Patents

Literature

1681results about How to "Prevent solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

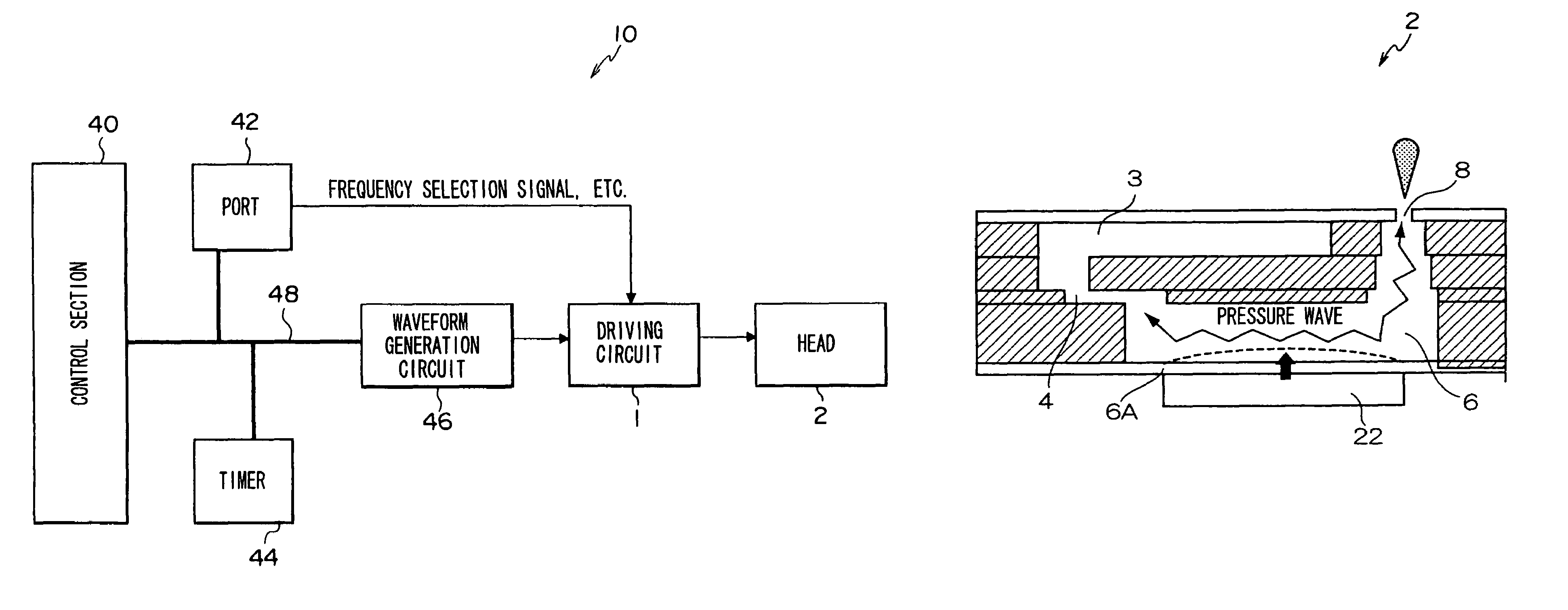

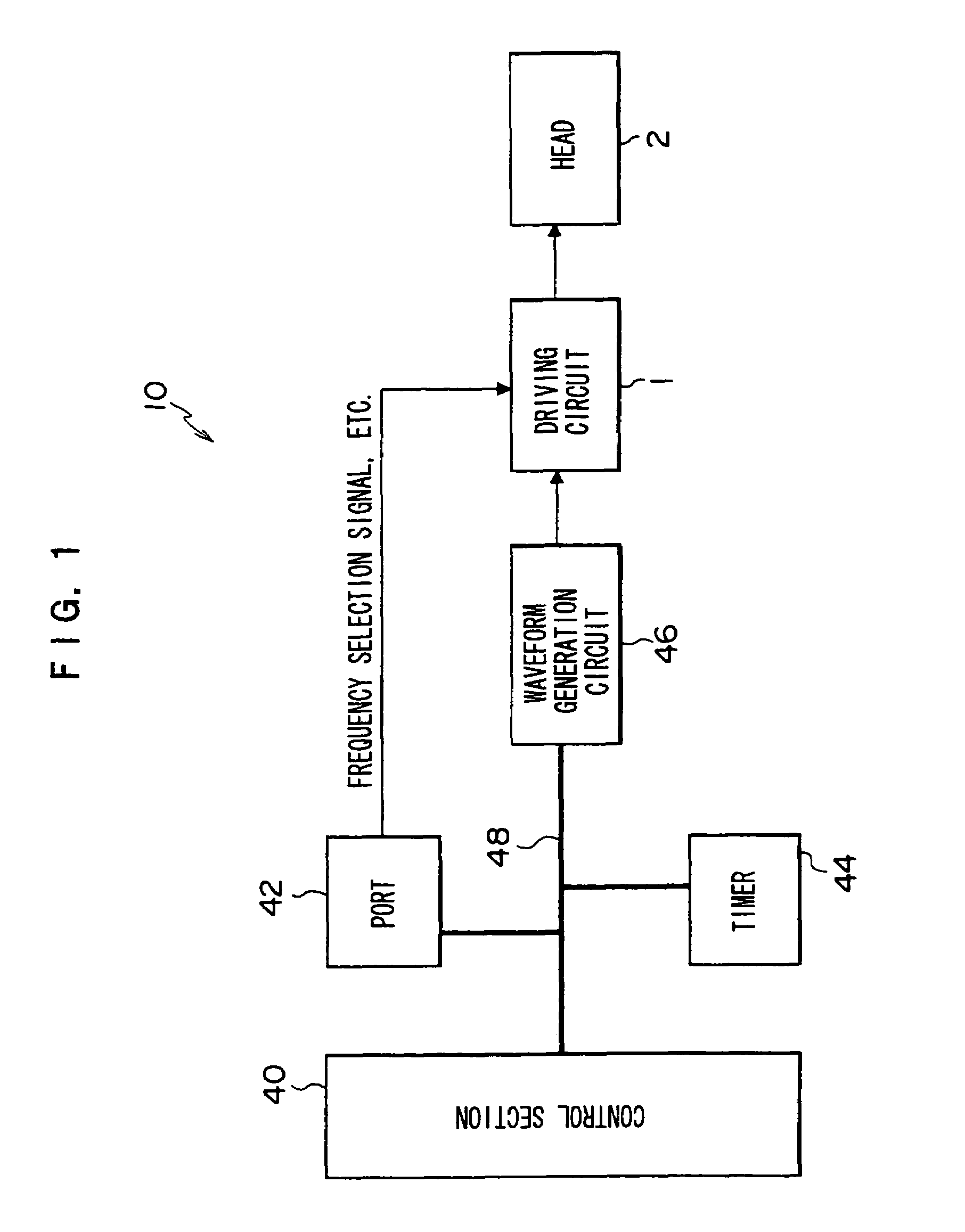

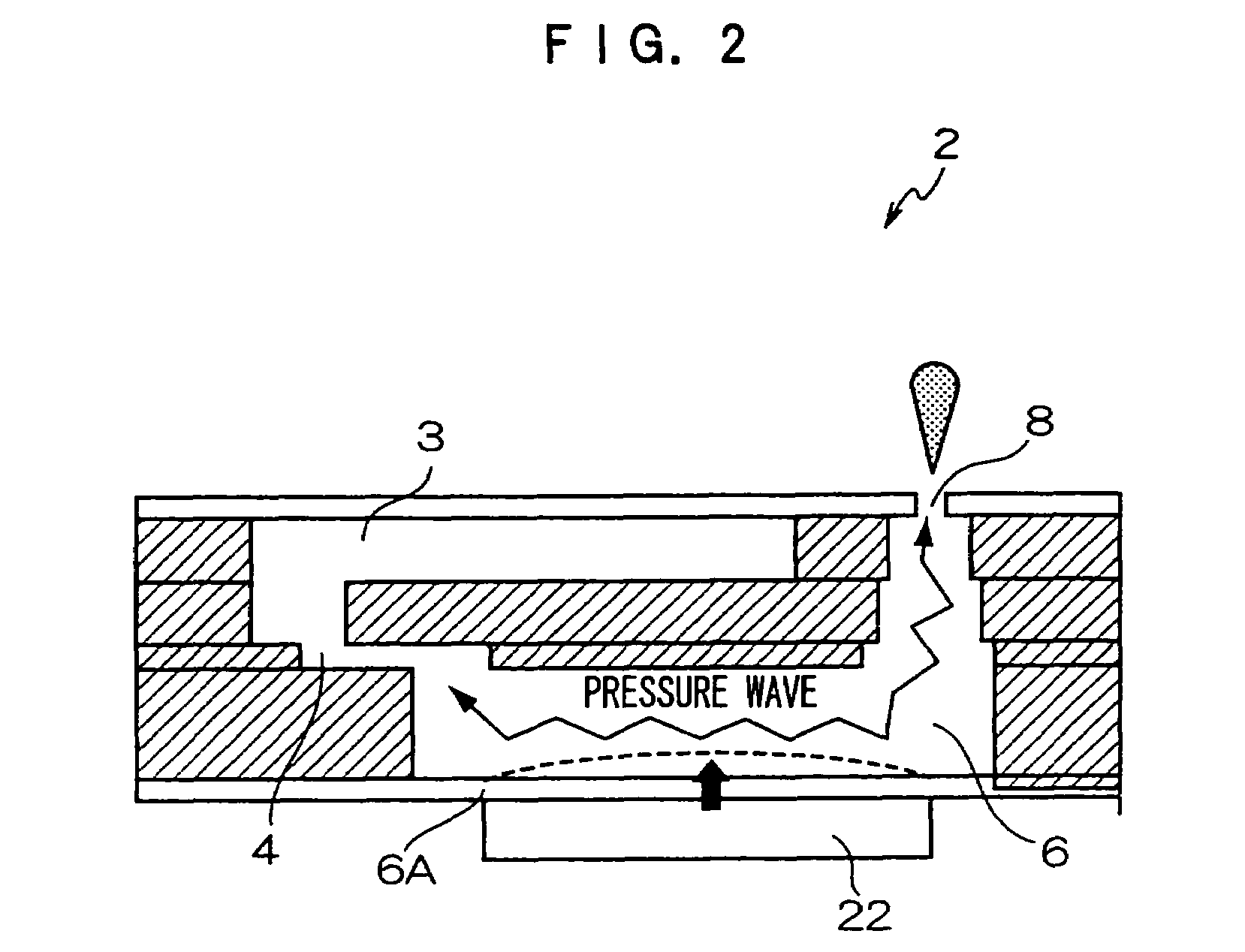

Droplet ejection head driving circuit and method, and droplet ejection device

InactiveUS20070165074A1Reduce power consumptionPrevent solidification of inkPrintingDriven elementFrequency selection

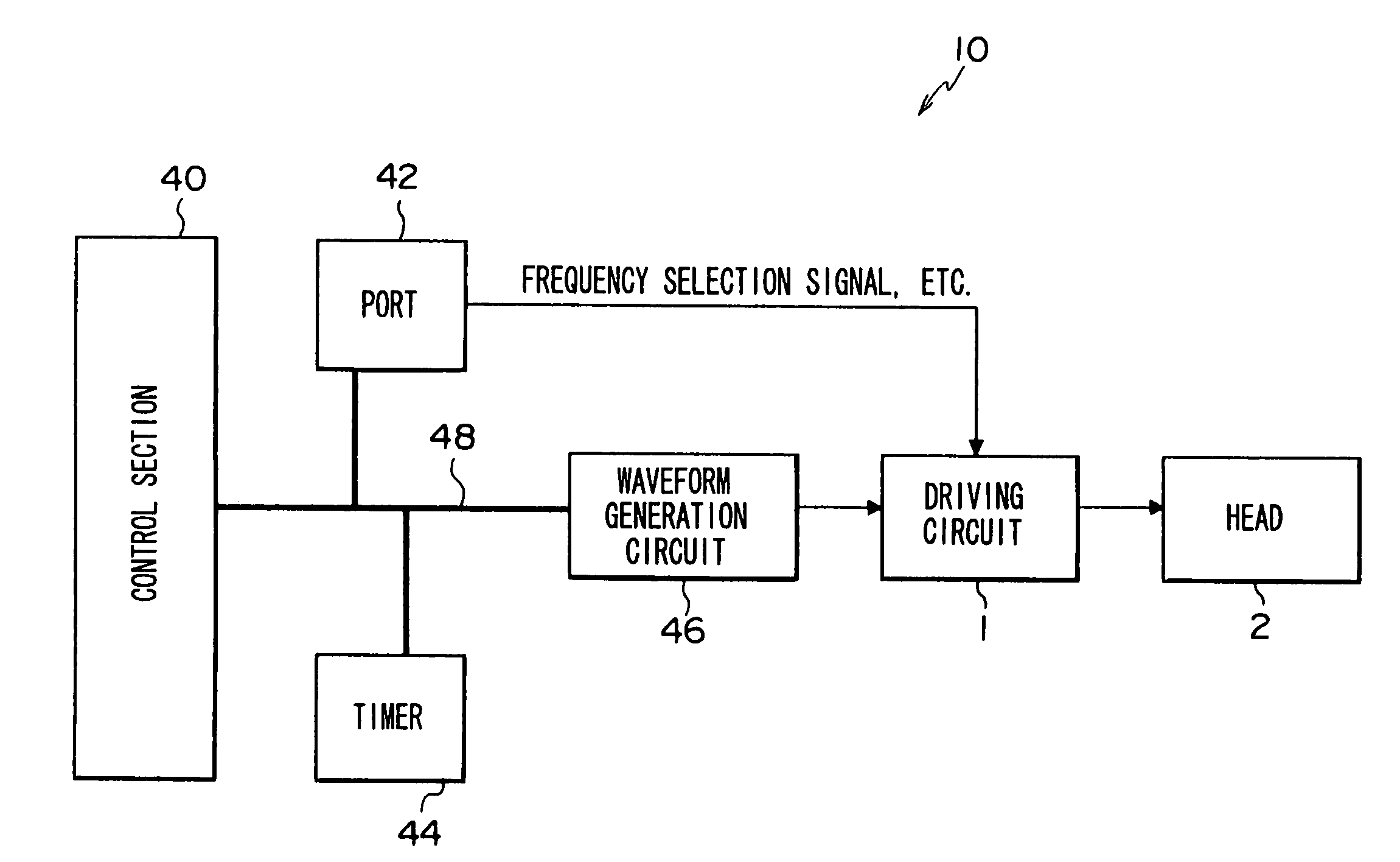

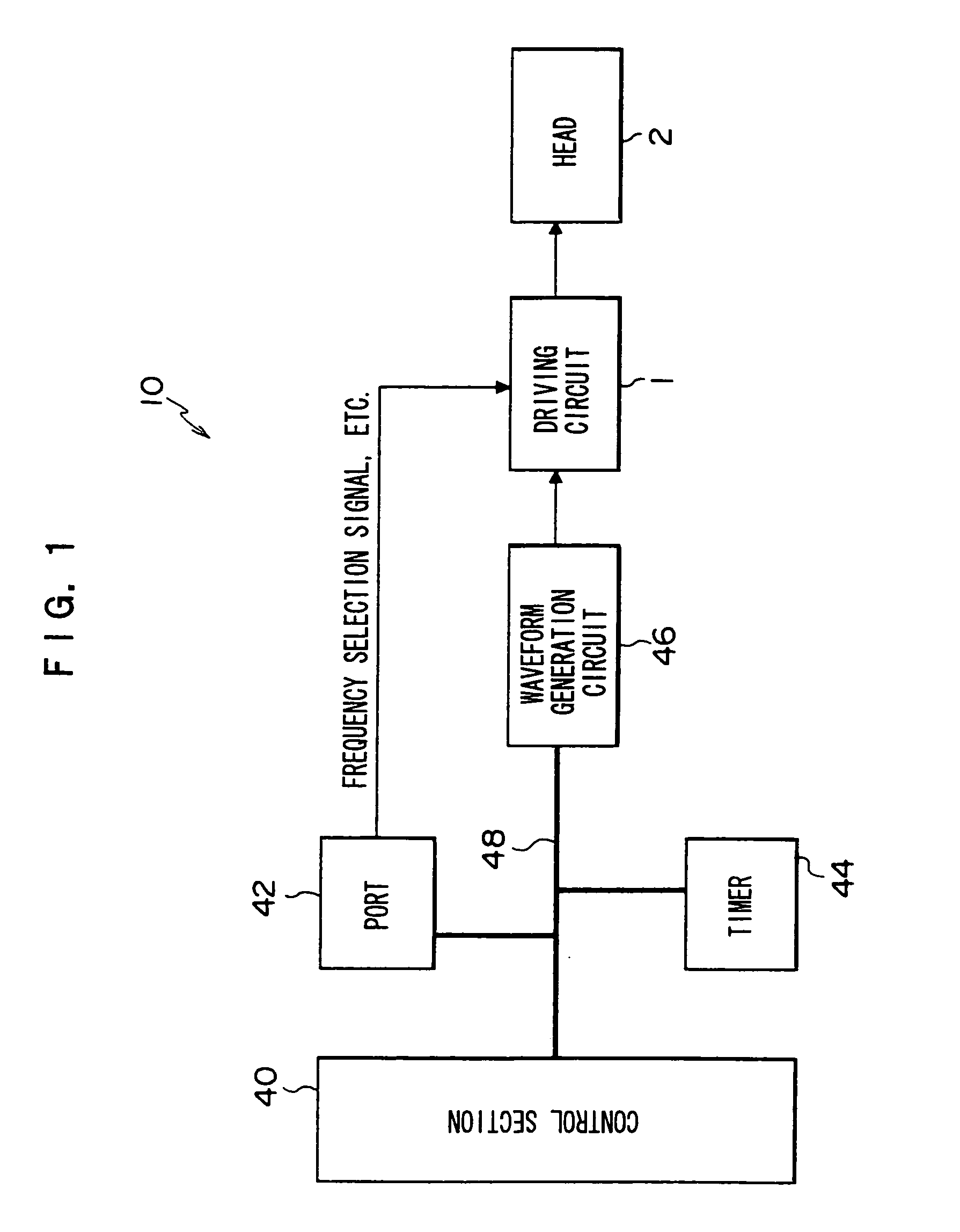

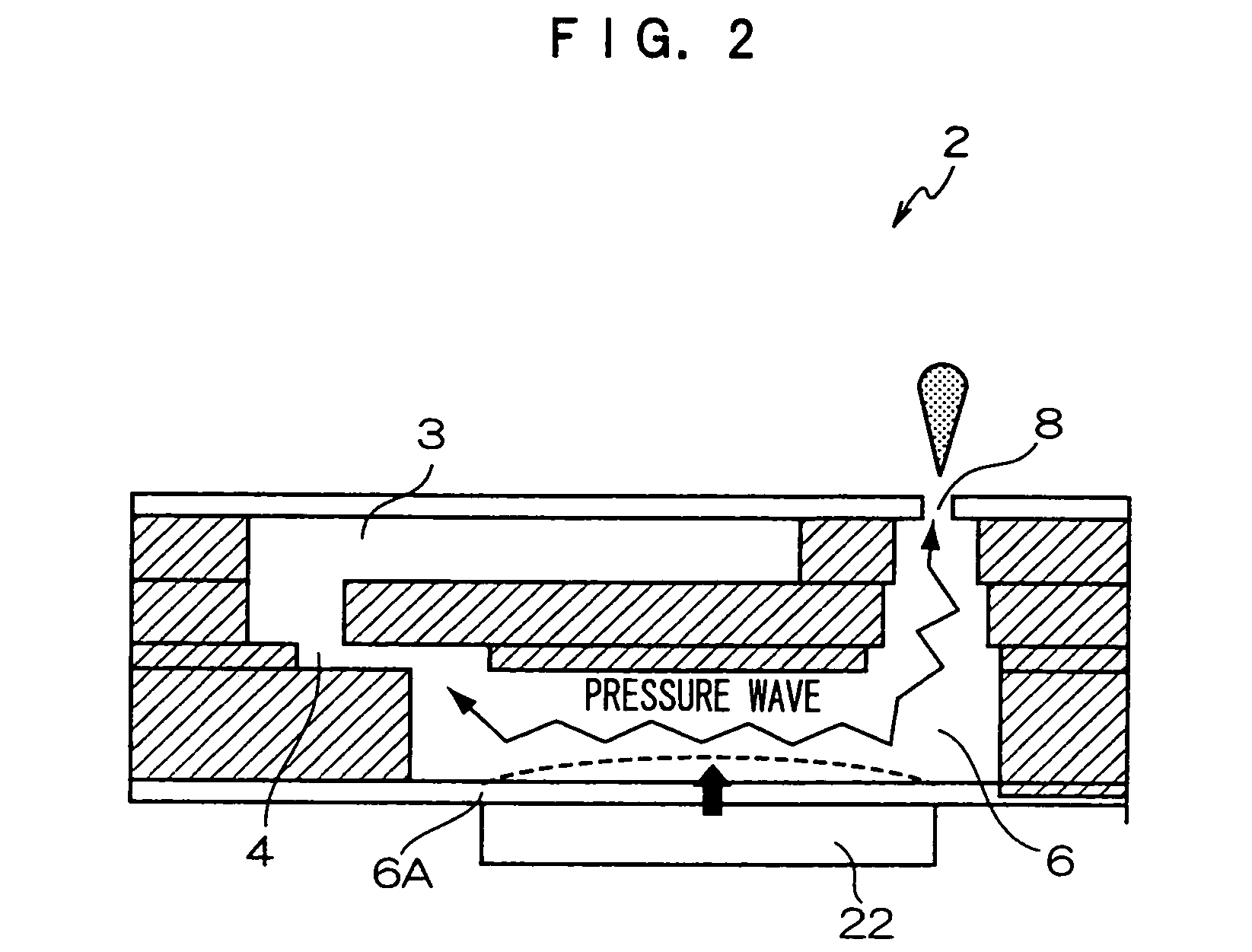

A driving circuit of a droplet ejection head which, by supplying analog driving signals to driving elements, ejects droplets from nozzles which are provided in correspondence with the driving elements. The driving circuit includes a driving signal generation unit, a pulse modulation unit, a switching signal generation unit, an amplification unit and a frequency-setting unit. The driving signal generation unit selectively outputs a first and a second analog driving signal. The pulse modulation unit pulse-modulates the analog driving signal and outputs a digital signal. The switching signal generation unit generates a switching signal. The amplification unit amplifies the digital signal by switching in accordance with the switching signal, and supplies the amplified digital signal to the driving elements. The frequency-setting unit sets a switching frequency of the switching signal in accordance with a frequency selection signal, which corresponds to the analog driving signal.

Owner:FUJIFILM BUSINESS INNOVATION CORP

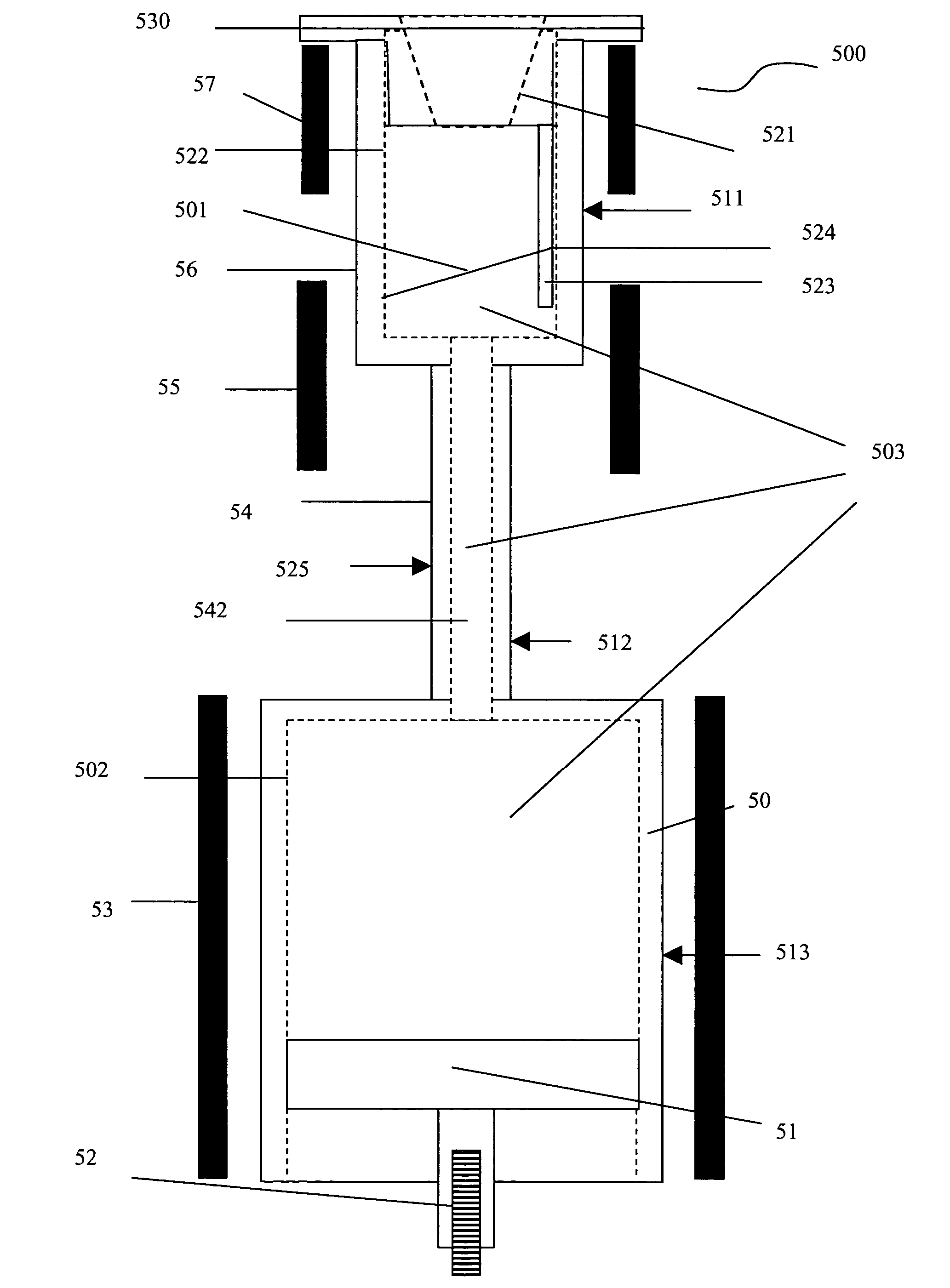

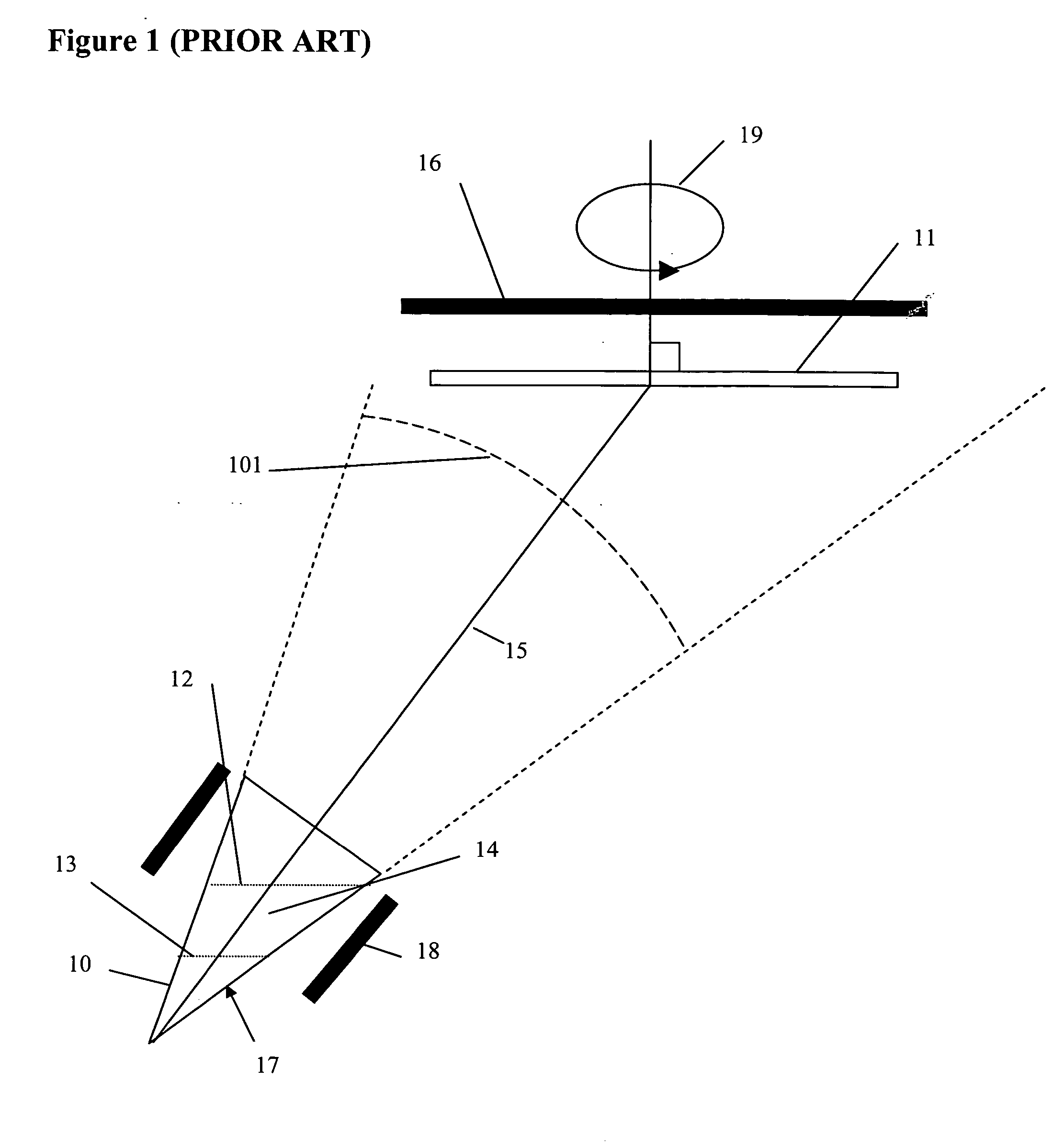

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

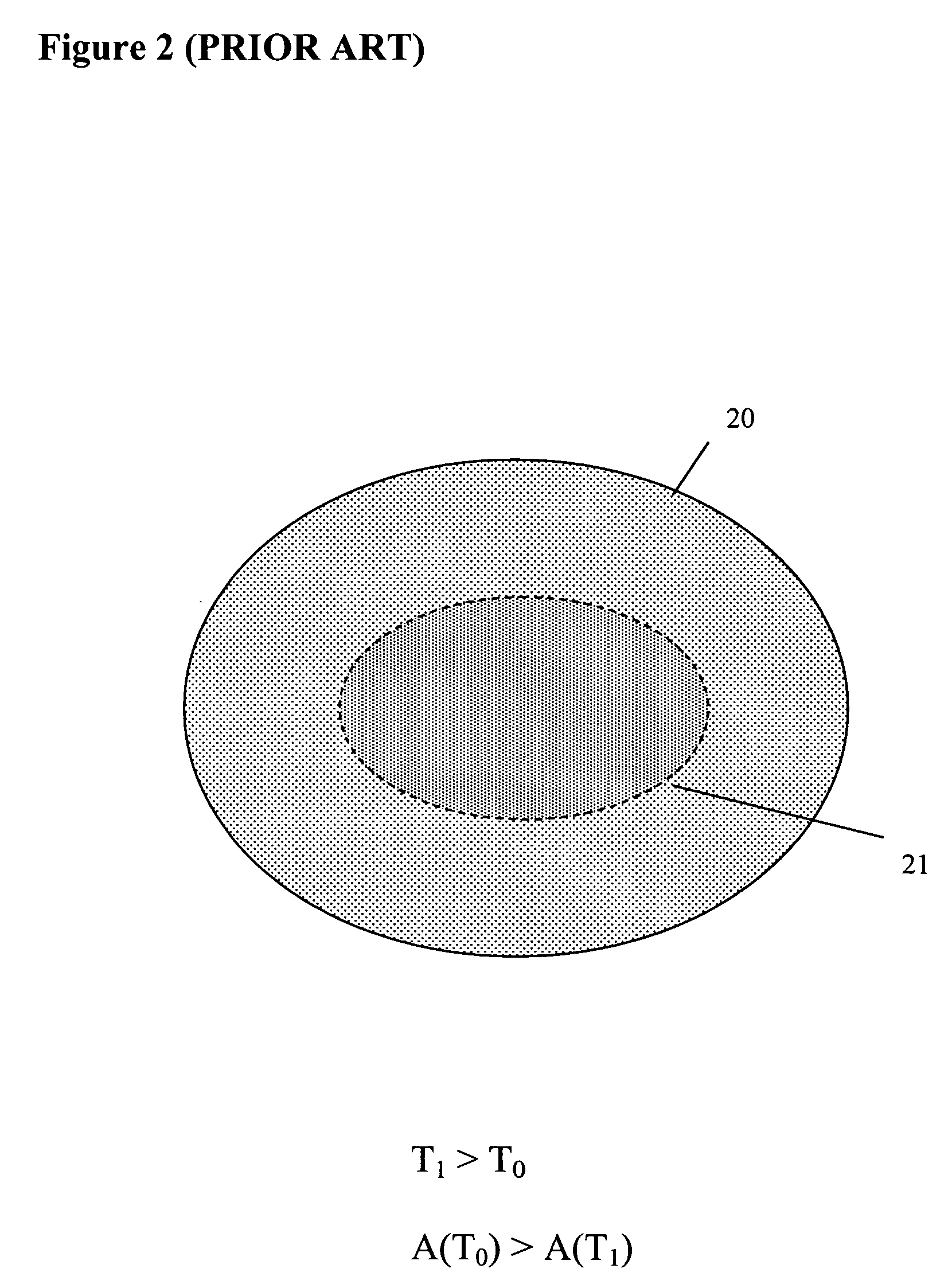

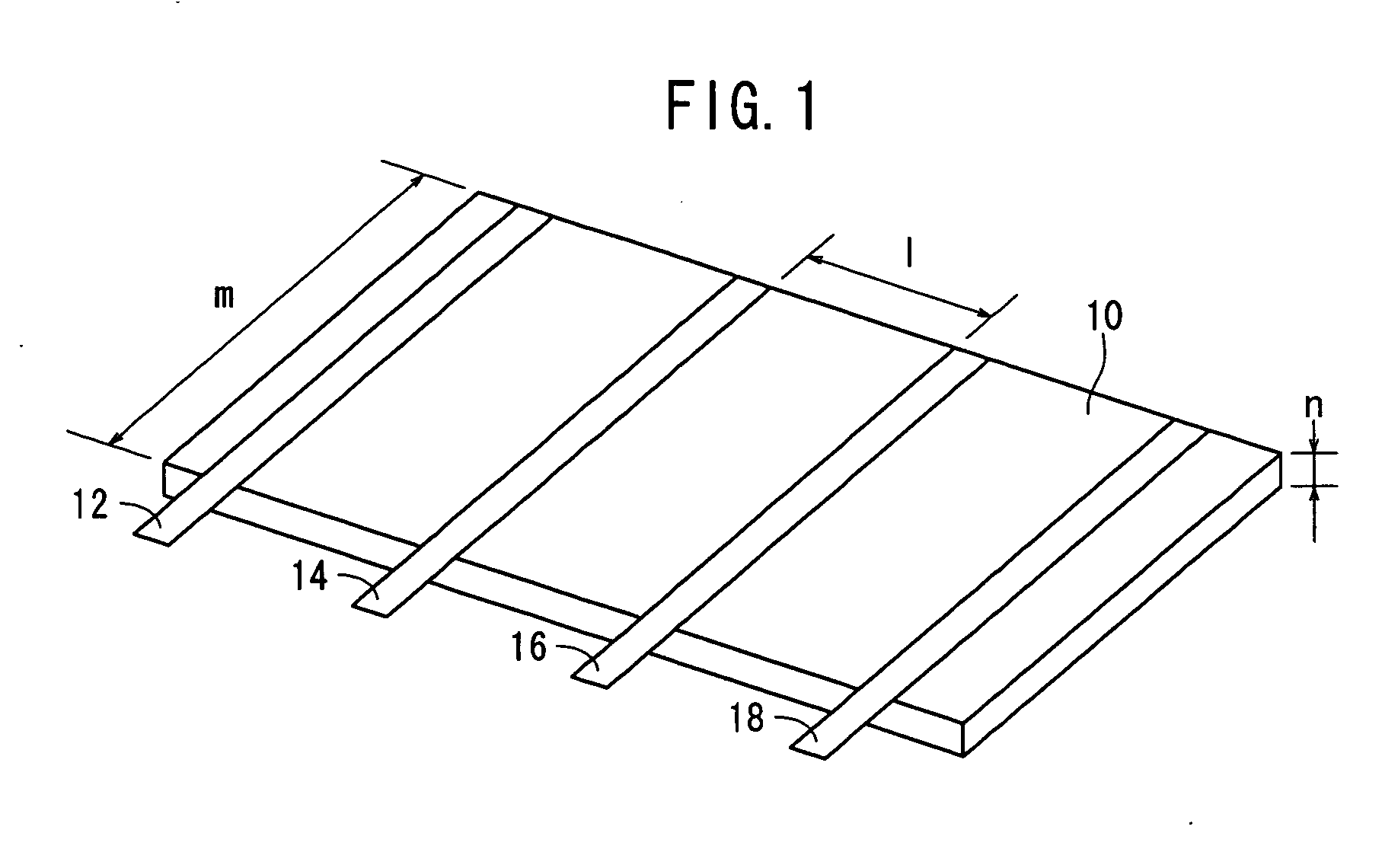

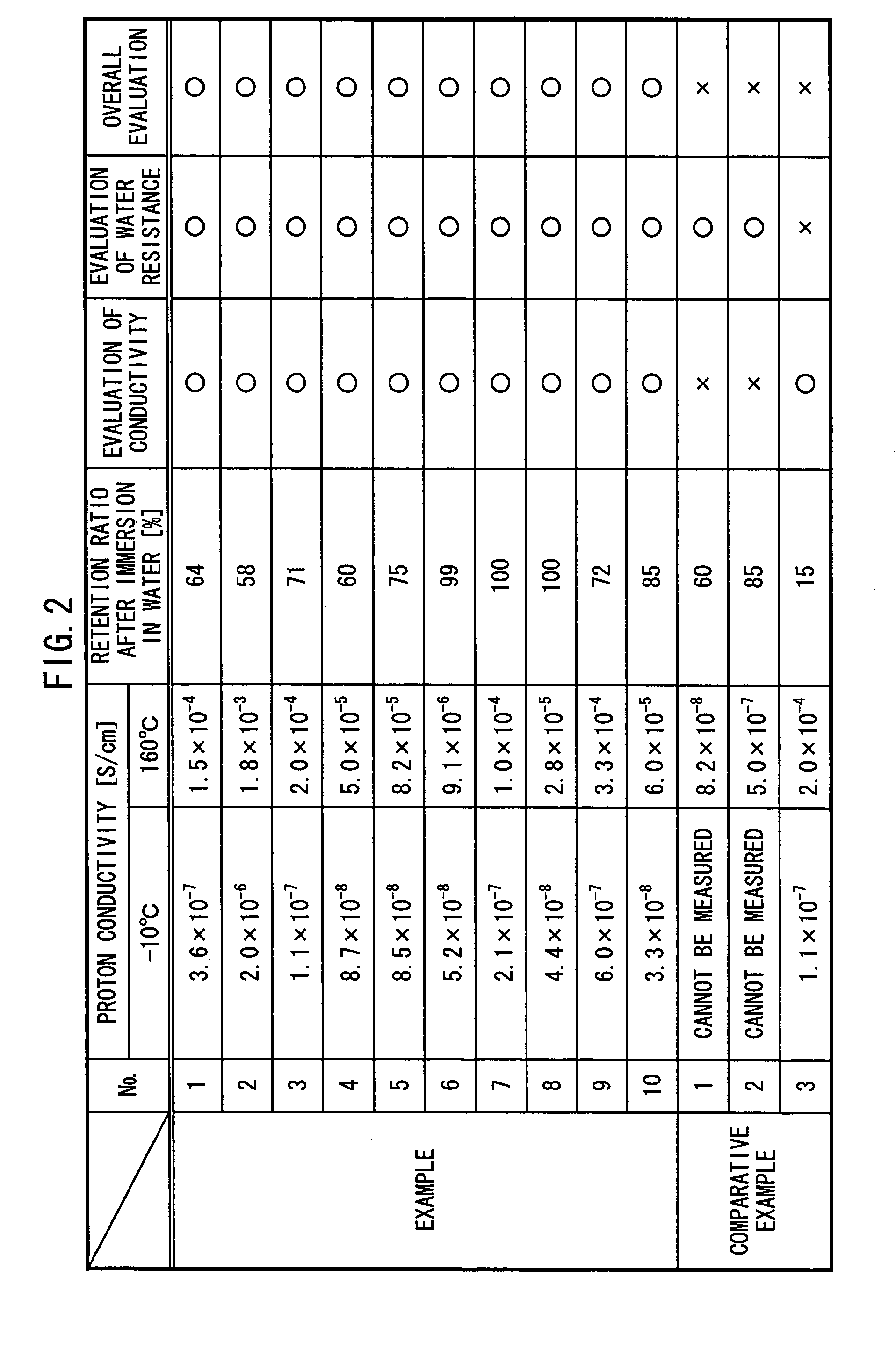

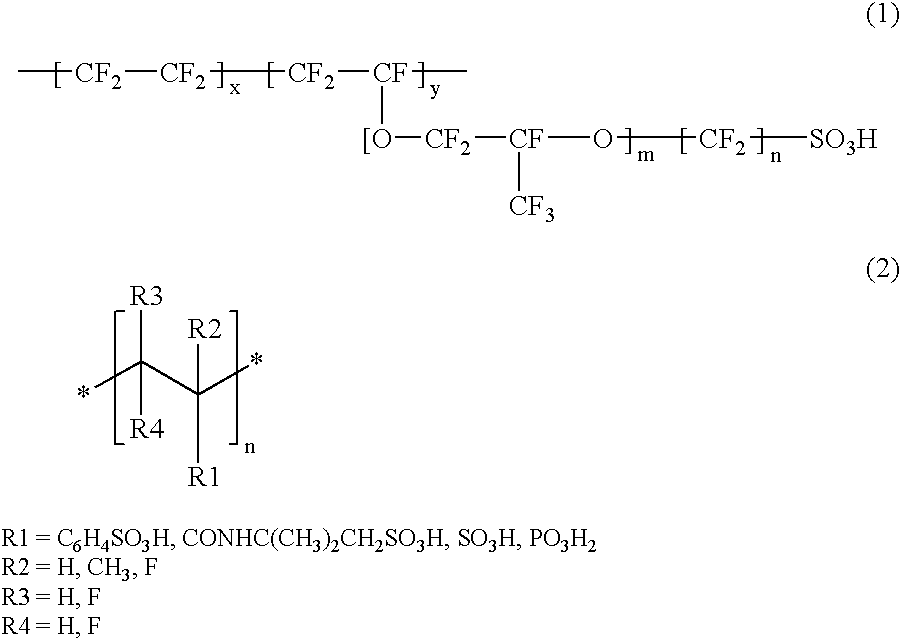

Proton conductor

InactiveUS20050197467A1Easy to evaporateExcellent proton conductionSolid electrolytesConductive materialSimple Organic CompoundsElectrical conductor

An acidic group-containing polymer which has an acidic group such as sulfonic acid group, phosphoric acid group, and phosphonic acid group, and a proton acceptor which has a boiling point at 1 atmosphere higher than 100° C. and which functions as a medium for conducting proton dissociated from the acidic group are retained in pores of a porous member. Preferred examples of the proton acceptor include a salt structure composed of an anion and a cation derived from a basic organic compound, a basic organic compound, and a dissociation-facilitating polymer which facilitates dissociation of proton. Any one of the acidic group-containing polymer and the proton acceptor may be retained first, or both may be retained simultaneously.

Owner:HONDA MOTOR CO LTD

Droplet ejection head driving circuit and method, and droplet ejection device

InactiveUS7571989B2Prevent solidificationReduce power consumptionPrintingSwitching signalEngineering

A driving circuit of a droplet ejection head which, by supplying analog driving signals to driving elements, ejects droplets from nozzles which are provided in correspondence with the driving elements. The driving circuit includes a driving signal generation unit, a pulse modulation unit, a switching signal generation unit, an amplification unit and a frequency-setting unit. The driving signal generation unit selectively outputs a first and a second analog driving signal. The pulse modulation unit pulse-modulates the analog driving signal and outputs a digital signal. The switching signal generation unit generates a switching signal. The amplification unit amplifies the digital signal by switching in accordance with the switching signal, and supplies the amplified digital signal to the driving elements. The frequency-setting unit sets a switching frequency of the switching signal in accordance with a frequency selection signal, which corresponds to the analog driving signal.

Owner:FUJIFILM BUSINESS INNOVATION CORP

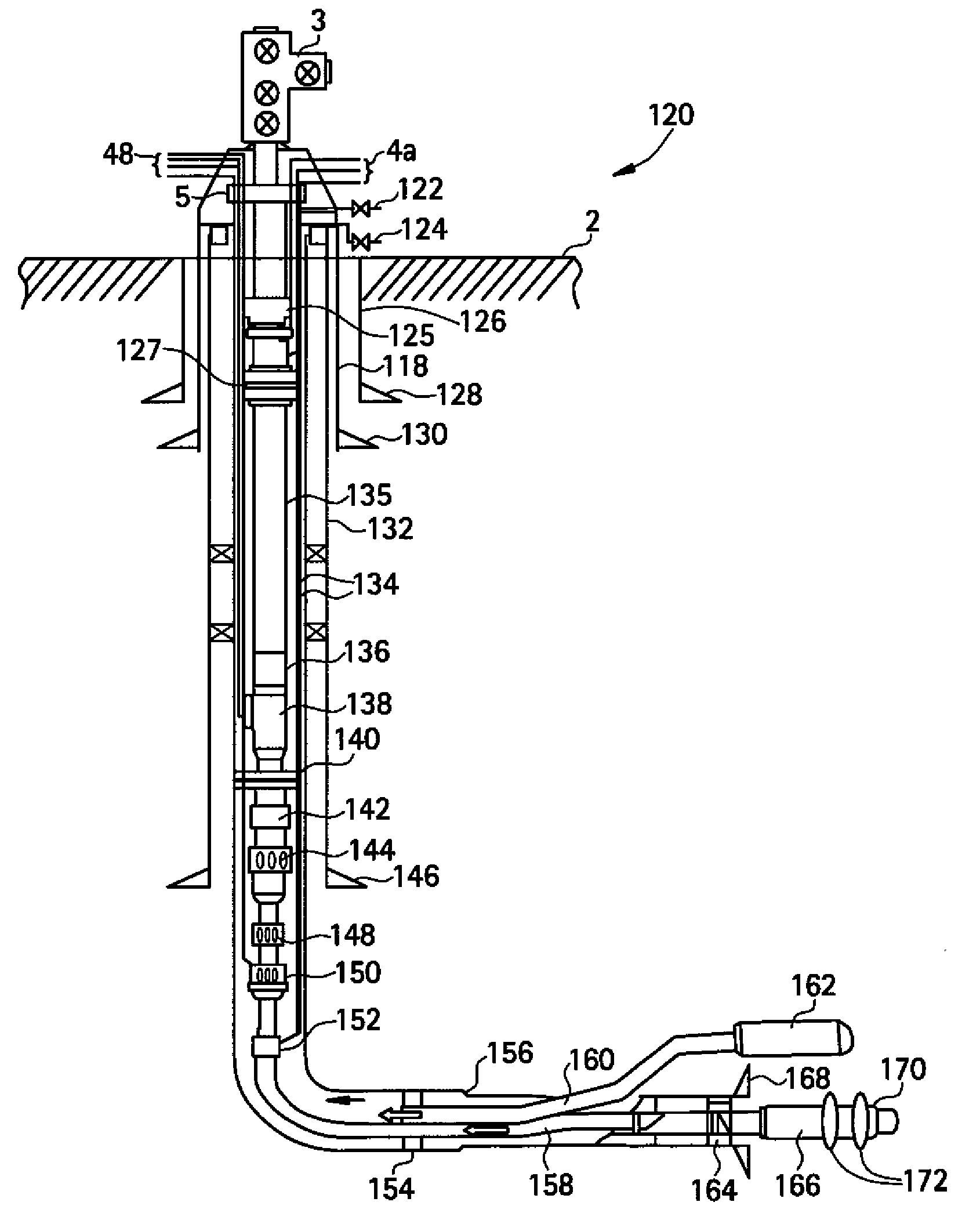

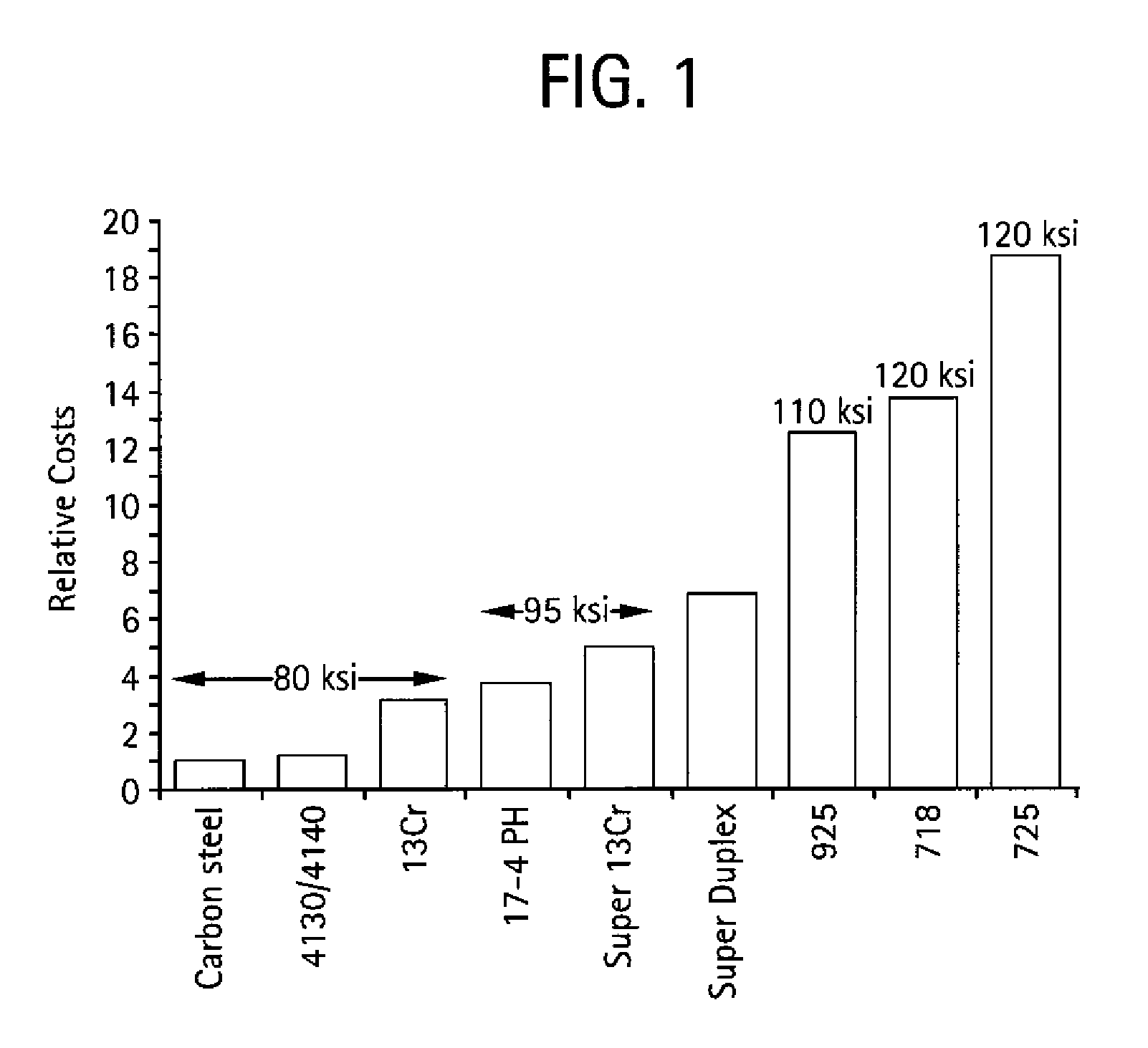

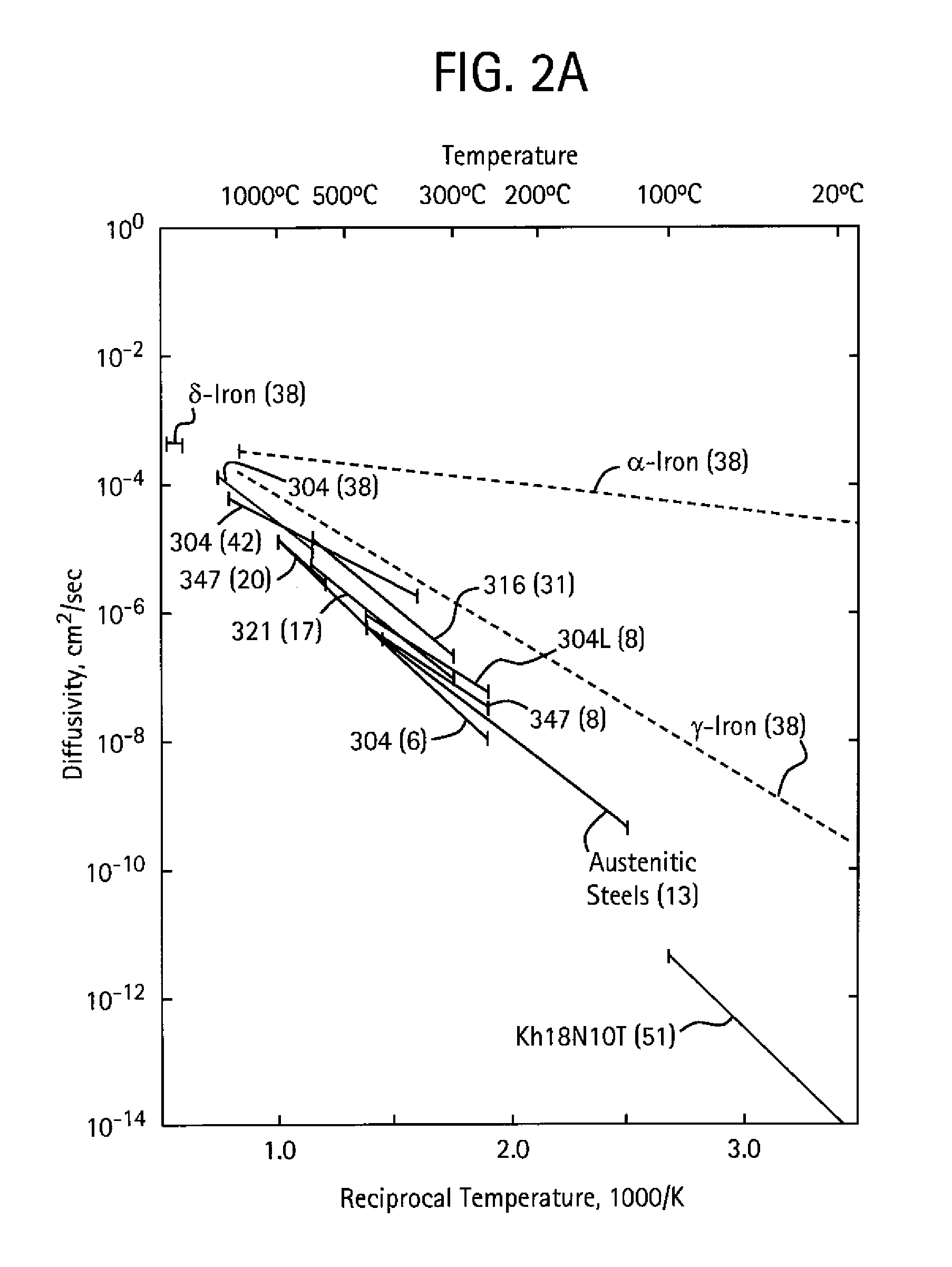

Interstitially strengthened high carbon and high nitrogen austenitic alloys, oilfield apparatus comprising same, and methods of making and using same

InactiveUS20080141826A1Material costHigh strengthQuenching agentsThin material handlingHigh carbonSubject matter

Novel carbon-plus-nitrogen corrosion-resistant ferrous and austenitic alloys, apparatus incorporating an inventive alloy, and methods of making and using the apparatus are described. The corrosion-resistant ferrous and austenitic alloys comprise no greater than about 4 wt. % nickel, are characterized by a strength greater than about 700 MPa (100 ksi), and, when being essentially free of molybdenum (<0.3 wt. %), have minimum Pitting Resistance Equivalence (PRE) numbers of 20 and minimum Measure of Alloying for Corrosion Resistance numbers (MARC) of 30 because of the use of both carbon and nitrogen. The ferrous and austenitic alloys are particularly formulated for use in oilfield operations, especially sour oil and gas wells and reservoirs. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

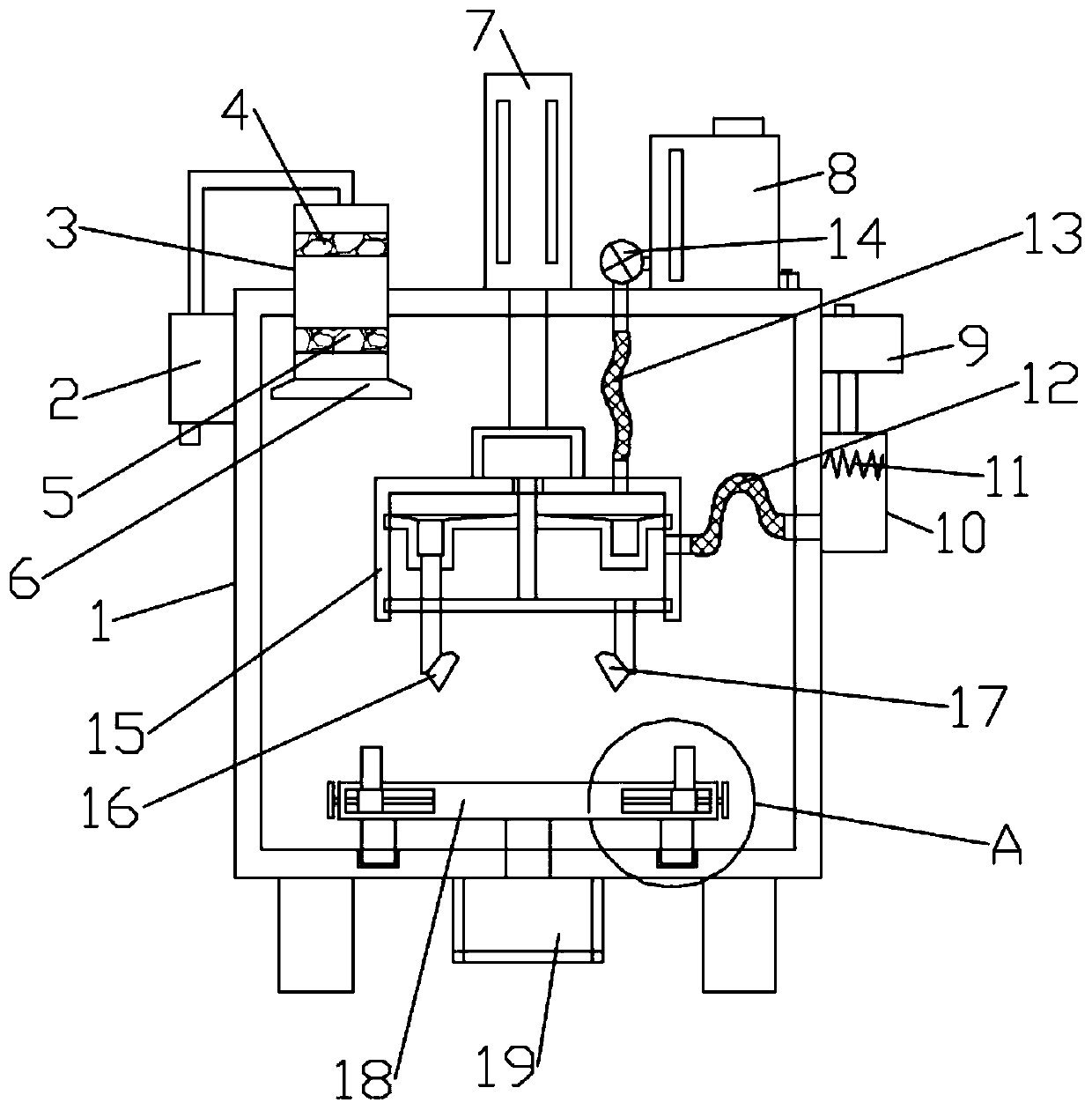

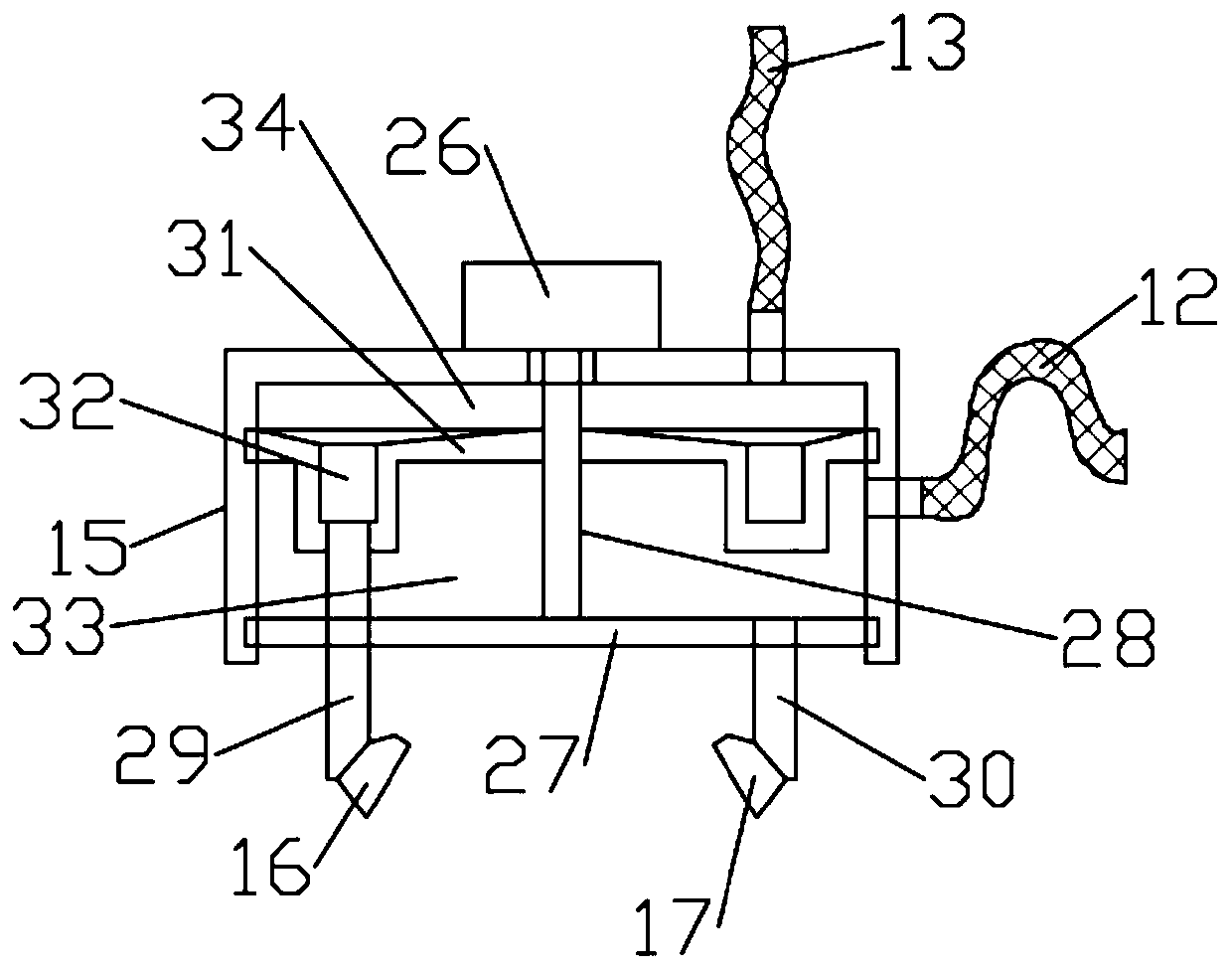

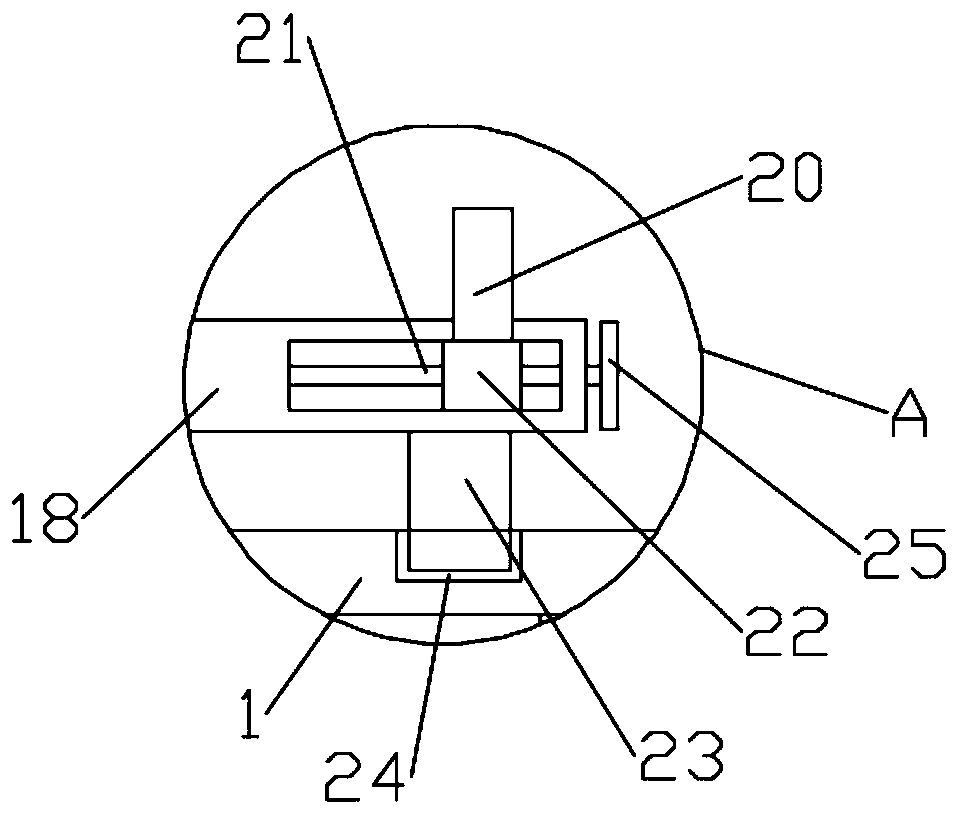

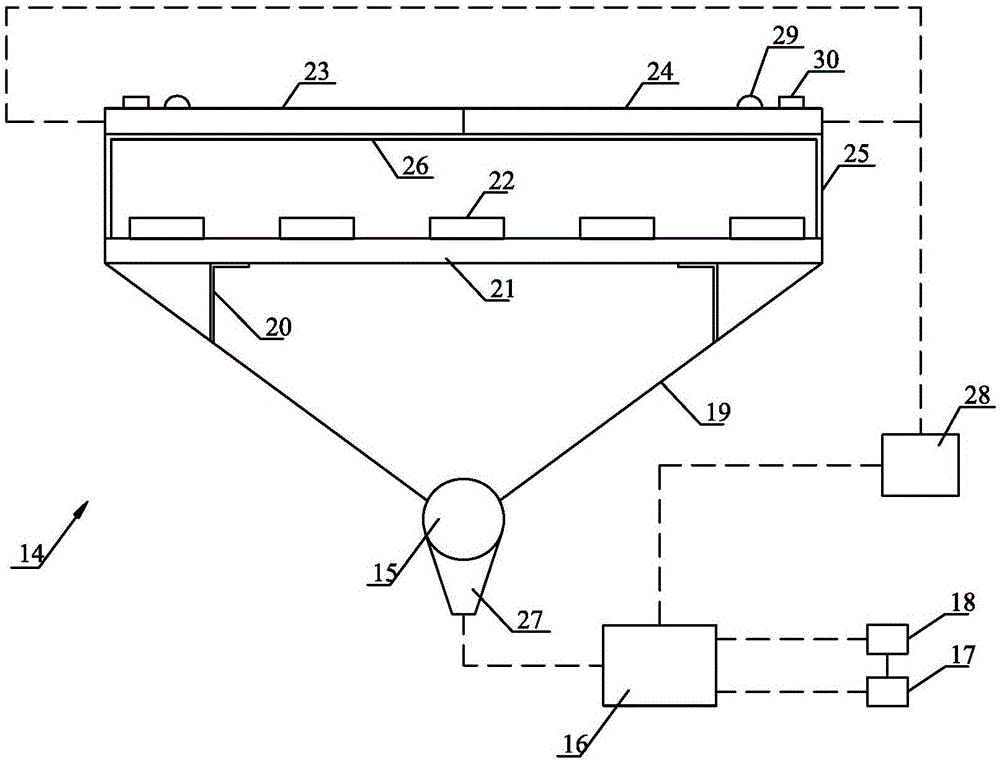

Multi-angle automatic paint spray equipment for machining mechanical part

ActiveCN110773365ADry evenlyGood effectPretreated surfacesLiquid spraying apparatusHot blastTelescopic cylinder

The invention relates to the field of automatic machining equipment and particularly discloses multi-angle automatic paint spray equipment for machining a mechanical part. The multi-angle automatic paint spray equipment comprises a box body; a supporting cylinder realizing height adjustment by virtue of a telescopic cylinder is arranged inside the box body; a rotating partition plate and a rotating plate are arranged in a synchronous rotation manner inside the supporting cylinder; an inner chamber of the supporting cylinder is divided into an upper chamber and a lower chamber, namely a paint liquid chamber and a hot air chamber by virtue of the rotating partition plate and the rotating plate; an air pipe used for exhausting hot air out of the hot air chamber is fixedly installed at one side of the rotating plate; a hot air nozzle is arranged at the bottom end of the air pipe; a paint liquid pipe used for discharging paint liquid inside the paint liquid chamber is fixedly installed at the other side of the rotating partition plate; and a paint mist sprayer used for atomizing the paint liquid is arranged at the bottom end of the paint liquid pipe which extends to a position below therotating plate. The multi-angle automatic paint spray equipment provided by the embodiment of the invention can effectively widen the paint spraying range, guarantees the uniformity of paint spraying, can also guarantee timely drying of the paint liquid at the surface of the part, and also realizes uniform drying and a good effect.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

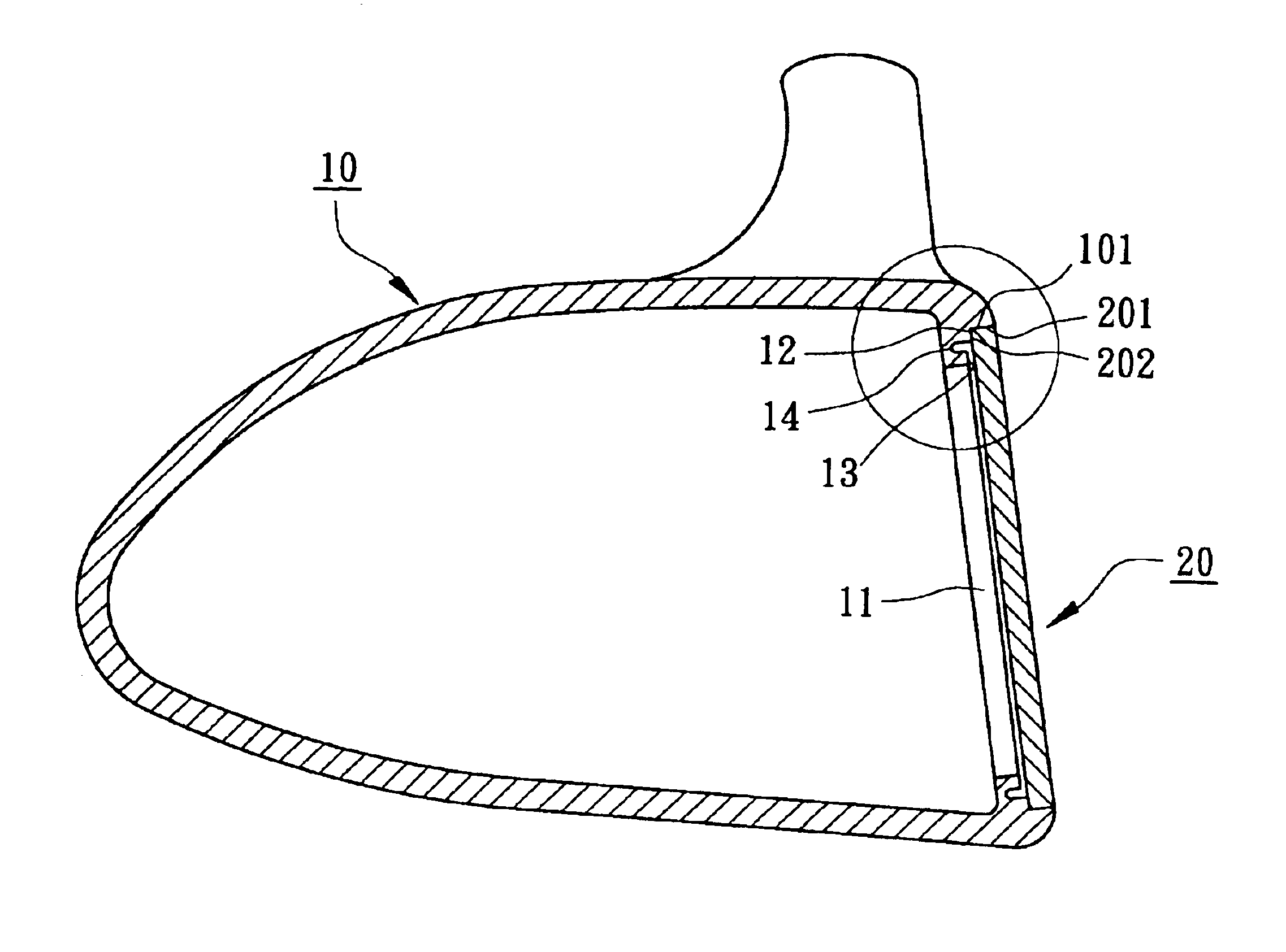

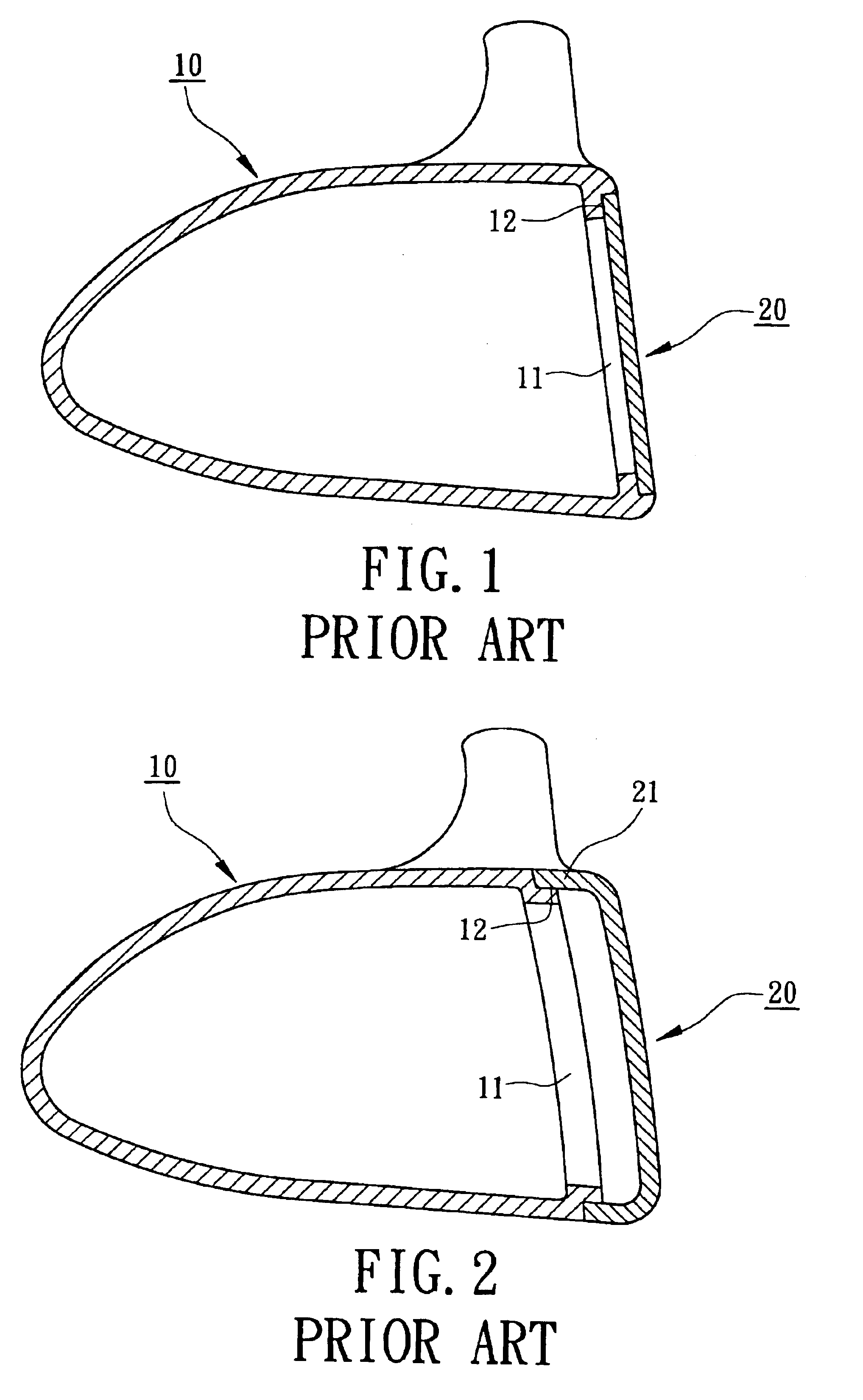

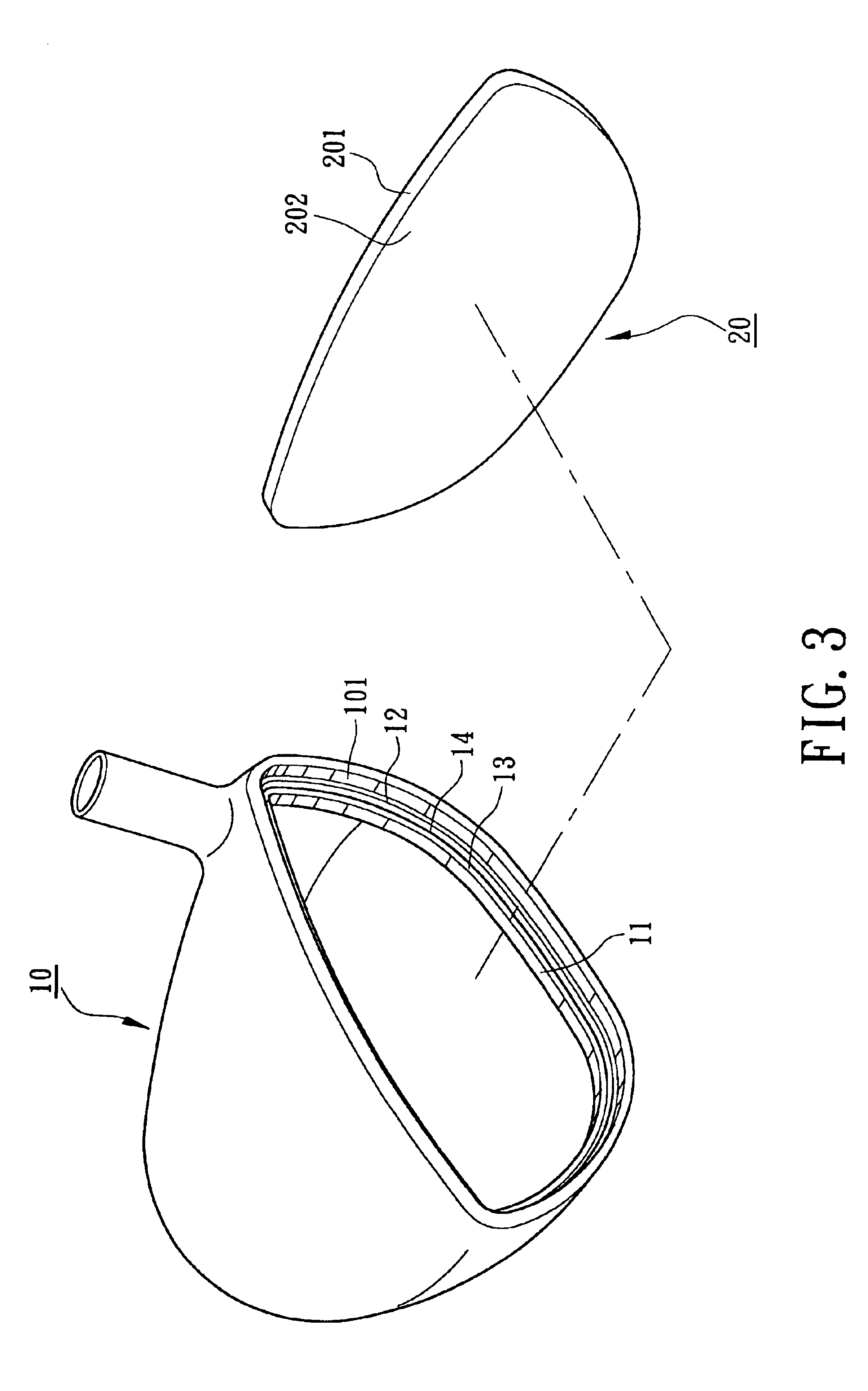

Golf club head

InactiveUS6918841B2Improve welding qualityAvoid formingGolf clubsRacket sportsCoefficient of restitutionWeld seam

A golf club head comprises a main body and a striking plate. The main body is provided with an opening formed with a first stepped portion and a second stepped portion. The first stepped portion and the second stepped portion define a groove therebetween. The first stepped portion supports the striking plate with a reduced contact surface area so as to increase the effective elastically deforming area of the striking plate. Further, when the striking plate is combined with the main body by welding, the groove of the main body can obstruct an overflow of melting metal from a welding seam between the main body and the striking plate. Thereby the groove of the main body enhances welding quality and thereby overcomes the problems of club head noises and disturbance caused by flux beads and an inadequate coefficient of restitution caused by insufficient deforming area of the striking plate.

Owner:FUSHENG PRECISION

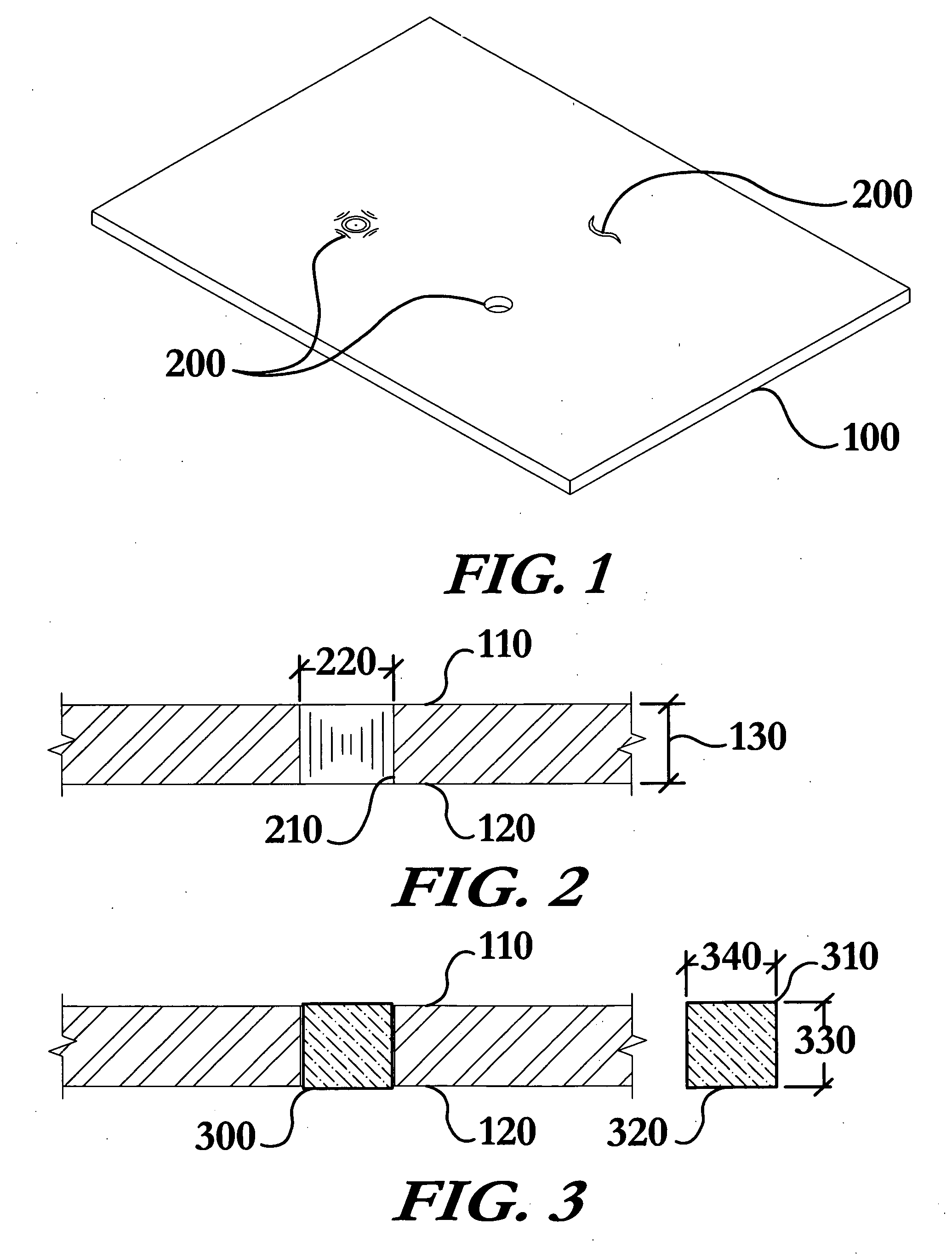

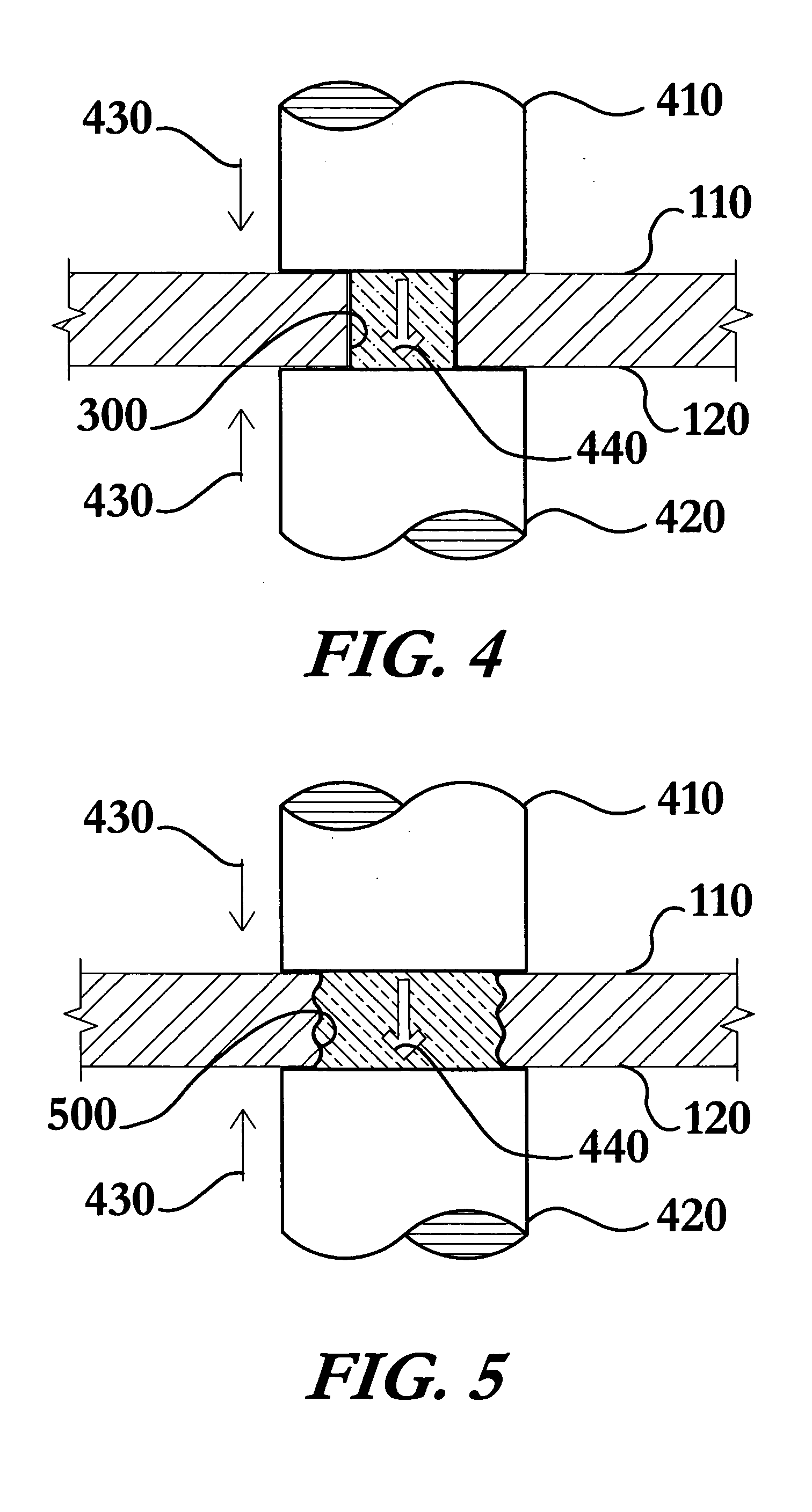

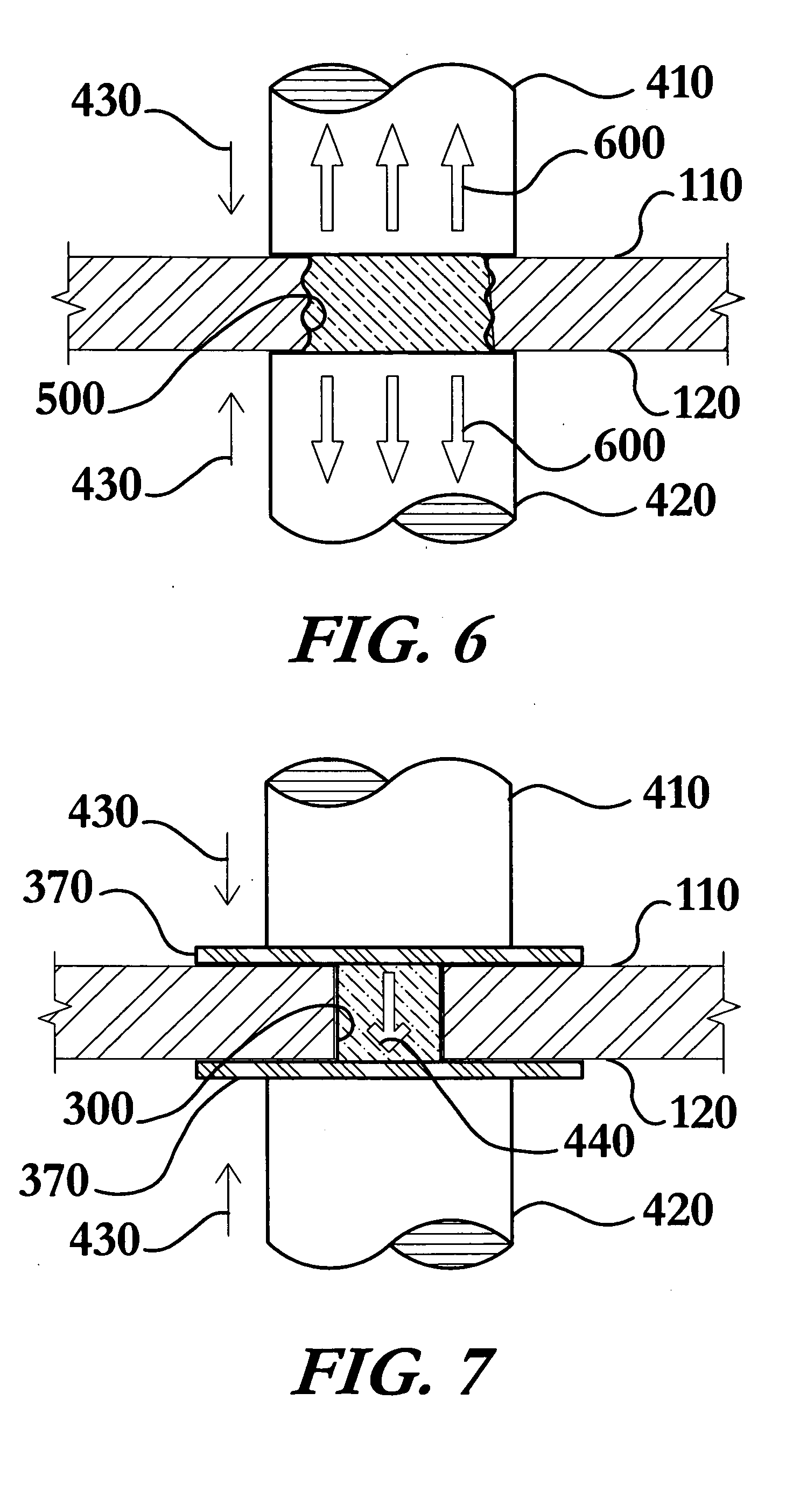

Method for repairing defects in a conductive substrate using welding

ActiveUS20050173493A1Low costImprove versatilityCooking-vessel materialsSoldering apparatusElectrical resistance and conductanceEngineering

A method for repairing defects in a substrate comprising the steps of placing a consumable filler slug in contact with the substrate in the vicinity of the defect; placing at least one electrically conductive cover sheet in contact with a portion of the consumable filler slug; bringing a first electrode and a second electrode in contact with the at least one cover sheet and applying a force; and transmitting electrical current between the electrodes, thereby resistively heating the at least one cover sheet and conductively heating the consumable slug and a portion of the substrate resulting in coalescence in a substantially liquid pool that fills the defect. The pool is then cooled to solidification under pressure. Alternative embodiments eliminate the need for the conductive cover sheet(s) by utilizing electrodes having increased electrical and thermal resistance. The consumable slug may be formed as a single unit or multiple sections, and may incorporate sacrificial retainers.

Owner:EDISON WELDING INSTITUTE INC

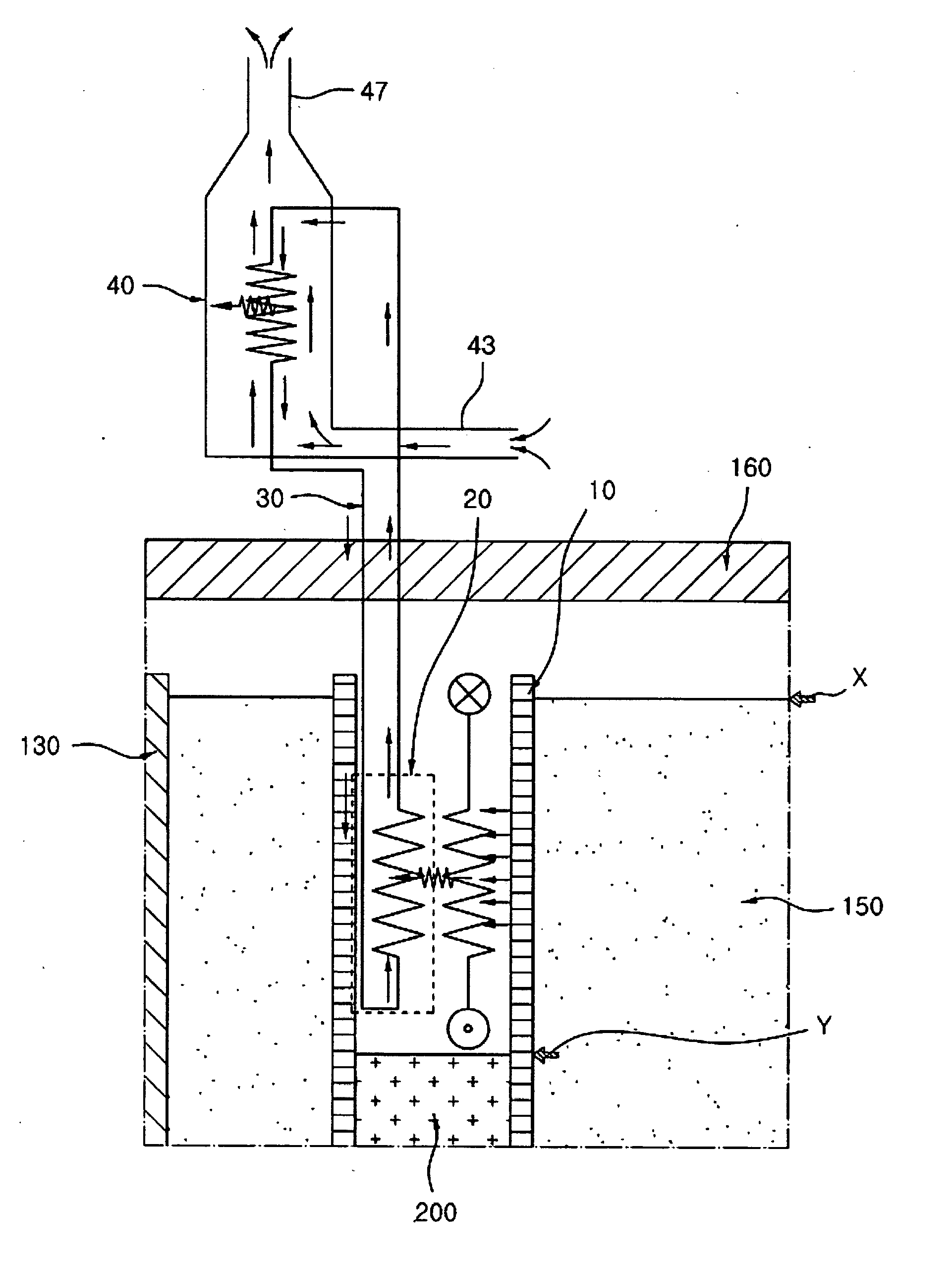

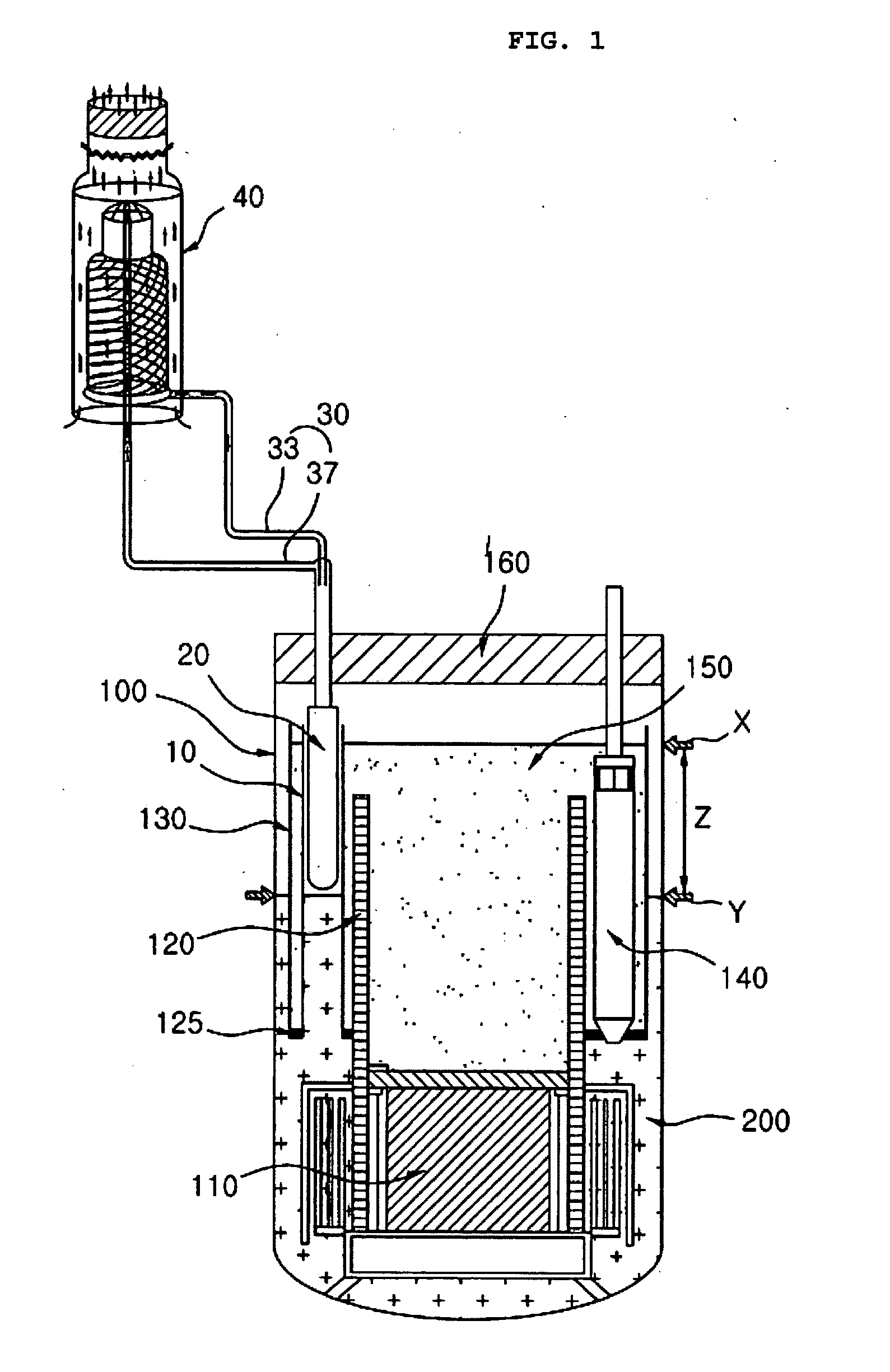

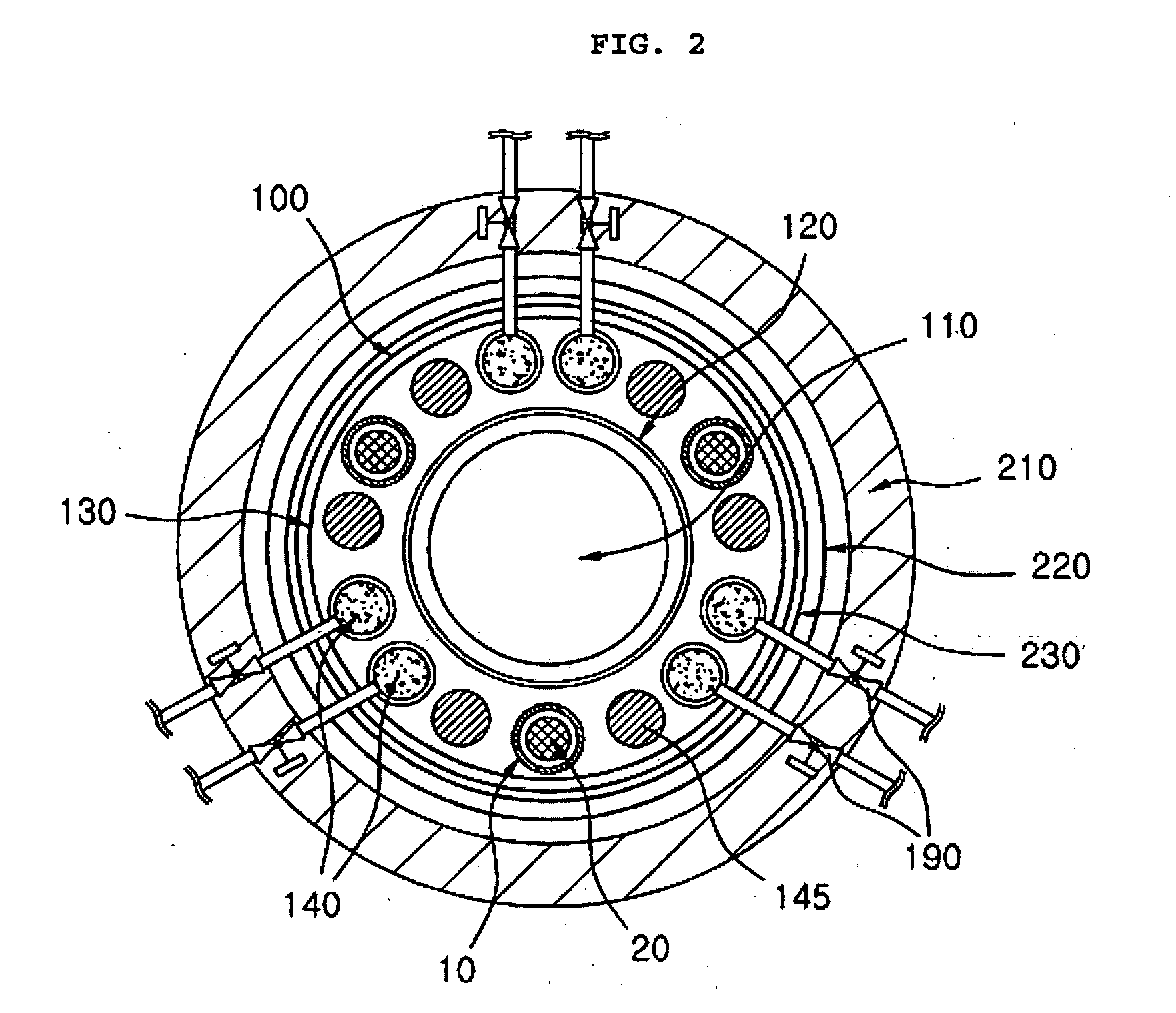

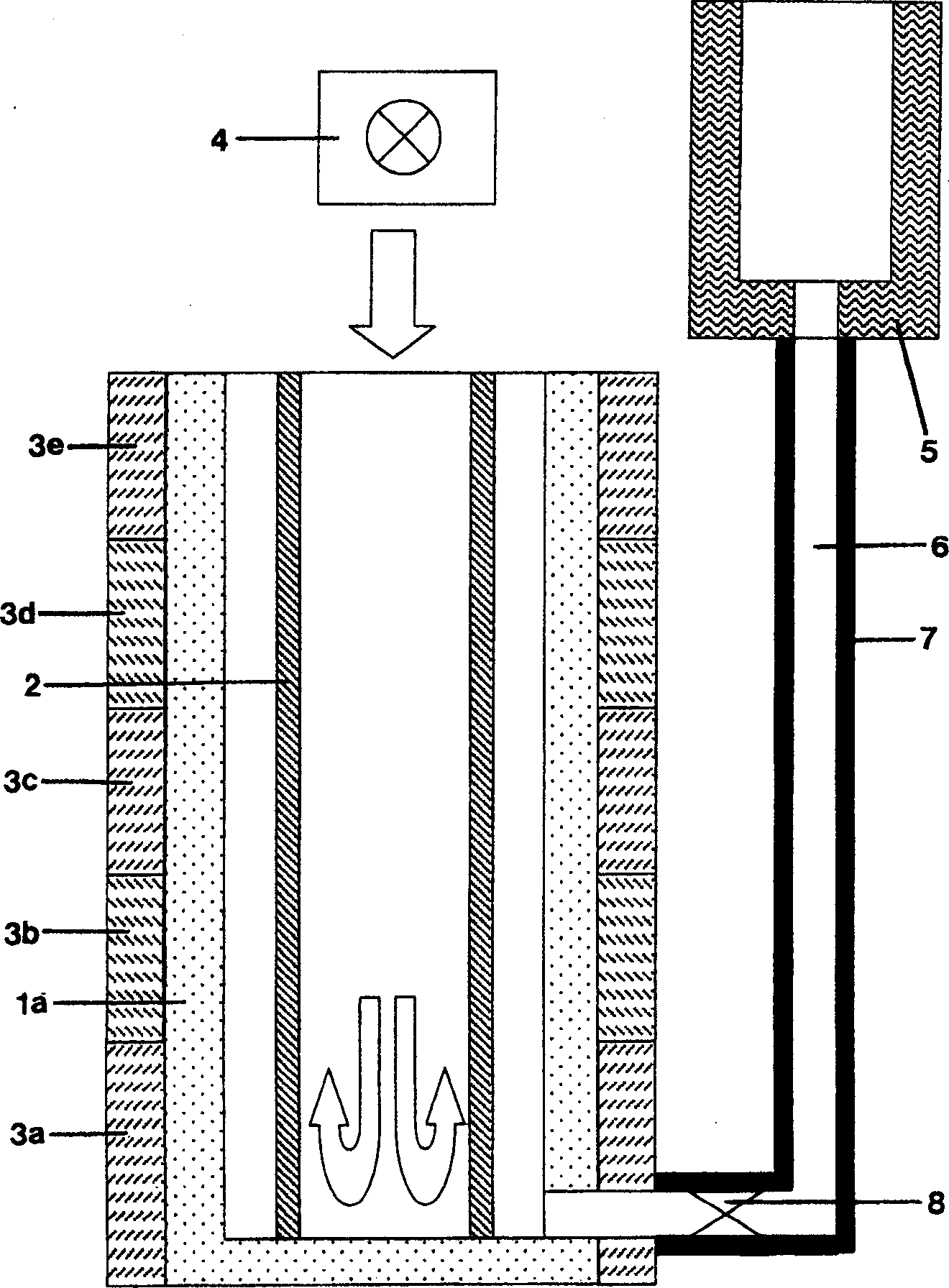

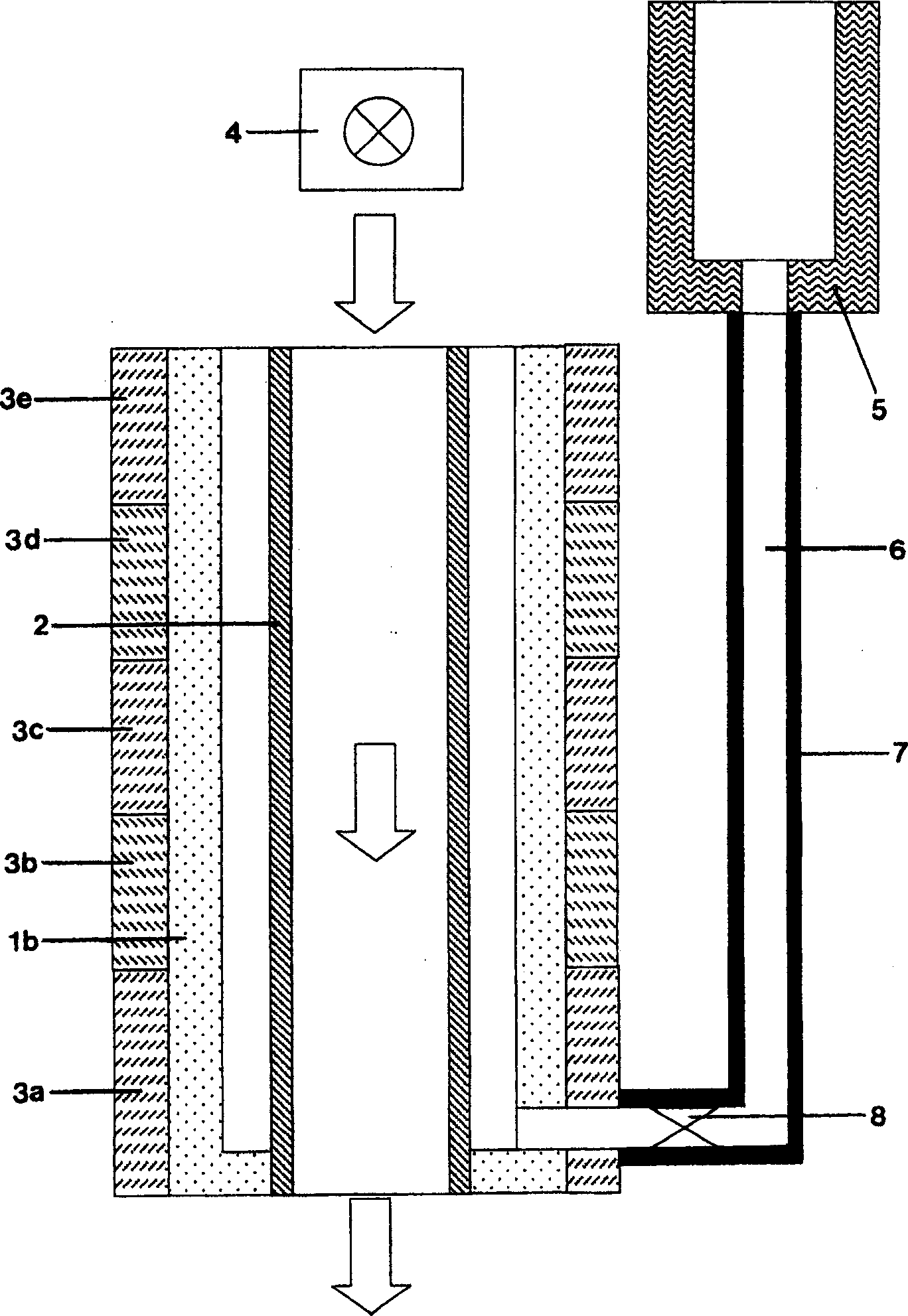

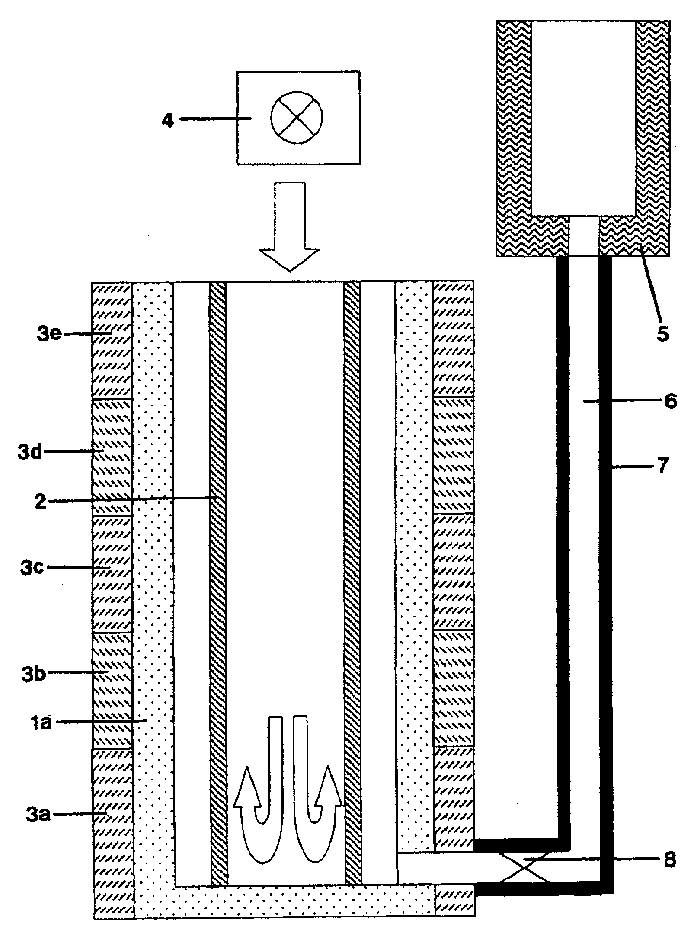

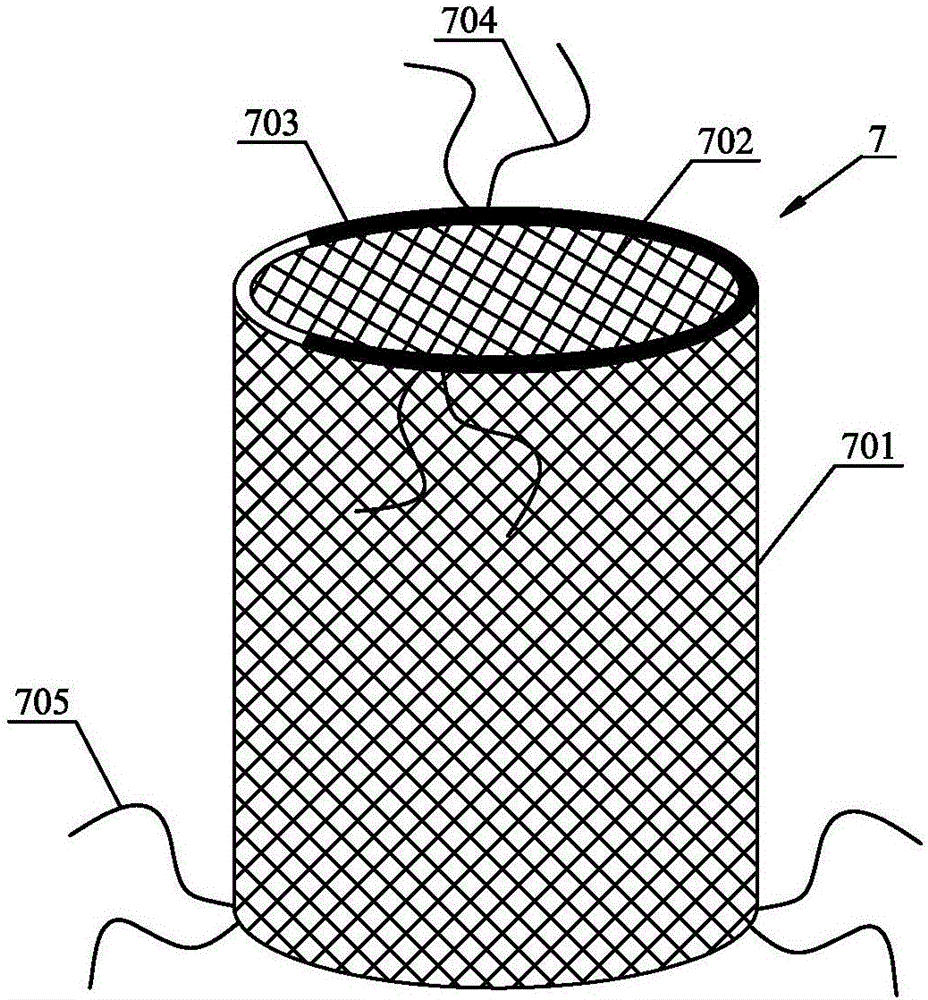

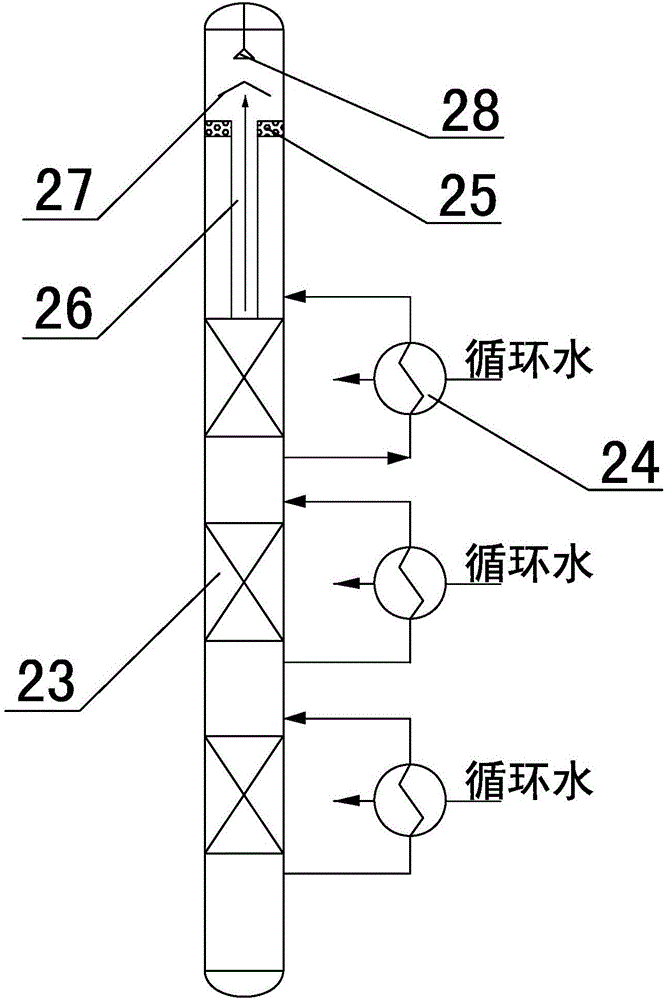

Passive safety-grade decay-heat removal method and decay-heat removal system for LMR with pool direct heat cooling process

InactiveUS20050135544A1Large heat removal capacityReduce heat lossNuclear energy generationFast fission reactorsVertical tubeLiquid metal

Dis0closed herein is a direct pool cooling type passive safety grade decay heat removal method and system for removing core decay heat in a pool type liquid metal reactor when a normal heat removal system breaks down. In the liquid metal reactor comprising a reactor vessel, the interior of which is partitioned into a hot pool above a core and a cold pool around the core so that liquid level difference between the hot pool and the cold pool is maintained by a primary pumping head under normal steady-state conditions, is disposed at least one circular vertical tube in such a manner that the sodium in the circular vertical tube is maintained with the same liquid level as the liquid level of the sodium in the cold pool. In the circular vertical tube is disposed a sodium-sodium heat exchanger, which is connected to a sodium-air heat exchanger mounted above a reactor building via a heat removing sodium loop, in such a manner that it is placed at the position higher than a liquid level of the sodium in the cold pool under the normal steady-state conditions. Under transient conditions, for example, when the normal heat removal system breaks down, the primary pump is automatically tripped, and accordingly the liquid level of the cold pool rises with the result that the liquid level difference between the hot pool and the cold pool is eliminated. Consequently, the sodium-sodium heat exchanger makes direct contact with the hot sodium so that core decay heat is discharged into a final heat sink, for example, the atmosphere. In this way, the decay heat removal system of the present invention is operated on the basis of a completely passive concept with improved operational reliability. Heat loss incurred by the decay heat removal system is minimized under normal steady-state conditions, whereby economical efficiency is maximized. The decay heat removal system of the present invention can effectively remove core decay heat under transient conditions. Moreover, the decay heat removal system of the present invention provides an additional heat removal capacity obtained by the passive vessel cooling system, whereby the decay heat removal system of the present invention can be easily applied to a large thermal rated liquid metal reactor.

Owner:KOREA ATOMIC ENERGY RES INST +1

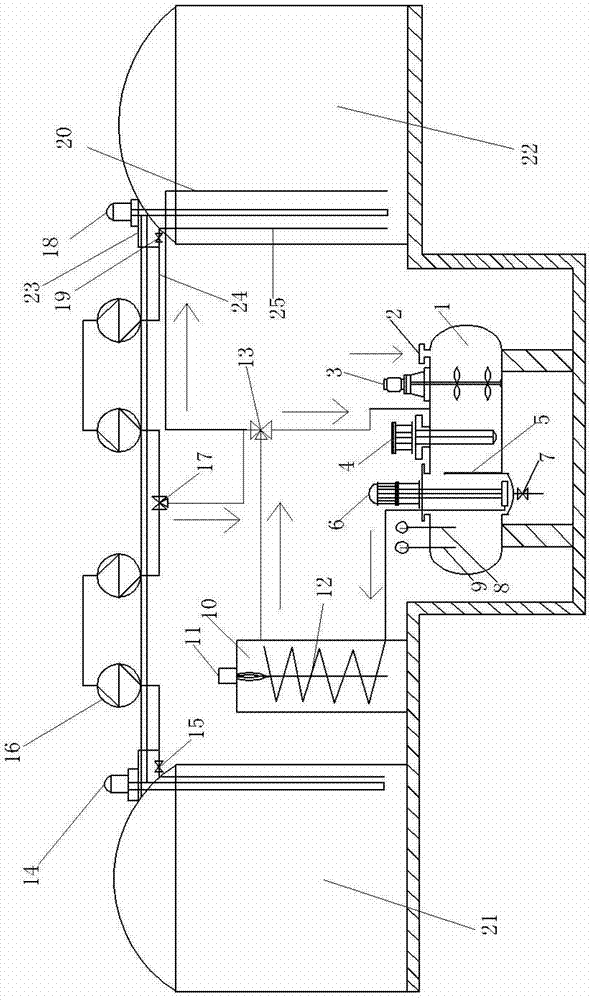

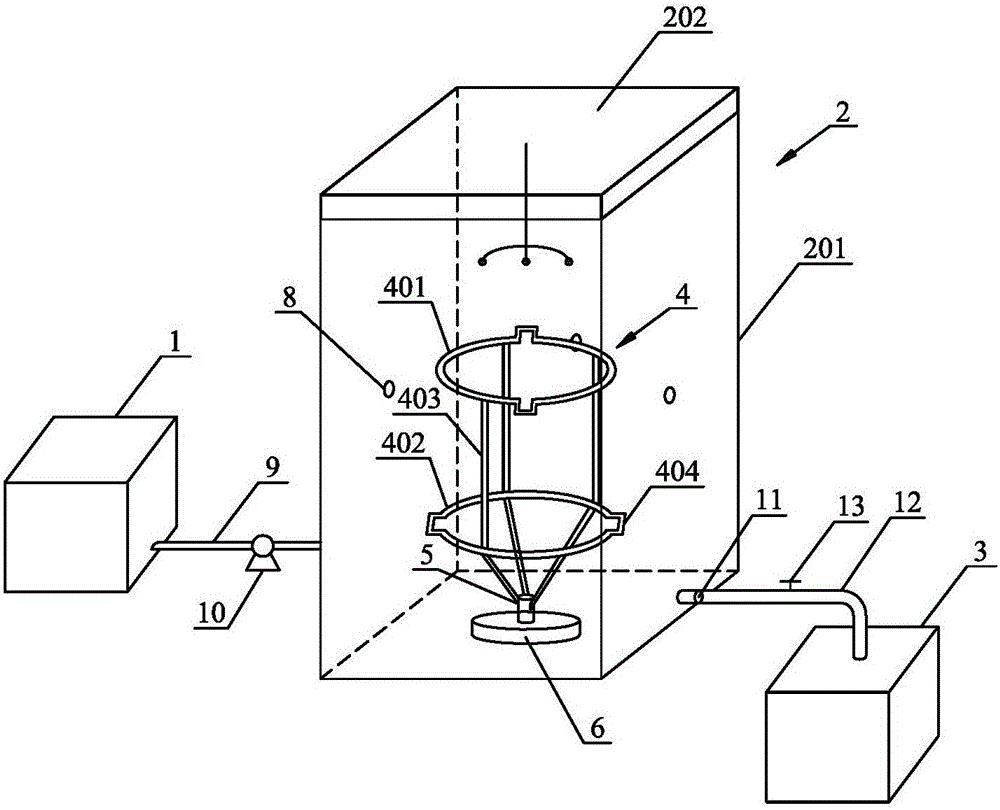

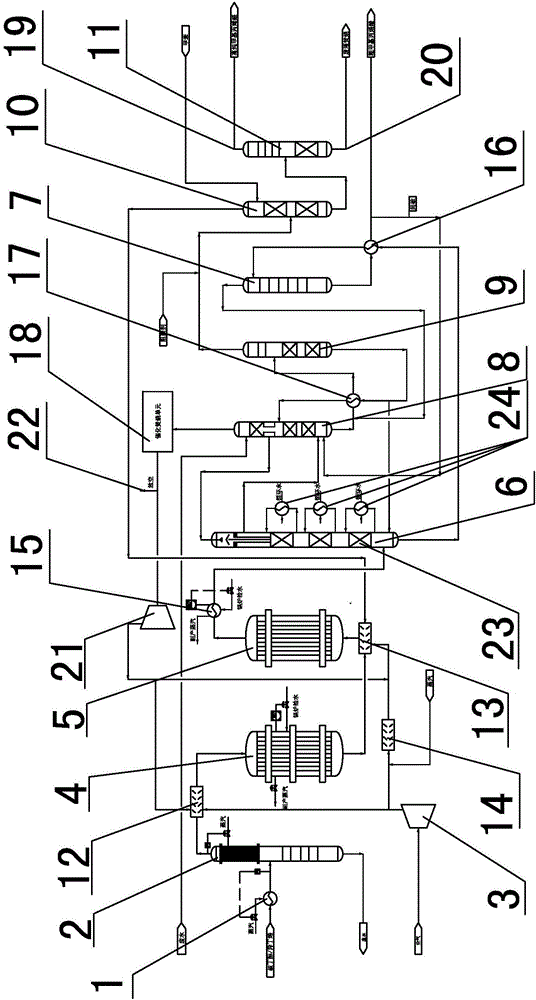

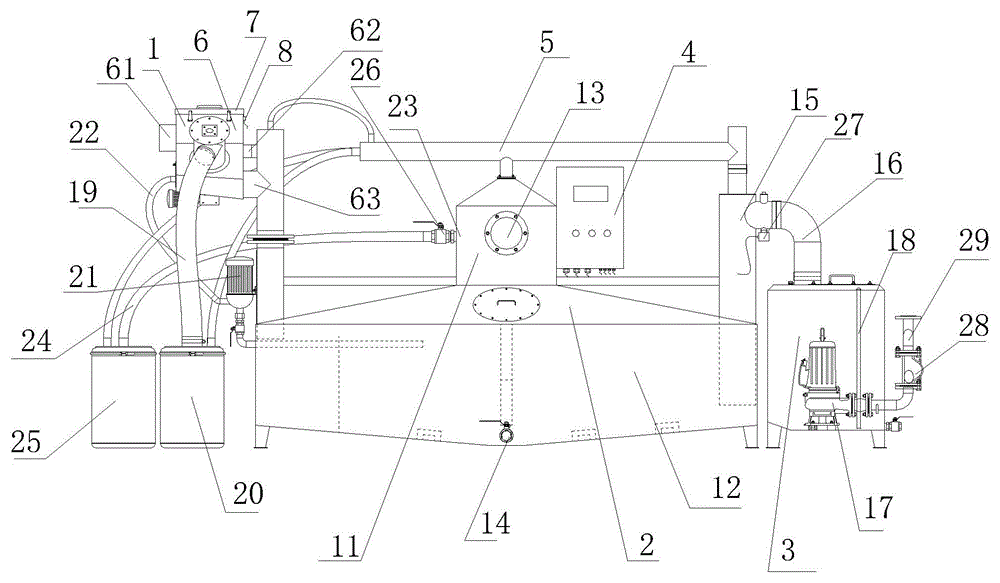

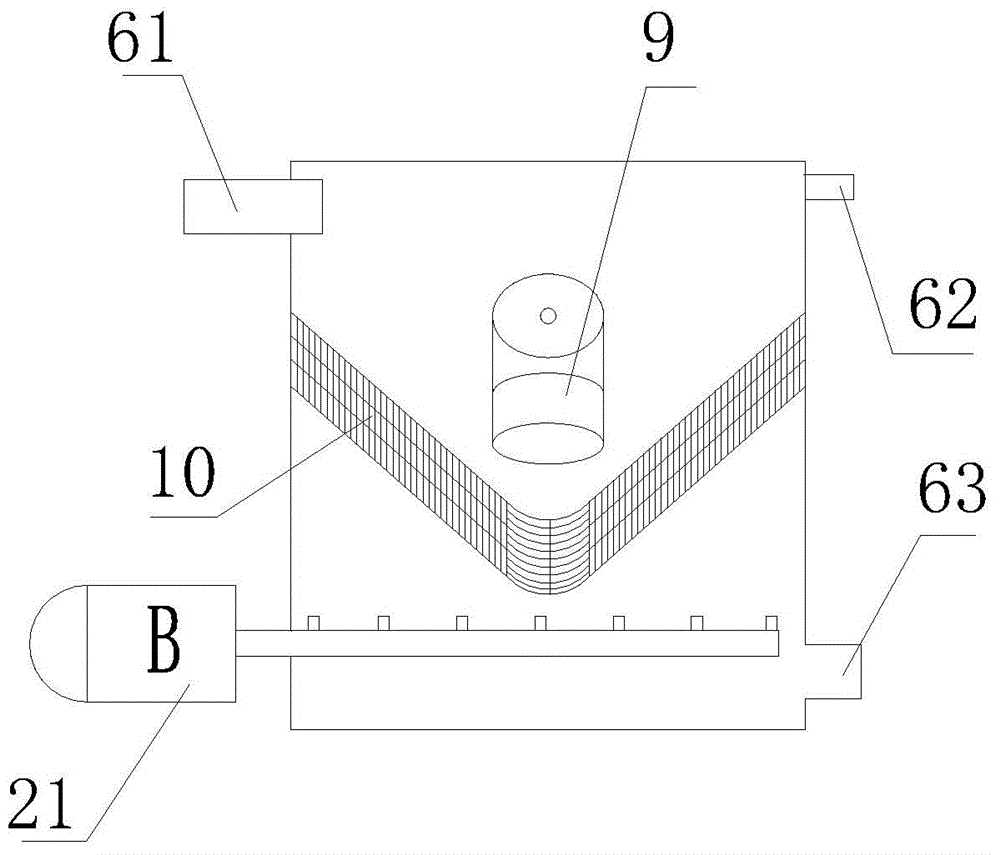

Molten salt heating and discharging system for solar thermal power

ActiveCN102734929AAccelerate the melting process of molten saltReduce energy consumptionStorage heatersMolten saltMaterials science

The invention relates to a molten salt heating and discharging system for solar thermal power. The system comprises molten salt storage equipment, a heat exchange system and molten salt heating and discharging equipment, wherein the molten salt storage equipment, the heat exchange system and the molten salt heating and discharging equipment form a sealed system through pipelines. The molten salt heating and discharging equipment comprises a molten salt bath and a molten salt furnace, the molten salt bath and the molten salt furnace are communicated through a pipeline; the molten salt storage equipment consists of one or two or more than two molten salt storage tanks; a plurality of molten salt storage tanks are connected with one another through pipelines, and the pipelines are provided with a heat exchanger system. According to the molten salt heating and discharging system for the solar thermal power, molten salt can be molten before a solar-thermal power station is put into production and can be heated during running of the solar-thermal power station; and simultaneously, in emergency situation and long-term rainy or snowy weather, the molten salt in a heat exchanger can be discharged, and problems that molten salt in the heat exchanger is laid aside for a long time, crystallized and solidified are solved.

Owner:江苏太阳宝新能源有限公司

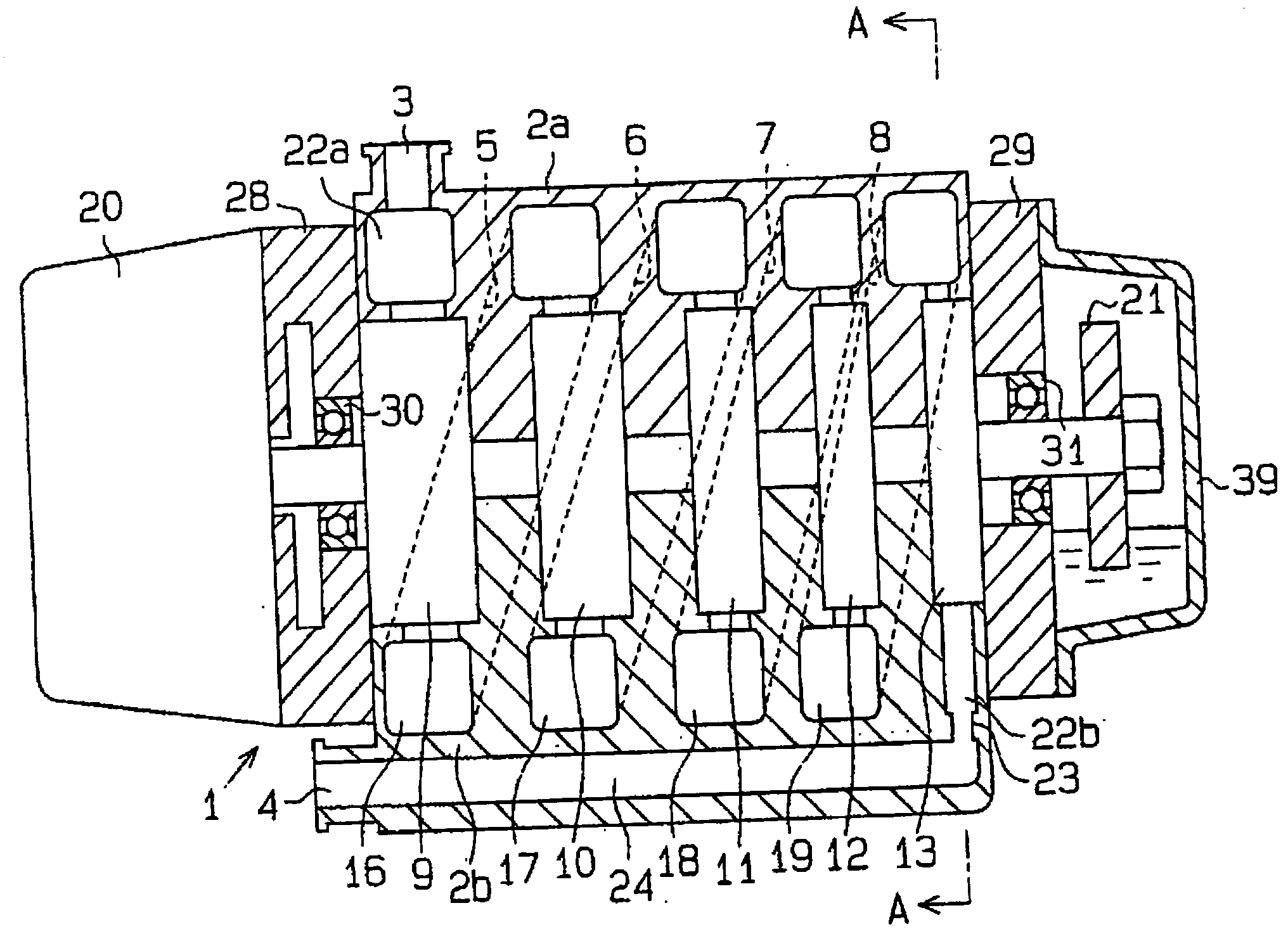

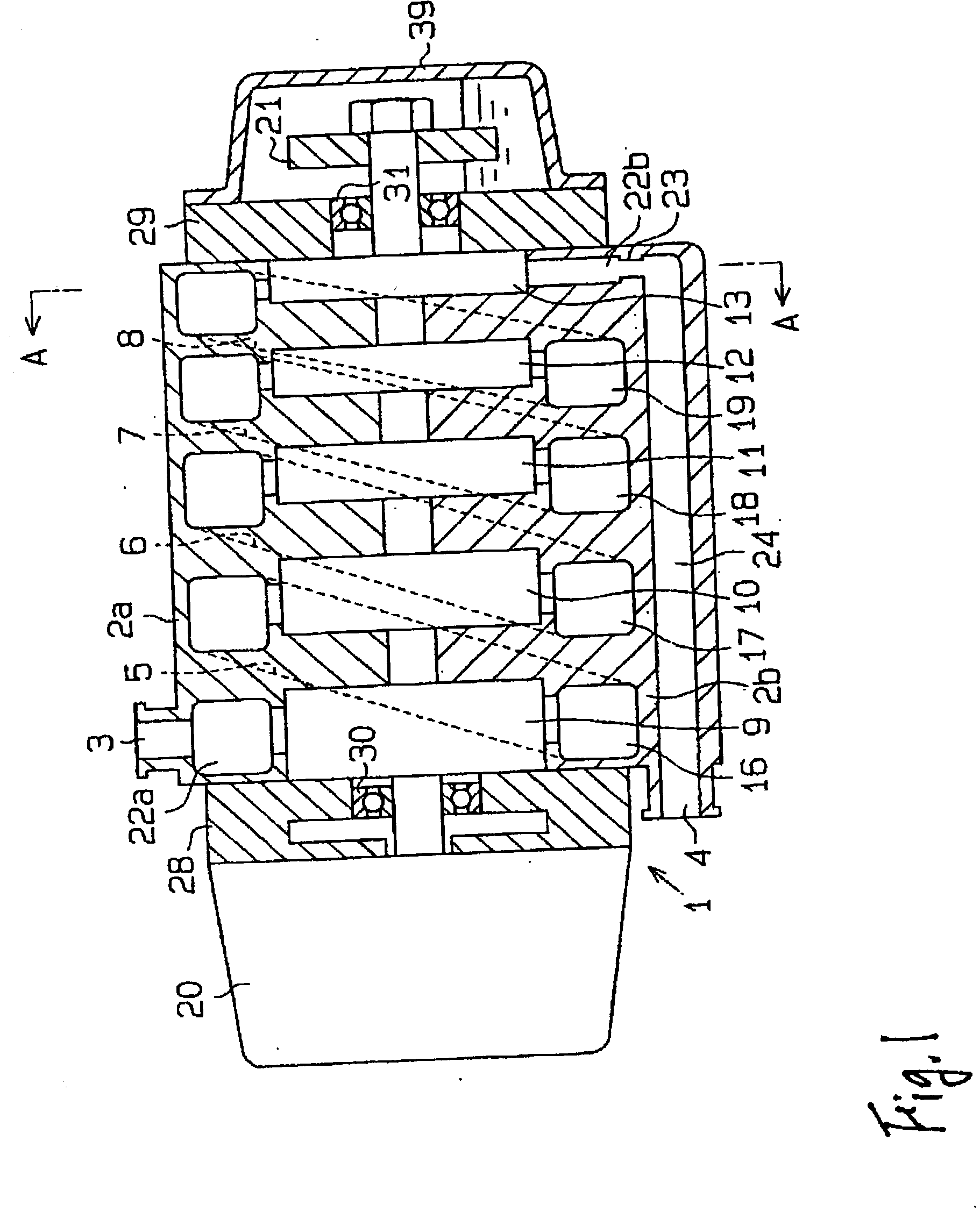

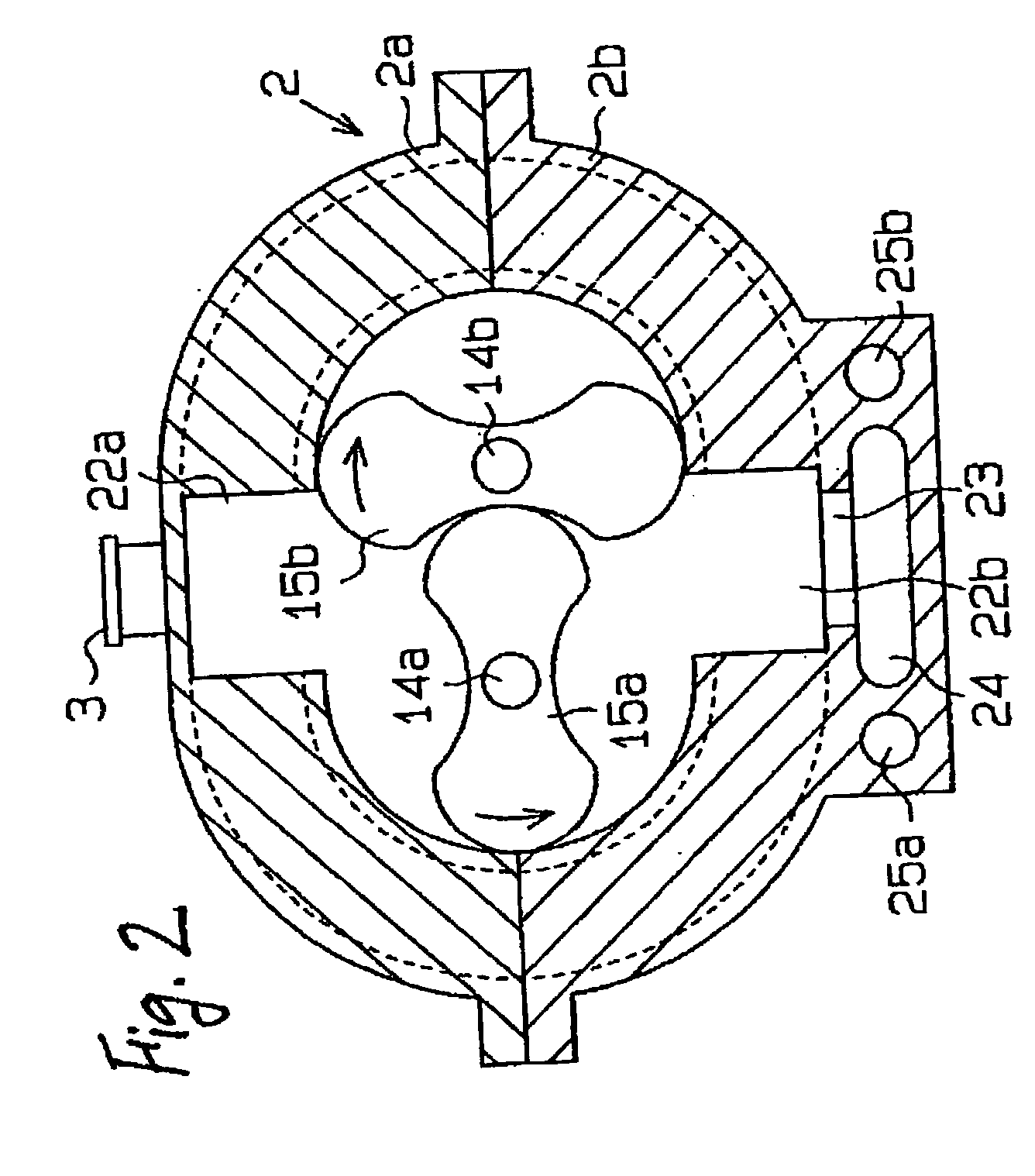

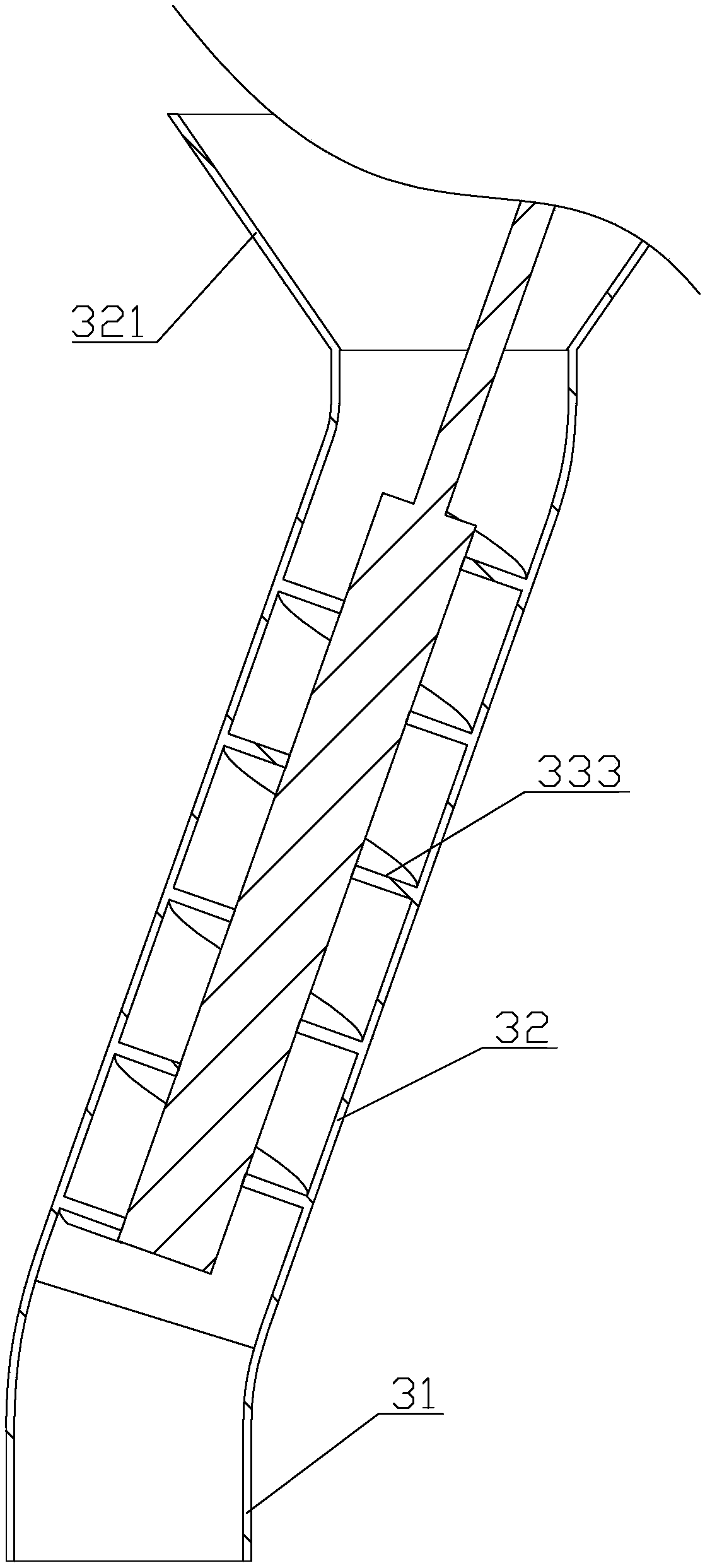

Multi-stage vacuum pump

InactiveUS20030077182A1Improve cooling effectPrecise temperature controlRotary/oscillating piston combinations for elastic fluidsCombination enginesPump chamberEngineering

The present invention provides a multi-stage vacuum pump which includes: a housing in which a plurality of pumping chambers are formed, the pumping chambers being arranged in series and being in fluid communication with one another, one of the pumping chambers which is at one end of the series acting as an initial stage pumping chamber, another of the pumping chamber which is at the other end of the series acting as a final stage pumping chamber, the housing being provided with an inlet port for sucking a gas from a space to be evacuated into the initial stage pumping chamber, the housing being provided with an outlet port for exhausting the gas from the final stage pumping chamber; a Roots-type pump section occupying each of the pumping chambers; and a device for decreasing a temperature differential between the initial stage pumping chamber and the final stage pumping chamber.

Owner:AISIN SEIKI KK

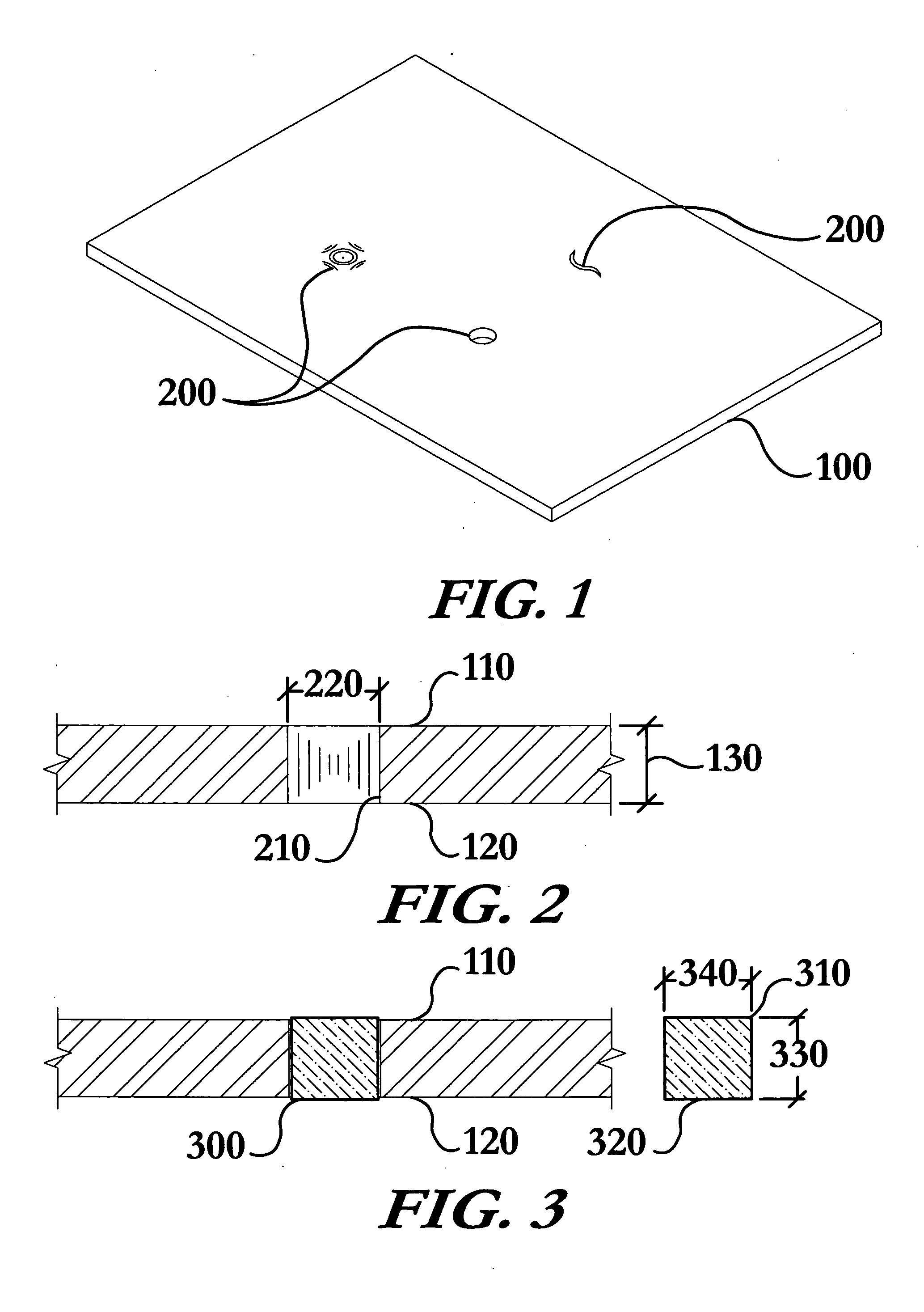

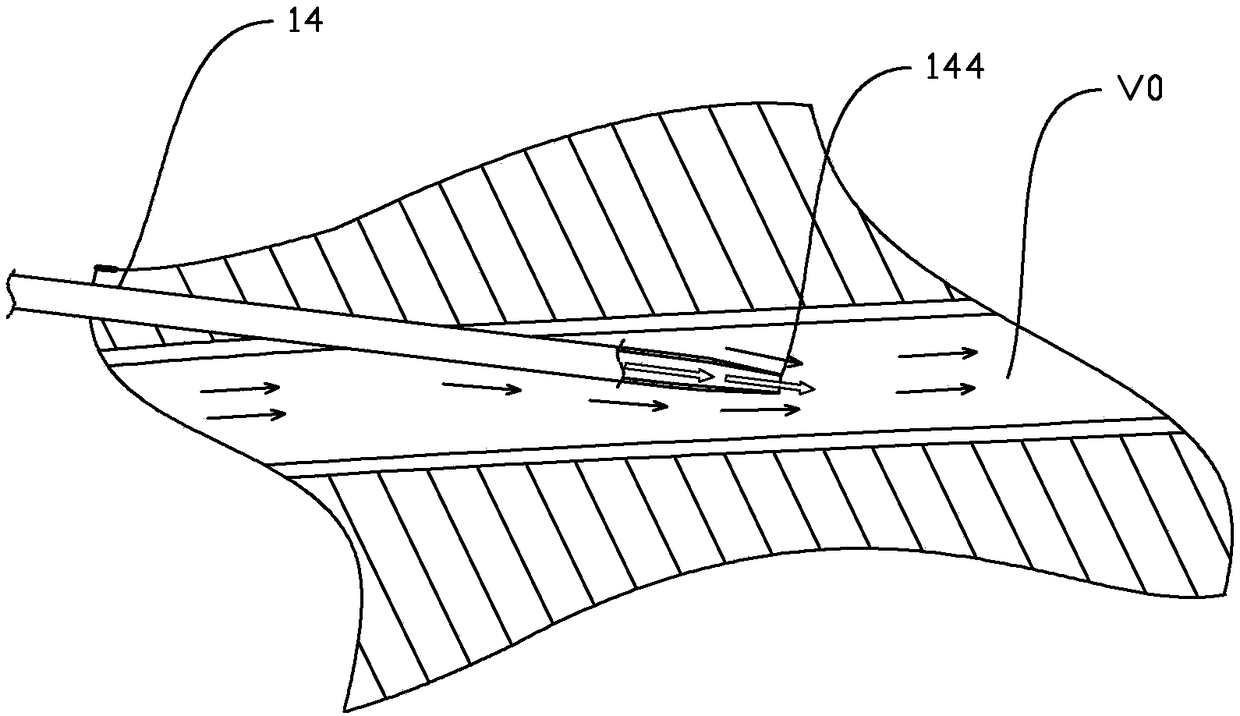

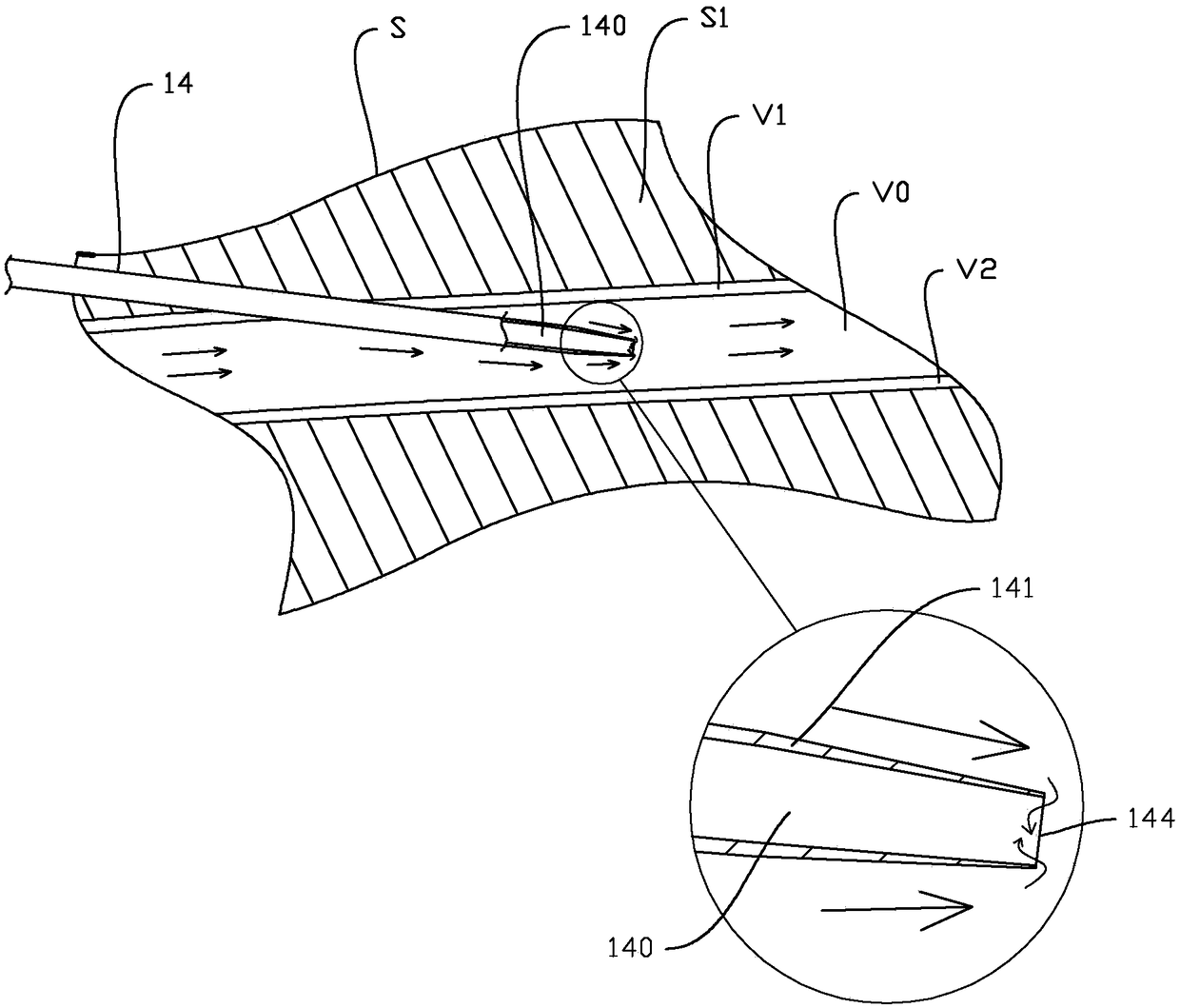

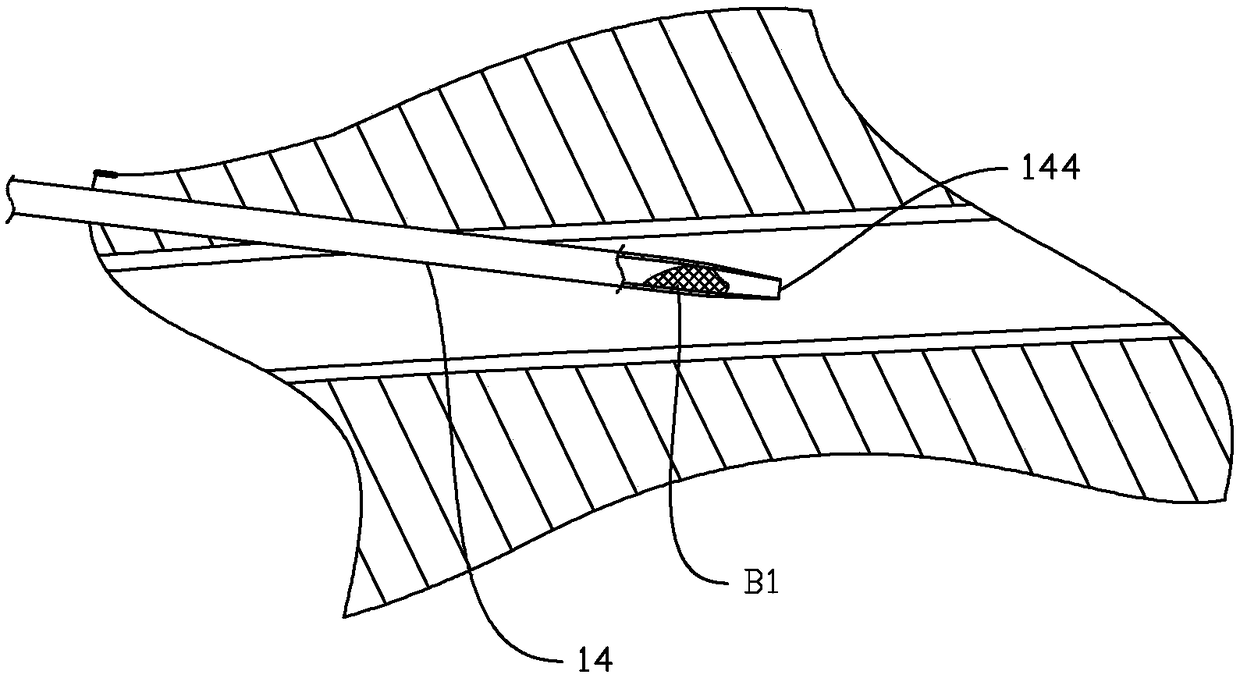

Manufacture of tubular targets

InactiveCN1363716APrevent solidificationAvoid inhomogeneityVacuum evaporation coatingIngot casting plantsMolten stateHeater Rod

A process for producing a tube target for cathode sputtering plants, in which the tube target is formed from a metallic inner tube made of a first material with a first melting point of Ts1>=900 K and a metallic outer tube that concentrically surrounds the inner tube and that is made of a second material with a second melting point of Ts2<=800 K. The inside diameter of the outer tube and the outside diameter of the inner tube are proportioned in such a way that the two tubes fit together tightly and are mechanically firmly joined. The outer tube is formed by casting the second material in a molten state in a heated, vertical, A cylindrical permanent mold, which has a heated mandrel that constitutes the inner tube. After a space between the mold and the inner tube has been filled with the molten second material, a first thermal gradient develops between the inner tube and the mold, a second thermal gradient develops between the bottom and the top of the mold, and the outer tube is simultaneously cooled from the inside to the outside and from the bottom to the top.

Owner:MATERION ADVANCED MATERIALS GERMANY GMBH

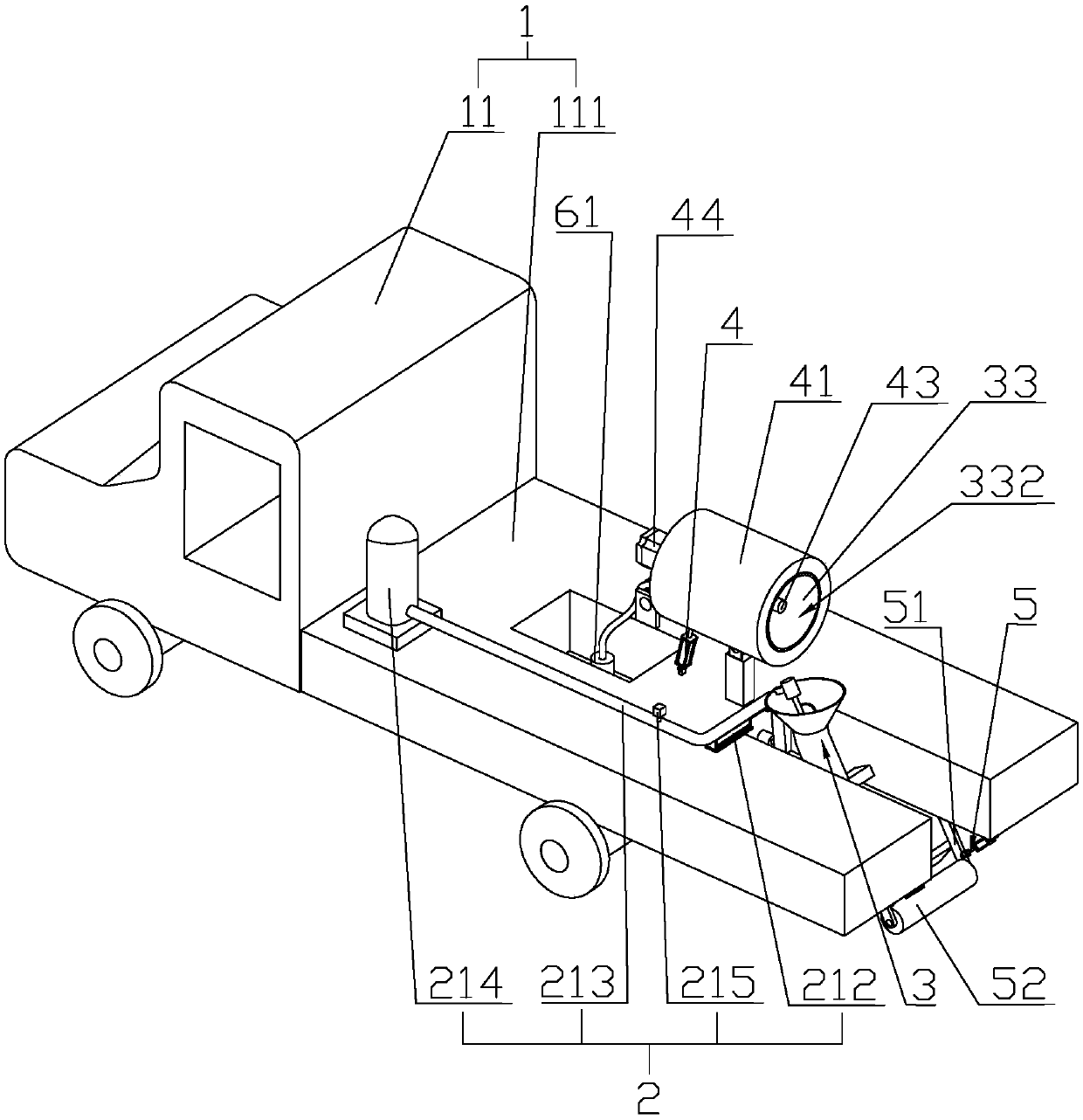

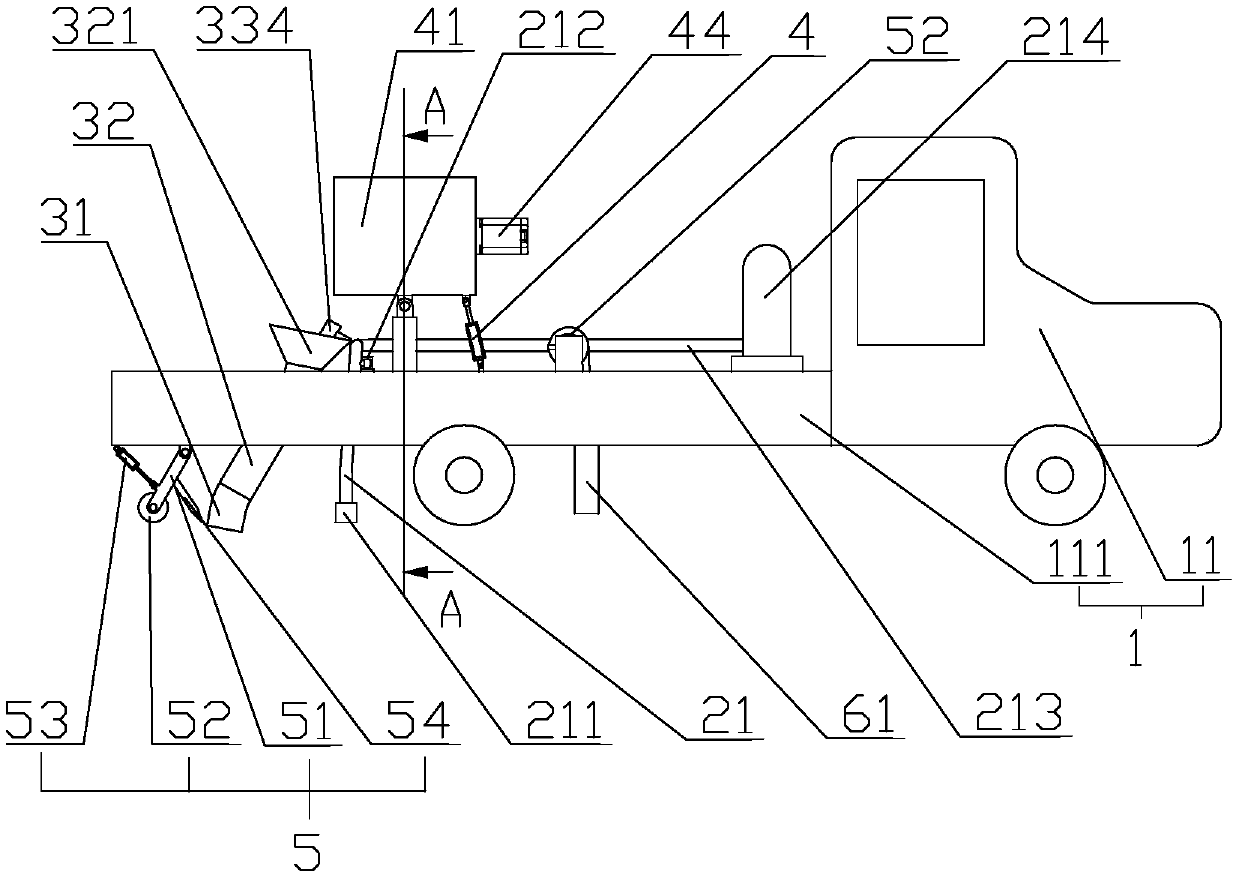

Road repair method and road repair truck

InactiveCN109629387AImprove connection strengthImprove smoothnessRoads maintainenceGas compressorSolenoid valve

The invention relates to the technical field of municipal engineering construction, in particular to a road repair truck. The road repair truck comprises a truck body, a cleaning mechanism arranged atthe bottom of the truck body, a filler mechanism arranged on the truck body, and a flattening mechanism arranged on the vehicle body; the cleaning mechanism comprises an air nozzle rotatably arrangedat a bottom of the truck body, a first air cylinder arranged at the bottom of the truck body, an air supply pipe communicated with the air nozzle, an air compressor communicated with the air supply pipe, and a solenoid valve arranged on the air supply pipe, and a piston rod of the first air cylinder is hinged to the air nozzle to drive the air nozzle to rotate until the air nozzle is opposite toa road repair part. The road repair truck has the advantage of removing dust in the road repair part to improve the connection strength of concrete and a foundation.

Owner:广州市黄埔建筑工程总公司

Plant cultivation method

ActiveCN107173223AReduce workloadImprove protectionPhotovoltaic supportsElectric circuit arrangementsSolar power systemLighting system

The invention discloses a plant cultivation method which includes the step: cultivating tissue culture seedlings acquired by tissue culture in an energy-saving greenhouse or energy-saving planting greenhouse. A tissue culture process includes the steps: collection of explants; cleaning; disinfection; inoculation of the explants; subculture; rooting culture; transplant. The energy-saving greenhouse or energy-saving planting greenhouse comprises a solar power system, a spray irrigation system and a lighting system. According to the method, horticultural facilities applied in plant cultivation process are uniformly improved and comprise the solar power system, the lighting system, the spray irrigation system, a cleaning and disinfection device, a culture medium filling device and the like, wherein the cleaning and disinfection device and the culture medium filling device are used for the tissue culture process, the whole plant cultivation process is more complete by the aid of a series of improvements and combinations, working efficiency is improved, and each improvement is quite important.

Owner:杭州树联生态工程有限公司

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

Flame retardant environmentally friendly adhesive and producing method of plant fiberboard

ActiveCN105331294ARaw materials are easy to getFlame retardantNon-macromolecular adhesive additivesWood working apparatusFire retardantFiberboard

The present invention provides a flame retardant environmentally friendly adhesive, and the raw materials comprise magnesium sulfate, magnesium chloride, water, magnesium oxide, sodium dihydrogen phosphate, boric acid, and methyl cellulose. The flame retardant environmentally friendly adhesive is a formaldehyde-free environmentally friendly inorganic adhesive, not only has flame-retardant effect, but also can make a plant fiberboard highly stable in fiber structure and high in mechanical properties, and also allows the plant fiberboard to have waterproof, moistureproof, fireproof, rot-resistant, pest control and other functions; in addition, the flame retardant environmentally friendly adhesive has readily available raw materials, and cheap in price, so that the production cost of the flame retardant environmentally friendly adhesive is relatively low. The present invention also provides a producing method of the plant fiberboard by use of the flame retardant environmentally friendly adhesive.

Owner:河南国信联投环保科技有限公司

Water curtain filtering window device for filtering particle matter (PM) 2.5 by using air energy

InactiveCN103267323APrevent solidificationFresh airEnergy recovery in ventilation and heatingMechanical apparatusCold airEnvironmental engineering

A water curtain filtering window device for filtering particle matter (PM) 2.5 by using air energy is provided with a water curtain filtering device and an air energy water heater. An exhaust fan of the air energy water heater is used for exhausting indoor contaminated air outdoors, meanwhile an evaporator is used for absorbing indoor air heat energy, and cold water is heated to be hot water by using a condensing pipe. The water curtain filtering device uses the hot water to generate a filtering water curtain, prevents the filtering water curtain from being frozen by cold air, outdoor fresh cold air is sucked indoors through a ventilator, the filtering water curtain is used for absorbing dust and the PM 2.5 in air, and fresh purified air is provided for the indoor space.

Owner:CHINA NINGBO AKL ELECTRIC

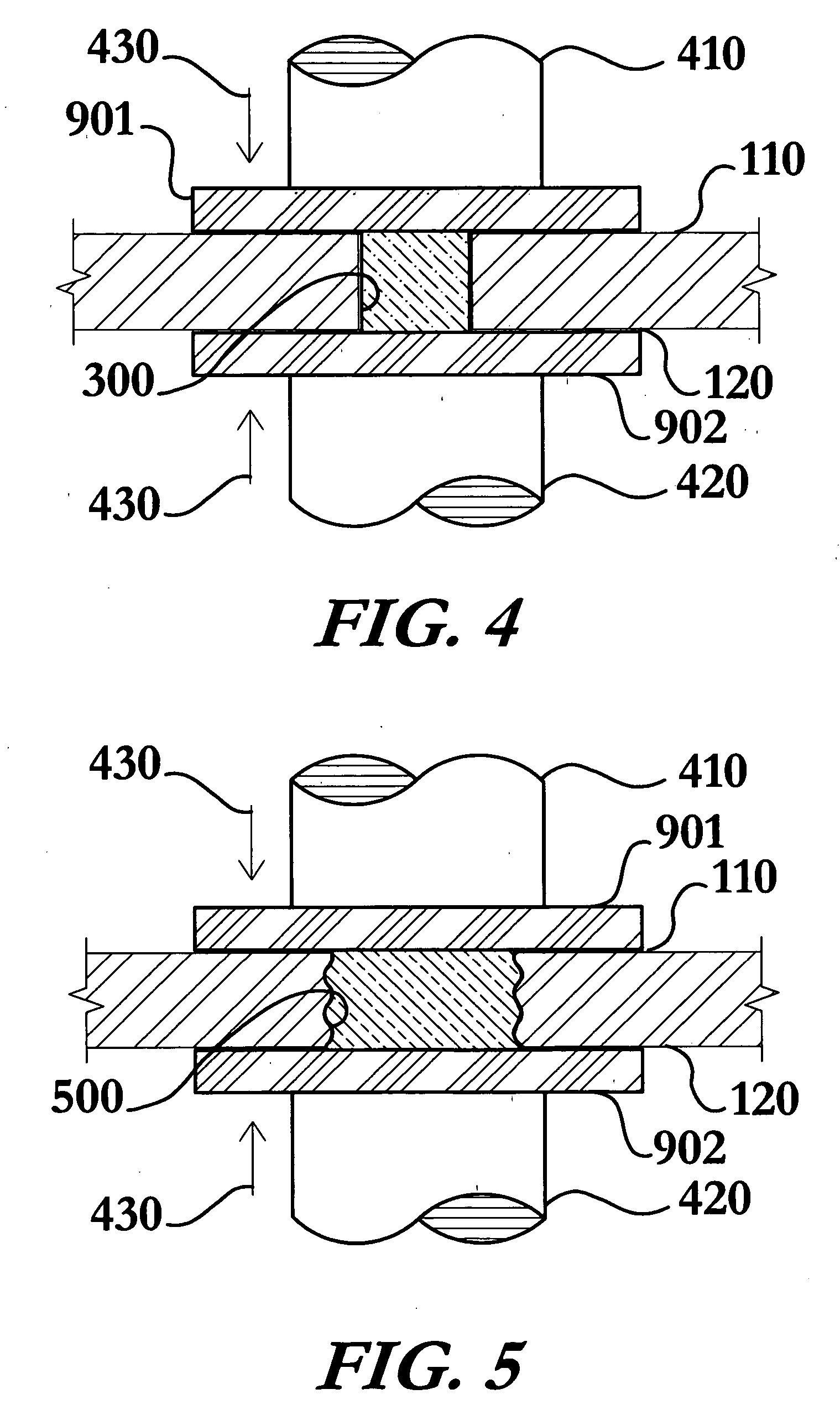

Method for repairing defects in a metallic substrate using welding

ActiveUS20050173492A1Low costImprove versatilityCooking-vessel materialsSoldering apparatusMaterial consumptionDefect filling

A method for repairing defects in a metallic substrate comprising the steps of placing a consumable filler slug in contact with the substrate in the vicinity of the defect; bringing a first electrode and a second electrode in contact with the consumable slug and applying a pressure to the consumable slug; and transmitting electrical current between the electrodes for a period, thereby resistively heating the consumable slug and the metallic substrate resulting in coalescence in a substantially liquid pool that fills the defect. The pool is then cooled to solidification under the pressure of the electrodes. The electrodes are then removed from contact with the consumable slug and excess material may be removed. The consumable slug may be formed as a single unit or multiple sections, and may incorporate sacrificial retainers to add additional defect filling material, retain the pool, and seal the pool from atmosphere.

Owner:EDISON WELDING INSTITUTE INC

Chinese patent medicine for treating gynaecologic disease and preparing method

InactiveCN1742993APrevent solidificationImprove liquiditySexual disorderPlant ingredientsDiseaseMedicinal herbs

The Chinese patent medicine for curing gynecopathy is made up by using 30-odd Chinese medicinal materials of ginseng, notoginseng, ass hide glue, velvet deerhorn, Chinese angelica root, cooked rehmannia root and others. Said invention also provides its preparation method, and said Chinese patent medicine can be made into capsule preparation.

Owner:四川泰华堂制药有限公司

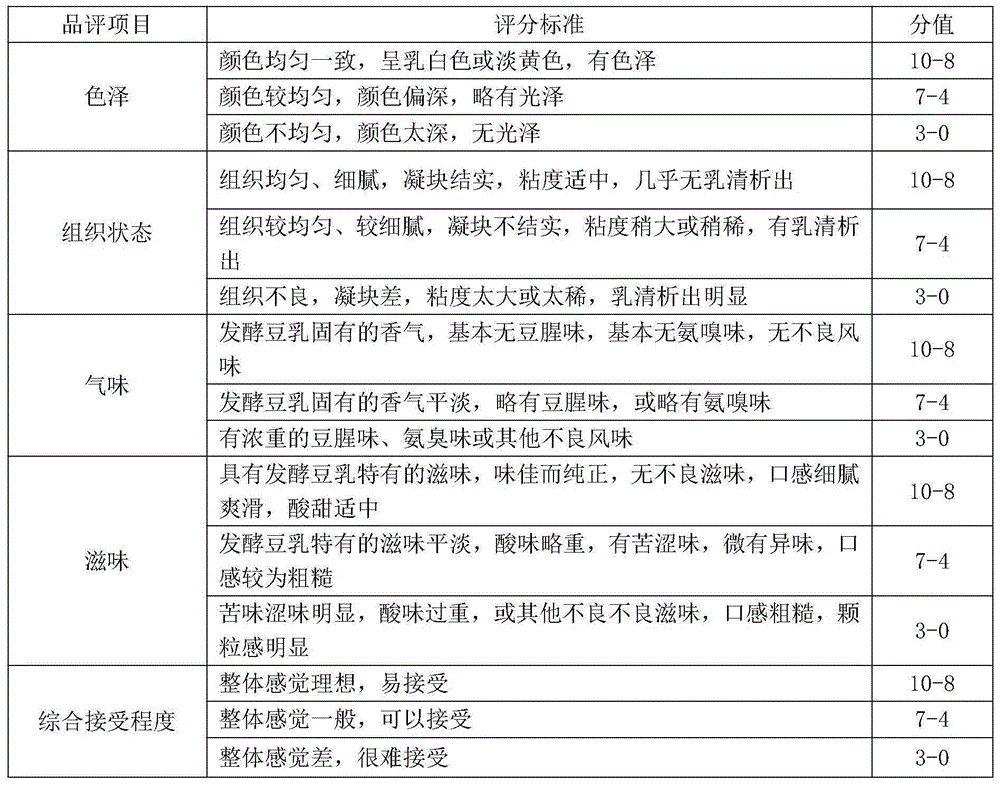

Method for improving flavor of bacillus natto fermented whole-soybean milk

InactiveCN105145852AAdd flavorGuaranteed functional factorMilk substitutesFood scienceLactobacillusSoybean product

The invention discloses a method for improving the flavor of bacillus natto fermented whole-soybean milk, and belongs to the technical field of fermented soybean product processing. With soybeans being raw materials, whole-soybean milk is prepared through the technology of selecting, soaking, hot water heating, coarse smashing, ultrafine smashing and high-pressure homogenizing, bacillus natto and lactic acid bacteria are separately inoculated into the sterilized and cooled whole-soybean milk to be fermented, then bacillus natto fermented soybean milk and lactic acid bacterium fermented soybean milk are mixed and blended according to a proportion, and then the whole-soybean milk is obtained. While the taste is guaranteed, the soybeans are fully utilized, in this way, pollution to the environment is avoided, and the capacity, for generating acid and aroma in the soybean milk, of lactic acid bacteria is utilized for effectively improving the flavor of the fermented soybean milk. Meanwhile, the liquid fermentation technology that bacillus natto and lactic acid bacteria are separately fermented and then blended is adopted, pipeline transportation can be achieved, control over fermentation conditions and a fermentation end point is easier, the range is easy to enlarge, the components are easy to control, and follow-up processing is simple.

Owner:JIANGNAN UNIV

Catering grease separator capable of automatically removing residues, discharging oil and lifting

InactiveCN105016498ASolve the low efficiency of slag removalClean up thoroughlyMultistage water/sewage treatmentOil and greaseSludge

The invention provides a catering grease separator capable of automatically removing residues, discharging oil and lifting. The catering grease separator comprises a solid-liquid separation box, an oil separating and sludge discharging box, sewage lifting equipment, a control cabinet and an exhaust pipe assembly, wherein all the solid-liquid separation box, the oil separating and sludge discharging box and the sewage lifting equipment are connected with the exhaust pipe assembly; a spiral conveying device is arranged inside the solid-liquid separation box; the oil separating and sludge discharging box comprises an oil collecting box and a separation box; the oil collecting box is provided with a grease observation mirror; and a sludge discharging hole is formed in the bottom of the separation box. By using the catering grease separator, solid impurities in wastewater can be effectively and thoroughly cleared away; the grease condition can be conveniently observed by working staffs so that grease can be cleared way in time; and all the parts are detachably connected, so that the catering grease separator is conveniently dismounted and carried.

Owner:HEFEI EPANEL HYDROTECHNY

Blocking type intravenous infusion catheter device

PendingCN108578825AEliminates the risk of thrombosisEliminate dead spaceMedical devicesHaemostasis valvesInfusion catheterIntravenous Infusions

The invention provides a blocking type intravenous infusion catheter device which comprises a rigid needle tube, a needle tube base, a flexible infusion catheter and an infusion catheter base, whereinthe rigid needle tube is used for piercing skin and vein walls; the bottom end of the needle tube is fixed in the needle tube base; the infusion catheter base is hermetically connected with the bottom end of the infusion catheter; the front end of the needle tube penetrates through a sealing plug and is positioned in the inner cavity of the infusion catheter; and the tip of the needle tube is exposed from an opening in the top end of the infusion catheter. The blocking type intravenous infusion catheter device is characterized by also comprising a movable blocking component which is externally isolated, at least the blocking part of the blocking component can enter the inner cavity of the infusion catheter through the inner cavity of the infusion catheter base under the driving of the external force, and the blocking part of the blocking component can move to the opening in the top end of the infusion catheter along the inner cavity of the infusion catheter and block the opening so asto prevent the blood from entering the inner cavity of the infusion catheter and simultaneously prevent the liquid medicine from entering veins.

Owner:ZHEJIANG BAIHUO HEALTH TECH CO LTD

Diluent for blood cell analyzer

InactiveCN101975850AAntisepticPrevent solidificationPreparing sample for investigationBiological testingDimethylol ureaSodium azide

The invention provides a diluent for a blood cell analyzer. The diluent consists of edentate, sodium sulfate, sodium chloride, dimethylol urea, biological buffer, a betain type nonionic surfactant, sodium azide and water. The diluent solves the problems that the osmotic pressure of a bottom layer is higher than that of an upper layer and the solution is not uniform or stable when the diluent for the blood cell analyzer stands for a long time.

Owner:南京卡博生物科技有限公司

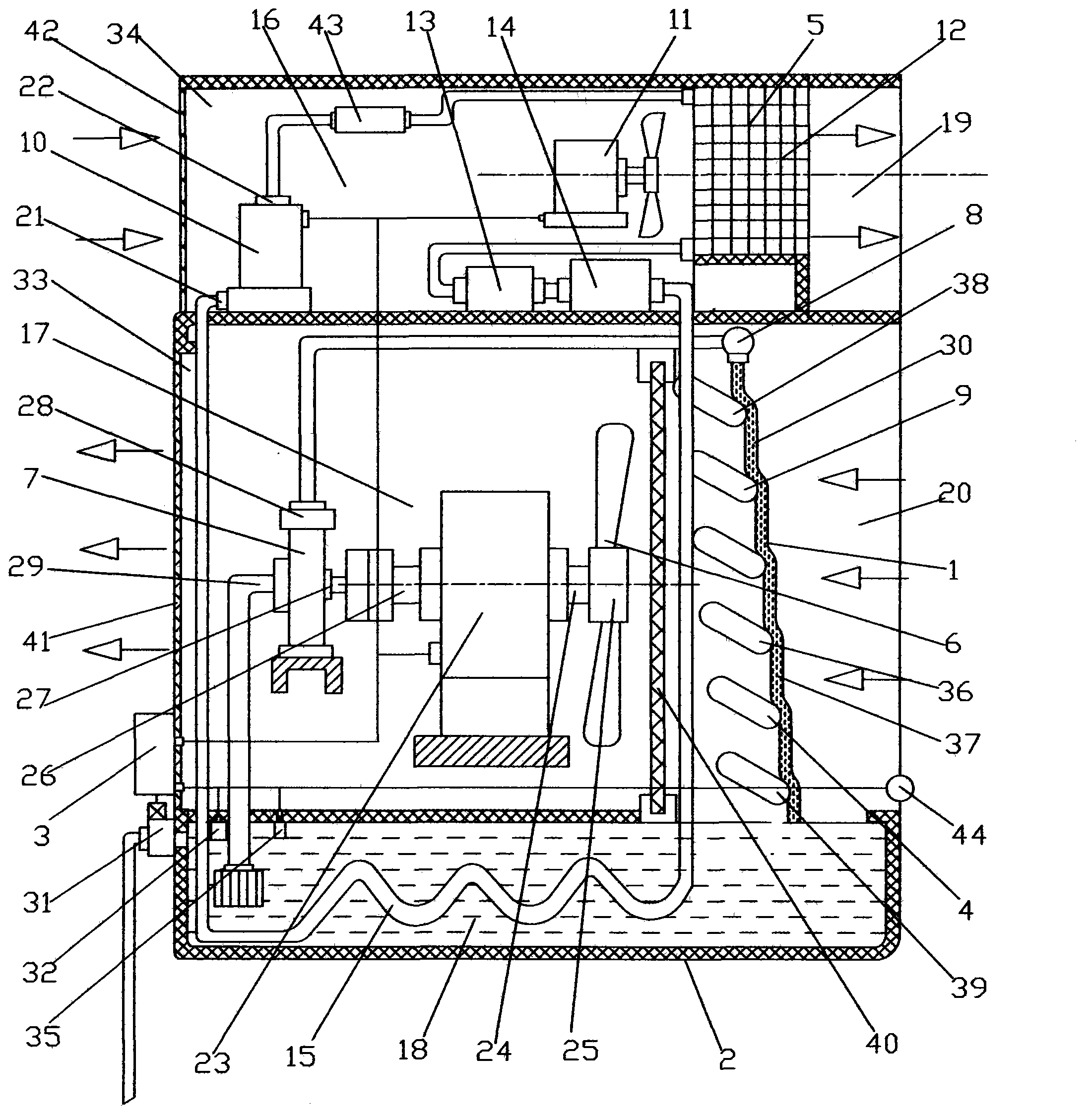

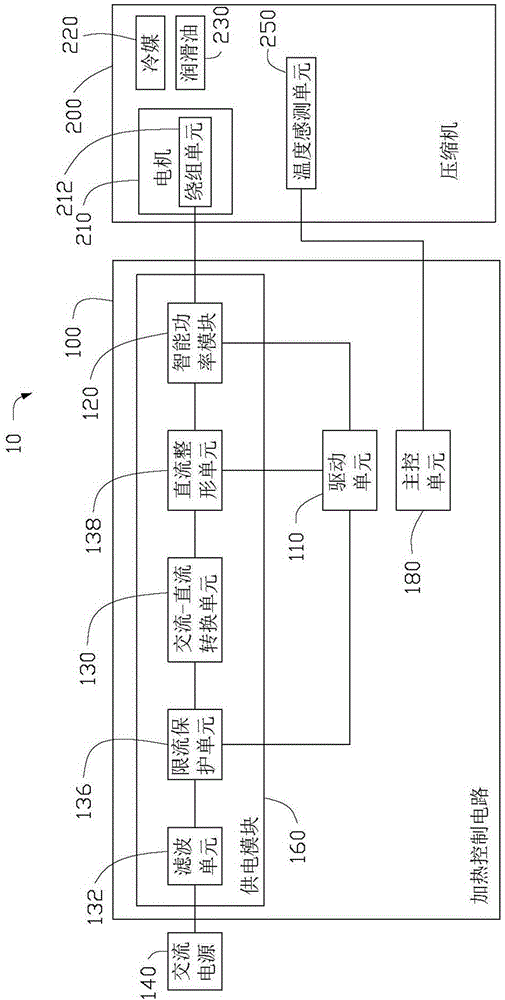

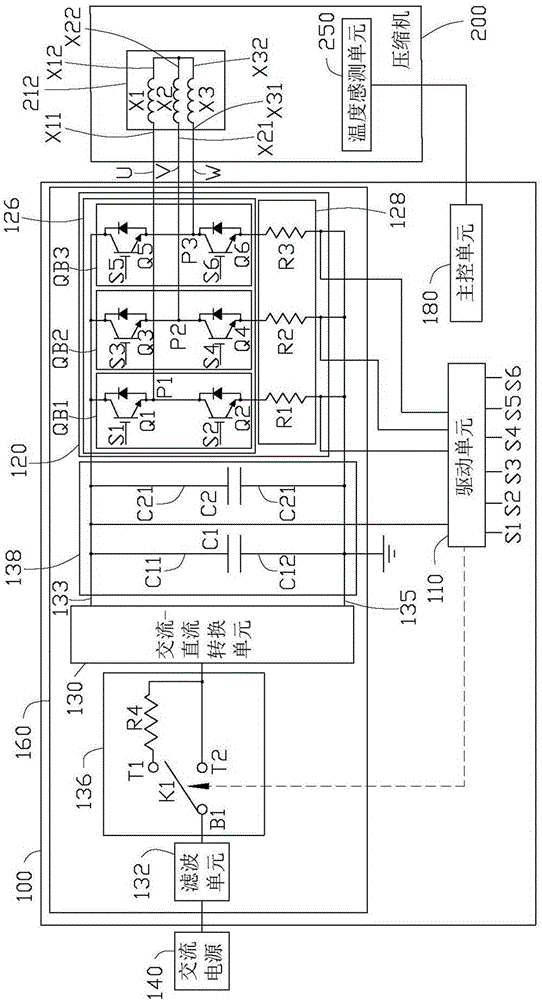

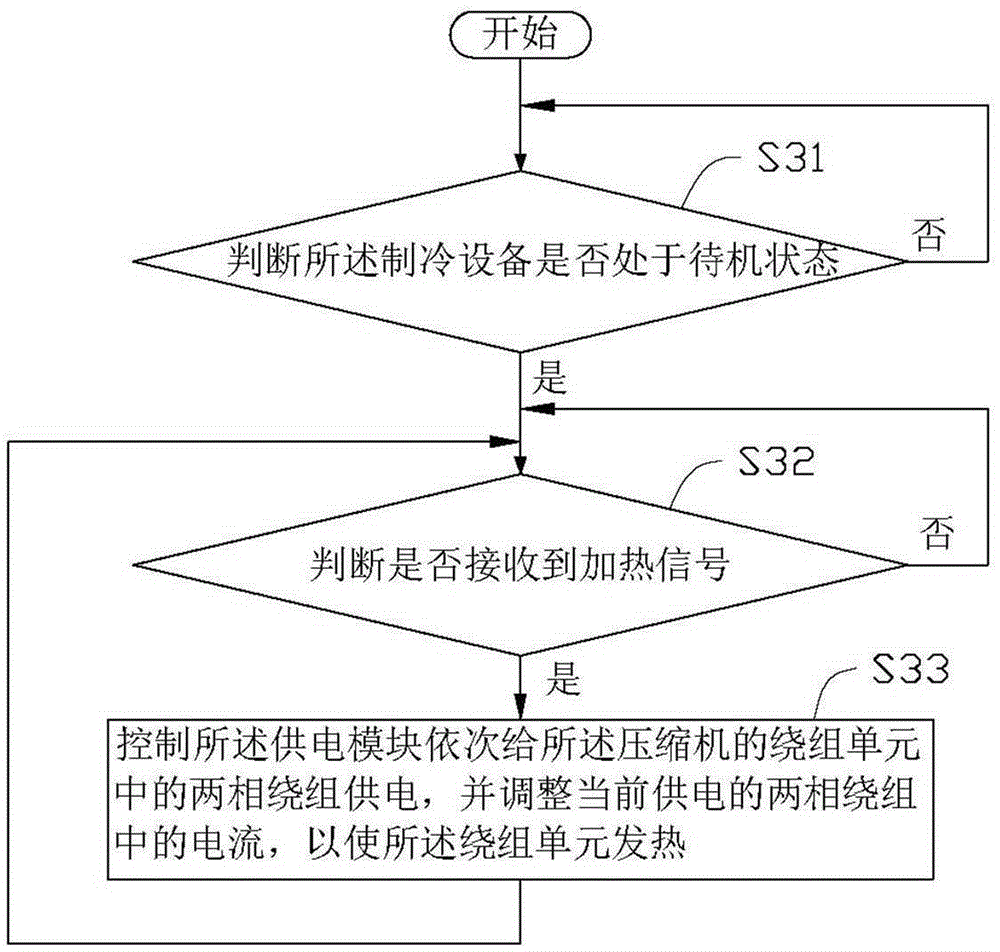

Refrigeration equipment and heating control circuit and heating control method of compressor thereof

The invention provides refrigeration equipment and a heating control circuit and a heating control method of a compressor thereof. The heating control circuit is used for controlling the compressor of the refrigeration equipment for heating. The heating control circuit comprises a driving unit and a power supply module. The driving unit is used for controlling the power supply module to supply power to two phases of windings in a winding unit of the compressor in sequence when the refrigeration equipment is in a standby state and receives heating signals so that the winding units are heated, and the compressor is heated. The invention also provides the refrigeration equipment applied to the heating control circuit and the heating control method. According to the refrigeration equipment and the heating control circuit and the heating control method thereof, the heating of the compressor can be controlled, and the heating efficiency is high.

Owner:GREE ELECTRIC APPLIANCES INC

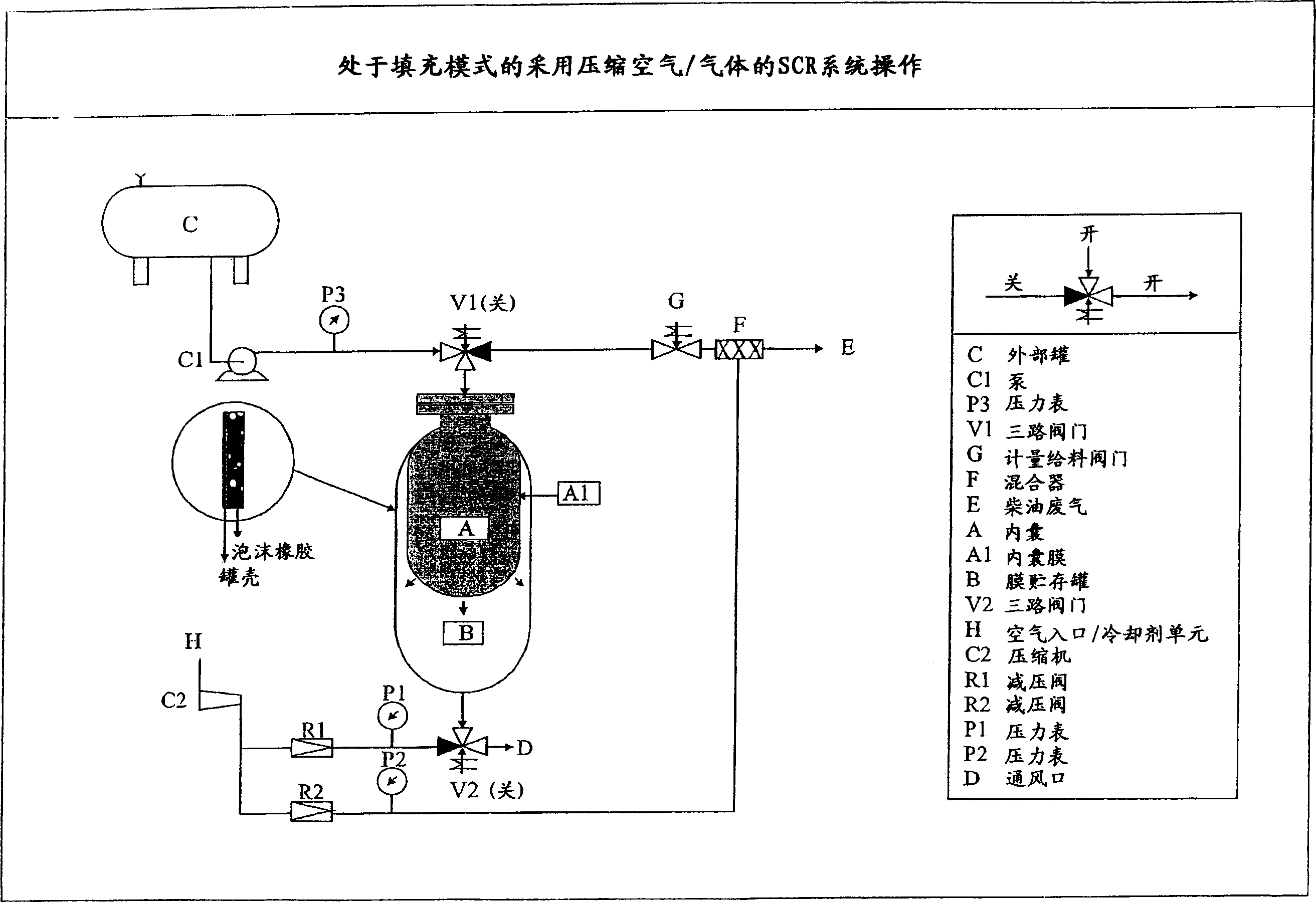

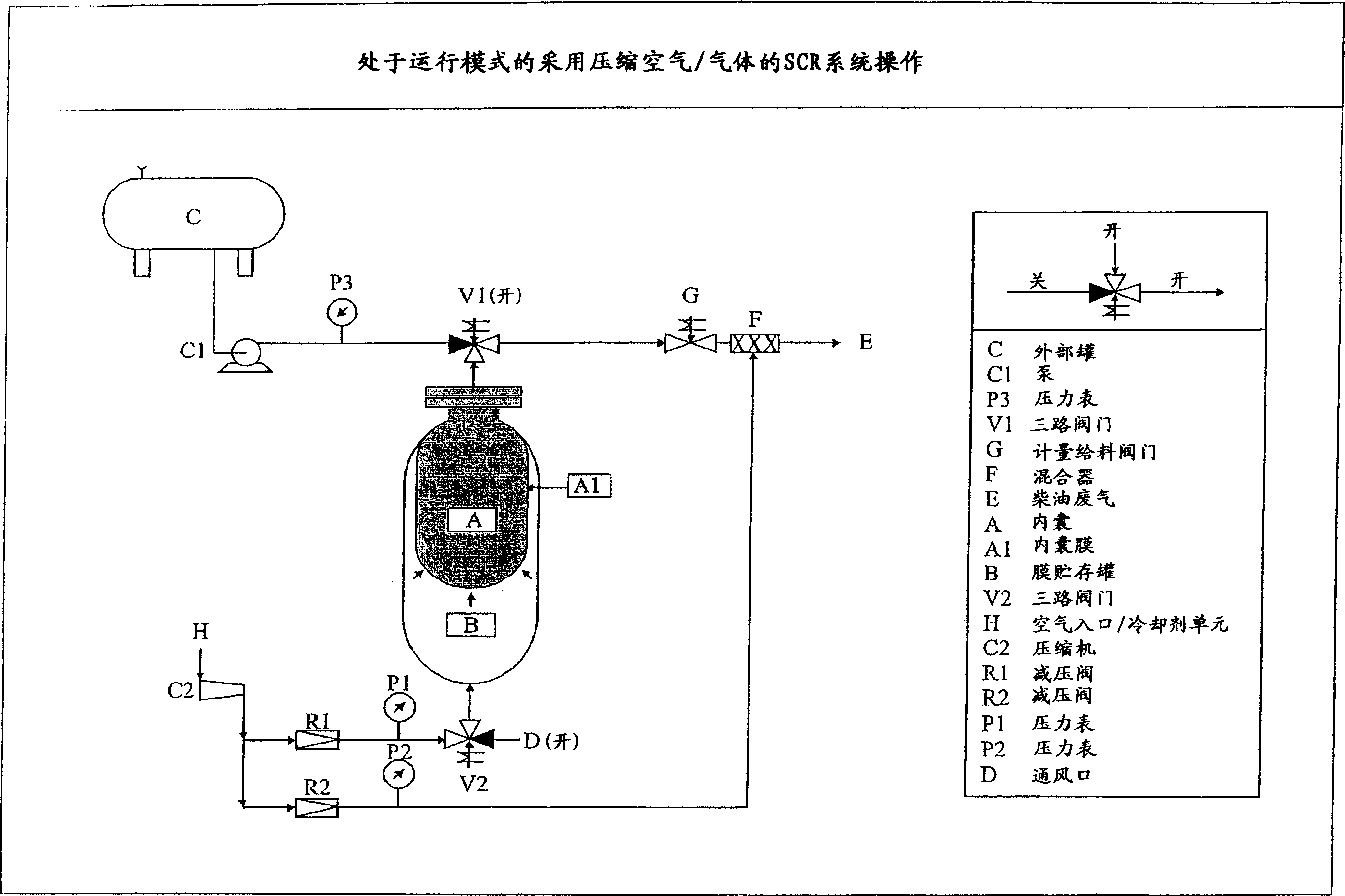

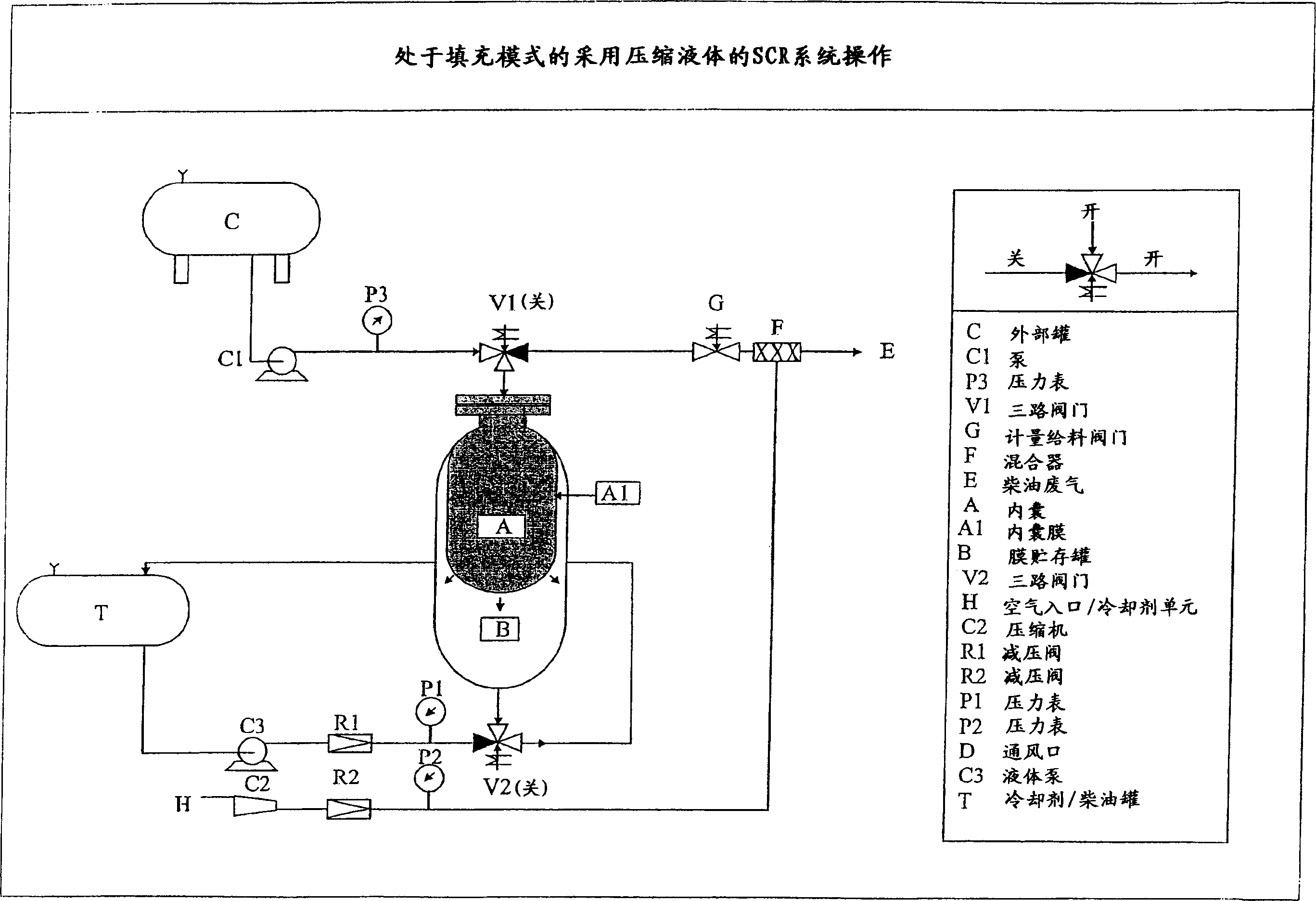

Method and appts. for reducing discharge of nitrogen oxide in selective catalytic reduction system

InactiveCN1382517AEliminate lossWill not induce permanent damageInternal combustion piston enginesExhaust apparatusExternal storageNitrogen oxides

The invention concerns a process and an apparatus for reducing the content of nitrogen oxides (NOx) in the exhaust gases of diesel engines or turbines for stationary or mobile applications / vehicles in an SCR system by providing a stored source of liquid reducing agent and feeding the stored reducing agent to the exhaust gases, said process comprising transferring the liquid reducing agent from the external storage tank to a membrane storage tank equipped with an inner bellow consisting of a non-permeable flexible membrane, and a hydraulic or pneumatic displacement fluid located outside the inner bellow, filling the flexible inner bellow with liquid reducing agent and transferring the liquid reducing agent from the flexible inner bellow to the exhaust gases. <IMAGE>

Owner:HALDOR TOPSOE AS

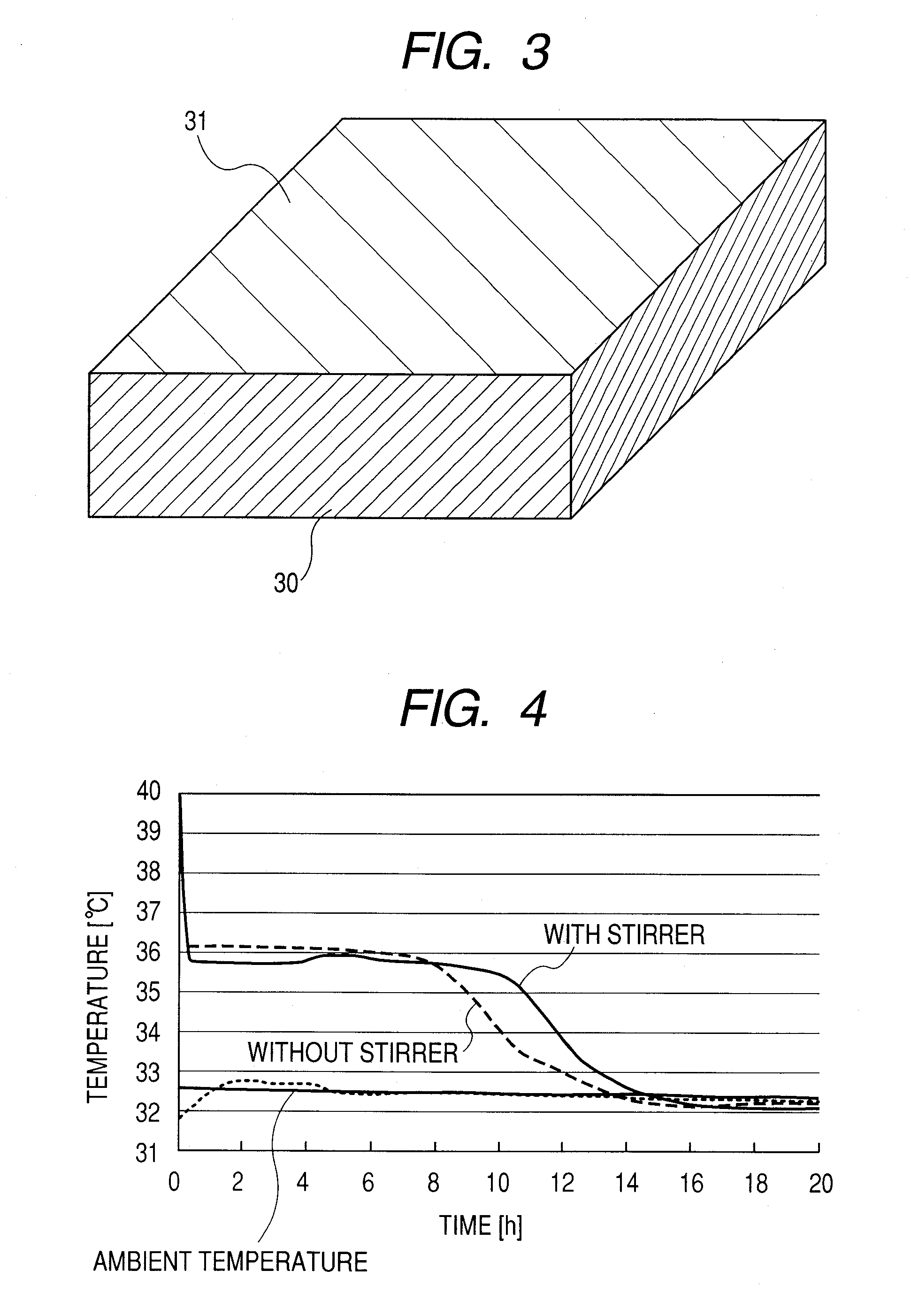

Temperature regulating member

InactiveUS20080029247A1Easy to controlEasy to shipHeat storage plantsMixersEngineeringHeat distribution

A temperature regulating member capable of avoiding deterioration in heat dissipation efficiency of a heat-accumulating material, and deterioration in a buffer function thereof, due to ununiformity in heat distribution inside the heat-accumulating material. With the use of a churning flow occurring by disposing one piece of stirrer or plural stirrers inside the heat-accumulating material, and by causing a relative position of the stirrer, inside the heat-accumulating material, to be changed during transportation, it is possible to eliminate ununiformity in heat distribution inside the heat-accumulating material. The temperature regulating member has a feature in that a phenomenon of a peripheral part of the heat-accumulating material being first cooled to be subsequently solidified is avoided, thereby enabling the heat dissipation efficiency and the buffer function to be maintained.

Owner:HITACHI LTD

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

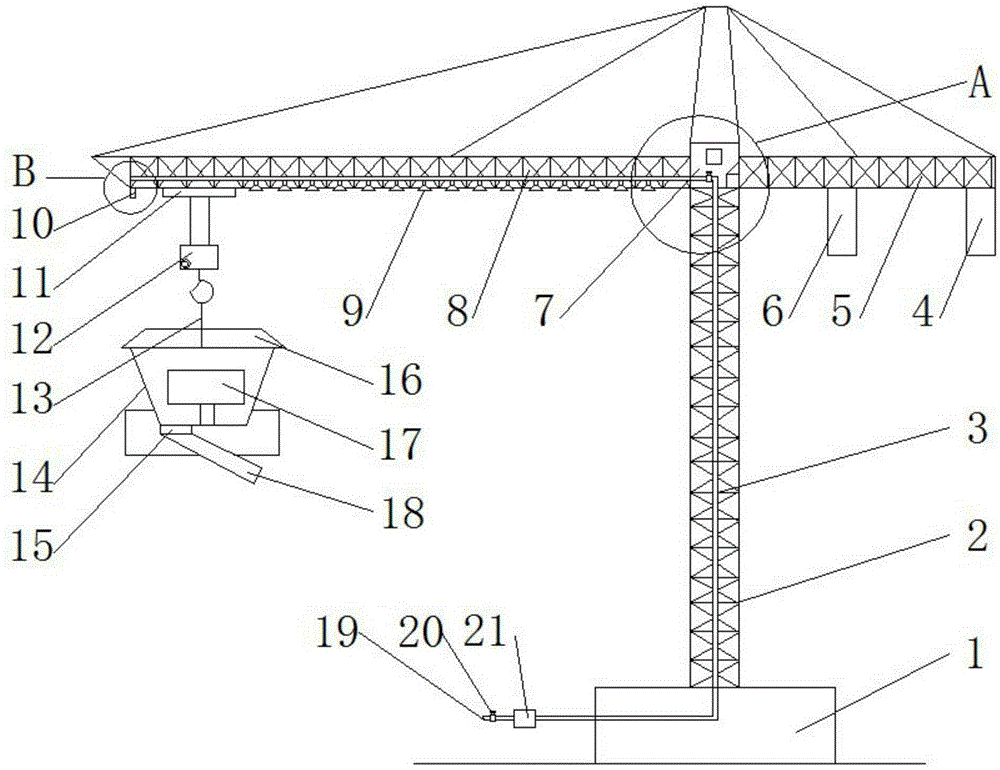

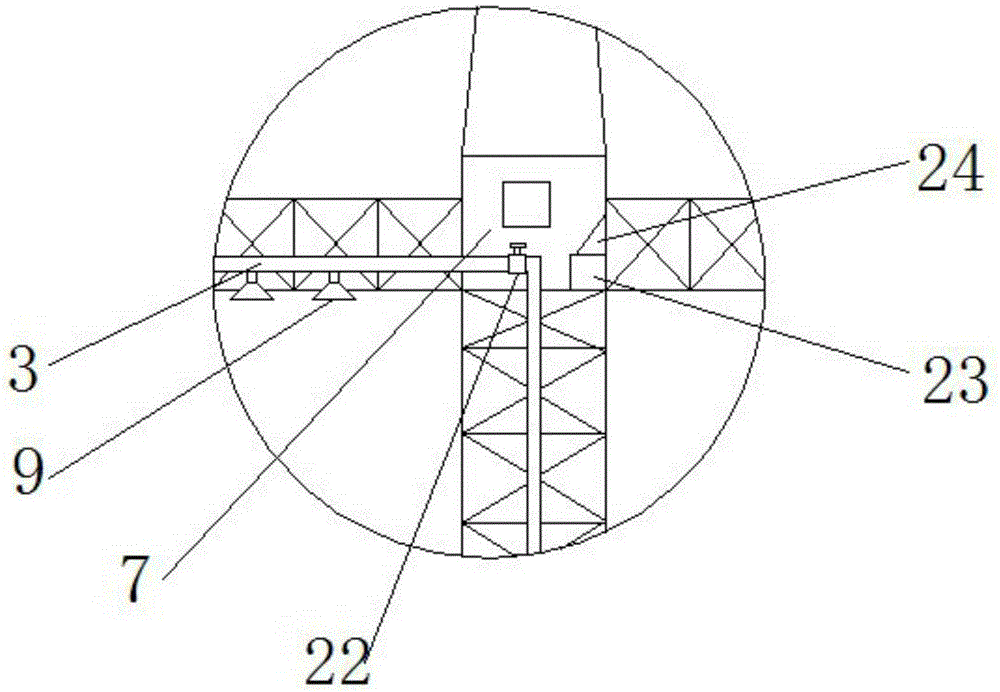

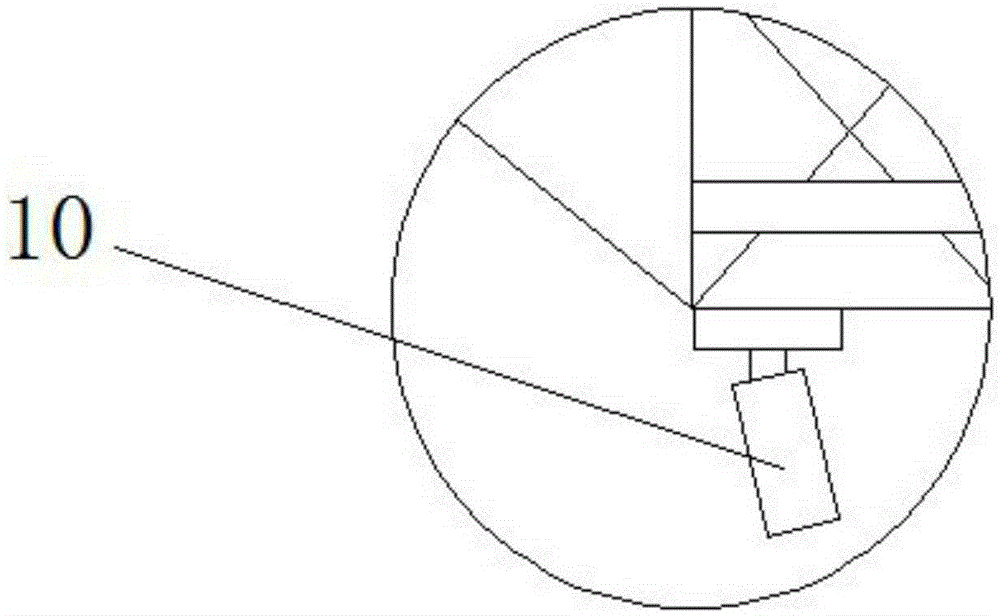

Construction method of multifunctional tower crane used for building construction

InactiveCN105668425AHelp outputPrevent compactionBuilding material handlingCranesSpray nozzleArchitectural engineering

The invention discloses a construction method of a multifunctional tower crane used for building construction. The multifunctional tower crane comprises a base, a hanging rack, a balancing arm, an operation room and a cargo boom. The balancing arm and the cargo boom are erected on the two sides of the hanging rack correspondingly in a balanced mode. A water pipe is vertically arranged in the hanging rack. A water pipe is transversely arranged in the cargo boom. A plurality of spray nozzles are uniformly distributed in the water pipe transversely arranged in the cargo boom. A sliding device is arranged on a front boom body of the cargo boom. A lifting hook is arranged below the sliding device. A cable is arranged below the lifting hook. The cable is connected with a concrete stirring box. Monitoring probes are arranged at the tail end of the cargo boom and the lifting hook. By the adoption of the construction method of the multifunctional tower crane used for building construction, a lifting and conveying function is achieved, and poured concrete can be wet and cooled through watering by spraying water mist, or dust removal can be achieved through mist spraying.

Owner:SUZHOU HUICHENG ZHIZAO IND DESIGN

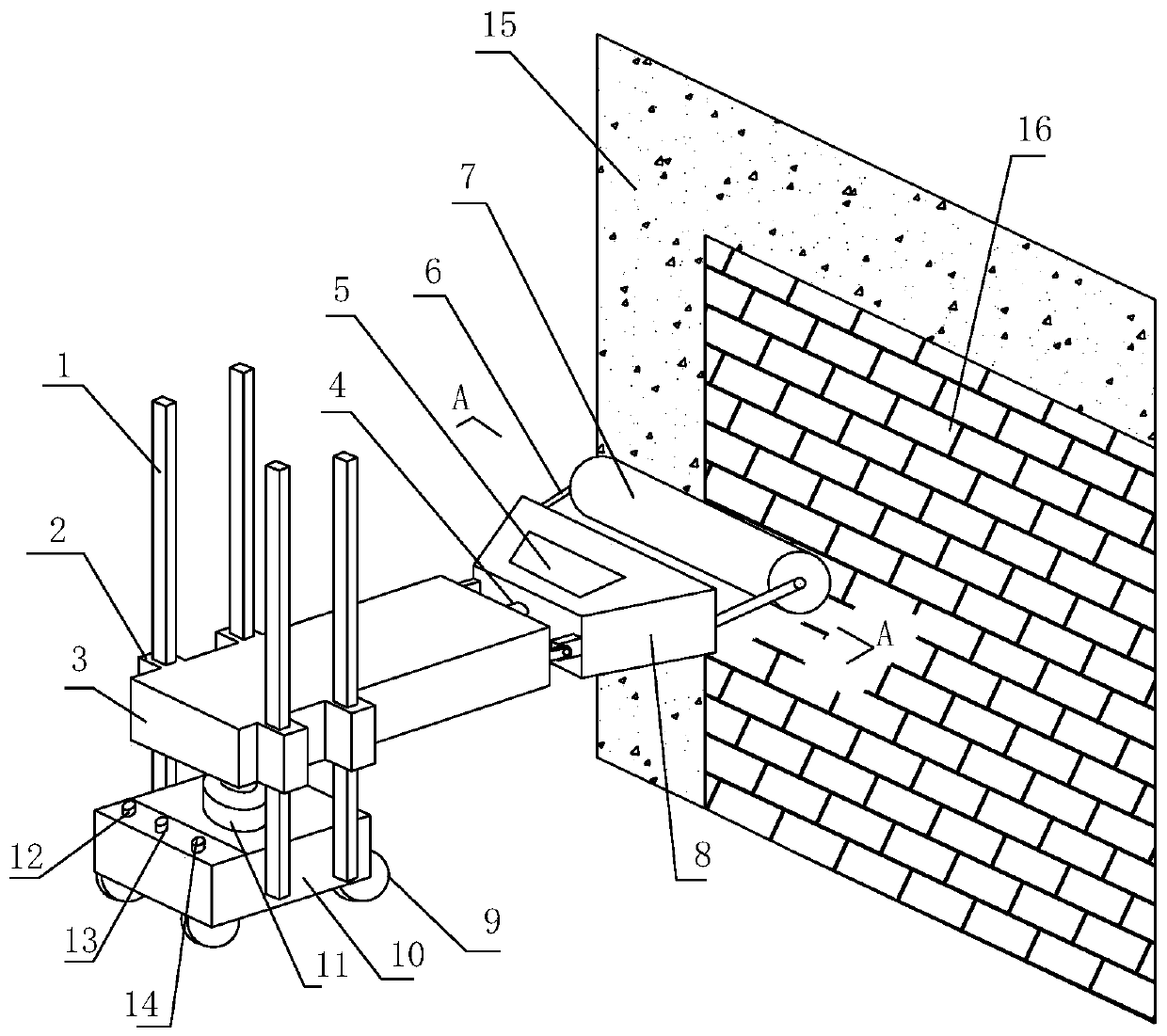

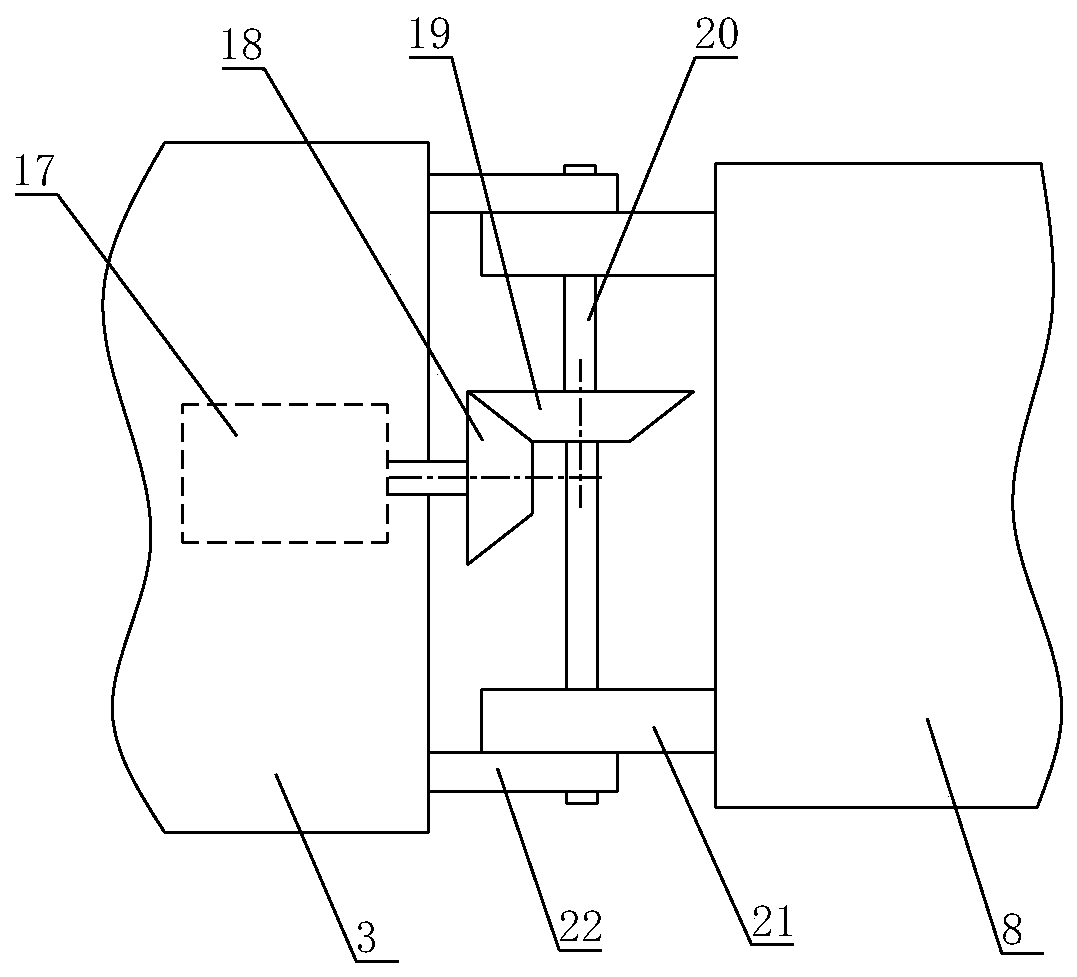

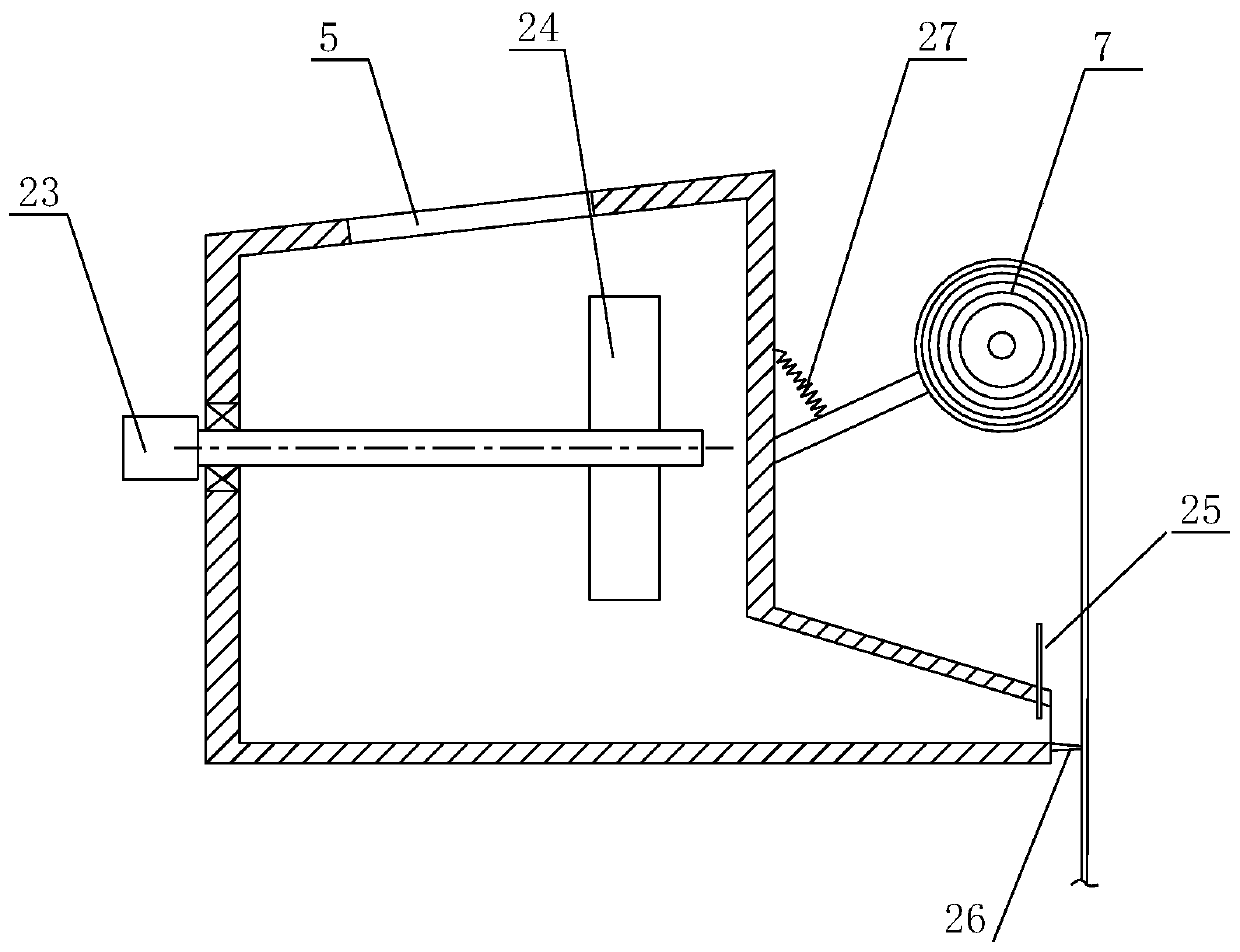

Concrete and masonry structure butting portion automatic net hanging device and method

The invention relates to a concrete and masonry structure butting portion automatic net hanging device and a concrete and masonry structure butting portion automatic net hanging method. The concrete and masonry structure butting portion automatic net hanging device comprises a moving trolley, a lifting device, a cantilever, a machine head rotation device, a gum and cement mixed extrusion box and aglass fiber net laying frame, wherein the cantilever is installed on the moving trolley through the lifting device, the gum and cement mixed extrusion box is arranged at one end of the cantilever, ahinge structure is arranged between the gum and cement mixed extrusion box and the cantilever, the gum and cement mixed extrusion box and the cantilever are connected through the machine head rotationdevice, a gum and cement feeding port is formed in the top of the gum and cement mixed extrusion box, a stirring device is arranged in the gum and cement mixed extrusion box, a gum and cement outletis formed in the bottom of the outer end of the gum and cement mixed extrusion box, a gum and cement scraper blade is arranged on the gum and cement outlet, a glass fiber net laying frame is arrangedabove the gum and cement outlet, and under the action of the machine head rotation device, a machine head composed of the gum and cement mixed extrusion box and the glass fiber net laying frame can overall rotate between the horizontal direction and the vertical direction. The concrete and masonry structure butting portion automatic net hanging device can complete the laying and gumming process ofa glass fiber gridding cloth in one time, is high in construction quality and high in efficiency, and greatly reduces labor intensity of constructors.

Owner:CHINA THIRD METALLURGICAL GRP

Lithium ion battery capable of low-temperature working

ActiveCN1790800AReduce the diffusion distance of solid phase ionsIncrease the reaction areaCell electrodesSecondary cellsSolid phasesOxide

The invention relates to a lithium ion cell fit to low temperature, which comprises: a positive electrode with active material as Li-containing transition metal oxide with D50 size less than 5ª–m, a negative electrode, a non-aqueous electrolyte contained straight-chain ester organic solvent with carbon atom number less than 5. This invention reduces solid-phase ion diffusion distance, enlarges reaction area to decrease reaction and solid-phase diffusion impedances, realizes discharge capacity at -20Deg even -50Deg, and avoids the salt separation and electrolyte solidification.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com