Patents

Literature

3632results about "Material fill-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial soil and method for land reclamation by aid of gold mine tailing slag backfill exploitation regions

InactiveCN109429610AHigh organic contentImprove breathabilityUnderground miningGrowth substratesResource utilizationCircular economy

The invention provides artificial soil and a method for land reclamation by the aid of gold mine tailing slag backfill exploitation regions. The method includes carrying out filling and compaction onthe tailing waste slag backfill exploitation regions; uniformly mixing various components of the optimally designed artificial soil with one another and ultimately covering tailing waste slag backfillsurfaces with the novel artificial soil with a certain thickness so as to effectively treat mine tailing. The artificial soil and the method have the advantages that the prepared artificial soil contains abundant nutrient components, the contents of organic matters can be increased, the gas permeability of the soil can be improved, and the artificial soil is excellent in water retention capacityand fertilizer preservation capability and suitable for growth of plants; organic thoroughly decomposed substances come from agricultural and forestry waste, are extensive in source and are easily available, accordingly, solid waste can be comprehensively utilized in a 'reduction, resource utilization and harmlessness' manner, and the artificial soil and the method conform to principles of circular economy; the land occupation problems of tailing ponds and the problems in the aspect of tasks of land reclamation of mined-out regions can be simultaneously solved by the aid of the artificial soiland the method, and the artificial soil and the method have large market spaces.

Owner:杰瑞(莱州)矿山治理有限公司

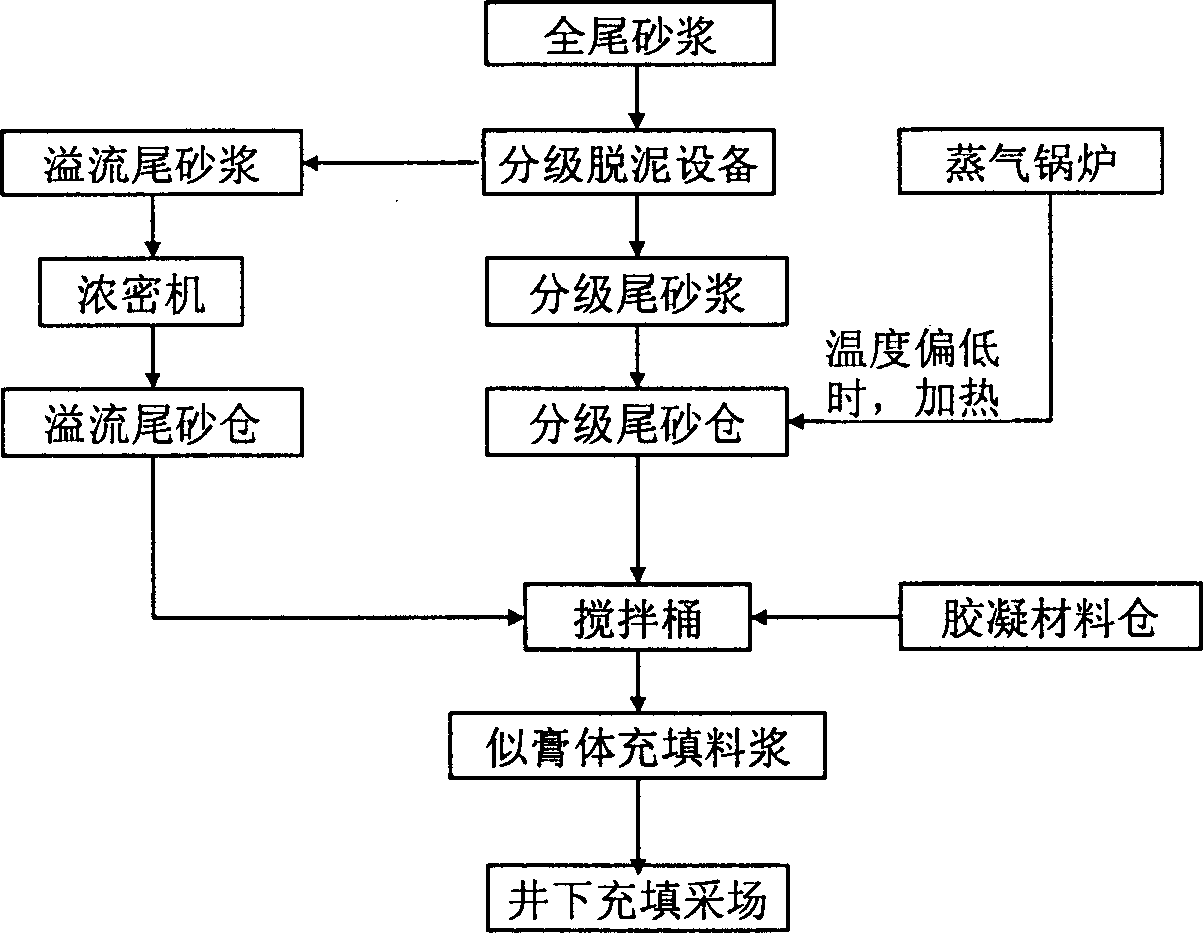

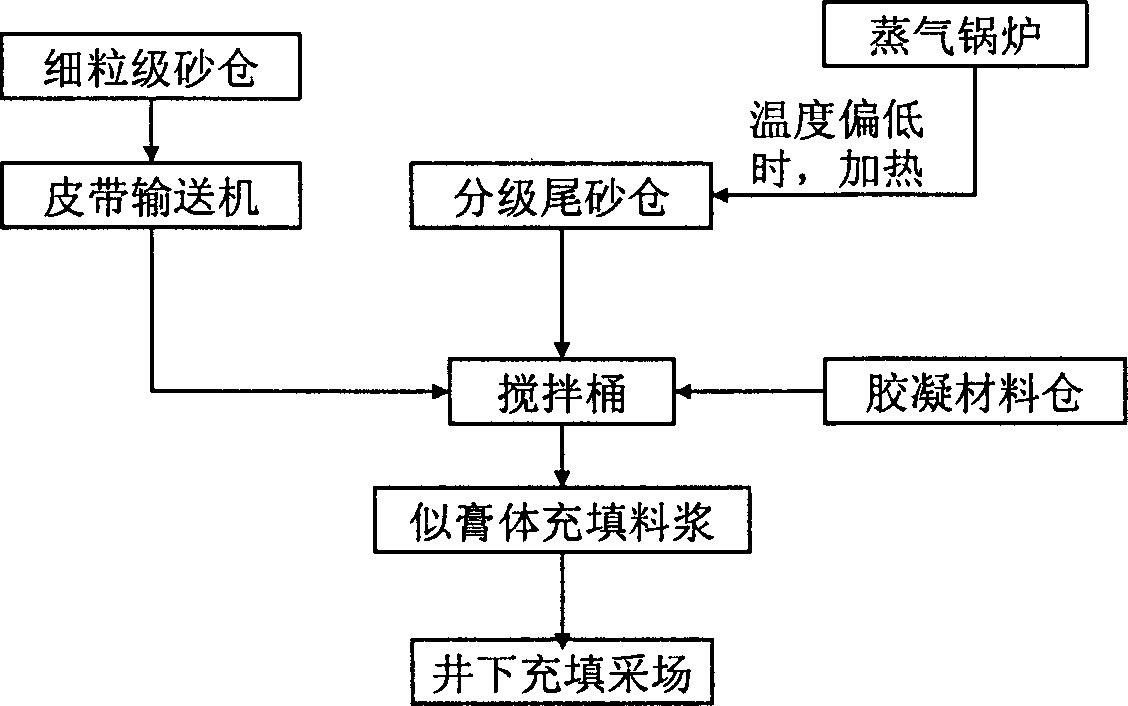

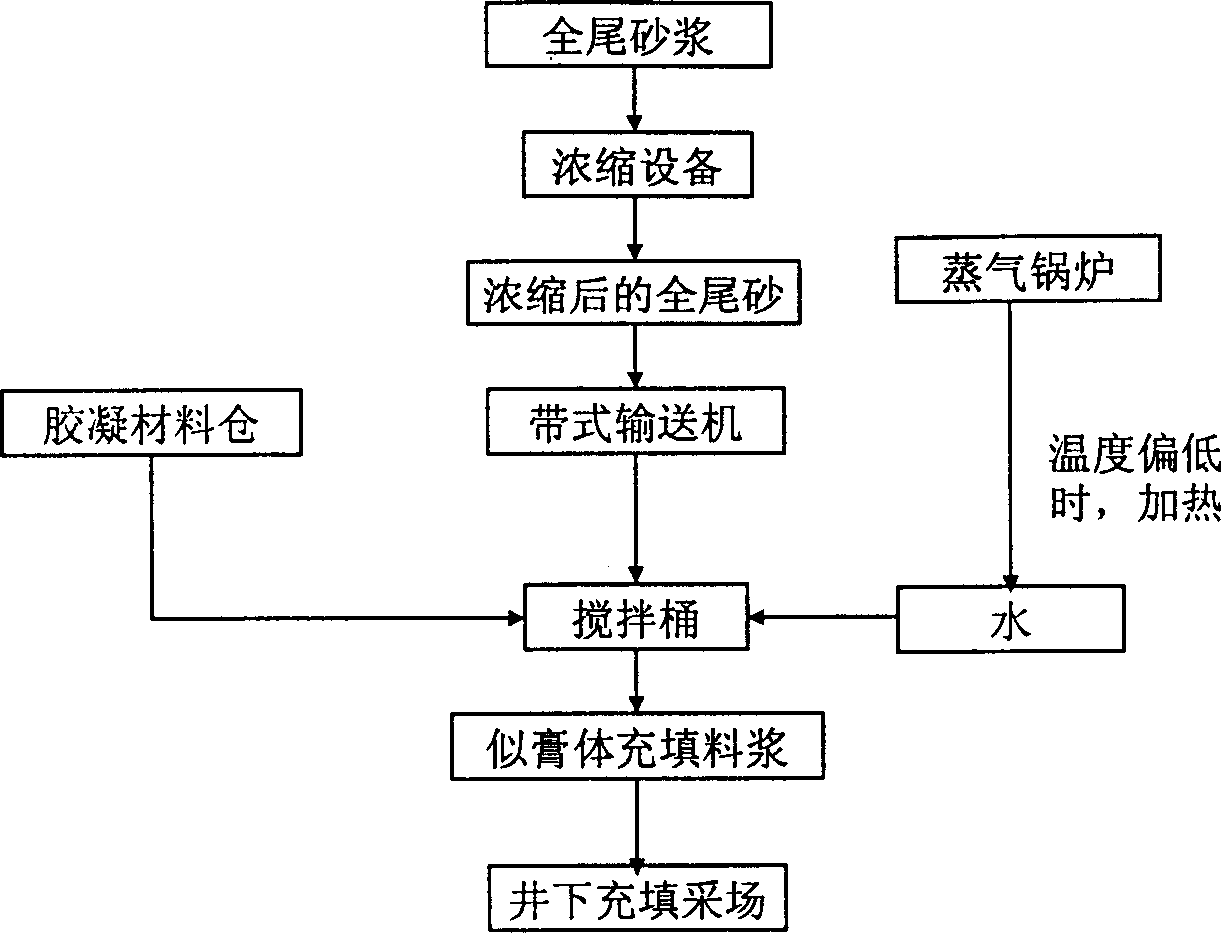

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

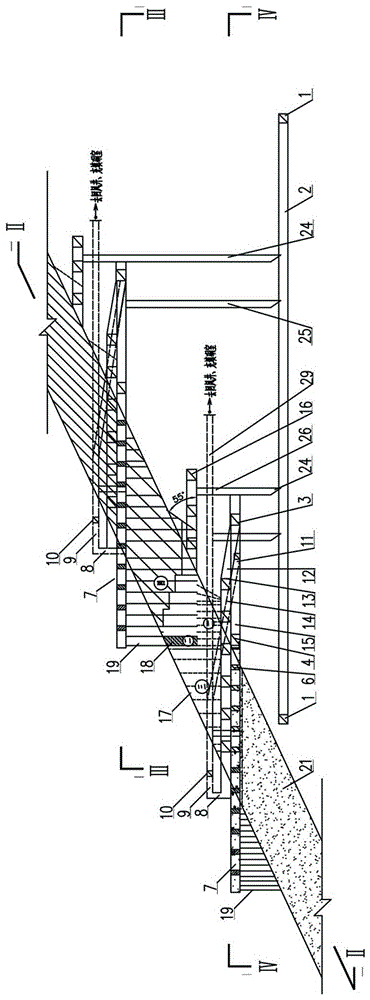

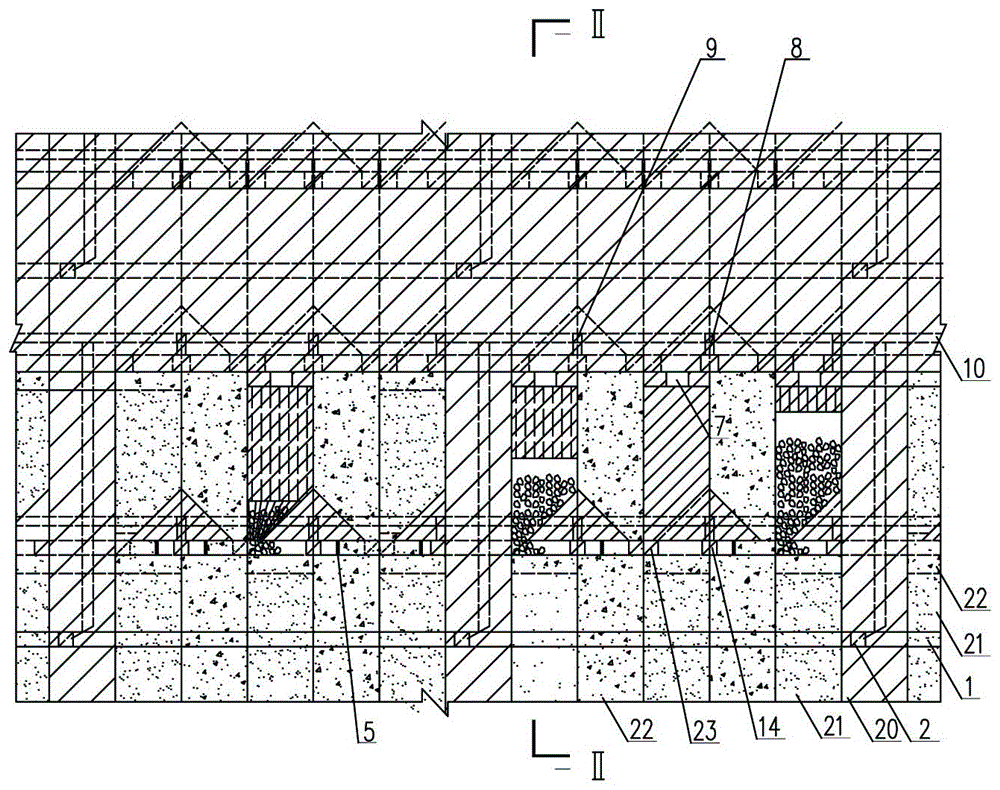

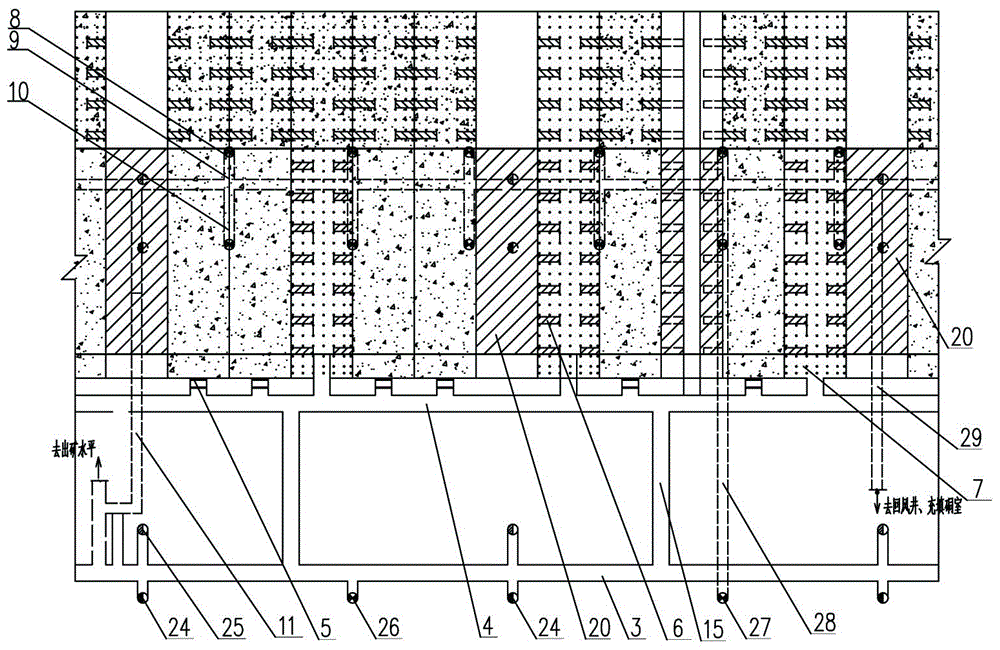

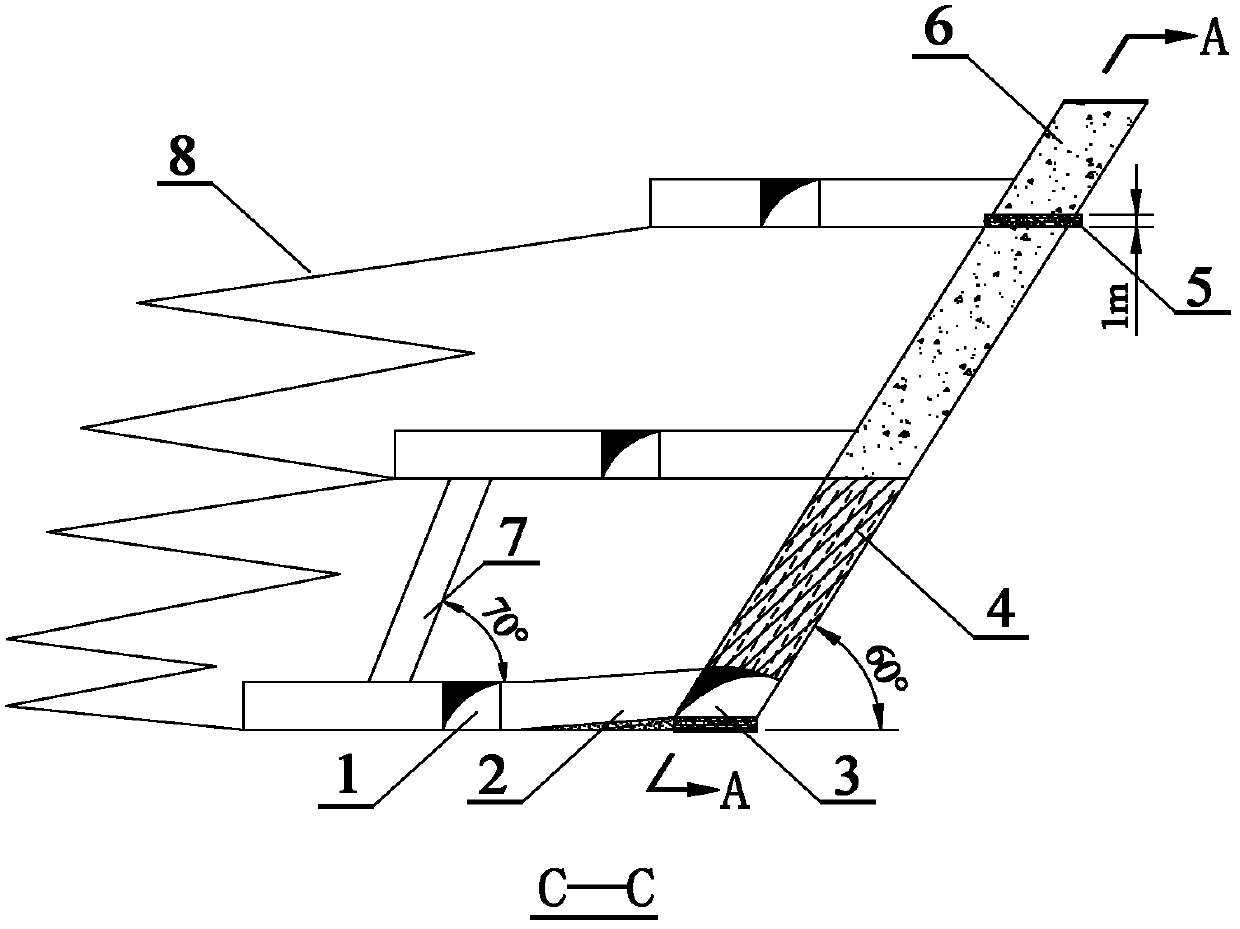

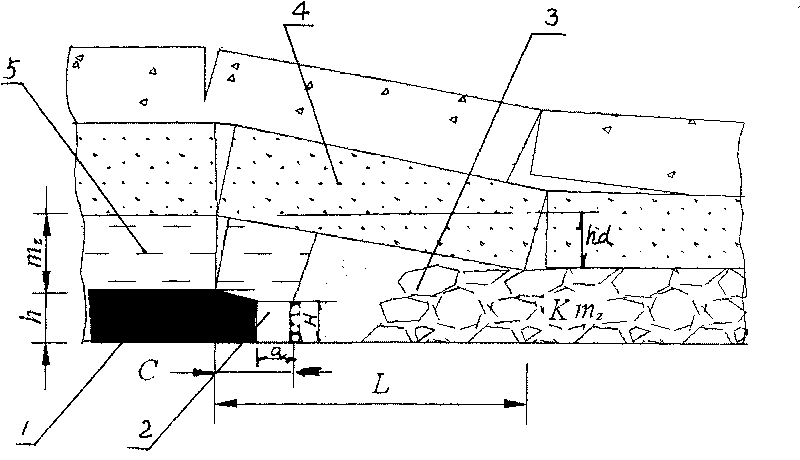

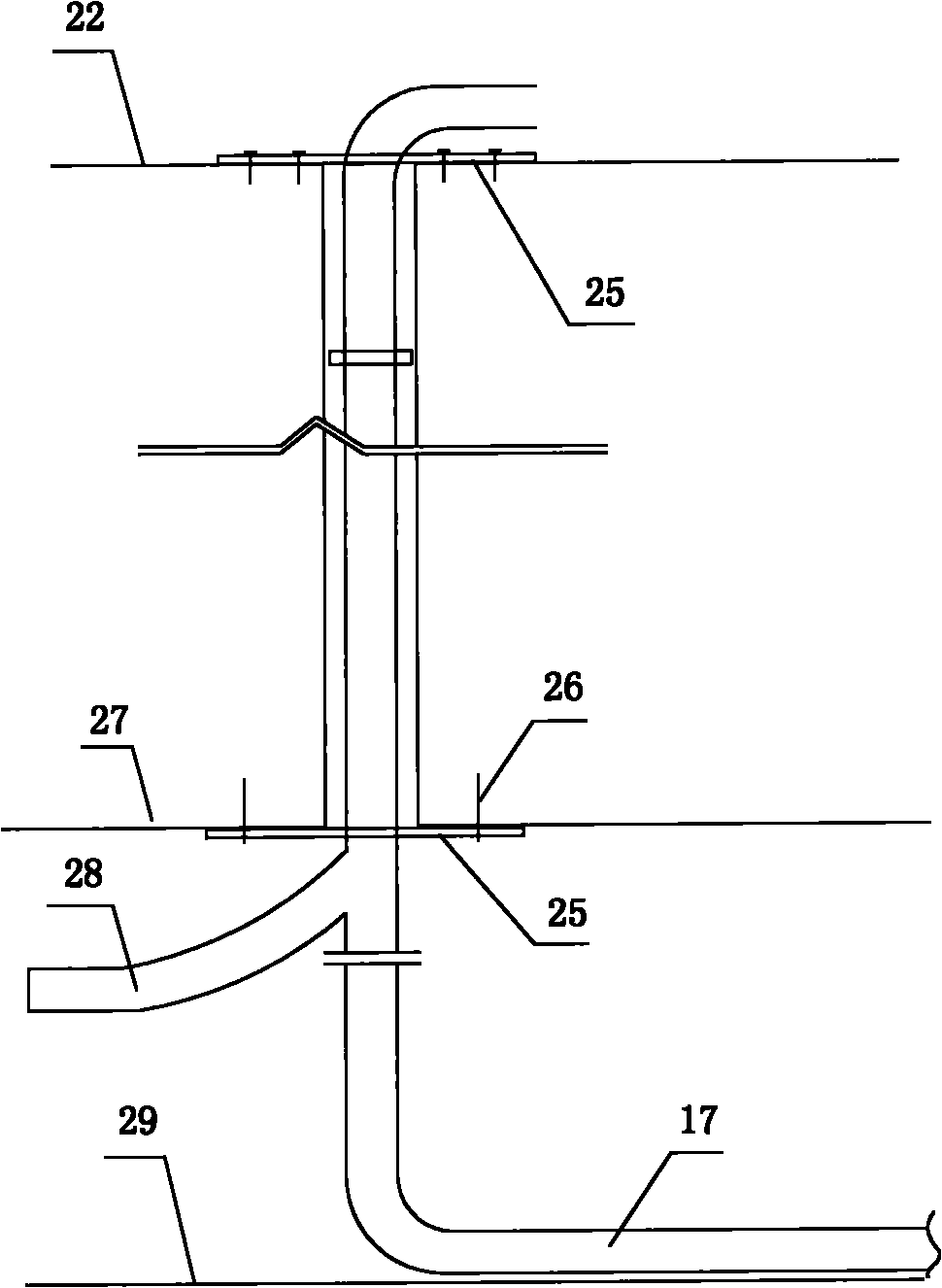

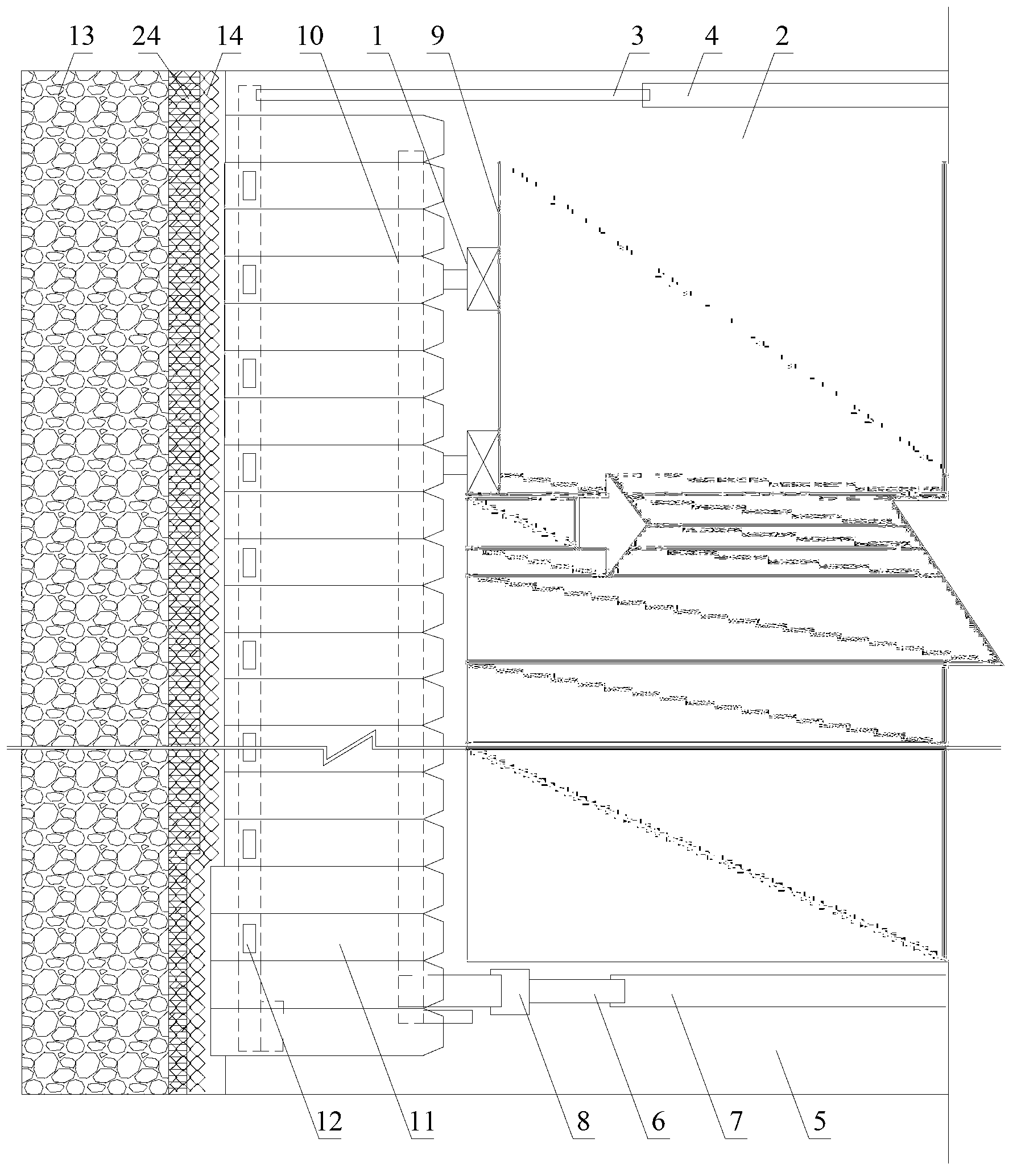

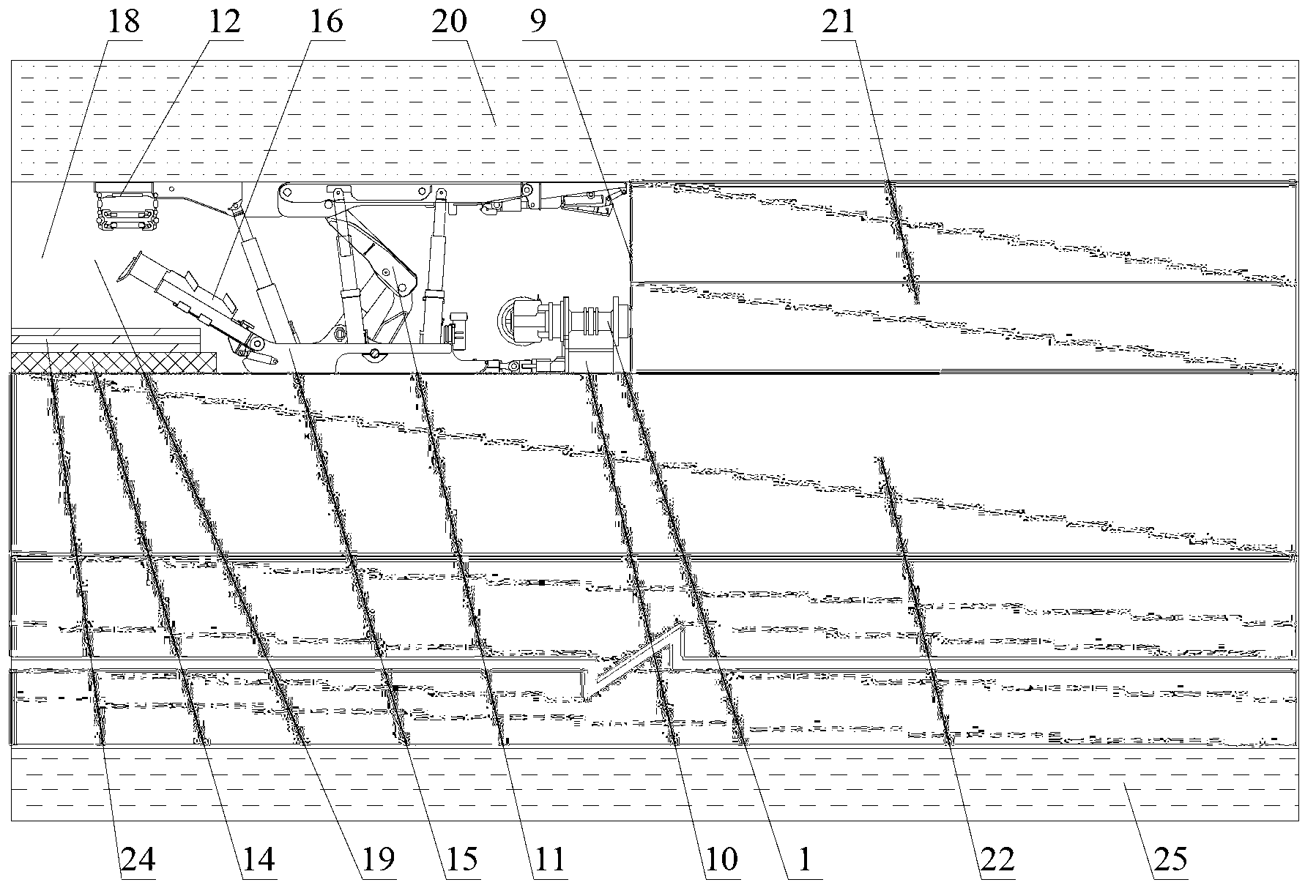

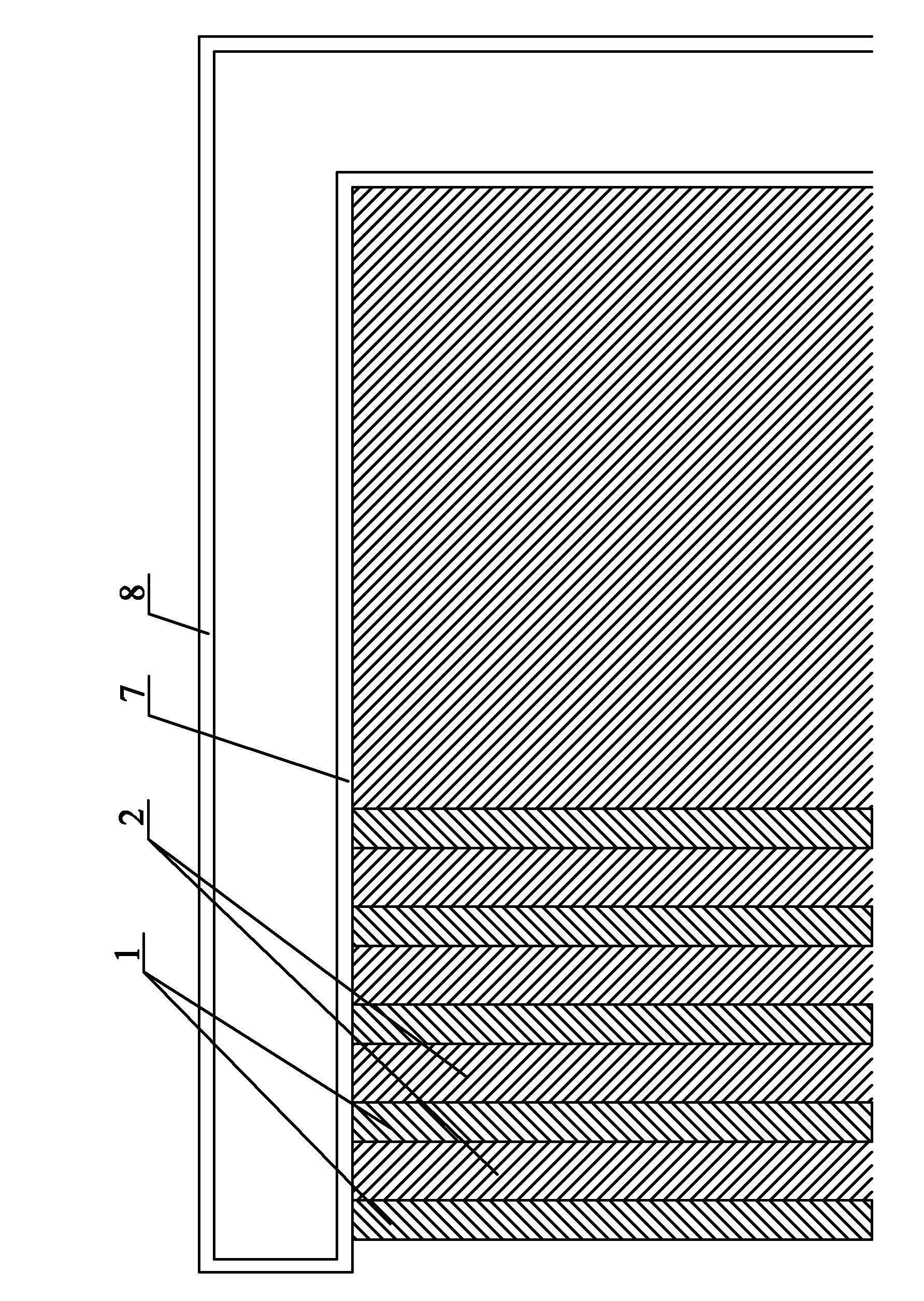

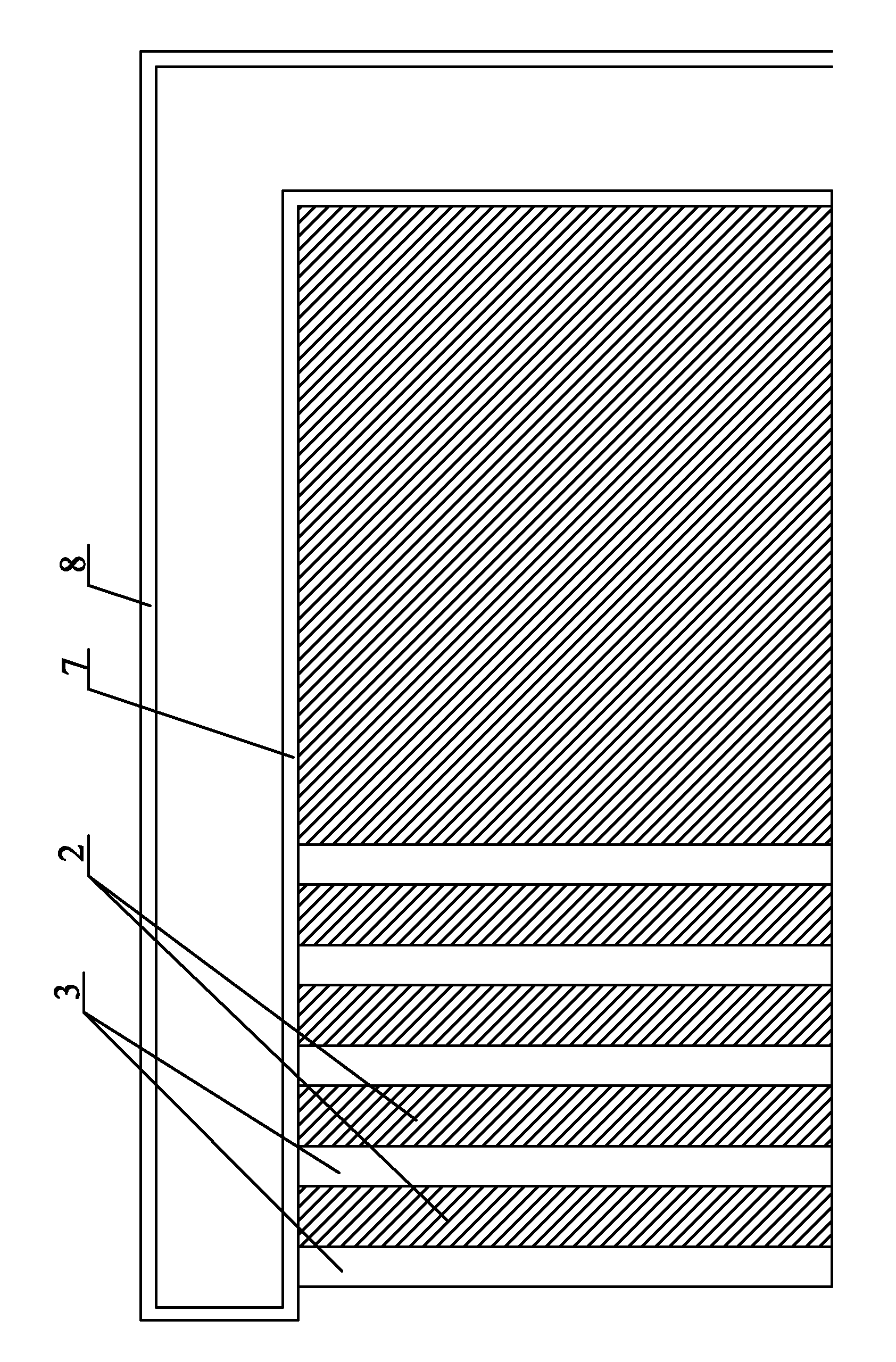

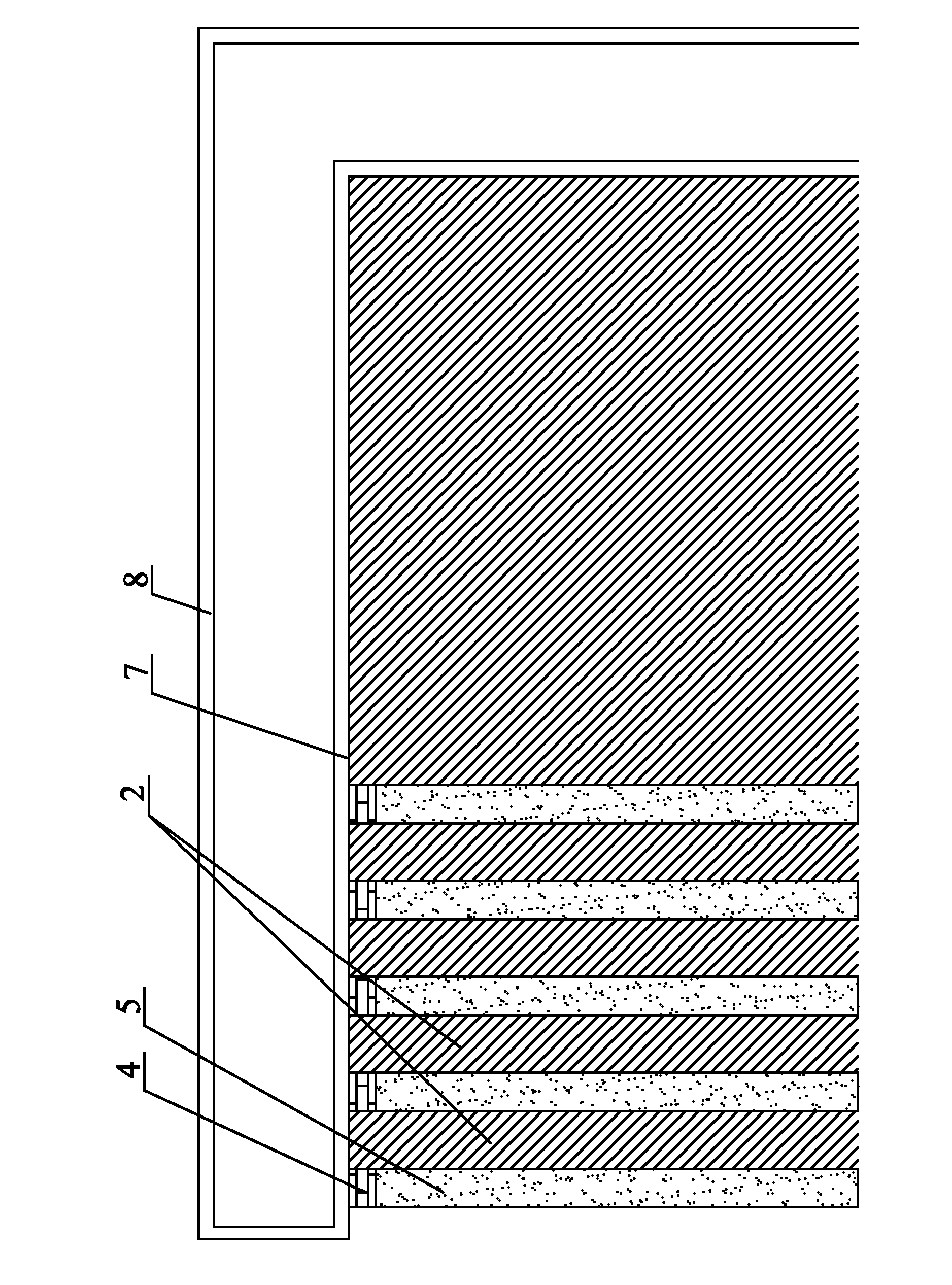

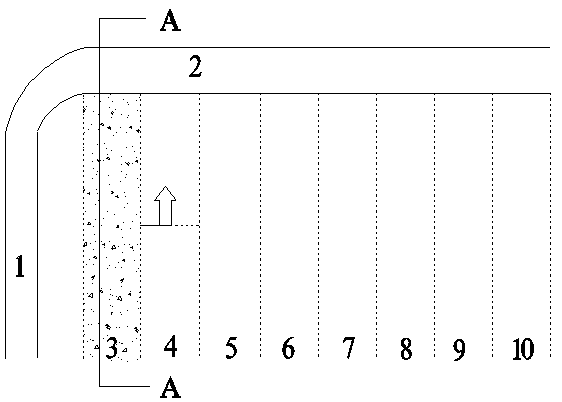

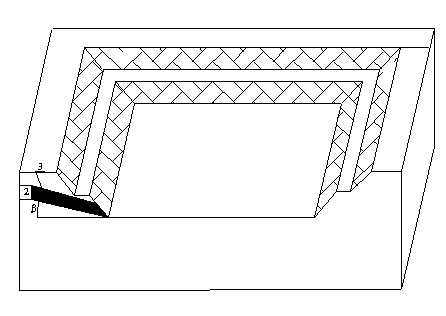

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

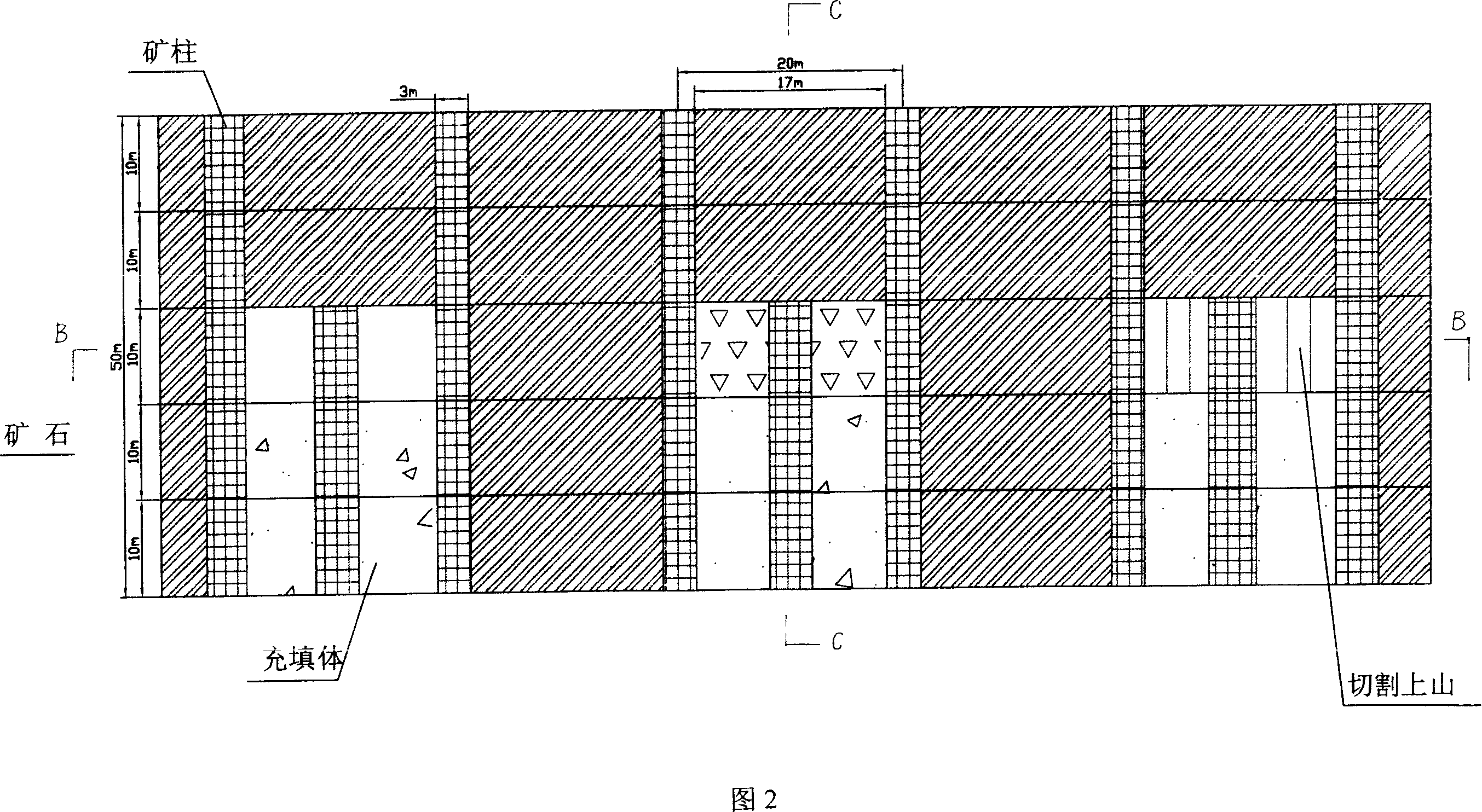

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

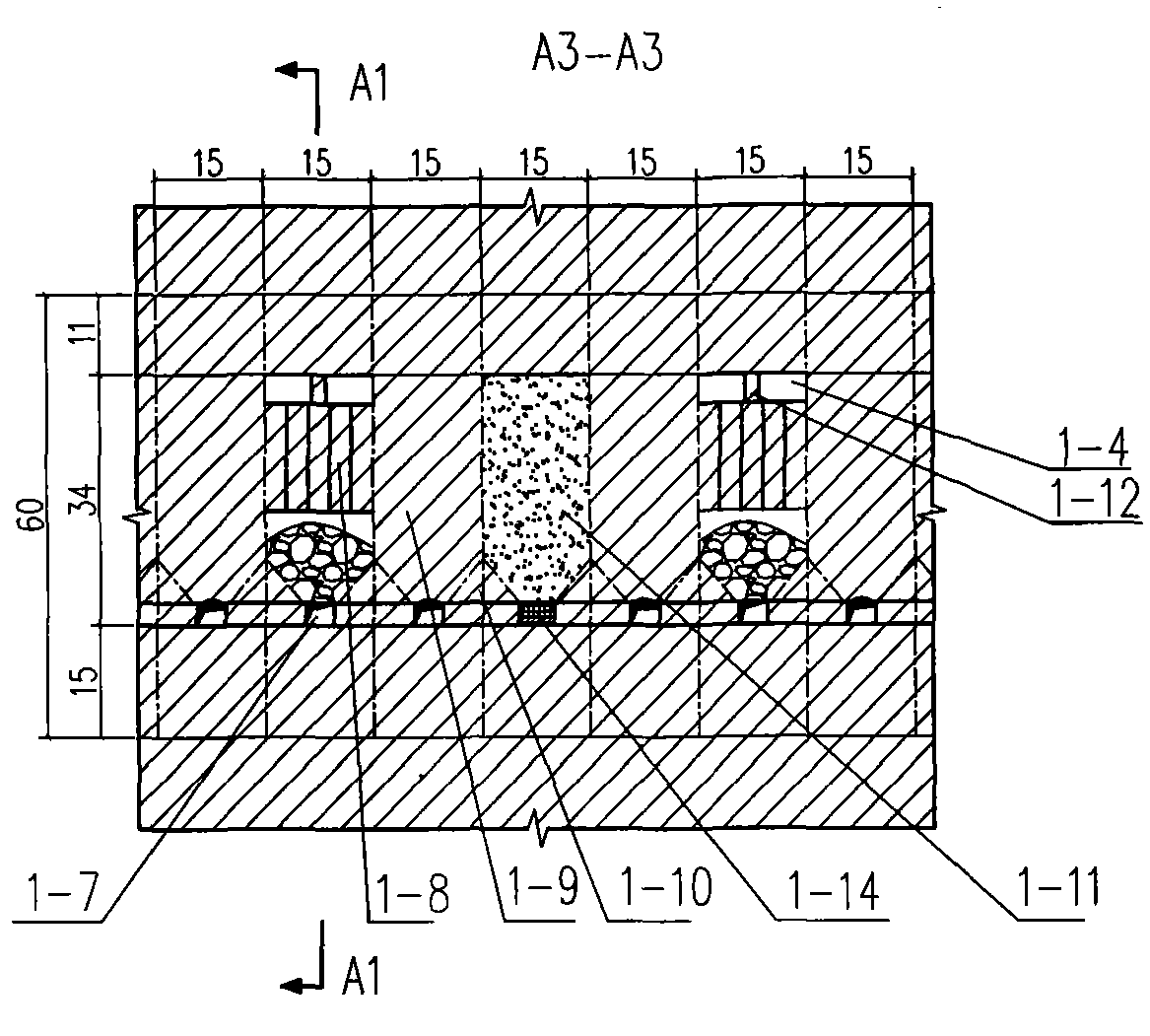

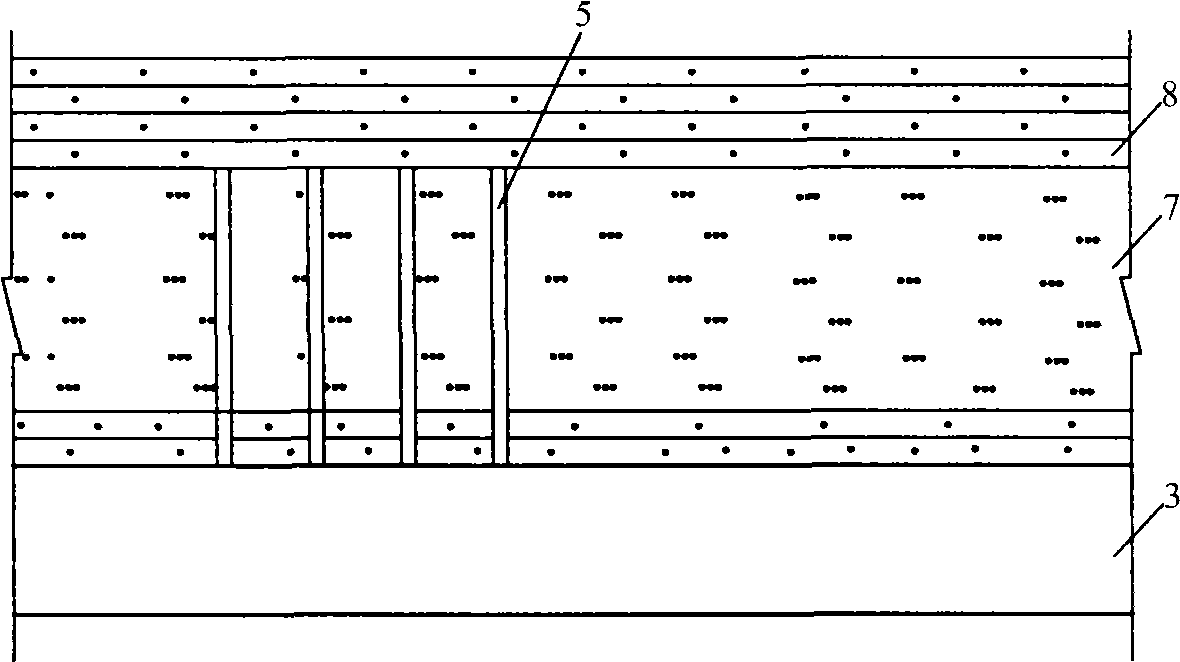

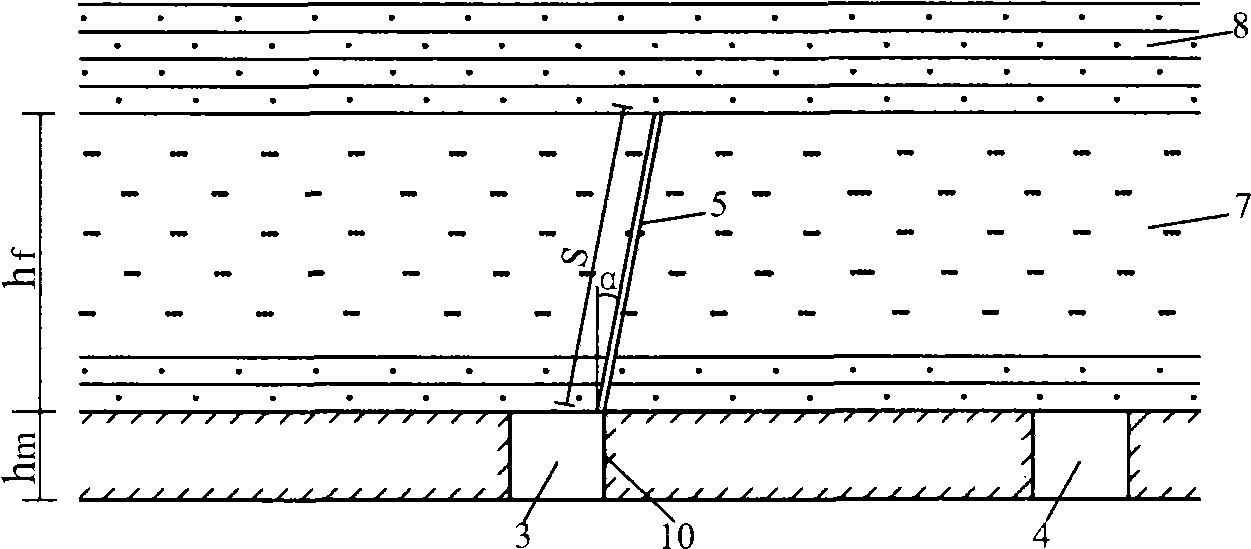

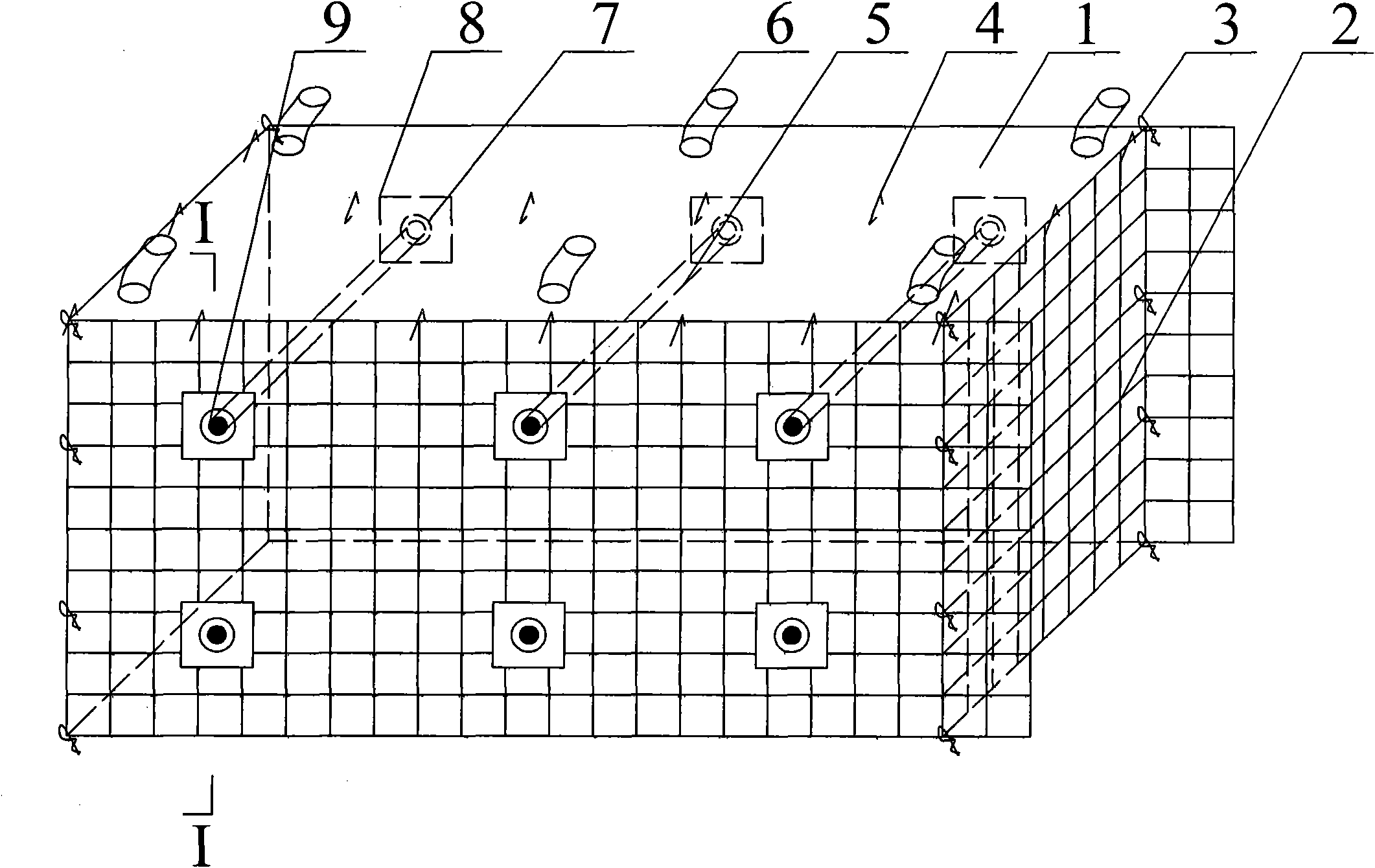

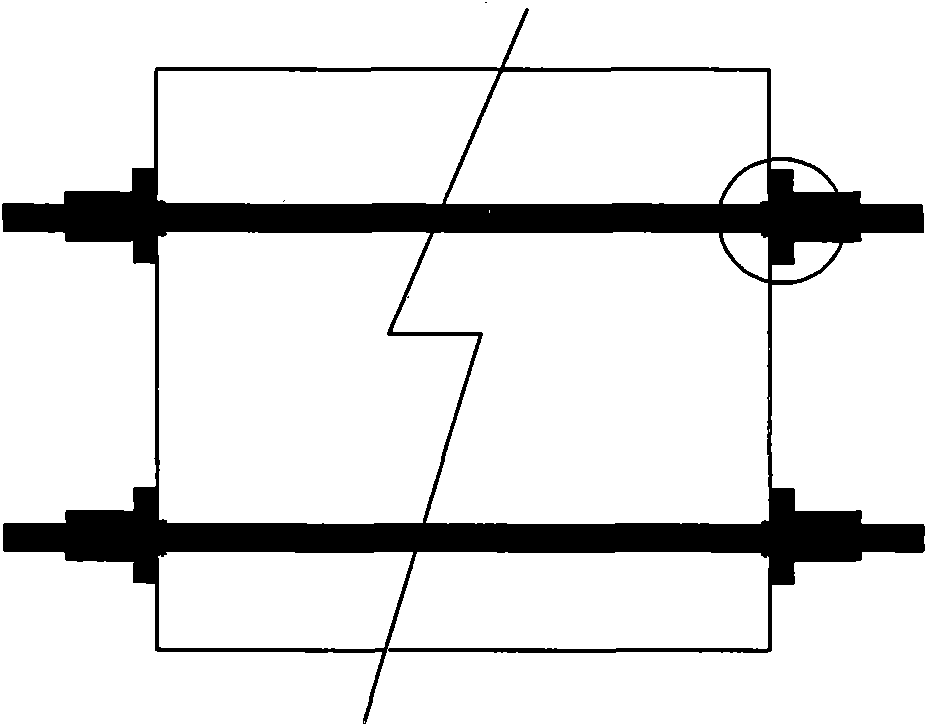

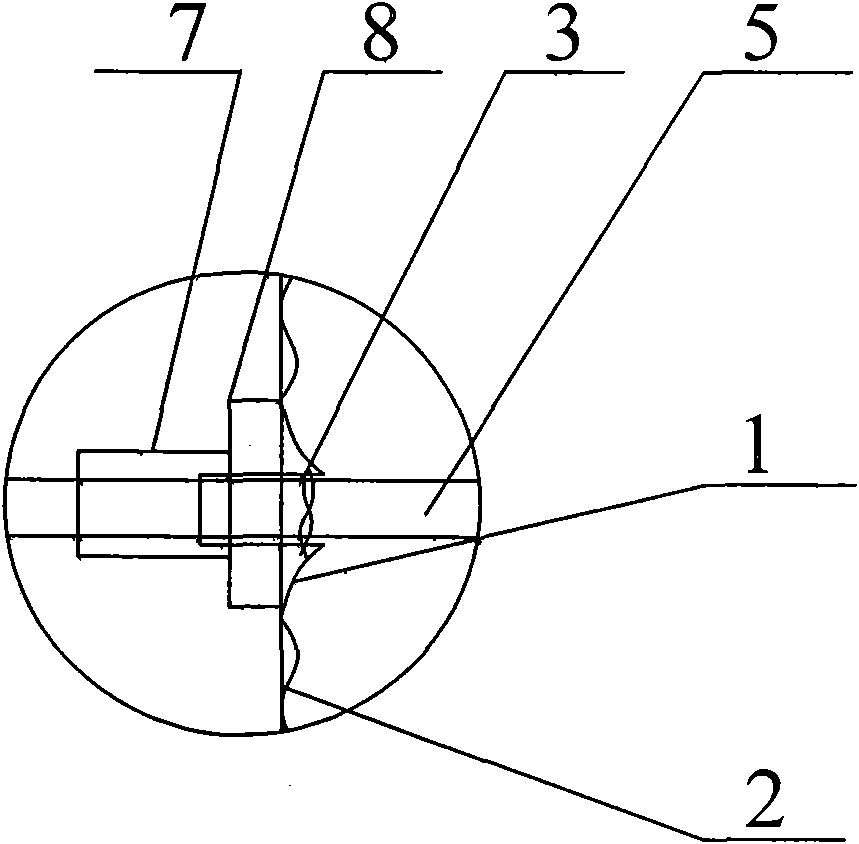

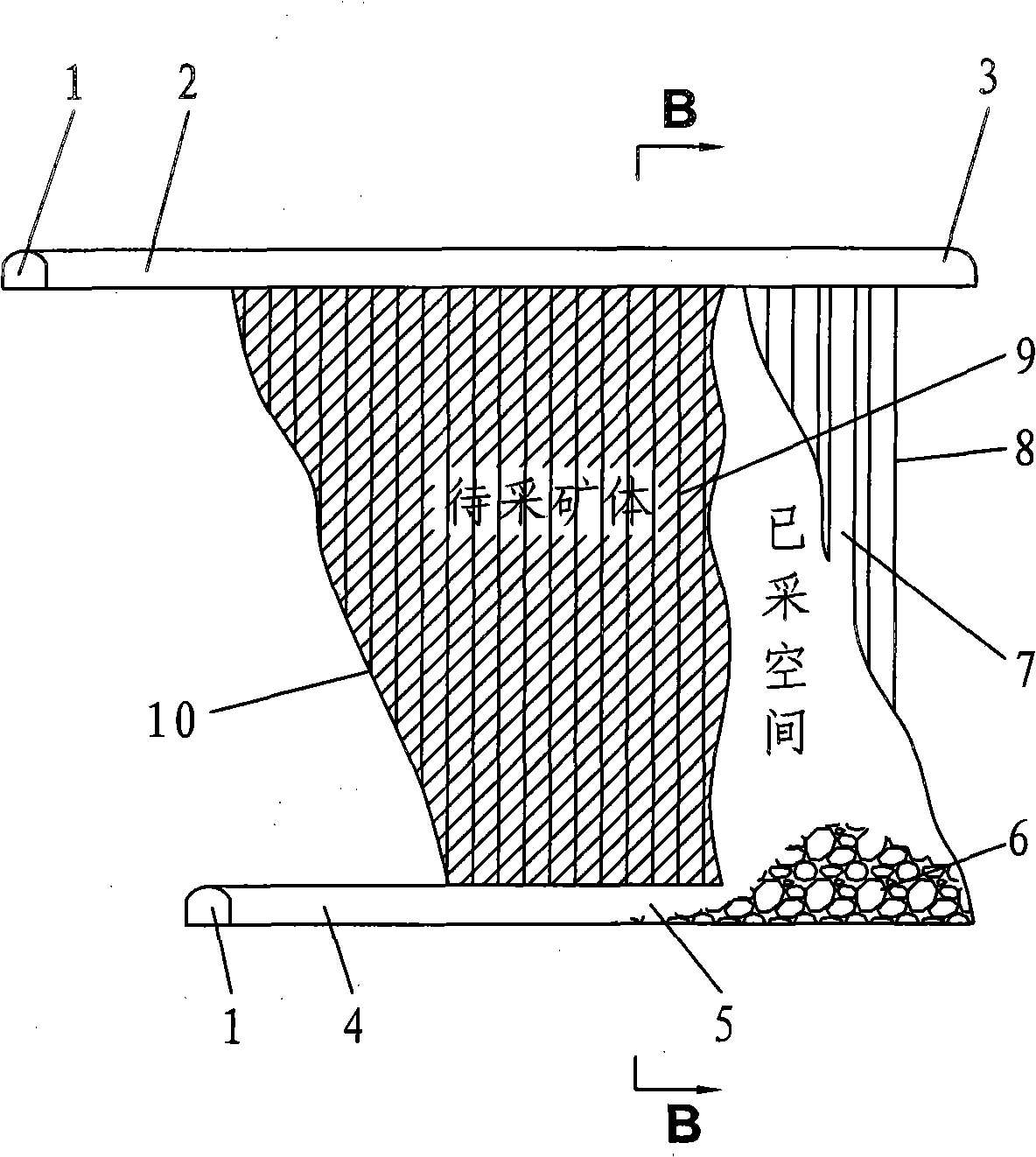

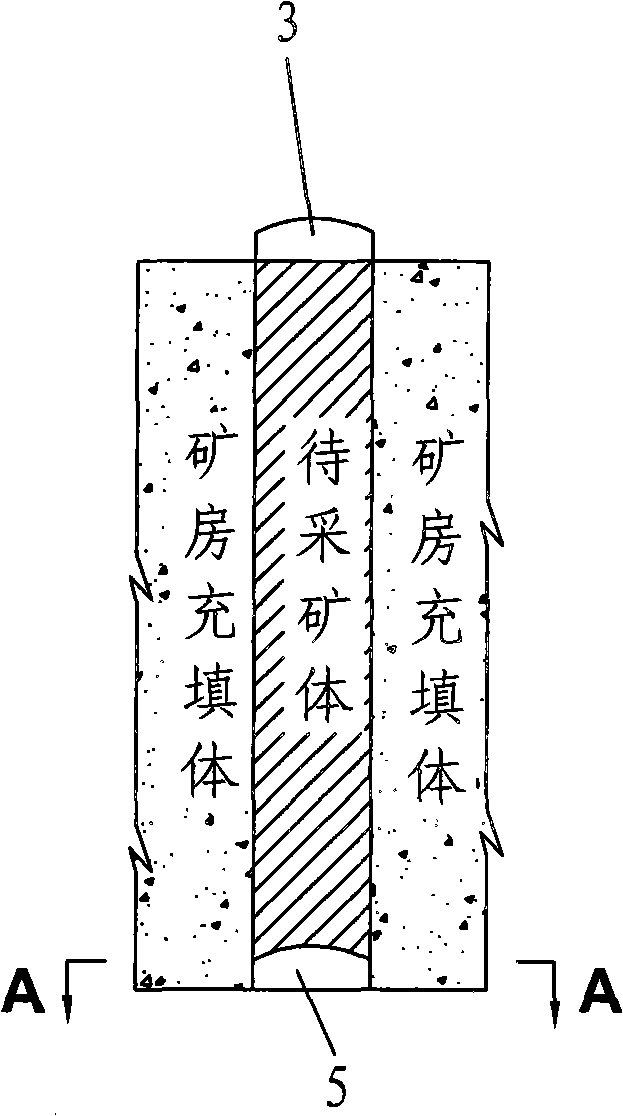

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

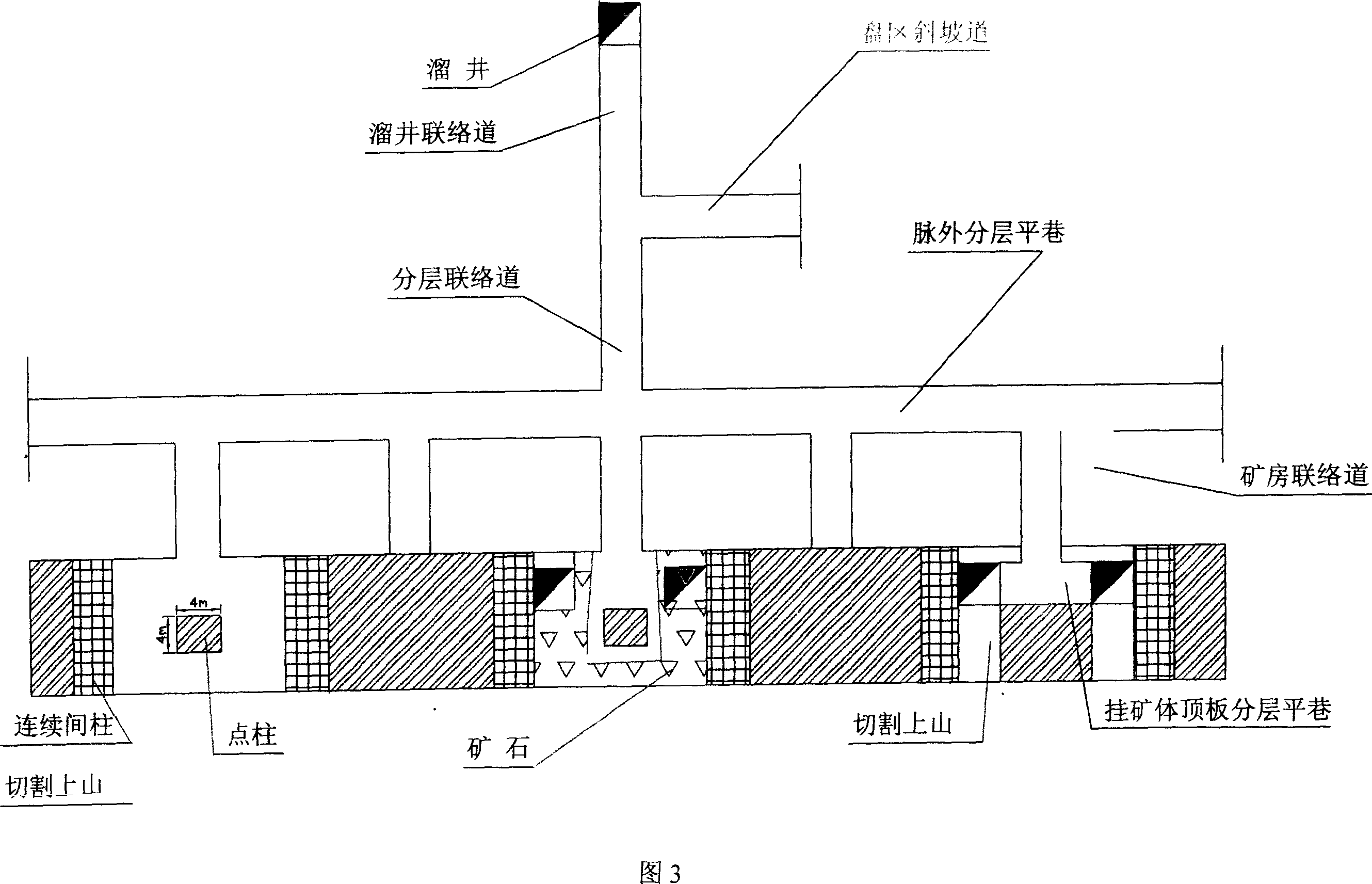

House pillar changeable panel upward demix filling mining method

InactiveCN101858217AReduced suspension heightImprove integrityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention discloses a house pillar changeable panel upward demix filling mining method. An ore body is divided into an ore house and an ore pillar arranged at intervals along the strike direction; a plurality of house pillars form a panel; a rock trackless preparation system is adopted and comprises a ramp, a rock slice drift, a demix ventilation connection and a rock concentrated ore removal winze; the mechanical upward demix filling mining method is adopted for mining, which mines a slice and fills the slice until the position required by the lower slice blasting compensation is reached. The backstopping order of the house pillars in the panel is the ore house first and then the ore pillar; all ore houses are subjected to upward backstopping at the same time; after a backstopping unit of the ore house is finished, the roof-contacted filling is carried out, and the mining of the ore house is temporarily stopped and the mining of the ore pillar is started; after two backstopping units of the ore pillar are finished, the roof-contacted filling is carried out, and the mining of the ore house is resumed; the abovementioned steps are repeated until the backstopping of the ore block is completed. The invention has the remarkable characteristics of improving the backstopping safety, reducing the resource dilution rate, lowering the support cost, increasing the enterprise profit, and the like.

Owner:CENT SOUTH UNIV +1

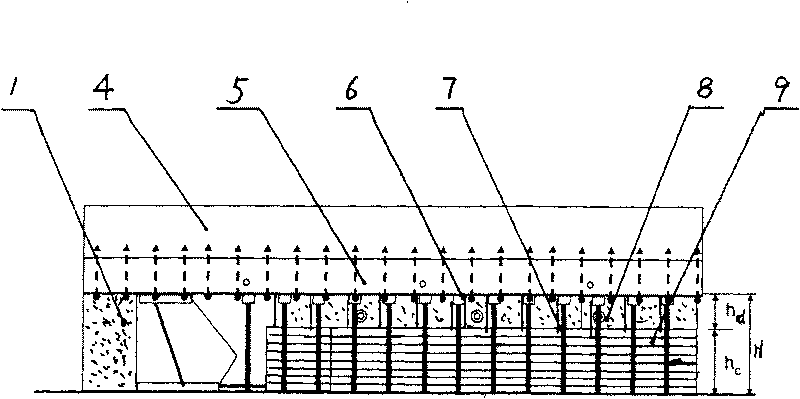

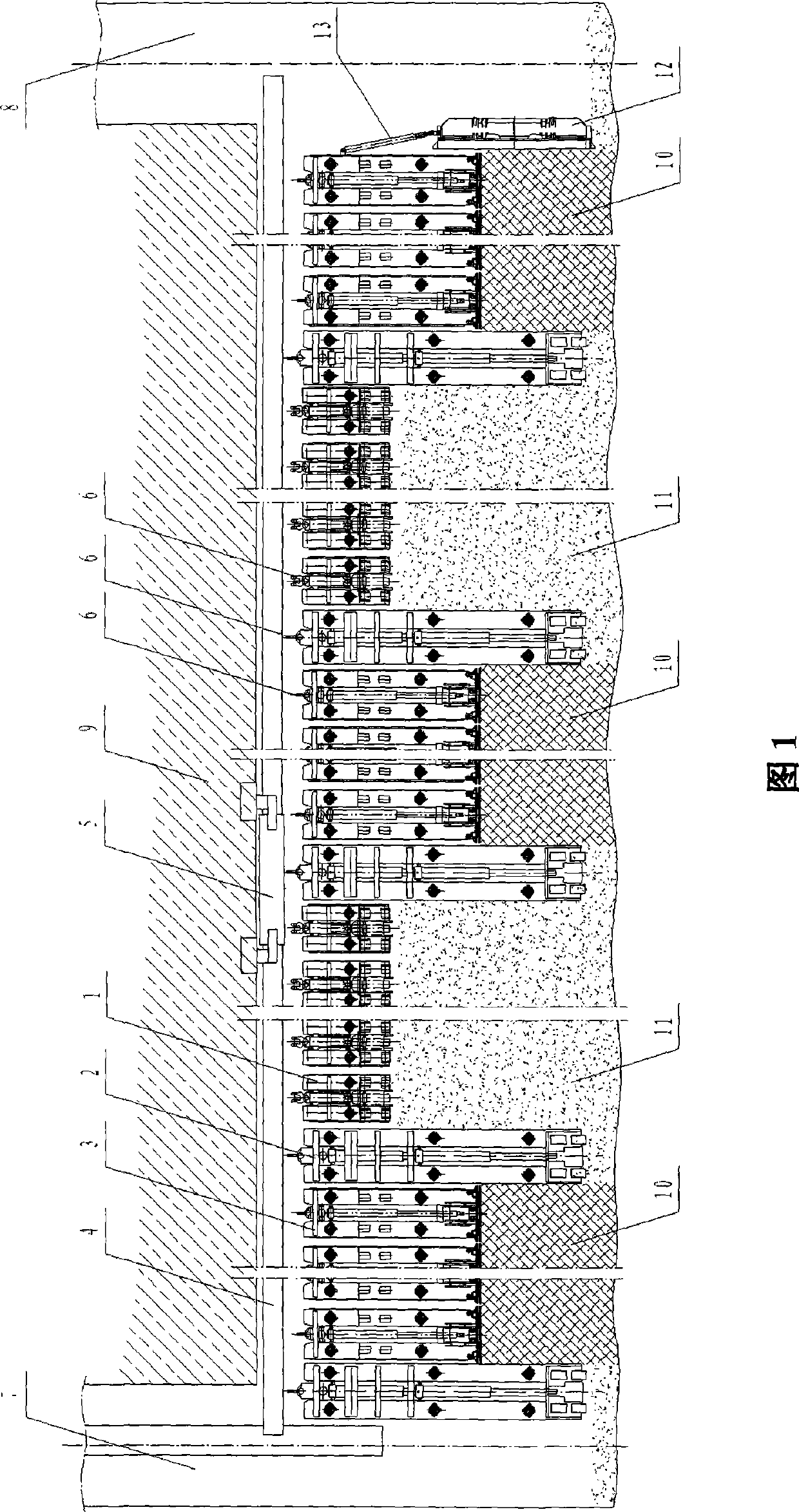

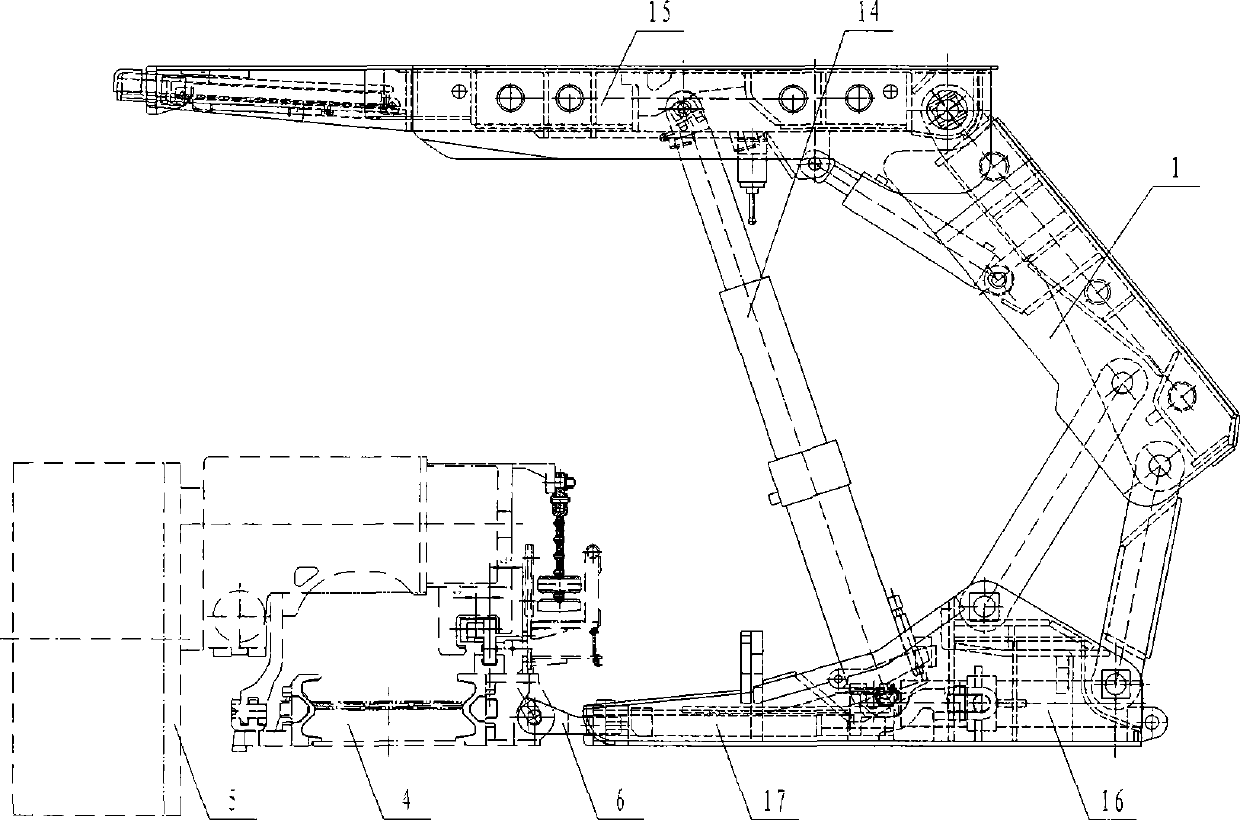

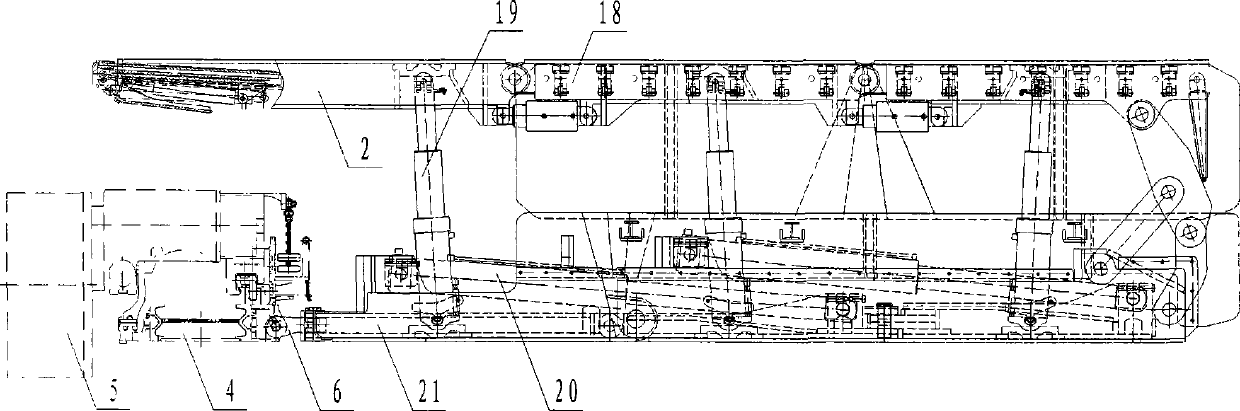

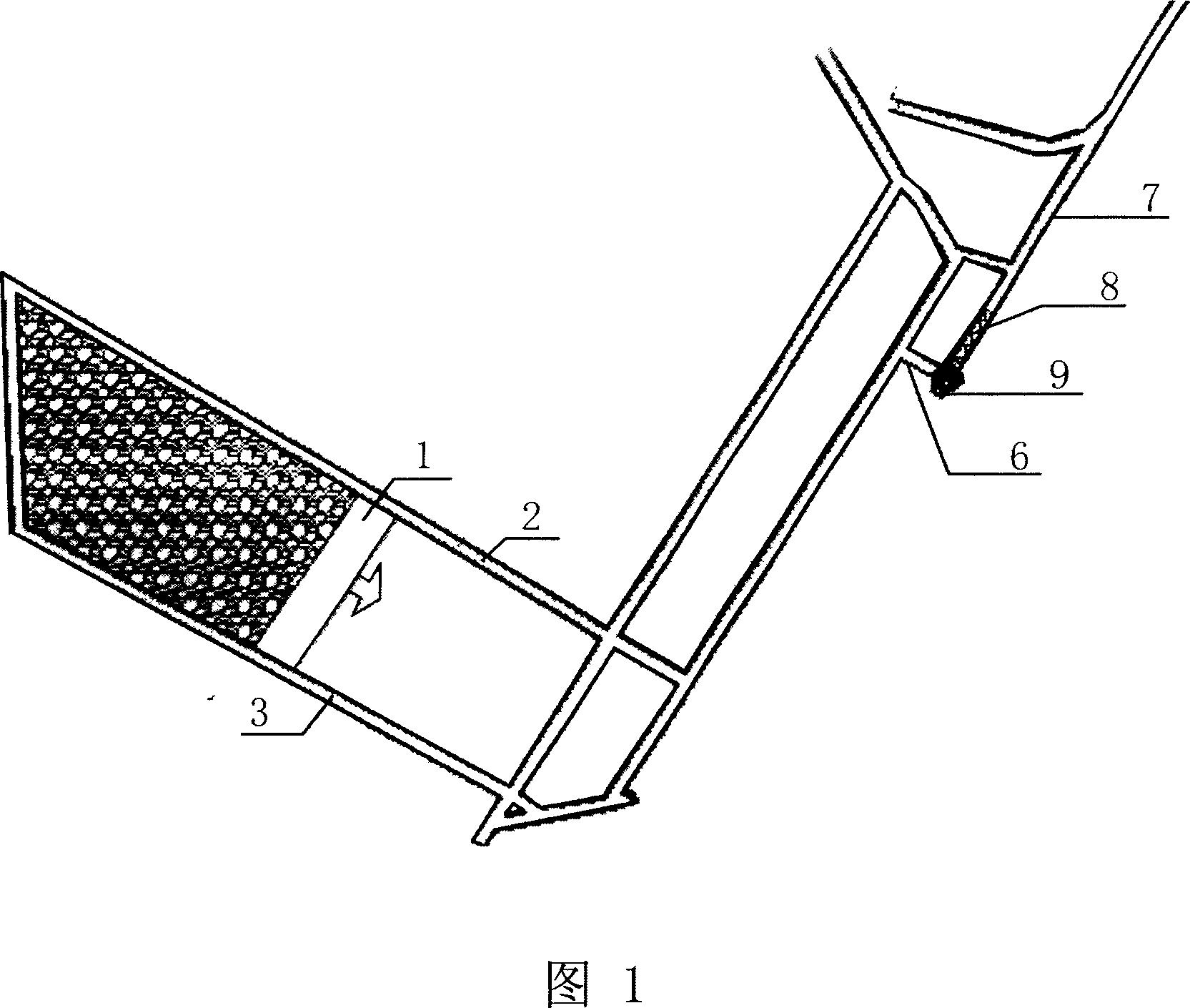

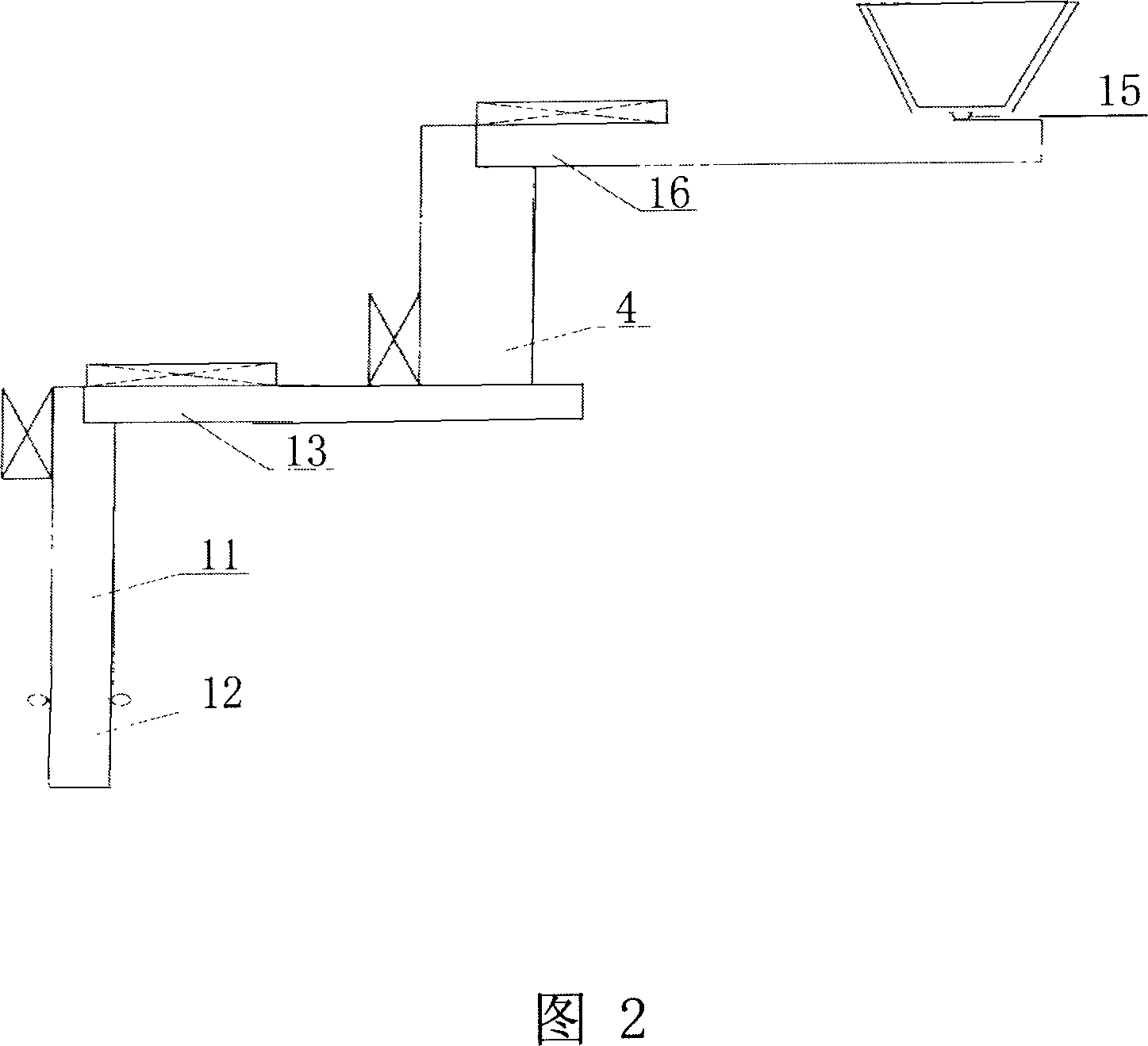

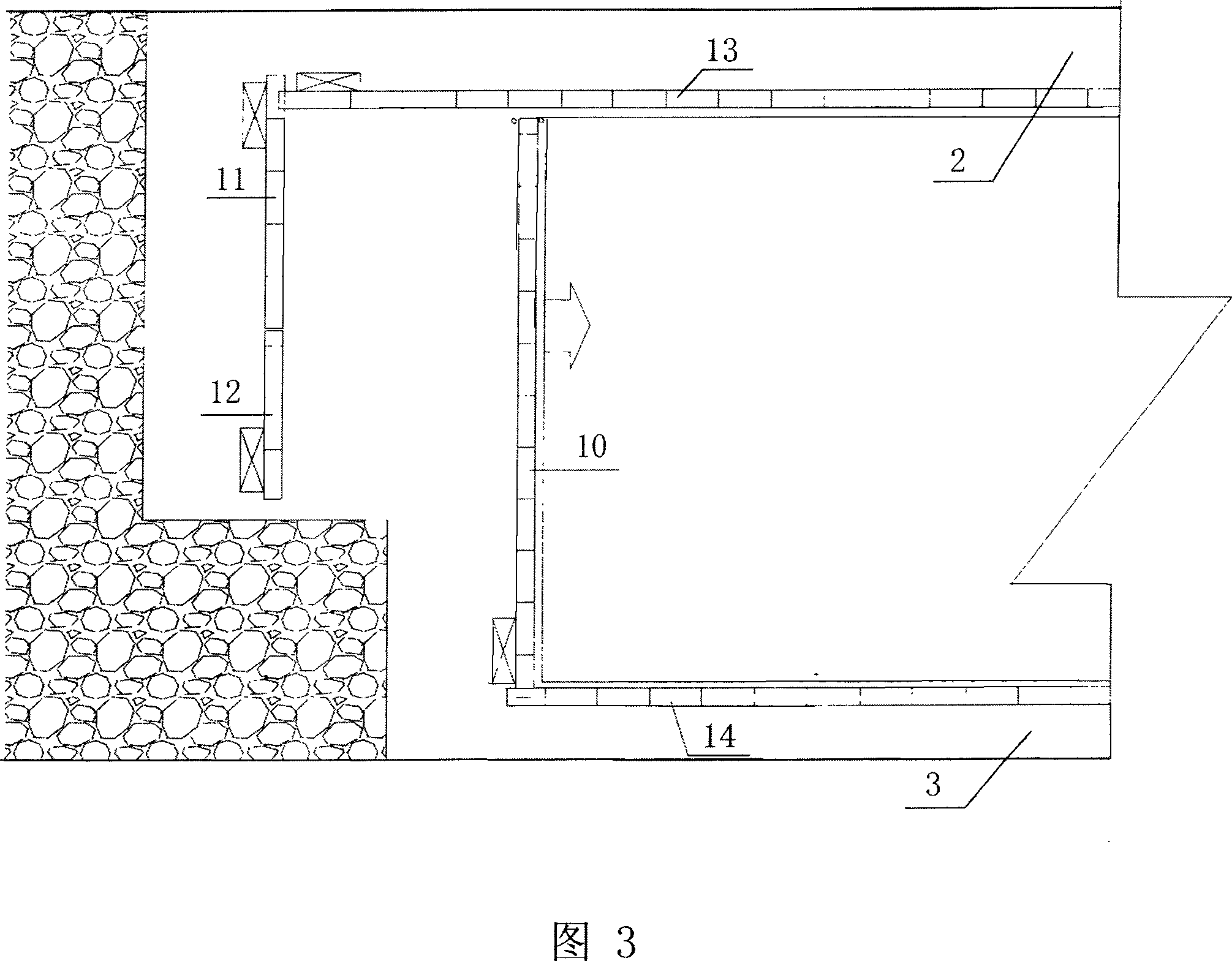

Coal mining solid filling method

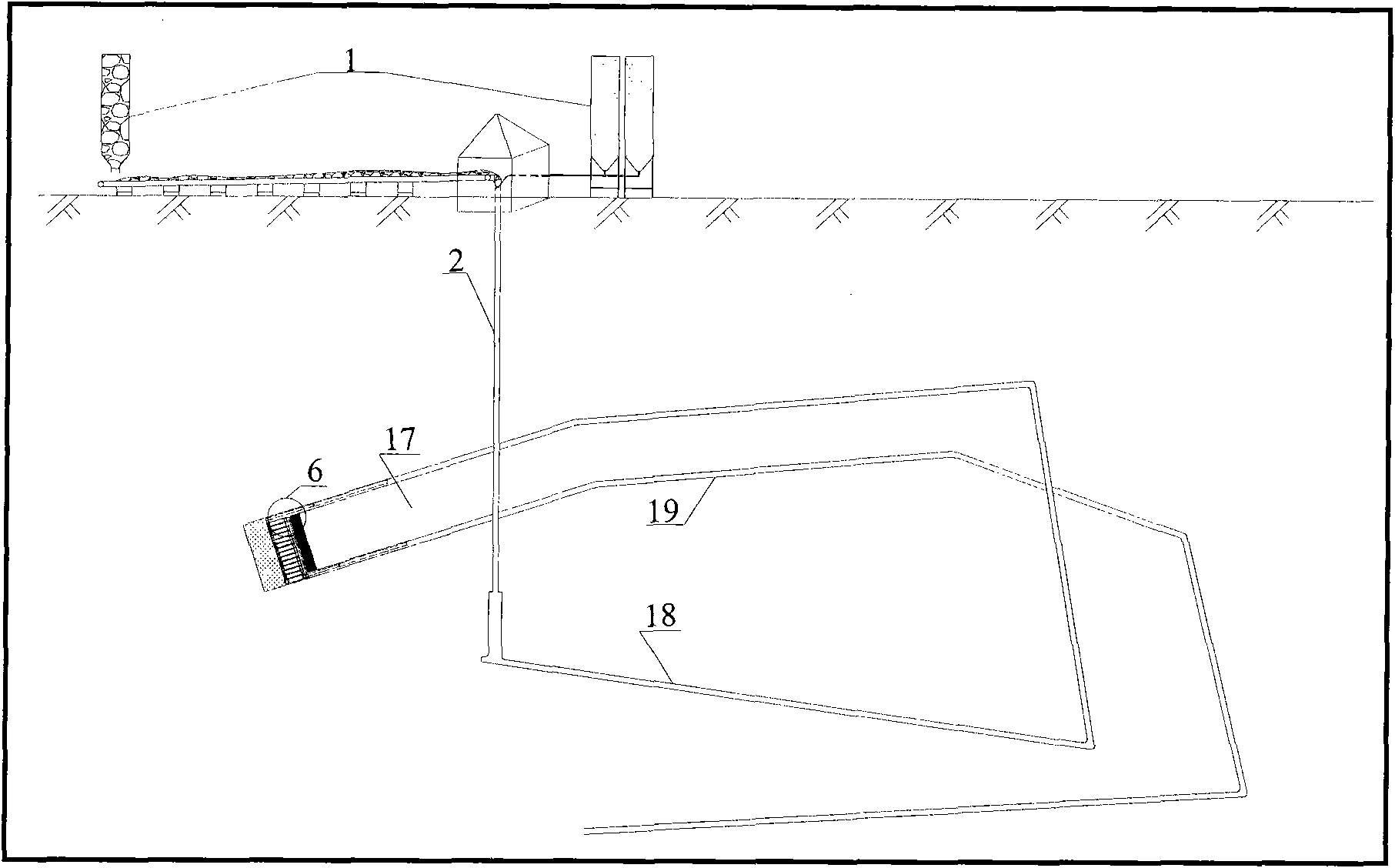

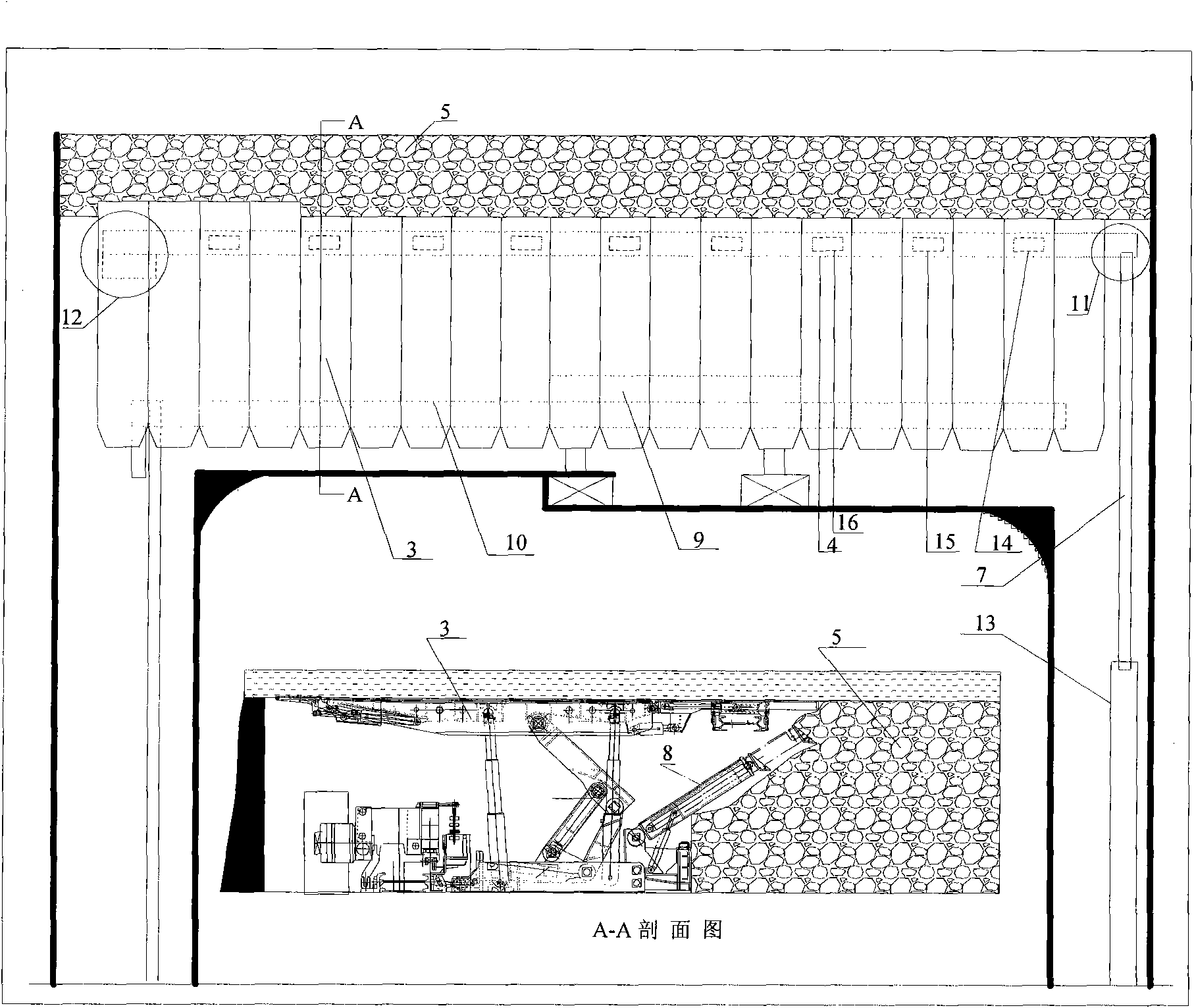

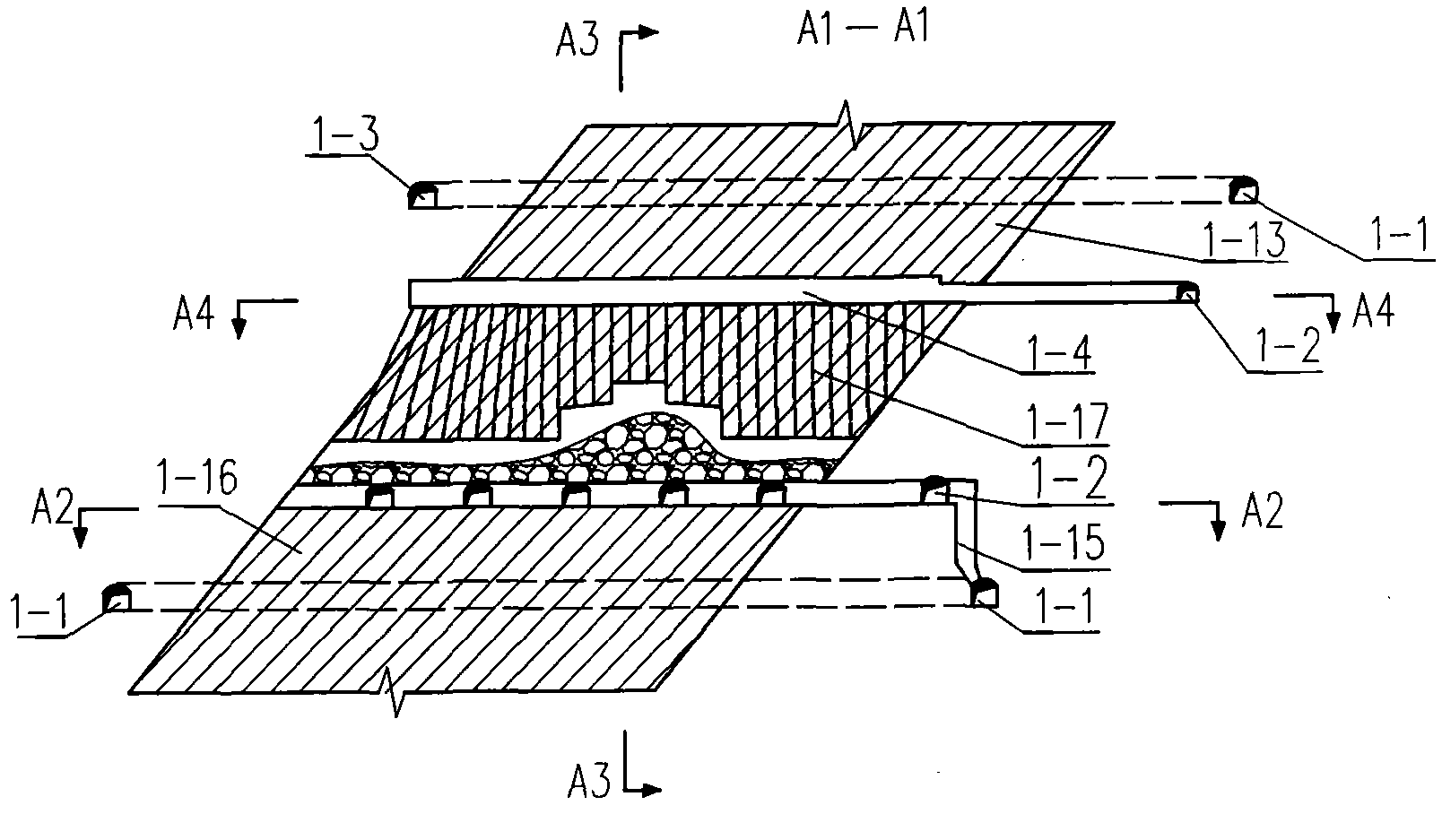

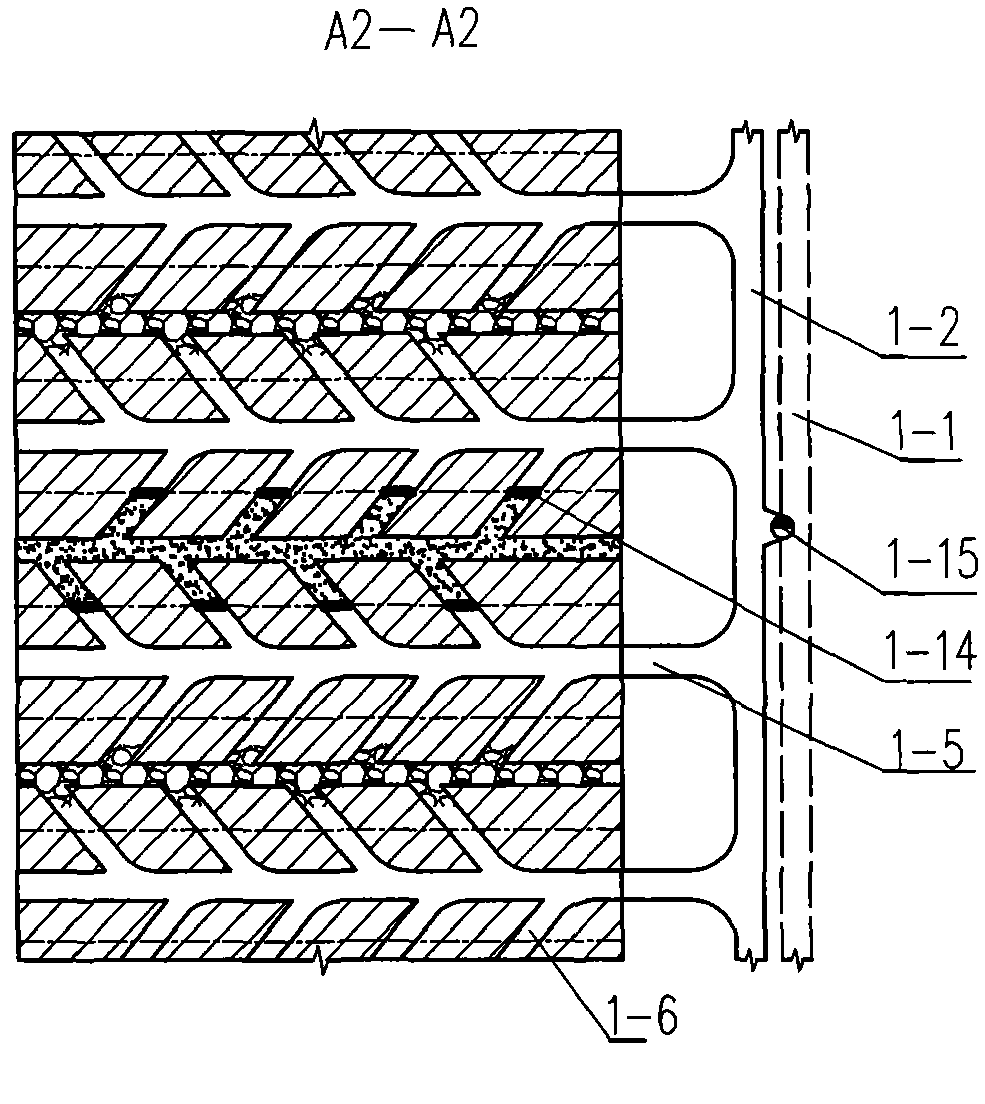

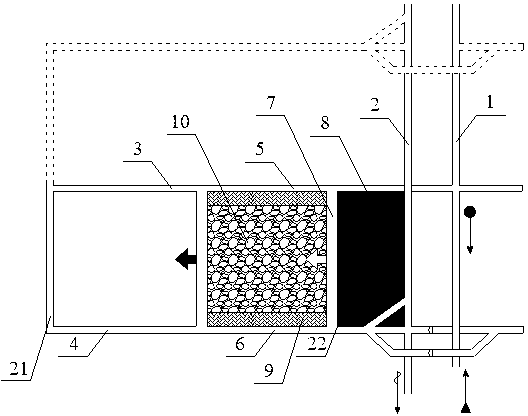

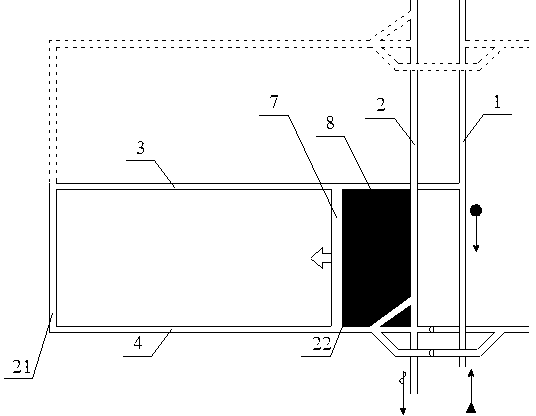

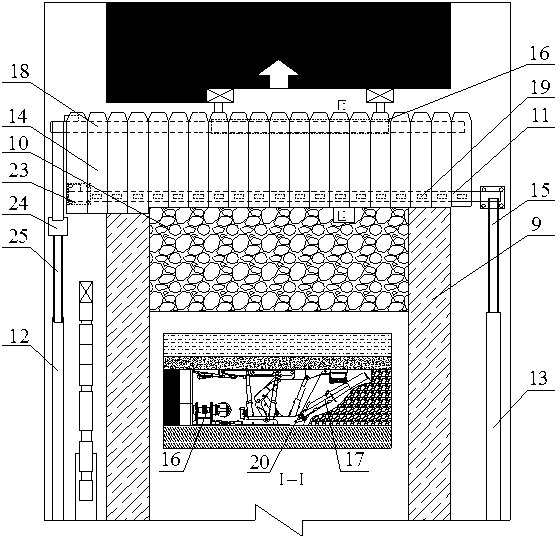

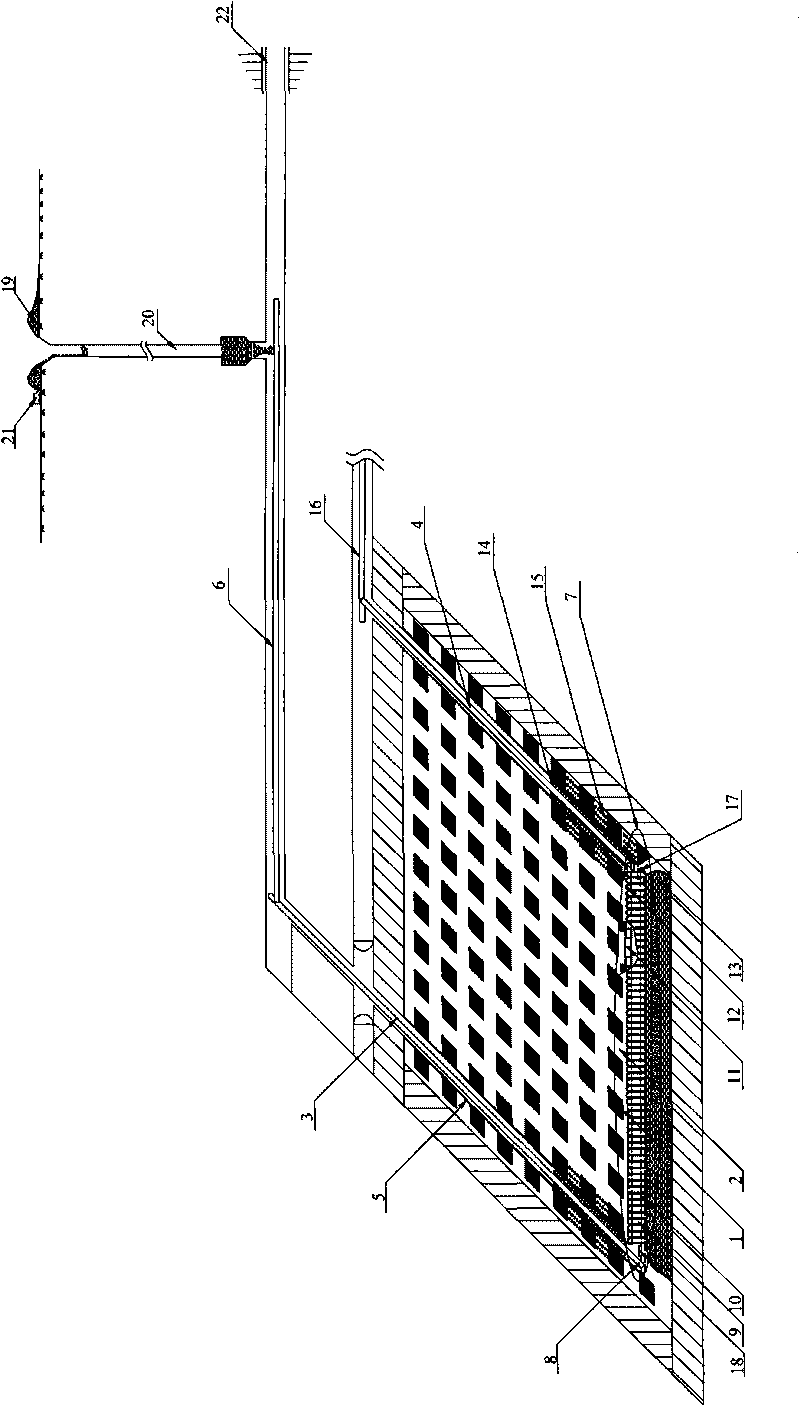

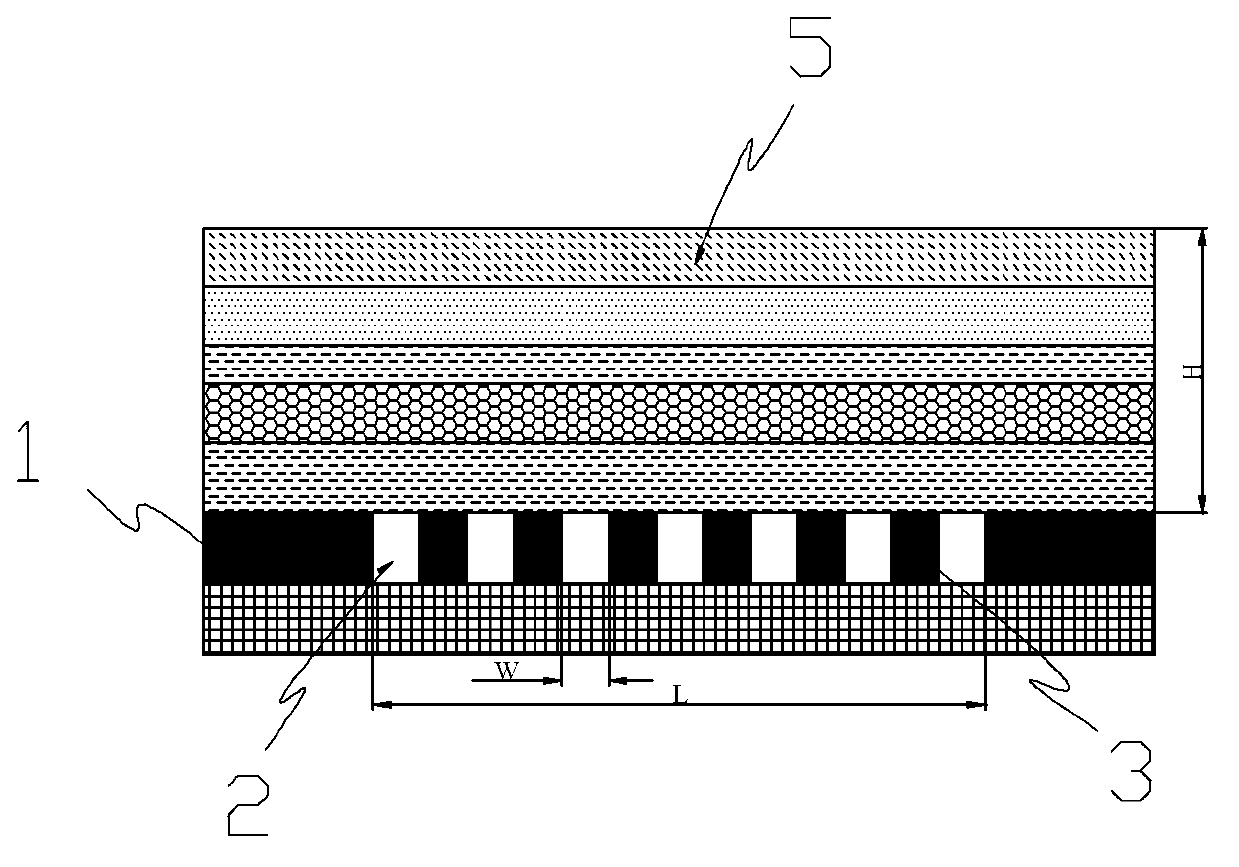

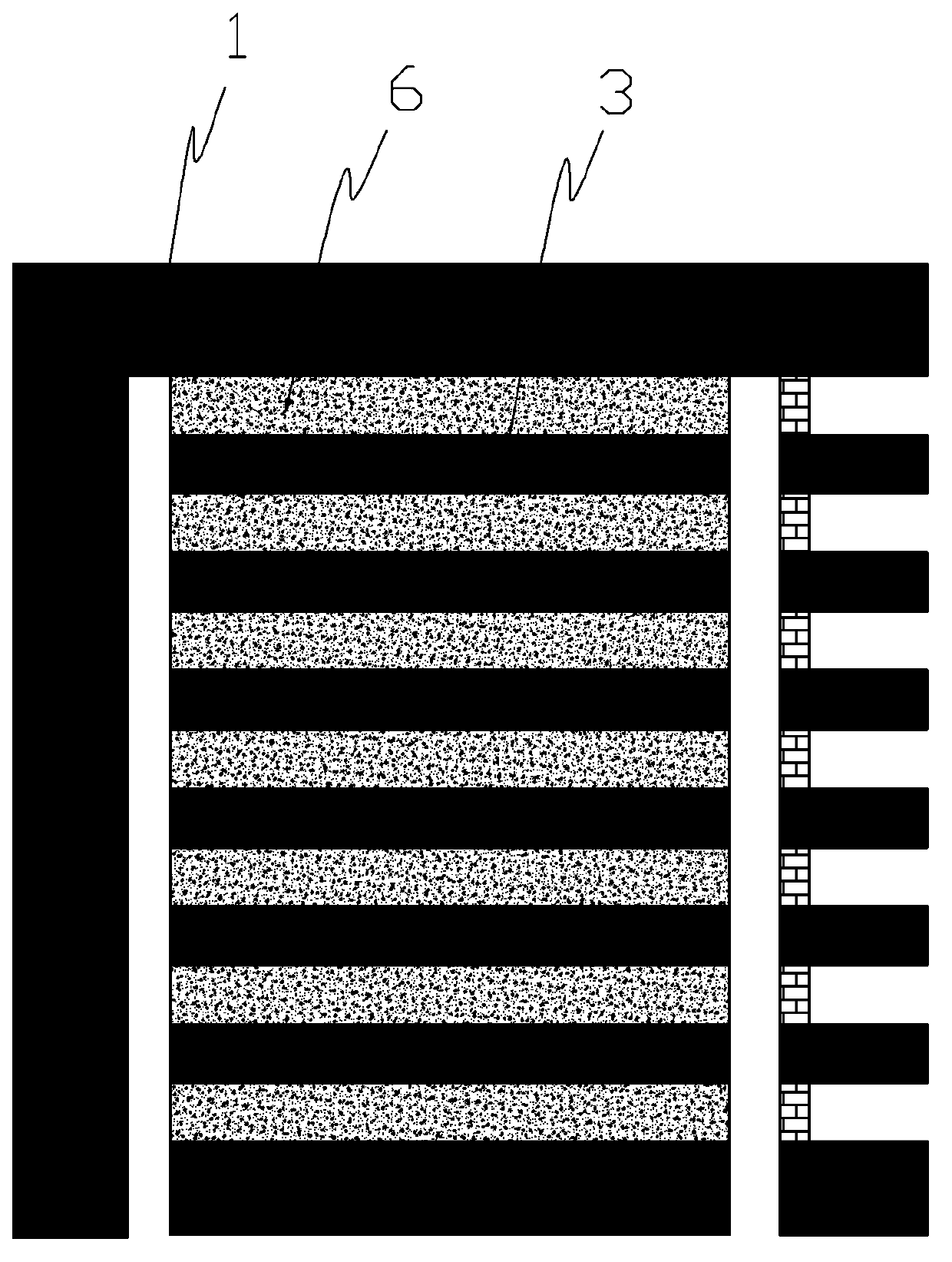

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

Thick seam large mining height working face gob-side entry retaining method

InactiveCN101725368APrevent overflowAvoid enteringMaterial fill-upMine roof capsSpontaneous combustionEngineering

The invention discloses a thick seam large mining height working face gob-side entry retaining method, wherein a flexible yield airbag is installed on the deformed space retained on the top part of the filling body besides the lane; the height of the filled airbag is equal to the prediction value of the sinking quantity of the top plate; the airbag is filled with air, the inflation pressure is 3MPa; a one-way decompression valve is installed on the bag body and the decompression pressure is 4MPa. The flexible yield airbag is arranged, thus on the one hand, effectively protecting the filling body besides the lane and achieving the purpose of gob-side entry retaining, and on the other hand, preventing the coal in the gob from spontaneous combustion, ensuring safe production and simultaneously improving the mining coefficient of the coal.

Owner:SHANDONG UNIV OF SCI & TECH

The roof caving and tunnel protecting method

InactiveCN101509395AHighlight substantiveReduce widthUnderground chambersMaterial fill-upMining engineeringFissure

The invention relates to a method for controlling caving and lane-guarding. The method is characterized in that in a working surface roadway, drilling, blasting or cracking are carried out on a roof of a coal seam of complete hard strata with large thickness of a hanging arch in a goaf; bursting or cutting off are carried out on a complete hard roof strata with large thickness to facilitate the hanging arch in the goaf to collapse at the back of a force piece; collapsed waste rock fills the goaf, supports superincumbent stratum in a fissure zone and releases high bearing stress passed into the coal body adjacent to the goaf from weight of the large-thickness complete hard strata of the hanging arch in the goaf and the superincumbent stratum in the fissure zone thereof, so that the bearing stress in the coal body adjacent to the goaf is reduced and laneways in the space are protected. The method of the invention fundamentally improves stability of surrounding rock of laneways adjacent to the goaf and increases coal mining rate of ends of thick coal seam caving coal working surface.

Owner:TAIYUAN UNIV OF TECH

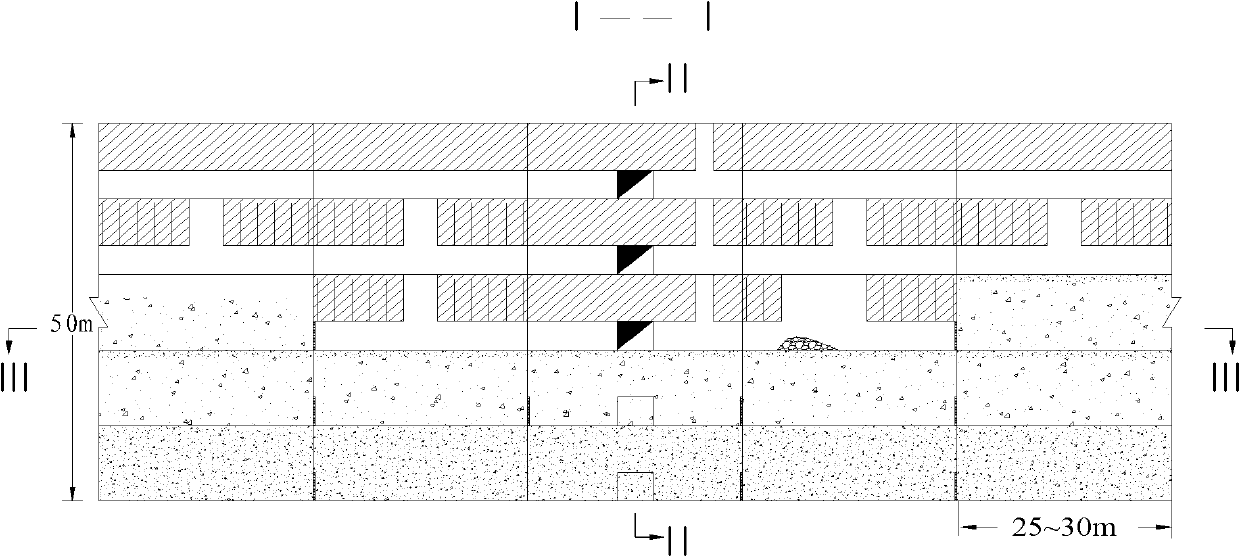

House pillar type cutting and filling method of medium coal seam for controlling movement deformation of overlying rock

InactiveCN102011588AImprove securityIncrease productivityUnderground miningSurface miningEngineeringCoal pillar

The invention belongs to the field of coal cutting and filling, in particular to a house pillar type cutting and filling method of the medium coal seam for controlling the movement deformation of the overlying rock, which is suitable for the coal face with the coal seam thickness more than 2 meters. The method comprises the following steps: determining the initial weighting interval L and the periodic weighting interval M of the main roof according to the main roof initial weighting interval theory; arranging the rooms and the coal pillars at intervals; and using the material with high expansibility in water during the filling according to the method comprising the following steps of mining the rooms, filling the empty rooms, mining the coal pillars and filling the empty zones of the coal pillars. The method provided by the invention can determine the most economical filling ratio through controlling the key layer to maximize the benefits; the method provided by the invention can control the movement deformation of the overlying rock absolutely within the allowed range when realizing the pulling without pillars, and realize the extremely small gentle uniform sinking of the ground; and the method provided by the invention can realize the mining of the coal resource with high recovery rate under any condition by using the material with high expansibility in water, and greatly enhance the security of coal face. When the rooms are mined, a plurality of coal face of rooms can be arranged at intervals to enhance the working efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

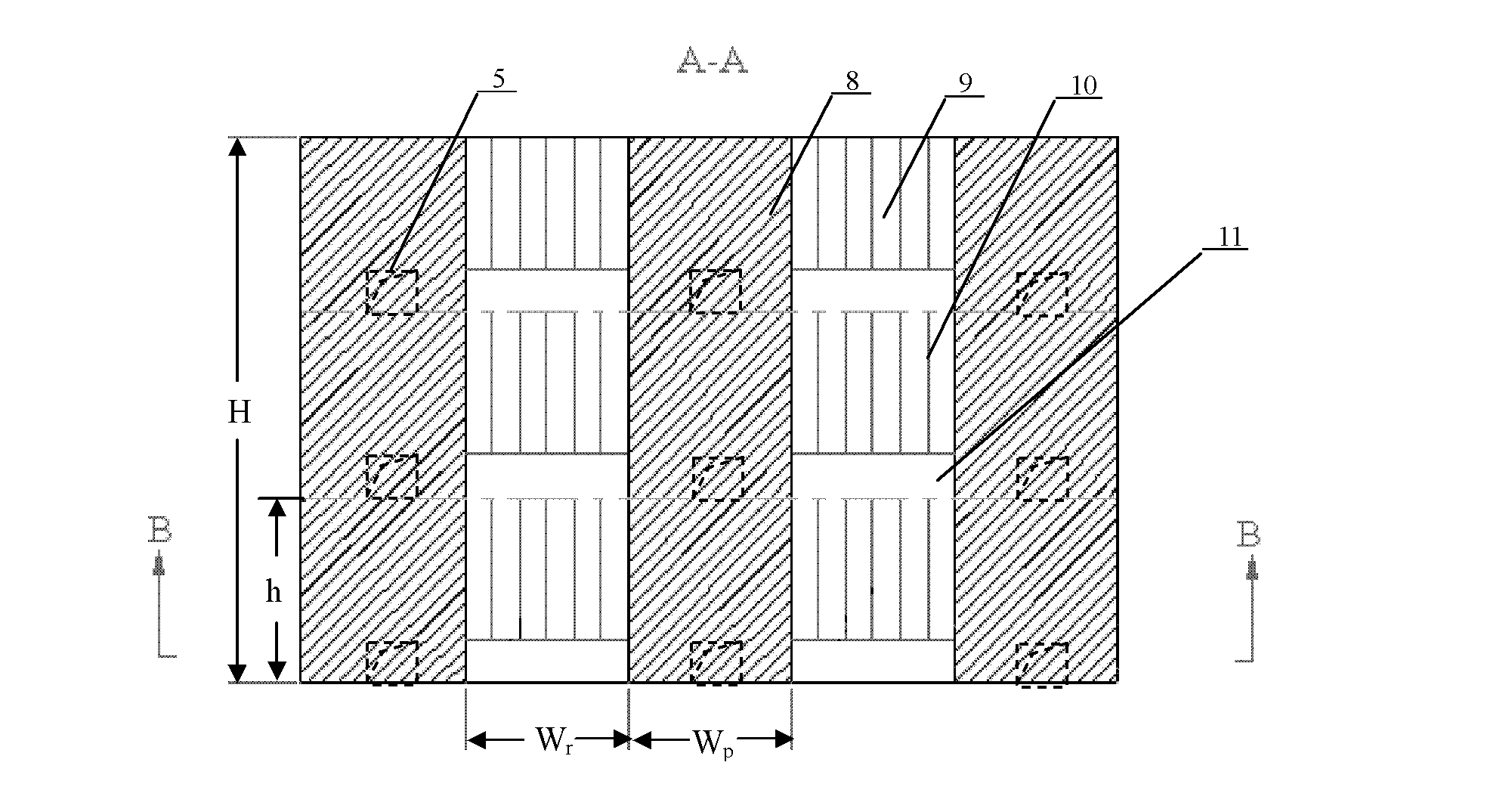

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

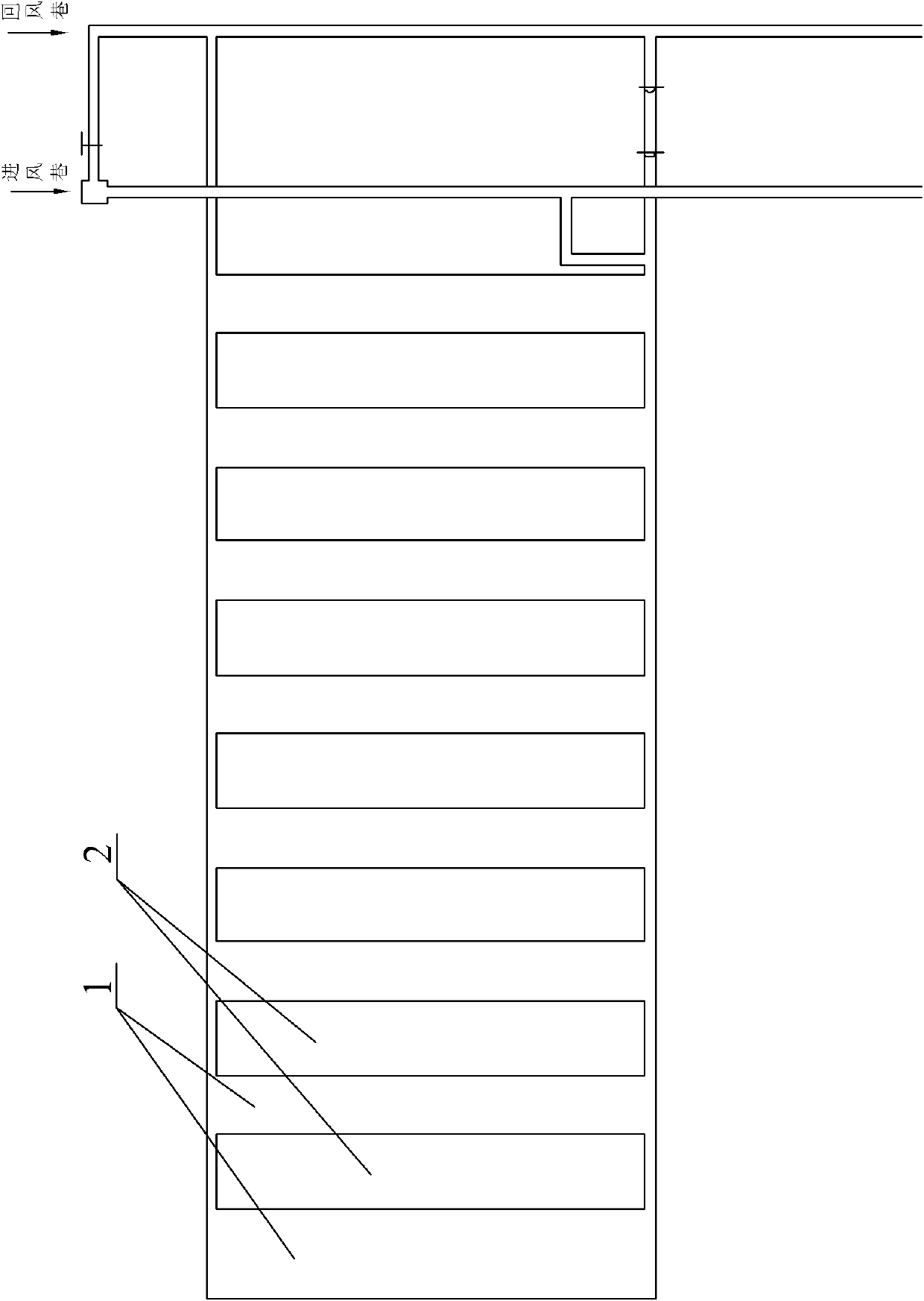

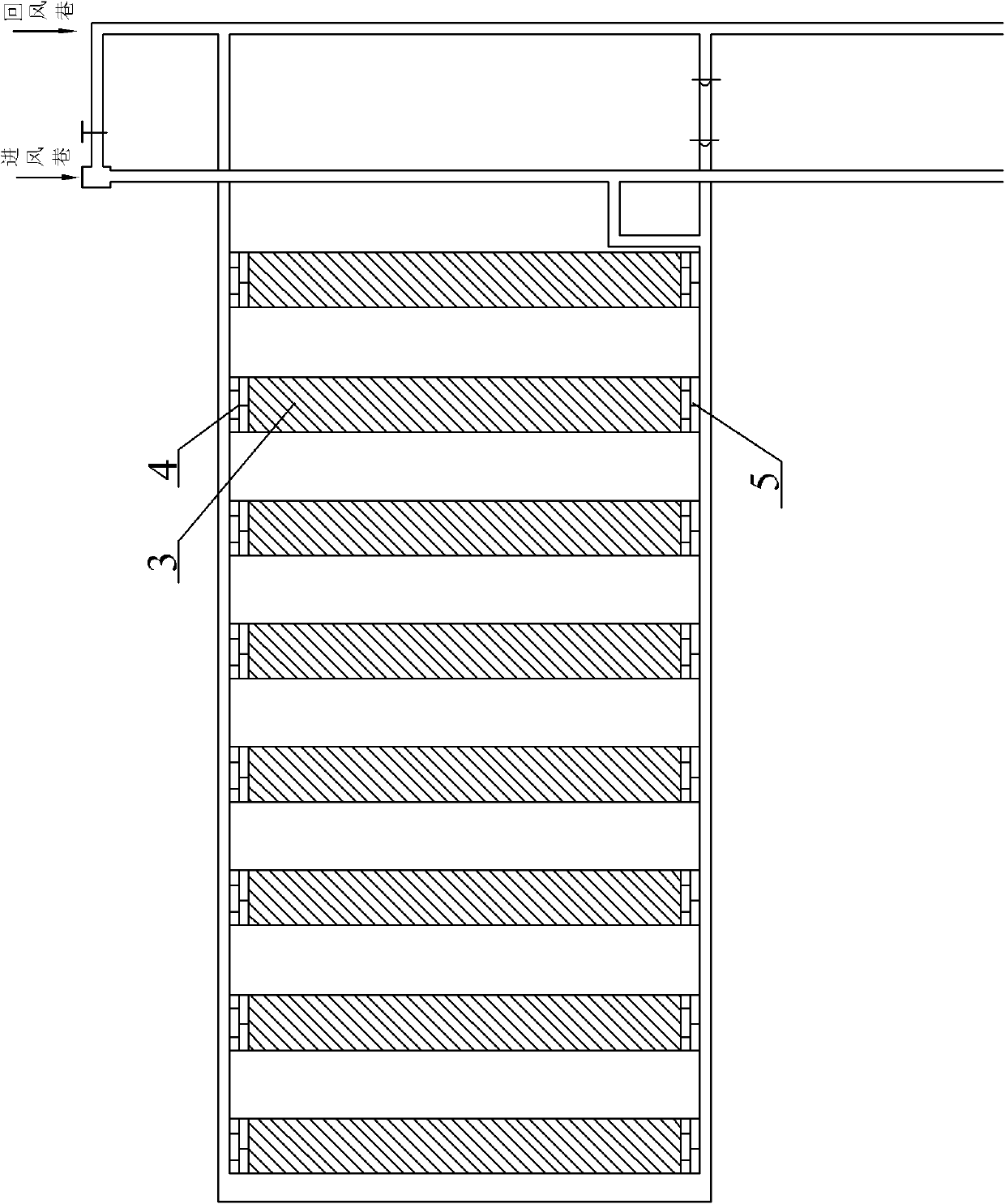

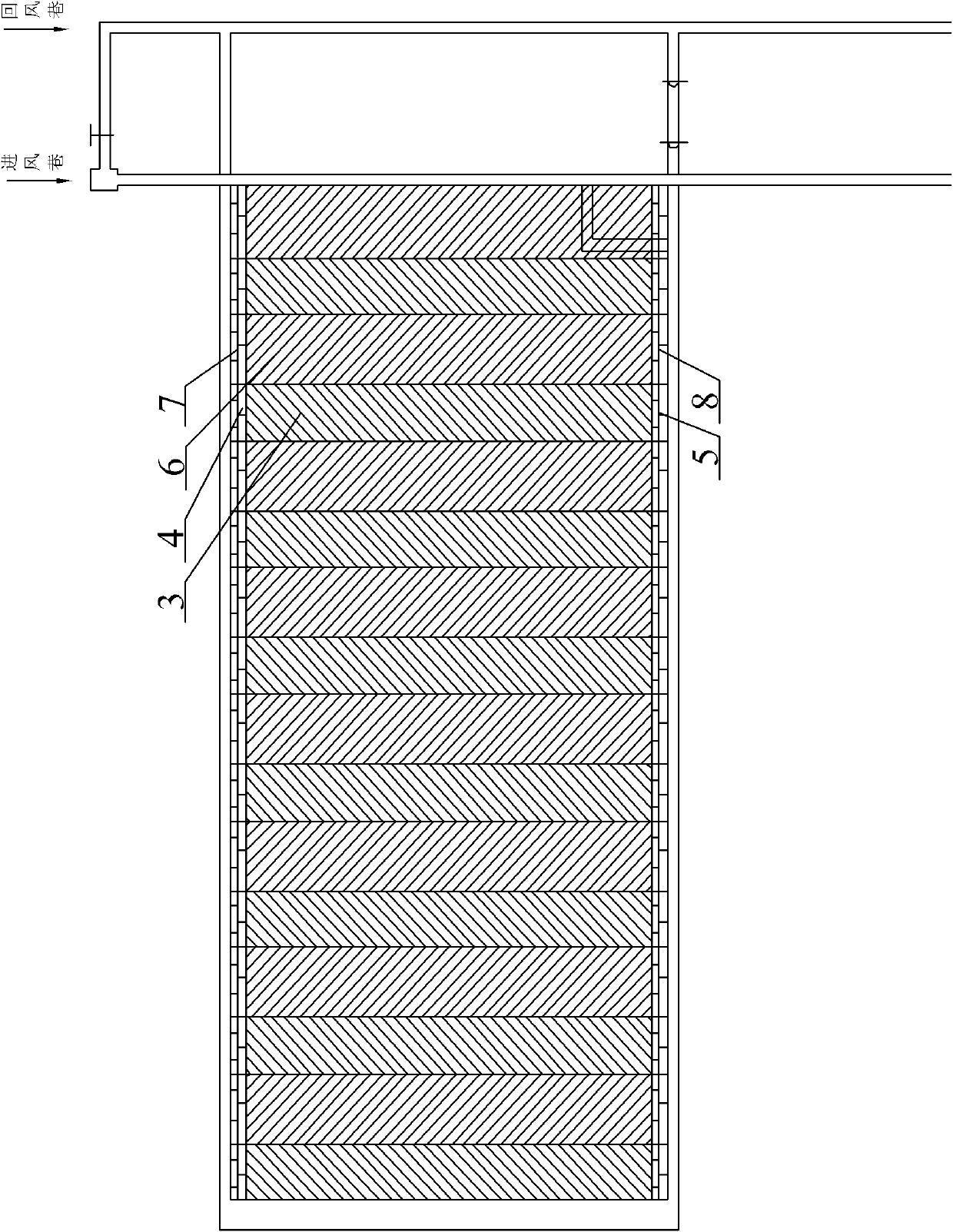

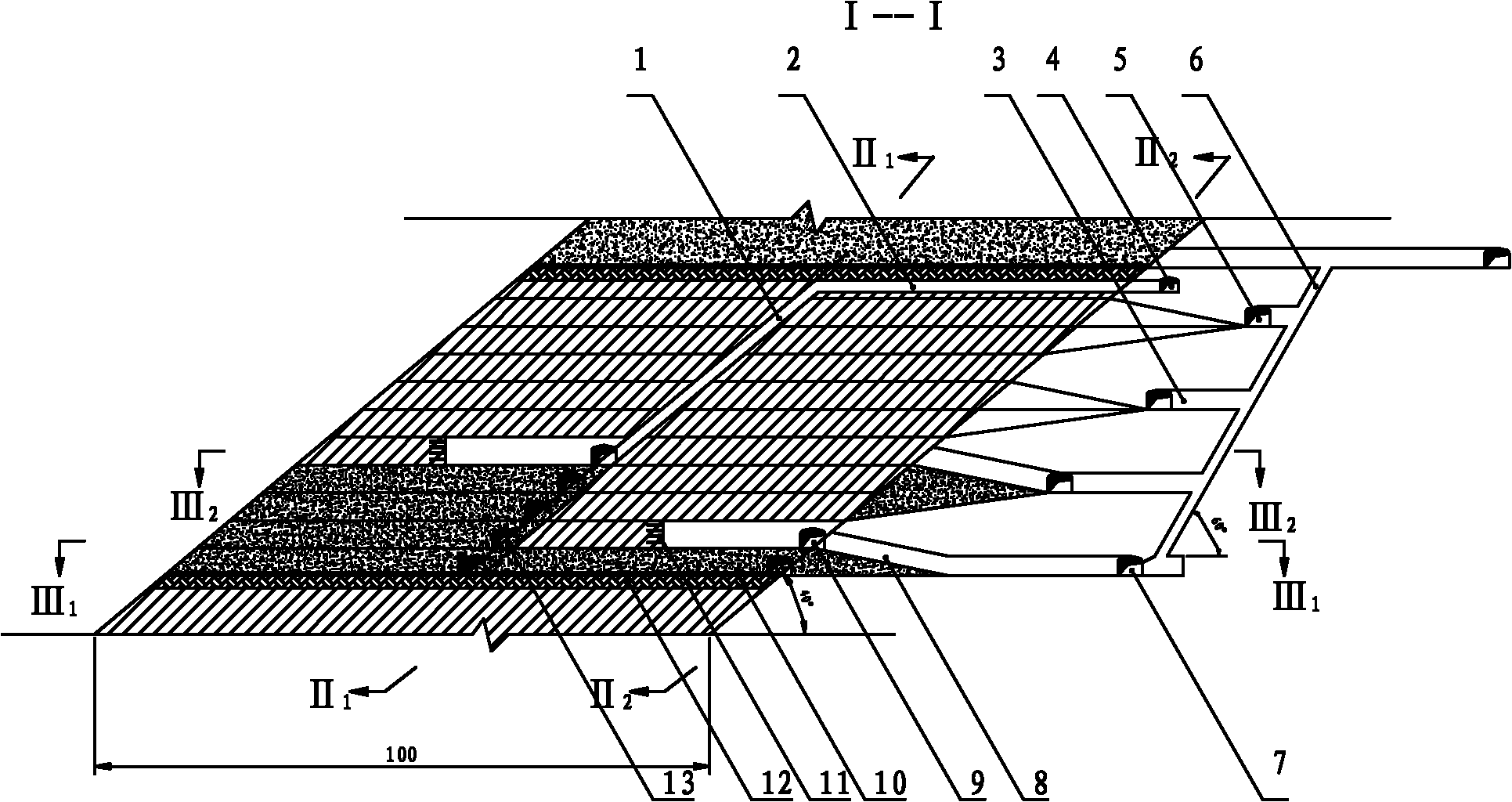

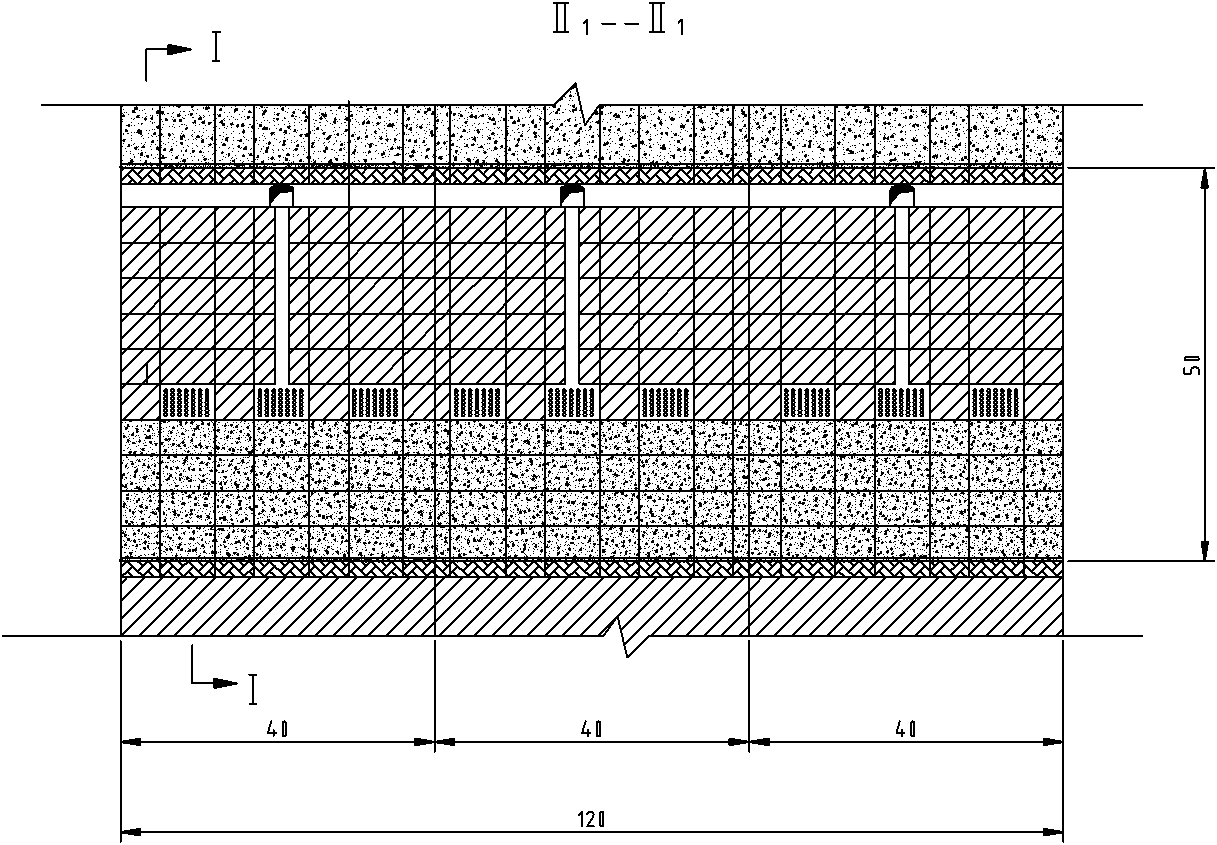

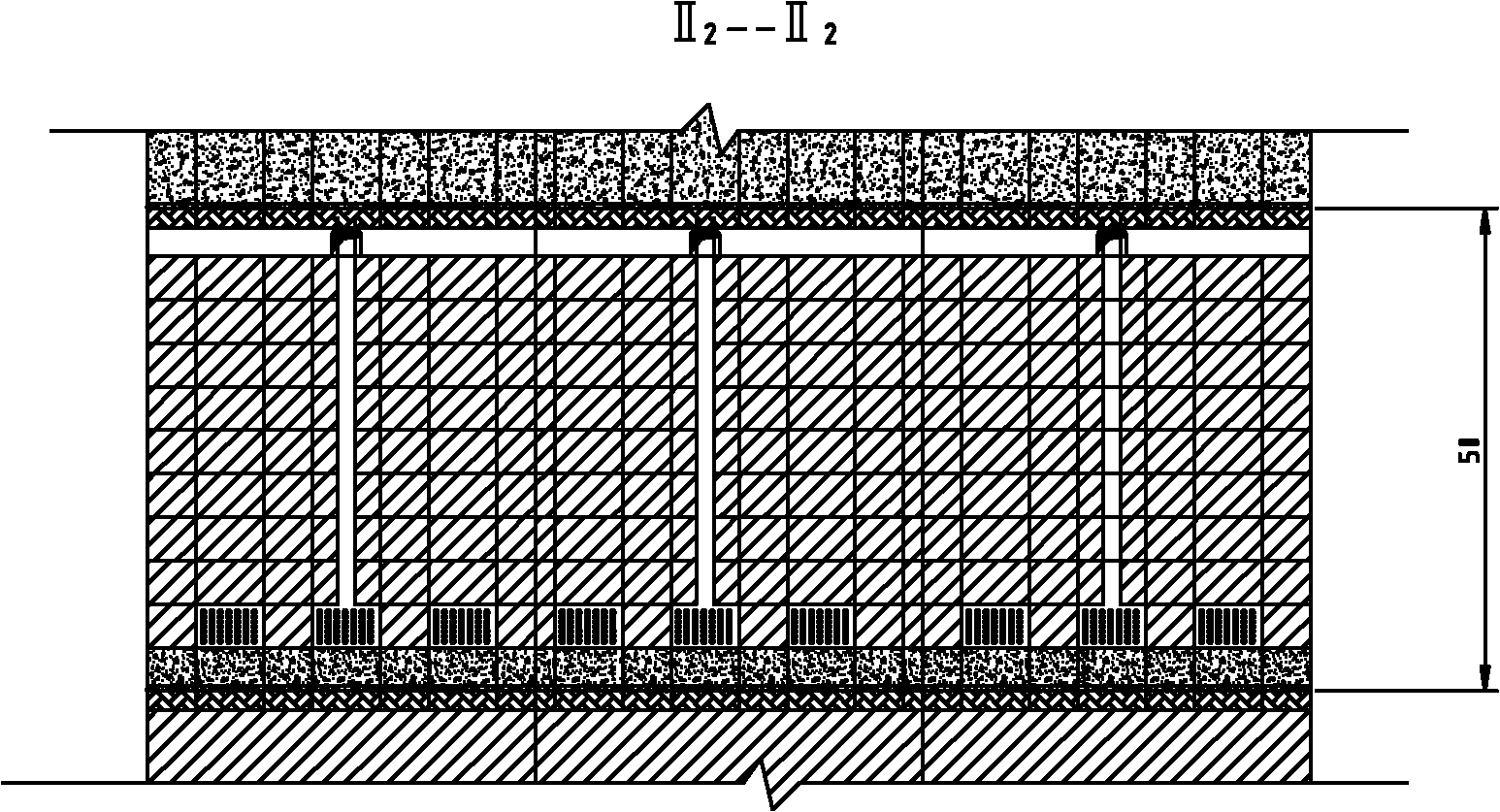

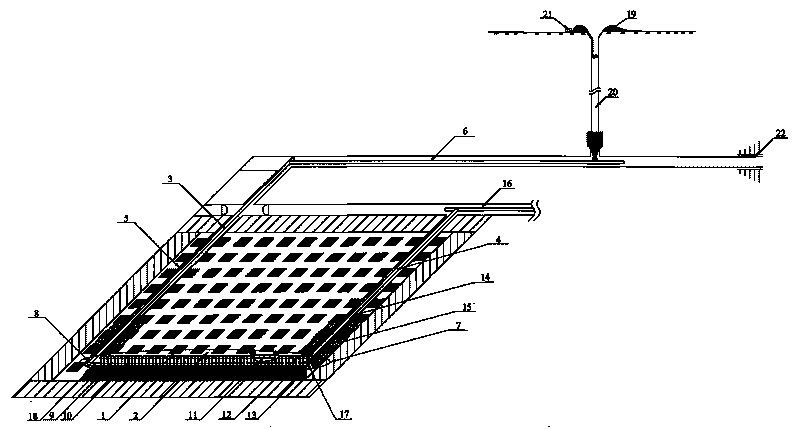

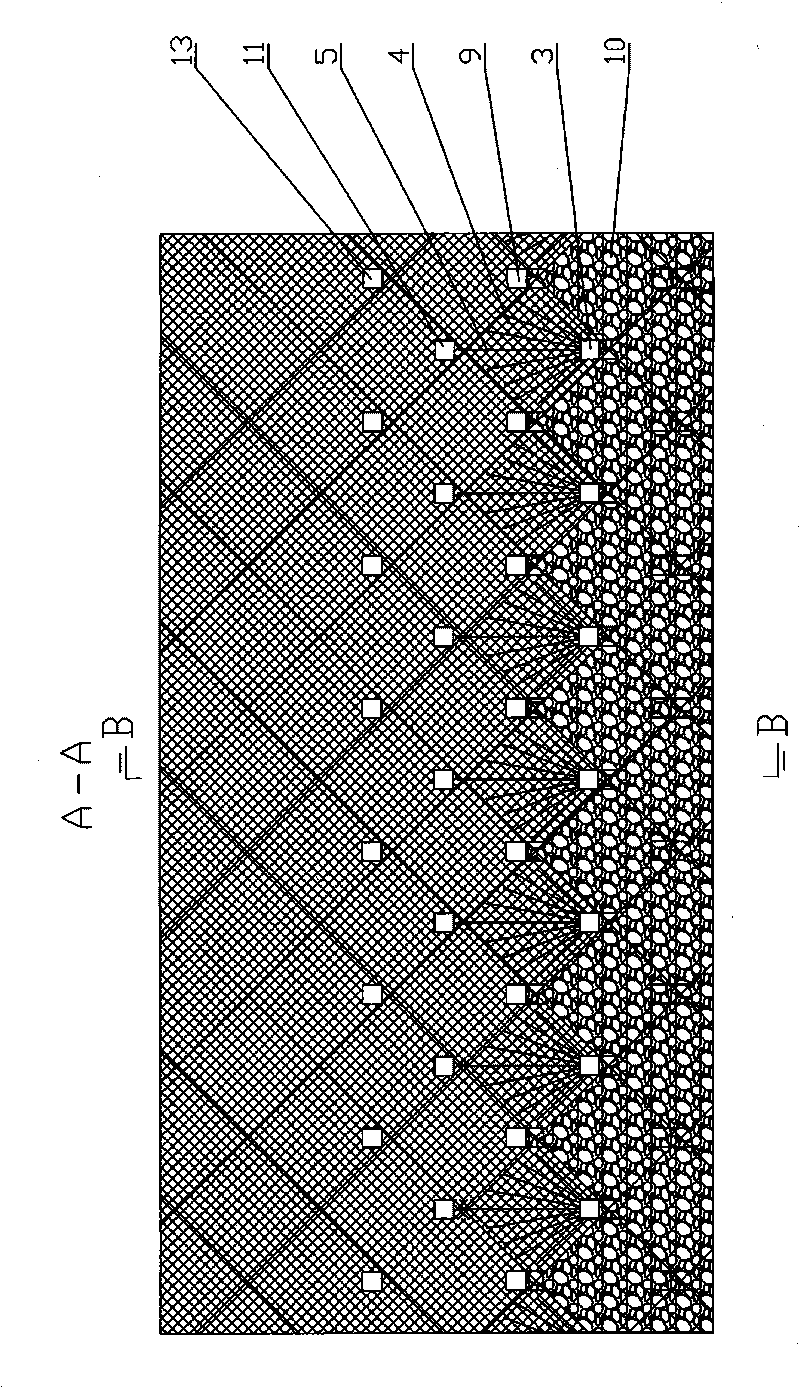

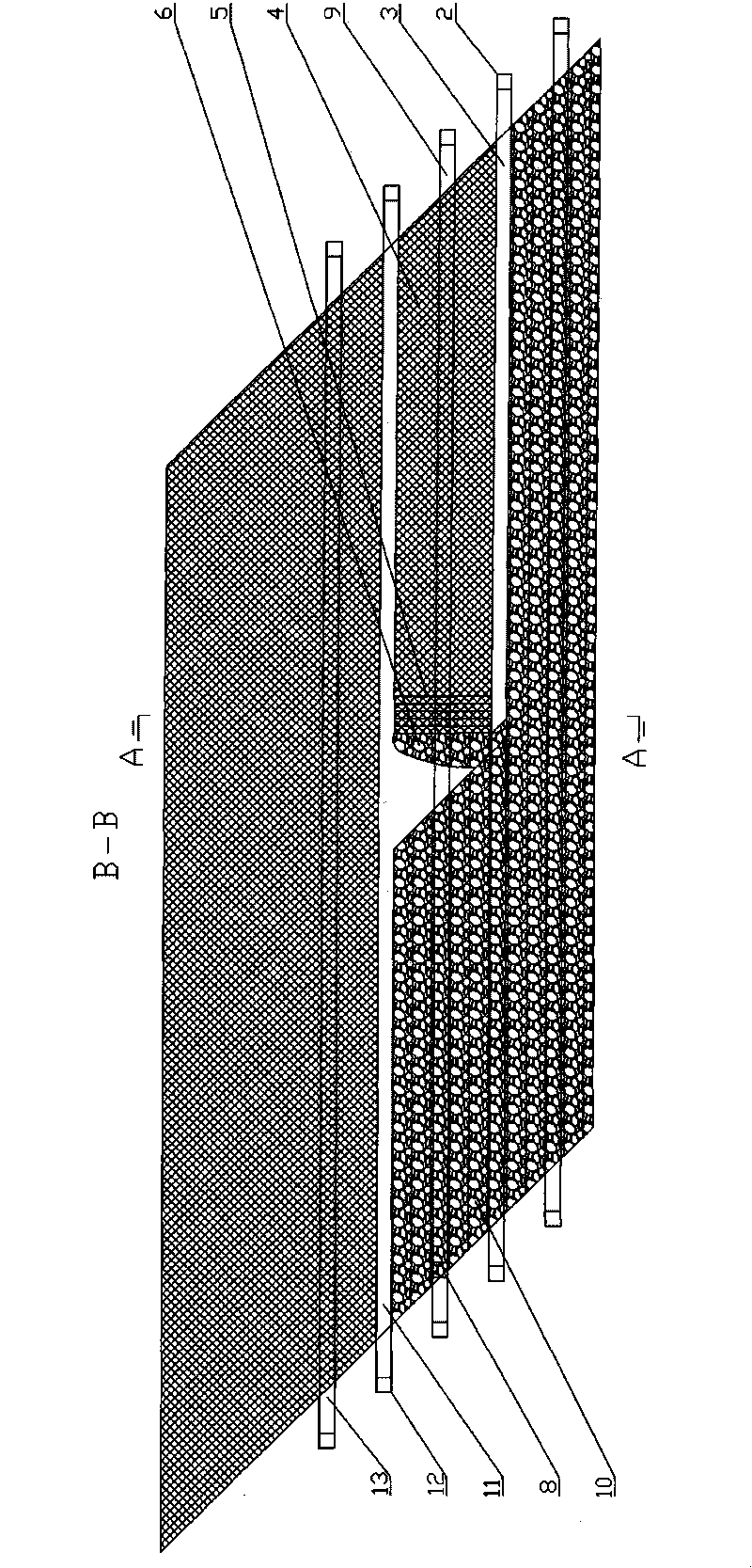

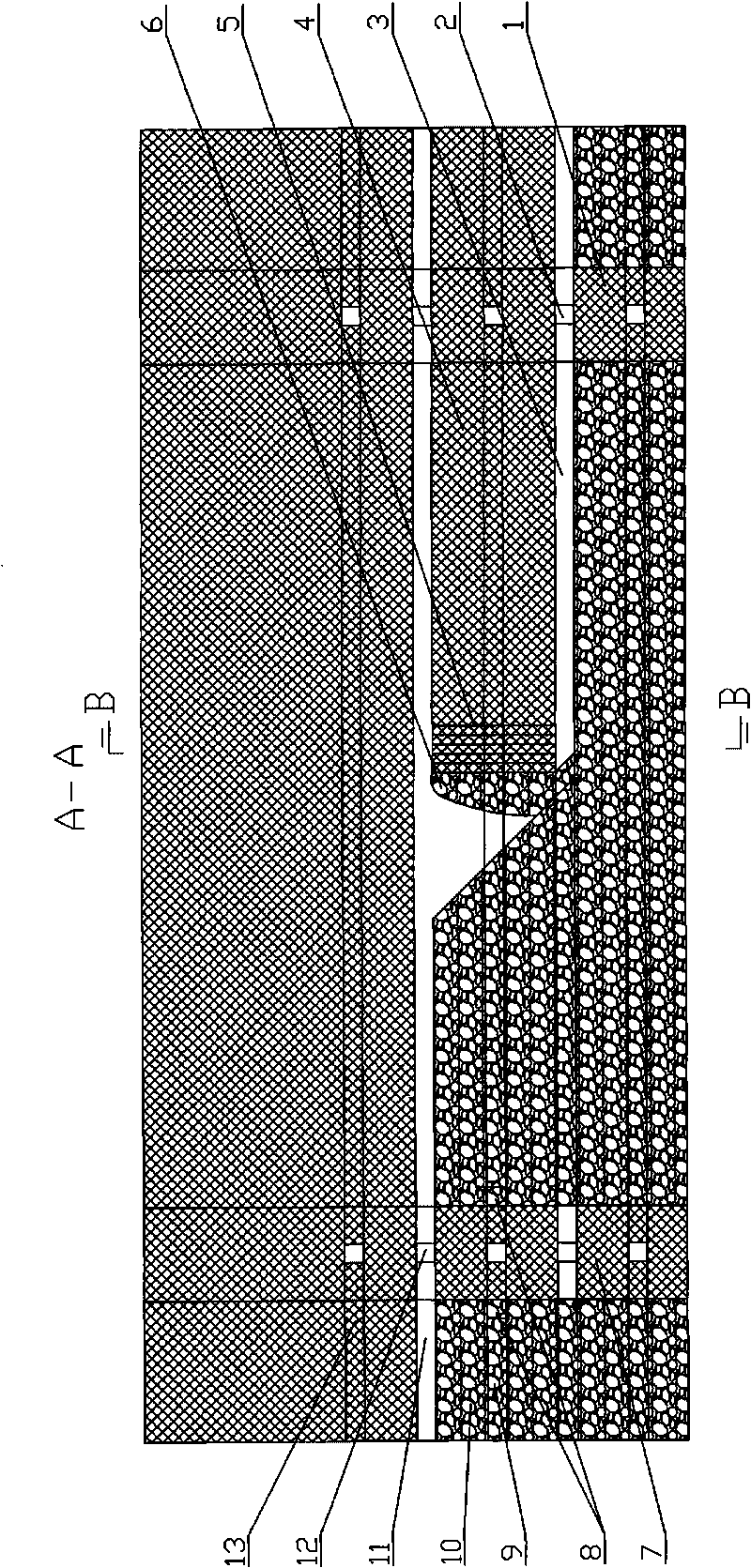

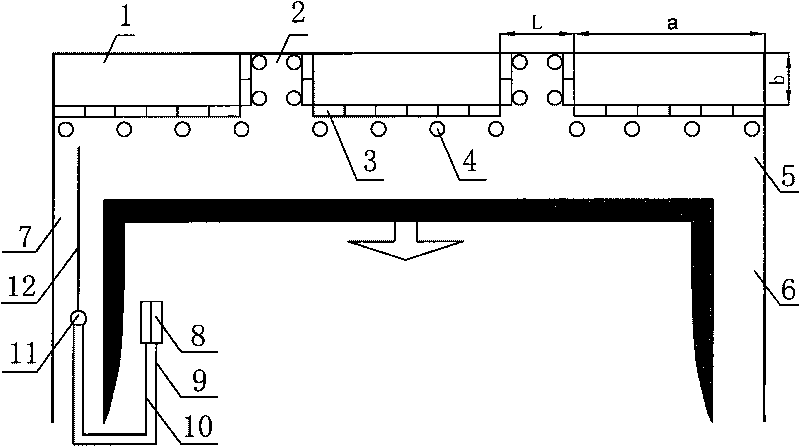

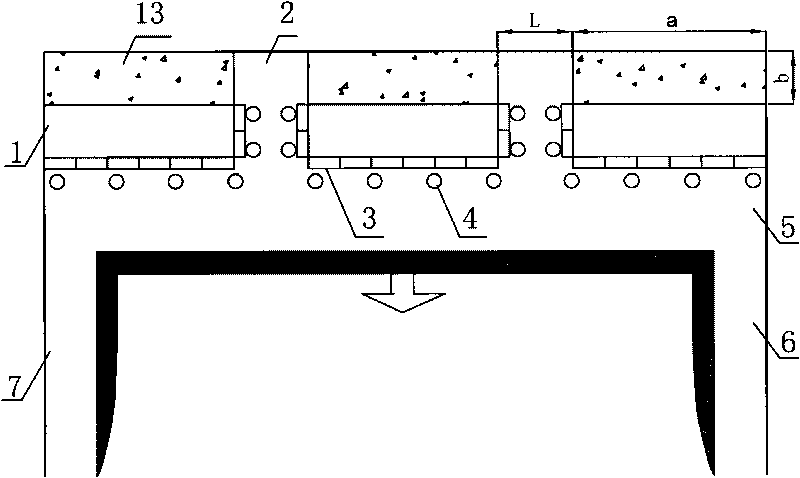

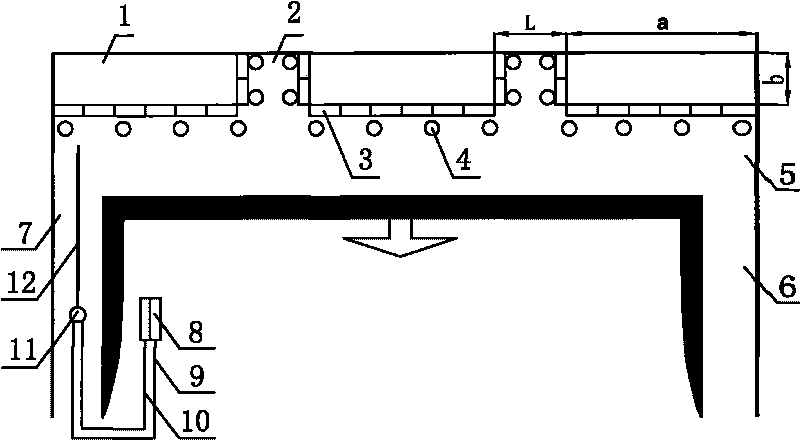

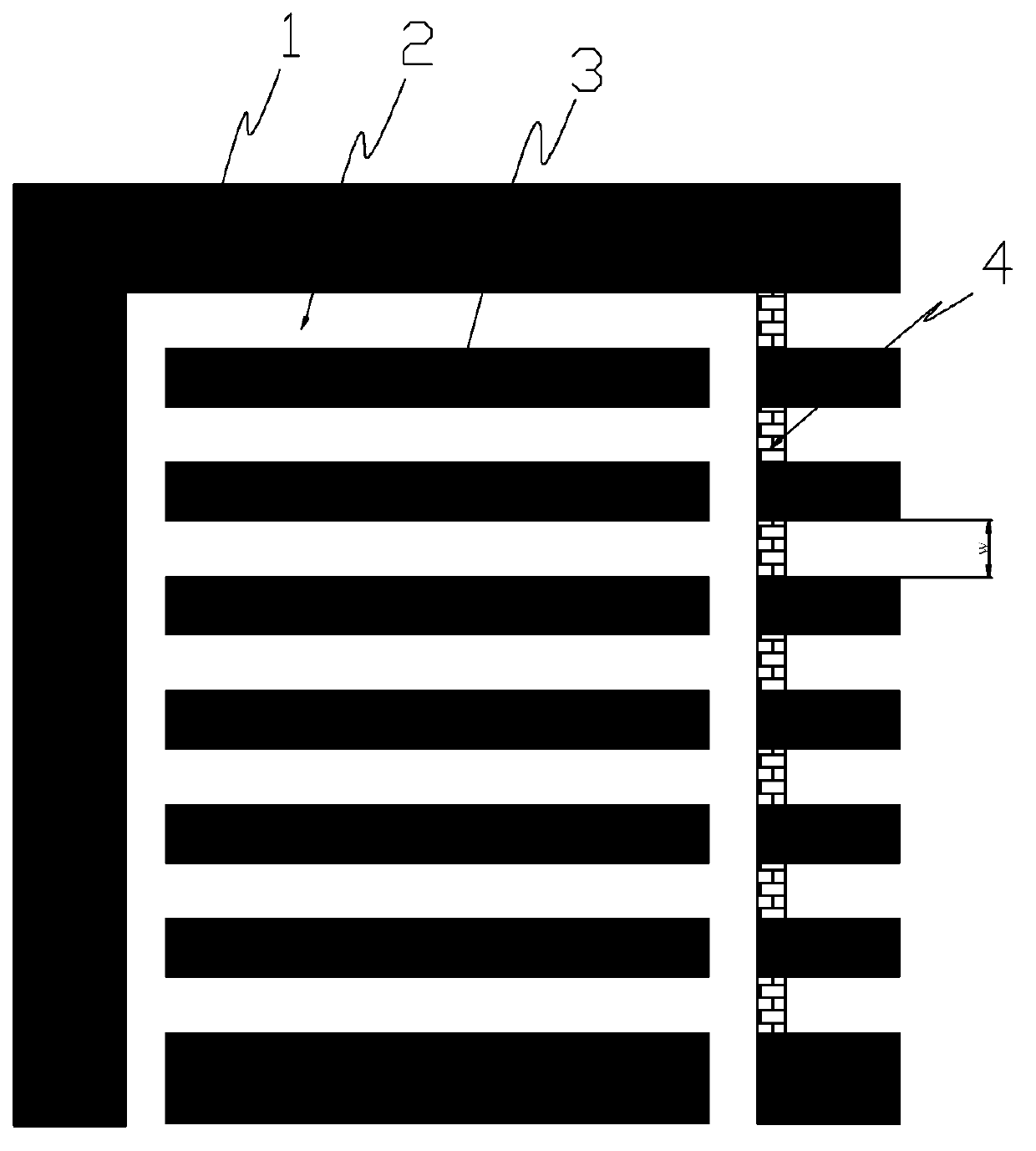

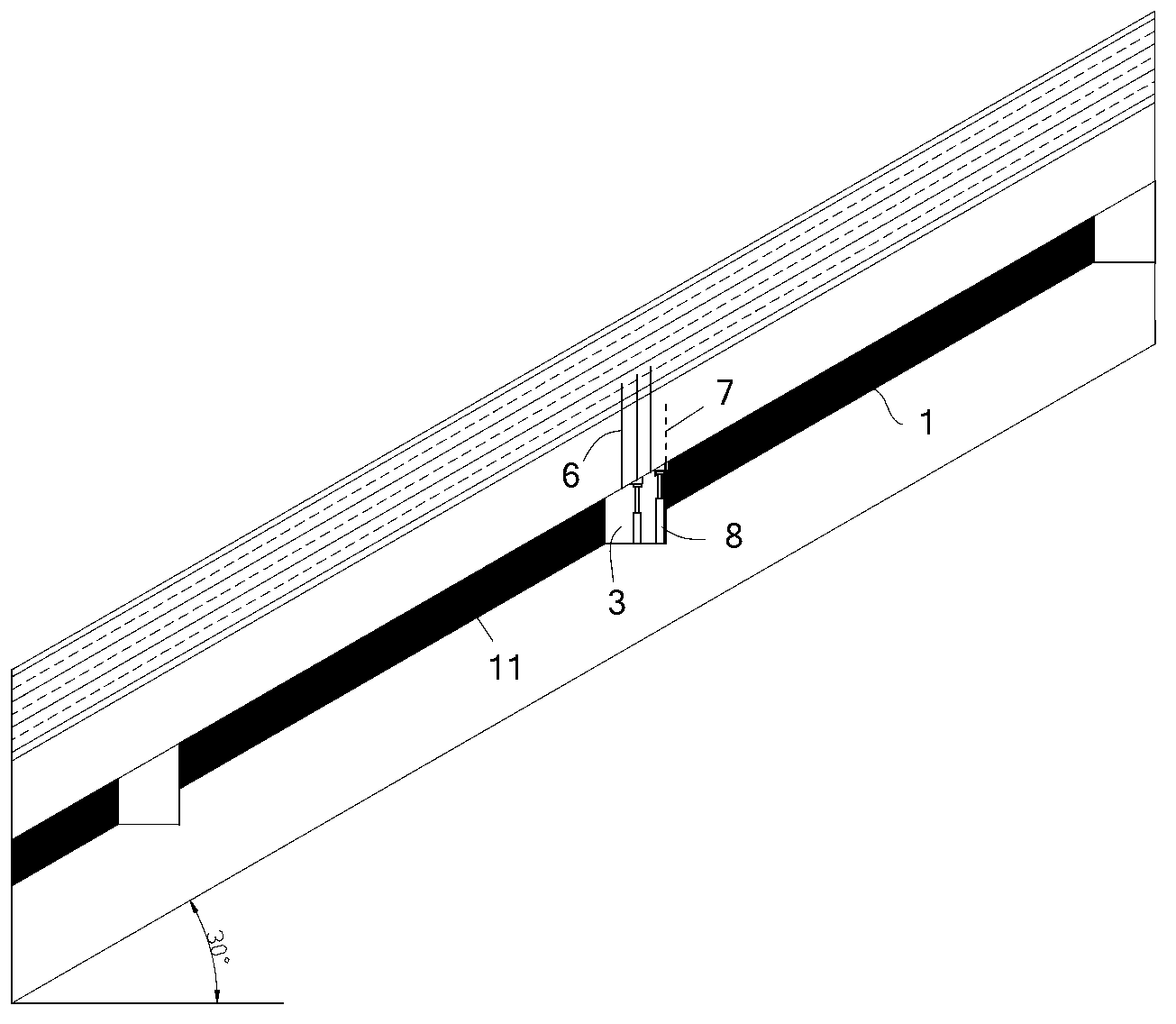

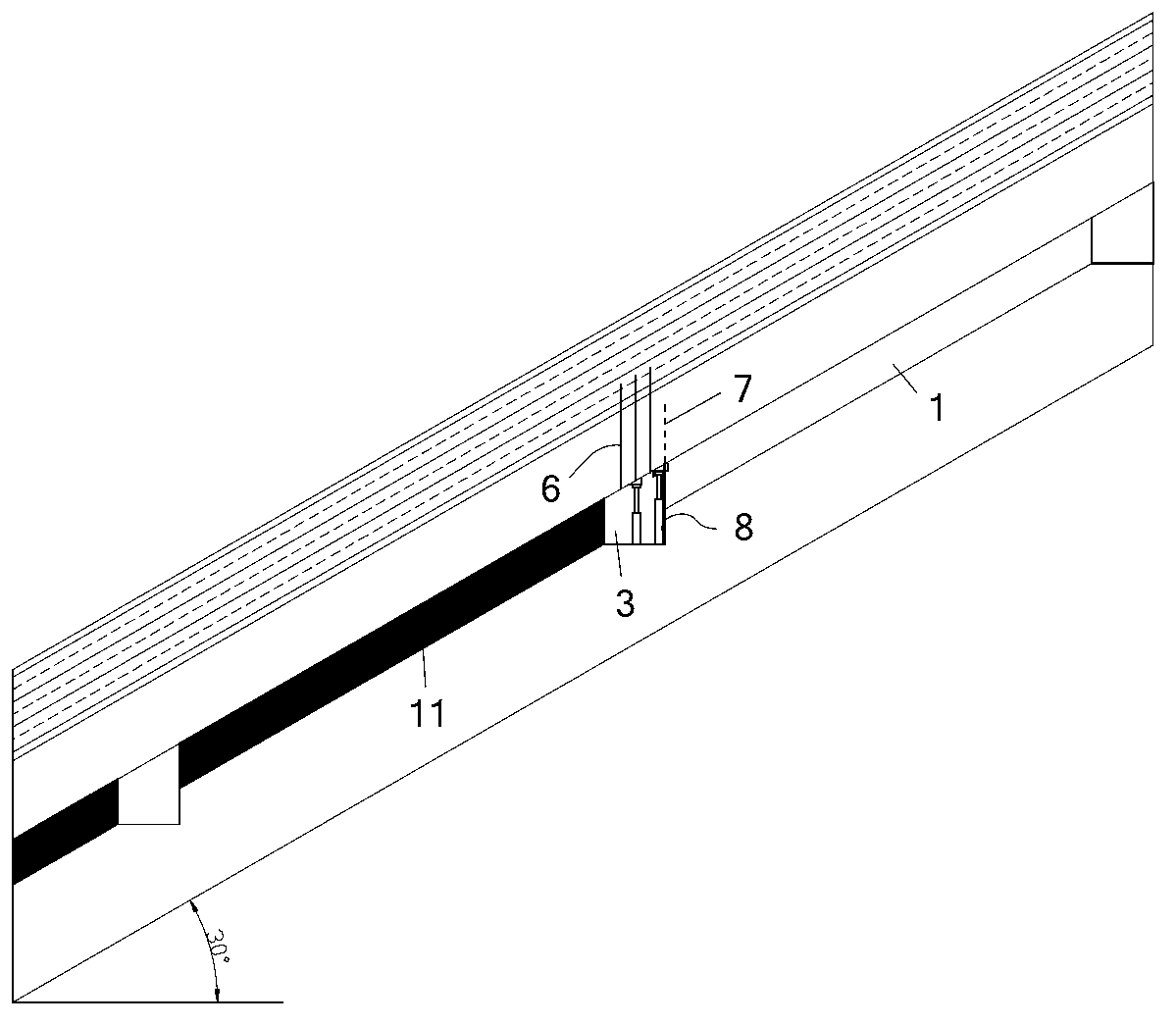

Solid-filling coal mining method with two pre-excavating tunnels for advancing

ActiveCN102996131ASolve the technical problems that cannot guarantee the filling effectEasy to useUnderground miningSurface miningFilling materialsMining engineering

The invention discloses a solid-filling coal mining method with two pre-excavating tunnels for advancing. A mining roadway adopts an arrangement mode that the pre-excavating tunnels are taken as air return and inlet roadways and a gob-side entry retaining roadway is taken as a roadway for transporting filling materials and coal; coal extraction and gob backfilling are carried out by a comprehensive mechanical solid-filling coal mining process; and according to the coal mining method, a mining sequence is propelled by making a filling coal mining work surface be back to the direction for transporting the coal to a mountain in a mining area. The pre-excavating tunnels are formed before the extraction of the work surface by tunneling, and the gob-side entry retaining roadway is formed by optimally designed filling bodies beside the roadway along with the implementation of advancing filling coal mining operation along the work surface. The coal mining method is simple in process and technically and completely realizes coal milling without pillars, and the resource extraction rate of the coal is high. The coal mining method can not only solve the technical problems that a draw-back-type down-mining and up-filling work surface cannot ensure a filling effect during a filling milling process of a mine with shortage of resources, but also materialize the comprehensive mechanical solid-filling coal mining of mines with limited geological conditions by virtue of an advancing up-milling and down-filling work surface.

Owner:CHINA UNIV OF MINING & TECH

Method for filling solid and fully mechanizing and recovering room type coal pillar

ActiveCN101725352AExtended service lifeHigh recovery rateUnderground miningSurface miningSpontaneous combustionSolid mass

The invention discloses a method for filling solid and recovering and fully mechanizing room type coal pillars, comprising the following steps of: reinforcing and supporting a coal pillar and a coal room top plate in a pre-recovering room type coal pillar area and suspending and hanging a wind curtain to form a solid substance haulage drift and a coal haulage drift which are connected with a large haulage drift; recovering the coal pillars by the conventional method, starting matching equipment after cutting a coal interval and transporting the solid substances to a goaf from the ground for filing and tamping; and cutting coal of next coal interval and filling the goaf, repeating the steps until finishing the recovery of all room type coal pillars. The method not only solves the problems that unstable coal pillar causes the safety accidents due to the superposition of stress of the front part and two sides of a workface because of the recovery of the traditional coal pillar, but also eliminates the potential safety trouble caused by the hurricane, large-area sinking and the like caused by the spontaneous combustion of the room type coal pillar and the large-area caving of hard top plates in the goaf. The invention has simple method, high production efficiency, low cost and over 85 percent of the recovery rate of the coal pillars.

Owner:CHINA UNIV OF MINING & TECH

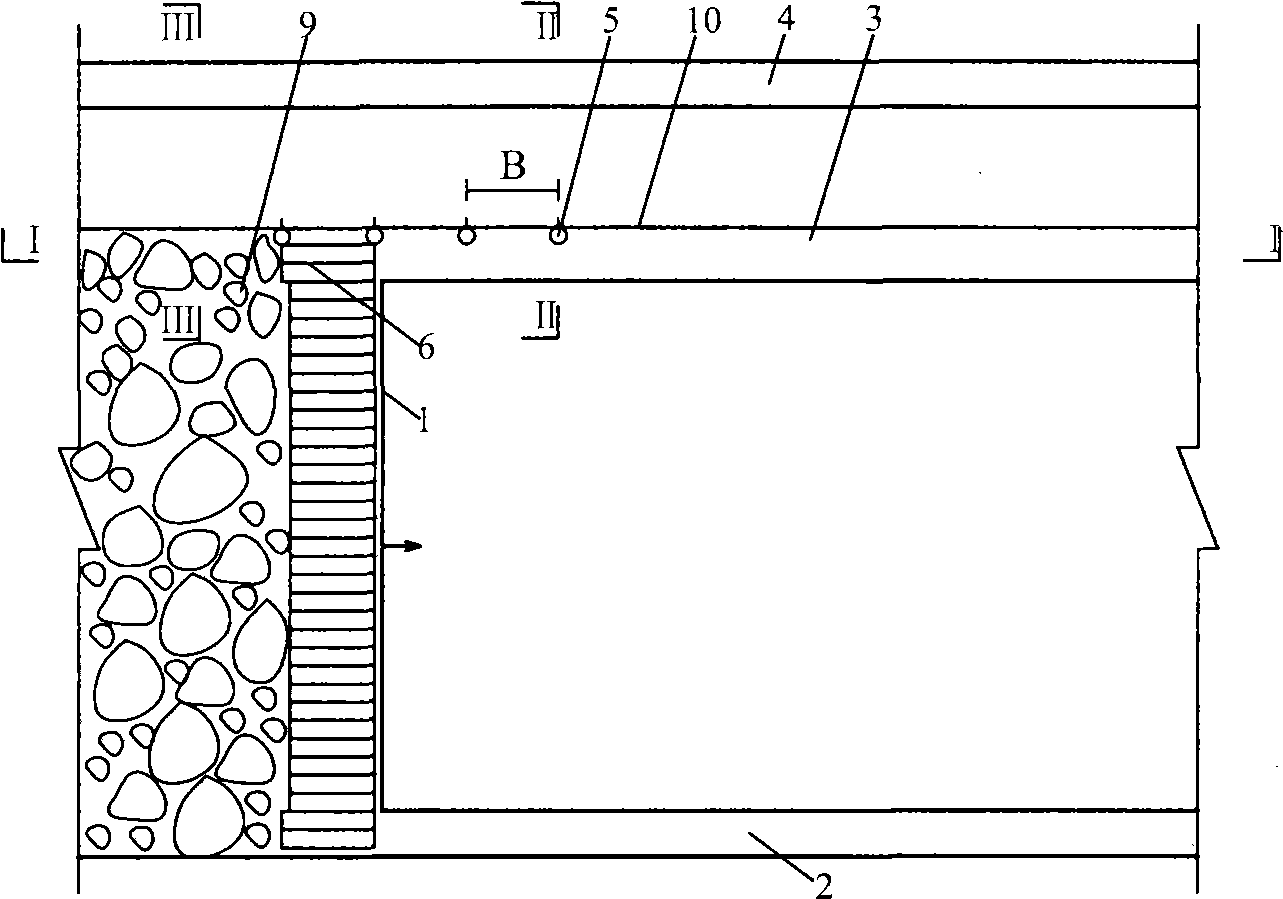

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

Strip filling integral backstopping coal mining method

ActiveCN101372891AHigh recovery rateMining operation safetyUnderground miningSurface miningResource recoveryBand shape

A band filling stoping mining method effectively solves the problems in the prior stoping mining of a 'three-low' coal bed, such as the sedimentation and distortion of the earth surface, the low recycling rate of coal and charcoal resources, the existence of safety hazards, etc. The method comprises the following steps: a transporter and a coal mining machine are laid on the working face of the mining area; in the direction perpendicular to the direction of the transporter movement, a timbering device which is composed of a hydraulic bracket of the working face, a side molding board bracket for filling beside the lane and a back molding board bracket for filling beside the lane, and connected with the connecting head of the transporter is arranged; after the brackets are pushed along the working face, paste concrete is injected through a pipeline into a filling mold cavity enclosed by the brackets, so as to form a band-shaped filling wall which is supported between the top plate above the goaf and the bottom plate of the coal bed. By the method, safe and convenient mining operation is ensured; the recycling rate for coal and charcoal is increased; meanwhile, the sedimentation and distortion of the overlying strata of the coal bed and the earth surface can be controlled in a very small range of deformation permitted by a building, thereby minimizing the amount of gentle sedimentation of the earth surface, and protecting buildings and attachments on the earth surface.

Owner:沈阳天安特种机器人有限公司

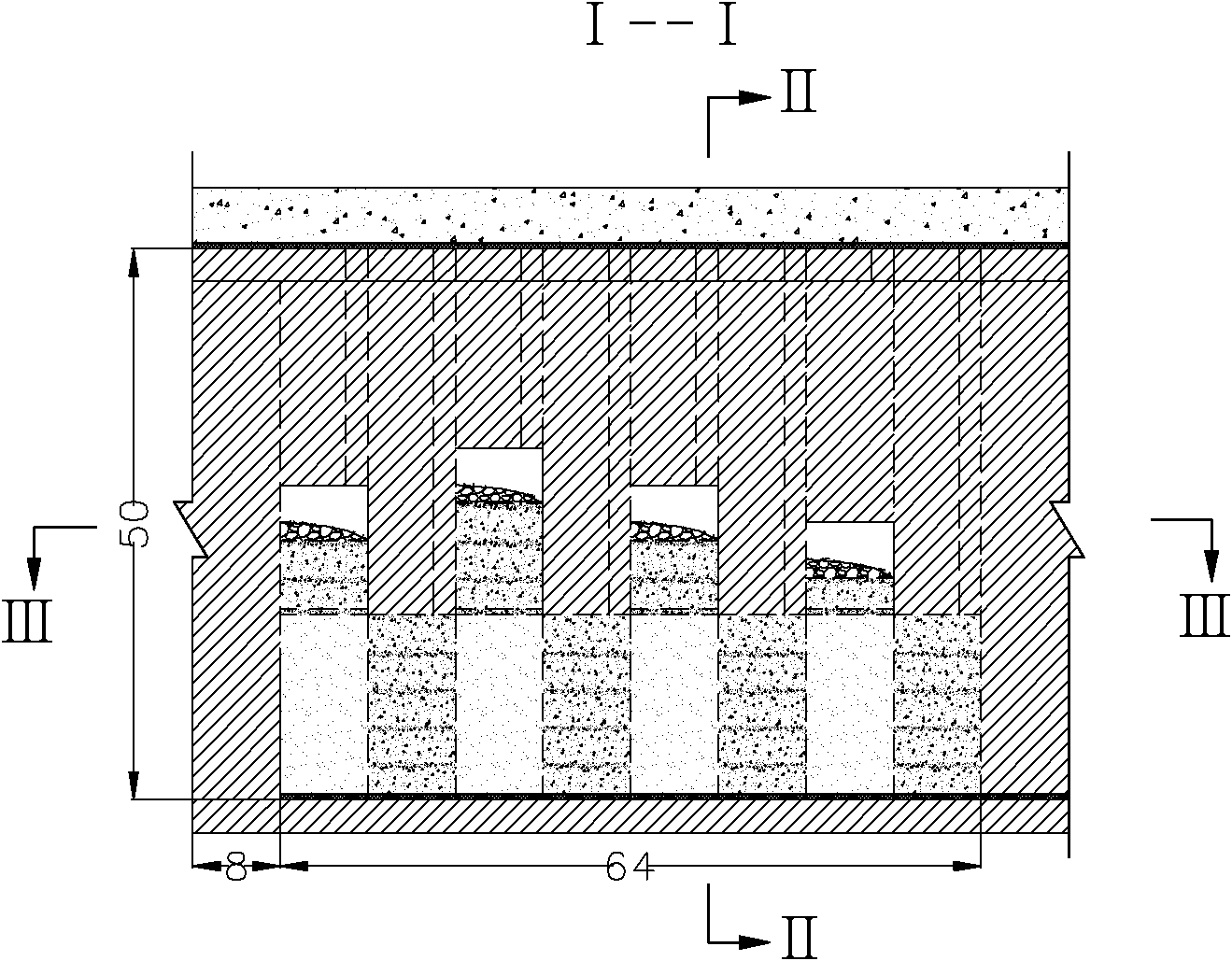

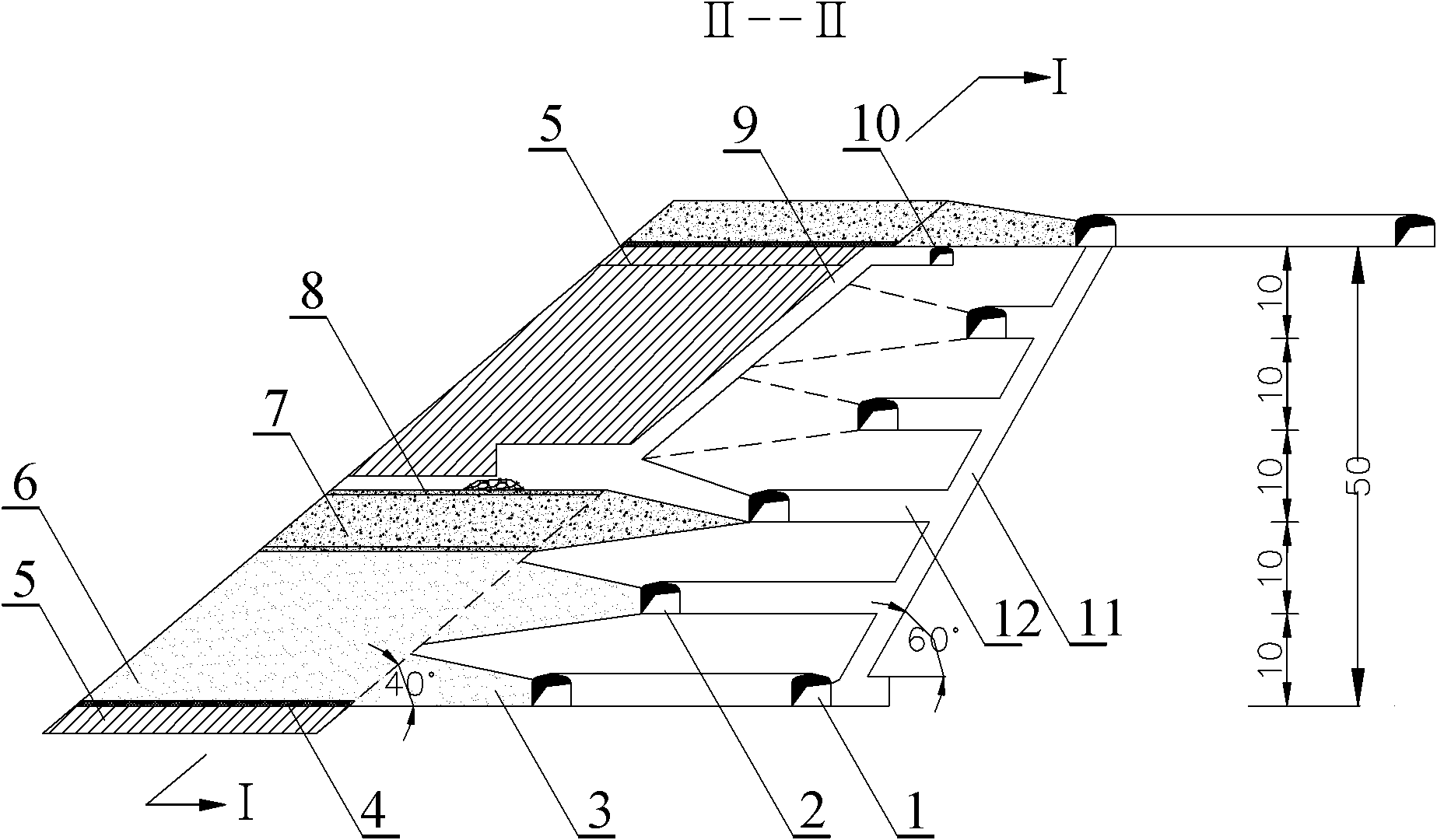

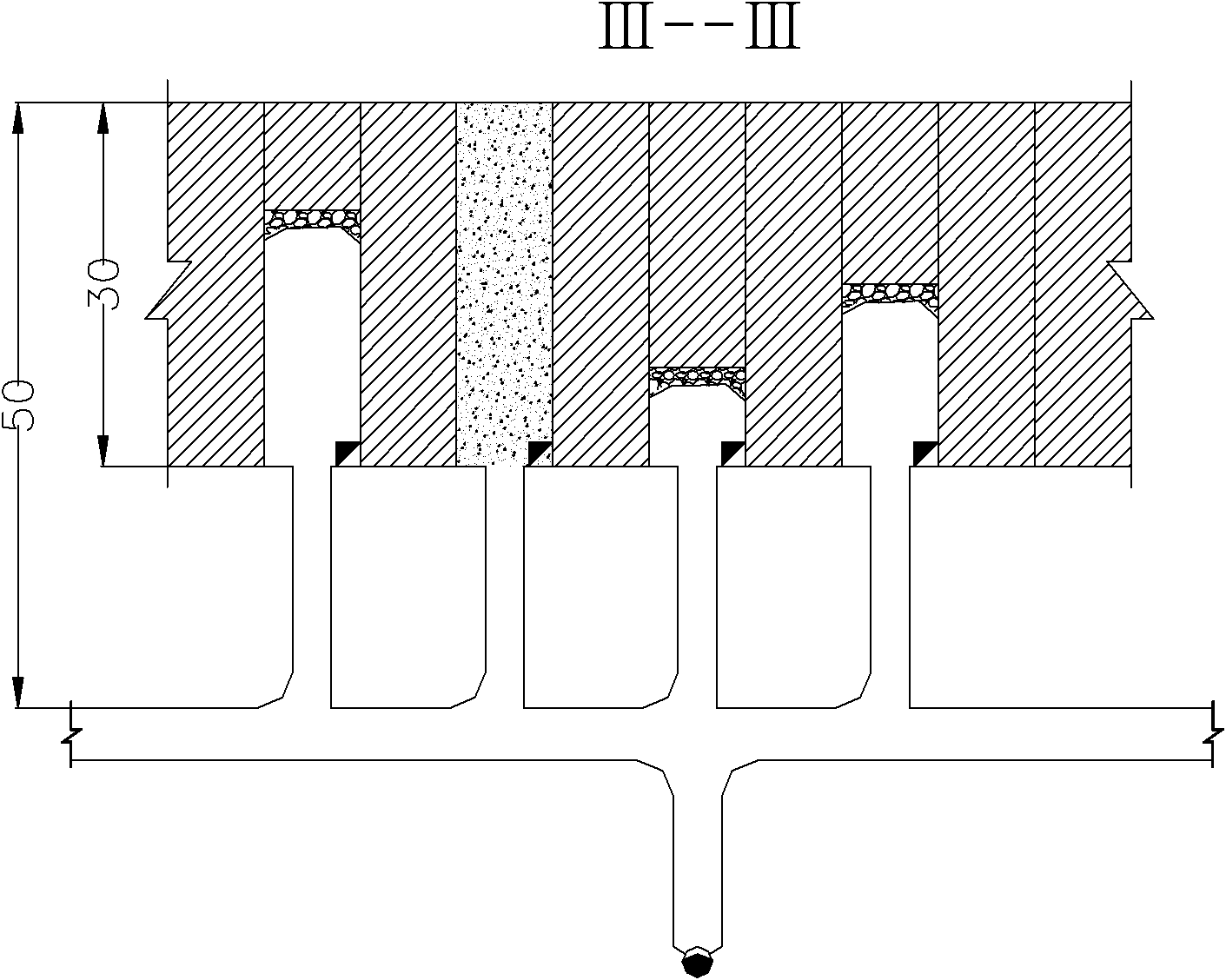

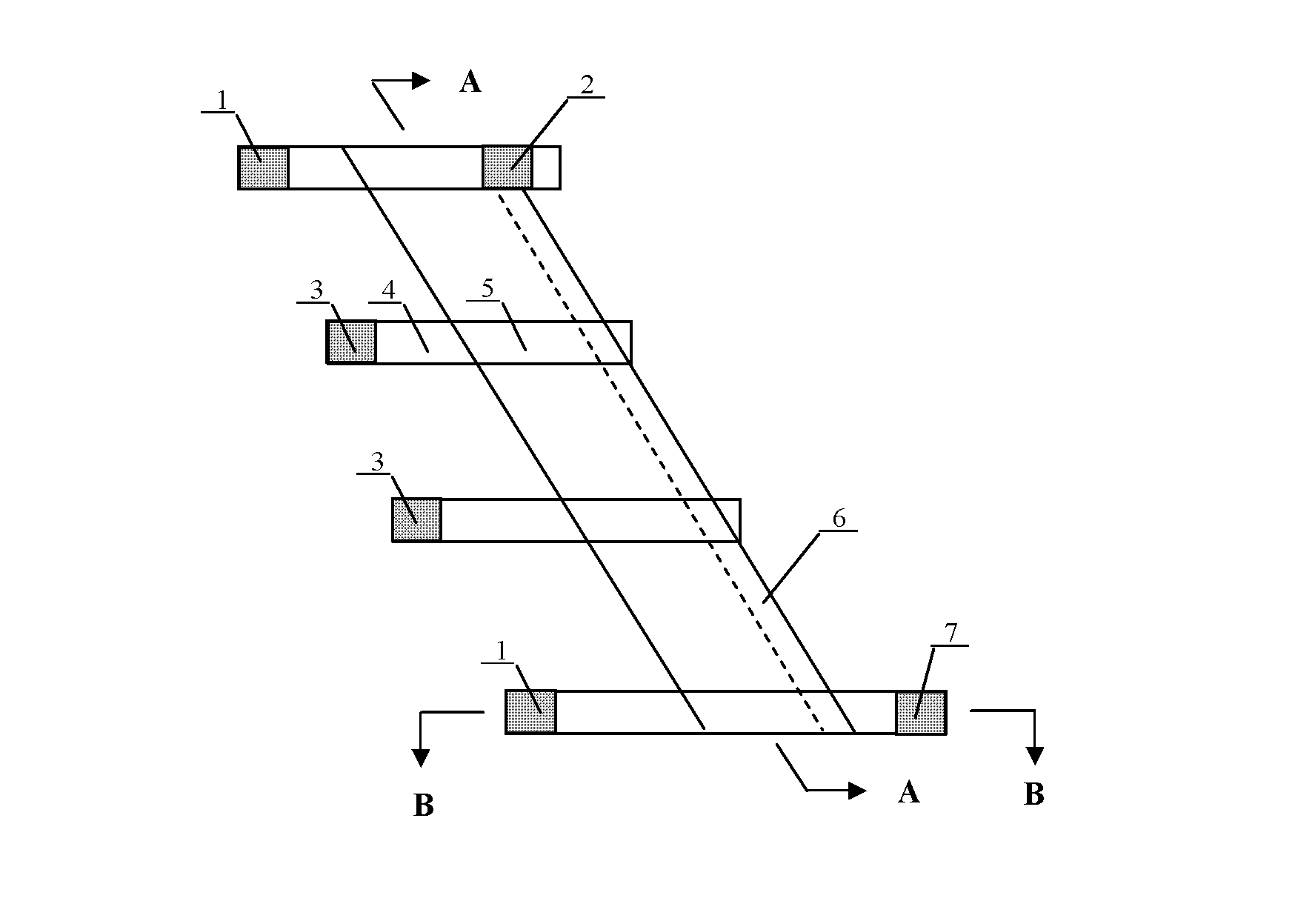

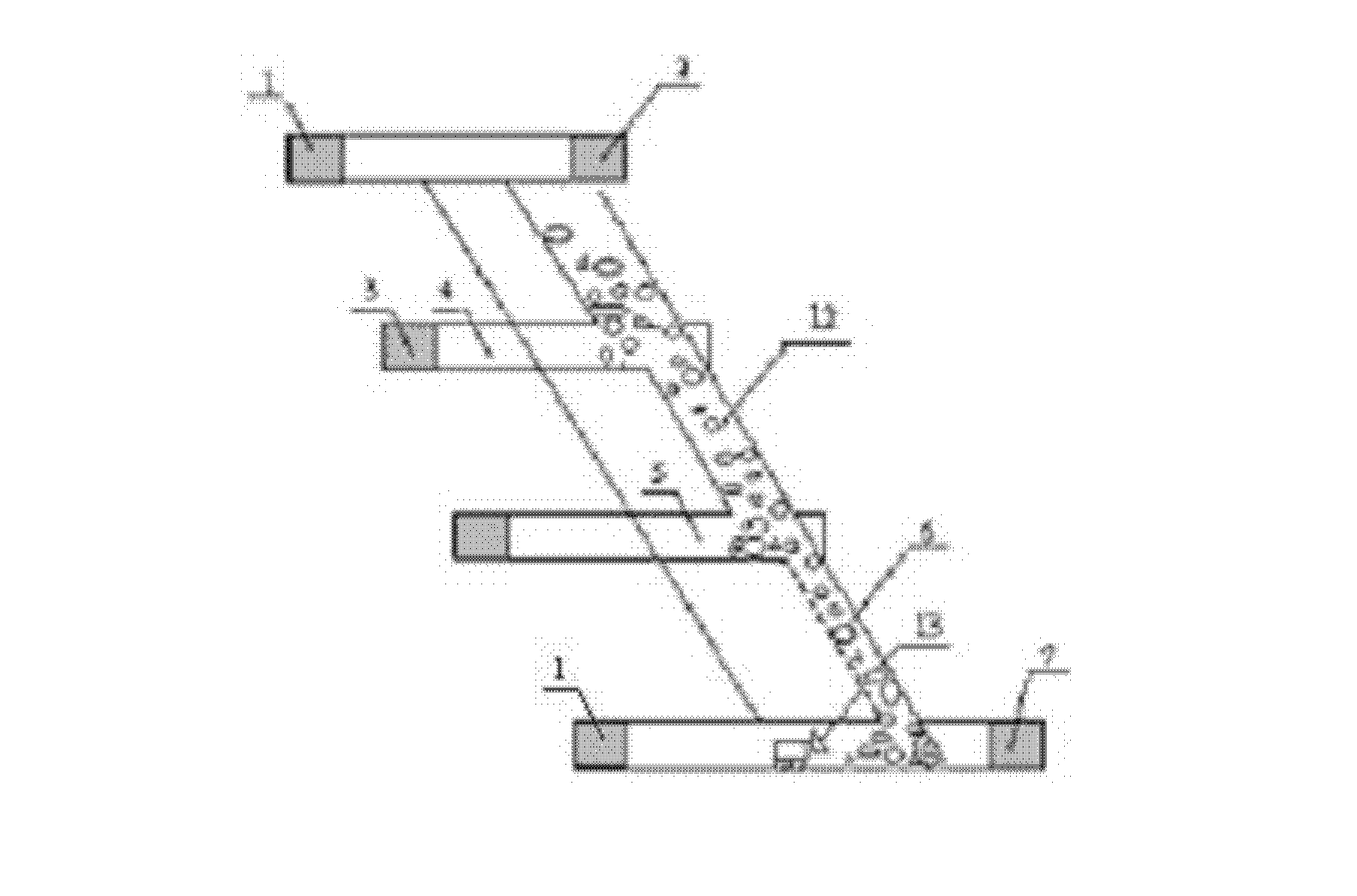

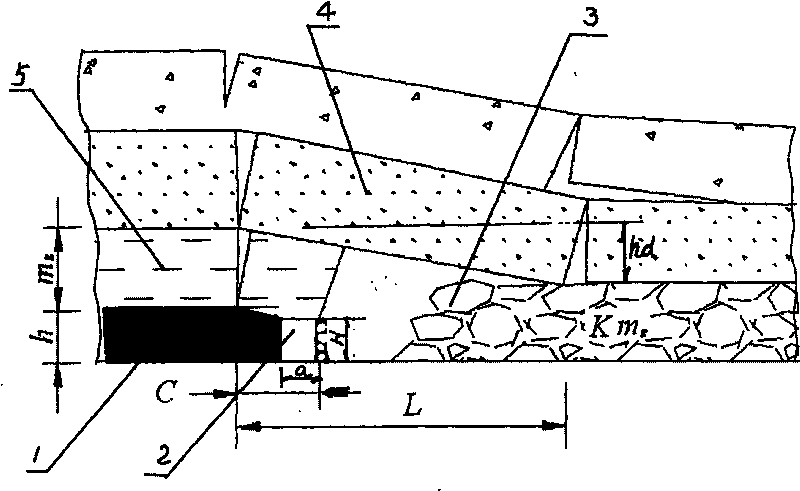

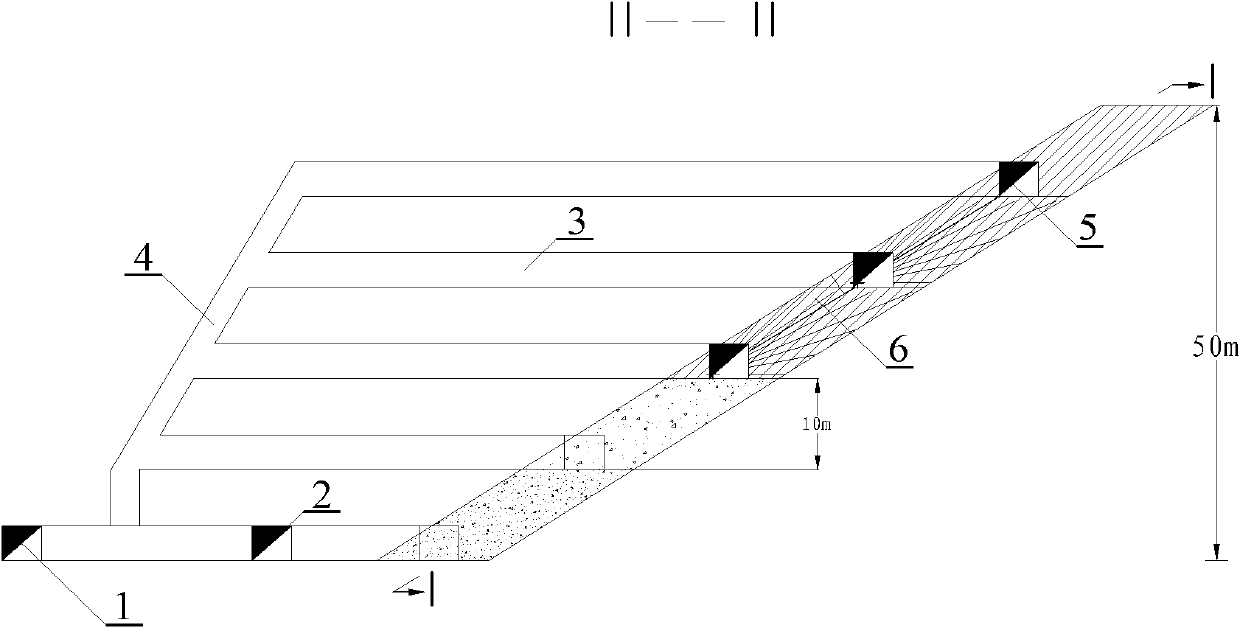

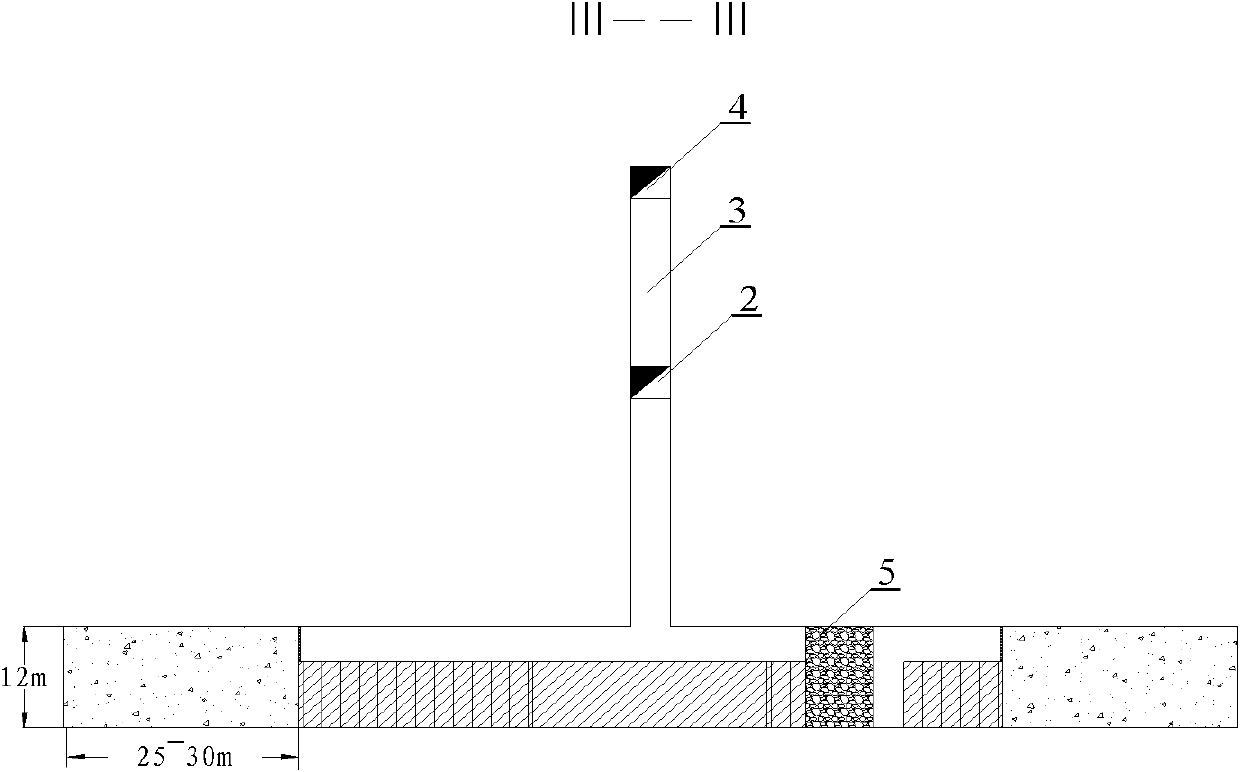

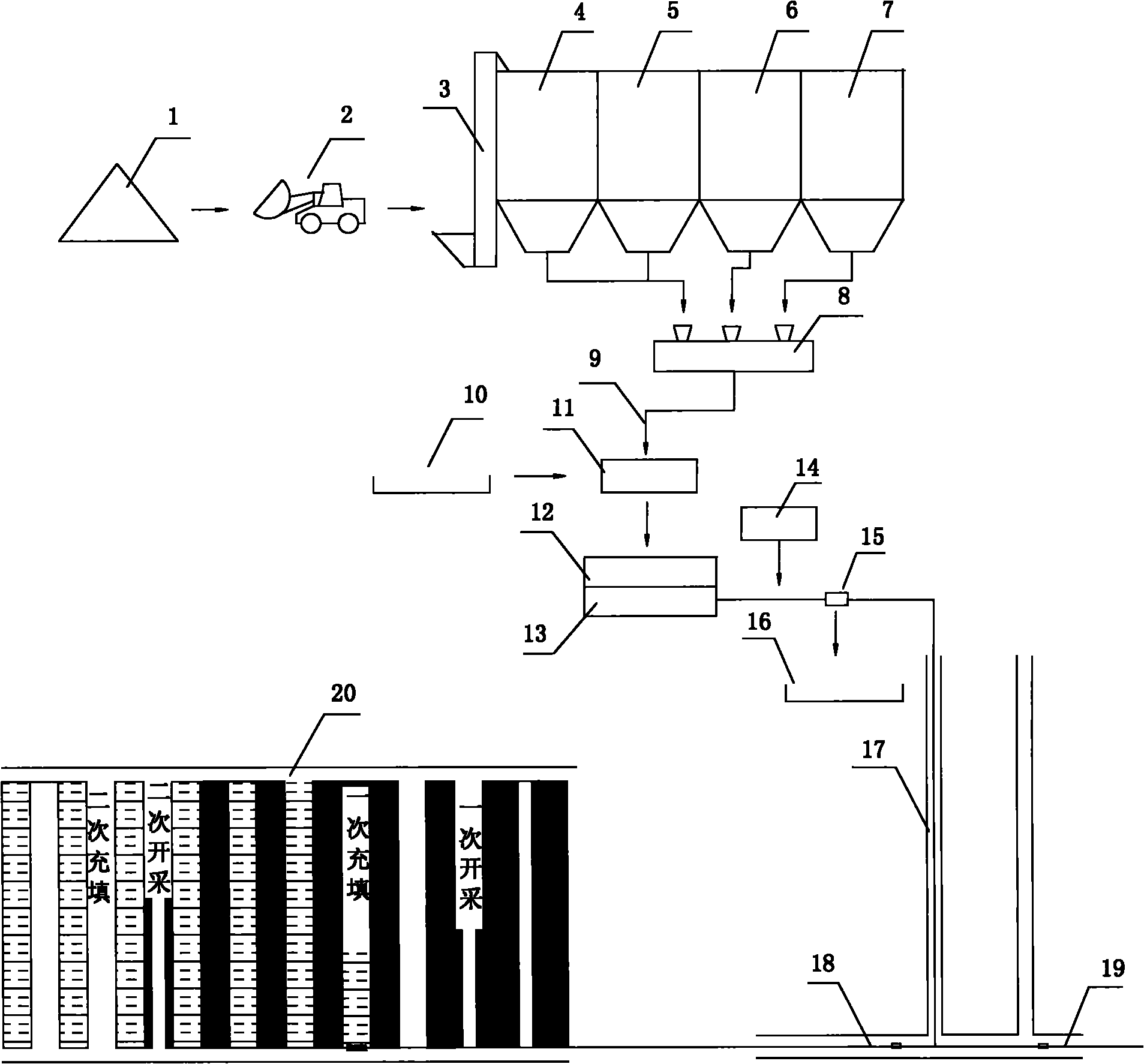

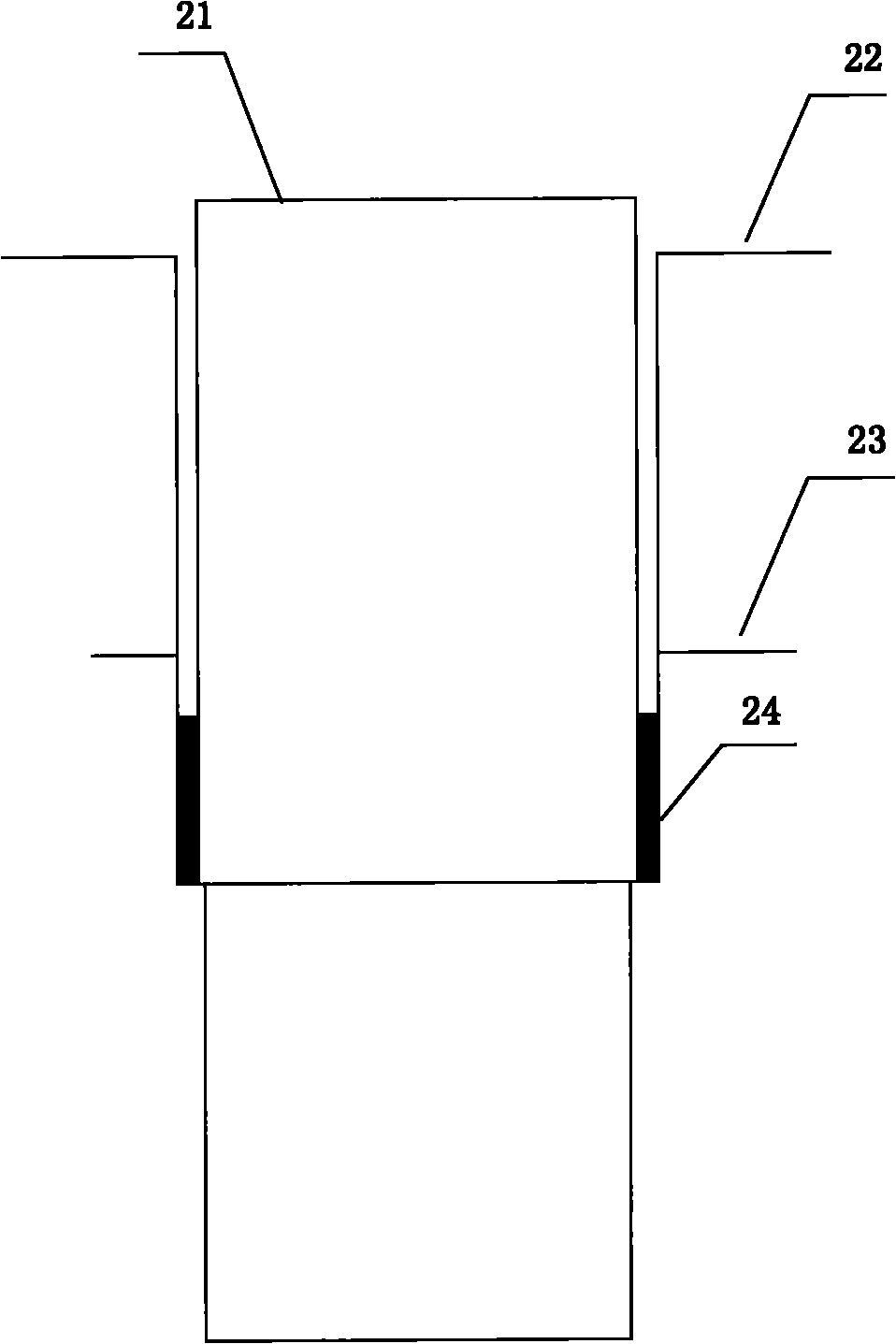

Rib-pillar-free continuous sublevel filling method for mining preparation in medium-thickness slope crushed ore body vein

The invention discloses a rib-pillar-free continuous sublevel filling method for mining preparation in a medium-thickness slope crushed ore body vein. The method comprises the following steps of: dividing a mine block into panel structures with a plurality of sections and bunches, namely dividing sections in a panel, not leaving a rib pillar in the sections, and dividing continuous extraction units; arranging a slope ramp of the panel on an ore body hanging wall, and arranging sectional roadways namely rock drilling ore removal gate ways in the vein; making all the sectional roadways in the panel mutually communicated, and the allocation and transportation of trackless equipment flexible and convenient; performing quarry central up cutting before the extraction, and ensuring the deep hole construction in a quarry upward sector in good conditions; performing operation such as multiple-section quarry rock drilling, blasting, supporting, ore removing, filling and paralleling; using a rib-pillar-free continuous extraction way backing from two wings of the panel to the center in the same sectional quarry, wherein an extraction process is performed sequentially; and filling a gob with tailings or waste stones. The invention relates to the rib-pillar-free continuous sublevel filling method suitable for medium-thickness slope crushed ore bodies, which has a low mining preparation ratio, low loss and high efficiency and the extraction is safe.

Owner:CENT SOUTH UNIV +1

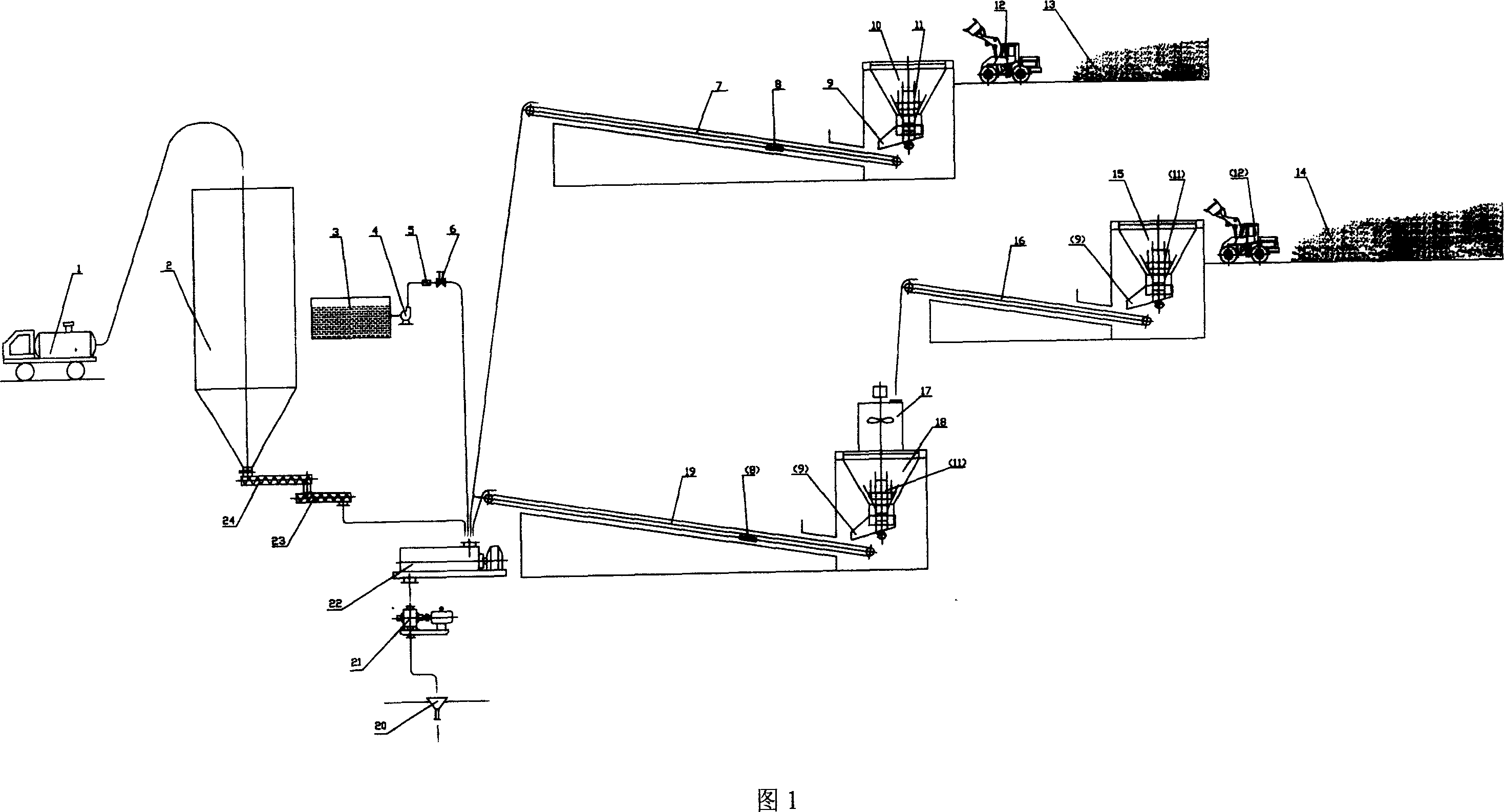

Filling process for recovering coal pillars by filling goaf with paste

The invention provides a filling process for recovering coal pillars by filling a goaf with paste. The filling process comprises three parts: preparing filling paste; conveying the paste via a pipe; and filling the goaf with the paste. The adopted filling paste comprises the following raw materials in percentage by weight: 40%-70% of aeolian sand, 10%-25% of coal ash, 3%-10% of cementing materials, 0.4%-1% of additive and 10%-30% of water. In the filling process, the goaf filling part comprises the procedures of primary filling and secondary filling, wherein, the coal pillars are recovered after primary filling; the whole goaf is fully filled after secondary filling; and roof-contacted supplementary filling is carried out in each filling procedure. The filling process has the advantages that the problems of filling the goaf formed after pillar-support mining and recovering the coal pillars are solved, the mining area environment can be protected more effectively, the increasingly exhausted coal resources are saved, and the filling cost is lowered.

Owner:TIANDI SCI & TECH CO LTD

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271ARealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a method to filling non-coal column face workplace by gangue. It includes the following steps: directly transferring the gangue to gangue storehouse, discharging to the slat conveyer through hopper gate, transferring the gangue to face through gangue transferring belt, face slat conveyer, and high speed gangue throwing belt. It needs not to smash the gangue and could realize zero stacking of gangue to improve coal mine environment. The invention supplies a new coal mining method for realizing environment protecting exploitation.

Owner:SHANDONG SHENGQUAN MINING

Goaf bag-type packing method

InactiveCN101701526AReduce bending and sinkingReduce the amount of delaminationMaterial fill-upEngineeringSlurry

The invention discloses a goaf bag-type packing method, comprising the following steps: suspending a plurality of flexible filling bags at intervals in a goaf from an open-off cut, arranging a plurality of individual props at the outer side of a plurality of flexible packing bags, then erecting a formwork supported by the individual props outside the flexible filling bags; filling high-water material seriflux containing more than 85% of moisture into the bags until the bags are full, and removing the framework and the individual props after the high-water material in the bags are consolidated to complete a row of filling cycle. With the propulsion of coal mining working face, the following row of filling work is carried out continuously, flexible filling bags are suspended next to the front row to perform bag suspension and filling circularly of the next cycle until the filling work of the whole goaf is finished. The invention can directly support the top plate of the goaf, thereby effectively reducing the submergence of the top plate and controlling ground surface movement. The bag-type packing method is particularly suitable for filling the goaf of an inclined mining working surface with smaller strike propulsion or coal seam pitch, and has the advantages of simple technology, easy construction, low cost, simple operation and high filling efficiency.

Owner:JIZHONG ENERGY HANDAN MINING GROUP +1

Stripe gob filling repeated-mining method

InactiveCN103104287AHigh recovery rateEliminate hidden dangers of geological disastersUnderground miningSurface miningFilling materialsInstability

The invention discloses a tripe gob filling repeated-mining method. The method comprises the following steps. A, a fire dam of a main tunnel of the stripe gob is opened to ventilate and discharge possible remained noxious gas. B, the tunnel of the strip gob is cleaned and a cracked roof is fastened and the cracked trail appears in the locality and stagnant is got rid of. C, paste filling materials are adopted to fill a empty stripe of the stripe gob in order to form a filling stripe1. D, after the filling stripe is reinforced, remained striped coal pillar in the stripe gob is stopped. E, a new gangue which is formed by stopping and adopted by the new empty stripe processes with non-cemented filling in order to form a filling stripe2. The strip gob is filled with the filling materials through the adoption of the paste filling method and the remained stripe coal pillar is stopped and the new empty stripe which is formed by stopping is dealt with the non-cemented filling by adopting the gangue. The method has the advantages of not only improving further recovery percent of the coal resources, but also eradicating hidden trouble of geological disaster in mining area caused by the instability of the strip coal pillar.

Owner:SHANDONG UNIV OF SCI & TECH

Phosphogypsum cementing and post-filling mining method and pulping technology thereof

ActiveCN101008316ASolve problems that are difficult to handle in large blocksIncrease profitMaterial fill-upAdhesivePhosphorite

The invention discloses a stuff mining method when the ardealite adhesive is solidified and relative pulp production. The stuff mining method comprises that preparing mine house, stuffing preparation, preparing pulp, and stuffing. The pulp preparation comprises that using ardealite, coal powder / dolostone and cement as the stuff material to be added into water and mixed into stuff pulp; the stuff pulp via the stuff drill hole or the pump station is input to the upper outer flat channel of the mining field via the stuff tube, to be fed into the mining field. The inventive stuff mining method can confirm the yield and stability of mine, to improve the recycle rate of mineral and protect the environment.

Owner:贵州开磷设计研究院有限责任公司

Paste combined filling method utilizing solid wastes of mine

InactiveCN102155261AIncrease profitSolve environmental problemsMaterial fill-upSlagEnvironmental engineering

The invention relates to a paste combined filling method utilizing solid wastes of a mine. The method comprises the following steps of: constructing a filling retaining wall at the inlet of an underground worked-out section, and filling waste stones in which target metal is not contained or the content of the target metal is less than a boundary level, wherein the lumpiness is 0 to 400 millimeters, the loose static angle is 40 to 45 degrees, and the filling volume rate of the waste stones is 10 to 45 percent; then mixing 6.25 to 21.25 weight percent of gelatinizing agent, 53.75 to 78.75 weight percent of filling aggregates and 15 to 25 weight percent of water into a stirrer so as to prepare a paste cement material with the weight concentration of 75 to 85 percent; and conveying the paste cement material to the worked-out section through pumping of a filling pipeline or self-flowing under the action of gravity along the filling pipe, wherein the paste cement material is penetrated into the gaps of the waste stones; and the solidified paste cement material and the waste stones form a combined filler. By the method, the utilization rate of beneficiation full tail sand, smelting water granulated slag and underground waste stones is up to 100 percent, so the tailings cannot enter the base, the waste stones cannot emerge from the groove and the smelting water granulated slag cannot be piled up; and the environment and safety problems due to stacking of the wastes on the earth surface are solved from the sources.

Owner:UNIV OF SCI & TECH BEIJING +1

Gob-side entry retaining reinforcing filling body structure and construction method thereof

InactiveCN101975085AAchieving Early Bearer FeaturesSimple structureMaterial fill-upGroutMechanical engineering

The invention relates to a gob-side entry retaining reinforcing filling body structure and a construction method thereof. The method comprises the following steps of: making a filling bag into an enclosed oblong-shaped structure and sewing a plurality of small bags at the top edge of the filling bag and at the same position on two side faces along the filling direction, wherein the top small bag is used for filling feedstock and exhausting and a cross anchor is inserted into small bags on the side face for reinforcing a filling body and protecting sides; sewing hooks with certain densities inthe top central area of the filling bag and four side face lines which are certain distances away from the top of the filling bag, hanging the hooks on a top plate or four sides of a filling space, molding the filling body by using a reinforcement mesh and taking the reinforcement mesh as a reinforcing filling body for the cross anchor; before filling, inserting the cross anchor into the small bags on the side face, binding the small bags with a steel wire, putting a tray in place and screwing a screw cap; and during filling, plumping the filling bag until the filling bag is close to the roofby using the grout outlet pressure of a filling pump and enhancing anchor anchorage force to a preset value after the filling body reaches certain intensity so as to further realize the filling and reinforcing of the filling body. The structure is simple and is convenient to construct.

Owner:CHINA UNIV OF MINING & TECH

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

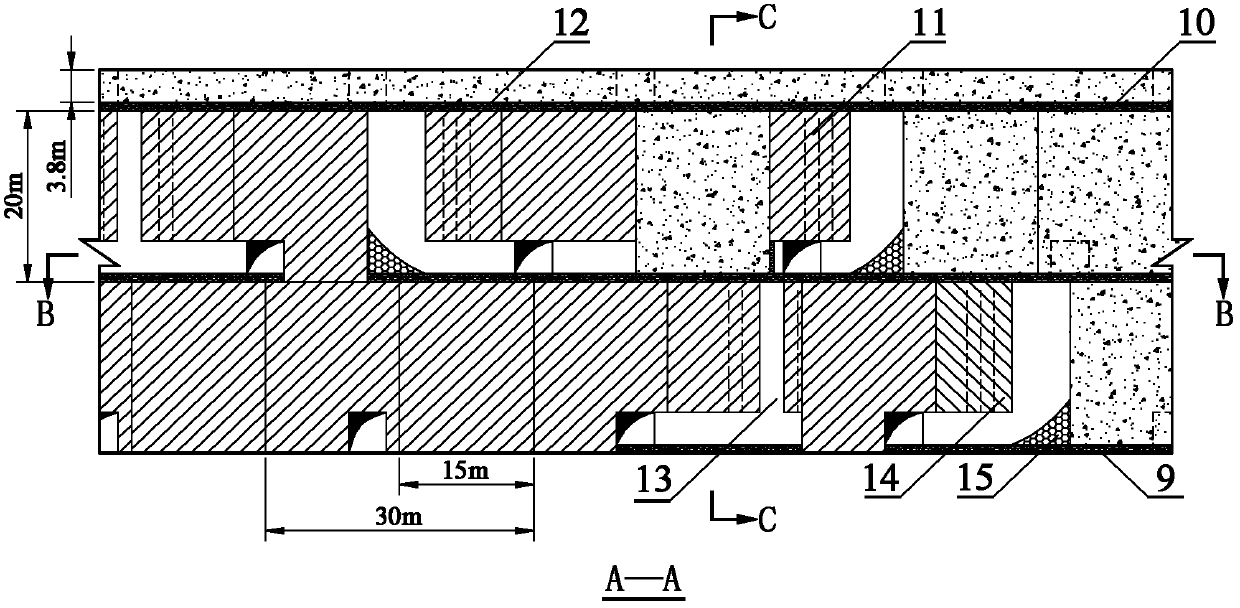

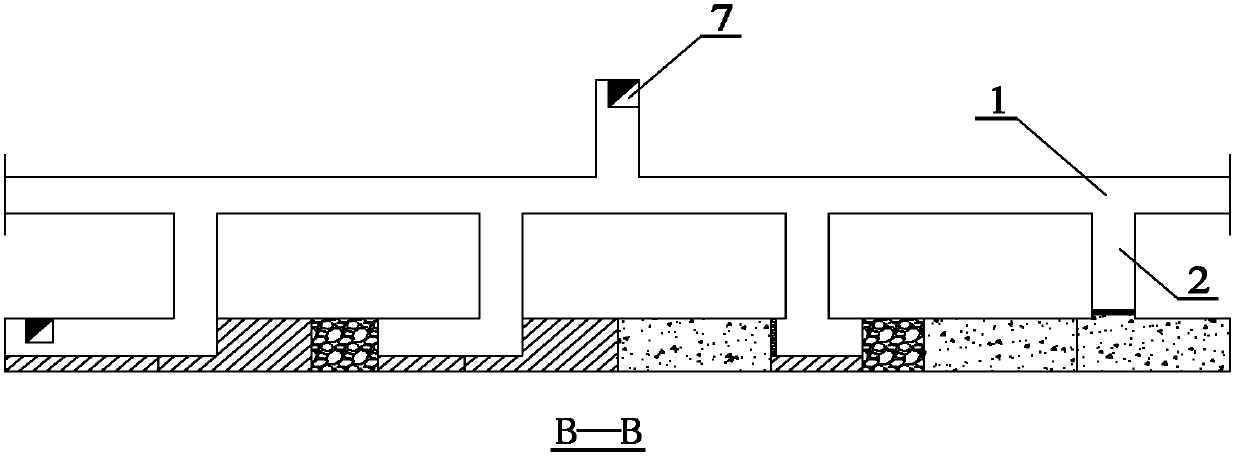

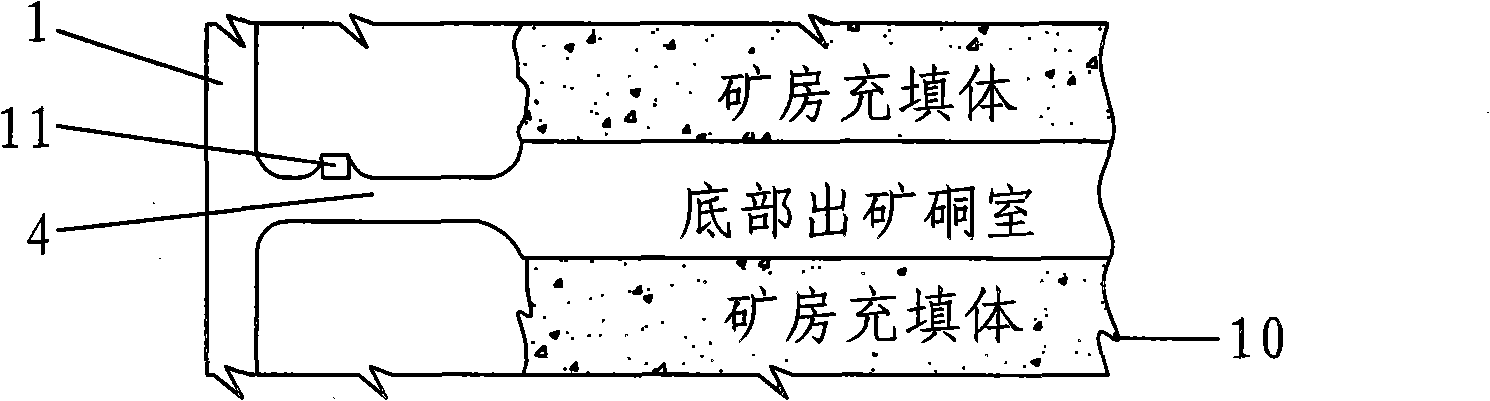

Non-bottom pillar deep hole falling-back type mining method

The invention relates to a non-pillar deep-hole backing-type mining method. The method is suitable for that: the digging height is between 10 and 50 m; the length of a stope is between 40 and 80 m; the width of the stope is between 7 and 9 m; the dip angle of an ore body is between 68 and 90 degrees; the height of a bottom ore removal chamber is between 2.5 and 3.5 m; the height of an upper part rock drilling chamber is between 3.4 and 3.8 m; meanwhile, an explosive charge structure, an explosion initiating sequence, stope side lacing and top plate control are determined according to the conditions of the stope, and a remote-control scraper and a remote-control crushing trolley are jointly used to treat large ore materials for ore removal. The mining method has the advantages of small mining-cutting engineering quantity, simple mining-cutting process, high rock drilling efficiency, good blasting effect, safe and efficient ore removal process, can effectively improve the wide-spacing stoping safety for underground metal mines nationwide, can upgrade the mining technical level for the underground metal mines in China, can promote the development of nationwide underground metal mine mining technology, and can reduce the dilution rate and loss rate of nationwide underground metal mine spacing stoping stopes, so as to promote the maximal recycling of metal resources.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

Roadway backfill mining method for coal seams with medium-high thickness

InactiveCN102155226AIncrease profitExtended service lifeUnderground miningSurface miningMining engineeringUltimate tensile strength

Owner:ZIBO WANGZHUANG COAL MINE

Mining method for replacement of banded coal under building by waste rock

The bone coal displacement strip coal block exploration under an architecture, concentrically sets 3-5 bone coals filling lane at the center of each strip coal block, based on the buried depth, width, laminated rock structure and protective degree required by the architecture build on the surface of each strip coal block, advancing coal mining for the 3-5 bone coals filling lane and then filling bone coals from the interior to the exterior inside the lane that has dug out coals. Ensuring the safety of the architectures, filling the displacement coal with bone coals, it can realize exploration rate no less than 20%, the total recovery rate of the strip mining area no less than 65%; Filling the mine with bone coals dug out can not only eliminates the bone coals on the land, reduces the encroachment of farmland, mitigates air and environmental pollution, gets rid of bone coal landslide or explosion and other hidden accidents that may affects the human life but also using bone coals working as the underground support of the mine and realizing second partial recovery for strip coal blocks under the architectures.

Owner:CHINA UNIV OF MINING & TECH

Steep-coal-seam long wall face non-pillar coal mining method

ActiveCN103195426AAvoid destructionAvoid enteringUnderground miningSurface miningShotcreteEngineering

The invention discloses a steel-coal-seam long wall face non-pillar coal mining method. The method comprises the steps of (1) excavating an upper crossheading roadway and a lower crosshead roadway; (2) mounting a constant-resistance large-deformation anchor rod, processing a row of vertical energy-gathering blasting holes, and implementing blasting and presplitting; (3) erecting a column body for supporting a top plate, and arranging a protective layer on the back of the column body; and (4) carrying out recovery, slipping the top plate of a recovery face along a presplitting kerf; (5) withdrawing the column, hanging a net and spraying concrete to form a support layer; (6) mounting a slip-casting constant-resistance long anchor rod, and grouting; (7) forming a roadway automatically in the original crosshead roadway and taking the roadway as the upper crosshead roadway of the next mining face; and (8) repeating the steps (2)-(7). According to the method, the top plate at a worked out section collapses along the presplitting kerf, and meanwhile, a lower crosshead top plate is prevented from being damaged, and small caving waste rocks are prevented from entering the lower crosshead roadway, so that the roadway is automatically formed in the original crosshead roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Opencast coal mine end slope filling mining method

InactiveCN103758568AReduce wasteSolve the problem of reduced recovery rateMaterial fill-upOpen-pit miningMining engineeringCoal pillar

Provided is an opencast coal mine end slope filling mining method. The opencast coal mine end slope filling mining method includes the steps that a coal pillar reserved at an opencast coal mine end slope is divided into a plurality of stalls which are equal to an end slope coal mining machine roller in width; a stowboard is tunnelled to the position of an earth surface safety boundary line in the coal seam trend direction, and a stowboard is tunnelled in the coal seam inclination direction; an end slope coal mining machine is used for mining the stalls on the side of the stowboard in the coal seam inclination direction at intervals, after mining of the stalls is completed, the end slope coal mining machine is removed, mining openings in the sides of stall side slopes are sealed, and filling is performed on the stalls which are mined at intervals; then, mining is performed on stalls at intervals, the stalls are not mined, filling is performed on the mined stalls, and the steps are repeated until mining of all the stalls which are not mined is completed. According to the opencast coal mine end slope filling mining method, rock and soil discharged by an opencast coal mine can be effectively used, the discharge amount of the rock and soil of the opencast coal mine is reduced, the stripping ratio is lowered, mines end slope coal resources are mined in a maximization mode, meanwhile the side slope safety is guaranteed, and the efficient environment-friendly production process of the opencast coal mine is achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com