Method for recovery of room-type coal pillar through loess filling

A coal mining method and coal pillar technology, which are applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of increasing the stress concentration factor of coal pillars, low recovery rate, mechanization degree, and endangering the life safety of personnel, etc. The effect of reducing the impact, solving the huge waste of resources and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

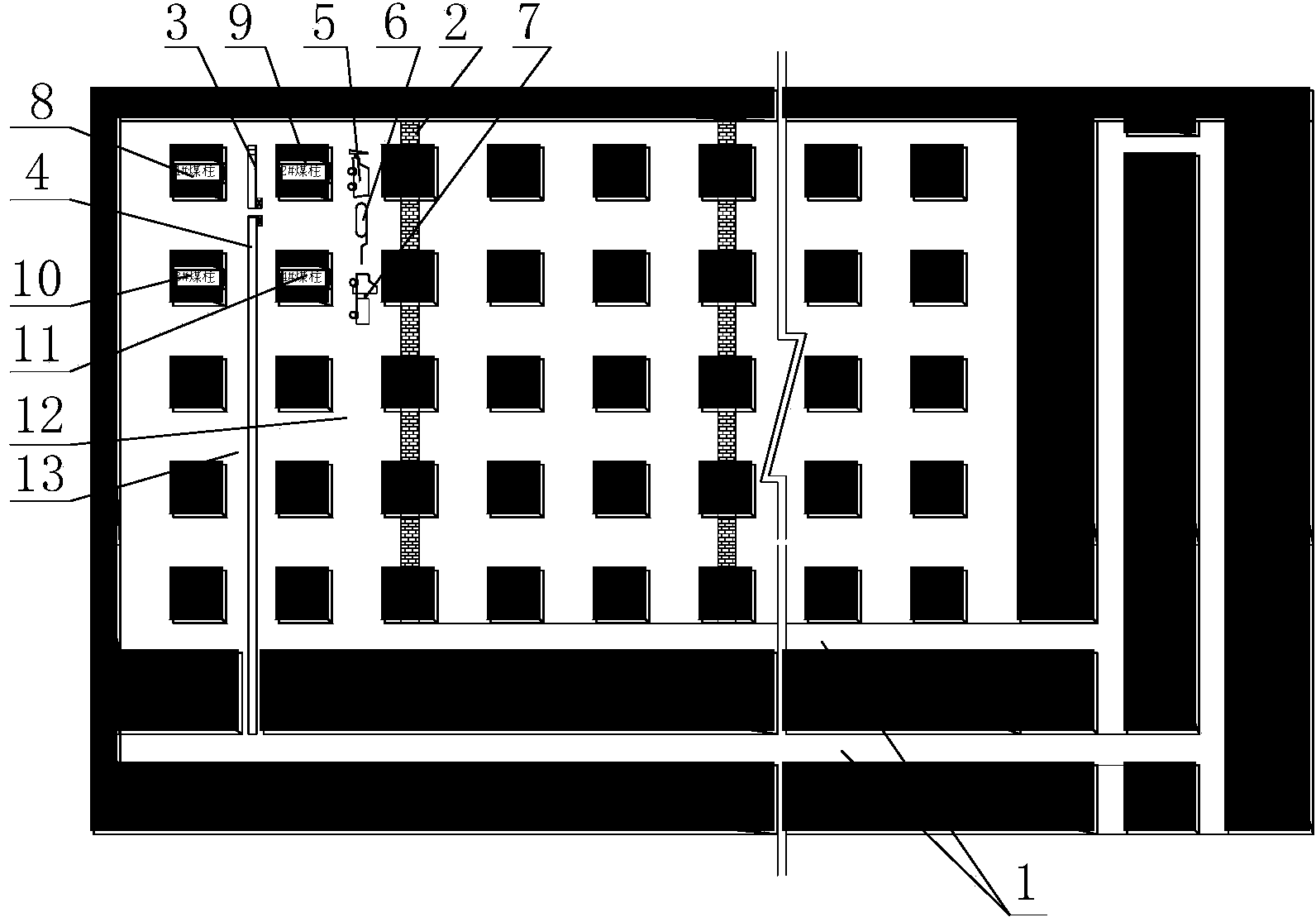

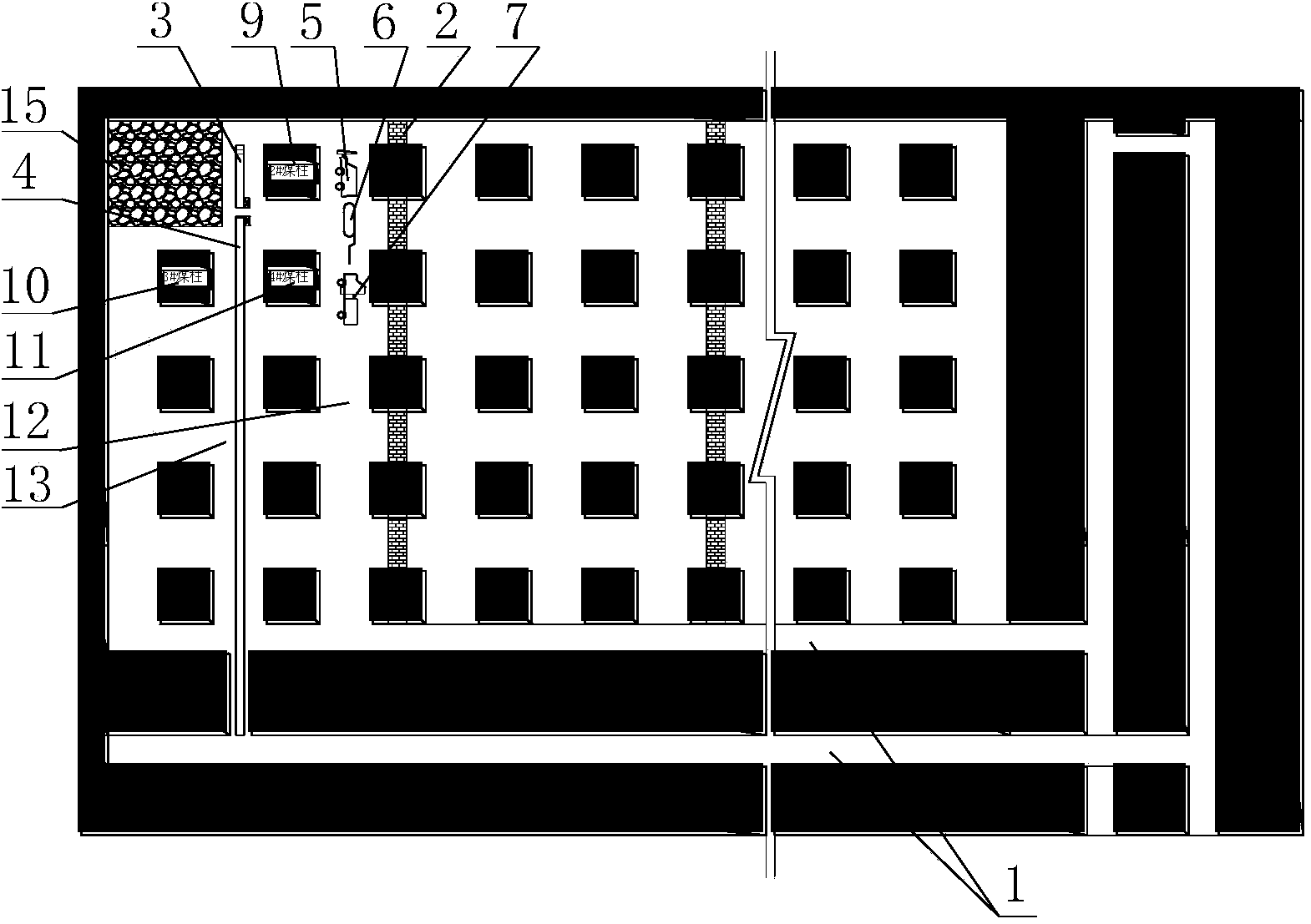

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

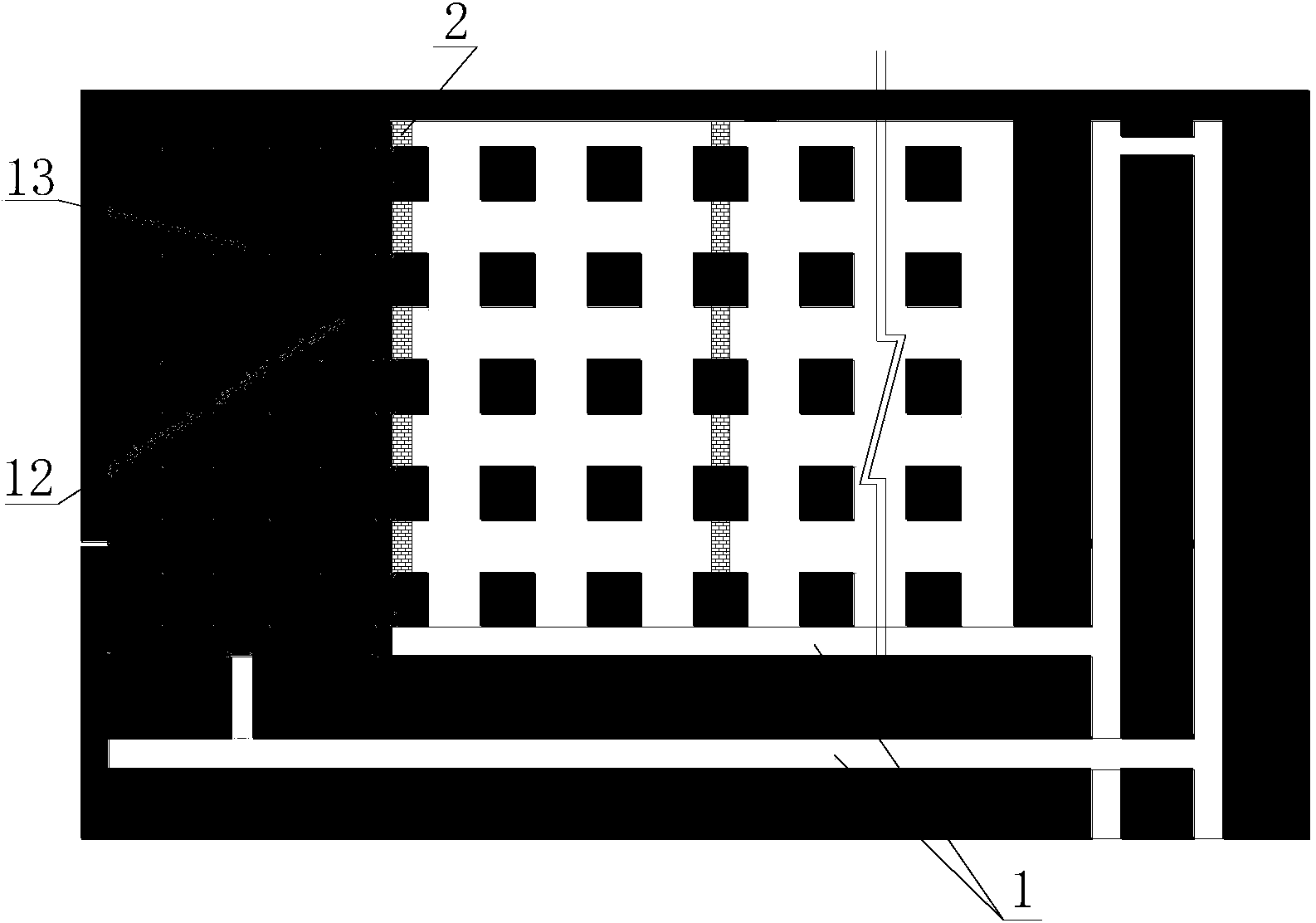

[0024] (1) The first mining working face of a certain mine is located on the southwest side of the three-panel area. Along the direction perpendicular to the section roadway 1, a mining working face is arranged for every two adjacent columns of coal pillars. The mining height of the working face is 4.5m, and the working face The strike length is 120m, the inclination length is 40m, and a column of coal pillars is reserved between adjacent mining faces as the separation wall 2, such as figure 1 shown;

[0025] (2) Along the direction perpendicular to the section roadway 1, the first row of mined coal houses on the left side of the separation wall is used as the coal transportation lane 12, and the second row of coal mining houses is used as the material transportation roadway 13;

[0026] (3) Arrange bulldozers 5, ZL5FB mining tire explosion-proof loaders 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com