Patents

Literature

133results about How to "Simple cleaning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

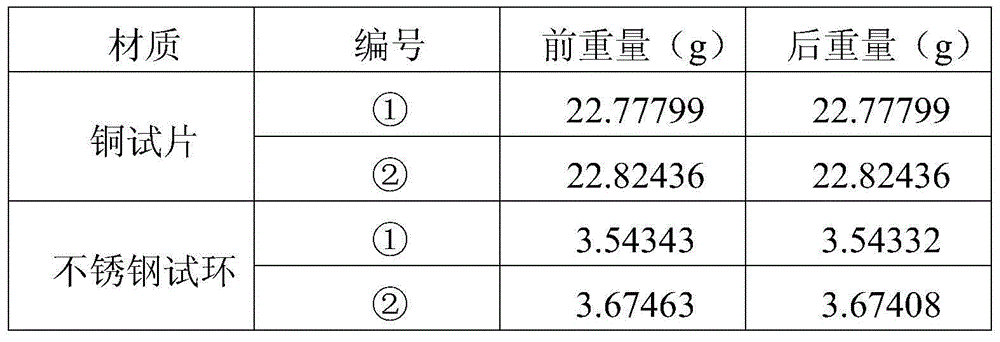

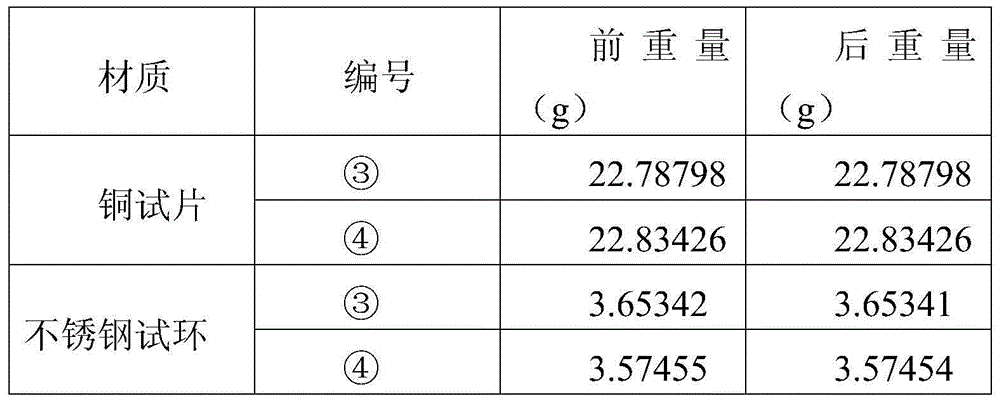

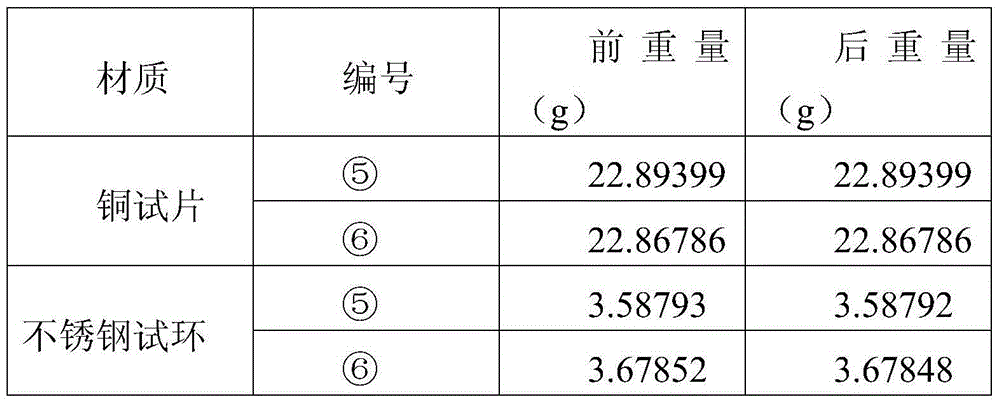

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

Method for preparing high-purity arsenic

The invention relates to a method for preparing a nonmetallic material, in particular to a method for preparing high-purity arsenic, solving the problems of high production cost, low output, impossible realization of industrialization, and the like of the traditional preparation methods. The method comprises the following steps of: loading industrial arsenic into a crucible and carrying out primary sublimation and distillation in a vacuum furnace; then loading the arsenic into an oxidation furnace, and introducing oxygen into the oxidation furnace to generate arsenic oxide; loading the arsenic oxide into a crucible and carrying out secondary sublimation and distillation in the vacuum furnace; loading the arsenic oxide subjected to twice distillation into a tube furnace, introducing high-purity argon and hydrogen into the tube furnace for reducing to obtain crystallized arsenic; loading uncrystallized black arsenic and unreduced arsenic oxide into a quartz tube, putting into the vacuum furnace for separating, and reducing obtained arsenic oxide; and finally, loading separated black arsenic and all reduced crystallized arsenic into the tube furnace together, introducing high-purity argon and hydrogen into the tube furnace for carrying out hydrogen sublimation protection to obtain 6N high-purity arsenic. The method has the advantages of simple impurity removal process, low cost and high output, solves the problem of pollution, eliminates potential safety hazards and achieves the purposes of generating the high-purity arsenic without pollution.

Owner:SHANXI LONGGANG MATERIAL

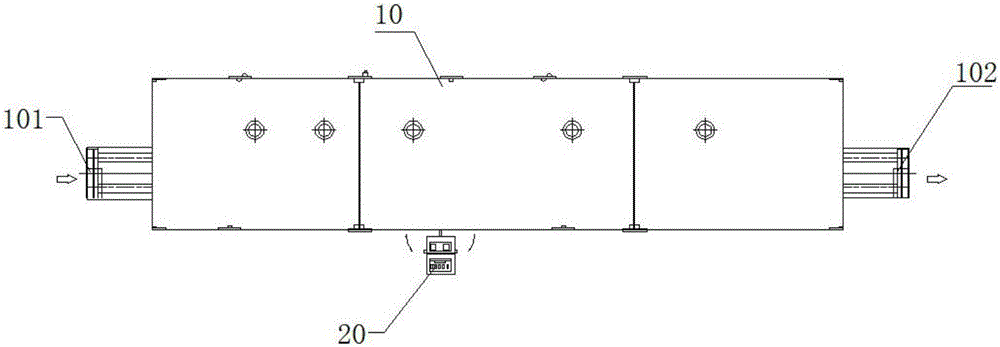

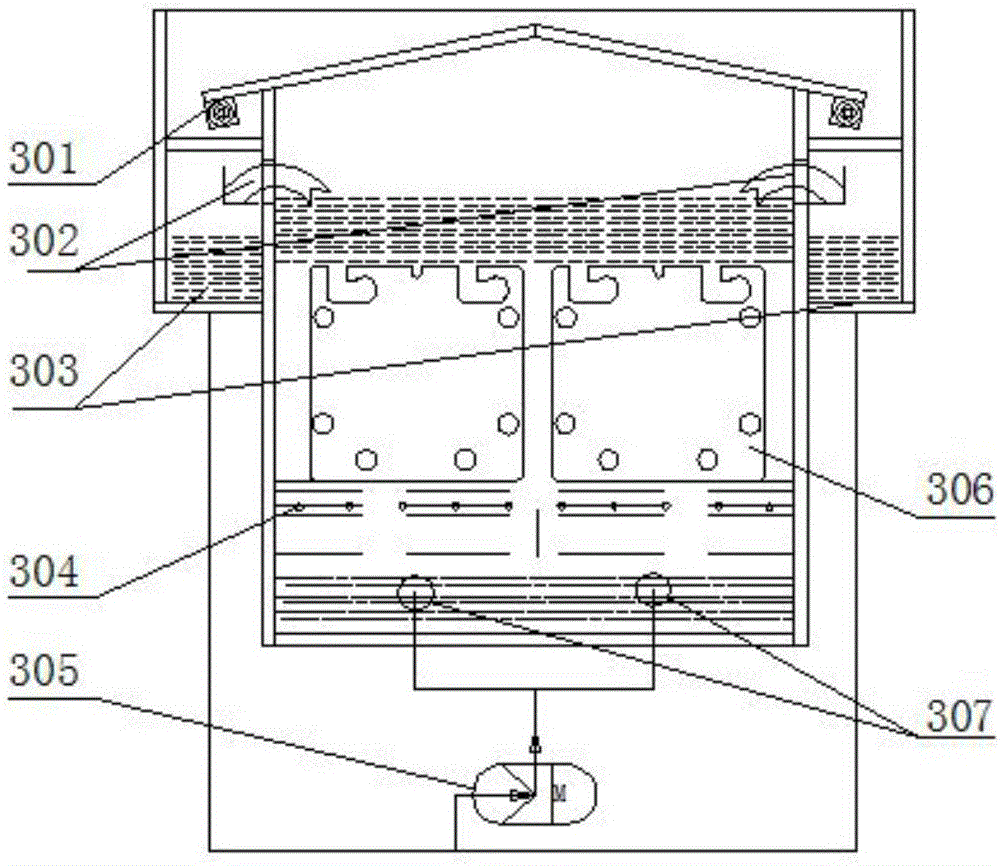

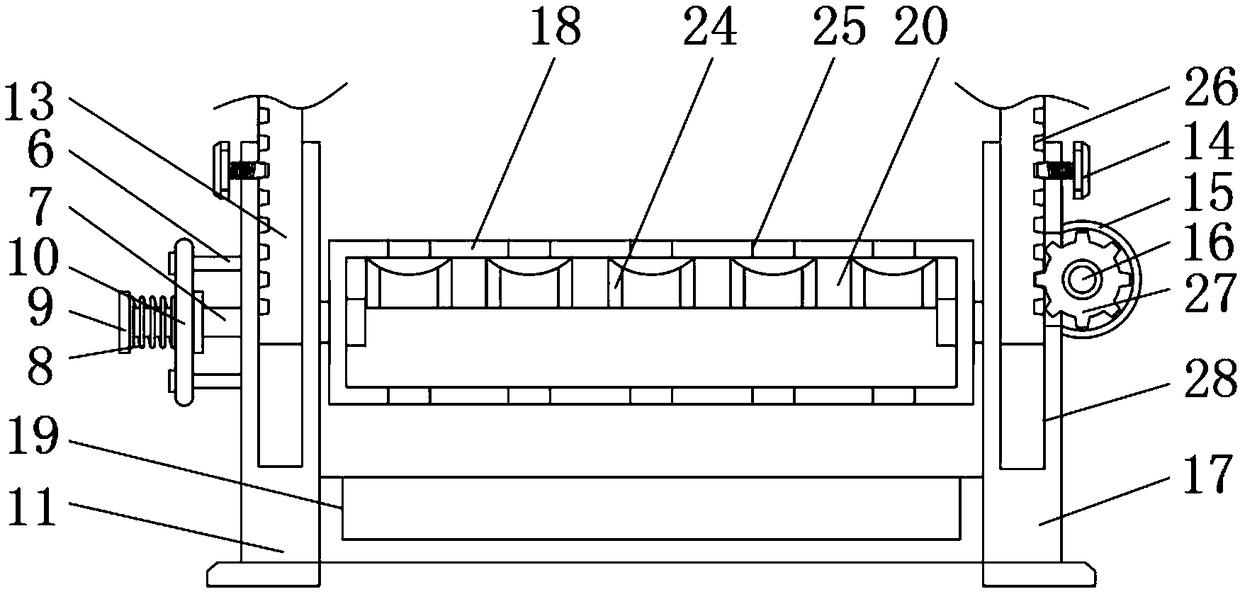

Monocrystal texturing cleaning machine and technological method therefor

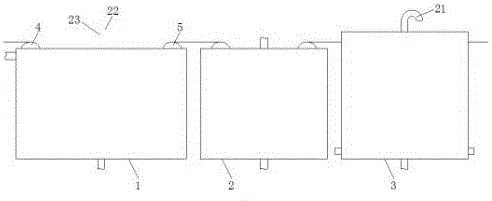

PendingCN106206381ASimple cleaning processImprove cleanlinessAfter-treatment detailsFinal product manufactureAcid washingSingle crystal

The invention discloses a monocrystal texturing cleaning machine. The monocrystal texturing cleaning machine comprises a cleaning body, wherein the cleaning body comprises three boxes; a material inlet is formed in the front end of the cleaning body while a material outlet is formed in the back end of the cleaning body; conveyor belts are arranged in the positions of the material inlet and the material outlet respectively; multiple mechanical arms for capturing materials are arranged above the conveyor belts; an air outlet is formed in an upper cover of the cleaning body; a texturing groove, an acid washing groove, a water washing groove, a pre-dewatering groove and a drying groove are also arranged in the cleaning body; a heating apparatus and a temperature sensor are arranged below each groove body; and liquid-distributing and liquid-supplementing systems connected with each of the groove bodies are also arranged in the cleaning body. By adoption of the monocrystal texturing cleaning machine, the automatic cleaning for the monocrystal texturing process can be realized; the overall cleaning process can be monitored and managed; and in addition, the monocrystal texturing cleaning machine adopts a box structure, so that the monocrystal texturing cleaning machine is applicable to industrial production.

Owner:苏州聚晶科技有限公司

Special high-efficiency steel strip cleaning device

PendingCN106563654AEfficient removalEasy to cleanDrying gas arrangementsDrying machines with progressive movementsMetal impuritiesEngineering

The invention discloses a special high-efficiency steel strip cleaning device which comprises a cleaning water tank, a rinsing tank and a drying box, wherein a feed roll and a discharge roll are arranged on two inner sides of each of the cleaning water tank, the rinsing tank and the drying box; three lower cleaning guide rolls, which are arranged at equal intervals, are arranged at the bottom of the cleaning water tank; two upper cleaning guide rolls are arranged over the lower cleaning guide rolls; and each upper cleaning guide roll is located between two adjacent lower cleaning guide rolls. The special high-efficiency steel strip cleaning device can effectively remove oil stain or metal impurity particles from a steel strip, is simple in structure, convenient to operate and simple in cleaning process, effectively improves the steel strip cleaning effect, and can quickly remove water sticking to the cleaned steel strip to keep the steel strip dry and avoid adverse effects on storage of the steel strip caused by the water sticking to the steel strip.

Owner:WUXI QIANTAI METAL COMPONENTS FACTORY

Lead-free solder water-soluble soldering fluid

InactiveCN101264558ASimple cleaning processLow costWelding/cutting media/materialsSoldering mediaDefoamerRosin

The invention relates to a lead-free solder water soluble flux; wherein, the weight proportions of the components are as follows: organic acid activator is 2 to 5%, amine halogen acid salt is 05 to 2.5%, nonionic surface-active material is 40 to 60%, nondrying oil is 2 to 5%, defoamer is 0.1 to 0.5%, and the rest is deionized water. The lead-free solder water soluble flux has the advantages of scientific design, reasonable ratio, and simple manufacturing technology, thus being applicable to Sn-Ag-Cu, Sn-Cu and Sn-Zn base lead-free solder, and providing a new welding material for electronic product encapsulation with no rosin, no toxin, no harms, no corrosiveness, while with good wettability and good welding performance, and safe and easy rinsing.

Owner:太仓市首创锡业有限公司

Cleaning agent for flue dust scale on surface of gas heat exchanger of gas desulfurization system and preparation method thereof

InactiveCN101892489AThorough cleaning and descalingShort cleaning timeCleansing AgentsHydroxyethylidene Diphosphonic Acid

The invention discloses a cleaning agent for flue dust scale on the surface of a gas heat exchanger of a gas desulfurization system and a preparation method thereof. The cleaning agent is characterized by comprising the following components in percentage by mass: 5 to 25 percent of main cleaning agent, 3 to 15 percent of auxiliary cleaning agent, 2 to 10 percent of release agent, 2 to 8 percent of corrosion inhibitor, and the balance water, wherein the main cleaning agent is one or two of nitric acid, hydrochloric acid and sulfuric acid; the auxiliary cleaning agent is more than one of methanoic acid, acetic acid, ethylene diamine tetraacetic acid, sulfamic acid, glycollic acid, oxalic acid and hydroxyethylidene diphosphonic acid; the release agent is one of dodecyl dimethyl benzyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride and distearyl dimethyl ammonium chloride; and the corrosion inhibitor is pickling inhibitor. The cleaning agent can realize online cleaning at normal temperature, complete scale removal, short cleaning time, lower cleaning cost and no corrosion to enamel on the surface of a heat exchange element.

Owner:广州普凯热伏微能源科技有限公司

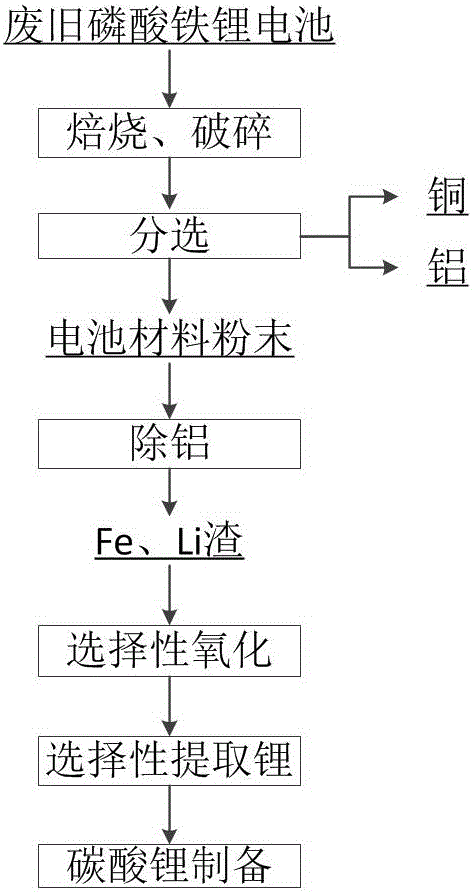

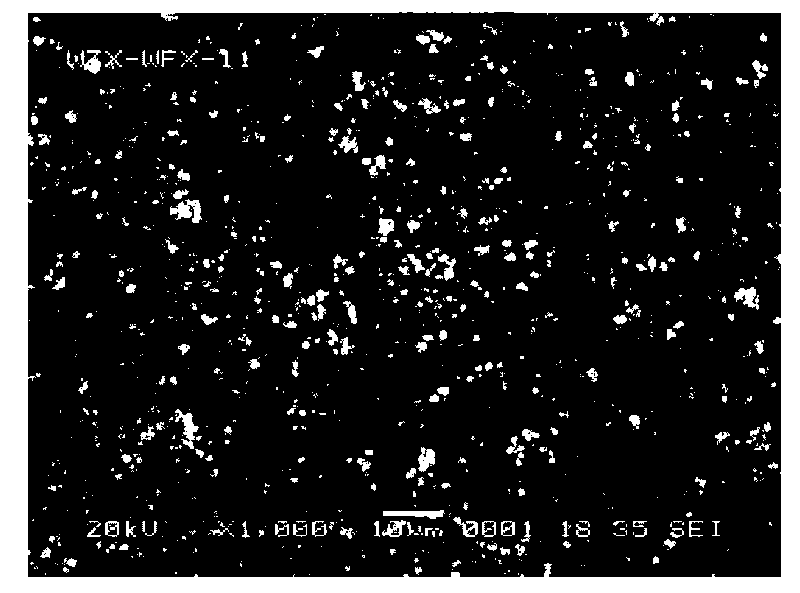

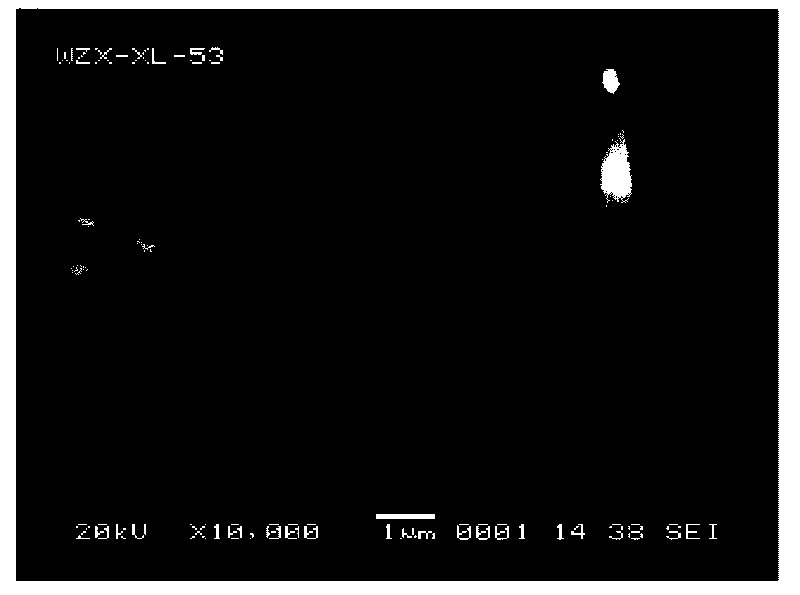

Selective recovery method of lithium in waste and old lithium iron phosphate batteries

ActiveCN106848473AReduce contentSimple cleaning processWaste accumulators reclaimingBattery recyclingAluminiumCell material

The invention provides a selective recovery method of lithium in waste and old lithium iron phosphate batteries. The method comprises roasting and sorting waste batteries to obtain battery material powder containing aluminum, iron and lithium, removing aluminum to obtain mixed residues containing iron and lithium, carrying out ball milling on the mixed residues containing iron and lithium to obtain powder, carrying out oxidation treatment on the powder under oxidizing conditions / medium so that ferrous iron is converted into ferric iron, wherein pH is adjusted in oxidation treatment and lithium in a ferric hydroxide stable region is selectively leached, and carrying out further treatment to obtain high purity lithium carbonate. The method simplifies a waste battery recycling process and the obtained leachate has low impurity content so that an additional leaching solution purification process is avoided, sodium carbonate solution consumption is reduced and the production of high salt waste water is avoided or greatly reduced. Compared with the prior art, the method has simple processes, realizes a low cost, prevents high salt waste water from the source, can acquire a high purity lithium carbonate product and has an excellent market application prospect.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Bidirectional injection moulding method of stator rubber of screw drilling tools

The invention discloses a bidirectional injection moulding method of stator rubber of screw drilling tools, which belongs to the technical field of stator rubber injection of screw drilling tools andcomprises the following steps: grit-blasting; washing and drying; brushing adhesive; assembling a mould core into an internal hole of a steel pipe; putting a stator and an injection moulding mould inan oven and heating; carrying out vacuum negative-pressure rubber injection from two ends to the center of the stator; sealing the stator and putting the stator in a vulcanizing boiler to carry out vulcanization; taking out the stator and cooling; disassembling screw nuts, end caps and shims used for positioning on two ends of the stator, and pushing the mould core out of the rubber layer of the internal hole of the stator so as to be disengaged. The rubber injection method from two ends to the center of the stator prevents rubber from pressing the mould core to cause linear deformation of themould core, fundamentally eliminates the wrapping extent and the core shift of the rubber layer hole in the internal hole of the stator, greatly prolongs the service life of the stator, reduces air bubbles in the rubber layer of the stator and defects on the surface, such as pits, flow marks and the like and increases the qualification rate. The method overcomes the defects of low speed and longtime of rubber injection.

Owner:南京金三力橡塑有限公司

Method for preparing precursors of lithium titanate and lithium iron phosphate by comprehensively using ilmenite

InactiveCN101709374AImprove electrochemical performanceLow costCell electrodesTitanium dioxideChemistryTitanium

The invention discloses a method for preparing precursors of lithium titanate and lithium iron phosphate by comprehensively using ilmenite, which comprises the following steps of: 1) separating the ilmenite, namely crushing the ilmenite, leaching the ilmenite with hydrochloric acid, filtering the ilmenite to obtain a residue and a filtrate; 2) preparing the precursor of the lithium titanate, namely washing the residue prepared by step 1) with the hydrochloric acid, adding the washed residue in aqueous alkali, cooking the mixture, filtering the mixture after cooling, and then adding the obtained filter residue in the hydrochloric acid, cooking the mixture, and filtering, washing, drying and calcining the mixture after cooling to obtain the precursor of the lithium titanate; and 3) preparing the precursor of the lithium iron phosphate, namely taking the filtrate prepared by step 1) as a raw material, adding iron powder to reduce ferric iron, diluting the reduced filtrate, adding a complexing agent and a precipitant into the diluted mixture, controlling the pH value of the system, reacting the mixture at 30 to 80 DEG C, aging the reacted mixture, and filtering, washing and drying the obtained precipitate to obtain the precursor of the lithium iron phosphate. The method is wide in raw material source, simple in process flow, good and stable in product quality, low in cost and comprehensive and full in use of the ilmenite.

Owner:CENT SOUTH UNIV

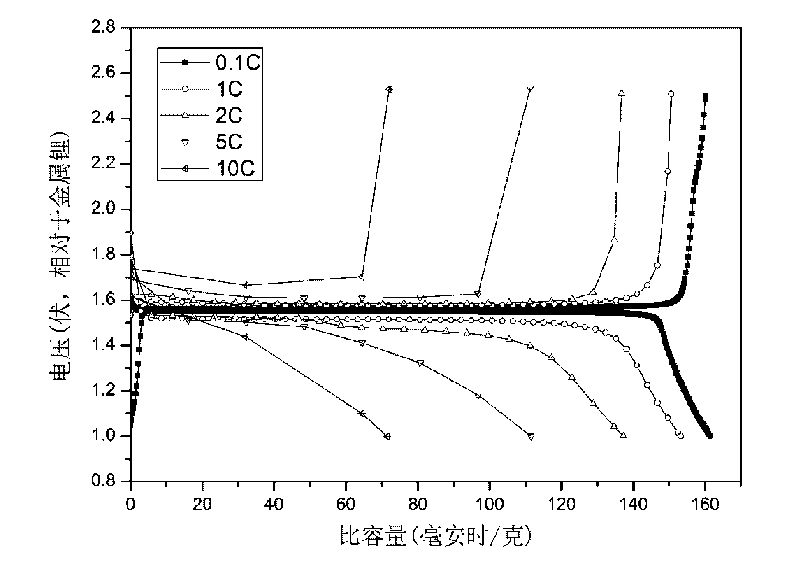

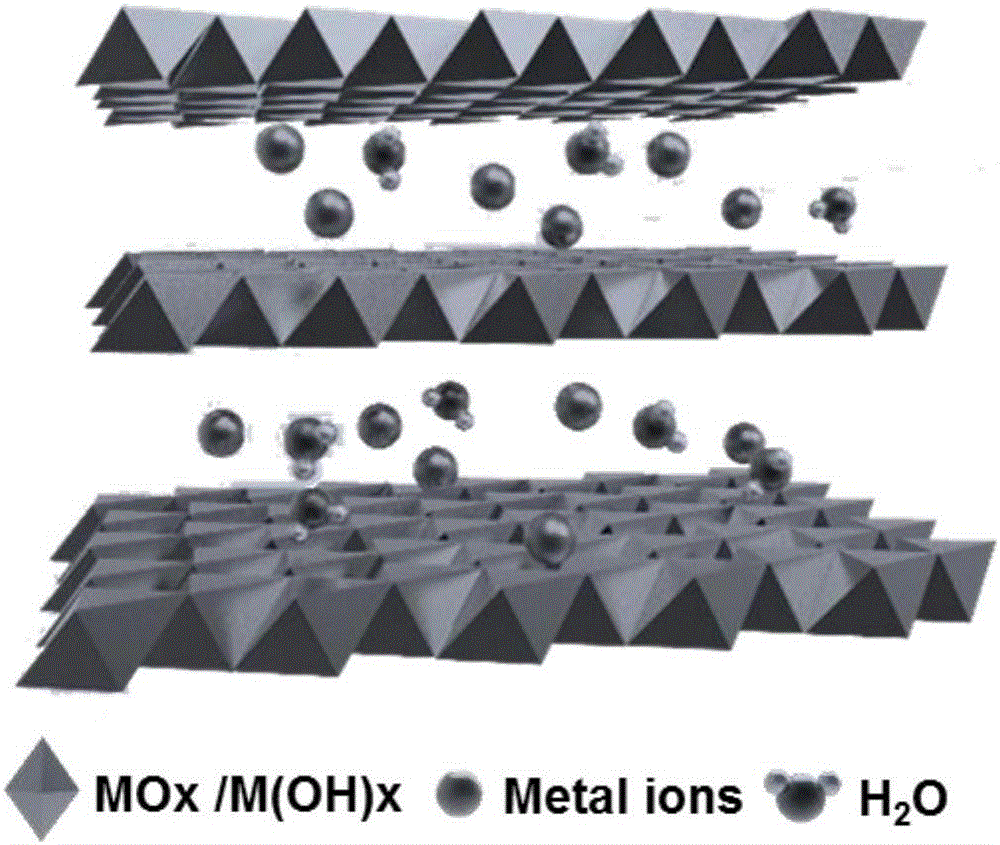

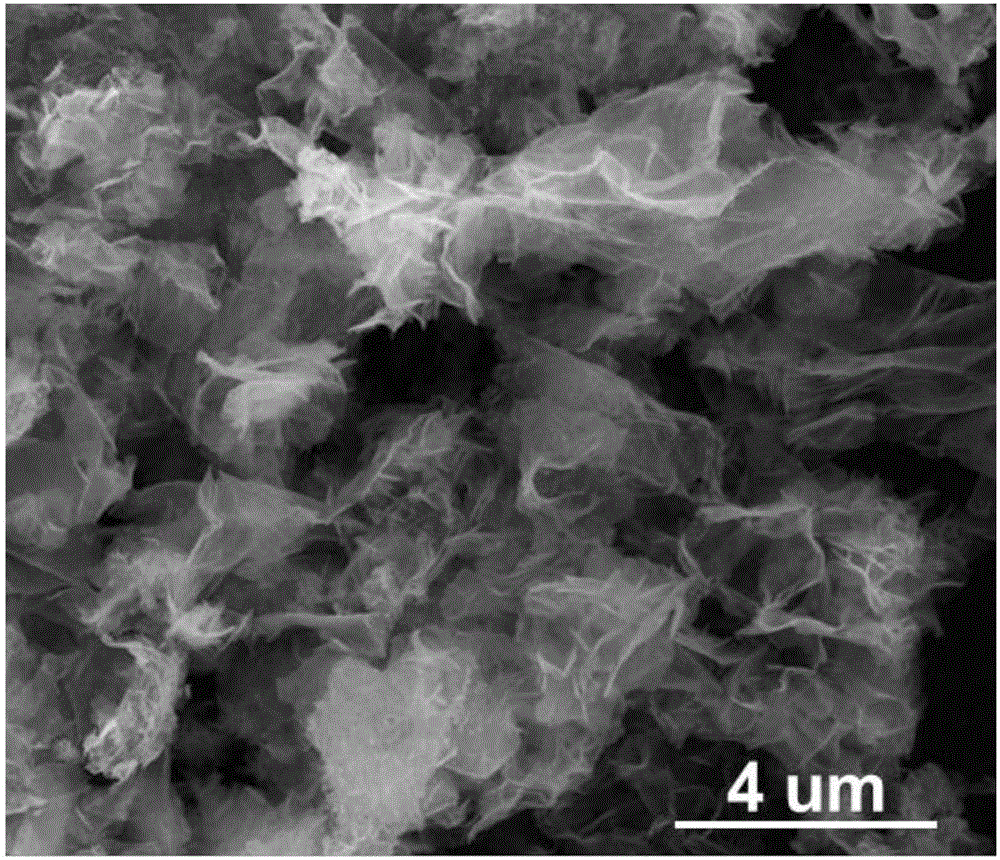

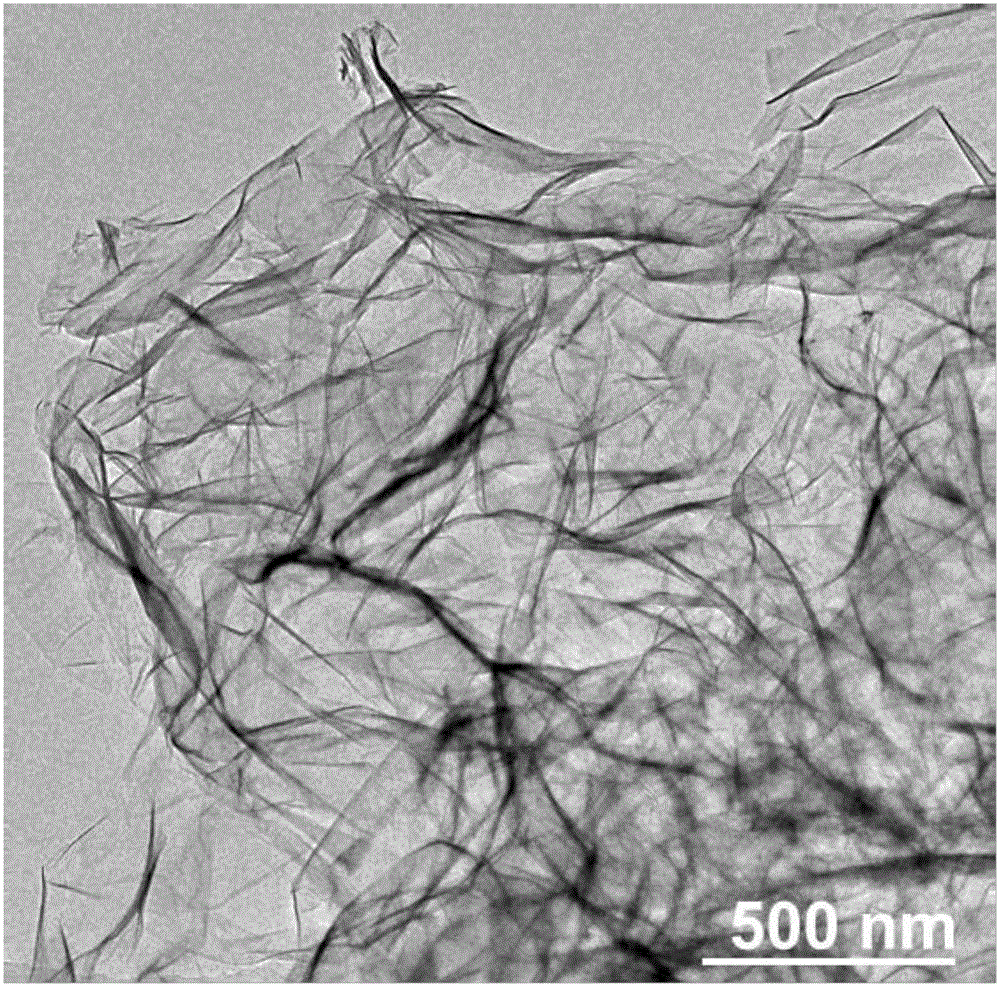

Preparation method of ionic intercalation type two-dimensional material

ActiveCN106629613AEfficient preparationEase of mass productionOxide/hydroxide preparationMolten stateAnion intercalation

The invention discloses a preparation method of an ionic intercalation type two-dimensional material. The preparation method comprises the following steps: enabling salt to be in a molten state at preset temperature by using a molten-salt growth method; adding a metal salt precursor in molten salt; and reacting for preset time and taking out, cooling, cleaning, carrying out suction filtering and drying to obtain the ionic intercalation type two-dimensional material. Positive ion intercalation type two-dimensional metallic oxide and negative ion intercalation type two-dimensional metal hydroxide can be prepared; types of positive ions and negative ions in the prepared two-dimensional material can be regulated and controlled by materials of the molten salt and metal salt; another ionic intercalation type two-dimensional material can also be prepared by the method; and the prepared ionic intercalation type two-dimensional material has quite large application prospect in the aspects of energy storage, catalysis, ion exchange and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of TiB2 ultrafine powder material

InactiveCN103265048AShort production processReduce energy consumptionMetal boridesGrinding millBall mill

The invention relates to a preparation method of a TiB2 ultrafine powder material. The preparation method comprises the following steps of: (1) blending the following components by mass percent: 33.76-43.96% of Mg, 18.42-23.98% of B2O3, 16.89-22.00% of ZrO2 and 10.07-30.92% of NaCl; (2) uniformly mixing weighed raw material powders on a ball grinding mill; (3) placing uniformly mixed powder into a mould, and pressing the powder into a cake blank at the pressure of 15-30MPa; placing an ignition agent into a copper crucible in a reaction kettle, and then placing the cake blank on the ignition agent; introducing argon into the reaction kettle at room temperature; turning on a heating switch, exhausting again when temperature in the reaction kettle is increased to 180-220 DEG C, and then introducing 1.5-3MPa argon; and combusting the ignition agent when the temperature in the reaction kettle is increased to 250-300 DEG C, initiating a self-propagating combustion reaction of the blank by virtue of heat produced by combustion of the ignition agent, and turning off the heating switch at the moment until all the materials react completely and are converted into a product containing TiB2 blocks; and (4) taking out the product and grinding the product into powder, then leaching TiB2 with hydrochloric acid, and carrying out vacuum drying to obtain TiB2 ultrafine powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

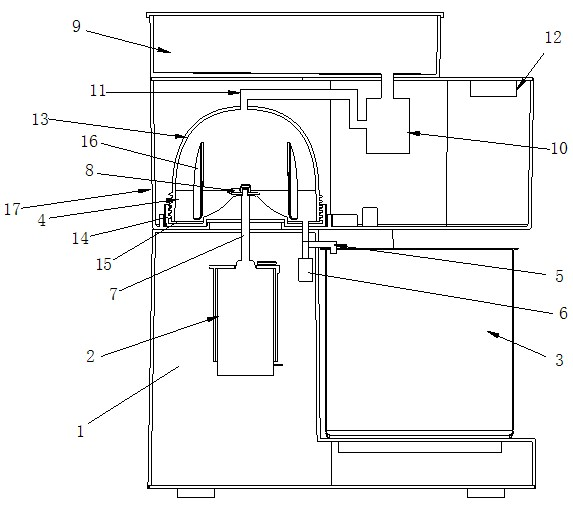

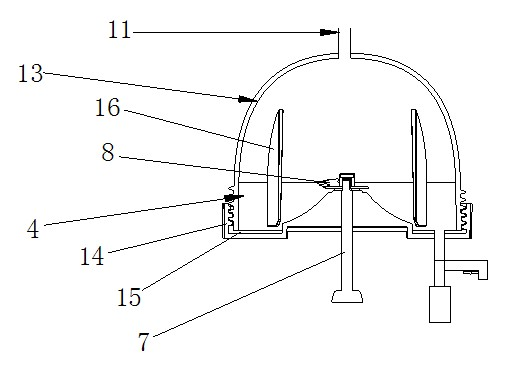

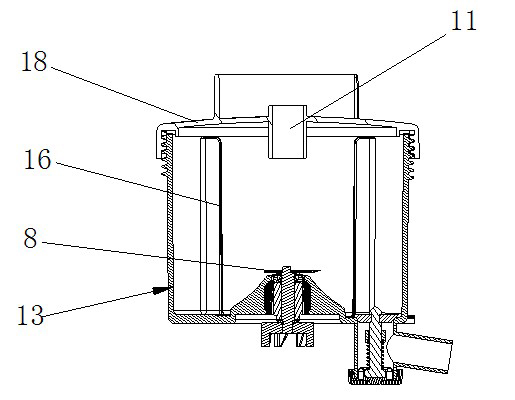

Milk making method of easy-cleaning soybean milk machine and soybean milk machine thereof

InactiveCN102326628ASimple cleaning processImprove efficiencyBeverage vesselsMilk substitutesNutrient contentEngineering

The invention discloses a milk making method of an easy-cleaning soybean milk machine. The soybean milk machine comprises a water tank, a crushing container, a water filling pipeline, a milk draining pipeline, a milk cooking cup, a crushing device, a first control switch and a second control switch. The method comprises the following steps of: controlling the second control switch to be switched on, introducing water of the water tank into the crushing container through the water filling pipeline, switching off the second control switch after a preset amount of water is filled, and starting the crushing device to crush materials in the crushing container; after crushing, controlling the first control switch to be switched on, draining milk into the milk cooking cup through the milk draining pipeline, and switching off the first control switch; and switching on the second control switch once again, adding a small amount of water into the crushing container, switching off the second control switch, starting the crushing device, draining water into the milk cooking cup after stirring, circularly performing the step for certain times, and ending milk making. The invention soybean milk machine has the advantages of convenience for cleaning, full absorption of residual nutritional ingredients of soybean milk and increase of milk making efficiency.

Owner:MIDEA GRP CO LTD

Cleaning and antirust agent for secondary processing of casting parts and preparation method thereof

The invention discloses a cleaning and antirust agent for secondary processing of casting parts and a preparation method thereof, and the cleaning and antirust agent has simple cleaning process, high operation efficiency, standard cleaning quality and capability to meet the antirust requirements of preparing process. The agent consists of the following raw materials by weight: 2-5% of potassium hydroxide, 3-6% of sodium hydroxide, 15-20% of sodium carbonate, 10-20% of sodium metasilicate pentahydrate, 10-20% of sodium tripolyphosphate, 10-20% of sodium nitrite, 1-1.5% of osmotic agent, 2-6% of nonionic block polyether surfactant, 2-6% of special surfactant for dewaxing fluid, and 4-6% of antifoaming agent. According to the preparation method of the agent, the above raw materials are gradually added into a mixer in order. The adding of each material is associated with 10-15min of stirring, and when the raw materials are all added, at least 30min are needed to stir the materials continuously.

Owner:DALIAN JIESHI CLEANING PRODS +1

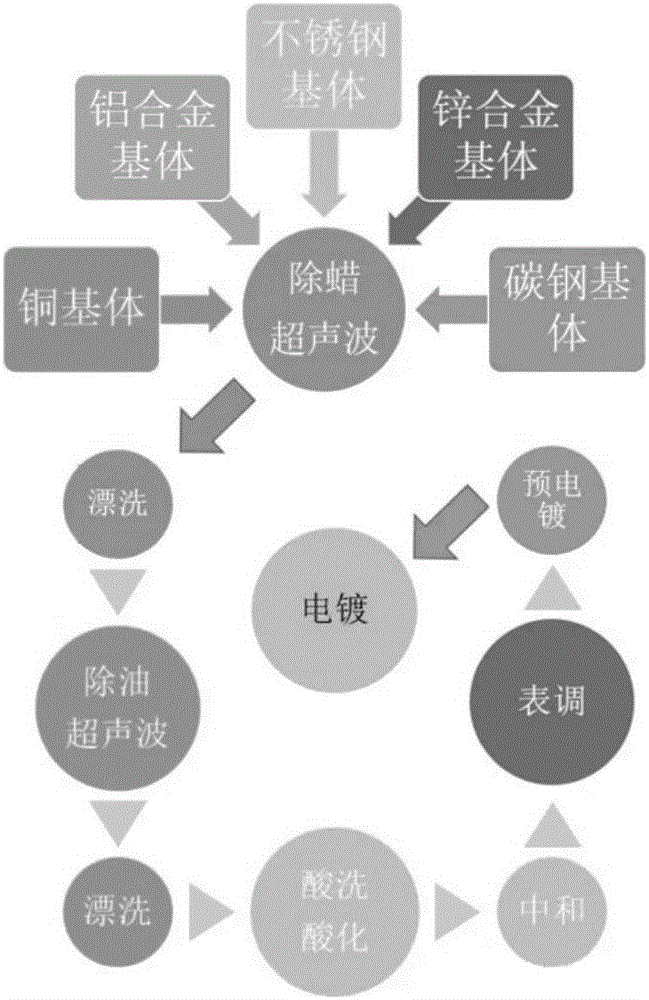

Water-soluble biodegradable cleaning agent and cleaning application method thereof

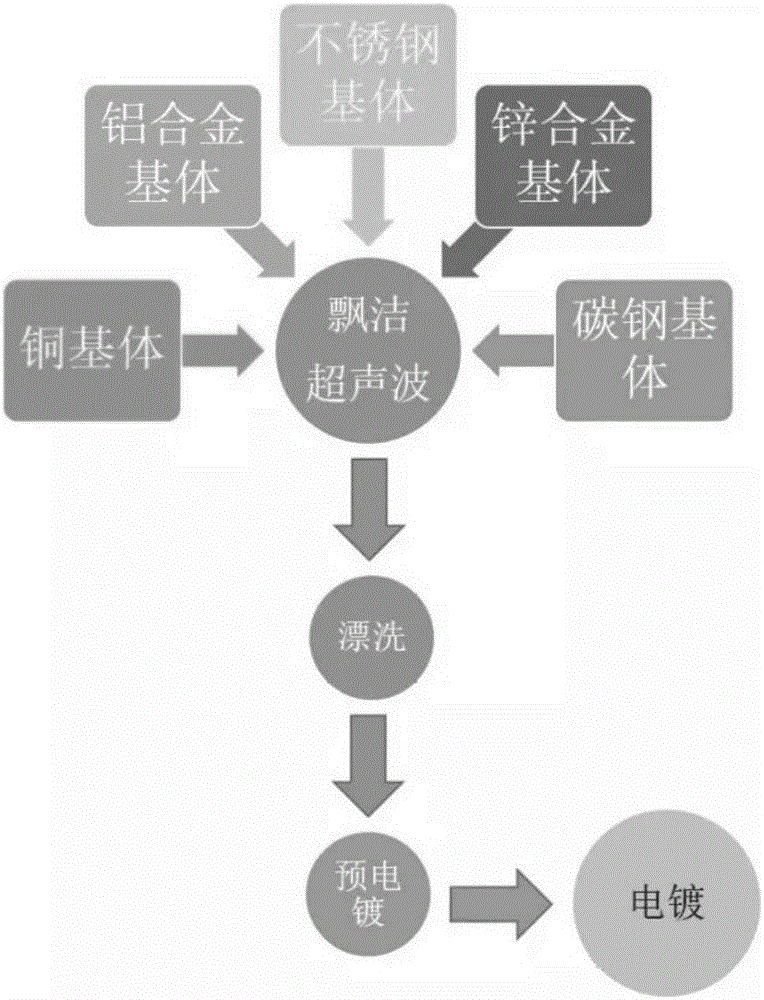

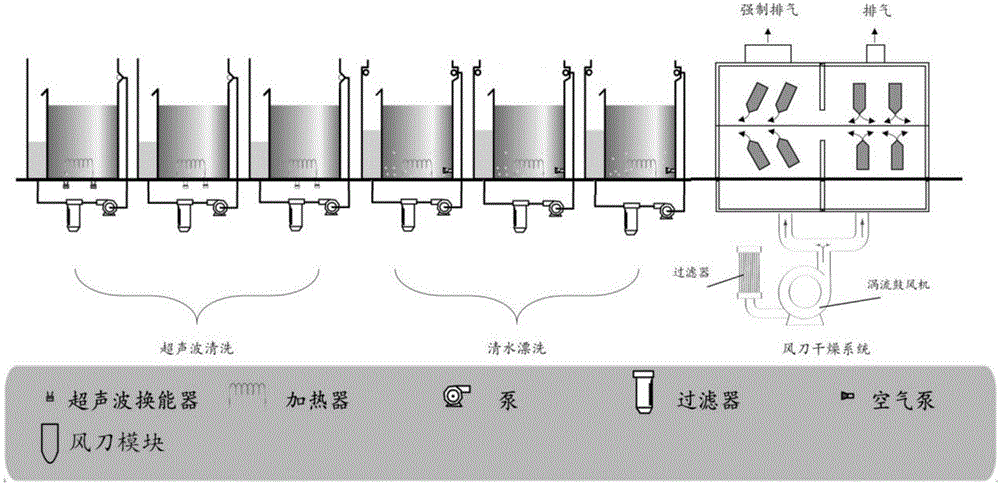

The invention discloses a water-soluble biodegradable cleaning agent and a cleaning application method of the water-soluble biodegradable cleaning agent. The water-soluble biodegradable cleaning agent comprises, by weight, 1%-15% of organic acid, 5%-20% of a surface active agent, 0.5%-1% of a stabilizer and 78%-79.5% of water. According to the cleaning application method of the water-soluble biodegradable cleaning agent, cleaning liquid containing the water-soluble biodegradable cleaning agent is used for ultrasonic cleaning of parts to be cleaned. According to the water-soluble biodegradable cleaning agent and the cleaning application method of the water-soluble biodegradable cleaning agent, the non-toxic food-grade biodegradable non-strong acid is adopted, the wetting performance, the permeability, the emulsibility, the dispersity, the capacity-increasing performance and the like of the water-soluble biodegradable cleaning agent are utilized, corresponding ultrasonic cleaning equipment is adopted in cooperation, under the mutual synergistic interaction of chemistry and machines, rust, oxides, polishing paste and all kinds of oil stains attached to the surfaces of metal, plastics and ceramics are washed away in a one-off manner; and in this way, traditional acid pickling technologies and the cleaning concept that oil removal, wax removal and oxide removal are executed separately are broken through, the cleaning process is shortened, time and energy are saved, cost is reduced, the safety of the environment and the safety of operators are guaranteed, and the effect of environment-friendly, efficient, energy-saving and safe enterprise production is achieved in real sense.

Owner:上海赛敏环保科技有限公司

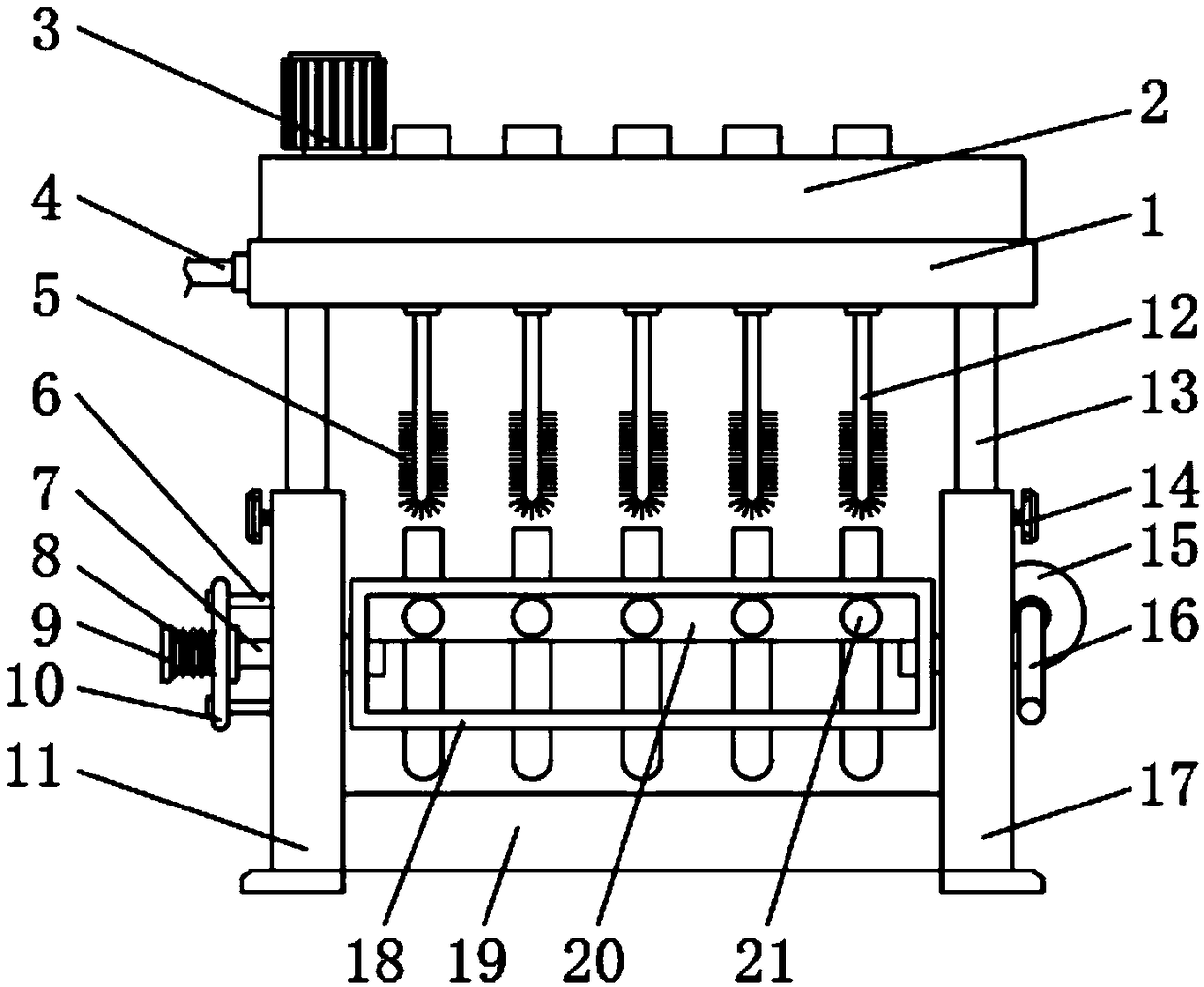

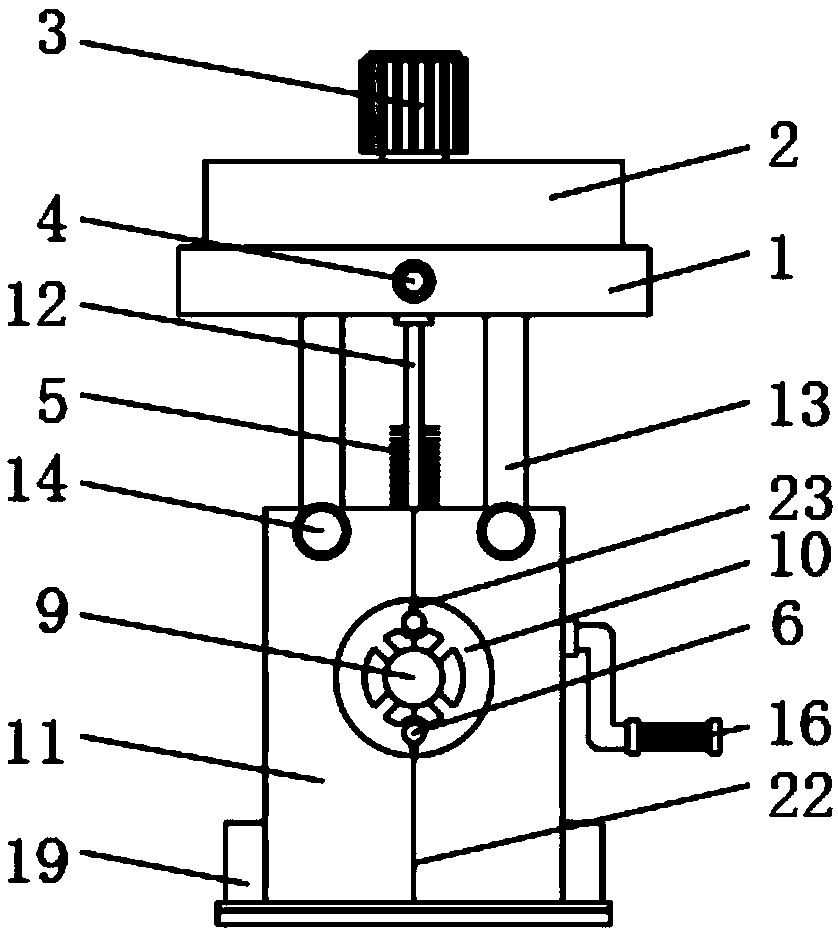

Test tube washing device for chemical laboratory

InactiveCN109127606ASimple cleaning processEasy to operateHollow article cleaningTest tubeDrive motor

The invention relates to the technical field of test tube washing equipment and discloses a test tube washing device for a chemical laboratory. The test tube washing device comprises a washing water tank. The top of the washing water tank is fixedly provided with a drive tank. The top of the drive tank is fixedly provided with a drive motor. The outer side of the washing water tank fixedly communicates with a water conveying capillary tube. An inner cavity of the washing water tank is rotationally connected with a water conveying cylinder. The bottom of the water conveying cylinder fixedly communicates with washing tubes. The bottom ends of the washing tubes penetrate and extend into the bottom of the washing water tank. According to the test tube washing device for the chemical laboratory, by arranging an adjusting gear and rotating an adjusting handle, the height of the washing tubes can be adjusted to be inserted into test tubes, by cooperating with washing holes, clean water can flow into the multiple test tubes at the same time, the problems that according to an existing test tube washing device for the chemical laboratory, after chemical experiments are completed, it needs toadd water to the used test tubes to wash the used test tubes one by one, the washing process is tedious, the labor intensity is large, and the washing efficiency is low are solved, and the washing efficiency is effectively improved.

Owner:黄超

Preparation method of semi water-based liquid crystal cleaning compound

InactiveCN105255621ALow toxicityEfficient removalOrganic detergent compounding agentsSurface-active detergent compositionsSodium metasilicateOrganic base

The invention discloses a preparation method of a semi water-based liquid crystal cleaning compound, and belongs to the technical field of cleaning. According to the preparation method, polyoxyethylene polyoxypropylene block polyether is taken as a surfactant; additives such as an emulsifier, a chelating agent, an organic base, and sodium metasilicate pentahydrate are added so as to obtain the semi water-based liquid crystal cleaning compound. Toxicity of the polyoxyethylene polyoxypropylene block polyether surfactant is low, and the surfactant possesses acidic and basic stability, and excellent decontamination effects; adding of the chelating agent and the organic base is capable of removing metal ions on liquid crystal surfaces; a cleaning method is simple; operation is simple; and the semi water-based liquid crystal cleaning compound is friendly to the environment.

Owner:CHANGZHOU OPTICAL MATERIAL

Aqueous cleaning low-temperature welding paste and preparation method thereof

ActiveCN102398122ADesign scienceReasonable ratioWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses aqueous cleaning low-temperature welding paste and a preparation method thereof. The welding paste comprises the following components in percentage by weight: 85 to 90 percent of soldering alloy powder, and 10 to 15 percent of scaling powder, wherein the soldering alloy powder consists of the following components in percentage by weight: 36 to 44 percent of Pb, 18 to 22 percent of Bi and the balance of Sn; and the scaling powder is formed by mixing 2 to 10 weight percent of active agent, 1 to 10 weight percent of pasting agent, 20 to 30 weight percent of wetting agent, 2 to 10 weight percent of thixotropic agent, and 50 to 70 weight percent of solvent and the total percentage of all components is 100 percent. The welding paste is suitable for various welding processes, is high in welding speed, does not damage components, does not contain halogen and does not have corrosiveness, and residues are few after welding.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

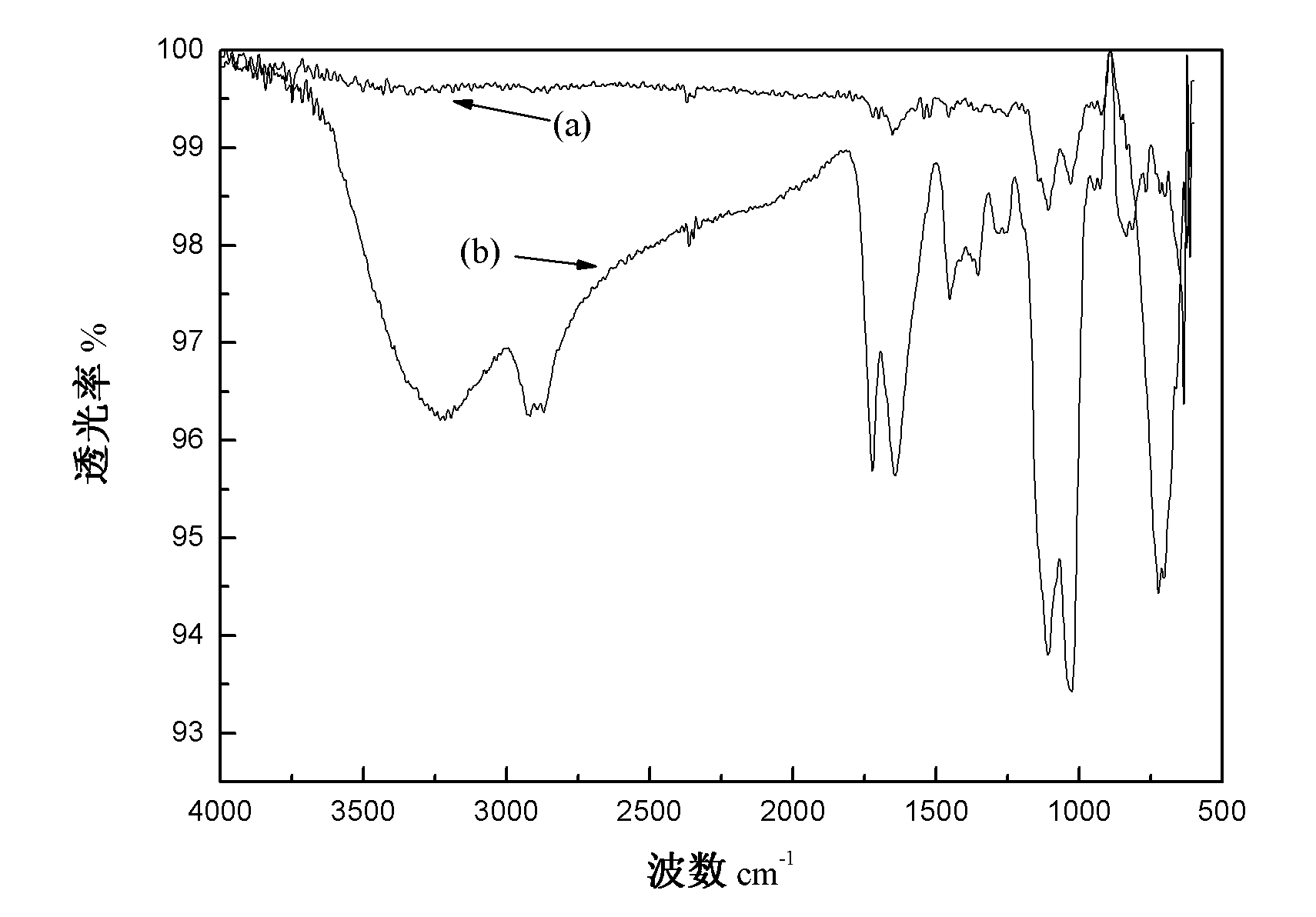

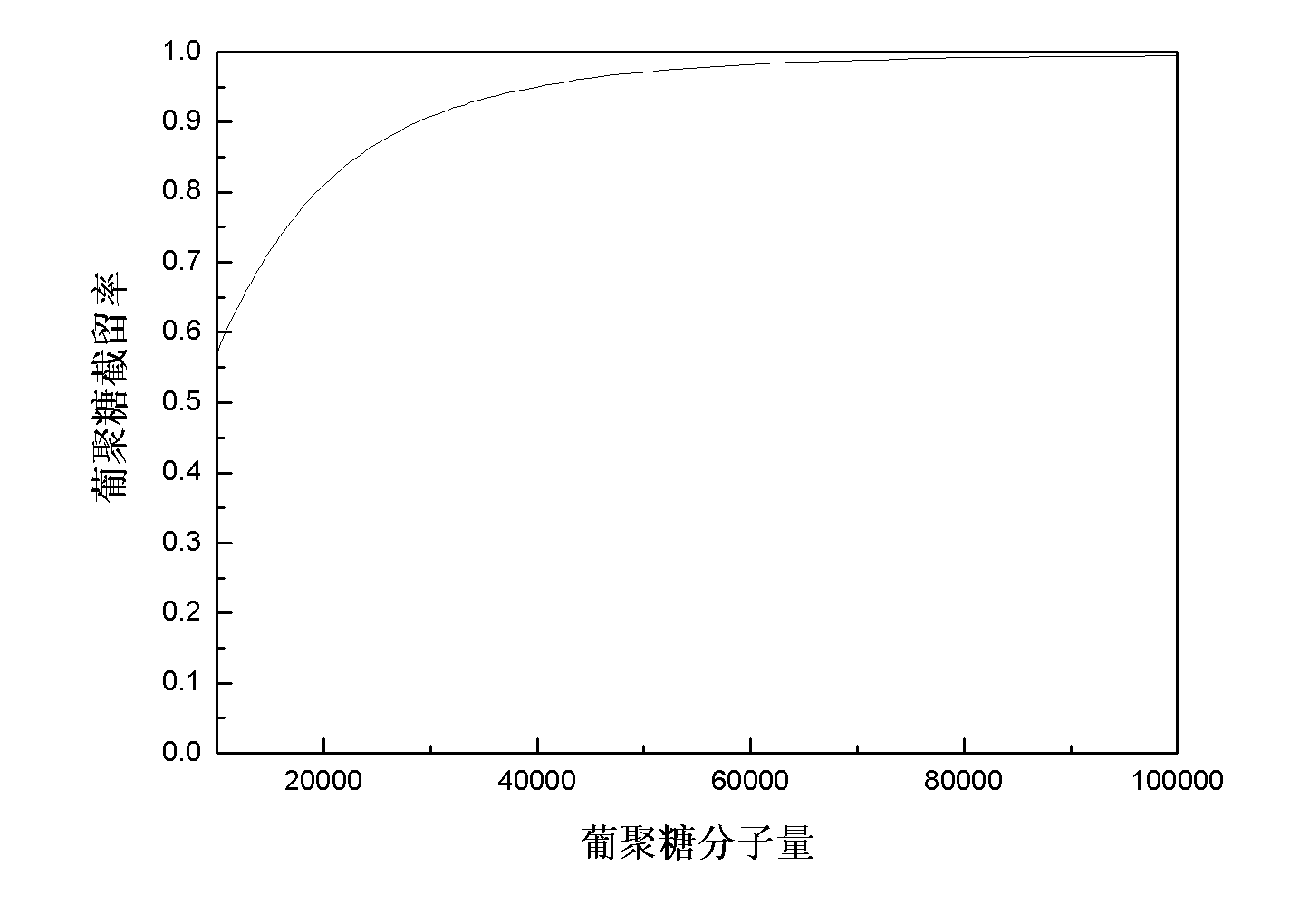

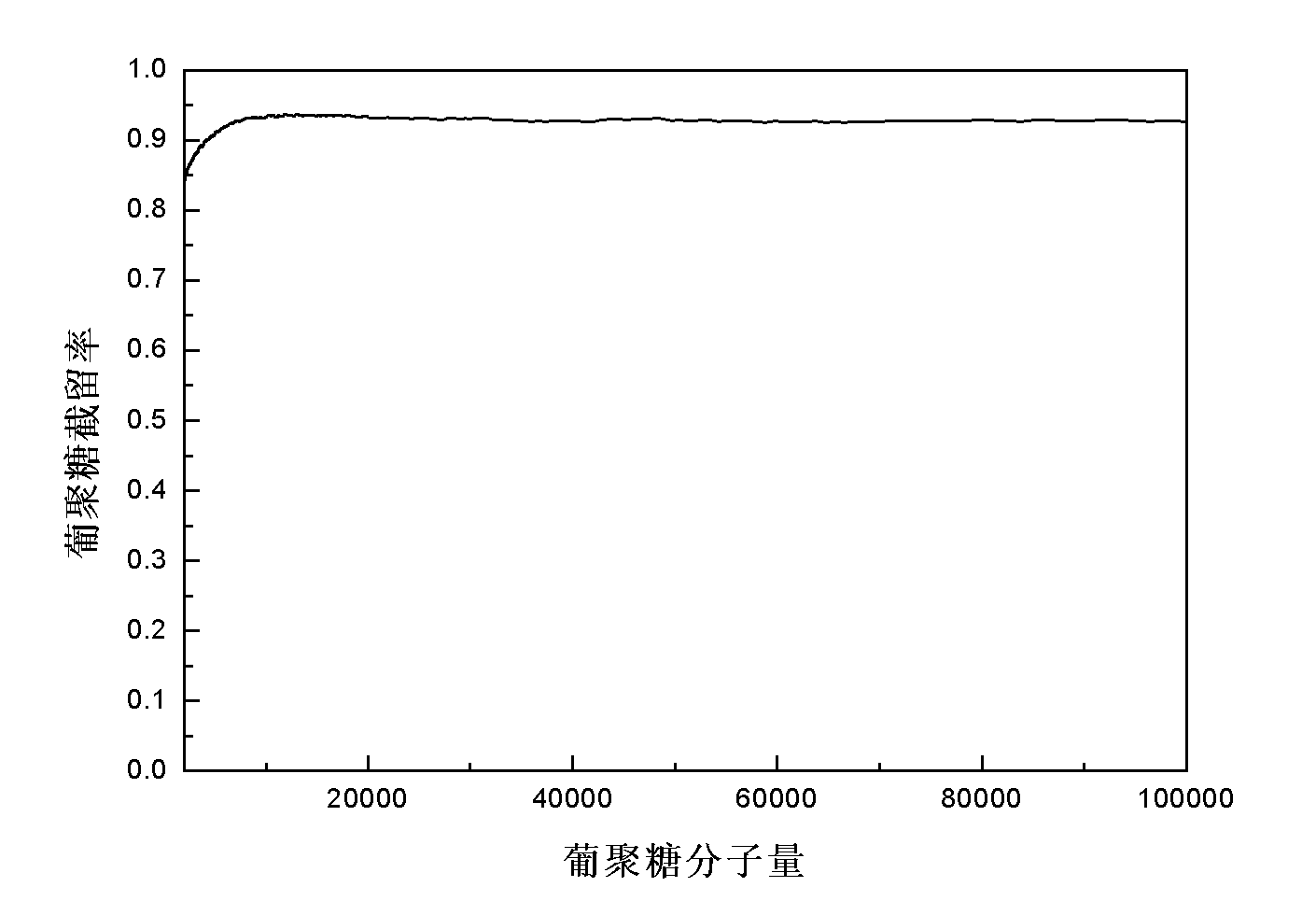

Method for preparing protein adsorption-resistant ceramic composite film

ActiveCN102059059AInhibition rejection is unstableImprove efficiencySemi-permeable membranesMethacrylateCeramic composite

The invention relates to a method for preparing a protein adsorption-resistanting ceramic composite film. In the method, methylacrylic acid oligomerization gylcol ester (OEGMA) is adopted as a functional monomer, and initiates polymerization through a silylanized initiator to prepare a silanizated poly(oligo(ethylene glycol) methacrylate) (POEGMA) molecular brush; alkylalkoxylsilane is formed on one end of the molecular brush, and can react with hydroxyl on the surface of a ceramic film; and the POEGMA molecular brush is grafted on the film surface to prepare the protein adsorption resistanceceramic composite film. The method realizes that the polymer molecular brush is only grafted on the surface of the ceramic film by adopting a method of grafting to surface, only changes the surface property of the film, and does not influence the property of the film pores. By the method, the protein adsorption resistance polymer molecular brush can be grafted on the surface of the porous ceramicfilm of 4 to 500nm.

Owner:NANJING UNIV OF TECH

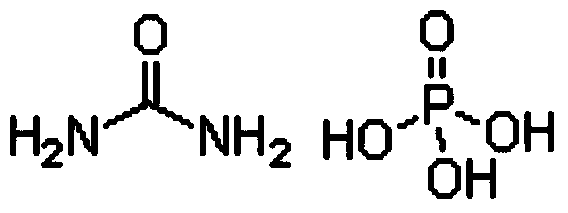

Production method for calcium hydrogen phosphate

InactiveCN104016326AQuality improvementLow impurity contentPhosphorus compoundsPhosphoric acidCalcium EDTA

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for calcium hydrogen phosphate. A calcium hydrogen phosphate product is prepared by reacting calcium oxide with a certain amount of water to form a calcium hydroxide solution; then reacting the calcium hydroxide solution with urea phosphate under stirring; controlling a pH value at 5.5-6.5; reacting for 5-20 min under stirring continuously and terminating the reaction. By adopting urea phosphate as a direct resource of phosphorus in the calcium hydrogen phosphate product, processes of removing impurities such as metal ions and fluorine in a process for producing feed level calcium hydrogen phosphate by using wet-process phosphoric acid are omitted; phosphorus utilization rate in the whole process is high; removal of a lot of wastes is prevented; and production cost of calcium hydrogen phosphate is reduced. In the obtained calcium hydrogen phosphate product, phosphorus content is 16.8-17.3%; calcium content is 20.35-22.2%; and fluorine content is 0.012-0.023%. The obtained calcium hydrogen phosphate product can fully meet the standard of feed level calcium hydrogen phosphate.

Owner:GUIZHOU KAILIN GRP MINERAL FERTILIZER CO LTD

Cleaning technology of generator rotor water cooling system

InactiveCN103915950AImprove heat transfer efficiencyLower operating temperatureManufacturing dynamo-electric machinesCopper conductorCopper oxide

The invention provides a cleaning technology of a generator rotor water cooling system. The generator rotor water cooling system is washed through forward and backward circulation washing and is subjected to the processes of system preheating, alkaline washing, water washing after alkaline washing, slow release in advance, acid pickling, water washing after acid pickling, pre-filming and water washing after pre-filming, so that the generator rotor water cooling system is washed. Compared with the prior art, the cleaning technology has the advantages that scale and corrosion deposition product copper oxide of the inner surface of a hollow core copper conductor of a rotor are removed through chemical cleaning, the water-passing capacity of the hollow core conductor is recovered, the heat exchange efficiency of the conductor is improved, the operation temperature and the temperature difference of a rotor coil are reduced, and the operation safety of a generator is guaranteed; the cleaning rate of the corrosion product of the hollow core copper conductor of the rotor of the generator is over 99%, and the phenomenon that due to the fact that cleaning is not thorough, secondary corrosion is caused is avoided; the technology is simple, cost is low, and the discharged washing water is discharged without pollution; energy consumption of a power plant is reduced and large economic benefits are generated.

Owner:GANSU HUAJIE ENVIRONMENTAL SCI & TECHCO

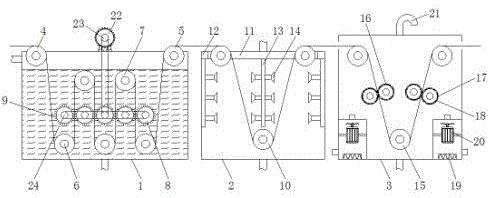

ERW welding pipe on-line external burr removing technique

InactiveCN101480772ASimple cleaning processPractical removal processPlaning/slotting machinesMilling equipment detailsProduction lineWeld seam

The invention relates to an on-line outer-burr eliminating technique for an ERW welding pipe, in particular to a method for a welding pipe welding-seam burr eliminating technique, and the method is especially suitable for the outer burr one-line elimination of a production line of the ERW welding pipe with a large caliber. An outer-burr scoring device, an outer-burr chipping device, an outer-burr milling device, a scoring roller, a chipping device, a used milling device, a standby milling device, a matched regulating device, a carrier roller, a press roller and a power system are sequentially arranged behind an extrusion stand on the production line of the ERW welding pipe to execute combined processing such as scoring, chopping, chipping and milling for the outer burr of a welding seam, thereby the invention can realize the function of the full-length continuous elimination of the outer burr of a welding seam in real time and achieve the purpose of the reliable and thorough on-line elimination of the outer burr of a welding seam. Furthermore, the invention not only can enhance the operating efficiency of a machine set, but also can improve the finished product ratio of the production line of the ERW welding pipe.

Owner:江苏嘉宝科技制管有限公司

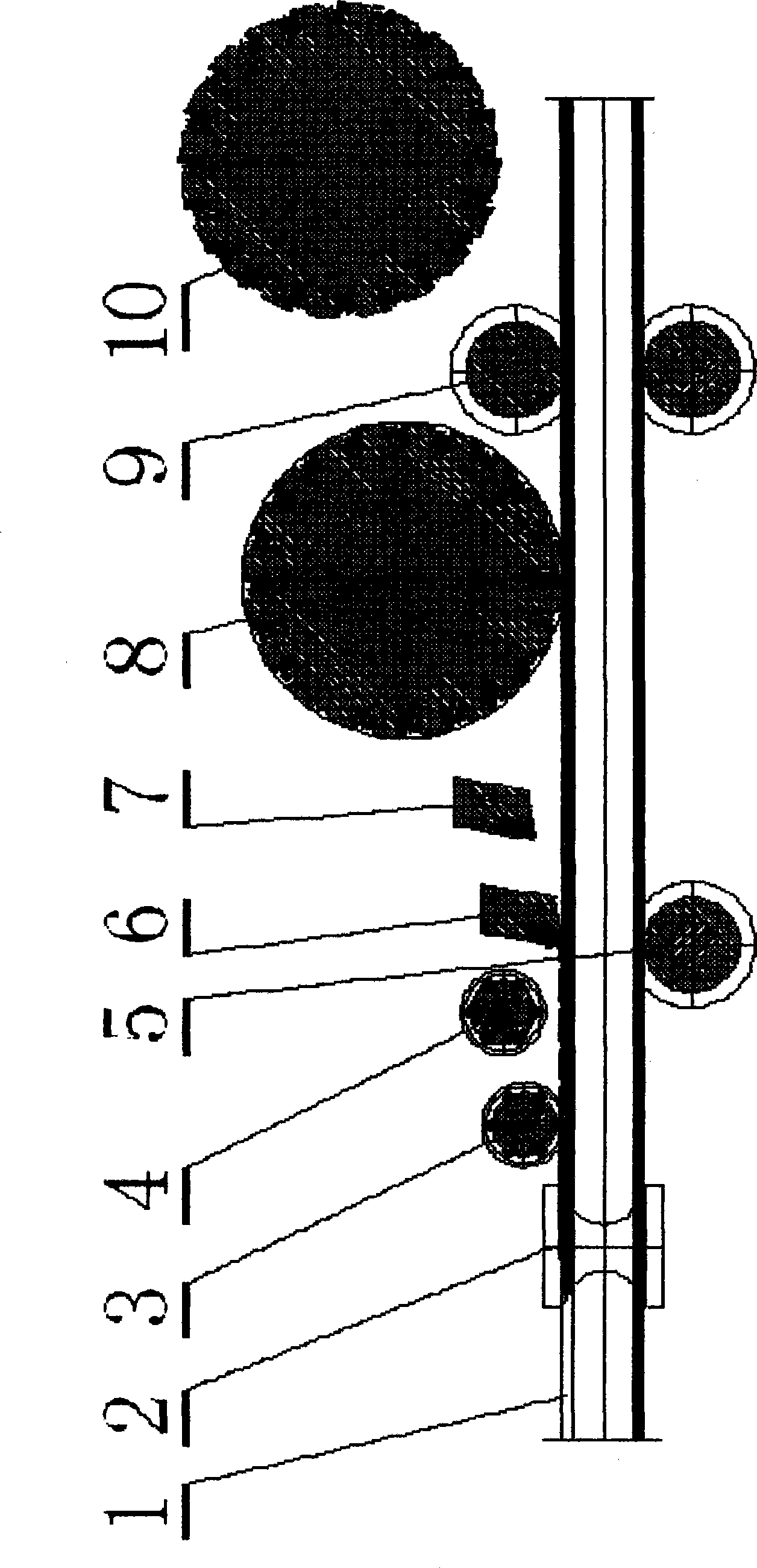

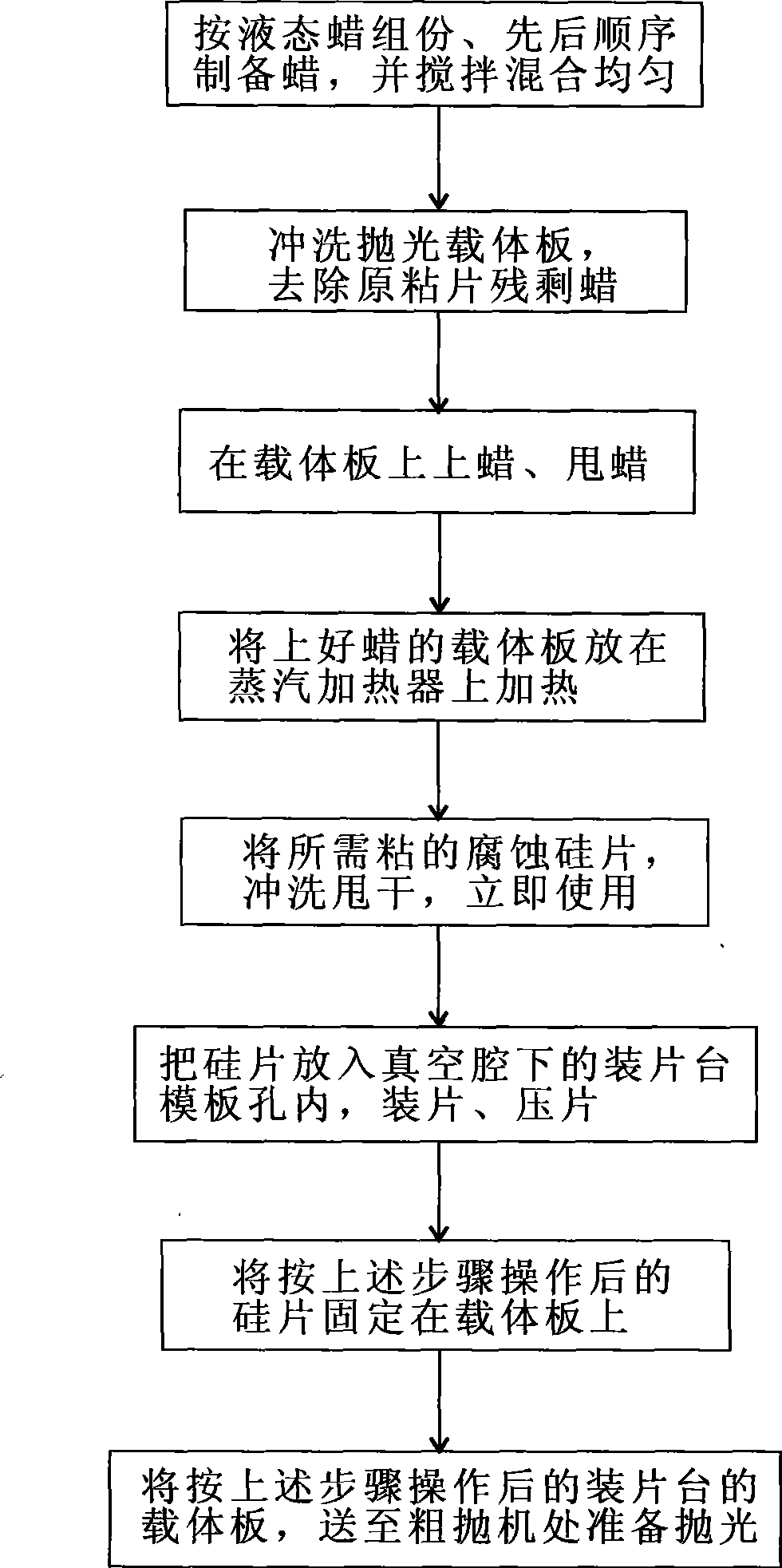

Liquid wax for polished bonding sheet, preparation thereof and process of polished bonding sheet

InactiveCN101376793ASimple cleaning processNo environmental pollutionPolishing compositionsWaxChemistry

The invention discloses a liquid wax used for polishing bonding sheets as well as a preparation method thereof and the technique of the polishing bonding sheets. The liquid wax comprises the components (counted according to the weight portions of 10,000g) as follows: 662.3 to 665.7 portions of polyethylene glycols, 198.5 to 201.5 portions of paint flake, 548.7 to 551.2 portions of isopropanol, 307.0 to 309.7 portions of ammonia with a concentration of 25 percent, 2347.8 to 2353.4 portions of de-ionized water of 18 M as well as 5913.1 to 5940.8 portions of 8030 resin; each component is poured into a wax barrel according to the sequence and weight portions in turn and the mixture is slowly mixed through magnetic stirring, thus obtaining the liquid wax; the liquid wax can ensure the uniformity of the wax liquid, the consistency of viscidity as well as high polishing speed and is suitable for the production demand in batch; besides, the surface quality of a polishing sheet is good.

Owner:MCL ELECTRONICS MATERIALS

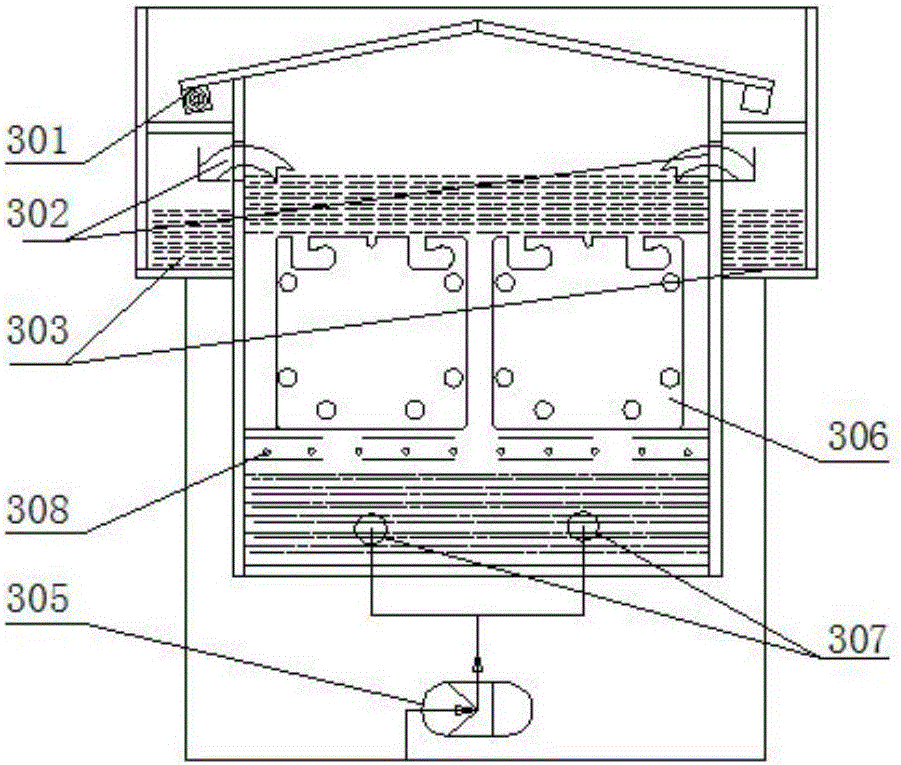

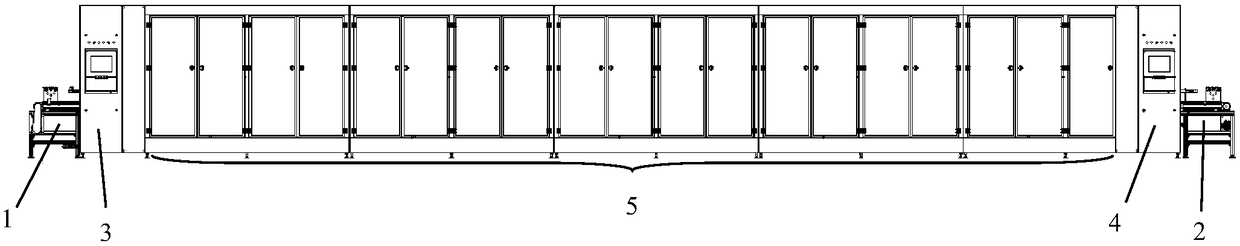

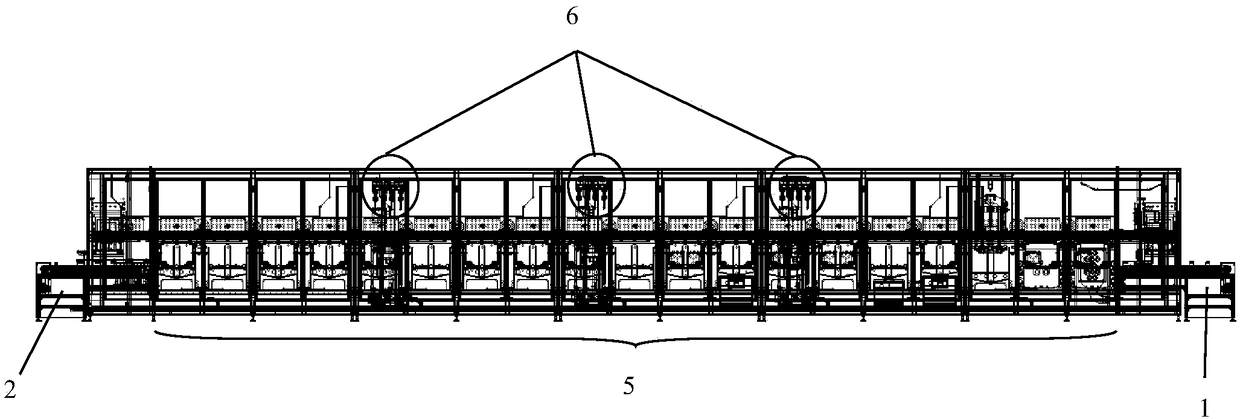

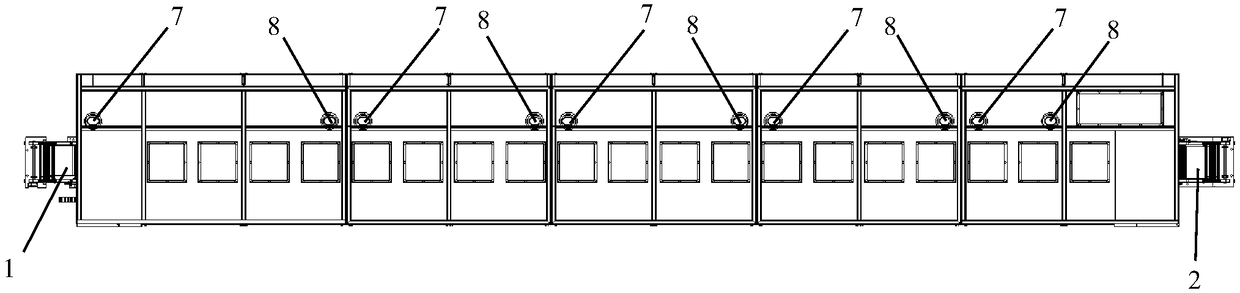

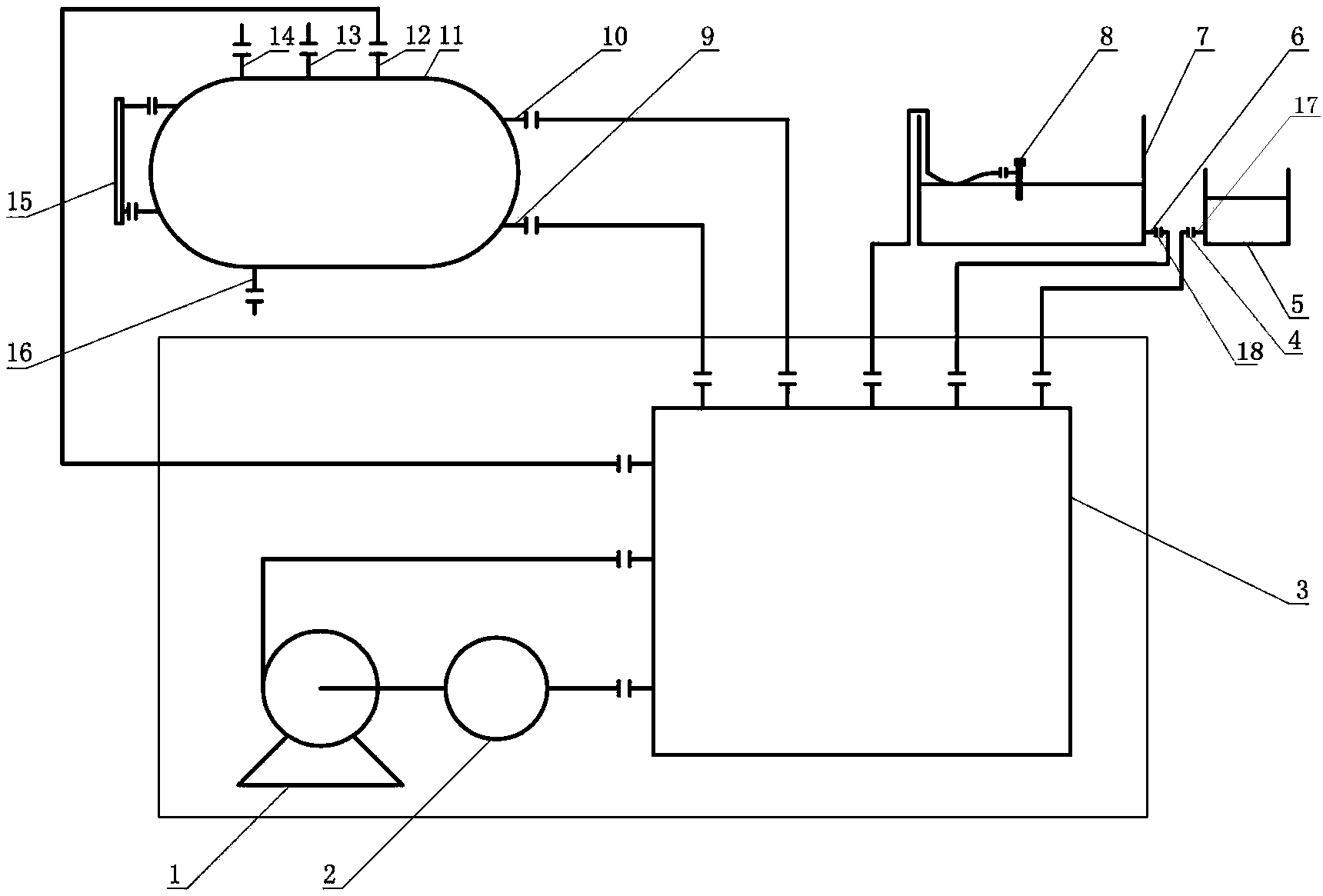

Single crystal texturing cleaning machine

InactiveCN108346714AImprove cleaning capacityGuaranteed circulationFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSingle crystal

A single crystal texturing cleaning machine comprises a cleaning body. The cleaning body comprises a plurality of box bodies 5. The front portion of the cleaning body is provided with a material loading bench 1. The rear portion of the cleaning body is provided with a blanking bench 2. A conveyor belt is arranged on the material loading bench 1 and the blanking bench 2. A plurality of mechanical arms 6 used for grabbing a material are arranged above the conveyor belt. One side of the cleaning body is provided with control cabinets 3 and 4 used for regulating and controlling a cleaning processin the cleaning body and monitoring the cleaning process in real time. The control cabinets 3 and 4 are provided with a visual interaction operation interface. Simultaneously, equipment integrates slowly-lifting and hot-air drying functions. On a basis of guarantee productivity, through the slowly-lifting and hot-air drying functions, a single crystal texturing effect is further ensured. Besides,through designing, a groove body can realize a quick exhaust function, a cover plate is included and functions of bubbling, overflow and the like can be realized, the size of the groove body is savedand more functions are realized.

Owner:KUNSHAN SEAGEAR AUTOMATION SYST CO LTD

Cleaning-free lead-based high-temperature soldering paste and preparation method thereof

ActiveCN107297582AHigh melting pointGood welding performanceWelding/cutting media/materialsSoldering mediaMetal coatingWorking life

The invention discloses cleaning-free lead-based high-temperature soldering paste and a preparation method thereof and belongs to the technical field of hybrid integrated circuits. The soldering paste is prepared from, by weight, 85%-90% of brazing filler metal alloy powder and 10%-15% of brazing flux. The brazing filler metal alloy powder is prepared from, by weight, 15.5%-16.5% of Sn, 7.0%-8.0% of Sb, 0.8-1.2% of Ag and the balance Pb. The brazing flux is prepared from, by weight, 5%-10% of activator, 5%-10% of paste forming agent, 20%-30% of wetting agent, 5%-10% of thixotropic agent and 40%-65% of solvent. The cleaning-free lead-based high-temperature soldering paste is prepared through the steps of brazing filler metal alloy smelting, brazing filler metal alloy powder preparation, brazing flux preparation and soldering paste preparation. The soldering paste is high in melting temperature, has good wettability for a metal coating, and is good in brazing manufacturability, long in working life and suitable for soft brazing of electronic device silver cladding, gold cladding and copper.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

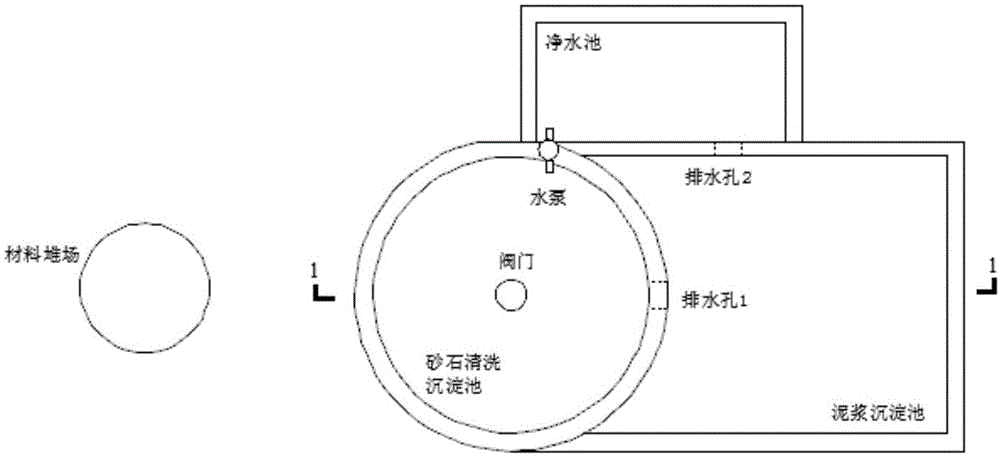

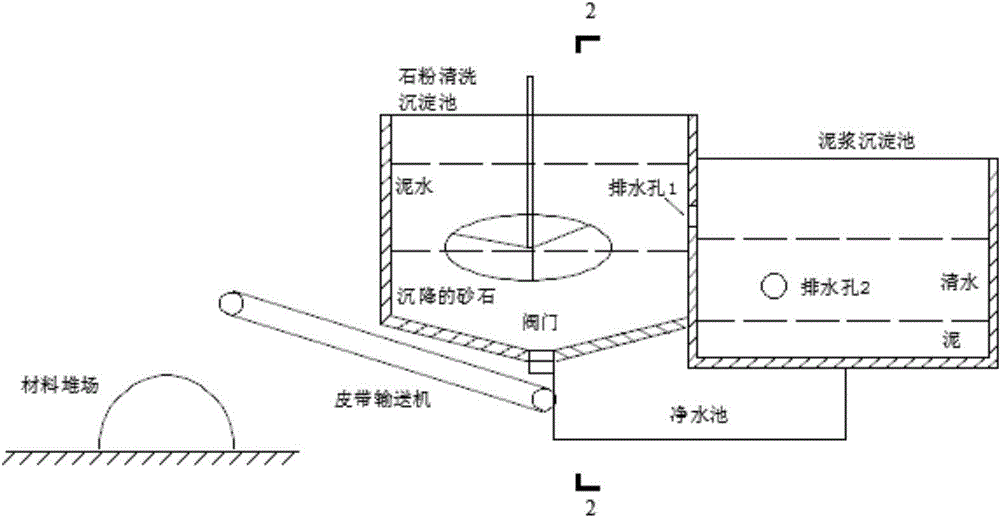

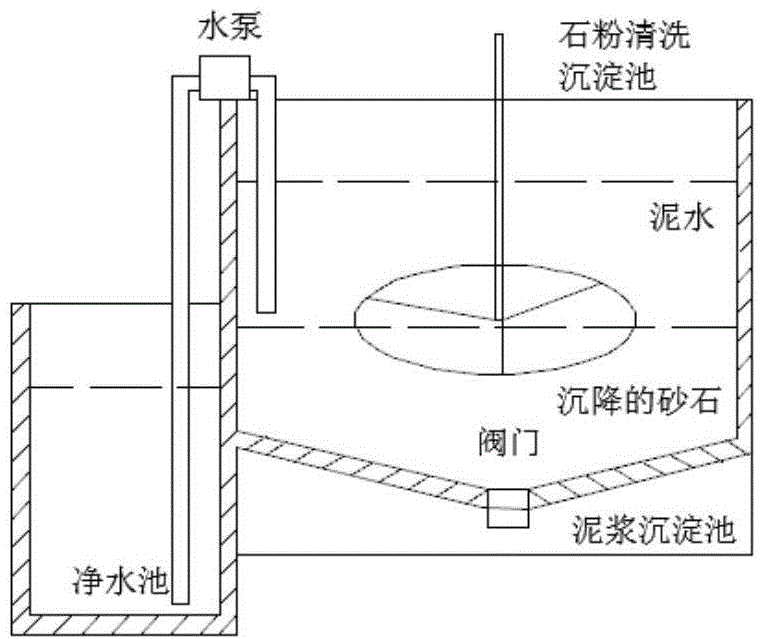

Process and system for cleaning waste residues in quarries and building sand

ActiveCN104858174ASimple cleaning processReduce water consumptionSolid waste managementCleaning using liquidsSiltMaterial recycling

The invention provides a process and system for cleaning waste residues in quarries and building sand and belongs to building waste residue cleaning processes and systems. The cleaning process comprises the following steps: 1), enabling sand stones to enter a pool; 2), enabling clear water to enter the pool; 3), stirring; 4), discharging mud water; 5), recycling clear water; 6), recycling sand stones; 7), cleaning mud; the cleaning process comprises a sand stone cleaning device (1), a mud sedimentation device (2), a clear water recycling device (3) and a material recycling device (4). The cleaning process has the advantages as follows: only 1-3 pools, one turbine stirrer and one belt conveying device are required, repeated cleaning can be carried out until rinsing, one-time cleaning can be completed by 3-5 minutes only, and water for cleaning can be used repeatedly after being purified; the cleaning process is simple, and low in water consumption, and can efficiently reduce silt content of sand stones with high quality, meanwhile, stone powder in the waste residues in quarries is retained fully, waste residues in the quarries and building sand can be cleaned in batches and industrial production is realized.

Owner:SUQIAN LIYIN IND

Magnesium alloy surface treatment cleaning liquid and treatment method

The invention relates to the technical field of magnesium alloy surface treatment, in particular to cleaning liquid used after deburring of magnesium alloy by an electrochemical method, and a treatment method thereof. The cleaning liquid mainly comprises the following ingredients in percentage by weight: 45 to 80 percent of nitric acid and 20 to 55 percent of hydrofluoric acid. The treatment method comprises the following steps: using the cleaning liquid for treatment; sequentially carrying out purified water cleaning, alkali solution treatment, purified water cleaning and final drying; and entering a next forming treatment work procedure. The invention has the advantages of low cost and simple cleaning process; and particularly, the invention has good cleaning effect, and can effectively clean corrosion black dots remained on castings after the electrochemical deburring treatment.

Owner:东莞东运镁业有限公司

Anti-corrosion rust remover and preparation method thereof

InactiveCN104005033AHigh anti-corrosion strengthPromote degradationMetallic material coating processesHexamethylenetetramineSulfamic acid

The invention discloses an anti-corrosion rust remover which comprises the following components in parts by weight: 1-3 parts of hexamethylenetetramine, 0.05-0.3 part of calcium hypophosphite, 0.1-0.3 part of lauryl sodium sulfate, 1-3 parts of ammonium bifluoride, 50-70 parts of sulfamic acid, 3-5 parts of barium petroleum sulfonate, 2-5 parts of polyisobutylene and 300-500 parts of water. The anti-corrosion rust remover disclosed by the invention is high in anti-corrosion intensity and high in biodegradability, can be used for effectively treating the scaling substances without damaging equipment self and also preventing the rusty scales from being generated by forming a compact phosphating film on equipment surface, is harmless on human bodies, greatly simplifies the cleaning process, shortens the working time, improves the production efficiency and is pollution-free in environment and low in cost.

Owner:刘晓萍

Closed cleaning technology for oil reservoir and device adopting closed cleaning technology

InactiveCN103381415ASimple cleaning processLow costHollow article cleaningNon-miscible liquid separationOil waterOil–water separator

A closed cleaning device for an oil reservoir comprises an oil tank to-be-cleaned, the oil reservoir, a craft valve island, a pressurizing pump, and a vacuum heat exchange oil-water separator, wherein pollution discharge pipes are mounted at both the bottoms of the oil tank to-be-cleaned and the oil reservoir; valves are mounted on the pollution discharge pipes; a vacuum pipe, a steam pipe, an oil outlet pipe, a liquid level meter, a separator outlet pipe and a separator inlet pipe, which are provided with valves, are mounted on the vacuum heat exchange oil-water separator respectively; the pollution discharge pipe at the bottom of the oil tank to-be-cleaned is connected with the craft valve island through a pipeline; the craft valve island is connected with a cleaning machine through a pipeline mounted with a valve; the pollution discharge pipe of the oil reservoir is connected with the craft valve island through a pipeline. The closed cleaning device has the advantages that the cleaning technology is simple; the device is connected with the pipelines to form a sealed circulating system; on-site fuel gas leakage is avoided; the size, manufacture cost and energy consumption are reduced; the safety is greatly improved; the transportation is convenient.

Owner:潘浩忠

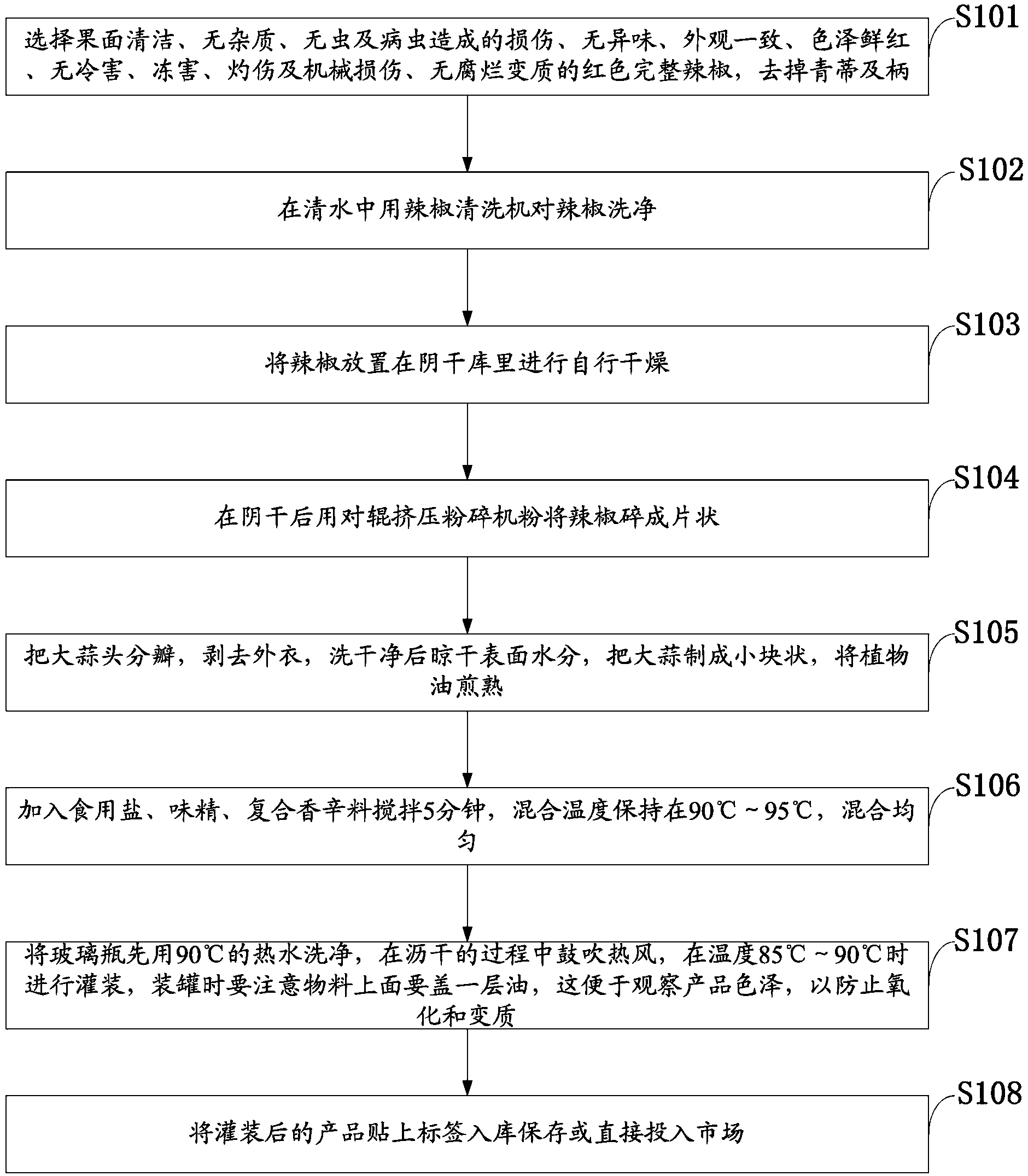

Formula and preparation method of hot and spicy sauce

InactiveCN103844245AAvoid perishableSimple cleaning processFood preparationMonosodium glutamateFlavor

The invention discloses a formula and a preparation method of hot and spicy sauce. According to the formula, the hot and spicy sauce is prepared from the following materials in percentage by mass: 25% of pepper from Tuo county, 15% of soybean paste, 1.5% of composite spice, 1.5% of garlic, 1% of edible salt, 1% of monosodium glutamate, and 55% of vegetable oil. The preparation method comprises the following steps: selecting red pepper; cleaning the selected red pepper in clear water by a pepper cleaning machine; naturally drying the cleaned pepper in a warehouse for drying in shade; crushing the dried pepper into pieces by a roller extrusion crusher; sectioning garlic, peeling the sectioned garlic, washing, air-drying till the moisture on the surface of the garlic is removed, making the garlic into small pieces, and frying the garlic pieces by vegetable oil; adding the edible salt, the monosodium glutamate and the composite spice, and then stirring; and washing a glass bottle by hot water at 90 DEG C, draining while blowing hot air, and filling. According to the invention, the problem that red pepper damaged in the washing process is likely to go bad is solved, the special flavor and the food safety of the hot and spicy sauce is guaranteed, the special aroma of pepper from Tuo county is maintained, and the hot and spicy sauce is suitable for the taste of most people.

Owner:INNER MONGOLIA ZHENGLONG GRAIN FOOD

Lead-free water-soluble environmental-friendly soldering flux for piezoelectric ceramics and preparation method thereof

InactiveCN102059478AHigh melting point and stable systemLess smokeWelding/cutting media/materialsSoldering mediaMaterials scienceEthanol

The invention provides a lead-free water-soluble environmental-friendly soldering flux for piezoelectric ceramics and a preparation method thereof. The soldering flux comprises the following components in the terms of total mass: 0.1-4 percent of activating agent, 0.01-1 percent of corrosion inhibitor, 1-10 percent of oxidation inhibitor, 1-30 percent of surface wetting agent and the balance of absolute ethyl alcohol. The preparation method of the soldering flux as a cleaning solution comprises the steps of: heating the surface wetting agent until boiled, stopping heating and then adding the activating agent, uniformly stirring with a glass rod, adding a proper amount of absolute ethyl alcohol, the oxidization inhibitor and benzotriazole (BTA) as the corrosion inhibitor after a mixed solution is cooled, slowly stirring with the glass rod until the solution is not demixed; and washing the product welded by using the soldering flux with flowing water for 5min or cleaning by using an ultrasonic water area method for half a minute, and then drying. By using the soldering flux, the product formed by the wave soldering of the piezoelectric ceramics has the advantages of full and smooth welded point, simplicity of cleaning and cost reduction; and the soldering flux contains no rosin, has small volatilization amount, and is beneficial to the guaranteeing of the health of employees.

Owner:HUNAN JIAYEDA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com