Patents

Literature

82 results about "Face lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic lines appear with movement i.e. the activity of facial muscles. Static lines are unchanged with muscle movement. Eventually dynamic lines become static. Crow's feet around the eyes are due to smiling and activity of the eyelid muscles (orbicularis oculi).

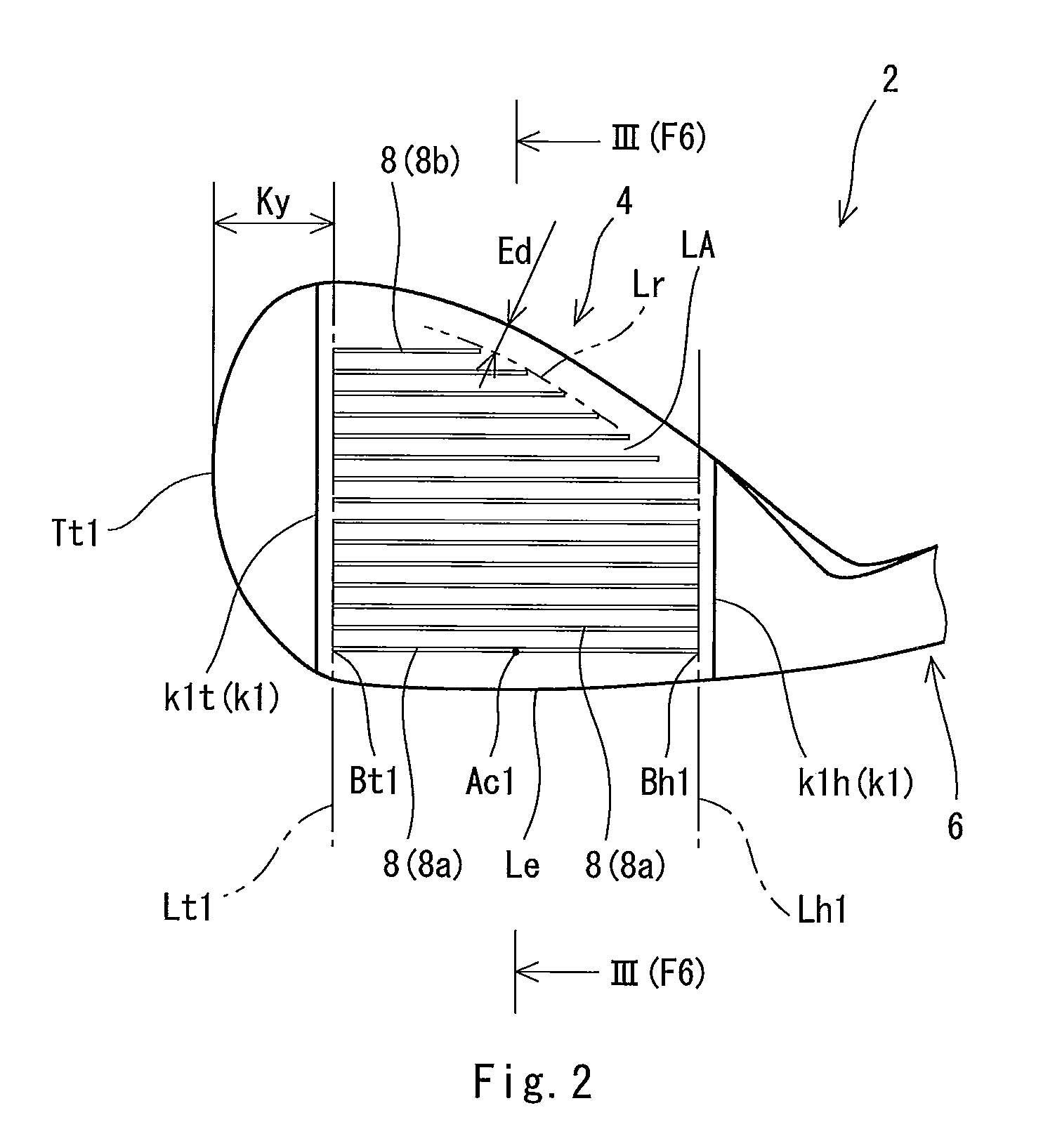

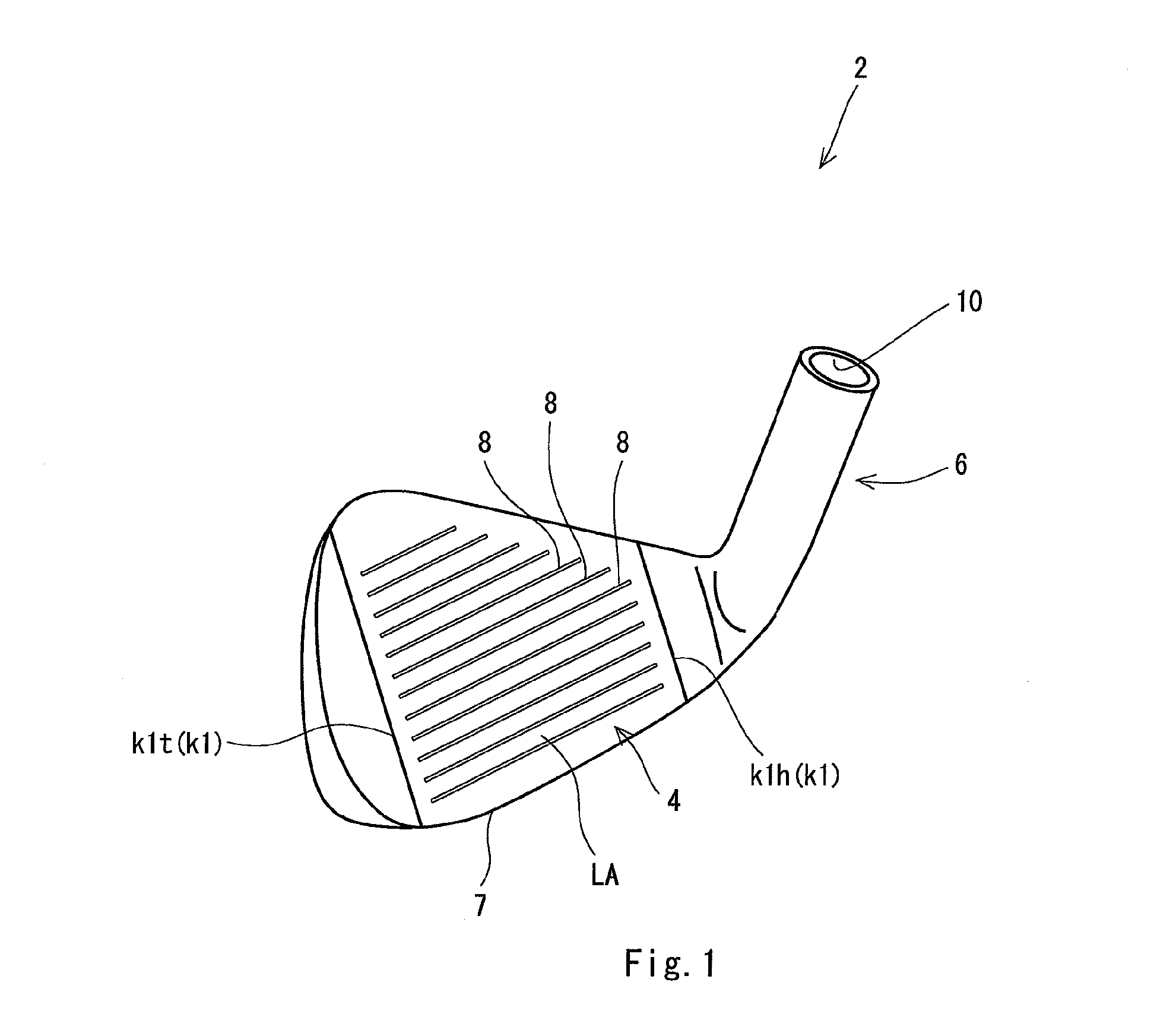

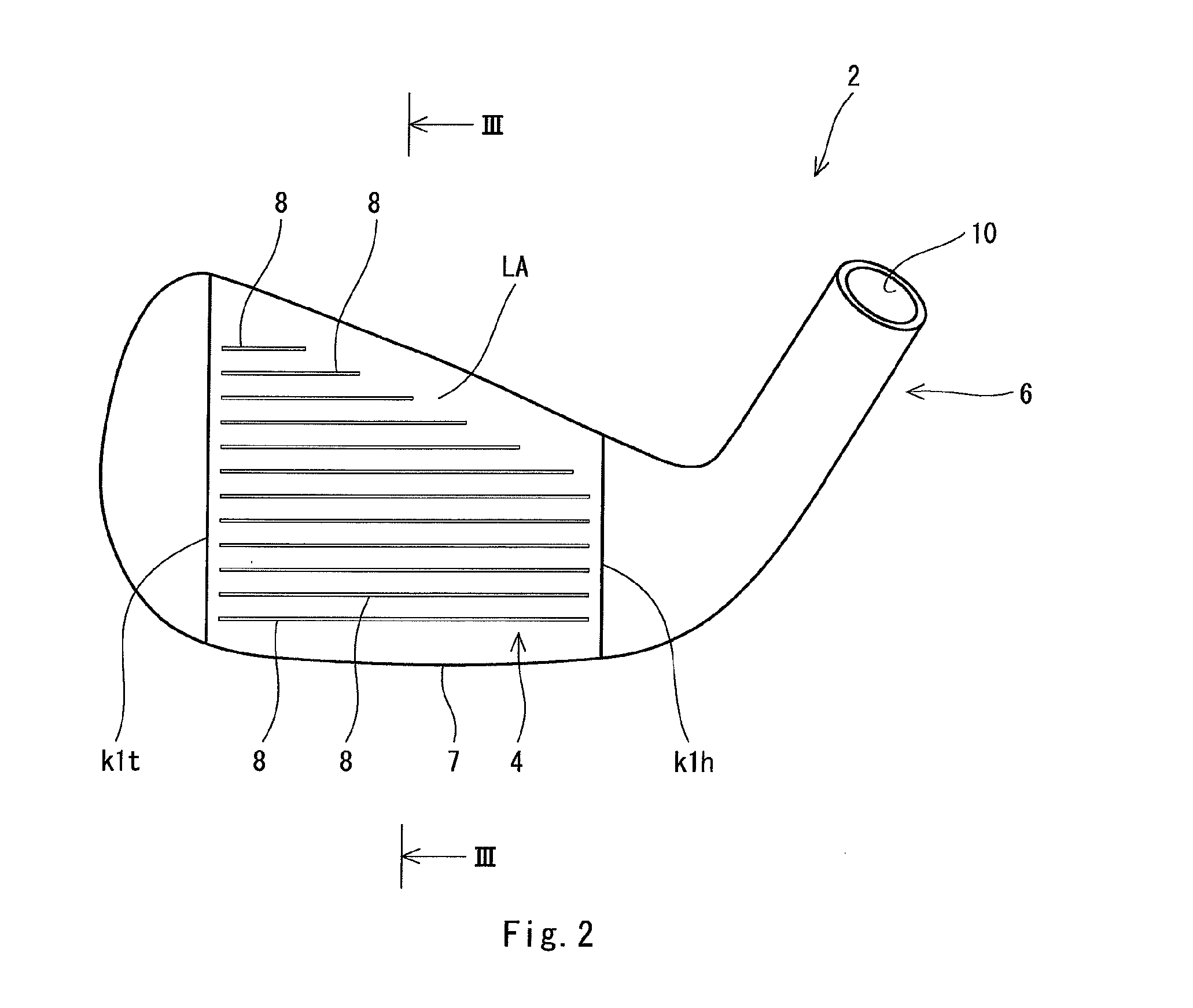

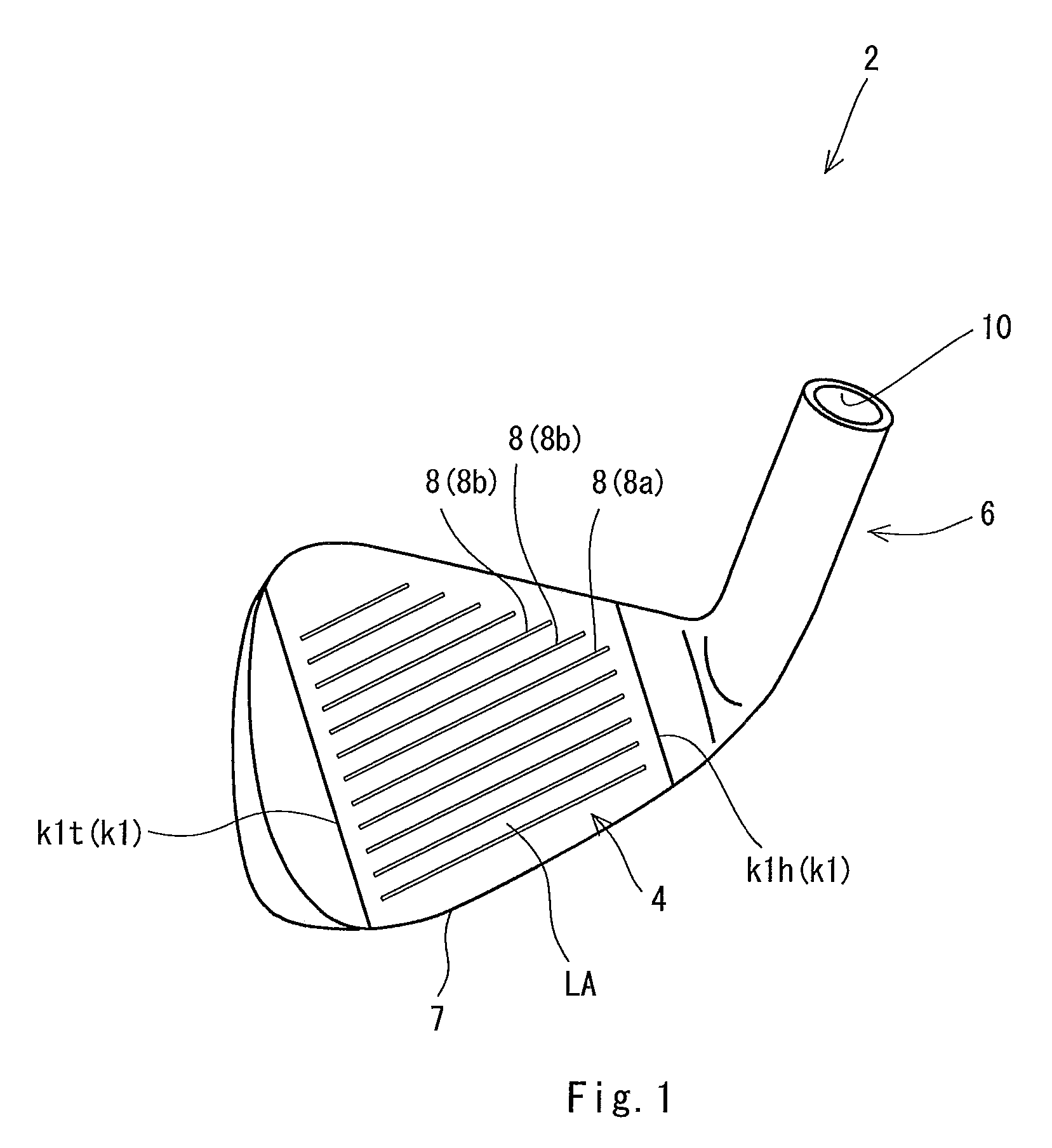

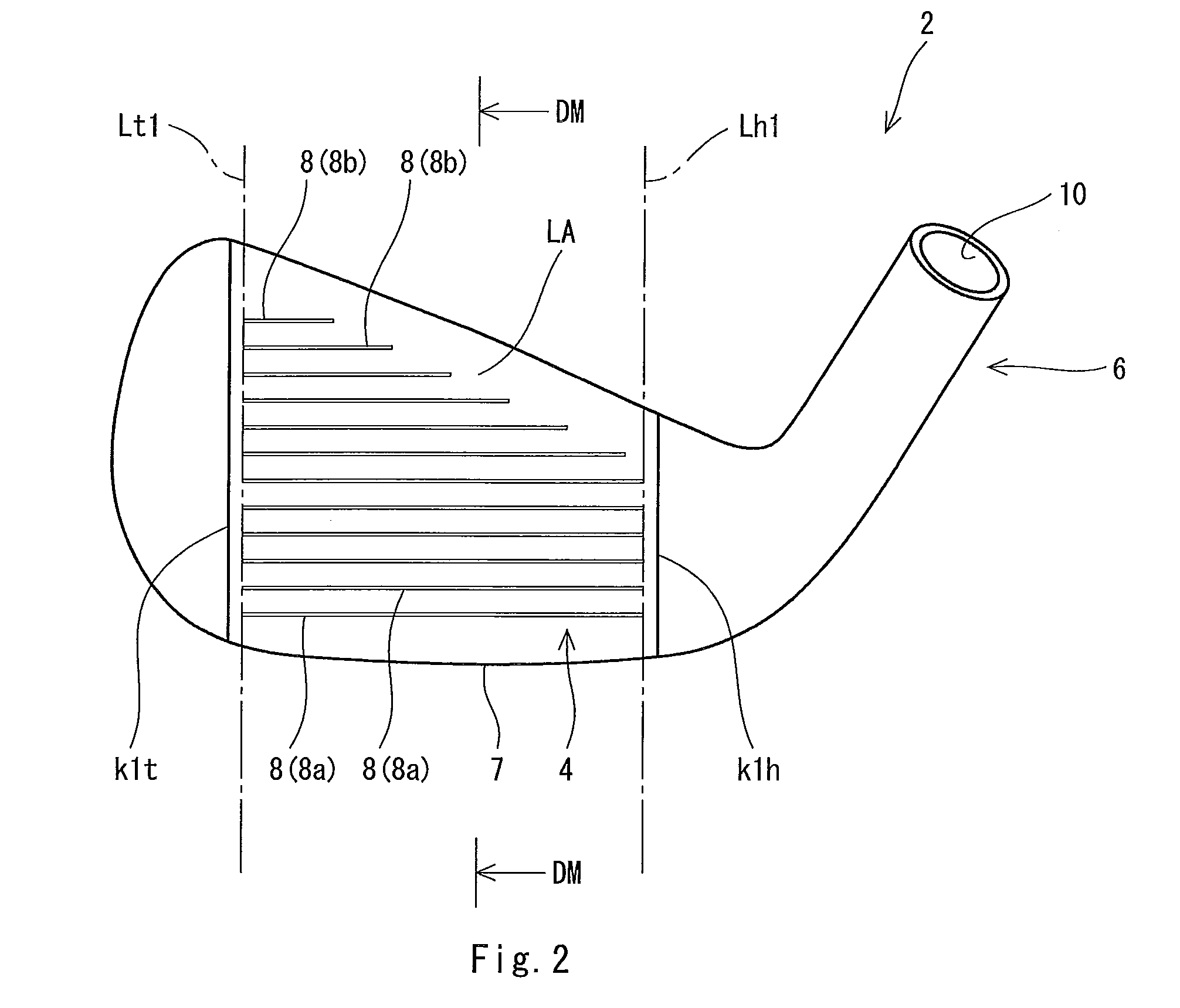

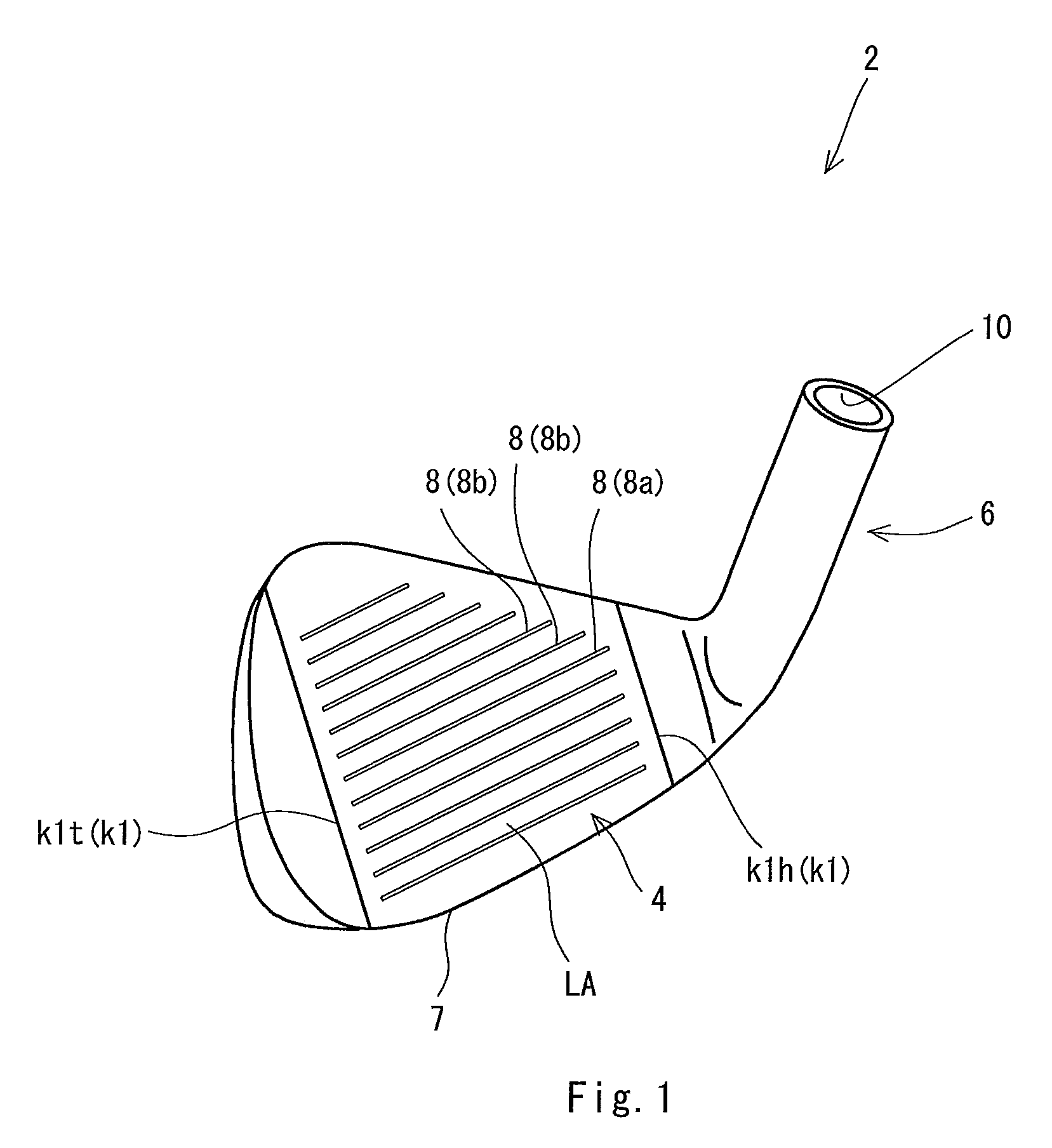

Golf club head

ActiveUS8328662B2Improve the rotation effectDamage suppressionGolf clubsMaintainance and safety accessoriesAlgorithmGolf Ball

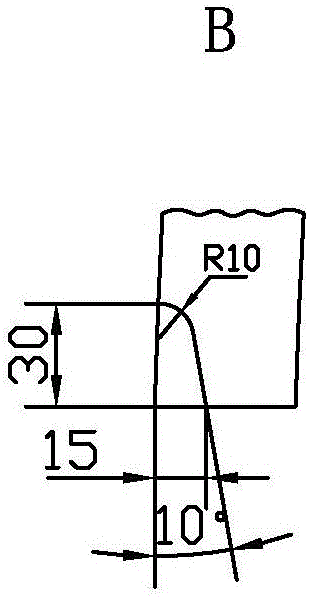

A head 2 has a face line 8 having a depth of D1 (mm). When a boundary between a land area and a face line is defined as a point Pa; a point of which a depth is [D1 / 4] (mm) is defined as a point Pb; a point of which a depth is [D1 / 2] (mm) is defined as a point Pc; a point of which a depth is [(D1)×(¾)] (mm) is defined as a point Pd; a point of which a depth is 0.002 (mm) is defined as a point Px; a radius of a circle CL1 passing through three points of the point Pa, the point Pb, and the point Pc is defined as R3 (mm); a straight line passing through the point Pa and the point Px is defined as a straight line Lax; and an angle between the land area and the straight line Lax is defined as θ2 (degree), the radius R3 is 0.2 (mm) or greater and 0.4 (mm) or less, and the angle θ2 is 10 degrees or greater and 50 degrees or less.

Owner:SUMITOMO RUBBER IND LTD

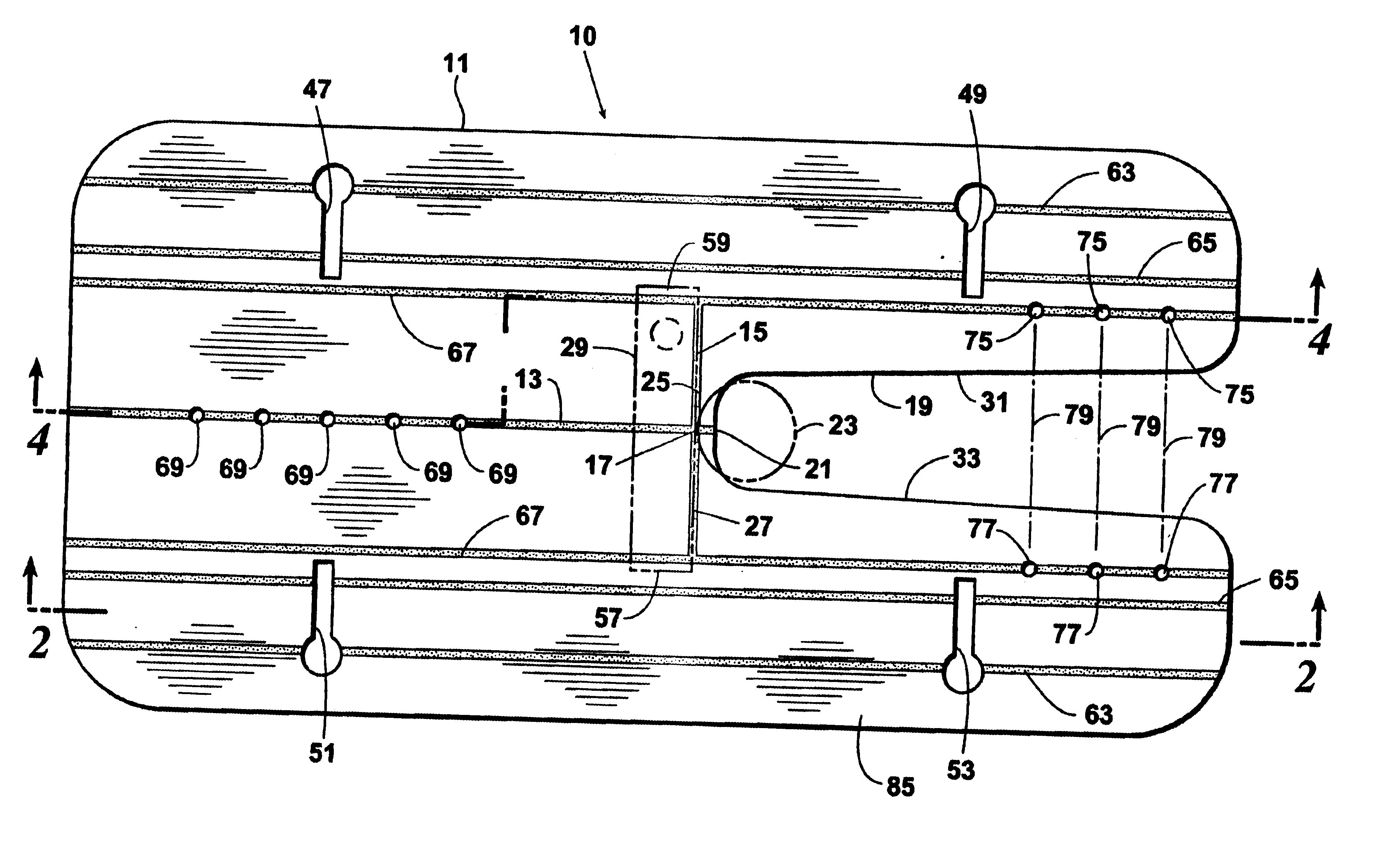

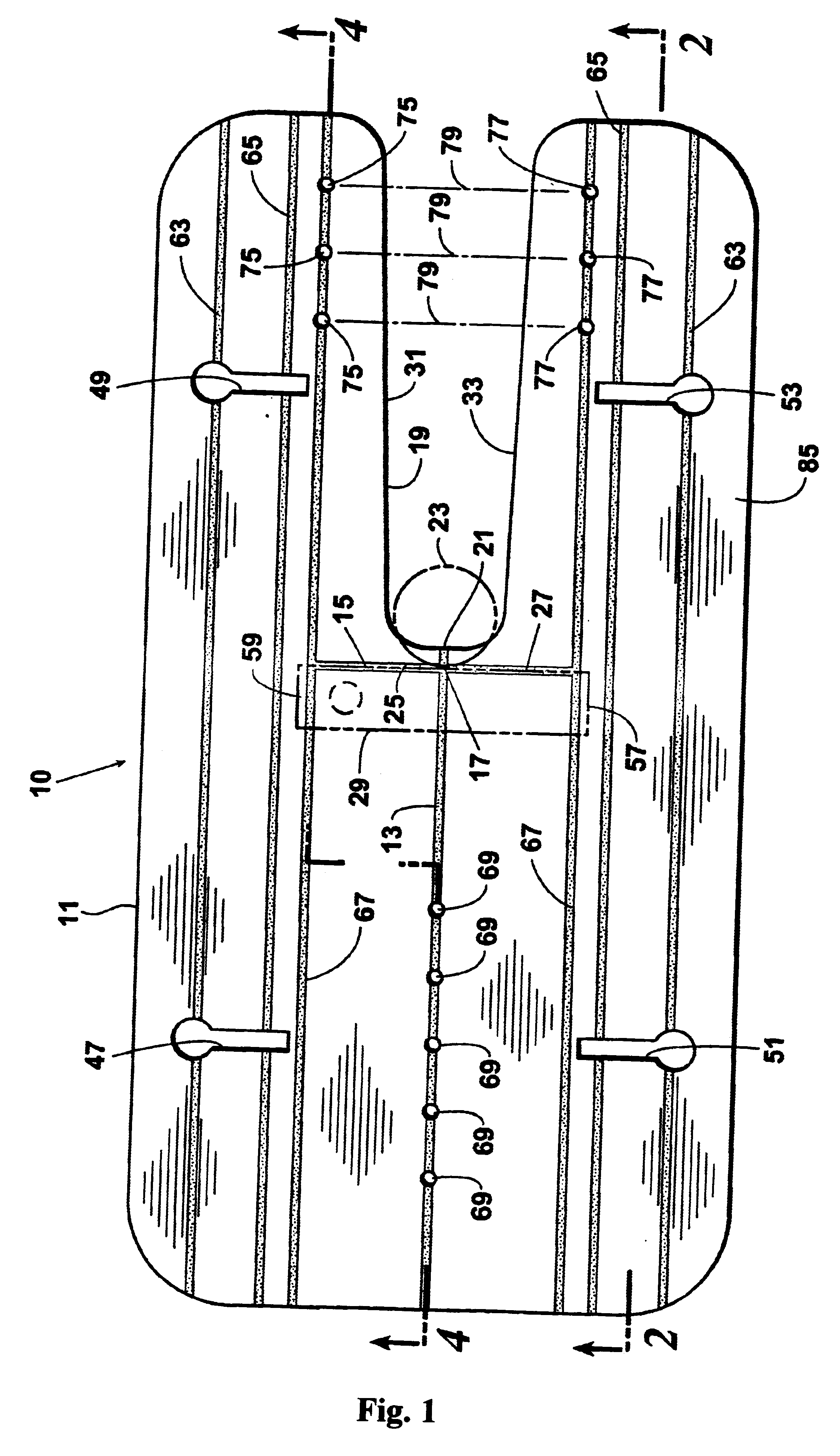

Alignment guide for practice putting

An alignment guide for practice putting has a base with perpendicular target and putter face lines. An unobstructed gap extends away from the putter face line along the target line. A pair of guide rails are secured to the base in parallel relationship to and on opposite sides of the target line and spaced apart by a distance slightly greater than the distance from the toe to the heel of the putter head. The putter head can, therefore, move freely between, but be guided by, the rails. An adjustable stop limits the backswing of the putter head to allow comparison of the length of the backswing with the travel distance of the ball. An adjustable pair of stops simultaneously limiting travel of the toe and the heel of the putter head in the follow through confirm that the putter face has remained square to the target line.

Owner:FROGGATTE SAMUEL D

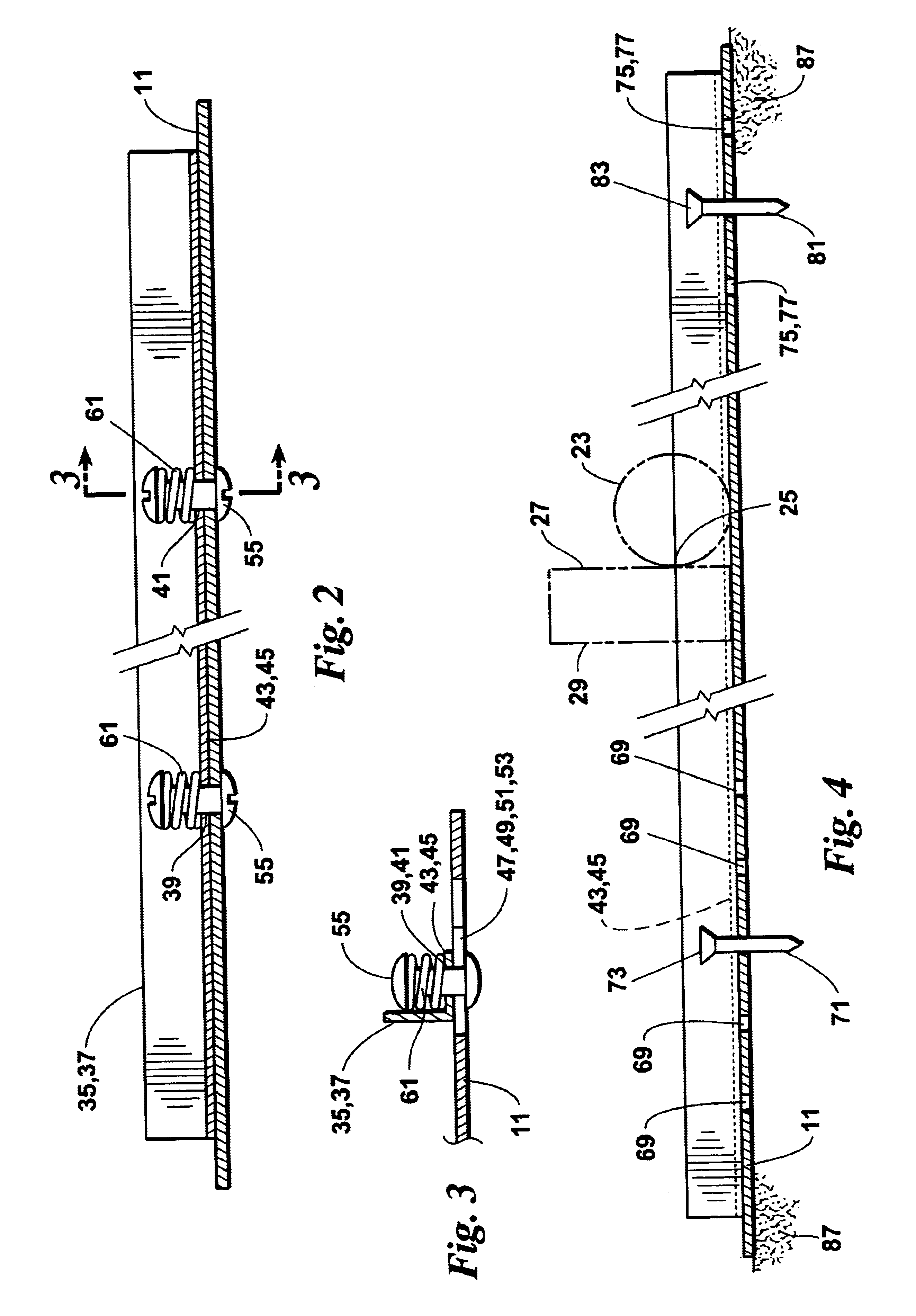

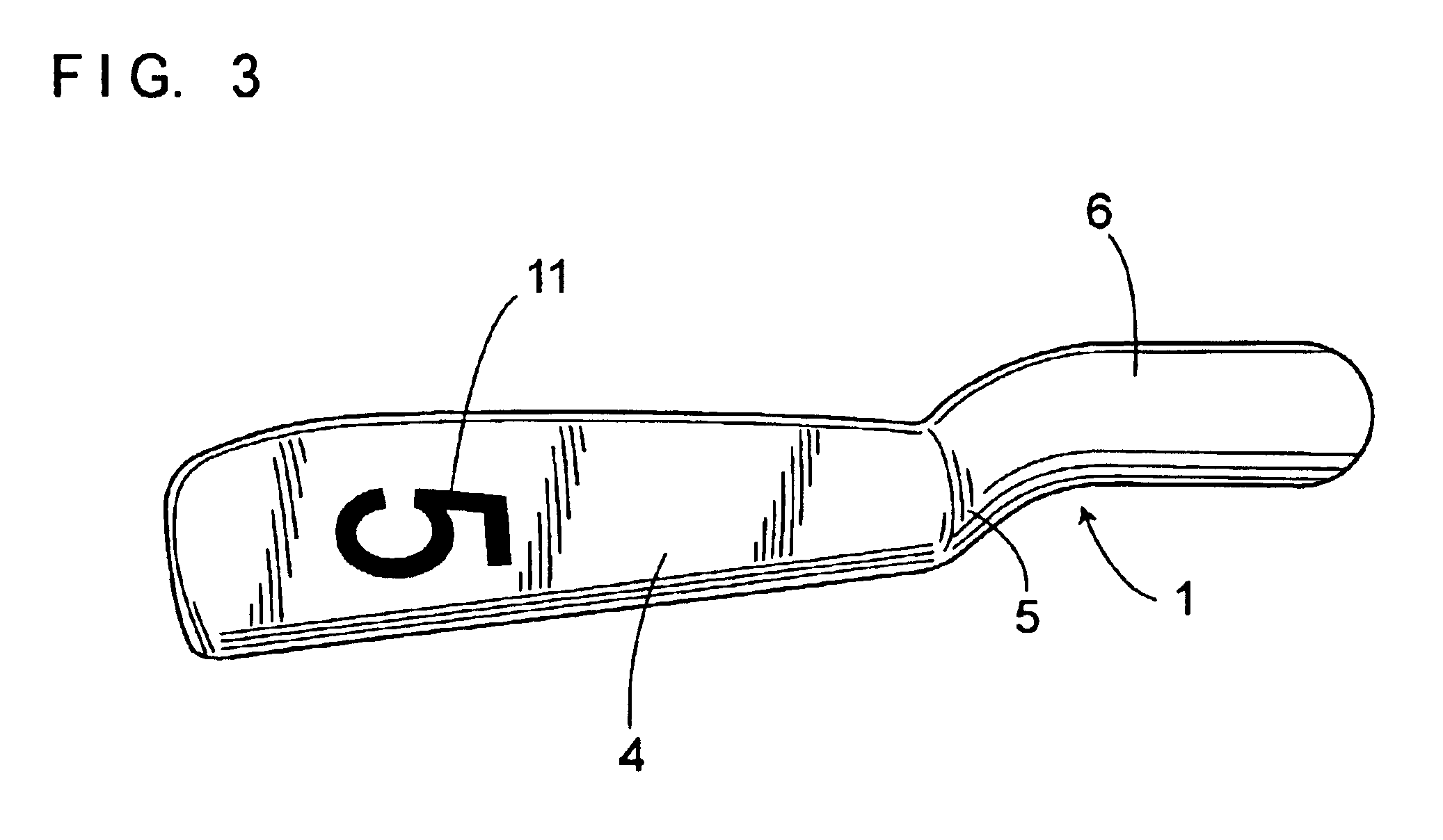

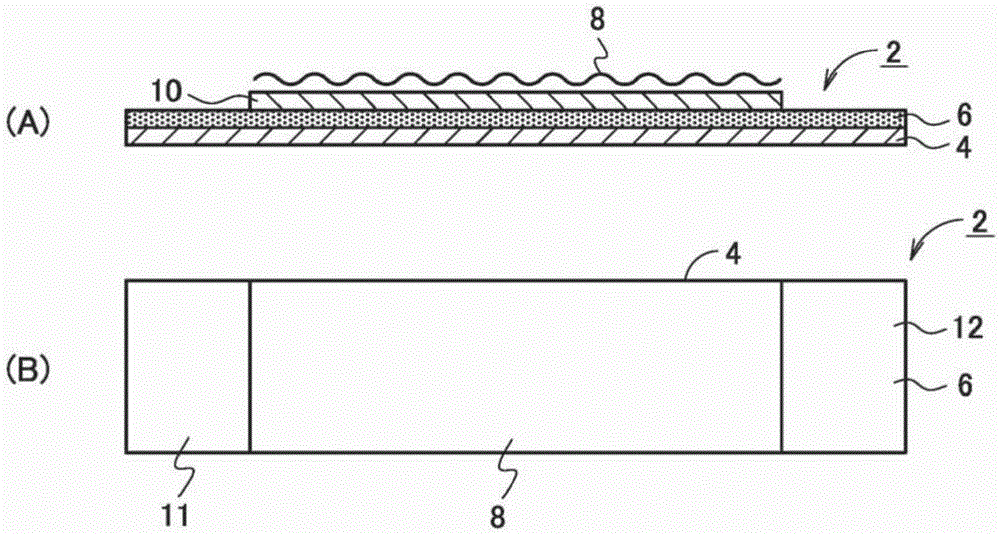

Method of manufacturing a golf club head

InactiveUS6713717B2Welding/soldering/cutting articlesMetal working apparatusDisplay deviceLaser beam machining

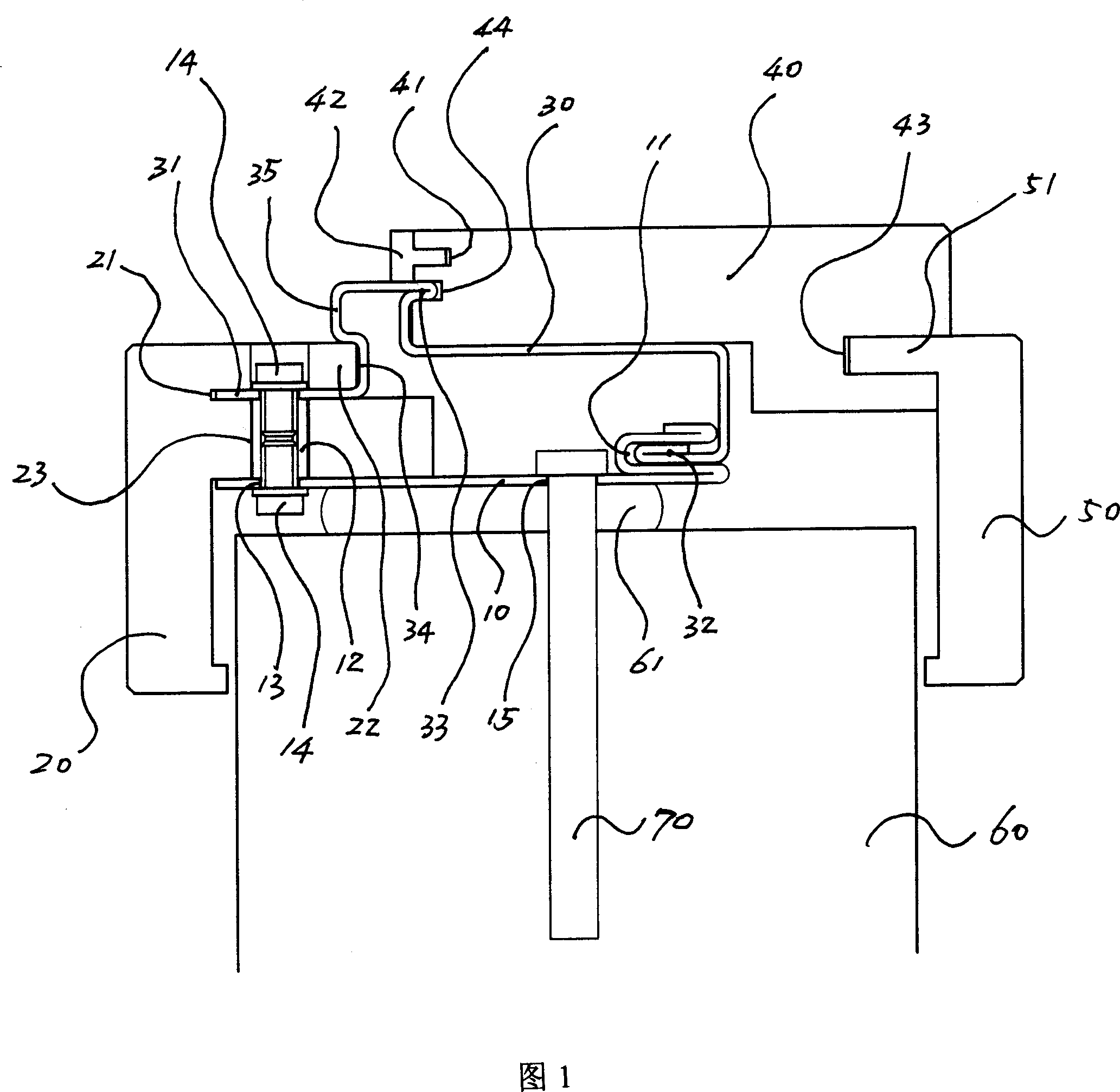

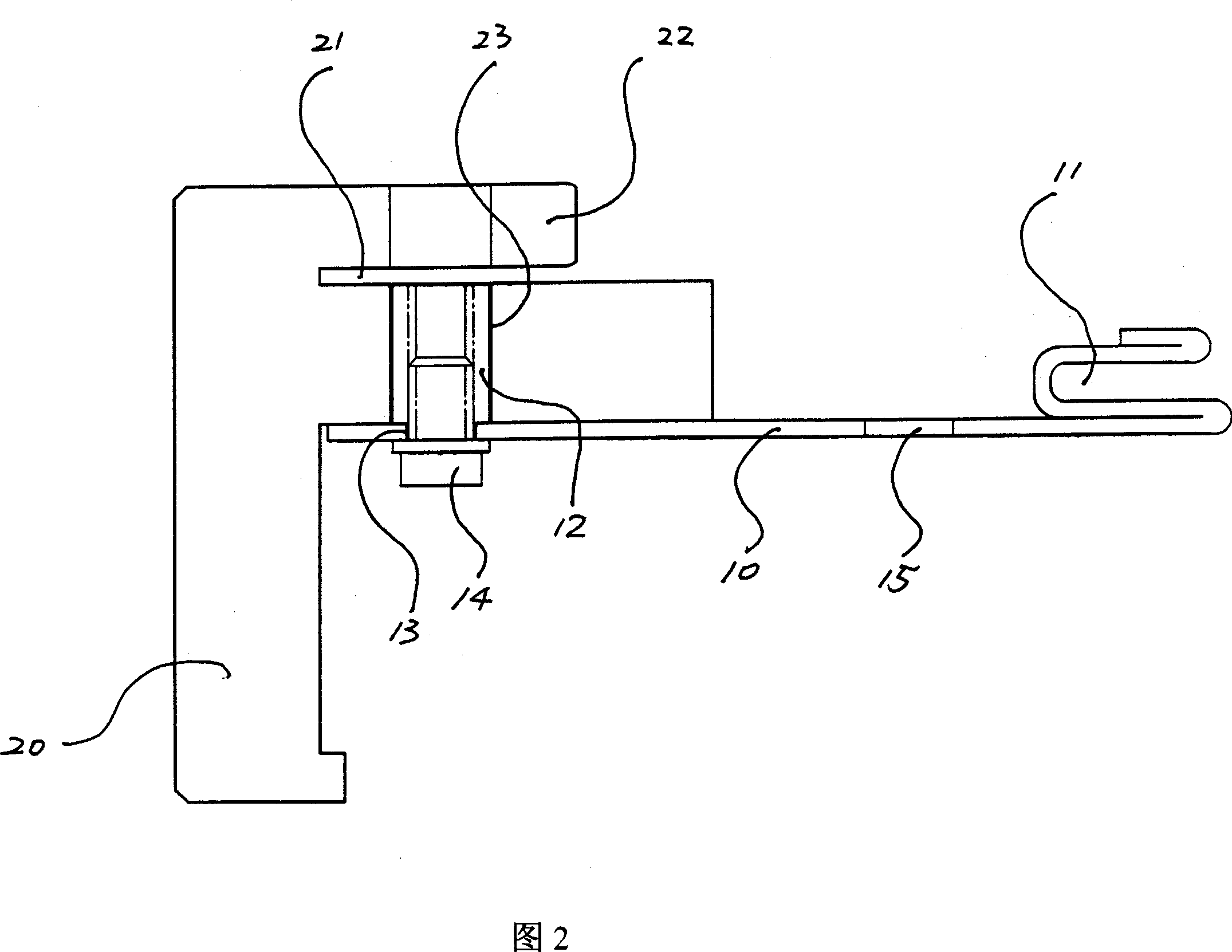

A method of manufacturing a golf club head by which face lines, a club number display and logo marks can be formed without being affected by the configuration and material of the club head. Face lines 10, a club number display 11 and logo marks 12 and 13 are formed on the surface of a golf club head 1, using a laser beam processing machine. Stamps and receiving dies are no longer required for a respective production lot number or a respective club number, so that costs and time required for fabricating impressing stamp dies and receiving dies can be saved. Further, face lines 10, club number display 11 and logo marks 12 and 13 are able to be formed without being affected by the configuration and material of the golf club head 1.

Owner:ENDO MFG COMPANY

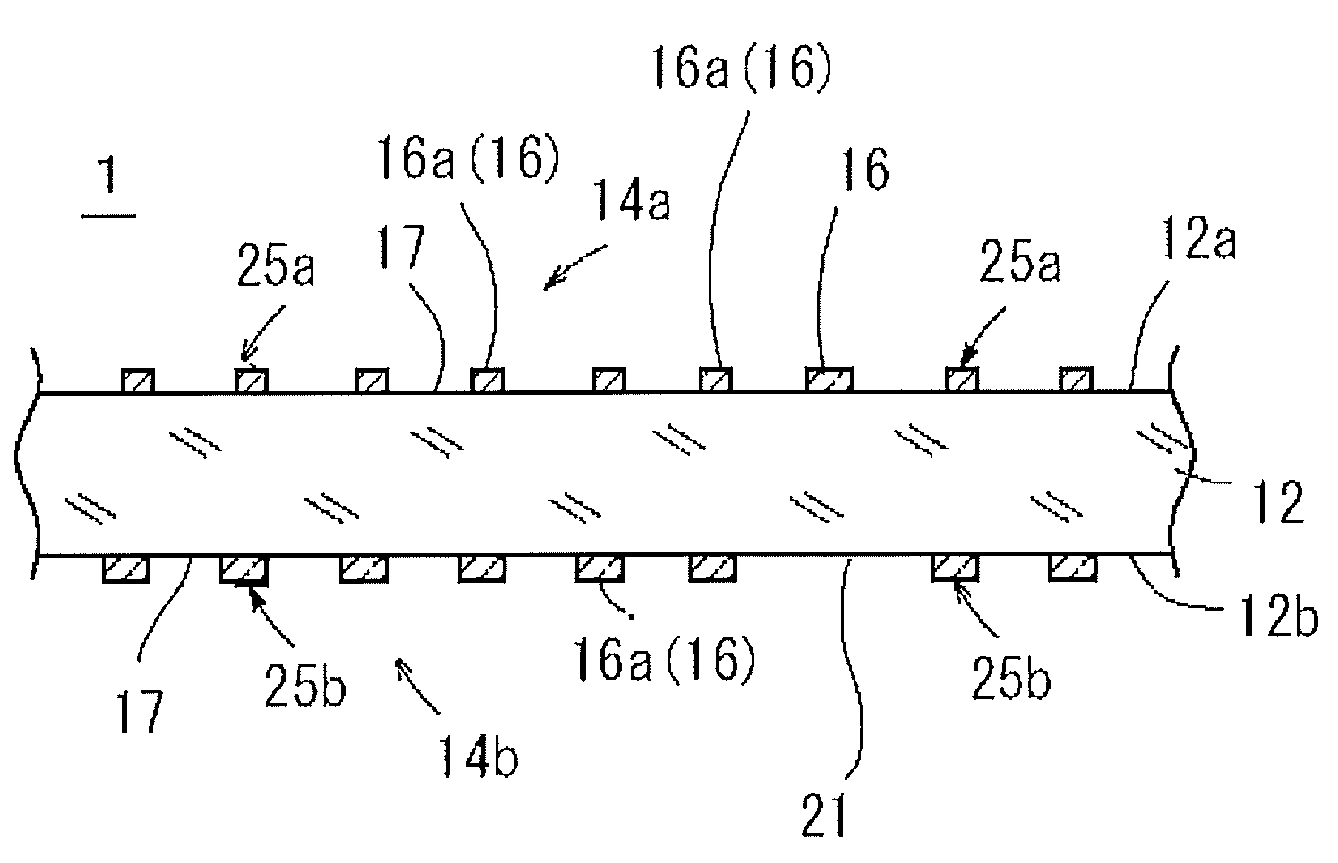

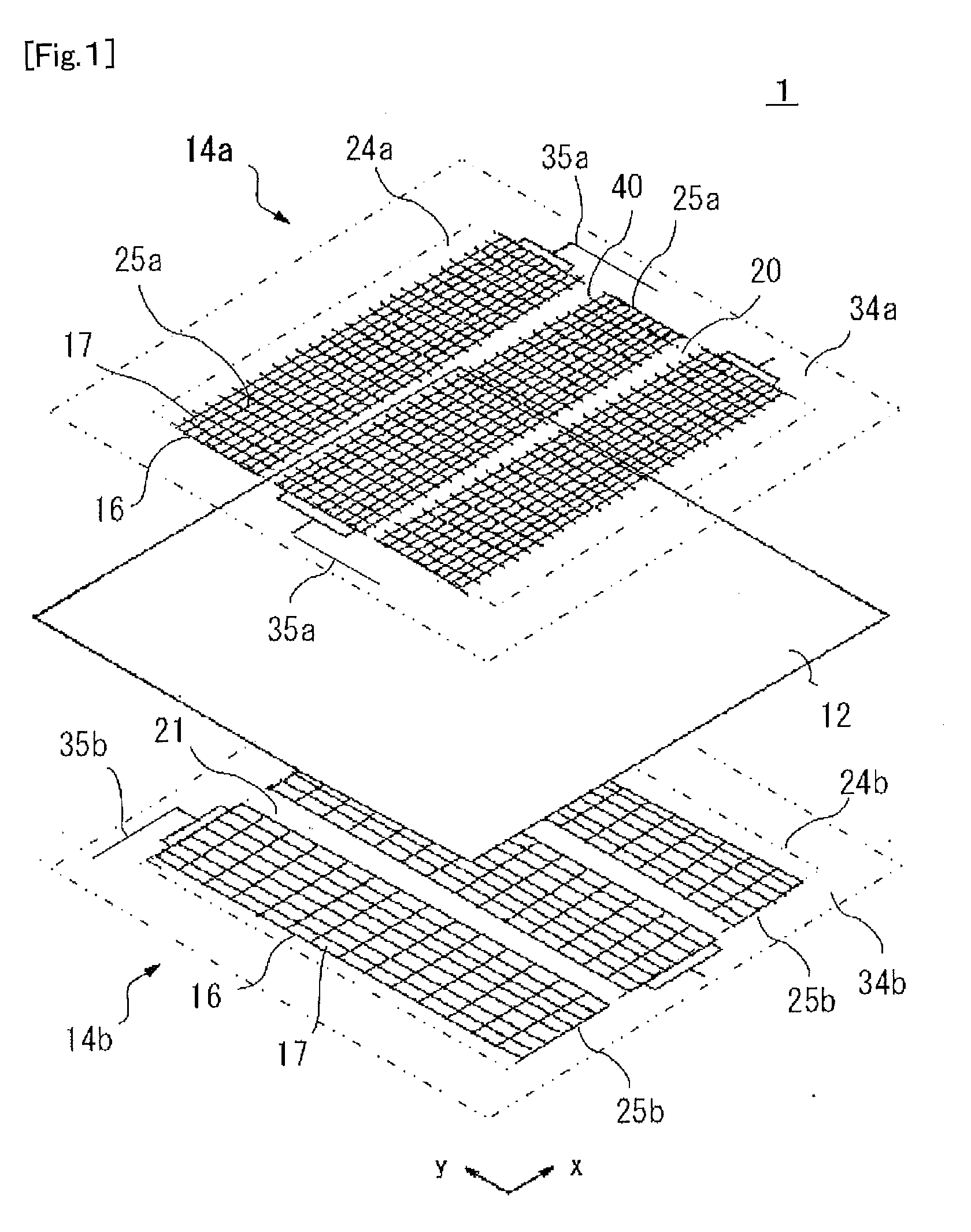

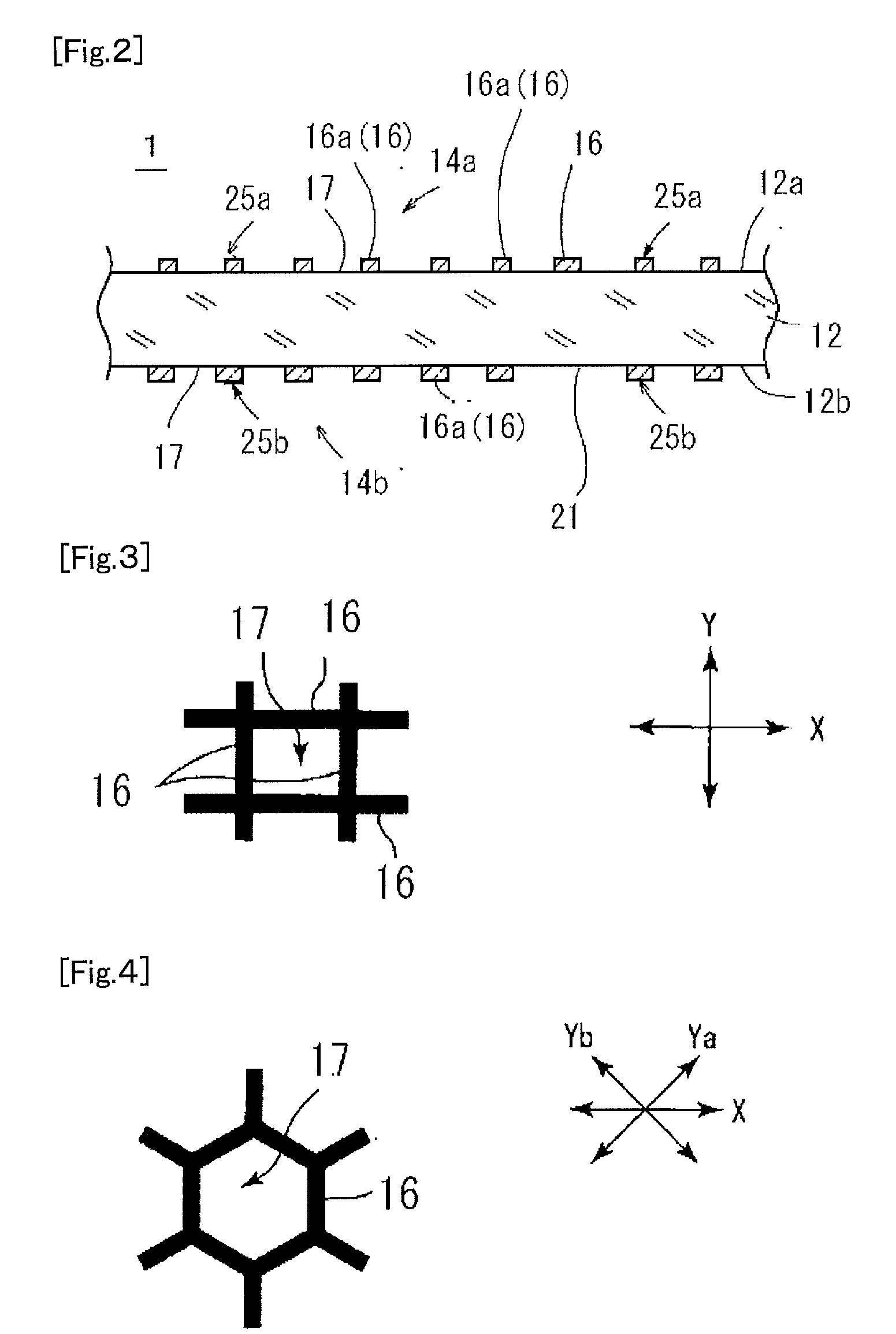

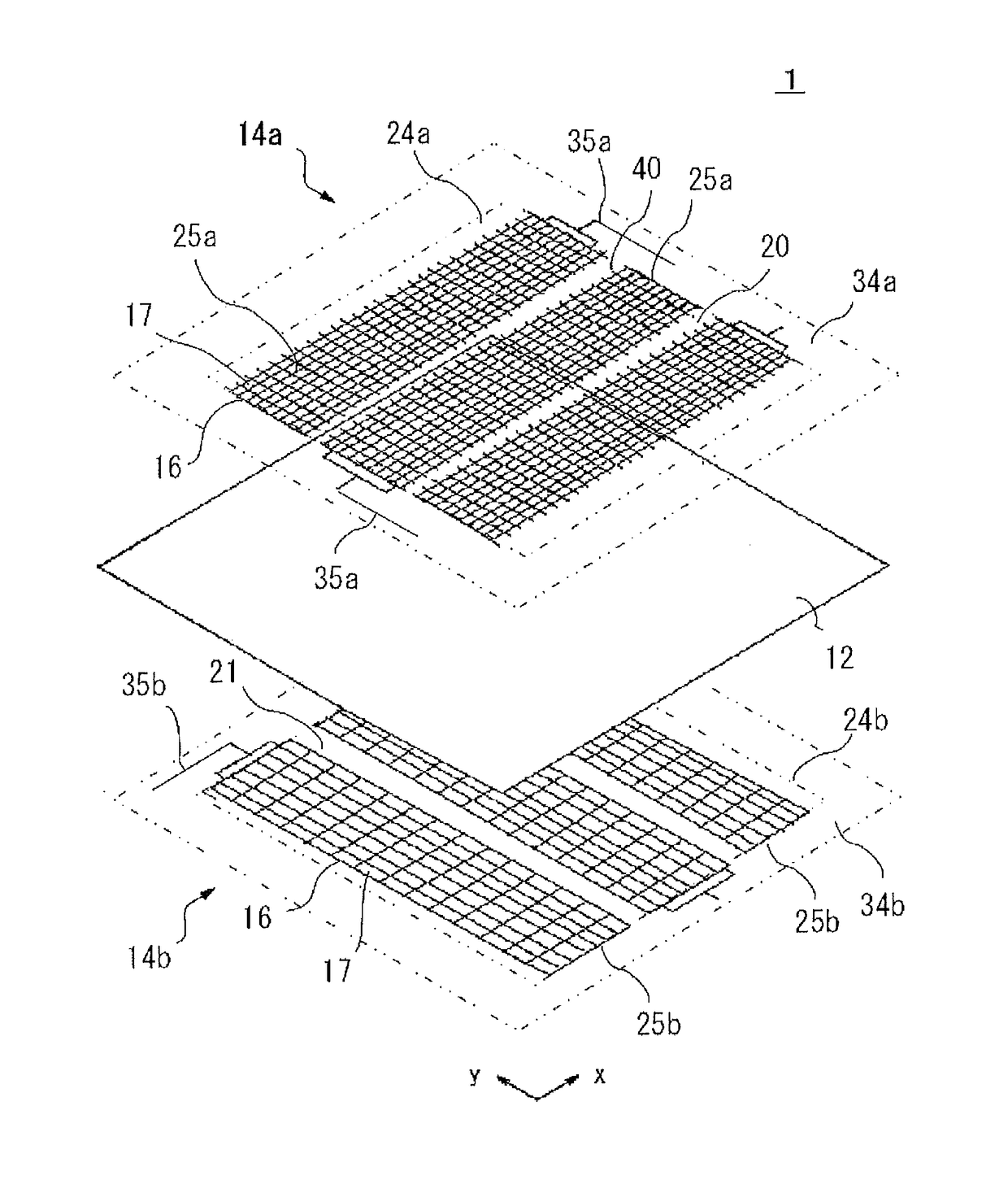

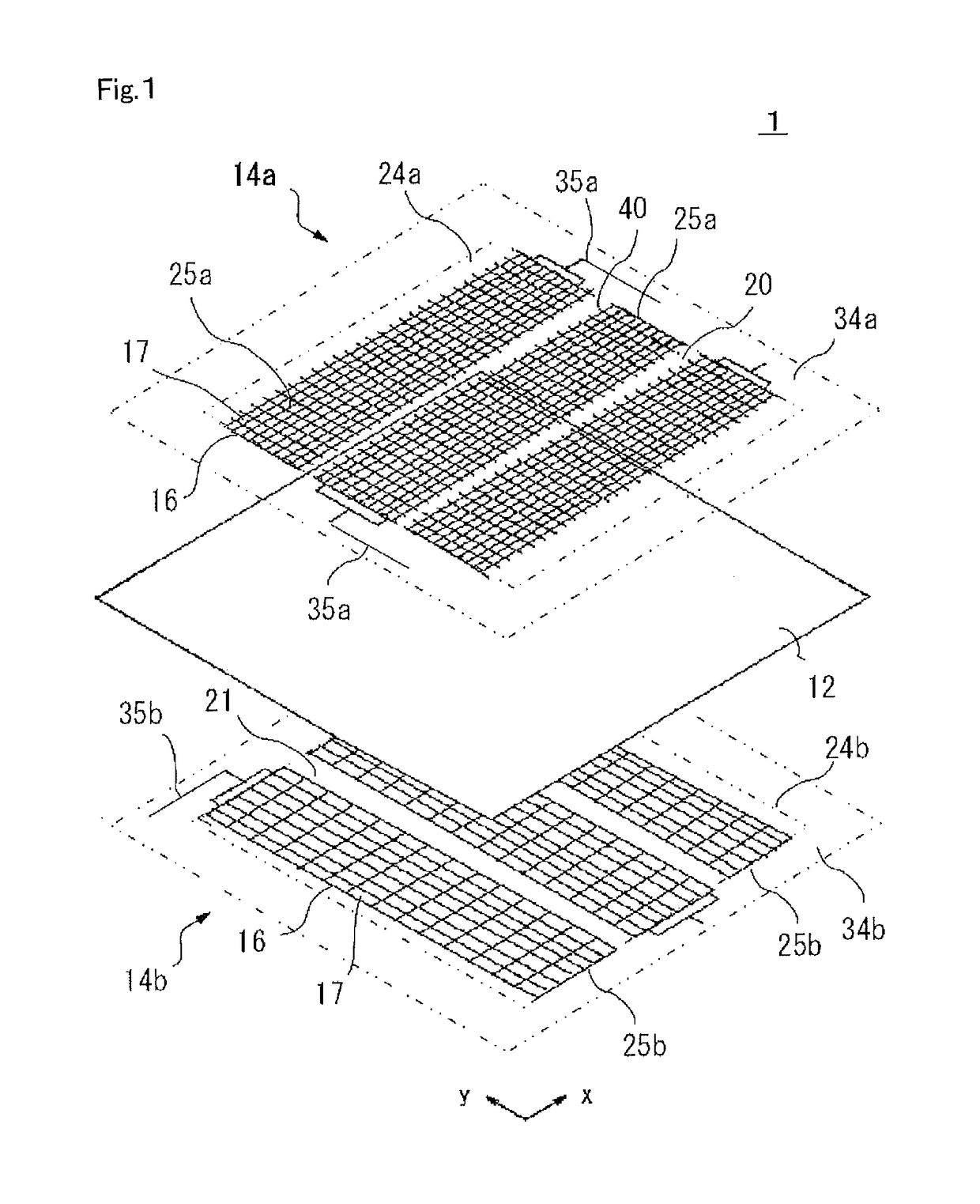

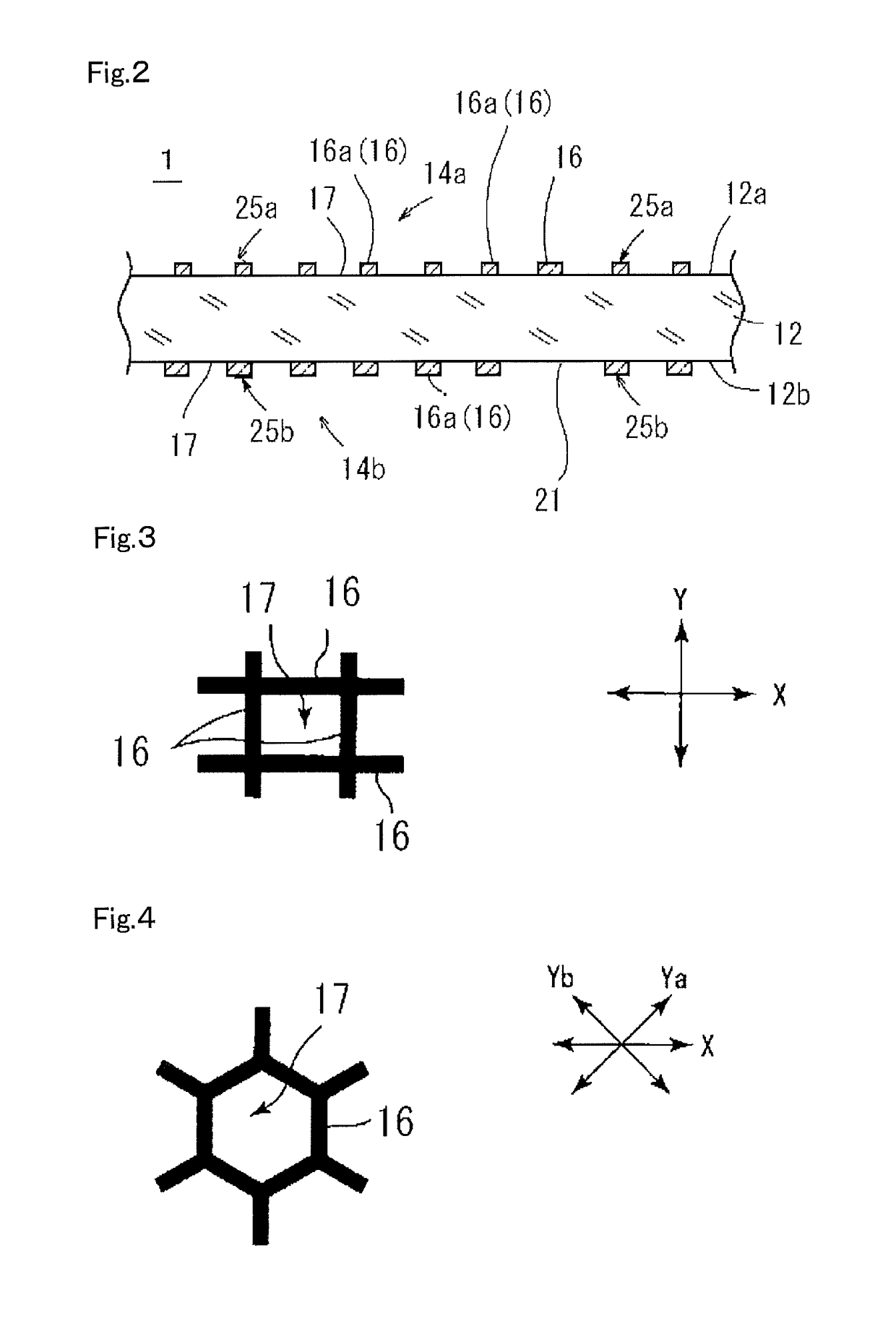

Electrode sheet for capacitance-type touch panel

ActiveUS20160370916A1High transparencyInput/output processes for data processingWire widthCapacitance

A first electrode pattern 25a and a second electrode pattern 25b, each composed of an opaque conductive fine line and a blank part 17 partitioned by the conductive fine line, have line segments 16a of the conductive fine lines 16, that face each other across a substrate 12, and the conductive fine line 16 in one of the first electrode pattern 25a and the second electrode pattern 25b is formed narrower in line width than that in the other of the first electrode pattern 25a and the second electrode pattern 25b only at the facing line segment 16a, thereby designed to have a non-uniform width.

Owner:NISSHA PRINTING COMPANY

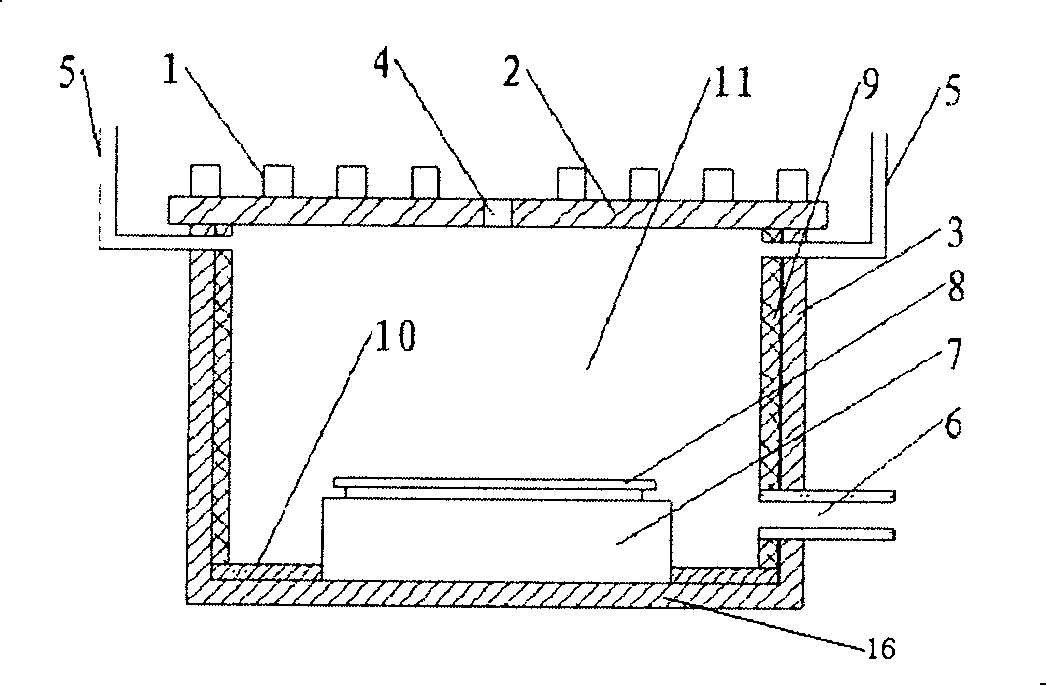

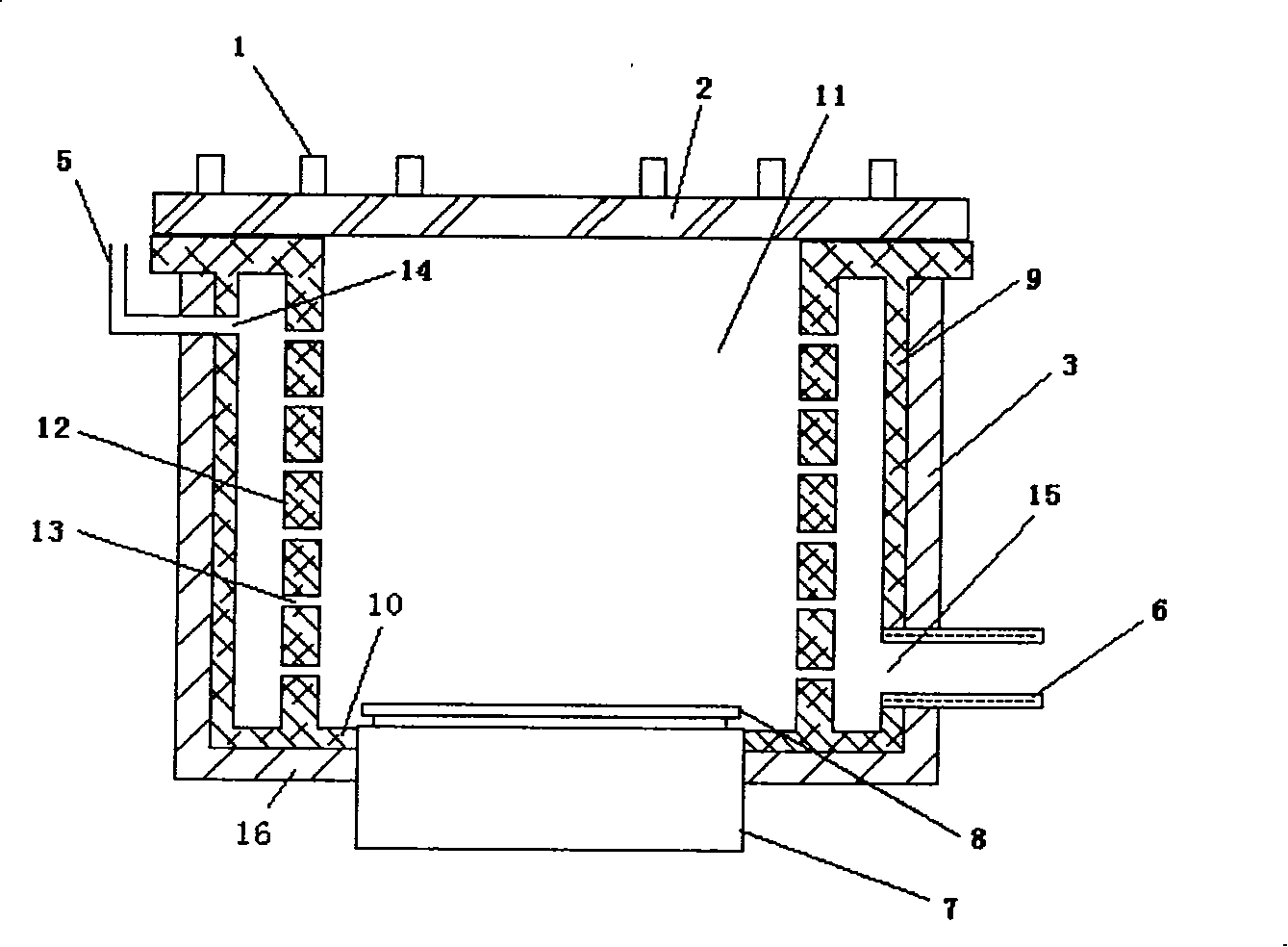

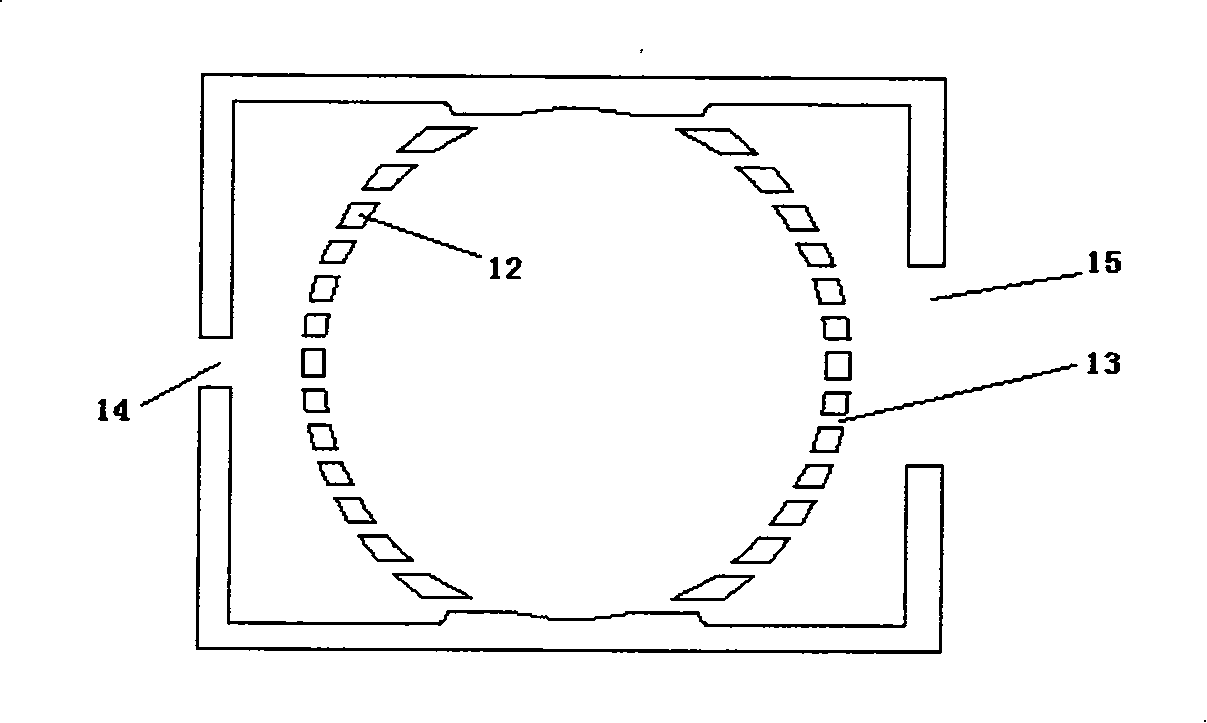

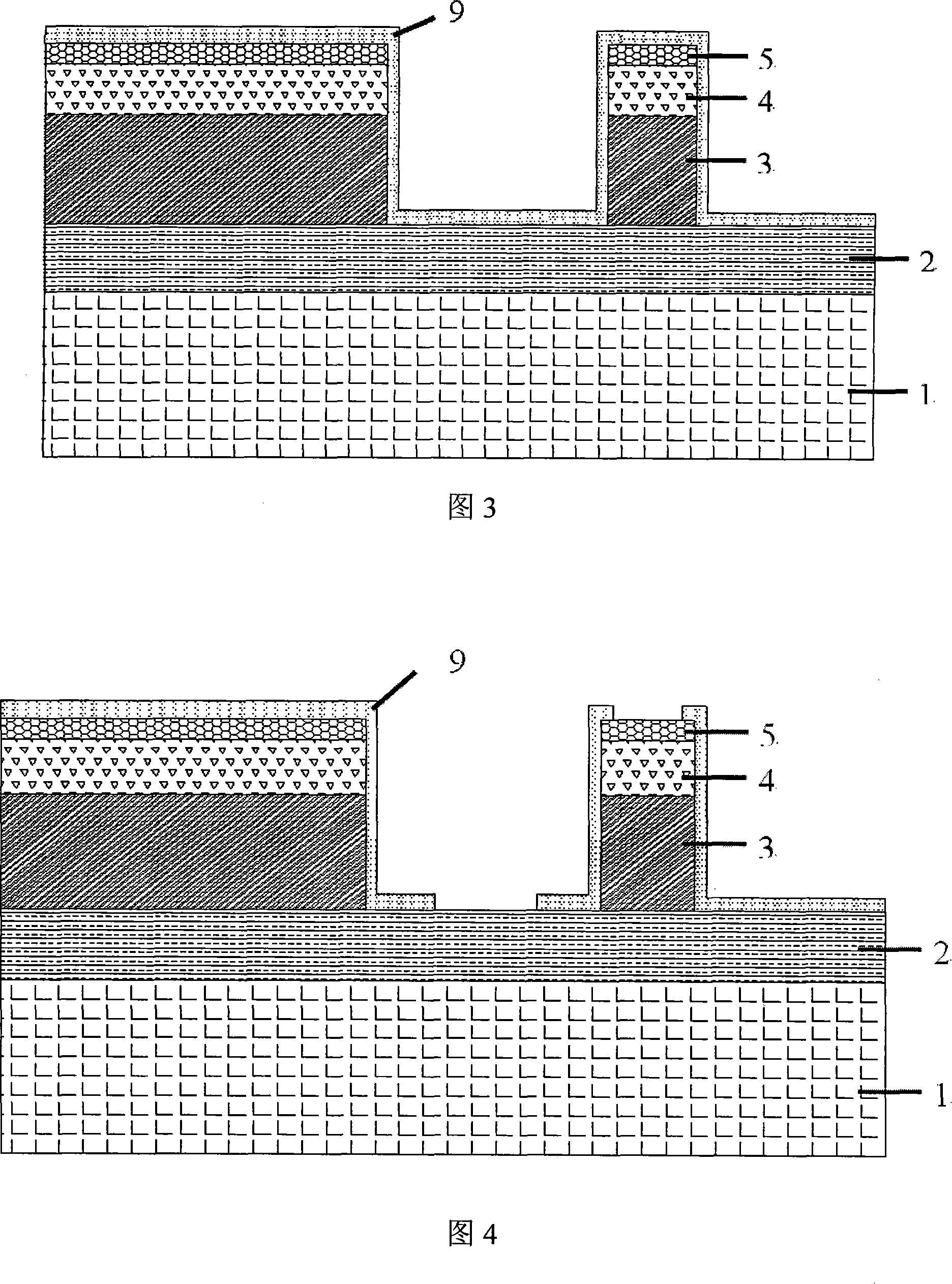

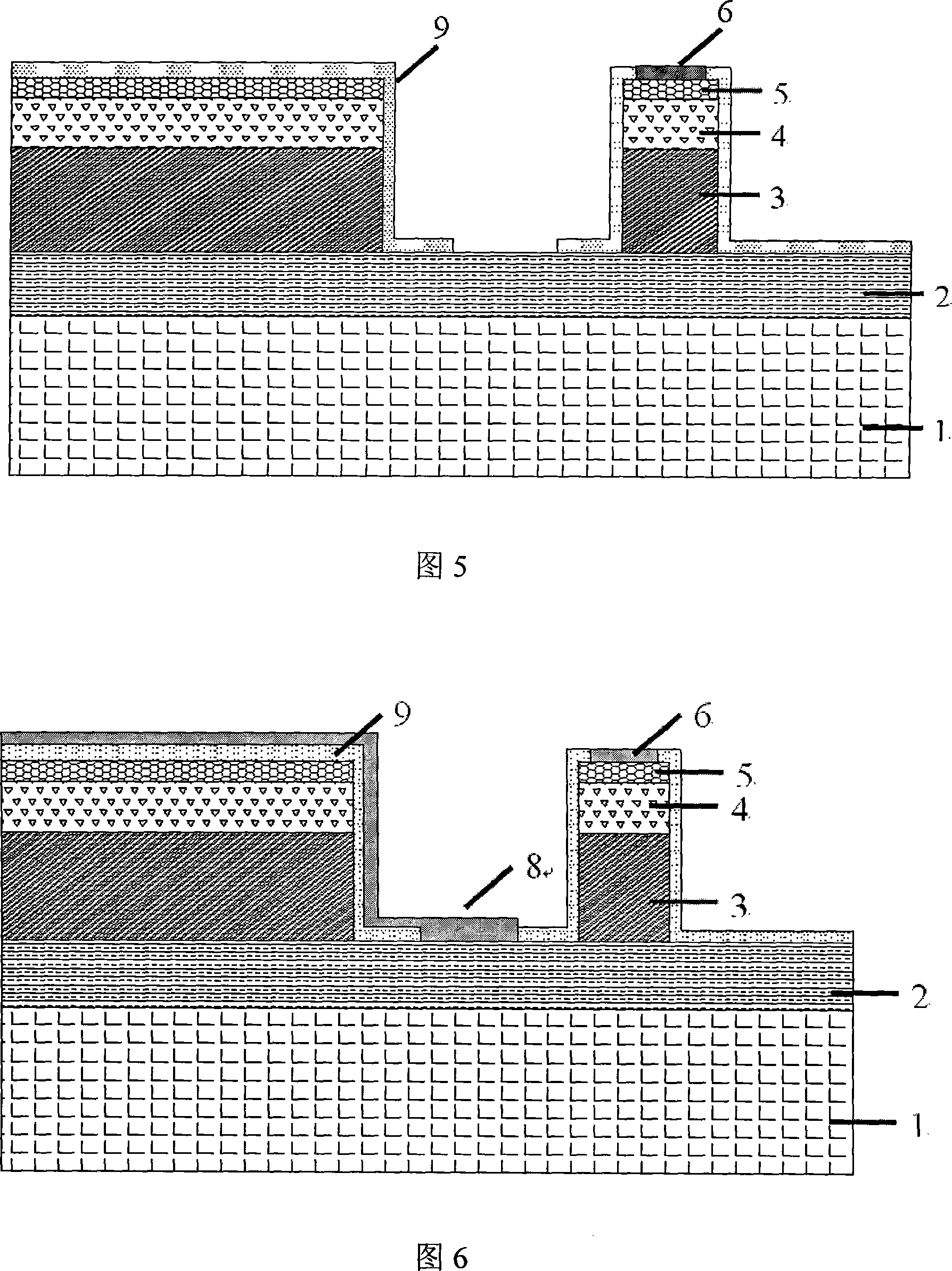

Reaction chamber inner lining and reaction chamber containing the inner lining

ActiveCN101202206AImprove uniformityUniform flow rateElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProcess engineering

The invention discloses a reaction cavity lining and a reaction cavity containing the lining. The invention comprises a side face lining and a bottom face lining. The side face lining is divided into an inner lining and an outer lining and a sealed space is formed between the two linings. A plurality of pores are cut on the inner lining, and a lining gas intake and a lining gas vent are cut on the outer lining and respectively correspond to the gas intake and the gas vent of the reaction cavity. The process gas first enters the sealed space between the inner lining and the outer lining, and then enters the reaction cavity through the pores of the inner lining. Then the gas enters the sealed space between the inner lining and the outer lining through the reaction cavity and is emitted through the gas vent. The speed of the gas flow in the reaction cavity can be lead to be equalized so as to not only protect cavity walls but also equally distribute the gas in the cavity. The invention is mainly applicable to the reaction cavity of the manufacturing equipment of semiconductors and other similar cavities.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

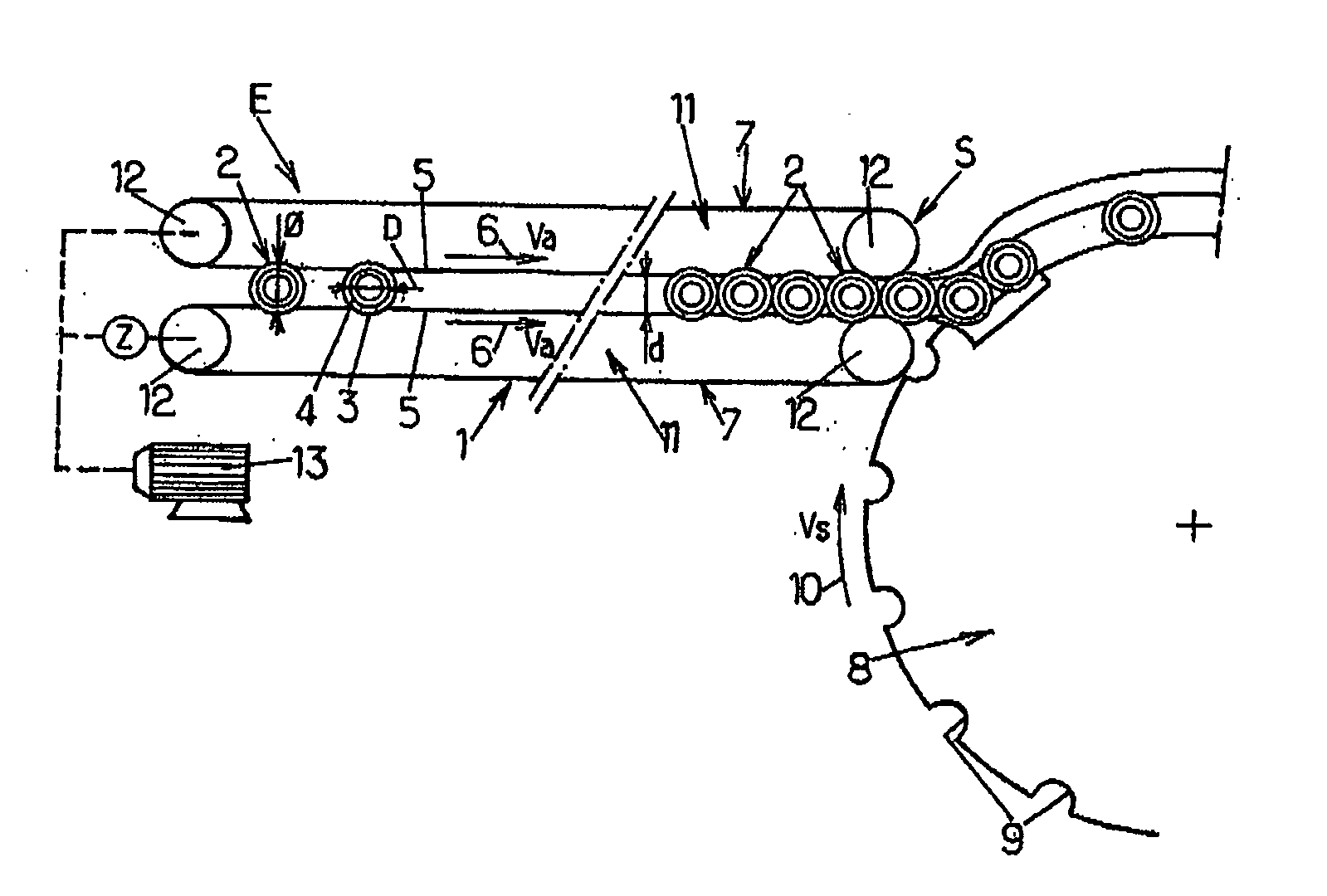

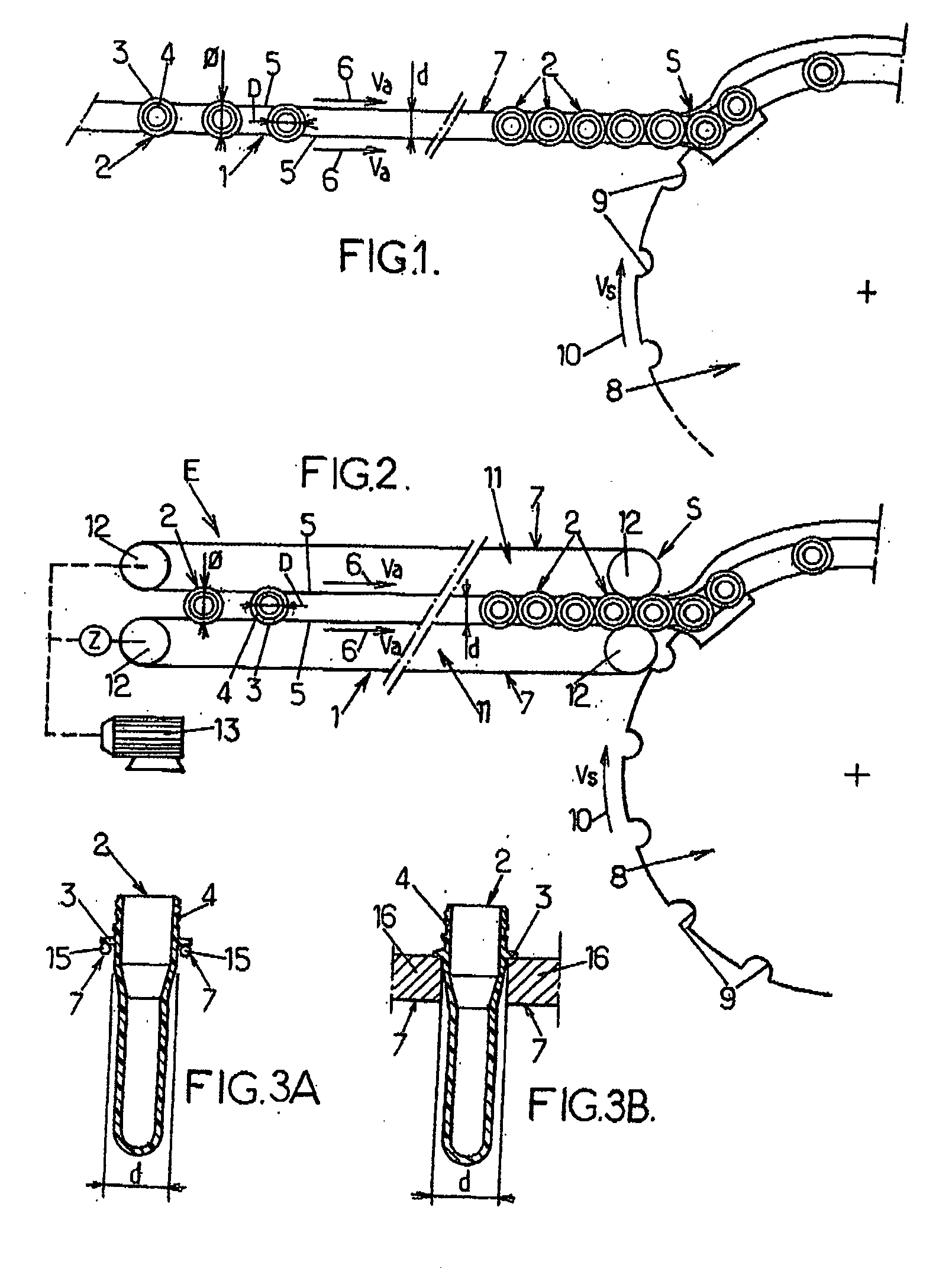

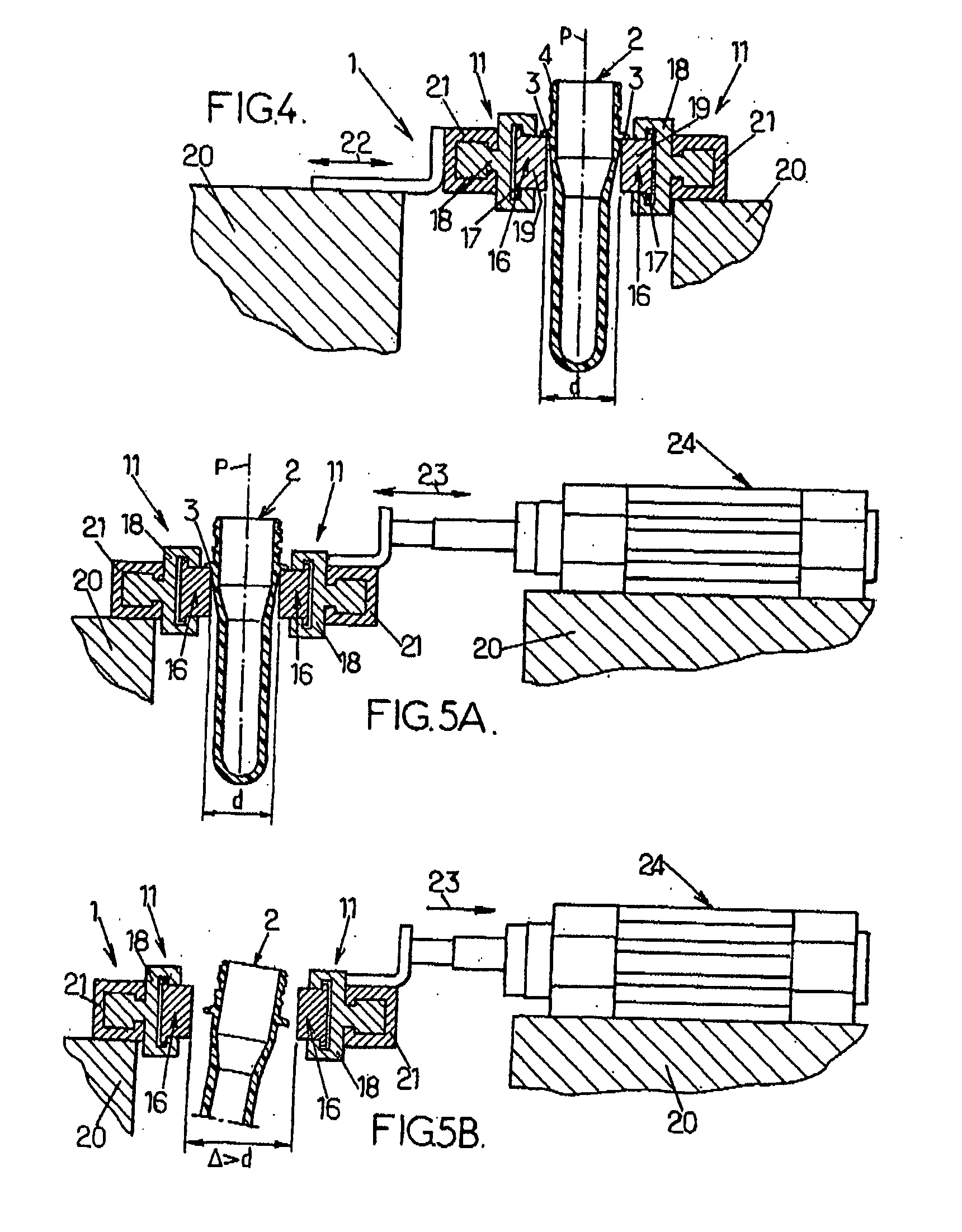

Conveyor Device for Containers Such as Preforms

InactiveUS20080142339A1Avoid disadvantagesEliminate badConveyor partsMechanical conveyorsEngineeringShaft collar

A linear, horizontal conveyor device for containers which are equipped with a collar at the base of the neck thereof. The invention includes two conveyors including endless links, which are each equipped with two parallel, mobile lines which face one another and which are driven in the same direction and at the same speed. The aforementioned lines are separated from one another by a distance that is greater than the diameter of the body of the containers and less than the diameter of the collars thereof. At least one conveyor includes a short segment that can be moved transversely outwards, such that the space between the two facing lines becomes greater than the diameter of the collar and the container falls.

Owner:SIDEL PARTICIPATIONS SAS

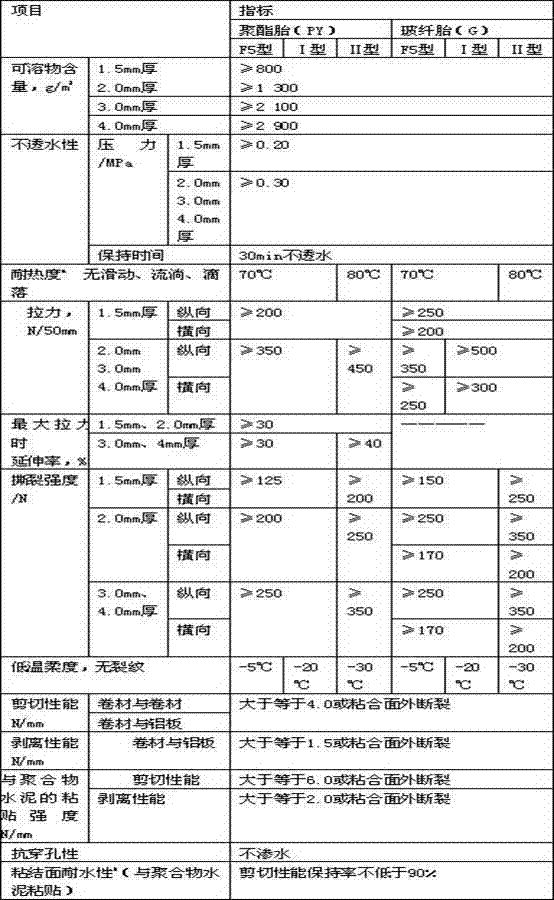

APF (advanced polarizer film) self-adhesive waterproof coiled material construction method

The invention discloses an APF (advanced polarizer film) self-adhesive waterproof coiled material construction method which includes a step of plane construction and a step of facade construction. The step of plane construction includes base layer cleaning, base face line snapping, polymer cement mortar preparing, node processing, reinforcing layer and internal and external corner adding, APF self-adhesive waterproof coiled material layer pre-paving, polymer cement mortar coating and scraping, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing, and the step of facade construction includes facade base layer cleaning, facade base face coiled material positioning and line snapping, base layer treating agent coating and scraping, node processing, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing. The polymer cement mortar is utilized as a bonding layer, so that the bonding layer can be quickly paved on a humid concrete base layer and can also be directly paved on a dry concrete face.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

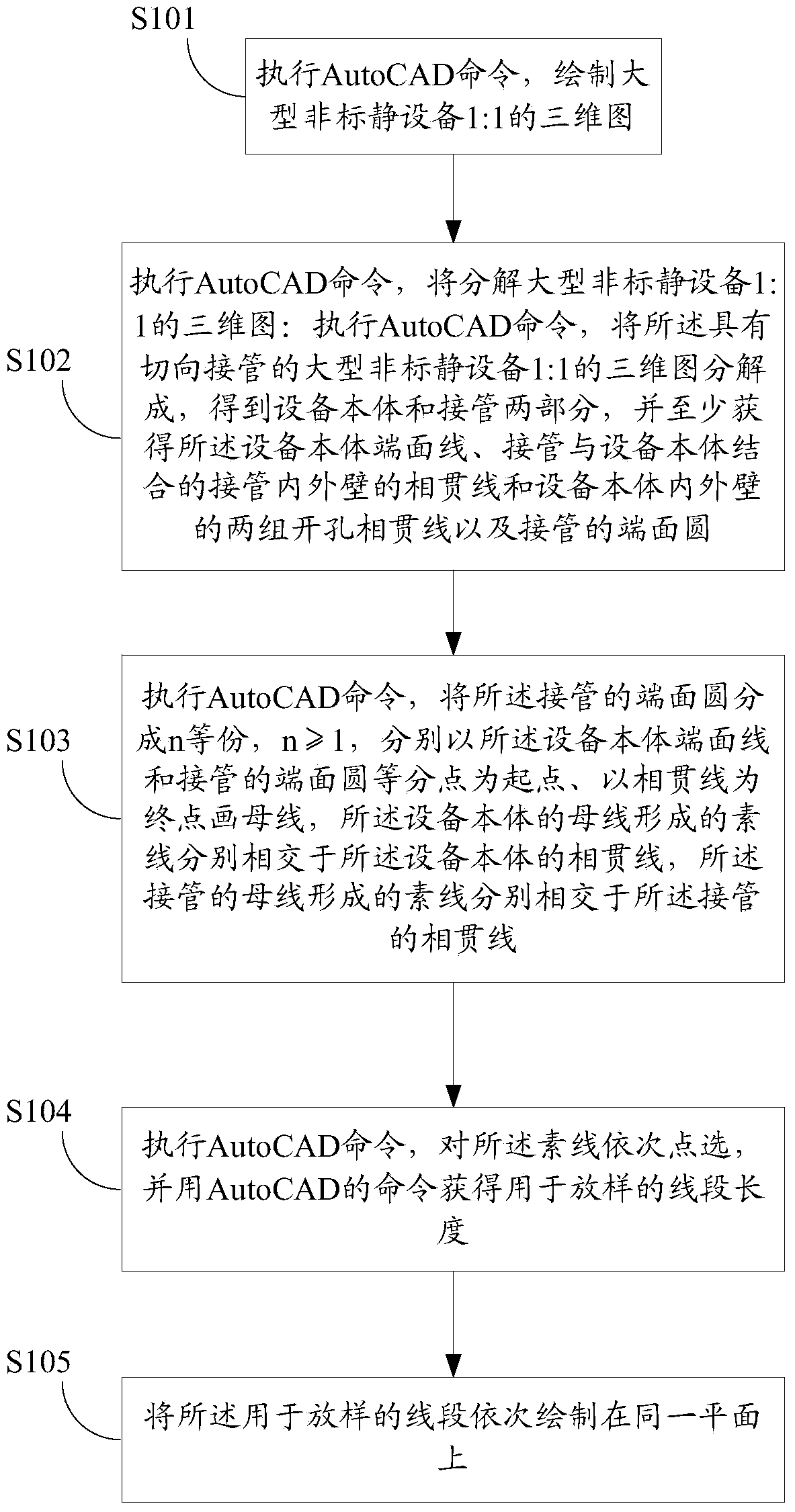

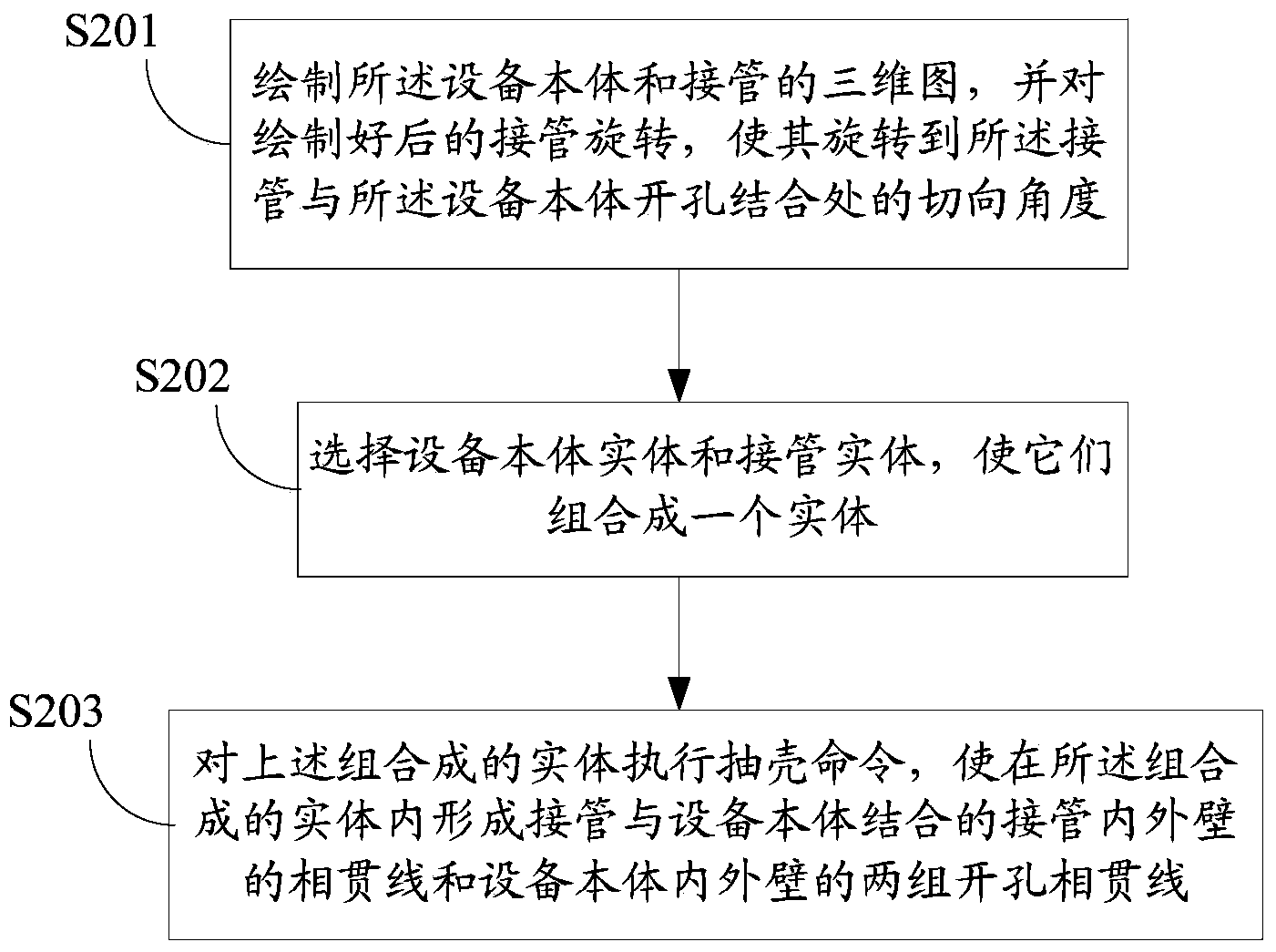

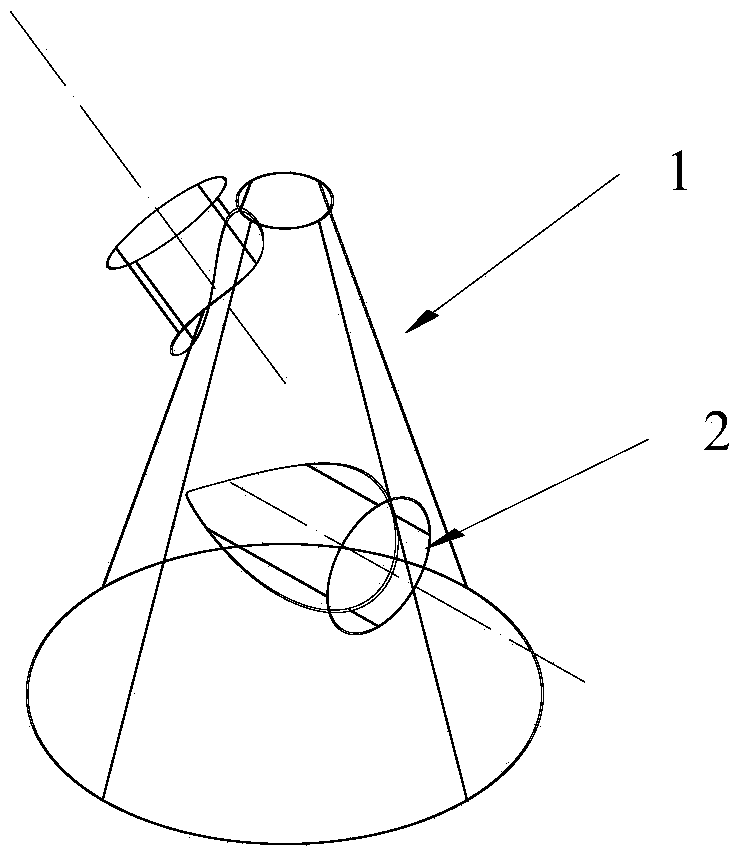

Unfolding lofting method for large-size non-standard static equipment with tangential connecting pipes

ActiveCN103530470AQuality improvementImprove efficiencySpecial data processing applicationsEngineeringLarge size

Provided is an unfolding lofting method for large-size non-standard static equipment with tangential connecting pipes. The non-standard static equipment comprises an equipment body and the connecting pipes in tangential connection with the equipment body, wherein the outer walls of the connecting pipes are connected with the outer walls of tangential open holes of the equipment body, and the inner walls of the connecting pipes are connected with the inner walls of the tangential open holes of the equipment body. The method comprises the steps that a three-dimensional diagram of the non-standard static equipment at 1:1 scale is drawn by using commands of AutoCAD and is decomposed into the equipment body and the connecting pipes, at least the end face lines of the equipment body, the intersecting lines of the inner walls and the outer walls of the connecting pipes at the combined positions of the connecting pipes and the equipment body, the intersecting lines of the open holes of the inner wall and the outer wall of the equipment body and the end face circles of the connecting pipes are obtained, the end face circles of the connecting pipes are divided into multiple equal parts, generatrices are drawn with the end face lines and the equal division points of the end face circles as starting points and the intersecting lines as end points, tessellation lines formed by the generatrices of the equipment body and the connecting pipes intersect on the intersecting lines of the equipment body and the connecting pipes respectively, point selection is carried out on the tessellation lines in sequence, and the length of the line segments of lofting is obtained, and the line segments used for the lofting are drawn on the same plane in sequence. According to the method, the intersecting lines are directly obtained through the function of the AutoCAD, and thus the method improves the lofting efficiency and is simple and reliable.

Owner:CHONGQING INDAL EQUIP INSTALLATION GROUPCO

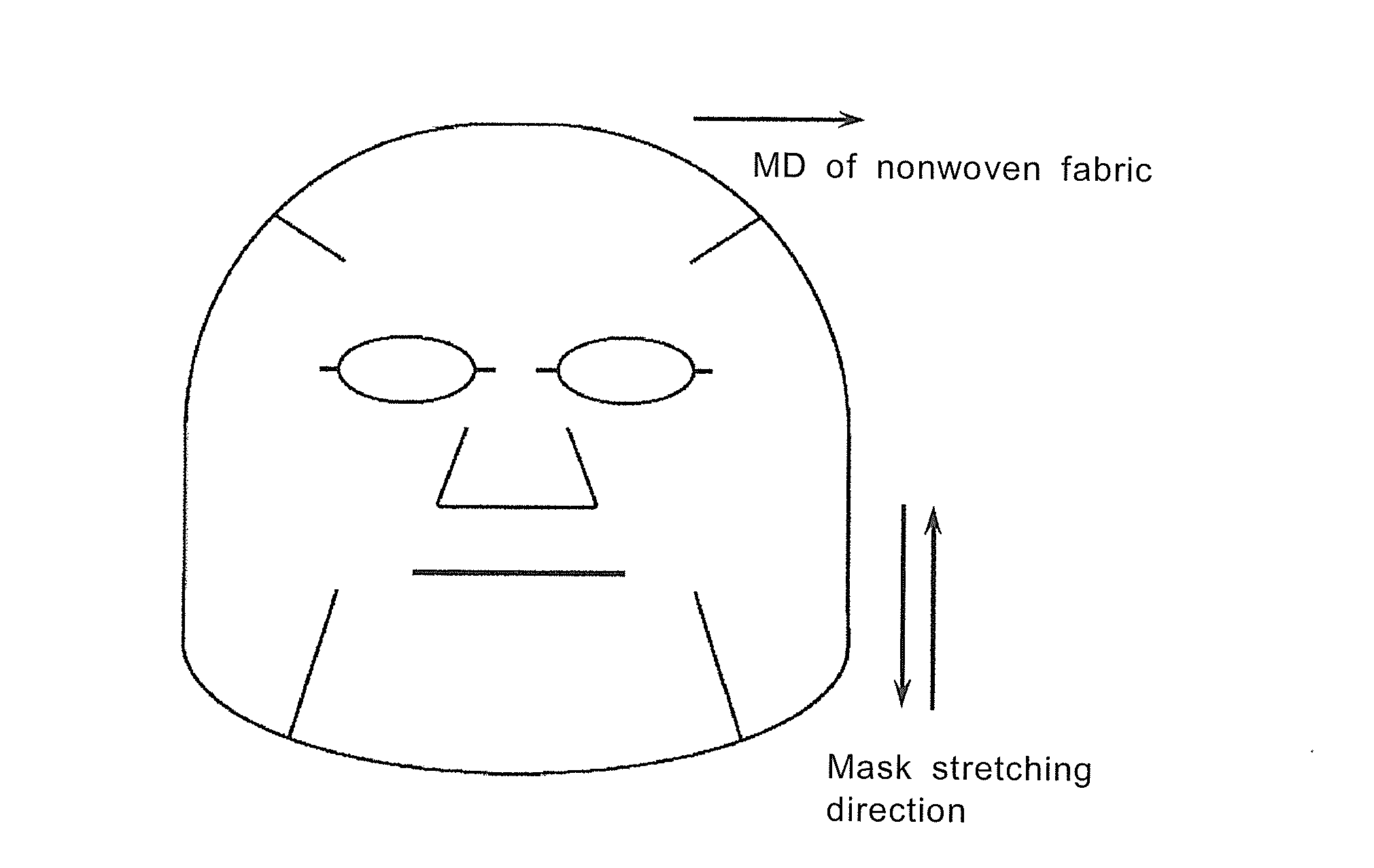

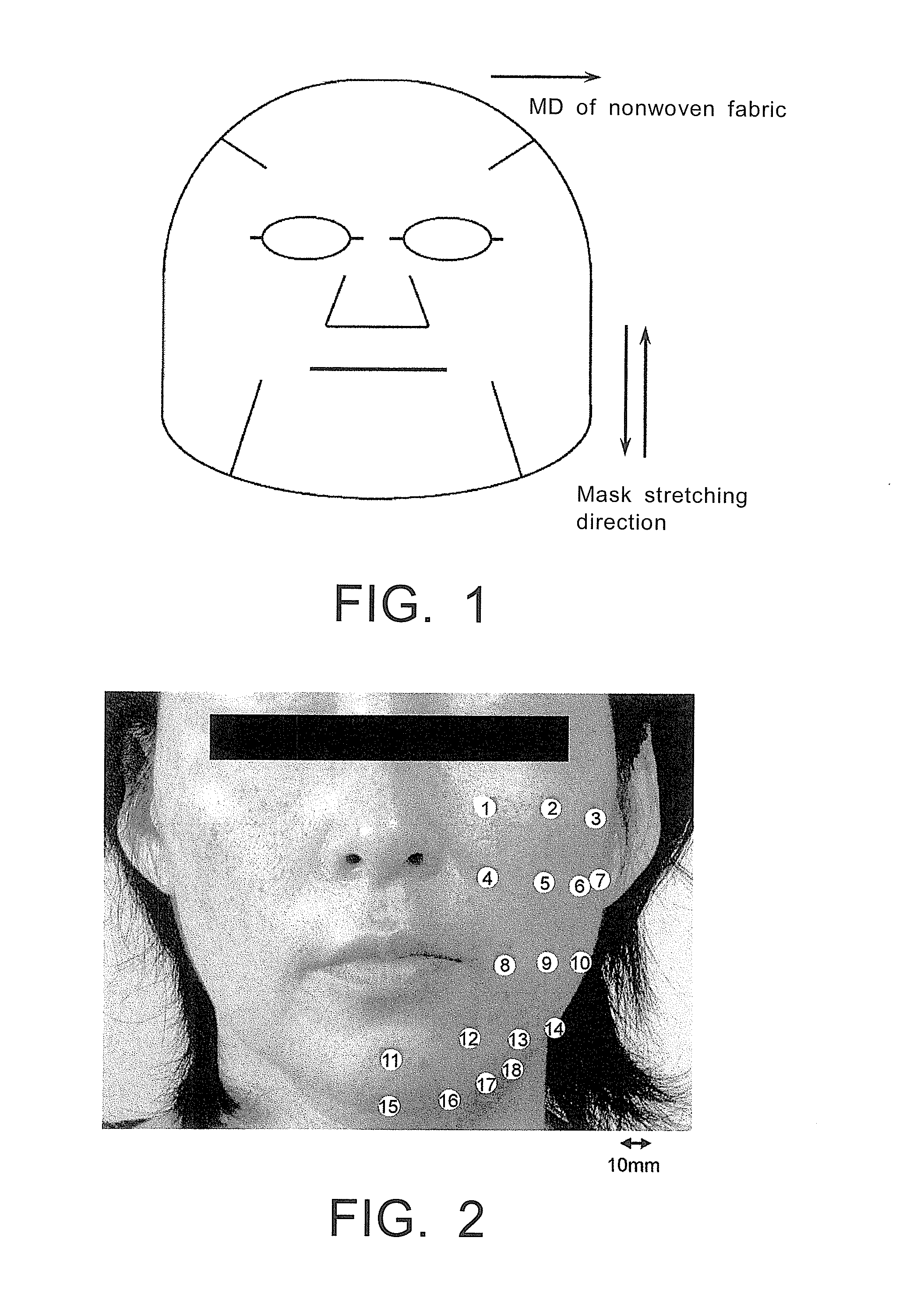

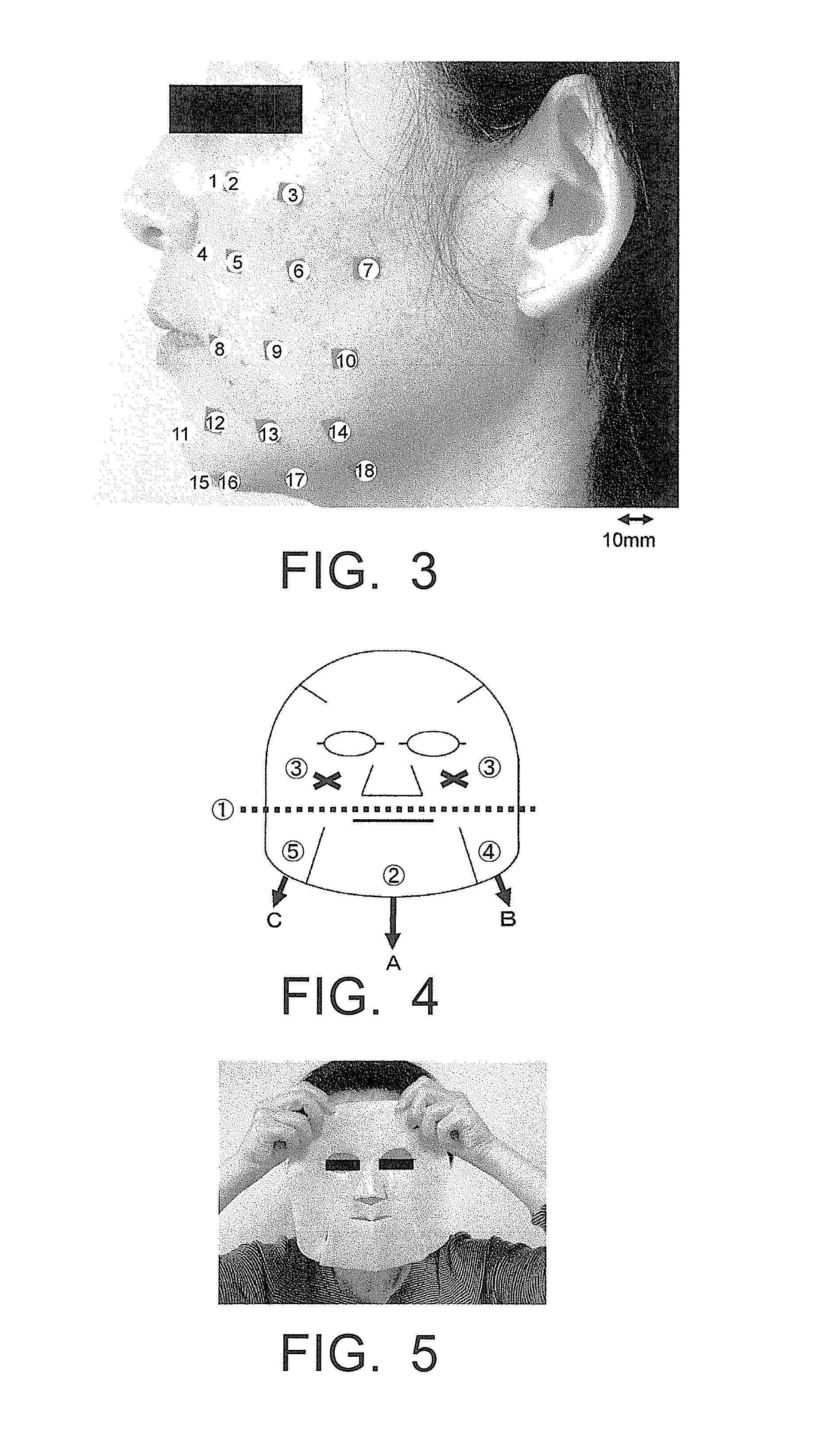

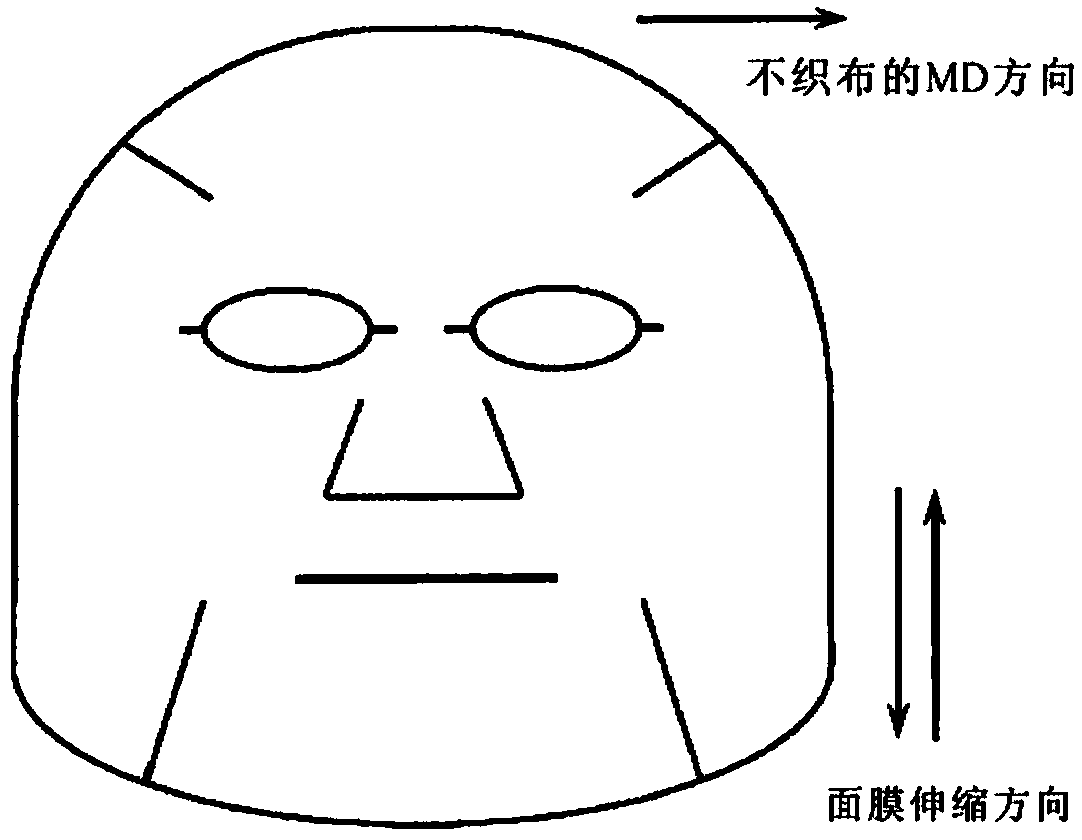

Cosmetic facial mask

ActiveUS20140318565A1Moderate stretchabilitySatisfactory wearing feelingHead bandagesCurling devicesElastomerMedicine

A cosmetic facial mask is described, having high fitting properties onto skin, an excellent skin tightening effect, and an excellent lift-up effect on a flaccid cheek or face line. The cosmetic facial mask includes a laminate in which a non-elastomeric fiber layer and an elastomer layer are integrated through lamination, and has stretchability in a vertical direction of a face.

Owner:JNC CORP +1

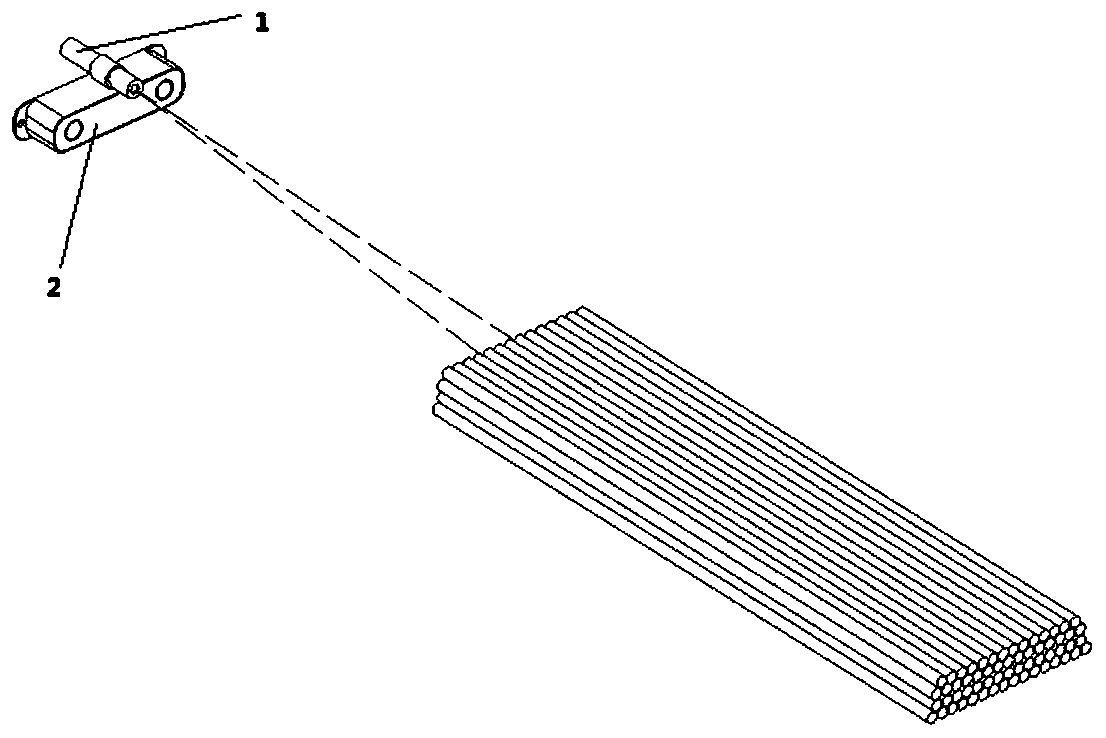

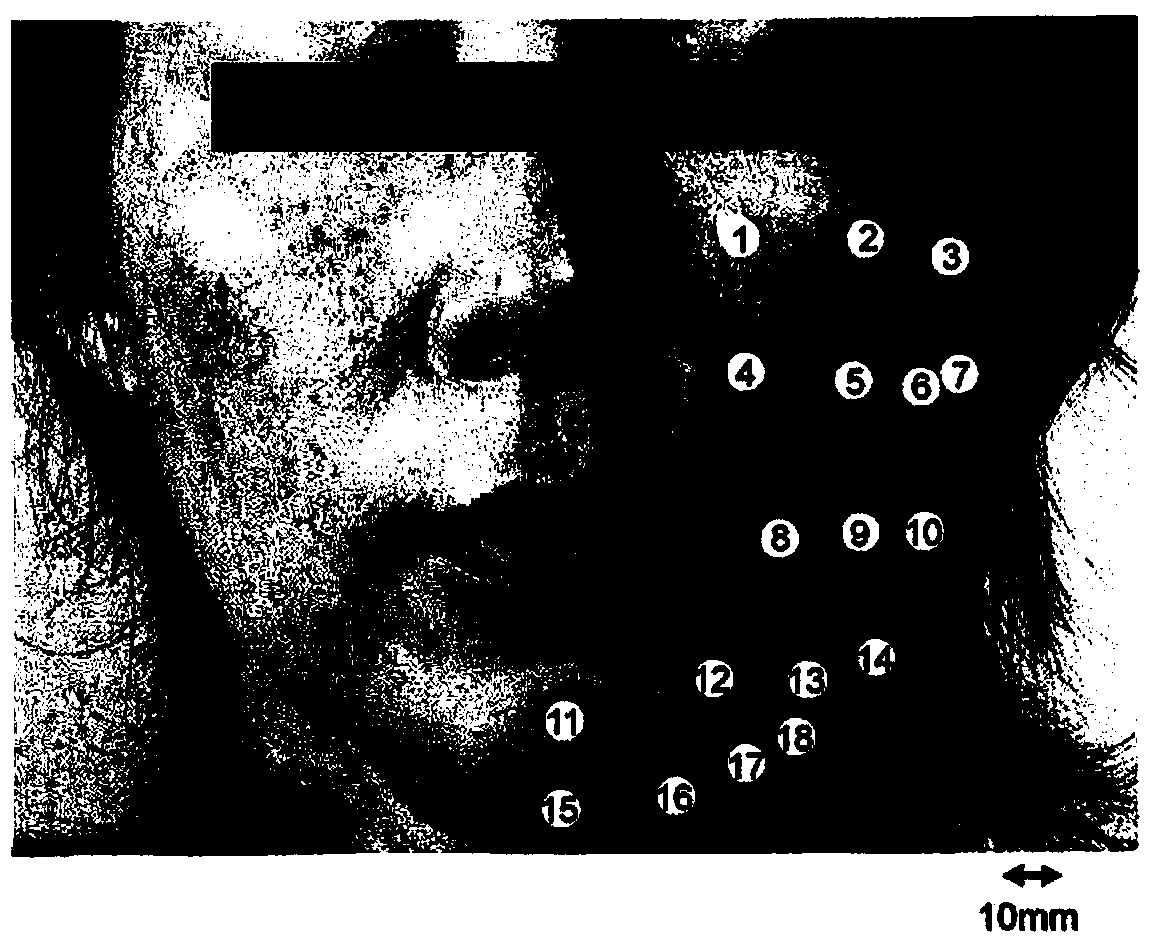

Steel bar counting method

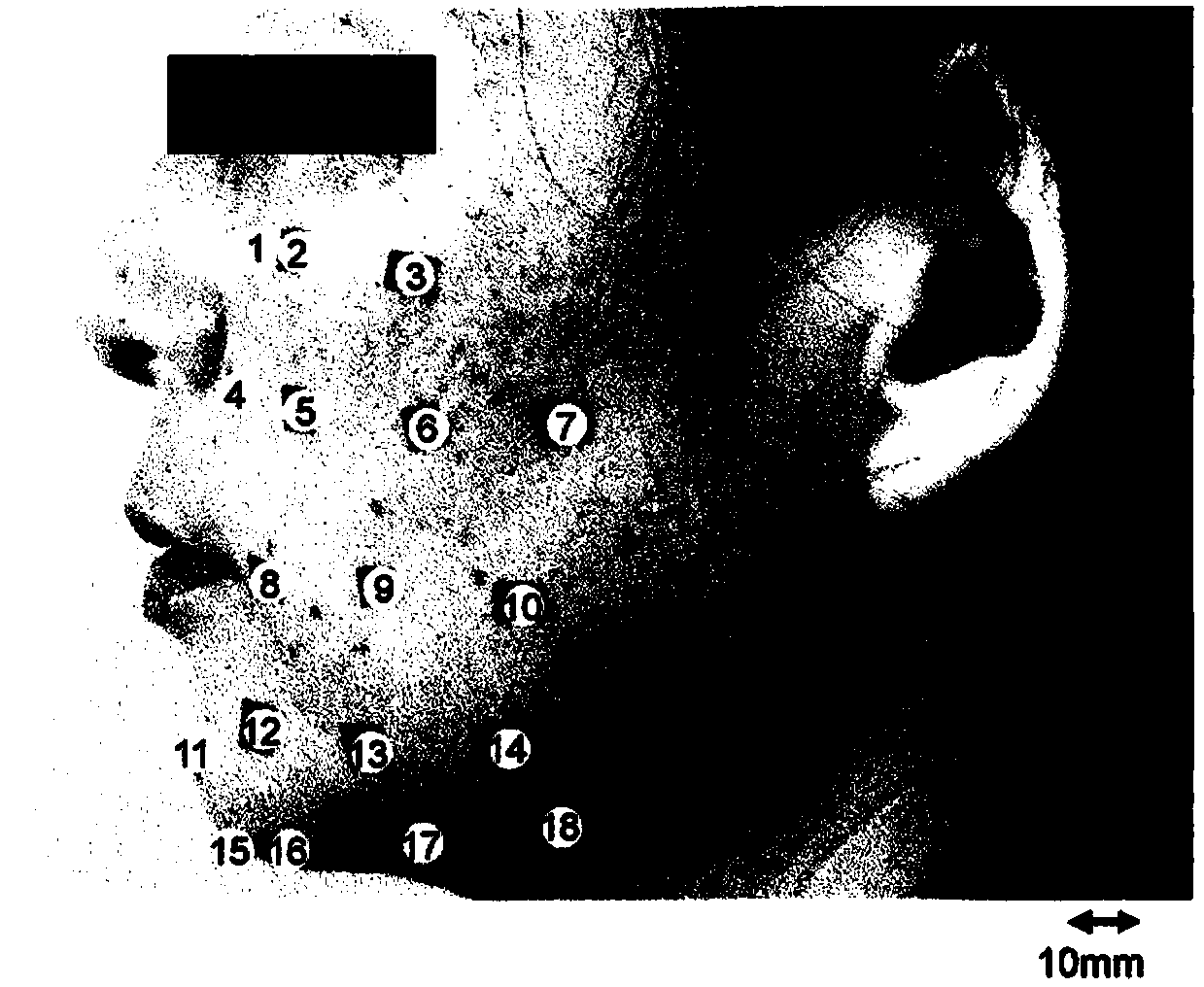

PendingCN109712180AStrong interferenceTime-consuming and labor-intensive solutionImage analysisInterference resistanceLaser scanning

The invention provides a steel bar counting method. The method comprises the steps that measuring three-dimensional data of steel bar end face line laser scanning lines through a line laser binocularmeasurement method; completely scanning the end surface of the reinforcing steel bar by using line laser, and obtaining complete contour three-dimensional data of the end surface of the reinforcing steel bar by using a line laser binocular measurement method; and counting steel bars by using a particle segmentation counting method. According to the invention, the moving line laser and the binocular camera are used to obtain the end face contour image of the bundled steel bar; obtaining steel bar number information by processing end face contour image data, line laser can perfectly restore thesteel bar end face contour image information, and a binocular camera can stably obtain laser line images, can adapt to various illumination environments and is high in environmental interference resistance. The three-dimensional data is quantized, watershed transformation is utilized to be converted into the gray level image, the center point and the number of the steel bars are determined according to the gray level image, the number of the steel bars can be rapidly and accurately analyzed, and the problems that labor and time are wasted, efficiency is low and accuracy is low when the steel bars are counted in piles or bundles are solved.

Owner:北京伟景智能科技有限公司

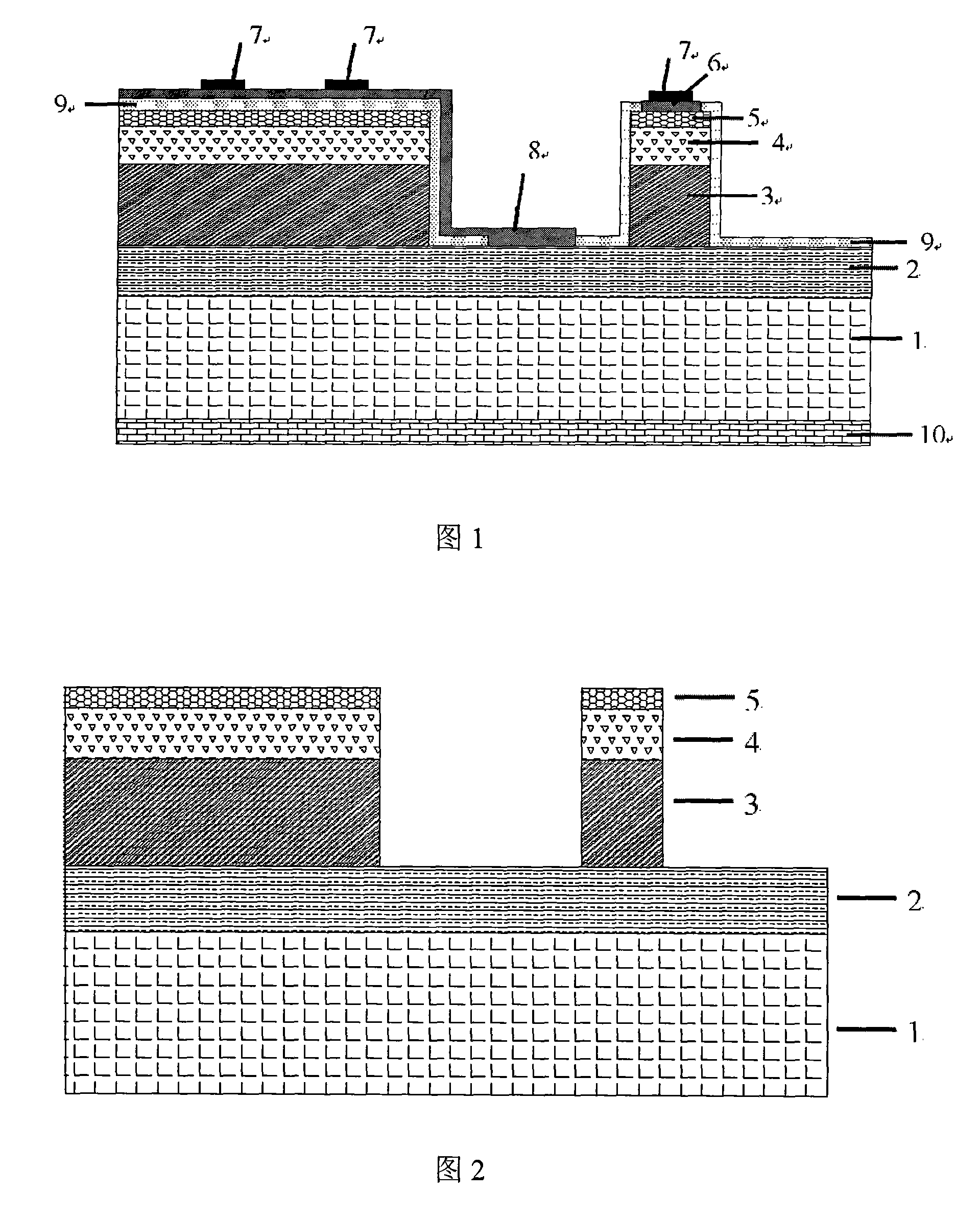

Back irradiation arsenic indium table face line array or face array detector chip and its making technology

ActiveCN101241946AReduce compoundingLow densityFinal product manufactureSemiconductor devicesLow temperature depositionIndium

The present invention discloses a back-irradiating indium gallium arsenic micro-table-board detector chip and the preparation technique thereof, the preparation technique comprises etching on the p-InGaAs / p-InP / i-InGaAs / n-InP epitaxial slice to form the p-InGaAs / p-InP / i-InGaAs micro-table-board, the thickness of the InGaAs absorption layer is designed to 1.1um to 1.5um, the doping concentration is 3-5*10<16>cm<-3>, the +SiNx passivating film is vulcanized and the annealing technique is leaded in, and the purposes of effectively reducing the combination of surface and side surface, reducing the density of interfacial state and increasing the detectivity and homogeneity of the device, the leading-out area of the p type electrode is grown with a layer of p-InGaAs electrode transition layer, the contact between the Ti / Pt / Au electrode grown by the evaporation of the electron beam and the p-InGaAs is excellent ohm contact, the small contact resistance increases the capability of the detector, at the same time the back-irradiating mode is adopted and the incident light will not be absorbed by the p-InGaAs of the p type electrode leading-out layer, the response ratio of the device is facilitated to be increased and the back low-temperature deposition ZnS reflection reducting coating can further increase the repose ratio and quantum efficiency of the device.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

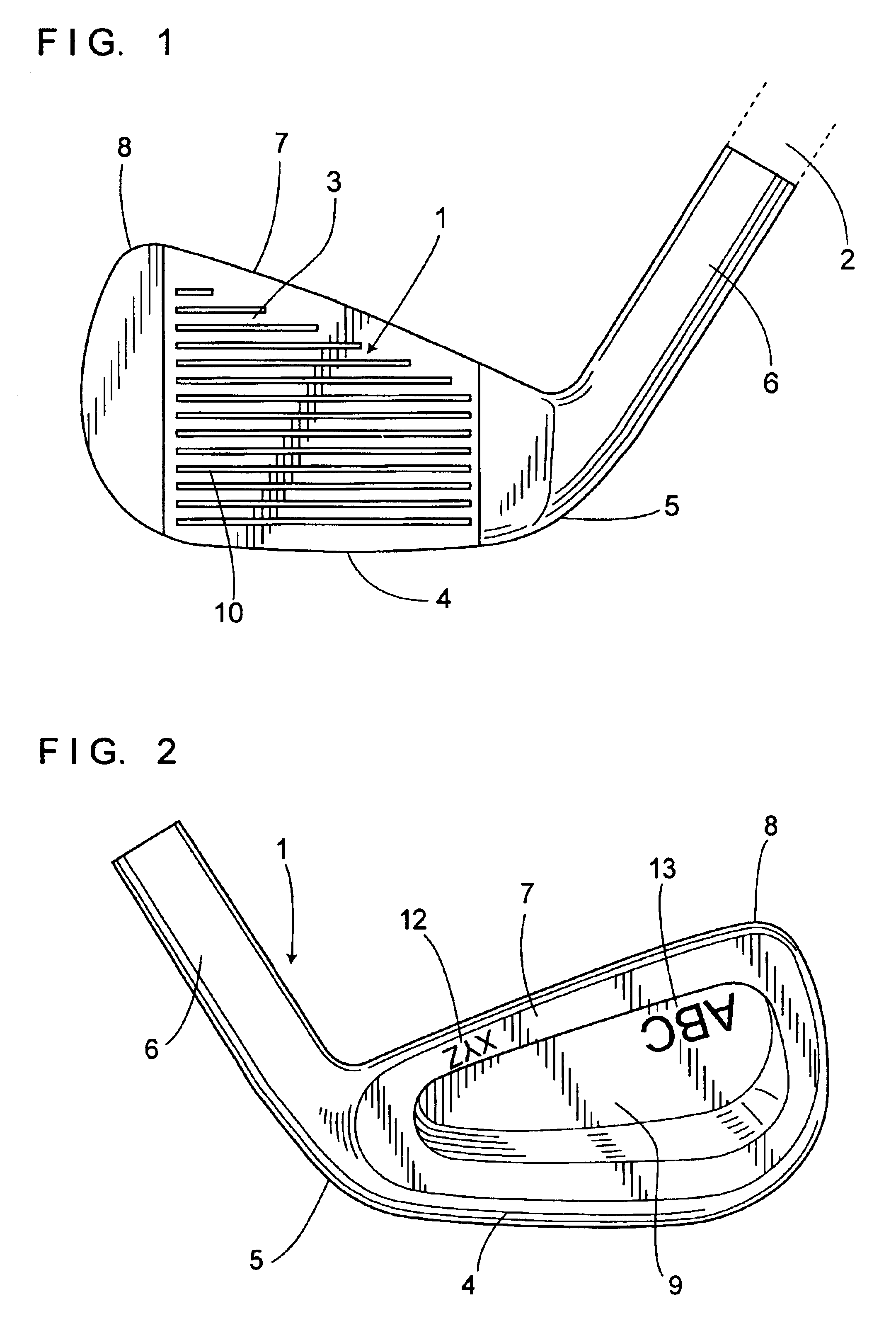

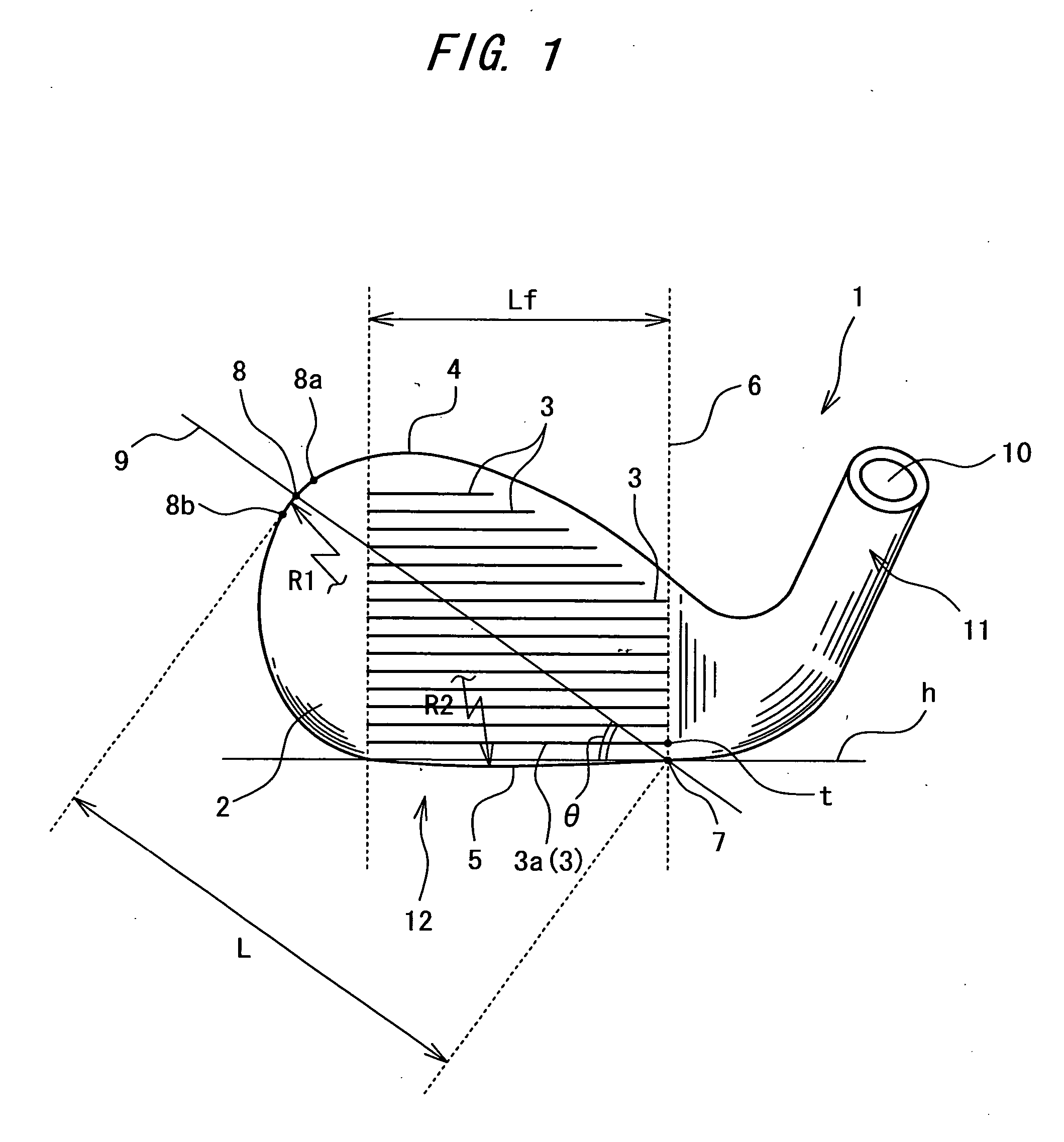

Iron golf-club head and an iron golf club including the same

InactiveUS20050209018A1Convenient lengthReduce the possibilityGolf clubsRacket sportsEngineeringGravity center

A configuration of an iron golf-club head is defined as follows in order to offer ease of addressing a ball with face open. In a projected figure of the head focused on a projection plane including a sweet spot and normal to a perpendicular from a center of gravity of the head to a face thereof, a maximum transversal is defined by a straight line cutting across a face contour over the greatest length as passing through an intersection of a leading edge and a straight line drawn from a heel-side end point of a face line in a predetermined direction of the projected figure, and forms an angle of 39° to 50° (inclusive) relative to a horizontal line. The face contour has a radius of curvature of 10 mm to 22 mm (inclusive) in the vicinity of a toe-side intersection of the face contour and the maximum transversal.

Owner:SUMITOMO RUBBER IND LTD

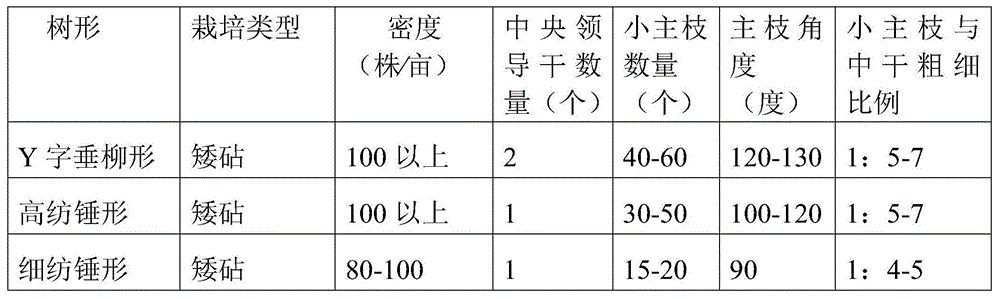

Y-shaped weeping willow-shaped apple tree and pruning method thereof

InactiveCN104472297AIncrease the number ofReduce laborCultivating equipmentsHorticulture methodsMain branchTree shaped

The invention discloses a Y-shaped weeping willow-shaped apple tree and a pruning method thereof. The tree comprises a main trunk and two central leading trunks on the main trunk, the two central leading trunks face line space, the included angle between the central leading trunks is 25-35 degrees, and the main trunk and the two central leading trunks form a Y shape; 20-30 main branches are grown on each central leading trunk, the angle of each main branch is 120-130 degrees in average, and the interval of each two main branches in different heights is at least 25cm; fruit bearing branches are directly grown on the main branches, and the fruit bearing branches are in drooping state and similar to weeping willow under the action of gravity after fruit bearing. The Y-shaped weeping willow-shaped tree can bear fruits 2-3 years earlier than fine spindle-shaped trees and high spindle-shaped trees, the yield is increased by 10%-20%, and labor force of an orchard is reduced by about 40%. According to the Y-shaped weeping willow-shaped apple tree and the pruning method thereof, the tree shape is a novel shape that is suitable for dwarfing stock close planting apple orchards, and cultivation of national apple dwarfing stock and wide-row close planting is facilitated.

Owner:NORTHWEST A & F UNIV

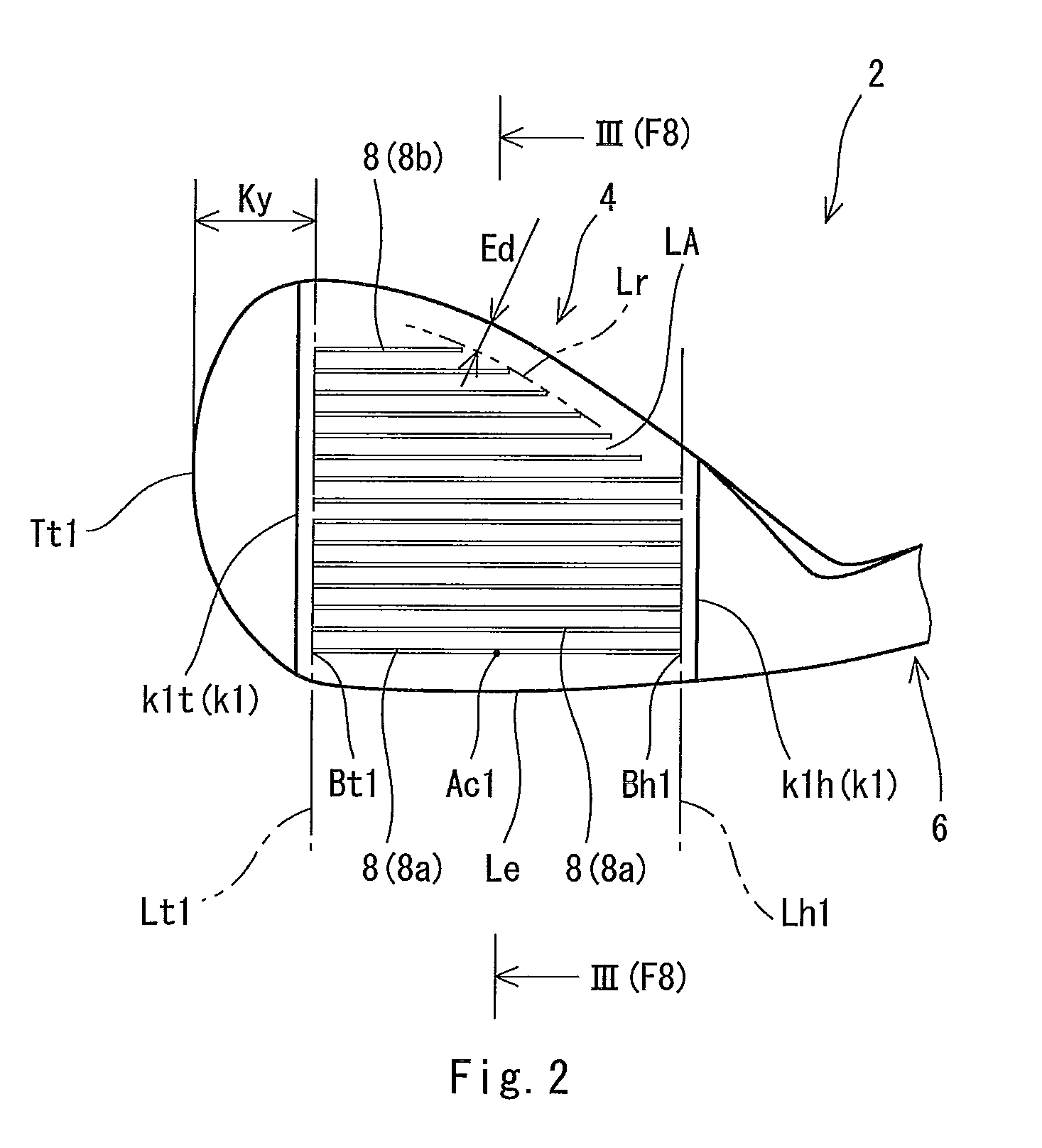

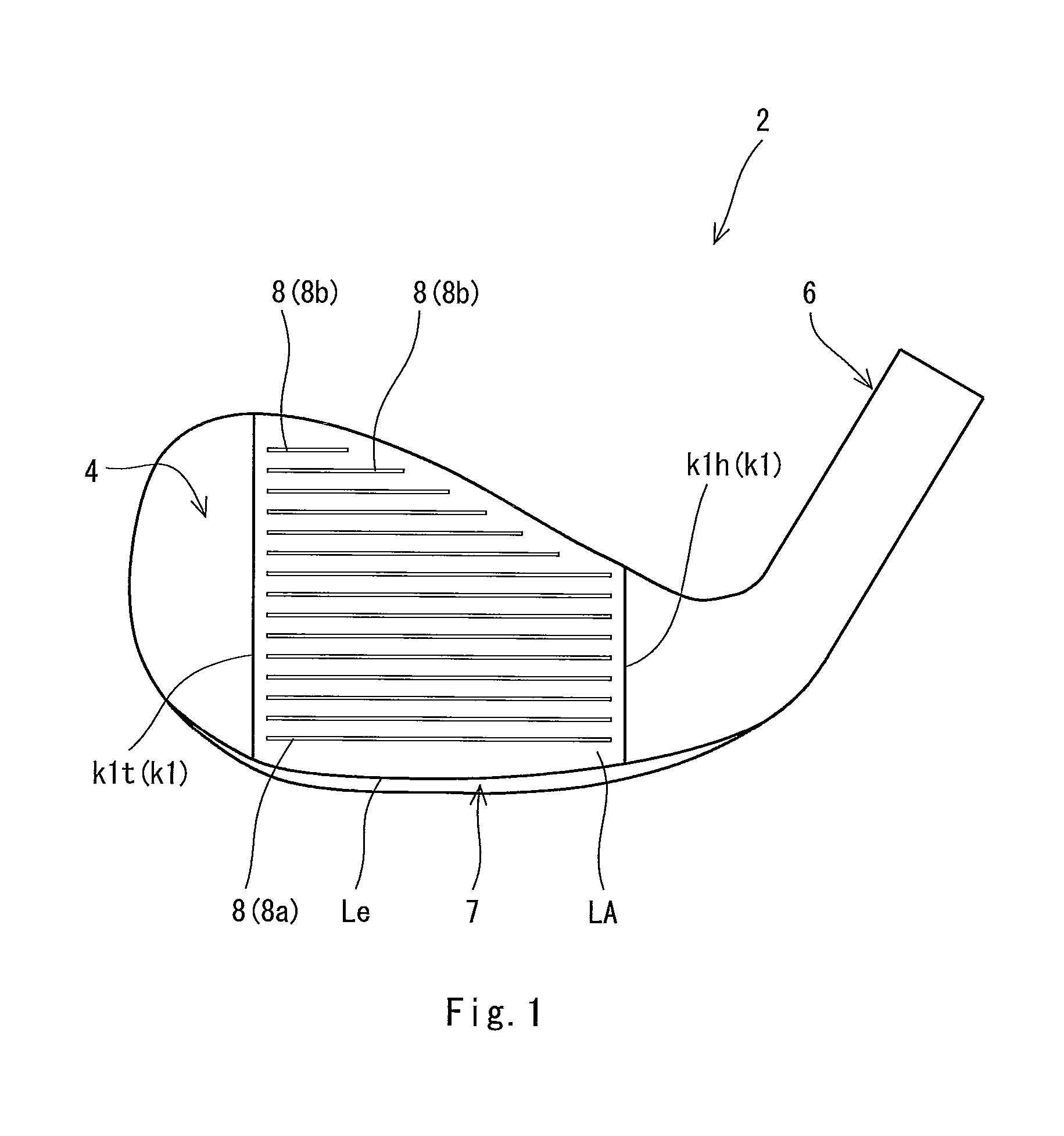

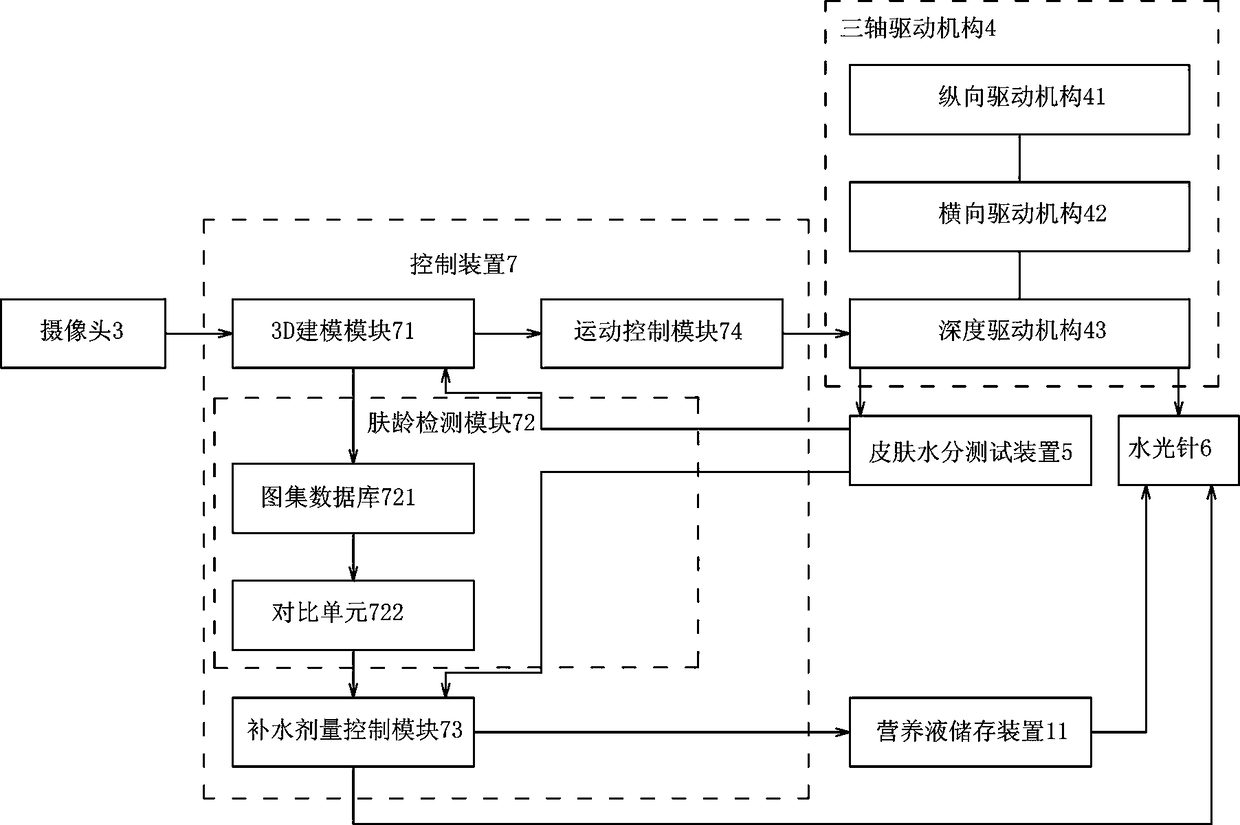

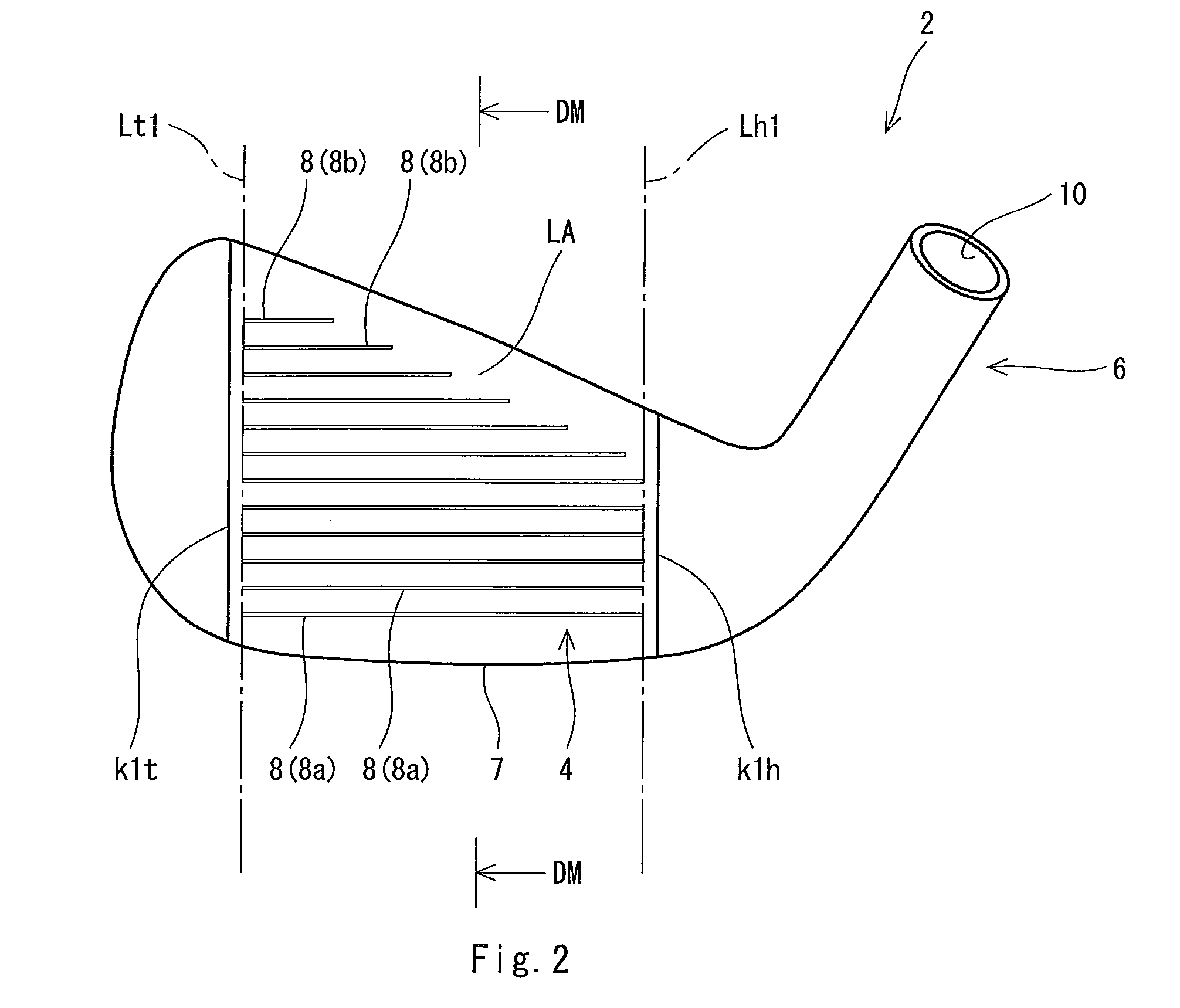

Golf club head

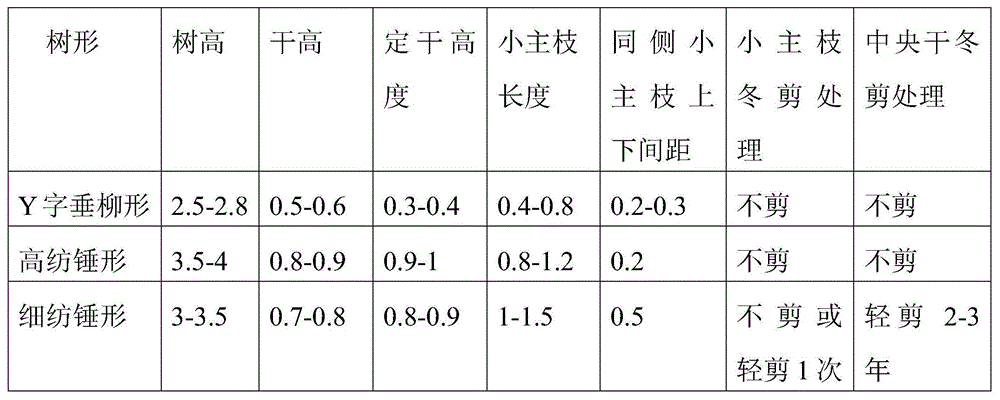

ActiveUS8444503B2Suppression of a damage of a ball and spin performanceDamage of performanceGolf clubsRacket sportsEngineeringGolf Ball

A head 2 has a face line 8 having a depth of D1 (mm). In a section line of a surface of the face line 8, a boundary between a land area LA and the face line 8 is defined as a point Pa; a point of which a depth is [D¼] (mm) is defined as a point Pb; a point of which a depth is [D½] (mm) is defined as a point Pc; a point of which a depth is [(D1)×(¾)] (mm) is defined as a point Pd; a radius of a circle CL1 passing through three points of the point Pa, the point Pb, and the point Pc is defined as R3 (mm); a straight line passing through the point Pc and the point Pd is defined as a straight line Lcd; a straight line perpendicular to the land area LA is defined as a straight line Lp; and an angle between the straight line Lcd and the straight line Lp is defined as θm. At that time, the radius R3 is 0.01 (mm) or greater and 0.10 (mm) or less, and the angle θm is 40 degrees or greater and 70 degrees or less.

Owner:SUMITOMO RUBBER IND LTD

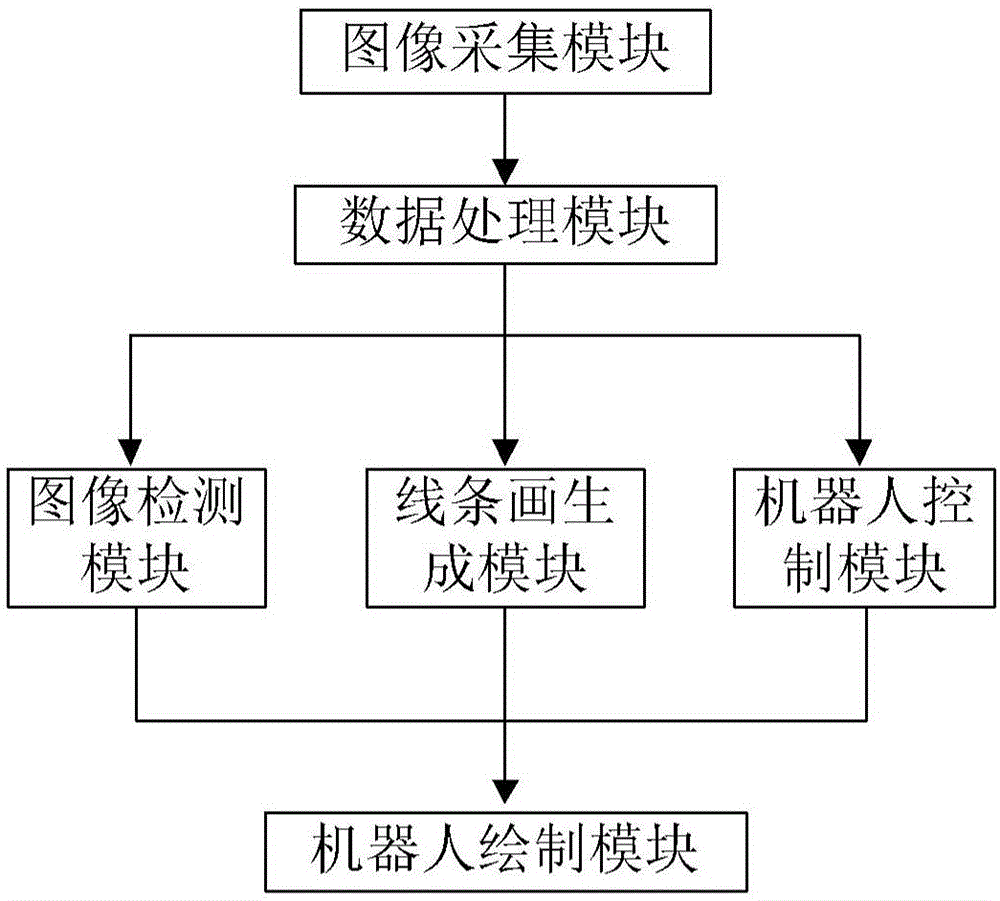

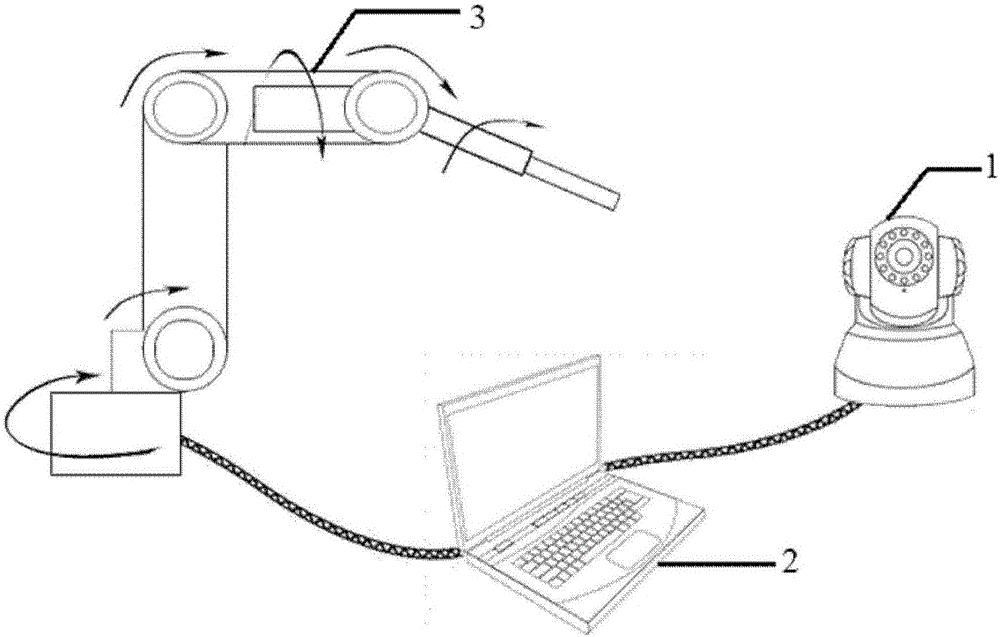

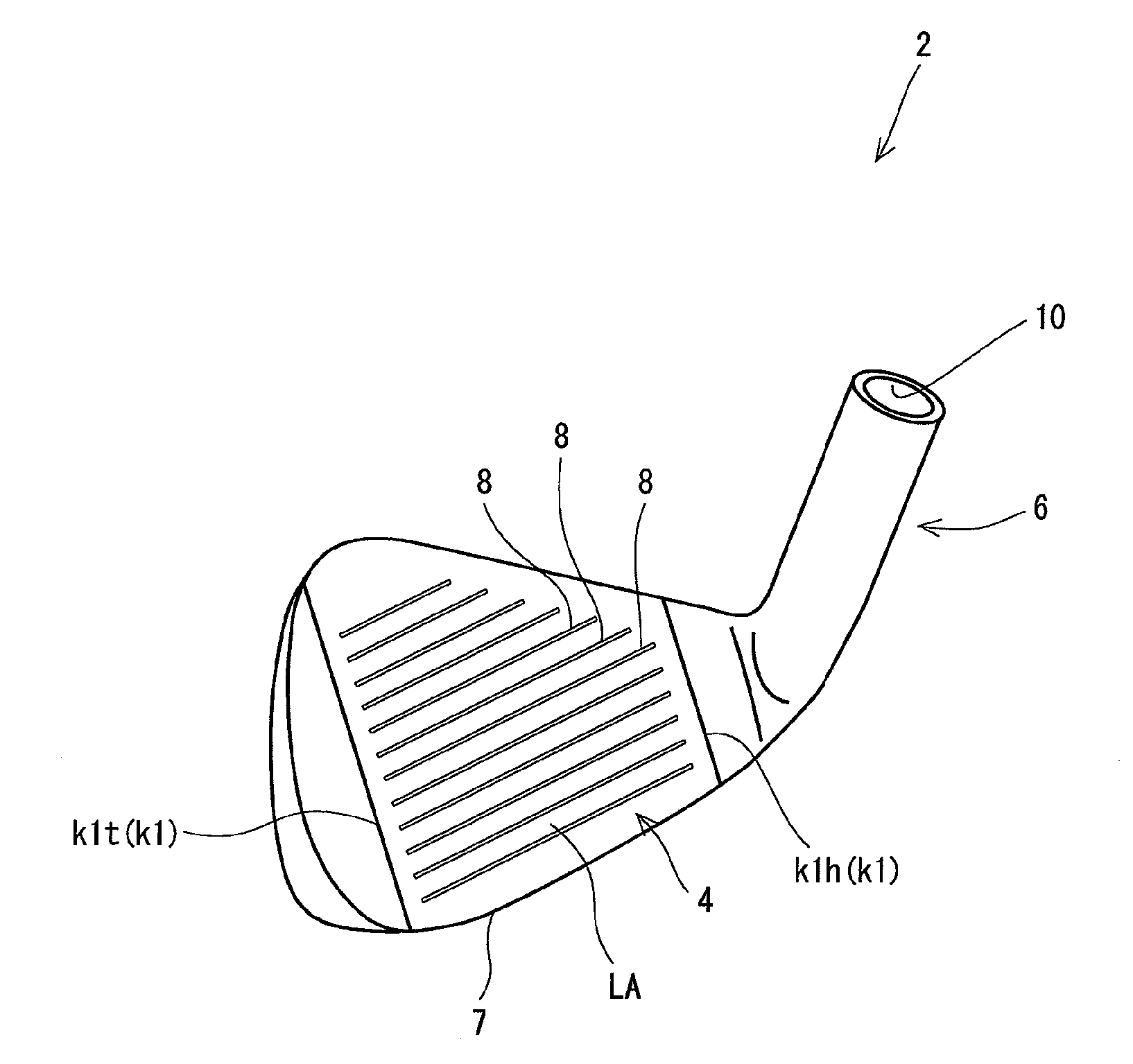

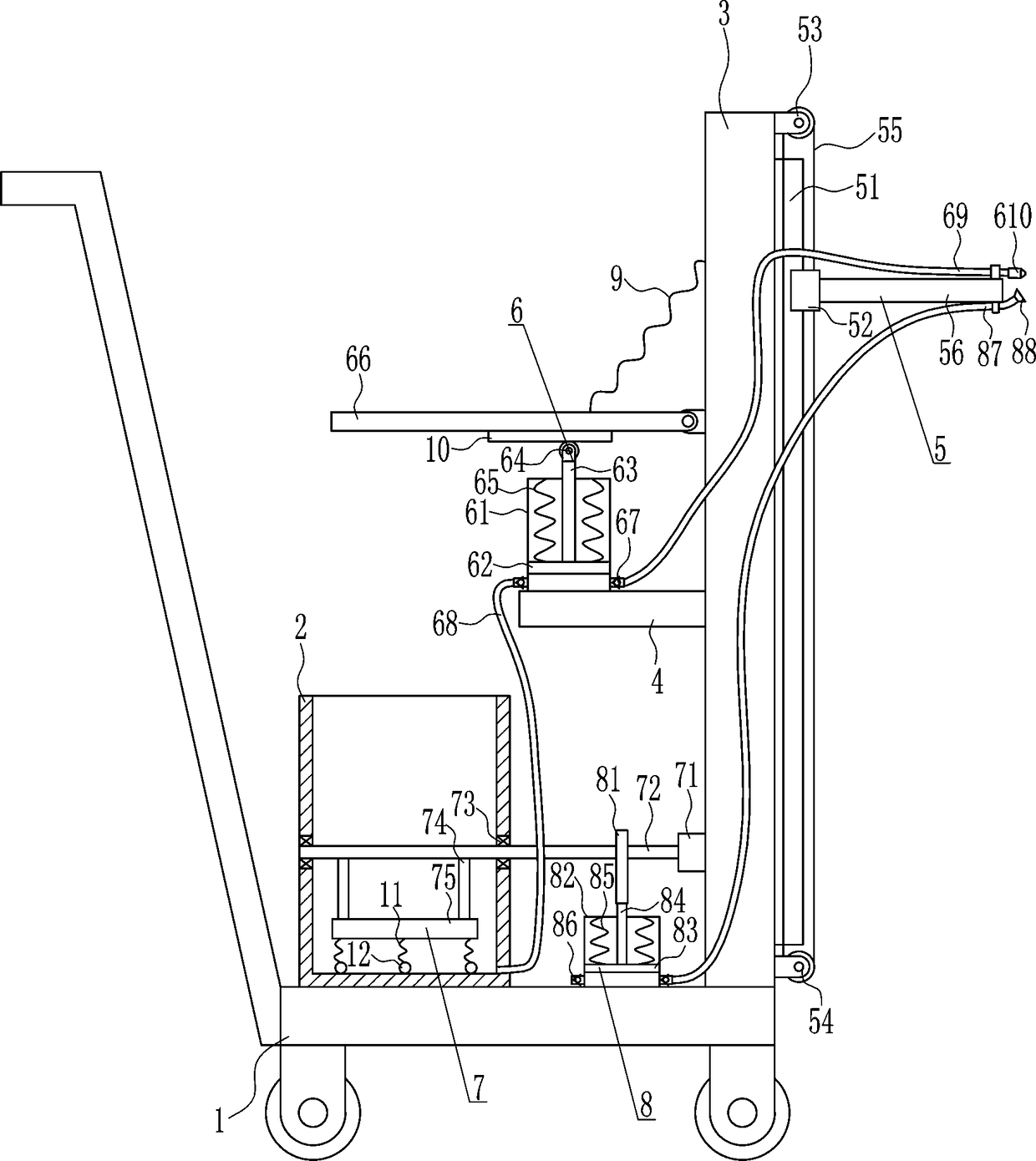

Automatic drawing system for face line paint

InactiveCN106651988AContinuous edgeDrawing from basic elementsEditing/combining figures or textComputer graphics (images)Transformation of text

The invention discloses an automatic drawing system for a face line paint. The system is composed of an image acquisition module, a data processing control module, and a robot drawing module. The image acquisition module is used for collecting an image in front of the module. The data processing control module connected with the image acquisition module is used for extracting a face image from the image collected by the image acquisition module and generating a face image line paint, for receiving a text inputted by an external input device, converting the inputted text into an art word image, and converting the art word image into an art word line paint, and for controlling the robot drawing module to complete drawing of the face image line paint and the art word line paint. The robot drawing module connected with the data processing control module is used for drawing the generated face image line paint and the art word line paint under control of the data processing control module.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

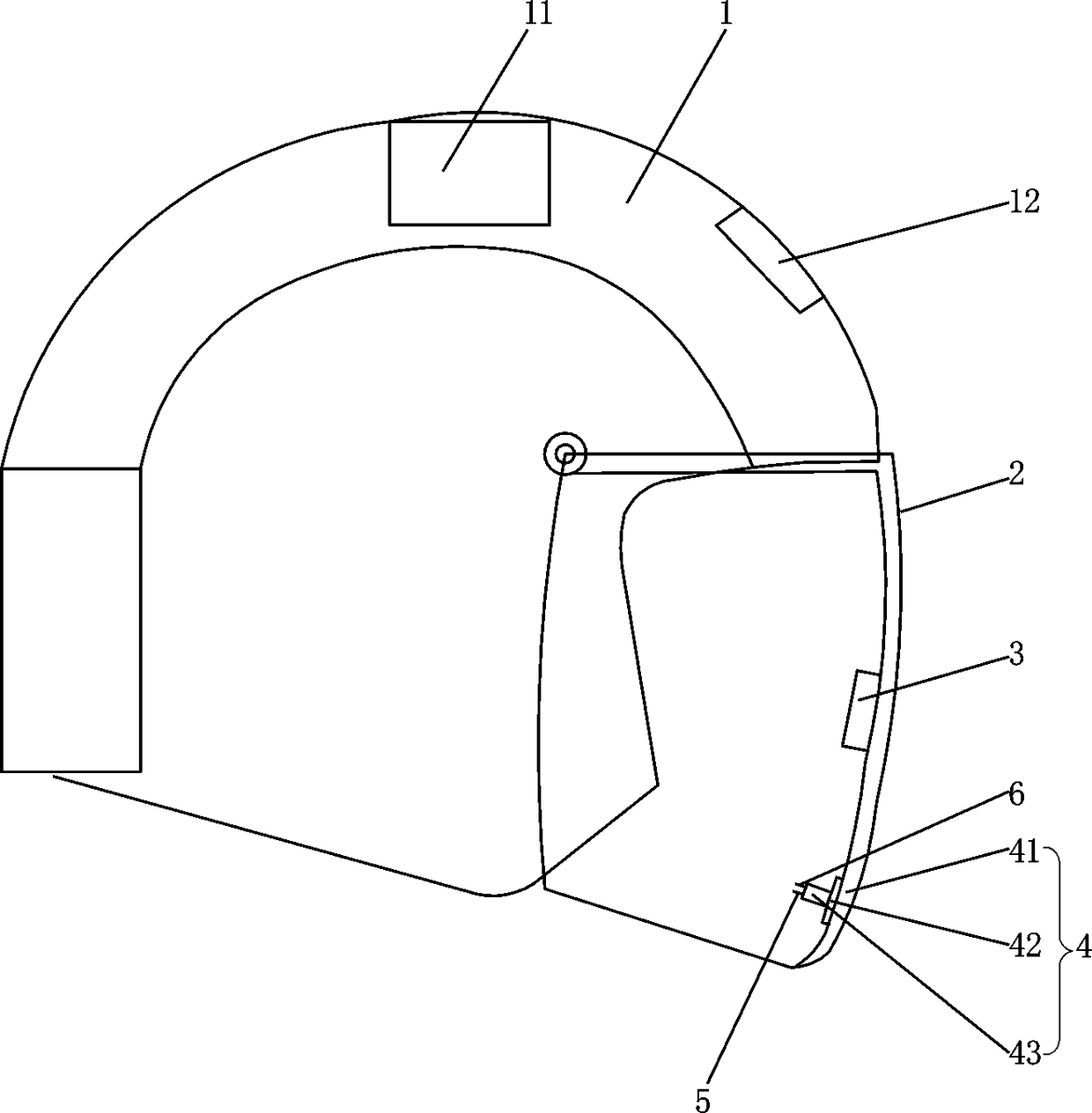

Fully-automatic face moisturizing method and instrument

ActiveCN108211102AMaintain healthy functionTargetedMedical applicatorsDiagnostic recording/measuringPattern recognitionFully automatic

The invention provides a fully-automatic face moisturizing method. The method comprises the steps of scanning and photographing a human face by a camera to form scanning data; establishing a 3D modelof the face, wherein the 3D model of the face is in one-to-one correspondence to human face coordinates; detecting the water content and oil content of the human face line by line to form skin type information; dividing the 3D model into regions according to the information of the face coordinates and the skin type information at corresponding positions, and making similar skin type information inthe same moisturizing region; obtaining the skin age information of the human face by comparing with the 3D model of the face; determining the moisturizing amount of each moisturizing region of the skin according to skin type information and skin age information; and moisturizing the human face according to the moisturizing regions and the moisturizing amount. The invention also provides a fully-automatic face moisturizing instrument adopting the fully-automatic face moisturizing method. The method is simple and safe, can make moisturizing more targeted, has more prominent effects, and can beused by ordinary people at home.

Owner:汕头高新区梦禾生物科技研究所有限公司

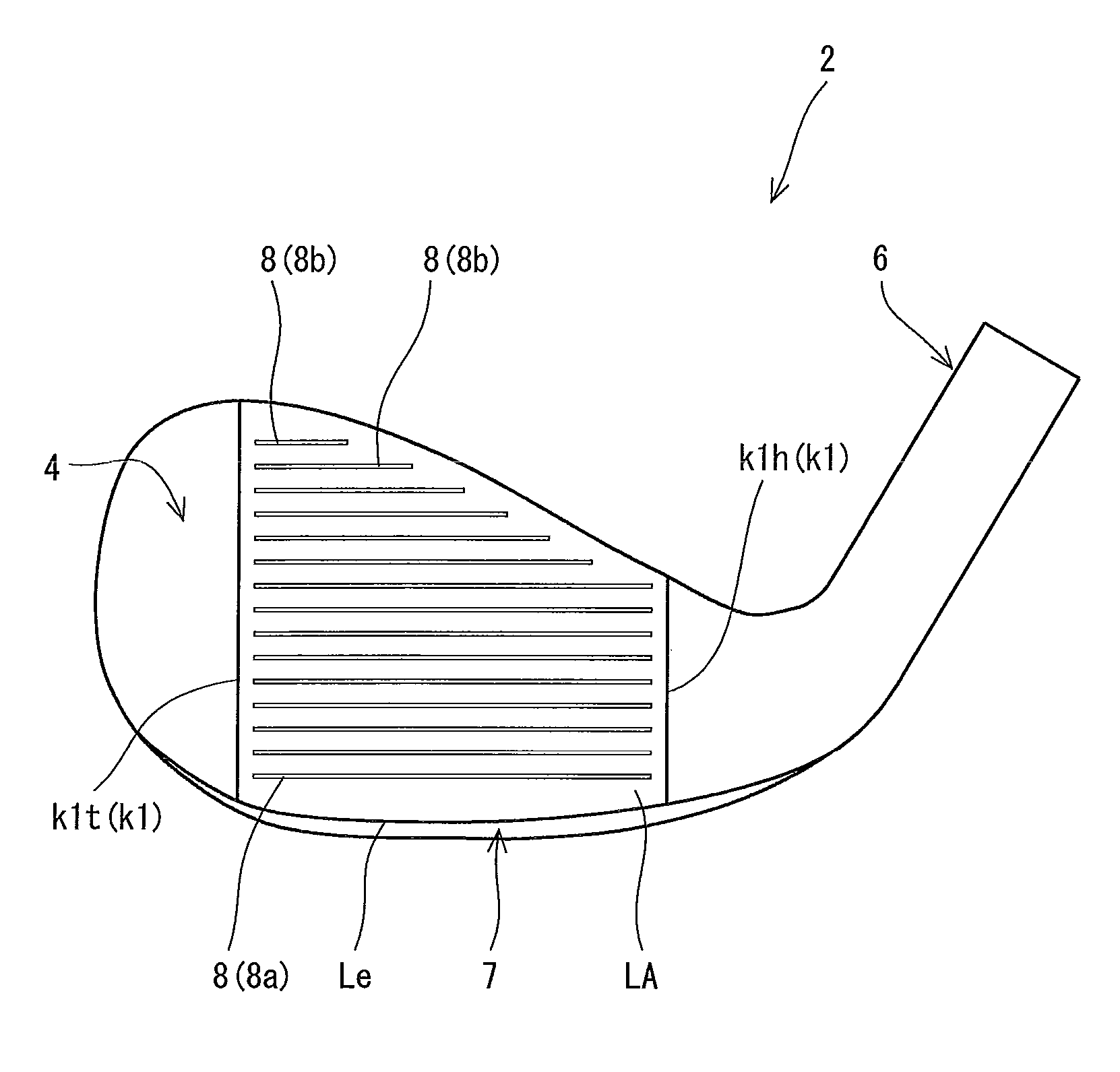

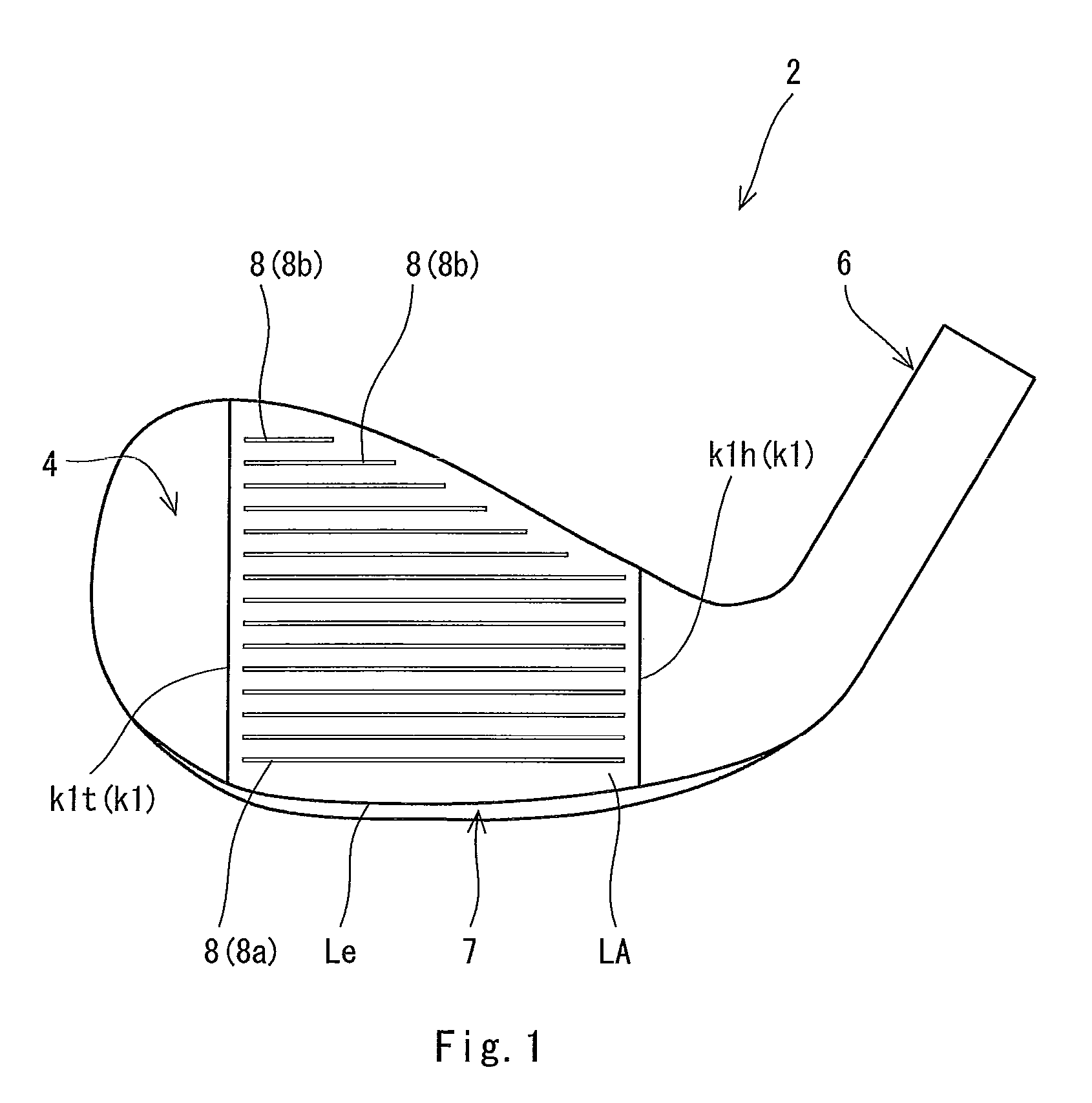

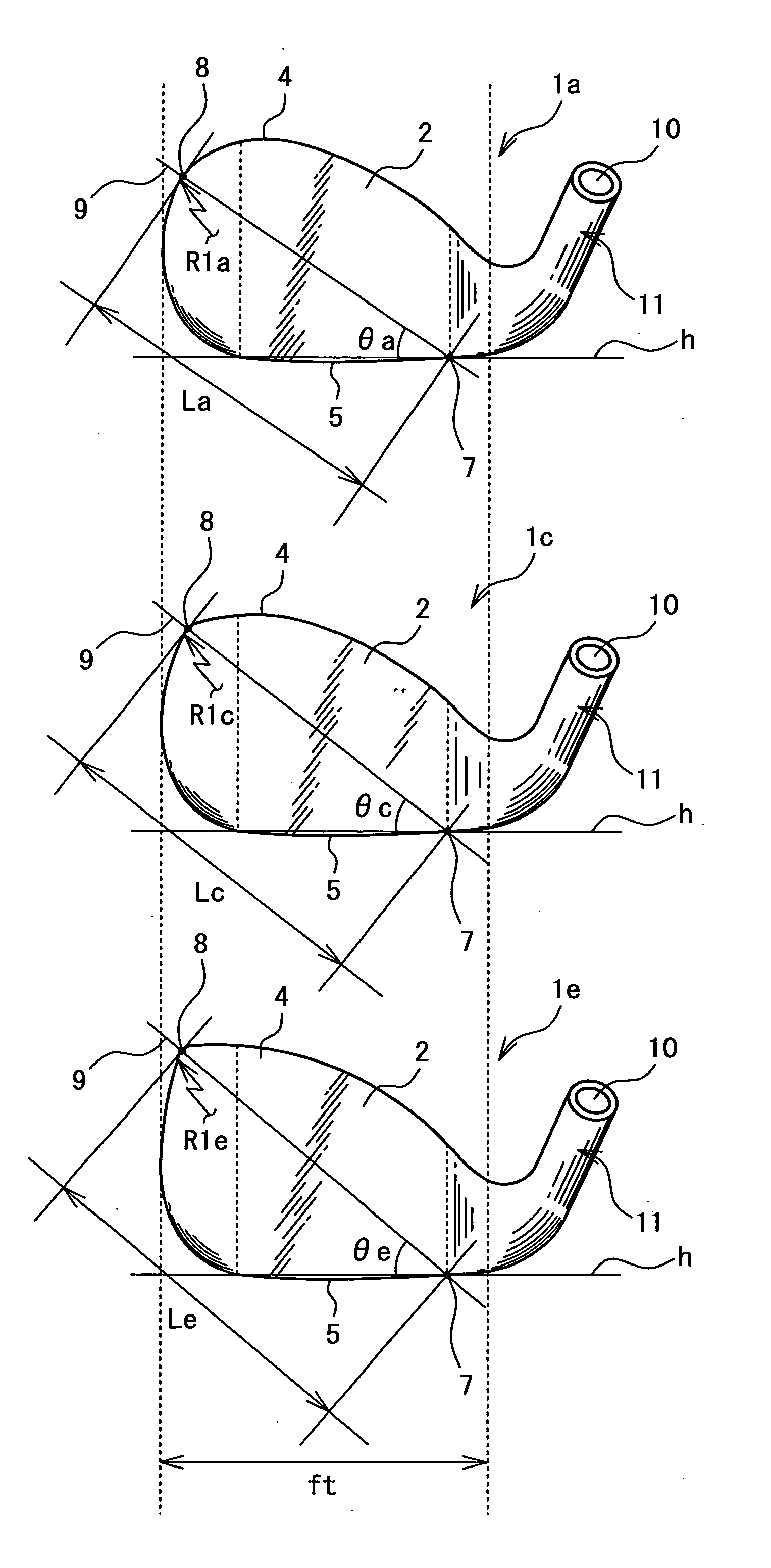

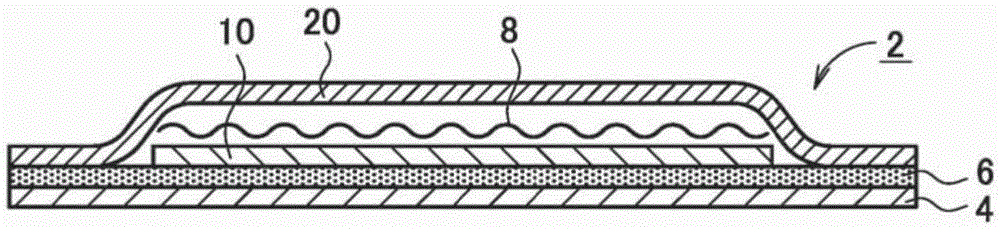

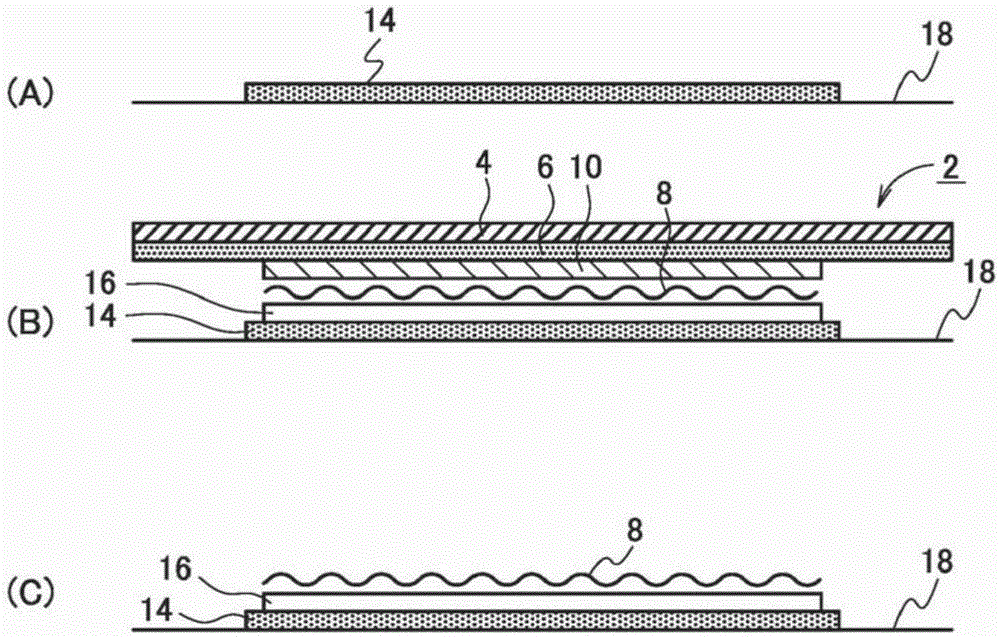

Golf club head

ActiveUS20110098129A1Lower performance requirementsHigh dimensional accuracyGolf clubsRacket sportsEngineeringGolf Ball

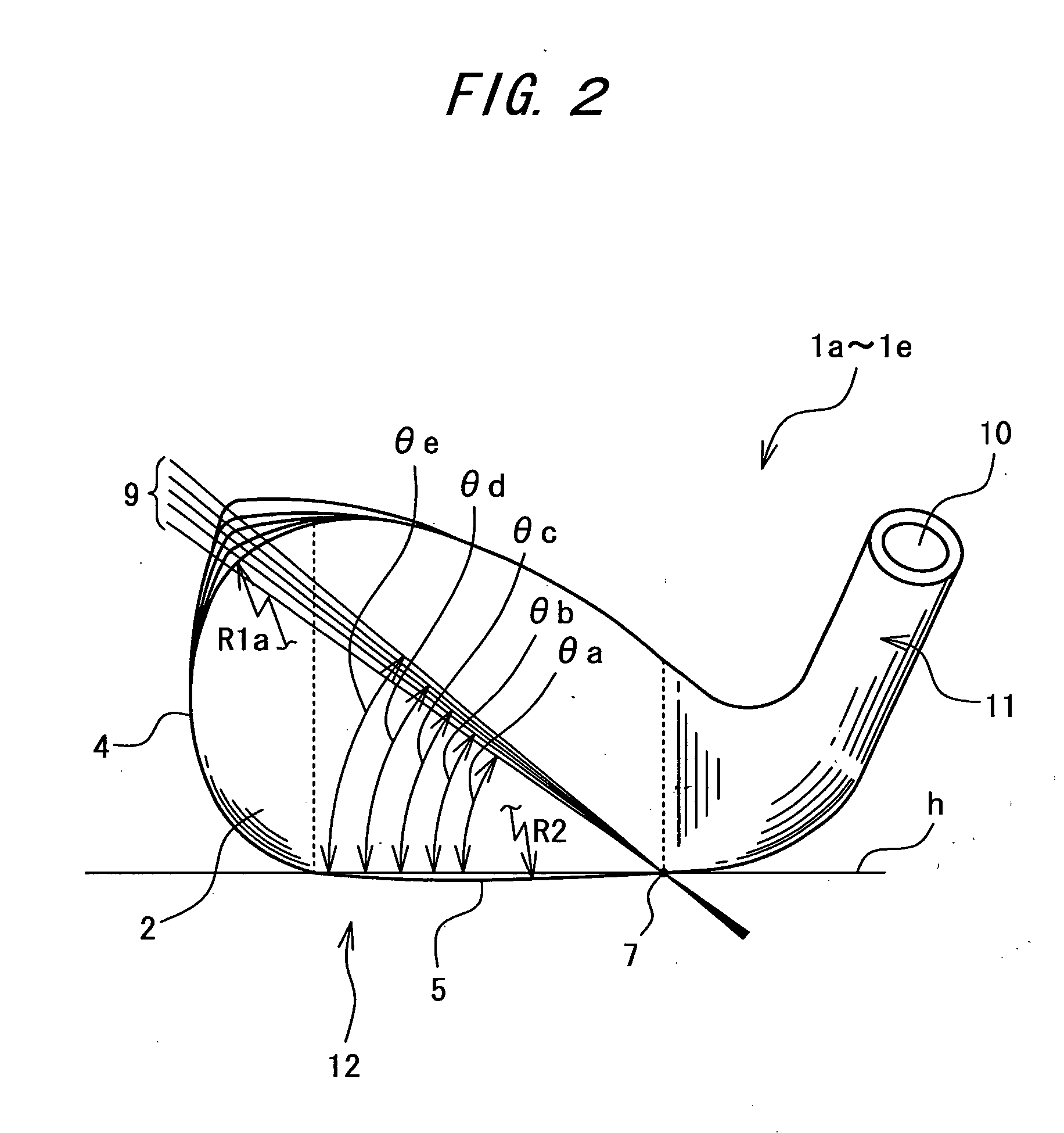

A golf club head 2 includes a face line 8 having a depth of D1 (mm) and a land area LA. When a boundary point between the land area LA and the face line 8 in a section line of a surface of the face line 8 is defined as Pa; a point of which a depth is T1 (mm) is defined as Pb; and a curvature radius of the section line between the point Pa and the point Pb is defined as R1 (mm), the golf club head 2 satisfies the following formulae (1) and (2):R1>T1 (1)0.10≦T1≦0.5 (2)Preferably, a ratio (R1 / T1) is greater than 1.0 and is equal to or less than 3.0.

Owner:SUMITOMO RUBBER IND LTD

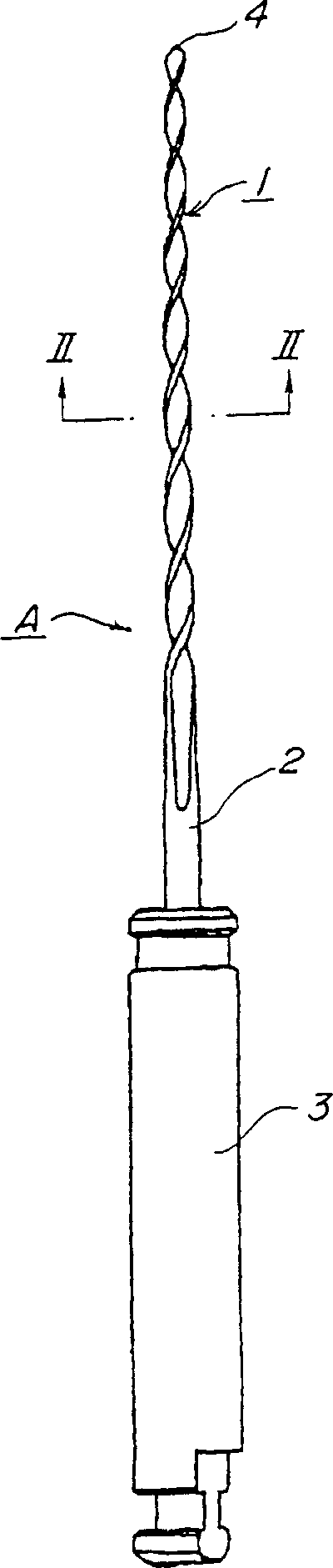

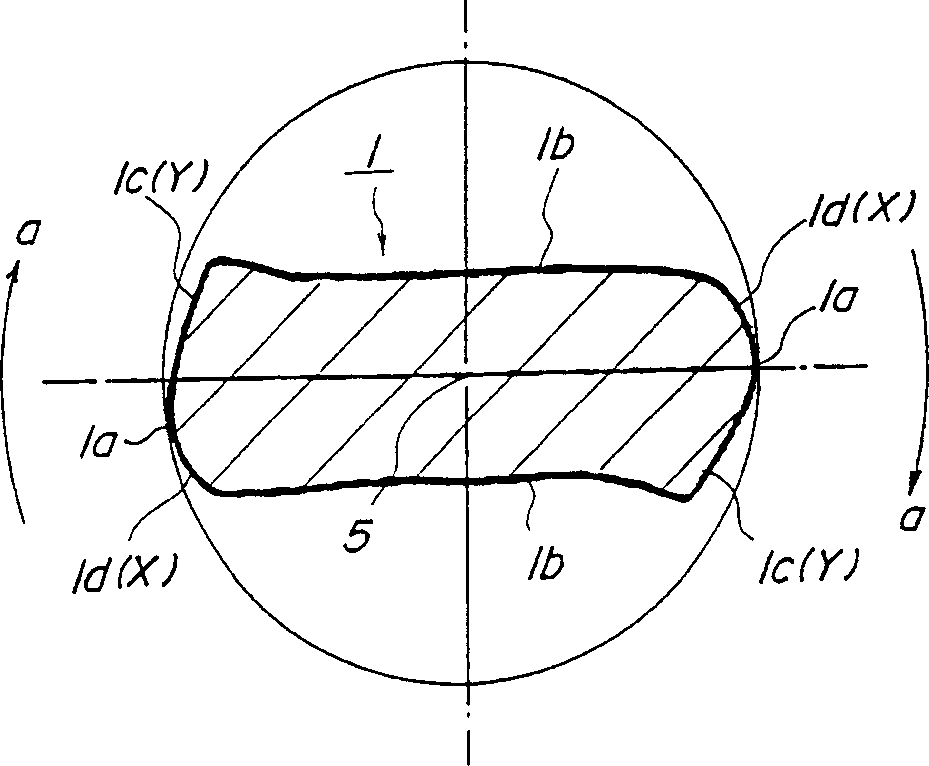

Dental tooth drill

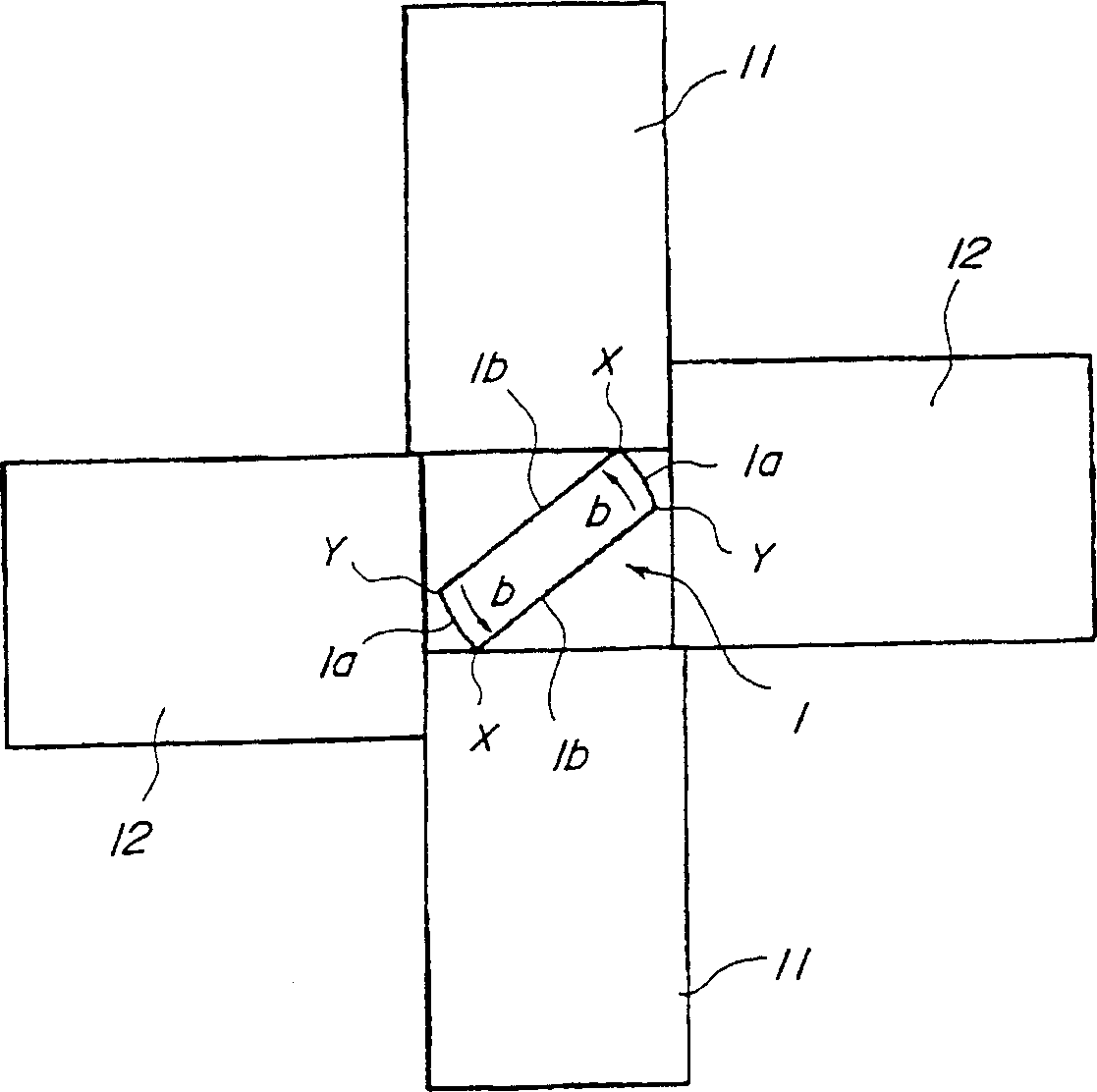

A dental drill (A) grinds a tapered rod with two opposite lines (1b), thereby forming a rod with two arcs (1a) and a center (5). This rod is inserted into a forming space formed by a pair of pressing clamps (11) and a supporting clamp (12) and then twisted, thereby forming a spiral working part. During this twisting process, a cutting part (1c) and a backlash part (1d) are formed at both ends of the working part (1). During dental treatment for forming root canals, the dental drill of the present invention can prevent the intrusion and deviation of the root canal wall even if it is installed on a handle and driven by an engine.

Owner:MATSUTANI SEISAKUSHO CO LTD

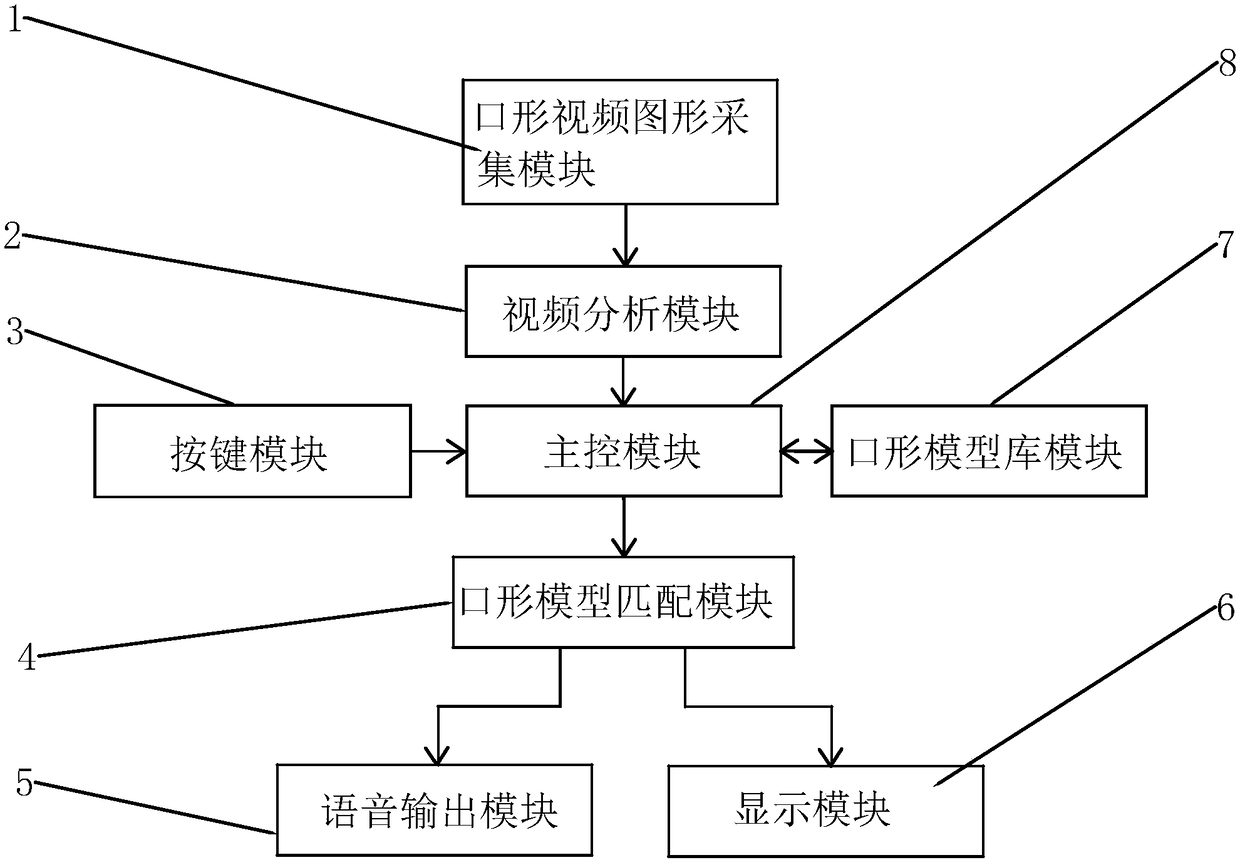

Mouth shape image recognition system based on machine learning and method of identifying sound production through face line

InactiveCN108446641AQuickly handle conversionsAdapt to the habit of expressingCharacter and pattern recognitionSpeech recognitionInformation processingMouth shape

The invention discloses a mouth shape image recognition system based on machine learning. The mouth shape image recognition system based on machine learning comprises a mouth shape video image acquisition module, a video analysis module, a main control module, a mouth shape model matching module and a voice output module. The mouth shape video image acquisition module, the video analysis module, the main control module, the mouth shape model matching module and the voice output module are electrically connected in sequence. The system further comprises a mouth shape model library module, whichis electrically connected with the main control module. The mouth shape video image acquisition module acquires a lip video image of a target person through a front camera arranged in the image acquisition module. The invention also provides a method of identifying sound production through face lines. According to the invention, lip language is converted into image information through the camera,and information processing and conversion can be rapidly carried out. The system has a deep learning function, can be gradually adapted to expression habits of a user, and has certain real-time performance and practicability.

Owner:SHENZHEN DBK ELECTRONICS

Cosmetic mask

InactiveCN104080364AModerate scalabilityGood application feelingHead bandagesPackaging toiletriesElastomerSkin tightening

The purpose of the invention is to provide a cosmetic mask that adheres closely to the skin and has excellent skin-tightening effects and sagging cheek- and face line-lifting effects. The invention is a cosmetic mask, which is configured from a laminate obtained by integrally laminating a non-elastomer fiber layer with an elastomer layer and which expands and contracts in the vertical direction of the face.

Owner:JNC CORP +1

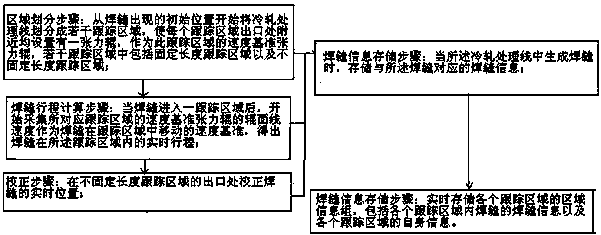

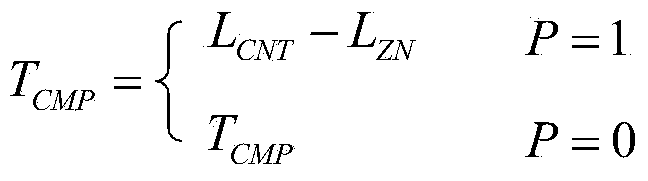

Cold rolling processing line welding seam tracking method

InactiveCN103753071ATracking results are accurateAccurate seam tracking resultsWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention relates to a cold rolling processing line welding seam tracking method which is applied in a cold rolling processing line. According to the welding seam tracking method, welding seam tracking is conducted in a subarea mode, so that the welding seam tracking is made to be more accurate. The method comprises the steps that the cold rolling processing line is divided into a plurality of tracking areas, a tension roller is arranged in an outlet of each tracking area and is used as a speed standard tension roller of the corresponding tracking area, and the tracking areas comprise fixed-length tracking areas and non-fixed-length tracking areas; when a welding seam is generated in the cold rolling processing line, welding information corresponding to the welding seam is generated, and the welding seam information of the welding seam is stored in real time; when the welding seam enters one tracking area, collection of the roller face line speed of the speed standard tension roller of the corresponding tracking area is started, the roller face line speed is used as the moving speed standard of the welding seam in the tracking area, and the real-time stroke of the welding seam in the corresponding tracking area is obtained; the real-time position of the welding seam is rectified in the outlets of the non-fixed-length tracking areas; area information groups of all the tracking areas are stored in real time.

Owner:上海宝菱电气控制设备有限公司

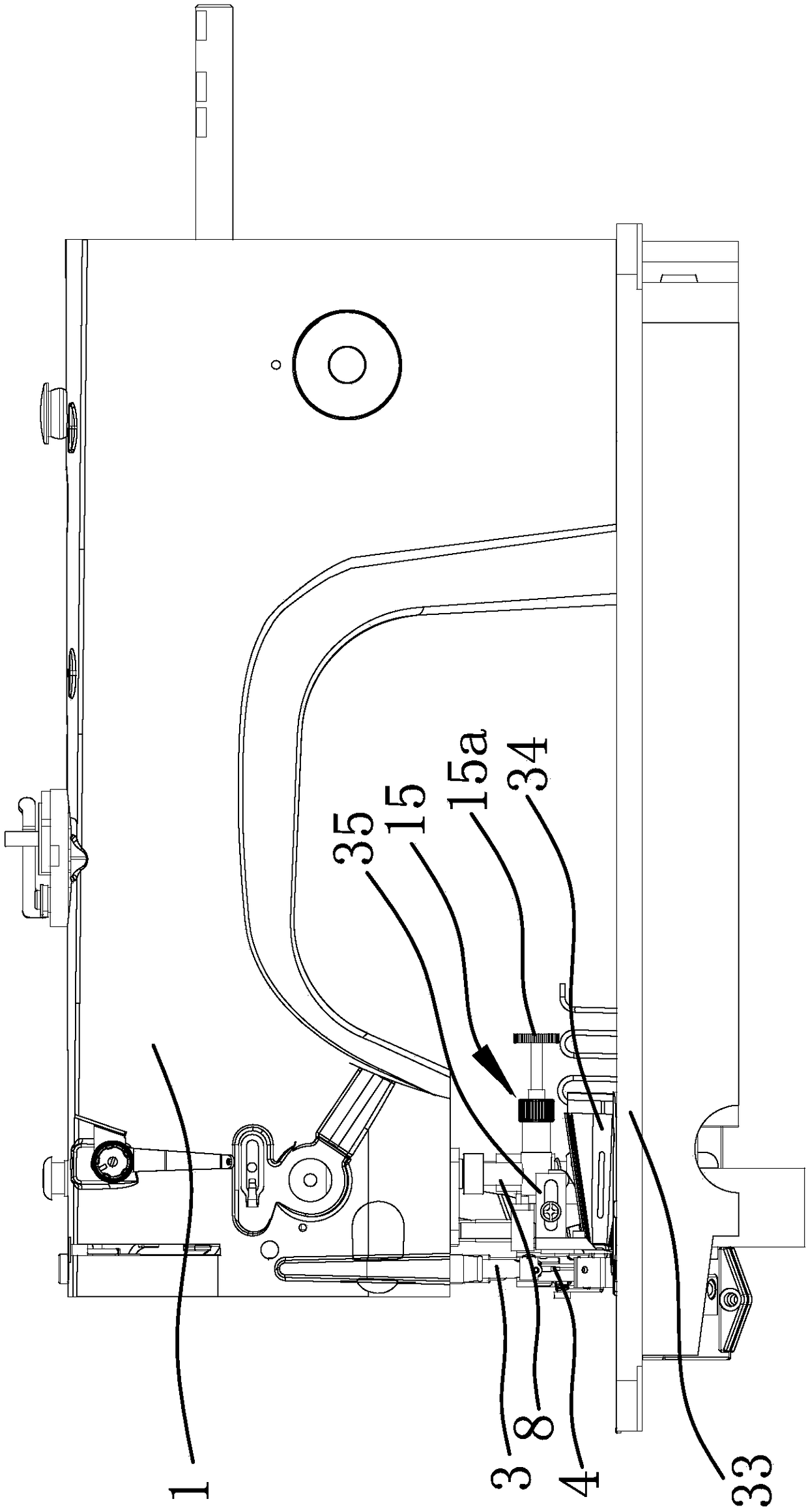

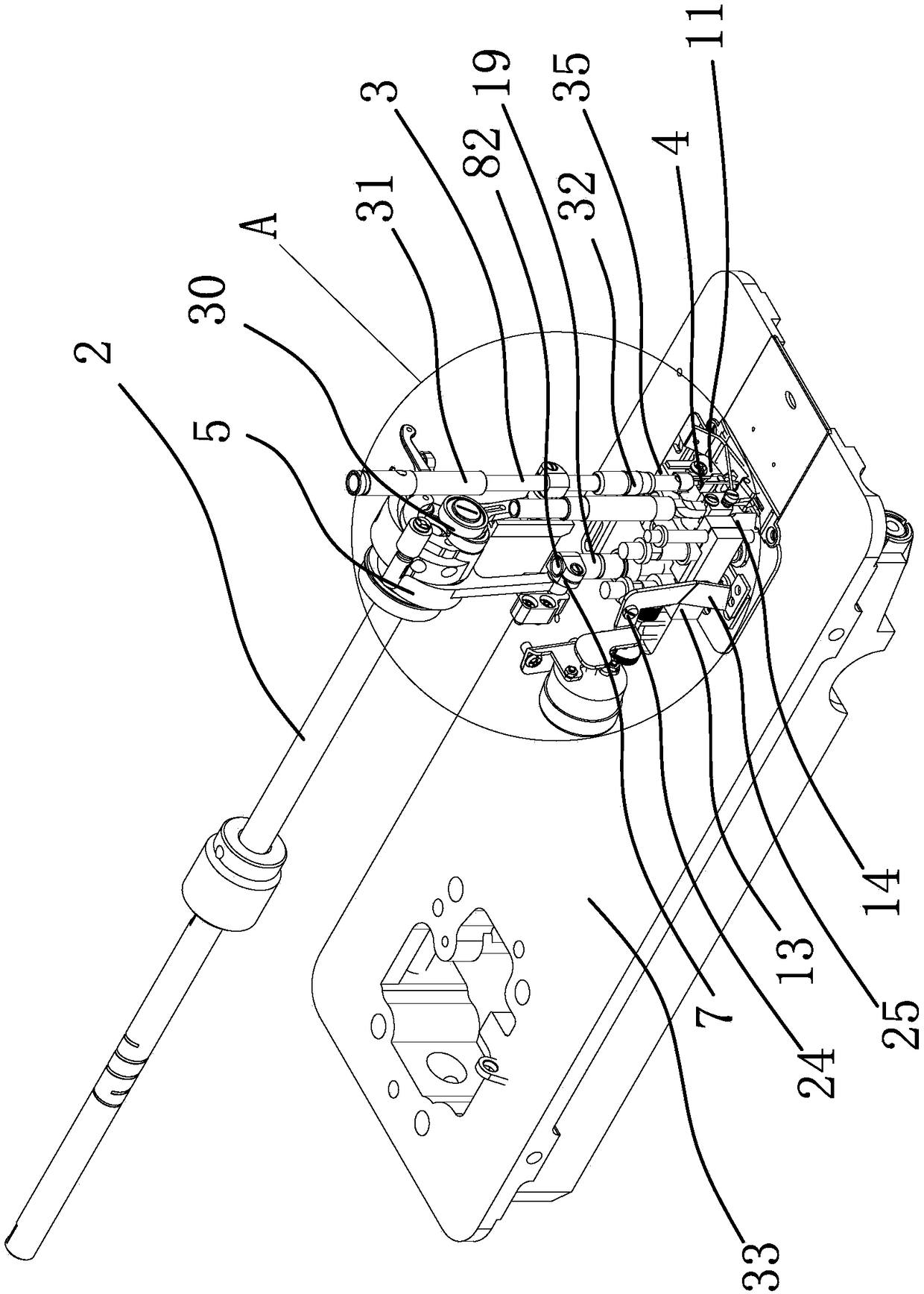

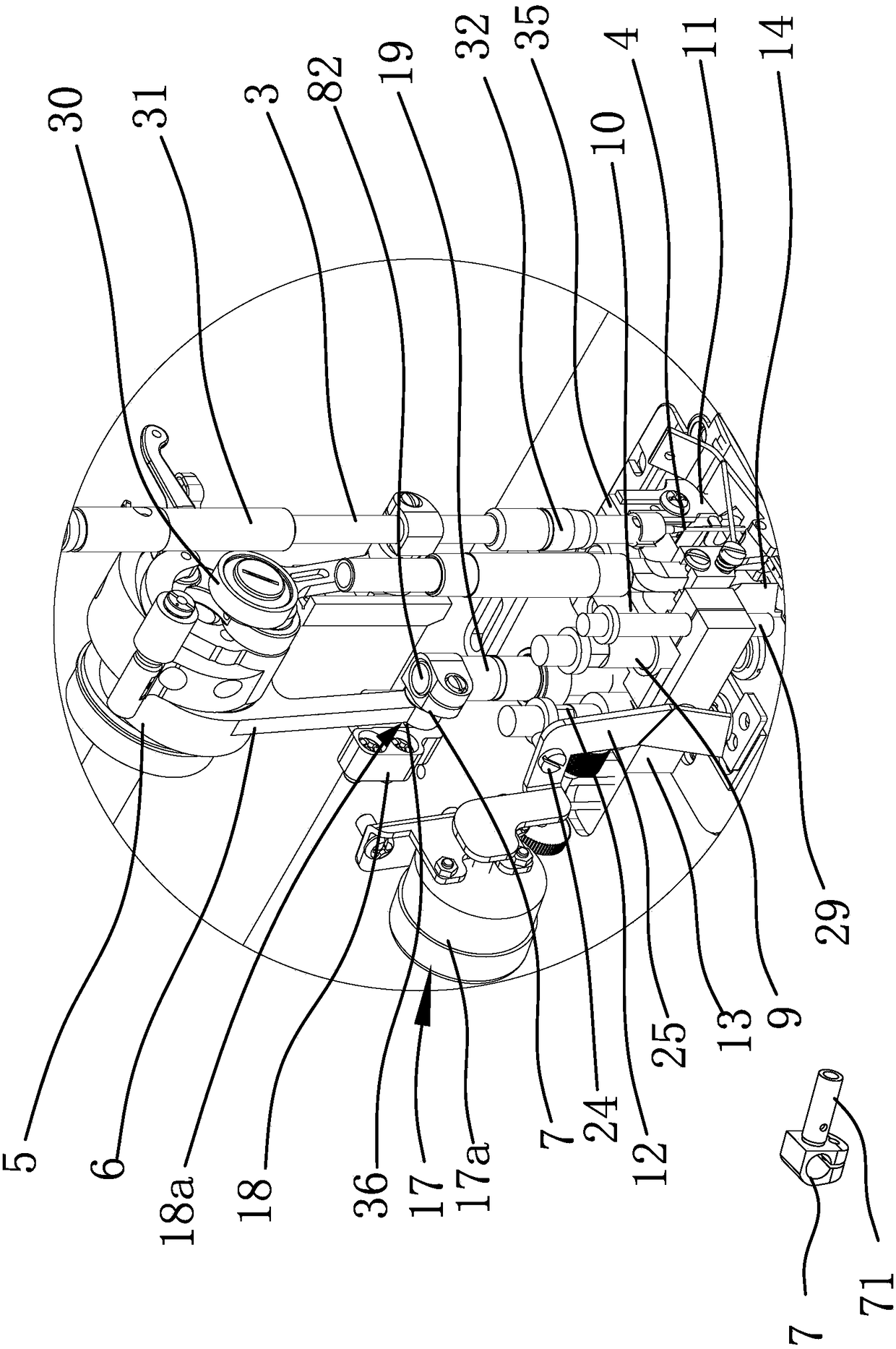

Over-edging sewing machine automatically cutting fabric and cutting over-edging strip

InactiveCN108060512AImprove sewing efficiencyEasy to controlWorkpiece carriersWork-feeding meansReciprocating motionEngineering

The invention provides an over-edging sewing machine automatically cutting fabric and cutting a over-edging strip, and belongs to the technical field of sewing equipment manufacturing. The over-edgingsewing machine solves the technical problem that an existing over-edging sewing machine is monotonous in function, low in efficiency and the like. The over-edging sewing machine comprises a machine shell, a main shaft and a needle rod capable of reciprocating vertically, a clutch support is connected to the main shaft through a connecting rod, and the main shaft can drive the clutch support to reciprocate vertically; the machine shell is provided with a cutter base and a lifting base, wherein the cutter base and the lifting base can move vertically, a fabric cutter is fixedly connected to thecutter base through a cutter mounting frame, and a cutter is fixedly connected to the lifting base; the cutter base is further provided with a locking rod capable of making the clutch support connected with the cutter base; the lifting base is provided with a movable pin capable of being inserted into the cutter base, and the machine shell is provided with a driving part driving the movable pin to move. By means of the over-edging sewing machine, a power source of the over-edging sewing machine itself can be adopted to automatically cut fabric edges, the over-edging strip and a bottom face line, and the efficiency is high.

Owner:叶国宝

Cosmetic kit

The present invention provides a cosmetic kit and a cosmetic solution that is capable of lifting up the face line without requiring a dedicated makeup material that matches the material such as nonwoven fabric or sheet. The present invention is a cosmetic kit, which is a set consisting of a cosmetic solution and a cosmetic sheet affixed on skin to which makeup has been applied for pulling up sagging of skin while stretching wrinkles simultaneously to make the sagging and wrinkles inconspicuous. The cosmetic sheet has a nanofiber sheet consisting of a nanofiber, which is spun by electrospinning on a support and has a fiber diameter of 80-800 nanometers, and a weight per unit area of the nanofiber sheet is 0.2-2.0g / m2. The cosmetic solution for affixing the nanofiber sheet on top of makeup comprises 1-10% by weight ofmicroparticles with a mean particle diameter equal to or greater than 0.2 microns and equal to or less than 10 microns and 0.1-10% by weight of a water-soluble polymeric thickening agent.

Owner:KIKOH

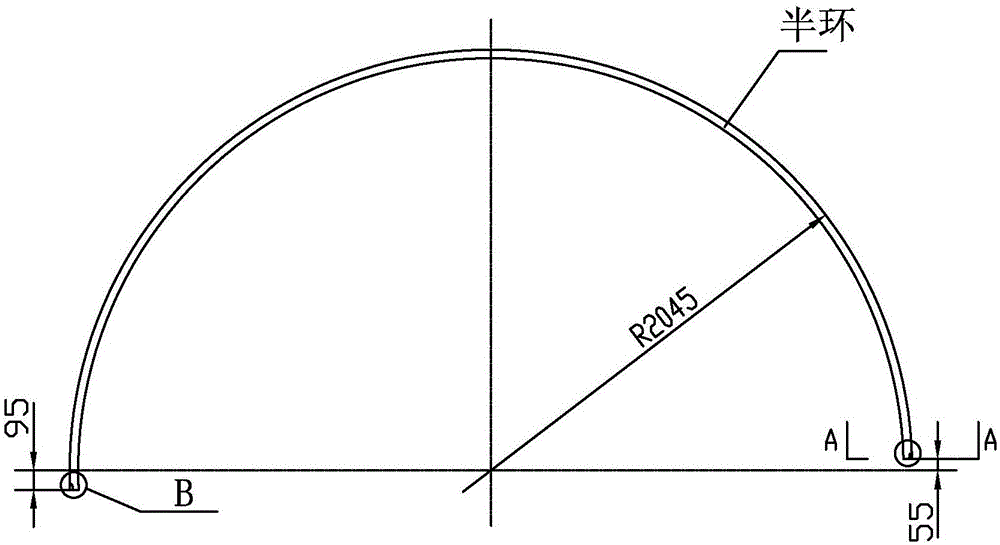

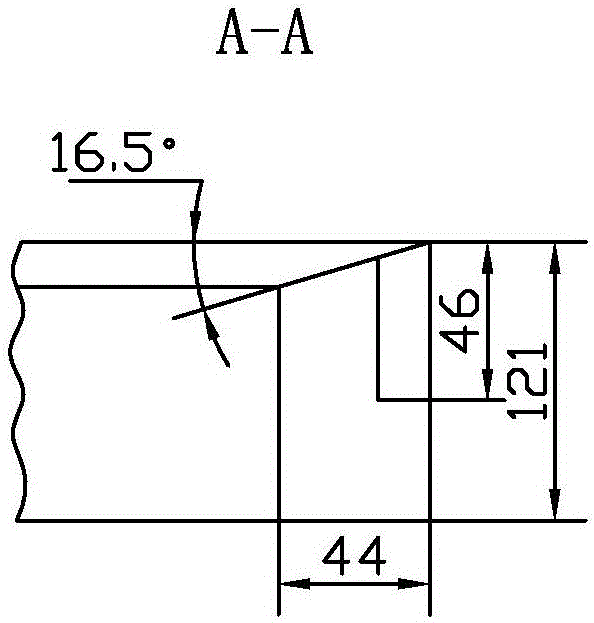

Nuclear power semi-ring machining method

The invention belongs to the field of machining and relates to a machining method, in particular to a nuclear power semi-ring machining method. The problems that according to an existing technological scheme, the machining precision of a nuclear power semi-ring cannot be guaranteed, the working difficulty is increased for subsequent welding, and the welding quality is lowered are solved. The machining method specifically comprises the steps that firstly, a semi-ring blank is formed through casting; secondly, the surface of the semi-ring is turned by 121 mm on a vertical lathe, and the two planes are turned to 122 mm; thirdly, an inner hole, the outer circle line and two end face lines are marked on the semi-ring, and a line is marked in the position 55 mm away from the right side according to the dimension of 95 mm; fourthly, the two end faces of the semi-ring are milled on a boring mill, and the two end faces of the semi-ring are machined according to the dimension of 95mm; fifthly, the standard inner hole of the semi-ring is turned on the vertical lathe, and the volume of the outer circle is 3-5 mm; sixthly, tie bars are welded to the semi-ring in a matched mode by a bench worker; and seventhly, the tie bars are welded through electric welding.

Owner:HARBIN TURBINE

Electrode sheet for capacitance-type touch panel

A first electrode pattern 25a and a second electrode pattern 25b, each composed of an opaque conductive fine line and a blank part 17 partitioned by the conductive fine line, have line segments 16a of the conductive fine lines 16, that face each other across a substrate 12, and the conductive fine line 16 in one of the first electrode pattern 25a and the second electrode pattern 25b is formed narrower in line width than that in the other of the first electrode pattern 25a and the second electrode pattern 25b only at the facing line segment 16a, thereby designed to have a non-uniform width.

Owner:NISSHA PRINTING COMPANY

Combined wood-face steel-core anti-theft door frame and mounting method

InactiveCN101025069AFirmly connectedGood pry resistanceBurglary protectionFrame fasteningEngineeringFace lines

The invention relates to a combined wooden-face and steel-core doorframe structure and the installing method thereof, characterized in that: its main doorframe is composed of steel reference frame and wooden reference frame, where one end of the steel reference frame is equipped with a second locating groove but the other end not equipped with any locating groove and the first locating groove is arranged on the wooden reference frame. And the installing method: firstly connecting the steel reference frame with the wooden reference frame to form a main doorframe; then prefixing the main doorframe in door holes and fixing the main doorframe on wall by foamed adhesive and expansion bolt; then socketing an auxiliary doorframe with the main doorframe; installing face lines and finishing the installing operation.

Owner:刁宏伟

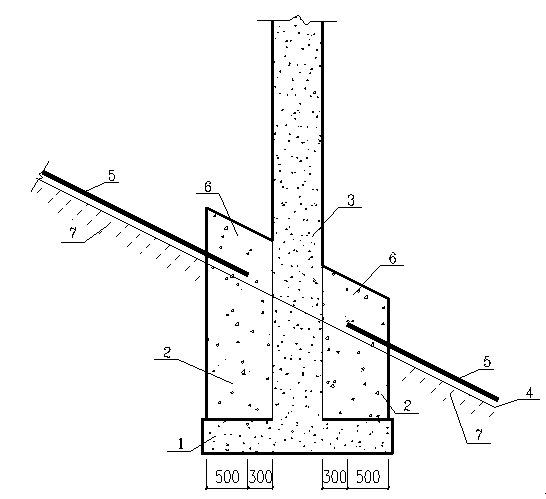

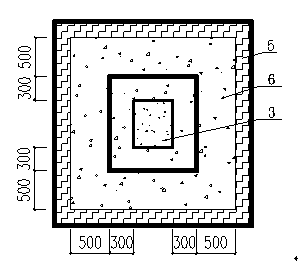

Connecting structure of red mud storage yard anti-seepage film and concrete column and construction method

ActiveCN103669419AEasy to operateReduce environmental problemsProtective foundationAlkaline waterRed mud

The invention discloses a connecting structure of a red mud storage yard anti-seepage film and a concrete column and a construction method. According to the connecting structure, a film pressing platform (2) is arranged above a column base (1) and below a field level line (4) of a storage yard foundation (7), an upper end face line of the film pressing platform (2) is consistent with the field level line (4), a micro-expansion concrete layer (6) is arranged on the upper end face of the film pressing platform (2), the film pressing platform (2) and the micro-expansion concrete layer (6) respectively surround the column (3) from bottom to top, and the anti-seepage film (5) is laid above the field level line (4) and extends into the poured micro-expansion concrete layer (6) to form an integral anti-seepage body. According to the connecting structure, the anti-seepage film and the concrete column can be effectively connected to form the stable anti-seepage body, potential danger can be eliminated, alkaline water is prevented from permeating into the foundation along the periphery of the column, the alkaline water pollution possibility is reduced, and the anti-seepage effect of a storage yard is improved. The structure and the construction method are economical, practical and convenient to operate.

Owner:GUIYANG AL-MG DESIGN & RES INST

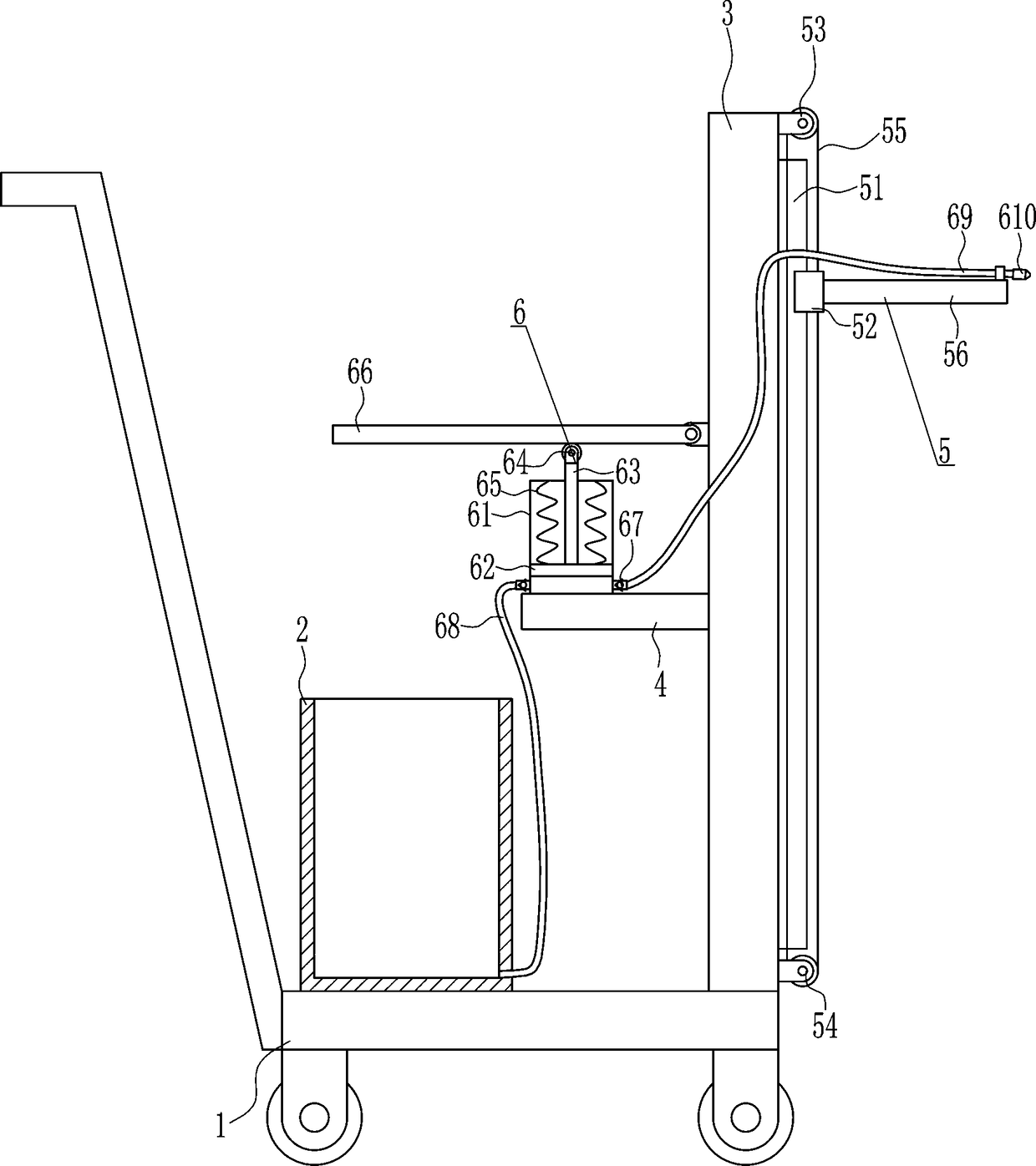

Wall face line drawer for tunnel construction

InactiveCN108114832ADry fastImprove the mixing effectPretreated surfacesLiquid spraying apparatusEngineeringTunnel wall

The invention relates to a line drawer, and particularly relates to a wall face line drawer for tunnel construction. The technical problem to be solved is to provide a wall face line drawer for the tunnel construction, which has high efficiency and is straight. In order to solve the technical scheme, the wall face line drawer for tunnel construction comprises a push cart and others; the left sideof the top part of the push cart plate is connected with a holding frame, the right side at the top part of the push cart plate is connected with a supporting plate; the middle of the left side of thesupporting plate is connected with a cross plate, the right side of the supporting plate is provided with a height adjusting device; the top part of the cross plate is provided with a spraying device. Through a height adjusting device, the line drawing height can be adjusted; the spraying device drives pigment solution and sprays it to the tunnel wall face; a stirring device stirs the pigment solution to prevent settlement; a blowing device accelerates the pigment drying speed on the tunnel wall face; thus the wall face line drawer is high in efficiency and straight.

Owner:刘占明

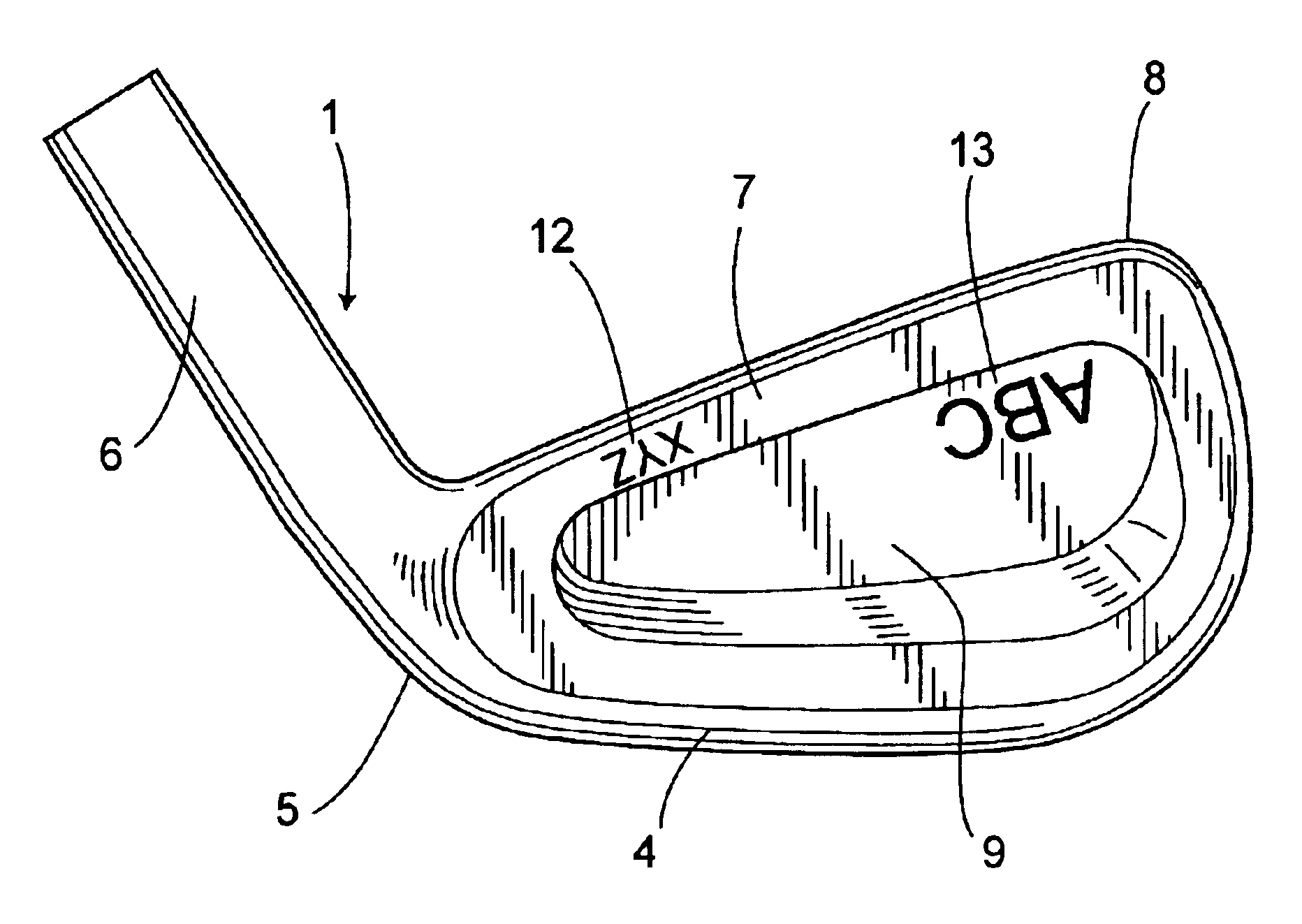

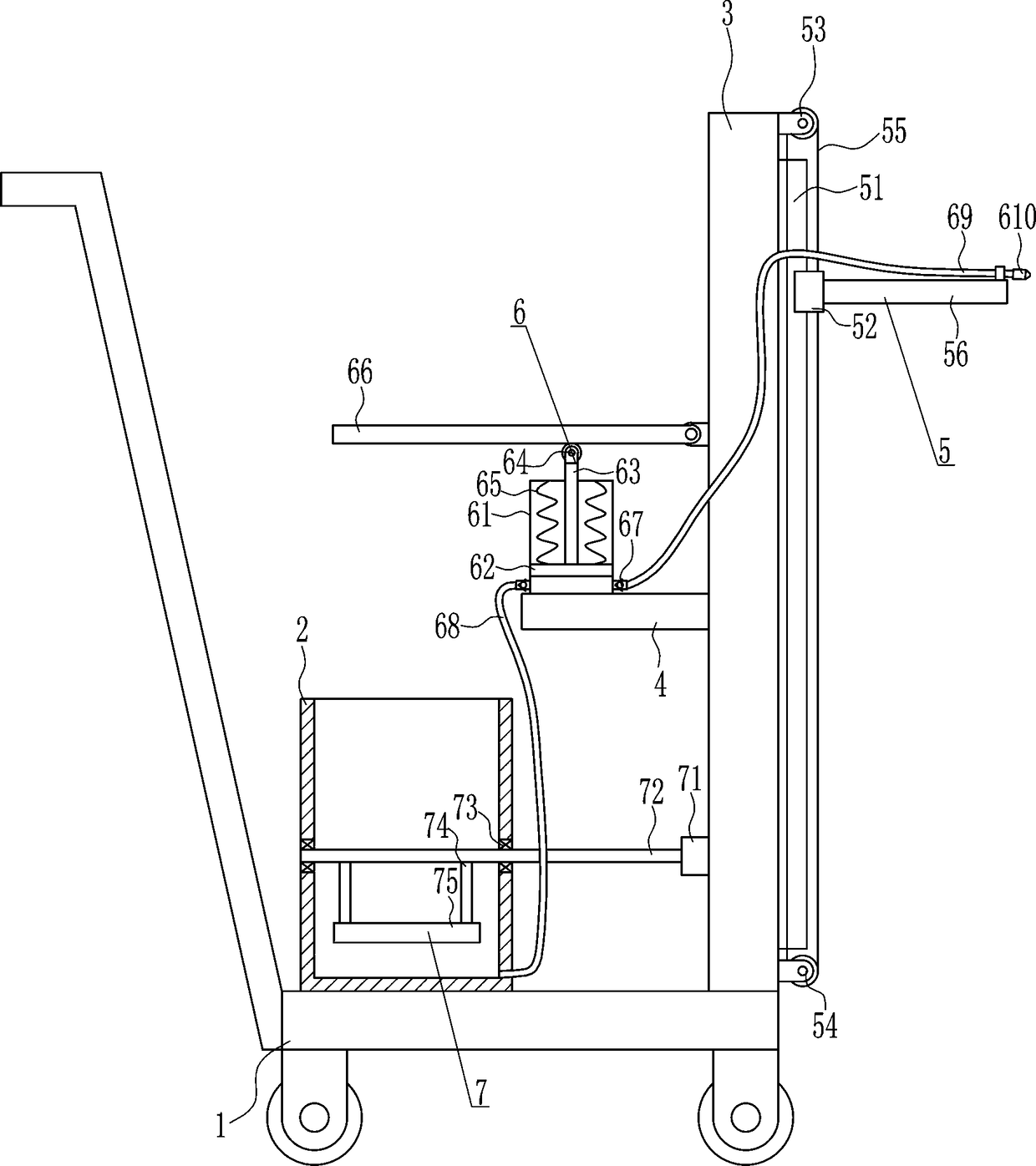

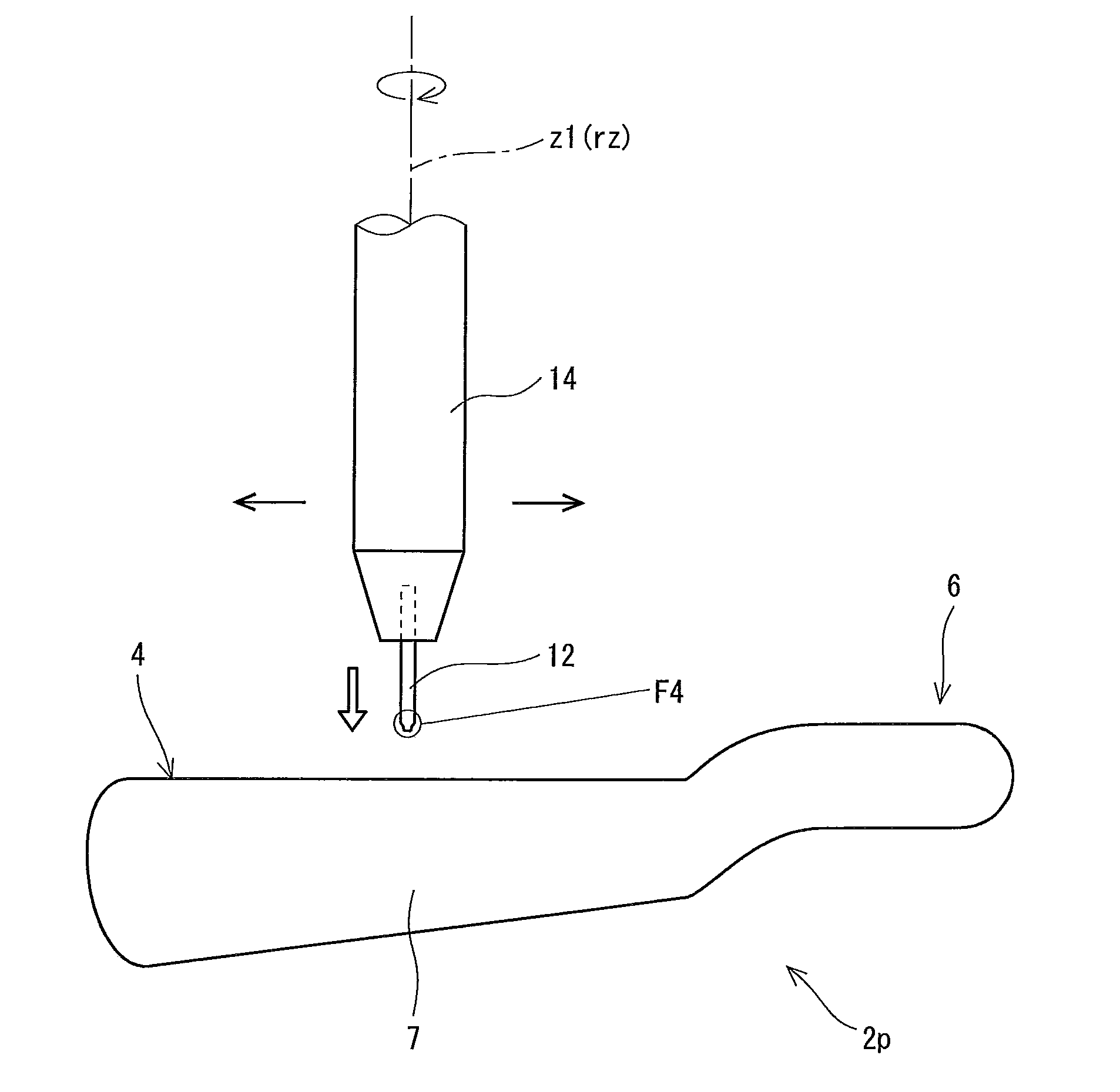

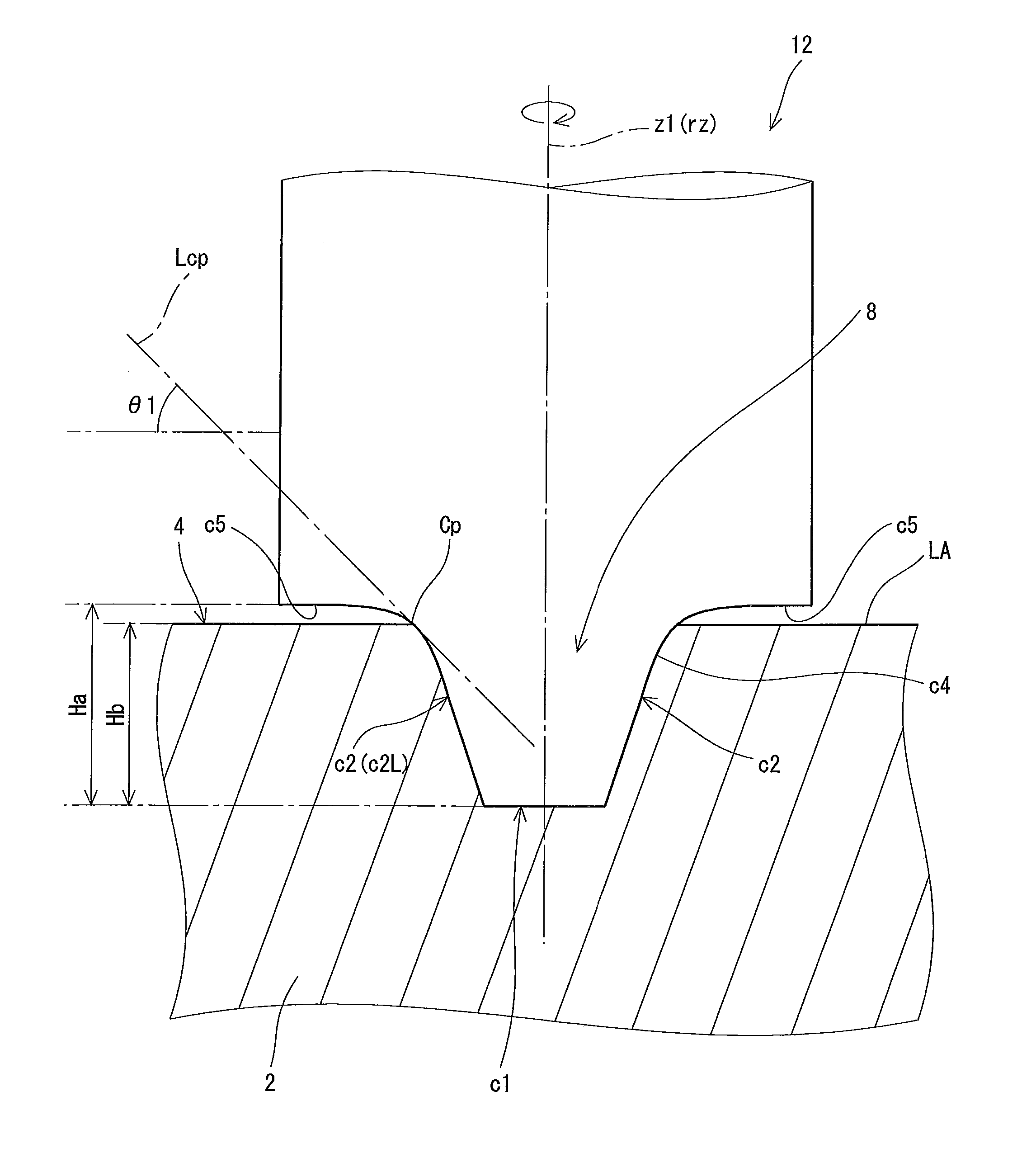

Manufacturing method of golf club head

A manufacturing method of the present invention includes the steps of: preparing a pre-line forming member having no face line; and cutting the pre-line forming member using a cutter 12 to form the face line on the pre-line forming member. The cutter 8 has a tip part having a cutting surface. The cutting surface has a recessed curved surface c4. An edge of the face line 8 is cut by the recessed curved surface c4. Preferably, the step of cutting is carried out by axial rotation of the cutter 8. Preferably, the cutting surface has a plane part c5 formed on an upper side of the recessed curved surface c4. Preferably, the upper side plane part c5 is perpendicular to a rotation axis rz of the cutter 12. Preferably, the cutting surface has a conical surface Fc formed on a lower side of the recessed curved surface c4.

Owner:SUMITOMO RUBBER IND LTD

Manufacturing method of golf club head

A manufacturing method of the present invention includes the steps of: preparing a pre-line forming member having no face line; and cutting the pre-line forming member using a cutter 12 to form the face line on the pre-line forming member. The cutter 8 has a tip part having a cutting surface. The cutting surface has a recessed curved surface c4. An edge of the face line 8 is cut by the recessed curved surface c4. Preferably, the step of cutting is carried out by axial rotation of the cutter 8. Preferably, the cutting surface has a plane part c5 formed on an upper side of the recessed curved surface c4. Preferably, the upper side plane part c5 is perpendicular to a rotation axis rz of the cutter 12. Preferably, the cutting surface has a conical surface Fc formed on a lower side of the recessed curved surface c4.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com