Anti-folding stress whitening resistant polypropylene (PP) material and preparation method thereof

A stress-whitening and polypropylene technology, which is applied in the field of folding-resistant and stress-whitening polypropylene materials and their preparation, can solve the problems of whitening of products, whitening of PP materials, affecting product performance and quality, and the cost of preparation can be reduced. The effect of low and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

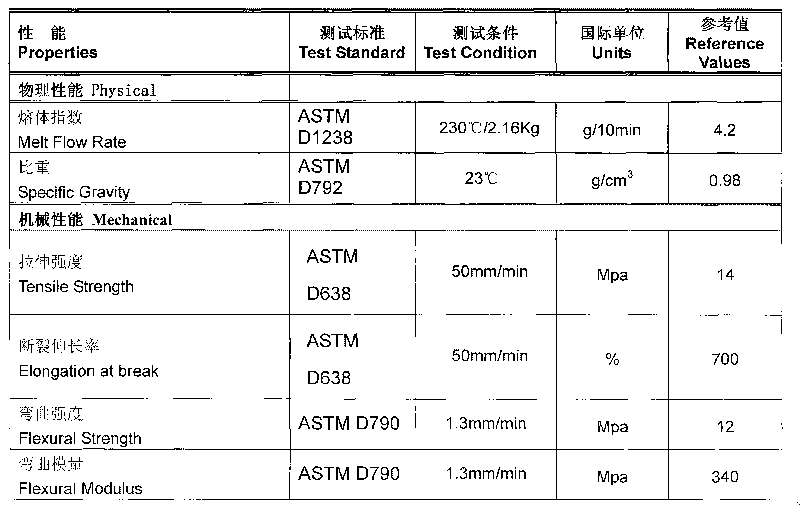

Embodiment 1

[0031] The anti-folding and anti-stress whitening polypropylene (PP) material of the present embodiment is characterized in that: it comprises the following raw materials by weight:

[0032] Copolymer polypropylene 55

[0033] POE Lc670 5

[0034] Anti-stress whitening masterbatch 5

[0035] White mineral oil 0.05

[0036] Hindered phenolic antioxidant 1010 0.1

[0037] Phosphite antioxidant 168 0.1

[0039] The self-made anti-stress whitening masterbatch includes the following ingredients by weight:

[0040] EPDM or EPR or POE 40

[0041] Nano active light CaCO3 30

[0042] Low molecular weight polyethylene sodium 0.5.

[0043] The preparation method of the above-mentioned anti-folding and anti-stress whitening polypropylene (PP) material is: according to the above-mentioned ingredients and proportioning, the ingredients are mixed through a high-speed mixer, and the CTE35 twin-screw extruder is used for production. With 9 standard temper...

Embodiment 2

[0050] The anti-folding and anti-stress whitening polypropylene (PP) material of the present embodiment is characterized in that: it comprises the following raw materials by weight:

[0051] Copolymer polypropylene 65

[0052] POE Lc670 15

[0053] Anti-stress whitening masterbatch 20

[0054] White mineral oil 0.1

[0055] Hindered phenolic antioxidant 1010 0.2

[0056] Phosphite antioxidant 168 0.2

[0058] The self-made anti-stress whitening masterbatch includes the following ingredients by weight:

[0059] EPDM or EPR or POE 48

[0060] Nano active light CaCO3 40

[0061] Low molecular weight polyethylene sodium 1.

[0062] The preparation method of the above-mentioned anti-folding and anti-stress whitening polypropylene (PP) material is produced by using a CTE35 twin-screw extruder according to the above-mentioned ingredients and proportioning ingredients. This machine has 9 sections of standard temperature control area;

[0063] Ex...

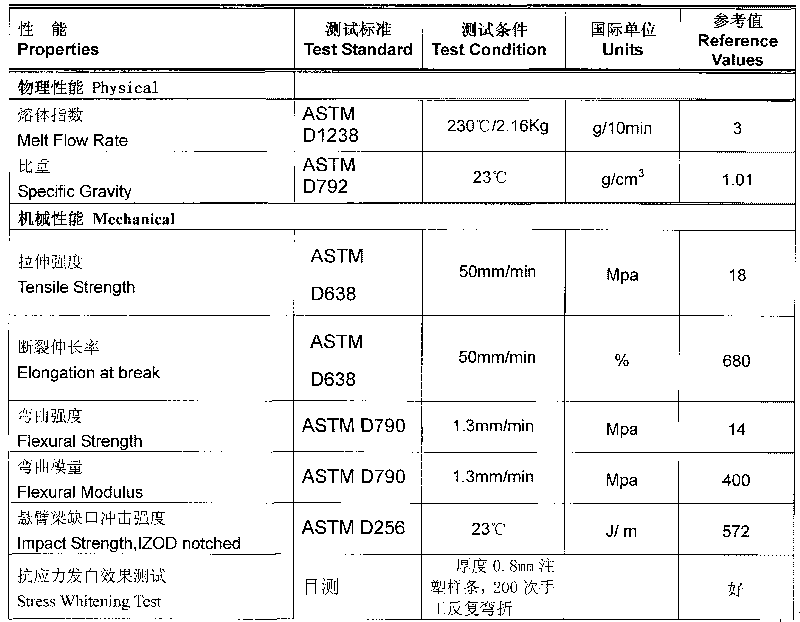

Embodiment 3

[0068] The anti-folding and anti-stress whitening polypropylene (PP) material of the present embodiment comprises the following raw materials by weight:

[0069] Copolymer polypropylene 75

[0070] POE Lc670 20

[0071] Anti-stress whitening masterbatch 30

[0072] White mineral oil 0.15

[0073] Hindered phenolic antioxidant 1010 0.3

[0074] Phosphite antioxidant 168 0.3

[0075] Calcium stearate 0.3

[0076] The self-made anti-stress whitening masterbatch includes the following ingredients by weight:

[0077] EPDM or EPR or POE 65

[0078] Nano active light CaCO3 50

[0079] Low molecular weight polyethylene sodium 2.

[0080] Preparation rights The preparation method of the anti-folding and stress-resistant whitening polypropylene (PP) material described above is produced by using a CTE35 twin-screw extruder according to the above-mentioned ingredients and proportioning ingredients, and the machine has a 9-stage standard temperature control zone;

[0081] The par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com