Wear-resistant filling material, wear-resistant composite material prepared from same and preparation method for composite material

A wear-resistant filler and composite material technology, which is applied to the wear-resistant filler and the wear-resistant composite material prepared therefrom and the field of preparation, can solve the problem of insufficient hardness of the wear-resistant filler, and achieve low friction coefficient, high hardness and wear resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

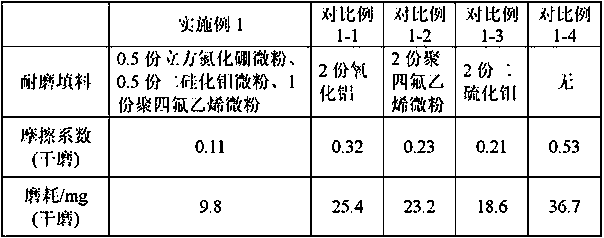

Embodiment 1

[0041] The preparation of polyethylene (PE) wear-resistant composites is as follows:

[0042] (1) Add 0.15 parts of coupling agent KH550 and 0.15 parts of coupling agent NDZ-102 to 100 parts by weight of plastic resin PE, mix at room temperature with a high-speed mixer, and then mix 0.5 parts of cubic boron nitride micropowder (particle size 0.5 μm ), 0.5 parts of molybdenum disilicide micropowder (0.5 μm in particle size), and 1 part of polytetrafluoroethylene micropowder (0.5 μm in particle size) were added for high-speed mixing at room temperature, and then 0.2 parts of silicone powder were added for high-speed mixing at room temperature, During the whole mixing process, the mixing speed was 120 r / min, and the mixing time was 5 minutes;

[0043] (2) Extrude the blend mixed in step (1) through a twin-screw extruder to granulate. The temperature of each zone of the twin-screw extruder is 100°C, 120°C, and 120°C from the feeding section to the die head. ℃, 140℃, 140℃, 160℃, 1...

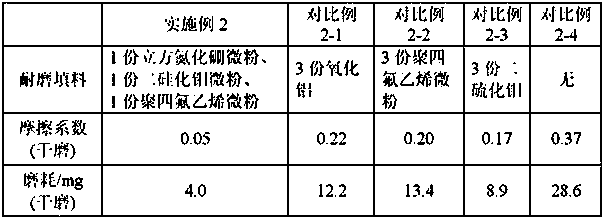

Embodiment 2

[0073] Polyethylene terephthalate (PET) wear-resistant composites were prepared as follows:

[0074] (1) Add 0.15 parts of coupling agent KH550 and 0.15 parts of coupling agent NDZ-102 to 100 parts by weight of PET, mix at room temperature with a high-speed mixer, and then mix 1 part of cubic boron nitride micropowder (particle size is 0.1 μm), Add 1 part of molybdenum disilicide micropowder (0.1 μm in particle size) and 1 part of polytetrafluoroethylene micropowder (0.1 μm in particle size) into it for high-speed mixing at room temperature, then add 0.2 part of zinc stearate for high-speed mixing at room temperature, the whole During the mixing process, the mixing speed was 120 r / min, and the mixing time was 5 minutes;

[0075] (2) Extrude and granulate the blend mixed in step (1) through a twin-screw extruder. The temperature of each zone of the twin-screw extruder is 220°C, 240°C, and 260°C from the feeding section to the head temperature. ℃, 260℃, 280℃, 280℃, 280℃, 280℃, ...

Embodiment 3

[0106] Polyetheretherketone (PEEK) wear-resistant composites were prepared as follows:

[0107] (1) Add 0.15 parts of coupling agent KH550 and 0.15 parts of coupling agent NDZ-102 to 100 parts by weight of PEEK, mix at room temperature with a high-speed mixer, and then mix 1.5 parts of cubic boron nitride micropowder (with a particle size of 5 μm), 1.5 One part of molybdenum disilicide micropowder (with a particle size of 5 μm) and 2 parts of polytetrafluoroethylene micropowder (with a particle size of 5 μm) were added for high-speed mixing at room temperature, and then 0.2 parts of simethicone oil were added for high-speed mixing at room temperature. During the entire mixing process The mixing speed is 120 r / min, and the mixing time is 5min;

[0108] (2) Extrude the blend mixed in step (1) through a twin-screw extruder to granulate. The temperature of each zone of the twin-screw extruder is 280°C, 320°C, and 340°C from the feeding section to the head temperature. ℃, 340℃, 34...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com