Preparation method for ion battery porous diaphragm and ion battery

A porous separator and ion battery technology, applied in the field of membrane materials, can solve the problems of expensive solvents, high prices, and non-recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a battery porous diaphragm, which is characterized in that it comprises the following steps:

[0030] a), disperse the polymer and the pore-forming agent in solvent I to obtain a solution containing the complex; the polymer is selected from polyvinylidene fluoride and / or polyvinylidene fluoride-hexafluoropropylene copolymer and polyvinylidene fluoride One or more of aramid fibers; the pore-forming agent is selected from alkali metal salts; the total mass of the polymer and the pore-forming agent accounts for 1-40% of the solution, and the molar ratio of the pore-forming agent to the polymer is 0.05- 5:1; the solvent I is selected from N-methylpyrrolidone, dimethylacetamide, dimethylformamide, acetone, triethyl phosphate, hexamethylphosphoramide, diethylformamide, tetramethyl One or more of urea, sulfolane and dimethyl sulfoxide;

[0031] b), coating the solution containing the complex on the substrate, and drying to obtain ...

Embodiment 1

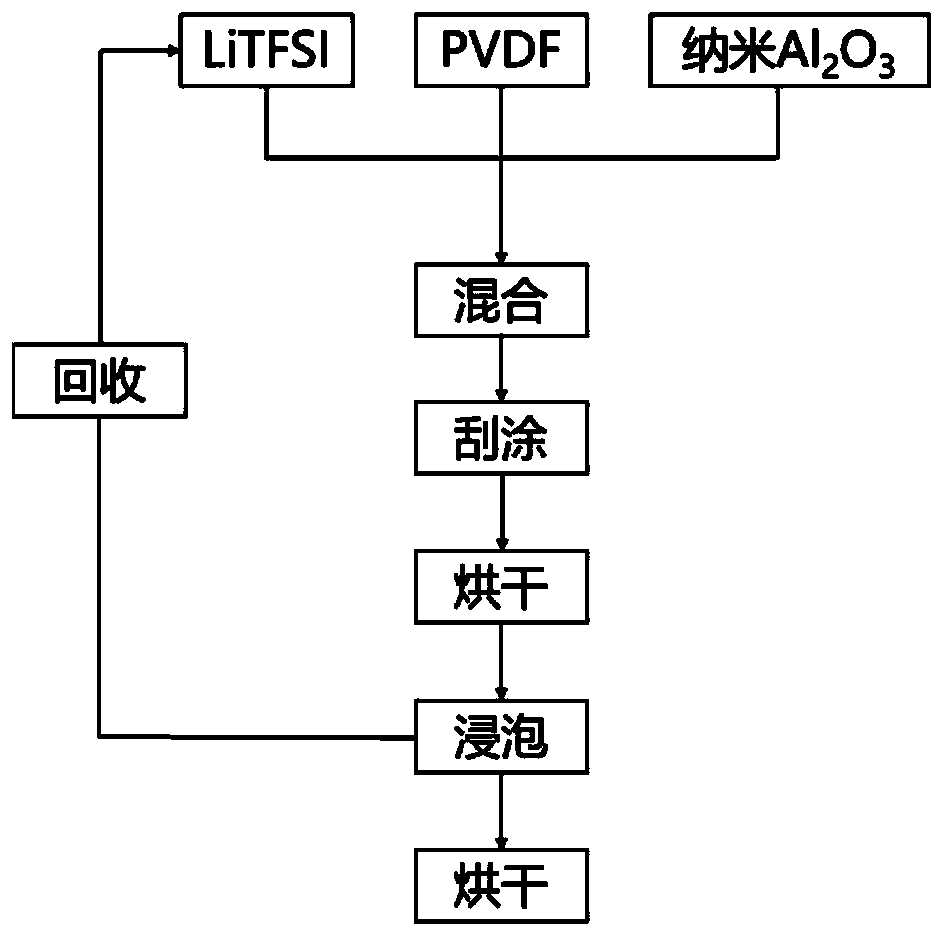

[0052] see figure 1 , figure 1 It is the preparation flowchart of Example 1 of the present invention;

[0053] 10g PVDF, 2g LiTFSI and 0.2g nano-Al 2 o 3 Dissolve in 20g of NMP, stir at 40°C for 5 hours, scrape the liquid on a glass plate with a thickness of 450μm, and place it in a blast oven at 45°C. After 10 hours, the membrane was removed from the glass plate, soaked in alcohol and washed three times, and the washed LiTFSI could be dried and recycled. Place the membrane in a vacuum oven at 60° C. for 20 hours to obtain a porous diaphragm with a thickness of 32 μm, a porosity of 50%, and an average pore diameter of 55 nm.

[0054] figure 2 SEM image of the porous membrane prepared in Example 1 of the present invention. image 3 It is the SEM picture of the commercial PP film. From figure 2 and image 3 It can be seen from the comparison that the pore diameter distribution of the porous diaphragm prepared in Example 1 of the present invention is uniform, and all a...

Embodiment 2

[0058] 15g PVDF, 1.5g LiPF 6 Dissolve in 40 g of dimethyl sulfoxide, stir at 45°C for 8 hours, scrape the liquid on a glass plate with a thickness of 750 μm, and place it in a blast oven at 70°C. After 12 hours, the membrane was removed from the glass plate, soaked in dimethyl carbonate and washed three times to remove the LiPF 6 Can be recycled. The membrane was placed in a vacuum oven at 75° C. for 20 hours to obtain a porous diaphragm with a thickness of 28 μm, a porosity of 56%, and an average pore diameter of 62 nm.

[0059] Figure 4 SEM image of the porous membrane prepared in Example 2 of the present invention.

[0060] The present invention tests the tensile strength of the porous diaphragm, and the test results are: the transverse tensile strength of the porous diaphragm prepared in Example 2 is 408 MPa, and the longitudinal tensile strength is 106 MPa.

[0061] With NCA as the positive electrode, metal Li as the negative electrode, and LiPF 6(EC:DMC=1:1) is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com