Intelligent flexible electric heating system and preparation method thereof

A heating system, flexible electric technology, applied in ohmic resistance heating, ohmic resistance heating components, electric heating devices, etc., can solve the problem of small proportion of heating area, electric heating sheet water washing, poor kneading performance, poor flexibility and comfort, etc. problems, to achieve the effect of large economic and use benefits, excellent electric heating performance, and high heat-generating conductive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

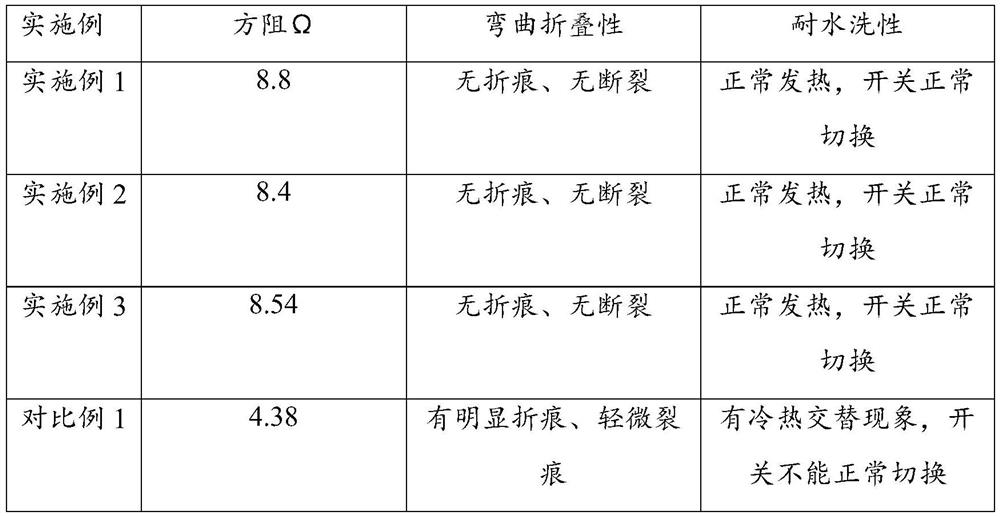

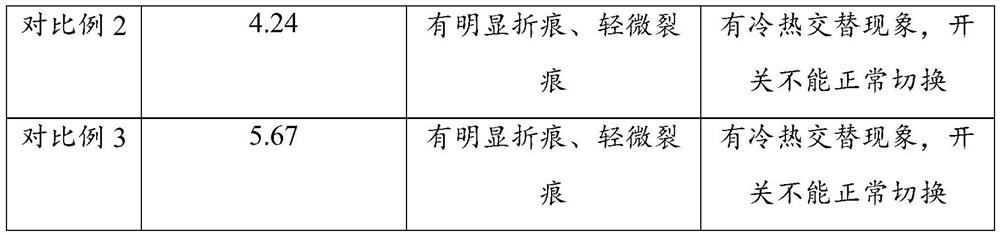

Embodiment 1

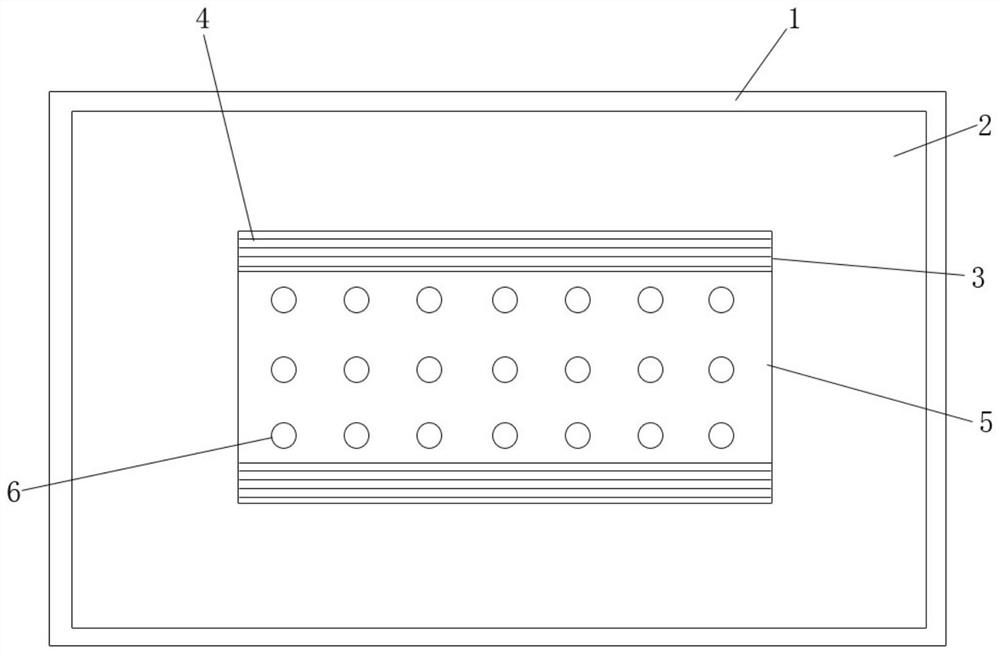

[0056] Embodiment 1 The first aspect provides an intelligent flexible electric heating system, the structure at least includes: a carbon material composite film, a flexible conductive electrode, a heat conduction film and a surface flexible substrate.

[0057] The surface of the carbon material composite film also has a conductive silver paste layer with a square resistance of 7 milliohms and a thickness of 4.5 μm.

[0058] The carbon material composite film has circular air-permeable perforated structures arranged in an orderly manner; the circle diameter of the circular air-permeable perforated structures is 0.3 cm, and the distance between the circular air-permeable perforated structures is 0.4 cm. The thickness of the carbon material composite film is 55 μm.

[0059] The raw materials of the carbon material composite film are (in parts by weight): 80 parts of multidimensional carbon material and 20 parts of polyurethane resin.

[0060] The multi-dimensional carbon materia...

Embodiment 2

[0079] The specific implementation of this example is the same as that of Example 1, except that the viscosity of the polyurethane resin is 15000 cps at 25°C.

Embodiment 3

[0081] The specific implementation of this embodiment is the same as that of Embodiment 1, except that the fineness of the nano-carbon powder is 80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com