Patents

Literature

209results about How to "Good matting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

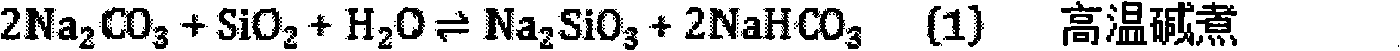

Method for producing porous nano silica and active carbon by utilizing rice hull ash

InactiveCN101920966AIncrease the reaction areaImprove reaction speedSilicaSolid waste disposalActive carbonChemistry

The invention discloses a method for producing porous nano silica and active carbon by utilizing rice hull ash, which comprises the following steps of: at lower temperature and normal pressure, performing secondary alkali dissolution on subcarbonate, and filtering to obtain alkali-dissolved filter liquor and filter residue; adding a certain amount of dispersing agent into the filter liquor, reducing temperature for ageing, filtering, washing, and removing the dispersing agent to obtain the porous nano silica; and adding an activating agent into the alkali-dissolved filter residue, activating, washing and drying to obtain the high specific surface area active carbon. The alkali and the active carbon can be recycled, and only a small amount of alkali and active carbon is lost. The method has the advantages of not seriously corroding equipment due to no high-temperature and high-pressure alkali boiling, sufficient raw materials, low price, no environmental pollution, and higher quality of the obtained active carbon and silica.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

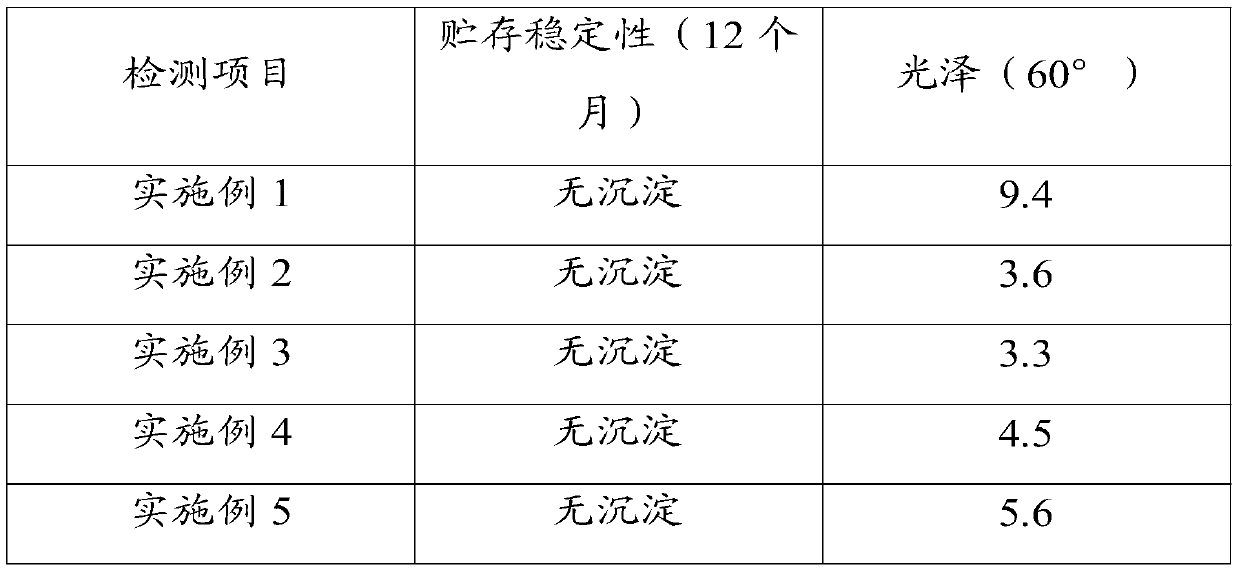

Low-luster polypropylene blending modified material and preparation method thereof

The present invention relates to the blending and modifying field of the polymer material, and discloses a polypropylene blend modified material with the lowered surface gloss. The polypropylene blend modified material of the present invention consists of the following components and weight percentages: 20 to 90 percent of polypropylene, 10 to 80 percent of polyethylene, 0 to 2 percent of peroxide cross-linking agent, 0 to 5 percent of antioxidant, 0 to 5 percent of processing aid, and 0 to 30 percent of filler. The preparation method is: the components are blended in the high-speed mixer for 5 to 15 minutes according to the proportion; the twin-screw extruder is used to melt and blend; the temperature of the extruder is set to be between 100 and 220 Celsius system, and the rotating speed of the screw to be 150 to 400 rounds per minute; after pelletizing and drying, the polypropylene blend modified material can be made. The polypropylene blend modified material of the present invention has the lowered surface gloss and the good extinction effects, and can be used in the fields such as the packaging, daily necessities and building materials, and so on.

Owner:广东波斯科技股份有限公司

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

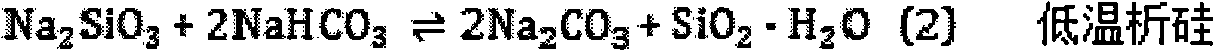

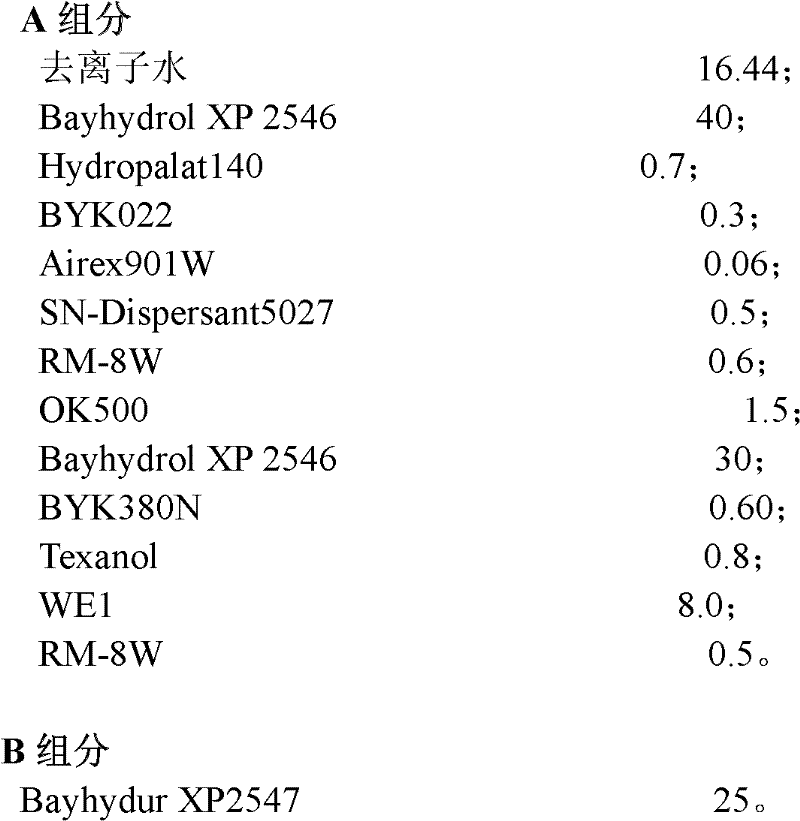

Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

InactiveCN102533077AReduce glossOvercome the disadvantage of uneven mattingPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a double-component water-based polyurethane high-abrasion-resistance matte coating and a preparation thereof. The coating comprises two components A and B, wherein the component A is prepared by using an acrylic resin dispersion body as a basic component and adding deionized water, a wetting agent, a defoaming agent, a dispersing agent, a thickening agent, a delustering agent, a leveling agent, a film forming additive and a water resistant additive to the acrylic resin dispersion body to disperse the acrylic resin dispersion body; and the component B is aliphatic polyisocyanate. The invention provides a water-based matte coating with low VOC (Volatile Organic Compounds), low gloss, good adhesion force, wear resistance and corrosion resistance; and the water-based matte coating can be very well combined with a water-based or solvent type epoxy resin floor coating and a polyurethane floor coating. The water-based matte coating disclosed by the invention has the advantages of low delustering agent adding quantity and stability in storage; the gloss of the coating system can be effectively reduced; and the comprehensive performance of the coating system is improved. By using the double-component water-based polyurethane high-abrasion-resistance matte coating disclosed by the invention, the water-based coating system solution with environment friendliness, high performance, stability in storage and low cost can be provided.

Owner:CENT SOUTH UNIV +1

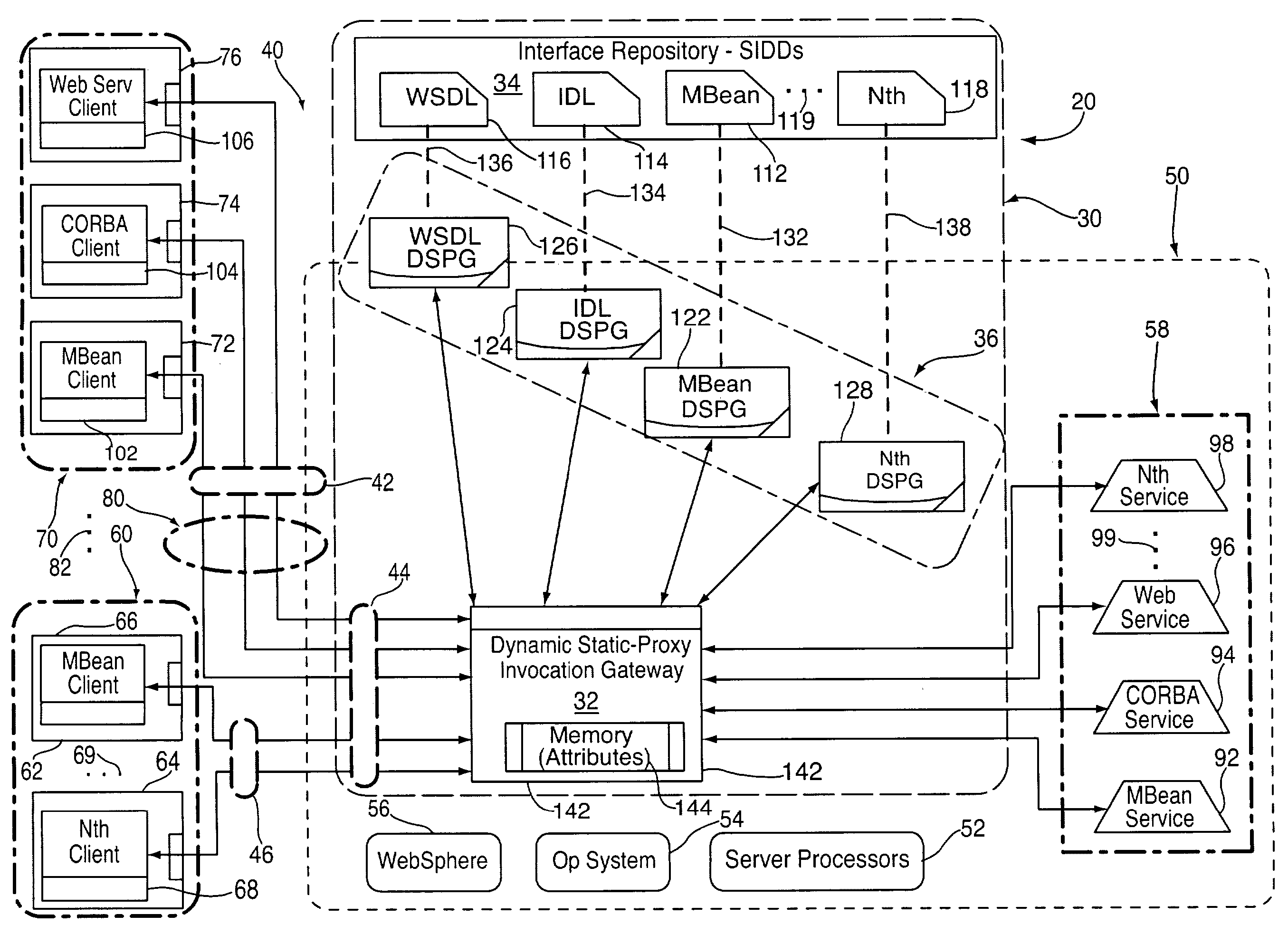

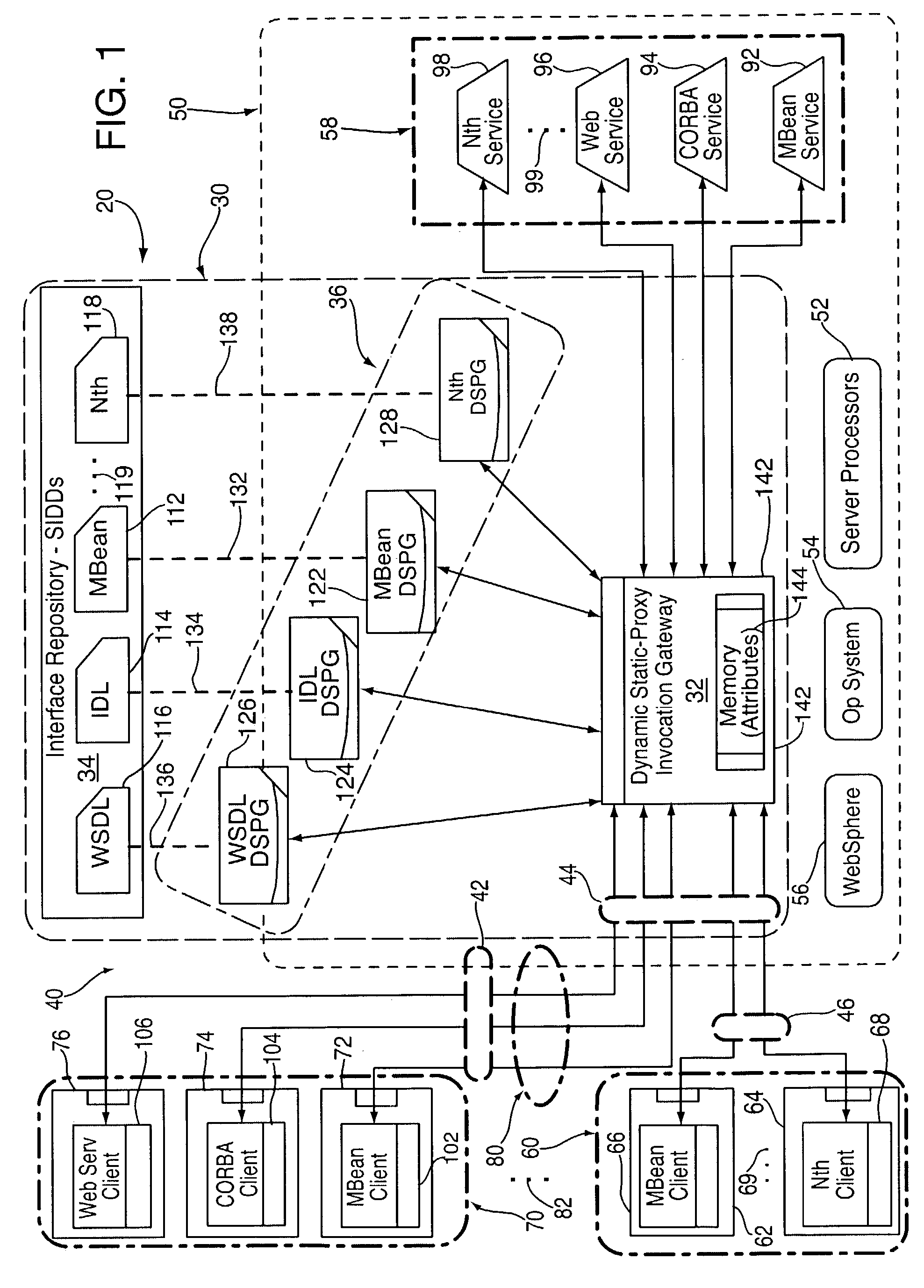

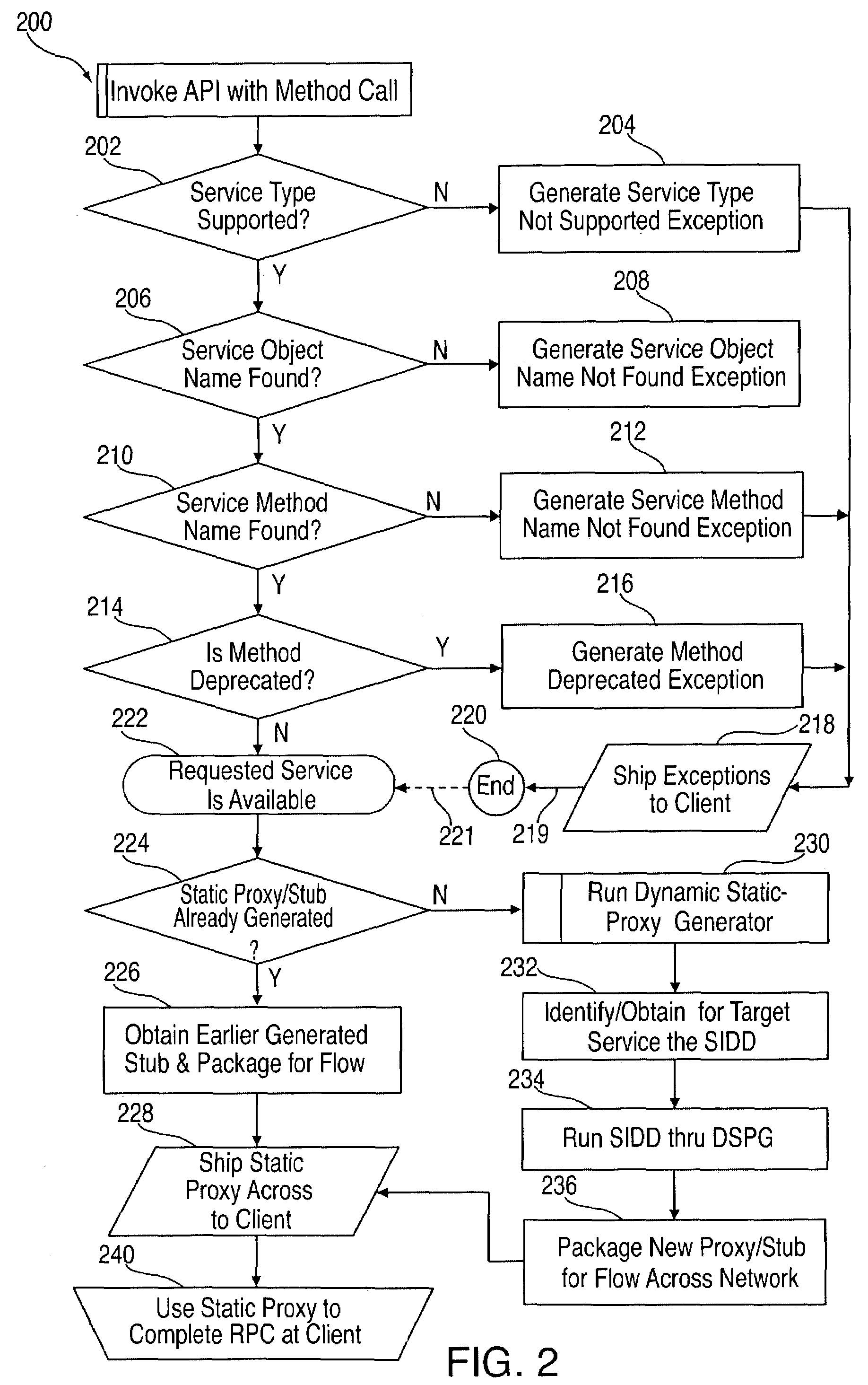

Dynamic generator for fast-client static proxy from service interface definition document

InactiveUS7356562B2Faster deploymentGood mattingMultiple digital computer combinationsSecuring communicationClient-sideType of service

Providing APIs for dynamically generating fast client-side proxies given any type of service interface specification / definition document, such as IDL, WSDL or JMX MBean descriptors, so as to provide fast communication with distributed clients as well as dynamically allowing server interfaces to be updated without burdening clients for generation / assembly of distributed communication client stubs. A dynamic static-proxy invocation gateway is utilized along with a plurality of novel dynamic static-proxy invocation generators, one being associated with each specific service available for use on the servers. The invocation gateway receives requests for service from a client side stub, ascertains the service to be accessed by the client requests, and causes the appropriate generator to create dynamically a static client-side proxy for the requested service, if one does not yet exist.

Owner:GOOGLE LLC

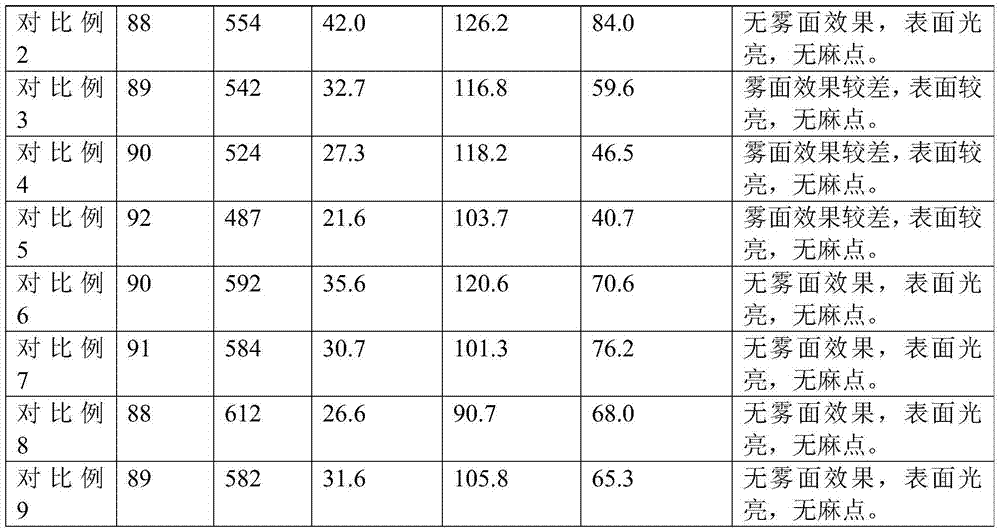

Delustering waterborne polyurethane leather finishing agent and preparation method thereof

ActiveCN105506997AImprove compactnessImprove stabilityFibre treatmentLeather surface finishingMechanical propertyRaw material

The invention provides a delustering waterborne polyurethane leather finishing agent and a preparation method thereof. The delustering waterborne polyurethane leather finishing agent is mainly prepared from diisocyanate, polyether glycol, organosiloxane, a hydrophilic chain extender, a catalyst and a neutralizer. According to the delustering waterborne polyurethane leather finishing agent, the specific raw material composition and dosage are adopted, and an excellent delustering effect is obtained without adding a delusterant. The delustering waterborne polyurethane leather finishing agent is good in compactness, stability and coating property, can guarantee the mechanical property and waster resistance of a leather coating and is environmentally friendly, nontoxic and safe. The preparation method of the delustering waterborne polyurethane leather finishing agent is simple in technology, the waterborne polyurethane leather finishing agent with an excellent delustering property is synthesized in a step-by-step feeding reaction mode, and the preparation method is suitable for large-scale production.

Owner:优美特(北京)环境材料科技股份公司

Production method for full-dull nylon 6-slice

ActiveCN101314673AGood dispersionPrevent precipitationArtifical filament manufactureMonocomponent polyamides artificial filamentNylon 6Engineering

The invention provides a method for manufacturing full-dull nylon-6 chips, which belongs to the field of spinning chip, in particular to full-dull nylon-6 chips manufactured by using titanium dioxide (TiO2) as a dulling agent. The method aims to solve the problem in the production of the prior dulling agent solvent. The method has the technical scheme that (1) a proper TiO2 and TiO2 solution collocation method is selected; (2) proper formulation and process are selected; and (3) a stirring device for dispersing TiO2 dulling agent solution is selected. The technical scheme can improve the TiO2 content in the polymerization process of nylon-6, and the polymer melt is filtered to remove large-diameter TiO2. Accordingly, high-performance chips with good dull performance, good TiO2 dispersion and good spinning performance can be obtained.

Owner:GUANGDONG XINHUI MEIDA NYLON

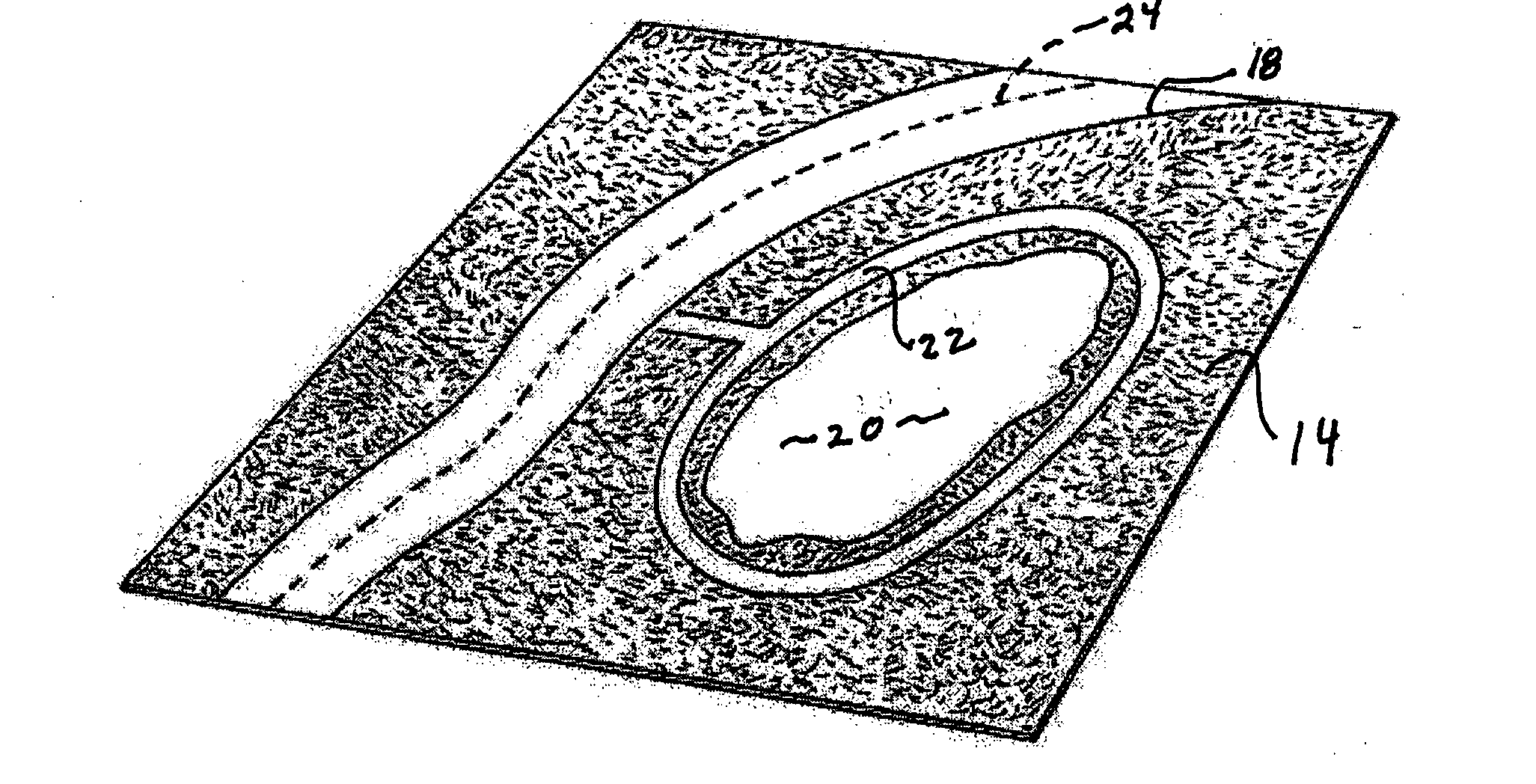

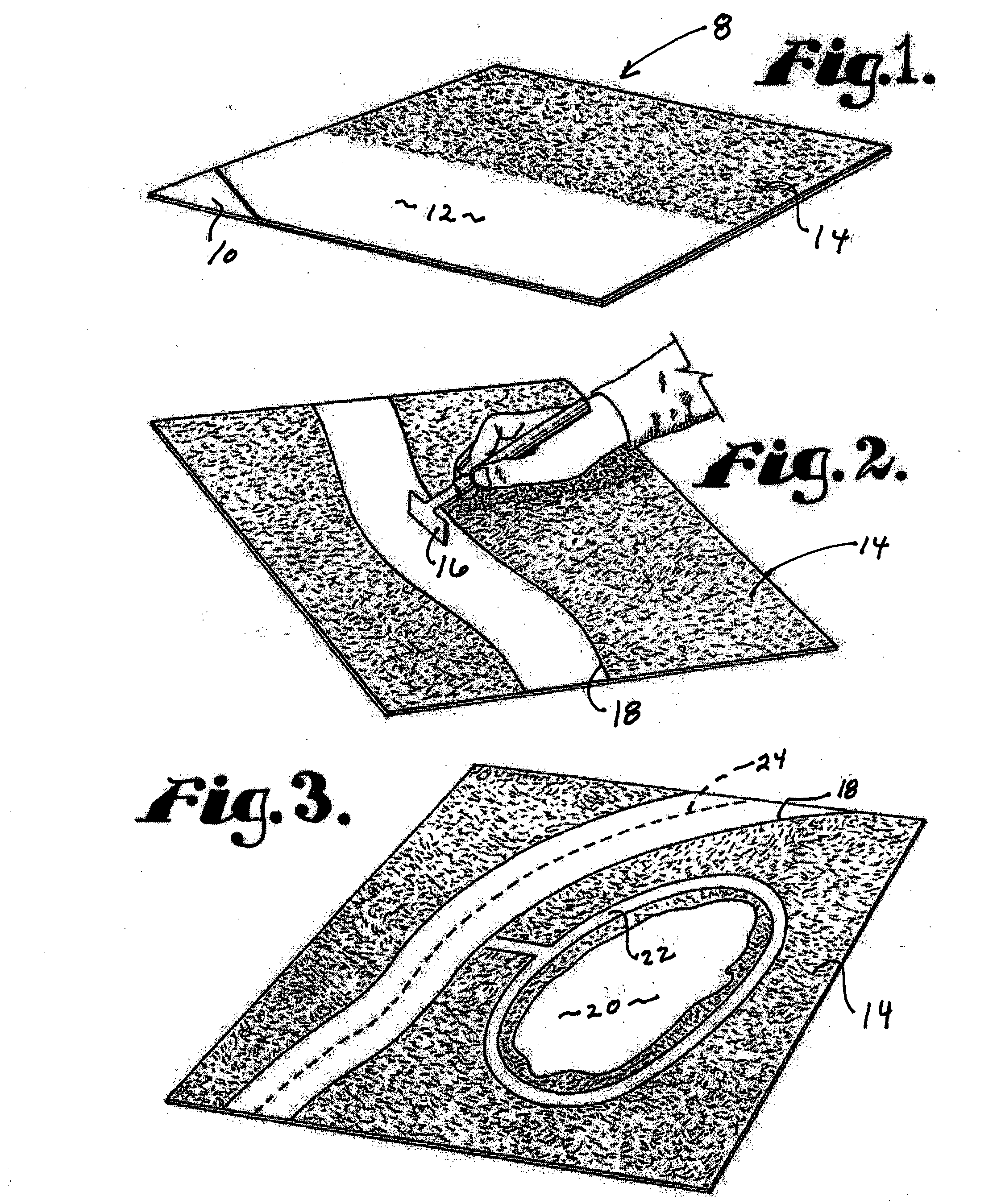

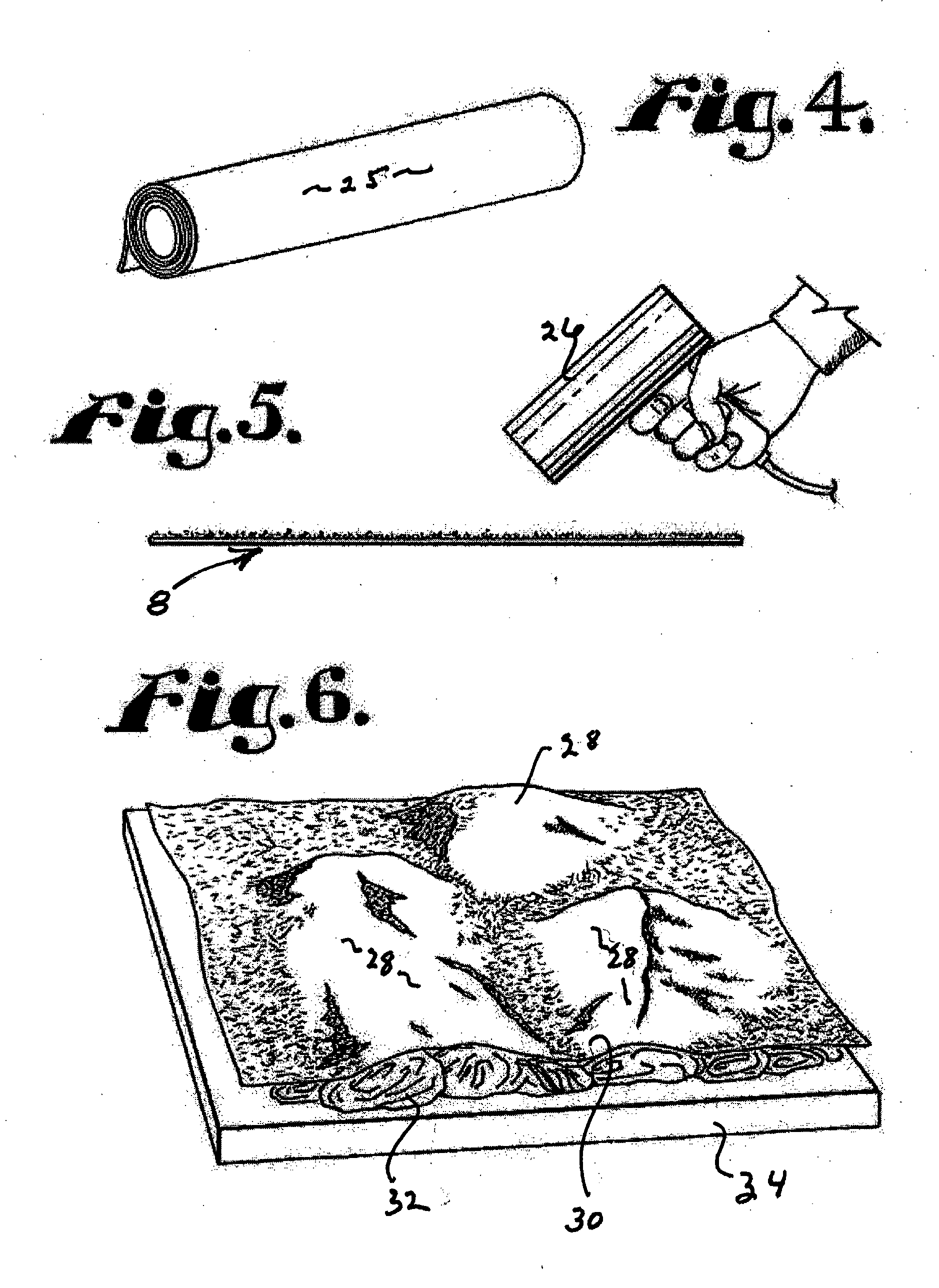

Simulated turf and method of making same

A mat for simulating natural terrain for use in an indoors display is the subject of this invention. The mat comprises a sheet of water impervious resinous material, a water base latex emulsion coating applied to the resinous material and a quantity of terrain simulating particles which are adhered to the sheet by the dried coating. The particles are fixed to the sheet by a sealant which is sprayed on the particles after the coating has dried. The particles may comprise flocking, ground foam rubber or rigid solid pieces. The invention also encompasses a method of preparing a simulated natural terrain utilizing the mat as afore described. This method includes outlining desired terrain features, applying water to the outlined area, scraping the substrate to remove particles from the outlined area and then coloring the area. Additional terrain features can be incorporated into the mat by scraping the mat to expose the underlying substrate in the shape of a design in the roadway such as a centerline, crosswalk or the like. Still further terrain simulating features may by utilizing a heat source to raise the temperature of the substrate and then shaping it into hills and valleys.

Owner:OSMENT MODELS

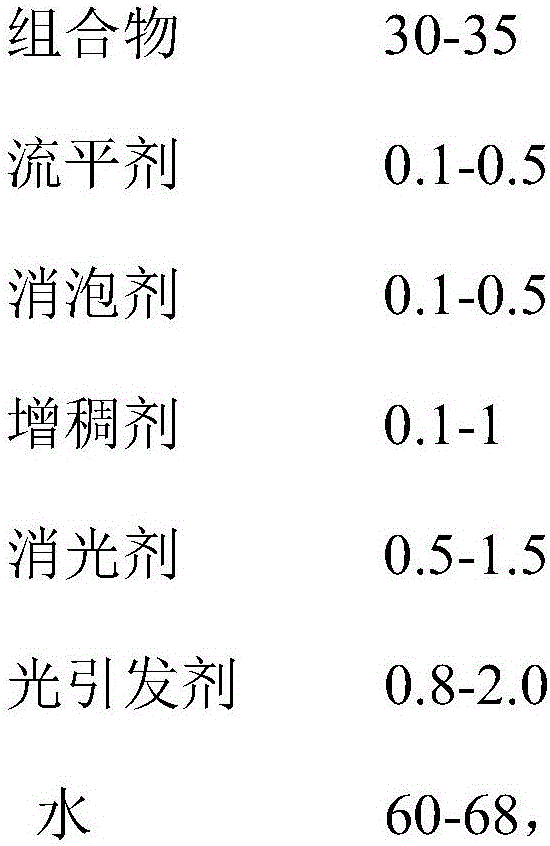

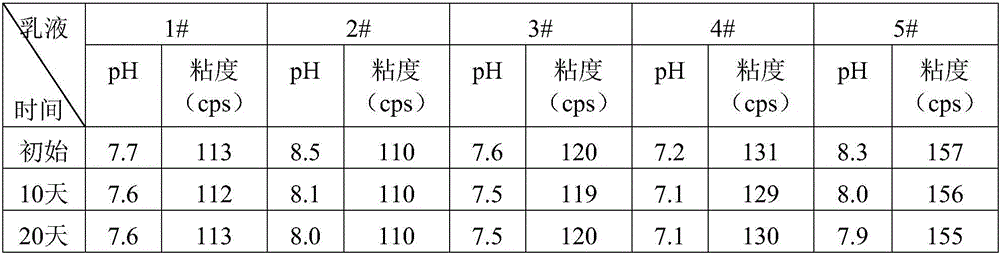

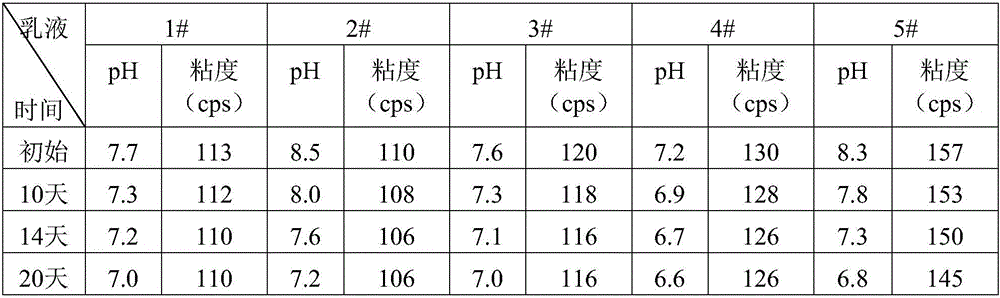

Waterborne radiation-supportive curing polyurethane acrylate combination, preparation method and coating

ActiveCN105669938AReduce the degree of hydrolysisEvenly distributedPolyurea/polyurethane coatingsOligomerWater dispersible

The invention provides a waterborne radiation-supportive curing polyurethane acrylate combination. The combination comprises, by weight, 20-80 parts of polyurethane acrylate oligomer A and 20-80 parts of water dispersible polyurethane polymer B. The combination is high in stability, pH value is 7.5-9, and viscosity is 10-500 cps; when being stored at temperature below 25 DEG C for 20 days, the pH value is lowered by less than 10% than an initial value, and the viscosity is changed by less than 10% than an initial value; when being stored at temperature below 50 DEG C, the pH value is lowered by less than 20% than an initial value, and the viscosity is changed by less than 10% than an initial value.

Owner:WANHUA CHEM GRP CO LTD +1

Matte resin film

InactiveUS20090246483A1Improve Design PerformanceGood mattingDecorative surface effectsDuplicating/marking methodsHazeComposite material

A matte resin film comprising a resin film substrate and a matte layer formed on at least one surface of the substrate, wherein a 60 degree specular gloss Gs on the surface of the matte layer is 5% to 100%, a haze H satisfies the equation: H(%)<1400 / Gs(%), and a 85 degree specular gloss Gs′ on the surface of the matte layer is smaller than Gs, which exhibits an excellent matte effect even when a pattern is viewed at any viewing angle.

Owner:SUMITOMO CHEM CO LTD

Aqueous dumb paint and method for preparing same

Disclosed is a watersoluble whose components and content of mass are:latex base material, wax powder 0.7-0.8%, water 20-25%, assistant 2-3%. Besides,the preparing method for the watersoluble is also disclosed. It is a watersoluble polyacrylate latex,with better hardness and flexibility,when it is coated on the paper surface,its wear resistance and film forming performance are all good,as well as hand feeling.

Owner:广州电器科学研究院

Production method of full-dull polyester fiber

InactiveCN103451768AAbsolute Addition ReductionIncrease drapeFilament/thread formingMonocomponent polyesters artificial filamentPolyesterMaterials science

The invention provides a production method of a full-dull polyester fiber. According to the production method, common semi-dull polyester chips are taken as a main producing material, and melt spinning is performed by adding full-dull master batch so as to produce the full-dull polyester fiber. A composite spinning component is used in the melt spinning process, correspondingly, the material chips are divided into two or more components, the full-dull master batch is added into one component in the feeding process, and the content of titanium dioxide particles accounts for 1wt%-5wt% of the total weight parts of the fiber.

Owner:SUZHOU LONGJIE SPECIAL FIBER

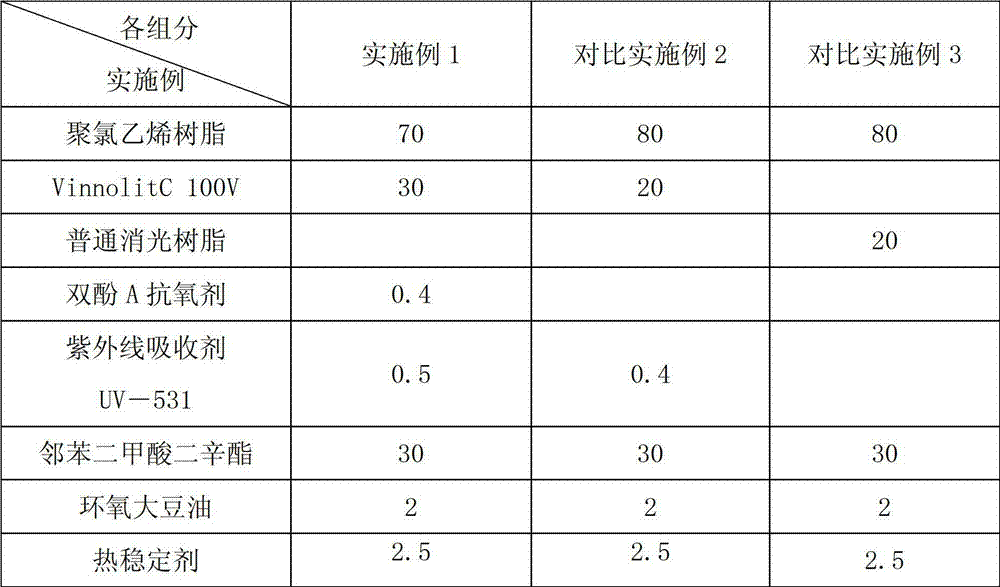

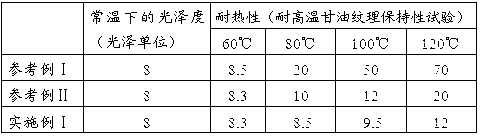

Matting resin modified polyvinyl chloride (PVC) matt film

The invention relates to a matting resin modified polyvinyl chloride (PVC) matt film, belonging to the technical field of PVC matt films. The matting resin modified PVC matt film comprises the following components: 60 to 90 weight parts of polyvinyl chloride resin, 10 to 40 weight parts of matting resin (VinnolitC 100V), 20 to 50PHR of dioctyl phthalate, 2 to 10PHR of epoxy soybean oil, 2 to 5PHR of a thermal stabilizer, 0.3 to 0.5PHR of an antioxidant, and 0.1 to 1.0PHR of an ultraviolet absorbent. The modified matt film can achieve surface effects of anti-sticking, matting, grain forming and the like, has a good surface matting effect, has high adaptability to processing conditions, and has the advantages of good matting effect and the like in a broad plasticizing temperature range.

Owner:TIANJIN TIANSU SCI & TECH GROUP

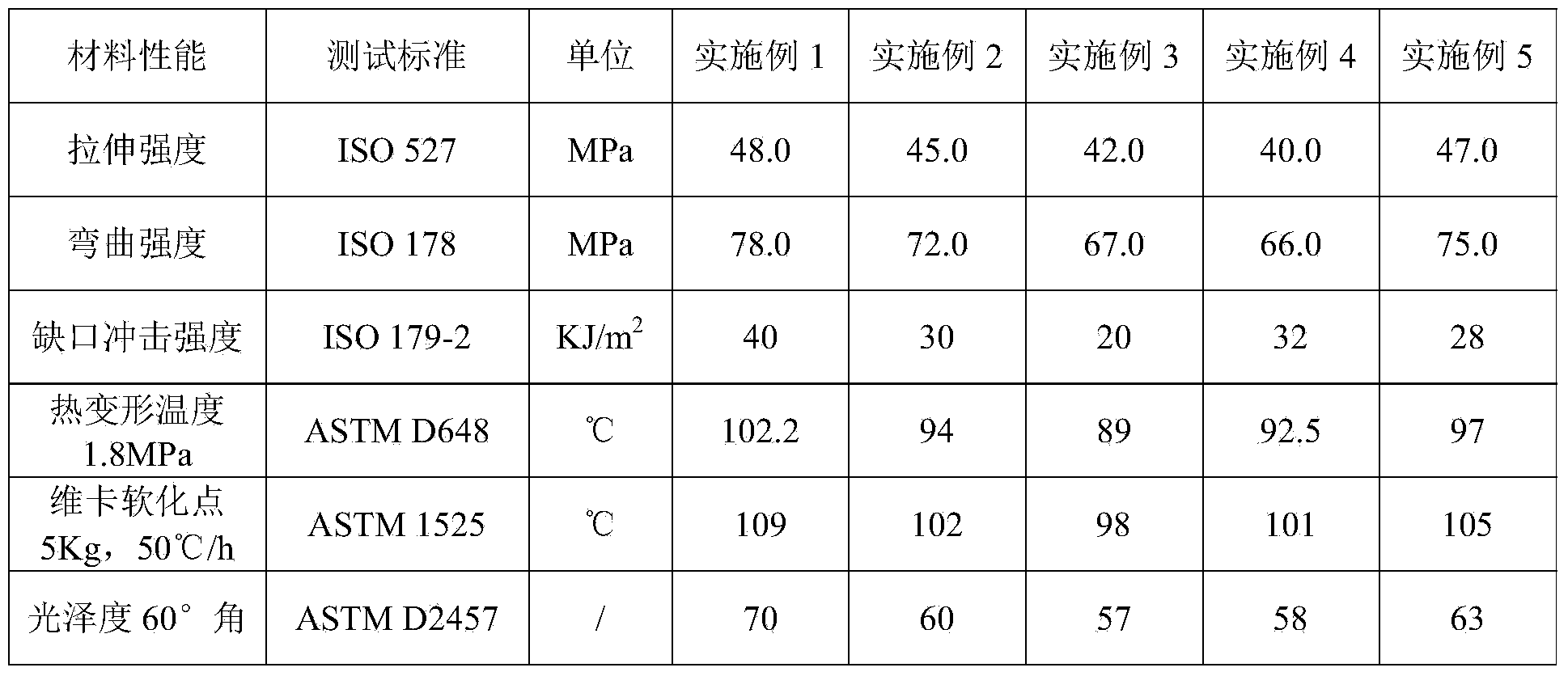

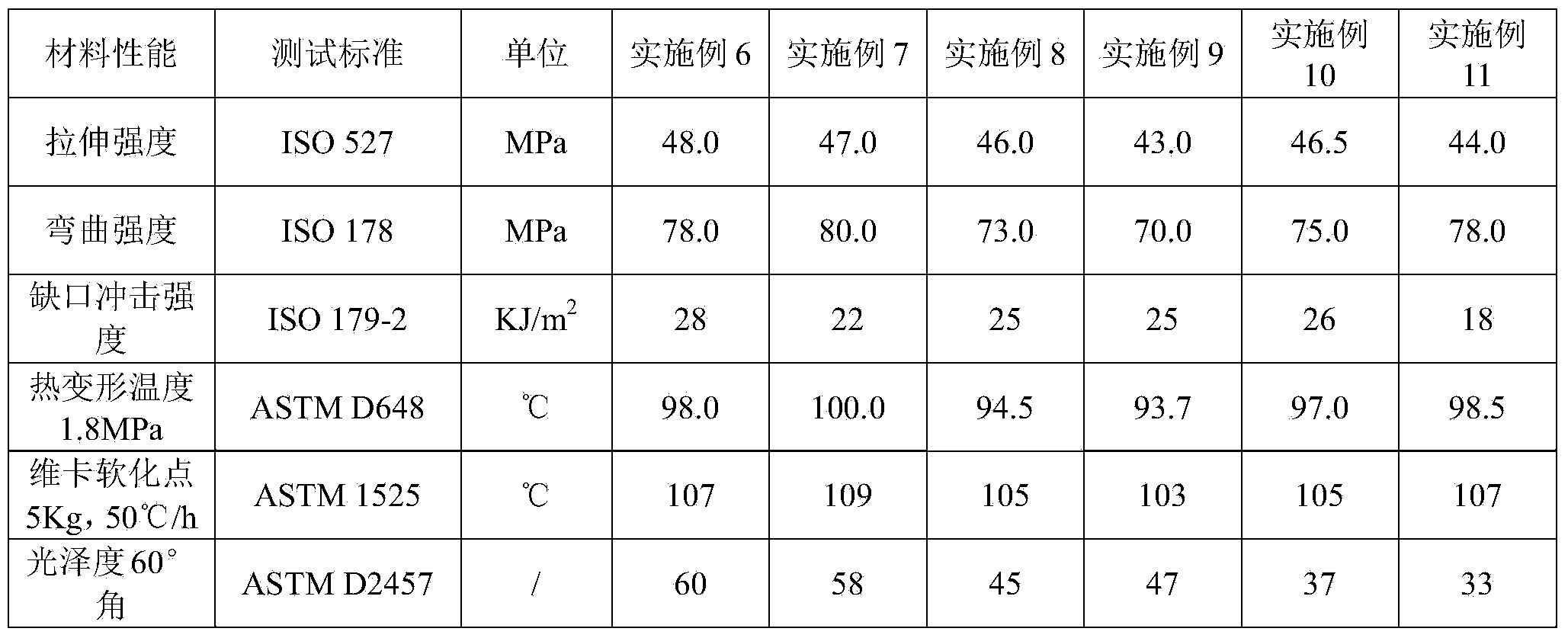

Extinctive PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) plastic alloy and manufacturing method thereof

The invention provides an extinctive PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) plastic alloy which is prepared from the following components in percentage by weight: 30-50% of PC, 40-65% of ABS, 1-10% of compatilizer, 1-5% of flatting agent, 0.2-1% of lubricant and 0.2-1% of antioxidant. The extinctive PC / ABS plastic alloy provided by the invention has the advantages of low surface glossiness, good toughness and flowability, low cost and the like. The manufacturing method is simple in processing step and low in comprehensive cost and is especially suitable for the fields of electronics, home appliances, automotive trims and the like.

Owner:青岛中新华美塑料有限公司

Preparation method of high polymerization degree delustering polyvinyl chloride resin

The invention provides a preparation method of high polymerization degree delustering polyvinyl chloride resin. The method includes: adding deionized water, an initiator, a dispersant, a buffering agent, a vinyl chloride monomer, a crosslinking agent and other materials into a polymerization kettle, and carrying out polymerization reaction at a suitable temperature to obtain the high polymerization degree delustering resin with delustering effect. The crosslinking agent is a monomer containing two or more reaction activity functional group structures. The crosslinking agent is added before the polymerization reaction or when the conversion rate is 0.5%-50%, or by a combined way of the two. At an appropriate temperature, the prepared high polymerization degree delustering polyvinyl chloride resin has the characteristics of neat particles, loose structure and good delustering effect. While acquiring a high polymerization degree with an average polymerization degree up to 1700 or more, the product also has good delustering effect, and is suitable for processing high polymerization degree delustering plastic products.

Owner:HANGZHOU ELECTROCHEM GROUP

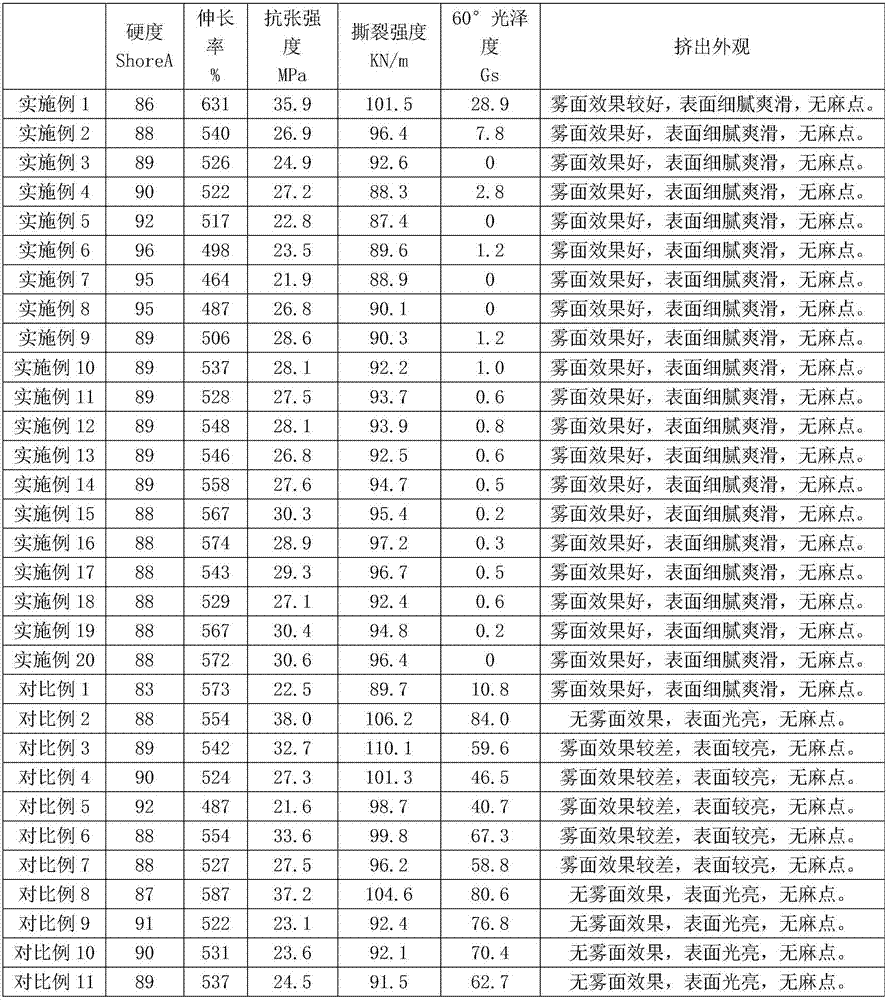

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The composition comprises, by weight, (A) 50%-95% of thermoplastic polyurethane elastomer, (B) 3%-45% of thermoplastic polyamide polymer or commixture of thermoplastic polyamide and thermoplastic polyamide polymer; (C) 1%-20% of a third component, wherein the third component is selected from one or more of inorganic filler, polycarbonate powder, PTFE (polytetrafluoroethylene) powder and organic (hypophosphite)phosphate. According to standard ASTM D523 tests, 60-degree surface glossiness is lower than 30Gs, and the composition is great in mechanical property and processability, uniform and delicate in surface matting effect, smooth in handfeel and suitable for preparation of cables, pipes, belts and film products.

Owner:WANHUA CHEM GRP CO LTD

Graft copolymer and thermoplastic resin composition

InactiveCN1486347AGood mattingGood lookingDispersed particle separationDisinfectionFunctional monomerMeth-

A thermoplastic resin composition comprising 10 to 98 parts by weight of a graft polymer (1A) containing a rubber-like polymer (1G) having a diene unit content of 50% by weight or less, 2 to 50 parts by weight of a hydroxyl group-containing acrylic copolymer (1B) and 0 to 80 parts by weight of other thermoplastic resin (1F), wherein the rubber-like polymer (1G) is at least one selected from the group consisting of a diene-based rubber, a polyorganosiloxane-based rubber and an olefin-based rubber; and, a graft copolymer (2A) obtained by grafting a vinyl-based polymer to a (meth)acrylate-based rubber-like polymer (2G) expansion-treated with an acid group-containing copolymer latex (2K) wherein the (meth)acrylate-based rubber-like polymer contains two or more poly-functional monomer units.

Owner:MITSUBISHI CHEM CORP

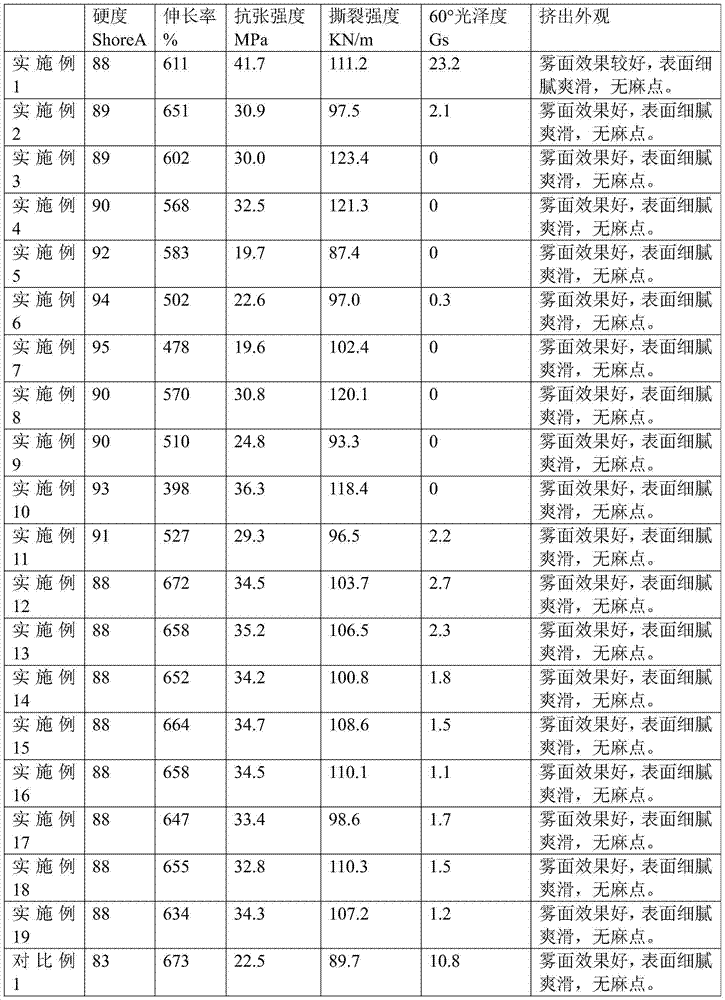

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

ActiveCN106928693AGood compatibilityImprove mechanical propertiesPolyesterThermoplastic polyurethane

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The low-glossiness thermoplastic polyurethane composition comprises, by mass percentage, 50-95% preferably 70-85% of thermoplastic polyurethane elastomer, 3-45% preferably 10-20% of thermoplastic polyester polymer and 1-20% preferably 5-10% of inorganic filler. The preparation method includes: melting and blending the components according to a certain proportion to obtain composition granules, and using melt extrusion equipment to extrude sheets of about 1mm. The low-glossiness thermoplastic polyurethane composition has the advantages that standard ASTM D523 tests show that the 60-degree-angle surface glossiness of the composition is lower than 30Gs, and the composition is good in mechanical performance and machining performance, even and fine and smooth in surface dulling effect, smooth in touch and suitable for being used for producing cables, pipes, belts and thin film products.

Owner:WANHUA CHEM GRP CO LTD

Matte wet and unsmooth feeling treating agent for synthetic leather and preparation method of treating agent

The invention discloses a matte wet and unsmooth feeling treating agent for synthetic leather and a preparation method of the treating agent. The matte wet and unsmooth feeling treating agent for the synthetic leather is formed by the following components: modified polyurethane resin, DMF (Dimethyl Formamide), n-butyl acetate, silicon dioxide extinction powder, wool grease, polyoxyethylene ether, castor oil and an organic silicon flatting agent. Compared with a conventional common matte leather surfactant, the matte wet and unsmooth feeling treating agent for the synthetic leather, disclosed by the invention, can obviously enable the matte extinction effect of the surface of a leather face to be good after treatment of the synthetic leather, so that the leather face has the unique wet and unsmooth wax feeling and the genuine leather effect of the leather face is strong; and the synthetic leather applying the matte wet and unsmooth feeling treating agent has the wet and unsmooth hand feeling and the comprehensive effect is good.

Owner:JIANGSU BAOZE POLYMER MATERIAL

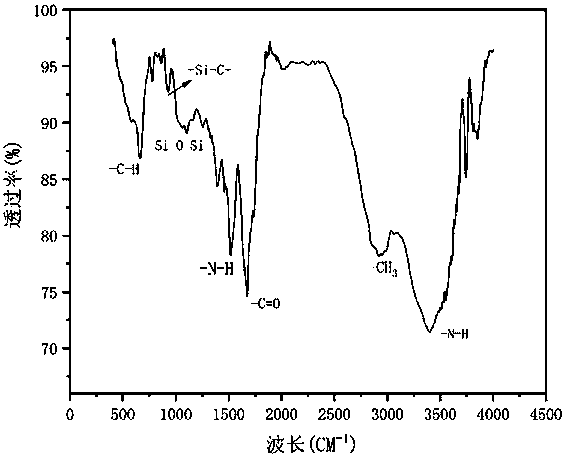

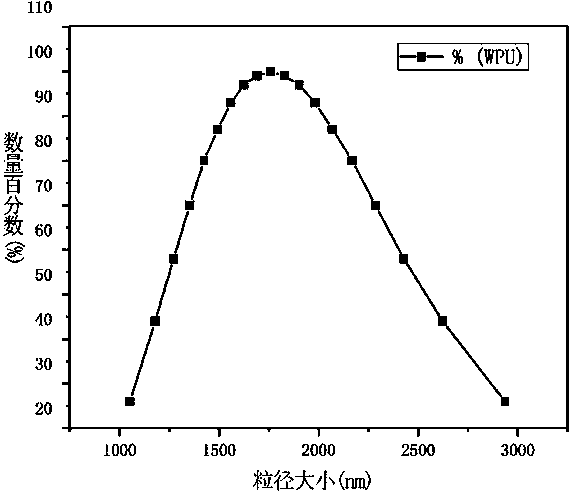

Environment-friendly self-extinction waterborne polyurethane and preparation method and application thereof

InactiveCN110951039AImprove wear resistanceEliminate durability concernsPolyurea/polyurethane coatingsLeather surface finishingSulfonatePolymer science

The invention discloses environment-friendly self-extinction waterborne polyurethane and a preparation method and application thereof. The preparation method comprises the following steps: first, preparing a polyurethane prepolymer, namely, respectively adding water-removed oligomer polymerized dihydric alcohol, a small-molecular trihydric alcohol compound and terminal hydroxyl-terminated organicsilicone oil into a reaction container, adding aliphatic diisocyanate and a catalyst, and performing reaction to obtain the prepolymer; adding a carboxylic acid type hydrophilic chain extender, and adding a neutralizer for neutralization reaction; and carrying out primary emulsification chain extension on an amine sulfonate hydrophilic chain extender and deionized water, adding a small-molecular chain extender containing active hydrogen, and carrying out secondary post-chain extension. The environment-friendly self-extinction waterborne polyurethane resin is large in particle size and wide indistribution, has micro-nano roughness, does not need to be added with any delustering agent, shrinks after a coating film is dried and dewatered, and is low in leather surface gloss, good in hand feeling, natural in surface, simple in preparation technological process and convenient to use.

Owner:SOUTH CHINA UNIV OF TECH

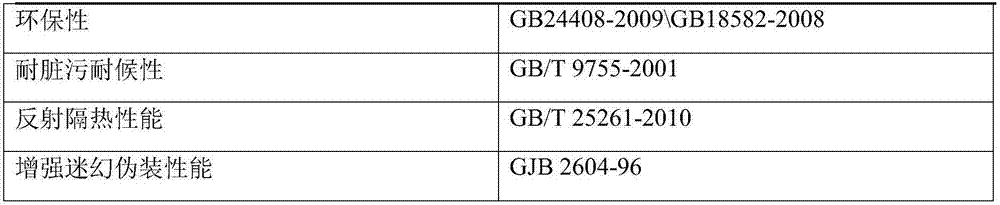

Psychedelic pseudo-decorative surface coating and preparation method thereof

ActiveCN107573789AEasy to operateNo four wastesAntifouling/underwater paintsPaints with biocidesWater basedContamination

The invention provides psychedelic pseudo-decorative surface coating. The psychedelic pseudo-decorative surface coating comprises base material water, aids, functional fillers and water-based resin, wherein the aids comprises preservative, a dispersing agent, a defoaming agent, propylene glycol, a film-forming agent, an anti-contamination aid and a thickening agent; the functional fillers compriseceramic silicon carbonate, ferrite magnetic powder, ferric oxide inorganic pigment, chlorophyll, hollow ceramic microbeads, aluminum plating powder and silicon dioxide; and the water-based resin comprises one or two of silicone acrylic emulsion, fluorocarbon emulsion, pure acrylic emulsion, polyurethane emulsion, epoxy resin, acrylic acid emulsion, alkyd resin and phenolic resin. In the technicalscheme of the invention, all the raw materials are environmentally friendly and are water-soluble environment-friendly raw materials. The psychedelic pseudo-decorative surface coating has non-toxic,odorless and environment-friendly effects; and the product has multiple functions of realizing reflective insulation, resisting dirt and weather, enhancing visible light near infrared radar magnetic wave detective psychedelic illusion, pretending blindage, realizing floating cloud psychedelic illusion, resisting ultraviolet rays, protecting bottom color paint, prolonging service life and the like.

Owner:宜昌市大棒科技有限公司

High-strength antistatic weather-resistant flame-retardant shell for electric power meters and preparation method thereof

InactiveCN107216549AIncreased insulation properties and mechanical strengthHigh hardnessPolypropyleneFlexural strength

The invention discloses a high-strength antistatic weather-resistant flame-retardant shell for electric power meters. The shell is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 25-35 parts of a polyolefin elastomer, 2-4 parts of graphene, 10-20 parts of glass fibers, 0.5-0.8 part of an antistatic agent, 8-12 parts of a processing aid, 0.8-1.6 parts of a coupling agent, 8-12 parts of hexamethylphosphoramide, 4-8 parts of nano-titania powder, 0.5-1.5 parts of nano-silica and 12-16 parts of a flame-retardant additive. The shell for the electric power meters is safe and environment-friendly, can resist static electricity, wear and aging, has relatively high tensile strength, bending strength and notch impact strength and is relatively long in service life and excellent in comprehensive property; and meanwhile, the raw materials are easily available, and the preparation method is relatively low in material cost and simple and clear in process and has relatively high practical values and good application prospects.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

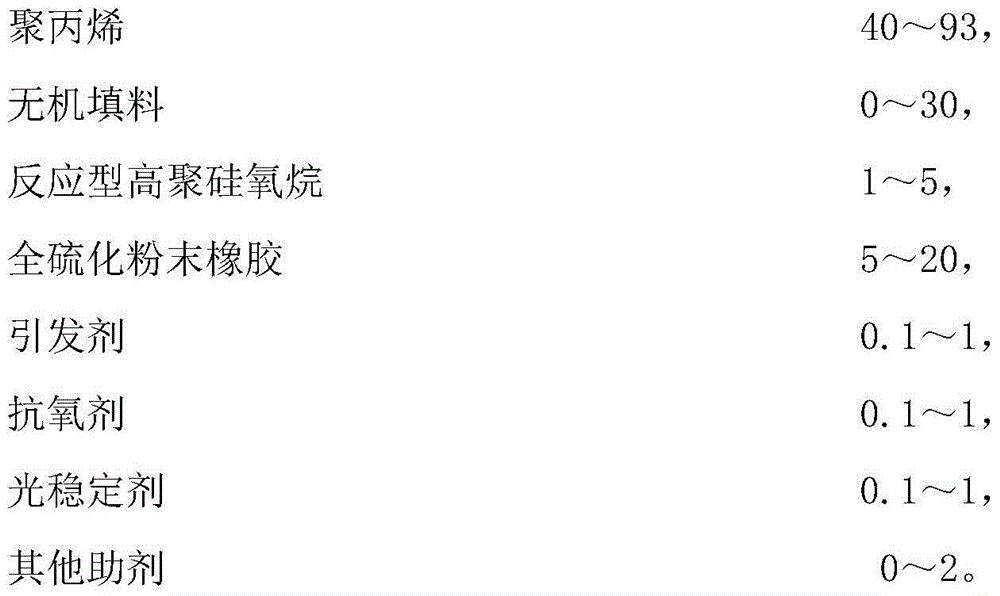

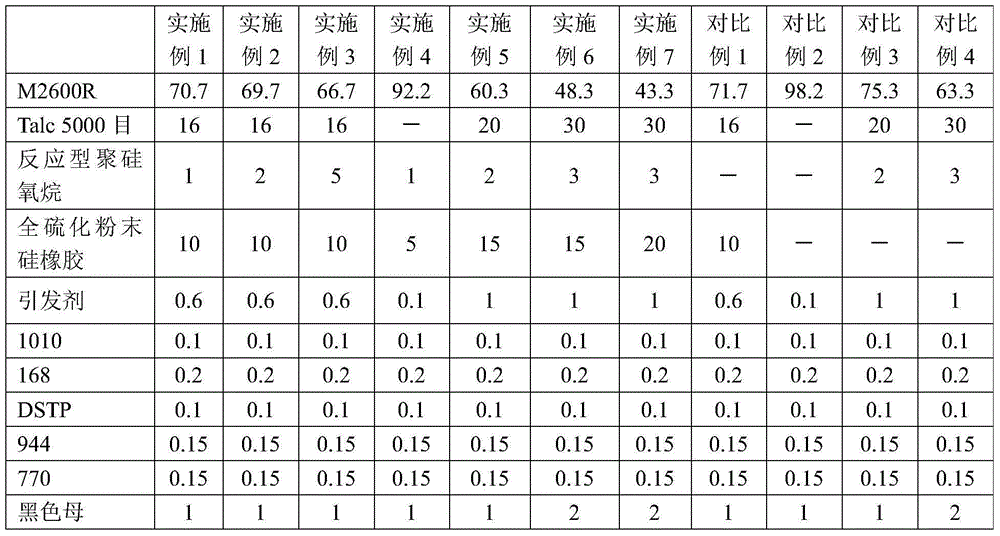

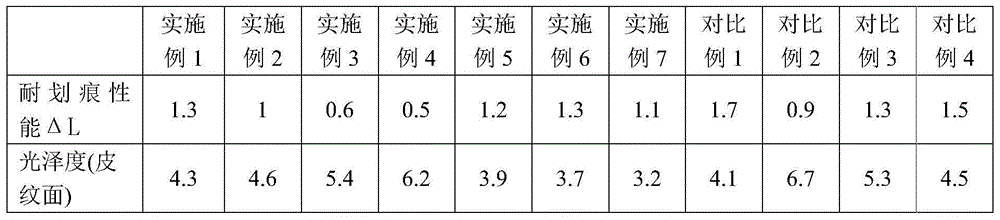

Scratching-resistant low-gloss polypropylene composite material and preparation method thereof

InactiveCN104558837AImprove scratch resistanceReduce surface glossPolypropylene compositesPolymer science

The invention discloses a scratching-resistant low-gloss polypropylene composite material and a preparation method thereof. The scratching-resistant low-gloss polypropylene composite material is prepared from the following raw materials in percentage by weight: 40-93% of polypropylene, 0-30% of an inorganic filler, 1-5% of reaction type high polysiloxane, 5-20% of fully vulcanizated powdered rubber, 0.1-1% of an initiator, 0.1-1% of an antioxidant, 0.1-1% of a light stabilizer, and 0-2% of other auxiliaries. According to the preparation method disclosed by the invention, the reaction type high polysiloxane and the fully vulcanizated powdered rubber are added to the basic formula, so that when the scratching resistance of the polypropylene material is improved, the high gloss problem of the product caused by addition of polysiloxane can be solved; the obtained polypropylene composite material is low in surface gloss, good in light extinction effect, and suitable for automobiles, household appliances and other fields.

Owner:SHANGHAI PRET COMPOSITES +2

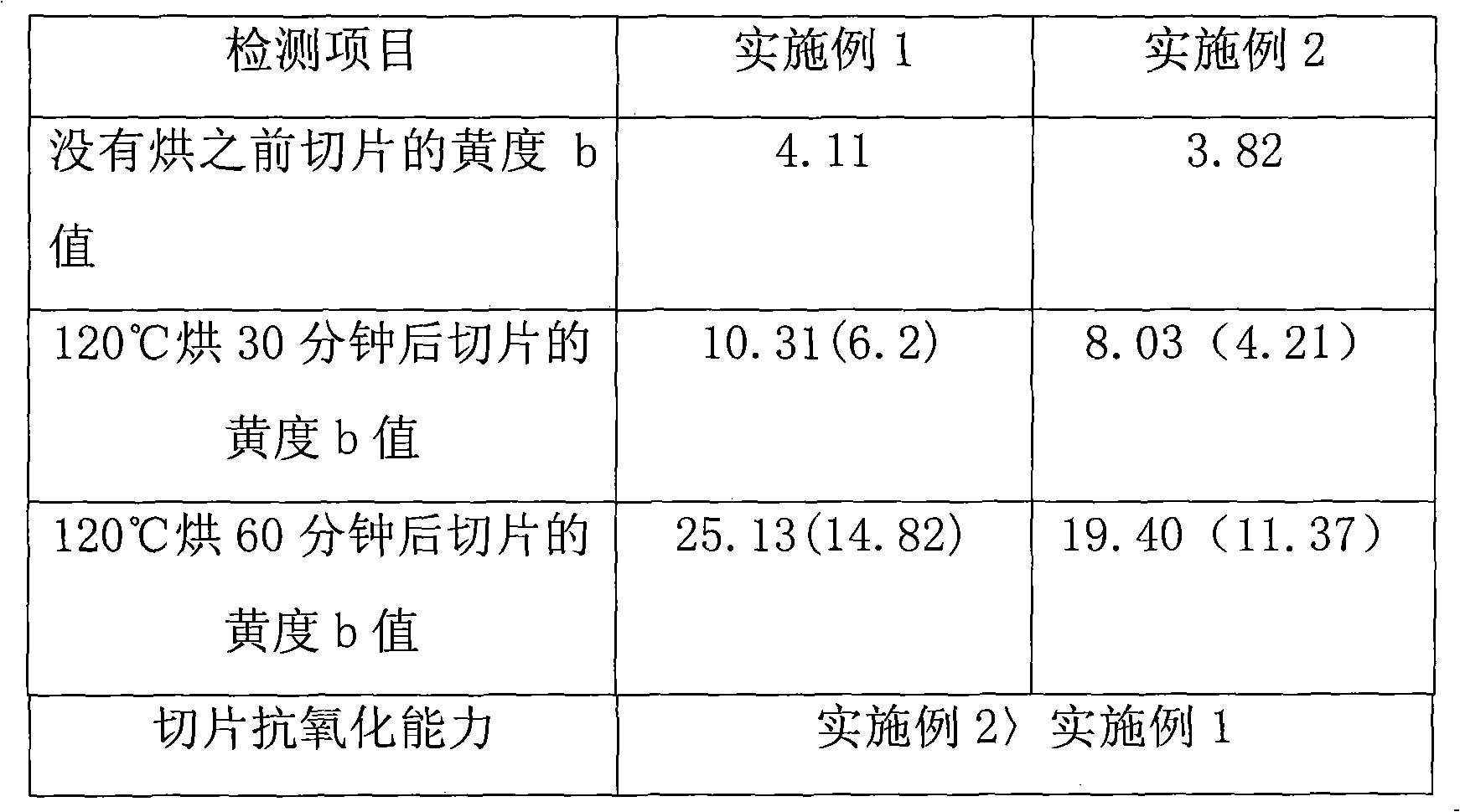

Polyester/epoxy mixed powder coating flatting agent and application thereof

PendingCN109575670ACoated evenlyEnsure structural stabilityPowdery paintsEpoxy resin coatingsPolyesterEpoxy

The invention discloses a polyester / epoxy mixed powder coating flatting agent which comprises, in weight percent, 15-95% of acrylic resin and 5-85% of metal organic compounds. The acrylic resin includes carboxyl acrylic resin and epoxy acrylic resin, and the metal organic compounds comprise at least one of benzothiazole thiol zinc salt, long-chain fatty acid metal salt, lauric acid metal salt andpalmitic acid metal salt. The invention further discloses an application of the polyester / epoxy mixed powder coating flatting agent to polyester / epoxy mixed powder coating flatting. The polyester / epoxy mixed powder coating flatting agent solves the problem that an original flatting agent is easily yellowed, and a powder coating prepared from the flatting agent is smooth in coating film and good inmechanical property and powder storage stability.

Owner:梧州市泽和高分子材料有限公司

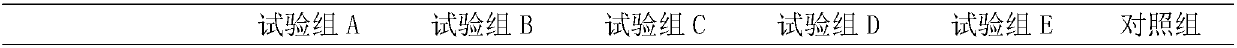

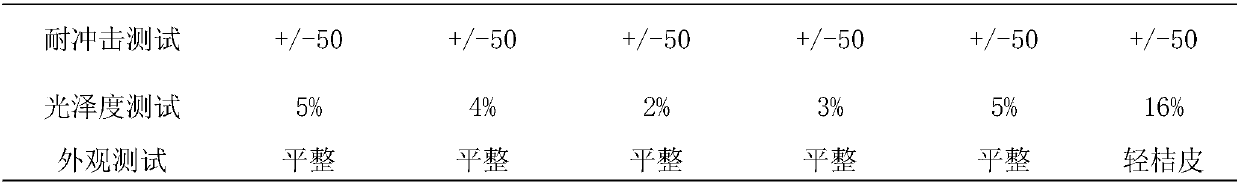

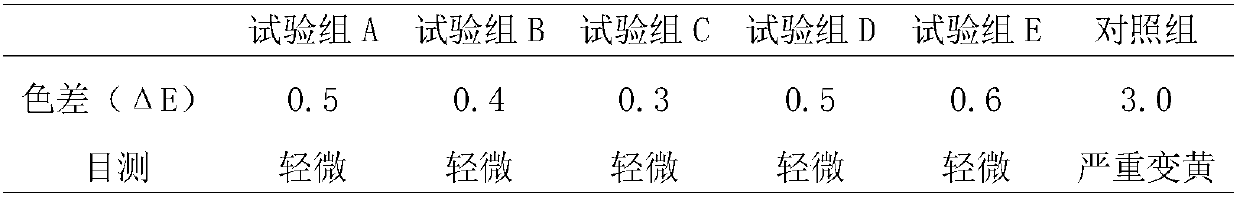

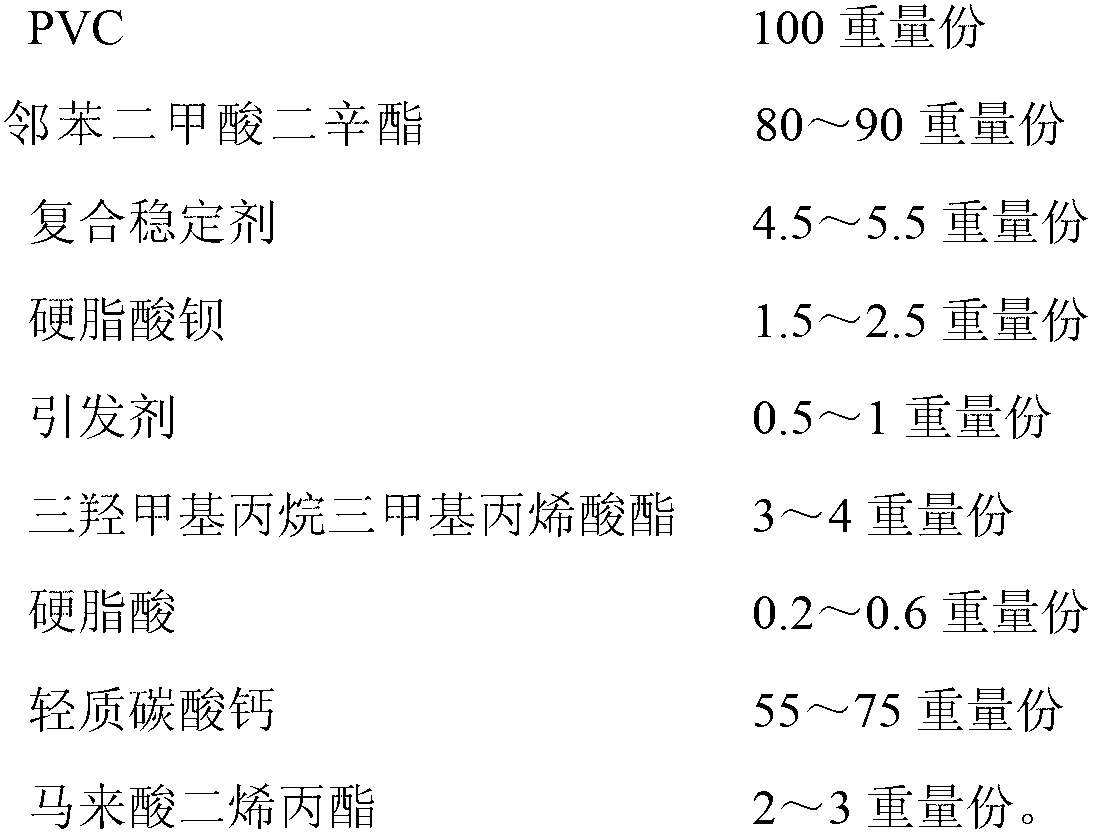

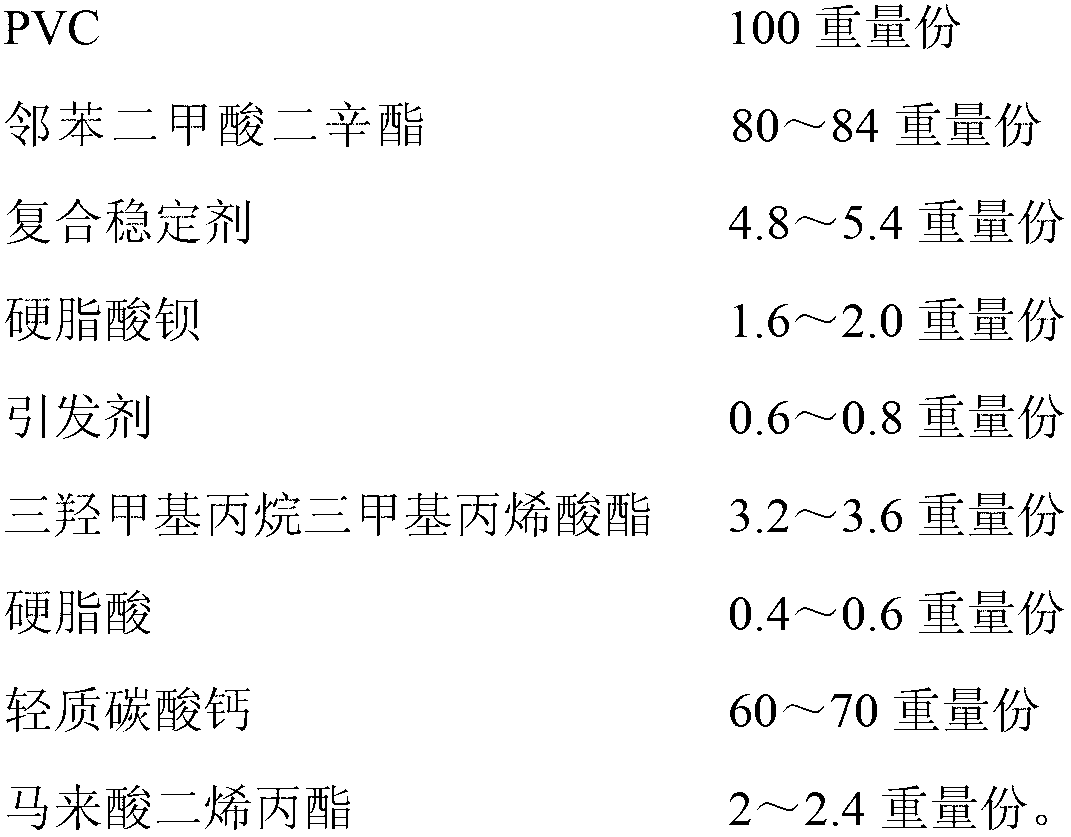

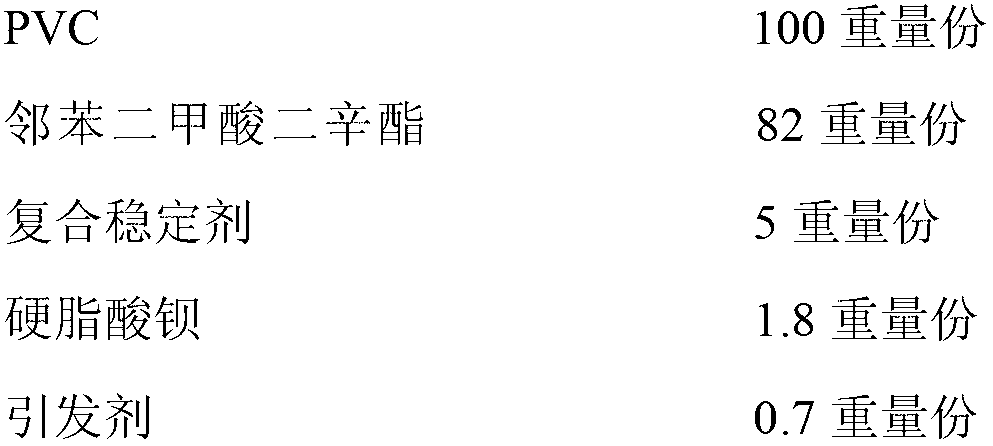

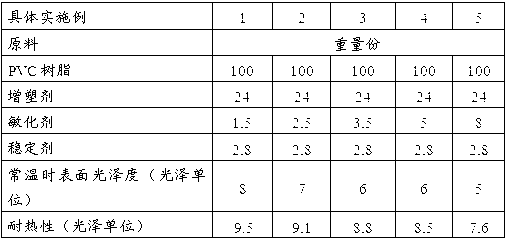

Polyvinyl-chloride extinction material and production method thereof

The invention discloses a polyvinyl-chloride extinction material and a production method thereof. The polyvinyl-chloride extinction material comprises the following components in parts by weight: 100 parts of PVC (polyvinyl chloride), 80 to 90 parts of dioctyl phthalate, 4.5 to 5.5 parts of compound stabilizers, 1.5 to 2.5 parts of barium stearate, 0.5 to 1 part of initiator, 3 to 4 parts of trimethylolpropane trimethylacrylate, 0.2 to 0.6 part of stearic acid, 55 to 75 parts of light calcium carbonate, and 2 to 3 parts of diallyl maleate. The raw materials are blended at a high speed, mixed and extruded in a reaction manner to prepare the polyvinyl-chloride extinction material. The polyvinyl-chloride extinction material has excellent extinction performance and can be applied to industries of building materials, electric wires and the like.

Owner:JIANGSU HENGFENG CABLE

Biaxially stretched polyamide resin film

ActiveUS20110236635A1Difficult to satisfyHigh surface glossSynthetic resin layered productsRecord information storageIn planeStatic friction coefficient

Disclosed is a polyamide resin film which has excellent dimensional stability with respect to moisture absorption, excellent mechanical characteristics and sliding properties under high temperature and high humidity conditions, and excellent handling properties. Specifically disclosed is a biaxially stretched polyamide resin film, to which 0.3-10% by weight of an inorganic material including a layered compound is added. The biaxially stretched polyamide resin film is characterized in that the layered compound is in-plane oriented, and that the film has a haze of 1.0-20%, an elastic modulus in the longitudinal direction of 1.7-3.5 GPa at a relative humidity (RH) of 35%, a surface roughness (Sa) of 0.01-0.1 μm, and a coefficient of static friction (F / B) of 0.3-1.0 at a normal stress of 0.5 N / cm2.

Owner:TOYO TOYOBO CO LTD

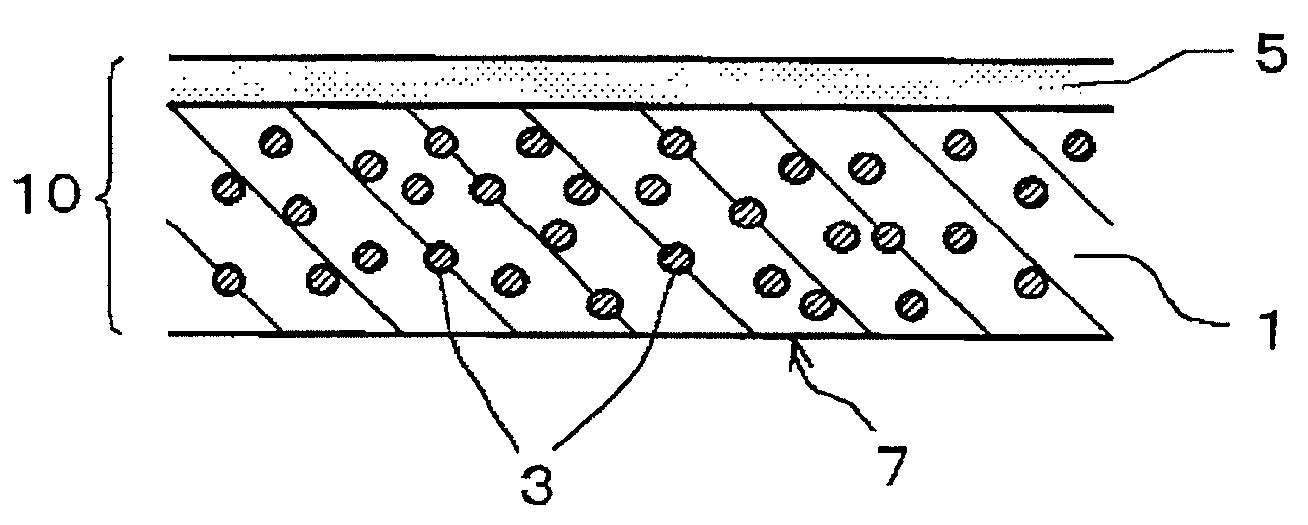

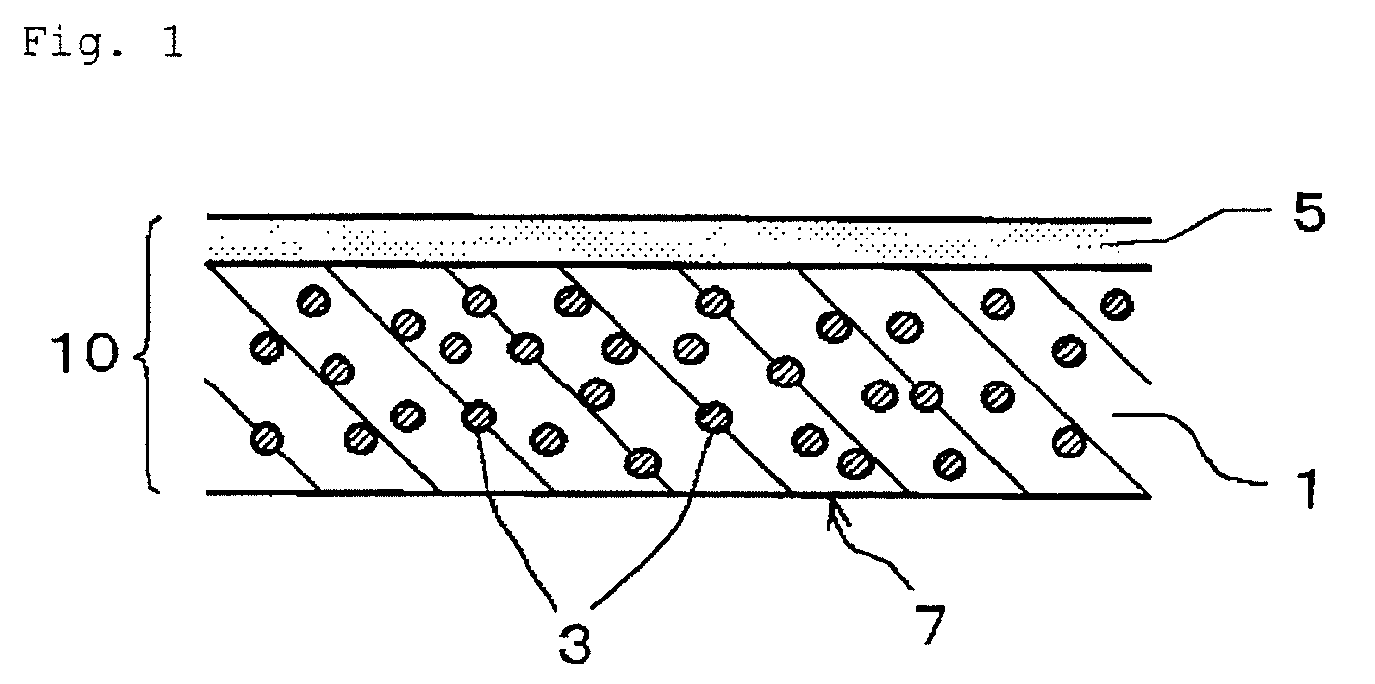

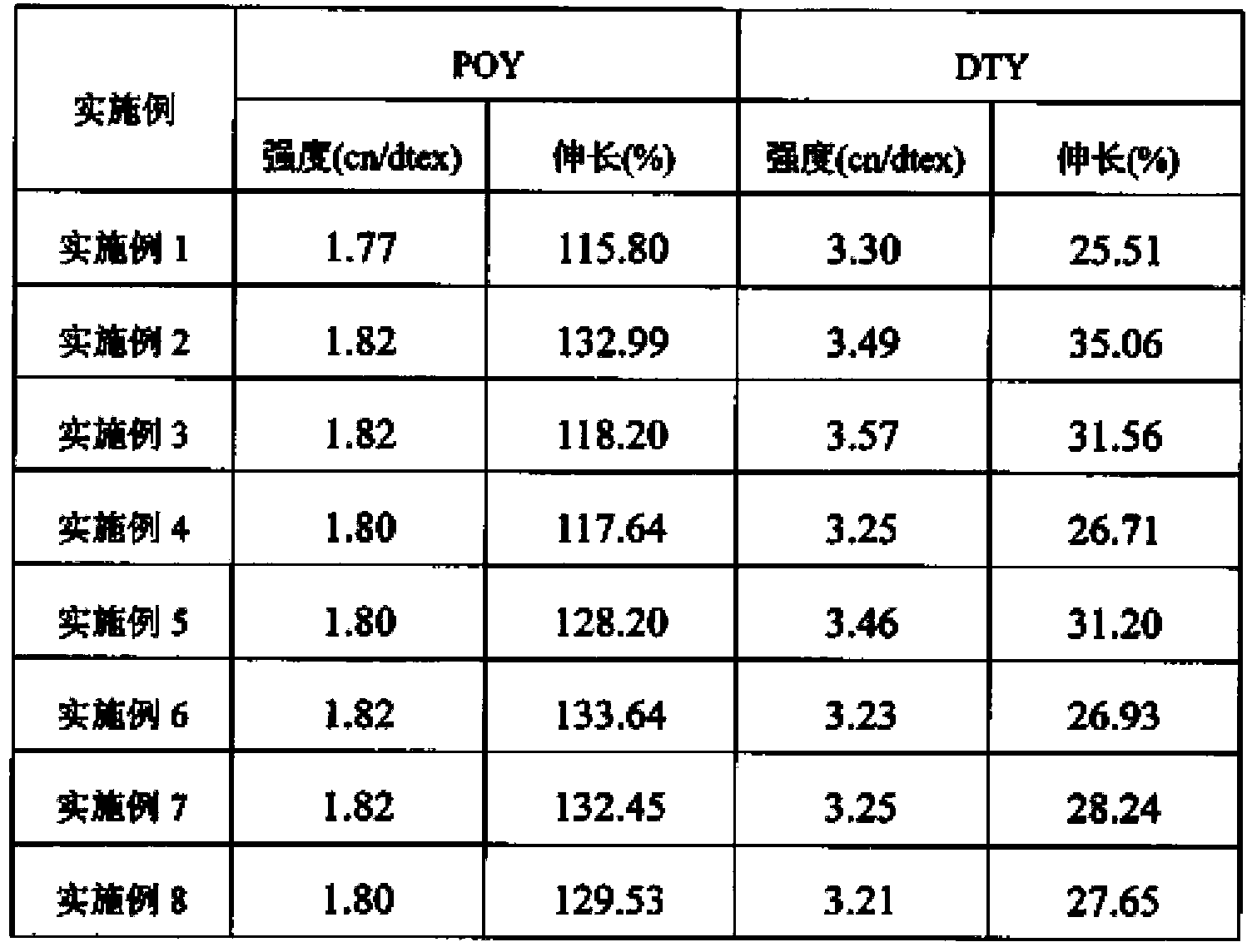

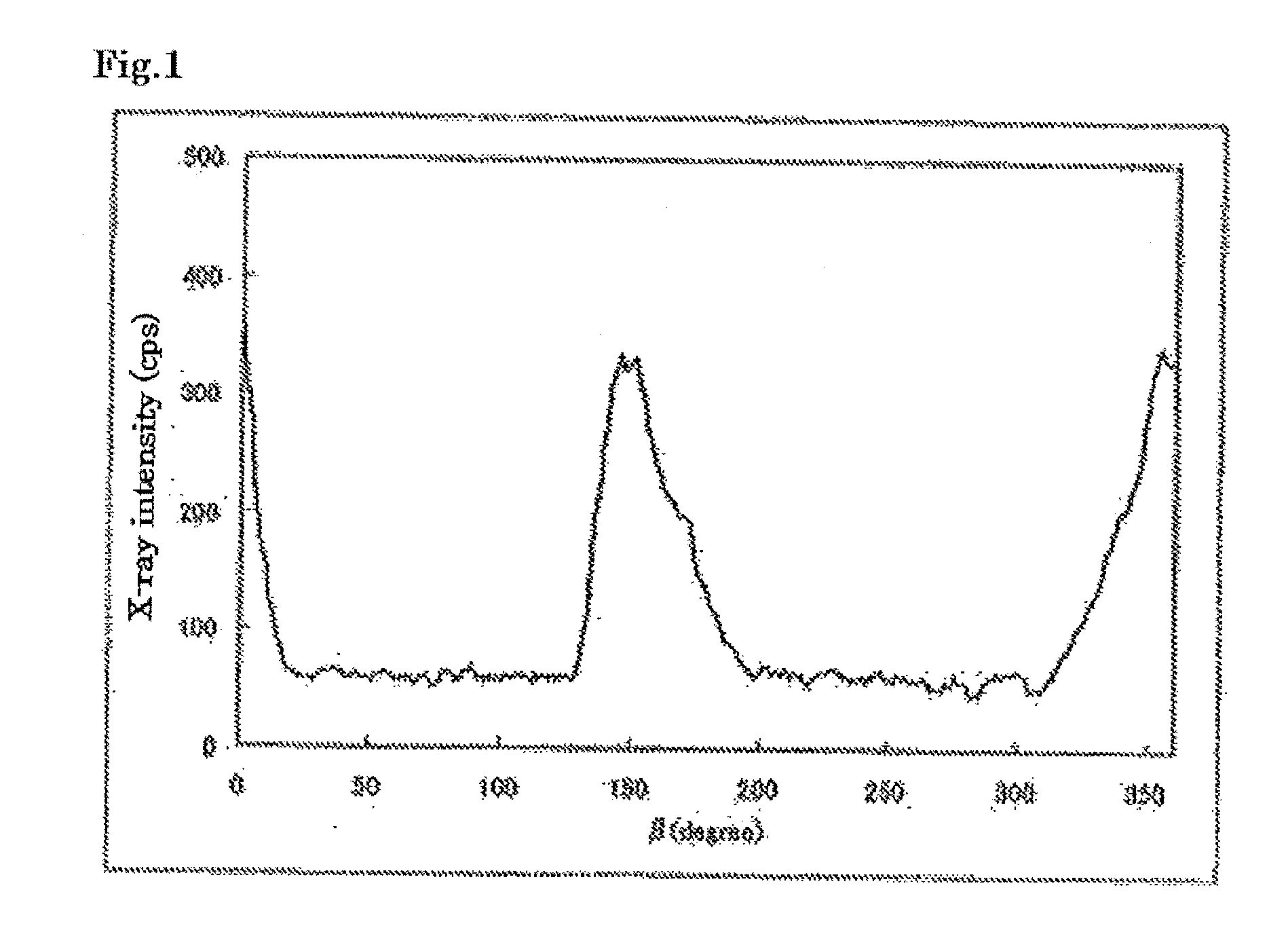

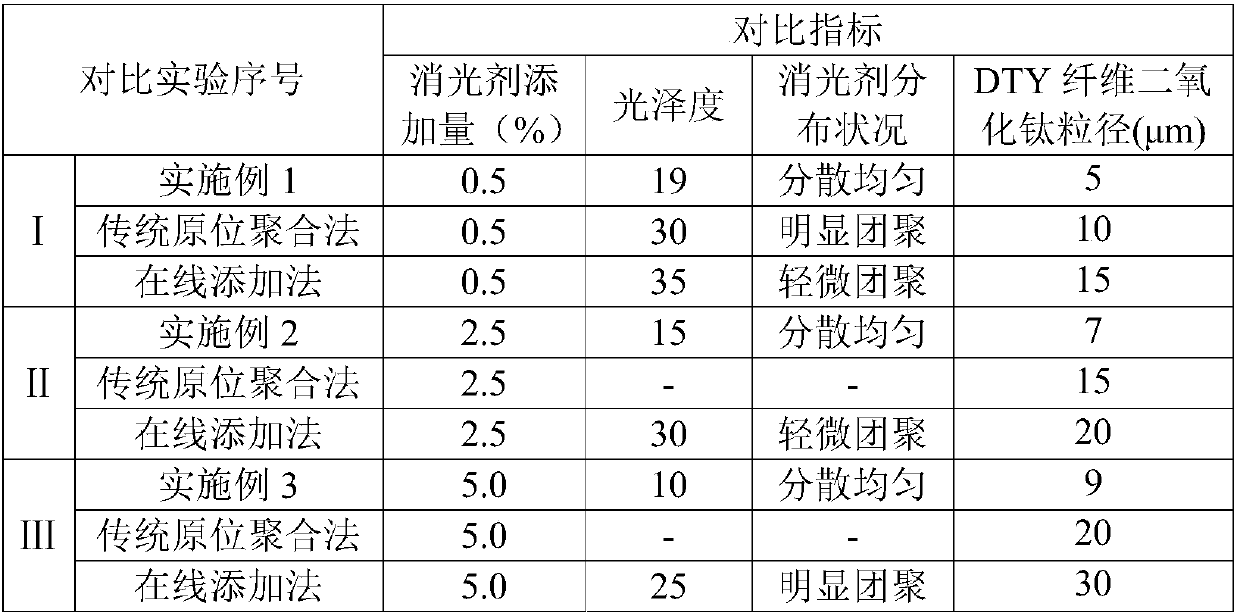

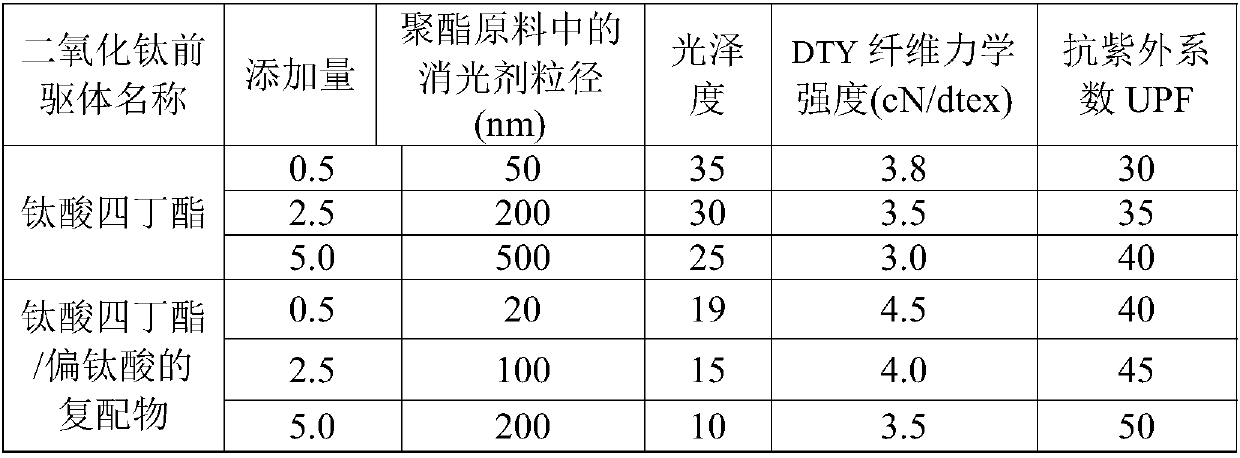

Light extinction polyester and low-gloss elastic composite fiber

ActiveCN107641196AEvenly dispersedGood mattingConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterFiber

The invention provides light extinction polyester and a low-gloss elastic composite fiber. The light extinction polyester comprises the following component in percentage by mass: 0.5-5.0% of titaniumdioxide nano granules, wherein the particle size of the titanium dioxide nano granules is 20-200 nm; detection with incident rays of 45 degrees shows that the gloss of the light extinction polyester is less than 20. The titanium dioxide nano granules are uniformly dispersed in the light extinction polyester and are not agglomerated. The mass ratio of a PET component to a PTT component in the low-gloss PET / PTT elastic composite fiber is (40:60)-(60:40), the composite fiber is formed through a composite melting spinning component, titanium dioxide is uniformly dispersed in the composite fiber, no agglomeration phenomenon is caused, the particle size of the titanium dioxide dispersed in the fiber is less than 10 [mu]m, the strength of the composite elastic fiber is greater than 3.0 cN / dtex, the gloss on the surface of the fiber is less than 20, and the elastic recovery rate is greater than or equal to 90%.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD +1

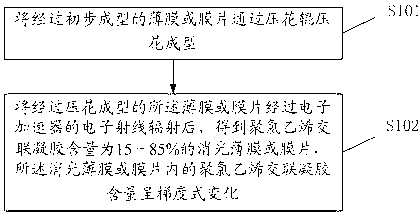

Extinction film or diaphragm and preparation method for same

The invention discloses an extinction film or diaphragm. The extinction film or diaphragm is formed by a framework agent and a sensitizer, and the content of a polyvinyl chloride cross-linked gel in the extinction film or diaphragm is controlled to be 15-85% after electron ray irradiation; the content of the polyvinyl chloride cross-linked gel in the extinction film or diaphragm presents a gradient change; and the framework agent is polyvinyl chloride resin having a polymerization degree of 500-2800, and the sensitizer is a polyfunctional unsaturated monomer. Correspondingly, the invention further discloses a preparation method for the extinction film or diaphragm. The preparation method comprises the following steps of: performing embossing forming on the primarily-formed film or diaphragm via an embossing roll; and then performing the electron ray irradiation of an electron accelerator. With the adoption of the preparation method disclosed by the invention, the extinction film or diaphragm is excellent in extinction property, low in glossiness, high in haze, good in diffuse reflection extinction effect, excellent in texture heat-resistant retainability, simple in processing technique, low in energy consumption, high in yield, pollution-free, and wider in industrial application prospect.

Owner:GUANGDONG TIANAN NEW MATERIAL

Abrasion-resistant flame-retardant environment-friendly PVC (polyvinyl chloride) material and preparation method thereof

InactiveCN106987064AIncreased insulation properties and mechanical strengthLow priceChemistryGraphene

The invention discloses an abrasion-resistant flame-retardant environment-friendly PVC (polyvinyl chloride) material which is characterized by comprising, by weight, 70-80 parts of PVC, 5-7 parts of butadiene-acrylonitrile rubber, 2-3 parts of graphene, 6-9 parts of barium-zinc stabilizers, 13-17 parts of processing agents, 0.8-1.6 parts of coupling agents, 10-16 parts of kaolin, 8-12 parts of hexamethylphosphoric triamide, 4-8 parts of nano-titanium dioxide powder, 0.5-1.5 parts of nano-silicon dioxide, 12-16 parts of flame-retardant additives, 10-20 parts of brominated epoxy resins and 5-10 parts of inorganic pigments. The PVC decoration material is safe, environmentally friendly, retardant in static electricity, abrasion and age, long in service life and excellent in comprehensive performance. The invention provides a preparation method of the abrasion-resistant flame-retardant environment-friendly PVC decoration material. Material cost is low, raw materials are easily acquired, processes are simple and clear, and the material has high practical value and good application prospect when being used for indoor decoration.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

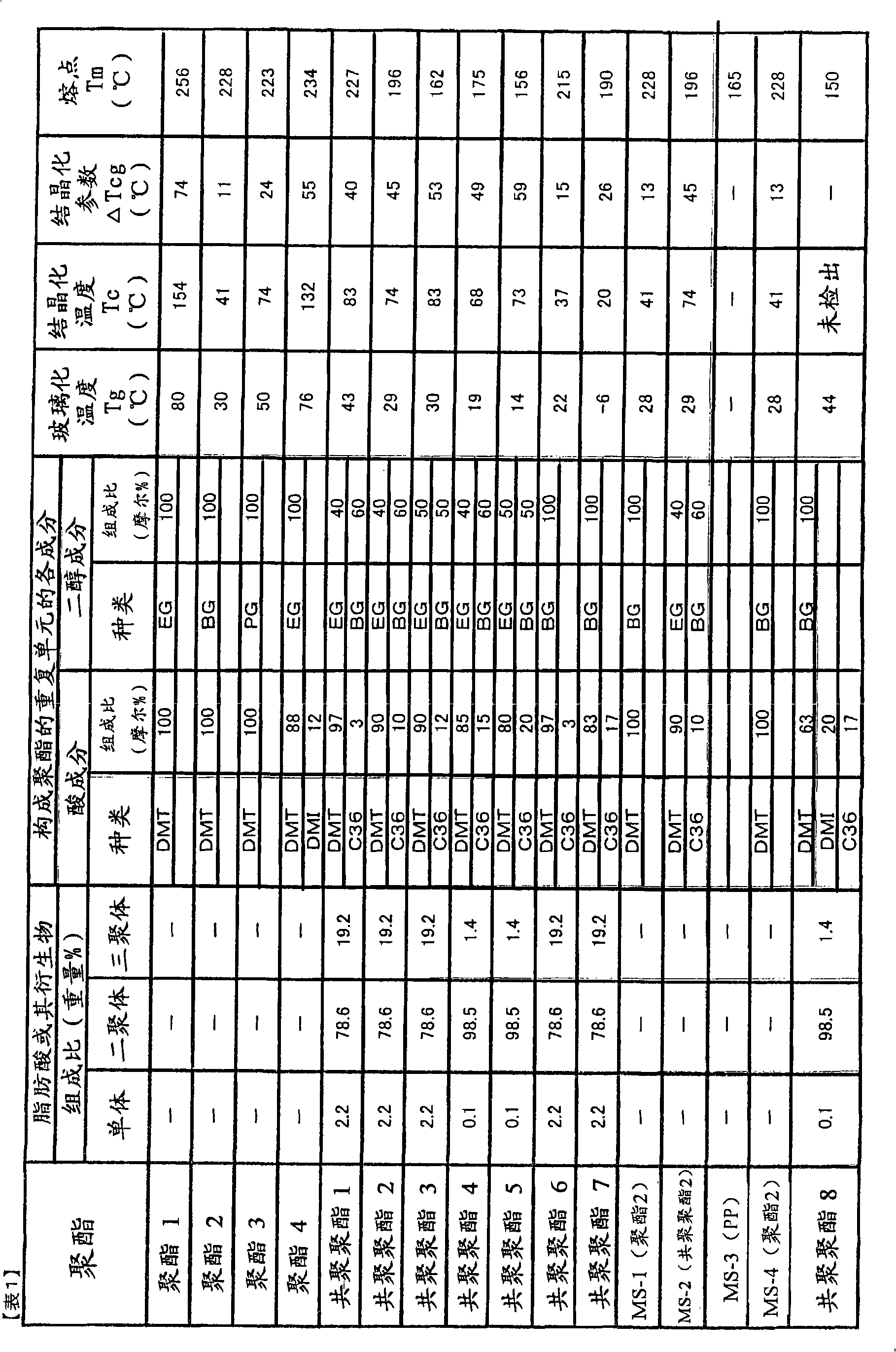

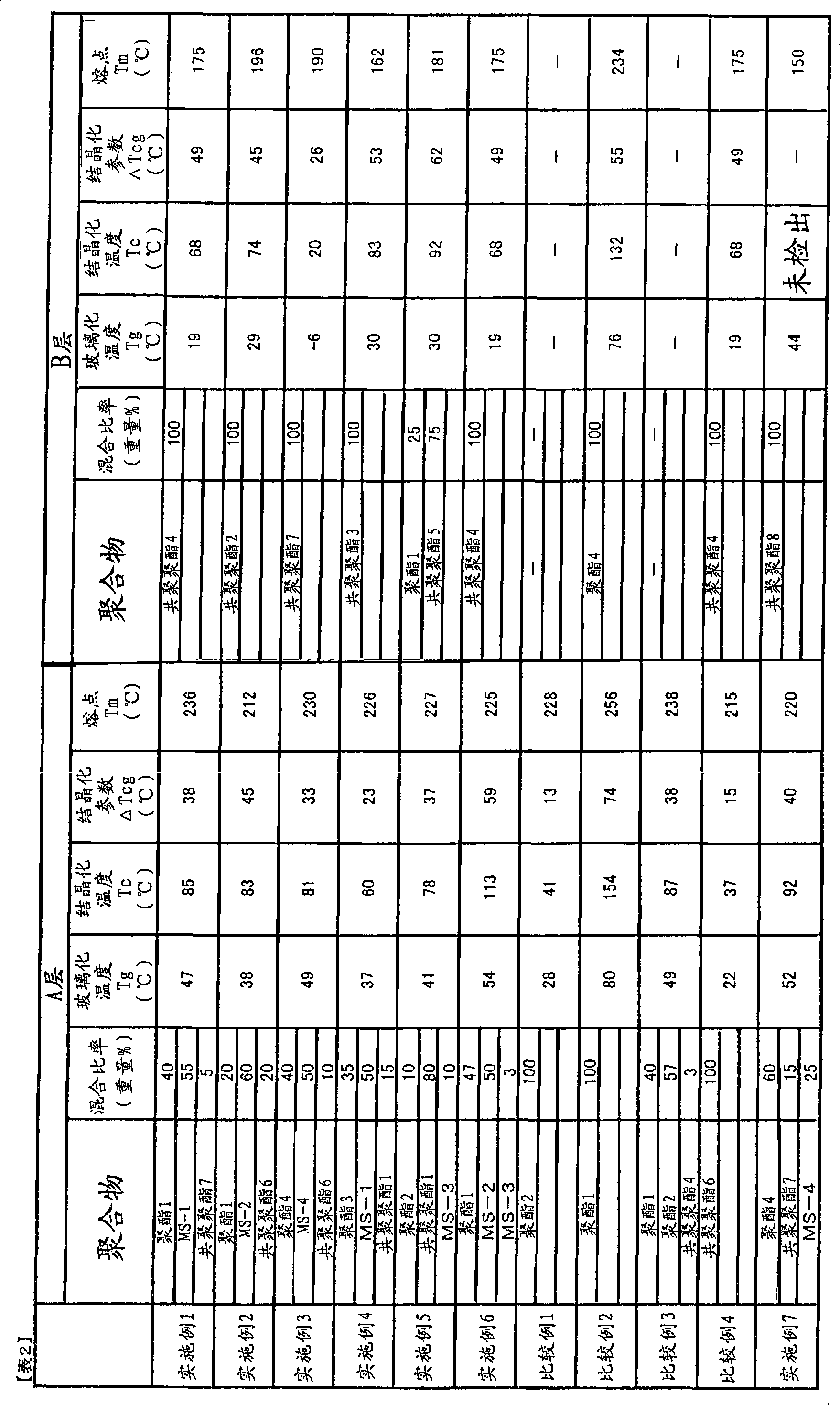

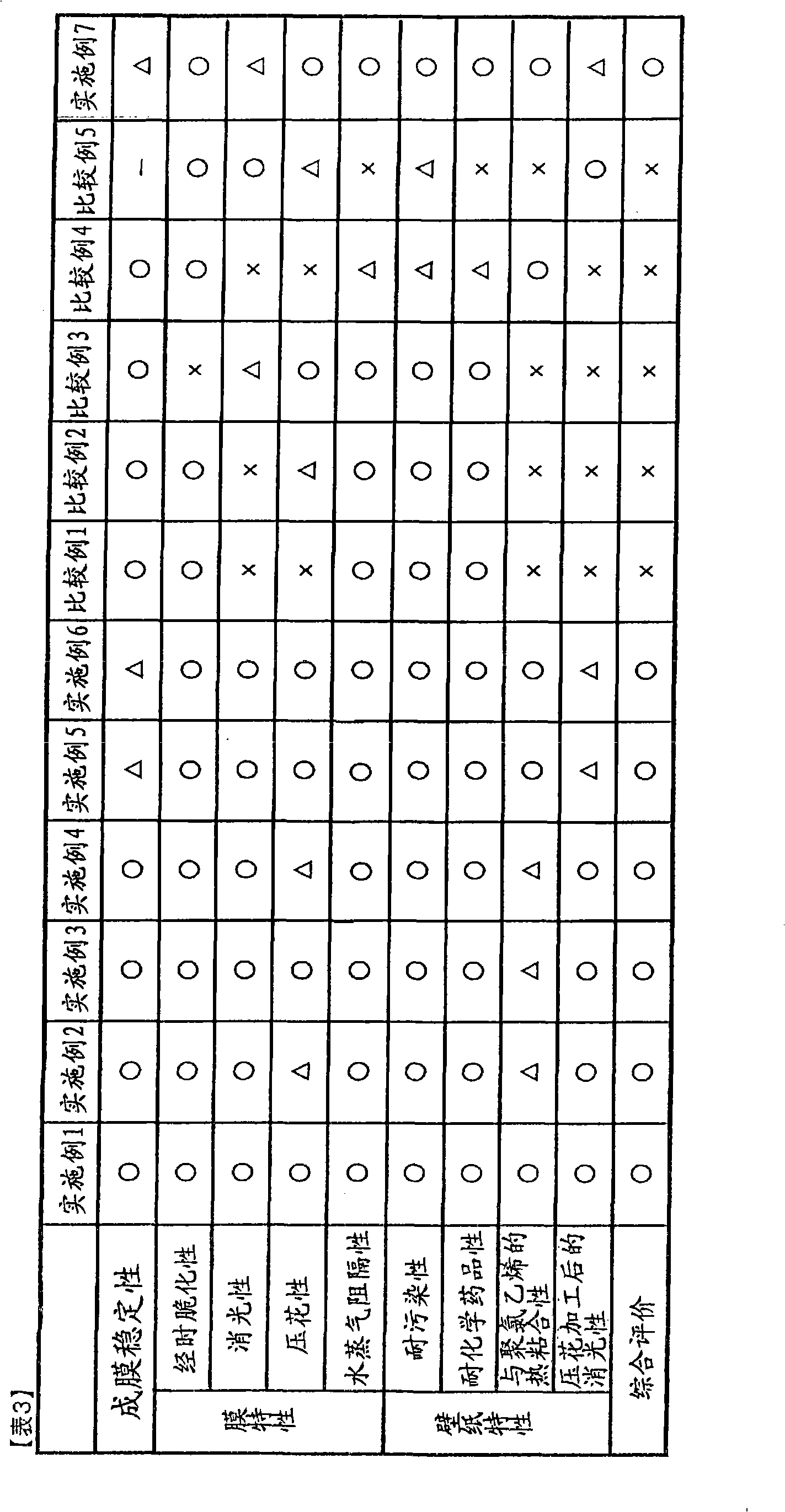

Matte multilayer polyester film

InactiveCN101296797AGood mattingImprove embossing effectSynthetic resin layered productsFloor coveringsPolyesterWater vapor

Disclosed is a matte multilayer polyester film excellent in contamination resistance, chemical resistance, formability, heat bondability, delustering properties, embossing properties, water vapor barrier properties and the like, which is particularly suitable for wallpapers. Specifically disclosed is a matte multilayer polyester film having at least a two-layer structure of A / B. The polyester of layer A is composed of a composition containing 60-95% by weight of a polyester (a) and 5-40% by weight of an incompatible resin (b), while having a glass transition temperature TgA of 30-70 DEG C. The polyester of layer B is mainly composed of a copolymerized polyester having a melting point TmB of 120-210 DEG C. The degree of surface glossiness of the layer A is less than 50%.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com