Patents

Literature

142 results about "Plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma (from Ancient Greek πλάσμα, meaning 'moldable substance') is one of the four fundamental states of matter, and was first described by chemist Irving Langmuir in the 1920s. It consists of a gas of ions – atoms which have some of their orbital electrons removed – and free electrons. Plasma can be artificially generated by heating or subjecting a neutral gas to a strong electromagnetic field to the point where an ionized gaseous substance becomes increasingly electrically conductive. The resulting charged ions and electrons become influenced by long-range electromagnetic fields, making the plasma dynamics more sensitive to these fields than a neutral gas.

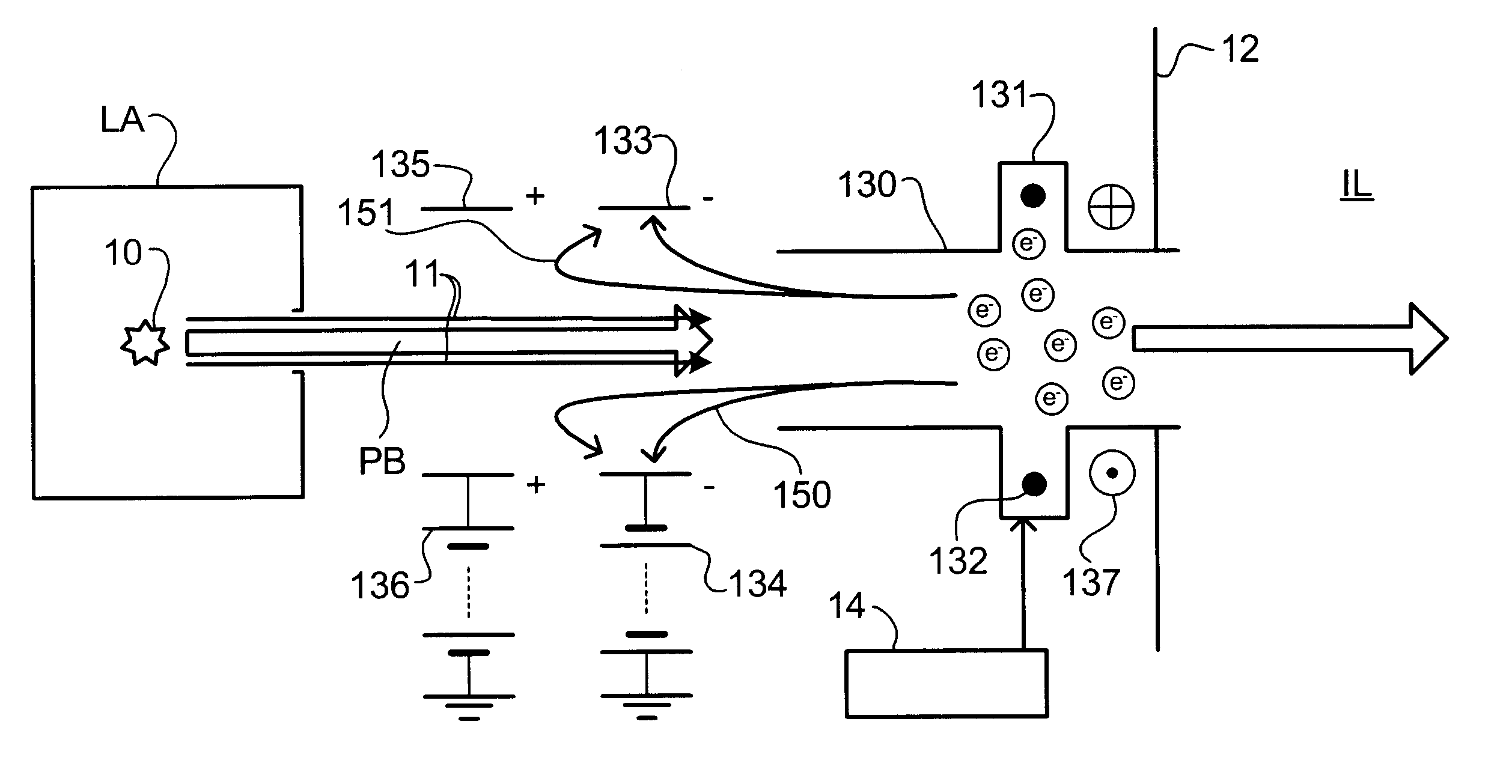

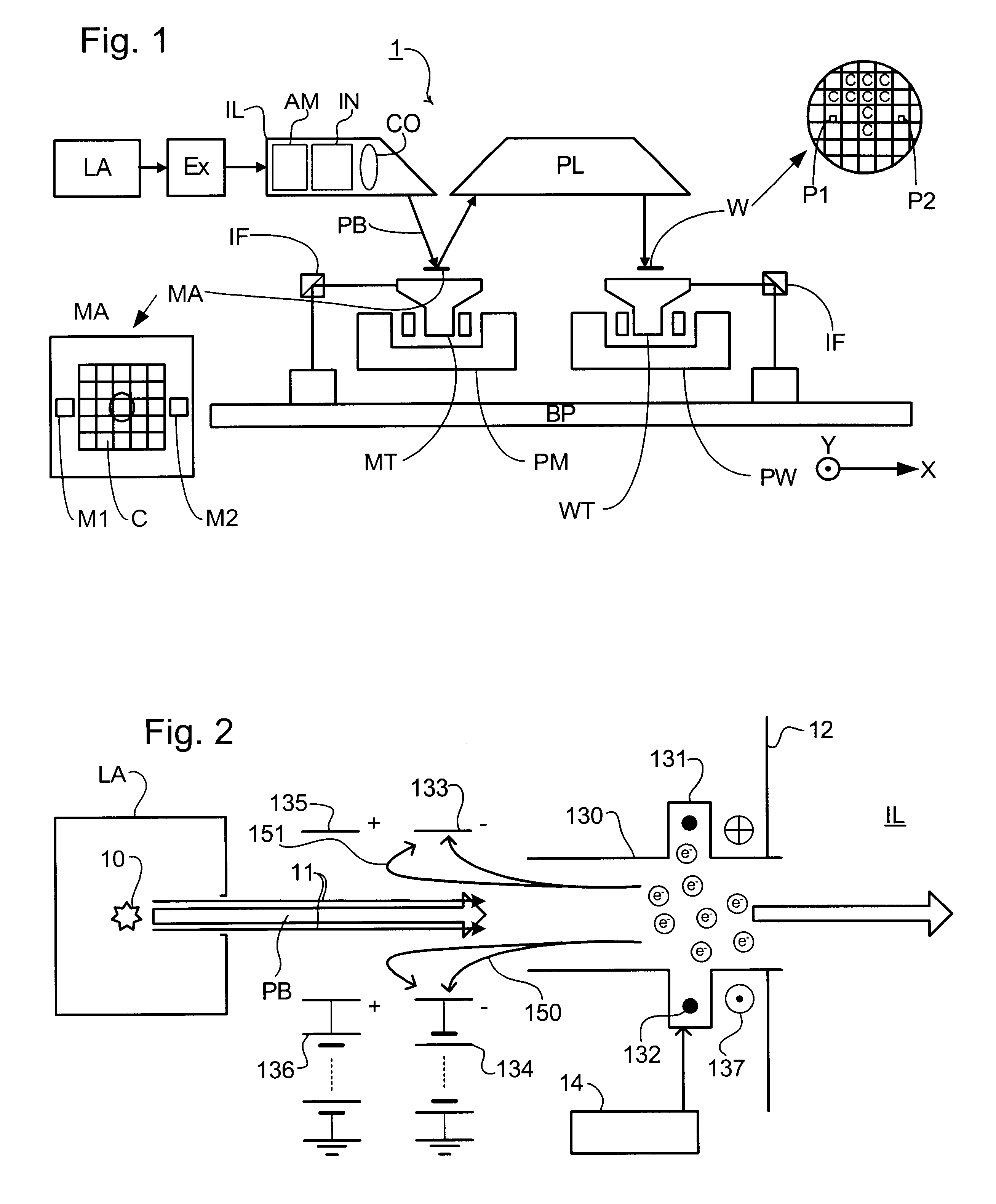

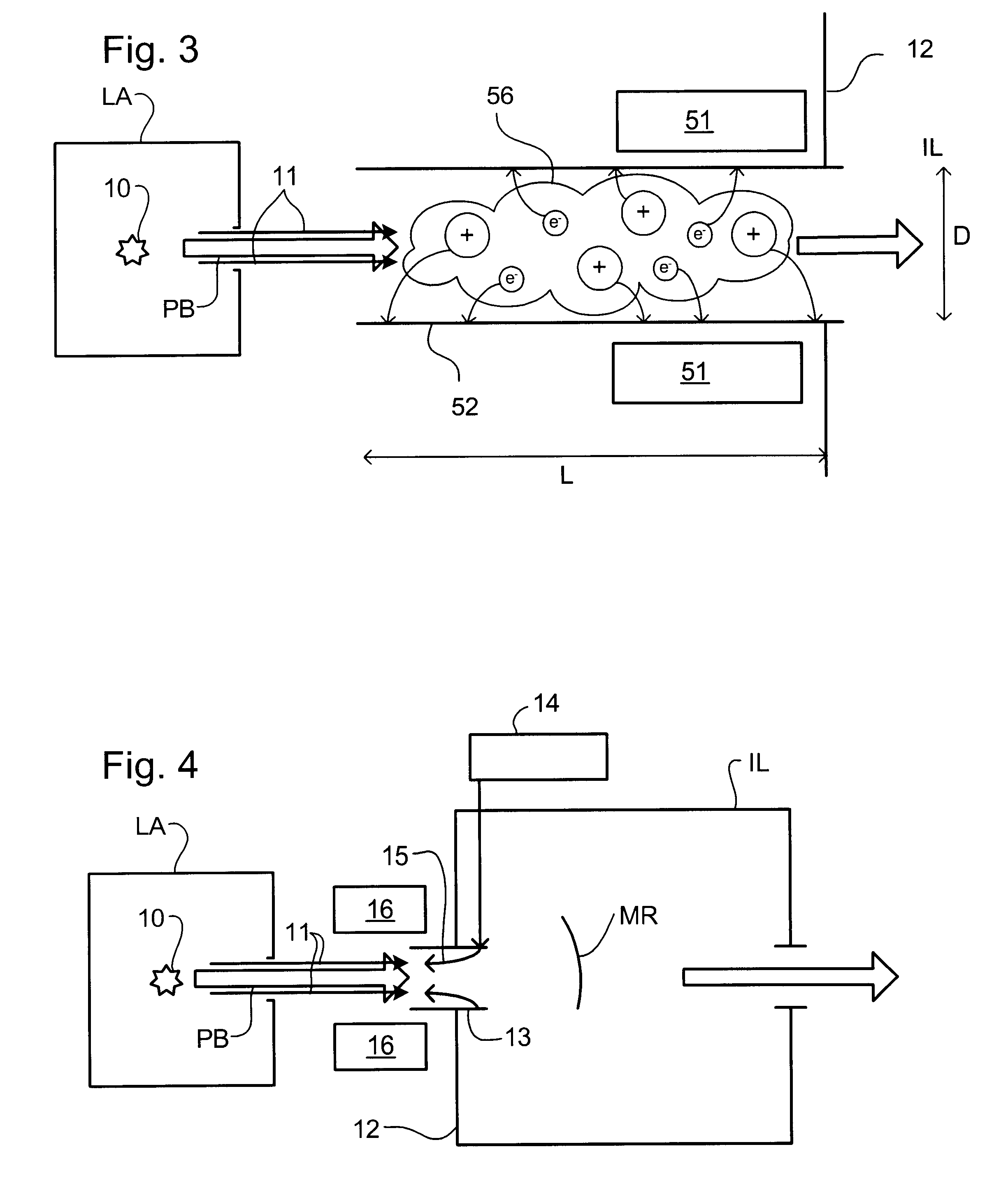

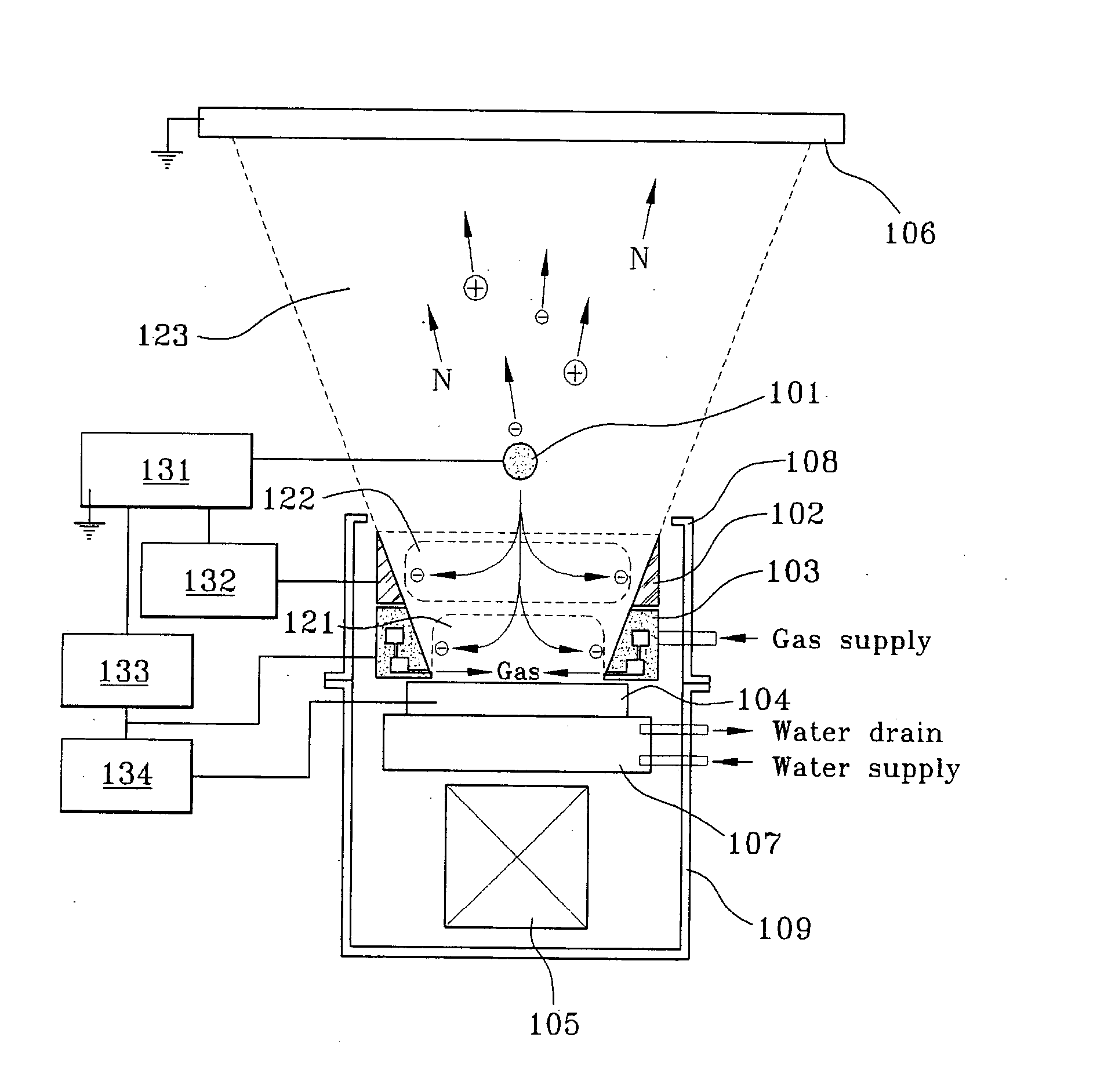

Lithographic projection apparatus, device manufacturing method, and device manufactured thereby

InactiveUS6614505B2Good removal effectImprove the ionization effectInvestigating moving sheetsSemiconductor/solid-state device manufacturingIonizationGas supply

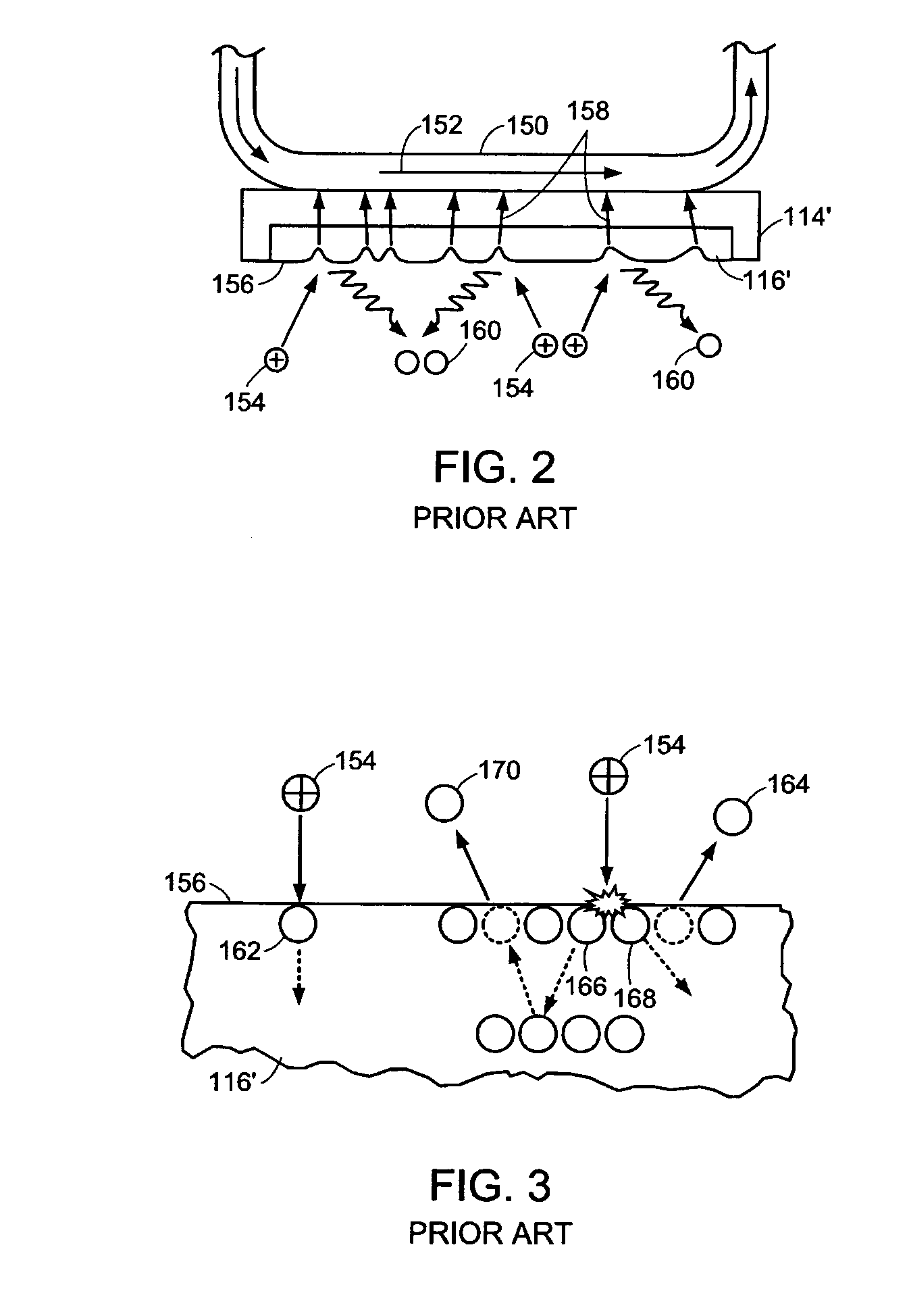

Contaminant particles travelling with a projection beam in a lithographic projection apparatus are ionized. A purge gas may be attracted towards getter plates provided upstream of the purge gas supply. A magnetic field traps electrons generated by the ionizer to improve the ionization of the purge gas. The contaminant particles can be ionized by generating a plasma in a tube having a greater length than width.

Owner:ASML NETHERLANDS BV

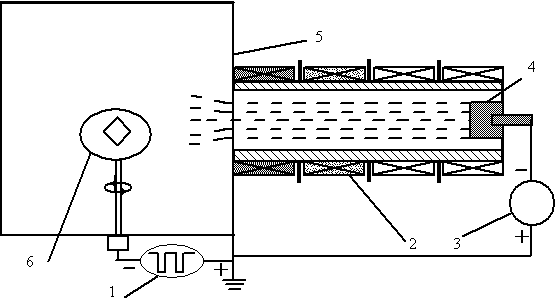

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

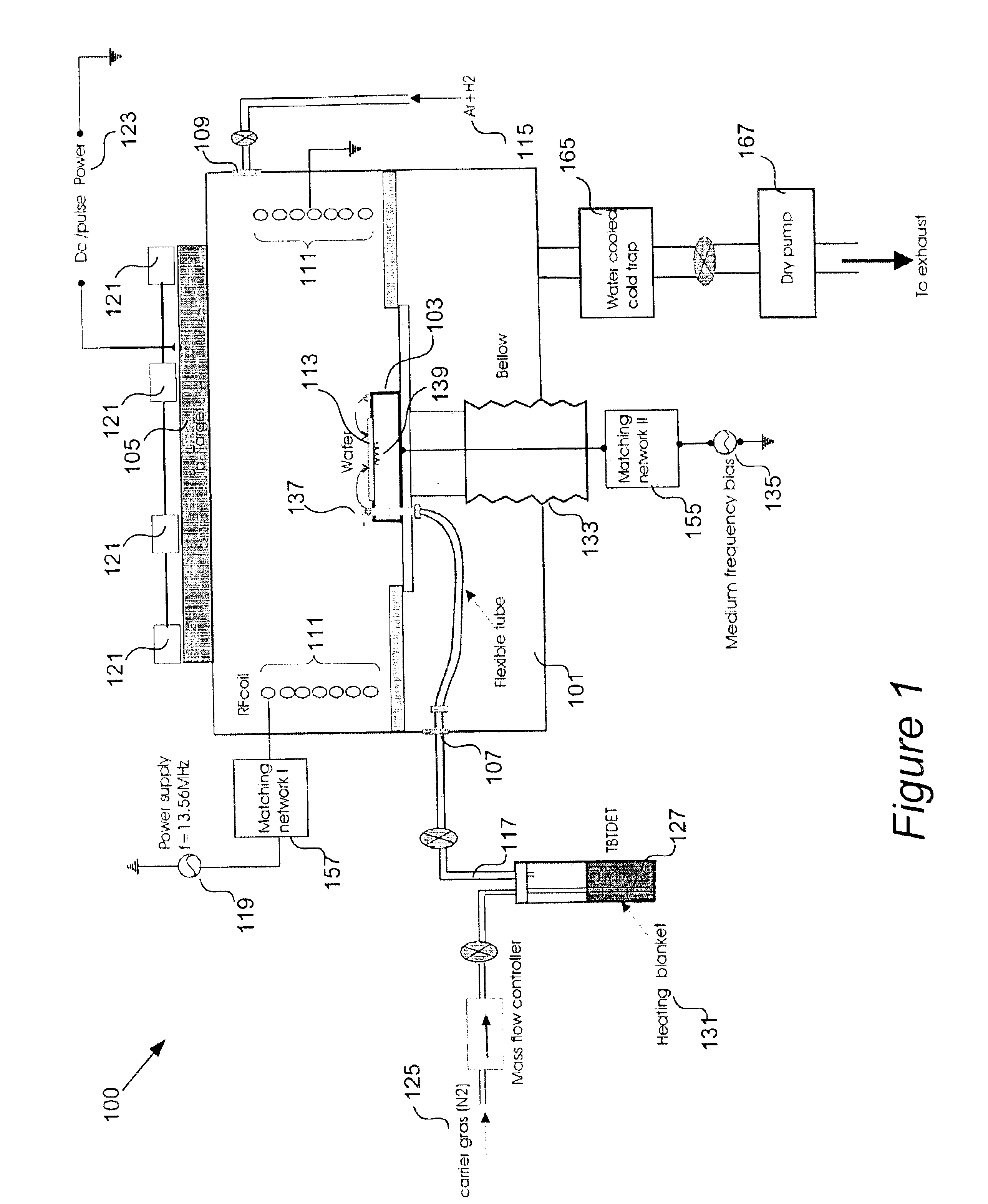

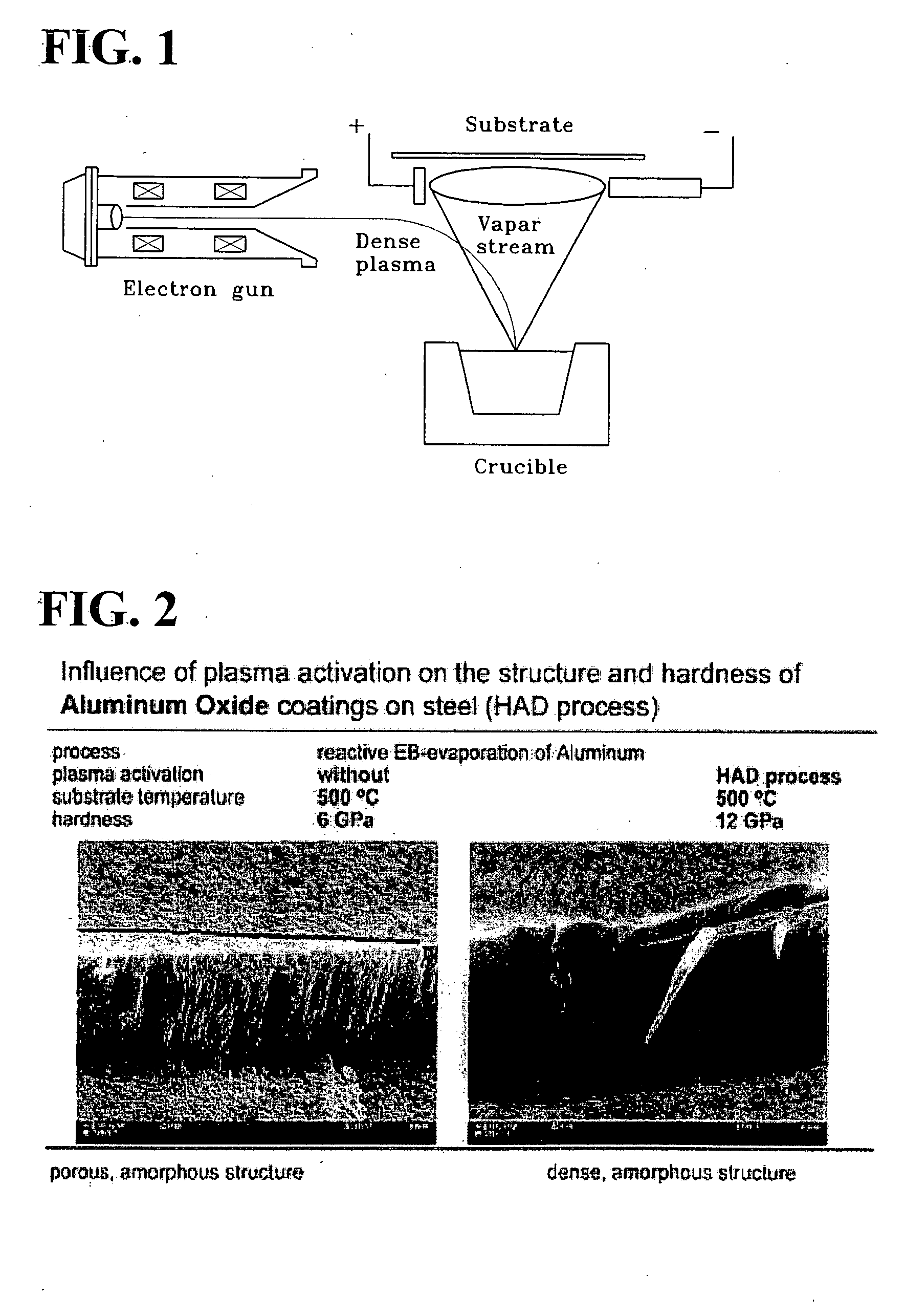

Chemically-enhanced physical vapor deposition

A process merges chemical vapor deposition and physical vapor deposition technologies. It allows physical and chemical vapor deposition to occur in the same process chamber, contemporaneously. The “physical” component involves creation of ionized metal atoms. Ionization is typically accomplished via a plasma within the chamber. If the metal vapor is generated by sputtering, a separate plasma generation mechanism may be employed, which is different from the mechanism employed to generate a “source plasma” for generating sputtering species (e.g., argon ions). Alternatively, a single plasma source may be employed to generate the sputtering species and provide additional ionization of the metal vapor, as is the case with hollow cathode magnetron chambers. In some cases, the CVD precursor is introduced through a first line into the process chamber, while a sputtering gas is introduced via a second line.

Owner:NOVELLUS SYSTEMS

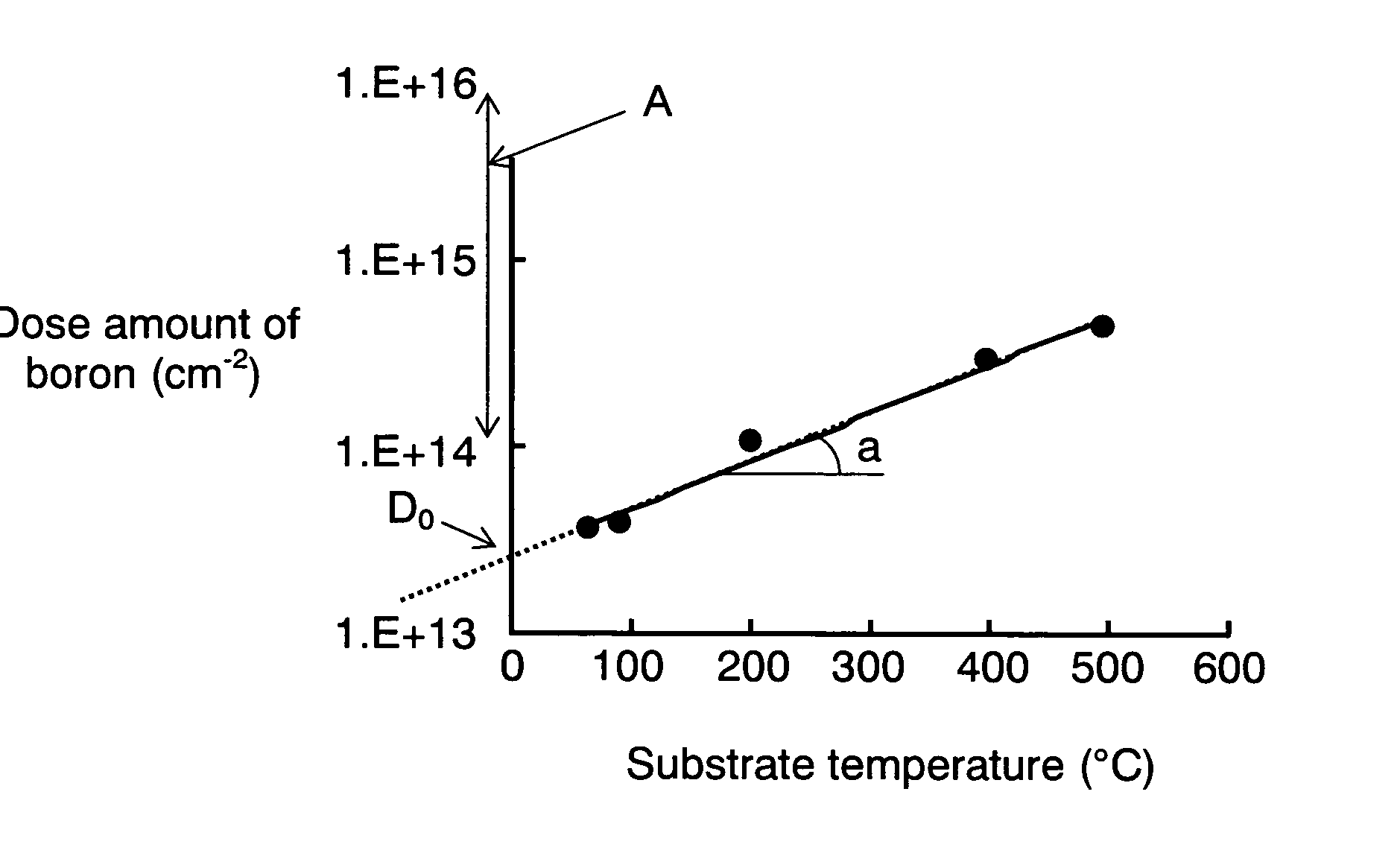

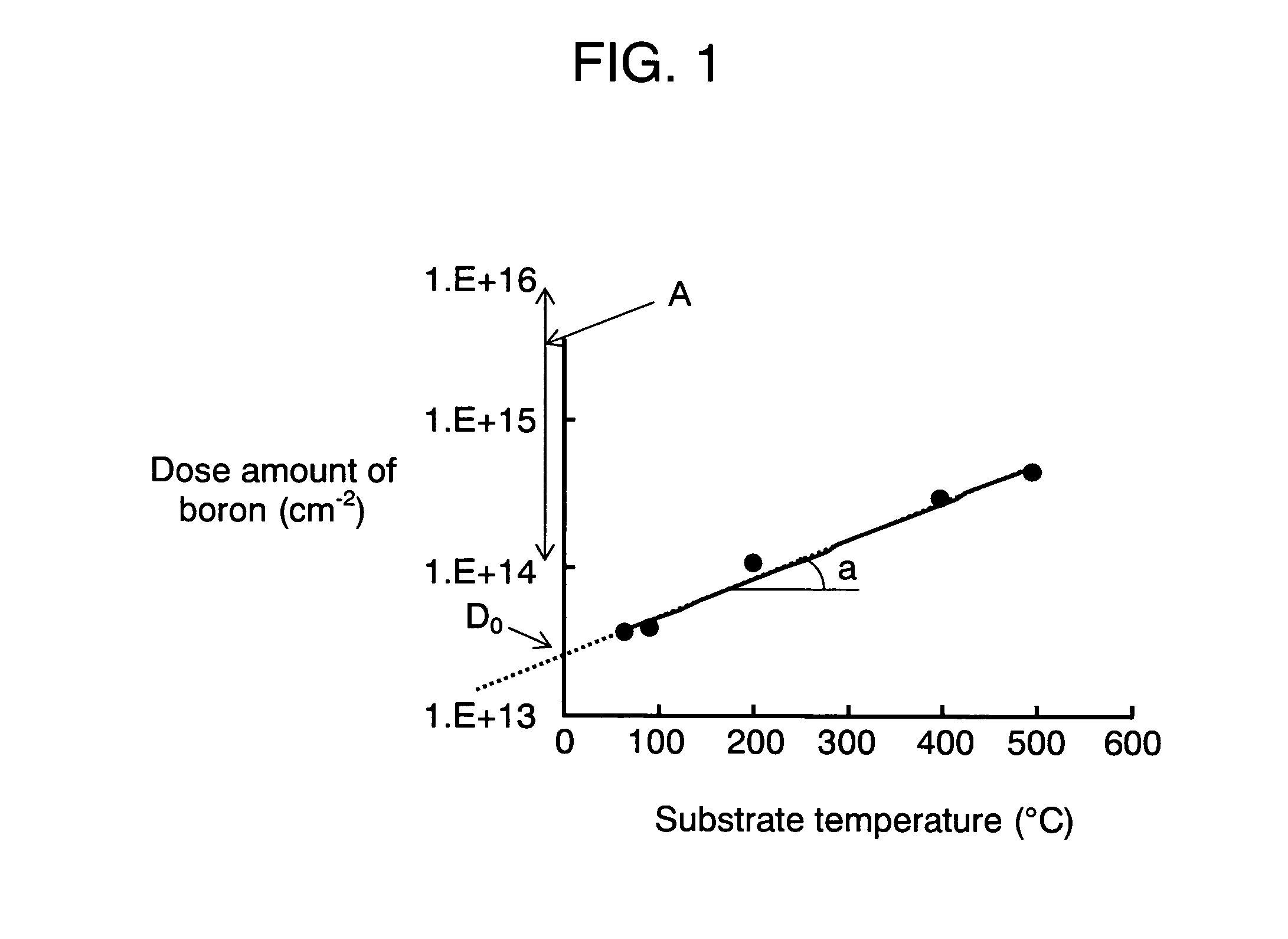

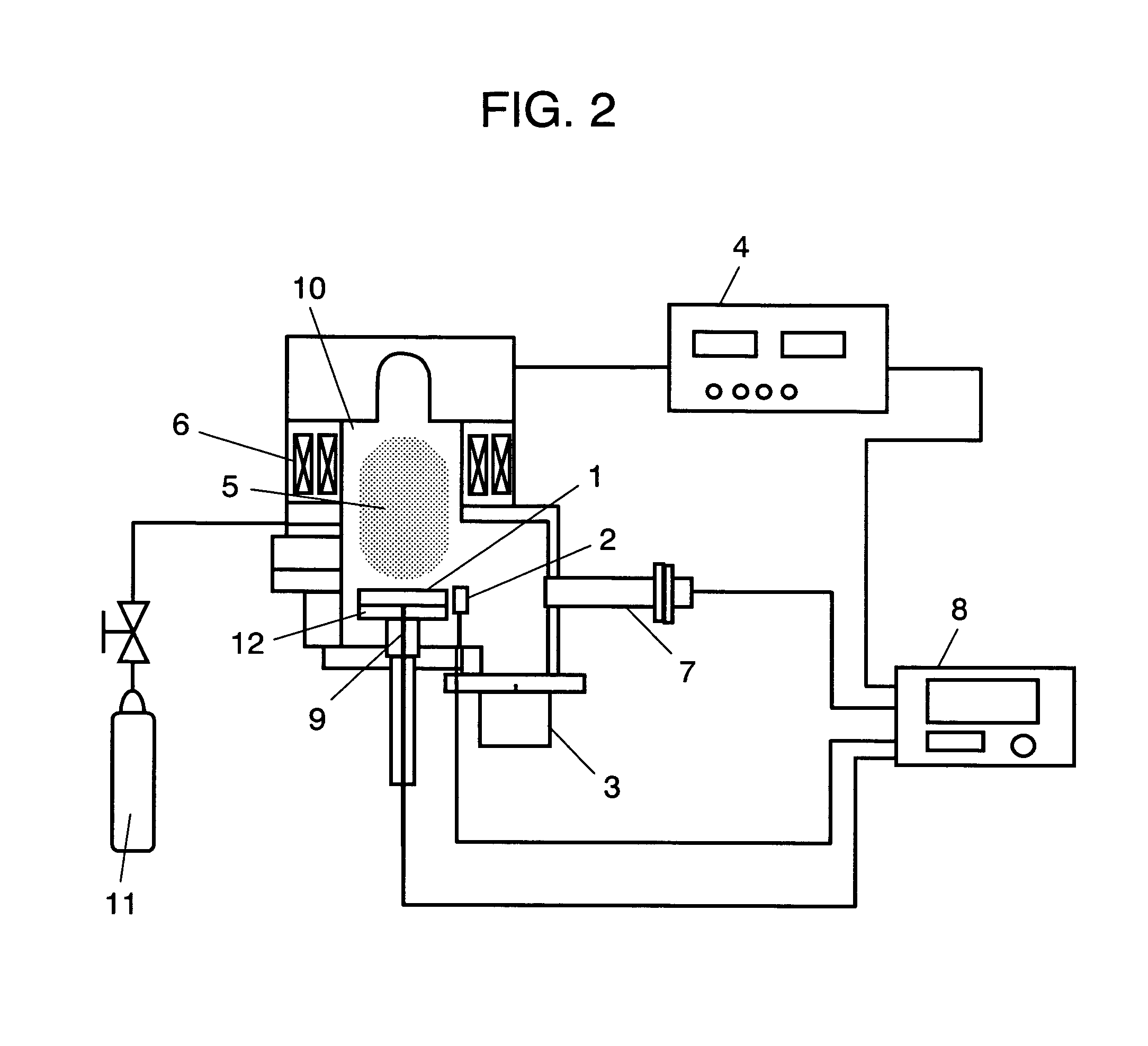

Method of controlling impurity doping and impurity doping apparatus

InactiveUS20070059848A1Minimized variation in qualityImprove accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDopantImpurity doping

Disclosed here is a method of controlling a dose amount of dopant to be doped into object (1) to be processed in plasma doping. According to the method, the doping control is formed of the following processes: determining the temperature of object (1), the amount of ions having dopant in plasma that collide with object (1), and types of gases in plasma during doping; calculating a dose amount by neutral gas according to the temperature of object (1), and a dose amount by ions from the determined amount of ions containing dopant that collide with object (1); and carrying out doping so that the sum of the dose amount by neutral gas and the dose amount by ions equal to a predetermined dose amount.

Owner:PANASONIC CORP

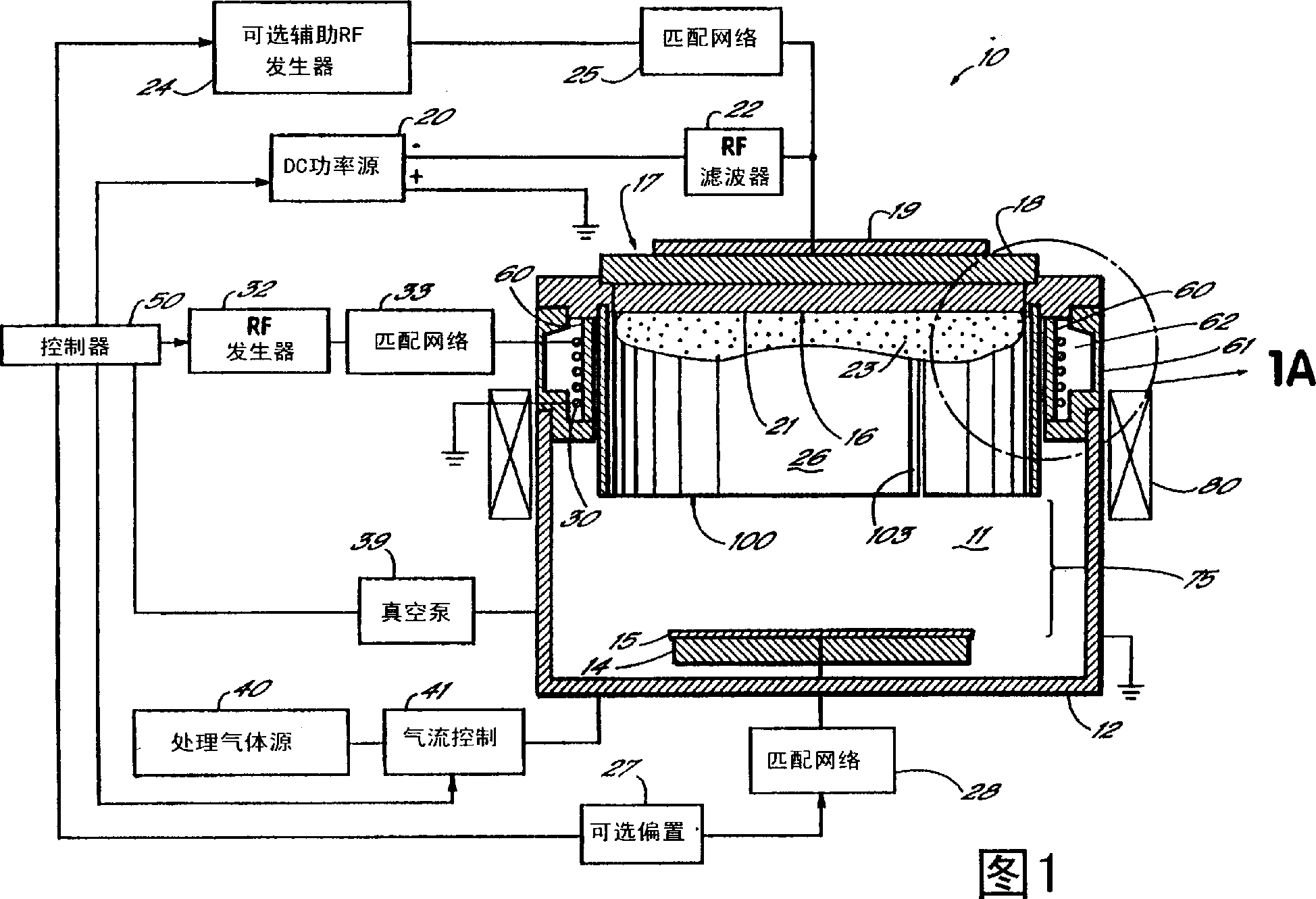

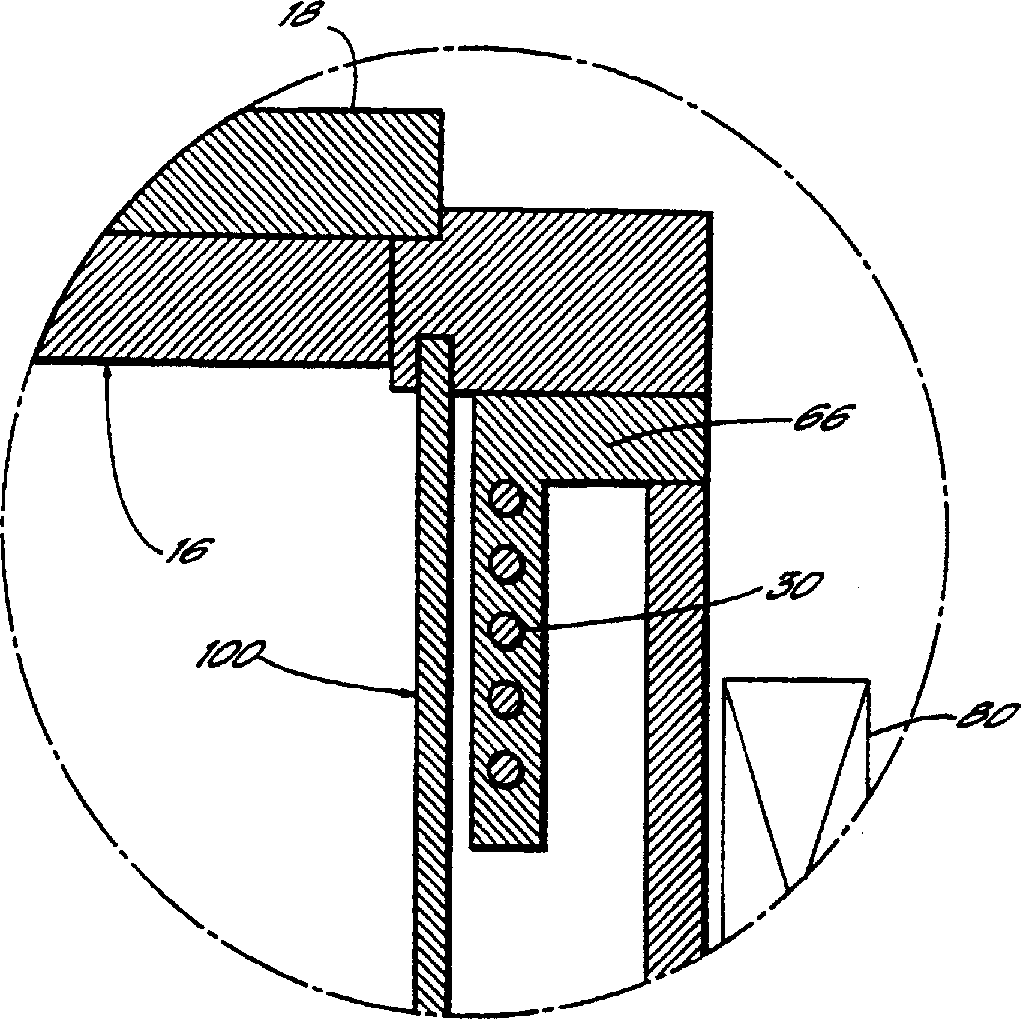

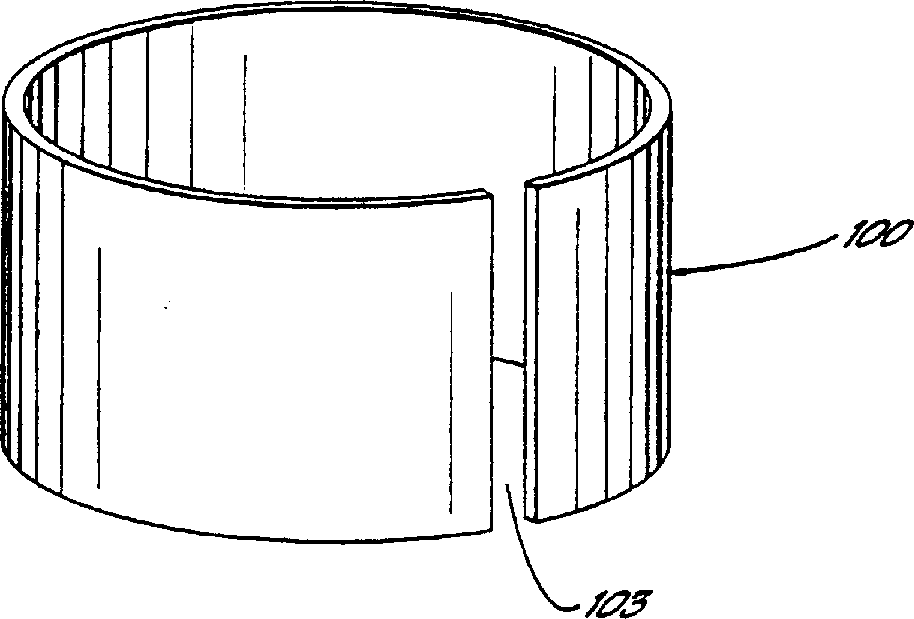

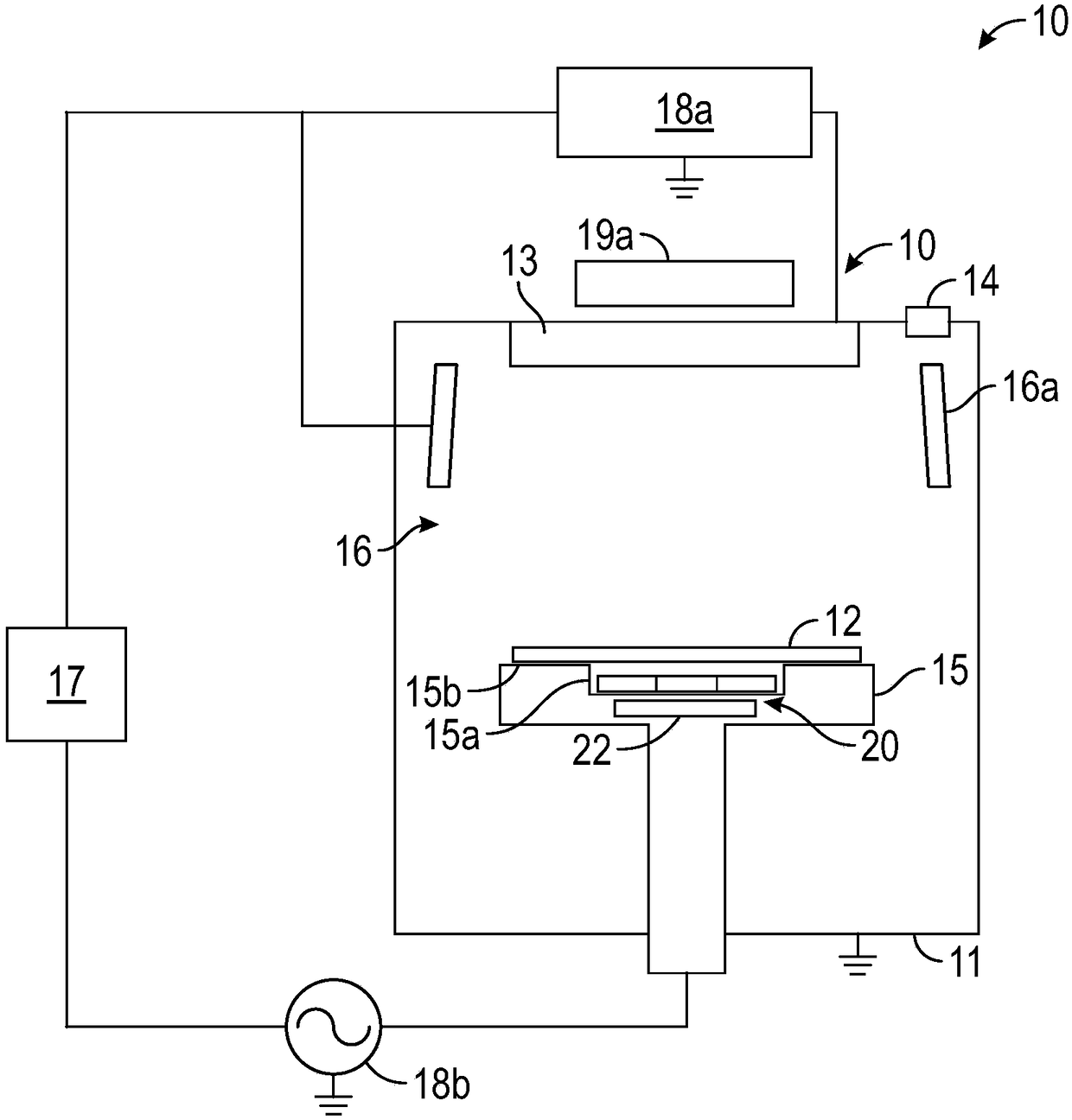

Method and appts. for ionized sputtering of materials

InactiveCN1265222APrevent loss of orientationAvoid side effectsElectric discharge tubesVacuum evaporation coatingElectrically conductiveAspect ratio

An ionized physical vapor deposition apparatus (10, 10a, 10b) is provided with an RF element, preferably a helical coil (30), that surrounds space (11) within a vacuum chamber (12) between a target (16) and a substrate holder (14). RF energy, preferably at about 2 MHz or elsewhere in the 0.1 to 60 MHz range, is coupled into the space to form a secondary plasma (29) in a volume (26) of the space between the substrate holder and the main plasma that is adjacent the target. The secondary plasma ionizes sputtered material which is then attracted toward a substrate (15) on the support by a bias on the substrate and / or by an axial magnetic field to impart directionality to the moving ionized sputtered particles to render them perpendicular to the substrate at incidence, so as to coat the bottoms of narrow high aspect ratio features on the substrate. A window (60) of dielectric material such as quartz, either in the wall of the chamber or inside the chamber, or insulation on the coil, protects the coil from adverse interaction with plasma. Shields (100, 200, 300) between the space and the dielectric material prevent sputtered particles coating the dielectric material. The shields are partitioned or slotted to prevent induced currents in the shields. The shields may be biased to control contamination and may be commonly or individually biased to optimize the uniformity of coating on the substrate and the directionality of the flux of ionized material at the substrate. The shield may be formed of a plurality of angled segments (302) that are spaced to facilitate communication of a secondary RF plasma from adjacent the window to the volume of the chamber where the sputtered material is ionized, with the sections angled and spaced to shadow at least most of the target from the window. Alternatively, electrically conductive shield (100) may be provided in close proximity to the window or insulation.

Owner:TOKYO ELECTRON ARIZONA +1

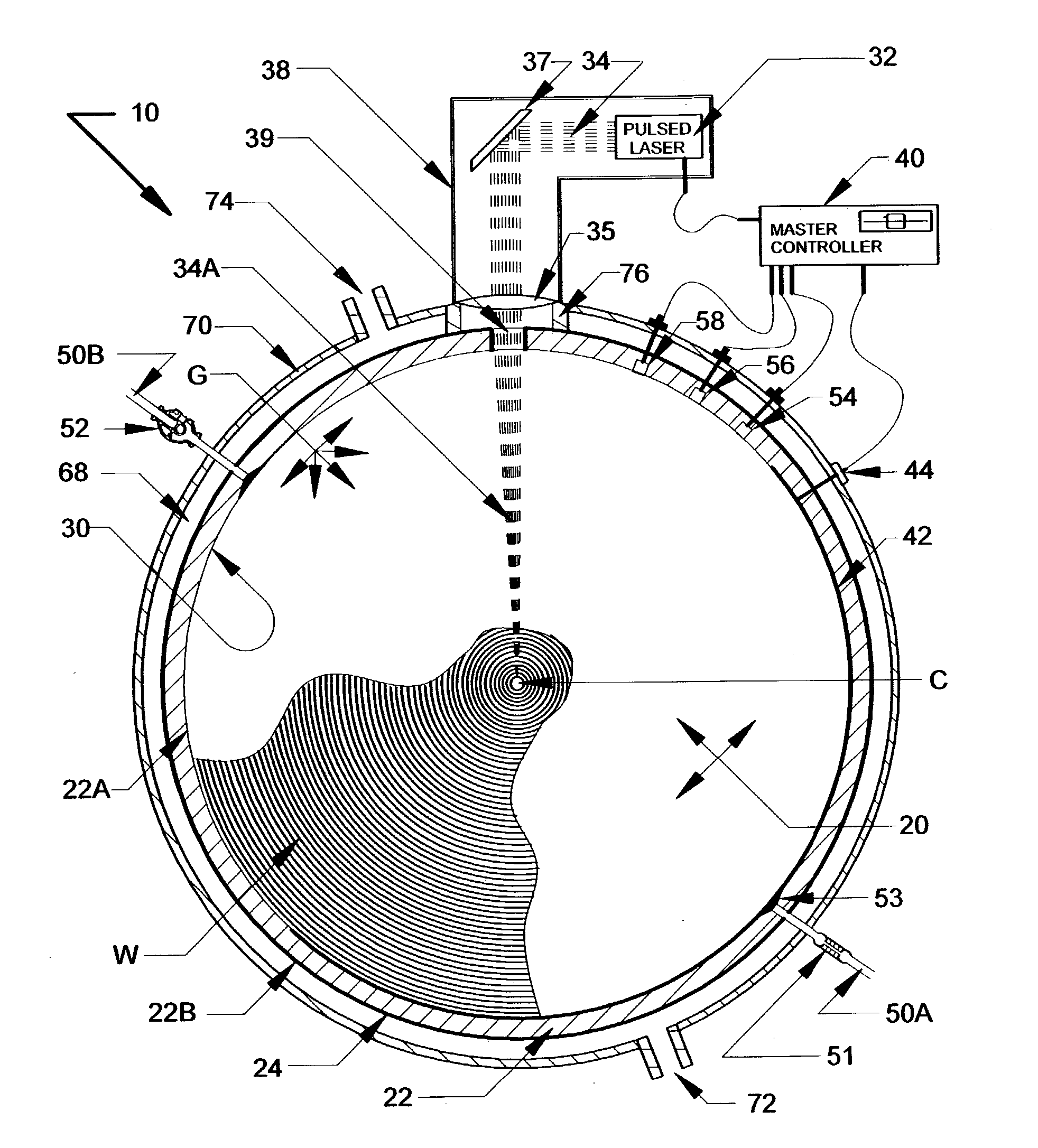

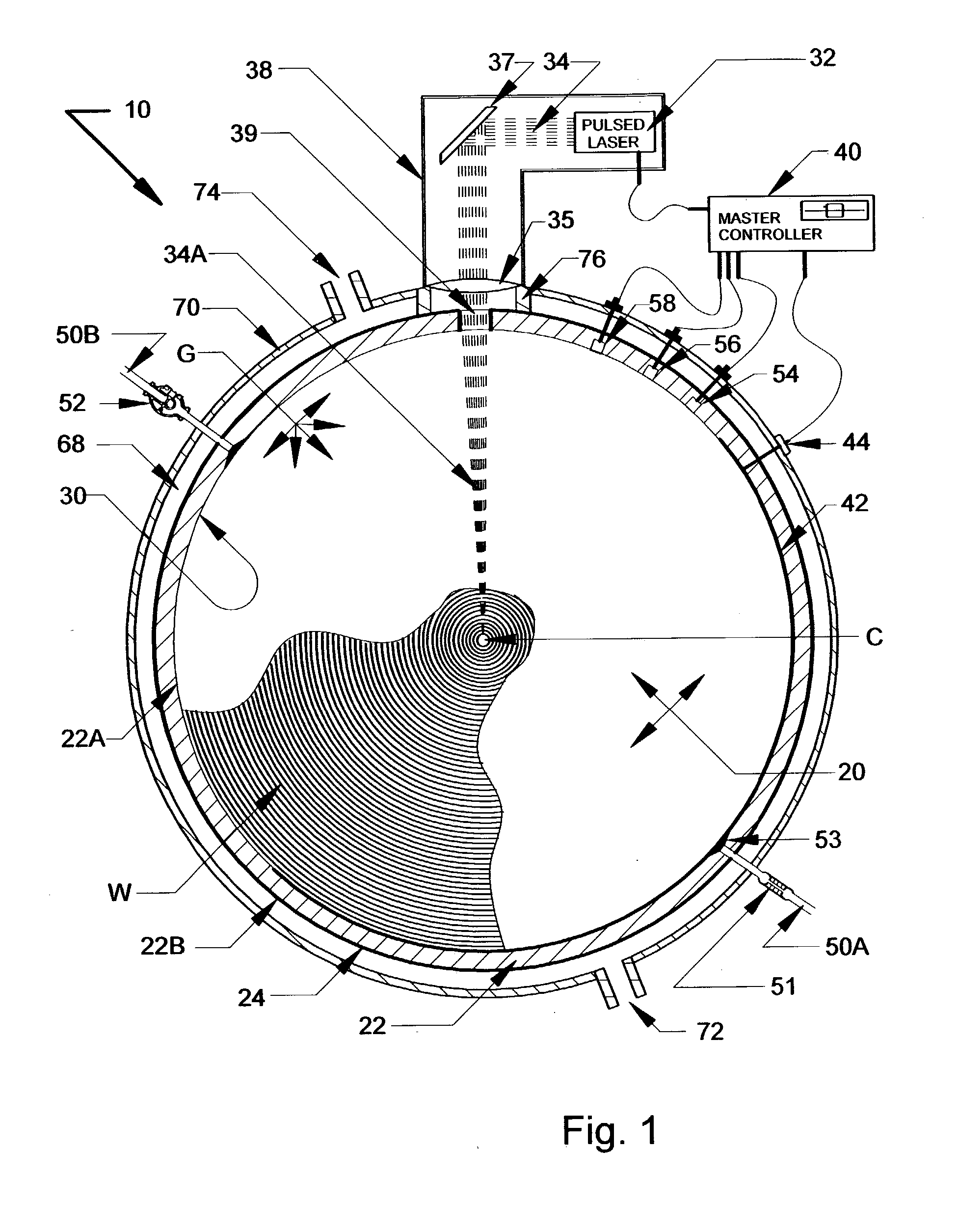

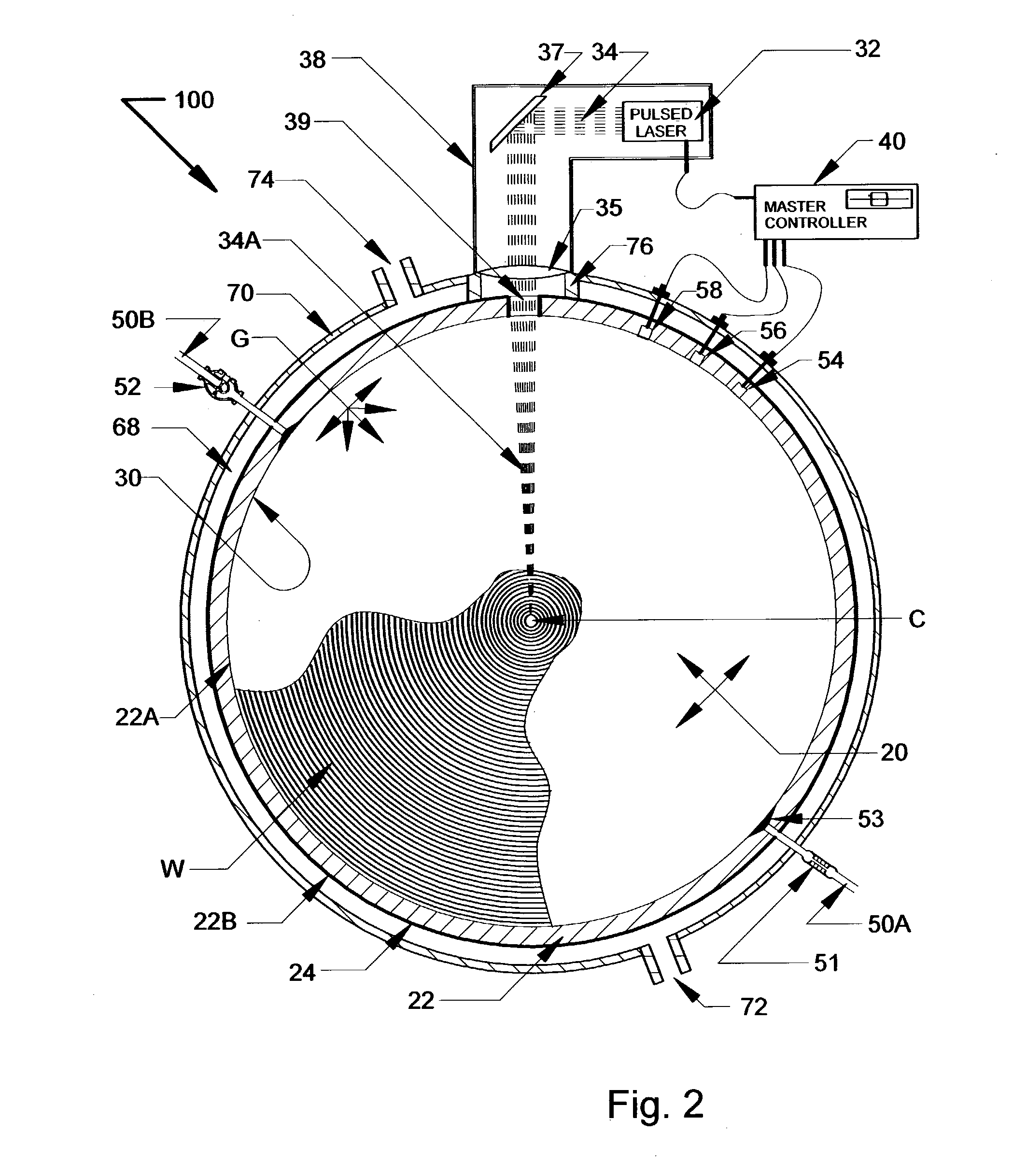

Nuclear fusion reactor and method

A nuclear fusion reactor comprising a spherical reaction chamber with a mirrored interior surface filled with a nuclear fusible and laser active gaseous medium such as deuterium. Using rapid gaseous expansion caused by a focused pulsed laser source and / or timed oscillations from piezoelectric transducer, a harmonic spherical acoustic wave pattern centered within the reaction chamber is created. This wave pattern is created near a desired frequency and centered in the sphere. The wave pattern contains a central gaseous ball of high-density, pressure, and temperature that causes ionization and radiation to occur. This radiation causes the mirrored chamber to activate a spherical laser effect focused on the high pressure plasma at the center of the reaction chamber. This spherical laser pulse acting on high pressure high-density of the central standing wave produces ignition of the gas and fusion. The tremendous energy from fusion drives the acoustic process which ideally allows for a self sustaining ignition temperature plasma requiring the addition of fuel only.

Owner:ENFINGER ARTHUR L

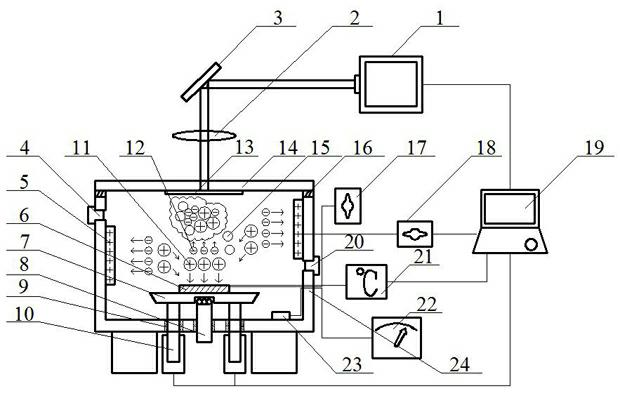

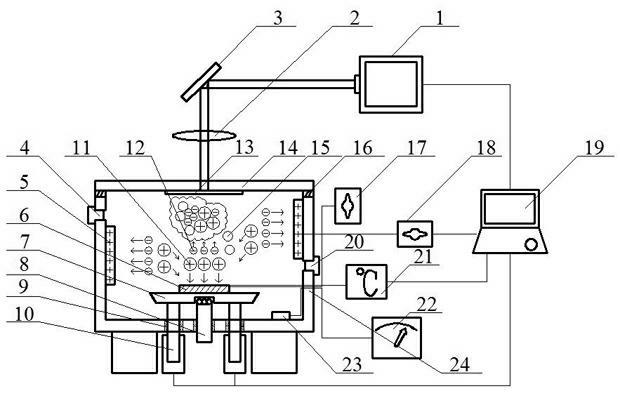

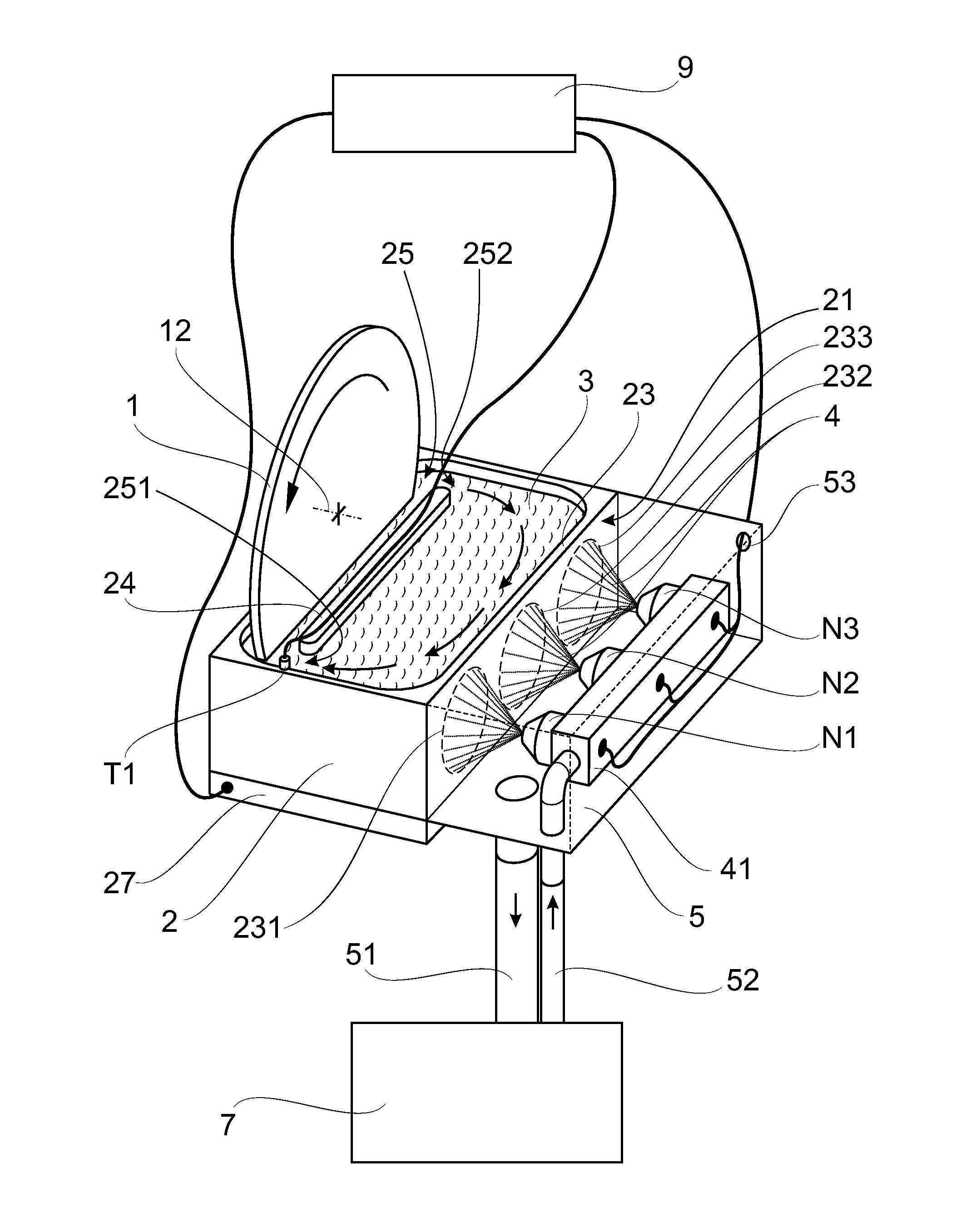

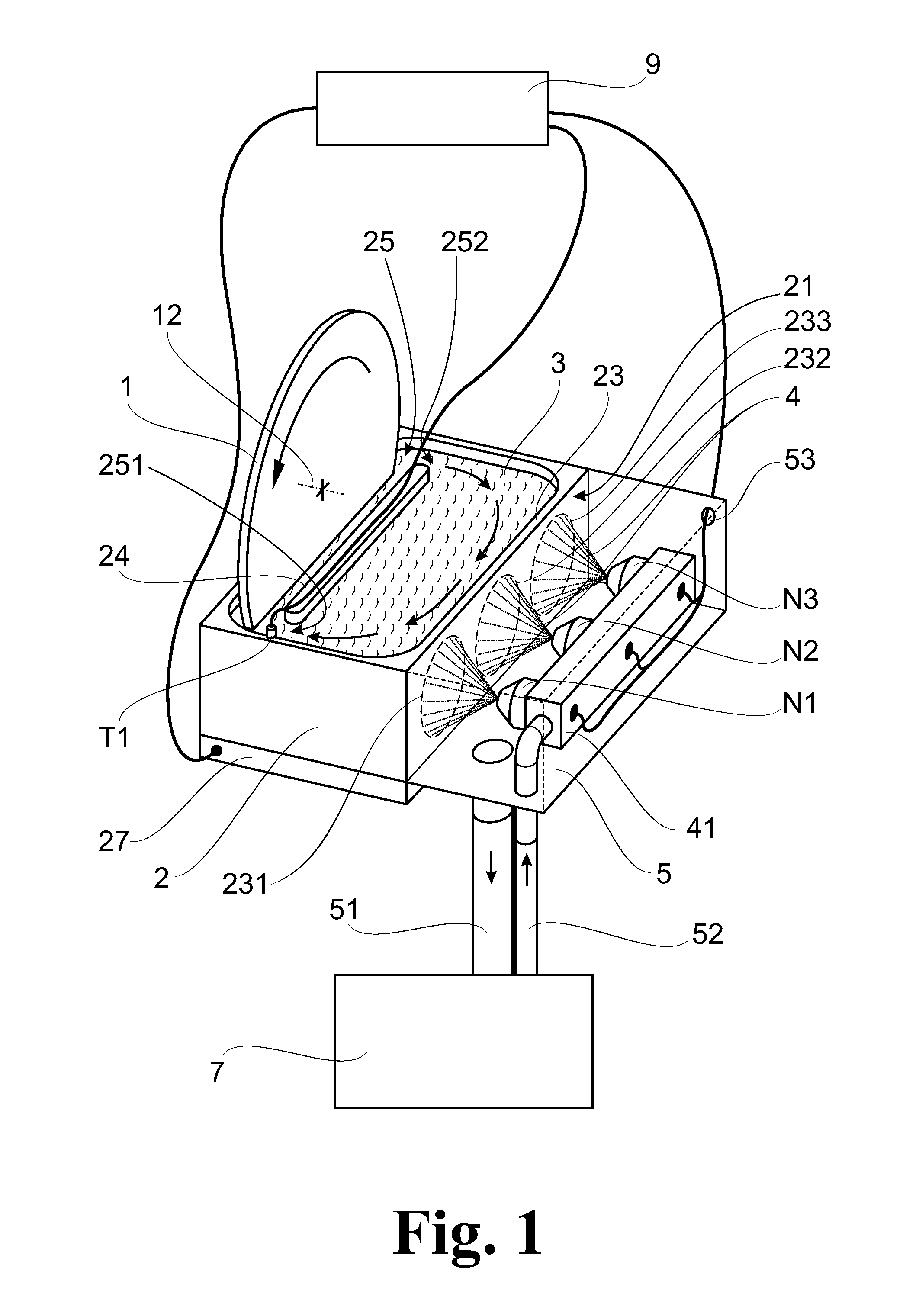

Method and apparatus for laser to induce plasma to inject into substrate

InactiveCN102208321AAdd depthHigh hardnessElectric discharge tubesVacuum evaporation coatingShock waveHigh energy

The invention relates to a method and apparatus for a laser to induce plasmas to inject into a substrate and is directed to the fields of plasma injection apparatus and plasma injection material processing technology. A high energy burst pulse strong laser initiated by a laser impacts on tinsel which absorbs the high energy burst pulse laser energy. The high energy burst pulse laser energy is instantly gasified and ionized, thereby producing hot plasmas. The hot plasmas are composed of metal ions, electrons and uncharged atoms. The plasmas absorb subsequent laser energy to expand and blast. During the blast process of the plasmas, an expulsive force between the electrons and a workpiece connected to the negative potential drives the electrons to move against the workpiece. A positive charge plate neutralizes a part of the electrons. Suction between positive valency metal ions and the negative potential workpiece drives the metal ions to move towards the workpiece. Under the superposedeffects of a shock wave effect formed in the expansion and blast of the plasmas and an attraction effect of an electric field, the metal ions hit on the workpiece at a great speed; hence the injection of the metal ions is completed.

Owner:JIANGSU UNIV +1

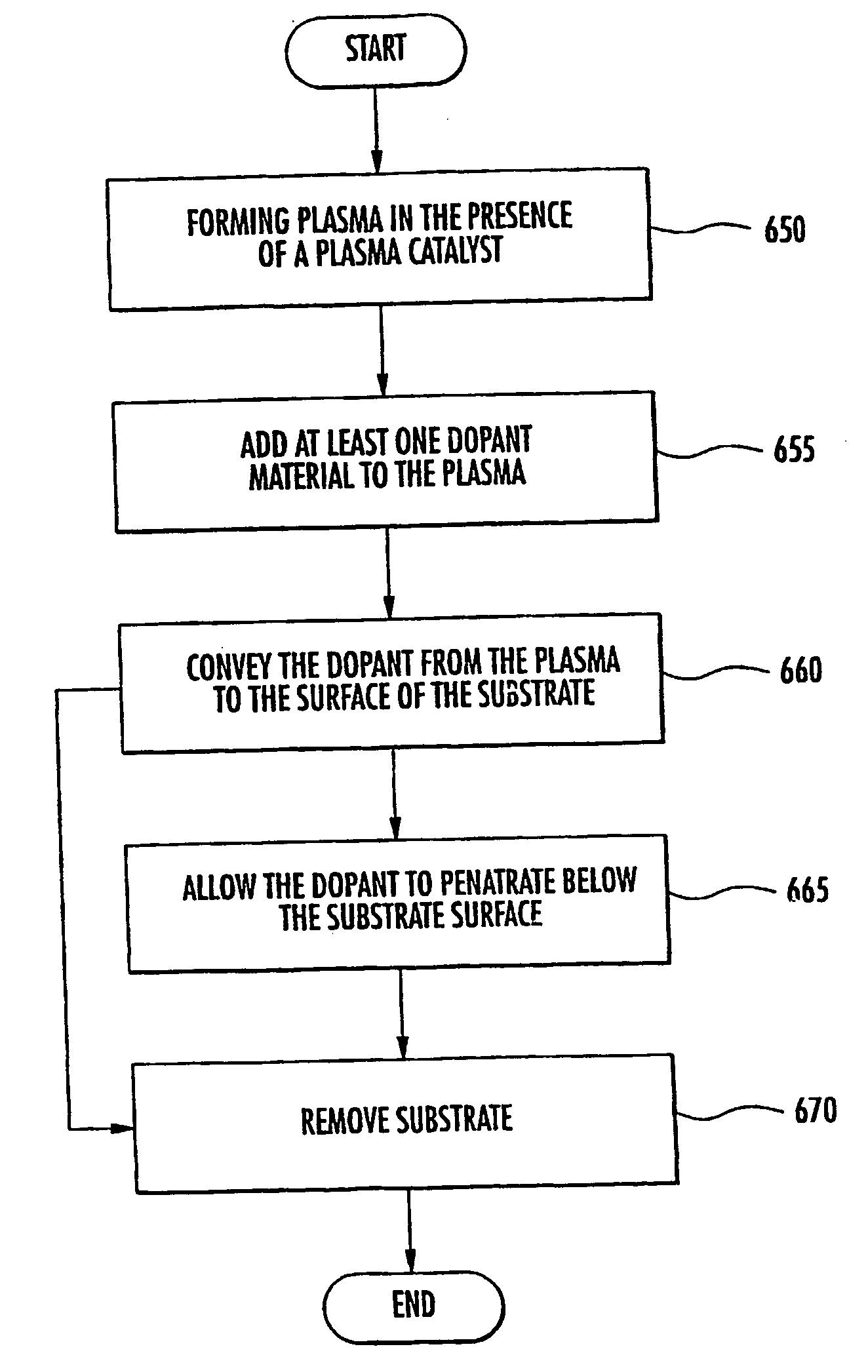

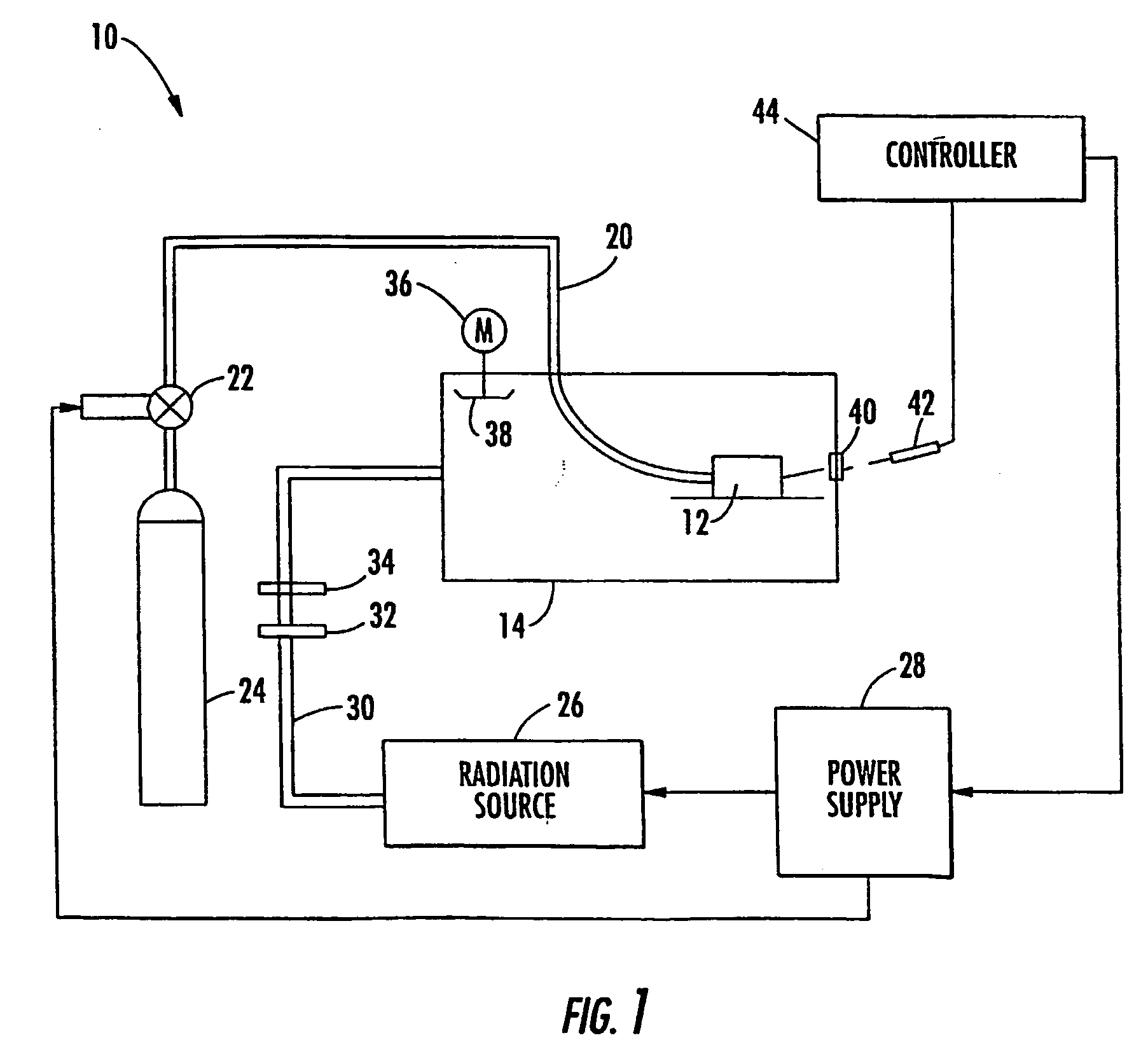

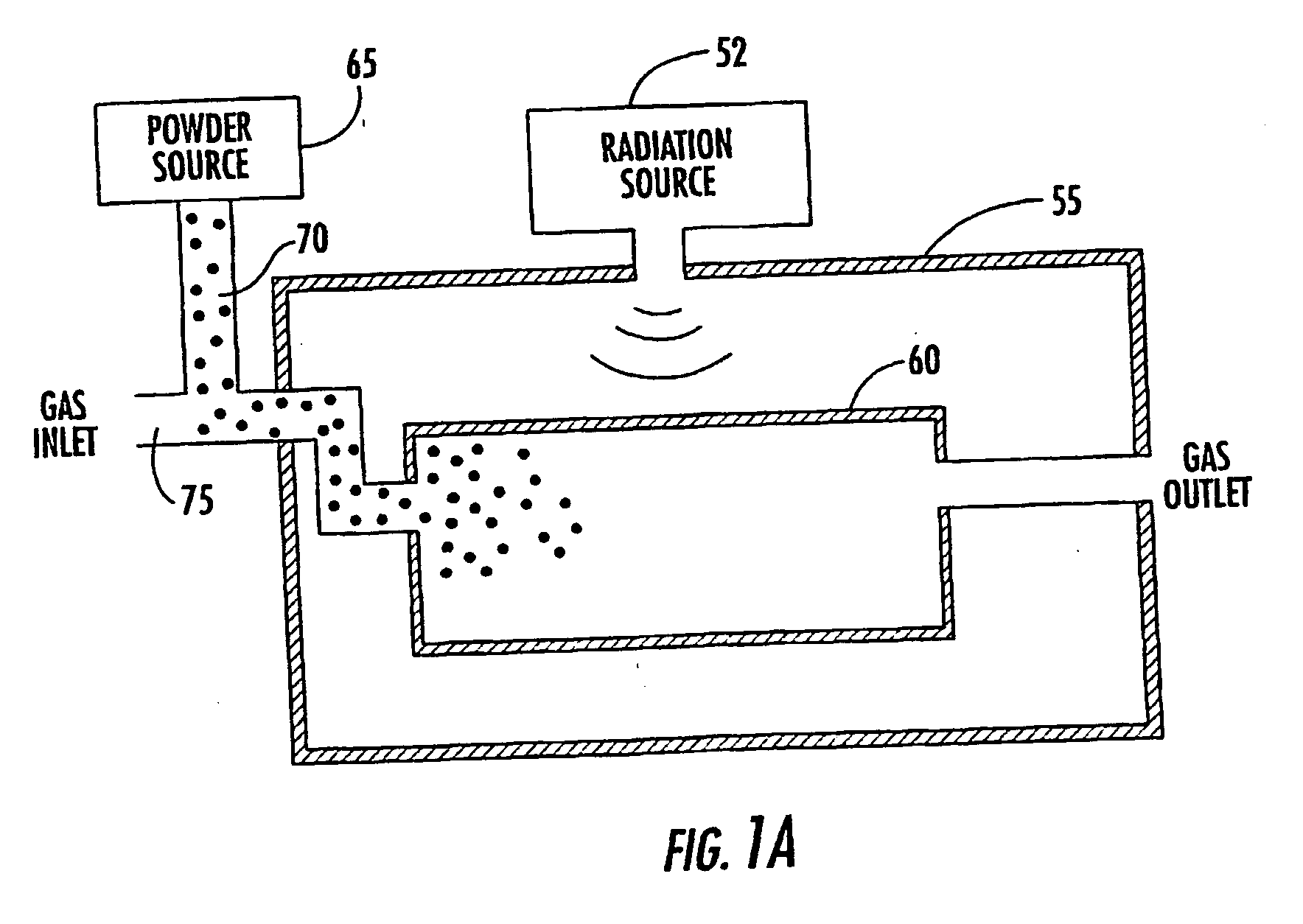

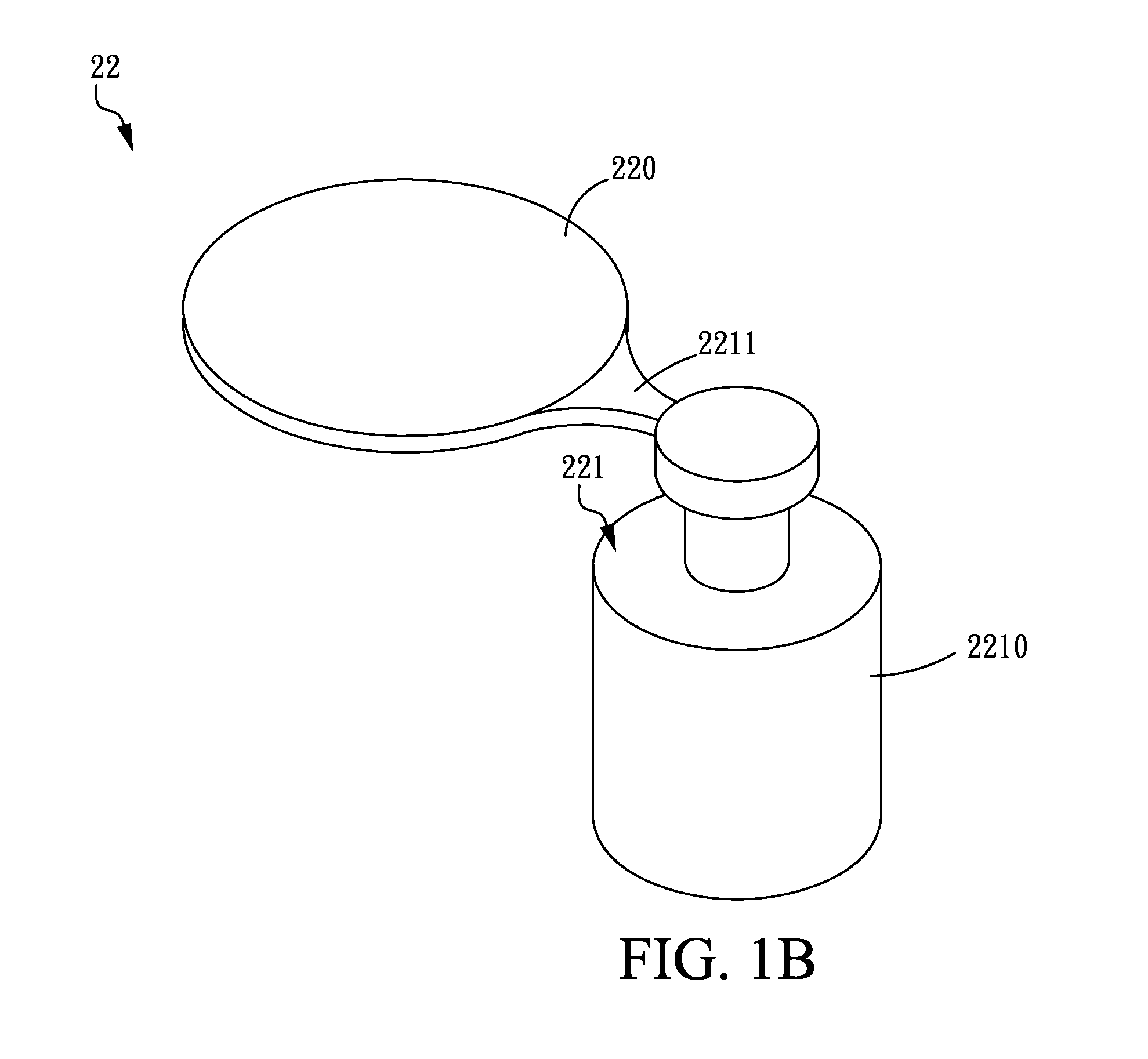

Plasma-assisted doping

InactiveUS20060063361A1Electric discharge tubesSemiconductor/solid-state device manufacturingDopantElectromagnetic radiation

Methods and apparatus are provided for igniting, modulating, and sustaining a plasma for various doping processes. In one embodiment, a substrate (250) can be doped by forming a plasma (610) in a cavity (285) by subjecting a gas to an amount of electromagnetic radiation in the presence of a plasma catalyst (240) and adding at least one dopant material to the plasma. The material is then allowed to penetrate into the substrate. Various active and passive catalysts are provided.

Owner:BTU INTERNATIONAL

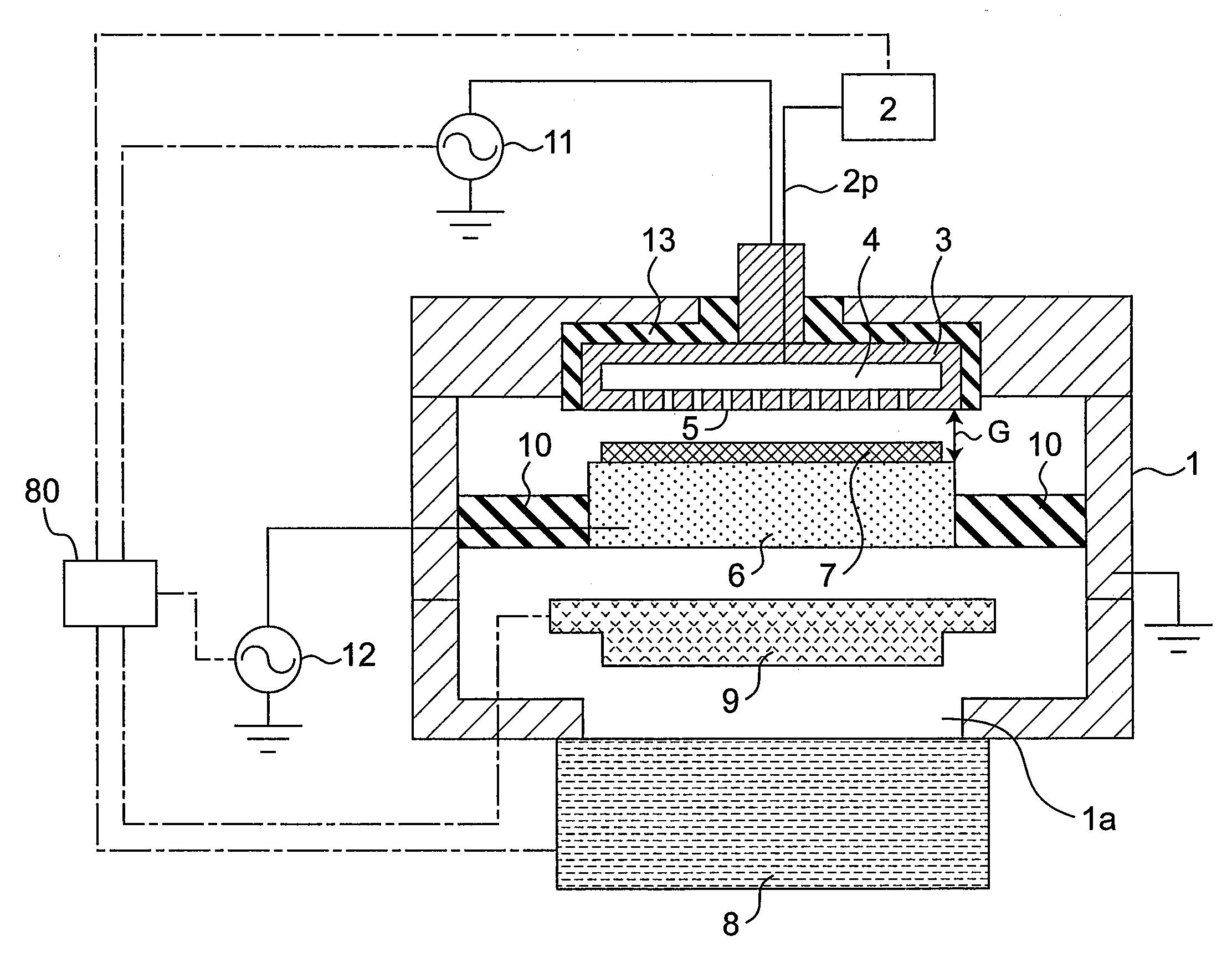

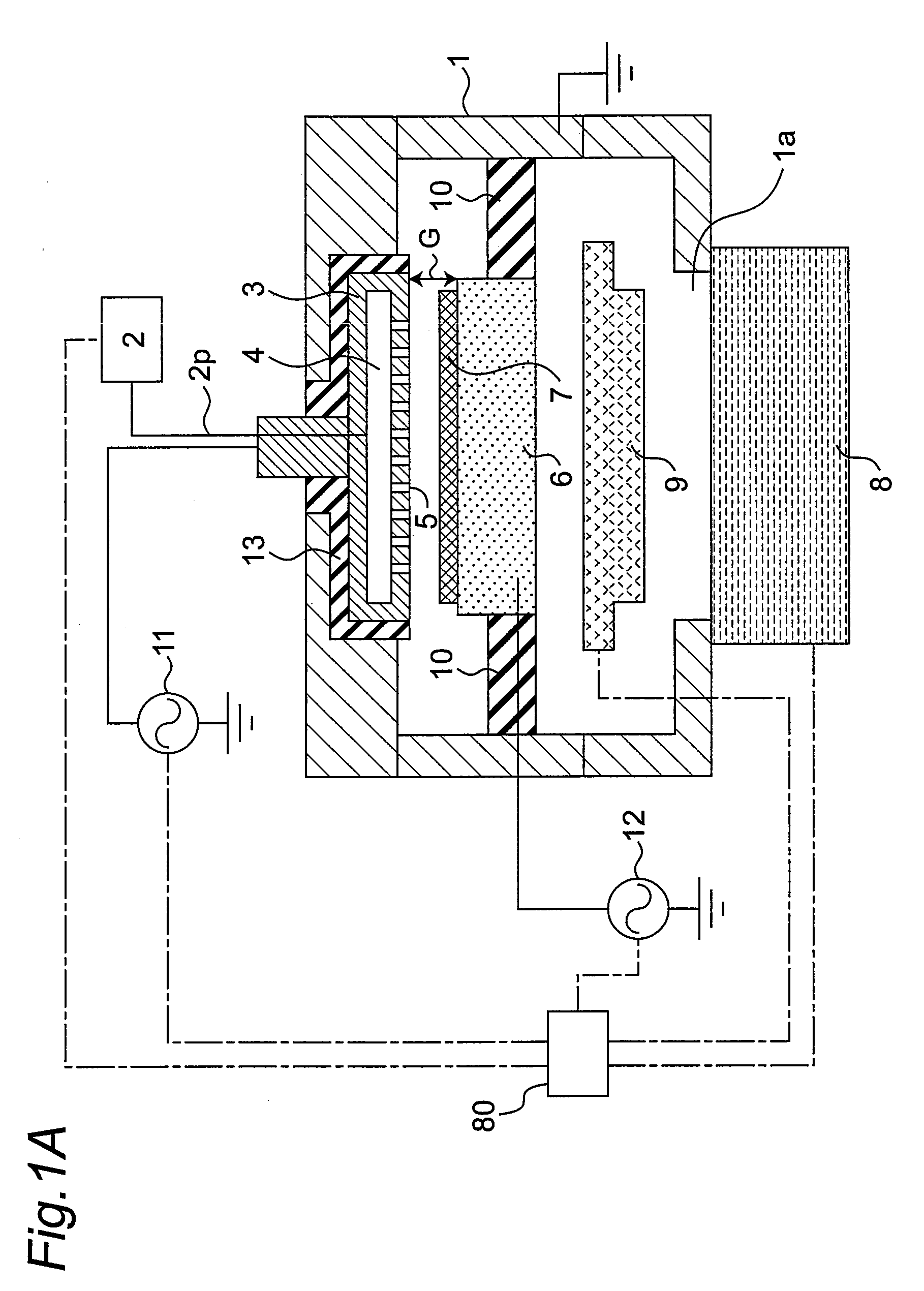

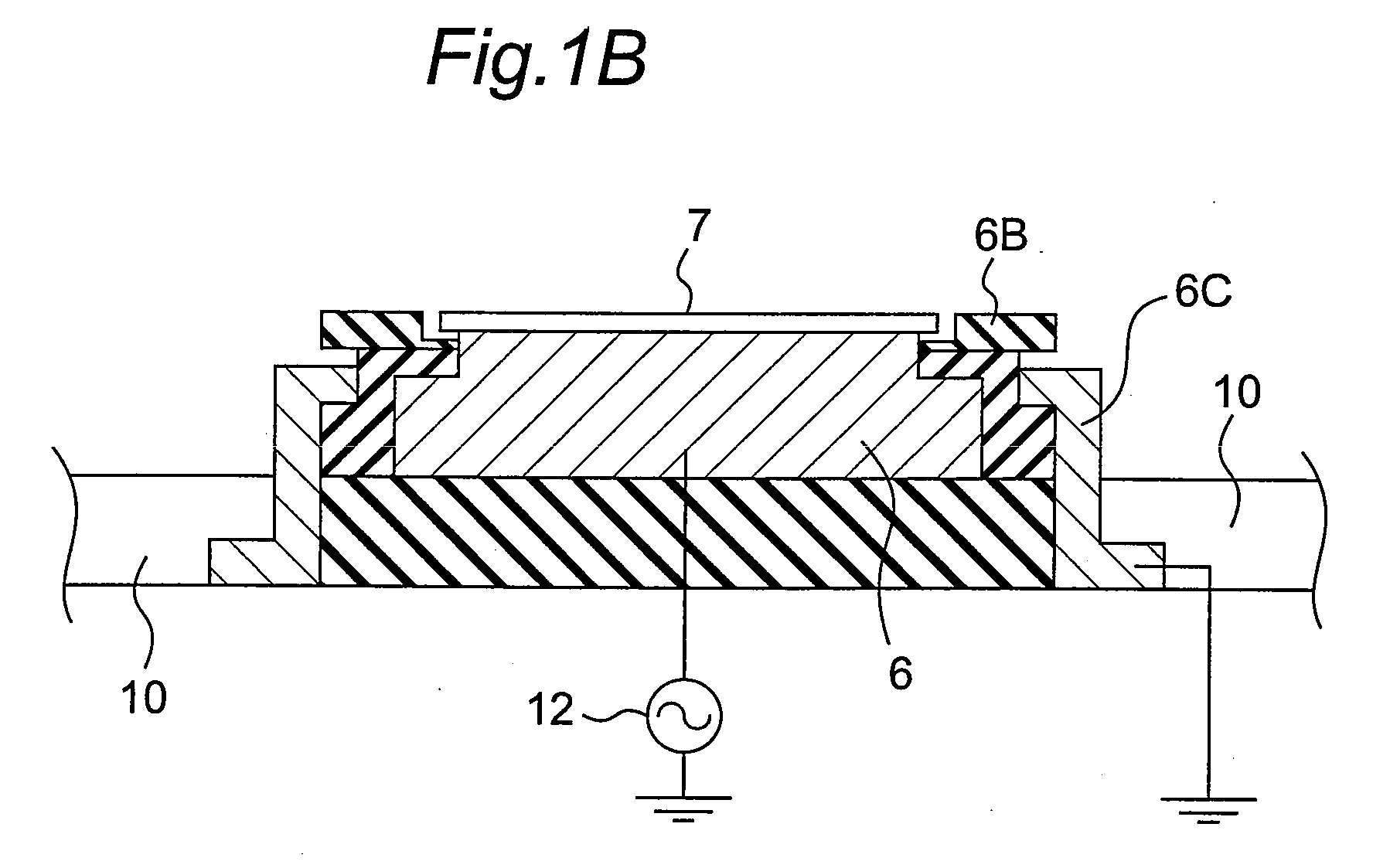

Plasma doping method and apparatus

InactiveUS20080233723A1Prevent implantationGood reproducibilityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceEngineering

There are provided a plasma doping method and an apparatus which have excellent reproducibility of the concentration of impurities implanted into the surfaces of samples. In a vacuum container, in a state where gas is ejected toward a substrate placed on a sample electrode through gas ejection holes provided in a counter electrode, gas is exhausted from the vacuum container through a turbo molecular pump as an exhaust device, and the inside of the vacuum container is maintained at a predetermined pressure through a pressure adjustment valve, the distance between the counter electrode and the sample electrode is set to be sufficiently small with respect to the area of the counter electrode to prevent plasma from being diffused outward, and capacitive-coupled plasma is generated between the counter electrode and the sample electrode to perform plasma doping. The gas used herein is a gas with a low concentration which contains impurities such as diborane or phosphine.

Owner:PANASONIC CORP

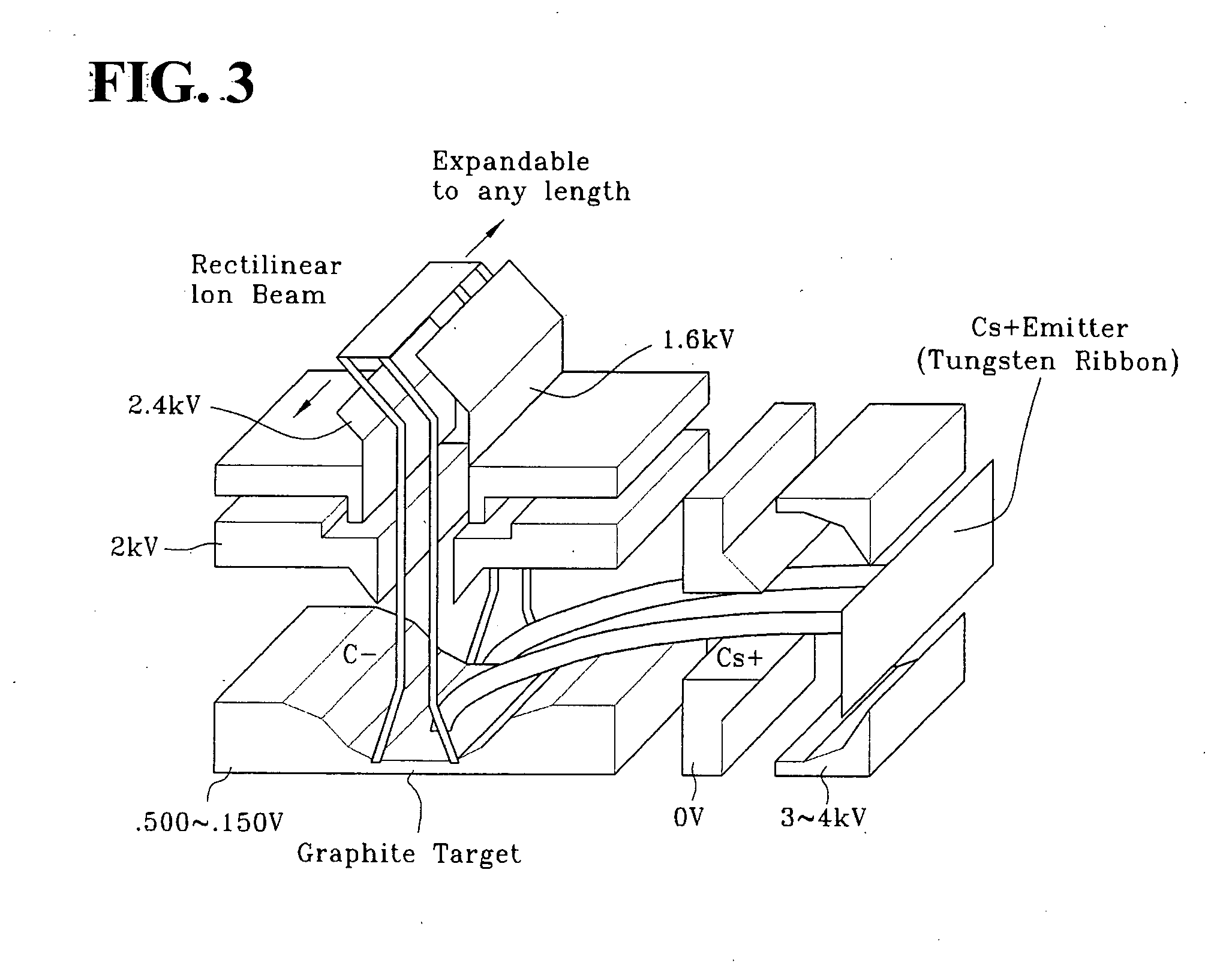

Direct ion beam deposition method and system

InactiveUS20060225998A1Avoid overall overheatingFacilitating ion emission of the deposit materialCellsElectric discharge tubesIonizationElectron

Disclosed herein is a direct ion beam deposition method through ion beam sputtering. The method comprises the steps of: a) providing a workpiece on which a certain material is to be deposited with a certain desired thickness; b) providing a deposit material having a certain area from which the deposit material is discharged into a certain working gas atmosphere; c) transforming the working gas atmosphere into a plasma atmosphere by bombarding electrons widely to the working gas atmosphere; d) emitting a surface material by means of a sputter from the deposit material exposed in the plasma atmosphere; e) exposing the emitted deposit material to an ionization environment; f) and providing energy to the deposit material by applying an electric potential to the step e) to thereby be radiated on a corresponding face of the workpiece. A direct ion beam deposition system is also disclosed.

Owner:SONG SEOK KYUN

High deposition rate sputtering

Methods and apparatus for high-deposition sputtering are described. A sputtering source includes an anode and a cathode assembly that is positioned adjacent to the anode. The cathode assembly includes a sputtering target. An ionization source generates a weakly-ionized plasma proximate to the anode and the cathode assembly. A power supply produces an electric field between the anode and the cathode assembly that creates a strongly-ionized plasma from the weakly-ionized plasma. The strongly-ionized plasma includes a first plurality of ions that impact the sputtering target to generate sufficient thermal energy in the sputtering target to cause a sputtering yield of the sputtering target to be non-linearly related to a temperature of the sputtering target.

Owner:ZOND

Hall effect ringlike ion thruster

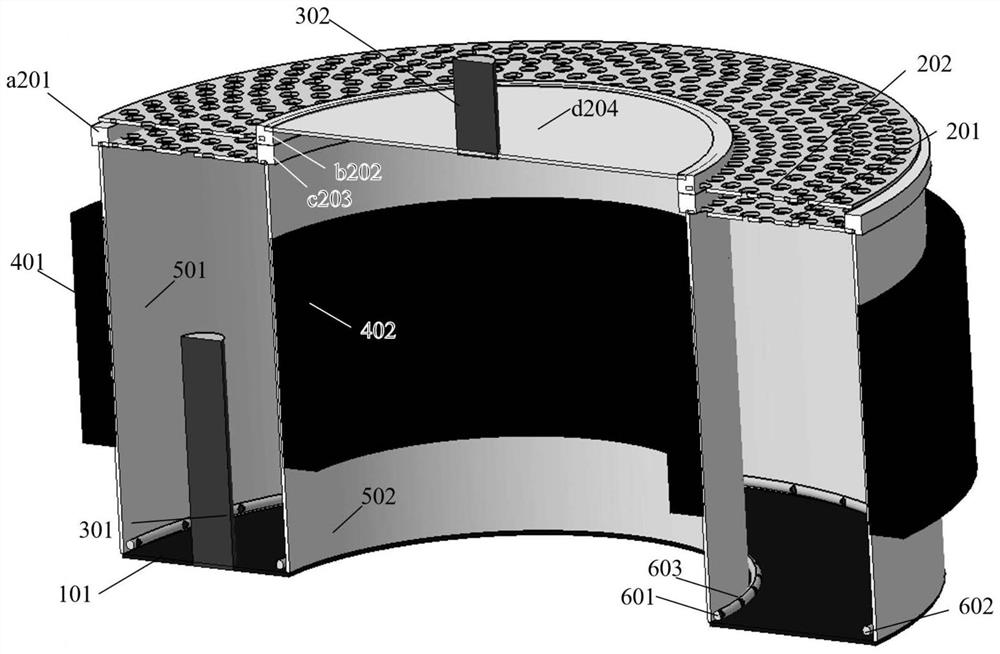

ActiveCN111852802AReduce spanReduce manufacturing difficultyMachines/enginesUsing plasmaPlasmaElectric field

The invention discloses a Hall effect ringlike ion thruster and belongs to the technical field of ion thrusters. The ringlike ion thruster comprises a bottom positive pole, a ringlike grid electrode,ringlike permanent magnets, insulating sleeves, a working medium distributor set, a bias discharging negative pole and a neutralizer. Working medium gas enters a discharging chamber through bottom working medium distributors. Nozzles of the working medium distributors are oriented along the wall face so that the gas can be more uniform in a cavity. An axial electric field is formed among the positive pole, the negative pole and the grid electrode. A radial magnetic field is formed by the inner ringlike permanent magnet and the outer ringlike permanent magnet, and an E*B orthogonal field is formed by the radial magnetic field and the axial electric field. Electrons sprayed out of the negative pole are subjected to Hall drift under the effect of the orthogonal field, and the working medium gas is ionized to generate plasmas. Then, the plasmas are extracted and accelerated by the ringlike grid electrode and neutralized by electrons emitted by the neutralizer to generate thrust. The ionization rate and input power of the thrust generated by the Hall effect ringlike ion thruster are far higher than those of a traditional ion thruster, and performance of the ion thruster can be remarkably improved.

Owner:DALIAN UNIV OF TECH

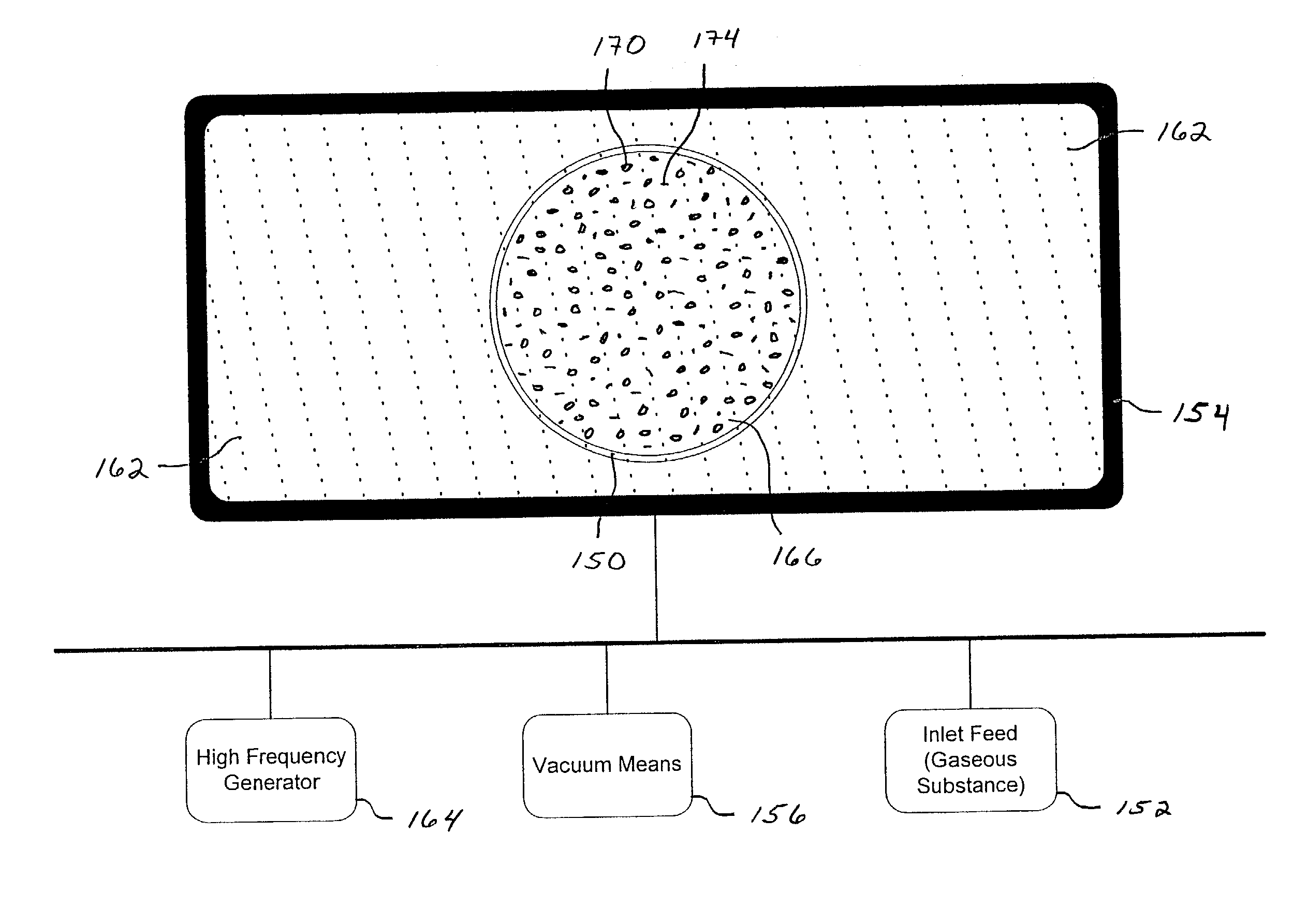

Methods and systems for generating high energy photons or quantum energy

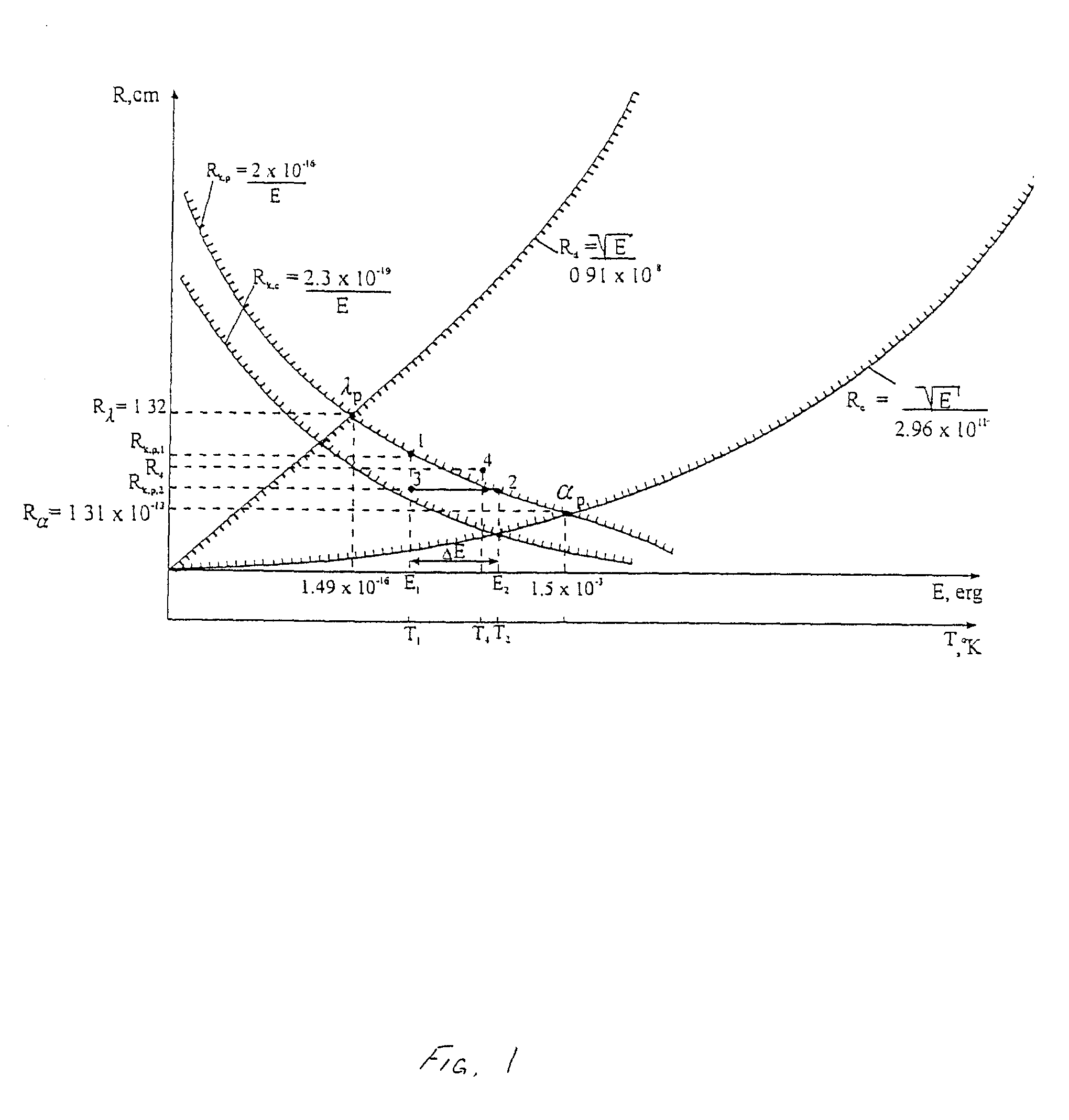

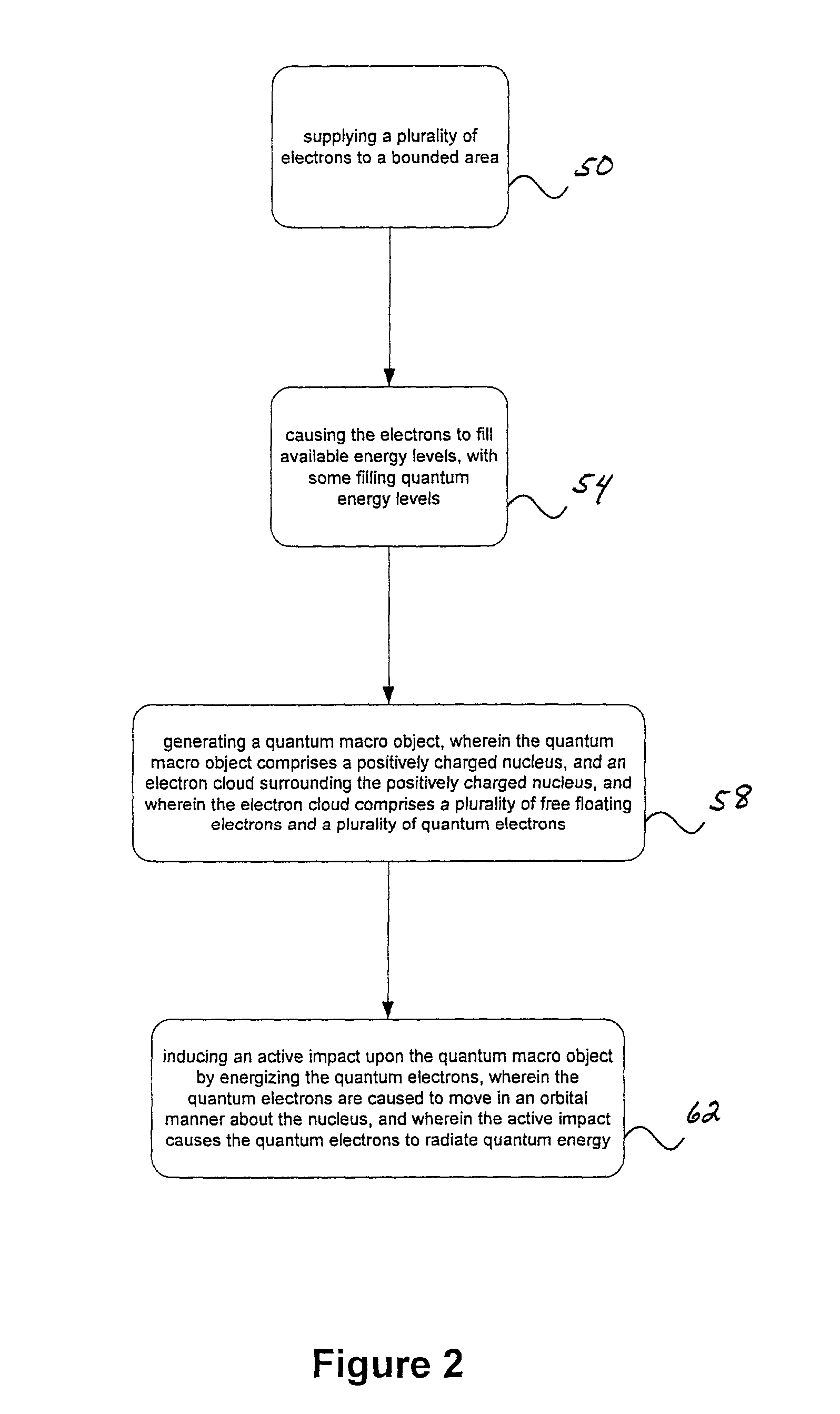

InactiveUS20030094911A1Potential energyIncrease gas pressureRadiation/particle handlingNuclear energy generationDielectricEnergy particle

Methods and systems are described for generating high-energy particles, or quantum energy, from a quantum macro object. Specifically, the method of generating high-energy photons, or quantum energy, comprises in general: (a) isolating a gaseous substance within a bounded area, wherein the gaseous substance and the bounded area contain a plurality of composition particles; (b) energizing the gaseous substance, and particularly the particles within the gaseous substance and the bounded area, thus causing the gaseous substance to transition into a glow discharge plasma state, wherein the particles are separated into their component atomic nuclei and electron parts; (c) increasing the gas pressure within the bounded area to transition the glow discharge plasma to a quantum macro object, wherein the quantum macro object comprises a positively charged nucleus and an electron cloud surrounding the positively charged nucleus, the electron cloud comprising a plurality of quantum electrons and a plurality of free-floating electrons, the quantum electrons comprising large amounts of potential quantum energy; (d) energizing the quantum electrons by inducing an active impact upon the quantum macro object, wherein the quantum electrons are caused to orbit the nucleus of the quantum macro object such that the potential energy existing within the quantum electrons is converted and released in the form of quantum energy in a continuous and inexhaustible manner. The bounded area is typically created by a dielectric of various sorts, such as within a dielectric container or properly charged air.

Owner:CHUKANOV QUANTUM ENERGY

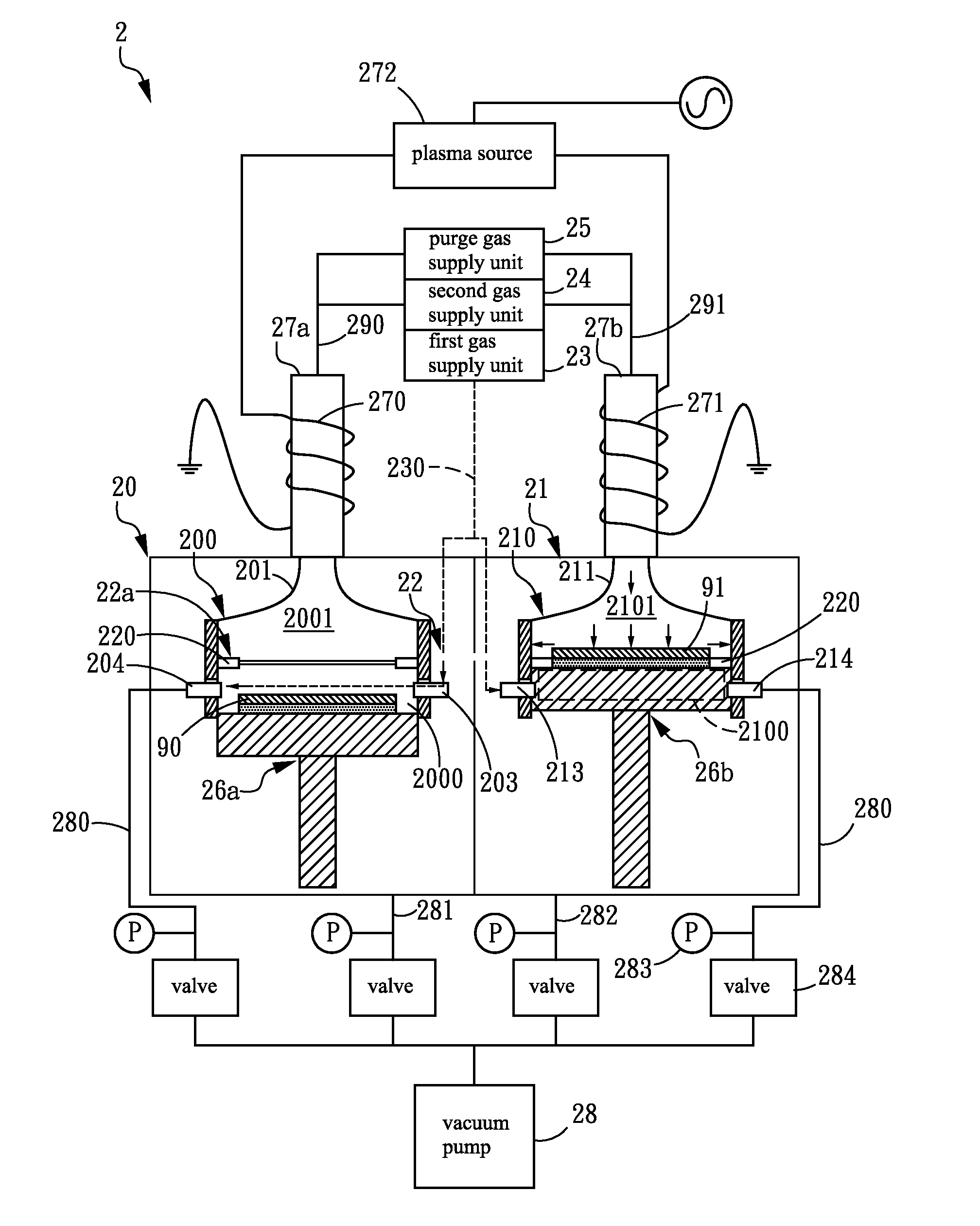

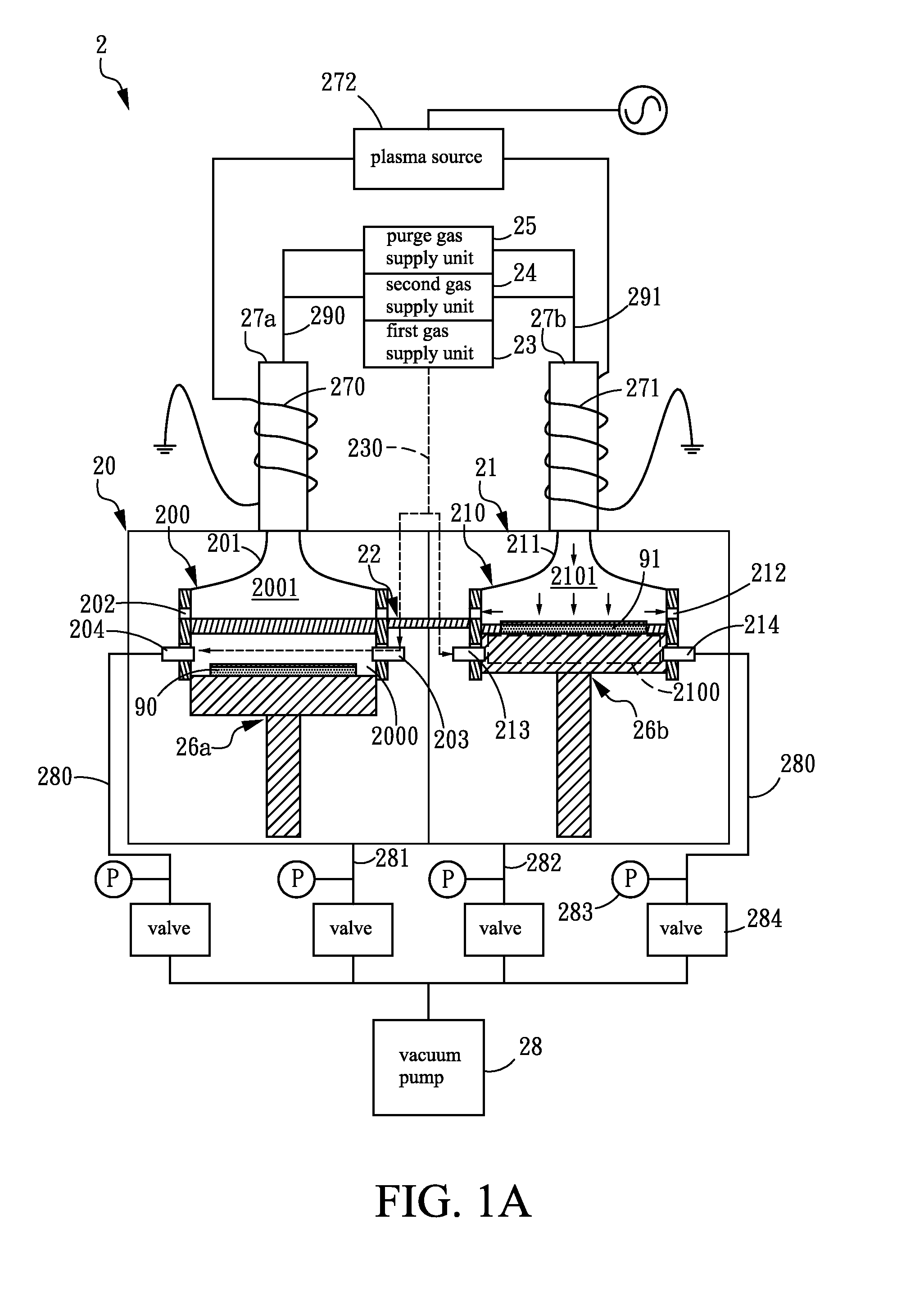

Plasma enhanced atomic layer deposition apparatus and the controlling method thereof

InactiveUS20120070590A1Low costImprove throughputPretreated surfacesChemical vapor deposition coatingEngineeringAtomic layer deposition

This prevent disclosure provides a plasma enhanced atomic layer deposition apparatus and the controlling method thereof. The plasma enhanced atomic layer deposition apparatus includes: a plurality of reaction chambers, each of the reaction chambers having a first reaction space and a second reaction space; an adjustable partition unit controlled to separate or communicate the first and the second reaction spaces; and a plurality of heating carriers respectively disposed in the plurality of reaction chambers. The method manipulates the movement of the partition plate, leading to separation or communication between the first and second reaction spaces, so as to avoid the interference or inter-reaction between process gases and the resultant particles contaminating the substrates.

Owner:IND TECH RES INST

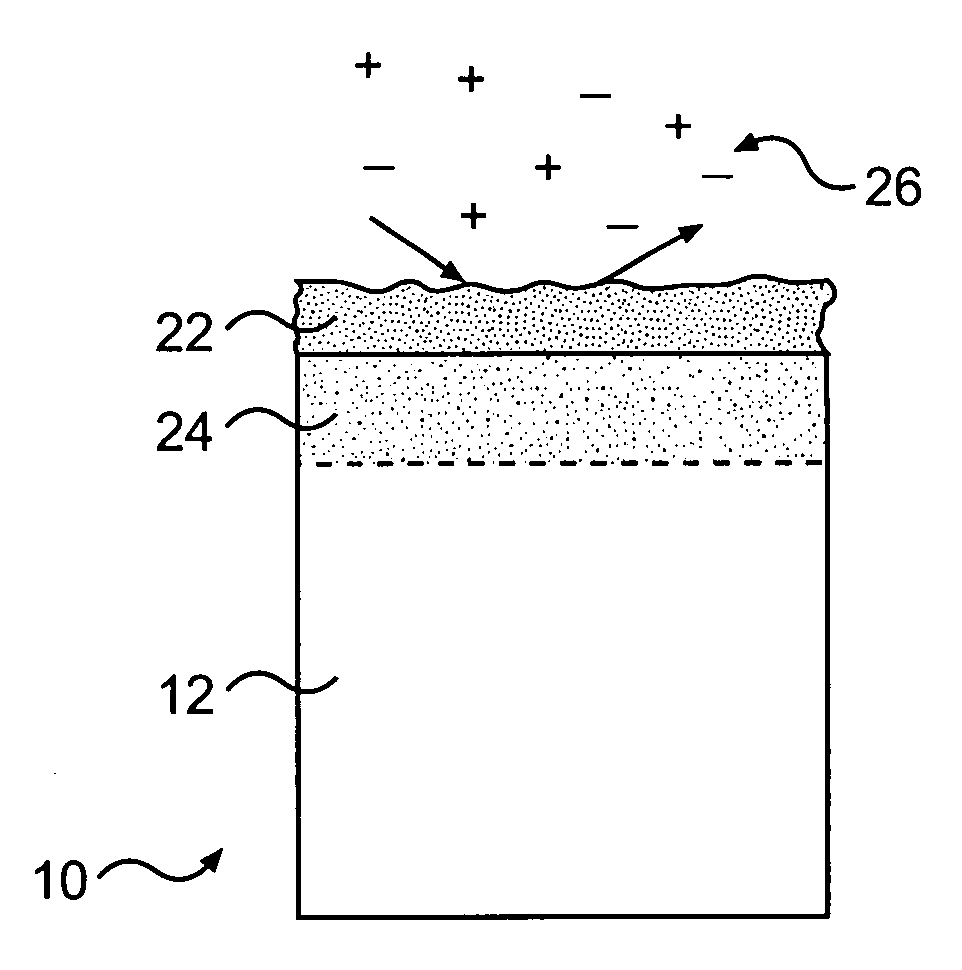

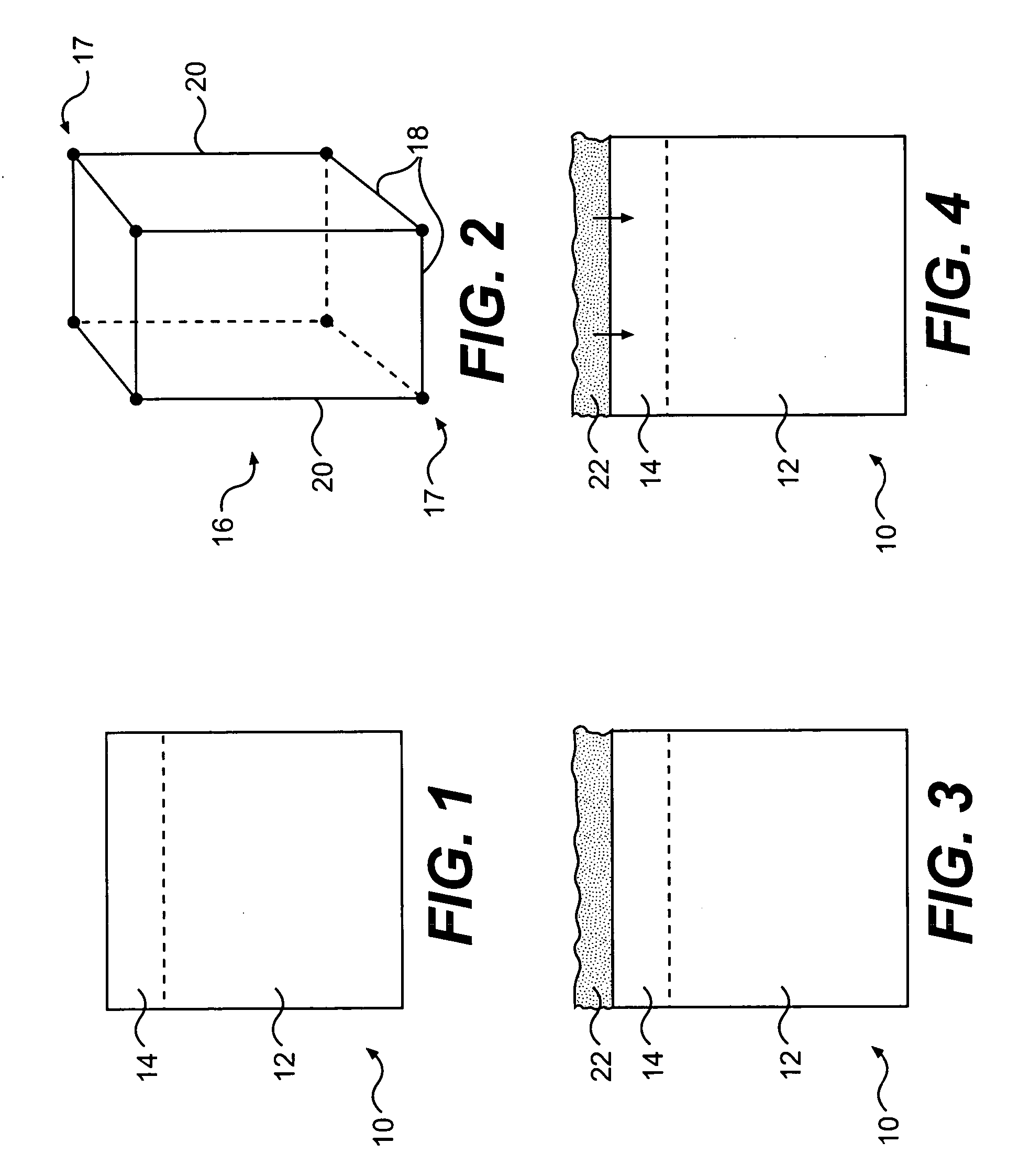

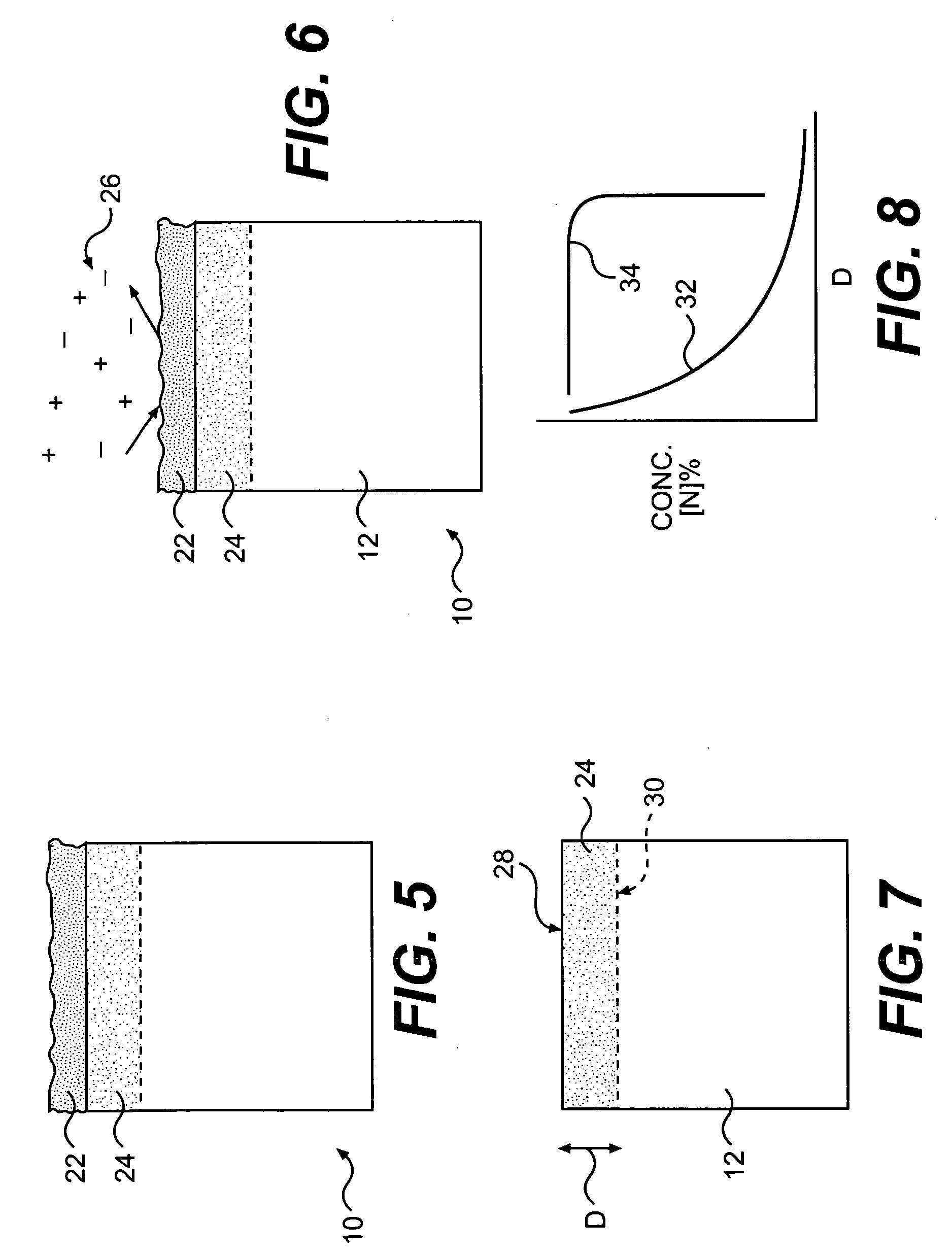

Method of plasma nitriding of metals via nitrogen charging

InactiveUS20050279426A1Promote formationInhibition formationSolid state diffusion coatingThin material handlingNitrogen plasmaNitrogen gas

A method of nitriding a metal includes transforming a surface region of a generally nitrogen-free metal into a nitrogen-containing solid solution surface region. A first heating process heats the surface region at a first temperature in the presence of a nitrogen gas partial pressure to form a nitrogen-charged surface portion on the surface region. A second heating process heats the surface region and nitrogen-charged surface portion at a second temperature for a predetermined time to interstitially diffuse nitrogen from the nitrogen-charged surface portion a depth into the surface region. Coincident with the second heating process, an ionized inert or reducing gas removes the nitrogen-charged surface portion. The resulting nitrogen-containing solid solution surface region has a gradual transition in nitrogen concentration.

Owner:COOPER CLARK VANTINE +2

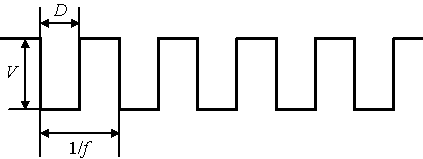

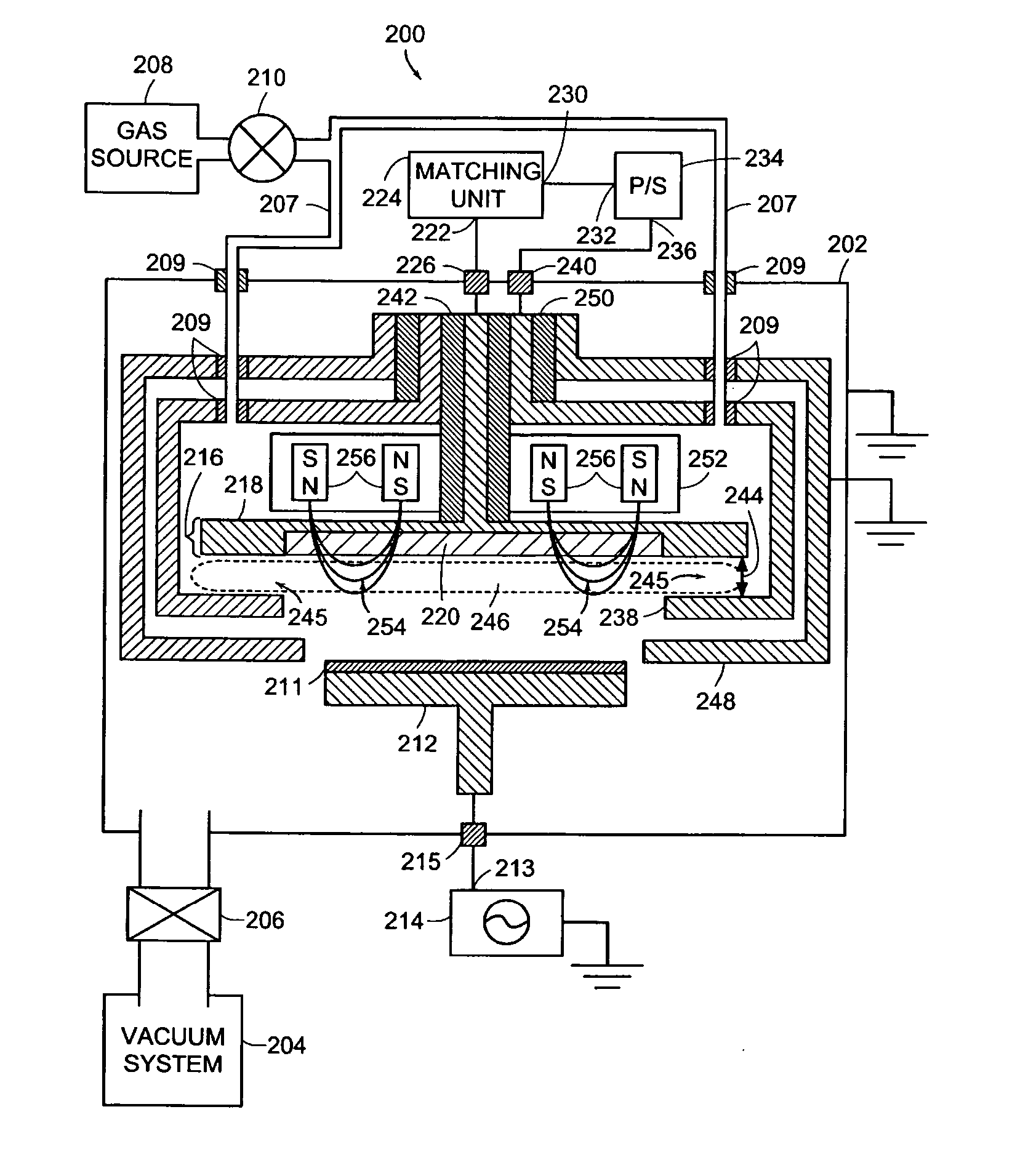

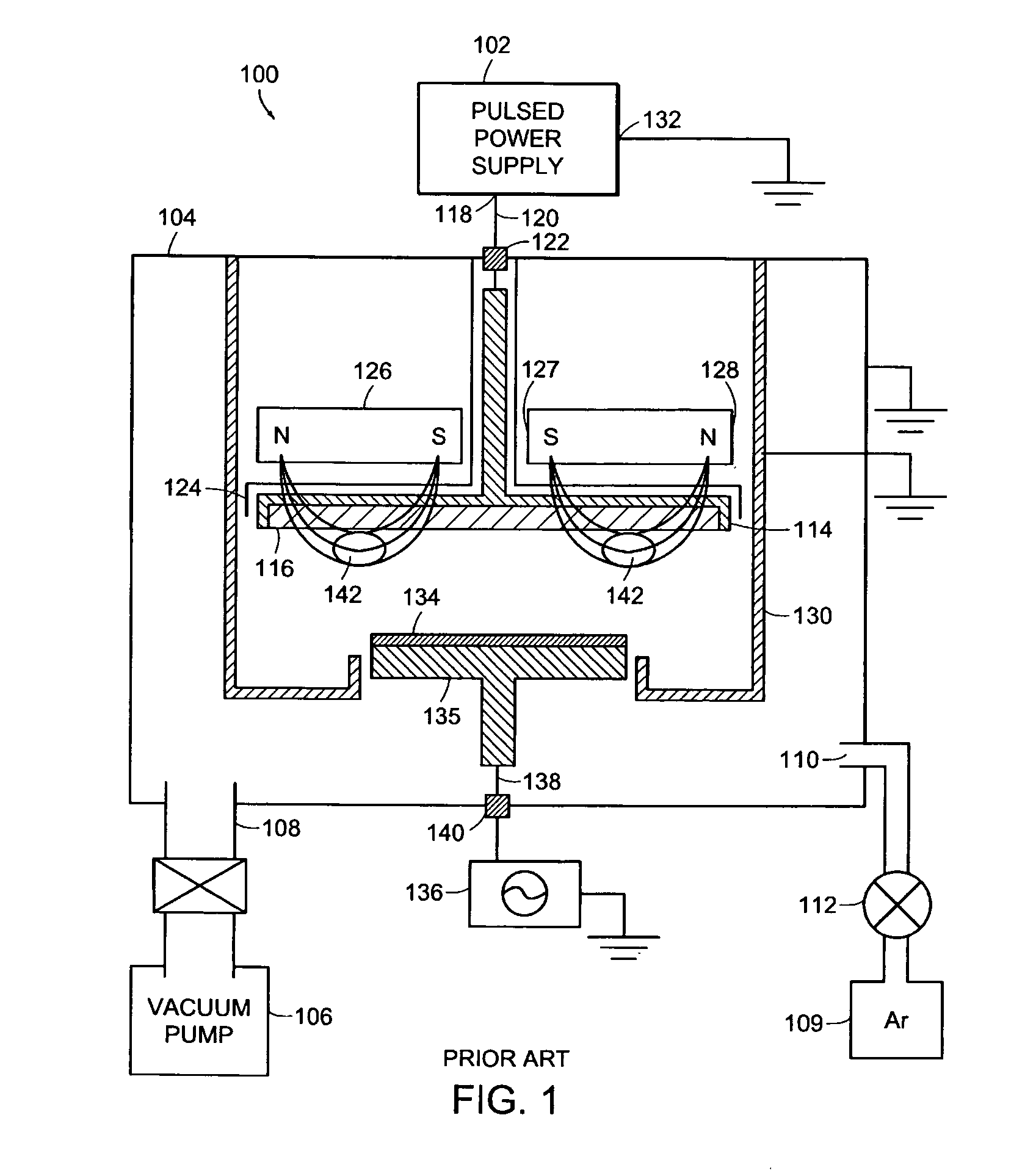

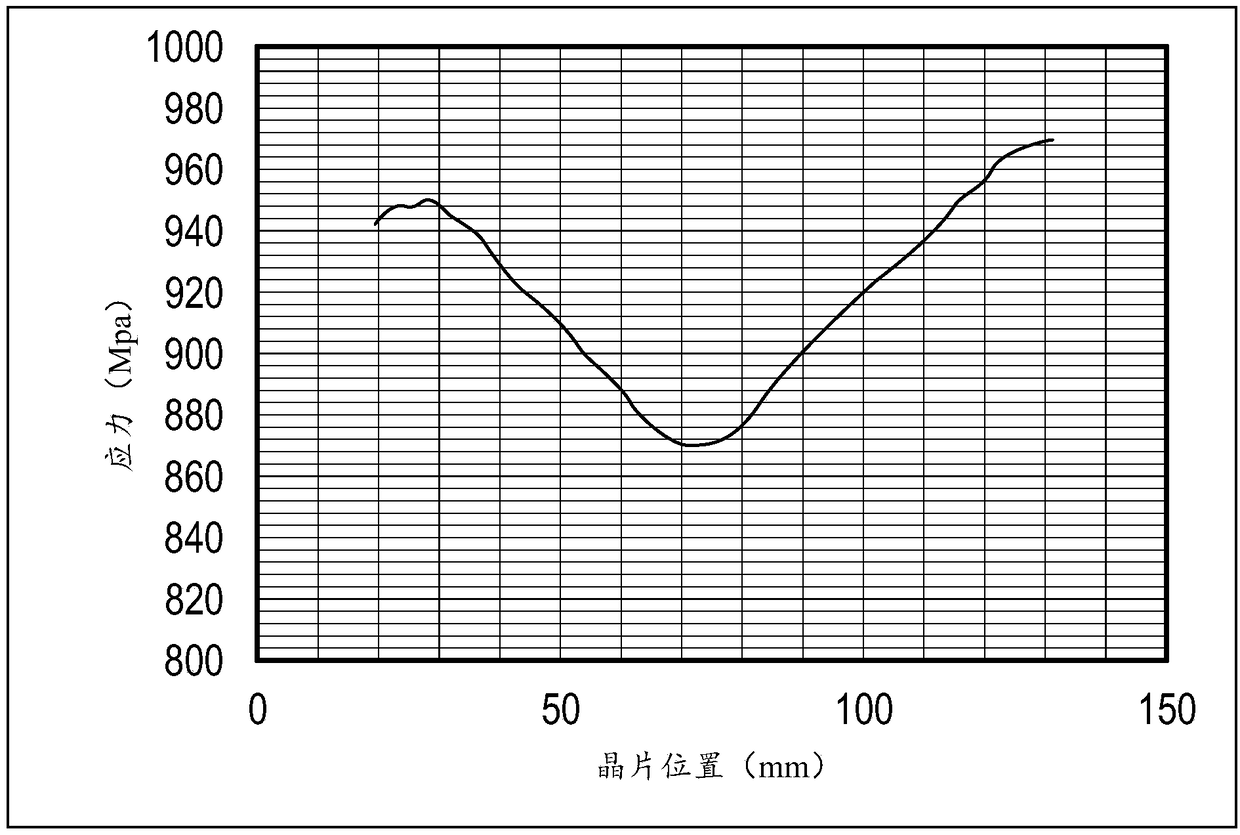

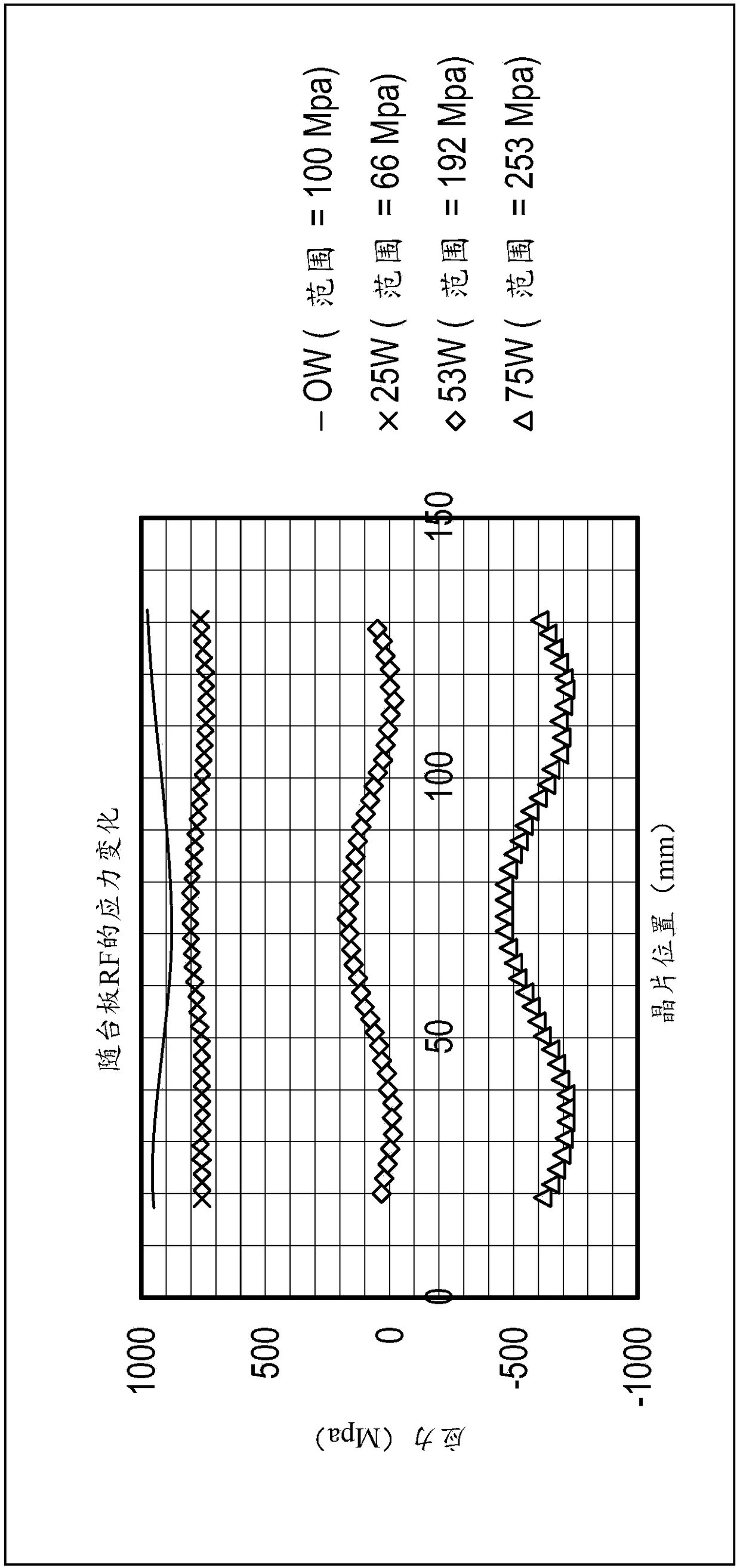

A method and apparatus for controlling stress variation in a material layer formed via pulsed DC physcial vapor deposition

A method and apparatus is disclosed for controlling stress variation in a material layer formed via pulsed DC physical vapour deposition (PVD). The method comprises the steps of providing a chamber comprising a target from which the material layer is formed and a substrate upon which the material layer is formable, and subsequently introducing a gas within the chamber. The method further comprisesgenerating a plasma within the chamber and applying a first magnetic field proximate the target to substantially localise the plasma adjacent the target. An RF bias is applied to the substrate to attract gas ions from the plasma toward the substrate and a second magnetic field is applied proximate the substrate to steer gas ions from the plasma to selective regions upon the material layer formedon the substrate.

Owner:SPTS TECH LTD

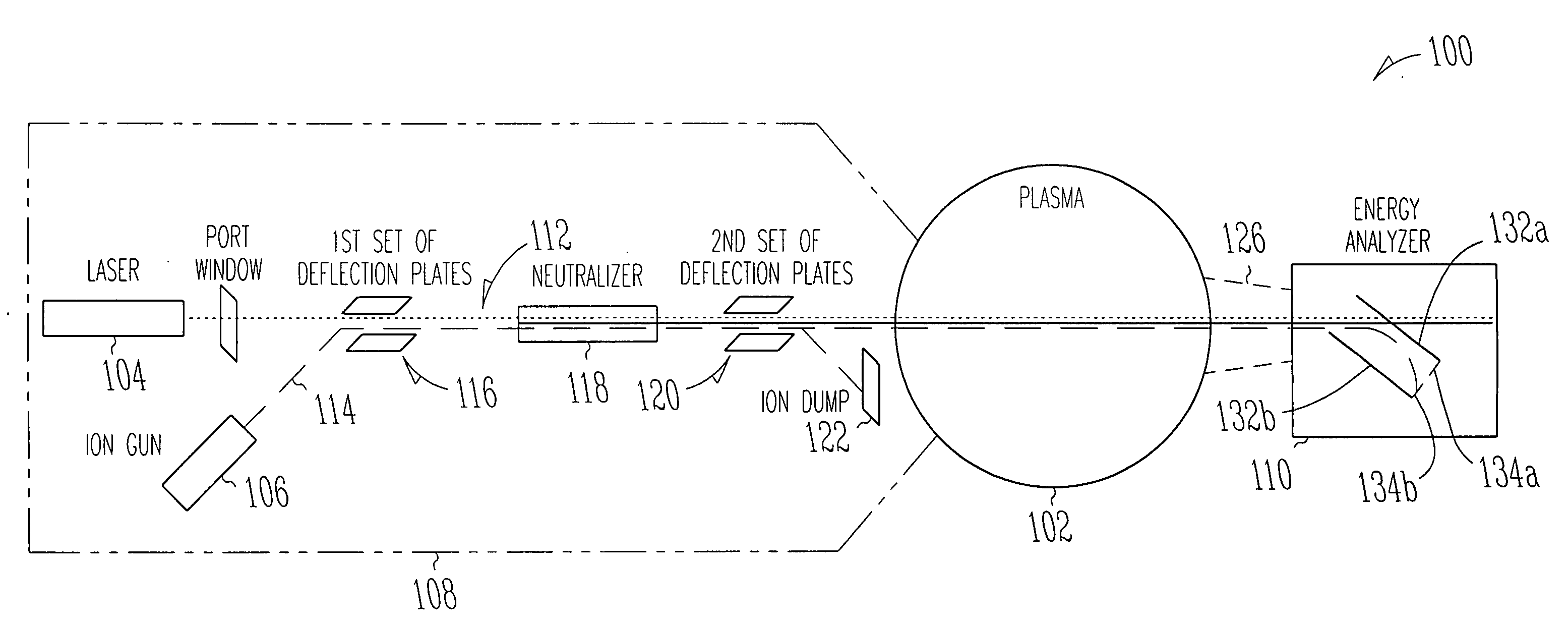

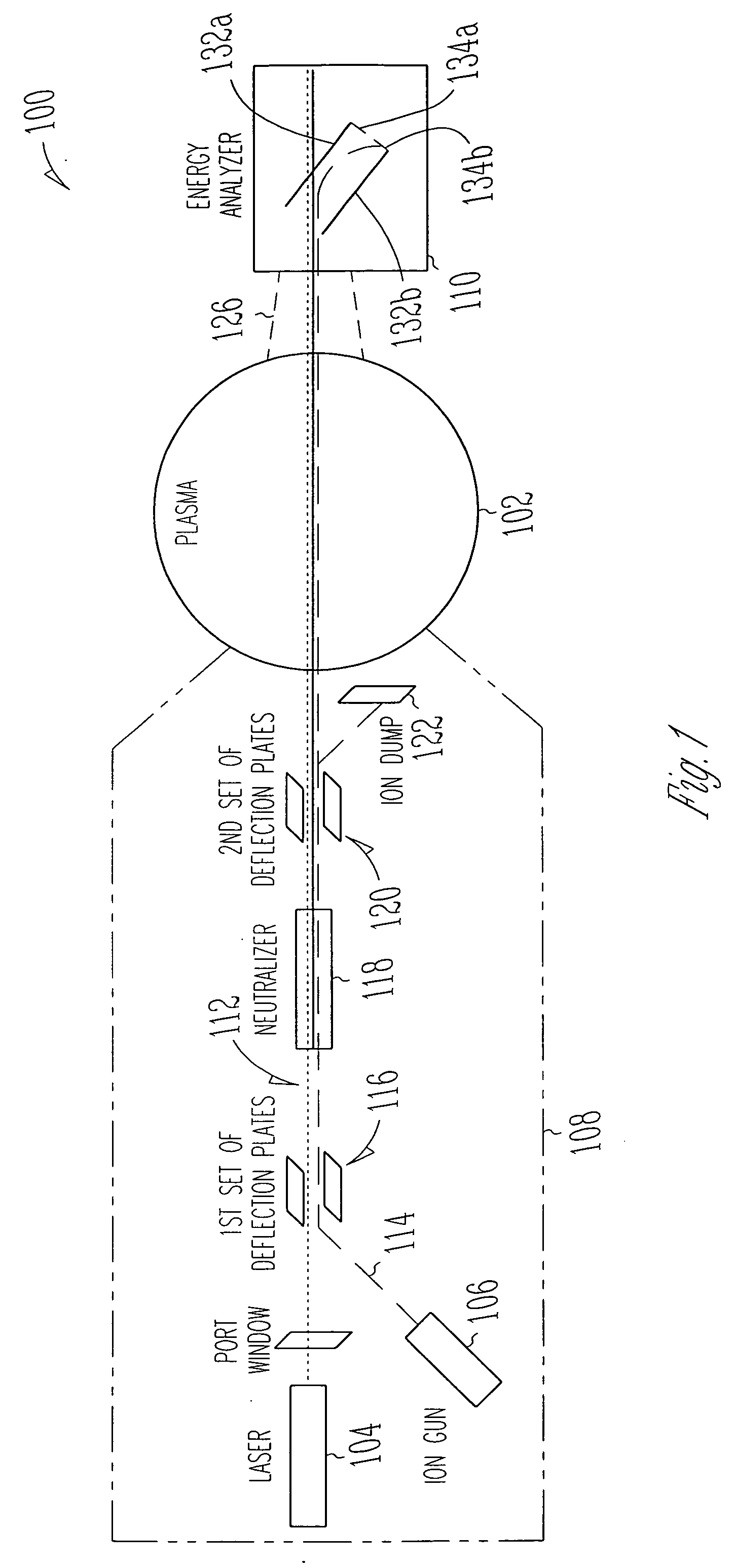

Method and apparatus for photon-assisted evaluation of a plasma

ActiveUS20100090106A1Net energy increaseLaser detailsMaterial analysis using wave/particle radiationLight beamIonization

Described are a method and apparatus for evaluating a least one characteristic of a plasma. The described method uses photons to raise the excitation state to or past the point of ionization of atoms which will traverse the plasma to be evaluated. The ionization of the atoms, followed by the measurement of the energy of any resulting secondary ions, facilitates the determining of one or more characteristics of the plasma. In one example, the photons are provided by a laser which directs a beam to intersect, and in some examples to be collinear with, a beam of atoms directed through the plasma.

Owner:DE GORORDO ALVARO GARCIA

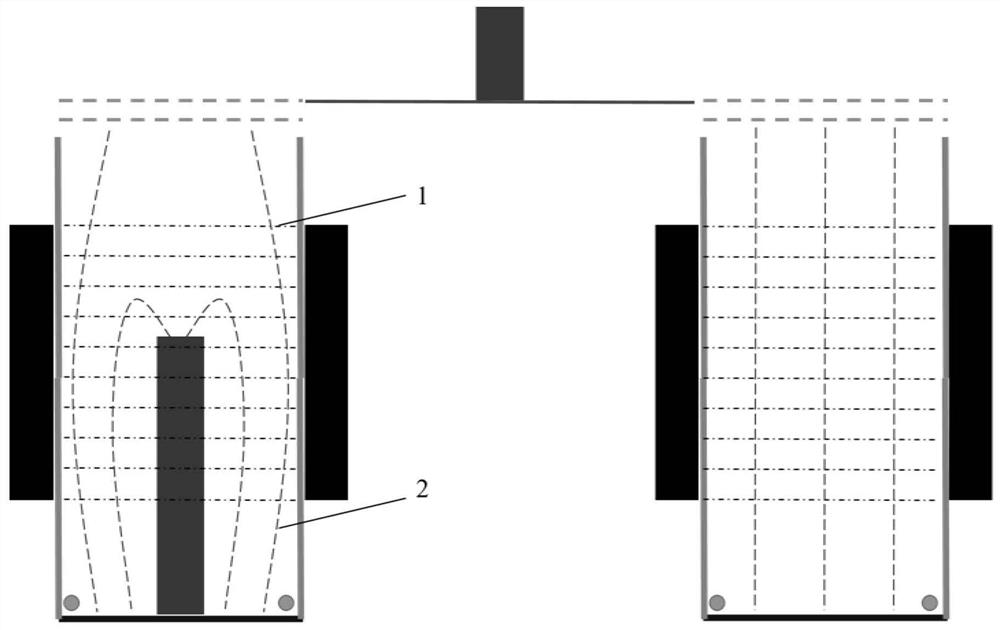

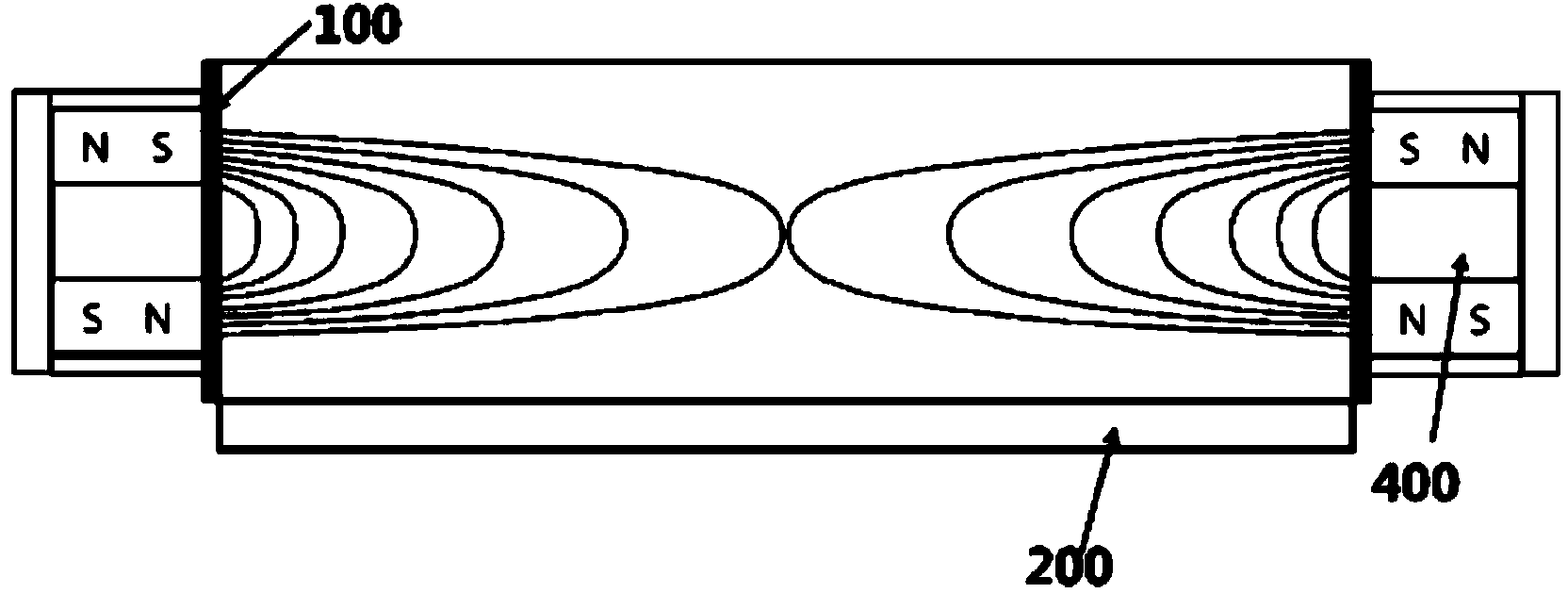

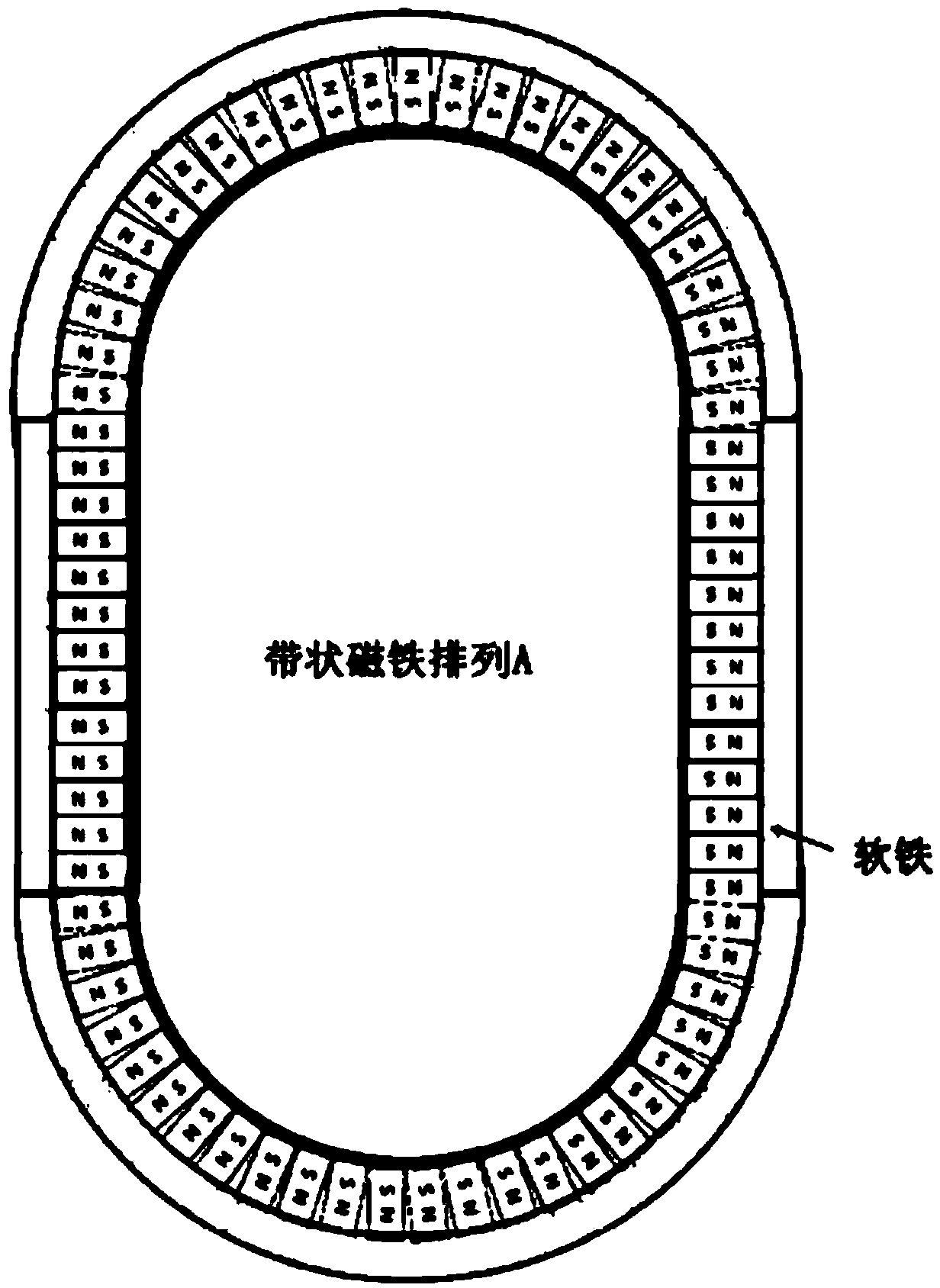

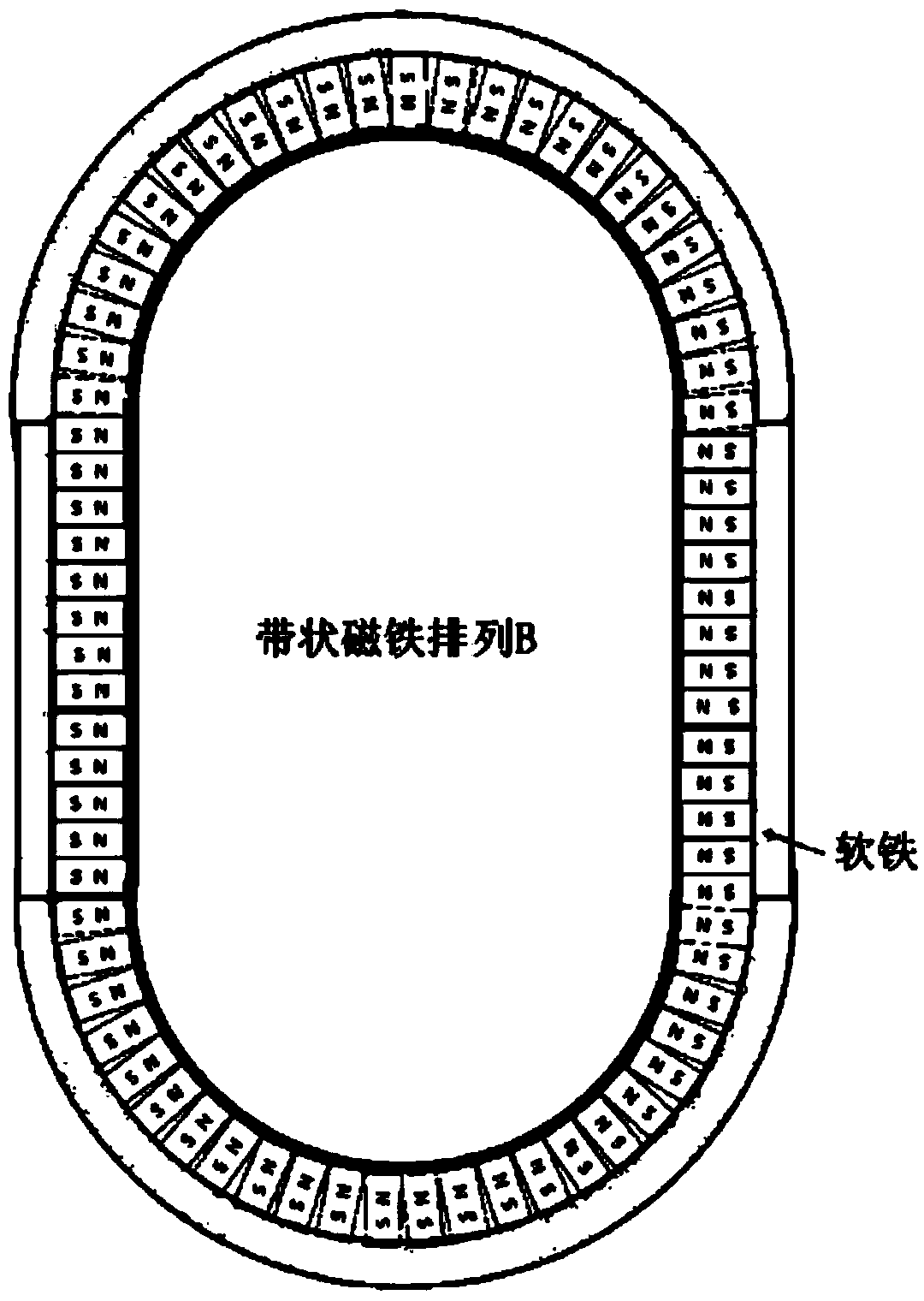

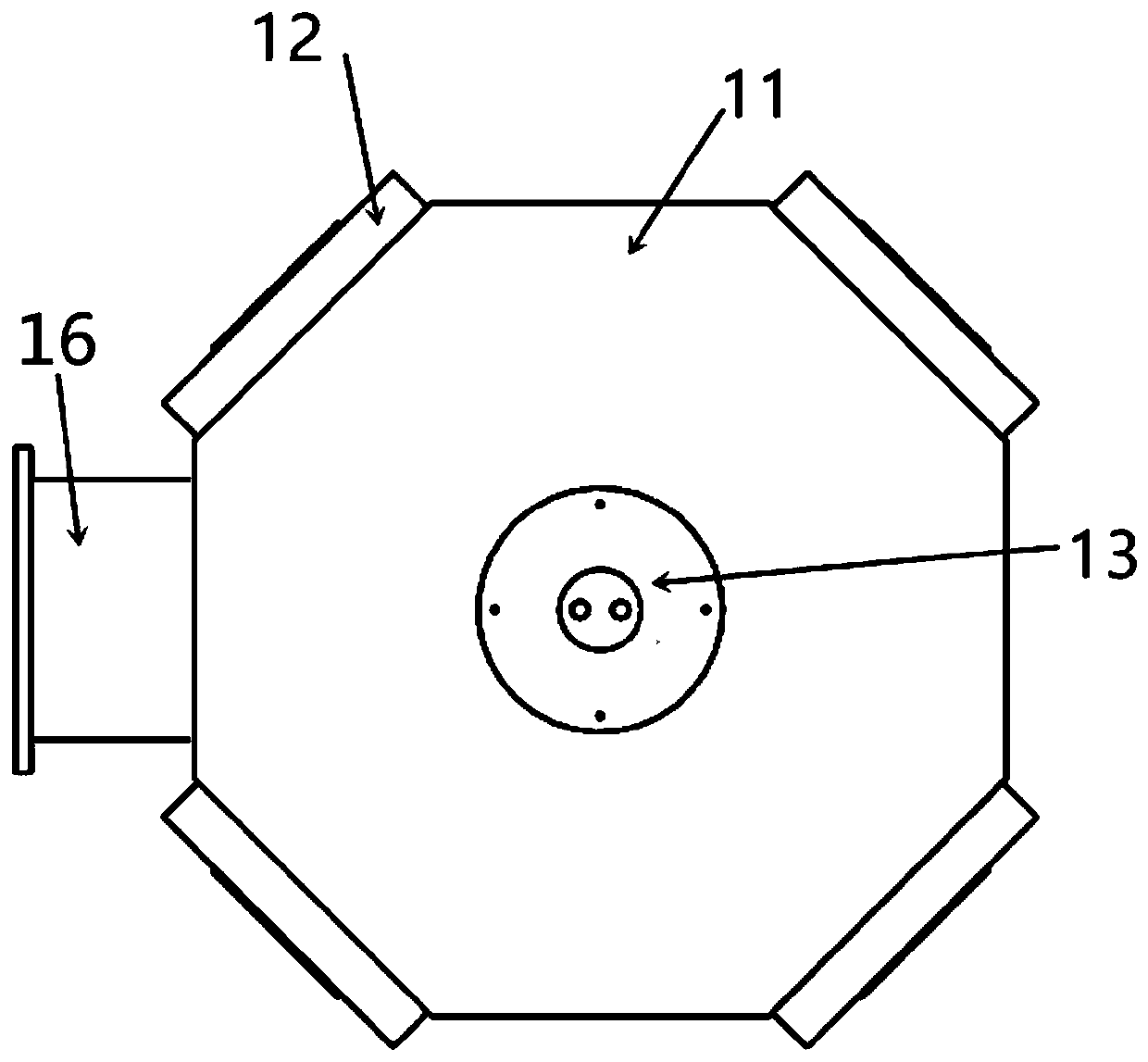

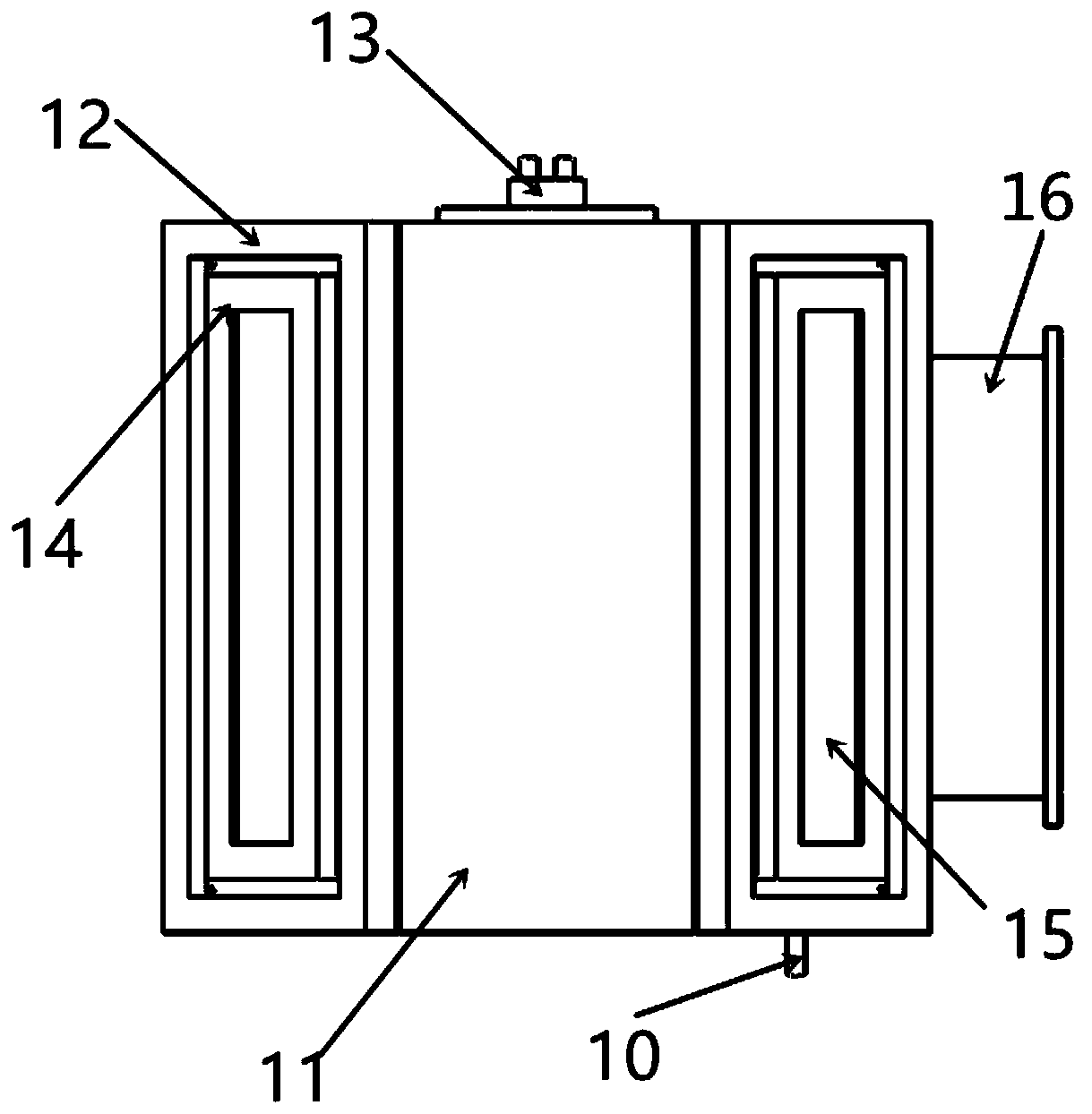

Plasma-generating source comprising a belt-type magnet, and thin-film deposition system using same

ActiveCN103766002AEvenly distributedUniform depositionElectric discharge tubesVacuum evaporation coatingSputteringHigh density

The present invention relates to a plasma-generating source which generates uniform and high-density plasma at a high vacuum level, and to a use thereof. The object of the present invention is to obtain a high-quality thin film by using the plasma-generating source in a thin-film deposition system which comprises: a device for sputtering a similar plasma-generating source, a neutral particle-beam generating source, or a combination of the device for sputtering and the neutral particle-beam generating source. According to the present invention, a magnetic field formed by at least one pair of belt-type magnets, and microwaves generated by a microwave-radiation device, are used to generate plasma, and a continuous structure of the belt-type magnets is used to induce a return path for electrons so as to maximize a plasma-confinement effect, thereby achieving the above object.

Owner:KOREA INST OF FUSION ENERGY

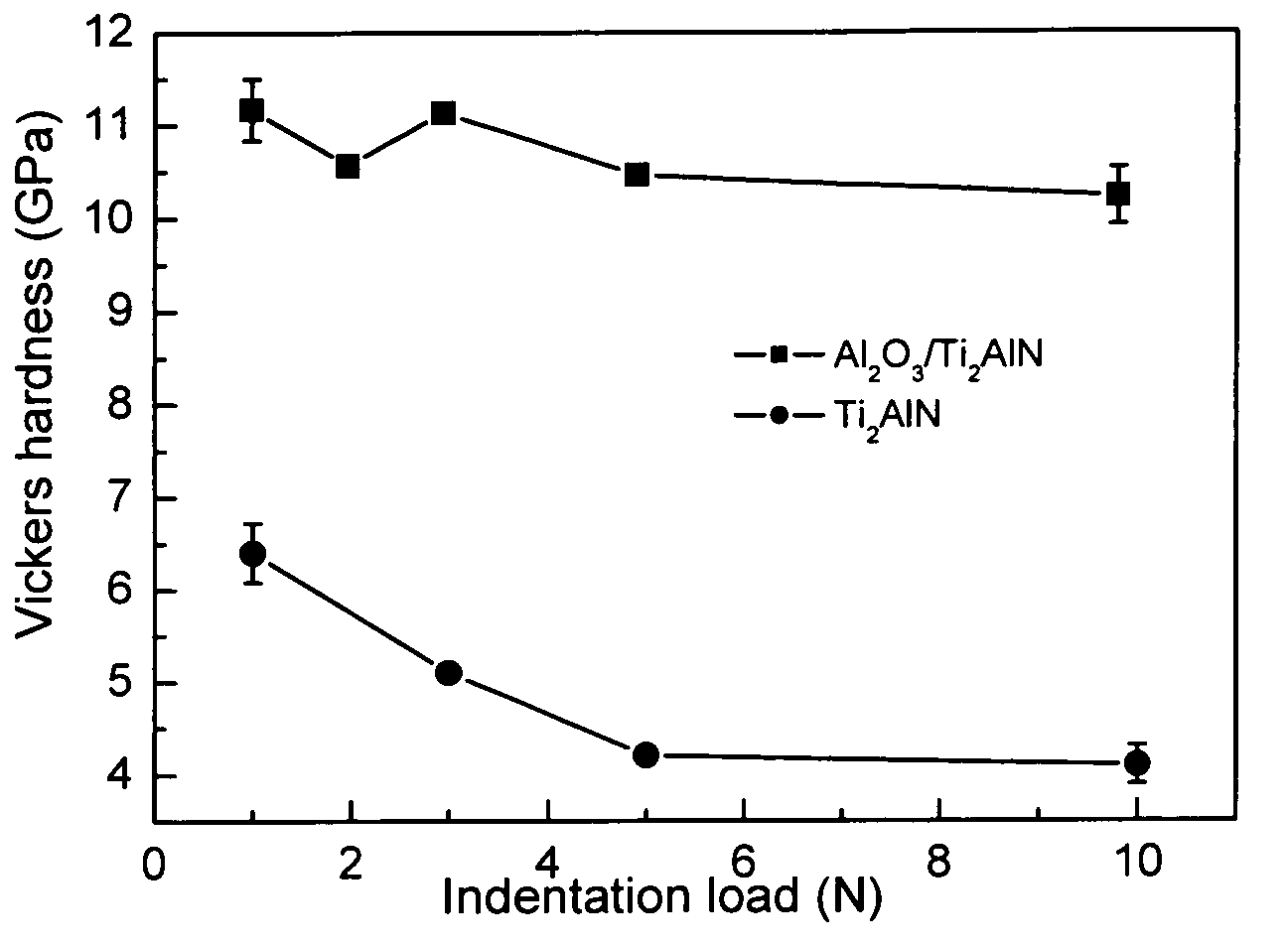

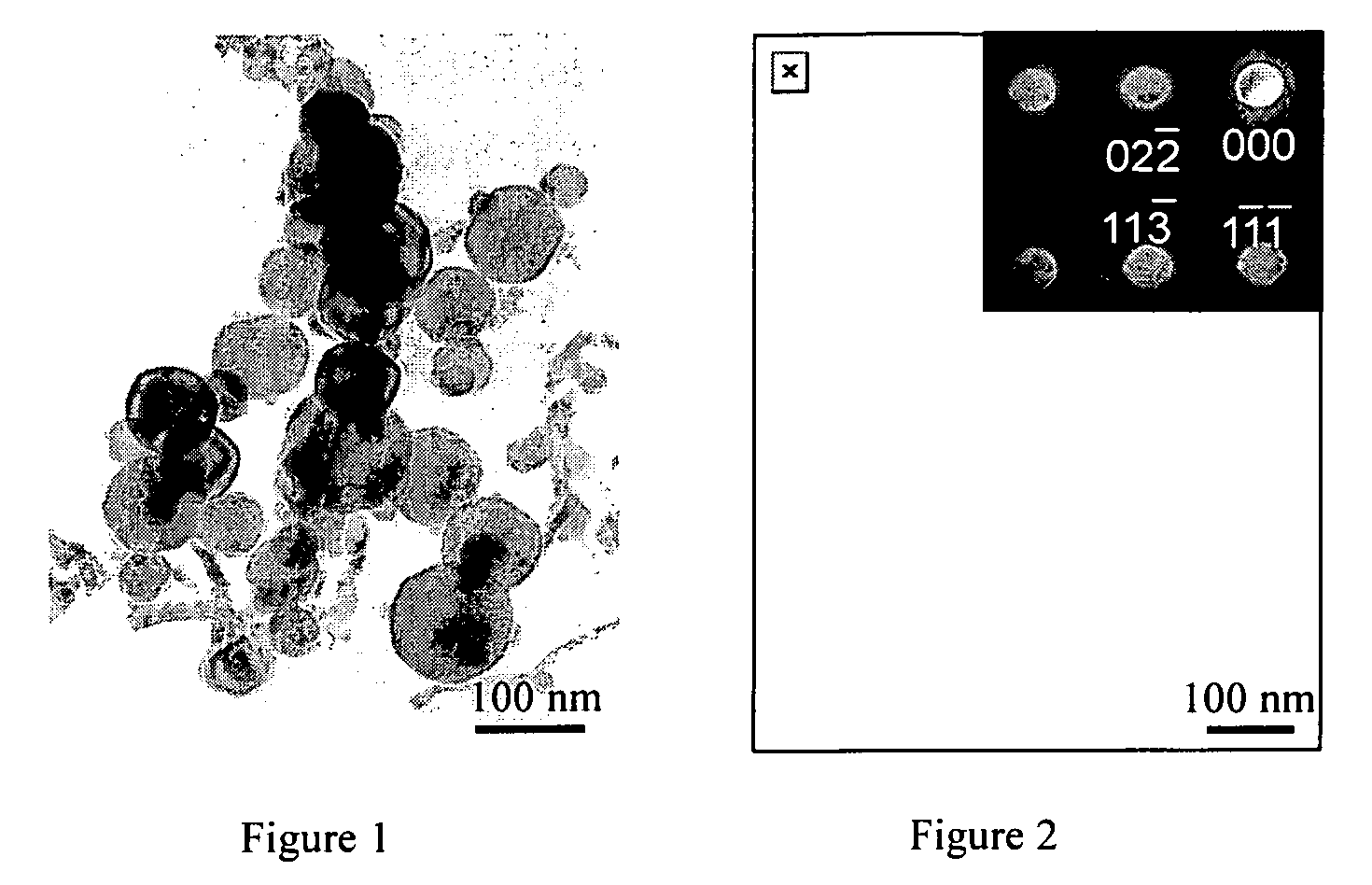

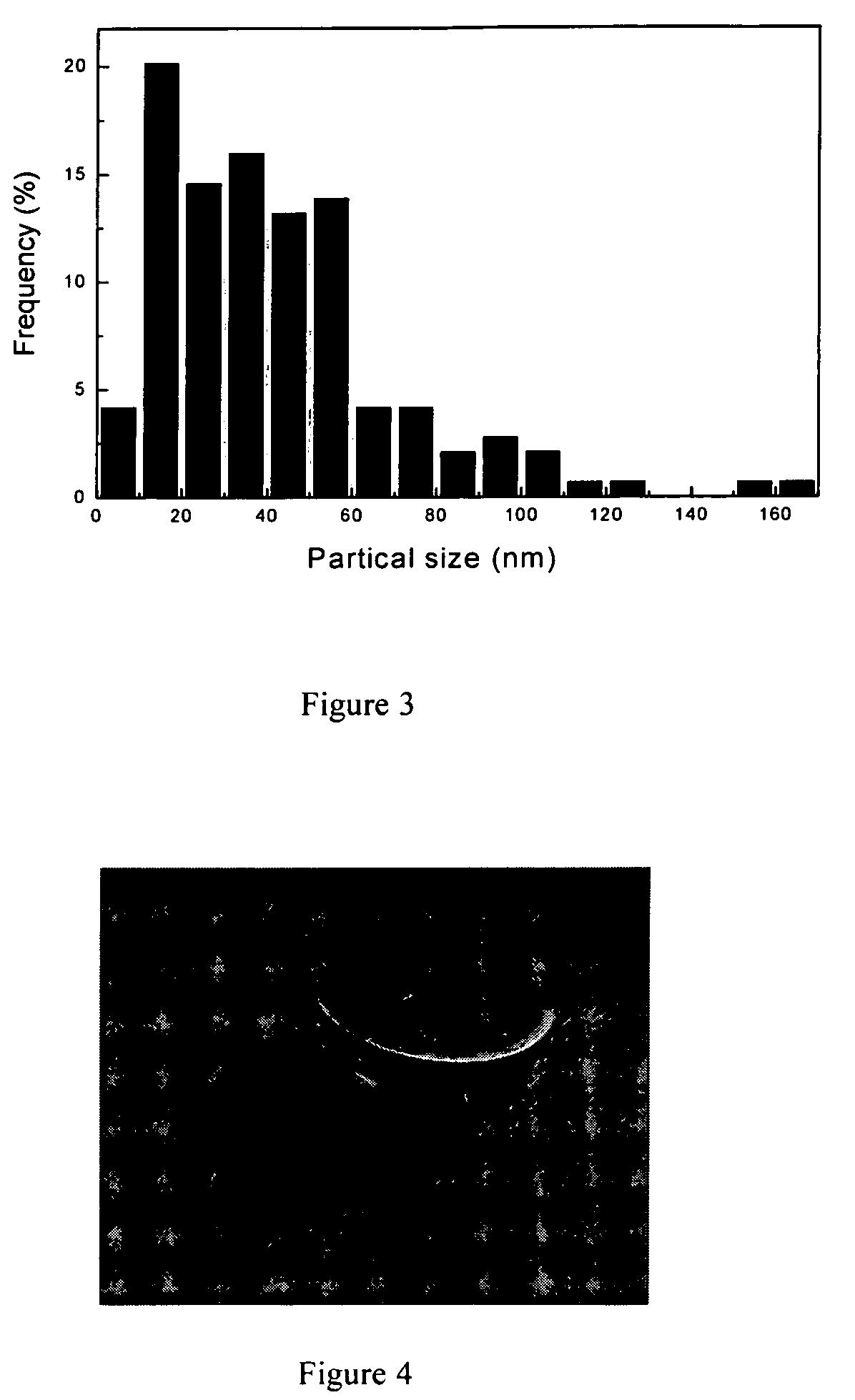

Al2O3 dispersion-strengthened Ti2AlN composites and a method for producing the same

InactiveUS7459408B2High hardnessHigh strengthMaterial nanotechnologyCeramic shaping apparatusHydrogenElectrical conductor

The invention provides Al2O3 dispersion-strengthened Ti2AlN composites, wherein Ti2AlN matrix and Al2O3 strengthening phase both are reactively formed in situ. The volume fraction of Al2O3 is 5% to 50%; the particle size of Al2O3 ranges from 500 nm to 2 μm, with the mean size of Al2O3 particles about 0.8 μm to 1.2 μm; the shape of Ti2AlN grain is plate-like about 80 nm to 120 nm thick and 0.5 μm to 2 μm long. The composites exhibit excellent deformability at high temperature under compression and flexure stresses, and possess excellent oxidation resistance at 1100° C. to 1350° C. for long time (100 h). The composites show typical metallic conductor behavior and the electrical resistivity at room temperature is 0.3 to 0.8 μΩ·m. The invention also provides a method for preparing the same: First, nanoparticles in Ti—Al binary system were prepared in continuous way by hydrogen plasma-metal reaction (HPMR) using Ti—Al alloy rods with Al content 20% to 60% by atom, or pure Al rods and pure Ti rods. The atmosphere used in HPMR is the mixture atmosphere of nitrogen-containing gas, H2 and Ar, with total pressure of 0.8 to 1.2 atm, wherein volume ratio of H2 and Ar is 1:0.8-1.2, and volume fraction of nitrogen-containing gas is 0 to about 20%. Second, the nanoparticles were compacted by vacuum hot pressing at temperature of 800° C. to 1200° C., pressure of 40 MPa to 60 MPa, time of 4 h to 6 h, and vacuum of 2×10−2 Pa to 5×10−3 Pa.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

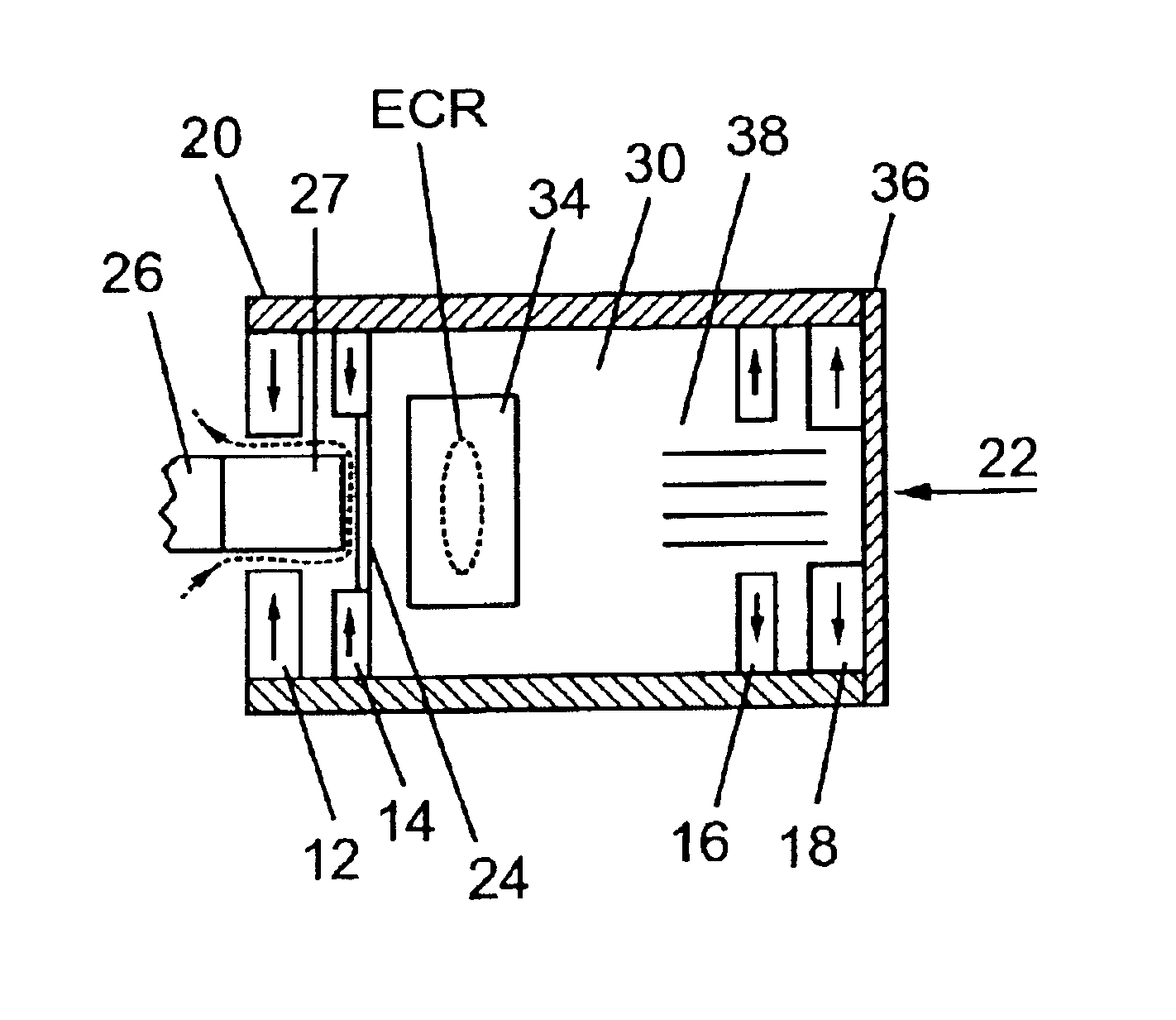

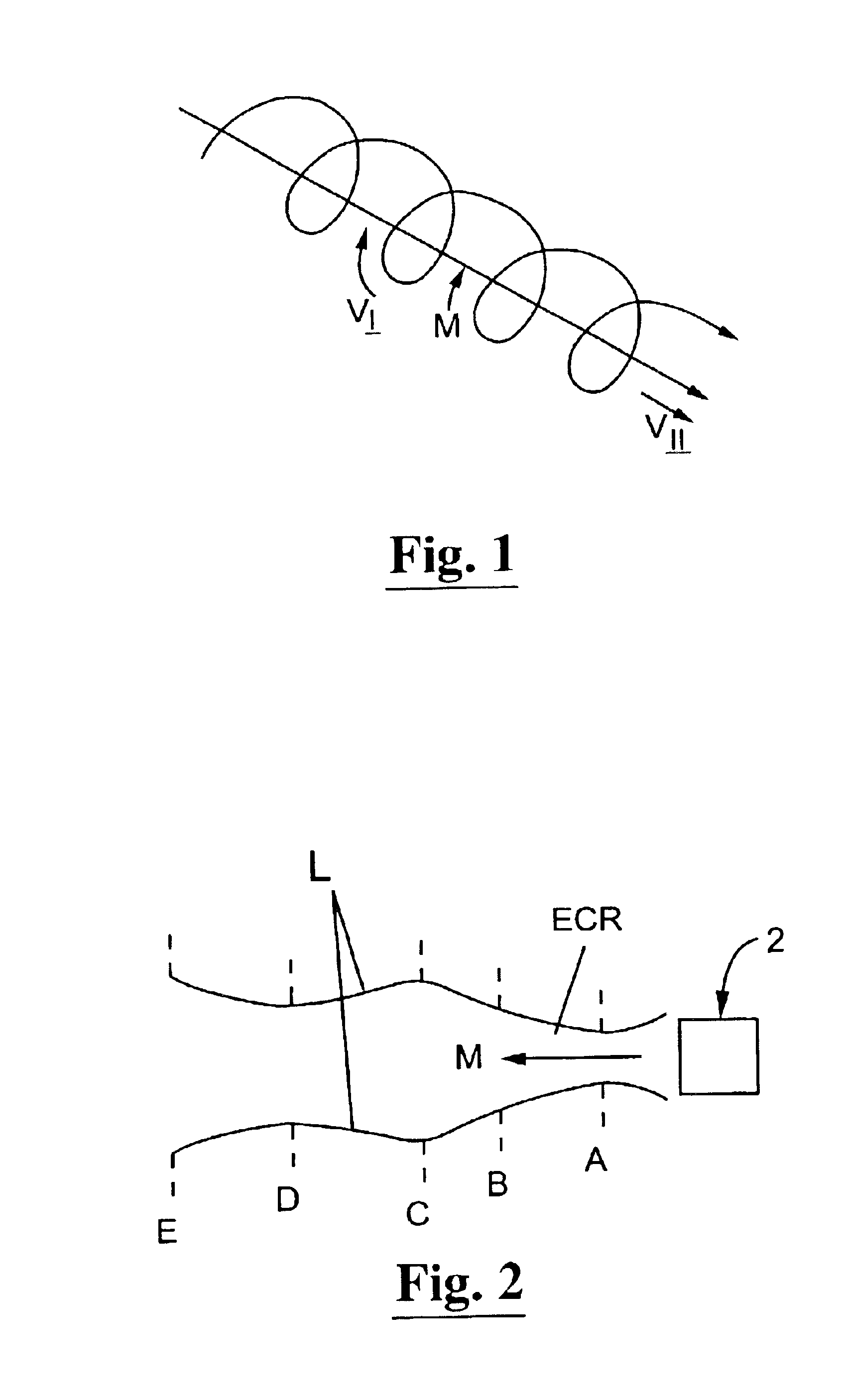

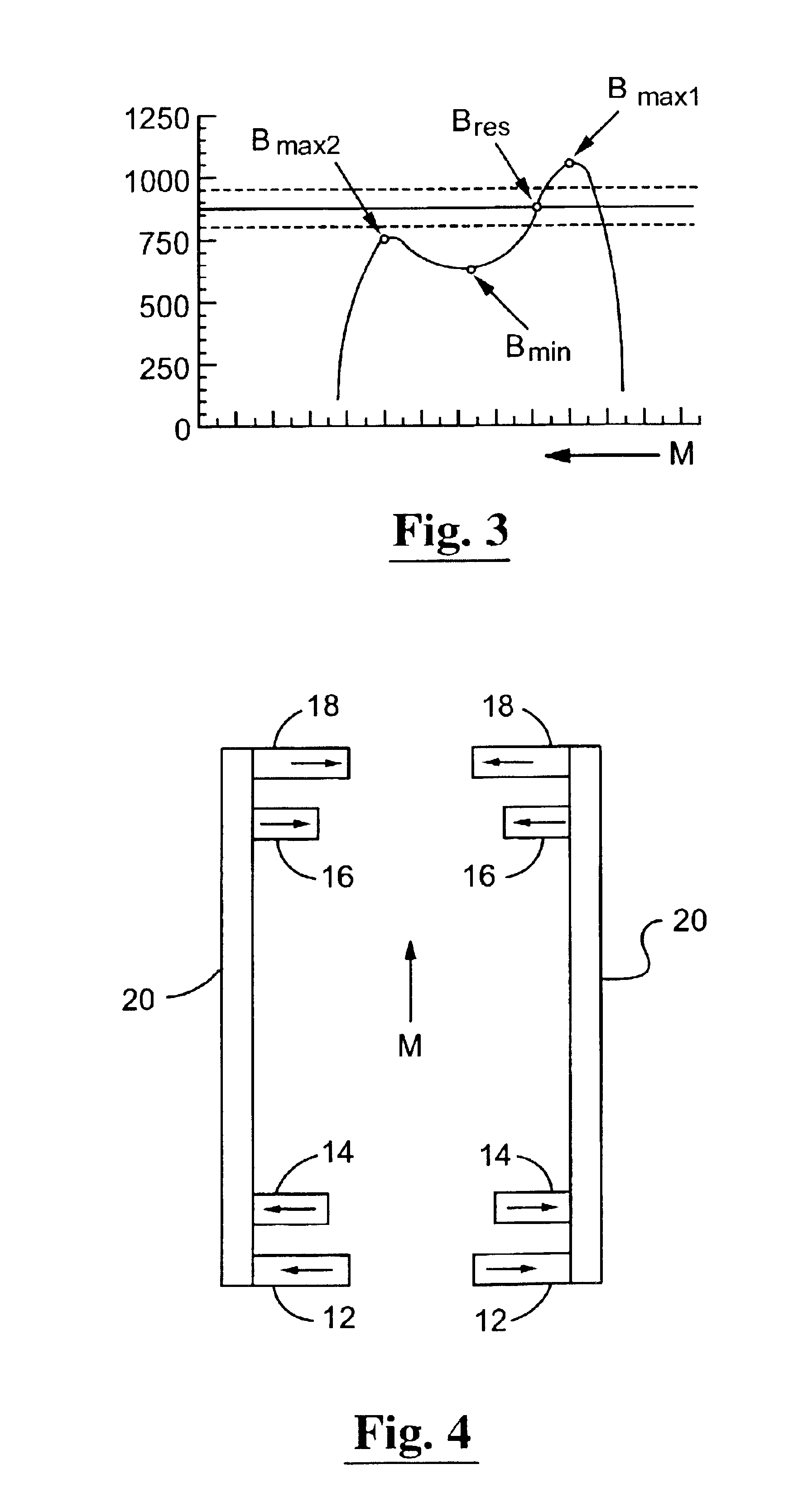

Stand alone plasma vacuum pump

InactiveUS6873113B2Easy to moveAvoid flowPump componentsElectric arc lampsElectricityMicrowave power

A stand-alone plasma vacuum pump for pumping gas from a low-pressure inlet to a high-pressure outlet, composed of: a housing enclosing one or more pumping regions located between the inlet and the outlet; a plurality of permanent magnet assemblies providing magnetic fields that extend in the pumping region between the inlet and the outlet, the magnetic field forming magnetic flux channels for guiding and confining plasmas; elements disposed for coupling microwave power into the flux channels to heat electrons, ionize gas, and accelerate plasma ions in a direction from the inlet to the outlet; elements disposed for creating an electric in the magnetic flux channels to accelerate ions in the flux channels toward the outlet by momentum transfer; and a differential conductance baffle proximate to the outlet for promoting flow of plasma ions and neutral atoms to the outlet.

Owner:TOKYO ELECTRON LTD +1

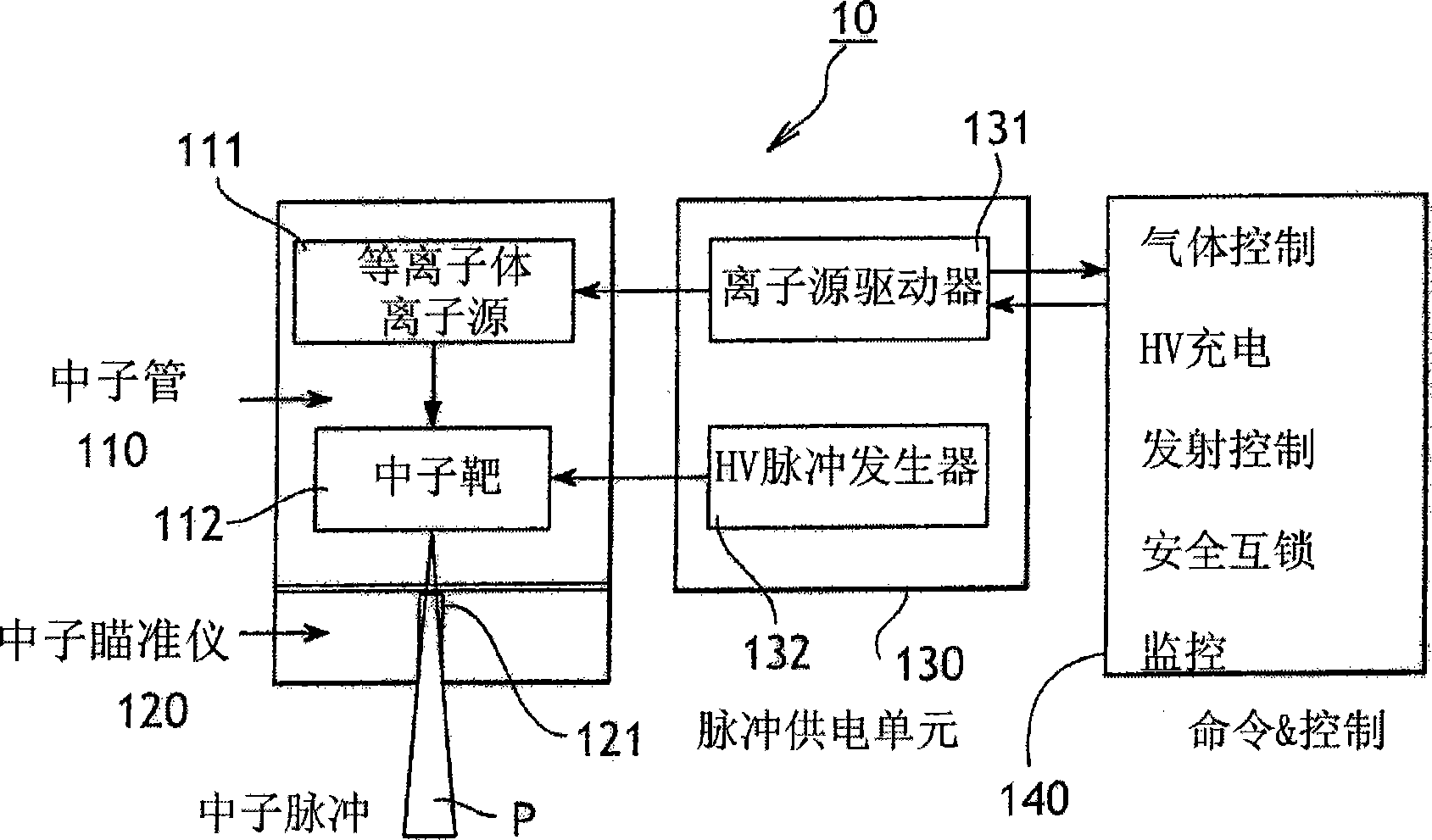

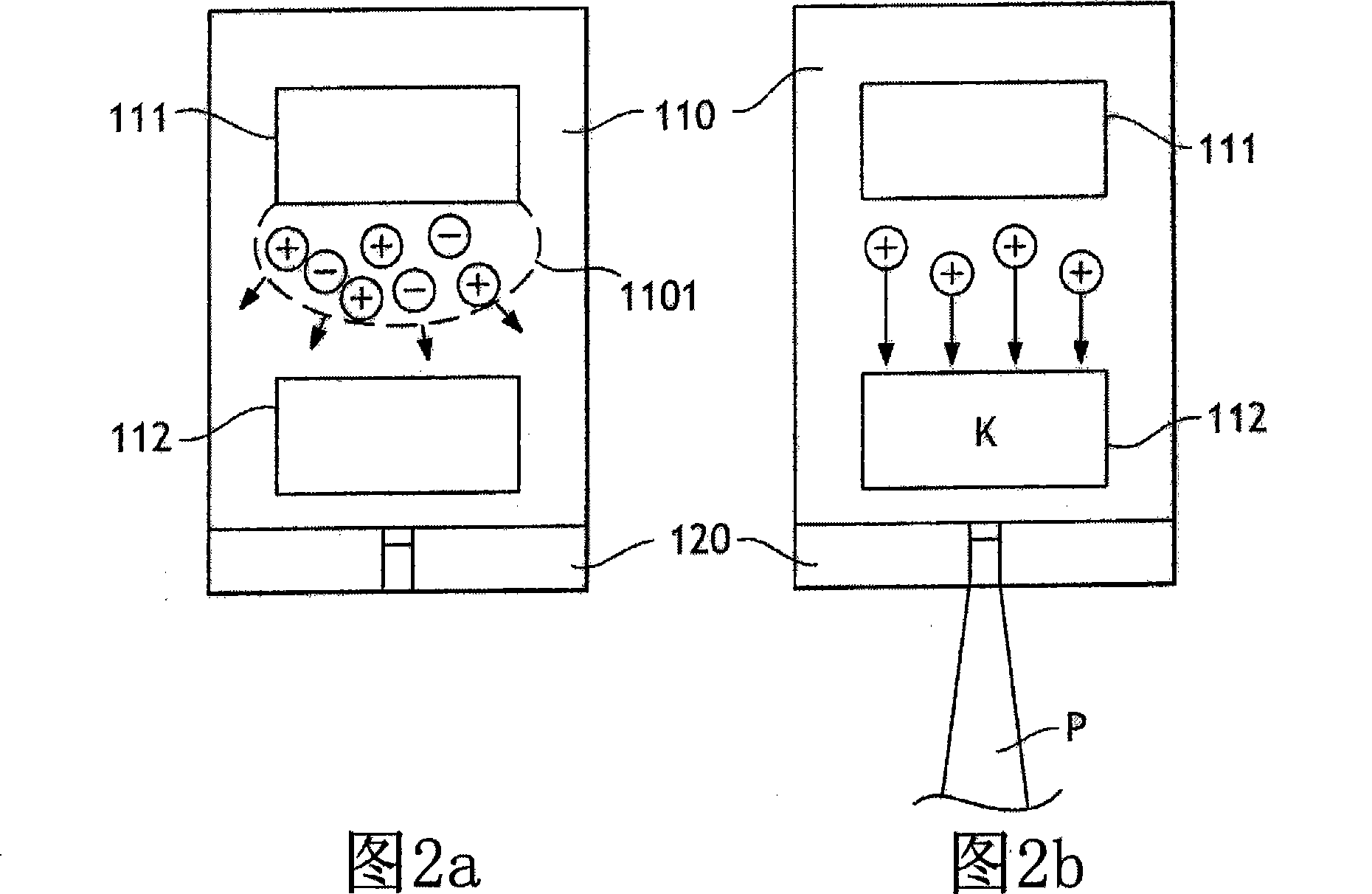

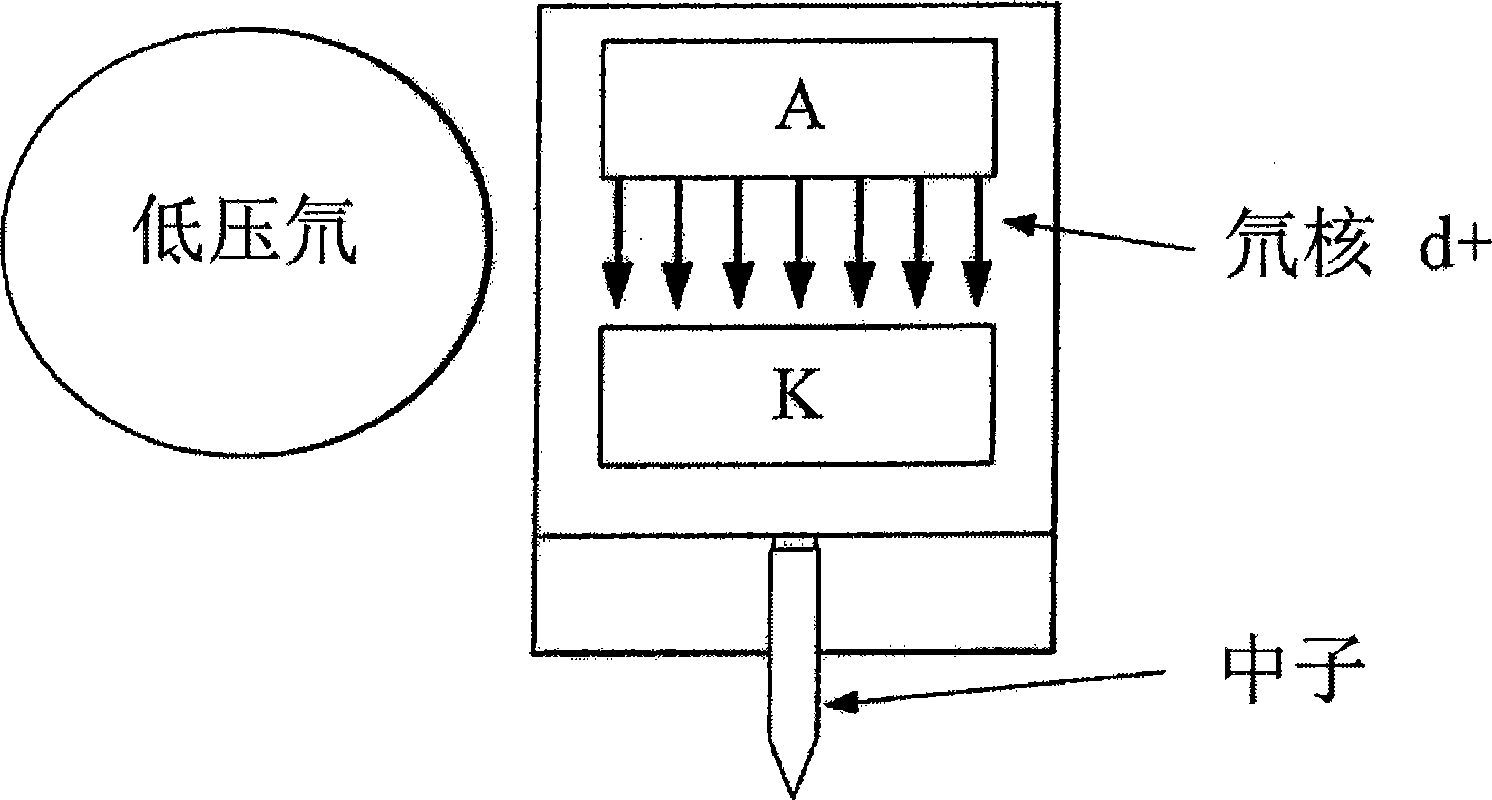

A method for generating a pulsed flux of energetic particles, and a particle source operating accordingly

A method for generating a pulsed flux of energetic particles comprises the following steps: - initiating an ion plasma at a first electrode (111 ) in a vacuum chamber (110) and allowing said plasma to develop towards a second electrode (112) in said vacuum chamber, - at a time at which said ion plasma is in a transitional state with a space distribution of ions or electrons at a distance from said second electrode, applying between said electrodes a short high voltage pulse so as to accelerate said distributed ions or electrons towards said second electrode, whereby a high-energy flux of charged particles is generated while overcoming the space charge current limit of a conventional vacuum diode, and - generating said energetic particles at said second electrode (112). A particle source is also disclosed. Application in particular to ultra-short pulse neutron generation.

Owner:SAGE INNOVATIONS

Multielement hard coating and electromagnetic enhancement magnetron sputtering preparation process thereof

InactiveCN111519151AHigh densityEasy to cleanVacuum evaporation coatingSputtering coatingSputteringParticle physics

The invention relates to a multielement hard coating and an electromagnetic enhancement magnetron sputtering preparation process thereof. An electromagnetic enhancement magnetron sputtering technologyis characterized by sleeving electromagnetic coils on a magnetron sputtering cathode, using multiple groups of cathode unbalanced magnetic fields for forming a closed magnetic field, forming a crossed electric and magnetic field through the closed magnetic field and a center anode, and improving the ionization rate of sputtered particles. The multielement hard coating comprises an underpainting transition layer, a function layer, and a covering layer. Through electromagnetic enhancement magnetron sputtering, a sputtering area can be increased, a sputtering channel is widened, the magnetic field intensity of the closed magnetic field can be further improved, and the ionization rate of the sputtered particles is favorably improved; and through the closed magnetic field, a free path of an electron is increased, the plasma intensity is improved, the cleaning efficiency and a cleaning effect are improved, and the ionization rate of the sputtered particles can be greatly improved, so that auxiliary deposition is realized, and a binding force of the coating is improved.

Owner:苏州艾钛科纳米科技有限公司

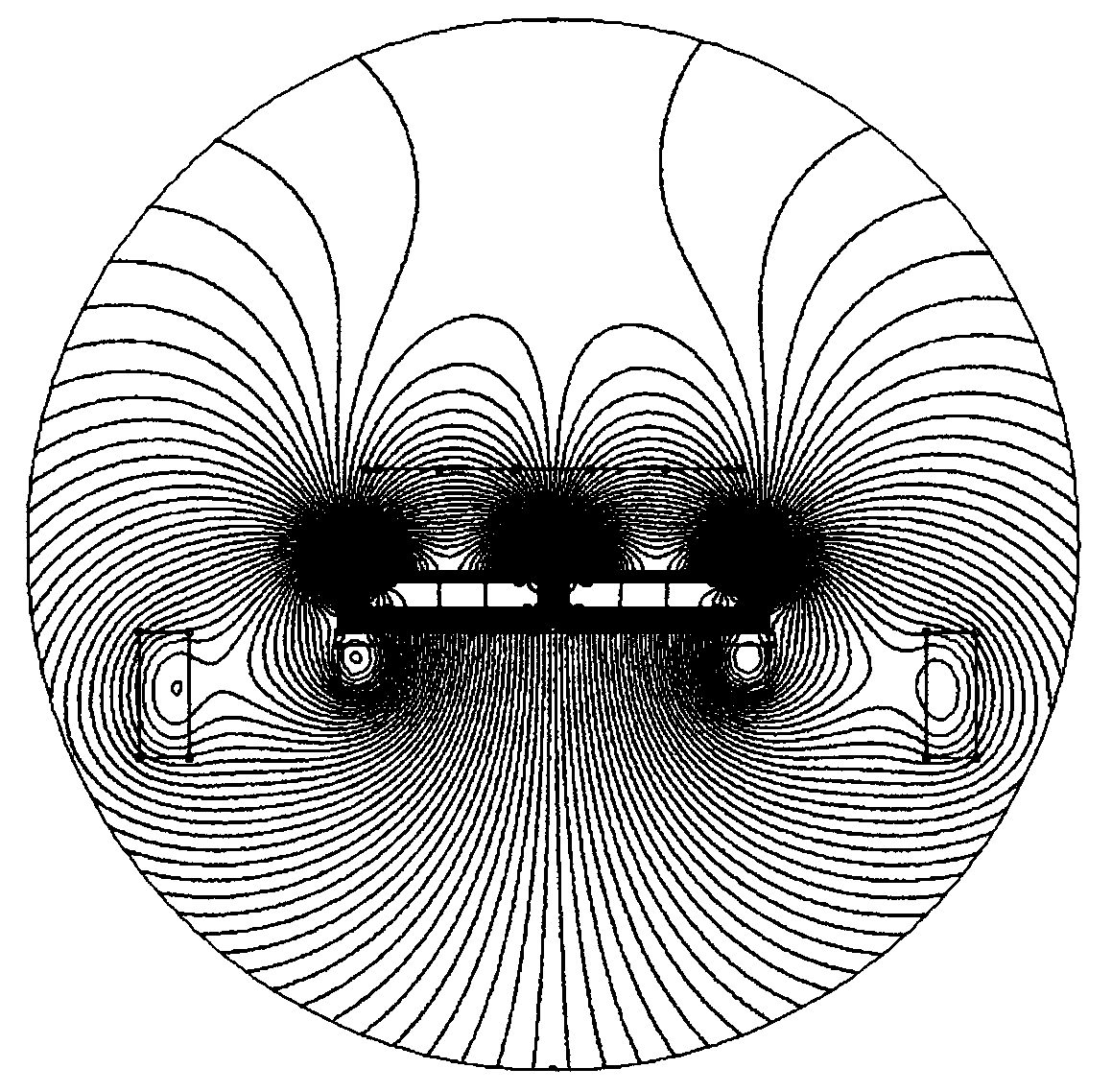

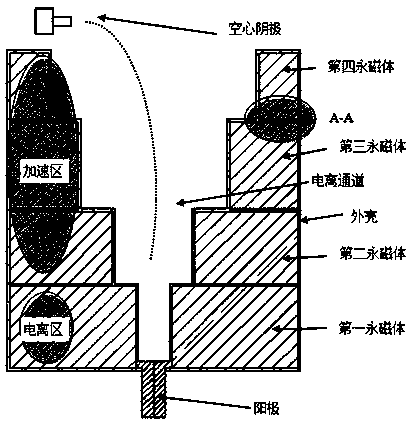

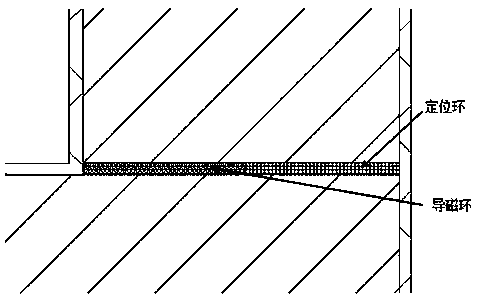

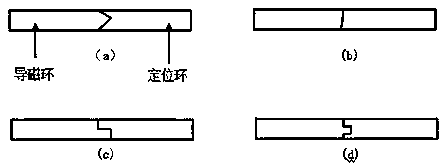

Cusped magnetic field plasma thruster

InactiveCN111536008AImprove working fluid utilizationFully ionizedMachines/enginesUsing plasmaEngineeringRight trapezoid

The invention relates to a cusped magnetic field plasma thruster. The technical problems to be solved are that a gas working medium cannot be sufficiently ionized at the position of a passageway wallface and cooling of a gas gap between the outer walls of magnets and the inner wall of a ceramic passageway is slow. In order to solve the technical problems, the thruster comprises an ionization passageway, permanent magnets, an anode, a hollow cathode, magnetic conductive rings, positioning rings and a shell. The longitudinal section of the side wall of the side, along the ionization passageway,of each permanent magnet is in a right trapezoid shape or a rectangular shape, and therefore the inner diameter, in the direction from the bottom of the ionization passageway to an outlet, of the ionization passageway is increased in a sequential discrete stair manner. Due to the adoption of the structure, electrons reciprocating between two magnetic tips at a high speed can be sufficiently ionized, and the technical effect that the gas working medium utilization rate is high is achieved. According to the cusped magnetic field plasma thruster, by arranging a heat exchange device on the thruster, the temperature of the gas gap between the outer walls of the magnets and the inner wall of the ceramic passageway is lowered, the paramagnetic phenomenon caused by the fact that temperature of the permanent magnets is too high is avoided, and the service life of the thruster is prolonged.

Owner:金群英

Arrangement and method for cooling a plasma-based radiation source

ActiveUS20150108365A1Prevent solidificationImprove cooling efficiencyScattering properties measurementsX-ray tube with very high currentNuclear engineeringControl cell

An arrangements and methods for cooling a plasma-based radiation source having a revolving element which is to be cooled, particularly for application in EUV radiation sources, is disclosed. The revolving element is immersed in the metal coolant in a first vessel of a primary cooling circuit, and a secondary cooling circuit with a cooling liquid evaporating at the desired operating temperature of the metal coolant has a control unit for controlling at least one atomizing arrangement in a differentiated manner and for selectively controlling a heater in case the determined temperature falls below a minimum operating temperature of the metal coolant. The at least one atomizing arrangement in a cooling section selectively sprays individual wall regions of the first vessel with the cooling liquid depending on the determined temperature of the metal coolant.

Owner:USHIO DENKI KK

Method for micro-wave plasma low-temperature synthesizing film

InactiveCN101024893APromote excitationImprove stabilityPolycrystalline material growthFrom condensed vaporsProduct gasMicrowave power

The invention is a method for synthesizing diamond membrane at low temperature by microwave plasma, comprising the steps of: charging Ar and H2 gases into a microwave plasma synthesizing cavity; at a microwave power of 600-750W and a gas pressure of 900-1100Pa, ionizing the gases into plasma; when the plasma is stable, charging CH4 gas into the plasma cavity and able to implement deposition of diamond membrane without intensifying external magnetic field. And the method has advantages of simple process, easy to implement, high deposition rate, etc.

Owner:WUHAN UNIV OF TECH

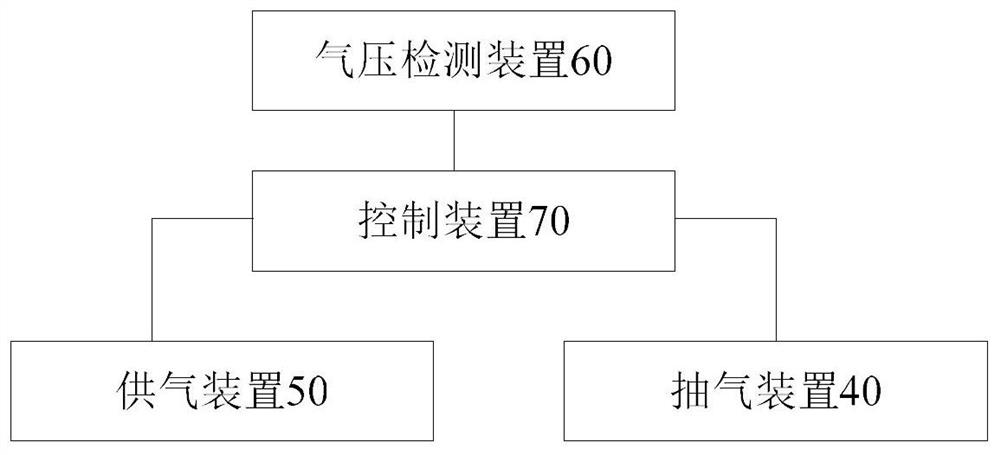

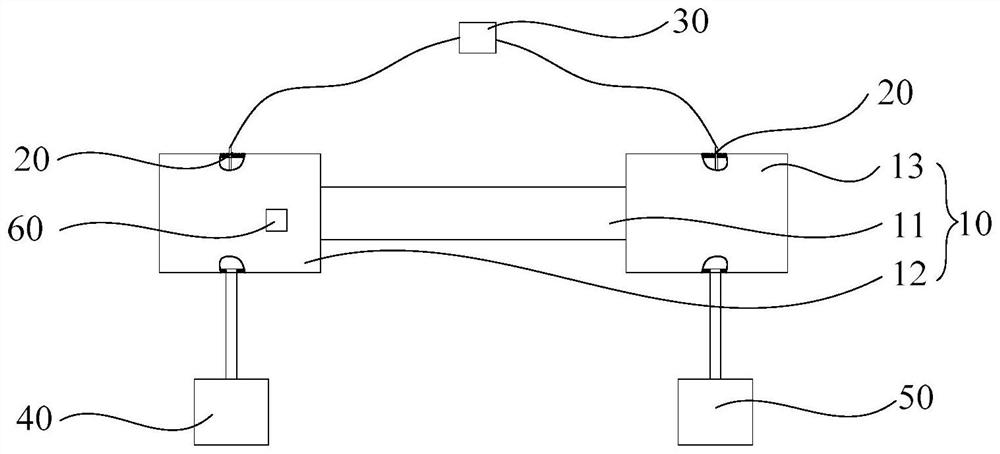

Plasma generating device and method

ActiveCN112188715AAvoid fatigueStable ionization mediumNuclear energy generationPlasma techniqueVoltage pulseEngineering

The invention provides a plasma generating device and method, and the device comprises a reaction housing, two electrodes with opposite polarities, an air extractor, an air supply device, an air pressure detection device, and a control device. According to the plasma generating device provided by the invention, the air extractor strongly and rapidly extracts air in the reaction chamber at a firstrate; when the reaction chamber reaches a first set air pressure, gas for ionization is provided for the reaction chamber through the air supply device, and when the reaction chamber reaches a secondset air pressure, the high-voltage pulse power supply supplies power to the two electrodes so as to ionize the gas, so that plasma is generated in the reaction chamber; the air extractor continuouslyand slowly extracts the gas in the reaction chamber at a second rate, and the ionized gas slowly and dynamically flows in the reaction chamber in a balanced manner, so that low-pressure gas flow withrelatively stable density is generated in the reaction chamber, the fatigue of the ionized gas is prevented; and meanwhile, a relatively stable plasma ionization medium is provided.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

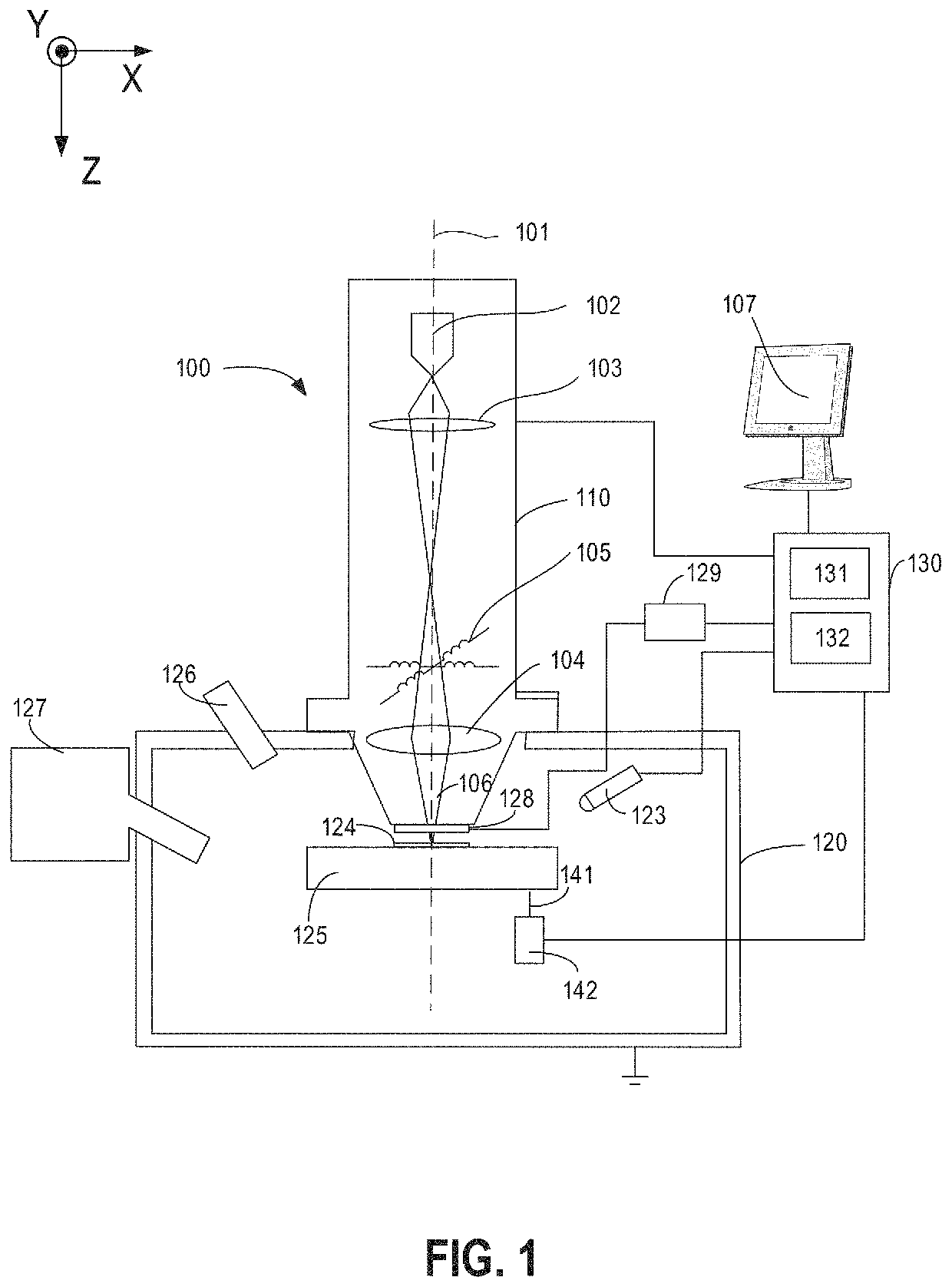

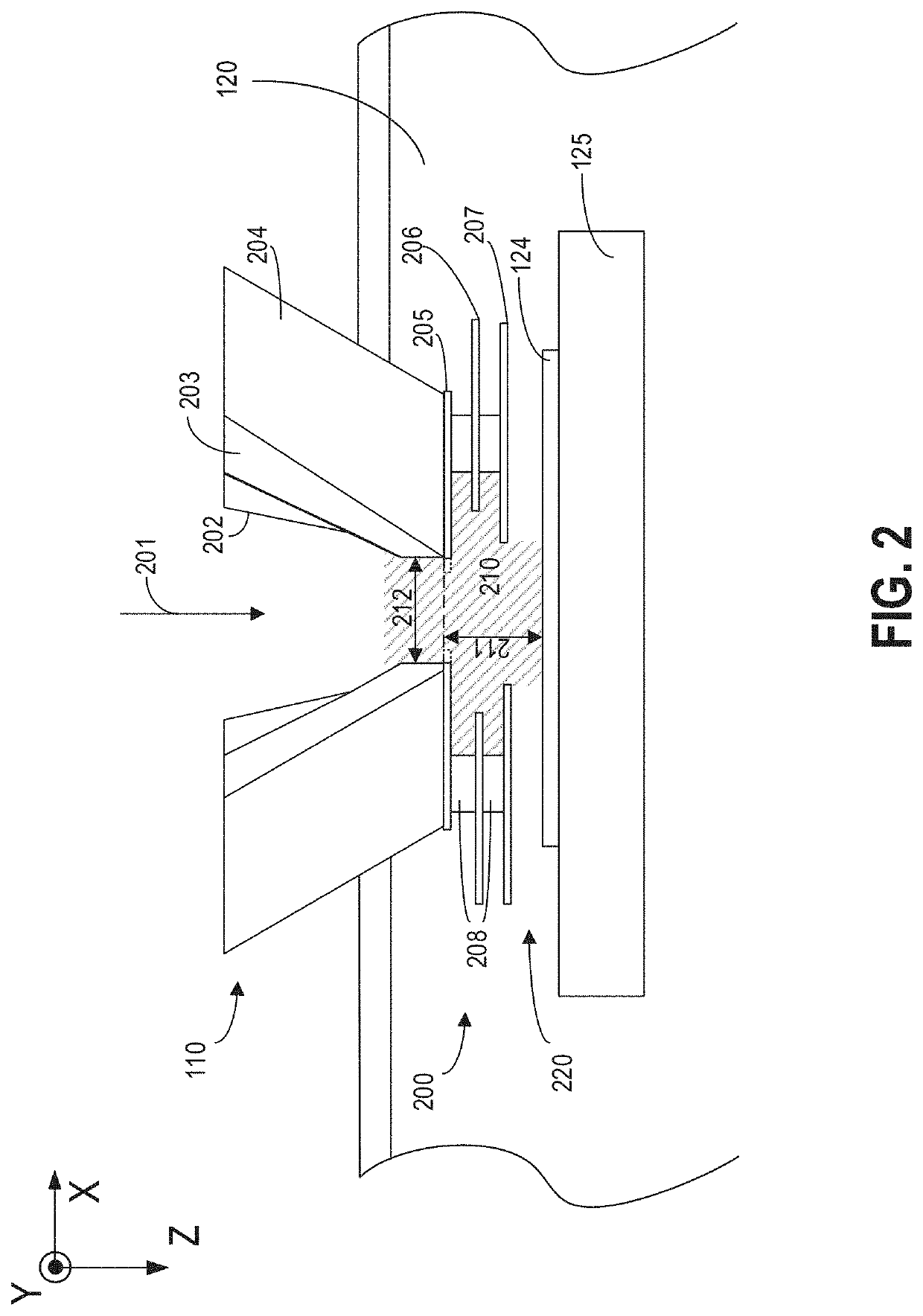

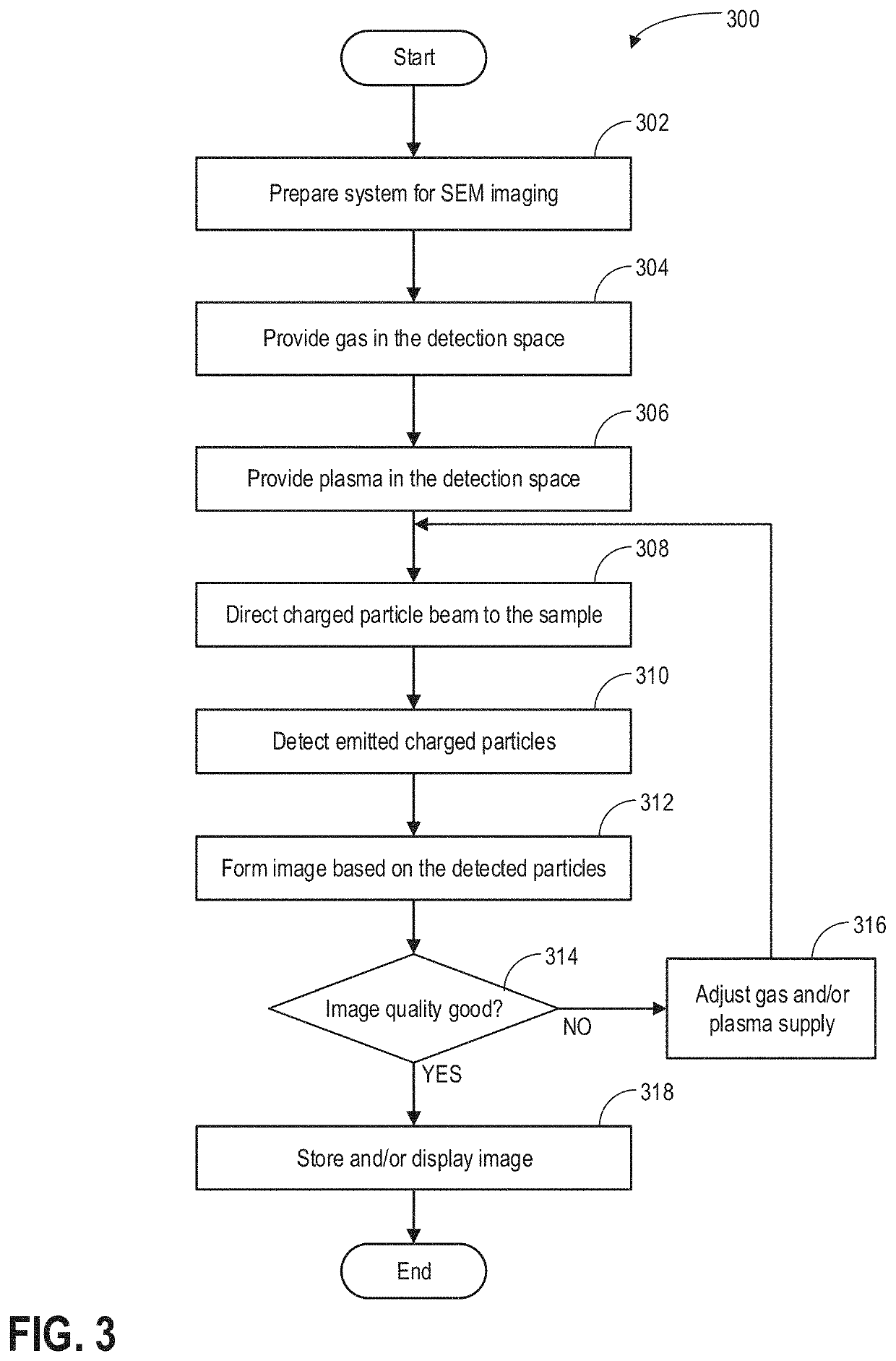

Method and system for plasma assisted low vacuum charged-particle microscopy

ActiveUS11152189B2Improve image qualityIncreased detector gainMaterial analysis using wave/particle radiationElectric discharge tubesParticle beamSample image

Various methods and systems are provided for imaging a sample under low vacuum with a charged particle beam. A magnetic field is provided in a detection area of the detector. Gas and plasma are provided in the detection area while detecting charged particles emitted from the sample. Sample image is formed based on the detected charged particles.

Owner:FEI CO

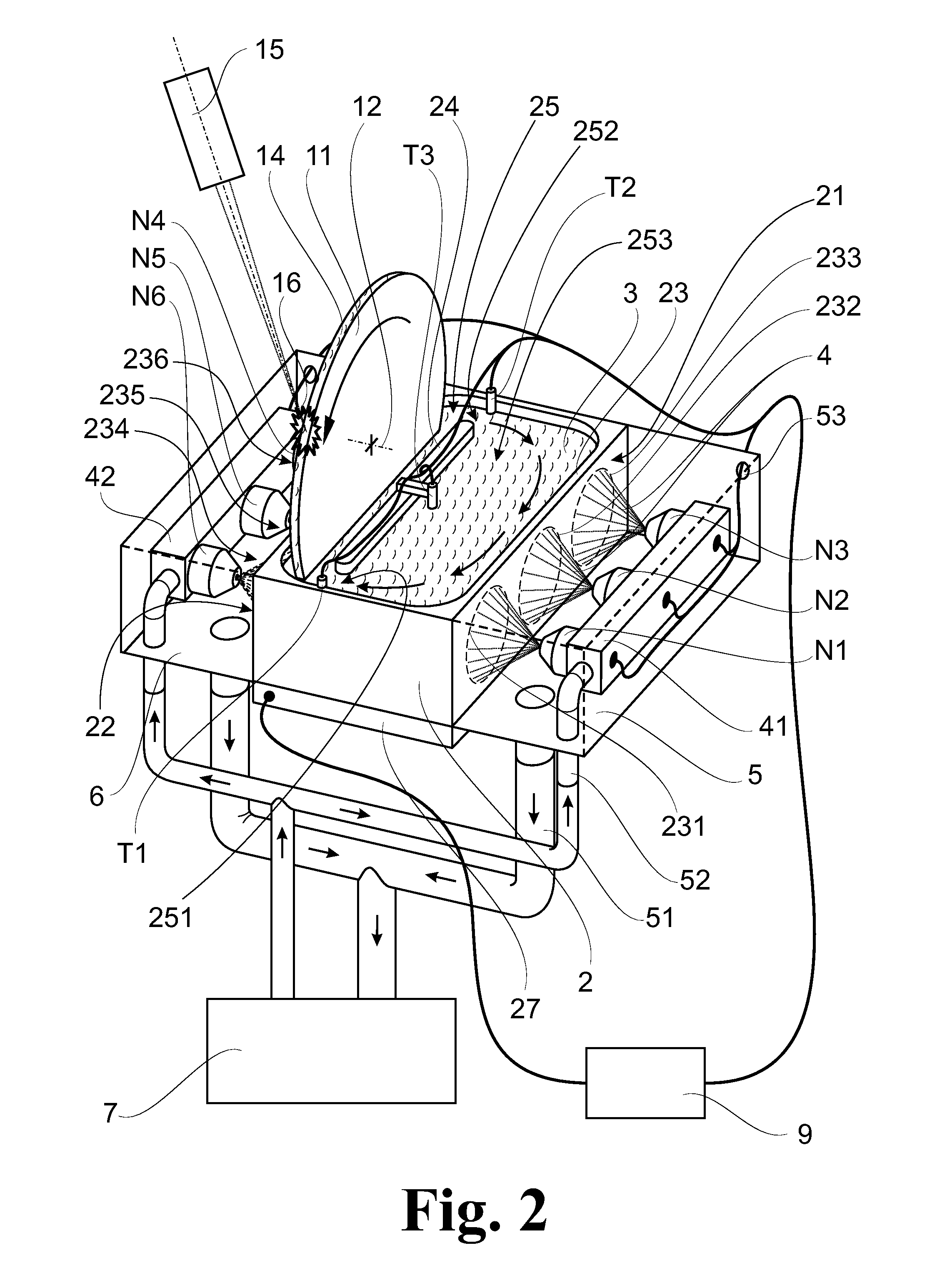

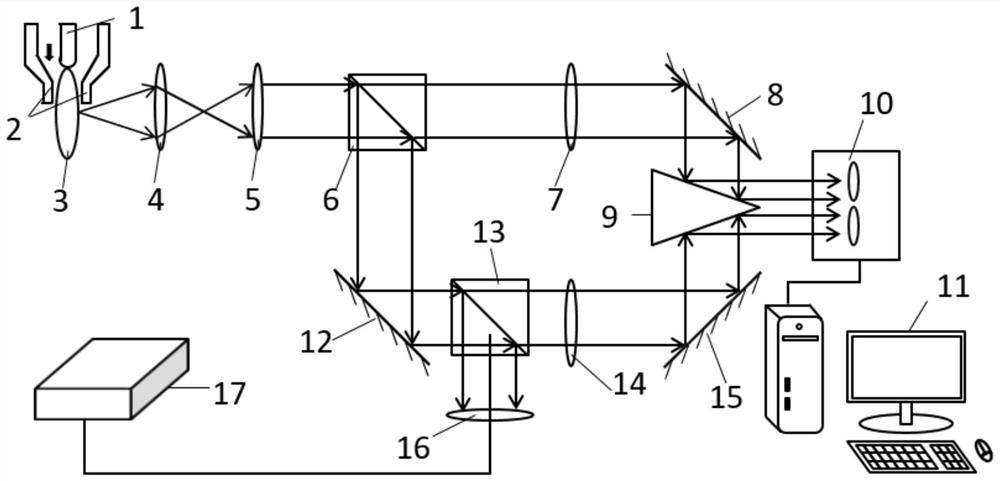

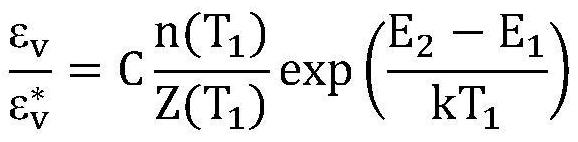

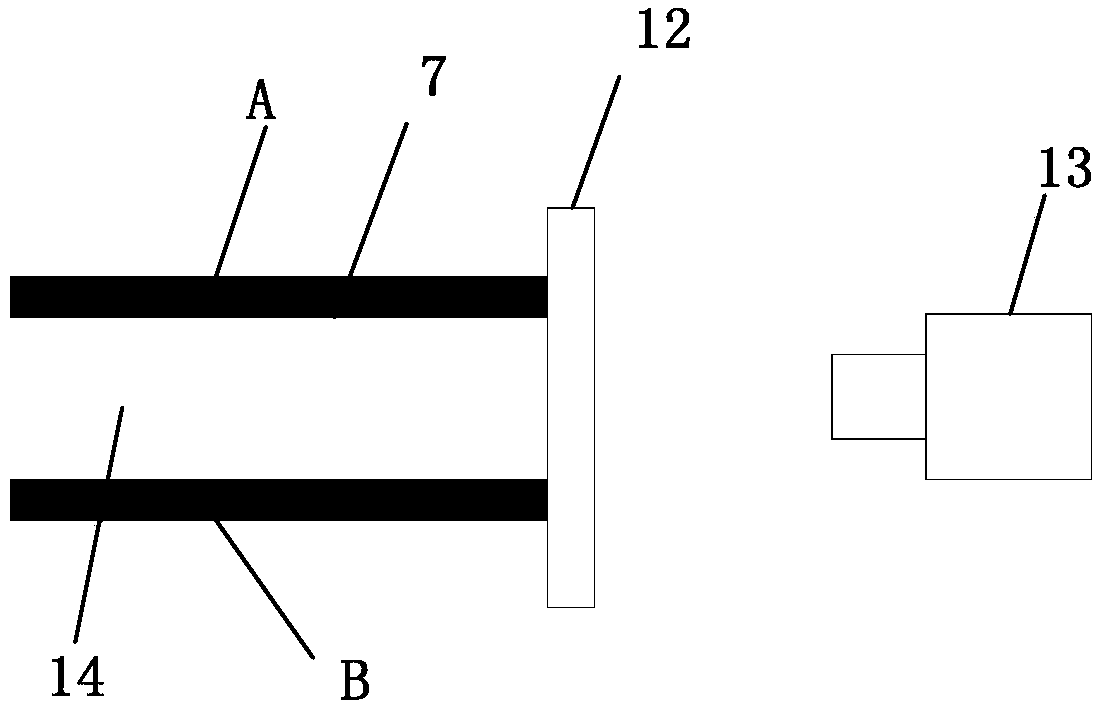

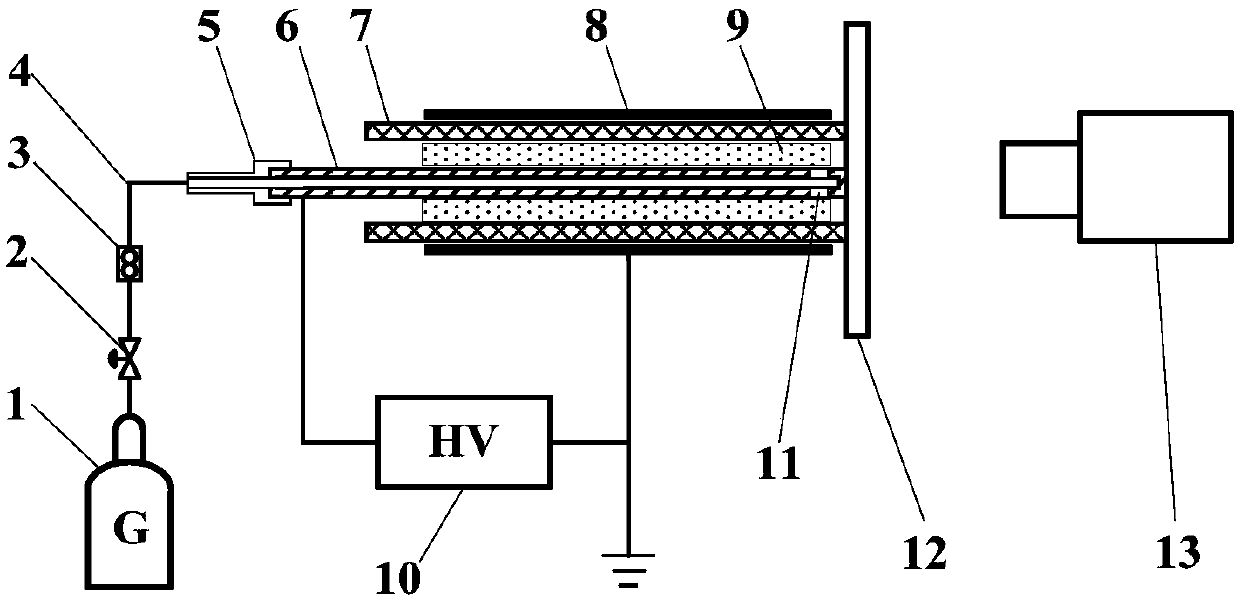

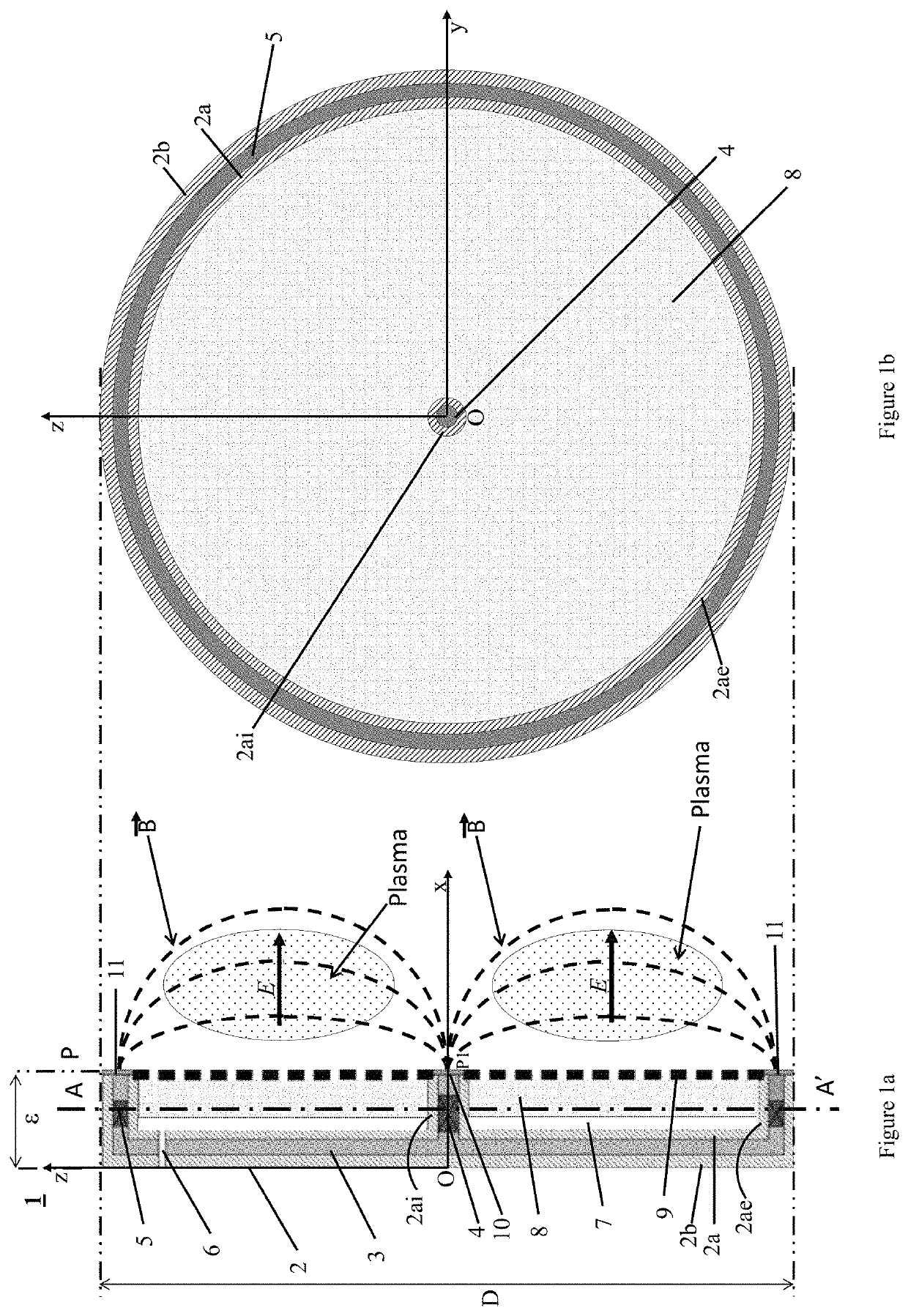

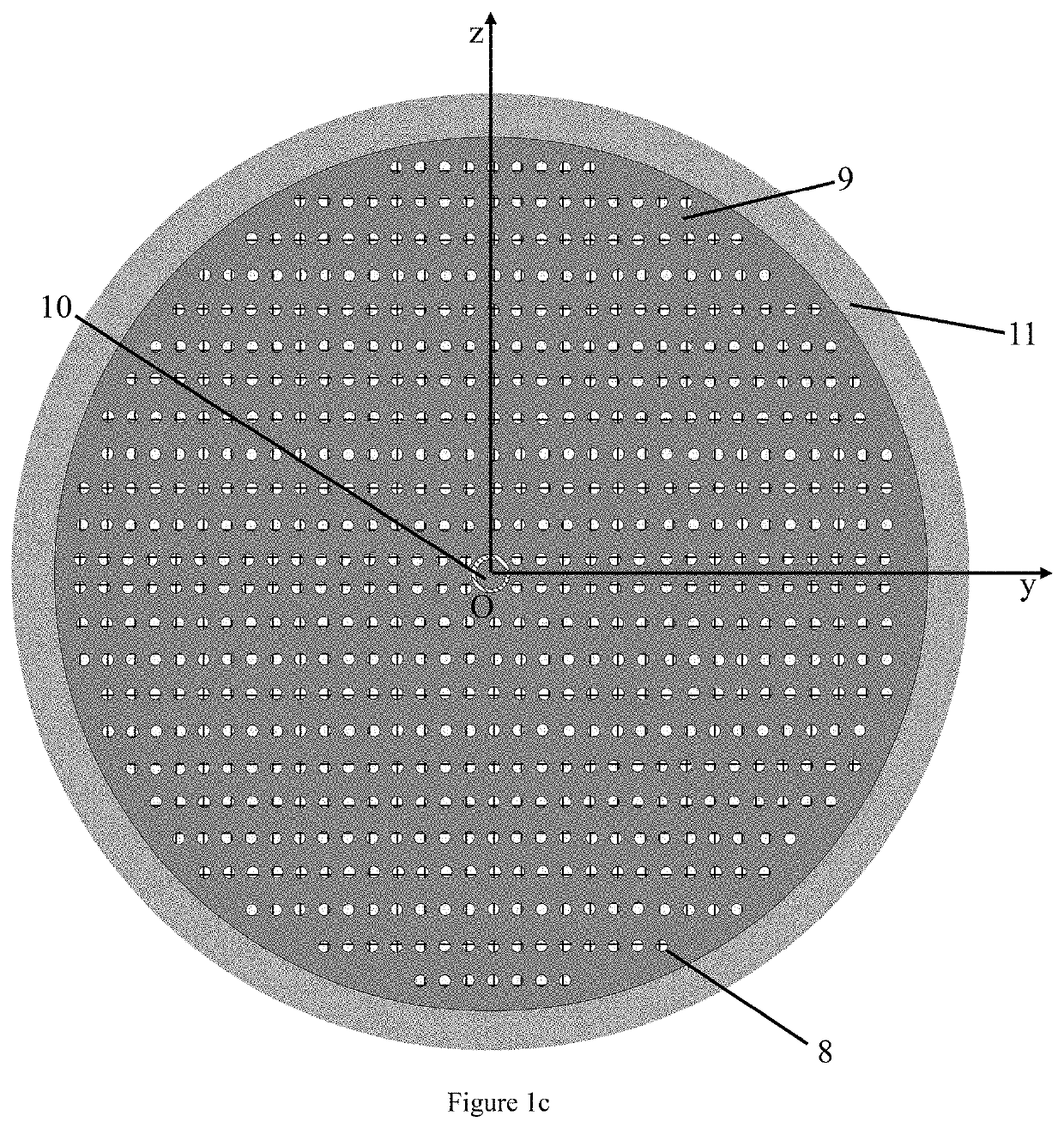

Method for synchronously diagnosing plasma temperature field through adoption of standard temperature method and relative spectral line method

ActiveCN112729555AImprove accuracyWide diagnostic temperature rangeRadiation pyrometryEngineeringPlasma

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

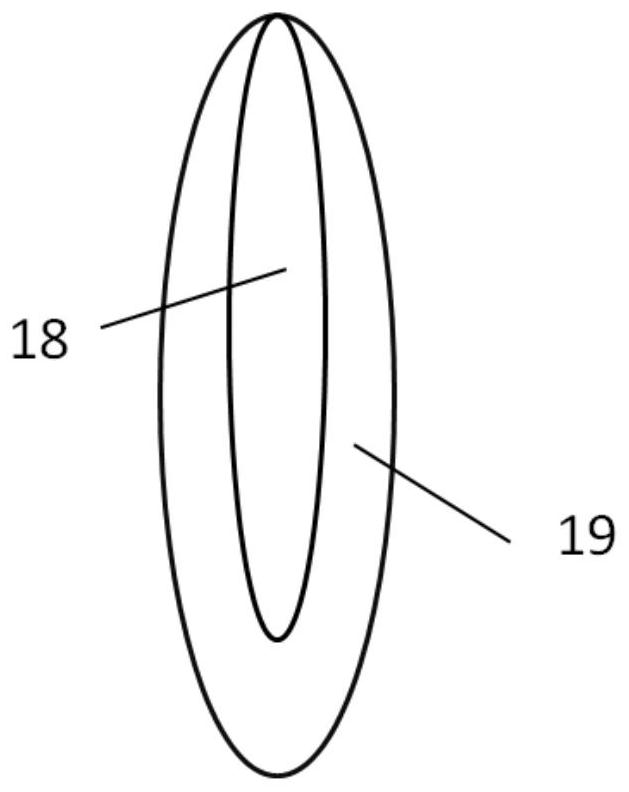

Plasma temperature distribution measurement system

The invention relates to the technical field of plasmas, and specifically relates to a plasma temperature distribution measurement system. The system comprises a plasma generating module and an infrared measurement module, wherein the plasma generating module comprises a positive electrode, a negative electrode and an insulating barrier medium, the positive electrode and the negative electrode areoppositely arranged, the insulating barrier medium is arranged between the positive electrode and the negative electrode in a spaced mode, the insulating barrier medium forms a cavity with an openingin one side, and at least one of the other side surfaces of the cavity is blocked by an infrared-transmitting blocking material; and the infrared measurement module is arranged at a position which isseparated from the side surface, which is blocked by the infrared-transmitting blocking material, of the cavity by a preset distance, and is used for measuring infrared distribution of plasmas generated in the cavity so as to measure temperature distribution of the plasmas. The plasma temperature distribution measurement system can measure the temperature distribution of the plasmas by measuringthe infrared distribution of the plasmas, so that non-destructive and accurate temperature distribution measurement can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com