Optical mount with UV adhesive and protective layer

a technology of optical mounts and adhesives, applied in the field of assembly, can solve the problems of uv absorbing fillers in the adhesive mass, failure of the boundary layer, and known mount adhesives based on epoxy resin, and achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

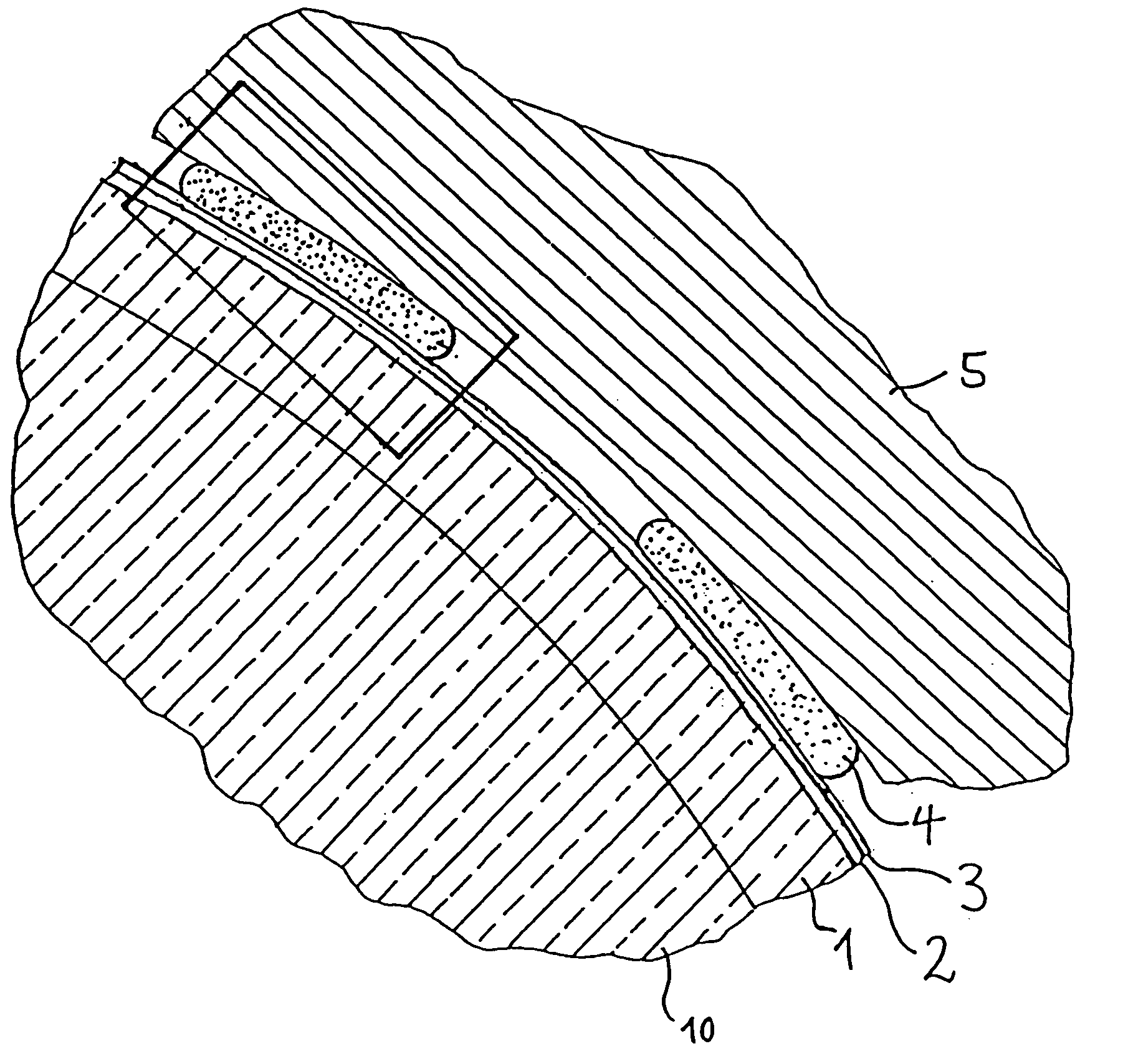

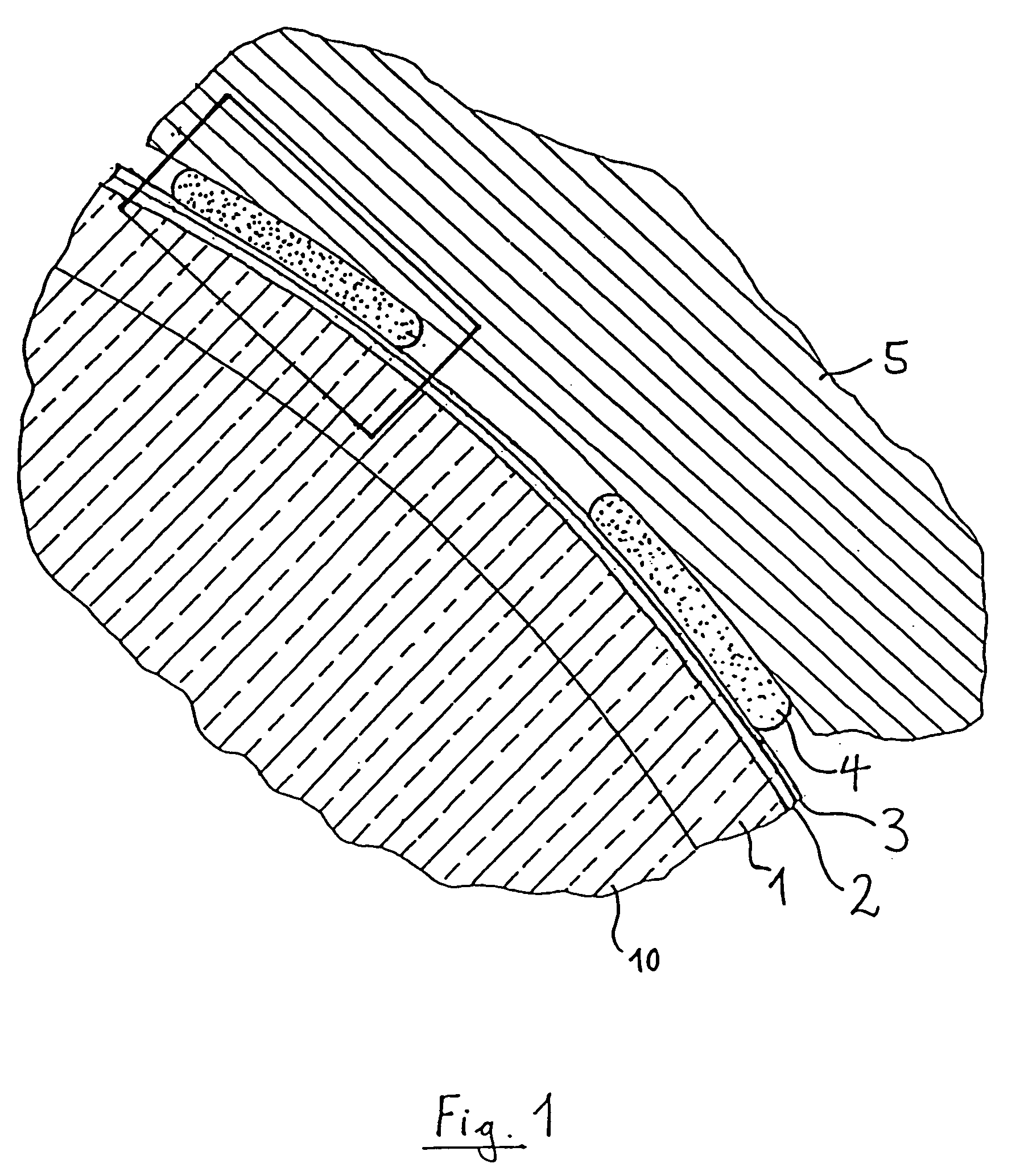

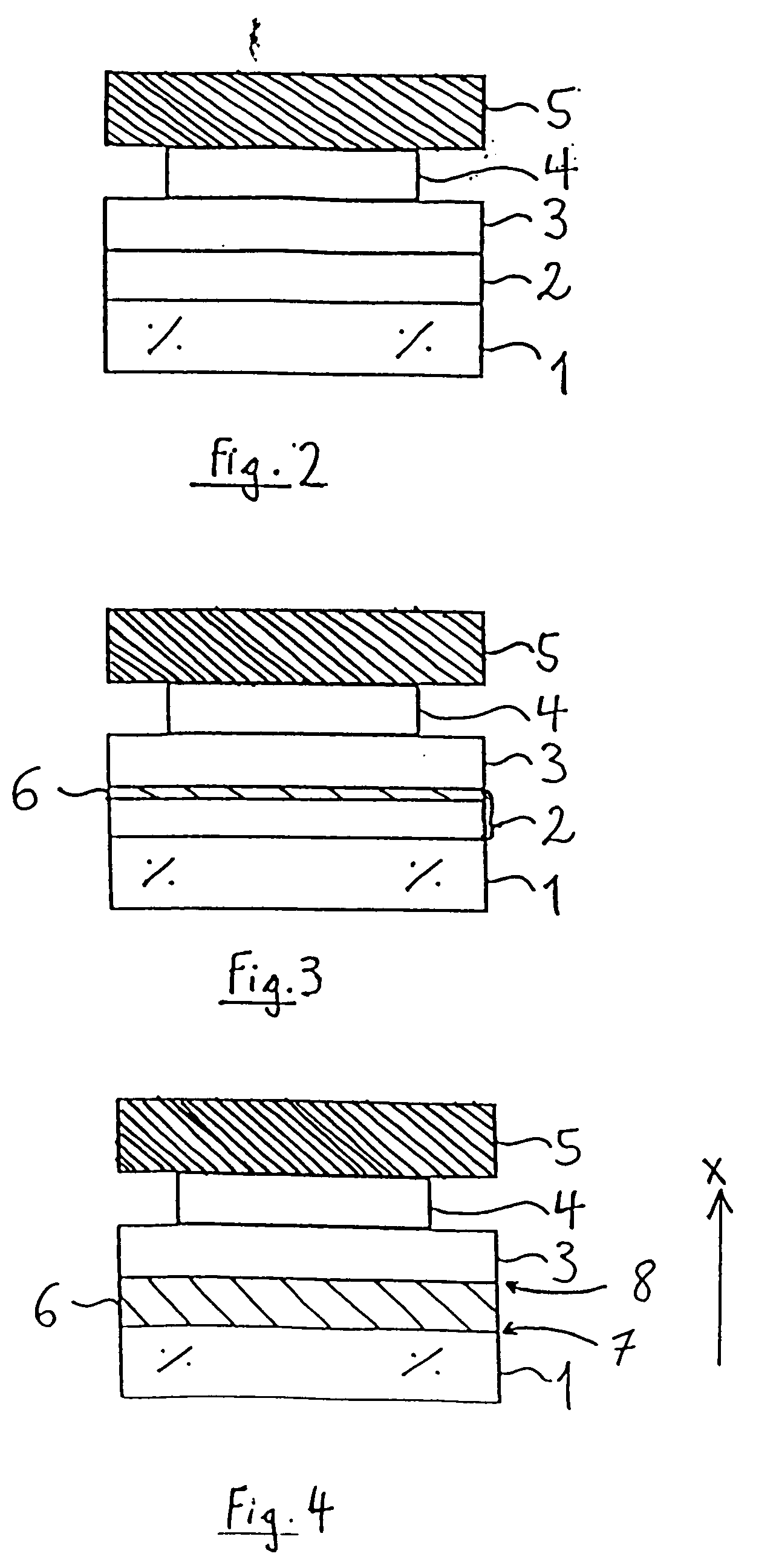

[0028] The assembly schematically shown in FIG. 1 has an optical component 1, namely a lens. In other embodiments, the optical component may be a flat plate, a prism, a Mangin mirror or a transmitting diffractive optical element. The optical component 1 includes a circular transmitting zone 10, within which the component 1 is capable of transmitting UV radiation from the VUV or DUV region, e.g. laser radiation at about 248 nm, 193 nm or 157 nm, essentially without absorption. Outside of the transmitting zone 10, on the edge of the transparent component 1, an adhesion-enhancing second layer 2 is applied, covering the edge of the component 1 continuously or as a distributed section. The adhesion-enhancing layer 2 is covered continuously by an adhesive-protecting first layer 3. The assembly additionally includes a holder (lens mount 5) made of metal. In other embodiments, the holder may be made of plastics or ceramic / glass-ceramic. The holder material is not transparent to ultraviolet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com