Perovskite monocrystal material and microcrystalline silicon composite material combined thin film solar cell and preparation method thereof

A technology of thin-film solar cells and single crystal materials, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor stability, low photoelectric conversion efficiency, and high preparation costs, and achieve the effect of overcoming prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

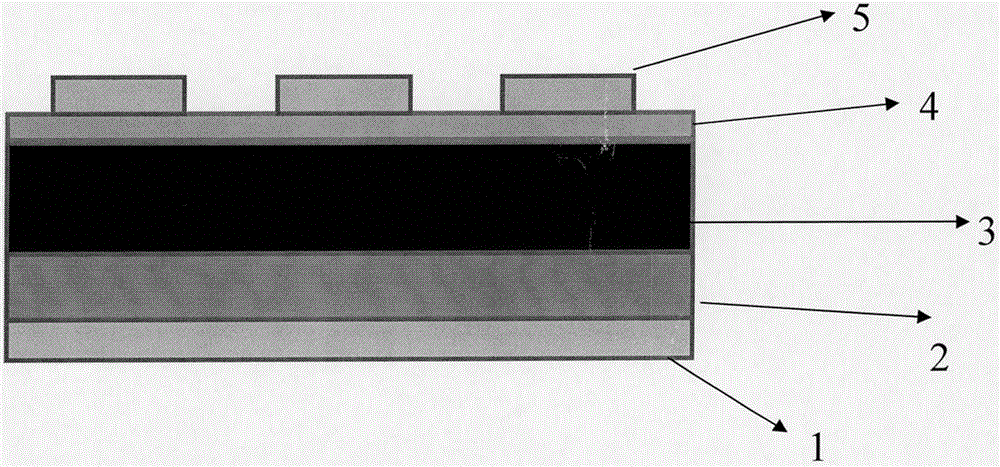

[0055] The thin film solar cell combined with perovskite single crystal material and microcrystalline silicon composite material consists of bottom electrode, dense zinc dioxide layer, single crystal perovskite light absorbing layer, microcrystalline silicon hole transport layer, and top electrode electrode. Parts are matched and compounded together to form a thin-film solar cell combined with the perovskite single crystal material and the microcrystalline silicon composite material of the present invention. The dense ZnO electron transport layer is deposited on the surface of the perovskite single crystal by sputtering, the microcrystalline silicon hole transport layer is deposited to cover the surface of the perovskite single crystal, and the film made of aluminum or silver is plated Bottom and top electrodes are formed on the surface of the electron transport layer and the hole transport layer.

[0056] A thin-film solar cell combined with a perovskite single crystal materi...

Embodiment 2

[0071] The thin film solar cell combined with perovskite single crystal material and microcrystalline silicon composite material consists of bottom electrode, dense zinc dioxide layer, single crystal perovskite light absorbing layer, microcrystalline silicon hole transport layer, and top electrode electrode. Parts are matched and compounded with each other to constitute the thin film sun combined with the perovskite single crystal material and the microcrystalline silicon composite material of the present invention. The dense ZnO electron transport layer is deposited on the surface of the perovskite single crystal by sputtering, the microcrystalline silicon hole transport layer is deposited to cover the surface of the perovskite single crystal, and the film made of aluminum or silver is plated Bottom and top electrodes are formed on the surface of the electron transport layer and the hole transport layer.

[0072] A thin-film solar cell combined with a perovskite single crysta...

Embodiment 3

[0087]The thin film solar cell combined with perovskite single crystal material and microcrystalline silicon composite material consists of bottom electrode, dense zinc dioxide layer, single crystal perovskite light absorbing layer, microcrystalline silicon hole transport layer, and top electrode electrode. Parts are matched and compounded with each other to constitute the thin film sun combined with the perovskite single crystal material and the microcrystalline silicon composite material of the present invention. The dense ZnO electron transport layer is deposited on the surface of the perovskite single crystal by sputtering, the microcrystalline silicon hole transport layer is deposited to cover the surface of the perovskite single crystal, and the film made of aluminum or silver is plated Bottom and top electrodes are formed on the surface of the electron transport layer and the hole transport layer.

[0088] A thin-film solar cell combined with a perovskite single crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com