Patents

Literature

397results about How to "Excellent film performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

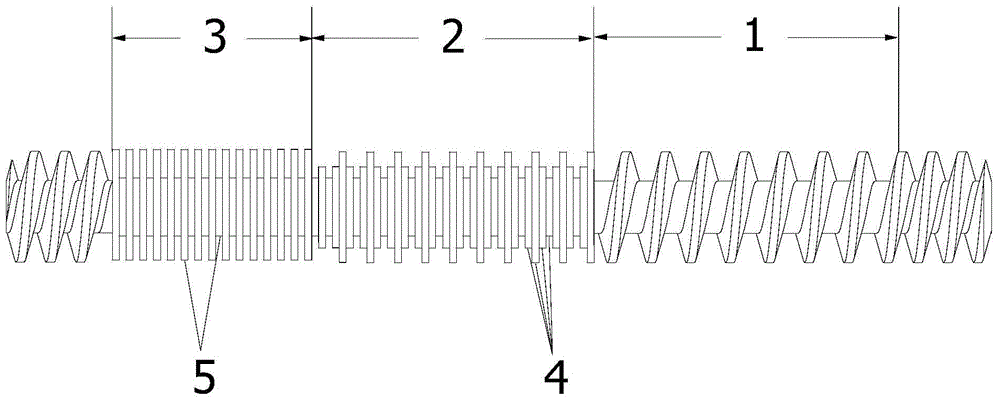

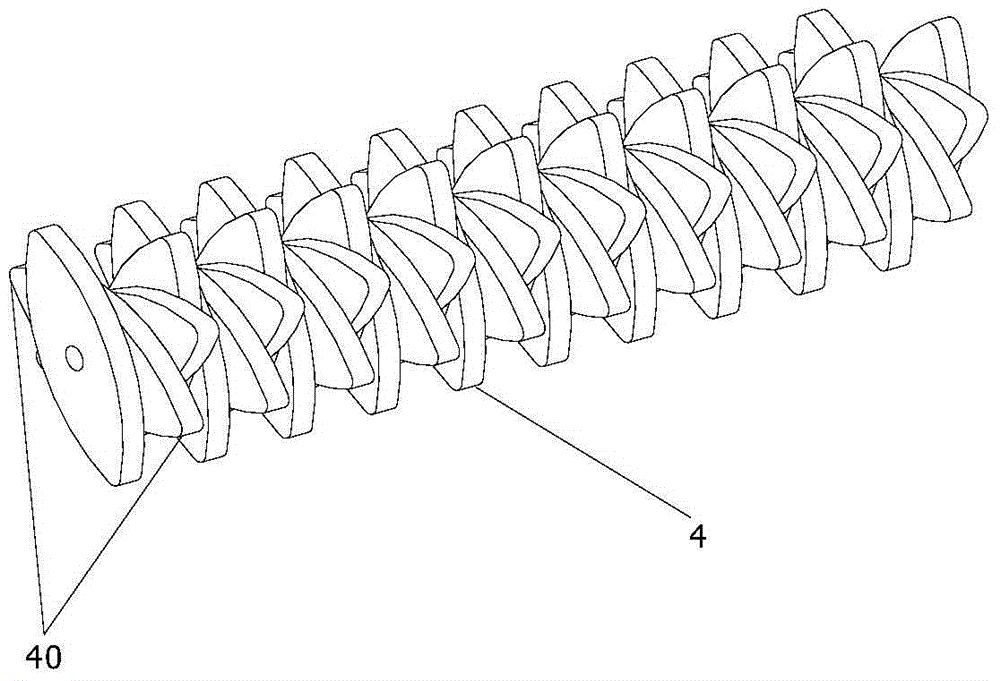

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

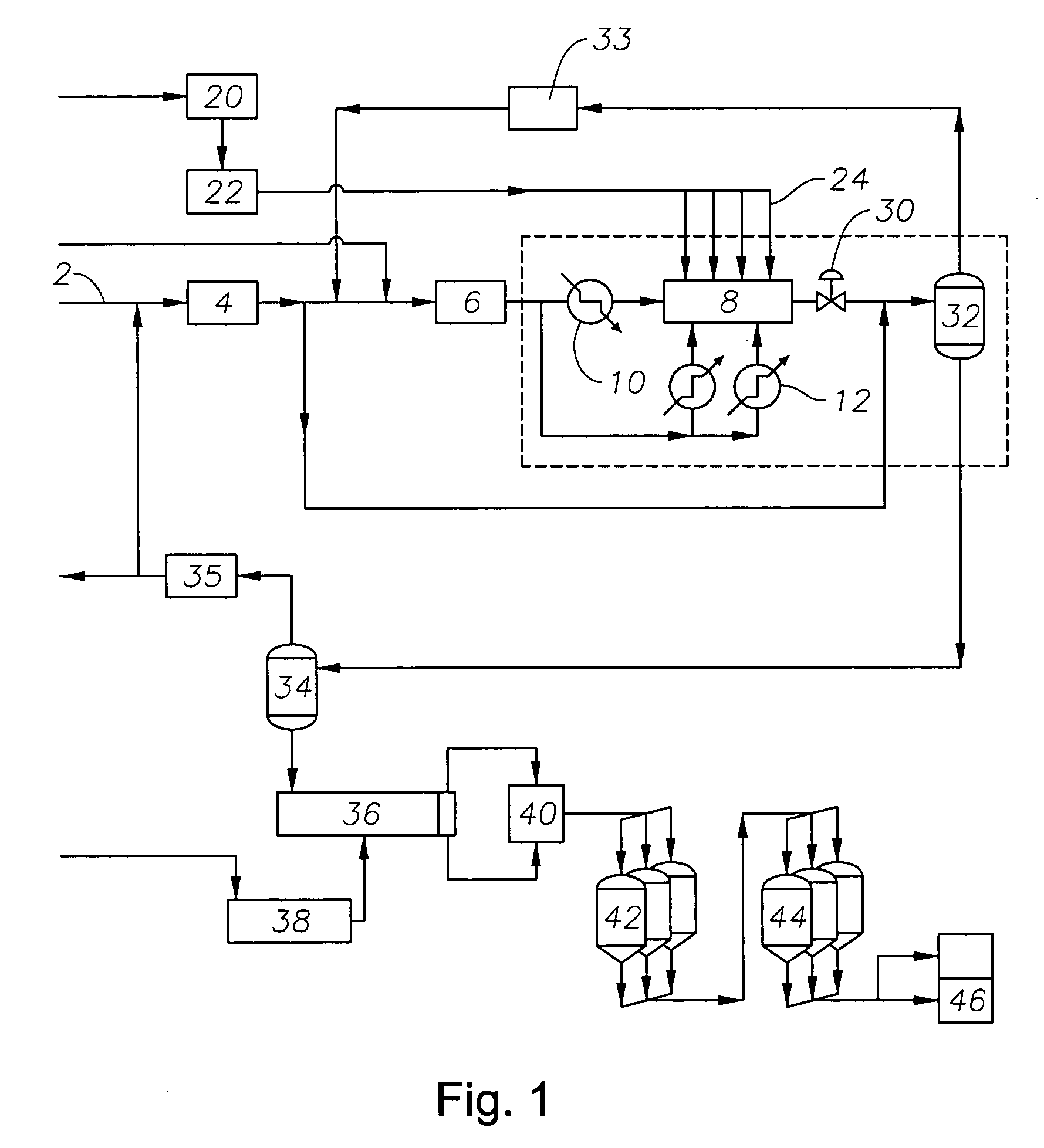

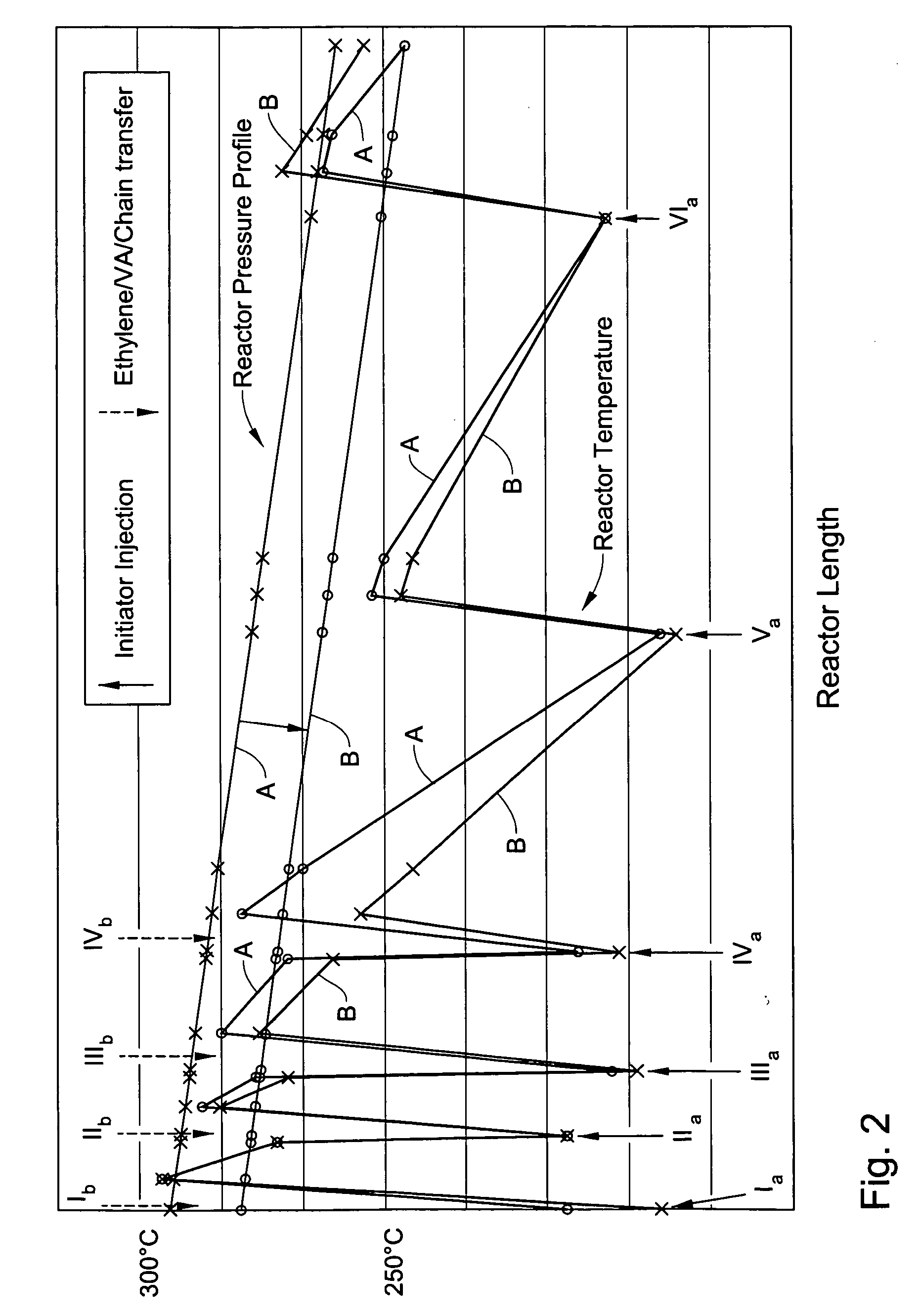

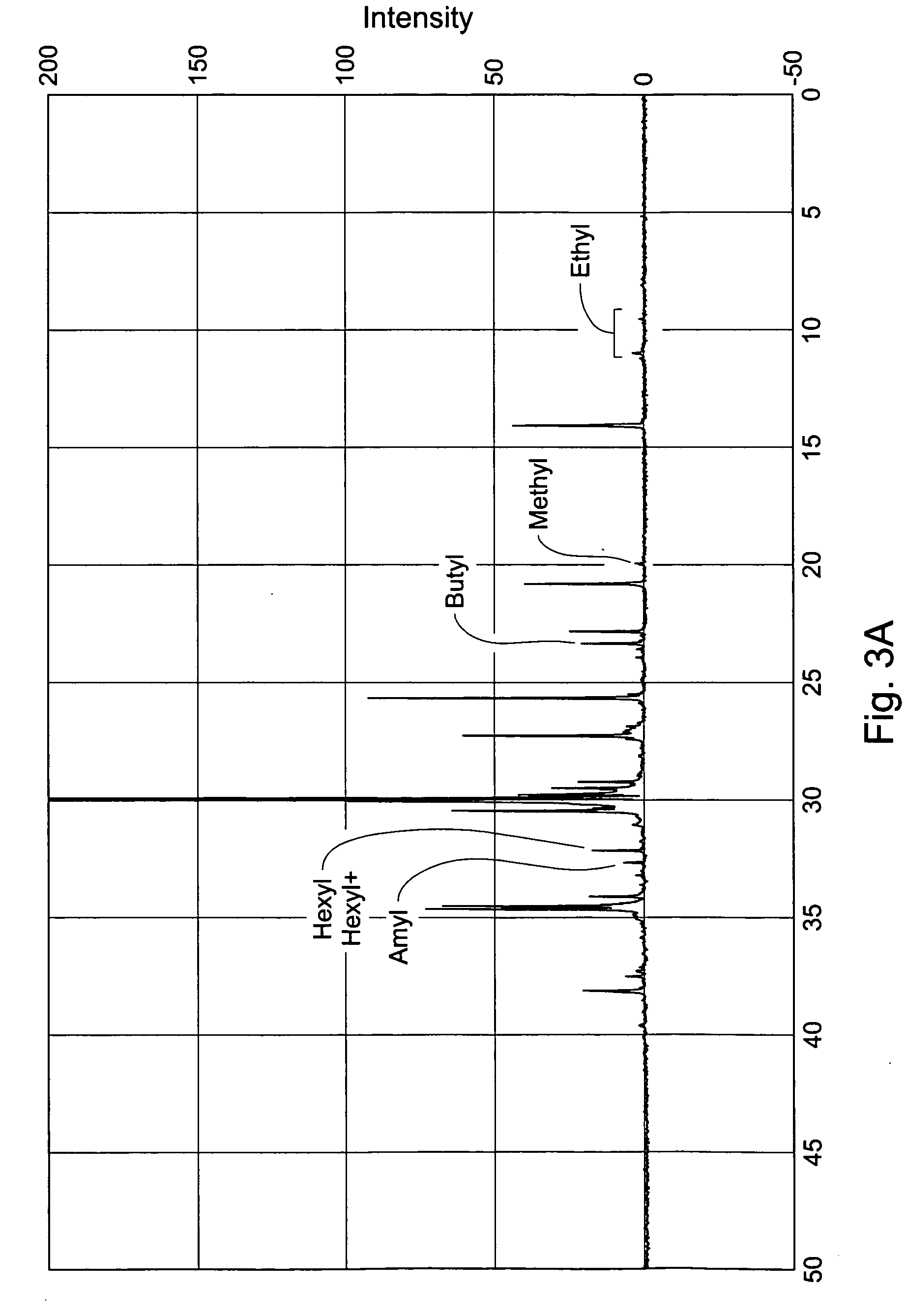

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

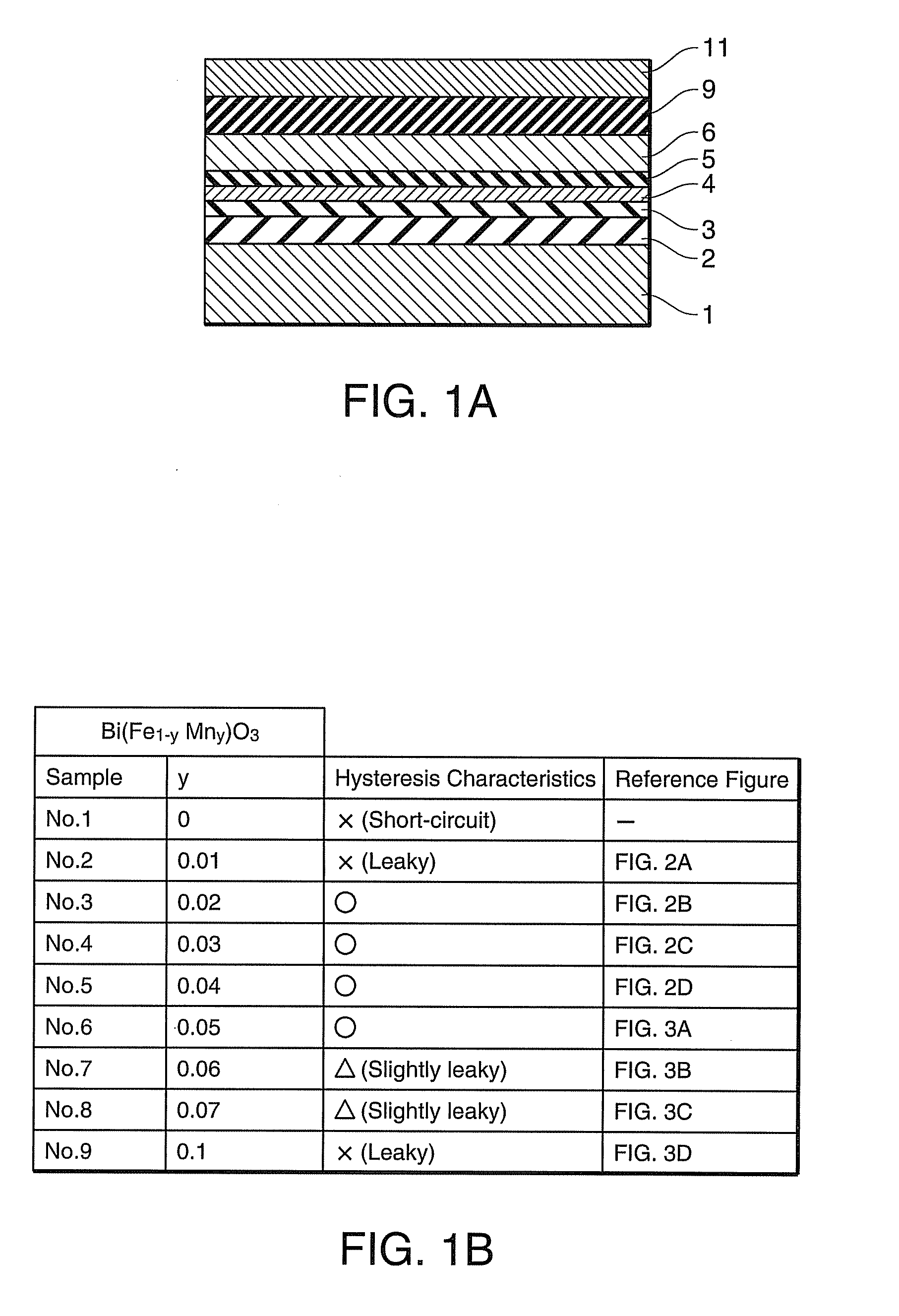

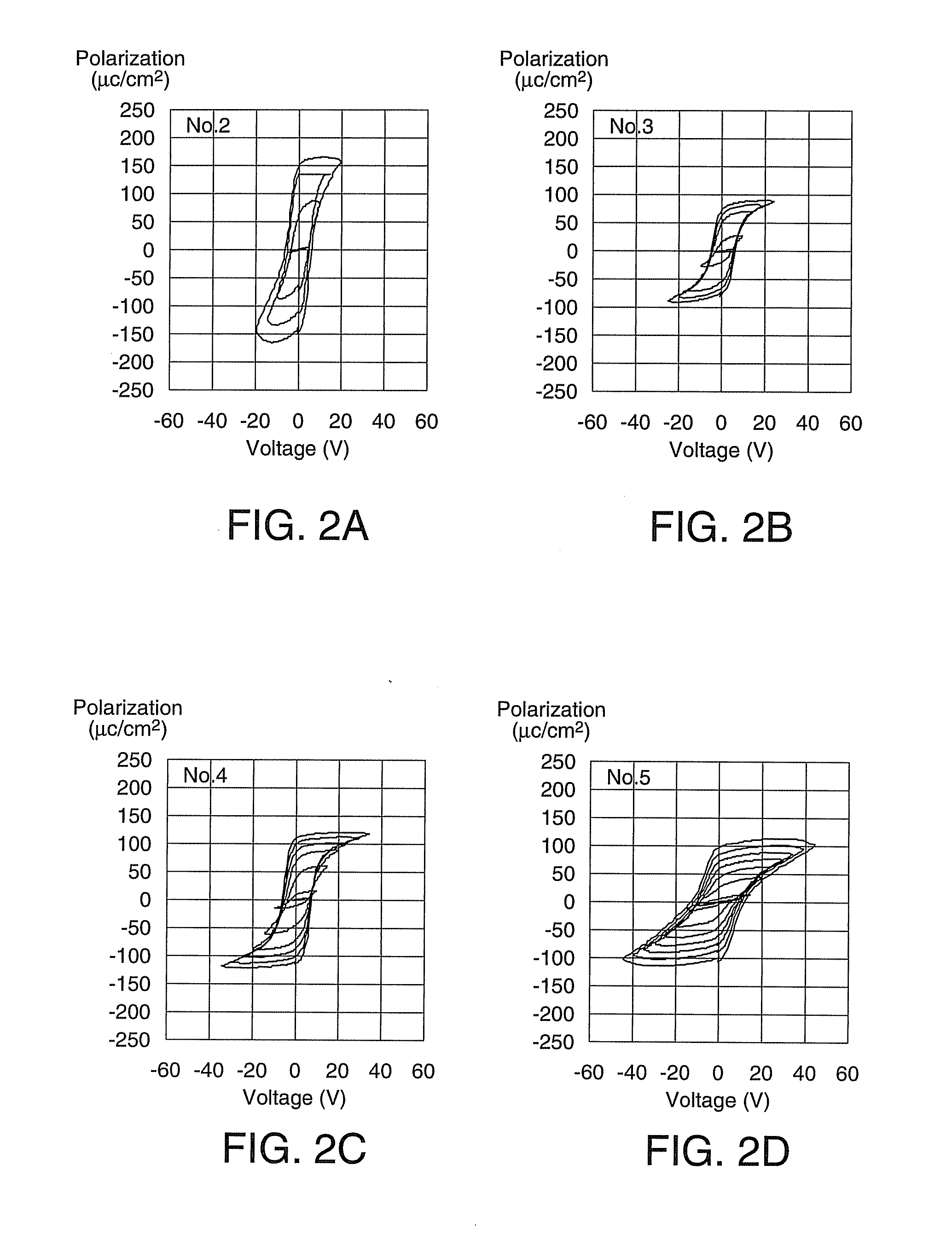

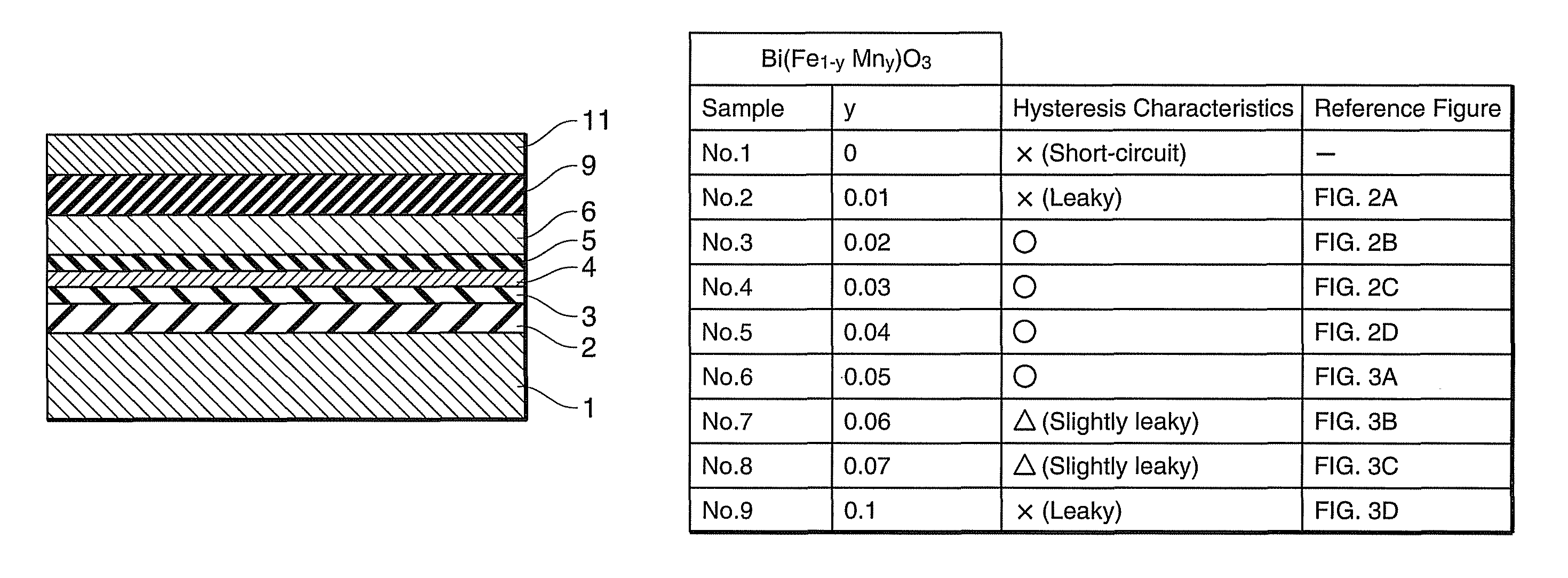

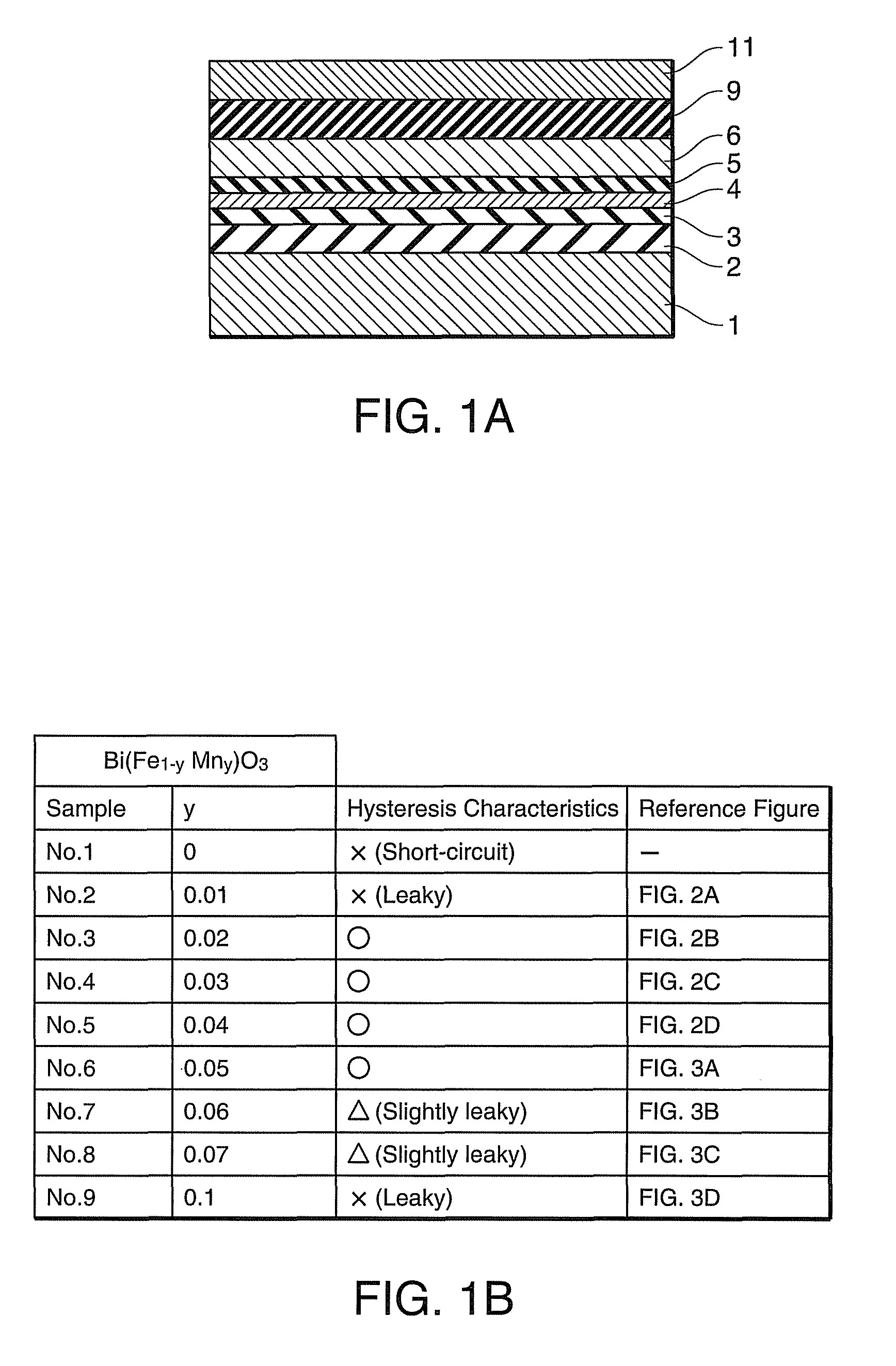

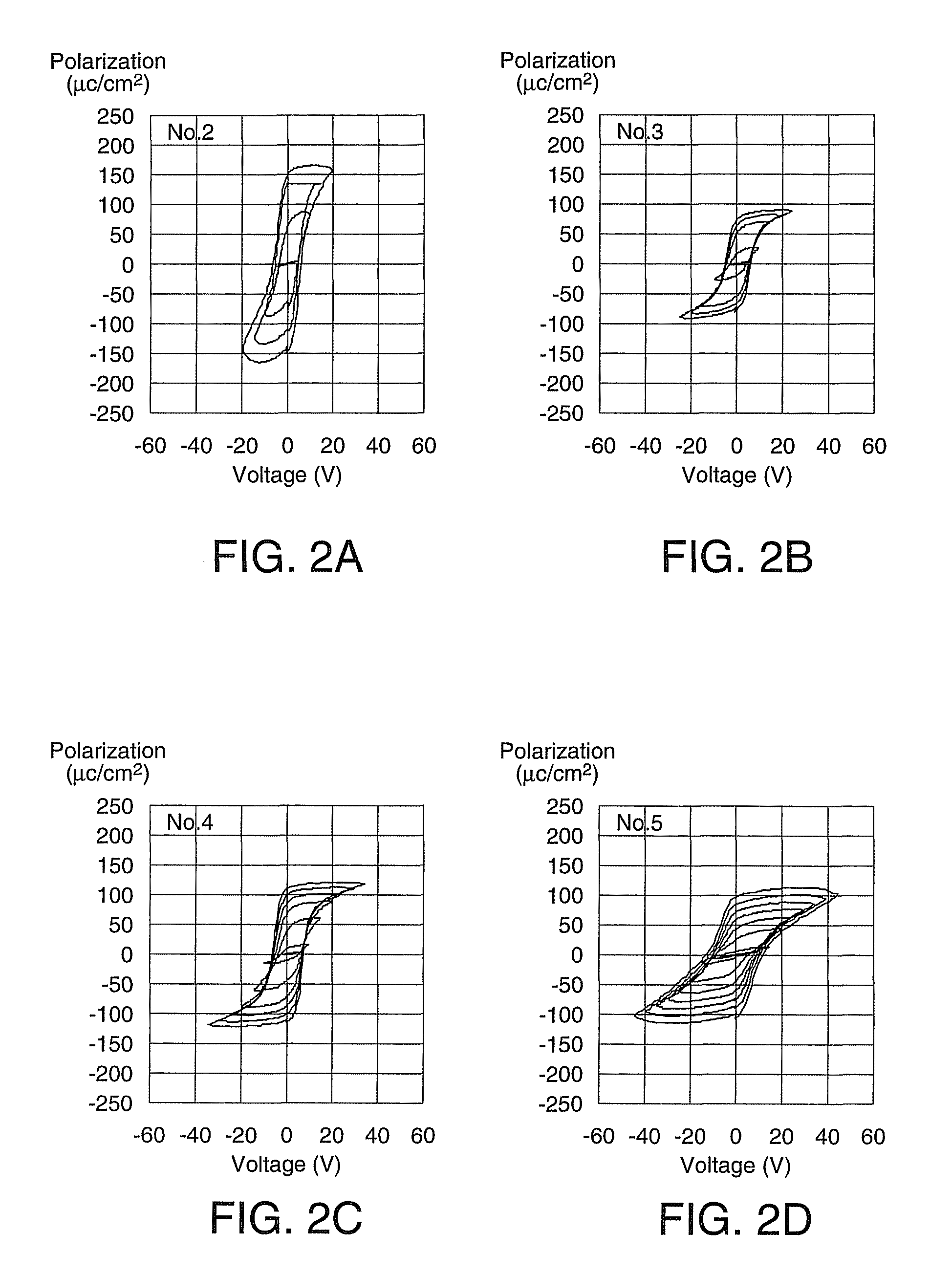

Piezoelectric material and piezoelectric element

ActiveUS20090243438A1Large piezoelectric constantHigh Curie temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesComposite materialSpontaneous polarization

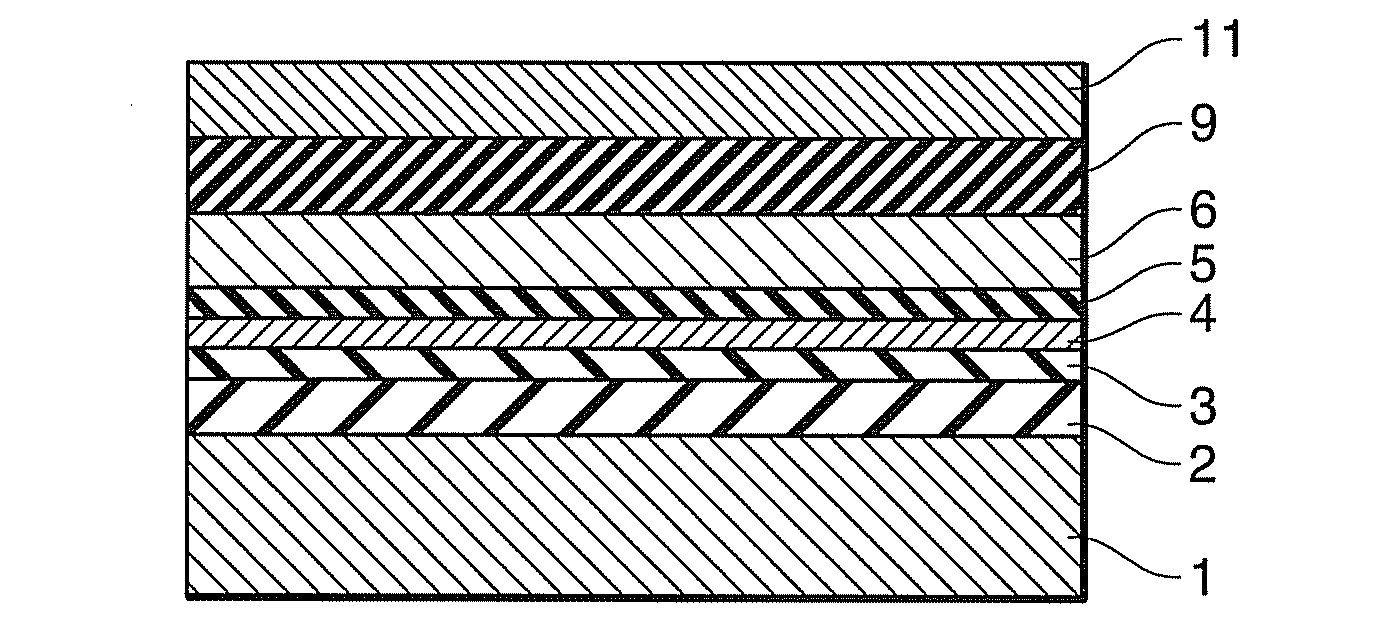

A piezoelectric element includes a first electrode, a piezoelectric film disposed on the first electrode, and a second electrode disposed on the piezoelectric film. The piezoelectric film is composed of piezoelectric material that is lead free and formed by mixing 100(1−x)% of material A having a spontaneous polarization of 0.5 C / m2 or greater at 25° C. and 100 x % of material B having piezoelectric characteristics and a dielectric constant of 1000 or greater at 25° C., wherein (1−x)Tc(A)+xTc(B)≧300° C., where Tc(A) is the Curie temperature of the material A and Tc(B) is the Curie temperature of the material B.

Owner:SEIKO EPSON CORP

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

Thin spray powder coating and preparation method thereof

ActiveCN104861840AReduce dosageStrong charged particlesPolyurea/polyurethane coatingsPowdery paintsPhenolEnergy consumption

The invention discloses a thin spray powder coating and a preparation method thereof. The thin spray powder coating is mainly prepared from the following raw materials by weight percent: 50-75% of resin, 3-25% of curing agent, 1-12.5% of pigment, 0.3-20% of filler and 0.1-10% of addition agent; the curing agent comprises one or more of an epoxy curing agent, a polyisocyanates curing agent, a polyamine curing agent and a phenols curing agent; the addition agent comprises a flatting agent, a sensitizer and benzoin. The method for preparing the thin spray powder coating comprises the following steps: adding the flatting agent in the resin production process to obtain a modified resin raw material; mixing the modified resin raw material, the curing agent, the pigment, the filler and the other addition agent, and squeezing in a double-screw extruder to obtain the extrudate; and tabletting, cooling, milling and sieving the extrudate to obtain the powder coating. By adopting the thin spray powder coating and the preparation method thereof, the spraying thickness is small, the energy consumption is reduced and the cost is reduced.

Owner:BAZHOU JINCHANG ENVIRONMENTAL PROTECTION MATERIALS CO LTD

Aqueous two-package type clear coating composition and process for the formation of multilayer finish coating film

ActiveUS20090274846A1Remarkable effectExcellent film performancePretreated surfacesPolyurea/polyurethane coatingsAcrylic resinGlass transition

The present invention provides an aqueous two-package type clear coating composition comprising: (A) an aqueous dispersion of a hydroxyl group- and acid group-containing acrylic resin having a hydroxyl value of 30 to 200 mg KOH / g, an acid value of 5 to 50 mg KOH / g, a weight average molecular weight of 3,000 to 30,000, and a glass transition temperature of −30 to +40° C. obtained by radical polymerization of 10 to 50 mass % of a secondary hydroxyl group-containing monomer (a) and 50 to 90 mass % of at least one other unsaturated monomer (b); and (B) a polyisocyanate curing agent obtained by mixing (c) a polyisocyanate compound and (d) a compound containing an anionic functional group, a polyoxyethylene group, and a hydrocarbon group, and a process for forming a multilayer topcoat film using the same.

Owner:KANSAI PAINT CO LTD

Method for preparing acrylic aqueous dispersion with hydroxyl through two-step polymerization

The invention provides a method for preparing acrylic aqueous dispersions with hydroxyl through two-step polymerization and the method comprises the synthesis of hydroxy acrylic resin, the removal ofsolvent, the neutralization and salt-formation and the deionized water dispersion, wherein the synthesis of hydroxy acrylic resin adopts two-step feeding synthesis method instead of one-step feeding method in prior art, the composition of the first added monomer mixture is different from that of the second added monomer mixture and preferentially, the weight percent of the second added hydrophilicmonomer is higher than that of the first added monomer when feeding tends to end up. The aqueous dispersions obtained by the technical solution of the invention reduces the dosage of monomer with hydroxyl so as to increase the water resistance of coating which is formed by combining aqueous dispersions and curing agent, reduce the grain size of dispersions, lower the viscosity and increase the stability obviously.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

Normal-temperature multiple curing organic-inorganic hybridized aqueous nano polyurethane woodware coating and preparation method thereof

InactiveCN101798483ANo pollution in the processNon-flammablePolyurea/polyurethane coatingsIn situ polymerizationDouble bond

The invention discloses a normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating and a preparation method thereof. The coating mainly contains organic-inorganic hybridized aqueous nano polyurethane latex, a film-forming assistant, a defoaming and foam inhibitor, a flatting agent, a base material wetting agent, a stable dispersing agent, a thickening agent and an aqueous photo initiator, wherein the organic-inorganic hybridized aqueous nano polyurethane latex is prepared by firstly obtaining a polyurethane prepolymer by pre-polymerizing, and then adding an inorganic nano material in an organic-inorganic hybridization way by an in-situ polymerization technology, and finally grafting a photo-curing end-capping agent containing active functional groups and C-C double bonds. The normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating is obtained by adding and dispersing pigment fillings and an assistant evenly in the organic-inorganic hybridized aqueous nano polyurethane latex. The invention not only solves the pollution problem of a solvent-type VOC (Volatile Organic Compound) coating, but also solves the problem of aqueous coatings which have the defects of poor toughness and poor performances in weather resistance, aging resistance, acid resistance, alkaline resistance and solvent resistance.

Owner:SICHUAN UNIV +1

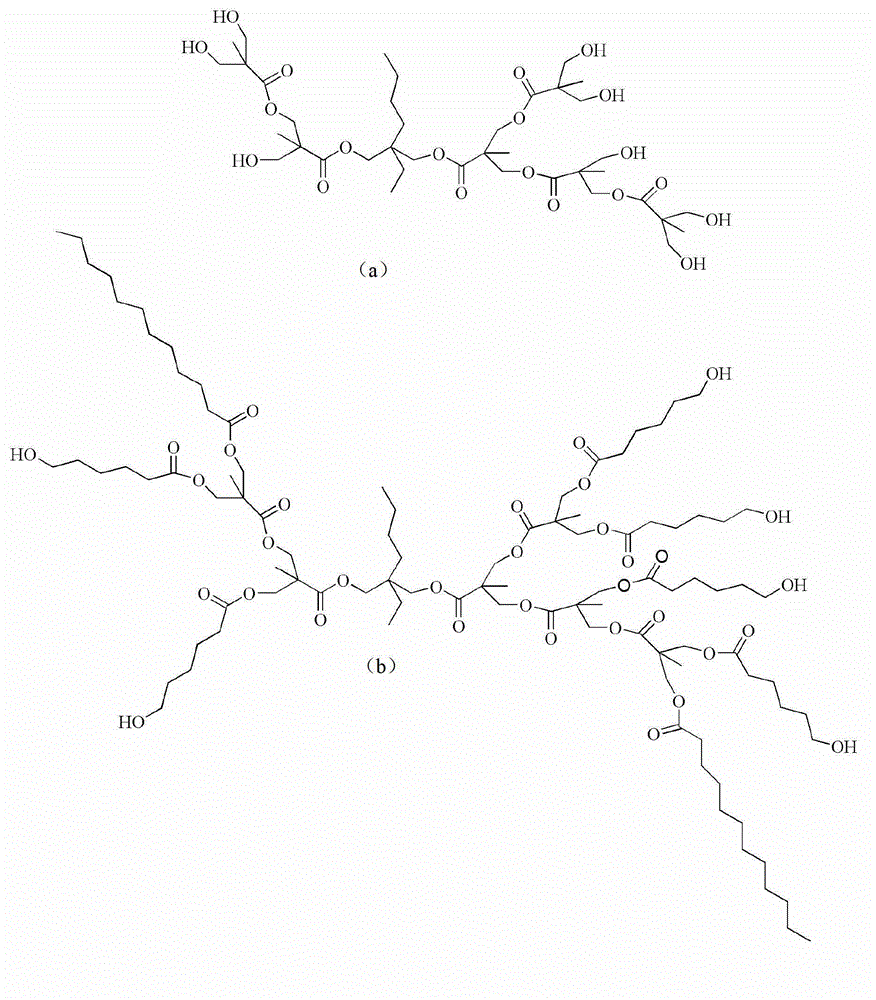

Caprolactone modified hyperbranched polyester and preparation method and application thereof

The invention discloses caprolactone modified hyperbranched polyester, and a preparation method and an application thereof. The preparation method includes mixing polyatomic alcohol with dihydroxytoluene alkyl carboxylic acid by mole part, adding acid catalysts and reflux solvents to react under N2 protection at 140-230 DEG C so as to obtain hyperbranched polyester; adding fatty acid into the hyperbranched polyester serving as the substrate, adding the acid catalysts and the reflux solvents to carry out reflux reaction under N2 protection at 140-240 DEG C until the acid value is lower than 15mgKOH / g so as to obtain the fatty acid modified hyperbranched polyester; and finally adding caprolactone and organic tin catalysts into the fatty acid modified hyperbranched polyester to react under N2 protection at 130-230 DEG C, and removing the organic solvents to obtain the caprolactone modified hyperbranched polyester. The caprolactone modified hyperbranched polyester has no defect of overhigh viscosity as the conventional hyperbranched resin, and good-performance coating films can be obtained after the caprolactone modified hyperbranched polyester is in crosslinking with the polyurethane curing agents. The preparation method can be used for preparing high-solid-content and solvent-free coatings.

Owner:SOUTH CHINA UNIV OF TECH

Sand texture type polyester/epoxy powder coating and preparation method thereof

InactiveCN103160192AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyPollution

The invention discloses a sand texture type polyester / epoxy powder coating and a preparation method thereof. The sand texture type polyester / epoxy powder coating comprises the following raw materials, by weight, 350-400 parts of polyester resin (P5040), 240-280 parts of epoxy resin (E-12), 100-150 parts of extinction barium sulfate, 40-60 parts of spherical silica powder, 8-12 parts of modified polyethylene wax powder, 10-15 parts of organic coated titanium dioxide, 5-10 parts of sand texture agent (SWMBX-30), 4-6 parts of benzoin, 5-8 parts of 2-phenyl imidazoline, 4-6 parts of 2-methylimidazole, 5-10 parts of ferrite yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The prepared powder coating has the advantages of being high in hardness, high in intensity, high in abrasion resistance, good in heat resistance, good in ageing resistance, short in solidifying time, environment-friendly, free of pollution and the like. The solidified coating produces a texture effect of the sand texture, the sand texture is meticulous and clear, distribution is even, visual comfort is provided for people, and combination properties of the coating are good.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Water-borne acrylic resin anticorrosive coating and preparation method thereof

InactiveCN105885690AExtended storage timeGood film performanceAnti-corrosive paintsEpoxy resin coatingsEmulsionAcrylic acid

The invention relates to a water-borne acrylic resin anticorrosive coating and a preparation method thereof, and belongs to the technical field of coatings. The water-borne acrylic resin anticorrosive coating is prepared from, by weigh , 30-55 parts of modified acrylic emulsion, 16-25 parts of water-borne epoxy resin, 10-16 parts of silica sol, 4-6 parts of aluminum triphosphate, 5-15 parts of anticorrosive pigment, 20-40 parts of pigment filler, 0.5-5 parts of additive and 10-15 parts of water. The water-borne acrylic coating has the advantage of being long in storage time, and still has the good coating property after being stored for 12 months or longer.

Owner:宋介珍

Delustering waterborne polyurethane leather finishing agent and preparation method thereof

ActiveCN105506997AImprove compactnessImprove stabilityFibre treatmentLeather surface finishingMechanical propertyRaw material

The invention provides a delustering waterborne polyurethane leather finishing agent and a preparation method thereof. The delustering waterborne polyurethane leather finishing agent is mainly prepared from diisocyanate, polyether glycol, organosiloxane, a hydrophilic chain extender, a catalyst and a neutralizer. According to the delustering waterborne polyurethane leather finishing agent, the specific raw material composition and dosage are adopted, and an excellent delustering effect is obtained without adding a delusterant. The delustering waterborne polyurethane leather finishing agent is good in compactness, stability and coating property, can guarantee the mechanical property and waster resistance of a leather coating and is environmentally friendly, nontoxic and safe. The preparation method of the delustering waterborne polyurethane leather finishing agent is simple in technology, the waterborne polyurethane leather finishing agent with an excellent delustering property is synthesized in a step-by-step feeding reaction mode, and the preparation method is suitable for large-scale production.

Owner:优美特(北京)环境材料科技股份公司

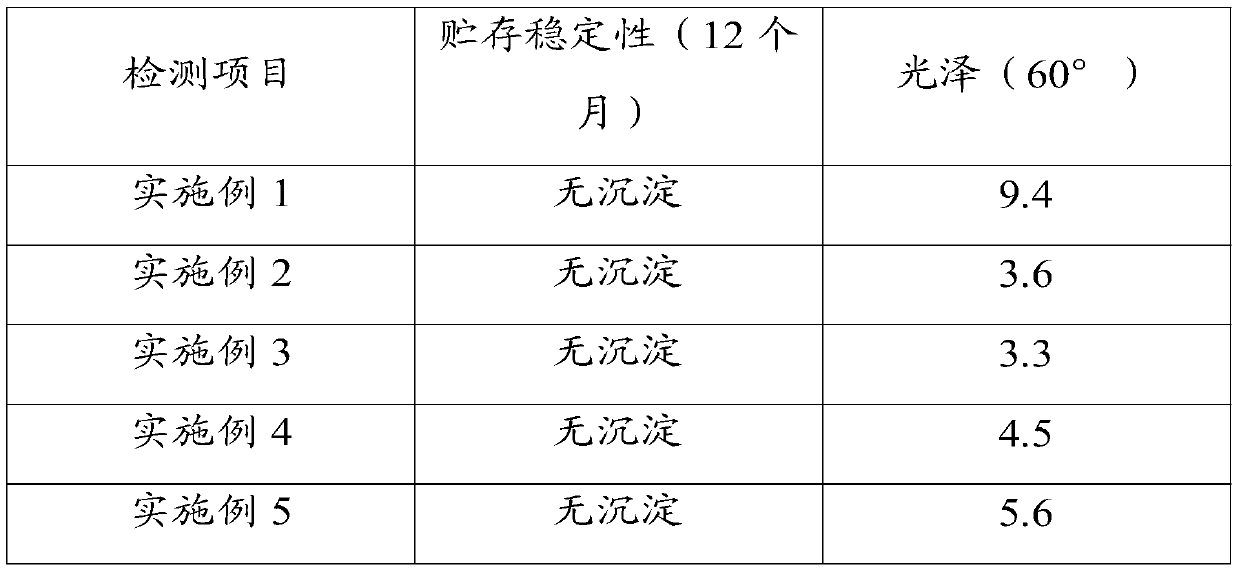

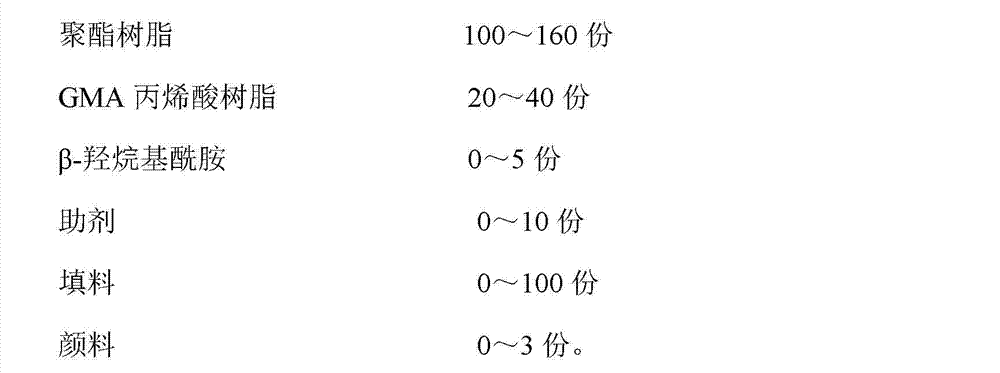

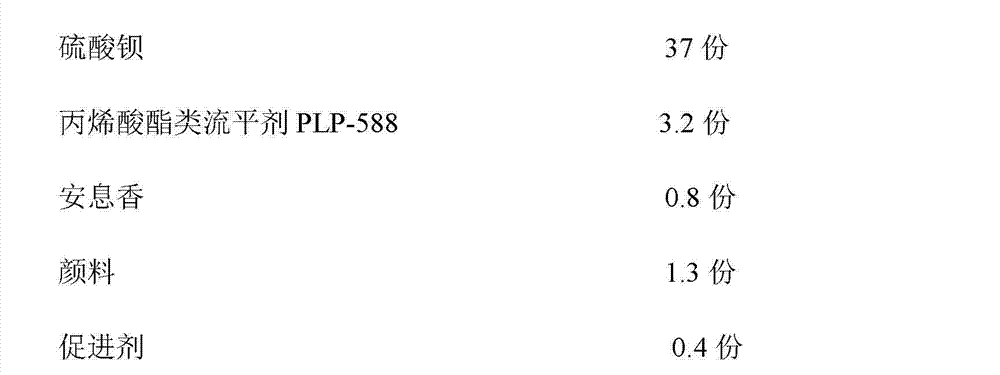

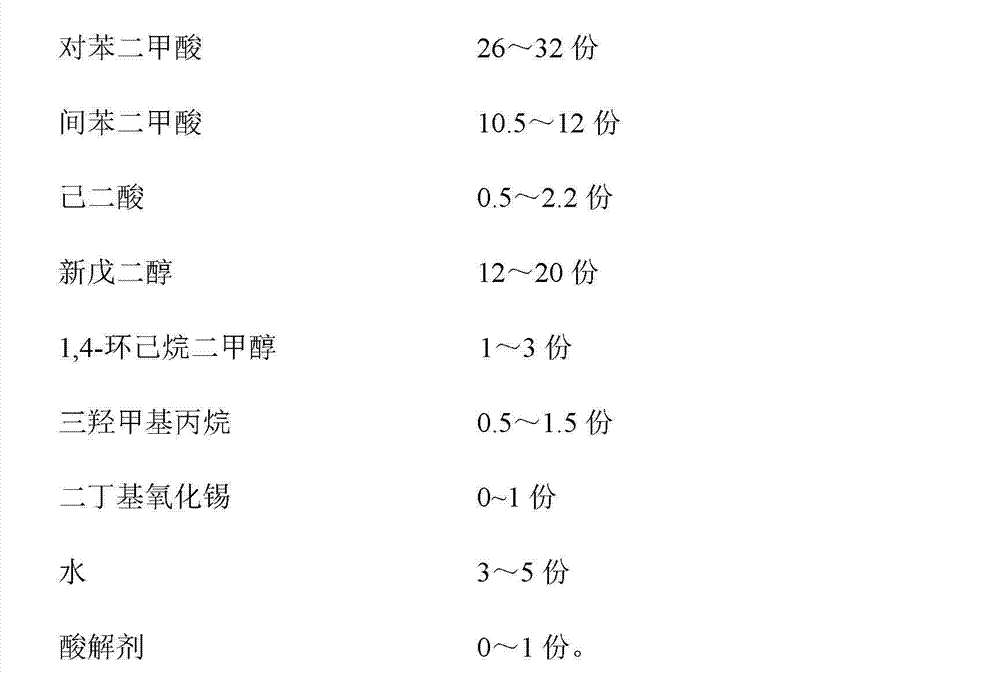

High weather-proof and corrosion-resistant powder paint for satellite earth antenna and preparation method thereof

ActiveCN102898933AGood electrificationShort curing timePowdery paintsPolyester coatingsAcrylic resinPolyester resin

The invention discloses a high weather-proof and corrosion-resistant powder paint for a satellite earth antenna. The paint comprises, by weight, 100-150 parts of polyester resin, 20-40 parts of GMA acrylic resin, 0-5 parts of beta-hydroxyalkylamide, 0-10 parts of assistants, 0-100 parts of paddings and 0-3 parts of pigments. The invention further discloses a preparation method for the powder paint. A coating after being coated by the paint and curing is good in mechanical properties, super-weather-proof, salt mist resistant, and provided with stable low gloss area.

Owner:GUANGZHOU KINTE IND

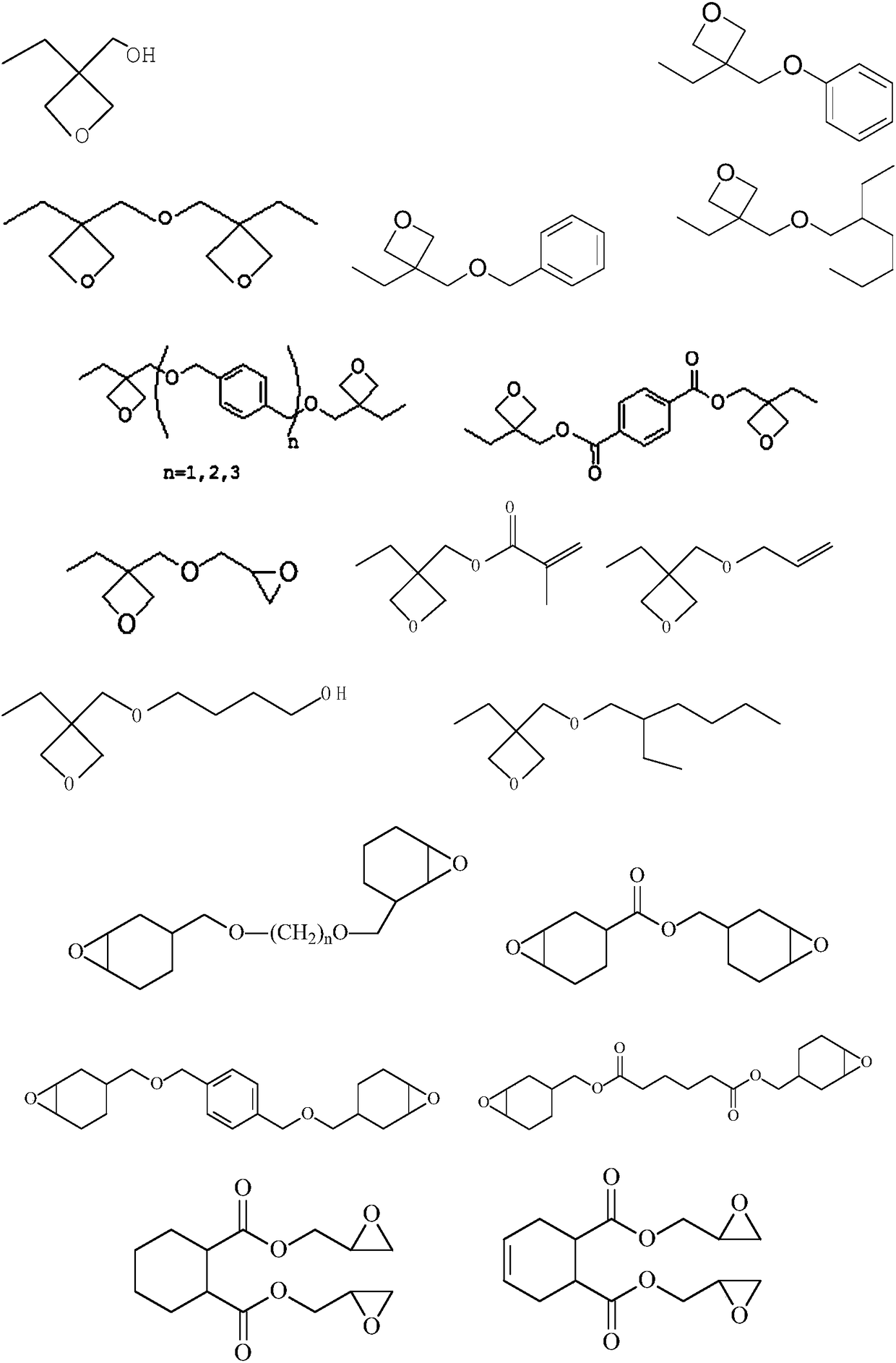

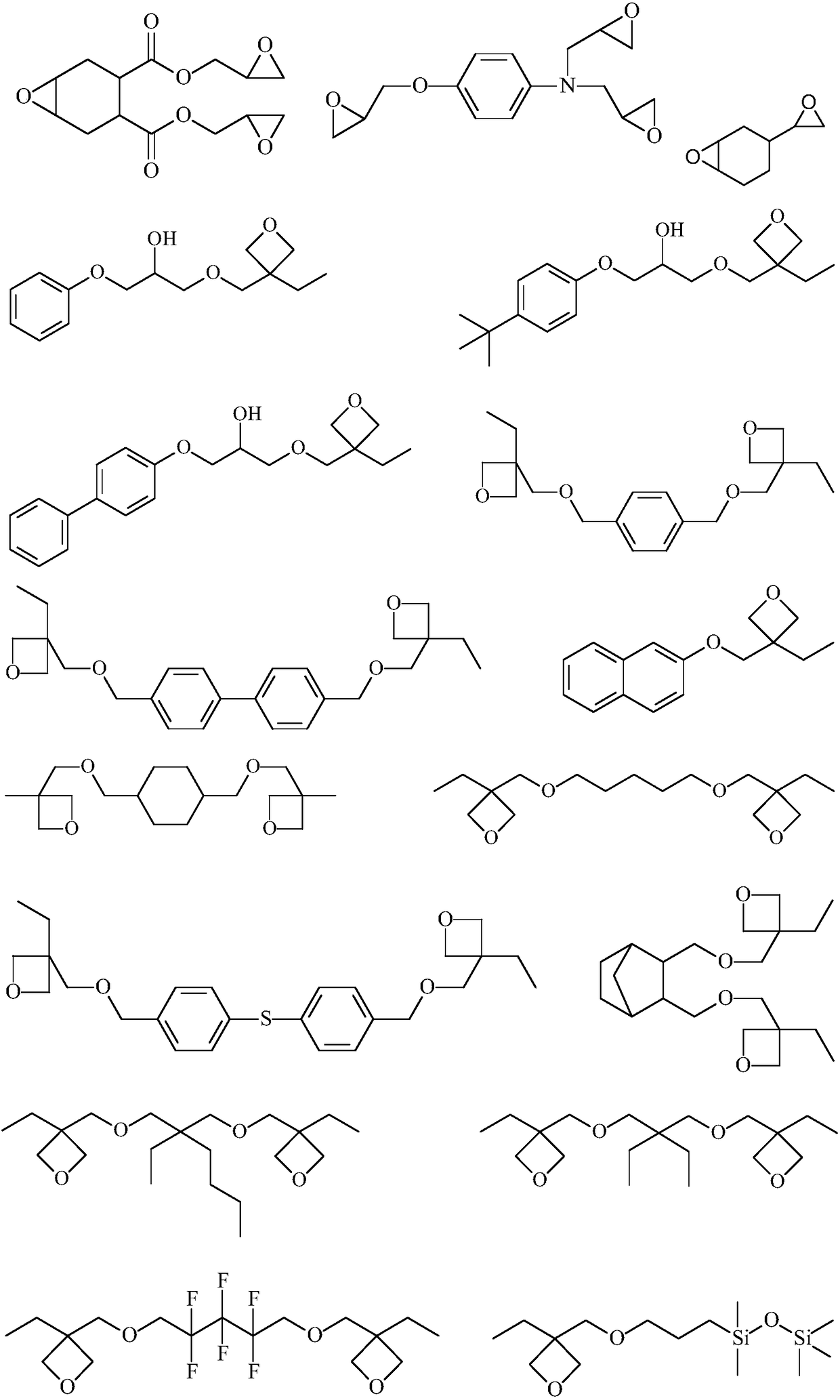

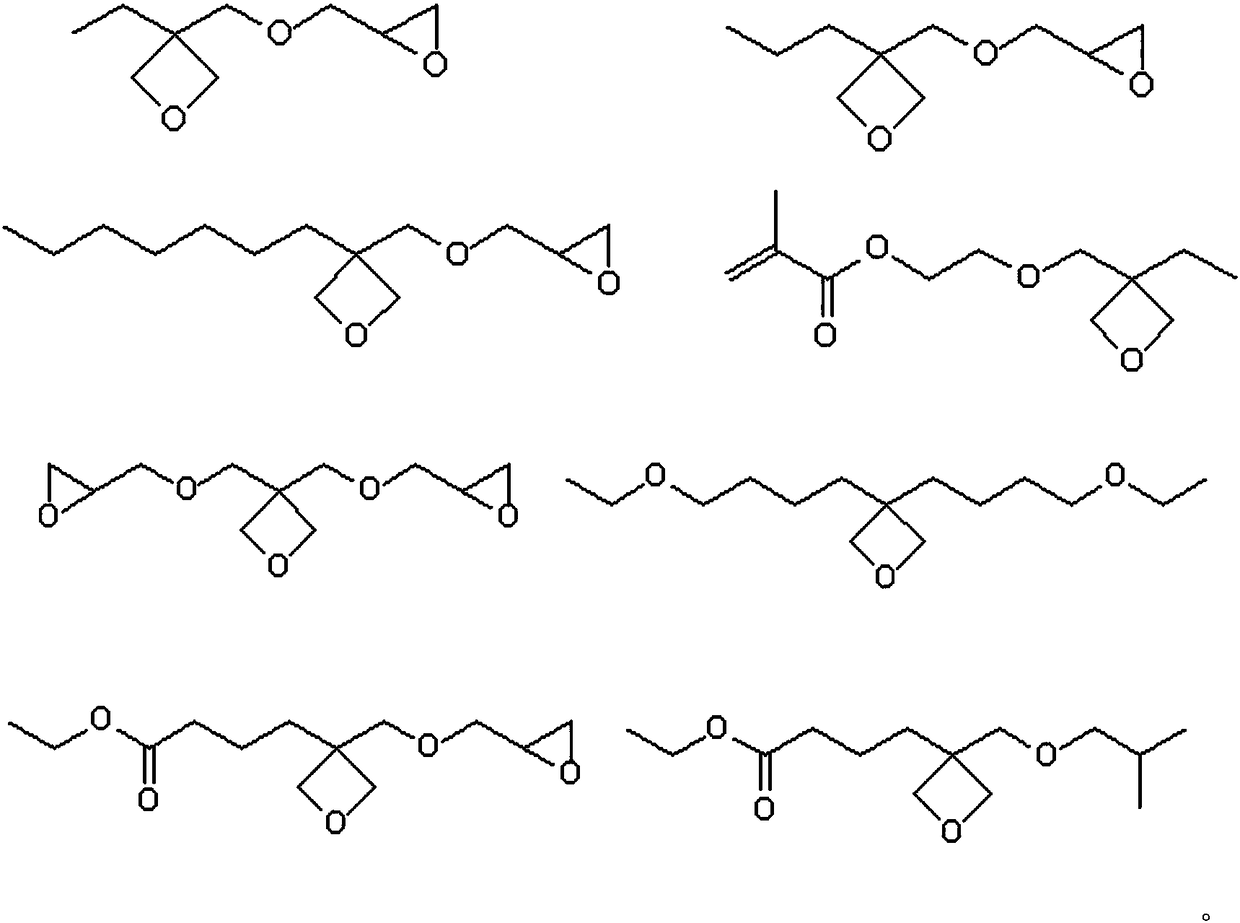

UVLED light curing composition and application thereof in floor coating

ActiveCN108314912AResponsiveFast curingPolyurea/polyurethane coatingsEpoxy resin coatingsLight sourceChemistry

The invention discloses an UVLED light curing composition used in a floor coating and application thereof, the composition comprises a compound containing a (methyl acrylate group, an epoxy-group-containing compound, a diluent, a cationic photoinitiator, and optionally, a free radical photoinitiator and sensitizer, and the UVLED light curing composition has excellent response to an UVLED light source in the wavelength range of 200 to 500 nm, and has the advantages of fast curing speed, excellent coating performance, zero VOC emission, and the like. Layer hardness, wear resistance, adhesion, water resistance and chemical resistance of the UVLED light curing composition after curing can meet the performance requirements of a floor coating material.

Owner:CHANGZHOU GREEN PHOTOSENSITIVE MATERIALS CO LTD

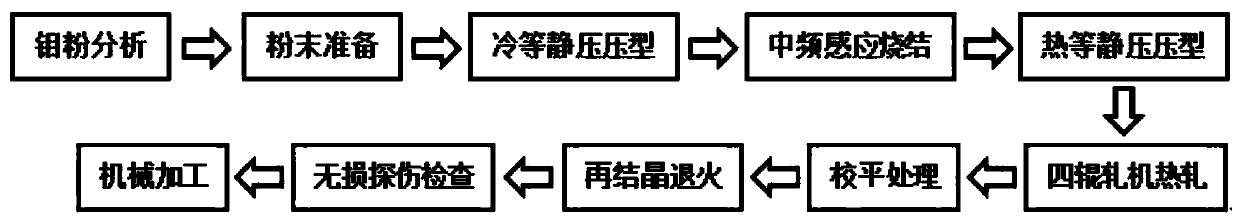

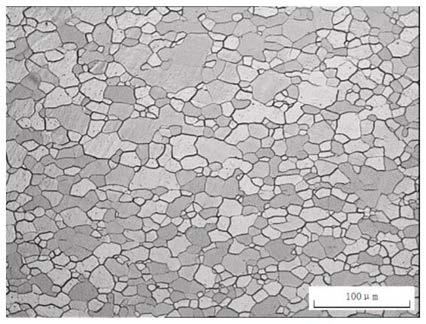

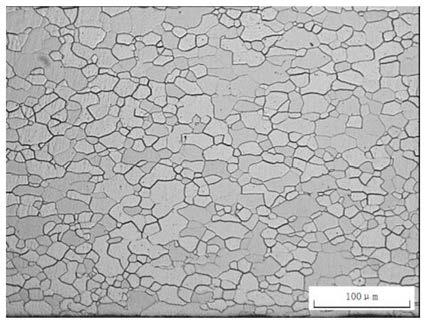

Preparing method of high-densification ultra-fine grain large-size molybdenum target

ActiveCN109778126ASputtering speed is fastQuality improvementVacuum evaporation coatingSputtering coatingSputteringMicrometer

The invention provides a preparing method of a high-densification ultra-fine grain large-size molybdenum target. According to the preparing method, through the processes of isostatic cool pressing profiling, sintering, hot isostatic pressing profiling, hot rolling, annealing and machining, the molybdenum target is prepared, the molybdenum target is subjected to hot isostatic pressing treatment, the molybdenum target blank is subjected to primary densification treatment, the blank is subjected to hot rolling treatment, the molybdenum target blank is subjected to secondary densification treatment, and finally, through procedures of annealing treatment, mechanical machining and the like at the temperature of 950 DEG C to 1100 DEG C and heat preservation for 60 to 90 min, the molybdenum targetwith the needed property is obtained. The preparing method can manufacture the molybdenum target with high purity (purity above 99.9%), full densification (density above 99.9%), and ultra-fine grains(grain size smaller than 20 micrometers), the sputtering technology with the higher and higher requirement can be met, the thin film sputtering speed is improved, the molybdenum metal sputtering thinfilm quality is improved, and the thin film property is improved.

Owner:安泰天龙钨钼科技有限公司 +1

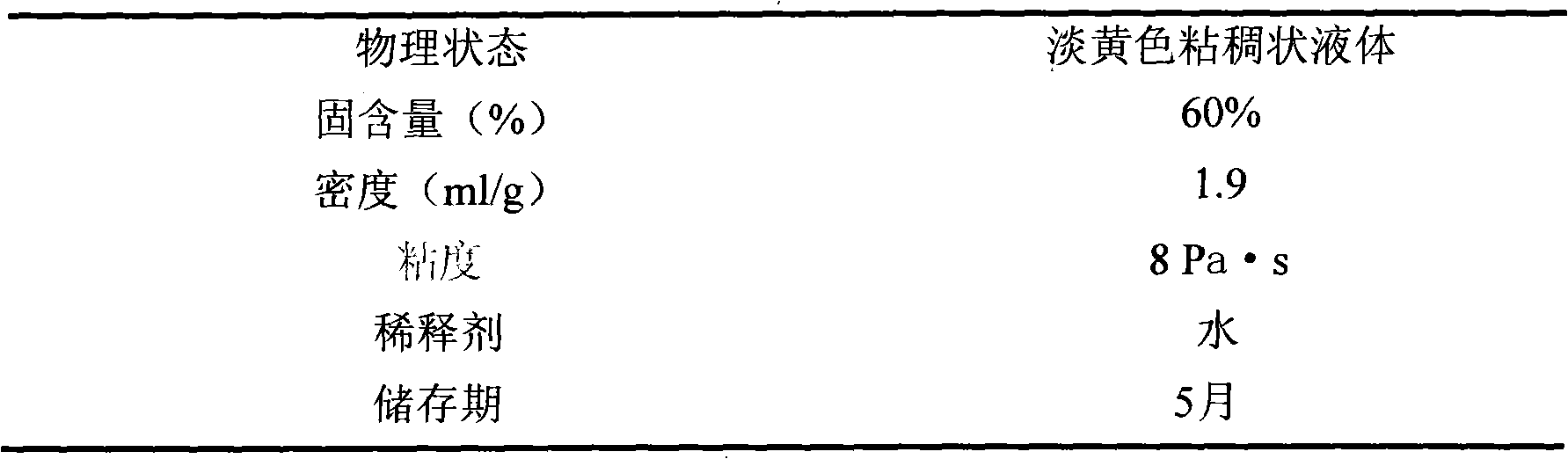

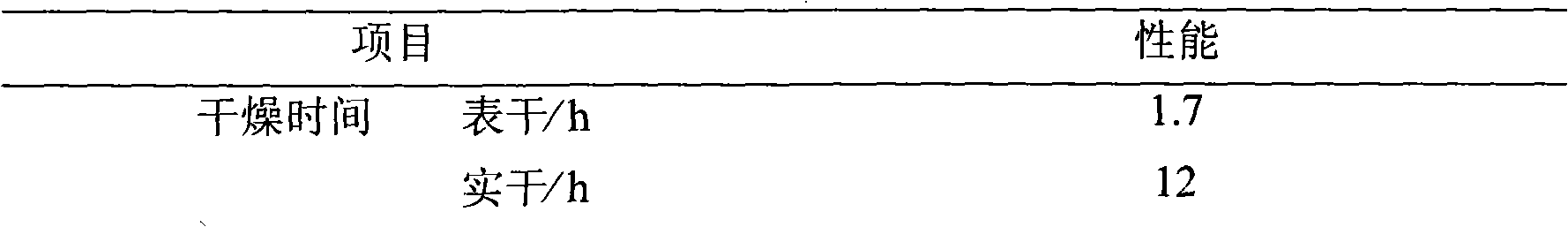

Process for producing cold curing watersoluble solidifying agent of epoxy resin

The invention relates to a room temperature curing waterborne epoxy resin curing agent and a preparation method thereof. The method comprises the following detailed steps of: (1) sealed end: at constant temperature between 60 DEG C and 90 DEG C, mono epoxy is dripped into diethylene triamine and the reaction lasts for 3h to 6h; (2) addition: bi-epoxy is dripped into the mixture obtained at Step (1) at a constant temperature of 60 DEG C to 90 DEG C and the reaction lasts for 4h to 8h; (3) salifying: acetate is added into the mixture obtained at the step (2) at a constant temperature of 60 DEG C to 90 DEG C to carry out salifying, the mixture is stirred for a while, then water is added into the mixture to dilute until the solid content is 60 percent and stirring is kept on for 1h to 3h; and (4) a curing catalyst is added into the mixture obtained at the step (3) at constant temperature of 60 DEG C to 90 DEG C, the content of the curing catalyst is 0.1 percent to 5 percent, stirring is kept on for 0.2h to 1h and then the finished product is discharged. The waterborne epoxy resin curing agent has relatively good curing performance and water-solubility, contains 60 percent of solid content and is a pale yellow liquid. The addition of the curing catalyst solves the problems of the too low speed and too long period of curing at room temperature and excellent curing performance and film properties can be fulfilled at room temperature.

Owner:TIANJIN UNIV

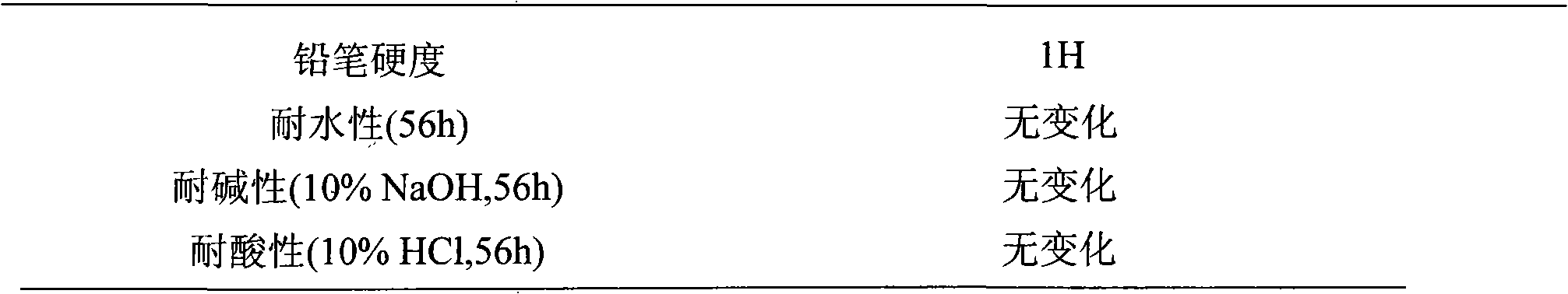

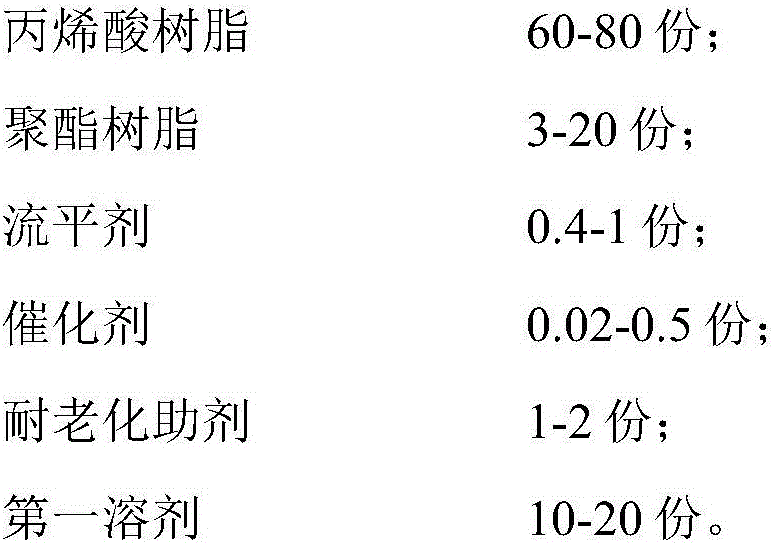

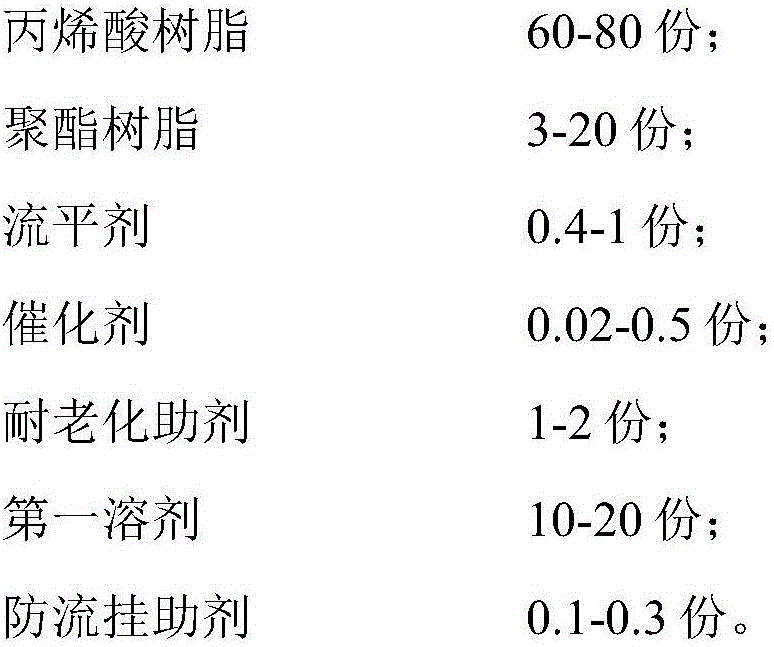

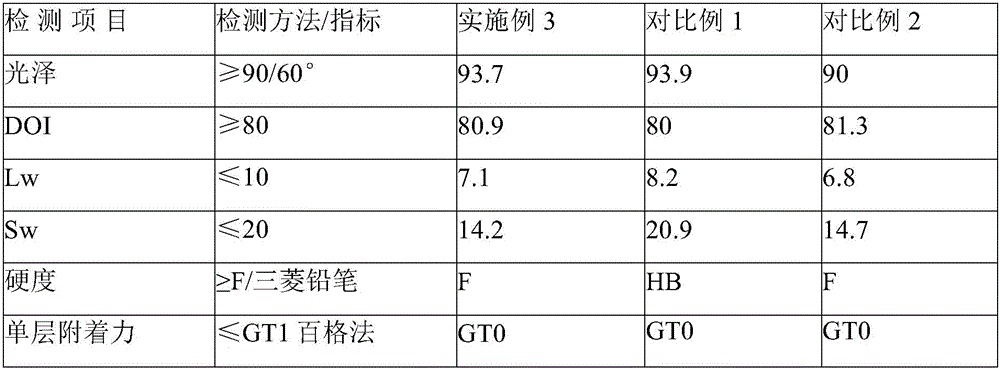

Quick-drying scratch-resistant varnish composition with high solid content as well as preparation method and application of quick-drying scratch-resistant varnish composition

ActiveCN105949983AGood lookingImprove performancePolyurea/polyurethane coatingsAcrylic resinPolyester resin

The invention discloses quick-drying scratch-resistant varnish composition with high solid content. The quick-drying scratch-resistant varnish composition comprises varnish and a curing agent in a volume ratio being 2:1, wherein the varnish comprises components in parts by weight as follows: 60-80 parts of acrylic resin, 3-20 parts of polyester resin, 0.4-1 part of a leveling agent, 0.02-0.5 parts of a catalyst, 1-2 parts of an ageing-resistant auxiliary and 10-20 parts of a first solvent; the curing agent comprises components in parts by weight as follows: 60-80 parts of isocyanate and 10-20 parts of a second solvent. The quick-drying scratch-resistant varnish composition with high solid content has quick-drying performance and scratch resistance, further has good paint film property, workability and high construction solid content and is particularly applicable to painting for automobile repairing, and the VOC (volatile organic compounds) can be reduced to 420 g / L or lower.

Owner:NIPPON PAINT CHINA +1

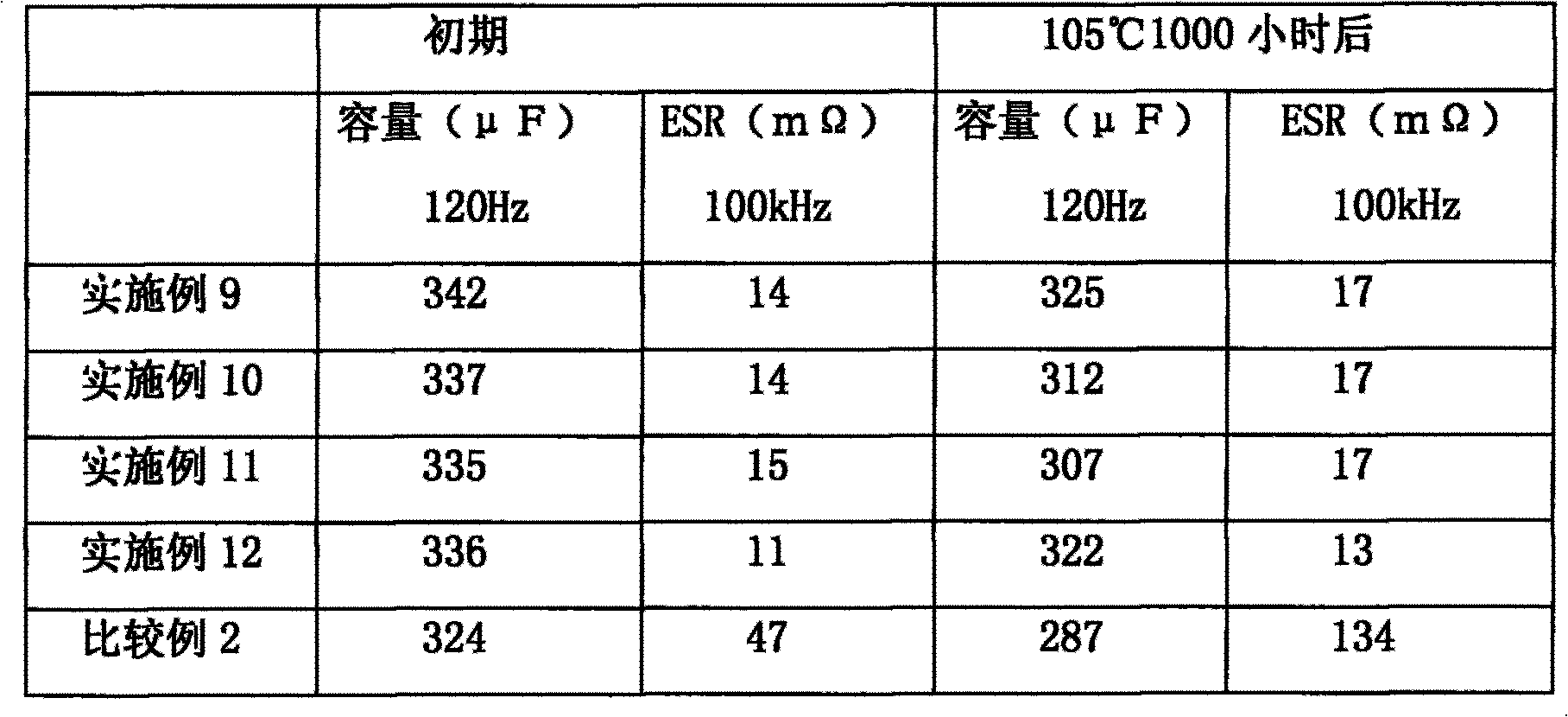

Conductive composite body, conductive polymer composition and electronic component using the conductive polymer composition

InactiveCN101302340AImprove long-term stabilityExcellent solvent solubilityOrganic conductorsConductive polymerDisplay device

The invention provides a conducting complex which is combined by a conducting polymer A and a compound B except for the conducting polymer, and also can comprise polyanion, wherein, the compound B is polyethylene and derivates thereof, polyvinyl ether and derivates thereof, polyacrylamide and derivates thereof, polyacrylic acid and derivates thereof, etc. The conducting complex improves clinging property and filming property for matrix, and can maintain low specific resistance in a high-temperature environment. A conducting polymer composition comprises the conducting complex, has reduced specific resistance, and can maintain low specific resistance in a high-temperature environment. The invention also provides an electronic element with excellent performance through using a coating of the conducting complex and the conducting polymer composition. The coating of the conducting complex or the conducting polymer composition can be used in a solid electrolytic capacitor, a solar cell, an organic light emitting diode, an electroluminance, a display, an electrostatic copying part, a transfer printing part, a battery, epaper, a touch panel, an organic thin-filmtransistor, a field emission display (FED) and so on.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

Piezoelectric material and piezoelectric element

ActiveUS8102100B2Free and easy to prepareLarge constantPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCurie temperatureComposite material

A piezoelectric element includes a first electrode, a piezoelectric film disposed on the first electrode, and a second electrode disposed on the piezoelectric film. The piezoelectric film is composed of piezoelectric material that is lead free and formed by mixing 100(1−x)% of material A having a spontaneous polarization of 0.5 C / m2 or greater at 25° C. and 100 x % of material B having piezoelectric characteristics and a dielectric constant of 1000 or greater at 25° C., wherein (1−x)Tc(A)+xTc(B)≧300° C., where Tc(A) is the Curie temperature of the material A and Tc(B) is the Curie temperature of the material B.

Owner:SEIKO EPSON CORP

Polyacrylate emulsion and preparation method thereof

The invention discloses a polyacrylate emulsion and a preparation method thereof. The polyacrylate emulsion is prepared from the following raw materials in parts by weight: 21.1-35.3 parts of a pre-emulsion in a nuclear layer, 21.3-34.1 parts of a pre-emulsion in a crosslinking layer, 8.05-12.2 parts of a pre-emulsion in a shell, 22.21-34.43 parts of initiator aqueous liquor, 0.01-0.08 part of an anionic emulsifier d, 0.04-0.32 part of a non-ionic emulsifier d and 20 parts of deionized water d. The solid content of the target emulsion product disclosed by the invention is over 45%, the storage stability of the emulsion through freeze-thaw stability test is longer than 6 months, and the coating is good in temperature resistance. The emulsion is non-sticky at 200 DEG C, and the adhesive force of the coating to a PVC (polyvinyl chloride) substrate reaches level 1, so that the problems that PVC wallpaper is sticky at high temperature, easy in separation of a plasticizer and intolerant to wiping by organic solvents such as alcohol and the like can be effectively solved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

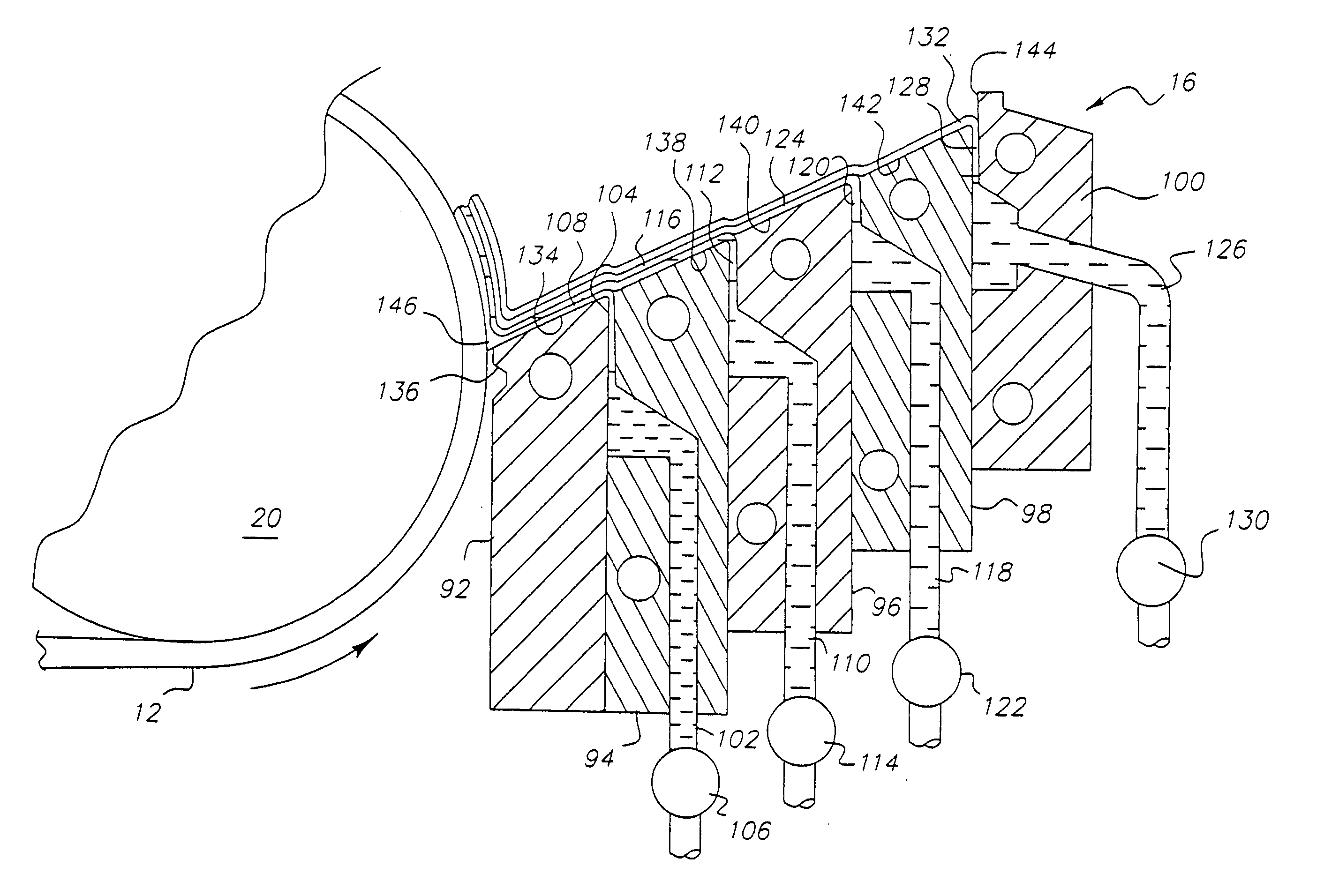

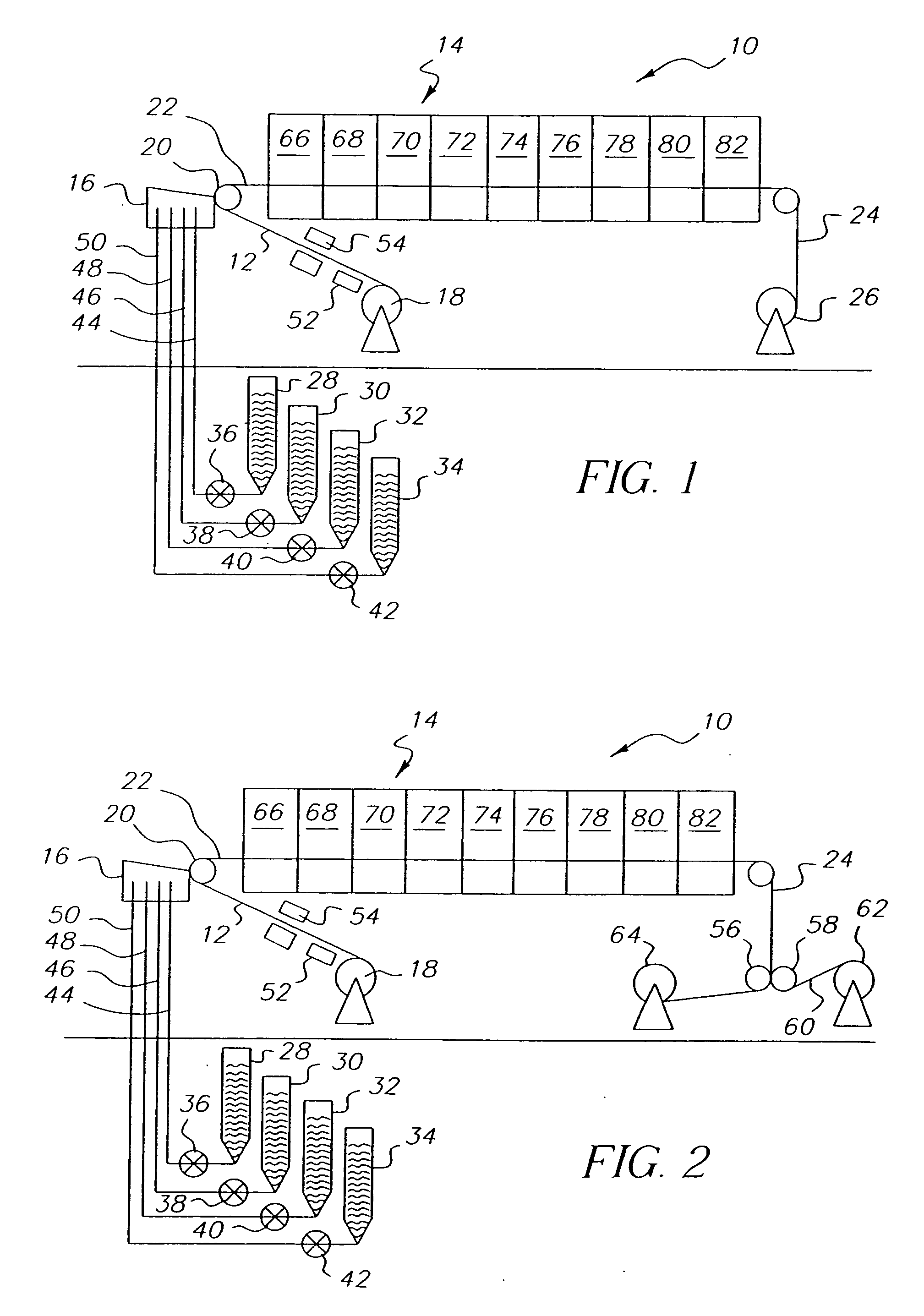

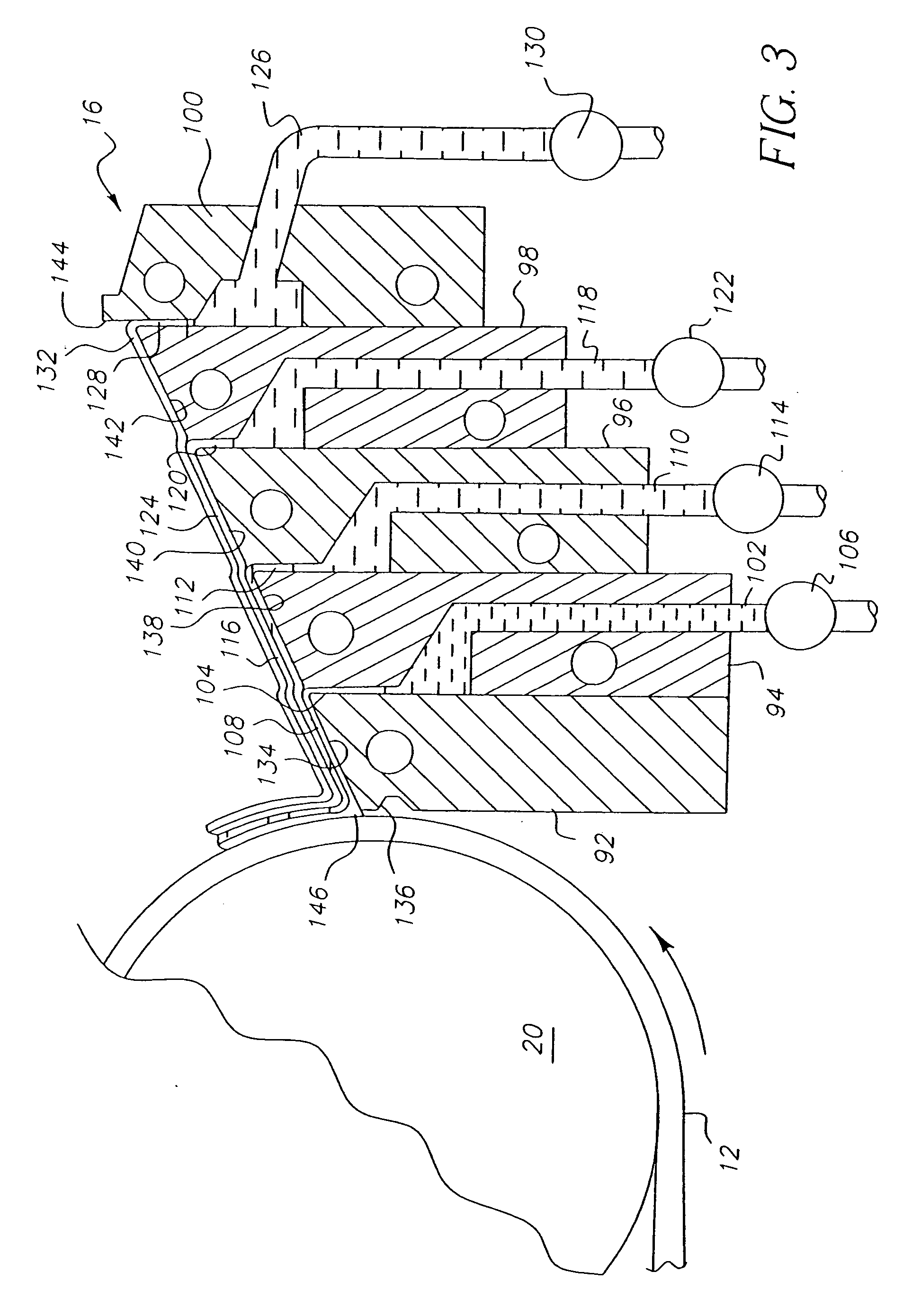

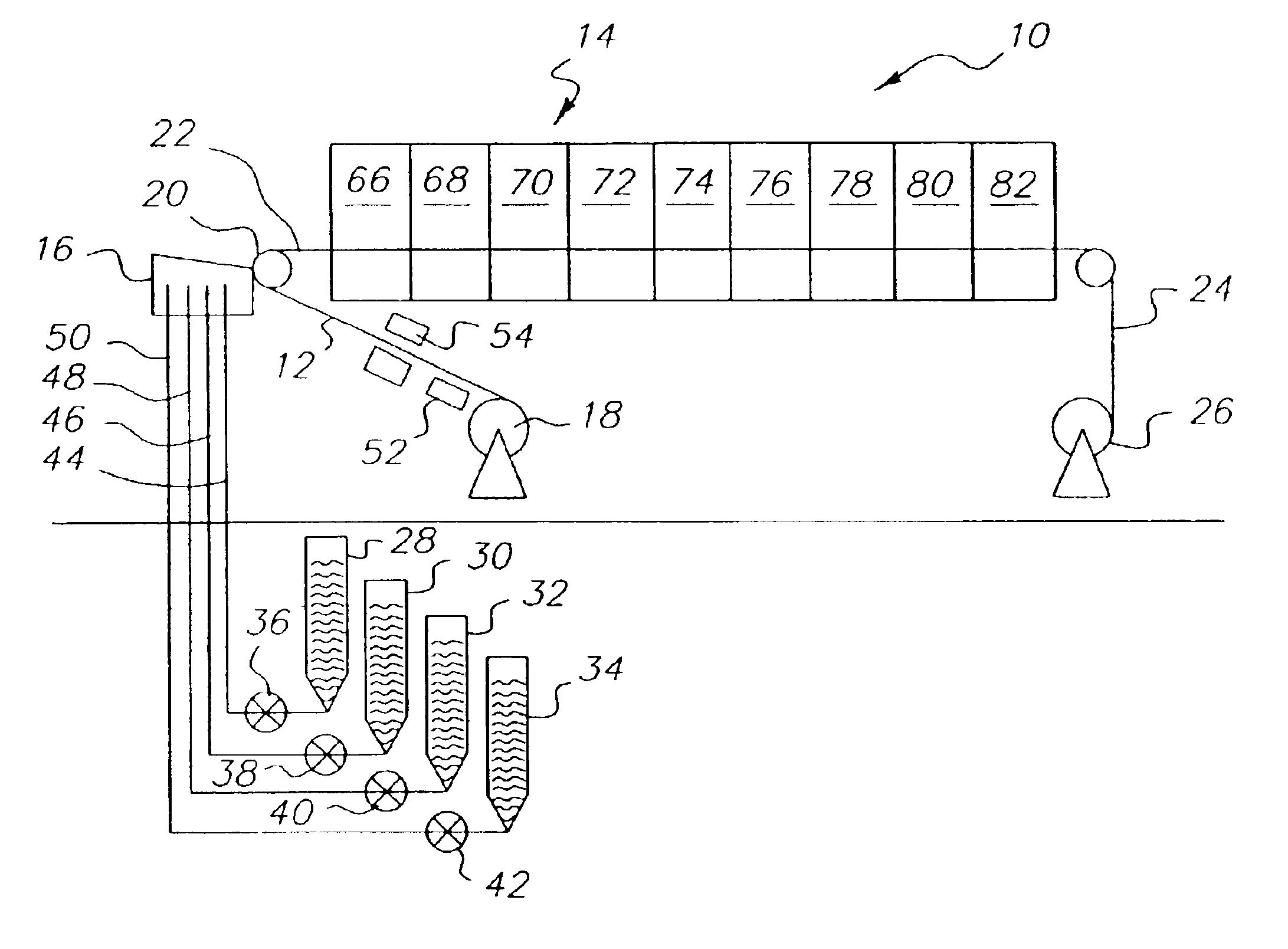

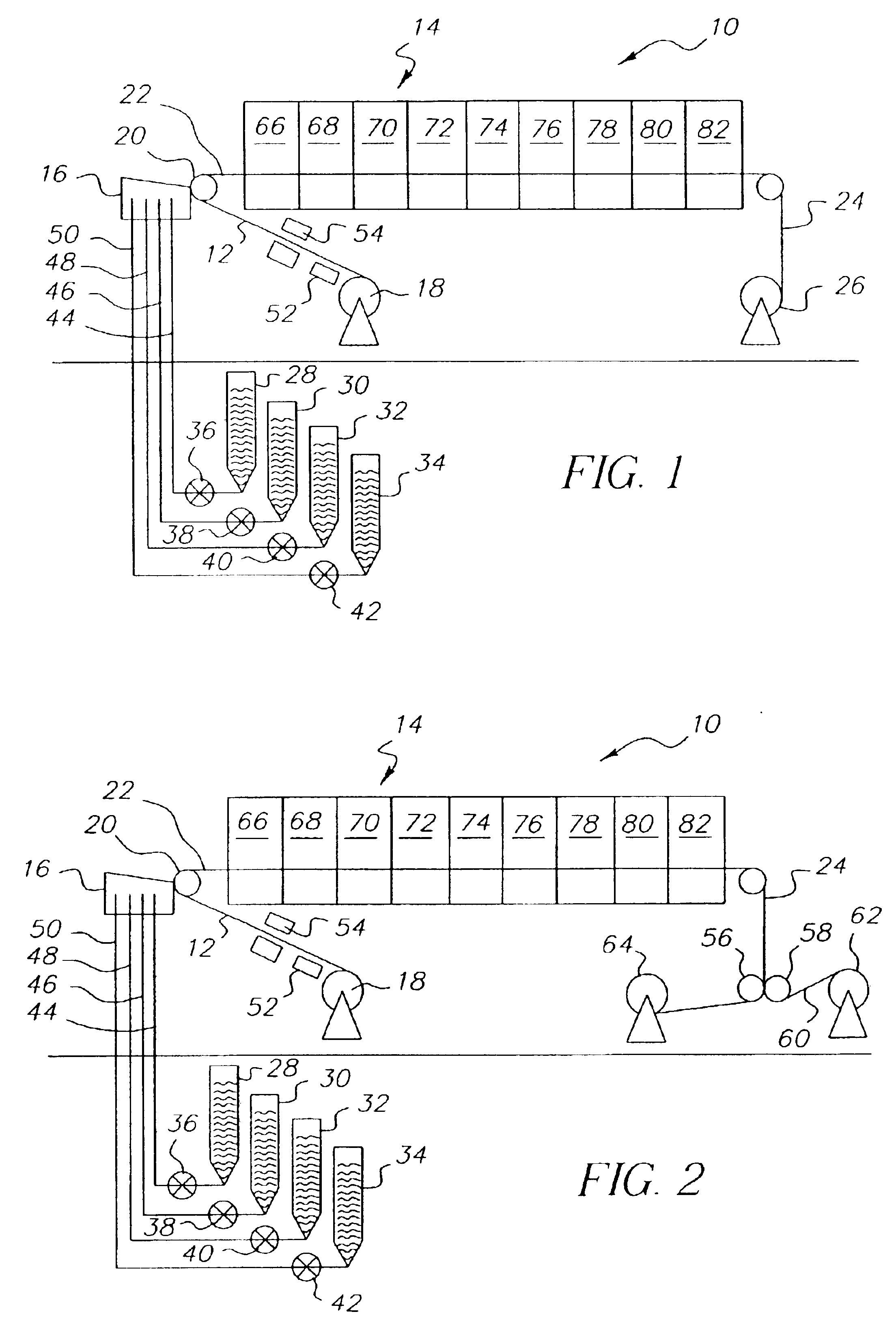

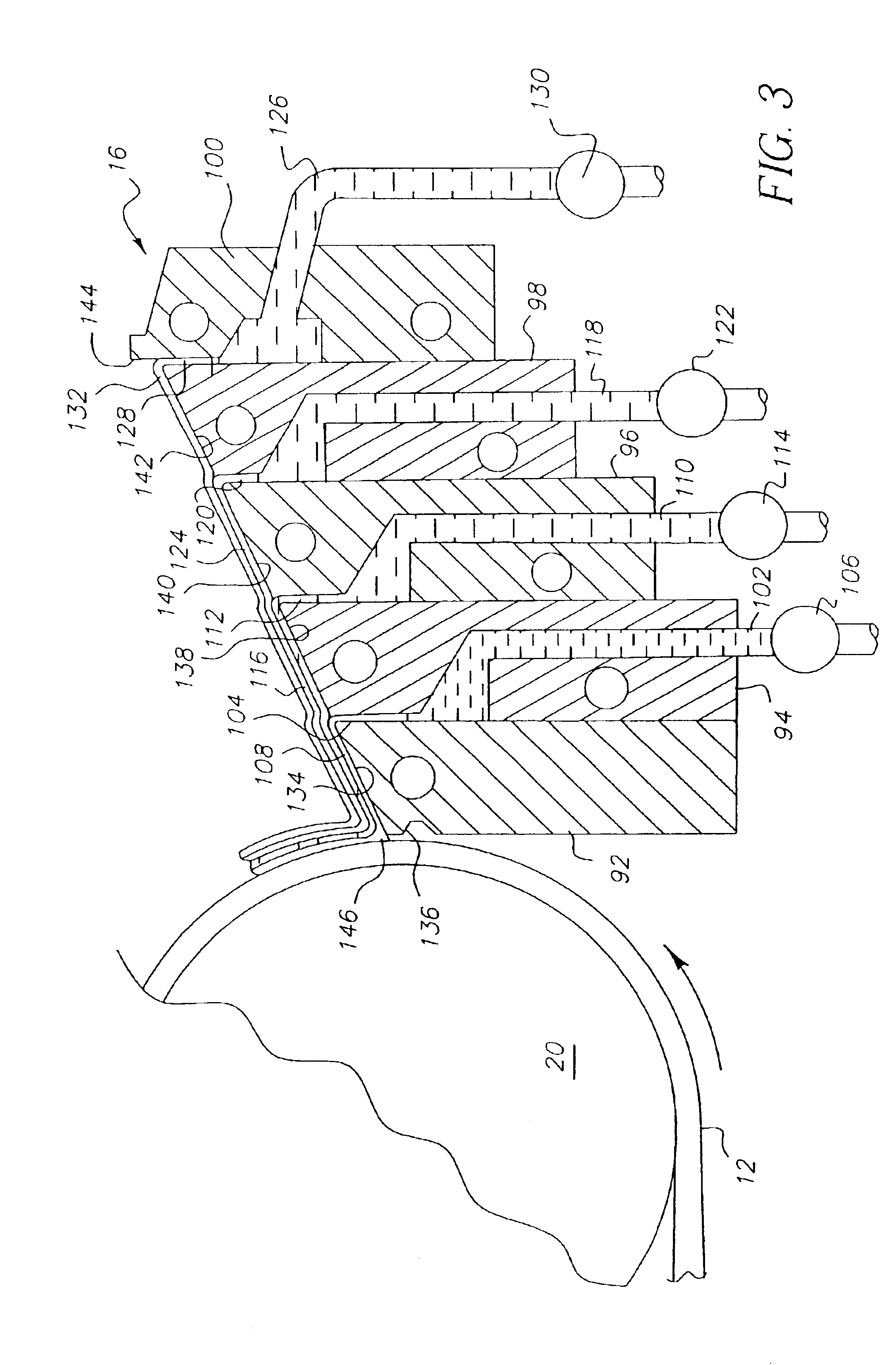

Cellulose acetate films prepared by coating methods

InactiveUS20060188708A1Improve handlingImprove stabilityDecorative surface effectsPolarising elementsLiquid layerCellulose acetate film

A method of film fabrication is taught that uses a coating and drying apparatus to fabricate resin films suitable for optical applications. In particular, cellulose acetate films are prepared by simultaneous application of multiple liquid layers to a moving carrier substrate. After solvent removal, the cellulose acetate films are peeled from the sacrificial carrier substrate. Cellulose acetate films prepared by the current invention exhibit good dimensional stability and low birefringence.

Owner:EASTMAN KODAK CO

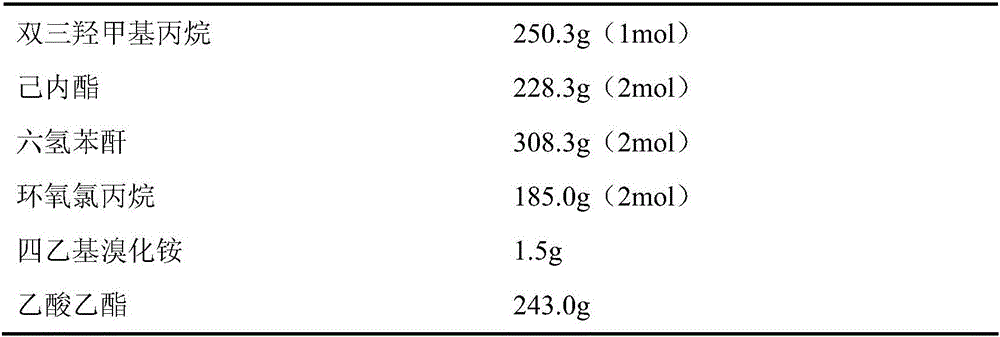

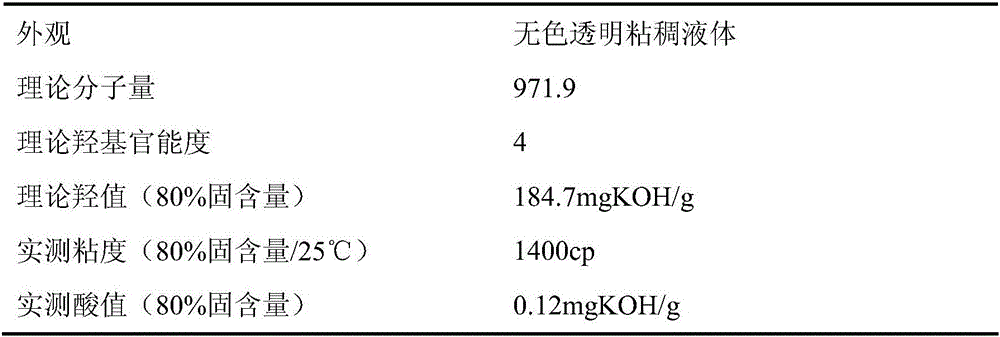

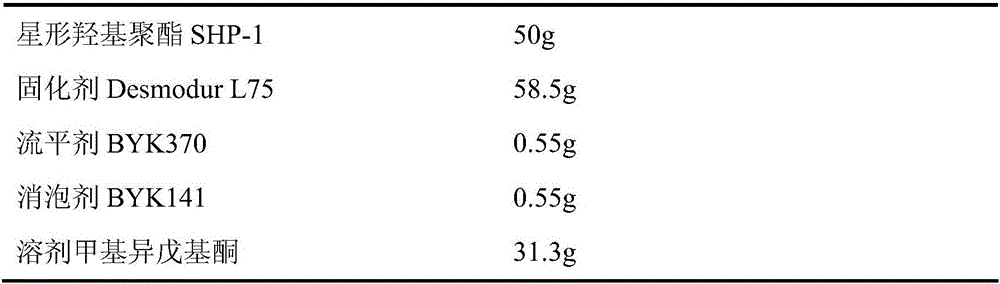

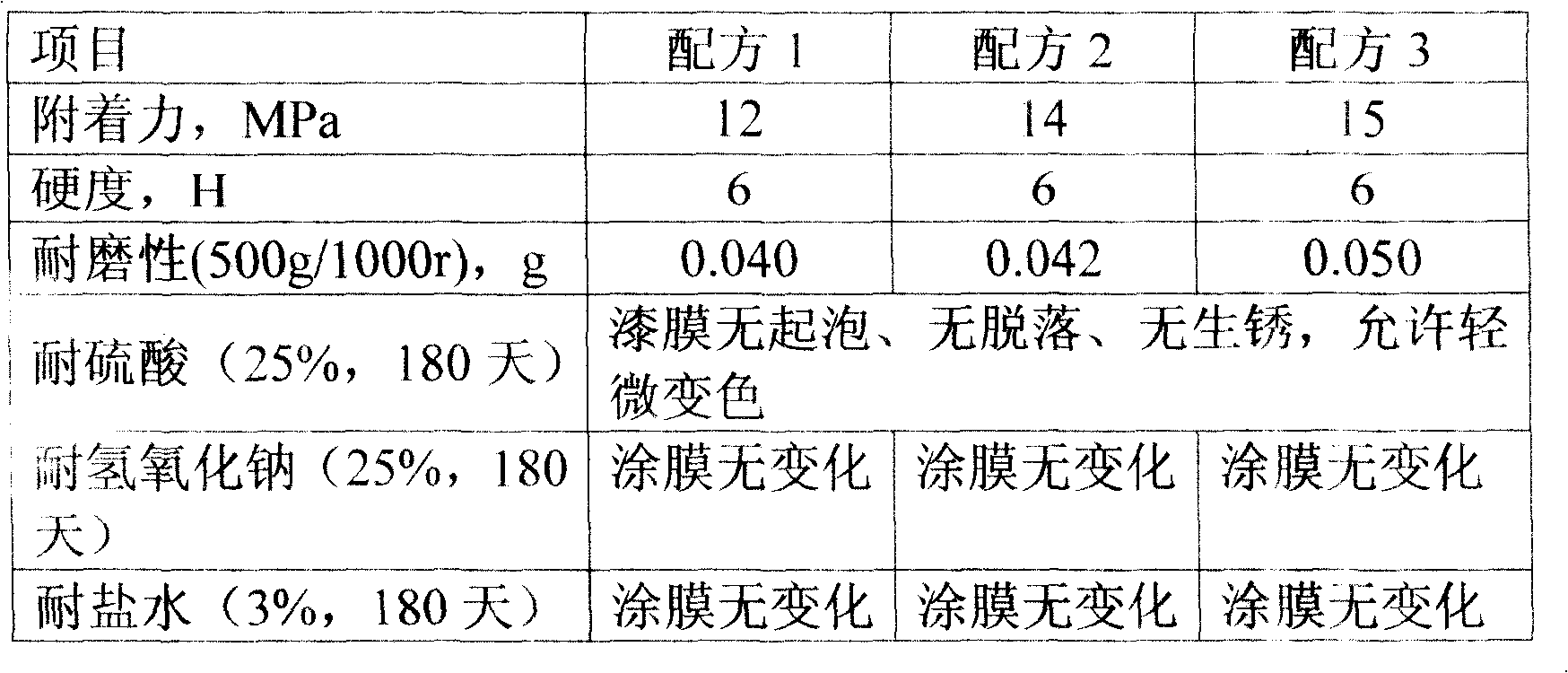

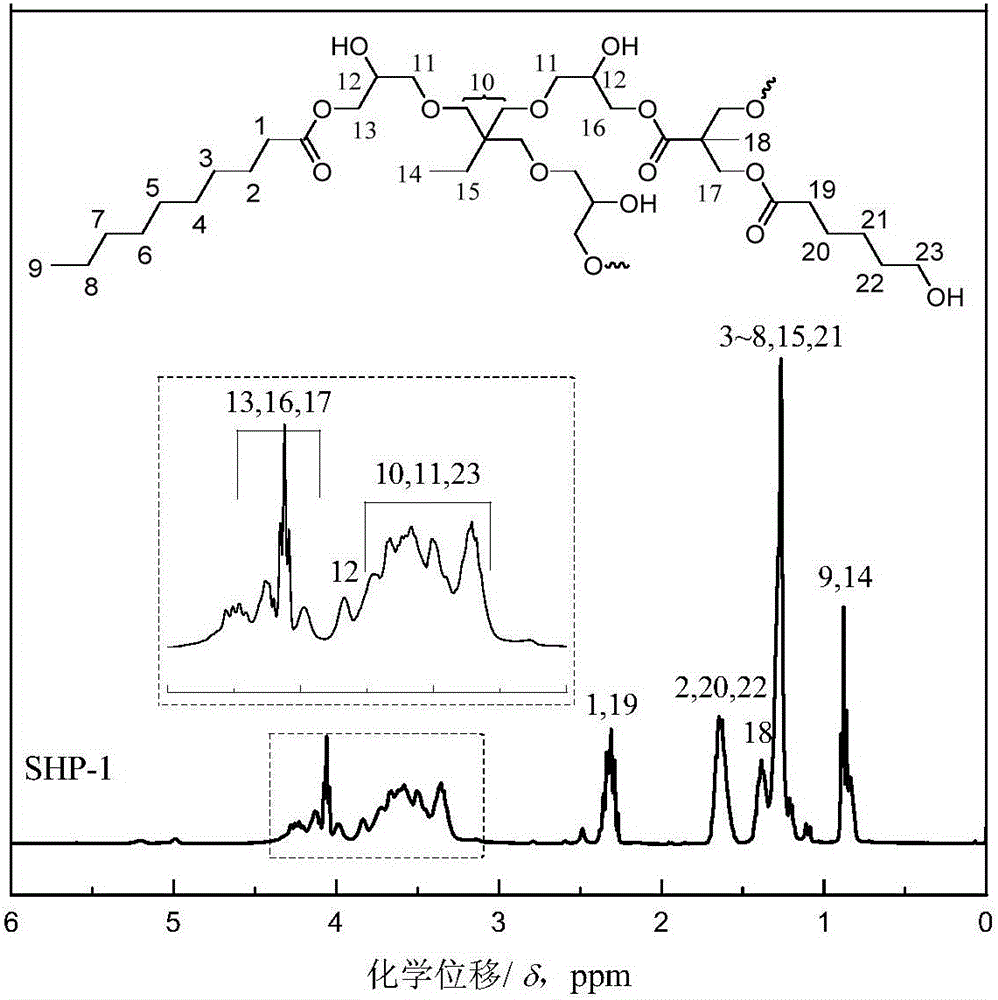

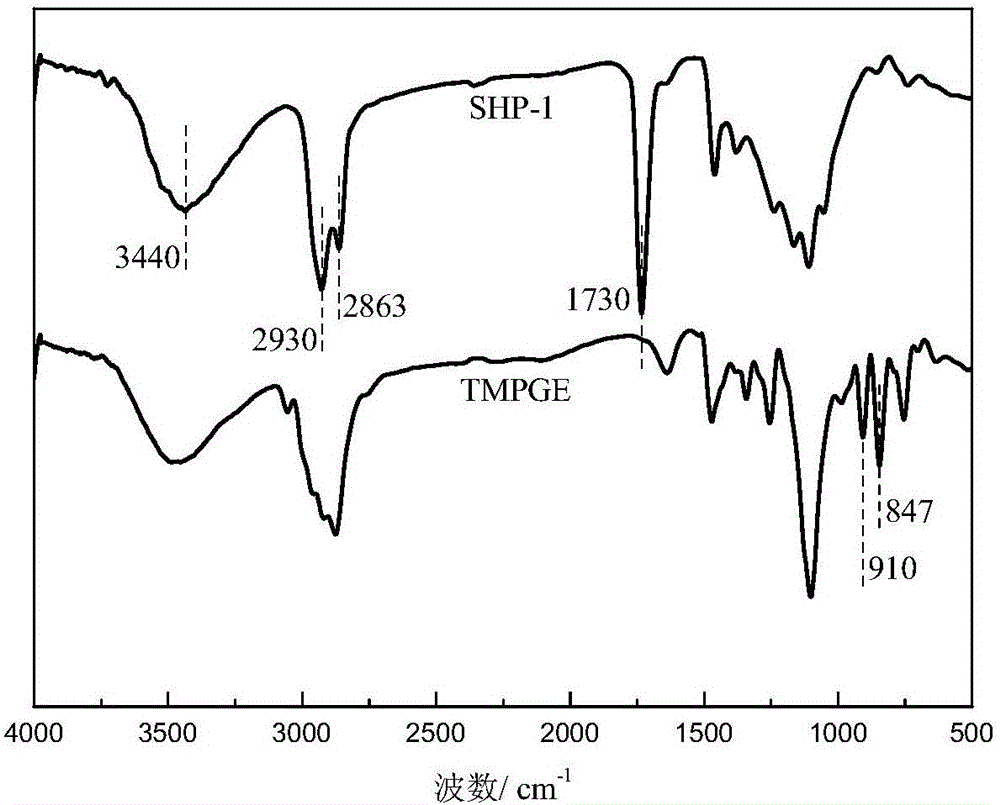

Star-shaped hydroxyl polyester adopting polyhydric alcohol as nucleus and preparation method and application of star-shaped hydroxyl polyester

ActiveCN106279659AAffect activation periodImprove catalytic abilityPolyurea/polyurethane coatingsPolyesterSolvent

The invention discloses star-shaped hydroxyl polyester adopting polyhydric alcoho as a nucleus and a preparation method and an application of the star-shaped hydroxyl polyester. The preparation method comprises the following steps: enabling 1 to 8 molar caprolactone and 1 to 4 molar anhydride to react for 6 to 10 h at 80 to 140 DEG C by adopting 1 molar small molecular polylasic alcohol as a core molecule to obtain a matrix star-shaped polyester, then reacting with 1 to 4 molar monoglycidyl ether at 90 to 150 DEG C to obtain star-shaped hydroxyl polyester. The prepared star-shaped hydroxyl polyester has the advantages of simple synthesis process, high solid content and low viscosity, a hydroxyl value is 140 to 250 mg KOH / g (80 percent of solid content), the viscosity at 25 DEG C when the solid content is 80 percent is 300 to 3000cp, the star-shaped hydroxyl polyester can be cross-linked with a polyurethane curing agent containing an isocyanate group and can be used for preparing a coating with a high solid content, the VOC content at the construction viscosity is smaller than 380 g / L, and the film performance can satisfy the national standard of the solvent-type dual-component polyurethane wood coatings.

Owner:SOUTH CHINA UNIV OF TECH +1

Heavy corrosion protection coating for ocean steel construction

InactiveCN101245213AConducive to labor protectionMeet environmental protection requirementsAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to a heavy-duty coating used in ocean steel structure, which adopts three-component combination; wherein, A component consists of epoxy resin, a plasticizer, a flatting agent and a defoamer; B component is an epoxy curing agent; C component consists of wear-resistant pigment, alkaline water absorbent, antirust pigment and anti-cracking pigment; the weight percentage of each component are that: A component: 60 to 100 parts of epoxy resin, 10 to 30 parts of plasticizer, 0.1 to 1 part of flatting agent, and 0.1 to 1part of defoamer; B component: epoxy curing agent; C component: 60 to 100 parts of wear-resistant agent, 30 to 50 parts of alkaline water absorbent, 2 to 10 parts of antirust pigment and 2 to 10 parts of anti-cracking pigment. Before coating, A component and B component are mixed evenly according to certain proportion, and C component is added according to proportion; the mixture is mixed evenly; the proportion of the three components can be adjusted within certain scope according to the difference of construction environment temperature, and the proportion of A, B, and C components is 100: 20: 200 when temperature is 25 DEG C. The heavy-duty coating used in ocean steel structure has good adhesion, abrasion resistance, and corrosion resistance.

Owner:洛阳双瑞防腐工程技术有限公司

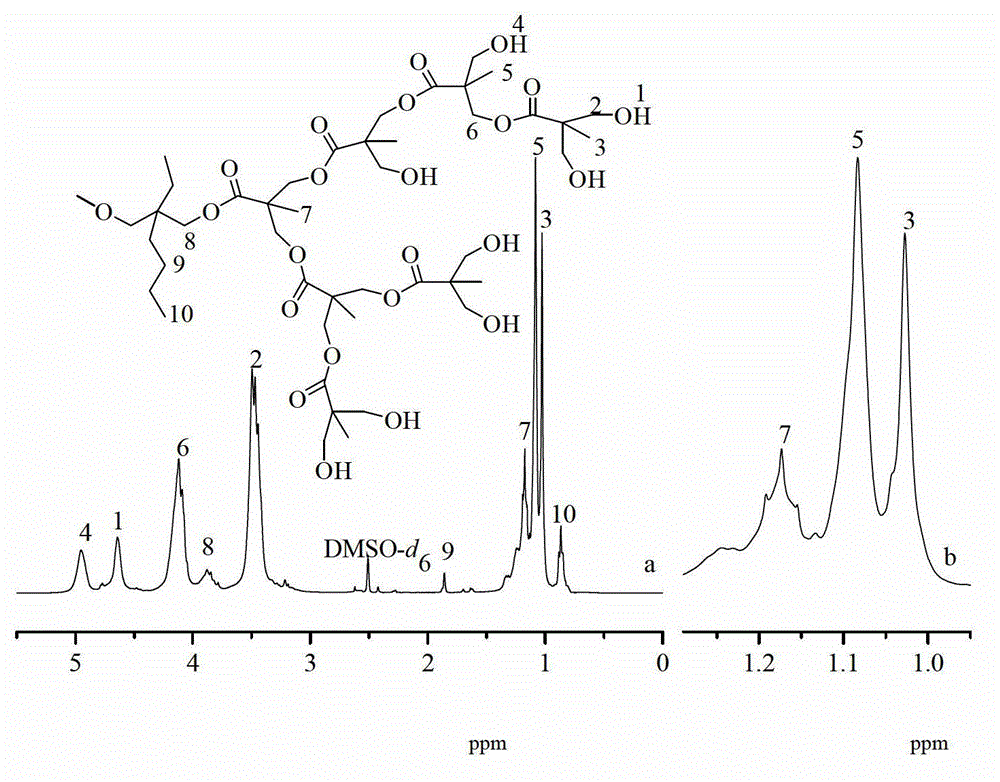

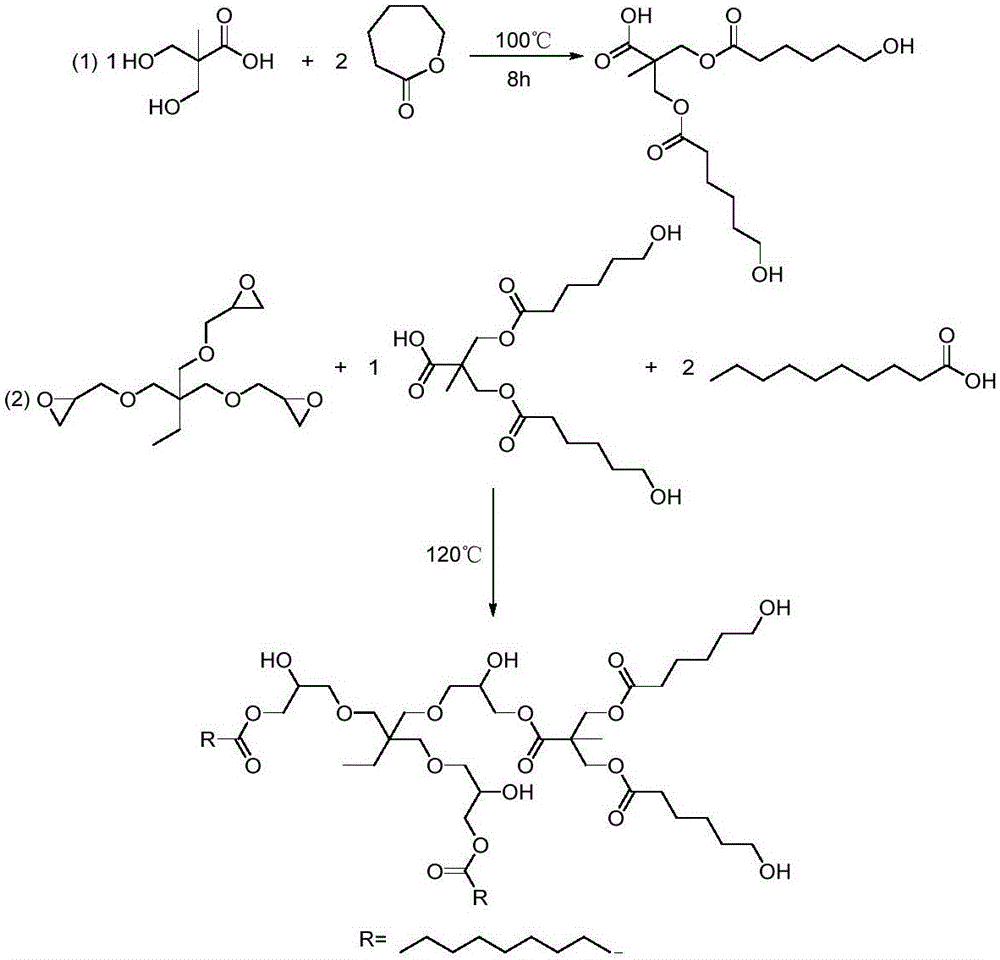

Low-viscosity star-shaped hydroxyl polyester as well as preparation method and application thereof

ActiveCN105820048ALow viscosityHigh solid contentOrganic compound preparationCarboxylic acid esters preparationPolyesterCarboxylic acid

The invention discloses low-viscosity star-shaped hydroxyl polyester as well as a preparation method and application thereof, and belongs to the field of macromolecules of polyester. According to the preparation method, a caprolactone modified AB2 type branched monomer is first prepared, and is prepared by a reaction between 1 mole of dihydroxymethyl alkyl carboxylic acid and 1-4 moles of caprolactone at 80-160 DEG C, afterwards, a polybasic glycidyl ether nucleus, monocarboxylic acid and the caprolactone modified AB2 type branched monomer are mixed and subjected to reaction at 100-160 DEG C, and a ring cleavage reaction between a carboxyl group and an epoxy group is catalyzed by utilizing a quaternary ammonium salt as a catalyst to generate a secondary carbonyl group for preparing the low-viscosity star-shaped hydroxyl polyester. The low-viscosity star-shaped hydroxyl polyester provided by the invention has the advantages that a synthetic process is simple, the adjustable range of the hydroxyl value of a product is large, the viscosity is low, and the like; the low-viscosity star-shaped hydroxyl polyester has the hydroxyl value between 1500mgKOH / g and 350mgKOH / g, has the viscosity as low as 3000-15000cp below 25 DEG C, and can be cross-linked with a polyurethane curing agent containing an isocyanate group; high-solid-content paint can be prepared, and the film coating performance meets a national standard for solvent type bi-component polyurethane paint for woodenware.

Owner:SOUTH CHINA UNIV OF TECH +1

Cellulose acetate films prepared by coating methods

InactiveUS7083752B2Reduce decreaseImprove handlingPretreated surfacesOptical articlesLiquid layerCellulose acetate film

A method of film fabrication is taught that uses a coating and drying apparatus to fabricate resin films suitable for optical applications. In particular, cellulose acetate films are prepared by simultaneous application of multiple liquid layers to a moving carrier substrate. After solvent removal, the cellulose acetate films are peeled from the sacrificial carrier substrate. Cellulose acetate films prepared by the current invention exhibit good dimensional stability and low birefringence.

Owner:EASTMAN KODAK CO

Self-emulsifying water-borne epoxy resin curing agent and preparation method thereof

The invention discloses a self-emulsifying water-borne epoxy resin curing agent and a preparation method thereof. The method comprises the following steps: S1, mixing and reacting single polyamine with epoxy resin according to the molar ratio of (1.8:2) to (2.1:1), so as to obtain an intermediate addition product; S2, blocking the intermediate addition product by adopting a single epoxy compound, so as to obtain the self-emulsifying water-borne epoxy resin curing agent; controlling the molar ratio of the single polyamine to the epoxy resin within a certain range; blocking the addition product by adopting the single epoxy compound, so as to obtain the curing agent which meets the water soluble requirements and has excellent application performance. The self-emulsifying water-borne epoxy resin curing agent has a good adaptive phase and coating property when being applied to a coating. The mode of neutralizing and blocking by adopting an organic acid when the self-emulsifying water-borne epoxy resin curing agent is prepared at present is abandoned, the process is simplified, and the problems that the cation water-soluble epoxy curing agent neutralized and prepared by adopting the organic acid is sensitive to pH value, and the unstability is generated when a basic dye and a filler are used together are solved.

Owner:BEIJING BSS CORROSION PROTECTION IND +1

Modified polyacrylate microemulsion, synthesis mehtod and use thereof

The present invention belongs to the field of high-molecular material, and is related to a modified polyacrylate microemulsion, its synthesis method and application. Said synthesis method includes the following three steps: (1). pre-emulsifying nuclear monomer; (2). pre-emulsifying shell monomer; and (3) making polymerization by using nucle-shell polymerization process. The microemulsion composition contains 28-34 wt% of modified polyacrylate polymer, 2-3 wt% of emulsifier, 3-4 wt% of surfactant adjuvant and the rest is water, and the average grain size of the modified polyacrylate polymer in the emulsion is less than 100 nm. Said microemulsion can be used as adhesive of textiles.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Conductive macromolecular solution, preparation thereof, conductive polymer coated film and solid electrolyte capacitor

InactiveCN101486836AImprove conductivityHigh light transmittanceCapacitor electrolytes/absorbentsOrganic conductorsElectrolysisPolymer science

An electroconductive polymer solution contains electroconductive high molecules and polyanion. Under 25 DEG C, the oxygen content in the electroconductive polymer solution is below 8 weight ppm. An electroconductive coating film using the solution has high transmittance and low resistance. Applied to a solid electrolytic capacitor, the electroconductive polymer solution can improve the conductivity of solid electrolysis and filling behavior, therefore, a solid electrolytic capacitor with low ESR and other excellent properties is obtained.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

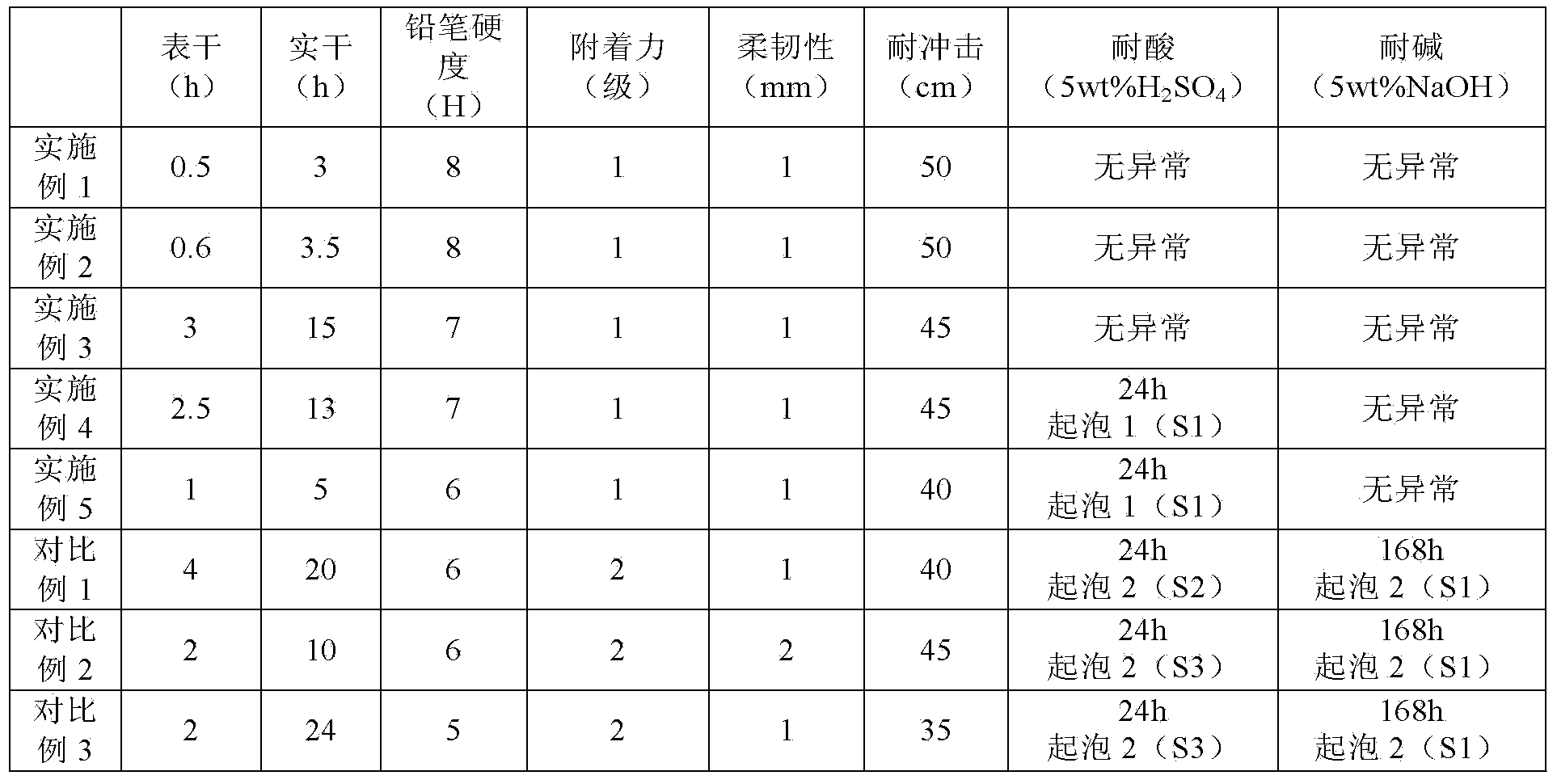

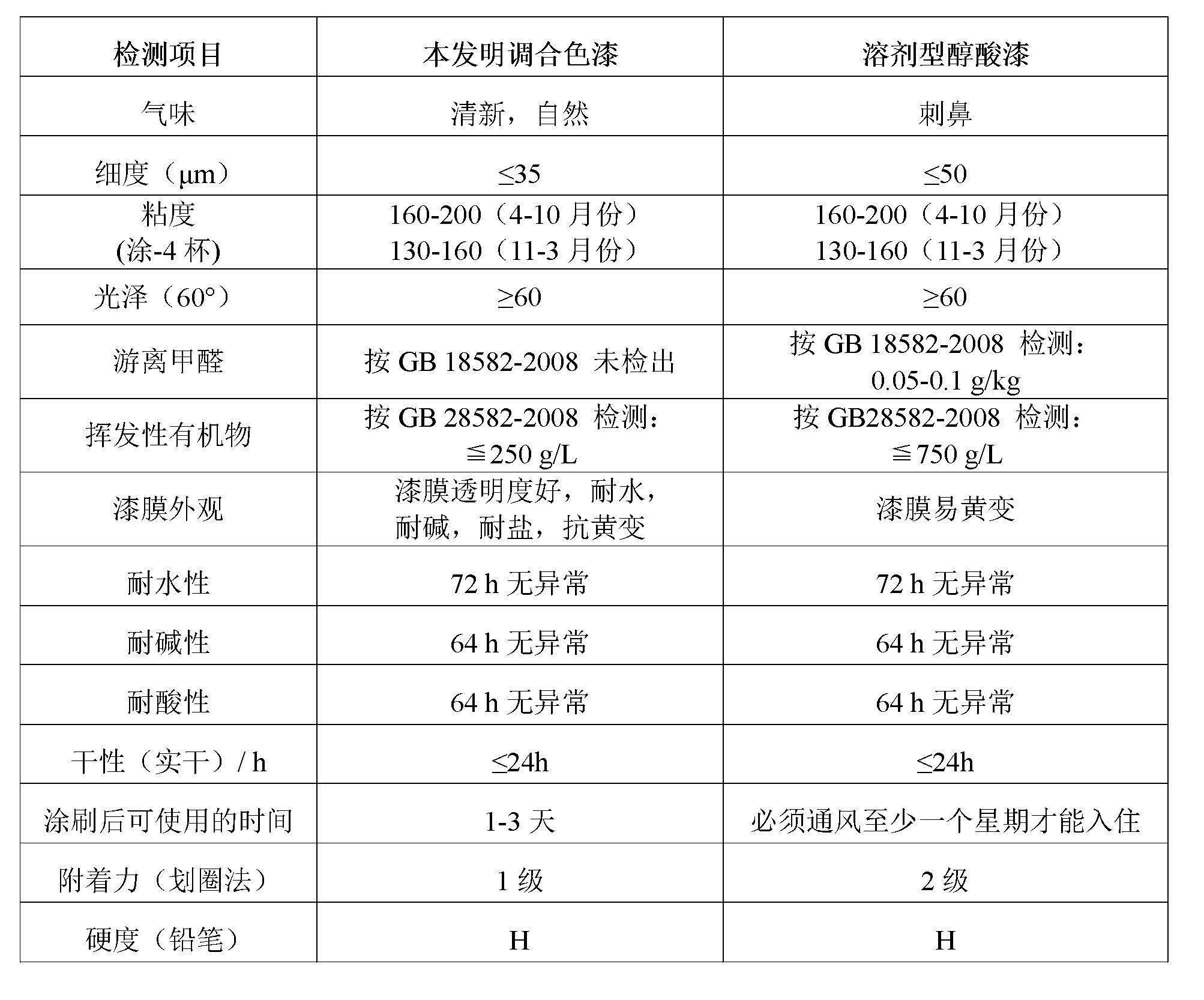

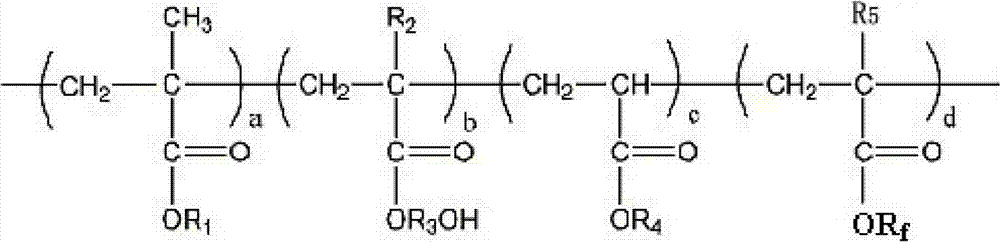

Aqueous dispersed alkyd blend colored paint and preparation method thereof

ActiveCN102690589AIncreasing the thicknessDry fastPolyester coatingsWater dispersibleOrganic solvent

The invention discloses aqueous dispersed alkyd blend colored paint and a preparation method thereof. The aqueous dispersed alkyd blend colored paint is made of, by weight, 40%-46% of alkyd resin, 2%-6% of petroleum resin, 10%-28% of color filler, 0.3%-0.8% of defoaming agent, 0.4%-0.8% of organic clay, 0.3%-0.6% of wetting agent, 0.5%-1% of drier, 0.1%-0.3% of anti-skinning agent, 20%-35% of cosolvent and 5%-10% of organic solvent. The aqueous dispersed alkyd blend colored paint is fresh and natural in smell and has excellent gloss, bonding force, flexibility, water resistance, corrosion resistance and outdoor durability.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

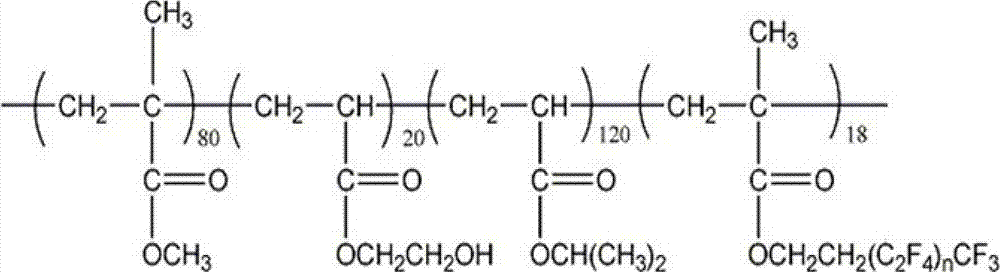

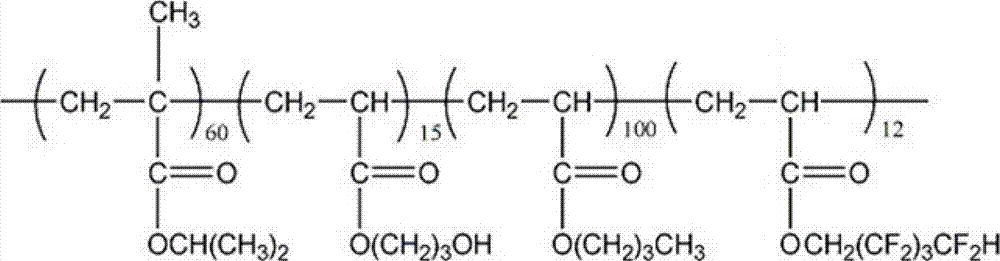

Cross-linked fluorine (methyl)-containing acrylic segmented copolymer and its preparation method and use

InactiveCN102827335AStrong process controllabilitySmall molecular weight distributionPolyurea/polyurethane coatingsCross-linkPolymer science

The invention discloses a cross-linked fluorine (methyl)-containing acrylic segmented copolymer and its preparation method and use, and belongs to the field of chemical materials. The preparation method comprises that various (methyl) acrylate functional monomers are copolymerized into the cross-linked fluorine (methyl)-containing acrylic segmented copolymer by an atom transfer radical polymerization (ATRP) method. A structure, molecular weight and molecular weight distribution of the cross-linked fluorine (methyl)-containing acrylic segmented copolymer can be controlled. The molecular weight of the cross-linked fluorine (methyl)-containing acrylic segmented copolymer is in a range of 10000 to 35000 and the molecular weight distribution is less than 1.4. The cross-linked fluorine (methyl)-containing acrylic segmented copolymer is mixed with a curing agent according to a certain ratio and the mixture self-assembles in a selective solvent so that a micellar solution having an average particle size of about 100 to 450nm is formed. Through a solvent evaporation film-forming method, the micellar solution is prepared into a super-hydrophobic coating film having a contact angle of more than 150 degrees, hardness H and second-level adhesion. The preparation method has simple and feasible operation processes, a low cost and a wide application prospect in the field of water-proofing and moisture-proofing coatings.

Owner:SOUTH CHINA UNIV OF TECH

Organic-inorganic hybrid super-hydrophobic coating and preparation method thereof

InactiveCN105153866AExcellent superhydrophobic propertiesImprove hydrophobicityCoatingsSolventOrganic polymer

The invention relates to an organic-inorganic hybrid super-hydrophobic coating. The coating is prepared by mixing a granule-polymer grafted hybrid with a solvent, then forming a film by coating and drying the film, wherein the granule-polymer grafted hybrid is a copolymer prepared by grafting after mixing modified inorganic nanoparticles with an organic polymer in a mass ratio of 1 to (1-4). The drop contact angle of the super-hydrophobic coating does not exceed 160 degrees and the angle of slide is 2+ / -2 degrees. The super-hydrophobic coating not only has excellent super-hydrophobicity but also has the special properties, such as freedom from dust and self-cleaning. Meanwhile, the coating prepared by grafting the polymer after modification of the inorganic nanoparticles is more uniform and dispersive and has better coating effects. A preparation method is simple, is easy to operate and is suitable for industrial production.

Owner:江苏丰彩建材(集团)有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com