Patents

Literature

121results about How to "Low production environment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of breeding method of East Asian flower bug

InactiveCN102293182AShorten the production cycleRich in nutrientsAnimal husbandryAgricultural scienceOrius sauteri

The invention relates to the field of plant protection and the insect raising technology, in particular to an orius sauteri raising method adopting drosophila carcinophila as feedstuff. The method changes the traditional method of adopting aphid or frankliniella occidentalis as feedstuff, the defect of the orius sauteri raising caused by the problems of the two kinds of feedstuff per se is changed, the characteristics of short growth period of the drosophila carcinophila and low production environment requirement are utilized, the feedstuff basis is provided for the large-scale raising of theorius sauteri, and in addition, the feeding effect is very excellent.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

Method for preparing pharmaceutics of hydrolysate of brain protein

ActiveCN1562339ATo achieve the separation effectNo pollution in the processPowder deliveryNervous disorderHydrolysateTyrosine

A hydrate of brain protein is prepared from pig's brain through adding purified water, homogenizing, heating, cooling, regulating pH=1.5-2.0, enzymolyzing, regulating pH=7.7-8.0, enzymolyzing, regulating pH=2.5-3.0 freezing, thawing, filter, regulating pH to become neutral, ultrafiltering, concentrating, sterilizing, adding amino acids, regulating peptide map, diluting, and steam sterilizing.

Owner:赛隆药业集团股份有限公司

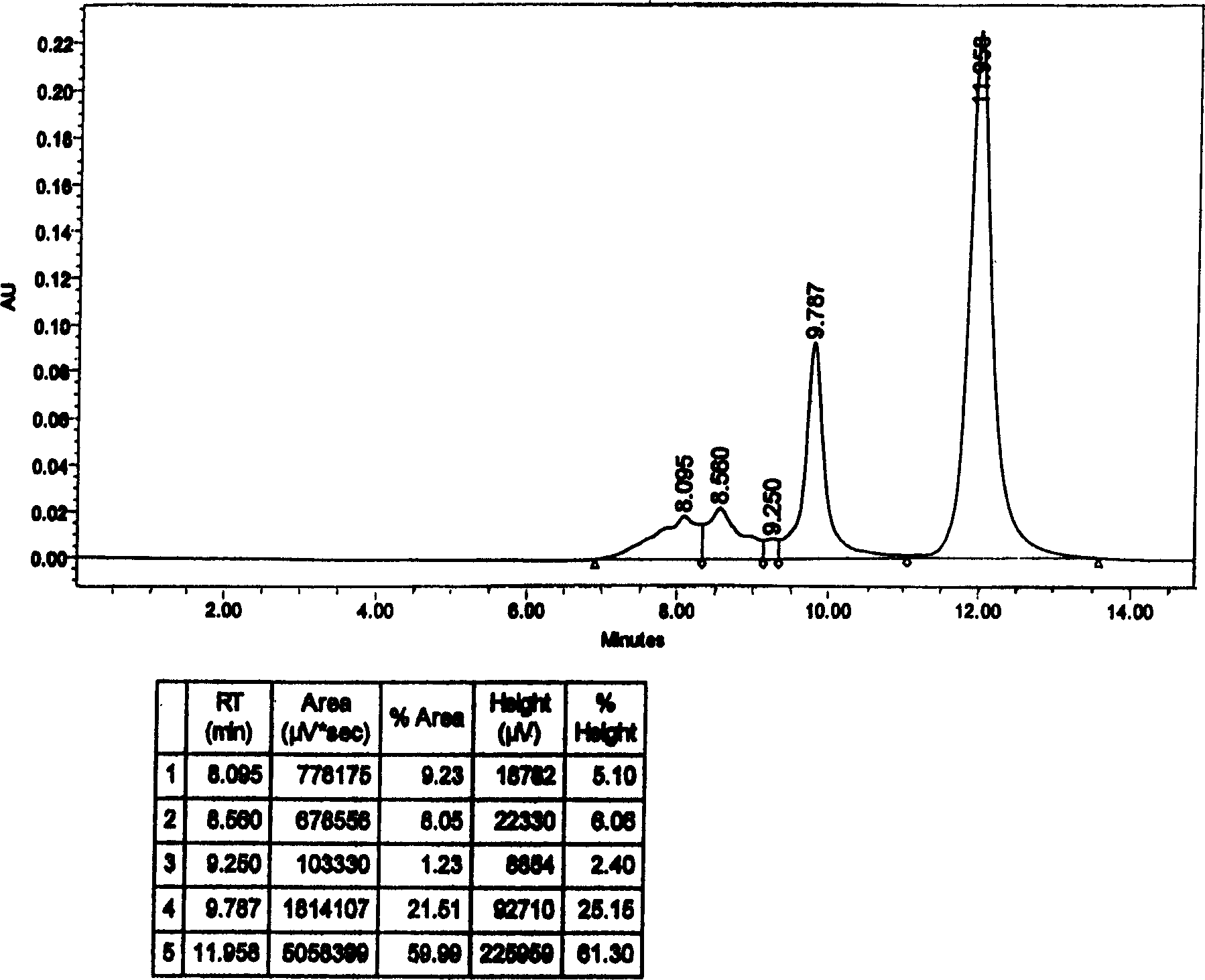

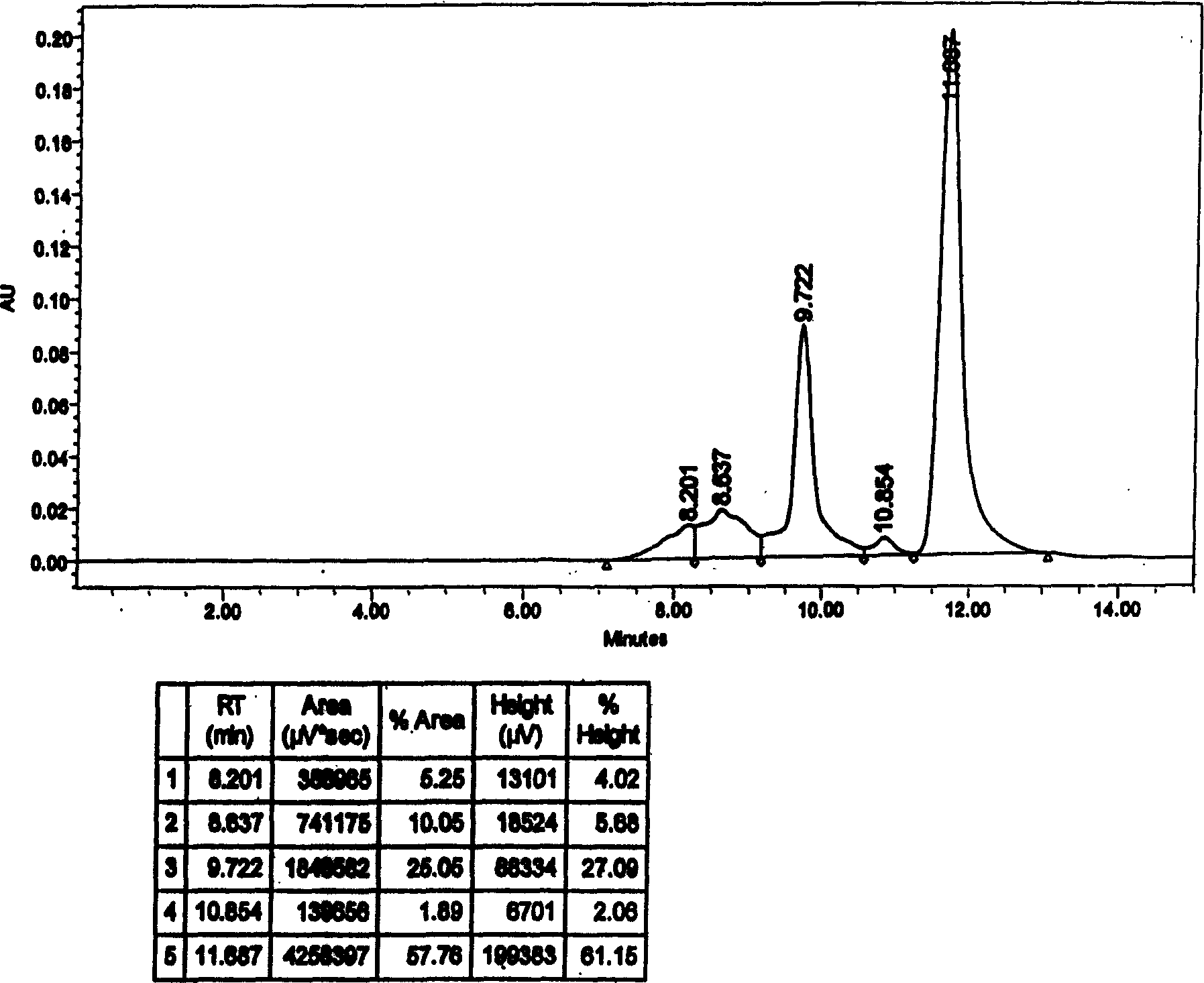

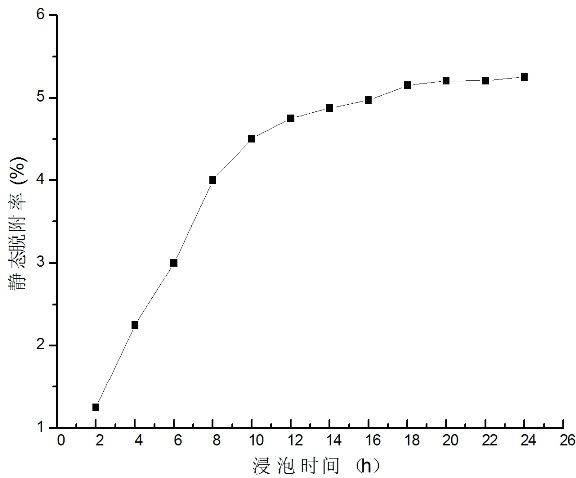

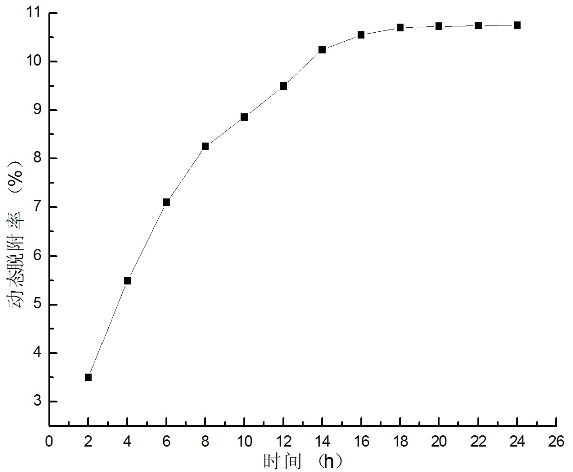

Method for preparing radioisotope tracer

The invention discloses a method for preparing a radioisotope tracer. The method comprises the following steps of: dissolving carbonate which contains a radioisotope by using an acid; immersing a porous carrier into a solution, absorbing an isotope ion, and then stirring at the temperature of 100 to 300 DEG C for a certain time until the porous carrier is dried; after the porous carrier is dried, fixing the isotope ion by using a precipitant, and drying at the temperature of 100 to 300 DEG C; carrying out surface treatment on the dried porous carrier, and adding a resin adhesive, an antistatic agent, temperature-resistant resin and a surfactant sequentially; and carrying out surface treatment on the porous carrier to obtain the radioisotope tracer for injection profile logging. The method is simple and convenient to operate; the prepared injection profile logging tracer is low and uniform in density and good in suspension property, avoids agglomeration in a water suction solution and cannot sink or float upwards; and the radioisotope tracer is low in isotope desorption rate, stable in radiation strength and low in isotope contamination, and resists high temperature of 120 DEG C and pressure of 60 MPa.

Owner:河南省同新科技有限责任公司

Method for breeding frankliniella occidentalis

The invention relates to the field of plant protection and the technology of insect cultivation, and in particular relates to a method for breeding frankliniella occidentalis by using water planting soya bean seedlings as fodder. According to the conventional method, kidney beans are used as the fodder, while the soya bean seedlings are used for feeding the frankliniella occidentalis according to the method, and therefore, the defect of feeding the frankliniella occidentalis caused by the problem of the fodder per se is changed. As the water planting soya bean seedlings have a short growth cycle, a low production environment requirement and low production cost and can be supplied throughout the year, according to the method for breeding the frankliniella occidentalis, the fodder basis for feeding the frankliniella occidentalis in a large scale can be provided and an excellent feeding effect can be realized.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

Brain protein hydrolysate and production process of its freeze dried preparation

InactiveCN1857711ANo pollution in the processReduce investmentPowder deliveryNervous disorderFreeze-dryingNitrogen

The present invention relates to a kind of brain protein hydrolysate and the production process of its freeze dried preparation. The brain protein hydrolysate for injection is prepared with pig brain and through the steps of homogenating in a colloid mill to collect slurry, hydrolyzing with pepsase and pancreatin to collect supernatant, filtering with filer paper to collect filtrate, separating and purifying the filtrate with hydroxyapetite column, regulating peptide map and collecting object, ultrafiltering with membrane of intercepting molecular weight 8 KD to collecting filtrate, nitrogen and amino acid analysis and adding amino acid in the required amount, and fine filtering with 0.22 micron filtering membrane. The brain protein hydrolysate for injection may be further freeze dried to obtain freeze dried brain protein hydrolysate preparation. The production process is environment friendly, high in yield and low in cost.

Owner:HAINAN JINXING PHARMA

Formula of making hollow capsule and its preparation method

A hollow capsule is prepared from purified water, potato starch, carragheenin, surfactant and plasticizer. Its preparing process is also disclosed. Its advantages are high quality and low cost.

Owner:ZHEJIANG UNIV OF TECH

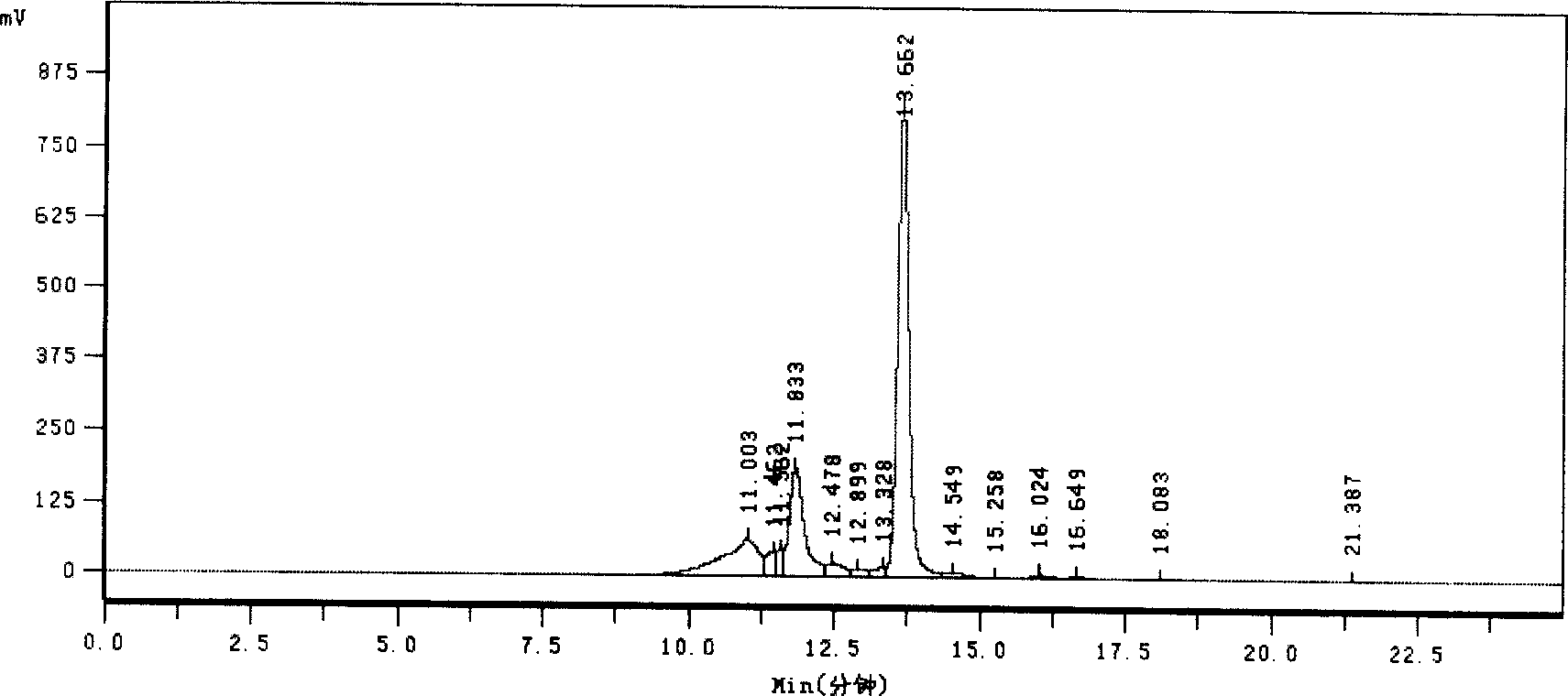

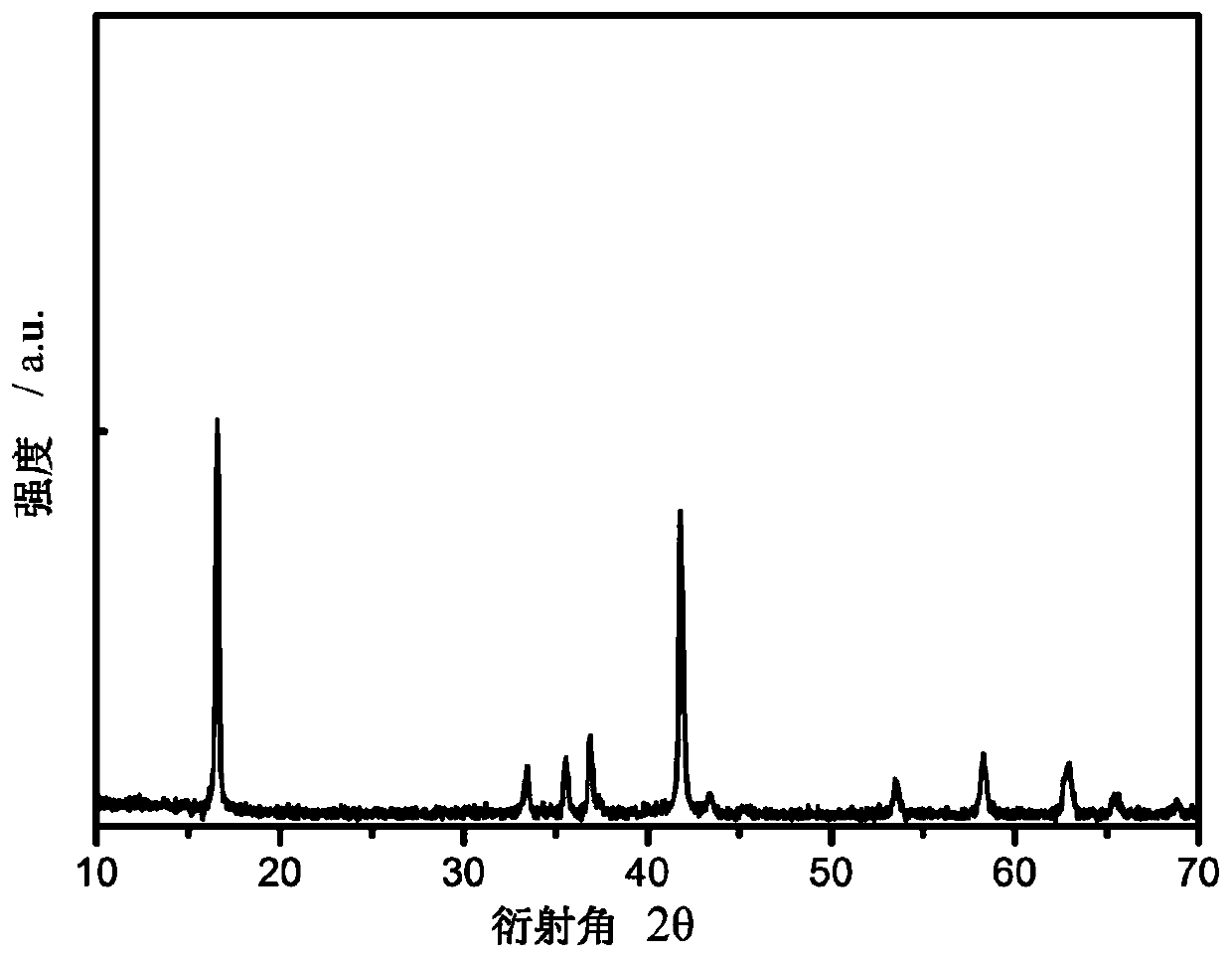

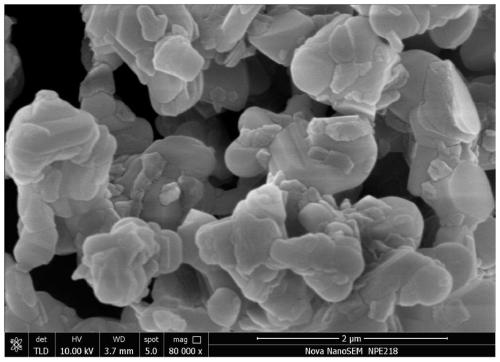

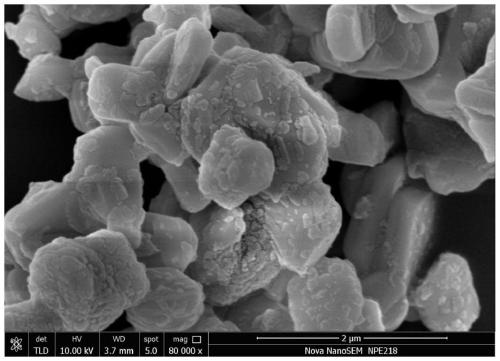

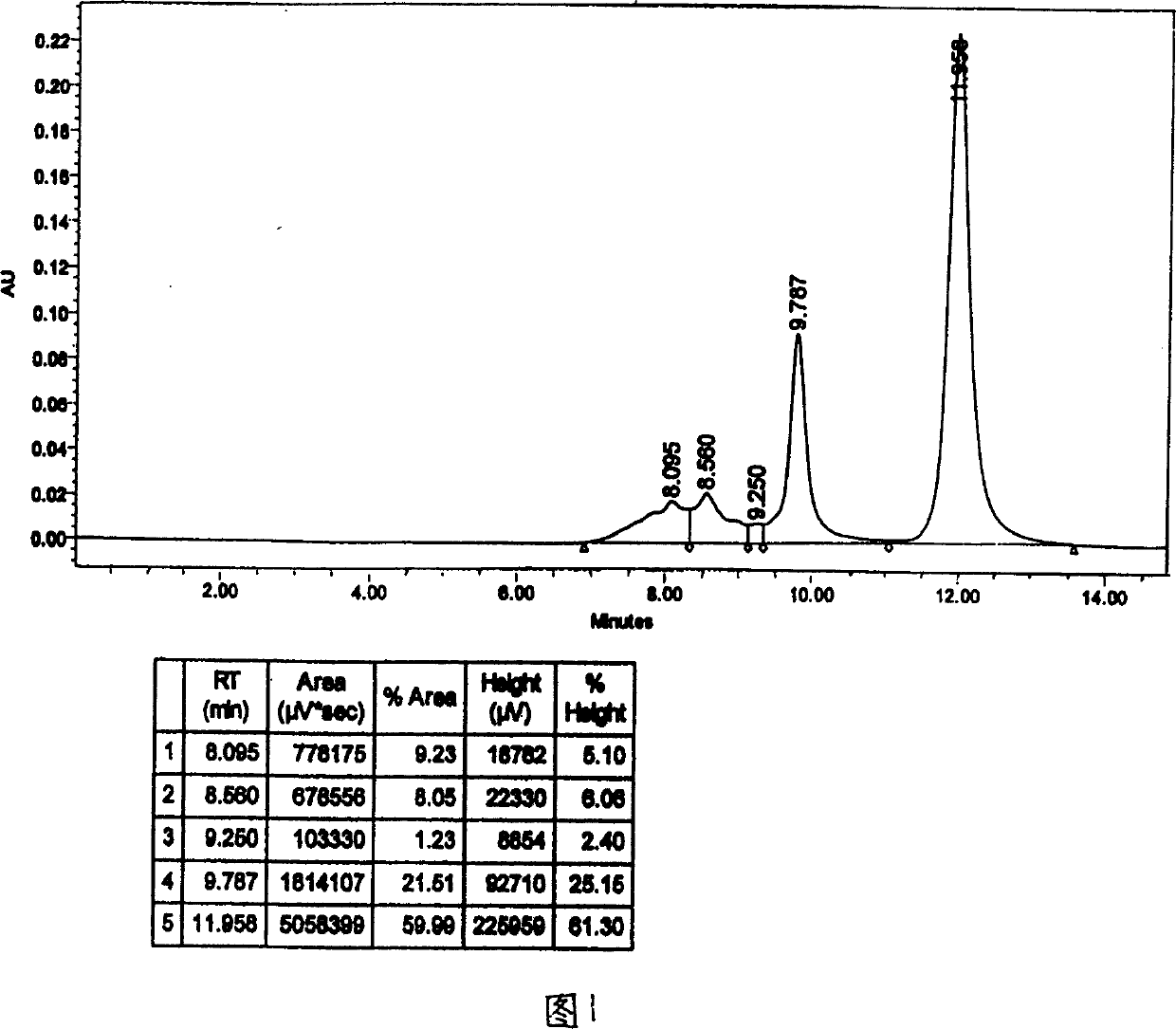

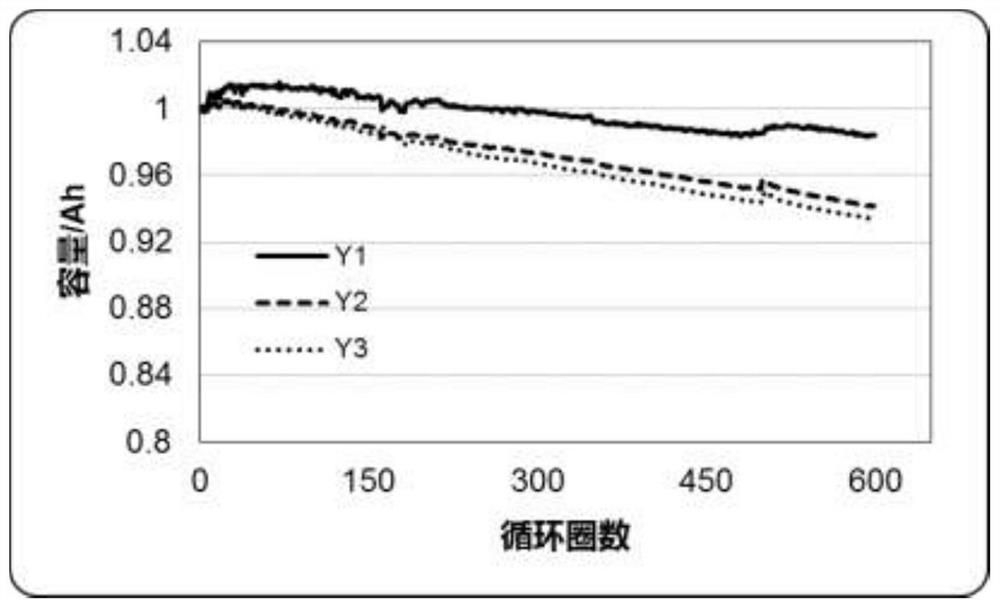

Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery

PendingCN111403729AImprove cycle performanceImproved magnification performanceSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention discloses a sodium ion battery positive electrode material, a preparation method thereof and a sodium ion battery. The positive electrode material has a core-shell structure, whereinthecomposition of the core is NaxFeyM1-yO2, the composition of the shell is NazMnO2; 0.6 < x < = 1, 0.5 < = y < 1, and 0.44 < = z < 1; M is one or more of Mn, Ni, Ti, Cu, Sn, Mg, Co, V, Cr and Nd. The preparation method of the positive electrode material is simple in process, and the prepared positive electrode material has the advantages of being low in price, high in safety, low in battery manufacturing environment requirement and the like, and can be applied to preparation of sodium ion batteries. The shell material and the core material can generate an ingenious mutual synergistic effect, so the charge-discharge specific capacity of the positive electrode material, the cycle performance and the rate capability of the battery are improved, and particularly, the cycle stability of the battery has outstanding advantages.

Owner:SHANGHAI ZIJIAN CHEM TECH CO LTD

Method for extracting carnosine

InactiveCN1970784AReduce investmentNo pollution in the processPeptide preparation methodsFermentationMuscle tissueSlurry

The invention discloses an extracting method of carnosine, which comprises the following steps: removing non-muscle tissue in the animal meat; washing; drying; grinding; adding water to stir into slurry; proceeding double-enzyme hydrolysis; proceeding enzyme inactivation; separating supernatant; adsorbing through hydroxy agustite chromatographic column; hyperfiltering through hyperfiltering film; collecting filtrate; spraying to dry carnosine liquid; collecting dried powder; packing in the vacuum.

Owner:HAINAN STAND BIO TECH

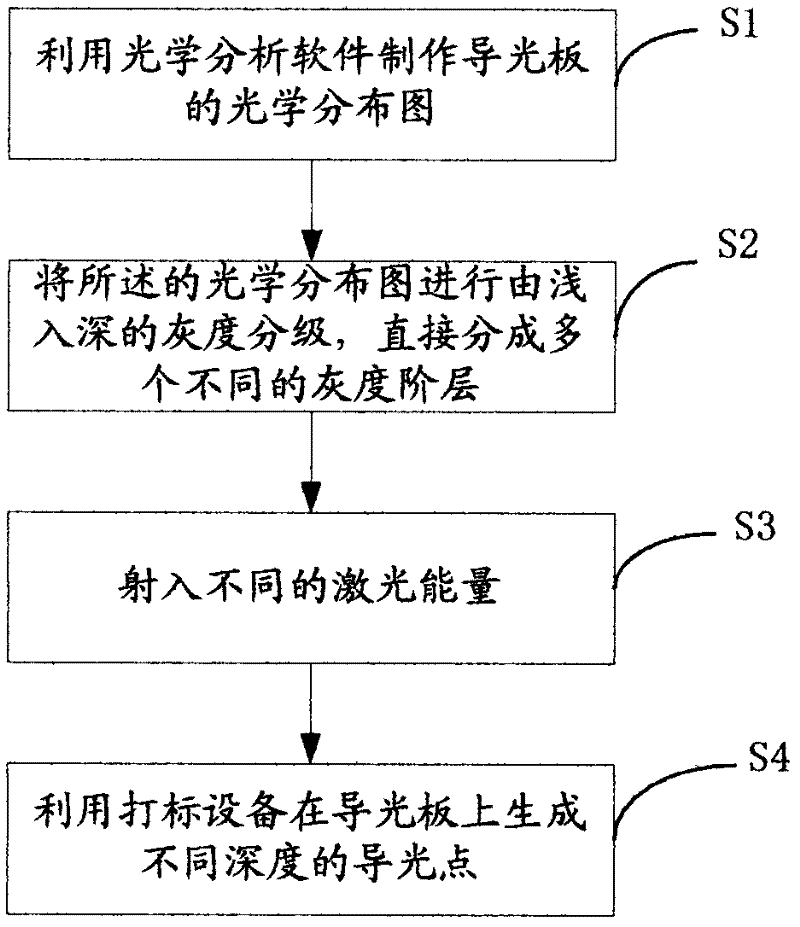

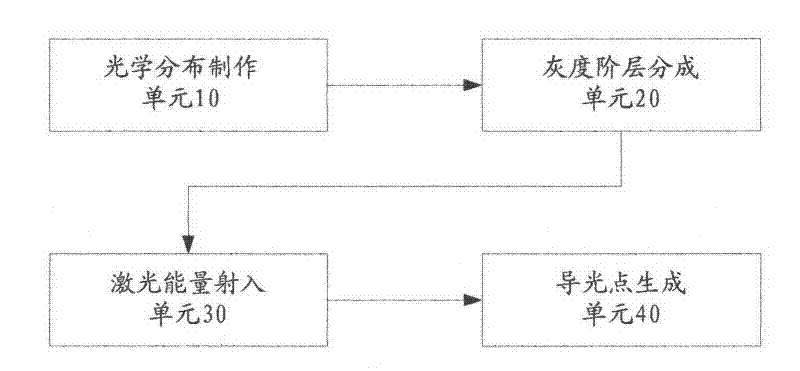

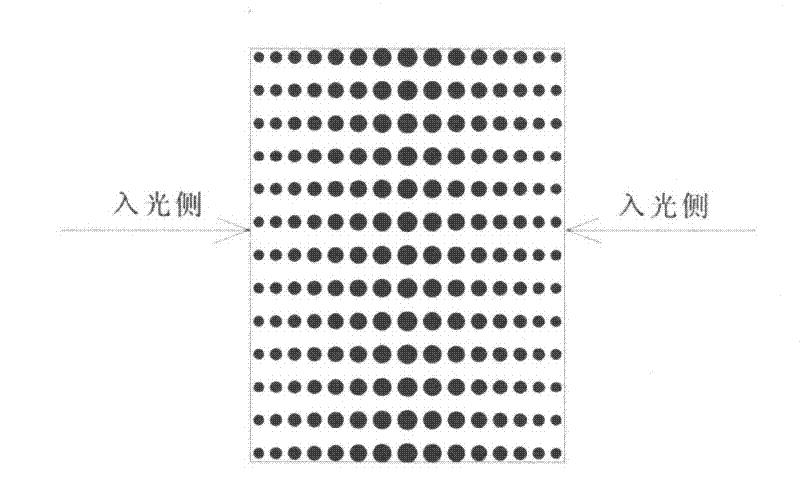

Light guide plate manufacture method and device

ActiveCN102520473ANo chemical pollutionIncrease productivityOptical light guidesGray levelLight guide

The invention discloses a light guide plate manufacture method, which comprises the following steps that: S1, an optical distribution map of a light guide plate is manufactured by using optical analysis software; S2, the optical distribution map is subjected to gray level grading from shallow to deep and is directly divided into a plurality of different gray levels; S3, different laser energy is emitted according to different gray levels; and S4, light guide points with different depths are generated on the light guide plate by labeling equipment according to different laser energy. The invention also discloses a light guide plate manufacture device. When the light guide plate manufacture method and the light guide plate manufacture device provided by the invention are implemented, laser net points are realized by a pure physical method, the environment is protected, no chemical pollution is caused, durability is realized, the production efficiency is greatly improved, the energy is saved, and the light ray material internal loss is reduced.

Owner:广州市金明激光科技有限公司

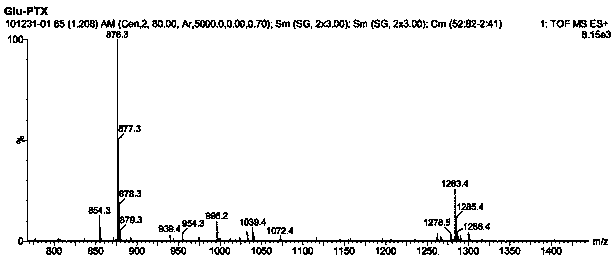

Small-molecule modified target paclitaxel precursor medicament, as well as preparation method and application thereof

InactiveCN103948936ASolve the problem of water solubilityAddressing targetingOrganic active ingredientsPharmaceutical non-active ingredientsSolubilityConnexon

The invention discloses a small-molecule modified target paclitaxel precursor medicament, as well as a preparation method and application thereof. The molecular structure of the precursor medicament comprises folic acid, amino acid and paclitaxel, wherein the folic acid is used as a targeting ligand, and the amino acid is used as a connexon. The precursor medicament also comprises a fluorescent dye. Compared with the prior art, the precursor medicament has the advantages that the problem of water solubility and targeting of paclitaxel can be solved, the toxicity of the paclitaxel medicament can be reduced, the treatment effect of the paclitaxel medicament can be improved, body immunogen toxin caused by macro-molecular protein can be avoided, and the defects of poor encapsulation rate, unstable structure and the like caused by using lipidosome as an insoluble medicinal carrier can be overcome.

Owner:宿州学院

Aquaculture rapid propagation method for potato virus-free tissue culture plantlets

ActiveCN104304031ALow production environment requirementsLow costPlant tissue cultureHorticulture methodsSeedlingShoot apex

The invention provides an aquaculture rapid propagation method for potato virus-free tissue culture plantlets. The aquaculture rapid propagation method is characterized by comprising the following steps: 1, shearing stem tip sections off potato virus-free test-tube plantlets and inserting in holes of a foam plate, putting in an aquaculture plantlet tray, standing and floating in a rooting nutrient solution, culturing for five to seven days, and finishing rooting; 2, standing and floating the plantlets in step 1 in a plantlet strengthening nutrient solution to culture for 12-15 days, and using the plantlets growing four to five leaves as parent seedlings; 3, shearing stem tips off the parent seedlings cultured in step 2, carrying out cuttage by step 1 and step 2, rooting, culturing, using as parent seedlings again after the seedlings grow four to five leaves, shearing off stem tips, carrying out cuttage by step 1 and step 2, rooting and culturing; 4, shearing stem tips off the parent seedlings in step 3 for six to eight times, transplanting as seedlings, and producing breeder's seeds. When the method is used for propagating the potato virus-free test-tube plantlets, the production cost is low, and the quality is good.

Owner:LIJIANG BOFU AGRI TECH DEV

Jujube yoghourt containing medlar leaf and preparation method thereof

InactiveCN103168845AFragrant tasteHigh medicinal valueMilk preparationVitamin CTrichosanthes kirilowii

The invention discloses jujube yoghourt containing medlar leaves. The jujube yoghourt containing the medlar leaves consists of the following raw materials in parts by weight: 100-110 parts of pure milk, 10-20 parts of white sugar, 4-6 parts of jujube, 3-4 parts of chrysanthemum, 1-2 parts of pseudo-ginseng, 1-2 parts of rhodiola rosea, 2-3 parts of pumpkin powder, 1-2 parts of grape leaves, 1-2 parts of trichosanthes kirilowii maxim leaves, 1-2 parts of the medlar leaves, 0.5-1 part of propylene glycol alginate, 1-2 parts of sodium carboxymethylcellulose, 0.1-0.4 part of a mixing strain and 0.001-0.002 part of vitamin C. The jujube yoghourt containing the medlar leaves, disclosed by the invention, is safe, simple, rapid and pollution-free in process, low in requirement on production environment, low in possibilities of microorganism pollution and degeneration of a product, and the jujube yoghourt with jujube pulp is high in medicinal value, abundant in nutrient substances, easy to absorb by a human body, and easy to accept by market and customers; and the jujube yoghourt containing the coconut milk improves the homogenization by two times, enhances the stability of the product, improves the appearance quality of the conventional yoghourt, and increases the absorptivity of the human body to the nutrient substances.

Owner:BENGBU FULIN DAIRY

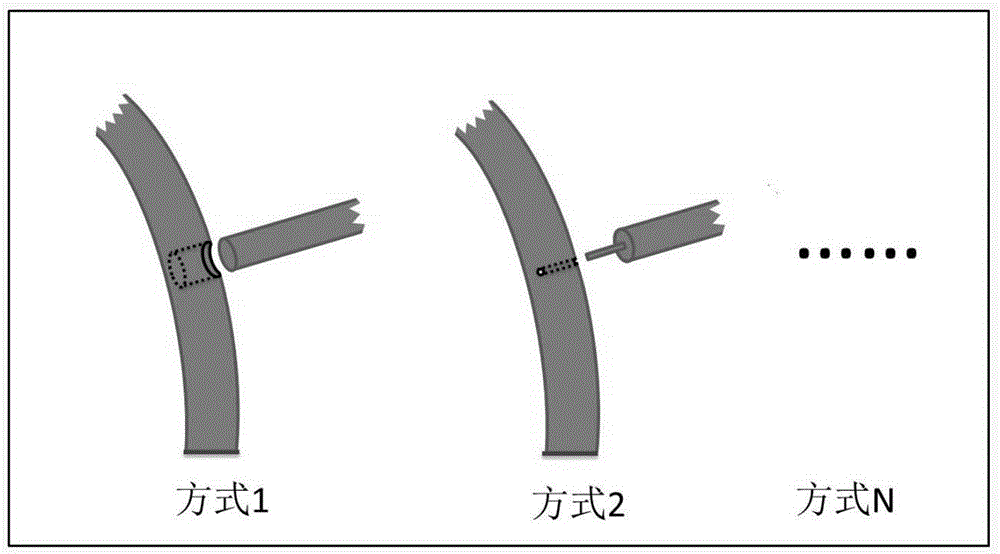

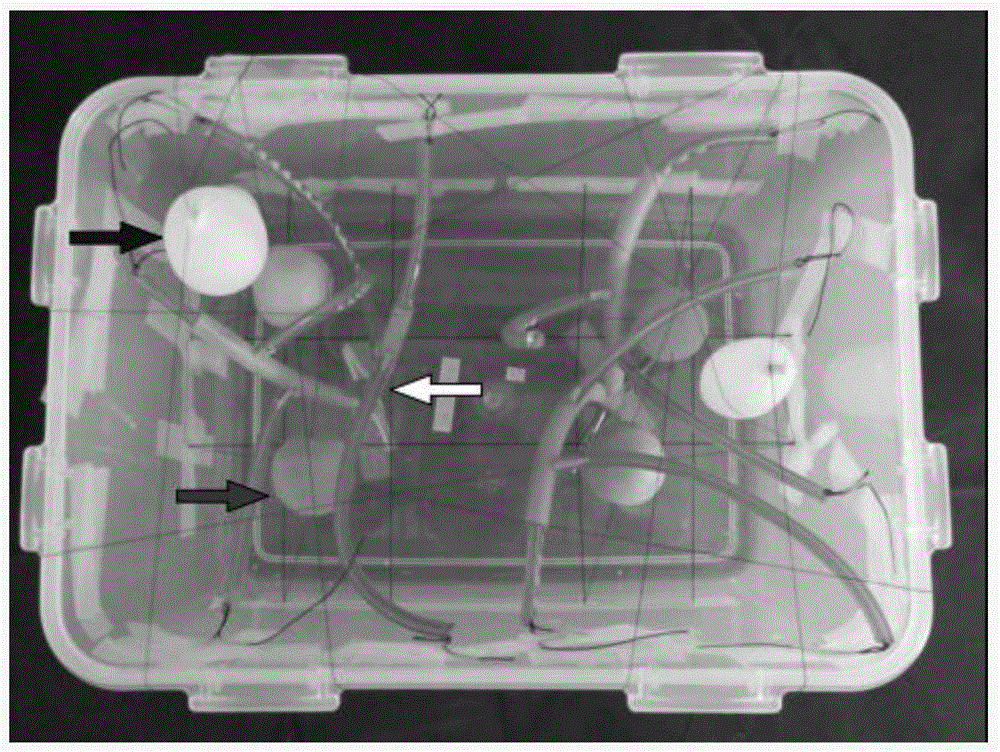

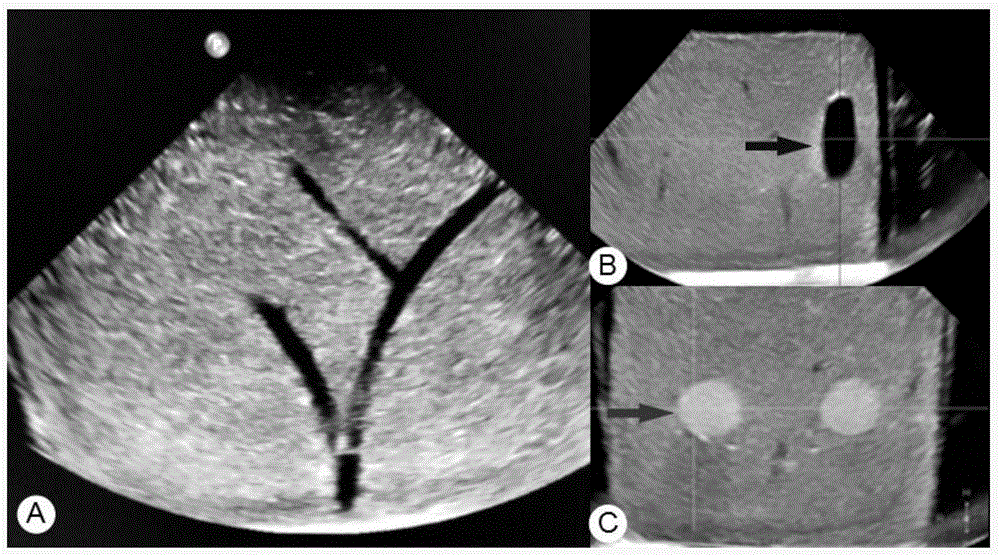

Phantom model containing tree-shaped pipeline structure

The invention belongs to the field of medical care and health, and relates to a phantom model, particularly to a phantom model containing a tree-shaped pipeline structure. The phantom model provided by the invention includes a peripheral tissue colloid model and a hollow pipeline model, the hollow pipeline model is a pipeline directly formed inside the peripheral tissue colloid model, and no partition membrane or partition wall exists between the hollow pipeline model and peripheral tissue glue. The model has the advantage of good sound transmission performance, effectively guarantees the quality of a sonogram echogram, and can effectively simulate important pipeline structures in a human body (such as liver), thereby obtaining better simulation, and enabling the range of application of the model to be wider, and the phantom model can be used as a sign structure in melting technology planning, and can also be used for training of a cavity radiographic technology.

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Purple sweet potato virus-free seedling water culture fast breeding method

InactiveCN105706880ALow production environment requirementsLow costCultivating equipmentsSoilless cultivationShoot apexNutrient solution

A method for hydroponic rapid propagation of virus-free purple potato seedlings, belonging to the field of crop seedlings, the steps are: 1. Disinfection: cut the stem tip of virus-free purple potato seedlings to a length of 2.0cm to 3.0cm, and fix it on a foam board with a sponge or cotton ball In the hole, float in 1‰ carbendazim solution, soak the roots for 30 minutes, and rinse with water for 3 to 5 times; 2. Rooting: Put the sterilized seedlings in step 1 into the water culture seedling tray and let them float Cultivate in the rooting nutrient solution for 5-7 days, and the aquatic roots grow to 1.0 cm to 3.0 cm; 3. Cultivation: the purple potato seedlings with water roots in step 2 are cultivated in the strong seedling nutrient solution for 12-15 days to grow into 4 to 5 leaves are used as mother seedlings; 4, cut 2.0cm to 3.0cm long stem tips on the mother seedlings cultivated in step 3, and carry out disinfection, rooting and cultivation; 5, cut 8 to 10 stem tips from the mother seedlings in step 3 Transplanted as seedlings after the second time. The virus-free purple potato seedlings propagated by the method of the invention have low production cost and good quality.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

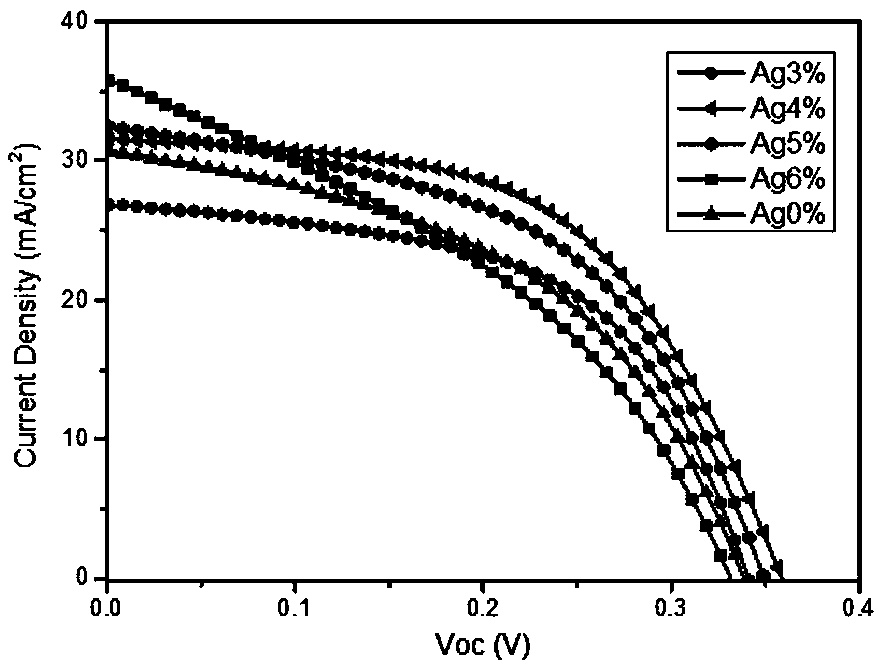

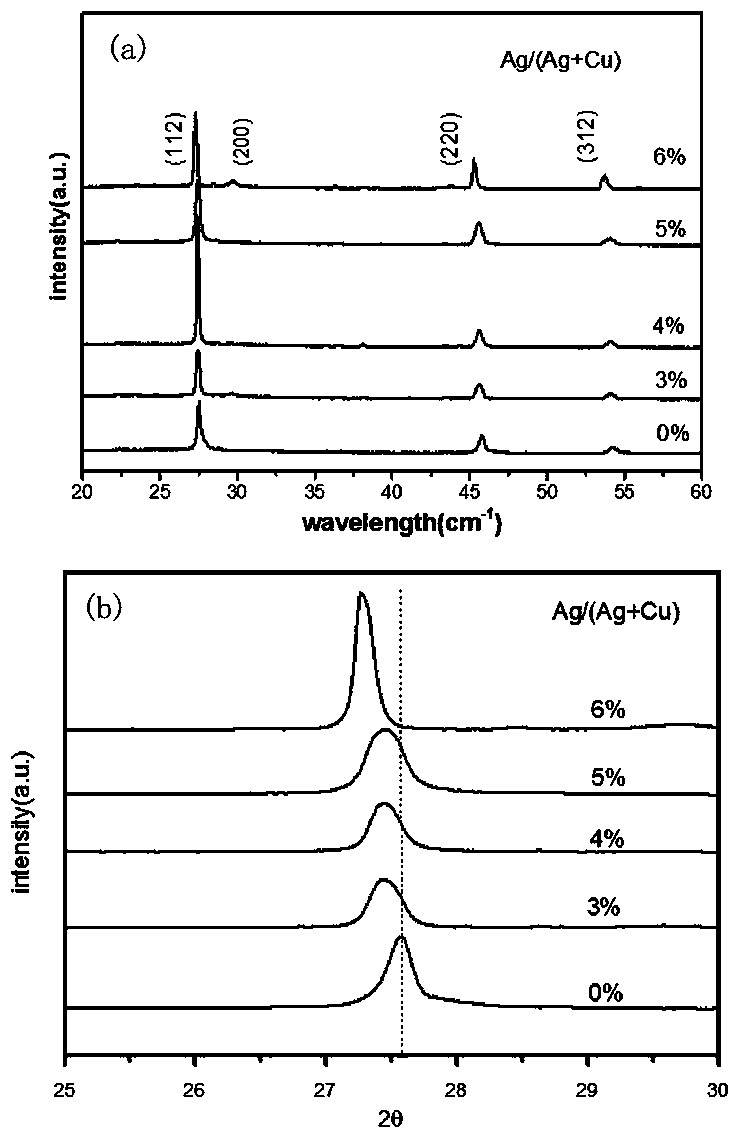

Preparation method and application of elemental silver-doped CZTSSe thin film

ActiveCN107910390AEasy to makeLow reaction conditionsPhotovoltaic energy generationSemiconductor devicesOpen-circuit voltageChemistry

The invention discloses a preparation method of an elemental silver-doped CZTSSe thin film and application of the elemental silver-doped CZTSSe thin film in a flexible solar cell. The quality of the thin film can be improved by Ag doping, the open-circuit voltage, the filling factor, the photoelectric conversion efficiency and a band-tail state phenomenon of the device are effectively improved, the repeatability and the stability of an experiment are relatively good, and the thin film has relatively good application value in an aspect of the solar cell.

Owner:FUZHOU UNIV

Electrostatic dissipation ceramic material and preparation thereof

InactiveCN101279845AStable static dissipative performanceGood mechanical and physical propertiesNon-conductive material with dispersed conductive materialSurface resistivityCeramic

The invention relates to an electrostatic dissipation ceramic material and a method for the production thereof. The electrostatic dissipation ceramic takes a mixture of zirconia or aluminum oxide or zirconia and aluminum oxide as a matrix, and adds a proper titanium carbide as a resistivity regulator, and the adopted materials comprise (1) 70 to 90 percent of zirconia content and 10 to 30 percent of titanium carbide content by weight percentage; (2) 70 to 90 percent of aluminum oxide content and 10 to 30 percent of titanium carbide content by weight percentage; and (3) 20 to 60 percent of zirconia content and 20 to 60 percent of aluminum oxide content by weight percentage; and 10 to 30 percent of titanium carbide content by weight percentage. The electrostatic dissipation ceramic having a surface resistivity ranging from 10<5> to 10<10>ohms / square is made after mixing, forming and sintering. The material can be used for making antistatic electronic components and various antistatic tools and tool equipment.

Owner:胡忠辉

Menthol-containing potato starch capsule shell

InactiveCN106177971AImprove the feeling of astringent tasteImprove palatabilityPharmaceutical non-active ingredientsCapsule deliveryFood colouringAntioxidant

The invention discloses a potato starch capsule shell containing menthol, which belongs to pharmaceutical or food processing; it aims to provide a starch capsule with good palatability, cool taste, antiemetic and antibacterial effects, and increased comfort in the oral cavity and stomach shell. It is prepared from potato starch and auxiliary materials: menthol, enhancer, plasticizer, food coloring, lubricant, disintegrant, surfactant, diluent, antioxidant, filler, flavoring agent: disperse potato starch Heating in water to obtain gelatinized glue; add the auxiliary materials and stir evenly to obtain dipping glue; ensure that the temperature of the dipping glue is 72-75°C, the temperature of the rubber plate is 45-48°C, and the temperature of the drying tunnel is 62-65°C ℃; dip in the glue solution to decompress and defoam, then use the glue dipping method to prepare the capsule shell, and dry for 48 hours.

Owner:GUIZHOU INST OF TECH

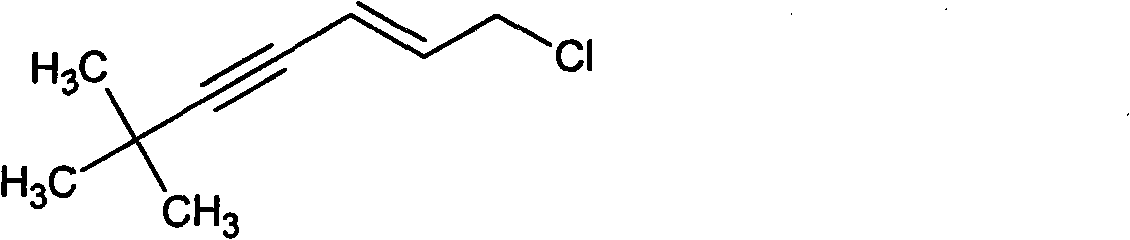

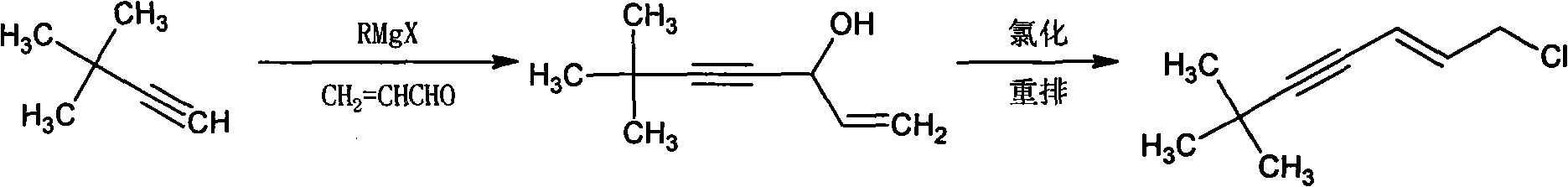

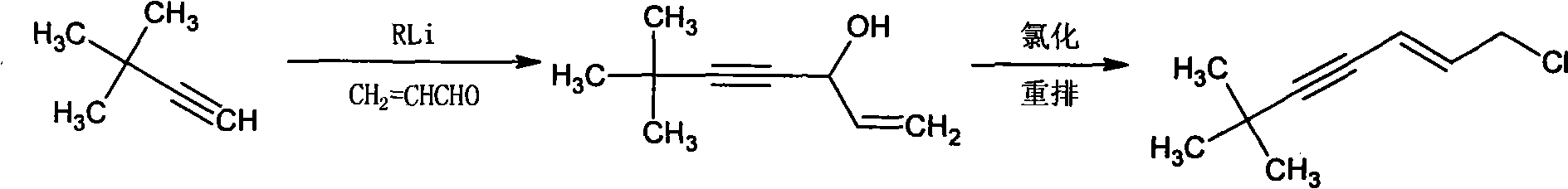

Method for synthesizing (E)-1-chlorine-6, 6-dimethyl-2-heptylene-4-alkyne

ActiveCN101624328ANo pollution in the processFew stepsOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationAlkynePhotochemistry

The invention discloses a method for synthesizing compound (E)-1-chlorine-6, 6-dimethyl-2-heptylene-4-alkyne. The method has the technical scheme that trans-1, 3-dichloropropylene and tertiary butyl ethyne are taken as raw materials which are processed by condensation reaction to synthesize the (E)-1-chlorine-6, 6-dimethyl-2-heptylene-4-alkyne in one step. Compared with the existing synthesis technique, the method has the advantages of fewer steps, high yield, no pollution for the environment, advancement, simple technique, simple and convenient operation, low requirements for equipment and production environment, and good applicability.

Owner:SHANDONG BOYUAN PHARM CO LTD

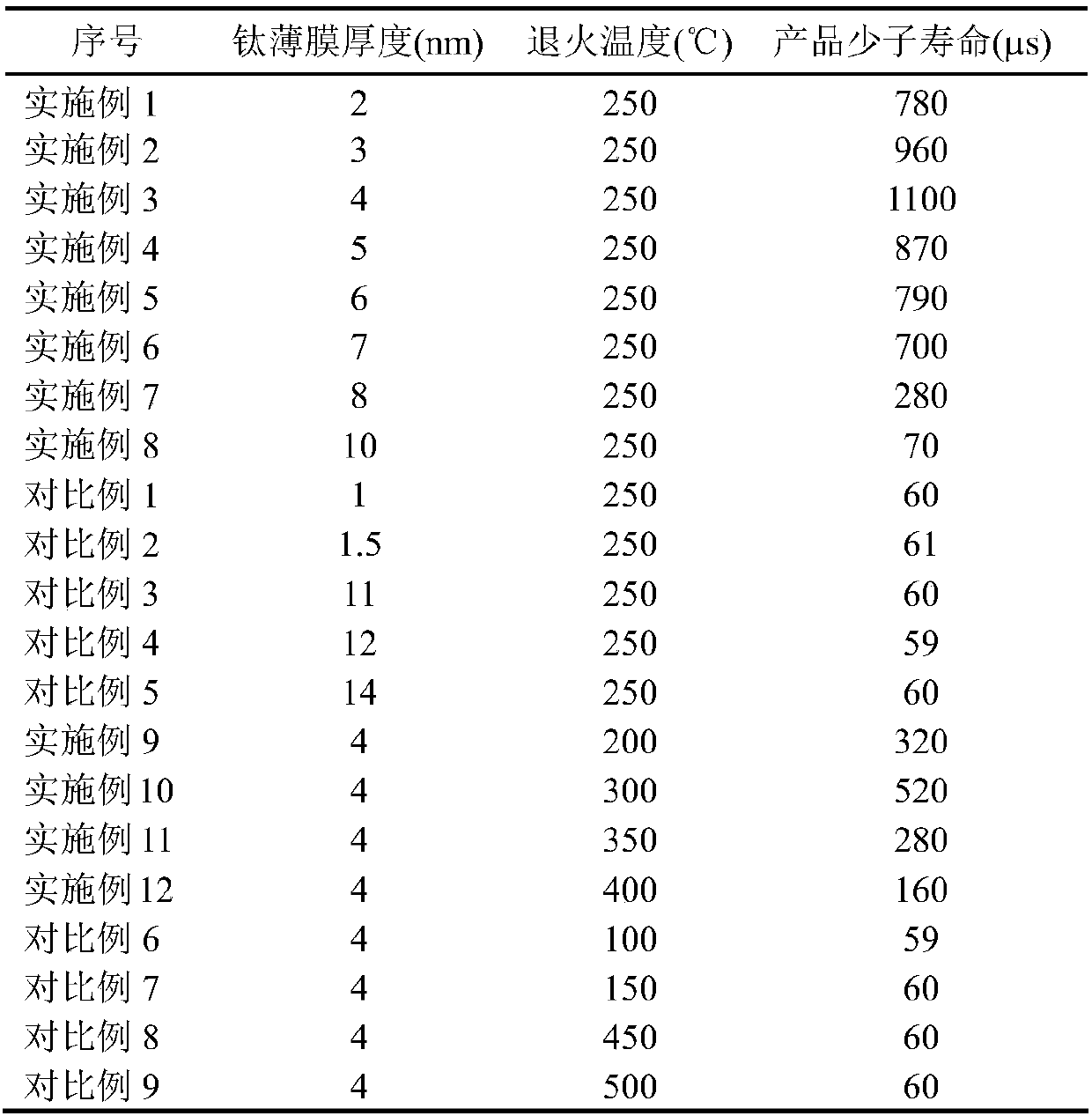

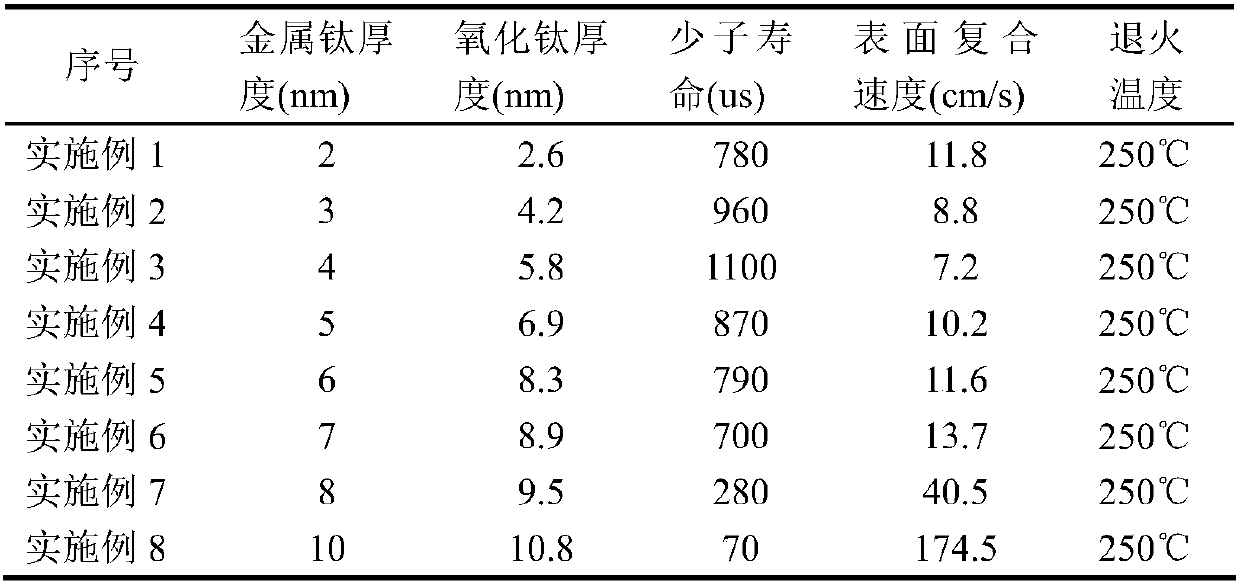

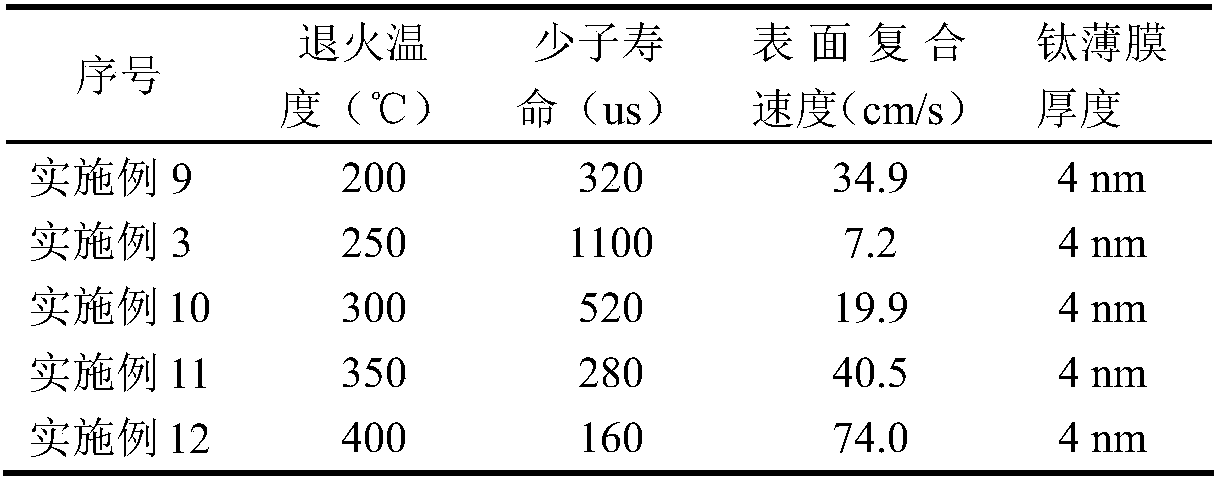

Titanium oxide passivation film preparation method and solar energy cell prepared through utilizing titanium oxide passivation film preparation method

InactiveCN107634122AImprove life expectancyReduce surface recombination rateFinal product manufactureSemiconductor devicesEvaporationOperation mode

The invention discloses a titanium oxide passivation film preparation method. The method comprises steps that an electron beam deposition method is utilized to deposit a metal titanium film with certain thickness at the surface of a silicon chip after pretreatment, then annealing is carried out in the oxygen atmosphere, and cooling in the nitrogen atmosphere is then carried out. The electron beamdeposition method and the metal titanium film are utilized to directly carry out oxidation of the metal titanium film to form a titanium oxide film, compared with the ALD / CVD process, equipment requirements are low, an operation mode and the operation flow are simpler, adjustment on the thickness of the metal titanium film and the oxidation process is facilitated to adapt to different silicon chippassivation demands, the titanium oxide passivation film and other passivation medium layers can excellently form laminated layers, so the better passivation result is realized; the method is suitable for a thermal evaporation method, a magnetron sputtering method to deposit the metal titanium film; deposition of microscale active metal can be easily realized, and thereby doped modification of the final titanium oxide film is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Jujube yoghourt containing poria cocos and preparation method thereof

InactiveCN103168852AFragrant tasteHigh medicinal valueMilk preparationBiotechnologyTrichosanthes kirilowii

The invention discloses jujube yoghourt containing poria cocos. The jujube yoghourt containing the poria cocos consists of the following raw materials in parts by weight: 98-105 parts of pure milk, 10-13 parts of white sugar, 6-7 parts of jujube, 1-2 parts of moutan bark, 2-3 parts of the poria cocos, 1-2 parts of grape leaves, 1-2 parts of ginseng leaves, 1-2 parts of trichosanthes kirilowii maxim leaves, 2-3 parts of medlar leaves, 0.5-1 part of gelatin, 1-2 parts of sodium carboxymethylcellulose, 0.2-0.4 part of a mixing strain and 0.6-1 part of whey powder. The jujube yoghourt containing the poria cocos, disclosed by the invention, is safe, simple, rapid and pollution-free in process, low in requirement on production environment, low in possibility of microorganism pollution and degeneration of products, and the jujube yoghourt with jujube pulp is high in medicinal value, abundant in nutrient substances, easy to absorb by a human body, and easy to accept by market and customers; and the jujube yoghourt containing the coconut milk improves the homogenization by two times, enhances the stability of the products, improves the appearance quality of conventional yoghourt, and increases the absorptivity of the human body to the nutrient substances.

Owner:BENGBU FULIN DAIRY

An extracting method of carnosine

InactiveCN100465285CHigh purityReduce investmentPeptide preparation methodsFermentationMuscle tissueSlurry

The invention discloses an extracting method of carnosine, which comprises the following steps: removing non-muscle tissue in the animal meat; washing; drying; grinding; adding water to stir into slurry; proceeding double-enzyme hydrolysis; proceeding enzyme inactivation; separating supernatant; adsorbing through hydroxy agustite chromatographic column; hyperfiltering through hyperfiltering film; collecting filtrate; spraying to dry carnosine liquid; collecting dried powder; packing in the vacuum.

Owner:HAINAN STAND BIO TECH

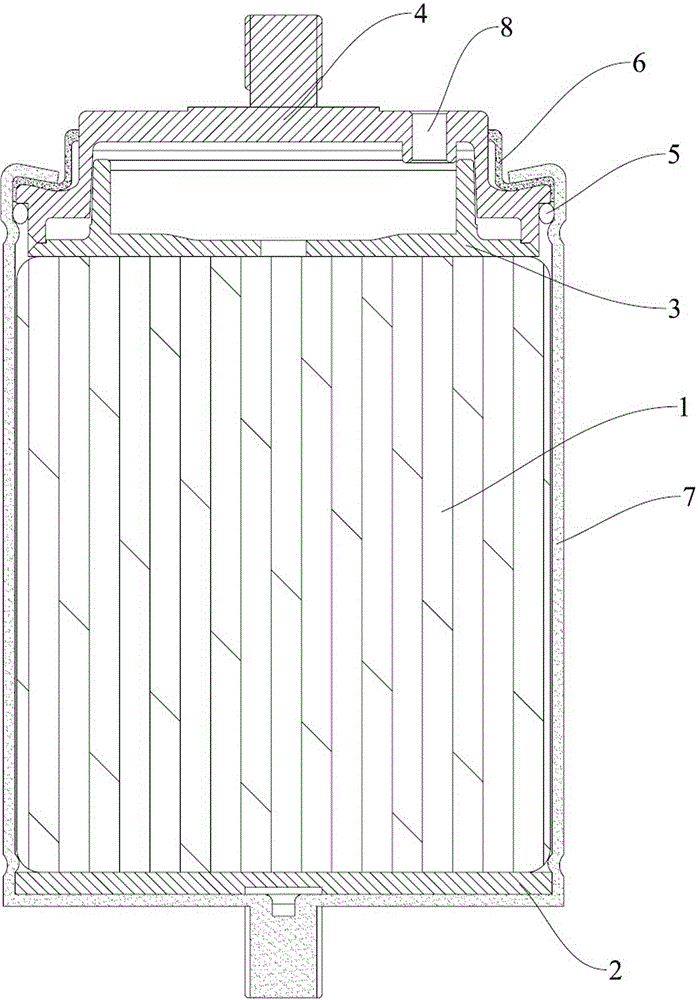

Manufacturing method of supercapacitor

ActiveCN104867701AMeet very low waterFulfil requirementsHybrid/EDL manufactureNitrogenSupercapacitor

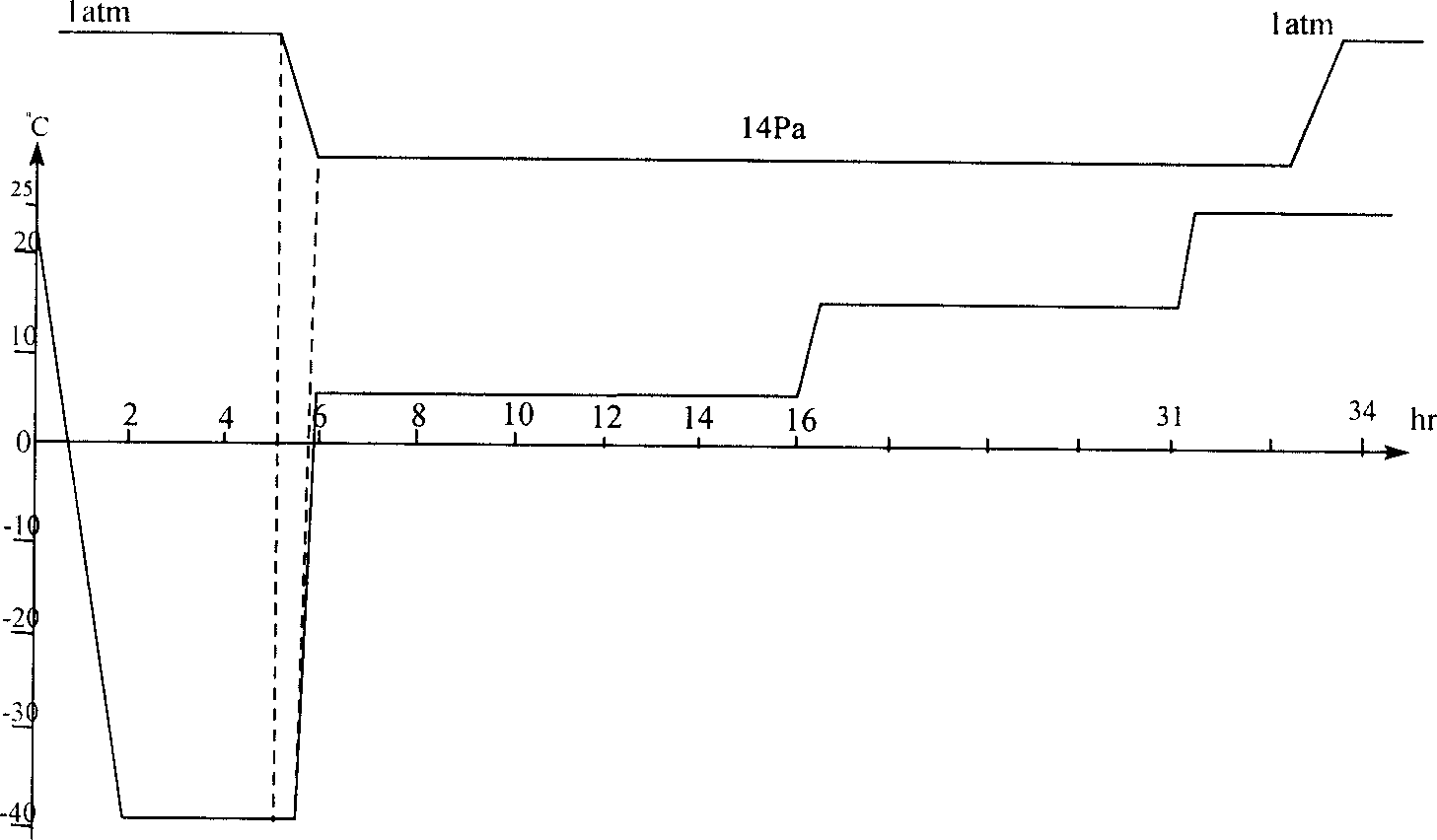

The invention discloses a manufacturing method of a supercapacitor. The manufacturing method comprises the following steps: (1) winding to form an electrode core; (2) welding; (3) installing the electrode core in a shell and carrying out slot rolling to prepare a supercapacitor single body; (4) carrying out vacuum heat treatment: putting the supercapacitor single body in the step (3) in an environment at 100-120 DEG C, vacuumizing until the pressure is lower than 6Pa, maintaining the pressure for 1-3.5 hours, then filling dry nitrogen and maintaining the pressure for 1-3.5 hours; repeating the step at least three times; (5) adding a seal rubber plug and sealing an electrolyte injection hole after electrolyte injection. The method has the beneficial effects that the method has low requirements for the production environment and is high in production efficiency; meanwhile, replacement of water and oxygen inside the supercapacitor, especially water and oxygen molecules adsorbed on surfaces of foils and carbon, with dry nitrogen is carried out multiple times at a proper drying temperature to effectively remove heat and meet the extremely low requirements of the supercapacitor for the contents of water and oxygen, thus not only avoiding affecting the properties and stability of the supercapacitor as the materials inside the supercapacitor are damaged but also reducing fluctuation of various indexes after leakage and life tests carried out on the supercapacitor.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Method for preparing pharmaceutics of hydrolysate of brain protein

ActiveCN1228082CTo achieve the separation effectNo pollution in the processPowder deliveryNervous disorderHydrolysateTyrosine

A hydrate of brain protein is prepared from pig's brain through adding purified water, homogenizing, heating, cooling, regulating pH=1.5-2.0, enzymolyzing, regulating pH=7.7-8.0, enzymolyzing, regulating pH=2.5-3.0 freezing, thawing, filter, regulating pH to become neutral, ultrafiltering, concentrating, sterilizing, adding amino acids, regulating peptide map, diluting, and steam sterilizing.

Owner:赛隆药业集团股份有限公司

Negative prelithiated electrode and preparation method thereof

InactiveCN112038577AReduce the risk of oxidationImprove first-time efficiencySecondary cellsElectrode collector coatingOrganic solventElectrical polarity

The invention discloses a negative prelithiated electrode. The negative prelithiated electrode comprises a metal current collector, and an active substance layer, a lithium supplementing layer and a functional polymer film protection layer which sequentially coat the surface of the metal current collector, wherein a functional polymer is a polymer containing a lithium-philic polar functional group. The invention discloses a preparation method of the negative prelithiated electrode. The preparation methodcomprises the following steps: S1, coating the surface of the metal current collector withthe active substance, and carrying out prelithiation treatment to obtain an intermediate electrode; and S2, mixing and stirring the functional polymer and an organic solvent for 6-10h, conducting standing for 12-24h, uniformly coating the surface of the intermediate electrode with a formed supernatant, and performing vacuum drying at 45-85 DEG C to obtain the negative prelithiated electrode. The risk that the lithium supplementing layer of the prelithiated electrode is oxidized can be effectively reduced, and the initial efficiency, the energy density, the cycling stability and the safety performance of a lithium ion battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

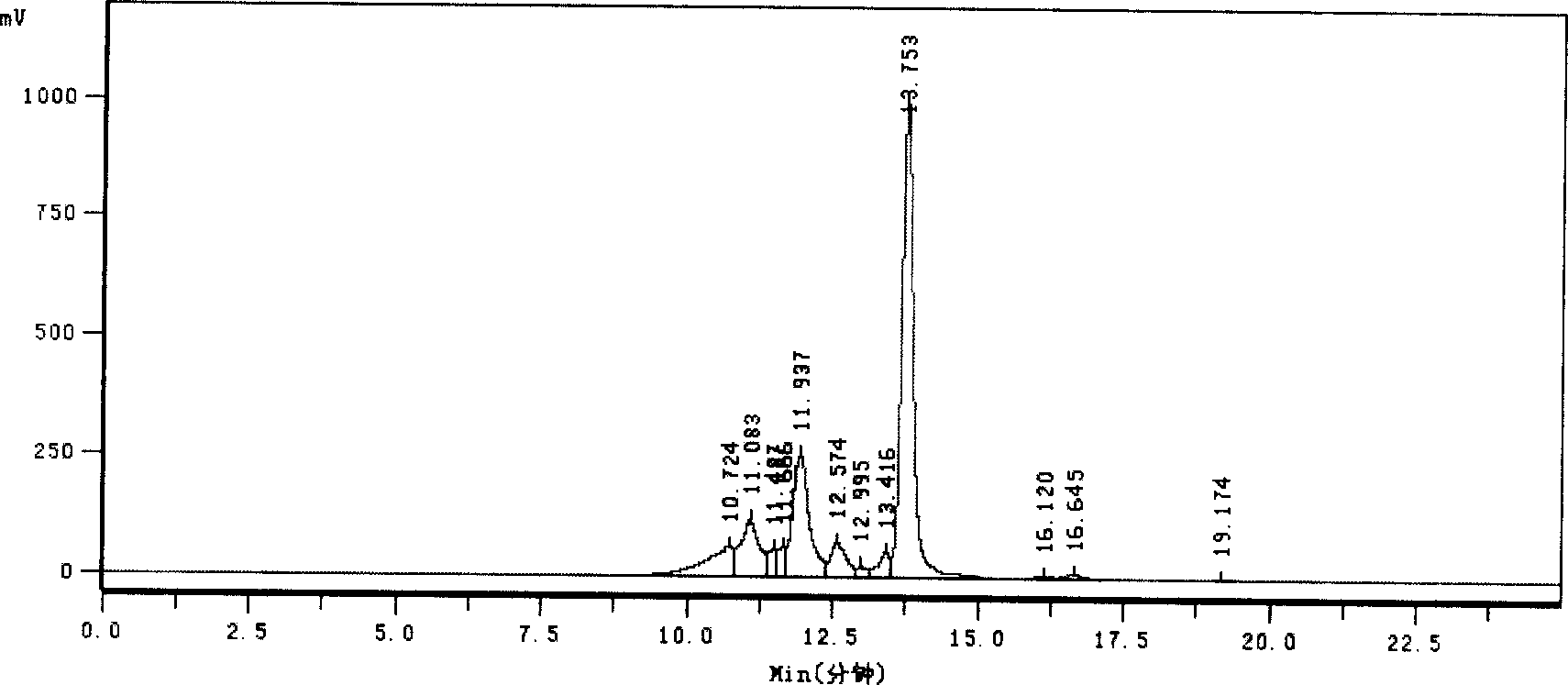

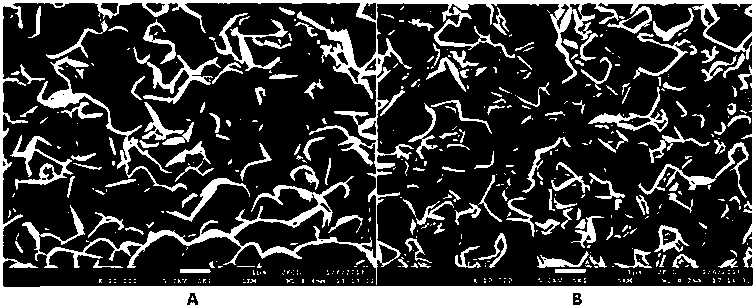

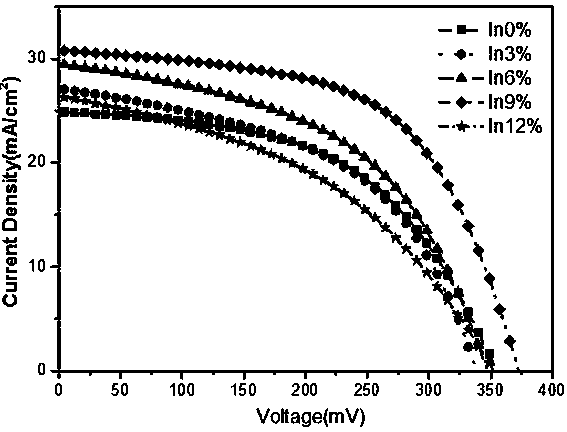

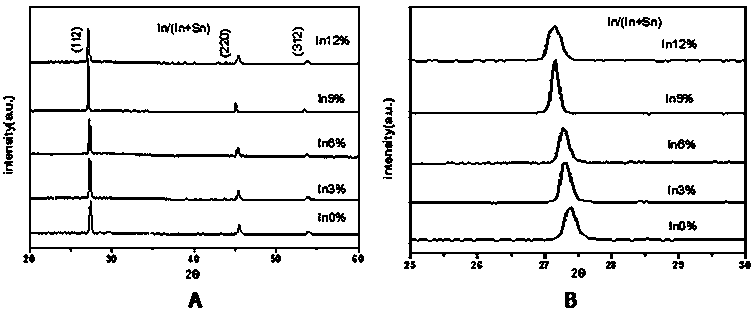

Preparation method and application of indium doped CZTSSe film

ActiveCN108400184AStoichiometric ratio is easy to controlReduction of transposition defectsFinal product manufactureSemiconductor/solid-state device manufacturingIndiumFill factor

The invention discloses a preparation method of an indium doped CZTSSe film and an application of the same in a flexible solar battery. According to the preparation method provided by the invention, the In is doped in the CZTSSe film to replace the part of Sn atoms, so that the phase defect of the film body is improved, the carrier concentration is improved, the prepared solar battery is significantly improved in short circuit current density, open-circuit voltage, filling factor and photoelectric conversion efficiency, and thus the solar battery has relative good application value.

Owner:FUZHOU UNIV

Method for producing flavouring lotion by using saccharomycopsis fibuligera

InactiveCN105112263ASafeNo irritationAlcoholic beverage preparationMicroorganism based processesBiotechnologySaccharomycopsis fibuligera

The invention discloses a method for producing flavouring lotion by using saccharomycopsis fibuligera. The method comprises the following steps of slant culture: saccharomycopsis fibuligera FBKL 2.0094 is inoculated on a slant culture medium for culturing at 28 DEG C for 24 to 48 hours until hyphae grow fully in a test tube; strains are activated; a seed solution is prepared; solid state fermentation is performed in a triangular flask and a fermented product is obtained; preparation of the flavouring lotion: 26.47 percent of salt solution, 10 percent v / v of ethanol solution and the fermented product are mixed by a ratio of 1 ml:1 ml:1g; the mixture is evenly stirred and the stirring time is 5 to 10 minutes; the stirred mixture is put into a water bath kettle with the temperature of 50 DEG C to be subjected to water bath for 30 minutes; air distillation is performed and the temperature is controlled at 100 DEG C; the timing is started when cut fraction is distilled off; the distillation time is 20 to 40 minutes; 25 to 75 ml of cut fraction is collected into a volumetric flask, and the volumetric flask is subjected to cold storage at 4 DEG C in a refrigerator. The method for producing flavouring lotion by using saccharomycopsis fibuligera provided by the invention is short in production cycle, high in quality rate, and low in production cost.

Owner:GUIZHOU UNIV

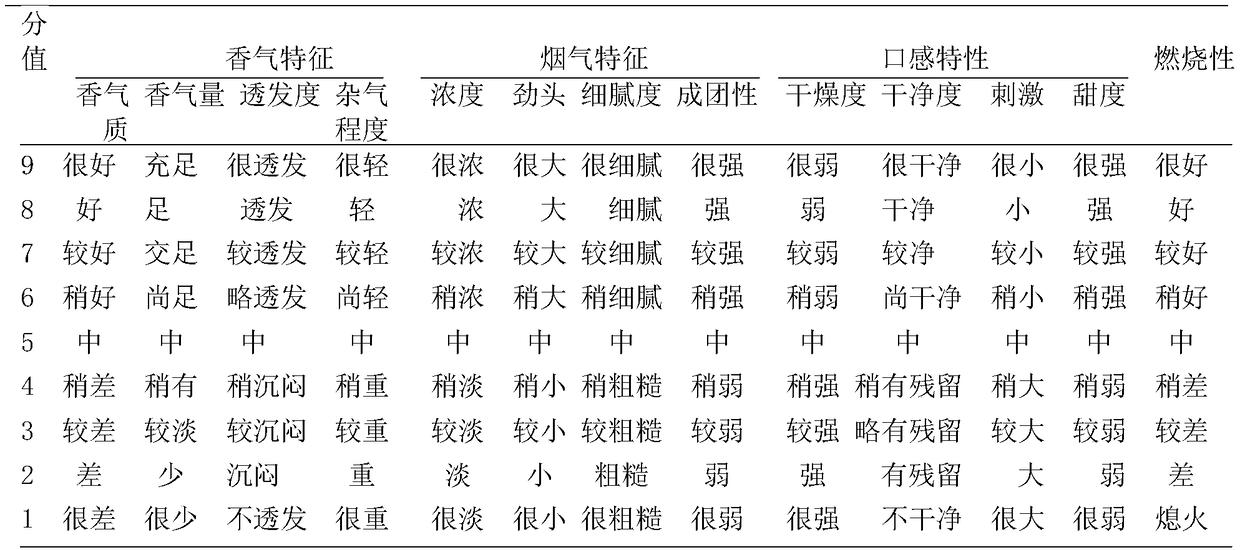

Mixed-strain tobacco fermentation method

ActiveCN109090697AStrong ability to produce phenethyl acetateStrong wine production capacityTobacco treatmentPichia pastorisNicotiana tabacum

The invention discloses a mixed-strain tobacco fermentation method. The method comprises the steps that strains that Pichia pastoris FBKL2.0008 and Issatchenkia orientalis FBKL2.0002 are inoculated toa slope culture medium to be cultured for 24 h-48 h at the temperature of 28 DEG C until a test tube is full of strains; slope cultured strains are activated by drawing lines on a beer wort agar culture medium and cultured for 24 h-48 h at the temperature of 28 DEG C; seed liquid is prepared, mixed-strain liquid is obtained by mixing the yeast seed liquid of the Pichia pastoris and the yeast seedliquid of Issatchenkia orientalis which are obtained by culturing, and the yeast seed liquid of the Pichia pastoris takes up 60%-80% of the mixed strain liquid; the mixed-strain liquid is added to tobaccos according to the concentration of 0.4 ml / g, sterilized water with the concentration of 0.2 ml / g is added every 3 days, the tobaccos are cultured for 15-20 days at the temperature of 28 DEG C-30DEG C, drying is conducted for 15-30 minutes at the low temperature of 40-60 DEG C, and the tobaccos are obtained. The tobaccos have rose fragrance, powder fragrance, sweet fragrance and bouquet, andthe method has the advantages of simple process, difficult contamination and wide product application.

Owner:GUIZHOU UNIV

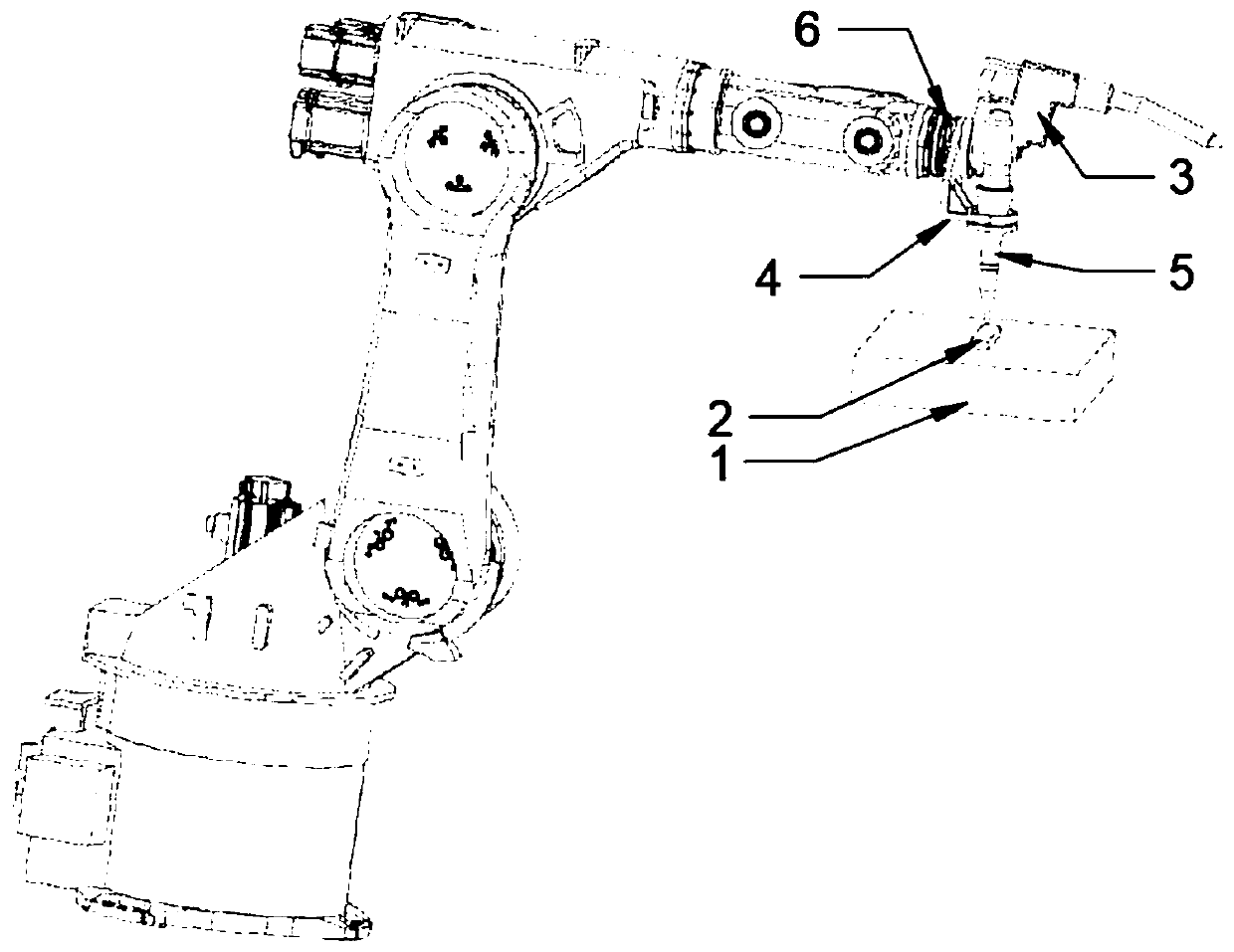

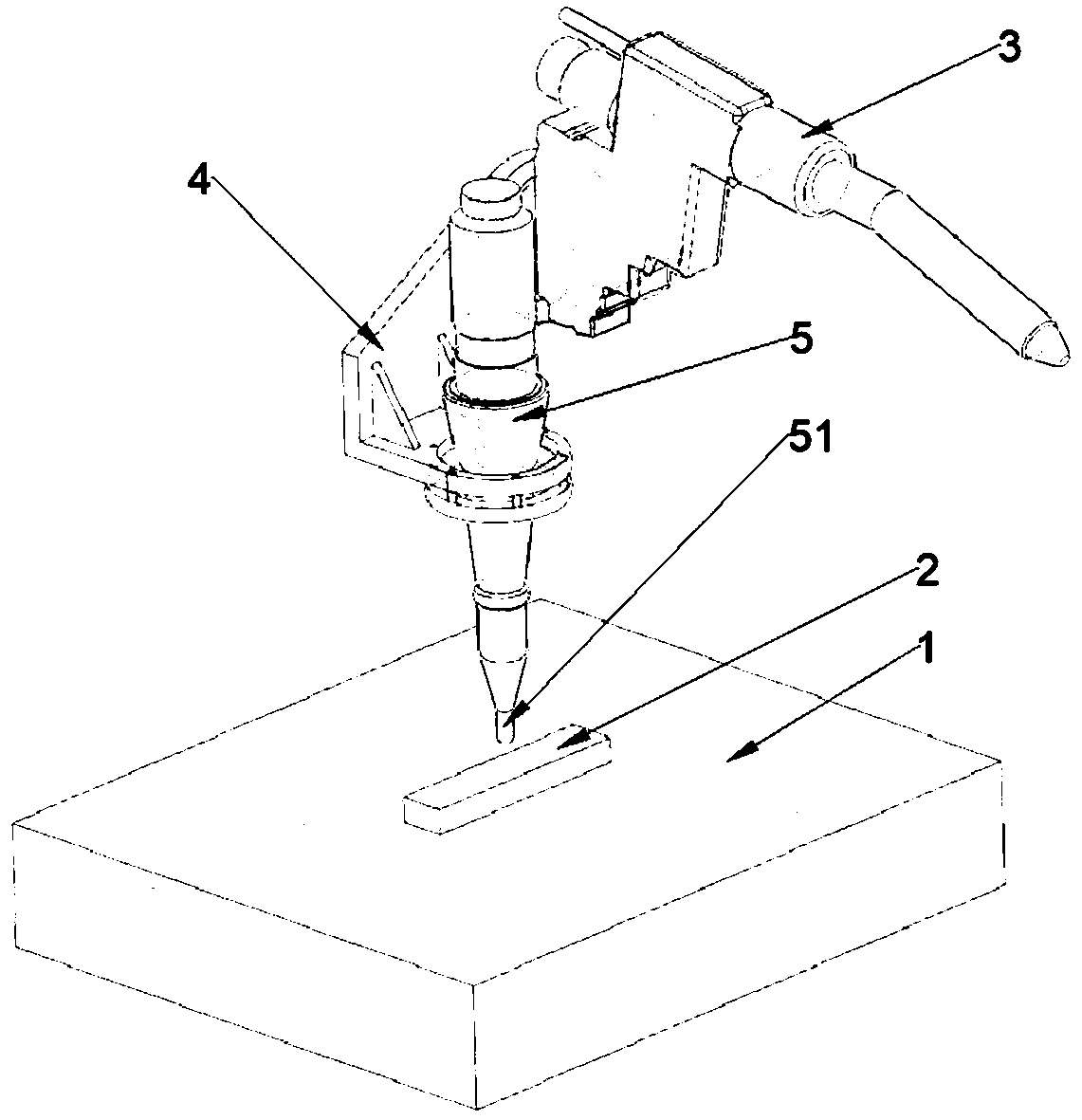

5xxx-series aluminum alloy electric-arc additive surface treatment device

PendingCN110653454AEfficient removalLow priceAdditive manufacturing apparatusElectrode holder supportersSand blastingCase hardening

The invention discloses a 5xxx-series aluminum alloy electric-arc additive surface treatment device. The 5xxx-series aluminum alloy electric-arc additive surface treatment device is characterized by comprising a base plate, a six-axis robot, a welding gun, a connecting bracket and a spray gun, wherein the welding gun and the spray gun are mounted on the six-axis robot through the connecting bracket; and the six-axis robot rotates to drive the connecting bracket to rotate, so that the welding gun and the spray gun are controlled to perform additive and sand-spraying operation on the base plate,and surface hardening on the surface of an aluminum alloy deposited layer is performed while black ash and oxides on the surface of the deposited layer are removed, and therefore, mechanical propertyof the aluminum alloy additive-manufactured part is improved, a welding machine additive program can be quickly transplanted to a sand spraying program, program design time is greatly shortened, andan application prospect is very strong.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

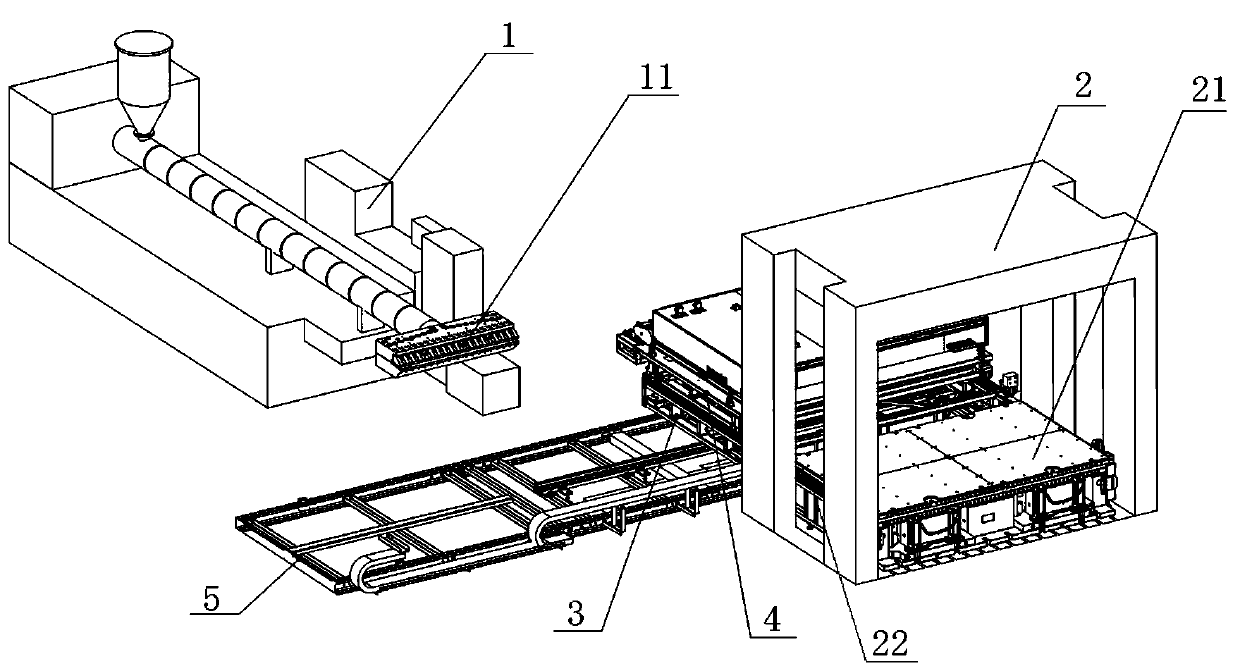

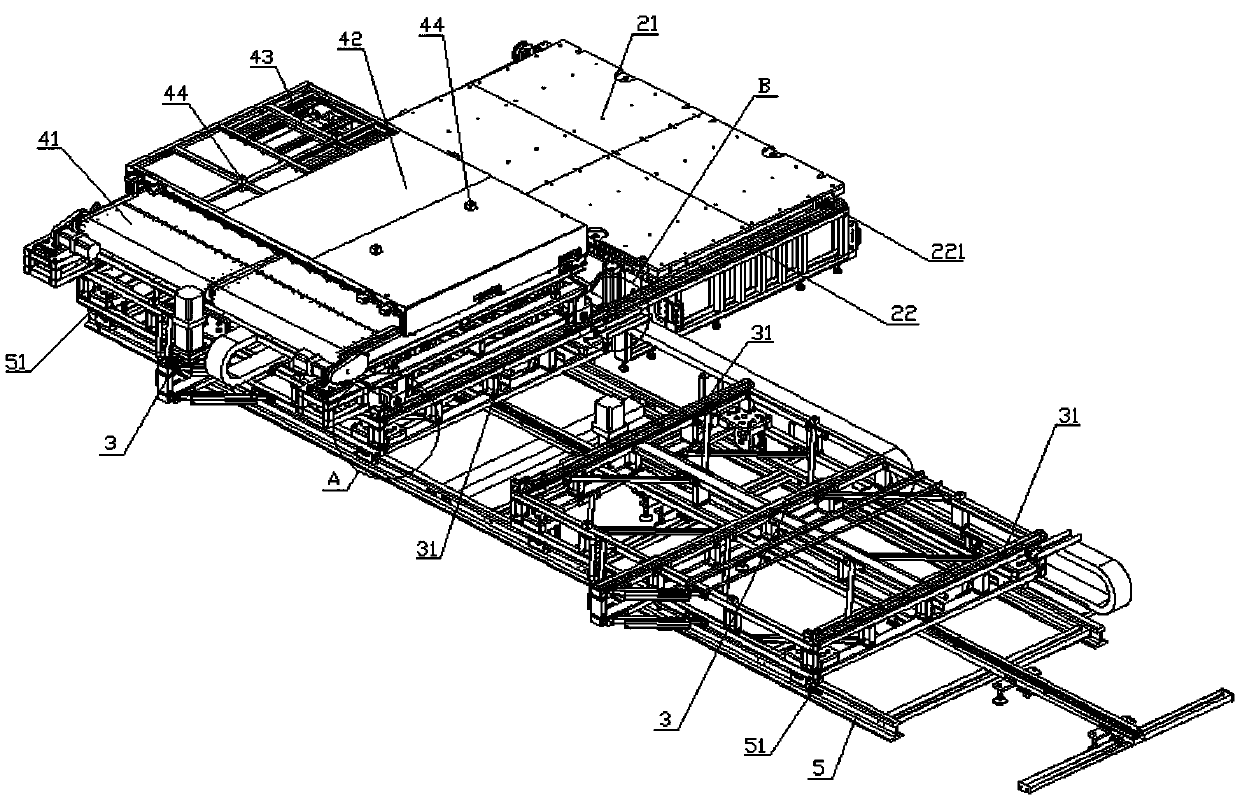

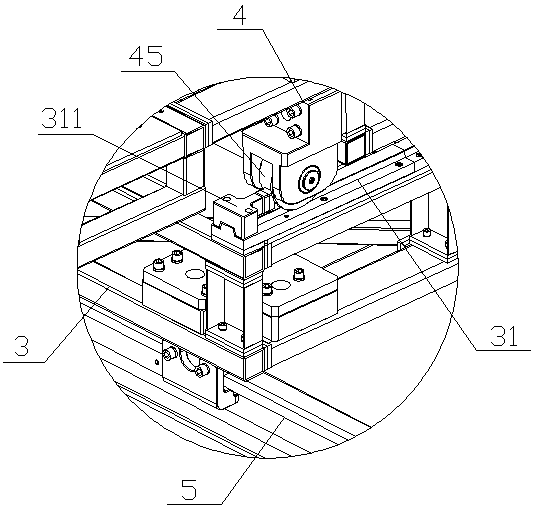

Base plate production system and base plate production process

The invention relates to the technical field of base plate production, and particularly relates to a base plate production system and a base plate production process. The base plate production systemcomprises an extruder, a hydraulic machine, a transport trolley, a discharging trolley and a third conveying rail assembly, wherein an extrusion die is installed on the extruder; a die pressing die and a first conveying rail assembly are installed on the hydraulic machine; a second conveying rail assembly is installed on the transport trolley; a conveying mechanism used for conveying base plates and a heat preservation mechanism used for heat preservation of the base plates are installed on the discharging trolley; and the transport trolley moves in a reciprocating mode along the third conveying rail assembly so that the discharging trolley can bear the base plates extruded by the extrusion die and send the base plates into the die pressing die. The base plate production system and the base plate production process have the beneficial effects that the production and machining of the base plates are realized through the cooperation of the extrusion die and the die pressing die, the production quality and the production efficiency are improved, the temperature of the molten blocky base plates in the conveying process is guaranteed, the requirement for the production environment is reduced, the occupied space is small, and the transportation is convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

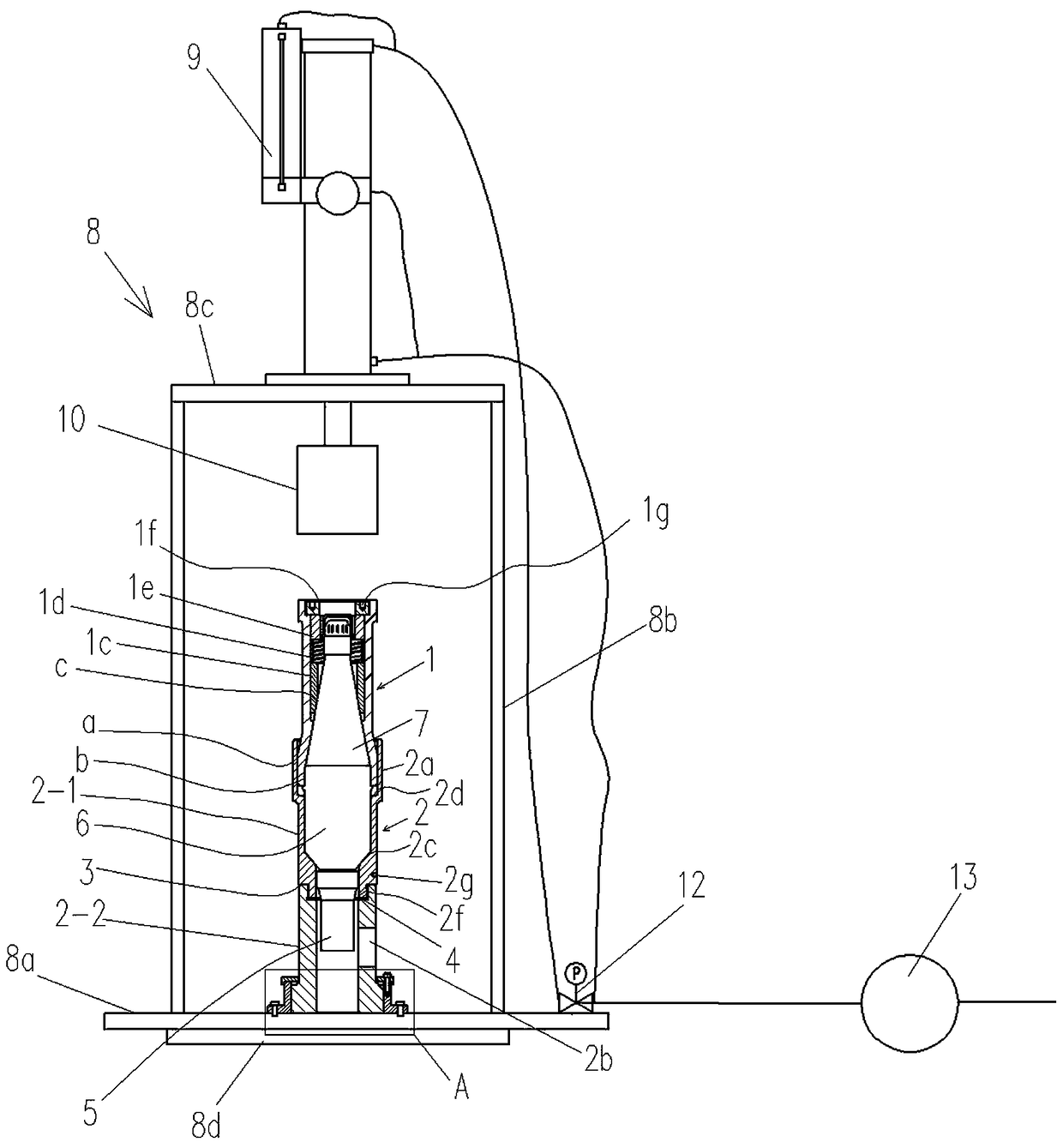

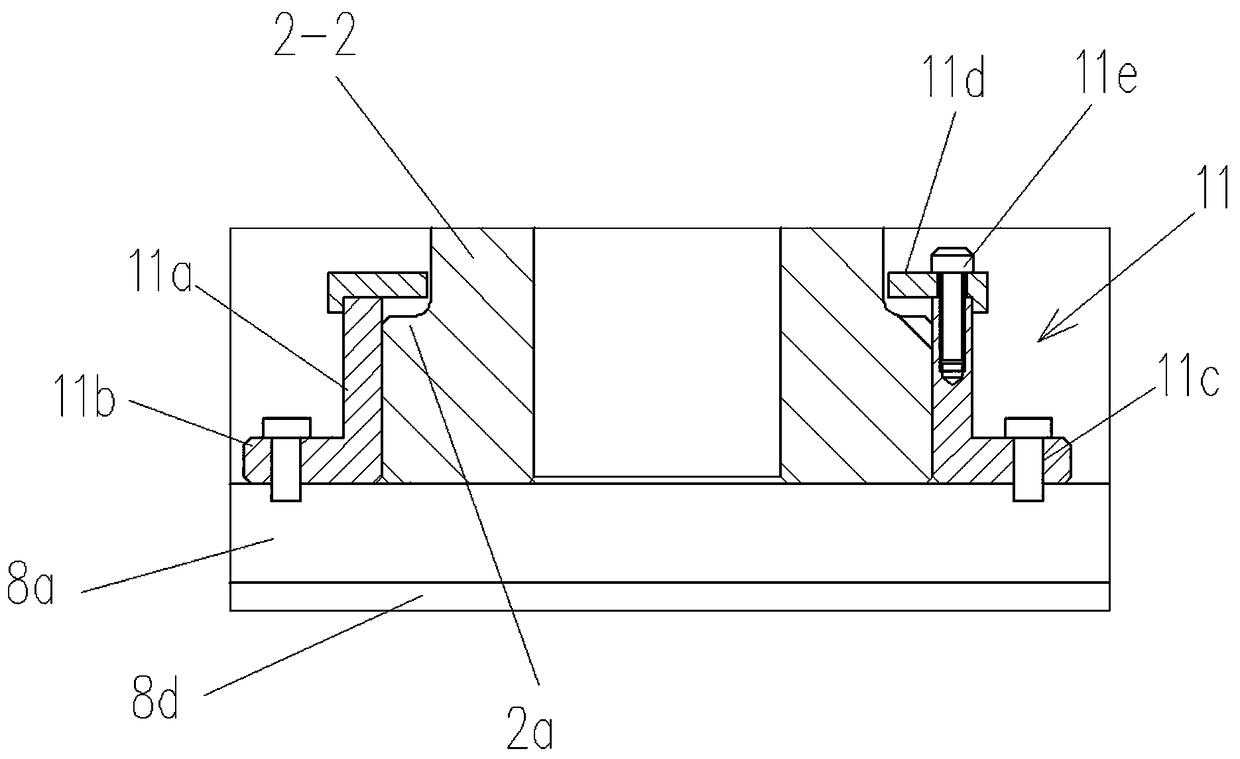

Fitting assembly for hood and projectile body

The invention provides a fitting assembly for a hood and a projectile body. The fitting assembly is characterized in that the fitting assembly comprises a press machine device and a necking-in devicecorrespondingly matched with the press machine device, the press machine device comprises a machine frame (8) and an air-liquid supercharging cylinder (9), a pressure head (10) is arranged on an output shaft of the air-liquid supercharging cylinder (9), the machine frame (8) is provided with a clamping groove (11) corresponding to the pressure head (10) and a control valve (12) connected and matched with the air-liquid supercharging cylinder (9), and the control valve (12) communicates with an air source through a pressure control valve (13); and the necking-in device comprises an upper die-sleeve (1) and a lower die-sleeve (2) which are coaxially matched, and an expanding portion (2a) correspondingly matched with the clamping groove (11) is arranged at the outer wall of the lower end portion of the lower die-sleeve (2). The fitting assembly has the advantages of being simple in structure, easy to operate, high in safety, low in cost, wide in application, and low in follow-up maintenance expense.

Owner:ANHUI FANGYUAN MECHANICAL & ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com