Cold rolling processing line welding seam tracking method

A technology for processing lines and tracking areas, applied in the field of welding seam tracking, which can solve problems such as confusion in welding seam tracking, and achieve the effect of precise control and accurate welding seam tracking results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

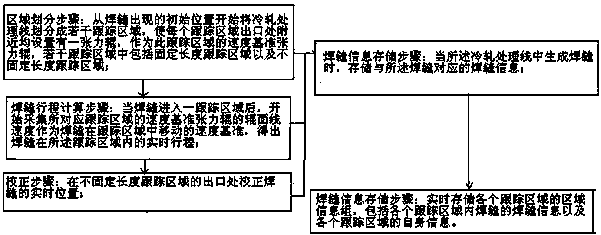

[0022] attached figure 1 It is a flow chart of a method for tracking a weld seam of a cold rolling processing line provided by the present invention. A method for tracking a weld seam of a cold rolling processing line provided by the present invention includes the following steps:

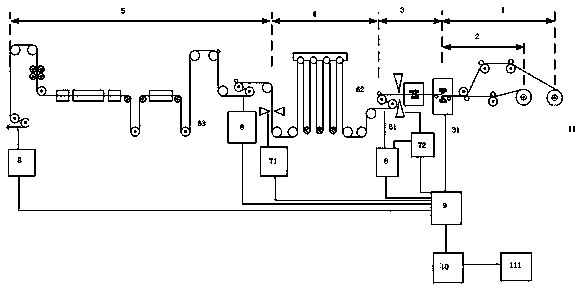

[0023] Area division step: divide the cold rolling treatment line into several tracking areas from the initial position where the weld seam appears, so that a tension roller is arranged near the exit of several tracking areas, as the speed reference tension roll of this tracking area, in several tracking areas Includes fixed-length tracking regions and variable-length tracking regions.

[0024] Such as figure 1 As shown in , taking the unit from the uncoiler to the tension roll as an example, the cold strip production line is divided into the first area 1, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com