Patents

Literature

292results about How to "Reduce stress deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optimized design method of overall static rigidity of machine

InactiveCN104156501AIncrease the static stiffness value at the end of the machineReduce stress deformationSpecial data processing applicationsReduced modelElement model

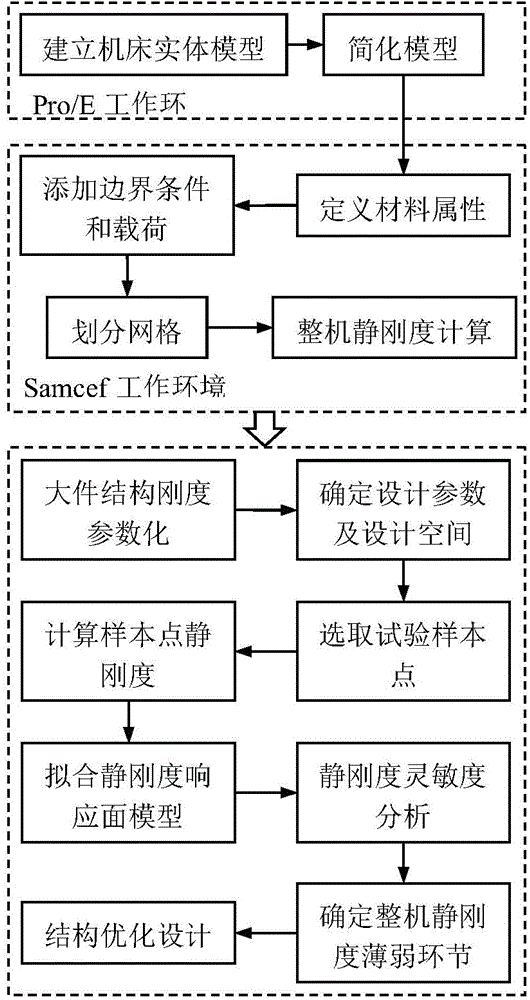

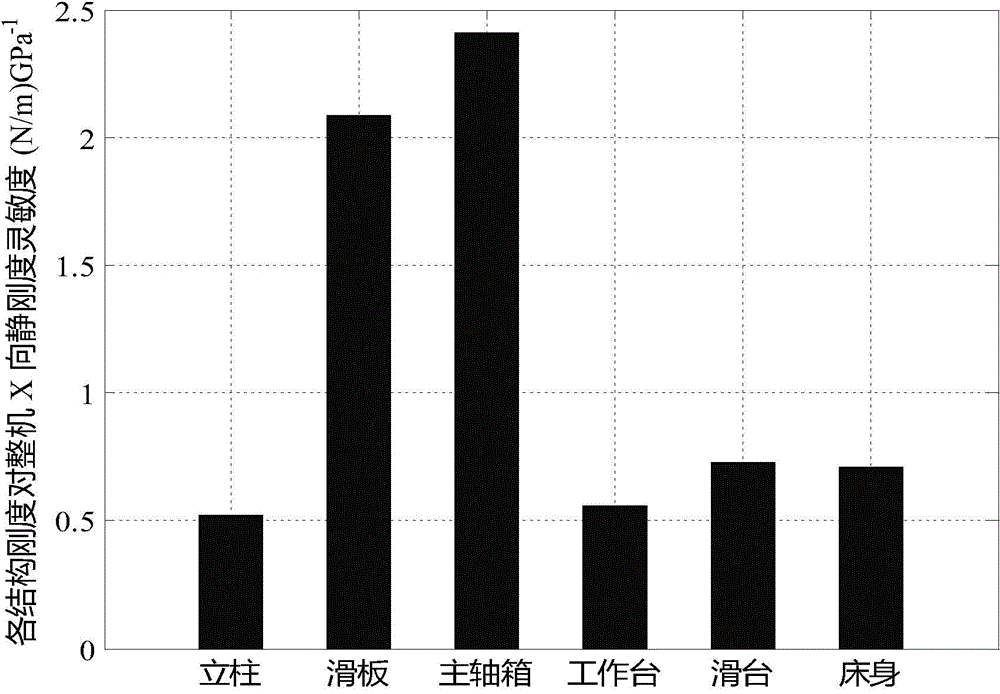

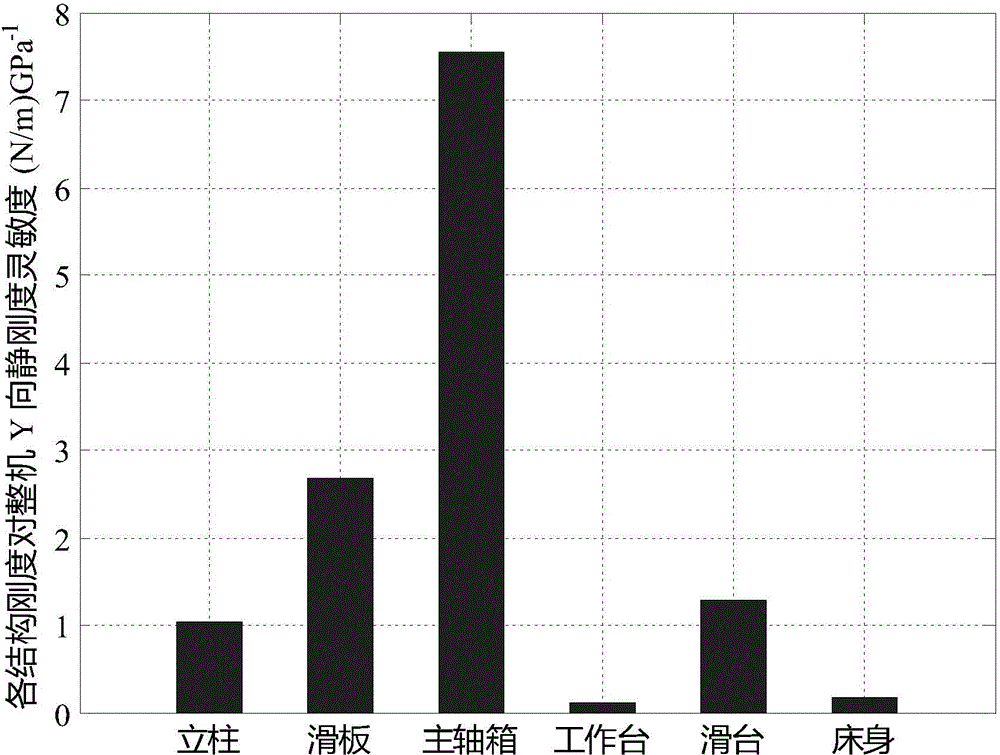

The invention discloses an optimized design method of overall static rigidity of a machine. The method includes the steps of establishing a simple machine model by Pro / E software; importing the simple machine model into SAMCEF software to establish a machine finite element model; parameterizing rigidity features of large structures of the machine to determine design parameters and a design space; selecting test sample points for finite element analysis by a central composite experiment design method; subjecting the test sample points to finite element analysis to obtain machine static rigidity response values of the test sample points; establishing a response surface model for large structure rigidity feature parameters and machine static rigidity; analyzing sensitivities of large structure rigidities to the machine static rigidity so as to determine a static rigidity weak link, and performing optimized design. The optimized design method of overall static rigidity of the machine has the advantages that the sensitivities of the structures of the machine to the machine static rigidity are effectively determined, the weak link restricting the improvement of the machine static rigidity is effectively found, and accordingly important basis for the optimized design of machine structure is provided to guide designers to optimally design the weak large structures of the machine.

Owner:TIANJIN UNIV

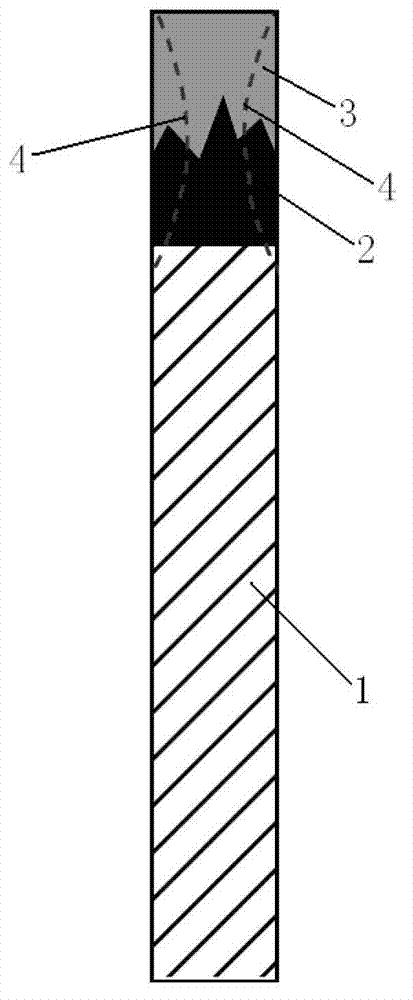

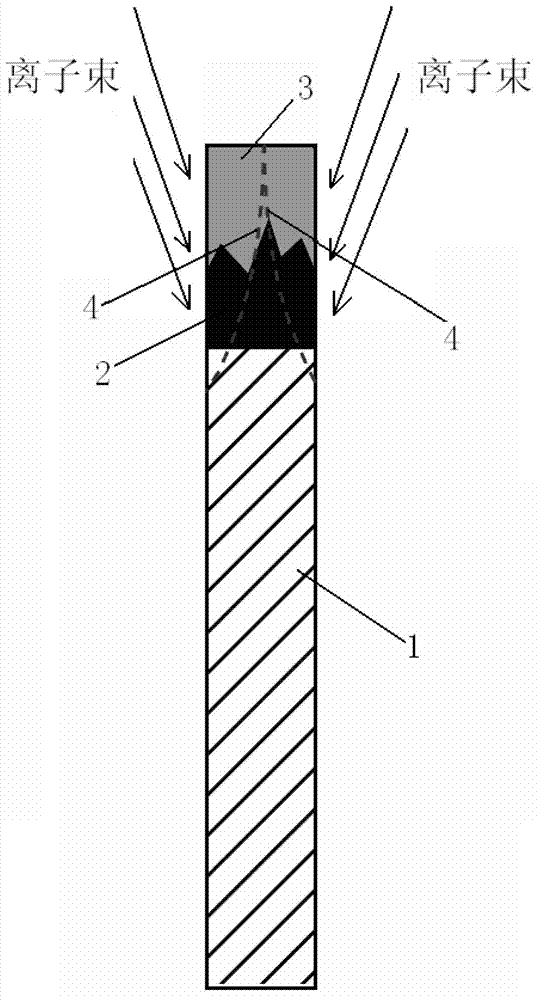

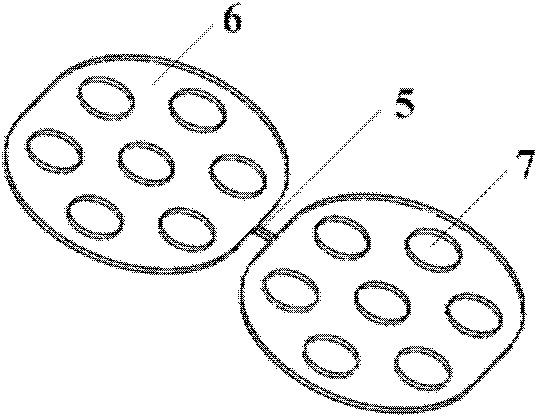

Preparation method of a sample with rust layer for in-situ observation of transmission electron microscope

InactiveCN103196720AEasy to observe in situUnderstanding the Corrosion ProcessPreparing sample for investigationMaterial analysis by measuring secondary emissionConventional transmission electron microscopeCopper

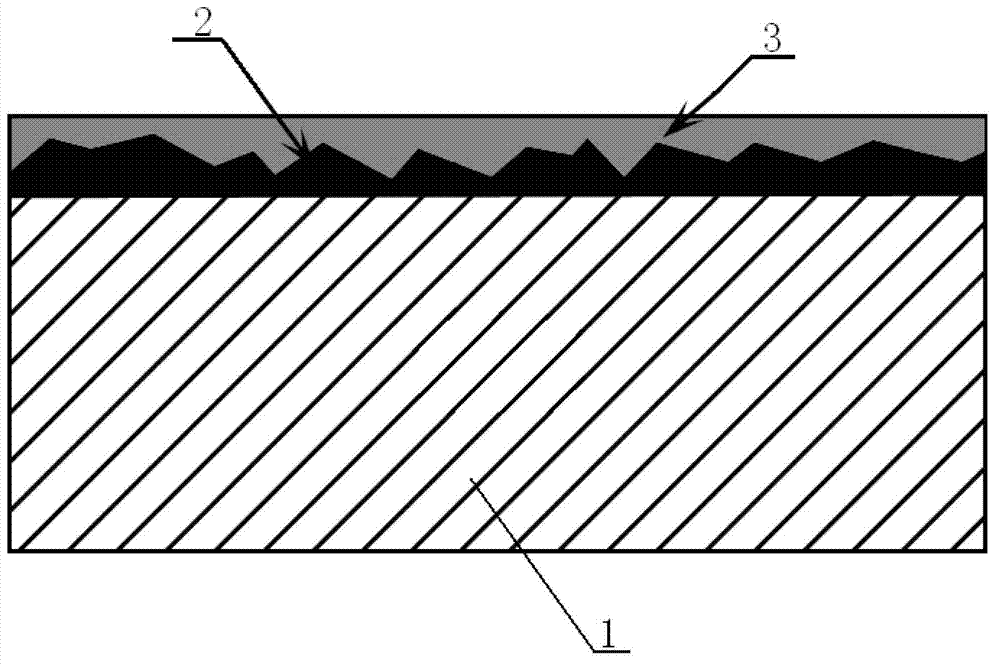

The invention discloses a preparation method of a sample with a rust layer for in-situ observation of a transmission electron microscope. The method comprises the following steps of: (1), integrally packaging an obtained sample with a rust layer by a cold embedding method; 2), cutting the sample according to the sample size facilitating observation of the transmission electron microscope; 3), thinning the sample primarily; 4), forming a thin sample area which can be observed by the transmission electron microscope; and 5), bonding the prepared sample to a phi3mm round copper mesh, so as to obtain the sample with the rust layer for the in-situ observation of the transmission electron microscope. By adopting the preparation method, the initial shape of the rust layer is remained completely, and the method is very suitable for preparing of the sample with the rust layer for observation of the transmission electron microscope; and the prepared sample is representative, can truly indicate the whole characteristics of the analyzed material, and has great significant in the corrosion resistance research of steel and iron materials.

Owner:武汉钢铁有限公司

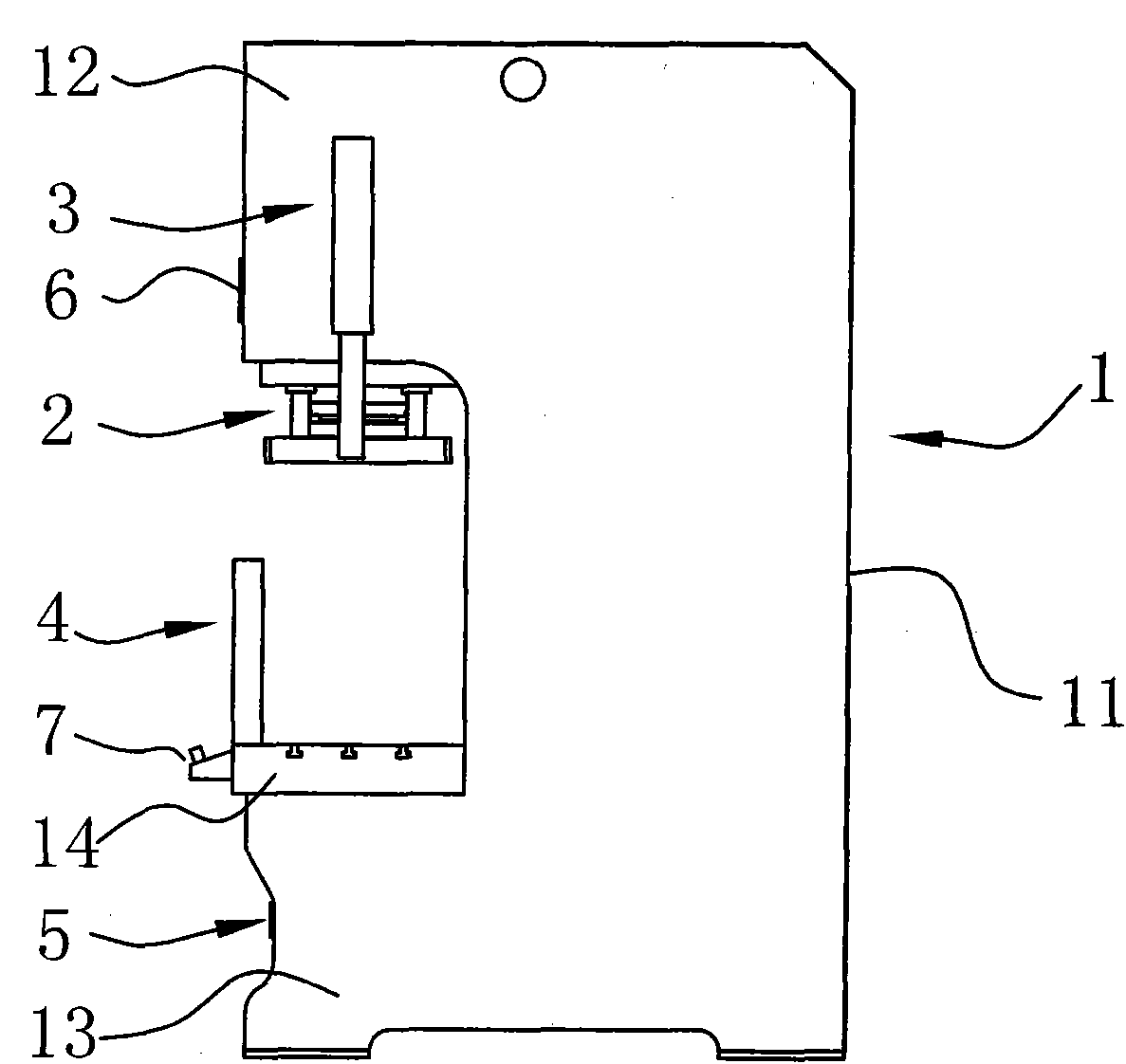

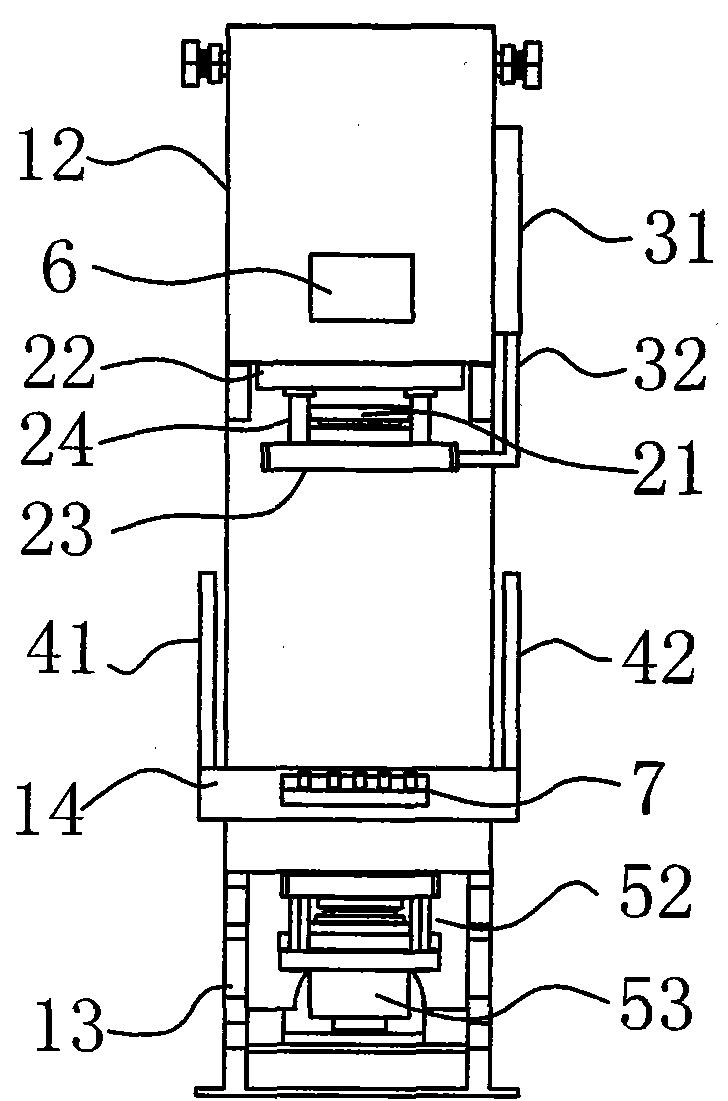

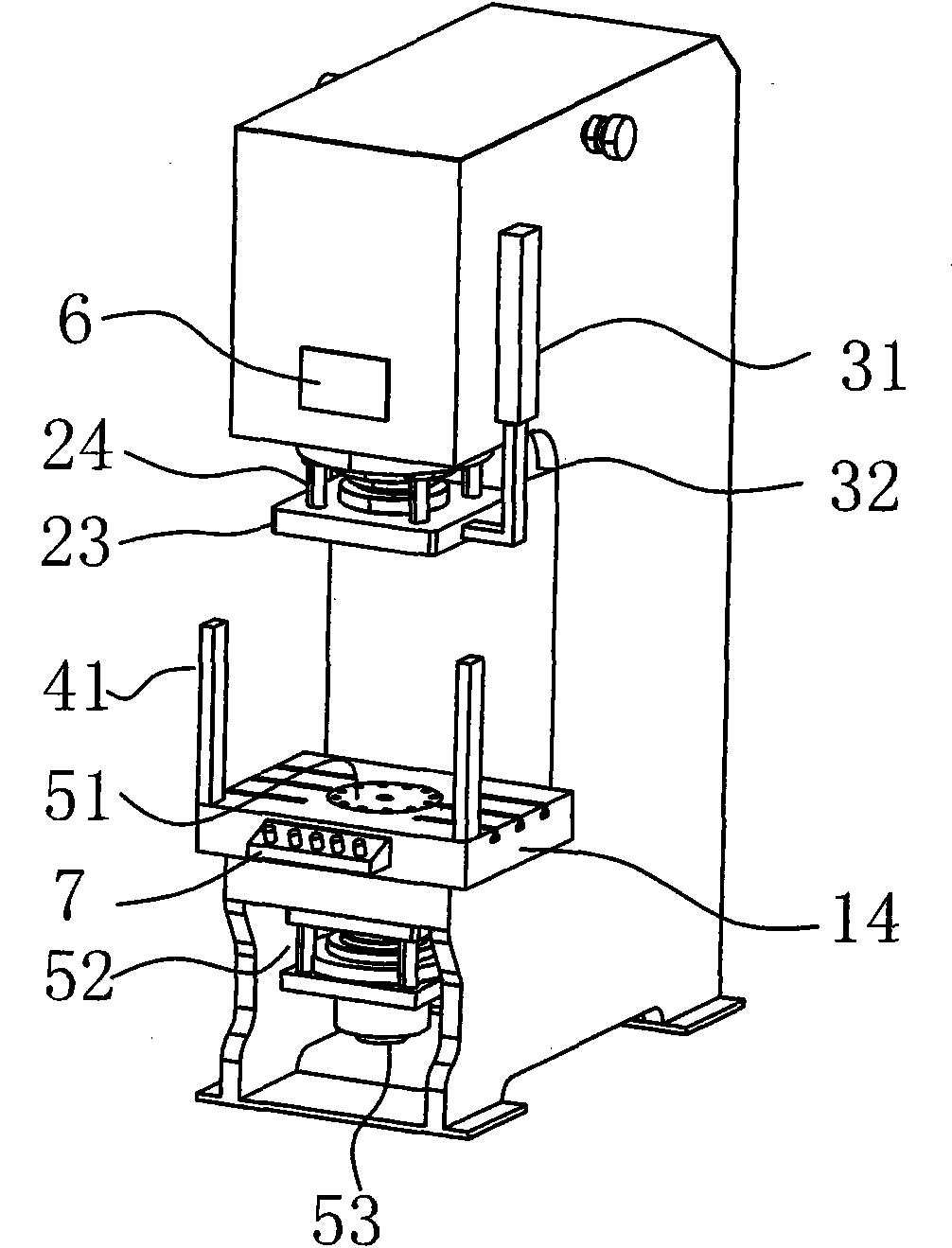

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578AImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

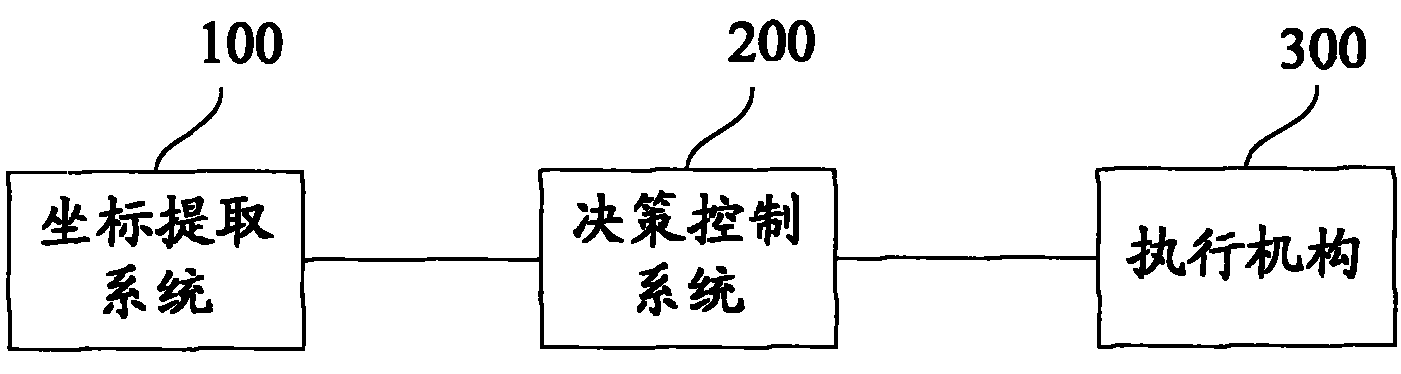

Flexible tool equipment intelligent control system of aircraft

InactiveCN101804867ASimple mechanical structureReduce the burden onAircraft assemblyNumerical controlDecision controlMovement control

The invention provides a flexible tool equipment intelligent control system of an aircraft, which comprises a coordinate extracting system, a decision control system and an executing mechanism, wherein the coordinate extracting system is used for carrying out curve digital modeling on a workpiece to be processed, extracting the support point coordinate information of the workpiecce and generatingand transmitting a workpiece coordinate information file to the decision control system; and the decision control system is used for planning and deciding the action of the executing mechanism according to the workpiece coordinate information file and generating and transmitting a corresponding control command to the executing mechanism. The invention provides a flexible tool equipment intelligent control system for realizing clamping and positioning in the processing of a large curve thin wall part of an aircraft, carries out calculation and control by adopting a high-performance industrial control computer as a core and realizes the synergy movement control on double robots by an intelligent control main board and the reasonable and uniform distribution of all support units on a flexible tool equipment machine tool by the moving operation on all the support units on the flexible tool equipment.

Owner:TSINGHUA UNIV

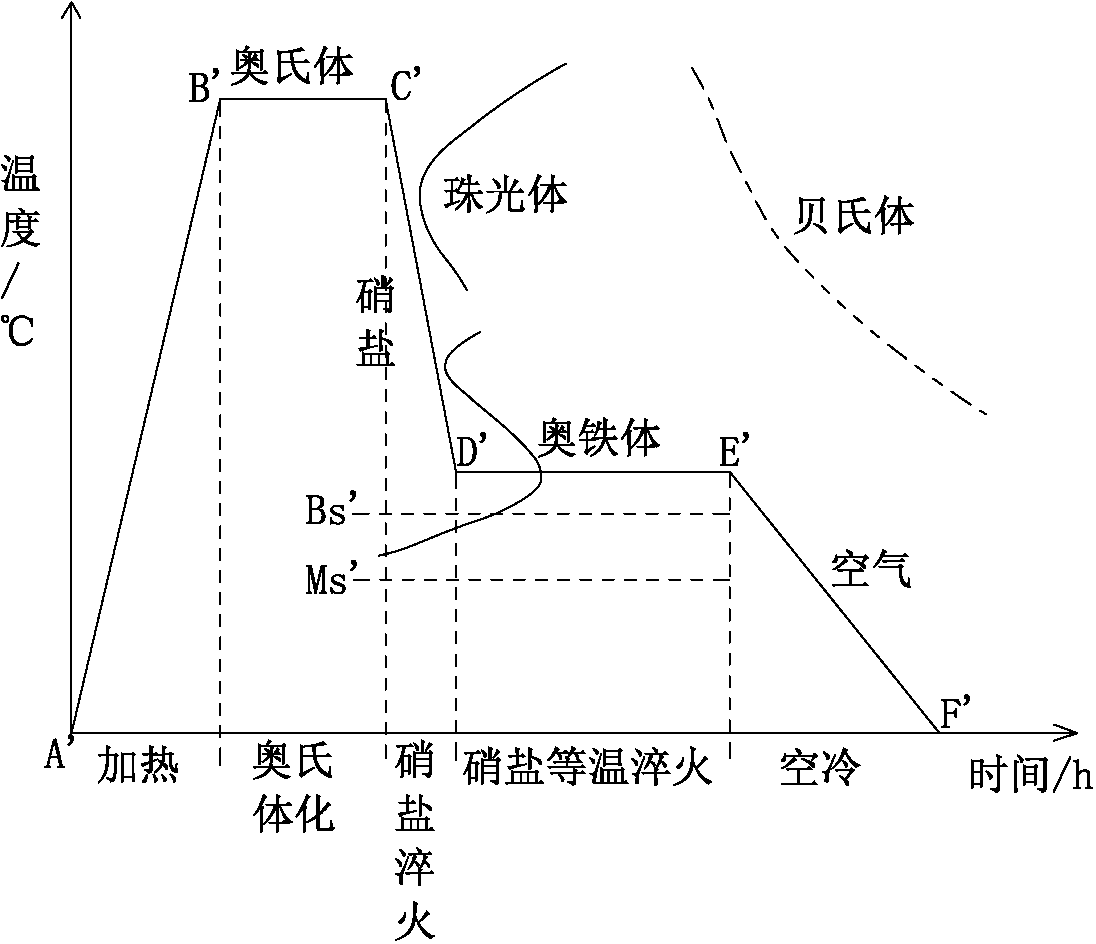

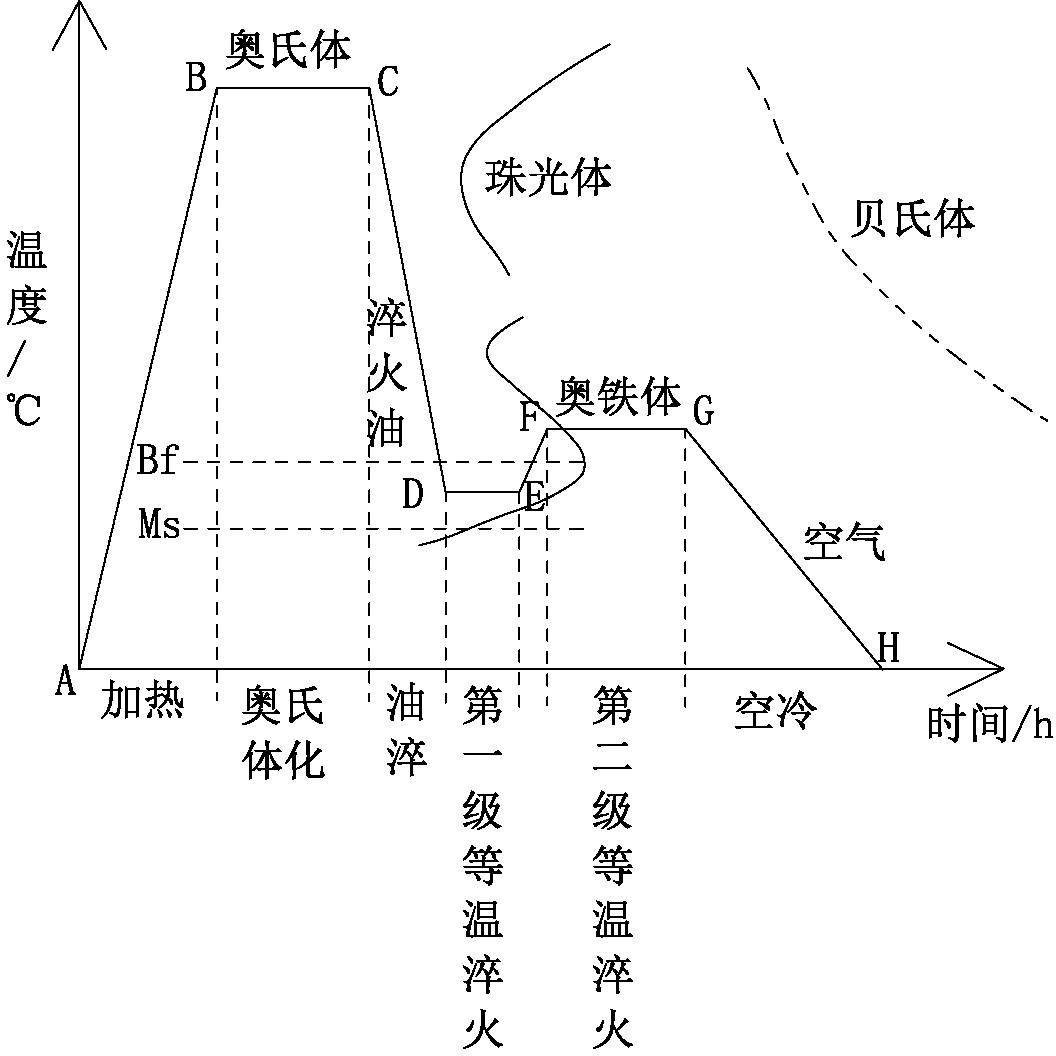

Austempered ductile iron and quenching technology thereof

The invention provides an austempered ductile iron adjusting chemical component. The chemical component uses Mn and Si as a base to substitute Mo and Ni, and contains a plurality of elements comprising Cu, B, Nb and Cr to realize low and micro alloying, so the respective effects of all elements are fully performed, the interactive effect promotion is realized, the hardenability is increased, the alloy consumption is reduced, and the cost is reduced. The invention also provides a new austempered ductile iron quenching technology matched with the austempered ductile iron. The technology is a step austempering technology using step quenching oil and an air isothermal furnace. The heat treatment of a workpiece through the technology realizes crystal grain refinement, good hardenability, high strength and toughness, low hardness (HB190-240) before the step austempering treatment, and good processing performances; and the obtained processed austempered ductile iron has a high hardness (HRC35-56) and extremely less oxidation and deformation, so the precision is guaranteed, and finishing treatments comprising grinding and the like are not needed. Compared with traditional nitrate bath austempering technologies, the austempered ductile iron quenching technology has the advantages of low cost, no generation of large amounts of harmful substances comprising nitrite or the like, low pollution and safety.

Owner:高州创建铸造有限公司

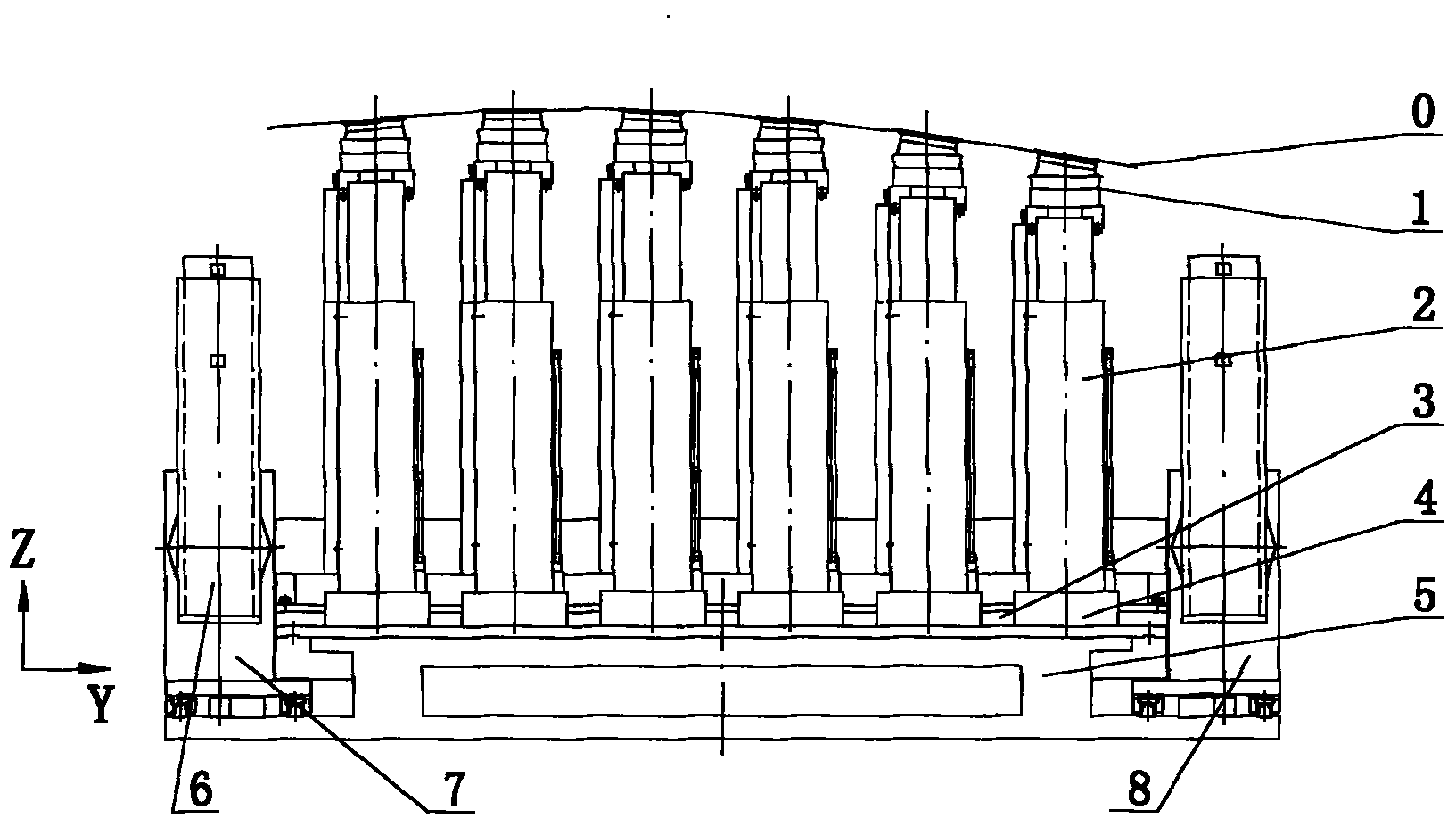

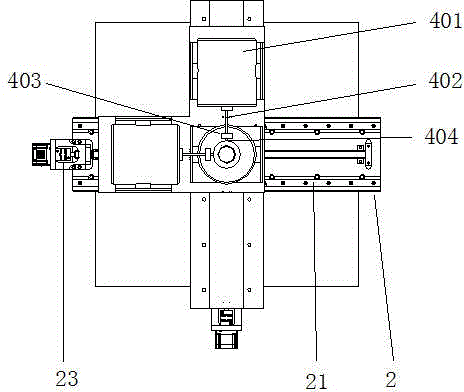

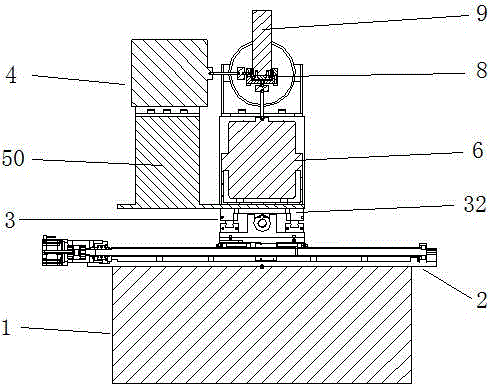

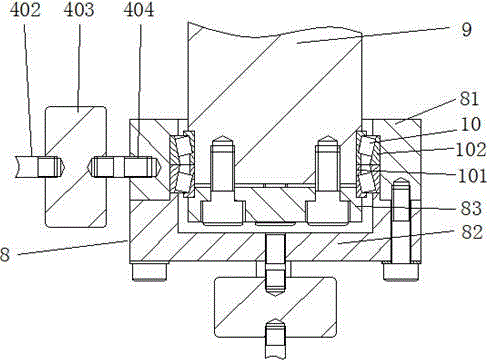

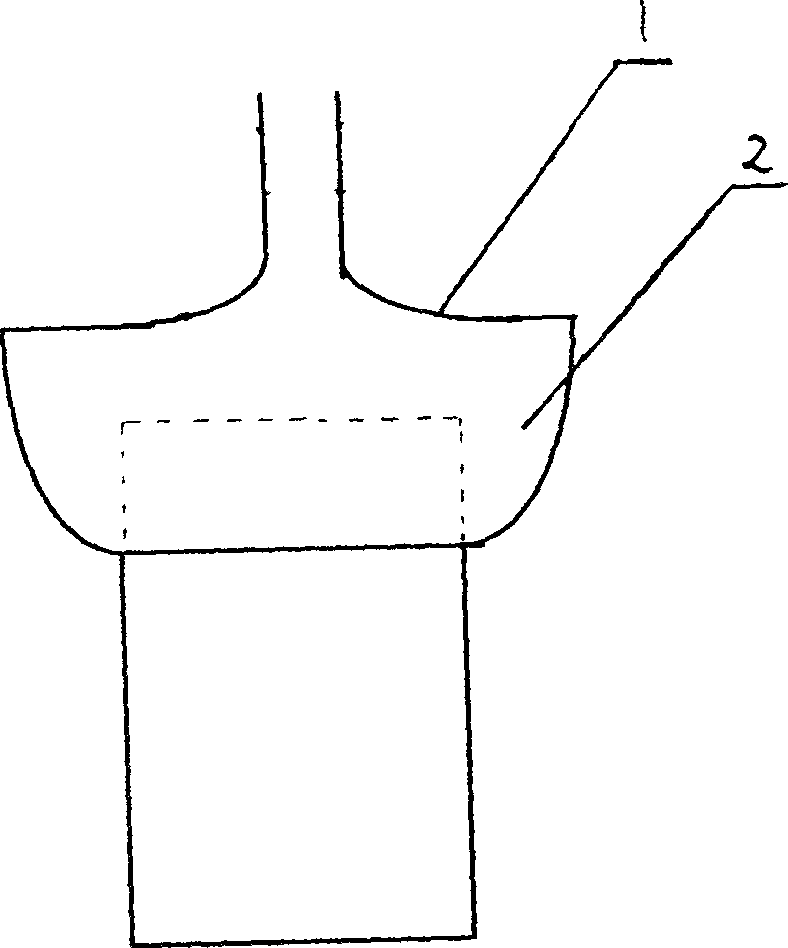

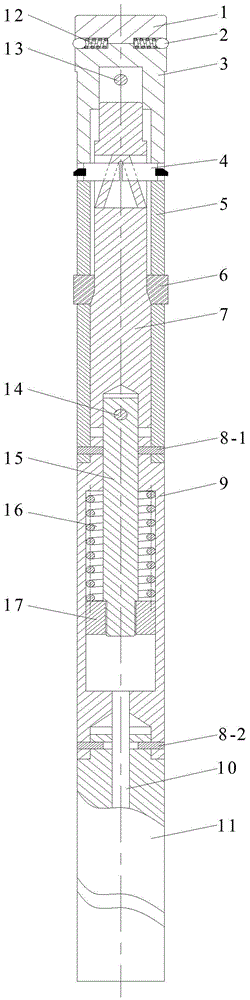

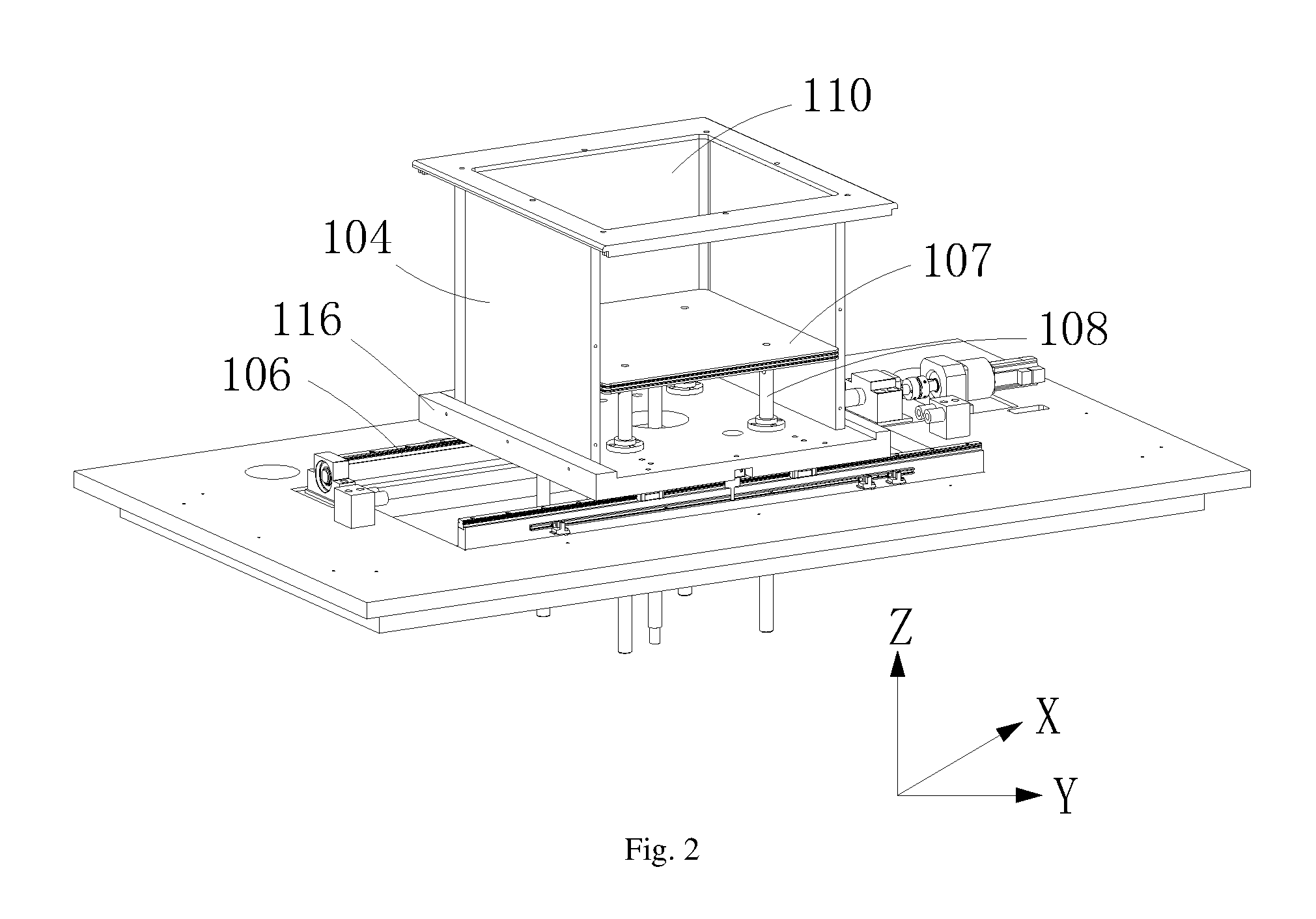

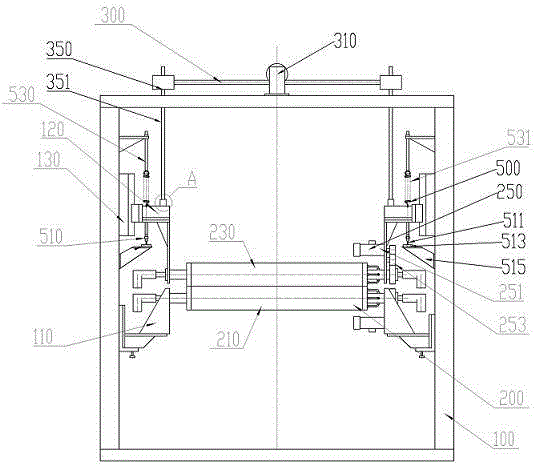

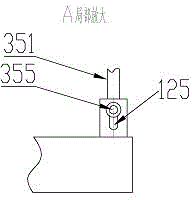

Machine tool three-dimensional dynamic cutting force follow-up analog loading device

ActiveCN104568485AReduce stress deformationImprove machining accuracyStructural/machines measurementStructural engineeringCutting force

The invention discloses a machine tool three-dimensional dynamic cutting force follow-up analog loading device. The machine tool three-dimensional dynamic cutting force follow-up analog loading device comprises a machine tool working table, a main shaft core rod, a Y-axis sliding pair, an X-axis sliding pair, a bearing system, an L-shaped base plate, a force loading system and a follow-up loading control circuit. The Y-axis sliding pair is fixedly connected with the machine tool working table, the X-axis sliding pair is installed on a sliding block of the Y-axis sliding pair, and the L-shaped base plate is fixedly connected with the X-axis sliding pair. The lower end of the main shaft core rod is connected with the bearing system to bear cutting force analog loading. A Z-axis force loading device is installed at a corner part of the L-shaped base plate, and an output shaft of the Z-axis force loading device is connected with a bearing end cover through a tension and pressure sensor. A Y-axis force loading device and an X-axis force loading device are installed at the two ends of the L-shaped base plate respectively, and output shafts of the Y-axis force loading device and the X-axis force loading device are connected with an outer circular face of a bearing outer base through the tension and pressure sensor. By means of the device, machining errors of a machine tool during cutting machining can be measured, and an analysis platform is provided for measurement and analysis of deformation errors, caused by cutting force, of the machine tool.

Owner:江苏中智自动化股份有限公司

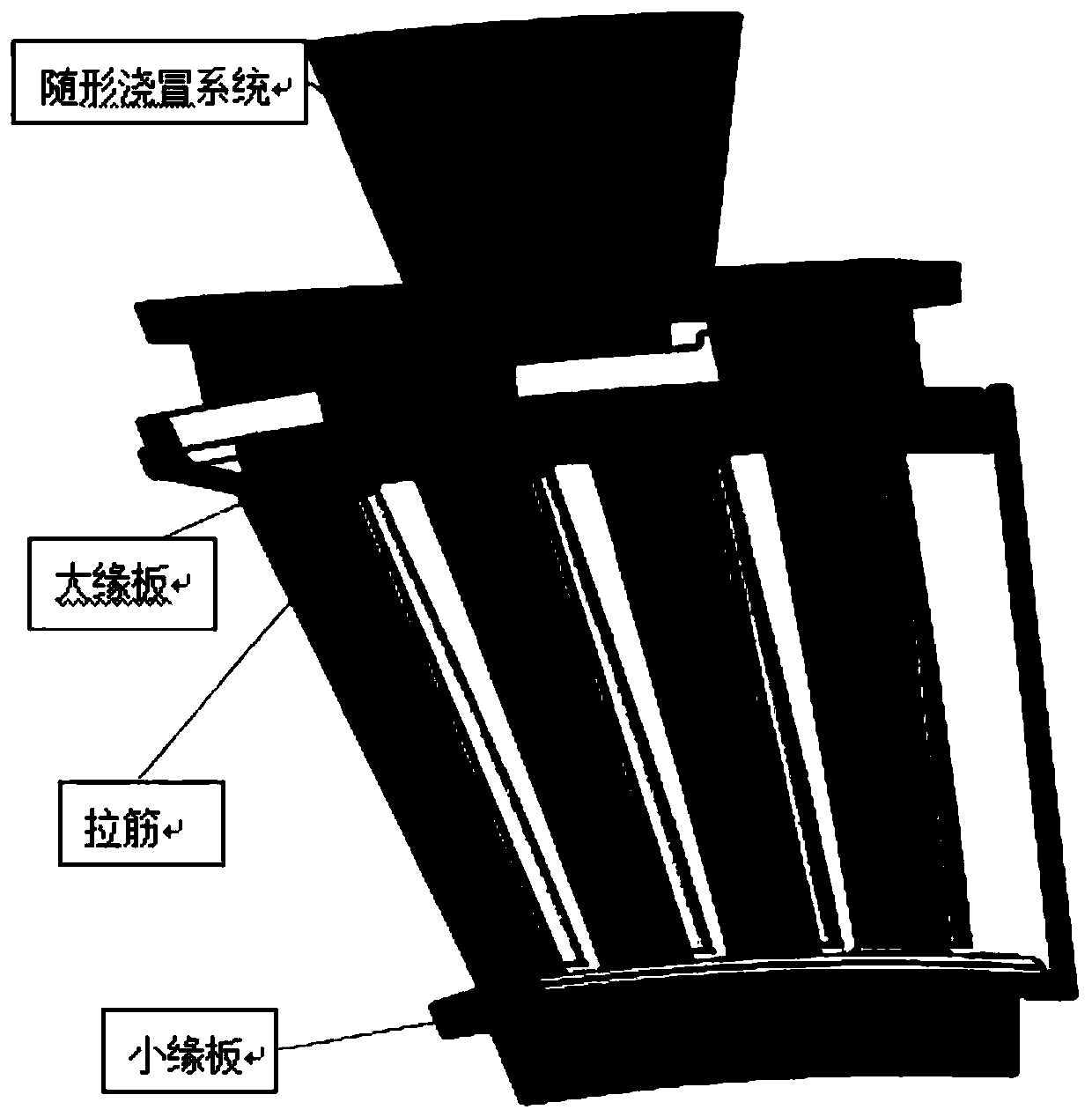

Casting forming process of complex high temperature alloy multi-union guide vane casting

The invention discloses a casting forming process of a complex high temperature alloy multi-union guide vane casting, and belongs to the technical field of precision casting. The process is characterized in that a casting body wax mold is prepared, and the casting body wax mold and a rigging system are assembled into a module; the module is coated with refractory coating layer by layer, is sent into a dewaxing kettle for dewaxing, and is sent into a baking furnace for high temperature pre-baking; the exterior of a shell is wrapped in a step type and is tied with refractory insulation cotton; ahigh temperature alloy rod is remelted and smelted to obtain high temperature alloy metal liquid; before pouring, the shell is sent into the baking furnace again, and then is sent into a vacuum induction casting furnace, and the high temperature alloy metal liquid is poured into the shell; and after pouring is completed, heat preservation is carried out, and shell removal, cutting, sand blastingand polishing are carried out after furnace exiting. The casting forming process effectively reduces or eliminates casting defects such as looseness and cracking easily generated at the connecting positions of hot joint vanes and small edge plates, the yield is improved to 75% to 80%, and the process is suitable for complex high temperature alloy multi-union guide vane casting.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

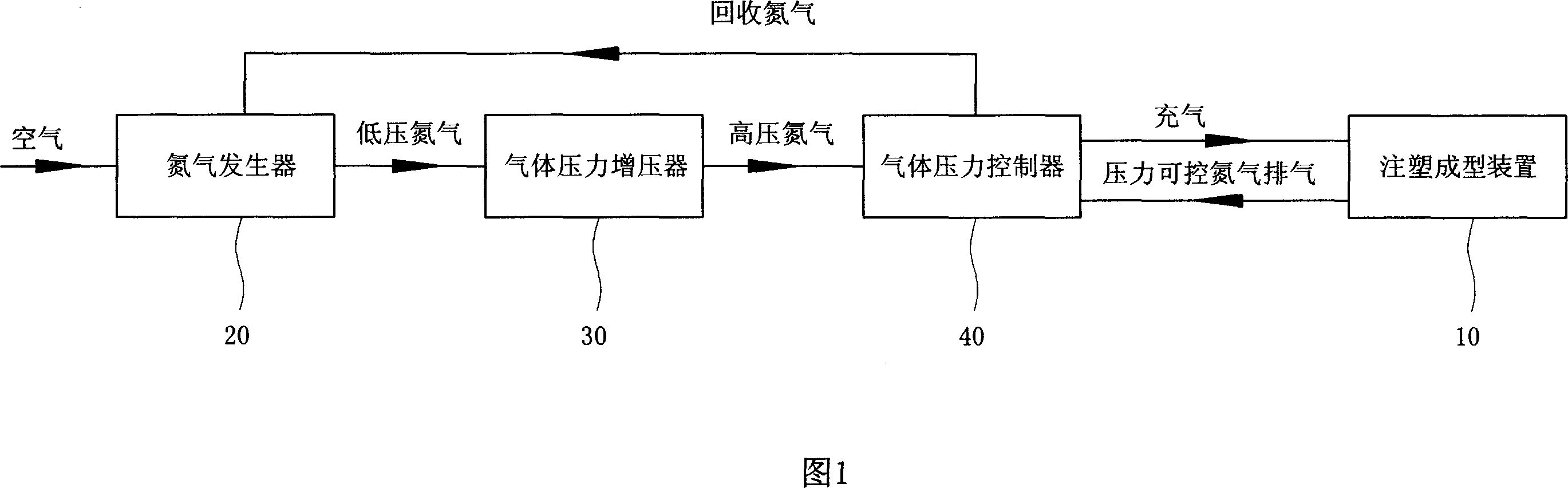

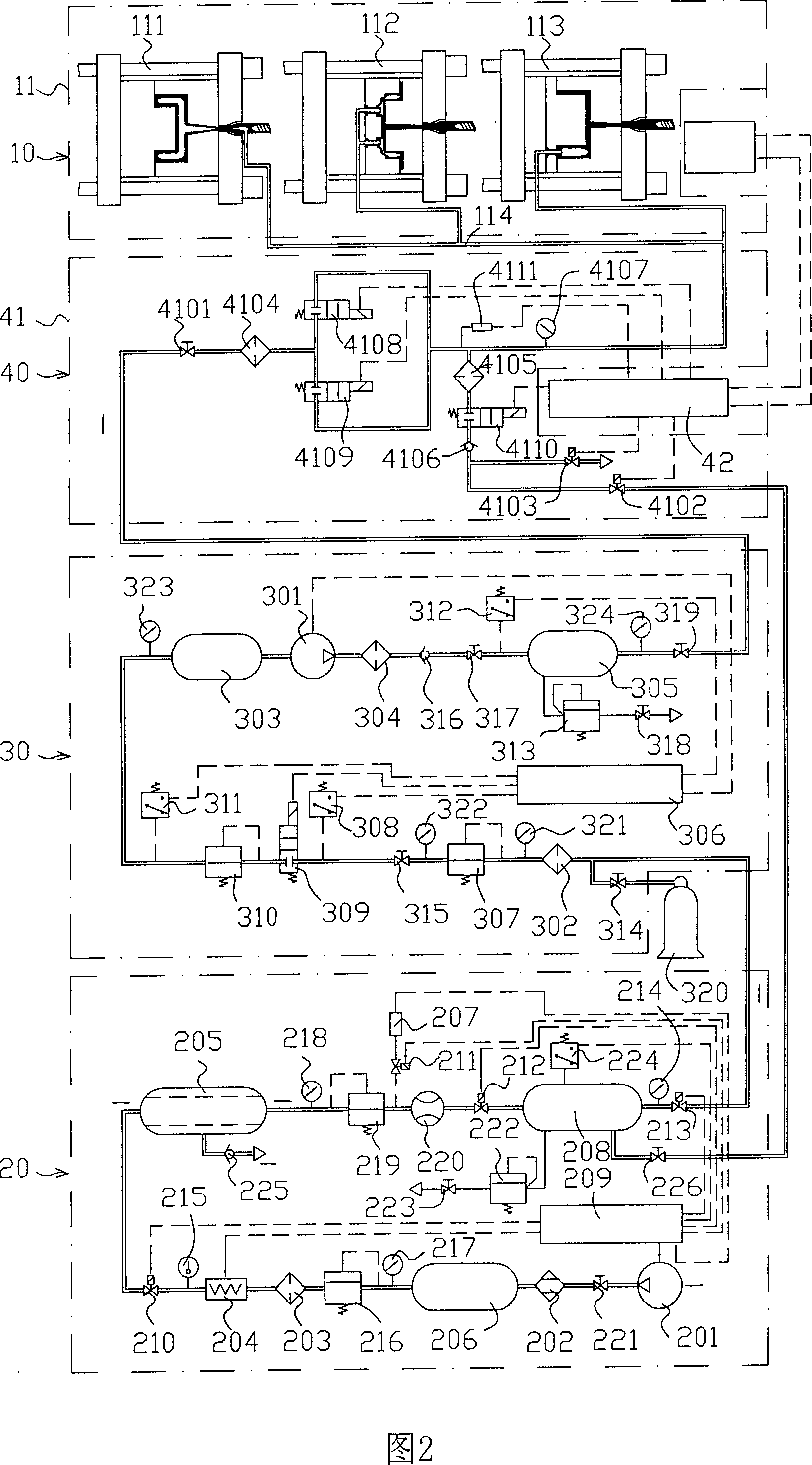

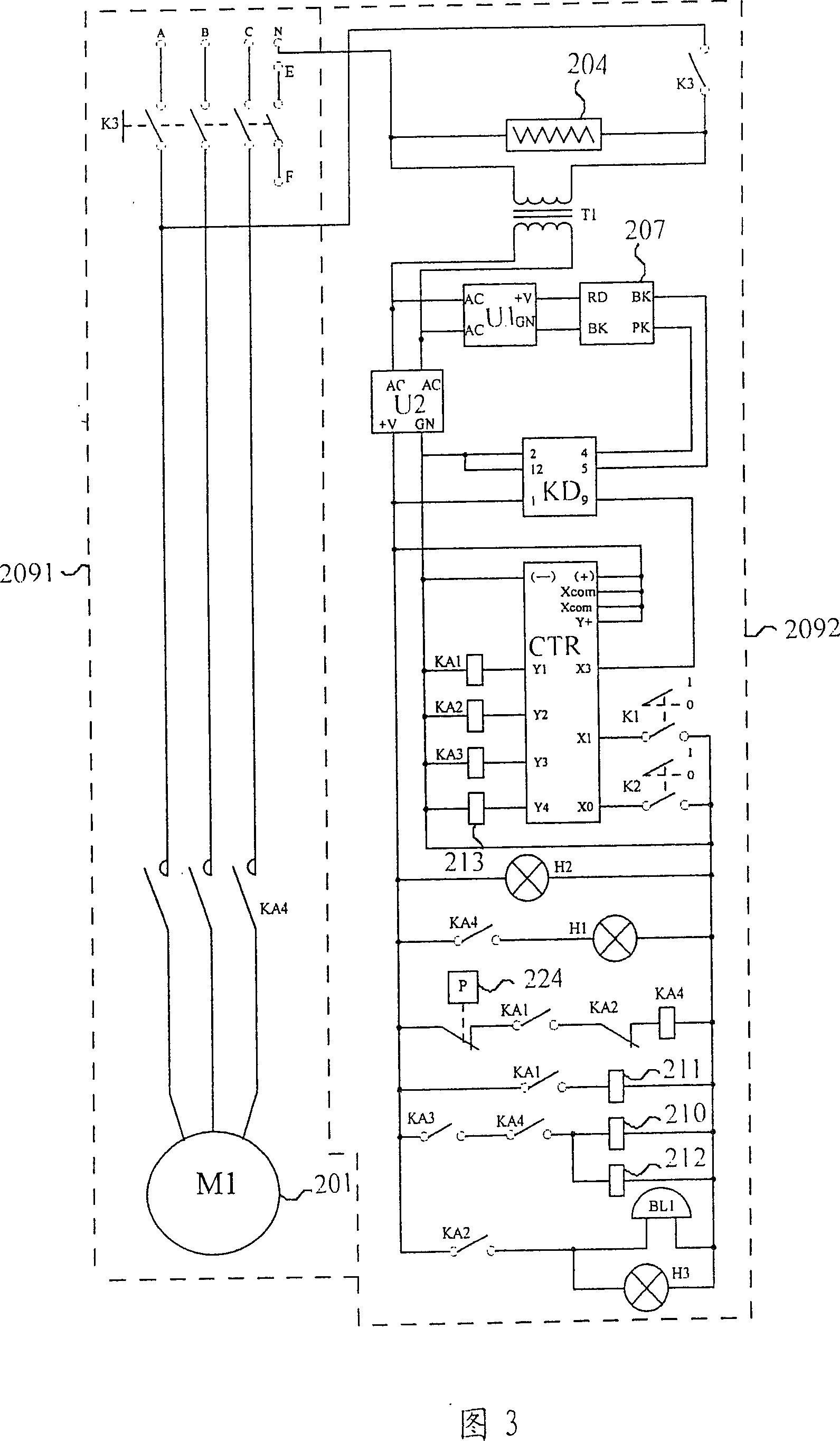

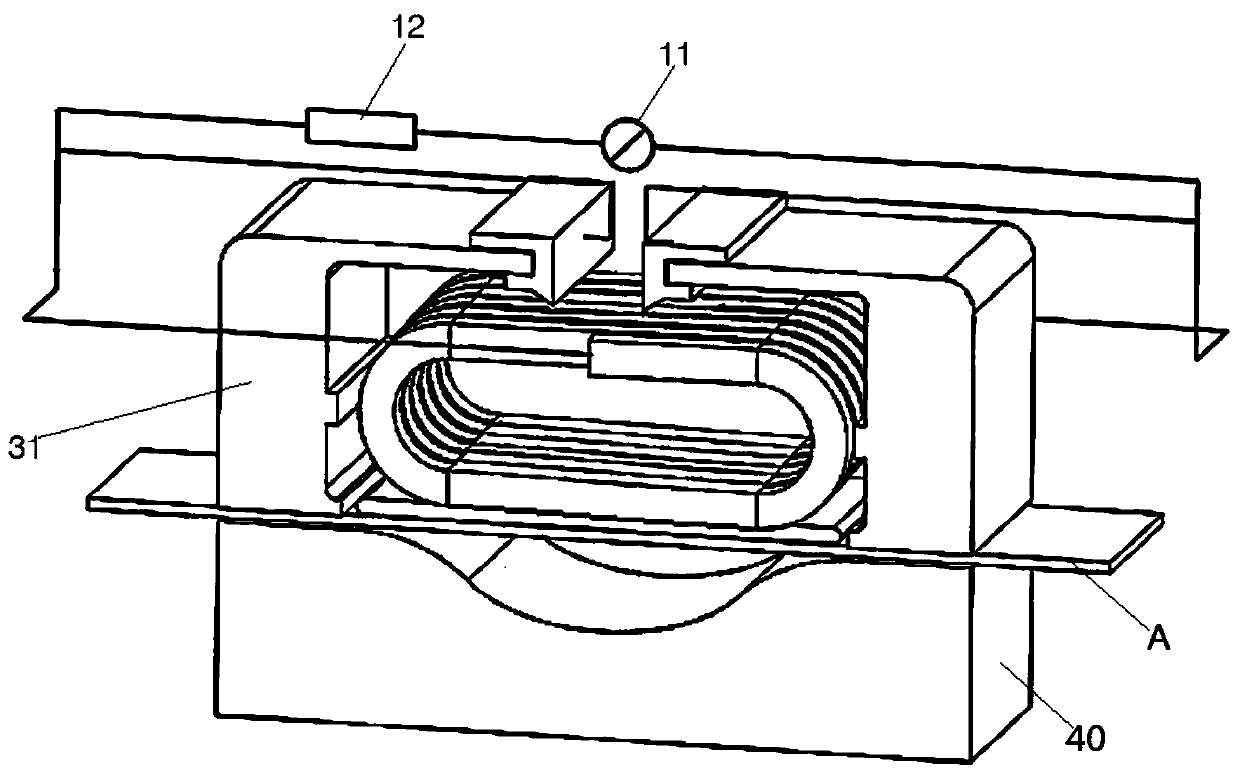

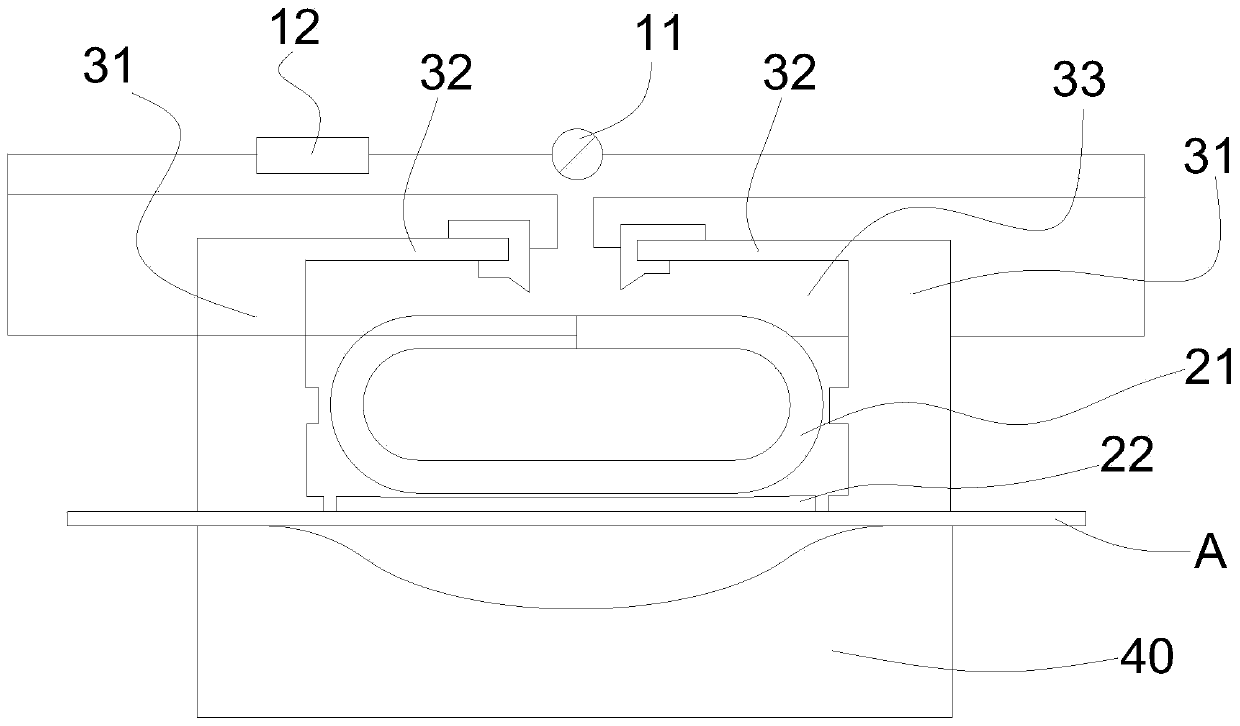

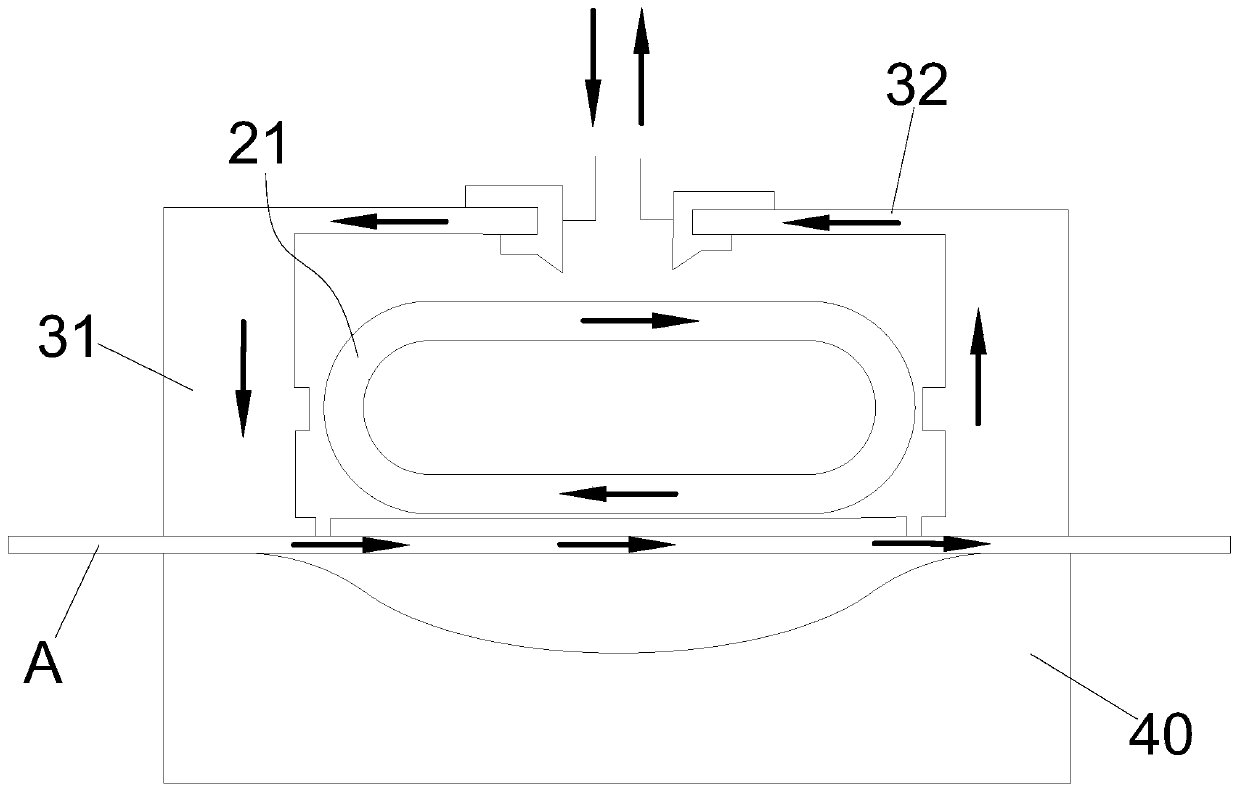

Pressure-sustaining gas assistant injection molding system

InactiveCN1990212AQuality improvementSmooth gas injectionNitrogen purification/separationNitrogen generatorAutomatic control

The invention discloses an auxiliary injection molding system of constant pressure gas, which comprises the following parts: injection molding device (10), nitrogen generator (20), gas pressure booster (30) and gas pressure controller (40), wherein the gas pressure controller (40) connects injection molding device (10) and gas pressure booster (30); the gas pressure booster connects nitrogen generator (20).

Owner:韩国海 +1

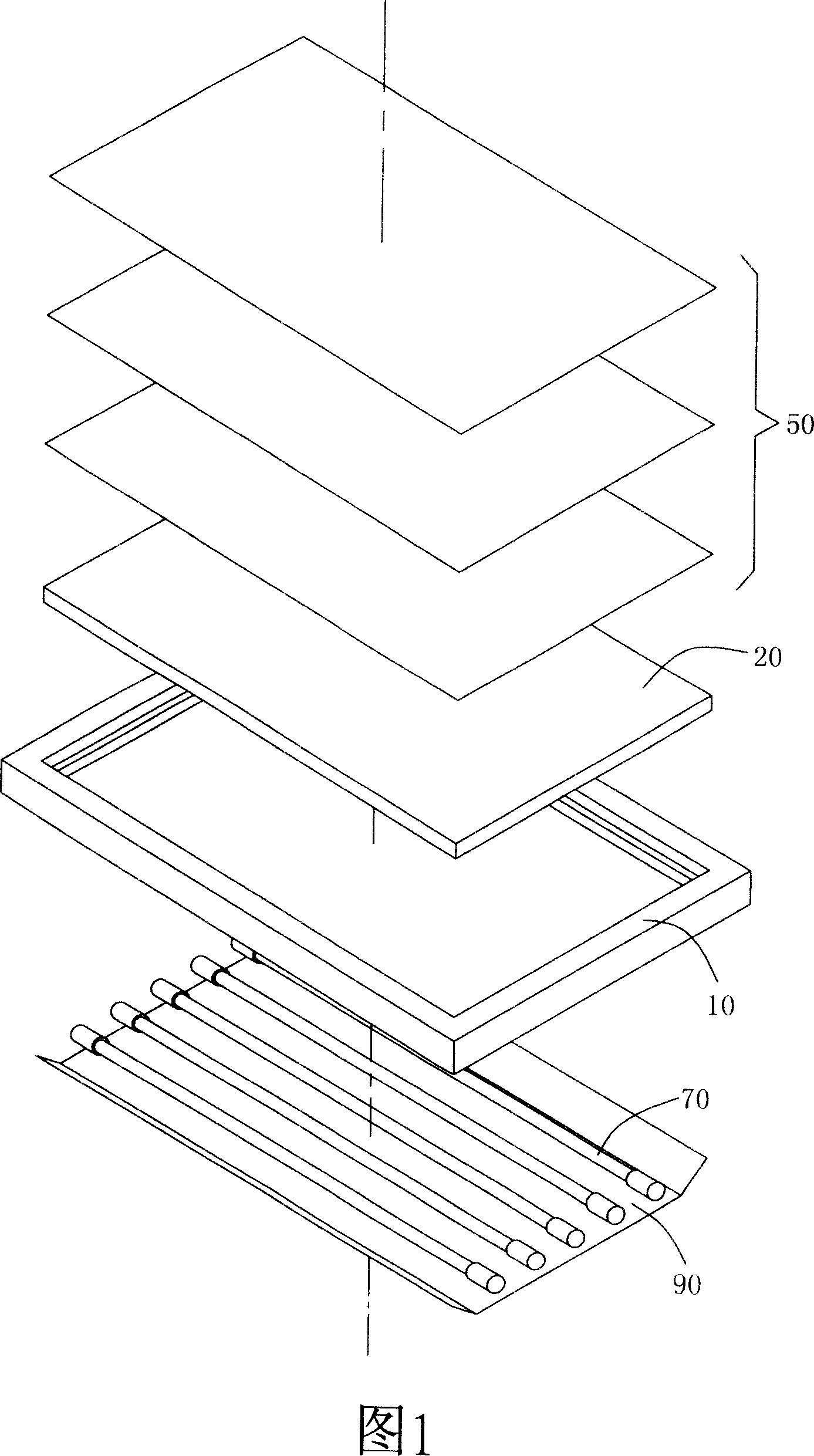

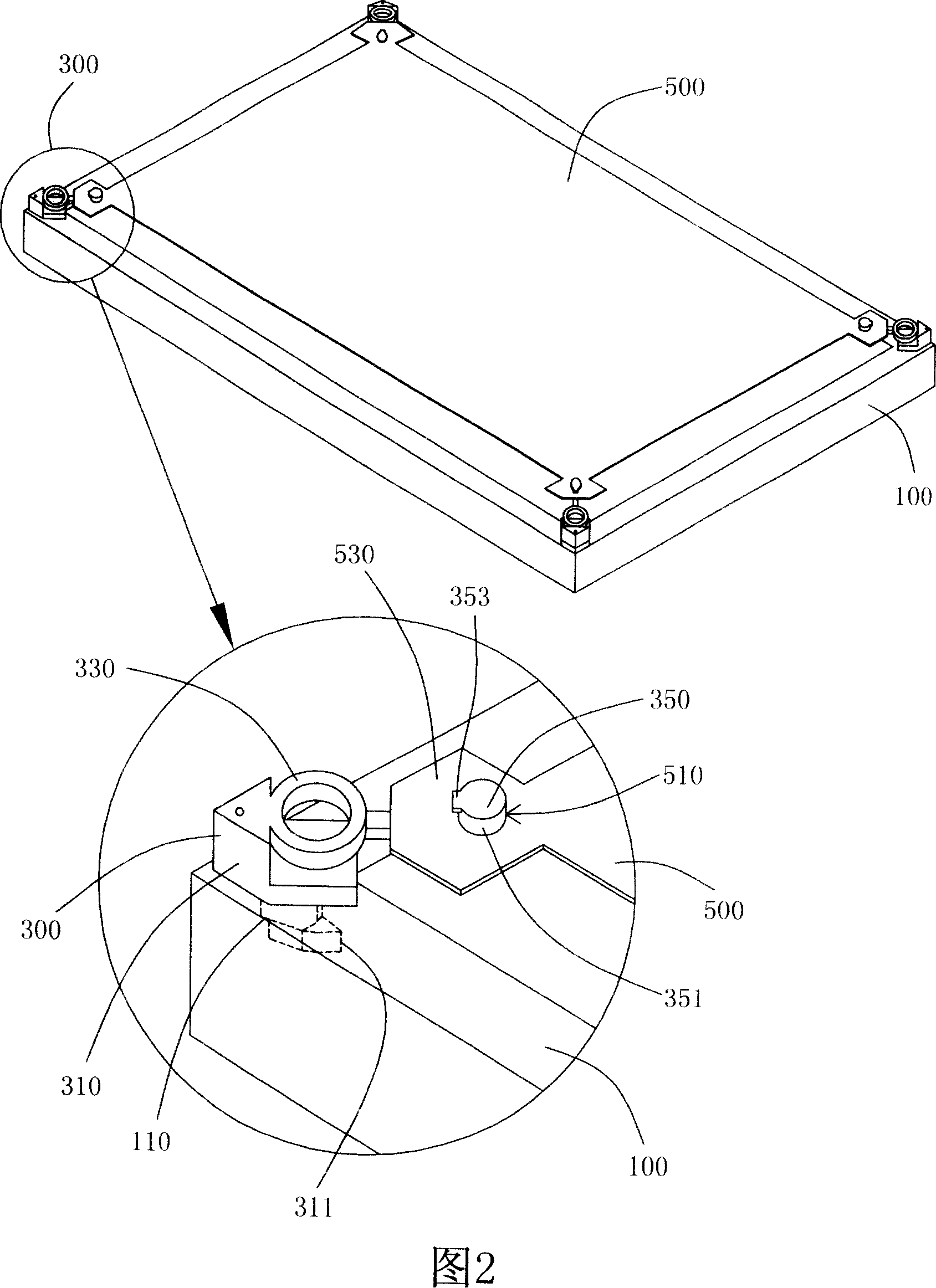

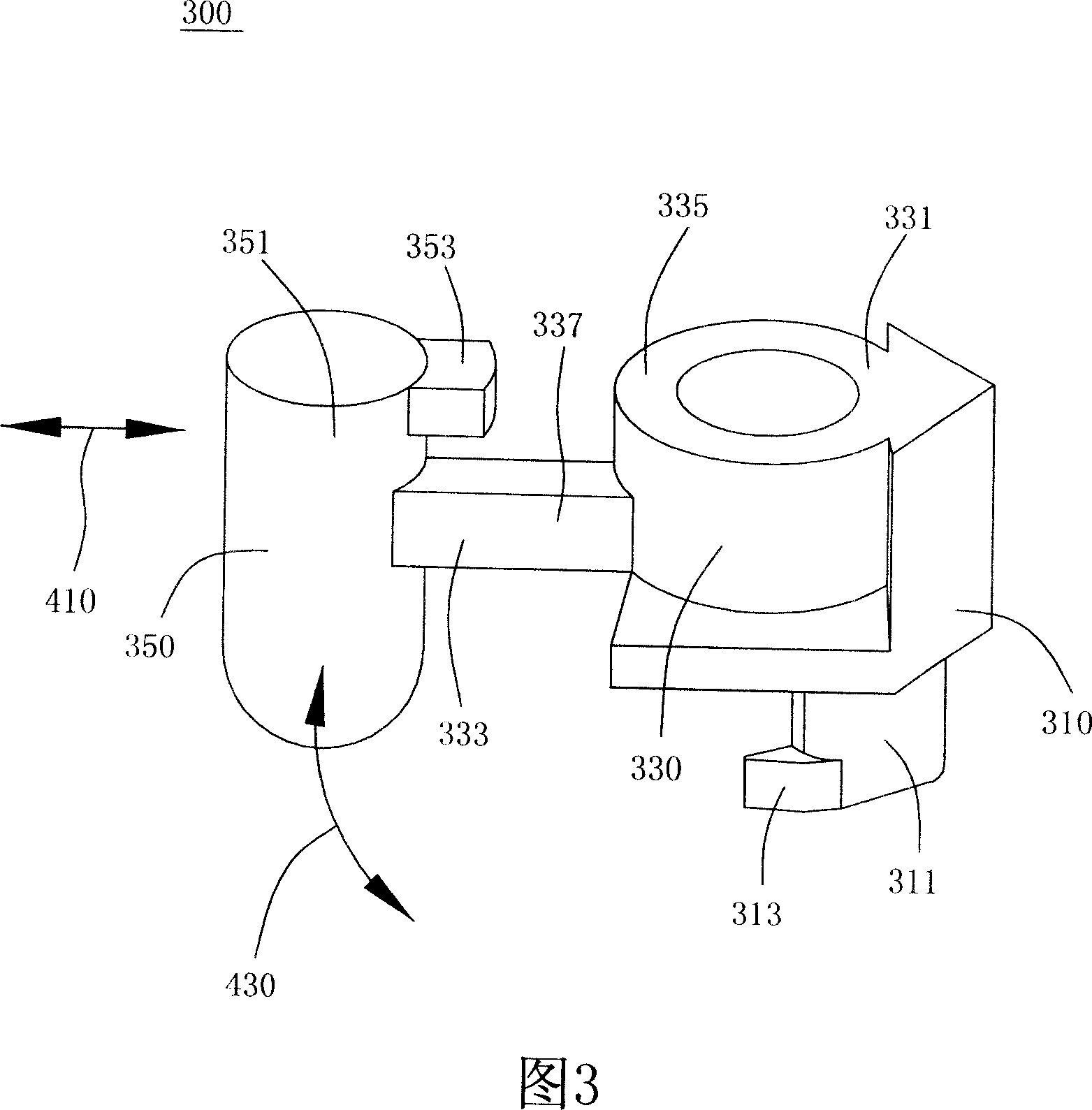

Diaphragm suspension system and its used diaphragm suspension device

A diaphragm suspension system comprises support body, diaphragm suspension device and diaphragm. The said diaphragm suspension device is formed by support connection unit, elastic element and diaphragm connection unit.

Owner:AU OPTRONICS CORP

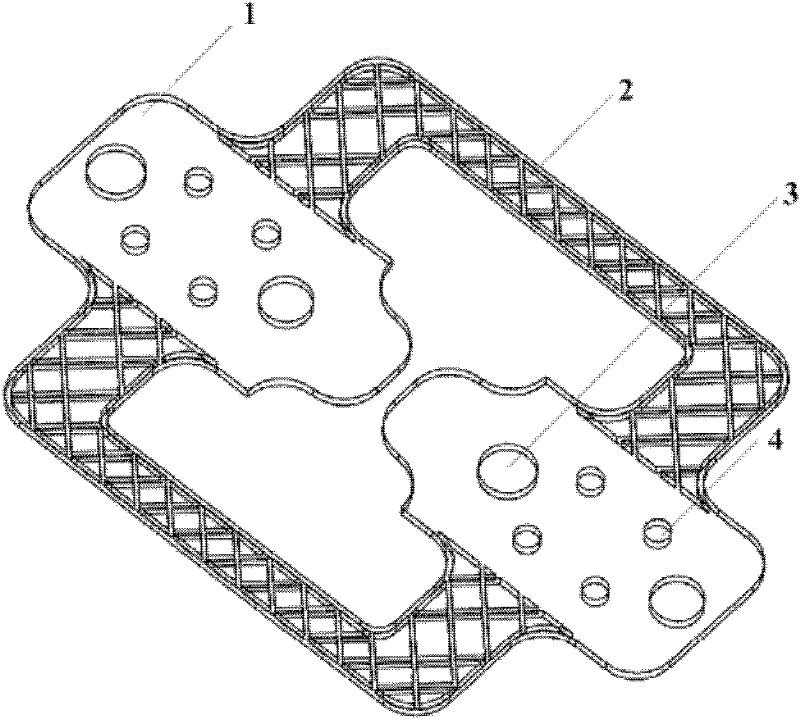

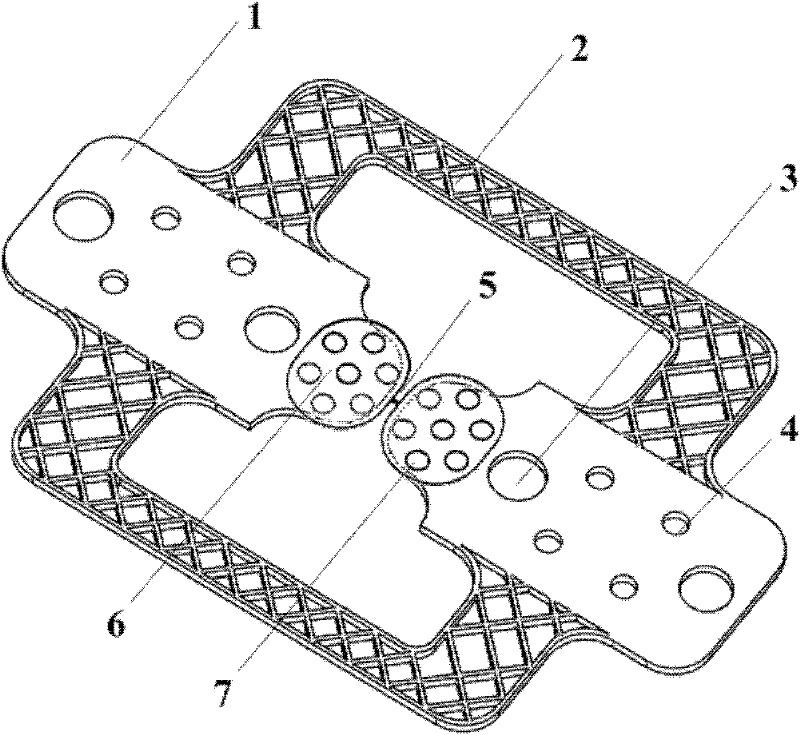

Method for preparing low-stress micro-tensile test sample with mesh support frame

InactiveCN102519762AReduce stressReduce distortionPreparing sample for investigationTest sampleBiological activation

The invention discloses a method for preparing a low-stress micro-tensile test sample with a mesh support frame, relating to the technical field of testing of films. The method comprises the following steps of: spinning photoresist on a glass substrate used as a sacrificial layer to be pre-baked, sputtering a metal Ti layer on the sacrificial layer, carrying out surface activation treatment of the sacrificial layer used as a seeding layer, and spinning, exposing and developing on the seeding layer; realizing imaging of a photoresist structure according to the shape of a micro-tensile test sample layer designed by a mask template; electroplating a Cu-TSV (Through Silicon Via) test sample layer on the Ti layer with the activated surface; carrying out electrochemical deposition of a support frame layer on the Cu-TSV plated layer; and finally, removing a photoresist graphical layer, a Ti sputtered layer and the sacrificial layer to obtain an independent suspension Cu-TSV micro-tensile test sample with the mesh support frame. The micro-tensile test sample prepared by using the method disclosed by the invention is capable of effectively reducing the film stress and has the advantages of being simple in structure, easy for preparation and low in cost; therefore, the in-situ independent tension of the Cu-TSV film is realized, and the micro-tensile test sample is beneficial to a micro-tensile precise test.

Owner:SHANGHAI JIAO TONG UNIV

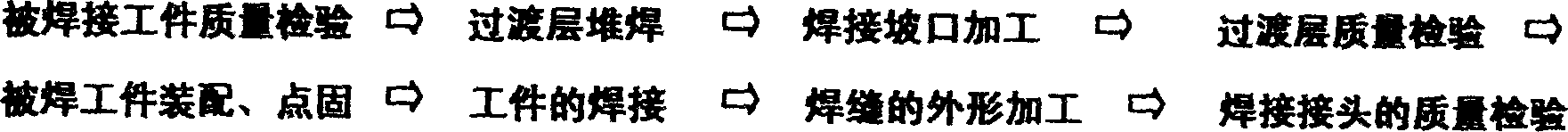

High carbon steel rail and high manganese steel frog welding technology

InactiveCN1442265AEasy to trainLess investmentWelding/cutting auxillary devicesAuxillary welding devicesShielded metal arc weldingHigh carbon

A technology for welding high-C steel rail and high-Mn steel switch fork of railway includes such steps as build-up welding of Cr-Ni-Mo alloy transition layer on the steel rail, build-up welding of Mn-Cr-Ni alloy transition layer on the switch fork and solid dissolving, matching their U-shaped bevel joint surfaces, and manual arc welding. Its advantages are high welding quality and stability and low cost.

Owner:唐山铁路道岔厂 +1

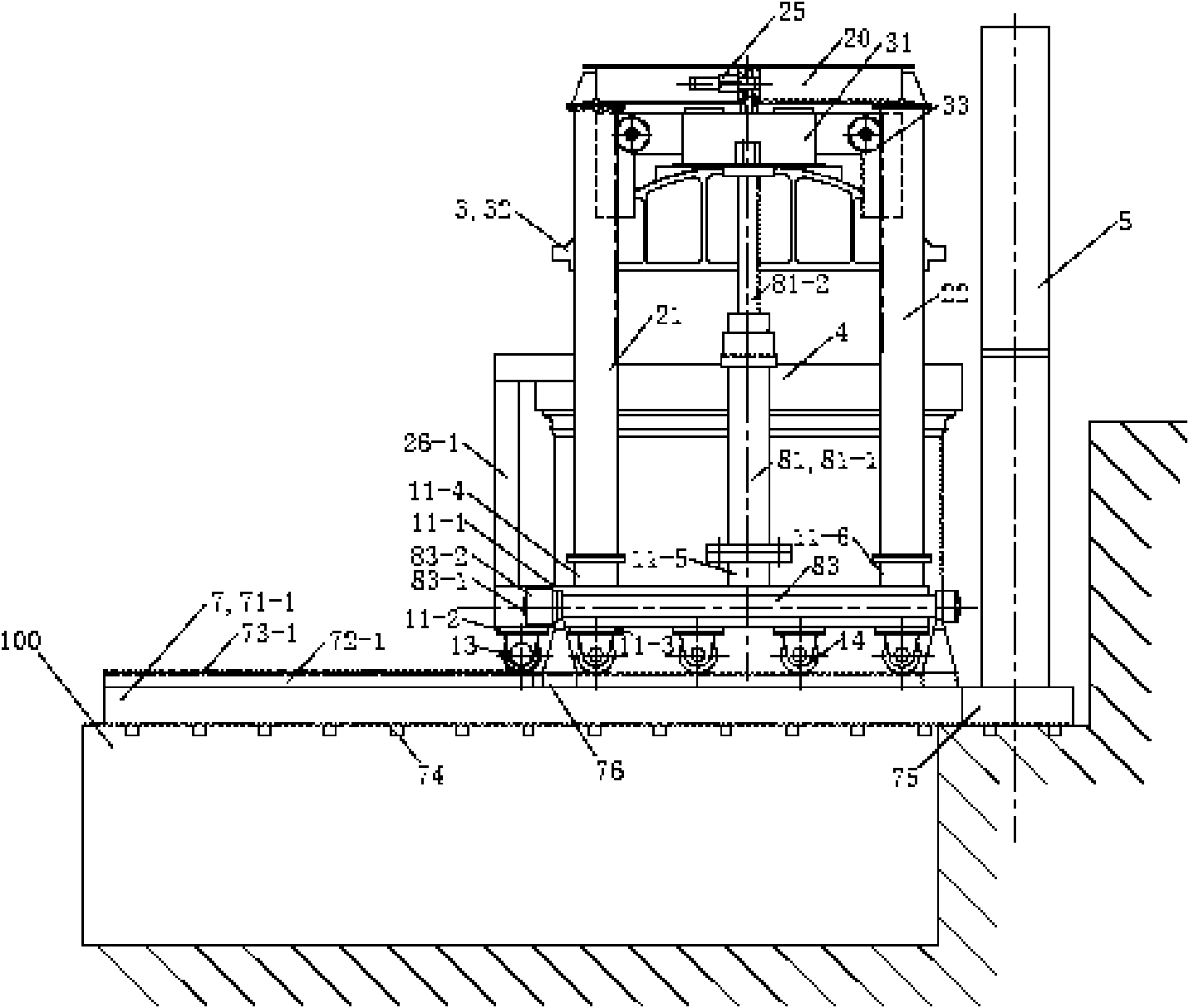

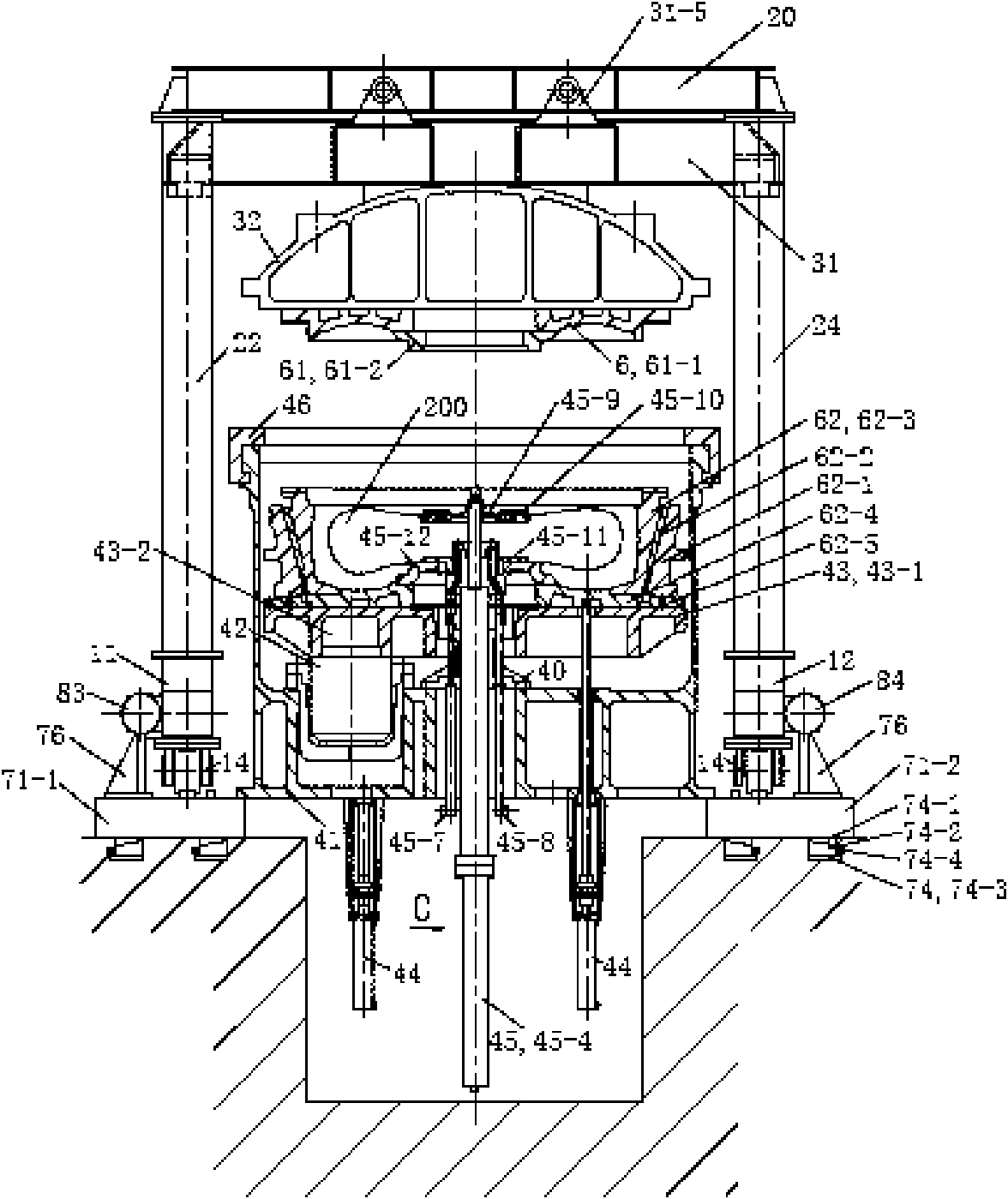

Translational vulcanizer

The present invention relates to a translational vulcanizer, including a translational mechanism, a translational frame, an upper vulcanizing chamber, a lower vulcanizing chamber, a device for assembling and disassembling a tyre, a radial parting mould, a stand body, a second stand, a switching mould oil cylinder and a translational oil cylinder. The translational frame and the switching mould oil cylinder are arranged on the translational mechanism, the upper vulcanizing chamber is arranged on a piston rod of the switching mould oil cylinder, the lower vulcanizing chamber is arranged on the stand body, and the device for assembling and disassembling the tyre is arranged on the second stand. The radial parting mould is divided into an upper mould and a lower mould, the lower mould is arranged in the lower vulcanizing chamber, and the upper mould is fixed below the upper vulcanizing chamber. Left and right supports of the translational mechanism are provided with three to five wheeled kinematic mechanisms locating below the support separately, and each wheeled kinematic mechanism is arranged on a wheeled guide rail fixed on the supports locating on the right and left sides of a stand component. the vulcanizer is used for vulcanizing a giant engineering tyre, has a stable and smooth operation by employing the wheeled kinematic mechanism, is not easy to break a movable member, reduces the cost and time for maintenance, and has a long service life.

Owner:江苏华瑞重工机械有限公司

Thin-wall sleeve part processing method

The invention discloses a thin-wall sleeve part processing method which comprises the steps of firstly roughly turning an excircle and drilling and boring an inner hole; after roughly turning the excircle and roughly boring the inner hole to the reserved processing allowance, semi-extractive turning an excircle of a thin-wall sleeve part, obtaining a semi-finished product of the thin-wall sleeve part, and cutting off from a bar material; loading the semi-finished product on a digital controlled lathe, precisely turning an incircle and an excircle of the semi-finished product to the set processing allowance, half cutting-off, reserving the set thickness during half cutting-off after chamfering an excircle of a part at the cut-off end, and semi-extractive turning the excircle to the design dimension again; and thoroughly cutting off the processed thin-wall sleeve part from the semi-finished product. The process method provided by the invention is simple and feasible, no working procedureis increased, the deformation in the part processing process is greatly reduced, the excircle dimension tolerance can be ensured to meet the technical requirement of the process design, the product qualification rate is remarkably improved, the method can be completed by adopting a cutting manner, the production period is short, and no auxiliary fixture with high cost is required to be configured.

Owner:AECC AVIATION POWER CO LTD

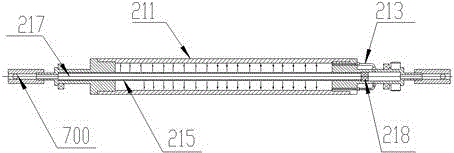

Boring bar special for machining deep hole and inner groove

InactiveCN105642929AIncrease stiffnessImprove local stiffnessBoring barsHydraulic cylinderTangential force

The invention discloses a segmented type boring bar with a guide support part and special for machining a deep and long hole and an inner groove. The boring bar comprises the guide support part, a tool bit part, a feeding and retracting mechanism, a rod body part and a hydraulic drive part. The guide support part comprises a guide head and an auxiliary support part. The guide head is divided into a front guide head body and a rear guide head body which are connected through a screw. The rear guide head body is connected with the front end of a sleeve through a pin, a hydraulic cylinder is connected with the rear end of the sleeve through a pin, and a cutter bar is connected with the bottom of the hydraulic cylinder through a pin. When the inner groove is bored, the guide support part has a supporting effect, and the local static rigidity of the tool bit part can be improved. By means of the feeding and retracting mechanism, the axial positioning and the feeding and retracting movement of the tool can be achieved. The segmented type special tool with the guide support part is suitable for machining the multi-layer inner groove and can also be used for boring the inner wall of the deep and long hole; a blade is symmetrically arranged, so radial force and tangential force counteract, the rigidity of the cutter bar is greatly improved, and machining conditions are remarkably improved.

Owner:NANJING UNIV OF SCI & TECH

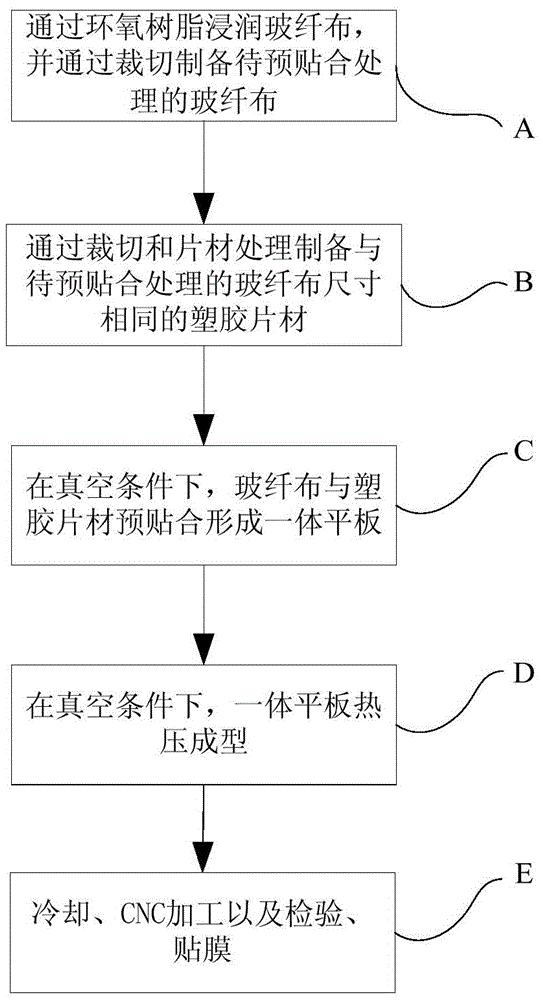

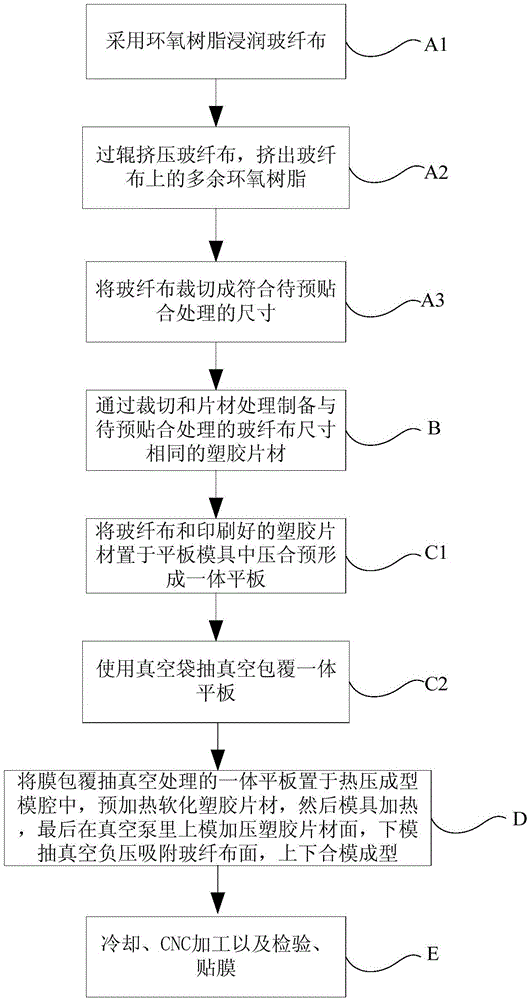

Making technology of shell possessing stereoscopic glass effect, the shell and electronic product

ActiveCN105611757AReduce stress deformationImprove the bonding force between layersCasings/cabinets/drawers detailsGlass fiber

The invention discloses a making technology of a shell possessing a stereoscopic glass effect and relates to the electronic product shell technology field. The making technology of the shell possessing the stereoscopic glass effect is characterized in that an epoxy resin is used to infiltrate glass fiber cloth; under a uncured state, the glass fiber cloth and plastic sheet material are preliminarily jointed so as form one body under a vacuum condition; and hot-pressing integral forming is performed under the vacuum condition so that making of the shell possessing the stereoscopic glass effect is completed. Simultaneously the invention also discloses the shell made through using the making technology of the shell possessing the stereoscopic glass effect and an electronic product including the shell. In the invention, stress deformation is reduced and an interlayer combination force is increased; simultaneously, bubble and impurity influences are avoided; problems that composite hot-pressing deformation of a glass fiber plate and the plastic sheet material is large, interlayer peeling is possessed and a surface is poor are solved; product quality is increased; a decorative effect of using the plastic to substitute the glass is realized and cost is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

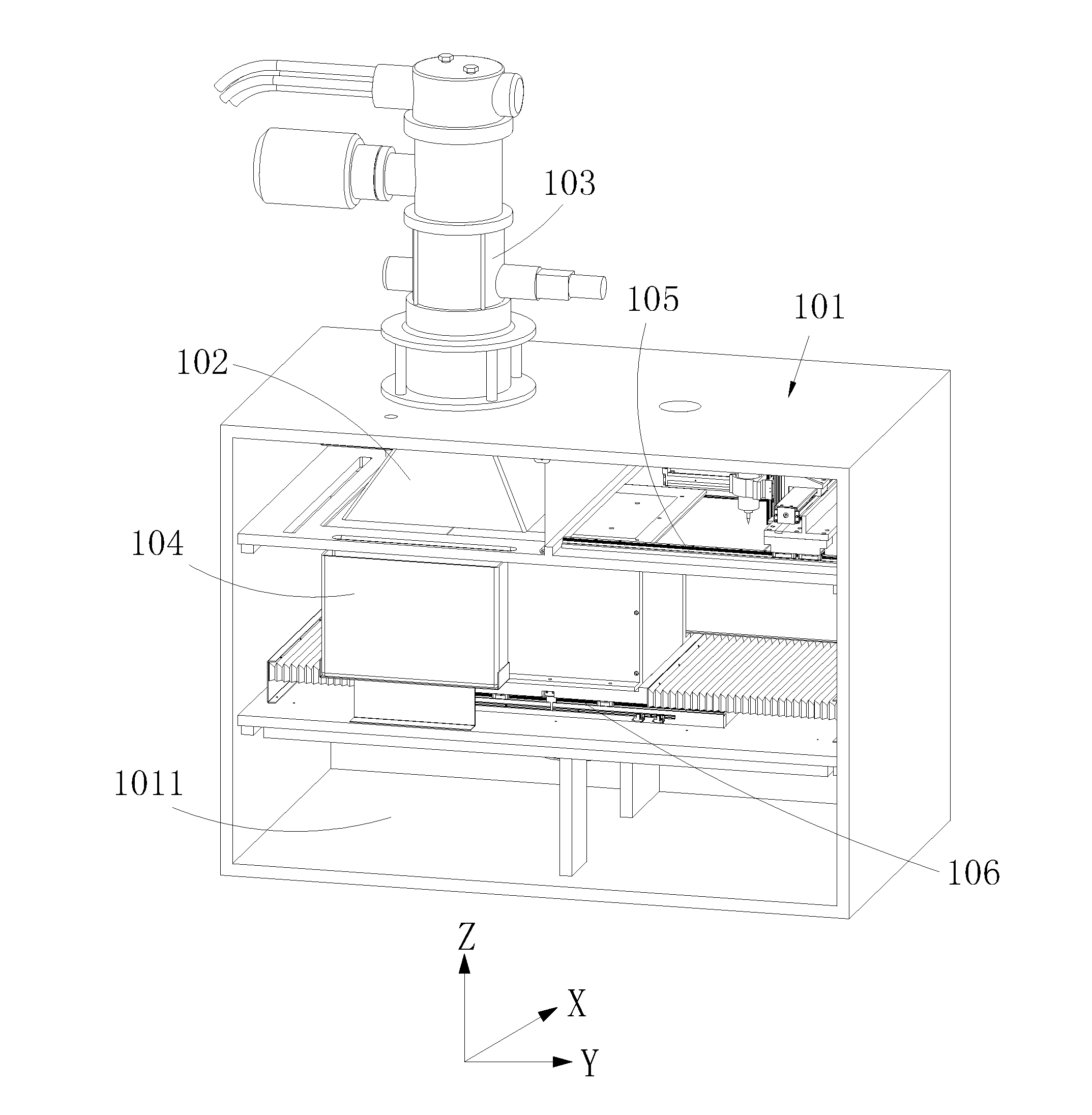

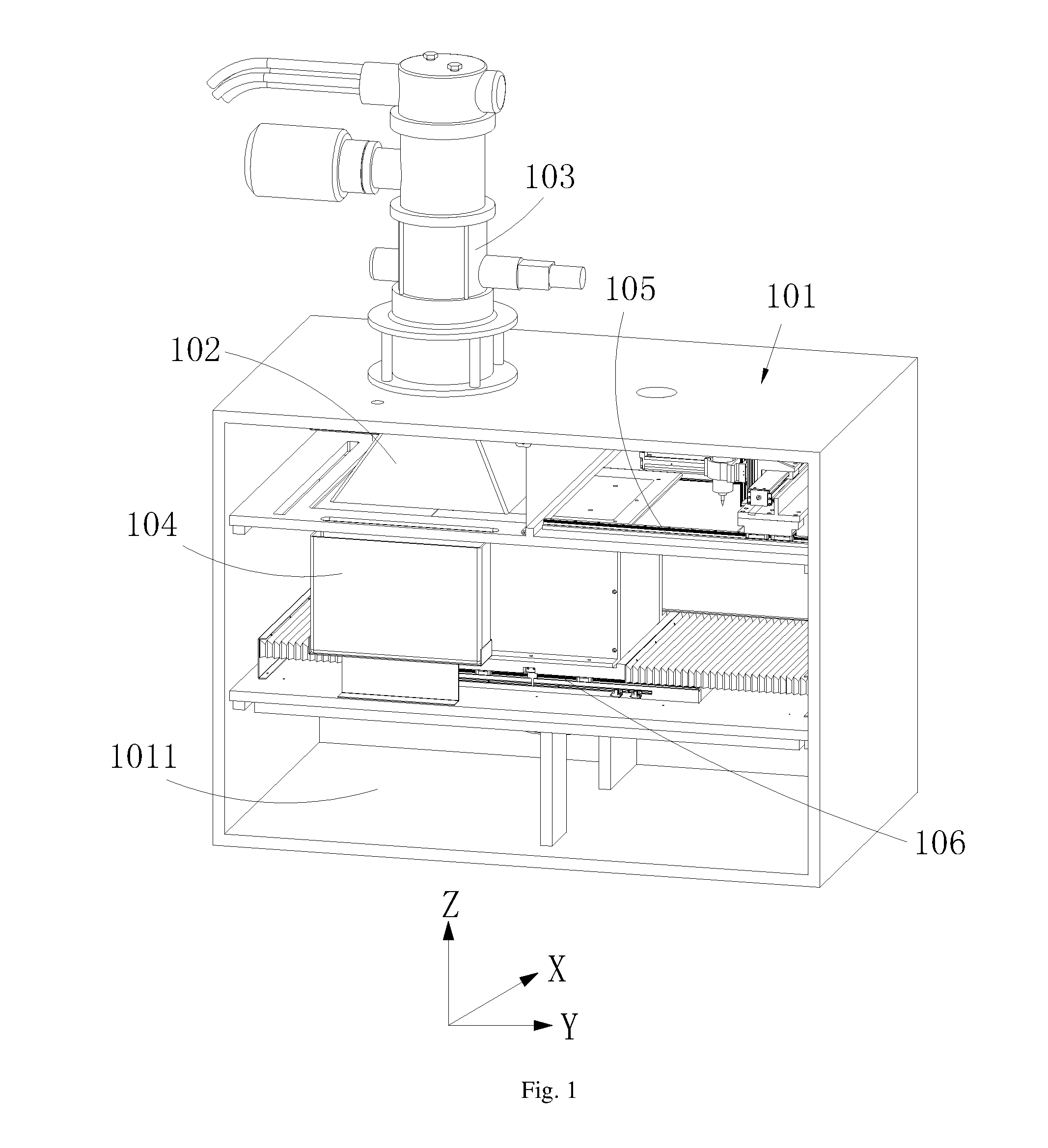

Electron beam melting and cutting composite 3D printing apparatus

ActiveUS20170050261A1Reduce thermal effectsReduce stress deformationAdditive manufacturing apparatusIncreasing energy efficiencyElectronElectrical and Electronics engineering

The present application relates to the technical field of 3D printing apparatus, and discloses an electron beam melting and cutting composite 3D printing apparatus which comprises a box and an electron beam gun, in which the box has a cavity formed therein, the cavity is provided therein with a cutting structure, a first Y-direction guide rail and a Y-direction movable platform, the electron beam gun has an emitting head formed in the cavity, the Y-direction movable platform is provided thereon with a Z-direction movable platform, the Z-direction movable platform is provided thereon with a powder spreading structure, the cutting structure has a cutting head, a shielding case is arranged between the emitting head and the Z-direction movable platform, the emitting head of the electron beam gun is inserted in an upper opening of the shielding case, and a lower opening of the shielding case is aligned with the Z-direction movable platform.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

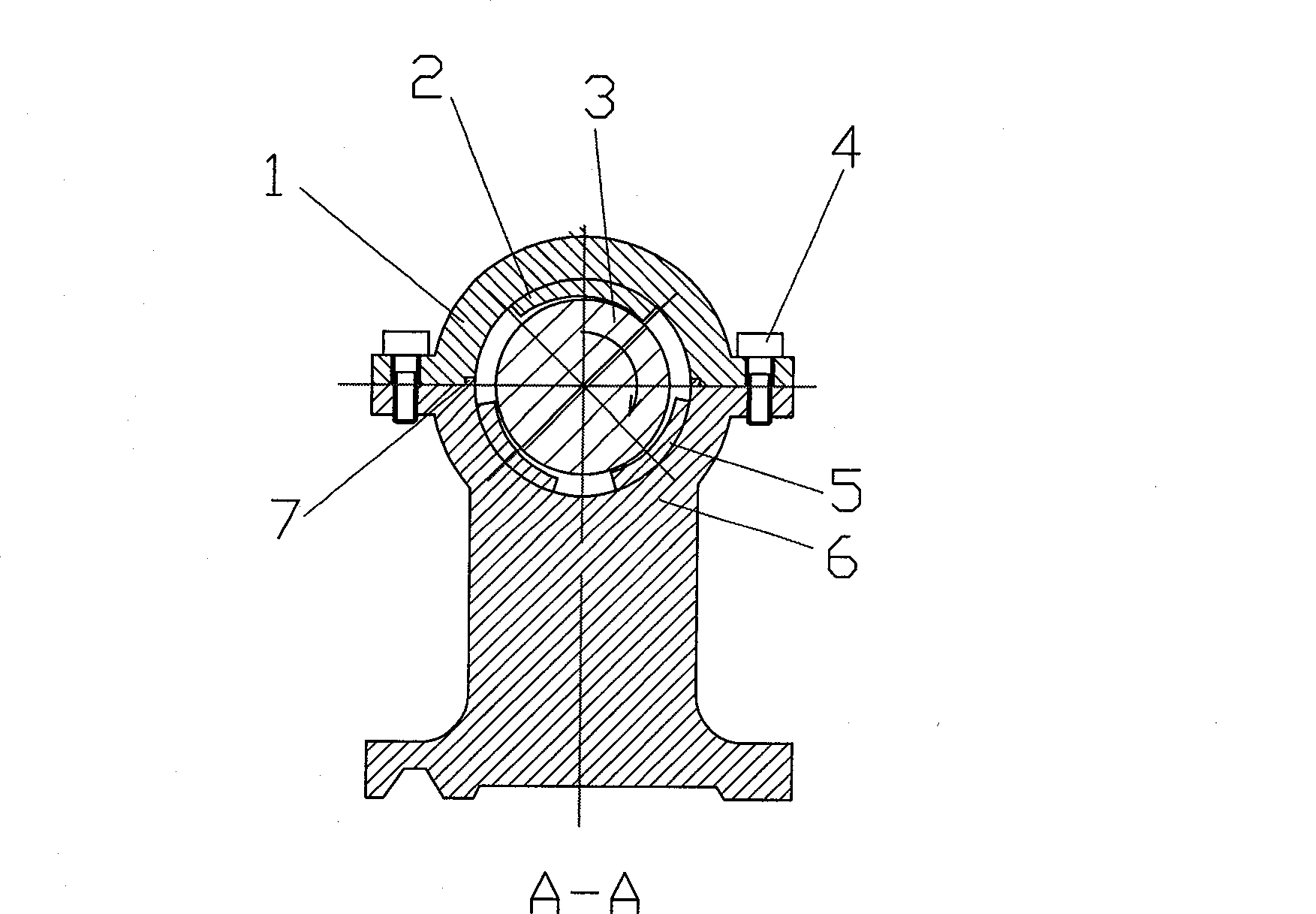

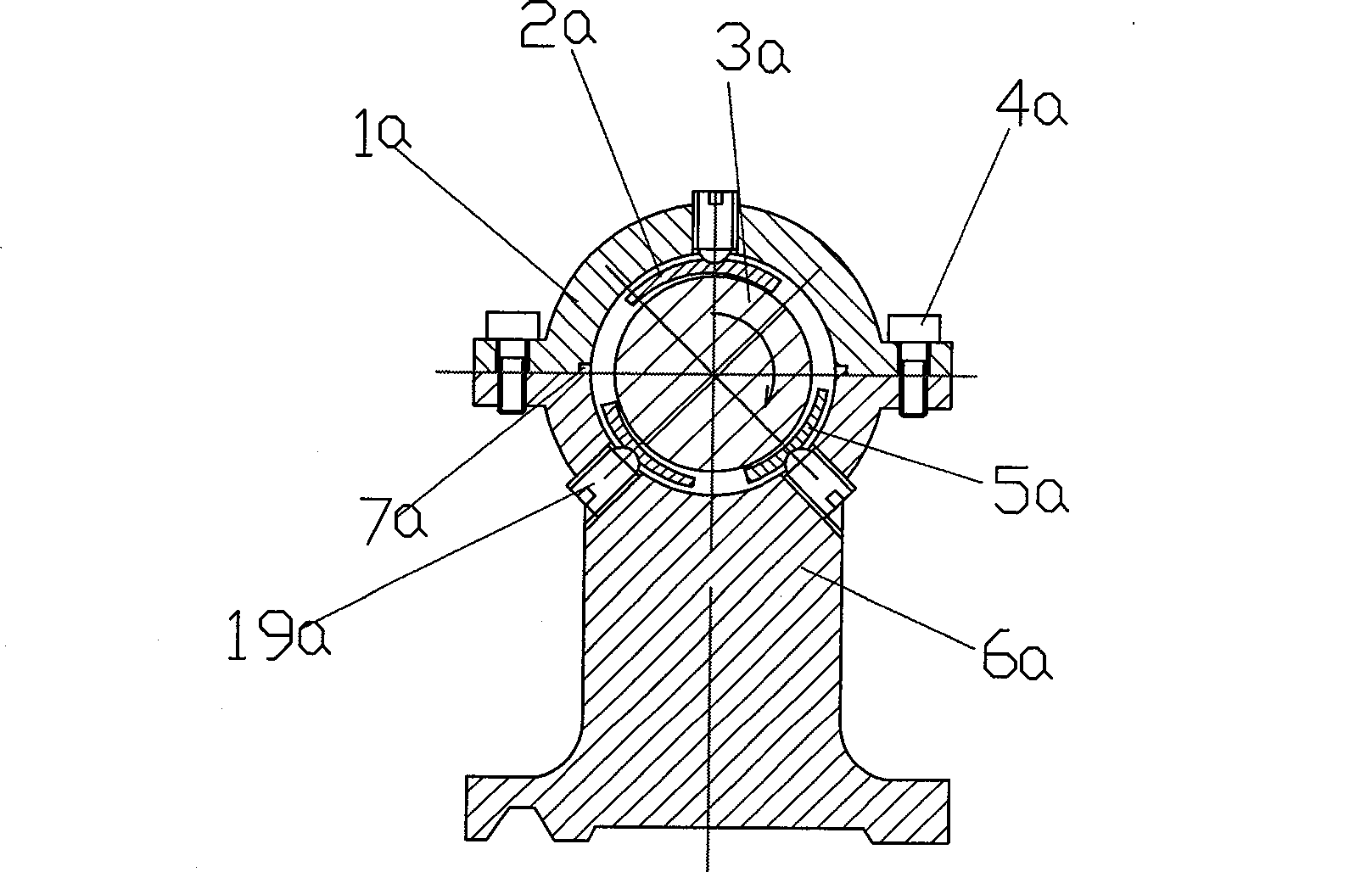

Machine tool liquid kinetic pressure center frame

InactiveCN101439469AAbsorb and dampen vibrationsNo wearRevolution surface grinding machinesAuxillary equipmentLiquid dynamicsEngineering

The invention relates to a liquid dynamic-pressing central frame of a machine tool, which solves the problems that the rigid central frame bearing of the machine tool has poor capability of absorbing the vibration of the workpiece, abrades the surface of the processed workpiece and has low bearing precision. The liquid dynamic-pressing central frame comprises an upper pressing cover and a central supporter which are correspondingly matched and fixed by screws. The liquid dynamic-pressing central frame is characterized in that the internal ring surface of the upper pressing cover is provided with an upper bearing; the lower concave semi-round surface of the central supporter is provided with more than one lower bearings; the working surface of the upper bearing and the lower bearing is Archimedean curved surface or eccentric arc surface; two side surfaces of the upper pressing cover in the axial direction are respectively provided with an upper-half end cover; two side surfaces of the lower-concave semi-round surface of the central supporter in the axial direction are respectively provided with a lower-semi end cover; the lower-half end cover at one side is provided with an oil inlet and the upper-half end cover is provided with an oil outlet. The liquid dynamic-pressing central frame is not rigidly contacted with the workpiece directly, generates no abrasion on the surface of the workpiece, can absorb and restrict the vibration of the supported bearing and has high bearing precision.

Owner:HEFEI UNIV OF TECH

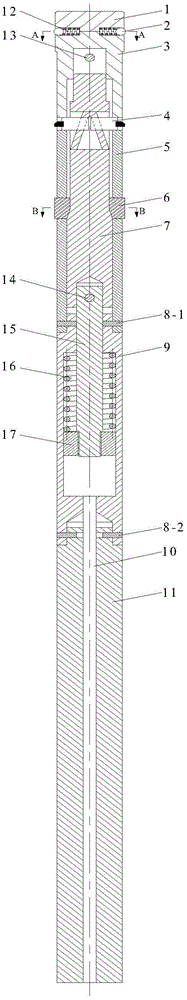

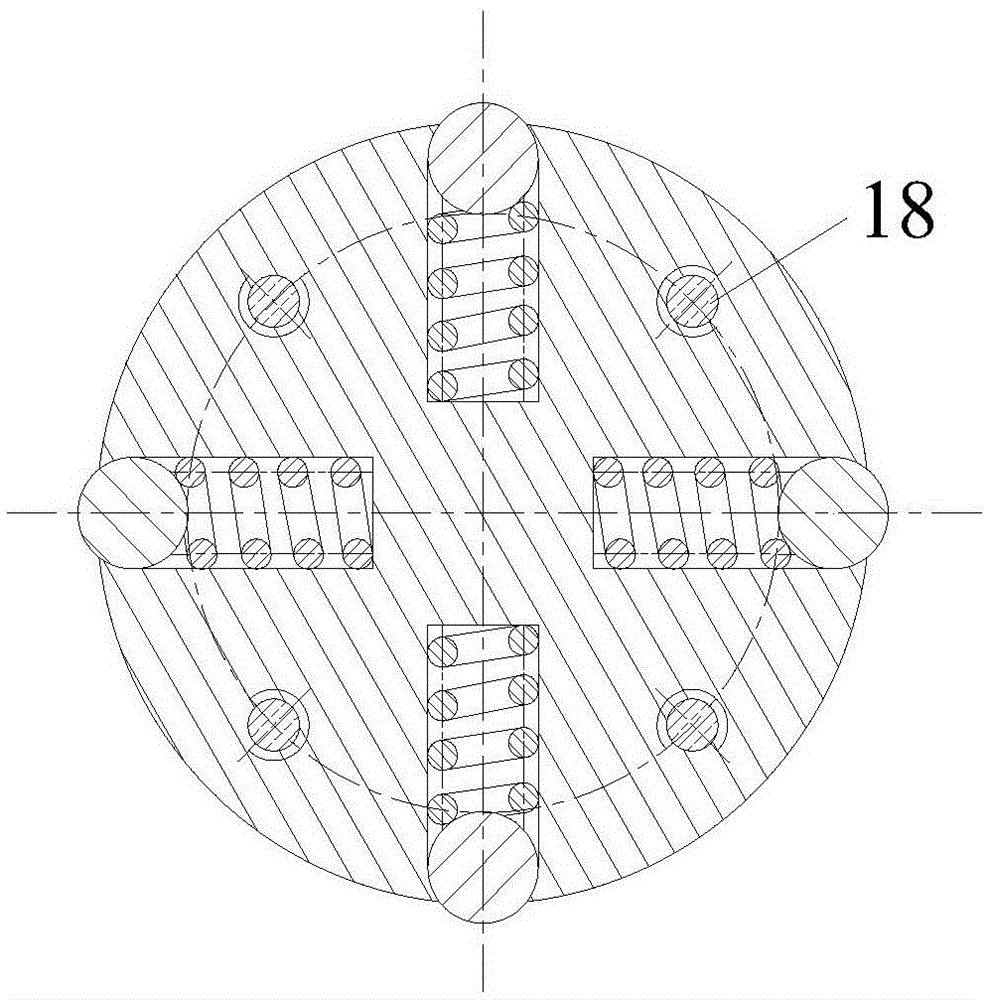

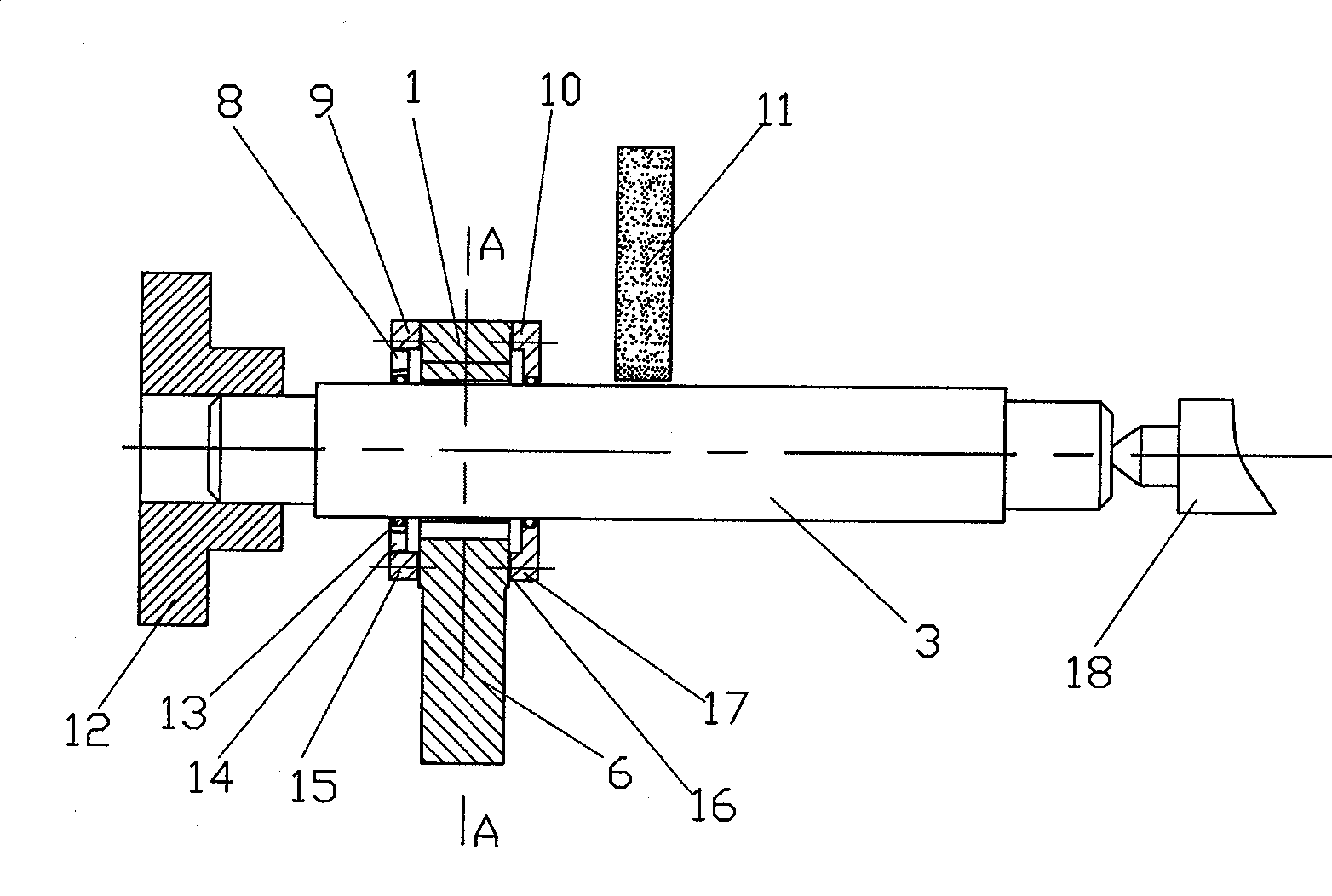

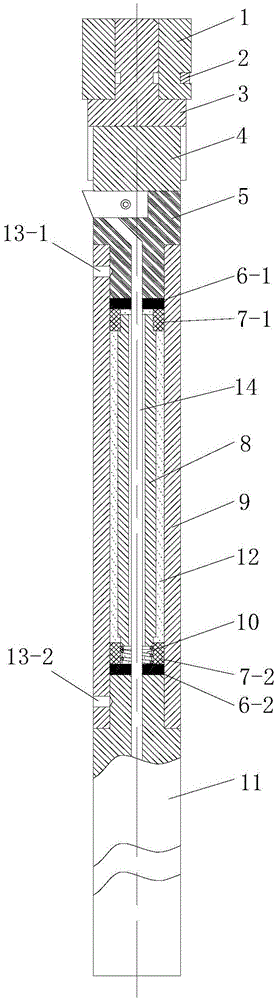

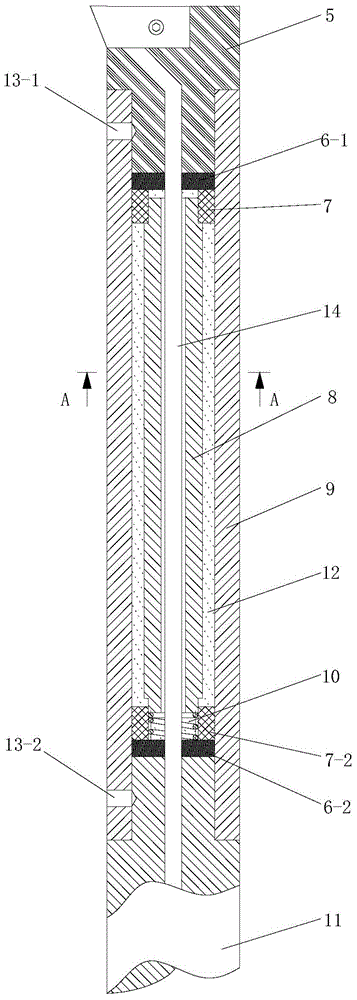

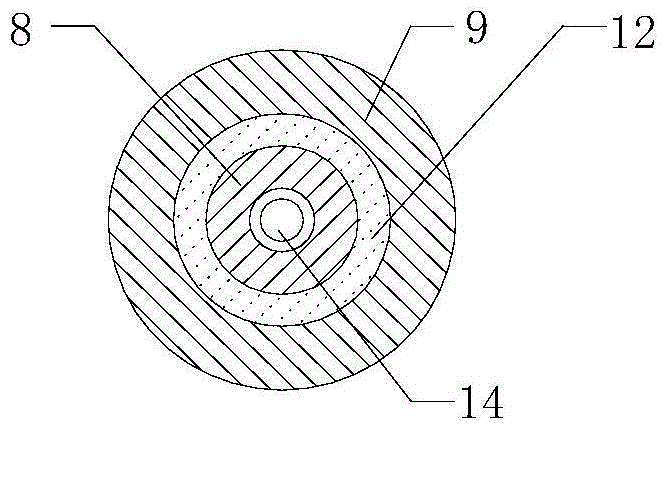

Segmented power damping boring rod with guide function

InactiveCN104874822ASimple manufacturing processReduce stress deformationBoring barsTurning toolsDiameter ratioEngineering

The invention discloses a segmented power damping boring rod with a guide function for deep hole machining. The segmented power damping boring rod comprises a solid rod body, a hollow rod body, an elastic positioning part, a damping block, a tool bit part and a guide part, wherein the hollow rod body and the solid rod body are connected with each other through threads and a positioning screw; the damping block is arranged in the center of the hollow rod body through the elastic positioning part; a gap between the inner wall of the hollow rod body and the damping block is filled with a viscoelastic body, namely, damping fluid; the tool bit part is arranged on the end part of the hollow rod body through threads and a positioning screw; the guide part is arranged on the end part of a tool bit through a screw, and can be detached and arranged freely. During cutting, the guide part plays a role in supporting and preventing vibration. The segmented power damping boring rod with the guide function disclosed by the invention is suitable for deep-long hole boring machining. Compared with a damping boring rod in the prior art, the segmented power damping boring rod with the guide function has the advantages that deep-long holes of smaller diameters and larger length-diameter ratios can be machined, the damping performance can be enhanced greatly, machining conditions of deep-long holes are improved greatly, and the machining accuracy and machining surface quality are improved.

Owner:NANJING UNIV OF SCI & TECH

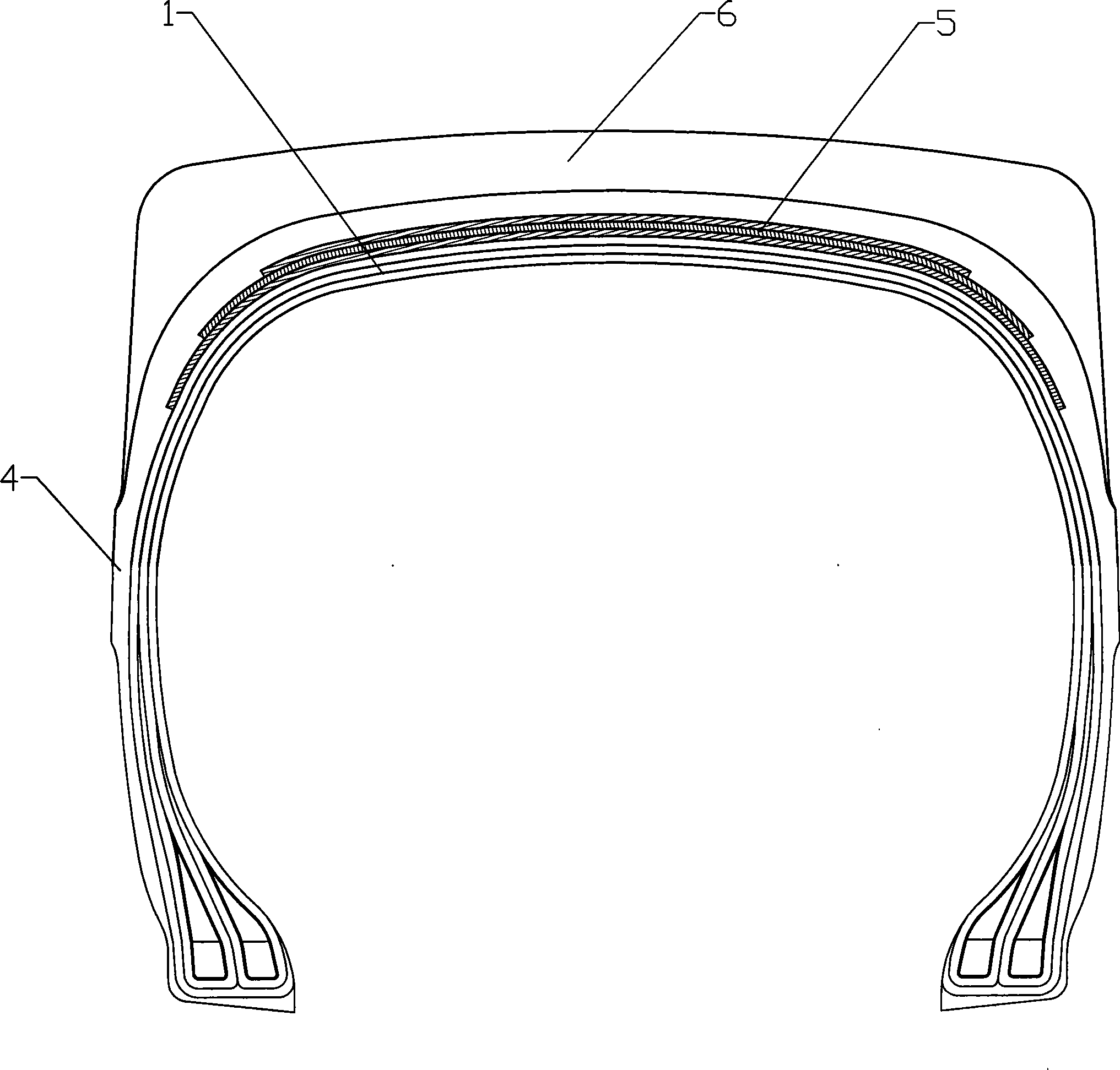

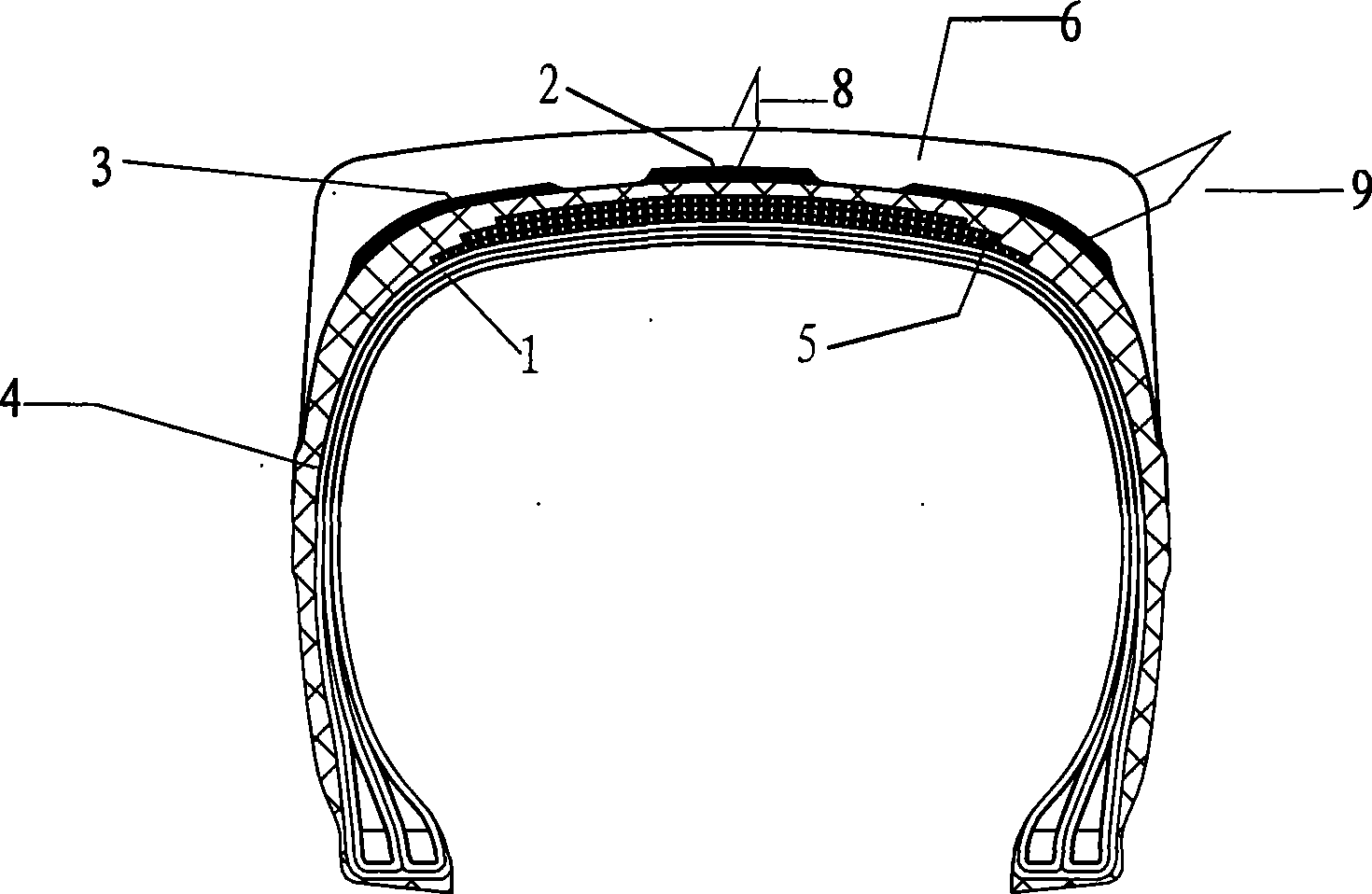

High piercing-resistance, cutting-resistant semi-steel engineering tyre and manufacturing method thereof

InactiveCN101412349AImprove puncture resistanceImprove cut resistanceTyresPneumatic tyre reinforcementsFiberRolling resistance

The invention discloses a high pierce-resistant, cutting-resistant semi-steel engineering tire and a preparation method thereof. The engineering tire comprises a tire body consisting of a plurality layers of high intensity fiber cord fabric, wherein the outside of the tire body is fixedly adhered with a tire thread made of tire thread rubber; the tire thread comprises a tire crown face and a tire side face; and a steel wire buffer layer is arranged between the tire crown face and the tire side face, and comprises two to ten layers of steel wire cord fabric. As the tire body adopts the plurality layers of high intensity fiber cord fabric, the engineering tire has high bearing capacity and high efficiency. As the buffer layer adopts the steel wire cord fabric, the tire crown has high rigidity and strong pierce-resistant performance; the tire body has little circumferential deformation during the driving of a vehicle; and the vehicle drives stably, has little rolling resistance, strong performance of passing rigid rocky mining areas and saves fuel.

Owner:山东银宝轮胎集团有限公司

Device and method for constant-pressure electromagnetic forming of metal plate under action of heterodromous currents

The invention provides a device for constant-pressure electromagnetic forming of a metal plate under the action of heterodromous currents. The device comprises a u-shaped mold, and further comprises acapacitance power module, a magnet supply branch and two vertical side pressing plates. The capacitance power module comprises an energy storage capacitor. The magnet supply branch comprises a constant-pressure coil and is connected to the two ends of the capacitance power module. The upper ends of the side pressing plates are bent oppositely and extend to form closed plates, and therefore a containing cavity with an opening being downward is formed between the two side pressing plates and below the two closed plates. The constant-pressure coil is fixedly arranged in the containing cavity. During use, a power supply branch is formed by the two closed plates, the two side pressing plates and the to-be-formed metal plate; the power supply branch and the magnet supply branch are connected inparallel and are connected to the two ends of the capacitance power module by taking the free ends of the two closed plates as the electric access points. When the energy storage capacitor carries out discharge, discharge currents opposite in direction are formed in the constant-pressure coil and the power supply branch. According to the device, the magnitude of the currents on the formed plate is enhanced, the stress balance performance of the constant-pressure coil is improved, and processing capacity is improved.

Owner:WUHAN UNIV OF TECH

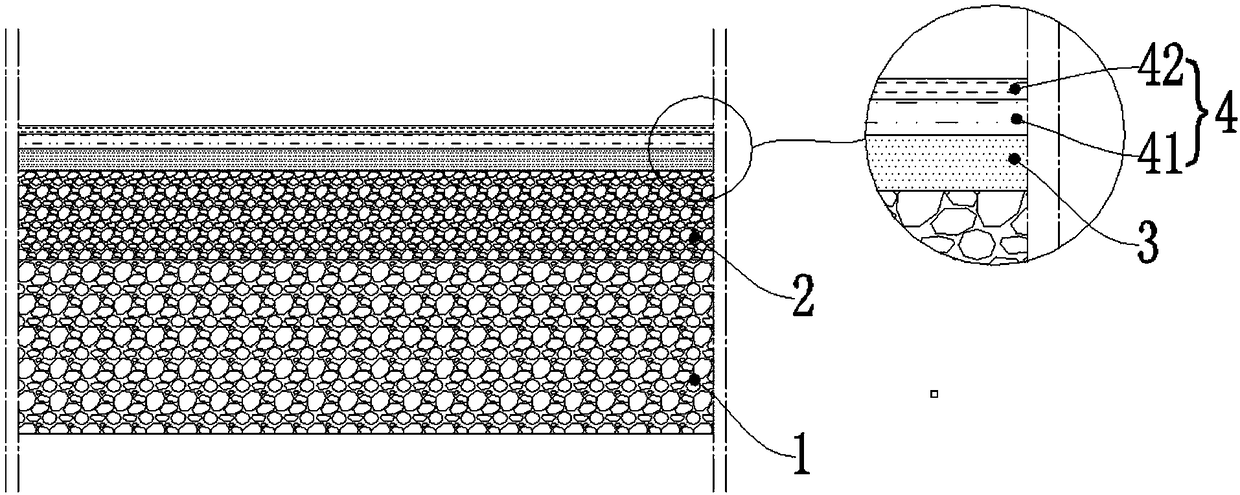

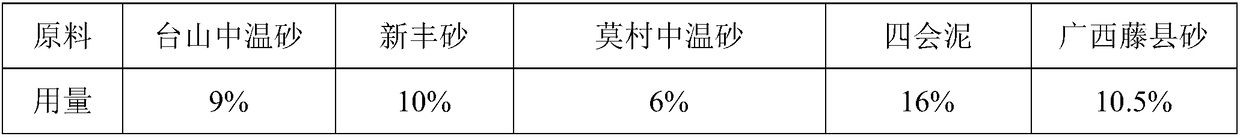

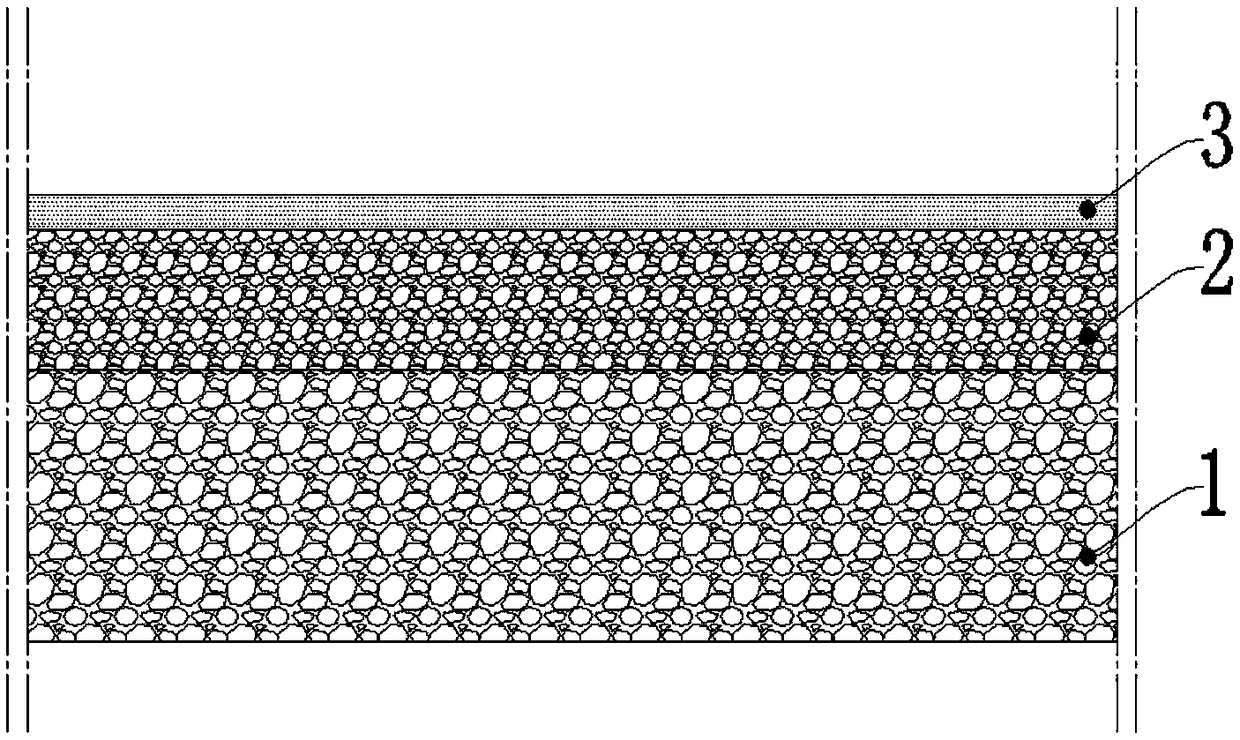

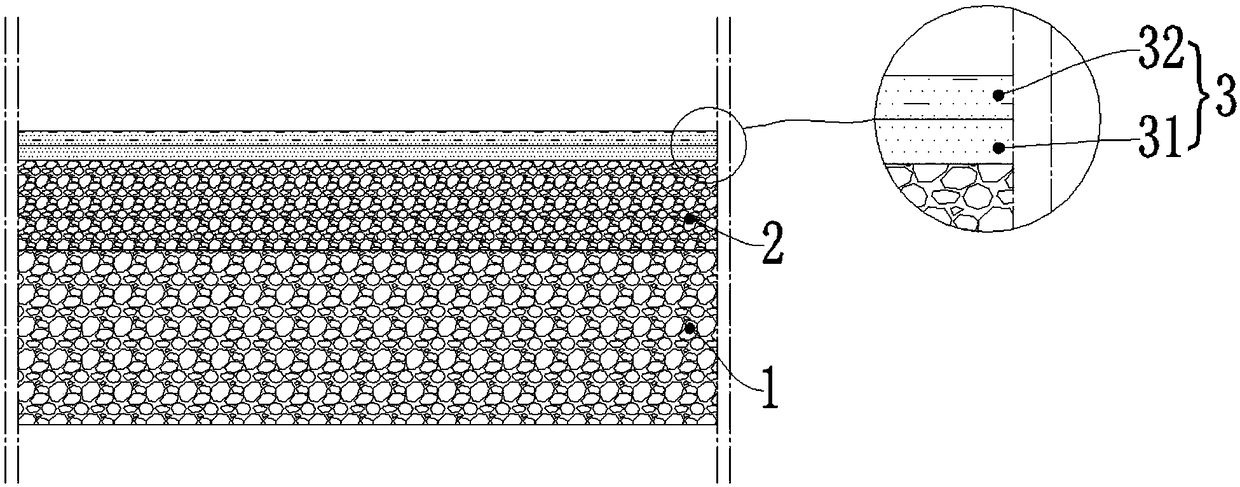

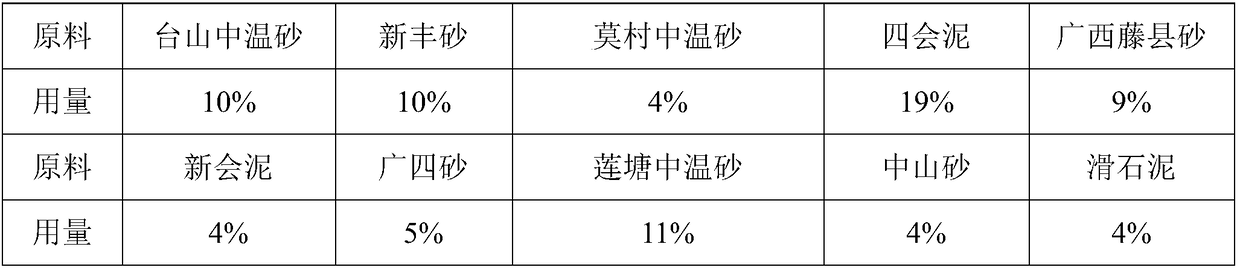

Once-firing multi-density composite foamed ceramic decorative board and preparation method thereof

The invention discloses a once-firing multi-density composite foamed ceramic decorative board. The once-firing multi-density composite foamed ceramic decorative board comprises a first foamed layer, asecond foamed layer, a sealing layer and a surface decorative layer arranged in order from bottom to top, wherein the density of the second foaming layer is less than the density of the first foaminglayer; the first foaming layer, the second foaming layer, the sealing layer and the surface decorative layer are fired once; the sealing layer is used for sealing a hole in the surface of the secondfoaming layer; the sealing layer is an engobe layer, or the sealing layer is a non-foamed ceramic slurry layer and an engobe layer, and the non-foamed ceramic slurry layer is located between the foamed layer and the engobe layer; the surface decorative layer is a glazed layer. Correspondingly, the invention also discloses a preparation method of the decorative board. The sealing layer can improvethe flatness of the product and improve the decorative effect of the product. The foamed ceramic decorative board is easy to clean. The foamed layers, the sealing layer and the surface decorative layer are fired once, and the layers are firmly bonded.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +1

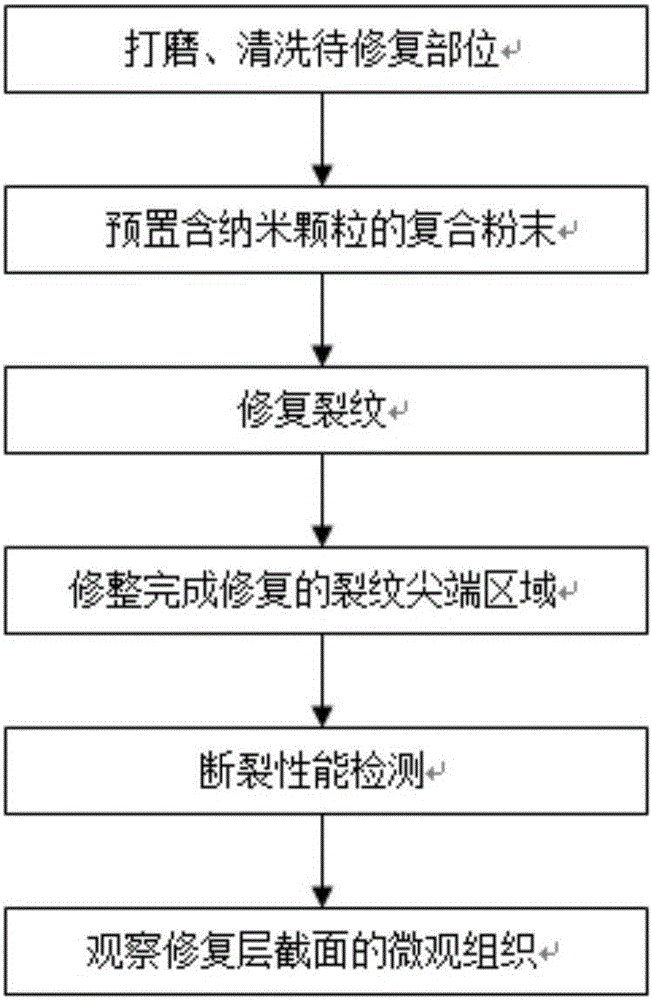

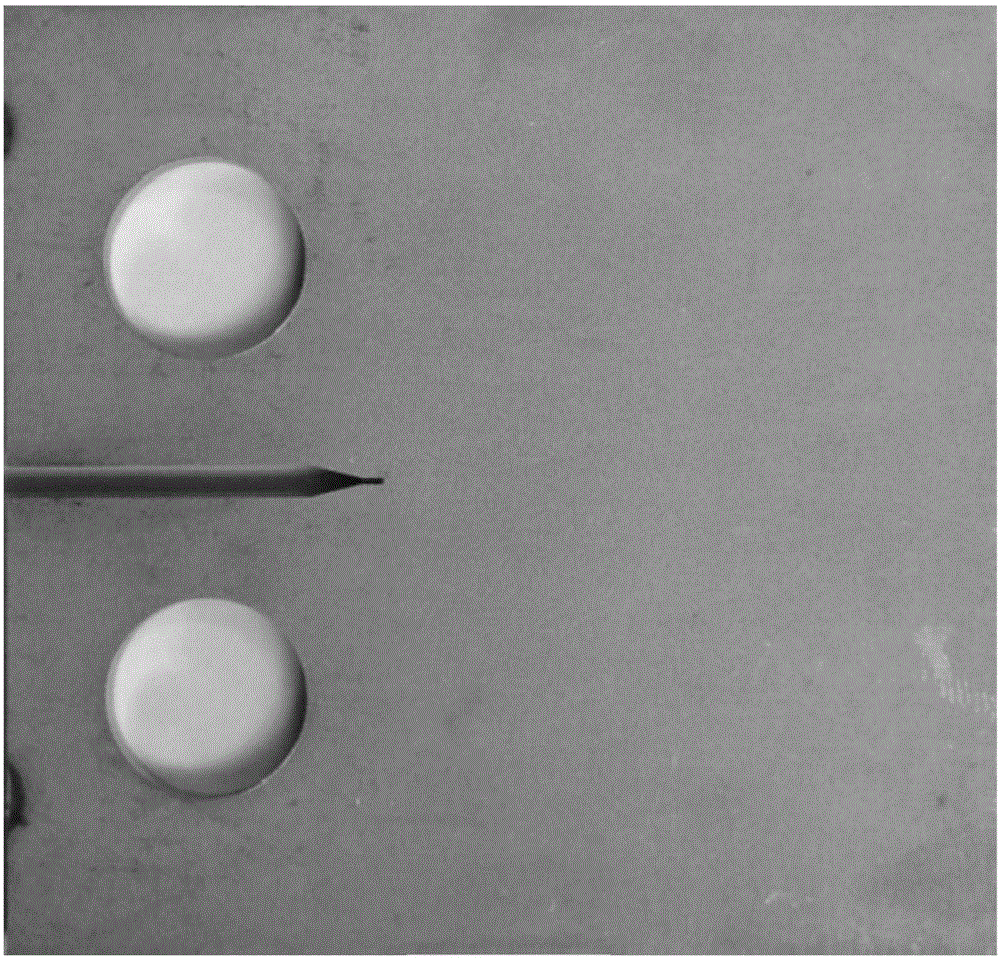

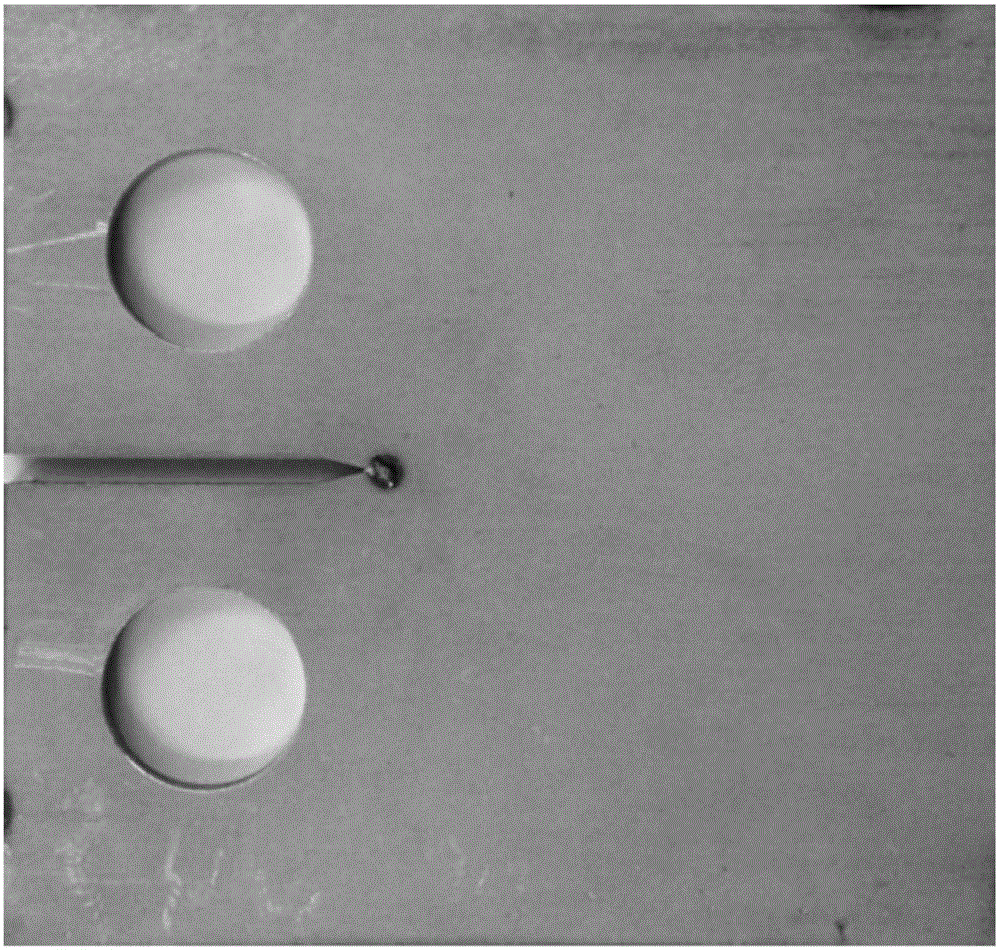

Method for repairing microcrack tip on stainless steel surface by means of nano-particles

ActiveCN105714286AImprove densification performanceExtended service lifeMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

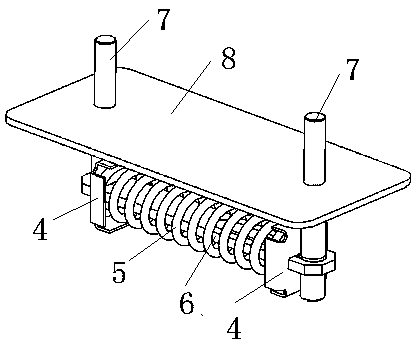

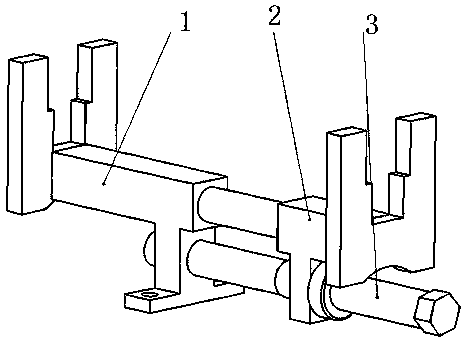

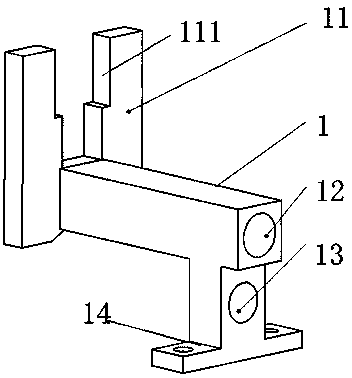

Spring assembly auxiliary loading and unloading tooling

ActiveCN109249349ARealize loading and unloadingLoading and unloading is realized through this auxiliary loading and unloading toolMetal-working hand toolsPull forceEngineering

The invention relates to a spring assembly auxiliary loading and unloading tooling. The spring assembly auxiliary loading and unloading tooling comprises a first base, a second base and a driving mechanism, wherein the driving mechanism is used for driving the first base and the second base to move oppositely and move on the contrary, the first base is in guided cooperation with the second base through a telescopic guide structure, and the first base and the second base are provided with force application parts arranged at the two ends of a corresponding spring assembly respectively to exert pressure or tension on a spring in the corresponding spring assembly. The spring assembly auxiliary loading and unloading tooling has the advantages that loading and unloading of the spring assembly are achieved, one person can perform operation, the operation time is saved, and the operation efficiency is increased; through the arrangement of the guide structure, the loading and unloading toolingcan achieve the stationarity of the guide movement in the process of pulling and pressing the spring and reduce the axial deformation by force of the spring assembly during compression.

Owner:PINGGAO GRP +2

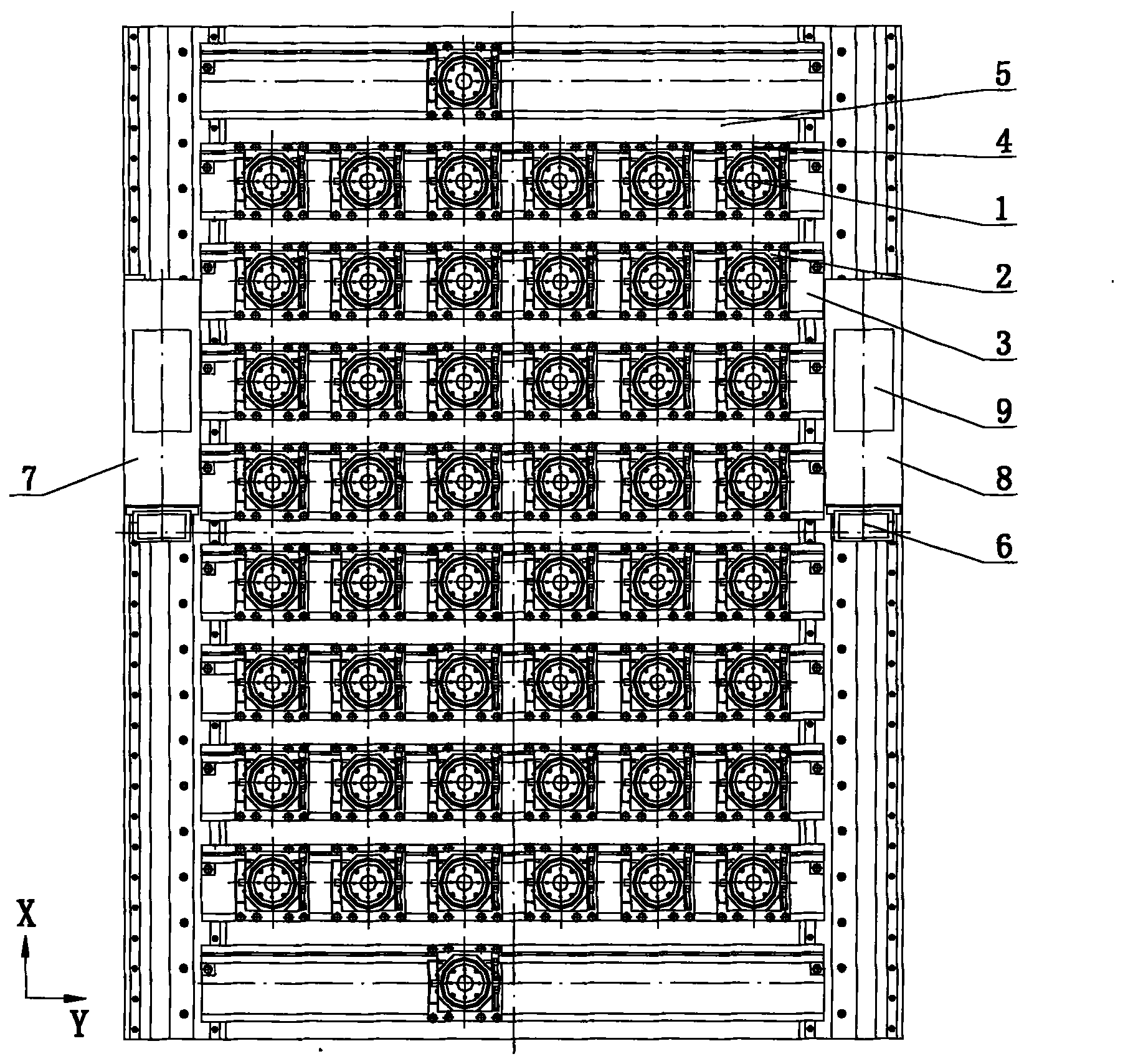

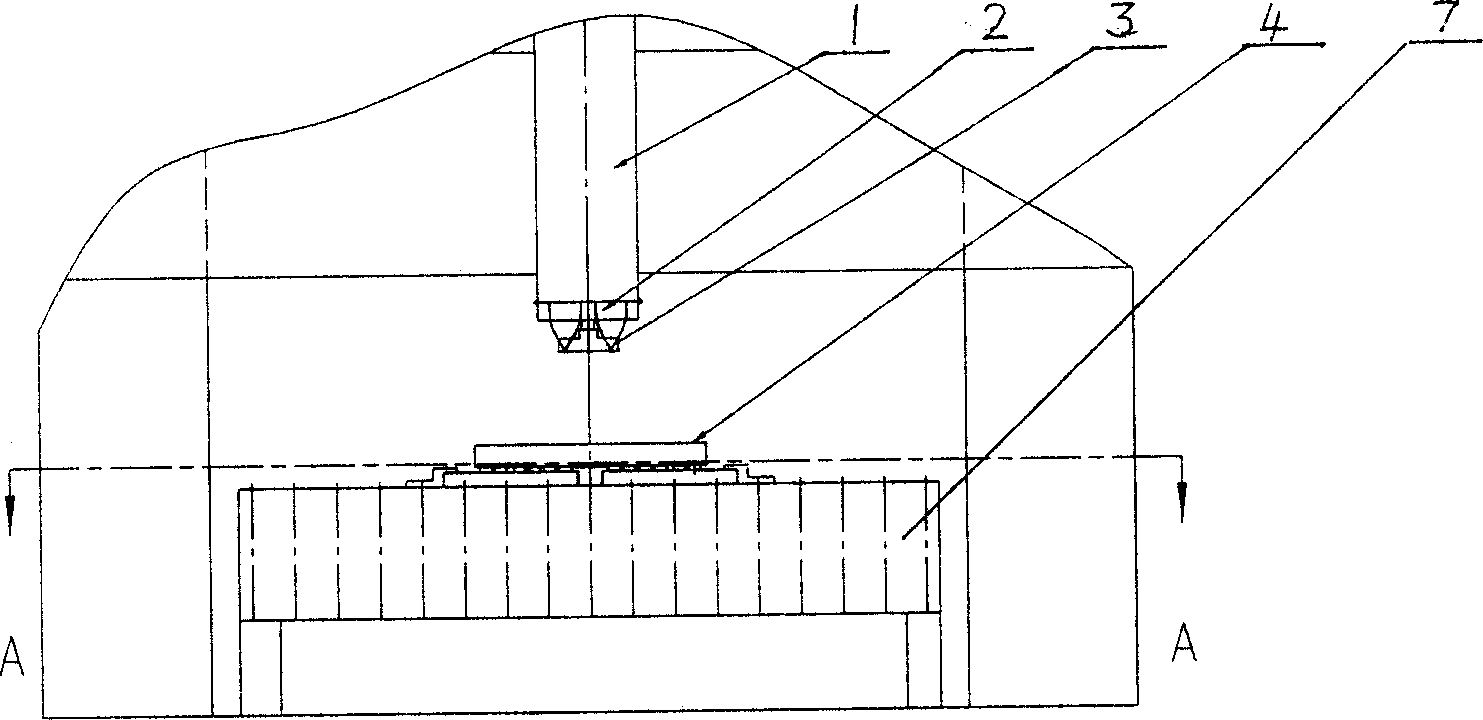

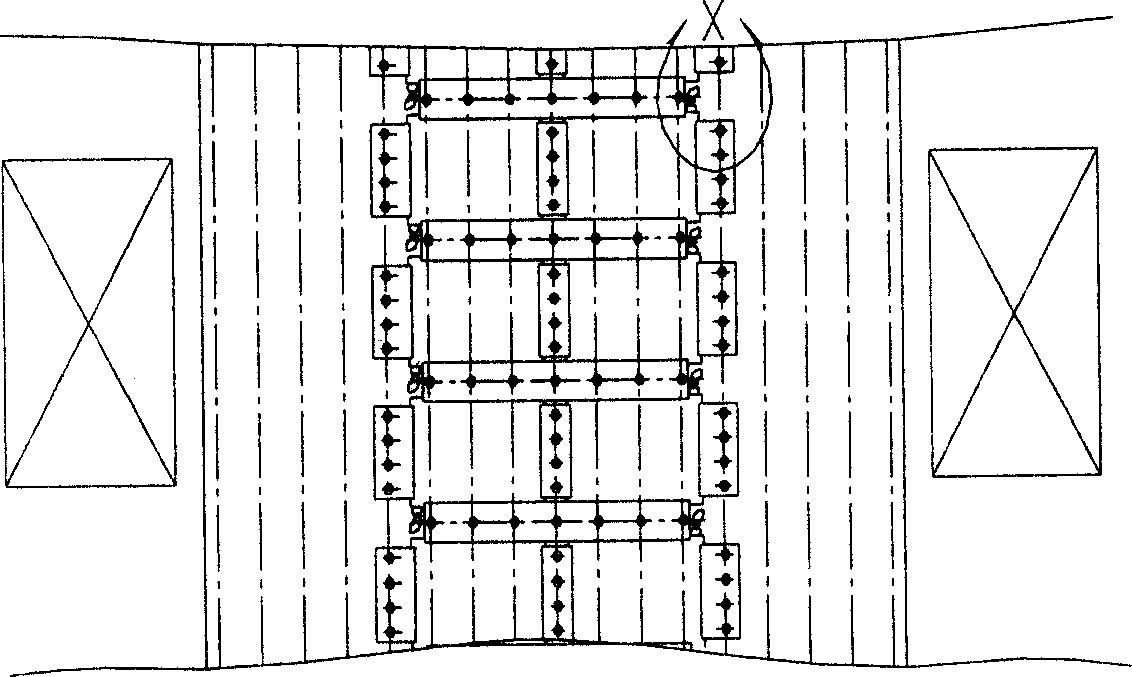

Processing method for artificial board hot-press hot pressing board plane

InactiveCN1907612AReduce stress deformationConsistent forcePlywood pressesVeneer pressesPre treatmentEngineering

The invention relates to a method for processing the plane of artificial sheet thermal compressor, which uses national general digit-control crane boring-mill machine to bore and mill the plane to realize the high roughness and flatness, wherein said thermal compressed sheet is the pretreated mould steel, whose rigidity is HRC40, and the plane size of work-piece is large. The invention adjusts the accuracy of machine, adjusts the plane milling blade, and the work-piece is clamped via the electromagnetic absorb disc, via special parameters and digit-control program, using high-pressure air to cool it, to realize the high accuracy demand. The smoothness of inventive product can reach Ra0.4-Ra0.2, and flatness can reach 0.10.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

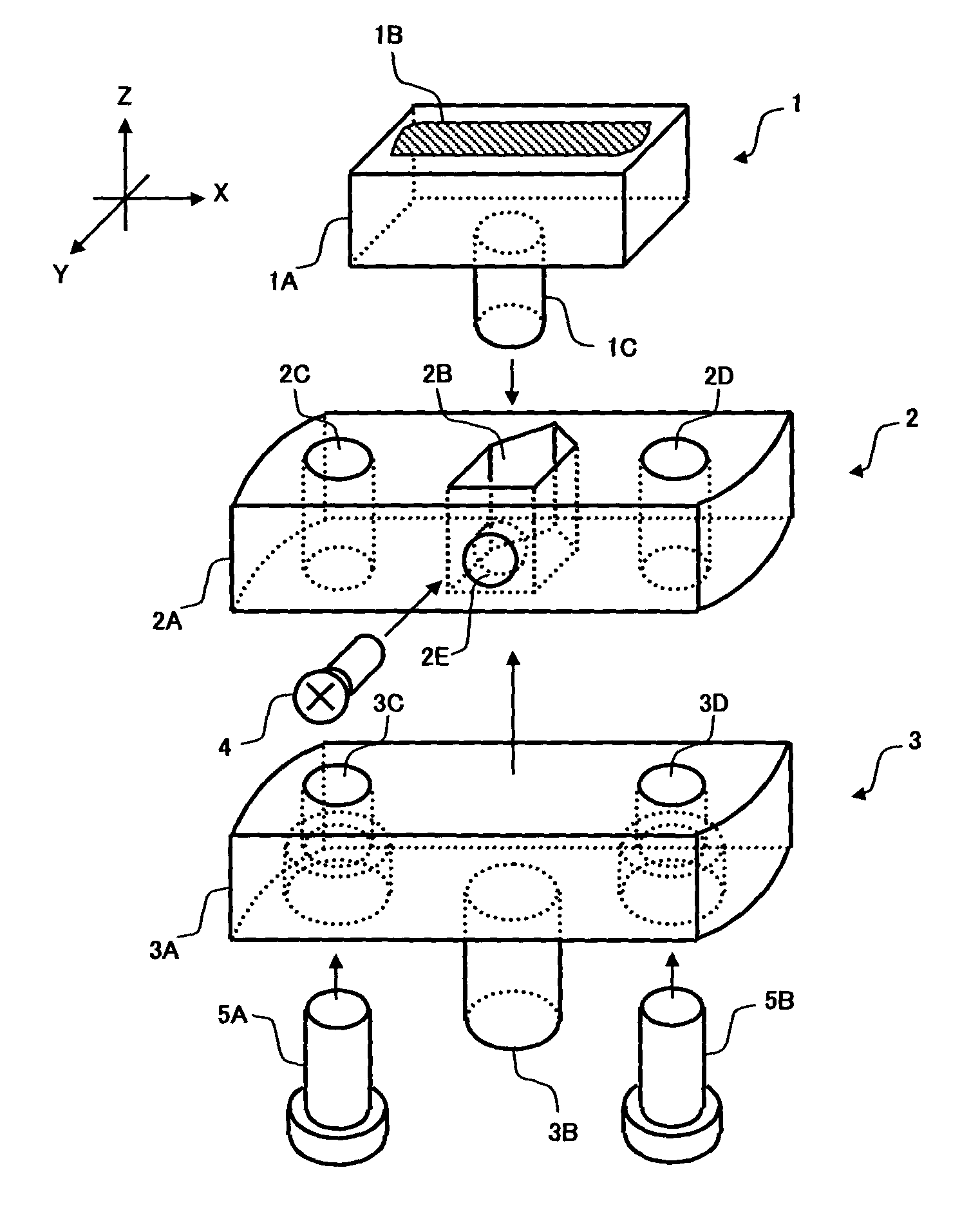

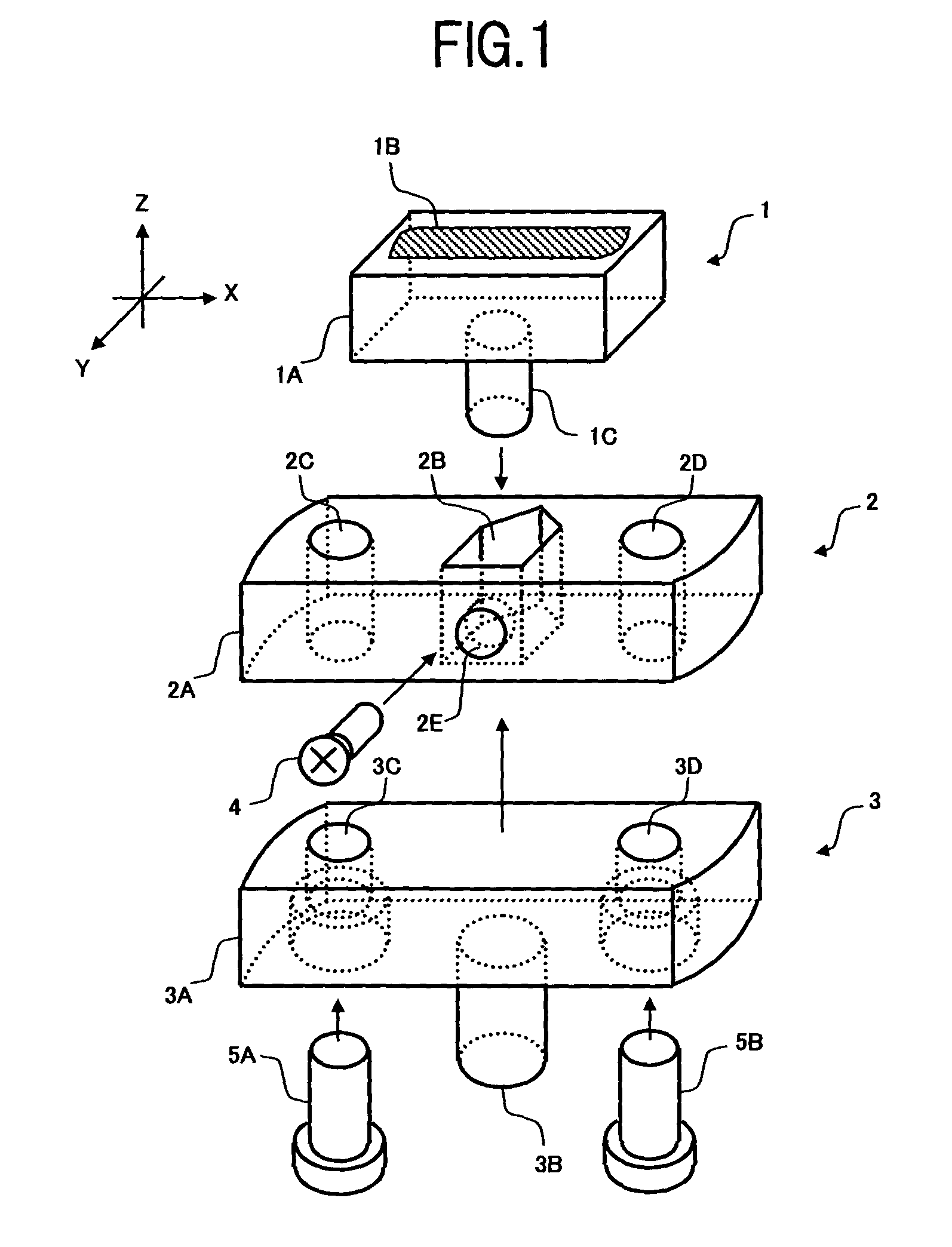

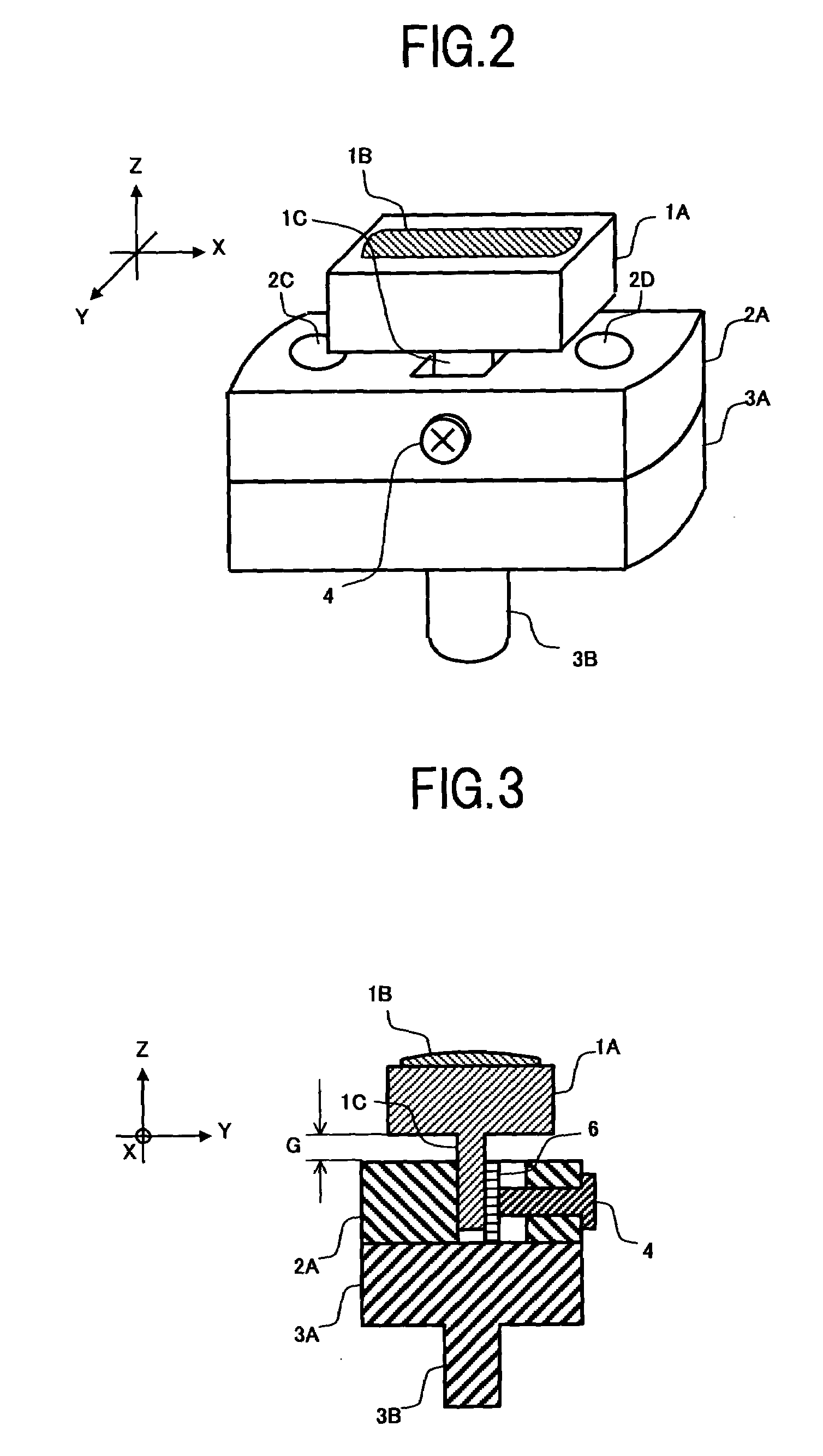

Mirror fixing method and optical apparatus

InactiveUS7073915B2Improve performanceImprove accuracyMirrorsCoupling light guidesEngineeringOptic system

An object of the invention is to provide a mirror fixing method capable of reducing stress distortion of a surface of a mirror which constitutes an optical system, with hardly deforming a surface shape of the mirror. To this end, the present mirror fixing method is characterized in that a mirror part including a base plate formed with a mirror on one face thereof, is provided with a boss on the other face of the base plate opposite to the face on which the mirror is formed, and only the boss is fixed, so that the mirror part excluding the boss is not in contact with other members.

Owner:FUJITSU LTD

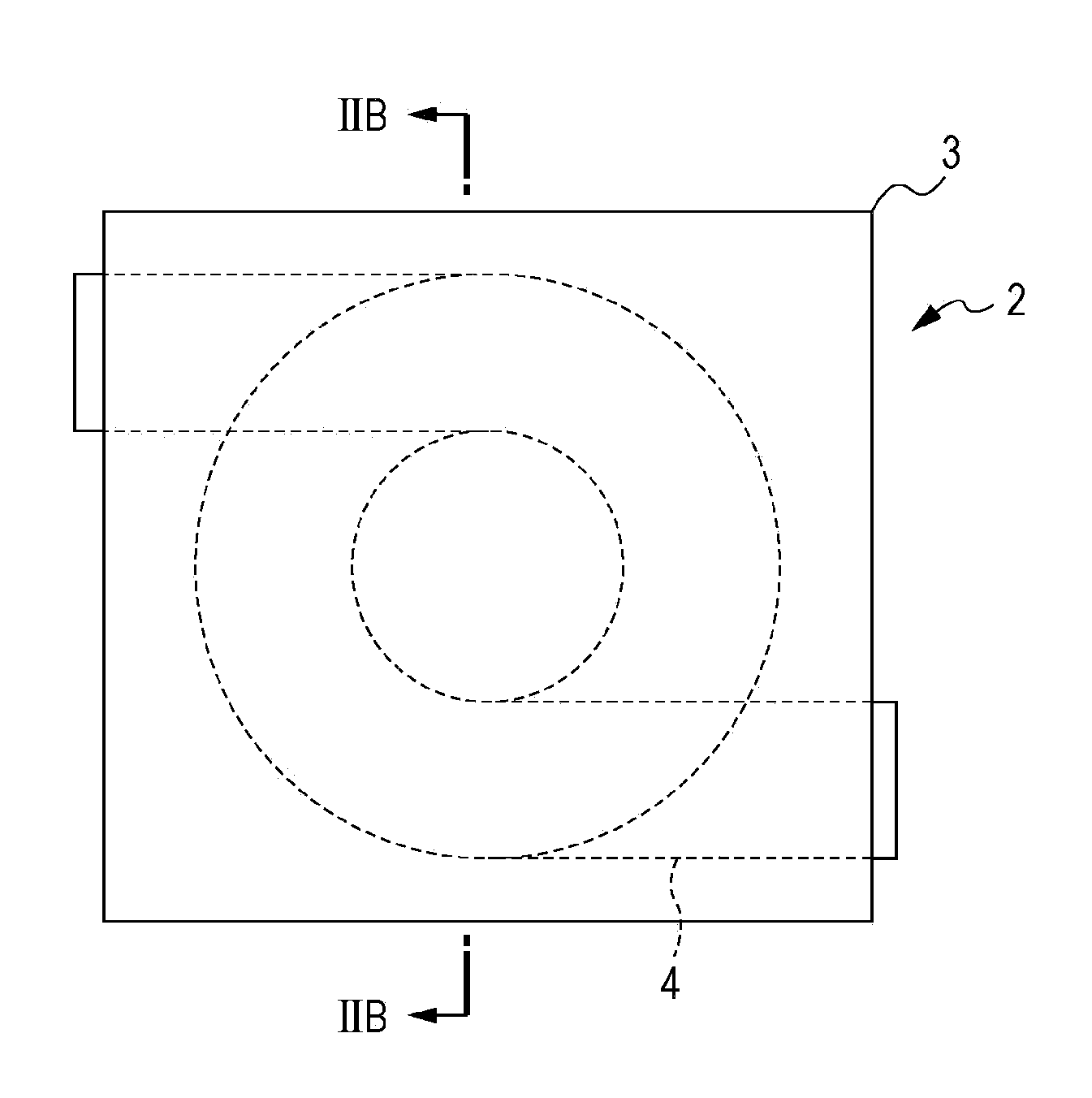

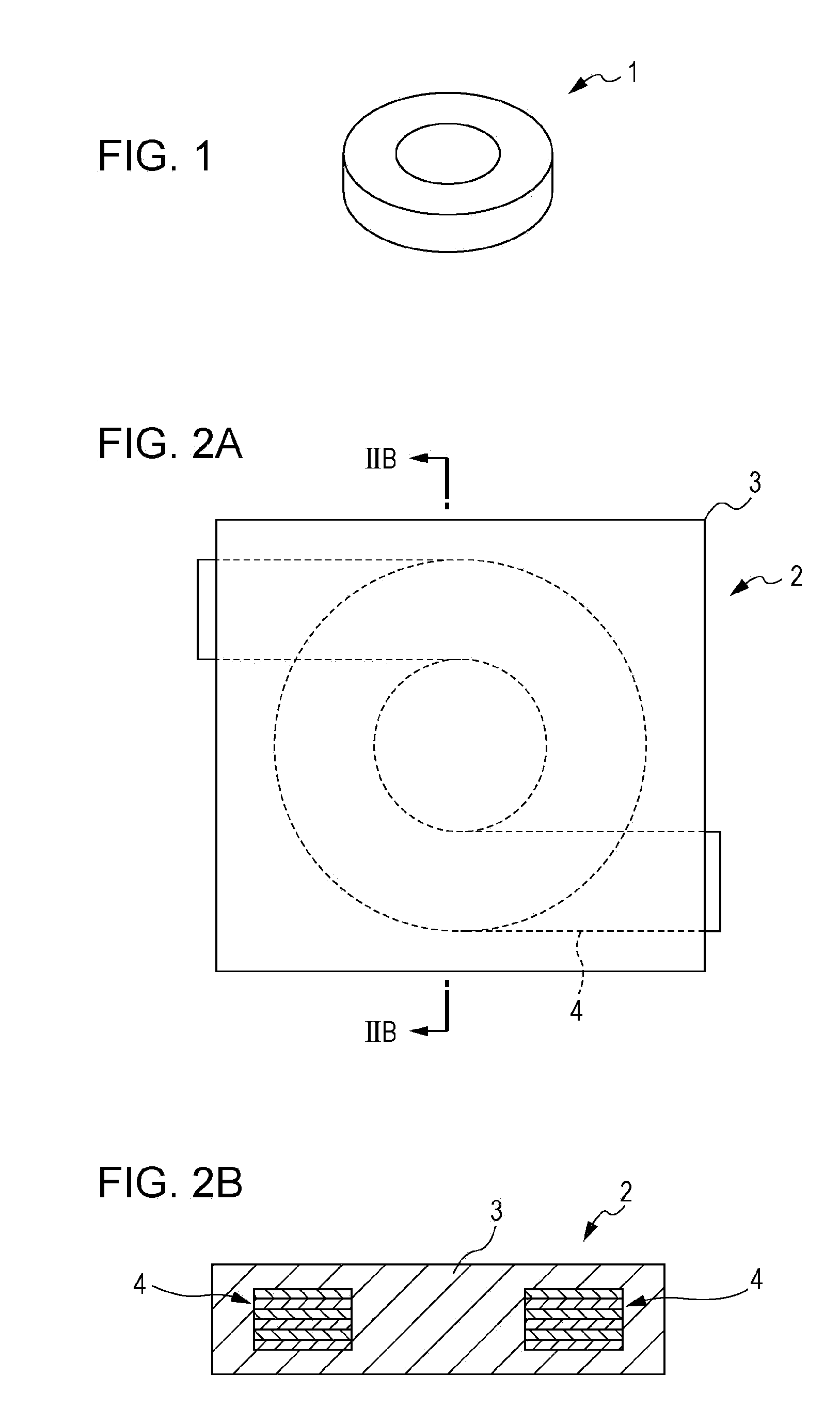

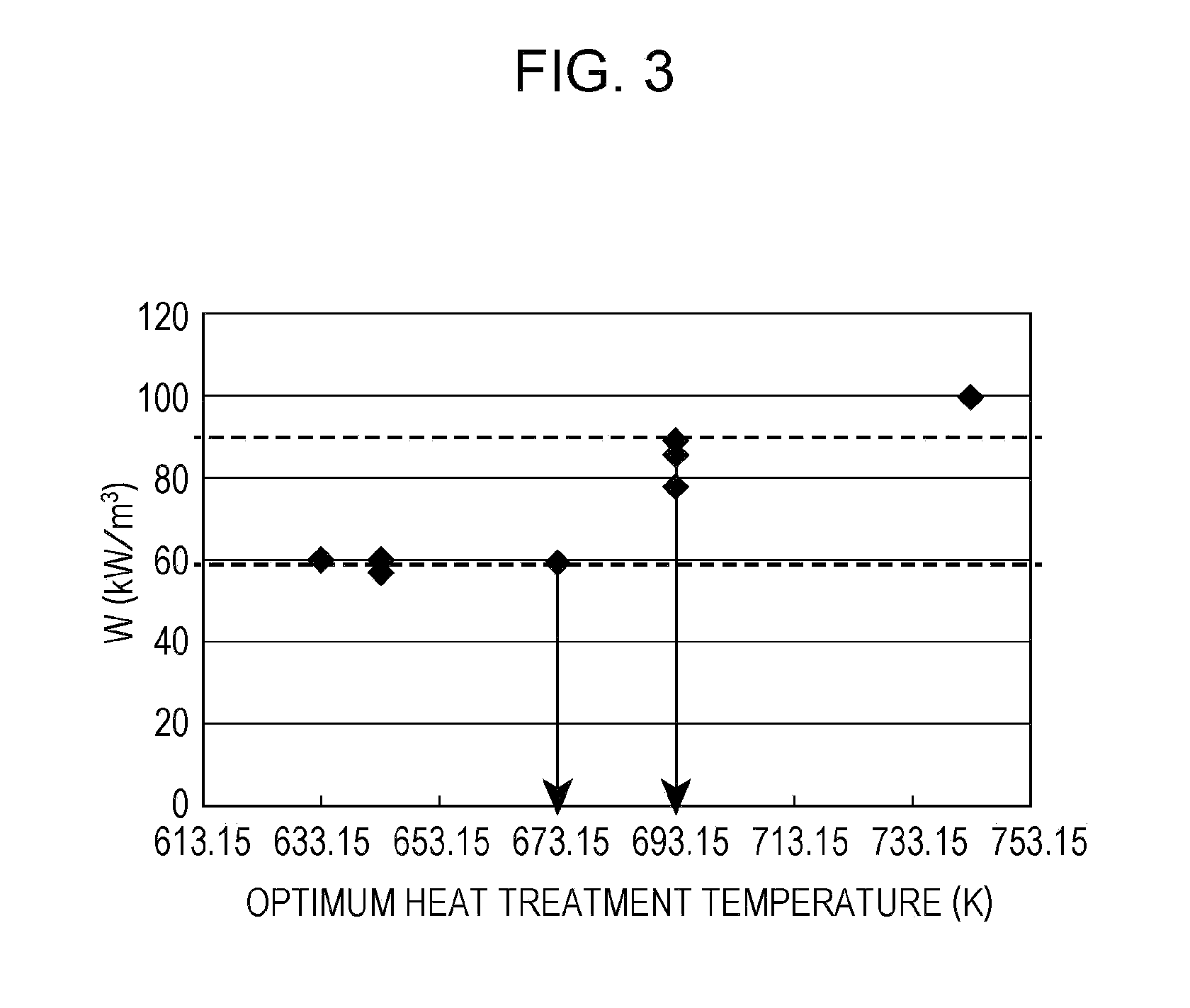

Fe-BASED AMORPHOUS ALLOY, POWDER CORE USING THE SAME, AND COIL ENCAPSULATED POWDER CORE

ActiveUS20120092111A1Optimum heat treatment temperatureImprove power efficiencyTransformers/inductances casingsInorganic material magnetismVitrificationMagnetization

An Fe-based amorphous alloy of the present invention has a composition formula represented by Fe100-a-b-c-x-y-z-tNiaSnbCrcPxCyBzSit, and in the formula, 0 at %≦a≦10 at %, 0 at %≦b≦3 at %, 0 at %≦c≦6 at %, 6.8 at %≦x≦10.8 at %, 2.2 at %≦y≦9.8 at %, 0 at %≦z≦4.2 at %, and 0 at %≦t≦3.9 at % hold. Accordingly, an Fe-based amorphous alloy used for a powder core and / or a coil encapsulated powder core having a low glass transition temperature (Tg), a high conversion vitrification temperature (Tg / Tm), and excellent magnetization and corrosion resistance can be manufactured.

Owner:ALPS ALPINE CO LTD

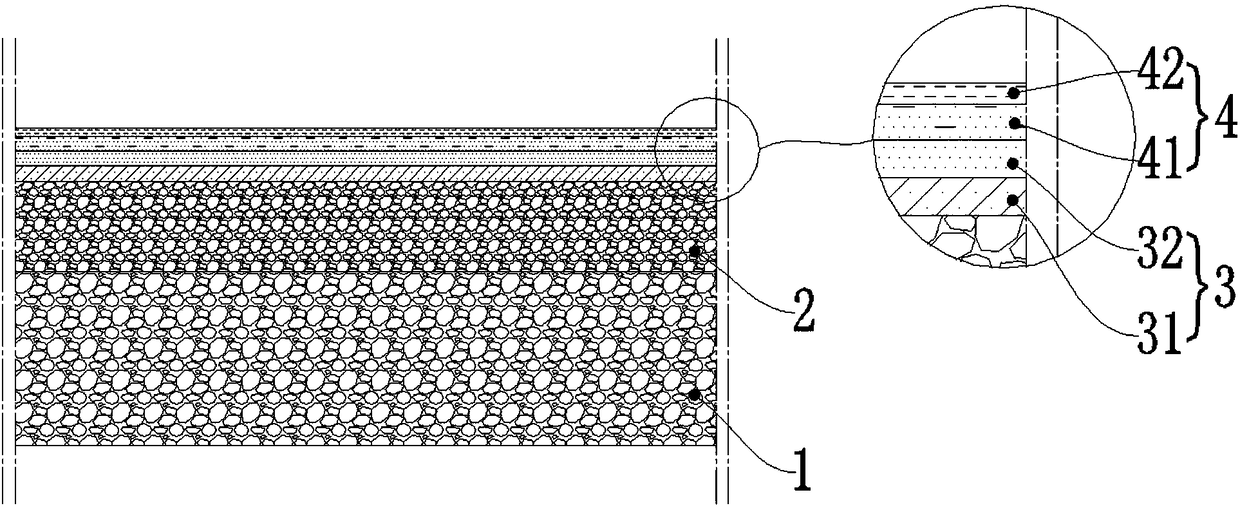

Once-firing multi-density composite foaming through-body decorative board and preparation method thereof

ActiveCN108546080AAvoid problemsEasy to cleanLayered productsConstructions elementsSpray GranulationMetallurgy

The invention discloses a once-firing multi-density composite foaming through-body decorative board comprising a first foaming layer, a second foaming layer and a sealing layer which is used for sealing holes on the surface of the second foaming layer, wherein the first foaming layer, the second foaming layer and the sealing layer are arranged from bottom to top successively; the density of the second foaming layer is less than that of the first foaming layer, and each of the first foaming layer, the second foaming layer and the sealing layer contains a pigment in formula; the sealing layer isan engobe layer, or the sealing layer is a non-foaming ceramic billet slurry layer and an engobe layer, and the non-foaming ceramic billet slurry layer is located between the second foaming layer andthe engobe layer. Correspondingly, the invention also discloses a preparation method for the decorative board, wherein the preparation method comprises the steps: carrying out ball milling of a billet raw material of the foaming layer, aging with a slurry pool, carrying out spray granulation, aging with a bin, pressing into a green body, drying, and applying with the engobe layer, or applying with non-foaming ceramic slurry and engobe soil. The decorative board is a decorative board with through-body color, and has the characteristics of easy cleaning, high surface smoothness and appropriatedensity of the product.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +1

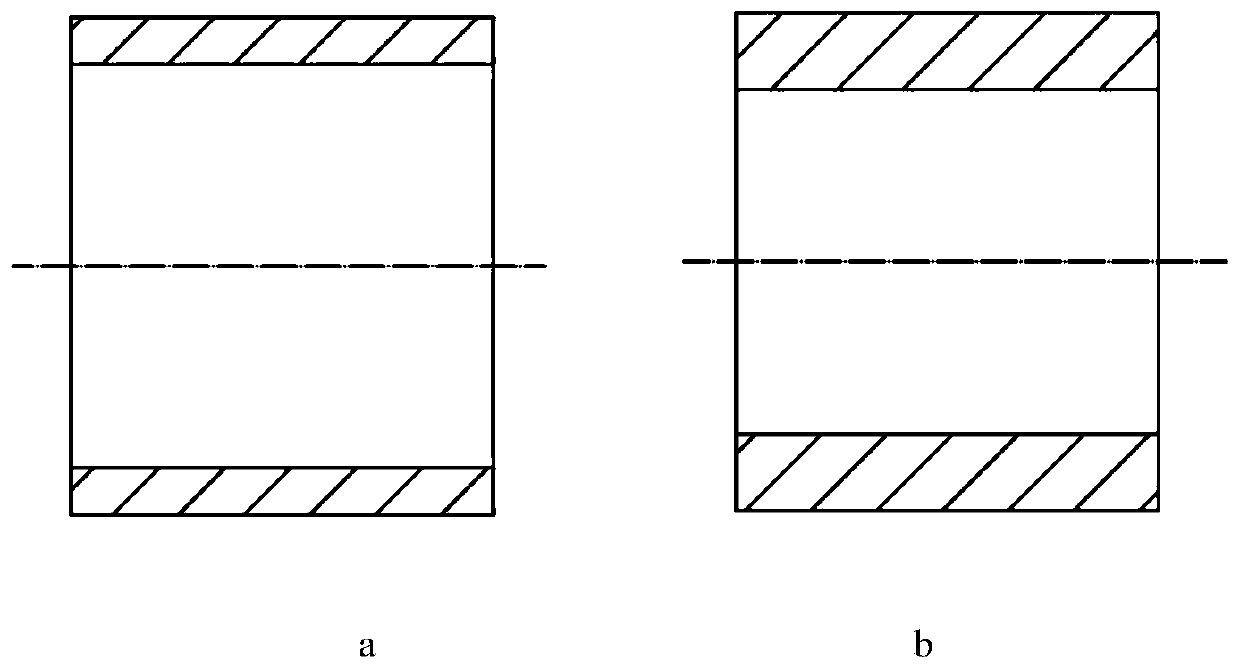

Quenching apparatus for glass toughening production line

ActiveCN104692637ARealize quenching treatmentReduce stress deformationGlass tempering apparatusCooling effectThin glass

The invention discloses a quenching apparatus for a glass toughening production line. The quenching apparatus comprises a frame, a cooling mechanism and a lifting mechanism. The cooling mechanism comprises an upper cooling roller bed, a lower cooling roller bed, a driving mechanism and a liquid coolant circulation system. The lifting mechanism adjusts a gap between the upper cooling roller bed and the lower cooling roller bed by lifting and dropping the upper cooling roller bed. The driving mechanism is used for driving the upper and lower cooling roller beds to rotate so as to convey heated and to-be-quenched glass plates; and when the to-be-quenched glass plates pass through between the upper and lower cooling roller beds, the upper and lower cooling roller beds contact with the to-be-quenched glass plates, certain pressure is applied on the to-be-quenched glass plates via the gravity of the upper cooling roller bed, so quenching of the to-be-quenched glass plates is realized. The quenching apparatus has simple and practicable structure, can effectively realize quenching of ultrathin glass plates, improves cooling intensity in the process of quenching, enables cooling effect to be more uniform and reduces stress deformation of ultrathin glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

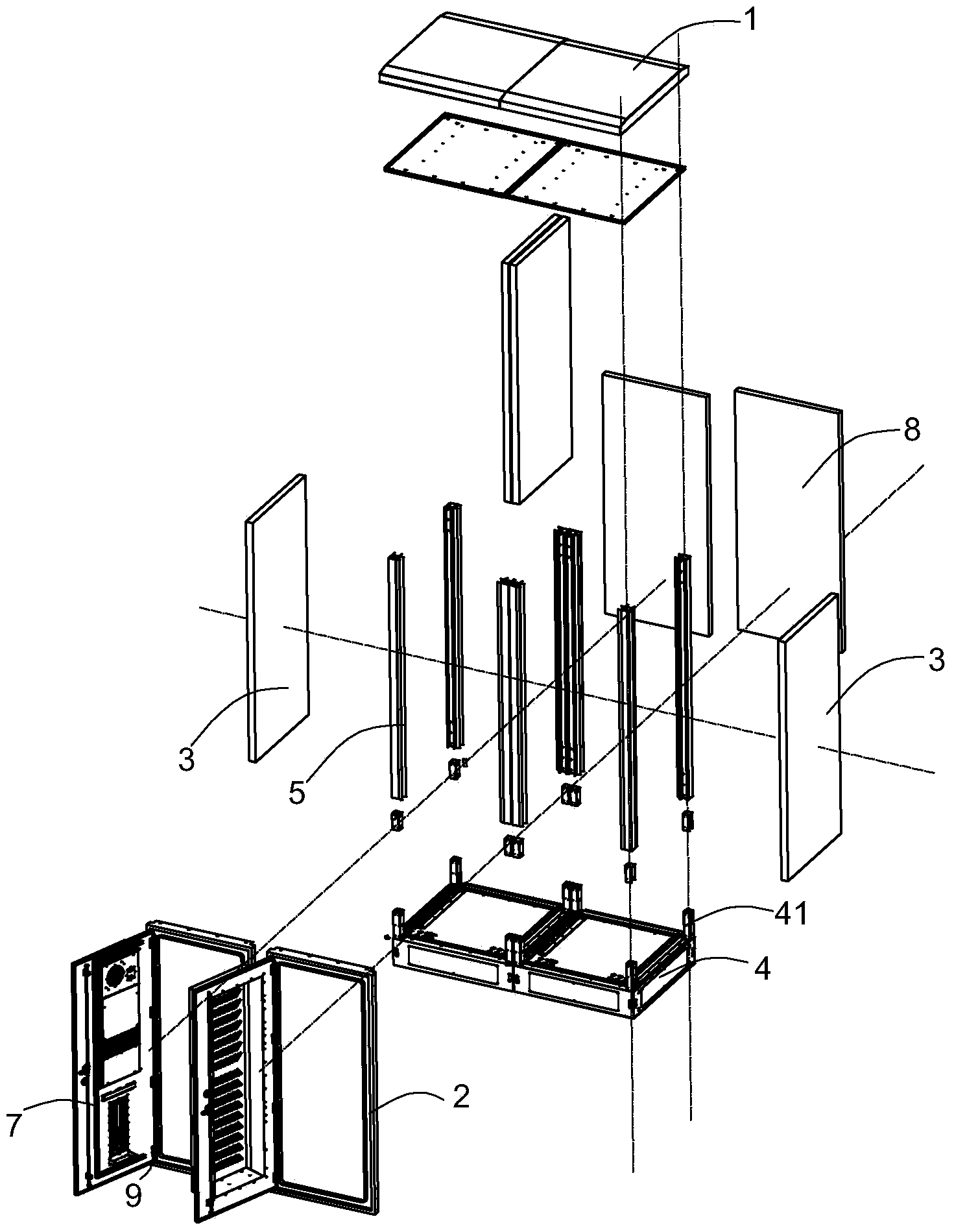

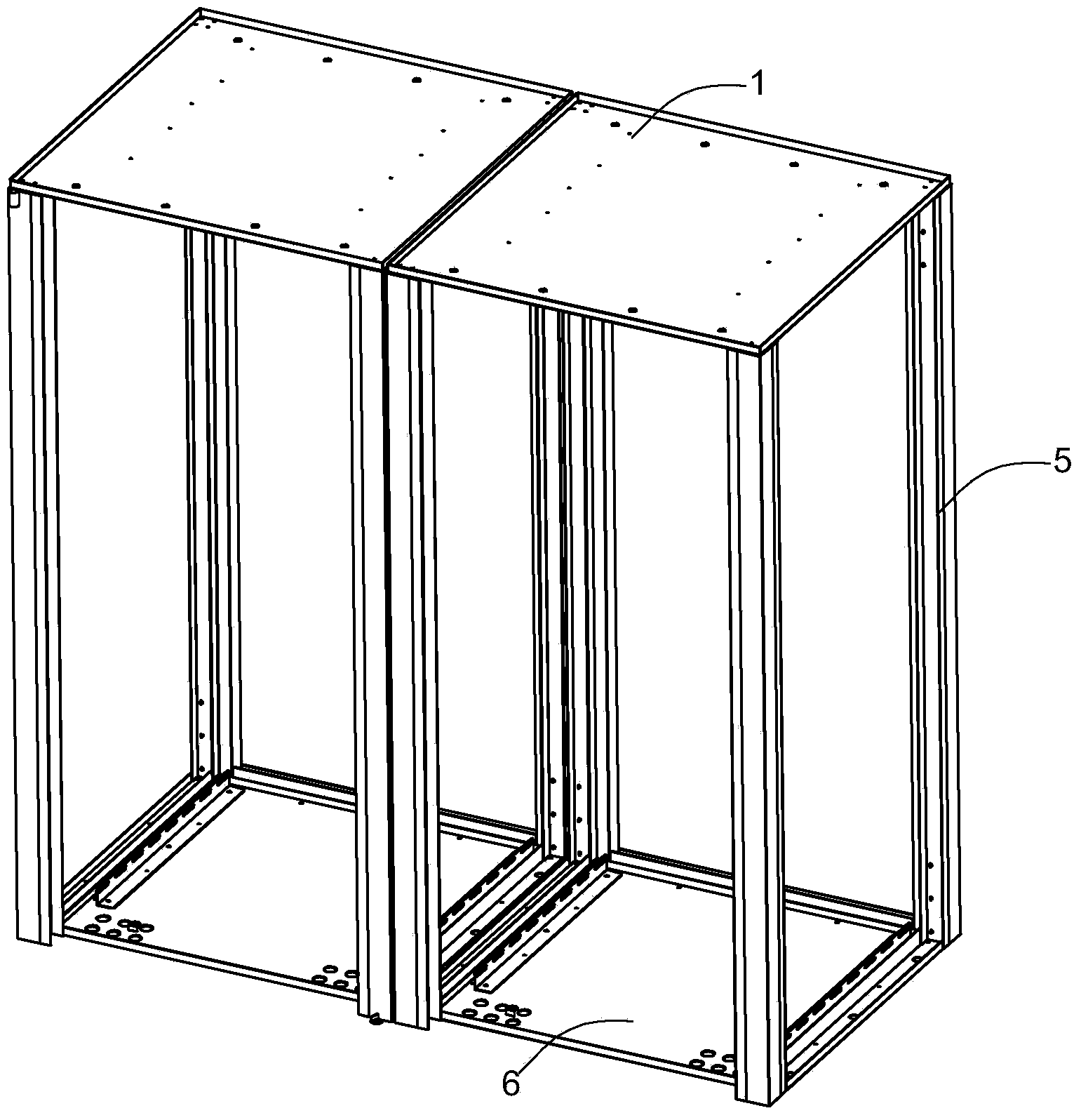

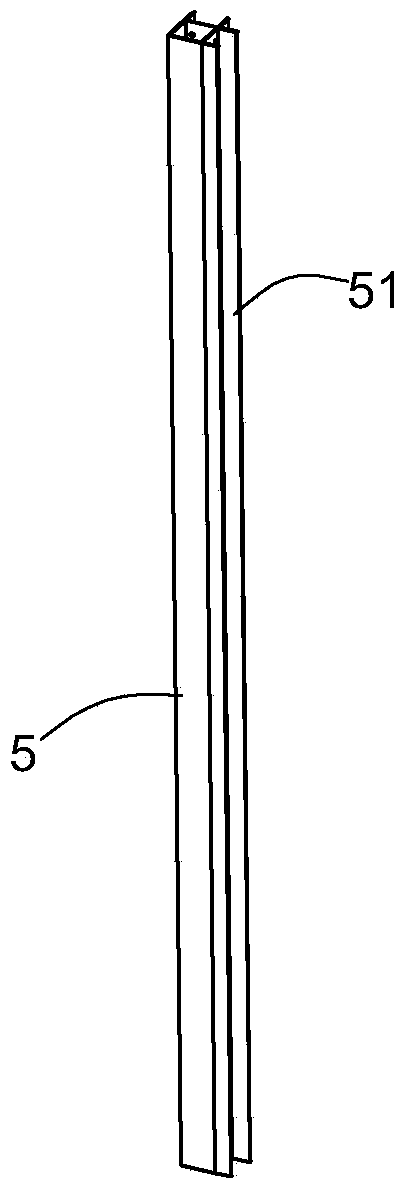

Assembled cabinet

InactiveCN103889177AImprove sealingImprove tamper resistanceCasings/cabinets/drawers detailsRack/frame constructionBack door

The invention relates to an assembled cabinet comprising a frame and a cabinet assembly which covers the outer surface of the frame. The frame is mainly formed by a base and upright columns. The cabinet assembly comprises a top cover, a door frame and side plates. The top cover is detachably arranged at the top of the frame. The side plates can cover the side faces of the frame. The assembled cabinet is characterized in that the upright columns are at least four hollow square columns which are provided with jacks at least at end parts, correspondingly the four corners of the base are provided with convex blocks which can be inserted into the upright column jacks, the four corners of the top cover are also provided with convex blocks which can be inserted into the upright column jacks, thus the frame is formed together, at least two adjacent side walls of the upright columns are provided with slots which extend outwards along mutually vertical directions and hold the door frame and the side plates, and the door frame is also rotatingly connected with a front door or a back door. Compared with the prior art, the assembled cabinet has the advantages that an assembled structure is employed overall, the modular disassembly, assembly and repair of the cabinet can be carried out after the cabinet is damaged accidentally, the modification is easy, and the field engineering installation is convenient.

Owner:宁波隆兴电信设备制造有限公司

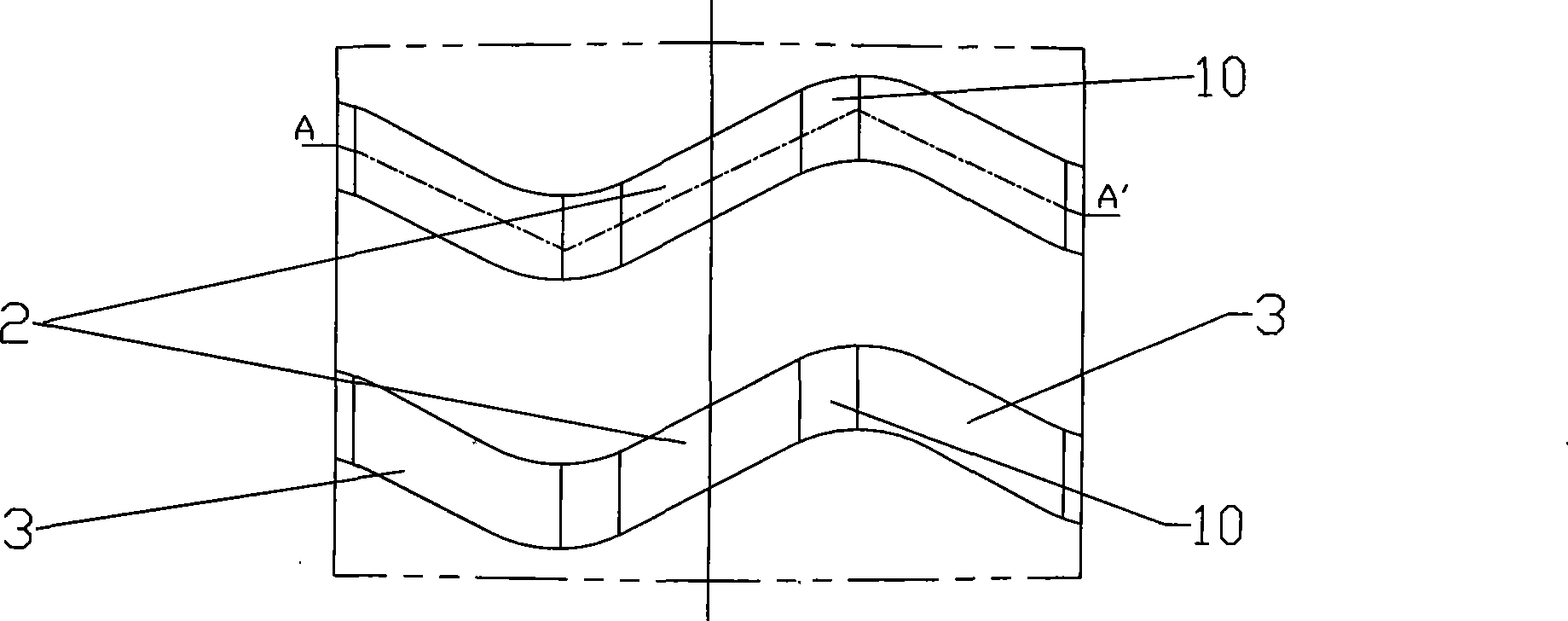

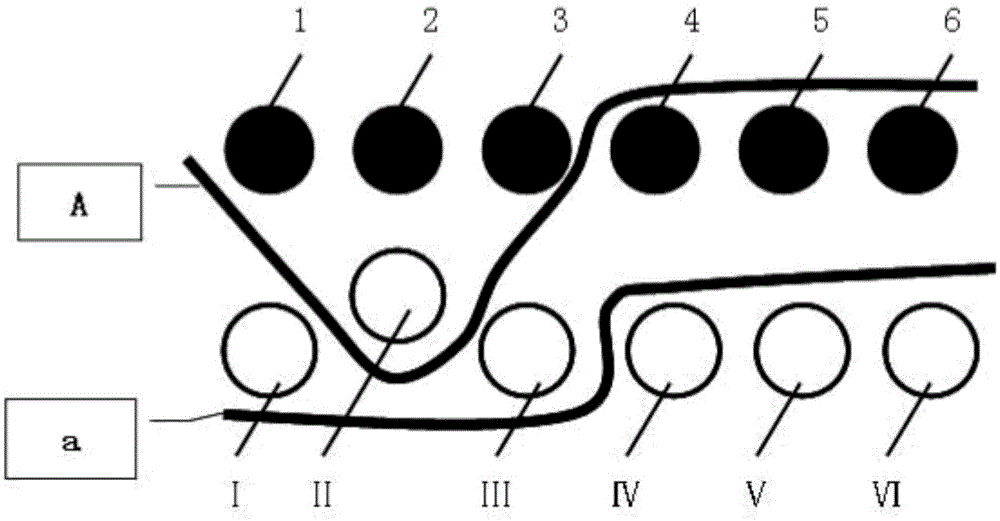

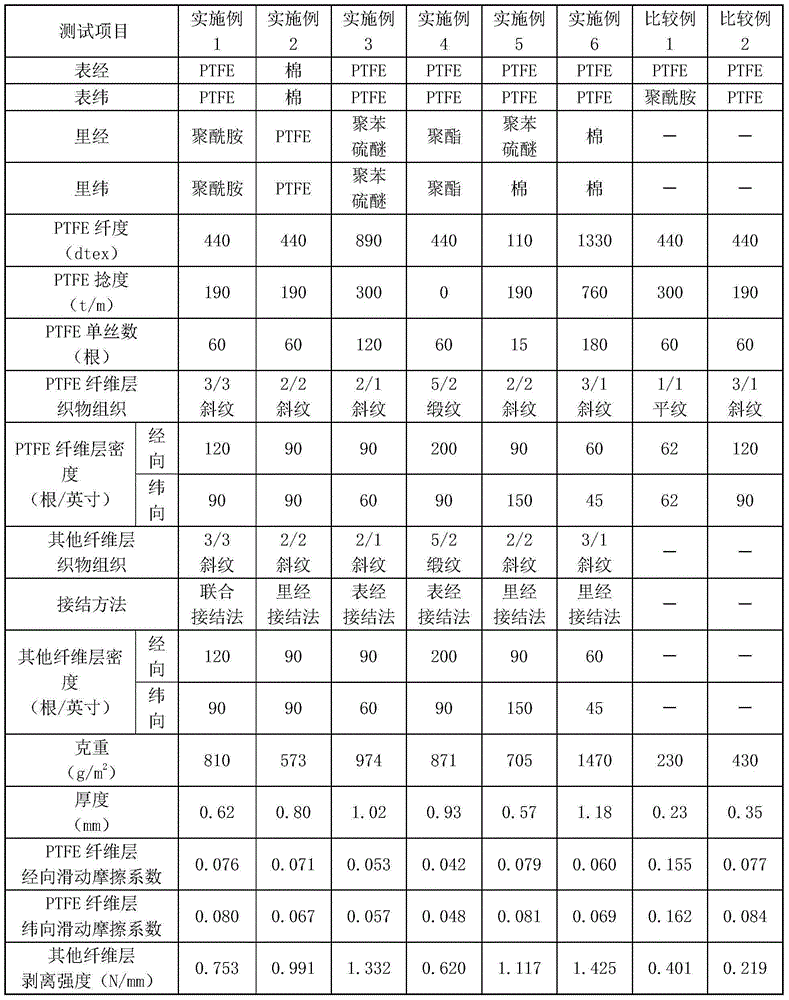

Double-layer fabric containing polytetrafluoroethylene fiber and application of double-layer fabric

ActiveCN105088489AReduce coefficient of frictionHigh peel strengthMulti-ply fabricsPolyesterPolyamide

The invention discloses a double-layer fabric containing Teflon fiber and an application thereof. The double-layer fabric is formed by integrally tying a Teflon fiber layer and other fiber layers through tying points, wherein the fineness of fiber forming the Teflon fiber layer is 50-1400dtex, the twist degree is 0-800t / m, and other fiber is one or more of cotton, polyester, polyamide and polyphenylene sulfide. The low-friction-coefficient fabric has the advantages of being small in friction coefficient, high in peeling strength, small in stress deformation and simple in process and can be applied to mechanical moving parts.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com