Water-cleaning gluing head for multi-component polyurethane needle valve

A polyurethane and glue-applying head technology, applied in the directions of coating, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problem of not being able to use water for cleaning, and achieve the effects of reducing cleaning times, saving energy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

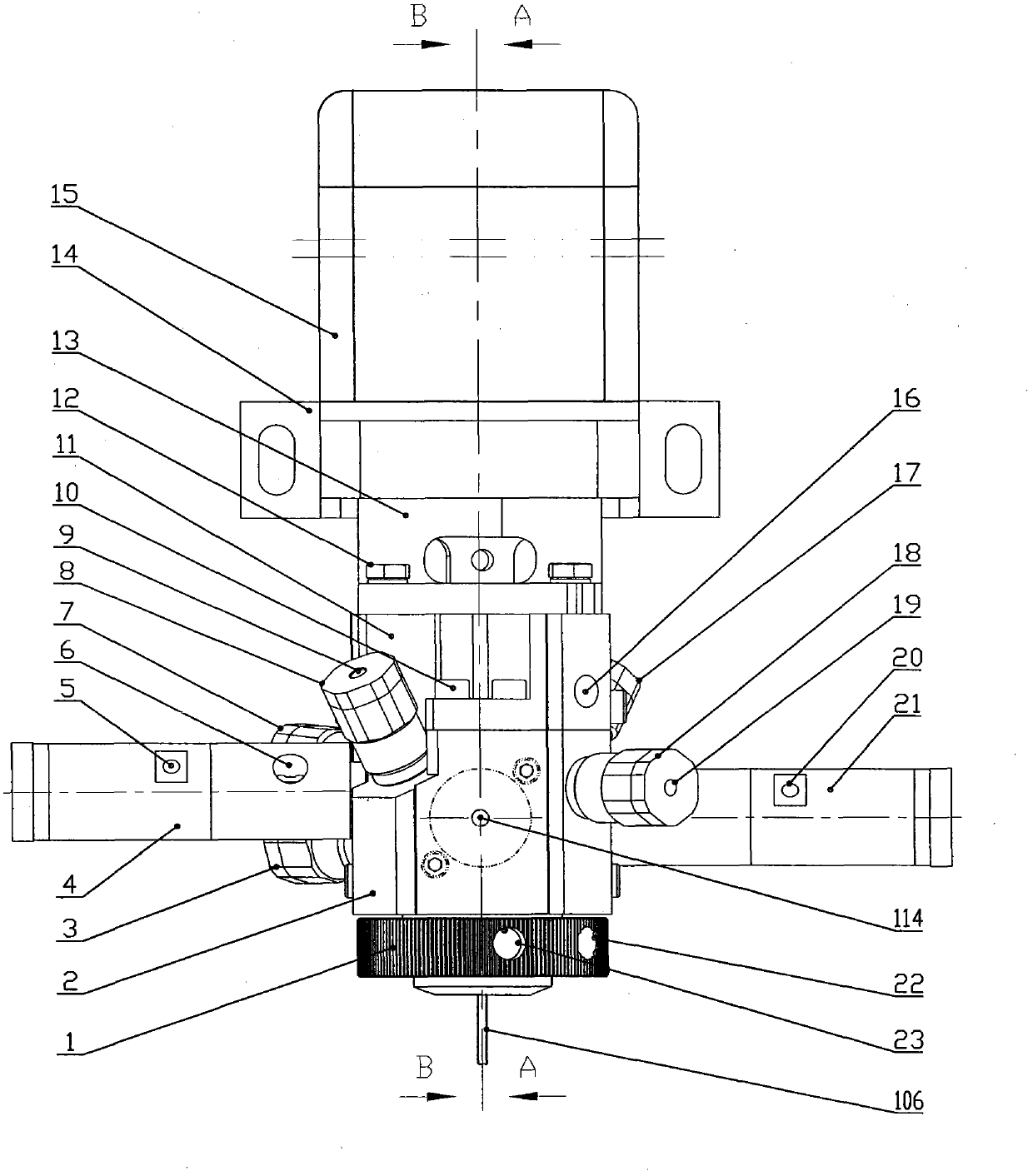

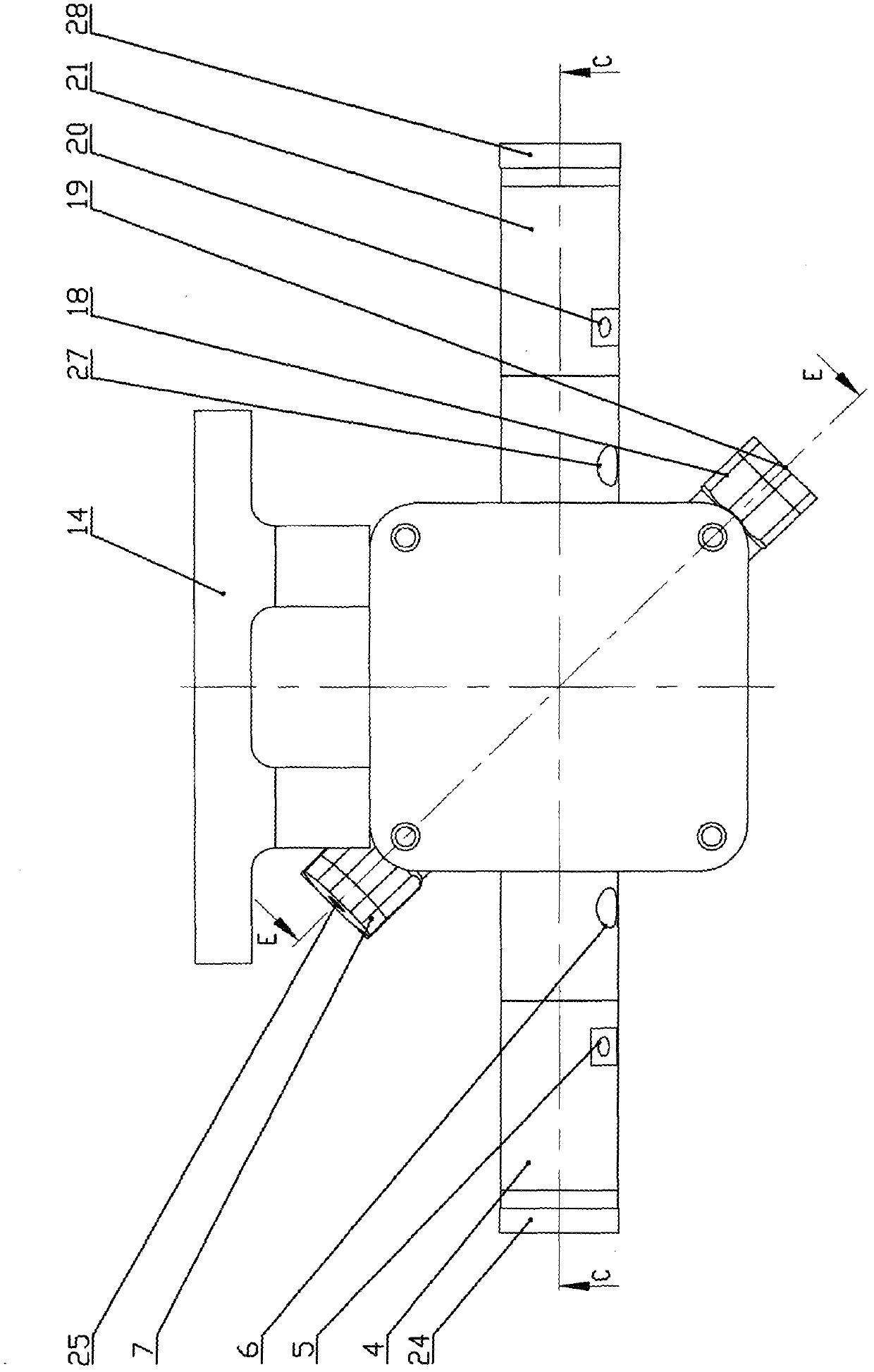

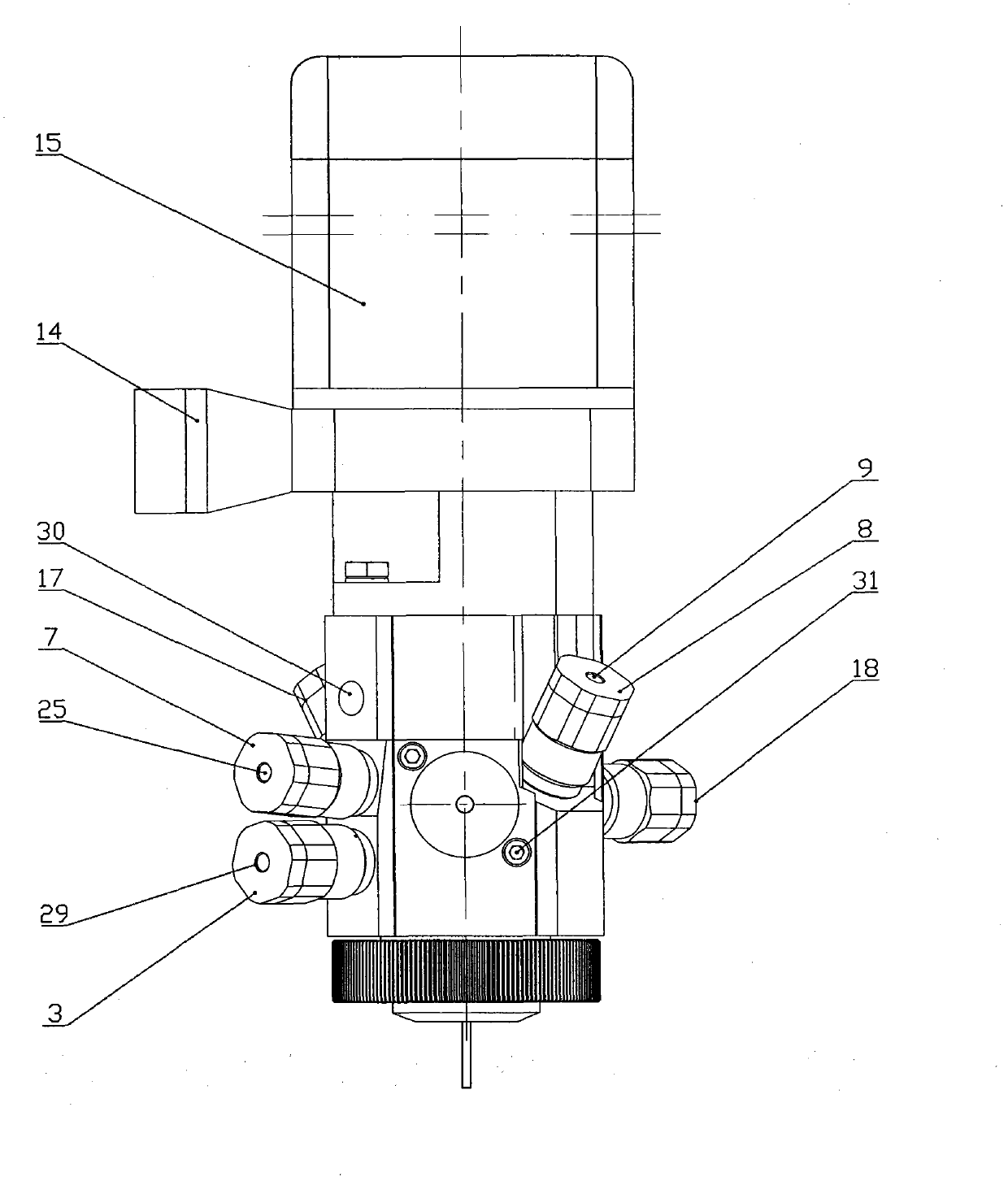

[0023] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the multi-component polyurethane needle valve water cleaning gluing head of the present invention includes a motor 15, a transmission shaft 61, a stirring blade 39, a cup moving part 1, a valve seat 2, an intermediate valve body 11, an upper valve body 13, Valve fixing plate 14, component A needle valve 4, component B needle valve 21, water valve A3, water valve B17, water valve C8, water valve D18 and air valve 7, etc., are connected together with screws or threads. Turn on the metering pump to supply glue, and the polyurethane glue of two components, A and B, enters the A chamber 107 and the B chamber 108 from the glue inlet hole 6 of the component A and the glue inlet hole 65 of the B component respectively. Needle B110, the polyurethane glue of two components A and B respectively enters the C cavity 109 through the A glue inlet nozzl...

specific Embodiment approach 2

[0031] Specific implementation mode two: if in figure 1 Add a glue inlet channel to the position shown by the double-dot dash line, and add a C component needle valve to become a three-component polyurethane needle valve water cleaning gluing head. The three components (A component, B component , C) polyurethane enters C cavity 109 from A component needle 4, B component needle valve 21 and C component needle valve respectively, and other structures remain unchanged. Water cleaning, compressed air cleaning, and three-component polyurethane glue feeding methods are the same as those in Embodiment 1.

[0032] working principle

[0033] Turn on the metering pump to supply the glue, the polyurethane glue of the two components A and B enters the cavity C through the glue inlet nozzle of A and the glue inlet nozzle of B respectively, and the motor drives the stirring blade to rotate, and the polyurethane glue of the two components A and B The glue is mixed evenly and starts to reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com