Patents

Literature

1333 results about "Loess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loess (US: /lɛs, ˈloʊ.əs, lʌs/, UK: /lɜːs/; from German Löss [lœs]) is a clastic, predominantly silt-sized sediment that is formed by the accumulation of wind-blown dust. Ten percent of the Earth's land area is covered by loess or similar deposits.

Lightweight ecological nutrient soil for roof greening and method for preparing lightweight ecological nutrient soil

InactiveCN102875227AMeet the requirements of green environmental protectionUltra-thin soil layerFertilizer mixturesSlagMushroom

The invention relates to lightweight ecological nutrient soil for roof greening and a method for preparing the lightweight ecological nutrient soil. The nutrient soil is made of dry basis raw materials including 10-20% of biogas residues, 5-15% of slag, 10-20% of loess, 25-35% of rice hulls, 15-25% of mushroom residues and 15-30% of pine needle soil, and living earthworms accounting for 0.2-1% of the total mass of the dry basis raw materials. The nutrient soil is light in load, low in volume weight, free from hardening, resistant to trampling, fine in moisture and fertility preserving performance, pollution-free, extensive in source of raw materials, low in cost, simple in production process and easy to popularize.

Owner:HENAN XIFANGE GREENING PROJECT

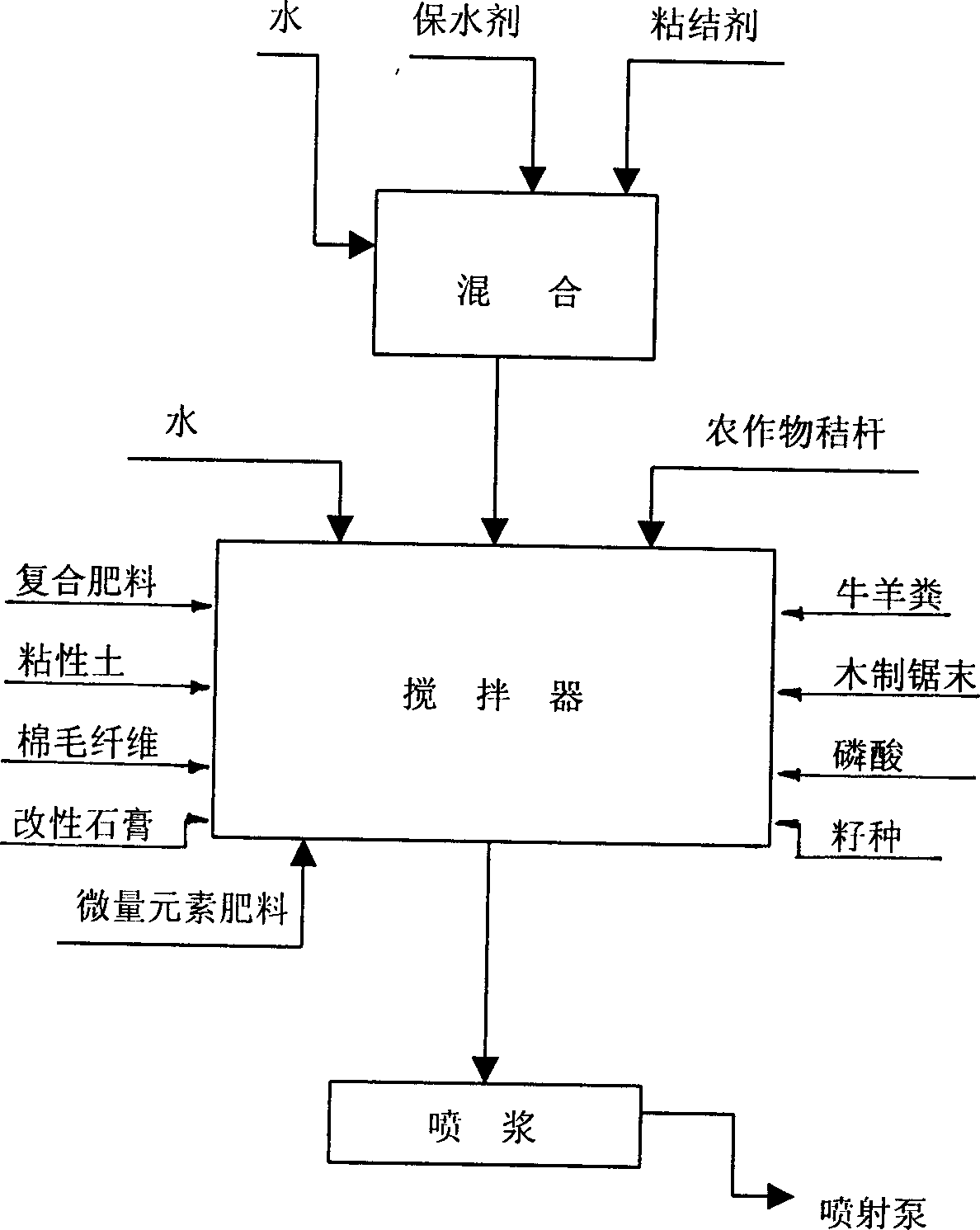

Gunite and method for fixing sand through forming covering by gunite

InactiveCN1466869AWill not polluteFast greeningCultivating equipmentsSoilless cultivationAdhesivePhosphoric acid

A method for fixating sand while growing plants by spraying slurry to form a cover layer on the surface of desert or ground includes such steps as proportionally preparing slurry from water, strew or stalk or industrial fibrous dregs, adhesive loess or laterite, water-preserving agent, adhesive, cotton or wool fibres, composite fertilizer, trace element fertilizer, modified gypsum, ox(or sheep) dung, saw dust, phosphoric acid and plant seeds, and spraying it onto surface of desert or ground. Its advantages are high effect and low cost.

Owner:格尔木昆成农业科技开发有限公司

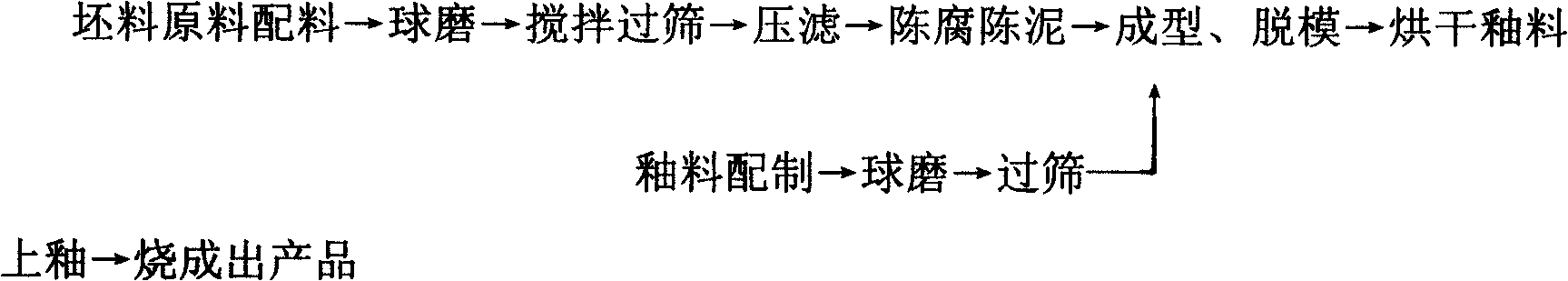

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Open pit coal mine mining process

ActiveCN103216237AConvenience to workGuaranteed continuity of fitUnderground miningSurface miningCoal waterMining engineering

The present invention provides an open pit coal mine mining process, which comprises the following operation steps: 1, adopting a bucket wheel excavator to dig a loess layer on the upper portion, placing the dug loess onto a conveying belt of a belt type conveyor, and discharging the loess to an outer dump; 2, adopting a single bucket truck to convey crushed stone in a rock layer on the middle portion to the outer dump, and adopting the single bucket truck to convey into an inner dump until a rock layer on the lower portion is exposed after a pit formed by the rock layer on the middle portion has a enough space; 3, adopting a casting-blasting method to blast the rock layer on the lower portion, adopting a bulldozer to flatten the top surface of the blasting stack to form a combination extension platform, adopting a dragline to inversely stack the blasting amount into the inner dump, directly discharging the blasting amount into the inner dump with matching with the single bucket until a coal layer is exposed; and 4, adopting the single bucket truck to convey coal in the coal layer to a crushing plant, and then conveying the crushed coal to a designated location with a belt conveyor.

Owner:CHINA SHENHUA ENERGY CO LTD +1

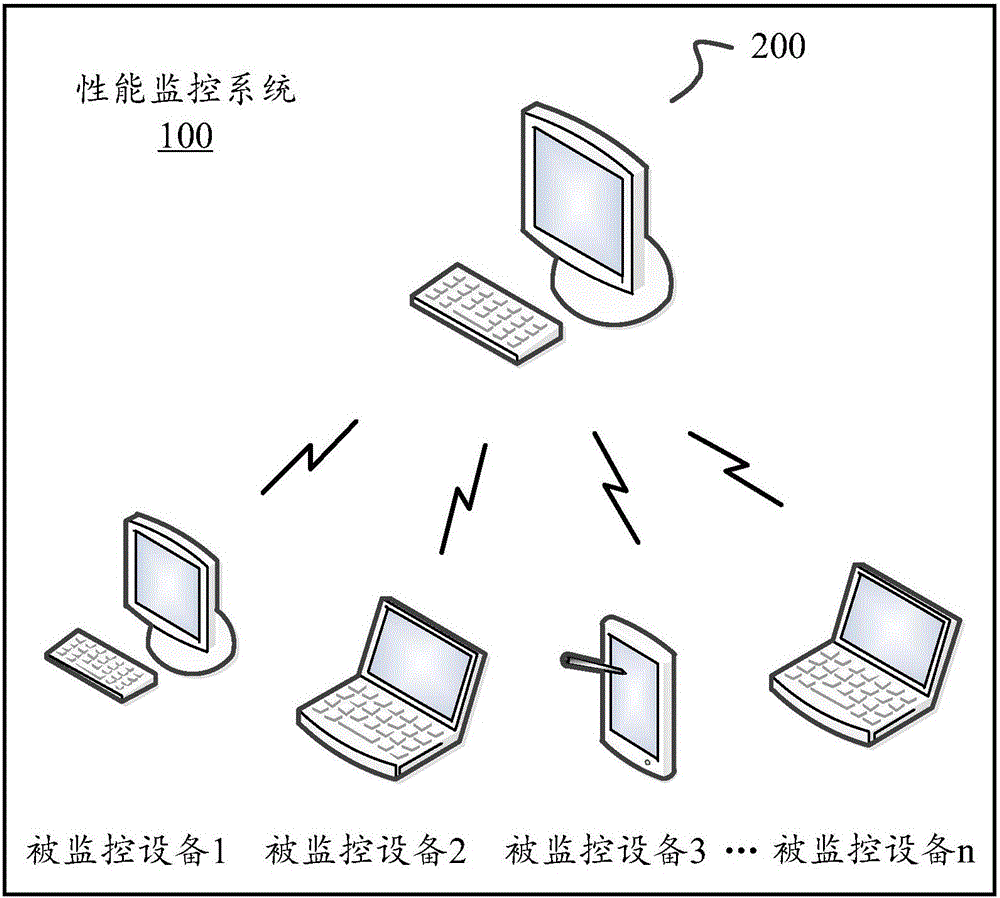

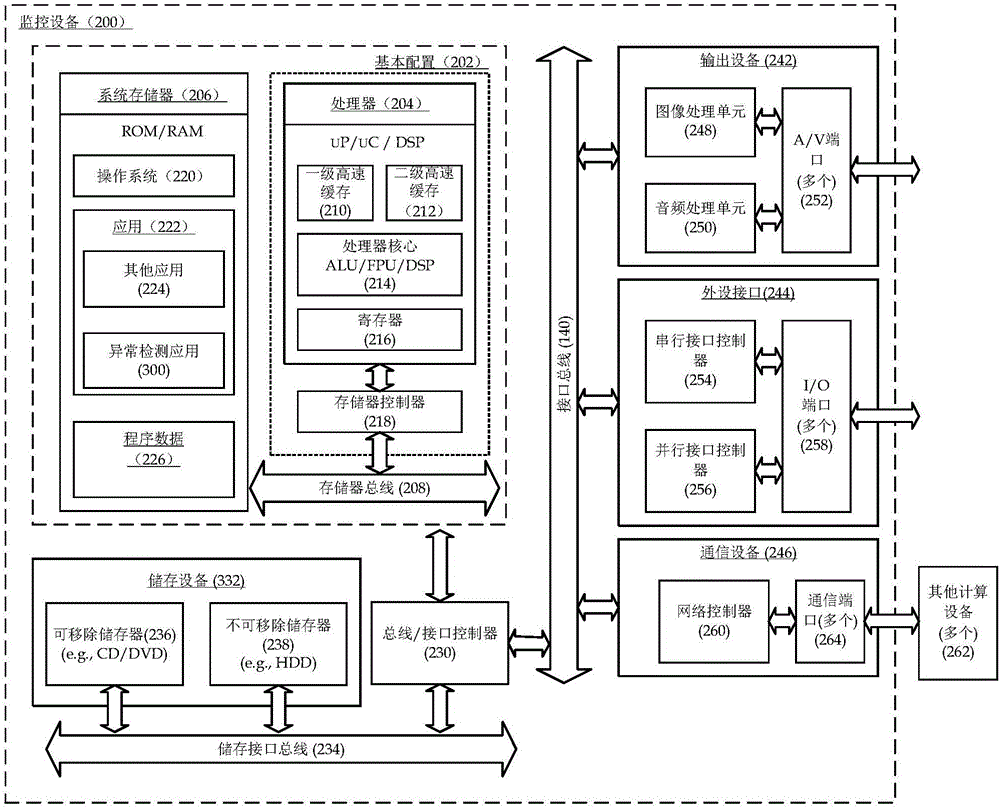

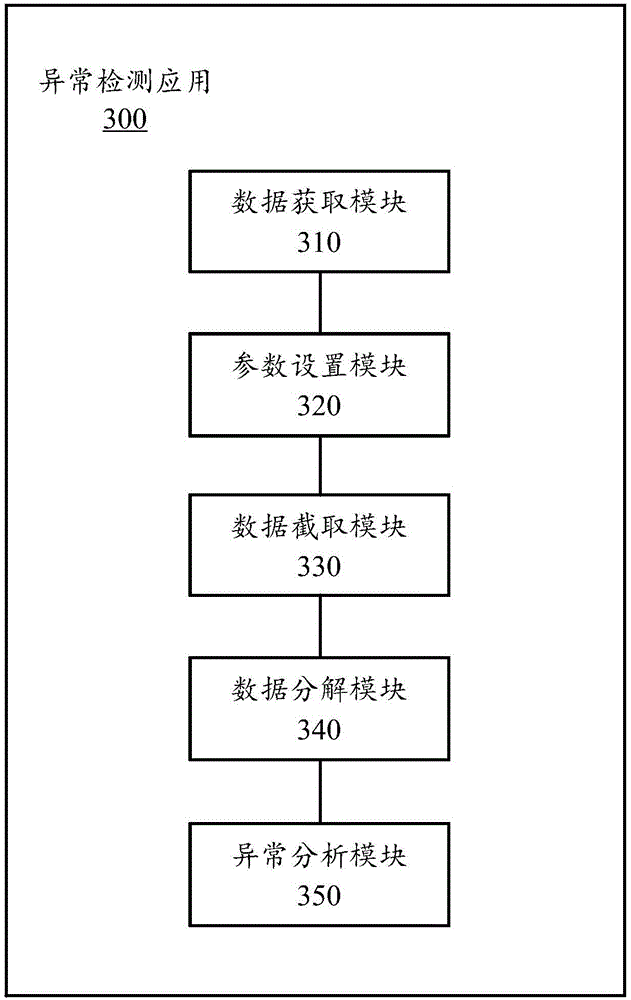

Exception detection method and application, and monitoring equipment

ActiveCN106095655AReduce time consumptionReduce source data volumeHardware monitoringArray data structureAnomaly detection

The invention discloses an exception detection method, which is executed in monitoring equipment and is suitable for carry out real-time exception detection on one or a plurality of periodic performance indexes of monitored equipment. The method comprises the following steps: obtaining the first time sequence of a certain periodic performance index of the monitored equipment, wherein the first time sequence comprises a plurality of observation values of the periodic performance index in a time period [t0, tnow]; setting each periodic data size n0; according to the each periodic data size n0 and the first time sequence, determining a second time sequence X, wherein the second time sequence comprises a plurality of observation values of the periodic performance index in a time period [tnow-[Delta]*n0+1, tnow]; carrying out STL (Seasonal and Trend decomposition using Loess) on X, and splitting X into a periodic sequence S, a tendency sequence T and a residual sequence R; according to X and R, determining an array D to be detected; and adopting an improved ESD (Extreme Studentized Deviate) algorithm to determine exceptional points in D, and the separate score of each exceptional point. The invention also discloses an exception detection application which can implement the above method, and the monitoring equipment which comprises the above application.

Owner:北京睿象科技有限公司

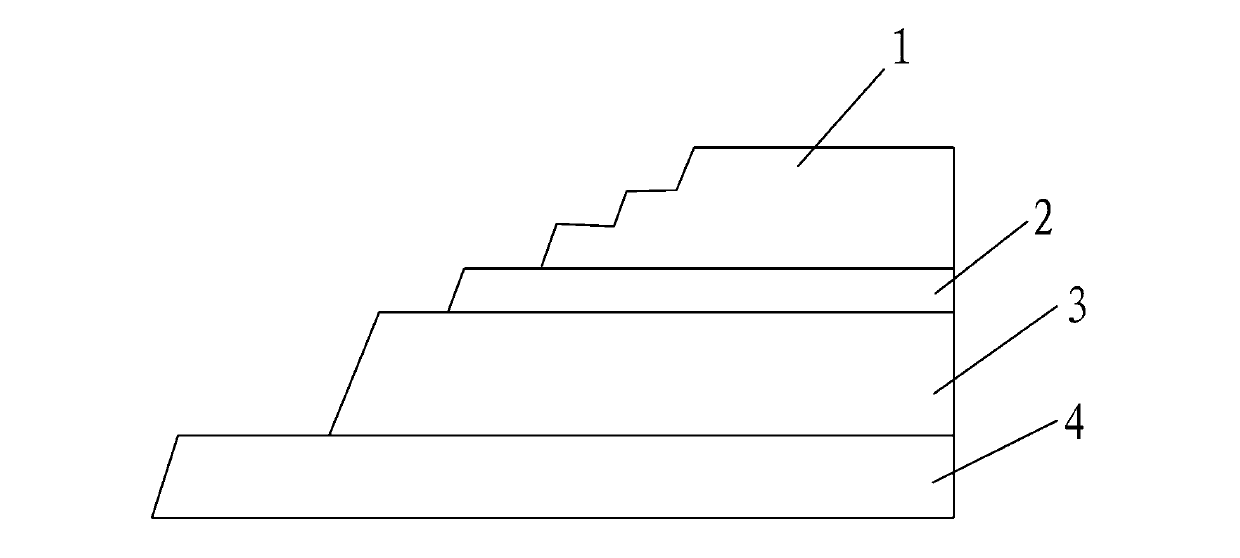

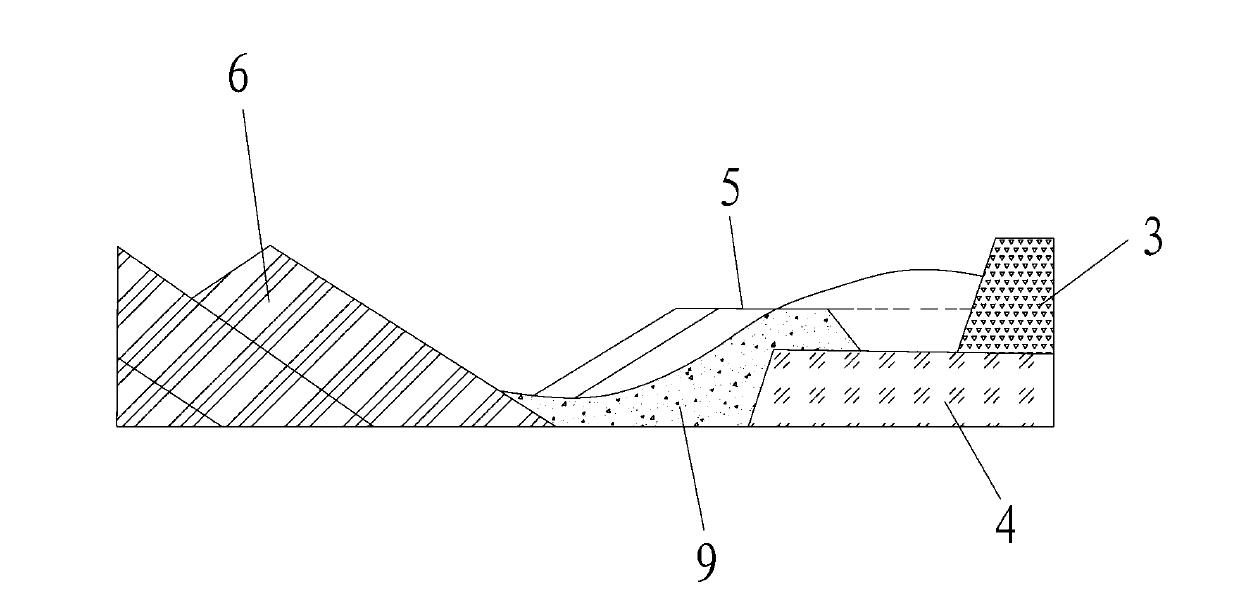

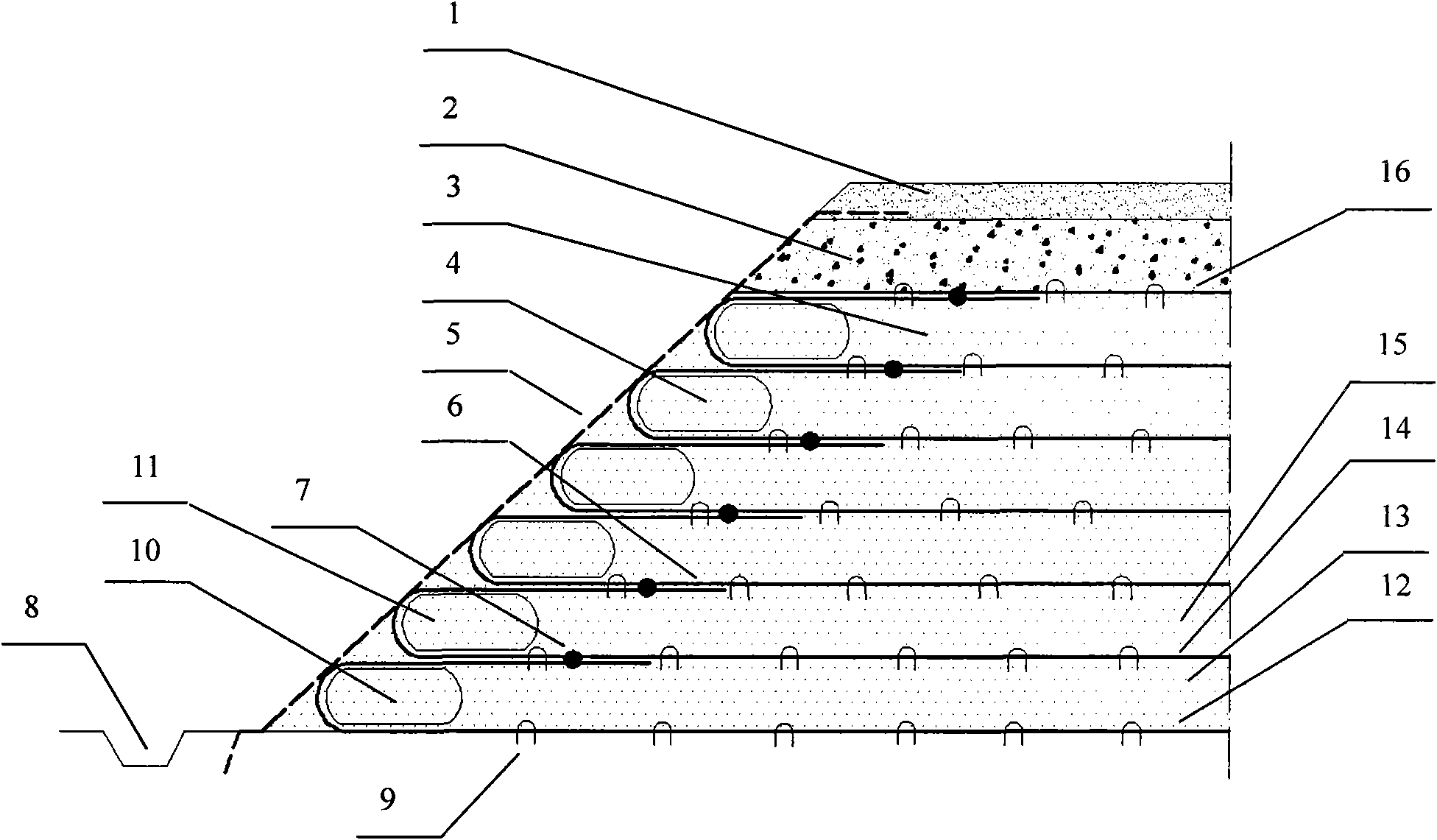

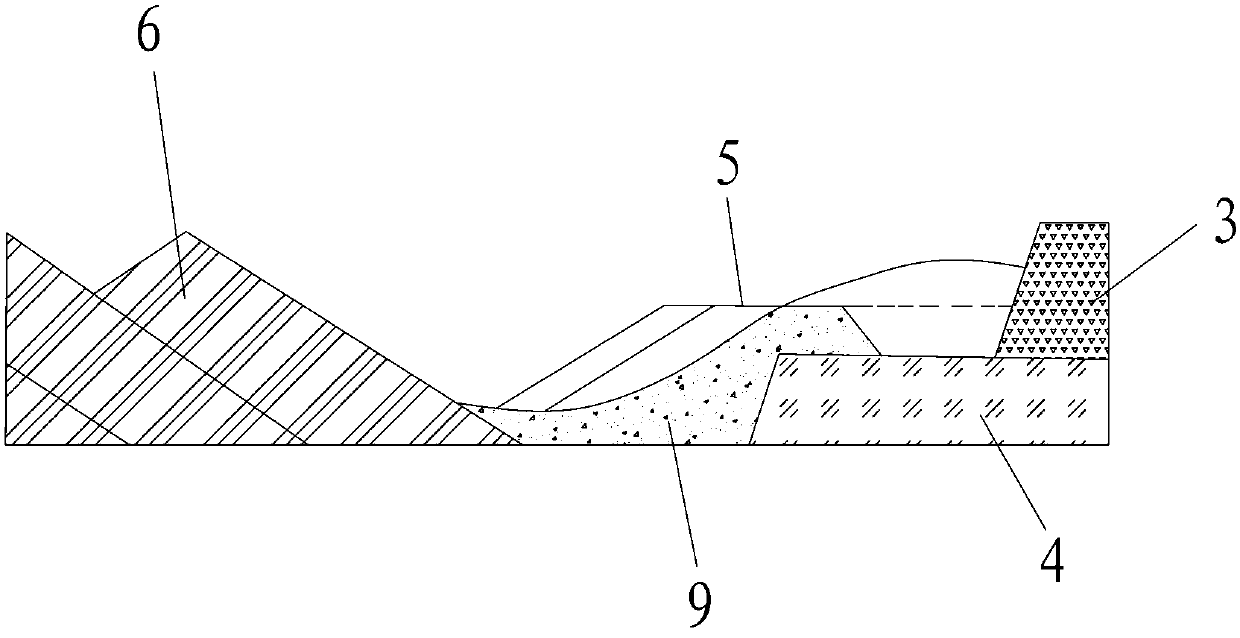

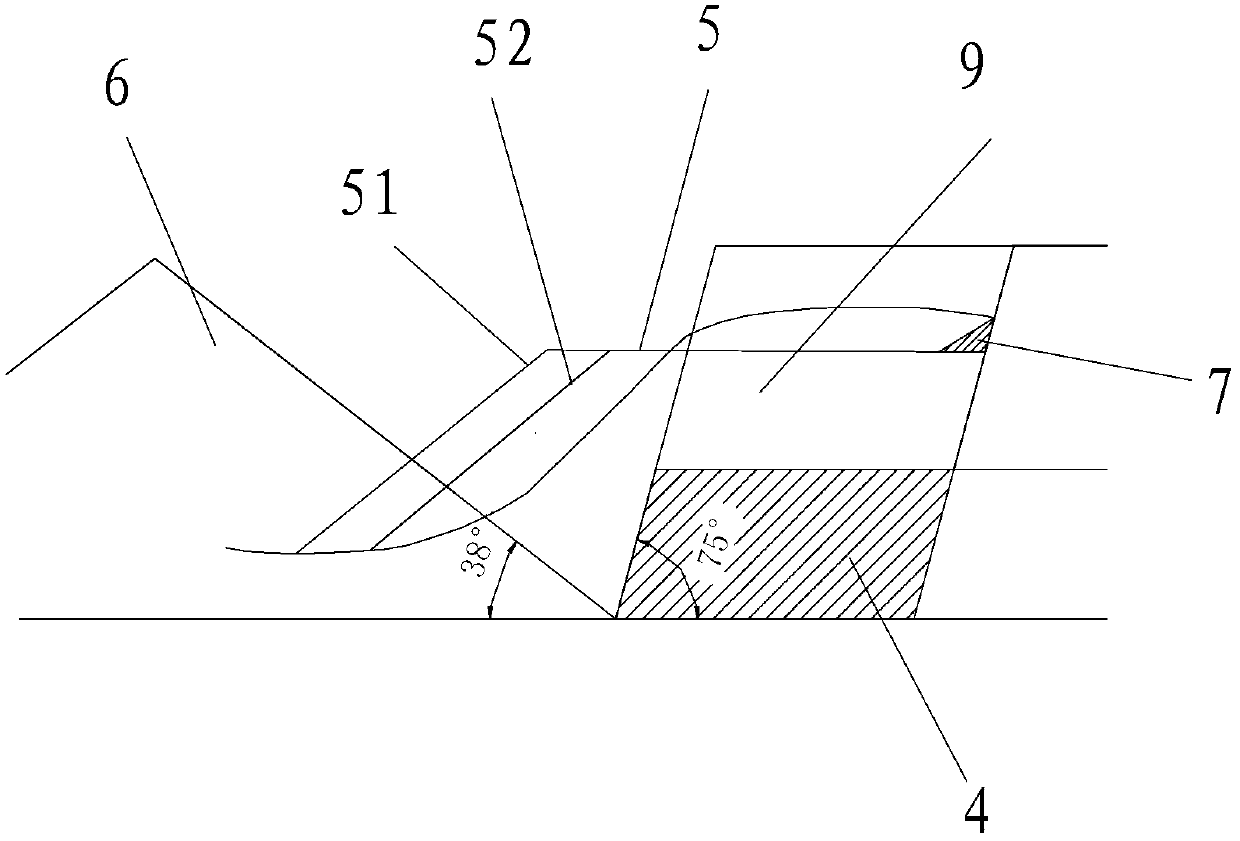

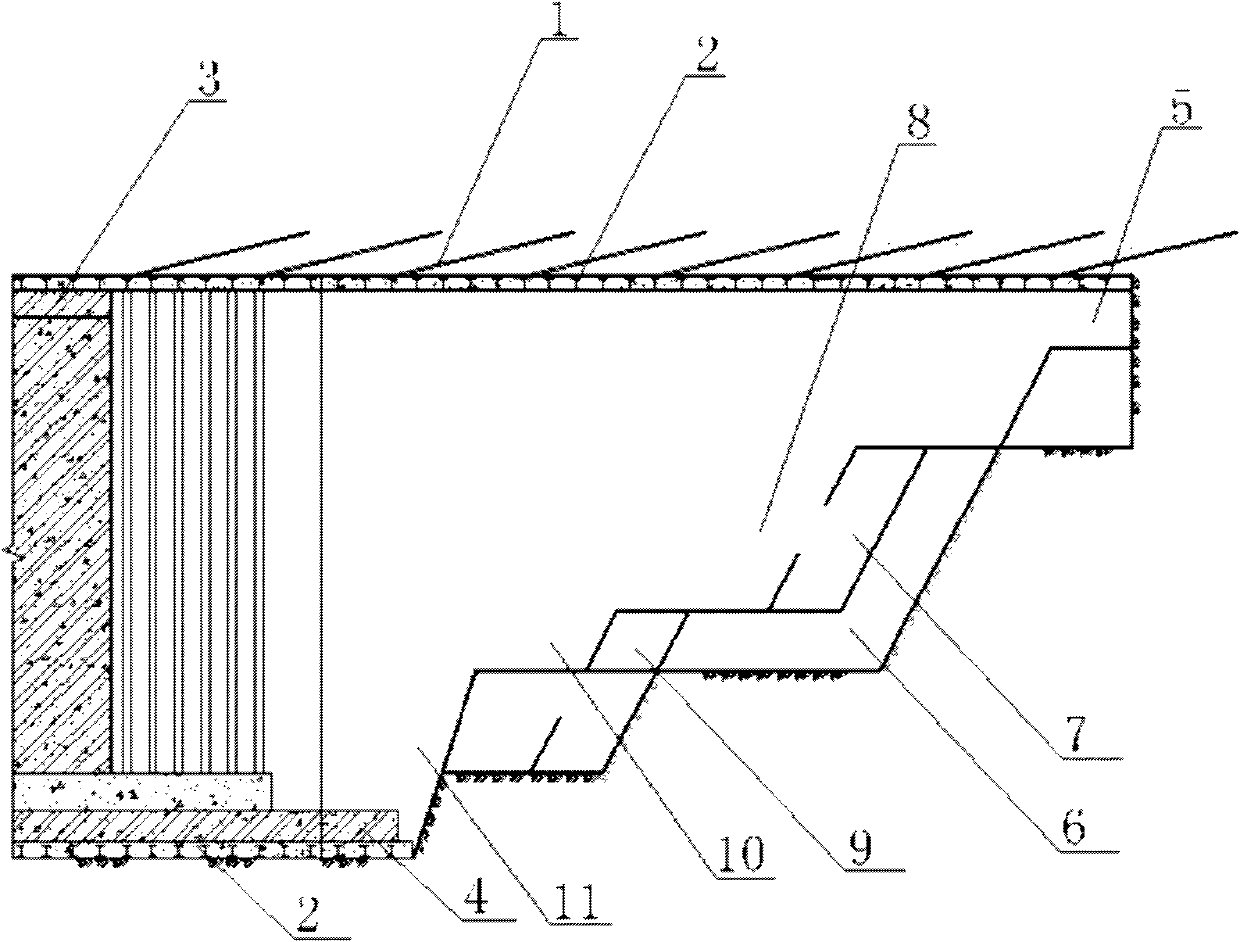

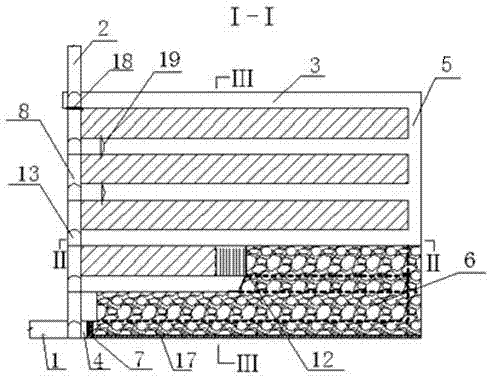

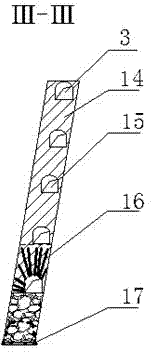

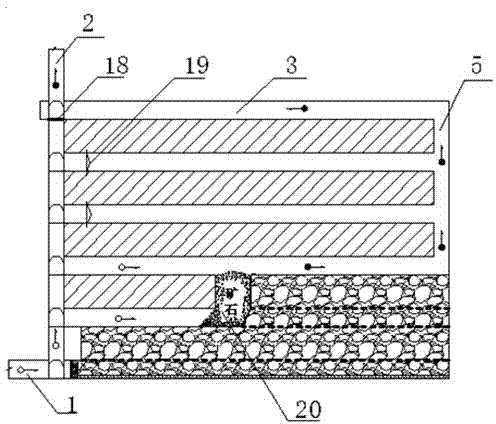

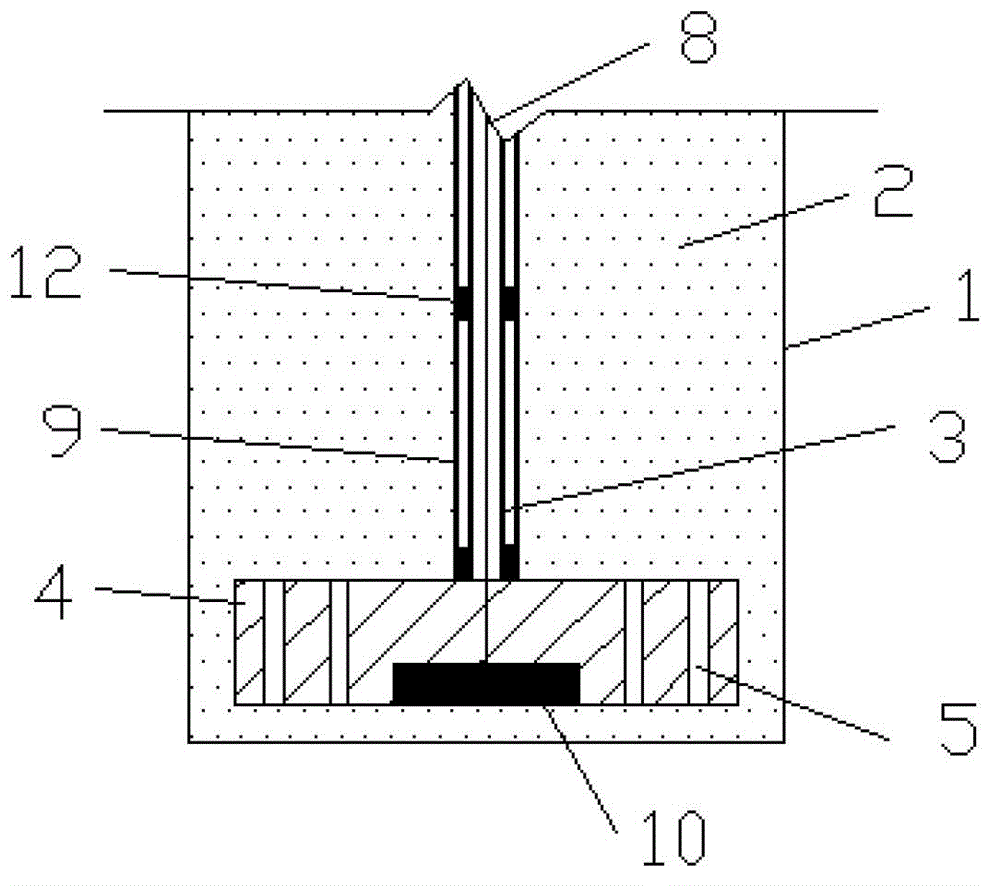

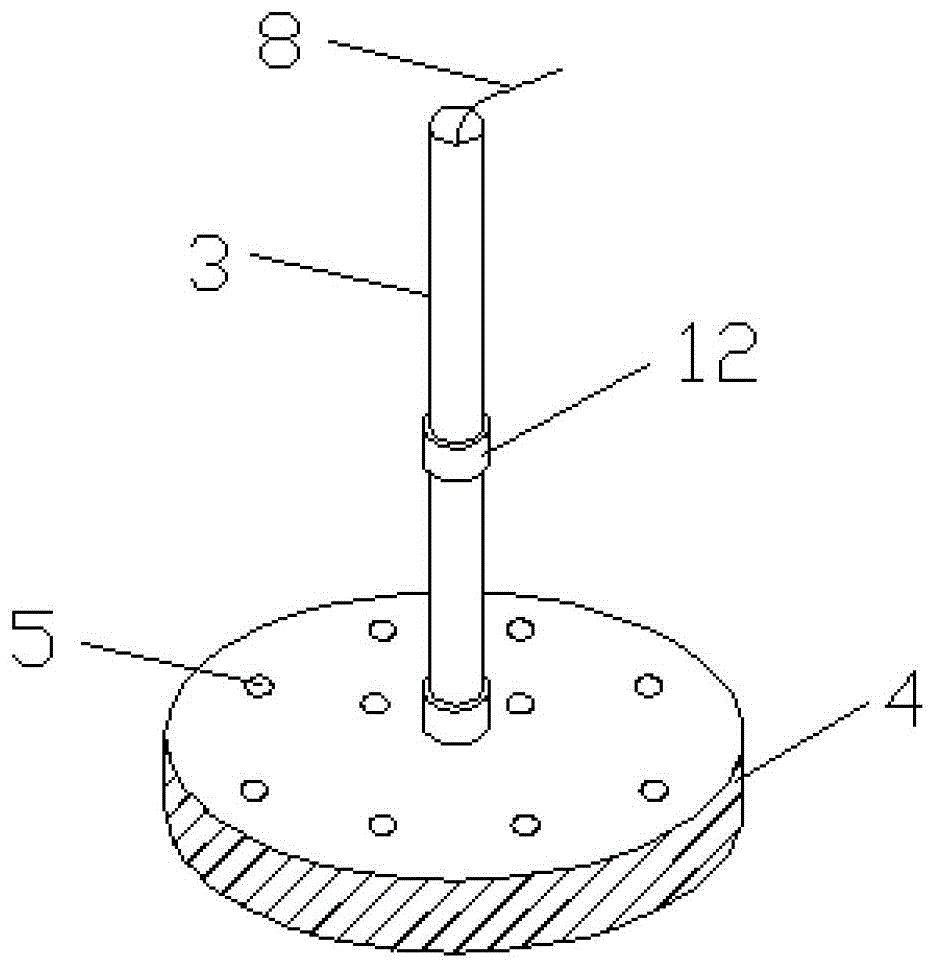

Method for improving and protecting collapsible loess slope project

InactiveCN101851928ARealize comprehensive utilizationFix stability issuesExcavationsCalcium in biologyGeogrid

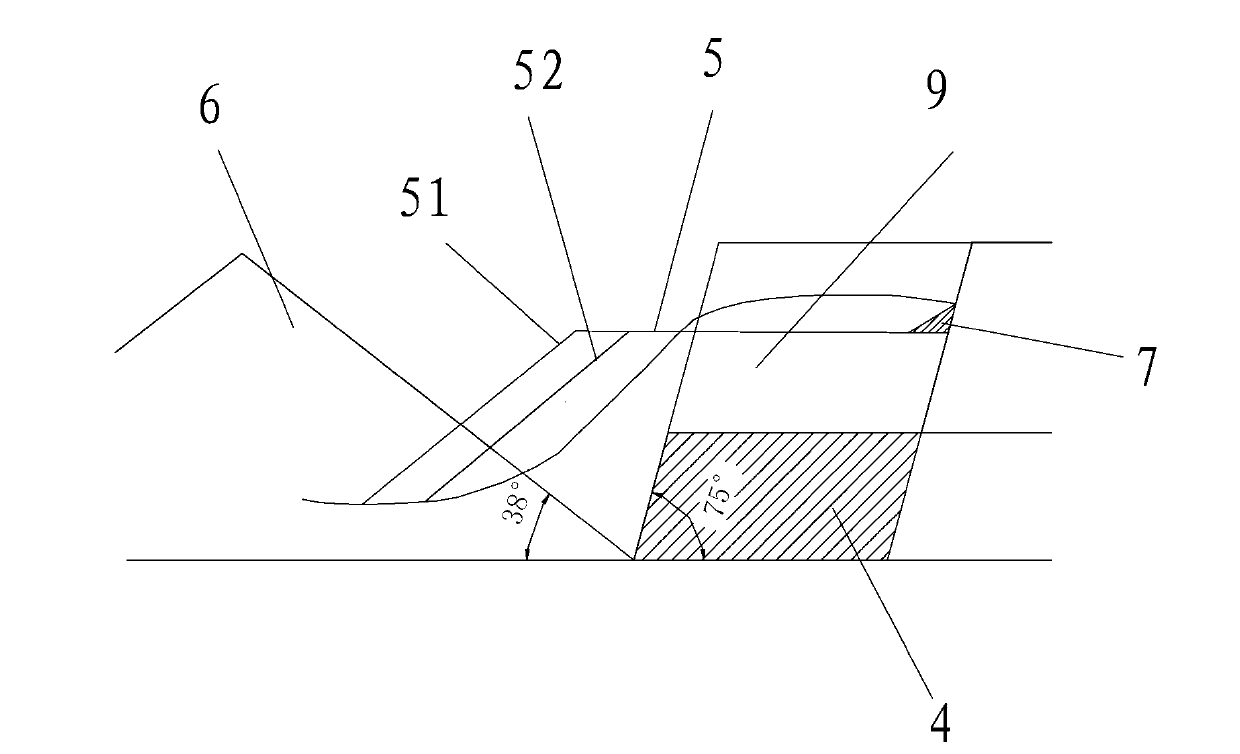

The invention relates to a method for improving and protecting a collapsible loess slope project, which is characterized in that: the loess slope project is protected by adopting improved loess (3), gunny bags (4), a protective net (5), a geogrid (6) and a drainage ditch (8), wherein the improved loess is prepared by stirring and blending lime, fly ash and loess in a volume ratio, the total volume of the lime and fly ash accounts for no less than 30 percent of the volume of the admixture, the SiO2 and Al2O3 total content of the fly ash is no less than 75 percent, and the lime is calcium quicklime or calcium hydrated lime; the geogrid (6) is high-density polyethylene uniaxial geogrid; the gunny bags (4) are jute gunny bags; and the protective net (5) is made of a flexible stainless steel material. The method has the advantages of stabilizing the slope, solving the stability problem of the fill slope, realizing waste utilization, afforesting the environment and preventing soil erosion by improving the structural protective system consisting of the loess and geogrid; and the method is suitable for improving the collapsible loess project in civil engineering and can be used for projects such as highway embankment filling, building foundation improvement, retaining wall reinforcement and the like.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

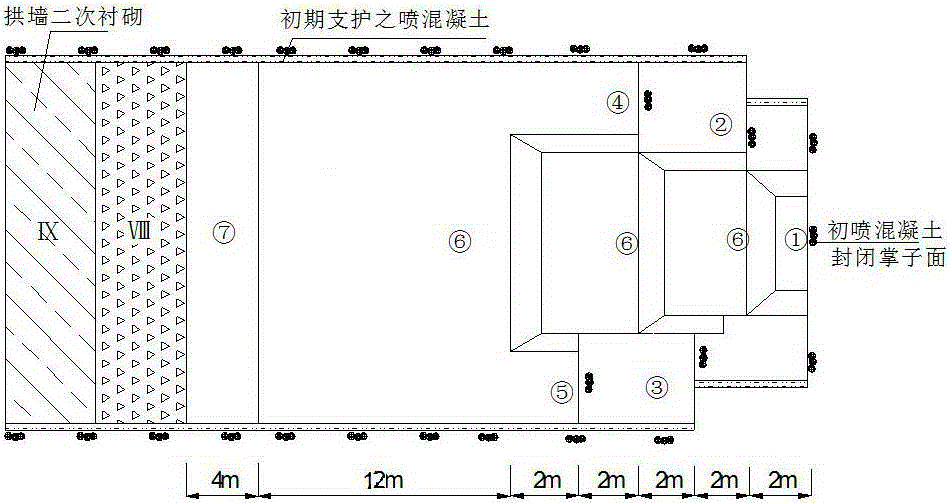

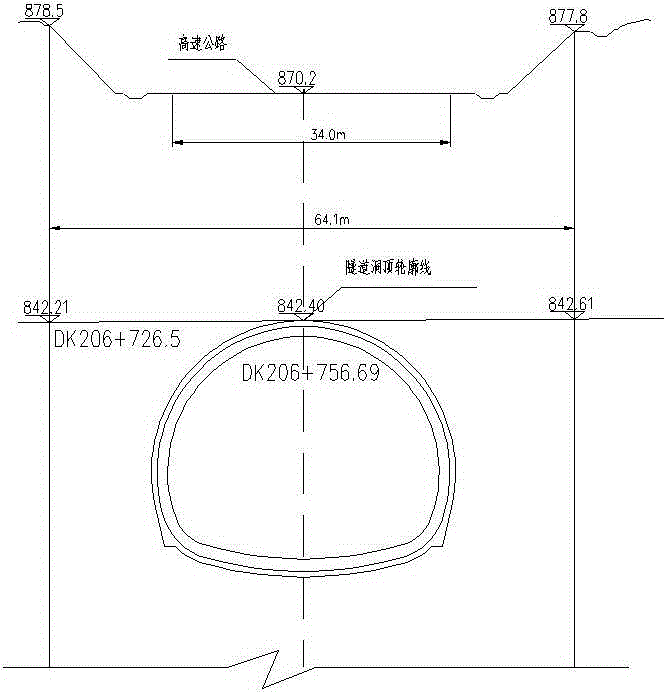

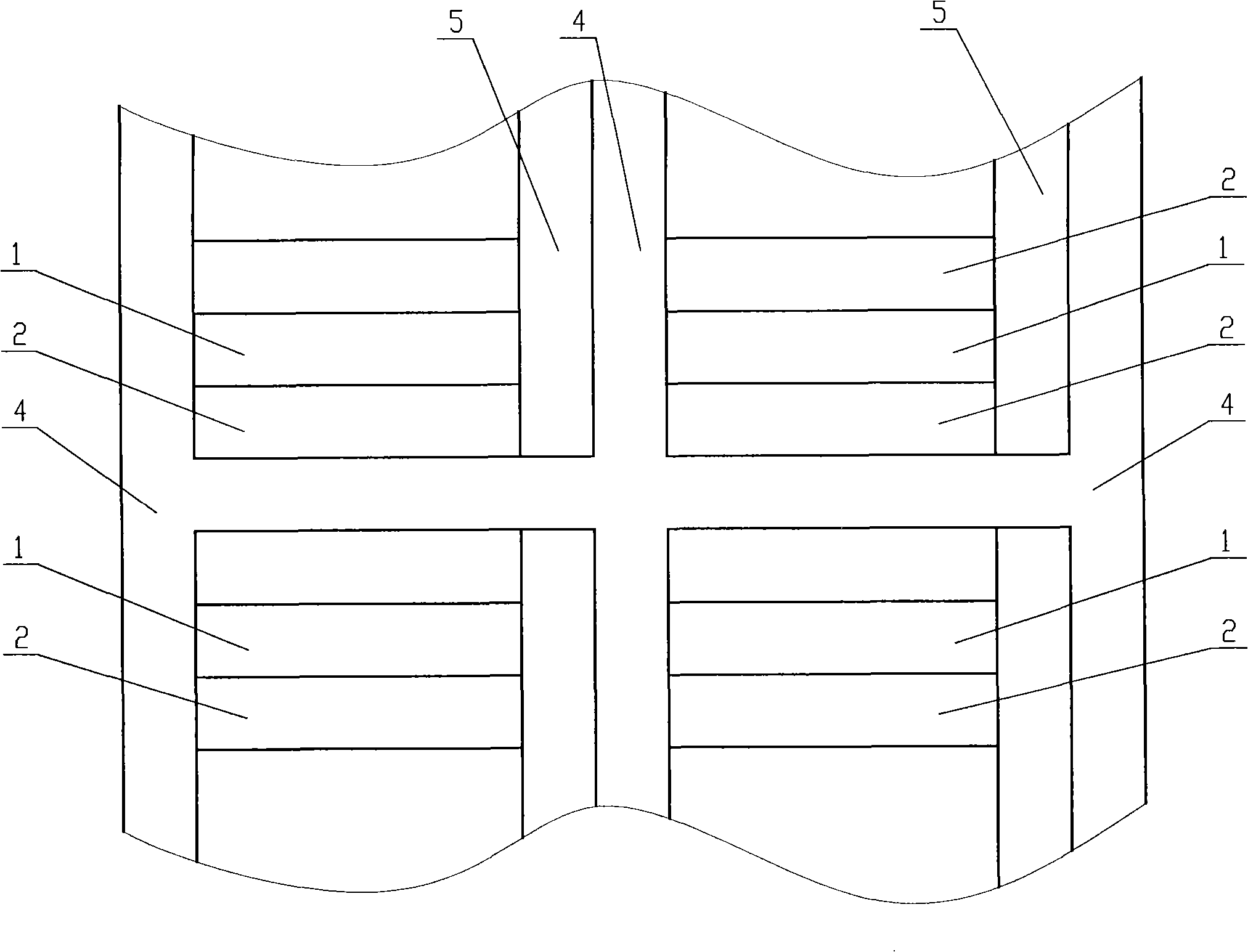

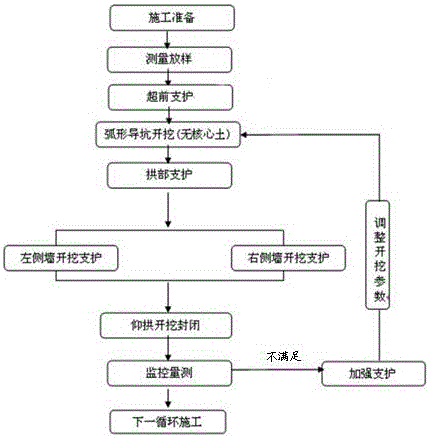

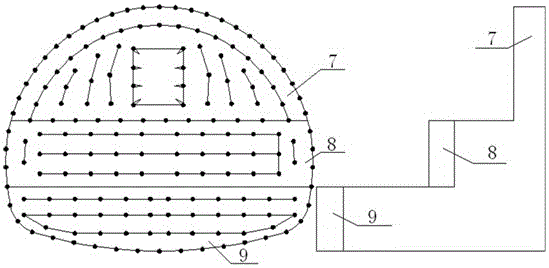

Construction method for large-span section loess tunnel under-crossing highway

InactiveCN105350973AReduce the impactImprove construction progressUnderground chambersTunnel liningGlass fiberGuide tube

Owner:TONGJI UNIV +1

Large-section loess tunnel construction method

The invention discloses a large-section loess tunnel construction method, which comprises the following steps that: the whole section is divided into an upper part, a middle part, a lower part and a bottom part, wherein the middle part is divided into a middle left area, a middle right area and a middle intermediate area, the lower part is divided into a lower left area, a lower right area and a lower intermediate area, the four parts are excavated in a benching tunneling method with altitude differences, the upper part is 3-5m in front of the front middle part, the middle part is 3-5m in front of the front lower part, the lower part is 10m in front of the front bottom part, and the step-by-step tunneling excavation is carried out. The invention is suitable for collapsed loess areas, realizes the safe and reliable construction and saves a large number of temporary supporting steel frames. Due to the arc-shaped pilot tunnel method, the loop can be formed rapidly during excavation, the disturbance to the surrounding rock is low, the primary support is stable, the traditional construction method is further improved to be the 'two-step and four-part excavation method', and the construction cycle period is short. Moreover, the invention can speed up the progress of the project, shorten the construction period, and reduce the cost of the project.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

Open pit coal mine mining process

ActiveCN103216238AReduce the amount of secondary dumpingGuaranteed continuity of fitUnderground miningSurface miningMining engineeringExcavator

The present invention provides an open pit coal mine mining process, which comprises the following operation steps: 1, adopting a bucket wheel excavator to dig a loess layer on the upper portion, and adopting a dumping plough to dump the loess on a conveying belt into a dump; 2, adopting a loosening blasting method to blast a rock layer on the upper portion, and then adopting a single bucket truck to convey rocks to the dump until a rock layer on the lower portion is exposed; 3, adopting a casting-blasting method to blast the rock layer on the lower portion, adopting a bulldozer to form a combination extension platform, and adopting match of the single bucket truck and a dragline to directly dump the blasting amount into the dump on the combination extension platform until a coal layer is exposed; and 4, adopting the loosening blasting method to blast the coal layer with a thickness of 30 m in one time, carrying out tracking type mining along a dragline work line direction in two coal mining benches, adopting the single bucket truck to convey the mined coal to a crushing plant, and then conveying the crushed coal to a designated location with a belt conveyor.

Owner:CHINA SHENHUA ENERGY CO LTD +1

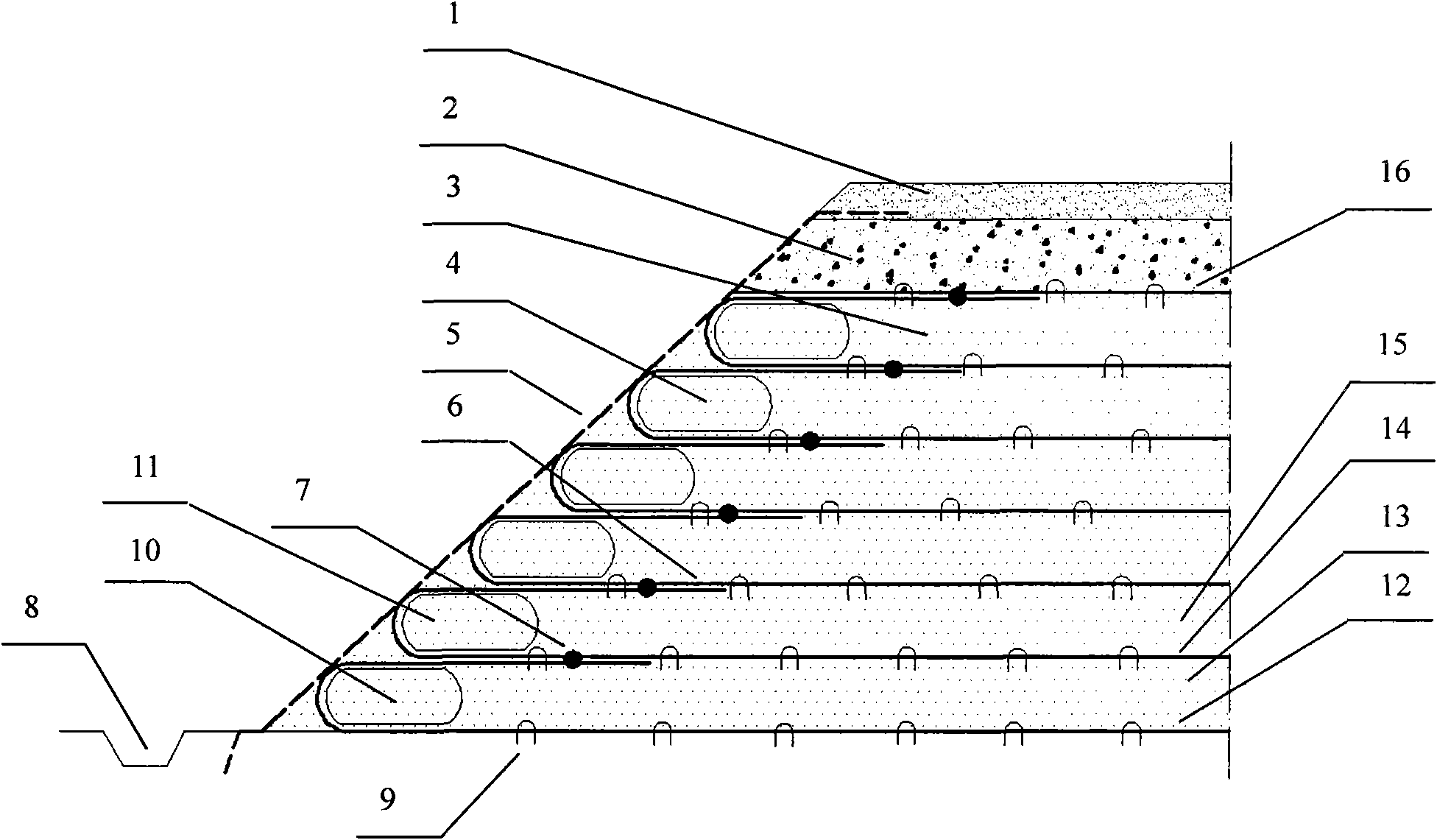

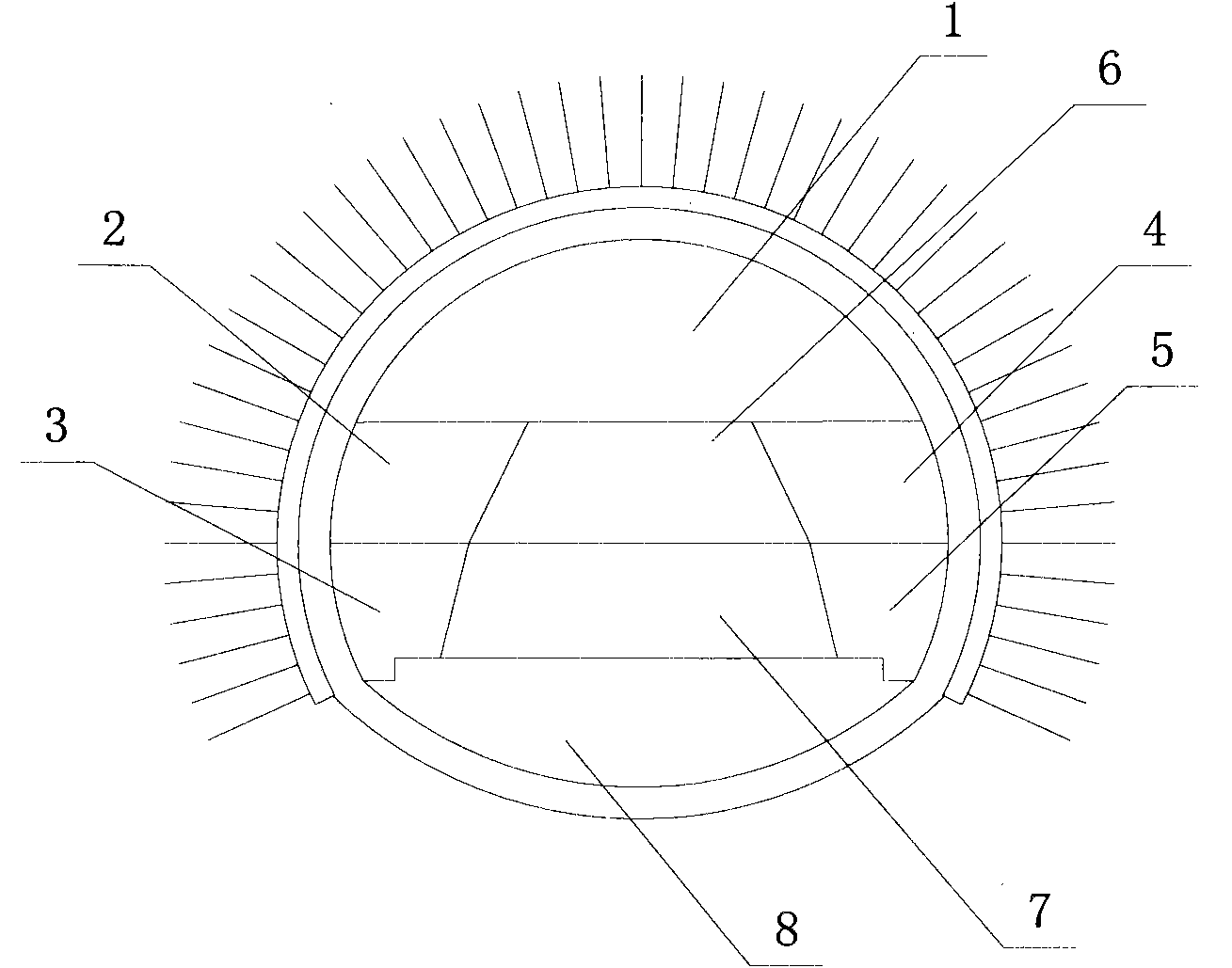

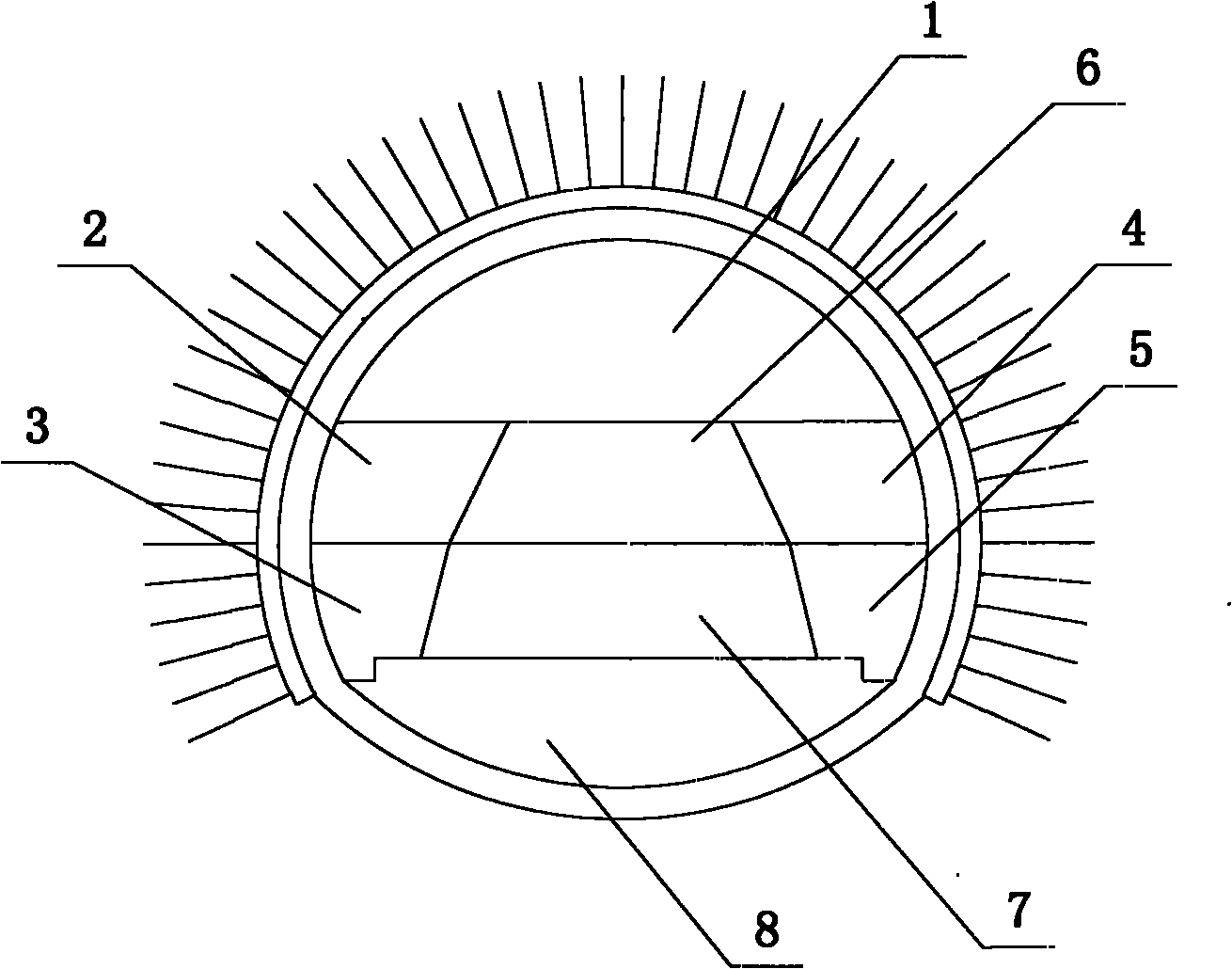

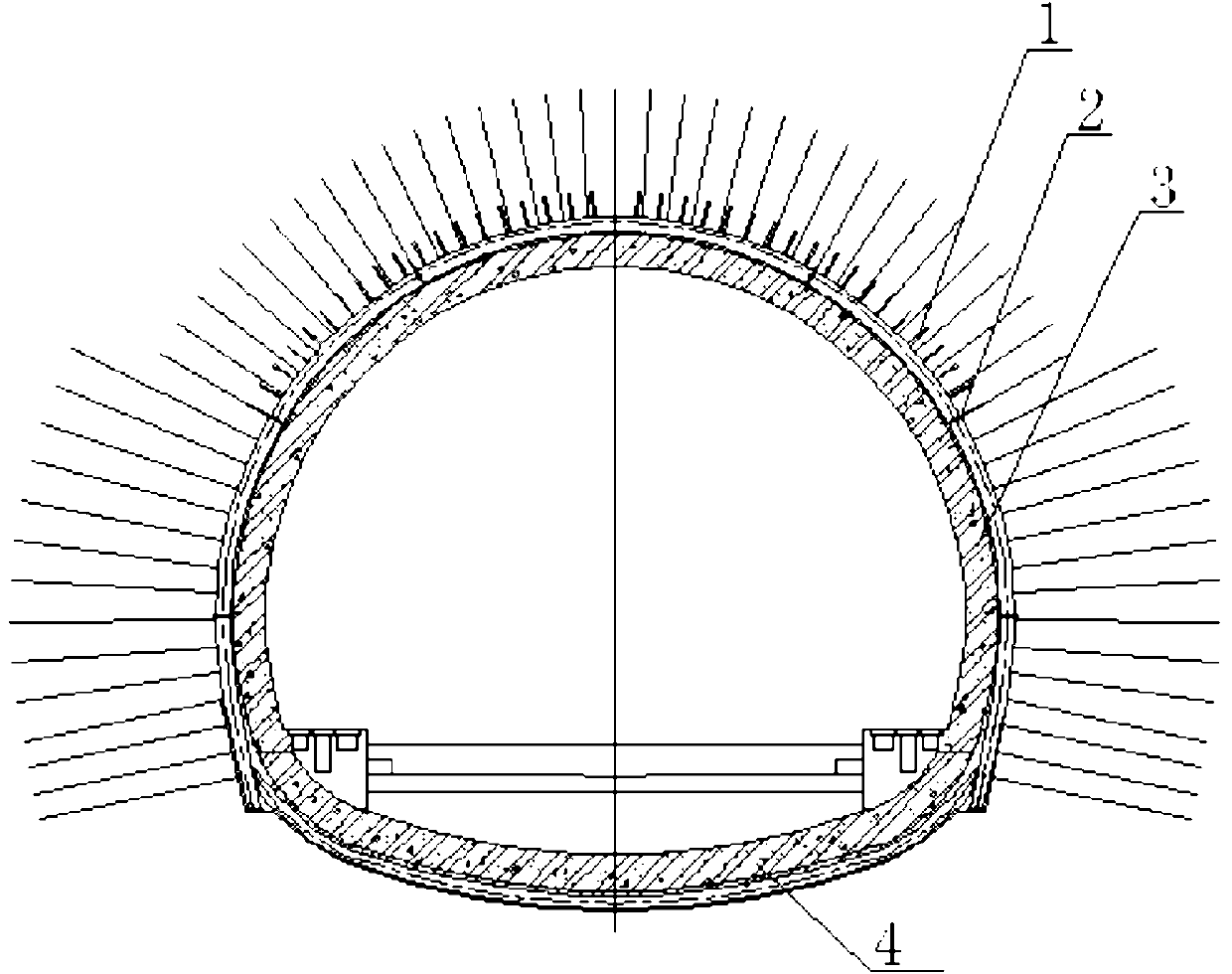

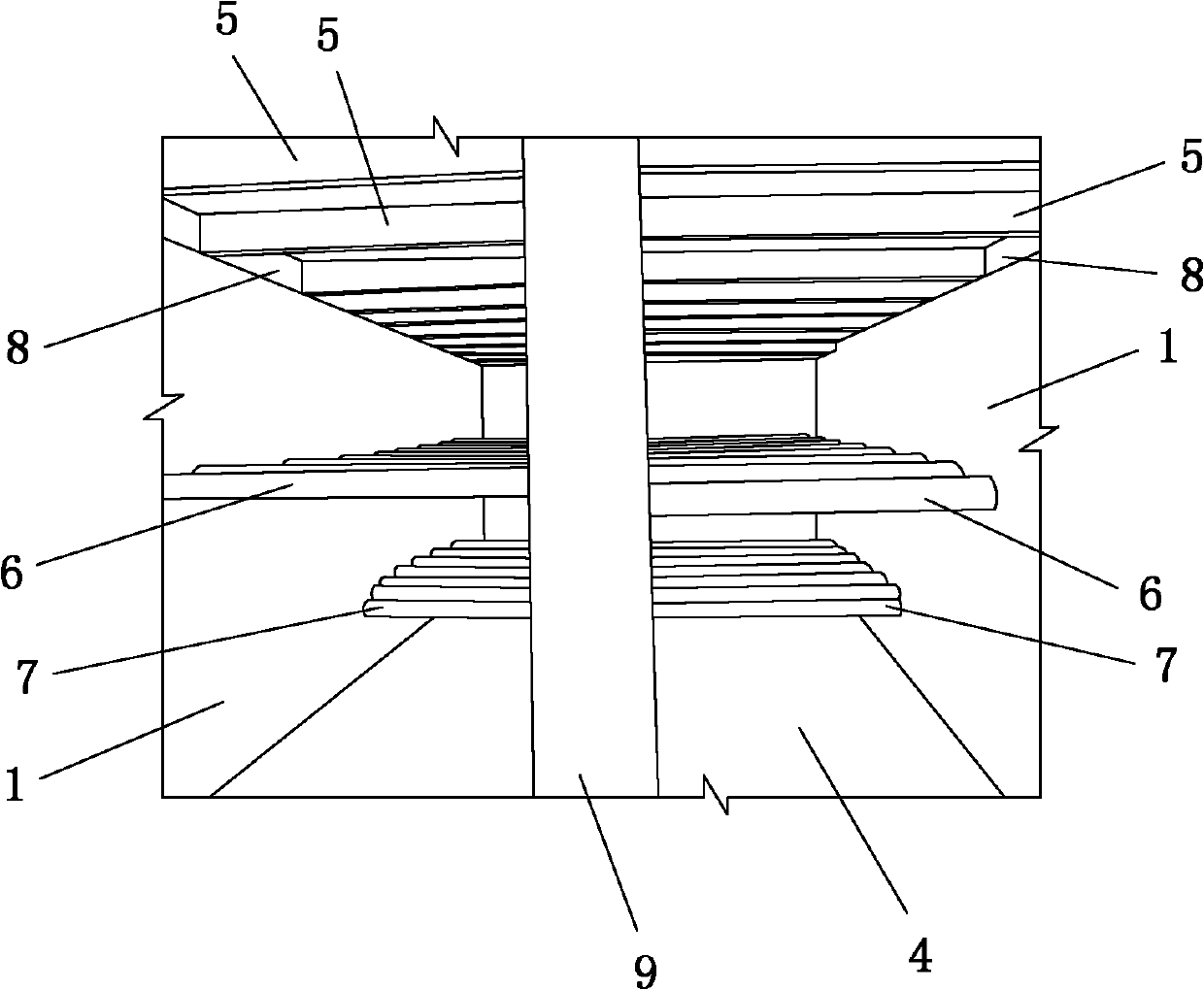

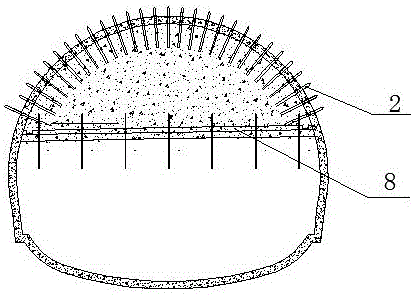

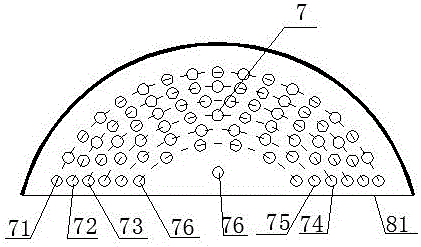

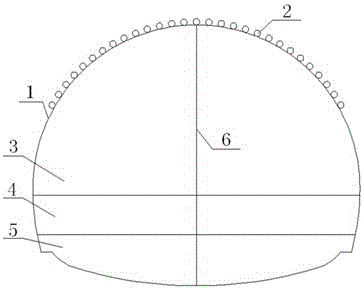

Supporting structure of extra-large cross-section loess tunnel and construction method thereof

InactiveCN101906974AEnsure construction safetyImprove construction progressUnderground chambersTunnel liningLarge deformationLarge size

The invention relates to a supporting structure of an extra-large cross-section loess tunnel and a construction method thereof. Larger deformation and even collapse accidents occur in the construction process of the loess tunnel easily. At present, aiming at the large cross-section loess tunnels, the construction of the large cross-section loess tunnel with the excavating area of 140 m<2> is realized by a reserved core soil short step method successfully; the construction of a new loess tunnel with the burial depth of 25 m and the excavating area of 120 m<2> under-passing the existing railway is realized by a CRD method; and the difficulty and the risk of the construction increase gradually along with further increment of the excavated cross-section of the loess tunnel. The supporting structure comprises an initial support, an archwall secondary lining and an inverted arch, wherein a small conduit leading support is arranged along the contour line of the tunnel arch part; and a waterproof layer is arranged between the initial support and the archwall secondary lining. The supporting structure and the construction method thereof have the advantages of effective guarantee of construction safety of the extra-large cross-section loess tunnel, simple construction process, large excavating space, convenient operation for a large-size machine and fast tunnel construction progress.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

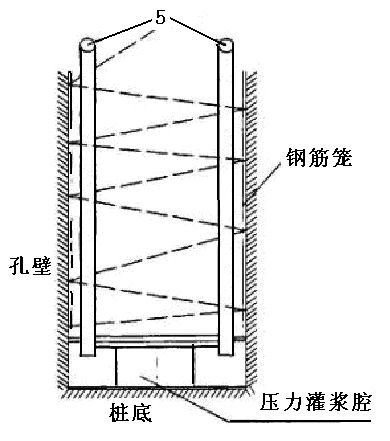

A construction method of collapsible loess foundation

InactiveCN102277867ASolve the carrying capacitySettlementFoundation testingIn situ soil foundationHigh riseSoil compaction

The invention discloses a construction method for a collapsible loess foundation. The construction method comprises the following steps of: firstly, performing foundation treatment on a loess field with collapsibility by using a super downhole dynamic consolidation (SDDC) pile; secondly, collecting undisturbed soil on site, normally performing an indoor experiment to measure an inter-pile soil compaction coefficient and an SDDC pile body compaction coefficient, evaluating the collapsibility, and if any one of the three indexes cannot meet a design requirement, performing pile compensation construction on the SDDC pile until the design requirement is met; and finally, pouring the pile and mudjacking. The method has the advantages of economy, environment friendliness, high treatment depth, good treatment effect, large bearing potential, high complicated load resistance and the like. By application of the method, various side effects caused by the collapsibility of the deep collapsible loess field can be eliminated, and requirements of upper-part high rise buildings on the bearing capability and settlement of the foundation can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

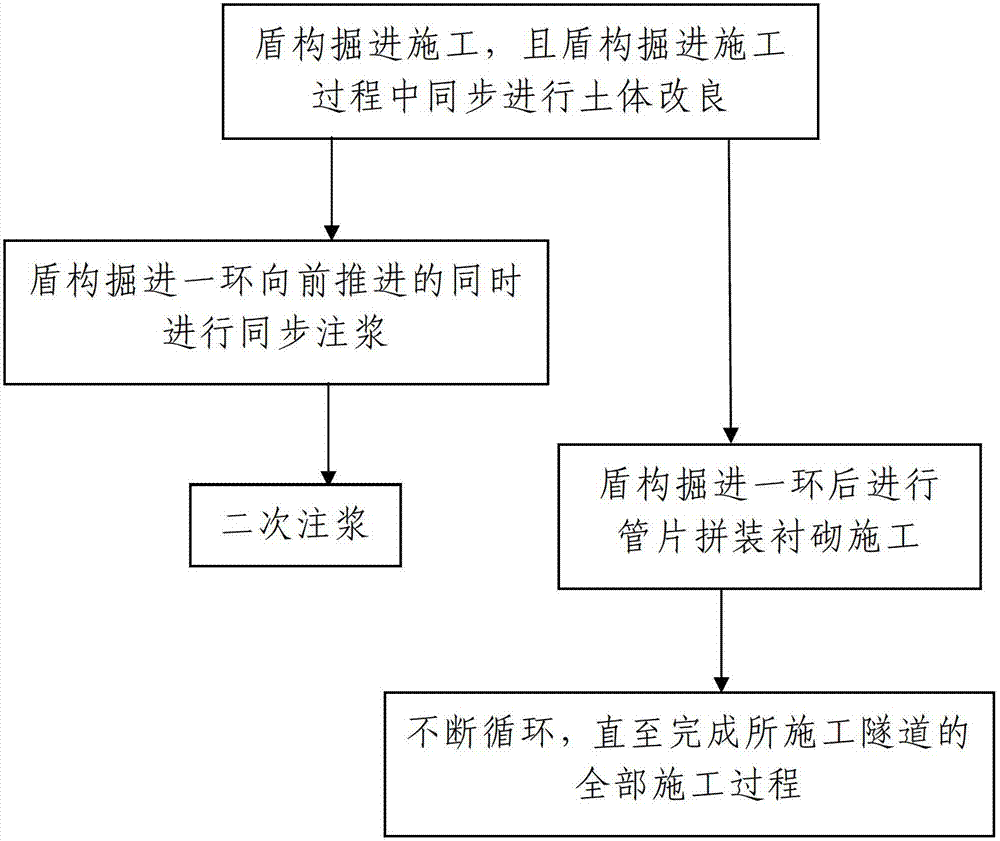

Loess strata subway tunnel earth pressure balance shield construction method

ActiveCN102767377AThe construction process steps are simpleEasy to implementUnderground chambersTunnel liningInternal pressureArchitectural engineering

The invention discloses a loess strata subway tunnel earth pressure balance shield construction method. The method comprises that firstly, shield excavation construction is performed by using a earth pressure balance shield machine; the excavation speed in no more than 10cm / min, the total thrust is no more than 15000KN, and the inner pressure of a soil warehouse is kept in a range between 1bar and 2 bar; the aperture opening ratio of a spoke panel type cutter is in a range of 40-70%, and the rotating speed of the cutter is no more than 1.5rpm; cement, pulverized fuel ash, fine sand, bentonite and water is mixed uniformly to obtain synchronous grouting liquid and second grouting is performed by using double-liquid grouting composed of cement paste and water glass; performing shield duct piece assembly construction after completion of one cycle of the shield excavation construction; and the process is repeated until the overall construction of the subway tunnel is achieved. The construction method is simple in step, easy to operate, fast in construction speed, high in construction quality, low in interference on the environment, high in construction safety and capable of guaranteeing successful construction of loess strata subway tunnels.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

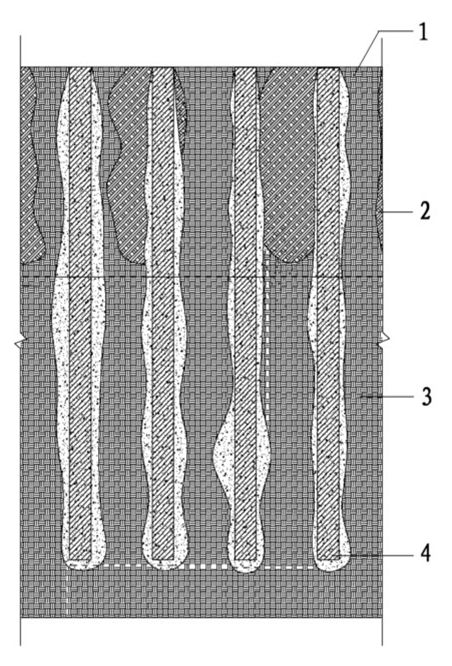

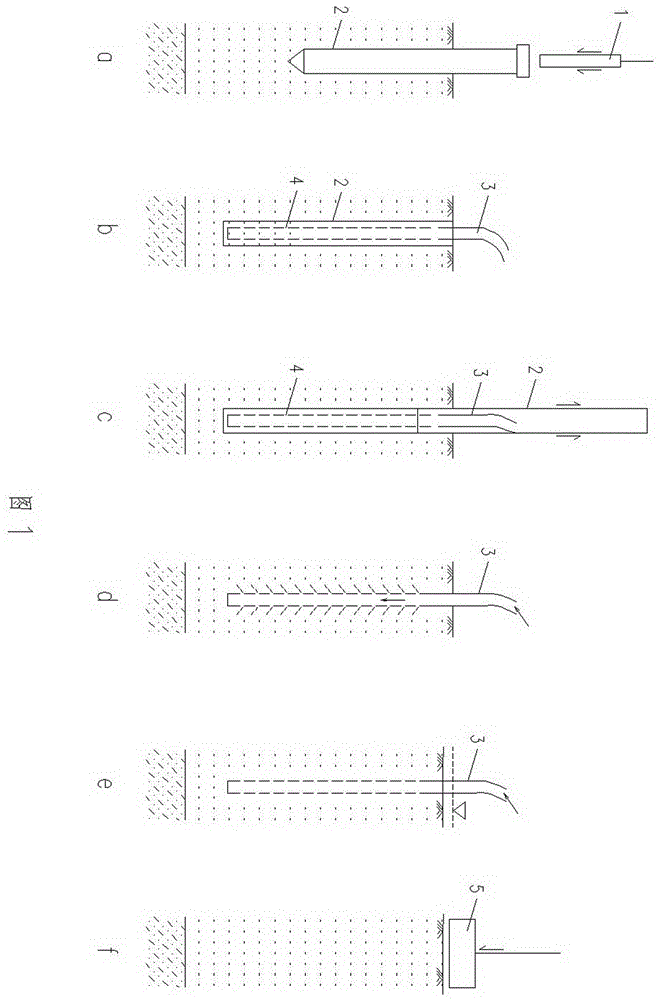

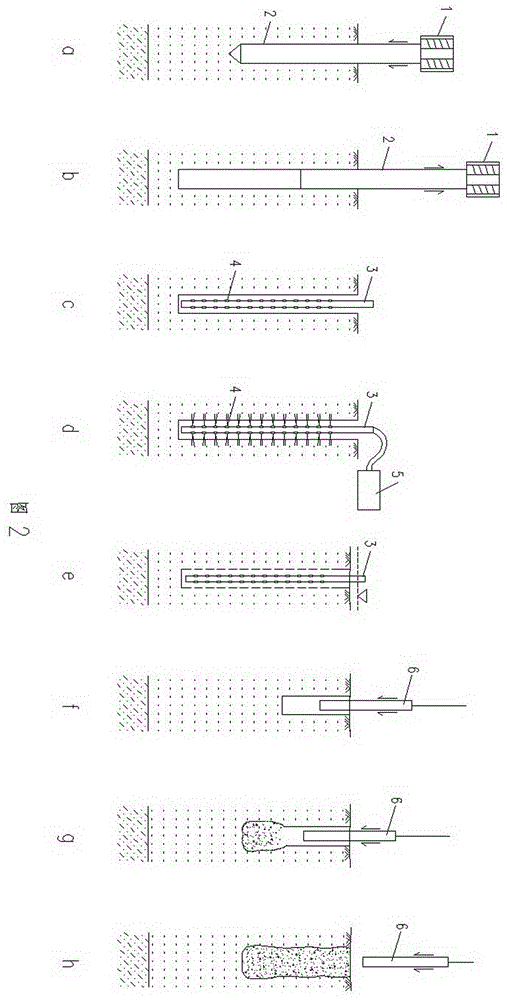

Treatment method for large-thickness collapsible loess

ActiveCN105970911ASmall sinking resistanceAvoid cloggingSoil preservationDynamic compactionSoil horizon

The invention provides a treatment method for large-thickness collapsible loess. The treatment method comprises the following steps: 1) sinking small-diameter steel casing into soil to form pile holes each having a depth equal to or smaller than the thickness of the collapsible loess stratum; 2) inserting (1) 1-6 drain boards or (2) hollow water pipes with a plurality of drain holes or (3) hollow steel pipes with a plurality of nozzles into the pile holes to bottom ends thereof; 3) repeating the steps 1) and 2) until the pile holes with the water injection fittings are formed everywhere in the field; 4) injecting water or injecting water under pressure into the water injection fittings in the pile holes to cause self-weight collapsible settlement of the collapsible loess after immersion; 5) observing and recoding the collapsible settlement amount of the soil mass in a foundation until the collapsible deformation of the soil mass in the foundation is stable; and 6) reinforcing the top-layer soil mass of the foundation by use of a filling compaction method or a dynamic compaction method. The treatment method has the characteristics and advantages of high construction speed, remarkable effect of eliminating loess collapse, dry operation, high bearing capacity, and the like.

Owner:王继忠

Method for recovery of room-type coal pillar through loess filling

ActiveCN103527196AExtended service lifeReduce the impactUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a method for recovery of a room-type coal pillar through loess filling. Along the vertical section laneway direction, formed channels in mined coal rooms are taken as an arrangement form of coal transport lanes and material transport lanes; two adjacent coal pillars are arranged to be a stope face, a row of coal pillars are retained between adjacent stope faces as a partition wall; The recovery of coal pillars employs a blasting technology, loess of ground is taken as a filling material of mined-out area, the backfill of the mined-out area is carried out through a way of cooperation operation of high-speed power throwing machines and bulldozers, A room-type remaining coal pillar is replaced by a compact loess filling body for supporting the mined-out area roof. The method recovers precious coal resource, lowers great resource waste caused by room-type mining, and provides a new technical approach for mines with similar conditions in our country.

Owner:CHINA UNIV OF MINING & TECH

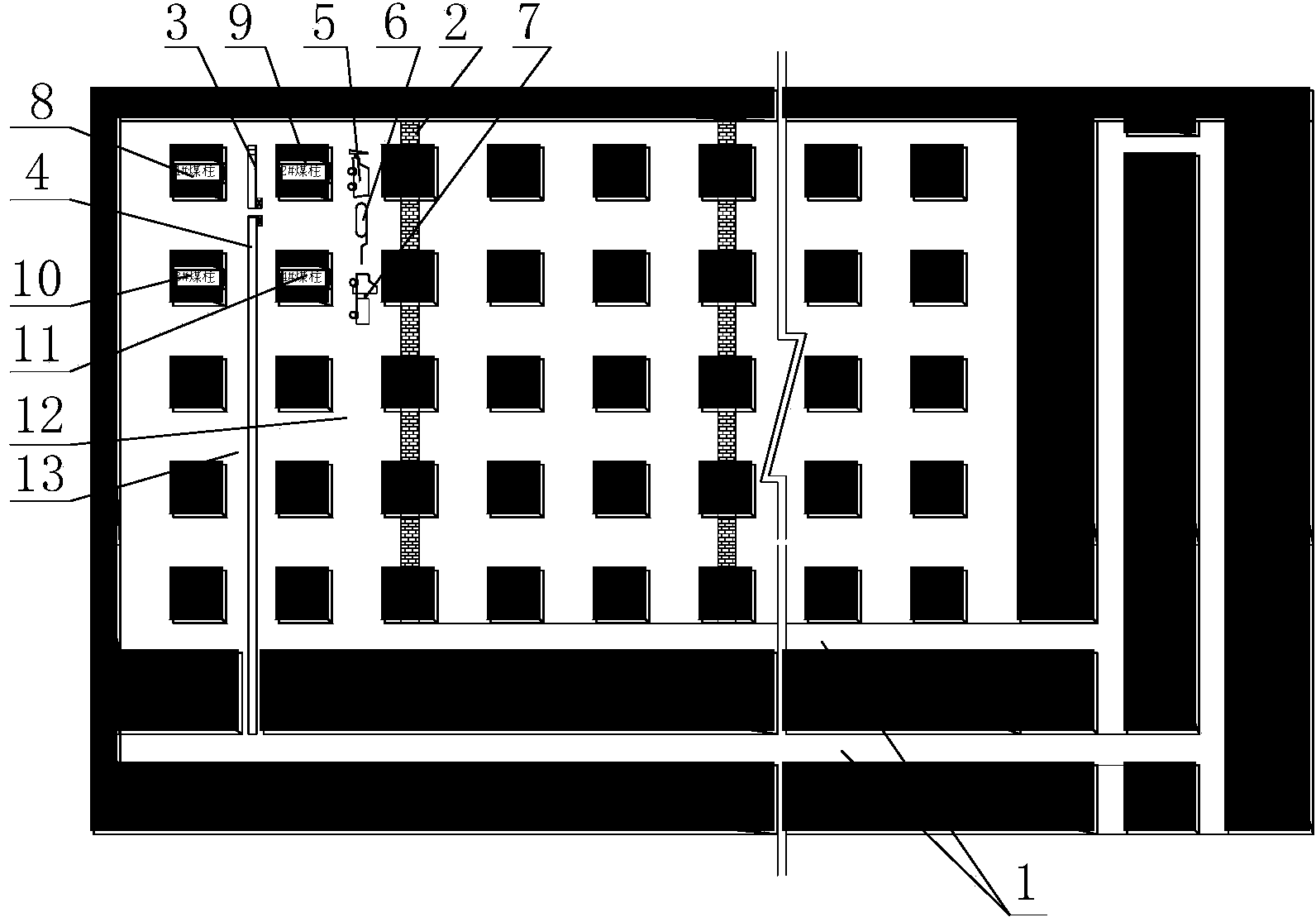

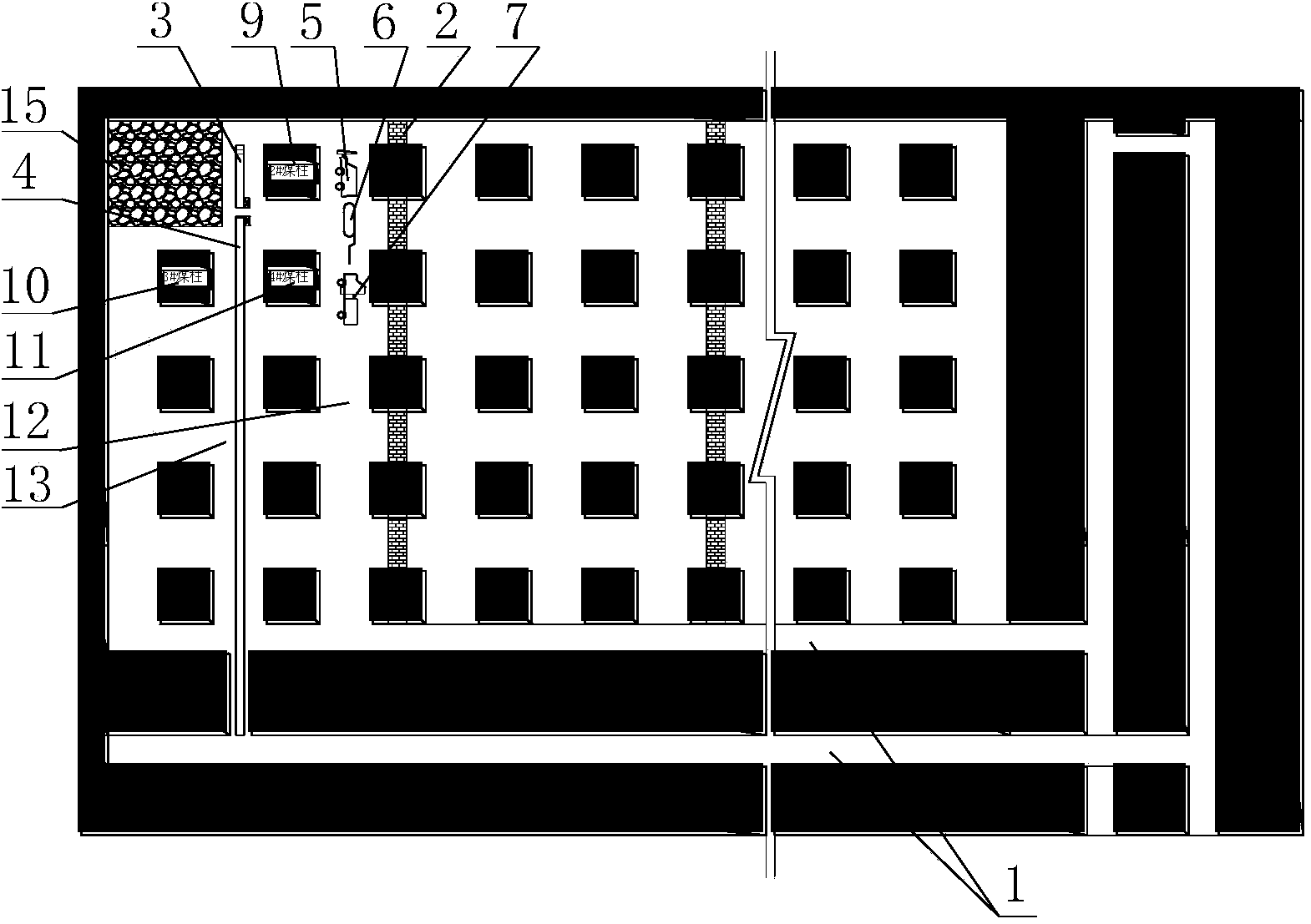

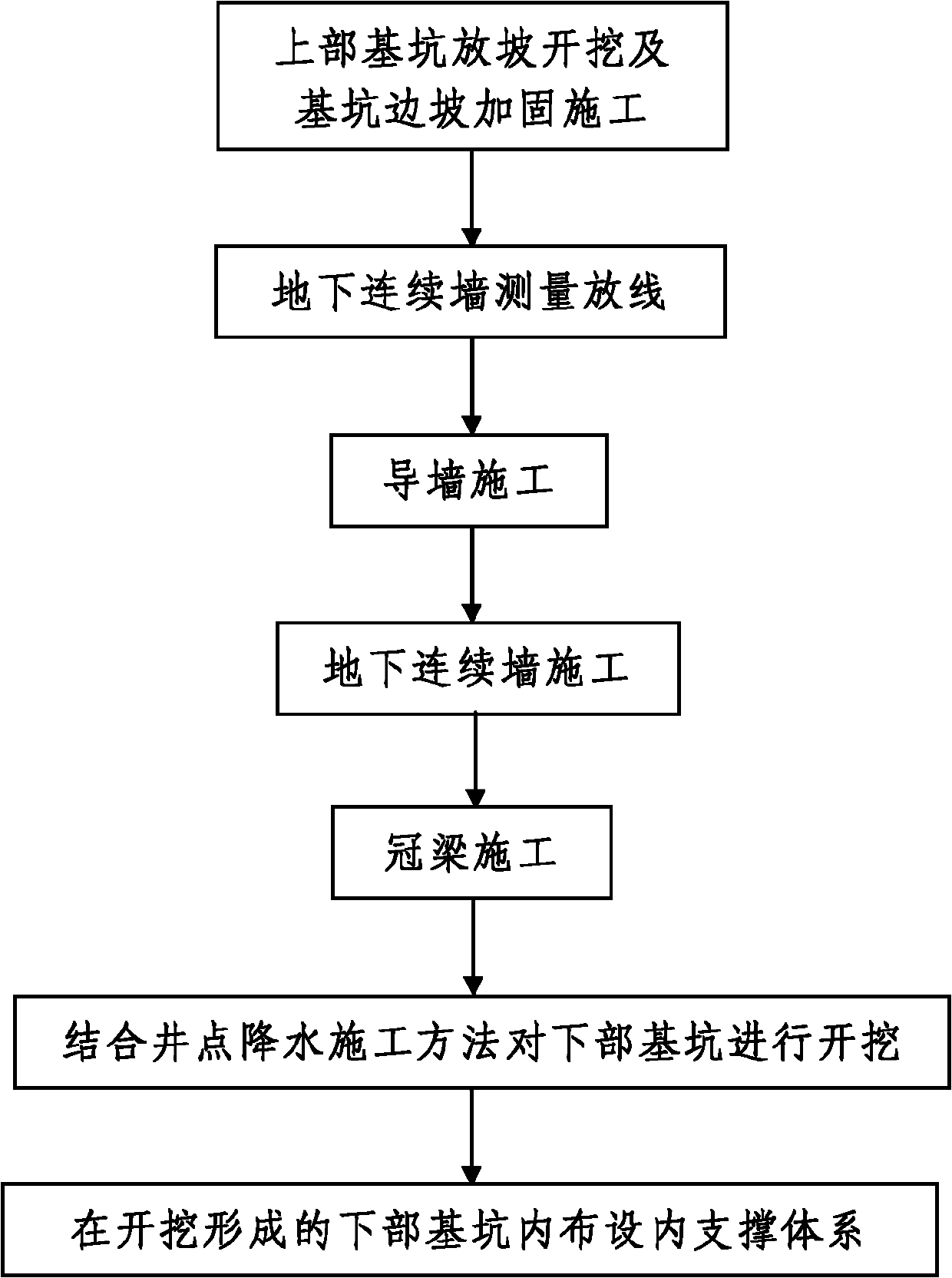

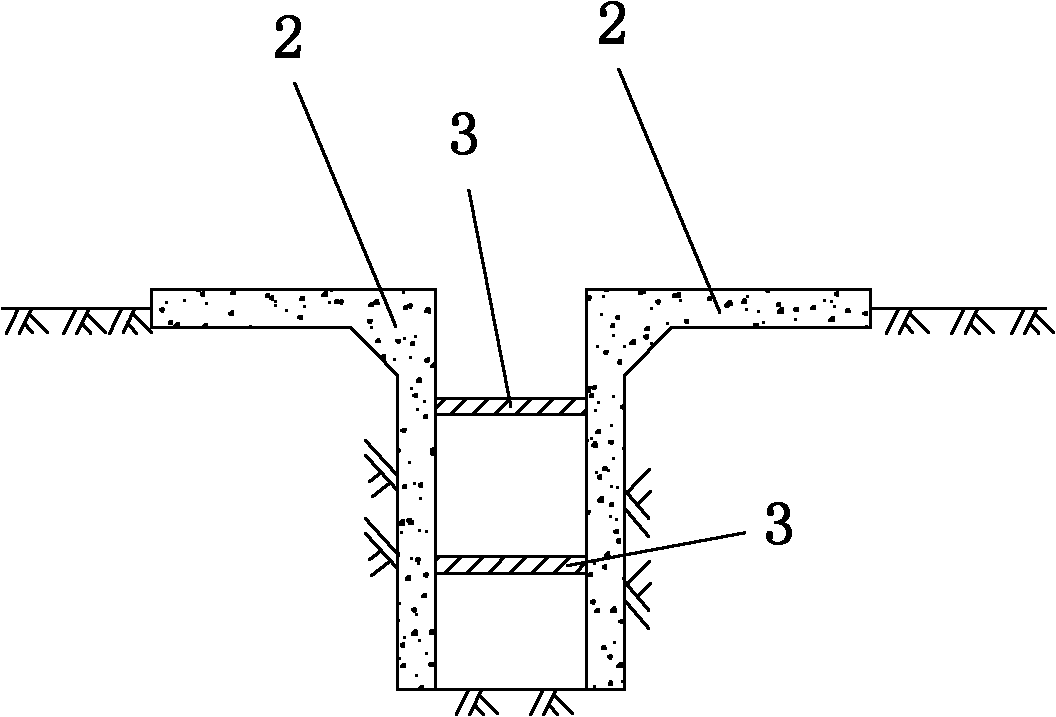

Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

InactiveCN102322064AReasonable designSimplify construction stepsArtificial islandsExcavationsSlurry wallSubway station

The invention discloses a construction method for an underground diaphragm wall of a deep foundation pit for a subway station in collapsible loess areas. The constructed station deep foundation pit for the subway station is divided into an upper-part foundation pit and a lower-part foundation pit from top to bottom; the building enclosure of the lower-part foundation pit is the underground diaphragm wall; and the upper-part foundation pit is a foundation pit formed by slope excavation. The construction method disclosed by the invention has the following steps of: (1) construction for upper-part foundation pit slope excavation and foundation pit slope reinforcement; (2) construction for lower-part foundation pit building enclosure: surveying and paying off, guide wall construction and underground diaphragm wall construction; and (3) construction for cap beam, and then carrying out excavation on the lower-part foundation pit through combining a well-point dewatering construction method and arranging a bracing system in the excavated lower-part foundation pit. The construction method disclosed by the invention has the advantages of reasonable design, simplicity and convenience for construction, safety and reliability for construction and good construction effect, high construction quality and capability of effectively solving the practical problems, such as high difficulty for construction, complicated construction procedure, difficulty for ensuring the construction quality of deep foundation pits and the like, in a process of constructing the deep foundation pits for subway stations in the collapsible loess areas.

Owner:CHINA RAILWAY 20 BUREAU GRP

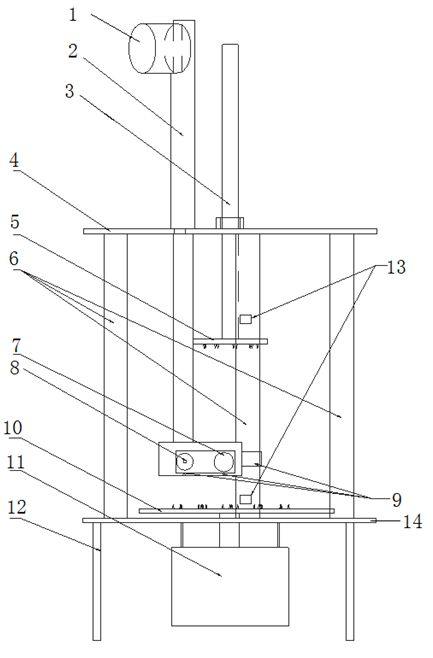

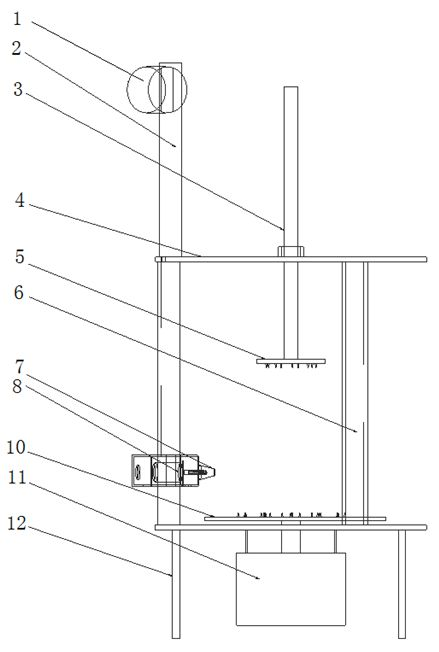

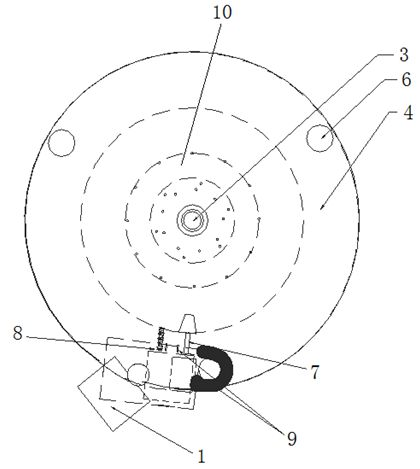

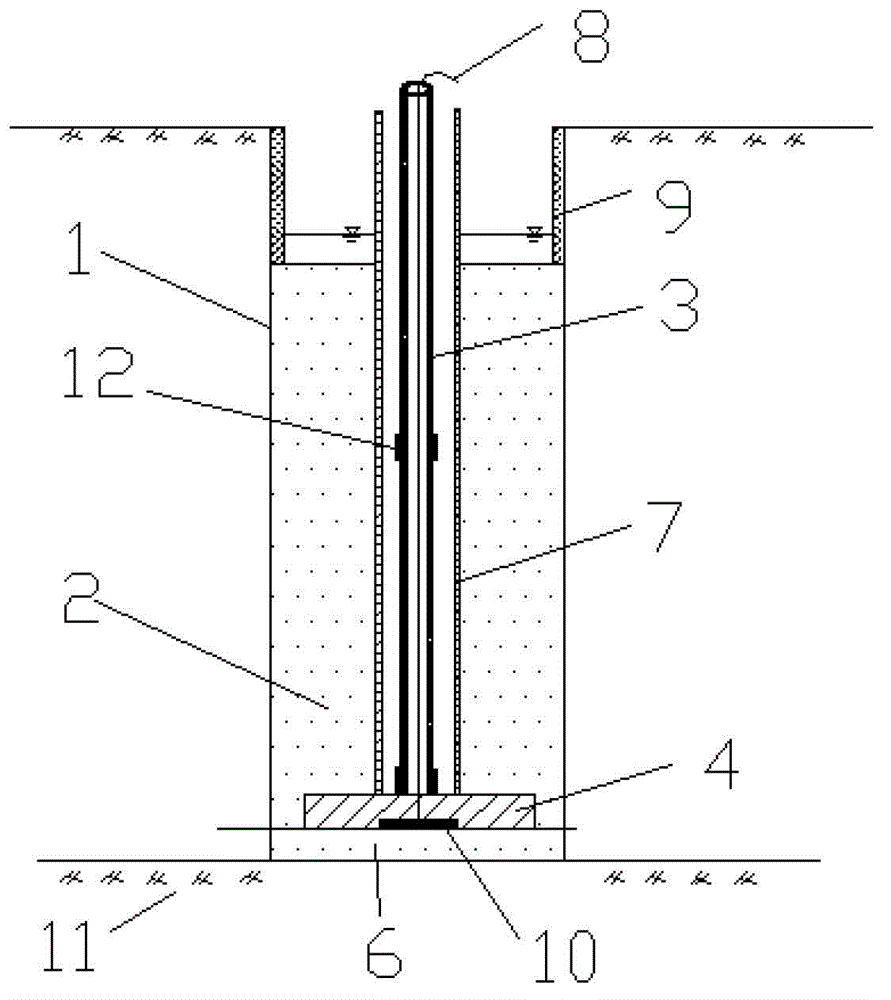

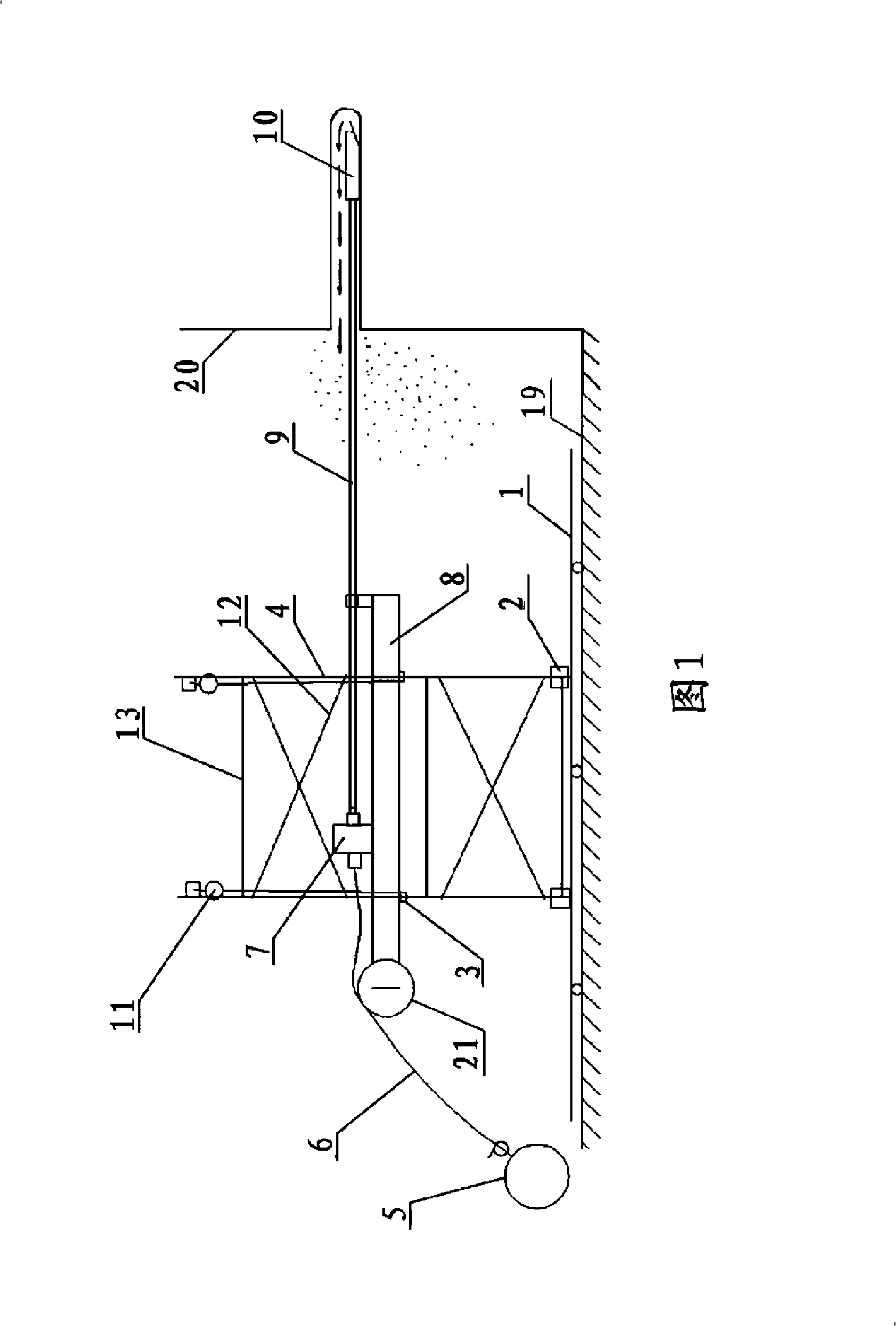

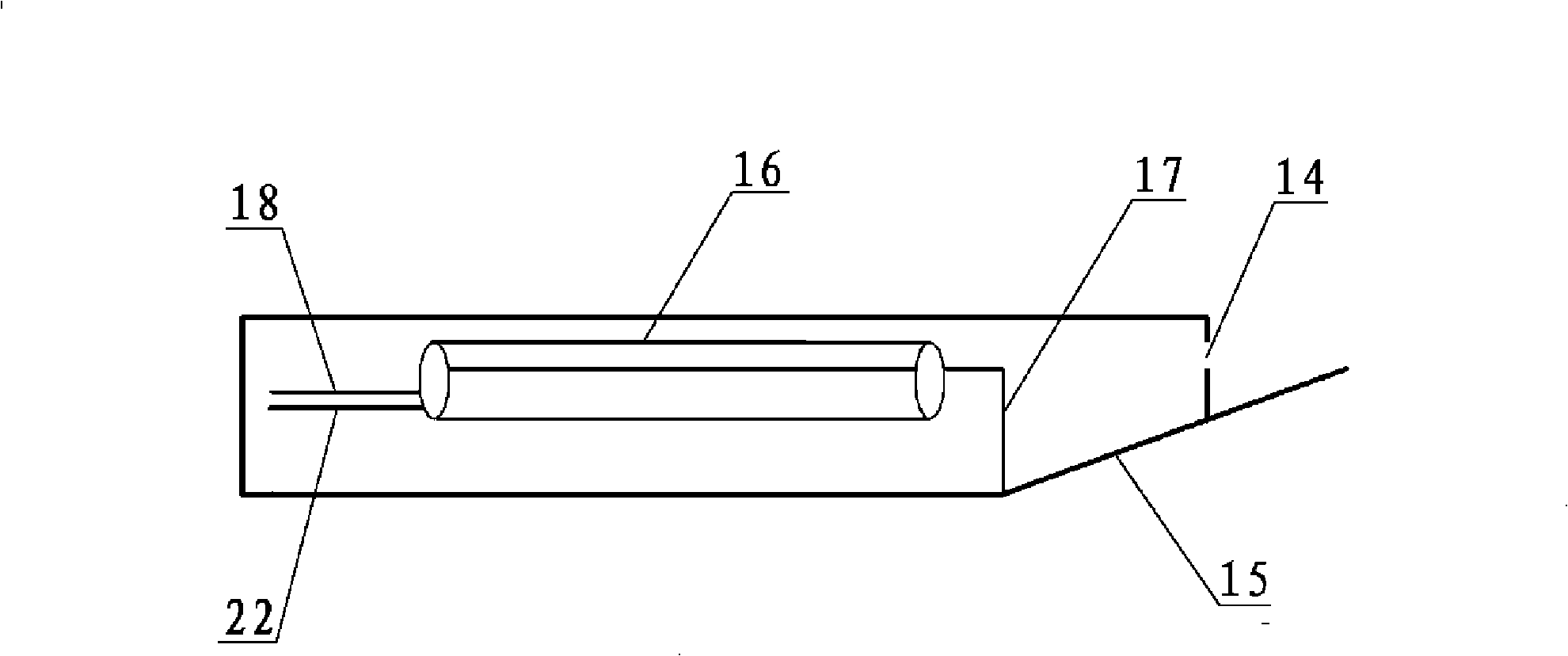

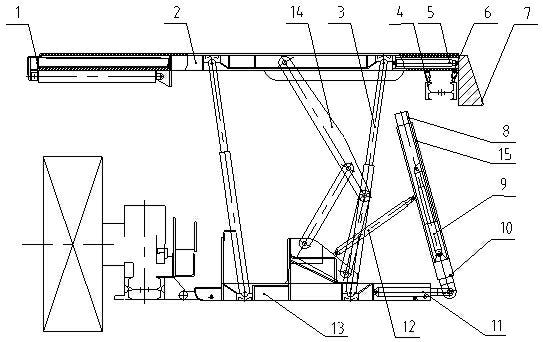

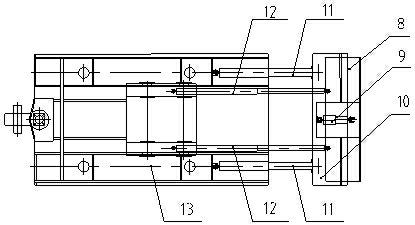

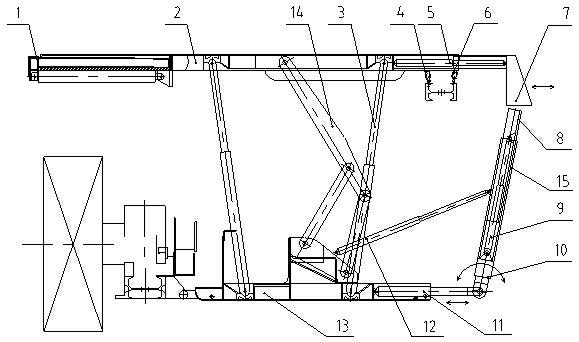

Sample cutter for preparing undisturbed loess sample for triaxial test

InactiveCN102169062AHigh precisionHigh degree of automationPreparing sample for investigationTriaxial shear testSynchronous motor

The invention discloses a sample cutter for preparing an undisturbed loess sample for a triaxial test. The sample cutter comprises a bracket on which a base plate is arranged; a synchronous motor is arranged below the base plate; a loess downward cutting disk is arranged on the base plate; the loess downward cutting disk is driven by the synchronous motor to rotate; a supporting stand column is distributed on the base plate; a top plate is arranged on the supporting stand column; a connecting shaft is arranged on the top plate; the connecting shaft is provided with a loess upward cutting disk corresponding to the loess downward cutting disk; a telescopic push rod is arranged on the top plate; a direct-current motor is arranged above the telescopic push rod; a loess cutter frame and a linear motor are arranged below the telescopic push rod; a loess cutter is arranged on the loess cutter frame; and the linear motor drives the loess cutter frame to do reciprocating motion on a guide rail. The sample cutter is convenient to use and can precisely control the size of a sample during sample preparation; moreover, the automation degree is high and the sample preparation efficiency can be improved.

Owner:NORTHWEST UNIV(CN)

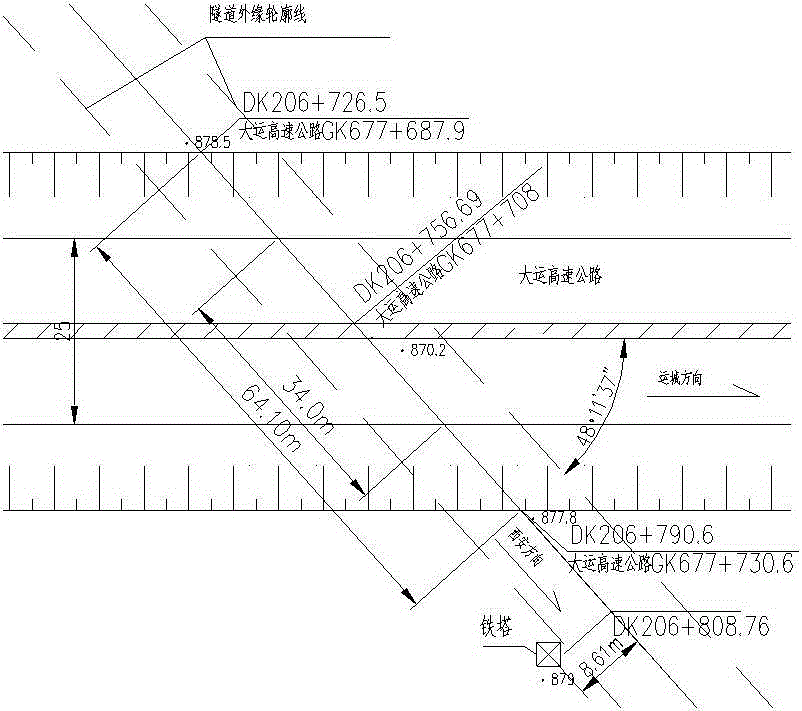

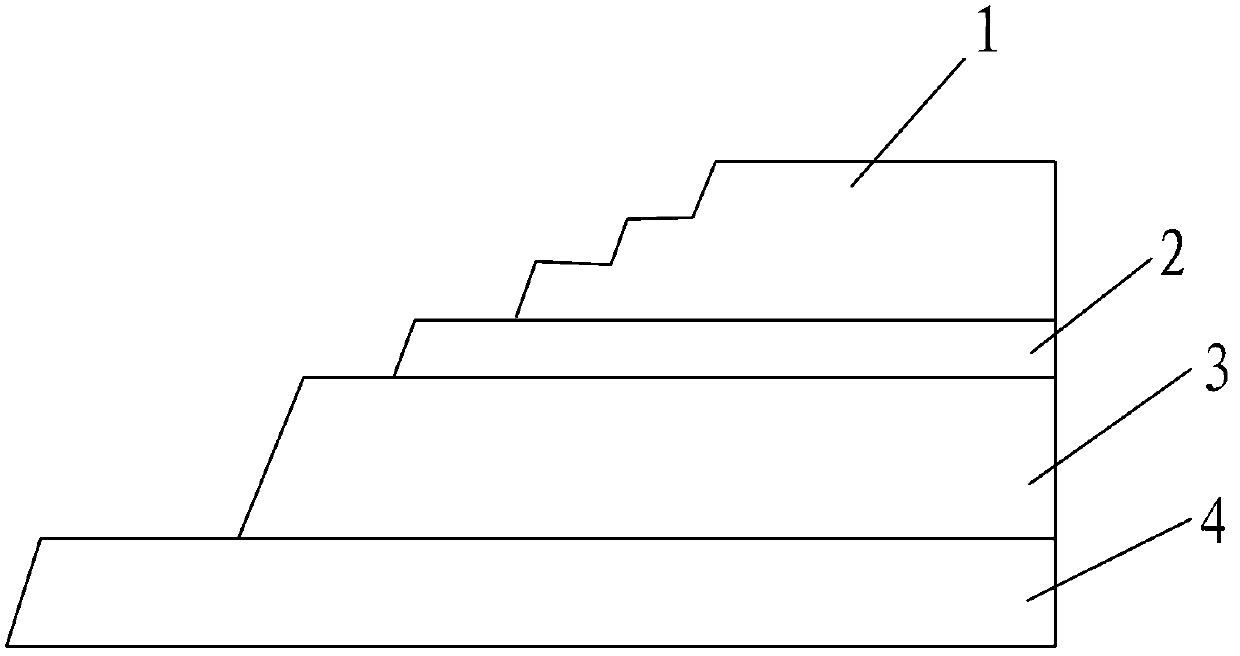

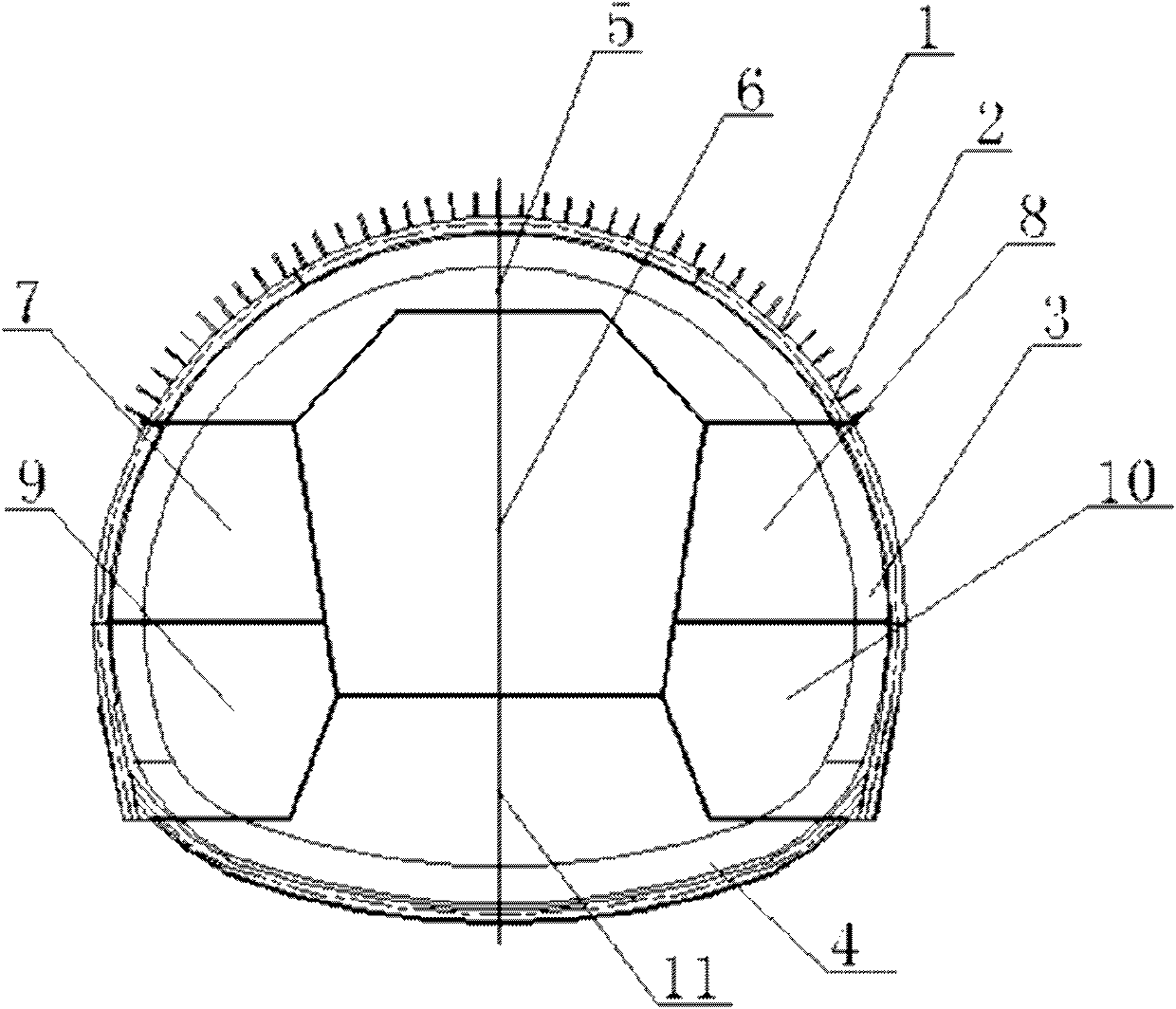

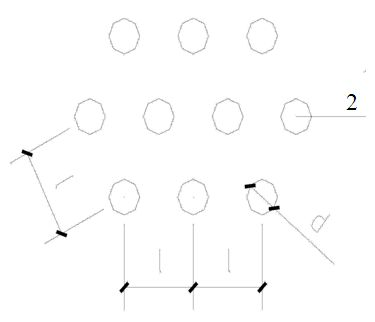

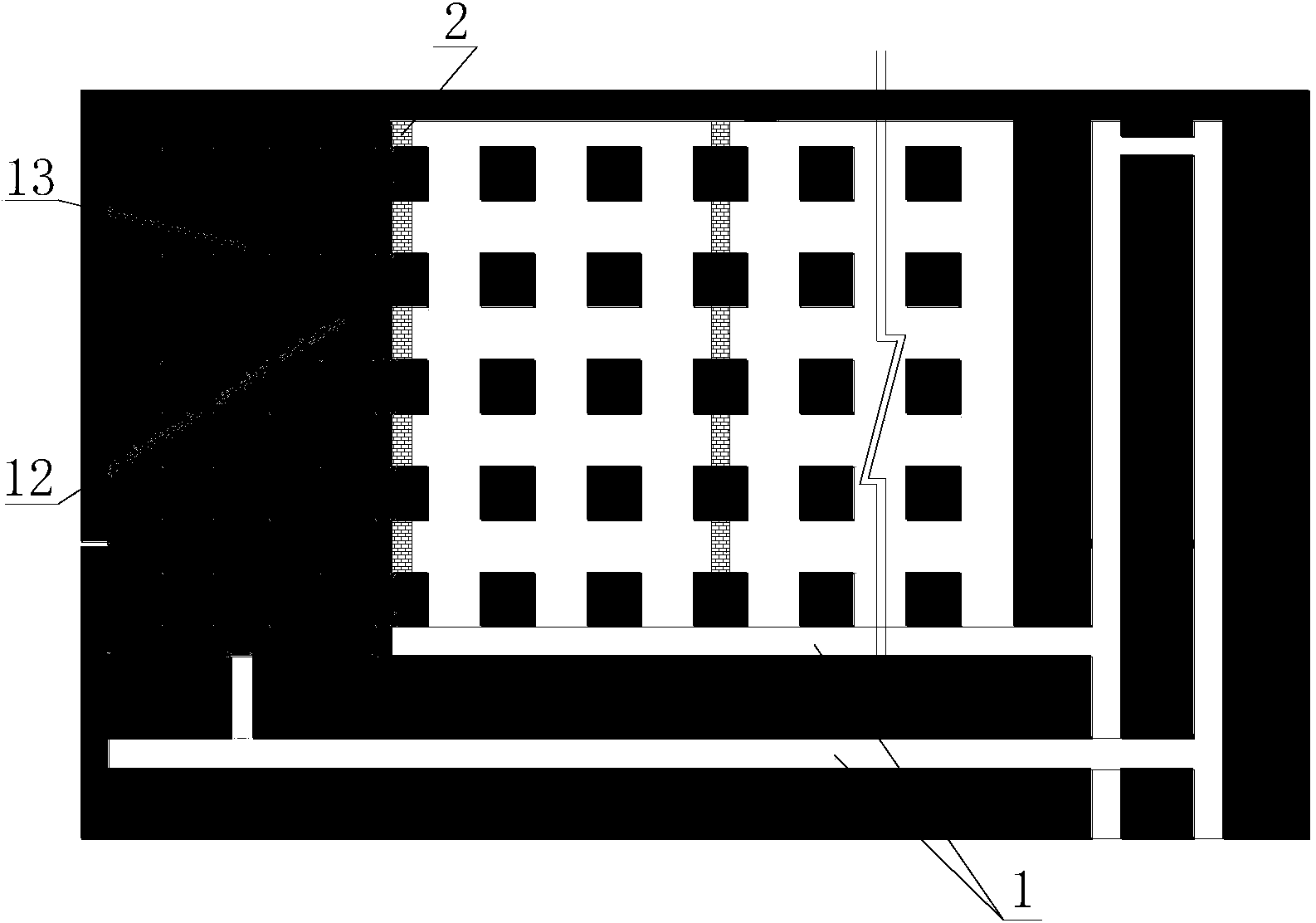

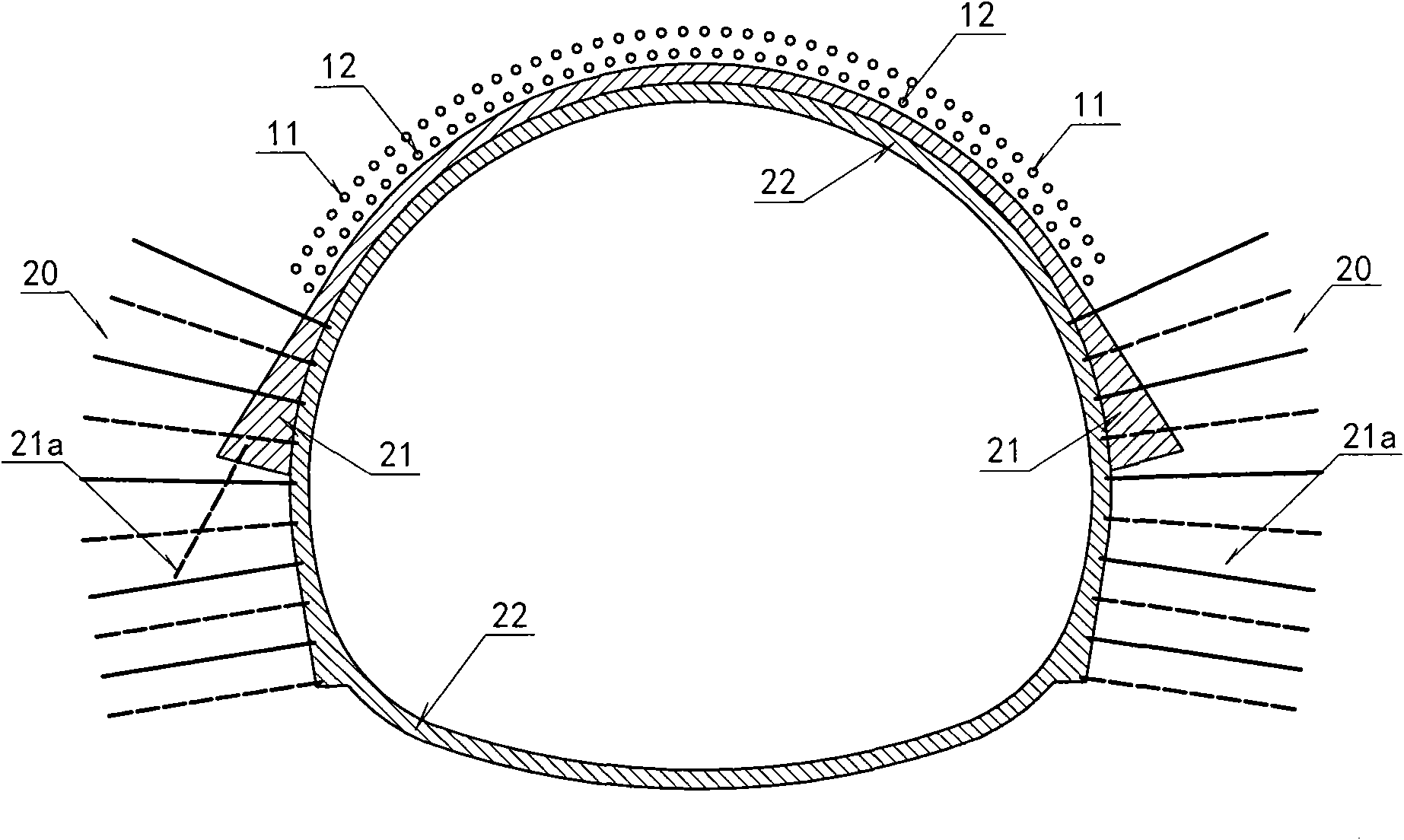

Primary support construction for shallow-buried extra-large section tunnel crossing highway underneath in uneven strata

InactiveCN101592032AIncrease stiffnessReduce spacingUnderground chambersTunnel liningEarth surfaceRock bolt

The invention discloses a primary support construction for a shallow-buried extra-large section tunnel crossing a highway underneath in uneven strata, which aims to effectively control the settlement of tunnel construction and the ground settlement. The primary support construction comprises an advanced support structure and a primary support structure, wherein the advanced support structure is formed by combining external big pipe sheds (11) and internal big pipe sheds (12) which are radially arranged at intervals; and the primary support structure is formed by combining an arch external support layer (21) and a whole-ring internal support layer (22) which are formed by spraying concrete, and the side wall section of the primary support structure is distributed with side wall system anchor rods (20). The primary support construction has the advantages of effectively reducing the influence of excavation deformation on the ground, improving the stress of the primary support, strengthening the stability of soil body, effectively solving the technical problem of big section loess tunnel construction, controlling the settlement value of the tunnel construction and the ground settlement value within 30 mm, and ensuring the safety of the tunnel construction and highway operation.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Ore tailings ceramsite air brick and preparation method thereof

The invention discloses an ore tailings ceramsite air brick and a preparation method thereof. The ore tailings ceramsite air brick is prepared from the following raw materials in parts by weight: 20-30 parts of slate, 30-50 parts of coal gangue, 15-20 parts of building rubbish, 10-15 parts of modified loess, 8-12 parts of quicklime powder, 15-25 parts of ore tailings, 5-10 parts of rice husk, 8-12 parts of barite, 10-15 parts of limestone, 5-10 parts of volcanic ash, 3-6 parts of aluminum silicate fiber, 2-4 parts of calcium sulfate whisker and a defined amount of water. According to the invention, ore tailings are taken as the main raw material to prepare ceramsite to produce the air brick, which not only reduces a great amount of cultivated land occupied by accumulated iron ore tailings and environment pollution, but also improves the heat-insulating property and mechanical strength of the air brick. The air brick provided by the invention has the advantages of high strength, low density, good heat-insulating property, anti-seismic property and weatherability, environmental friendliness, energy conservation and the like and is suitable for large-scale popularization and application.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

Saline and alkali land improvement method

InactiveCN101536643AGood technical effectHorticultureSoil-working methodsLand improvementAgropyron elongatum

The invention relates to a land transformation method, in particular to a saline and alkali land improvement method. The method comprises the following steps: the saline and alkali land to be improved to is changed into an alternant land for a trench land and ridges; a layer of fine flowing sand or sandy loess with thickness of 3-3.5 cm is evenly laid on the trench land, the saw powder and the chopped grass with thickness of 1-1.5 cm are laid, and the plowing depth is 5-15 cm and is not excessively deep; the trench land is filled with water during the watering process and the ridge cannot be filled with water as possible; the saline and alkali tolerant high-quality corn variety is selected and planted or the agropyron elongatum can be planted; after the young seedlings grow out, the traditional intertillage management is carried out; after the seeds are harvested, the straw returning is carried out; as for the land tillage in the second year, the sand with thickness of 2-5 cm is laid, the saw powder and the chopped grass with thickness of 1-3 cm are laid, then a certain amount of farmyard manure is applied and the rest is the same as the tillage in the first year; as for the land tillage in the third year, the ridges on both sides of the land are respectively taken as the lands with one eighth width during the tractor-ploughing process, so the trench land is increased, and other parts are repeated according to the tillage in the second year; as for the land tillage from the fourth year to the sixth year, the tillage method in the third year is repeated; and the improvement of the whole saline and alkali land is finished after six years. The invention can enable the saline and alkali land to be changed into a fertile land, thereby thoroughly harnessing the saline-alkali land.

Owner:朱高升

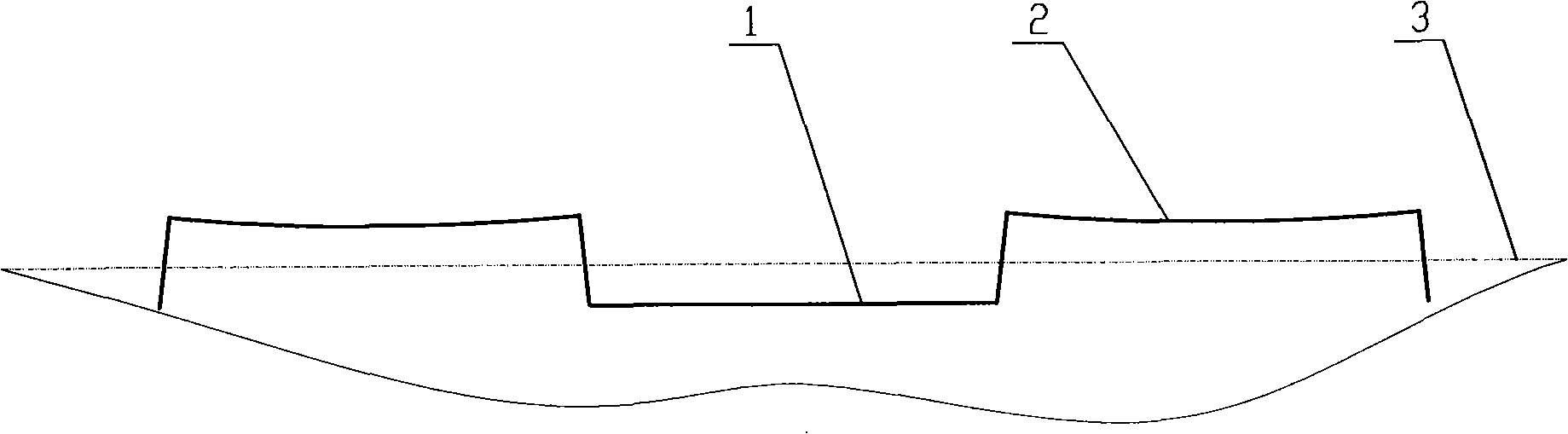

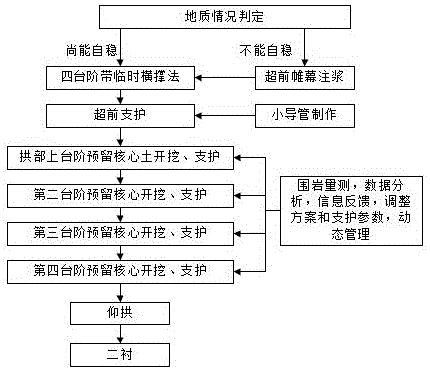

Construction method for tunnel trunk penetrating through loess interface water-rich strata

InactiveCN106121661APrevent sinking deformation damageSuppress vertical displacementUnderground chambersTunnel liningTruckCross bracing

The invention relates to the technical field of tunnel construction, in particular to a construction method for a tunnel trunk penetrating through loess interface water-rich strata. The construction method comprises the following steps that (1) the geological condition of the strata where the tunnel truck passes is surveyed and analyzed, and the geological condition in front of a tunnel face is analyzed at the same time; (2) whether advance longhole curtain grouting is adopted or not is determined according to the stability situation of the tunnel face; (3) advance supporting is conducted, and excavation and supporting are conducted by means of a four-step and temporary cross bracing method; and (4) excavation, supporting and lining building are conducted on an inverted arch of a tunnel. According to the construction method for the tunnel trunk penetrating through the loess interface water-rich strata, the geologic structure of a loess interface is analyzed, and advance grouting and the four-step and temporary cross bracing method are adopted for the interface water-rich strata, so that mud bursting of the tunnel face in the water-rich interface strata is effectively suppressed, and conditions are created for excavation; and the four-step and temporary cross bracing method effectively prevents overlarge overall sinking and deformation damage of the tunnel trunk when the tunnel truck penetrates through the loess interface water-rich strata, and the construction method has very important guiding significance for design and construction of tunneling in loess-like strata.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

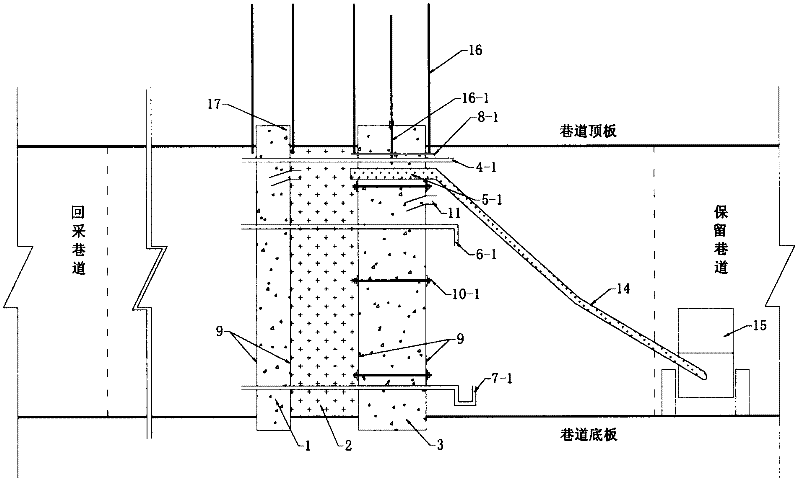

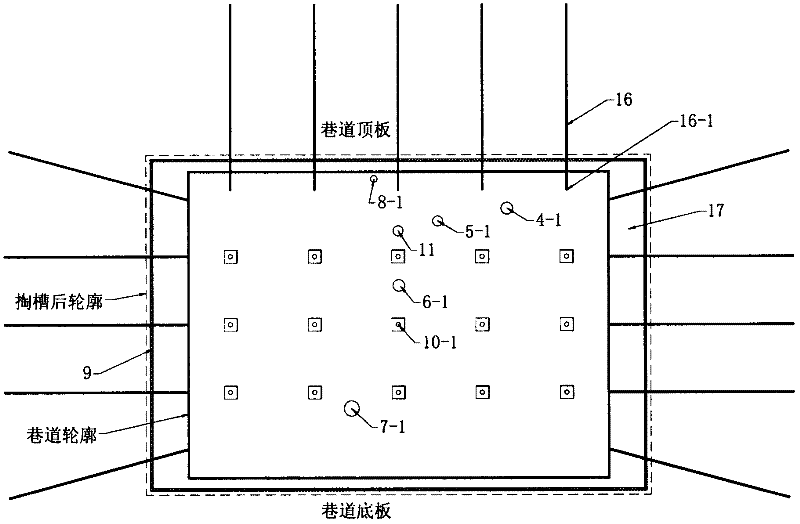

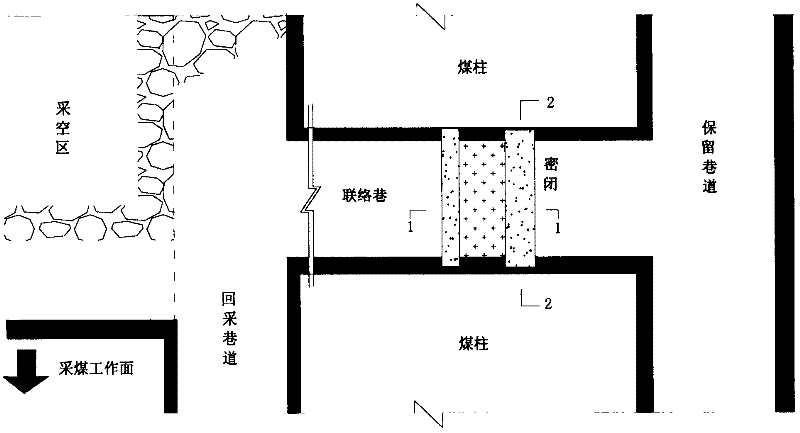

Construction method for pouring airtight partition wall between recovered roadway and reserved roadway

The invention discloses a construction method for pouring an airtight partition wall between a recovered roadway and a reserved roadway. The airtight partition wall is formed by an inner concrete single wall, an outer concrete single wall and a middle loess concrete wall; and the airtight structure is provided with three layers of walls: the inner side and the outer side are respectively provided with the airtight single wall which is formed in a way that a concrete pump pours concrete into a fiber flexible template, and the loess concrete wall filled by loess-based materials is arranged between the two single walls. The flexible templates are made in advance according to design requirements; a slot is drilled on a preset airtight surrounding rock connecting the roadways; anchor rods are constructed in the slot; after the flexible templates are hung onto the slot through a single hydraulic prop or the anchor rods, the concrete is successively poured into the inner side flexible template and the outer side flexible template by a concrete conveying pipe and a pouring opening through the concrete pump to form the inner single wall and the outer single wall; and after the inner single wall and the outer single wall are poured completely, the loess is poured between the inner single wall and the outer single wall to form the concrete airtight wall. The structure is safe and reliable, the construction cost is low, the construction speed is fast, the labor intensity is low, and the requirements of mine production with high production and high efficiency are met.

Owner:XIAN UNIV OF SCI & TECH +1

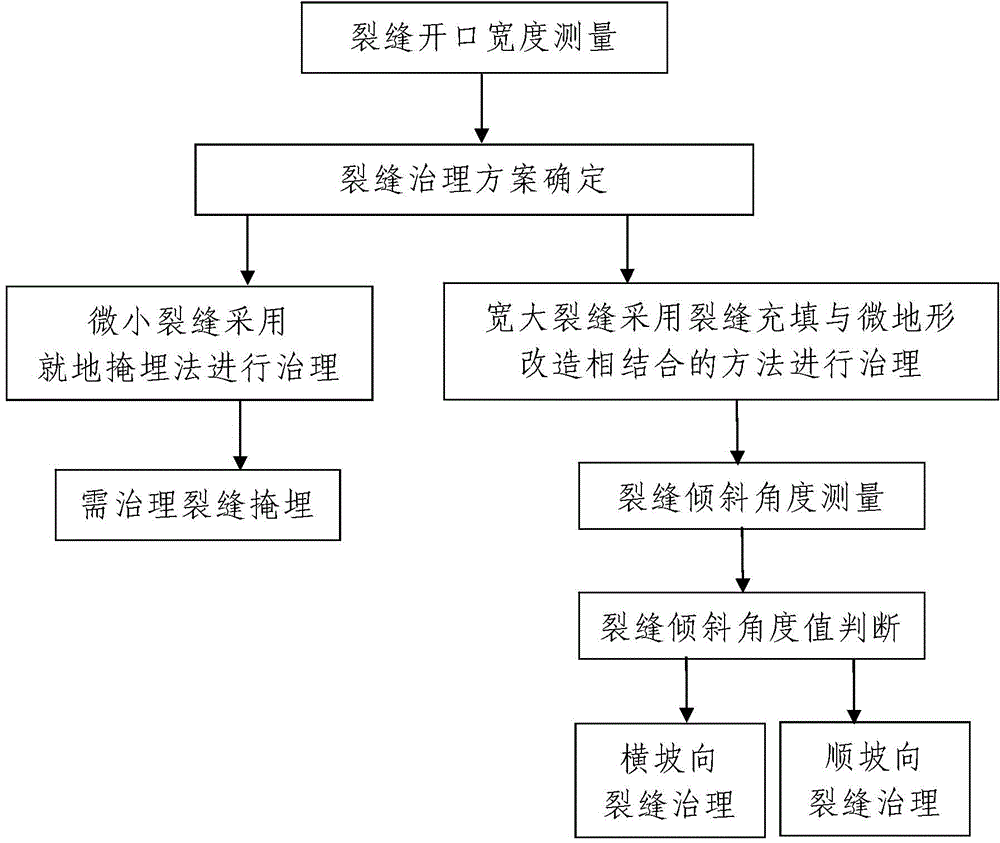

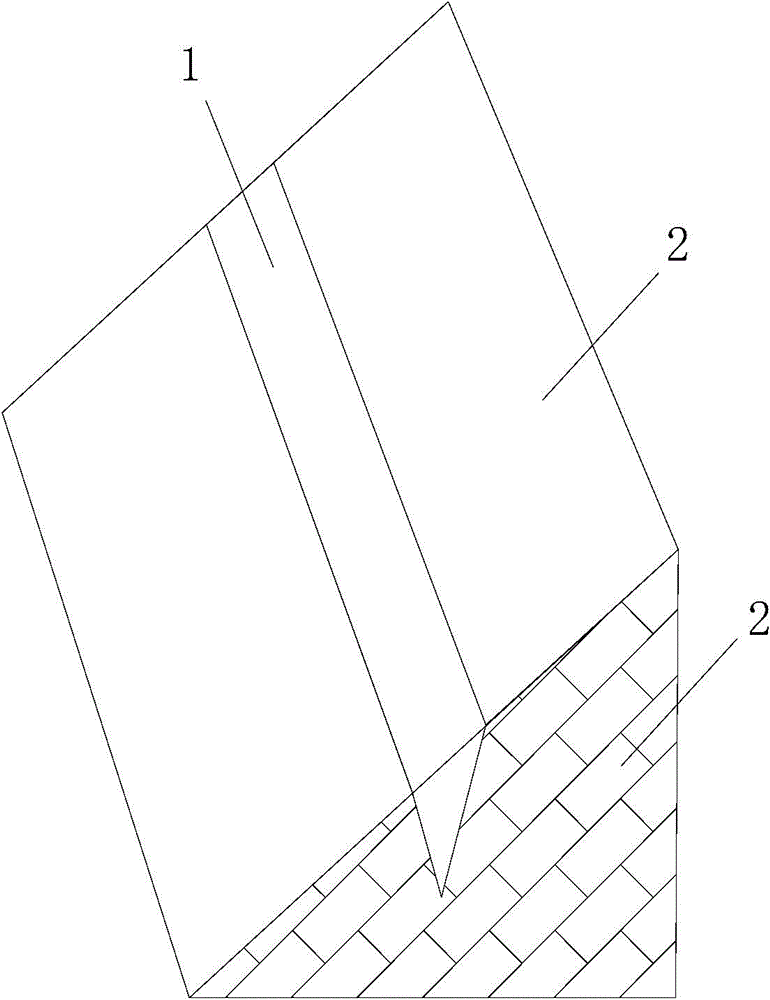

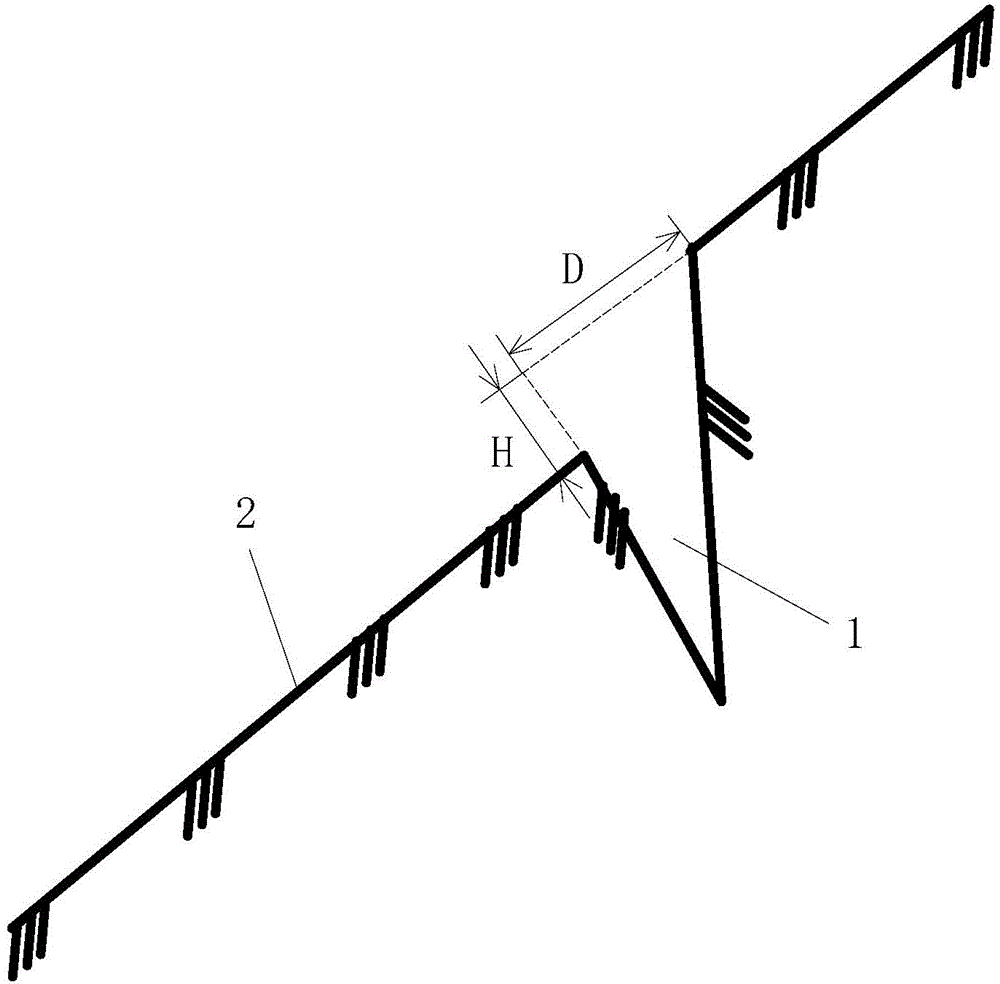

Coal mining subsidence area administration method for loess hilly-gully region

InactiveCN104652451AThe method steps are simpleReasonable designEmbankmentsCultivating equipmentsMedicineLandform

The invention discloses a coal mining subsidence area administration method for a loess hilly-gully region. The method comprises the following steps: 1, measuring the width of a crack opening; 2, determining a crack administration scheme, wherein the crack administration scheme is an on-site filling method or a combined crack filling and micro-slope reconstruction administration method; 3, performing crack administration, wherein a crack to be administrated is filled with a soil body when the on-site filling method is adopted; the combined crack filling and micro-slope reconstruction administration method for administration comprises the following steps: 301, measuring an inclination angle of the crack; 302, judging an inclination angle value of the crack; 303, performing cross slope crack administration; 304, along-slope crack administration; 4, repeating step 1 to step 3 for many times until all subsided cracks in a loess slope of a coal mining subsidence area are administrated. The steps are simple, the method is reasonable in design, convenient to implement and construct and shorter in construction cycle, and has good administration effects, and the coal mining subsidence area of the loess hilly-gully region can be effectively administrated.

Owner:XIAN UNIV OF SCI & TECH

Gray iron casting moulding sand and preparation method thereof

The invention discloses gray iron casting moulding sand which is prepared from the following raw materials in parts by weight: 250-280 parts by weight of quartz sand, 40-45 parts by weight of sepiolite, 160-170 parts by weight of loess, 30-35 parts by weight of shell powder, 20-25 parts by weight of titanium dioxide, 40-45 parts by weight of grass meal, 2-3 parts by weight of acrylic emulsion, 30-40 parts by weight of silicon carbide, 10-15 parts by weight of pulverized coal, 50-60 parts by weight of gypsum, 3-4 parts by weight of zinc stearate, 10-15 parts by weight of bentonite, 3-4 parts by weight of ammonium dihydrogen phosphate, 4-5 parts by weight of sodium bicarbonate, 2-3 parts by weight of sodium dodecyl benzene sulfonate, 4-6 parts by weight of urea, 10-12 parts by weight of flour, 40-45 parts by weight of wood-bamboo powder and a proper amount of water. The sepiolite, the loess, the bentonite and the like are calcined, thus the gray iron casting moulding sand has excellent plasticity and caking property; by using the shell powder, the grass meal, the wood-bamboo powder and the like, the air permeability is increased; by using the titanium dioxide, the dispersity is increased and the high-temperature collapsibility is good; by using the pulverized coal, the surface of a casting is bright. The yield of the casting is increased.

Owner:张志功

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Sandy soil water-immersion testing method for loess collapsible deformation

InactiveCN102912780AReflect the actual collapsibilitySimple and fast operationIn situ soil foundationSoil massWater immersion

The invention discloses a sandy soil water-immersion testing method for loess collapsible deformation. The method includes the steps: digging an exploratory well on the stratum surface, and taking collapsible loess below the exploratory well as to-be-tested soil mass; selecting a bearing plate, fixing a sedimentation rod above the bearing plate, and mounting a soil pressure gauge on the bearing plate; removing dig fictitious soil at the bottom of the exploratory well, laying a sand bed, placing the bearing plate on the sand bed, and enabling the measuring signal line of the soil pressure gauge to extend out of the stratum surface upwards; and filling sand gravels in the exploratory well, filling water after sufficient sand gravels are filled, and measuring the earth pillar pressure formed by the sand gravels by the soil pressure gauge, wherein sedimentation displacement change of the sedimentation rod refers to collapsible deformation of the collapsible loess. By the sandy soil water-immersion testing method for loess collapsible deformation, the defects of disturbance of soil sample obtaining and sample preparation on loess structuredness in indoor collapsibility tests, high on-site water-immersion test pit testing cost and limited testing points are overcome.

Owner:XIAN UNIV OF TECH +1

Three-step non-reserved-core-soil construction method for large-cross-section tunnel at collapsible loess area

InactiveCN106194195ALarge space for construction workImprove construction efficiencyUnderground chambersBlastingSocial benefitsService efficiency

The invention discloses a three-step non-reserved-core-soil construction method for a large-cross-section tunnel at a collapsible loess area, and relates to the technical field of tunnel construction. During upper step excavation construction, reserved core soil of an upper parenthetic pilot tunnel is omitted, so that the upper step excavation quantity is made to account for 73% of the excavation area of a whole tunnel face; the one-time excavation area is large, deslagging efficiency is improved, machine and labor force service efficiency is improved, the tunnel face excavation and construction time is shortened, the sealing time of structural steel in a tunnel hole is shortened correspondingly, and the tunnel hole support safety coefficient is increased; and the construction progress is greatly accelerated, the construction cost is lowered, and good economic and social benefits can be achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

Tunnel advanced support air circulated drilling construction method and drilling tool

InactiveCN101260784AAvoid disturbanceEnsure construction safetyEarth drilling toolsUnderground chambersPosition angleAir compressor

The invention provides a tunnel forepoling air circulating drilling construction method. The construction steps are as follows: a driller is firstly installed and is moved to the appointed hole position along a track, according to the tunnel position line, the position angle of the driller is adjusted to ensure that the driller is parallel with the tunnel position line, the driller is fastened with a frame; an air compressor is turned on, the wind pressure is controlled above 0.4MPa, and then the driller is turned on to ensure that a drill pipe drills towards the earth at a constant speed, the compressed air is sent to an aiguille part through an internal cavity of the drill pipe and air-cools the aiguille, drilling cuttings are blown out of the drill hole from the gap between the drill pipe and the earth; the inner part of the aiguille is provided with a guide drilling device; finally, the hole drilling is finished and the grout is cast, the grout is cast into the inner cavity of the drill pipe by a casting pipe, the grout is filled into the inner cavity of the drill pipe and the ring-shaped gap out of the drill pipe, and the next hole position is turned to construct. The tunnel forepoling air circulating drilling construction method solves the problems of low security and slow drilling of the earth layer, especially the fourth new loess area pipe roofing timbering construction, can avoid the landslide and minimize the potential safety hazard.

Owner:BEIJING SHOUER ENG TECH

Automatic tamper type waste filling hydraulic support

InactiveCN102135006AGood topping effectSmooth connectionMaterial fill-upMine roof supportsGround subsidenceCut and fill

The invention discloses an automatic tamper type waste filling hydraulic support which comprises a base and a top beam, wherein the base and the top beam are connected by uprights, the front end of the top beam is provided with a forepole, the rear end of the top beam is provided with a scraper conveyor and further connected with an internally-telescopic extrusion scraping plate by a retractable jack which is arranged horizontally; the rear side of the base is provided with the extrusion scraping plate by a first and a second extrusion jacks, and the first extrusion jack is horizontally arranged. The automatic tamper type waste filling hydraulic support solves the problems that conventional cut and fill hydraulic support equipment can not ensure top filling of filler and has poor tamper intensity; in addition, the automatic tamper type waste filling hydraulic support realizes the high-strength supporting for a gob roof by virtue of waste fillers, effectively eliminates the defect of ground subsidence, realizes safe recovery for part of permanent coal pillars, corner coals and coal under buildings on the premise of not destroying factories and relocating villages, and improves the recovery of the coal resources. The invention is also suitable for various solid fillers such as coal ash, river sand, loess and the like.

Owner:HENAN POLYTECHNIC UNIV

Alien soil for slope protection of loess slope plants

The invention relates to alien soil for slope protection of loess slope plants, which not only meets the physical structures for the growth of the slop plants in the semi-arid loess area, but also has good water storage capacity, water retention and nutrient preserving capability, provides moisture and nutrient for the growth of the plants, and has certain cementitiousness so as to be attached to the loess slope by means of engineering measures. The alien soil comprises the following components by weight part: 800-900 parts of sandy loess, 100-200 parts of soil conditioner, 1-2 parts of water retention agent, 0 to 1 part of caking agent, and 2-5 parts of compound fertilizer. The invention not only can improve the structure of sandy loess, but also provide the soil environment for the growth of the slop plants, and more importantly, effectively solves the problems of difficult vegetation protection of slopes due to the lack of water and difficult water retention in the northern semi-arid loess area. The invention mainly adopts disused soil, and has the advantages of readily available raw materials, low cost, simple construction and being favorable for reducing slope protection engineering investment.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Preparation method for tea dust temmoku glaze

Owner:SHAANXI UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com