Delustering waterborne polyurethane leather finishing agent and preparation method thereof

A water-based polyurethane and leather finishing agent technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Problems such as the compactness of emulsion film formation and the influence of film performance, to achieve low surface tension, excellent matting effect, and the effect of being suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

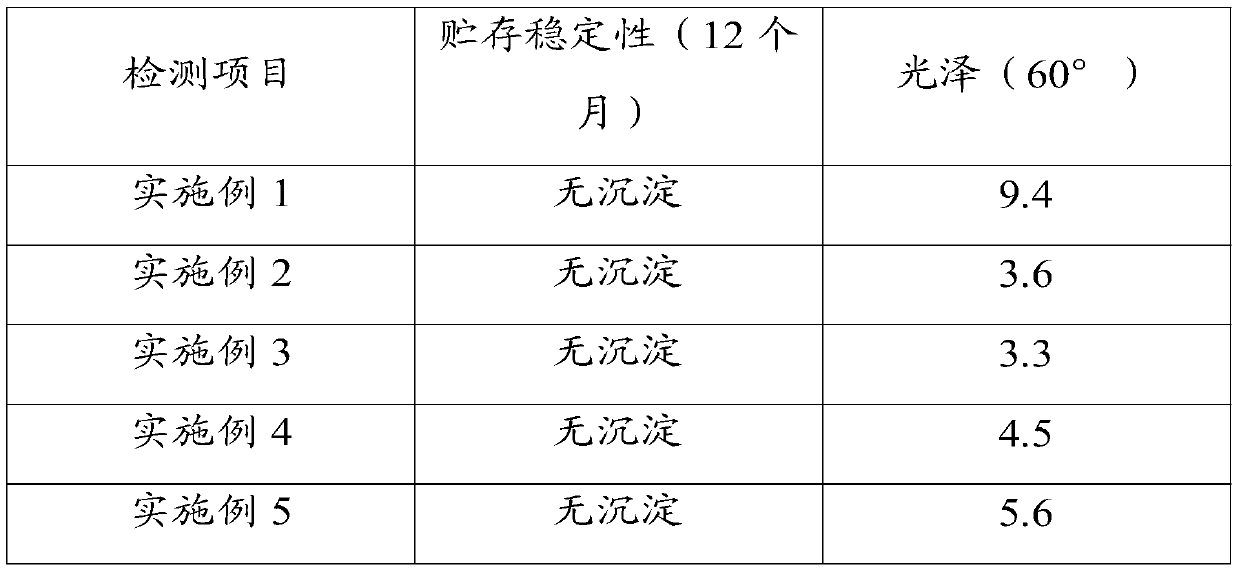

Examples

Embodiment 1

[0058] A kind of preparation method of matting type waterborne polyurethane leather finishing agent, comprises the steps:

[0059] Weigh 21.632g of aminopropyl polydimethylsiloxane and 10.816g of PEG, add them into the flask, and vacuumize at 100°C for 1h to remove water. The temperature was lowered to 40°C, 8.7g TDI and 3 drops of T12 were added, and the temperature was raised to 90°C for 4h. Cool down to 50°C, add 20g of acetone and 2.255g of DMPA, raise the temperature to 70°C, and react for 2 hours. After the temperature drops to about 10°C, pour the product into a beaker, quickly add 1.700g of triethylamine and 150.3g of water at a stirring speed of 1000r / min, and emulsify at a speed of 3000r / min for 5min. The acetone was removed by rotating the emulsion at 36°C to obtain a matte water-based polyurethane leather finishing agent.

Embodiment 2

[0061] A kind of preparation method of matting type waterborne polyurethane leather finishing agent, comprises the steps:

[0062] Weigh 26.826g of hydroxyl-terminated polydimethylsiloxane and 6.67g of PPG1000, add them into the flask, and vacuumize at 90°C for 2h to remove moisture. Lower the temperature to 60°C, add 8.433g TDI and 5 drops of T12, and react at 85°C for 3h. Cool down to 45°C, add 30g of acetone and 2.3g of DMPA, raise the temperature to 65°C, and react for 4 hours. After the temperature dropped to about 5°C, pour the product into a beaker, quickly add 1.734g triethylamine and 153.9g water at a stirring speed of 1000r / min, and emulsify at a speed of 3000r / min for 5min. The acetone was removed by rotating the emulsion at 36°C to obtain a matte water-based polyurethane leather finishing agent.

Embodiment 3

[0064] A kind of preparation method of matting type waterborne polyurethane leather finishing agent, comprises the steps:

[0065] Weigh 28.91g of silanol-based polydimethylsiloxane and 4.818g of PTMG, add them into the flask, and vacuumize at 110°C for 1 hour to remove moisture. Lower the temperature to 85°C, add 8.242g HDI and 5 drops of T12, and react for 4h. Cool down to 40°C, add 25g of acetone and 2.3g of DMPA, raise the temperature to 65°C, and react for 4 hours. After the temperature drops to about 15°C, pour the product into a beaker, quickly add 1.734g triethylamine and 107.3g water at a stirring speed of 1000r / min, and emulsify for 5min at a rotating speed of 2000r / min. The acetone was removed by rotating the emulsion at 36°C to obtain a matte water-based polyurethane leather finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com