High carbon steel rail and high manganese steel frog welding technology

A welding process, high-carbon steel technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of flexible and convenient operation, less investment in welding equipment and tooling, and less investment in factory construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

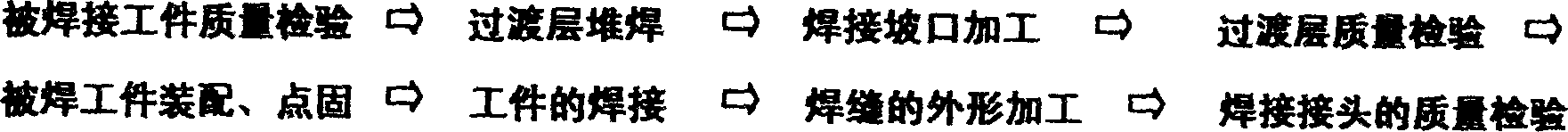

[0035] Using the method of manual arc welding, using the welding consumables shown in Table 1, using figure 1The welding process shown in , the high manganese steel short rail (length 600mm) and high carbon steel rail (length 600mm) standard parts were welded in batches. The static bending test and fatigue test were carried out by the Product Quality Supervision and Inspection Center of the Ministry of Railways, the mechanical properties of the welded joints were tested, and the metallographic structure analysis of the welded joints was carried out. The test results are shown in Table 2-Table 5. The above test results all meet and exceed the technical index requirements of relevant domestic and foreign standards, especially the static bending and fatigue test data are very close and stable, and the fractured parts are not in the welded joints. According to the metallographic analysis results, there is no carbide precipitation and hardened structure in the heat-affected zone. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com