Patents

Literature

867 results about "Dry grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

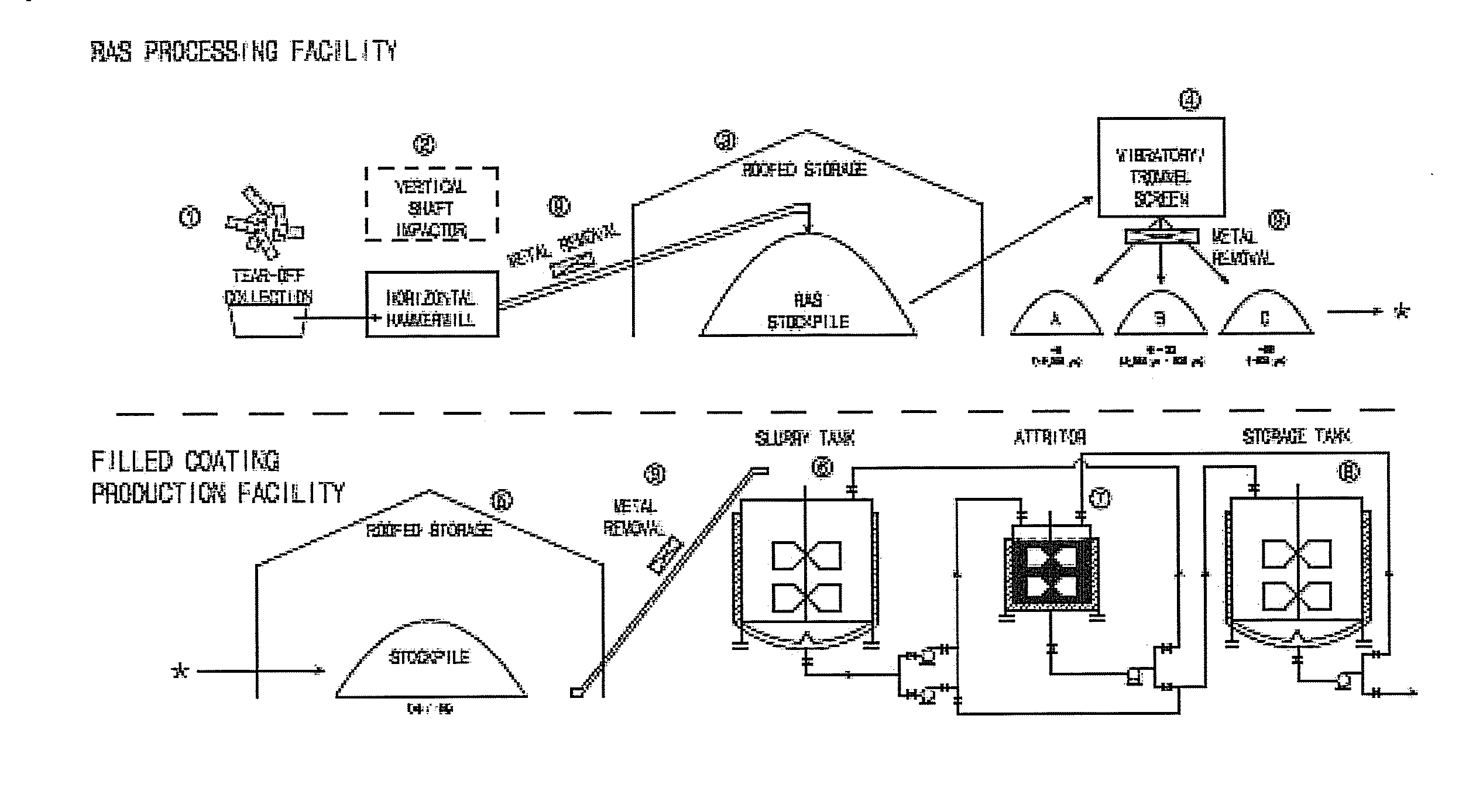

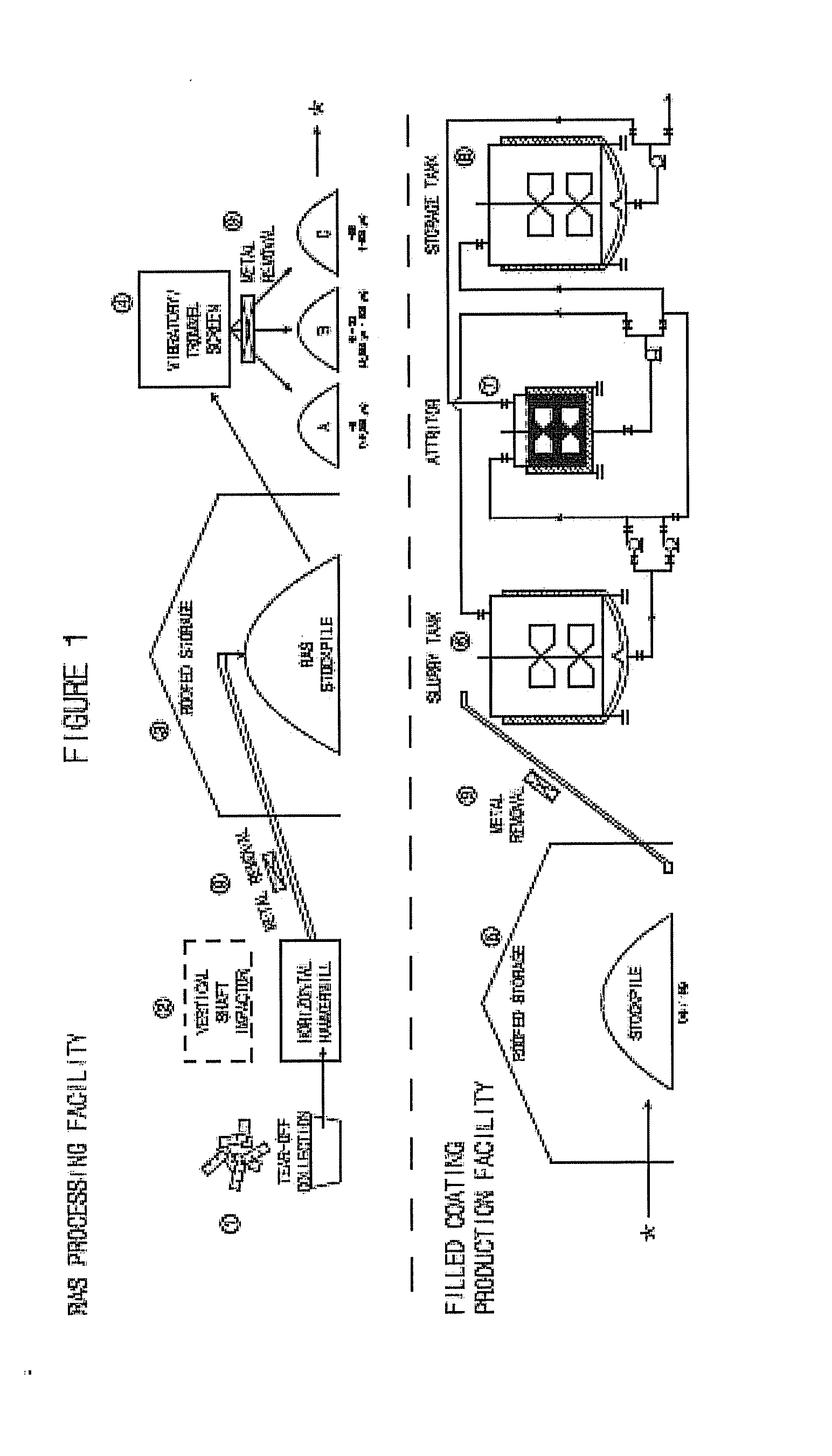

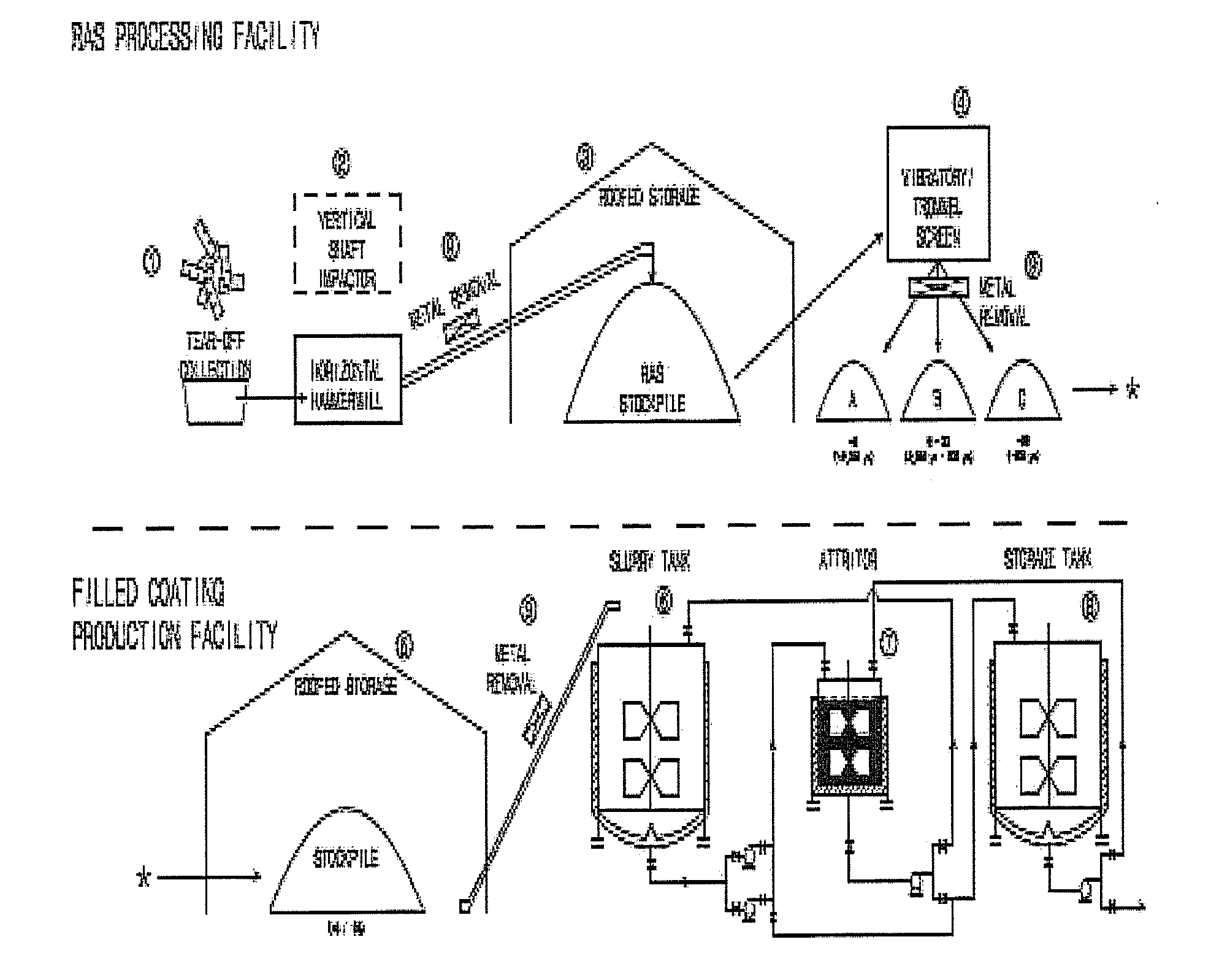

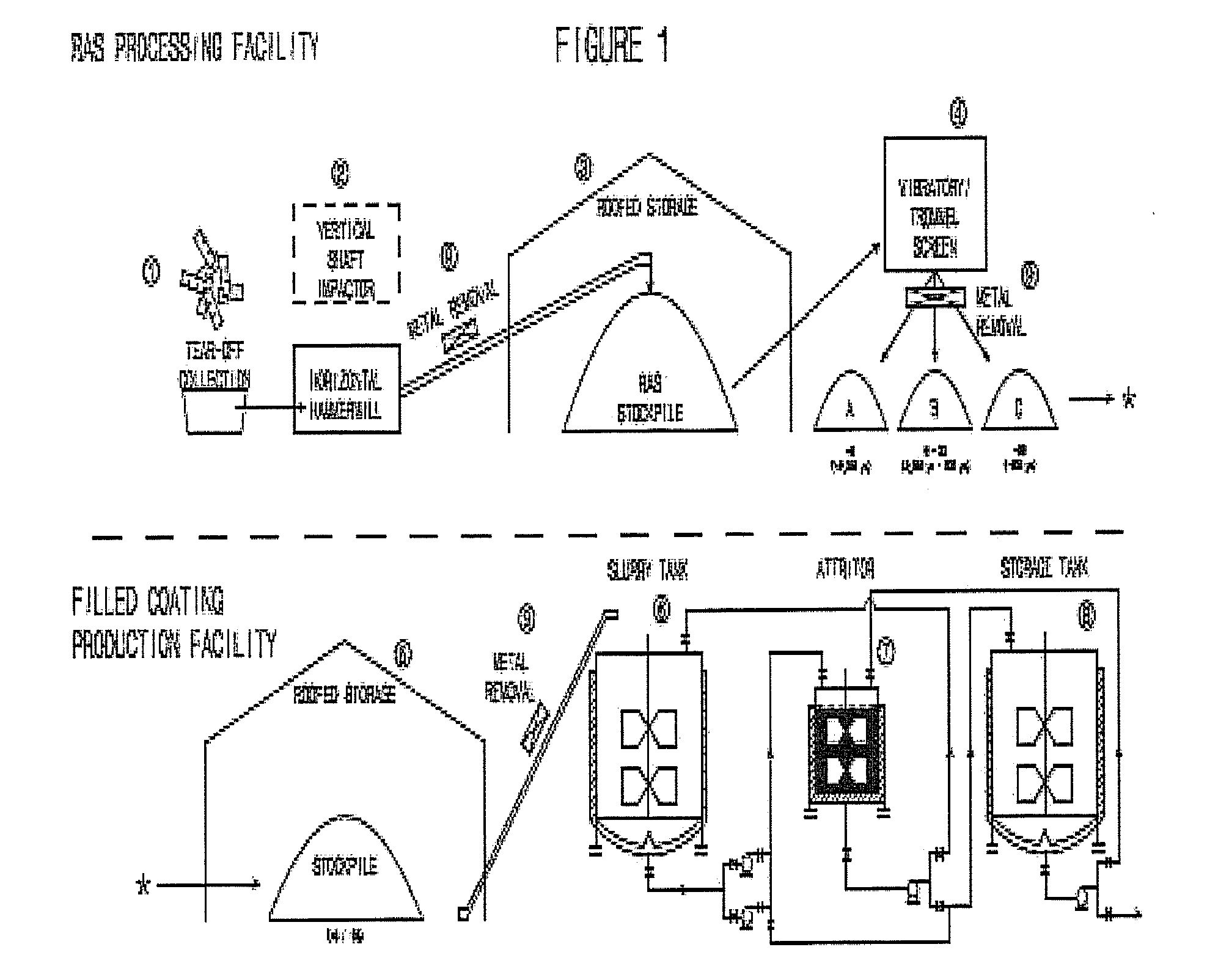

System and method for manufacturing asphalt products with recycled asphalt shingles

InactiveUS20140014000A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shingleSlurry

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE ENVIRONMENTAL SERVICES

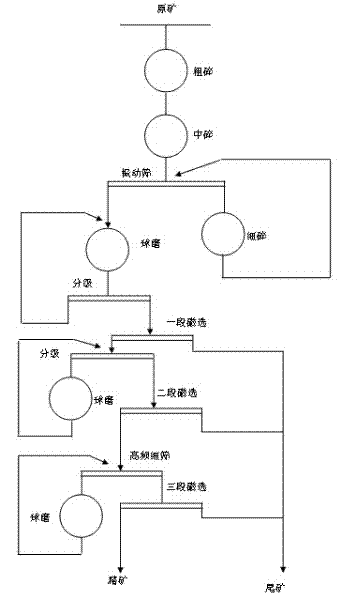

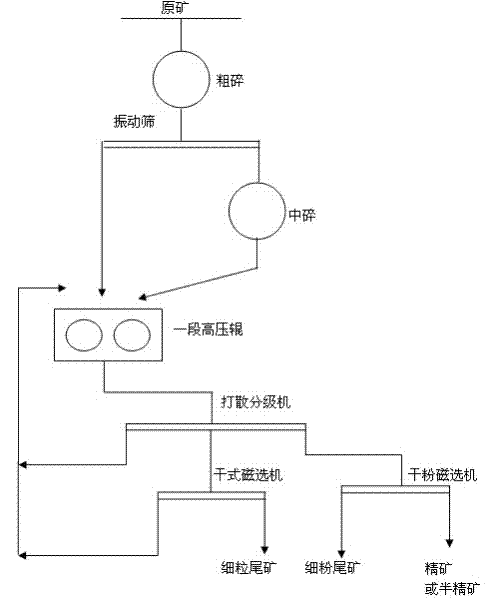

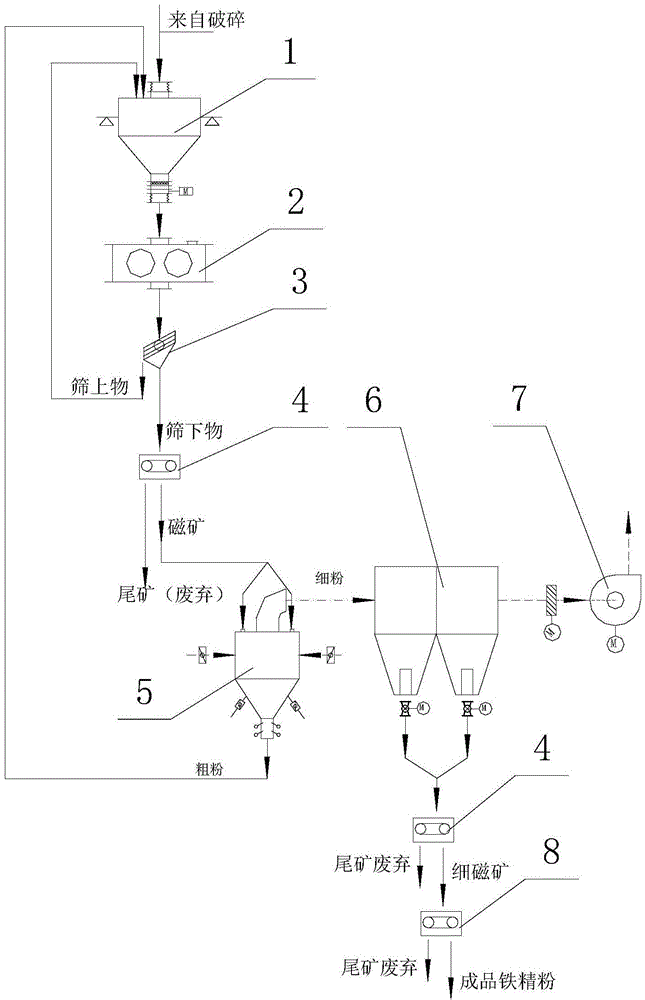

Dry-grinding and dry-separation method of magnetite

ActiveCN102240588ASimplify the crushing processSave moneyGas current separationGrain treatmentsMagnetiteClosed loop

The invention discloses a dry-grinding and dry-separation method of magnetite, which comprises the following steps of: feeding the crude ore of magnetite into a crusher for coarse crushing, and then feeding the crushed magnetite into a vibrating sieve for sieving; controlling the sieve meshes within a range of 35-75 mm; feeding the oversize product to the crusher for intermediate crushing and then feeding the crushed oversize product into a high-pressure roller mill along with the undersize product for fine crushing; breaking and grading the fine-crushed ore by a breaking-grading machine, thereby obtaining the products of three grain grades, i.e. coarse grains, fine grains and fine powder; returning the coarse-grain grade product to the high-pressure roller mill through an elevator, and feeding the fine-grain grade product to a dry type magnetic separator for magnetic separation and discarding tailings, wherein the magnetic field intensity is controlled within a range of 1200-3000 Gs; directly dryly stacking the discarded fine-grain grade tailings, and returning the fine-grain grade concentrate to the high-pressure roller mill through a belt conveyor and the elevator to form a closed loop; and feeding the fine-powder grade product into a cyclone magnetic separator, wherein the magnetic field intensity is controlled within a range of 600-1200 Gs, thereby obtaining concentrate or semi-concentrate. The dry-grinding and dry-separation method is low in power consumption, steel consumption and water consumption, and the tailings are easy to be disposed of.

Owner:CHENGDU LEEJUN IND

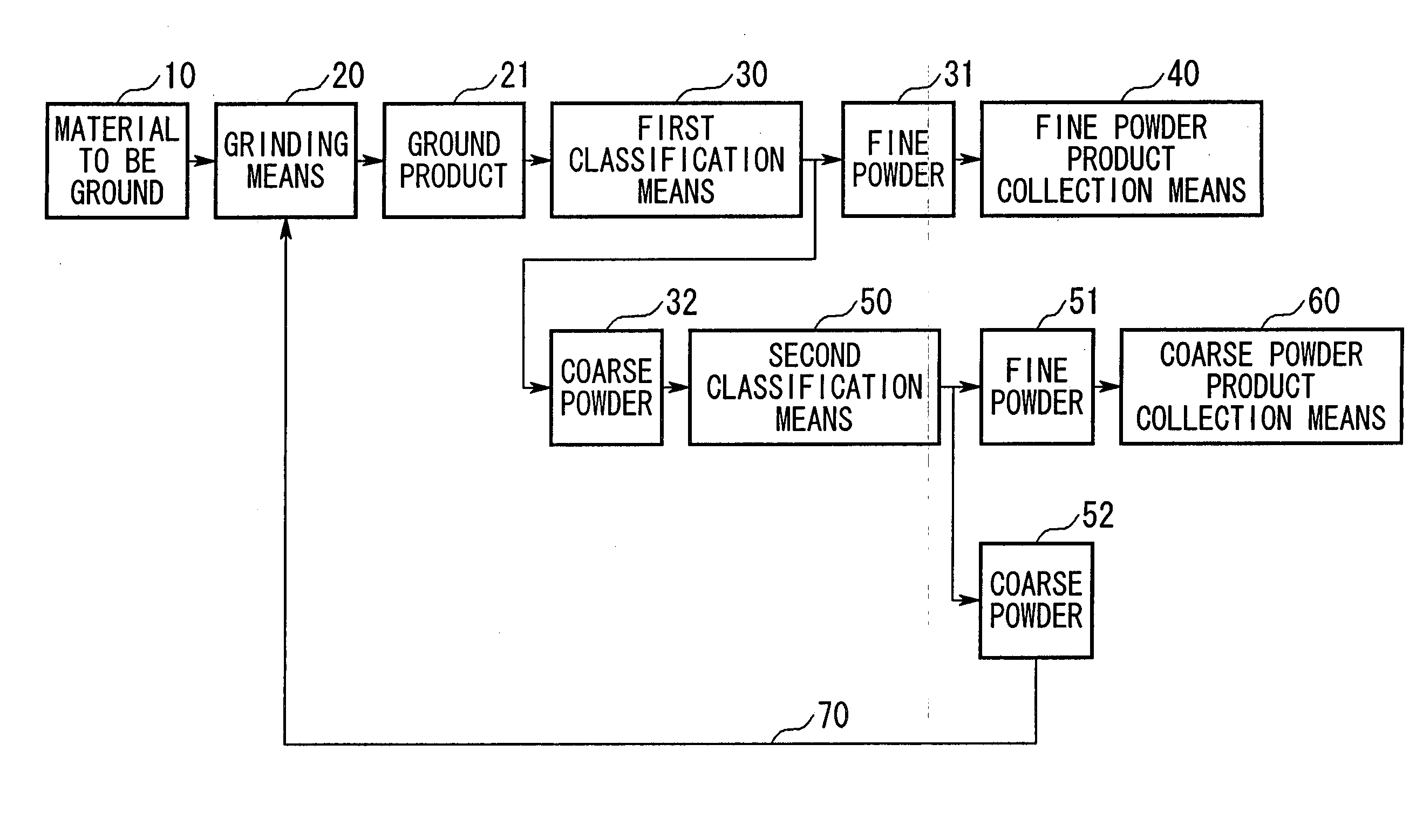

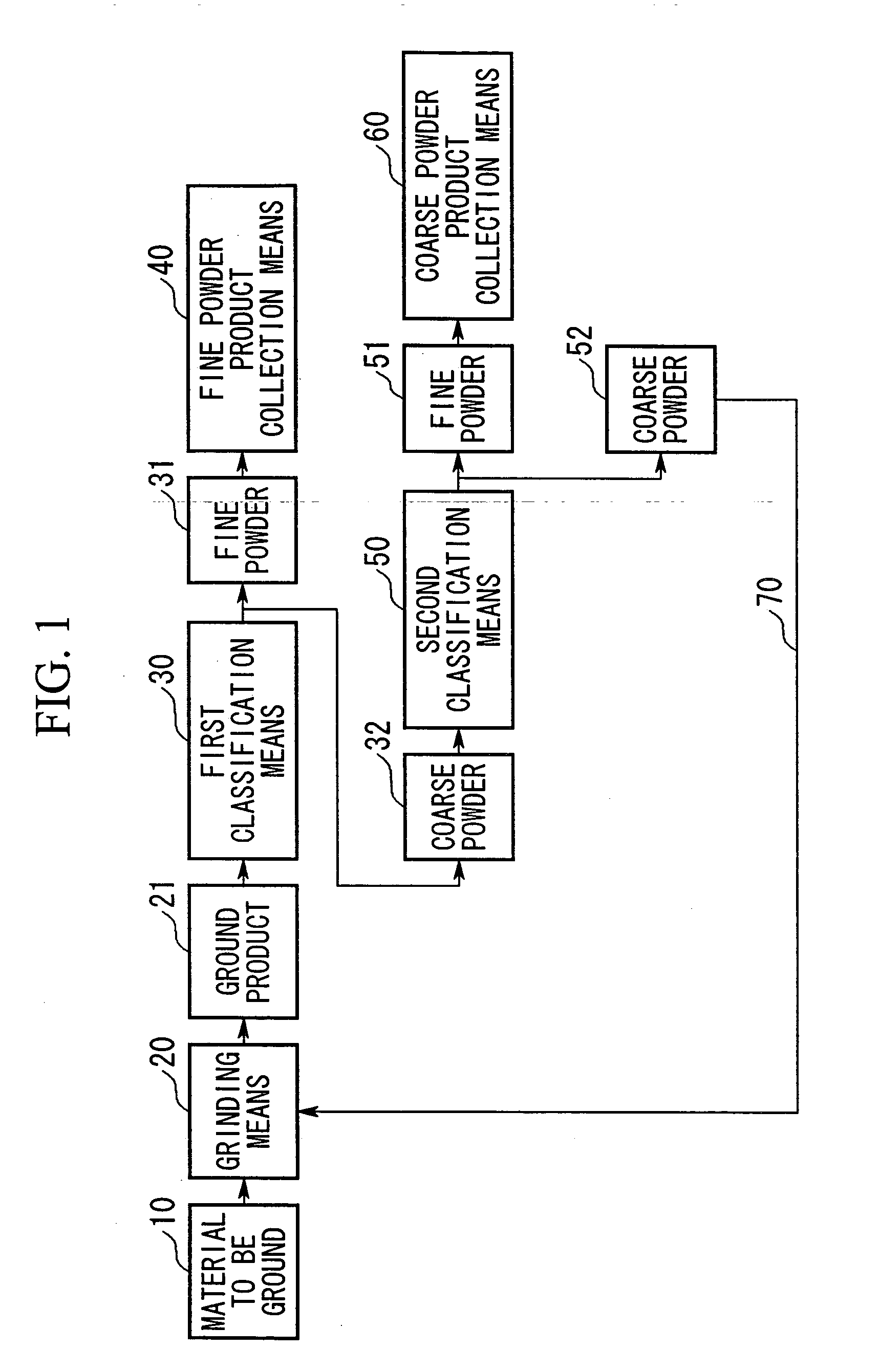

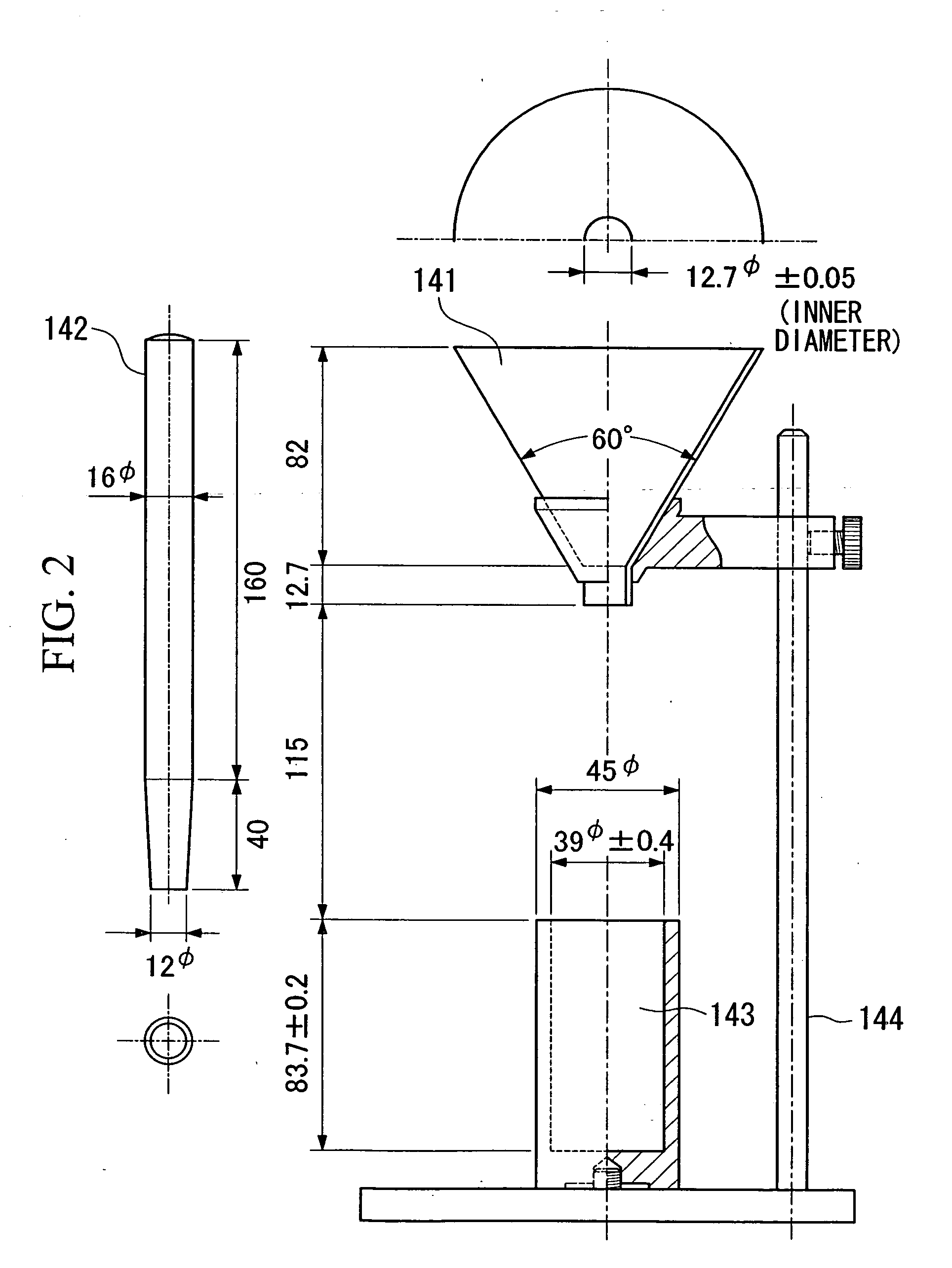

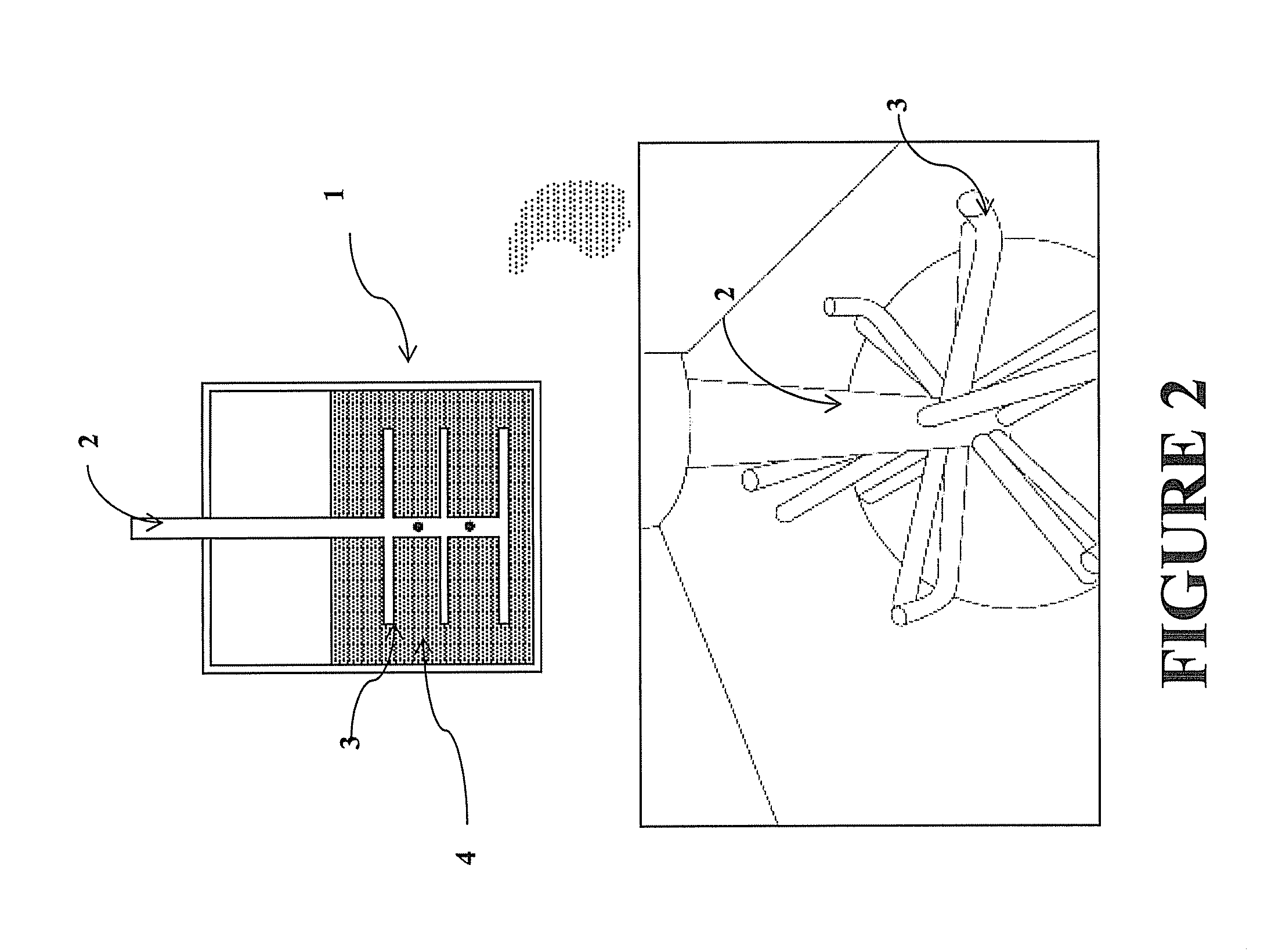

Dry grinding system and dry grinding method

The invention provides a dry grinding system including grinding means for dry-grinding a material to be ground; first classification means for classifying a ground product obtained through the grinding means, into fine powder having a relatively small average particle size and coarse powder having a relatively large average particle size; second classification means for further classifying the coarse powder obtained through the first classification means, into fine powder having a relatively small average particle size and coarse powder having a relatively large average particle size; and returning means for returning to the grinding means the coarse powder obtained through the second classification means. The invention enables production of a powder product having a desired average particle size at high efficiency.

Owner:SHOWA DENKO KK

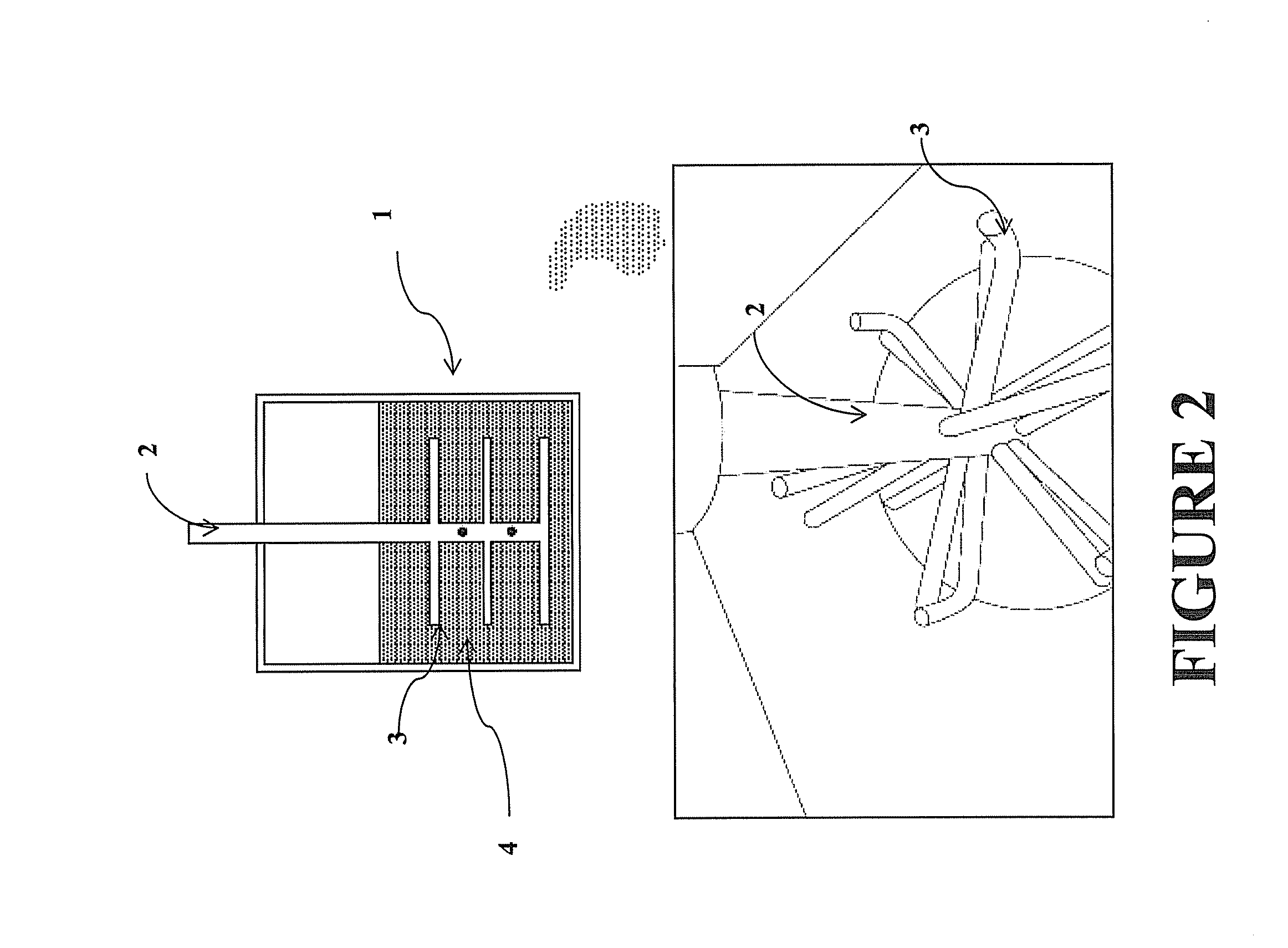

Diamond dry grinding disc and manufacturing method thereof

InactiveCN101722478ALarge amount of grindingLong grinding timeAbrasion apparatusGrinding devicesWear resistantTemperature resistance

The invention relates to a diamond dry grinding disc and a manufacturing method thereof, relating to the diamond dry grinding disc. The invention provides the diamond dry grinding disc with large grinding amount, long grinding time, good high-temperature resistance and good wearing resistance and the manufacturing method thereof. The diamond dry grinding disc is provided with a grinding material layer and a connecting piece, wherein the connecting piece is fixedly connected with the grinding aid layer; the connecting piece is externally connected with a power transmission piece; and the grinding material layer comprises the following components in parts by weight: 30% to 50% of high-temperature resistant resin, 15% to 30% of diamond particles and 30% to 50% of wearing resistant radiating additive. The raw materials are weighed according to formula percentage, and are uniformly mixed. The uniformly mixed raw materials are poured into a mould for matching mould. The raw materials are heated in an oven after matching mould and are demoulded after solidifying to obtain a molding green body, the molding green body is heated for solidifying in the oven to obtain the grinding aid layer, and the grinding aid layer is spliced with the connecting piece to obtain a finished product.

Owner:厦门致力金刚石工具有限公司

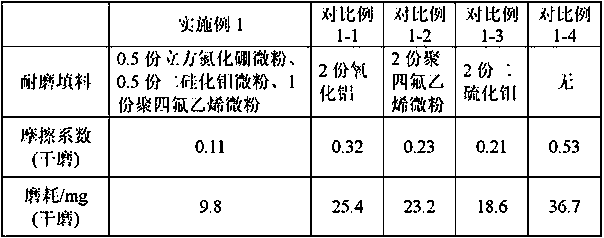

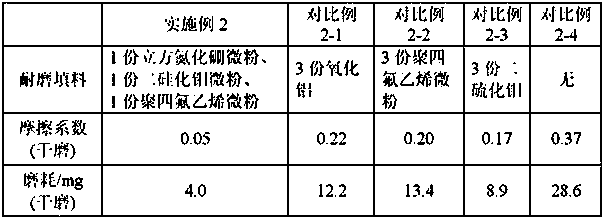

Wear-resistant filling material, wear-resistant composite material prepared from same and preparation method for composite material

The invention discloses a wear-resistant filling material, a wear-resistant composite material prepared from the same and a preparation method for the composite material. The wear-resistant filling material is prepared from the following components by weight: 0.15 to 7.5 parts of cubic boron nitride micro powder, 0.15 to 7.5 parts of molybdenum disilicide micro powder and 0.2 to 10 parts of polytetrafluoroethylene micro powder. The wear-resistant composite material is prepared from the following components by weight: 100 parts of a plastic resin, 0.5 to 25 parts of the wear-resistant filling material, 0 to 2 parts of a coupling agent and 0 to 2 parts of a processing aid. The preparation method for the wear-resistant composite material comprises the following steps: mixing the above-mentioned components at a high speed and carrying out extrusion with an extruder. According to the invention, cubic boron nitride micro powder, molybdenum disilicide micro powder and polytetrafluoroethylene micro powder are compounded to prepare the wear-resistant filling material which is applied to a plastic matrix, so the wear-resistant composite material with good wear resistance, a low friction coefficient and low dry grinding abrasion is prepared; and the application scopes of cubic boron nitride and molybdenum disilicide are broadened at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

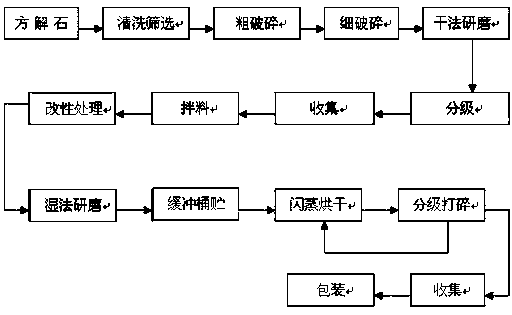

Preparation process of wet-process superfine modified calcium carbonate

InactiveCN104744971AIncrease productivityHigh activityInorganic compound additionPigment treatment with macromolecular organic compoundsSodium stearateMicrosphere

The invention discloses a preparation process of wet-process superfine modified calcium carbonate. The preparation process comprises the following steps: performing cleaning and screening, rough crushing, fine crushing, dry grinding and grading on calcite ores; collecting fine powder of 600 meshes and preparing slurry with water in such a manner that the solid content is 70%-80%; adding a modifier sodium stearate to the slurry for modification treatment and then performing wet grinding, and adding a grinding medium zirconium oxide microspheres and a dispersant sodium polyacrylate during grinding, wherein the volume ratio of the grinding medium to the slurry is 1: 1.5, and the dosage of the modifier is 0.6%-1.2% of the solid content; and putting the slurry obtained after the wet grinding through a vibrating screen, collecting the obtained wet-process superfine modified calcium carbonate slurry into a slurry barrel for flashing drying, collecting the finished product and packaging. The new preparation process is adopted; the wet grinding-modifying integrated technique and the flashing drying technique are adopted so that the production efficiency is high and the production cost is low; the product has the advantages of small particle size, low oil absorption value, high activity and the like; and the major product quality indices are at the international leading level.

Owner:江西科越科技有限公司

Method for chrome-free tanning beach woolfell by adopting chrome-free tanning agent

InactiveCN102758029AHigh whitenessLow free formaldehyde contentTanning treatmentPre-tanning chemical treatmentSewageSewage treatment

The invention discloses a processing method for chrome-free tanning a beach woolfell by adopting a chrome-free tanning agent DESOTAN H30, which comprises the following steps: soaking, fleshing, degreasing, softening, pickling, tanning, extracting alkali, wet grinding, re-tanning, drying, wetting back, dry cleaning, staking, conditioning, reducing, oxidizing, drying, wetting back, staking, dry grinding, dedusting, and obtaining the finished product. The method is the technology for preparing the beach white woolfell, adopts the chrome-free tanning agent to process the beach white woolfell, uses no chrome during the tanning process, and obtains the finished product, which is pure white, slightly curled and distinctive in style, keeps the natural property, contains less than 150ppm of free formaldehyde, has a shrinkage temperature higher than 75 DEG C and has practical production significances. The technology can not only realize zero emission of waste chrome and lower the sewage treatment cost for an enterprise, but also obtain the finished product which is pure white, slightly curled and artistic in appearance, feels plump and soft, contains 130mg / kg of formaldehyde and has a shrinkage temperature of 75 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH +1

Load type nano selenium and preparation method

InactiveCN1686789ASolve reunionFix stability issuesAnimal feeding stuffAccessory food factorsNanoreactorAquatic product

The present invention discloses a load-type nano selenium and its preparation method. It is a nano-elementary selenium loaded no the porous mineral material, the average particle size of said elementary selenium is less than 100 nano. By weight percentage, selenium content in the porous mineral material is 0.1-1%. It is made up by using porous mineral material as miniature nano reactor and adding reductant into selenium salt to make reduction reaction to obtain the nano elementary selenium, drying-grinding or spray-drying so as to obtain the invented product.

Owner:BEIJING BOAI XIKANG NITRITION TECH

High potential gradient zinc oxide pressure-sensitive resistor material and preparation process thereof

InactiveCN102515742AExtended service lifeReduce energy consumptionVaristor coresHigh energyElectric power system

The invention relates to a high potential gradient zinc oxide pressure-sensitive resistor material and a preparation process thereof. The high potential gradient zinc oxide pressure-sensitive resistor material with uniform particle sizes is obtained by weighing a main material ZnO, a doping oxide, and a product rare earth oxide obtained by carrying out thermal decomposition on a rare earth oxalate or / and carbonate or / and hydroxide according to proportions, carrying out high energy wet grinding, drying, presintering at 200-800DEG C, carrying out high energy dry grinding, and sintering at 800-1100DEG C. The preparation process of the invention has the advantages of simplicity, low cost, environmental protection and low energy consumption, and the prepared zinc oxide pressure-sensitive resistor material can be used for preparing high quality lightning arrester products for ultrahigh electric power systems.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Stains which bake to a red-brown color, process for their preparation and their methods of use

InactiveUS6228160B1Adequate spatial separationIncrease contentPigmenting treatmentClaywaresX-raySilicone oil

The invention provides new stains which fire to a red-brown color for coloring ceramic compositions. The stains comprise Fe2O3 and / or an Fe compound which forms Fe2O3 on firing, in uniform distribution in a pulverulent matrix based on an oxide-like and / or silicate-like material which is amorphous to X-rays to the extent of at least 50% and has a specific surface area (BET) of at least 40 m2 / g, and are obtainable by bringing the constituents into intensive contact together. The matrix preferably comprises 80 to 100% amorphous SiO2 or SiO2-rich silicate with a BET surface area of 90 to 300 m2 / g and 0 to 20% of an auxiliary substance, such as silicone oil. The stains can be prepared by intensive dry grinding.

Owner:CERDEC AKTIENGES KERAMISCHE FARBEN

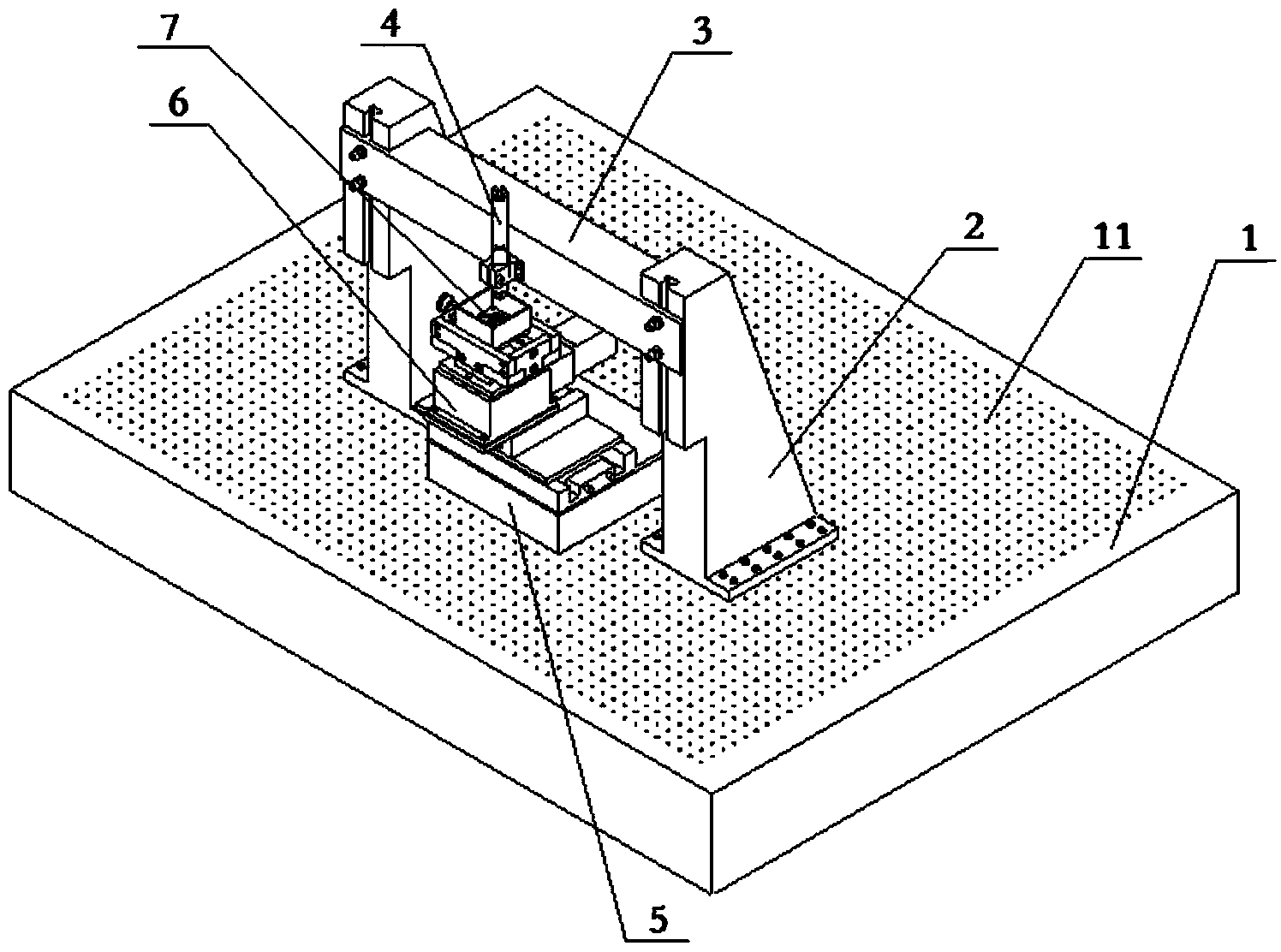

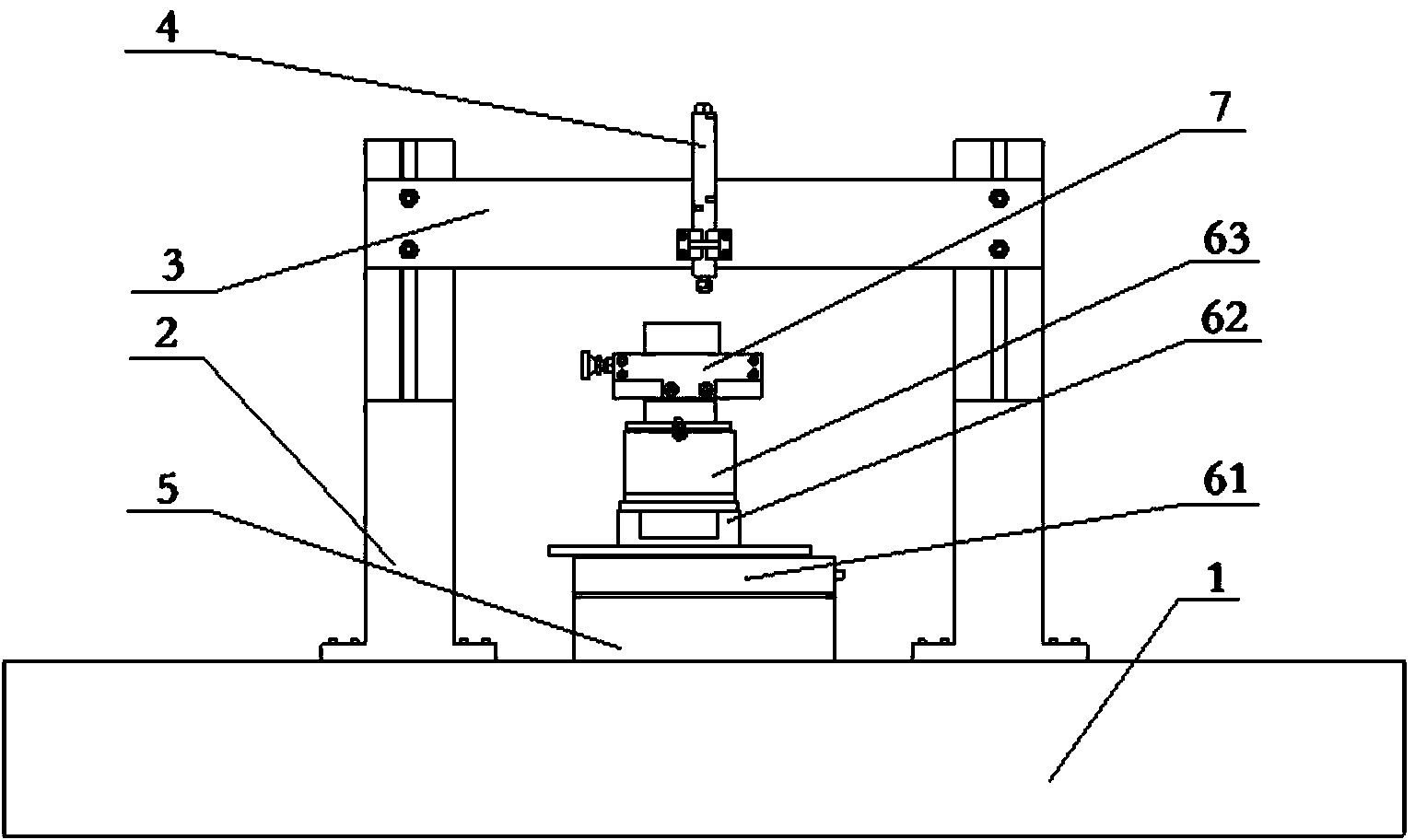

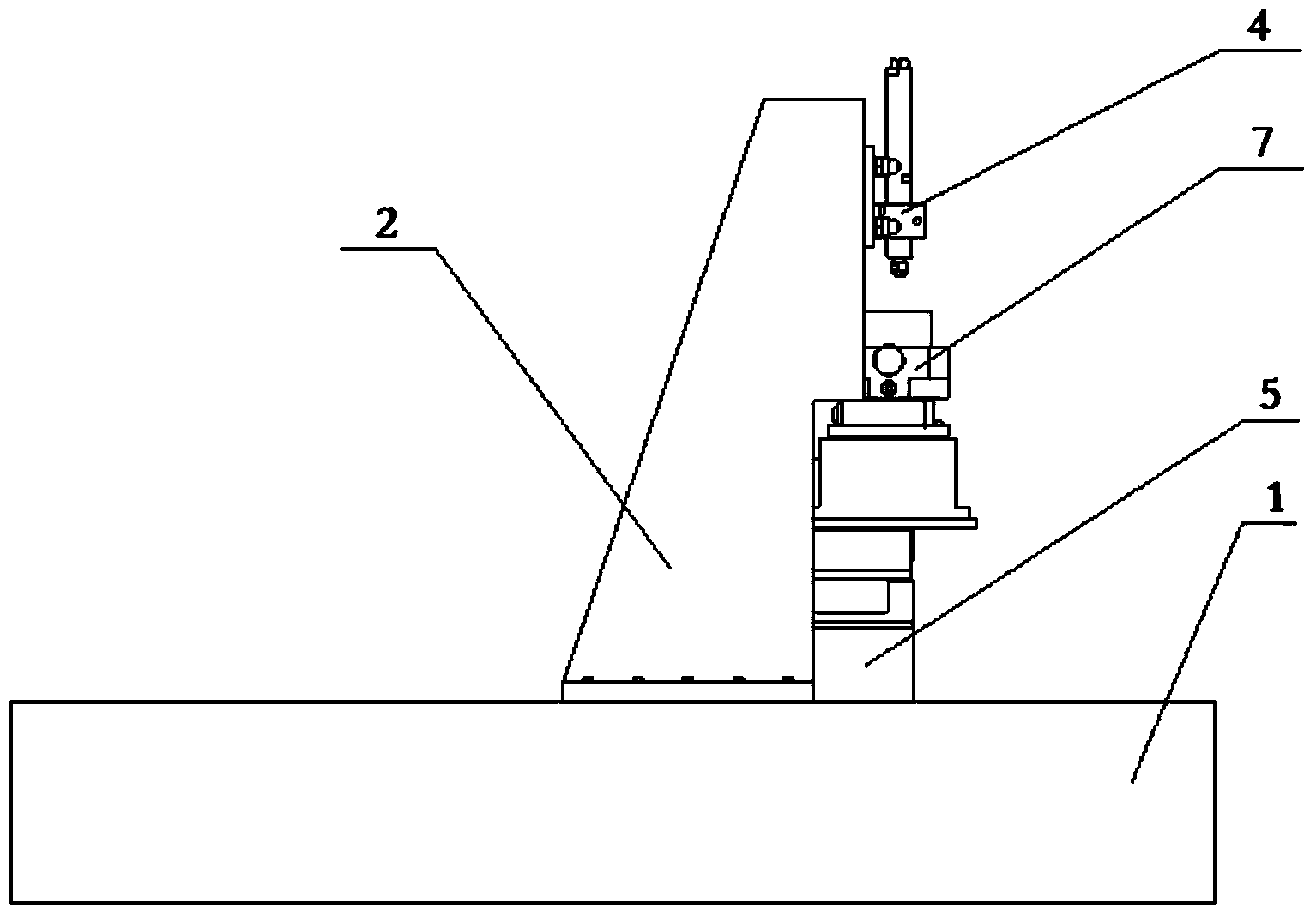

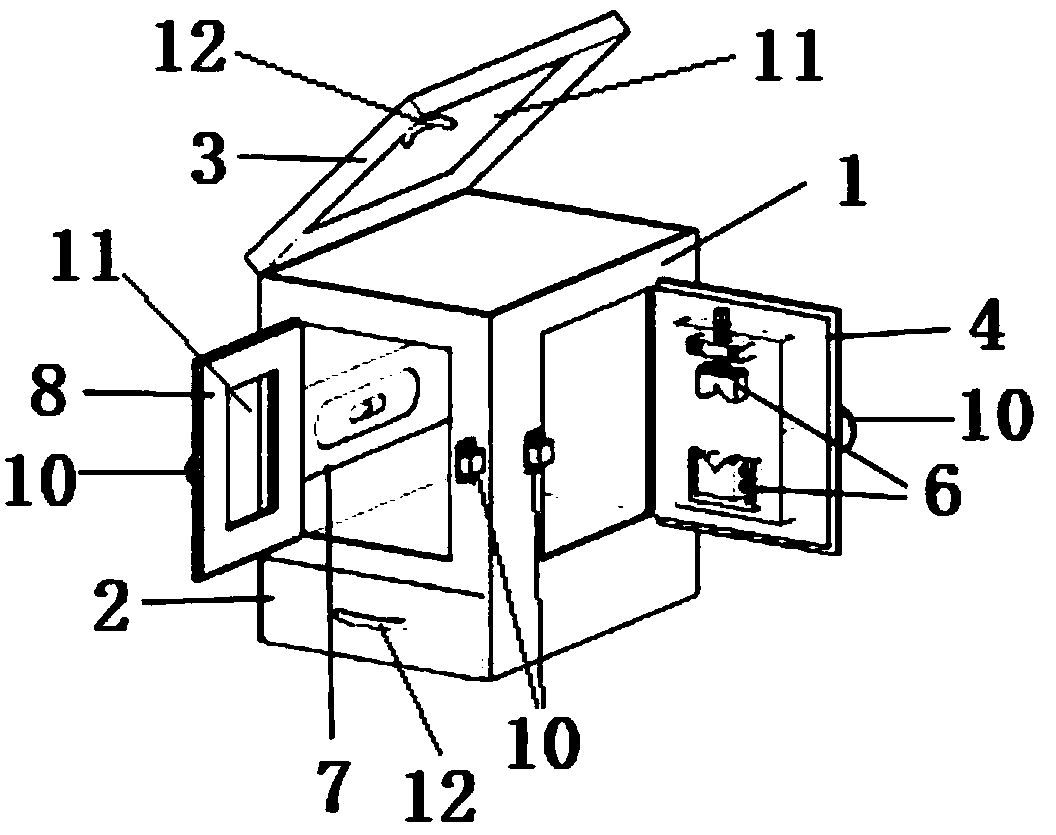

Ultrasonic micro grinding and processing equipment and technology thereof

InactiveCN103769959ASimple structureRich use functionGrinding machine componentsEngineeringUltrasonic vibration

The invention discloses ultrasonic micro grinding and processing equipment and a technology thereof. The equipment comprises a vibration isolation operating table, wherein columns which are in left-right symmetric arrangement are fixed on the vibration isolation operating table, the columns are connected via a beam, a main shaft component which drives a grinding device to rotate at a high speed is arranged on the beam, an ultrasonic vibration platform is arranged below the main shaft component, and the ultrasonic vibration platform is a two-dimensional ultrasonic vibration platform which is driven by a piezoelectric stack actuator and takes a polar coordinate system as an operating coordinate system. According to the single-drive polar coordinate two-dimensional ultrasonic micro grinding and processing equipment, provided by the invention, during processing, the piezoelectric stack actuator is selected for replacing the existing common ultrasonic amplitude transformer as a driving source, amplitude and frequency can be adjusted, and at the same time, the structure of the ultrasonic vibration platform is greatly simplified; besides, multiple grinding modes, such as dry grinding, wet grinding, peripheral grinding, face grinding and the like, are provided, and processing effects are better; after the ultrasonic micro grinding and processing equipment is used for processing workpieces, the processing is simpler and more diversified, and the precision of processed workpieces is higher.

Owner:HEBEI UNIV OF TECH

System and method for manufacturing asphalt products with recycled asphalt shingles

ActiveUS20160362339A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shinglePrill

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE RES GROUP LLC

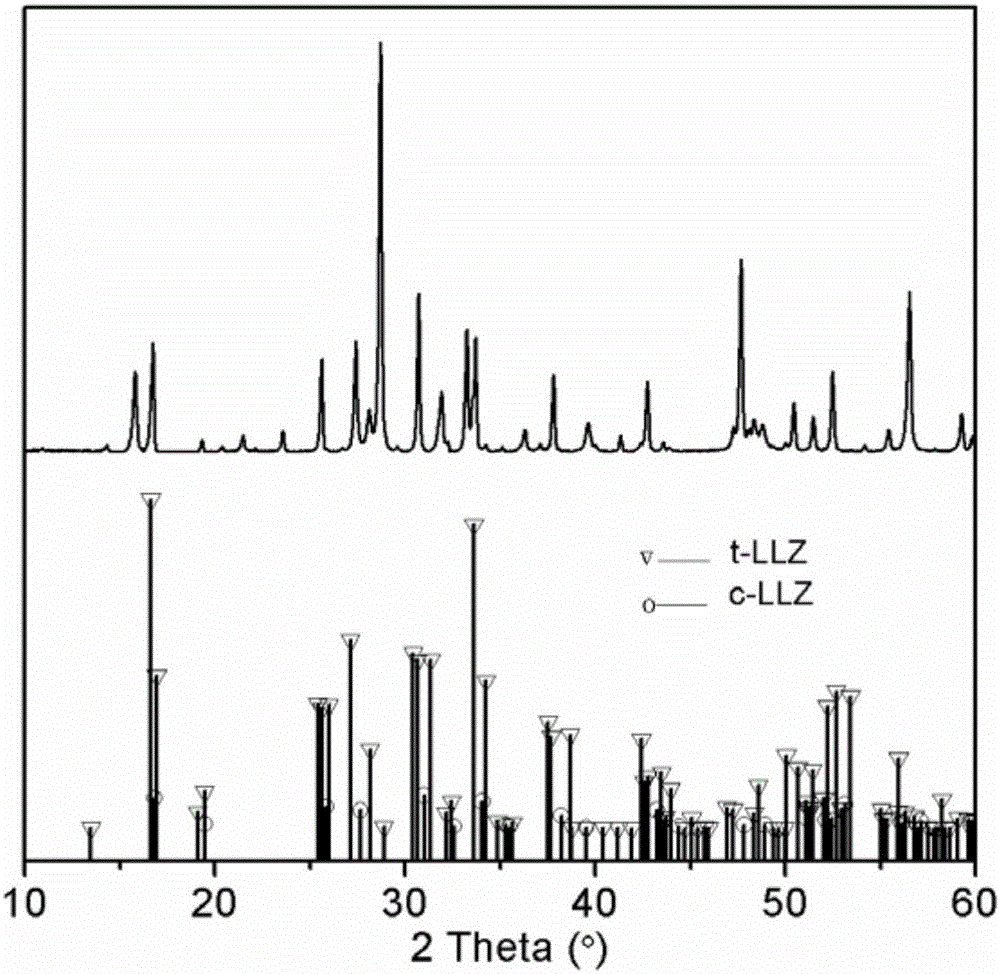

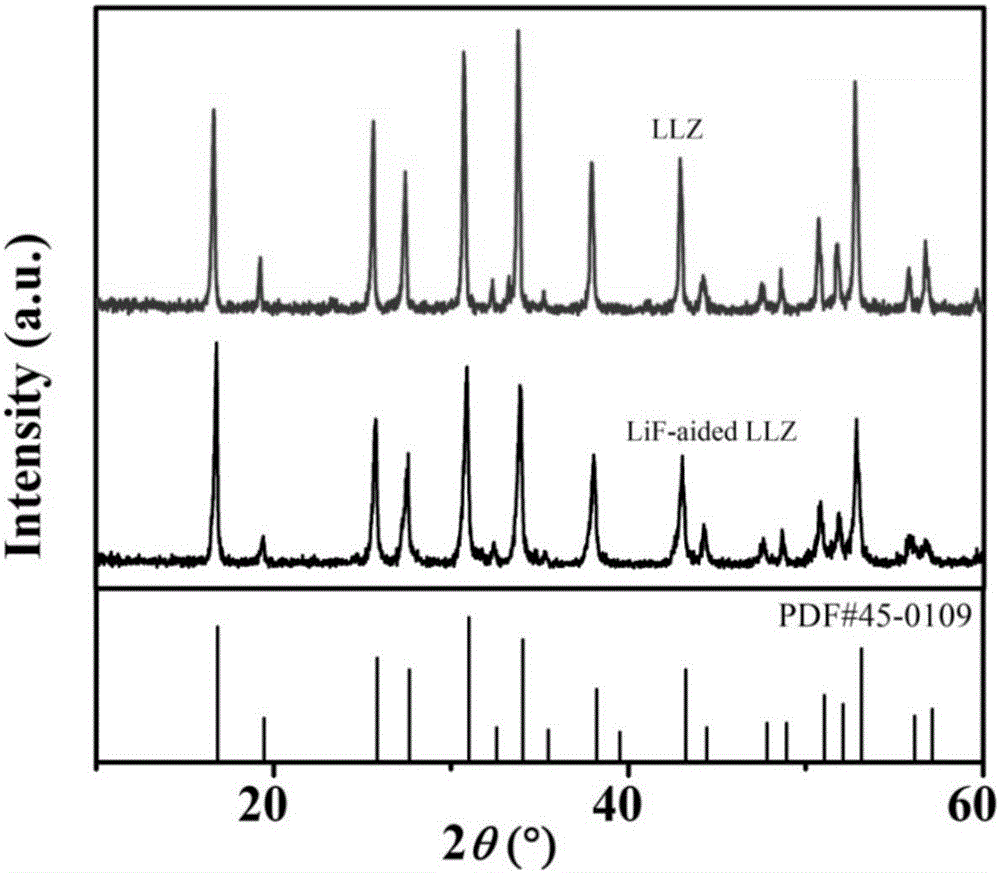

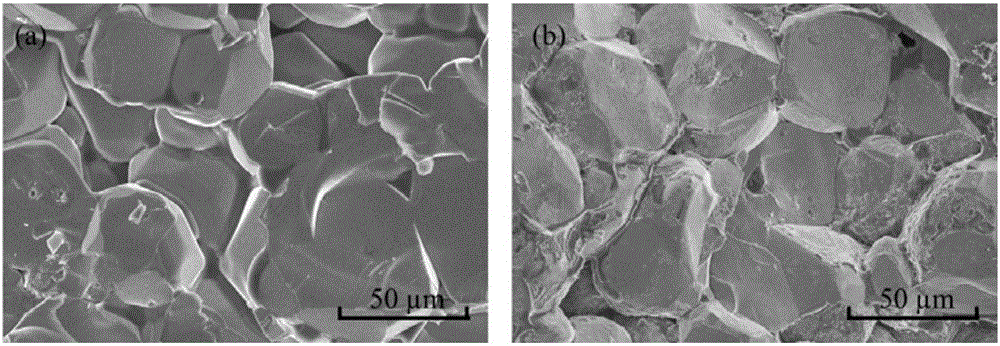

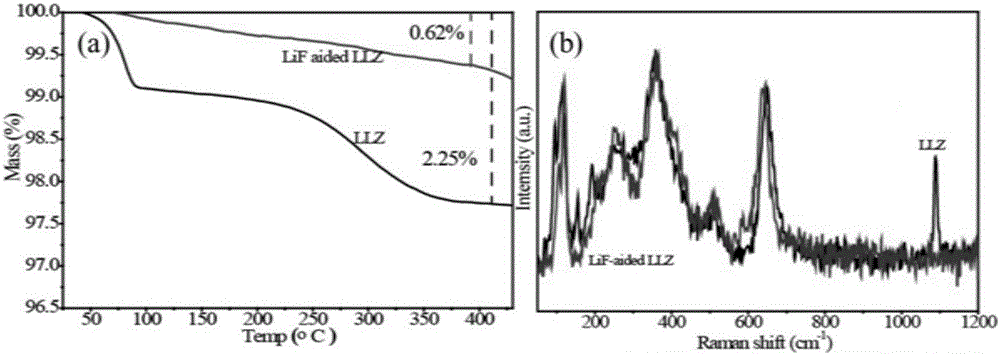

Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

InactiveCN106848392AImprove microstructureImprove sintering performanceSecondary cellsSolid state electrolyteIonic conductance

The invention relates to a solid electrolyte for inhibiting lithium dendrites growth in a full-solid-state battery, and a preparation method thereof. The solid electrolyte is prepared from lithium-lanthanum-zirconium oxide ceramic and 0.1 to 10 weight percent of low-melting-point sintering aid. The preparation method comprises the following steps of dry grinding and uniformly mixing stoichiometric lithium carbonate, lanthanum oxide and zirconium oxide, and then presintering in a muffle furnace at the temperature of 900 DEG C to form a phase; adding the low-melting-point sintering aid into presintering powder, and dry grinding and mixing to obtain a manual pressed sheet sample; densifying during a further high-temperature sintering process to form the solid electrolyte with high ionic conductance, stable performance and high repeatability. Compared with the prior art, without influencing a conductive property of a lithium-contained garnet lithium ion, a low-cost second phase is used so that the conductive property of the lithium ion at a crystal boundary part is improved, the solid electrolyte can better realize lithium ion transmission and plays a role in inhibiting the lithium dendrites growth in the full-solid-state battery, and the safety of the lithium battery is improved.

Owner:SHANGHAI JIAO TONG UNIV

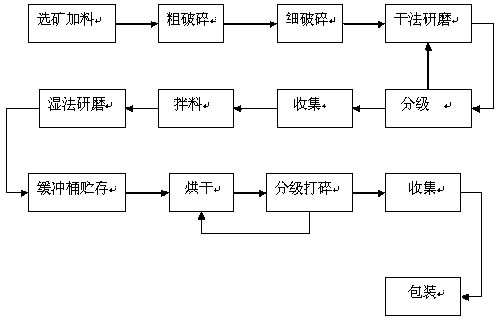

Process for preparing and purifying quartz sand and quartz powder and products thereby

The invention discloses a process for preparing and purifying quartz sand and quartz powder and products thereby, which consists of quartz ore selection, squashing, water selection, sintering, water disintegrating, oxalic acid or citric acid immersing, dry grinding or wet grinding, magnetic selection, fractionation, floating selection, deionized water washing, special type drying and vacuum-packing.

Owner:刘少云

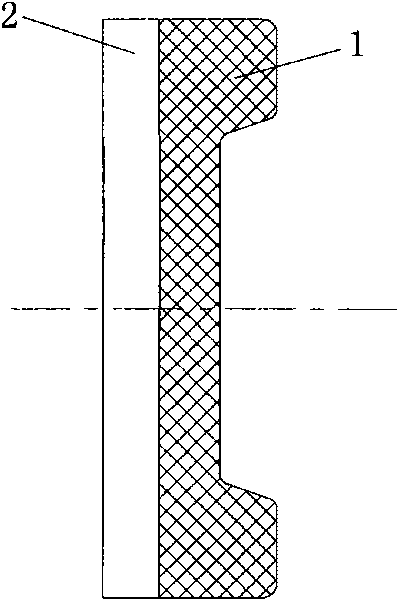

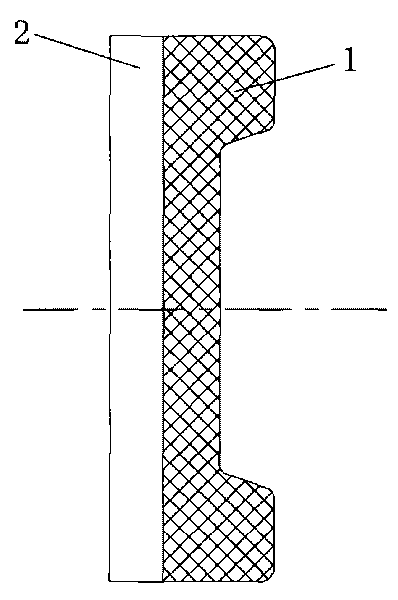

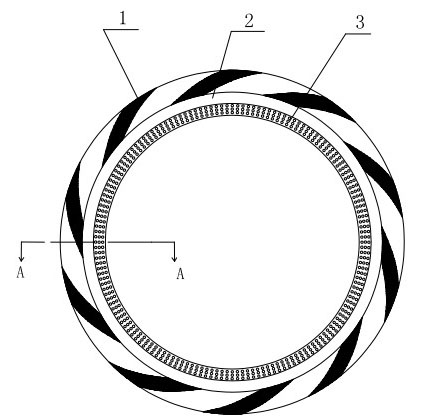

Self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure

ActiveCN101975274AReduce leakageReduce or avoid wear and tearEngine sealsDynamic pressureFace structure

The invention discloses a self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure, which comprises a dynamic ring and a static ring which are mechanically sealed, wherein at least one sealed end face of the dynamic ring or the static ring is a composite molded surface consisting of a microgroove dynamic pressure ring belt, a sealed dam and a hydrophobic molded surface distributed in turn from high to low direction. The structure has the advantages that: the self-sealing property of the narrow hydrophobic molded surface can obviously reduce the leakage and even reaches zero leakage; by adopting one or more hydrophobic molded surfaces, the abrasion of the end faces can be reduced or avoided, and the integral sealing property and the abrasion resistance of mechanical seal can be greatly improved; and by adopting the combination mode of the microgroove dynamic pressure ring belt and the hydrophobic molded surface, a lubricating medium can be stored in the end faces to prevent dry grinding of the end faces when the machine is started and improve the opening property and the reliability of mechanical seal.

Owner:SICHUAN ZIGONG IND PUMP

Production of instant water-gas slurry

InactiveCN101029260AEasy to oxidizeNot easily oxidizedLiquid carbonaceous fuelsLump/pulverulent fuel preparationMixed materialsBall mill

Production of quick-dissolving powdered water gas slurry is carried out by mixing various additive solutions with raw material coal proportionally, delivering mixed materials into ball mill, and dry grinding to obtain the final product. It has better stability, shorter working time, less producer and consumption and higher efficiency.

Owner:陕西升基利科技有限公司

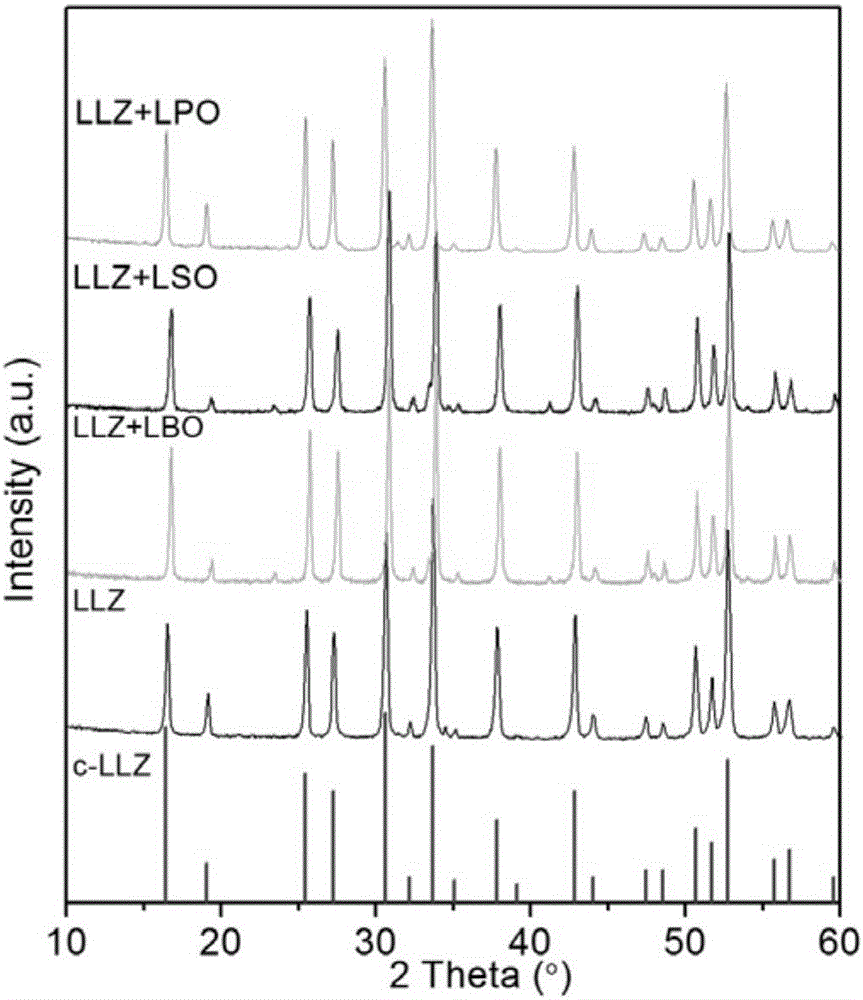

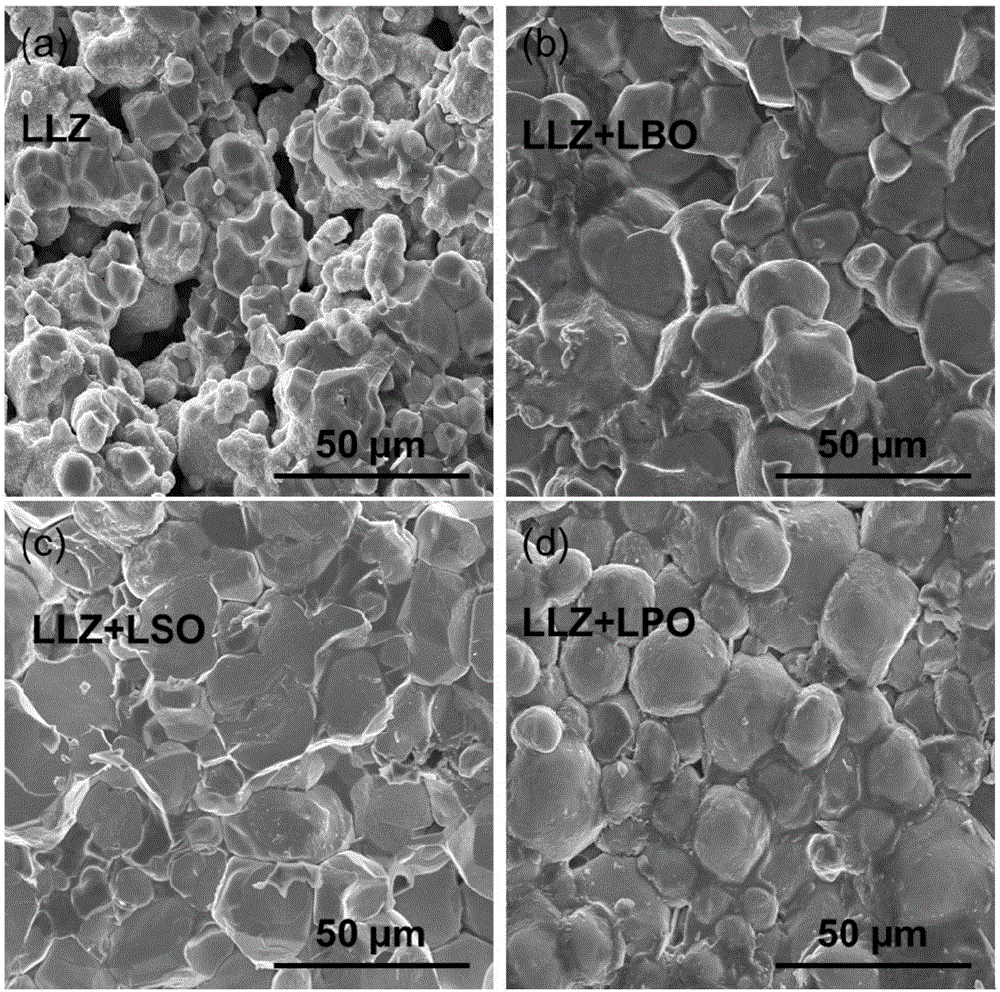

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

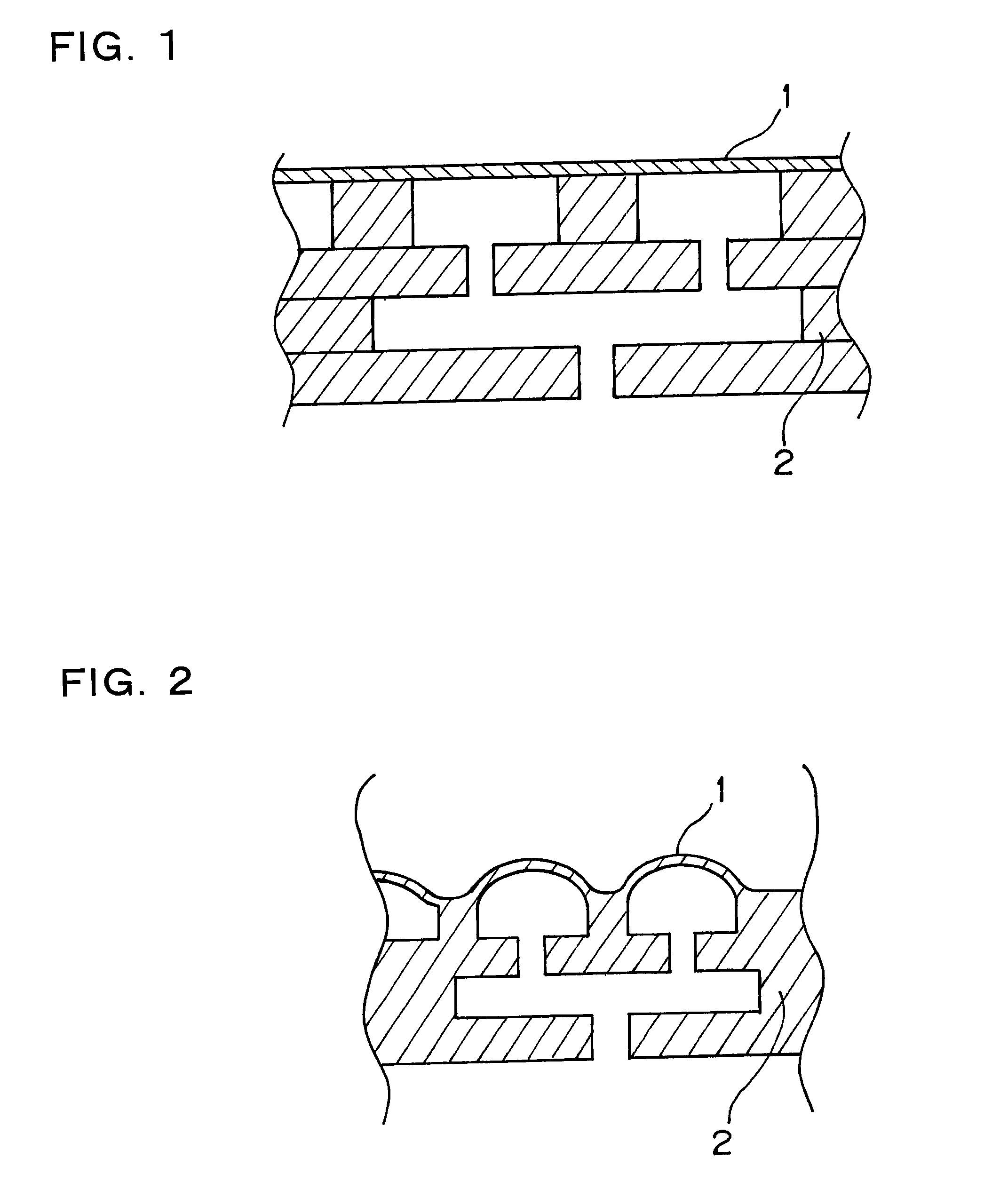

Method for producing ceramic green sheet

InactiveUS6395117B1Layered productsCeramic shaping apparatusSurface roughnessVolumetric Mass Density

Provided are a method for producing ceramic green sheets used for making a ceramic substrate which is reduced in cracking failure and improved in adhesion between laminated layers and is high in lamination property, high in strength and excellent in surface roughness, said method including heat-treating the ceramic powder having a specific particle size by dry grinding a ceramic powder to prepare ceramic powder having a specific average degree of aggregation and preparing a slurry using the ceramic powder so that a green density of the resulting ceramic green sheets is in a desired range, and a method for making a ceramic laminated substrate having excellent various properties by laminating the above ceramic green sheets and firing the laminate.

Owner:NGK INSULATORS LTD

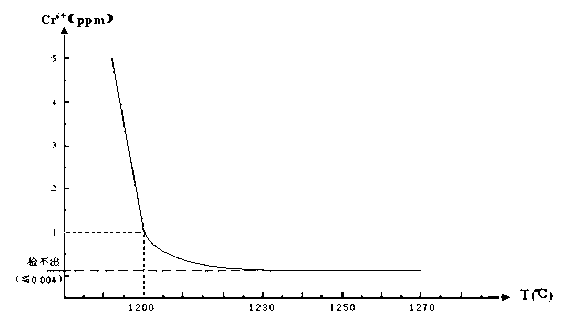

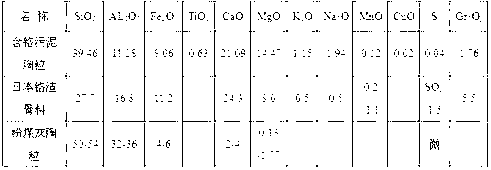

Method for preparing chromium-containing sludge ceramsite

InactiveCN102875116AThorough detoxificationReliable detoxificationCeramic materials productionClaywaresBrickSludge

The invention discloses a method for preparing chromium-containing sludge ceramsite. The method comprises the following steps of: performing wet grinding on chromium sludge to be 120 meshes; drying municipal sludge, decomposed rock, silt or kaolin and performing dry grinding together with a reducing agent to be 100 meshes; uniformly mixing and pressing into strip-shaped particles with diameter of 10 mm and length of 20 mm; and balling, drying and then feeding into a rotary kiln to calcine at the high temperature of 1,230-1,330 DEG C for 45 minutes to obtain the chromium-containing sludge ceramsite. The method has the characteristics of capability of treating chromium-containing sludge produced by leather production, complete and reliable detoxication, simple process, large sludge consumption, capability of simultaneously treating most of heavy metal pollutants and low production cost, and has the advantages of feasible technology and minimum cost compared with various methods for treating heavy metal in China at present. Inspection shows that a finished product meets the control index requirement of being used as a road bed material, concrete aggregate and light brick filler and being used for producing cement.

Owner:福建微水环保股份有限公司

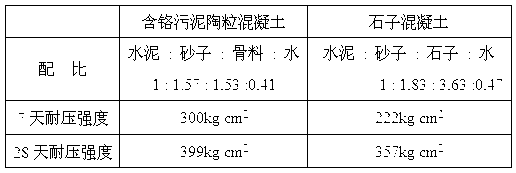

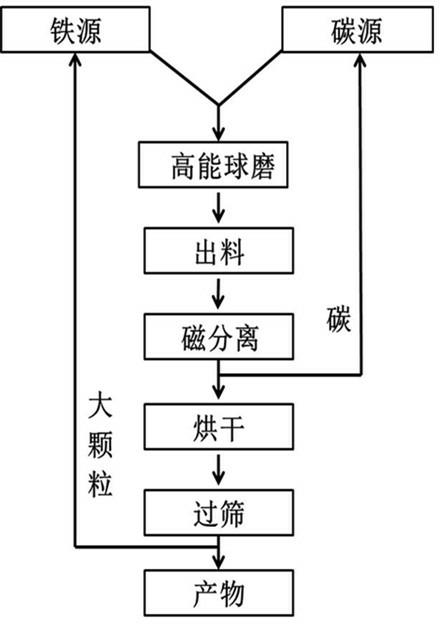

Method for preparing anode material of ferroferric oxide and carbon composite lithium battery

InactiveCN102623692ASmall particle sizeLarge specific surface areaCell electrodesCarbon compositesOxide composite

Owner:XINJIANG UNIVERSITY

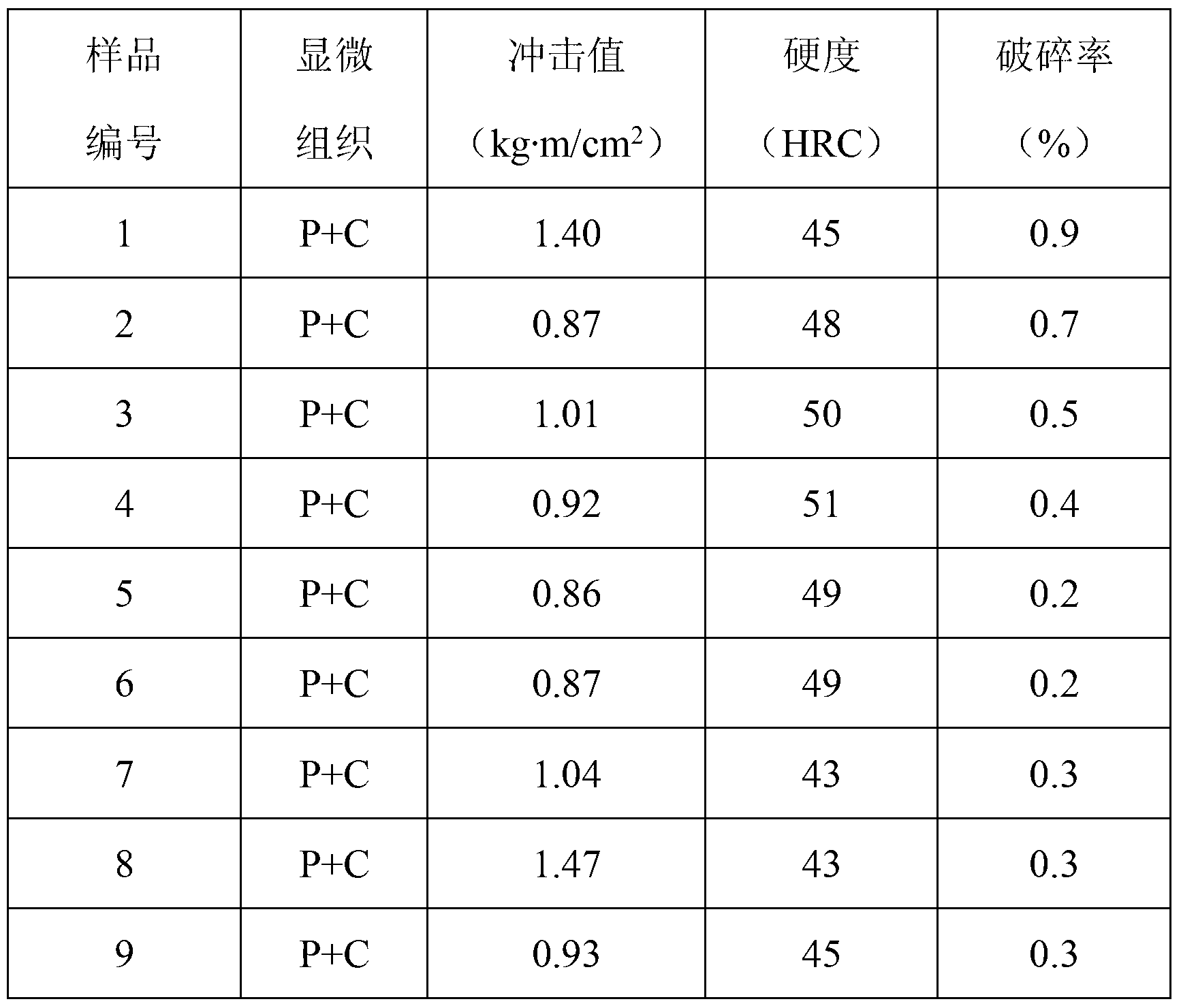

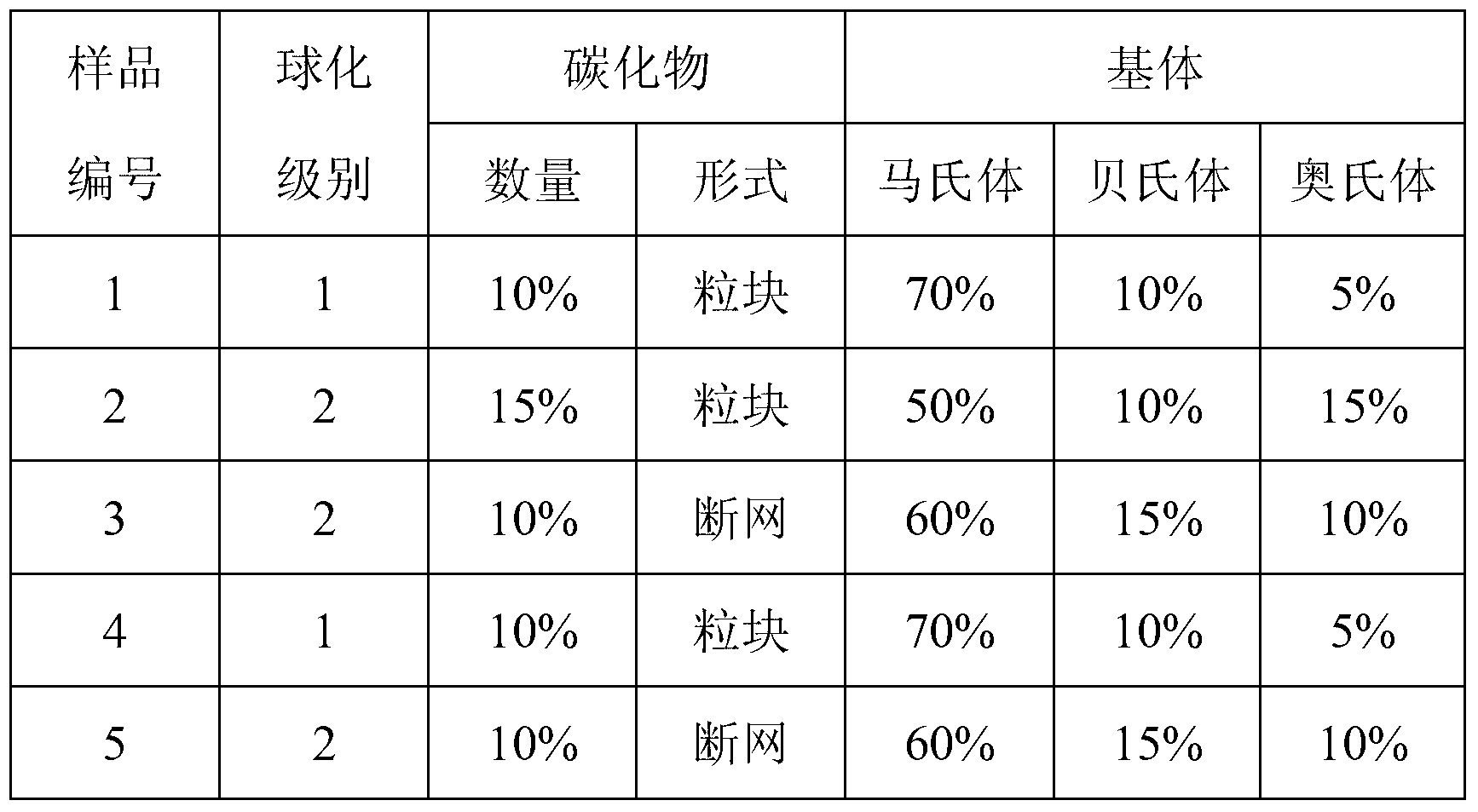

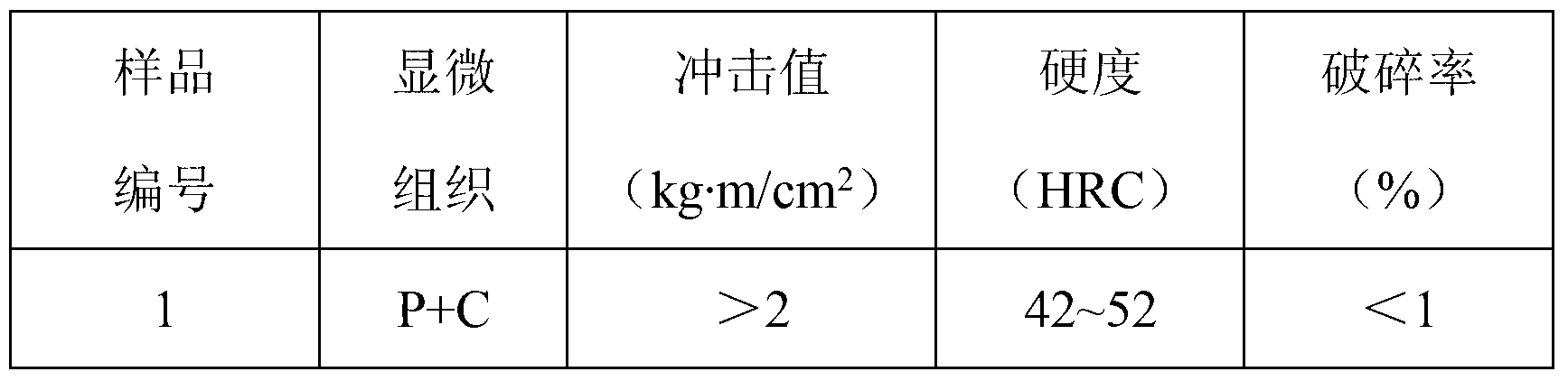

Multi-component alloy casting ball

The invention discloses a multi-component alloy casting ball which comprises the following main chemical components in percentage by weight: 1.8-3.2% of carbon (C), 0.5-1.0% of silicon (Si), 0.4-0.8% of manganese (Mn), 2.0-3.8% of chromium (Cr), no more than 0.5% of molybdenum (Mo), no more than 0.5% of copper (Cu), no more than 0.5% of nickel (Ni), no more than 0.2% of niobium (Nb), no more than 0.5% of zirconium (Zr), no more than 0.5% of vanadium (V), no more than 0.01% of boron (B), no more than 0.15% of phosphorus (P), no more than 0.15% of sulfur (S), 0.5-0.6% of rare earth yttrium (Y-Re) and the balance of iron (Fe). According to the invention, the cost is saved, the corrosion resistance and high temperature resistance of the multi-component alloy casting ball in a wet grinding environment can be improved, the breakage rate can be reduced, and the hardness and shock resistance of the multi-component alloy casting ball in a dry grinding environment can be ensured.

Owner:贵州省遵义市永力机电安装有限公司

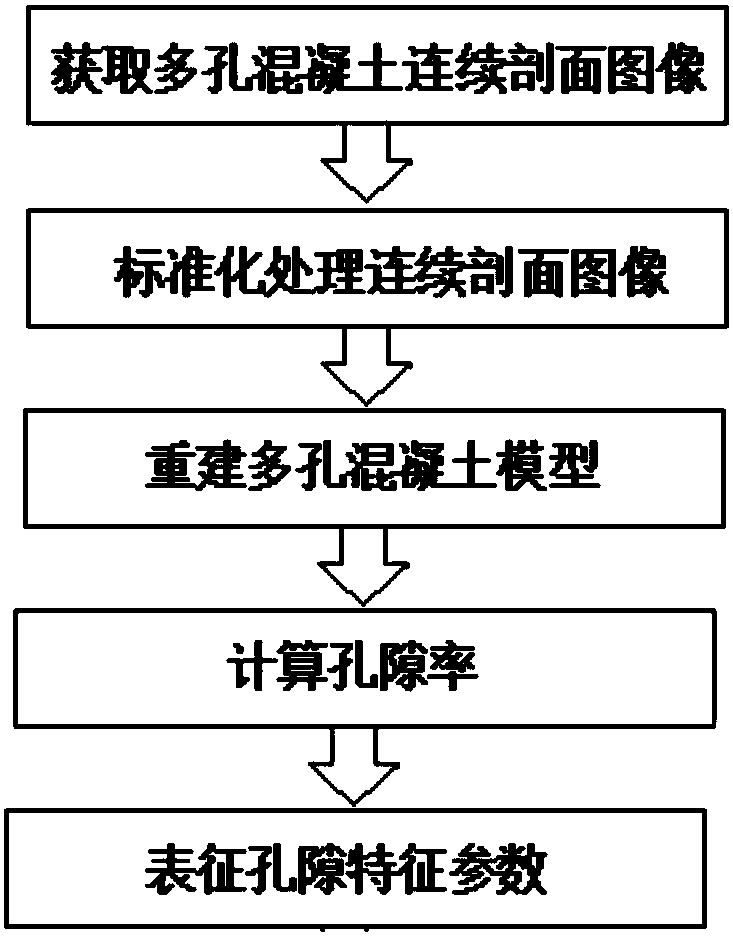

Method for calculating porosity and characterizing pore parameter of porous concrete

The invention belongs to the technical field of analysis of a pore parameter of concrete, and relates to a method for calculating the porosity and characterizing a pore parameter of porous concrete. An optimal-design grinding chamber having a profile made from a brittle material is adopted to cooperate with a grinding cutter for performing layer-by-layer dry grinding on a polyphase material test piece layer at a constant spacing; a continuous profile image of the polyphase material test piece is shot, and an image processing software is used for performing registration, standardization processing and pretreatment on the continuous profile image of the polyphase material test piece to obtain a standard usable continuous profile image of the polyphase material test piece. During acquisitionof the continuous profile image, registration of the profile image in a Z axis is taken into consideration, so that the continuous profile image with a relatively small interlayer spacing and comparatively high calibration degree is obtained. The image has the feature of a ''CT-simulative'' image, and the obtained true color image overcomes the defect of loss of information content of a CT-scannedgrayscale image. The method is simple and fast in image acquisition, is low in cost of image acquisition, and is convenient for application and popularization, and the information content of an obtained image is complete.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

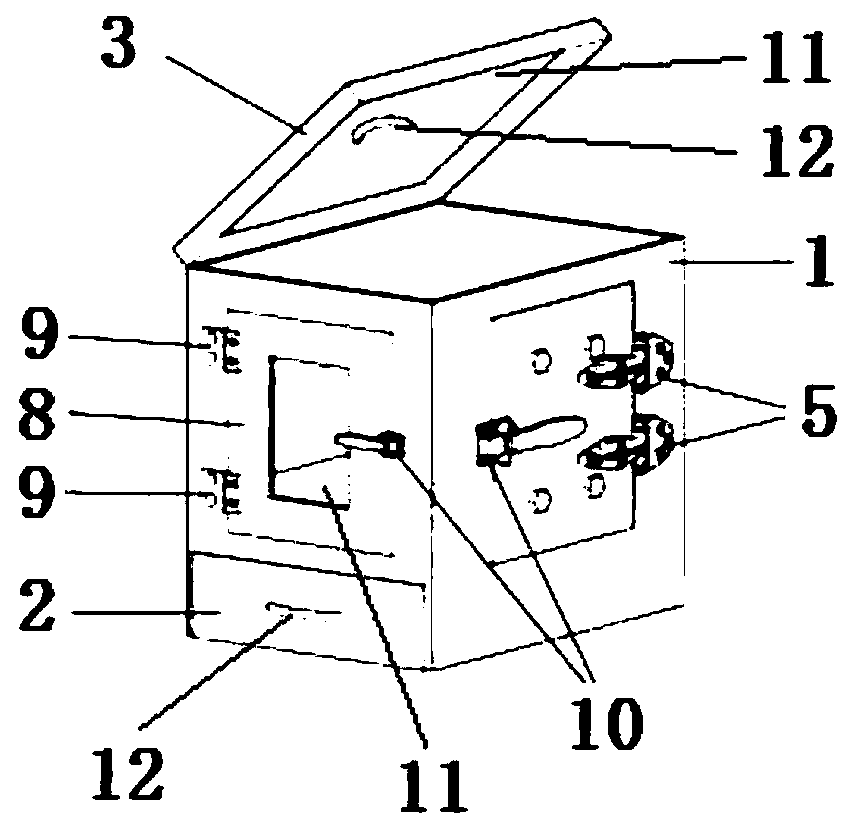

Method for preparing reductive iron powder and high-purity refined iron powder by using iron ores

The invention discloses a method for preparing reductive iron powder and high-purity refined iron powder by using iron ores. The method comprises the following steps of: ore crushing, dry grinding for preparing powder, reducing agent preparation, uniform mixing of pellet materials, pellet preparation, pellet roasting, water quenching, grinding and classification, magnetic separation, product dehydration and drying and the like so as to obtain the high-purity refined iron powder. The method has the advantages of simple process, wide application range and strong operability; the products are diversified, and the reductive iron powder and the high-purity refined iron powder can be obtained; the waste gas is reclaimed for recycling, the tailings are used as raw materials for slag cement and the tail water is used in a closed cycle mode, so the method belongs to an environment-friendly process; and the products have stable quality. The method is particularly adaptive to chlorination and reduction of the iron ores with characteristics of thin disseminated grain size, complex ore composition, high impurity (sulfur, phosphorus, arsenic and silicon) content and the like.

Owner:昆明晶石矿冶有限公司

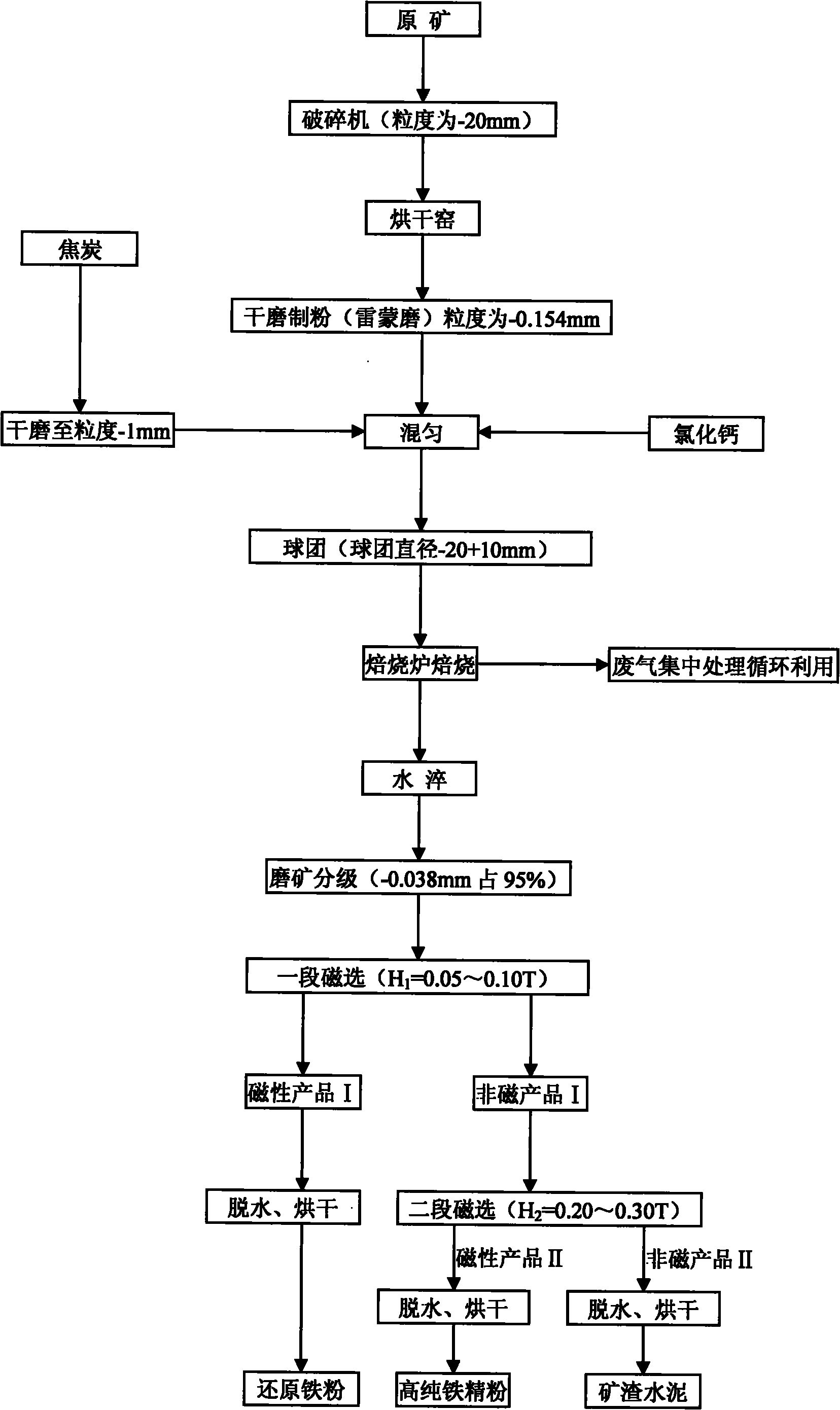

Process for recovering zinc from hot-dip coating zinc ash

InactiveCN101979684AReduce energy consumptionHigh purityProcess efficiency improvementBound waterFerrosilicon

The invention relates to a process for recovering zinc from hot-dip coating zinc ash. The process comprises the following steps of: separating the hot-dip coating zinc ash after dry grinding and screening to obtain an oversize product and an undersize product; removing bound water and a small amount of zinc chloride from the oversize product under the condition that the temperature is between 400 and 500 DEG C and the vacuum degree is 10 to 50 Pa; performing vacuum distillation on the oversize product under the condition that the temperature is between 650 and 800 DEG C and the vacuum degree is 10 to 30 Pa to obtain zinc; and performing alkali cleaning on the undersize product to remove chlorine, and then performing vacuum thermal reduction on the undersize product to obtain the zinc from zinc oxide by using ferrosilicon as a reducing agent and calcium oxide as a slagging agent under the condition that the vacuum degree is 10 to 30 Pa and the temperature is between 1,050 and 1,200 DEG C. The process has a high recovery rate for recovering the zinc from the hot-dip coating zinc ash, and the obtained zinc has a good crystallized shape.

Owner:CENT SOUTH UNIV

Resin abrasive wheel containing teflon dry-grinding lubricant agent and manufacturing method thereof

InactiveCN101134299AReduce contentGood self-sharpeningAbrasion apparatusGrinding devicesGrinding wheelChemical corrosion

The present invention is one kind of resin grinding wheel with teflon dry grinding lubricant and its making process, and belongs to the field of metal cutting and grinding utensil. The resin grinding wheel is made through preparing adhesive abrasive material mixture with brown corundum abrasive material 40-80 %, phenolic resin liquid 1-5 %, phenolic resin powder 3-15 %, teflon dry grinding lubricant 0.5-5 % and cryolite stuffing 2-10 %, and pressure forming. The resin grinding wheel with teflon dry grinding lubricant has high grinding and cutting efficiency, long service life, capacity of destructing obstruction and no chemical corrosion to the machined metal.

Owner:武汉法山磨料磨具有限公司

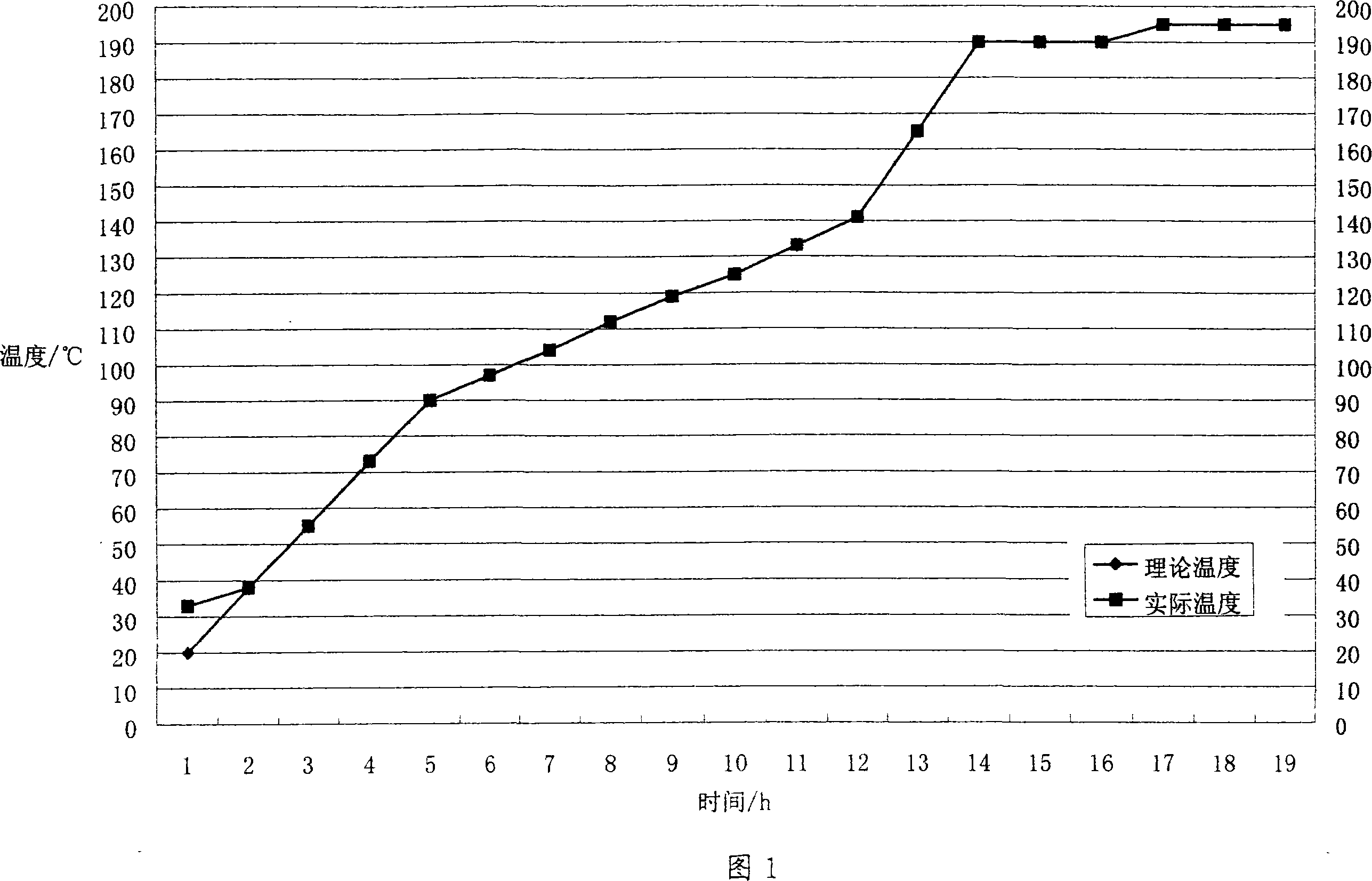

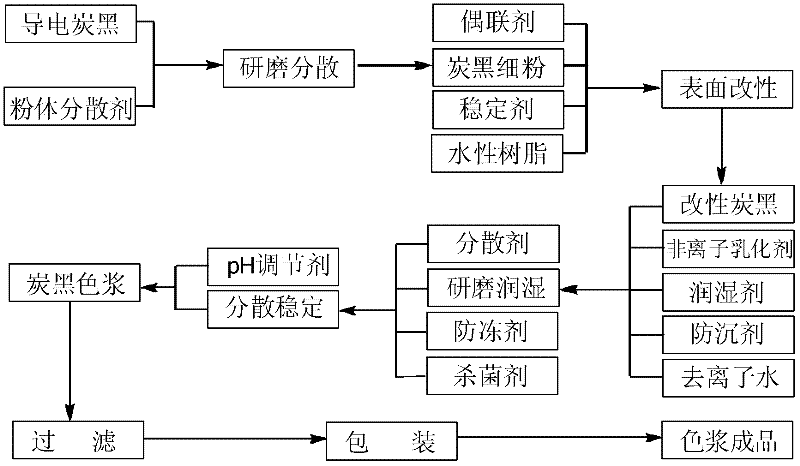

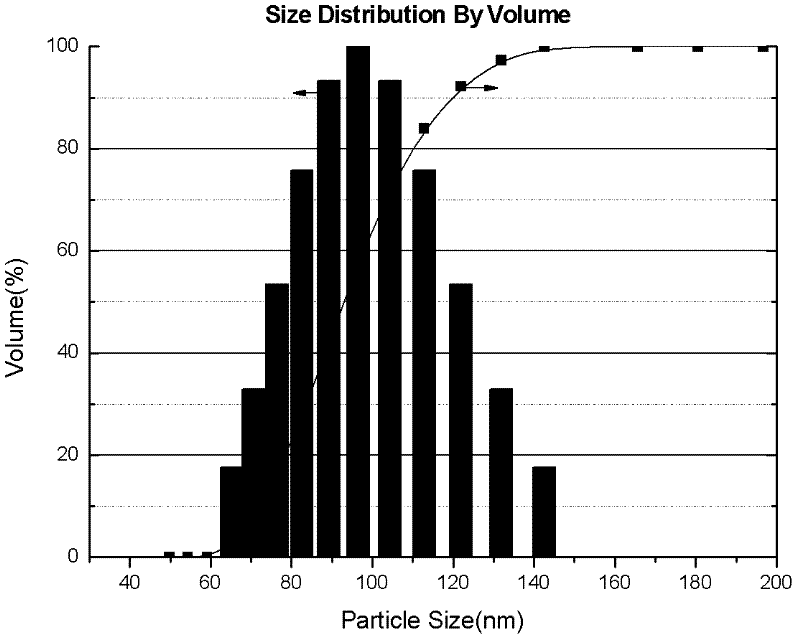

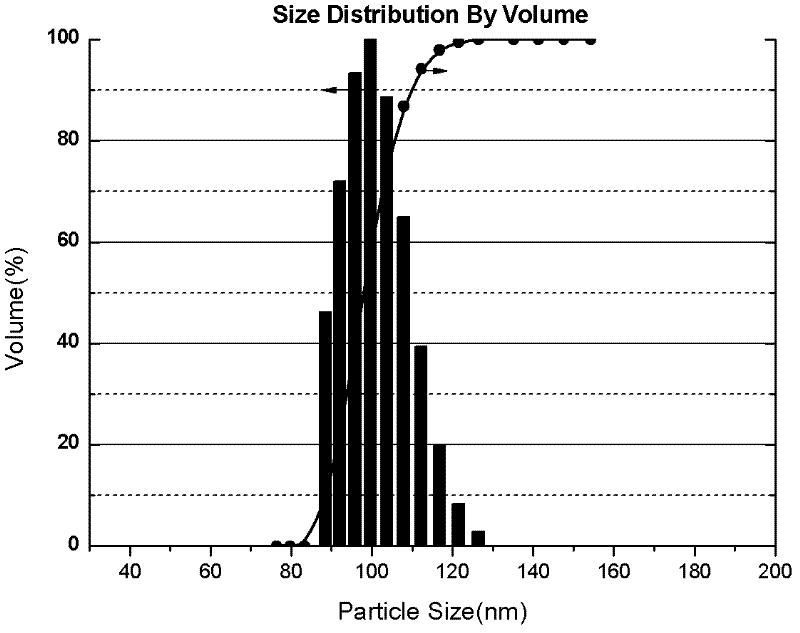

Nano aqueous conductive carbon black color paste and preparation method thereof

ActiveCN102532975ALarge particle sizeGood dispersionAntifouling/underwater paintsPaints with biocidesParticle-size distributionSurface modification

The invention provides a nano aqueous conductive carbon black color paste which comprises the following components by weight percent: 18.0-30.0% of conductive carbon black, 0.35-1.4% of powder dispersing agent, 0.7-2.0% of coupling agent, 0.02-0.24% of stabilizing agent, 0.35-1.4% of water-soluble resin, 2.0-5.5% of dispersing agent, 1.0-3.2% of wetting agent, 0.04-0.26% of anti-sedimentation agent, 0.3-1.3% of nonionic emulsifying agent, 0.002-0.008% of pH regulating agent and 55-75% of deionized water. According to the invention, the conductive carbon black color paste is prepared through a method of combing physics and chemistry by adopting dry grinding and dispersing, dry surface modification and wet grinding technologies, thus the problem that the conductive carbon black is difficult to disperse is solved, the particle size distribution of the color paste is narrow, the color paste has good compatibility with adhesive resin and is high in carbon black content, filmed paint can reduce the resistance of a coating to the greatest extent, and the prepared conductive color paste is good in stability.

Owner:GUANGDONG LEPUTAI NEW MATERIAL TECH

Method for preparing foamed ceramic insulation board by coal ash

InactiveCN101597178AImprove protectionSave natural resourcesSolid waste disposalCeramic shaping apparatusSlurryBall mill

The invention relates to a method for preparing a foamed ceramic insulation board by coal ash. The coal ash and potash feldspar are respectively put into a ball mill for dry grinding and then sieved by a 1000-mesh sieve, iron in the sieved coal ash is removed, the coal ash after iron removal, potash feldspar after dry grinding and sieving, kaolin and cerium oxide are put into the ball mill for wet grinding to be even, so as to form mixed slurry; the mixed slurry is dried by a pressure GLZ, the dried powder material is put into a steel mould to be pressed into a flat green body; and the pressed green body is put into an aluminum oxide sagger which is evenly spread with aluminium oxide powder at the bottom, sintered in a silicon carbon rod resistance furnace and cooled naturally, thus obtaining the foamed ceramic insulation board for building. The coal ash is used for preparing the foamed ceramic insulation board, which is not only beneficial for saving natural resources and reducing production cost but also beneficial for environmental protection. The coal ash contains a great amount of hollow cenospheres and melikaria and has low heat conductivity and thermostability characteristic. The cerium oxide is used as foaming agent, which can lower sintering temperature of the foamed ceramic and reduce energy consumption.

Owner:SHAANXI UNIV OF SCI & TECH

Method for manufacturing ceramic diamond composite grinding wheel

ActiveCN102699833AHigh rotational strengthImprove retentionAbrasion apparatusGrinding devicesCompression moldingAdhesive

The invention discloses a method for manufacturing a ceramic diamond composite grinding wheel, which is characterized by comprising the following steps of: by mass, mixing and pelletizing diamond, silicon carbide and a bonding agent, carrying out compression molding, drying, pre-burning and then sintering to obtain a joint unit; and placing the joint unit and a grinding wheel matrix into a die, pouring a polyimide composite material between the joint unit and the grinding wheel, carrying out pressing, then carrying out cooling and sintering to obtain the grinding wheel. According to the composite grinding wheel manufactured by the method disclosed by the invention, an integrated pressing sintering or embedding splicing mode is adopted; the polyimide composite material is used as a transition adhesive; and the integral grinding wheel is manufactured after carrying out secondary hot pressing and sintering. The chip accommodating and drainage space surface coverage rate of the ceramic diamond composite grinding wheel can reach 30 to 70 percent. The ceramic diamond composite grinding wheel has the following excellent grinding characteristics that the cutting depth is large; the grinding precision is high; in the forming and grinding process, the retentivity of a molded surface is good; the application range is wide; the grinding wheel can be used for dry grinding and has resistance to the high temperature of 350 DEG C and splicing units cannot fall off and blocks cannot fall off; and the grinding wheel has high revolving strength.

Owner:贵州荣清工具有限公司

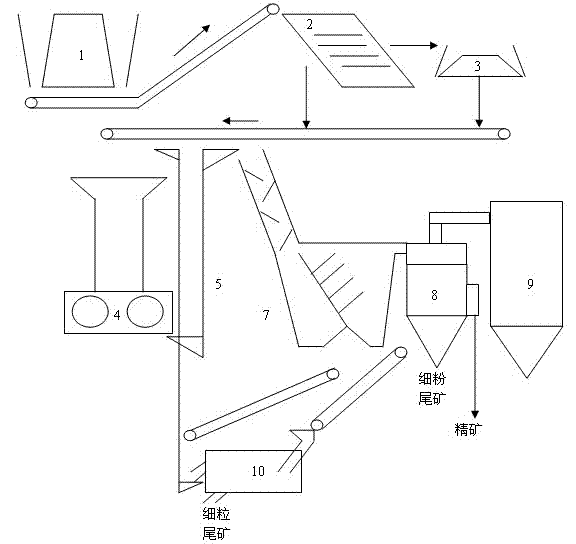

Magnetite dry grinding and dry separation method and device

ActiveCN104815739AReach granularity requirementsReduce power consumptionMagnetic separationGrain treatmentsHigh pressureMechanical screening

The invention discloses a magnetite dry grinding and dry separation method and a magnetite dry grinding and dry separation device, and belongs to the technical field of iron ore selection and grinding. The method comprises the steps of mixing secondarily crushed ore with particle size less than 80mm and coarse-grain return scrap to obtain a mixture I, extruding the mixture I by virtue of a high pressure roller, and mechanically screening the mixture I, wherein the screening granularity is 3mm; returning an oversize product adopted as the coarse-grain return scrap to the high pressure roller to be continuously extruded, separating screen underflow in a dry-type magnetic separator, grading rough concentrate separated by the dry-type magnetic separator by virtue of a wind power powder separation machine, returning coarse powder graded by the wind power powder separation machine and adopted as coarse-grain return scrap to the high pressure roller to be continuously extruded, collecting fine powder meeting the fineness requirement of iron fine powder after the grading of the wind power powder separation machine, separating the fine powder by virtue of the dry-type magnetic separator, and finally carrying out the wet-type magnetic separation for fine magnetic minerals meeting the fineness requirement of the iron fine powder after the separation of the dry-type magnetic separator. By adopting the magnetite dry grinding and dry separation method, the crushing grinding and the magnetic separation of the ore are reasonably matched, so that the system energy consumption is reduced, consumption of steel and water is reduced, and the environmental pollution is alleviated.

Owner:成都建筑材料工业设计研究院有限公司

Manufacturing method of underglaze white double crystal fancy glaze

The invention relates to a manufacturing method of an underglaze white double crystal fancy glaze. The method comprises the steps of preparing materials according to a formula, manufacturing a frit, sieving by using a ball mill and modulating, wherein the frit is made from borax, potash feldspar and quartz; a ground glaze is made from potash feldspar, zinc oxide, calcite, quartz and frit; and an overglaze is made from frit, barium carbonate, iron red, potash feldspar, titanium oxide, zinc oxide, bentonite, quartz, iron oxide red and zirconium silicate; dry grinding frit materials, burning the frit materials at 1250 DEG C, and cooling fast to obtain the frit; sieving ground glaze and overglaze materials by using the ball mill; wet ball milling, and sieving by using a 250 mesh sieve; modulating the ground glaze and the overglaze: mixing the crushed frit respectively with the ground glaze and overglaze materials which are sieved and wet ball milling mixtures so as to modulate the mixtures into slurries at 45-50 baume degree; burning: spraying glaze on a green body, wherein the thickness of the ground glaze is 0.4-0.7mm, the thickness of the overglaze is 0.3 mm, and feeding the green body into a roller way to be burnt into the underglaze white double crystal fancy glaze in an oxidizing atmosphere; after burning, natural, smooth and crystal clear decorative patterns can be generated.

Owner:湖南泉湘陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com