Patents

Literature

1365 results about "Hindered phenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

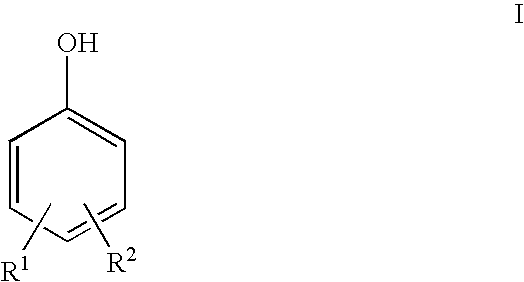

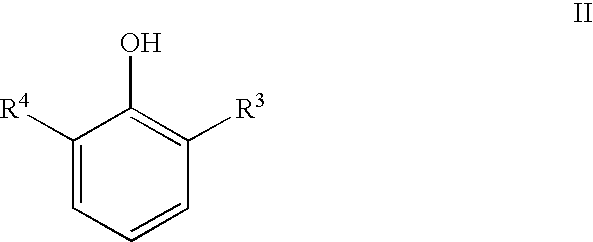

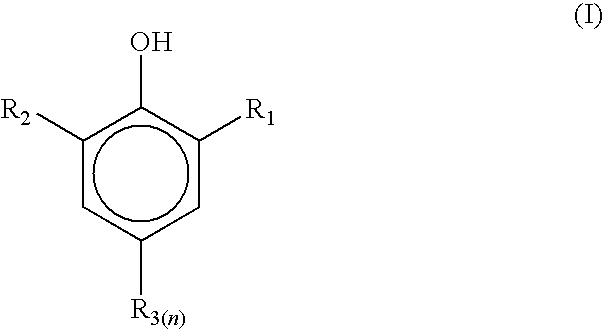

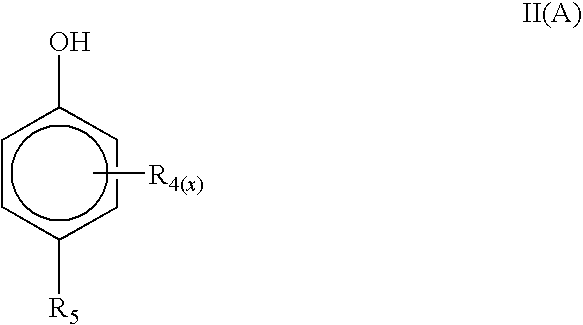

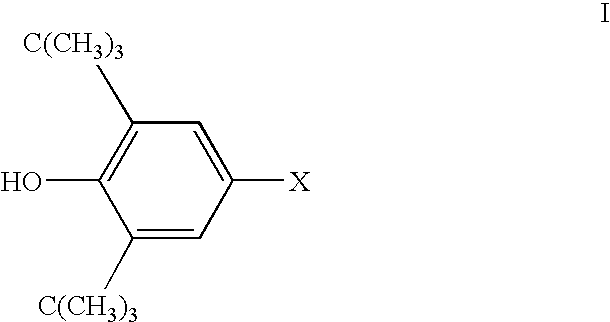

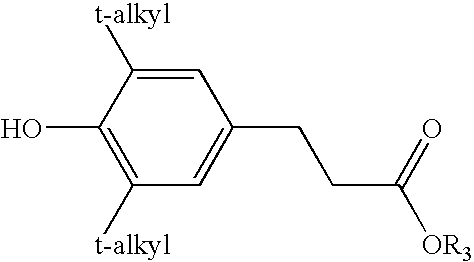

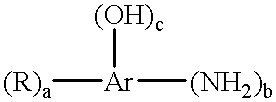

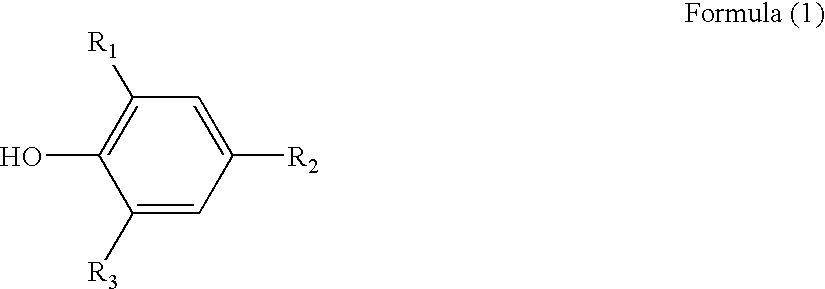

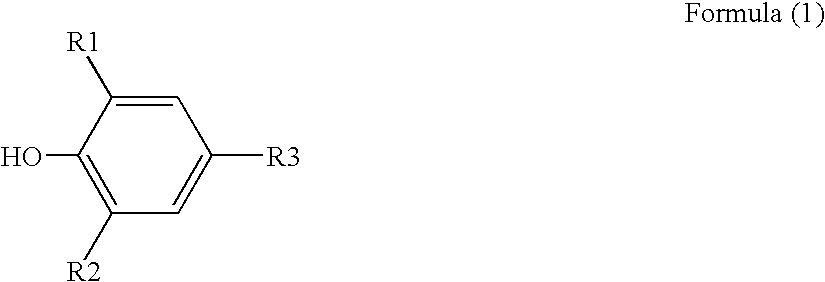

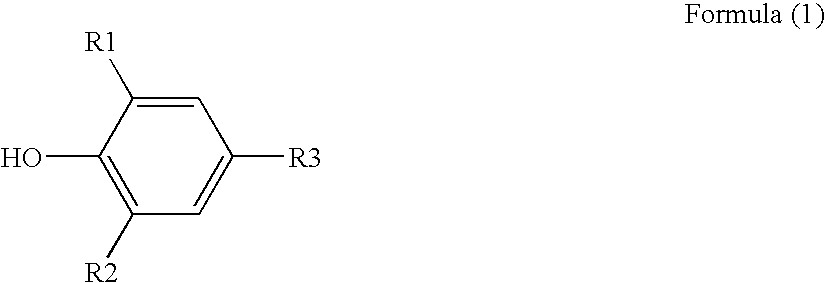

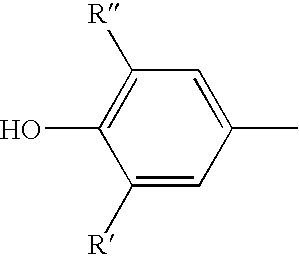

Hindered Phenols are nothing but a phenolic stabilizers. Phenolic stabilizers are primary antioxidants that act as hydrogen donors. A typical manufacturing process for a hindered phenol antioxidant uses a substituted cresol raw material for the phenolic ring portion of the molecule, and an aldehyde raw material for the bridging or connecting group.

Catalytic antioxidants

The present invention is directed to lubricating oils exhibiting improved resistance to oxidation and deposit / sludge formation comprising a lubricant base oil and catalytic antioxidants comprising an effective amount of a) one or more polymetal organometallic compound; and, b) effective amounts of one or more substituted N,N′-diaryl-o-phenylenediamine compounds or c) one or more hindered phenol compounds or both, to a method for improving the antioxidancy and the resistance to deposit / sludge formation of formulated lubricating oil compositions by the addition thereto of an effective amount of the aforementioned catalytic antioxidants, and to an additive concentrate containing the aforementioned catalytic antioxidants.

Owner:EXXON RES & ENG CO

Moisture curable polyolefin compositions

Owner:NIPPON YUNIKAA

Compounds and methods of making the compounds

InactiveUS20080090743A1Organic compound preparationLiquid carbonaceous fuelsArylCombinatorial chemistry

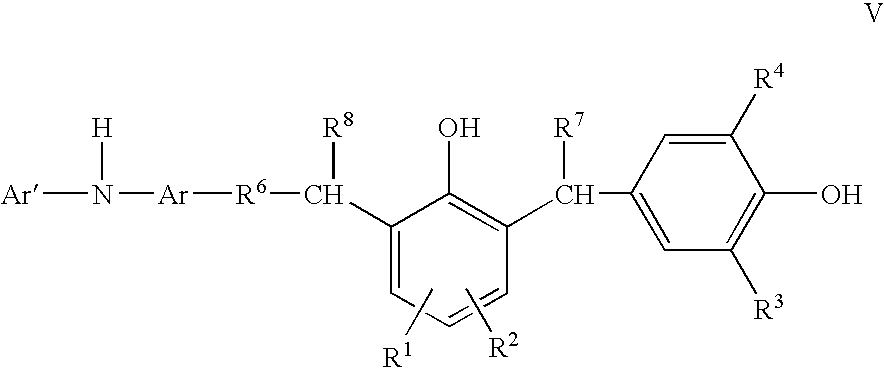

The present application is directed to compounds that are the reaction product of (i) a hydrocarbyl phenol, (ii) a hindered phenol; (iii) an diaryldiamine and (iv) an aldehyde. Methods of making and using the compounds of the present application are disclosed.

Owner:AFTON CHEMICAL

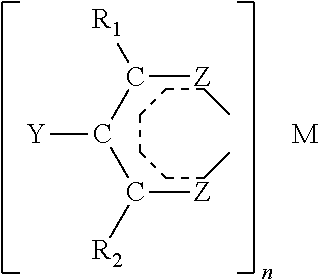

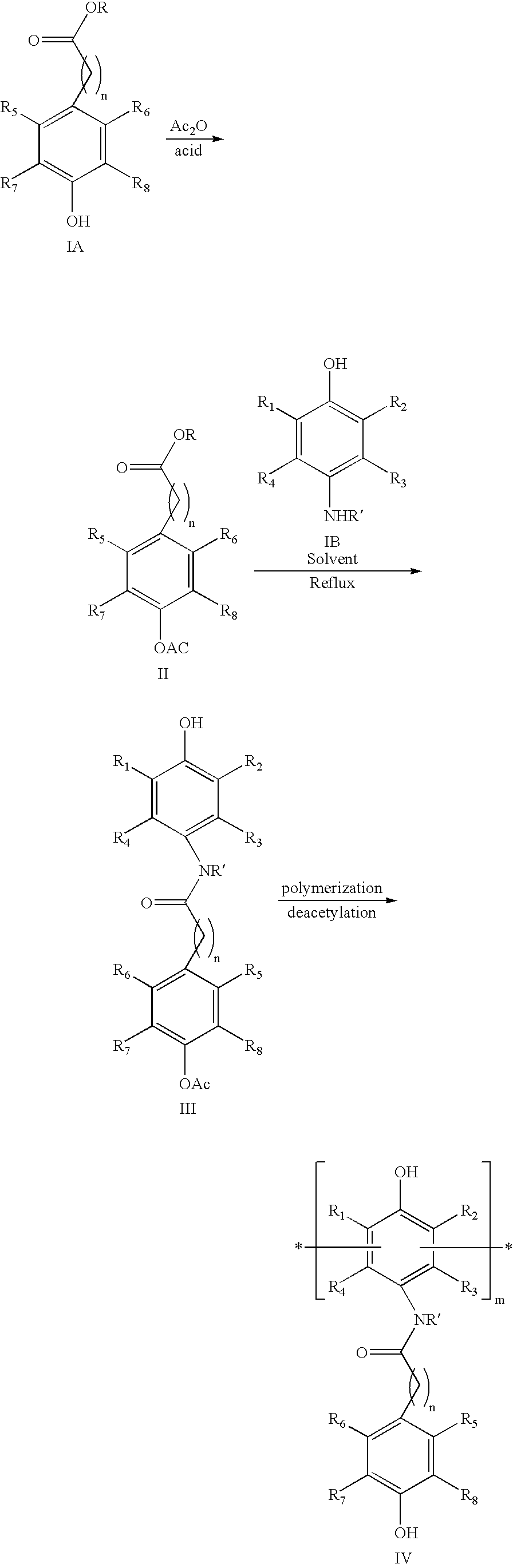

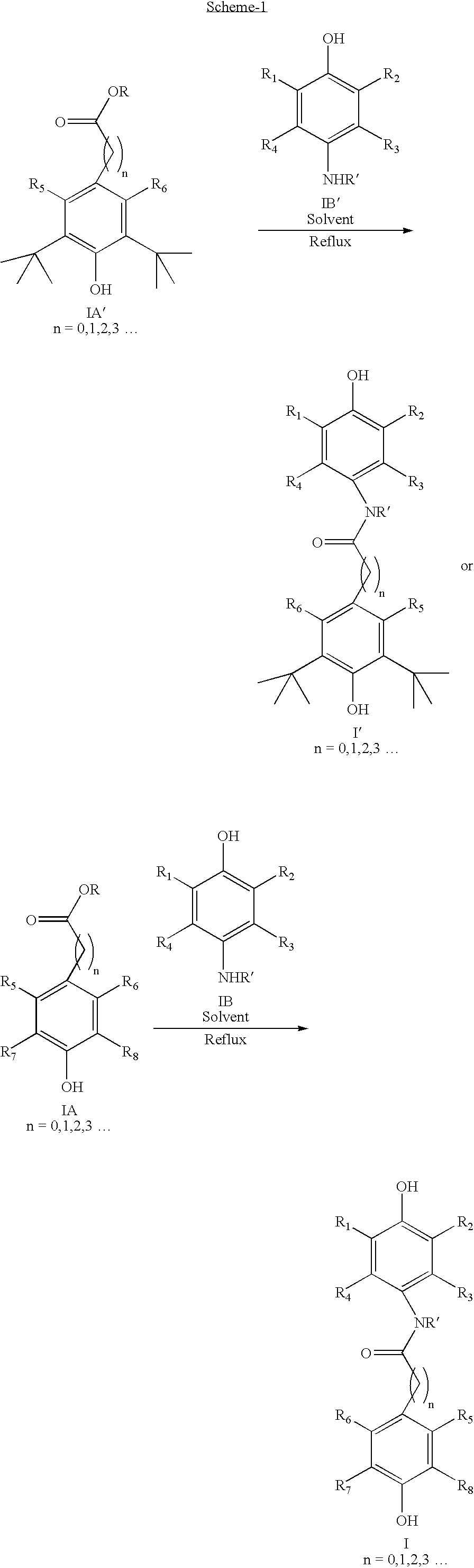

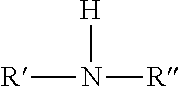

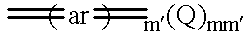

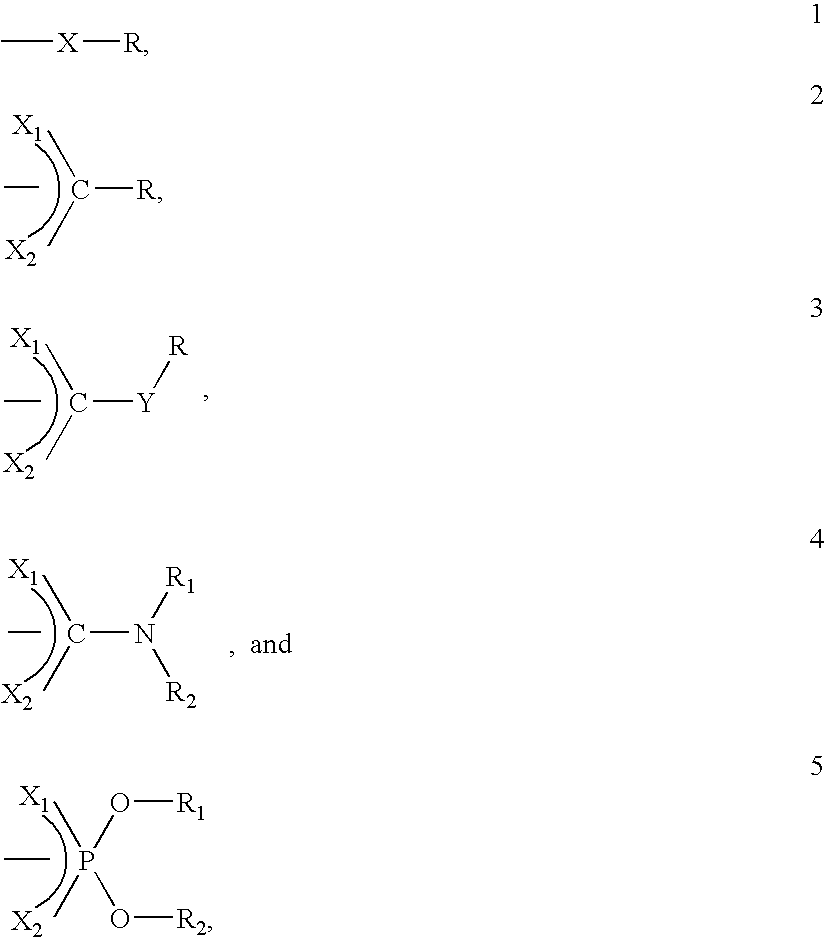

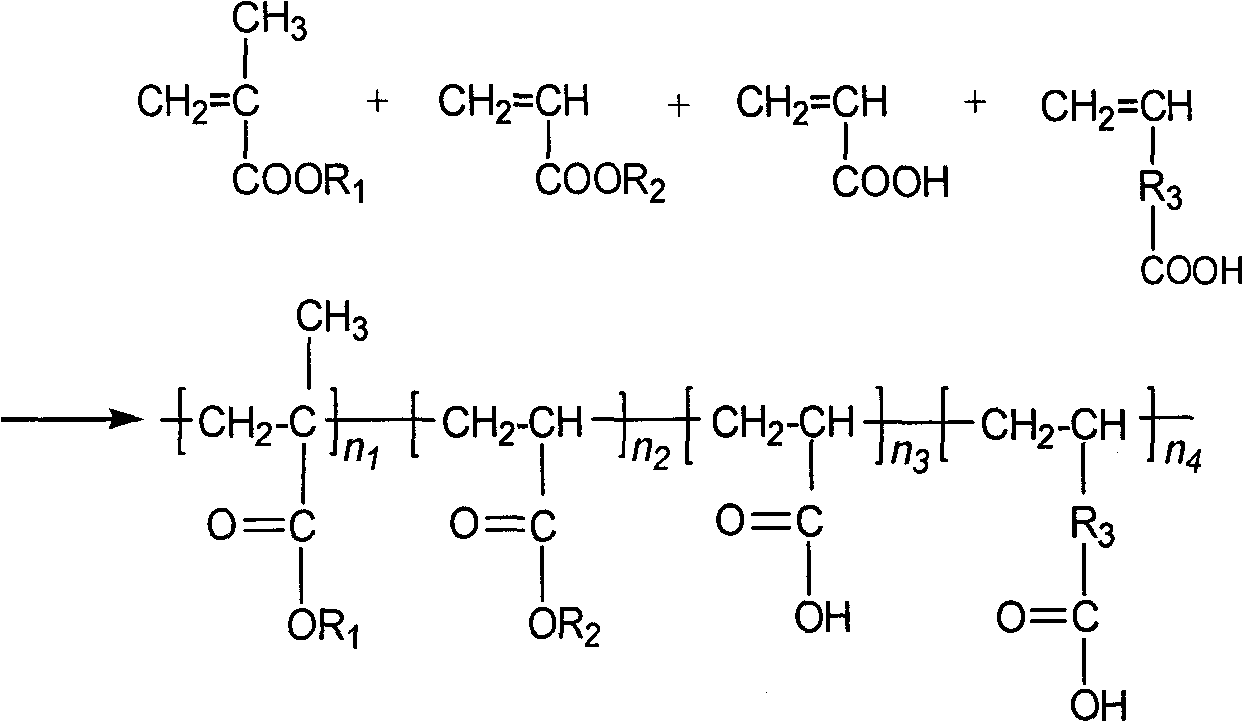

Synthesis of aniline and phenol-based antioxidant macromonomers and corresponding polymers

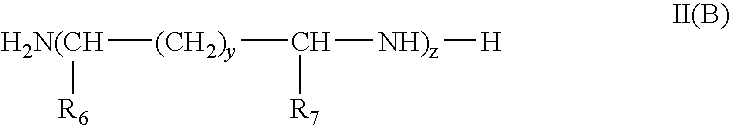

InactiveUS20060128931A1Improve reaction speedHigh yieldOrganic compound preparationCarboxylic acid amides preparationElastomerAniline

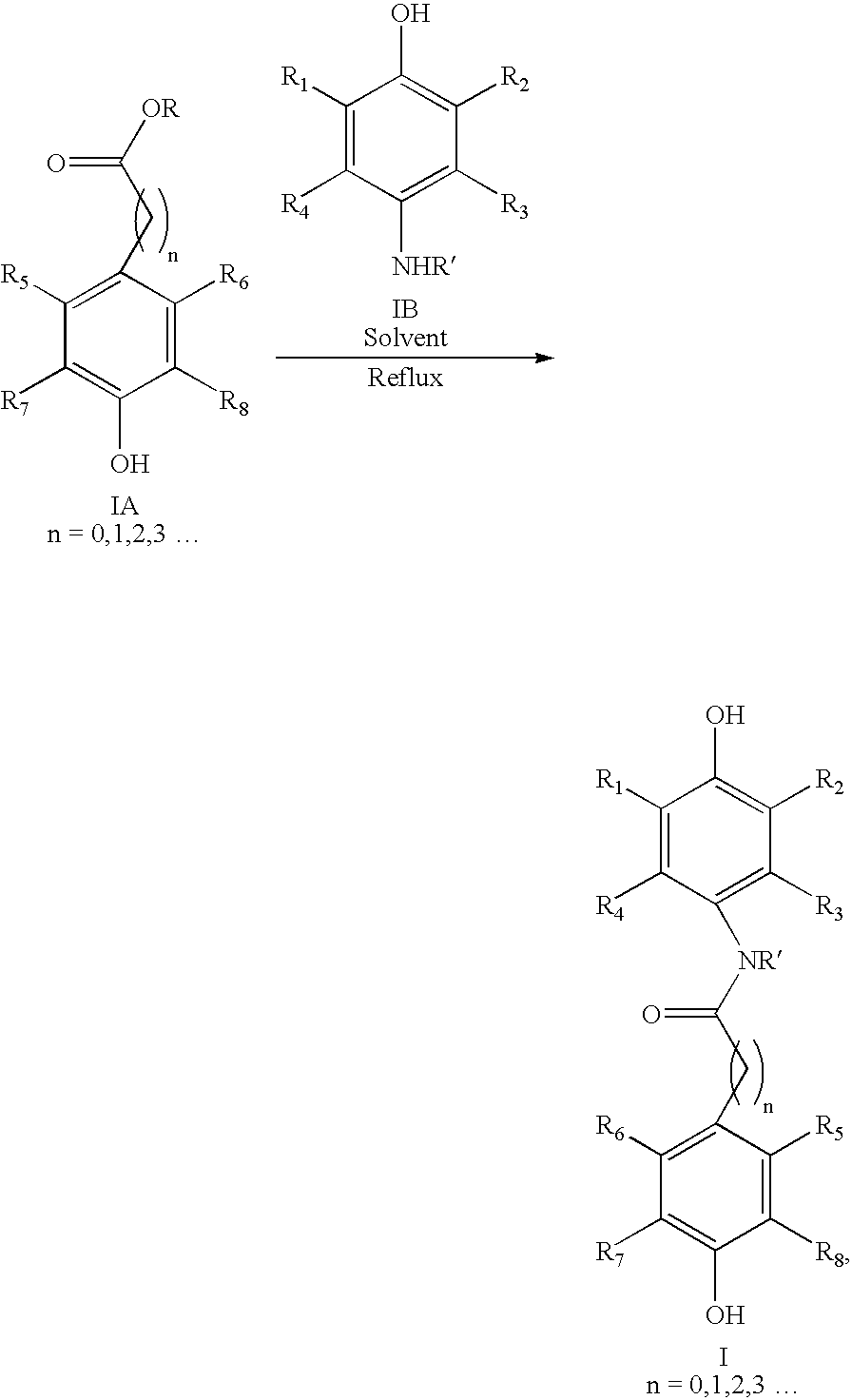

Compounds are synthesized that contain nitrogen and hindered phenol functionalities of an aromatic amine and hindered phenol for use as oxidative stabilizers for organic materials, paints, lubricants, elastomers, and in other applications. The disclosed methods can efficiently synthesize target monomers and polymers without the use of expensive catalysts. Further, the disclosed methods can scale up to industrially useful quantities. In general, the methods provide an improved, highly efficient and economical process for the synthesis of macromonomers having nitrogen containing moiety and sterically hindered phenols and their corresponding polymers.

Owner:POLNOX CORP

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

Methods and compositions for improving stability of biodiesel and blended biodiesel fuel

Methods and compositions for improving stability of biodiesel fuel. The methods comprise adding to said biodiesel fuel, an effective amount of a combined treatment that includes a (I) hindered phenol and (II) a Mannich reaction product. The compositions comprise I and II dissolved or dispersed in an organic solvent.

Owner:AFTON CHEMICAL

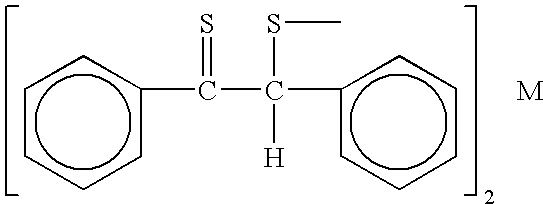

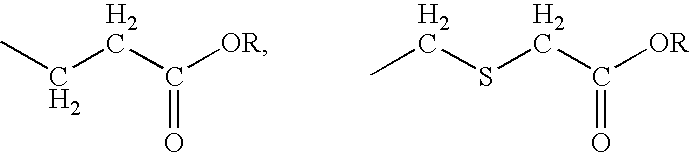

Lubricant compositions comprising an antioxidant blend

InactiveUS20050170978A1Improve Oxidation StabilityPrevent oxidationOrganic chemistryAdditivesOxidation stabilityHindered phenol

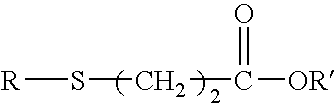

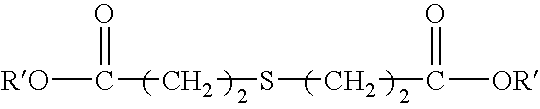

A composition is disclosed that comprises a lubricant and at least a first antioxidant and a second antioxidant, the first antioxidant being a hindered phenolic and the second antioxidant being a thioether. Also disclosed is a method of increasing the oxidation stability of a lubricant comprising adding thereto at least a first antioxidant and a second antioxidant, the first antioxidant being a hindered phenolic and the second antioxidant being a thioether.

Owner:CHEMTURA CORP

Antistatic adhesion-resistant slippery linear low density polyethylene composition and method of making the same

ActiveCN101012322AGuaranteed performanceMeet production requirementsLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antistatic blocking resistant smooth linear low-density polyethylene composition based on LLDPE as base, which comprises the following parts: 0.05-0.2% opening agent, 0.05-0.3% smooth agent, 0.05-0.3% antistatic agent, 0.05-0.2% anti-oxidant and 0.05-0.2% manufacturing and heat stabilizer, wherein the opening agent contains inorganic blocking resistant agent or organic opening agent; the smooth agent is amide, soap or organic silicane; the main auxiliary anti-oxidant is hindered phenol and phosphorus anti-oxidant; the antistatic agent adopts composite pattern of non-ionic typed antistatic agent and ion-typed antistatic agent. The making method compress the following steps: adopting LLDPE as base; adding blended auxiliary material into graining stage; or graining auxiliary agent into mother grain; adding mother grain; manufacturing specific material.

Owner:SINOPEC YANGZI PETROCHEM

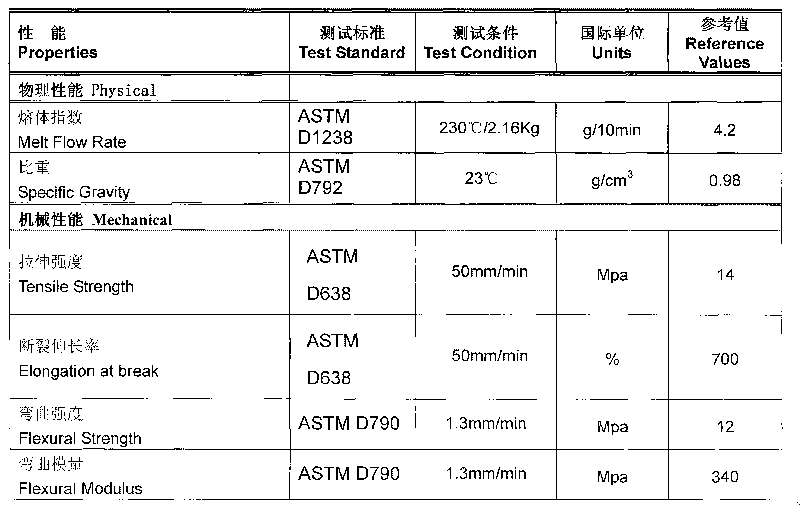

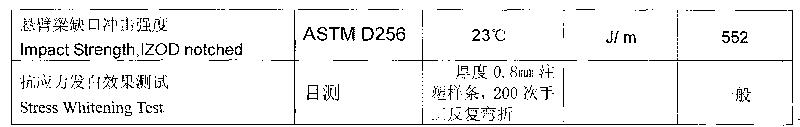

Anti-folding stress whitening resistant polypropylene (PP) material and preparation method thereof

The invention discloses an anti-folding stress whitening resistant polypropylene (PP) material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 55 to 75 parts of co-polypropylene, 5 to 20 parts of POE Lc670, 10 to 30 parts of stress whitening resistant master batch, 0.05 to 0.15 part of white mineral oil, 0.1 to 0.3 part of hindered phenol antioxidant 1010, 0.1 to 0.3 part of phosphite ester antioxidant 1680 and 0.1 to 0.3 part of calcium stearate. The stress whitening resistant master batch comprises the following components in part by weight: 40 to 65 parts of EPDM or EPR or POE, 30 to 50 parts of nano active light CaCO3, and 0.5 to 2 parts of sodium polyethylene with low molecular weight. The polypropylene (PP) material is prepared by using a double-screw extruder with 9 temperature control areas according to the specific process conditions. The material has the advantages of good repeated bending resistance and stress whitening resistance, simple preparation process and low preparation cost.

Owner:重庆启蓝塑料有限公司

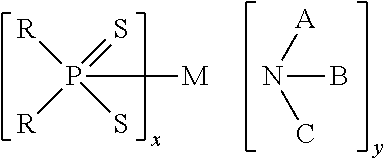

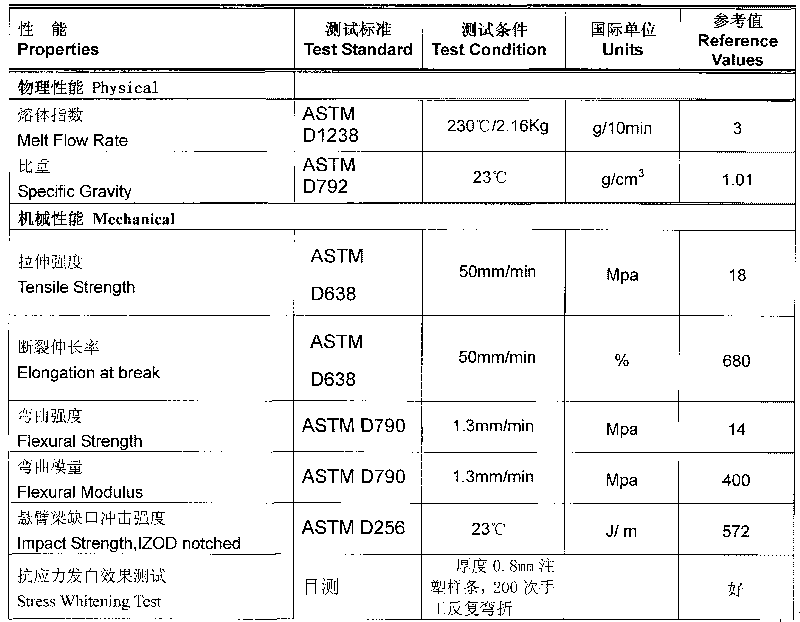

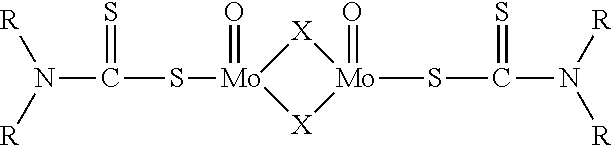

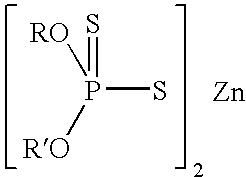

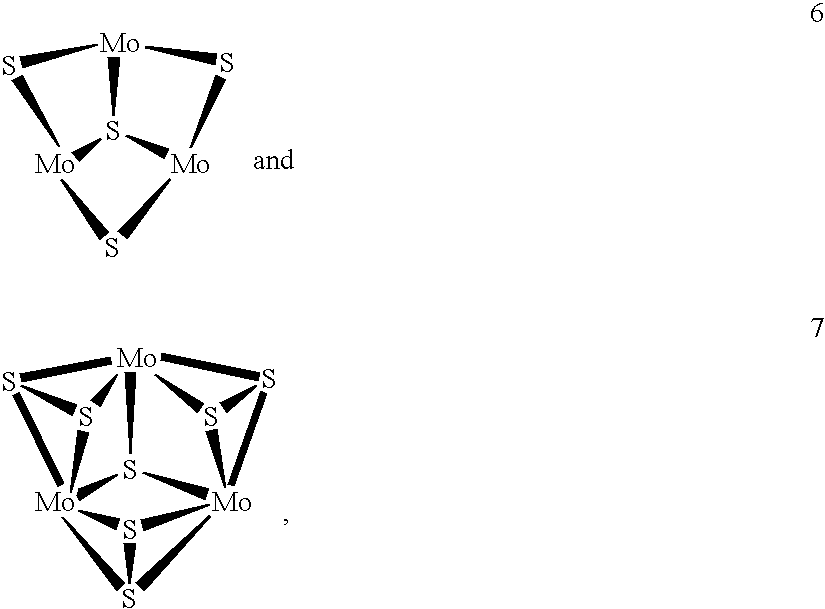

Ultra Low Phosphorus Lubricant Compositions

A low-phosphorus lubricating composition has less than 600 ppm phosphorus, comprising at least 85 weight % of a lubricating base blend, and an additive comprising the following, as weight % of the total composition:(1) an organomolybdenum compound at an amount which provides about 0.1-800 ppm Mo;(2) a hindered phenol at about 0.1-2%; and(3) a dithiocarbamate at about 0.1-2%; with a first proviso that where the dithiocarbamate does not comprise a metal dithiocarbamate, the additive additionally comprises:(4) an alkylated diphenylamine at about 0.1-2%, and with a second proviso that where the organomolybdenum compound comprises molybdenum dithiocarbamate, it is considered a metal dithiocarbamate for purposes of the first proviso[G1], but is considered an organomolybdenum compound for the purposes of calculation of the amount present in the total composition.

Owner:VANDERBILT CHEM LLC

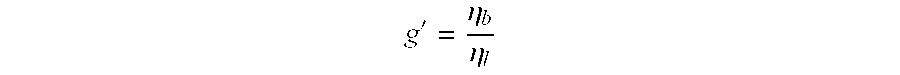

Polyolefin-based crosslinked articles

ActiveUS7867433B2Little to no loss in tensile strengthMaintain good propertiesImpression capsElectric discharge tubesElastomerFiber

Methods for making a crosslinked elastomeric composition and articles made of the same are provided. In at least one specific embodiment, an elastomeric composition comprising at least one propylene-based polymer is blended with at least one component selected from the group consisting of multifunctional acrylates, multifunctional methacrylates, functionalized polybutadiene resins, functionalized cyanurate, and allyl isocyanurate; and blended with at least one component selected from the group consisting of hindered phenols, phosphites, and hindered amines. The propylene-based polymer can include propylene derived units and one or more dienes, and have a triad tacticity of from 50% to 99% and a heat of fusion of less than 80 J / g. The blended composition can then be extruded and crosslinked. The extruded polymer can be crosslinked using electron beam radiation having an e-beam dose of about 100 KGy or less. The crosslinked polymers are particularly useful for making fibers and films.

Owner:EXXONMOBIL CHEM PAT INC

Two-stroke cycle lubricant and method of using same

A lubricant composition suitable for fuel injected two-stroke cycle engines includes an oil of lubricating viscosity, an amount, sufficient to reduce or prevent piston scuffing, of a mixture of (A) at least one phenol selected from (A-1) an aminophenol and (A-2) a reaction product of a nitrophenol and an amino compound, and (B) at least one Mannich dispersant, amine dispersant, nitrogen-containing carboxylic dispersant, or ester dispersant. The composition further includes an amount, sufficient to reduce degradation of the lubricant composition upon exposure to oxygen or oxides of nitrogen, of a nitrogen-containing inhibitor, a hindered phenol inhibitor, or a sulfur-containing organic inhibitor.

Owner:THE LUBRIZOL CORP

Polymer material for ammeter case

The invention relates to a high molecular material for an ammeter shell, which consists of PC-based resin, glass fiber, main flame retardant, dripping resistant agent, toughening agent, compatilizer, lubricant, and hindered phenol and phosphate ester of antioxidant. The high molecular material is characterized in that the PC is a mixture of two or more than two different PC with 5 to 24 of melt index, the main flame retardant is decabromodiphenylethane, the compatilizer is maleic anhydride grafting ABS, the toughening agent is PTW, and the lubricant is PETS and OP wax; and each component has the following adding weight portion: 490 to 770 portions of the PC-based resin, 100 to 300 portions of the glass fiber, 50 to 70 portions of the main flame retardant, 50 to 100 portions of the compatilizer, 20 to 40 portions of the toughening agent, 5 to 10 portions of the dripping resistant agent, 5 to 10 portions of the lubricant, and 4 to 6 portions of the antioxidant.

Owner:CHONGQNG PRET NEW MATERIAL +2

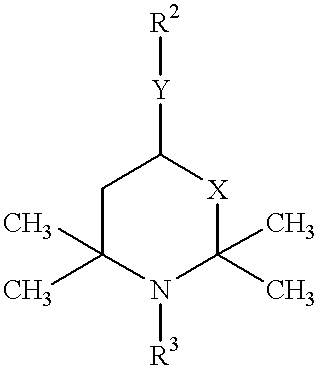

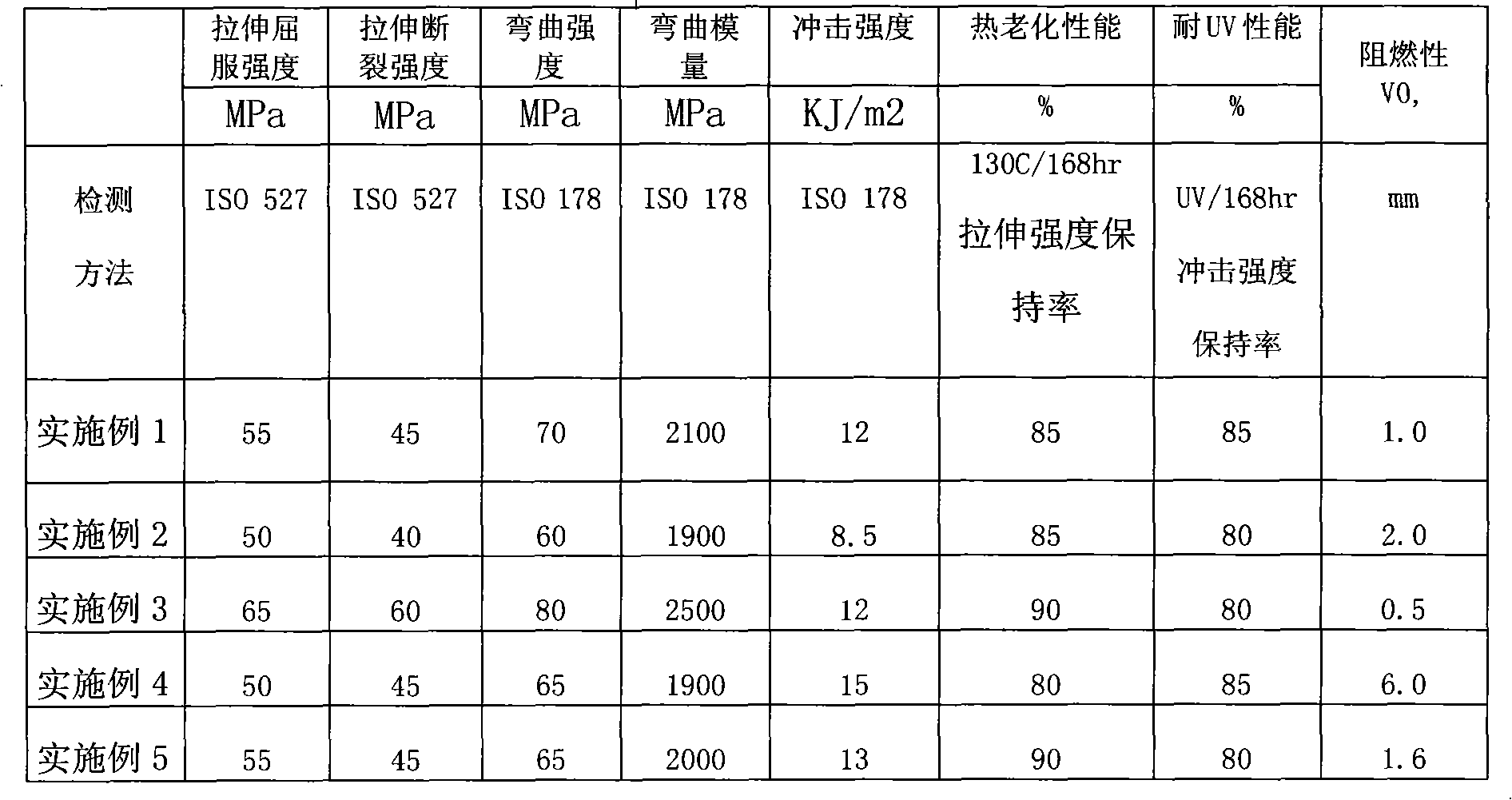

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

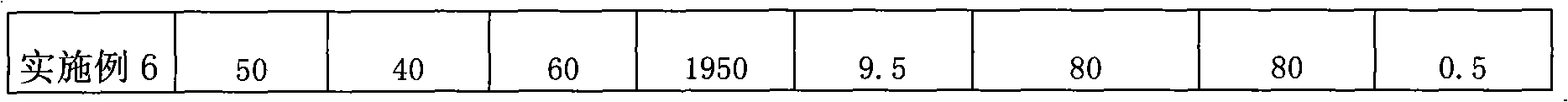

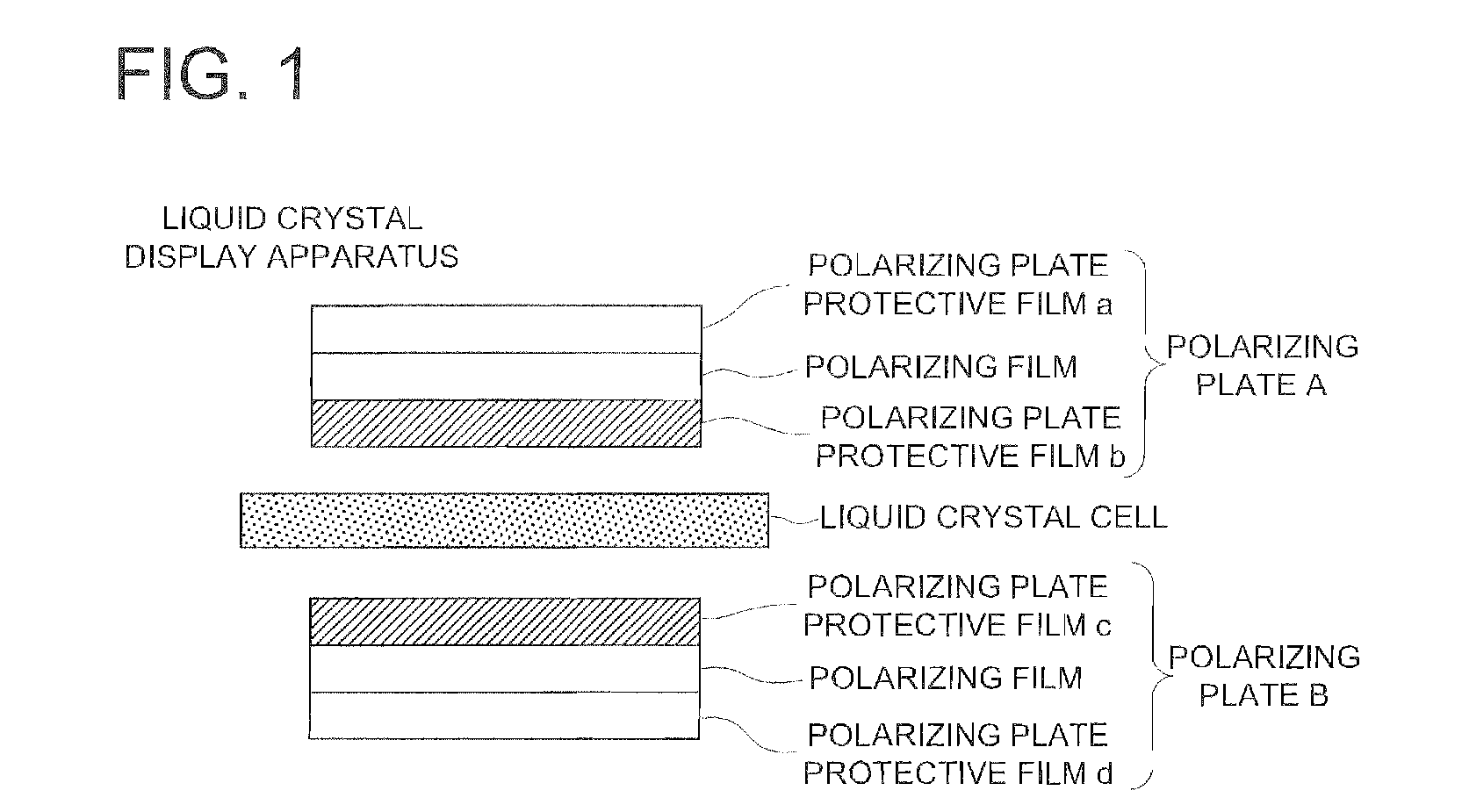

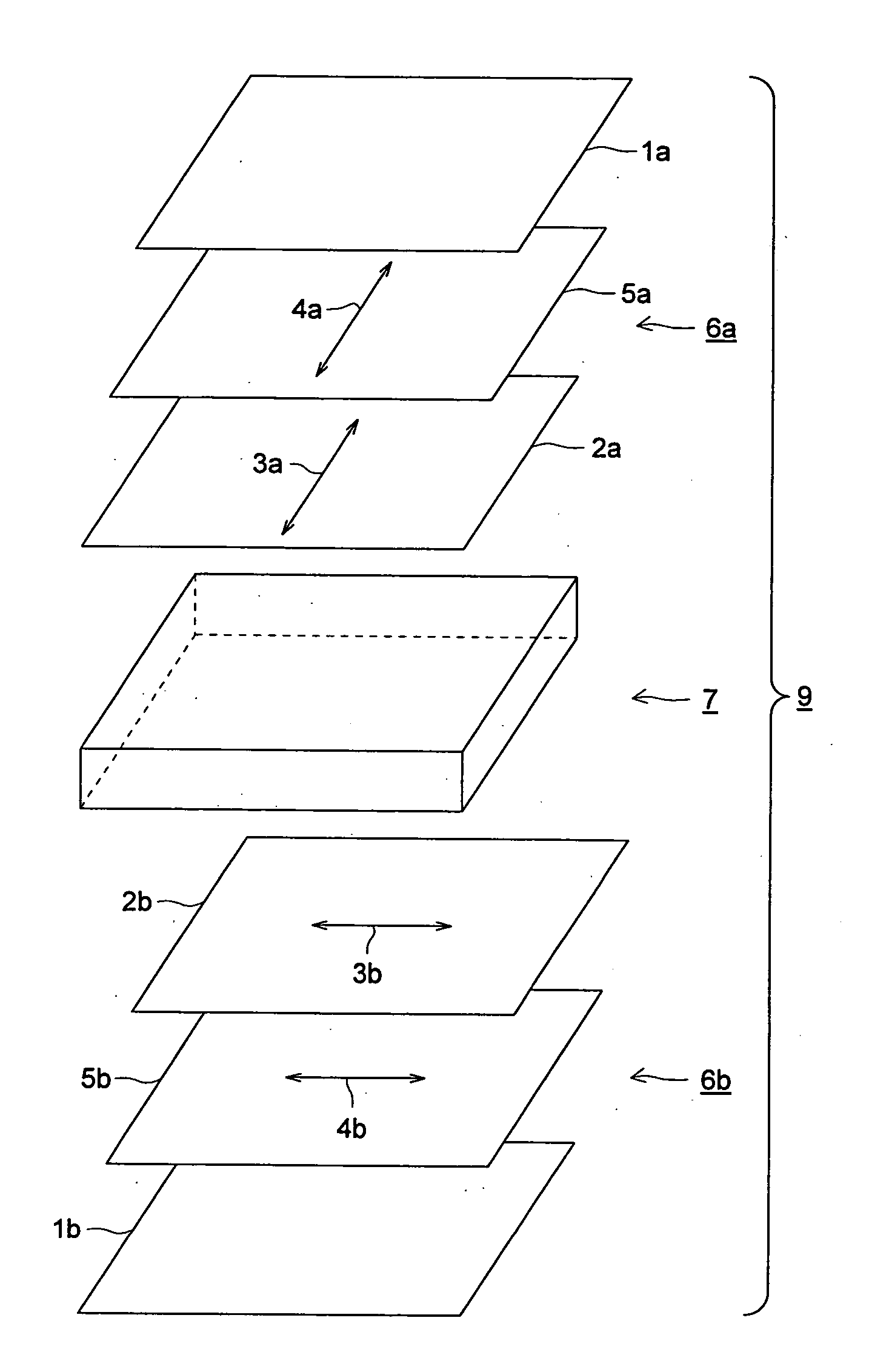

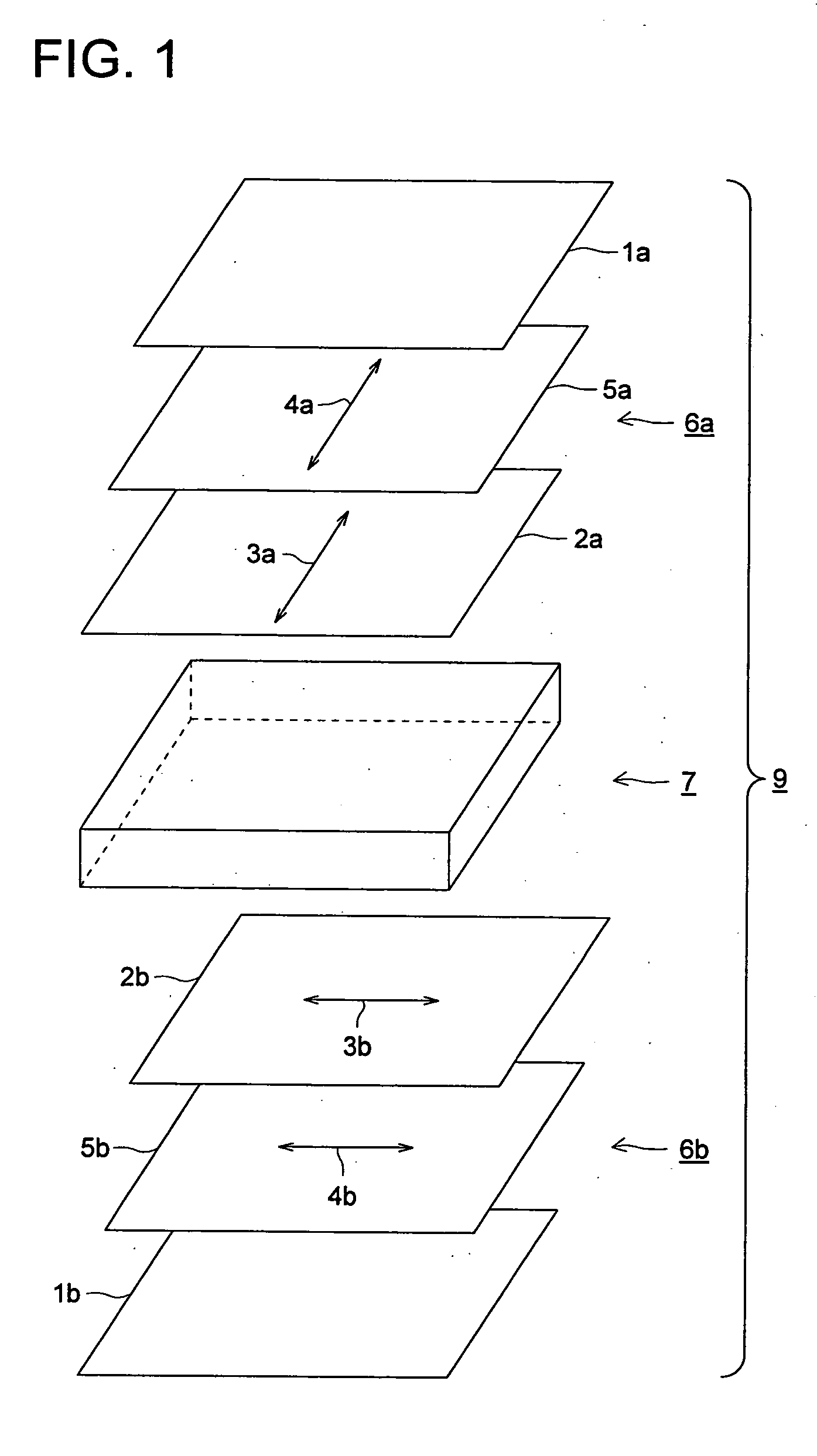

Polarizing plate, manufacturing method of polarizing plate and liquid crystal display apparatus

InactiveUS20090251643A1Facilitates film laminationIncrease contrastSynthetic resin layered productsLaminationTectorial membraneCellulose

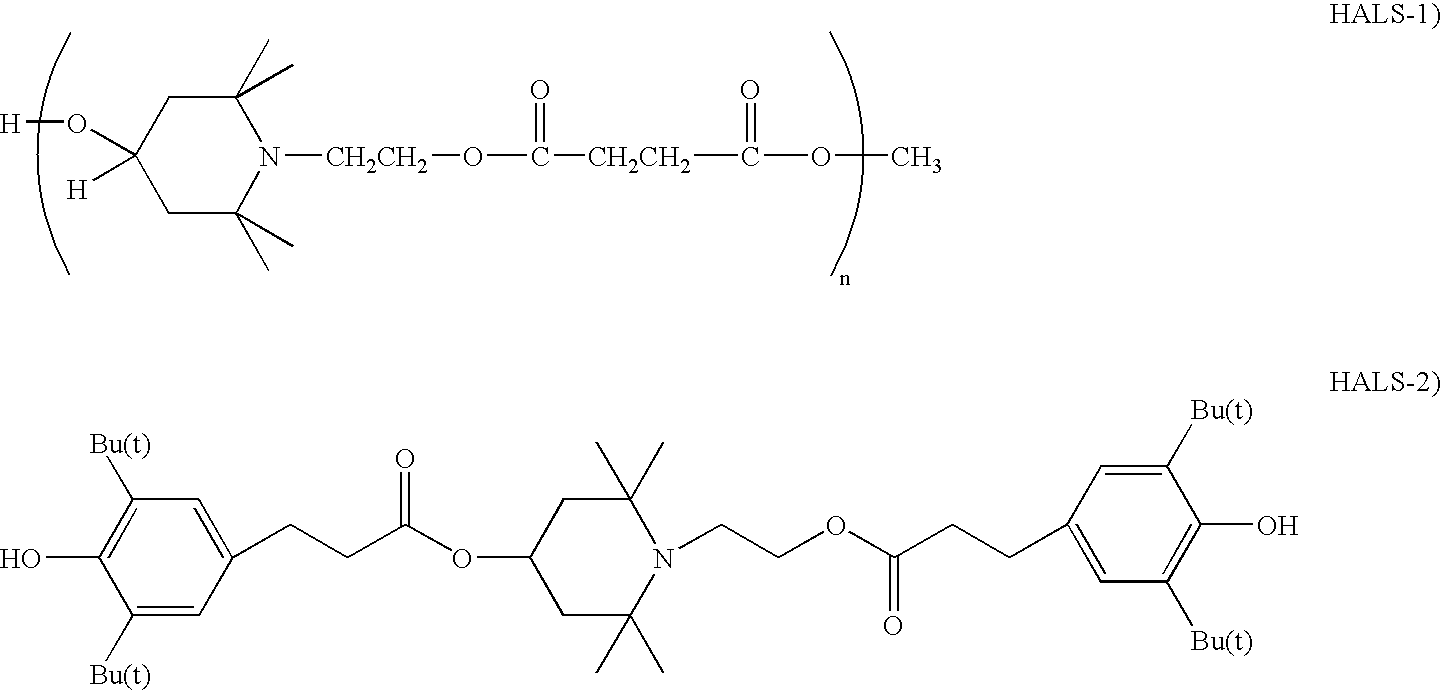

A polarizing plate arranged on at least one surface of a liquid crystal cell for use in a liquid crystal display apparatus, comprising a first polarizing plate protective film, a polarizing film, and a second polarizing plate protective film, the first polarizing plate protective film being arranged on the liquid crystal cell side with respect to a polarizing film, and the second polarizing plate protective film being arranged on the side opposite to the liquid crystal cell intervening the polarizing film, wherein the first polarizing plate protective film contains a cellulose ester and a hindered phenol compound in an amount of 0.01 to 5.0 weight % based on the total weight of the cellulose ester.

Owner:KONICA MINOLTA OPTO

Polarizing plate protecting film and its manufacturing method, polarizing plate and liquid crystal display

InactiveUS20060062935A1Reduce pollutionMinimizes ruptureLiquid crystal compositionsOptical articlesTectorial membraneCellulose

Disclosed is a process for manufacturing a polarizing plate protecting film comprising the steps of providing a film formation composition containing cellulose resin having a total acyl substitution degree of from 2.5 to 2.9, a plasticizer and a hindered amine or hindered phenol compound, heat-melting the film formation composition to obtain a melt, extruding the melt to be in the form of sheet, and cooling the extruded sheet to form a film, wherein the cellulose resin contains an alkaline earth metal in an amount of from 1 to 50 ppm and a residual sulfuric acid (in terms of sulfur content) in an amount of from 0.1 to 45 ppm, based on the weight of cellulose resin.

Owner:KONICA MINOLTA OPTO

Medium voltage cable insulation

Compositions comprising:A. Ethylene-based polymer, e.g., LDPE;B. Polyalkylene glycol, e.g., PEG;C. Tertiary hindered amine stabilizer;D. Sulphur-containing hindered phenol antioxidant;E. Peroxide; andF. Optional coagentare useful in the preparation of TRXLPE insulation for medium voltage cable that exhibits a commercially desirable balance of long term heat aging retardancy and water-tree resistance.

Owner:UNION CARBIDE CORP

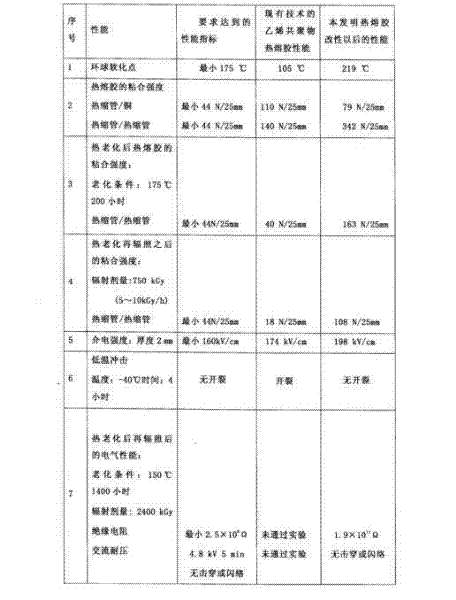

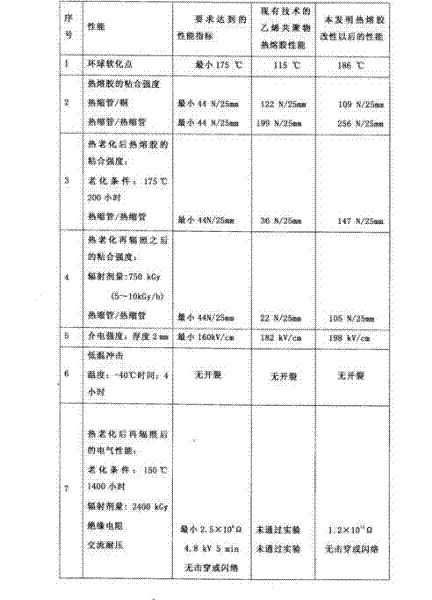

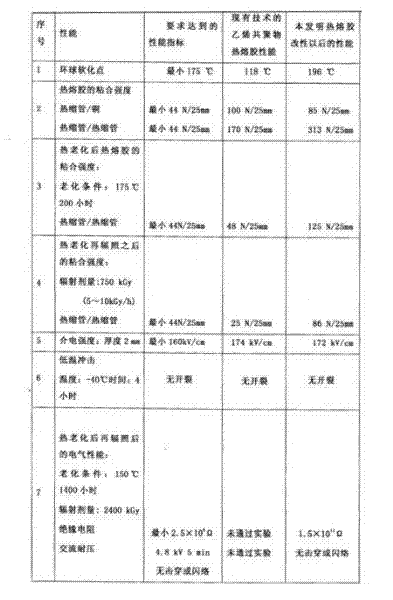

Hot melt adhesive for cable accessories in nuclear island of nuclear power plant and preparation method thereof

ActiveCN102250563AImprove performanceReduce liquidityNon-macromolecular adhesive additivesElastomerPolyolefin

The invention relates to a hot melt adhesive for cable accessories in a nuclear island of a nuclear power plant, and the hot melt adhesive is composed of the following components in parts by weight: 100 parts of ethylene copolymer hot melt adhesive, 30-100 parts of polyolefin elastomer and 5-10 parts of composite antioxidant, wherein the ethylene copolymer hot melt adhesive comprises one or more of ethylene-vinyl acetate copolymer hot melt adhesive, ethylene-ethyl acrylate copolymer hot melt adhesive, and ethylene-methyl acrylate copolymer hot melt adhesive; the polyolefin elastomer is a molecular-chain-saturated ethylene and C3-C20 alpha-olefin copolymer; and the composite antioxidant is one or more of a hindered phenolic antioxidant, a sulfur-containing antioxidant and an ester antioxidant. The hot melt adhesive provided by the invention can be applied to the cable accessories in the nuclear island of the nuclear power plant, and can also be used in aviation, shipping, nuclear submarine and other fields with higher performance requirements on the hot melt adhesive.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

Method for manufacturing cellulose ester film, and cellulose ester film, optical film, polarizing plate and liquid crystal display device using the same

InactiveUS20060069192A1Excellent optical propertiesGood dimensional stabilityAbsorbent padsThin material handlingCellulose ester membranePolymer science

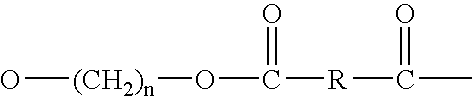

A method for manufacturing a cellulose ester film comprising the steps of 1) mixing a cellulose ester exhibiting a water content of not greater than 3.0 weight %, at least one plasticizer selected from the groups A and B in an amount of one to thirty weight % of the cellulose ester, and at least one additive selected from the groups of C and D in an amount of 0.01 to 5 weight % of the cellulose ester to obtain a mixture, group A: ester plasticizers formed from a polyhydric alcohol and a monohydric carboxylic acid; group B: ester plasicizers formed from a polyhydlic carboxylic acid and a monohydric alcohol; group C: hindered phenol anti-oxidants; group D: hindered amine light stabilizers, 2) heating to melt the mixture at a temperature (Tm) of between 150 and 300° C., and 3) forming a cellulose ester film with a melt casting method employing the melted mixture.

Owner:KONICA MINOLTA OPTO

Lubricating oil compositions

InactiveUS7018958B2Non-fuel substance addition to fuelCombustion enginesTotal Base NumberChemical composition

A lubricating oil composition having a total base number of at least about 8, comprising a major amount of oil of lubricating viscosity; an amount of one or more dihydrocarbyl dithiophosphate metal salt introducing into the lubricating oil composition no more than 0.06 wt. % of phosphorus; at least 1.2 wt. % of hindered phenol antioxidant; and boron, and / or a boron-containing compound or compounds in an amount providing the lubricating oil composition with at least 200 ppm by weight of boron, all weight percentages being based on the total weight of the lubricating oil composition.

Owner:INFINEUM INT LTD

Wide-temperature range and high-performance water-based damping paint and preparation method of same

ActiveCN103289490AHigh dampingImprove flame retardant performancePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a wide-temperature range and high-performance water-based damping paint. By the compounding of core-shell structure water-based polyacrylic emulsion and interpenetrated network structure water-based epoxy / polyurethane emulsion, the paint is combined with the advantages of three resins including acrylic resin, epoxy resin and polyurethane resin, based on different viscoelastic state temperature scopes of acrylic resin and epoxy / polyurethane resin, the temperature range after compounding is expanded, the wide temperature range scope from -20 to 60 DEG C is realized, and the paint is excellent in mechanical property; meanwhile, functional fillers including hindered phenol, lamellar mica powder and flake graphite are added, by the friction between viscoelastic state macromolecular chain segments, the hydrogen-bond interaction between the small molecular hindered phenol, the friction between the lamellar filler mica powder and the flake graphite, and the friction between the fillers and the macromolecular chain segment, the damping performance of the material is improved; with the additional flame retardant, the flame retardant property of the material is improved, so that the paint is environment-friendly and safe, and the oxygen index of the paint is more than 30; the technology is simple, special equipment is not needed, and the price is low.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

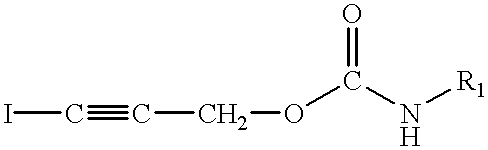

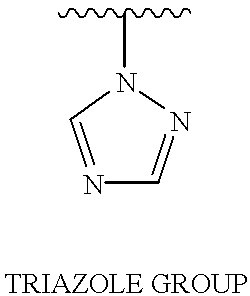

Enhanced wood preservative composition

InactiveUS6231651B1Increase profitEnhanced and synergistic biocidal effectFireproof paintsBiocideCost effectivenessWoody plant

A wood preservative composition comprising at least one biocide, such as an iodopropargyl compound or a triazole compound, in combination with at least one antioxidant, such as a hindered phenol, a flavonoid compound, or a naturally occurring polyphenol derived from a woody plant, is useful as a cost-effective and environmentally safe wood preservative. The invention also provides a method for the use of such composition and compositions so treated.

Owner:MISSISSIPPI STATE UNIVERSITY

3D printing weather-resistant nylon powder composite material and preparation method thereof

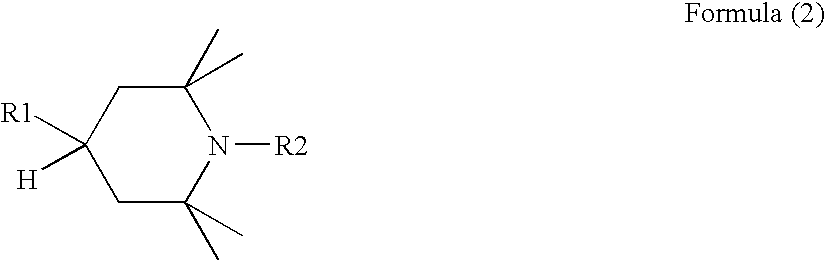

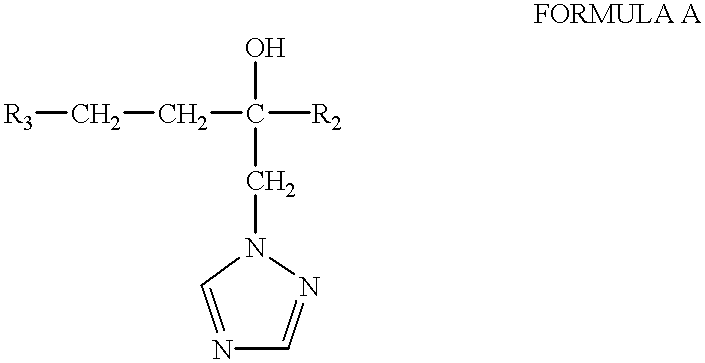

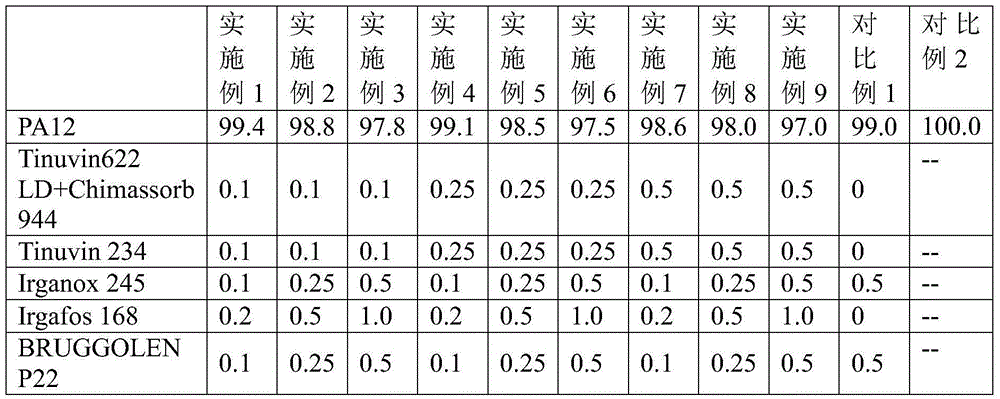

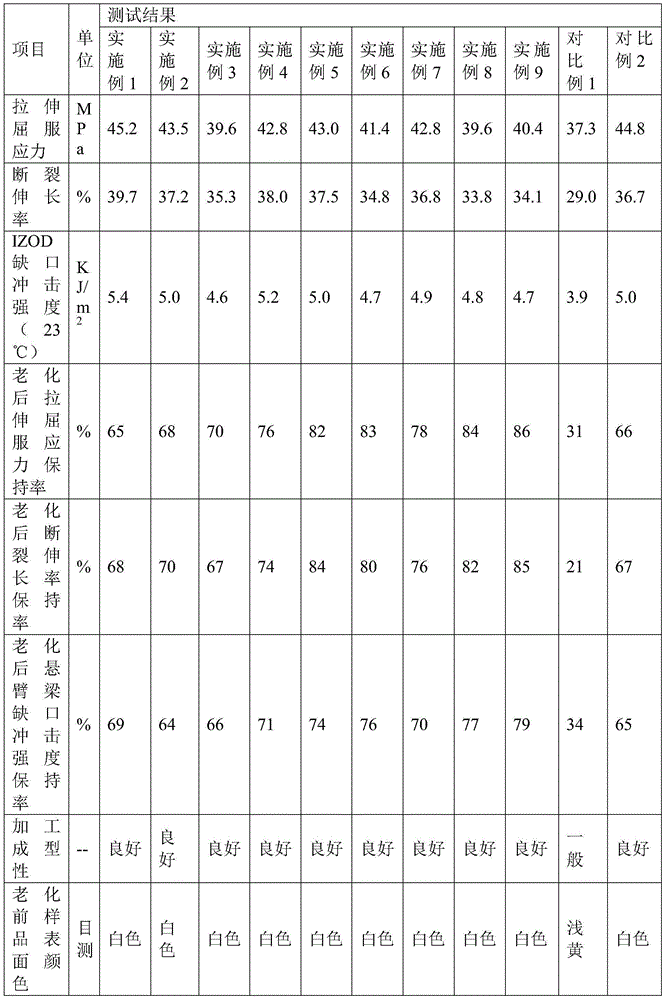

The invention discloses a 3D printing weather-resistant nylon powder composite material and a preparation method thereof. The 3D printing weather-resistant nylon powder composite material is characterized by being prepared from the following components in percentage by mass: 97-99.4wt% of nylon, 0.1-0.5wt% of a hindered amine light stabilizer, 0.1-0.5wt% of an ultraviolet light absorber, 0.1-0.5wt% of a hindered phenol antioxidant, 0.2-1.0wt% of a phosphite ester antioxidant and 0.1-0.5wt% of other additives, wherein the other additives comprise one or combination of multiple components of a dispersing agent, a nucleating agent and a lubricant. With the combination of the hindered amine light stabilizer, the ultraviolet light absorber, the hindered phenol antioxidant and the phosphite ester antioxidant, the 3D printing weather-resistant nylon powder composite material prepared through spray-drying is excellent in weather resistance and small in mechanical property change before and after being modified, can be recycled and reused for multiple times, is narrow in spherical granule distribution, good in flowing property, free of layering or powder dropping, and moreover is high in preparation efficiency, small in energy consumption and simple and easy to process.

Owner:QINGDAO UNIV OF SCI & TECH +2

Polylactic acid composition

ActiveUS20120289625A1Improve heat stabilityImprove hydrolysis resistanceOrganic chemistryPlastic/resin/waxes insulatorsNitrogenPhosphite ester

A resin composition which comprises polylactic acid, does not release an isocyanate group at the time of production and has excellent hydrolysis resistance and a low environmental burden.The resin composition comprises:(A) 100 parts by weight of a resin component (component A) containing polylactic acid (component A-α);(B) 0.001 to 10 parts by weight of a compound (component B) having one carbodiimide group and a cyclic structure in which first nitrogen and second nitrogen are bonded to each other via a bonding group, the cyclic structure consisting of 8 to 50 atoms; and(C) 0.001 to 2 parts by weight of at least one antioxidant (component C) selected from the group consisting of a hindered phenol-based compound, a phosphite-based compound, a phosphonite-based compound and a thioether-based compound.

Owner:TEIJIN LTD

Powdered composite calcium zinc stabilizing agent and preparation method thereof

The invention relates to a powdered composite calcium zinc stabilizing agent and a preparation method thereof and belongs to the preparation of a stabilizing agent for plastic processing. The stabilizing agent consists of the following components in percentage by weight: 14 to 38 percent of poly-fatty acid resin calcium zinc, 20 to 45 percent of epoxy fatty acid calcium zinc soap, 10 to 15 percent of phosphite ester, 10 to 15 percent of beta-diketone compound, 11 to 23 percent of hindered phenol antioxidant and 10 to 15 percent of lubricant. The preparation method comprises the following steps of: throwing a poly-fatty acid resin, a hydroxide of an alkali-earth metal, an oxide of zinc, high alcohol and oleic acid according to proportion into a reactor to perform salifying reaction to obtain the poly-fatty acid resin calcium zinc; performing epoxidation of the oleic acid, hydrogen peroxide and glacial acetic acid serving as raw materials in the presence of concentrated sulfuric acid serving as a catalyst according to the proportion to generate epoxy fatty acid, directly reacting the epoxy fatty acid with calcium hydroxide to obtain the high-purity epoxy fatty acid calcium soap; and compounding the poly-fatty acid resin calcium zinc with the epoxy fatty acid calcium soap reasonably and then adding other auxiliary agents to obtain the stabilizing agent. The powdered composite calcium zinc stabilizing agent and the preparation method thereof can effectively solve the problems of low compatibility and low dyeing property at an initial stage of the conventional polyvinyl chloride (PVC) calcium zinc stabilizing agent.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

1E-grade K1 type halogen-free flame retardant material for nuclear power plants and application thereof

ActiveCN102731895AImprove thermal stabilityStrong absorption capacityPlastic/resin/waxes insulatorsInsulated cablesNuclear powerPhosphoric acid

The invention discloses a 1E-grade K1 type halogen-free flame retardant material for nuclear power plants. The material comprises the following substances: 100 parts of vinyl polymers, 1-20 parts by weight of polymer compatilizer, 0.5-10 parts by weight of organosilicon polymers, 1-10 parts by weight of complex antioxidant, 0.1-10 parts by weight of light stabilizer and 0.1-100 parts by weight of high molecular weight ammonium polyphosphate and / or 0.1-50 parts by weight of phosphate flame retardants and / or 0.1-50 parts by weight of melamine cyanurate and / or 0.1-50 parts by weight of melamine pyrophosphate, wherein the complex antioxidant is a complexing agent formed by blending hindered phenol main antioxidants, thioether auxiliary antioxidants, hindered amine auxiliary antioxidants and an anti-copper agent in a weight ratio of 1:(1-4):(1-2):(0.5-1). The material can serve as the insulating material of 1E-grade K1 type halogen-free flame retardant heat shrink tubes, wires and cables and cable accessories for nuclear power plants.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

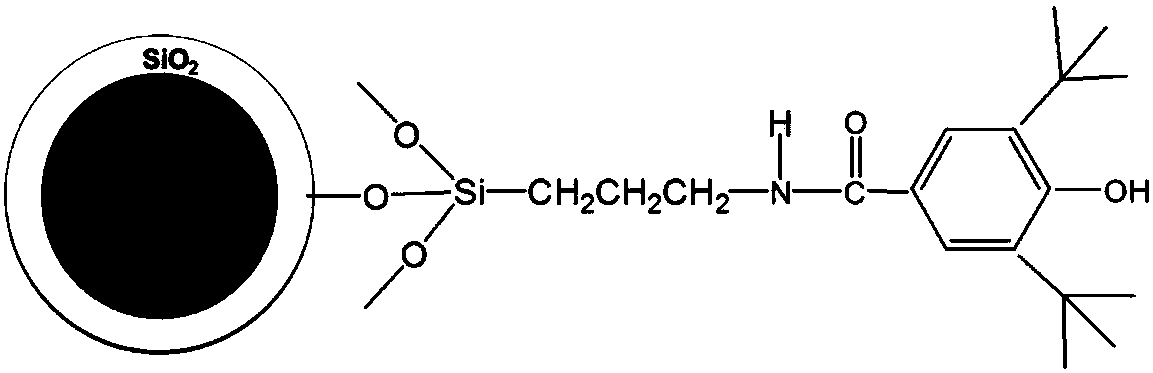

Functional nano-titanium dioxide grafted with antioxidant molecules on surface and preparation method of functional nano-titanium dioxide

InactiveCN108084494AImproves anti-photoagingImprove heat aging resistanceAging resistanceSilicon dioxide

The invention relates to a functional nano titanium dioxide grafted with antioxidant molecules on the surface. The surface of the nano-titanium dioxide is coated with silica; an aminosilane coupling agent reacts with the silica and is grafted with an antioxidant. Meanwhile, the invention also relates to a preparation method of the functional nano-titanium dioxide grafted with the antioxidant molecules on the surface. According to the preparation method disclosed by the invention, the surface of the nano-titanium dioxide is coated with a layer of the silica and then the aminosilane coupling agent is used for bridging, and a hindered phenol antioxidant is chemically grafted onto functional nano-titanium dioxide particles. According to the functional nano-titanium dioxide grafted with the antioxidant on the surface, disclosed by the invention, light weathering property and thermal aging resistance of a polymer can be simultaneously improved; in addition, an additive has the advantages ofno toxicity, low possibility of seeping and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Slush molded elastomeric layer

A slush molded layer comprised of a copolyether ester elastomer as a major component, a hindered phenol antioxidant, a thioether antioxidant, and a hindered amine light stabilizer is provided. The slush molded layer may further include a polysiloxane.

Owner:EI DU PONT DE NEMOURS & CO

High-damping rubber support base and manufacturing method thereof

InactiveCN103865130AWide temperature rangeForm pollutionMetal layered productsMicrocrystalline waxEngineering

The invention relates to a high-damping rubber support base and a manufacturing method thereof. The high-damping rubber support base disclosed by the invention comprises the following components in parts by weight: 60-80 parts of rubber, 10-50 parts of plastic particles, 15-50 parts of resin, 5-25 parts of carbon black, 30-100 parts of mica powder, 5-30 parts of plasticizer, 5-30 parts of hindered phenol, 2-5 parts of microcrystalline wax, 1-3 parts of anti-aging agent, 1-3 parts of stabilizer, 2-5 parts of accelerant, and 1-4 parts of vulcanizing agent. The preparation method disclosed by the invention comprises the steps of preparing raw materials, mixing, adding sulphur, rolling a rubber piece, forming and vulcanizing. The equivalent damping ratio of the prepared high-damping rubber support base achieves 20-30%. The high-damping rubber support base prepared by the manufacturing method disclosed by the invention is high in damping; all the components are natural components; pollution to the environment cannot be caused; the preparation method of the high-damping rubber support base is simple in process.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Polyester molding composition

A thermoplastic resin molding composition comprising an alkylene aryl polyester, a core-shell impact modifier for enhancing heat resistance having a shell derived from an alkylacrylate and a rubbery acrylate core derived from an acrylate having 4 to 12 carbon atoms, an effective amount of a difunctional epoxy compound for enhancing hydrolysis resistance of the resin, and a combination of color enhancing stabilizers comprising a thioester stabilizer, a phosphite or phosphonite stabilizer and a hindered phenol stabilizer.

Owner:SABIC GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com