Patents

Literature

74results about How to "Reduce surface recombination rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

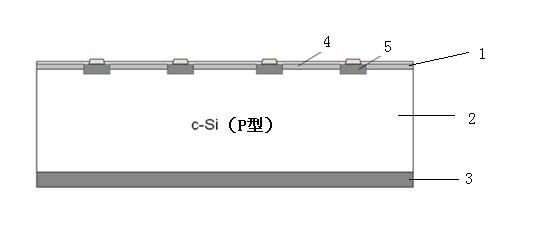

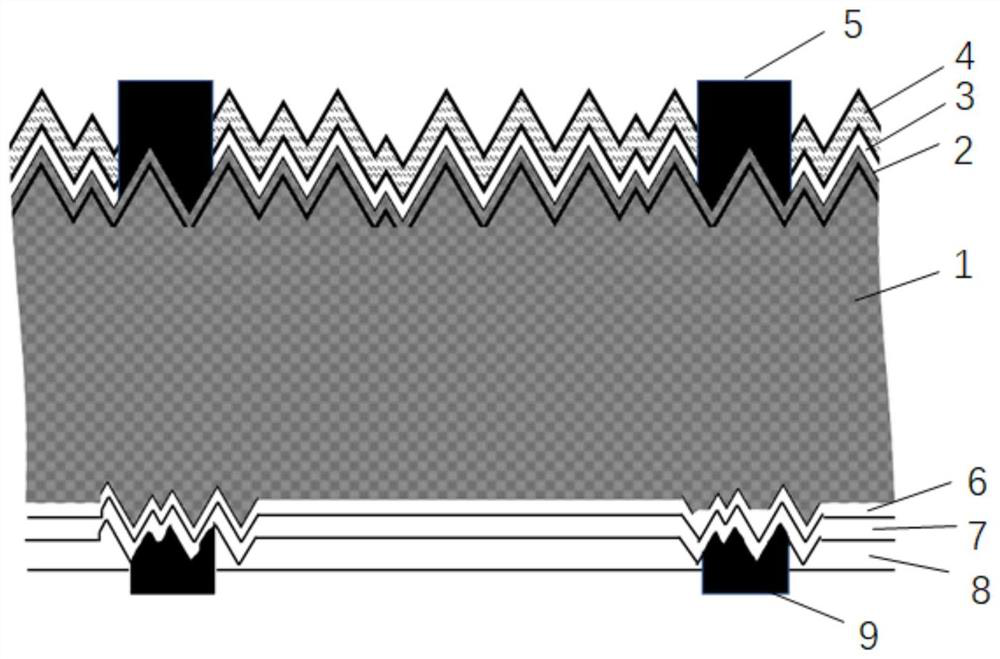

Novel crystalline silicon solar cell and manufacturing method thereof

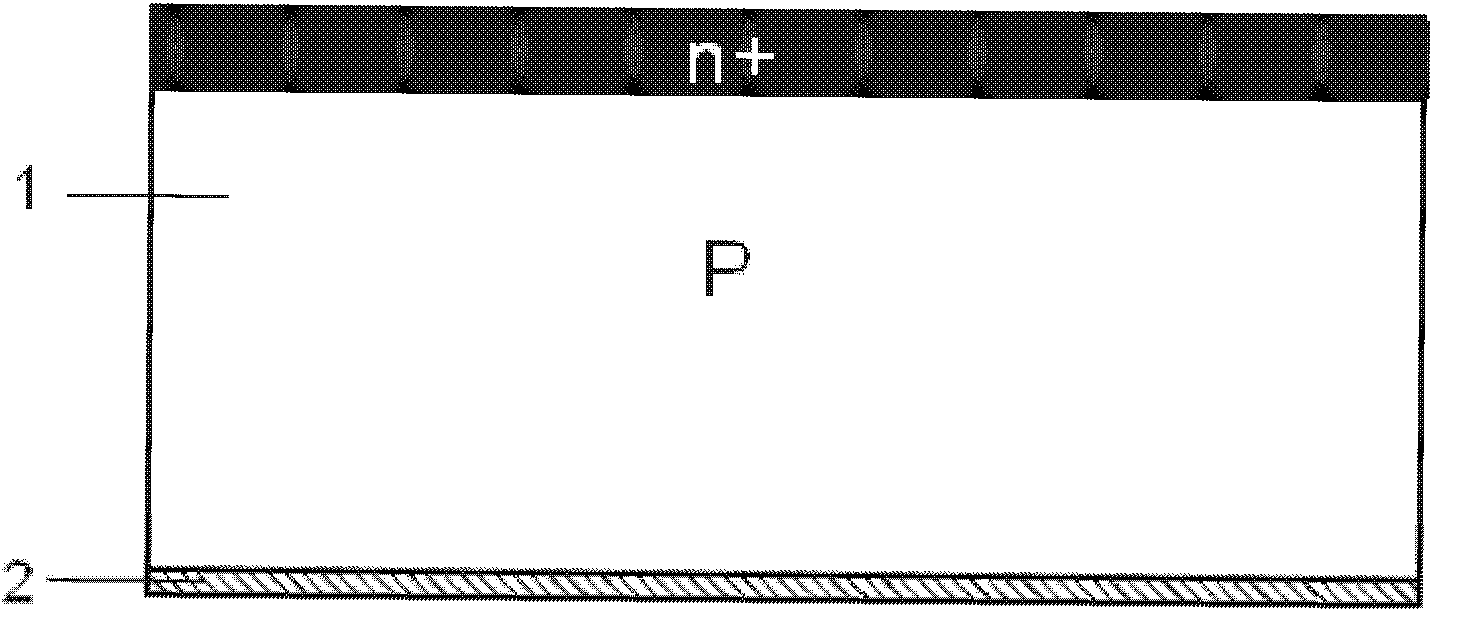

InactiveCN102064216AImprove surface passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationHeterojunctionMaterials science

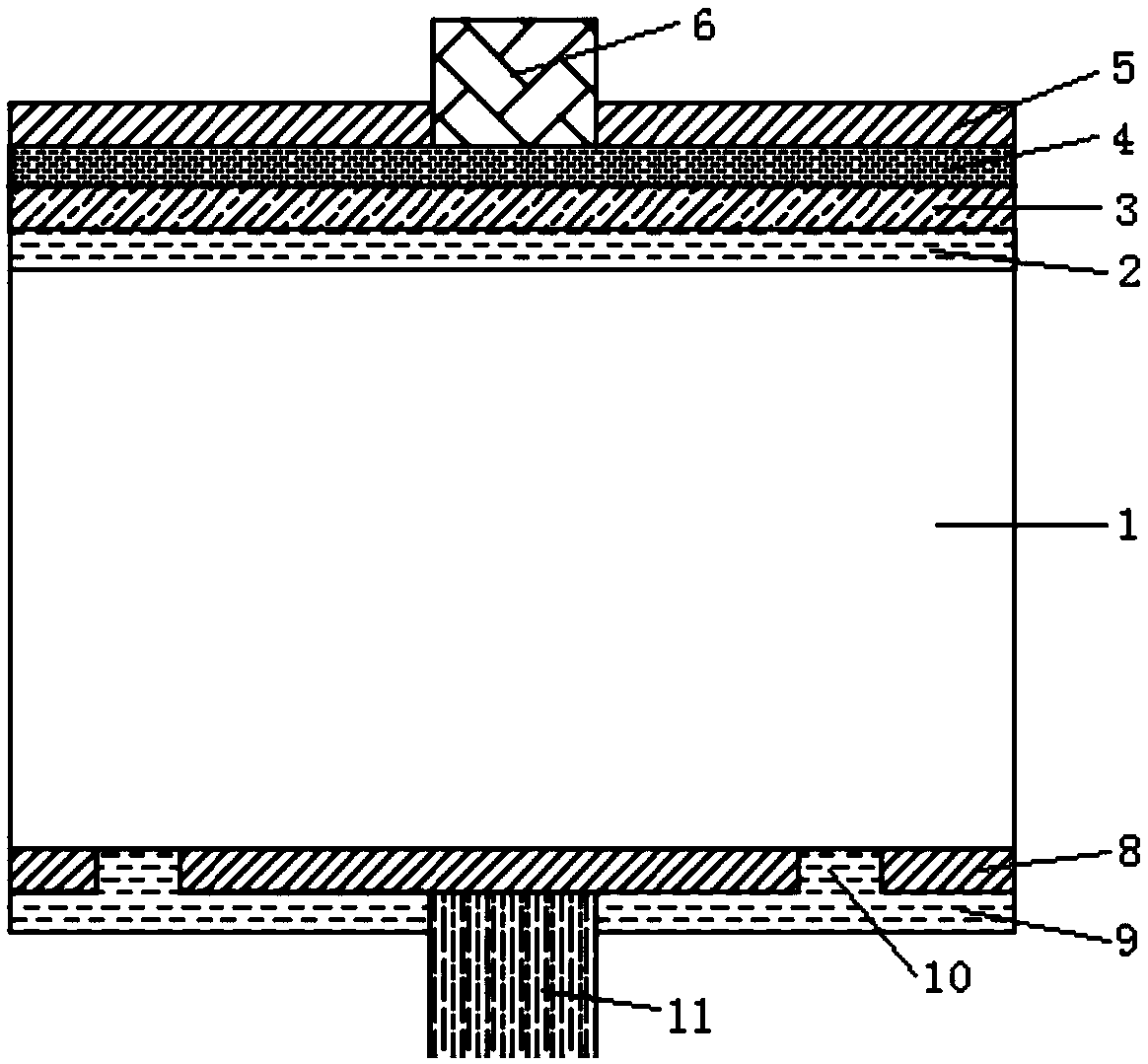

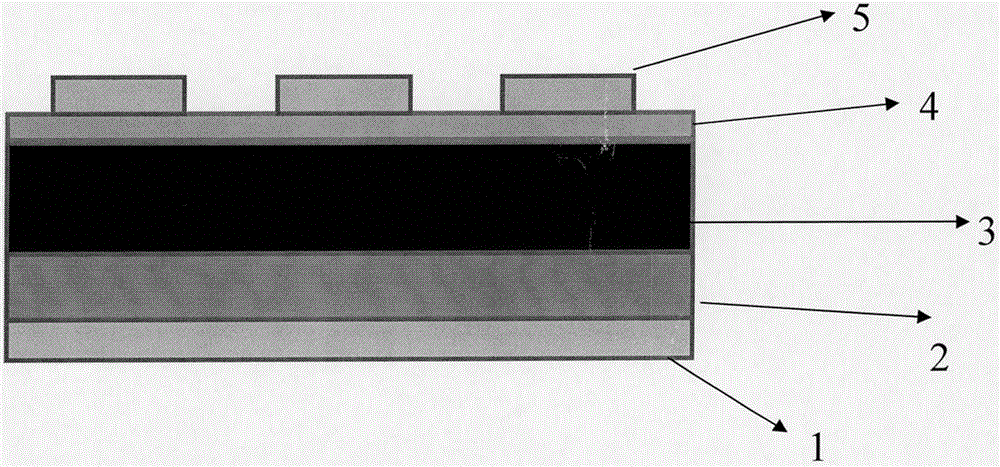

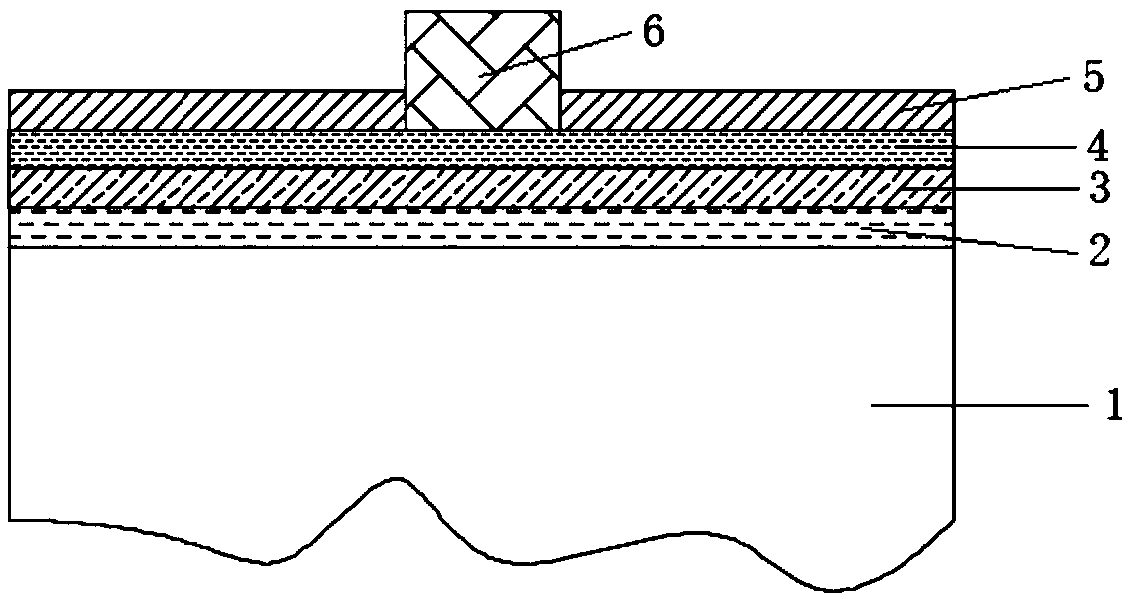

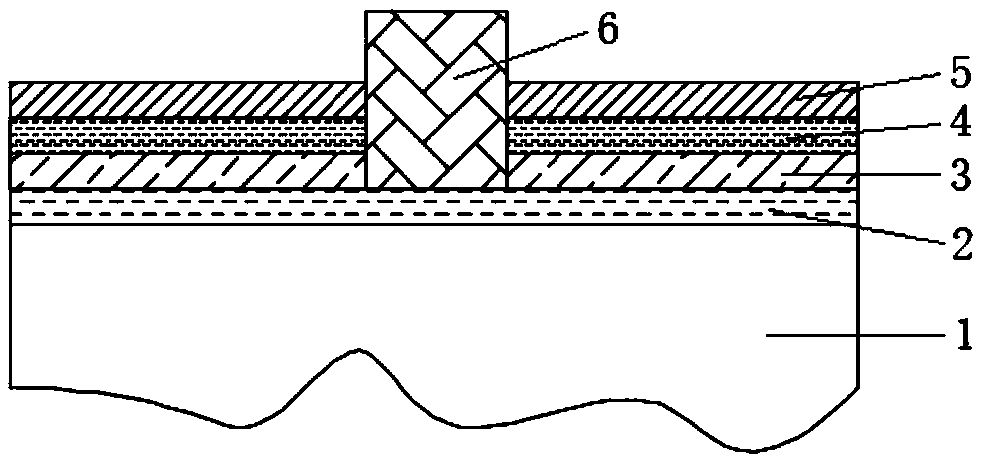

The invention discloses a novel crystalline silicon solar cell. The novel crystalline silicon solar cell comprises a crystalline silicon matrix, wherein the front surface of the crystalline silicon matrix has an emitter structure, and the back surface of the crystalline silicon matrix has a heterojunction structure; the heterojunction structure comprises an intrinsically hydrogenated amorphous silicon film, a hydrogenated amorphous silicon film, a transparent conductive oxide film and a metal conductive electrode in turn; the intrinsically hydrogenated amorphous silicon film covers the entire back surface of the crystalline silicon matrix; the hydrogenated amorphous silicon film is heavily doped by using a dopant which has the same conduction type as that of the matrix; and the metal conductive electrode passes through the transparent conductive oxide film and is in ohmic contact with a heavily doped layer. The invention also discloses a manufacturing method of the crystalline silicon solar cell. The crystalline silicon solar cell with the structure can reduce composite loss on the surface; meanwhile, the back surface of the solar cell forms a better light trap structure to improve open-circuit voltage of the solar cell, so that conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

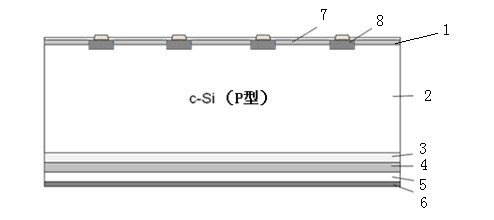

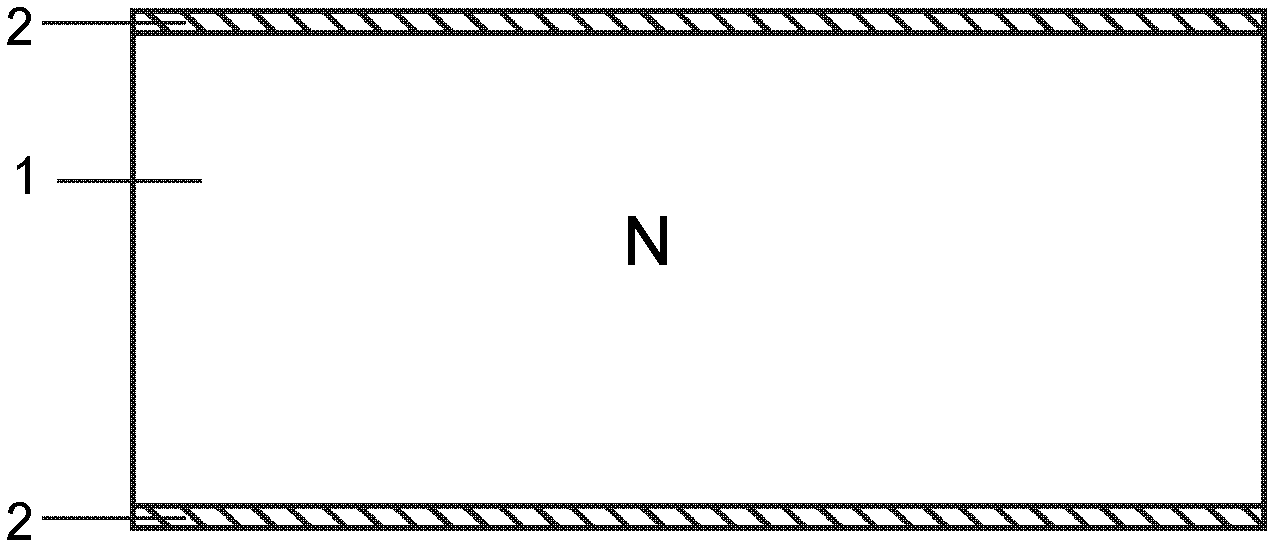

Heterojunction with intrinsic thin layer (HIT) solar cell structure with heterogeneous floating junction back passivation, and preparation process thereof

ActiveCN102437243AReduce surface recombination rateIncrease the open circuit voltagePhotovoltaic energy generationSemiconductor devicesHeterojunctionAmorphous silicon

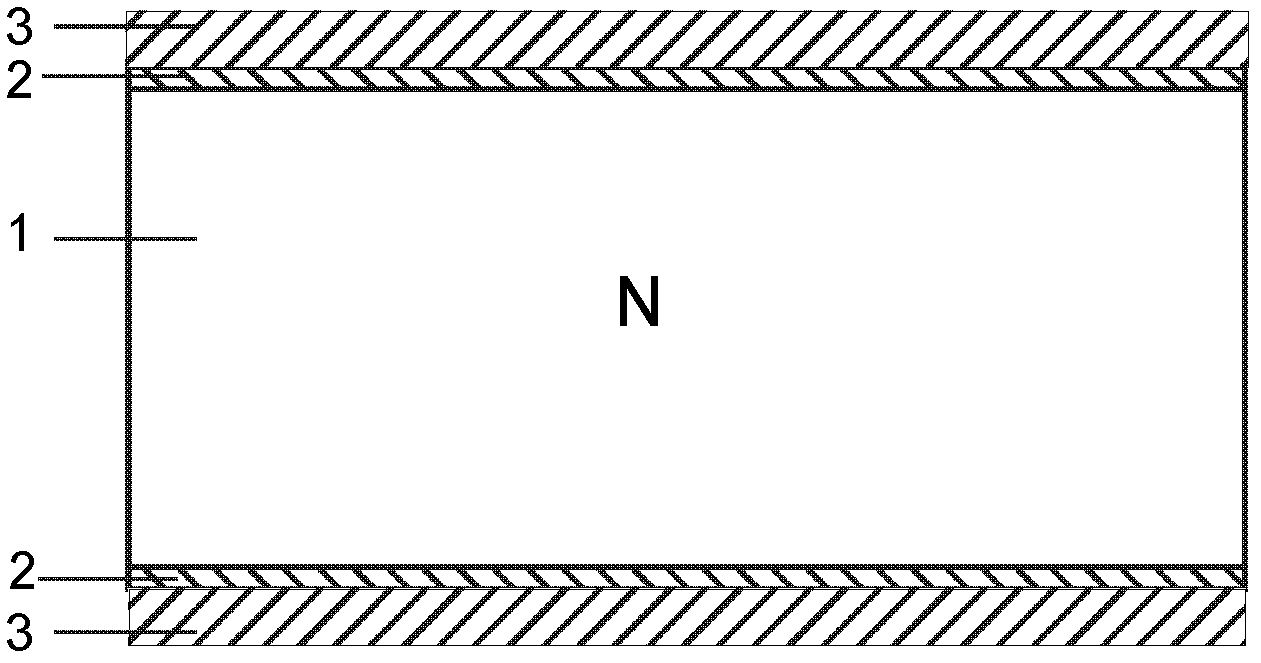

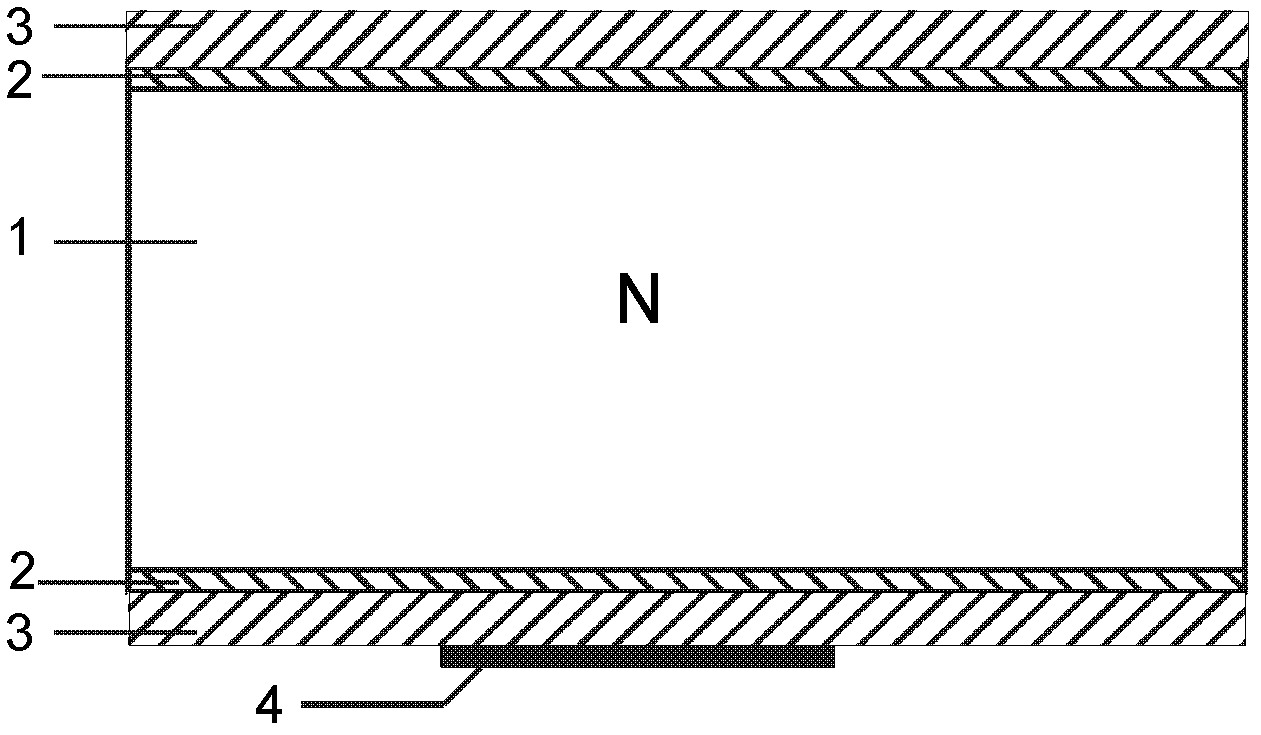

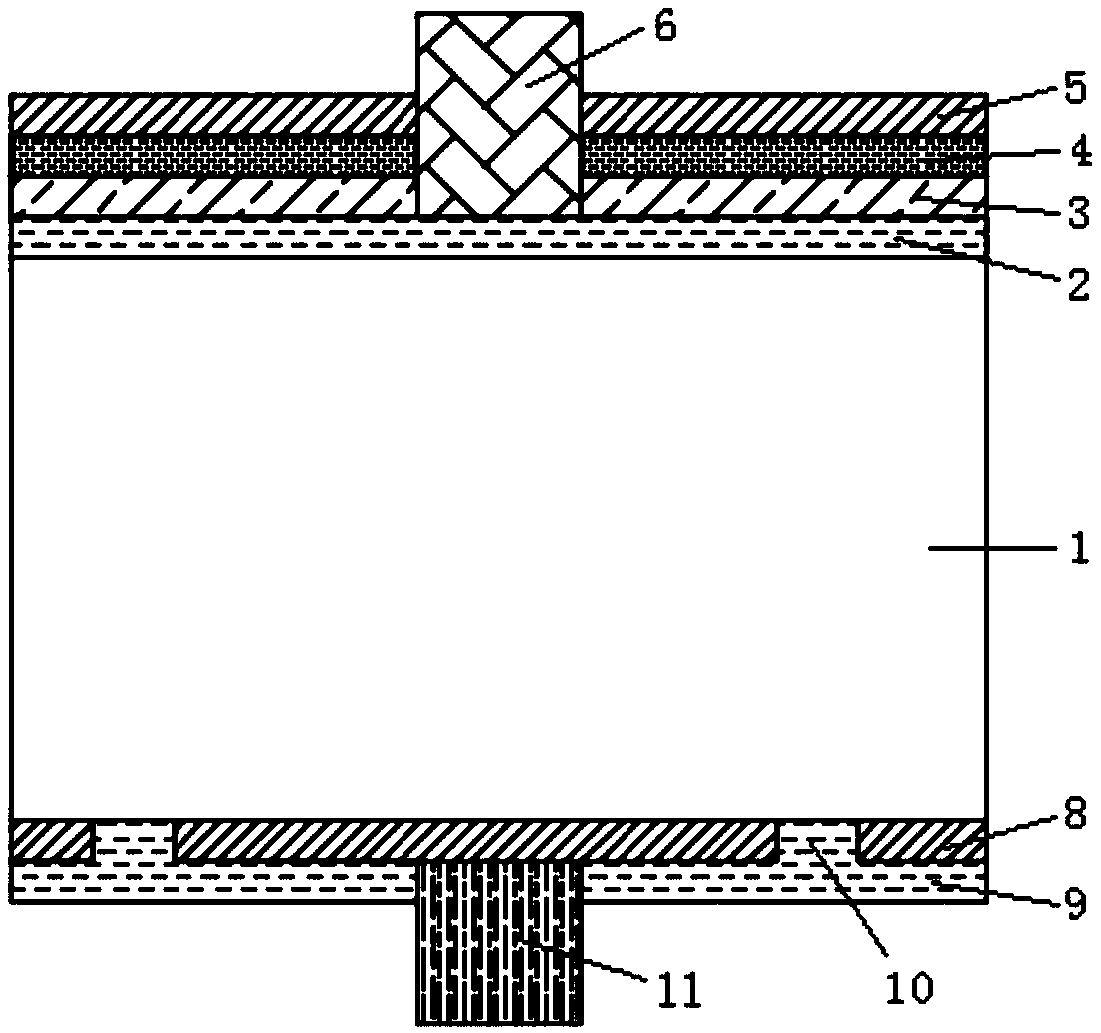

The invention relates to the technical field of solar cells, in particular to a heterojunction with intrinsic thin layer (HIT) solar cell structure with heterogeneous floating junction back passivation, and a preparation process thereof. P-type amorphous silicon layers are deposited on the upper surface and the lower surface of an N-type crystal silicon substrate so as to form heterogeneous P-N junction structures; a mask is manufactured on the heterogeneous P-N junction structure on the lower surface; selective etching is performed so as to form isolated heterogeneous P-N junction structures; the mask layer is removed and an insulation thin film layer is deposited on the lower surface; a mask is manufactured on the insulation thin film layer; secondary selective etching is performed, so that the side surface and the back surface of the heterogeneous P-N junction structure on the lower surface of the N-type crystal silicon substrate are encircled by the insulation thin film layer, and a floating junction back passivation structure is formed; and an N-type amorphous silicon back electrode and a P-type amorphous silicon floating junction back passivation structure are strictly separated from each other by the insulation thin film layer. Compared with an HIT standard process and a structure of the Sanyo, the HIT solar cell structure has the advantages that: the floating P-N junction back passivation structure is introduced into the back surface of the N-type crystal silicon, so that the surface compounding rate is lower and the open-circuit voltage is higher.

Owner:TRINA SOLAR CO LTD

Novel SINP silicone blue-violet battery and preparation method thereof

InactiveCN101587913AImprove quantum efficiencyReduce the impactFinal product manufacturePhotovoltaic energy generationRadio frequency magnetron sputteringSingle crystal

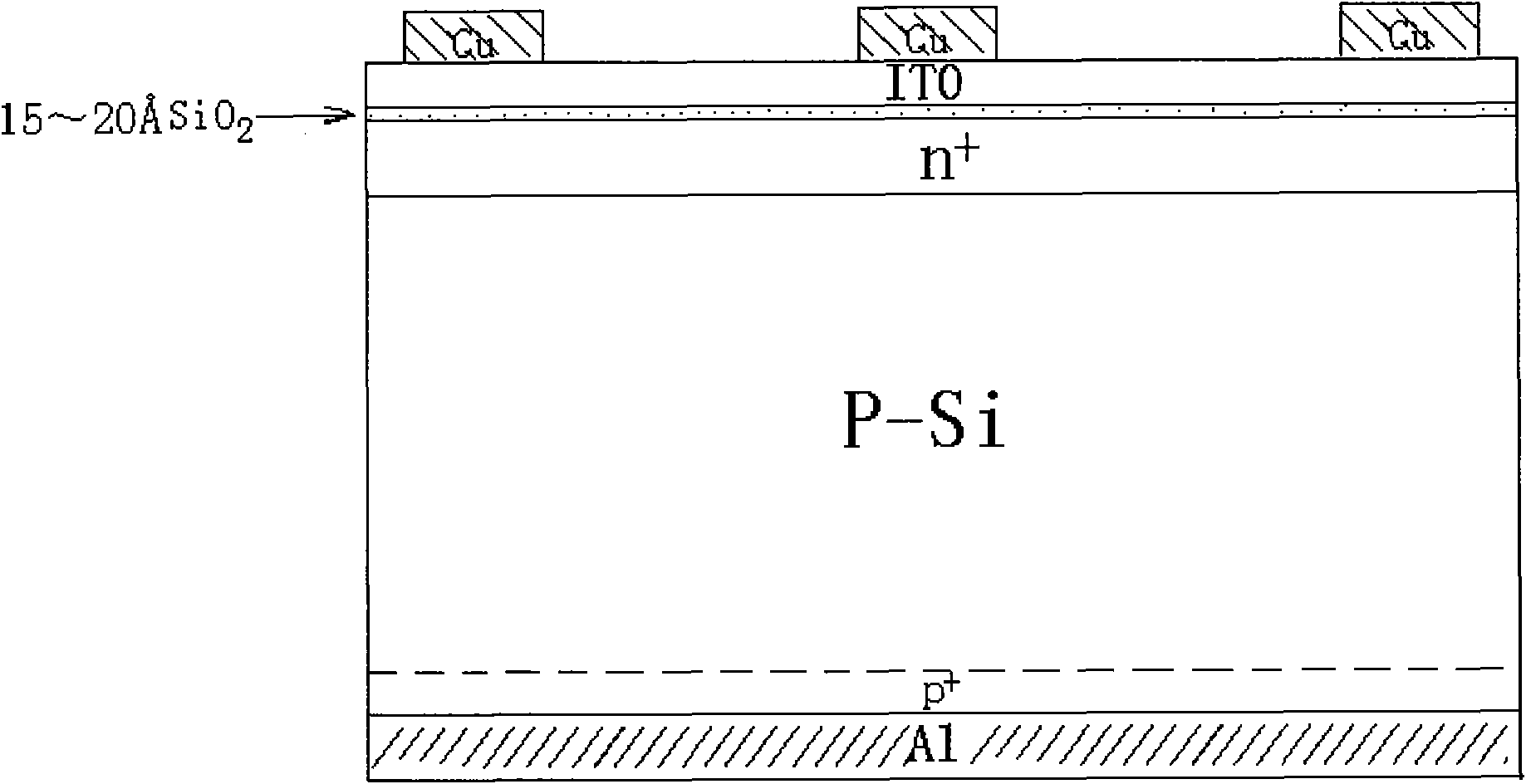

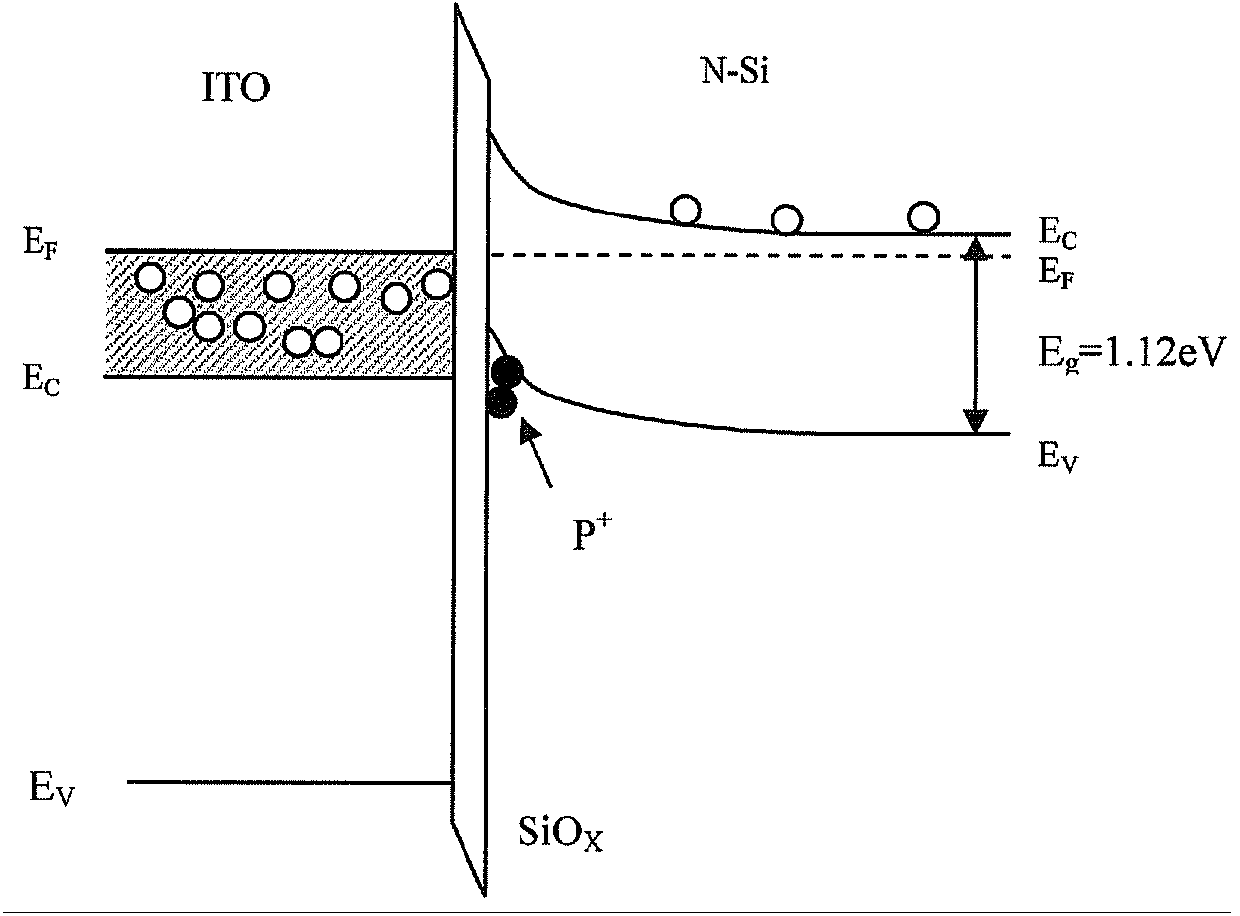

he invention relates to a novel SINP silicone blue-violet battery and a preparation method thereof. The invention uses shallow junctions formed from thermally diffused phosphorus, an ultra-thin SiO2 layer formed by low-temperature thermal oxidization and an ITO dereflection / collection electrode film formed by RF magnetron sputtering to prepares a novel ITO / SiO2 / np blue-violet reinforced SINP silicone photo-battery. Preparation method of the invention is to take a silicon single crystal flake which is P type, and has crystallographic orientation of 100, electric resistivity of 2 2omega.cm and thickness of 220mu m, as a substrate. The substrate is cleaned and is etched by routine chemistry, and then is thermally diffused by POC3 liquid source to form n regions (the invention prepares two pieces of novel SINP photo-batteries, one being routine SINP photo-battery having emitting region square resistance of 10 Omega / square and junction depth of 1 Mu m, and the other one being SINP silicone blue-violet battery having emitting region square resistance of 37 Omega / square and junction depth of 0.4 Mu m). Removing the phosphorosilicate glass (HF:H2O=1:10) at front face; steaming Al at back of the silicon chip; thermally oxidizing the silicon chip at 400 to 500 DEG C and condition of V2:O2=4:1 for 15 to 30min to generate a layer of 15 to 20 ultra-thin SiO2 layer, and at the same time alloying the Al at the back. Then RF magnetron sputtering the ITO dereflection / collection electrode film (ITO film is also deposited on the glass to study electrooptical characteristic thereof) having high transmittance and high conductivity, and sputtering a Cu gate electrode by metal mask direct-current magnetron. Finally, cutting the outer edge part of the battery by a diamond excircle downward cutting / a dicing saw so as to prevent short circuit of the edge of the photo-battery.

Owner:SHANGHAI UNIV

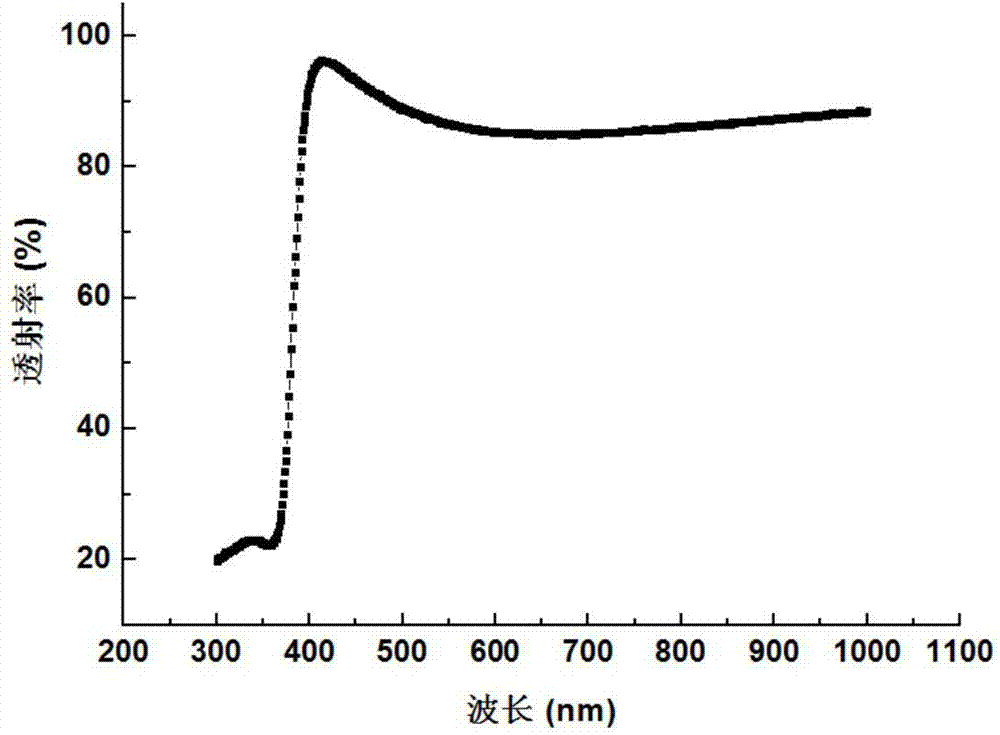

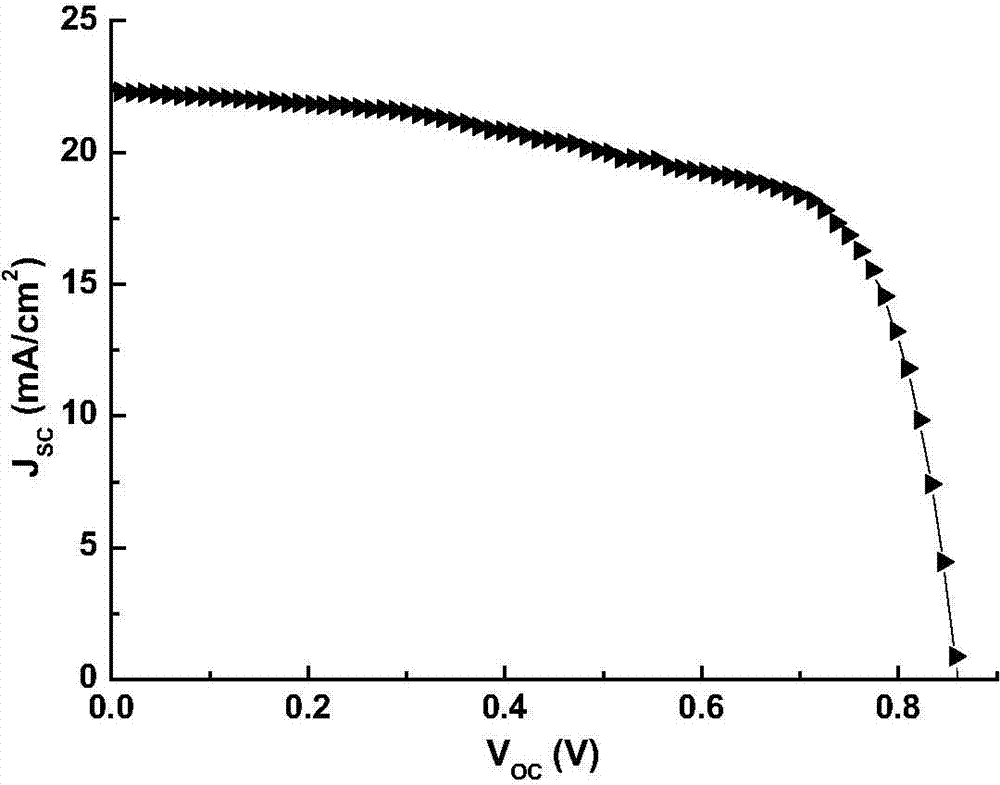

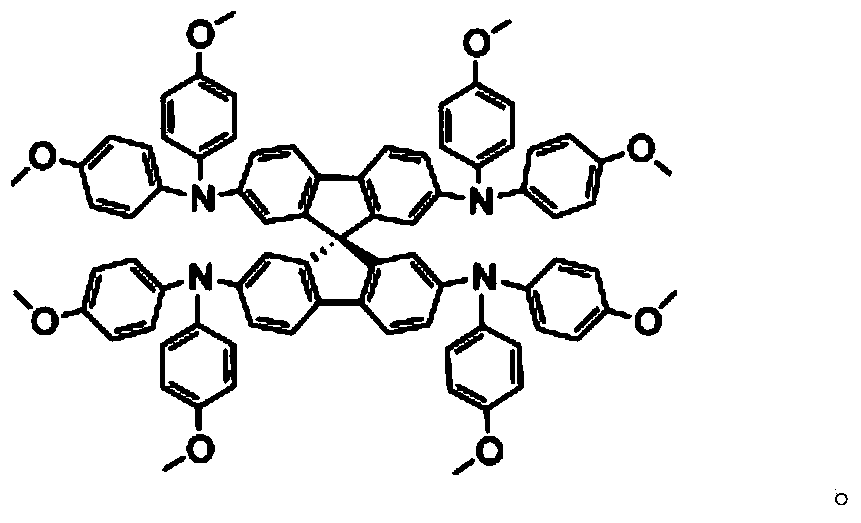

Preparation method of organic-inorganic perovskite solar battery

InactiveCN104518091AImprove uniformityImprove compactnessVacuum evaporation coatingSolid-state devicesGas phaseMetal particle

The invention discloses a preparation method of an organic-inorganic hybridization perovskite solar battery in a plane structure. The preparation method comprises the steps of selection and pretreatment of a transparent conduction substrate, magnetron sputtering of an n-type metal oxide layer or pulse laser preparation, preparation of an organic metal perovskite structure light absorption layer by a normal-pressure gas phase assistance solution method, preparation of a hole conduction layer structure, preparation of a metal alloy back electrode and the like. The method overcomes the problems of discontinuity, insufficient density, pinholes and the like of an n-type metal oxide film, an intermediate phase, pinholes, impure phases and the like of hydration organic metal halogen in a perovskite light absorption layer material, metal particle aggregation of the pure metal back electrode, layering of a hole layer and the like. The solar battery prepared by the method is high in efficiency, low in price, simple in technology, good in repeatability and suitable for mass production.

Owner:EAST CHINA NORMAL UNIV

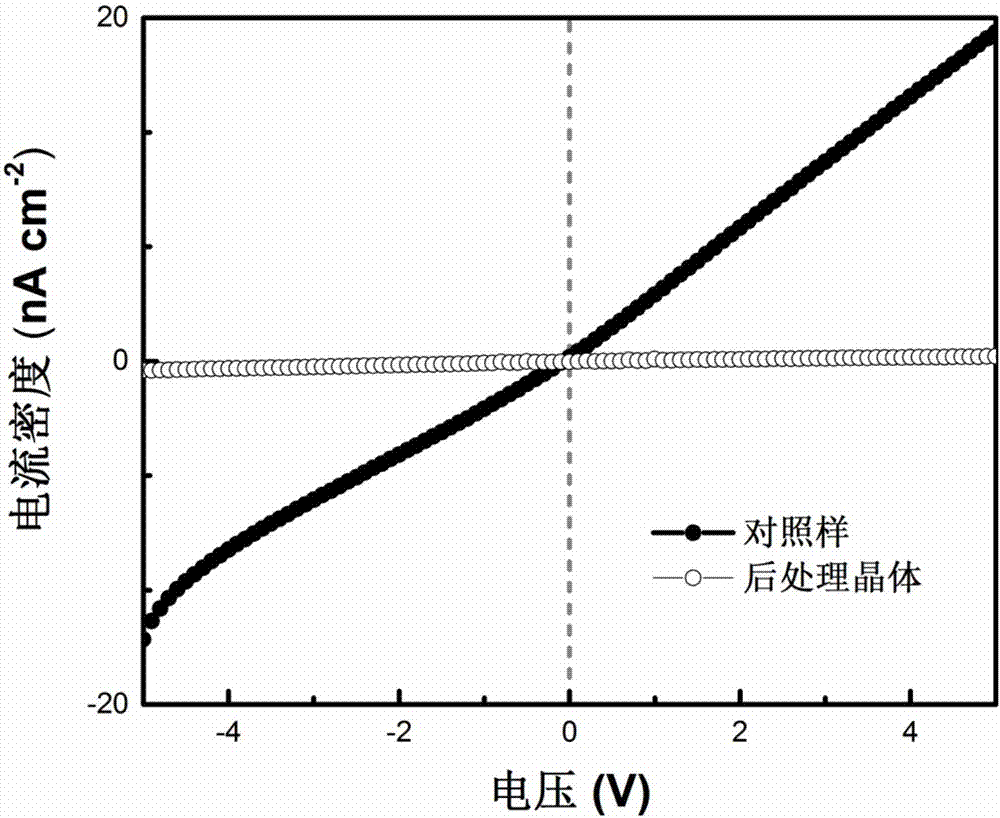

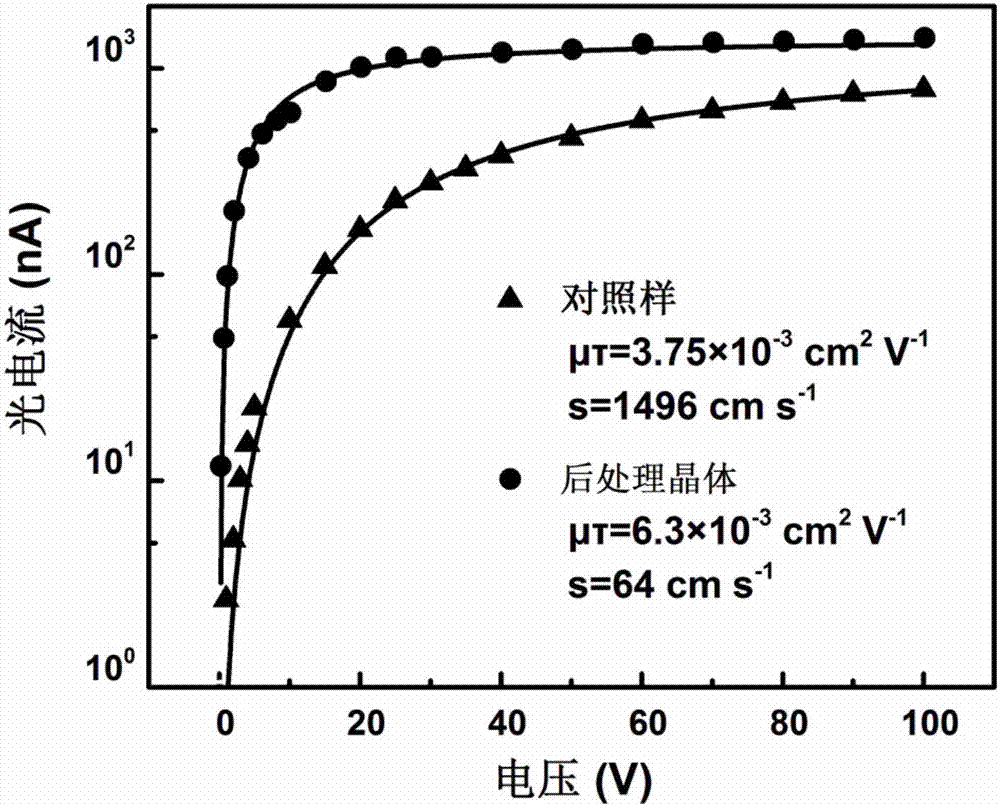

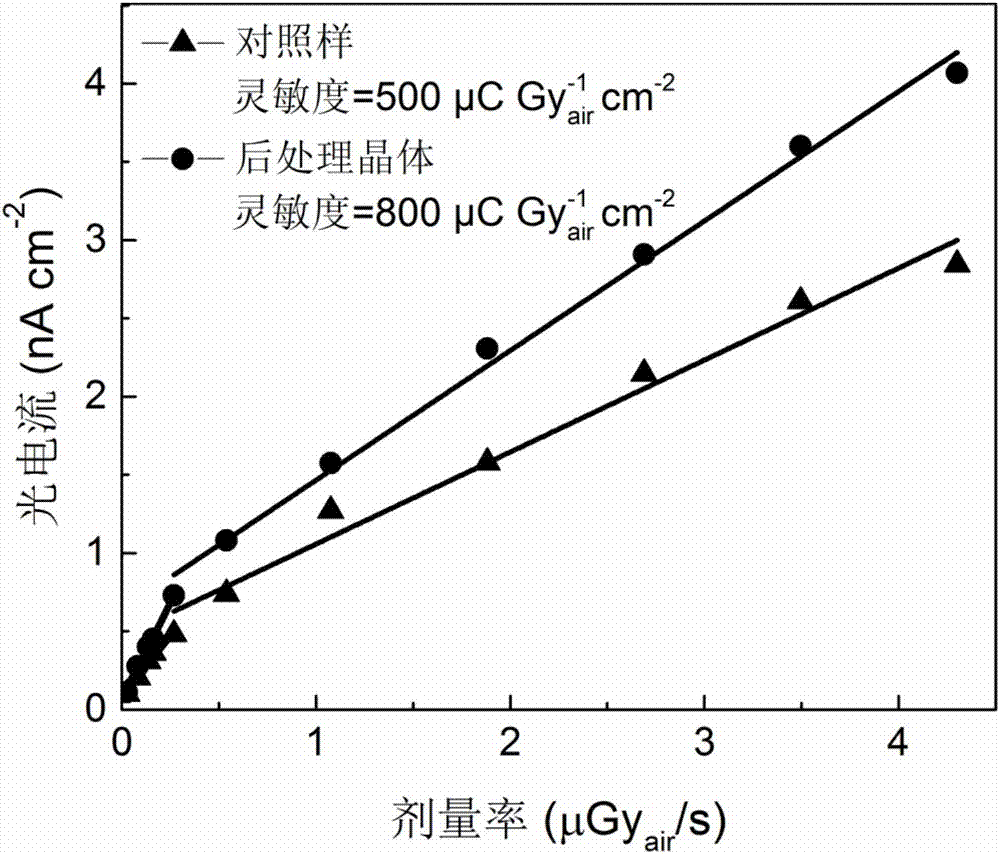

Post-processing method and application of double perovskite crystals

ActiveCN107248538ARaise the μτ productReduce leakage currentFinal product manufactureSemiconductor devicesCharge carrier mobilitySolvent

The invention discloses a post-processing method and application of double perovskite crystals. The post-processing method of double perovskite crystals comprises the following steps: performing annealing treatment on Cs2AgBiX6 double perovskite crystals; then cooling; and performing surface passivation treatment on the cooled crystals by means of a solvent to improve the mobility of the double perovskite crystals and reduce the surface recombination rate. The invention improves the technological process adopted in the key post-processing and the specific condition parameters adopted in each process step, therefore, the problems of the double perovskite Cs2AgBiX6 crystals in the prior art that the probability of occurrence of Ag and Bi dislocation is high, the internal defects of the crystals are more, the product of the carrier mobility multiply by the carrier lifetime ([mu] [tau]) of the crystals is not high are effectively solved; moreover, the crystals obtained by means of the post-processing method disclosed by the invention are especially suitable for using in radiation detectors.

Owner:HUAZHONG UNIV OF SCI & TECH

N-type double-sided solar cell and preparation method thereof

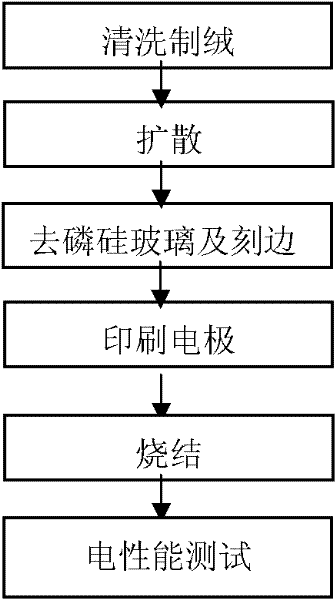

InactiveCN105489671AImprove photoelectric conversion efficiencyConcentrated efficiency distributionFinal product manufacturePhotovoltaic energy generationScreen printingEtching

The invention relates to an N-type double-sided solar cell and a preparation method thereof. According to the preparation method of the N-type double-sided solar cell, fabrication of a p+ doped region on the front surface of a silicon substrate and an n+ doped region on the back surface of the silicon substrate is achieved by a technique of combining boron diffusion and phosphorus ion implantation; passivation of the front surface and the rear surface of the silicon substrate and antireflection of the front surface are achieved by a composite dielectric film of two or three of SiO<2>, Al<2>O<3> and SiN<x>; and finally metal contact of the p+ doped region on the front surface of the silicon substrate and the n+ doped region on the back surface is achieved through silk-screen printing and co-sintering technologies, and fabrication of the N-type double-sided solar cell is facilitated. According to the preparation method provided by the invention, an ion implantation technique is introduced into a fabrication technology of the N-type double-sided solar cell, so that a mask technology can be omitted; edge etching is not required; and the N-type double-sided solar cell fabricated by the ion implantation technique is high in photoelectric conversion efficiency, relatively concentrated in efficiency distribution and high in yield.

Owner:JOLYWOOD SUZHOU SUNWATT

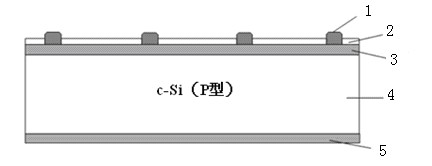

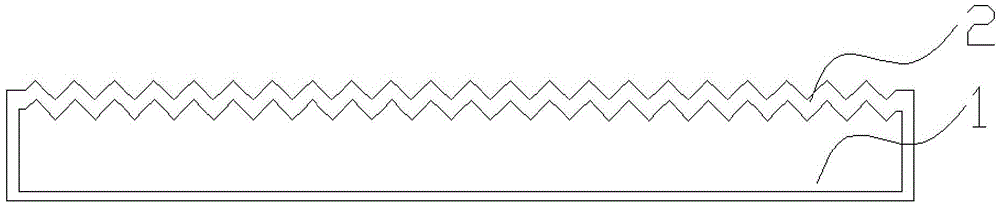

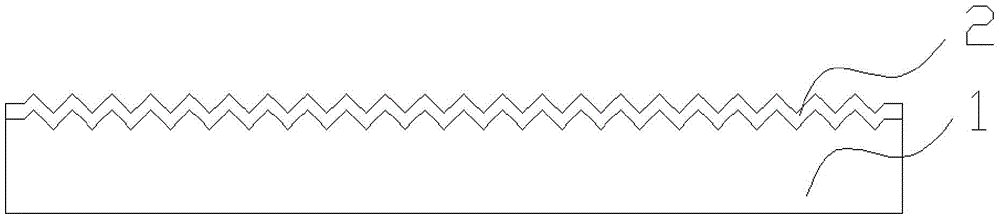

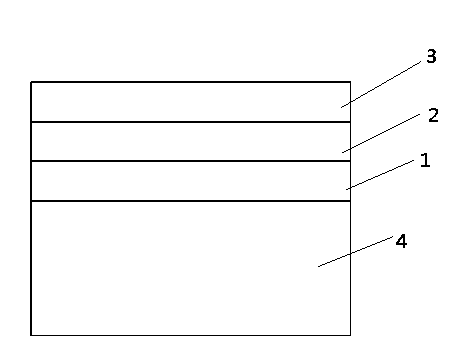

Crystalline silicon battery surface passive film and manufacturing method thereof

InactiveCN103996720AHigh relative permittivityDecrease the density of surface statesFinal product manufactureSemiconductor devicesCrystallographyCharge carrier

The invention discloses a crystalline silicon battery surface passive film and a manufacturing method of the crystalline silicon battery surface passive film. The crystalline silicon battery surface passive film comprises a first silicon oxide film, a silicon nitride film and a second silicon oxide film. The silicon nitride film is deposited on the first silicon oxide film. The second silicon oxide film is deposited on the silicon oxide film. The thickness d1 of the first silicon oxide film is 10 nm-30 nm. The thickness d2 of the silicon nitride film is 30 nm-50 nm. The thickness d3 of the second silicon oxide film is 25 nm-50 nm. The probability of light full reflection is substantially increased, and namely more light enters a silicon wafer, so that more charge carriers are generated, and battery efficiency is improved.

Owner:ALTUSVIA ENERGY TAICANG

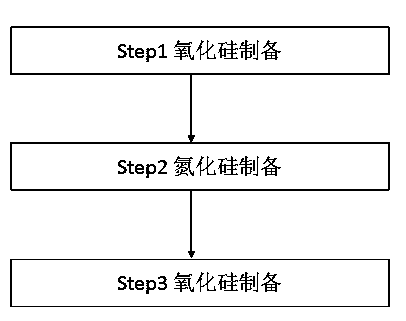

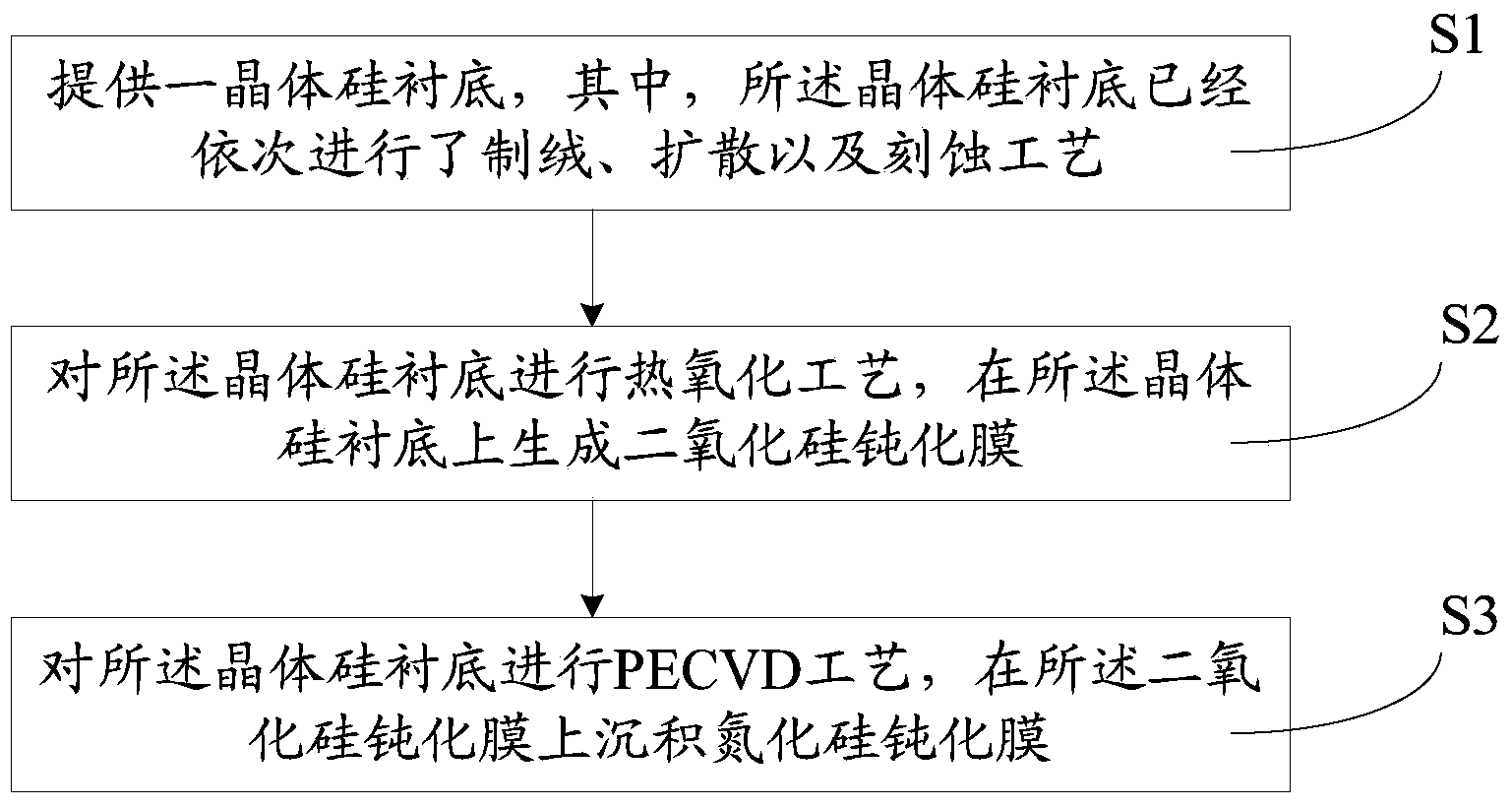

Solar cell surface passive layer structure and preparing method thereof

InactiveCN103413841ATaking into account the anti-reflection effectOvercome densityFinal product manufactureSemiconductor devicesSilicon dioxideMoisture

The invention discloses a solar cell surface passive layer structure. A laminate passive film structure composed of a silicon dioxide passive film and a silicon nitride passive film is adopted for the structure, and therefore the defects that the interface defect density of the silicon nitride passive film is high, silicon-hydrogen bonds are not stable, the capacity for resisting metal ions of the silicon dioxide passive film is poor, moisture can be easily adsorbed and the reducing and reflecting effect of light is not good are overcome. The thickness of the silicon dioxide passive film is optimized to range from 10 nanometers to 40 nanometers, therefore, the passivating effect for electrically active impurities of silicon materials and surface defects of the silicon materials is greatly improved on the basis that the light absorbing rate is ensured, the surface recombination rate of a photon-generated carrier is obviously lowered, and the conversion efficiency of crystalline silicon can be improved by 0.3%. Meanwhile, the invention further discloses a preparing method of the solar cell surface passive layer structure. According to the method, the silicon dioxide passive film is prepared through the thermal oxidation technology, the silicon nitride passive film is prepared through the PECVD technology, and the method can be compatible with the solar cell preparing technology.

Owner:SPIC XIAN SOLAR POWER CO LTD

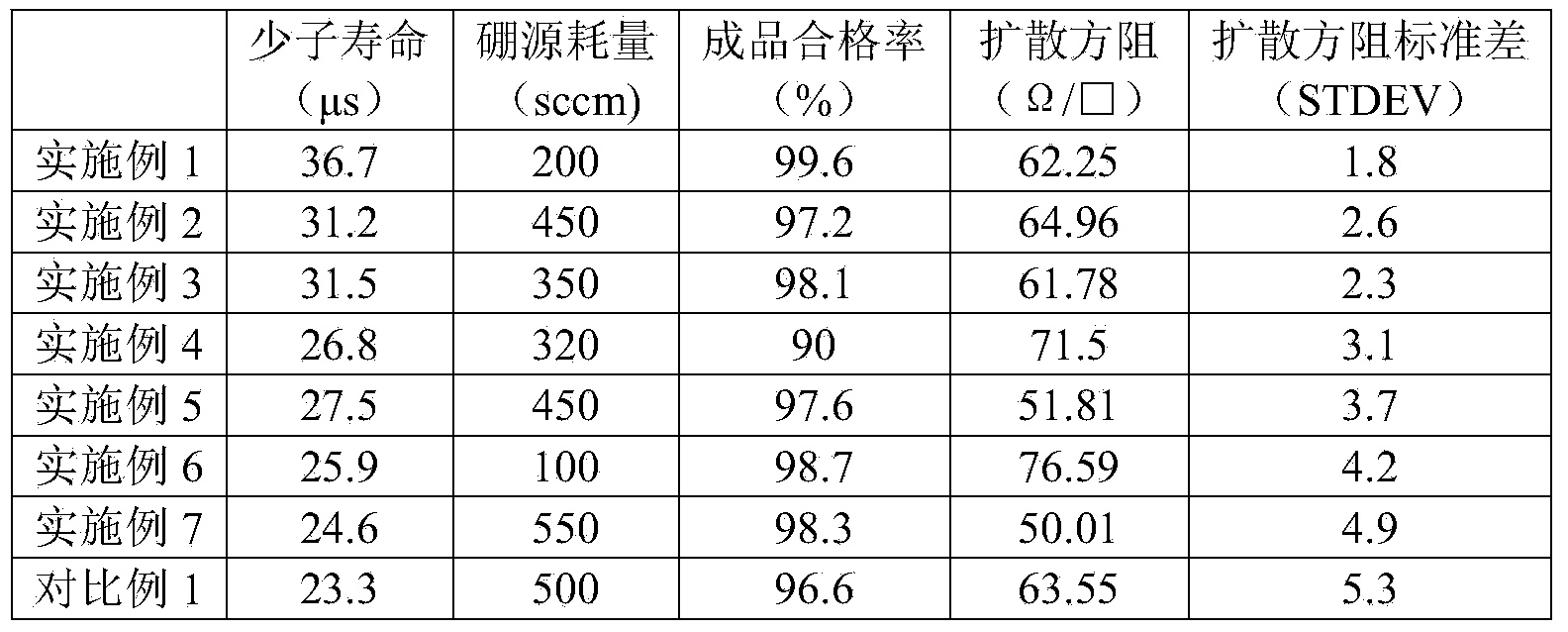

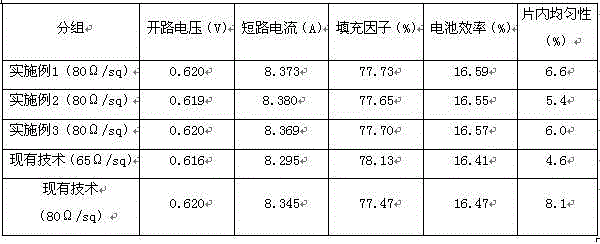

Boron diffusion method of N type silicon chip, crystalline silicon solar cell and manufacturing method of crystalline silicon solar cell

ActiveCN103632935ALower Boron Atomic ConcentrationReduce consumptionFinal product manufactureSemiconductor/solid-state device manufacturingEtchingNitrogen gas

The invention discloses a boron diffusion method of an N type silicon chip, a crystalline silicon solar cell and a manufacturing method of the crystalline silicon solar cell. The boron diffusion method comprises the following steps of a deposition stage: placing the silicon chip subjected to wet etching into a diffusion furnace, raising the temperature to 890-920 DEG C, and then introducing nitrogen, oxygen and a boron source for depositing the surface of the silicon chip; a diffusion stage: raising the temperature of the silicon chip with the surface being deposited to a preset temperature under the atmosphere of nitrogen for promoting the diffusion of boron; a post-oxidation stage: dropping the temperature of the silicon chip with the boron being diffused, and introducing oxygen and nitrogen to obtain the silicon chip with the boron being diffused. After the deposition diffusion process disclosed by the invention is adopted, the concentration of boron atoms on the surface of the silicon chip is reduced, the recombination rate and the lattice damage of the surface are reduced, the STDEV (standard deviation) of the sheet resistance is controlled to be about 2.0, the sheet resistance uniformity of boron diffusion is improved, the battery conversion efficiency is improved, the consumption of boron sources is also reduced, BGS (borosilicate glass) is prevented from being excessively generated, and the cost is reduced.

Owner:一道新能源科技股份有限公司

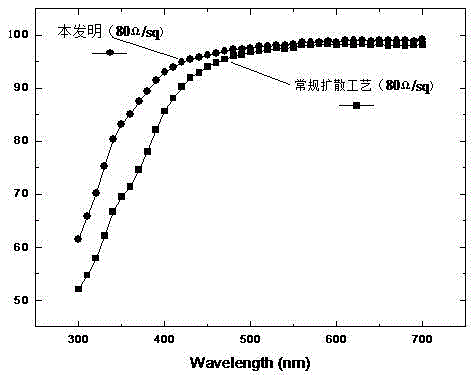

Diffusing process with low temperature, low surface concentration and high sheet resistance

InactiveCN102945797AReduce surface recombination rateImprove battery efficiencySemiconductor/solid-state device manufacturingSheet resistanceChemistry

The invention relates to a diffusing process with low temperature, low surface concentration and high sheet resistance. The diffusing process with low temperature, low surface concentration and high sheet resistance comprises an entering step, a depositing step, a propelling step and an exiting step. The diffusing process with low temperature, low surface concentration and high sheet resistance is characterized in that the reaction temperatures in the entering and depositing steps are lower than 800 DEG C. Preferably, at least one of the depositing step and the propelling step is carried out by steps according to different temperatures. Furthermore, the depositing step is divided into a first depositing step and a second depositing step. The propelling step comprises a first propelling step and a second propelling step. Preferably, an oxidizing step is further carried out between the entering step and the depositing step. The oxidizing step comprises the step of: introducing oxygen into a reactor. By utilizing the diffusing process with low temperature, low surface concentration and high sheet resistance provided by the invention, the reaction temperatures in the depositing and diffusing steps are reduced compared with the that in the conventional process, so that the surface compositing rate is reduced. Meanwhile, impurities are more beneficially migrated to the impurity absorbing point at the lower diffusing temperature in the diffusing process of polycrystalline silicon, so that the battery efficiency is further improved.

Owner:TIANWEI NEW ENERGY HLDG

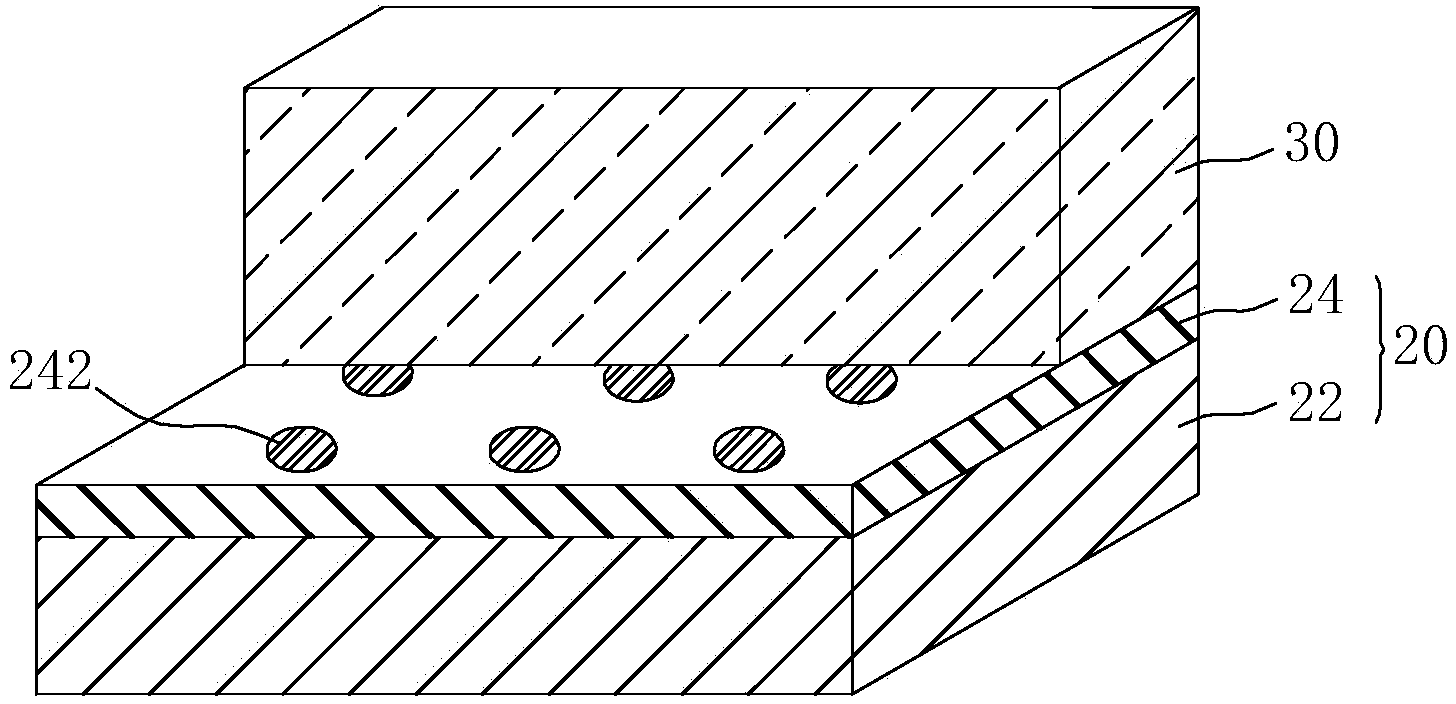

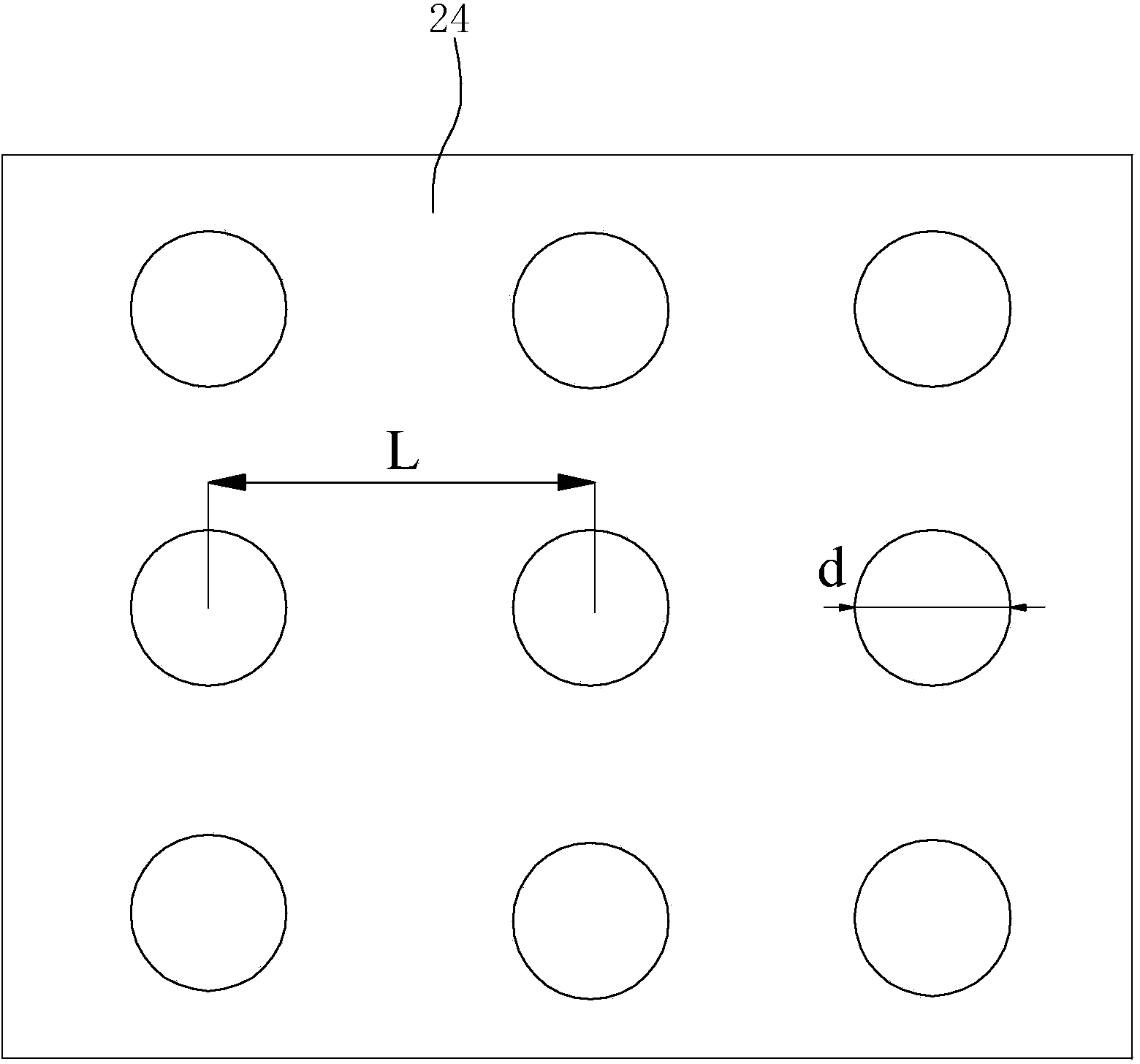

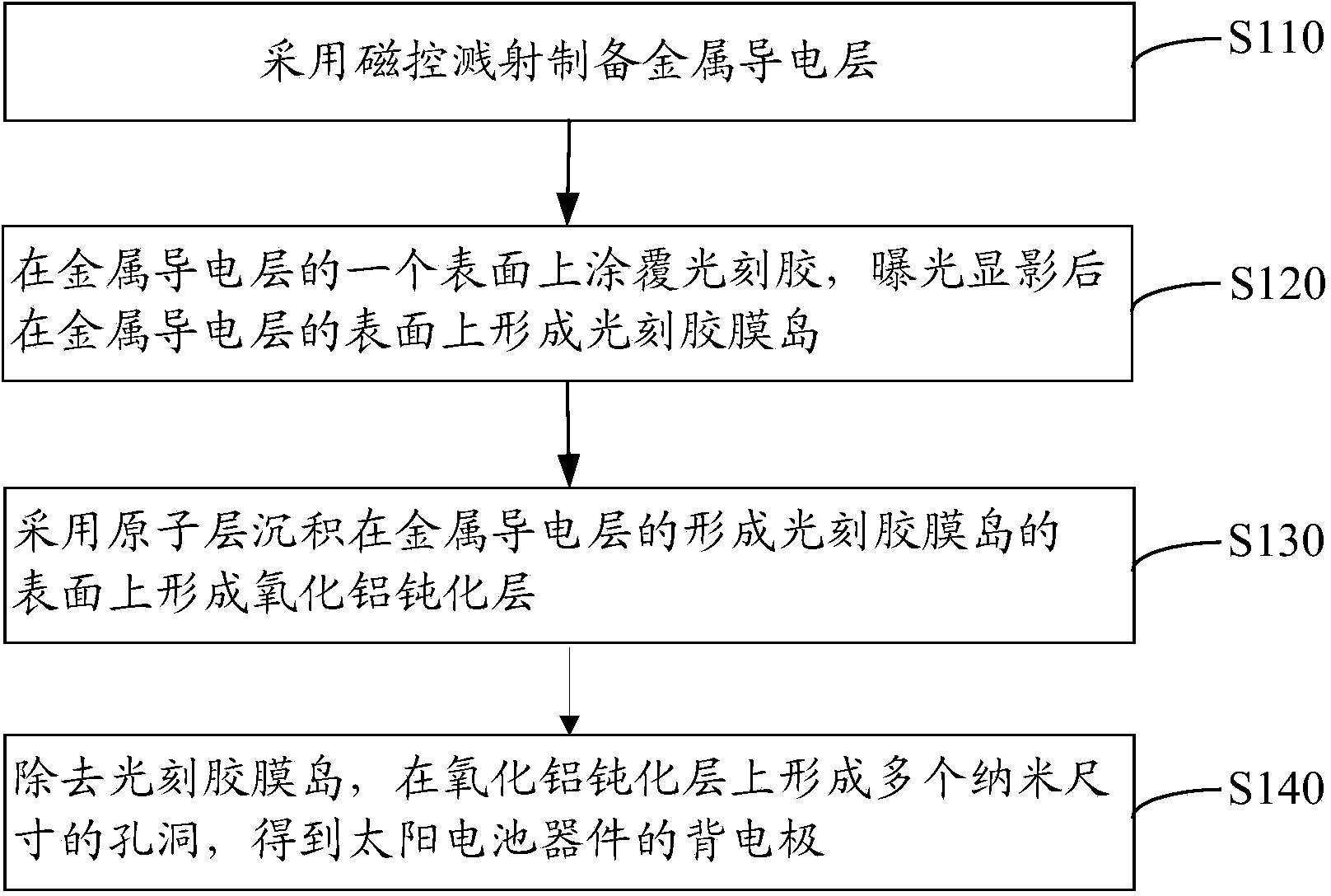

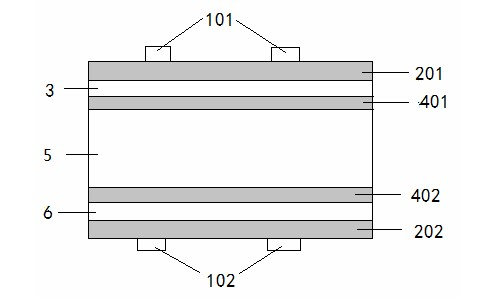

Back electrode of solar battery device, preparation method of back electrode and solar battery device

ActiveCN103474484AImprove photoelectric conversion efficiencyPlay a role in surface passivationFinal product manufactureSemiconductor devicesCurrent channelPower flow

The invention relates to a back electrode of a solar battery device, a preparation method of the back electrode and the solar battery device. The back electrode of the solar battery device comprises a metal conducting layer and an aluminum oxide passivation layer stacked on the metal conducting layer. A plurality of nanoscale holes are formed in the aluminum oxide passivation layer. The metal conducting layer serves as the positive electrode of the solar battery device and is used for collecting and transmitting the current. The surface carrier recombination is restrained through the aluminum oxide passivation layer, current channels are formed by the multiple nanoscale holes to be used for collecting and breaking over the current, the back electrode of the composite structure gives the passivation effect of the aluminum oxide passivation layer and does not obstruct passing of the photo-generated current, and the effects of reducing the interface defect mode density, reducing the surface recombination rate of photo-generated carriers and improving the photoelectric converting efficiency of the solar battery device are achieved.

Owner:SHENZHEN INST OF ADVANCED TECH +1

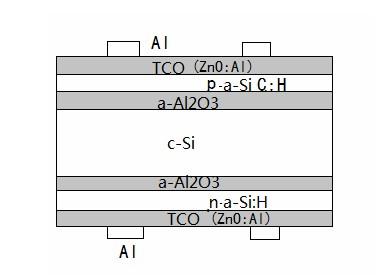

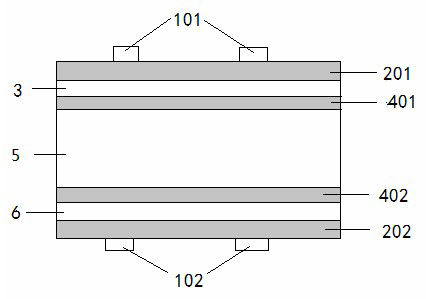

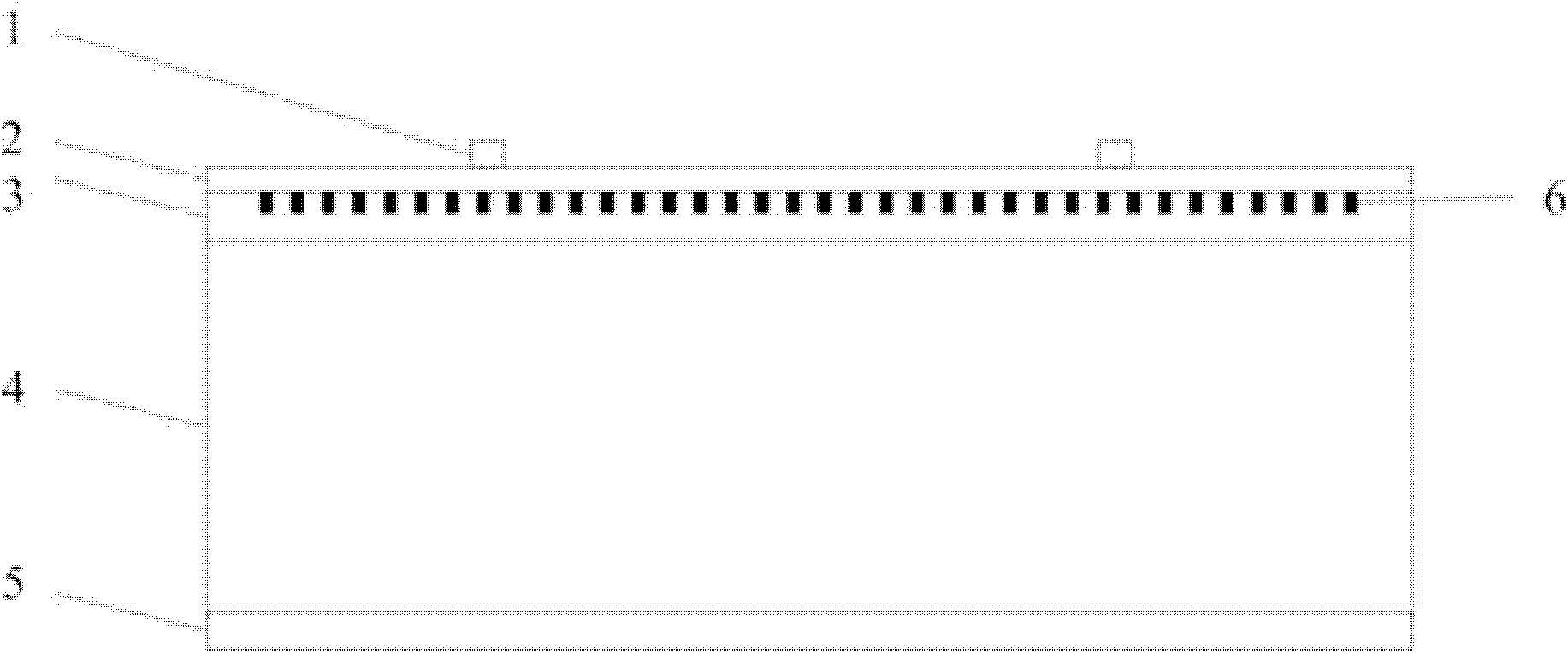

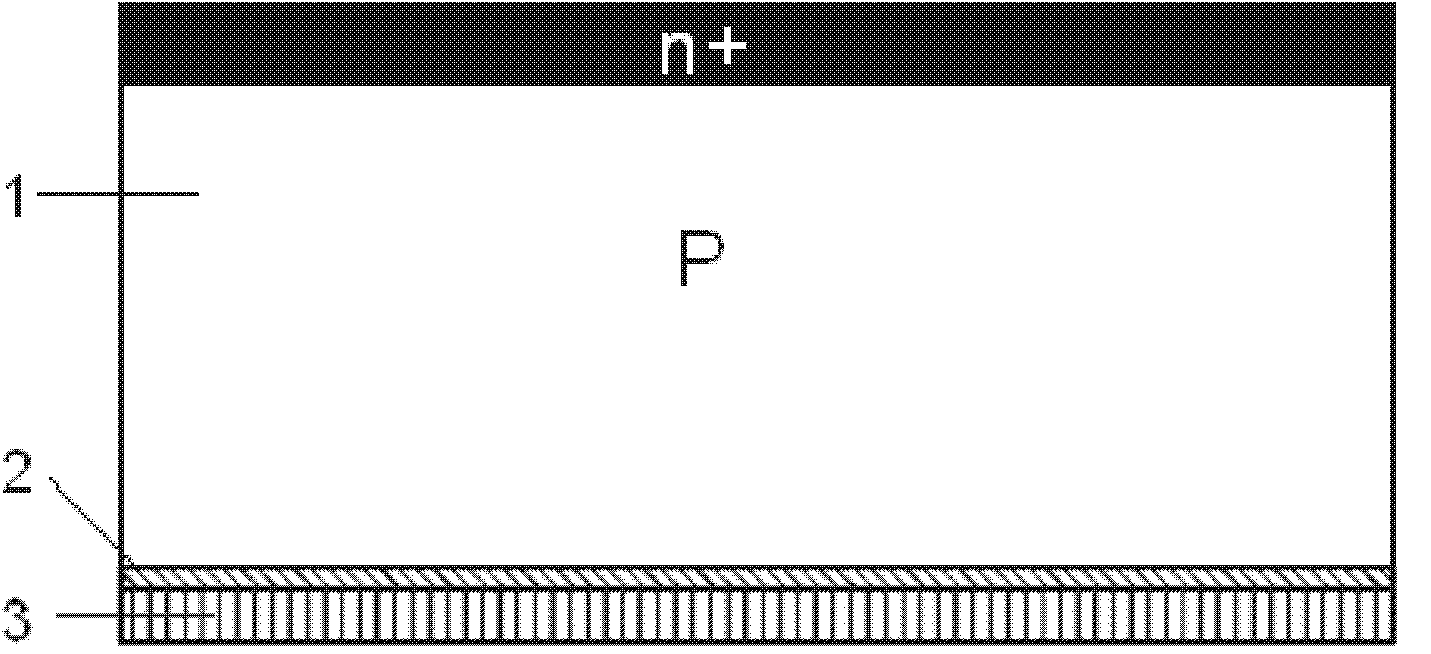

Hetero-junction-structured crystalline silicon solar cell with intrinsic layer and preparation method thereof

InactiveCN102222703AImprove passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationCarbon filmRadiation resistant

The invention discloses a hetero-junction-structured crystalline silicon solar cell with an intrinsic layer and a preparation method thereof. The crystalline silicon solar cell comprises a crystalline silicon substrate, and upper and lower amorphous alumina passivation dielectric layers; a p-type doped amorphous silicon carbon film and a TCO (Transparent Conductive Oxide) layer are arranged on the amorphous alumina passivation dielectric layer on the upper surface; an n-type doped amorphous silicon or micro-crystalline silicon film and a TCO layer are arranged below the amorphous alumina passivation dielectric layer on the lower surface; and the TCO layers on the upper and lower surfaces are both connected with a metal gate electrode. The preparation method comprises the steps of preparing the amorphous alumina passivation dielectric layers: preparing the ultra-thin amorphous alumina passivation dielectric layers simultaneously after the crystalline silicon substrate is acidized; and then preparing the p-type amorphous silicon carbon and the n-type amorphous silicon or micro-crystalline silicon and the TCO respectively to form the hetero-junction cell. The hetero-junction-structured crystalline silicon solar cell and the preparation method thereof have the advantages of simple process, good surface passivation performance of the crystalline silicon, good UV (ultraviolet) radiation-resistant performance, fully utilization of the sunlight and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

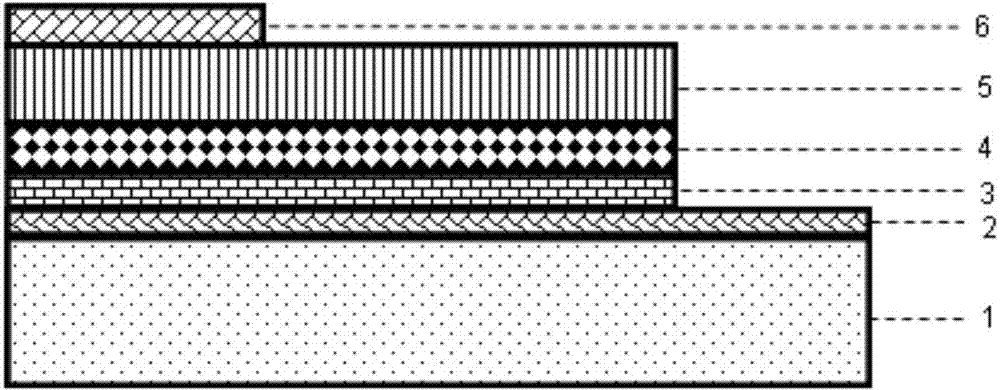

Perovskite phase organic metal halide-based solar cell and manufacturing method thereof

ActiveCN104393177AReduce contact areaReduce surface recombination rateSolid-state devicesSemiconductor/solid-state device manufacturingSynthesis methodsElectron transfer

The invention discloses a perovskite phase organic metal halide-based solar cell and a manufacturing method thereof. The solar cell uses a dense titanium dioxide nano film as an electron transfer layer, the surface recombination speed between the electron transfer layer and a semiconductor layer can be reduced, and a photovoltaic conversion rate of a photovoltaic device is improved; the solar cell with the structure can use a normal temperature and pressure full liquid phase synthesis method to manufacture the semiconductor layer of a perovskite phase organic metal halide, thereby saving energy consumption needed by manufacturing and reducing the cost of the solar cell. A two-step synthesis method is adopted during the process of manufacturing the semiconductor layer of the perovskite phase organic metal halide, a PbX2 layer formed in the first step is soaked in a 2-propanol solution between the two steps, the second-step synthesis is carried out, and thus, a chlorine and iodine mixed preparation method can be adopted, the halogen ion concentration and the annealing temperature are controlled, crystal growth during a liquid phase precipitation process is optimized, and the photovoltaic conversion efficiency of the solar cell is improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

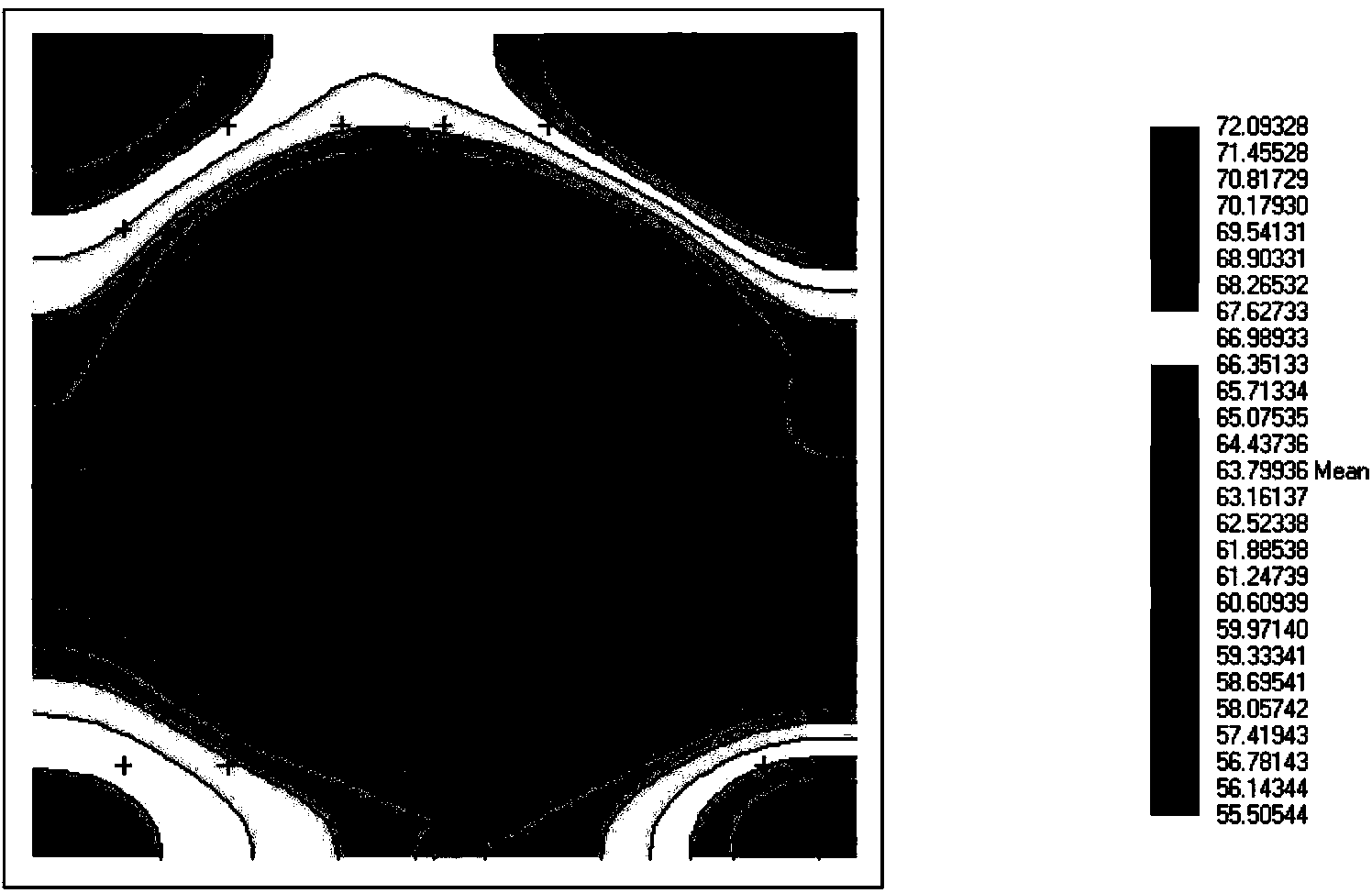

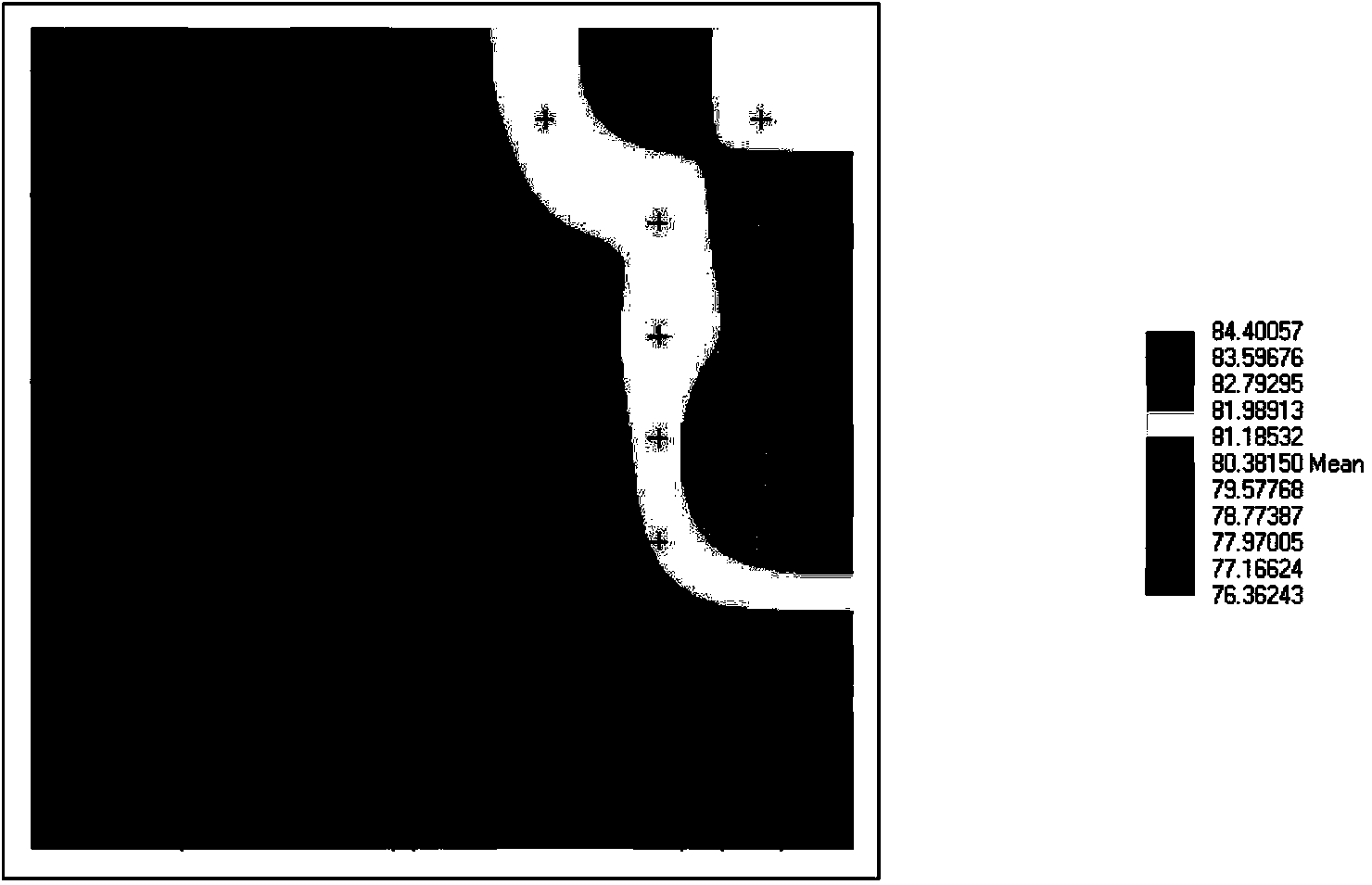

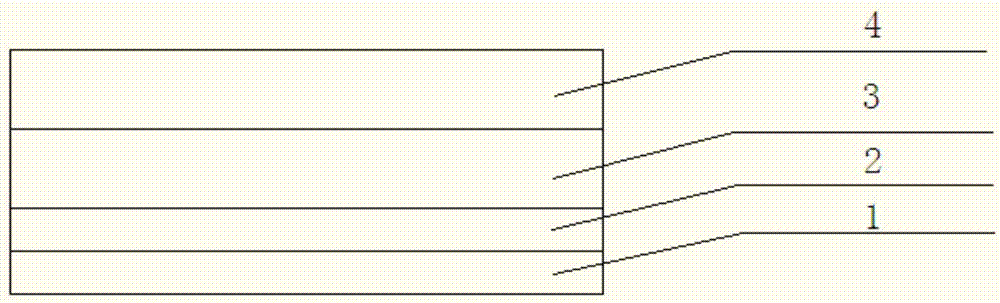

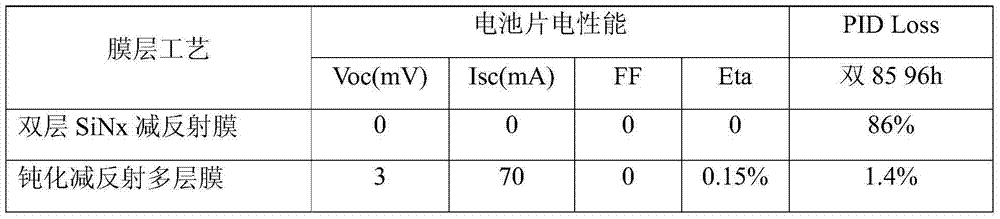

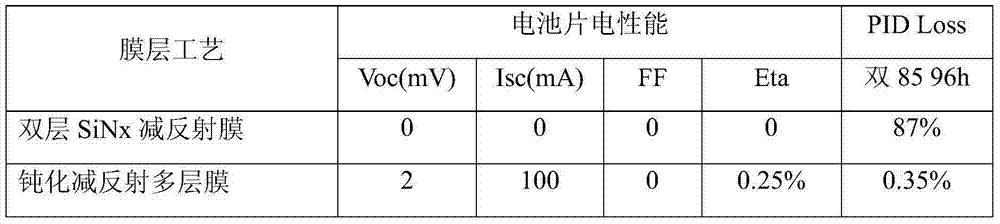

Passivating antireflection film of high PID resistance type polycrystalline cell and preparation process thereof

ActiveCN104752526AReduce surface interface stateImprove the anti-PID decay characteristicsFinal product manufacturePhotovoltaic energy generationRefractive indexMedia layer

The invention relates to a passivating antireflection film of a high PID resistance type polycrystalline cell and a preparation process thereof. The passivating antireflection film comprises a first SiOx layer used as a bottom layer, a second SiOx layer used as a medium layer, and a third SiNx layer used as a top layer, wherein the first SiOx layer, the second SiOx layer and the third SiNx layer are sequentially deposited on the front surface of a monocrystalline chip substrate, and the total film thickness of the first SiOx layer, the second SiOx layer and the third SiNx layer is 65 to 120nm; the refraction rate is 1.9 to 2.25; the film thickness of the SiNx layer used as the medium layer is 10 to 50nm, and the refraction rate is 2.2 to 2.4; the film thickness of the SiNx layer used as the top layer is 30 to 80nm, and the refraction rate is 1.9 to 2.2; one or a plurality of SiNx layers are arranged as the top layer. The passivating antireflection film can reduce the reflecting rate and improve the passivating effect, so that the solar cell efficiency can be increased; the passivating antireflection film is outstanding in PID attenuating resisting characteristic.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

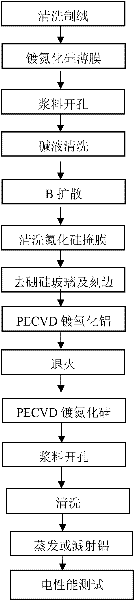

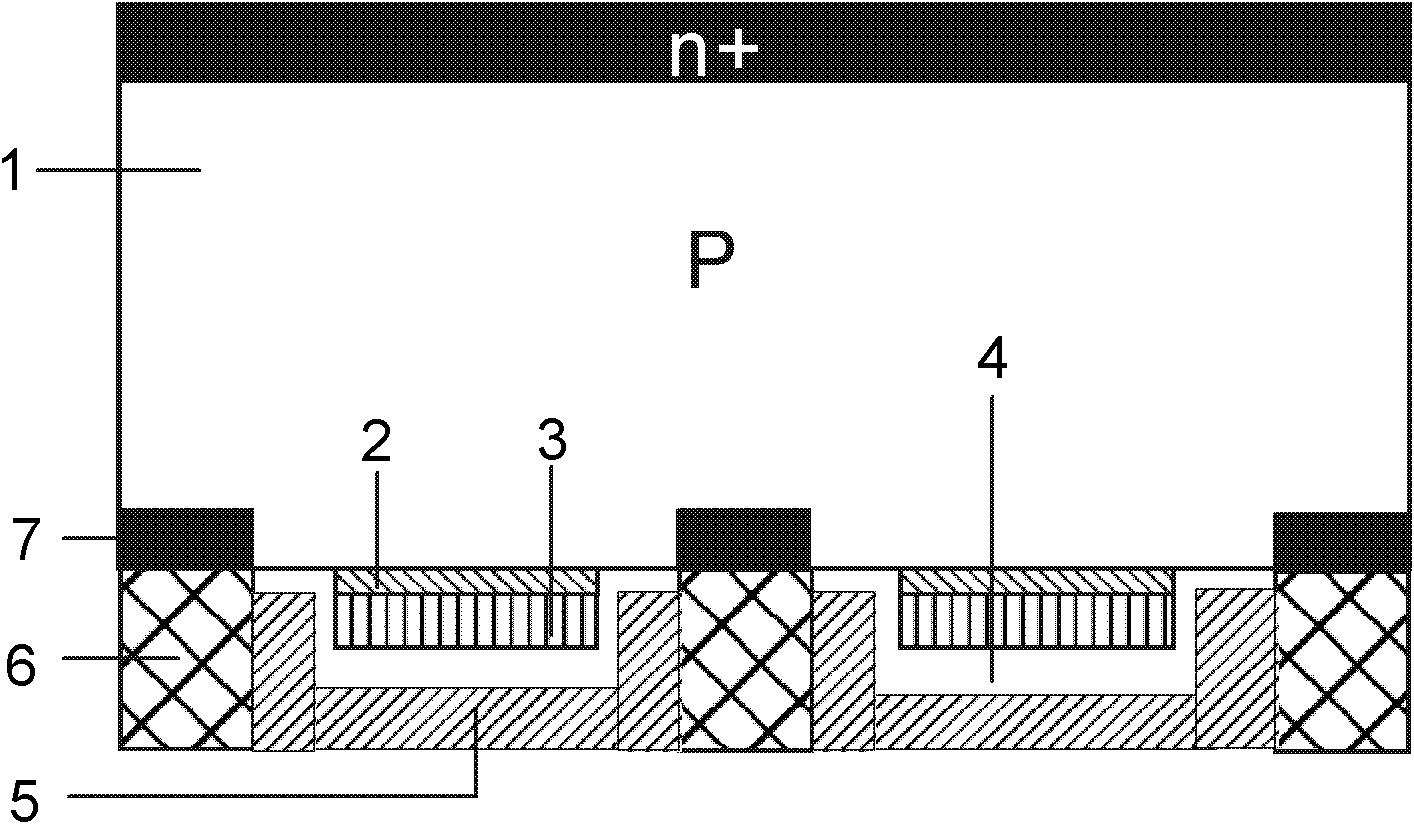

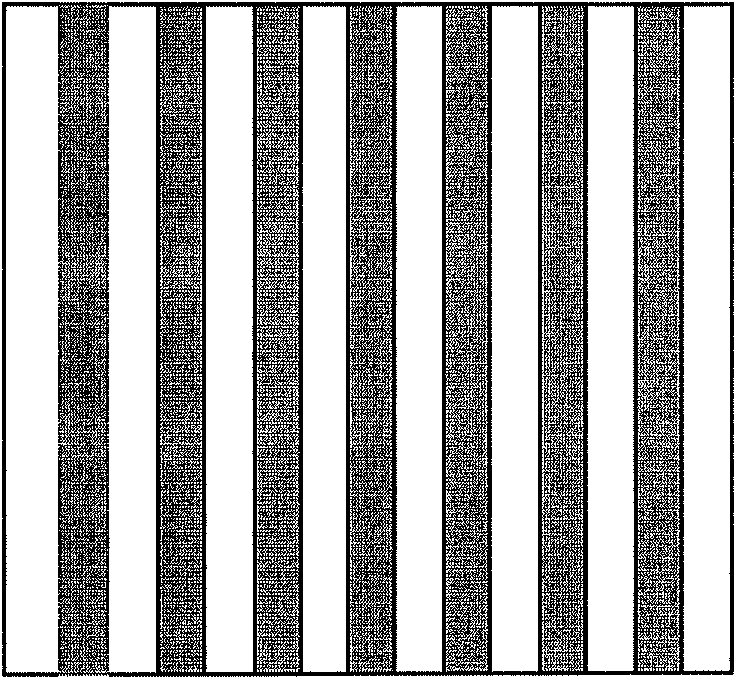

Passivation process for back of crystalline silicon solar cell and structure of back-passivated crystalline silicon solar cell

InactiveCN102376821AReduced series resistanceDestroy the passivation effectFinal product manufacturePhotovoltaic energy generationSputteringOhmic contact

The invention relates to a passivation process for a back of a crystalline silicon solar cell and a structure of a back-passivated crystalline silicon solar cell. The passivation process comprises: firstly, based on silicon nitride used as a mask on the back of a P-type silicon wafer, forming holes on the mask, then carrying out B diffusion to form heavy doping at the hole positions, washing away the silicon nitride mask, depositing a laminated film of aluminum oxide and silicon nitride, forming back contact patterns on the back of a cell, and manufacturing an aluminum electrode on the back of the cell. The invention has the beneficial effects that: the back-passivated solar cell has the following two characteristics: (1) a high-doped heavy-diffusion region is formed at the back contact and near position thereof of the cell, and the high-doped heavy-diffusion region is in good ohmic contact with the plated aluminum electrode, thus the series resistance of the cell is reduced; and (2) by annealing aluminum oxide, the back surface can be well passivated and the surface compounding rate is reduced, and silicon nitride has an action of protecting aluminum oxide, thus the destroy of aluminum oxide passivation effect in subsequent sputtering or evaporation process is avoided.

Owner:TRINA SOLAR CO LTD

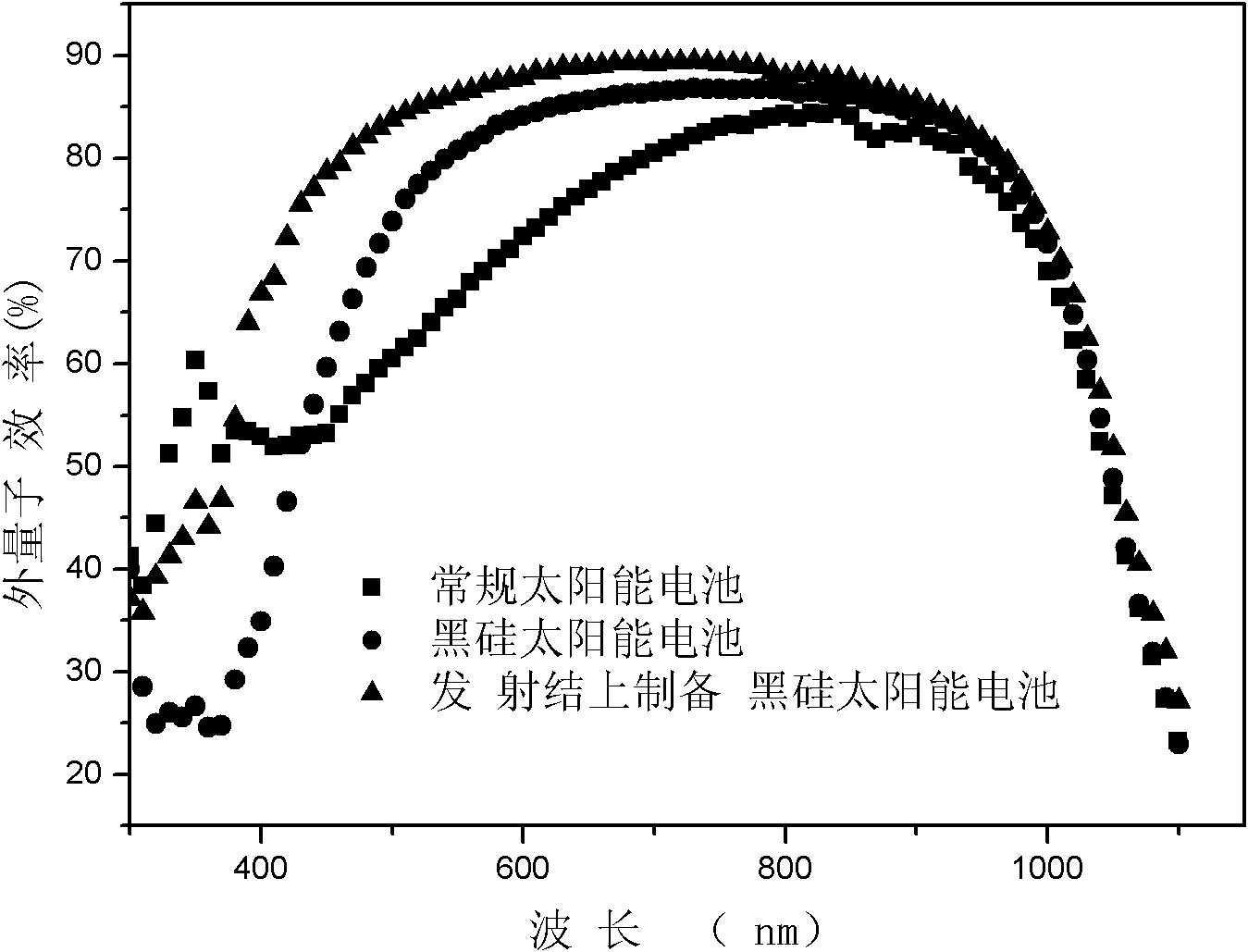

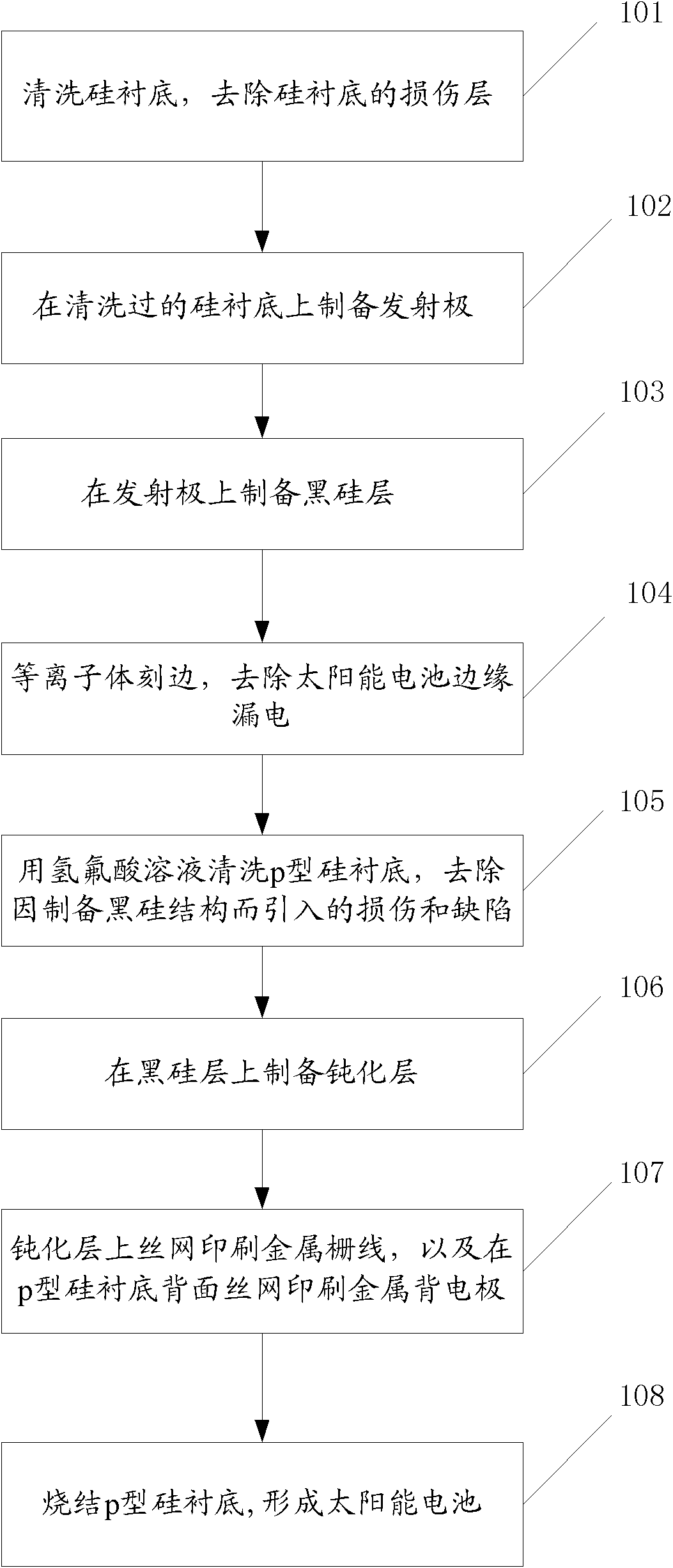

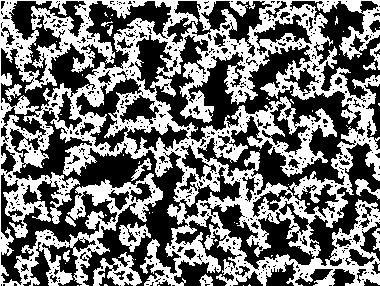

Solar battery with black silicon structure on emitter and preparation method of solar battery

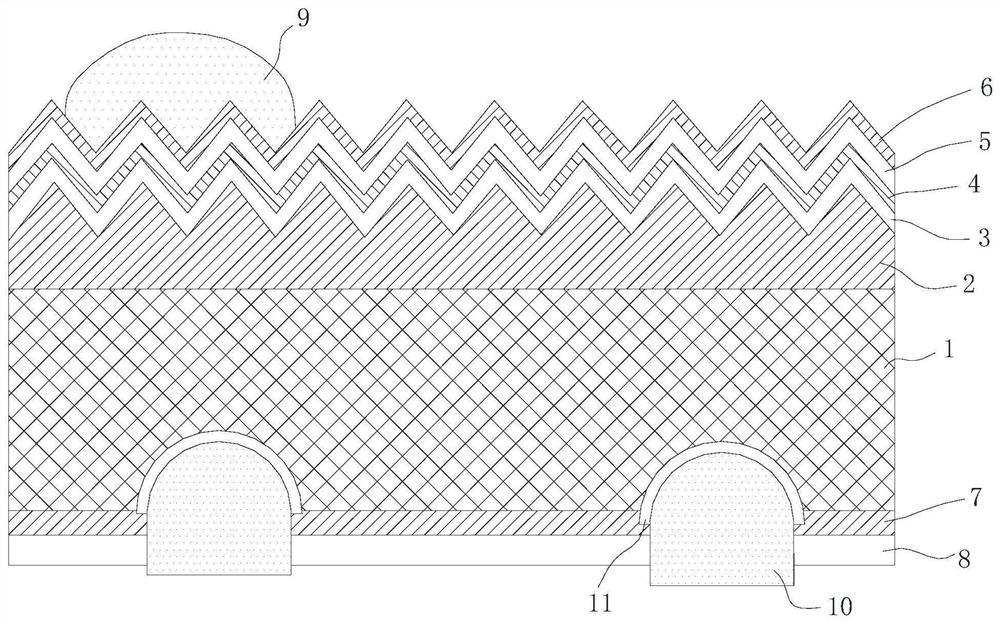

ActiveCN102306664AIncrease the open circuit voltageImprove short-wave quantum efficiencyPhotovoltaic energy generationSemiconductor devicesElectrical batterySolar battery

The invention discloses a solar battery with a black silicon structure on an emitter and a preparation method of the solar battery, and belongs to the technical field of manufacturing of solar battery devices. The solar battery comprises a metal grid line electrode, a passivation layer, the emitter, a black silicon layer, a silicon substrate and a metal back electrode, wherein the metal back electrode is positioned on the back surface of the silicon substrate; the emitter is positioned on the silicon substrate; the black silicon layer is positioned on the emitter; the passivation layer is positioned on the black silicon layer; and the metal grid line electrode is positioned on the passivation layer. The preparation method comprises the following steps of: preparing the metal back electrode on the back surface of the silicon substrate; preparing the emitter on the surface of the silicon substrate; preparing the black silicon layer on the emitter; preparing the passivation layer on the black silicon layer; preparing the metal grid line electrode on the passivation layer; and sintering the silicon substrate. By the structure of the solar battery provided by the invention, the uniformity of doping distribution of pn junctions can be effectively improved, and the open circuit voltage of the solar battery is improved, so that the efficiency of the solar battery is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

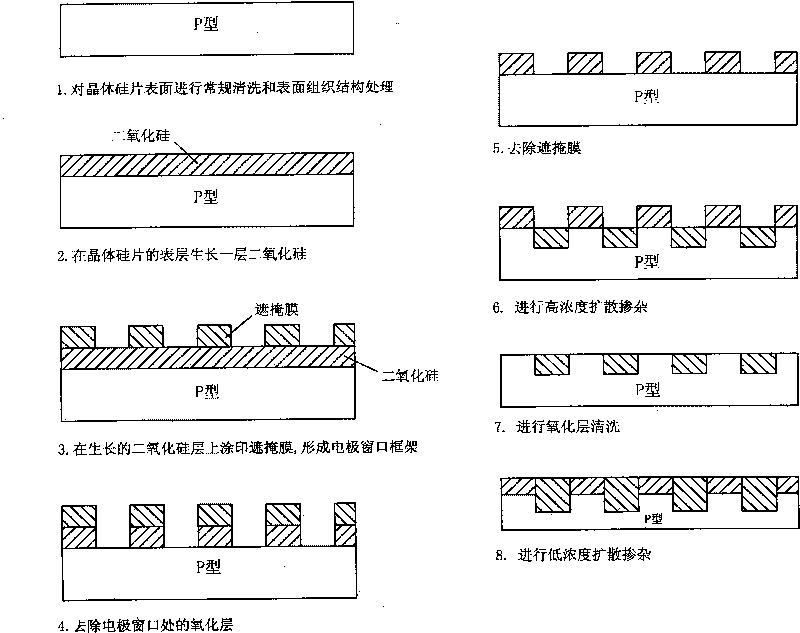

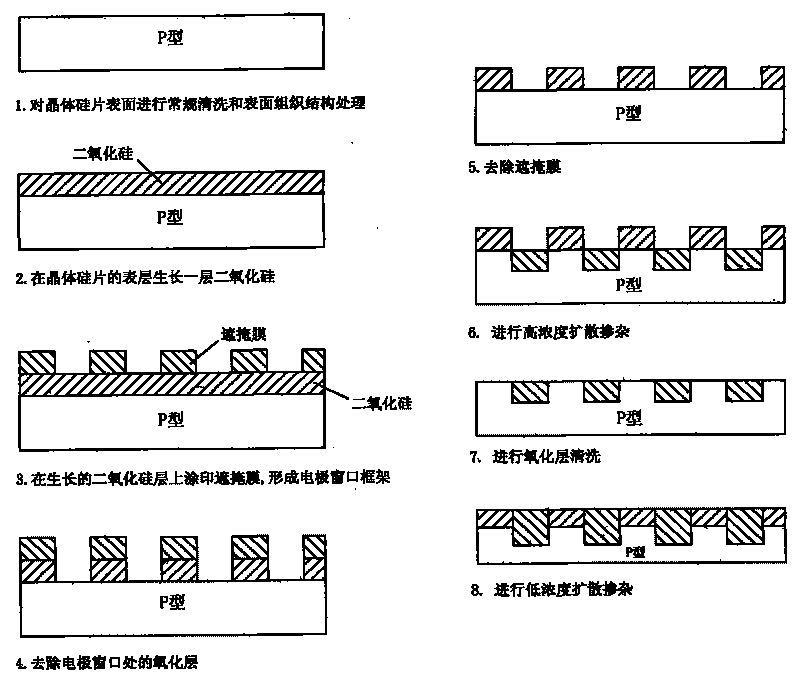

Method for preparing selective emission area of crystalline silicon solar cell

InactiveCN101740661AReduce recombination rateReduce surface recombination rateFinal product manufactureSemiconductor devicesHigh concentrationCrystalline silicon

The invention relates to a method for preparing a selective emission area of a crystalline silicon solar cell. The method comprises the following steps of: (1) growing a layer of silicon dioxide on the surface of a crystalline silicon slice; (2)coating a masking film on the grown silicon dioxide layer to form a frame of an electrode window; (3) removing an oxide layer at the position of the electrode window, namely removing the silicon dioxide layer not covered by the masking film; (4) removing the masking film; (5) performing high-concentration diffusion doping; (6) washing the oxide layer, namely removing the silicon dioxide layer originally covered by the masking film; and (7) performing low-concentration diffusion doping. The method has the advantages of simple preparation process, low cost, no pollution and an average cell conversion efficiency of 18.5 percent.

Owner:浙江向日葵聚辉新能源科技有限公司

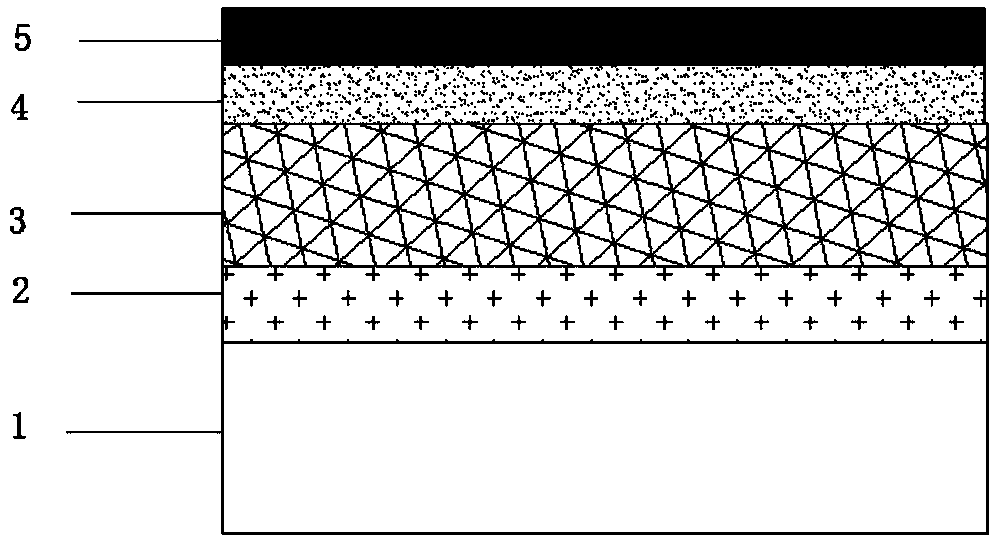

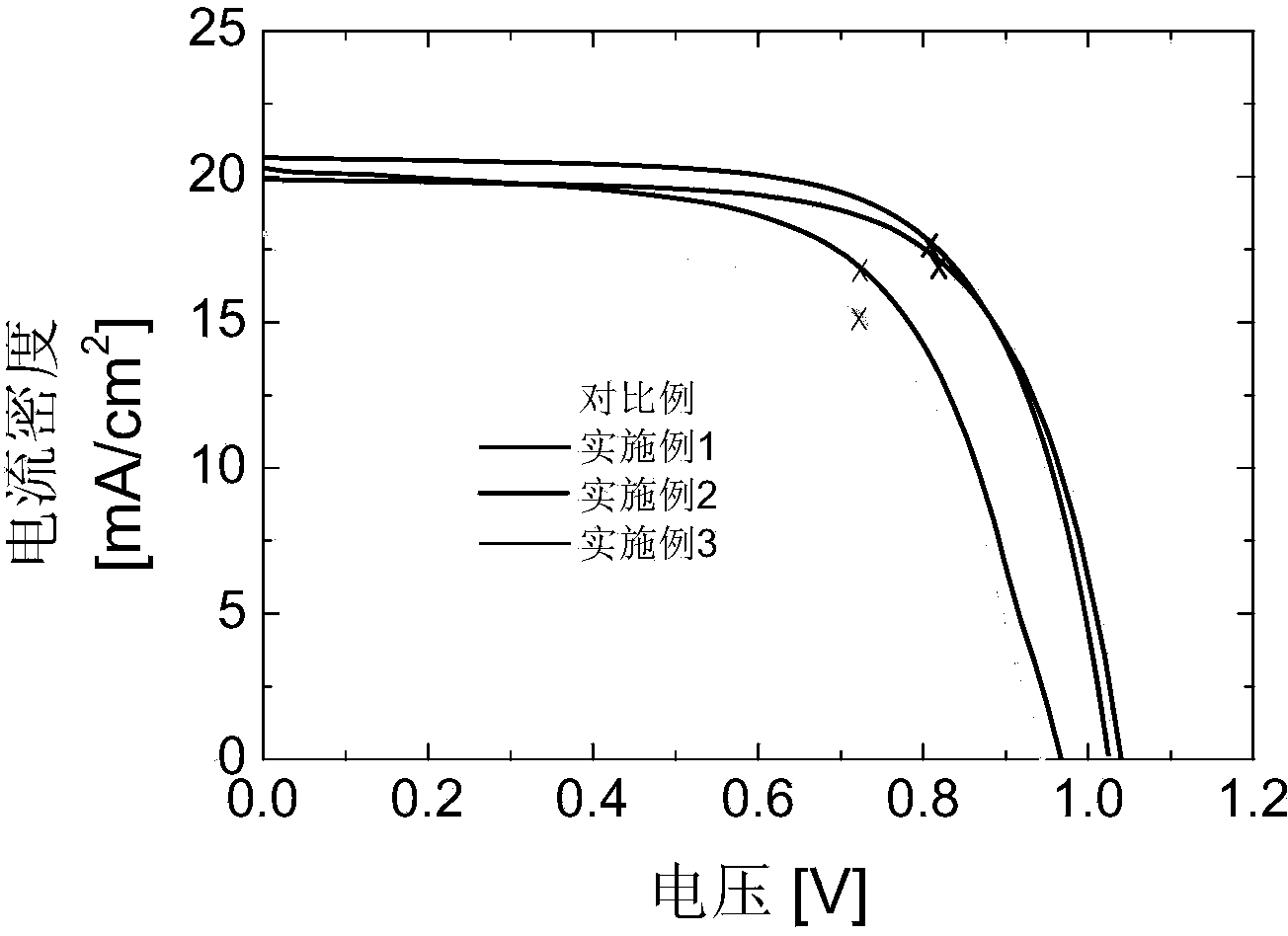

Solar cell and preparation method thereof

PendingCN109216491AReduce surface recombination rateImprove surface passivation effectFinal product manufacturePhotovoltaic energy generationFill factorFilling factor

The invention provides a solar cell and a preparation method thereof. The solar cell comprises a substrate, a front structure located on the front side of the substrate and a back structure located onthe back side of the substrate; The front structure comprises a first doping layer, a passivation tunneling layer, a second doping layer, a passivation antireflection layer and a front electrode. Thefirst doping layer, the passivation tunnel layer, the second doping layer and the passivation antireflection layer are arranged in sequence, and the front electrode is in contact with the second doping layer through the passivation antireflection layer; The backside structure comprises a backside passivation film and a backside electrode; The back electrode is in contact with the substrate through a contact area of the back passivation film. In the invention, a passivation tunneling layer is added, the surface recombination rate of the battery is effectively reduced, and the surface passivation performance of the battery is improved; The contact between the front electrode and the second doping layer can effectively improve the lateral transfer efficiency of the positive surface of the battery, reduce the series resistance of the battery, and thus improve the fill factor and conversion efficiency of the battery.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

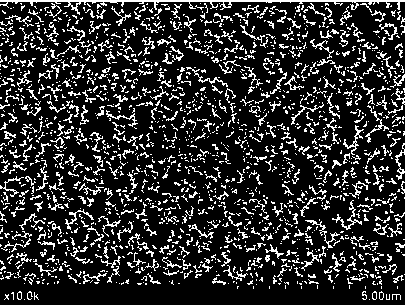

Method for removing micro-damage layer from crystalline silicon surface after RIE (Reactive Ion Etching) flocking

ActiveCN102364697AModerate etch rateProcess is easy to controlFinal product manufactureSemiconductor devicesIonMicrostructure

The invention relates to the field of surface treatment method for silicon chips, in particular to a method for removing a micro-damage layer from a crystalline silicon surface after RIE (Reactive Ion Etching) flocking. The method comprises the following steps of: cleaning an RIE-treated silicon chip with a mixed acid liquid of HNO3 and HF diluted with CH3COOH, wherein the volume percentage of the CH3COOH is 0.1-10 percent, and the volume percentage of the HNO3 is 85.0-99.5 percent; and thermally treating in a N2 atmosphere for 1-30 minutes at the temperature of 200 to 400 DEG C. Compared with an ordinary damage removing process, the invention has the advantages that: a non-aqueous acid etching liquid is adopted, and the ratio of HNO3 in an etching solution is increased simultaneously, sothat the etching rate is moderate, the process is easy to control, the etching uniformity is high, and the microscopic structure of an RIE flocked surface is kept; the method is suitable for industrial production; and a subsequent thermal treatment process is combined, so that the micro-damage layer on the surface of the silicon chip can be further reduced, and chemical residues are removed effectively.

Owner:TRINASOLAR CO LTD

P-type crystalline silicon solar cell with tunneling passivation and preparation method thereof

PendingCN112310231AReduce surface recombination rateImprove front passivationFinal product manufacturePhotovoltaic energy generationMetallic aluminumEngineering

The invention belongs to the technical field of crystalline silicon solar cells, and relates to a P-type crystalline silicon solar cell with tunneling passivation and a preparation method thereof. Thesolar cell comprises a P-type substrate, and is characterized in that a selective emitter, an ultrathin tunneling silicon oxide layer, a phosphorus-doped polycrystalline silicon layer, a front silicon oxide passivation layer and a front silicon nitride passivation layer are sequentially arranged on the front face of the P-type substrate from inside to outside, and a back aluminum oxide passivation layer and a back silicon nitride silicification layer are sequentially arranged on the back face of the P-type substrate from inside to outside; A front metal silver grid line is arranged on the front silicon nitride passivation layer, a back metal aluminum grid line is arranged on the back face of the P-type substrate, and the back metal aluminum grid line penetrates through the back aluminum oxide passivation layer and the back silicon nitride silicification layer. The structure is very thin, the problem of light absorption of the silicon wafer is solved, the surface recombination rate ofthe cell is effectively reduced, the front passivation of the cell is improved, and the performance of the cell is improved.

Owner:TRINA SOLAR CO LTD +1

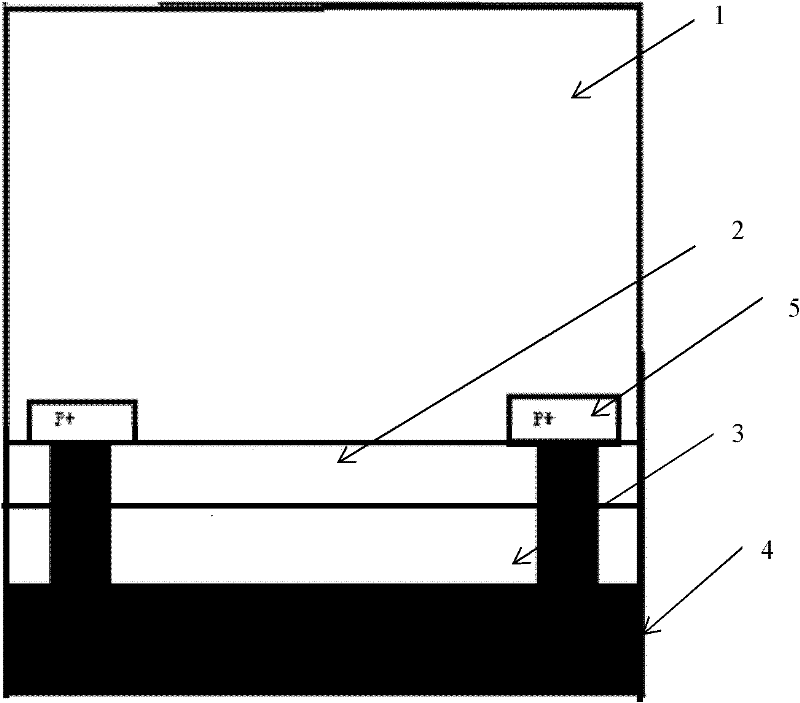

Floating junction solar cell back passivation structure based on heterojunction and preparation technology thereof

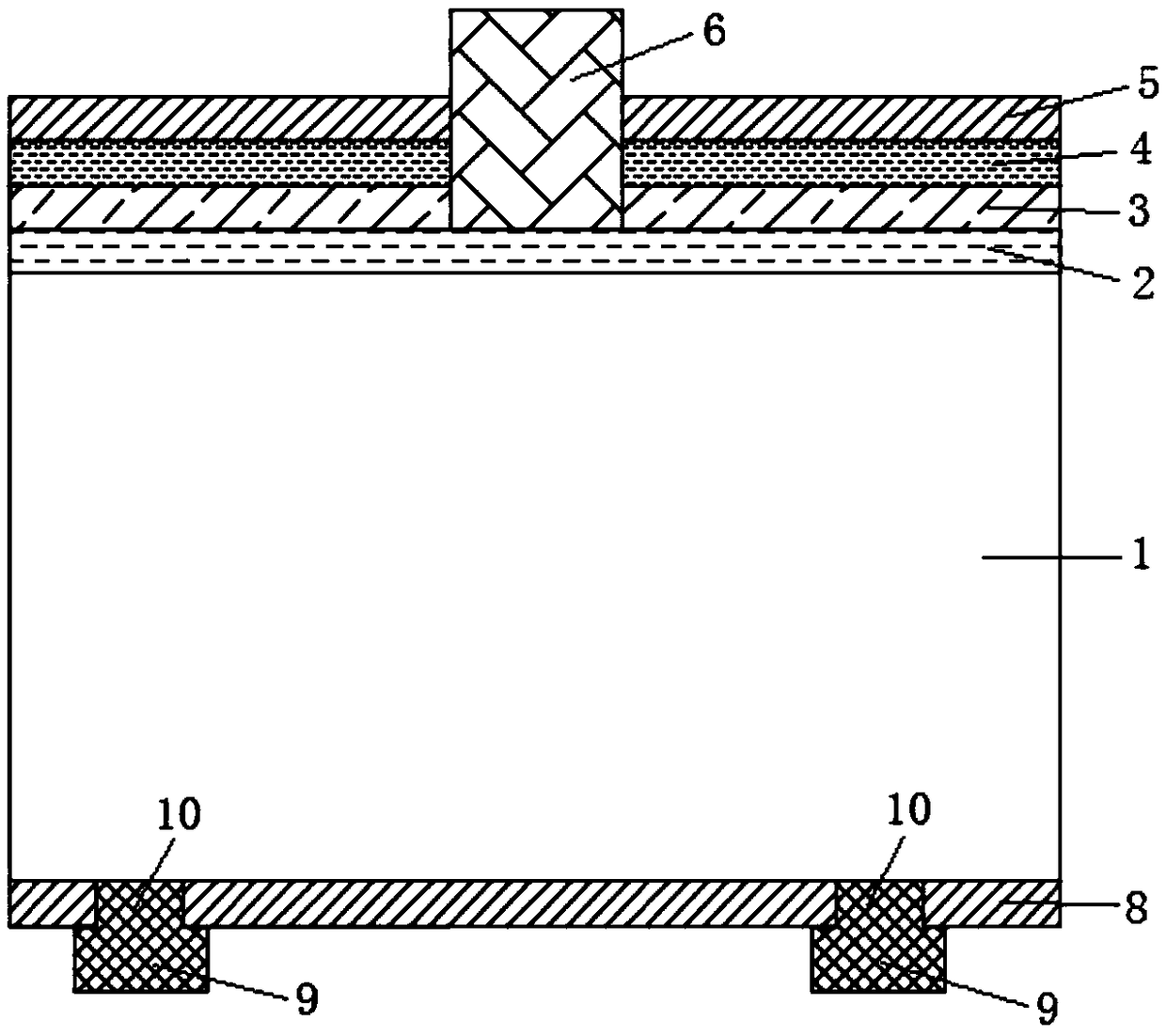

ActiveCN102522445APrevent proliferationSolving the problem of parasitic loopsFinal product manufacturePhotovoltaic energy generationHeterojunctionAluminum metal

The invention relates to a floating junction solar cell back passivation structure based on heterojunction. The structure comprises P-type crystalline silicon. A bottom of a P-type crystalline silicon substrate possesses a heterogeneous structure which is formed by an intrinsic heterogeneous material layer and an N-type heterogeneous material layer. The intrinsic heterogeneous material layer is inserted between the N-type heterogeneous material layer and the P-type crystalline silicon. An insulating layer wraps the N-type heterogeneous material layer. The bottom of the insulating layer is provided with an aluminum metal layer. Two ends of the bottom of the P-type crystalline silicon substrate are provided with P+ localized doping areas. Point contact aluminum sintering areas are arranged below the P+ localized doping areas. According to the invention, a good passivation effect of the heterojunction can be reserved and simultaneously a photo-generated hole can be well led out through a back structure. And a pin-hole parasitic loop problem of the homogenesis floating junction can be prevented.

Owner:TRINA SOLAR CO LTD

Front passivation process matching alkali polishing selective emitter

ActiveCN110416363AReduce surface recombination rateImprove surface densityFinal product manufactureSemiconductor devicesDeposition temperatureSingle crystal

The invention relates to the field of single-crystal PERC back etching alkali polishing process and discloses a front passivation process matching an alkali polishing selective emitter. In an oxidation process before an alkali polishing process, the oxygen layer deposition with high-temperature hot oxygen and a slot cooling rate are combined, which means that a process condition for depositing anoxide layer comprises a deposition temperature of 790 to 810 DEG C, a pressure of 100 to 120 mbar, an oxygen flow 3000 to 3500 sccm and a time 25 to 35 min, the cooling process has three steps, and then a boat is taken out of a tube and an existing process is employed. In the alkali polishing process coating process, a layer of silicon-rich film is separately added, that is, a first layer of silicon-rich film is deposited by PECVD.

Owner:SHANXI LUAN PHOTOVOLTAICS TECH

Method of oxidation corrosion removing defect layer at the surface of silicon nanowire solar cell

ActiveCN103022247AMinority Lifetime MeasurementAchieve controlled removalAfter-treatment detailsFinal product manufactureCell fabricationSilicon oxide

The invention relates to the technology of solar cell material and cell producing, in particular to monocrystalline silicon nanowire arrays prepared by using metal nanoparticles assisting electrodeless chemical etching method. The method firstly utilizes a first dry-oxygen oxidation process, due to low speed rate of dry-oxygen oxidation of silicon, by controlling oxidation time, an oxidation layer which is thickness-controllable is formed at the silicon nanowire, or the method utilizes hydrogen peroxide oxidation method to form an oxidation layer at the silicon nanowire; then the method utilizes HF(Hydrogen Fluoride) to corrode the silicon oxide layer at the surface of the silicon nanowire, while the silicon oxide layer is removed, the defect layer at the silicon nanowire surface is removed without damaging the shape of the silicon nanowire. The method can reduce the surface charge recombination rate and effectively improve minor carrier lifetime of the silicon nanowire, thereby the cell efficiency is improved.

Owner:南通东湖国际商务服务有限公司

N-type battery structure and preparation method thereof

PendingCN113078232AImprove contactEasy to fillFinal product manufacturePhotovoltaic energy generationEngineeringElectric current flow

The invention discloses an N-type battery structure and a preparation method thereof. The structure comprises an N-type silicon body material and a metal grid line electrode formed on the surface of the N-type silicon body material, and is characterized in that the back surface of the N-type silicon body material is provided with a suede part and a polished surface part, and the contact position of the metal grid line electrode and the N-type silicon body material is located in the suede part. The back metal grid line electrode adopts a suede structure, so the contact area between the metal grid line and silicon is increased, and the contact resistance is improved; the flat surface of the polished area can improve the back passivation effect, reduce the surface recombination rate, enhance the internal reflection of long waves and improve the front current.

Owner:CSI CELLS CO LTD +1

Low-pressure oxidization process for crystalline silicon small-textured structure

InactiveCN107681022ASolving Surface Passivation ProblemsExtend your lifeFinal product manufacturePhotovoltaic energy generationCrystalline siliconShort Waves

The invention discloses a low-pressure oxidization process for a crystalline silicon small-textured structure. The low-pressure oxidization process is carried out on a crystalline silicon wafer with the textured dimension of 0.1-2[mu]m to generate a layer of uniform SiO<2> layer on the surface of the crystalline silicon small-textured structure, so that the surface recombination rate is lowered, the minority carrier lifetime is prolonged, the problem of surface passivation of the crystalline silicon small-textured structure is solved, the surface doping concentration of an emitter can be lowered, the problem of overhigh surface doping concentration of the small-textured structure can be solved, the influence from "dead layer" can be weakened obviously, and the short-wave response of the battery can be improved; meanwhile, the oxidization process is performed in a low-pressure state, so that gas stability and uniformity and environment cleanliness in a diffusion furnace tube can be improved, the sheet resistance uniformity after oxidization is greatly improved and the battery efficiency is improved; and meanwhile, the problem of abnormal appearance of the silicon wafer surface in normal-pressure oxidization can be solved, the number of the abnormal white spots and the like on the silicon wafer surface can be obviously reduced, and the battery product quality is improved effectively.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

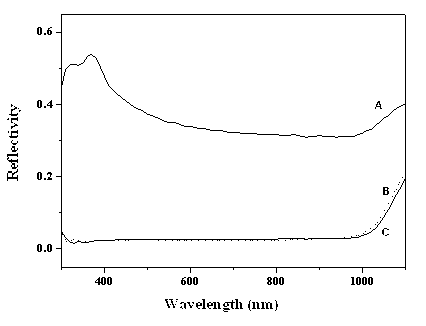

Etching-technology-based silicon science (SIS) junction solar cell

InactiveCN102163638AImprove optical absorptionReduce surface reflectionPhotovoltaic energy generationSemiconductor devicesMicron scaleNanoparticle

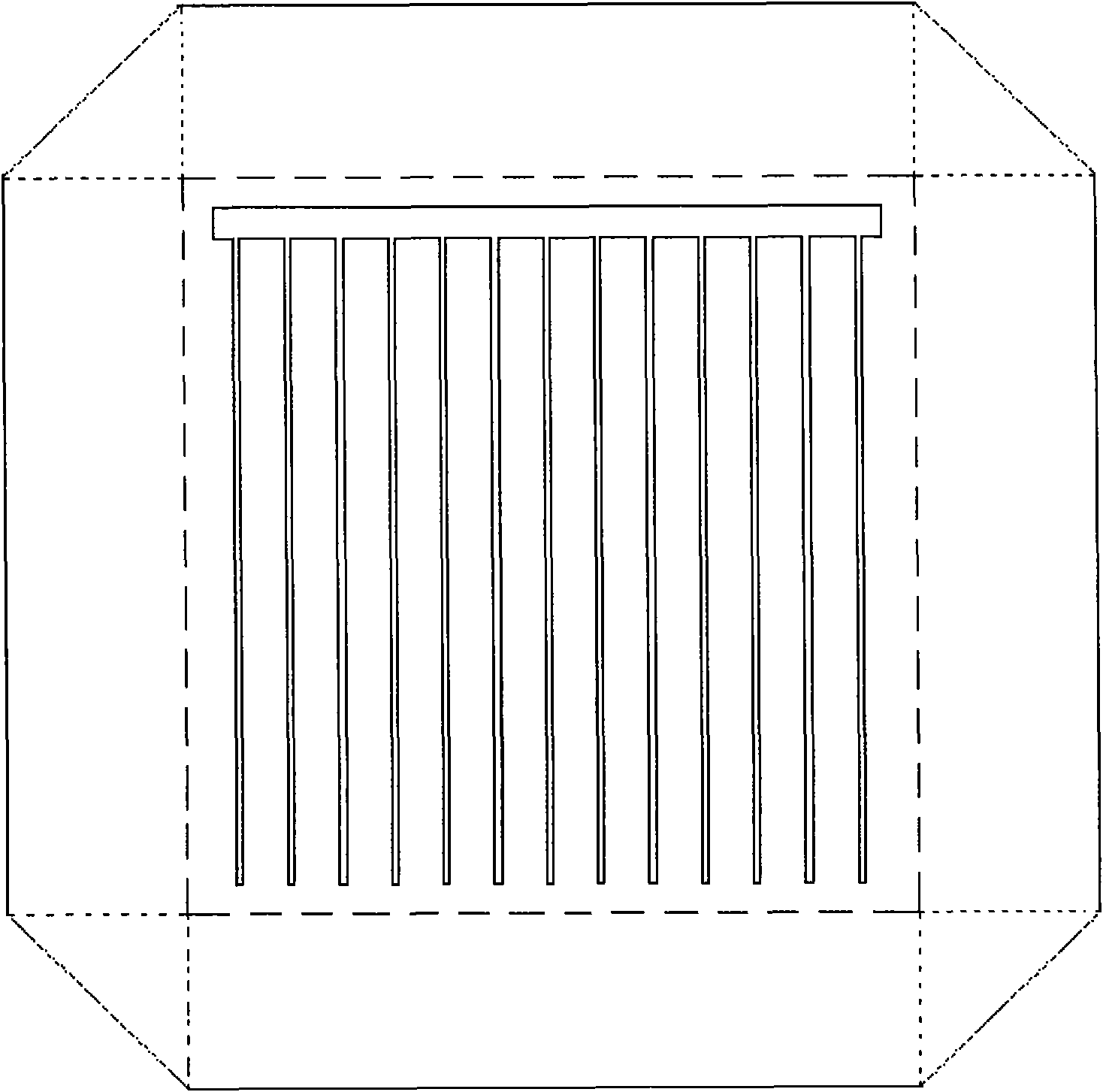

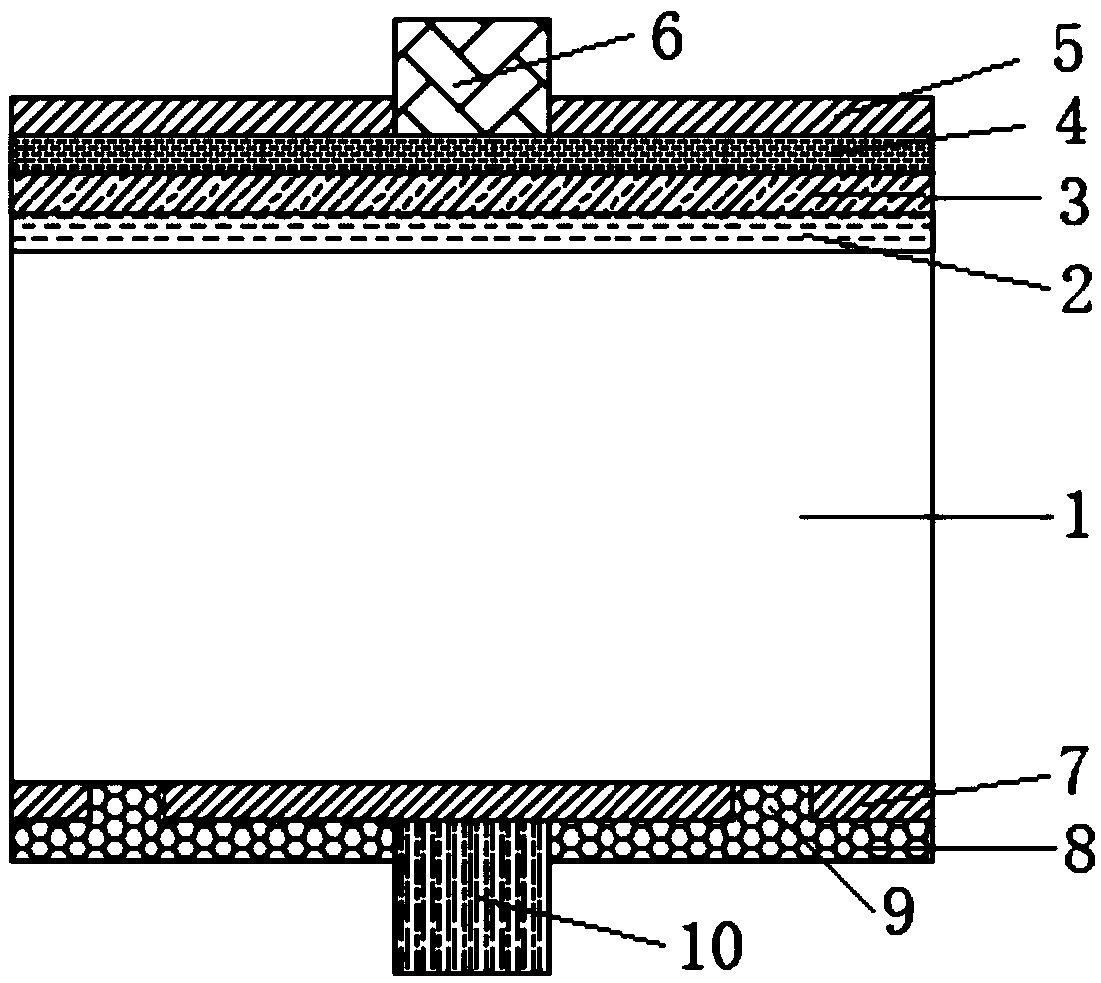

The invention discloses an etching-technology-based silicon science (SIS) junction solar cell, which comprises a lower electrode (10), a light absorption material layer (20), an oxide insulating layer (30), a total cost of ownership (TCO) thin-film layer (40), an upper pattern electrode (50) and nanoparticles (60), wherein the light absorption material layer (20) is prepared on the lower electrode (10); due to the etching technology, a micron-scale one-dimensional bar structure or two-dimensional columnar structure which has different periods and depths is prepared on the light absorption material layer (20); the oxide insulating layer (30) is formed by oxidizing the light absorption material layer (20) through a chemical method; the TCO thin-film layer (40) is deposited on the oxide insulating layer (30); the upper pattern electrode (50) is prepared on the TCO thin-film layer (40); and the nanoparticles (60) are arranged on the TCO thin-film layer (40). The problem that the conventional SIS junction solar cell has low conversion efficiency is solved, and the aim of improving the capacities of optical absorption of the cell and carrier extraction is fulfilled.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

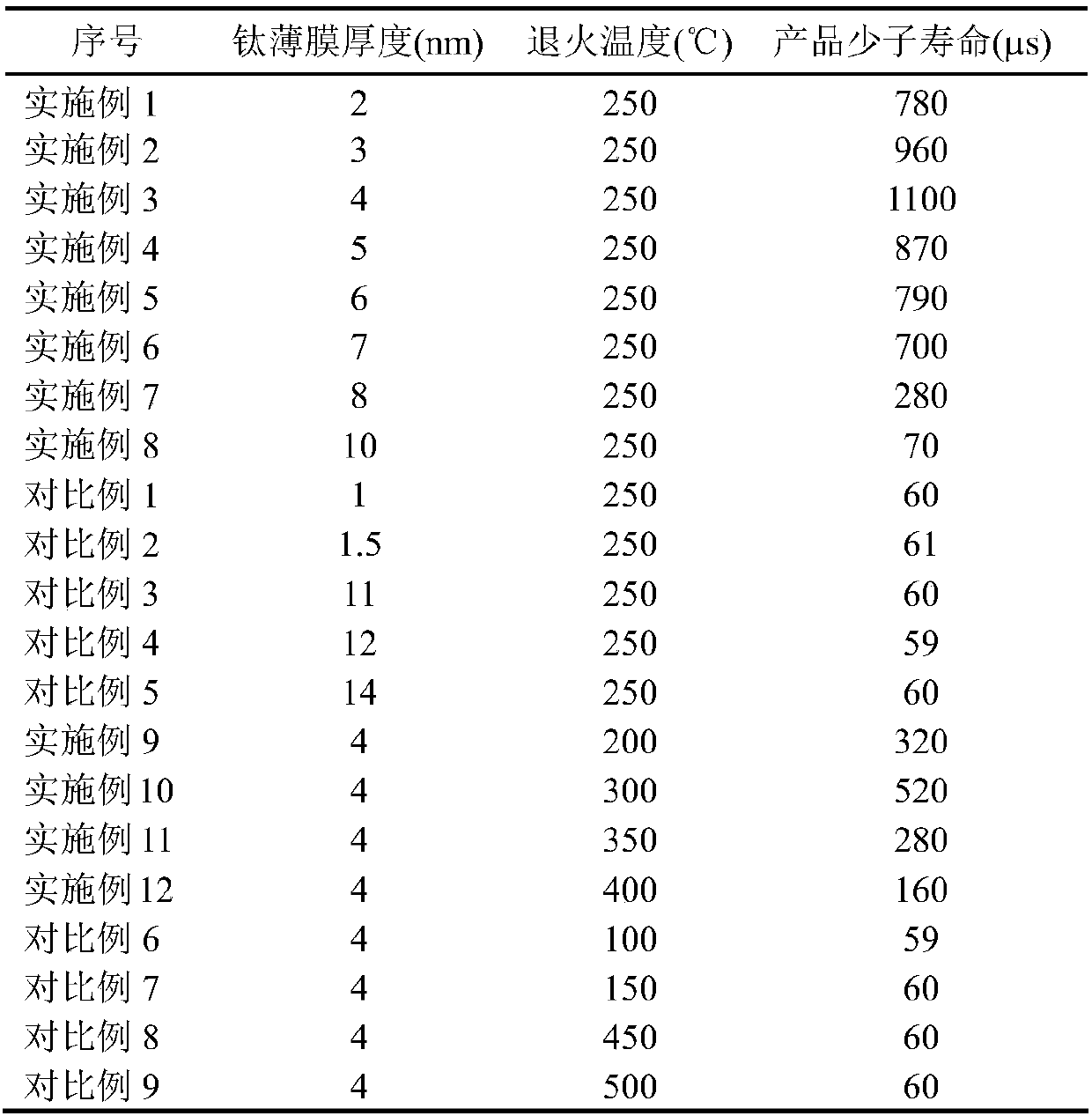

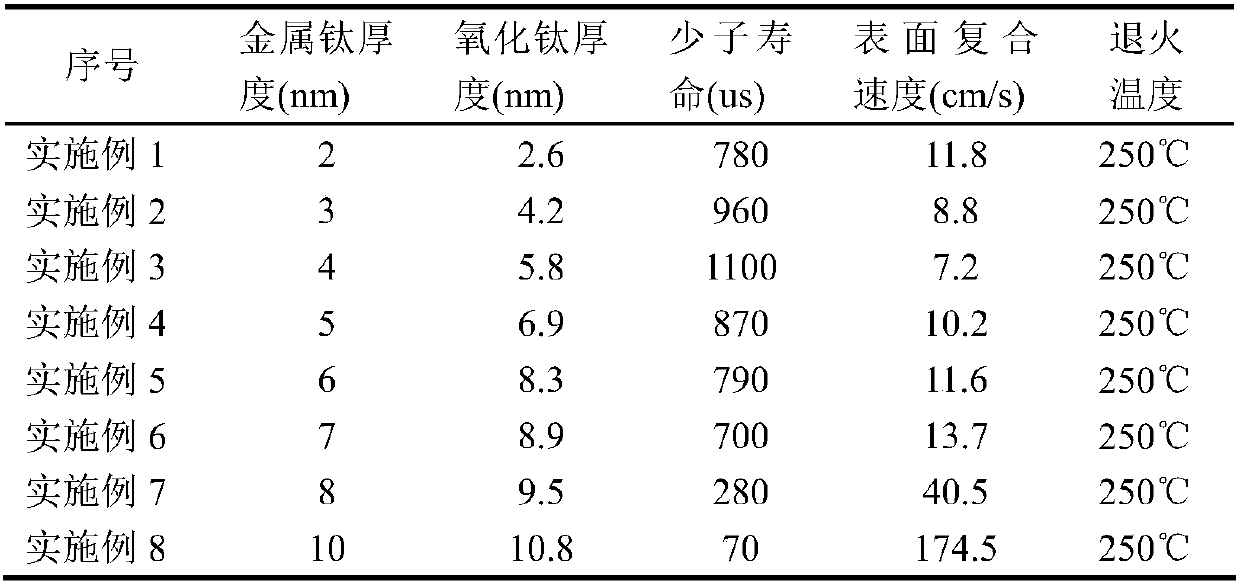

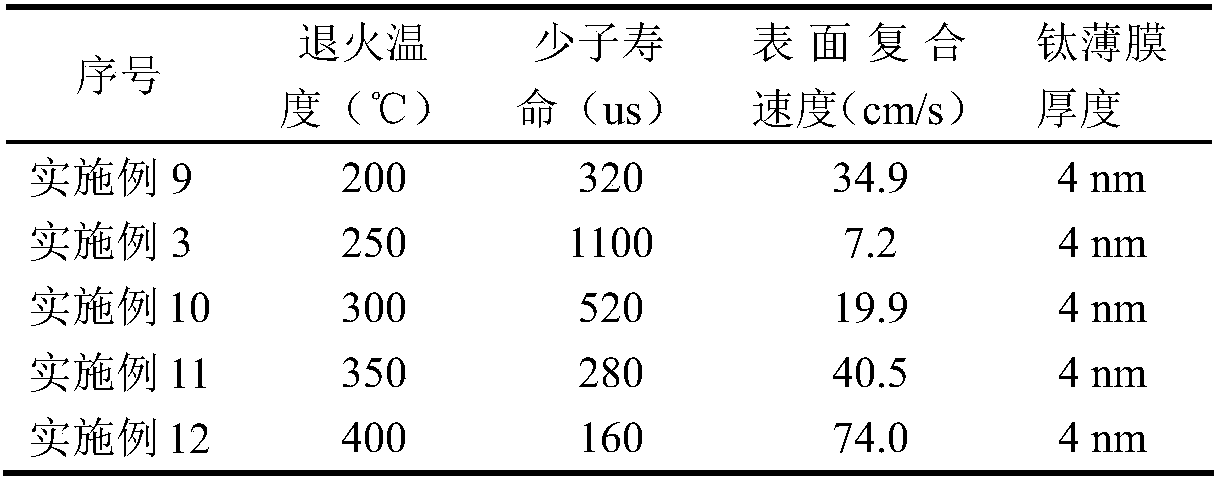

Titanium oxide passivation film preparation method and solar energy cell prepared through utilizing titanium oxide passivation film preparation method

InactiveCN107634122AImprove life expectancyReduce surface recombination rateFinal product manufactureSemiconductor devicesEvaporationOperation mode

The invention discloses a titanium oxide passivation film preparation method. The method comprises steps that an electron beam deposition method is utilized to deposit a metal titanium film with certain thickness at the surface of a silicon chip after pretreatment, then annealing is carried out in the oxygen atmosphere, and cooling in the nitrogen atmosphere is then carried out. The electron beamdeposition method and the metal titanium film are utilized to directly carry out oxidation of the metal titanium film to form a titanium oxide film, compared with the ALD / CVD process, equipment requirements are low, an operation mode and the operation flow are simpler, adjustment on the thickness of the metal titanium film and the oxidation process is facilitated to adapt to different silicon chippassivation demands, the titanium oxide passivation film and other passivation medium layers can excellently form laminated layers, so the better passivation result is realized; the method is suitable for a thermal evaporation method, a magnetron sputtering method to deposit the metal titanium film; deposition of microscale active metal can be easily realized, and thereby doped modification of the final titanium oxide film is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

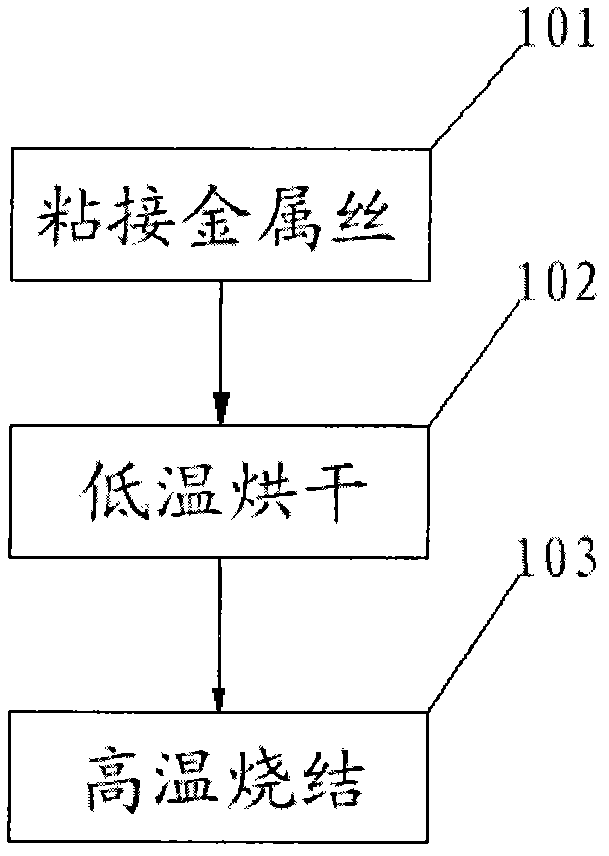

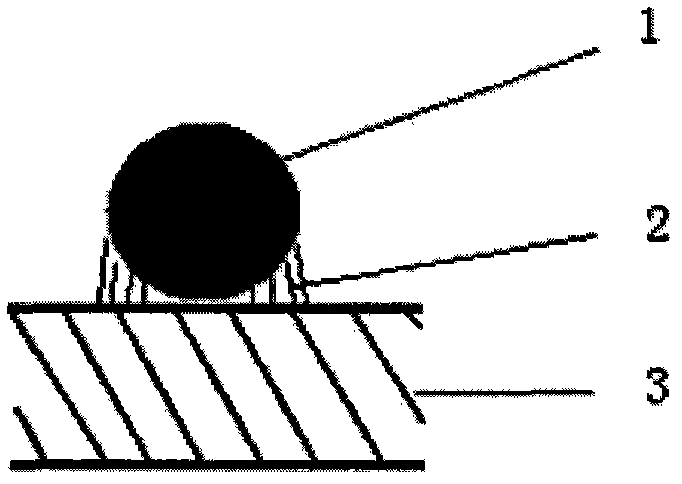

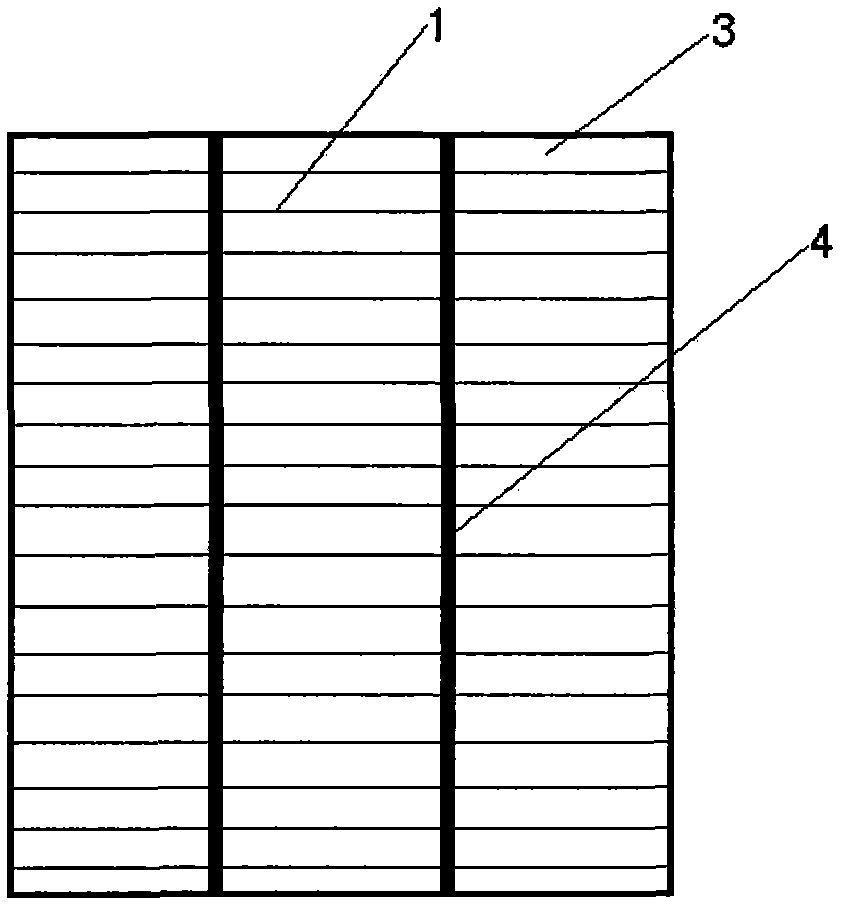

Electrode structure on back of solar cell and manufacturing method thereof

ActiveCN102683478AImprove conversion efficiencyReduce surface recombination rateFinal product manufactureSemiconductor devicesSpectral responseElectrical conductor

The invention relates to the field of solar cells and particularly discloses an electrode structure on the back of a solar cell and a manufacturing method thereof. The electrode structure comprises a silicon chip and a metal wire which are adhered through electrocondution slurry, and the electrocondution slurry and the metal wire are formed into an integrated conductor through the steps of drying and sintering. According to the electrode structure on the back of the solar cell and the manufacturing method, an electrode or a point electrode, which is formed by the metal wire, can replace a face electrode on an original silicon chip. A good passivating layer and a reflecting layer can be manufactured in a non-electrode area, the surface recombination speed can be reduced by the good passivating, the infrared spectral response can be improved by the good reflection, and accordingly the conversion efficiency of the solar cell is improved.

Owner:陕西众森电能科技有限公司

Perovskite monocrystal material and microcrystalline silicon composite material combined thin film solar cell and preparation method thereof

InactiveCN106784316AImprove instabilityAvoid priceFinal product manufactureSolid-state devicesEvaporationSingle crystal

The invention discloses a perovskite monocrystal material and microcrystalline silicon composite material combined thin film solar cell, and relates to a semiconductor device specially applied to converting an optical energy into an electric energy. The perovskite monocrystal material and microcrystalline silicon composite material combined thin film solar cell comprises a bottom electrode, an N type oxide semiconductor film, a perovskite monocrystal light absorption layer, a microcrystalline silicon hole transporting layer and a top electrode; the oxide semiconductor thin film is an N type zinc oxide semiconductor thin film obtained by sputtering; the perovskite monocrystal light absorption layer is a light absorption material of a perovskite structure; the hole transporting layer is a P type microcrystalline silicon composite material obtained by chemical vapor deposition; and the bottom and top electrodes are films made of aluminum or silver and obtained by thermal evaporation. According to the perovskite monocrystal material and microcrystalline silicon composite material combined thin film solar cell and a preparation method thereof, the perovskite monocrystal is taken as the light absorption material and the P type microcrystalline composite material is taken as the hole transporting layer, so the more stable and more efficient solar cell is obtained.

Owner:HEBEI UNIV OF TECH

Heterogeneous emitting electrode structure of solar cell and solar cell

PendingCN109301005AReduce surface recombination rateImprove surface passivation performancePhotovoltaic energy generationSemiconductor devicesFilling factorSolar cell

The present invention provides a heterogeneous emitting electrode structure of a solar cell and a solar cell. The heterogeneous emitting electrode structure of the solar cell comprises a substrate, afirst doping layer, a passivation tunnelling layer, a second doping layer, a passivation antireflection layer and a front electrode. The substrate, the first doping layer, the passivation tunnelling layer, the second doping layer and the passivation antireflection layer are arranged in order, and the front electrode passes through the passivation antireflection layer and is in contact with the second doping layer. In the invention, the passivation tunnelling layer is added to effectively reduce the surface recombination rate of the cell so as to improve the surface passivation performance of the cell; and the front electrode is in contact with the second doping layer to effectively improve the transverse transmission efficiency of the front surface of the cell and reduce the serial resistance of the cell so as to improve the cell filling factor and conversion efficiency and improve the solar cell conversion efficiency.

Owner:TAIZHOU LERRISOLAR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com