Patents

Literature

1527 results about "Melt flow index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

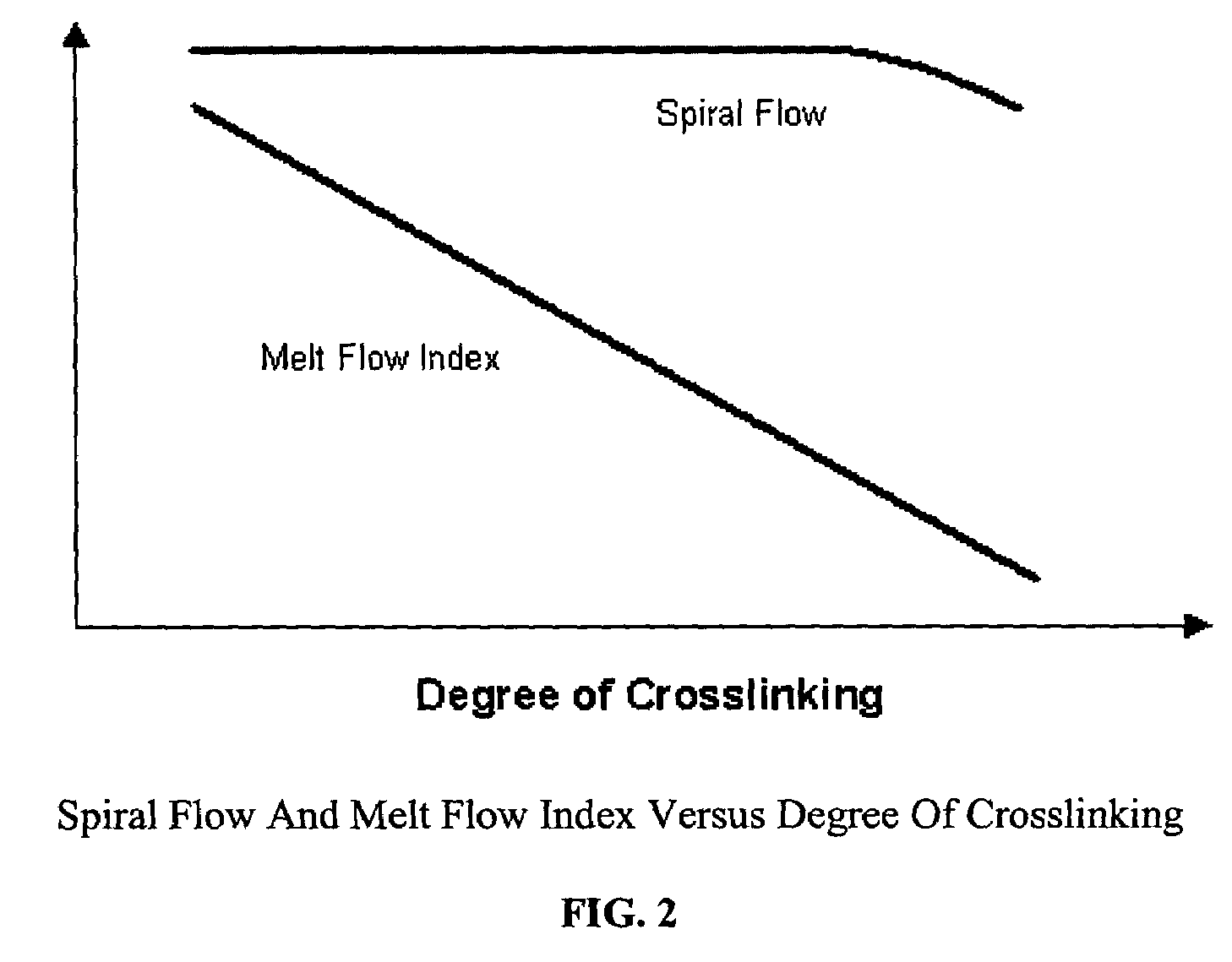

The Melt Flow Index (MFI) is a measure of the ease of flow of the melt of a thermoplastic polymer. It is defined as the mass of polymer, in grams, flowing in ten minutes through a capillary of a specific diameter and length by a pressure applied via prescribed alternative gravimetric weights for alternative prescribed temperatures. Polymer processors usually correlate the value of MFI with the polymer grade that they have to choose for different processes, and most often this value is not accompanied by the units, because it is taken for granted to be g/10min. Similarly, the test conditions of MFI measurement is normally expressed in kilograms rather than any other units. The method is described in the similar standards ASTM D1238 and ISO 1133.

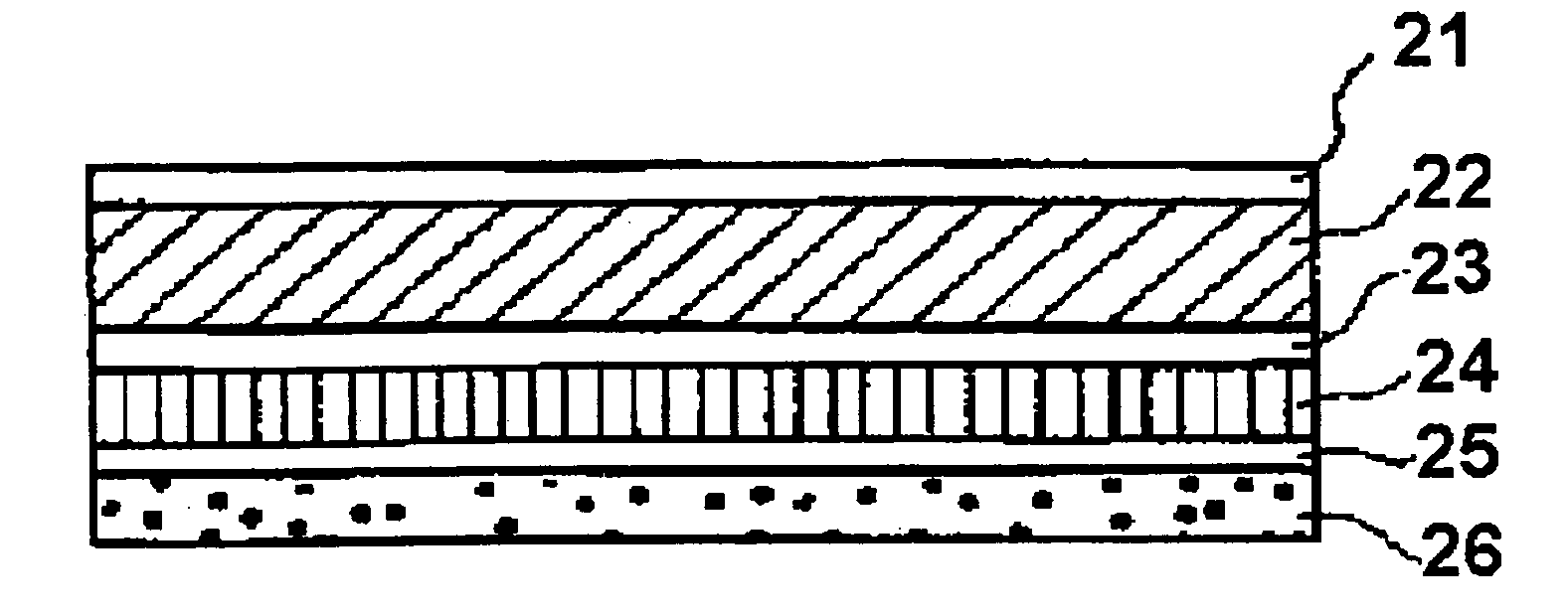

Laminated packaging material for paper container

InactiveUS6974612B1Easy to manufactureQuick heat sealEnvelopes/bags making machineryFlexible coversLow-density polyethyleneLinear low-density polyethylene

A paper packaging container is formed from the packaging material comprising constitution layers of at least an outside thermoplastic material layer, a paper substrate layer, and an inside thermoplastic material layer, wherein the inside thermoplastic material layer contains at least a linear low density polyethylene, and has properties parameters of an average density of 0.900–0.930, a predetermined peak melting point, a melt flow index of 5–15, and a swelling ratio of 1.3–1.8. The use of the packaging material allows easy filling and packaging to the packaging container and quick heat sealing, and results in more toughly and strongly sealed container, and the material can be used for achieved good sealing independently of the temperature of food contents and thus maintaining the non-scalping and quality preservability of the content product.

Owner:TETRA LAVAL HLDG & FINANCE SA

PP composite material of low VOC interior trim parts for automobiles and preparation method thereof

ActiveCN101570612AEfficient decompositionLow VOC contentVehicle componentsPolypropylene compositesAntioxidant

The invention relates to the field of automobiles, and belongs to a PP composite material special for low VOC (volatile organic compounds) high performance automobile interior trim parts and a preparation method thereof. The special material is prepared from the following compositions by mass portion: 60 to 80 portions of polypropylene (PP), 10 to 25 portions of reinforcing filler, 10 to 15 portions of toughening agent, 0.5 to 2 portions of inorganic photocatalyst, 0.2 to 0.5 portion of antioxidant and 0.1 to 0.5 portion of light stabilizer. The prepared polypropylene composite material has TVOC less than 40 mu gC / g, the notch impact strength of a cantilever beam at 23 DEG C between 10 and 42KJ / m, bending modulus between 1,000 and 2,400 MPa, and the melt index at 230 DEG C and 2.16 Kg between 10 and 30g / 10min. The PP composite material of the low VOC interior trim parts for the automobiles has low cost, good stability and the function of self-purification of VOC, and can be widely applied to production of the automobile interior trim parts.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

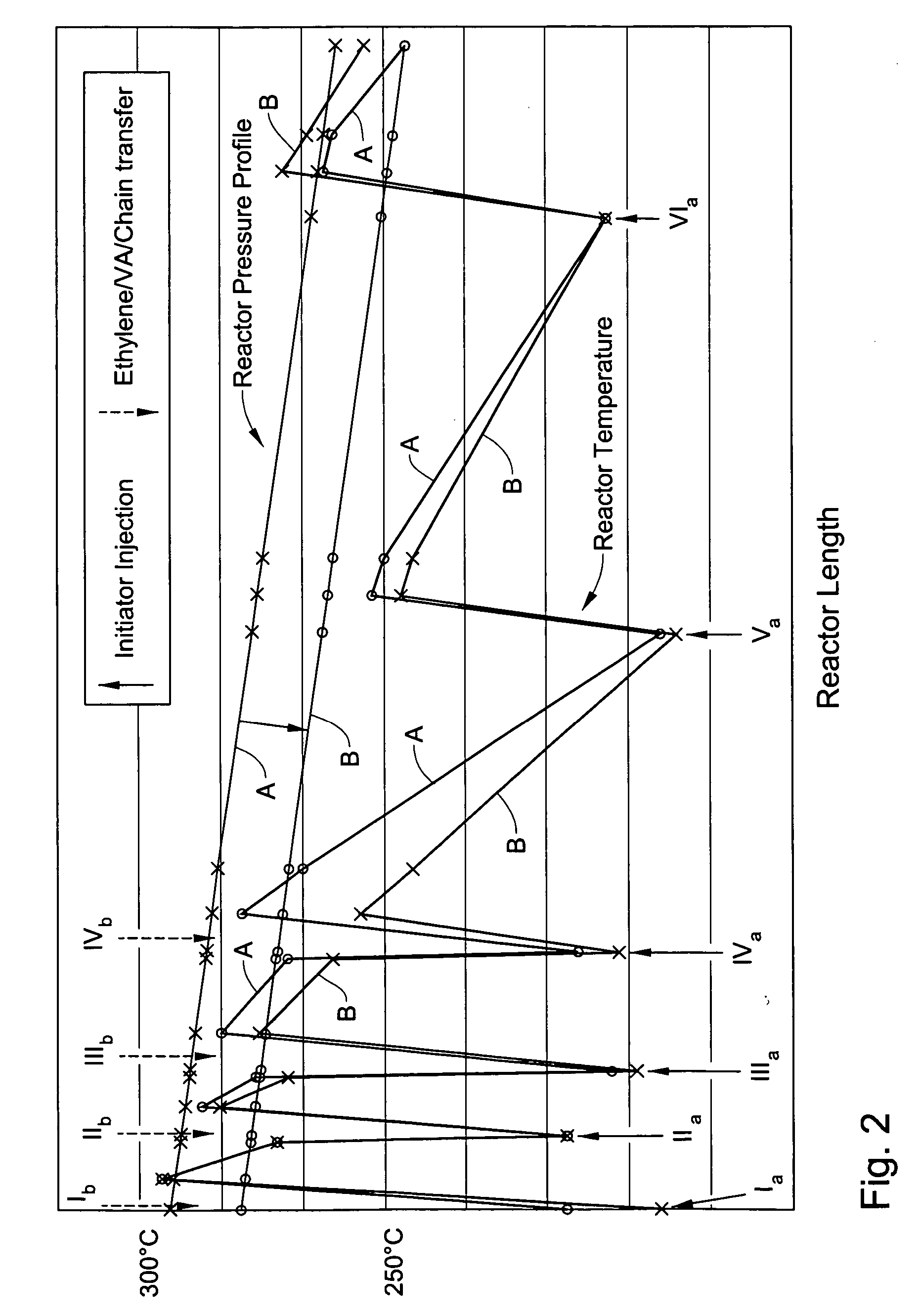

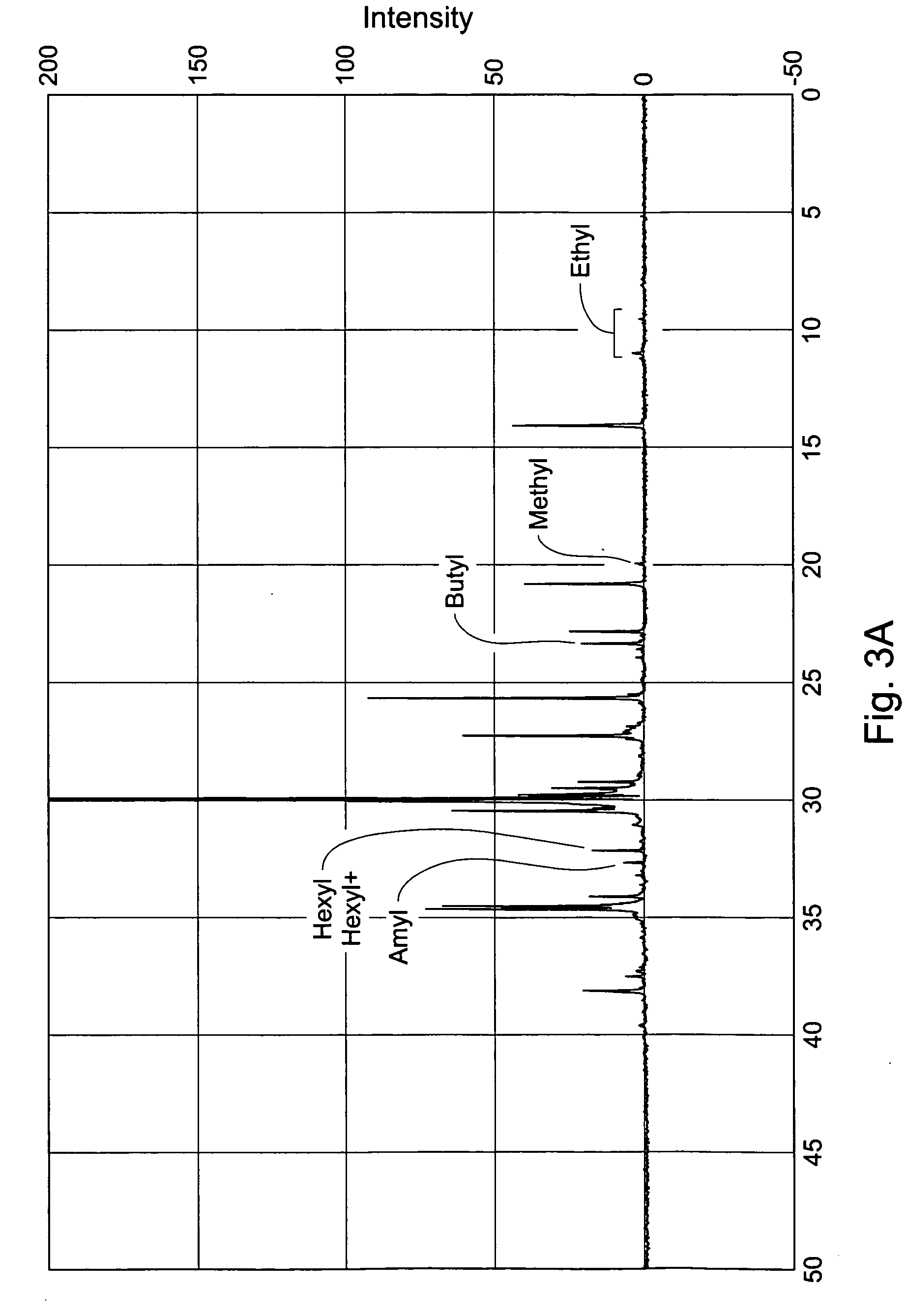

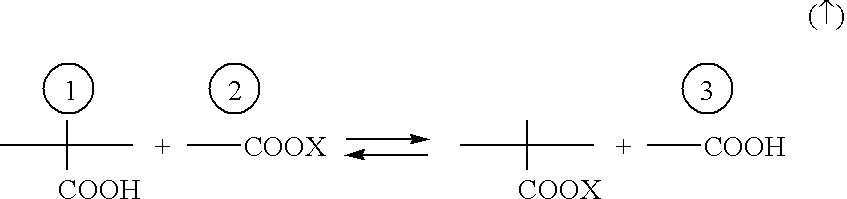

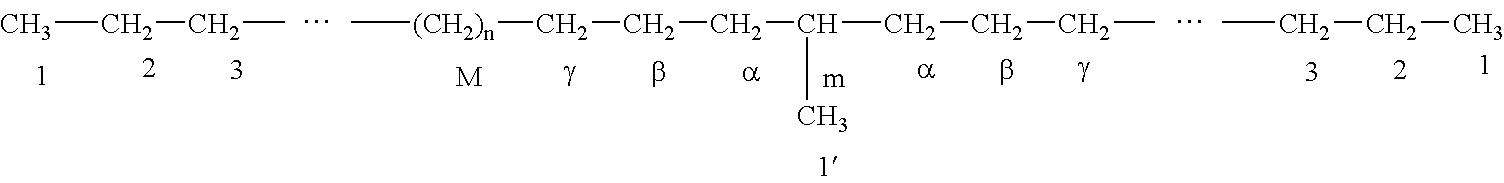

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

Coating composition containing a low MFI ethylene acrylic acid copolymer

InactiveUS6852792B1Improve water resistanceLow sealing temperatureEmulsion paintsMelt flow indexSolvent

This invention is directed to the discovery that ethylene-acid copolymers that have low melt flow index MFI (namely less than 100 g / 10 min measured according to ASTM D1238 at 190° C., 2.16 kg) even with low acid content (such as less than 20 wt. %) can provide stable aqueous dispersions directly in aqueous media (i.e. free from any other solvent) with less than 1 wt. % non-dispersibles in single bases even at mild dispersion process conditions, at temperature less than 100°C., atmospheric pressure, and with low agitation speed.

Owner:PERFORMANCE MATERIALS NA INC +1

Golf ball materials and golf ball

InactiveUS6962951B1Outstanding reboundEasy to reboundFibre treatmentSynthetic resin layered productsIonomerMetal

A golf ball material comprises a heated mixture having a melt index of at least 1.0 dg / min, which mixture is composed of (A) a thermoplastic resin, (B) a fatty acid or fatty acid derivative having a molecular weight of at least 280, and (C) a basic inorganic metal compound capable of neutralizing acidic groups in components A and B. The material including a highly neutralized ionomer resin has good thermal stability, flow characteristics and moldability. The invention is also directed at high-rebound golf balls which can be easily and efficiently manufactured using the same material.

Owner:BRIDGESTONE SPORTS

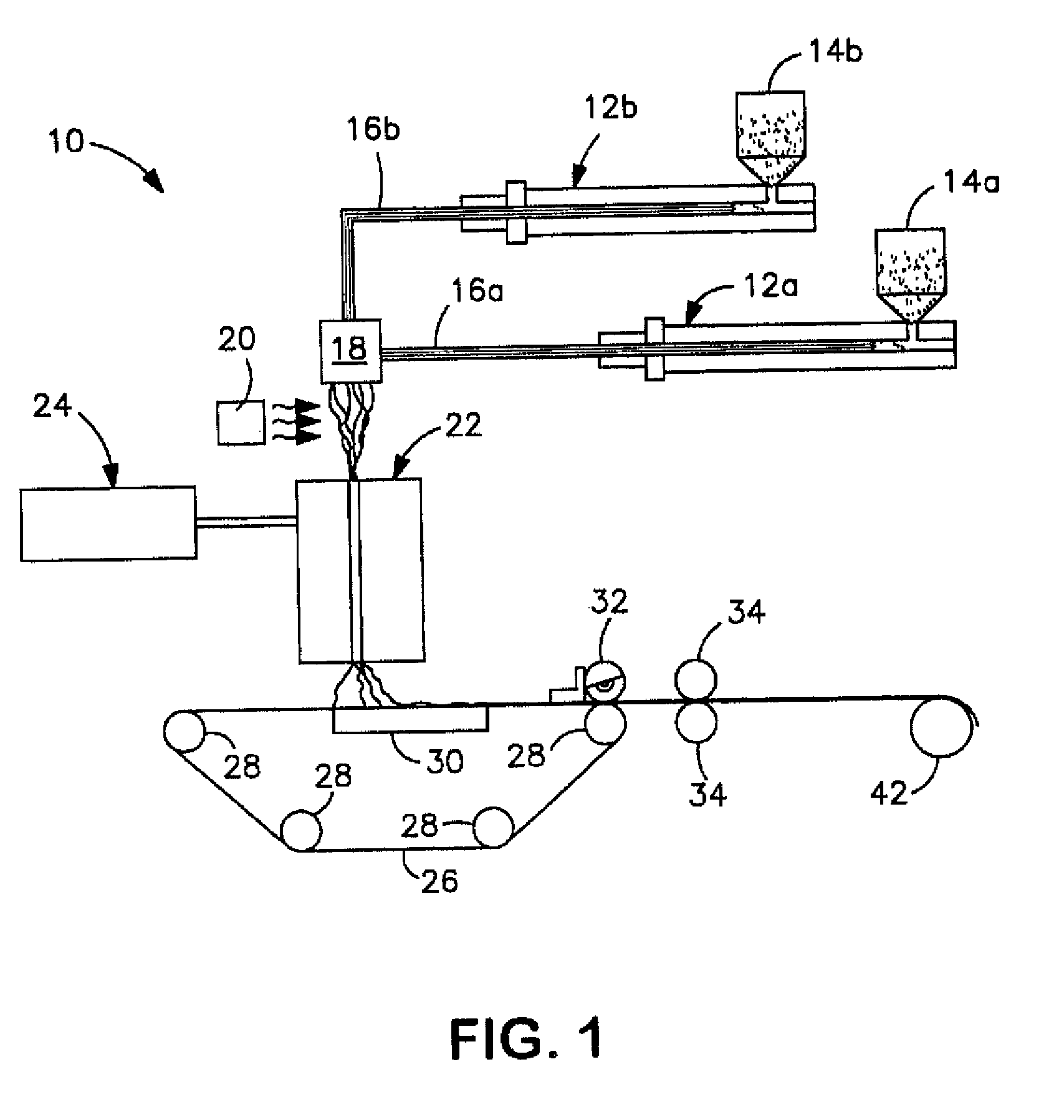

Multicomponent biodegradable filaments and nonwoven webs formed therefrom

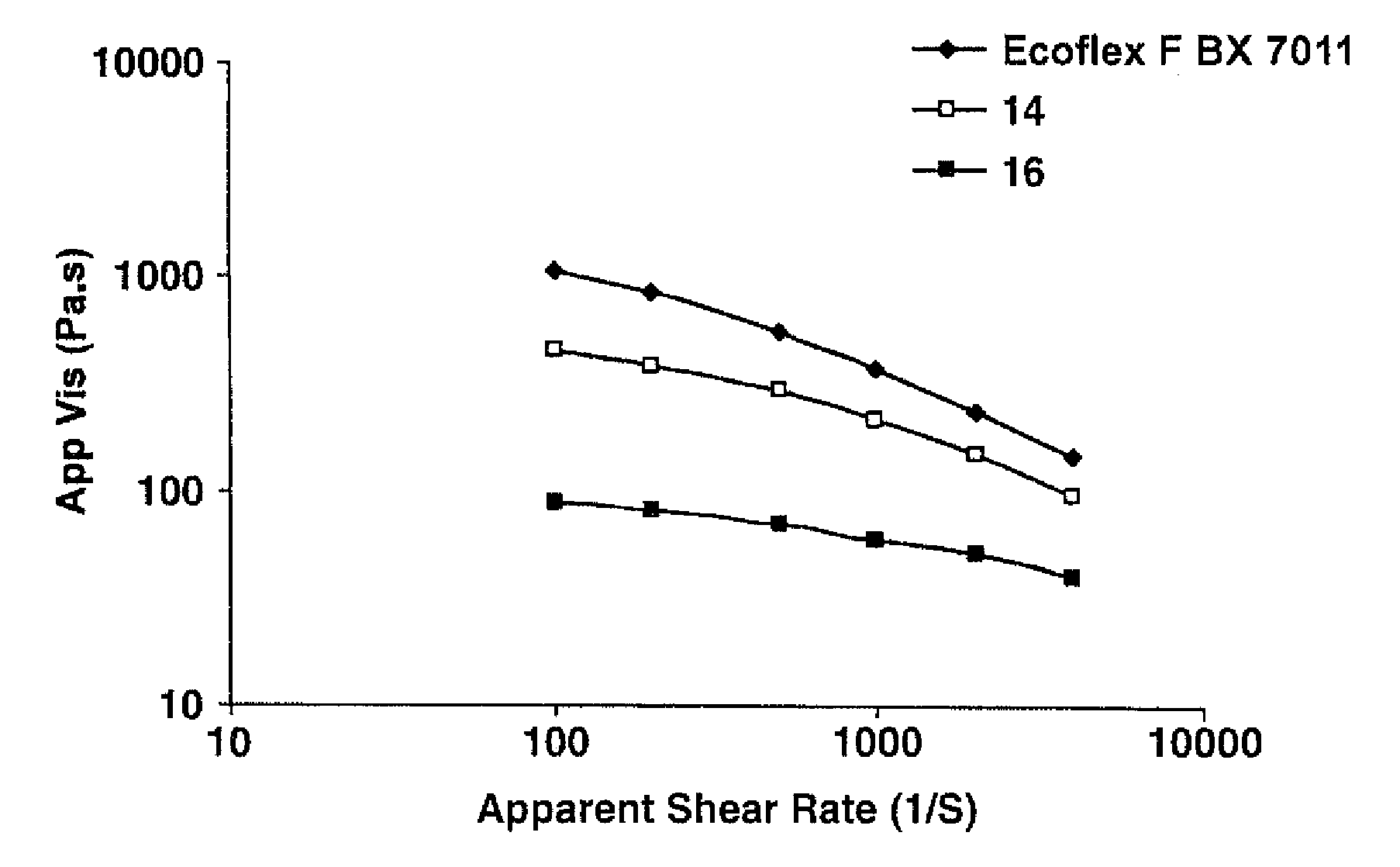

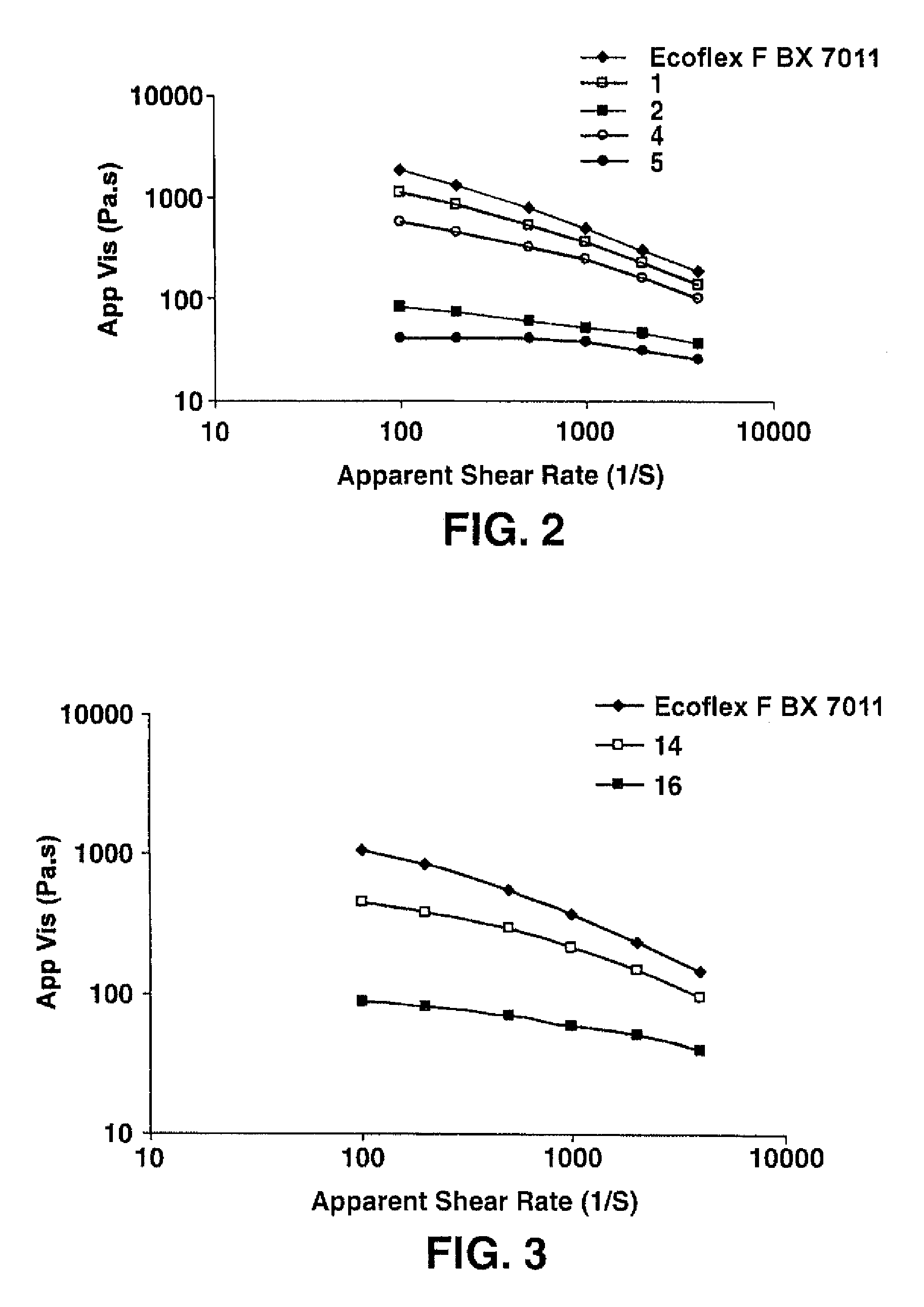

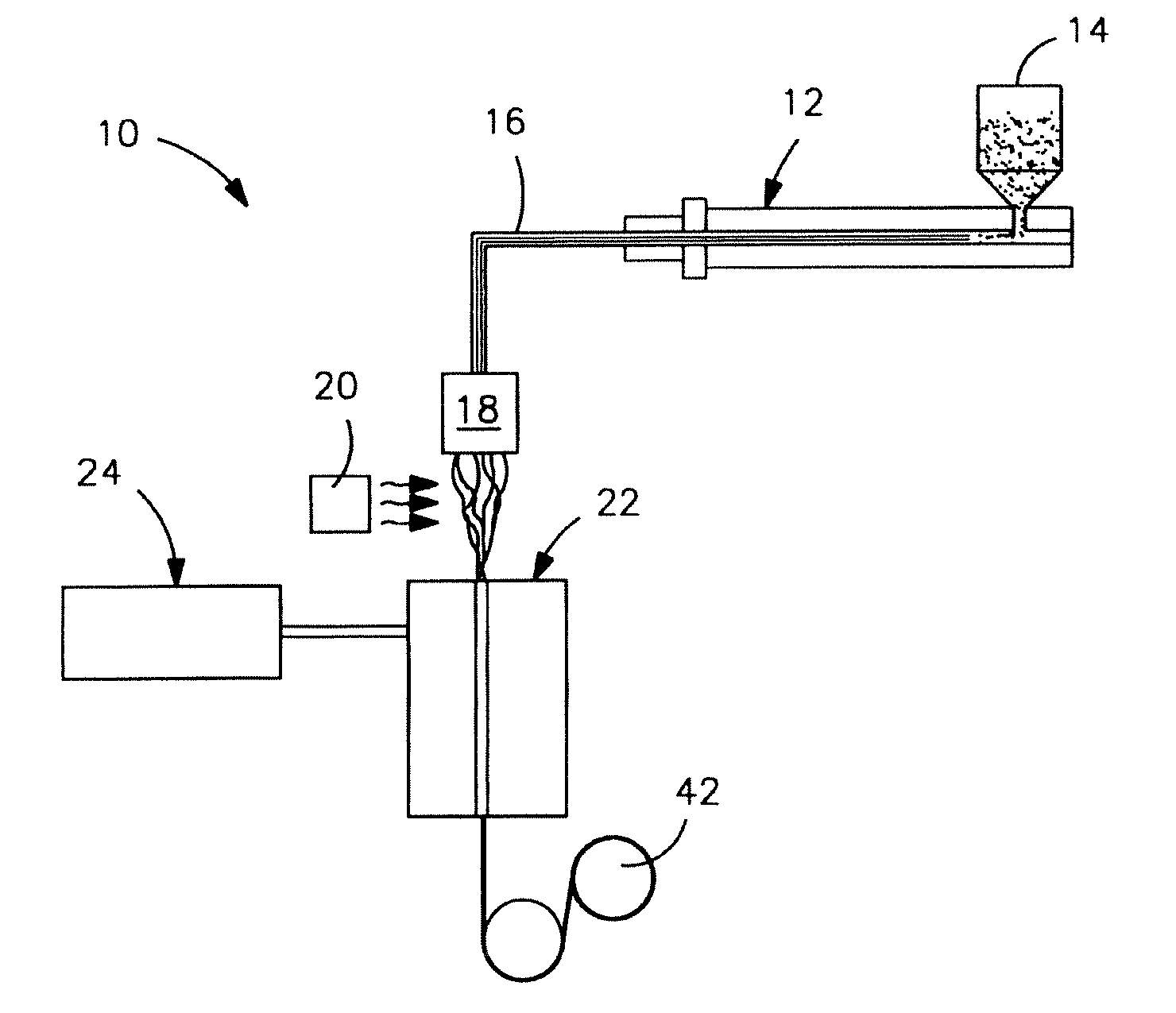

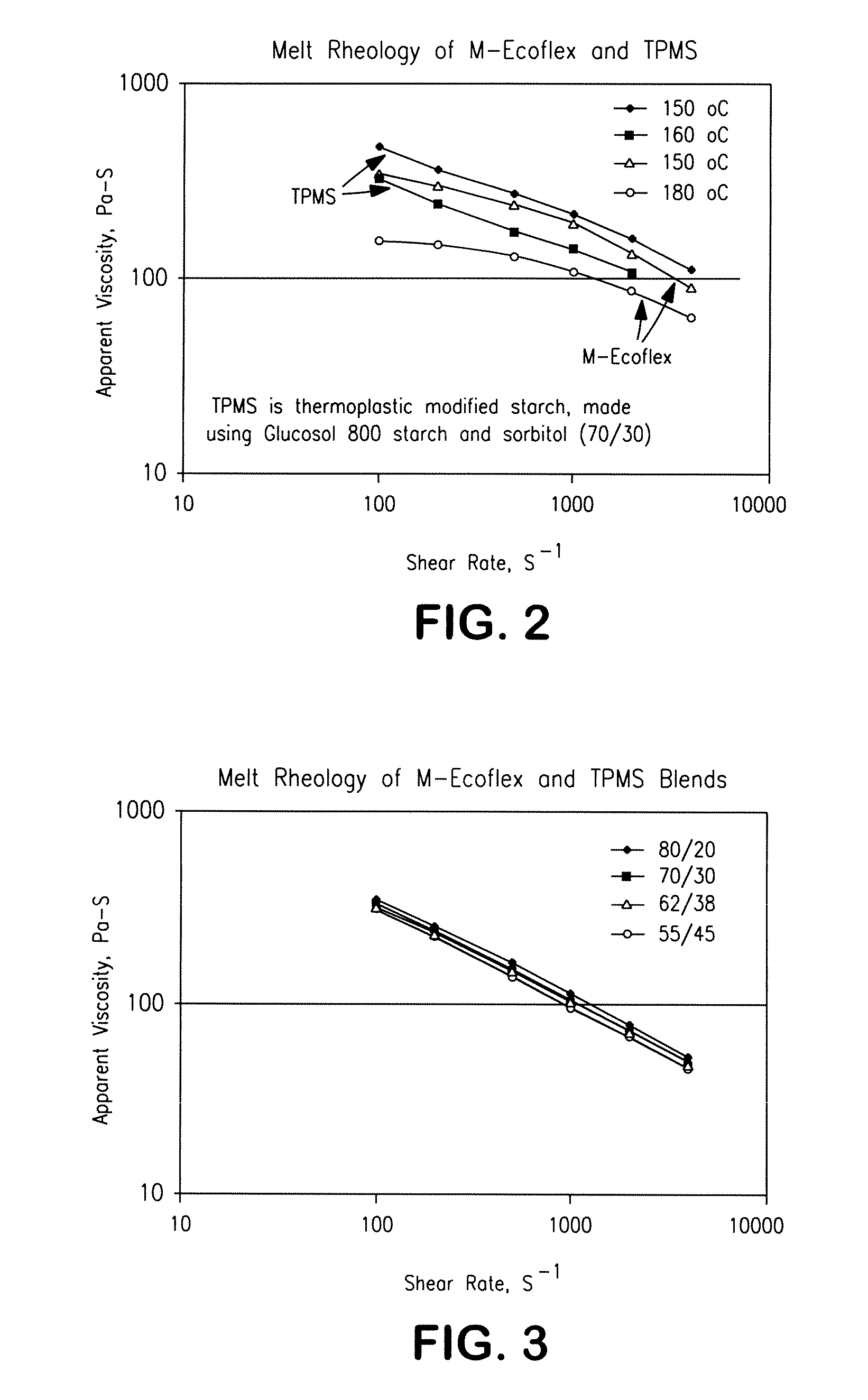

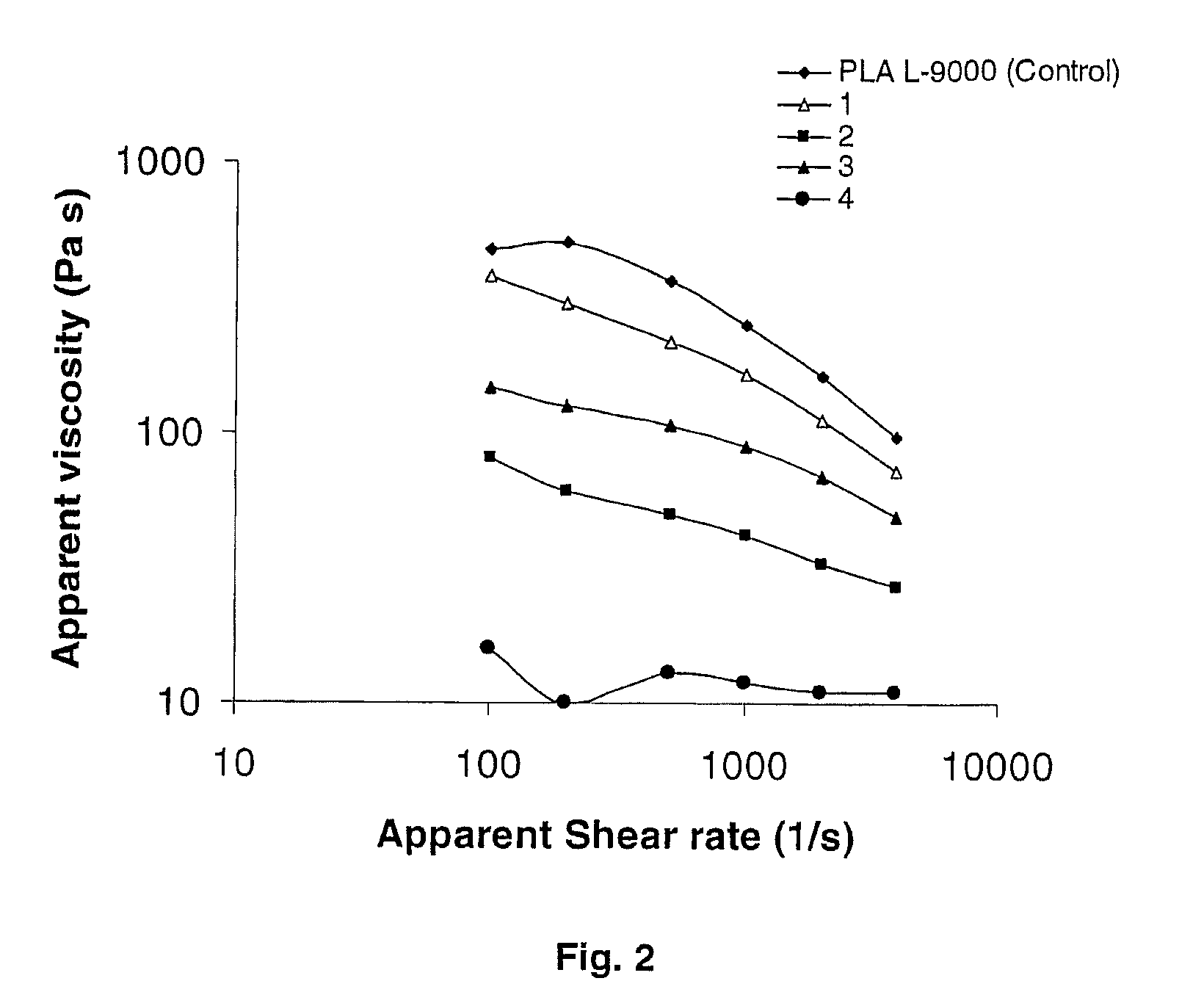

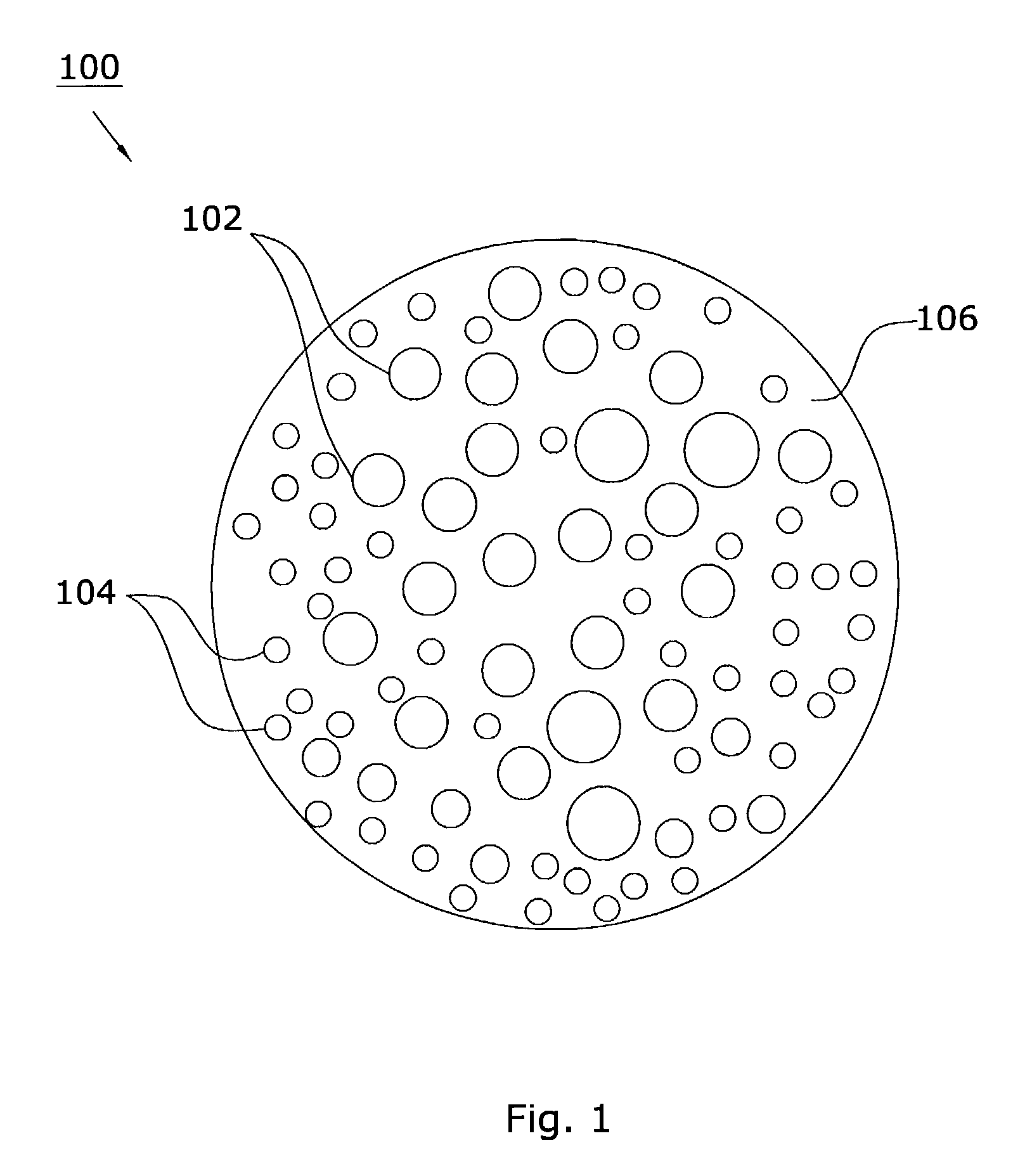

A biodegradable, substantially continuous filament is provided. The filament contains a first component formed from at least one high melting polyester and a second component formed from at least one low melting polyester. The low melting point polyester is an aliphatic-aromatic copolyester formed by melt blending a polymer and an alcohol to initiate an alcoholysis reaction that results in a copolyester having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and copolymer concentrations, catalysts, temperature, etc.), a modified aliphatic-aromatic copolyester may be achieved that has a molecular weight lower than the starting aliphatic-aromatic polymer. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in the formation of substantially continuous filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

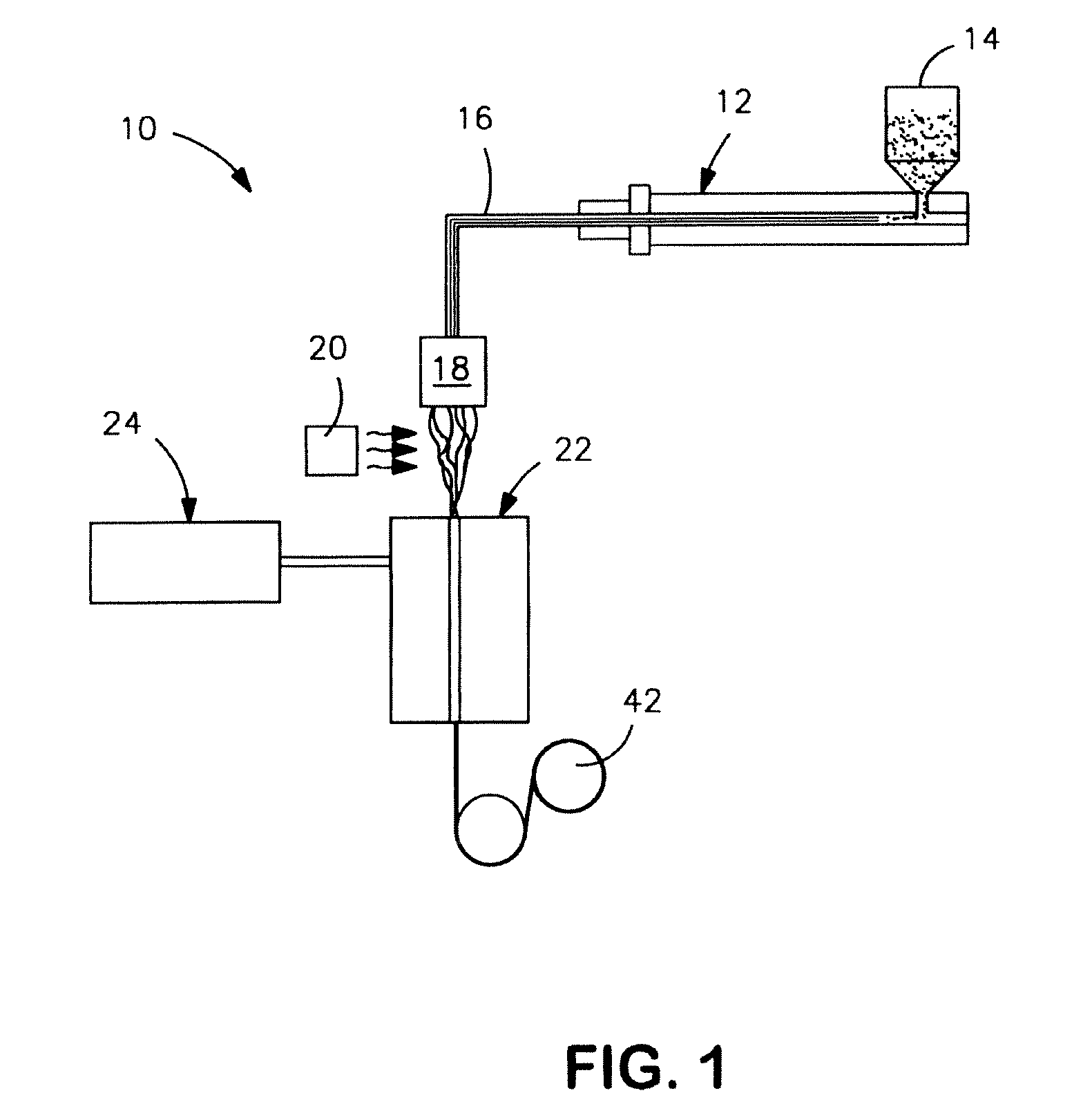

Fibers Formed from a Blend of a Modified Aliphatic-Aromatic Copolyester and Thermoplastic Starch

ActiveUS20090305592A1Ceramic shaping apparatusMonocomponent copolyesters artificial filamentFiberAlcohol

A fiber formed from a thermoplastic composition that contains a thermoplastic starch and an aliphatic-aromatic copolyester is provided. The copolyester enhances the strength of the starch-containing fibers and also facilitates the ability of the starch to be melt processed. Due to its relatively low melting point, the aliphatic-aromatic copolyester may also be extruded with the thermoplastic starch at a temperature that is low enough to avoid substantial removal of the moisture found in the starch. Furthermore, the aliphatic-aromatic copolyester is also modified with an alcohol so that it contains one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the conditions of the alcoholysis reaction (e.g., alcohol and copolymer concentrations, temperature, etc.), the resulting modified aliphatic-aromatic copolyester may have a molecular weight that is relatively low. Such low molecular weight polymers have the combination of a higher melt flow index and lower apparent viscosity, which is useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

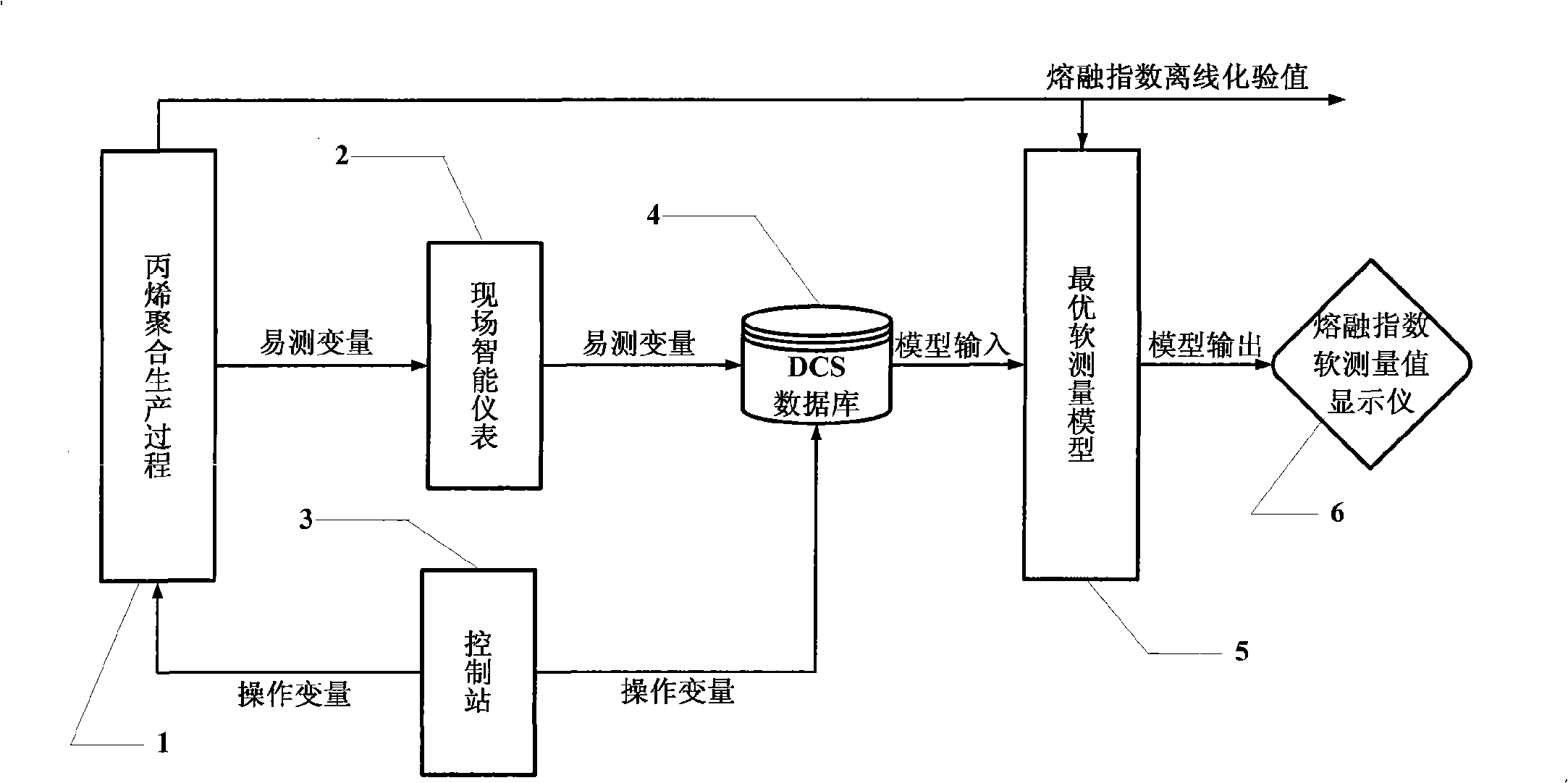

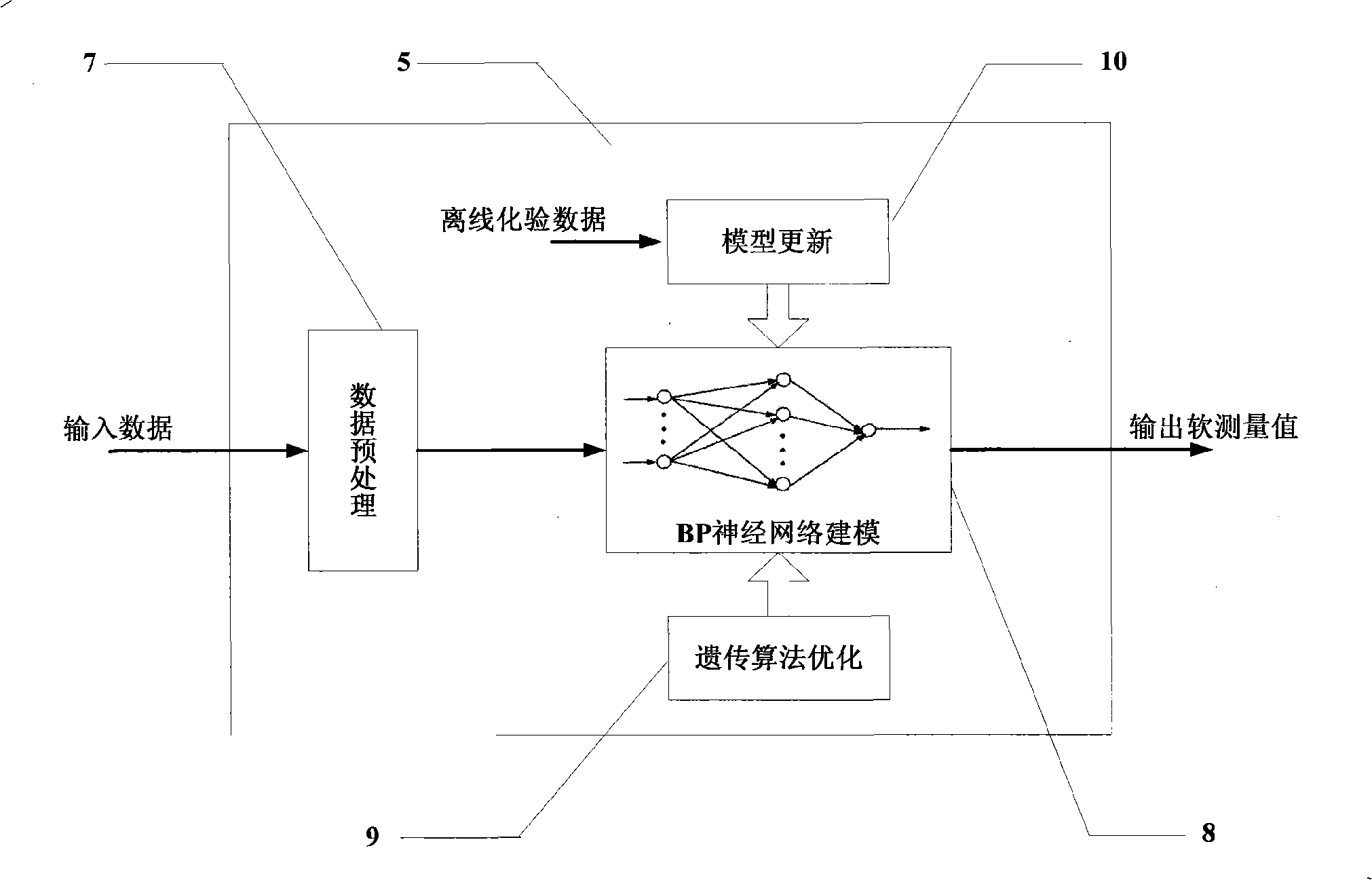

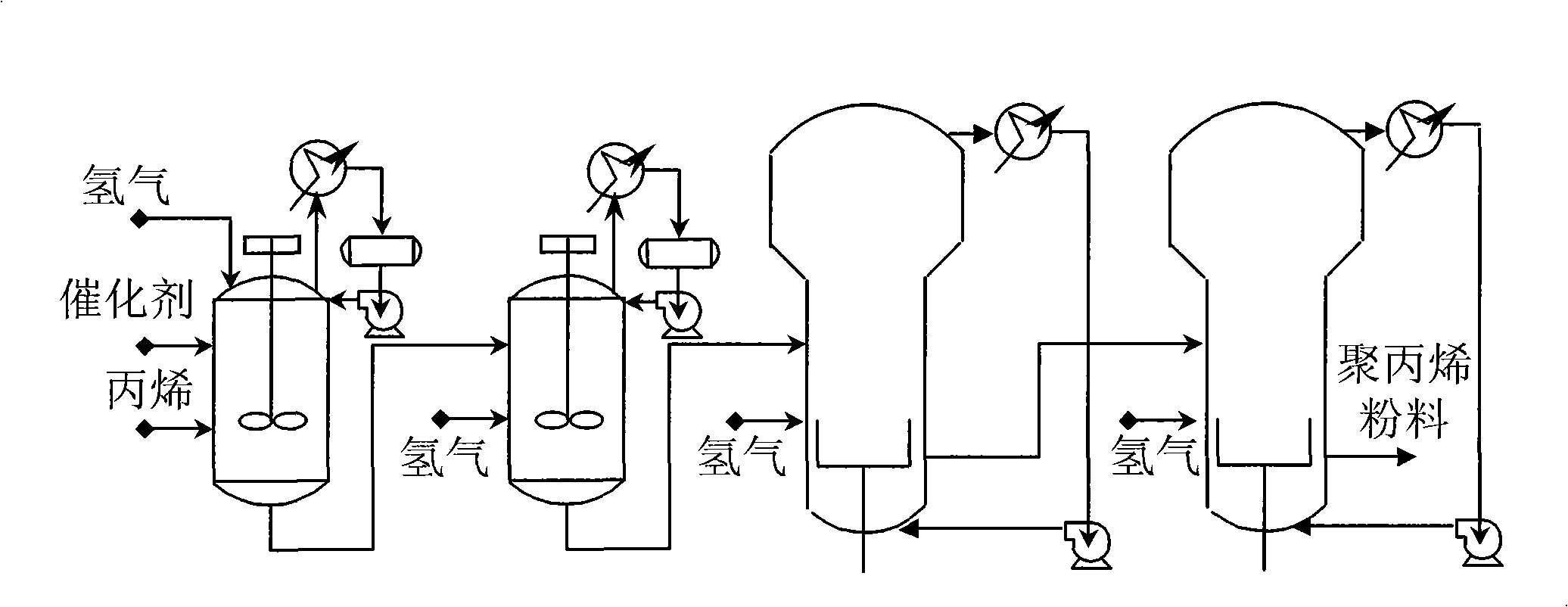

Propylene polymerization production process optimal soft survey instrument and method based on genetic algorithm optimization BP neural network

InactiveCN101315557AExcellent soft measurement resultsCalculation speedGenetic modelsBiological neural network modelsSurvey instrumentAlgorithm

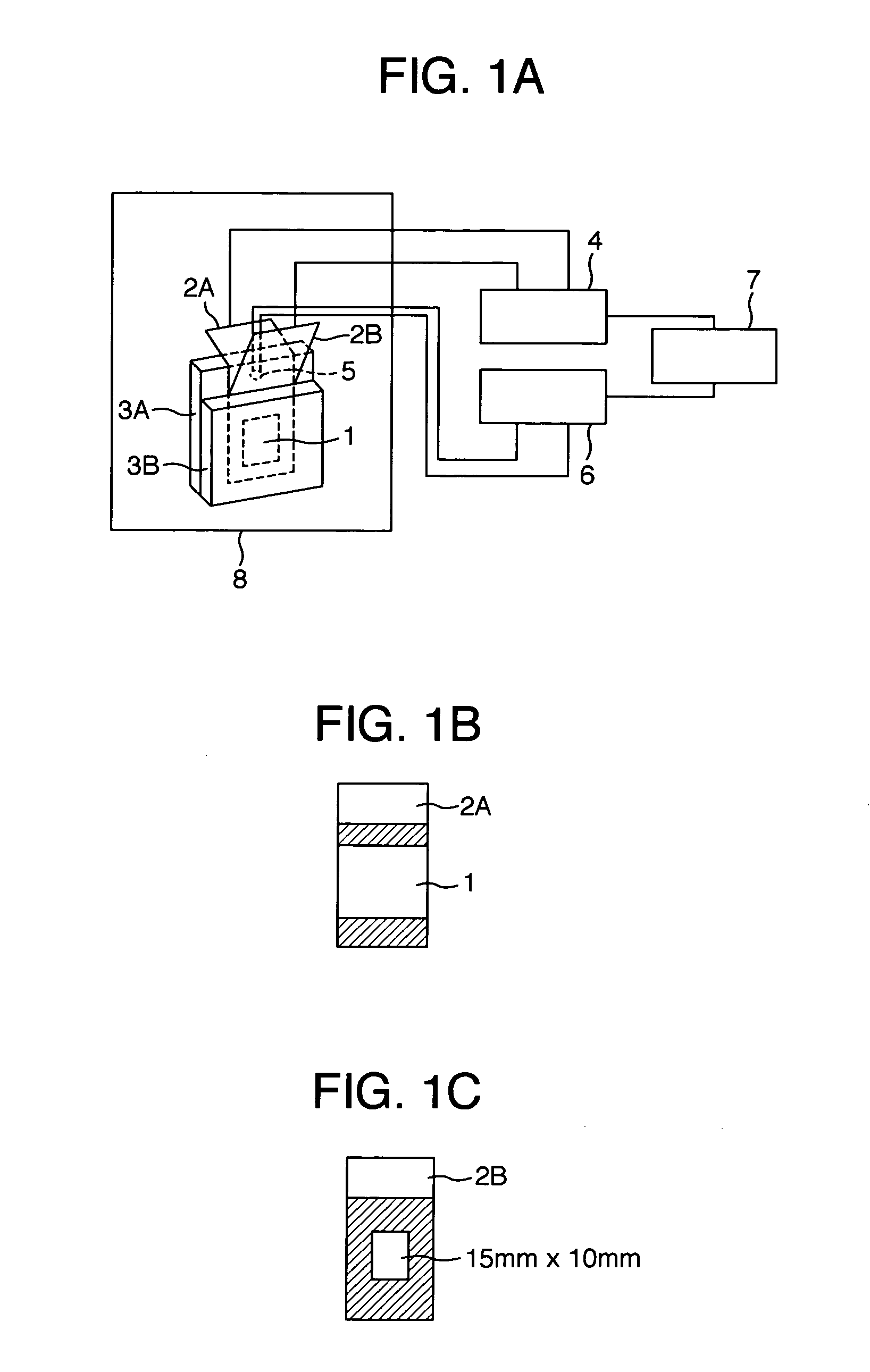

A propylene polymerization production process optimal soft-measurement meter based on genetic algorithm optimized BP neural network comprises a propylene polymerization production process, a site intelligent meter, a control station, a DCS databank used for storing data, an optimal soft measurement model based on genetic algorithm optimized BP neural network, and a melting index soft-measurement value indicator. The site intelligent meter and the control station are connected with the propylene polymerization production process and the DCS databank; the optimal soft-measurement model is connected with the DCS databank and the soft-measurement value indicator. The optimal soft measurement model based on genetic algorithm optimized BP neural network comprises a data pre-processing module, an ICA dependent-component analysis module, a BP neural network modeling module and a genetic algorithm optimized BP neural network module. The invention also provides a soft measurement method adopting the soft measurement meter. The invention can realize on-line measurement and on-line automatic parameter optimization, with quick calculation, automatic model updating, strong anti-interference capability and high accuracy.

Owner:ZHEJIANG UNIV

Microporous polyethylene film

InactiveUS20060177643A1Excels in mechanical strengthExcels in permeabilityElectrolyte holding meansMembranesAlpha-olefinViscosity

A microporous polyethylene film, including a blend that contains a high density polyethylene copolymer which has a melt index (MI) of 0.1 to 100 and a content of an α-olefin unit with 3 or more carbon atoms of 0.1 to 1% by mole; and a high density polyethylene which has a viscosity average molecular weight (Mv) of at least 500000 to 5000000, wherein the above described blend has an Mv of 300000 to 4000000 and a content of an α-olefin unit with 3 or more carbon atoms of 0.01 to 1% by mole.

Owner:ASAHI KASEI CHEM CORP

Transparent Thermoplastic Resin Composition with Improved Impact Strength and Melt Flow Index

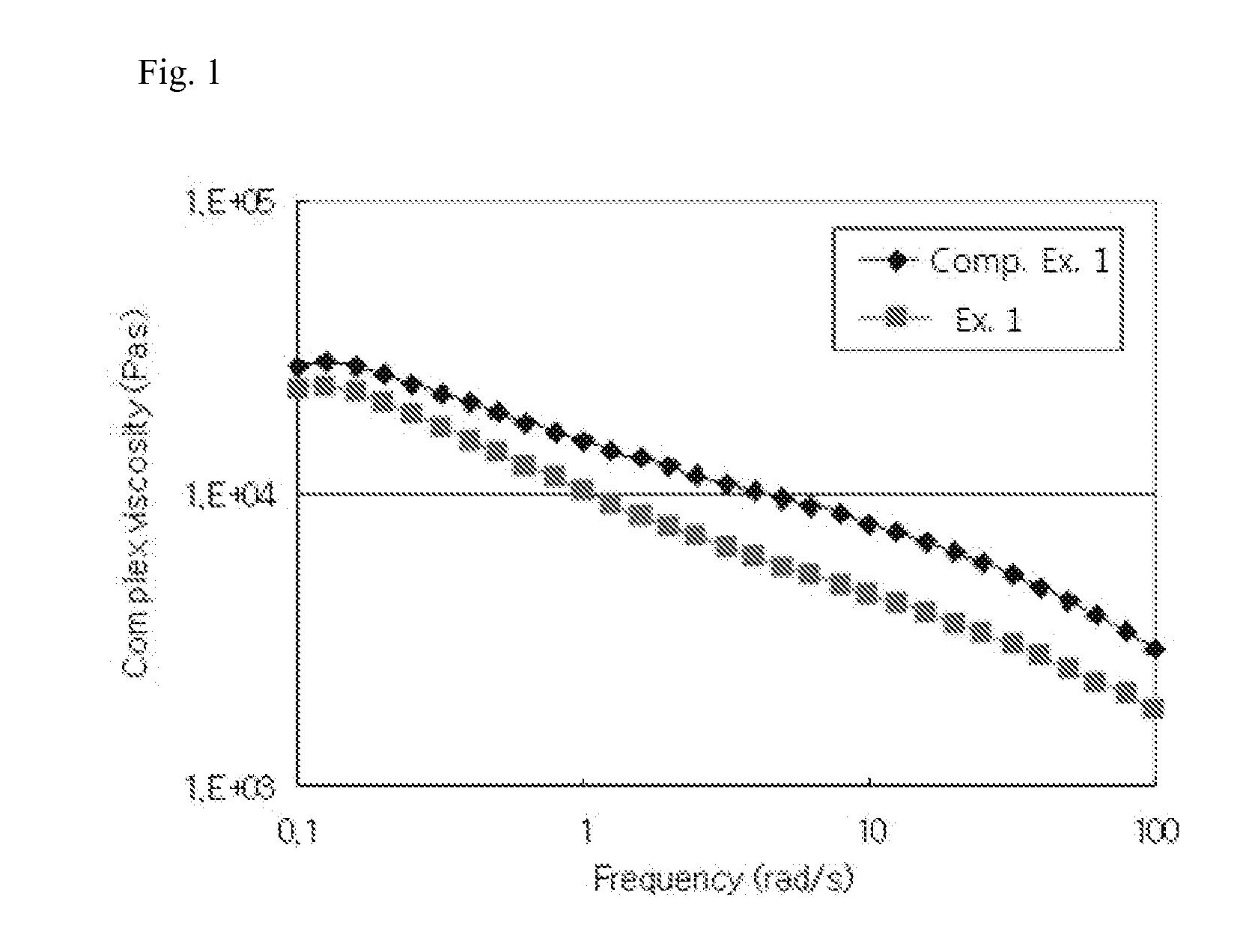

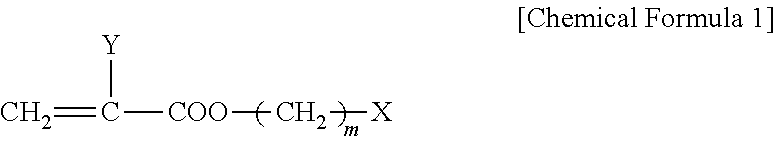

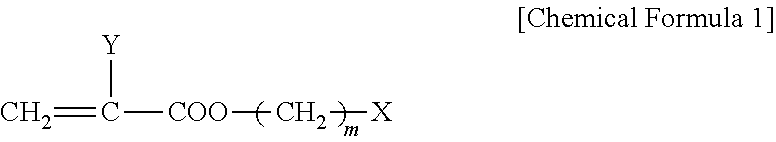

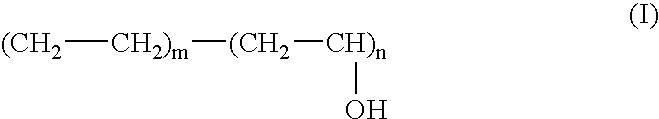

The present invention provides a transparent thermoplastic resin composition which may comprise (A) about 1 to about 100 parts by weight of an ultra-high molecular weight branched acrylic copolymer resin; (B) about 0 to about 99 parts by weight of an acrylic resin; and (C) about 0 to about 40 parts by weight of an acrylic impact modifier, based on 100 parts by weight of (A) and (B). The ultra-high molecular branched acrylic copolymer resin (A) may be prepared by polymerizing a monomer mixture comprising (a1) about 50 to about 99.899% by weight of a mono-functional monomer, (a2) about 0.1 to about 40% by weight of a (meth)acrylic monomer having a flexible segment represented following Chemical Formula 1, and (a3) about 0.001 to about 10% by weight of a branch-inducing monomer. The thermoplastic resin composition of the present invention can have improved transparency, scratch resistance, flowability, and impact strength.wherein m is an integer from 3 to 18, Y is methyl or hydrogen, and X is methyl or hydrocarbon.

Owner:LOTTE ADVANCED MATERIALS CO LTD

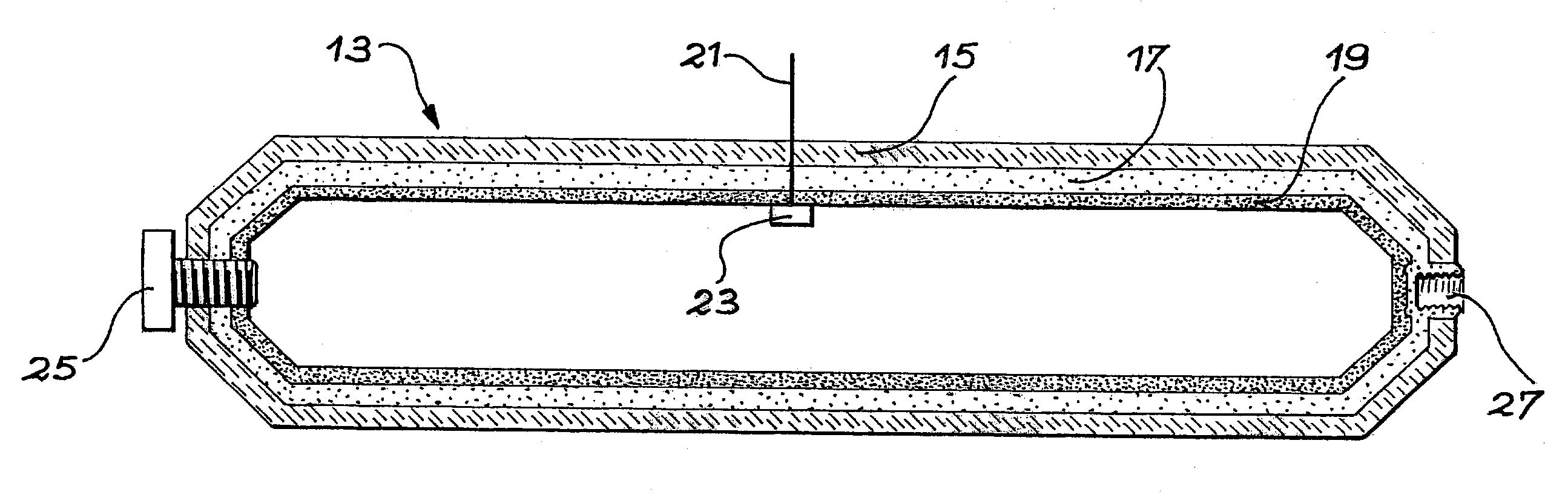

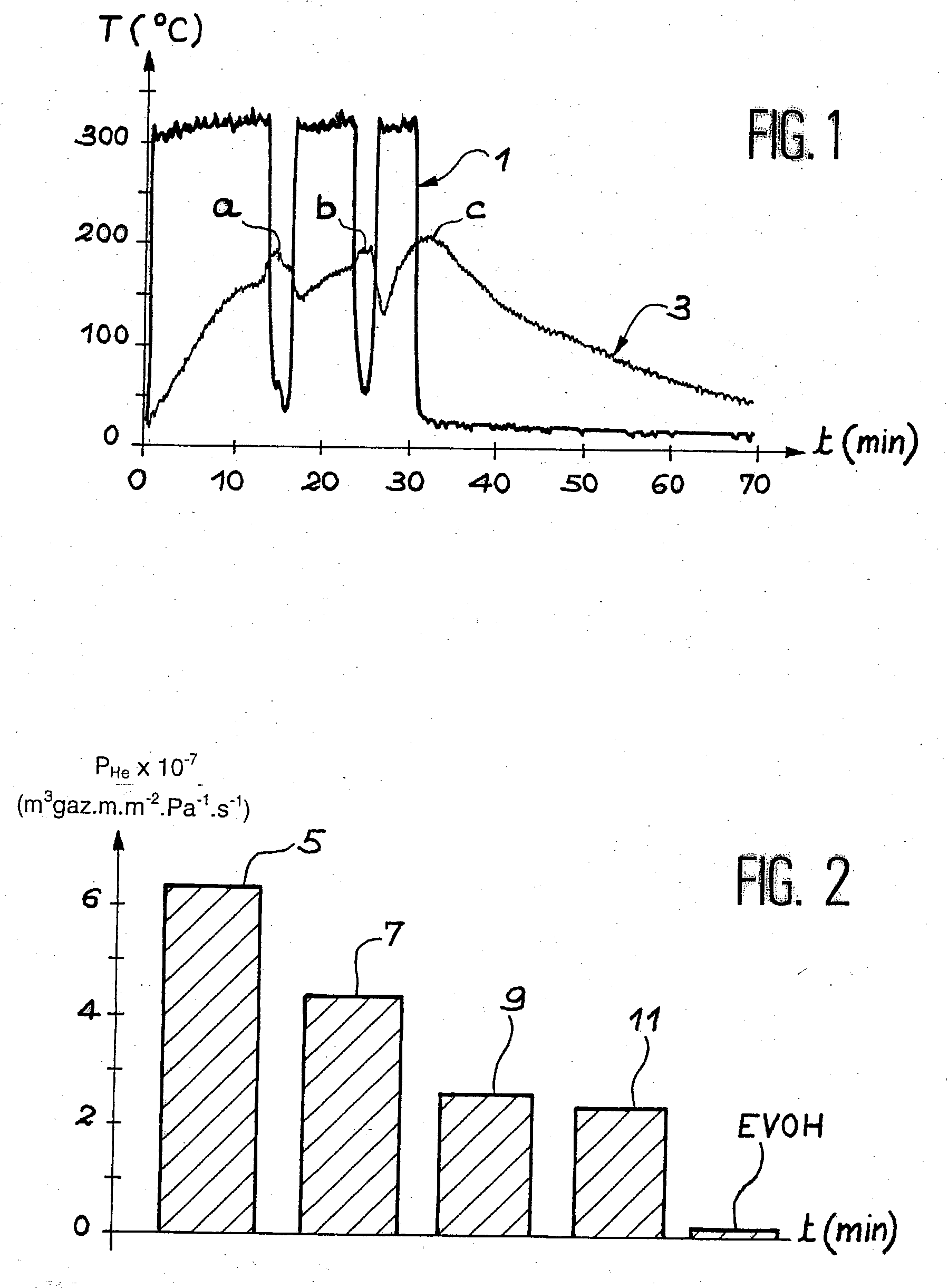

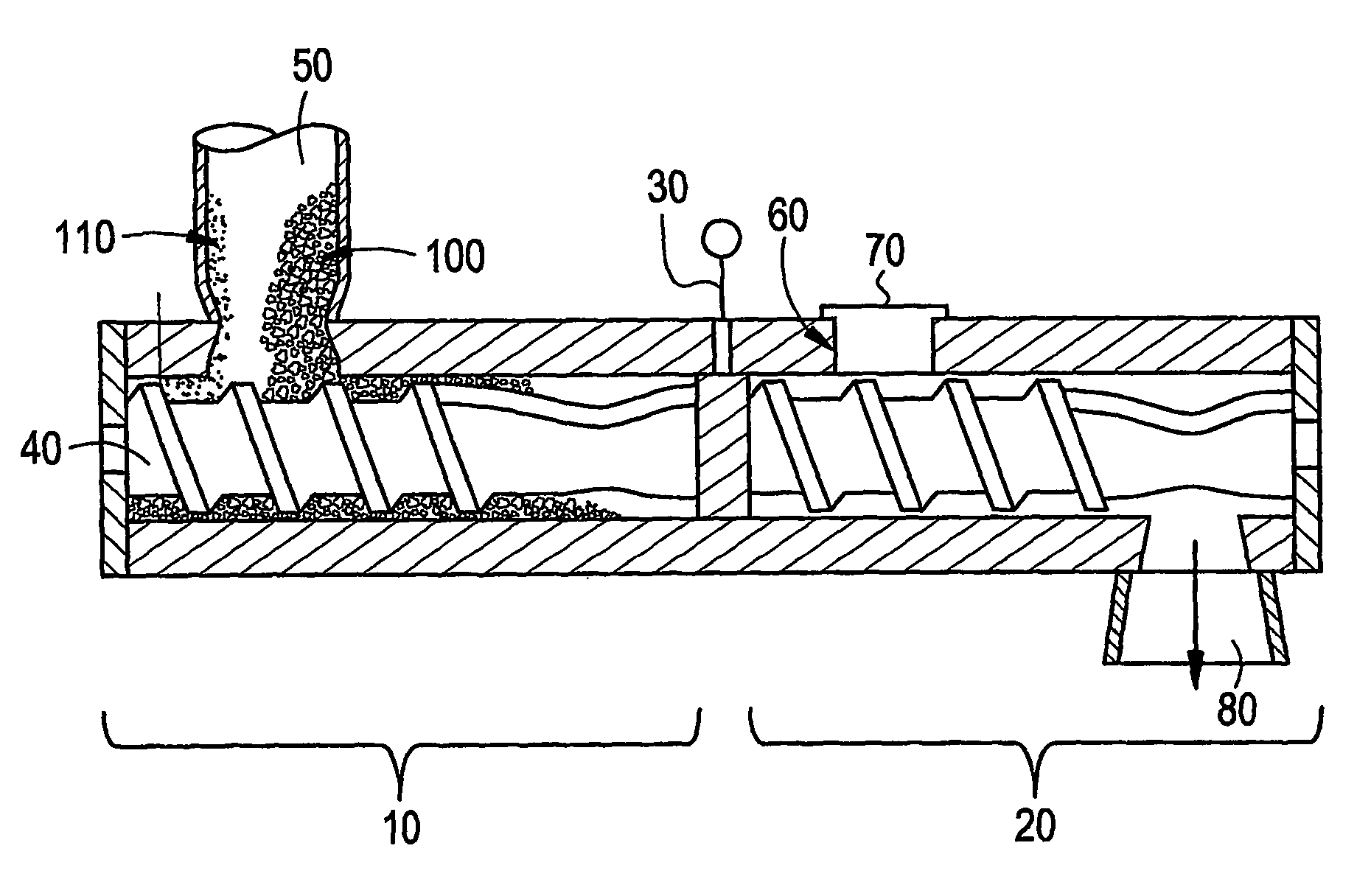

Mulitlayer thermoplastic structure for gas tank

InactiveUS20030175457A1Avoid the needControlling the riskUnderstructuresRecord information storageThermoplasticMelt flow index

This invention relates to a multiple layer thermoplastic structure, use of the said structure for manufacturing a tank, and a tank comprising the said structure. Multi-layer thermoplastic structure of the said invention comprising at least one layer composed of an ethylene-vinyl alcohol copolymer with a density of between 0.94 and 1.4, and a melt flow index of between 1.3 and 4.2 g / 10 minutes at a temperature between 170 and 240° C. It is used for manufacturing gas tanks.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

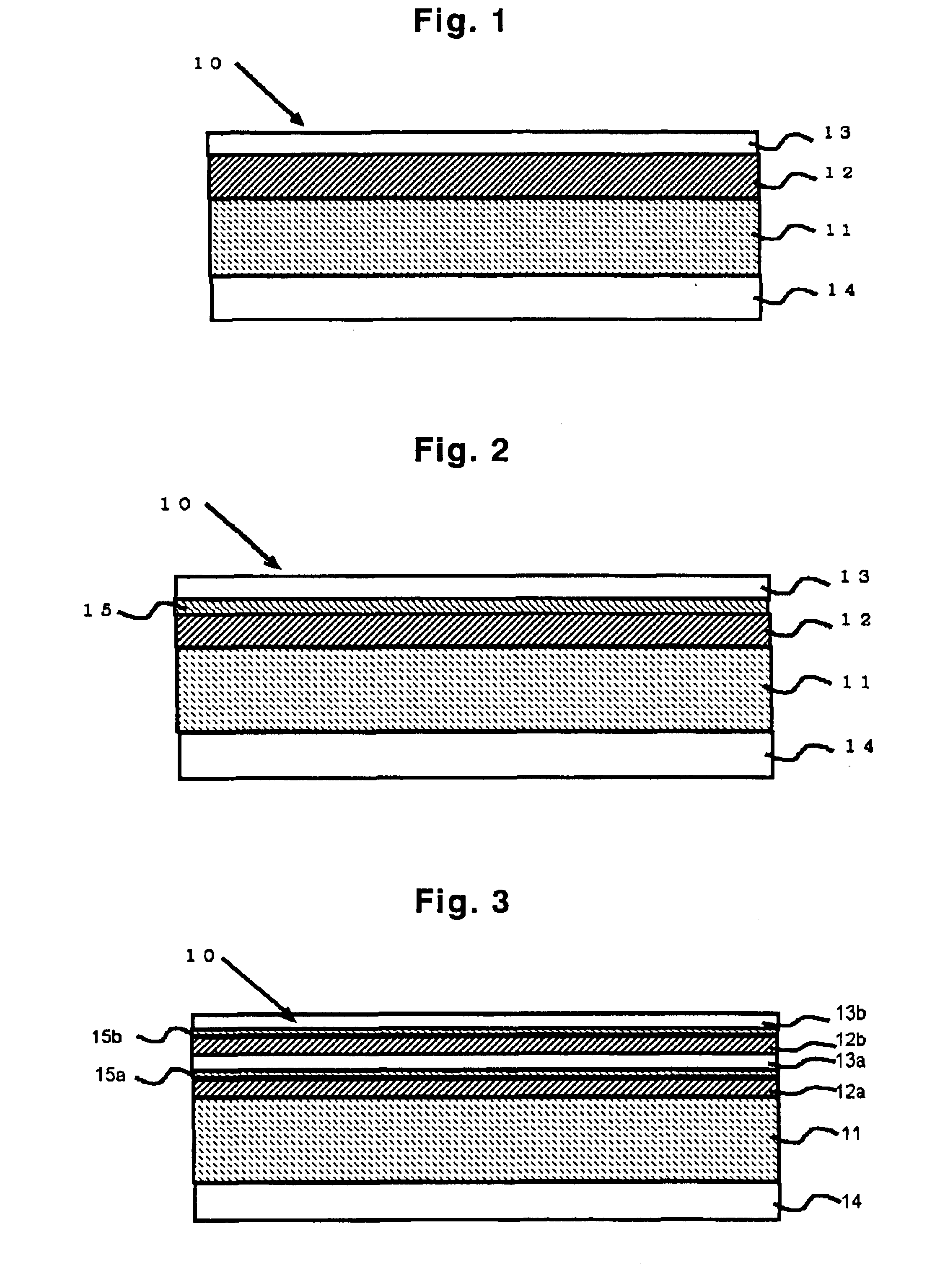

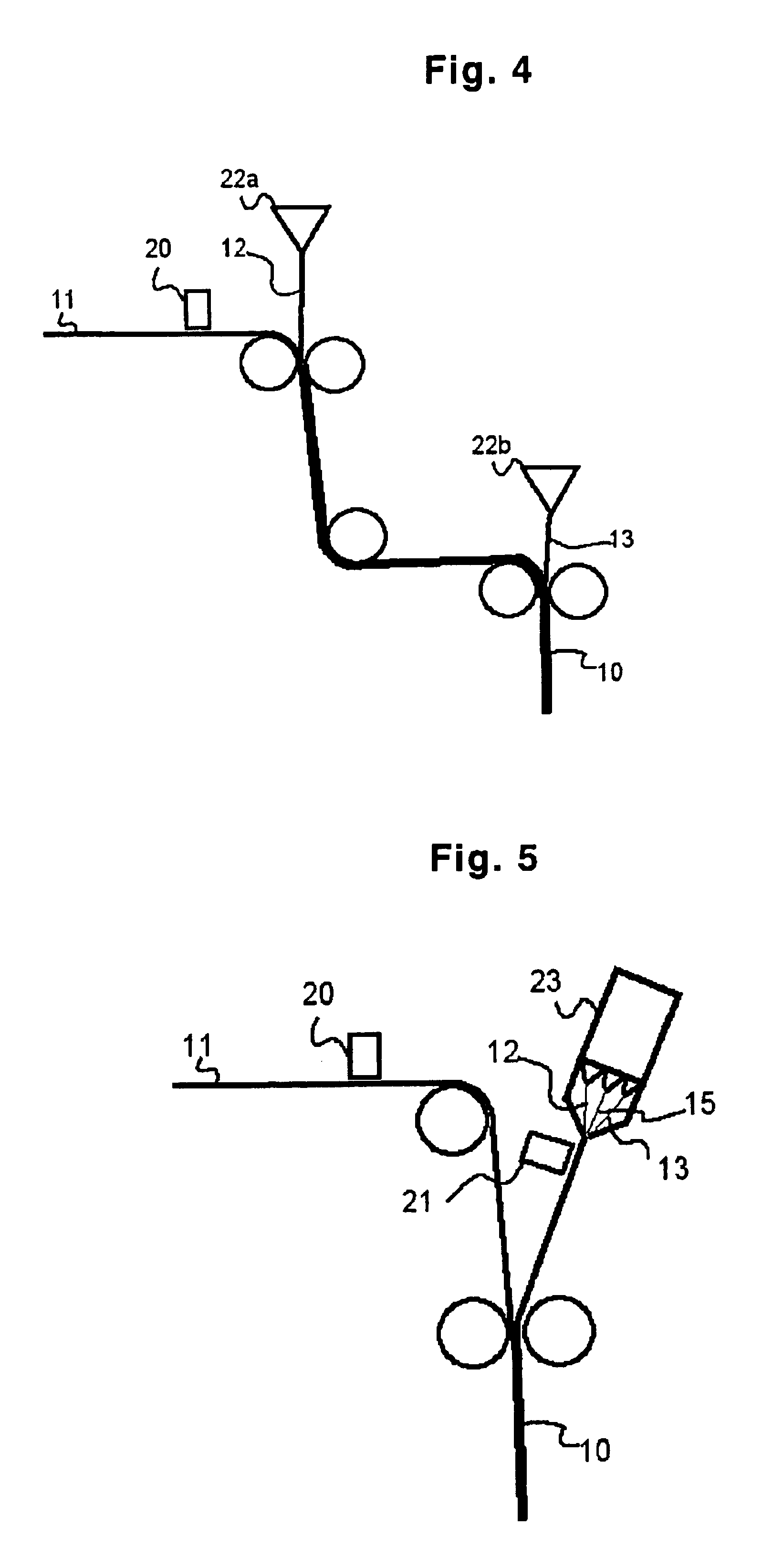

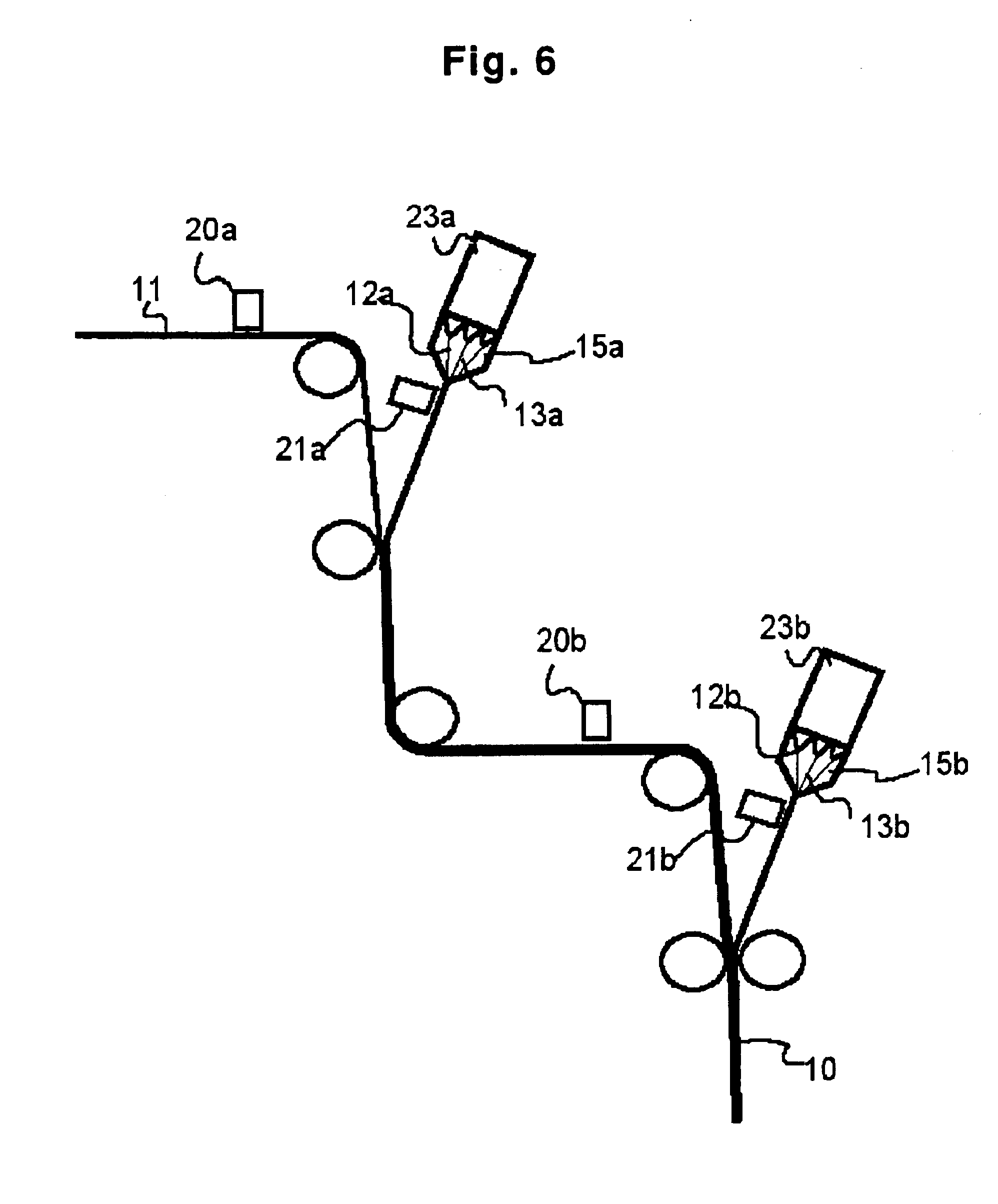

Laminated packaging material and method for producing the same

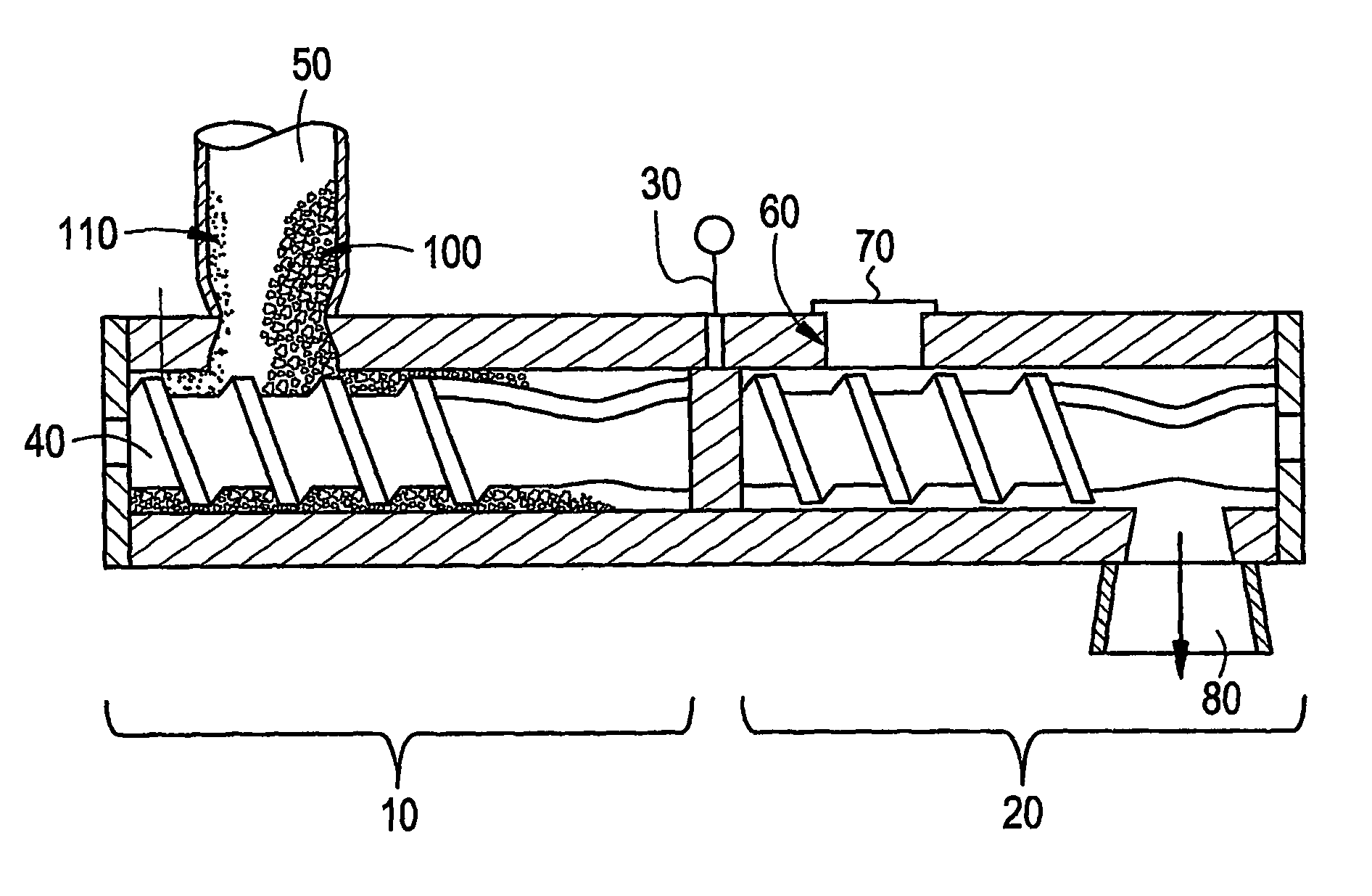

InactiveUS6872459B1Valid conversionExcellent in non-scalping and gas barrierLamination ancillary operationsLayered product treatmentLinear low-density polyethyleneSwelling ratio

This invention relates to the laminated material for food packaging, and its manufacturing process. The laminated material (10) consists of the quality keeping intermediate layer (12) laminated inside the paper core layer (11) and the core layer and the heat sealable innermost layer (13). The quality keeping intermediate layer comprises of an extrusion coatable blend polymer consisting of polymer component A 50-95% of nylon-MXD6 or EVOH and, polymer component B 5-50% of nylon 6, nylon 6, the blends or PET. The quality keeping intermediate layer is extruded and laminated directly in the core layer, the innermost layer contains at least the linear low density polyethylene which has a narrow molecular weight distribution, and has the properties parameter of mean density of 0.910-0.925, 100-122 degrees C. peak melting point, melt flow index of 5-20, swelling ratio (SR) of 1.4-1.6, and 5-50 micrometer layer thickness.The hardness, production efficiency, and cost performance of the barrier packaging container formed by the packaging material are improved.

Owner:TETRA LAVAL HLDG & FINANCE SA

Polymer composition and process to manufacture high molecular weight-high density polyethylene and film therefrom

The present invention is a multimodal polyethylene composition having (1) a density of at least about 0.940 g / cm3; (2) a melt flow index (I5) of from about 0.2 to about 1.5 g / 10 mm; (3) a melt flow index ratio (I21 / I5) of from about 20 to about 50; (4) a molecular weight distribution, Mw / Mn, of from about 20 to about 40; and (5) a bubble stability measured on an HS50S stationary extrusion system with an BF 10-25 die, HK 300 air ring, A8 take off, and WS8 surface winder, with a 100 mm die diameter having a 50 mm 21:1 L / D grooved feed extruder used for a film of about 6×10−6 m thickness of at least about 1.22 m / s line speed, at least about 45 kg / hr (0.013 kg / sec) output rate, or at least about 0.5 lb / hr / rpm (0.0000011 kg / s / rps) specific output rate or a combination thereof.

Owner:DOW GLOBAL TECH LLC

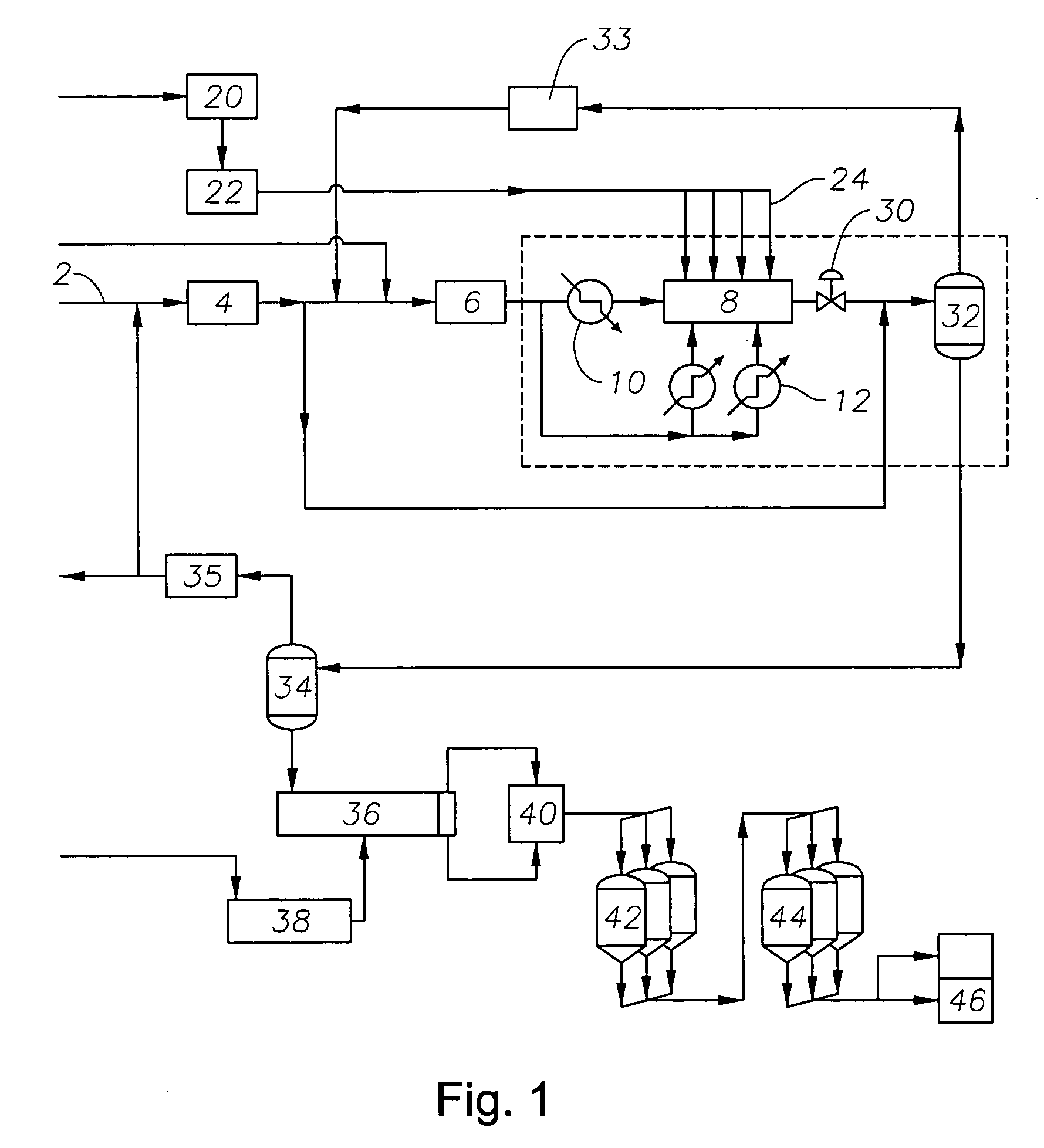

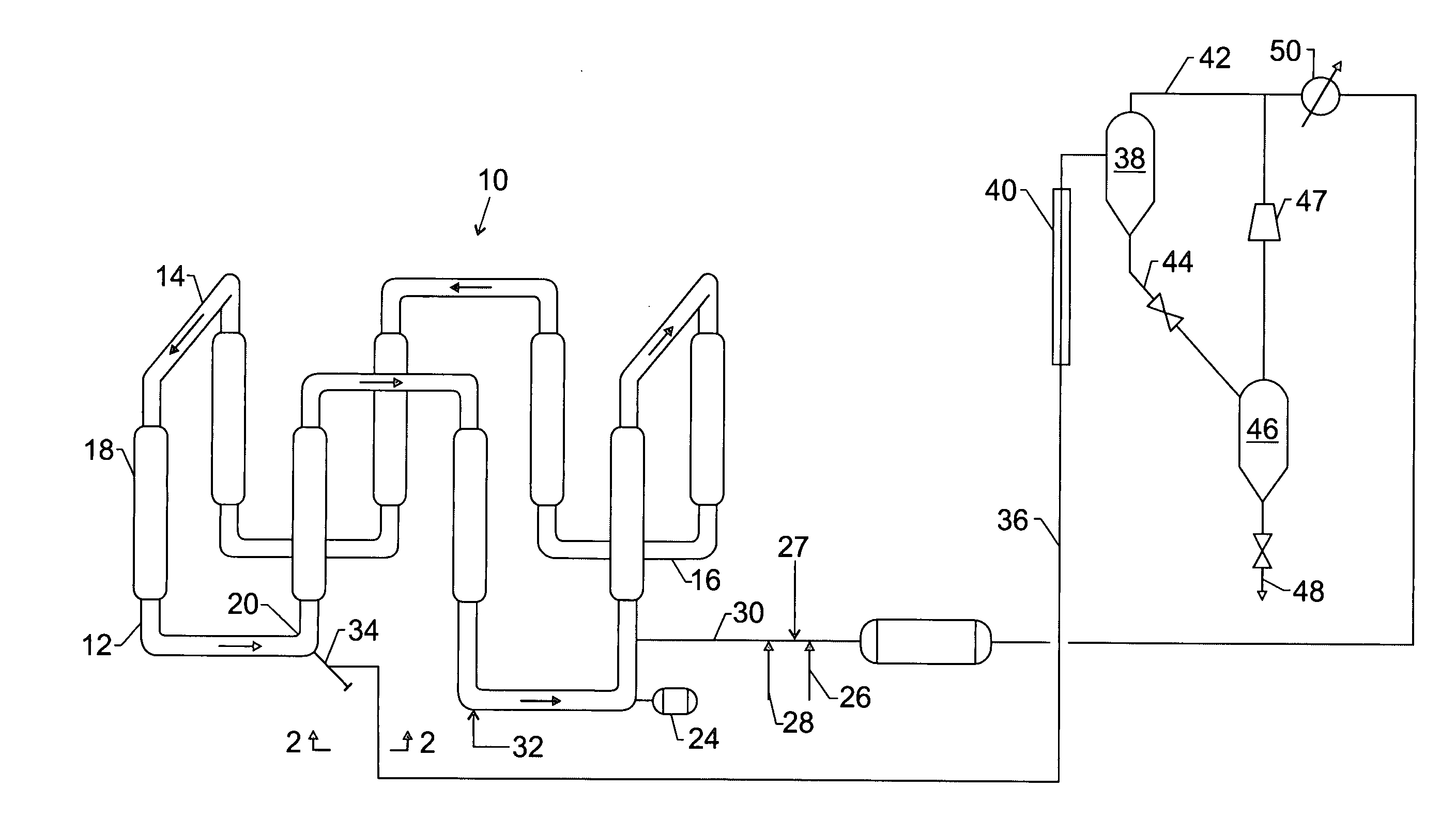

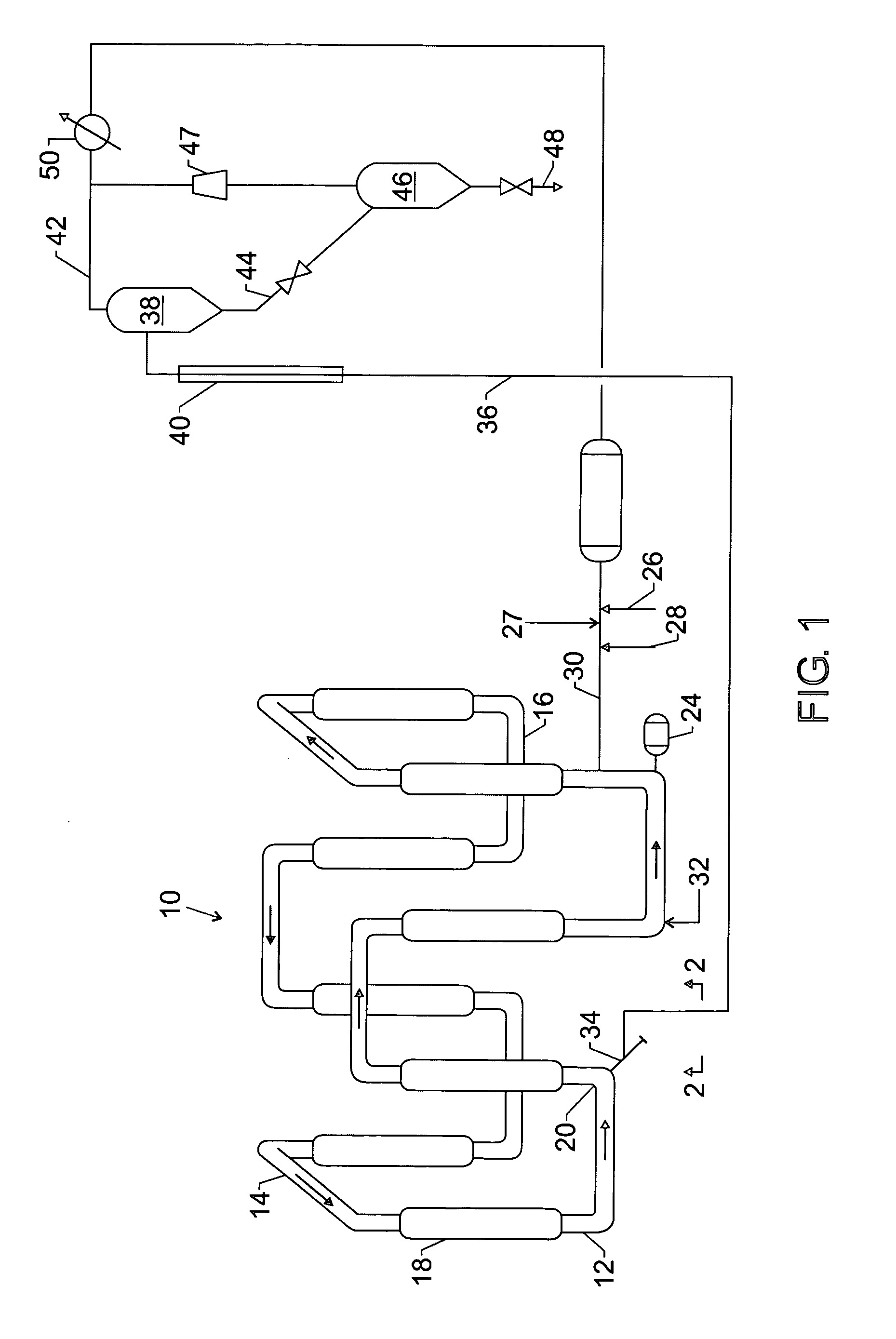

Method and apparatus for reducing reactor fines

InactiveUS20050095176A1Process control/regulationSynthetic resin layered productsPolymer scienceDiluent

A polymerization process and apparatus in which olefin monomer is polymerized in a liquid diluent in a loop reactor having a relatively smooth inner wall. Another aspect of the invention includes a first polymerization step in which at least one olefin monomer is polymerized in a liquid diluent in a loop reactor to produce a first product fluid slurry comprising liquid diluent and solid olefin polymer particles having a relatively low melt index. A second polymerization step is then provided in which at least one olefin monomer is polymerized in a liquid diluent in the same loop reactor to produce a fluid slurry comprising liquid diluent and solid olefin polymer particles having a relatively high melt index.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Coupling agents for natural fiber-filled polyolefins

InactiveUS20070208110A1Increased durabilityLow water absorptionVegetal fibresPolyolefinPolymer science

The invention is a coupling agent, which is made from a polyolefin composition and is for wetting a cellulosic fiber. The coupling agent desirably includes a polyolefin resin having a melt flow index at 190° C. and 2.16 kg of about 0.5 to 100 (g / 10 min). The polyolefin resin is combined with 1.6 to 4.0 weight percent maleic anhydride, and the composition has less than 1,500 ppm of free maleic anhydride. The coupling agent has a yellowness index of 20 to 70. A cellulosic composite can be made from the coupling agent by combining the coupling agent with cellulosic fiber and at least one thermoplastic polymer.

Owner:CHEMTURA CORP

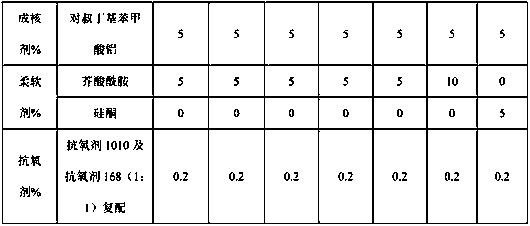

Electret master batch for melt-blown non-woven fabric for low-resistance mask and preparation method of electret master batch

ActiveCN111484678ALow breathing resistanceImprove filtration efficiencyNon-woven fabricsPolymer scienceMelt flow index

The invention discloses electret master batch for melt-blown non-woven fabric for a low-resistance mask and a preparation method of the electret master batch. The electret master batch for the melt-blown non-woven fabric for the low-resistance mask is prepared from the following components in percentage by weight: 65-85% of polypropylene resin; 1-3% of electret powder; 5-15% of a dispersant; 3-10%of a nucleating agent; 3-10% of a softening agent; 0.05%-0.5% of a processing aid; wherein the softening agent is erucyl amide; the polypropylene resin is homo-polypropylene and / or co-polypropylene,and the melt index MFI of the polypropylene resin is 230 DEG C / 2.16 kg and is not lower than 1000 g / 10 min. According to the electret master batch, the softening agent, the nucleating agent and othercomponents are added, so that when the electret master batch and the ultra-high melt index polypropylene are mixed to be used for producing the melt-blown non-woven fabric for the mask, the obtained melt-blown non-woven fabric for the mask can have low respiratory resistance while having high filtering efficiency, and therefore the electret master batch is particularly suitable for being used as amask material. The formula does not greatly adjust the formula of the existing electret master batch, and is easy to implement.

Owner:KINGFA SCI & TECH CO LTD +1

Polyolefin foams and methods of making the same

A non-crosslinked polyolefin foam comprises a plastics component and a blowing agent. The plastics component comprises a first constituent and a second constituent. The first constituent is a Ziegler-Natta catalyzed linear low density polyolefin and the second constituent is a low density polyolefin in one embodiment. The Ziegler-Natta catalyzed linear low density polyolefin has a polydispersity of less than 10 and a melt flow index less than 10 g / 10 minutes. The second constituent may be a polypropylene.

Owner:PREGIS INNOVATIVE PACKAGING

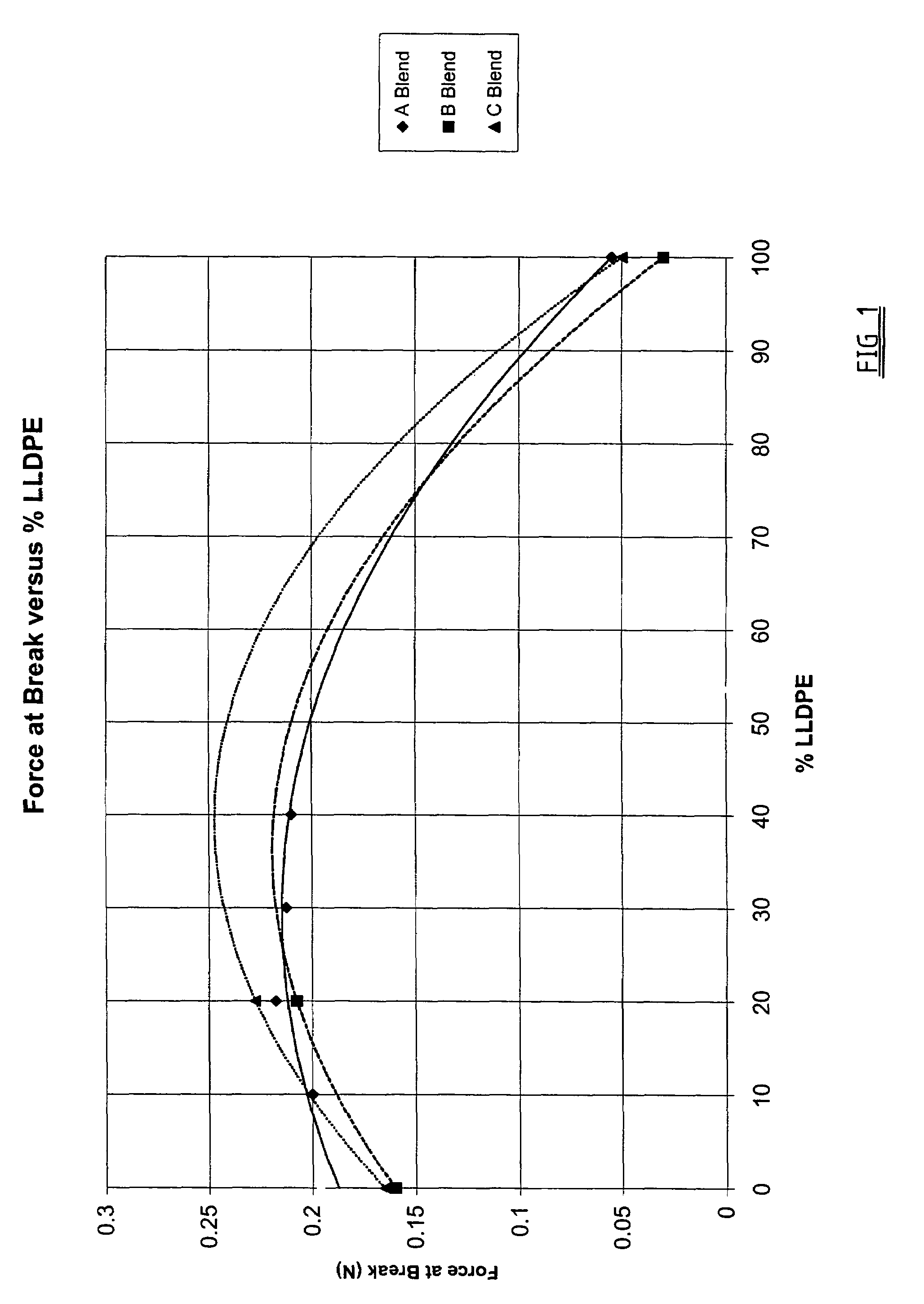

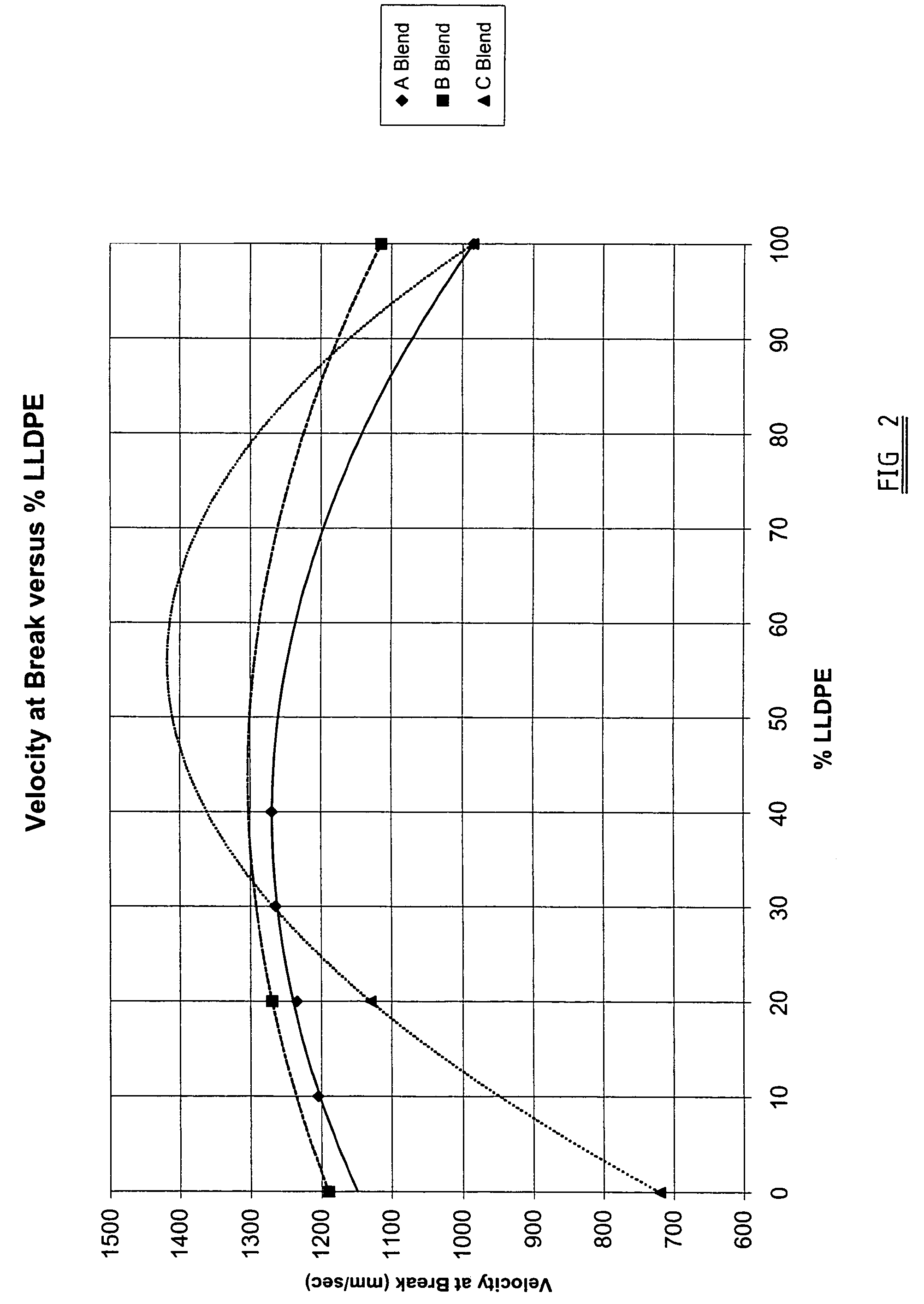

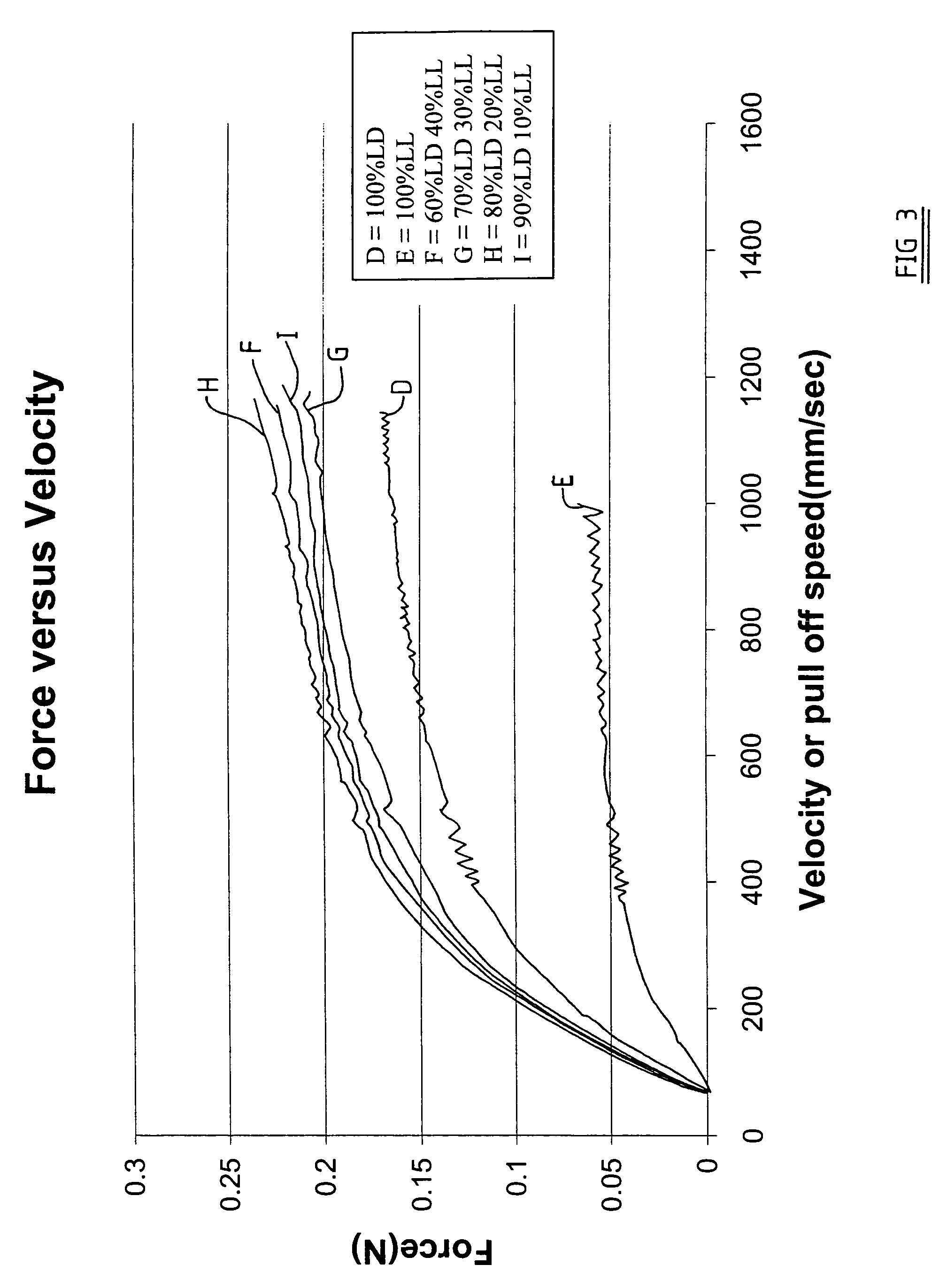

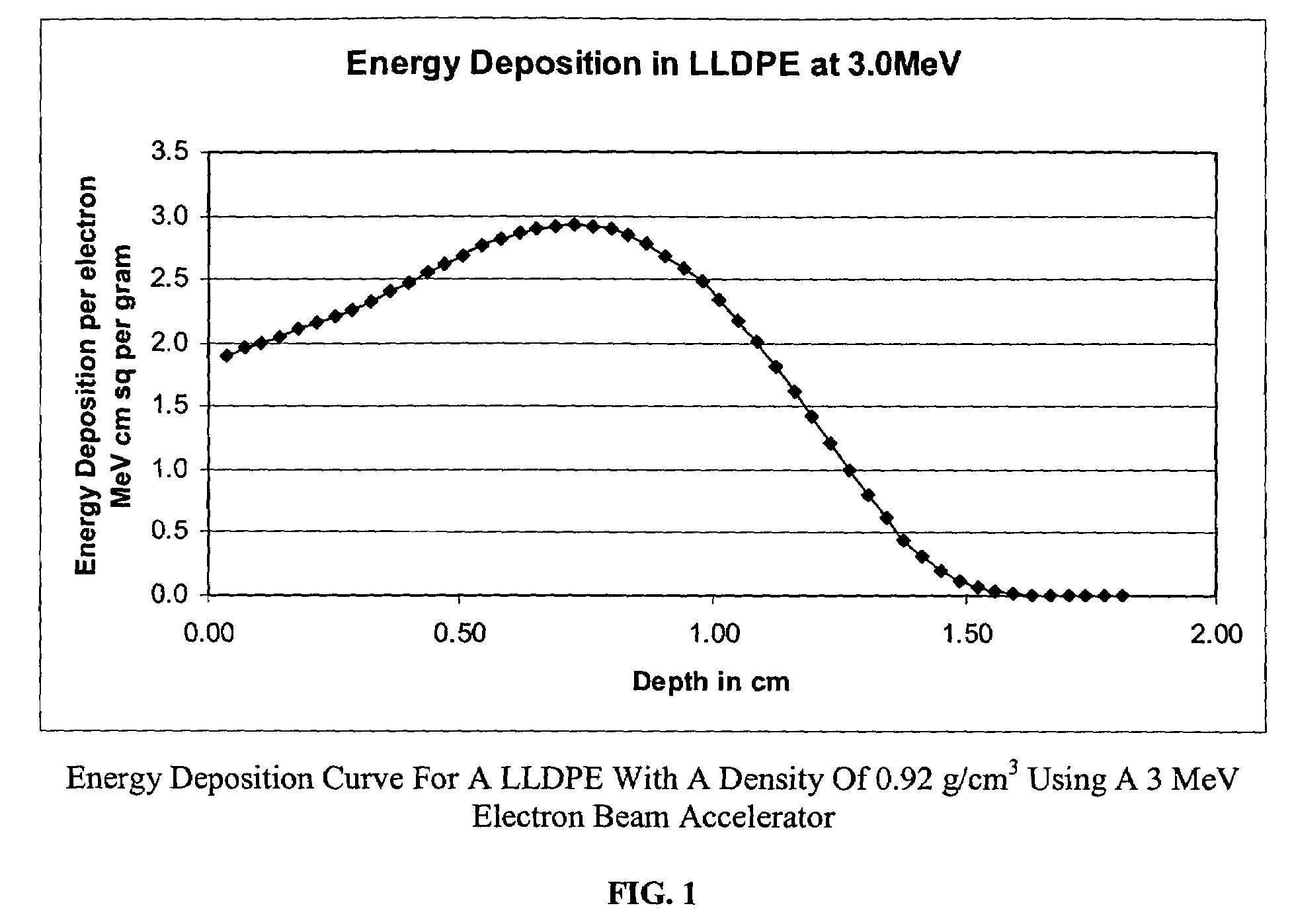

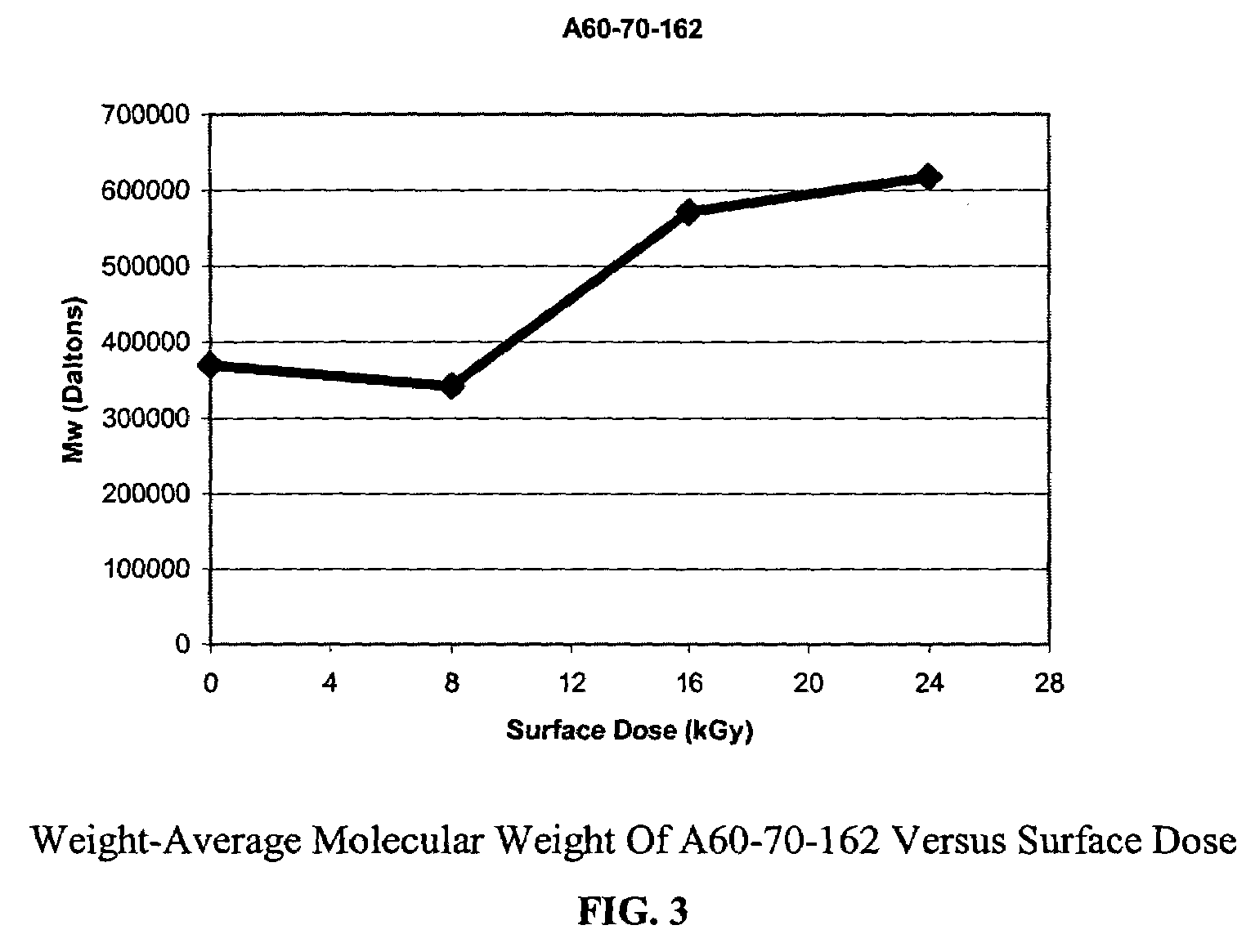

Radiation treated ethylene polymers and articles made from said polymers

InactiveUS7094472B2Improve mechanical propertiesHigh strengthSynthetic resin layered productsGranular deliveryPolymer scienceMelt flow index

Owner:GAMMATRON +1

Superhigh melt index polypropene and preparing process thereof

Owner:DONGHUA UNIV

Low modulus and autoclavable monolayer medical tubing

InactiveUS6303200B1Minimal dust adherenceLow setDiagnosticsLayered productsPolymer scienceMelt flow index

A steam sterilizable monolayer medical tubing comprising a blend of a melt strength enhancing agent of a homopolymer or copolymer of polypropylene having free-end long chain branches of propylene units, a melt flow index of greater than 10 and in an amount of 1-10% by weight and a second component selected from the group of (i) a selectively hydrogenated block copolymer of a vinyl aromatic hydrocarbon and a conjugated diene and (ii) a selectively hydrogenated block copolymer of a vinyl aromatic hydrocarbon and a conjugated diene to which has been grafted, an alpha, beta-olenfically unsaturated monocarboxylic or dicarboxylic acid reagent.

Owner:BAXTER INT INC

Acrylic resin with high toughness

The invention discloses acrylic resin with high toughness, which comprises the following components according to the weight portion: 50-75 of acrylic resin, 5-35 of polyethylene resin, 5-35 of compatilizer, 0.2-1 of processing materials, 4-15 of filling agent and 0.3-1 of dispersing agent, wherein the acrylic resin is one or the composition of more than two of isotactic PP, syndiotactic PP, block co-polymerized polypropylene or random co-polymerized polypropylene, and melting flow index of the acrylic resin is (0.4-30)g / 10min. The invention aims at overcoming the defects of the prior art, and providing the acrylic resin with rich source, low price, high elongation at break, strong temperature toleration, high softening point, excellent impact property, fatigue and bending resisting properties and wide application.

Owner:广东智汇赛特新材料有限公司

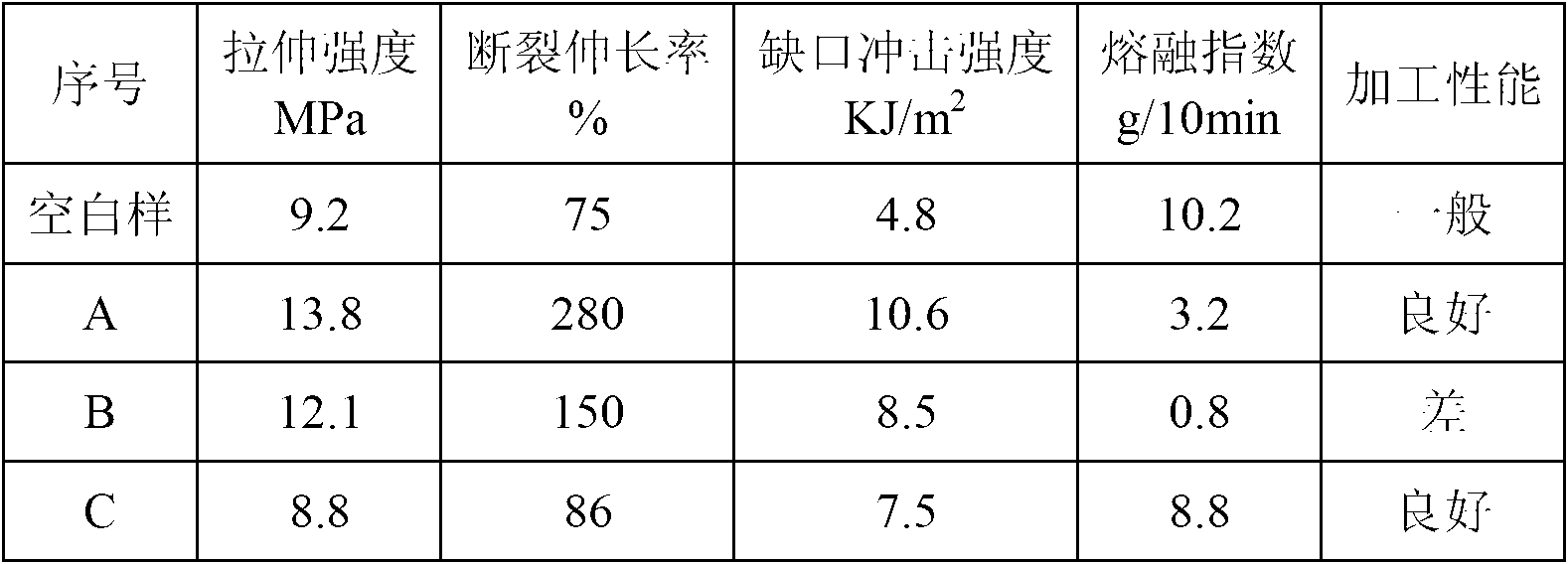

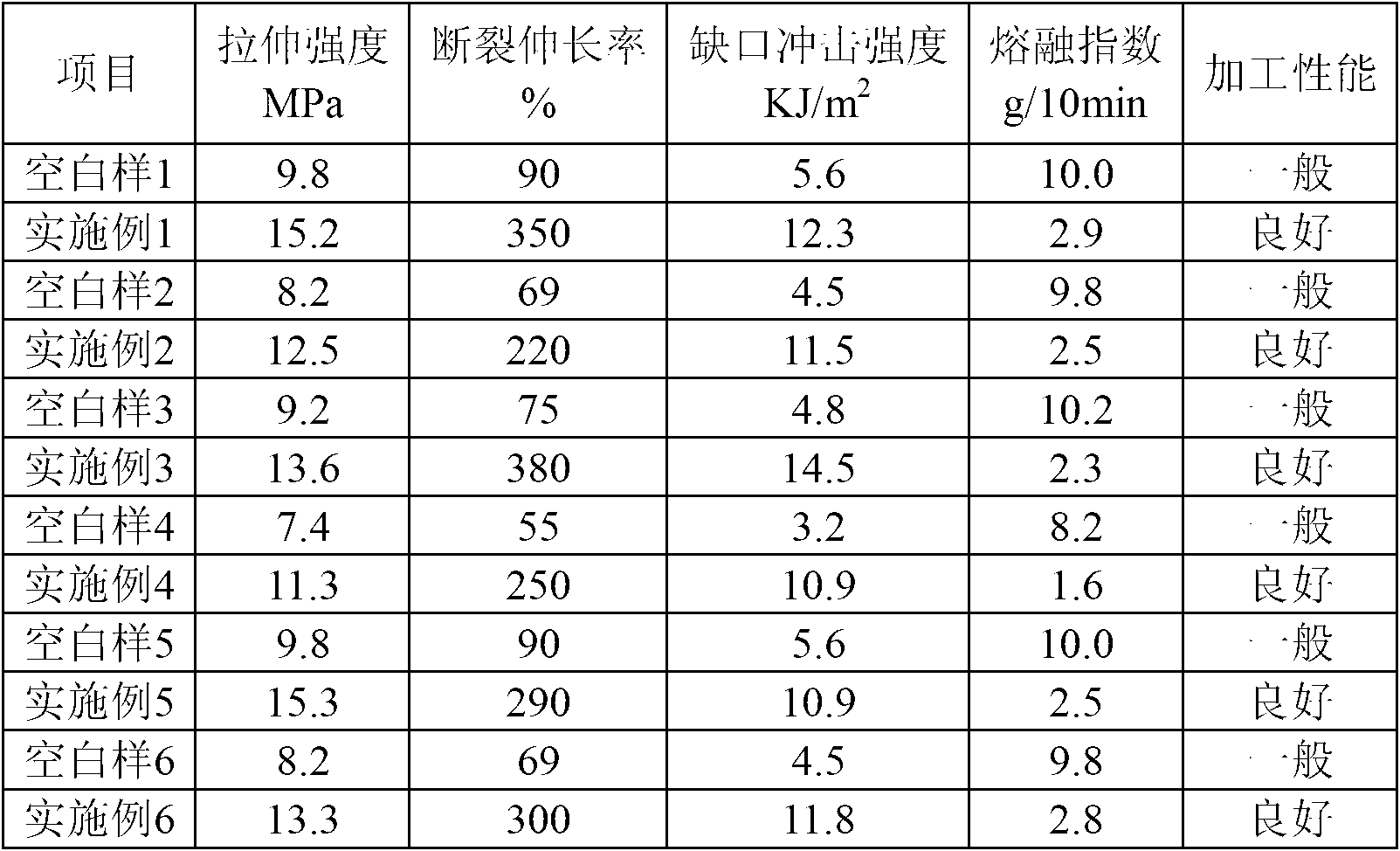

Enhanced toughening recycled polyethylene material and preparation method thereof

The invention relates to an enhanced toughening recycled polyethylene material. The enhanced toughening recycled polyethylene material is characterized by comprising, by mass, recycled polyethylene 100 parts, crosslinking masterbatch 1part to 5 parts, flexibilizer 0part to 3 parts, antioxygen 0.2 part to 1.5 parts, and processing agent 0.1 part to 0.5 part, wherein the crosslinking masterbatch is ethylene-vinyl acetate copolymer with a substrate as ethylene, a cross-linking agent is dicumyl peroxide and the like, an assistant cross-linking agent is melamine three allyl ester and the like, on the basis of total mass of the crosslinking masterbatch, by mass, a base body is 95%-98%, the cross-linking agent is 2%-5%, and the assistant cross-linking agent is 0%-2%. The tensile strength of the enhanced toughening recycled polyethylene material is 11.3-15.3MPa, the rupture elongation ratio is 220%-380%, the notch impact strength is 10.9-14.5KJ / m2, the melt index is 1.6g-2.9g / 10min, and the processability is good. The invention further discloses and a preparation method of the enhanced toughening recycled polyethylene material.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

Highly neutralized acid polymer compositions having a low moisture vapor transmission rate and their use in golf balls

The present invention is directed to a golf ball having at least one layer formed from a moisture resistant composition having a moisture vapor transmission rate of 12.5 g·mil / 100 in2 / day or less, a melt flow index of 1.0 g / 10 min or higher, and comprising a highly neutralized acid polymer. Golf balls of the present invention include one-piece, two-piece, multi-layer, and wound golf balls. The composition may be present in any one or more of a core layer, a cover layer, or an intermediate layer.

Owner:ACUSHNET CO

Biodegradable polylactic acid for use in nonwoven webs

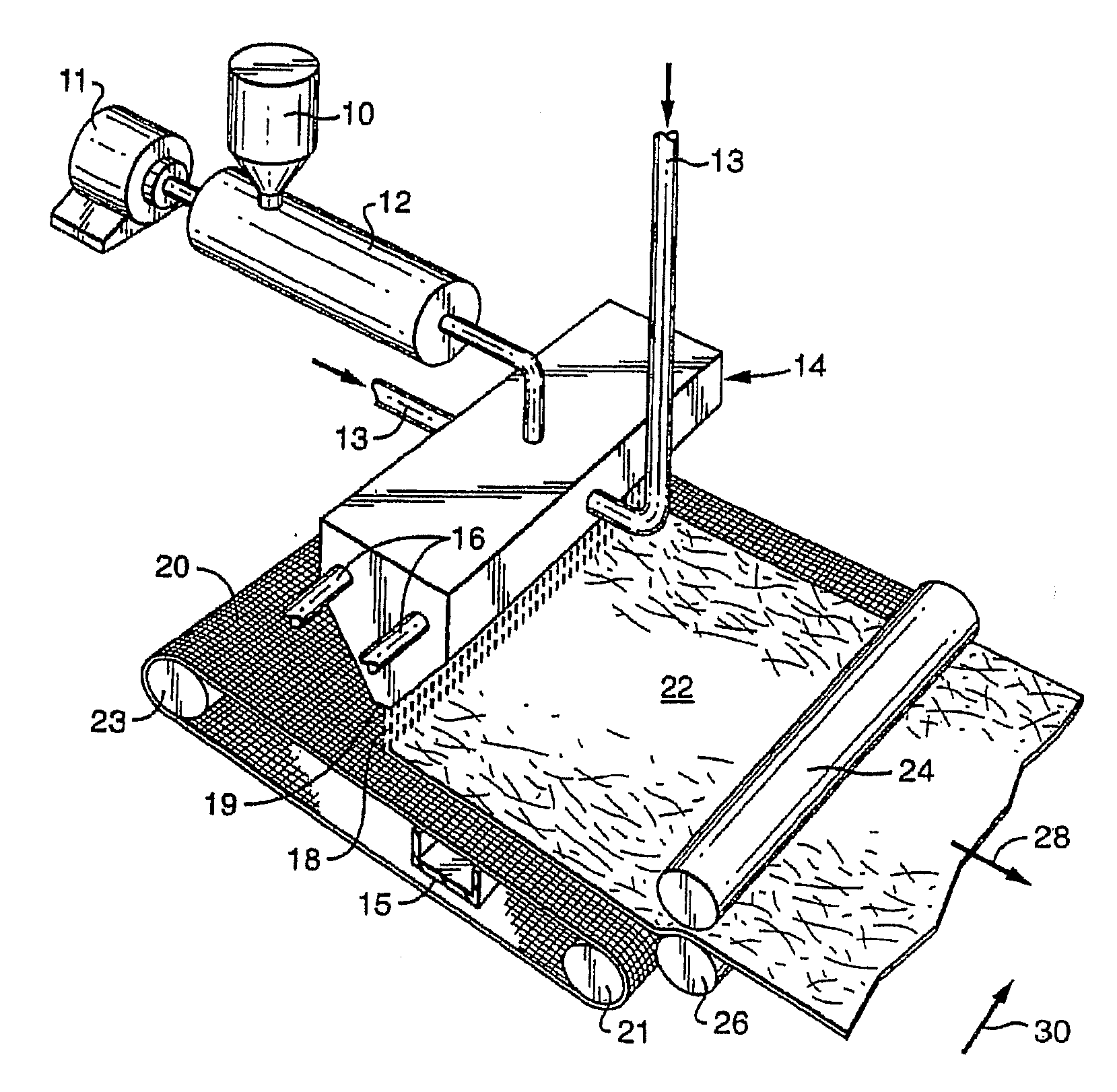

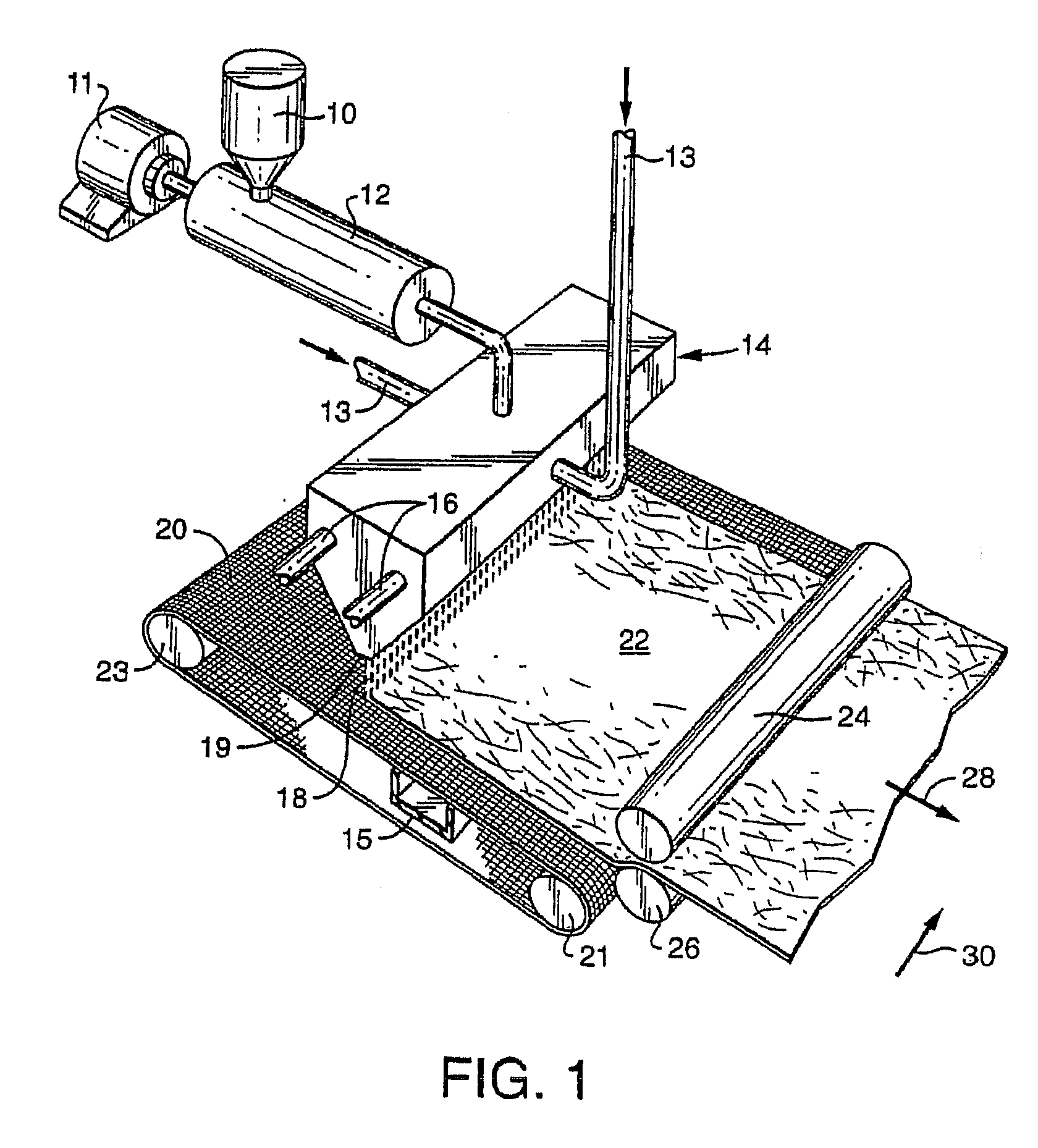

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. In one embodiment, for example, a polylactic acid is melt blended with an alcohol to initiate an alcoholysis reaction that results in a polylactic acid having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and polymer concentrations, catalysts, temperature, etc.), a modified polylactic acid may be achieved that has a molecular weight lower than the starting polylactic acid. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for producing ultrafine fiber and artificial leather

InactiveUS7025915B2Fastness of wet abrasionExcellent silk-like glossPattern makingLayered productsSolubilityPolymer dissolution

A method for producing an artificial leather includes mixed spinning an island polymer and a sea polymer having a different dissolving property from that of the island polymer at a predetermined temperature, producing a non-woven substrate from the fiber obtained, immersing the non-woven substrate into a polymer, dissolving and removing the sea polymer in the non-woven substrate to obtain an artificial leather as a semi-finished product, and polishing the surface of the artificial leather to obtain an artificial leather having excellent dyeability and advanced fluff-like property. The ratio of melt flow index of the sea polymer to relative viscosity of the island polymer is about 20 to about 55, in which the relative viscosity of the island polymer is about 2.7 to about 3.5 and the weight percentage of the sea polymer relative to the sum of the sea polymer and the island polymer is about 30% to about 70%.

Owner:SAN FANG CHEM IND

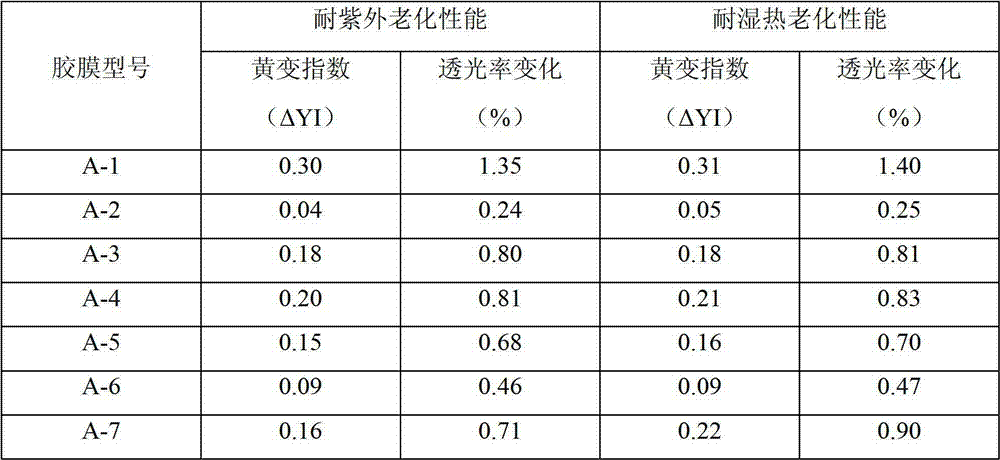

Aging-resistant glue film for packaging solar cell and preparation method for glue film

ActiveCN102876246AImprove aging resistanceImprove anti-yellowing effectNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerMelt flow index

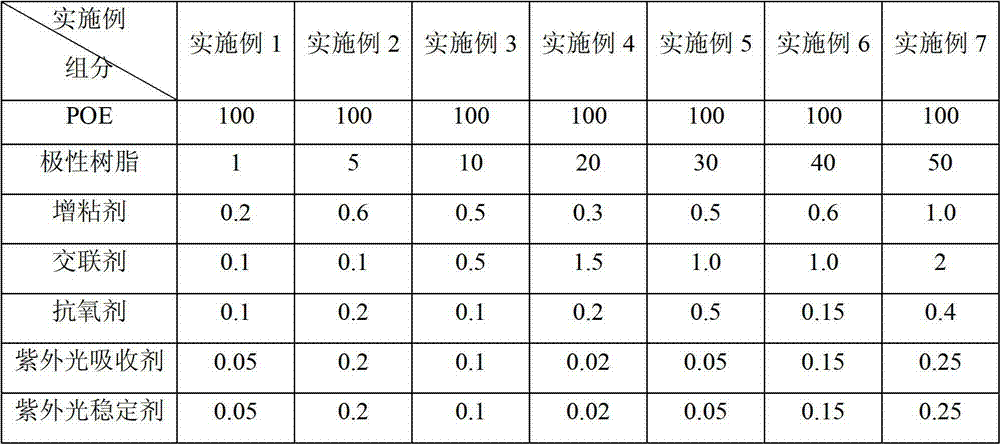

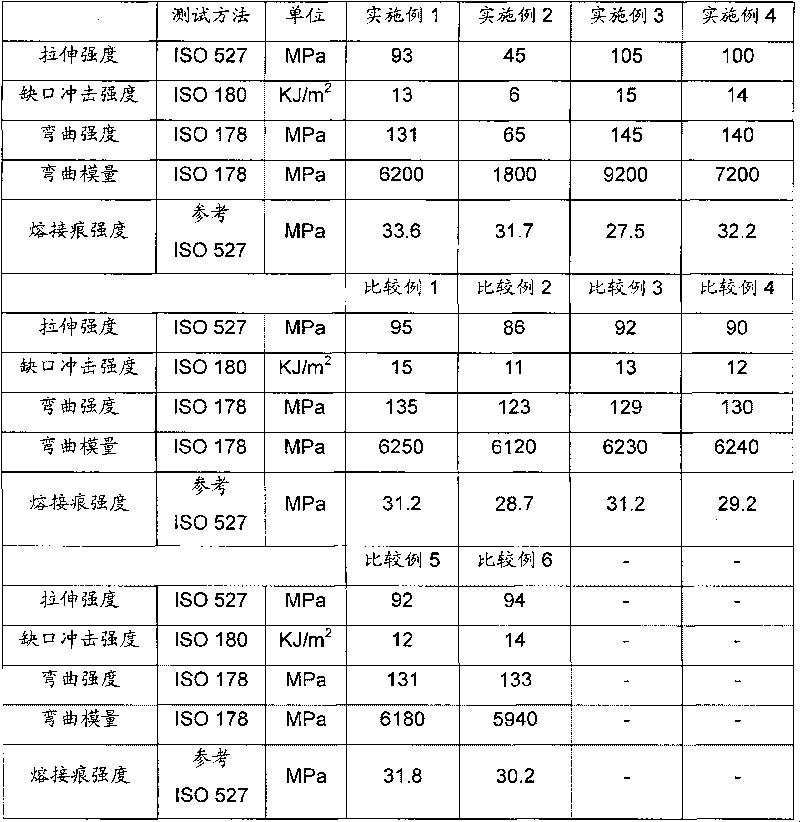

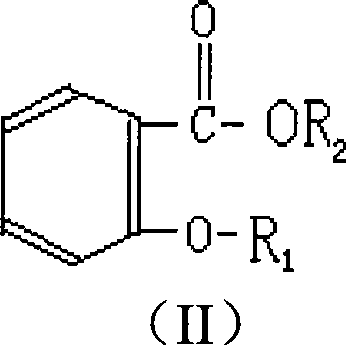

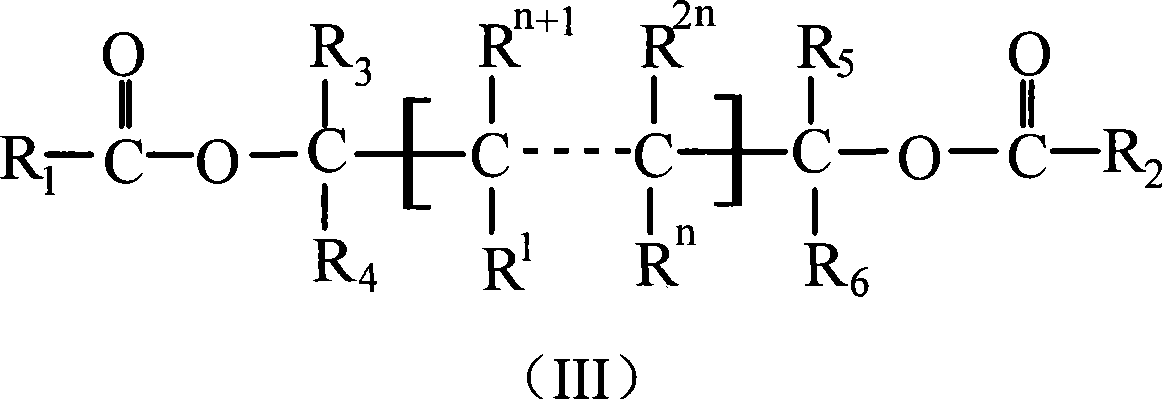

The invention relates to an aging-resistant glue film for packaging a solar cell and a preparation method for the glue film. The glue film is prepared from the following raw materials in part by mass: 100 parts of polyethylene octene elastomer (POE), 1 to 50 parts of polarity resin, 0.1 to 1.0 part of tackifier, 0.1 to 2 parts of cross-linking agent, 0.1 to 0.5 part of antioxidant, 0.05 to 0.25 part of ultraviolet absorber, and 0.05 to 0.25 part of ultraviolet stabilizer, wherein the melt flow index of POE is 0.5 to 30g / 10min, and the light transmittance of POE is more than or equal to 80 percent; the preparation method comprises the following steps of: uniformly mixing raw materials, putting mixed raw materials into an extruder, and blending; performing tape casting on the obtained extrudate, and rolling to obtain a film; cooling and drawing for shaping; and winding to obtain the glue film. The glue film for packaging the solar cell is aging-resistant, and cannot be yellowed easily; by using the glue film, the service life of the solar cell can be prolonged; the preparation method is simple; the glue film is low in cost and can be produced on large scale; and the production efficiency is high.

Owner:宁波威克丽特功能塑料有限公司

Very low melt viscosity resin

InactiveUS6855777B2Improve homogeneityImprove consistencyGranular deliveryPolymer sciencePolymer resin

A process is provided for the production of a very low melt viscosity (high melt flow index) polymer resin, suitable for use in meltblown processing. According to the process of the current invention, a high melt viscosity (low melt flow index) resin is subjected to post-reactor molecular weight alteration by extrusion with a chemical prodegradant. The process produces a very low melt viscosity resin that can be used in meltblown processing without further treatment to reduce the average molecular weight of the resin. Further, the very low melt viscosity resins produced according to the process of the current invention contain very little or no residual prodegradant.

Owner:SUNOCO INC (R&M)

High weld mark strength reinforced polypropylene material and preparation method thereof

The invention provides a high weld mark strength reinforced polypropylene material and a preparation method thereof. The high weld mark strength reinforced polypropylene material consists of 30 to 90 percent of polypropylene (PP) resin with a melt index range of between 0.5 and 100 g / 10min (230 DEG C, 2.16 kg), 5 to 50 percent of fiberglass treated by a surfactant, 0.5 to 5 percent of mineral filler treated by a surfactant, 0.5 to 10 percent of interface modifier and 0.5 to 5 percent of other additives. As the mineral filler, the interface modifier and the fiberglass are added into the polypropylene material and strong interface combination is formed between the interface modifier, the fiberglass and the polypropylene, the viscosity of disperse phase is improved and the orientation of a polypropylene molecular chain and fiberglass along the vertical flowing direction is blocked, so that the strength of a weld mark of the polypropylene material is improved.

Owner:KINGFA SCI & TECH CO LTD +1

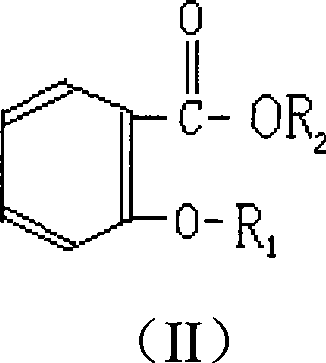

Catalyst component for olefinic polymerization , and catalyst thereof

The invention relates to a catalyst component used in olefin polymerization, which has a general formula as follows: MgX2-mROH-nE-pH2O, and is a product of contact between magnesium halide adduct and at least one titanium compound, wherein, X is chlorine or bromine, R is C1-C12 alkyl, C3-C10 naphthenic base or C6-C10 aryl, E is o-alkoxyphenyl acid ester compound, m is 1 to 5, n is 0.005 to 1.0, and p is 0 to 0.8. When the catalyst component is used in olefin polymerization, especially in propylene polymerization, not only the activity of polymerization is higher, the obtained polymer particle is shaped well, and the fine powder is less, but also the high melt index polymer obtained under high hydrogen concentration has high isotacticity, so the catalyst component is very applicable to the requirements of industrial production of polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly viscous silicone compositions for producing elastomeric molded parts by means of ballistic generative methods

ActiveUS20180208797A1Additive manufacturing apparatus3D object support structuresPolymer scienceMelt flow index

Curable silicone rubber compositions of high viscosity can be ballistically printed if the melt flow index is within a defined shear thinning range and the viscosity is also within a defined range.

Owner:WACKER CHEM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com