Patents

Literature

3228results about How to "Clean up thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

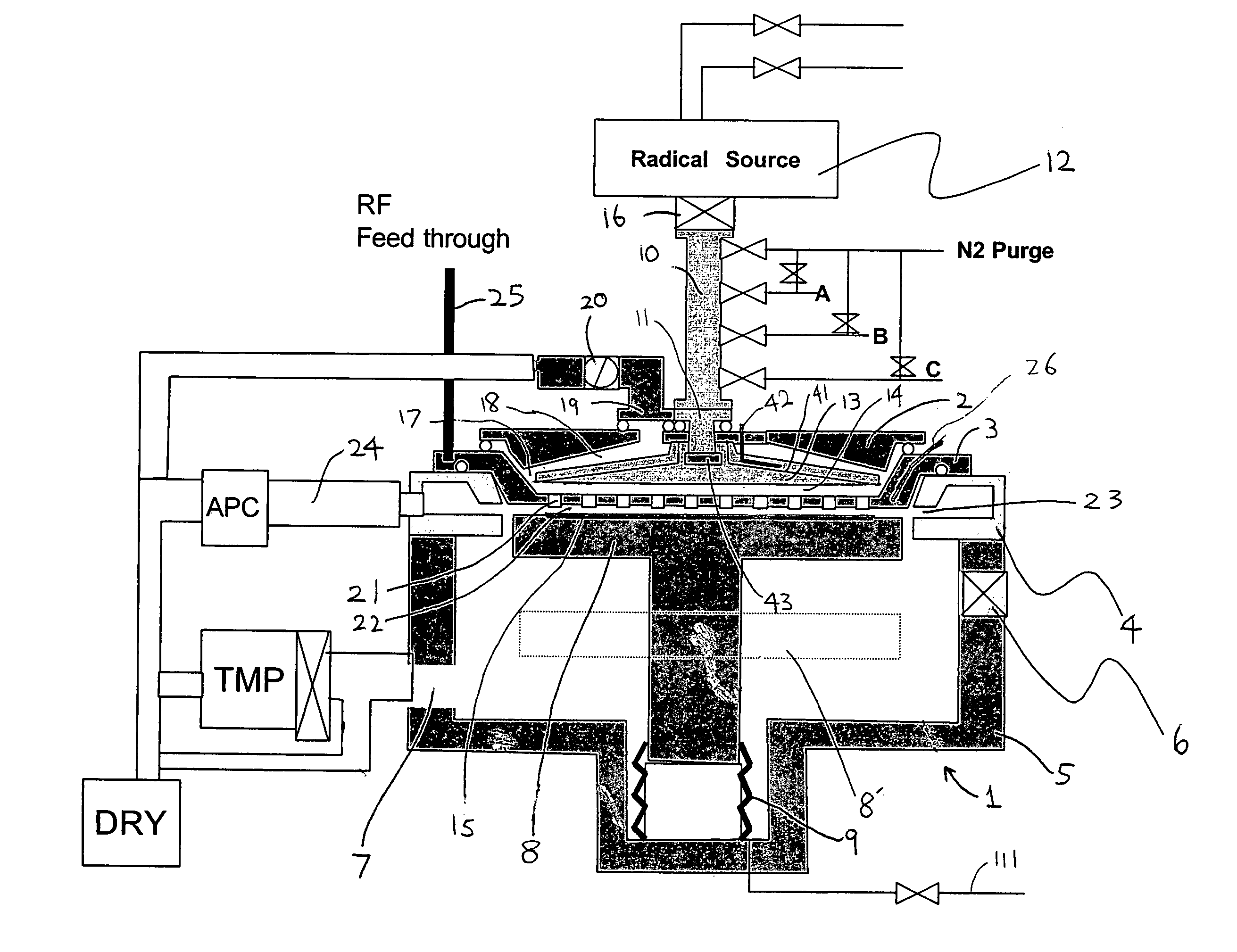

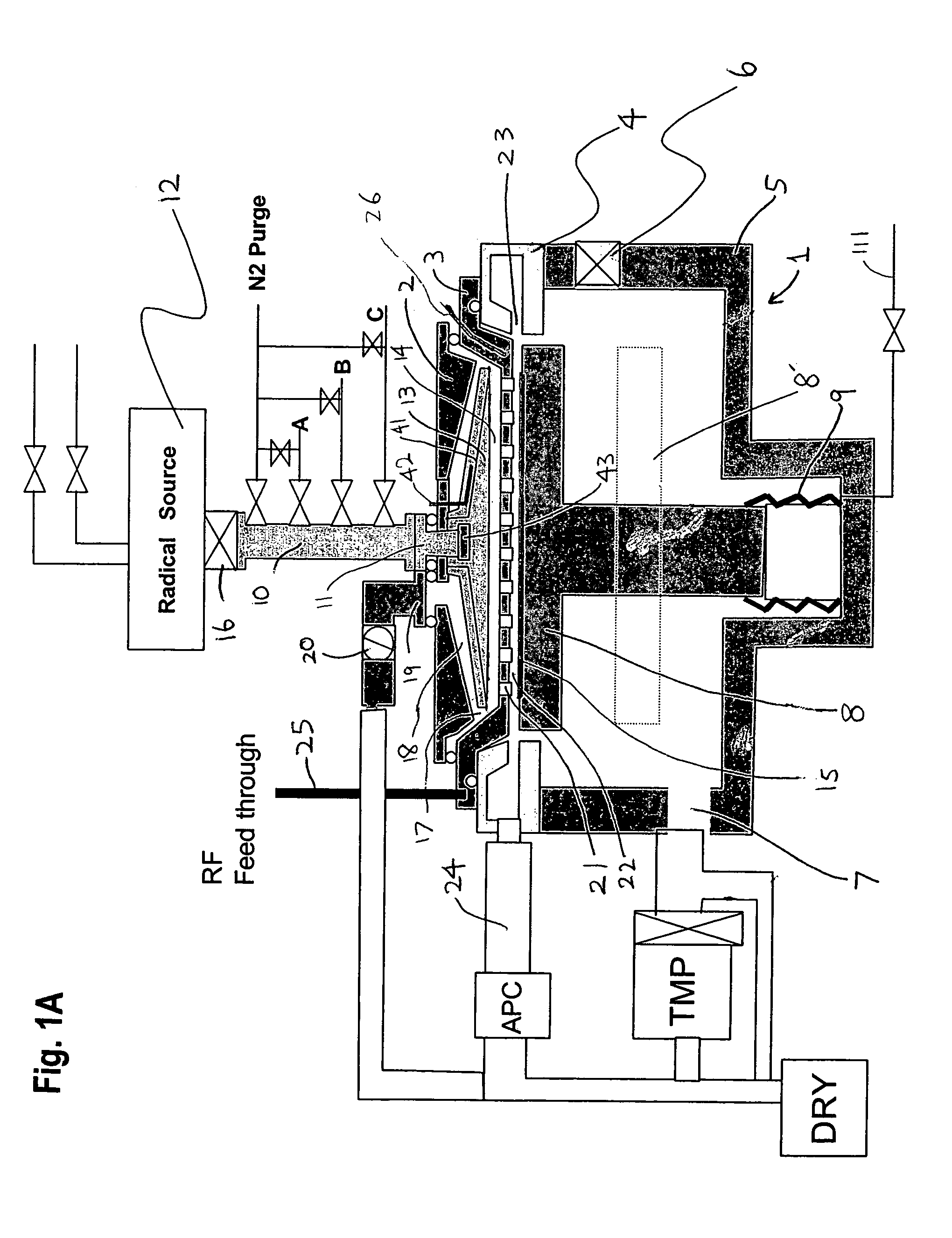

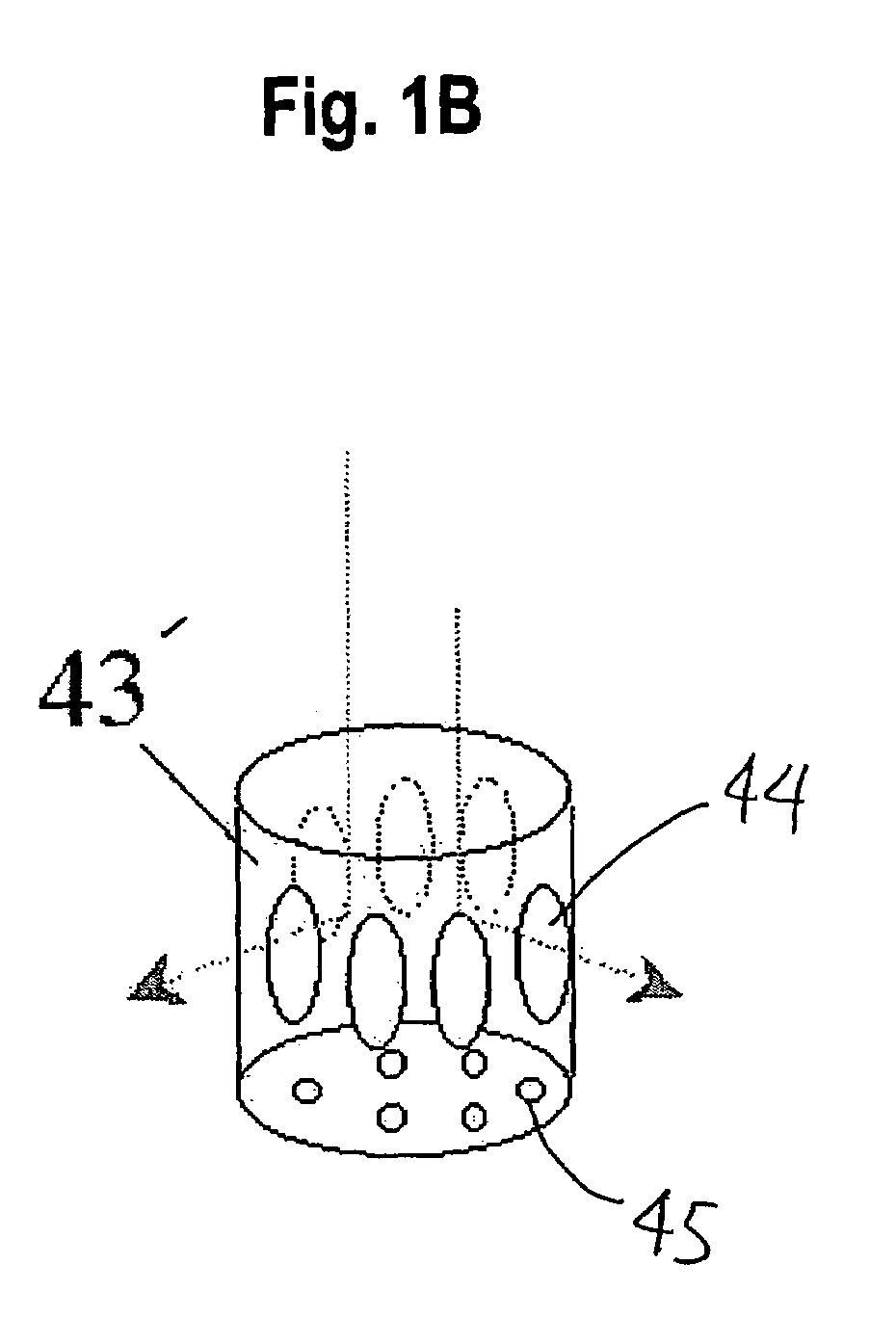

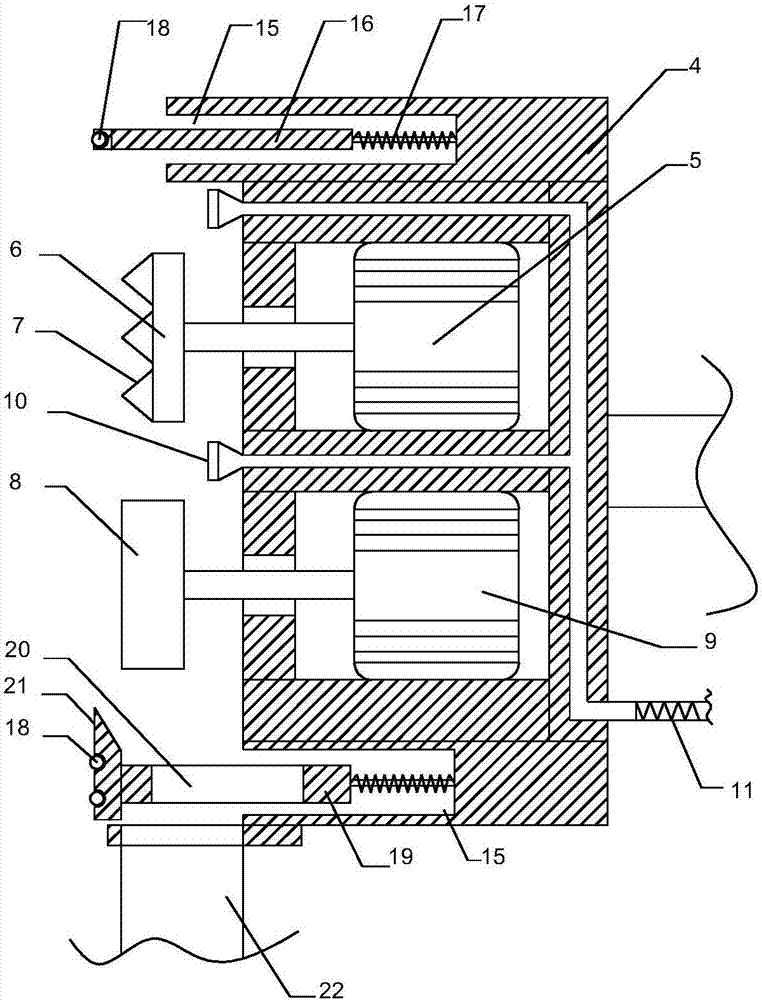

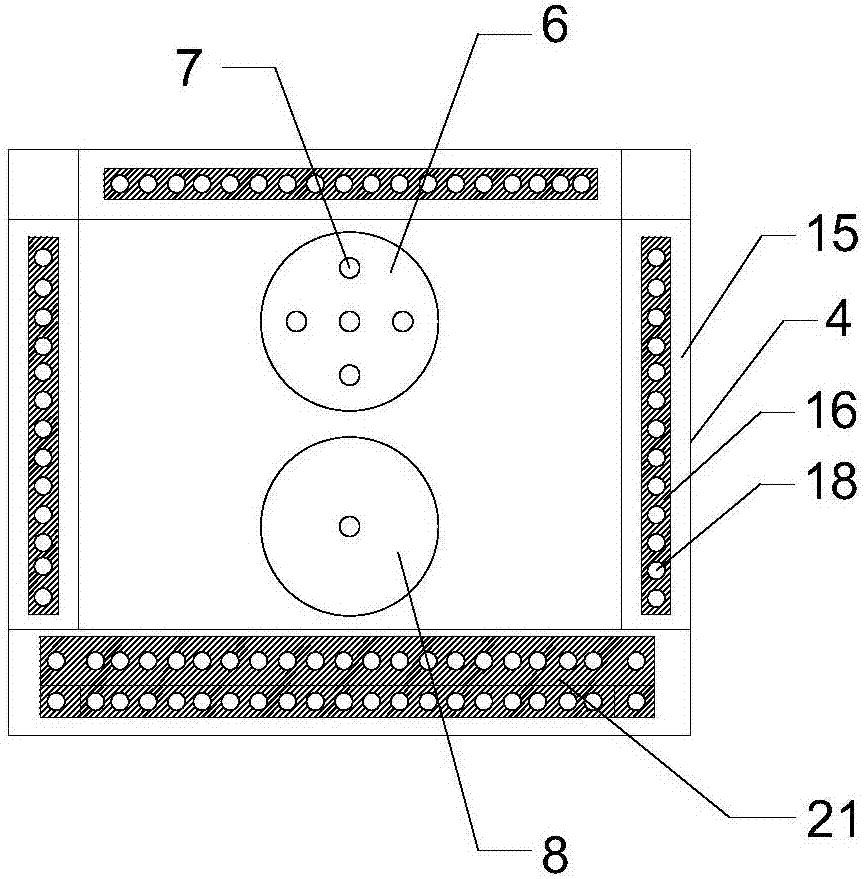

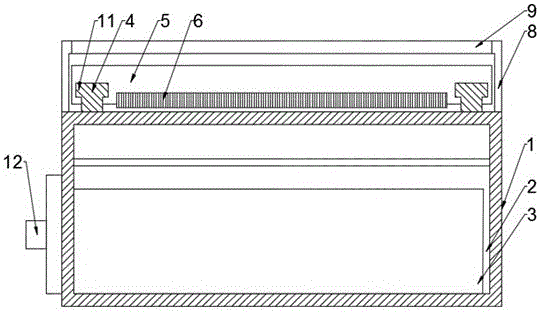

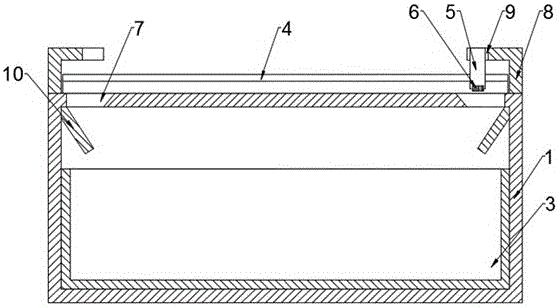

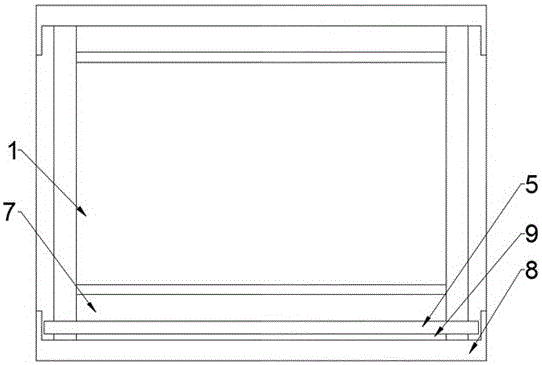

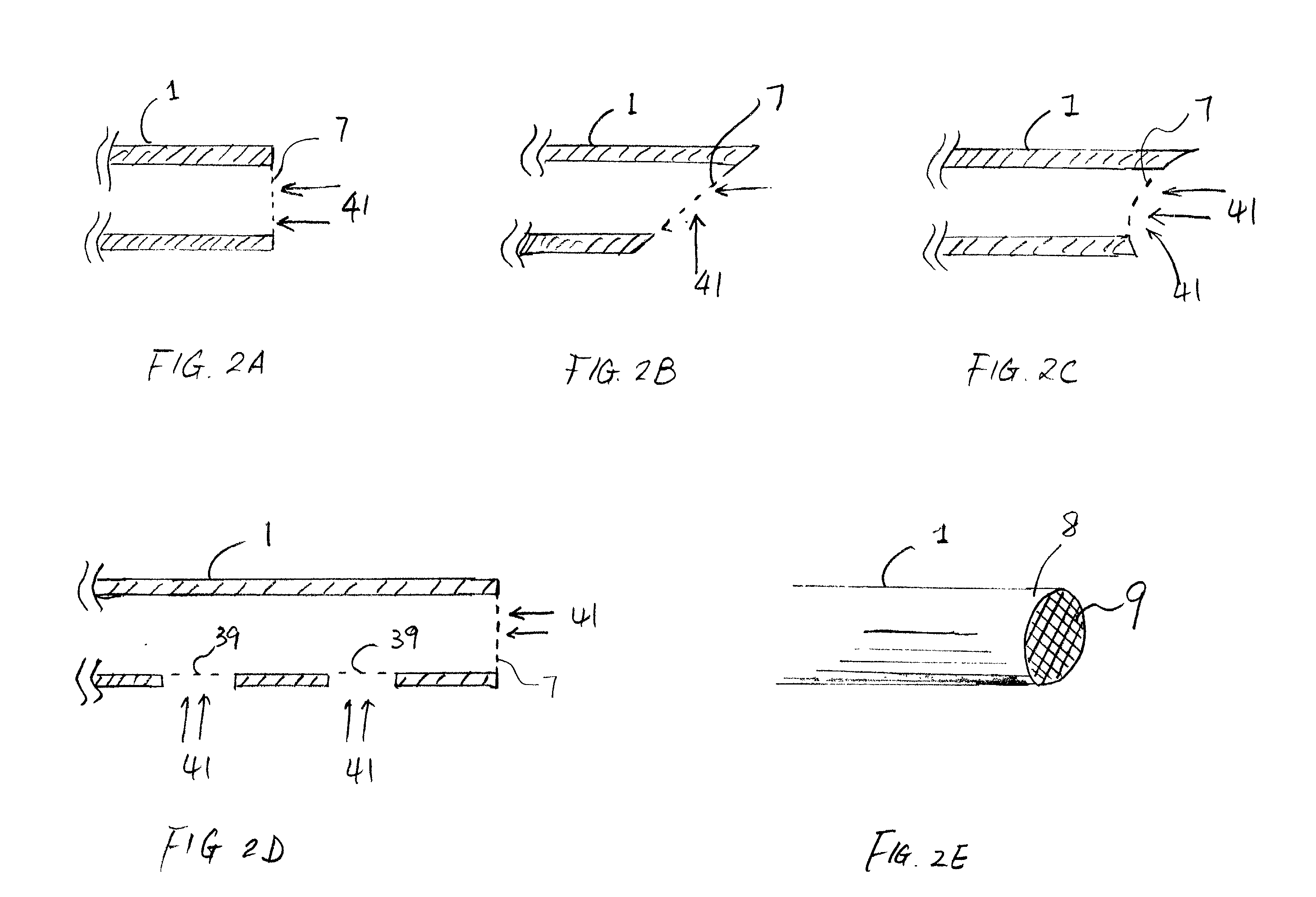

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS7408225B2Reduce impactEvenly distributedElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

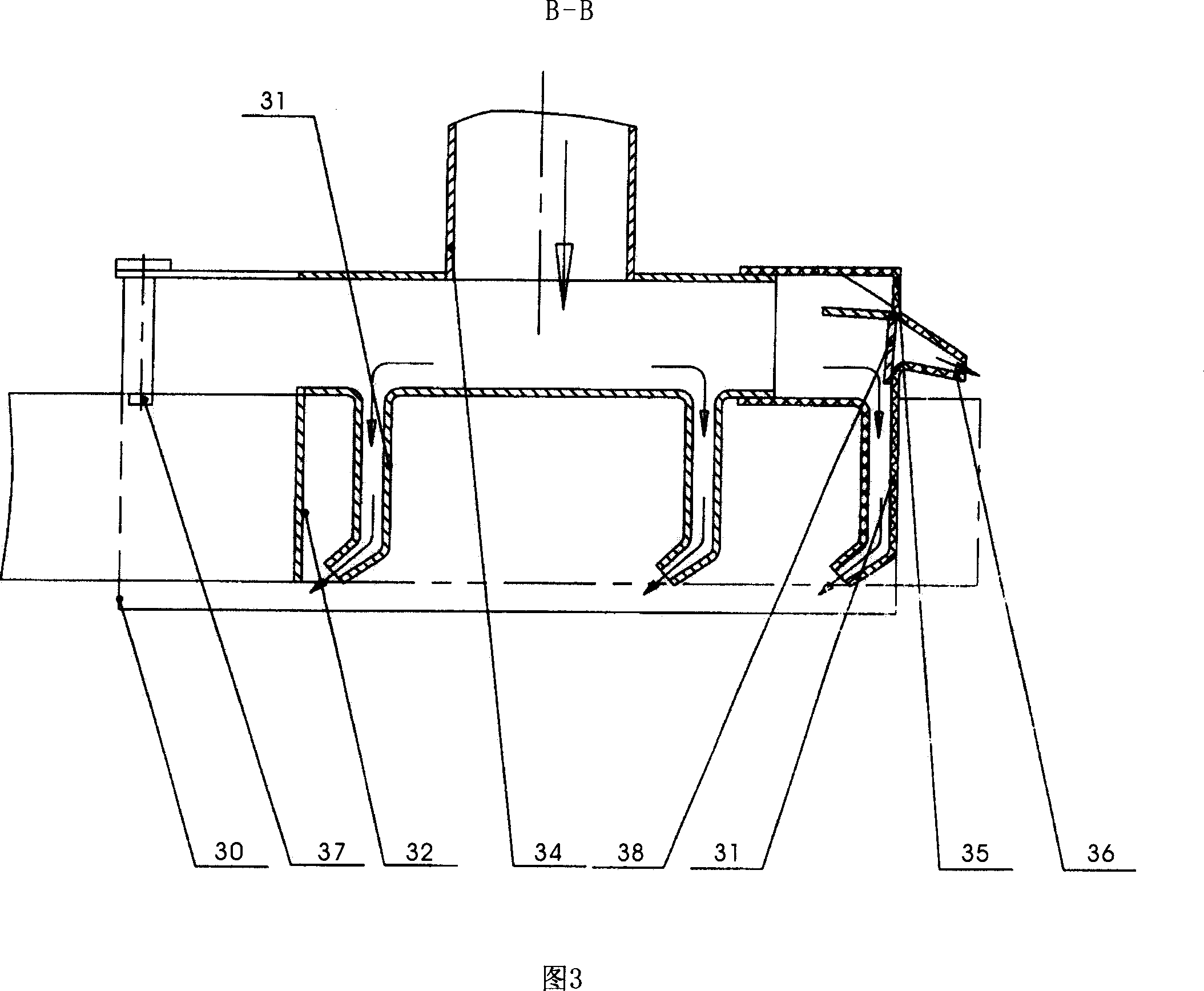

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

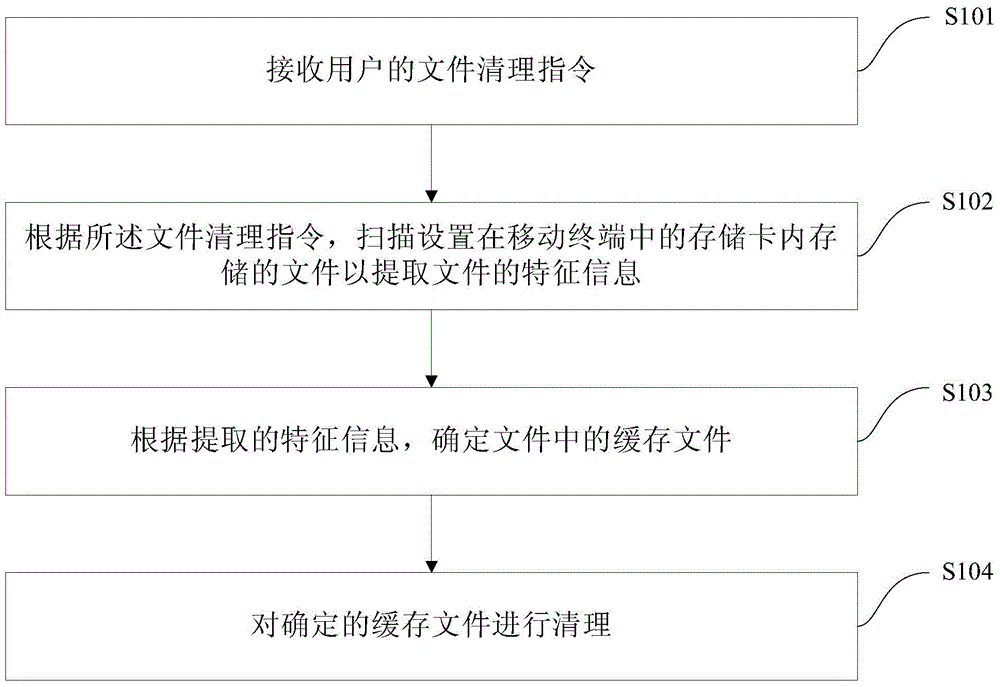

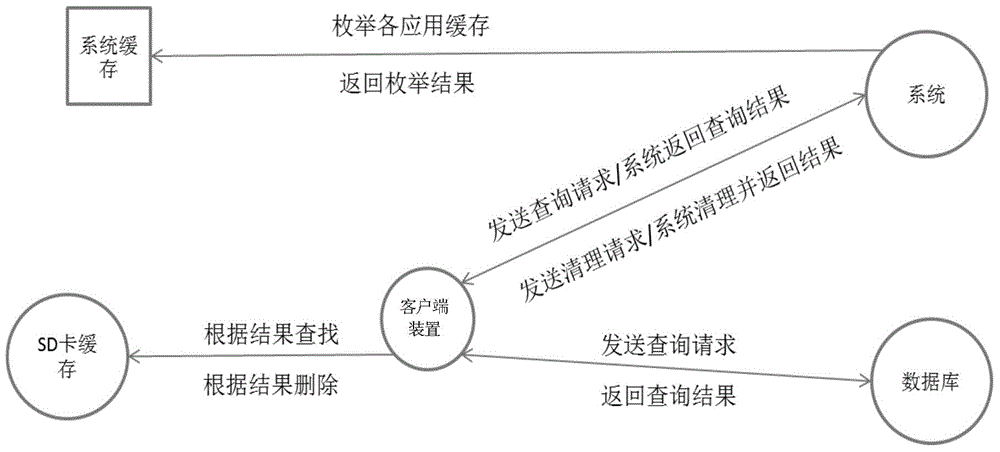

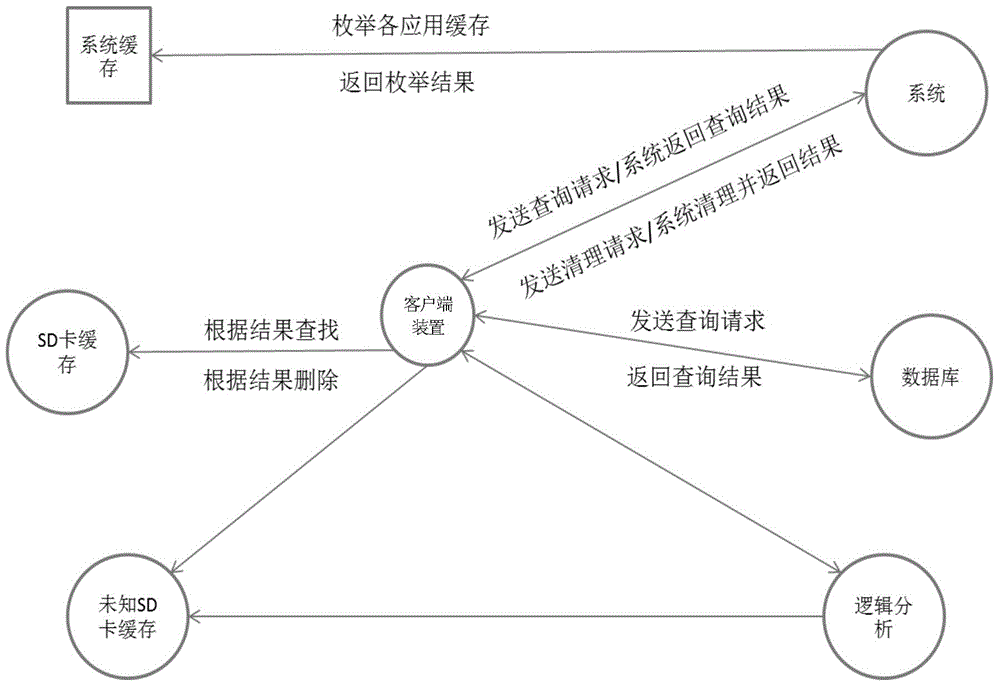

Method, device and mobile terminal for cleaning up files

ActiveCN103559299AImprove storage space utilizationClean up thoroughlyMemory architecture accessing/allocationSpecial data processing applicationsComputer scienceMemory cards

Owner:BEIJING CHEETAH MOBILE TECH CO LTD

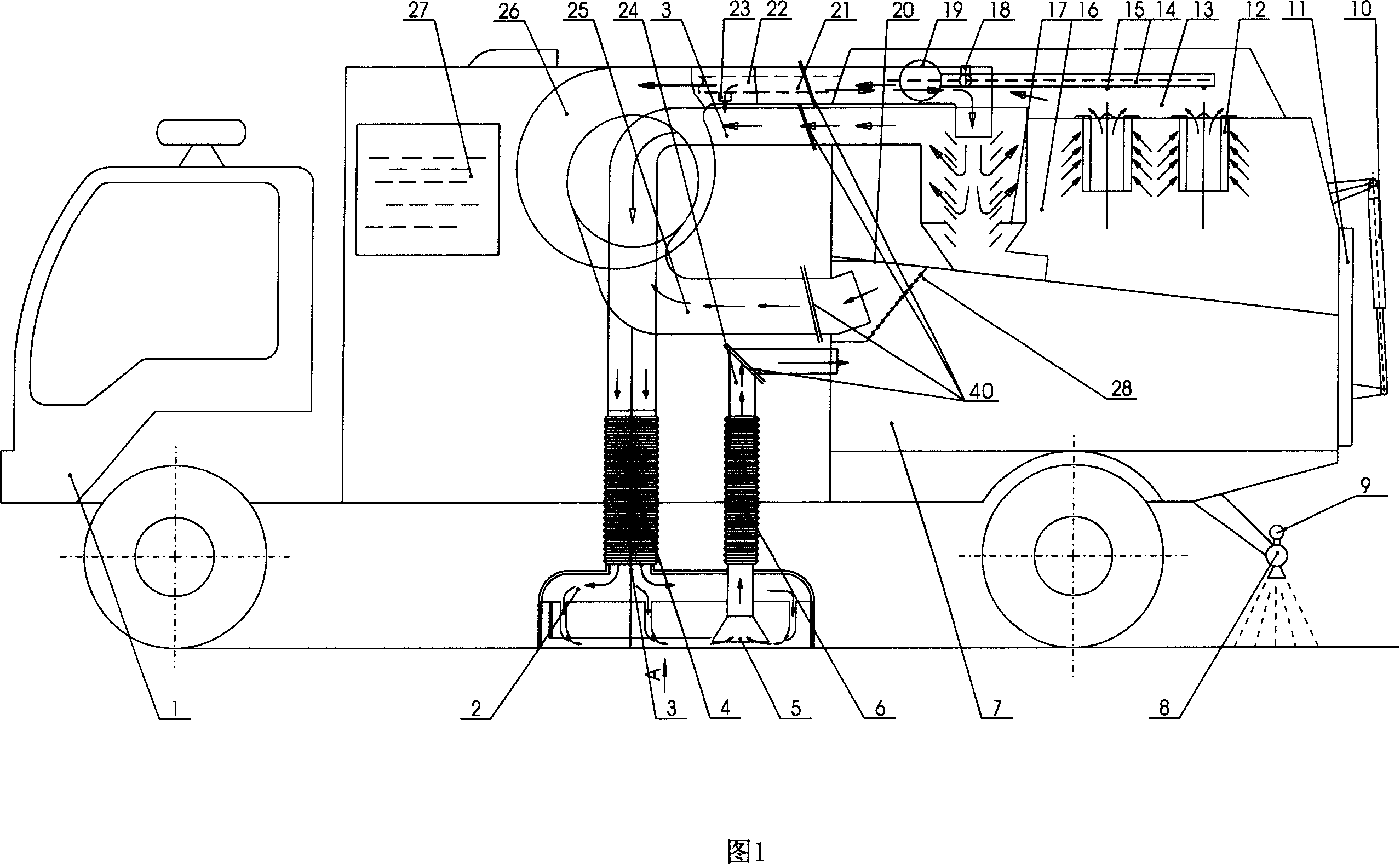

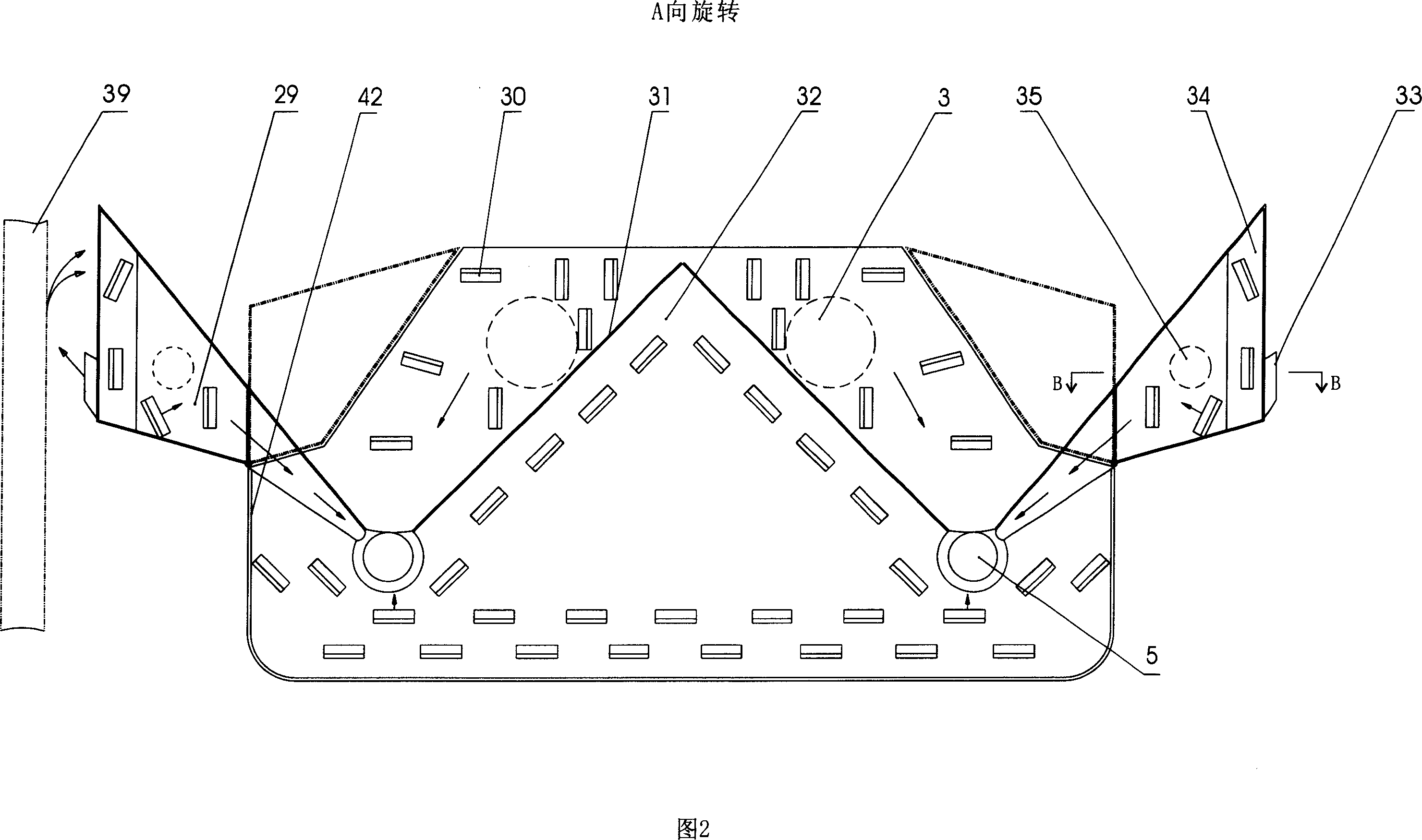

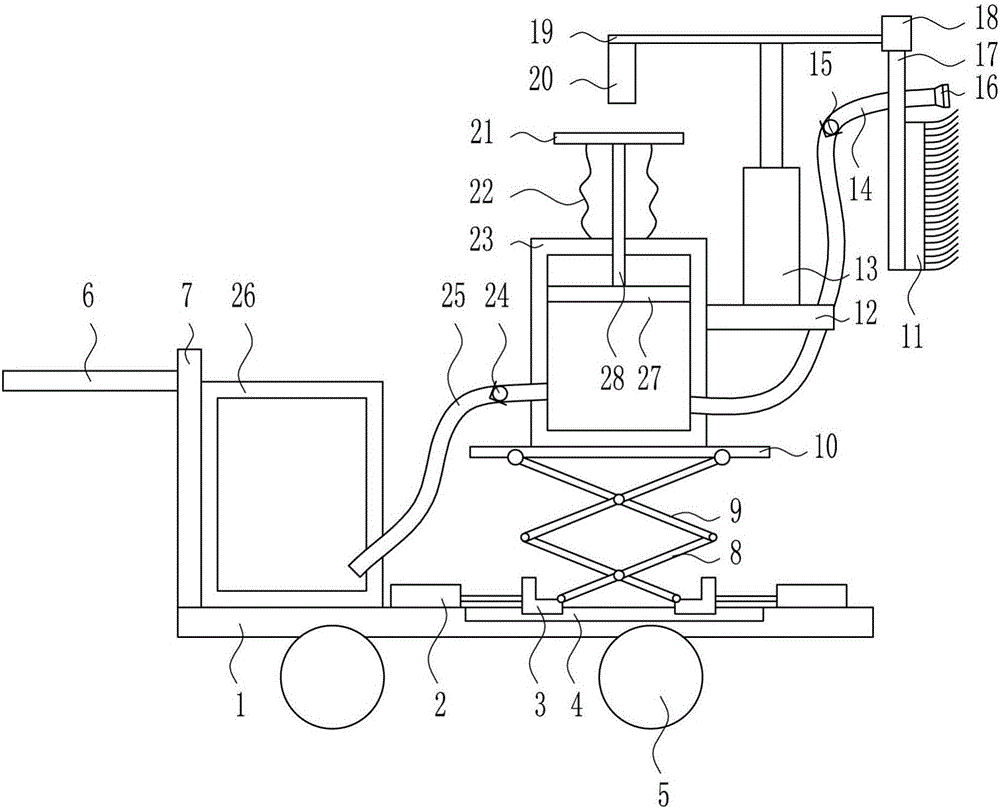

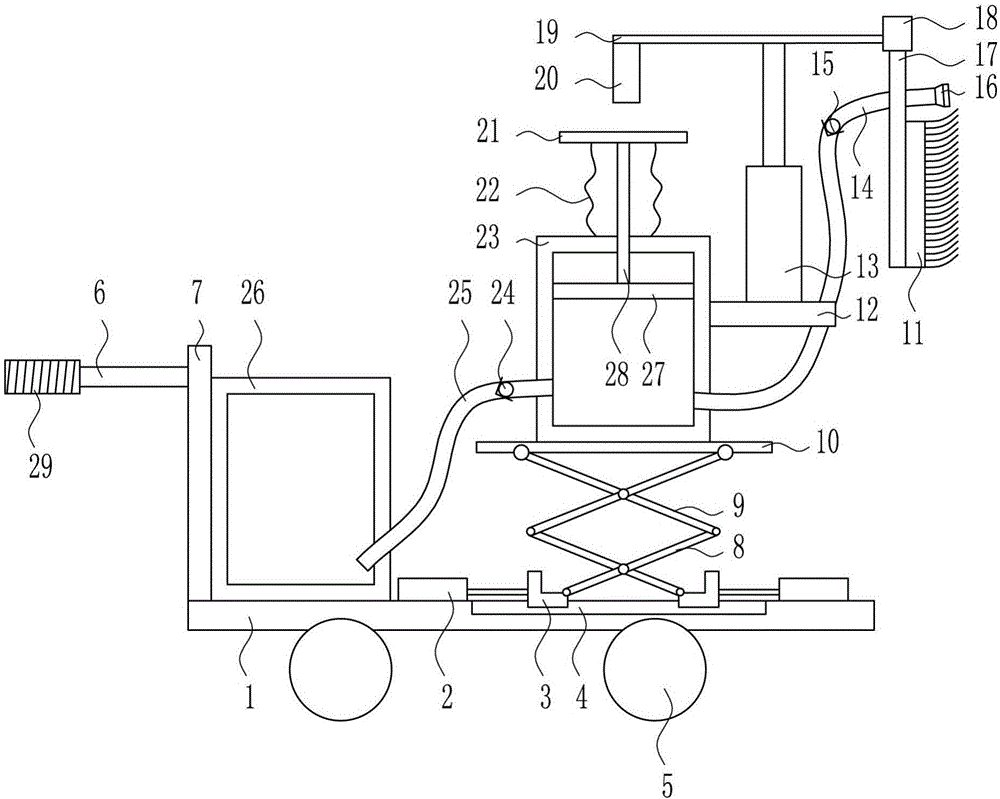

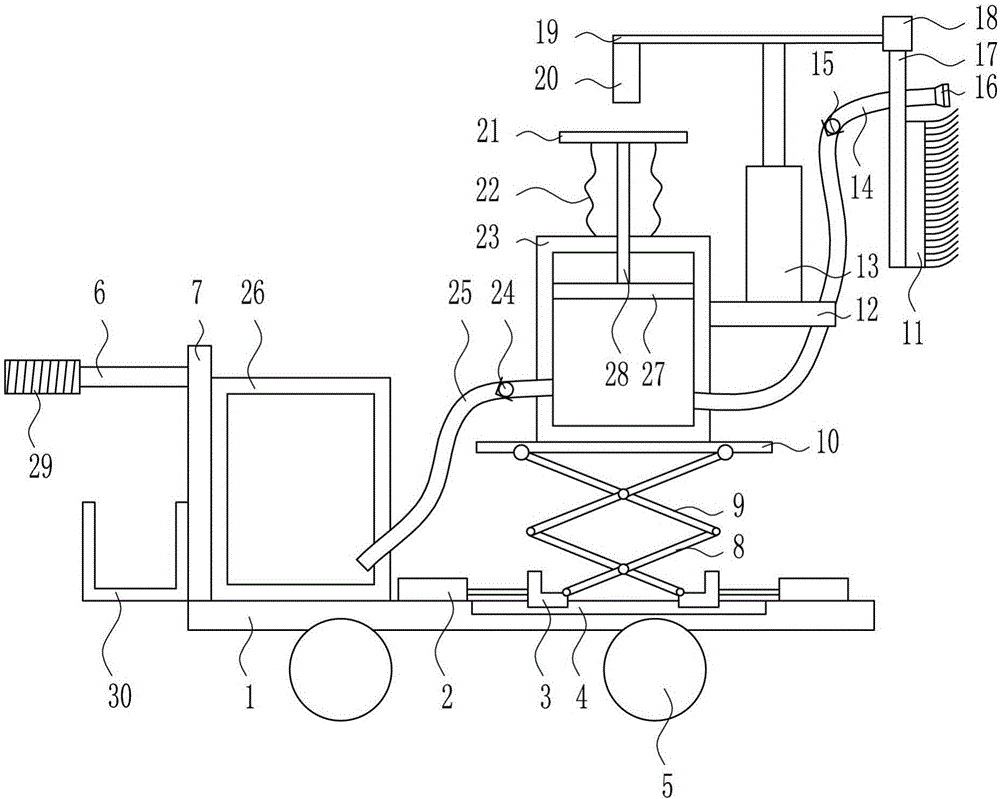

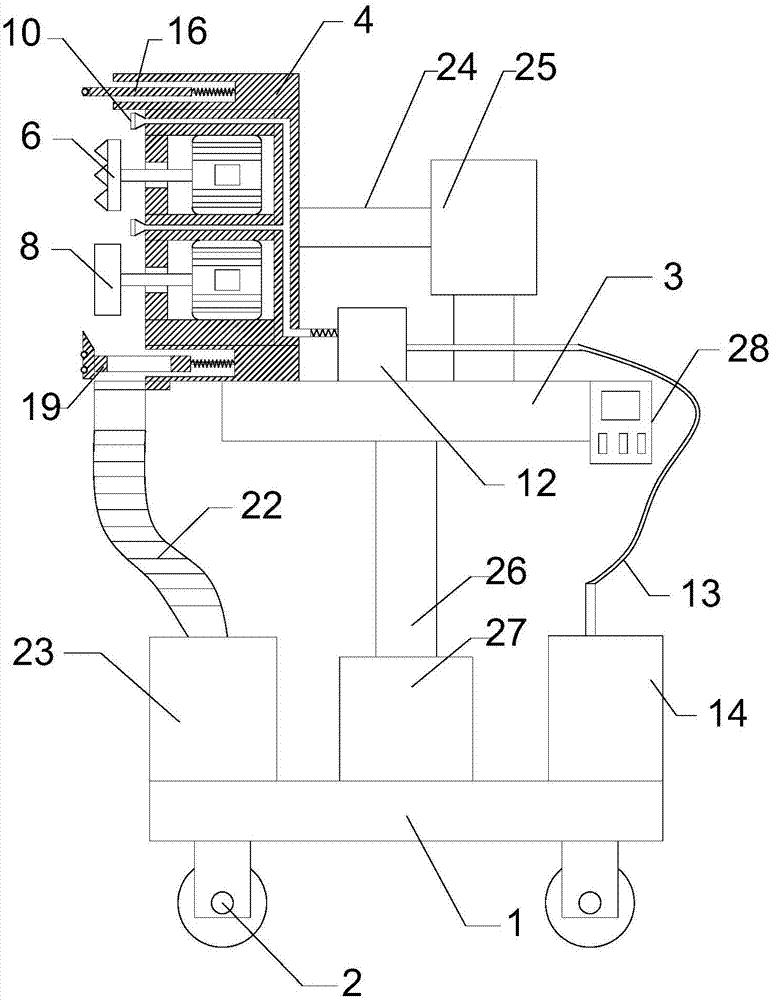

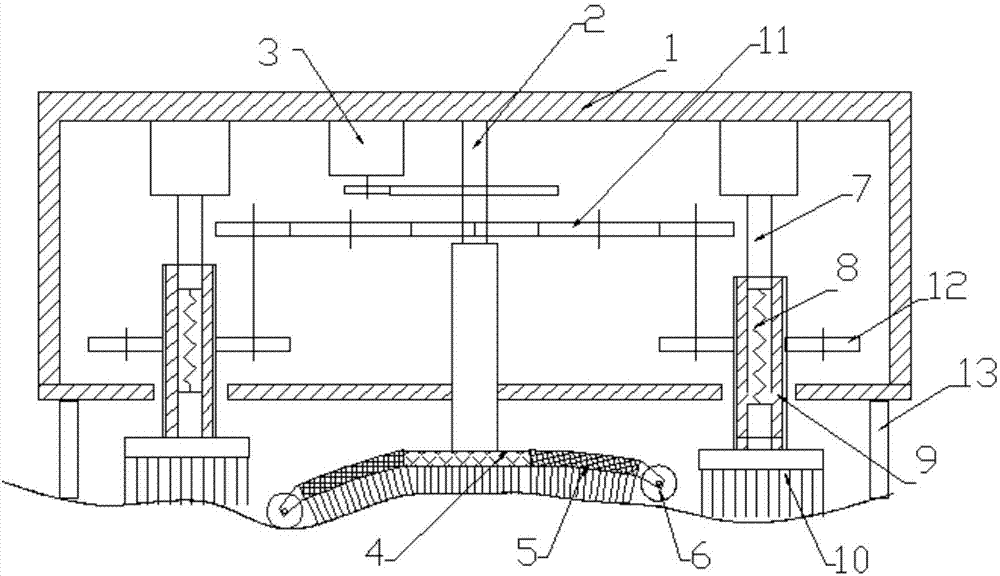

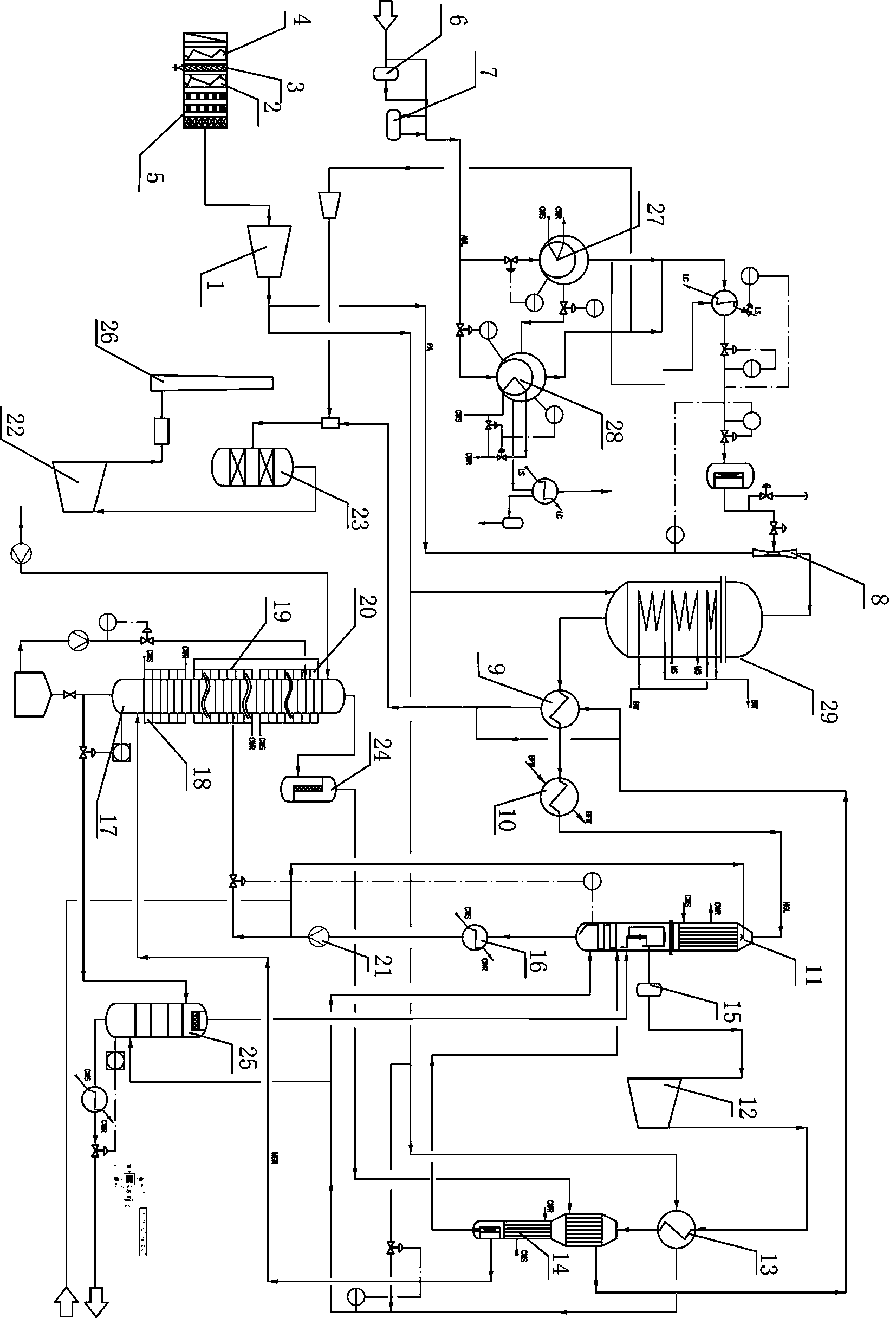

Multifunctional complete sucking type sweeping car

ActiveCN101003968AEfficient removalClean up thoroughlyRoad cleaningRefuse vehiclesParticulatesAir cleaning

The present invention relates to a multifunctional full-suction type roadsweeper. Said multifunctional fall-suction type roadsweeper includes the following several portions: upper dust-collecting tank, lower settlement negative-pressure tank, air-cleaning chamber, flower fan, air outlet pipe, air-blowing pipe, reverse-flow dust remover, filter dust-remover and power device. Said invention also provides the connection mode of all portions, also provides its working principle and concrete operation method.

Owner:高亚峰

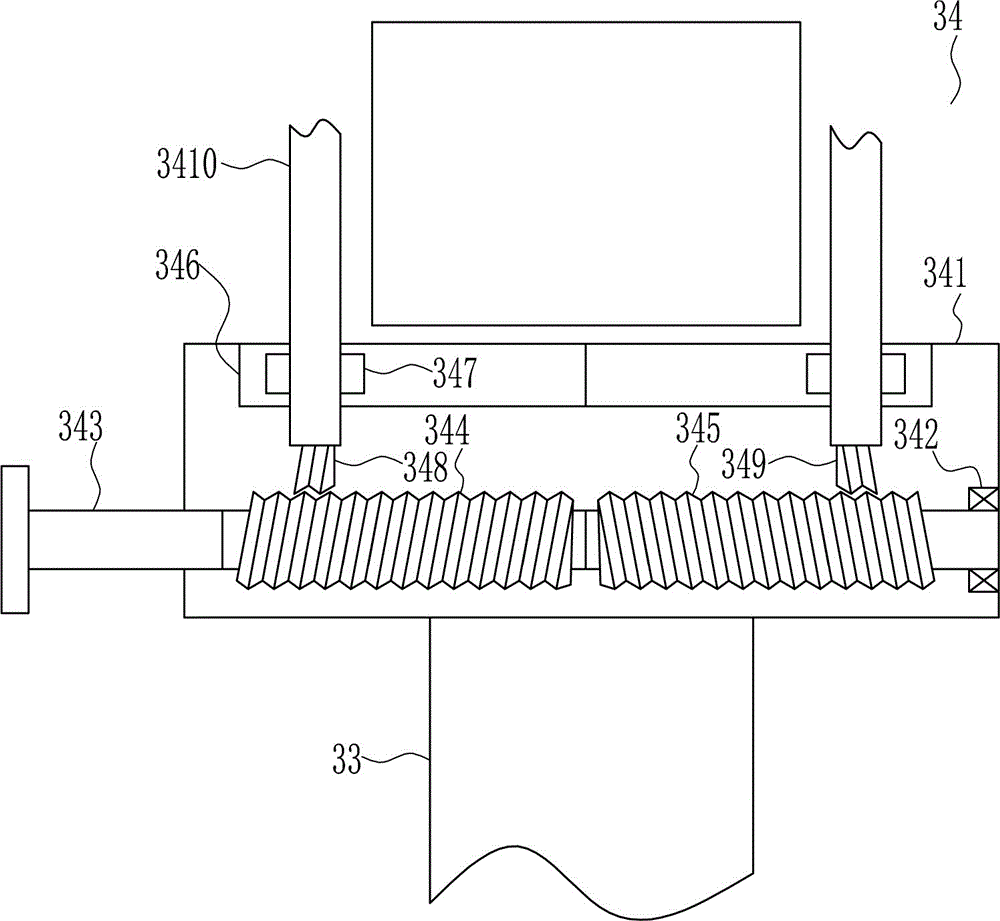

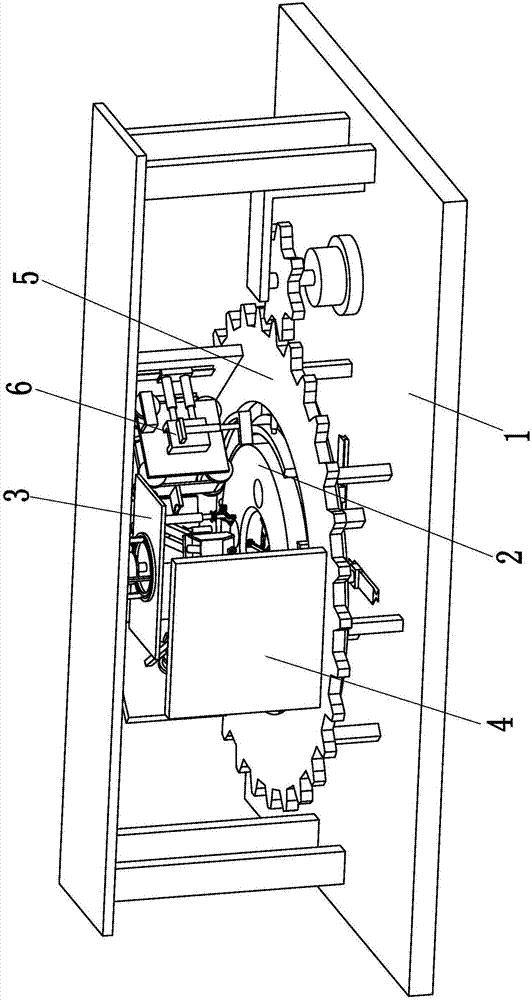

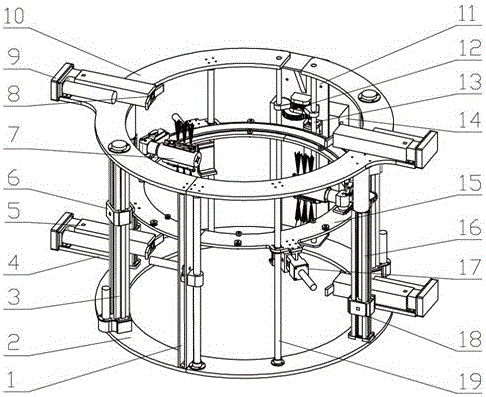

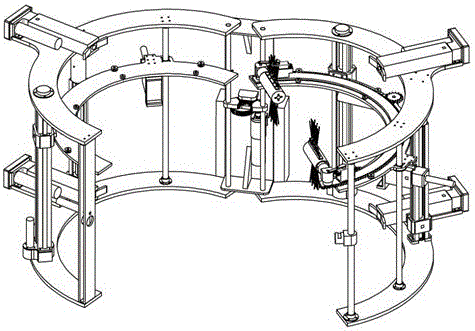

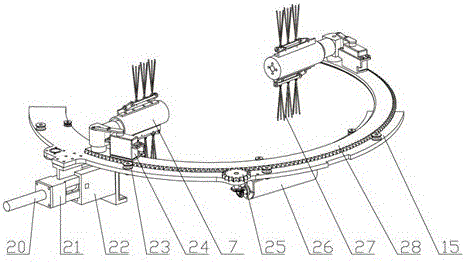

Helical motion type pipeline surface cleaning mechanical arm

InactiveCN101934279AImplement automatic cleanupClean up thoroughlyHollow article cleaningGear wheelSurface cleaning

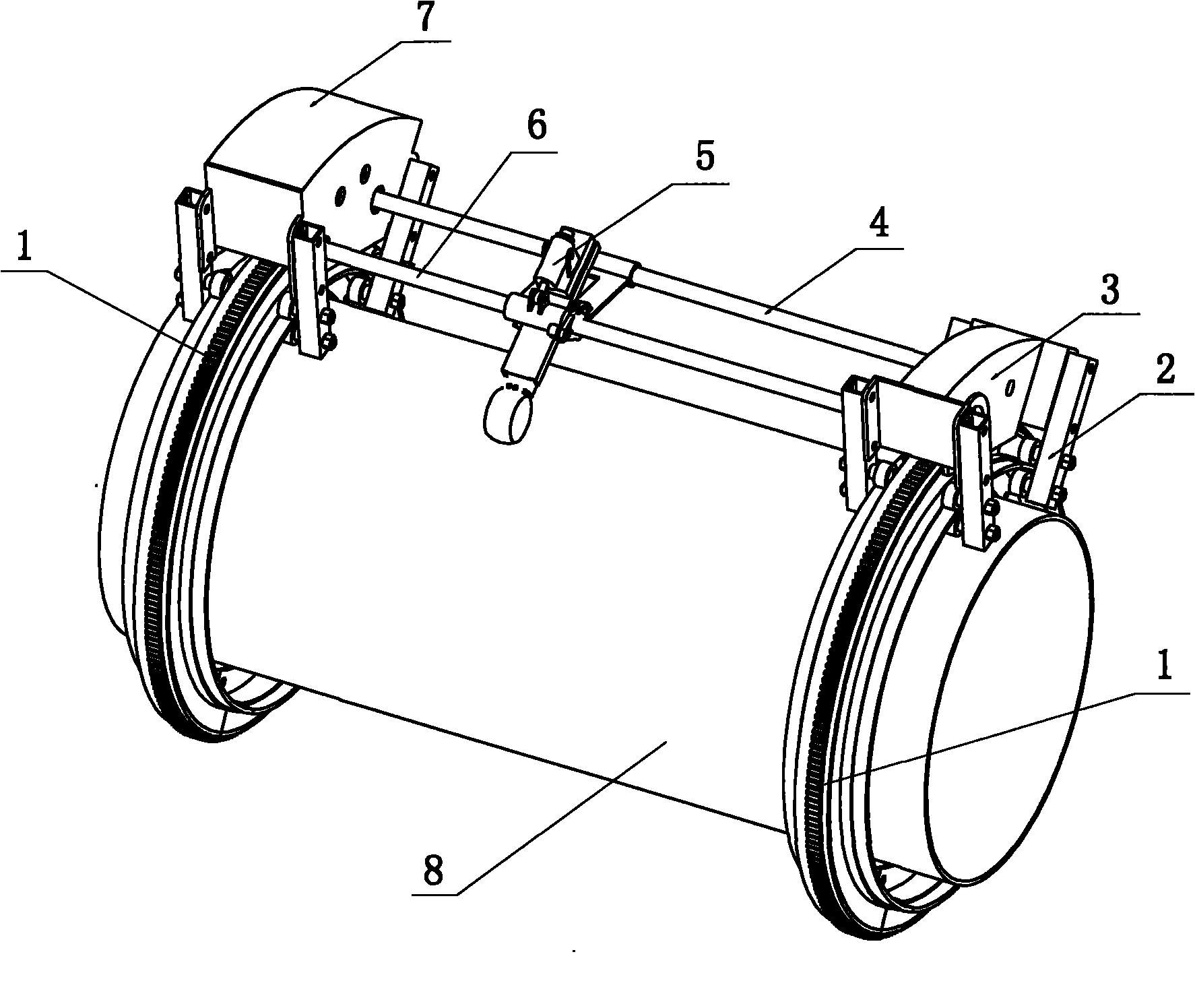

The invention provides a helical motion type pipeline surface cleaning mechanical arm. The mechanical arm comprises gear ring rails, a bracket, a drive case, a driven case, a screw rod, a feed rod, a working device and a power supply device, wherein the gear ring rails are two; the drive case and the driven case are arranged on the gear ring rails through the bracket with a roller respectively; a first gear connected with an output shaft of a motor reducer in the drive case, a second gear arranged at one end of the feed rod and a fourth gear on an input shaft in the driven case are engaged with the gear ring rail respectively, and rotate relatively along the gear ring rail; the other end of the feed rod is connected with the input shaft of the driven case; one end of the feed rod is connected with the output shaft of the driven case, while the other end is supported against the body of the drive case; the screw rod and the feed rod are parallel with each other; the working device is arranged on the screw rod and the feed rod, and translates along the screw rod and the feed rod; and the drive case and the working device are connected with the power supply device respectively. The mechanical arm can automatically clean the anticorrosion layer on the pipeline surface, saves time and power, and is suitable for maintenance and cleaning of petroleum pipelines, natural gas pipelines and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Halogen-and-rosin-free antibacterial no-clean soldering flux for lead-free solder

InactiveCN102357748AClean up thoroughlyGood welding activityWelding/cutting media/materialsSoldering mediaSolventInsulation resistance

The invention discloses a halogen-and-rosin-free antibacterial no-clean soldering flux for a lead-free solder. The halogen-and-rosin-free antibacterial no-clean soldering flux comprises the following components in percentage by weight: 0.5-10.0% of an organic acid activator, 5.0-30.0% of a cosolvent, 0.1-1.0% of a nonionic surfactant, 0.01-0.2% of a phenolic antioxidant, 0.01-0.1% of a bactericide, 0.01-0.02% of a corrosion inhibitor, 0.1-5.0% of a film-forming agent and the balance of deionized water. The soldering flux for the lead-free solder has the advantages of no halogen and rosin, antibacterial effect, excellent weld-aid property, bright and full welding spots, good spreadability, fewer post-welding residues and being free from a cleaning procedure; and in addition, a welded copper mirror is non-corrosive and nontoxic, and the surface insulation resistance of a welded substrate is more than 1*10+8 ohms, which meets the requirements of the electronical industry standard.

Owner:苏州之侨新材料科技有限公司

Cement barrel cleaning equipment for construction site

InactiveCN106733985AClean up thoroughlyClean up saves time and effortHollow article cleaningArchitectural engineeringCement

The invention relates to a cement barrel for a construction site, in particular to cement barrel cleaning equipment for the construction site. According to the technical aims, the cement barrel cleaning equipment for the construction site can clean the cement barrel relatively thoroughly, and time and labor are saved in the cleaning process. In order to achieve the above technical aims, the cement barrel cleaning equipment for the construction site comprises a base plate and the like; a supporting rod is installed at the left end of the base plate in a welding manner, a fixing device is arranged on the left of the lower side of the supporting rod, a first guide rail is installed on the left of the upper side of the supporting rod in a welding manner, and an in-barrel cleaning device is arranged on the first guide rail. The cement barrel cleaning equipment for the construction site has the effects that the cement barrel can be cleaned more thoroughly, and time and labor are saved in the cleaning process; and the manner that the cement barrel is placed on the fixing device to be rotated and fixed is adopted.

Owner:南昌诺义弘科技有限公司

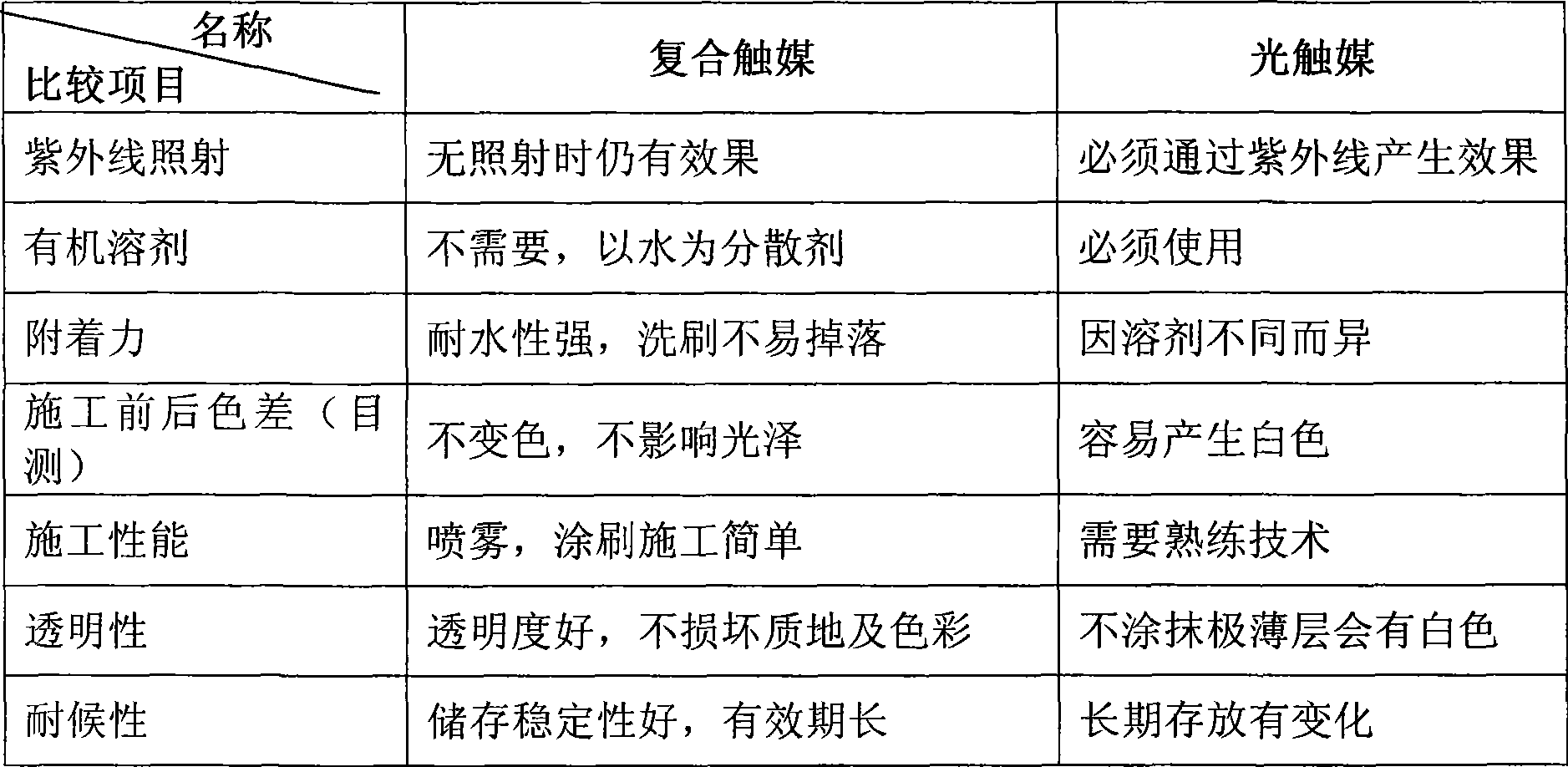

Compound catalytic material for purifying harmful gas

ActiveCN101474419ANo secondary pollutionNo light catalytic purification effectDeodrantsSide effectClearance rate

The invention relates to a compound catalytic material for purifying harmful gas. Deionized water is used as dispersant to compound nano-catalytic material, rare earth compound, p-type semiconductor, antimicrobial, plant extract and anion powder. The compound catalytic material can fast and thoroughly eliminate free formaldehyde, benzene homologue, ammonia and TVOC harmful gas. The compound catalytic material does not require ultraviolet light, has simple use and low cost and does not have toxic side effect and secondary pollution, and the purification effect can last for more than five years without rebound. At the same time, the compound catalytic material prevents bacteria, germina and mildew from invading human body, removes peculiar smell, odor, smoke, leather flavour, paint flavour and the like, increases anion and far infrared ray which are beneficial to human body and improves indoor air environmental quality comprehensively. The experiment detection shows that formaldehyde clearance rate within 24 hours is 91.6 percent; benzene clearance rate is 88.9 percent; ammonia clearance rate is 90.5 percent; TVOC clearance rate is 87.6 percent; sterilization and bacteriostasis rate is 99.99 percent; mould prevention is 0 grade; and acute oral toxicity is tested as actually nontoxic class.

Owner:HENAN MUBO INDAL

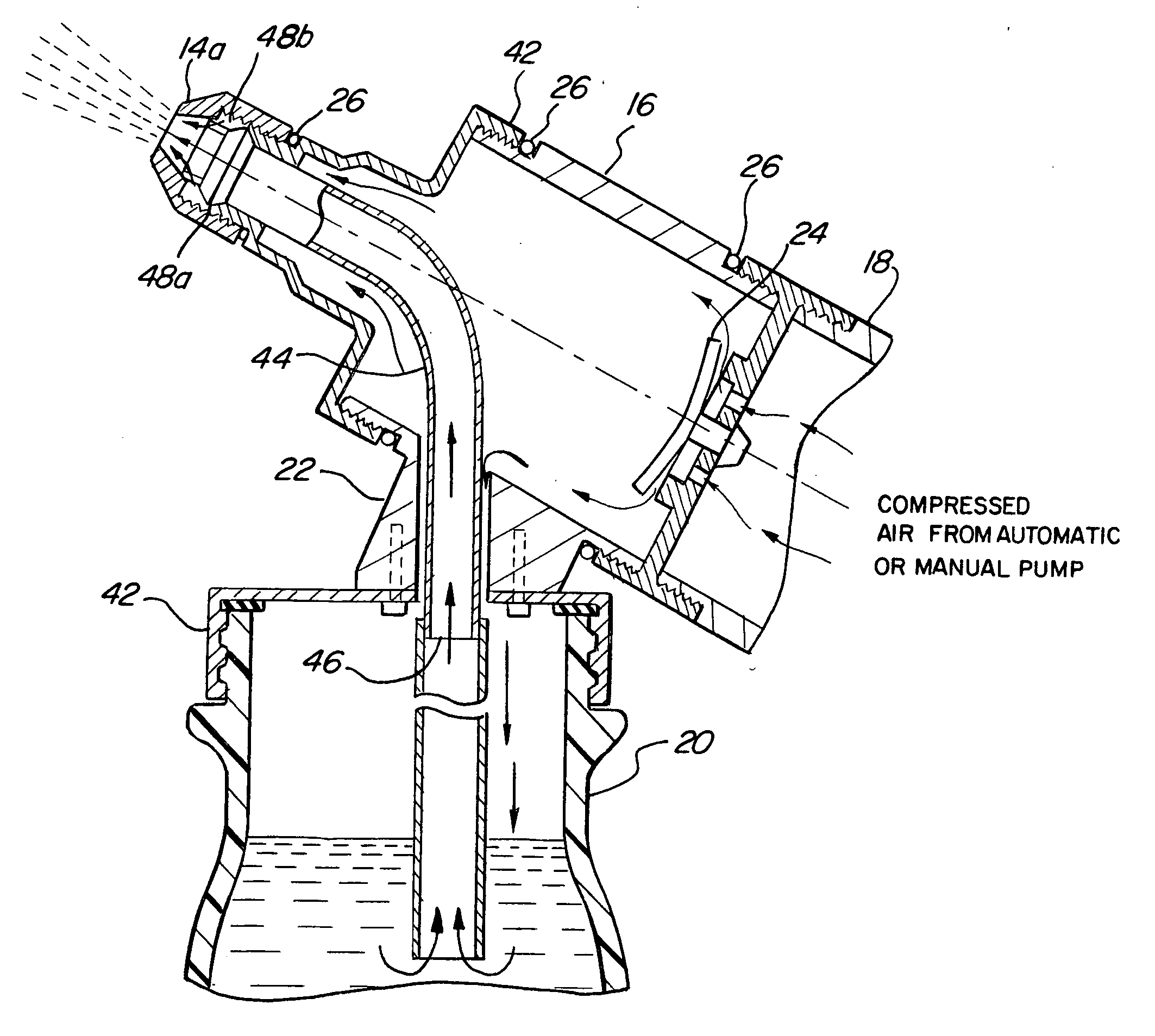

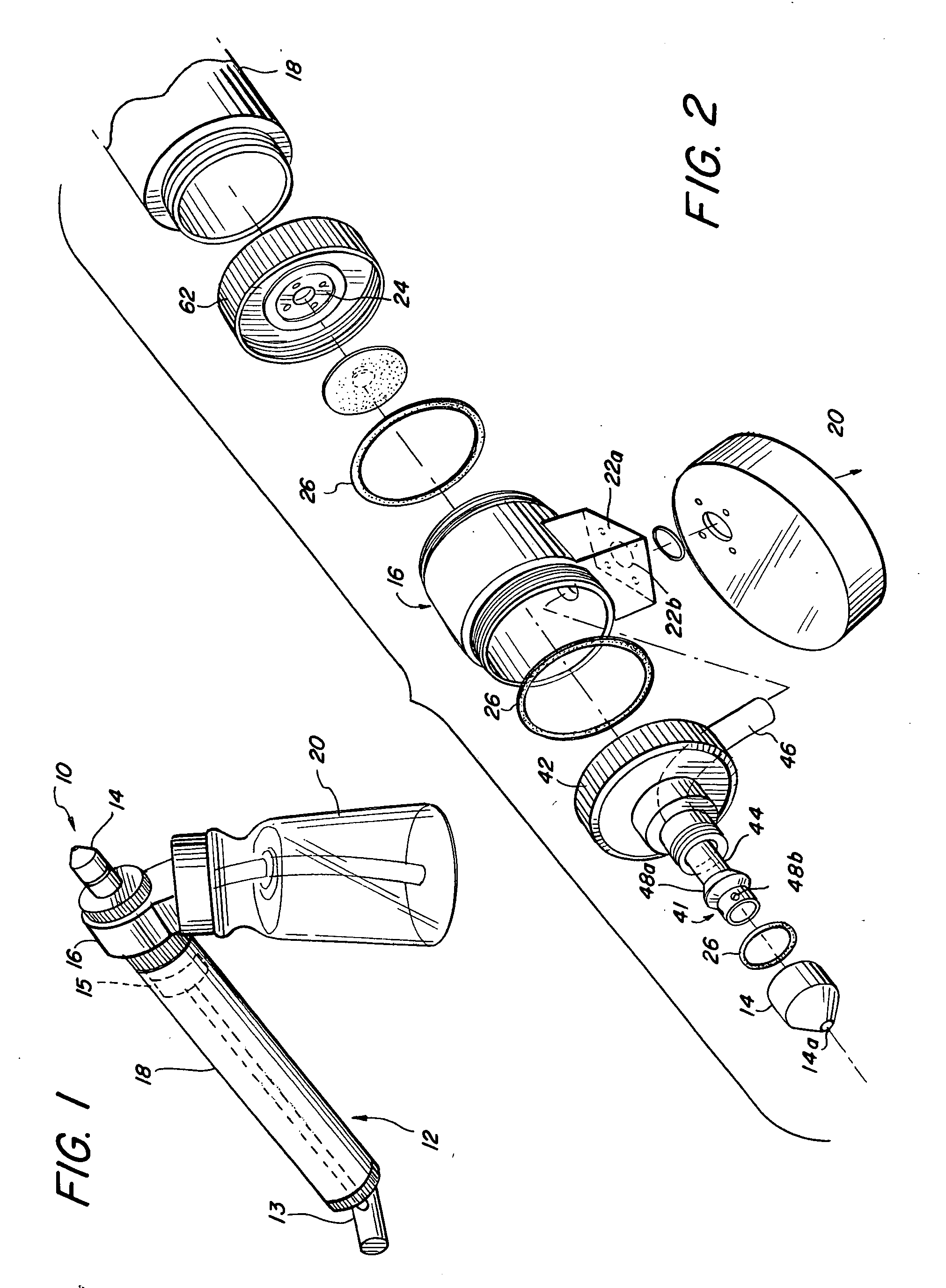

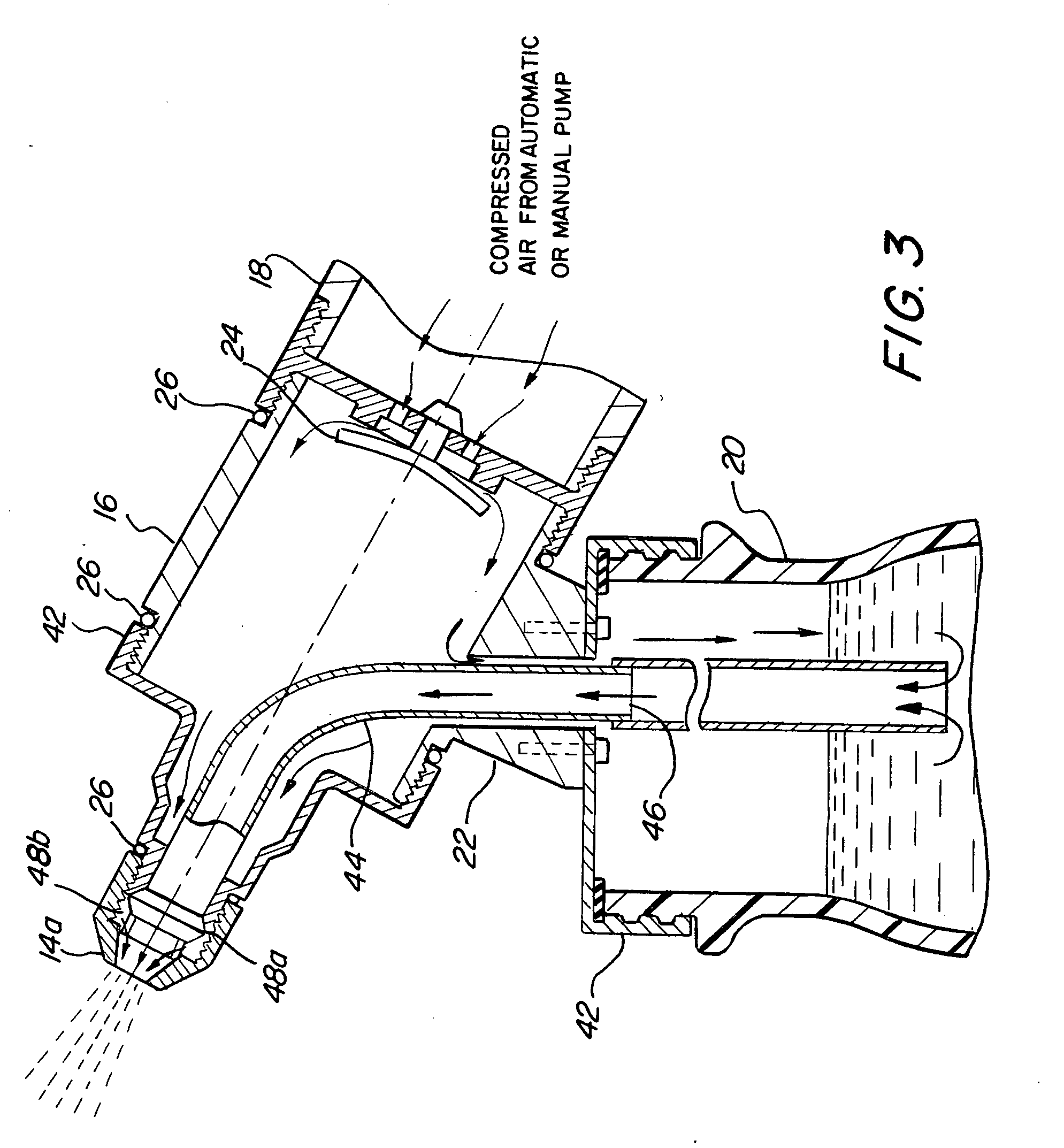

Drywall texture gun

InactiveUS20040089742A1Small dimensionEasy to disassembleFire rescueSingle-unit apparatusReciprocating motionEngineering

A drywall texture gun, having a chamber spray head with a one-way check valve installed at a first end thereof to allow compressed air flowing therein, a nozzle connected to a second end of the chamber spray head, and a supply tube extending across the chamber spray head with an inlet entering a texture supply and an outlet entering the nozzle. The outlet is restricted in the nozzle with an adjustable space to reciprocate responsive to the compressed air. Further, the outlet is so structured that the compressed air is introduced from the chamber spray head to adjust a pattern of a texture flowing therethrough. The inlet is so structured that the compressed air is able to flow from the chamber spray head to the texture supply to drive the texture into the tube. In an alternate embodiment, a compressed air gun is joined to the chamber spray head and includes a trigger assembly. An air bleed mechanism responds to the trigger during shut off to bleed off existing gun pressure.

Owner:ANTONUCCI LOUIS A

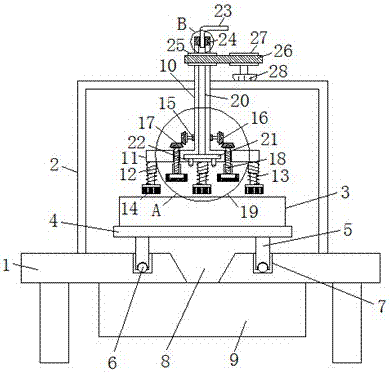

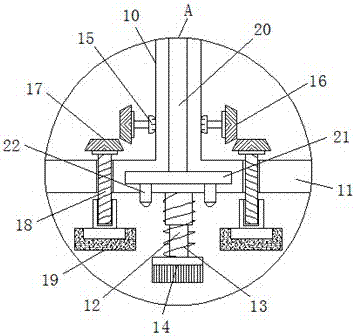

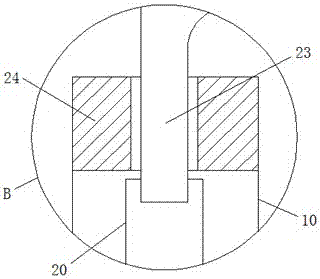

Automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints

InactiveCN107877075AImprove grinding effectEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesAfter treatmentEngineering

The invention relates to an automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints. The automatic welding treatment integrated machine comprisesa supporting base plate, a fixing device, a polishing device, a welding device, a rotating device and a post-weld treatment device, wherein the fixing device is arranged in the middle of the supporting base plate, the polishing device is located above the fixing device and is arranged on the supporting base plate, the rotating device is located on the outer side of the fixing device and is connected to the supporting base plate, the welding device and the post-weld treatment device are arranged on the rotating device, and the welding device is located on the front side of the post-weld treatment device. The automatic welding treatment integrated machine has the advantage that the existing problems that when flanges are welded to steel tubes, multiple fixation cannot be carried out on the flanges, the flanges are not fixed firmly and need to be polished manually before welding, the polishing effect on the flanges before welding is not good, the welding operation cannot be performed automatically, the flanges and the steel tubes need to be subjected to post-weld treatment manually, and the manual post-weld treatment is not thorough can be solved.

Owner:范满香

High-efficiency cleaning device for livestock shed for livestock farming

InactiveCN106180018AImprove corrosion resistanceStrong acid resistanceCleaning using toolsCleaning using liquidsSprayerEngineering

The invention relates to a cleaning device for a livestock shed for livestock farming, in particular to a high-efficiency cleaning device for the livestock shed for livestock farming. In order to achieve the technical purposes of thorough cleaning, high cleaning efficiency and convenient operation, the high-efficiency cleaning device for the livestock shed for livestock farming comprises a bottom board, a first electric push rod, an L-shaped sliding block, a sliding rail, wheels, a push handle, a left frame, a first connection rod, a second connection rod, a fixing board, a brush, a supporting board, a second electric push rod, a second hose, a second one-way valve, a sprayer, a fixing rod and the like, wherein the left frame and a water tank are arranged on the left side of the top of the bottom board; and the left frame is located on the left of the water tank. The high-efficiency cleaning device for the livestock shed for livestock farming achieves the effects of thorough cleaning, high cleaning efficiency and convenient operation. A livestock shed is closely linked with living of livestock, frequent cleaning of the livestock shed is beneficial for keeping the livestock shed clean, and the situation that the livestock get sick due to breeding of bacteria is avoided.

Owner:邵鹏程

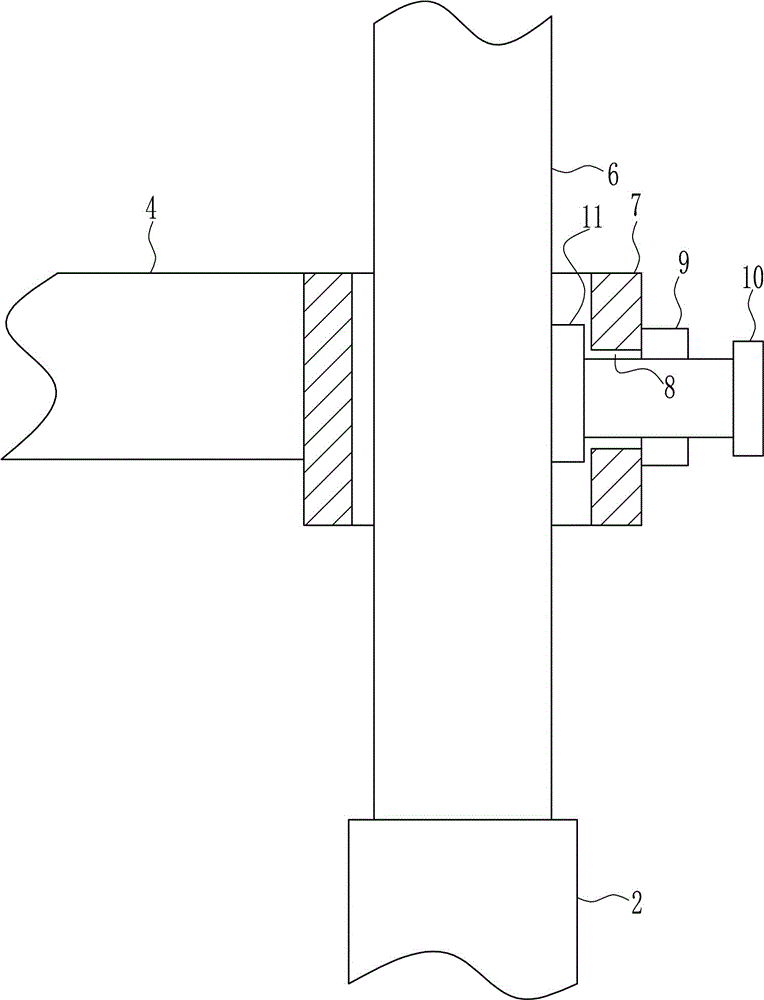

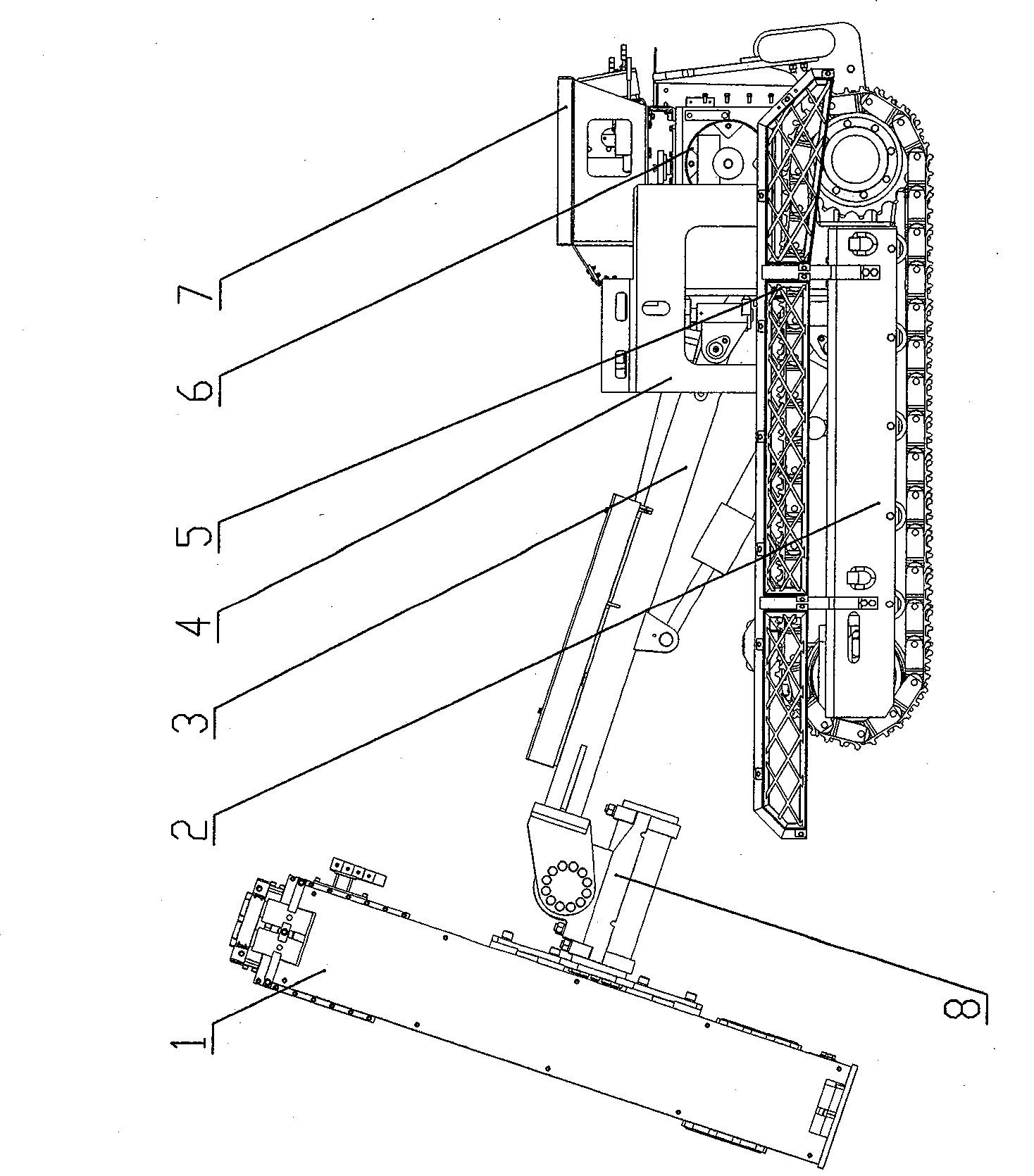

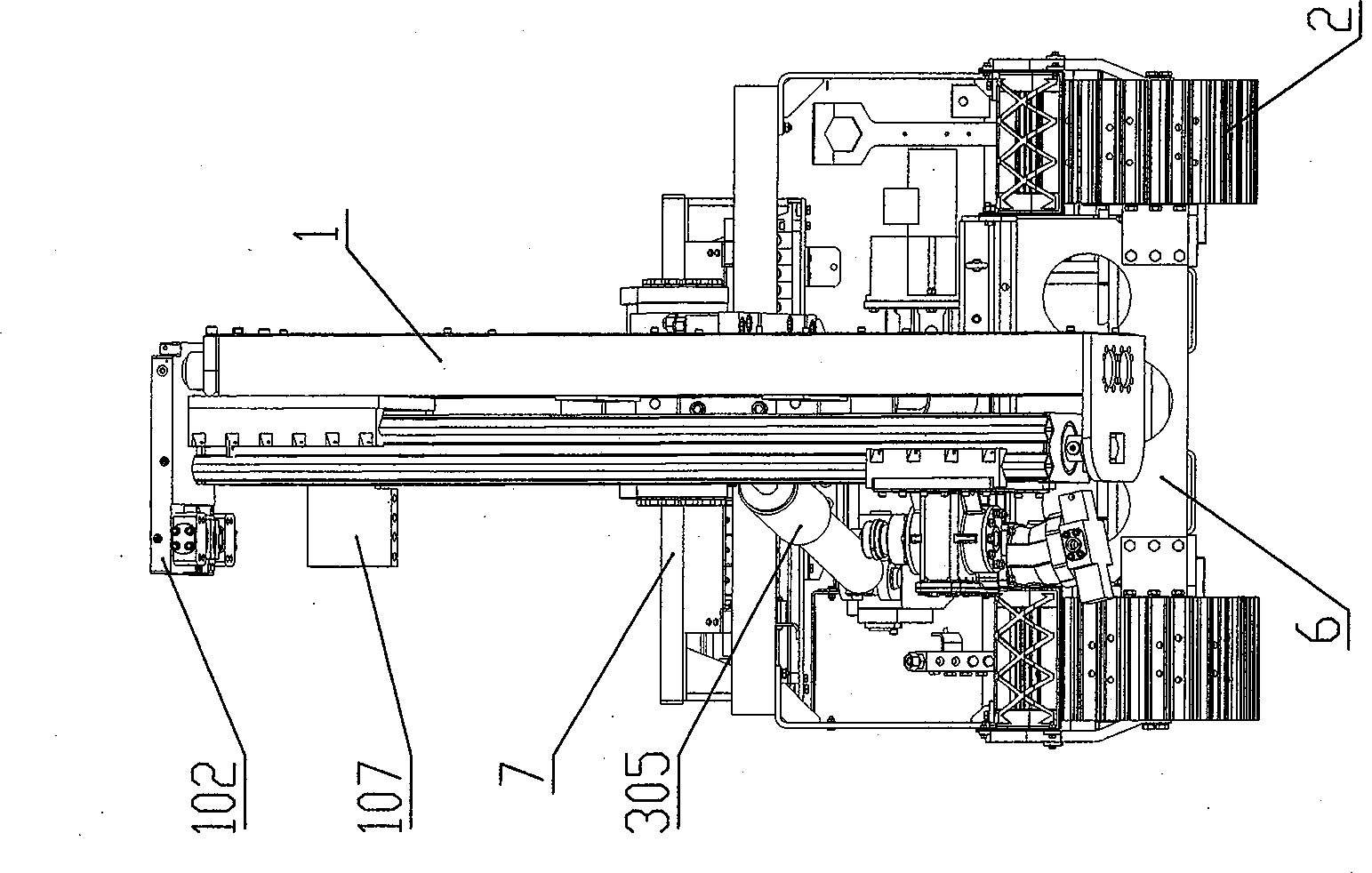

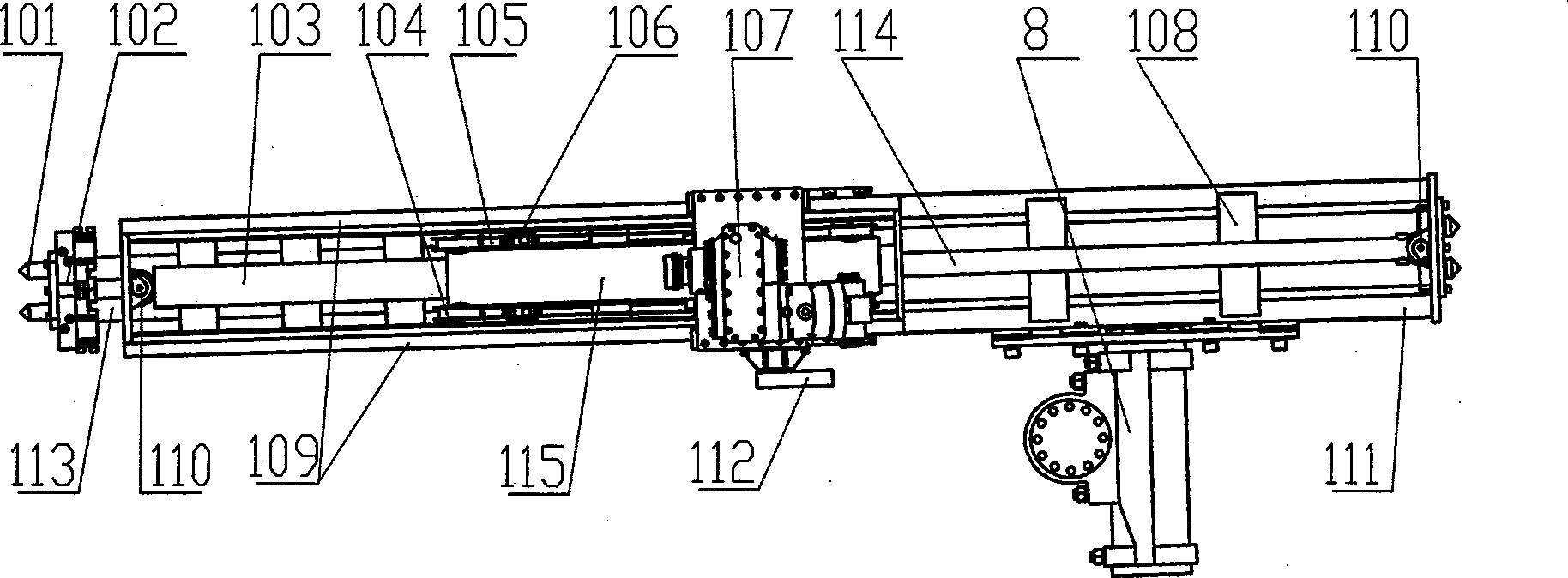

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

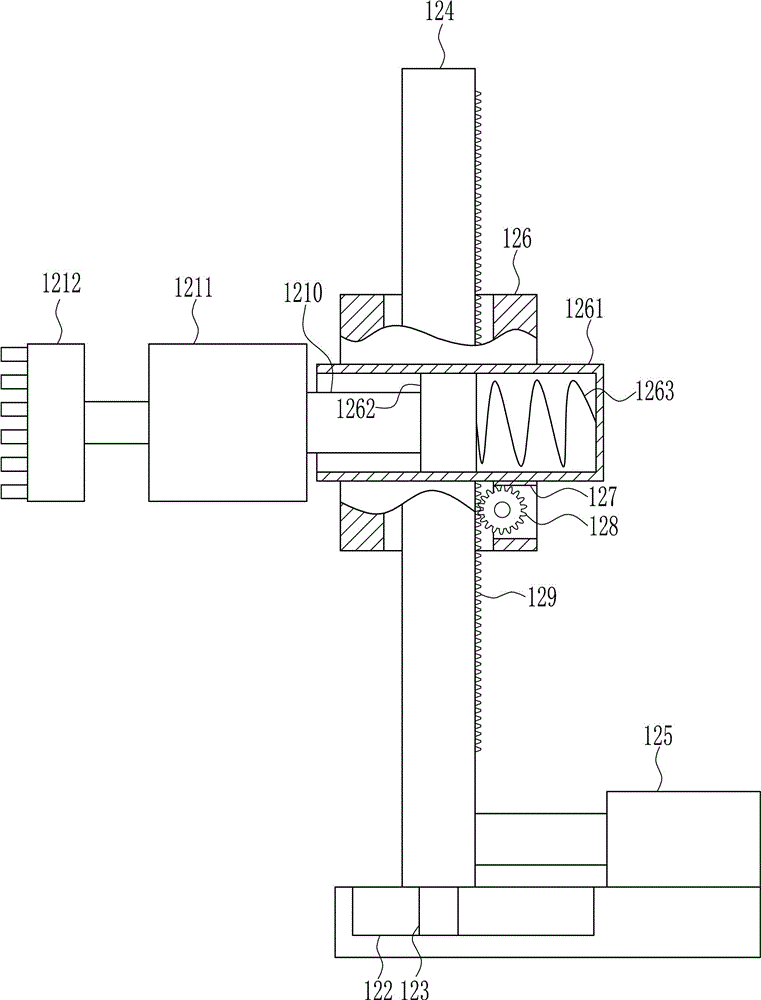

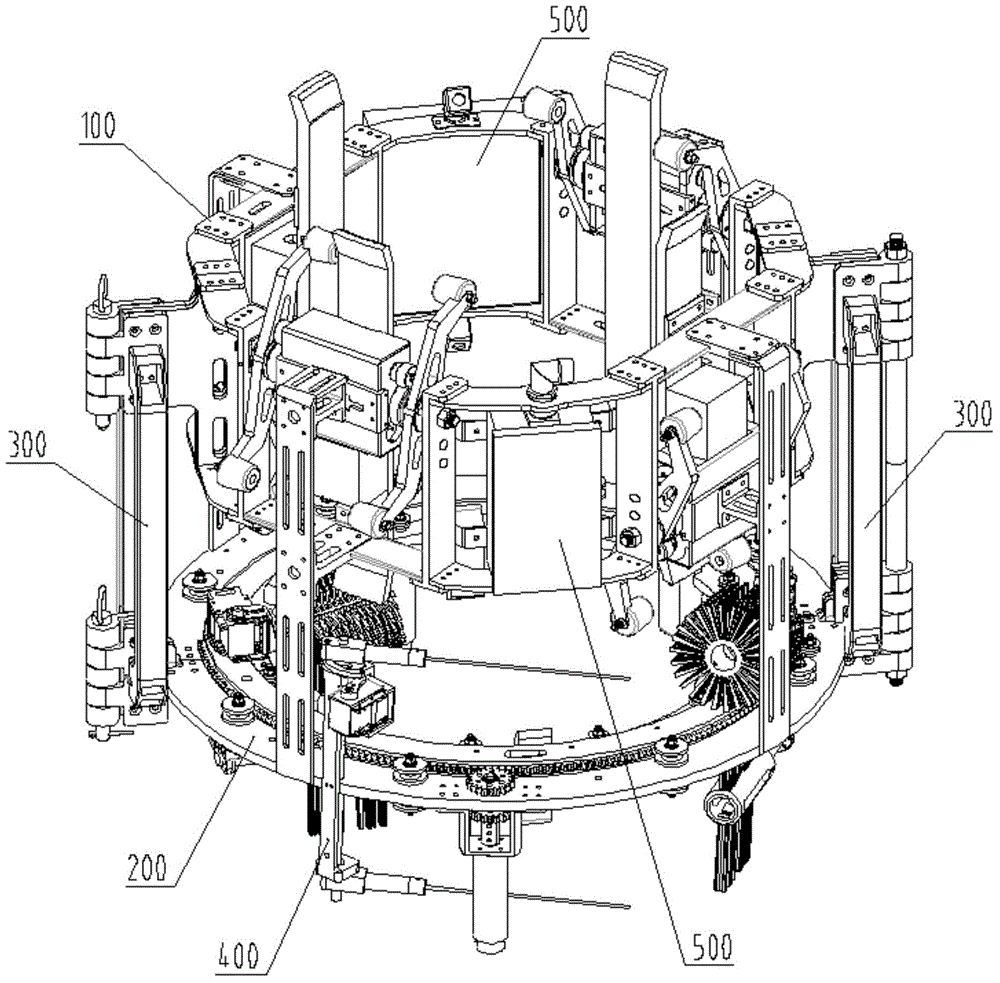

Insulator cleaning robot

ActiveCN104438164ARun smoothlyReduce wearElectrical testingCleaning using toolsMoving speedDisc diameter

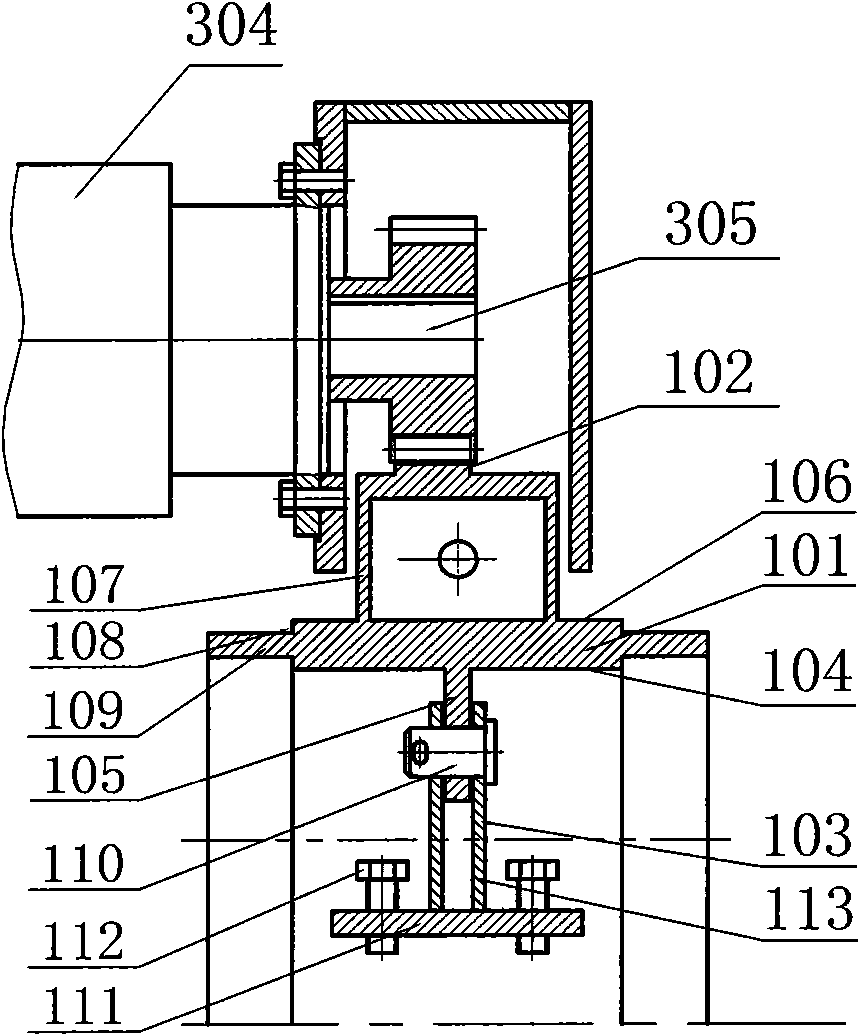

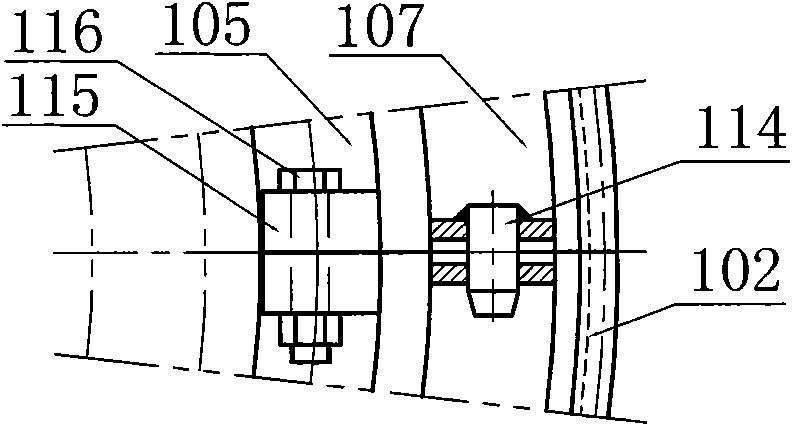

The invention discloses an insulator cleaning robot. The insulator cleaning robot comprises a crawling mechanism, a cleaning mechanism, a locking mechanism, a detection mechanism and a battery control system, wherein the crawling mechanism is of a closed circumferential structure, surrounds an insulator string and drives a robot body to continuously move along the insulator string; the cleaning mechanism is of a closed circumferential structure and surrounds the insulator string; the locking mechanism is evenly arranged on the crawling mechanism, and the crawling mechanism is connected with the cleaning mechanism through the locking mechanism; the detection mechanism is arranged on one side of the locking mechanism, and the battery control system is installed on the crawling mechanism. The insulator cleaning robot is simple in structure; due to the overall symmetrical structure, the stability of the robot is good; as the continuous type movement mode is adopted, the movement speed is high, the cleaning mode is simple, the cleaning speed is high, abrasion to coatings of insulators is small, locking is reliable, an adjustment mechanism can be suitable for insulator strings different in structural height and disc diameter, and electrification insulator string cleaning operation and insulator sheet quality detection can be carried out.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Efficient dustproof wall skin cleaning device

InactiveCN107350914AImprove cleaning efficiencyClean up thoroughlyGrinding carriagesBuilding repairsDrive motorOperating environment

The invention discloses a high-efficiency dust-proof wall skin cleaning device, which includes a mobile platform and rollers; a lifting plate is arranged above the moving plate, and a moving frame is slidably connected to the upper surface of the lifting plate; the moving frame is nested with a first A driving motor, the first driving motor is connected with a scraping wheel through a drive shaft; a grinding wheel is arranged under the scraping wheel. The invention is equipped with a motor-driven scraping wheel and a grinding wheel to efficiently scrape and polish the wall skin on the wall, greatly improving the cleaning efficiency of the wall skin, and at the same time making the wall skin cleaning more thorough; The invention is equipped with a retractable shielding plate and an atomizing nozzle to gather and settle the dust generated in the operation process, prevent the dust from spreading and settle and collect the dust, so as to ensure the cleanliness of the working environment and prevent the dust from threatening the health of personnel.

Owner:冯飞燕

Method for preparing high-purity arsenic

The invention relates to a method for preparing a nonmetallic material, in particular to a method for preparing high-purity arsenic, solving the problems of high production cost, low output, impossible realization of industrialization, and the like of the traditional preparation methods. The method comprises the following steps of: loading industrial arsenic into a crucible and carrying out primary sublimation and distillation in a vacuum furnace; then loading the arsenic into an oxidation furnace, and introducing oxygen into the oxidation furnace to generate arsenic oxide; loading the arsenic oxide into a crucible and carrying out secondary sublimation and distillation in the vacuum furnace; loading the arsenic oxide subjected to twice distillation into a tube furnace, introducing high-purity argon and hydrogen into the tube furnace for reducing to obtain crystallized arsenic; loading uncrystallized black arsenic and unreduced arsenic oxide into a quartz tube, putting into the vacuum furnace for separating, and reducing obtained arsenic oxide; and finally, loading separated black arsenic and all reduced crystallized arsenic into the tube furnace together, introducing high-purity argon and hydrogen into the tube furnace for carrying out hydrogen sublimation protection to obtain 6N high-purity arsenic. The method has the advantages of simple impurity removal process, low cost and high output, solves the problem of pollution, eliminates potential safety hazards and achieves the purposes of generating the high-purity arsenic without pollution.

Owner:SHANXI LONGGANG MATERIAL

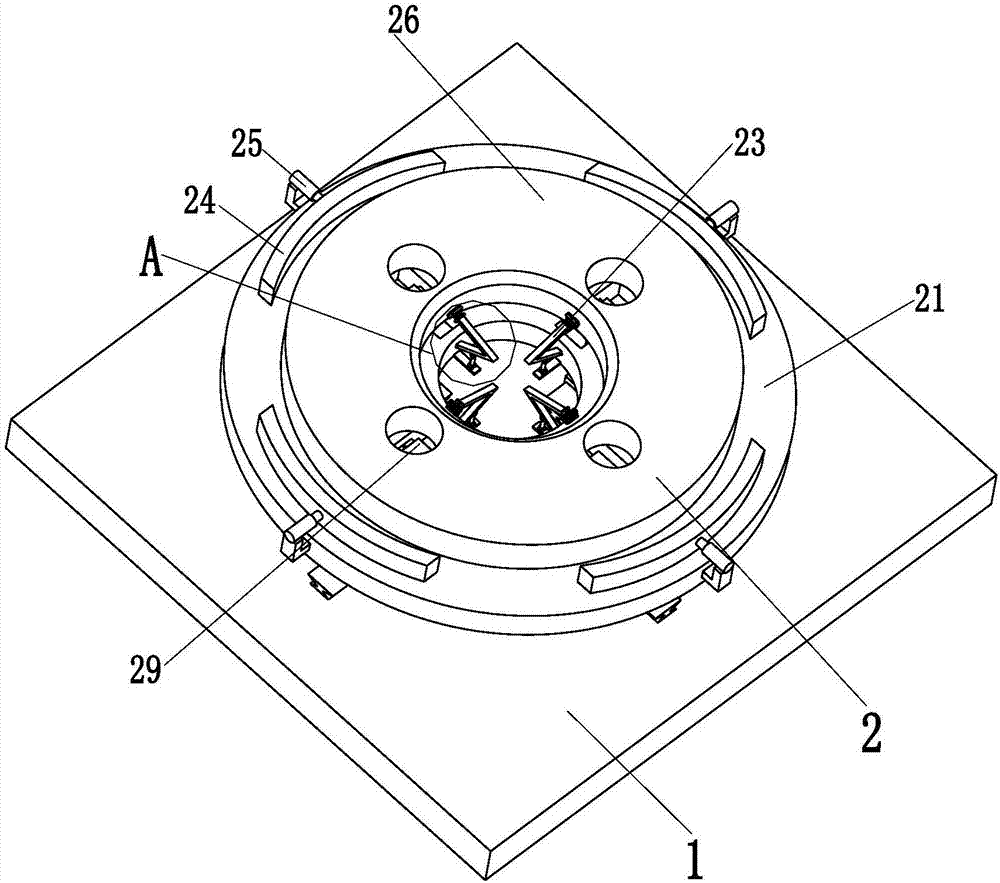

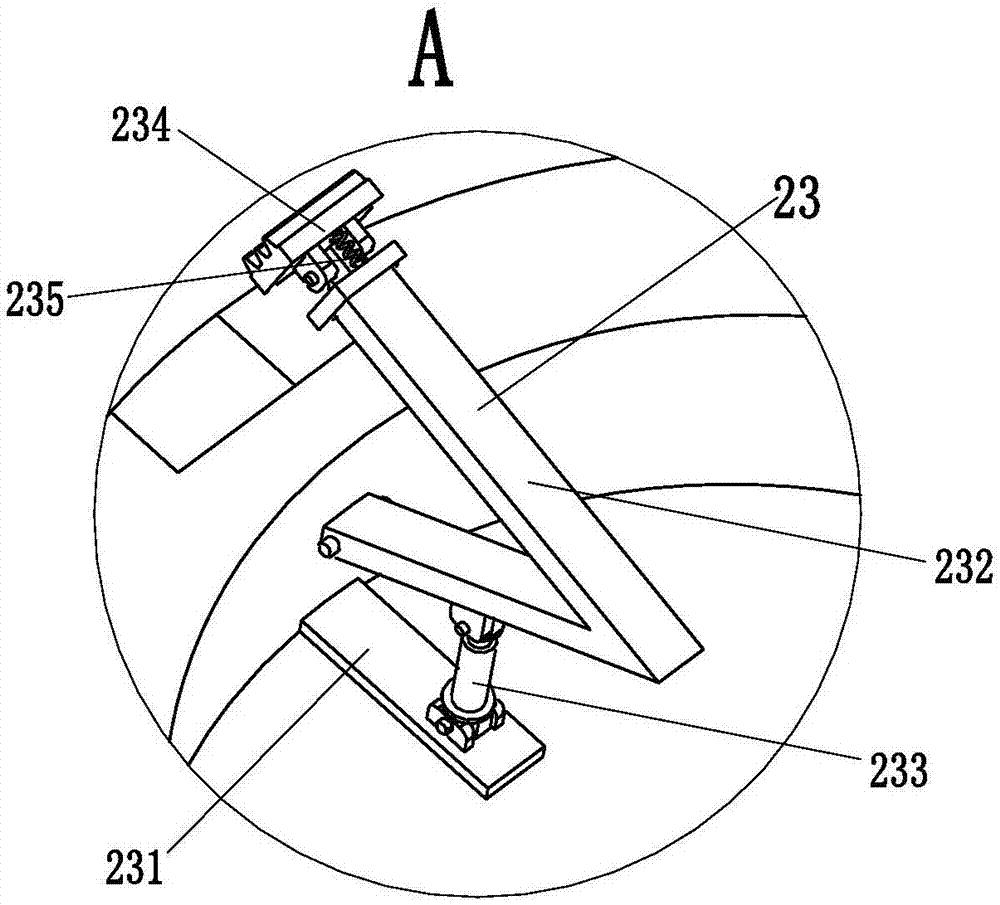

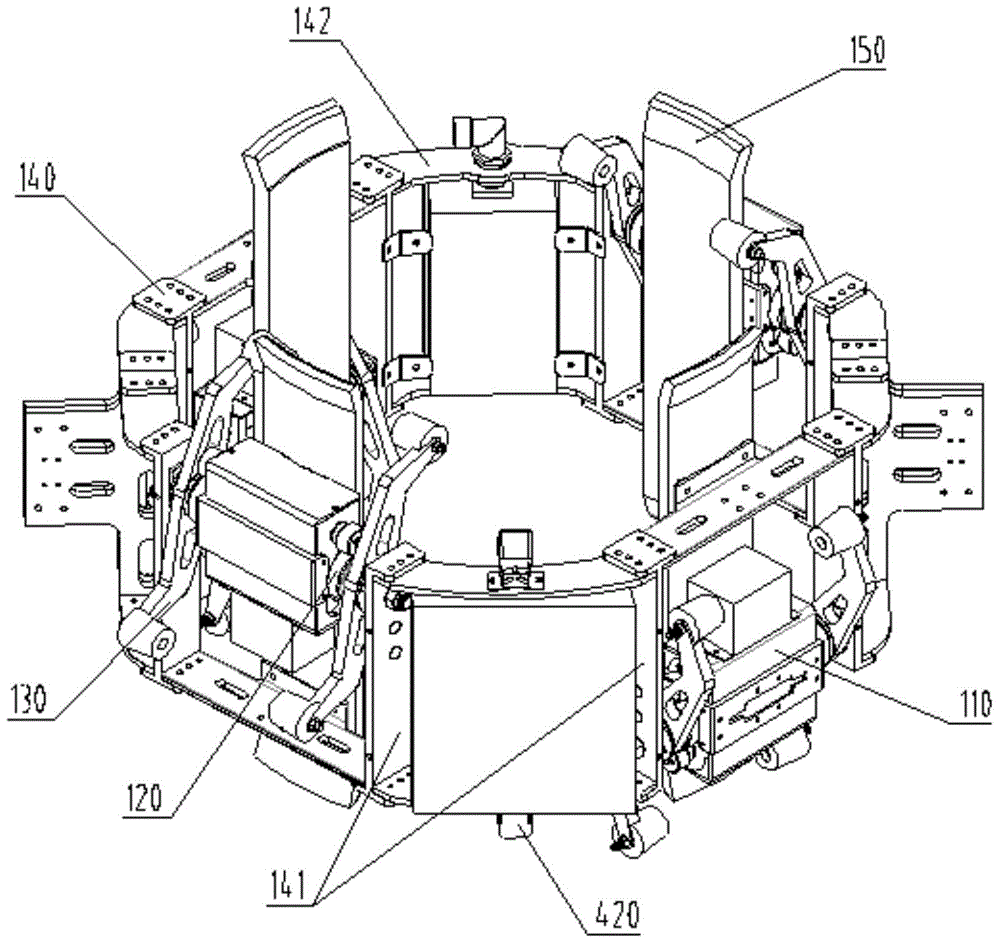

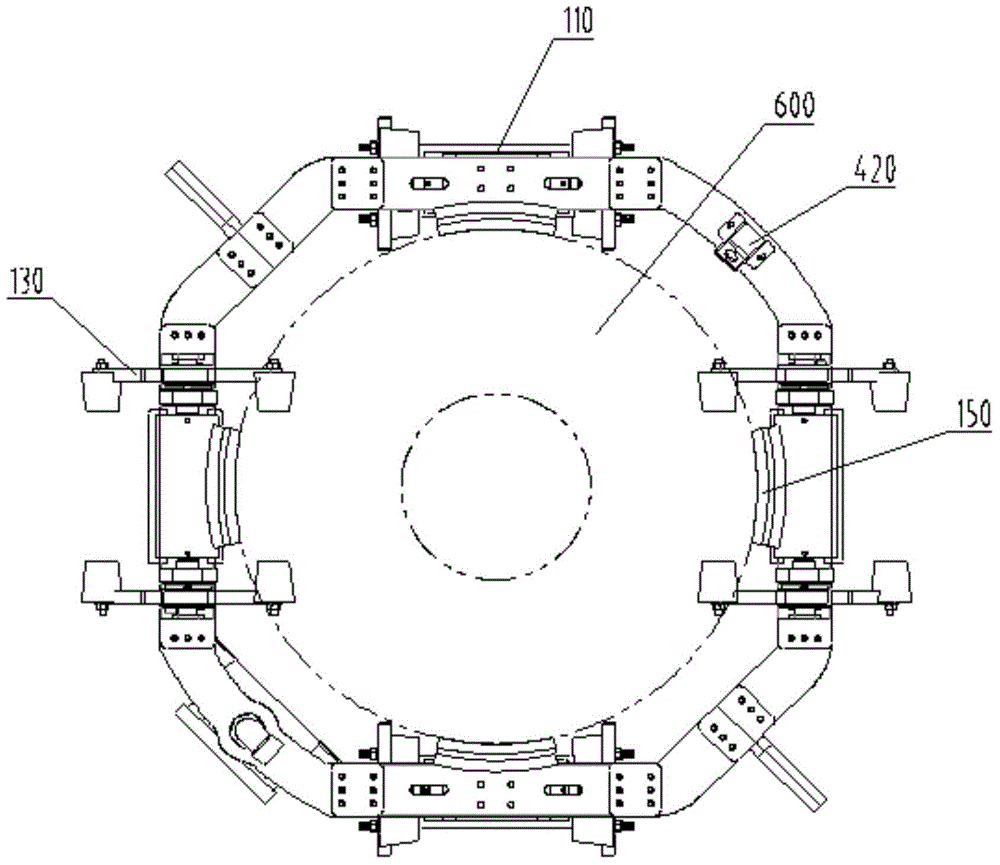

Insulator sweeping and detecting robot for high-voltage power transmission line

ActiveCN105855200AImprove practicalityCompact structureCleaning using toolsApparatus for overhead lines/cablesLocking mechanismElectric machine

The invention discloses an insulator sweeping and detecting robot for a high-voltage power transmission line. The robot comprises an annular frame and a control box; the annular frame is capable of being opened towards the two sides around a rotating shaft and comprises an upper layer bracket, a lower layer bracket and a middle layer bracket, wherein the upper layer bracket and the lower layer bracket are fixedly connected through a plurality of auxiliary brackets; the middle layer bracket is capable of moving up and down through a sweeping layer elevating mechanism; the upper layer bracket is provided with an upper clamping jaw for clamping an insulator; a detecting device is arranged on the upper clamping jaw; the middle layer bracket is provided with a sweeping device and an auxiliary clamping jaw which is used for clamping the skirt section of the insulator; a lower clamping jaw capable of moving up and down through a clamping jaw layer elevating mechanism is also arranged between the upper layer bracket and the lower layer bracket; the annular frame opposite to the rotating shaft is provided with a locking mechanism for locking the closed state of the annular frame; a power supply and a controller which is used for controlling the running and action sequence of a rotating mechanism and a servo motor are arranged inside the control box. The insulator sweeping and detecting robot disclosed by the invention is compact in structure, good in adaptablity, complete in sweeping, high in load capacity and applicable to hot-line sweeping and detection of horizontal and suspension insulator strings.

Owner:WUHAN UNIV

Efficient cleaning device used for mechanical casting mould

PendingCN107442471AImprove cleaning effectSimple structureCleaning using toolsCleaning using liquidsFixed frameEngineering

The invention discloses an efficient cleaning device used for a mechanical casting mould. The efficient cleaning device comprises a workbench, wherein the upper end of the workbench is fixedly connected with a machine body housing; a fixing frame is arranged in the machine body housing; a mould is placed at the upper end of the fixing frame; the periphery of the lower end of the fixing frame is fixedly connected with supporting posts; bottoms of the supporting posts are equipped with rolling balls; a rotary shaft is perpendicularly inserted into the upper-end center of the machine body housing; the lower end of the rotary shaft is horizontally fixedly connected with a cross rod; the end, away from the cross rod, of each telescopic pole is equipped with a cleaning brush; the outer wall of the end, penetrating through the inner wall of the machine body housing and extending outwards, of the rotary shaft is sleeved with a first transmission wheel; a belt is connected between a second transmission wheel and the first transmission wheel; and a water inlet tube is inserted into the inner wall of the upper end of the rotary shaft. The efficient cleaning device is simple in structure, is easy to operate, can effectively remove dust adhered on the inner wall of the casting mould, and ensures quality of cast products.

Owner:湖州永盛机械铸造有限公司

Workbench for cleaning and recycling waste scraps generated in machine element processing

InactiveCN105965316AIngenious structural designClean up thoroughlyMaintainance and safety accessoriesScrapWaste management

The invention discloses a workbench for cleaning and recycling waste scraps generated in machine element processing. The workbench comprises a workbench body. A scrap removal cavity is formed in the workbench body; a drawer is arranged in the scrap removal cavity; two guide rails are symmetrically arranged on the left end and the right end of a table top of the workbench body; a scraper blade is arranged right above the workbench body; hairbrushes are embedded into the bottom end of the scraper blade; guide slots matched with the guide rails are symmetrically formed on the bottom face of two ends of the scraper blade; two baffle plates are symmetrically arranged on the front end and the rear end of the workbench body and comprise vertical baffle plates and horizontal baffle plates; the cross section of the vertical baffle plates is of a concave structure; grooves are formed at opposite ends of the two horizontal baffle plates; the length of each groove is larger than the length of the scraper blade; the workbench body is provided with scrap removal holes near the baffle plates; guide plates for the scrap removal holes are arranged on the top end of the side wall of the scrap removal cavity, and are slantways arranged. The workbench for cleaning and recycling the waste scraps generated in machine element processing provided by the invention is ingenious in structural design, element waste scraps on the table top of the workbench body are swept to and fro so as to be cleanly and thoroughly swept, and the waste scraps are directly fallen into a scrap removal chamber, so that the personal safety of the cleaning crews is ensured.

Owner:江苏力栋机械科技有限公司

Anode oxidation pretreatment method for aluminium alloy

InactiveCN1654714ASand fastReduce aluminum consumptionSurface reaction electrolytic coatingWaxPretreatment method

The processing method of aluminum alloy part before anode oxidizing includes the following steps: eliminating oil and wax, water washing, brightening acid pickling, low temperature polishing, water washing, eliminating ash, and water washing. The said method has the advantages of powerful mechanical ripple eliminating ability, low aluminum loss, complete elimination of acid pickling ash, etc. and can make the processed surface have no ripple, ash and fine sand and be bright.

Owner:熊映明

Environmental protection and safety type hydrocarbon cleaning agent

InactiveCN101591590AClean up thoroughlyImprove cleanlinessOrganic non-surface-active detergent compositionsSewageFreon

The invention relates to an environmental protection and safety type hydrocarbon cleaning agent belonging to the field of chemical cleaning agents. The hydrocarbon cleaning agent comprises the following components by weight percent: 50-95 percent of C10H22 and 5-35 percent of C11H24. The hydrocarbon cleaning agent has extremely strong cleaning capacity, can thoroughly clean various sewages such as oil stains, water, dust, and the like, can be completely volatilized without any residues, has an ozone rupture coefficient of 0.00 and no harm to the human body and is the optimal choice for substituting for the Freon and halogenated hydrocarbon products having extremely great harm to the environment and human beings.

Owner:华阳新兴科技(天津)集团有限公司 +1

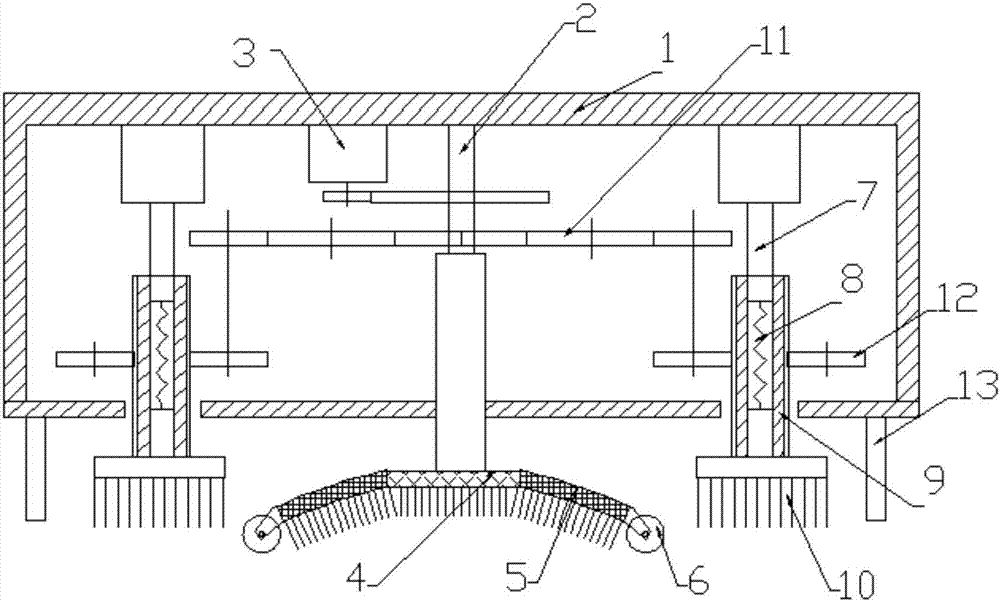

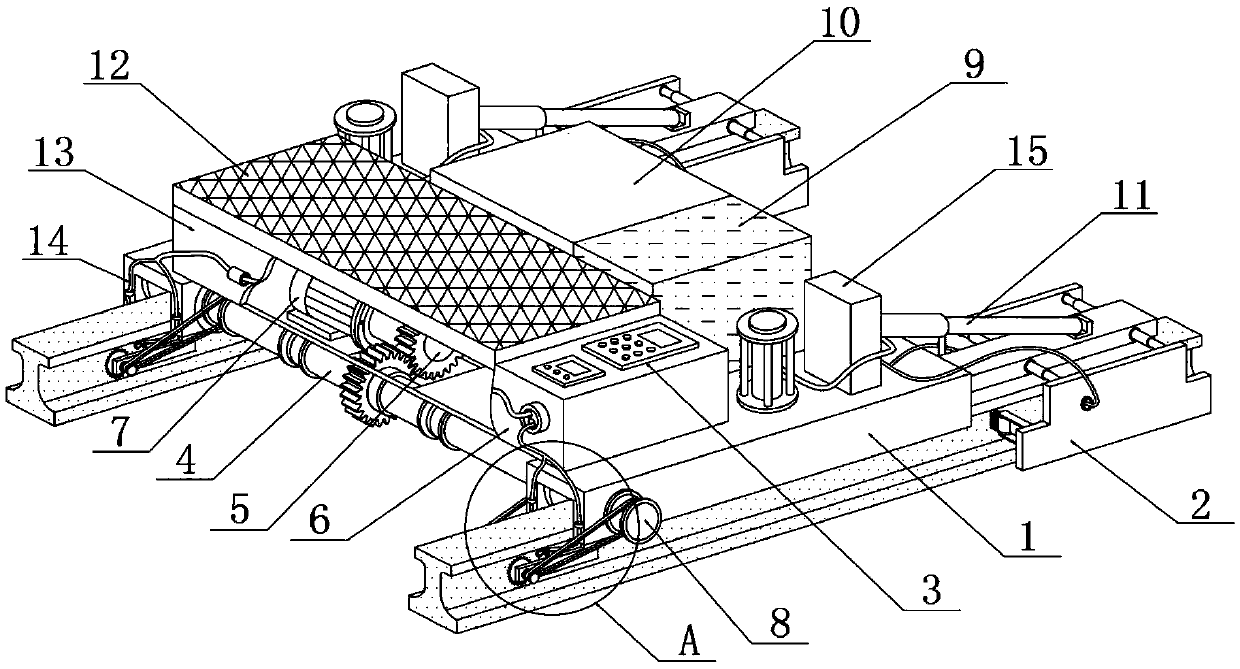

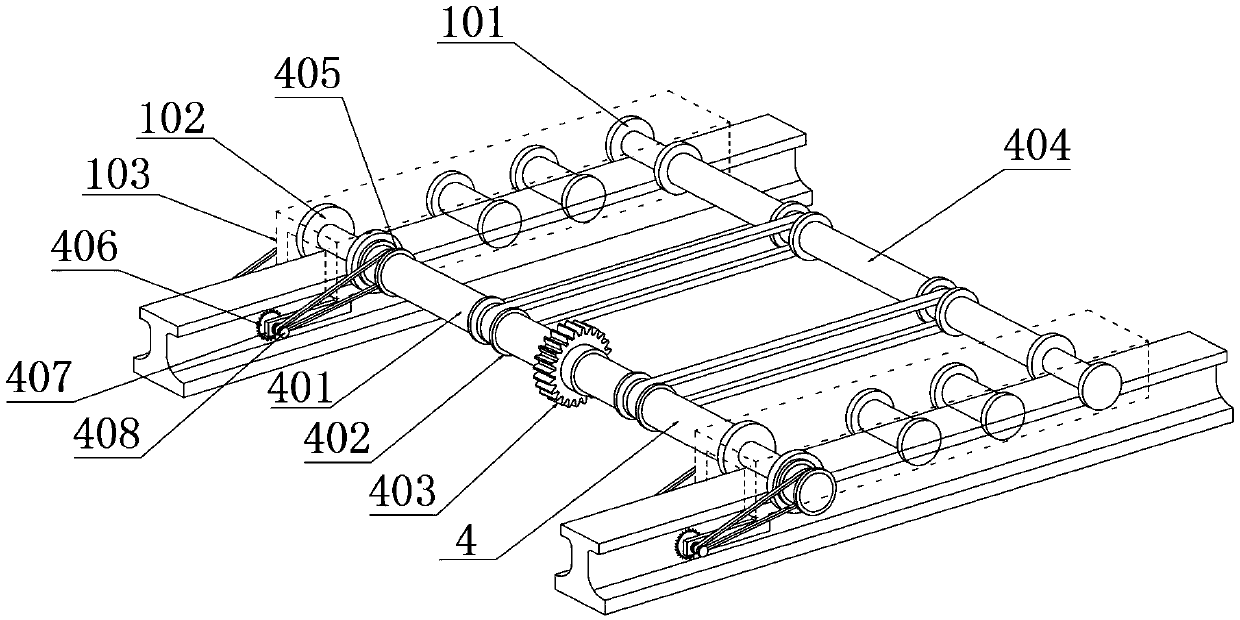

Intelligent floor sweeping robot suitable for uneven floor

The invention relates to the field of intelligent robots, in particular to an intelligent floor sweeping robot suitable for an uneven floor. A dust collection opening and a sweeper opening are formed in the lower end of a housing. The dust collection opening is connected with an air channel of a dust collection system. In the housing, a vertical rotary shaft is installed on the axis and is connected with a motor through a drive system. The lower end of the rotary shaft is connected with a deformable brush. Multiple vertical telescopic shafts are symmetrically installed around the rotary shaft, and the lower ends of the telescopic shafts are fixedly connected with bristle brushes. The telescopic shafts are connected with the rotary shaft through a transmission gear system. Wheels are further arranged at the lower end of the housing. A control panel of a control system is installed on the upper end face of the housing. The dust collection system, a battery and the control system are respectively installed in the housing, and the motor and the control system are respectively connected with the battery. The intelligent floor sweeping robot is suitable for cleaning of the uneven floor, the bristle brush and the deformable brush attach to the uneven floor to perform thorough cleaning, and then swept dirt and dust are collected and cleared by the dust collection system.

Owner:钟玲珑

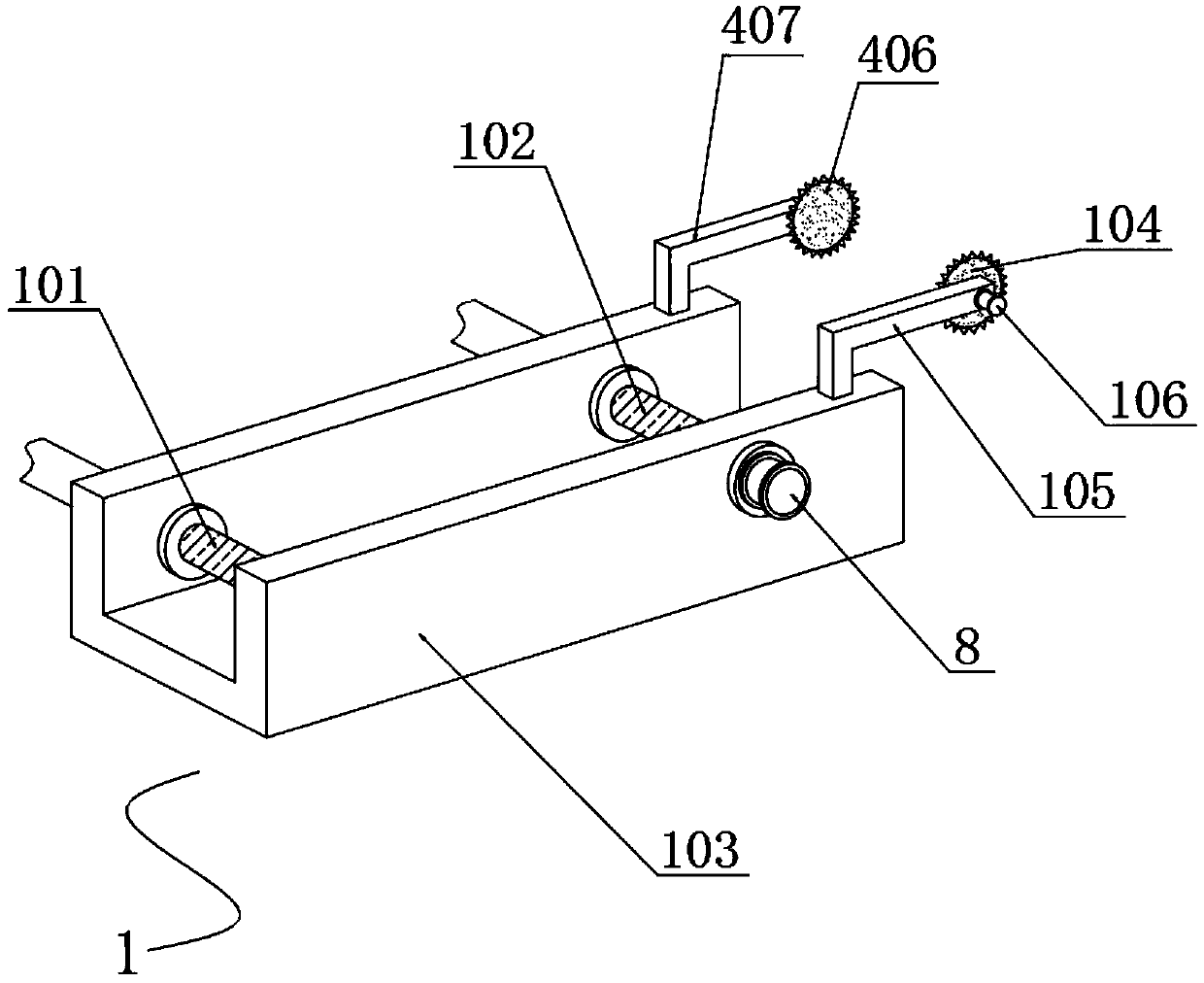

Self-propelled rust-removal grinding device for rail maintenance and with dust removal function

ActiveCN109629355AAffect the quality of useImprove rust resistanceRailway track constructionSpray nozzleEngineering

The invention discloses a self-propelled rust-removal grinding device for rail maintenance and with a dust removal function and relates to the technical field of rail rust removal. The device comprises two symmetrically-arranged walking mechanisms and fan boxes arranged at the upper ends of the walking mechanisms and used for placing fans, and control panels are arranged on the upper surfaces of the fan boxes. According to the device, the walking mechanisms are adopted for achieving self-propelled grinding, the upper surface, inner side and outer side of a rail are synchronously ground, one-time dust removal is achieved, and the dust is thoroughly cleared away; in cooperation with a blowing head, dust can be blown away, and the situation is avoided that since the dust falls on the rail, the application quality of the rail and spraying of an anti-rust solution in the later period are influenced; by adopting a sweeping mechanism, the ground rail is swept, in cooperation with a spray nozzle and a brush roller, the two side faces are sprayed with the anti-rust solution, the anti-dust effect of the rail is improved, and the service life of the rail is prolonged; the device is provided with a solar cell panel, and the cruising capacity during outdoor work is improved, so that the device continuously works.

Owner:成都中轨轨道设备有限公司

Preparation method of mangiferin

The invention relates to a preparation method of mangiferin. The preparation method adopts the process steps of saturated limewater solution soaking and extraction, macroporous resin adsorption, stepwise elution of water and ethanol solution of different concentration, concentration and crystallization under reduced pressure, and recrystallization by adjusting acidity through methanol. The obtained product has the advantages of high purity, high yield and low cost. The process is easy to popularize and industrialize.

Owner:NANJING ZELANG MEDICAL TECH

Technique for preparing high-purity vanadium pentoxide by high-vanadium edulcoration

InactiveCN101182036AClean up thoroughlyHigh vanadium deposition rateVanadium oxidesAluminium sulfateRoom temperature

The invention relates to a preparation technology of vanadium pentoxide with high purity by removing impurity from high vanadium. The method adopts hydrochloric acid to adjust the pH value of desorbed solution to 8-9 and adopts aluminum sulfate as purifying agent; the pH value of filtrate is adjusted by the hydrochloric acid to 8-9; the obtained solution is stirred under the normal temperature and is added with ammonium chloride for reaction for 3-4 days so as to obtain ammonium metavanadate crystals which are then treated with centrifugal dewatering after settling; the ammonium metavanadate obtained after dehydration is burned under the temperature of 500-550 DEG C in an electricity calcine stove for six to eight hours and is next cooled to obtain the vanadium pentoxide with high purity. The impurity removal by the technology of the invention is more thoroughly and the vanadium precipitation rate is improved and the purity of the obtained product can reach above 99.5 percent.

Owner:贾绍才

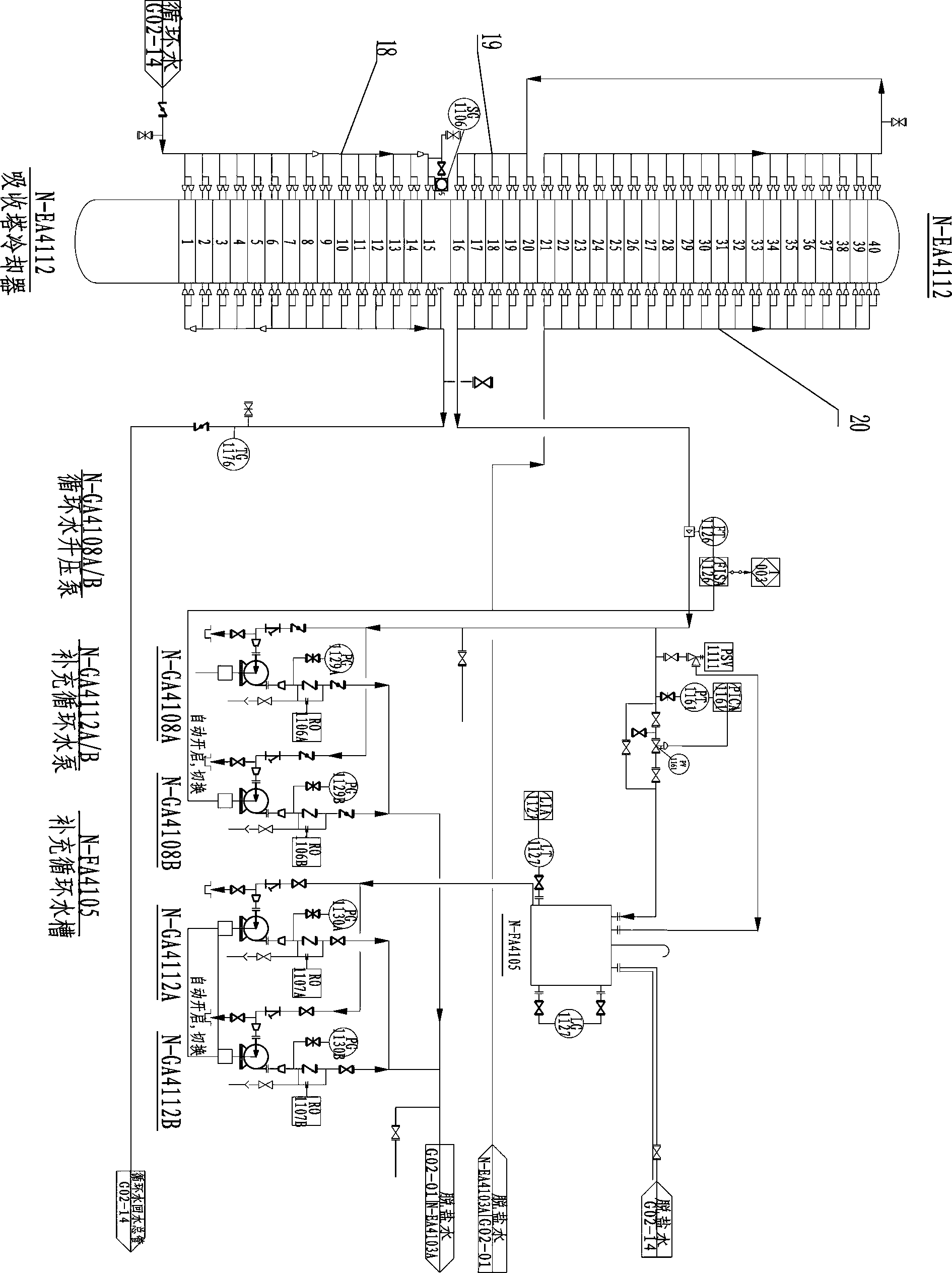

Method and device for preparing high-concentration dilute nitric acid

The invention discloses a method and device for preparing high-concentration dilute nitric acid. The method comprises the following steps: carrying out ammonia-air mixing, ammoxidation, condensation separation and fine separation on air subjected to impurity removal and dehumidification and liquid ammonia subjected to impurity removal, oil removal and evaporation, absorbing in an absorption tower in which 40 tower plates are arranged, meanwhile, carrying out cooling heat exchange by a three-stage water circulation technique to obtain the high-concentration dilute nitric acid of which the concentration is not lower than 68-70%. The method and device effectively enhance the nitric acid absorption efficiency, enhance the concentration of the dilute nitric acid, and can better satisfy the demands of modern industry for high-concentration dilute nitric acid.

Owner:TIANJI COAL CHEM IND GROUP

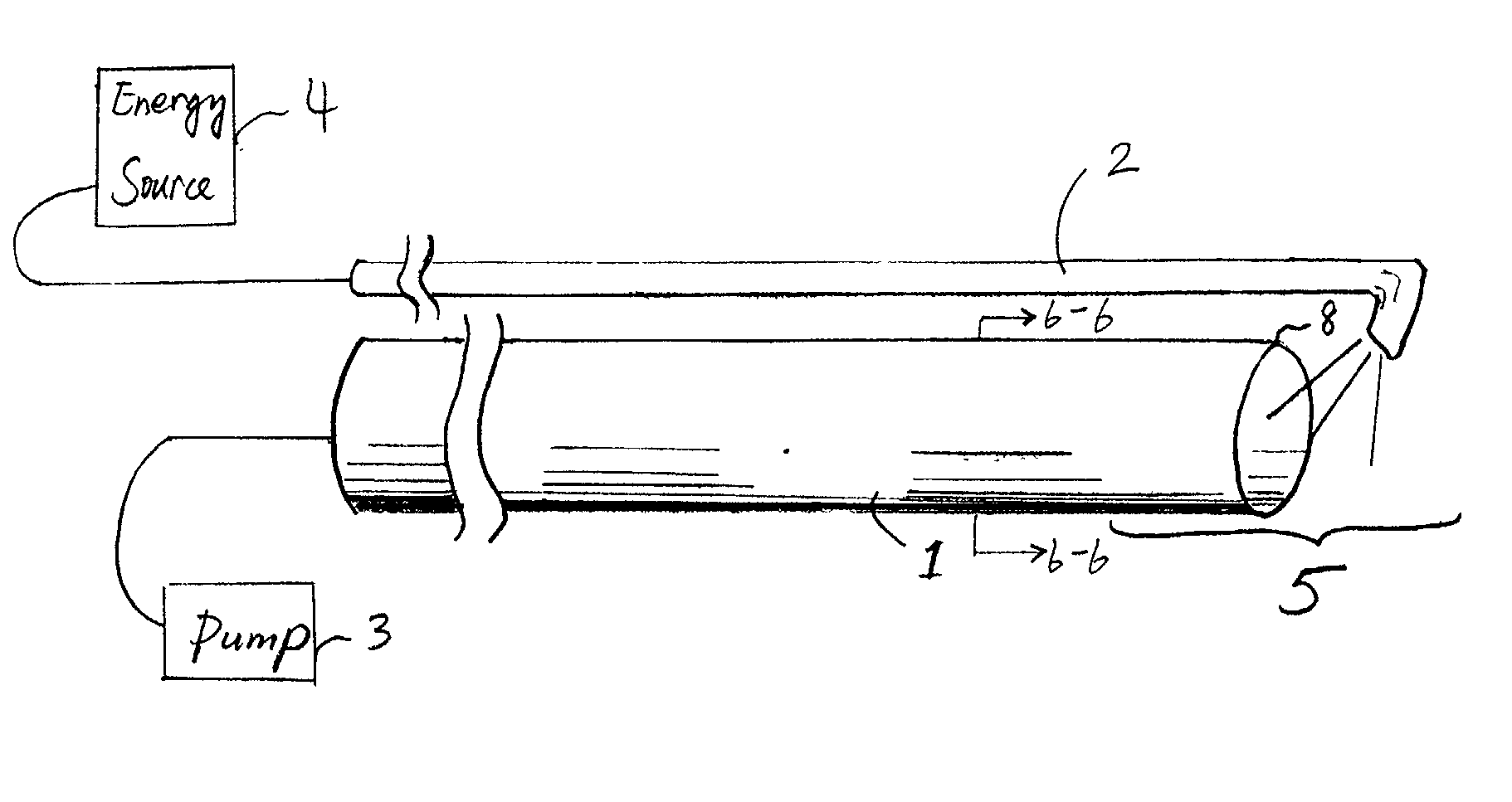

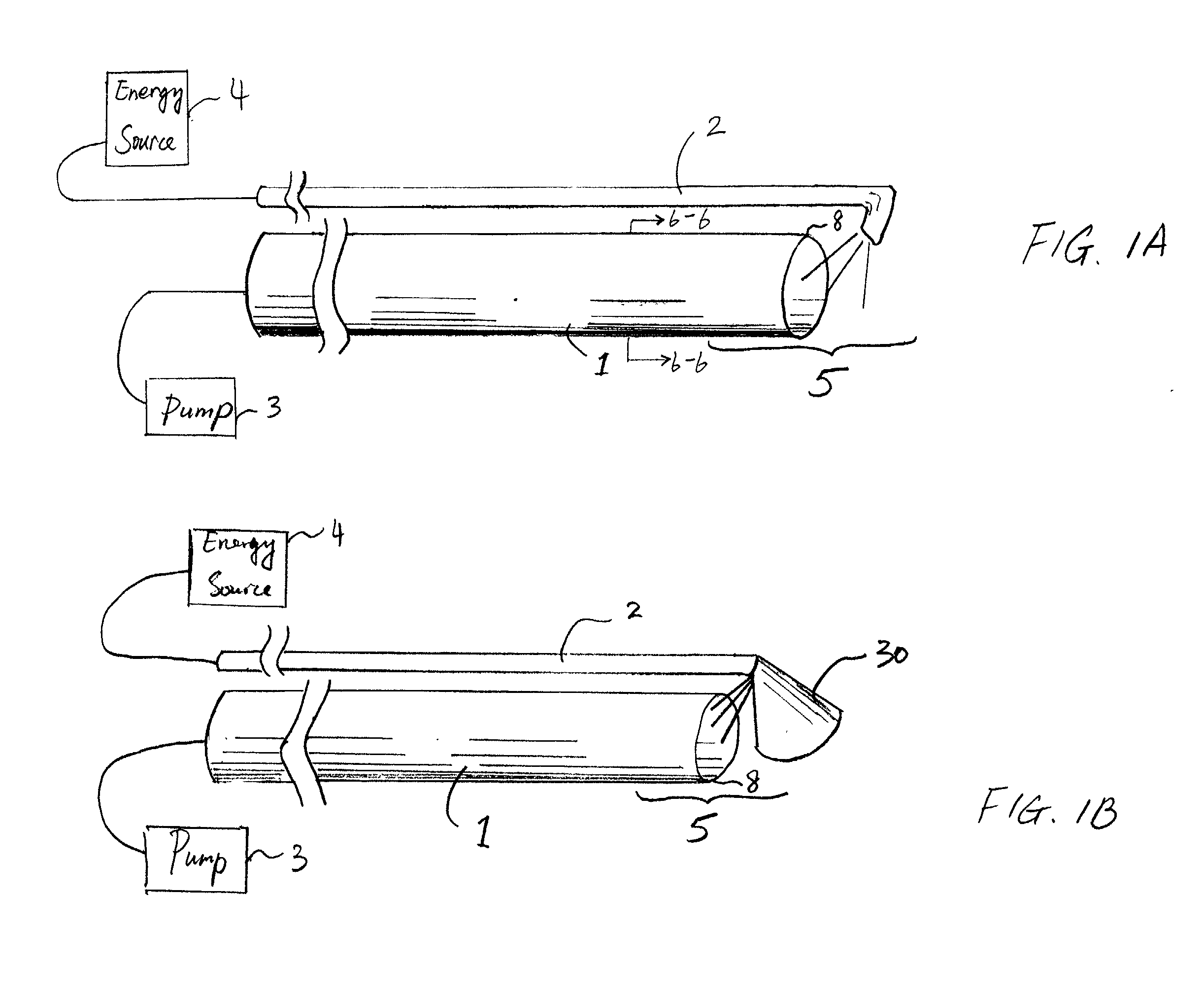

Laser lithotripsy device with suction

A medical device is provided which comprises a suction conduit and an energy-transmitting conduit wherein at least some of the transmitted energy is directed to the distal region of the suction conduit. The device may include an optical apparatus for directing the energy. The device has applications in lithotripsy and tissue-removal in a patient.

Owner:BOSTON SCI SCIMED INC

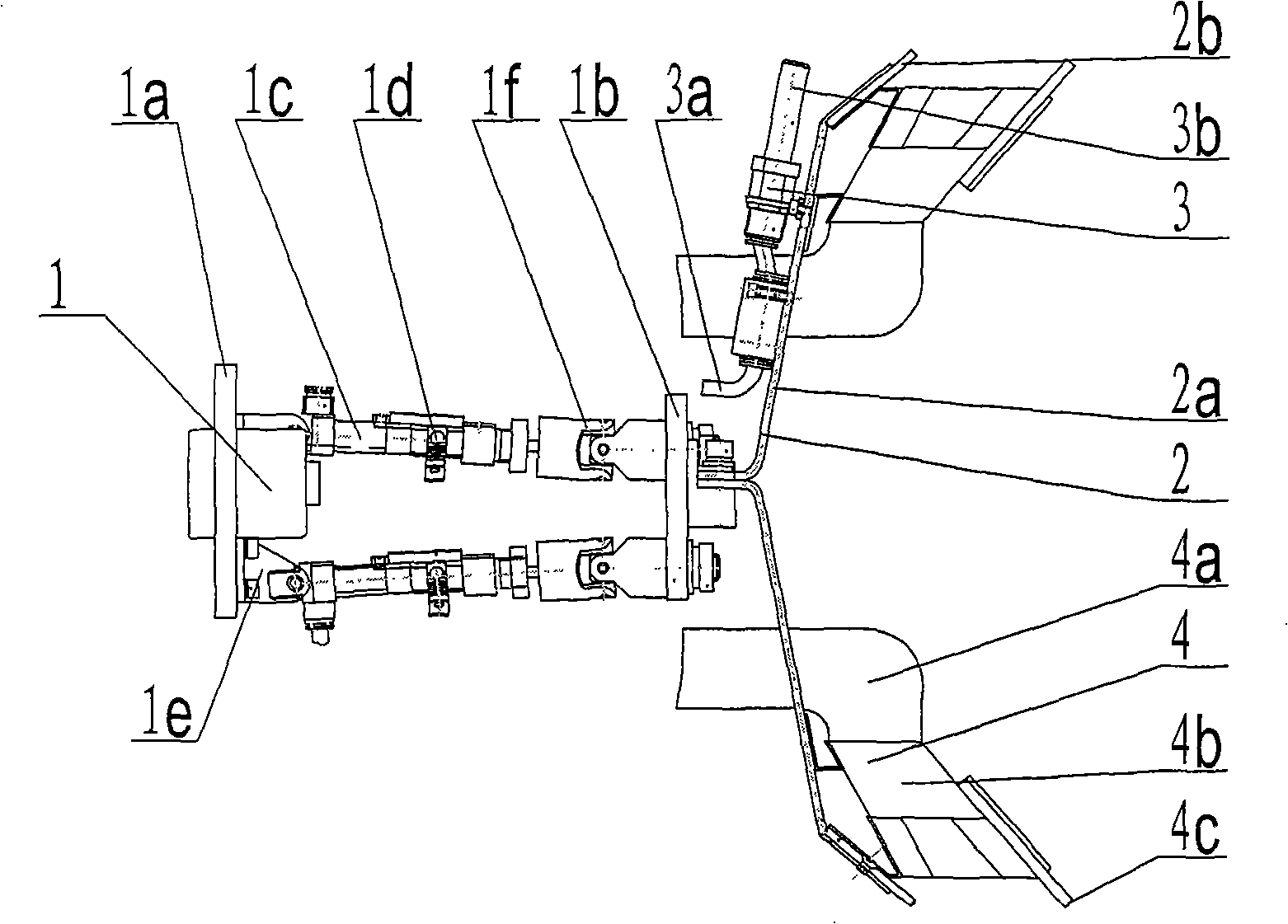

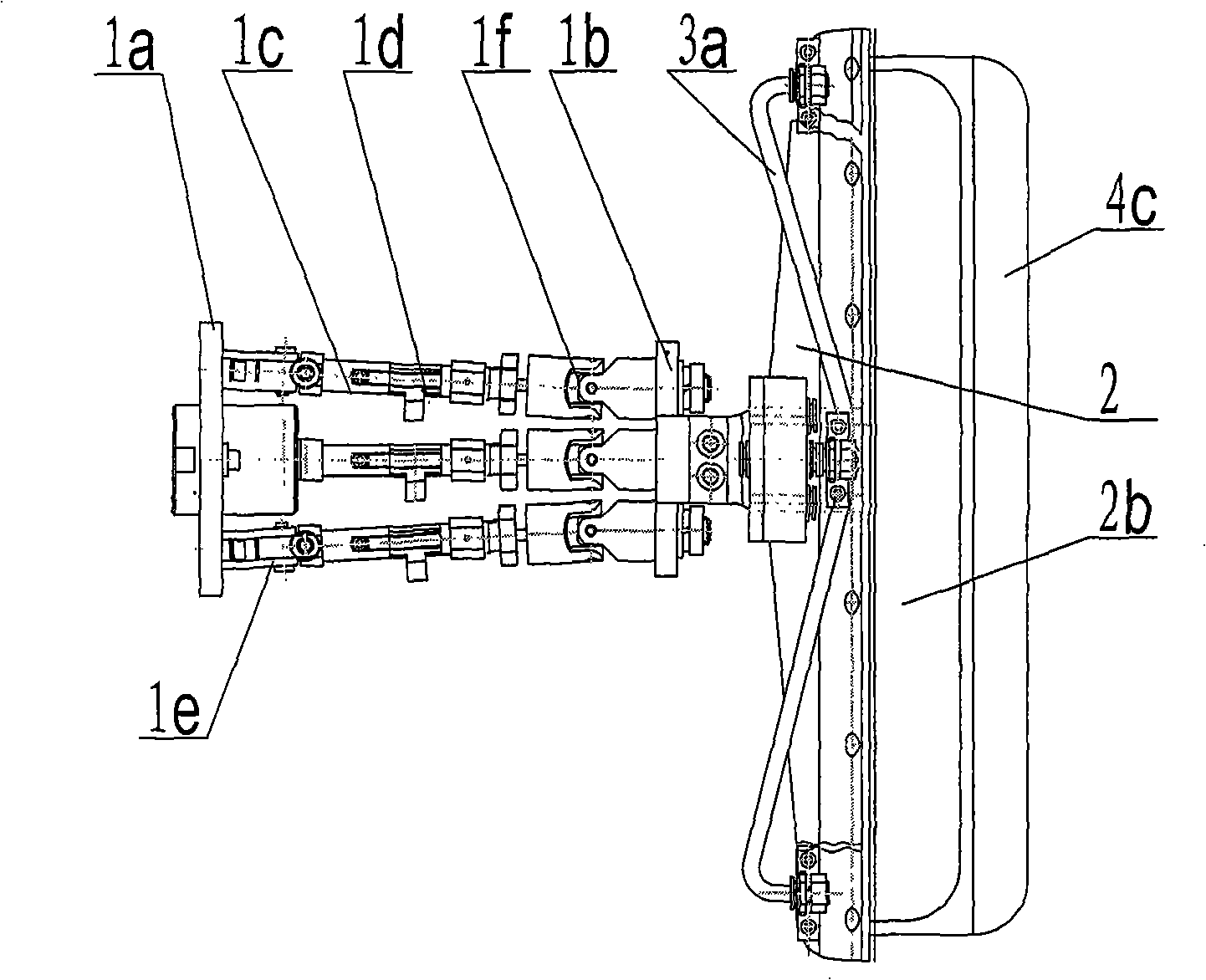

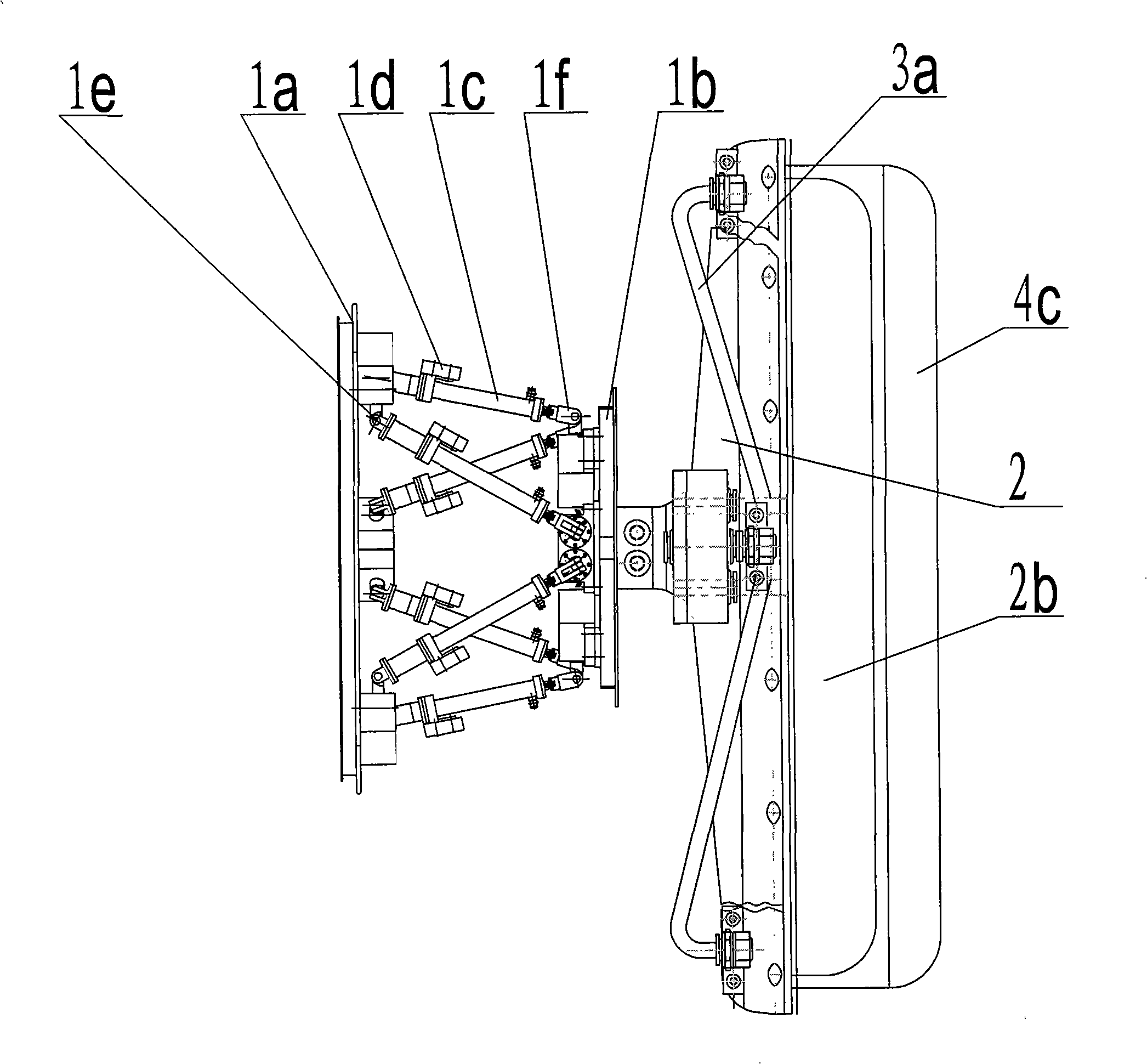

Robot flexibility clean-up paw

InactiveCN101284277AImprove reliabilitySimple structure and principleHollow article cleaningCleaning using gasesSelf adaptivePneumatic pressure

A flexible cleaning robot hand comprises an anti-collision detection device (1), a cleaning device (2) and an air pressure spray device (3); the anti-collision detection device comprises a mounting flange (1a) and a connecting flange (1b) which are formed at the both ends, a telescopic motion pair (1c) which are transversely or inclinedly hinged between the mounting flange and the connecting flange by hinge mechanisms (1e and 1f) and a position detection sensor (1d) which is arranged on the telescopic motion pair; the cleaning device comprises a scraper support (2a) which is arranged on the connecting flange and a flexible cleaning scraper (2b) which is arranged at the external end of the scraper support; the air pressure spray device is arranged on the scraper support, and comprises a spray air pipe (3a) which communicates with an air path system and an air pressure nozzle (3b) which is connected on the air pipe. The flexible cleaning robot hand has the anti-collision detection and the self-adaptive ability of the cleaning pressure, and can be arranged on a robot, thus realizing the automatic cleaning of the interior of a box body and having good cleaning effect.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Method for producing single-sided composite stainless steel cold rolling base stock

ActiveCN102248372AEfficient removalClean up thoroughlyTemperature control deviceWork treatment devicesProduction lineSocial benefits

The invention relates to a method for producing a single-sided composite stainless steel cold rolling base stock. The method comprises the following steps of: firstly, selecting carbon steel or low-alloy steel as a substrate, processing oxidation layer on surfaces of the substrate and a compound plate, and assembling and stacking the compound plate and the substrate; secondly, drilling, detectingleakage and vacuumizing; and finally, performing hot continuous rolling, coiling a hot rolled strip on a double coiling opening production line and trimming to form two strip coils serving as the cold rolling base stock, wherein the material and thickness of the cold rolling base stock can be combined freely to meet the requirements of different users, and the cold rolling base stock is widely applied in industries of petroleum, chemical engineering, salt industry, water conservancy, electric power and the like. The single-sided composite stainless steel cold rolling base stock is used as a resource-saved product to reduce the consumption of precious metal, reduce engineering cost substantially and realize the perfect combination of low cost and high performance, so the cold rolling base stock can create great social benefits.

Owner:河南盛荣金属复合新材料有限公司

Regeneration method for arsenic poisoning selective catalytic reduction denitration catalyst

InactiveCN103894240AClean up thoroughlyGain resistance to arsenic poisoningCatalyst regeneration/reactivationBULK ACTIVE INGREDIENTArsenic poisoning

The invention discloses a regeneration method for an arsenic poisoning selective catalytic reduction denitration catalyst. The regeneration method comprises the following four steps of blowing ash, dipping, dipping, and drying and roasting. According to the regeneration method, an arsenic component which can cause SCR (Selective Catalytic Reduction) denitration catalyst poisoning can be effectively removed by using regenerated liquid and active ingredients can be supplemented; an SCR denitration catalyst obtains a certain arsenic poisoning resisting capability; meanwhile, a regeneration process is greatly simplified and the regeneration cost of the SCR denitration catalyst is reduced; with the adoption of the method, the regenerated denitration catalyst can be used for carrying out denitration activity detection and the denitration rate can be up to 80-88%.

Owner:河北宏庚环保设备有限公司

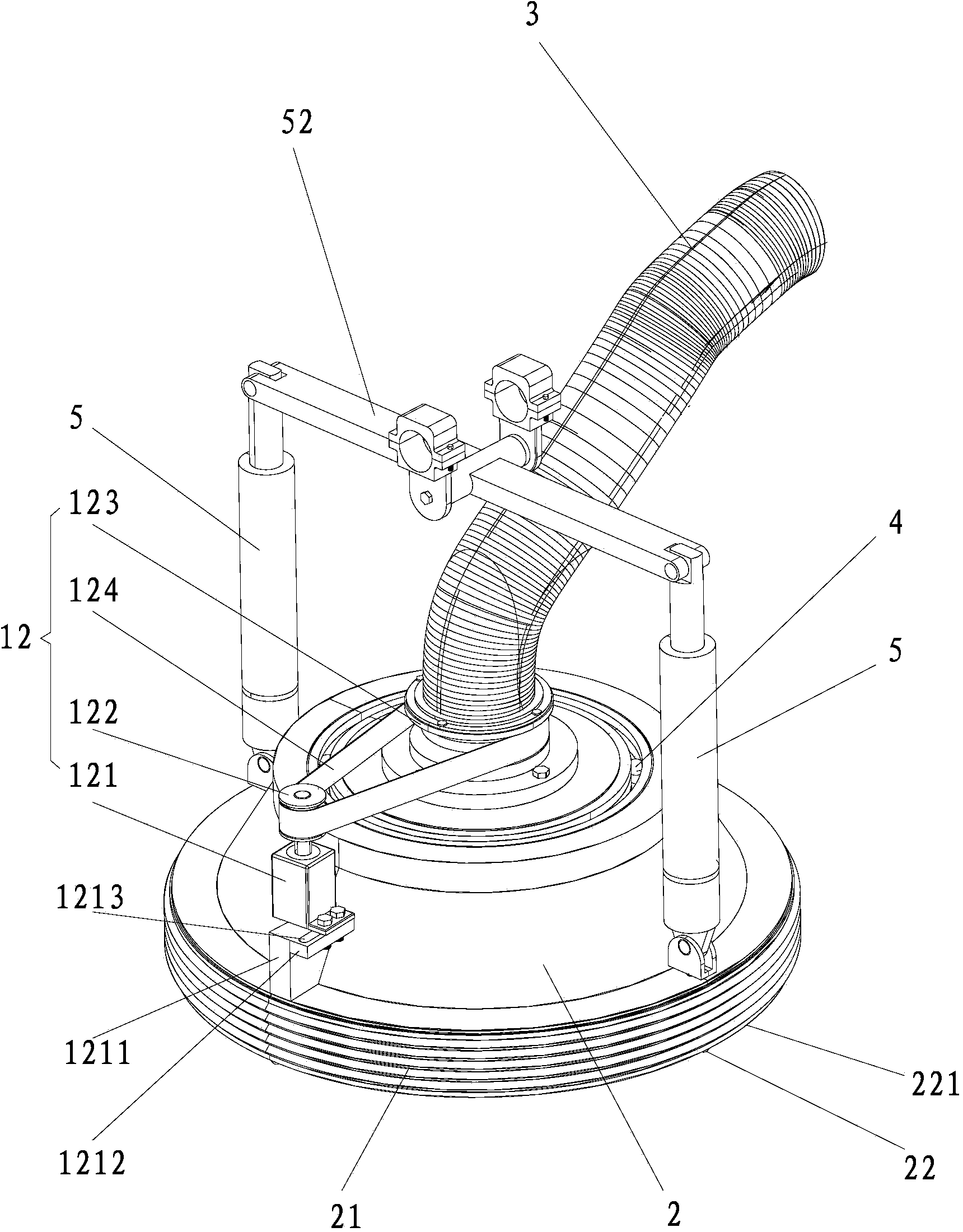

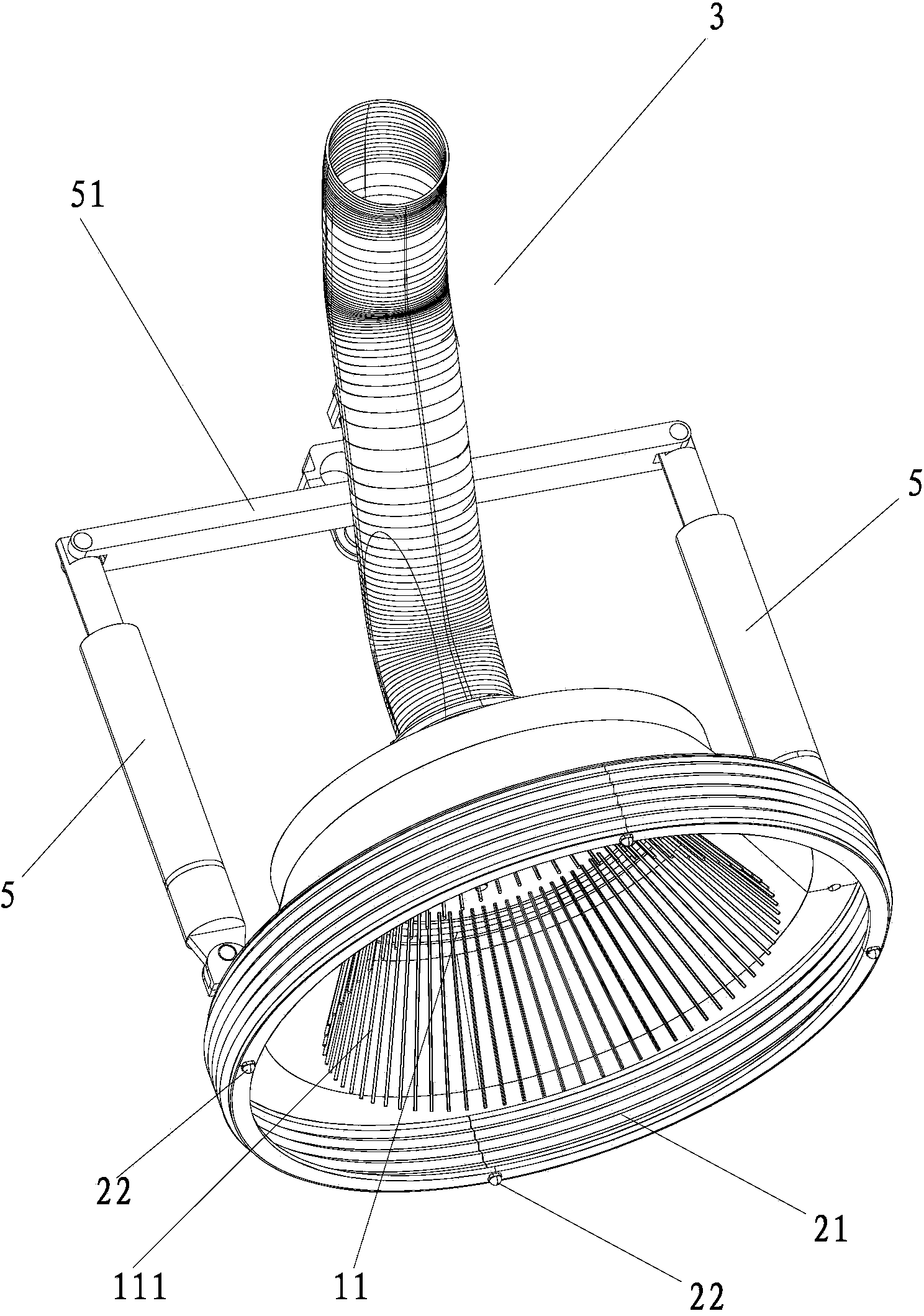

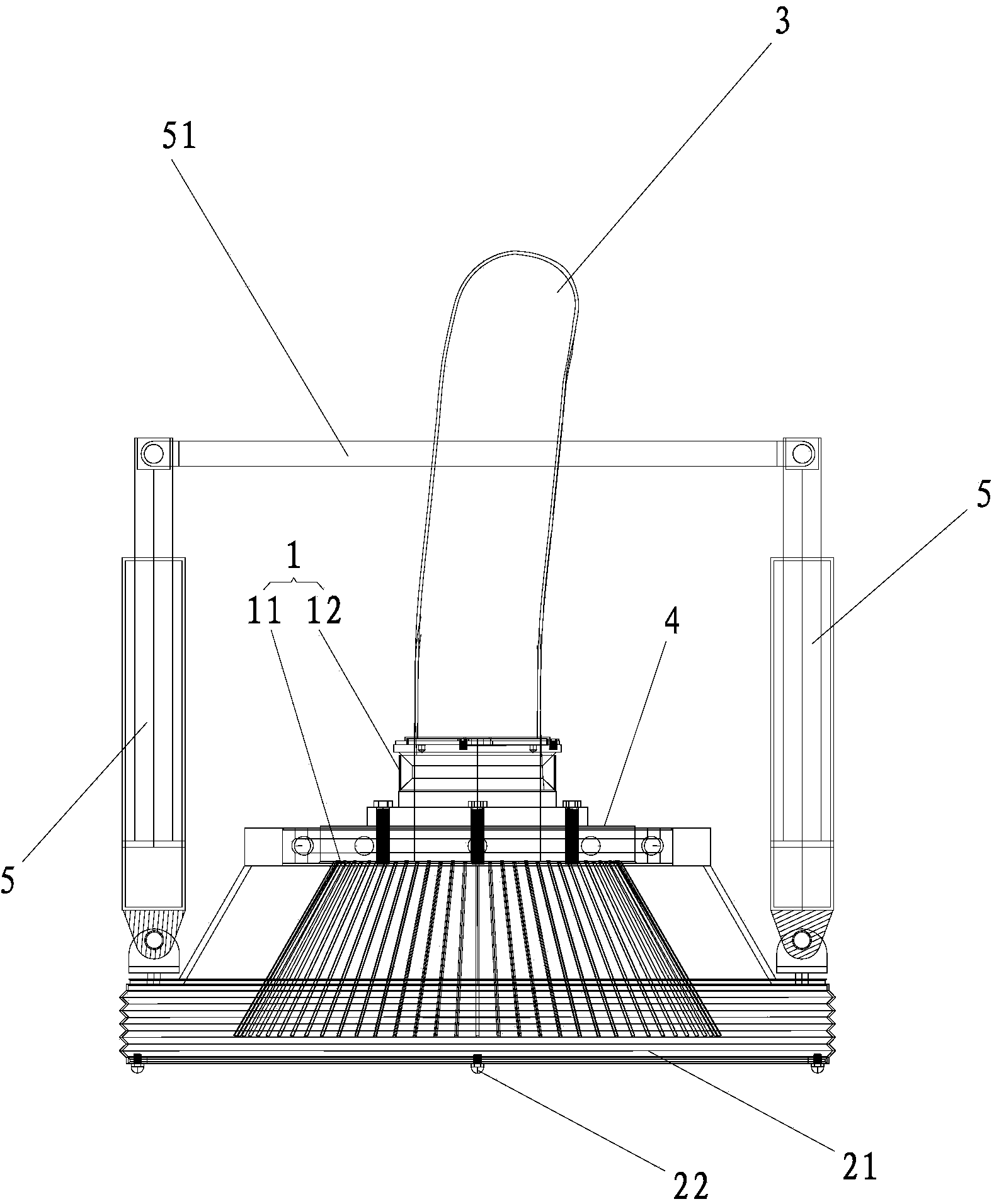

Novel sweeping and absorbing integrated cleaning mechanism

ActiveCN103510484AOvercome structureOvercome the defect of poor cleaning abilityRoad cleaningRoad surfaceEngineering

The invention provides a novel sweeping and absorbing integrated cleaning mechanism. The novel sweeping and absorbing integrated cleaning mechanism comprises a rotating cleaning brush carried by a sweeper. A shell making contact with the ground in a soft mode covers the rotating cleaning brush. A pumping pipeline is communicated with the upper portion of the shell. Due to the adoption of the technical scheme, the novel sweeping and absorbing integrated cleaning mechanism breaks through the structural form of traditional sweepers and integrates a rubbish brushing and sweeping mechanism and a rubbish pumping mechanism; the cleaning brush is rotated to brush and sweep rubbish in the shell in a rotating mode, is prevented from being absorbed on the ground and is in a free floating state. Negative pressure is formed in the shell through the pumping pipeline, the rubbish is pumped to a rubbish can of the sweeper through the pumping pipeline and is stored, and the cleaning brush is rotated to be matched with the shell and the pumping pipeline to form an Archimedes spiral type rubbish absorbing structure. The novel sweeping and absorbing integrated cleaning mechanism is strong in rubbish pumping and intake capacity and overcomes the defects that the traditional sweepers are single in structure and poor in cleaning ability. Compared with the prior art, the novel sweeping and absorbing integrated cleaning mechanism is thorough in road surface rubbish cleaning, efficient, novel and reasonable in structure and strong in practicability.

Owner:HUAQIAO UNIVERSITY

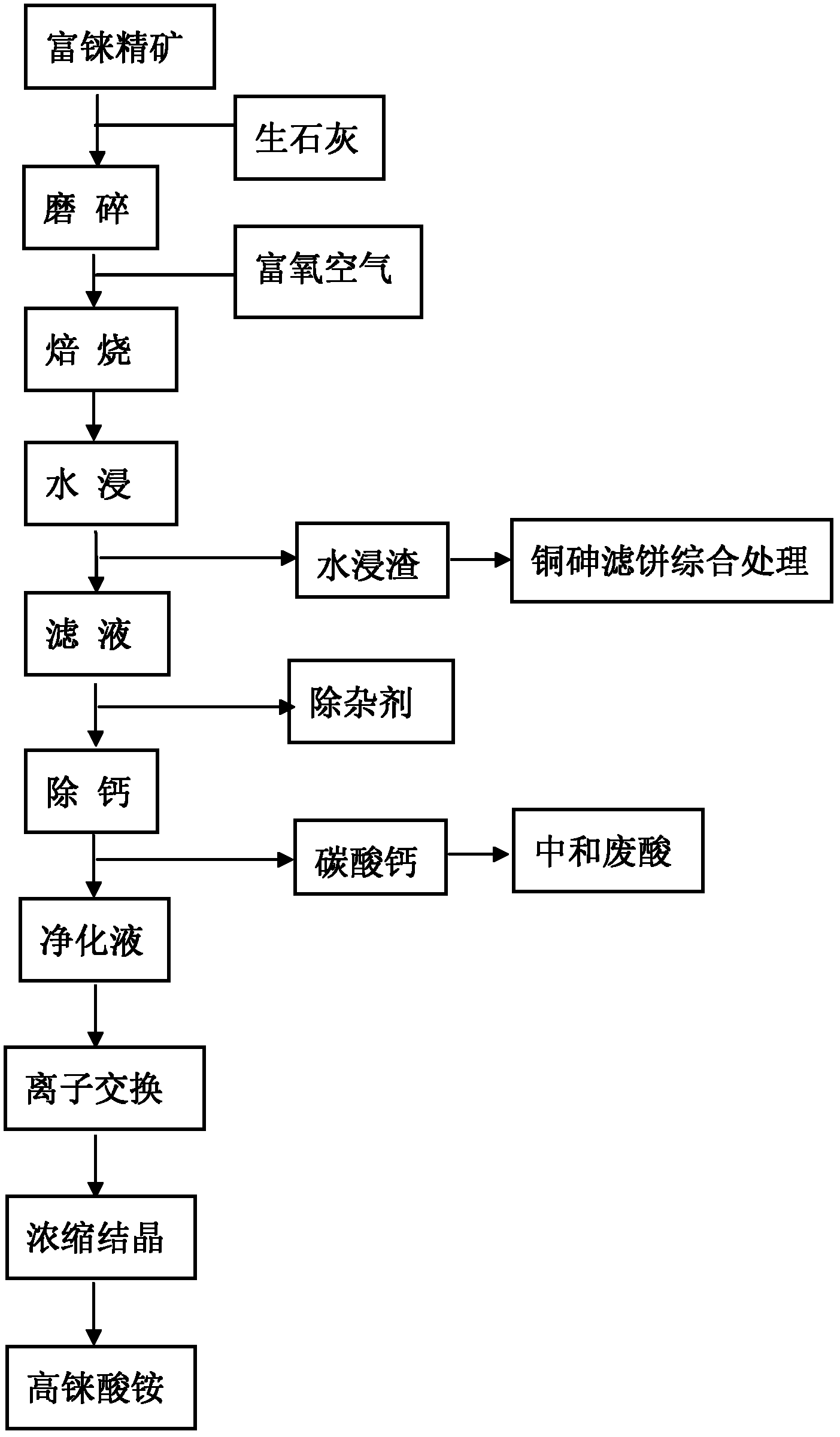

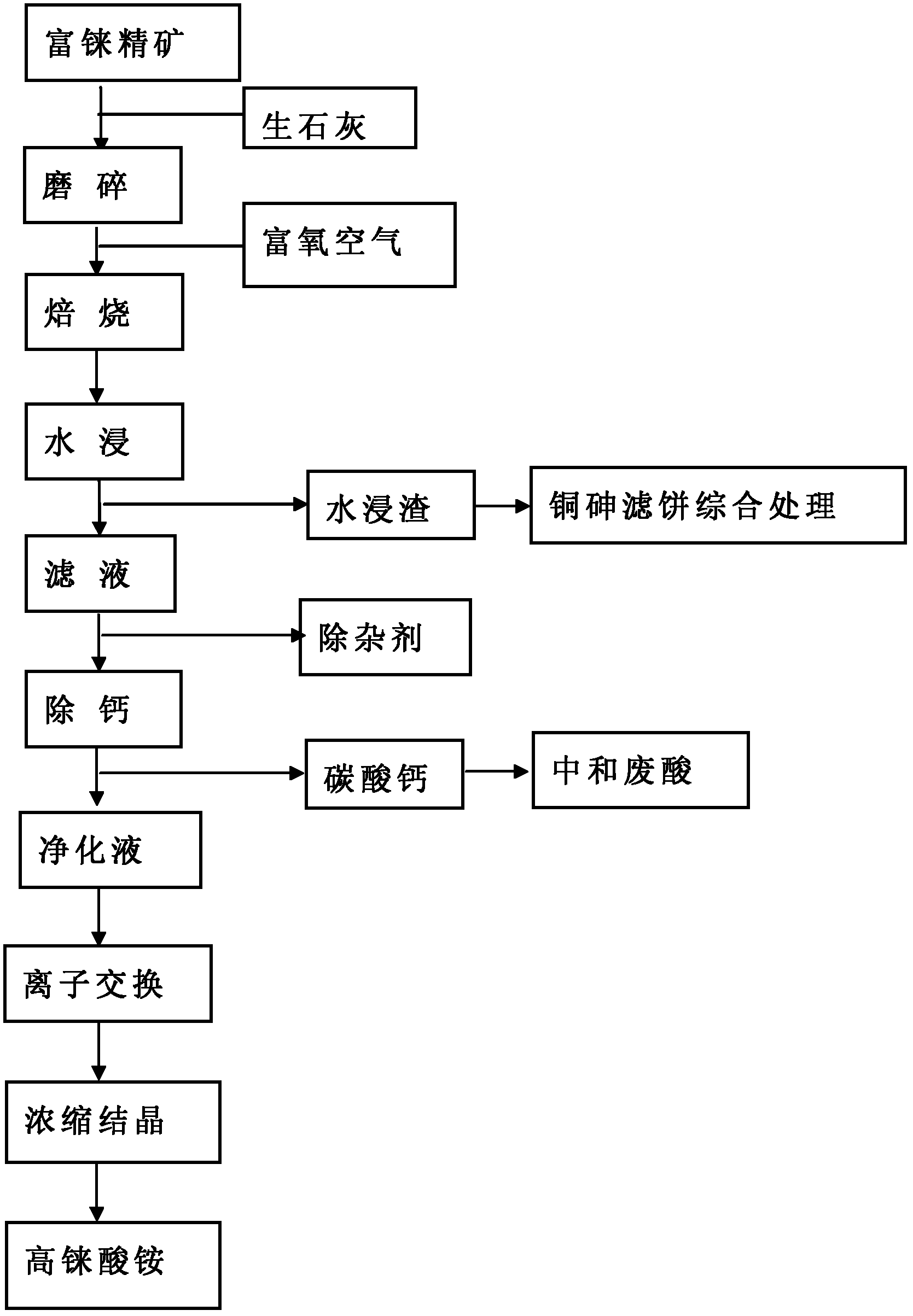

Method for extracting rhenium from rhenium-rich concentrates

ActiveCN102628111AThe effect is thoroughHigh recovery rate of rheniumProcess efficiency improvementIonIon exchange

The invention provides a method for extracting rhenium from rhenium-rich concentrates. The method comprises the following steps of: mixing the rhenium-rich concentrates with quick lime, grinding a mixture, feeding oxygen-enriched air into the mixture, and roasting the mixture at a temperature of 400-900 DEG C; sizing and immersing the roasted mixture by using water, and filtering after the immersion is finished; adding an impurity removing agent into the filtered liquid so as to remove calcium and trace heavy metal ions; filtering after removing impurities; and carrying out ion exchange process on the filtered liquid, which is subjected to impurity removal and filtering, through anion exchange resin, obtaining ammonium rhenate solution after desorption, and obtaining ammonium perrhenate through reconcentration and crystallization. According to the method provided by the invention, quick lime oxygen-enriched roasting and water immersion are used, so that the operations of decoppering, arsenic removal and desulfuration are carried out, therefore rhenium, arsenic and sulfur are oxidized sufficiently under the oxygen enrichment condition; the rhenium, arsenic and sulfur are combined with calcium oxide, so that insoluble substances are generated; the effects of removing copper, arsenic and sulfur are more thorough in the water immersion condition, and the disadvantage that the calcium content is high in the quick lime roasting and water immersion technology is solved through using the impurity removing agent to remove impurities; and the recovery rate of rhenium is high, so that the method provided by the invention is favorable to industrialized application.

Owner:YANGGU XIANGGUANG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com