Temperature-controllable electric heating long glass fiber reinforced material as well as preparation method and application thereof

A reinforced material and electric heating technology, applied in the field of composite materials, can solve problems such as not having electric heating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

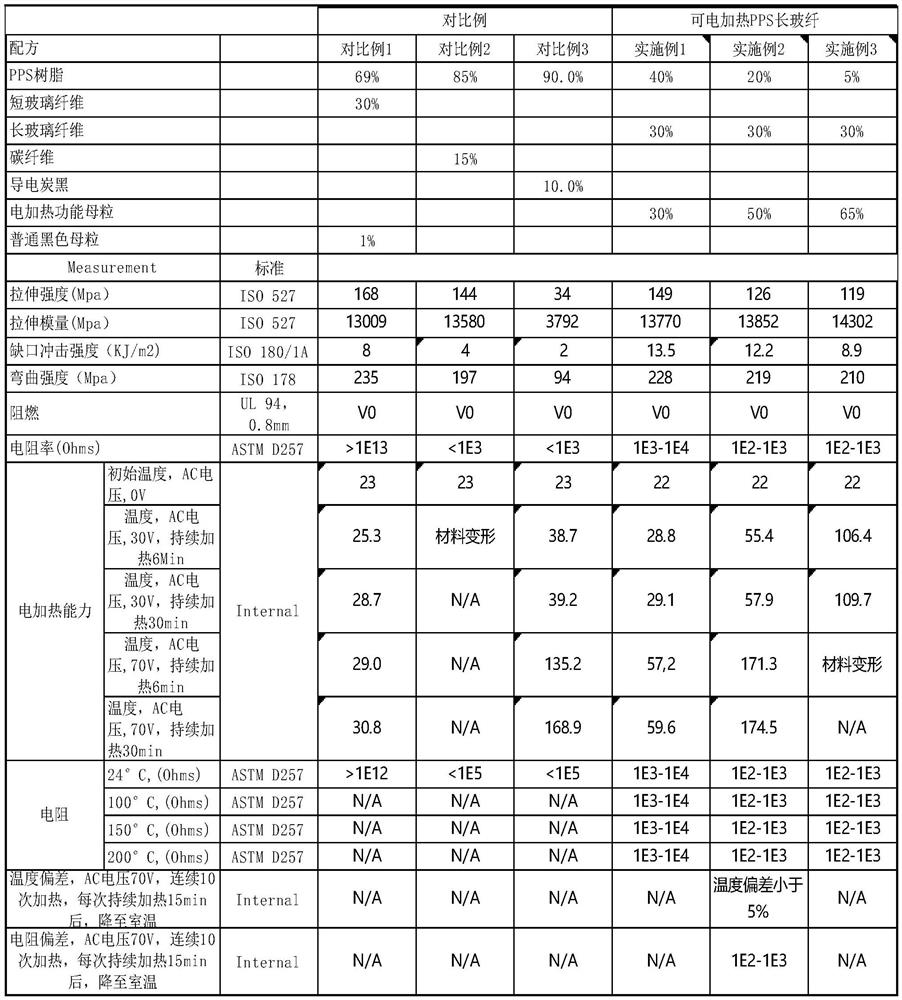

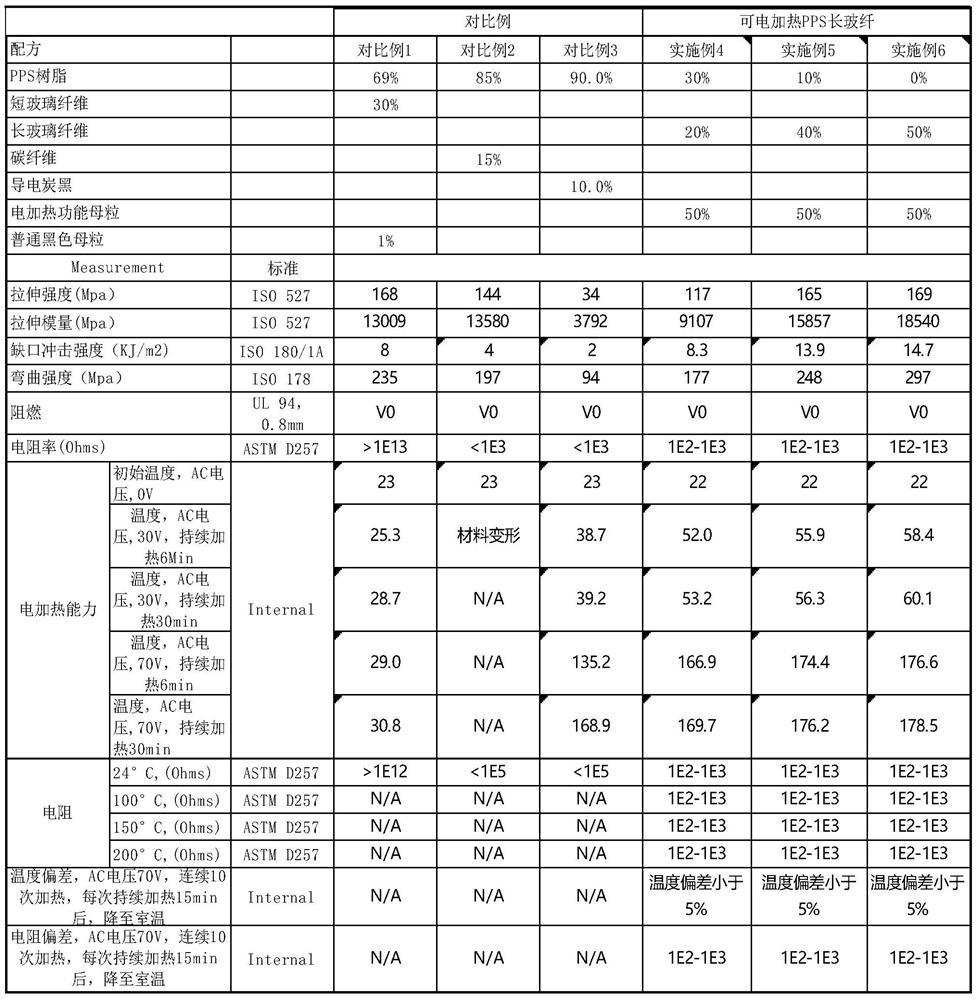

Embodiment 1

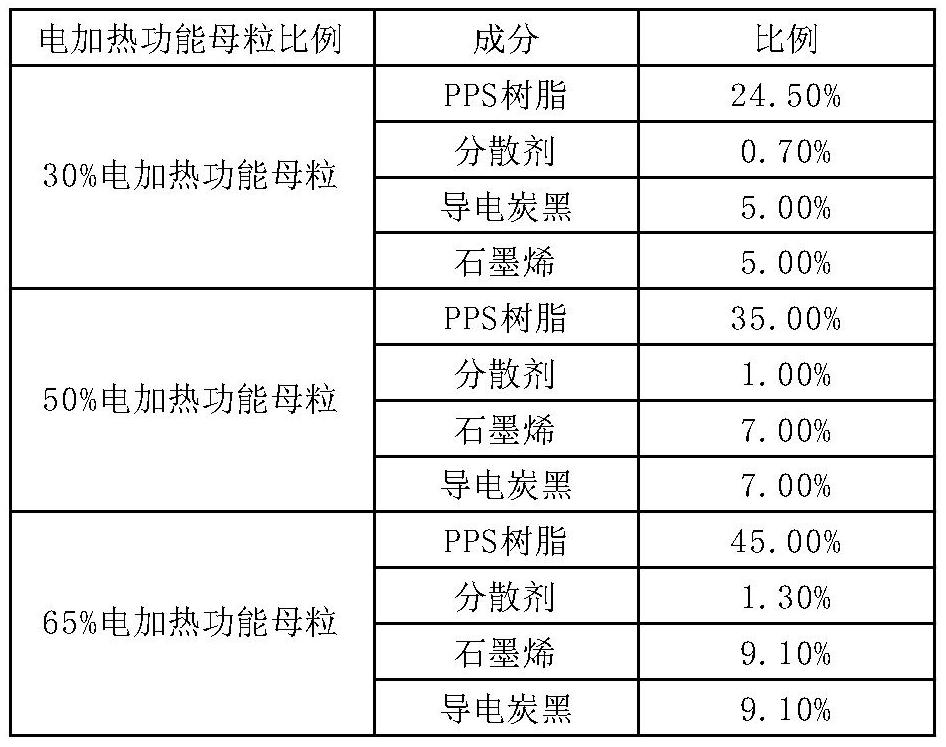

[0028] A temperature-controllable electric heating long glass fiber reinforced material is composed of the following components by weight percentage: 40% of the first PPS matrix resin, 30% of the electric heating function masterbatch, and 30% of the long glass fiber; wherein the electric heating function masterbatch includes: The following components are composed by weight percentage, the second PPS matrix resin is 24.5%, the light amide MPK dispersant is 0.7%, the few-layer graphene is 5%, and the conductive carbon black is 5%.

[0029] The preparation method of the temperature-controllable electric heating long glass fiber reinforced material comprises the following preparation steps:

[0030] (1) Mix few-layer graphene (half the amount), conductive carbon black and light amide MPK dispersant in a mixer at 100°C, and the mixing time is 6-10min;

[0031] (2) adding the second PPS matrix resin to the mixture obtained in step (1), and continuing to stir to obtain a pretreated m...

Embodiment 2

[0039] A temperature-controllable electric heating long glass fiber reinforced material is composed of the following components by weight percentage: 20% of the first PPS matrix resin, 50% of the electric heating function masterbatch, and 30% of the long glass fiber; wherein the electric heating function masterbatch includes: The following components are composed by weight percentage, the second PPS matrix resin is 35%, the light amide MPK dispersant is 1%, the few-layer graphene is 7%, and the conductive carbon black is 7%.

[0040] The preparation method of the temperature-controllable electric heating long glass fiber reinforced material is the same as that in Example 1.

Embodiment 3

[0042] A temperature-controllable electric heating long glass fiber reinforced material is composed of the following components by weight percentage: 5% of the first PPS matrix resin, 65% of the electric heating function masterbatch, and 30% of the long glass fiber; wherein the electric heating function masterbatch includes: The following components are composed by weight percentage, the second PPS matrix resin is 45%, the light amide MPK dispersant is 1.3%, the few-layer graphene is 9.1%, and the conductive carbon black is 9.1%.

[0043] The preparation method of the temperature-controllable electric heating long glass fiber reinforced material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com