Patents

Literature

210results about How to "Remove threat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

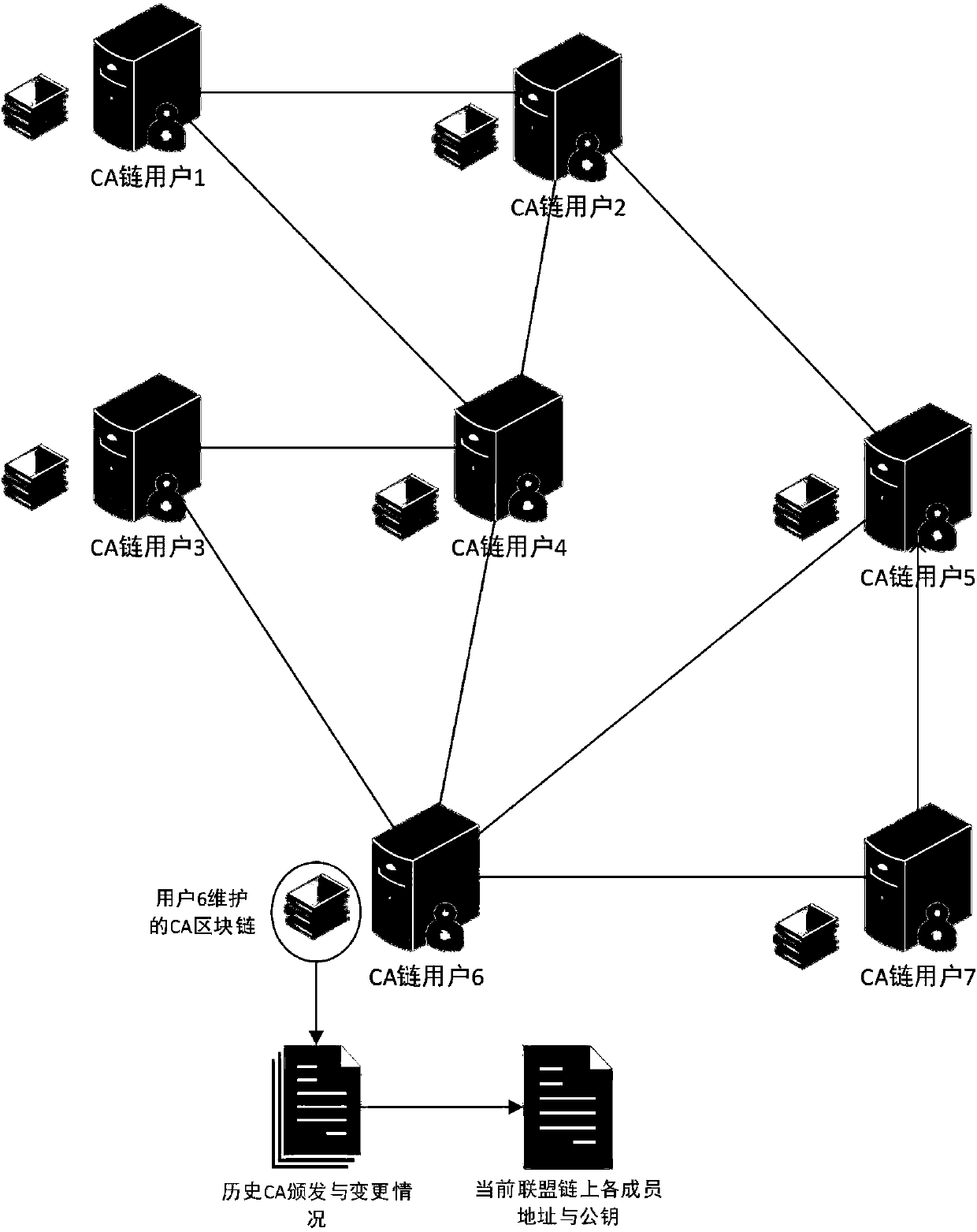

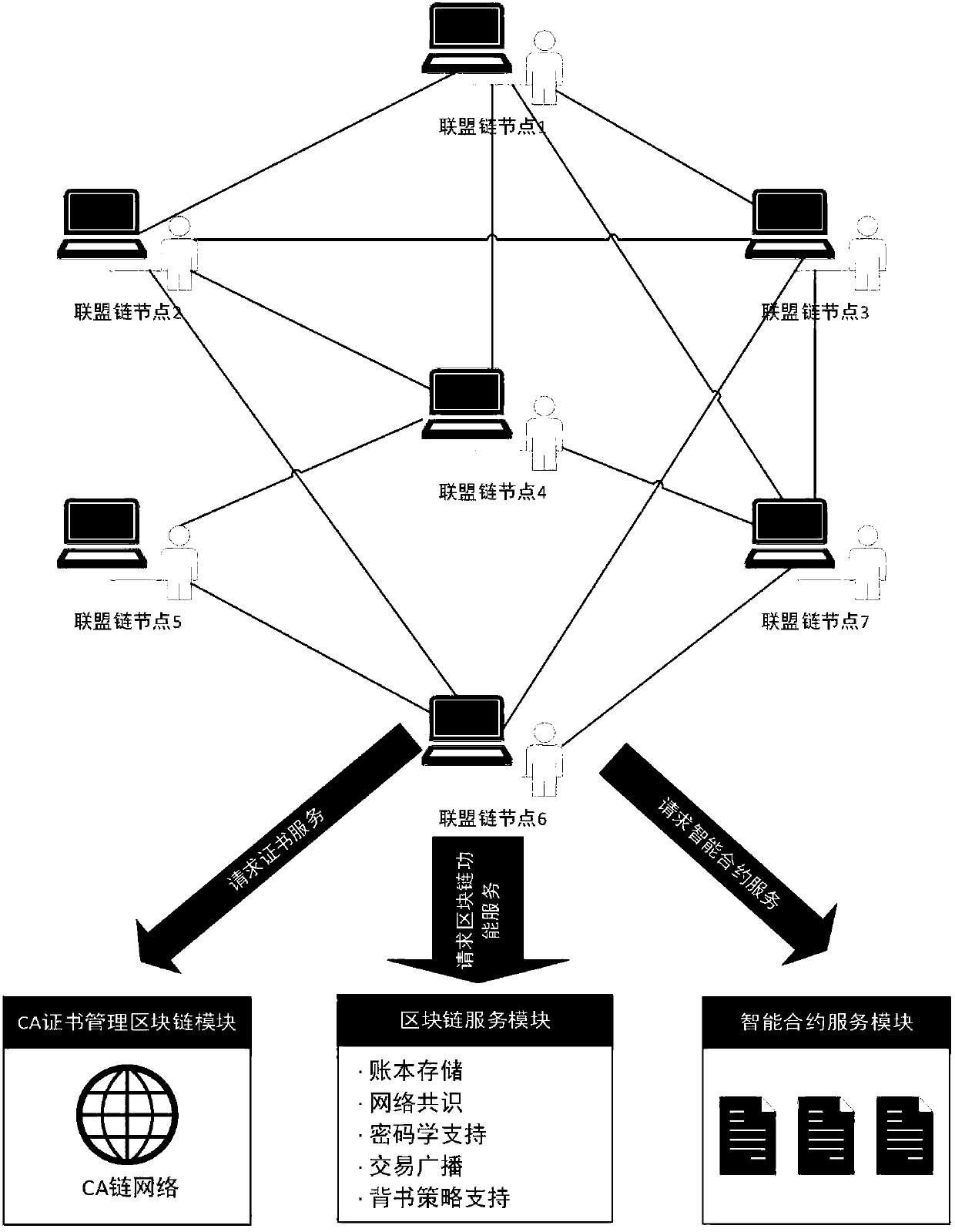

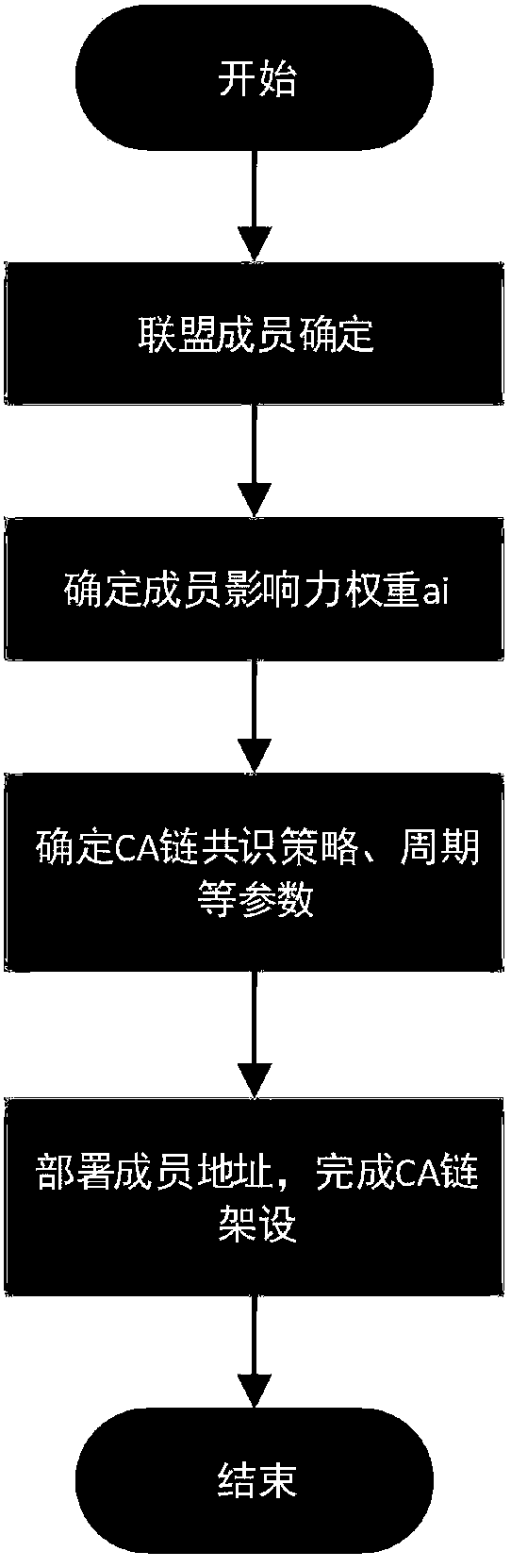

Alliance chain-based decentralized CA construction method and system

ActiveCN108052530ARemove threatNeutralize information sniffingPayment protocolsSpecial data processing applicationsPublic accountSmart contract

The invention discloses an alliance chain-based decentralized CA construction method and system, which is a set of complete CA service block chain process and design scheme, and comprises a CA chain initialization method, a consensus strategy and an anti-cheating strategy; and modification of certificate information is converted to be in a block chain transaction form and recorded in an unmodifiable public account book for members to look up. According to the alliance chain system applying a CA chain, provided by the invention, corresponding business work and alliance chain maintenance work are finished by calling services provided by a CA certificate management block chain module, a block chain service module and an intelligent contract module, so that the CA decentralization operation ofan alliance chain is realized, and the centralization threat possibly faced by the alliance chain containing centralized CA services is eliminated.

Owner:HANGZHOU YUNXIANG NETWORK TECH

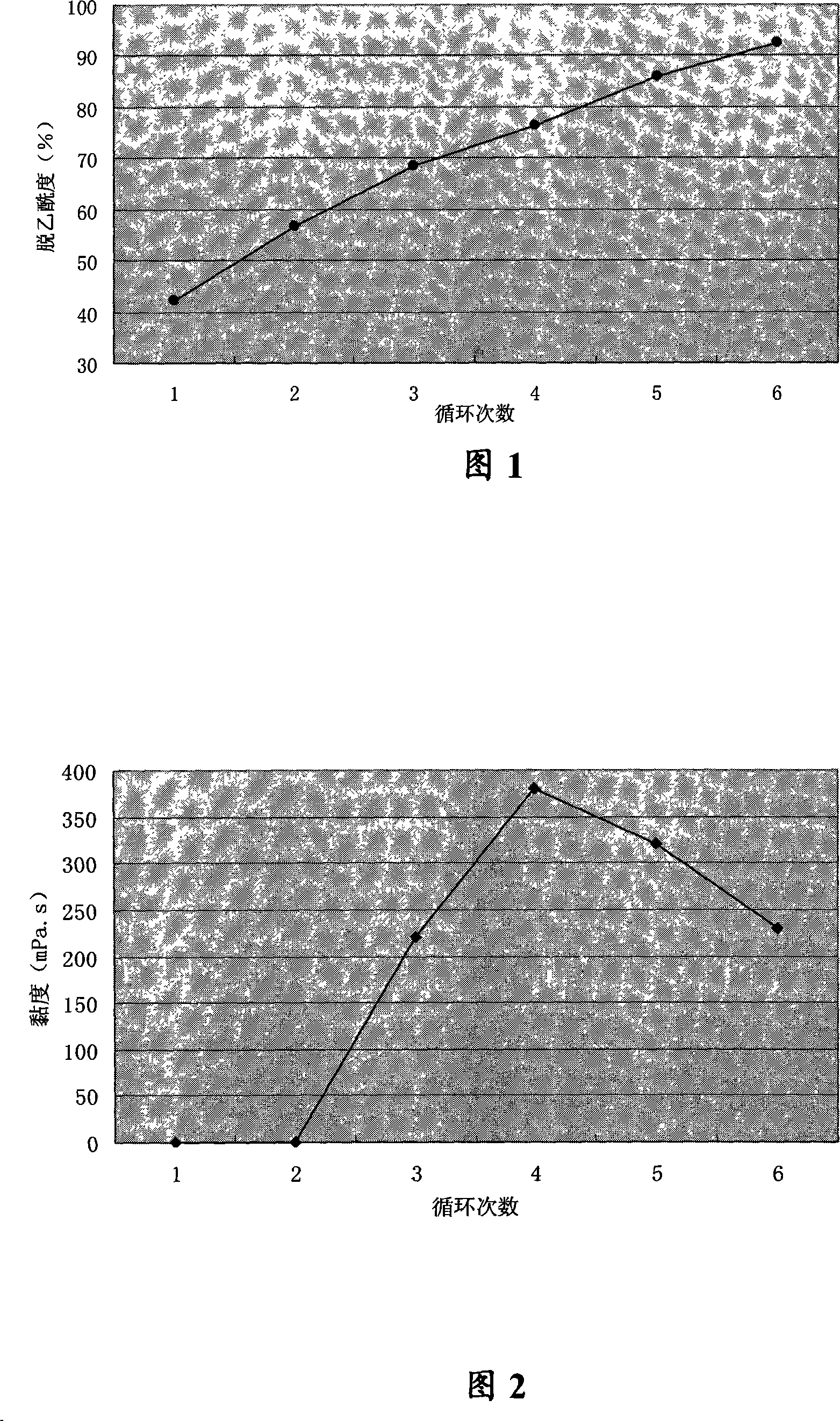

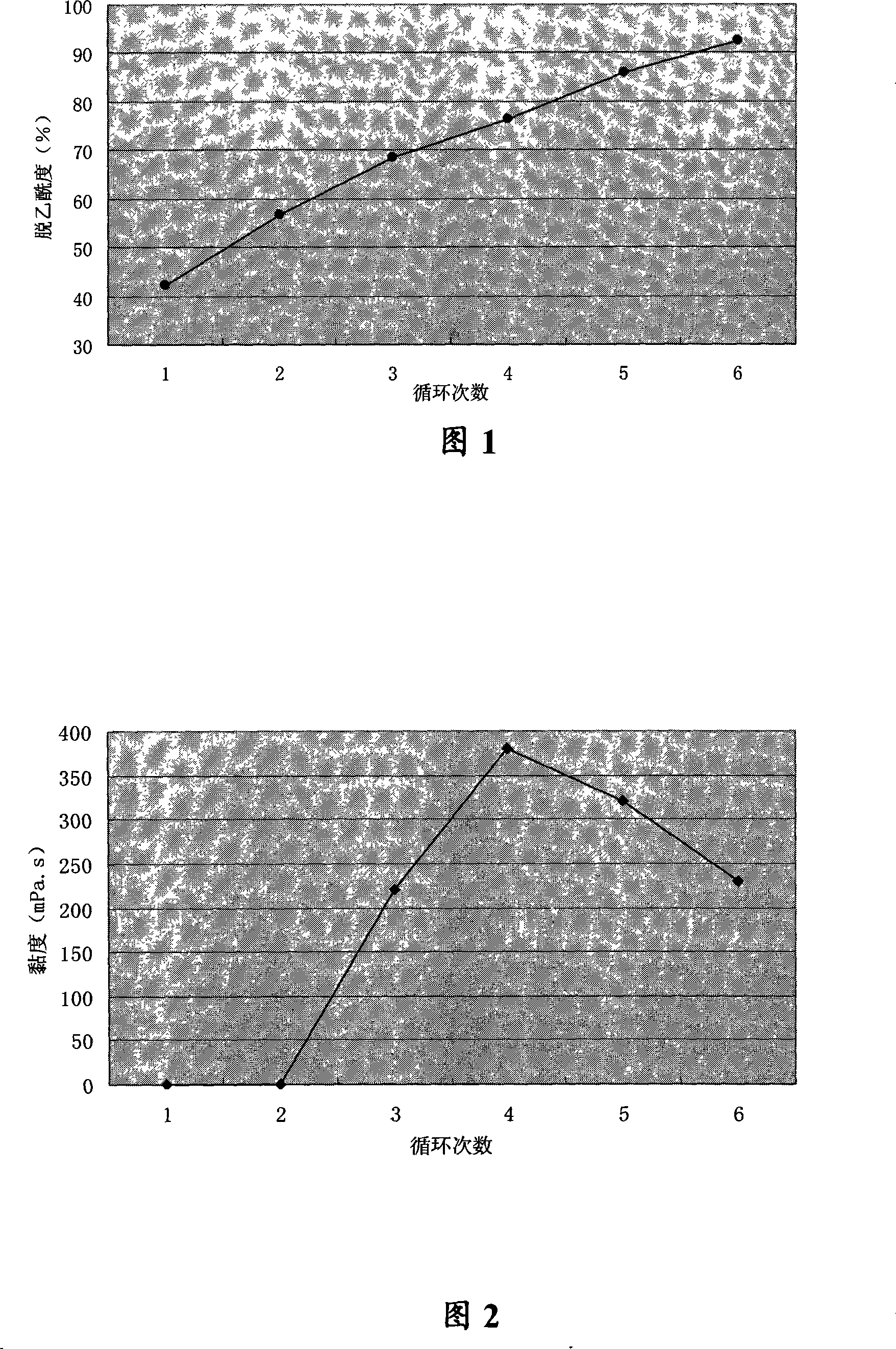

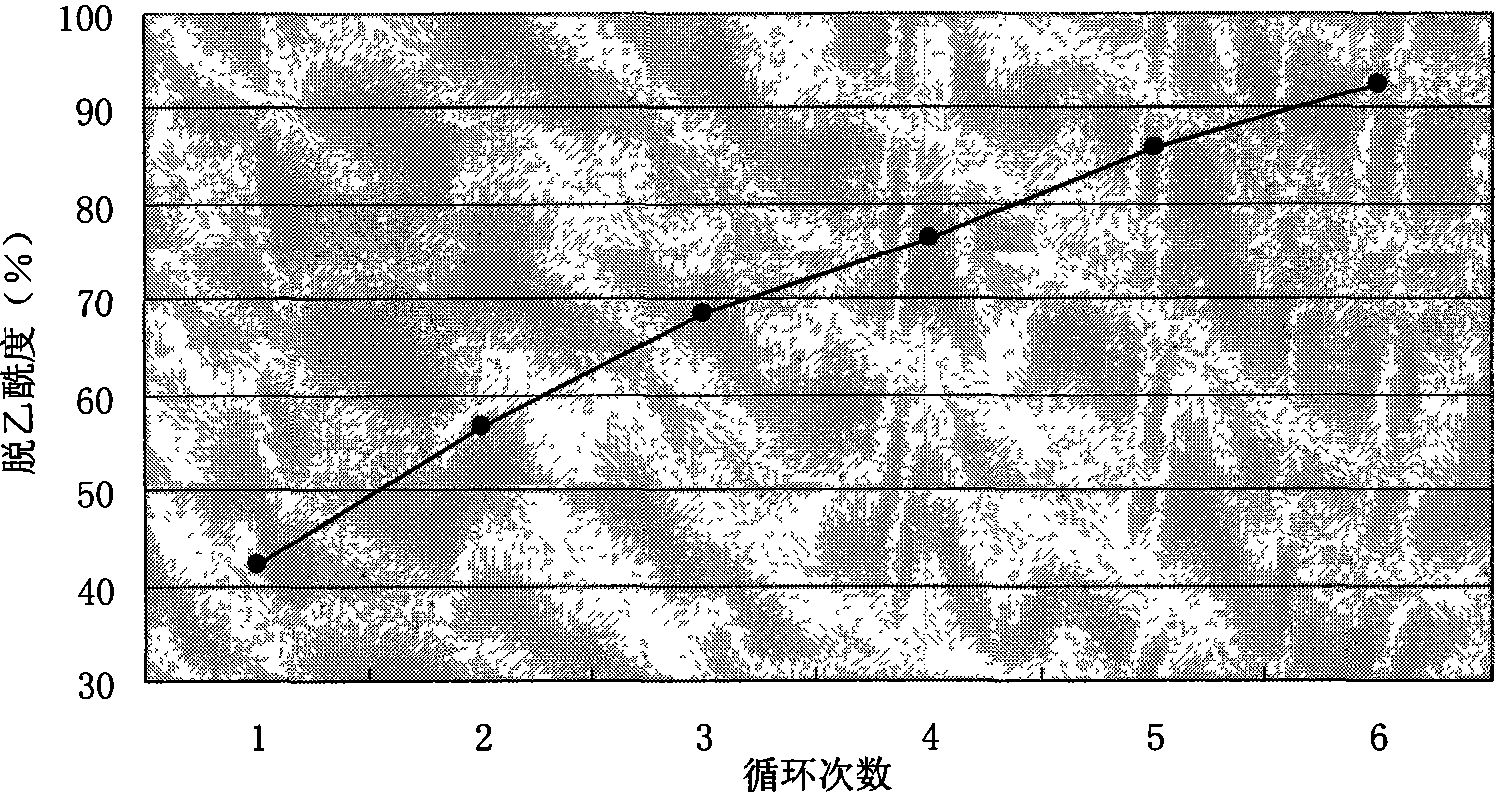

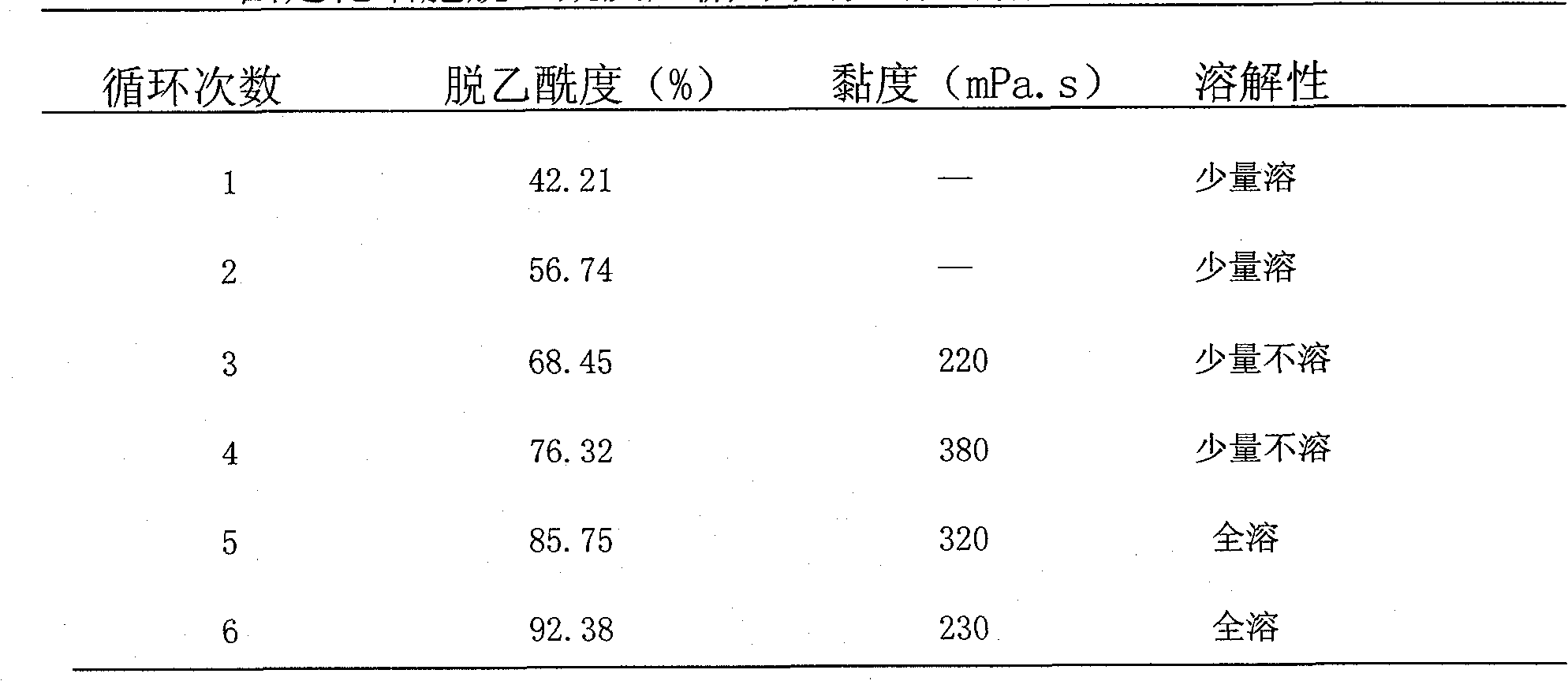

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097ATake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effect is attained.

Owner:重庆百奥帝克微生态科技有限公司

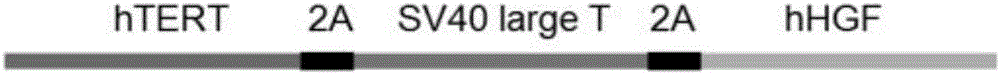

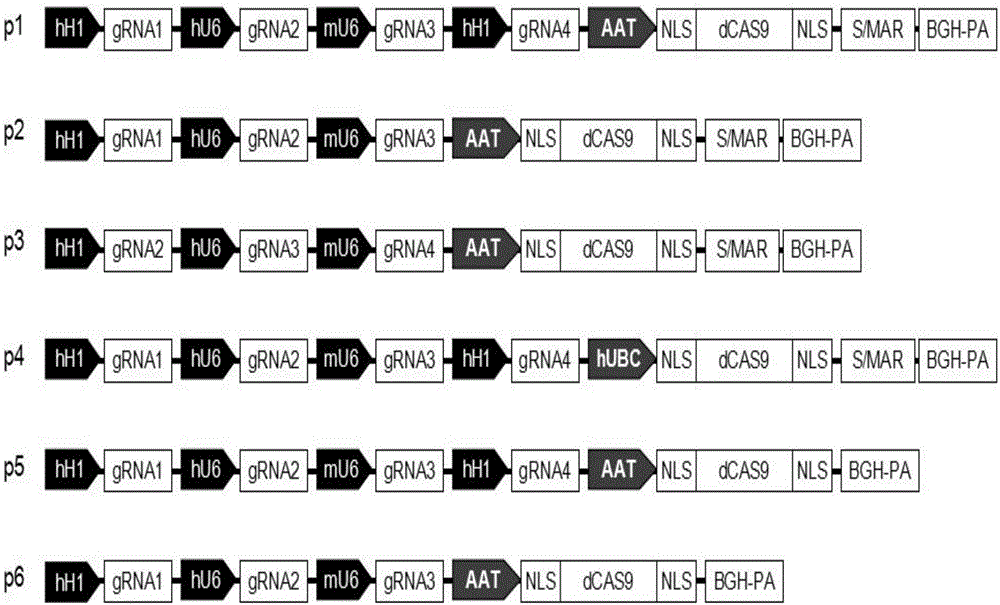

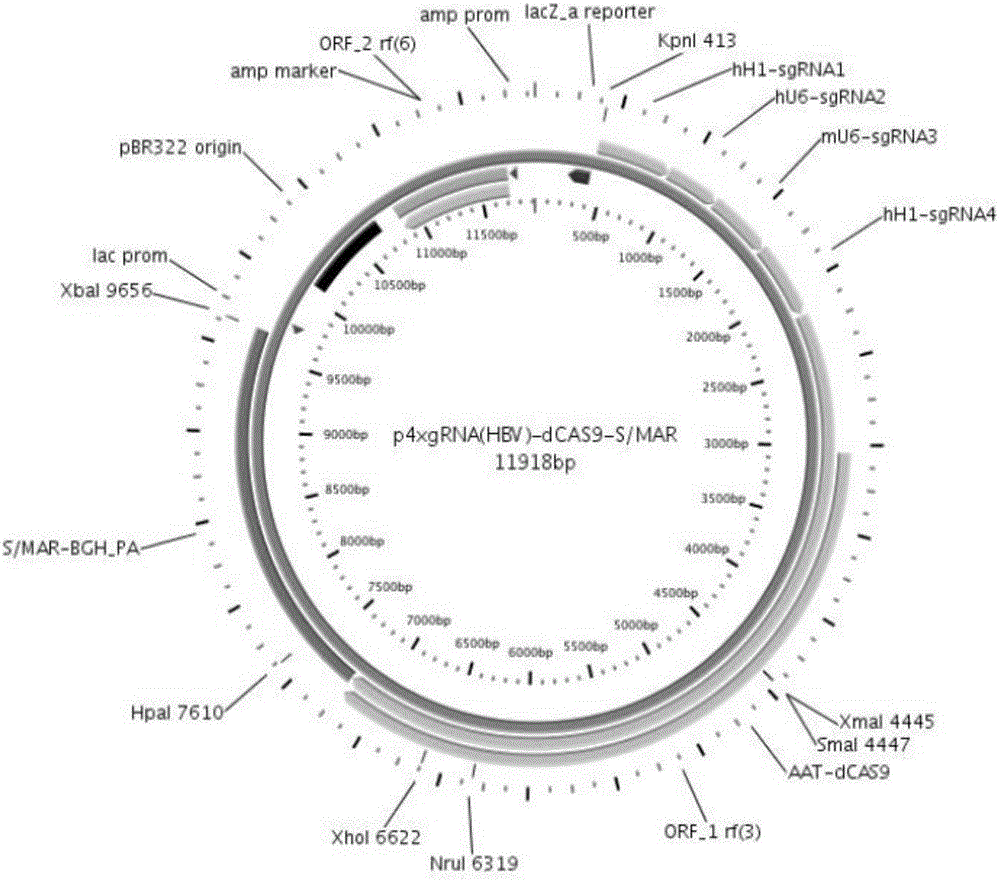

Liver cell membrane bionic liposome drug carrier as well as preparation method and application thereof

InactiveCN106109417AIncrease the number ofEnhanced generation abilityOrganic active ingredientsEnergy modified materialsCell membraneIn vivo

The invention relates to a liver cell membrane bionic liposome drug carrier, a preparation method of the liver cell membrane bionic liposome drug carrier, and application of the liver cell membrane bionic liposome drug carrier. The liver cell membrane bionic liposome drug carrier is characterized in that (1) the liposome drug carrier has a cell membrane protein component; (2) the liposome drug carrier is capable of loading drug in vitro, and is used for cell targeting fusion release; (3) the cell membrane protein component of the liposome comes from immortalized human liver cells, and is used for conveying targeted shear plasmids of a hepatitis virus genome; (4) the cell membrane protein component of the liposome comes from an immortalized liver tumor cell line, and is used for targeted drug delivery of liver tumor. The liver cell membrane bionic liposome drug carrier can be used for in vivo targeted hepatic cell transmission and drug delivery of CRISPR (Clustered Regularly Interspaced Short Palindromic Repeat) gene targeting plasmids.

Owner:李因传

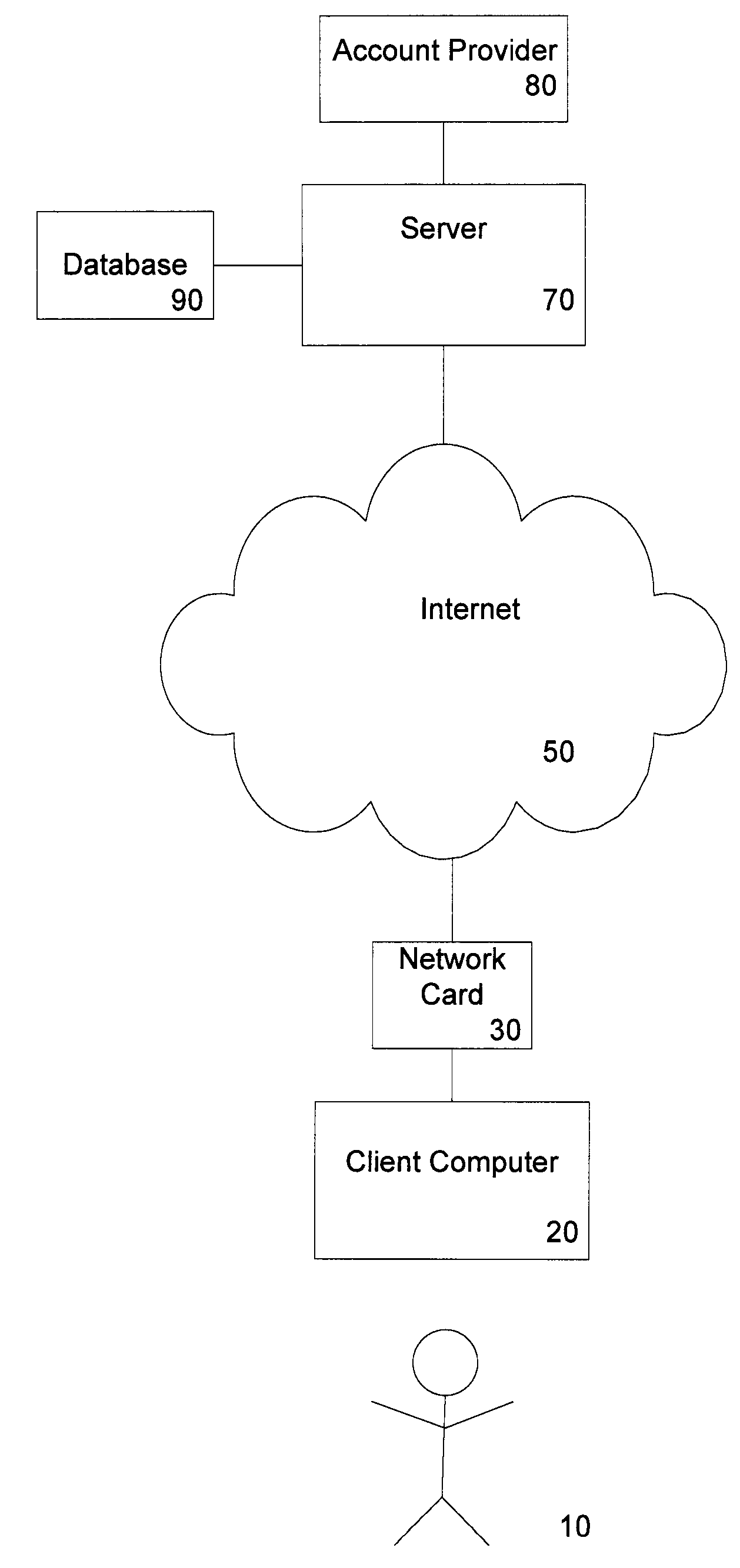

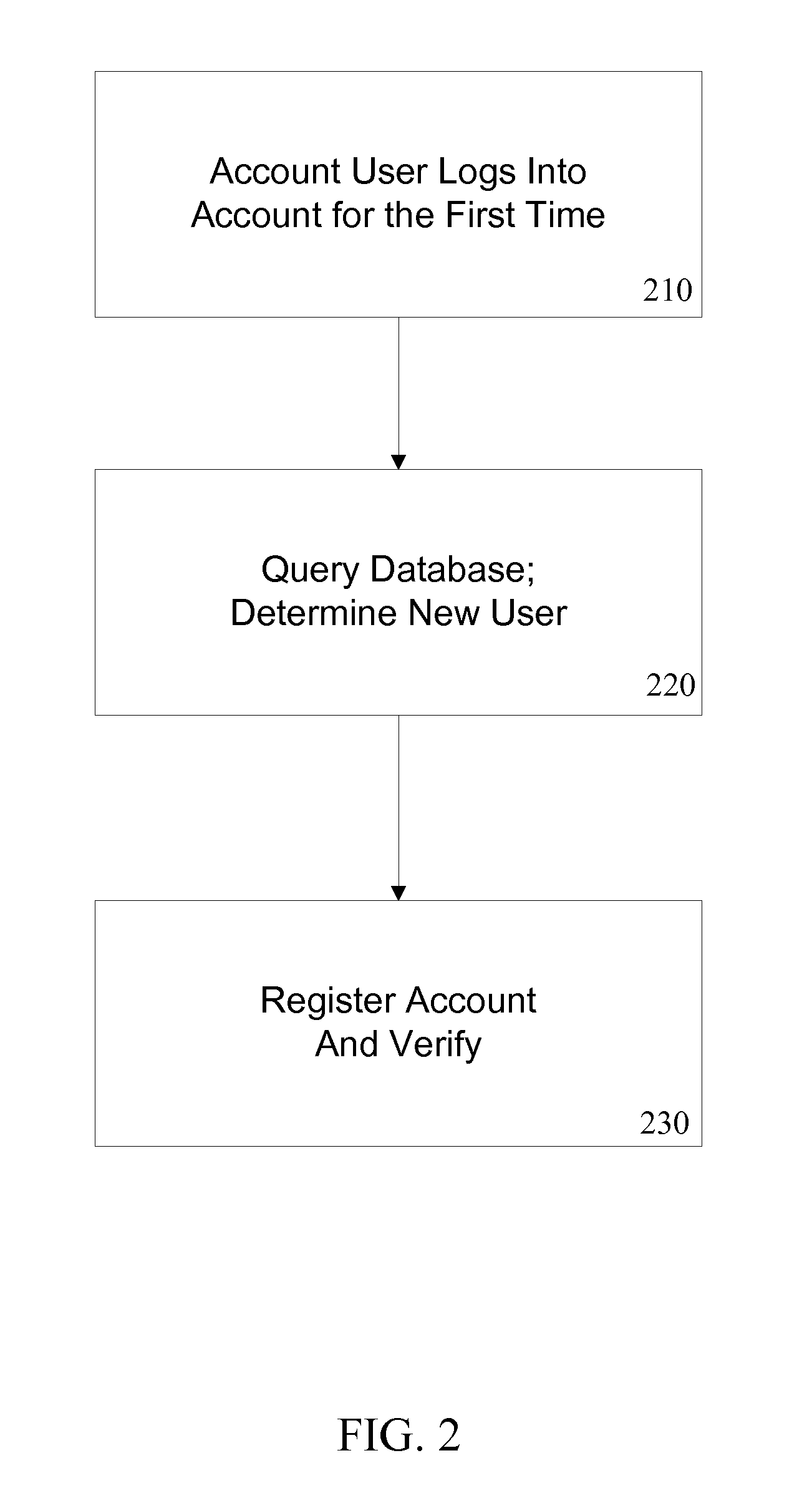

Method and system of securing accounts

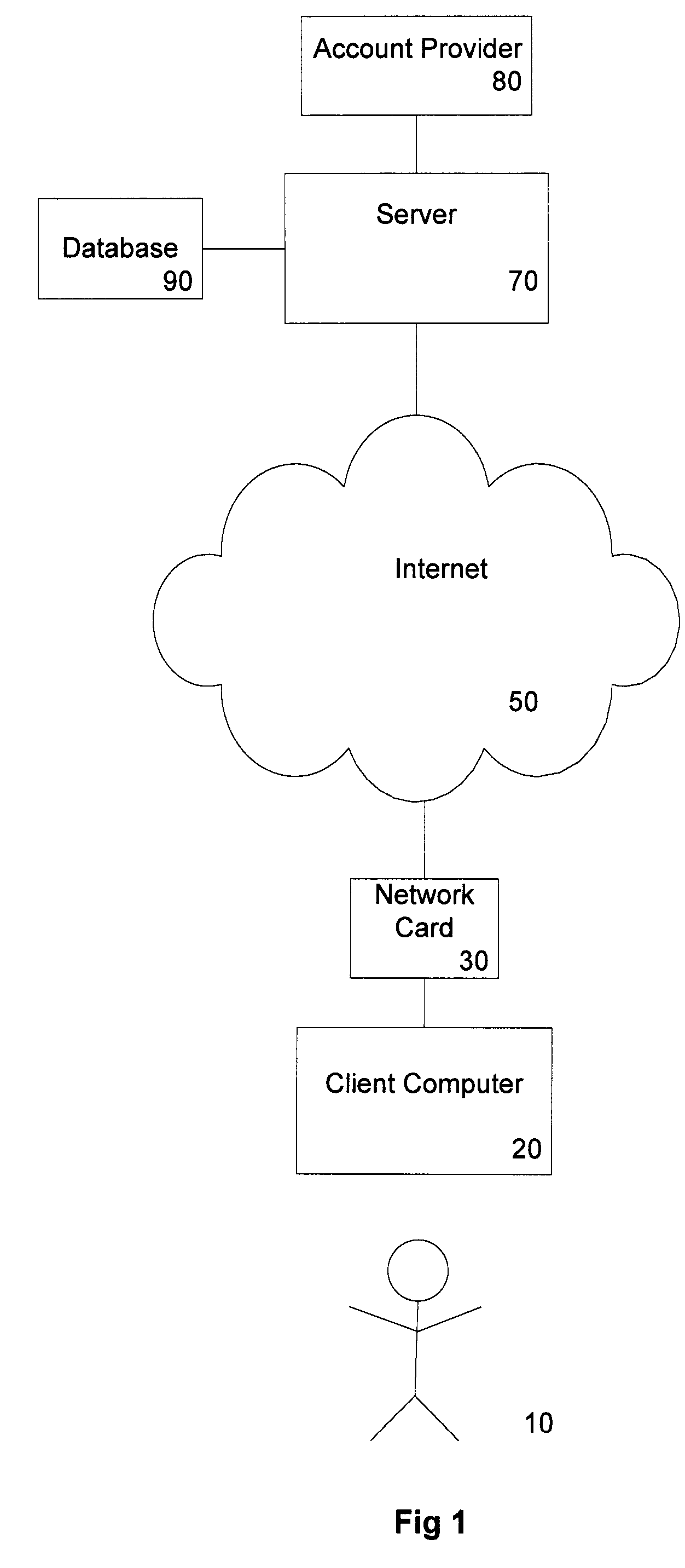

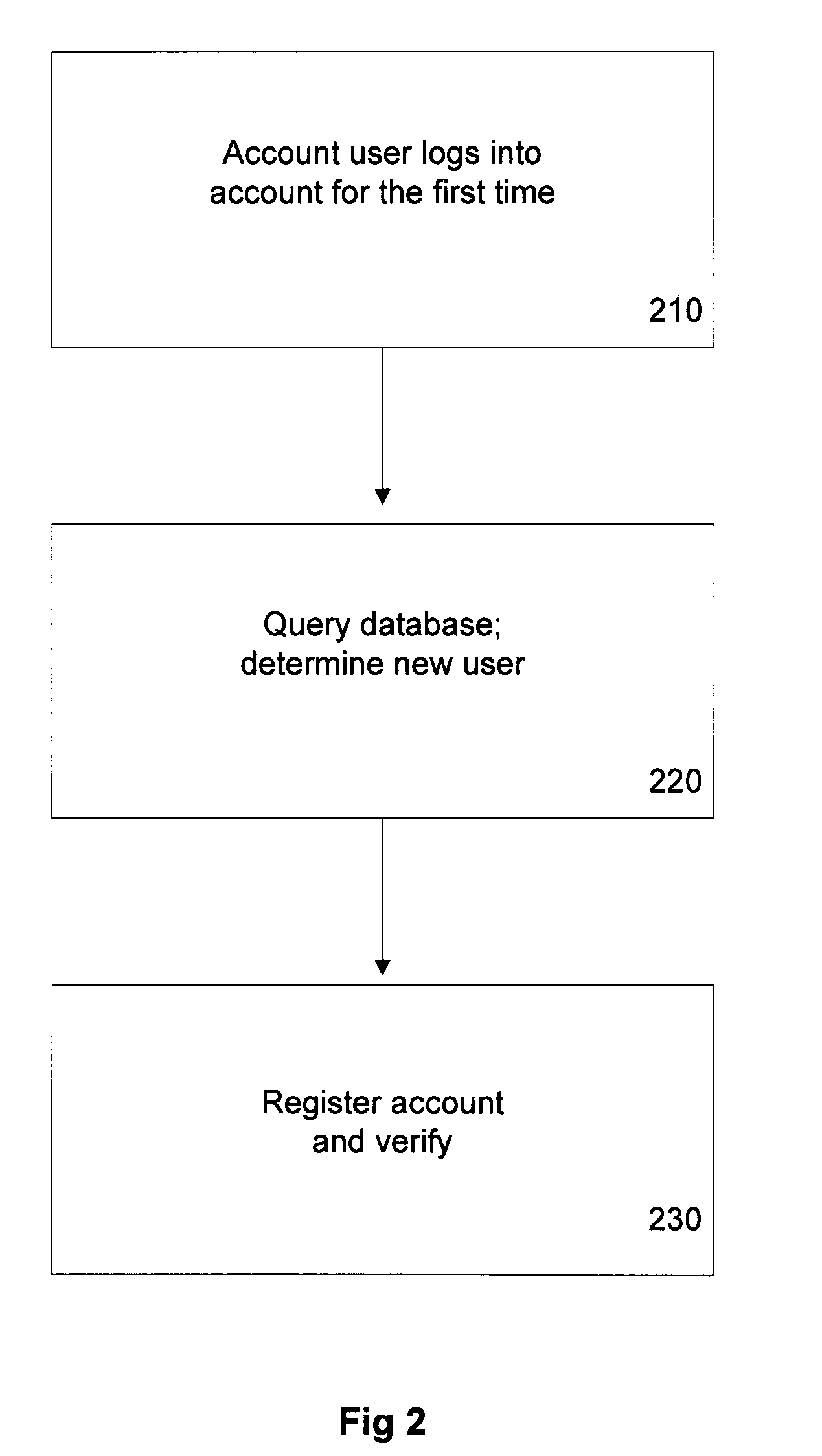

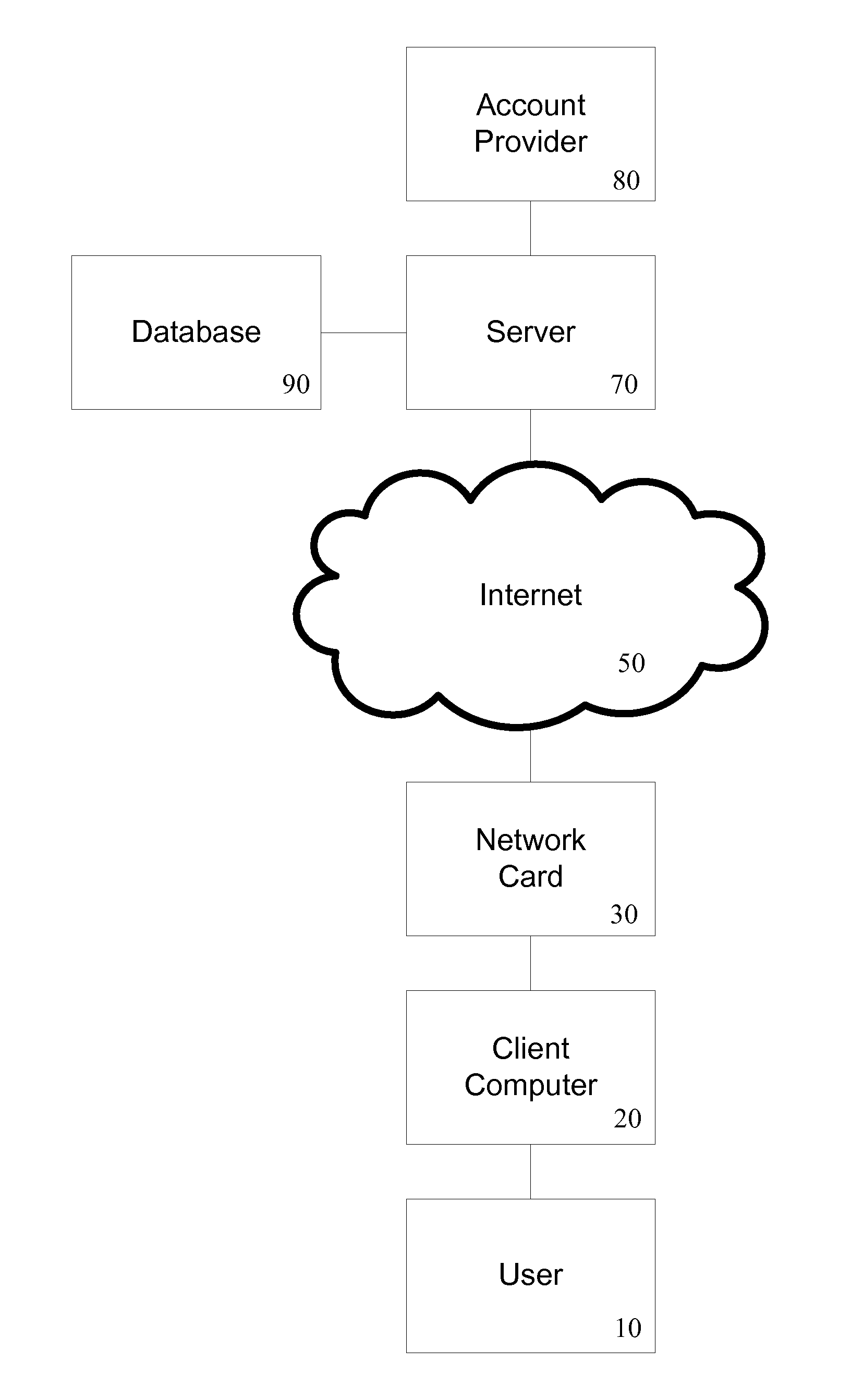

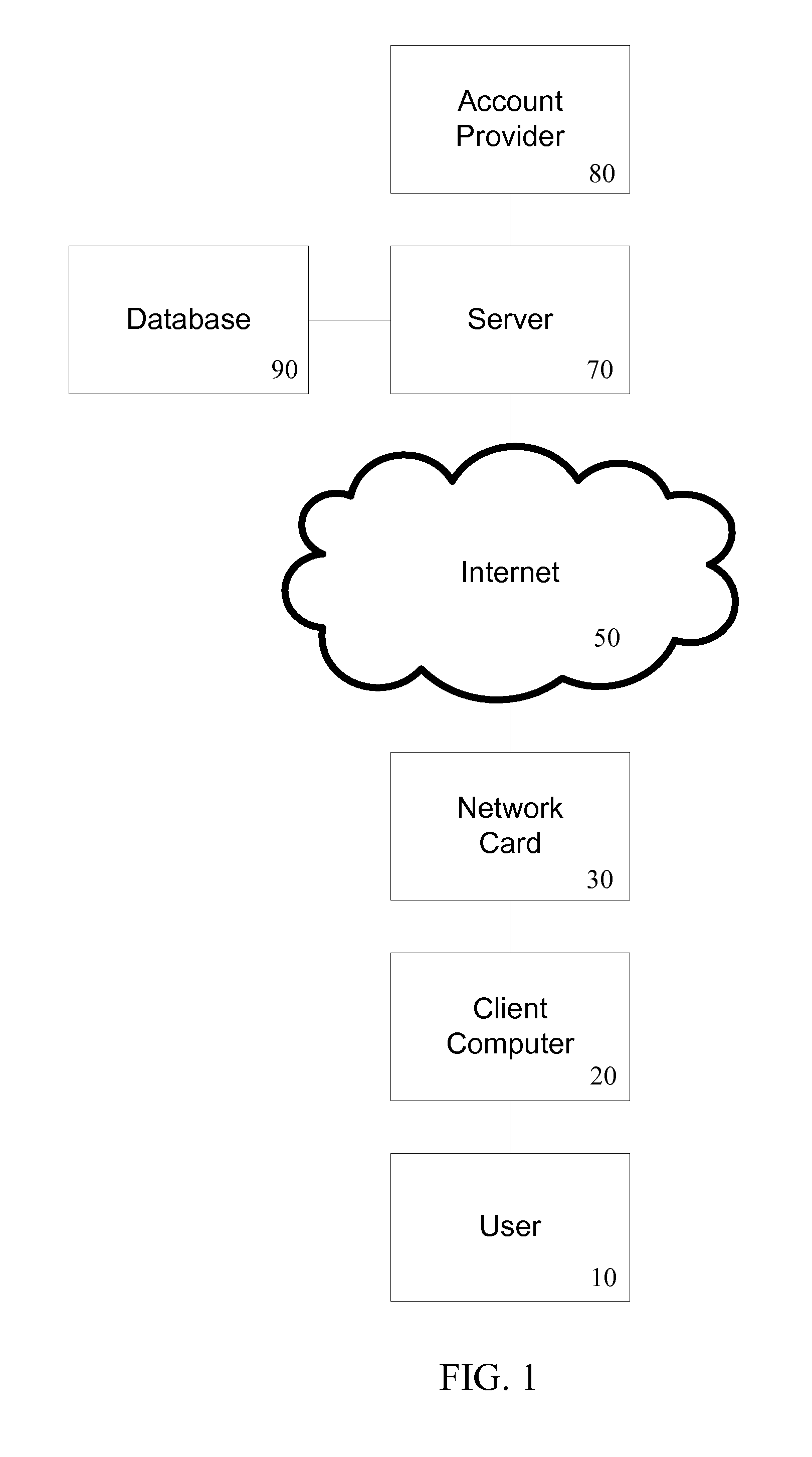

InactiveUS20100146609A1Remove threatLow costDigital data processing detailsUser identity/authority verificationUser verificationClient-side

A method and system of securing account is provided. When a client computer requests access to an account accessible via a server, the server determinates a mac address associated with the client computer and compares it to a mac address associated with the account. If the mac address of the client computer is not the same as the mac address associated with the account, the server initially denies access to the client computer, but may allow access after verification of the client computer by the user associated with the account.

Owner:BARTLETT ROB

Method and system of securing accounts

ActiveUS20130074164A1Remove threatLow costDigital data processing detailsMultiple digital computer combinationsClient-sideClient machine

A method and system of securing account is provided. When a client computer requests access to an account accessible via a server, the server determines a MAC address associated with the client computer and compares it to a MAC address associated with the account. If the MAC address of the client computer is not the same as the MAC address associated with the account, the server initially denies access to the client computer, but may allow access after verification of the client computer by the user associated with the account.

Owner:AAA INTERNET PUBLISHING

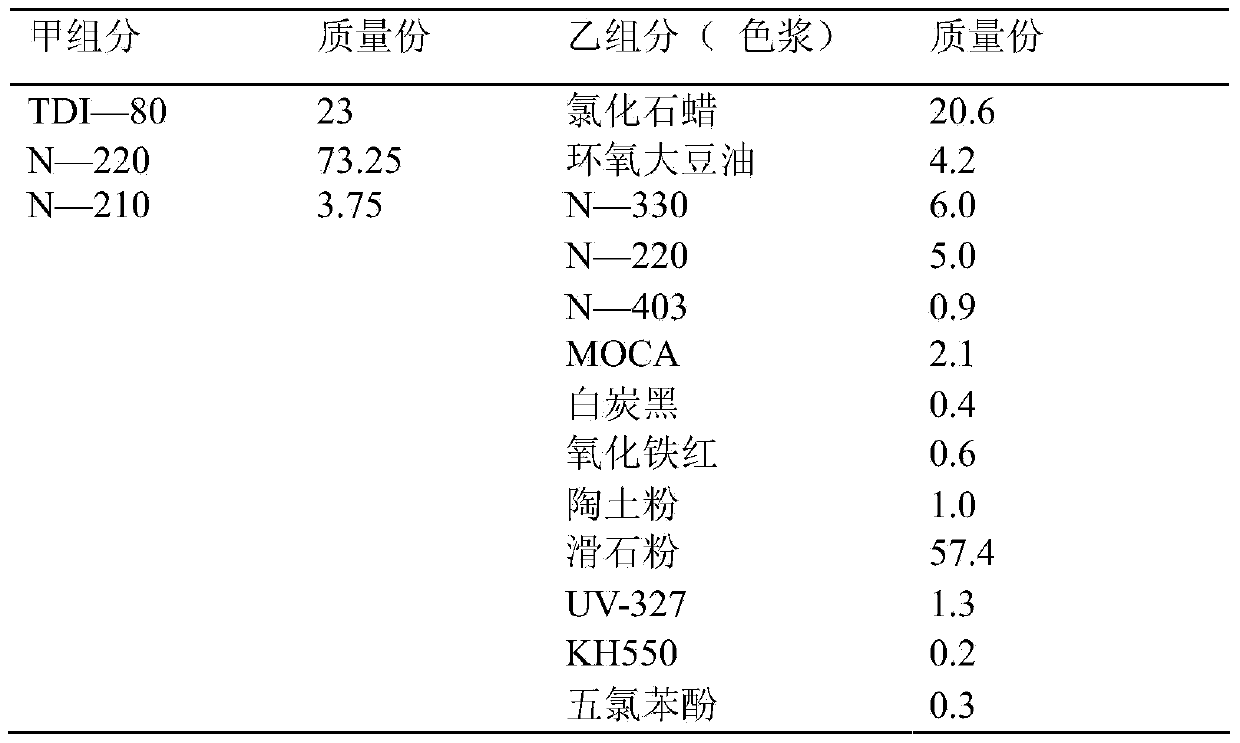

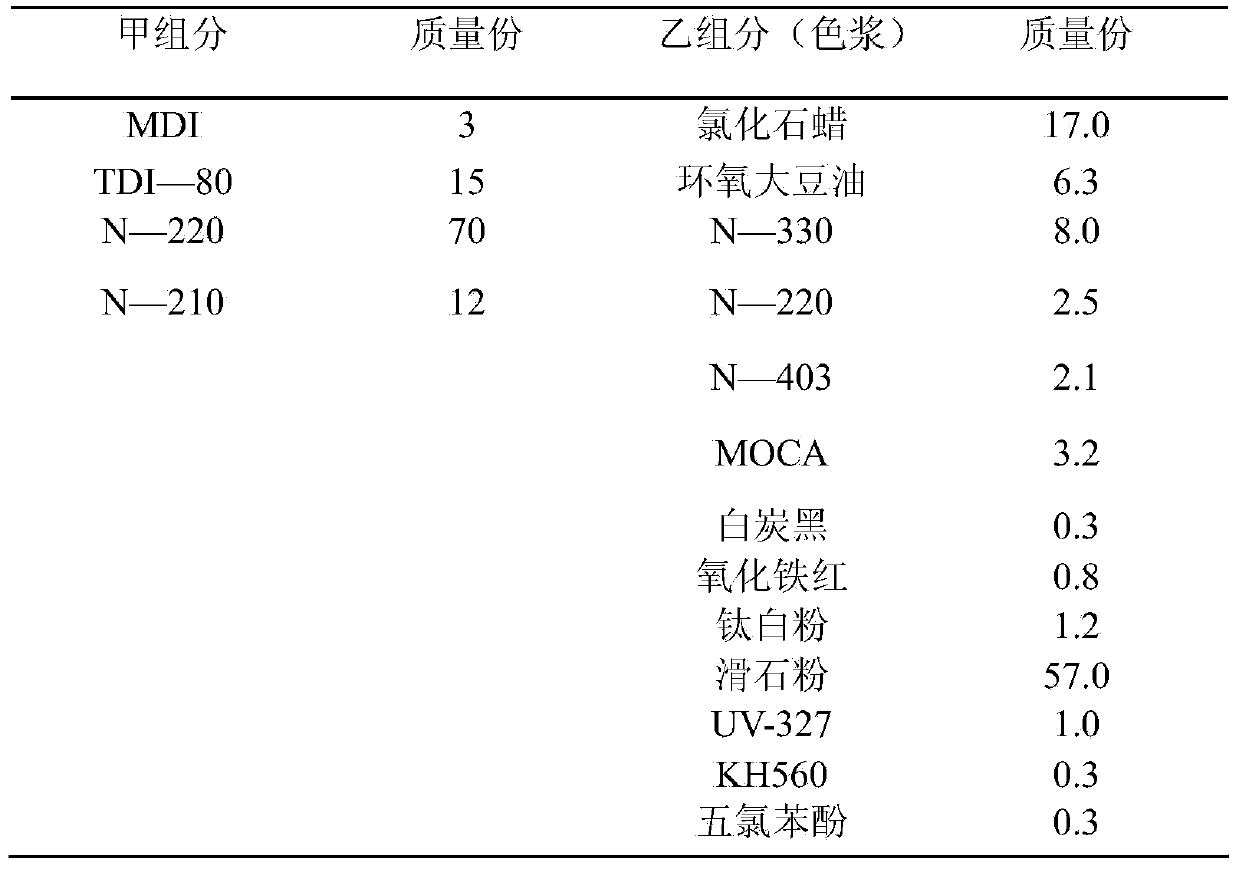

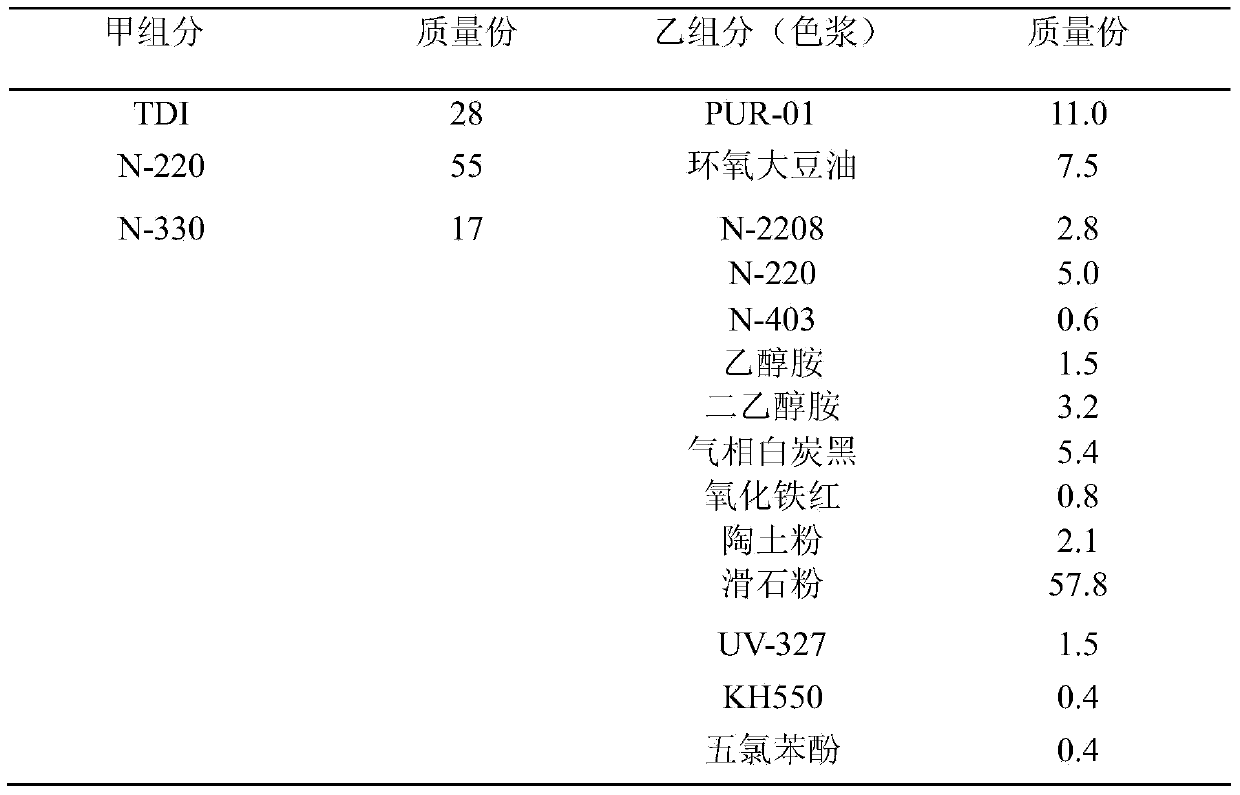

Preparation method of sprayed surface layer of environment-friendly polyurethane plastic track

InactiveCN103627310AGood curing effectRemove threatGround pavingsPolyurea/polyurethane coatingsIsocyanateSilane coupling

The invention discloses a preparation method of a sprayed surface layer of an environment-friendly polyurethane plastic track. The method comprises the steps of preparing a component A: adding polyether polyol into a reaction kettle, stirring and heating to 80-160 DEG C, dehydrating, cooling to 40-50 DEG C, adding isocyanate, stirring, and performing constant-temperature reaction at 80-85 DEG C for 2-4 hours; preparing a component B: uniformly mixing polyether polyol, a chain extender, a plasticizer, an ultraviolet light absorber anti-mildew agent, a thixotropic agent, a silane coupling agent and filler, shearing at a high speed, milling, and performing vacuum heating at 60-70 DEG C for 1-3 hours; mixing the component A and component B at a mass ratio of 1:(3-5.5); adding an inert amine dryer; stirring uniformly and spraying on the bottom layer of the polyurethane track. By adopting the method disclosed by the invention, the specific pungent smell of a conventional polyurethane track is avoided, the foaming effect is reduced, the usability of the track is improved, and the service life of the track is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

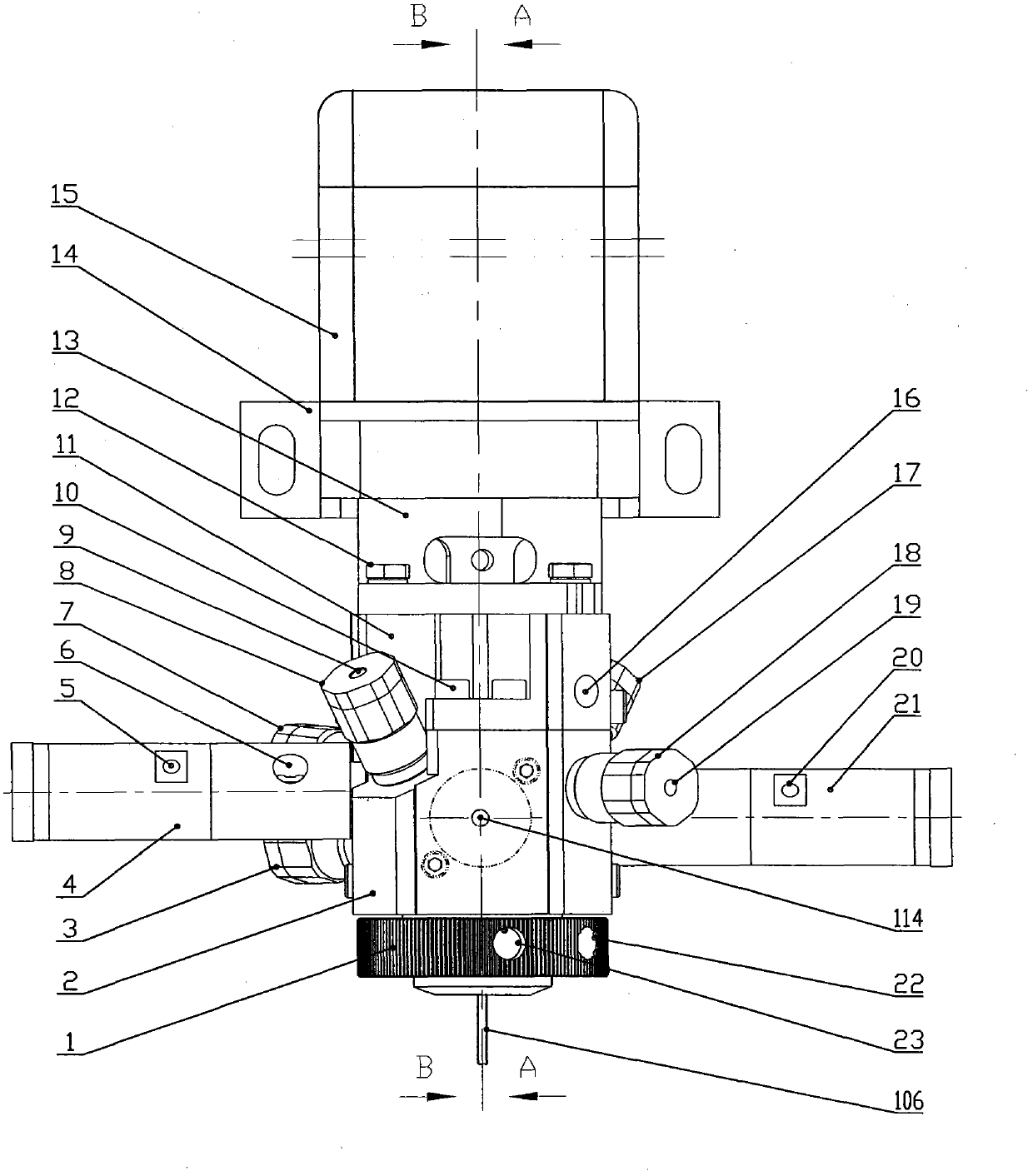

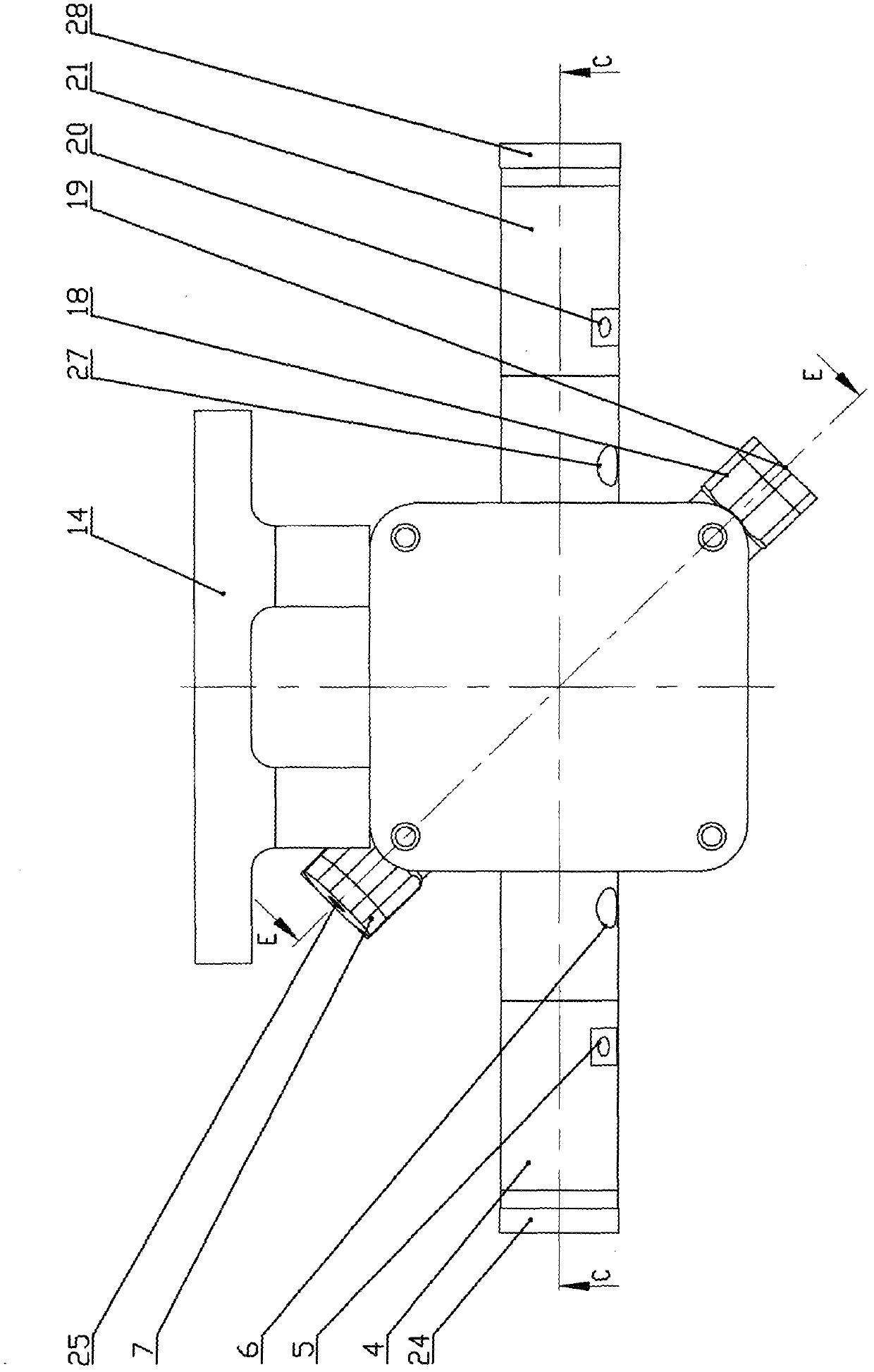

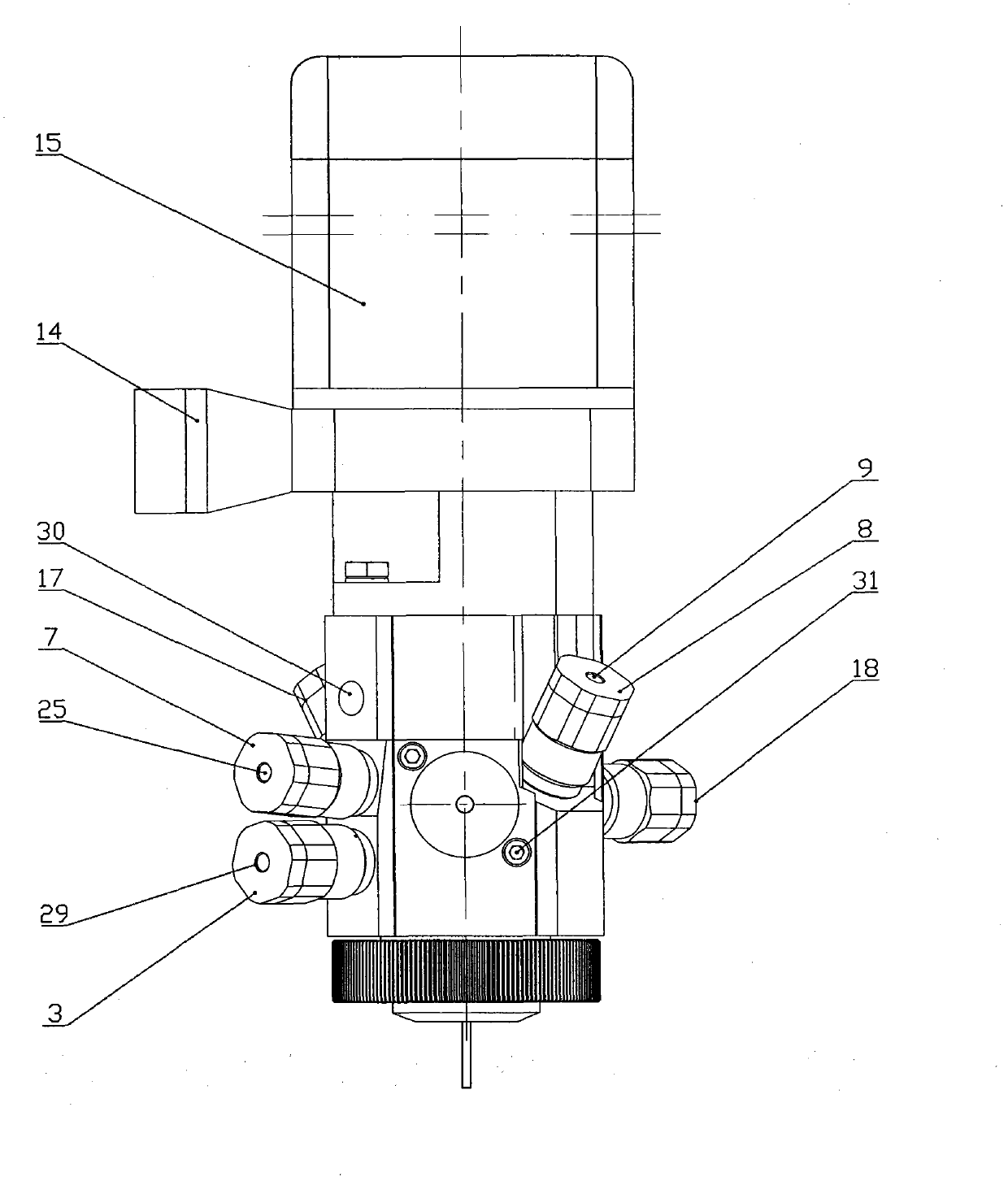

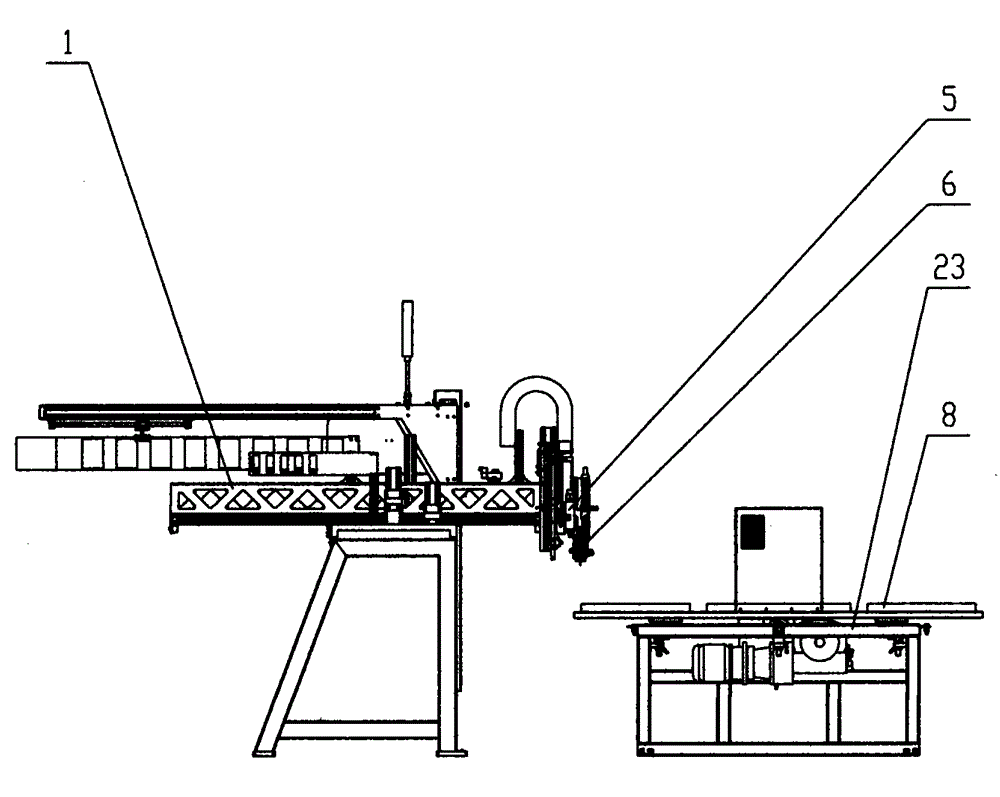

Water-cleaning gluing head for multi-component polyurethane needle valve

ActiveCN102601018ARemove threatEliminate pollutionLiquid surface applicatorsHollow article cleaningPhysical well beingEngineering

The invention relates to a water-cleaning gluing head for a multi-component polyurethane needle valve, in order to solve the problem that the traditional double-component polyurethane gluing head must be cleaned with a solvent and cannot be cleaned with water. The multi-component polyurethane water-cleaning gluing head comprises a motor, a transmission shaft, a stirring blade, a cup moving part, a valve base, a middle valve body, an upper valve body, a valve fixing plate, an component needle valve A, a component needle valve B, a water valve A, a water valve B, a water valve C, a water valve D and an air valve, wherein a cup base is connected with the valve base; a sealing ring A, a sealing ring B and a sealing ring C are mounted on an outer ring of a moving cup body; a check ring, a sealing circle and a sealing ring are mounted on an inner ring of the moving cup body; and a fixing sleeve is mounted between an ending opening on the cup base and the valve base. The manner of cleaning with water and then cleaning with compressed air is realized; the cleaning time is shortened; the threat to the health of operators and the environmental pollution caused by the solvent are eliminated; the structure is simple and compact; the mounting is convenient; the repairing is quick; and the stability is increased.

Owner:DALIAN HUAGONG INNOVATION TECH

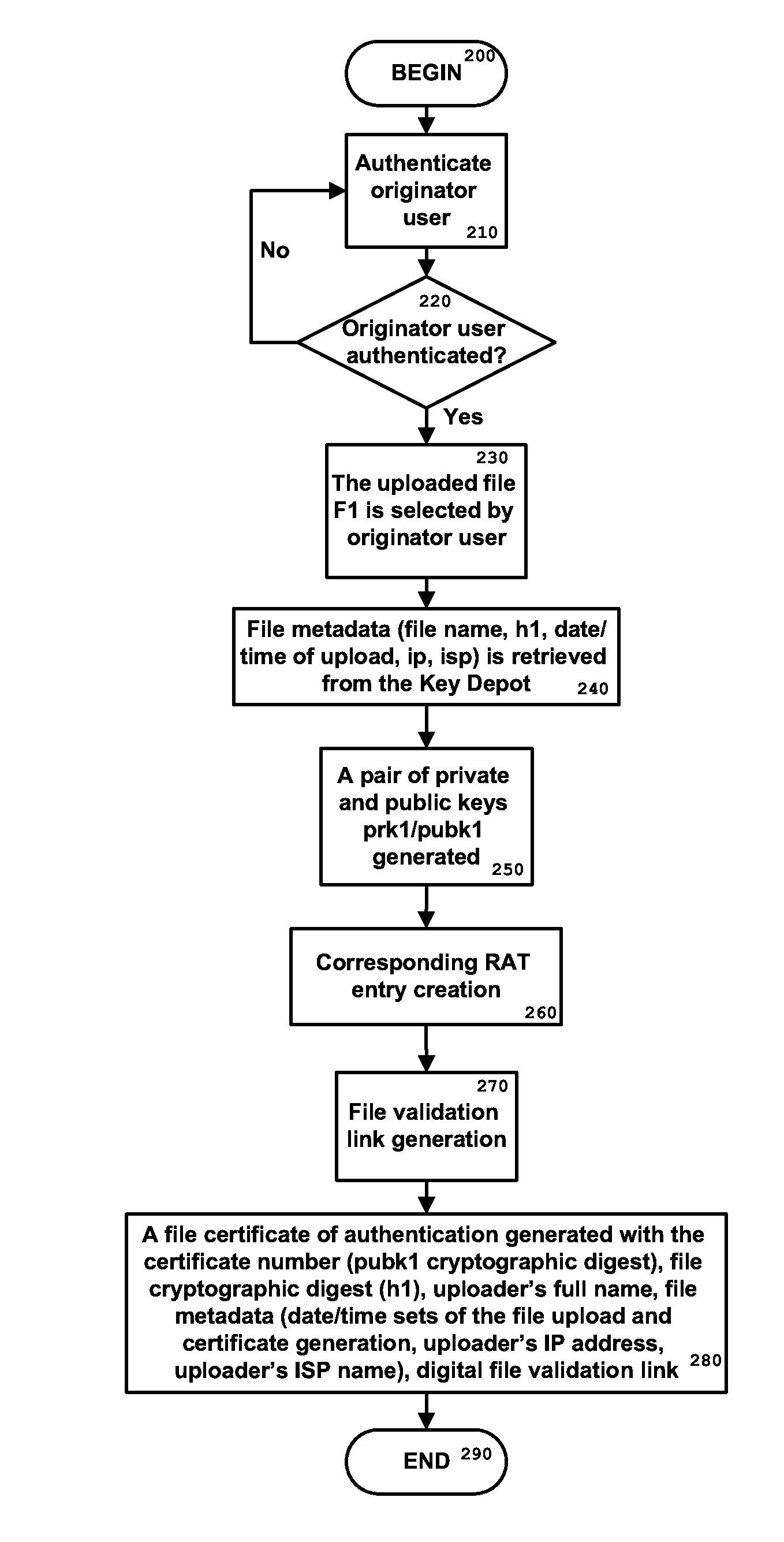

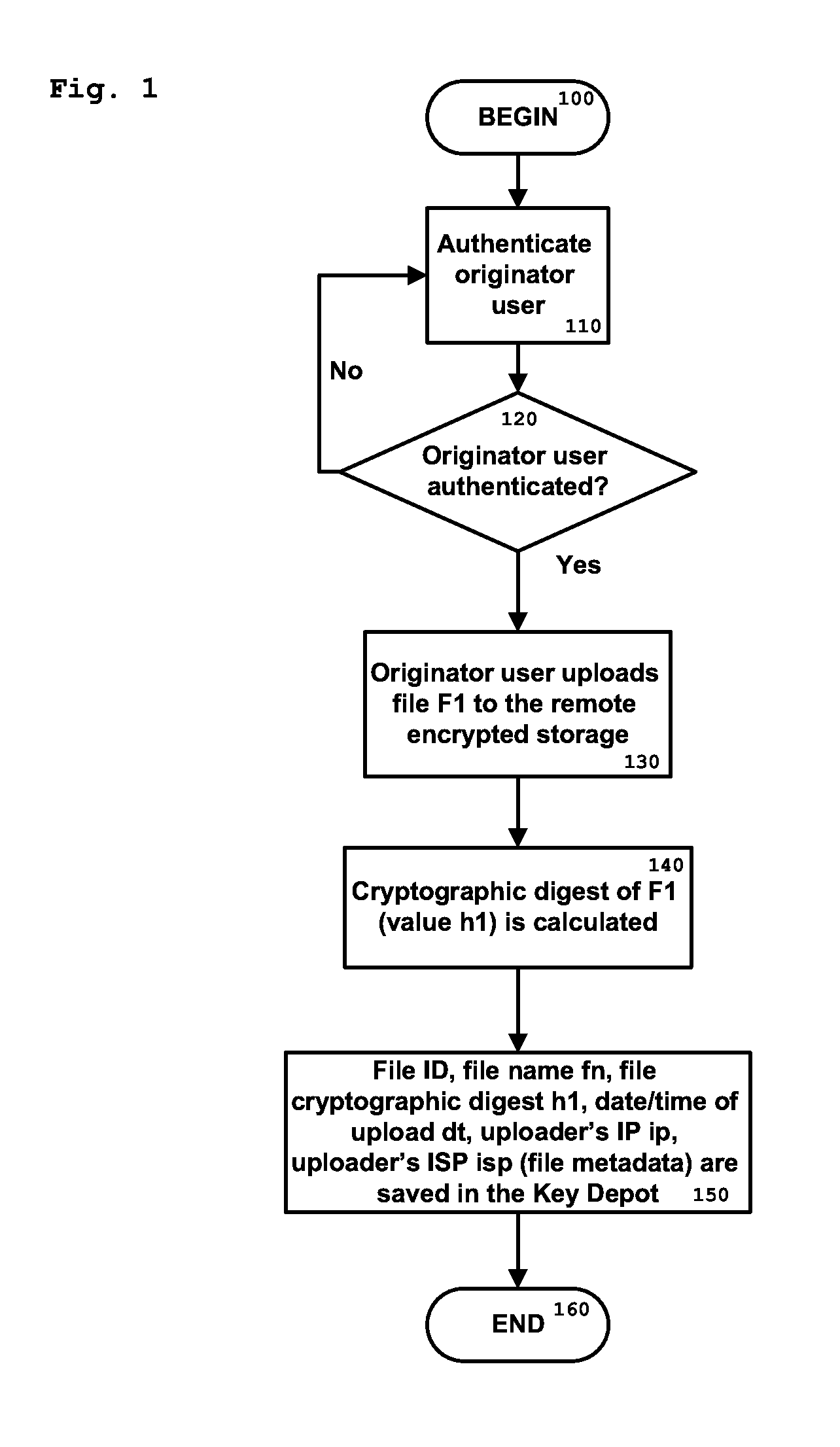

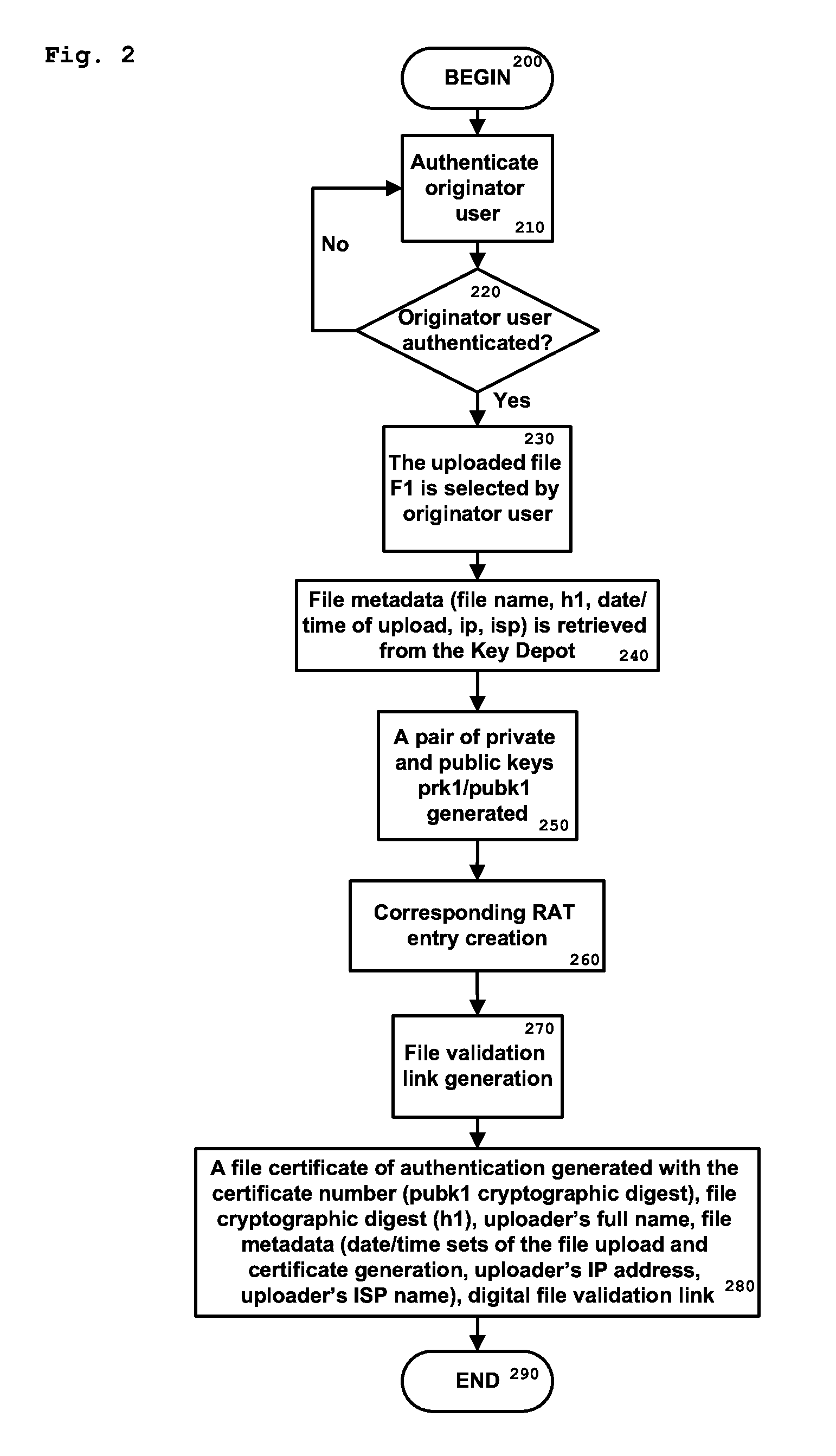

Method and system for authenticating and preserving data within a secure data repository

InactiveUS20140304512A1Eliminate CollisionsRemove threatMultiple keys/algorithms usageUser identity/authority verificationDigital signatureData source

A computer implemented method for identifying and linking a data originator and a data file or data batch from the originator through one or more data source systems. The system stores the data files and batches on a permanent basis for subsequent verification purposes, verifying the identity of the data file originator through originator-specific information from the data source system; and generating unique data entries associated with the originator identity, the file identity and / or a file verification cryptographic digest, and a unique originator signature. The data entries and signature are stored in encrypted form in a Relay Access Table (RAT), as are the public and private keys associated with both the data file and the originator. A certificate for verification of the data file is generated, that contains a digital signature, as well as a file cryptographic digest and metadata associated with filing conditions.

Owner:PRONIN SERGEI +3

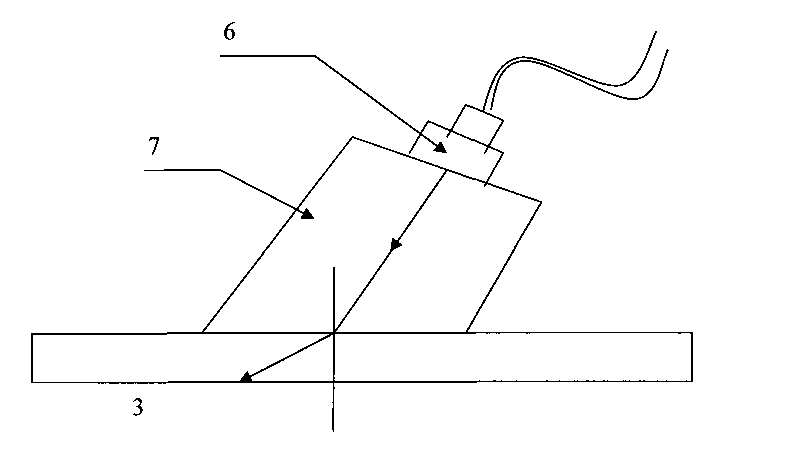

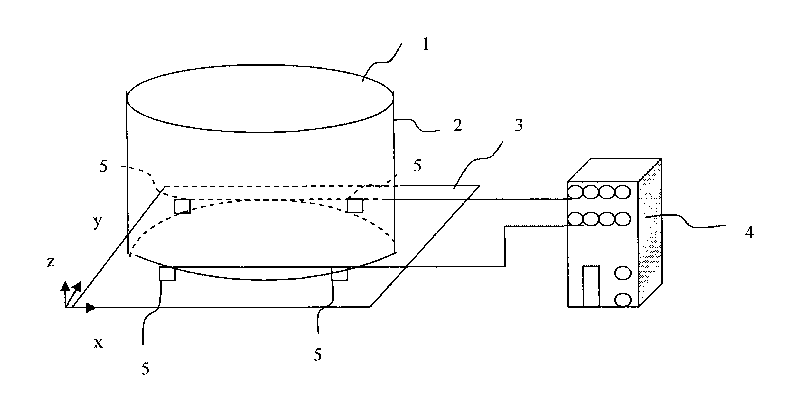

Method for detecting guide waves of steel storage tank bottom plate

InactiveCN101762635AEasy to detectRealize analysisAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWavelength

The invention relates to a method for detecting guide waves of a steel storage tank bottom plate, comprising the following steps in sequence; (1) selecting the number of ultrasonic probe arrays (5), and symmetrically distributing the ultrasonic probe arrays (5) along the steel storage tank bottom plate (3); (2) arranging two signal processing devices (4) on each ultrasound probe array (5), and arranging the ultrasound probe array (5) on the steel storage tank bottom plate (3) through a wedge block in a coupling way; (3) selecting a ultrasonic wave length which corresponds to the thickness of the steel storage tank bottom plate (3) and selecting a method for exciting Lamb waves; (4) transforming a travel time matrix with Radon algorithmic function to generate Lamb wave travel time projections of different incidence angles, which are used as the projection data for the subsequent tomography reconstruction; (5) reconstructing a tomography in the projection data with the filtered back projection algorithm; (6) analyzing the tomography to find the position of the defect and grade the defect level; and (7) if the defect existing, changing the positions of ultrasonic probes clockwise, repeating the steps (1), (2), (3), (4), (5) and (6), comparing the repeated detection and tomography reconstruction results, and eliminating the effect of noise and other factors if the position of the defect and the morphology existing.

Owner:PETROCHINA CO LTD

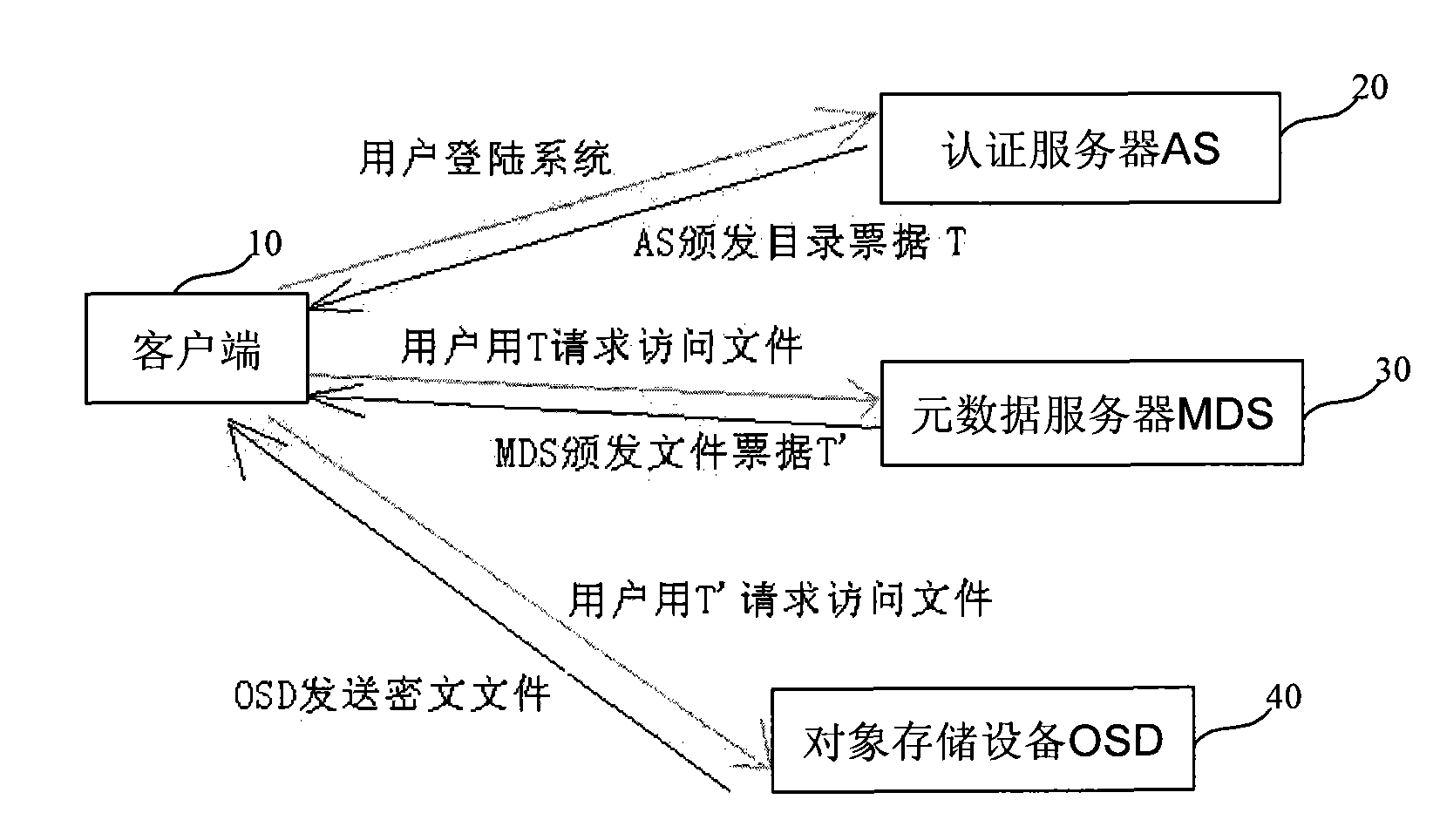

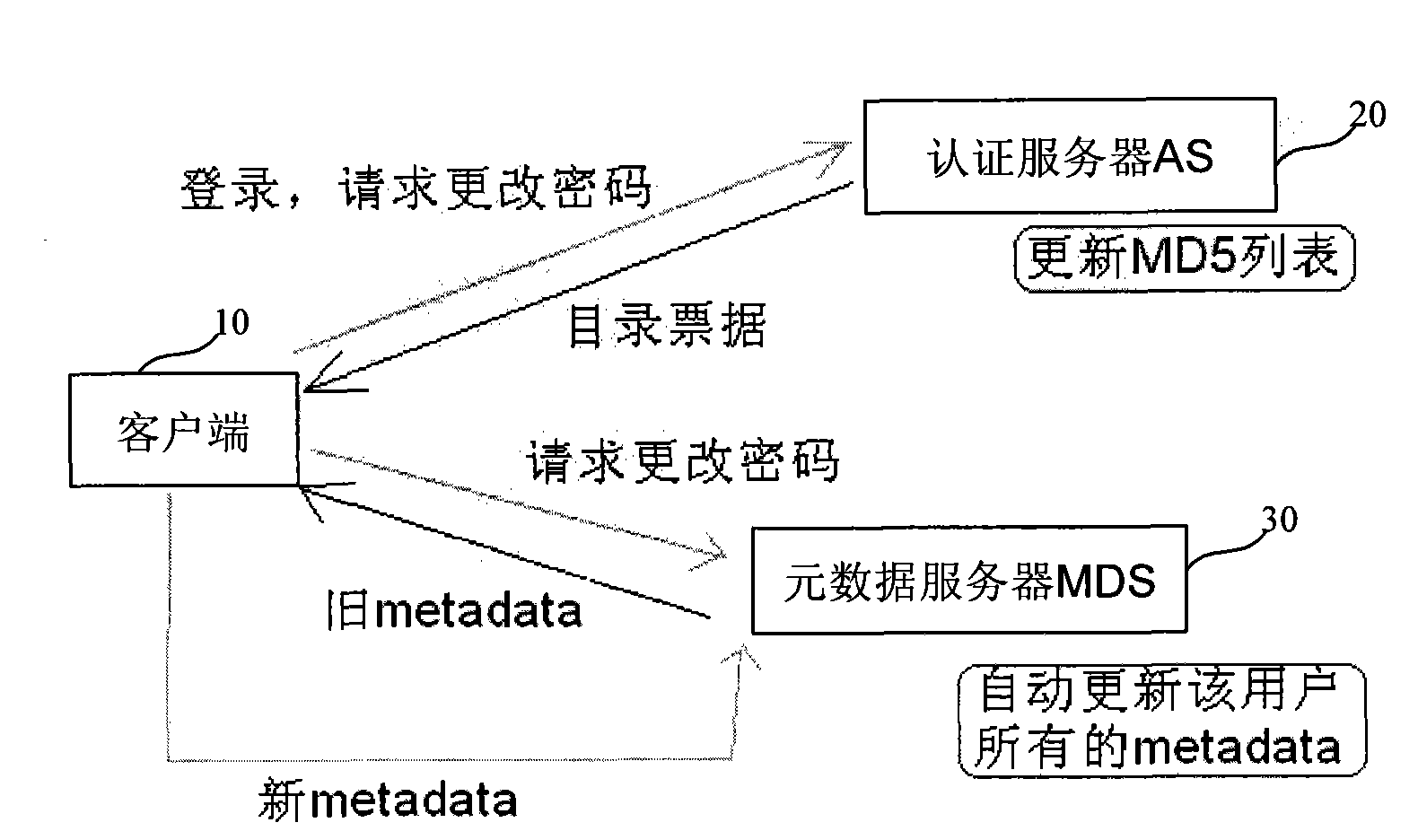

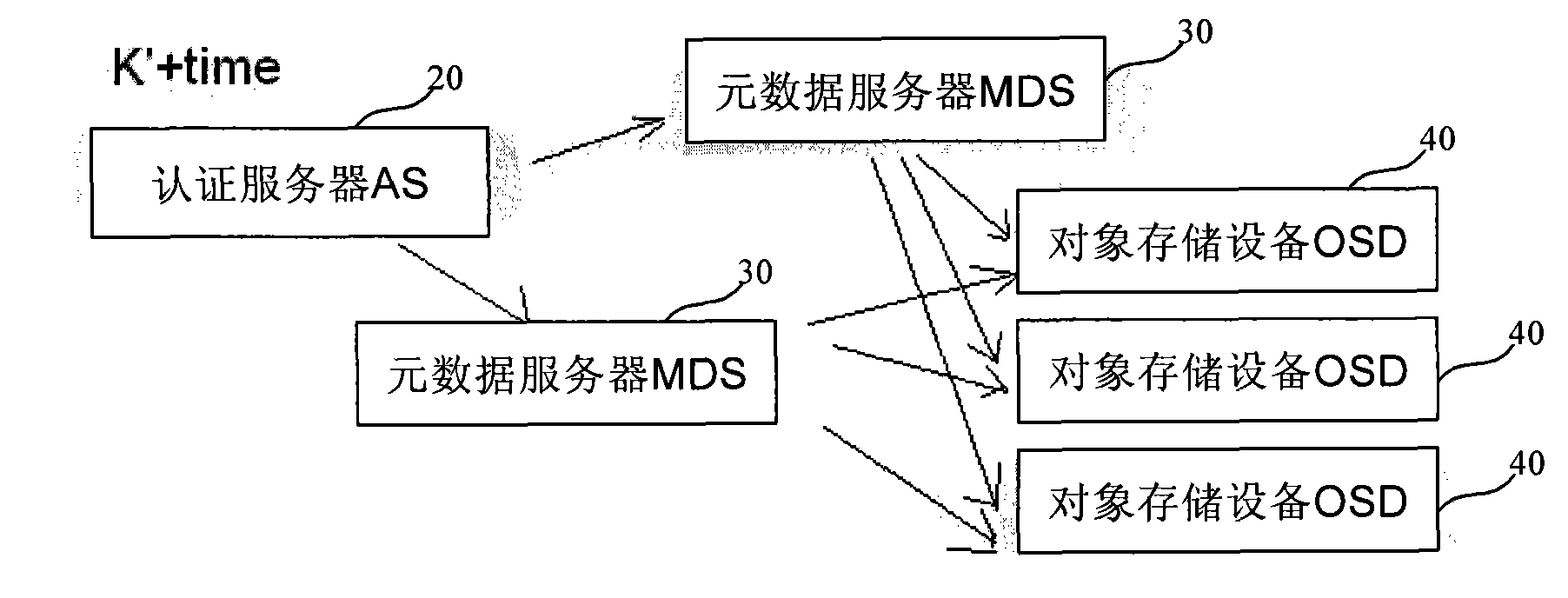

Safe distribution file system

InactiveCN101605137ARemove threatGuaranteed confidentialityKey distribution for secure communicationUser identity/authority verificationClient-sideObject storage

The invention relates to a safe distribution file system, which includes a registration server, a metadata server, an object storage apparatus and customer terminals. The registration server is used for verifying identity of customers, and providing content notes and a first session key for requesting access files by verifying the corresponding customer; the metadata server provides file notes for file access, head file and a second temporary session key to the corresponding customer according to the received directory notes and the access request ciphered by the first temporary session key; the object storage apparatus transmits cryptograph files to the corresponding customer according to the received file notes and the access request ciphered by the second temporary session key; and the customer terminals decipher cryptograph files using the access request corresponding to the first and the second temporary session key and through the head file for reading and writing of the corresponding customers. The invention can provide safe and effective guarantee to the access to the file of customers.

Owner:UNIV OF SCI & TECH OF CHINA

Waste dump extinguishing method

The invention concretely relates to a waste dump extinguishing method to solve problems of easy combustion resumption and generation of a large amount of harmful gases of present waste dumps. The method comprises the following steps: 1, initially grasping the spontaneous combustion case of a waste dump; 2, distributing points on the surface of the fire zone of the waste dump according to a 3-5m grid space, and calibrating and drafting an isothermal line and a gas isoline; 3, determining the depth of the fire zone or hidden combustion points; 4, carrying out waste dump classification and potential safety hazard screening, and treating in a zoning installment mode; 5, carrying out extinguishing cooling on the waste dump with naked fires, carrying out slope cutting, grading and packway construction on side slopes, and carrying out loess coverage; 6, punching and grouting, wherein a flushing solution used in punching is a colloid material, the end angle of a drill is 45DEG, and a composite gel extinguishing material is adopted as a grouting slurry; and 7, carrying out reclamation and ecological reconstruction according to a case that the loess layer thickness is 0.5-0.6m, the vibratory compaction frequency is 6-8, the compaction coefficient is 0.90-0.95, and green side slope plants adopt shrubs. The method has the advantages of elimination of threats of factors of landslip, harmful gas pollution and the like to residents, land reclamation, and repeated extinguishing investment reduction.

Owner:DATONG COAL MINE GRP

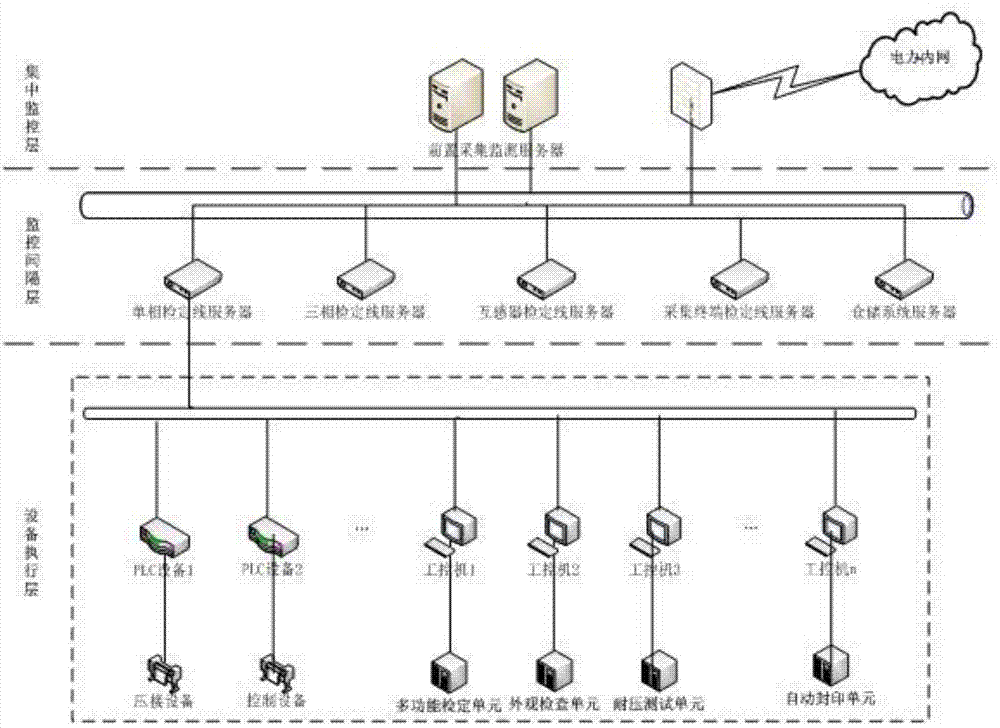

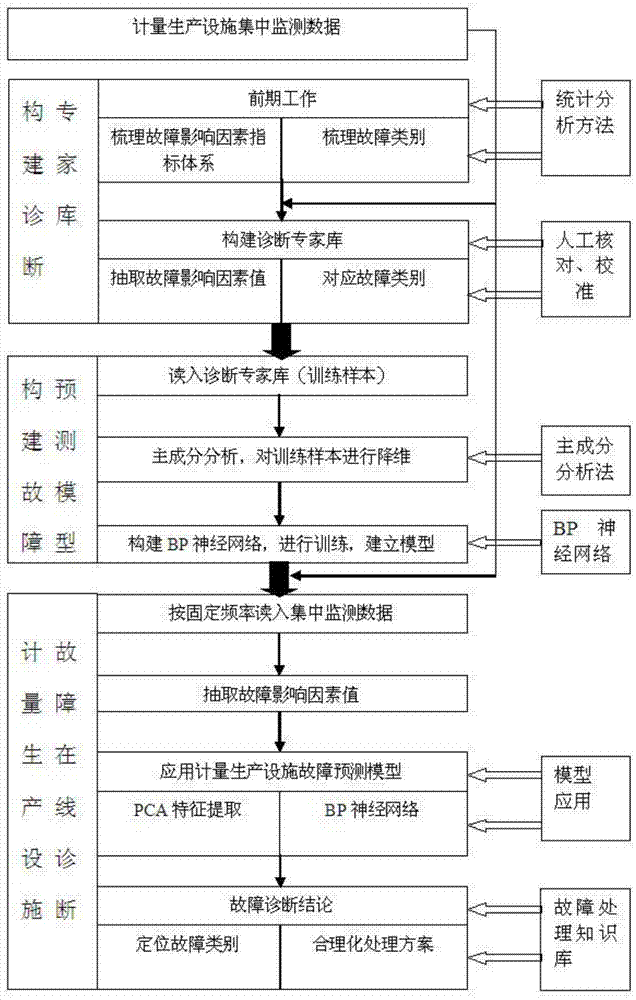

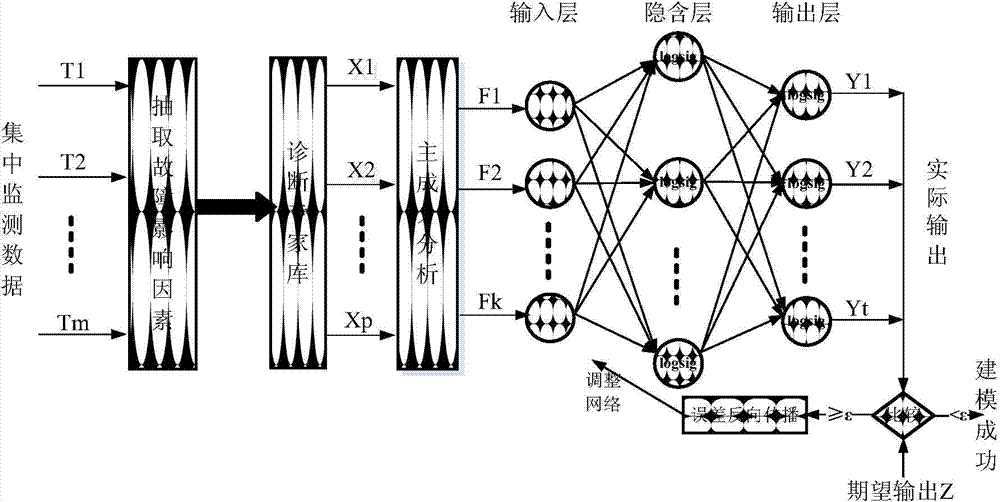

On-line diagnosing method for faults of metering production facility

ActiveCN104732276AImprove reliabilityRemove threatNeural learning methodsDependabilityDiagnostic system

The invention discloses an on-line diagnosing method for faults of a metering production facility. The method comprises the following steps that firstly, centralized monitoring data are collected; secondly, a diagnosing expert base (training sample) is established; thirdly, a fault prediction model based on an artificial neural network is established; fourthly, on-line diagnosis is carried out on the faults of the metering production facility. All of hardware production units of the metering production facility are provided with alarming equipment, however, when the faults actually occur, production is usually already influenced, and the alarming equipment does not send alarms aiming at production anomalies and some equipment faults. An on-line diagnosing system for the metering production facility constantly analyzes 'four-line-one-storeroom' system running data, a current system running state is judged, the faults are predicted, when the production anomalies or the equipment faults are predicted, staff can solve the problems in time, threats which might influence the production are eliminated, and the reliability of the metering production facility is greatly improved.

Owner:STATE GRID CORP OF CHINA +2

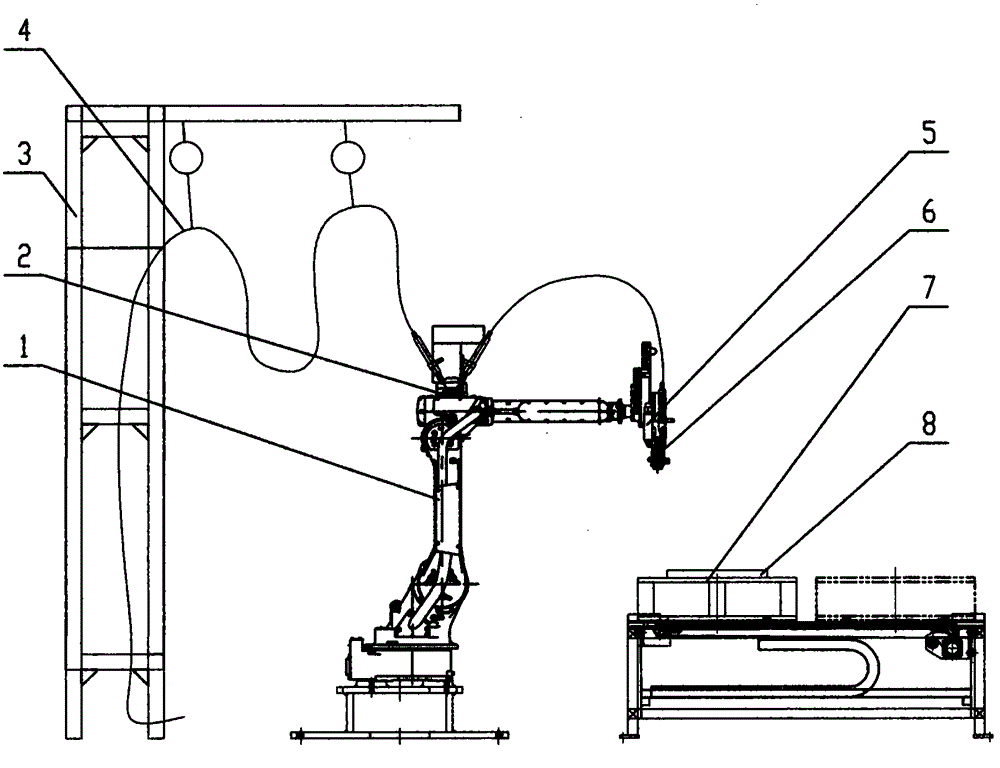

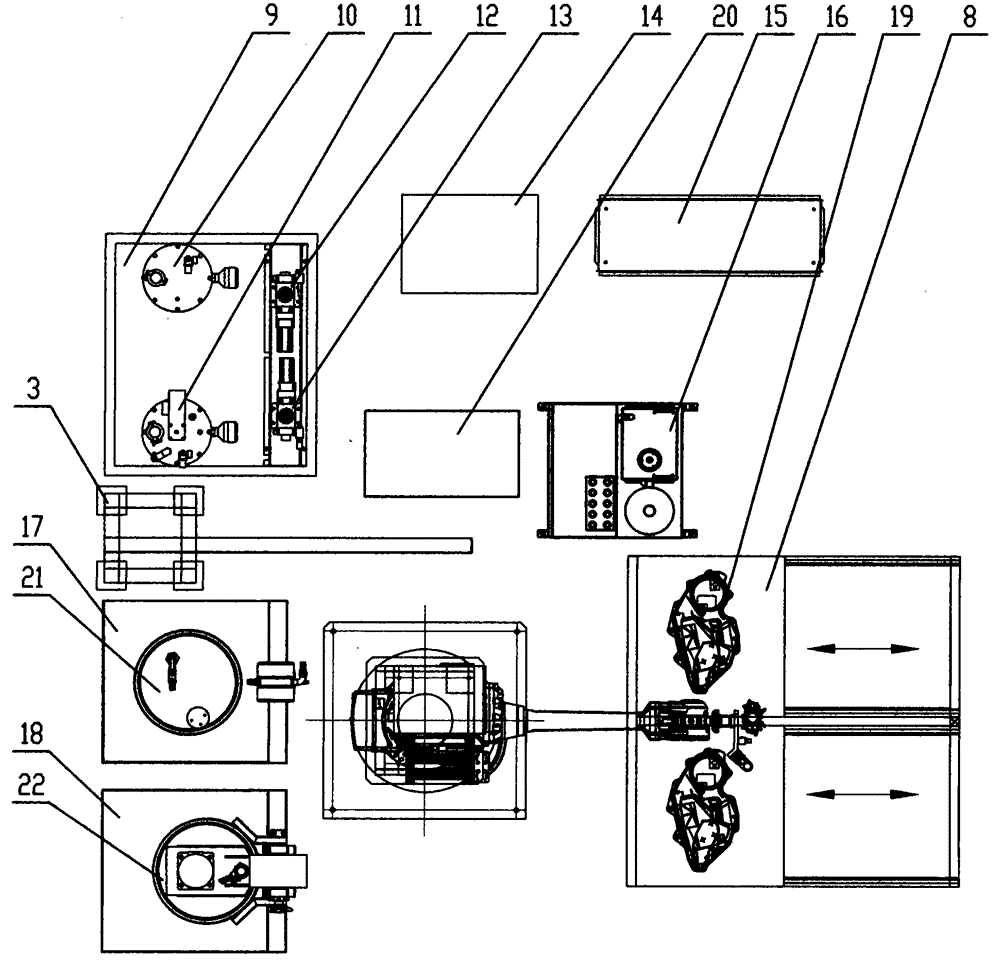

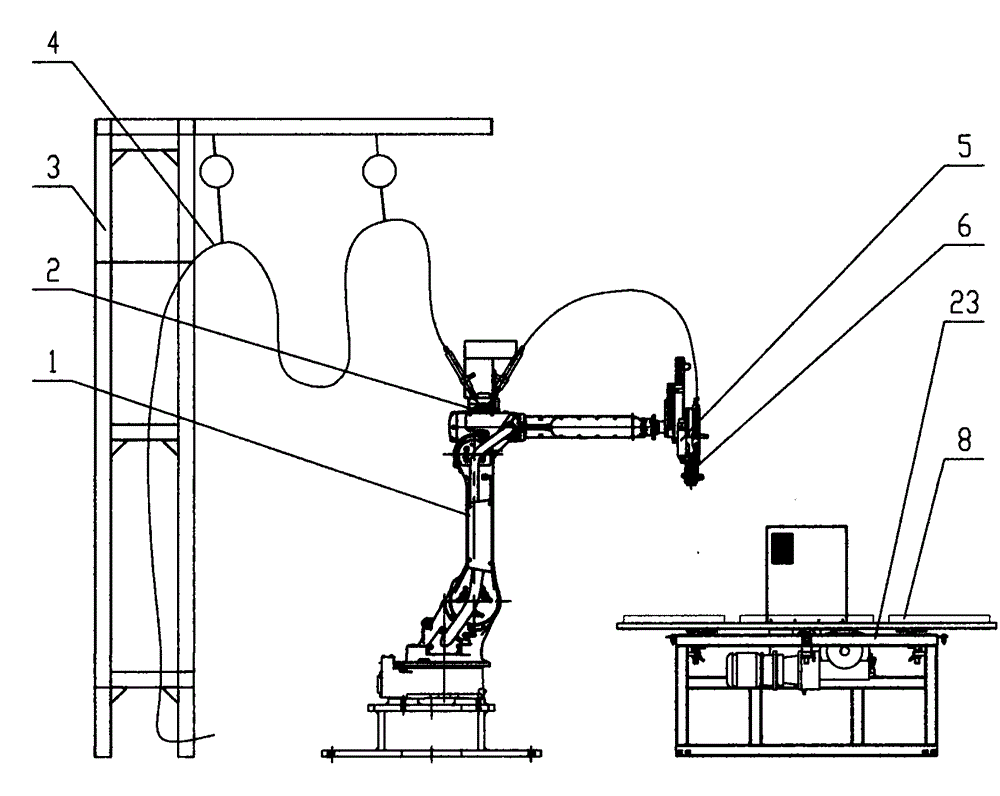

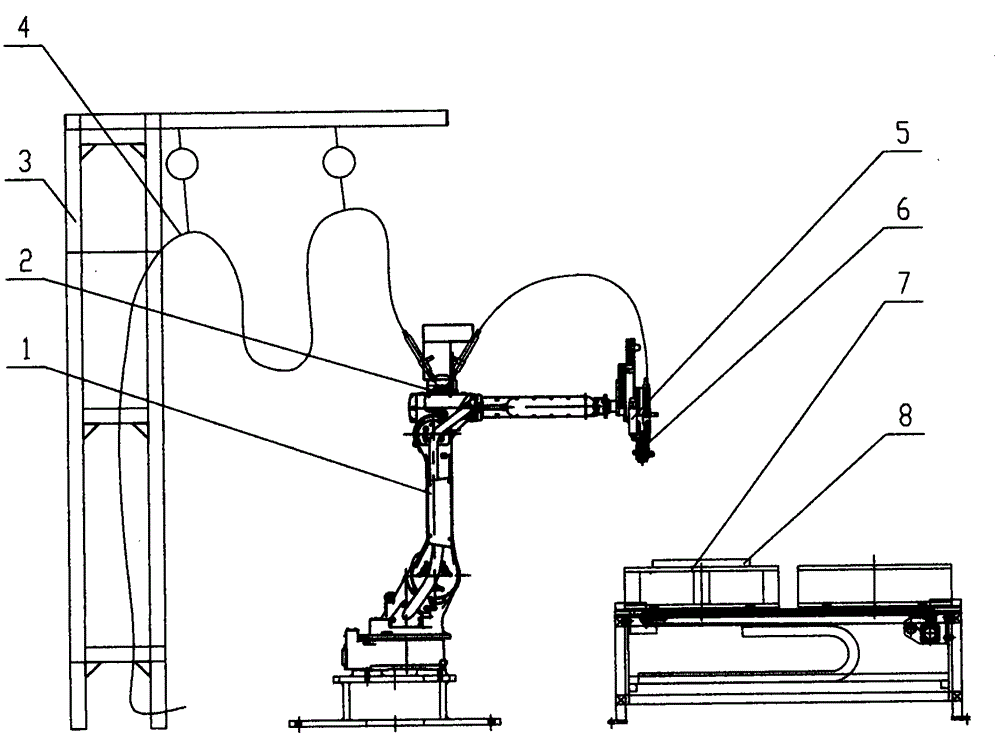

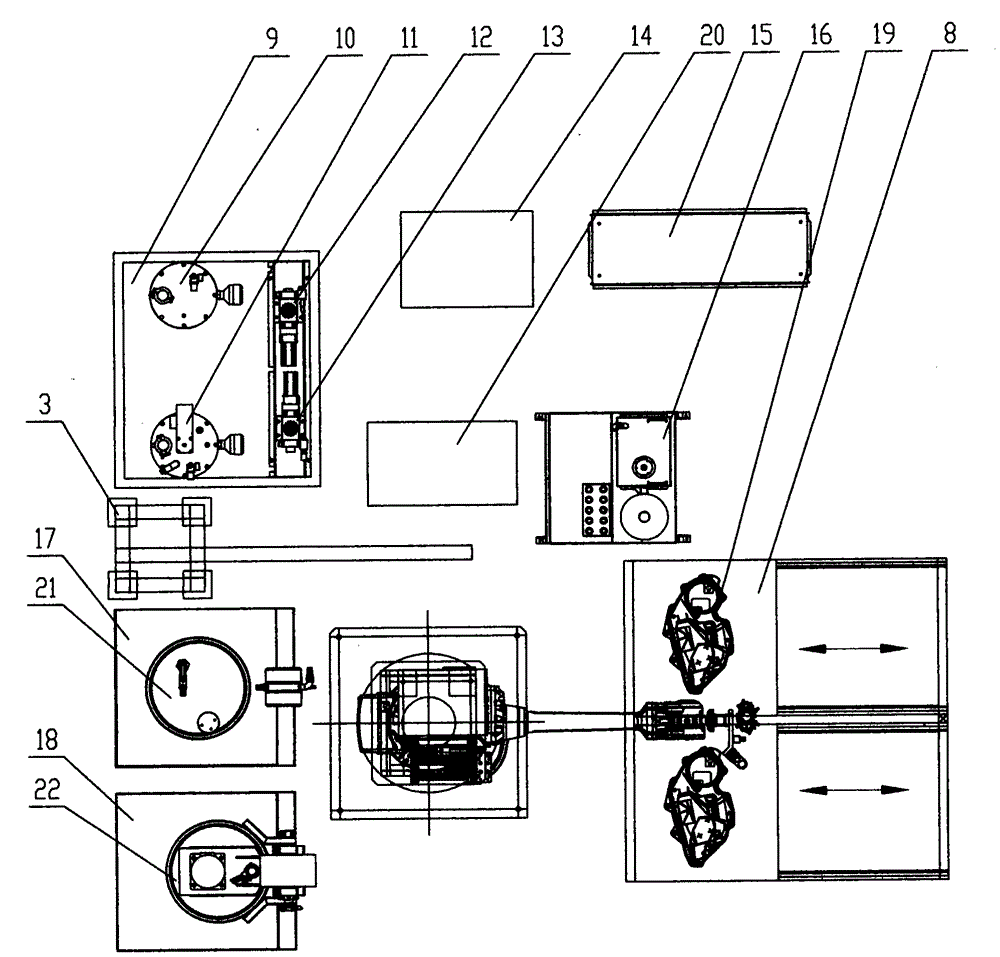

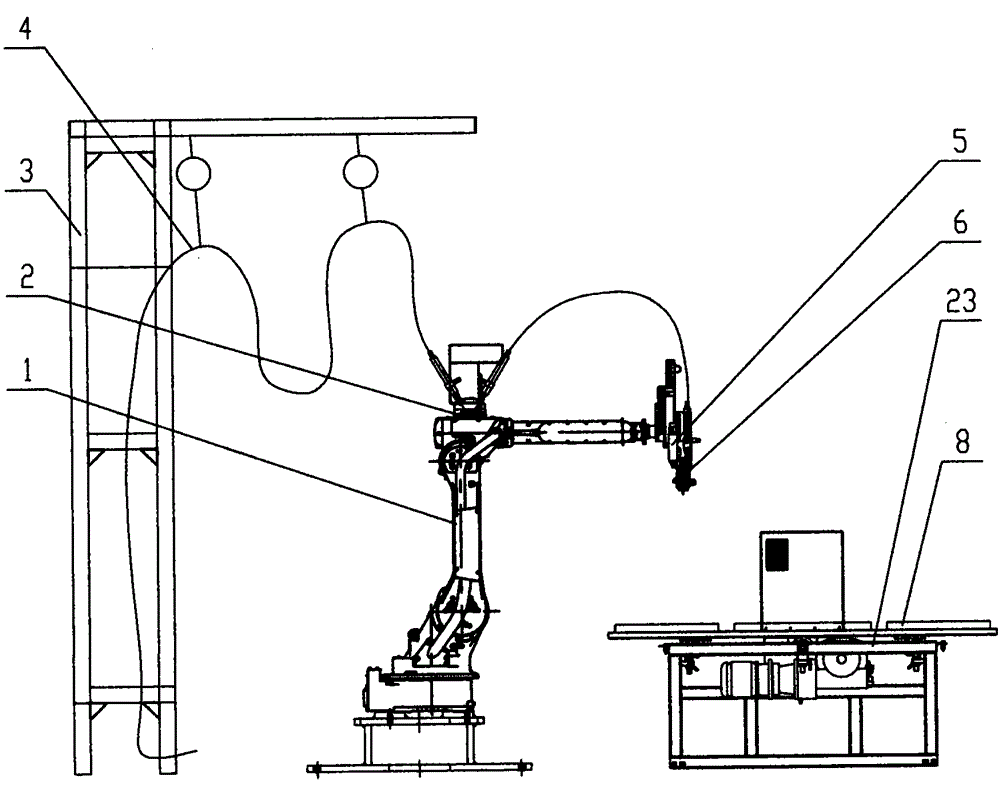

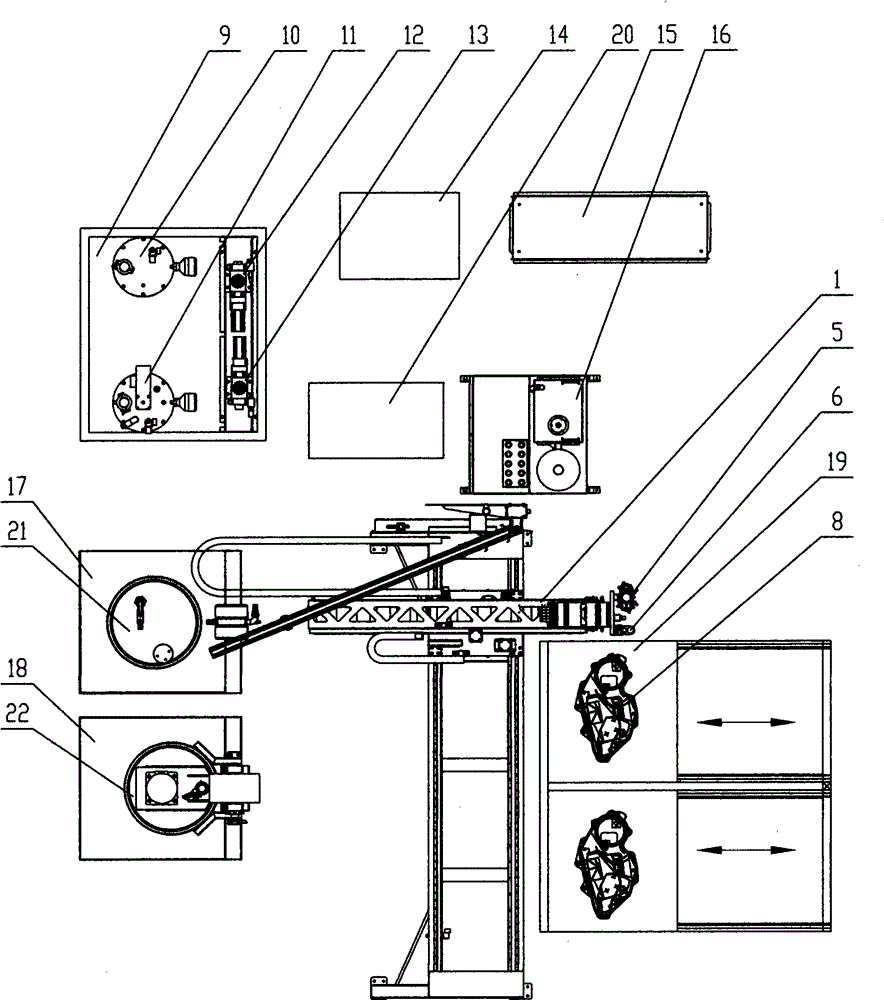

Full-automatic robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

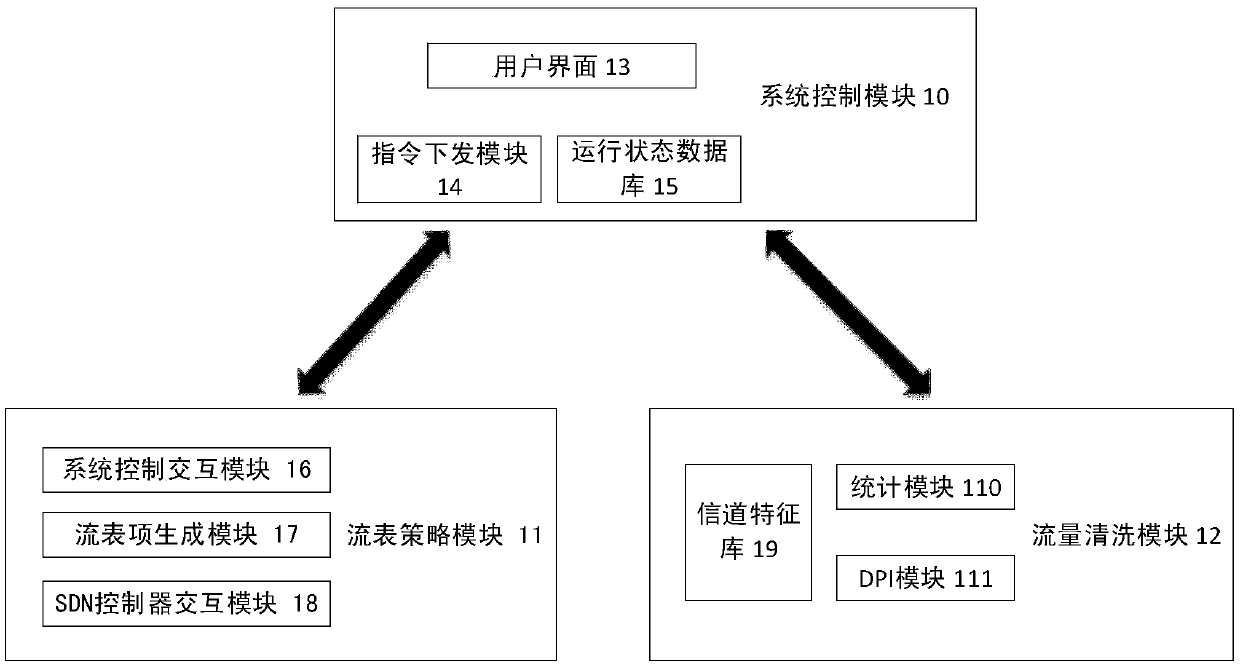

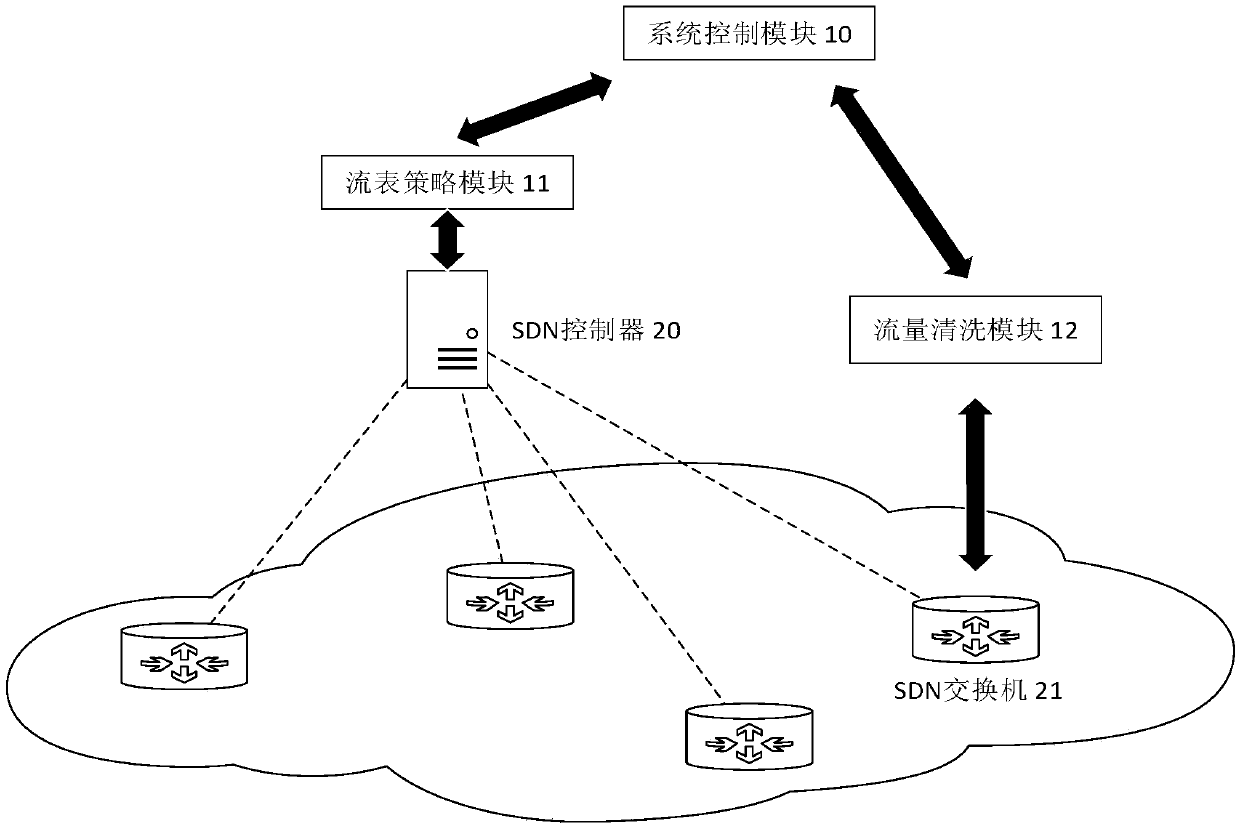

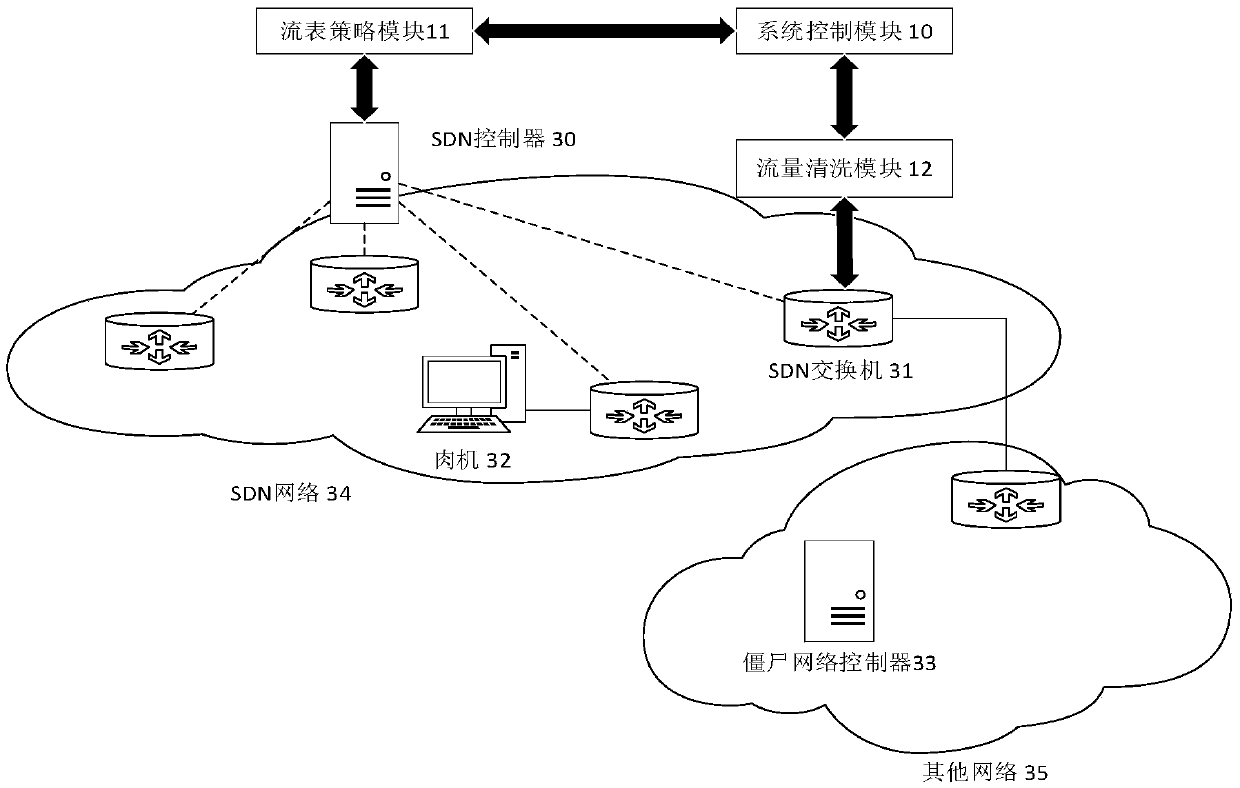

Method and device for blocking botnet control channel based on SDN (Software Defined Network) technology

InactiveCN105516129AReduce the impact of normal communicationHigh precisionData switching networksBotnetControl channel

The invention sets forth a method and a device for blocking a botnet control channel based on an SDN (Software Defined Network) technology. The device comprises a system control module, a flow table strategy module and a traffic cleaning module. The system control module is used for receiving key parameters configured by a user and transmitting the key parameters to the flow table strategy module and the traffic cleaning module, and simultaneously displaying the running state of a current system to the user. The flow table strategy module calculates a flow table according to the user configured parameters and the current network topological structure, and transmits the flow table to an SDN switch through an SDN controller, thus redirecting the traffic conforming to control channel characteristics in a network to the traffic cleaning module. The traffic cleaning module precisely matches the received traffic by using a technology of deep packet detection and the like, filters the traffic conforming to control channel characteristics, and returns other traffic to the network to ensure normal communication.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Complex breaking agent for trivalent chromium passivation rinsing water, and preparation method and application thereof

ActiveCN106915811AEfficient removalSimple preparation processWater contaminantsWaste water treatment from metallurgical processCross-linkFerrous salts

The invention discloses a complex breaking agent for trivalent chromium passivation rinsing water. The complex breaking agent is prepared with water-soluble metal salts as raw materials, water as a solvent and PAM as a cross-linking agent through cross-linking, wherein the water-soluble metal salts are two or more selected from a group consisting of a water-soluble zinc salt, a water-soluble ferrous salt, a water-soluble ferric salt, a water-soluble calcium salt and a water-soluble aluminum salt. The invention also discloses application of the complex breaking agent to treatment of trivalent chromium passivation rinsing water. The complex breaking agent provided by the invention has the characteristics of simple preparation process, substantial effect and wide applicability. The metal cation and PAM of the complex breaking agent are cross-linked in a physical form; the PAM allows the metal cation to fully contact with complexed organic matters in waste water and promotes interaction between the metal cation and the complexed organic matters; and when applied to treatment of passivation rinsing water containing trivalent chromium in a complex state, the complex breaking agent can effectively remove trivalent chromium in the complex state in waste water and eliminate latent threat of trivalent chromium to water environments, and the removal rate of trivalent chromium can reach 99.9%.

Owner:NANJING YUANQUAN TECH CO LTD

Externally-used hot compress mud plaster for treating pains of human body and preparation method thereof

ActiveCN102038783AEliminate accumulationStimulus loopHydroxy compound active ingredientsAntipyreticPoulticeHeadaches

The invention belongs to the field of externally-used traditional Chinese medicines, in particular to an externally-used hot compress mud plaster for treating pains of a human body and a preparation method thereof. The externally-used hot compress plaster comprises the following raw materials: 10-15% of natural jade mud powder, 3-5% of tourmaline micro powder, 3-5% of far infrared ceramic micro powder, 15-25% of Chinese medicinal herb, 10-20% of mud plaster matrix, 25-35% of beeswax and 5-15% of red lead. The externally-used hot compress mud plaster is used for acupuncture points of the human body. The mud plaster is heated to melt; after about 10-15 minutes, the cooling melted mud plaster is sticked to a pain area after being cleaned, so as to activate the vigor of skins, and expel toxins of the skins. The hot compress mud plaster has the advantages of heat absorption and heat preservation, even heat dissipation, consistent temperature, can get through the meridians, dispel the wind and remove the cold, activate blood circulation to dissipate blood stasis, eliminate goiter and tumour, thoroughly remove the pain, treat headache, toothache, prosopalgia, sore-throat, chest and hypochondriac pain, epigastric pain, bellyache, gout, backleg pain and cerv shoulder pain, herniated disk, ischialgia, rheumatalgia, and spinal pain; and the plaster in the invention is convenient to stick to the different parts of the human body, does not harden and flow, solidifies after taking away from the human body, and can be reused by repeated heating.

Owner:河南邱天道泥灸医药用品制造有限公司

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097BTake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effectis attained.

Owner:重庆百奥帝克微生态科技有限公司

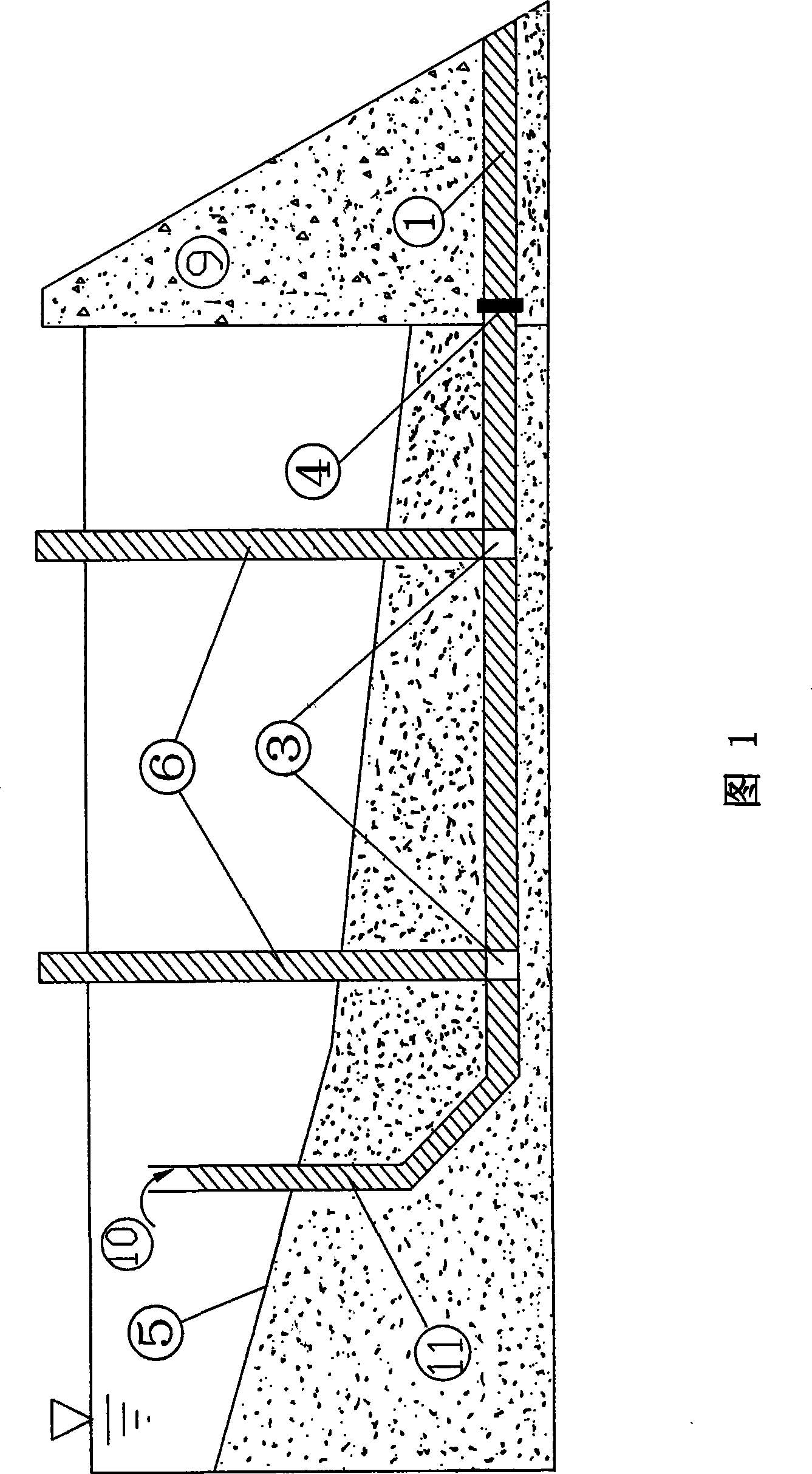

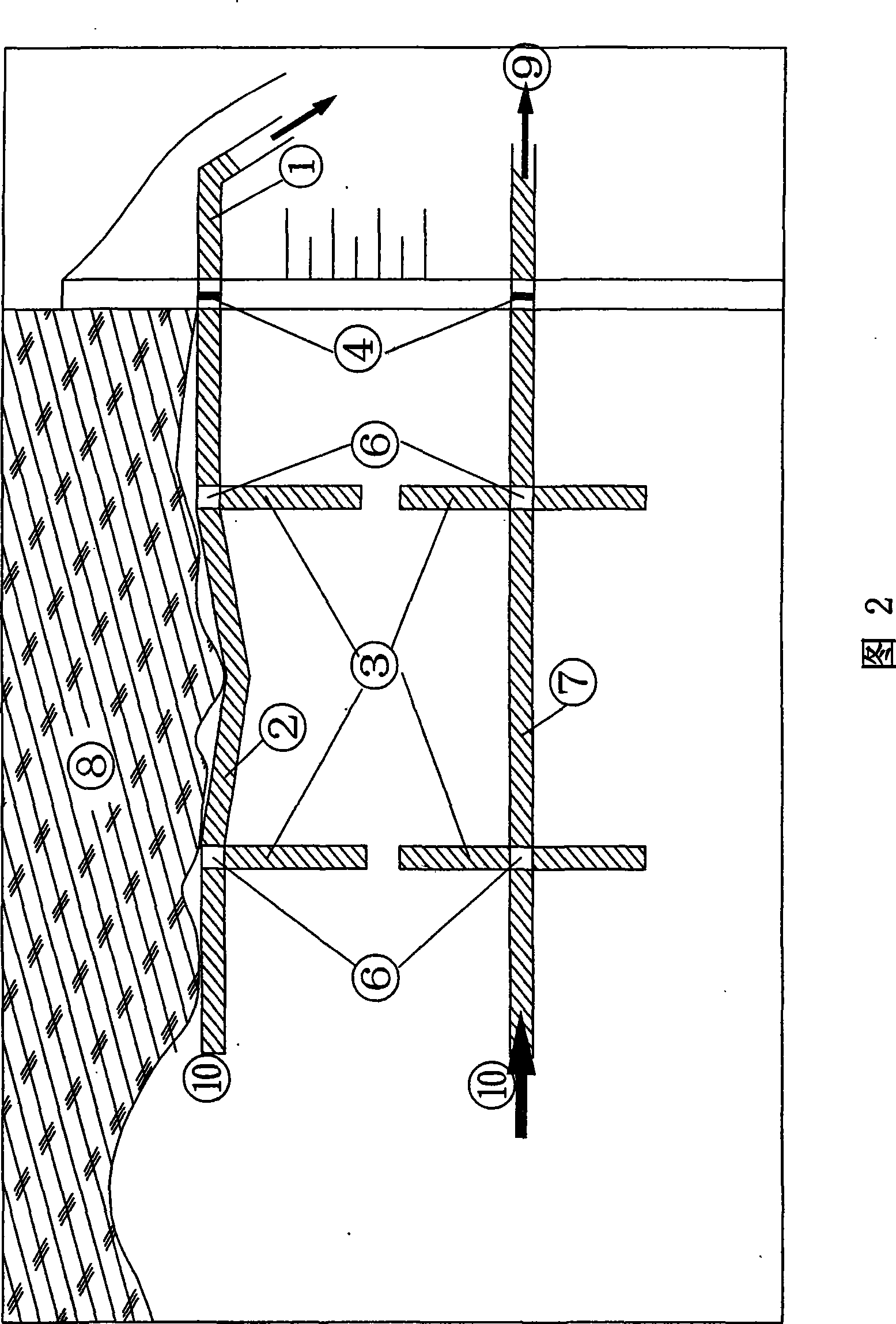

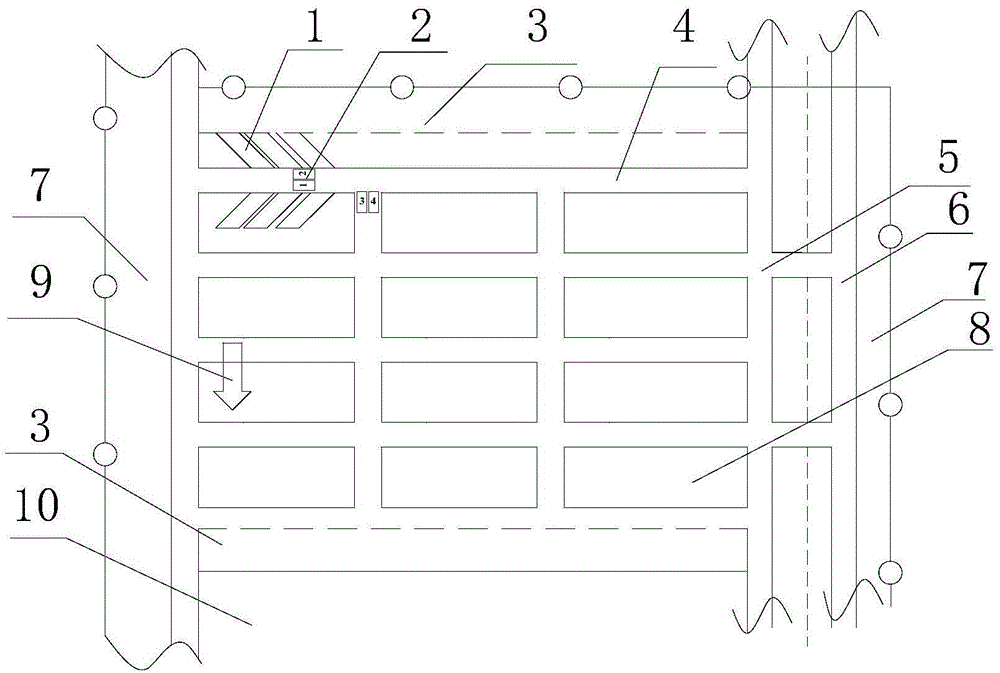

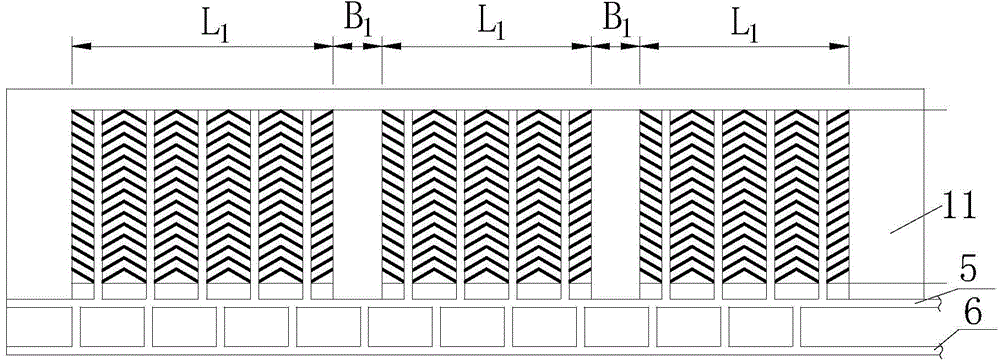

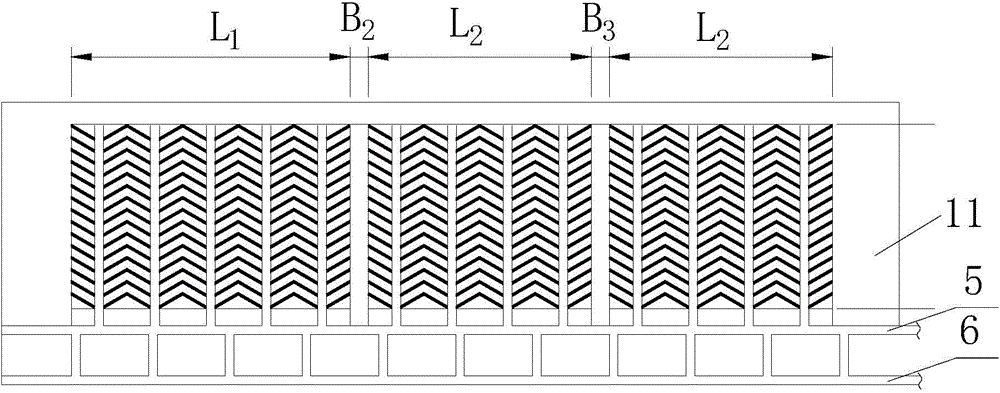

Hydraulic arrangement mode sediment ejection structure

ActiveCN101418555ARemove threatIncrease the amount of sand flushingBarrages/weirsDischarge efficiencyExternal energy

The invention discloses a hydraulic arrangement type sand discharging structure, which comprises sand discharging pipelines, wherein the sand discharging pipelines are laid on the bottom parts of a reservoir, the tail ends of the sand discharging pipelines are connected with a bottom hole or a tunnel of a dam body and provided with gate valves to control the discharge rate; the head ends of the sand discharging pipelines are extended toward up stream, the end parts or proper parts of the sand discharging pipelines are provided with curved pipe segments tilted upward, and upper end openings of the curved pipe segments are higher than the expected sand silting face; and one side or / and two side pipe walls of the sand discharging pipes is / are provided with branch pipelines, the upper side pipe walls are provided with gate wells, and the inside of each gate well is provided with control valves. The number of sand discharging pipelines is more than two, and the sand discharging pipelines are laid on the reservoir bottoms on the bank side and in the middle of the reservoir respectively. The number of the gate wells is more than one, the gate wells are arranged on different positions on the upper side pipe wall of each sand discharging pipeline. In the mode of changing the position of a water inlet of a sand discharging hole of the reservoir, the structure utilizes the distributing type space difference generated in laying the sand discharging pipelines to achieve the aim of widening the range of sand discharging; moreover, the structure also has the advantages of unnecessary external energy, high sand discharging efficiency and good social and economic benefits.

Owner:张金良

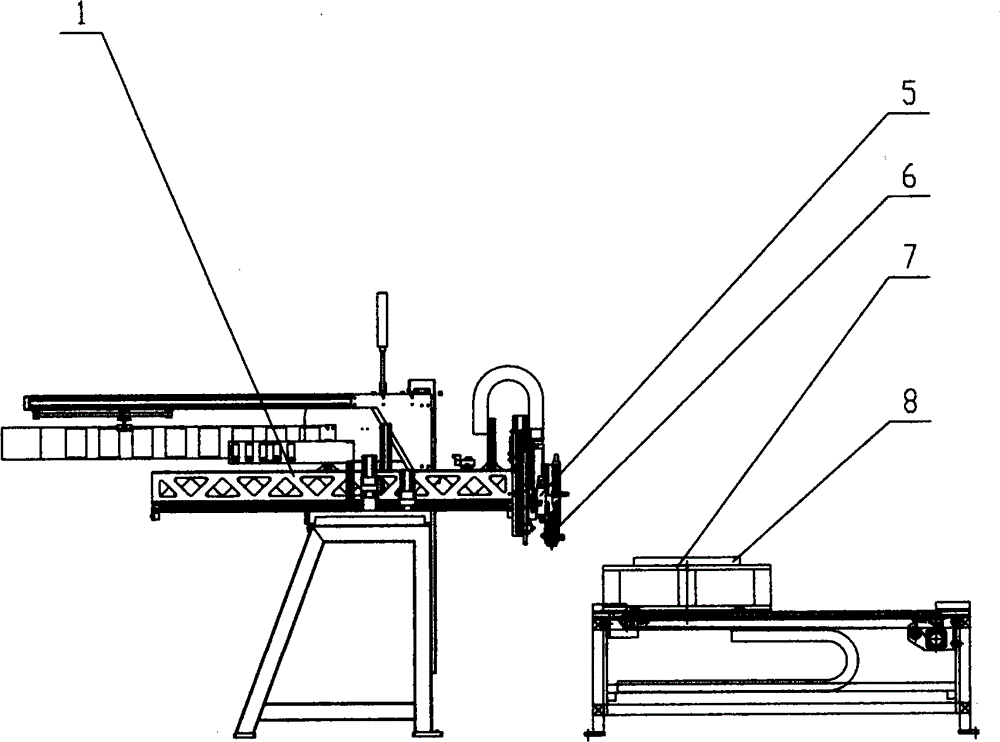

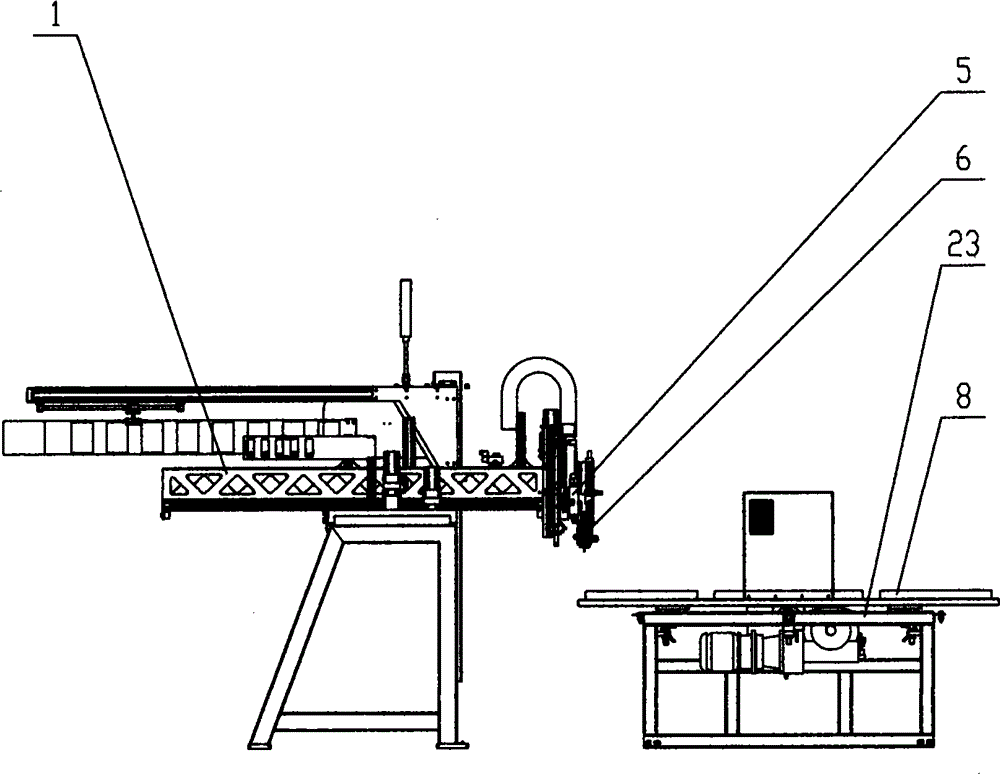

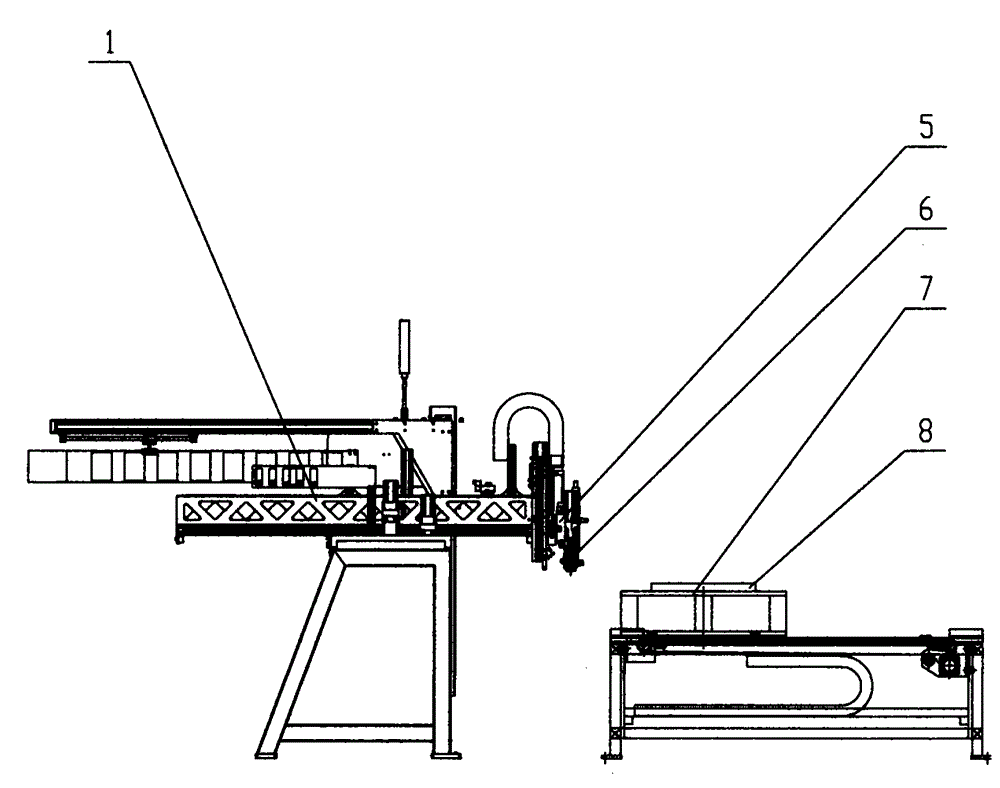

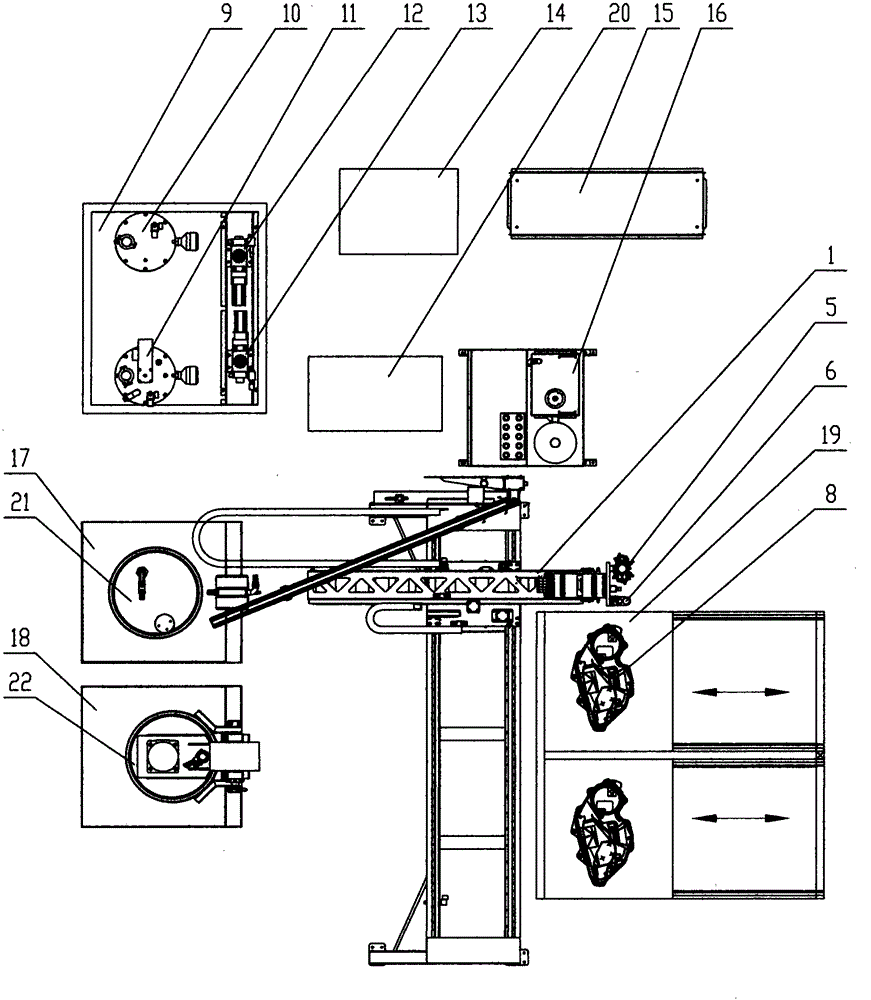

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

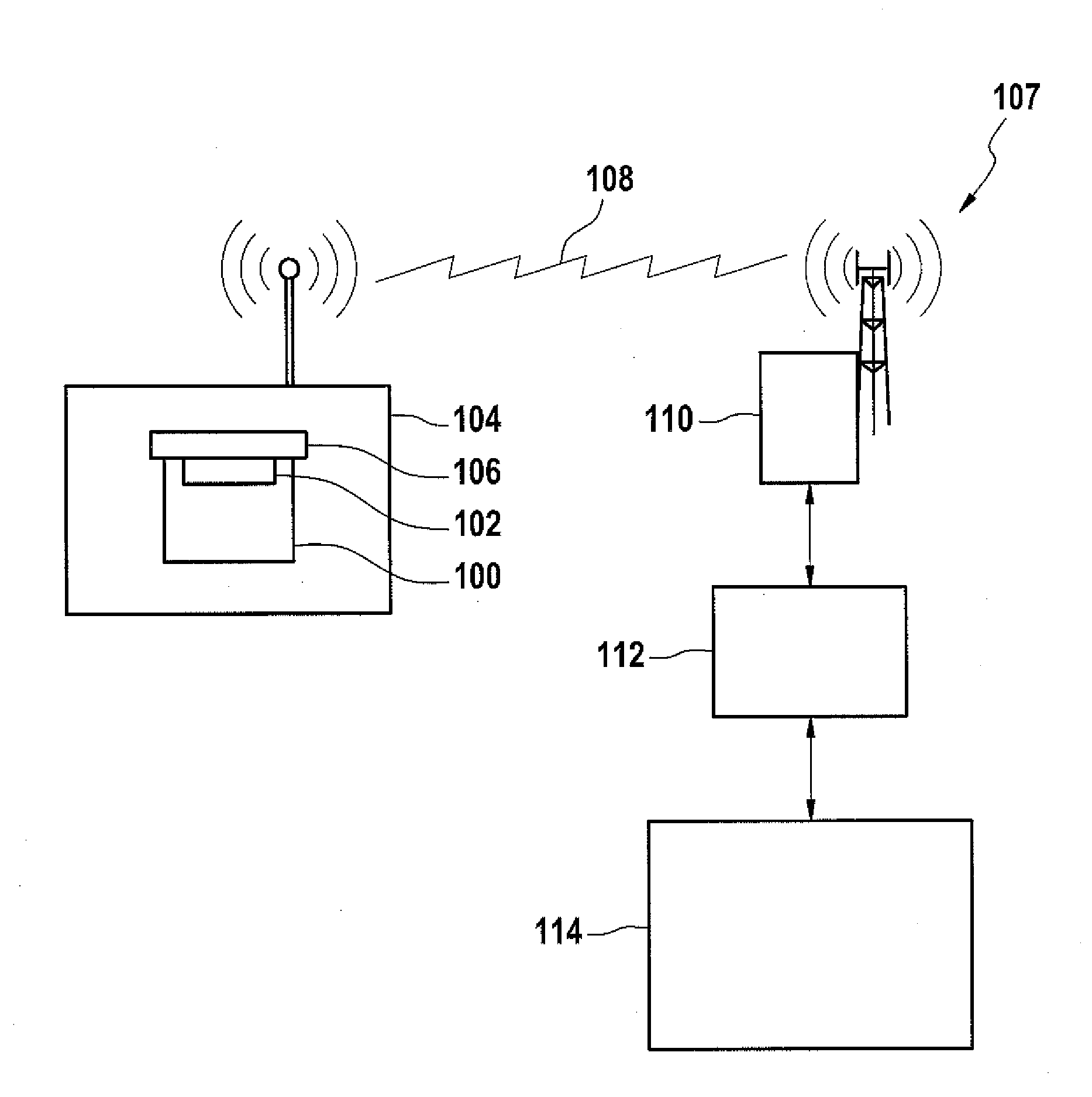

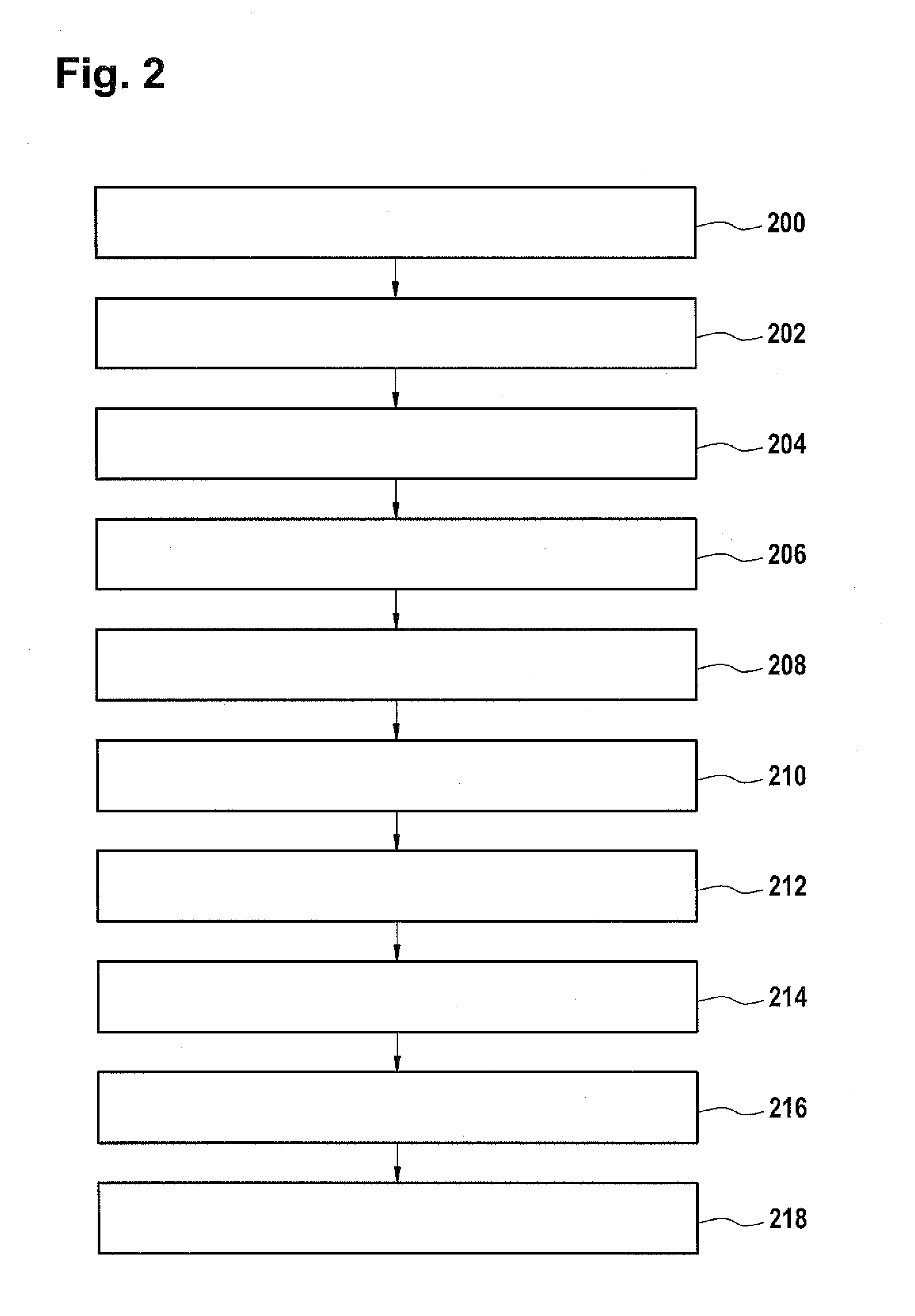

Telecommunications chip card

ActiveUS20150303964A1Improve security levelReduce chanceService provisioningNetwork topologiesTelecommunications networkTerminal equipment

The invention provides for a telecommunications chip card for logging into a mobile a digital cellular mobile telecommunications network (107). The telecommunications chip card comprises a chip card reader interface for communicating with a mobile telephone device, a chip card processor means, and a secure memory means (302) for storing programs for execution by the chip card processor means. The secure memory means contains a program (304). The program causes the chip card processor means to: perform (200) a first cryptographic mutual authentication between the telecommunications chip card and a terminal device (502), receive (214) a configuration message (400, 402, 404, 406, 408, 410, 524) via the chip card reader interface, store the (216) configuration message in the secure memory means, and delete (218) the program from the secure memory means.

Owner:MORPHO CARDS

Four-axis robot gumming equipment and technology

ActiveCN104971863ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusEngineeringCantilever

The invention relates to the technical field of gumming, in particular to four-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The four-axis robot gumming equipment is characterized by comprising a four-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The four-axis robot is of a gantry type or cantilever type structure. The two-component gumming head and aplasma processing head are fixed on the four-axis robot and can achieve X-axis, Y-axis and Z-axis linkage. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench and is fixed. The two-component gumming head and the plasma processing head are linked along the X-axis, Y-axis and Z-axis to achieve gumming. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

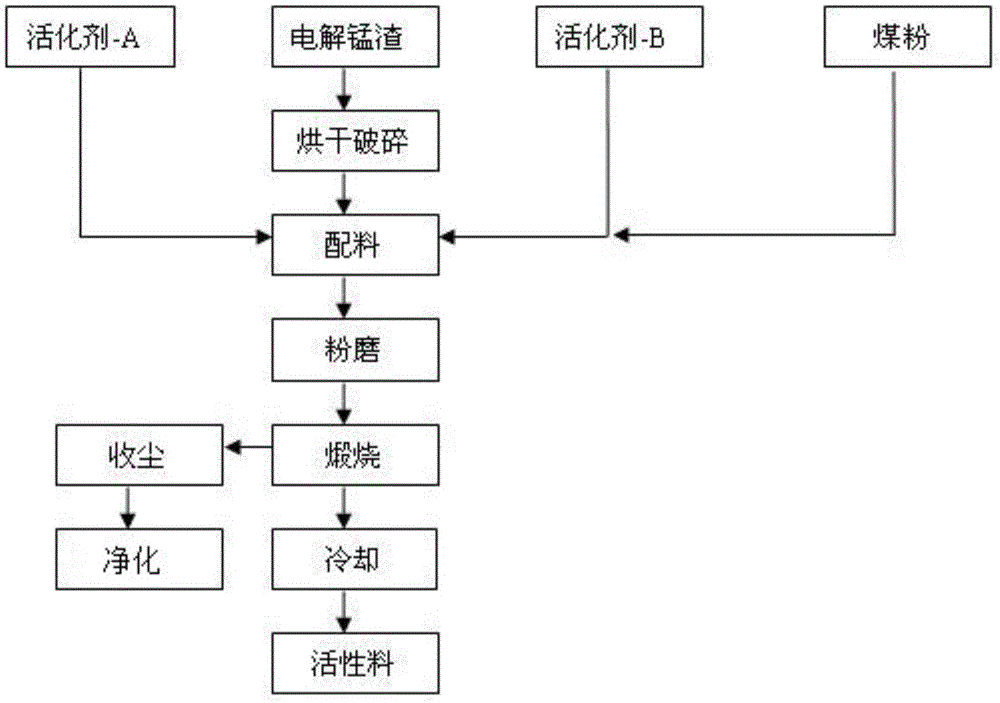

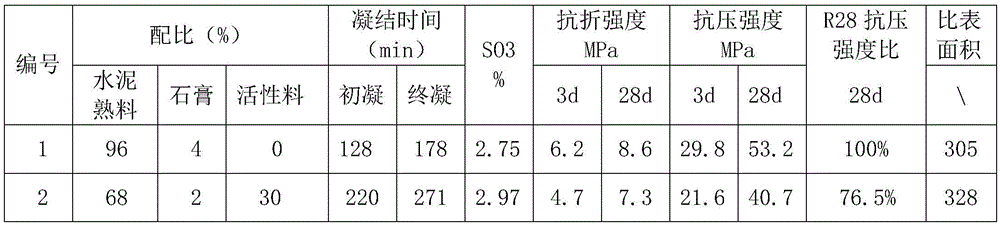

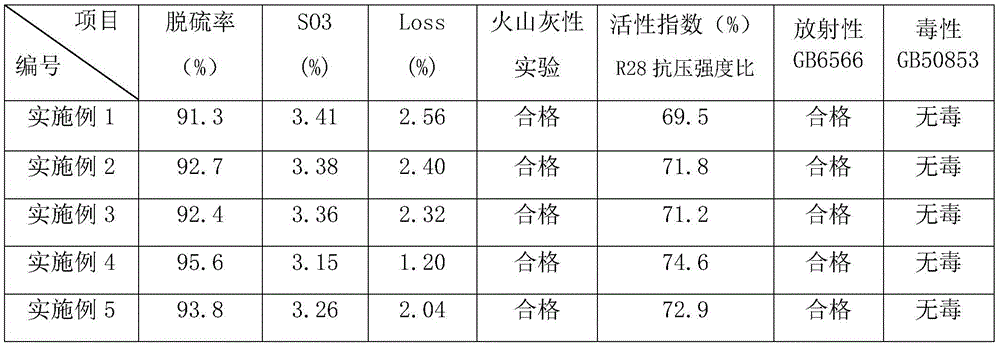

Method using electrolytic manganese slag to manufacture active mixed material

InactiveCN105645793ARemove threatIncrease production capacitySolid waste managementCement productionElectrolysisChemical reaction

The invention discloses a method using electrolytic manganese slag to manufacture an active mixed material. According to the preparation method, an activator and a reducing agent are added into electrolytic manganese slag according to a certain ratio so as to carry out physical and chemical reactions at a high temperature; the reaction products are calcined, and finally the calcined clinker is cooled to obtain the active mixed material. The active mixed material has the properties of volcanic ash, and can be used as the active mixing material in cement industry and composite blending material in commercial concrete industry. A large amount of acid leached slag discharged by electrolytic manganese plants can be used to produce the active mixed material, the environmental pollution generated by harmful components in electrolytic manganese slag is radically eliminated, the clean production of electrolytic manganese can be realized, the pollution is comprehensively controlled, and high economic benefit and environment protection benefit are generated.

Owner:石朝军

Three-axis robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to three-axis robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The three-axis robot gluing equipment is characterized in that the equipment comprises a three-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot and can be linked in the X axis, the Y axis and the Z axis. Workpieces are fixedly placed on the two-station automatic gluing workbench or the multi-station automatic rotary gluing workbench, and therefore gluing is achieved. The glue supply device comprises a glue A barrel, a glue B barrel, a glue A metering pump, a glue B metering pump, glue pipes, glue supply pipelines, a glue A bucket and a glue B bucket. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

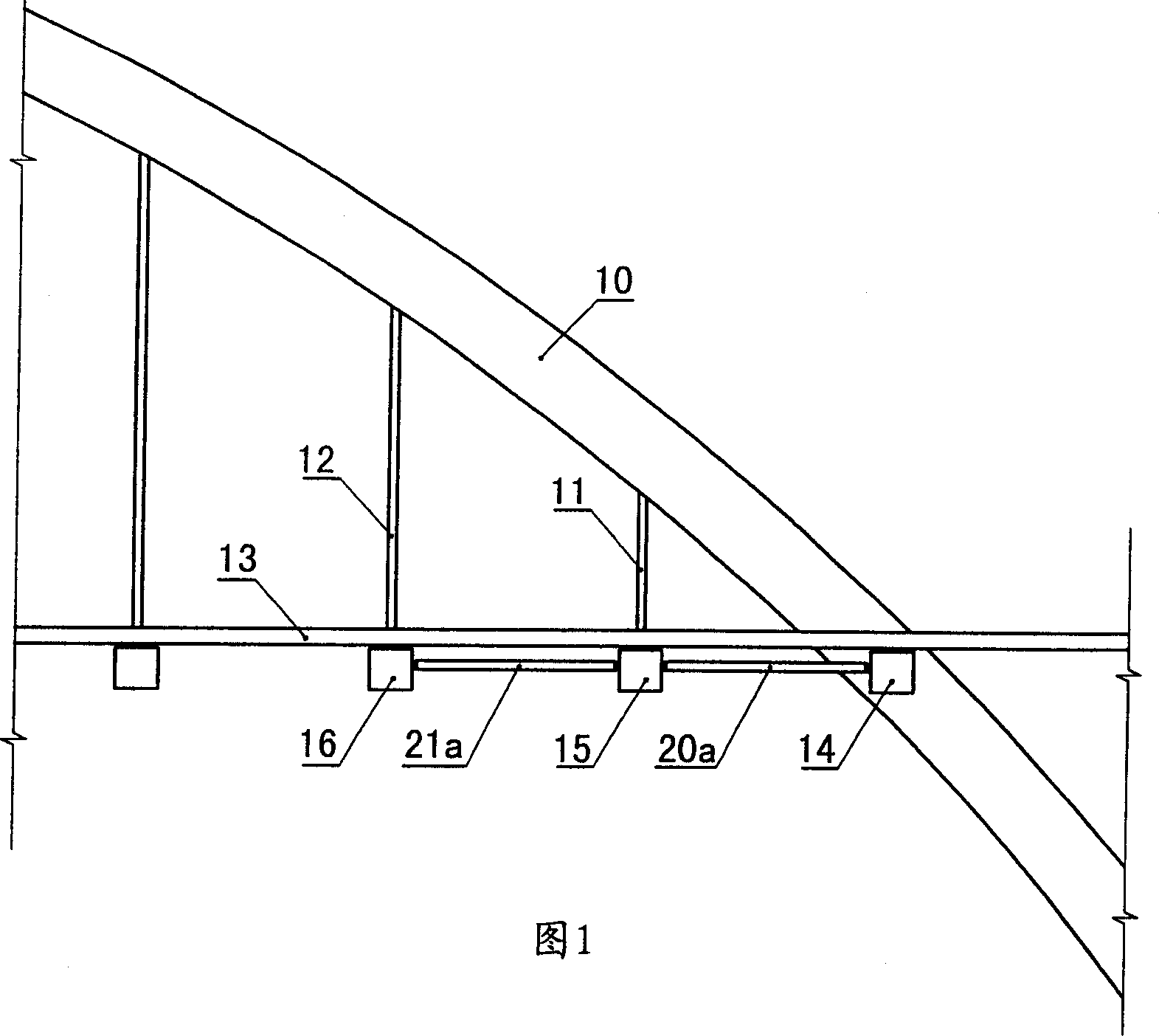

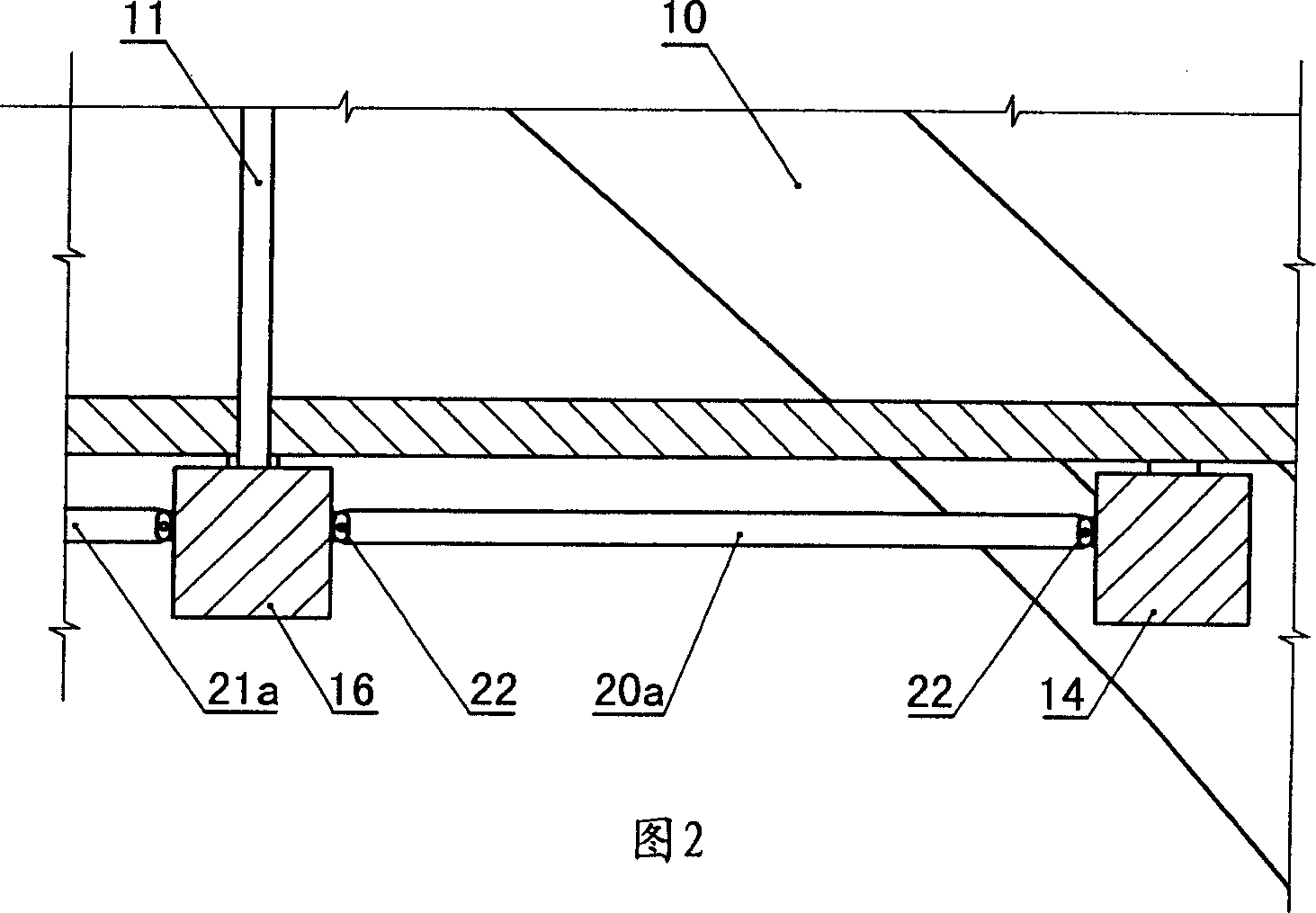

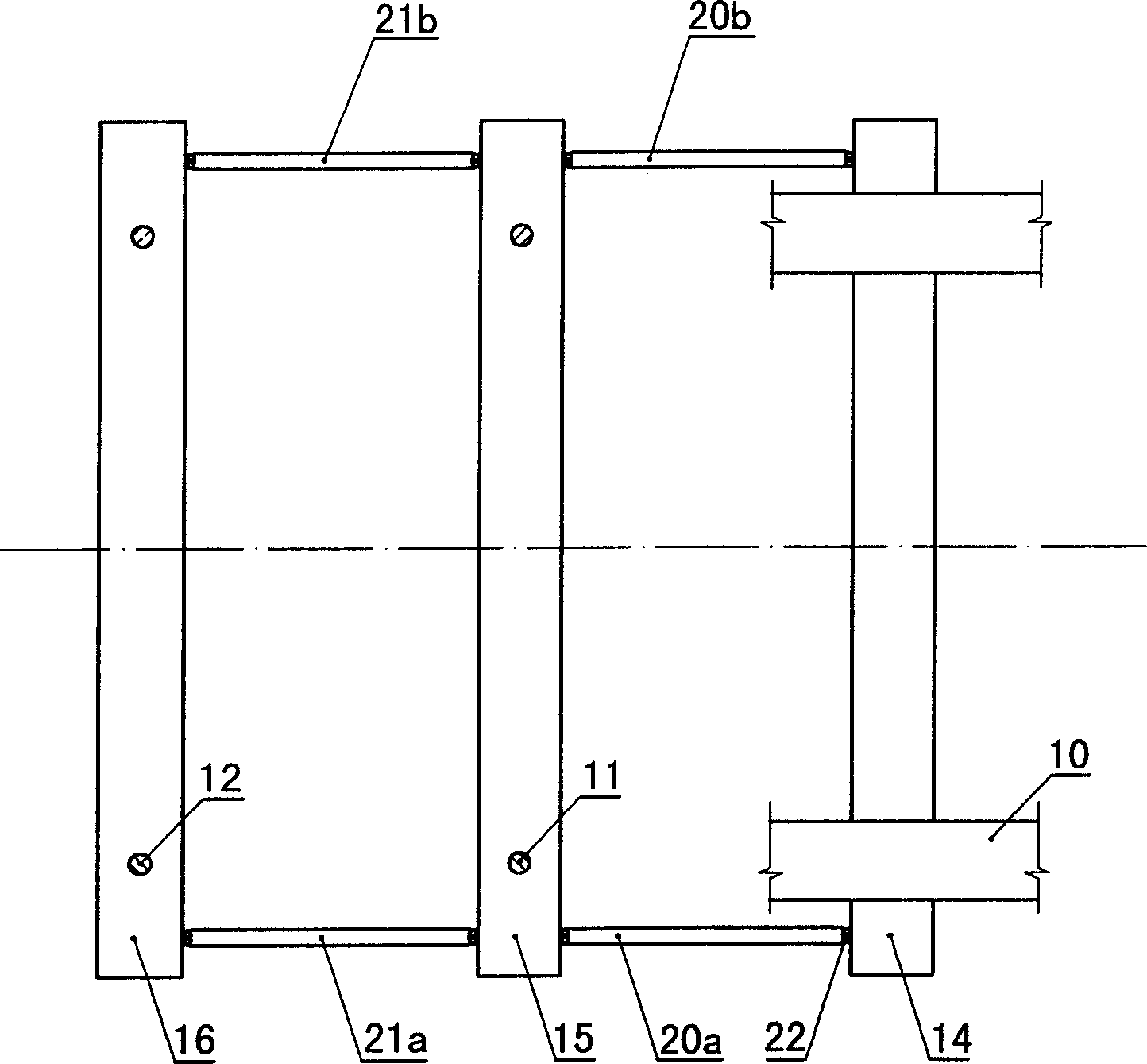

Longitudinal limiting device for half-through and through type arch bridge short suspension arm

InactiveCN1865596ALimit longitudinal displacementRemove threatBridge structural detailsArch-type bridgeArch bridgeCorrosion

The invention relates to a short hanger rod longitudinal limit device of middle or lower truss arch bridge, which can effectively limit the longitudinal displacement of short hanger rod, eliminate fatigue break-down and stress corrosion, to confirm the safety and prolong the service life of arch bridge. Wherein, it comprises at least two connecting rods between the cross beam (14) and the nearby short hanger rod beam (15), while said connecting rods are transversely distantly arranged along the bridge beam (13); two ends of each connecting rod are hinged with the cross beam (14) and the short hanger rod beam (15).

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

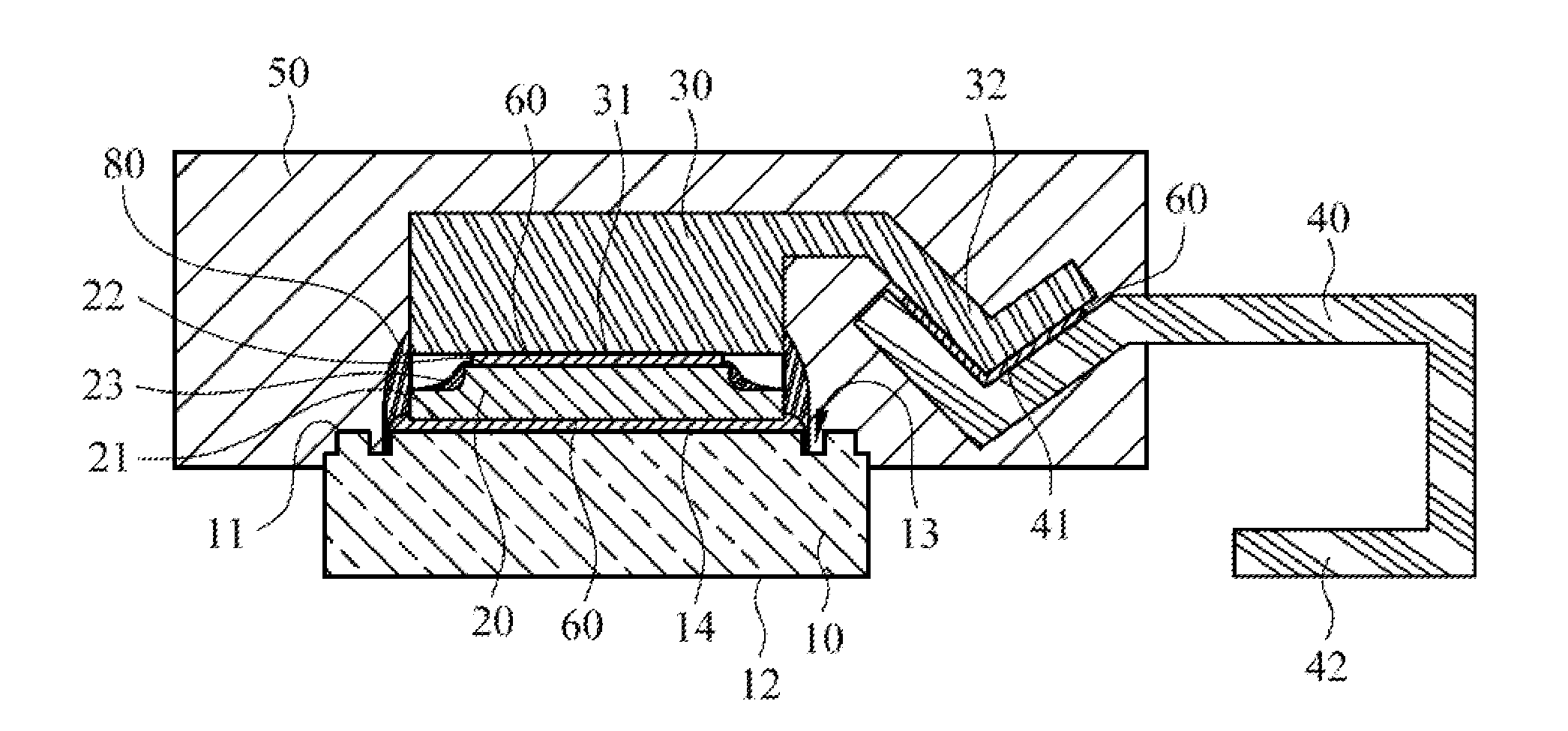

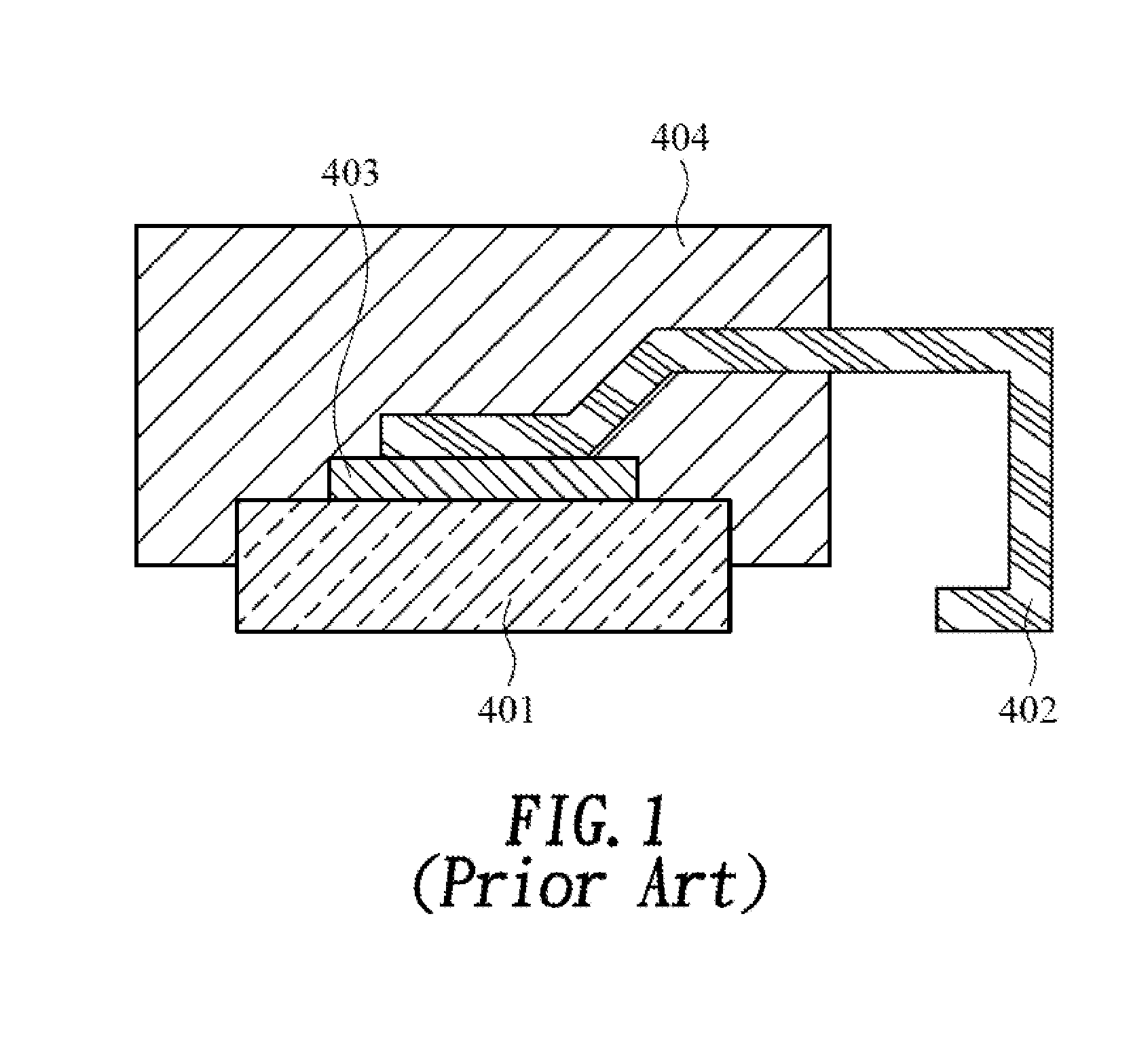

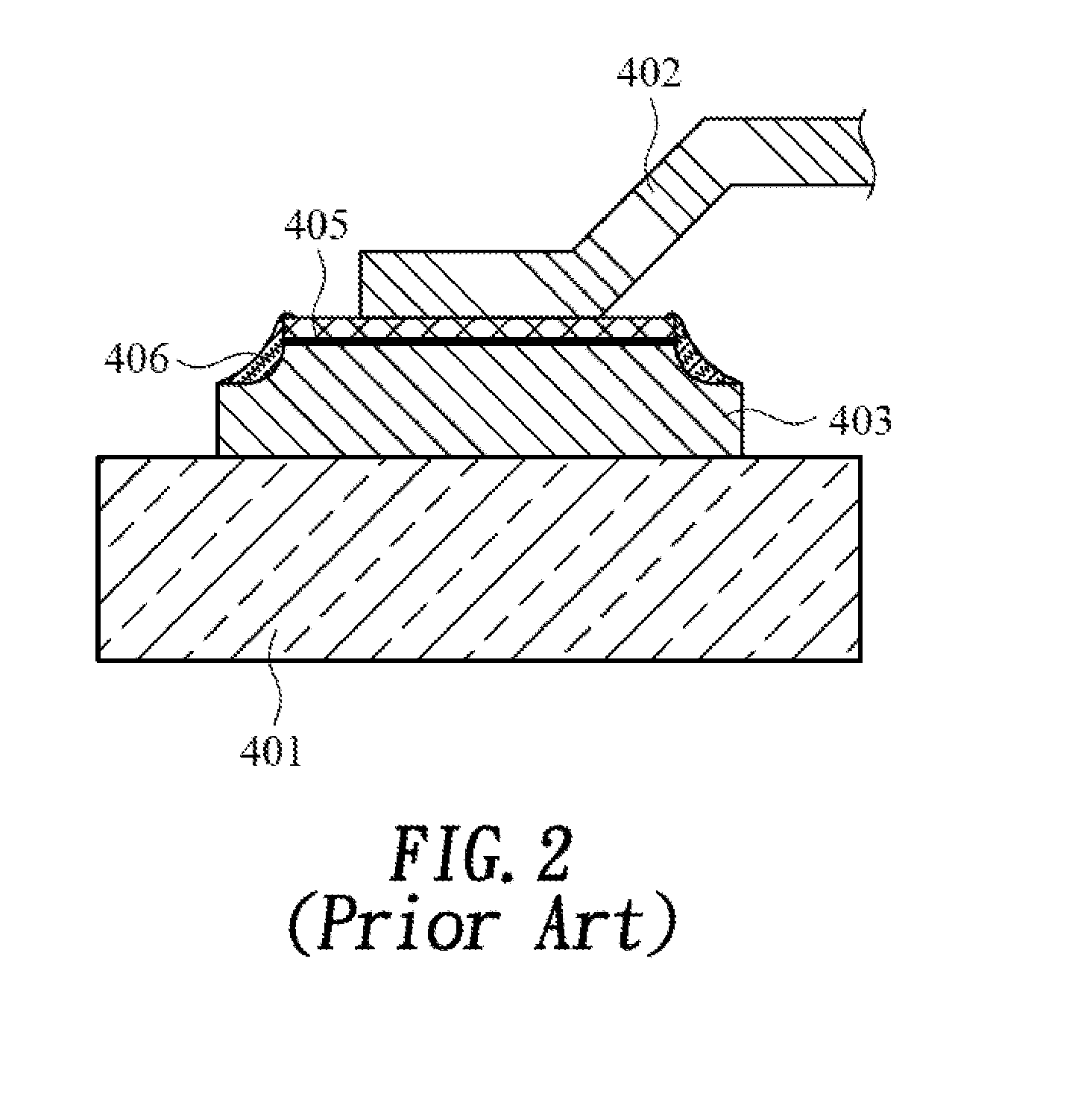

High reliability semiconductor package structure

ActiveUS20150243587A1Effective absorptionEffectively dissipateSemiconductor/solid-state device detailsSolid-state devicesElectricitySemiconductor package

The present invention discloses a high reliability semiconductor package structure, which includes a lower heat sink, a die, an upper heat sink, a lead frame and a package body. The lead frame and the upper heat sink contain separately a first bending unit and a second bending unit that are electrically connected. The upper and lower heat sinks are attached to two opposite surfaces of the die and sink the high power transient heat generated at the die. The lower heat sink also has an indentation that circles the die and contains extra solder that might otherwise contaminate the die. Package body contains and protects the die, the upper and lower heat sinks and the lead frame. With the implementation of the invention, the reliability of the semiconductor package structure is promoted and the EMC durability together with the operable power is enhanced.

Owner:ANOVA TECH

Method for preparing precipitation-method white carbon black by utilizing organosilicon dust-containing tail gas hydrolysate

ActiveCN103803558ARealize sustainable, healthy and balanced developmentSolve problems that cannot meet environmental protection requirements wellSilicaSolid waste disposalAlkaneHydrolysate

The invention relates to a method for preparing precipitation-method white carbon black by utilizing organosilicon dust-containing tail gas hydrolysate. The method comprises the following steps: a, mixing the organosilicon dust-containing tail gas hydrolysate with an dispersion aids at the mass ratio of 1:(0.1-0.5), wherein the dispersion aids are selected from low-carbon alkane, micromolecular alcohol or low-molecule aromatic hydrocarbon; b, adding caustic sodium solution into the mixture obtained in the step a under the stirring condition and mixing, after the reaction is finished, standing and layering, performing filtration and activated carbon decoloration to clear liquid in the middle layer, to obtain colorless clarified sodium silicate solution; c, adding surfactant into the sodium silicate solution, increasing the system temperature to be more than 60 DEG C, adding acid liquor while stirring until the pH value of a reaction system is equal to 7, stopping addition, standing and aging, filtering, performing azeotropy dewatering, and drying to obtain the product. The current organosilicone monomer plant always piles up or fills the organosilicon dust-containing tail gas hydrolysate, and the method can change wastes into valuables, and the organosilicon dust-containing tail gas hydrolysate can be converted into the white black carbon product.

Owner:浙江中天东方氟硅材料股份有限公司

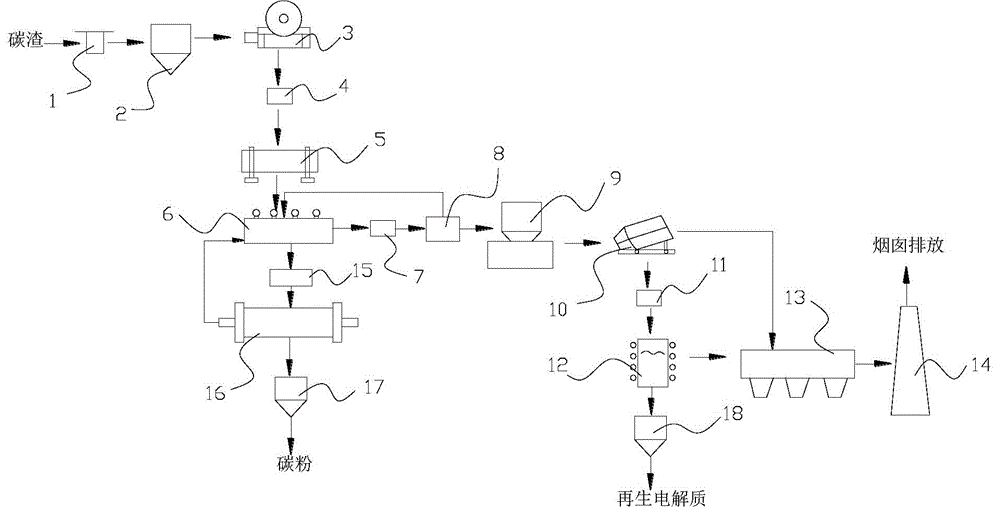

Device and method for producing regenerative electrolyte from aluminum-electrolysis carbon residues

InactiveCN103949460ANo dischargeSimple processSolid waste disposalIntermediate frequencyProcessing cost

The invention relates to a device and a method for producing regenerative electrolyte from aluminum-electrolysis carbon residues. The device comprises a sorting platform, a carbon residue stock bin, a crushing device, a first magnetic separation device, a ball milling device, a flotation tank, a second magnetic separation device, a sedimentation basin, a feeding device, a drying device, a third magnetic separation device, an intermediate frequency furnace, a dust-removal device and a chimney, which are sequentially connected with one another, wherein a carbon powder tank, a filter-press device and a carbon powder bin are further sequentially connected to the flotation tank, and a regenerative electrolyte bin is connected to the intermediate frequency furnace. The method comprises the following steps: (a) raw material sorting, (b) carbon residue crushing, (c) ball-milling, (d) flotation, (e) drying, (f) regenerative electrolyte refining, and (g) tail gas treatment. The method has the beneficial effects that the carbon residues are sorted to be a utilizable value resource, and basically no industrial waste residue is generated; the process is simple, the processing cost is low, the industrialized application is easily realized, the production water supply is completely recycled in the whole process, no polluted gas is discharged, and the method is a brand new method for processing and comprehensively utilizing the carbon residues and has a high promotional value.

Owner:JIANSHUI DEFU RENEWABLE RESOURCES

Boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods

InactiveCN104790953APrevent spontaneous combustionLow recovery rateUnderground miningSurface miningCoal spontaneous combustionStructure of the Earth

The invention discloses a boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods, according to three typical overlying rock structures, three coal pillar arrangement methods are proposed, and the three coal pillar arrangement methods are respectively a block section wide coal pillar arrangement method, a block section narrow coal pillar arrangement method and a block section non coal pillar arrangement method. Compared with the traditional shortwall continuously-mining tunnel technique tunnel arrangement and coal pillar preserving methods, by the boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods, the coal pillar size is reduced, the recovery rate of resources can be improved, the roof essential security can be realized, roof safety can be effectively controlled, tunnel excavation and maintenance amount can be reduced, and the risk of coal spontaneous combustion can be reduced.

Owner:SHANDONG UNIV OF SCI & TECH

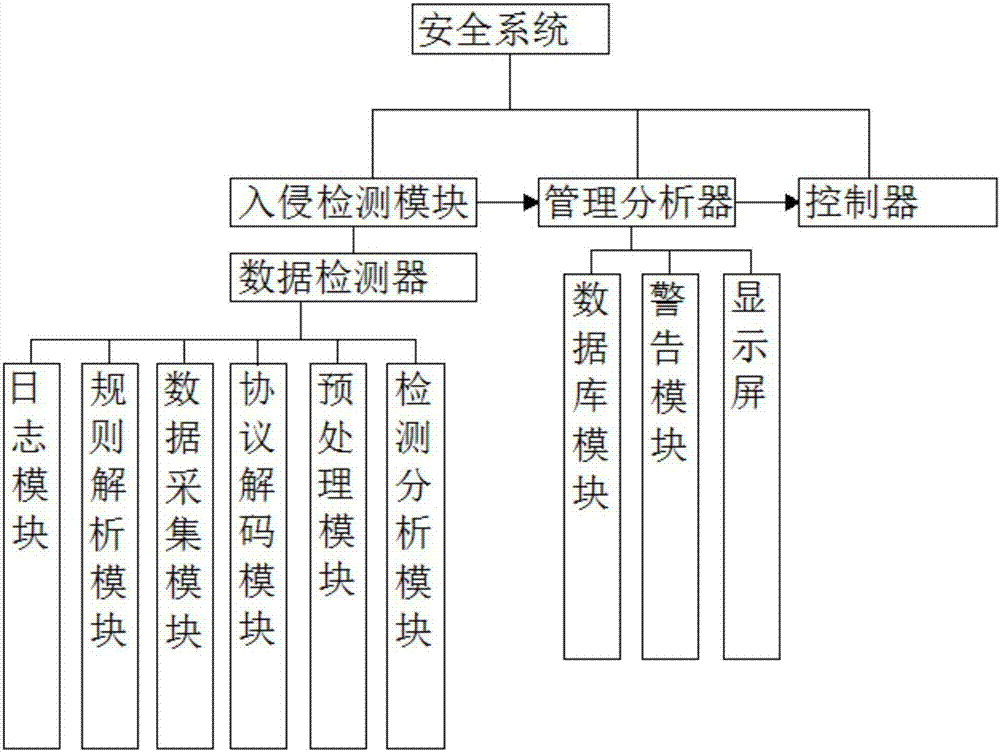

System and method for providing computer network security

InactiveCN107517214AImprove network securityRemove threatTransmissionAnalysis centerNetwork security policy

The invention discloses a system for providing computer network security. The system comprises multiple intrusion detection modules, multiple management analyzers and a controller. The intrusion detection modules are used for collecting data transmitted on the target network segment, according to an intrusion rule preset by an administrator through a region management analysis center, executing the real-time tracking detection to an intrusion behavior from the inside and outside network. The management analyzers are used for managing a data detector, and executing the analysis of warning information. The controller is used for, through the guidance of a corresponding instruction of a security management center, configuring a network device, eliminating a threat, intercepting an intruder, sending a warning to an inside network user, and repairing bugs. The system is capable of improving the network security of the computer, convenient for detecting the intrusion and reminding the administrator.

Owner:合肥丹朋科技有限公司

Civil aviation security information service system based on big data analysis

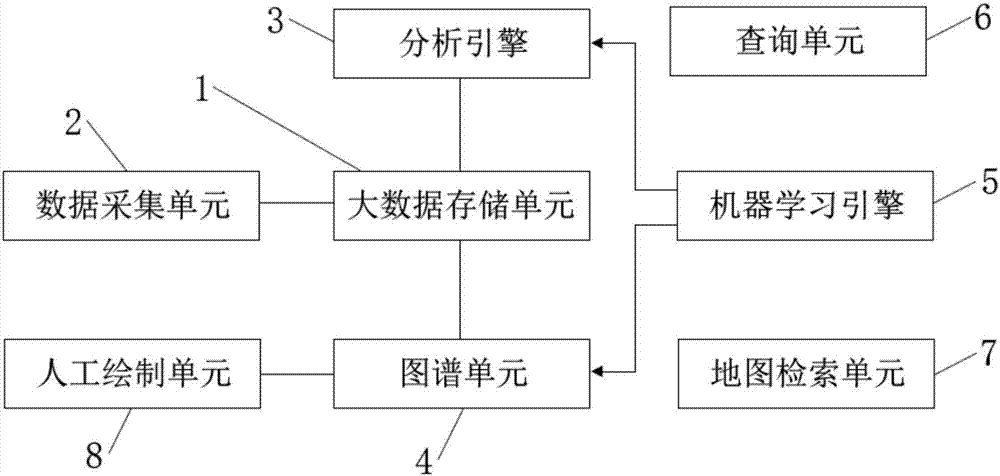

PendingCN107292517ATimely responseAccurate responseResourcesSpecial data processing applicationsFuzzy queryCivil aviation

The invention discloses a civil aviation security information service system based on big data analysis, which comprises a big data storage unit, a data acquisition unit, an analysis engine, a graphic unit, a machine learning engine and a query unit, wherein the data acquisition unit is used for collecting original service data and storing the original service data in the big data storage unit; the analysis engine makes an analysis based on the original service data to obtain early warning information related to the key concerned personnel; the graphic unit adopts the graphic database and force mapping visualization technology and restores the person relationship network of the key concerned personnel; the machine learning engine is used to provide algorithm models required in the working processes of the analysis engine and the graphic unit; and the query unit is used to provide fuzzy query and characteristic query based on the concerned factors related to the public security and civil aviation.

Owner:科技谷(厦门)信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com