P-type crystalline silicon solar cell with tunneling passivation and preparation method thereof

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

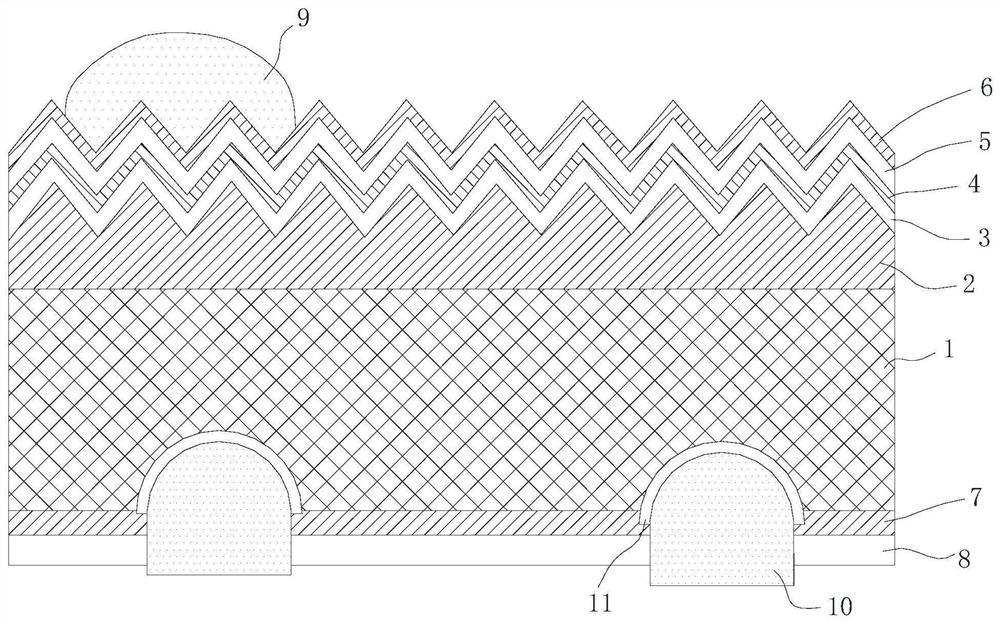

[0036] like figure 1 As shown, this embodiment provides a P-type crystalline silicon solar cell with tunneling passivation, including a P-type substrate 1, characterized in that the front of the P-type substrate 1 is sequentially provided with Selective emitter 2, ultra-thin tunneling silicon oxide layer 3, phosphorus-doped polysilicon layer 4, front silicon oxide passivation layer 5 and front silicon nitride passivation layer 6, the back of the P-type substrate 1 is composed of inner To the outside, the back aluminum oxide passivation layer 7 and the back silicon nitride siliconization layer 8 are sequentially arranged, the front silicon nitride passivation layer 6 is provided with a front metal silver grid line 9, and the back side of the P-type substrate 1 is provided with a back metal aluminum grid line 10 , the back metal aluminum grid line 10 runs through the back aluminum oxide passivation layer 7 and the back silicon nitride silicide layer 8 , and there is a back local...

Embodiment 2

[0040] like figure 1 Shown, a kind of preparation method of the p-type crystalline silicon solar cell with tunneling passivation comprises the following steps:

[0041] 1) Phosphorus diffusion is carried out on the front side of the silicon wafer after texturing. The phosphorus diffusion uses low pressure or normal pressure diffusion, and the square resistance is between 100ohm / sq-300ohm / sq.

[0042] 2) The front side is heavily doped with laser PSG to form a selective emitter layer. The difference between the rear resistance of laser PSG heavy doping and the original square resistance is between 30ohm / sq-150ohm / sq,

[0043] 3) After removing the PSG, an ultra-thin tunneling silicon oxide layer 3 and an amorphous silicon layer are sequentially prepared on the front side of the silicon wafer. The amorphous silicon layer is an in-situ phosphorus-doped amorphous silicon film or an intrinsic amorphous silicon film. When the amorphous silicon layer is an intrinsic amorphous silico...

Embodiment 3

[0055] A method for preparing a p-type crystalline silicon solar cell with tunneling passivation, specifically as follows:

[0056] P-type single crystal silicon is used as a substrate, and conventional texturing is carried out in a solution containing KOH and texturing additives. After cleaning with hydrofluoric acid and RCA, phosphorus is diffused on the front side of the silicon wafer, and the square resistance is about 150ohm / sq. The front side of the silicon wafer is heavily doped with conventional laser PSG, and the square resistance is 65-75ohm / sq. Because the thickness of amorphous silicon is very thin, the slurry is easy to burn through when the screen is sintered, so the emitter is in contact with the laser PSG heavily doped, that is, the front side is actually a selective emitter, and it has better opening pressure and touch. After cleaning with hydrofluoric acid and RCA, prepare a layer of ultra-thin tunneling silicon oxide with a thickness of 1nm-3nm on the fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com