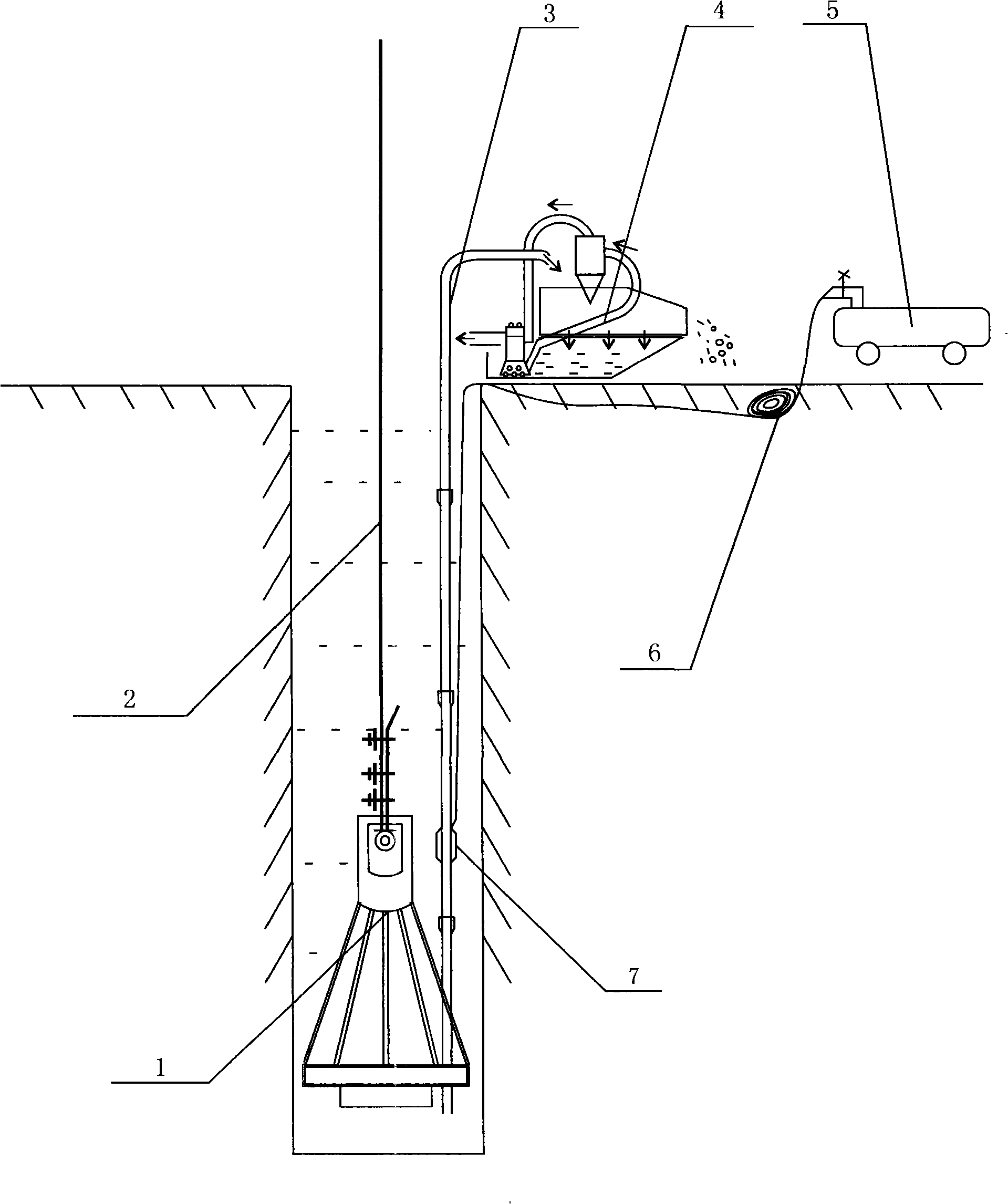

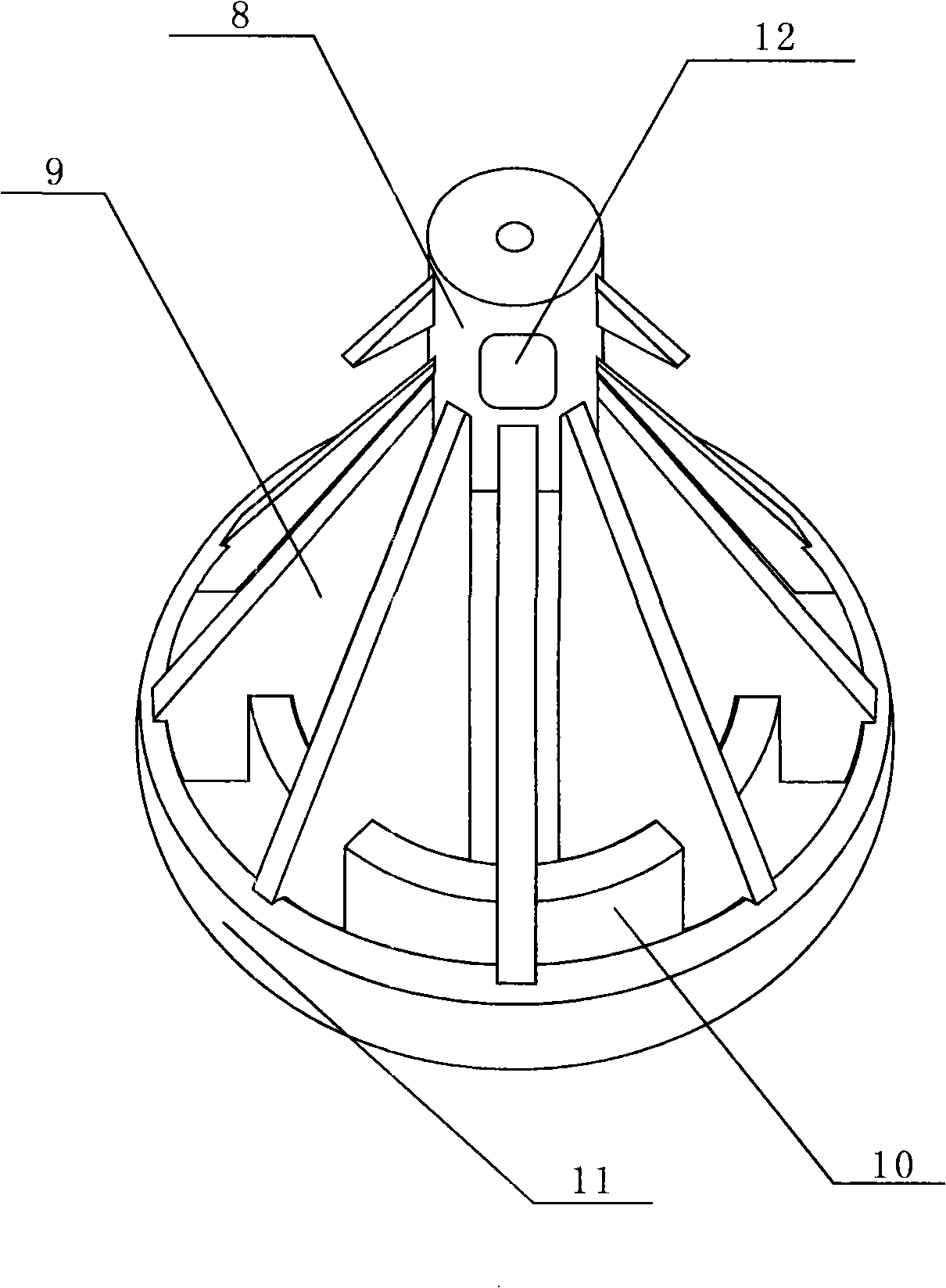

Reverse circulation construction technique and apparatus of single rope impact drill

InactiveCN101275458ARotation does not generateAvoid entanglementConstructionsReciprocating drilling machinesSlagEngineering

The invention discloses a process and a device for the reverse circulation execution of a single rope impact drill, the reverse circulation execution device comprises a percussion drill, a slurry pumping pipe at the hole bottom and a slurry purifier at the hole mouth, the drill bit is composed of a drill bit body and a cutting blade, the drill bit body is composed of a hammer body, corner boards and a base, the upper end of the hammer body is provided with a connecting hold connected with a non-rotating rope, the corner boards are distributed in the same angle axially on the cylindrical or circular-tube-shaped hammer body, the base is composed of coaxial inner base and outer base, which are tube-shaped, the upper surfaces of the two base are in the same plane, the inner base is higher than the outer base, the lower ends of the corner boards are connected with the two bases, the hammer body, the corner plate and the base are integrated by welding, casting or riveting, the lower end of the base is evenly equipped with multiple cutting blades; pile types of various section shapes can be dilled by the drill bit, the reverse circulation process of hole bottom slag pumping is used when drilling, the execution process is fastened, the energy consumption is reduced, the slag is cleaned completely and clearly, the time for cleaning the hole is shortened.

Owner:张安禄

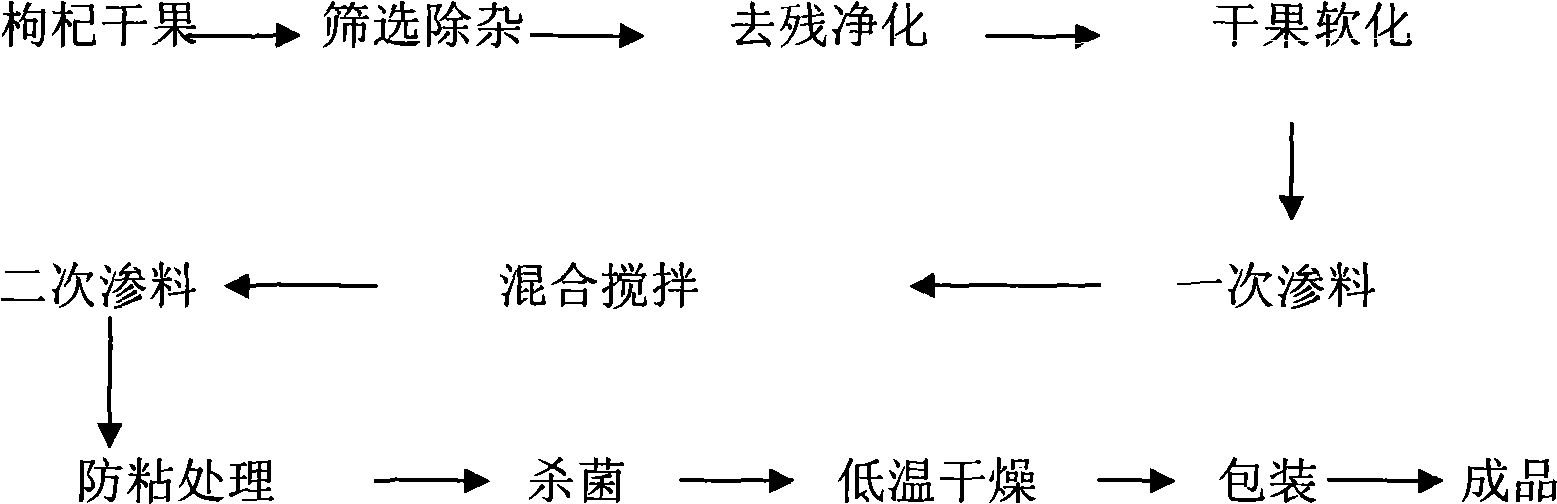

Medlar health-care preserved fruit and method of manufacturing the same

The present invention relates to a medlar health-care preserved fruit and a method of manufacturing the same, the product is composed of (by weight parts of raw material in finished product) 80 to 95% of medlar dried fruit, 2 to 15% of fruit juice, 0.3 to 5.0% of compatibility medicinal materials soaking juice, 0.1 to3.5% of citric acid, 0.1 to 1.0% of VC, the rest is pure water. The finished product is made by filtrating and edulcorating, purifying, dried fruit softening, stock leaked by medicament, mixing and agitating, stock leaked by fruit juice, antisticking process, sterilizing and low temperation drying of the medlar dried fruit.

Owner:宁夏沃福百瑞枸杞产业股份有限公司

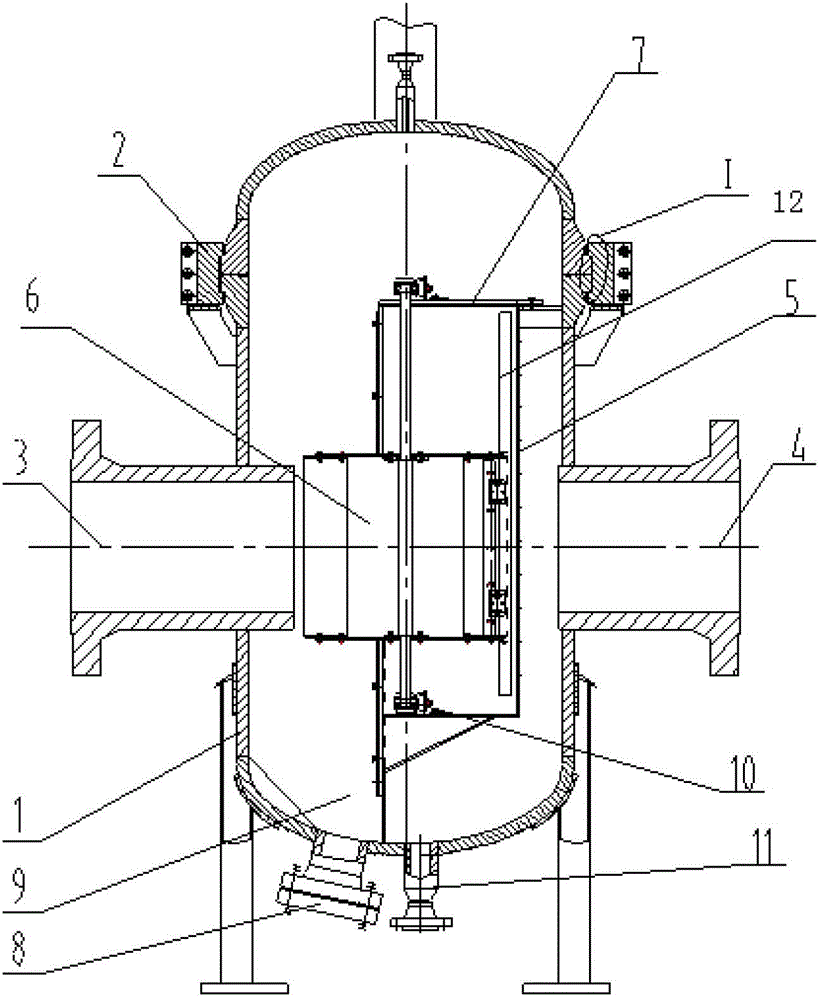

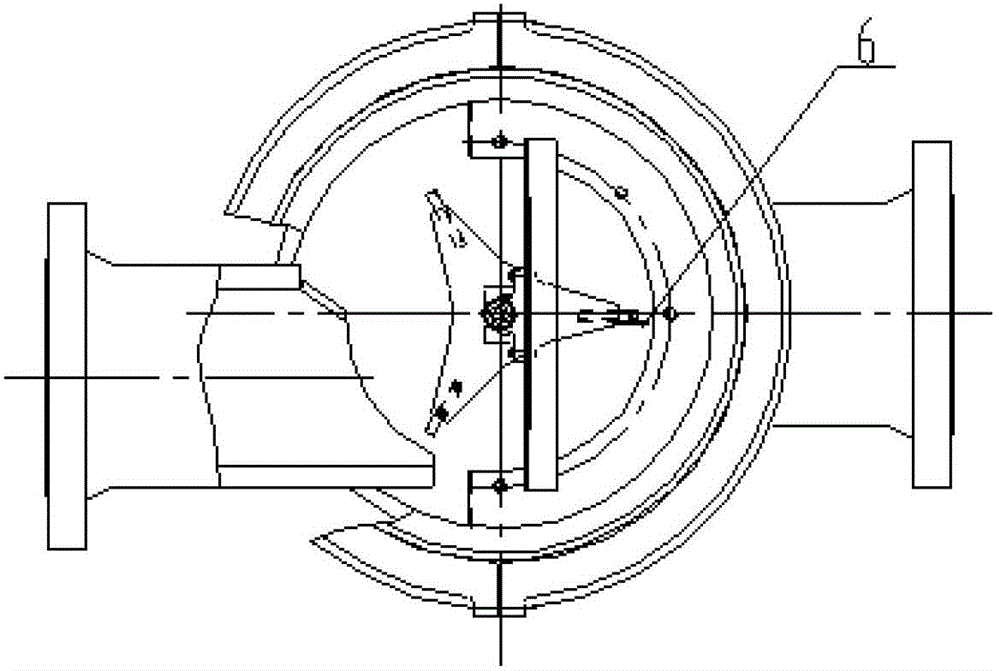

Hydraulic-driven self-cleaning filter provided with brushes

InactiveCN103331051AImprove reliabilityContinuously workingStationary filtering element filtersWater turbineEngineering

The invention relates to a self-cleaning filter which is capable of using the energy of liquid and is suitable for transmission pipelines of refined oil. A special-shaped swiveling wheel is arranged in the filter, and is provided with nylon brushes; a liquid inlet is arranged tangentially, and an optimized angle is formed between the liquid inlet and a liquid outlet. According to the operation principles of a water turbine, when the filter runs, the liquid enters into the filter and rotates in the filter to push the special-shaped swiveling wheel to rotate; and one nylon brush arranged on one blade of the swiveling wheel will be used for clearing impurities captured by a filter screen, so that the filter screen is prevented from being blocked. A top cover and a cylinder body of the filter are connected by a clamping hoop fastening structure, can be disassembled by dismounting 4 to 6 bolts, and are easy and convenient to be disassembled. The self-cleaning filter which is capable of using the energy of liquid for automatic cleaning of the filter screen disclosed in the invention helps to solve problems that: existing self-cleaning filter needs an extra drive unit and an extra control unit, and is only suitable for low pressure working conditions; liquid backwashing is required; and deslagging is uncomplete.

Owner:西安航天泵业有限公司

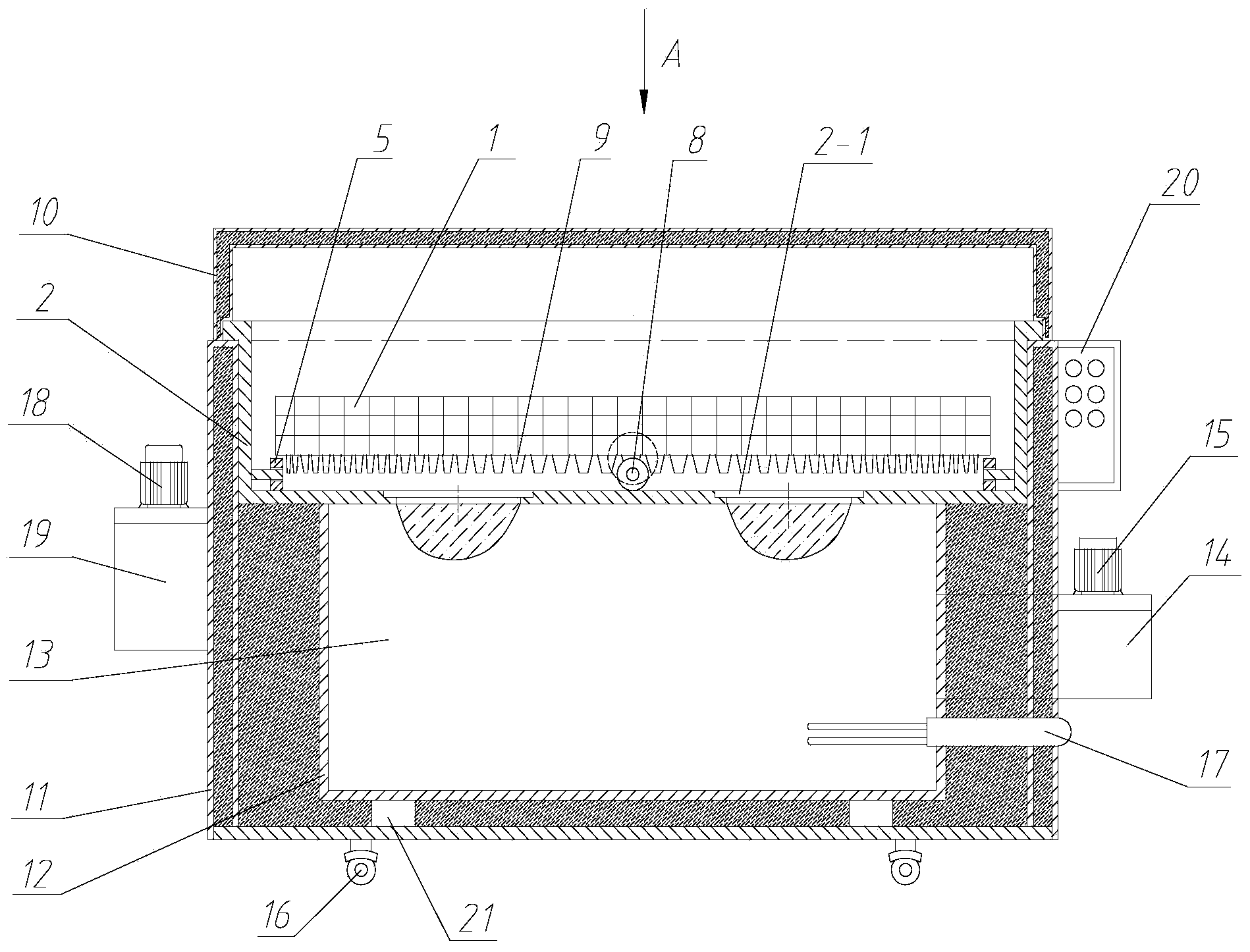

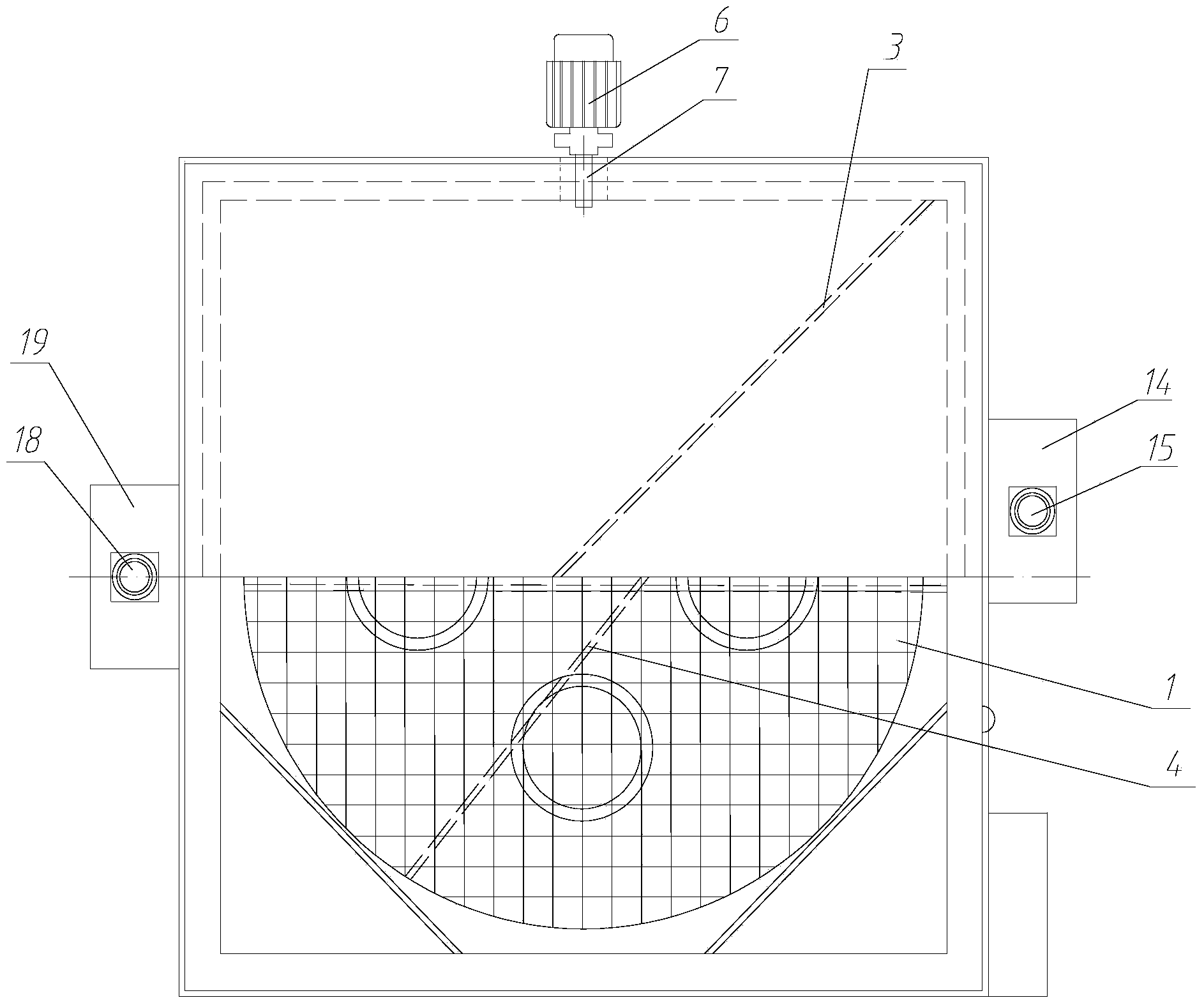

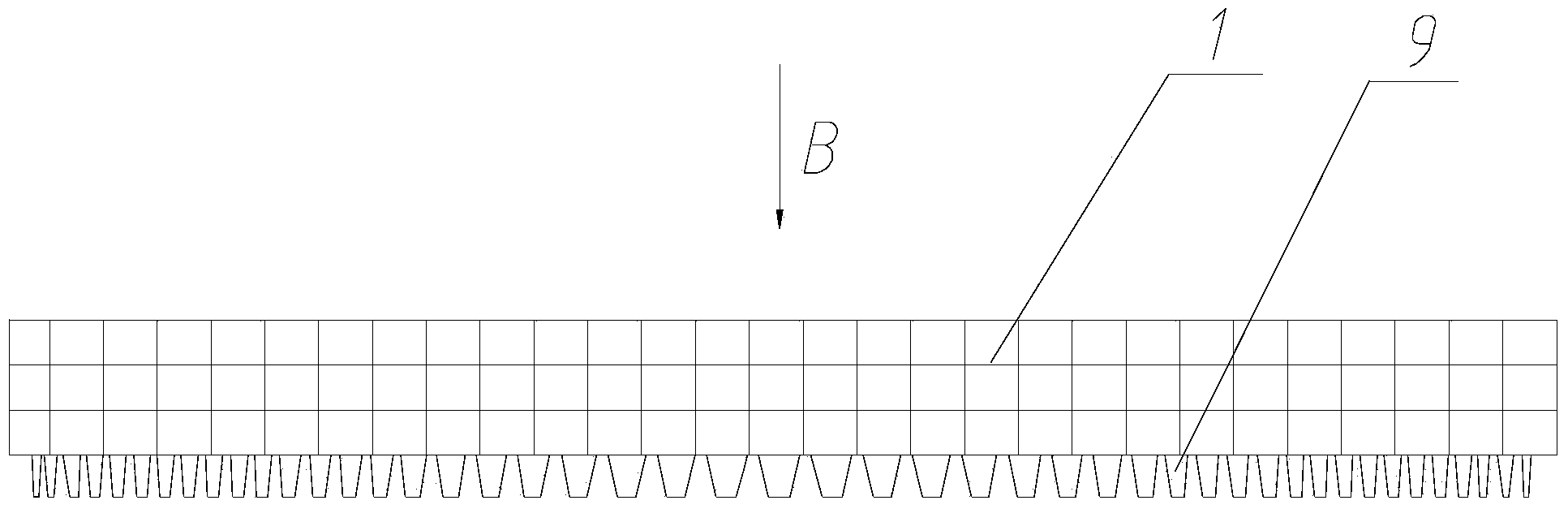

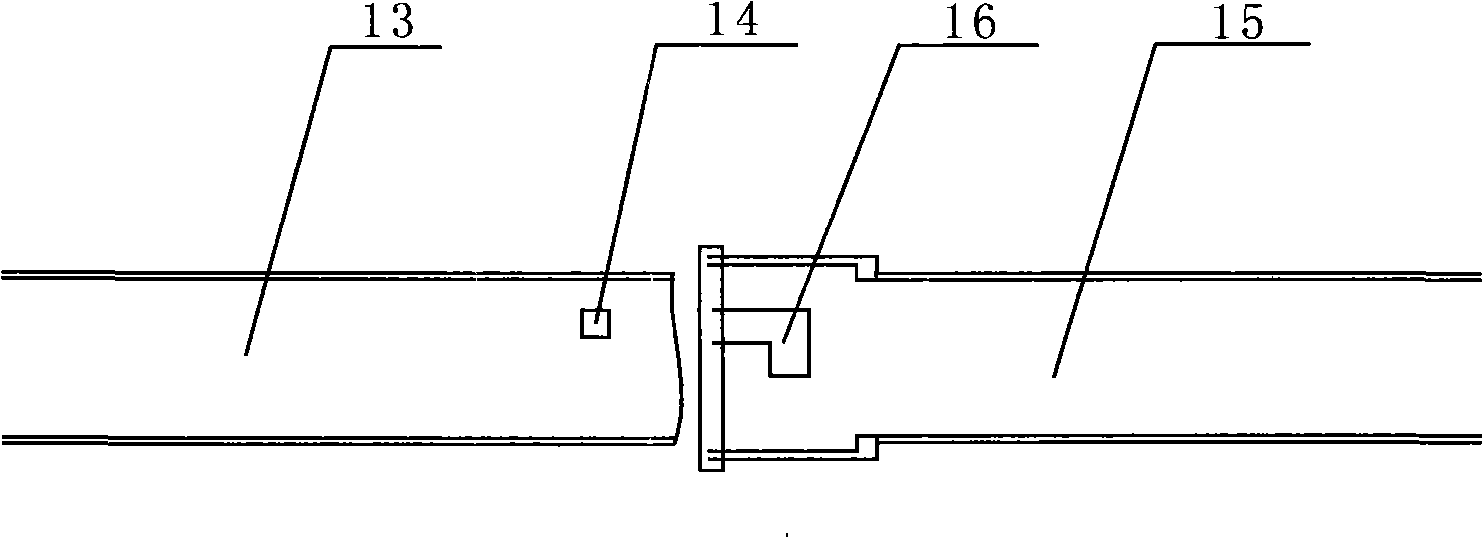

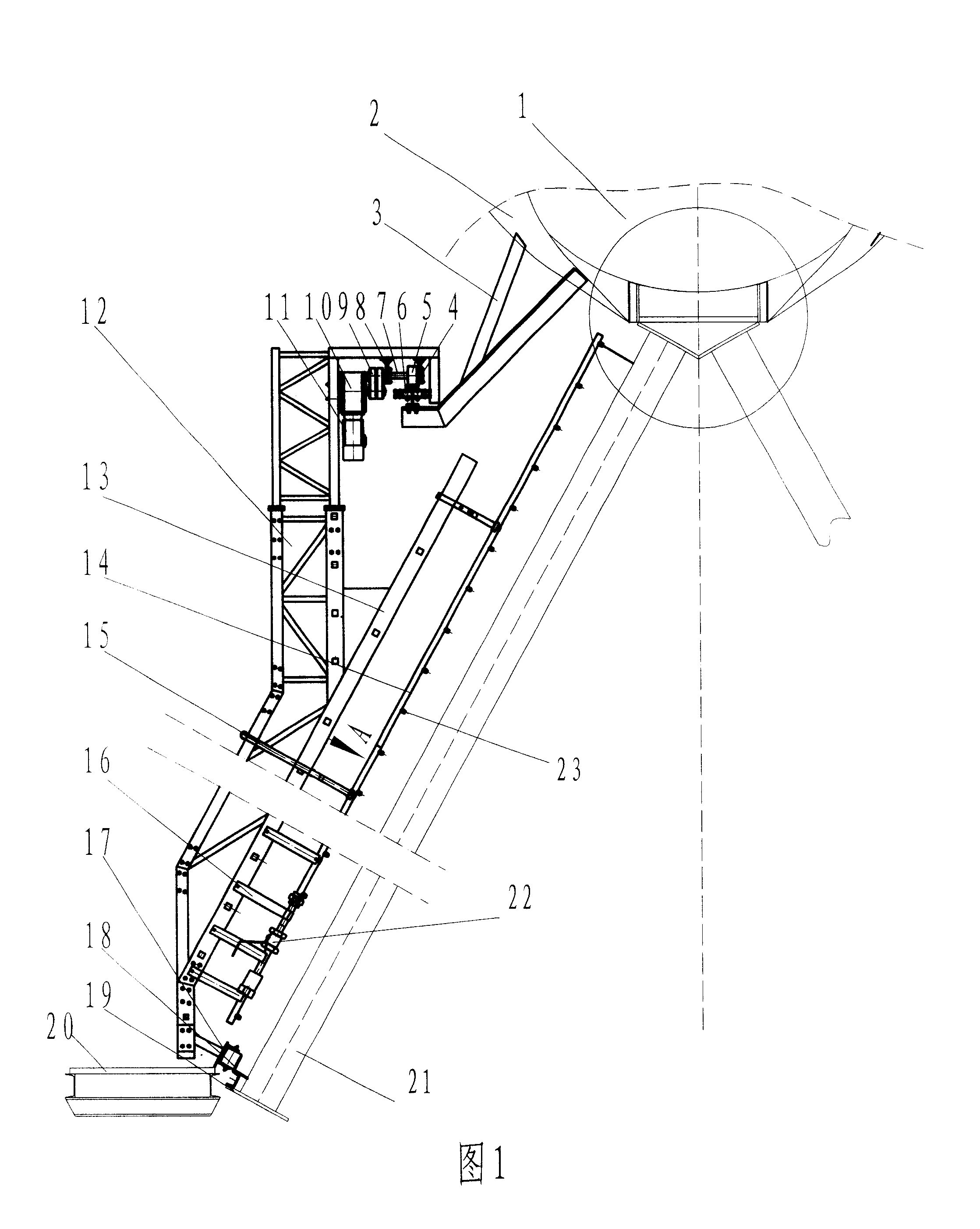

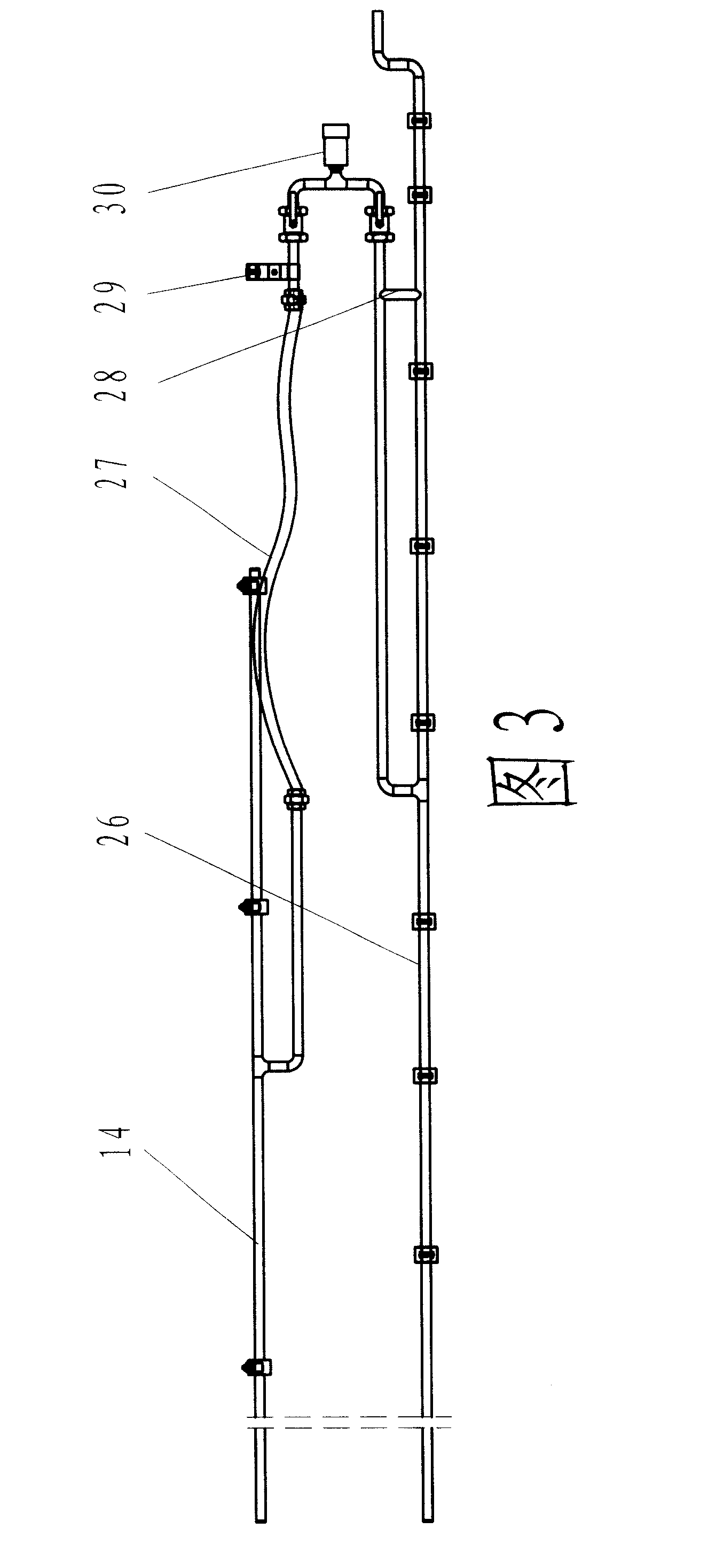

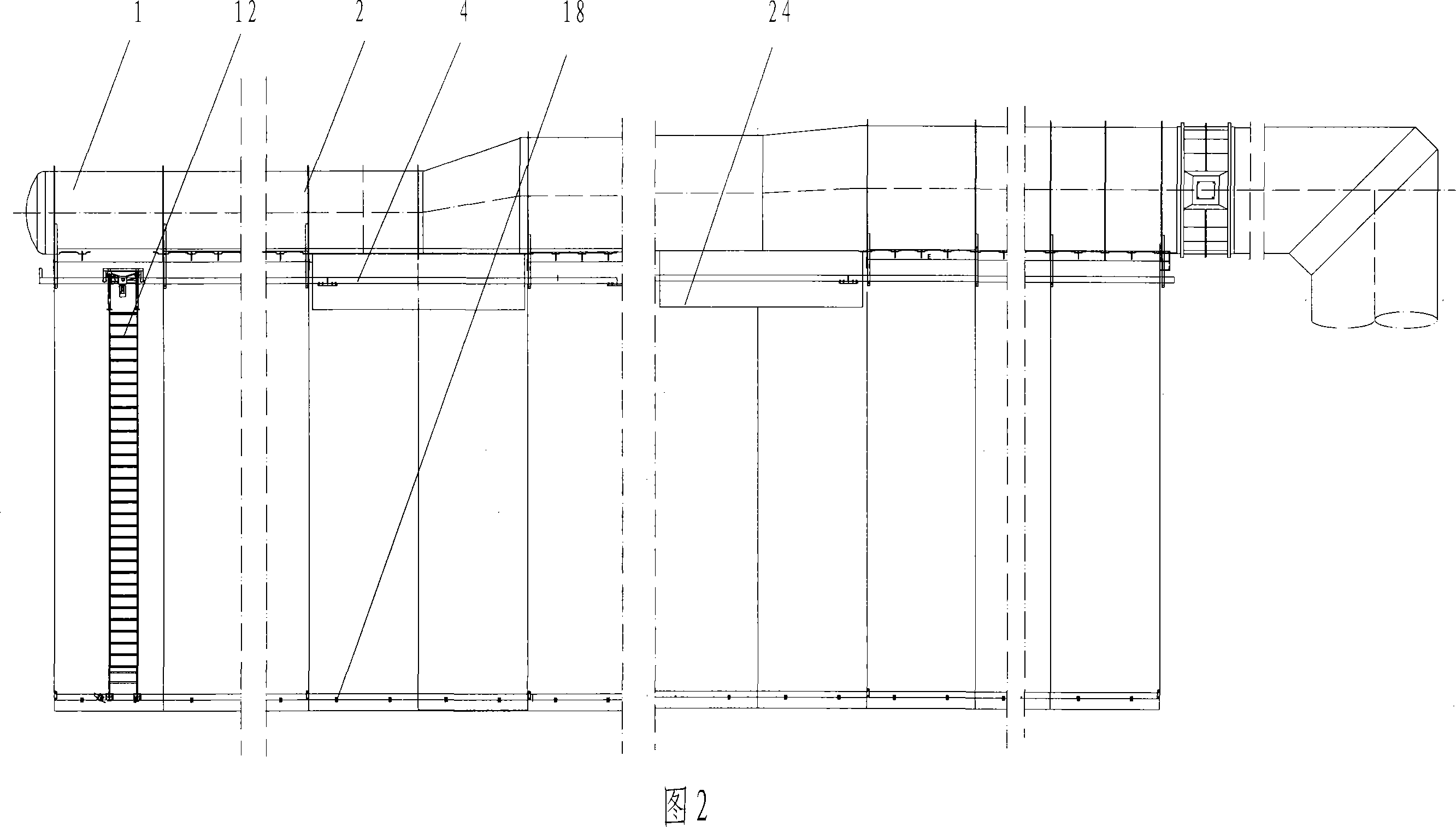

Air cooling condenser high-pressure door type or cantilever type track automatic cleaning device

The invention discloses an air cooling condenser high-pressure door type or cantilever type track automatic cleaning device, comprising a high-pressure water jet cleaning device and a support on whicha cleaning device assembly is arranged; the support has a door type structure and consists of two upright posts which are vertically arranged and a beam which is horizontally arranged; the cleaning device assembly is glidingly connected with the beam of the support; and the high-pressure water jet cleaning device is connected with the cleaning device assembly by a high-pressure water pipe. The invention uses an air cooling radiation triangle of a door / console through type cleaning air cooling island, and the mode is convenient and quick compared with the prior cleaning modes; in the invention, one radiation surface can be cleaned only by one stroke, and the total design is compact and scientific; compared with the prior two cleaning modes, the cleaning time is shortened by more than half,and the cleaning efficiency is improved by 2-3 times; the cleanliness rate reaches 100%, which is incomparable to the prior modes.

Owner:马庚

Rinse tank for rinsing semiconductor wafer

ActiveCN103871938AEasy to cleanWide range of cleaningSemiconductor/solid-state device manufacturingSpray nozzleSemiconductor

The invention provides a rinse tank for rinsing a semiconductor wafer and belongs to the technical field of the semiconductor wafer technology. The rinse tank comprises a rinse tank body and a sprinkler, wherein a tank cover used for sealing the rinsing tank body is arranged over the rinsing tank body, the sprinkler used for rinsing the wafer is arranged on the tank cover and comprises multiple sprinkler pipes and multiple nozzles communicated with the sprinkler pipes, the nozzles are evenly distributed on the tank cover in a matrix mode, the sprinkling angles of the nozzles can be adjusted, and valves used for controlling rinsing fluid to pass through are arranged on the sprinkler pipes. According to the rinse tank, the tank cover is arranged on the upper portion of the rinse tank, the multiple nozzles with adjustable sprinkling angles are evenly distributed on the tank cover, the rinsing fluid can be jetted to rinse the wafer from different directions, and different positions and angles of the wafer can be covered; the rinsing capacity is higher, the rinsing surface is wider, rinsing time can be shortened, and the yield can be increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Cleaning agent for dry-film developing tank of printed circuit board (PCB) and preparation method of cleaning agent

InactiveCN102757871AShorten cleaning timeShorten the timeSurface-active non-soap compounds and soap mixture detergentsPhotosensitive material processingAcetic acidDeveloping tank

The invention relates to a cleaning agent for a dry-film developing tank of a printed circuit board (PCB). The cleaning agent comprises a solvent A and a solvent B, wherein the solvent A comprises the following components in percentage by weight: 15% to 20% of phosphoric acid, 4% to 10% of acetic acid and the balance of water; and with the solvent A as the basic quantity, the solvent B comprises the following components in percentage by weight: 3% to 6% of emulsifying agent, 0.5% to 1% of solubilizer, and 1% to 3% of surfactant. The cleaning agent for the dry-film developing tank of the PCB has the advantages of low cleaning temperature, short cleaning time and good cleaning effect.

Owner:瀚宇博德科技(江阴)有限公司

Underwater real-time surface dirt cleaning and detecting device for optical-fiber laser

InactiveCN102700692AAchieve real-time laser cleaningReduce cleaning costsVessel cleaningHullsEngineeringGlobal Positioning System

The invention relates to the field of cleaning, in particular to an underwater real-time surface dirt cleaning and detecting device for an optical-fiber laser, which is a cleaning device special for a sonar board of a submarine. The device provided by the invention comprises an underwater cleaning device, a power supply, a global positioning system (GPS) positioning device, a control device, an optical-fiber laser, a charge-coupled device (CCD) sensor, a first wireless signal device, a second wireless signal device, a computer, a power circuit and a control circuit. By using the device, real-time laser cleaning for the sonar board of the submarine on voyage is realized; and compared with the conventional cleaning method, the submarine does not need to be driven back to a dock, so that the cleaning cost and the cleaning time for the sonar board are reduced obviously. According to the device, the automation degree in the cleaning process of the sonar board of the submarine is high, and the labor intensity of operating personnel is reduced.

Owner:JIANGSU UNIV

Phosphoric acid equipment pipeline scale inhibitor

ActiveCN102874938AExtended cleaning cycleShorten cleaning timeScale removal and water softeningPhosphorus compoundsSodium polyacrylateSodium Acrylate

The invention discloses a phosphoric acid equipment pipeline scale inhibitor and belongs to the field of scale prevention. The phosphoric acid equipment pipeline scale inhibitor is mainly composed of, by weight percentage, 0.5-1% of sodium dodecyl benzene sulfonate, 0.3-0.8% of sodium stearate, 1-2.5% of sodium lignin sulfonate and 1.5-2% of sodium polyacrylate. When in use, the scale inhibitor is heated to the temperature ranging from 20 DEG C to 80 DEG C and added in a phosphoric acid equipment pipeline, and addition amount of the scale inhibitor is 0.03-0.05% of phosphoric acid by wet process. By adopting the phosphoric acid equipment pipeline scale inhibitor, operation cycle of a phosphoric acid concentration system is prolonged, cleaning time is reduced, device operating rate is increased, and temperature application range of the scale inhibitor is wider than that of the prior art, so that the phosphoric acid equipment pipeline scale inhibitor has huge application value.

Owner:WENGFU (GRP) CO LTD

Double-screw high-efficiency environment-friendly pelletized particle cleaning agent and production method thereof

ActiveCN102618401AEasy to get materialsEasy to cleanDetergent mixture composition preparationOrganic non-surface-active detergent compositionsMixed materialsCleansing Agents

The invention discloses a double-screw high-efficiency environment-friendly pelletized particle cleaning agent and a production method thereof, and belongs to the technical field of high-molecular materials. The double-screw high-efficiency environment-friendly pelletized particle cleaning agent comprises matrix resin, inorganic powder, a lubricating agent and a coupling agent. The production method comprises the following steps of: (1) weighing the matrix resin, the inorganic powder, the lubricating agent and the coupling agent according to the proportioning part by weight; (2) drying the inorganic powder, adding the dried inorganic powder and the coupling agent into a highly-mixing machine, fully mixing and obtaining modified powder; (3) adding the modified powder in the step (2), the matrix resin and the lubricating agent in the high-speed mixing machine, adding the mixed materials into a hopper of an extruder, fusing, blending and extruding the mixed materials from the extruder, and carrying out bracing and granulation. The double-screw high-efficiency environment-friendly pelletized particle cleaning agent disclosed by the invention is convenient to take, low in price and convenient to clean and belongs to a nontoxic and pollution-free material.

Owner:杭州金州高分子科技有限公司

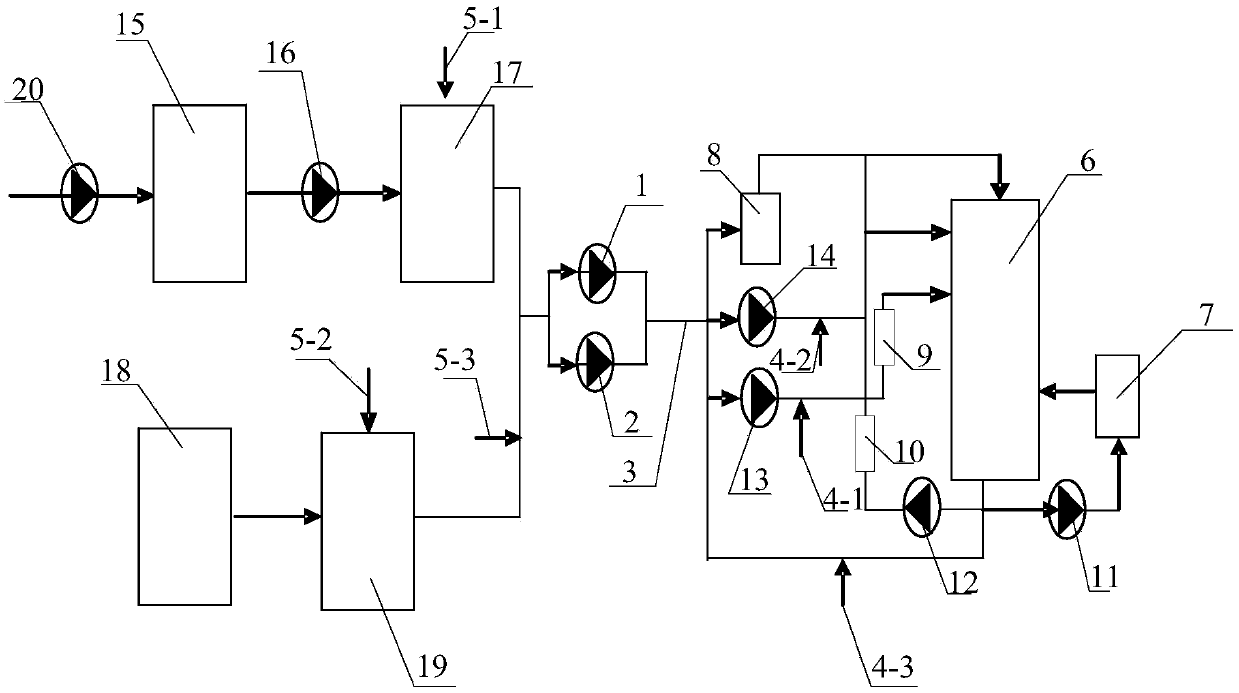

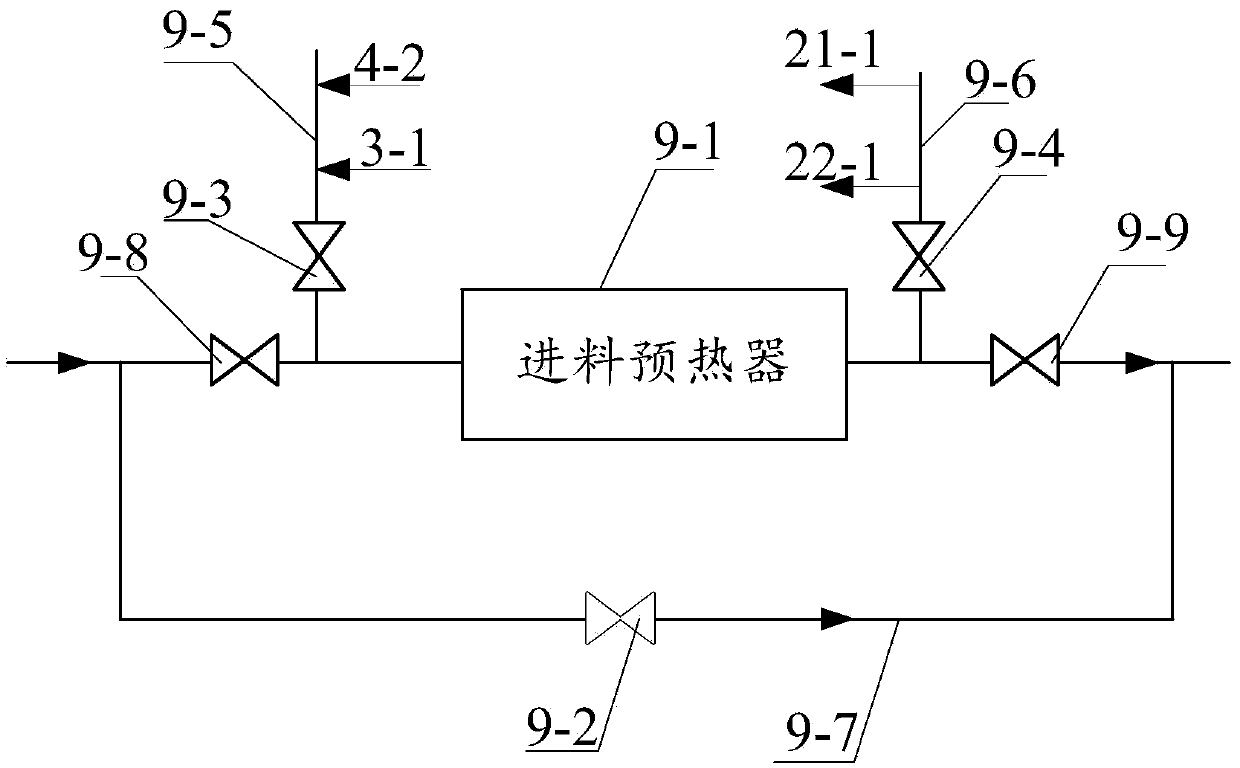

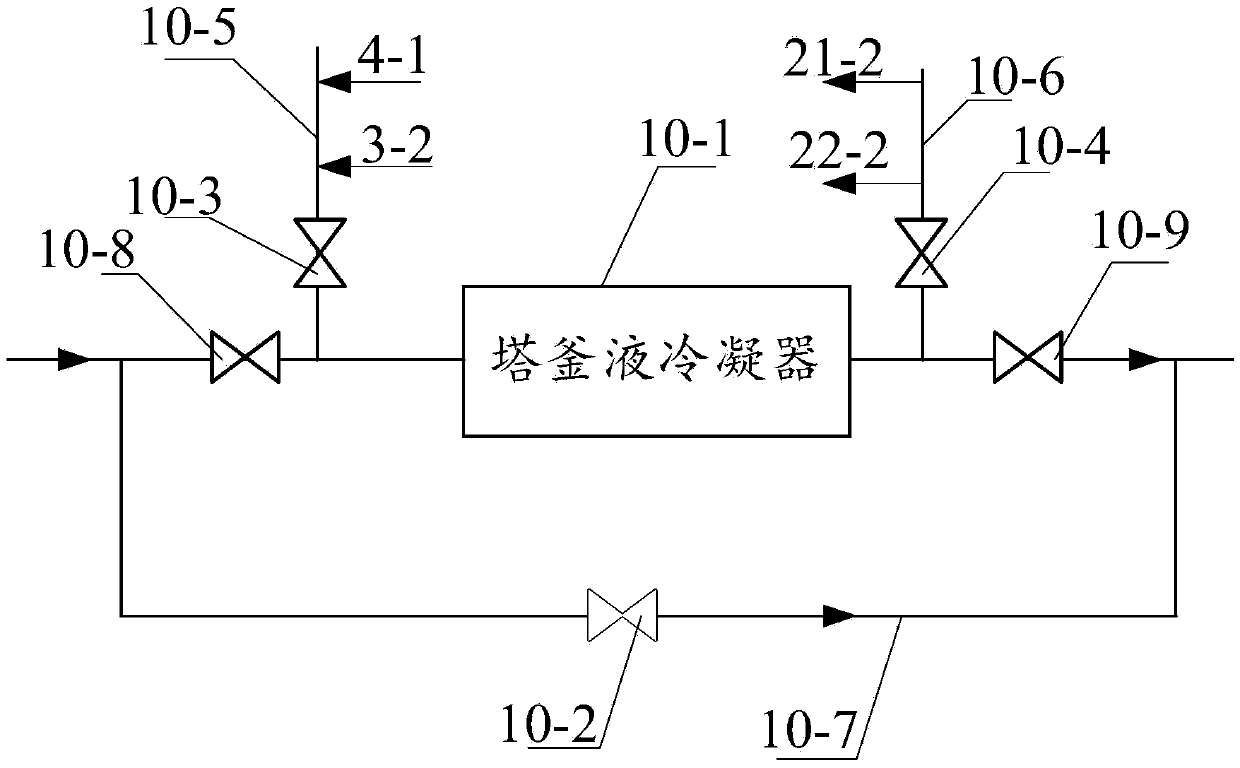

Clean-in-place system for distillation device, preparation for cleaning liquid, and cleaning method

ActiveCN105363237AEasy to cleanShorten cleaning timeDistillation regulation/controlCleaning using liquidsDistillationHeat transfer efficiency

The invention discloses a clean-in-place system for a distillation device, preparation for a cleaning liquid, and a cleaning method. The clean-in-place system comprises: the liquid outlet of a dilute alkali preparation unit is respectively connected with the liquid inlet of a first CIP pump and the liquid inlet of a second CIP pump; the liquid outlet of a citric acid blending unit is respectively connected with the liquid inlet of the first CIP pump and the liquid inlet of the second CIP pump; the liquid outlet of the first CIP pump and the liquid outlet of the second CIP pump are connected with the distillation device through a cleaning liquid inlet main pipeline; the liquid outlet of the first CIP pump is respectively connected with the dilute alkali preparation unit and the citric acid blending unit; the distillation device is respectively connected with the dilute alkali preparation unit and the citric acid blending unit through a cleaning liquid recycling main pipeline; the distillation device is connected with a process water inlet main pipeline and a process water outlet main pipeline; and the dilute alkali preparation unit and the citric acid blending unit are correspondingly connected with a process water inlet pipeline. The clean-in-place system provided by the invention solves the technical problem of influences on mass-transfer and heat-transfer efficiencies due to blockage of the distillation device in the process of preparation of ethanol by using a conventional coal-gas biological fermentation process, and realizes convenient and rapid cleaning in place for the distillation device.

Owner:河北首朗新能源科技有限公司

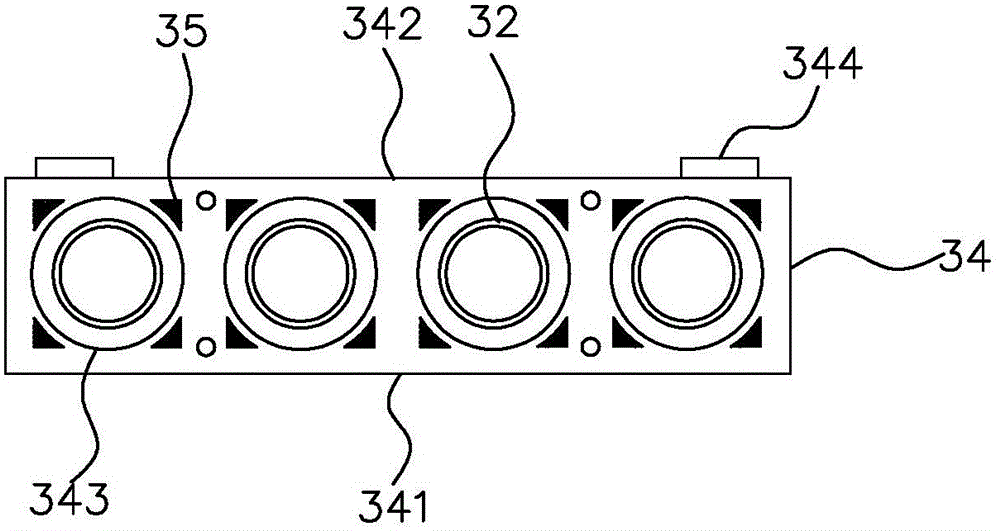

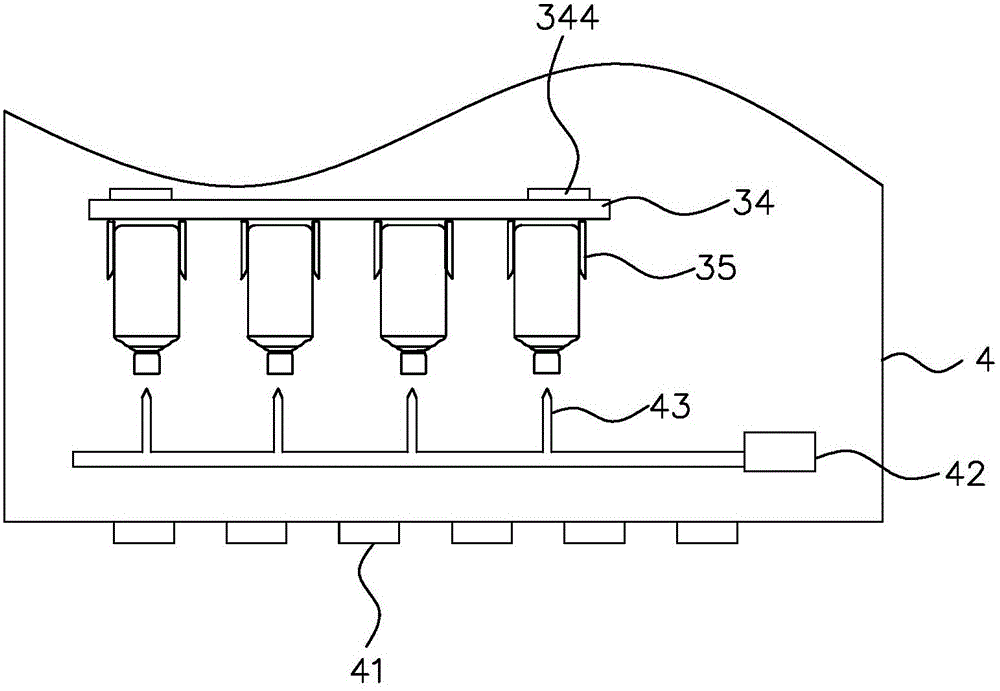

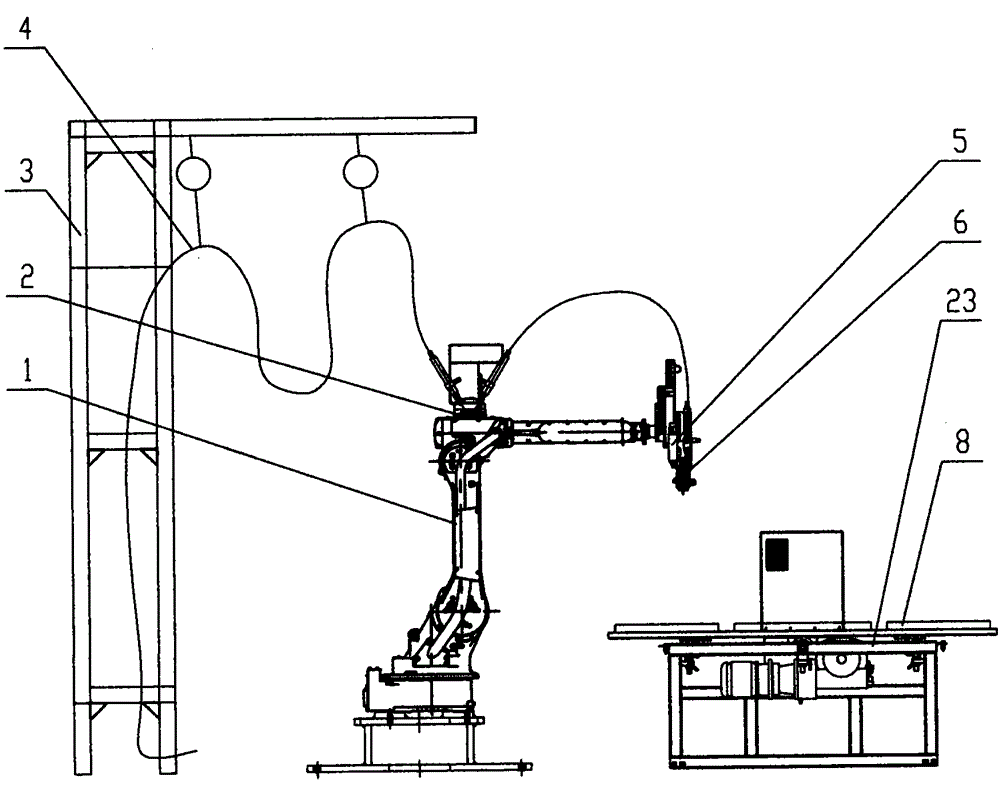

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

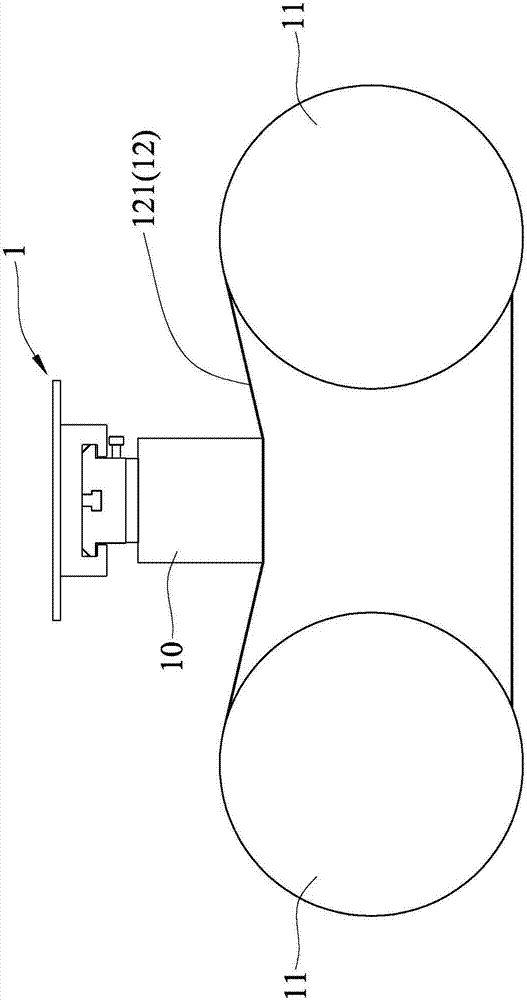

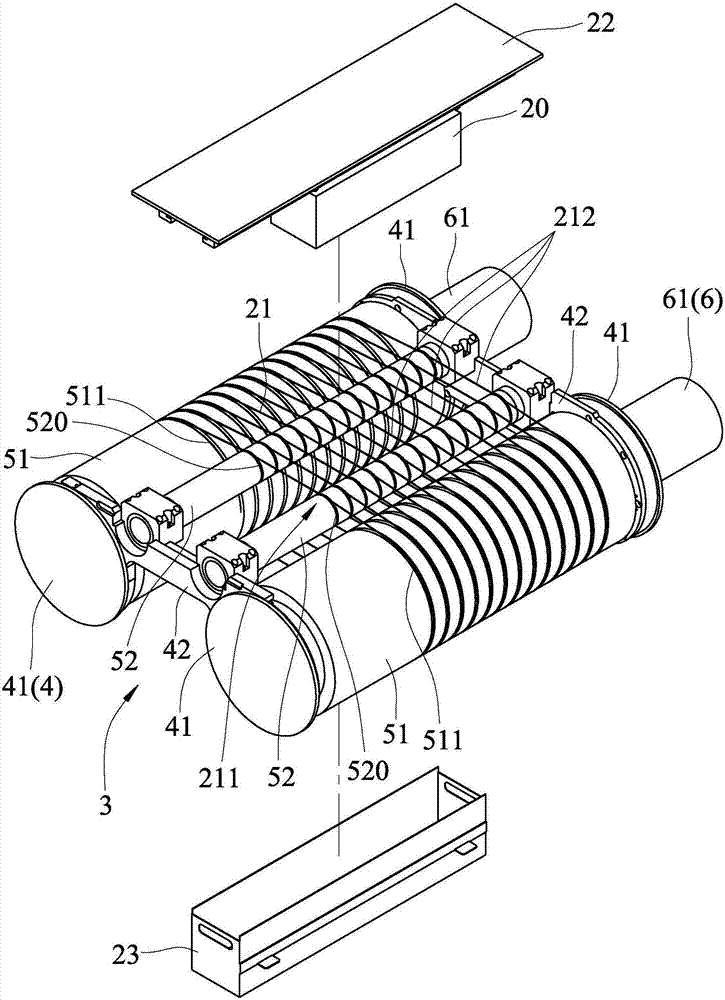

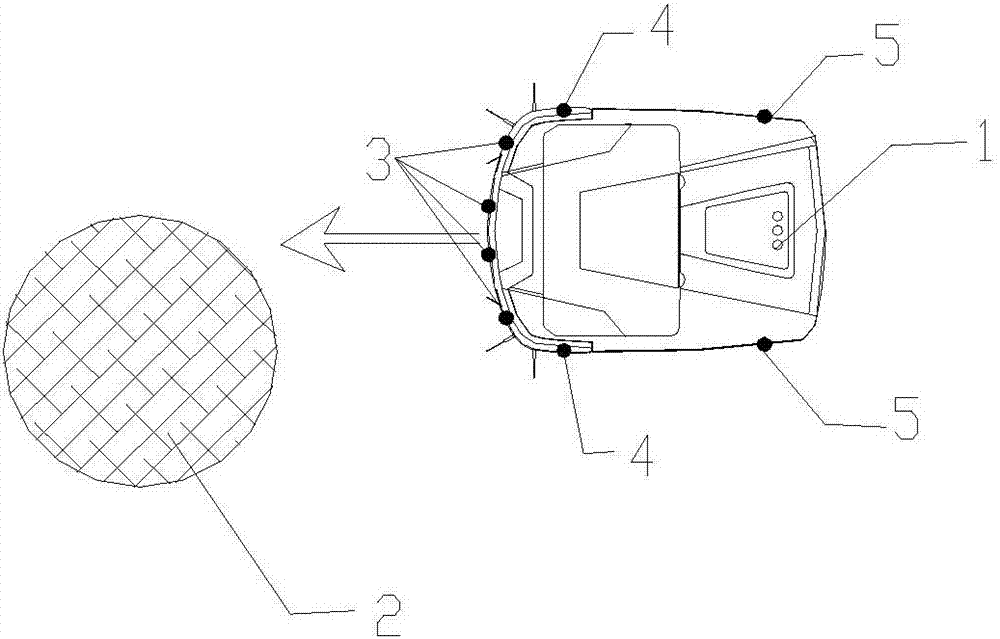

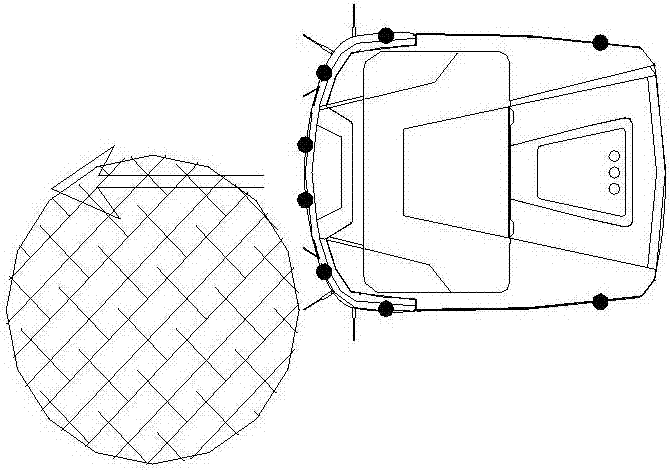

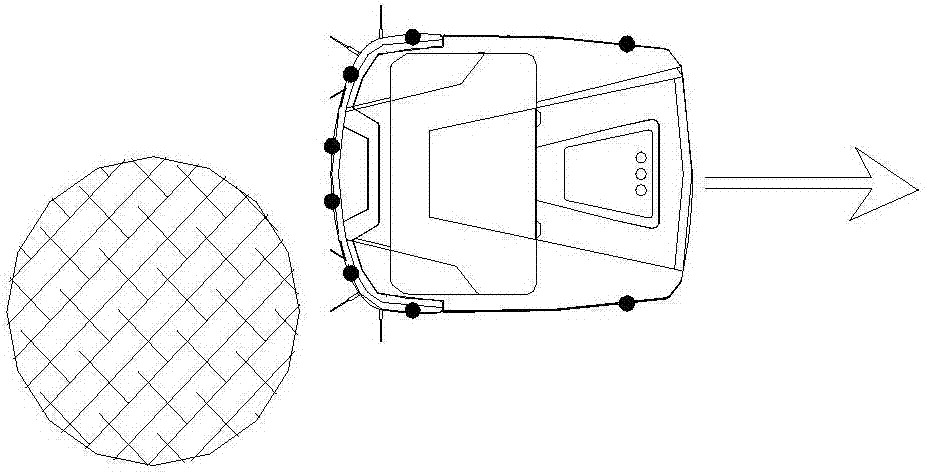

Wafer slicer, roller module thereof, and method for slicing wafer

InactiveCN107097362AReduce shakingAvoid interferenceMetal sawing devicesWorking accessoriesVertical planeIngot

A wafer slicer and a roller module thereof are provided. The wafer slicer comprises a feeding unit and the roller module. The roller module is used for driving a sawing wire to slice an ingot, and includes two spaced apart main rollers and an auxiliary roller. A horizontal plane is defined to pass through the rotating axes of the main rollers. Two vertical planes are defined to be perpendicular to the horizontal plane and respectively pass through the rotating axes. The auxiliary roller has a diameter smaller than one half of the diameter of each of the main rollers. The auxiliary roller is disposed above the horizontal plane and between the vertical planes. An uppermost side of the auxiliary roller is not lower than an uppermost side of each main roller. The main rollers and the auxiliary roller are adapted for the sawing wire to be wound thereon to form a wire net that spans over the main rollers and the auxiliary roller for slicing the ingot. Moderate support can be provided for the sawing wire to reduct vibration of the sawing wire, to achieve high slicing precision, and to avoid interference on saw ingot. The invention also provides a method for slicing the wafer.

Owner:AUO CRYSTAL

Cleaning robot obstacle avoidance system and method

InactiveCN106974593ACorrected walking pathExtended service lifeAutomatic obstacle detectionTravelling automatic controlSimulationObstacle avoidance

The invention relates to a clean robot obstacle avoidance system and method. The system comprises a cleaning robot, multiple obstacle avoidance units arranged around the cleaning robot and a center control unit electrically connected with the obstacle avoidance units; the obstacle avoidance units are used for detecting obstacle information around the cleaning robot and transmitting the detected information to the center control unit in real time, and the center control unit controls the cleaning robot to conduct real-time obstacle avoidance according to the received information and continues to operate according to a preset path after avoidance is finished. Accordingly, the walking path of the cleaning robot can be corrected, avoidance is conducted on obstacles, the situation of colliding with the obstacles is avoided, and then furniture or a cleaning robot body cannot be destroyed, and the service life of the cleaning robot can be prolonged.

Owner:SHENZHEN XINGHONGYUN TECH CO LTD

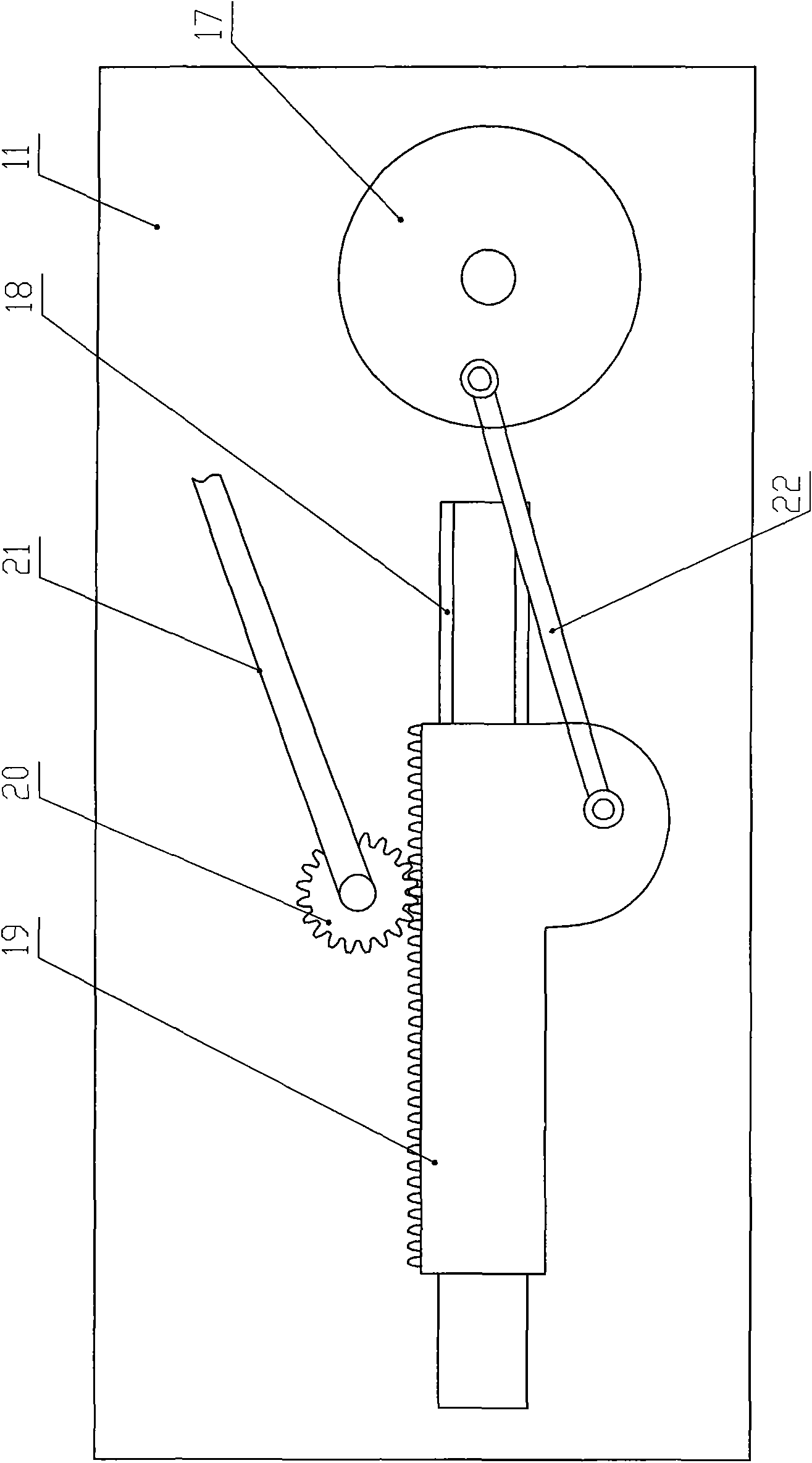

High pressure bundle array automatic cleaning device

InactiveCN101245975AShorten cleaning timeImprove cleaning efficiencyFlush cleaningEngineeringReducer

The invention provides a high pressure array-typed automatic cleaning device, comprising a supporting frame, a driving unit, a fan-covered cleaning pipe bundle and a nozzle. The technical key point is that the supporting frame is fixedly provided with a guideway which is provided with a bracket-typed cleaning platform with a travelling wheel; the cleaning platform is provided with a horizontal driving unit which can move along the guideway; the horizontal driving unit sequentially comprises a motor, a reducer, a synchronous gear-shaped belt, a synchronous gear-shaped belt pulley, an output shaft and a travelling wheel; the lower side of the cleaning platform is provided with a cleaning bracket; the lower side of the cleaning bracket is connected with at least a fan-covered cleaning pipe bundle where the nozzles are uniformly distributed by a hoisting frame. The high pressure array-typed automatic cleaning device adopts two rows of pipe bundles, firstly cleans the upper half plane with the upper pipe bundle, then cleans the lower half plane with the lower pipe bundle, namely by a half pipe bundle horizontal flat pushing type. Compared with other cleaning types, the high pressure array-typed automatic cleaning device saves the cleaning time of the reciprocating stroke along the vertical direction and greatly improves the cleaning efficiency.

Owner:SHENYANG ACAD OF INSTR SCI +1

Cleaning method of optical substrate for laser thin-film element

InactiveCN103042008AImprove cleaning efficiencyImprove surface qualityCleaning using toolsCleaning using liquidsOptoelectronicsCleaning methods

The invention relates to a cleaning method of an optical substrate for a laser thin-film element. The cleaning method includes the specific methods: using a cotton swab dipped with acetone for wiping the optical substrate until the surface of the substrate is free of macroscopic contaminants under the irradiation of an incandescent lamp; placing the wiped substrate in alkaline solution of a first tank, and respectively performing ultrasonic cleaning for the substrate successively by different frequencies; placing the substrate in a second tank, and using deionized water for spraying; and placing the substrate in deionized water of a third tank, successively subjecting the substrate to ultrasonic with different frequencies for 3-6 minutes, observing the surface cleanliness of the substrate under the incandescent lamp, and after the surface of the substrate is free of macroscopic particles, placing the substrate in deionized water of a fourth tank for slow lifting under ultrasonic of 80KHz, and drying the lifted substrate by hot blowing so that the required product is obtained. A cleaning processing and surface detection are combined together, a wiping method, a chemical cleaning method and an ultrasonic cleaning method are combined for comprehensive application, so that high cleaning efficiency and optimal cleaning effect less in damage to the smooth surface of the substrate are achieved.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com