Patents

Literature

12266 results about "Base oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

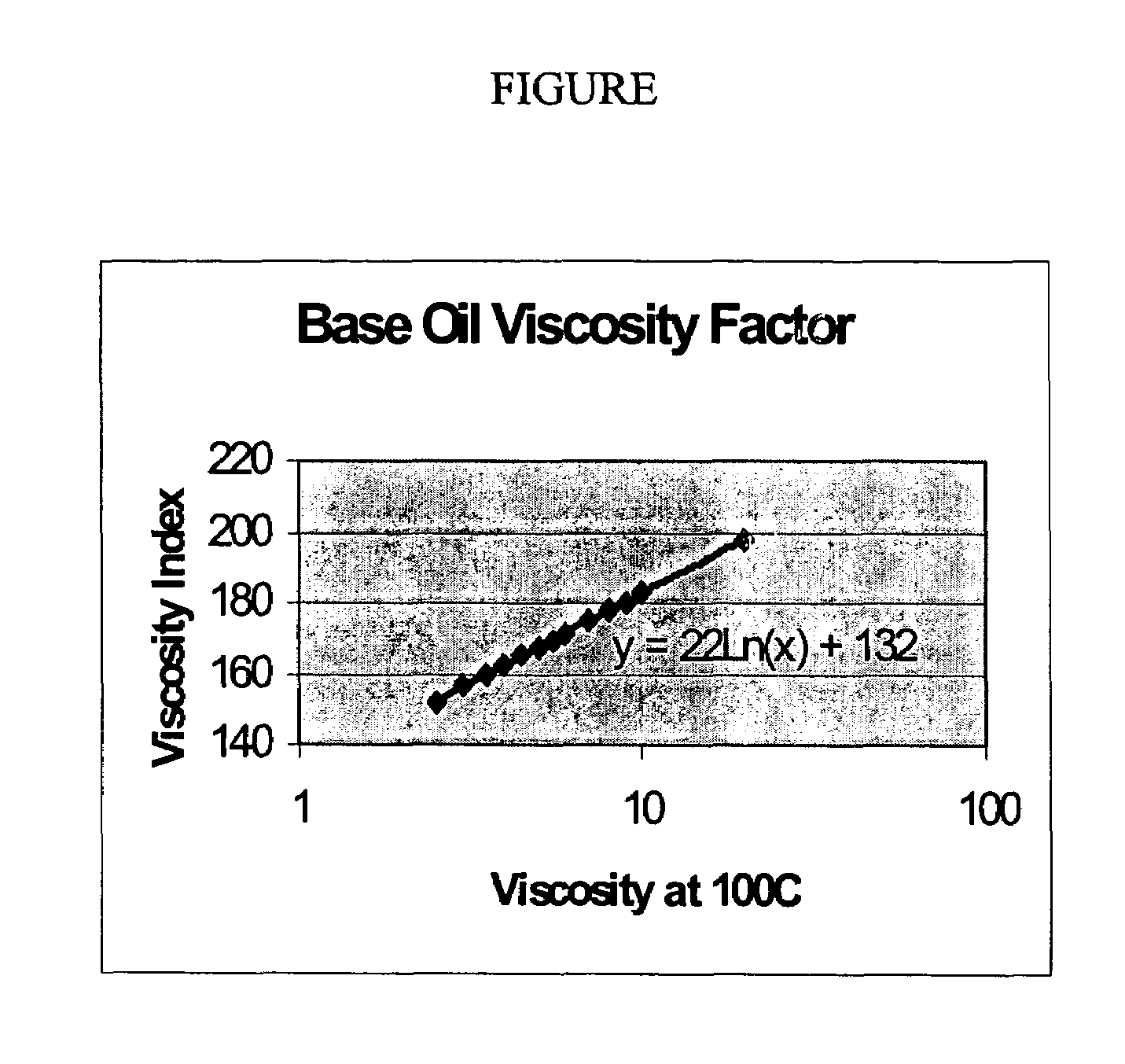

Base oils are used to manufacture products including lubricating greases, motor oil and metal processing fluids. Different products require different compositions and properties in the oil. One of the most important factors is the liquid’s viscosity at various temperatures. Whether or not a crude oil is suitable to be made into a base oil is determined by the concentration of base oil molecules as well as how easily these can be extracted.

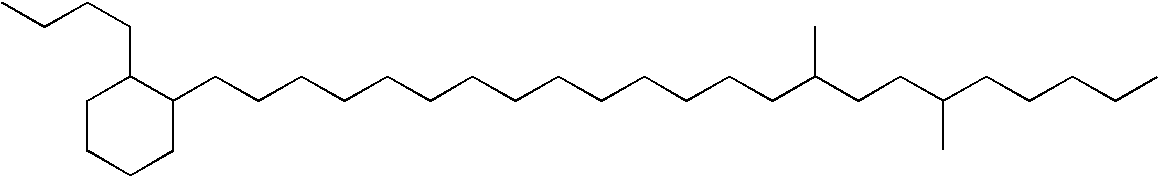

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

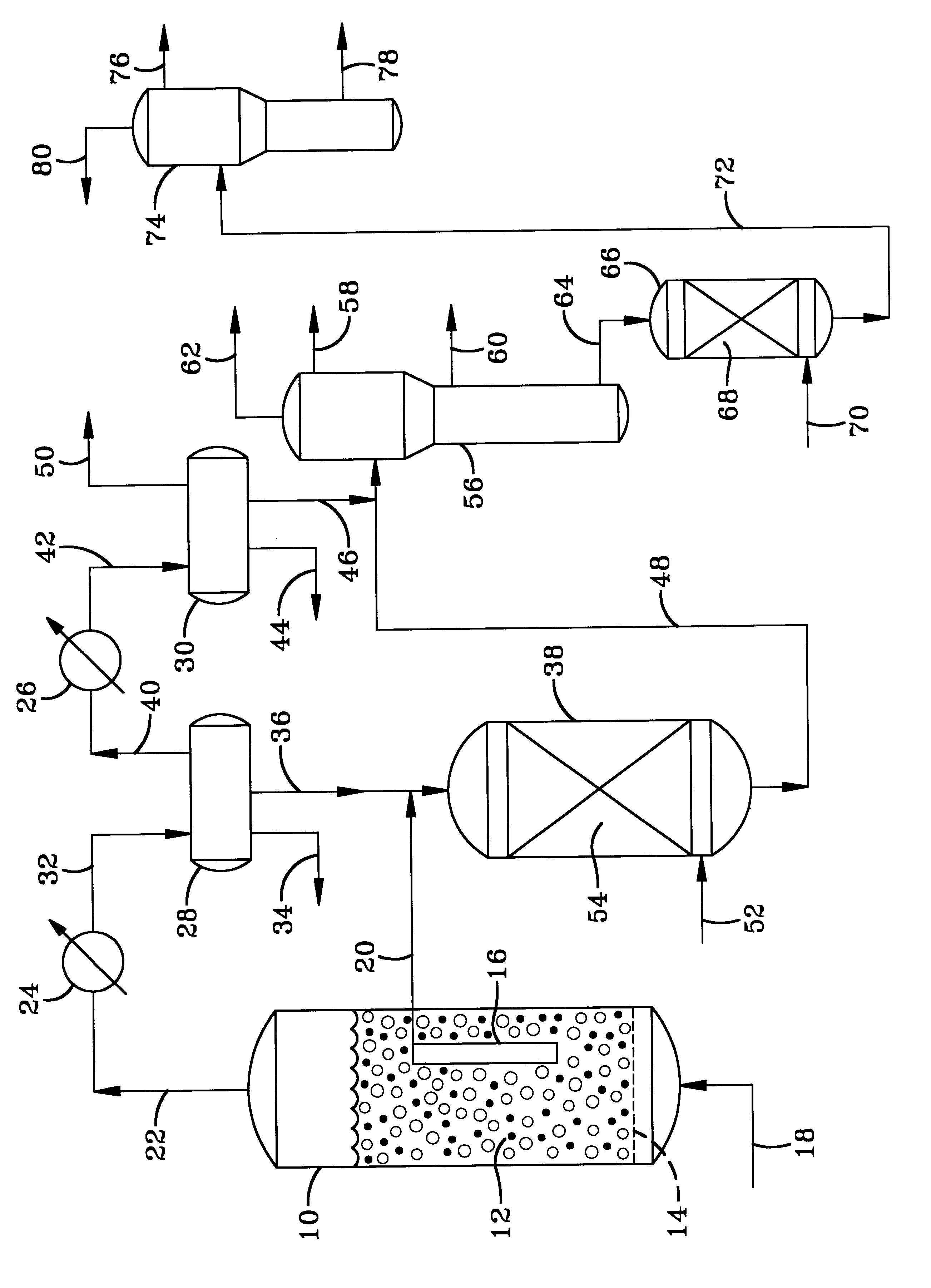

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

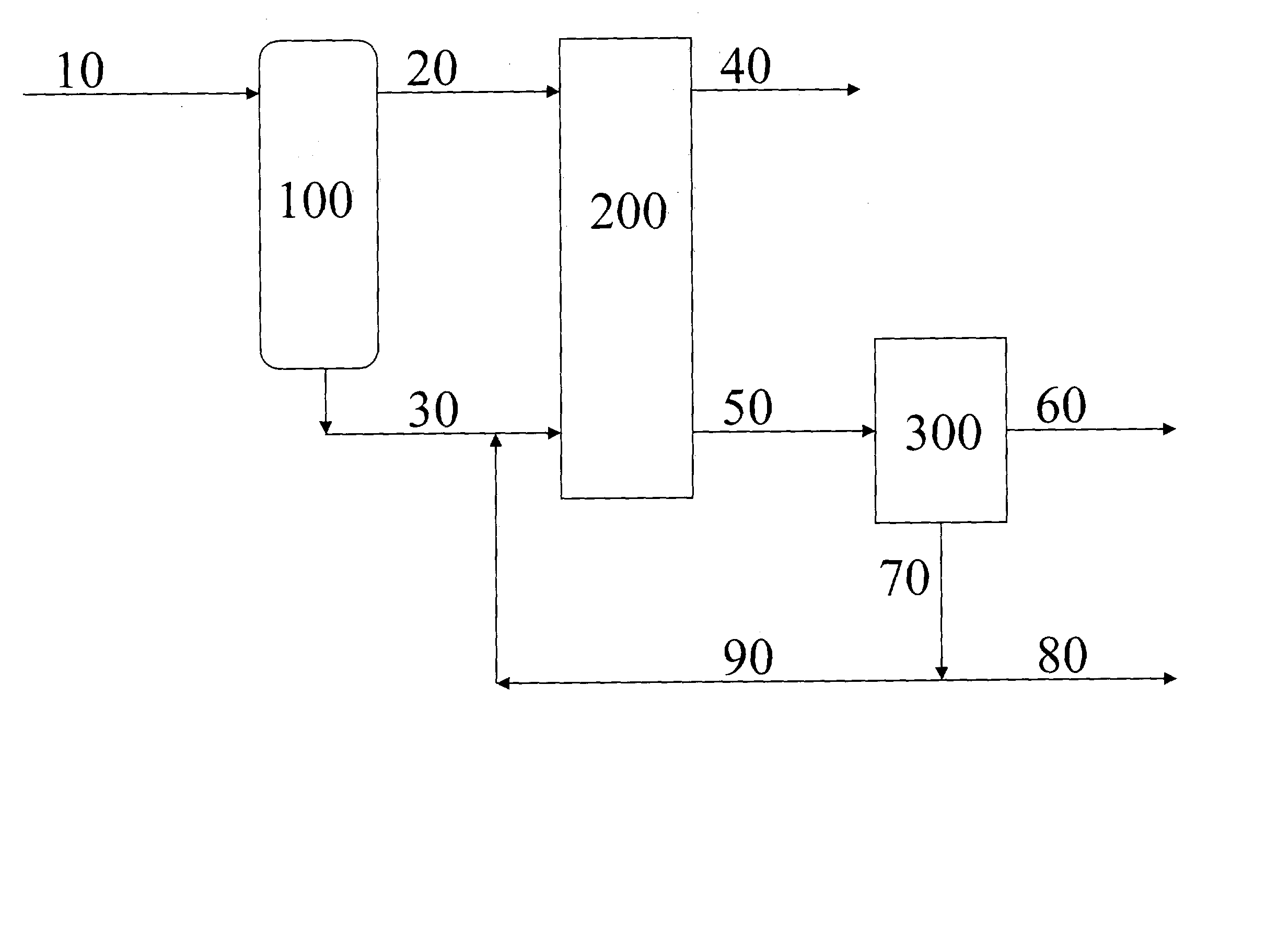

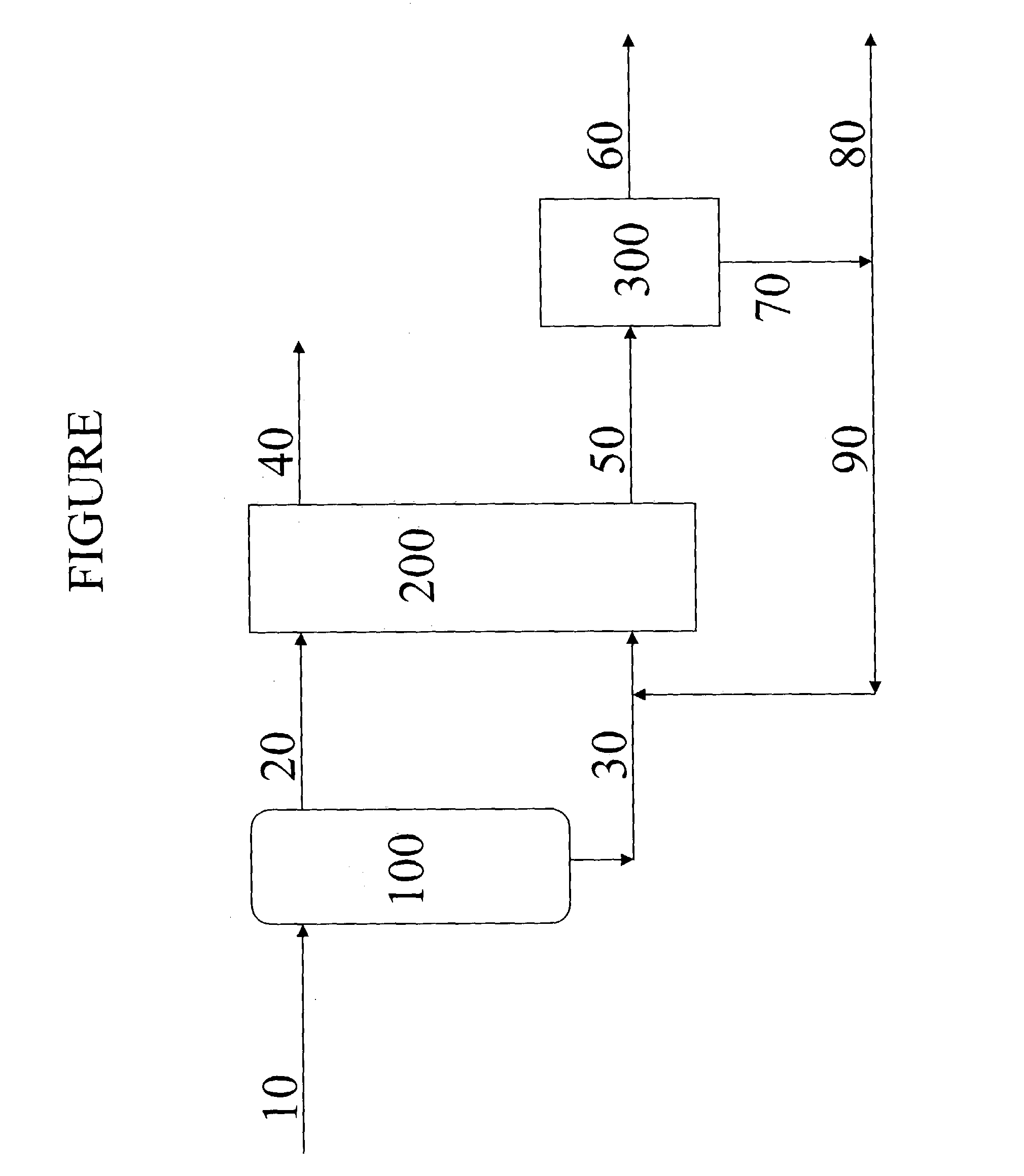

Vegetable oil hydroconversion process

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

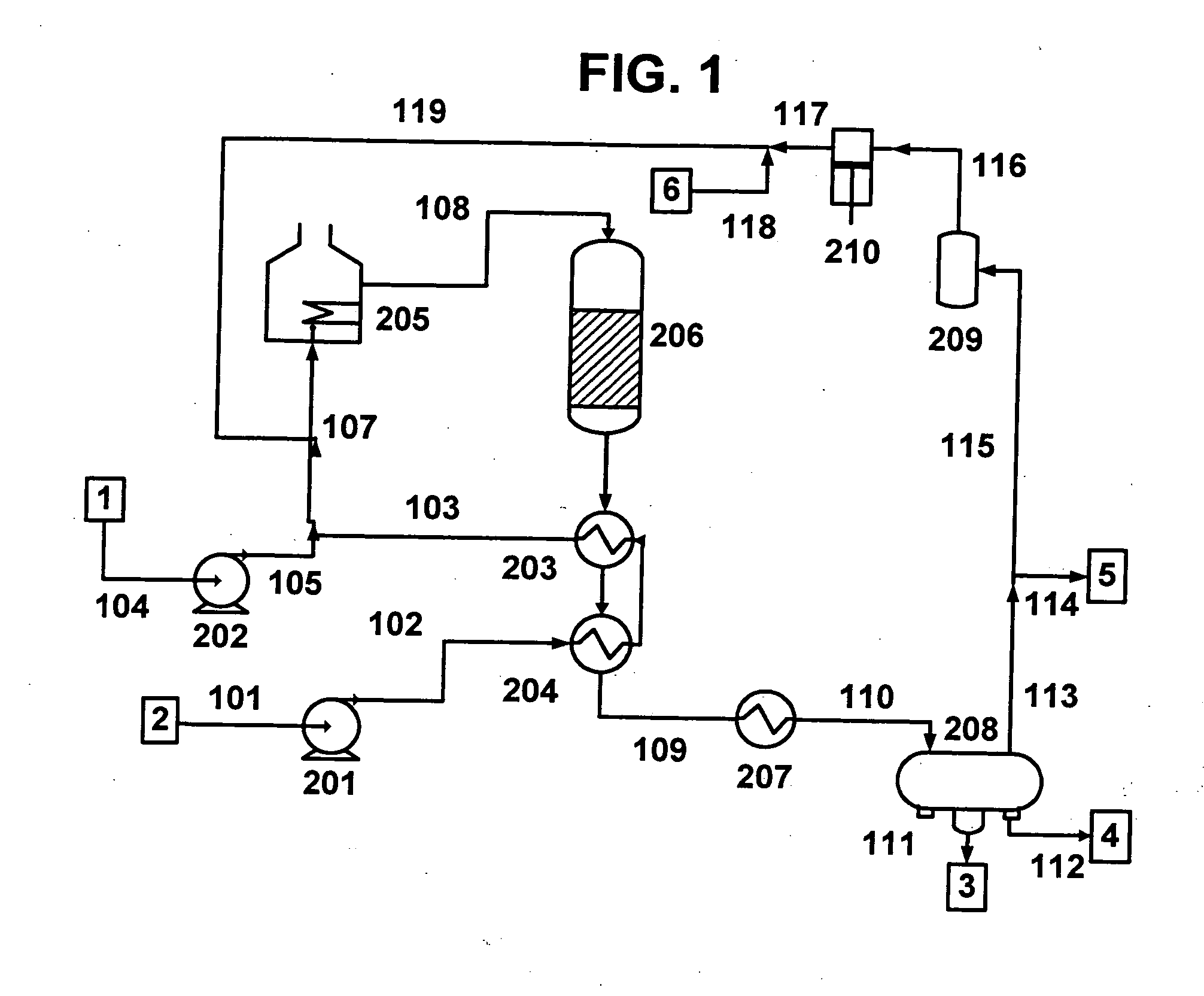

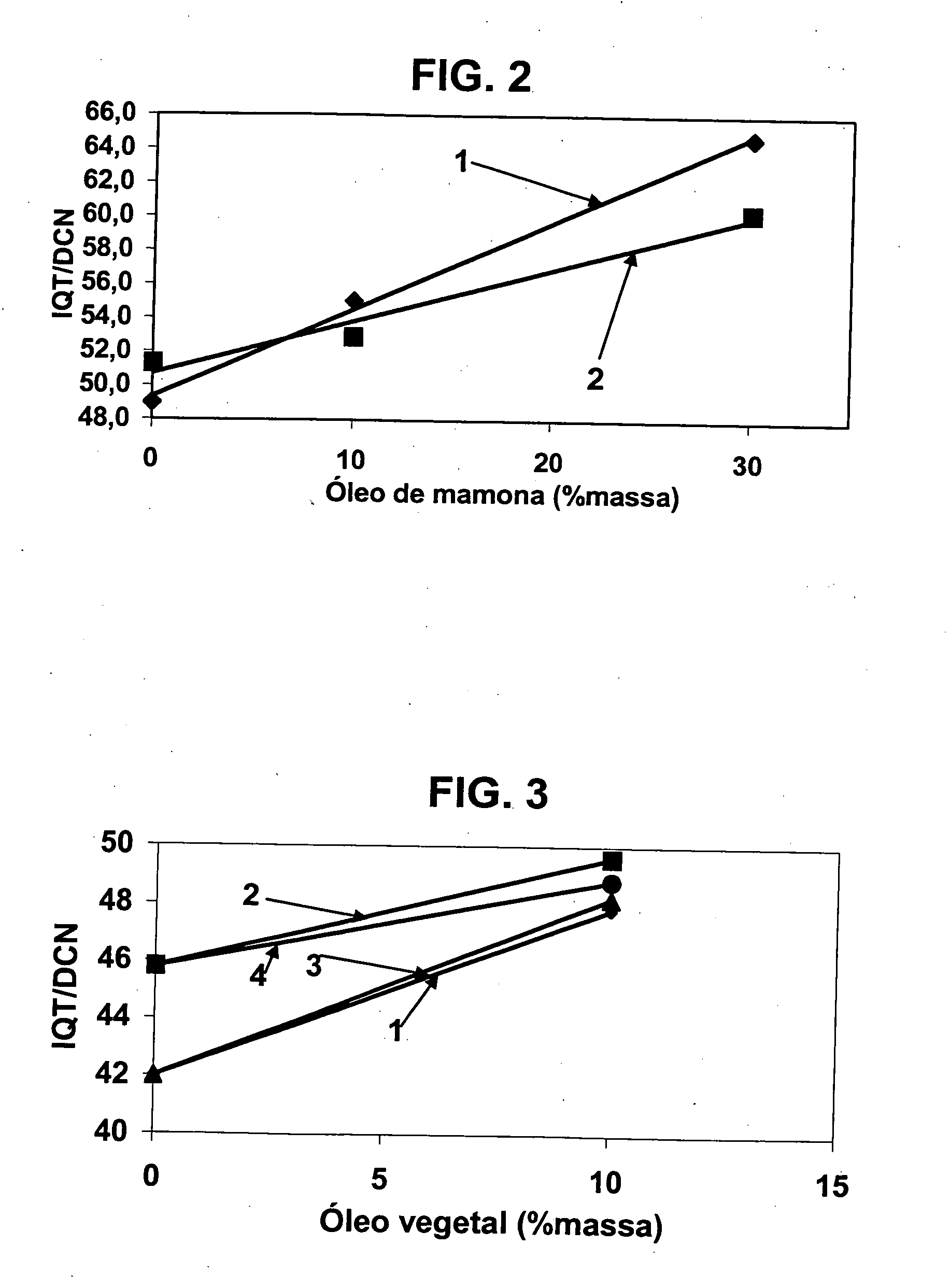

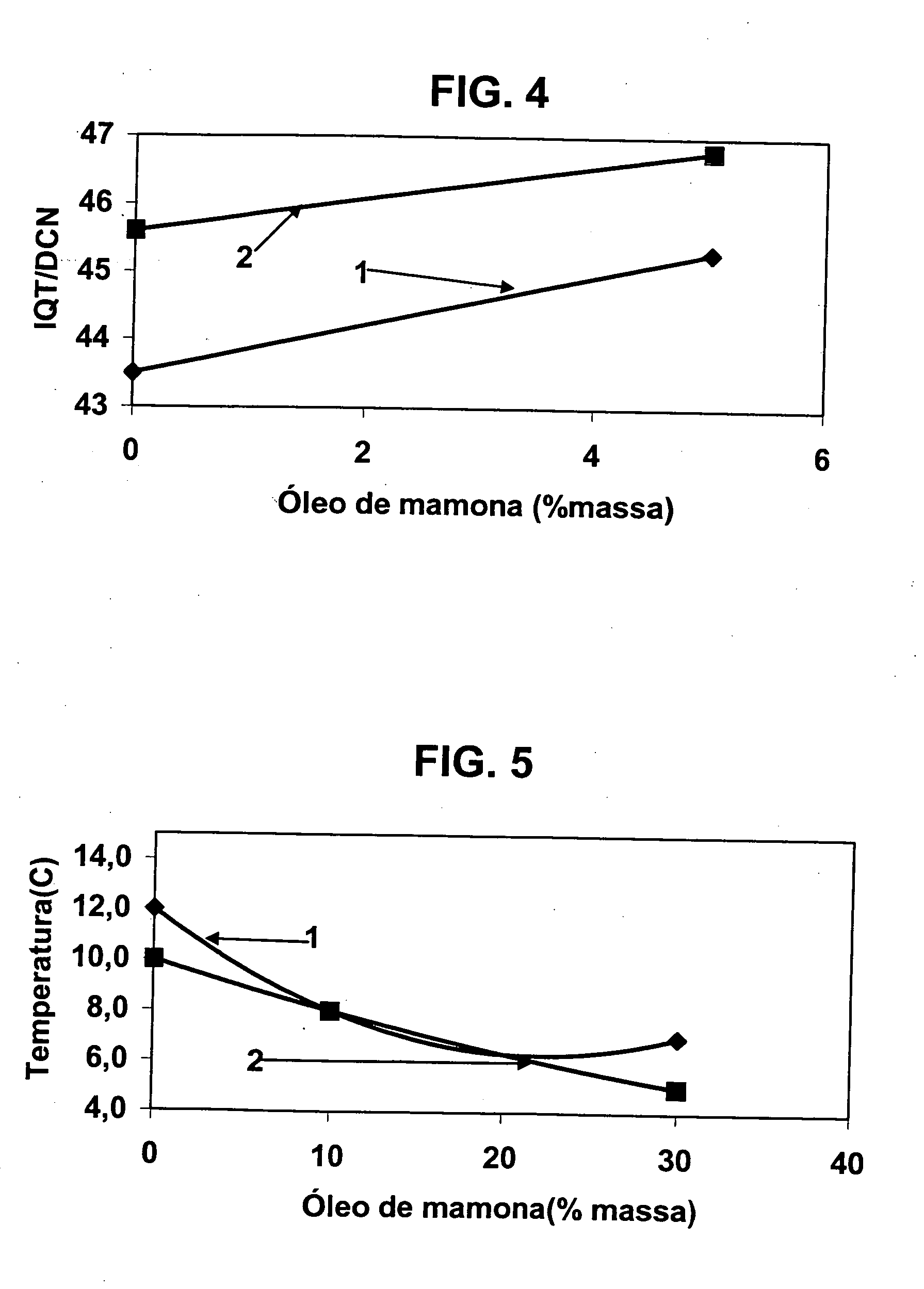

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

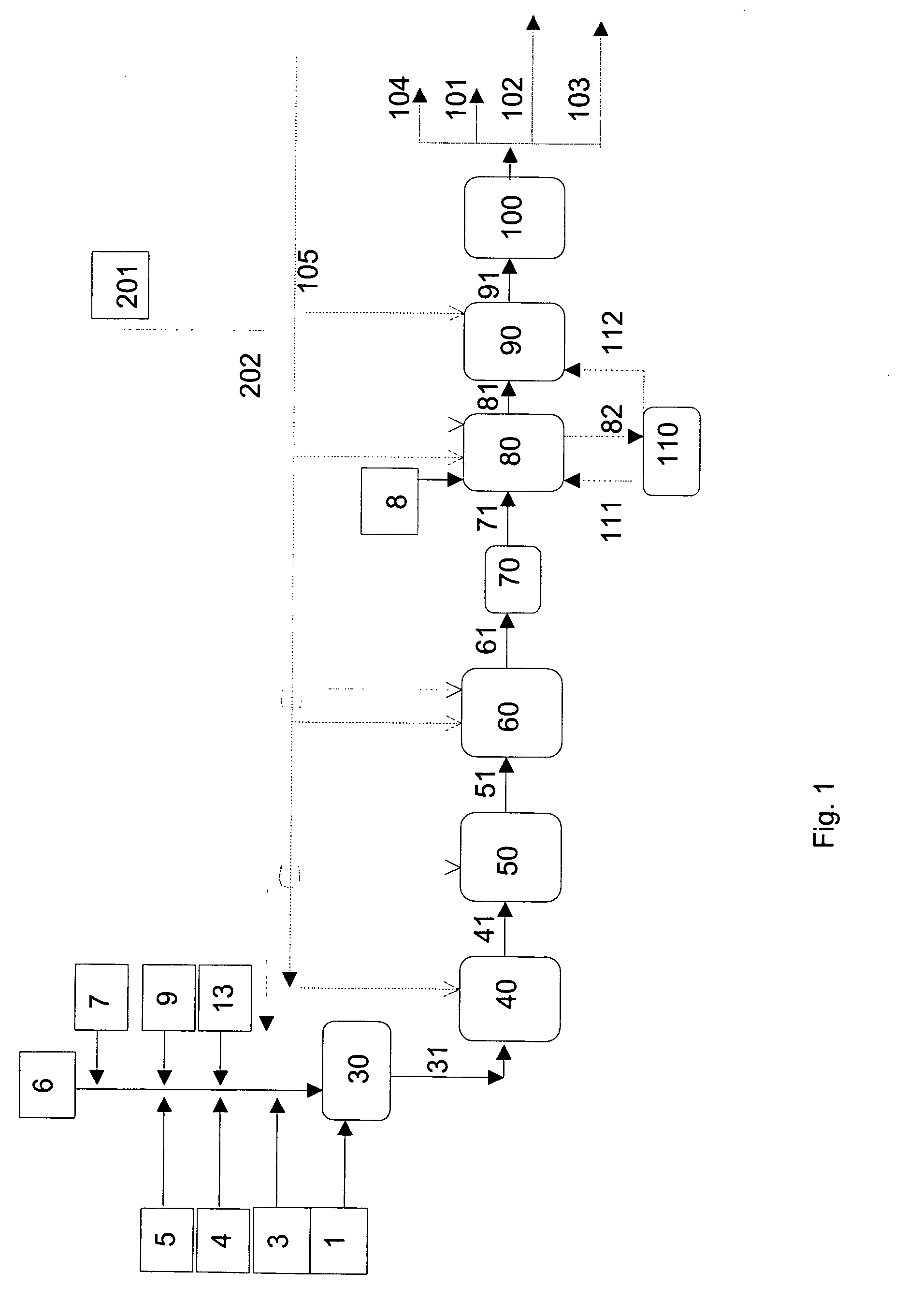

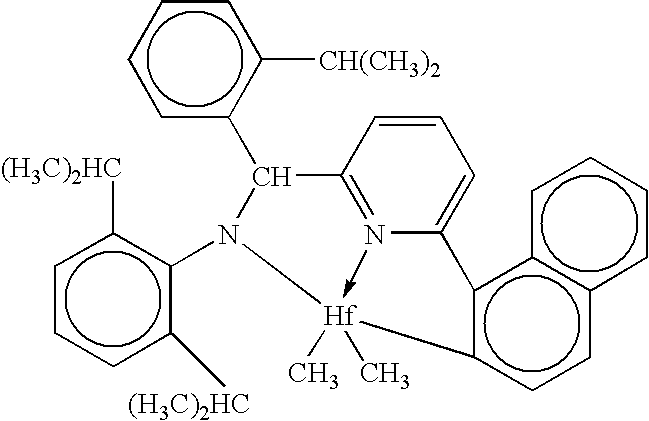

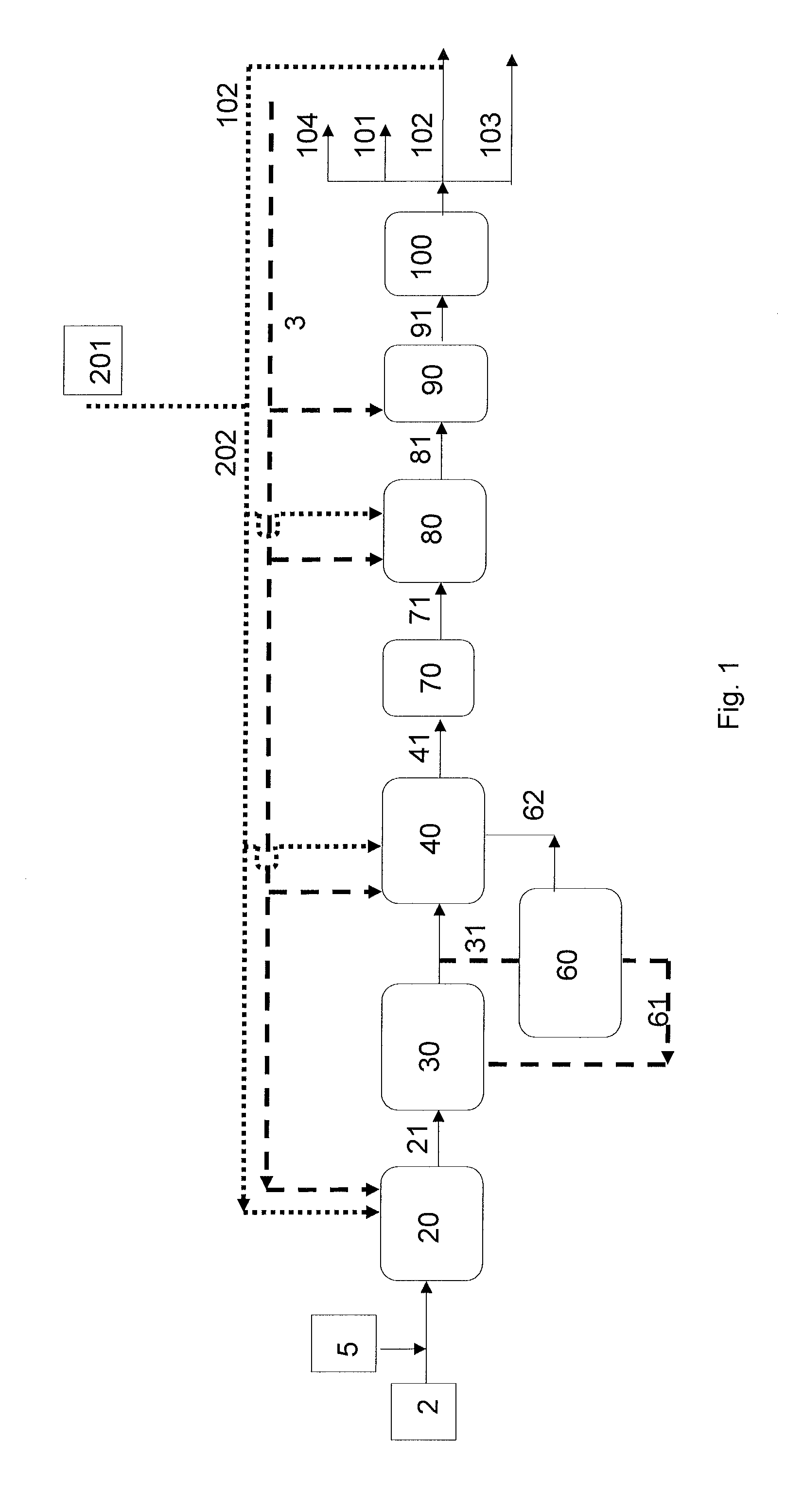

Process for producing a saturated hydrocarbon component

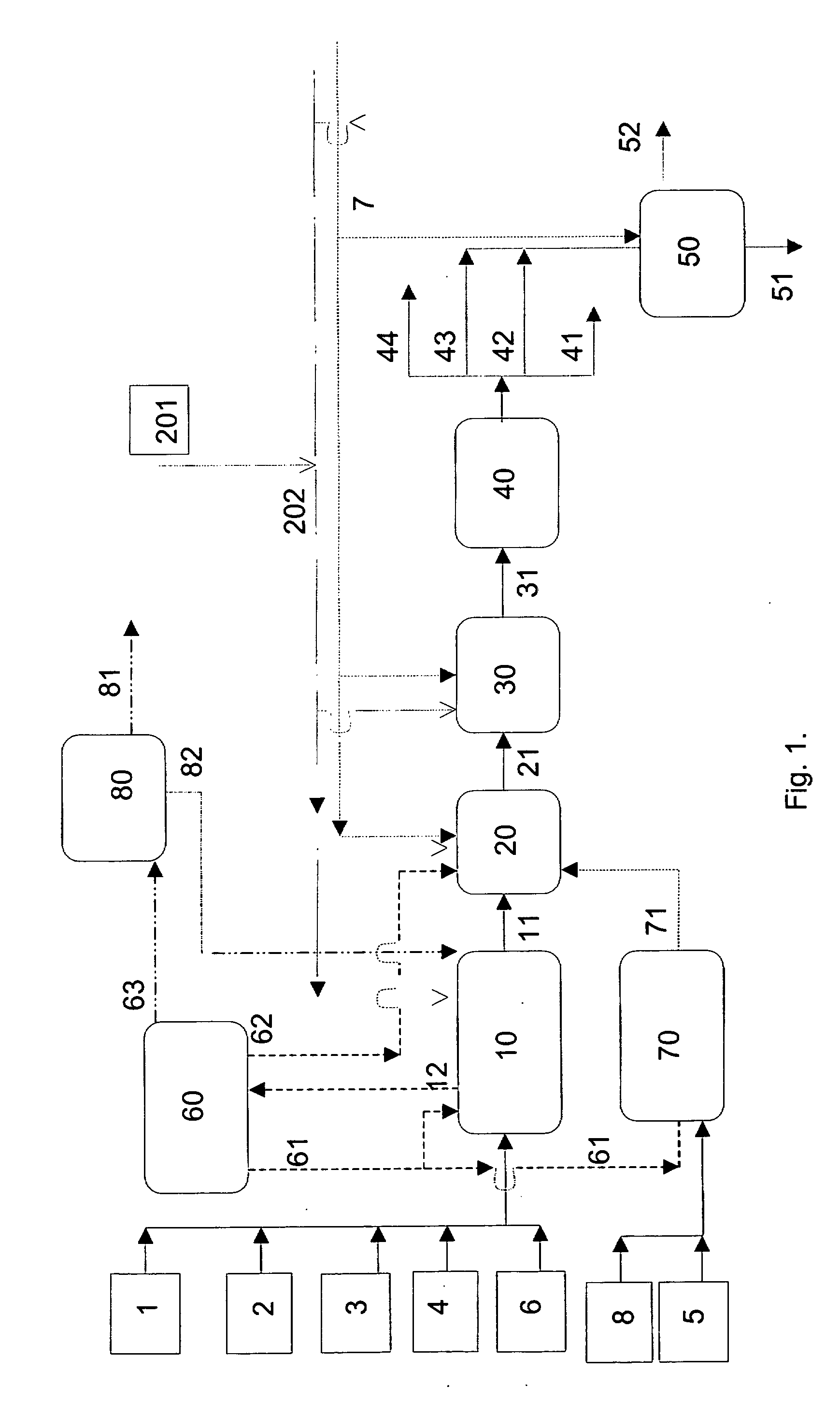

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

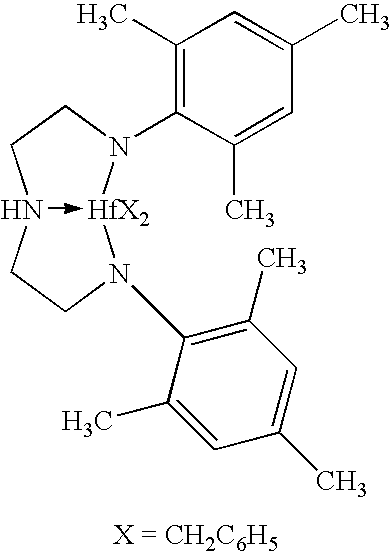

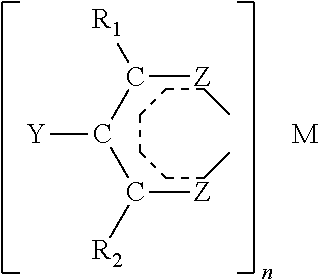

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

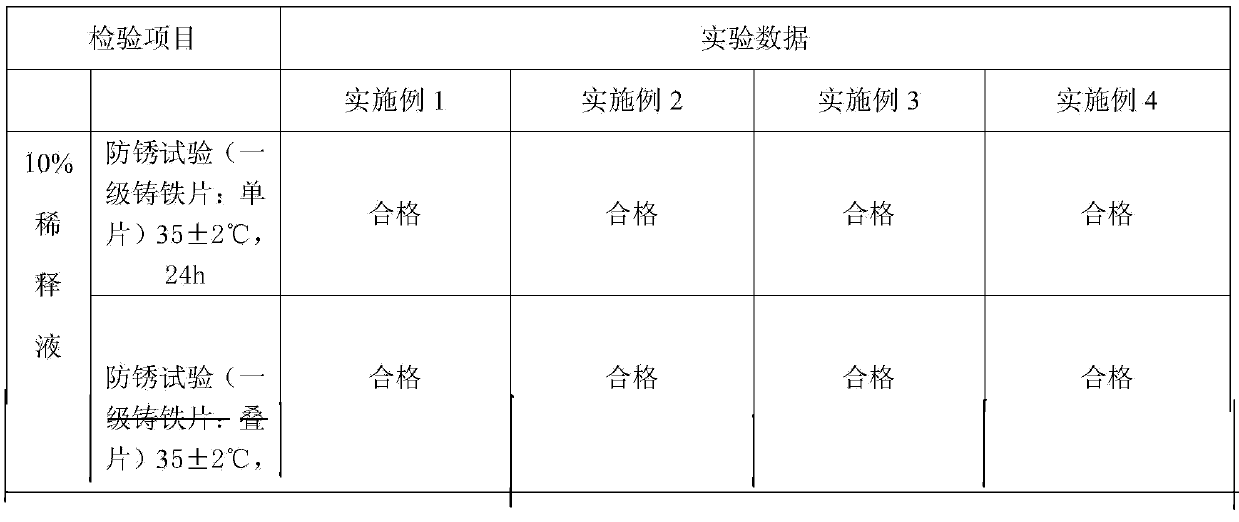

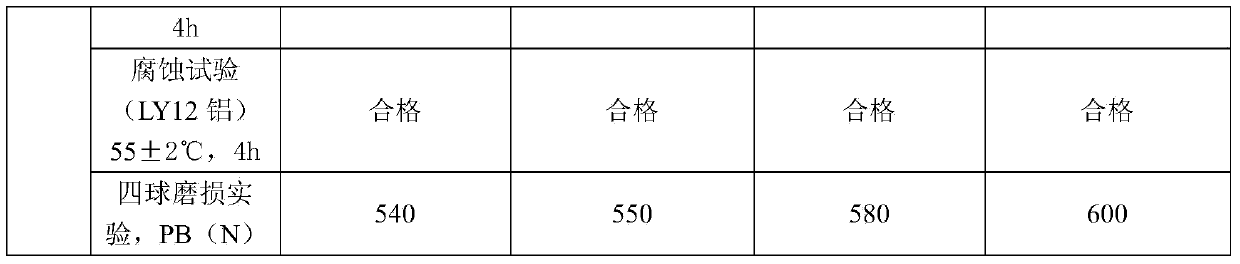

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

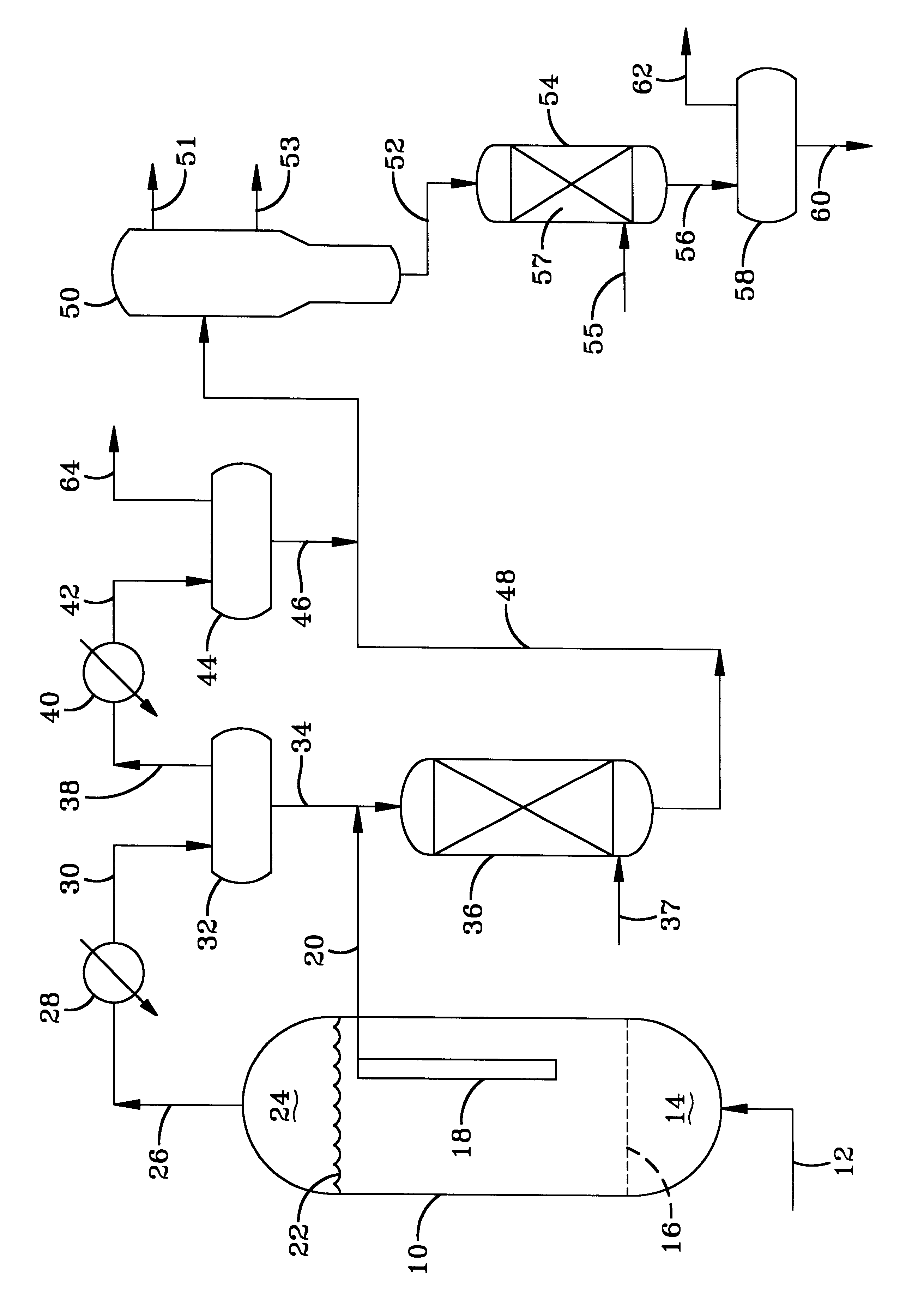

Process for manufacturing lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS20050133409A1Improve Oxidation StabilityHigh viscosity indexTreatment with hydrotreatment processesAdditivesSyngasMolecular sieve

A process for manufacturing a lubricating base oil by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an is dimerized oil; and d) hydrofinishing said isomerized oil to produce a lubricating base oil having specific desired properties.

Owner:CHEVROU USA INC

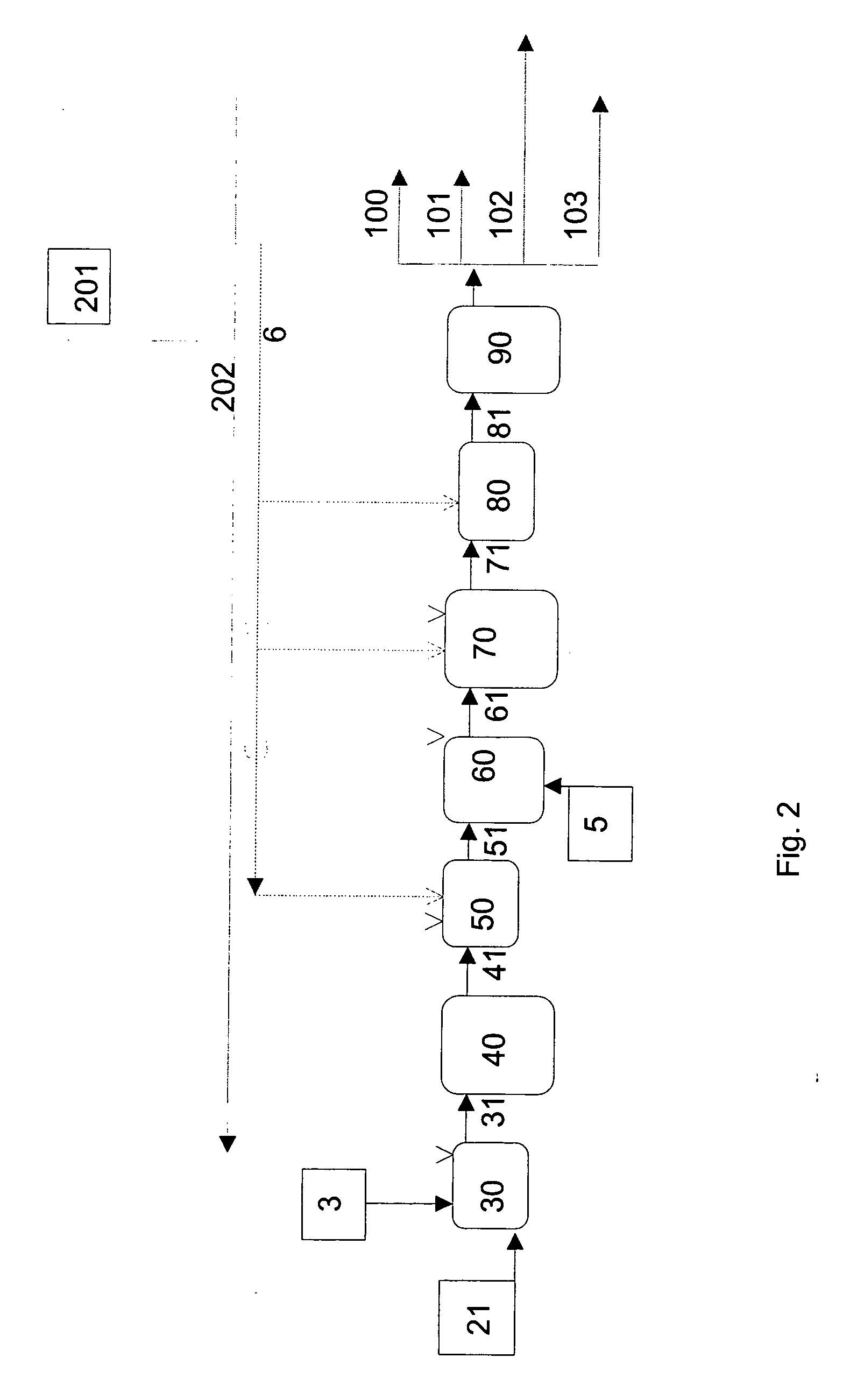

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

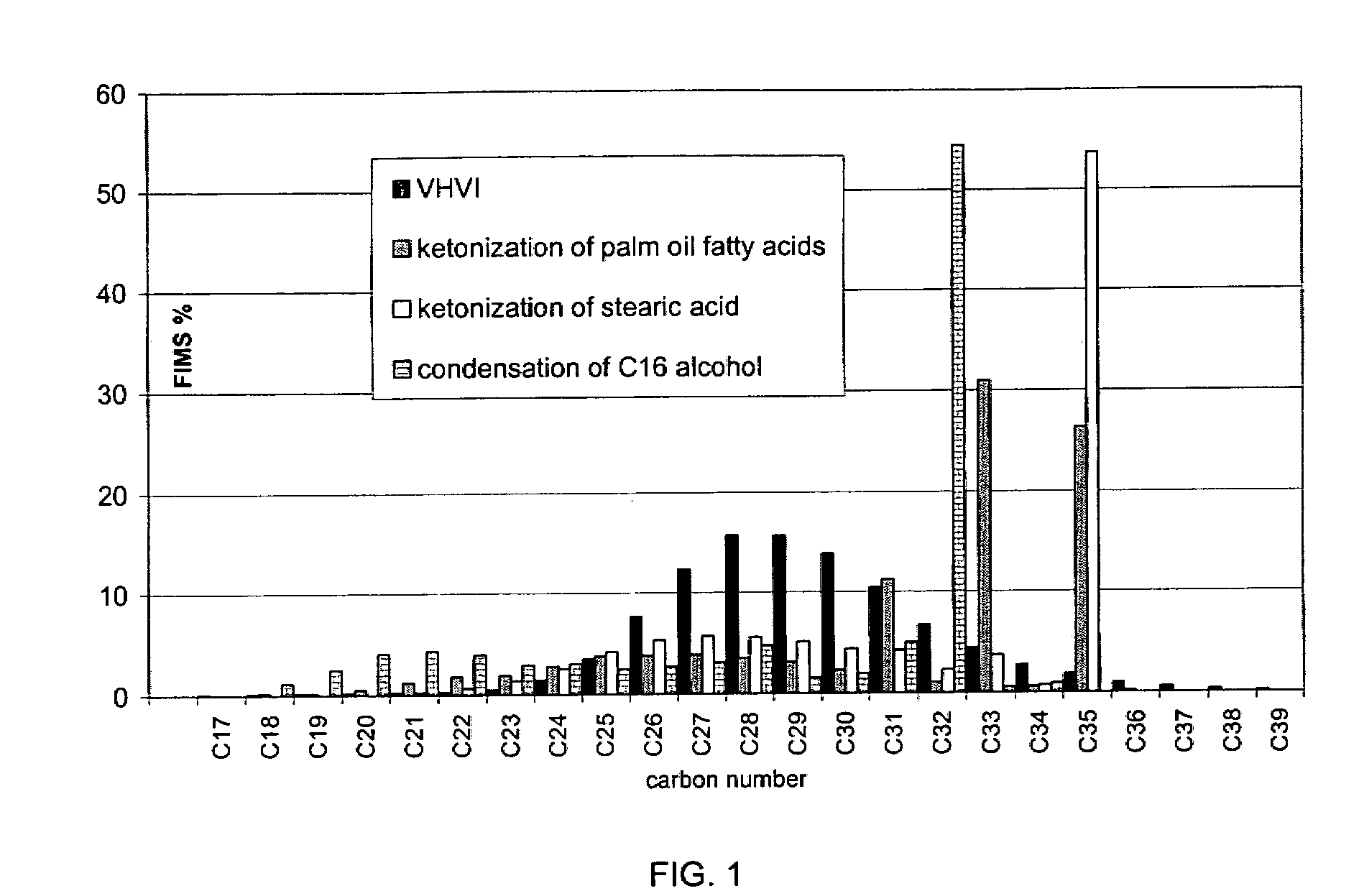

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

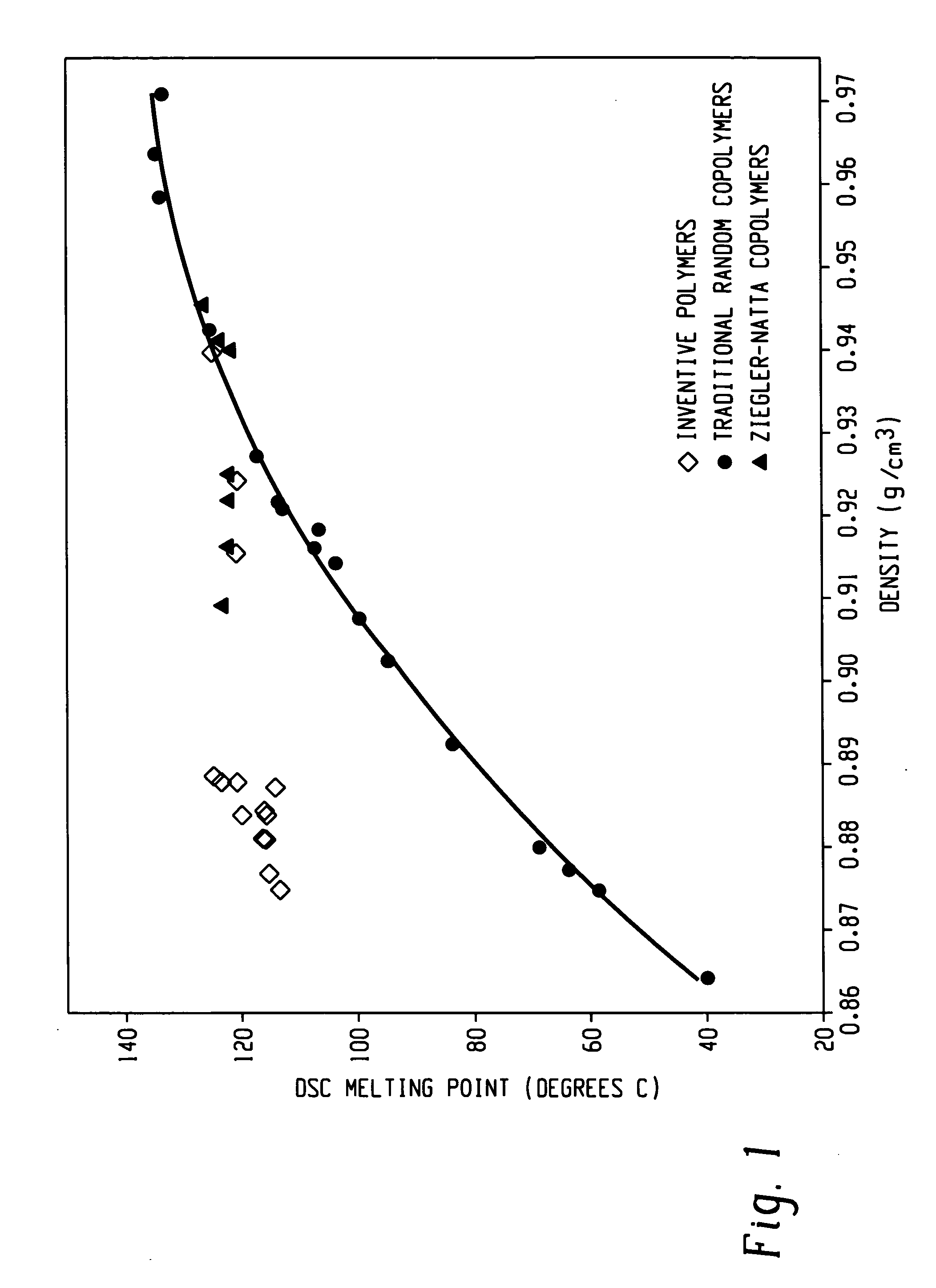

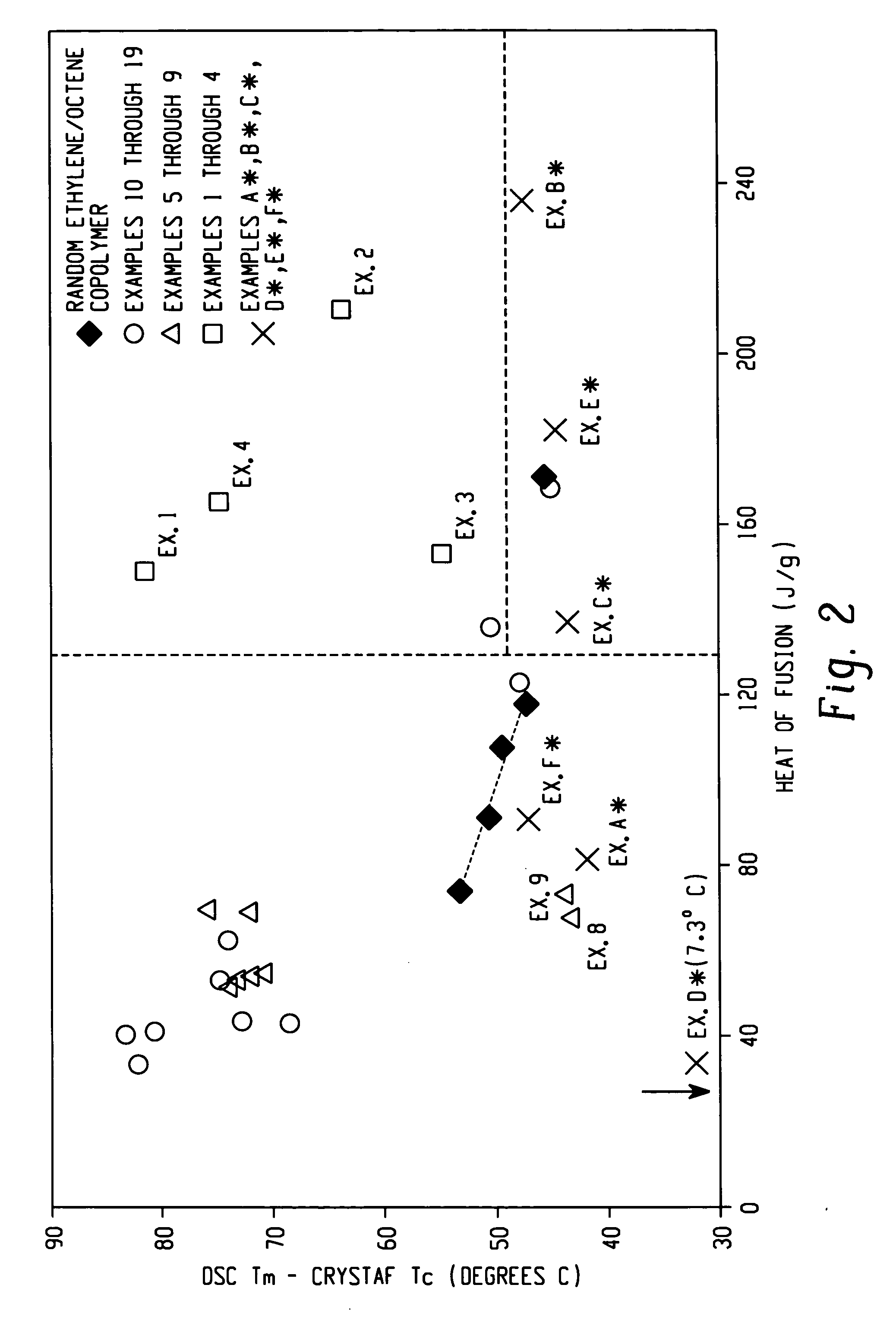

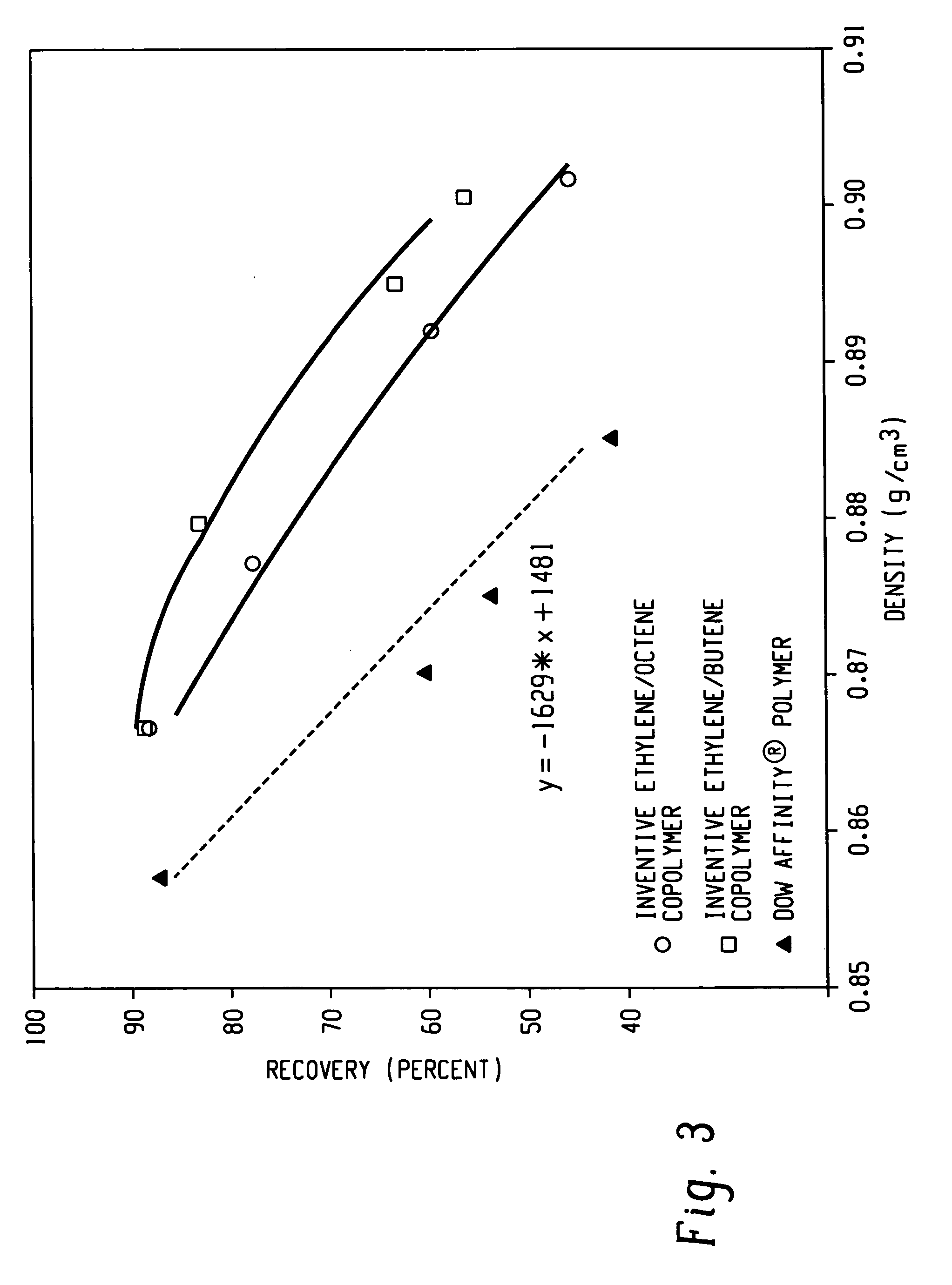

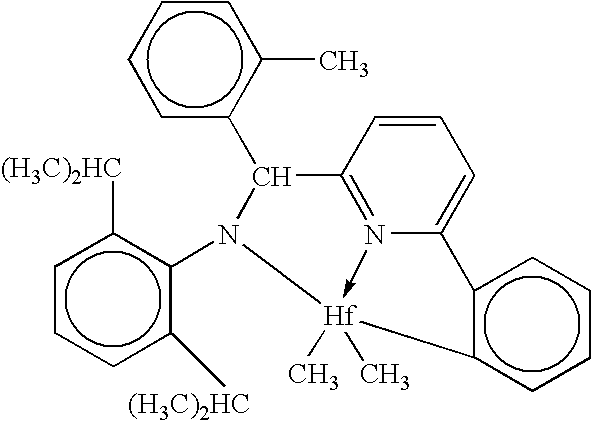

Low molecular weight ethylene/alpha-olefin interpolymer as base lubricant oils

A lubricant composition comprises an ethylene / α-olefin interpolymer having a number average molecular weight of less than 10,000 g / mol as a base oil and at least one oil additive. The ethylene / α-olefin interpolymer has at least one molecular fraction which elutes between 40° C. and 130° C. when fractionated using TREF, characterized in that the fraction has a molar comonomer content of at least 5 percent higher than that of a comparable random ethylene interpolymer fraction eluting between the same temperatures, wherein said comparable random ethylene interpolymer has the same comonomer(s) and has a melt index, density, and molar comonomer content (based on the whole polymer) within 10 percent of that of the ethylene / α-olefin interpolymer.

Owner:DOW GLOBAL TECH LLC

Finished lubricating comprising lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133407A1Improve Oxidation StabilityReduce wearRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionMolecular sieveWax

A process for manufacturing a finished lubricant by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an isomerized oil; and d) hydrofinishing said isomerized oil, whereby a lubricating base oil is produced having specific desired properties; and e) blending the lubricating base oil with at least one lubricant additive.

Owner:CHEVROU USA INC

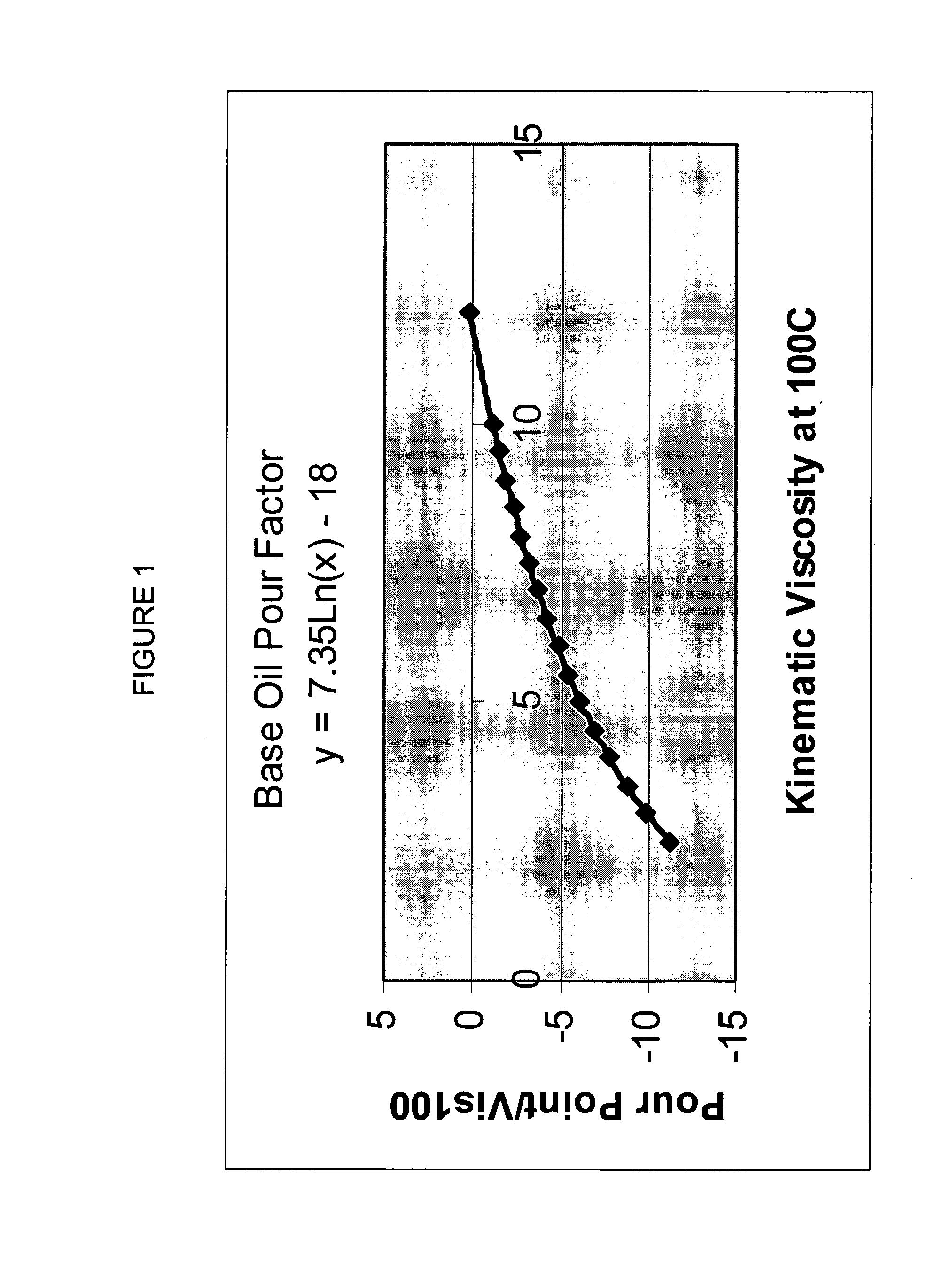

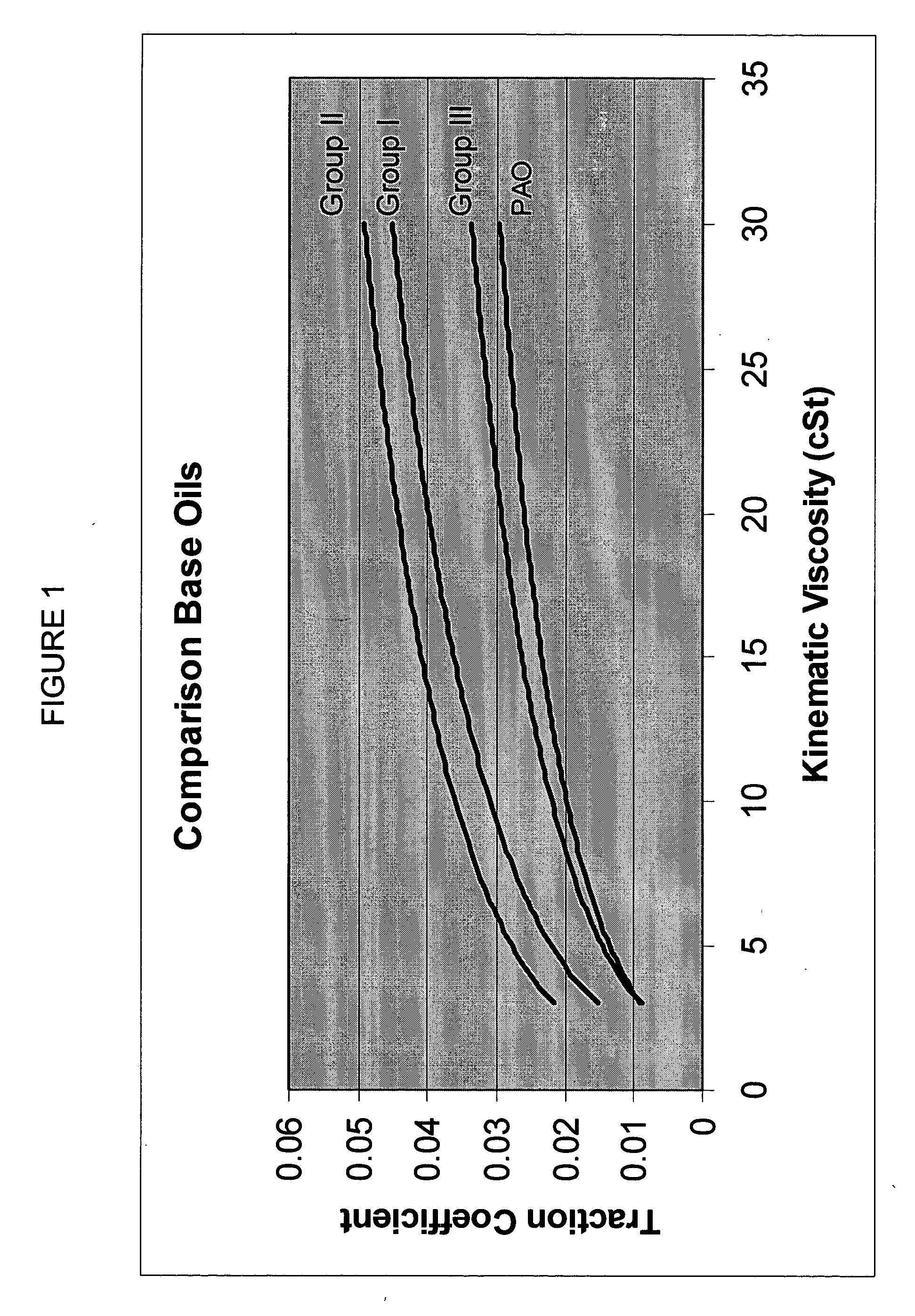

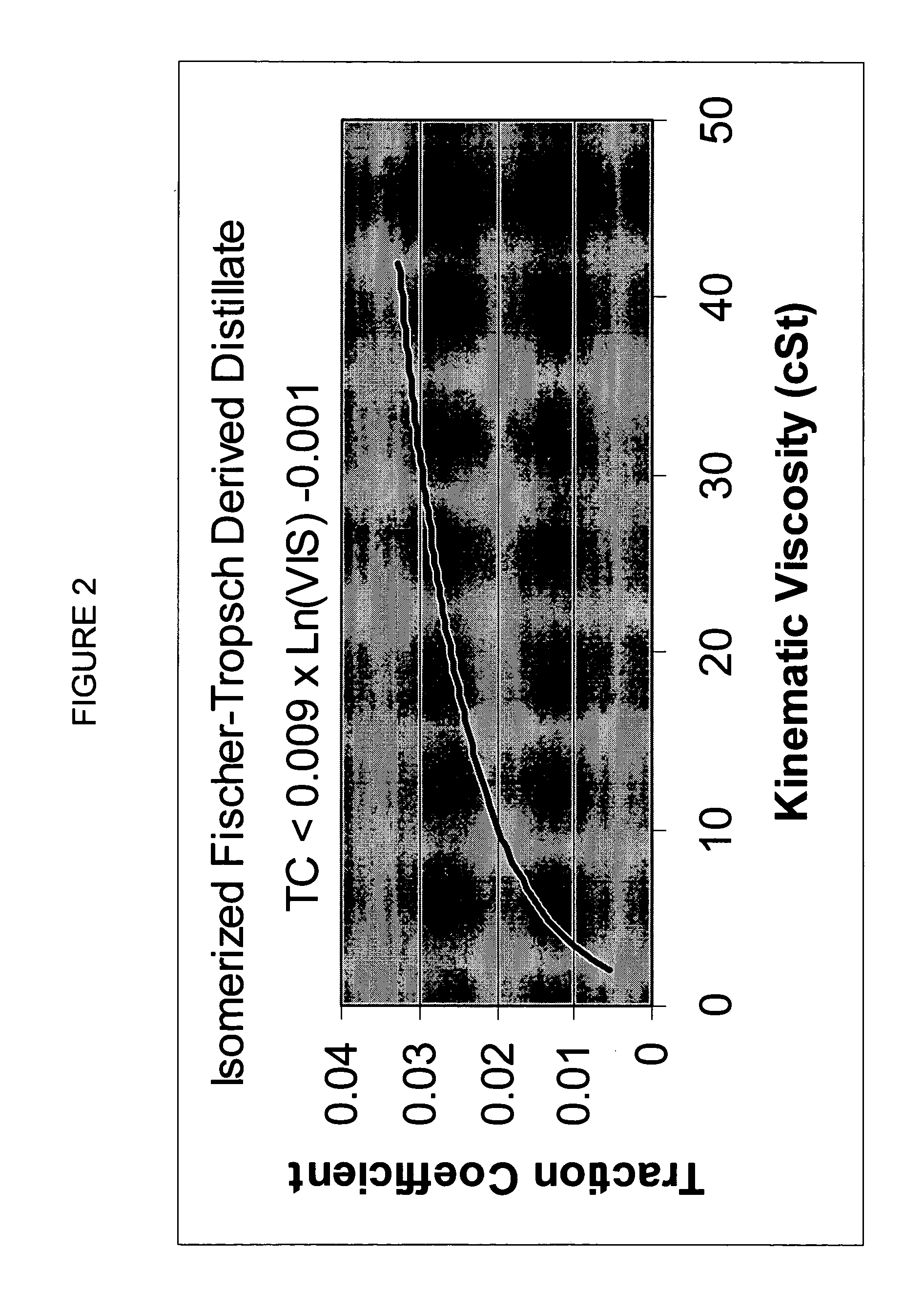

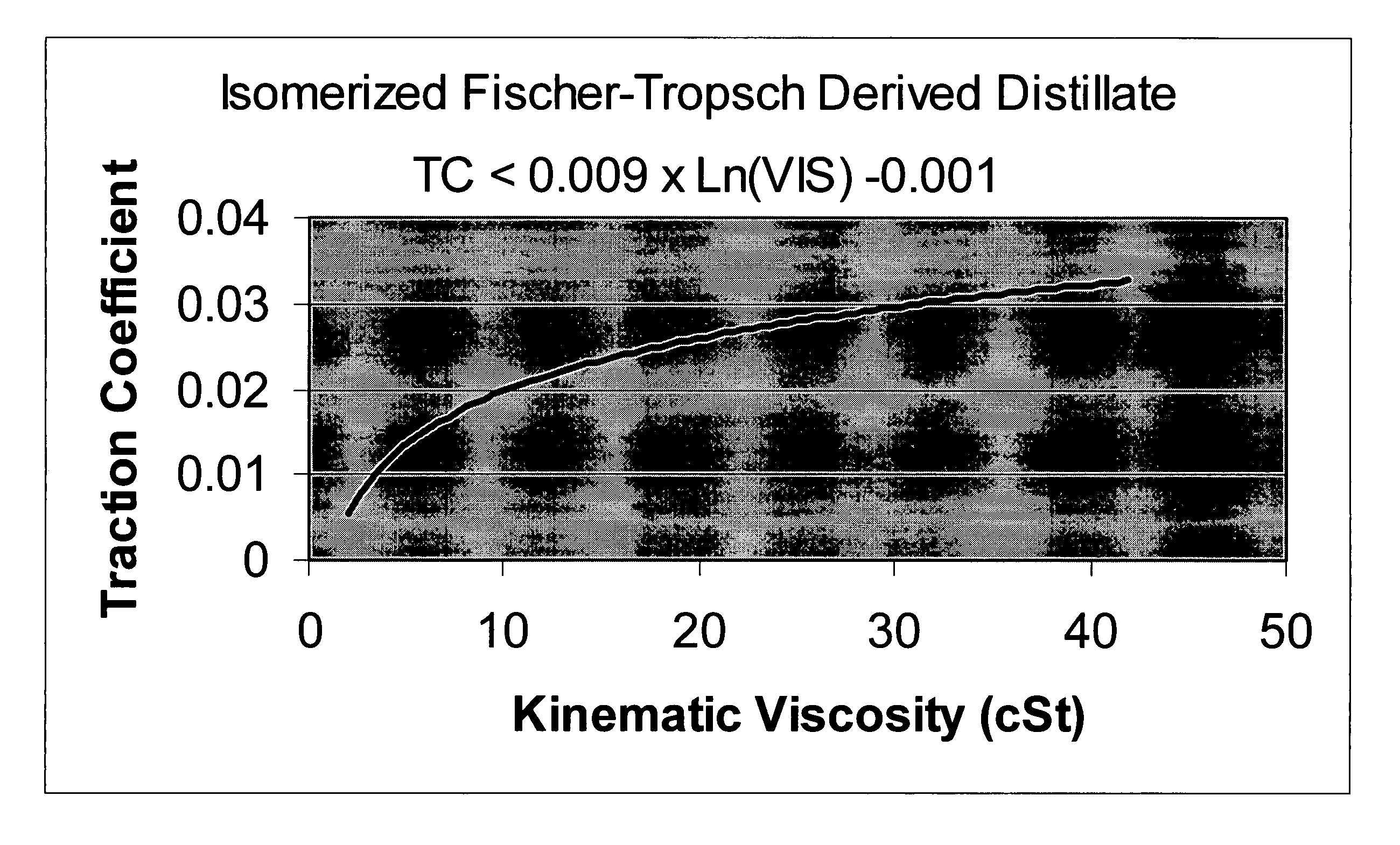

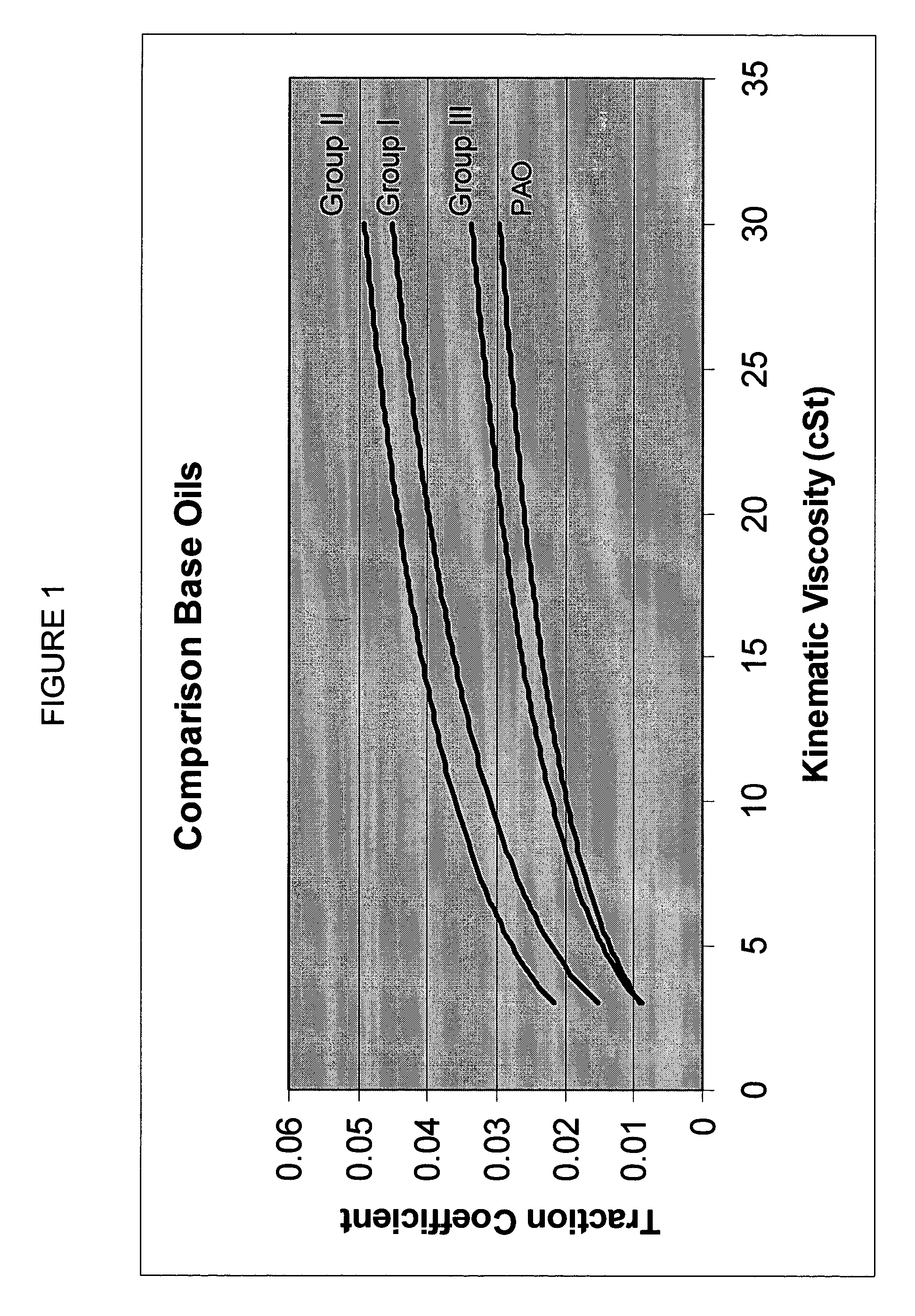

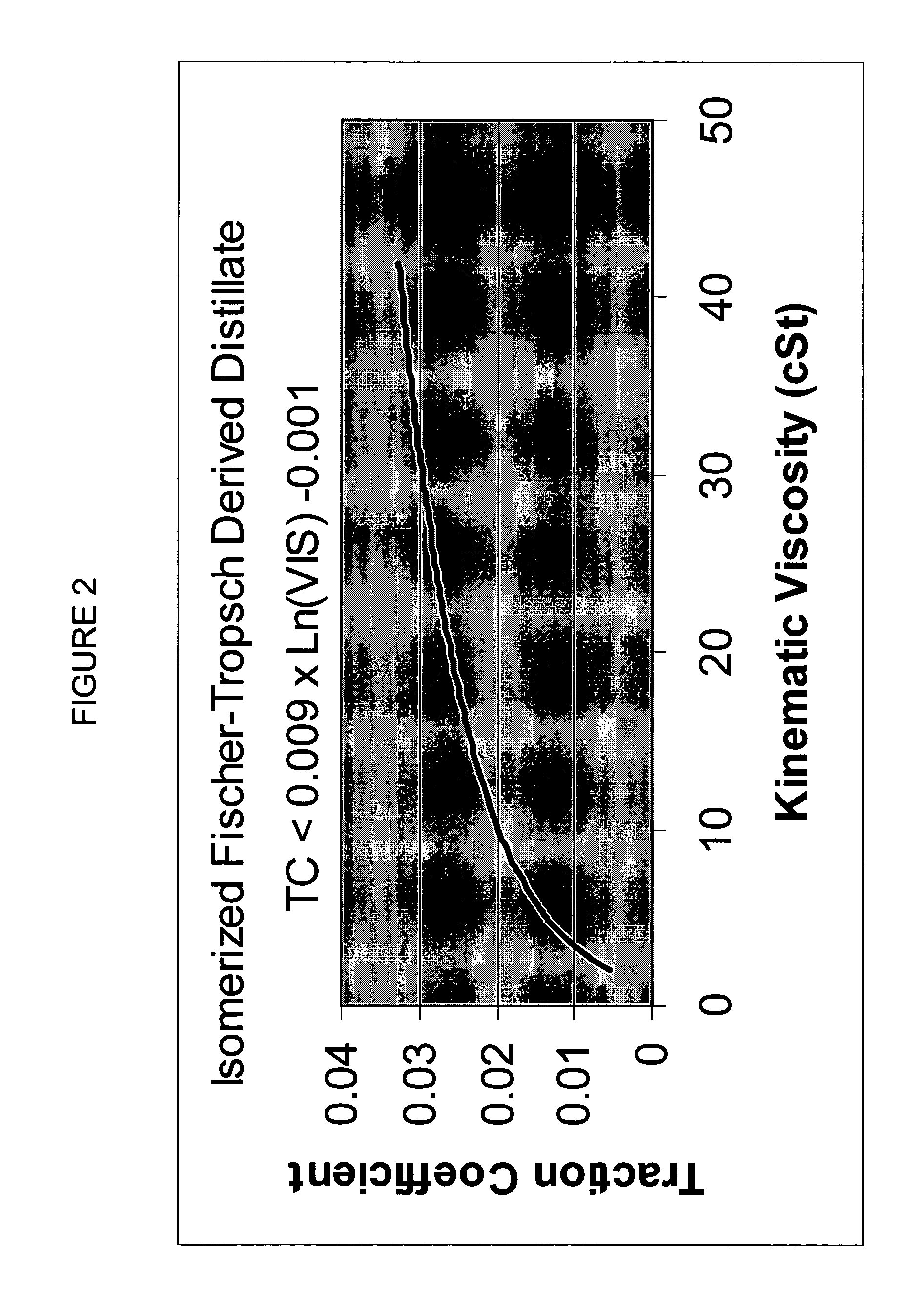

Method of operating a wormgear drive at high energy efficiency

InactiveUS20050241990A1Reducing traction coefficientToothed gearingsGear lubrication/coolingHigh energyBase oil

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

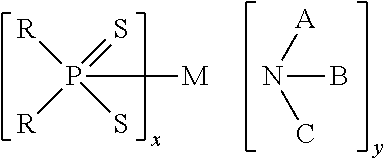

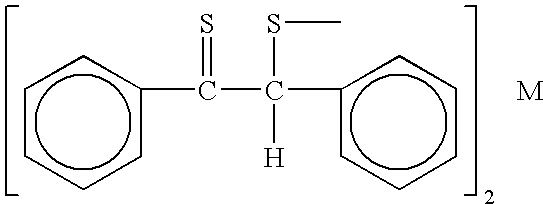

Catalytic antioxidants

The present invention is directed to lubricating oils exhibiting improved resistance to oxidation and deposit / sludge formation comprising a lubricant base oil and catalytic antioxidants comprising an effective amount of a) one or more polymetal organometallic compound; and, b) effective amounts of one or more substituted N,N′-diaryl-o-phenylenediamine compounds or c) one or more hindered phenol compounds or both, to a method for improving the antioxidancy and the resistance to deposit / sludge formation of formulated lubricating oil compositions by the addition thereto of an effective amount of the aforementioned catalytic antioxidants, and to an additive concentrate containing the aforementioned catalytic antioxidants.

Owner:EXXON RES & ENG CO

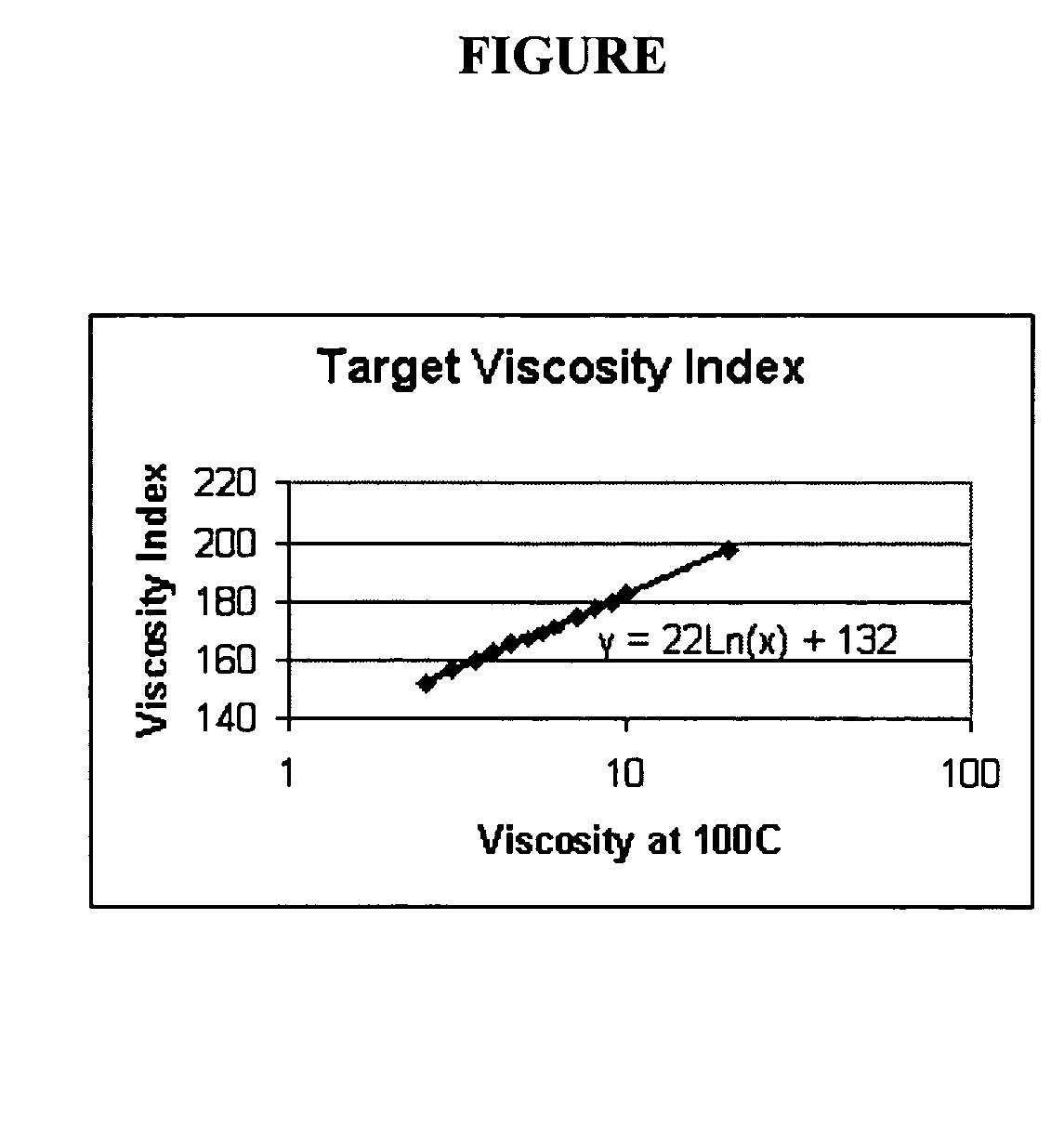

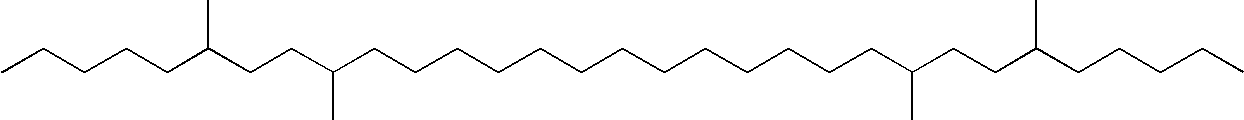

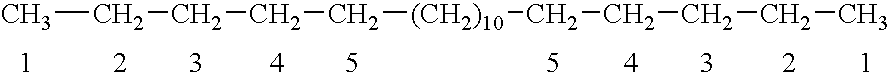

Lubricant base oils with optimized branching

The present invention relates to lubricant base oils comprising paraffinic hydrocarbon components having optimized branching. These lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching overall with the branching concentrated toward the center of the lubricant base oil molecules. The present invention also relates to processes of producing these lubricant base oils from waxy feeds and commercial finished lubricants comprising these lubricant base oils.

Owner:CHEVROU USA INC

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

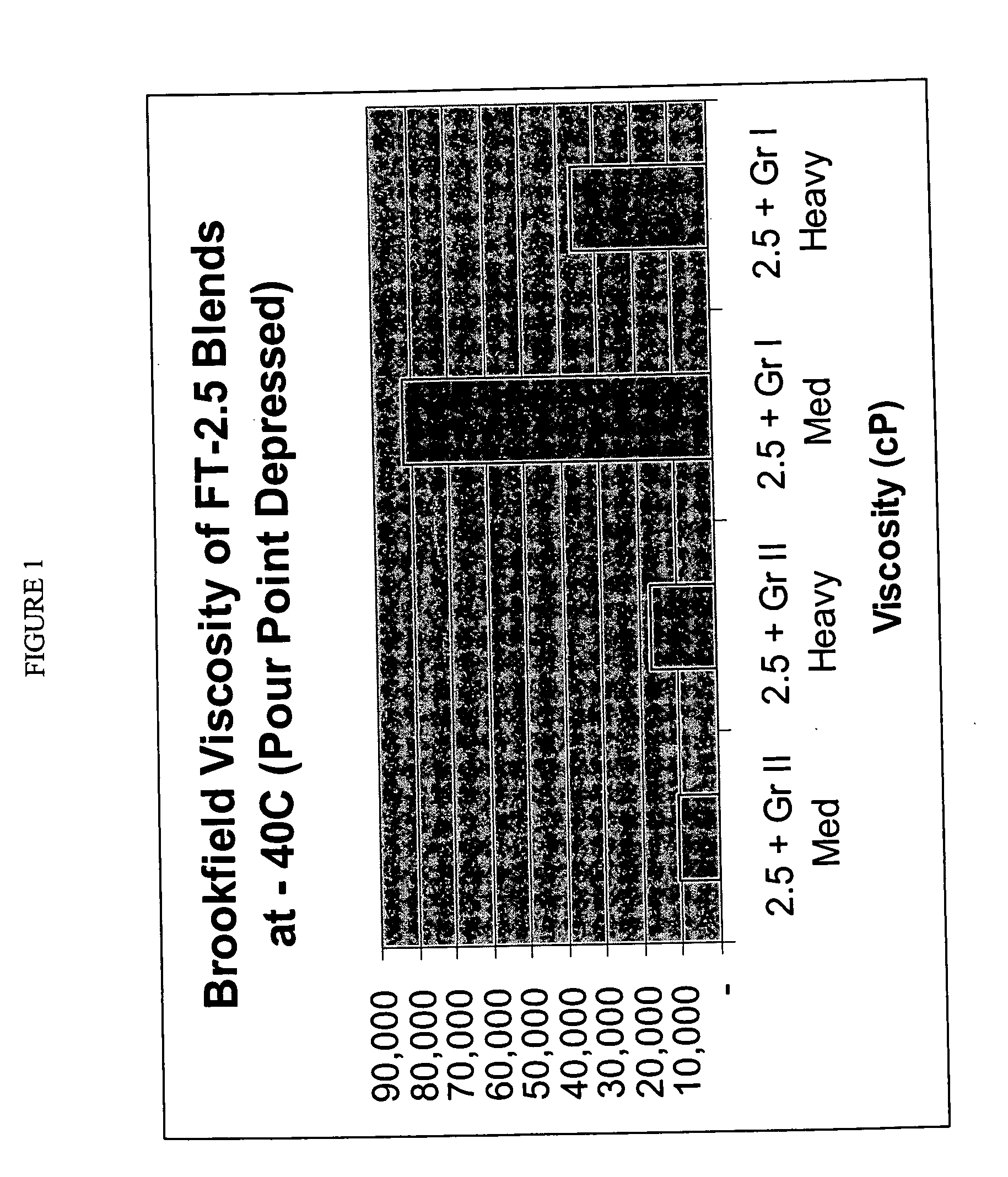

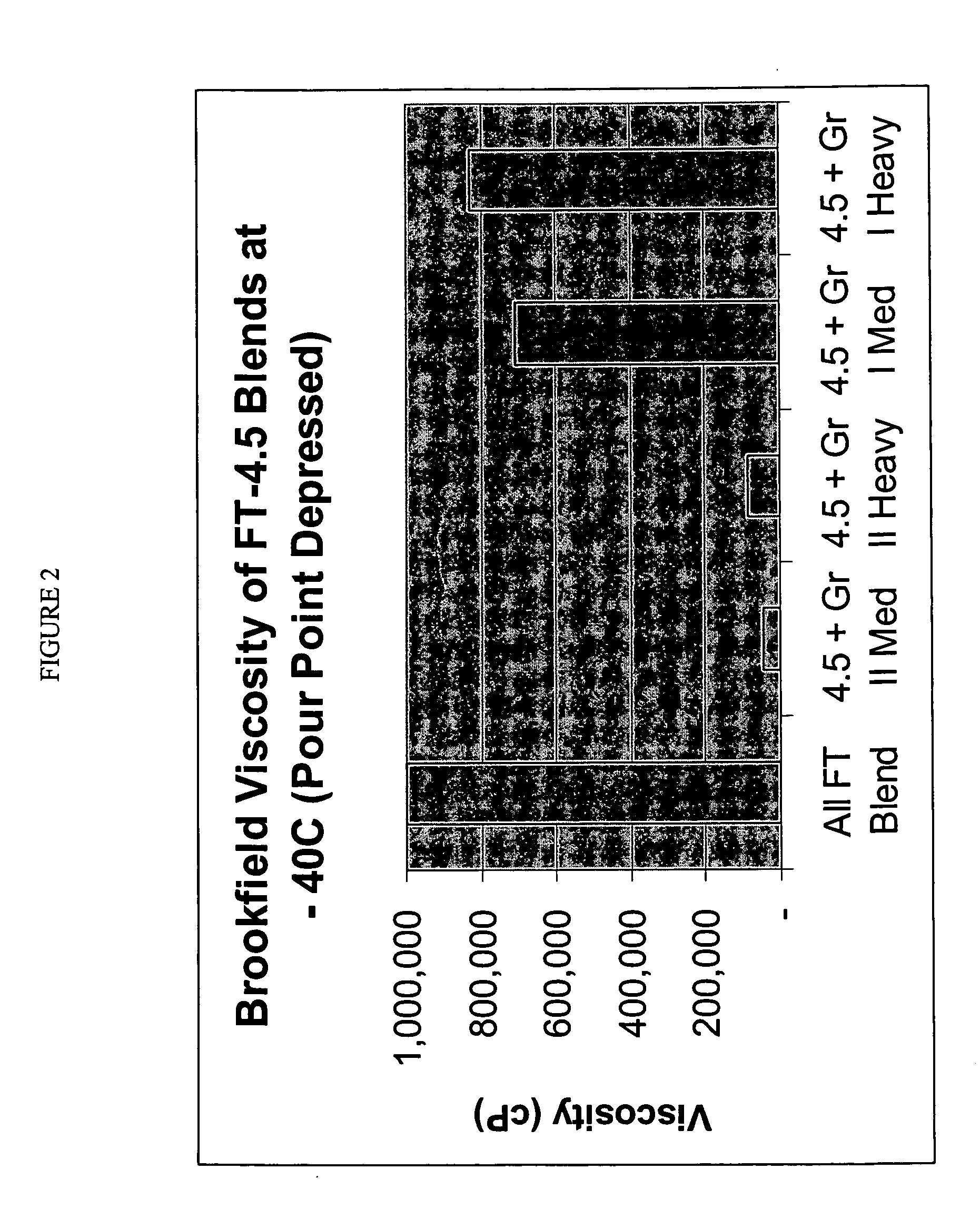

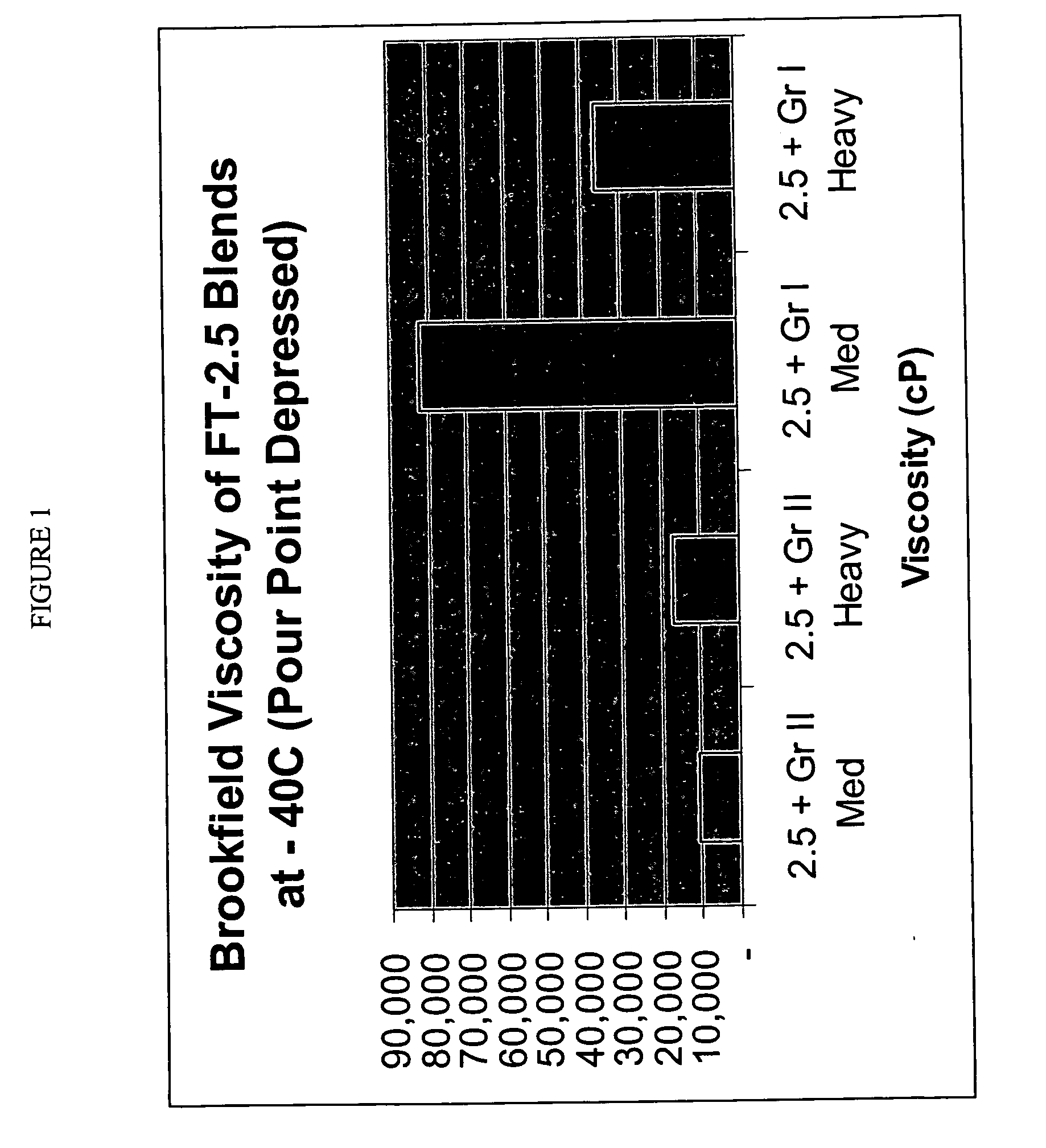

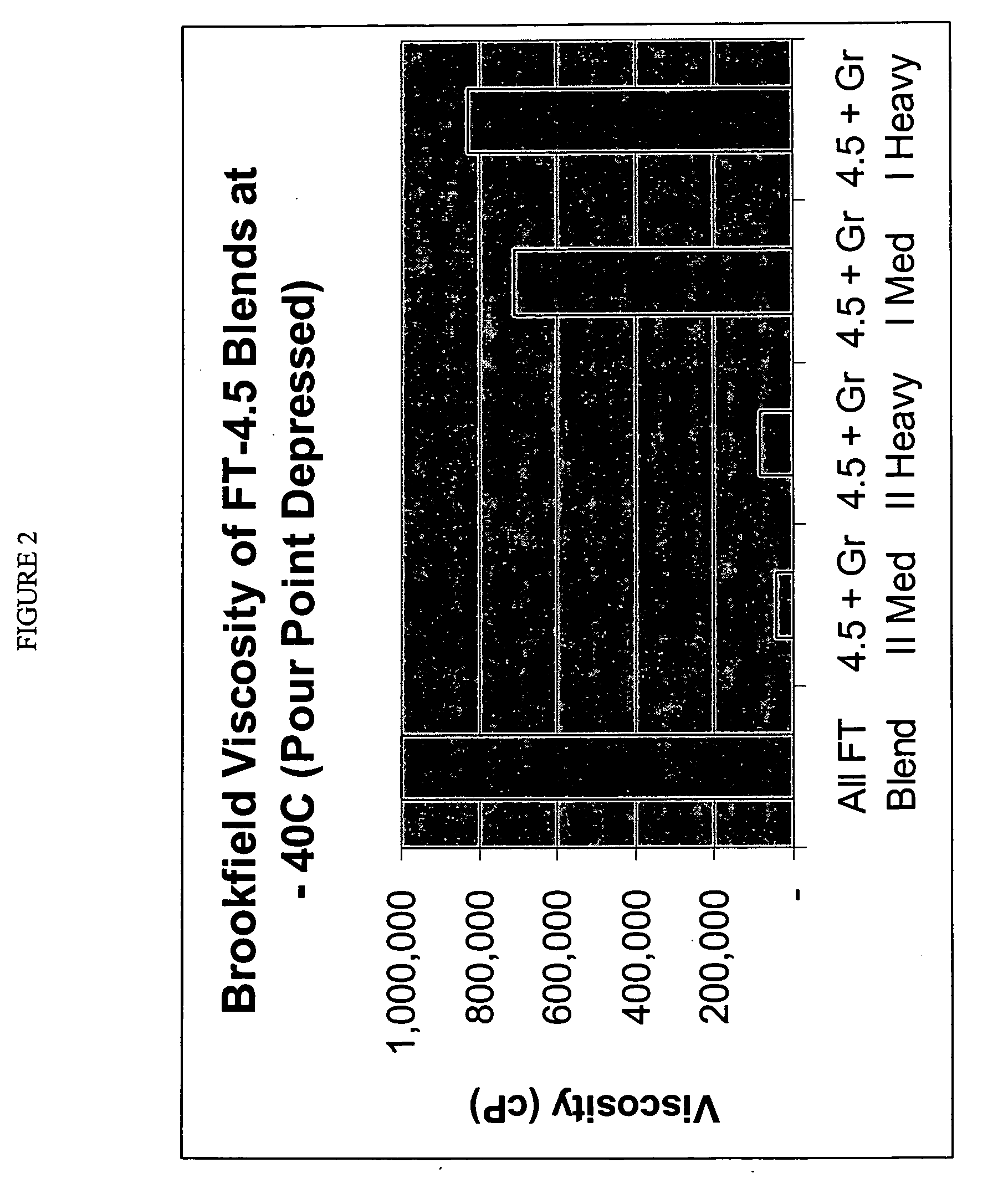

Lubricant blends with low brookfield viscosities

InactiveUS20050261147A1Improve low temperature performanceExcellent low Brookfield viscosityOrganic chemistryLiquid carbonaceous fuelsWaxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Wide-cut synthetic isoparaffinic lubricating oils

A wide-cut lubricant base stock is made by hydroisomerizing and then catalytically dewaxing a waxy Fischer-Tropsch synthesized hydrocarbon fraction feed and comprises the entire dewaxate having an initial boiling point in the 650-75O° F.+ range. Formulated lubricating oils made by admixing the base stock with a commercial automotive additive package meet all specifications, including low temperature properties, for multigrade internal combustion engine crankcase oils. The waxy feed has an initial boiling point in the 650-750° F. range and continuously boils to an end point of at least 1050° F.+. Lower boiling hydrocarbons produced by the process are separated from the base stock by simple flash distillation. The base stock comprises the entire dewaxate having an initial boiling point in the 650-750° F. range.

Owner:EXXON RES & ENG CO

Method of operating a wormgear drive at high energy efficiency

InactiveUS7045055B2Reducing traction coefficientGear lubrication/coolingToothed gearingsHigh energyFuel tank

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

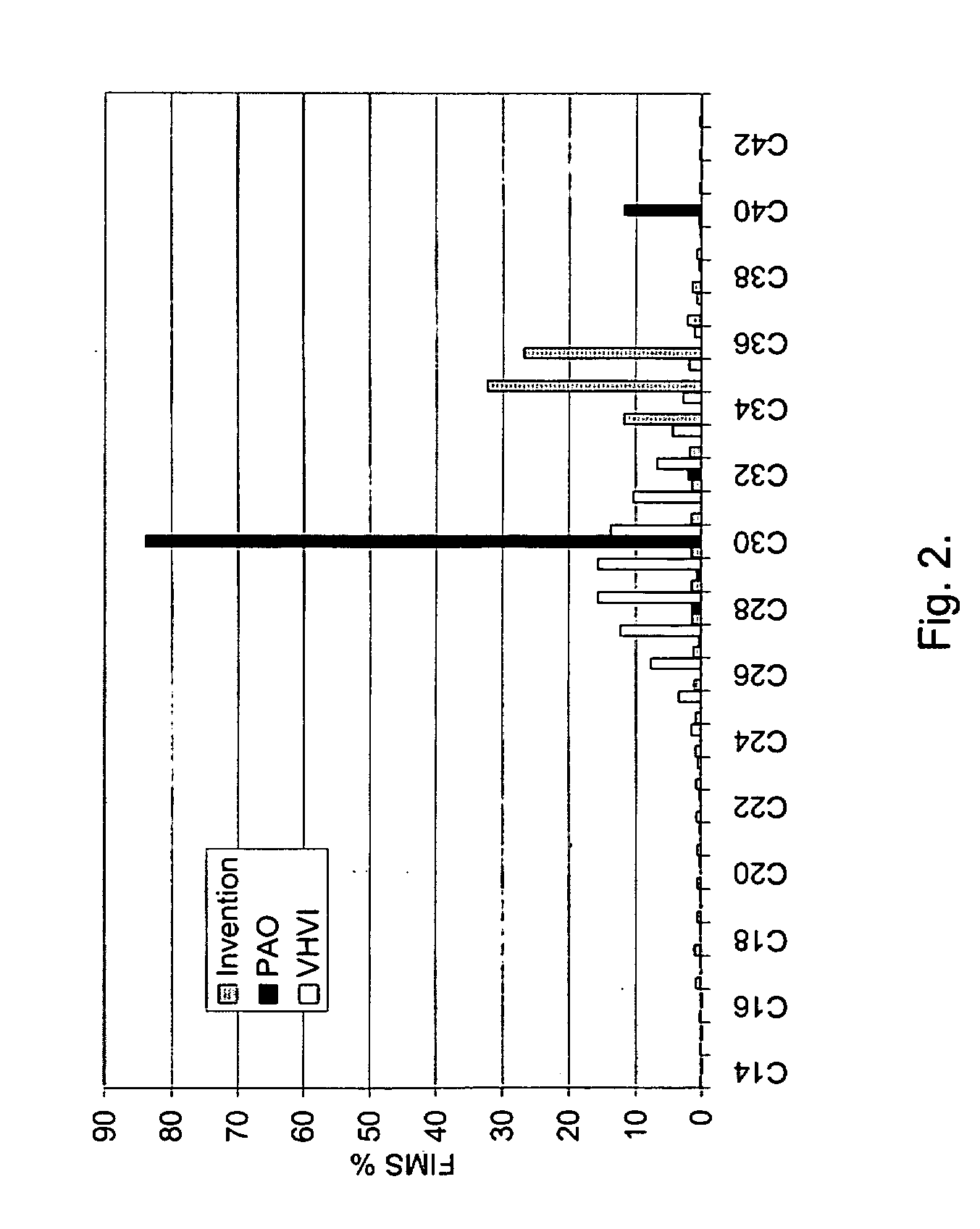

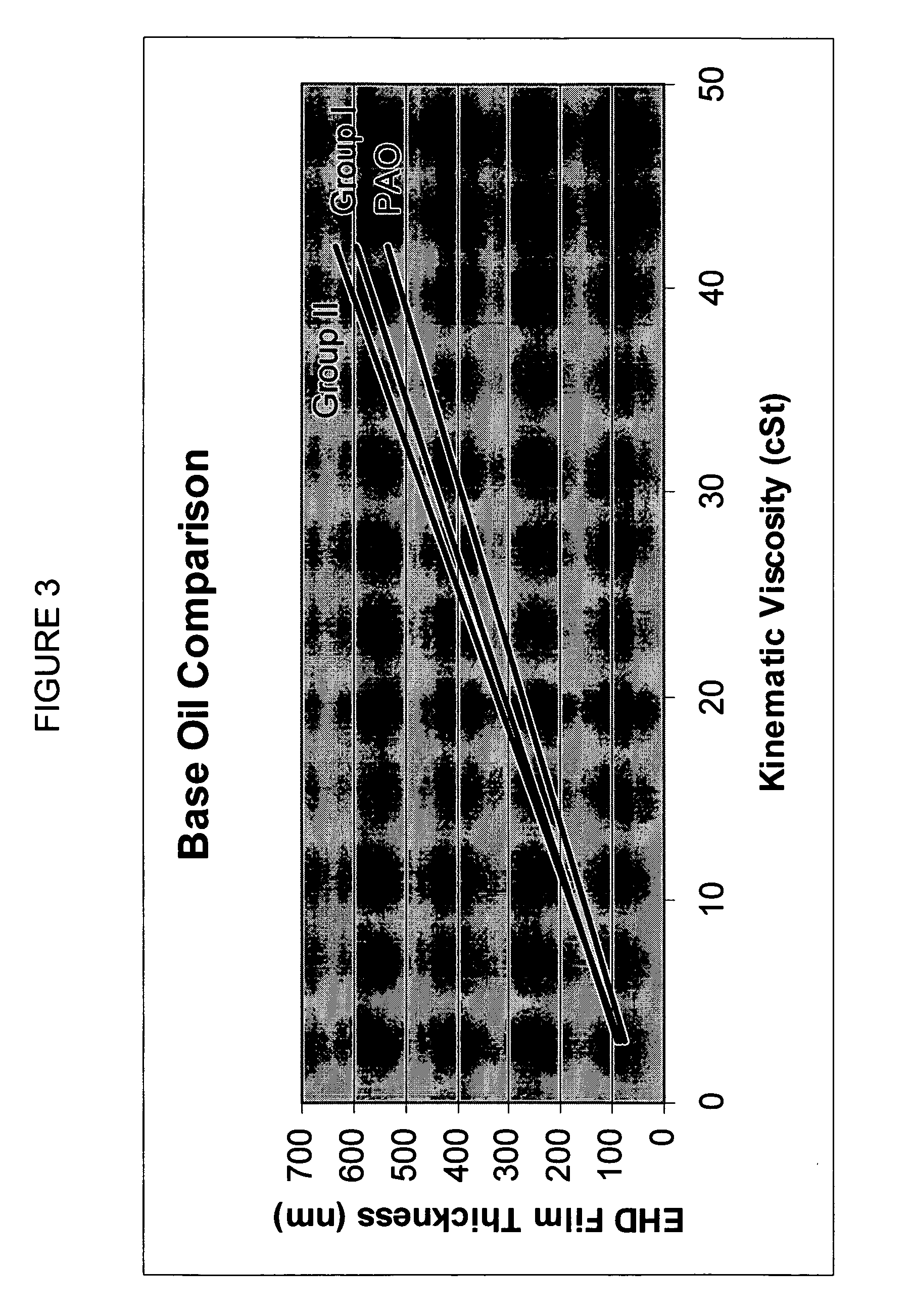

Polyalphaolefin & fischer-tropsch derived lubricant base oil lubricant blends

InactiveUS20060199743A1Increase frictionImproved wear propertyTreatment with hydrotreatment processesAdditivesBase oilViscosity

Blended lubricant base oils and blended finished lubricants comprising ≧70 weight percent Fischer-Tropsch derived lubricant base oils comprising ≧6 weight % molecules with monocycloparaffinic functionality and less than 0.05 weight % molecules with aromatic functionality; at least one polyalphaolefin lubricant base oil with a kinematic viscosity at 100° C. greater than about 30 cSt and less than 150 cSt are provided. These blended lubricant base oils and blended finished lubricants exhibit superior friction and wear properties, in addition to other highly desired properties. Also provided are processes for making these blended lubricant base oils and blended finished lubricants.

Owner:CHEVROU USA INC

Lubricant blends with low brookfield viscosities

ActiveUS20050261145A1Improve low temperature performanceLow viscosityOrganic compound preparationOxygen compounds preparation by reductionSulfurBase oil

Lubricant blends and finished gear oils comprising a Fischer-Tropsch derived lubricant base oil fraction, a petroleum derived base oil, and a pour point depressant are provided. The Fischer-Tropsch derived lubricant base oil fraction comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffnic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

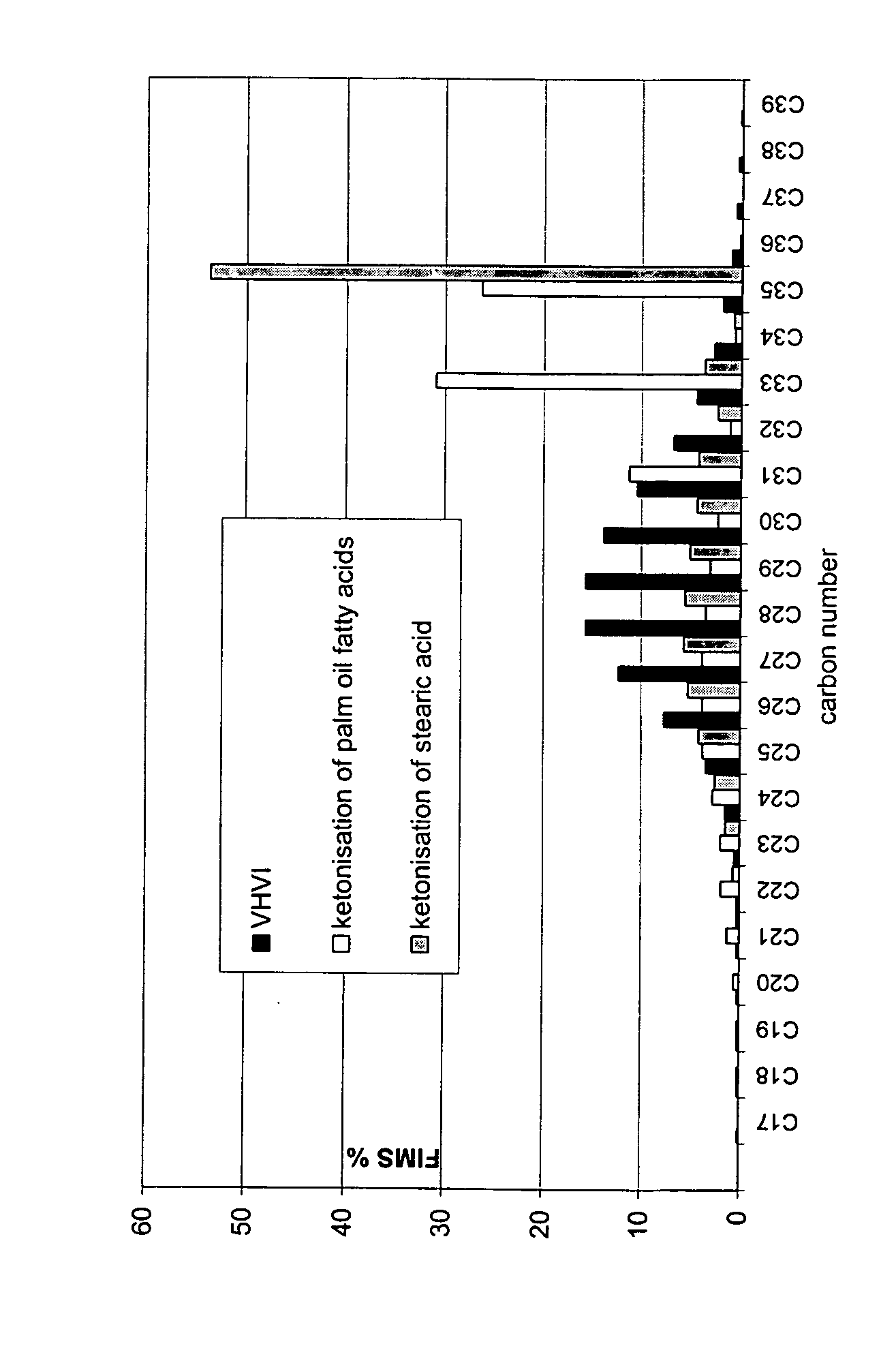

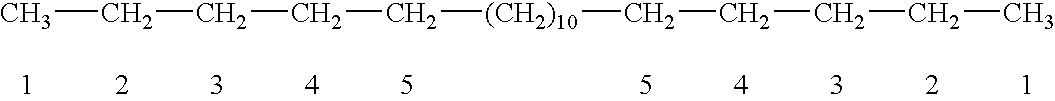

Base oil

ActiveUS20070135663A1Improve technical effectReduce fuel consumptionHydrocarbon purification/separationLiquid carbonaceous fuelsCarbon numberViscosity index

The invention relates to a new base stock material. Specifically the invention relates to a saturated hydrocarbon composition and particularly to a composition based on biological raw materials, to be used as a high-quality base oil or to be used as a component in the production of a base oil having a high viscosity index and good low temperature properties. The composition contains saturated hydrocarbons and has a narrow carbon number range.

Owner:NESTE OIL OY

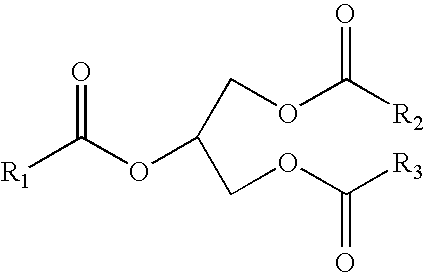

Lubricating oil for bearing

ActiveUS20060019840A1Improve performanceLiquid carbonaceous fuelsAdditivesGallic acid esterPHENOL LIQUID

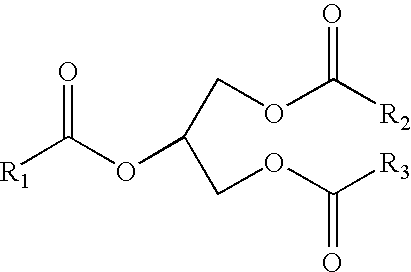

Disclosed herein is a lubricating oil for bearings comprising (a) a diester represented by General Formula (1) wherein R1 and R2 are the same or different, and each represents a C3-C17 linear alkyl group; A represents a C2-C10 linear alkylene group or A represents a branched alkylene group consisting of a linear alkylene group, the linear alkylene group being the principal chain, and one or more alkyl groups (branches) bonded to the linear alkylene group, wherein the total number of carbon atoms of the linear alkylene group and the one or more alkyl groups is 3 to 10; with the proviso that when A is a branched alkylene group and has two or more alkyl groups, the two or more alkyl groups are not bonded to the same carbon atom; or a mixture of the diester with an additional base oil and (b) at least one member selected from the group consisting of phenol-based antioxidants and amine-based antioxidants, and optionally containing (c) at least one member selected from the group consisting of phosphorus-based compounds and aliphatic linear monocarboxylic acids, and further optionally containing (d) at least one member selected from the group consisting of benzotriazole-based compounds and gallic acid-based compounds.

Owner:NEW JAPAN CHEM CO

Isomerization/dehazing process for base oils from Fischer-Tropsch wax

InactiveUS7198710B2Hydrocarbon by hydrogenationTreatment with hydrotreatment processesWaxMolecular sieve

A method for producing lubricant base oils is provided comprising the steps of: (a) separating a feedstock into a light lubricant base oil fraction and a heavy fraction; (b) hydroisomerizing the fractions over a medium pore size molecular sieve catalyst under hydroisomerization conditions to produce an isomerized light lubricant base oil fraction having a pour point less than or equal to a target pour point of the lubricant base oils and an isomerized heavy fraction having a pour point of equal to or greater than the target pour point of the lubricant base oils and a cloud point greater than the target cloud point of the lubricant base oils; and (c) dehazing the isomerized heavy fraction to provide a heavy lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a cloud point less than or equal to the target cloud point of the lubricant base oils.

Owner:CHEVROU USA INC

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

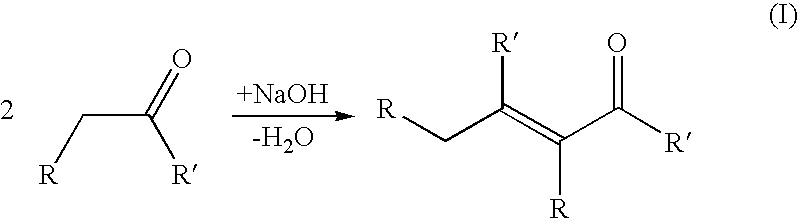

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

Processes for producing lubricant base oils with optimized branching

InactiveUS7018525B2Treatment with hydrotreatment processesHydrocarbon oils refiningViscosity indexBase oil

This invention relates to processes of producing lubricant base oils comprising paraffinic hydrocarbon components that have optimized branching. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching with the branching concentrated toward the center of the lubricant base oil molecules. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low pour points and extremely high viscosity indexes. The invention further relates to processes of producing commercial lubricants comprising the lubricant base oils comprising paraffinic hydrocarbon components with optimized branching from waxy feeds.

Owner:CHEVROU USA INC

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

Process for manufacturing lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS7282134B2Reduce weightHigh weight ratioTreatment with hydrotreatment processesAdditivesAlkaneWax

A process for manufacturing a lubricating base oil by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an is dimerized oil; and d) hydrofinishing said isomerized oil to produce a lubricating base oil having specific desired properties.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com