Patents

Literature

1797 results about "Perovskite (structure)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

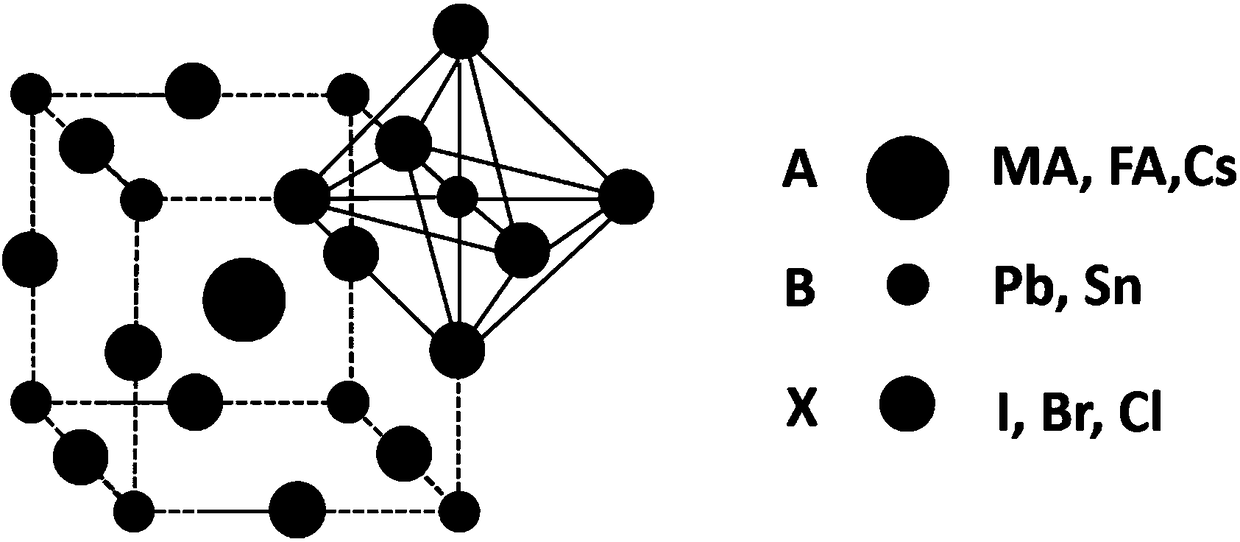

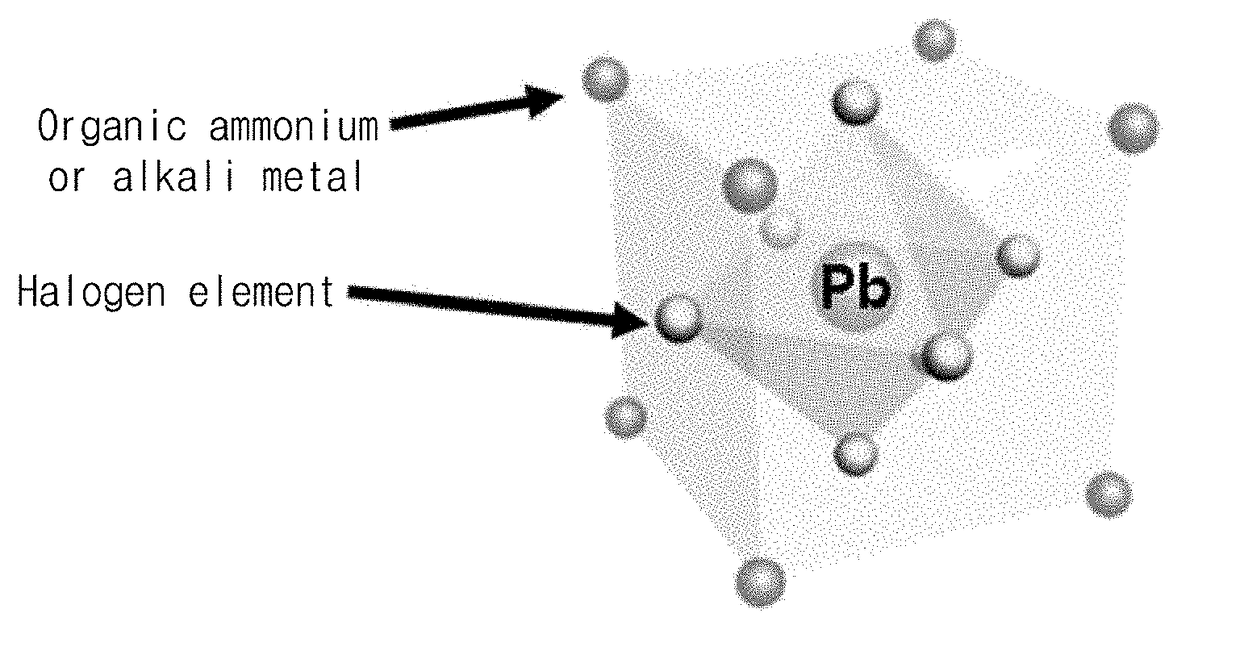

A perovskite is any material with the same type of crystal structure as calcium titanium oxide (CaTiO₃), known as the perovskite structure, or XᴵᴵA²⁺ⱽᴵB⁴⁺X²⁻₃ with the oxygen in the edge centers. Perovskites take their name from the mineral, which was first discovered in the Ural mountains of Russia by Gustav Rose in 1839 and is named after Russian mineralogist L. A. Perovski (1792–1856). The general chemical formula for perovskite compounds is ABX₃, where 'A' and 'B' are two cations of very different sizes, and X is an anion that bonds to both. The 'A' atoms are larger than the 'B' atoms. The ideal cubic structure has the B cation in 6-fold coordination, surrounded by an octahedron of anions, and the A cation in 12-fold cuboctahedral coordination. The relative ion size requirements for stability of the cubic structure are quite stringent, so slight buckling and distortion can produce several lower-symmetry distorted versions, in which the coordination numbers of A cations, B cations or both are reduced.

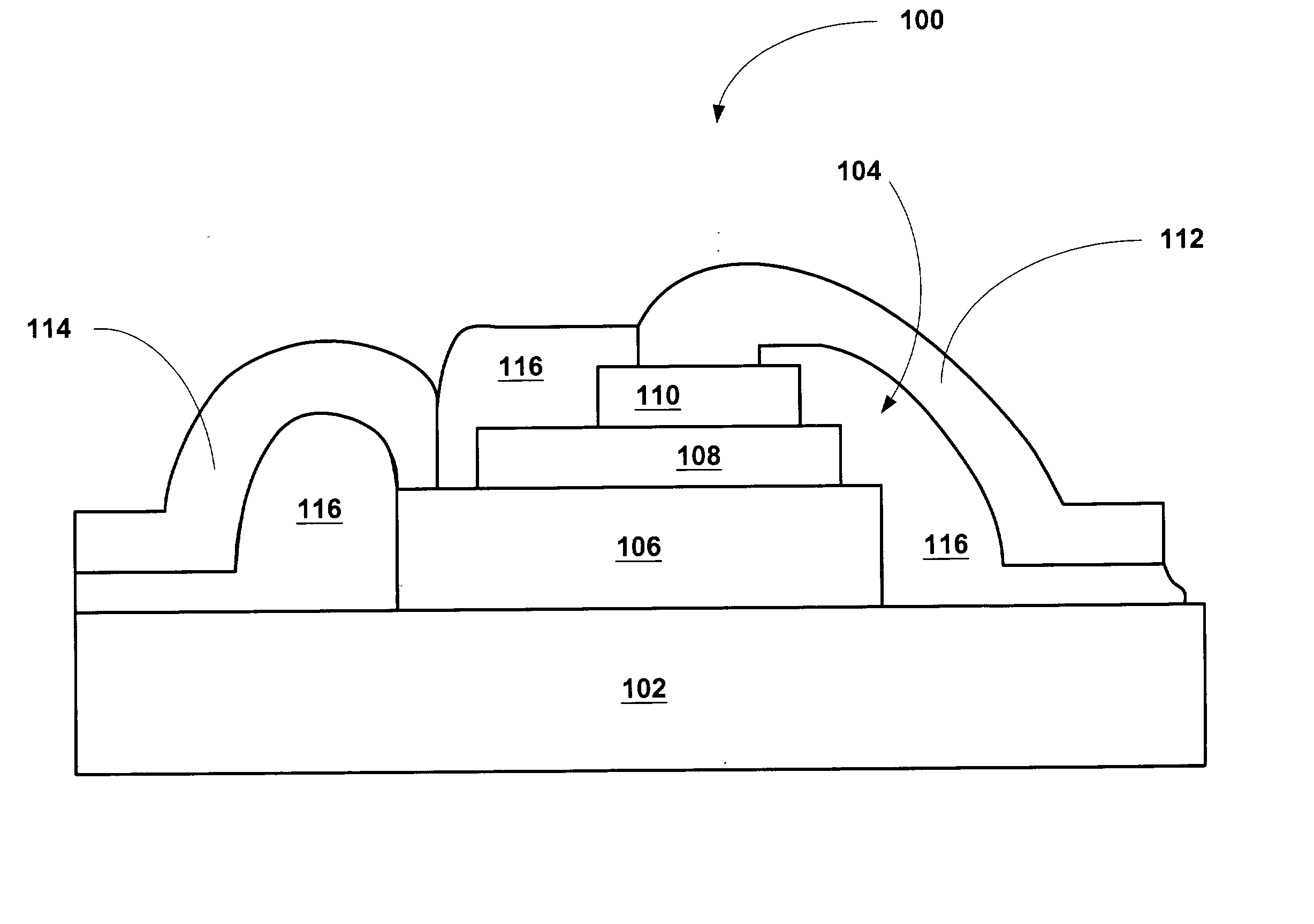

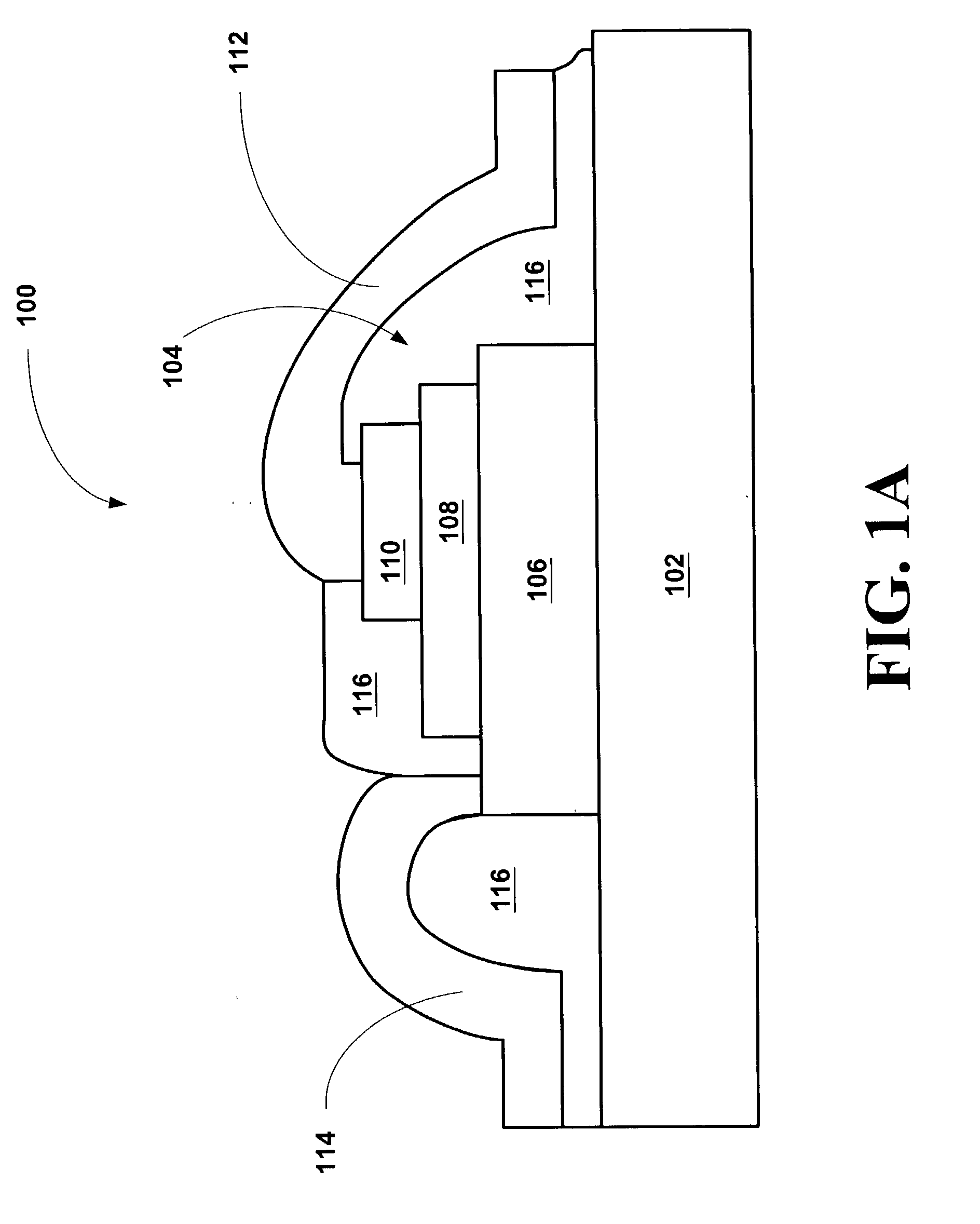

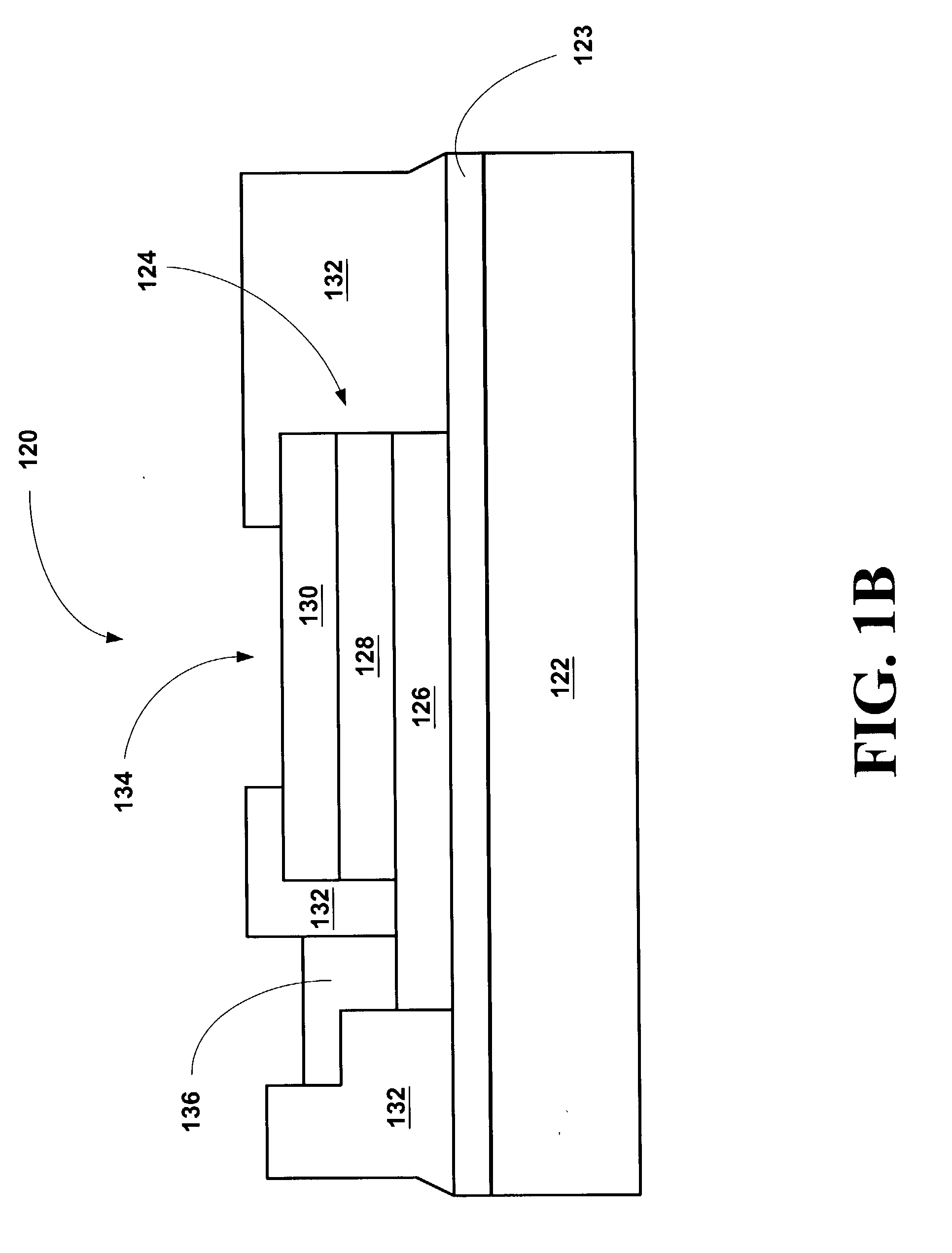

Perovskite-based thin film structures on miscut semiconductor substrates

InactiveUS20060288928A1Quality improvementGood metallic behaviorPolycrystalline material growthFrom chemically reactive gasesCrystal structureCrystal plane

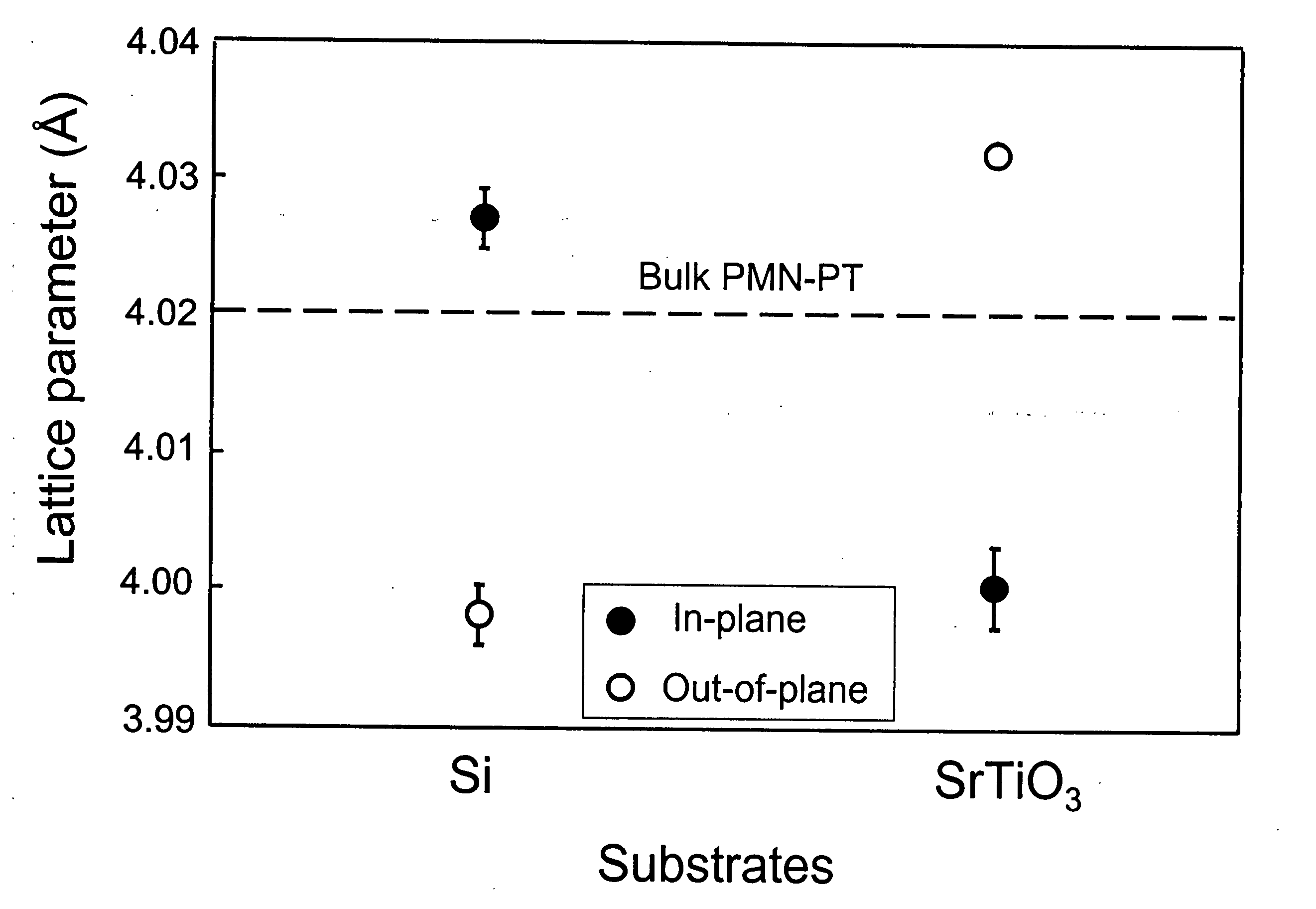

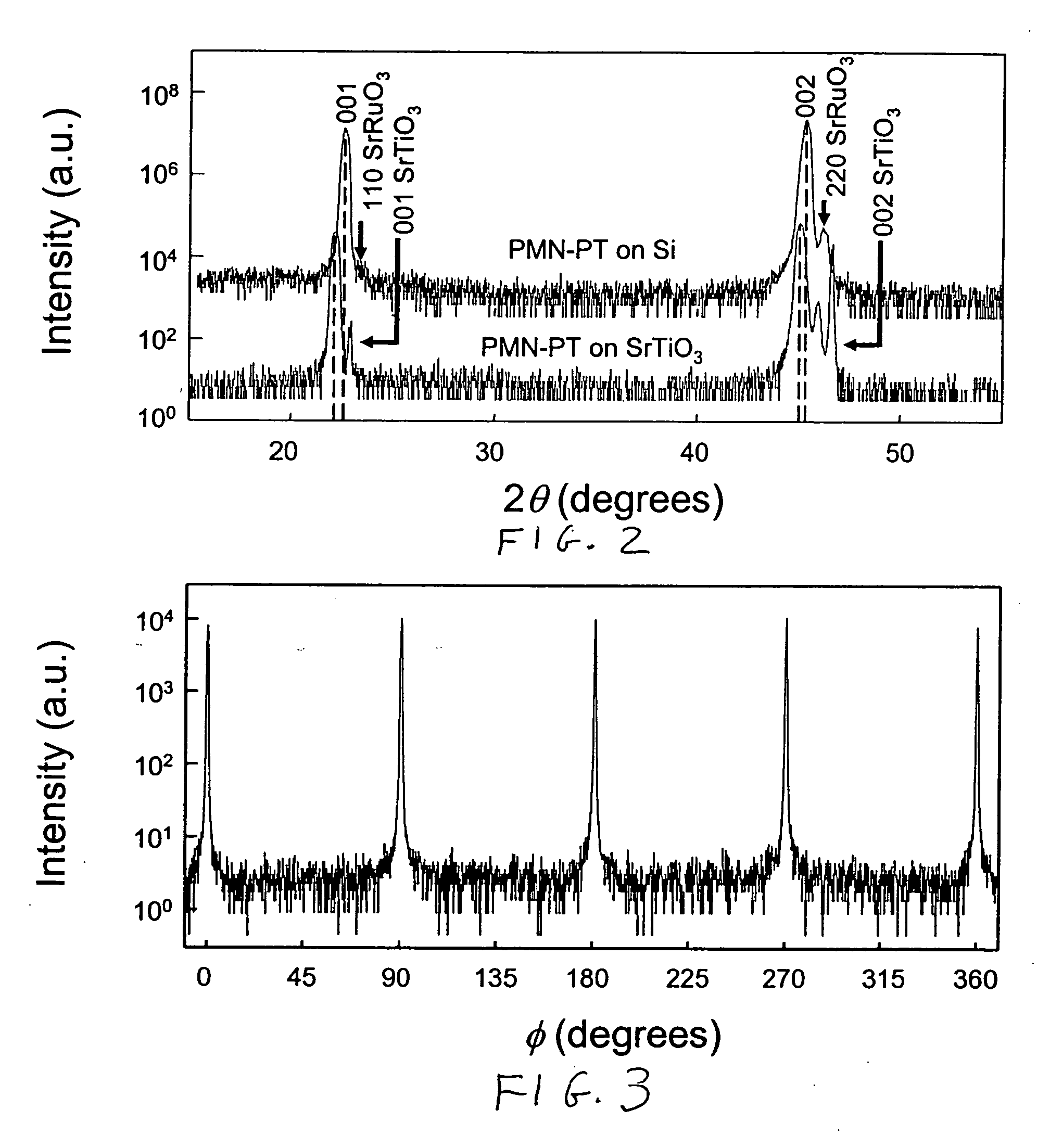

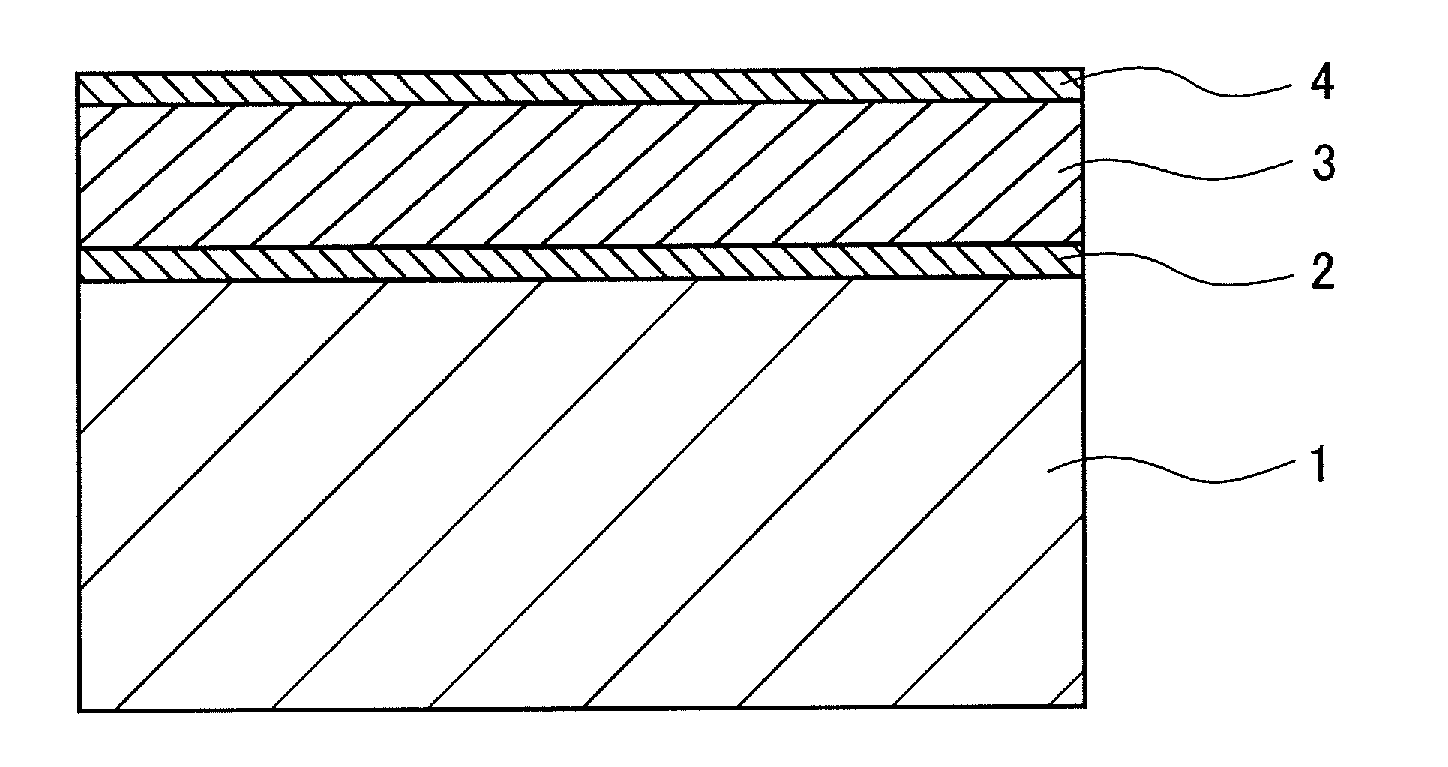

A perovskite-based thin film structure includes a semiconductor substrate layer, such as a crystalline silicon layer, having a top surface cut at an angle to the (001) crystal plane of the crystalline silicon. A perovskite seed layer is epitaxially grown on the top surface of the substrate layer. An overlayer of perovskite material is epitaxially grown above the seed layer. In some embodiments the perovskite overlayer is a piezoelectric layer grown to a thickness of at least 0.5 μm and having a substantially pure perovskite crystal structure, preferably substantially free of pyrochlore phase, resulting in large improvements in piezoelectric characteristics as compared to conventional thin film piezoelectric materials.

Owner:PENN STATE RES FOUND +1

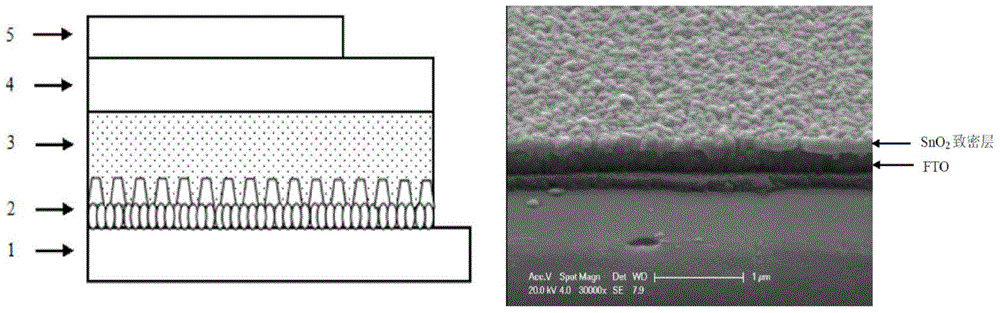

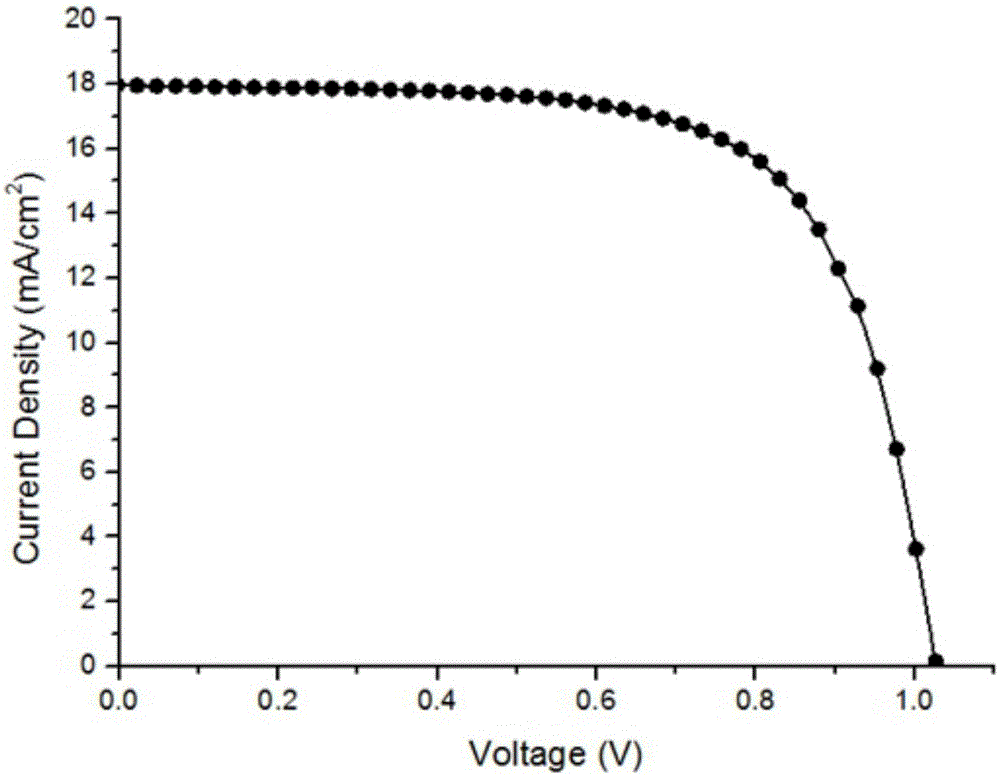

Perovskite solar cell and preparation method thereof

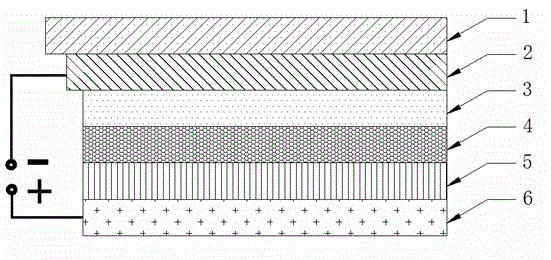

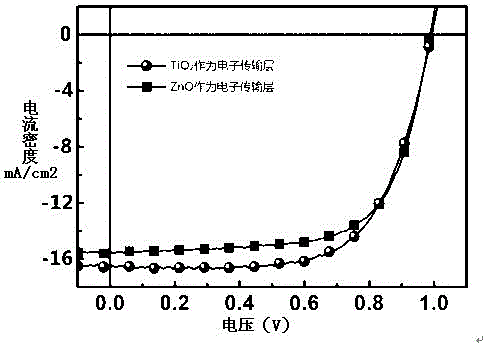

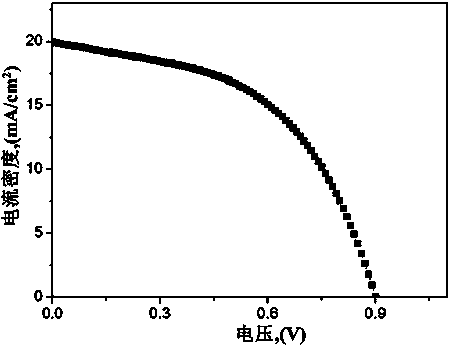

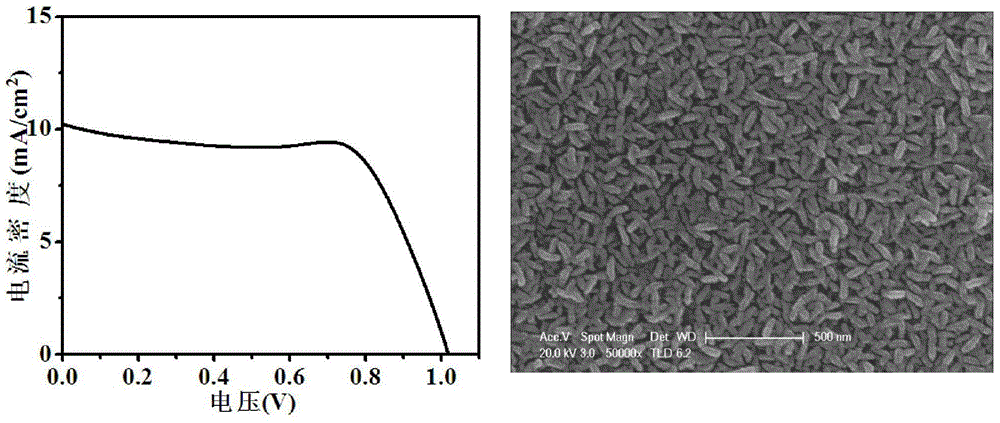

InactiveCN104091888AEasy to prepareControllable parametersSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellFill factor

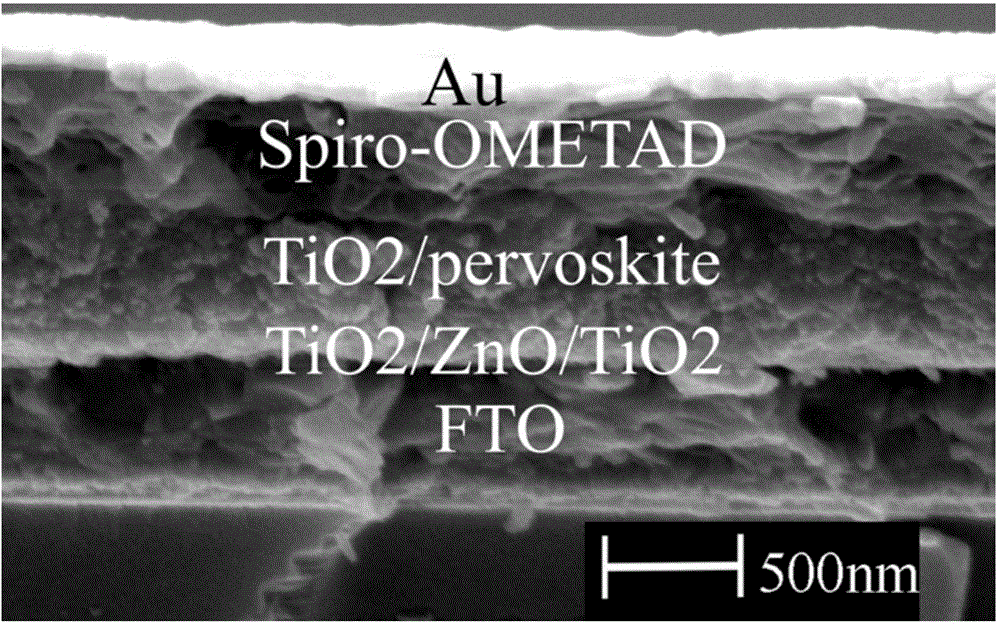

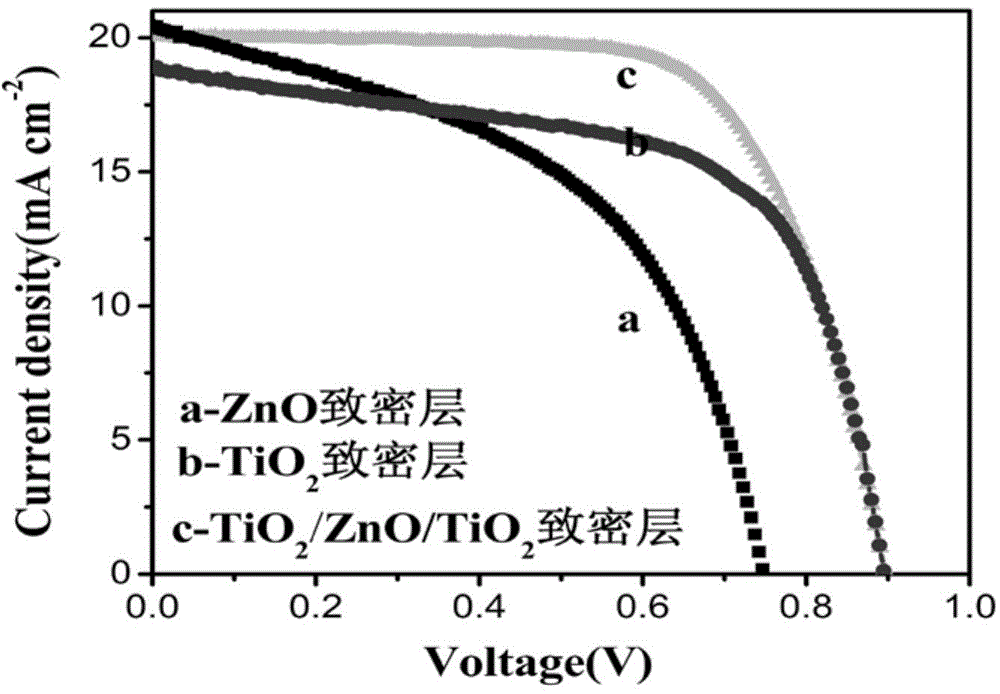

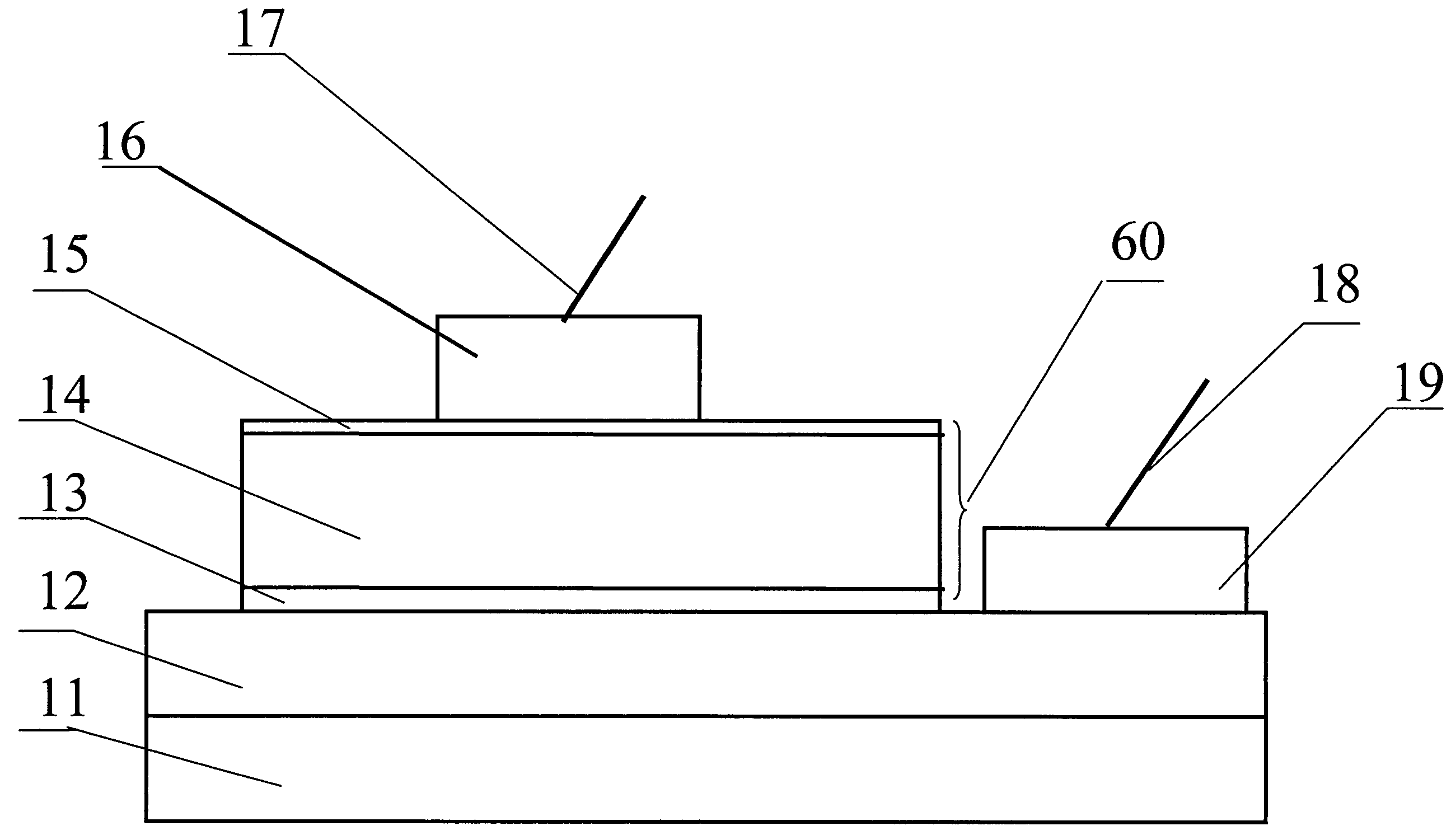

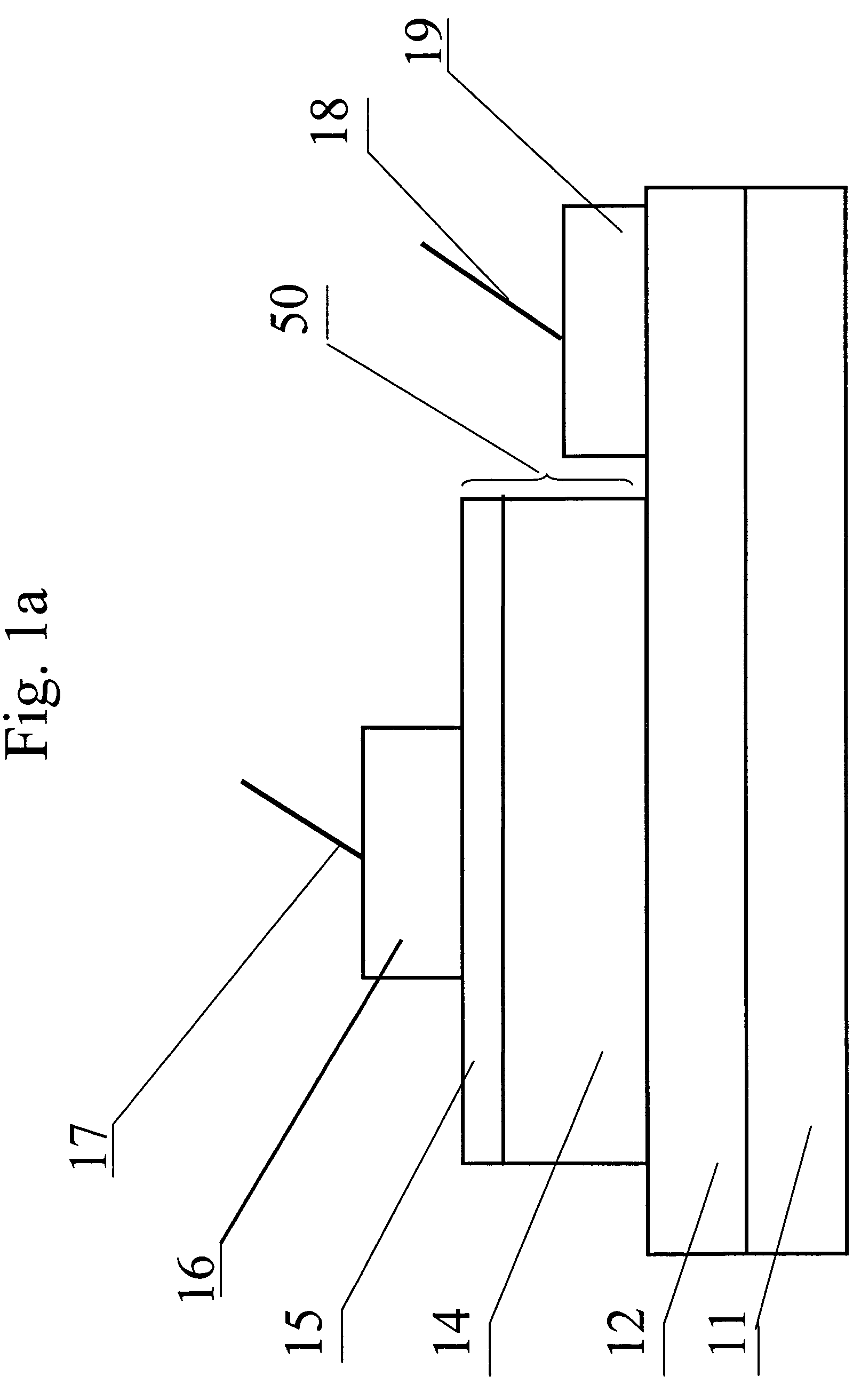

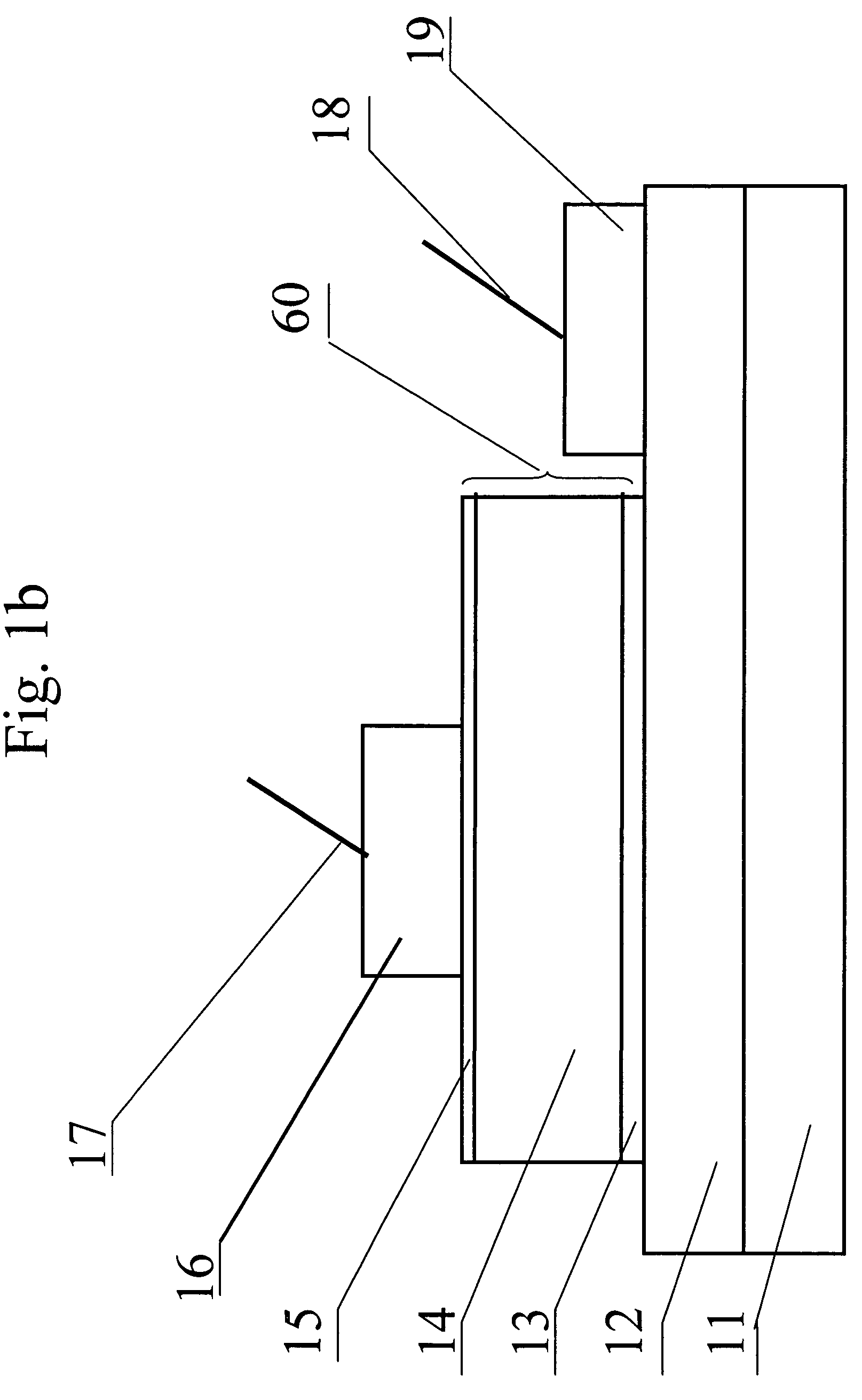

The invention relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell is composed of an FTO glass substrate, a sandwich structure TiO2 / ZnO / TiO2 compact layer, a TiO2 mesoporous / perovskite structure material active light absorption layer, a spiro-OMeTAD hole transferring layer and a gold electrode. Compared with the prior art, the sandwich structure TiO2 / ZnO / TiO2 compact layer combines with the advantages and disadvantages of TiO2 and ZnO, so that fill factors of the perovskite solar cell are improved to 70%, and the photoelectric conversion efficiency reaches 12.6%. Equipment for preparing the perovskite solar cell is simple, the preparing process is simple, control is easy, the cost is low, and the perovskite solar cell has a very good industrial application prospect.

Owner:HUBEI UNIV

Switchable resistive perovskite microelectronic device with multi-layer thin film structure

ActiveUS7608467B2Reduce voltageImprove configurationSemiconductor/solid-state device manufacturingDigital storageElectrical resistance and conductanceMagnification

A switchable resistive device has a multi-layer thin film structure interposed between an upper conductive electrode and a lower conductive electrode. The multi-layer thin film structure comprises a perovskite layer with one buffer layer on one side of the perovskite layer, or a perovskite layer with buffer layers on both sides of the perovskite layer. Reversible resistance changes are induced in the device under applied electrical pulses. The resistance changes of the device are retained after applied electric pulses. The functions of the buffer layer(s) added to the device include magnification of the resistance switching region, reduction of the pulse voltage needed to switch the device, protection of the device from being damaged by a large pulse shock, improvement of the temperature and radiation properties, and increased stability of the device allowing for multivalued memory applications.

Owner:UNIV HOUSTON SYST

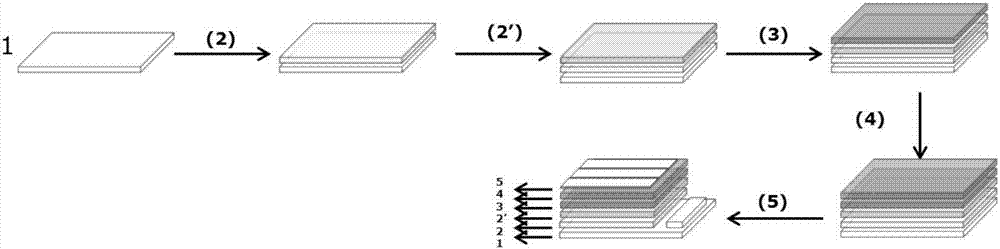

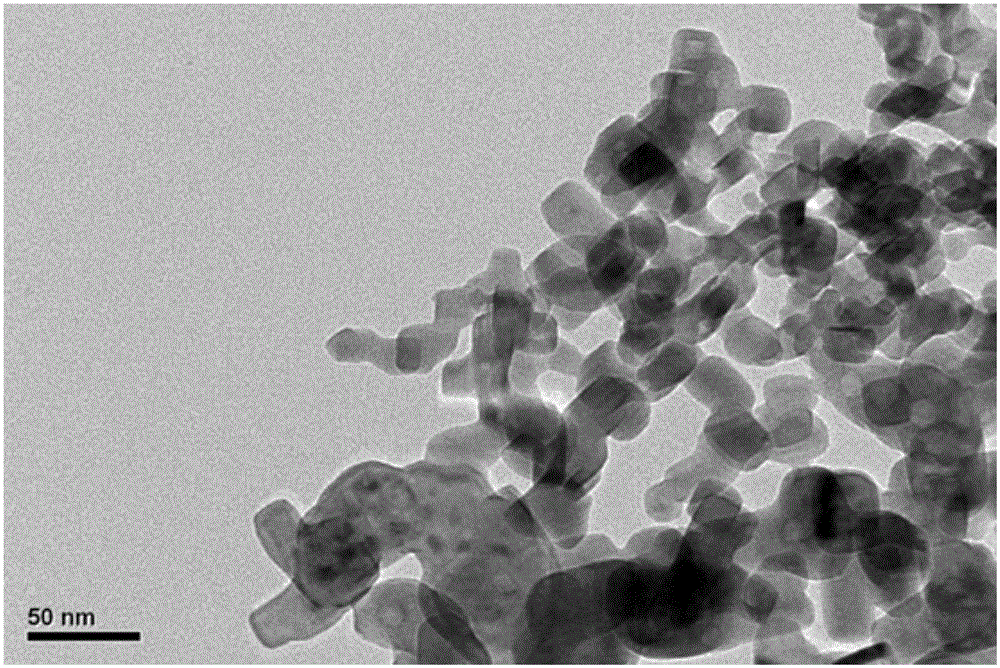

Perovskite solar cell and preparation method of perovskite solar cell by solution method

ActiveCN104134711AImprove production efficiencyEase of mass productionFinal product manufacturePhotovoltaic energy generationPerovskite solar cellNanoparticle

The invention discloses a perovskite solar cell and a preparation method of the perovskite solar cell by a solution method. The perovskite solar cell comprises a substrate, a transparent electrode, an electron transfer layer, a light absorption layer, a hole transfer layer and a top electrode which are sequentially laminated, wherein the light absorption layer is a photovoltaic material light absorption layer in a perovskite structure. The electron transfer layer, the perovskite material light absorption layer and the hole transfer layer can be prepared by the solution method in a low-temperature (below 200 DEG C) air environment, and particularly, the electron transfer layer does not require nano particles treated or synthetized at a high temperature (above 450 DEG C), so that a technological process can be simplified, the cost is lowered, the preparation efficiency of the cell is improved, and mass production is achieved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

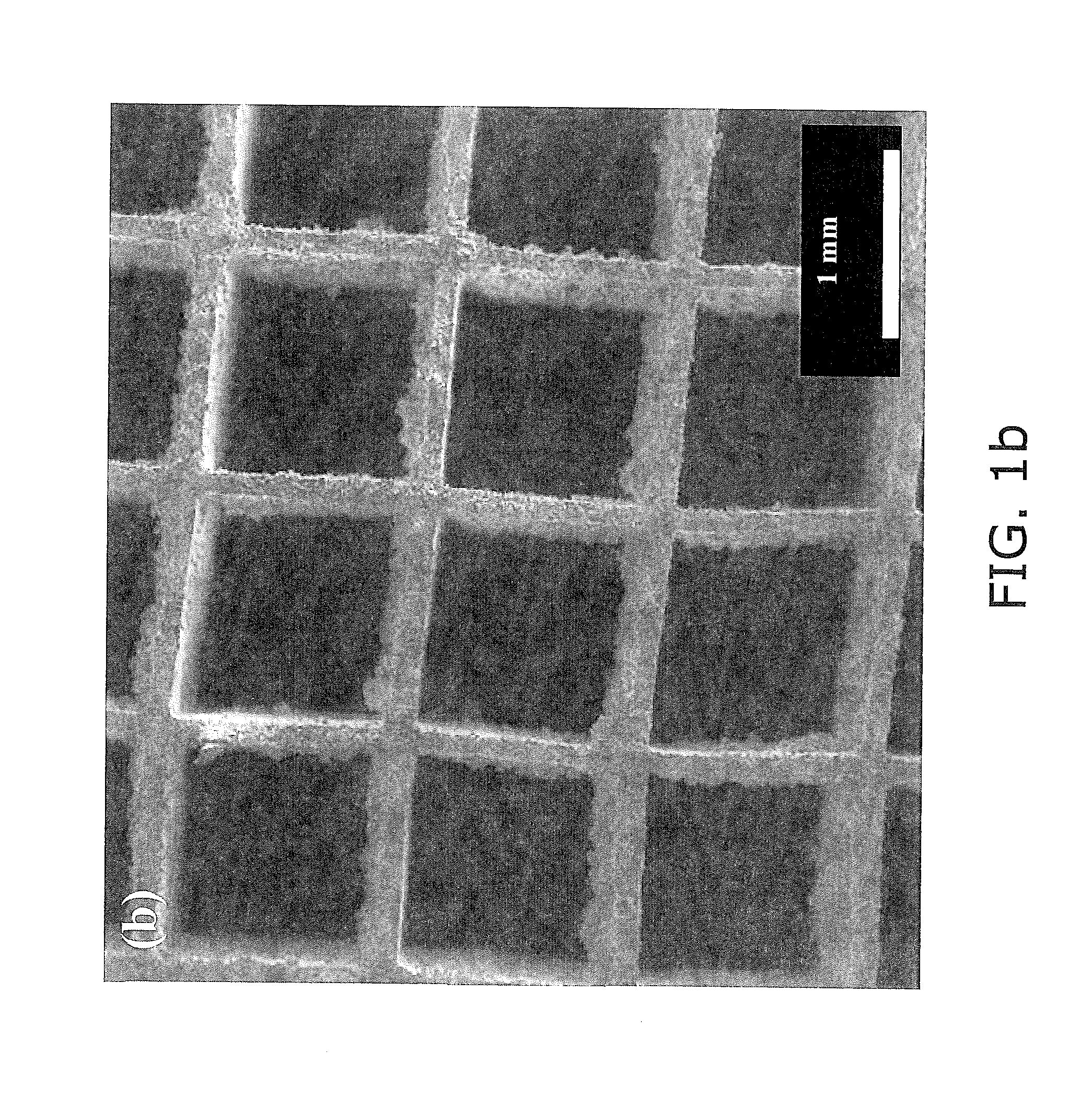

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

Electrically programmable nonvolatile variable capacitor

A basic form of a variable capacitive apparatus and its actuating method are disclosed. The apparatus is a simple two-terminal structure and may be set by short duration, low voltage electrical pulses. Materials with perovskite structure or perovskite-related structures, especially colossal magnetoresistive materials, are the active constituents of the apparatus. The apparatus overcomes the shortcomings of its predecessors and offers the advantages of non-volatility, two or multi-level storage, non-destructive reading, free-of-power maintenance and potential high radiation hardness.

Owner:UNIV HOUSTON SYST

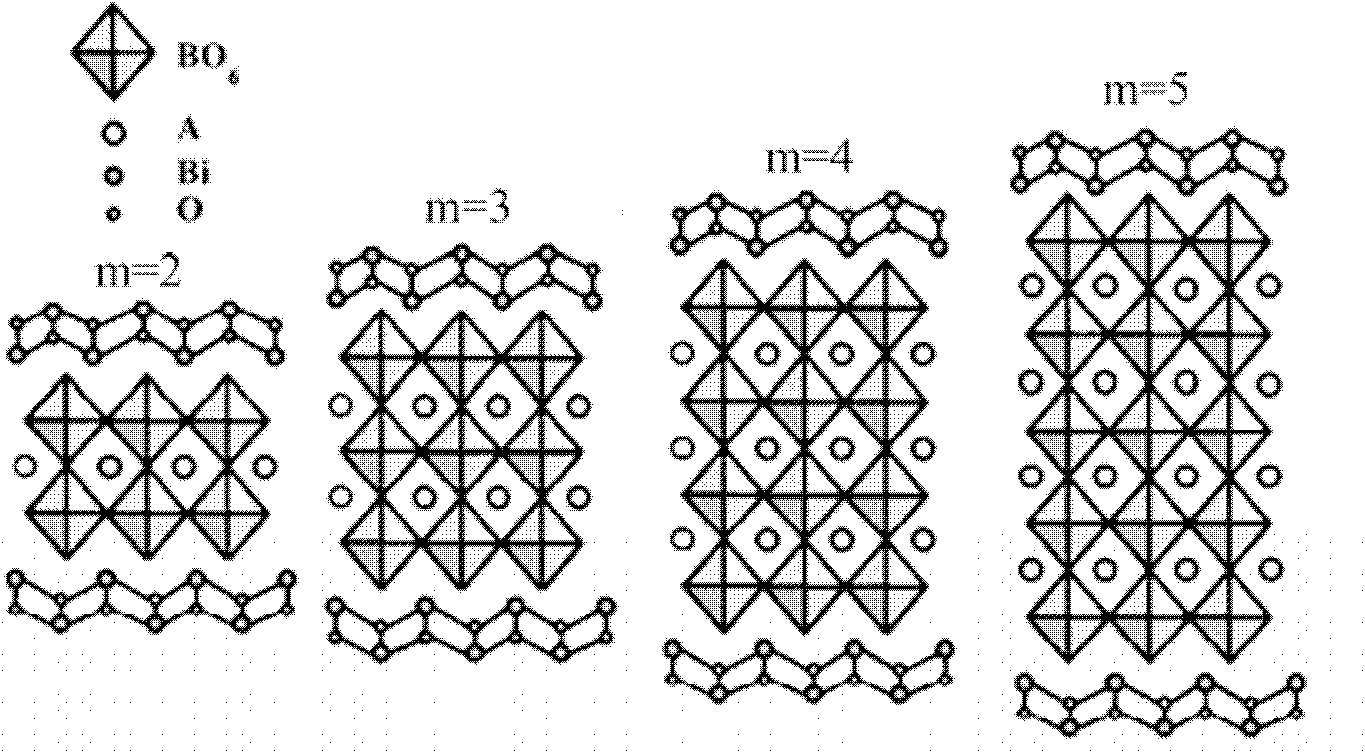

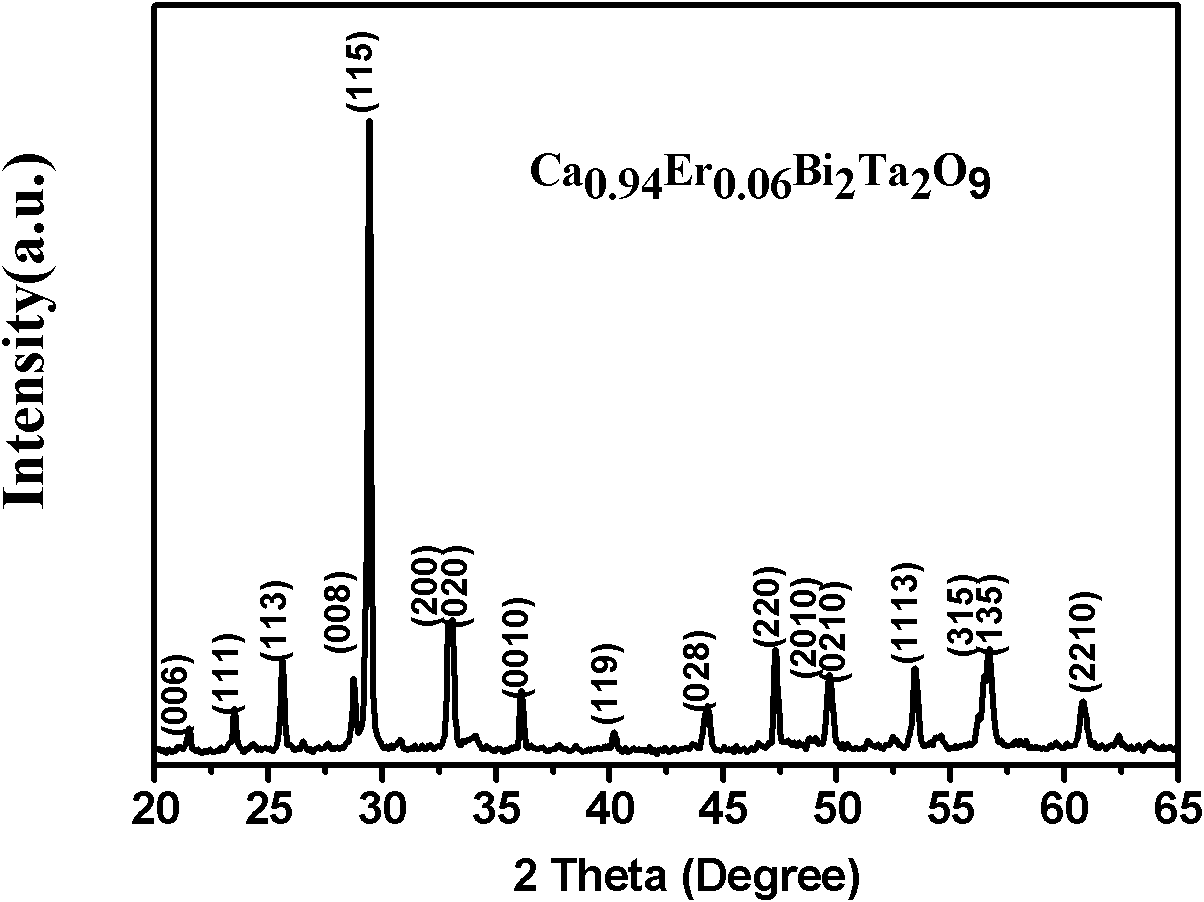

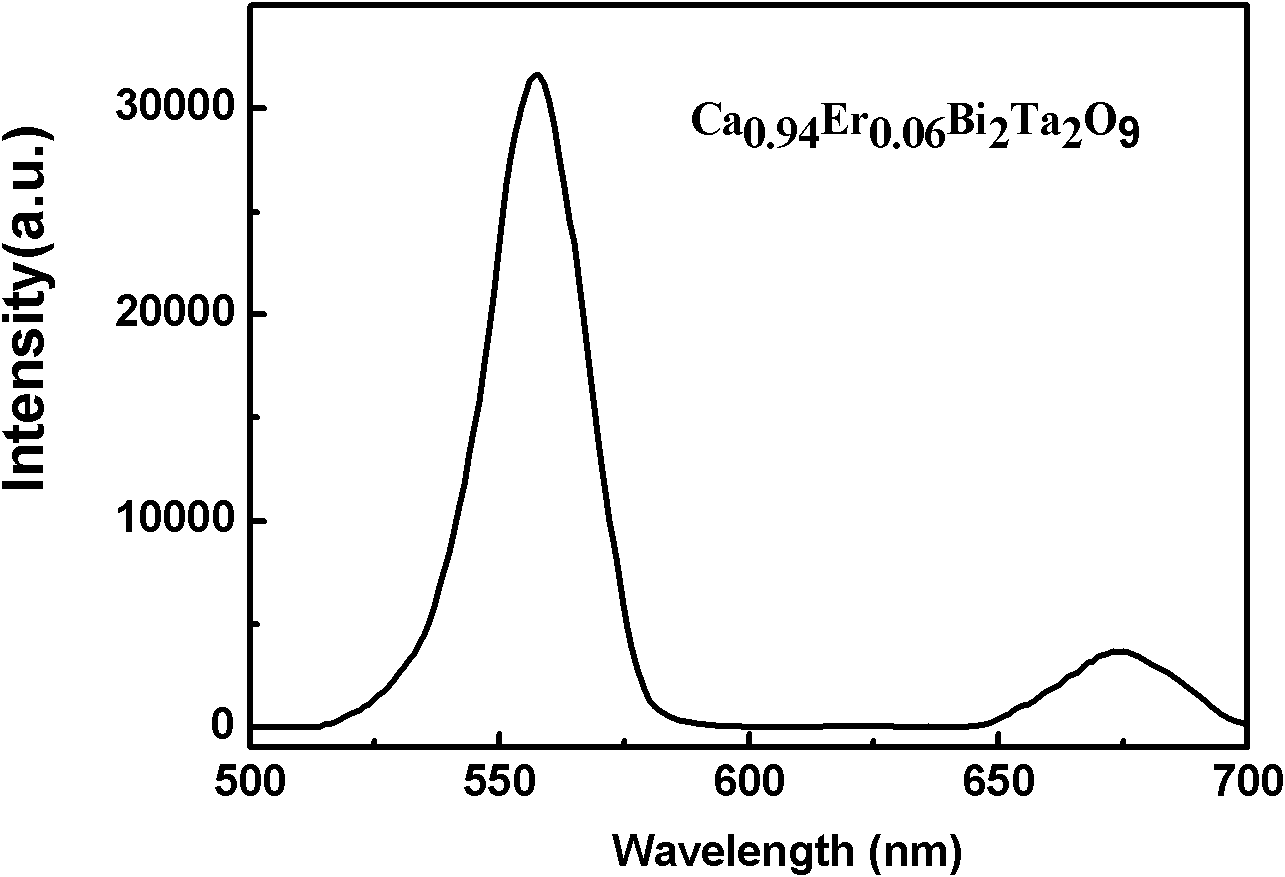

Bismuth layered perovskite-like structure oxide up-conversion luminescent piezoelectric material and preparation method thereof

InactiveCN102276248AHigh emission intensityThe synthesis process is simpleChemistryThree dimensional display

The invention relates to an infrared-excited oxide up-conversion luminescence piezoelectric material of a bismuth lamellar perovskite-like structure and a preparation method thereof. The up-conversion luminescence piezoelectric material has a chemical general formula of Am-1-x-RxYbyBi2BmO3M<+3>, wherein R is selected from Er<3+>, Ho<3+> and Tm<3+>, A is selected from Bi<3>, Ca<2+>, Sr<2+>, Ba<2+>, Pb<2+>, Na<+>, K<+>, La<3+> and Y<3+>, B is selected from Ti<4+>, Zr<4+>, Nb<5+>, Ta<5+>, W<6+> and Mo<6+>, m is a positive integer not smaller than 2 and not more than 8, x is not smaller than 0.000001 and not more than 0.3, and y is not smaller than 3.0 and not more than 0.6. The up-conversion luminescence piezoelectric material is prepared by adopting a solid-phase reaction method, has the characteristics of good thermal stability, good chemical stability, easiness for synthesis, high luminous intensity and adjustable color, and can be widely applied to various aspects such as three-dimensional display, infrared detection, counterfeiting prevention, solar cells and photoelectric integration, micro-electro-mechanical systems, photoelectric sensing and the like.

Owner:TONGJI UNIV

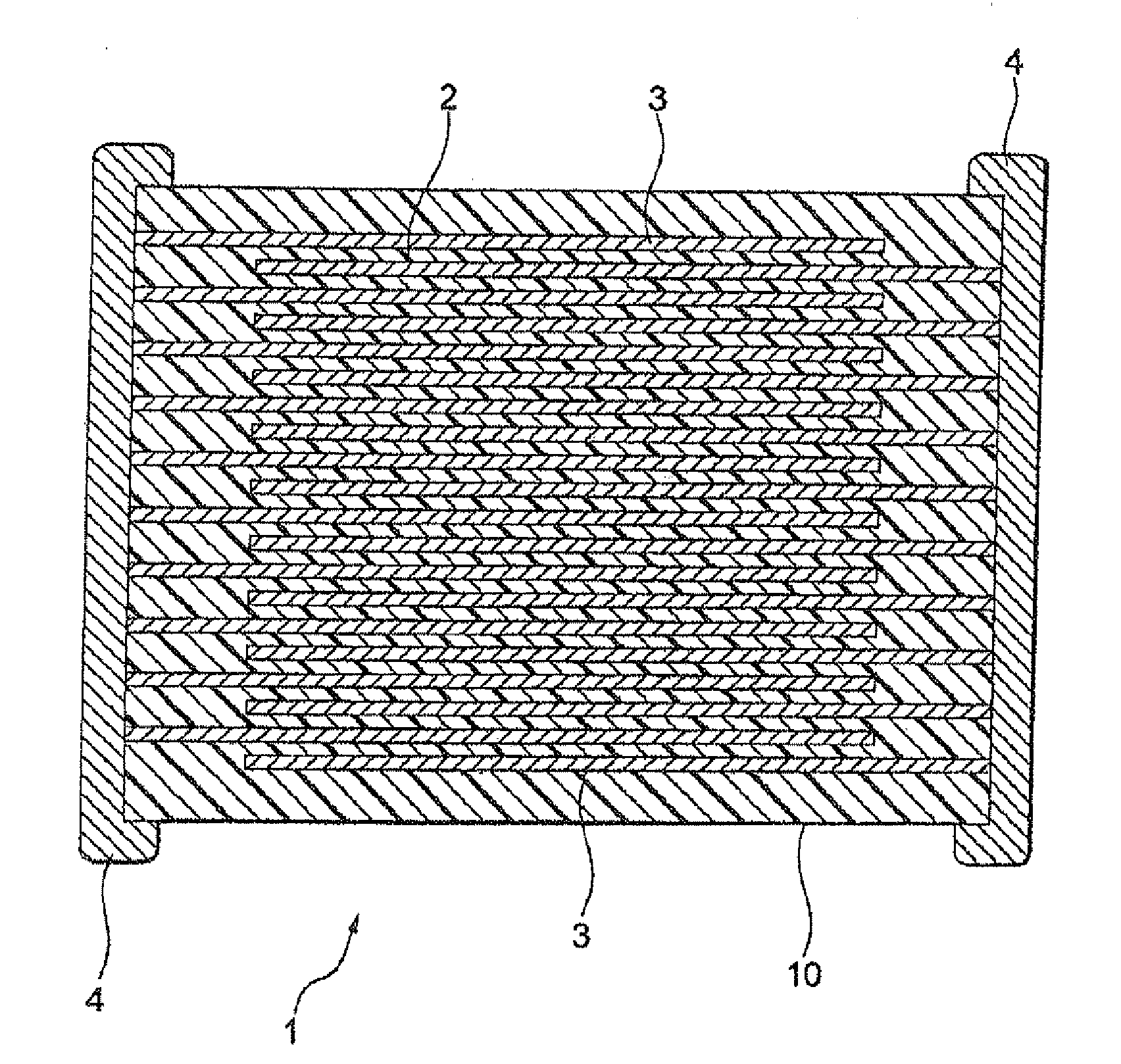

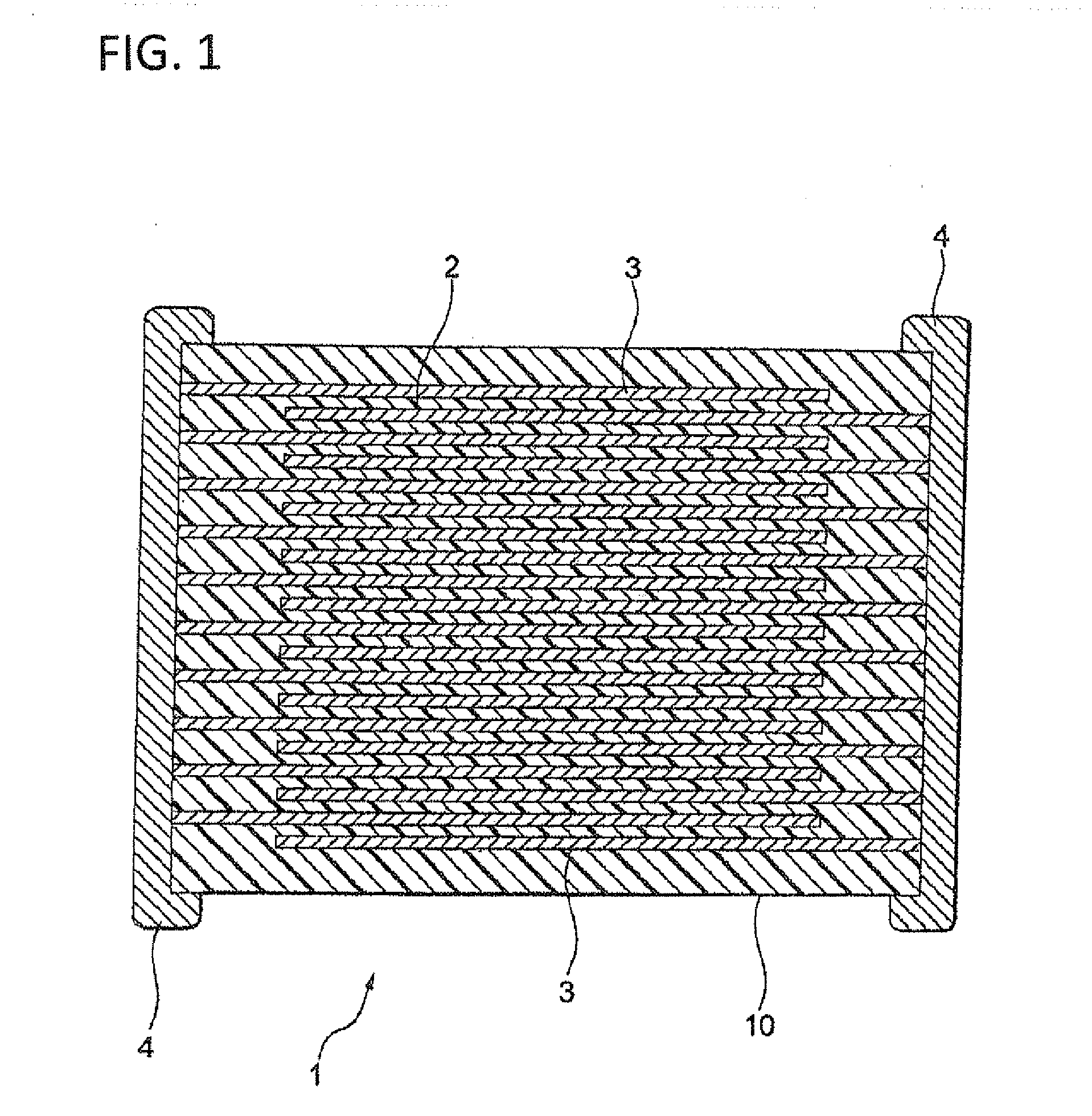

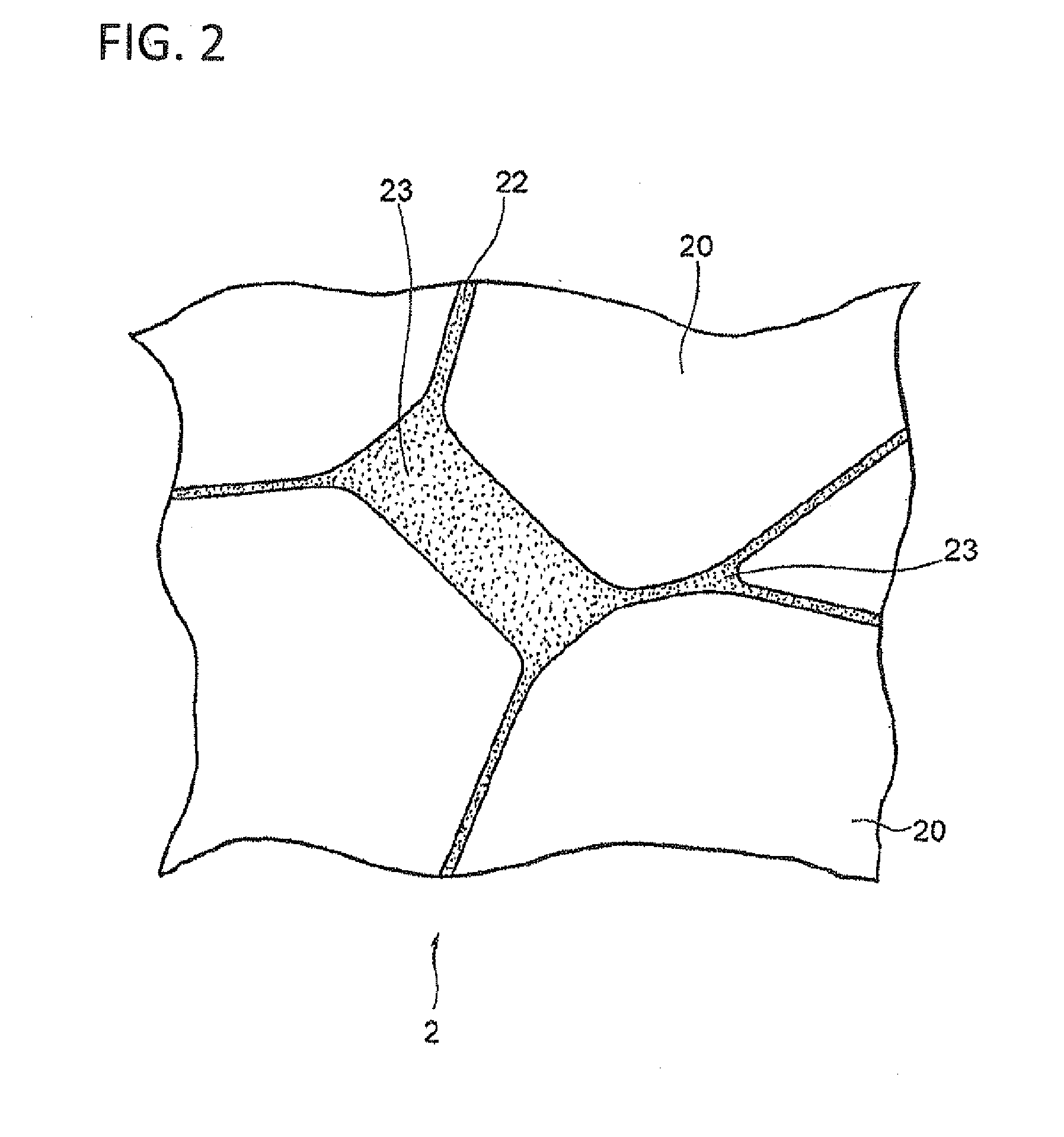

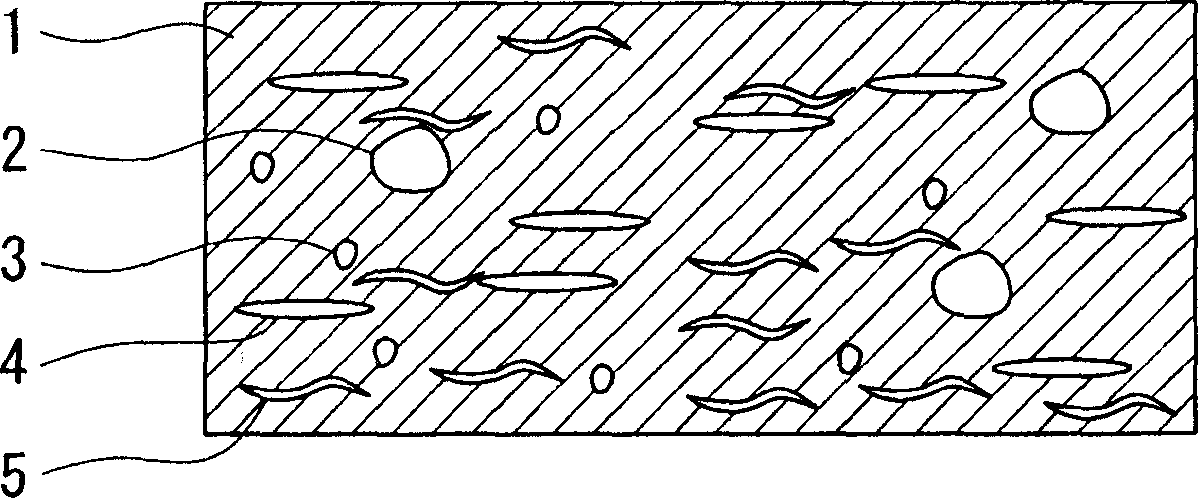

Laminated type ceramic electronic parts

ActiveUS20120162858A1Good effectImprove featuresFixed capacitor dielectricStacked capacitorsRare-earth elementElectronic component

A multilayer ceramic electronic component comprising an element body in which a dielectric layer and an internal electrode layer are stacked. The dielectric layer is constituted from a dielectric ceramic composition including; a compound having a perovskite structure expressed by a formula of ABO3 (A is at least one selected from Ba, Ca, and Sr; B is at least one selected from Ti, Zr, and Hf); an oxide of Mg; an oxide of rare earth elements including Sc and Y; and an oxide including Si. The dielectric ceramic composition comprises a plurality of dielectric particles and a grain boundary present in between the dielectric particles. In the grain boundary, when content ratios of Mg and Si are set to D(Mg) and D(Si) respectively, D(Mg) is 0.2 to 1.8 wt % in terms of MgO, and D(Si) is 0.4 to 8.0 wt % in terms of SiO2.

Owner:TDK CORPARATION

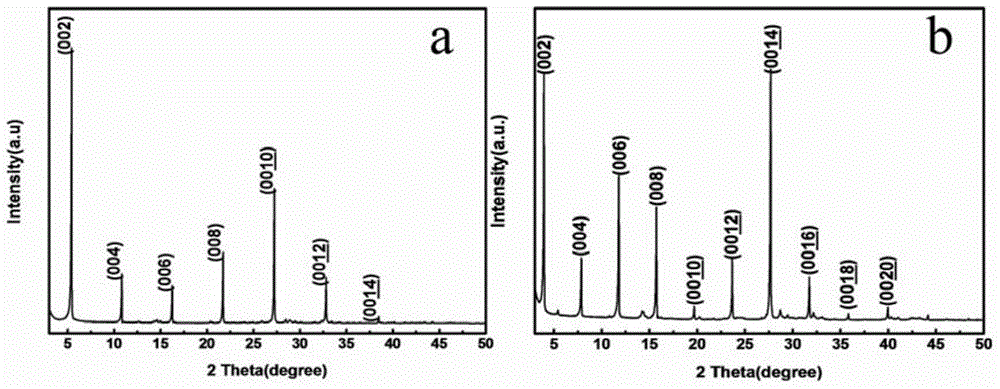

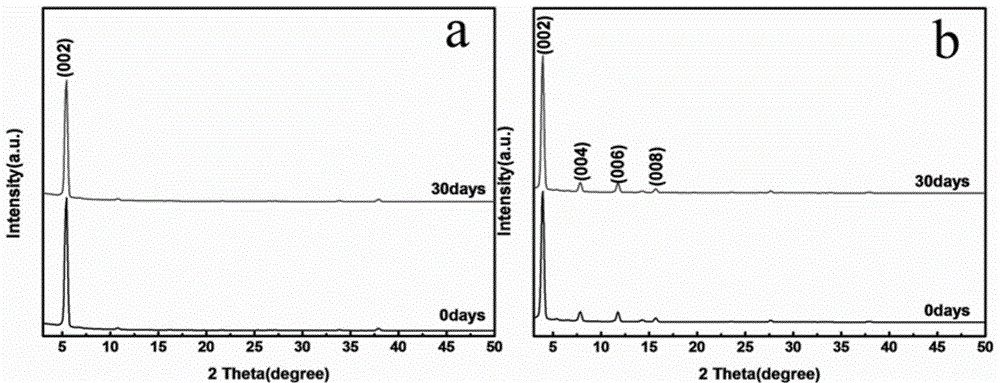

Perovskite solar cell and method for manufacturing same

InactiveCN104795501ASimple and fast operationLow costFinal product manufactureSolid-state devicesHole transport layerMetal electrodes

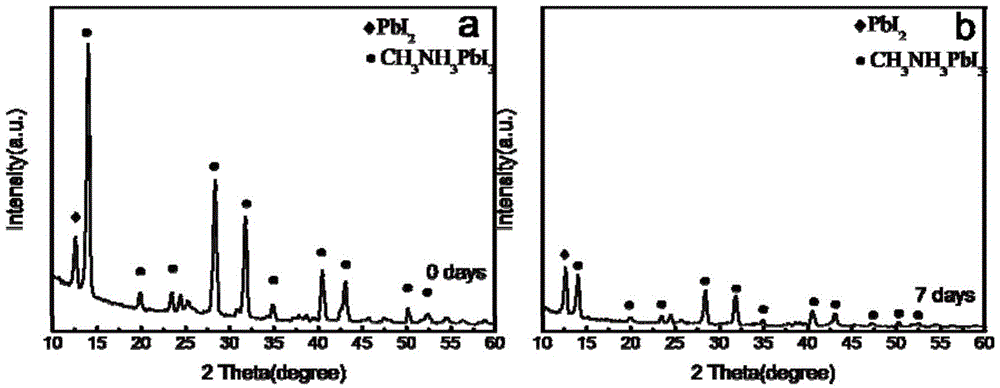

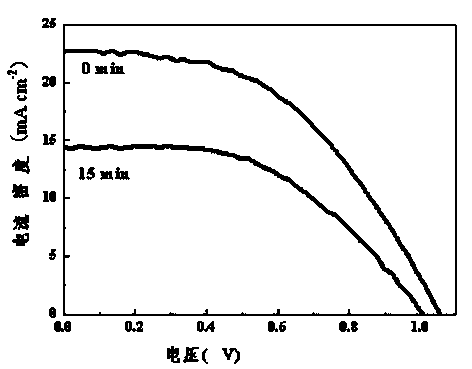

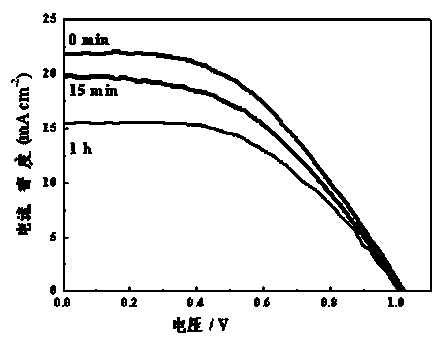

The invention relates to a perovskite solar cell and a method for manufacturing the same. The perovskite solar cell comprises an FTO (fluorine-doped tin oxide) transparent conducting glass substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. The light absorption layer is made of (C<6>H<5>CH<2>CH<2>NH<3>)<2>(CH<3>NH<3>)<n-1>Pb<n>I<3*n+1> (the n is equal to 1 or 2) materials which are of two-dimensional layered structures. The perovskite solar cell and the method have the advantages that the layered perovskite light absorption layer is manufactured by the aid of a spin coating process, the method is simple and is excellent in film-forming property, the materials of the light absorption layer can be changed along with the layer number n, gaps of the materials can be adjusted, and the materials are excellent in chemical stability and still can keep the excellent layered structures without chemical decomposition after being exposed at high air humidity (50-80%) for 30 days, solar cell prototype devices with excellent and stable performance can be obtained, and the perovskite solar cell and the method are favorable for promoting perovskite solar cell commercialization progress.

Owner:WUHAN UNIV OF TECH

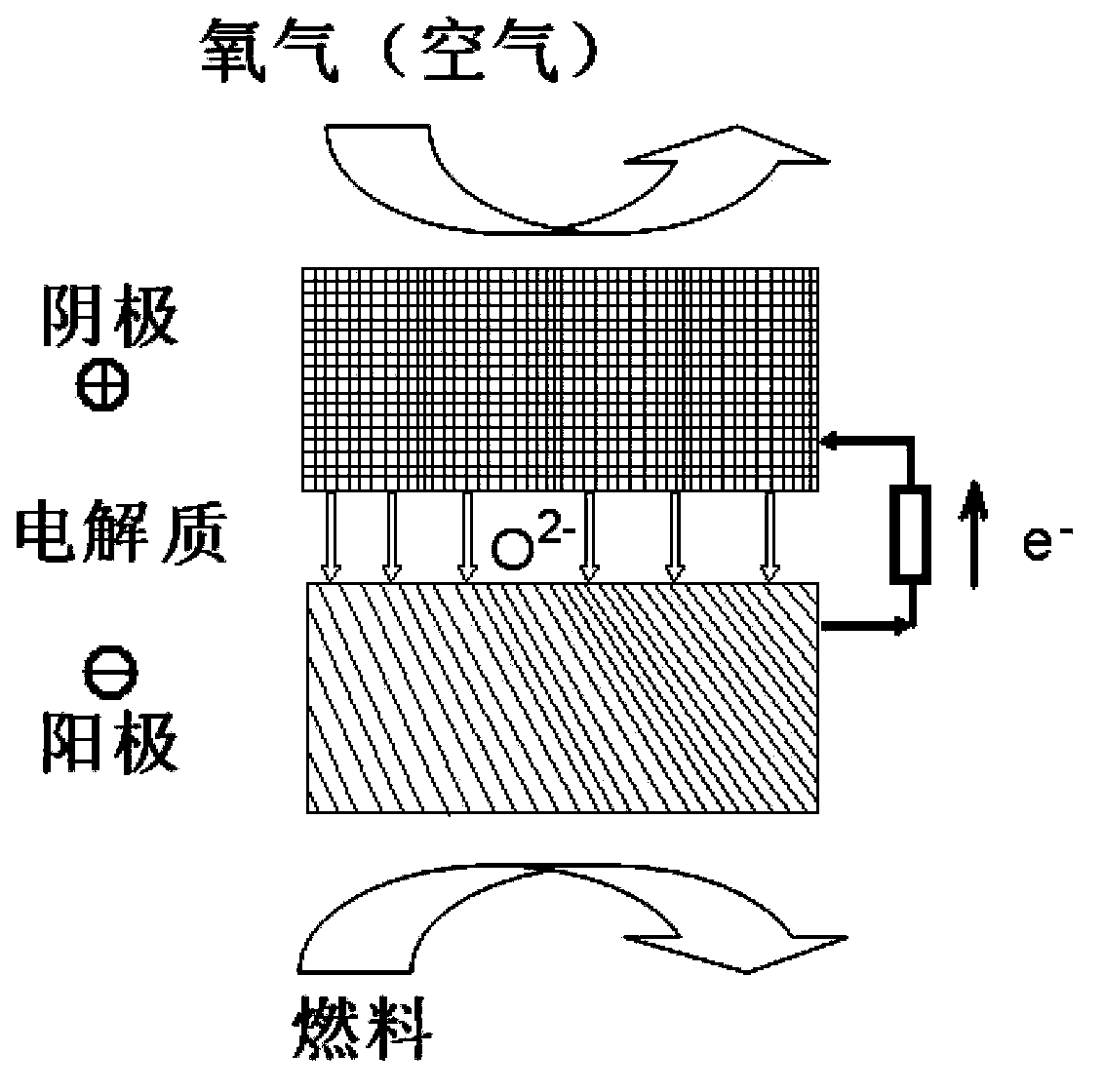

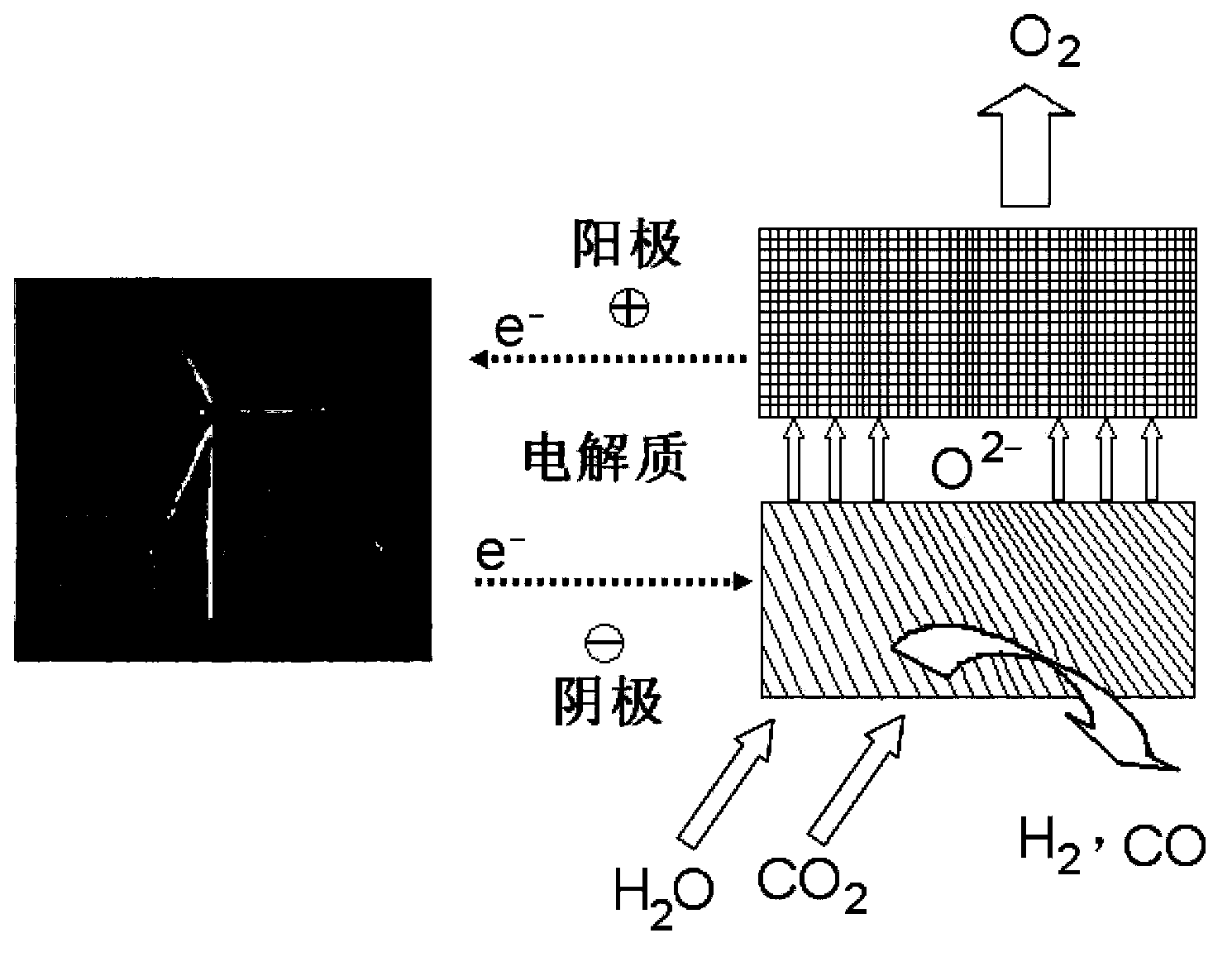

Composite material containing perovskite structure oxide, preparation method and application thereof

The invention provides a composite material containing a perovskite structure oxide, a preparation method and application thereof. The composite material contains, by weight, 20%-99.99% of the perovskite structure oxide and 0.01%-80% of an oxygen ion conductor oxide. According to the invention, a sol-gel method can be employed to prepare the perovskite structure oxide, a combustion method can be employed to prepare the oxygen ion conductor oxide, and then the perovskite structure oxide and the oxygen ion conductor oxide can be mixed uniformly by means of ball milling or mechanical grinding, thus obtaining the composite material. The invention also relates to application of the composite material in solid oxide fuel cells and solid oxide electrolysis cells.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

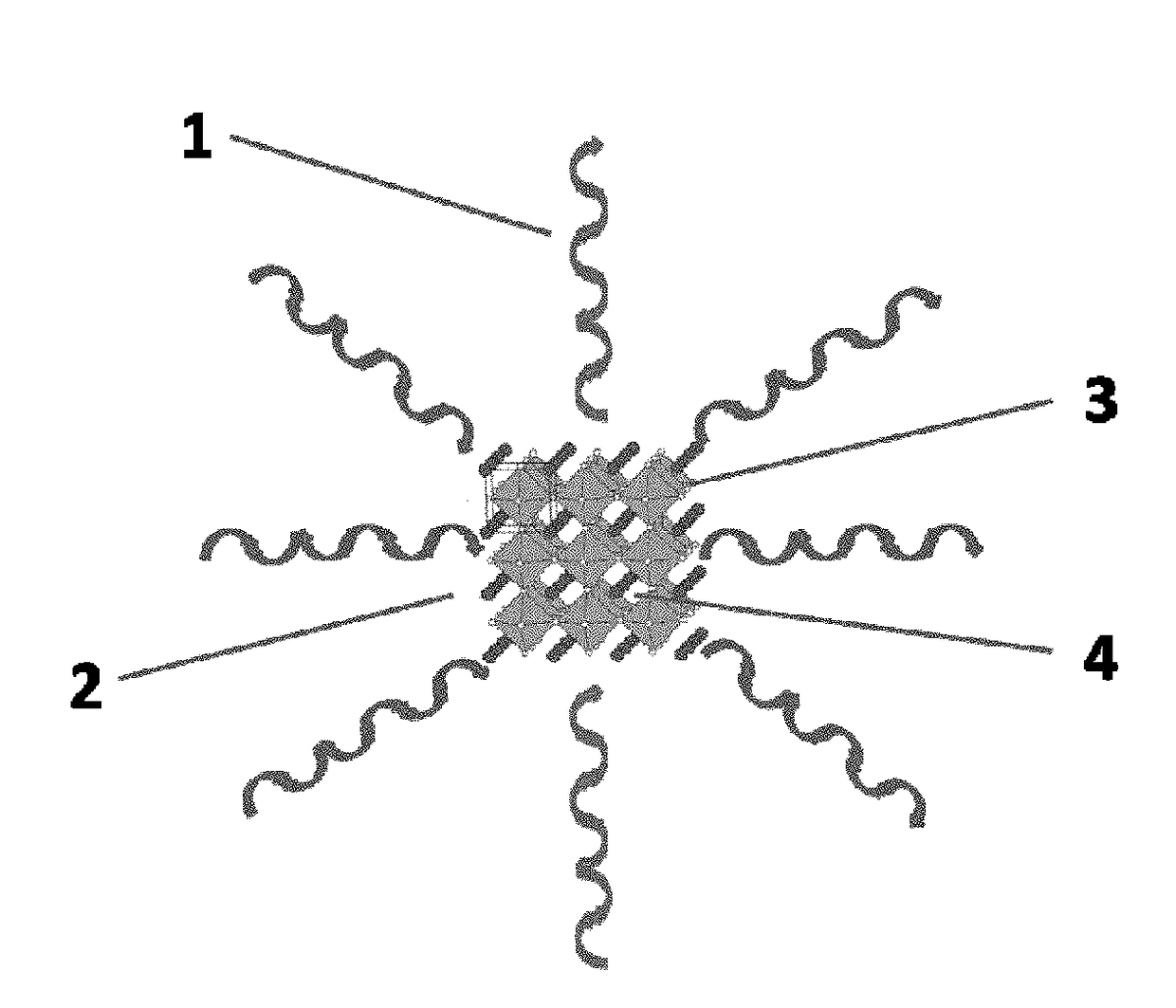

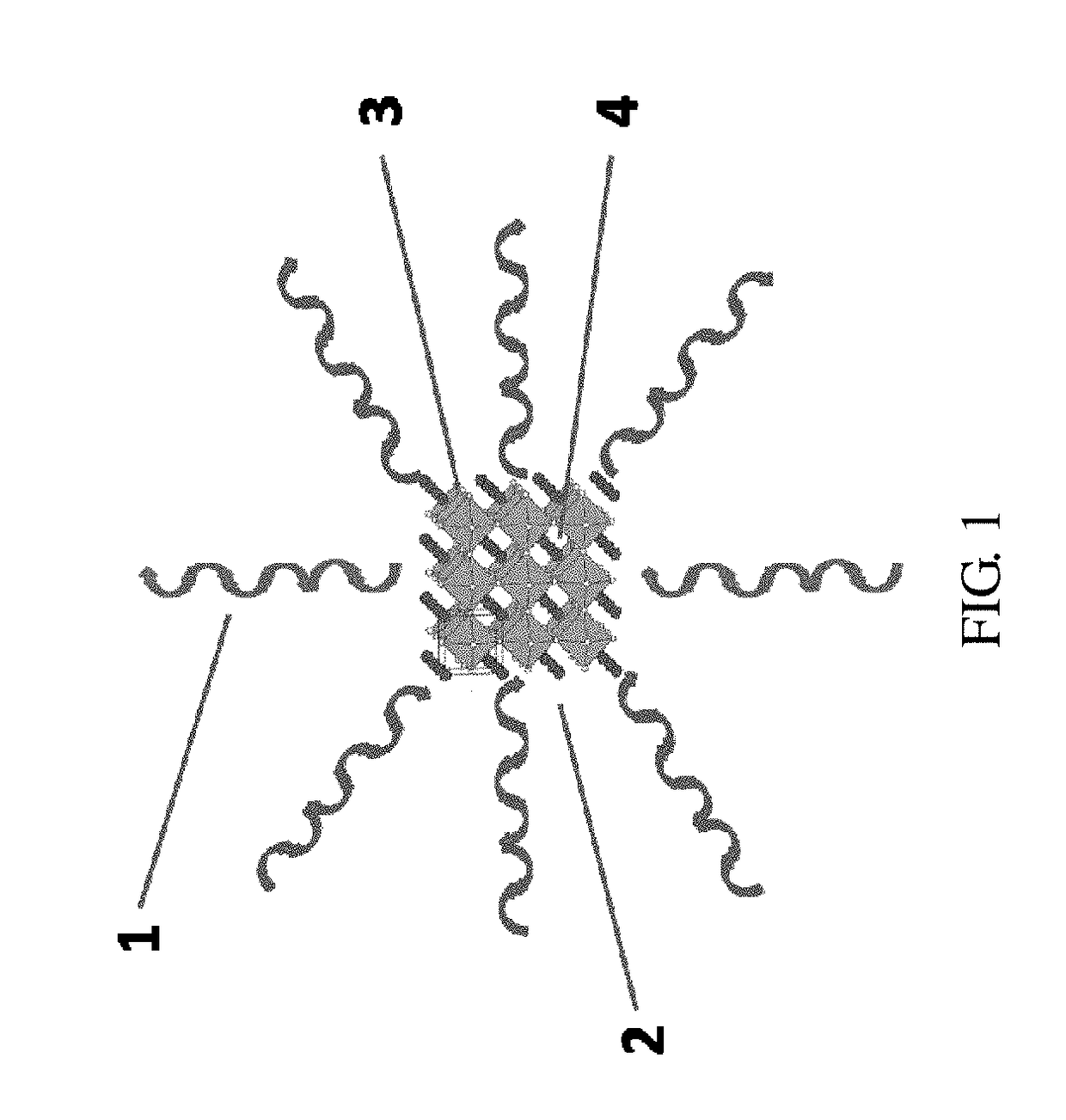

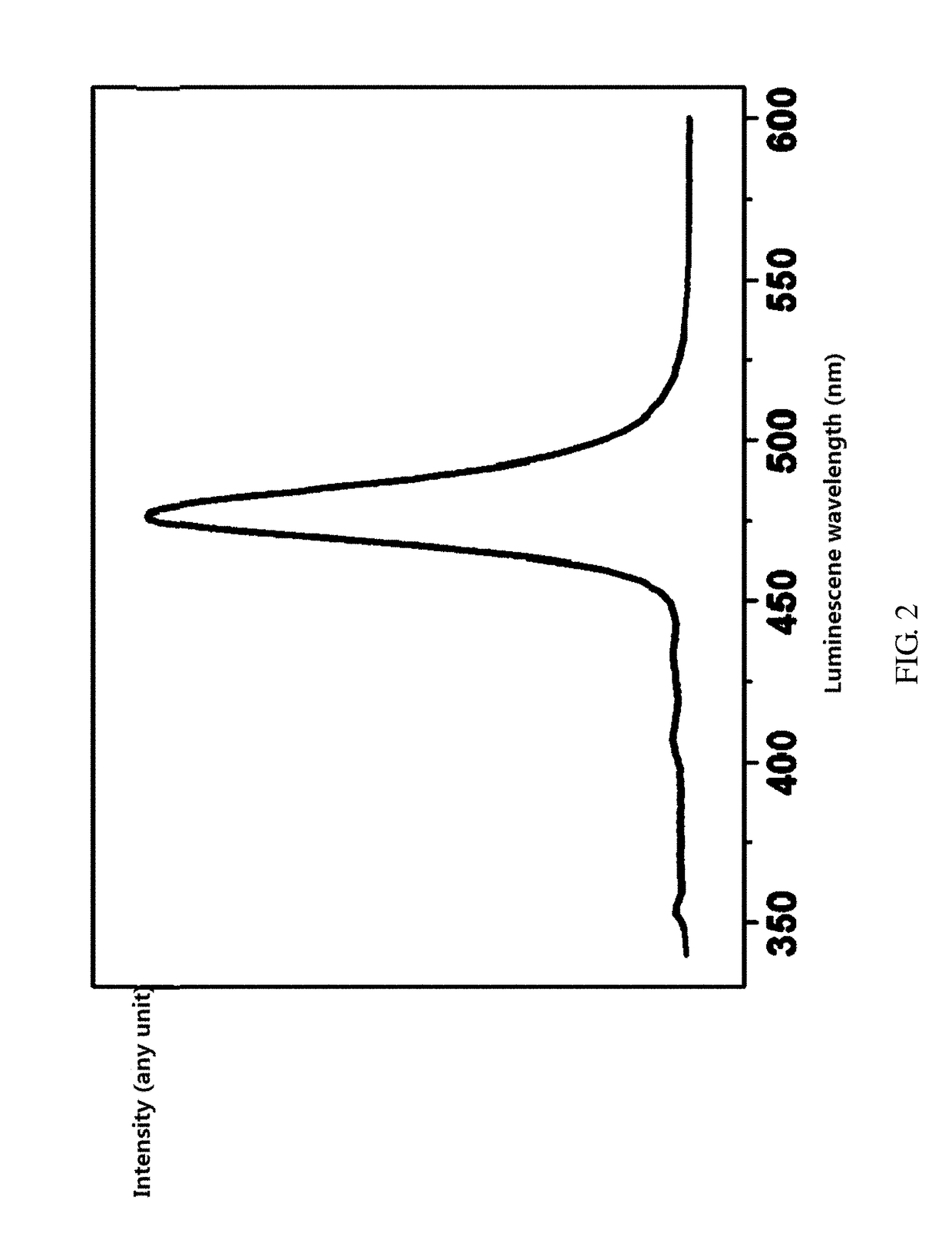

Perovskite quantum dot material and preparation method thereof

ActiveUS20170233645A1Reasonable structureMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidQuantum yield

Provided is a hybridized perovskite quantum dot material. The quantum dot material comprises a kernel and surface ligands. The kernel is formed by R1NH3AB3 or (R2NH3)2AB4, where R1 is methyl group, R2 is an organic molecular group, A is at least one selected from Ge, Sn, Pb, Sb, Bi, Cu and Mn, B is at least one selected from Cl, Br and I, A and B form a coordination octahedral structure, and R1NH3 or R2NH3 is filled in gaps of the coordination octahedral structure. The surface ligand is an organic acid or organic amine. The quantum dot material has a high fluorescence quantum yield.

Owner:SHENZHEN TCL NEW-TECH CO LTD

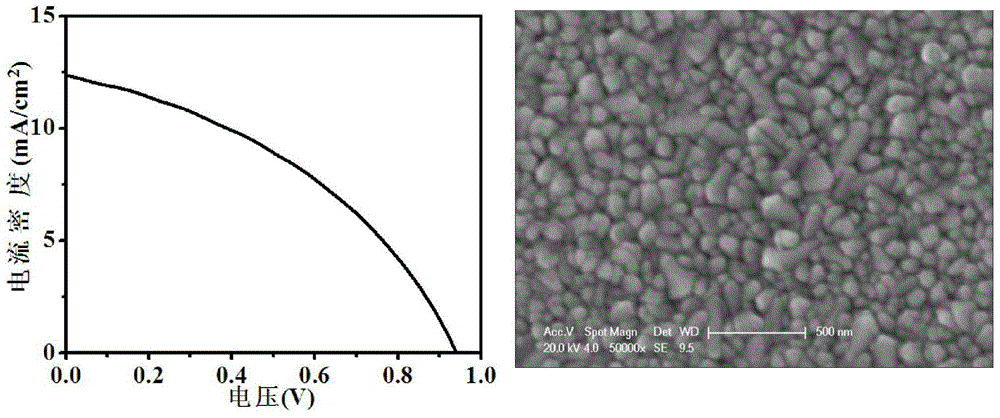

Perovskite thin-film photovoltaic cell and manufacturing method thereof

ActiveCN103872248ASimple structureReduce manufacturing costFinal product manufactureSolid-state devicesMetallic electrodeManufacturing technology

The invention relates to a perovskite thin-film photovoltaic cell and a manufacturing method of the perovskite thin-film photovoltaic cell. The perovskite thin-film photovoltaic cell is composed of a conducting transparent substrate, a perovskite light-absorbing layer, a hole transfer layer and a metal electrode. The perovskite thin-film photovoltaic cell has the advantages that the structure is quite simple, a traditional electron transfer layer which needs high-temperature sintering is omitted due to the fact that a perovskite material serves as the light-absorbing layer and achieves the electron transfer function, and a porous layer is not needed either; the perovskite material is high in light-absorbing performance, the whole cell is manufactured at a low temperature, the complicated processes such as high-temperature sintering are not needed, and therefore the manufacturing cost of the cell is effectively reduced; the great promotion function is achieved on the flexibility of the cell and the large-sized reel-to-reel printing manufacturing of the cell; the whole manufacturing technology of the cell is simple, the popularization of the technology is facilitated, high photoelectric converting efficiency (approximate to 14 percent) and good device stability are obtained particularly, and therefore the industrial application prospect is achieved.

Owner:WUHAN UNIV

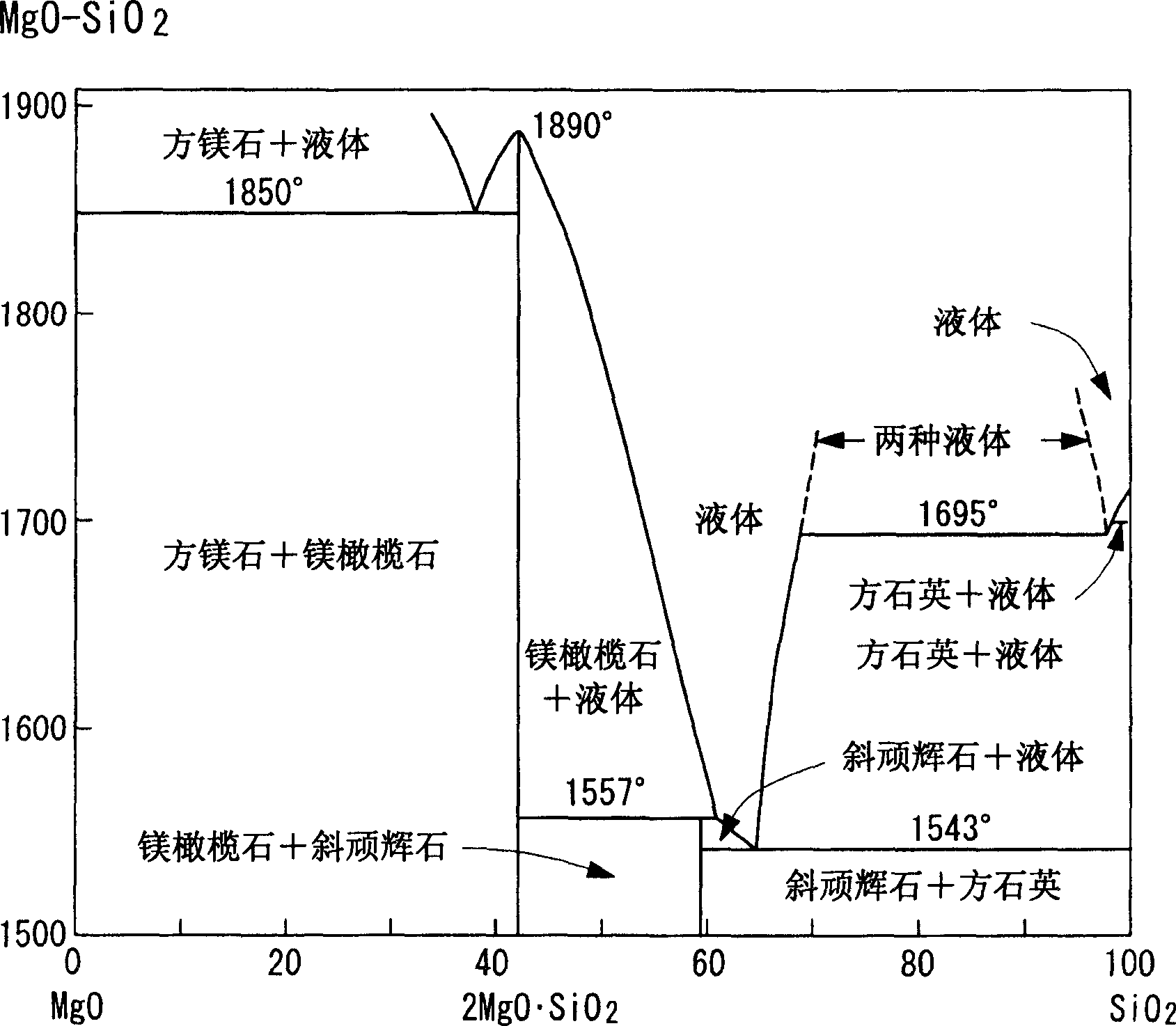

Material for thermal barrier coating

InactiveCN1764613AImprove efficiencyReduce weightMolten spray coatingEfficient propulsion technologiesCrystal structureThermal expansion

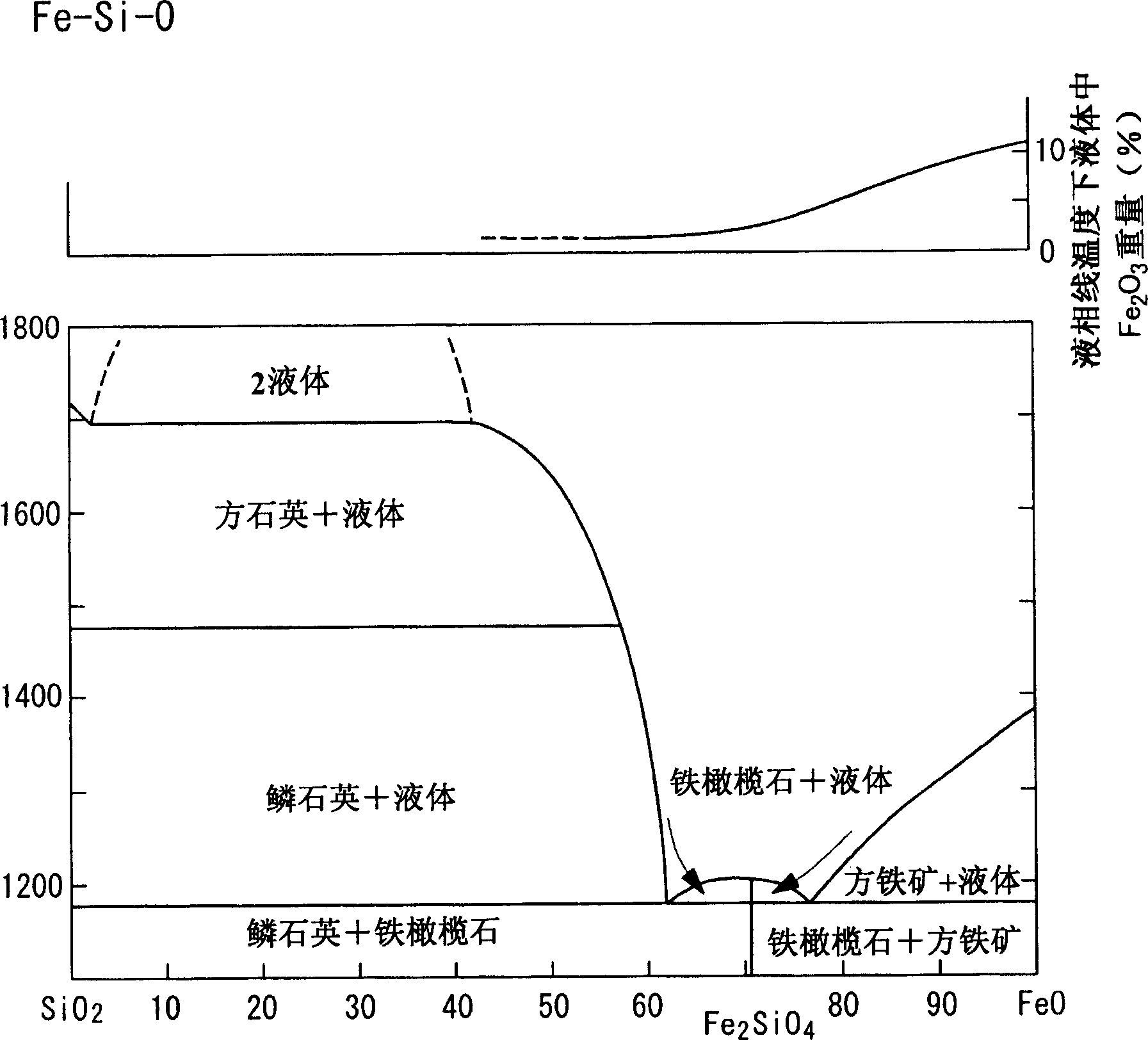

The invention provides a novel thermal insulation coating material with no phase transfer problem, a melting point higher than the working temperature range, a thermal conductivity lower than that of zirconia, and a thermal expansion rate higher than that of zirconia. The thermal barrier coating material has an orthorhombic or monoclinic crystal structure derived from perovskite (for example, a platy perovskite structure represented by the composition formula A2B2O7), or a c-axis / a-axis ratio of 3 or more The composition of the tetragonal layered structure (such as K2NiF4 structure and Sr3Ti2O7 structure, Sr4Ti3O10 structure), and the composition represented by the composition formula LaTaO4, and the composition with the composition formula M2SiO4 or (MM') 2SiO4 (wherein M, M 'is a divalent metal element) composition of the olivine structure represented as the main body.

Owner:MITSUBISHI HEAVY IND LTD

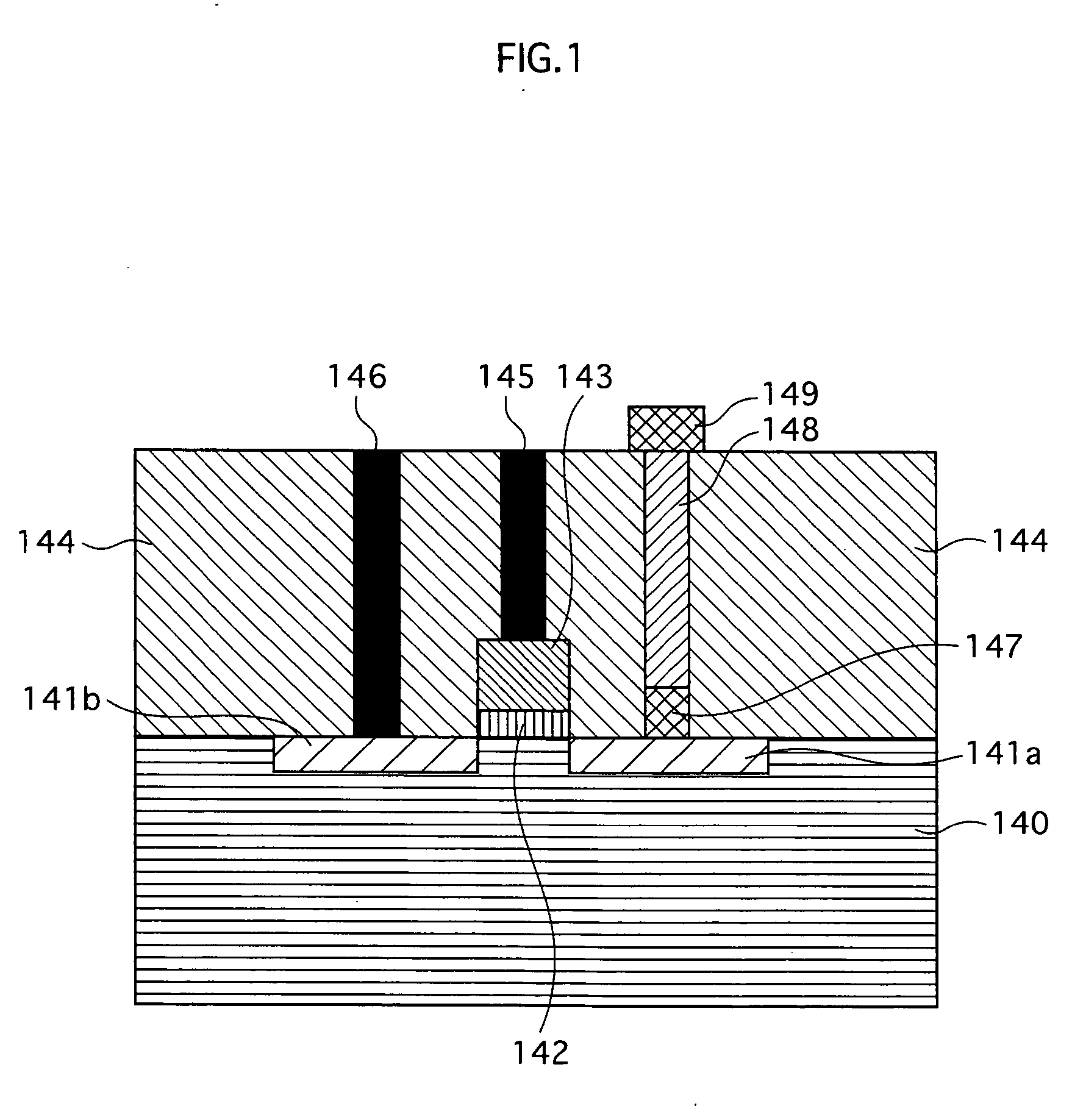

Piezoelectric thin film elemental device

ActiveUS20090302715A1Excellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesIn planeOptoelectronics

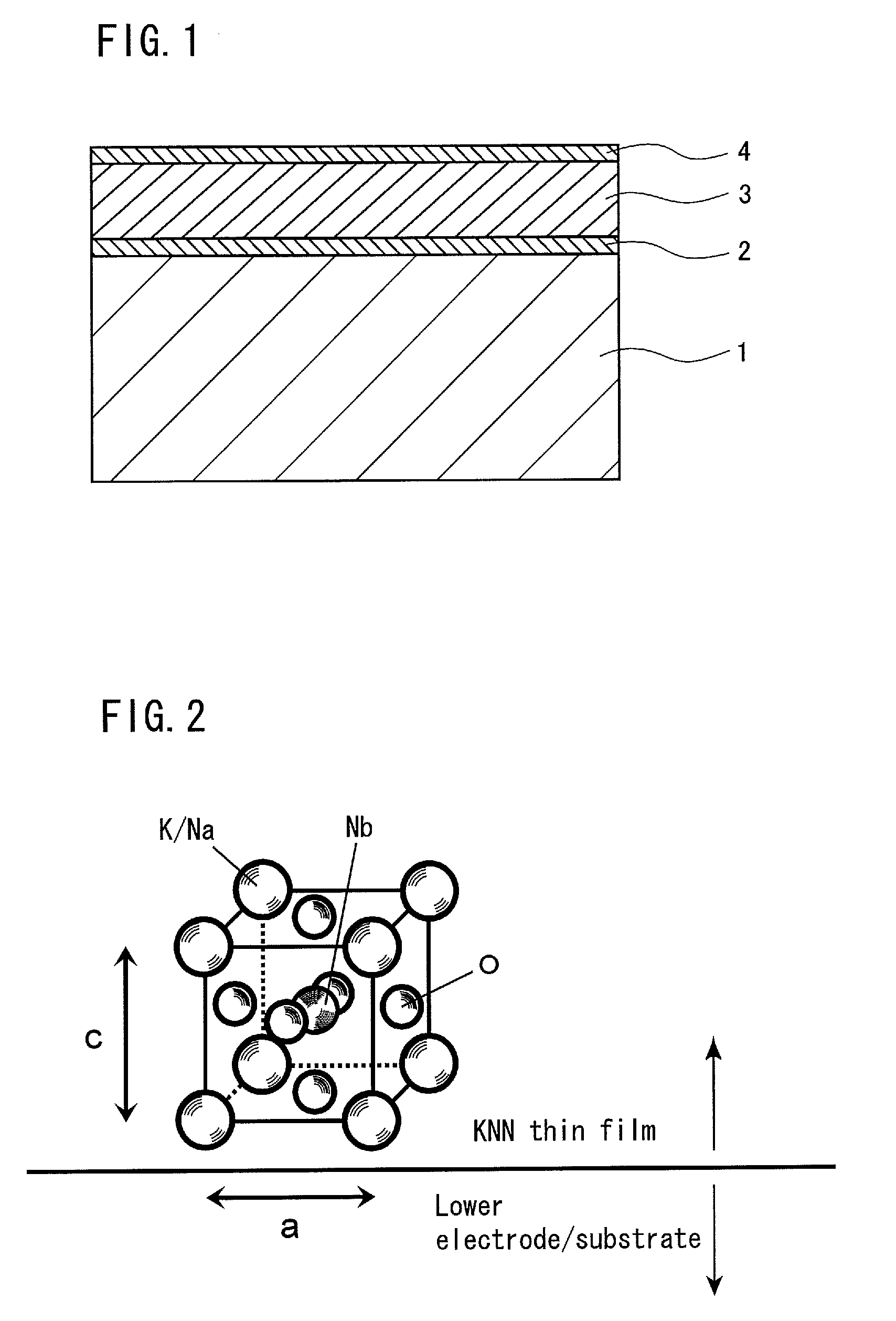

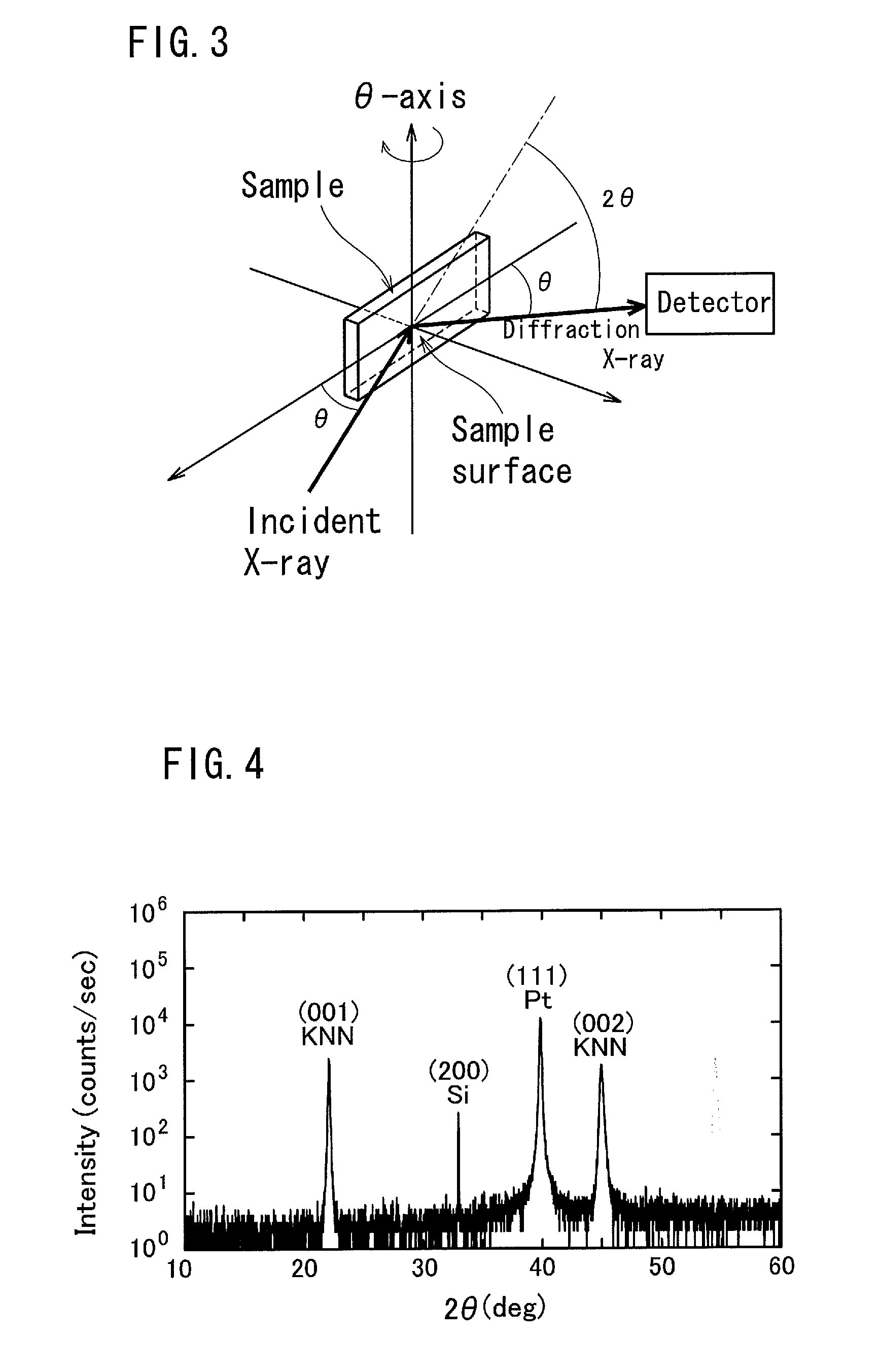

A piezoelectric thin film elemental device has a lower electrode, a piezoelectric thin film, and an upper electrode. The piezoelectric thin film has a thin film of a perovskite structure, expressed by a compositional formula (K1−xNax)NbO3 (0<x<1), and a c / a ratio of an out-of-plane directional lattice constant c to an in-plane directional lattice constant a of the (K1−xNax)NbO3 thin film is set within a range of 0.0980≦c / a≦1.0100.

Owner:SUMITOMO CHEM CO LTD

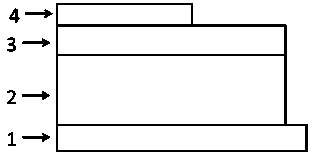

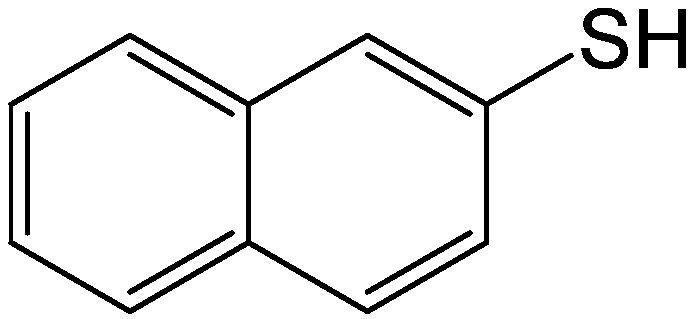

Perovskite solar cell with interface modification layers and preparation method of perovskite solar cell

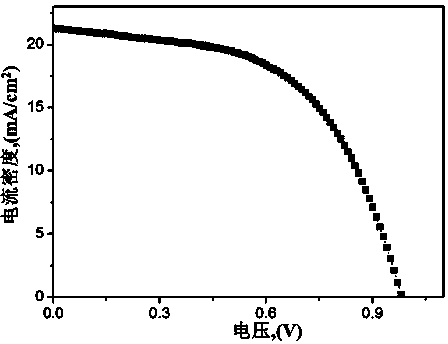

ActiveCN108258128AImprove crystal structureImprove photoelectric conversion efficiencyFinal product manufactureSolid-state devicesPerovskite solar cellCrystal structure

The invention relates to a perovskite solar cell with interface modification layers. The cross-sectional structure of the perovskite solar cell includes a transparent conductive substrate, a first transmission layer, a perovskite active layer, a second transmission layer and a back electrode; at least one first interface modification layer is disposed between the perovskite active layer and the first transmission layer; and no or at least one second interface modification layer is disposed between the perovskite active layer and the second transmission layer. The invention also discloses a preparation method of the perovskite solar cell. According to the method, the interface modification layers are additionally arranged between the perovskite active layer and transmission layers of a perovskite solar cell, so that the perovskite solar cell with the interface modification layers can be prepared; the surfaces of the transmission layers are passivated; the crystal structure of the perovskite is optimized; ion migration in the perovskite active layer is suppressed to a certain extent; and therefore, the photoelectric conversion efficiency and long-term stability of the perovskite cellare improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

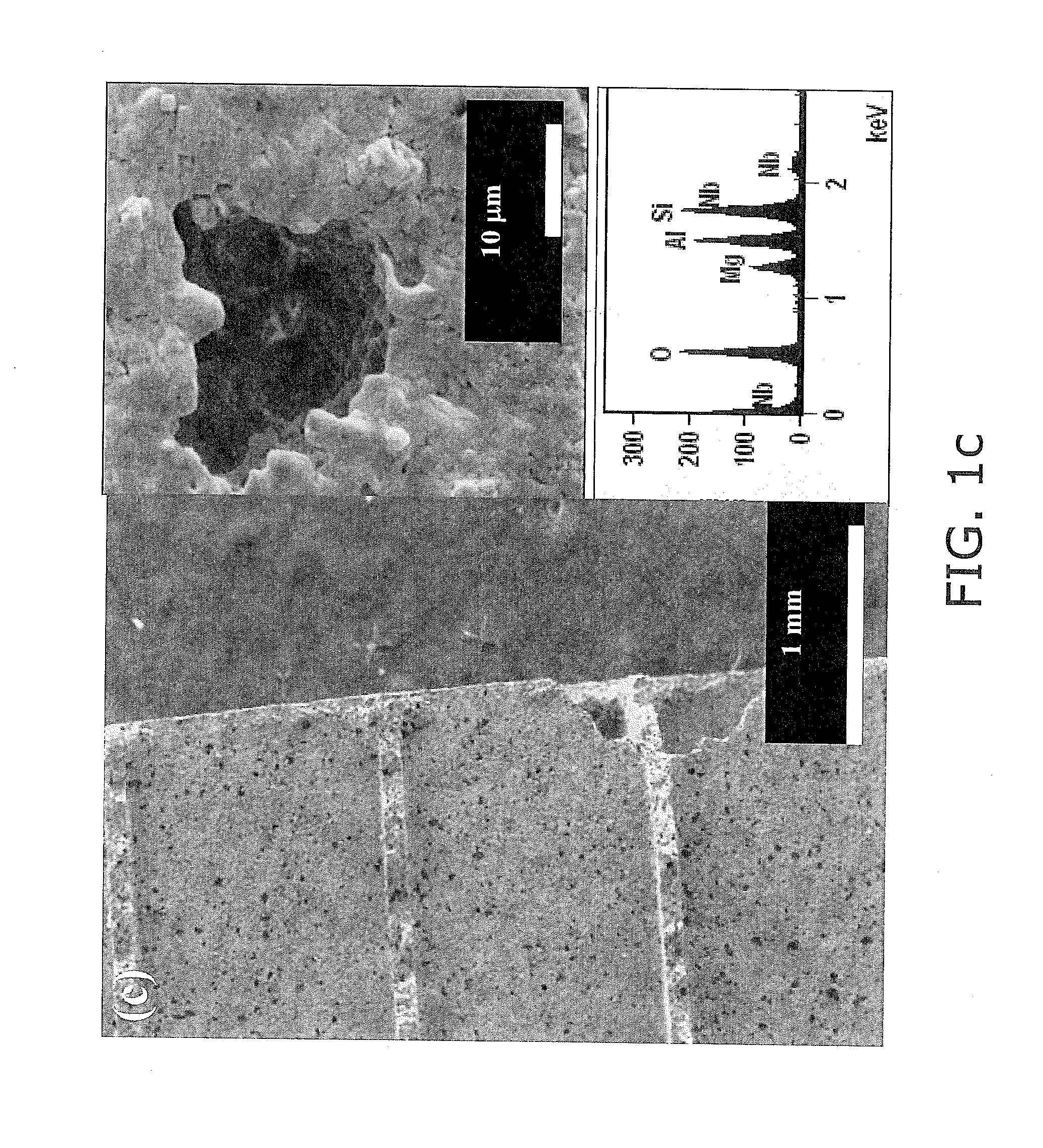

Fischer-tropsch catalyst support and catalyst

A Fischer-Tropsch catalyst support comprising at least 15 wt % of a material having the formula XaYbOc wherein: X comprises an element selected from the group consisting of magnesium, calcium, barium, strontium, cerium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, niobium, ruthenium, rhodium, palladium, cadmium, osmium, iridium, platinum, gold, mercury, tin, lead, lanthanides, and mixtures thereof; Y comprises a different element to X, Y selected from the group consisting of silicon, aluminium, titanium, zirconium, cerium, hafnium, gallium, and mixtures of these, preferably silicon, aluminium and titanium and mixtures thereof, especially titanium; O is oxygen; a and b are, independently, in the range of 1-6; c is in the range of 1-15. Preferably a perovskite-type structure results which is more stable and resistant to degradation.

Owner:SHELL OIL CO

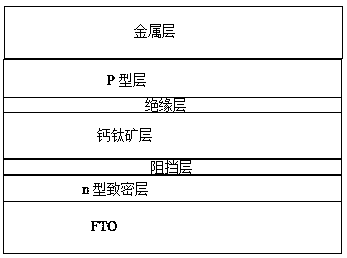

Solar cell of perovskite structure and preparing method of solar cell

ActiveCN104183697AImprove stabilityImprove photoelectric propertiesSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSolar cell

Owner:CHANGZHOU UNIV

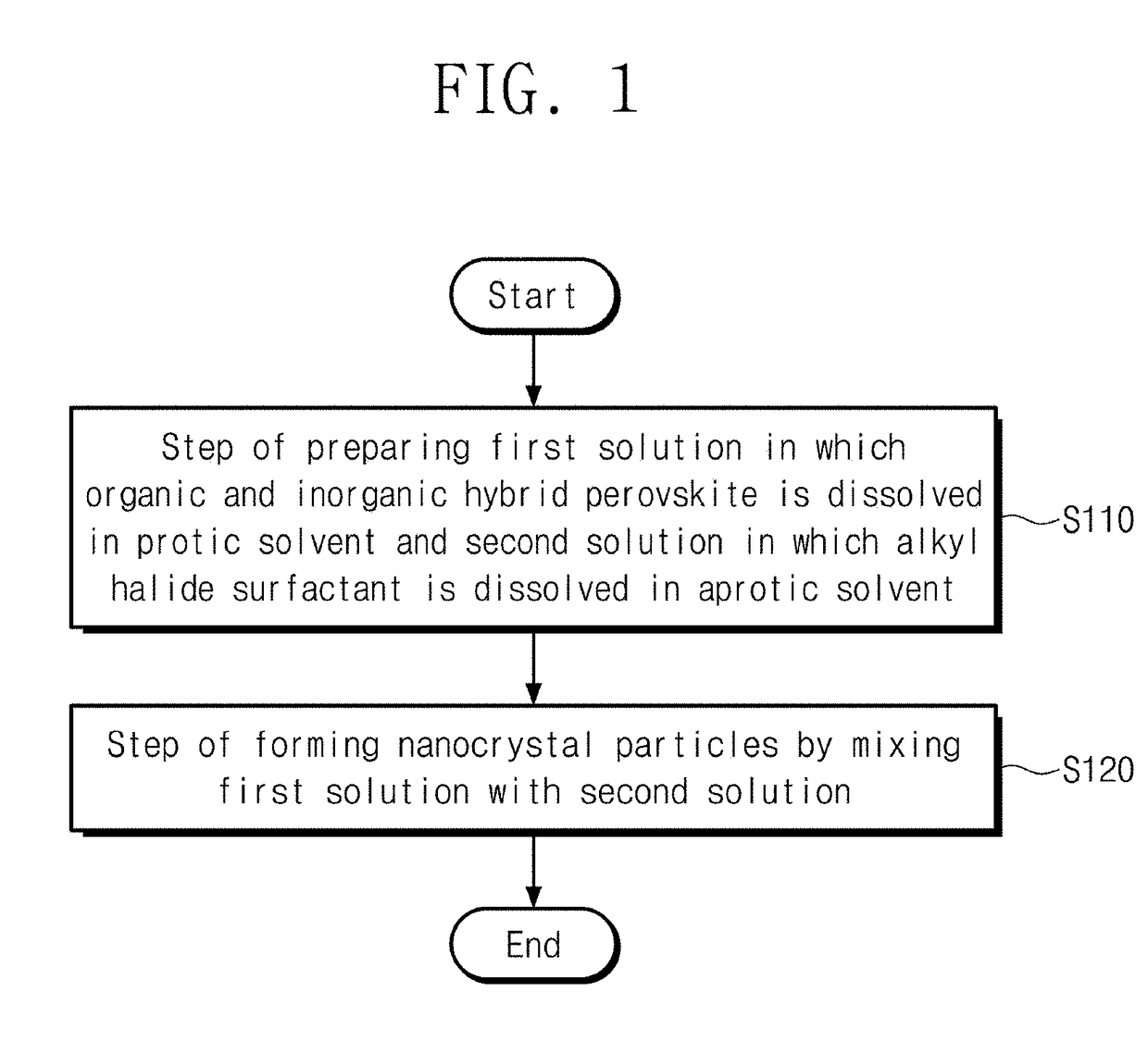

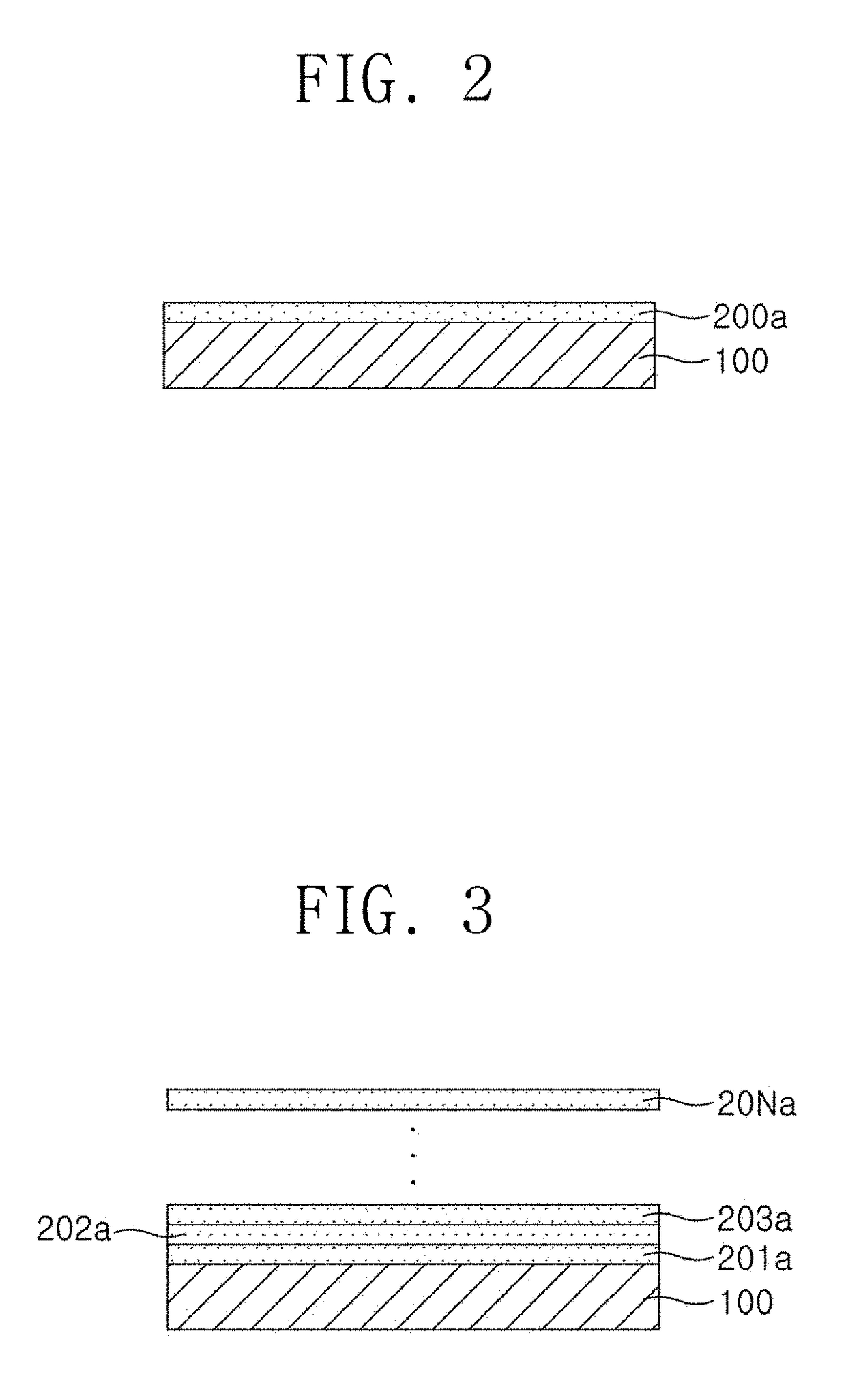

Light-emitting layer for perovskite light-emitting device, method for manufacturing same, and perovskite light-emitting device using same

ActiveUS20170358759A1Improve efficiencyHigh efficiencyMaterial nanotechnologySolid-state devicesNanometrePerovskite

Provided are: a light-emitting layer for a perovskite light-emitting device; a method for manufacturing the same; and a perovskite light-emitting device using the same. The method of the present invention for manufacturing a light-emitting layer for an organic and inorganic hybrid perovskite light-emitting device comprises a step of forming a first nanoparticle thin film by coating, on a member for coating a light-emitting layer, a solution comprising organic and inorganic perovskite nanoparticles including an organic and inorganic perovskite nanocrystalline structure. Thereby, a nanoparticle light emitter has therein an organic and inorganic hybrid perovskite having a crystalline structure in which FCC and BCC are combined; forms a lamella structure in which an organic plane and an inorganic plane are alternatively stacked; and can show high color purity since excitons are confined to the inorganic plane. In addition, it is possible to improve the luminescence efficiency and luminance of a device by making perovskite as nanoparticles and then introducing the same into a light-emitting layer.

Owner:SN DISPLAY CO LTD

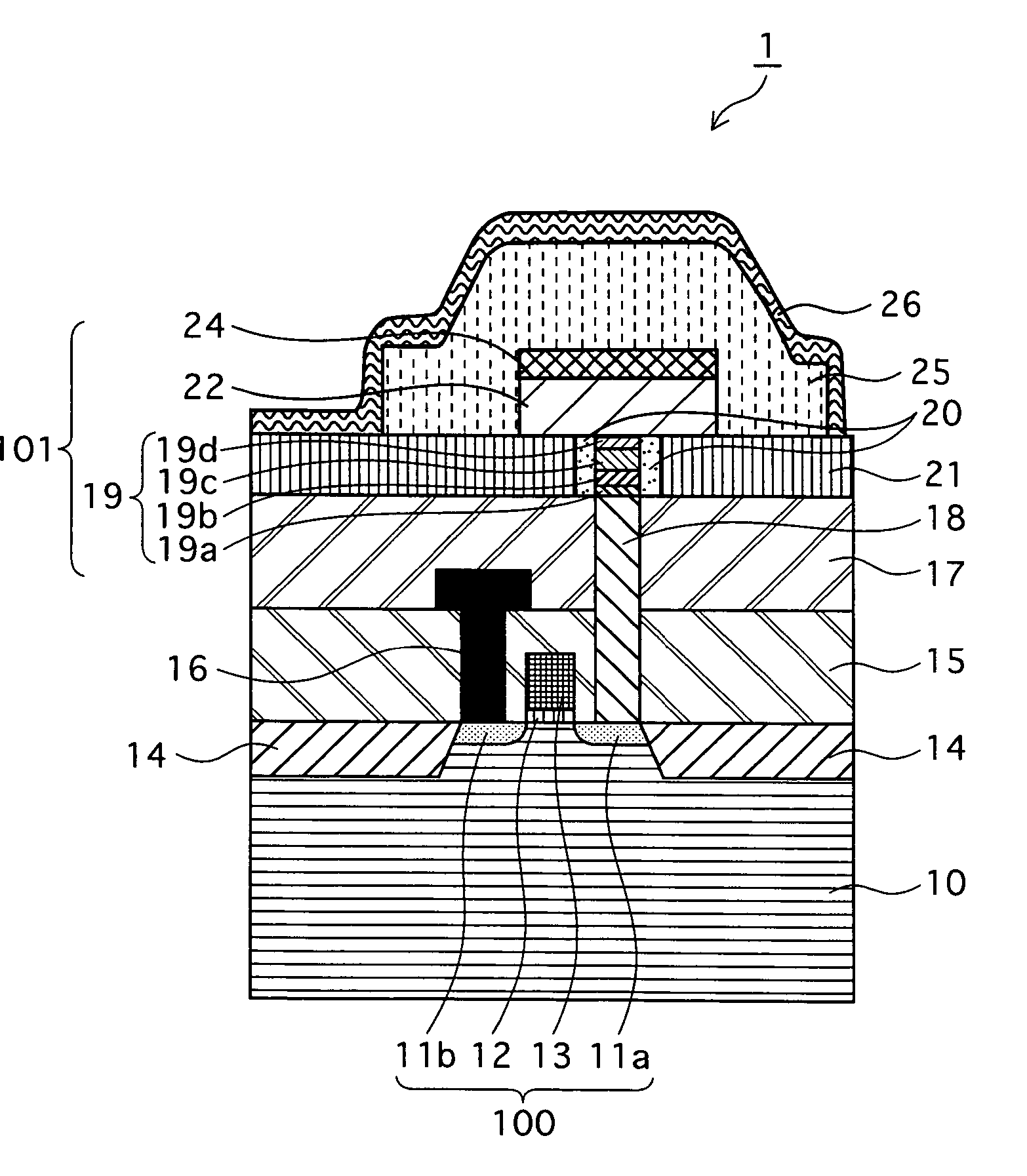

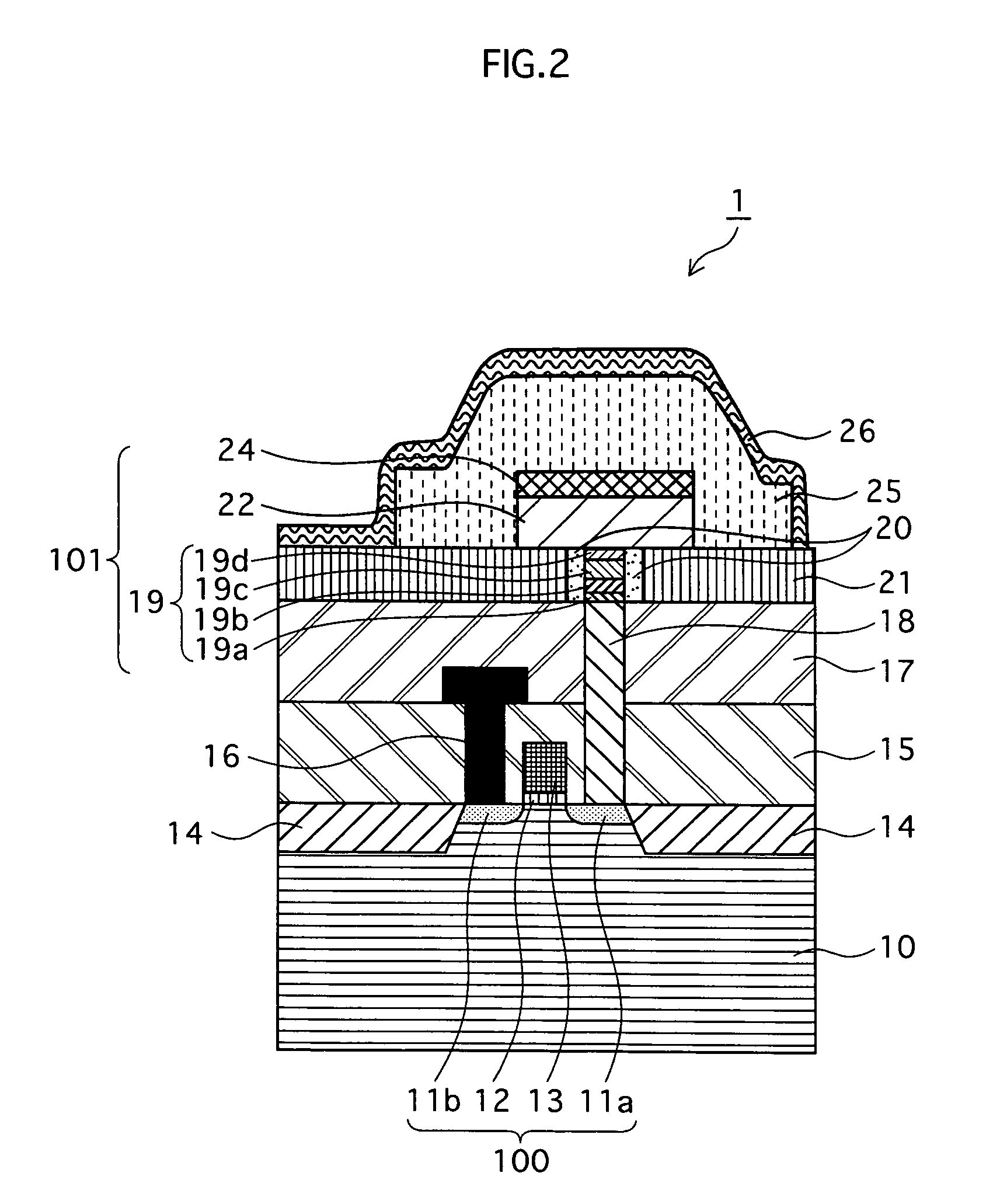

Variable resistance device and a semiconductor apparatus, including a variable resistance layer made of a material with a perovskite structure

InactiveUS20060081961A1Quality improvementHigh yieldSolid-state devicesSemiconductor devicesElectrical resistance and conductancePerovskite (structure)

The present invention offers a variable resistance device and a semiconductor apparatus that have component parts less subject to damage and thereby ensure stable quality at a high yield, even if the manufacturing processes include operations in a deoxidizing atmosphere or an oxidizing atmosphere. The variable resistance device of the present invention comprises: a variable resistance layer made of a metal oxide and causing changes in electric resistance thereof in accordance with control conditions; and a hydrogen-diffusion preventing layer which surrounds at least part of the variable resistance layer and prevents hydrogen from diffusing into the variable resistance layer.

Owner:PANASONIC CORP

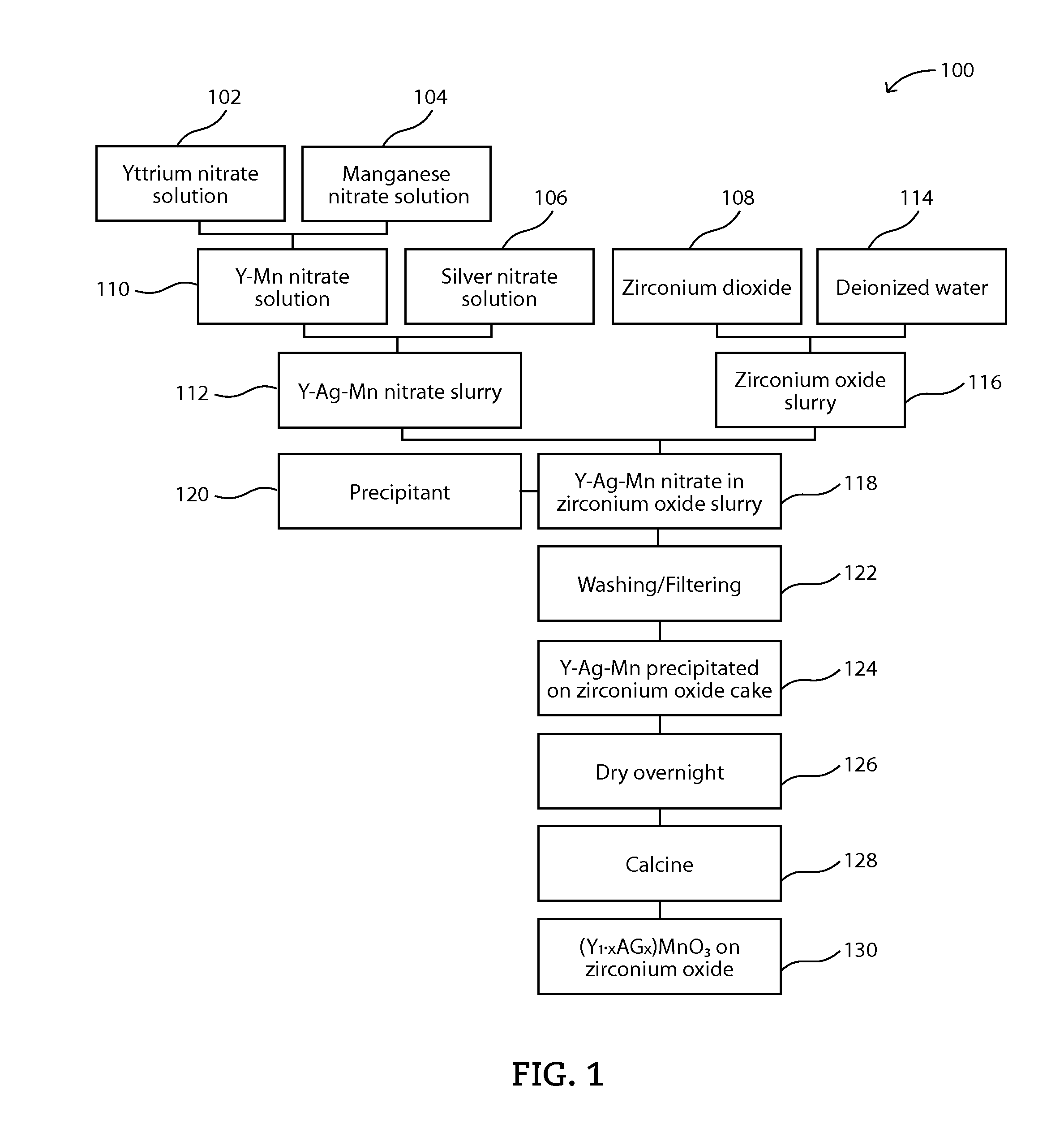

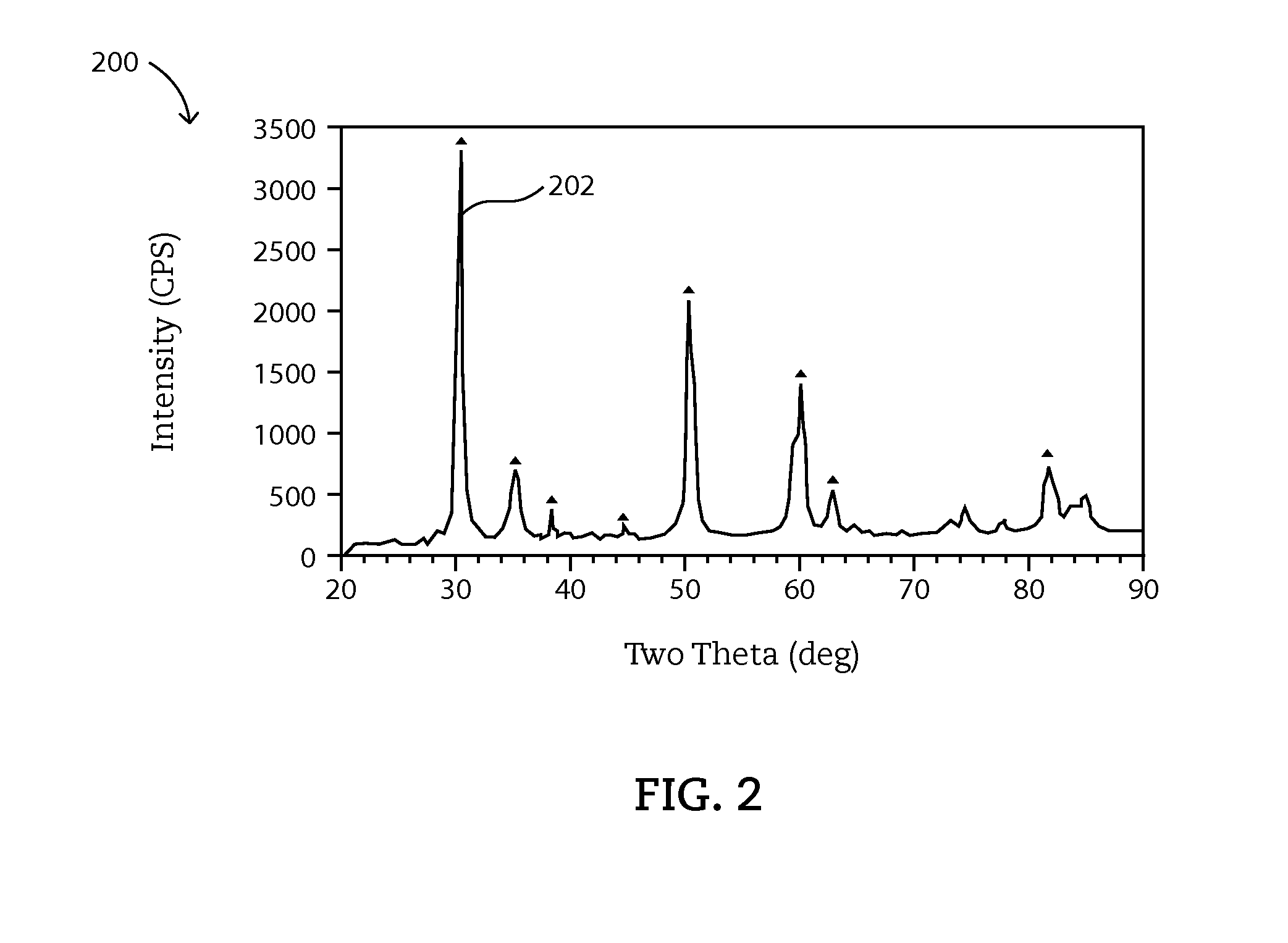

Perovskite and Mullite-like Structure Catalysts for Diesel Oxidation and Method of Making Same

InactiveUS20140336045A1Heterogenous catalyst chemical elementsDispersed particle separationPtru catalystPerovskite (structure)

Disclosed here are material formulations of use in the conversion of exhaust gases. A catalyst is formed by using a perovskite structure having the general formula ABO3 or a mullite structure having the general formula of AB2O5 where components “A” and “B” may be any suitable non-platinum group metals. Suitable materials may include Yttrium, Lanthanum, Silver, Manganese and formulations thereof.

Owner:CLEAN DIESEL TECHNOLOGIES

Method for preparing perovskite type catalyst for methane or methanol recapitalization

InactiveCN101185885AEliminates sinterable propertiesHigh catalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsWater bathsMetal nitrate

The invention discloses a preparation method of a perovskite catalyst used for reforming methane or methanol, which comprises the following steps: the metal nitrates of A, A', B and B' are added with a complexing agent and heated to dissolute; ammonia regulation solution with pH=5-7 is added; gel is formed after dehydrating in a constant temperature water bath at the temperature of sixty to ninety DEG C; catalyst powders are obtained after the gel is dried and roasted; the general formula of the catalyst composition is A1-xA'XB1-yB'yO3, wherein x is more than or equal to 0 and less than or equal to1,y is more than or equal to 0 and less than or equal to 1, A or A' is La, Ce, Pr, Gd or Sm; B or B' is Cr, Zr, Zn, Ni, Co, Mn, Fe, Ru, Rh, Pt or Pd. The technique of the invention is simple; the cost is low; the catalyst has the high activity and the high stability; the sulfur tolerance is good; the conversion is high; the service life is long; at the same time, the invention has the advantages of being aseismatic, the small resistance and being easy to be replaced, etc. after being coated on a honeycomb structure and is suitable for mass production. The invention belongs to the field of the catalyst reforming the methane or methanol.

Owner:HANERGY TECH

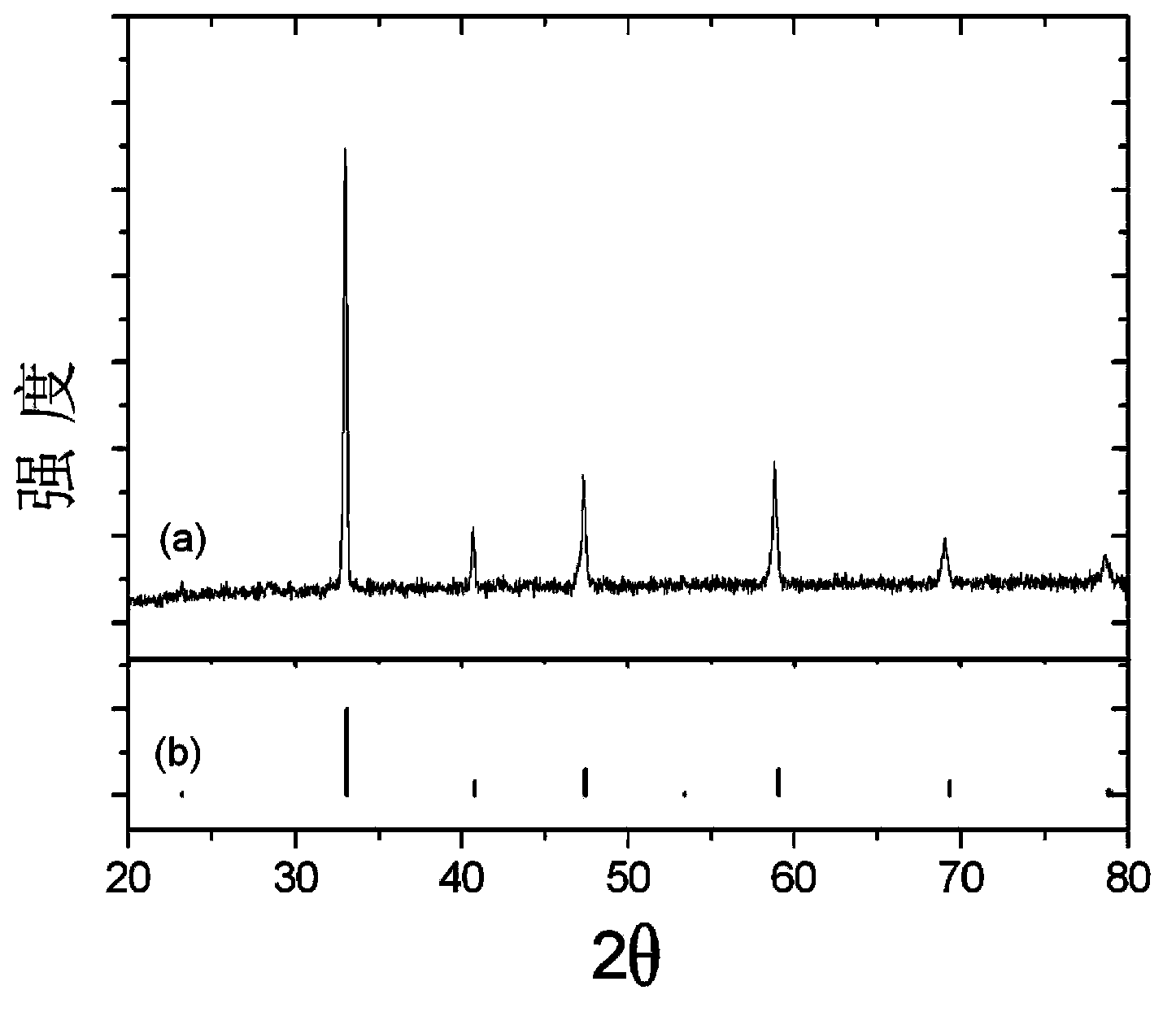

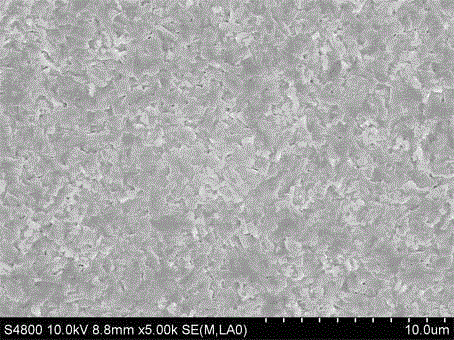

Novel method for improving uniformity and crystallinity of organic-inorganic perovskite thin film

InactiveCN104409641AImprove uniformityHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellHigh electron

The invention relates to a novel process for preparing an organic-inorganic perovskite thin film through adopting an experimental scheme in which two kinds of metal compounds are adopted as precursors. With the novel process adopted, an efficient solar battery device with a planar structure can be prepared. According to the novel process, the two kinds of metal compound precursors are compounded, and therefore, a pinhole defect of the perovskite thin film can be effectively avoided, and compound of electrons and holes can be alleviated, and short-circuiting risks of the perovskite thin film can be decreased. The novel process of the invention belongs to the photoelectric material field and is characterized in that the two kinds of metal compounds are selected as a source of metal ions in a perovskite material, wherein the general formula of the organic-inorganic perovskite material is ABX3, wherein A is CH3NH3 or NH2-CH=NH2, B is Pb or Sn, and X is I or Br. With the preparation method adopted, the thickness of the perovskite thin film is uniform, and the crystallinity of the perovskite thin film is high, the perovskite thin film can have high electron and hole transport ability. The preparation method is suitable for large-area preparation of organic-inorganic perovskite solar battery devices with planar structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

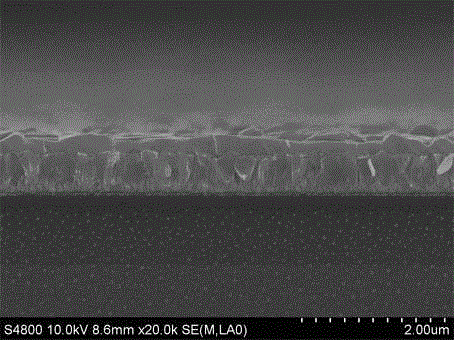

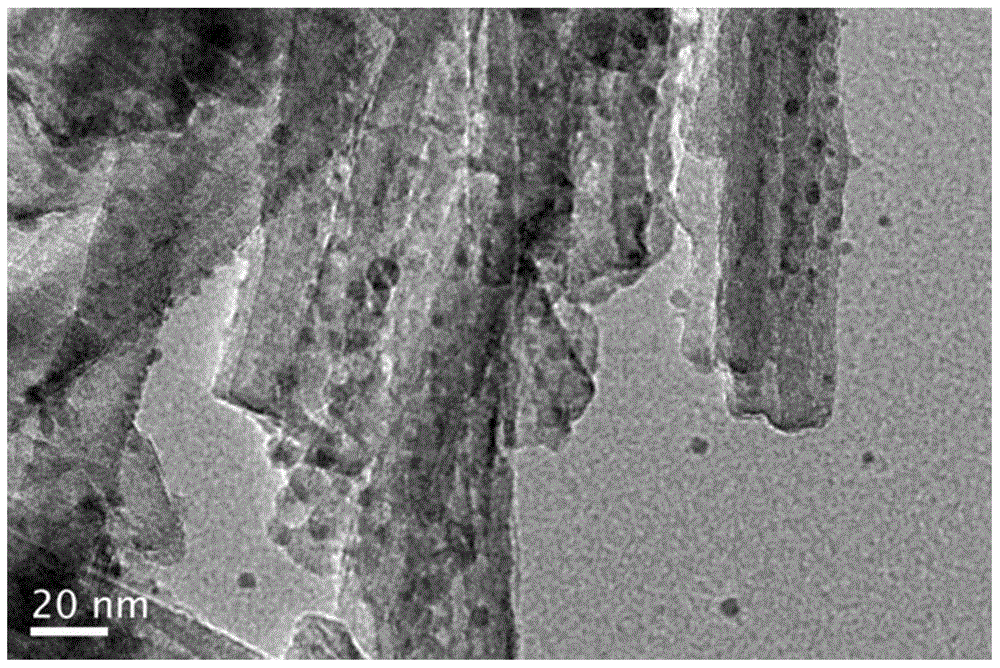

Mesoscopic perovskite photovoltaic cell with tin-oxide electron-transporting layer and preparation method thereof

InactiveCN104576932AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryPerovskite (structure)

The invention relates to a perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer and preparation method thereof. The cell comprises a conducting substrate, an electron-transporting layer with double-layer structure, a perovskite light absorption layer, a hole-transporting layer and metal electrodes. The perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer has the advantages that the SnO2 with one step method low-temperature growth, is used as the electron-transporting layer in the photovoltaic cell, replaces the TiO2 electron-transporting layer with two steps method high temperature sintering, and the preparation process is simplified. The mesoporous perovskite photovoltaic cell prepared with one step low-temperature growth method obtains 13.82% of highlight electricity transfer efficiency, and reduces the manufacturing cost effectively at the same time. Compared with a planer construction, the mesoporous structure used in the perovskite photovoltaic cell is liable for the adherence of the perovskite light absorption material. SnO2 conducts a smaller dissimilation on the perovskite light absorption layer than the TiO2 does, the performance and stability of the cell are improved in this way. The perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer and preparation method thereof plays a great promoting role in the development and popularization on the flexible solar cell, and further promotes the industrialized application on the perovskite solar cell.

Owner:WUHAN UNIV

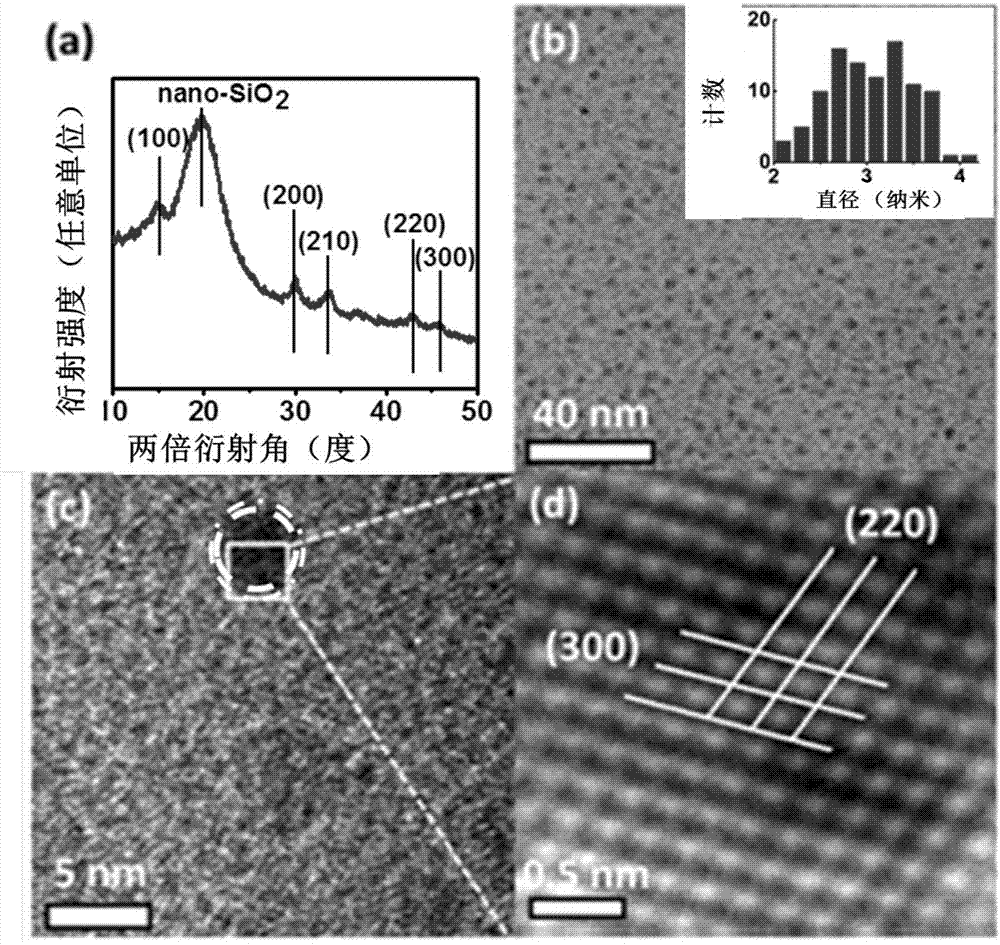

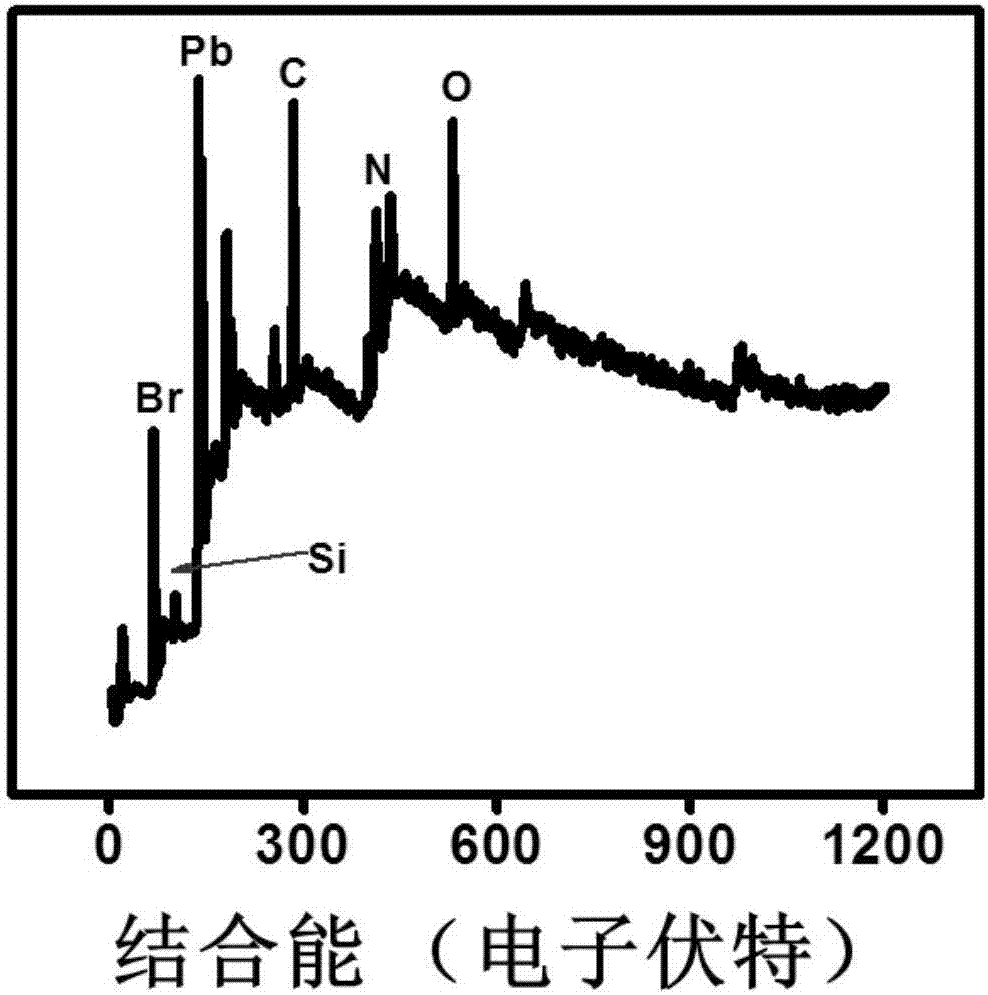

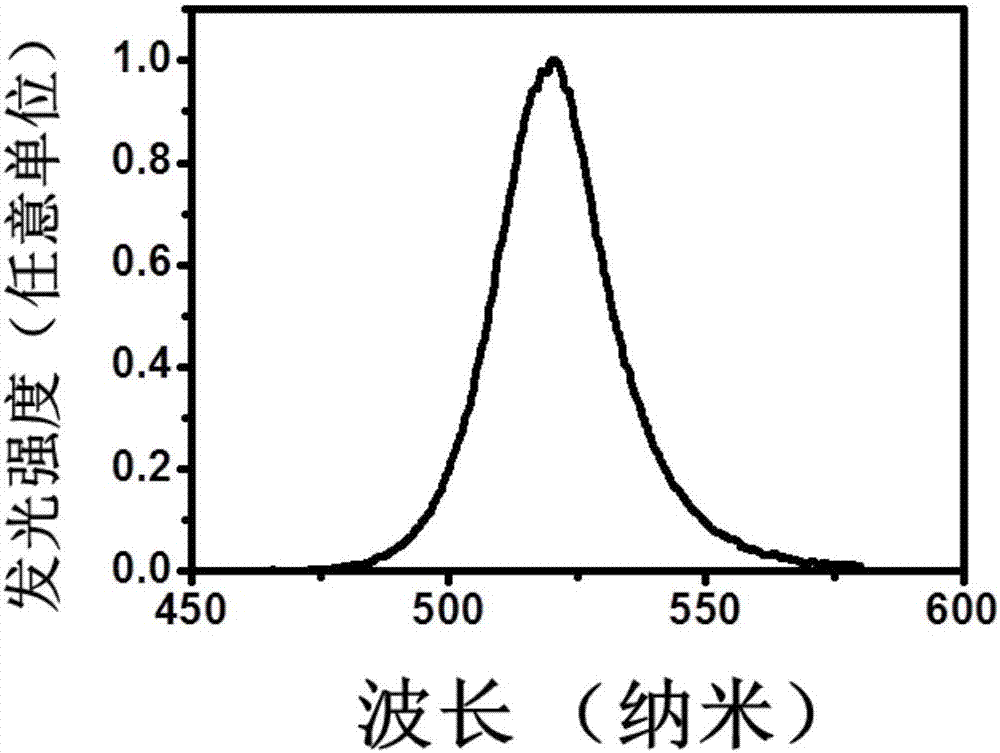

Method for synthesizing silicon dioxide cladded organic-inorganic perovskite structure quantum dot and application of quantum dot synthesized by method

InactiveCN107446572AAvoid Fluorescent Quantum Efficiency LossHigh fluorescence quantum efficiencyMaterial nanotechnologyNon-macromolecular adhesive additivesFluorescencePolystyrene

The invention relates to a method for synthesizing a silicon dioxide cladded organic-inorganic perovskite structure quantum dot and application of the quantum dot synthesized by the method, and belongs to the field of nano-material synthesis. The method comprises the following steps: taking methylammonium halide and lead halide as raw materials and taking oleic acid and an amino-containing silane coupling agent as ligands to synthesize the stable and efficient silicon dioxide cladded organic-inorganic perovskite structure quantum dot, which is capable of being processed in a solution, in one step through a solution method at room temperature. According to the method provided by the invention, the stability of the quantum dot is greatly increased through silicon dioxide cladding; meanwhile, high fluorescent quantum efficiency of the quantum dot is ensured and can reach 95 percent at maximum. Meanwhile, the quantum dot prepared by the method can be dispersed into solvents including toluene and the like to form a stable solution. A quantum dot solution and a toluene solution of polystyrene are mixed and can be used for preparing a warm white-light light emitting diode; the prepared white-light light emitting diode has a color coordinate (0.38, 0.43) and color temperature of 4500K, and can be applied to various fields including information storage, information encryption, counterfeiting prevention, illumination display and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Macroporous composite metal oxide catalyst for purifying soot of diesel and preparation method thereof

InactiveCN101683616AReduce the temperatureFacilitated DiffusionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMischmetalPtru catalyst

The invention relates to a macroporous composite metal oxide catalyst for purifying the soot of diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for the combustion of soot particulates discharged by diesel engine road vehicles, and the catalyst is perovskite type, perovskite-like type or spinel type composite metal oxide which takes more than two elements of rare earth metal, transition metal and basic metal as active components and has a macroporous structure, wherein the average aperture of the composite metal oxide is more than 50nm. The catalyst can reduce the temperature that the soot particulates are combusted into CO2 within an exhaust temperature range of tail gas of the diesel engine road vehicles; and the catalyst has the honeycomb macroporous structure, is favorable for the diffusion of the soot particulates in pore canals, improves the utilization rate of active surface area of the catalyst, and greatly reduces the combustion temperature of the soot particulates. The invention also provides a method for preparing the catalyst, which combines organic complexation with in-situ combustion to prepare the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

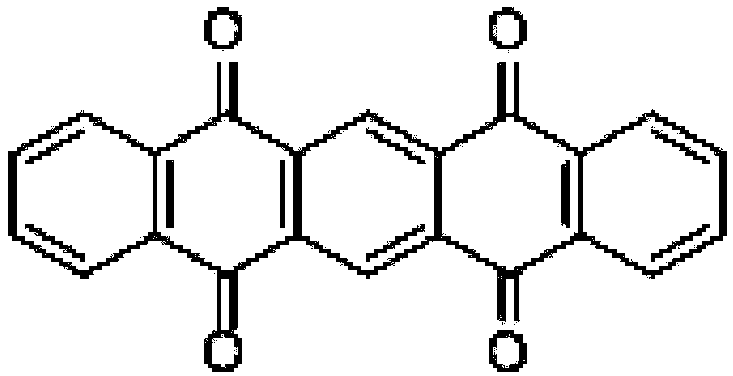

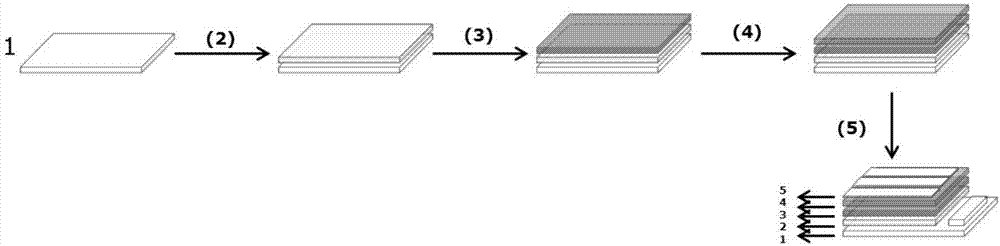

Solar energy cell with double-layer perovskite film structure and manufacturing method thereof

ActiveCN106910828AIncrease UV-Vis absorptionHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingSilver electrodeEngineering

The invention discloses a manufacturing method for the solar energy cell with double-layer perovskite film structure, and the method comprises the following steps: 1) selecting a conductive substrate; etching patterns on the conductive substrate and obtaining the etched conductive substrate; 2) preparing an electron transport layer or a hole transport layer; (3) preparing a film with a double-layer perovskite structure; 4) preparing a hole transport layer or an electron transport layer; and 5) hotly plating a gold or silver electrode on the hole transport layer or the electron transport layer to obtain an n-I-P-type or p-I-N-type solar cell with the double-layer perovskite thin film structure. The invention further discloses a solar energy cell manufactured and obtained from the above method. The manufacturing method is environmentally friendly, can change the morphology, the crystallinity and the interface of the perovskite film and increases the photoelectric performance of a device.

Owner:SOUTH CHINA NORMAL UNIVERSITY

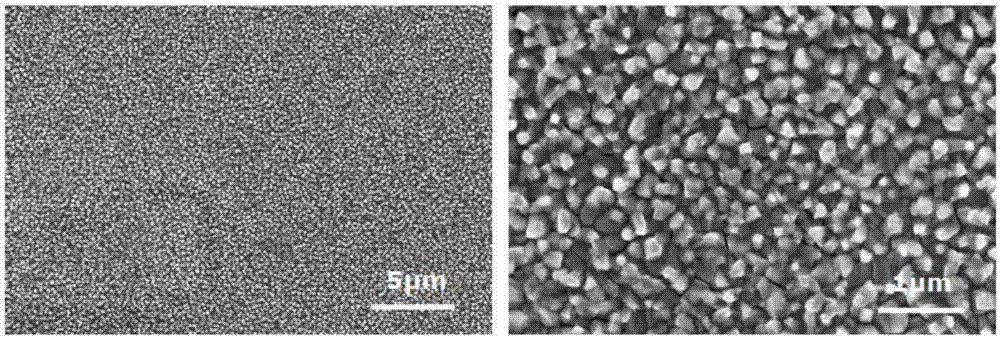

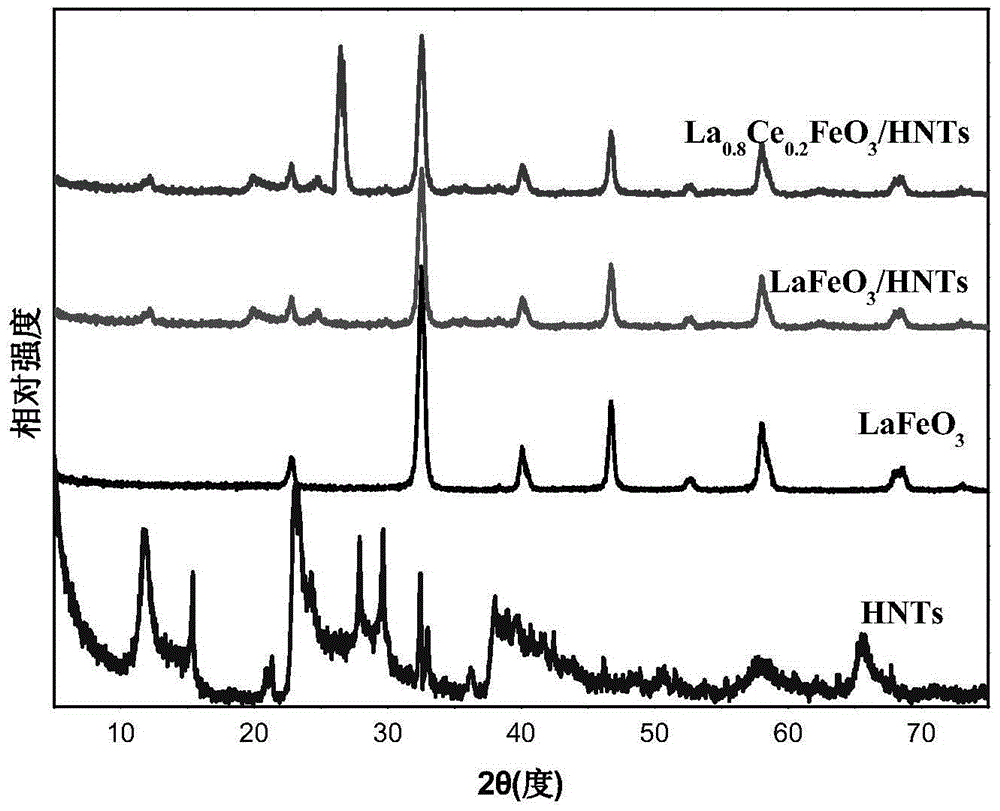

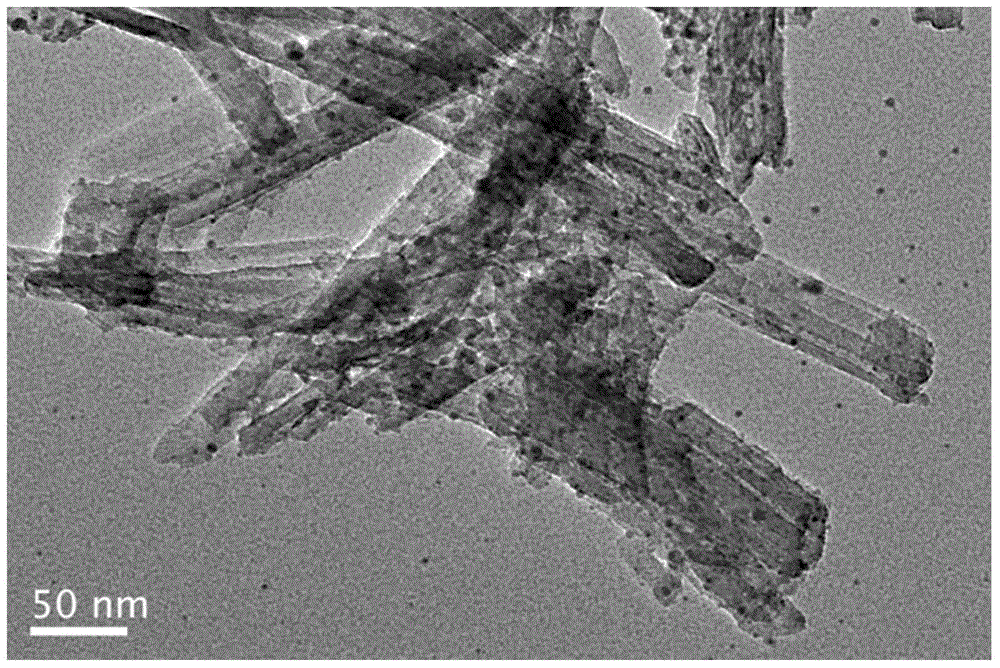

Preparation method of clay-perovskite composite material and application thereof

ActiveCN105688918ASmall particle sizeAvoid uneven loadWater/sewage treatment by irradiationWater treatment compoundsWater bathsChemical industry

The invention belongs to the field of the energy and chemical industry and particularly relates to a preparation method of a nanometer material using clay as a carrier and using a perovskite type compound as an active component and application of the nanometer material in photocatalytic degradation of antibiotics.Lanthanum nitrate, ferric nitrate, cerous nitrate, citric acid and the clay are added to deionized water and are mixed, then the mixture is transferred to a water bath kettle for evaporation to obtain wet gel, and drying, calcinations and dry grinding are performed to obtain the lanthanum ferrite / clay nano-structure composite material.The antibiotics are subjected to the photocatalytic degradation by adopting the composite material and can be rapidly degraded under visible light by utilizing the high catalytic activity of (cerium doped) lanthanum ferrite.The clay carrier facilitates antibiotic molecular adsorption in the antibiotic degradation process, the antibiotics are in contact with the lanthanum ferrite after being absorbed to the catalyst surface, and antibiotic molecules are decomposed under visible light irradiation to produce other active species.

Owner:CHANGZHOU UNIV

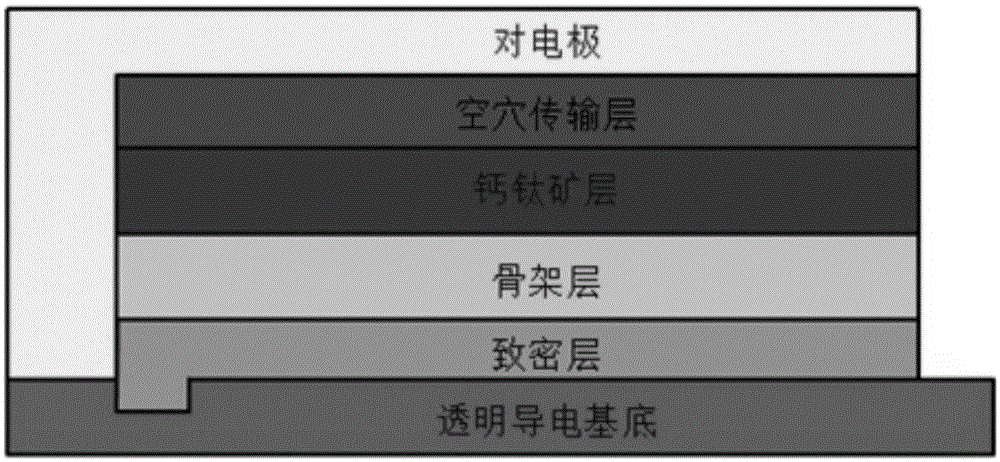

Mesoporous perovskite solar cell and preparation method thereof

InactiveCN105070836AHigh densityIncrease the open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite (structure)Hole transport layer

The invention discloses a mesoporous perovskite solar cell and a preparation method thereof. The mesoporous perovskite solar cell comprises a transparent conductive base, a compact layer, a skeleton layer, a perovskite layer, a hole transmission layer and a counter electrode, wherein the compact layer, the skeleton layer, the perovskite layer, the hole transmission layer and the counter electrode are sequentially stacked on the transparent conductive base; and the skeleton layer is a barium stannate film with a perovskite structure and the like, and has p-type conductivity or n-type conductivity or comprises an insulator. With a novel perovskite oxide as the skeleton layer, the mesoporous perovskite solar cell has relatively high charge collection efficiency, and is relatively good in contact with a perovskite layer interface. Compared with a traditional titanium dioxide compact layer, the photoelectric properties such as short-circuit current and filling factors can be effectively improved; leakage current caused by contact of the hollow transmission layer and an electron transmission layer is reduced; reverse recombination of photoelectrons is prevented; and the photoelectric conversion efficiency is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

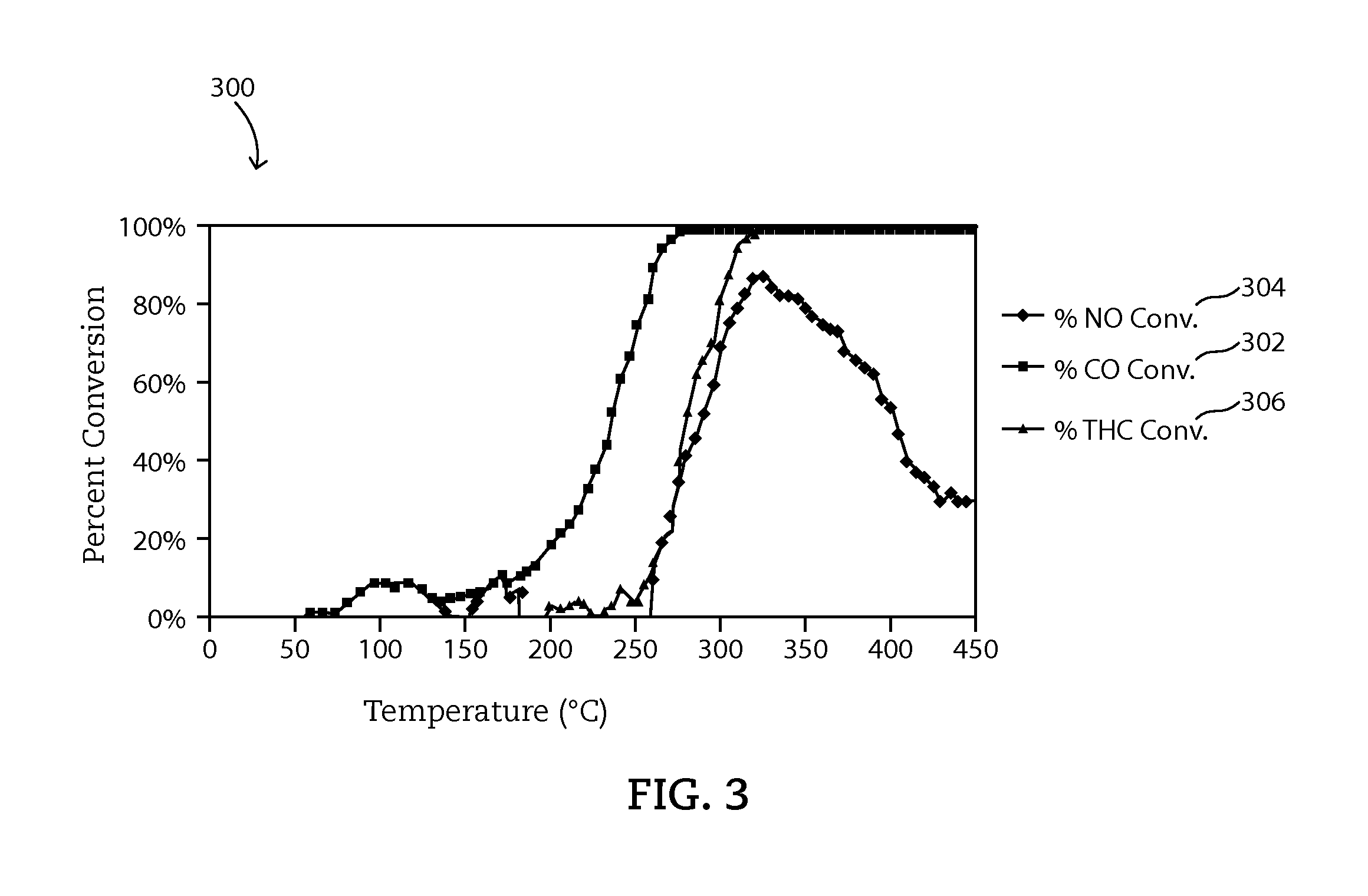

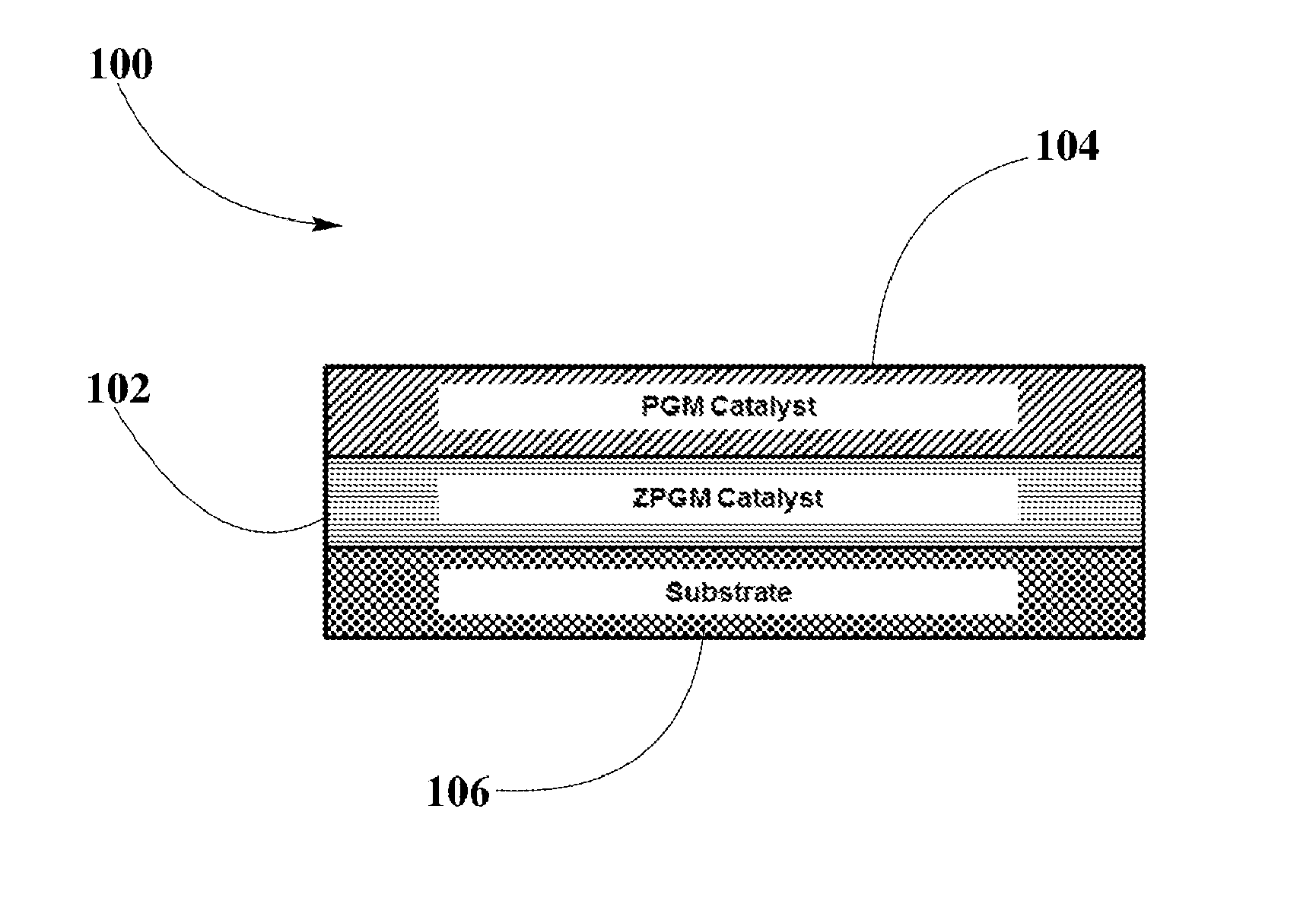

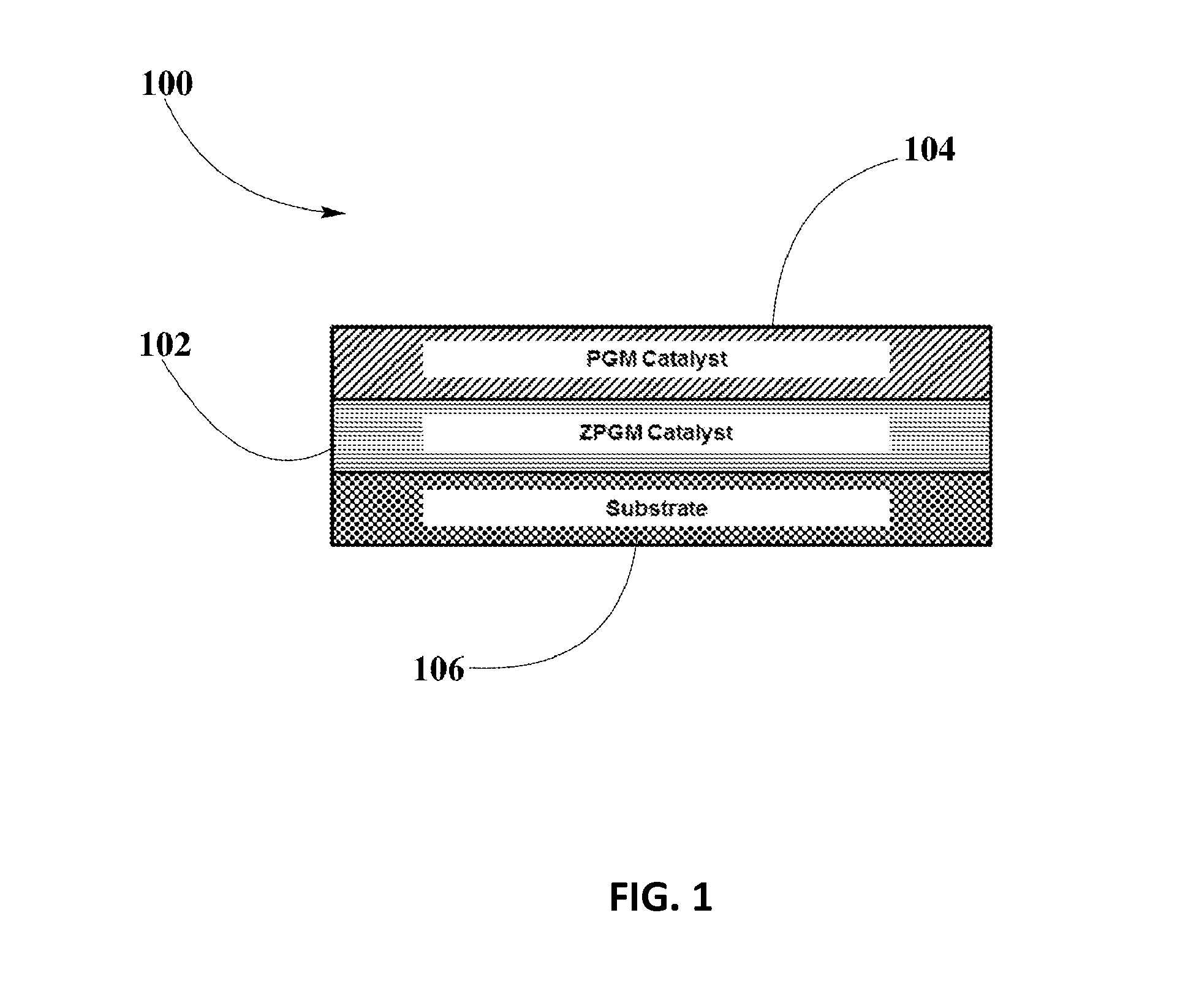

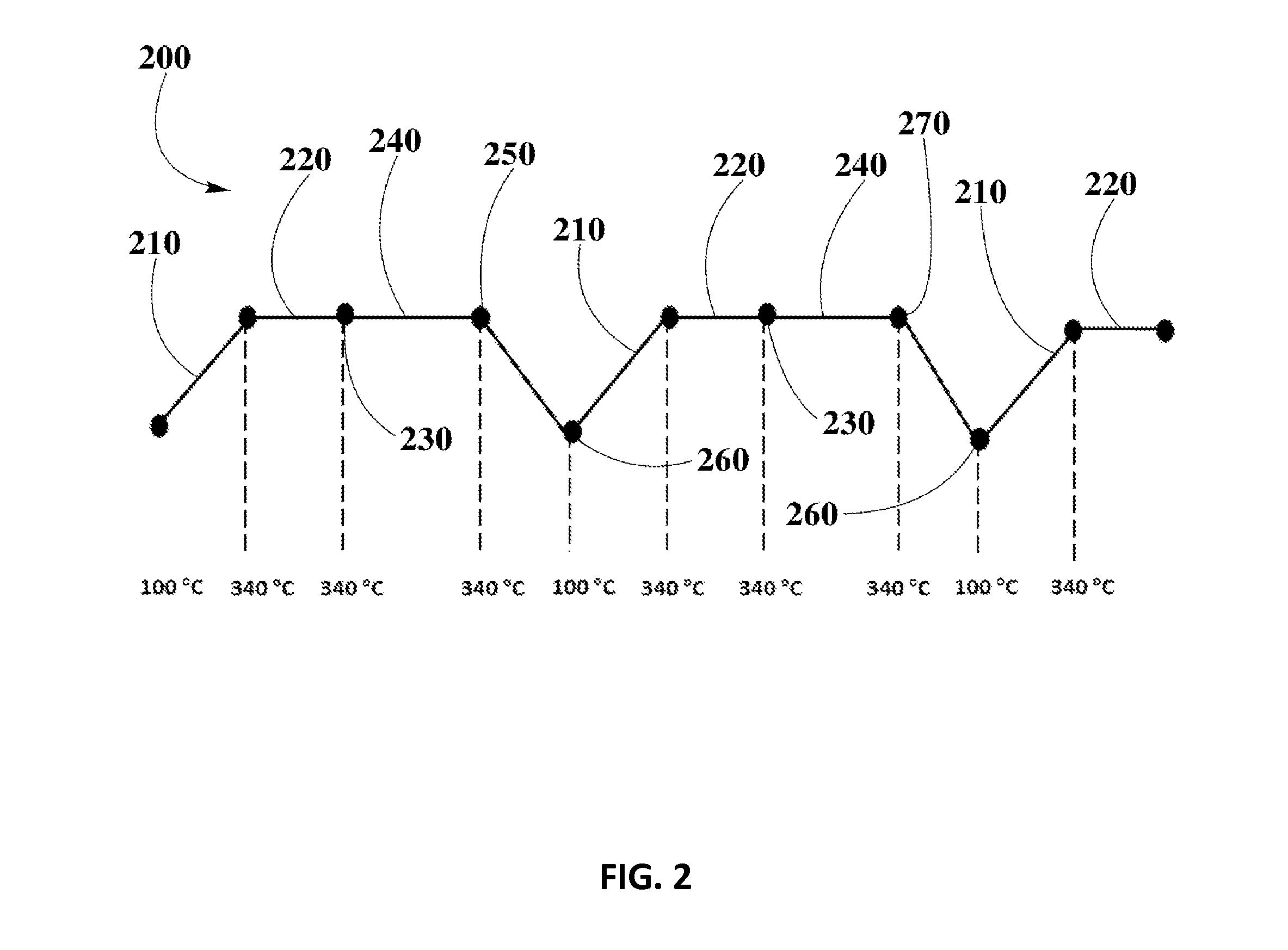

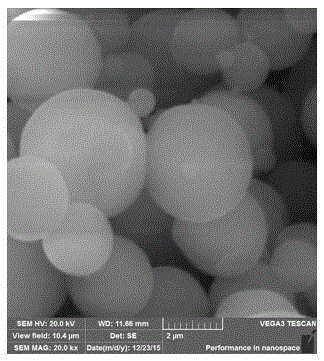

Synergized PGM Catalyst with Low PGM Loading and High Sulfur Resistance for Diesel Oxidation Application

InactiveUS20160136617A1Minimize deactivationMore efficiencyGas treatmentNitrogen compoundsSulfurSilicon dioxide

Sulfur-resistant SPGM catalysts with significant oxidation capabilities are disclosed. Catalytic layers of SPGM samples may be prepared using incipient wetness and metallizing techniques to structure a washcoat layer of ZPGM material of YMnO3 perovskite , and an overcoat layer including Pt / Pd composition on alumina-silica support oxide. Loading of PGM in OC layer is less than 5 g / ft3. A testing methodology for samples may be enabled including of DOC light-off, and soaking under isothermal DOC and sulfated DOC conditions to assess synergistic influence of adding ZPGM to PGM catalyst samples. Resistance to sulfur and catalytic stability may be observed under 5.2 gS / L condition to assess significant improvements in NO oxidation, HC conversion, and CO selectivity. Resistance to sulfur of disclosed SPGM catalyst may be compared with performance of an equivalent PGM control catalyst for DOC applications.

Owner:CLEAN DIESEL TECHNOLOGIES

Ceramic solid electrolyte and preparation method thereof

InactiveCN105406118AEnable mass manufacturingUniform size distributionSecondary cellsElectrolytesPerovskite (structure)Spray dried

The invention discloses a ceramic solid electrolyte and a preparation method thereof. The ceramic solid electrolyte comprises at least one of NASICON structure type (LiM<2>(PO<4>)<3>, M=Zr, Ge, Mg, Al), oxide (Li<3x>La<2 / 3-x>TiO<3>) of perovskite structure and oxide (Li<5>La<3>M<2>O<12>) of garnet structure. The preparation method of the ceramic solid electrolyte comprises the following steps of: a) weighing raw materials according to molar ratio of elements in chemical formula of the ceramic solid electrolyte, dissolving the raw materials in solvent, and obtaining mixed solution; b) preparing ceramic solid electrolyte precursor powder from the mixed solution through a spray drying process; c) sintering the precursor powder obtained by spray drying in the air, and finally obtaining the ceramic solid electrolyte with relatively high ionic conductivity and relatively low electronic conductivity. In the method provided by the invention, the spray drying process is used for preparing the ceramic solid electrolyte, spray drying has the advantages that the drying procedure is fast, the mixed solution is directly dried into powder and particle size distribution of the powder is uniform, and thus, large-scale preparation of the ceramic solid electrolyte is expected to be realized, and the method has practical value.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com