Patents

Literature

198 results about "Hexamethylphosphoramide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexamethylphosphoramide, often abbreviated HMPA, is a phosphoramide (i.e. an amide of phosphoric acid) with the formula [(CH₃)₂N]₃PO. This colorless liquid is a useful polar aprotic solvent and additive in organic synthesis.

Method for producing water dispersing magnetic nano particle with high-crystallinity

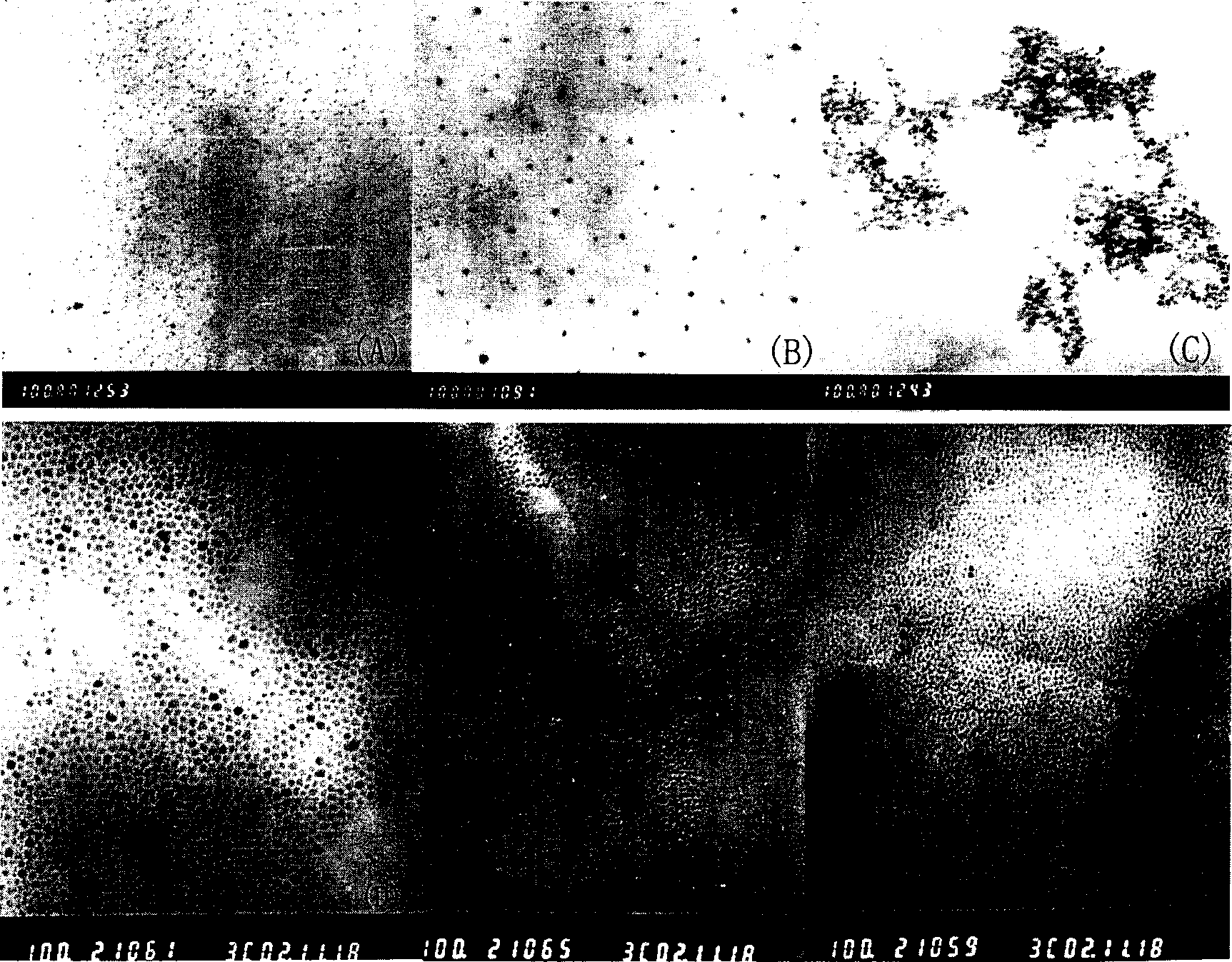

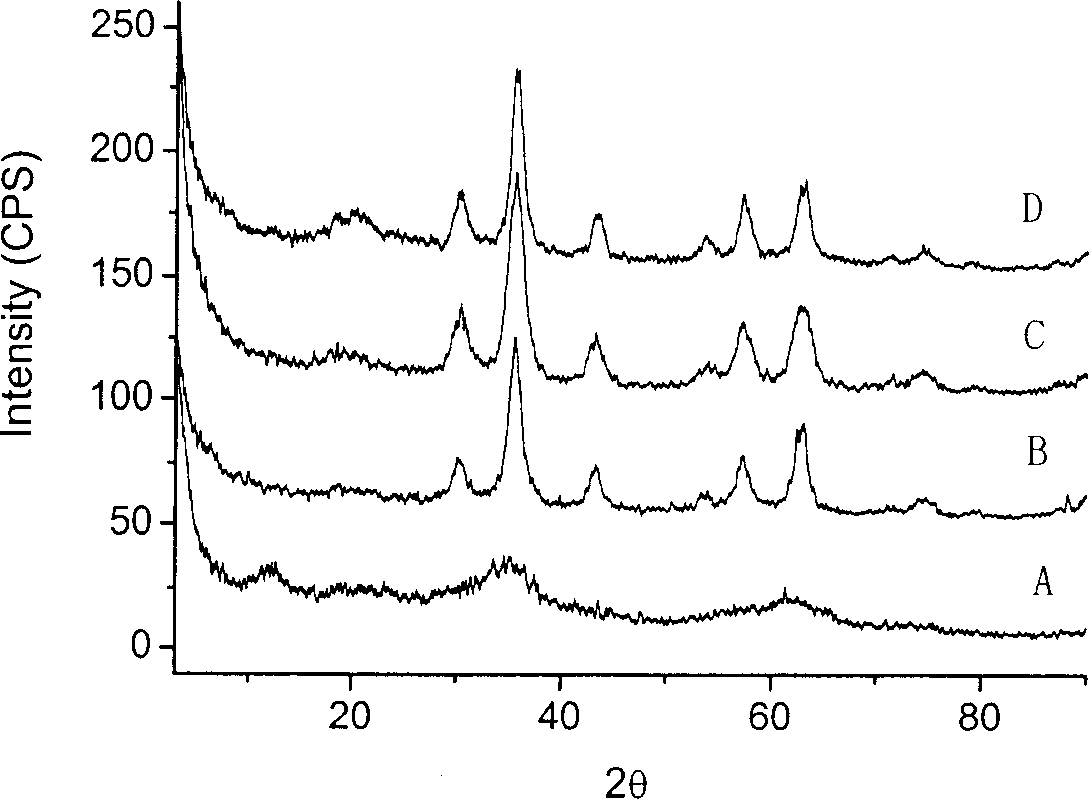

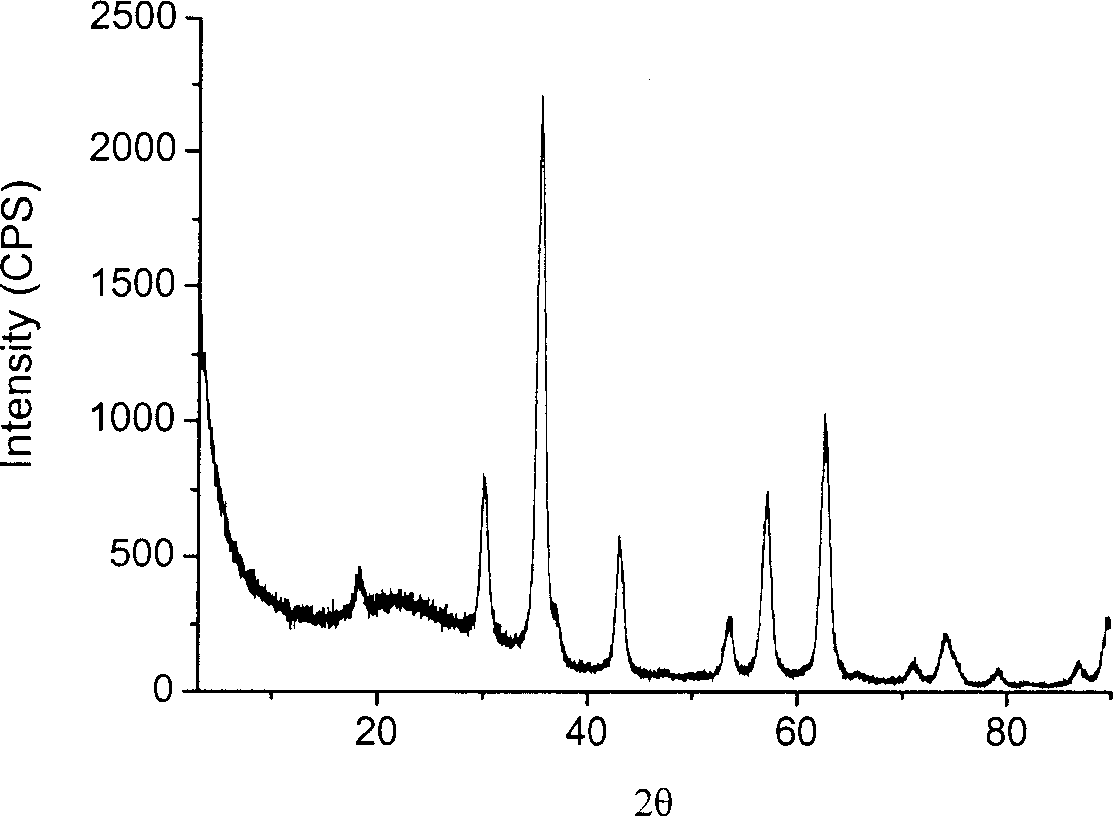

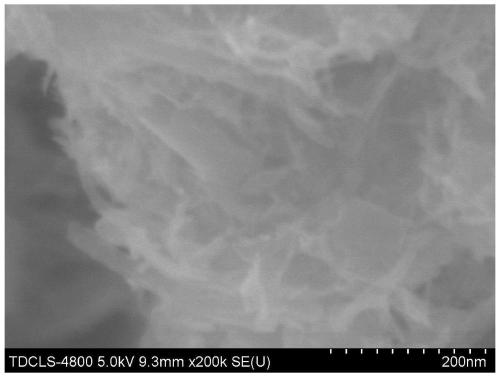

InactiveCN1549283AUniform and controllable particle sizeHigh crystallinityNanostructure manufactureInductances/transformers/magnets manufactureFerric oxalateIron salts

The new method for preparing high crystallinity monodisperse water-soluble magnetic nano microparticles is characterized by that it selects the inorganic iron salts of anhydrous iron trichloride and iron chloride, etc. or metal organic iron compounds (such as iron pentacarbonyl, iron triacetylacetonate, iron biacetylacetonate, complex of cupferron and iron salt, iron octoate and ferric oxalate, etc.) as iron raw material, and utilizes high-temp. decomposition of them in high boiling point polar solvent (for example alpha-pyrrolidone and its derivatives (N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone, etc.), N,N-dimethyl-2-imidazolone, hexametapol, gamma-butyrolactone and its derivative and low molecular weight (molecular weight M is less than or equal to 5000) polyglycol and its derivatives) to prepare magnetic nano microparticles. Said invention can adopts different iron raw materials and high boiling point polar solvents so as to obtain different types of magnetic nano microparticles (Fe, Fe2O3 and Fe3O4) with different sizes and crystallinities and different crystal structures.

Owner:苏州欣影生物医药技术有限公司

Copper corrosion inhibitor based on metal organic frame material MOFs and preparation method thereof

ActiveCN110129803AGood corrosion inhibitionStable structureVolatile corrosion inhibitorHexamethylphosphoramide

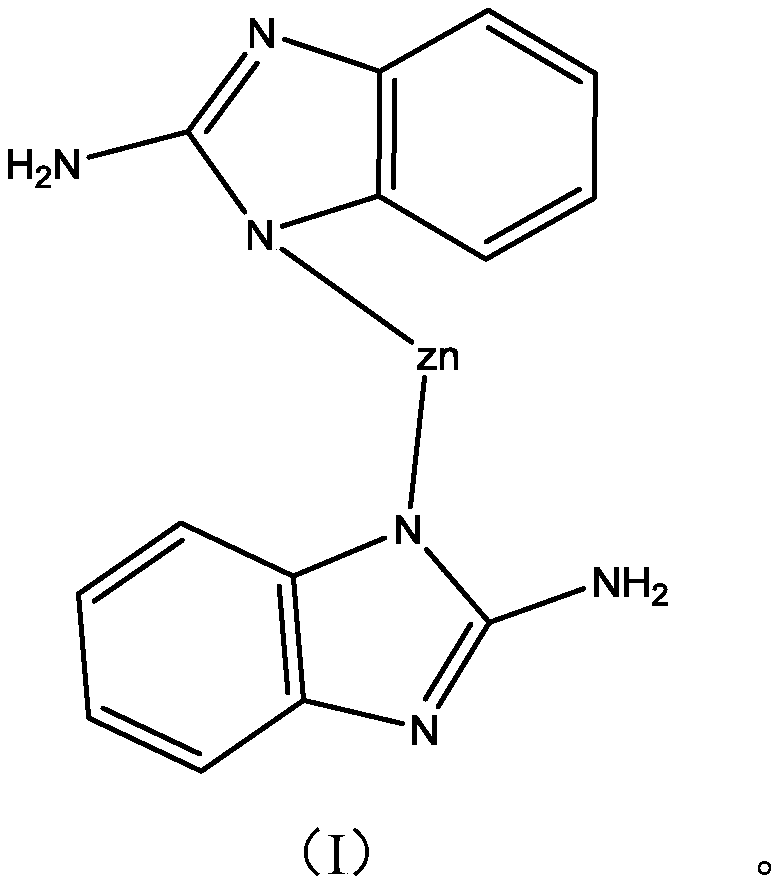

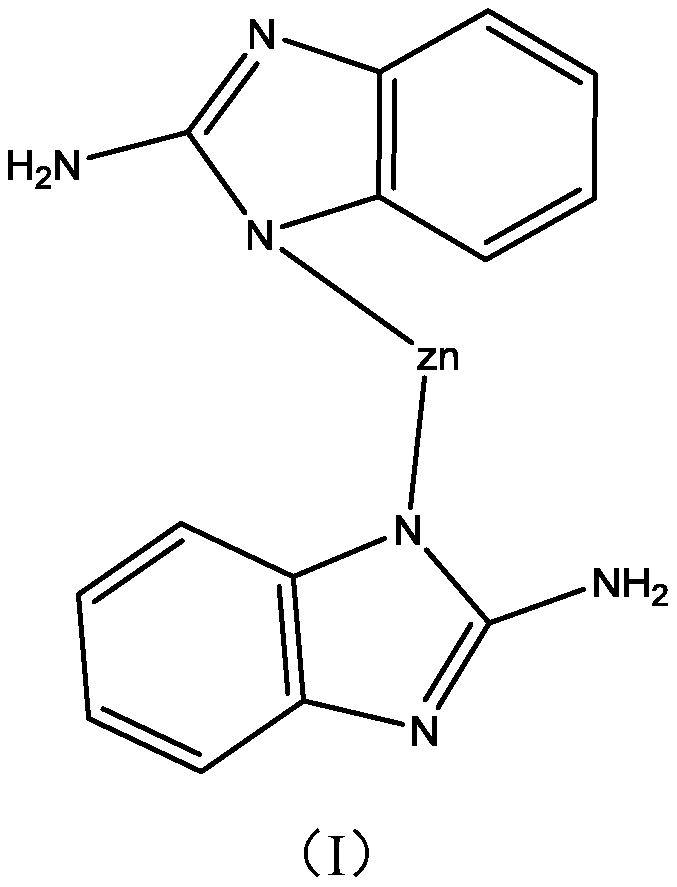

The invention belongs to the field of metal material corrosion inhibitors, and discloses a copper corrosion inhibitor based on metal organic frame material MOFs and a preparation method thereof. The copper corrosion inhibitor is prepared from the components in part by weight: 20-40 parts of aminobenzimidazole / Zn<2+>MOFs, 30-50 parts of small molecule alcohol with a molecular weight not exceeding 60, and 10-40 parts of strong polarity organic solvent, polarity of the strong polarity organic solvent is not weaker than hexamethylphosphamide, wherein the aminobenzimidazole / Zn<2+>MOFs have a structural formula shown in the following equation (I). According to the copper corrosion inhibitor based on the metal organic frame material MOFs and the preparation method thereof, key main materials of the copper corrosion inhibitor are improved, the aminobenzimidazole / Zn<2+>MOFs are used as the main materials, the characteristics of strong hydrophobicity of an adsorption group and structural stability of the aminobenzimidazole / Zn<2+>MOFs are used, and the good corrosion inhibition effect on a copper elementary substance or copper alloy materials is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Beta phase polyvinylidene fluoride composite film and preparation method thereof

This invention relates to a kind of beta phase polyvinylidene difluoride film laminate and its preparation method. The composition and quality ratio: inorganic hydrated salt 1 to 20 percent, polyvinylidene fluoride 80 to 99 percent; the inorganic hydrated salt is: Fe ( NO3) 3. 9H2O, Ni ( NO3) 2. 6H2O, or Co ( NO3) 2. 6H2O; The polyvinylidene fluoride is: polyvinylidene fluoride homopolymer or polyvinylidene fluoride- hexafluoropropylene copolymer. According to certain quality composition, dissolve polyvinylidene fluoride and inorganic hydrated salt in dimethyl formamide solvent, after misce bene, spincoating on glass or silicon chip, evaporate and crystallize for 24 hours at 20 to 100 deg, obtain polyvinylidene fluoride film laminate. This method avoids using of noxious solvent hexametapol.

Owner:长春中科应化特种材料股份有限公司

Low-odour SEBS (styrene butadiene styrene block copolymer) melt-grafting maleic anhydride and preparation method thereof

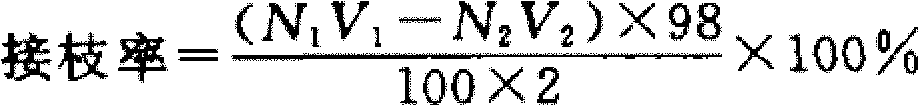

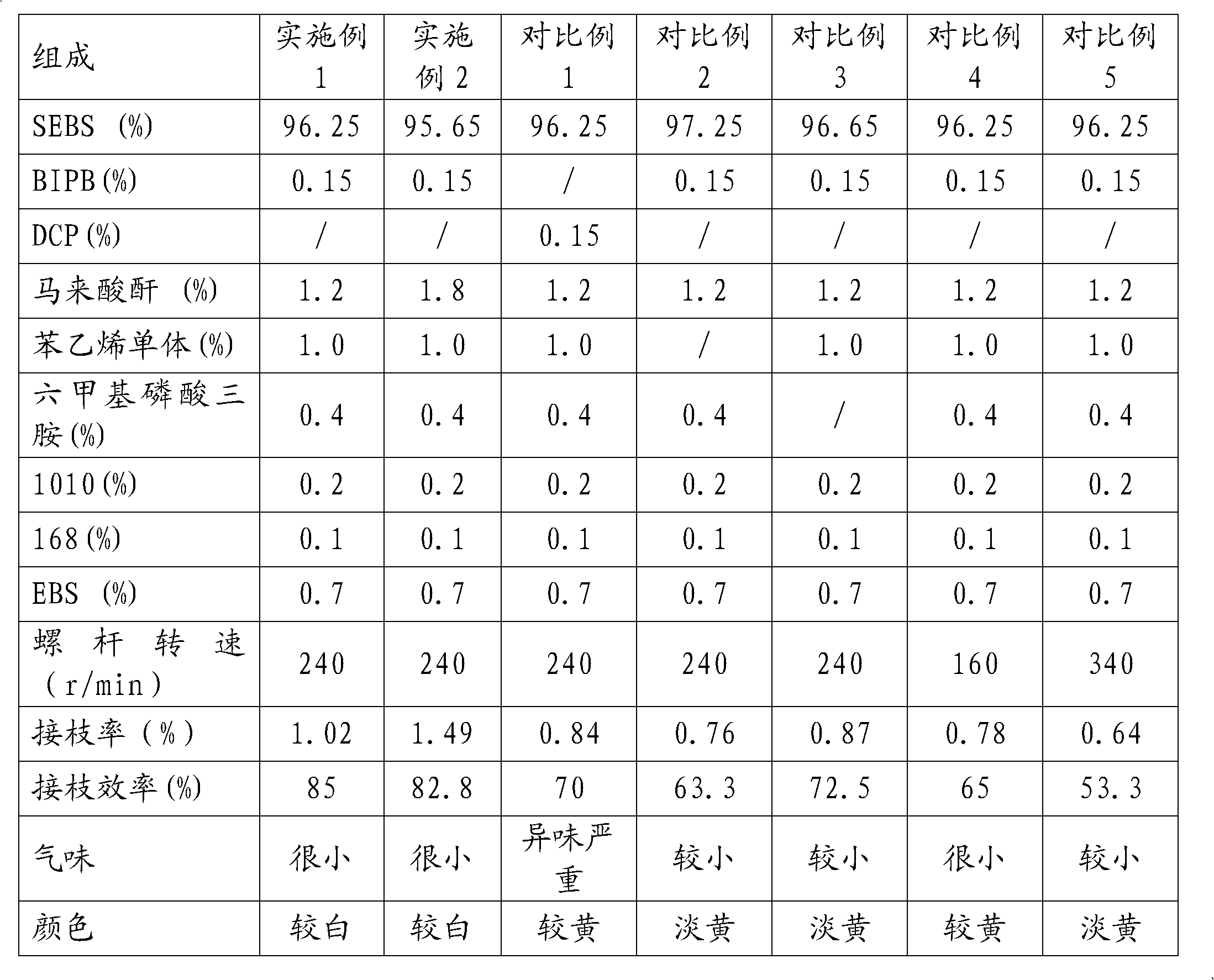

The invention discloses low-odour SEBS (styrene butadiene styrene block copolymer) melt-grafting maleic anhydride and a preparation method thereof. The low-odour SEBS melt-grafting maleic anhydride consists of the following components in percentage by weight: 95 to 97 percent of SEBS; 0 to 0.2 percent of initiator, 1.0 to 2.0 percent of maleic anhydride, 0.8 to 1.5 percent of styrene monomer, 0.2to 0.5 percent of Hexamethylphosphoramide, 0.2 to 0.4 percent of antioxidant and 0.5 to 1 percent of other auxiliaries. The low-odour SEBS melt-grafting maleic anhydride disclosed by the invention has high grafting efficiency which reaches 85 percent and 82.8 percent, has low odour and white color and cannot influence the color of a finished product when being blended with other materials.

Owner:SHENZHEN KEJU NEW MATERIAL

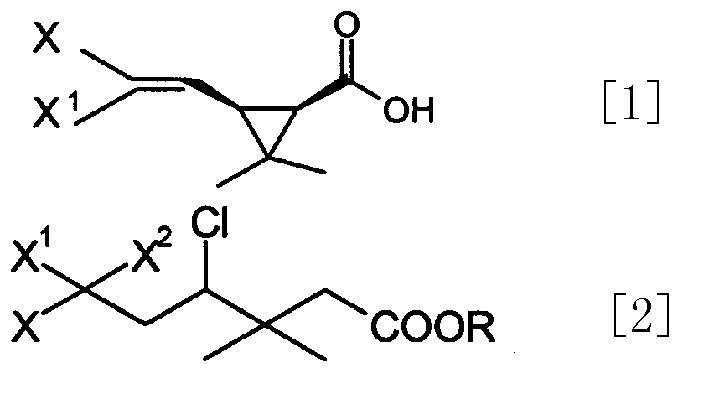

Process for preparing cis-halochrysanthemic acid

InactiveCN1390825AIncrease dosageReduce dosagePreparation from carboxylic acid esters/lactonesHexamethylphosphoramideTert butyl

A process for preparing cis-halochrysanthemic acid includes such steps as the addition reaction of raw material (sodium tert-butyl alkoxide), reaction for removing hydrogen chloride and hydrolysis, reflux with excess sodium hydroxide in the mixed solvent of methanol or ethanol and water to obtain cyclocompound, and acidation. Its advantages are simple process, high output rate, low cost and less pollution.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

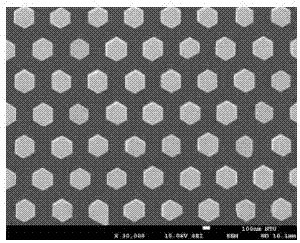

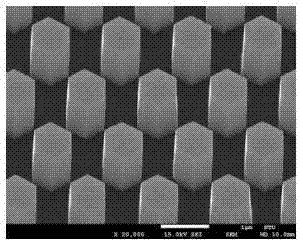

Method for preparing zinc oxide nanopillar array

InactiveCN107344730AReduce manufacturing costHigh degree of orderZinc oxides/hydroxidesHexamethylphosphoramideHexamethylphosphoric Triamide

The invention provides a method for preparing a zinc oxide nanopillar array. According to the method, the current micro-electronic processing technology with technical maturity is utilized. The method comprises the following steps: by taking an aqueous solution of Zn(NO3)2 and hexamethylphosphoramide as a precursor solution for growth of a ZnO nanopillar array on a GaN template with nano-array patterns, preparing the ZnO nanopillar array with ordered height and uniform size through gravity-assisted inverted growth by adopting a hydrothermal method. The nano-array templates of different patterns are manufactured to grow different ZnO nanopillar arrays; and the nanopillar size is regulated by adjusting the concentration of the Zn(NO3)2 and hexamethylphosphoramide and the growth temperature of the nanopillar array. According to the method disclosed by the invention, various ZnO nanopillar arrays with ordered heights and uniform sizes can be prepared by adjusting different process parameters.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Polyurethane thermal-insulation composite board

InactiveCN105860504AImprove wear resistanceGood oil resistanceSynthetic resin layered productsConstructions elementsPolyesterHexamethylphosphoramide

The invention discloses a polyurethane thermal-insulation composite board which comprises a polyurethane thermal-insulation layer and back lining layers arranged on the inner and lower surfaces of the polyurethane thermal-insulation layer, wherein the polyurethane thermal-insulation layer is prepared from a high-performance polyurethane rigid foam material. The high-performance polyurethane rigid foam material is prepared from polyester polyol, diphenylmethane diisocyanate, hexamethylene diisocyanate, polyacrylate, styrene-butadiene rubber, cyclohexylamine, triethylenediamine, stannous octoate, a foaming agent, hydroxy silicone oil, a flame retardant, expanded perlite, attapulgite, pentaerythritol and sorbitol. The flame retardant is prepared from red phosphorus, nano magnesium hydroxide, ammonium polyphosphate, aluminum diethyl hypophosphite, piperazidine pyrophosphate and hexametapol. The polyurethane thermal-insulation composite board disclosed by the invention has the advantages of high strength, favorable impact resistance, excellent flame retardancy and long service life.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

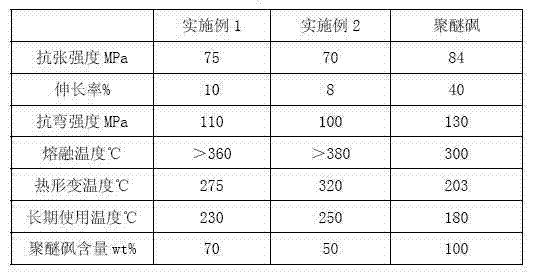

Production method of high-temperature-resistant workable polyimide plastic alloy

InactiveCN102199350AHigh heat distortion temperatureImprove high temperature resistanceSulfolaneHexamethylphosphoramide

The invention relates to a production method of a high-temperature-resistant workable polyimide plastic alloy. The production method comprises the following steps: reacting aromatic diamine with aromatic dianhydride in a polar solvent in an equimolar ratio so as to generate polyamide acid; diluting the polyamide acid with the polar solvent; adding polyarylsulfone resin the mass of which is 20-80% of total mass of the system for evenly dissolution; precipitating the solution in a coagulator, and smashing precipitate to powder; carrying out drying, thermal treatment and compression molding on the powder so as to prepare the polyimide plastic alloy. In the method, the polar solvent is one or a mixed solvent of multiple dimethylformamide, dimethylacetylamide, N-methylpyrrolidone, hexamethylphosphoramide, sulfolane and m-cresol; and the coagulator is alcohol, ketone or water. The polyimide plastic alloy prepared by using the production method has the advantages of high deformation temperature, good high temperature resistance and low cost, is workable, and can be used for a long term at the high temperature.

Owner:SHANGHAI TONGMING MATERIAL TECH

PVC formula

InactiveCN106479091AImprove impact resistanceHigh strengthHexamethylphosphoramideChlorinated paraffins

The invention discloses a PVC formula. The PVC is prepared from, by weight, 100-120 parts of PVC resin, 8-11 parts of calcium stearate, 7-10 parts of zinc oxide, 6-8 parts of hexamethylphosphoramide, 1-2 parts of an impact resistant agent, 4-6 parts of chlorinated paraffin and 0.5-1.3 parts of auxiliaries. The PVC formula has the advantages that for PVC pipes manufactured through the formula, the impact resistant property and strength can be enhanced, by means of added hexamethylphosphoramide, the antioxidant property of the PVC pipes can be greatly improved, the cost is low, and the PVC formula is suitable for application and popularization.

Owner:启东恒顺润滑设备有限公司

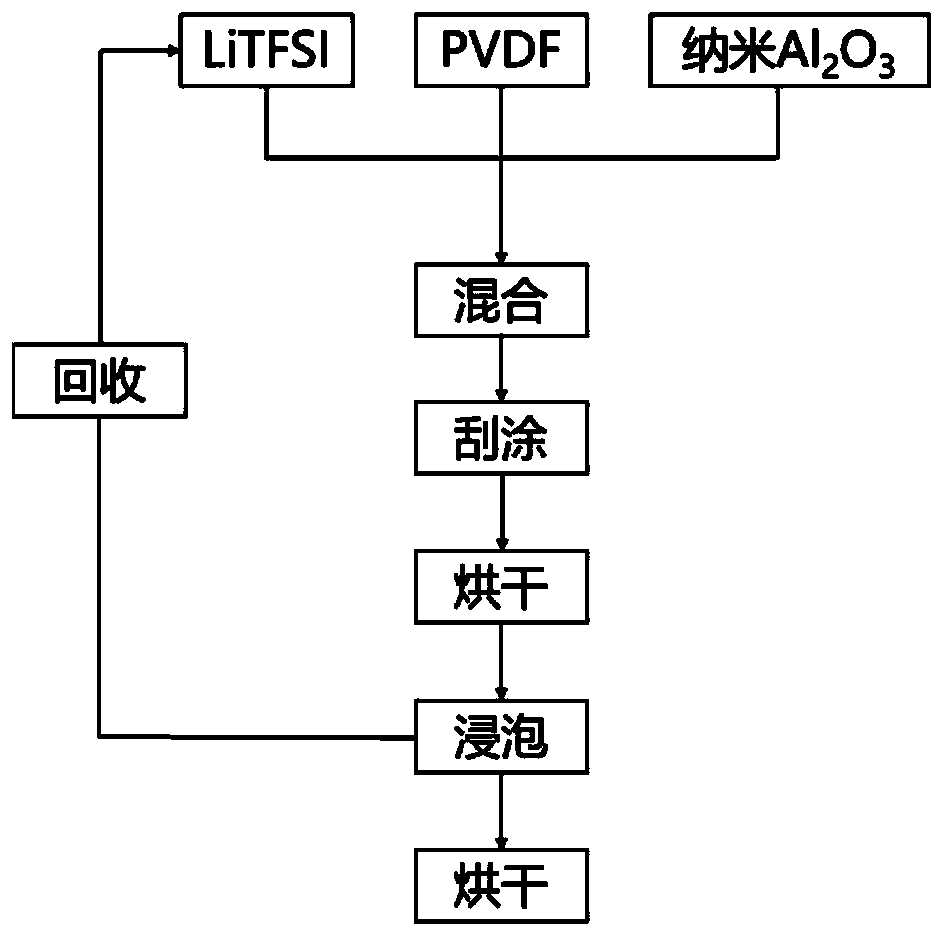

Preparation method for ion battery porous diaphragm and ion battery

InactiveCN109786624AAdjustable thicknessLow priceSecondary cellsCell component detailsPorosityN dimethylformamide

The invention provides a preparation method for ion battery porous diaphragm and an ion battery. The method comprises the steps of dispersing a polymer and a pore former into a solvent I, thereby obtaining the solution containing complex, wherein the polymer is selected from one or more of polyvinylidene fluoride, poly(vinylidene fluoride-hexaflouropropylene)copolymer and polyaramid, the pore former is selected from alkali metal salt, total mass of the polymer and the pore former occupies 1-40% of the solution, a molar ratio of the pore former and the polymer is 0.05-5:1, and the solvent I isselected from at least one of N-Methyl pyrrolidone, N, N-dimethylacetamide, N, N-dimethylformamide, acetone, triethyl phosphate, hexamethylphosphoramide, tetramethylurea, sulfolane and dimethyl sulfoxide; coating the solution and carrying out drying to obtain initial diaphragm, washing the initial diaphragm through utilization of a solvent which cannot dissolve the polymer, and carrying out drying. The method is simple. Thickness, a pore size and porosity of the porous diaphragm can be adjusted. Mechanical strength can be controlled. Mechanical strength is relatively high. Relatively high charge / discharge performance is achieved.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

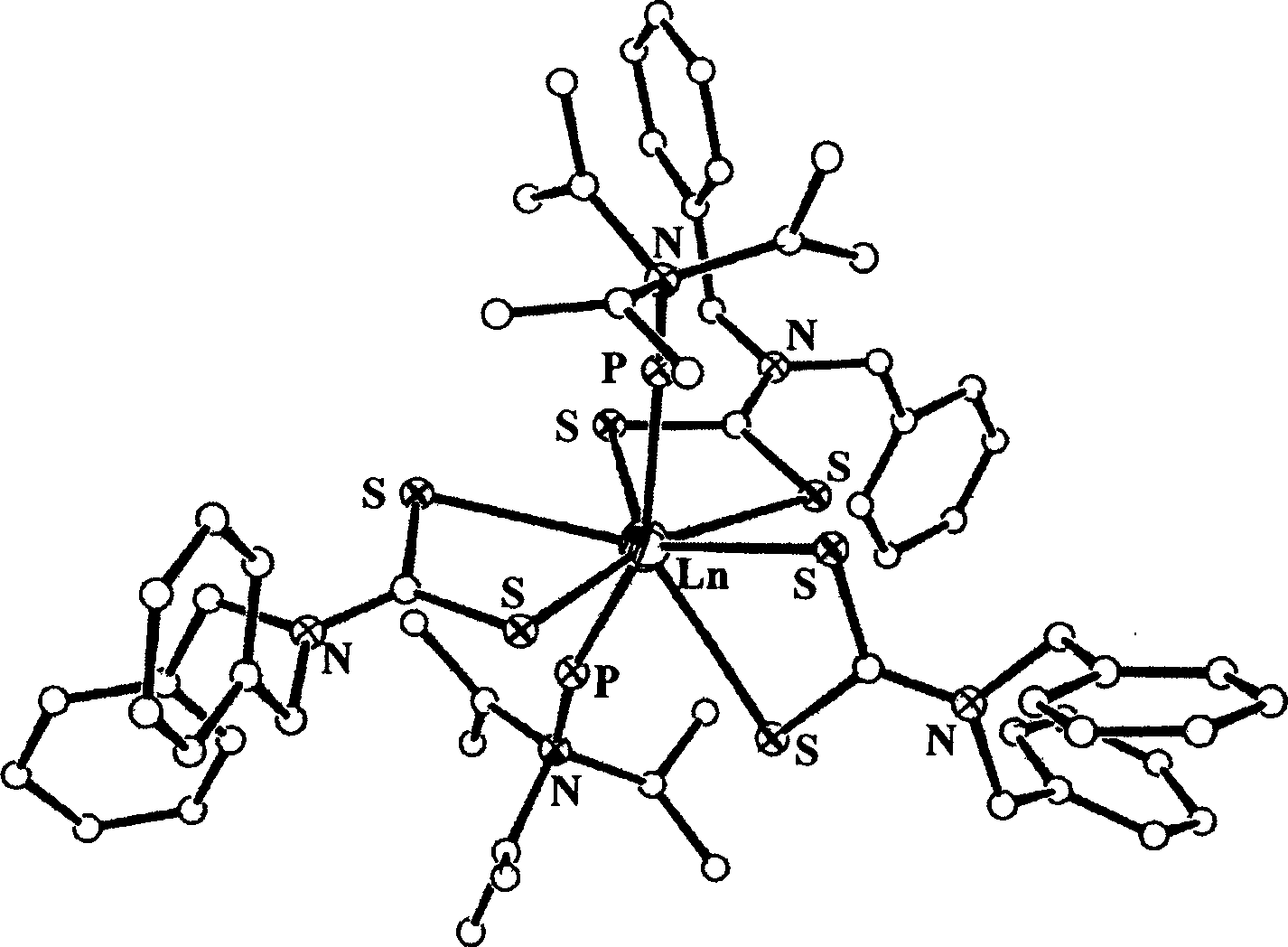

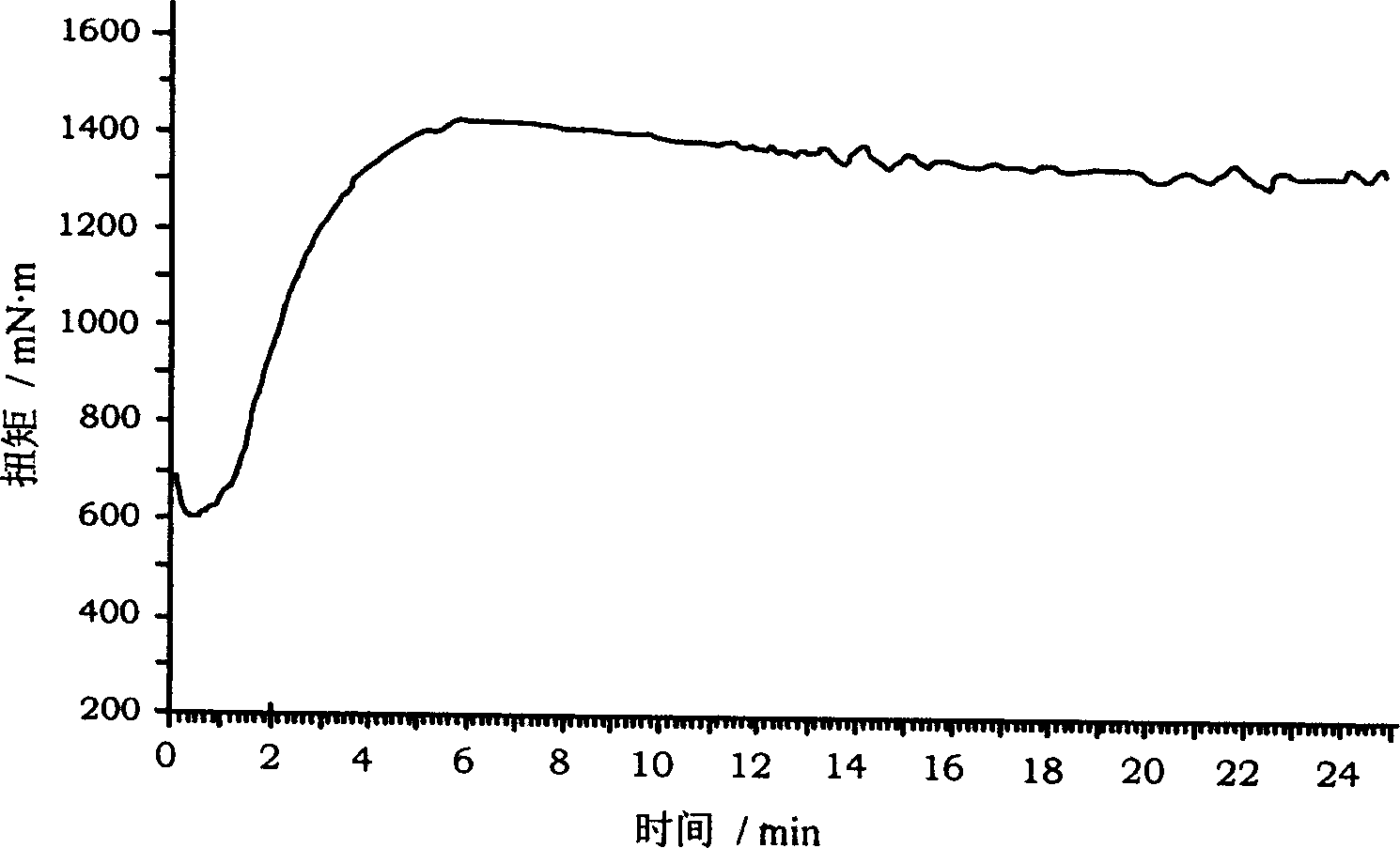

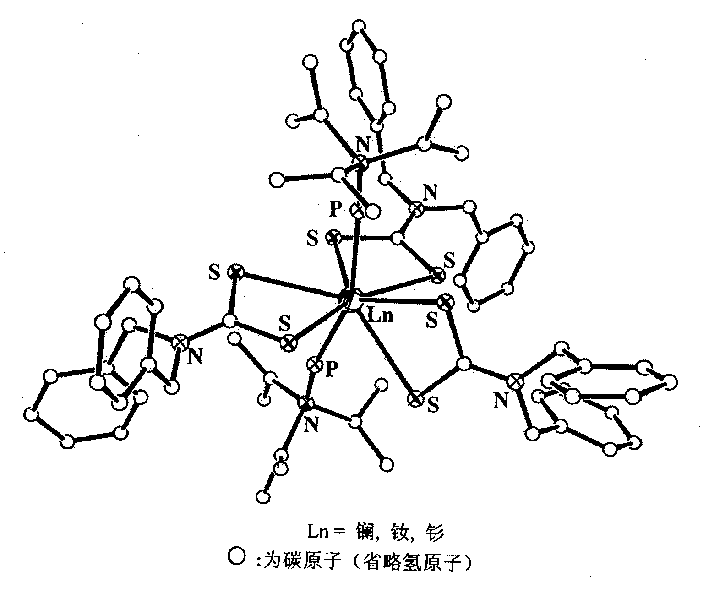

Rare earth dithiocarbamate vulcanization acalerator and its preparation method

The present invention relates to a dithiocarbamic acid rare earth sulfofication accelerant and its preparation method. It includes the following steps: firstly, using dibenzylamine, NaOH and CS2 as raw material to prepare ligand, then making the ligand react with rare earth chloride to prepare rare earth dibenzyl dithiocarbamate coordination compound intermediate body, and making said intermediate body react with hexamethylphosphoramide to obtain the required product.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Domestic wastewater treatment flocculant

InactiveCN106219711ANothing producedNo corrosionWater/sewage treatment by flocculation/precipitationHexamethylphosphoramideGluconates

The invention relates to a domestic wastewater treatment flocculant, made from the following components: tetrasodium hydroxyethylidene diphosphonate, polysilicone, pyridine, benzotriazole, sodium ferrate powder, chitosan, naphthalene, sodium dichloroisocyanurate, sodium dodecyl benzene sulfonate, magnesium stearate, quaternary ammonium salt, polyaluminum ferric chloride, sodium petroleum sulfonate, sodium lactate, sodium carboxymethyl cellulose, sodium lauroyl sarcosinate, zinc gluconate, ferric sulfate, pentaerythritol stearate, 1,2-propanediol, hexamethylphosphoramide, lemon essential oil, and deionized water. The domestic wastewater treatment flocculant reacts fast with no toxic, harmful gases produced; a resultant is stable and never decomposes into toxic matters; the domestic wastewater treatment flocculant is efficient and nontoxic, is safe to a human body both before and after reaction, and is non-corrosive to objects; the domestic wastewater treatment flocculant has high treating efficiency specific to wastewater.

Owner:余志娟

Modified polystyrene insulating material for toughened flame-retardant wiring harness for household appliances

InactiveCN103554699AImprove performanceImprove insulation performancePlastic/resin/waxes insulatorsCelluloseHexamethylphosphoramide

The invention relates to an insulating material for a wiring harness, and particularly relates to a modified polystyrene insulating material for a toughened flame-retardant wiring harness for household appliances. The material comprises the following raw materials in parts by weight: 8-9 parts of polyimide, 40-45 parts of polystyrene, 10-15 parts of SBS (Styrene Butadiene Styrene), 12-15 parts of silicon dioxide, 4-6 parts of aluminum nitride, 2-3 parts of maleic anhydride, 1-2 parts of lignocelluloses, 23-25 parts of montmorillonite, 23-26 parts of talcum powder, 23-25 parts of triethyl citrate, 1-2 parts of hexamethylphosphoramide, 1-2 parts of anti-aging agent NBC, 10-12 parts of hard kaolin, 3-4 parts of nanometer argil, 1-2 parts of nadic anhydride and 14-16 parts of auxiliaries. The insulating material combines the advantages of polystyrene, SBS and other raw materials, the properties of the traditional polystyrene material can be improved, the insulating material has good processability and mechanical property, the prepared material is flexible, impact-resistant, flame-retardant, good in insulating property, anti-aging, long in service life, and can be widely used for manufacturing insulating sheaths, wiring terminals, binding materials and the like of wiring harnesses for each part of a household appliances, thus having a wide market demand prospect.

Owner:合肥得润电子器件有限公司

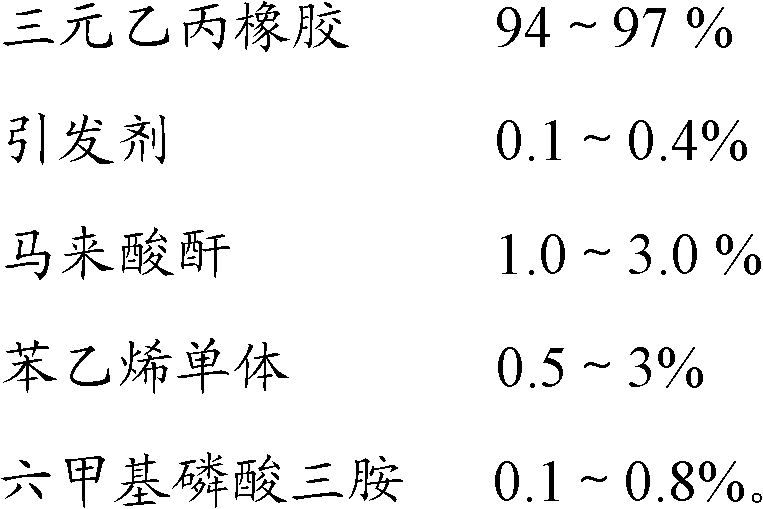

Soft type halogen-free flame-retardant cable material and preparation method thereof

ActiveCN103524820AGood weather resistanceLow smokePlastic/resin/waxes insulatorsInsulated cablesElastomerHexamethylphosphoramide

The invention provides a soft type halogen-free flame-retardant cable material prepared from the following raw materials in parts by weight: 20-40 parts of polyolefin resin, 8-10 parts of a thermoplastic elastomer, 5-6 parts of organosilicone mixed compound, 3-5 parts of hexamethylphosphoramide, 2-4 parts of a compatibilizer, 40-50 parts of magnesium hydroxide, 3-6 parts of zinc borate, 4-6 parts of stearic acid, 0.4-1.2 parts of a silane coupling agent KH560, 0.1-0.5 part of an antioxidant 168, 15-25 parts of aluminium hypophosphite, 1-2 parts of dimethylaminoethyl methacrylate, and 15-20 parts of a modified filler. The soft type halogen-free flame-retardant cable material adopts the low-hardness thermoplastic elastomer to be blended with the polyolefin resin, besides the good mechanical performance is kept, and the cable material softness degree is greatly improved so as to expand the use scope of the cable material.

Owner:JIANGSU ETERN +1

Fiber-reinforced composite coaxial cable material and preparation method thereof

InactiveCN105670151AHigh tensile strengthIdeal impact strengthPolymer scienceHexamethylphosphoramide

The invention discloses a fiber-reinforced composite coaxial cable material and a preparation method thereof. The preparation method comprises the following steps: (1) taking polystyrene, ethylene propylene diene monomer rubber, a melamine modified urea formaldehyde resin, hydroxypropyl methylcellulose, glass fibers, basalt fibers, hexametapol and allyl isothiocyanate according to parts by weight, adding the materials into a stirring tank, and stirring; (2) adding an antioxidant 1010, diamyl phthalate and propylene glycol monomethyl ether acetate into the stirring tank, and stirring while keeping the temperature constant; and (3) carrying out high-temperature extrusion on the mixed materials in the step (2) in a double screw extruder, and granulating, thereby obtaining the fiber-reinforced composite coaxial cable material. The fiber-reinforced composite coaxial cable disclosed by the invention has the characteristics of favorable properties and low cost.

Anti-ultraviolet modified nylon 66 material for automobile plastic members

The invention belongs to the field of high-molecular materials, and specifically relates to an anti-ultraviolet modified nylon 66 material for automobile plastic members. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 66, 10-12 parts of silicon carbide, 4-6 parts of titanium nitride, 20-24 parts of teflon, 13-16 parts of nanometer potter's clay, 4-5 parts of calcium stearate, 3-4 parts of hexamethylphosphoramide, 3-5 parts of alumina, 2-3 parts of bamboo-charcoal powder, 3-4 parts of stearic acid, 2-3 parts of iron oxide black, 6-9 parts of triolein, 2-3 parts of cross-linking agent TAIC and 12-15 parts of an auxiliary agent. The material combines the advantages of the raw materials such as nylon 66, teflon and the like; the material is subjected to modification processing by utilizing the raw materials such as nanometer potter's clay, silicon carbide and the like, so that the material has good processing performance and mechanical properties; and the prepared material is high in strength, practical, wear-resistant, resistant to high temperature, resistant to thermal ageing, resistant to ultraviolet ageing, flame-retardant, antistatic, safe and reliable, and is widely applicable to prepare various automobile plastic members.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

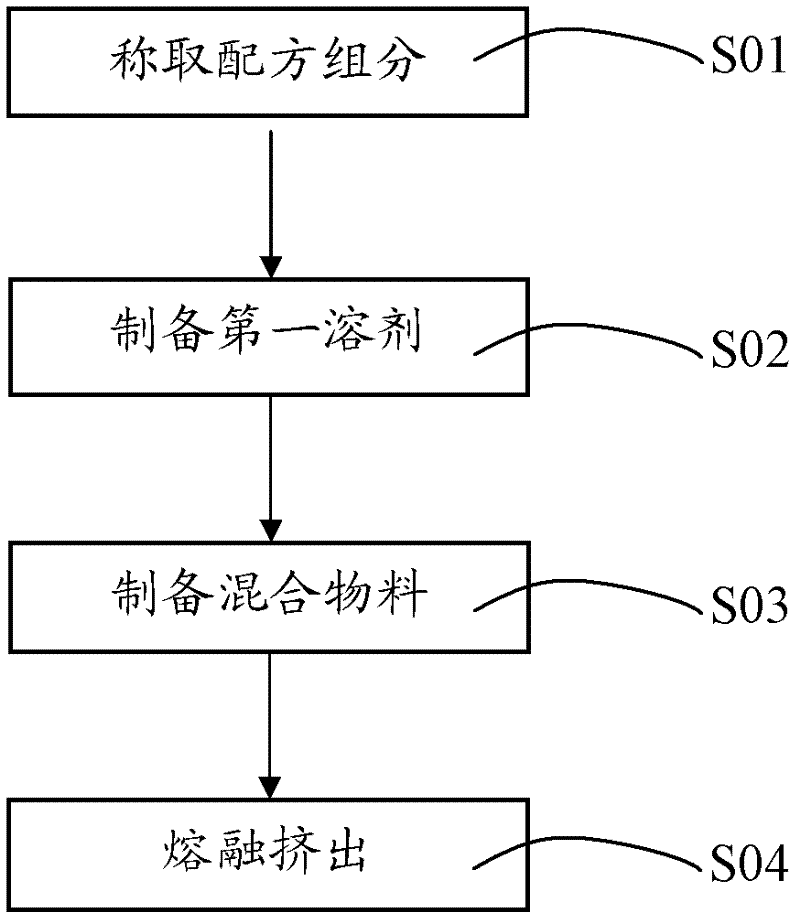

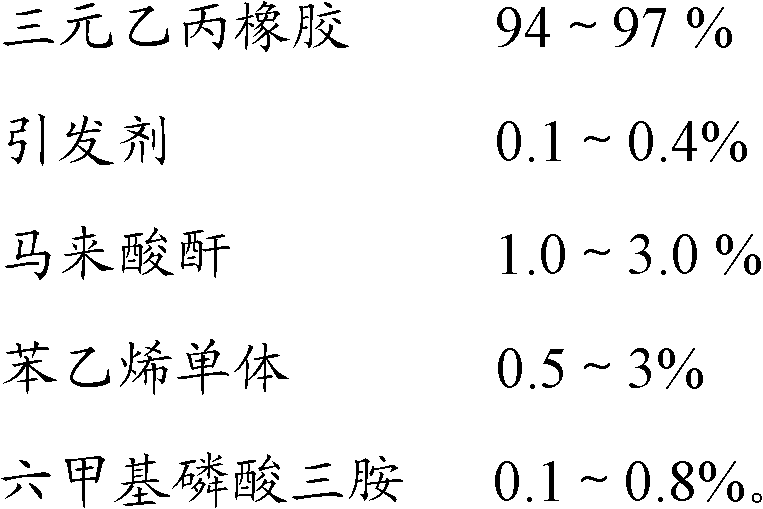

Ethylene propylene diene monomer grafted maleic anhydride and preparation method thereof

InactiveCN102643391AInhibition of crosslinkingHigh grafting rateHexamethylphosphoramidePolymer science

The invention discloses an ethylene propylene diene monomer grafted maleic anhydride and a preparation method thereof. The ethylene propylene diene monomer grafted maleic anhydride comprises the following components in percentage by weight: 95-97% of ethylene propylene diene monomer, 0.1-0.2% of initiator, 1.0-2.0% of maleic anhydride, 0.8-1.5% of styrene monomer and 0.2-0.5% of hexamethylphosphoramide. The grafting base maleic anhydride used as the grafting monomer is grafted in the melt extrusion process under the action of an initiator; and thus, the invention has the advantages of high grafting ratio, high grafting efficiency, small product peculiar smell, white color, environmental protection and high safety. The preparation method has the advantages of simple technique, easily controlled conditions, low cost and low facility request, and is suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

Preparation method of cast nylon composite material with high friction-reducing and anti-wear surface layer

InactiveCN103450469AHigh mechanical strengthIncreased mechanical toughnessHexamethylphosphoramideSurface layer

The invention discloses a preparation method of a cast nylon composite material with a high friction-reducing and anti-wear surface layer. The preparation method comprises the following steps of: preparing dispersive suspensoid by hexamethylphosphoramide, ultra-fine kaolin and toluene diisocynate in proportion; adding dispersive suspensoid and teflon micro powder to a caprolactam melt; initiating caprolactam anionic ring-opening polymerization through a sodium hydroxide-toluene diisocynate catalytic activating system; casting a reaction mass into a preheated and heat-preserved centrifugal rotating die under normal pressure; after the reacting and casting liquid is polymerized, solidified and formed, gradually cooling and demoulding, thus obtaining the cast nylon composite material with the high friction-reducing and anti-wear surface layer. The prepared cast nylon composite material has the characteristics that an inner matrix and an outer surface layer are different in structure and performance, so that the requirements on manufacturing and using various pulleys, idler wheels, rope wheels and guide wheels for a transportation mechanism, a hoisting device and mine equipment can be met.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Ethanol gasoline phase stabilizer and preparation method thereof

InactiveCN101812336AExtend the storage and transportation periodHigh phase stabilityLiquid carbonaceous fuelsFuel additivesCyclohexanoneHexamethylphosphoramide

The invention discloses an ethanol gasoline phase stabilizer. The stabilizer consists of the following raw materials in part by weight: 10 to 28 parts of isopropyl alcohol, 10 to 28 parts of isooctyl slcohol, 10 to 28 parts of normal heptane, 5 to 7 parts of methyl carbonate, 5 to 7 parts of diethyl phthalate, 5 to 7 parts of methyl isobutyrate, 1 to 2 parts of polyoxyethylene sorbitan monooleate, 1 to 2 parts of acetacetic ether, 1 to 3 parts of oleic acid n-butylamine, 1 to 3 parts of hexamethylphosphoramide, 1 to 2 parts of cyclohexanone, and 1 to 2 parts of hexadecyl dimethly ammonium chloride. The invention also discloses a method for preparing the ethanol gasoline phase stabilizer. The ethanol gasoline phase stabilizer of the invention can effectively improve the phase stability of ethanol gasoline products; when the ethanol gasoline phase stabilizer is used, the ethanol gasoline product is not layered when being stored for 6 months; and the additive also has the advantages of corrosion resistance, good detergent dispersing effect, easy preparation and convenient popularization and application.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

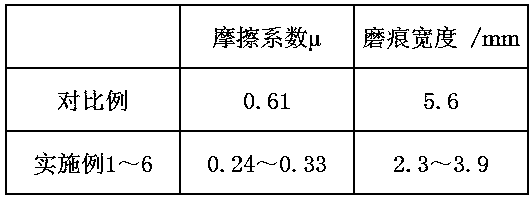

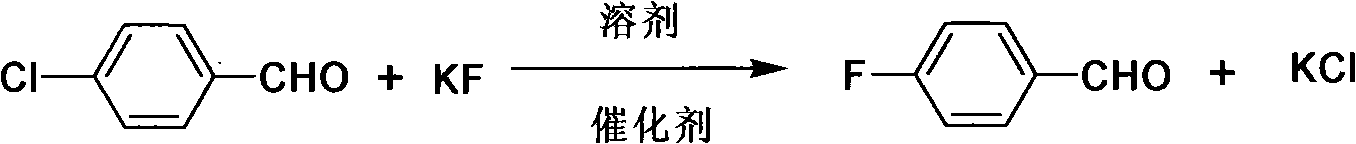

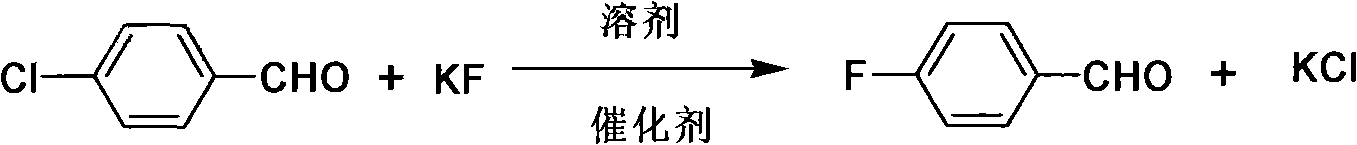

Synthetic method of 4-fluorobenzaldehyde

InactiveCN101353297ALow priceShort synthetic routeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSulfolaneHexamethylphosphoramide

The invention relates to a synthetic method of p-flurobenzaldehyde, which belongs to the chemical and pharmaceutical field. In the synthetic method, the p-chlorobenzaldehyde and potassium fluoride react under the condition of a solvent and a catalyst at high temperature, wherein, the solvent is one of sulfolane, dimethyl sulfoxide, dimethylformamide, dimethylacetamide, hexamethyl phosphoramide, nitrobenzene and ortho-nitrotoluene; the catalyst is one of or the mixture of two or more than two of benzyl triethyl amine chloride, tetrabutylammonium bromide, hexadecyltrimethylammonium chloride, methyltrioctylammonium chloride, tetraphenylphosphonium bromide, methyltriphenylphosphonium bromide, benzyl triphenyl phosphonium bromide and polyethylene glycol dimethyl ether. Compared with the conventional preparation method, the synthetic method of the invention has the advantages of cheap raw materials, short synthetic route and little 'three wastes' discharge. As the amount of the catalyst used is reduced and the price of the solvent is low, the production cost of the p-flurobenzaldehyde is decreased.

Owner:王俊华

Spinning sewage environmental-protection treating agent

InactiveCN106044894ANothing producedNo corrosionSpecific water treatment objectivesWater/sewage treatmentIsooctyl acrylateHexamethylphosphoramide

The invention relates to a spinning sewage environmental-protection treating agent, which is composed of the following ingredients: amino trimethylene phosphonic acid, pyrrolidine, starch xanthate, NPAM, copper chloride dehydrate, peracetic acid, boric acid, sodium formate, sodium hydrosulfite, sodium hypochlorite, DL-methionine, sodium citrate, white carbon black, caustic alkali, sodium aluminate, flyash, diatomite, activated carbon, hexamethyl phosphoramide, lemon essential oil, propylene glycol, acetic ether, ethylene oxide, triethanolamine, polymethyl hydrogen siloxane, polyethylene glycol octylphenol ether, poly(diallyldimethylammonium chloride), starch phosphate, 2-ethylhexyl acrylate, butyl hydroxyanisole and deionized water. The product has fast reaction speed, and no toxic or harmful gas is generated during the process. A product obtained after the reaction is stable and will no longer be decomposed into toxic substances. The spinning sewage environmental-protection treating agent is efficient and nontoxic, is safe to human before and after the reaction, is noncorrosive to objects, and has high sewage treatment efficiency.

Owner:余志娟

Sulfur-containing silane synthesizing method

ActiveCN107021979AAvoid wastingHigh purityGroup 4/14 element organic compoundsHexamethylphosphoramideSilanes

The invention provides a sulfur-containing silane synthesizing method. According to the synthesizing method, one or several of dimethyl formamide, dimethyl acetamide, hexamethyl phosphoramide and 1,3-dimethyl-2-imidazolidone is utilized as a solvent; sodium and sulfur are pretreated in the solvent to obtain sodium suspension liquid and sulfur suspension liquid; the sodium suspension liquid is added into the sulfur suspension liquid to react to obtain sodium polysulfide; halogenated alkyl alkoxy silane is added into the sodium polysulfide to react and be decontaminated to obtain a sulfur-containing silane finished product. According to the synthesizing method disclosed by the invention, sulfur-containing silane is synthesized in the solvent, so that not only is reaction efficiency in production improved, but also impurity introduction in a production process is avoided, quality of a final product is guaranteed, and purity, yield and calculation yield of the final product are improved; meanwhile, potential safety hazards and environmental pollution in a sodium and sulfur treating process are avoided, and environment-friendly treating cost in the production process is reduced.

Owner:江西宏柏新材料股份有限公司

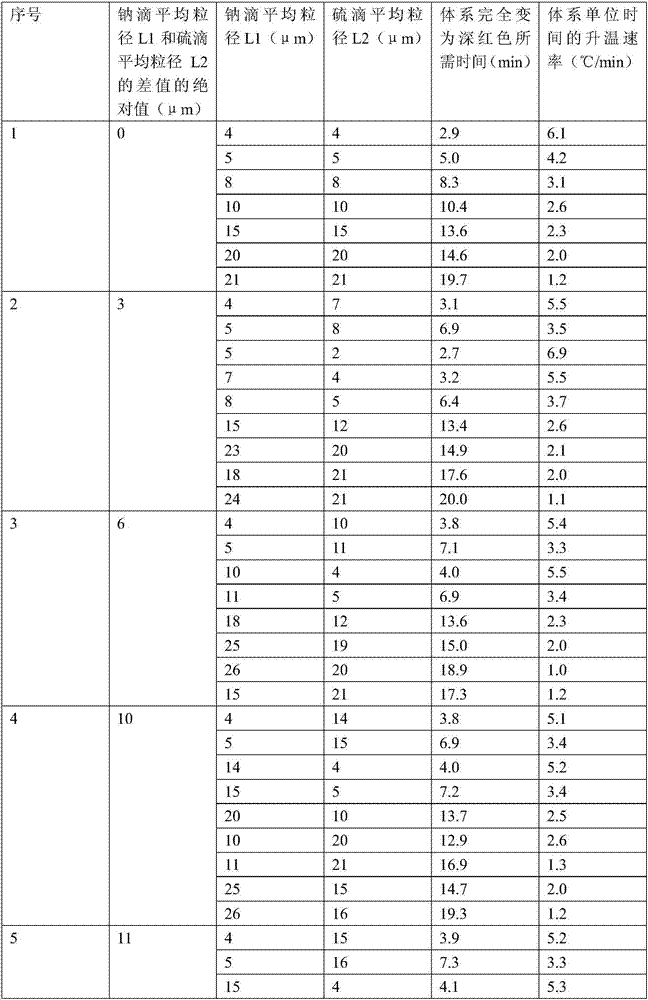

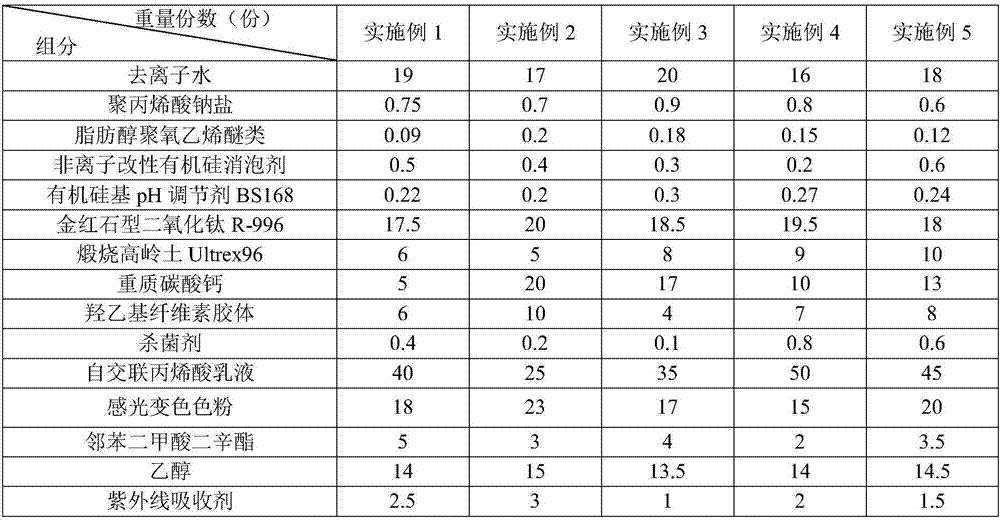

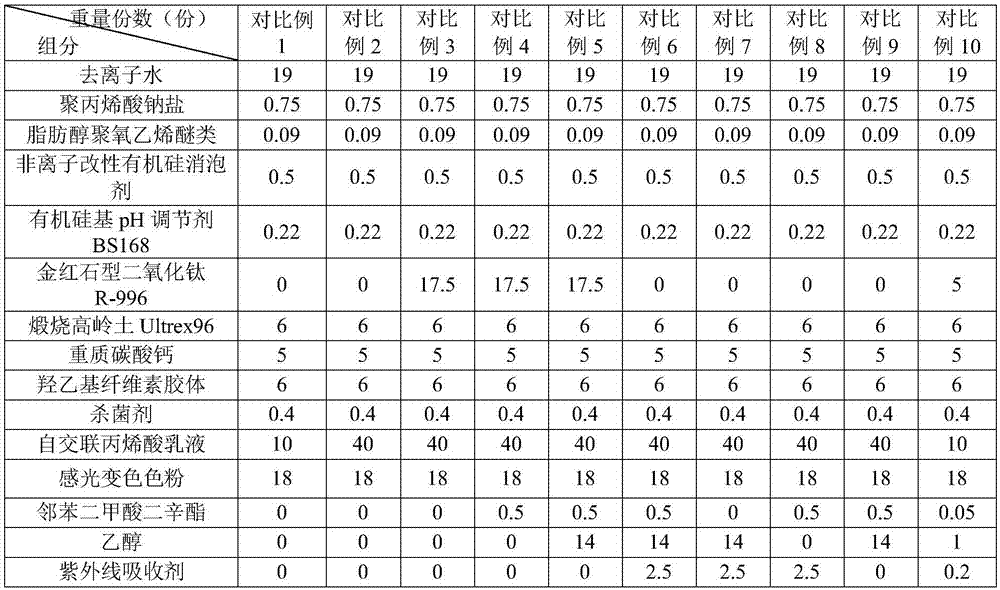

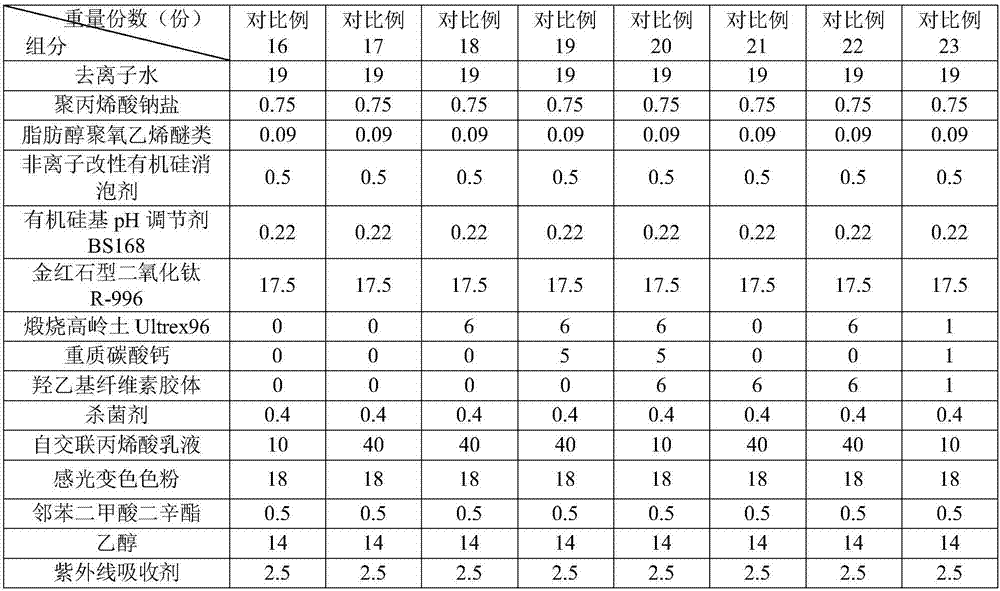

Light-sensitive coating and preparation process thereof

ActiveCN107141919AHigh bonding strengthAdd color variationRadiation-absorbing paintsHexamethylphosphoramideUltraviolet

The invention discloses light-sensitive coating and a preparation process thereof. The light-sensitive coating comprises deionized water, sodium polyacrylate, fatty alcohol polyoxyethylene ether, a non-ionic modified organic silicon defoamer, an organic silicon-based pH regulator BS168, rutile type titanium dioxide R-996, calcined kaolin Ultrex96, heavy calcium carbonate, hydroxyethyl cellulose colloid, bactericide, self-crosslinked acrylic emulsion, light-sensitive color-changing toner, dioctyl phthalate, ethanol and an ultraviolet absorbent, wherein the self-crosslinked acrylic emulsion is E-3030 self-crosslinked acrylic emulsion or SF-500 self-crosslinked acrylic emulsion; and the ultraviolet absorbent comprises at least two of phenyl salicylate, 2-hydroxyl-4-octyloxybenzophenone and hexamethylphosphoramide. The light-sensitive coating and the preparation process thereof have the advantages that the light-sensitive coating is harmless for a human body, can change colors, and is not liable to serous breakage when being subjected to an action force.

Owner:星空男孩(杭州)科技有限公司

PVC (polyvinyl chloride) tube formula

InactiveCN103483726AImprove antioxidant capacityInexpensive componentsHexamethylphosphoramidePolyvinyl chloride

The invention discloses a PVC (polyvinyl chloride) tube formula which comprises the following components in parts by weight: 40-60 parts of PVC resin, 2-3 parts of plasticizer, 15-20 parts of calcium carbonate, 1-5 parts of epoxy soybean oil, 3-5 parts of hexamethylphosphoramide, 5-10 parts of impact modifier, 2-8 parts of zinc oxide and 0.5-1 part of paraffin. The added hexamethylphosphoramide can greatly improve the oxidation resistance of a PVC tube and is low in cost, thereby being suitable for popularization and application. Compared with the prior art, the PVC tube prepared from the formula has the characteristics of high strength and high toughness, is high in impact resistance and low in price of product components, and has great market competitiveness.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

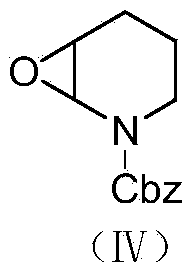

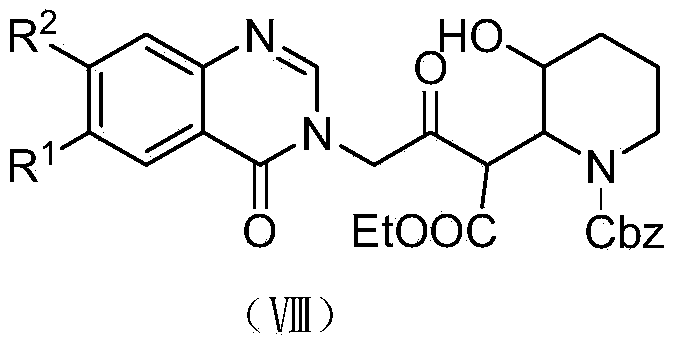

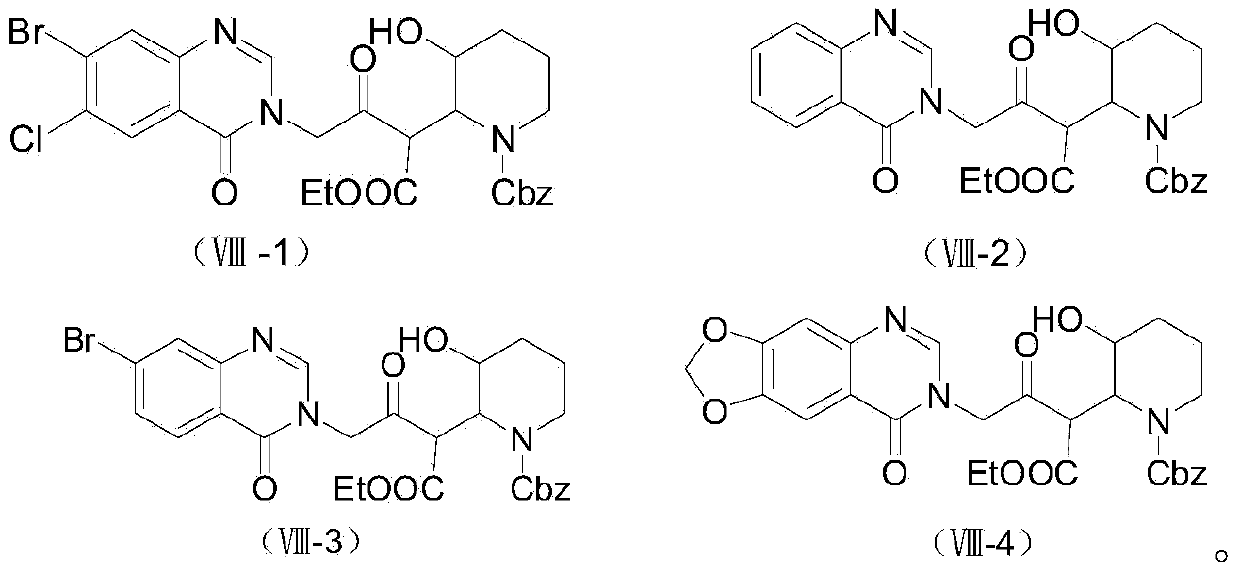

Piperidine derivative, and preparation method and application thereof in preparation of halofuginone

ActiveCN103467449AEasy to operateMild reaction conditionsOrganic chemistryBulk chemical productionHalofuginone hydrobromideHexamethylphosphoramide

The invention discloses a piperidine derivative represented by a formula (VIII), and a preparation method and an application thereof in preparation of halofuginone. Under an alkaline condition and under catalysis of HMPA (hexamethylphosphoramide), cuprous iodide, TMEDA (tetramethylethylenediamine) and the like, a 1,3 dicarbonyl compound which easily generates stable negative ions is adopted to highly selectively undergo a reaction with an epoxy compound to synthesize the compound (VIII) with high yields. Compared with other process routes of synthesis of halofuginone, a process route provided by the invention comprises that the piperidine derivative (VIII) undergoes a one-step reaction to simultaneously complete decarboxylation and removal of a Cbz protecting group, more effectively shortens synthetic steps of the process route, and thereby greatly improving the yield of halofuginone hydrobromide; and moreover, the whole process route is simple and feasible in operation, has mild reaction conditions, has the adopted catalysts which are low in cost and are easy to get, and quite easily realizes the large-scale industrialized production.

Owner:ZHEJIANG UNIV OF TECH

Heavyweight corrugated pipe for concrete

InactiveCN104072863AImprove the defects of light weight and easy floating in concrete constructionImprove the defect of easy floatingHexamethylphosphoramidePolyethylene glycol

The invention discloses a heavyweight corrugated pipe for concrete. The heavyweight corrugated pipe comprises the following materials in parts by weight: 1-2 parts of calcium acetylacetonate, 0.7-1 part of hexamethylphosphoramide, 1-2 parts of bisimidazolidinyl urea, 10-12 parts of vermiculite powder, 1-2 parts of polyethylene glycol 400, 1-2 parts of white mineral oil, 2-3 parts of heavy calcium carbonate, 1-2 parts of ethylene diamine tetra(methylene phosphonic acid) sodium, 2-3 parts of charcoal powder, 1-2 parts of butyl p-hydroxybenzoate, 0.2-0.4 part of ammonium ethoxylated alkylphenol sulfate, 90-100 parts of polypropylene and 4-7 parts of composite additives. By virtue of the heavy corrugated pipe disclosed by the invention, the defect that the current polyethylene corrugated pipe is easily floated in the concrete construction due to the light weight is improved and the heavy corrugated pipe has the characteristics of good tensile strength and ring stiffness, good tolerance and strong impact resistance.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

Multifunctional polyethylene plastics

The invention discloses multifunctional polyethylene plastics. The multifunctional polyethylene plastics comprises polyethylene, filler, an antistatic agent, an anti-aging agent, a toughening agent, a lubricant, a dispersing agent and a coupling agent, wherein the filler adopts glass powder; the antistatic agent adopts fatty alcohol polyoxyethylene ether; the anti-aging agent adopts hexamethylphosphoramide; the toughening agent adopts polyvinyl butyral; the lubricant adopts organic silicone oil; the dispersing agent adopts an ethylene-acrylic acid copolymer; the coupling agent adopts di(dioctylpyrophosphato) ethylene titanate. The multifunctional polyethylene plastics comprises polyethylene, the filler, the antistatic agent, the anti-aging agent, the toughening agent, the lubricant, the dispersing agent and the coupling agent and has the advantages of high hardness, high strength, antistatic performance, aging resistance, scraping resistance, good quality and long service life.

Owner:CHANGSHU JIANGSHUN PLASTIC PROD

Culture method of selenium-rich black fungus

InactiveCN107459413AImprove immunityGuaranteed normal growthCalcareous fertilisersMagnesium fertilisersHexamethylphosphoramideAdditive ingredient

The invention discloses a culture method of selenium-rich black fungus, and relates to the technical field of black fungus planting. According to the culture method of the selenium-rich black fungus, hexamethylphosphoramide is added into a culture medium and is combined with sodium selenite in the culture medium to generate organic selenium; sodium selenite inorganic selenium is converted into organic selenium, so that the absorption of the black fungus on the selenium element can be promoted; the goal of enriching the selenium enrichment by the black fungus is achieved; traditional Chinese medicine ingredients are also added in the culture medium; the effects of sterilization, mildew prevention, worm expelling, black fungus immunity improvement, growth promotion and yield increase are achieved; the normal growth of the black fungus is ensured; the survival rate is improved; the traditional Chinese medicine ingredients are plant sources, are easy to decompose, so that the pesticide residue cannot be caused; scientificalness and environment protection are realized; the health of eaters can be ensured.

Owner:灵川县金晨菌业有限公司

Heat insulating plastic bottle cap masterbatch

The invention discloses a heat insulating plastic bottle cap masterbatch. The heat insulating plastic bottle cap masterbatch is prepared from the following raw materials in parts by weight: 100-105 parts of a ABS (acrylonitrile-butadiene-styrene) copolymer, 0.6-1 part of basic bismuth chloride, 0.5-1 parts of dimethyl benzyl carbinol, 1-2 parts of difenoconazole, 3-4 parts of hollow glass beads, 0.5-1 part of tributyl tin trichloride, 1-2 parts of polybrominated styrene, 0.3-1 part of hexamethylphosphoramide, 0.6-1 part of 2-bromo-4-methylphenol, 0.8-1 part of ammonium metaborate, 0.8-2 parts of chromium carbonate, 2-3 parts of bisphenol A polycarbonate, 0.7-1 part of nano diatomite, 1-2 parts of glyceryl tristearate, 0.7-1 part of a silane coupling agent KH560 and 3-4 parts of a toughening packing. The added hollow glass beads and nano diatomite for preparing the heat insulating plastic bottle cap masterbatch have good heat insulating properties and have the effects of well protecting bottled items so that the service life of some bottled items stored in a high-temperature environment for a long time can be prolonged and the security of the bottled items can be improved, and the added toughening packing can further improve the toughness of the ABS copolymer and improve the wear resistance and the fracture resistance of plastic bottle caps so that the plastic bottle caps have good sealing and protecting effects.

Owner:HEFEI AOPAI METAL PROD

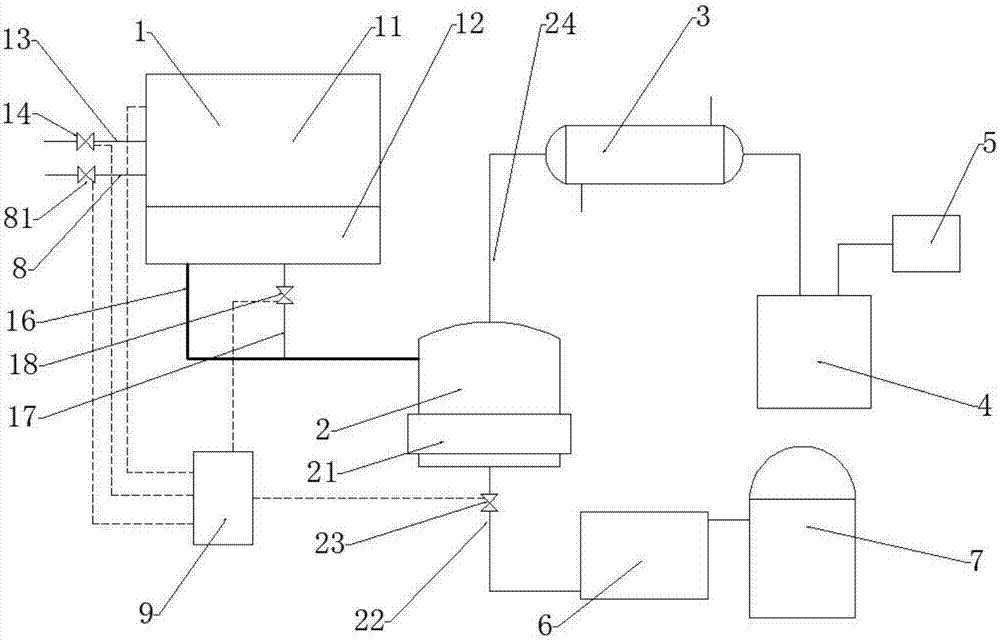

Long-life zinc-nickel battery and preparation method thereof

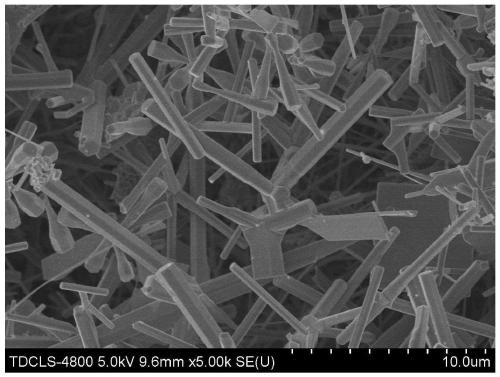

PendingCN111370782AImprove water retentionExtend your lifeCell electrodesCarbon nanotubesElectrolytic agentPolymer electrolytes

The invention discloses a zinc-nickel battery with long service life and a preparation method thereof. The preparation method comprises the following steps: putting foamed nickel into a clear solutionprepared from Ni (NO3) 2.6 H2O, hexamethylphosphoramide, functionalized CNT and ammonia water, reacting at 80-90 DEG C for 20-24 hours, and growing Ni (OH) 2 / CNT on a foamed nickel substrate to obtain a nickel electrode; by taking a zinc foil as a working electrode and a Co3O4 electrode as a counter electrode, carrying out electro-deposition in an electrolyte containing KOH and Zn (CH3COO) 2 to prepare a porous zinc electrode; by taking a nickel electrode as a positive electrode, and a porous zinc electrode as a negative electrode, separating the two electrodes by a PAM-sodium alginate polymer electrolyte, and assembling the zinc-nickel battery. According to the invention, the gel electrolyte with high ionic conductivity and water retention performance, the ultrathin nickel positive electrode with high surface area and conductivity and the porous zinc electrode are adopted; the stability of the battery is remarkably improved and the service life of the battery is prolonged.

Owner:湖南源达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com