Patents

Literature

732results about How to "No environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene foaming material and production method thereof

The invention discloses a polypropylene foaming material. The polypropylene foaming material comprises the following components according to proportioning by weight: 60-99 parts of polypropylene resin; 0.1-10 parts of nucleating agent; 0.1-5 parts of antioxidant; 0-5 parts of colorant; 0-5 parts of lubricant; and 0-20 parts of filling material; and the melt index of the polypropylene resin is 0.1-20 g / 10 min, and the foaming process adopts supercritical fluid as the foaming agent, i.e. 0.1-20 parts of supercritical fluid (proportioning by weight). The invention also discloses a production method of the foaming material. Compared with the prior art, the invention has the advantages that the universal polypropylene can be adopted as a base material, no polymer is provided, the cross-linking reaction does not occur, the foaming process is free from environmental pollution, and the production method is safe; the quality of the obtained foaming material is stable, the foaming percentage and the cell density are high, the distribution is uniform, and the invention is suitable for the industrial production at a large scale; and meanwhile, the overall production method is simple, the operation is easy, and the production cost is relatively lower.

Owner:合肥朗润中科材料有限公司

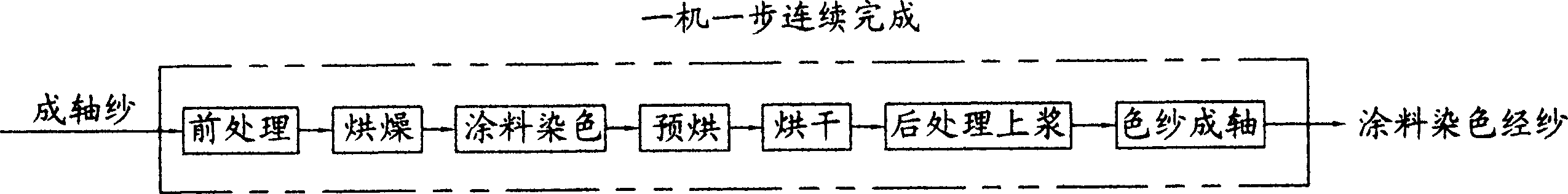

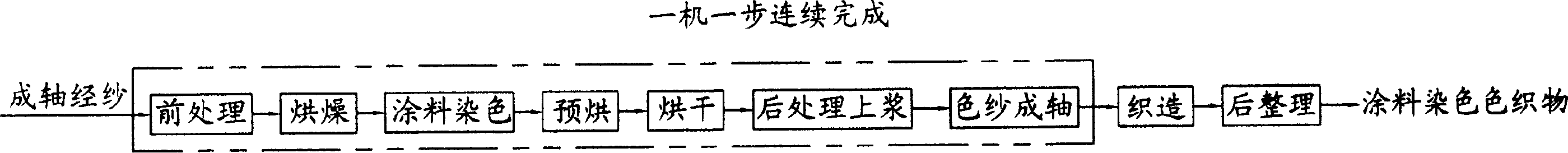

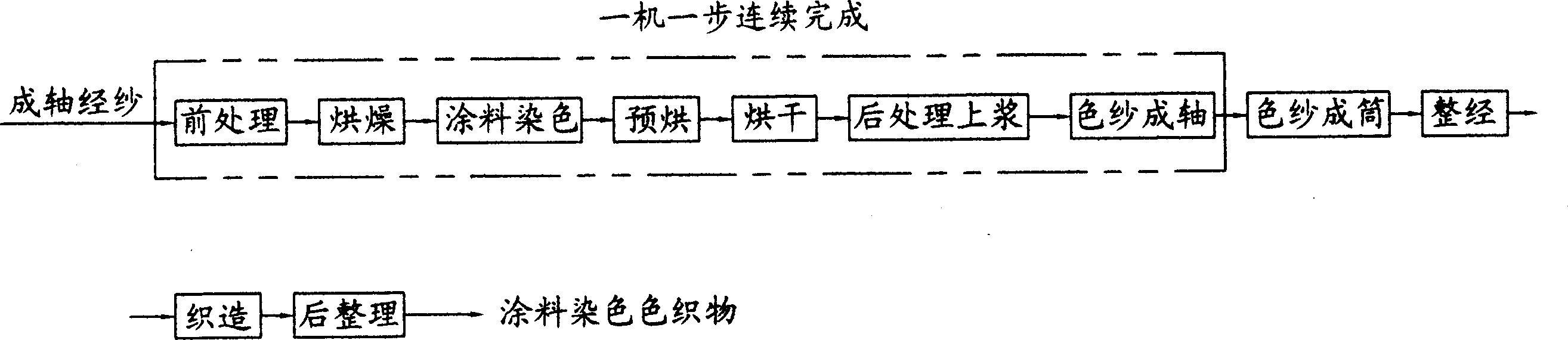

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

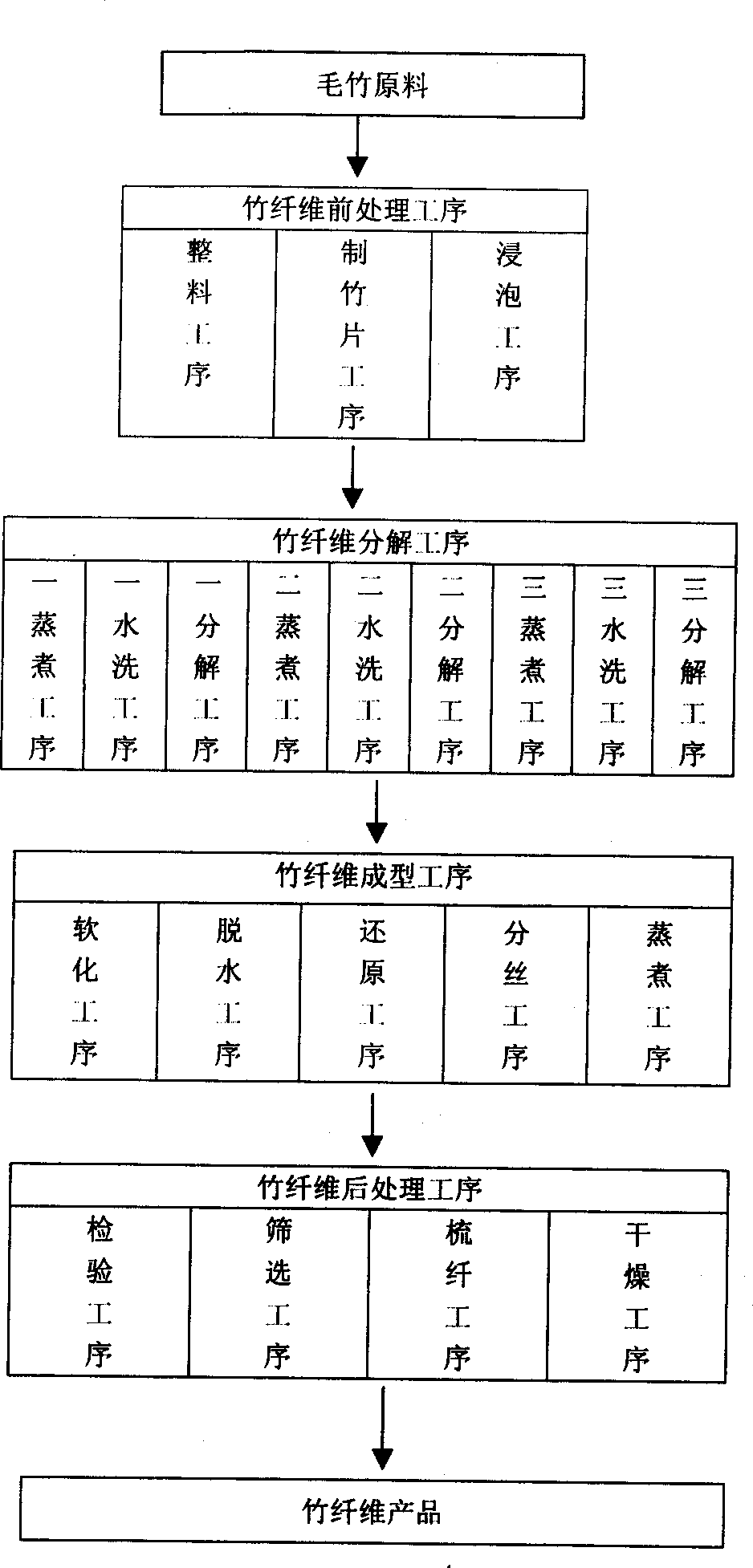

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

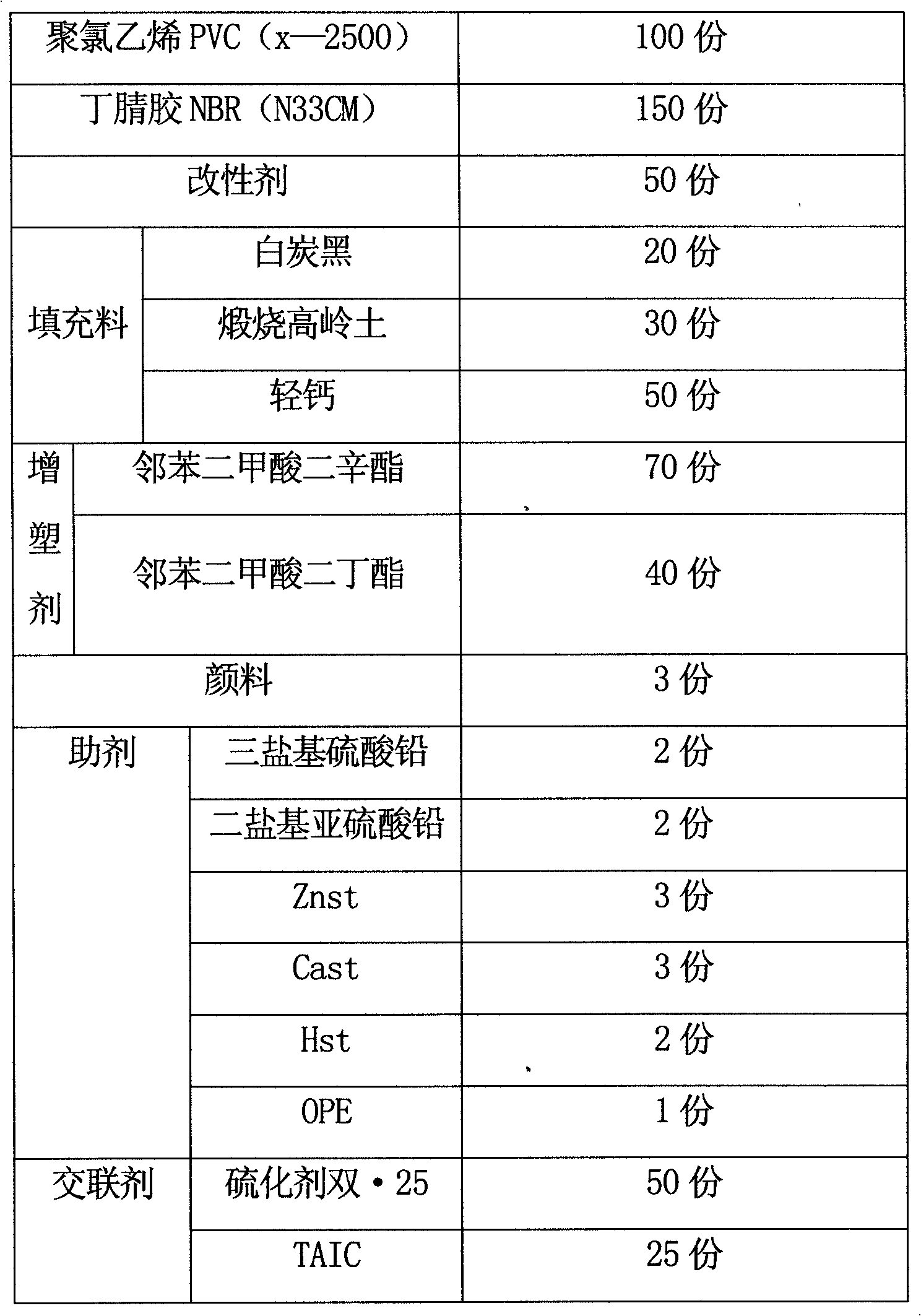

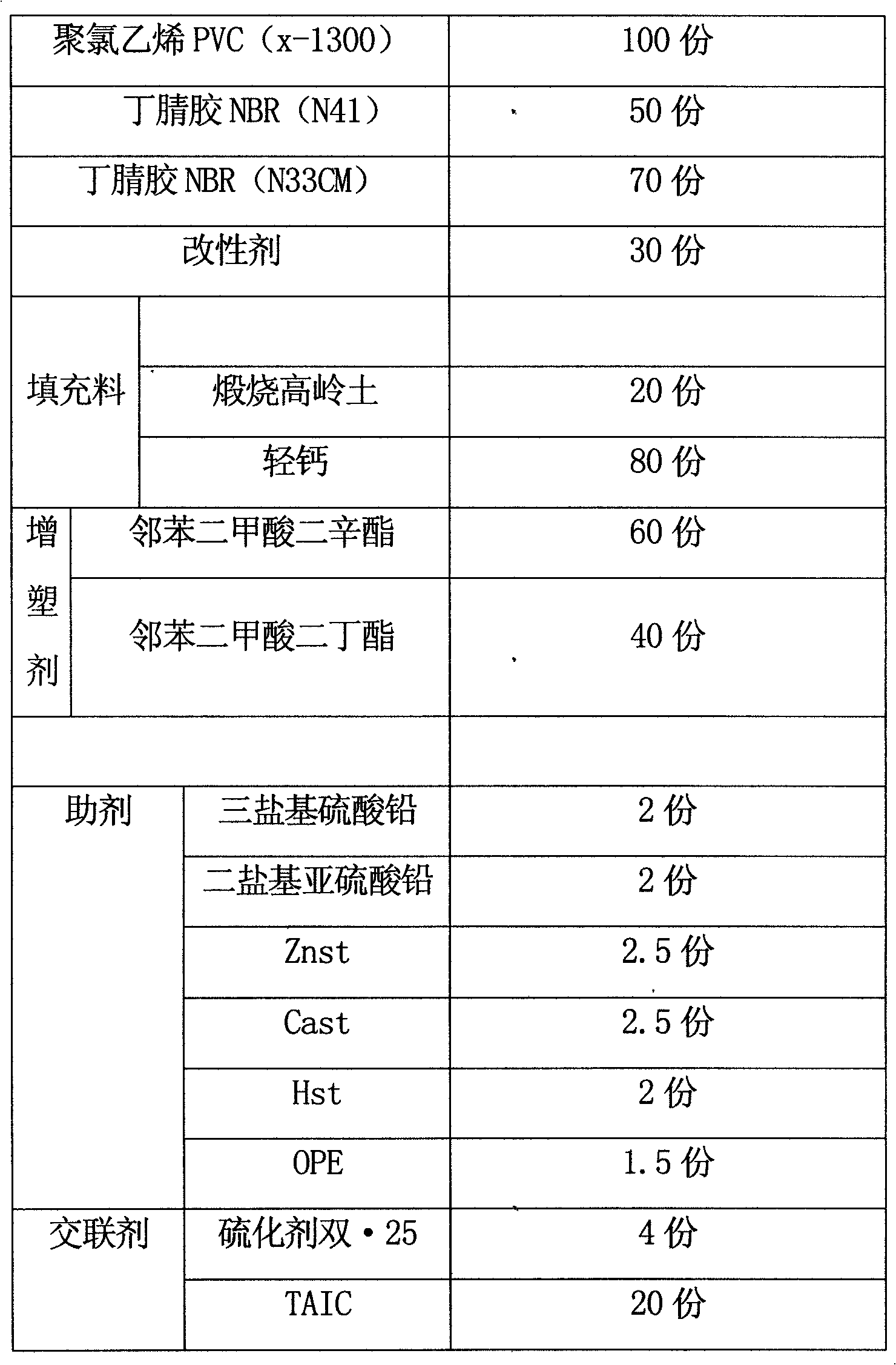

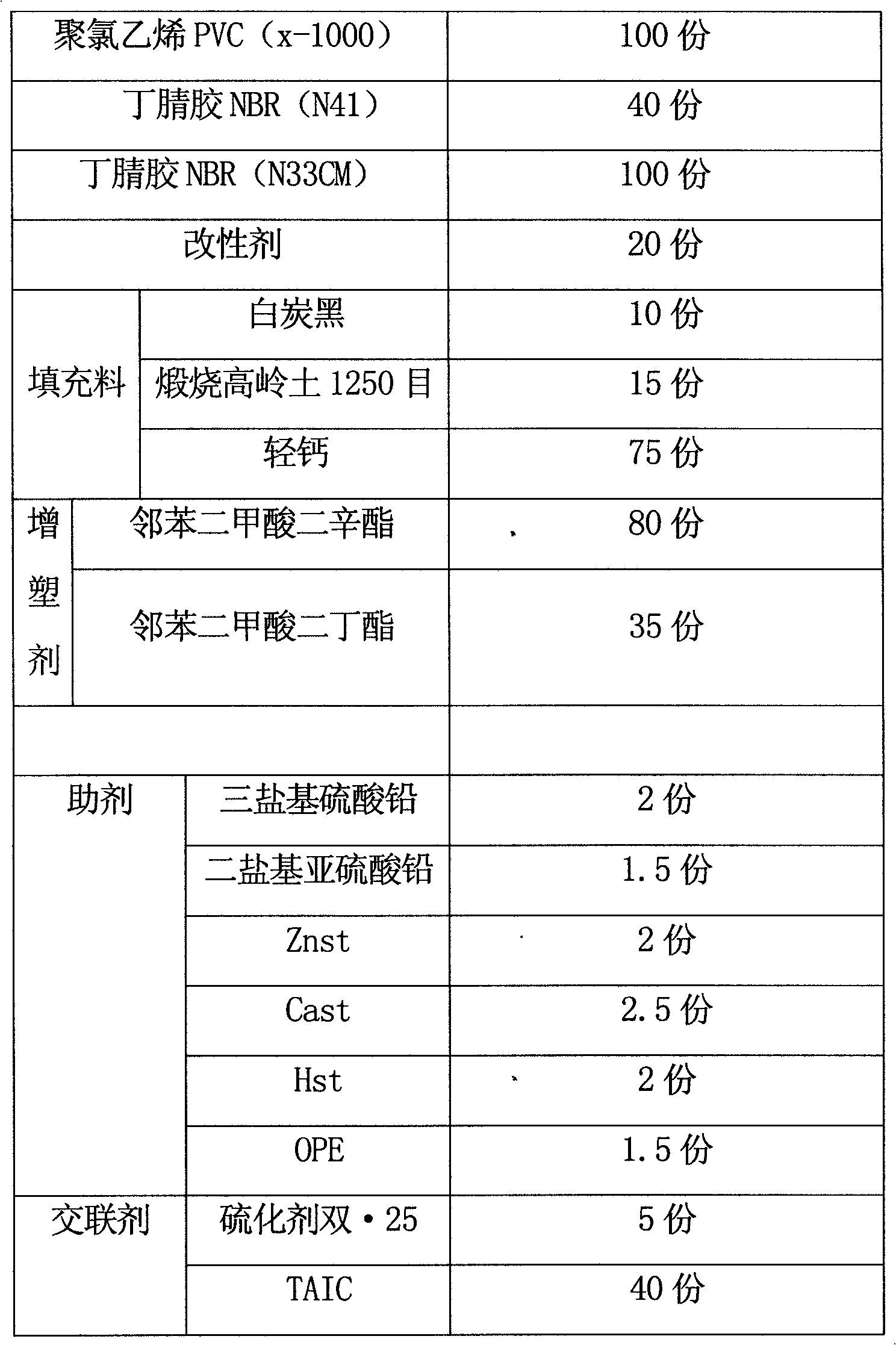

Oil-resistant and low temperature-resistant thermoplastic elastomer and production method

The invention provides an oil-resistant and low temperature-resistant thermoplastic elastomer and a production method according to the mechanism that the characters of a plurality of molecular materials are similar and compatible, mutually complementary and capable of mutually modifying. The oil-resistant and low temperature-resistant thermoplastic elastomer comprises the following components by weight parts: 100 parts of one or a plurality of polyvinyl chloride X-2000, X-2500, X1300 and X-1000, 40-150 parts of one or a plurality of nitrile butadiene rubber (NBR) N41, N33CM, N33M, N26 and N18,20-50 parts of modifier, 20-160 parts of filling agent, 70-150 parts of plasticizer, 15-75 parts of dynamic cross-linking agent, 0-5 parts of pigments and 8-20 parts of additives. The invention develops the modifier, selects the cross-linking agent and technological conditions of temperature, rotational speed and the like, thereby leading the product to achieve the technical requirements of oil resistance, low temperature resistance, acid-base resistance, aging resistance and smaller specific gravity than a vulcanized product with the same price. The elastomer can not only produce various oil-resistant pipes, ropes, wires and cables as well as sealing strips of aluminum-plastic doors and windows of vehicles, motor vehicles and buildings, but also manufacture various parts and products with different mechanical performance requirements on hardness, elasticity and the like through the different technologies of blow molding, extrusion molding, injection molding and the like.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as anti-settling dispersant

The invention relates to an anticorrosive coating, and particularly relates to a modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as an anti-settling dispersant. The modified silicate waterborne zinc-rich anticorrosive coating is prepared from components A and B, wherein the component A is prepared from 10-60% of flake zinc powder; the component B is prepared from 25-85% of silicone acrylic emulsion-modified potassium silicate solution, 0.1-5% of ricinate, 0.1-5% of organic montmorillonite, 0.1-5% of defoamer, and 0.01-2% of thickener, and the percent is weight percent. The modified silicate waterborne zinc-rich anticorrosive coating has the advantages that the dosage of zinc powder can be greatly reduced, and the cost of the coating is reduced. The water resistance of the coating is improved by the organic emulsion-modified potassium silicate solution; excellent painting hardness of the coating is achieved, the barrier property of the coating is improved, and meanwhile, the anticorrosive coating is almost zero in volatile organic compound (VOC) release property, and free of environmental pollution.

Owner:SHENYANG POLYTECHNIC UNIV

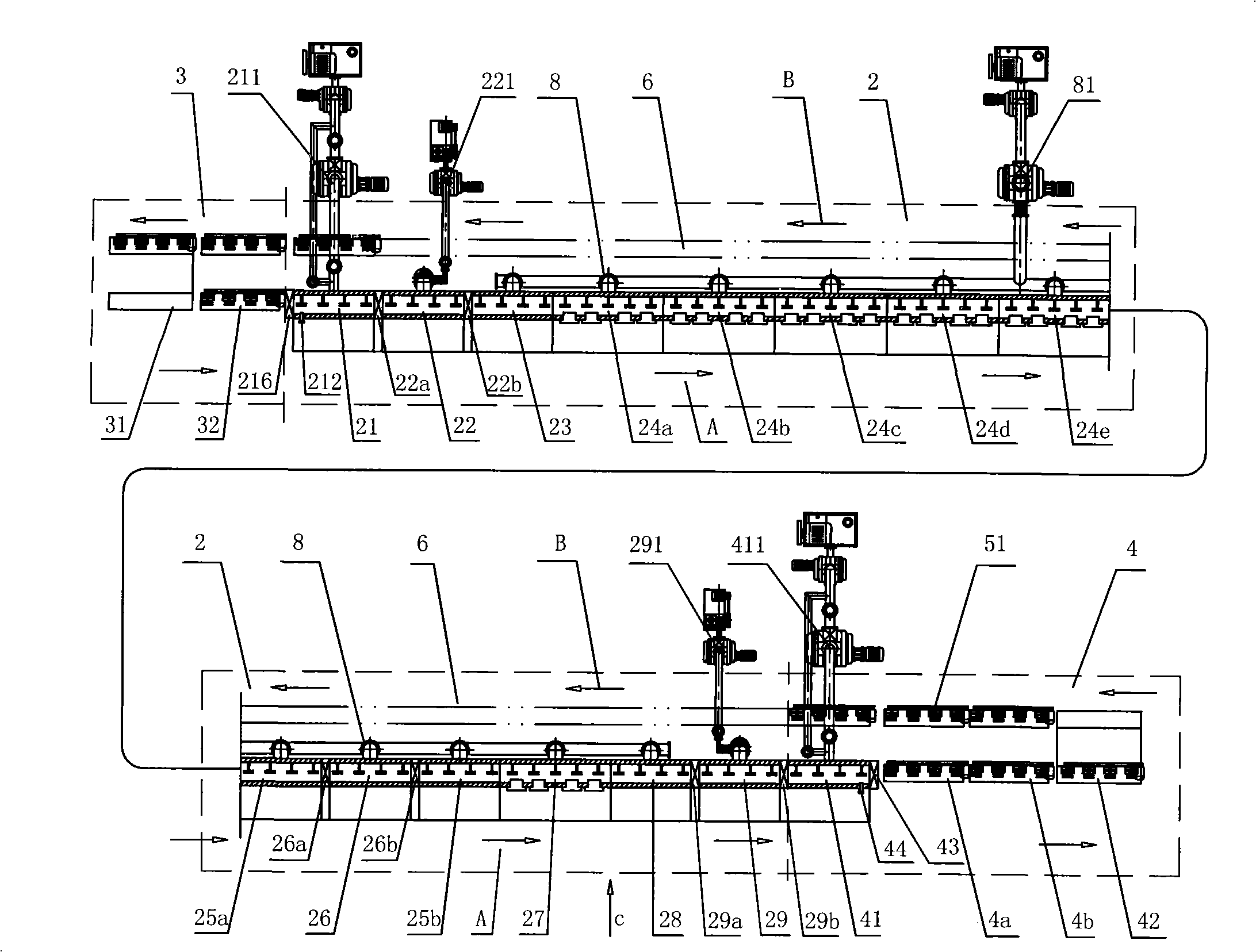

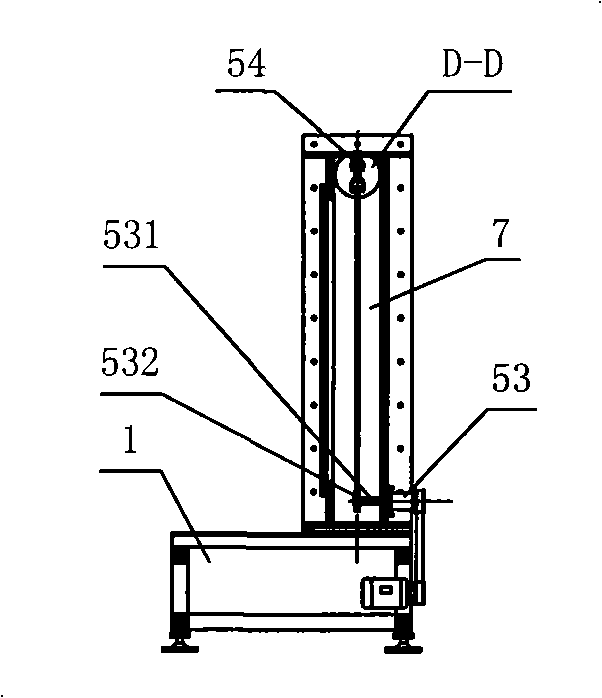

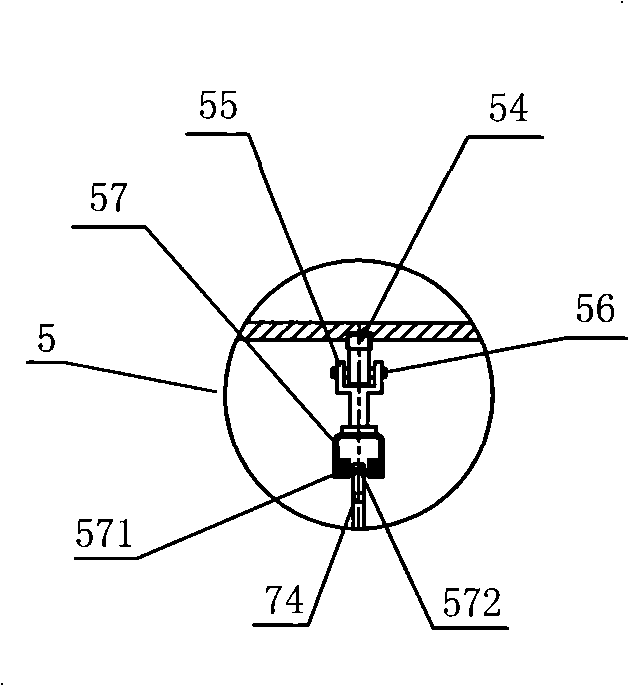

Large area anti-reflection conductive film continuous magnetron sputtering film coating production line

ActiveCN101353782AOvercome the defects of small transmission speed conversion ratio and low production efficiencyEffective isolationVacuum evaporation coatingSputtering coatingProduction lineTransmittance

The invention relates to a continuous magnetic control sputtering coating production line of a large-area anti-reflection conductive film, which comprises a plurality of vacuum chamber blocks which are adjacent in sequence, deployed in the transverse direction of a bedplate and communicated with a pumping system and comprise a pre-vacuum chamber and the like, a film advancing area and a film discharging area closely adjacent to the film advancing area, wherein, the film advancing area consists of a translational-motion rack for film advancing and the like, and the film discharging area consists of a translational-motion rack for film discharging and the like; magnetic-steering transport devices are arranged on the vacuum chamber blocks, the film advancing area and the film discharging area, together with an adaptive workpiece backing up rack form a production loop which runs continuously and circularly along the coating direction of a running loading frame and the backing up direction of the running loading frame so as to realize the technical proposal of continuous magnetic control sputtering coating of the large-area anti-reflection conductive film for a substrate. The production line of the invention overcomes the defects of the traditional transparent conducting film production line, namely, the transmittance range is narrow, no transport room is provided, the conversion ratio of transport speed of the substrate loading rack is small and production efficiency is low and the like. The production line of the invention is applicable to the production of the large-area sputtering coatings of transparent conductive films, anti-reflection films and high-reflection films and the like of various display panels, solar panels and decoration panels.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

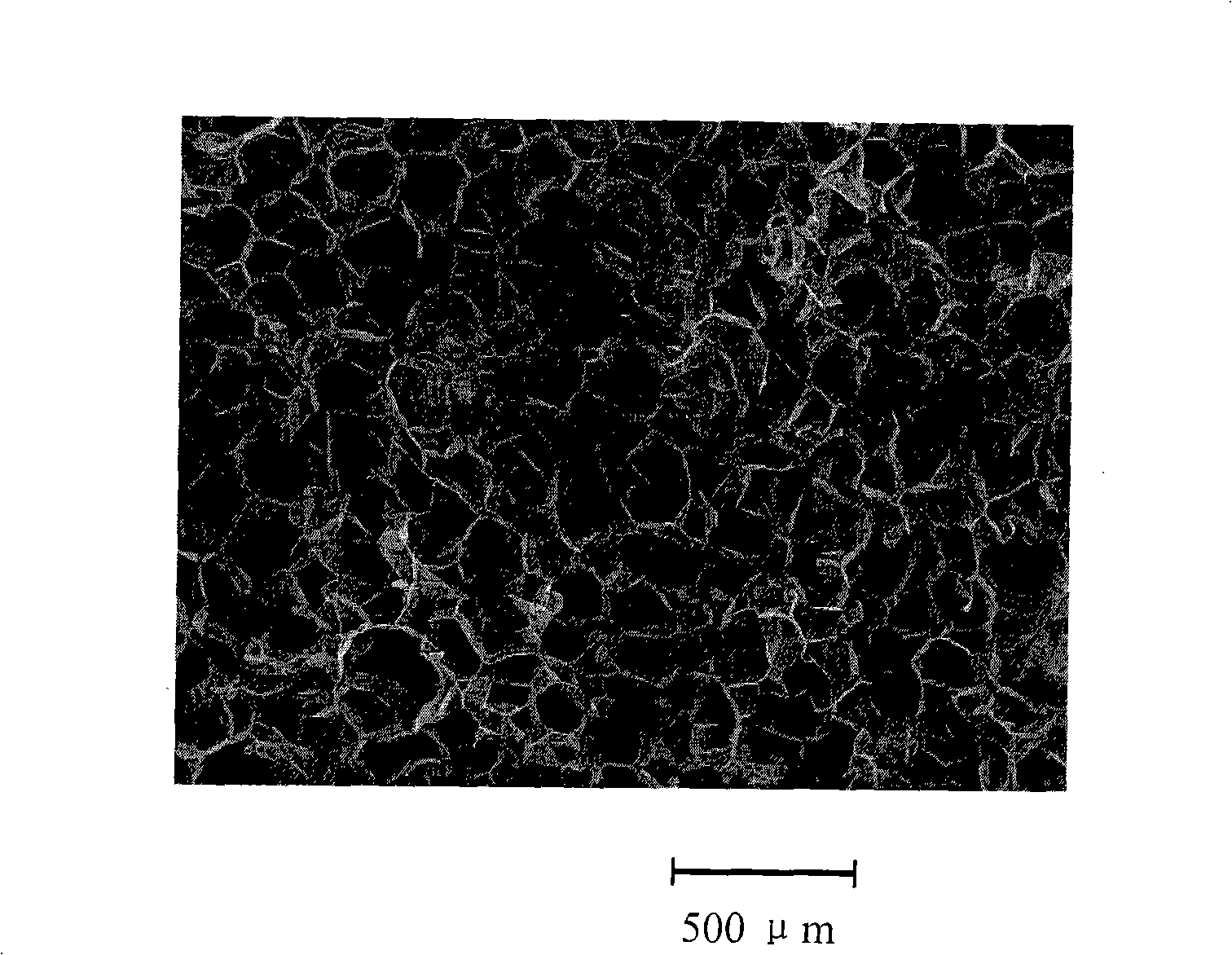

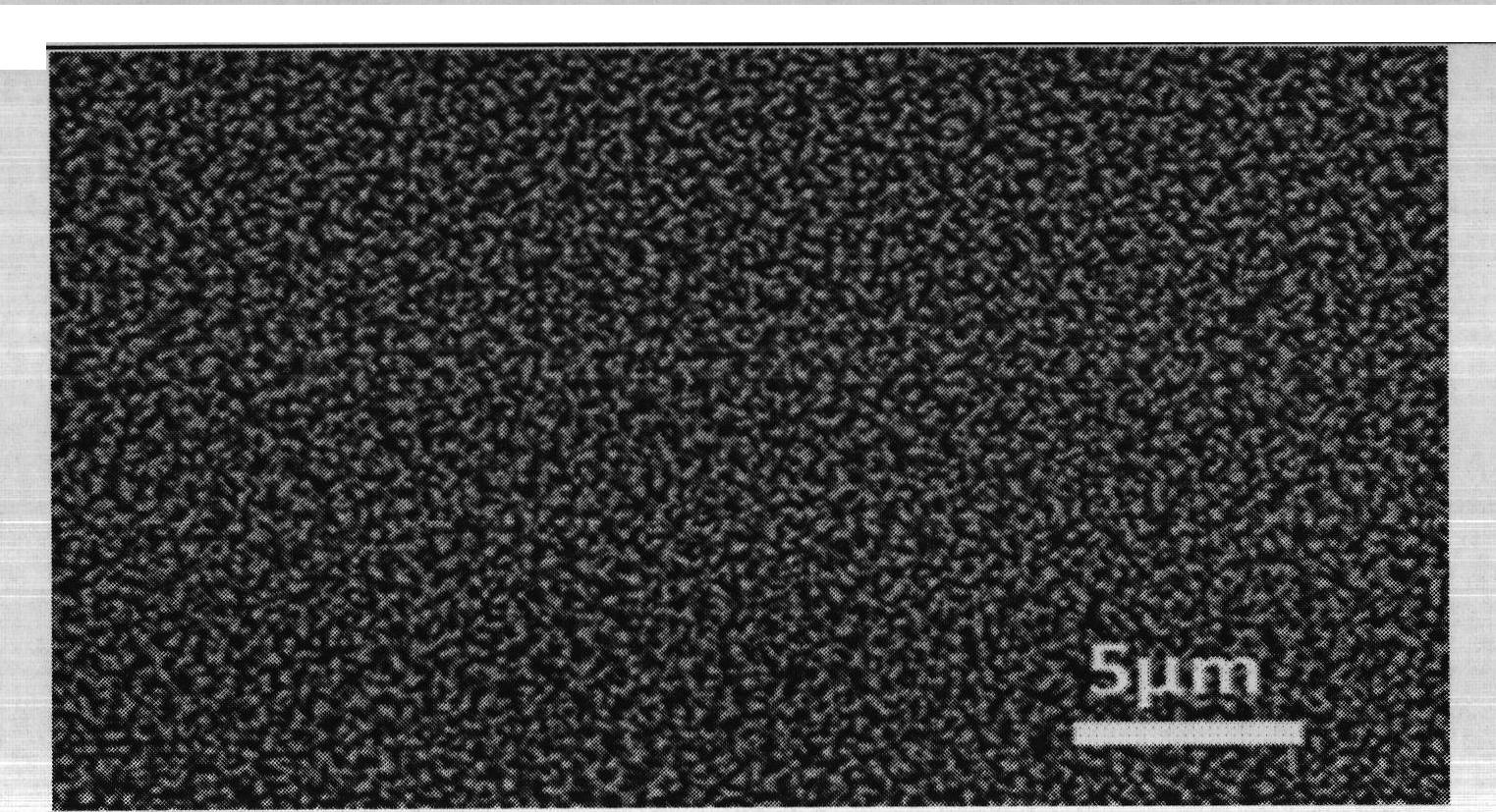

Preparation method for microporous diaphragm and microporous diaphragm

ActiveCN103633272AImprove longitudinal strengthUniform structureCell component detailsPolyolefinPolymer science

The invention relates to the field of the processing of lithium-ion battery diaphragms, and discloses a preparation method for a microporous diaphragm. The preparation method for the microporous diaphragm includes the following steps: 1) a principal polyolefin resin and an auxiliary additive are uniformly stirred through a stirring mixer to obtain a mixture I; 2) the obtained mixture I is added into an extruder to be uniformly melted and plasticized into a melt; 3) an intermediate diaphragm is prepared from a cast piece of the melt extruded from a die head; 4) annealing treatment is performed on the intermediate diaphragm under bi-directional micro-tension; 5) the annealed intermediate diaphragm is stretched longitudinally to prepare the diaphragm with a microporous structure. The invention further discloses the microporous diaphragm prepared through the method, which consists of the principal polyolefin resin with a weight percentage of 75 to 99.9 percent and the auxiliary additive with a weight percentage of 25 to 0.1 percent. The preparation method disclosed by the invention has the advantage that the lithium-ion battery diaphragm with a uniform structure, the specific microporous structure and high safety performance can be prepared.

Owner:SHENZHEN SENIOR TECH MATERIAL

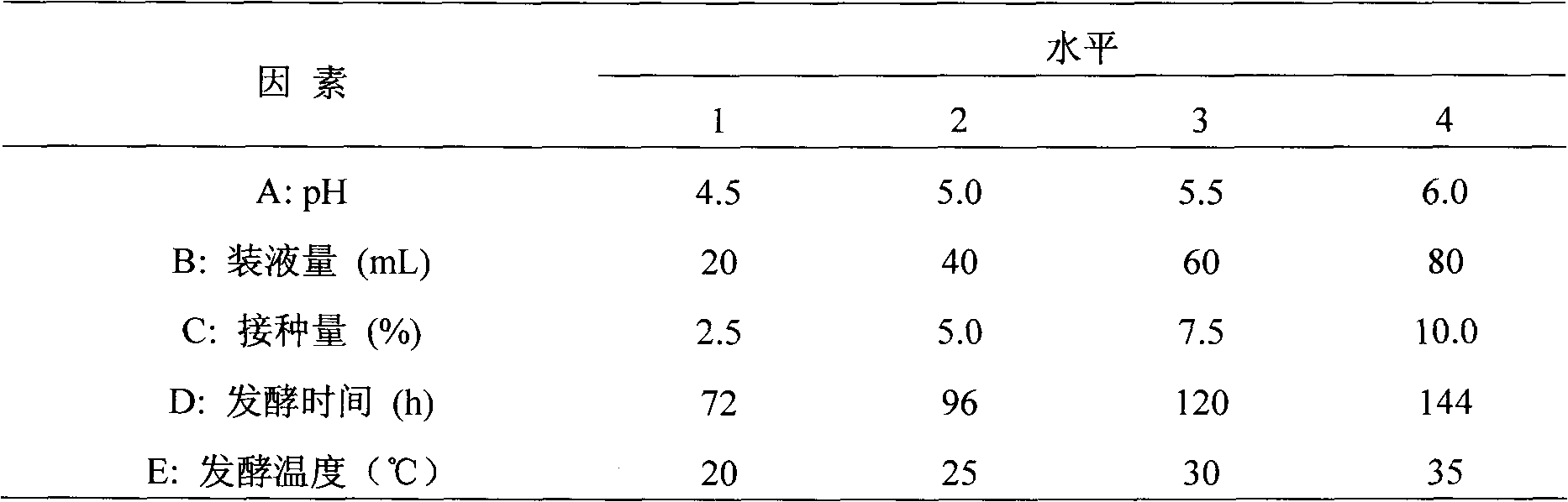

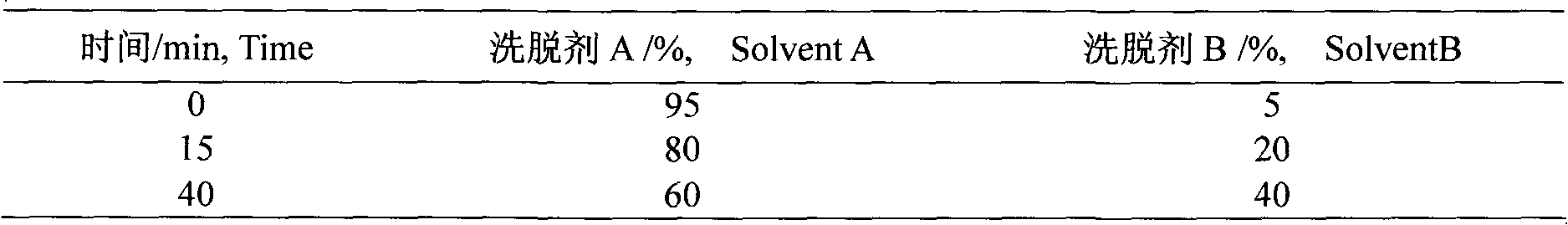

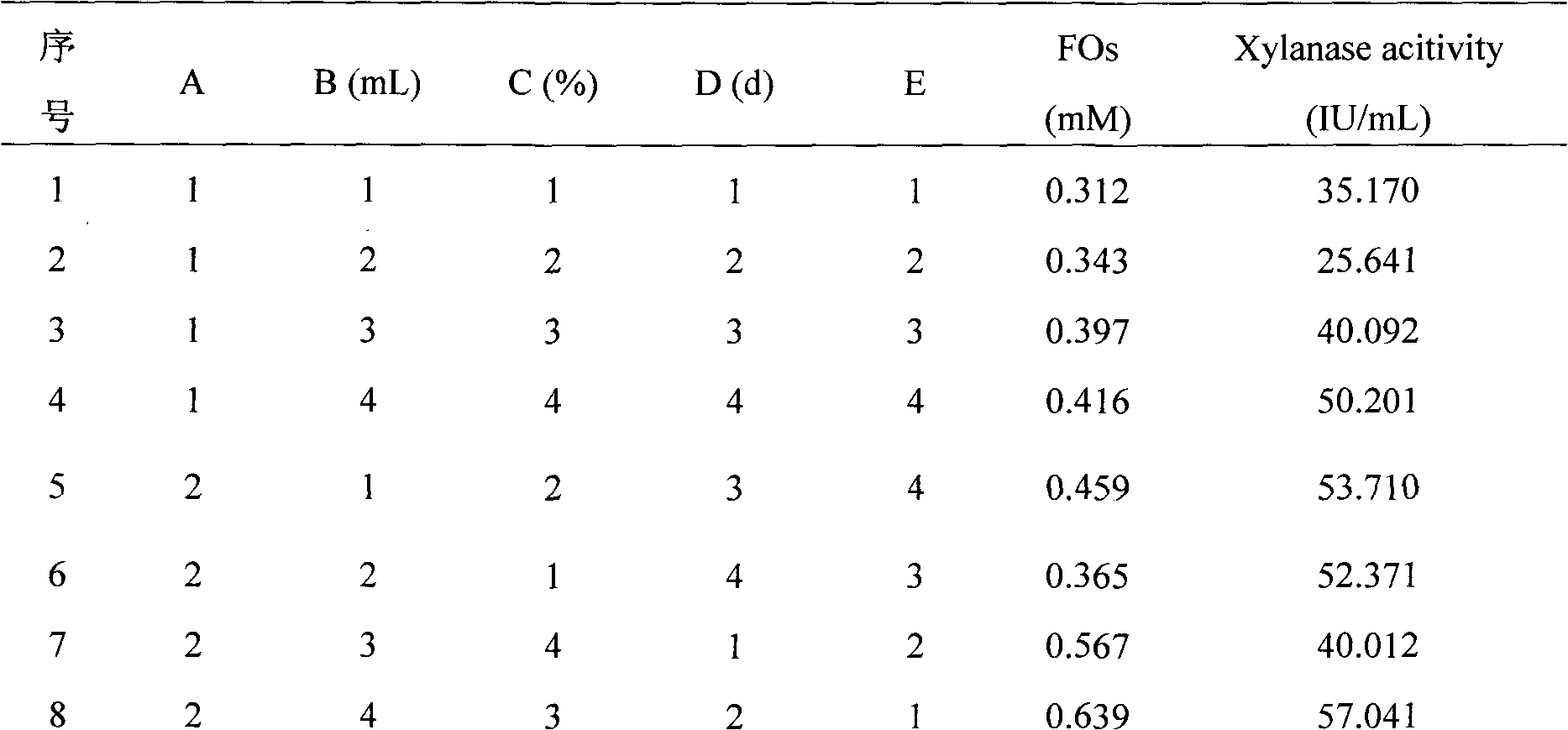

Method for co-production of oligose and dietary fiber through wheat bran fermentation

InactiveCN102605022AEliminate separation and purificationEliminate bad effectsClimate change adaptationMicroorganism based processesPullulanAdditive ingredient

The invention relates to application of a microbial fermentation method in co-production of wheat bran oligose and dietary fiber. The invention aims to developed and utilize the wheat bran comprehensively; an efficient biological process route is adopted to deeply processing wheat bran, and the microbial fermentation method is used to prepare wheat bran dietary fiber and functional oligose simultaneously. The microbe used in the method refers to a single strain, pullularia pullulans or mixed strains of aureobasidium pulluans and agrocybe aegerita; in fermentation of wheat bran, substances in the wheat bran, such as starch and protein, can be taken as nutritional ingredients for the growth of microbes, when digesting the substances, the microbes can generate xylanase so as to hydrolyze wheat bran hemicellulose to generate oligose and prepare dietary fiber simultaneously. According to the method, the research and development idea of developing a single product is broken through, the rate of multipurpose utilization of the resource is high, the production costs is low, chemical substance residual does not exist, the environment is not polluted, a new processing technology model of 'ecological, low-carbon and efficient circulating' is formed, and the additional value of the wheat bran product is increased.

Owner:YANCHENG INST OF TECH

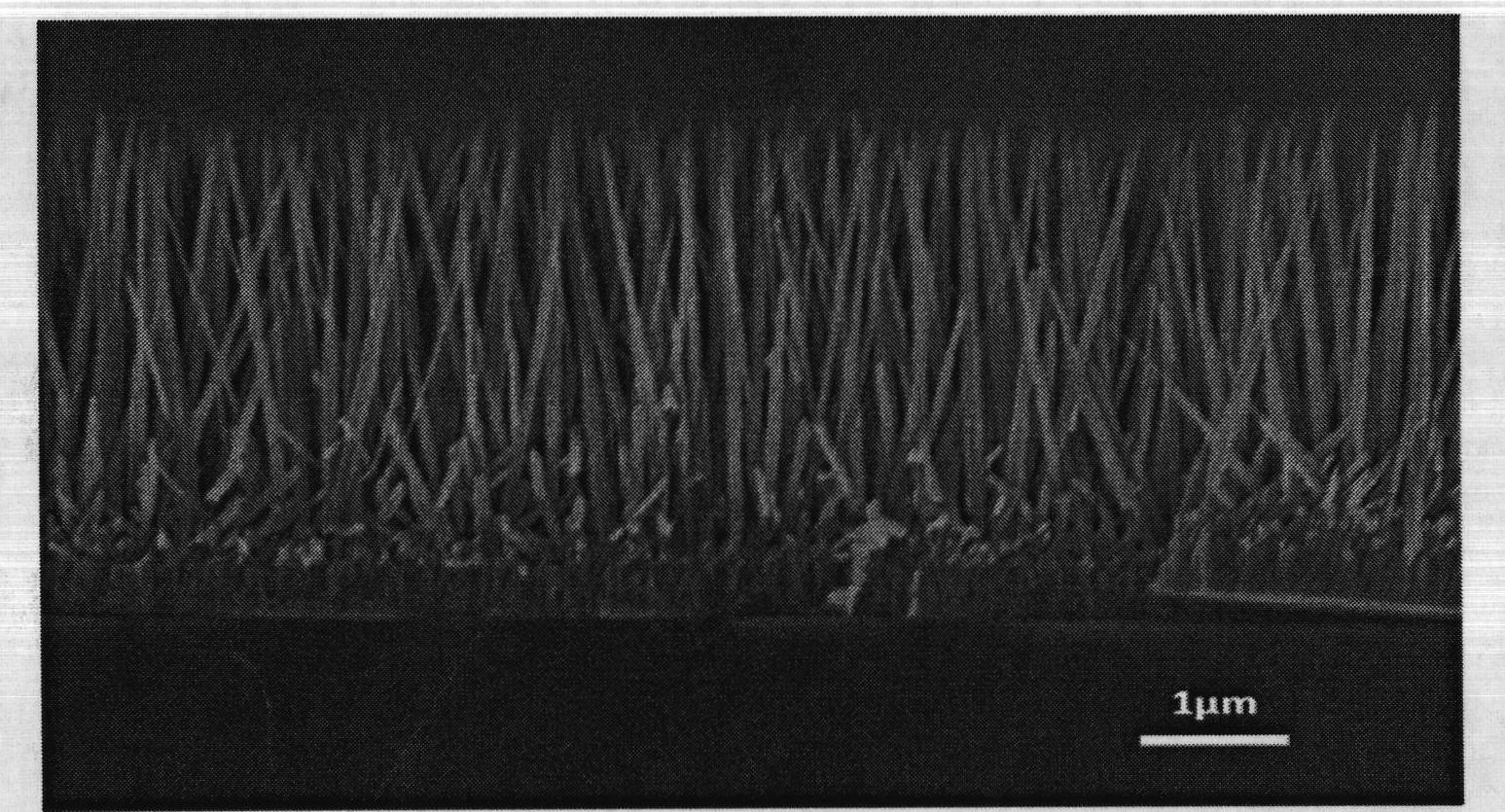

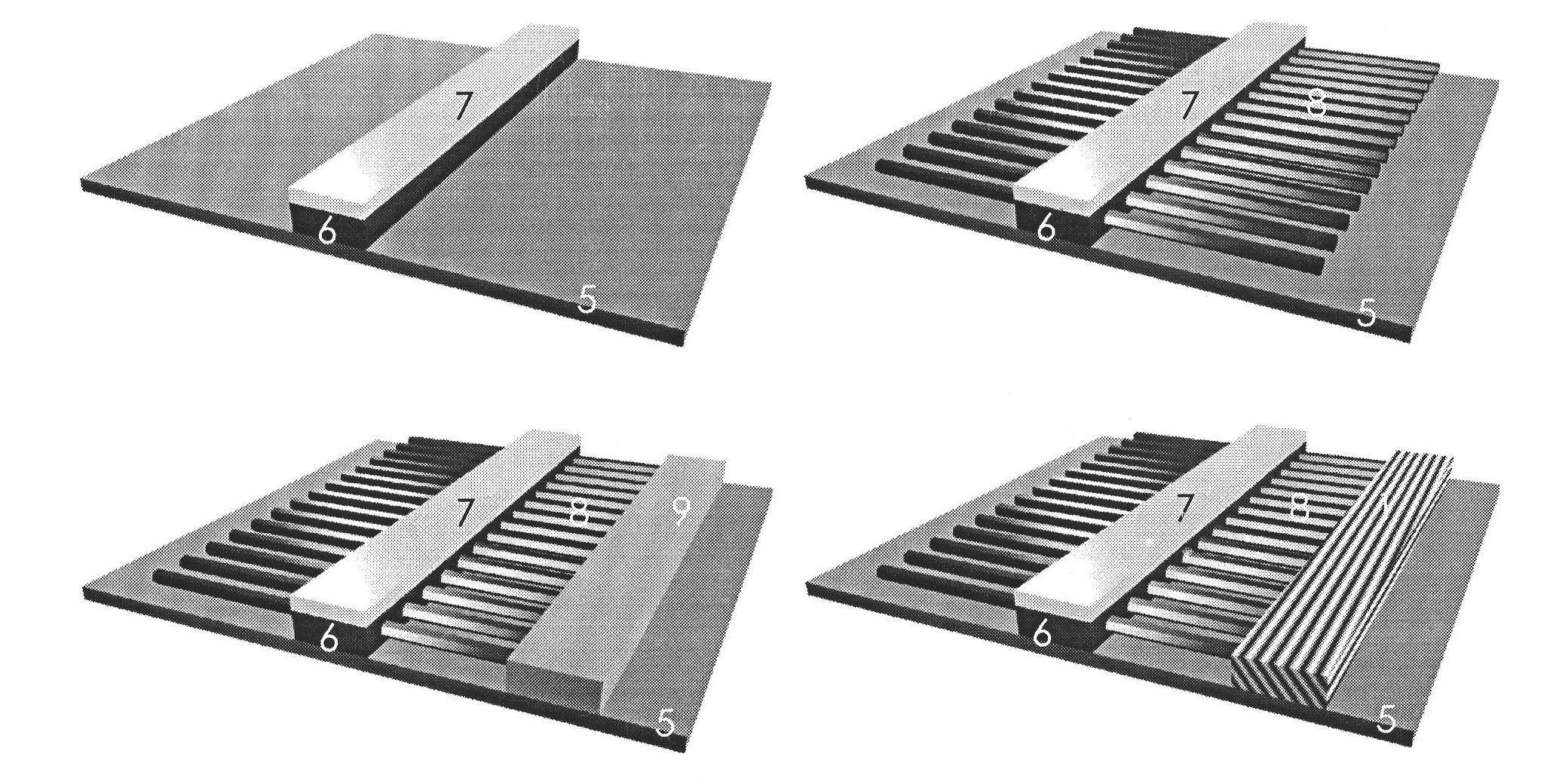

Semiconductor ultraviolet detection sensor and preparation method thereof

InactiveCN102110735AAvoid influenceService life of directorFinal product manufacturePhotometry using electric radiation detectorsUltravioletSemiconductor sensor

The invention discloses a semiconductor sensor for ultraviolet detection and a preparation method of the sensor. The semiconductor ultraviolet detection sensor comprises a baseplate, electrodes loaded on the baseplate and zinc oxide nanowires which are positioned between the electrodes, connected in parallel and integrated, wherein the electrodes are two comb tooth-shaped electrodes which are arranged oppositely, one comb tooth of one electrode is inserted between two comb teeth of the other electrode so as to form the tooth insertion shape, and the zinc oxide nanowires are respectively connected in parallel and integrated on the adjacent two comb teeth. The light response current of the semiconductor ultraviolet detection sensor can achieve the milliamp magnitude, thereby significantly reducing the ultraviolet detection difficulty and the characterization difficulty of the strength thereof.

Owner:LANZHOU UNIVERSITY

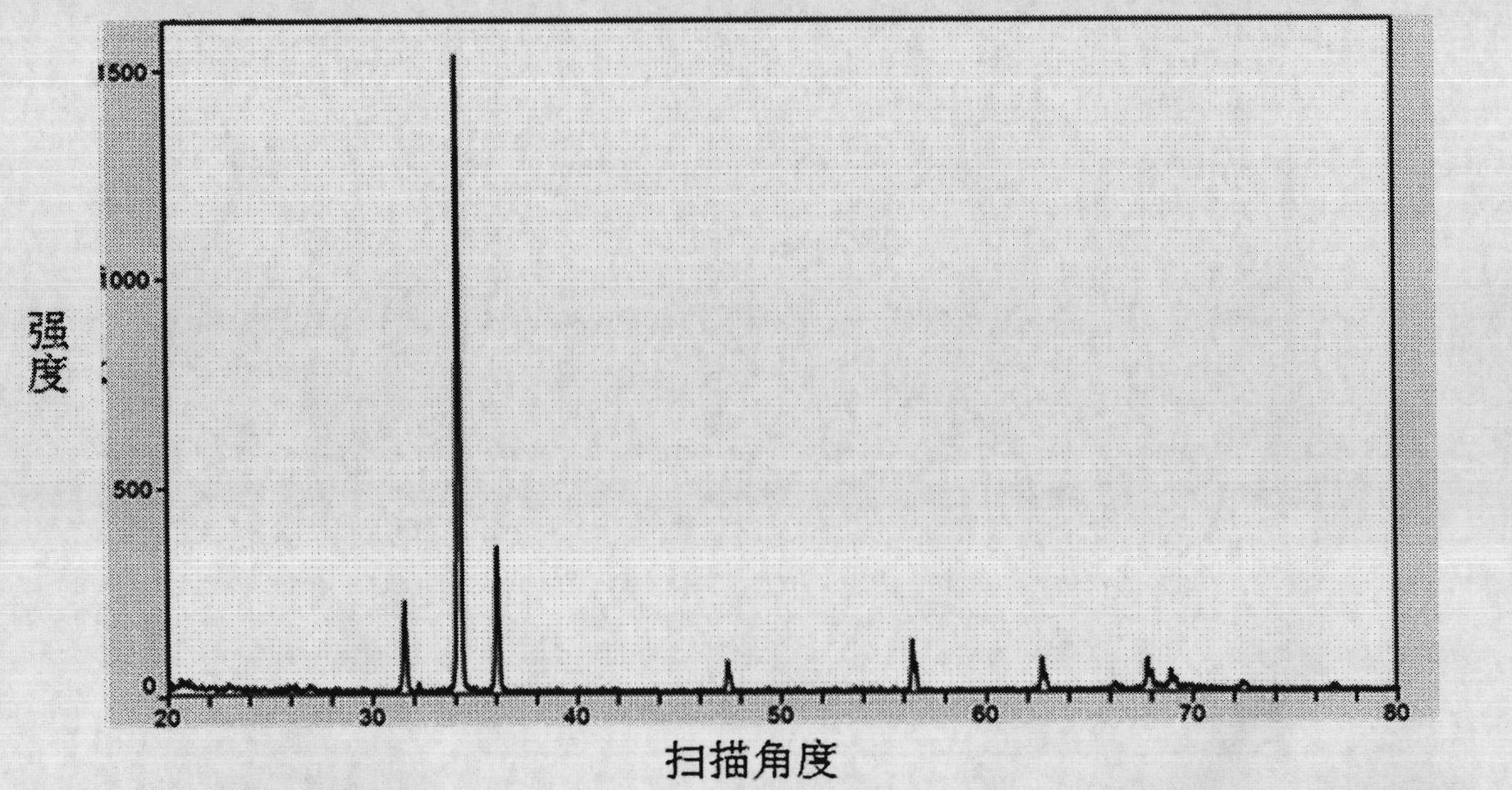

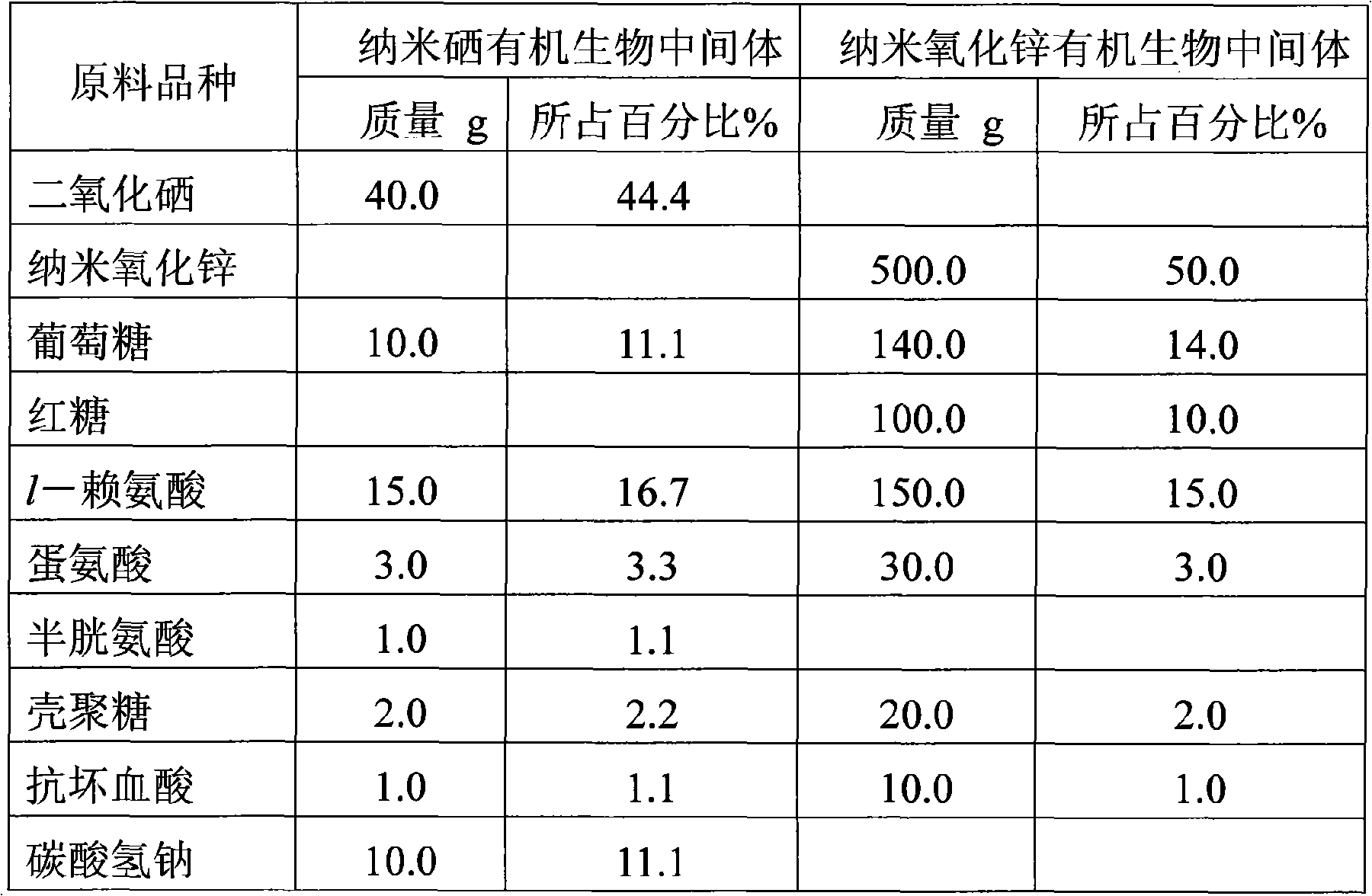

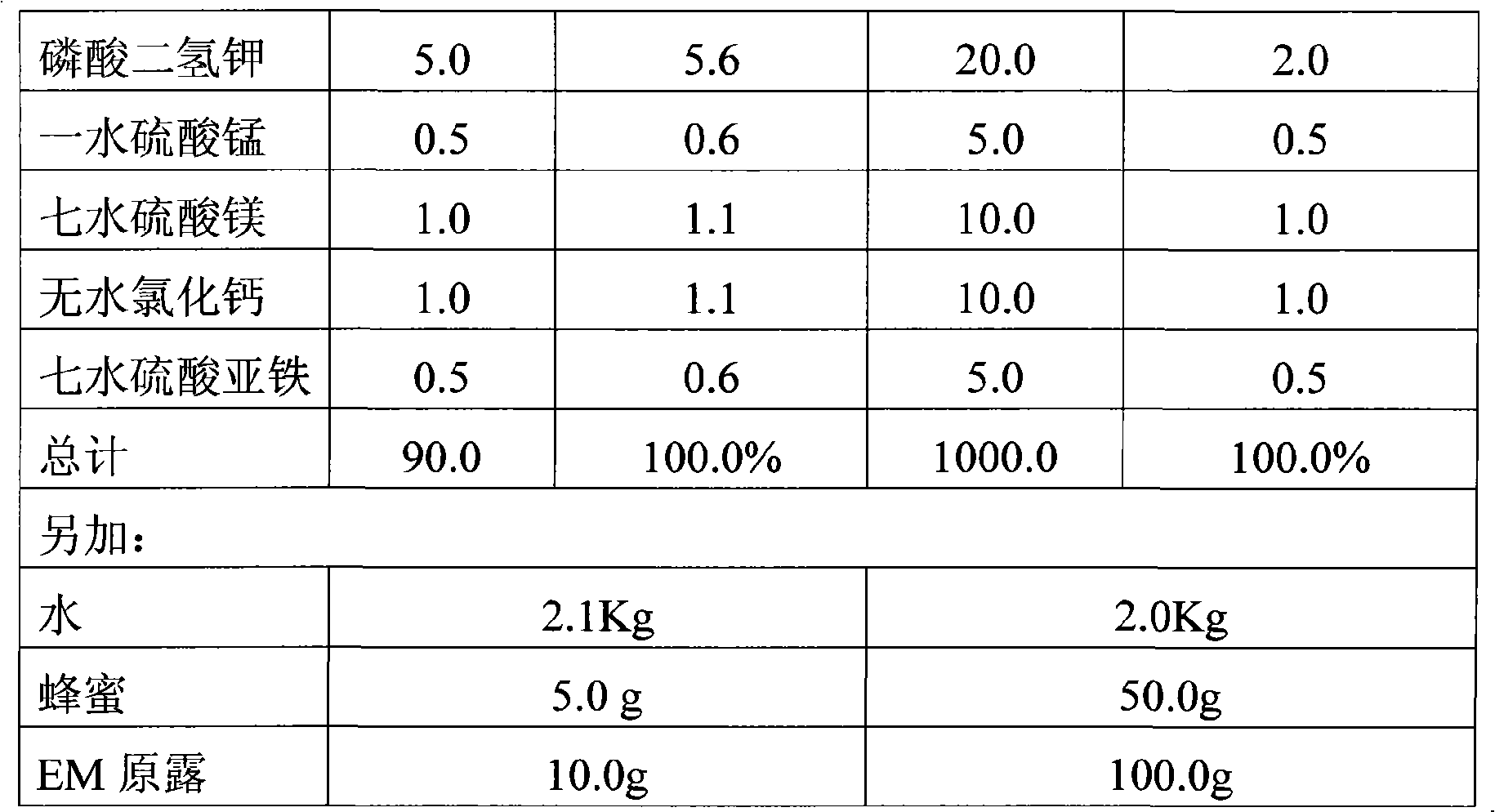

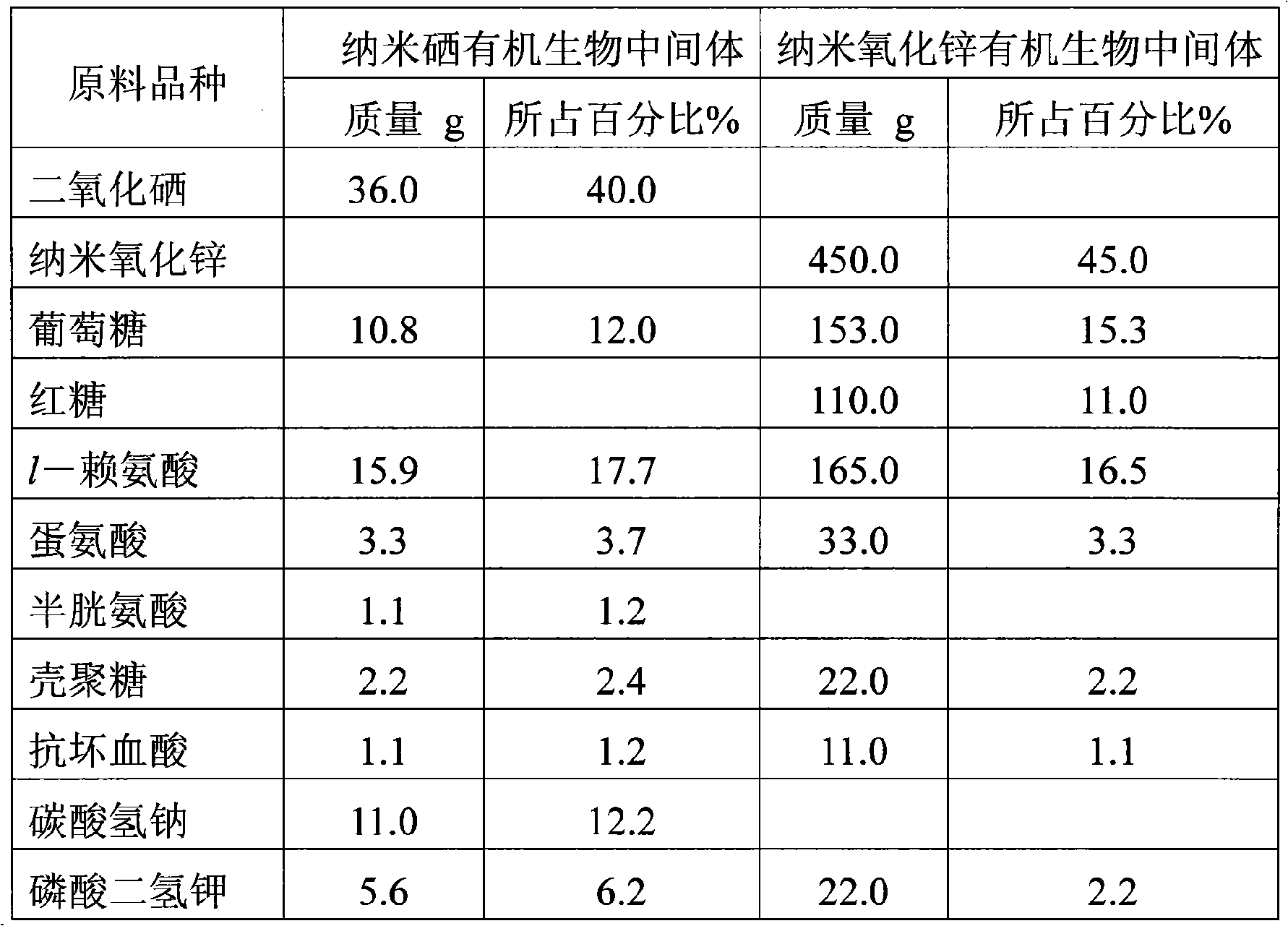

Organic biological feedstuff additive containing nano-selenium, zinc oxide, preparation and use method thereof

ActiveCN101313729ARaw materials are easy to getEasy to operateAnimal feeding stuffAccessory food factorsNutrientChemistry

The invention relates to organic biological feed additives containing nano selenium and zinc oxide, a preparation method and a use method. The product of the organic biological feed additives is russety dry powder with a granularity between 80 and 140 nanometers, and can form suspension with water; the selenium content is between 0.00 and 36.00 percent and the zinc content is between 0.00 and 45.00 percent; the selenium content and the zinc content can not be 0 simultaneously; the organic biological feed additives are prepared by nano selenium organic biological intermediates and nano zinc oxide organic biological intermediates which are respectively prepared by fermentation of selenium dioxide and nano zinc oxide through microorganisms in the presence of various nutrient components; and 2.3 to 11.5 mass times of water is uniformly mixed with the organic biological feed additives containing the nano selenium and the zinc oxide and then sprinkled in feed which is then used for feeding laying hens, milk cows or nanny goats for 5 to 10 days. Compared with contrast feed, the selenium content and the zinc content of produced eggs are respectively 2 to 5 times and 2 to 2.5 times; the selenium content and the zinc content of produced milk are respectively 3 to 6 times and 2 to 4 times; and the selenium content and the zinc content of produced goat milk are respectively 3 to 7 times and 3 to 6.5 times.

Owner:田福平

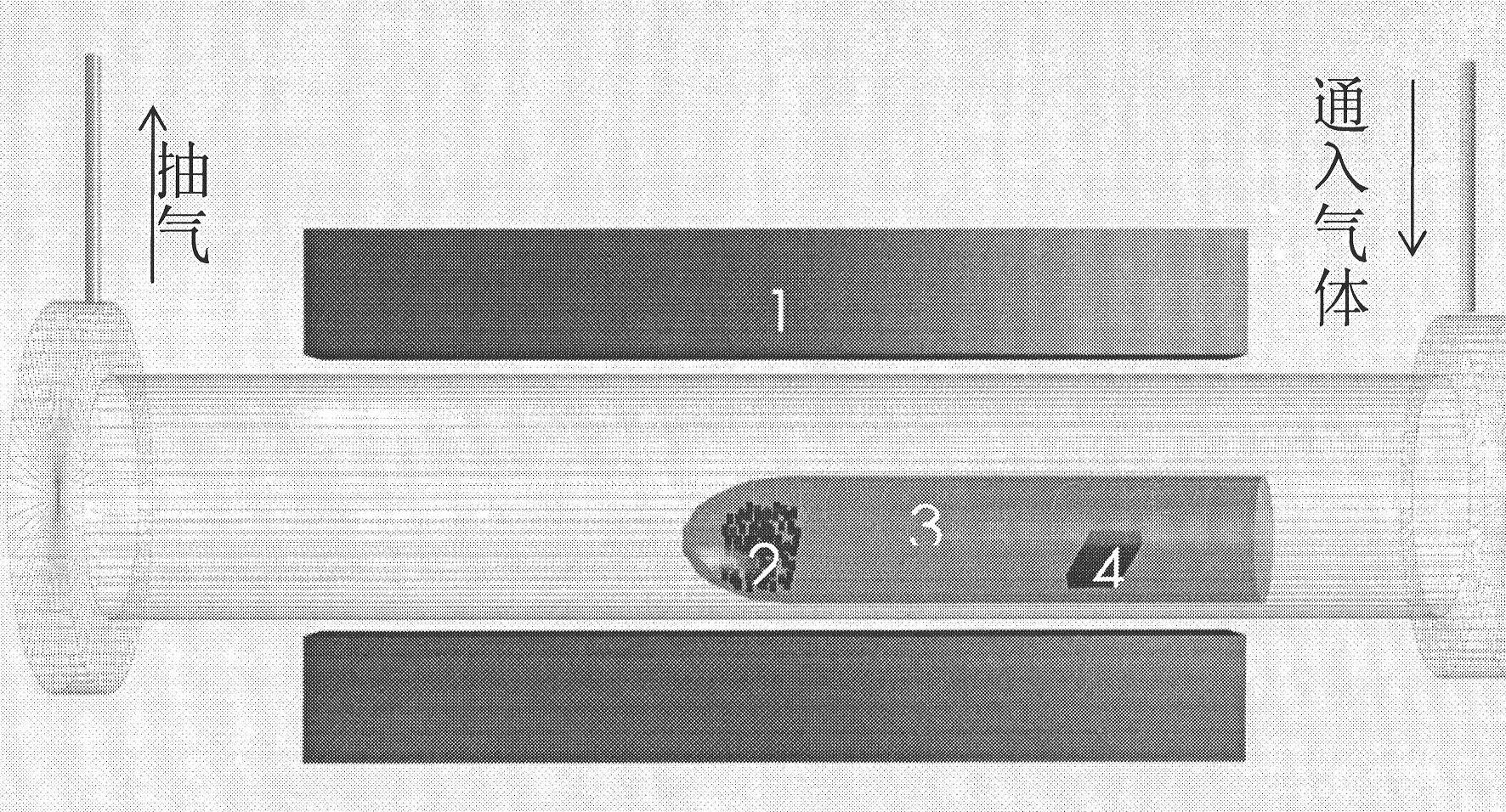

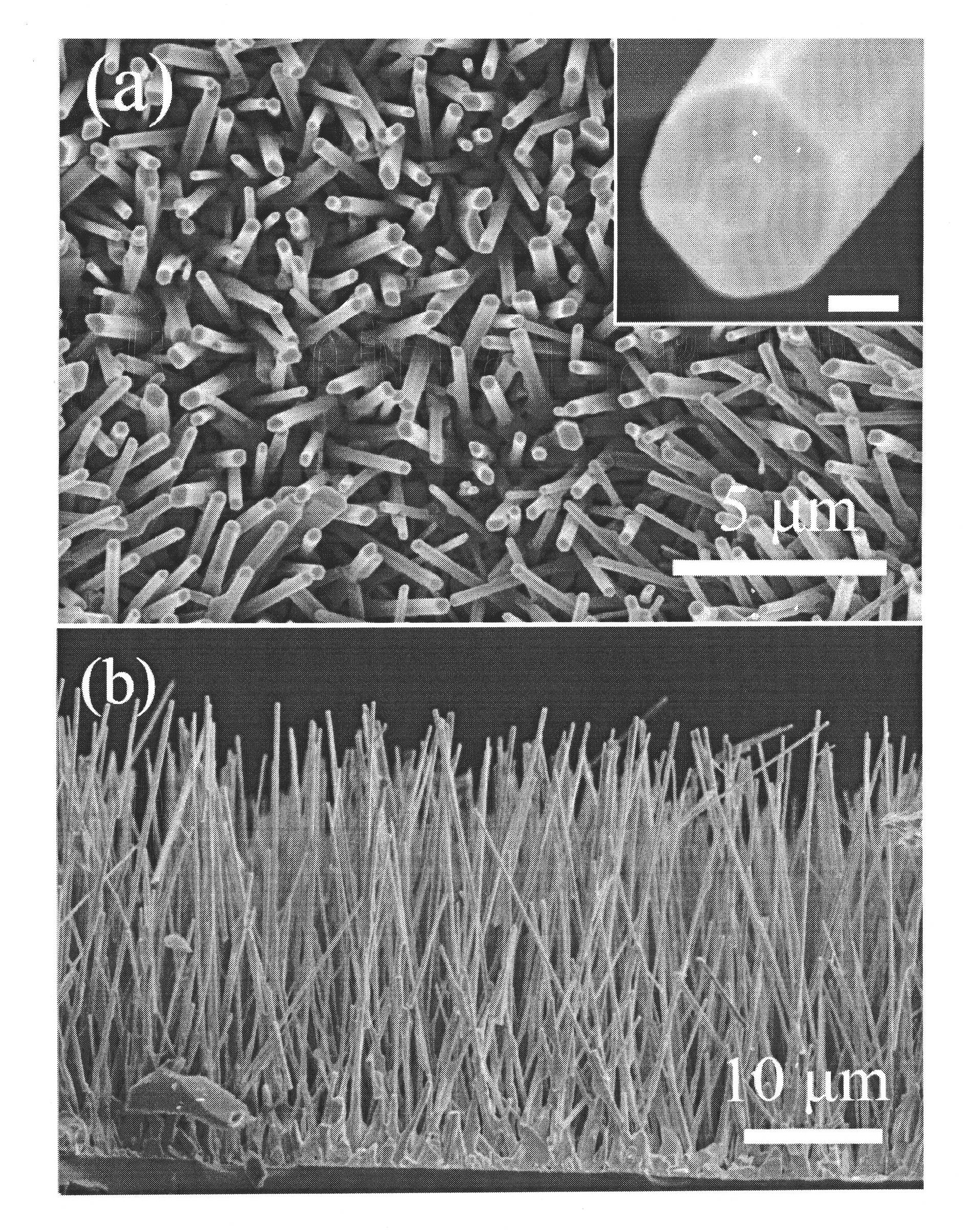

Semiconductor sensor and production method

InactiveCN101866975ALow priceGood repeatabilityFinal product manufactureSemiconductor devicesSemiconductor sensorNanometre

The invention discloses a sensor for ultraviolet detection and a production method thereof. The semiconductor sensor of the invention is integrated by two electrodes, and a zinc oxide nanowire positioned between the two electrodes in a parallel way. The production method of the semiconductor sensor of the invention comprises the following steps of: firstly growing a layer of zinc oxide nanowire array which is vertical to a substrate surface on a first substrate, then transferring the zinc oxide nanowire array onto the surface of a second substrate, placing an electrode pattern on a masking film plate onto a gluing surface, making the electrode pattern be vertical to the two ends of the oriented nanowire and cover the end parts of the nanowire so as to carry out exposing, developing and photoetching, then depositing at least one electric conduction metal-made electrode in an electrode area which is formed by photoetching in a physical method, then stripping the electrodes and the nanowire from the second substrate, connecting leads onto the electrodes, and finally obtaining the required device.

Owner:LANZHOU UNIVERSITY

Dyeing process for elastic polyester-polyurethane fabric

InactiveCN101046064AEasy to dyeNo pollution in the processFibre treatmentDyeing processColour fastnessDisperse dye

The dyeing process for elastic polyester-polyurethane fabric includes one dyeing step and one reducing and cleaning step. The dyeing step using disperse dye, ammonium acetate and dyeing assistant is performed in certain bath ratio and at certain temperature. The reducing and cleaning step using sodium hydrosulfite, sodium hydroxide and cleaning assistant is performed in certain bath ratio. The dyeing process can dye polyester component well at low temperature dyeing condition, and has well dyeing on polyurethane component and high color fastness.

Owner:毛中水

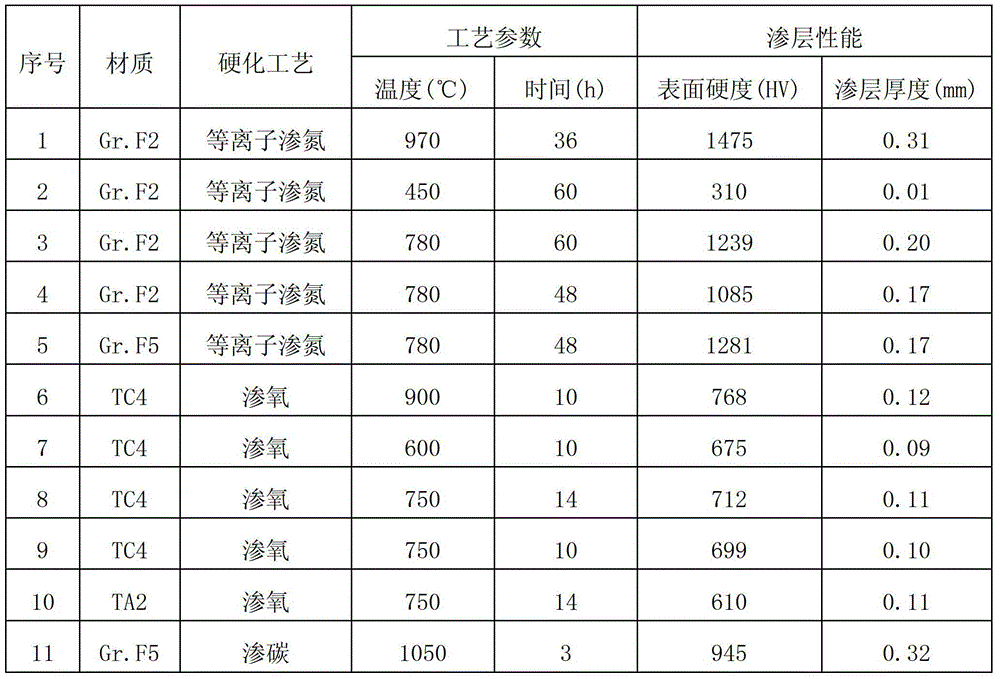

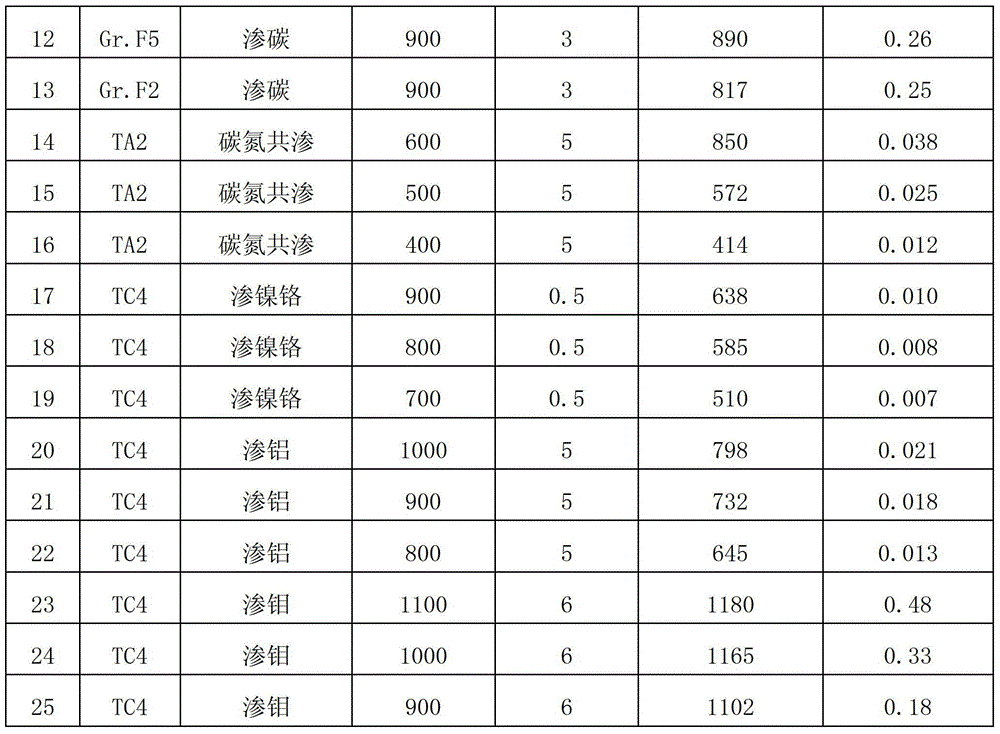

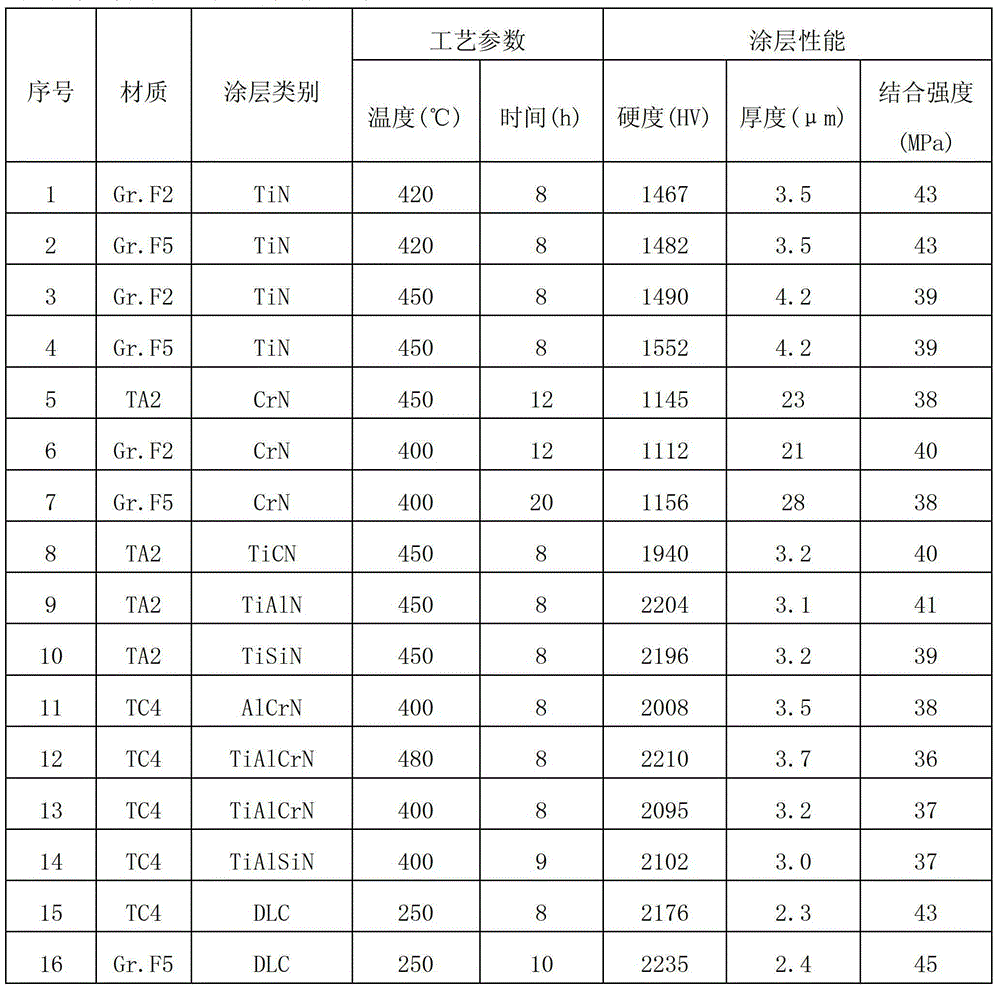

Surface-hardening treatment method of sealing pairs and friction pairs of titanium and titanium alloy ball valves

ActiveCN103334106AImprove reliabilityNo environmental pollutionVacuum evaporation coatingSputtering coatingCase hardeningBall valve

The invention discloses a surface-hardening treatment method of sealing pairs and friction pairs of titanium and titanium alloy ball valves. The sealing pairs are related sealing parts at all sealing positions in a valve, a ball and a valve base, and the friction pairs are related friction parts at all transmission connection positions in the valve, the ball and the valve base. The surface-hardening treatment method relates to chemical heat treatment and a vapor deposition hard coating. The chemical heat treatment and the vapor deposition hard coating are simultaneously used for the sealing pairs and the friction pairs of titanium and titanium alloy ball valves so that the problem that surface hardness of the titanium and titanium alloy ball valves treated by a single chemical heat treatment process is low. Based on the chemical heat treatment, the vapor deposition hard coating is adopted so that a hardness difference of a chemical heat treatment infiltrated layer is reduced. The vapor deposition hard coating further improves bonding strength of the chemical heat treatment infiltrated layer and improves surface hardness of the titanium and titanium alloy ball valves. Even if the vapor deposition hard coating is damaged in actual use, a hardened layer formed from the chemical heat treatment infiltrated layer still has a protection effect so that dual protection is realized.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for preparing nuclear power-grade high-purity boracic acid

InactiveCN102001675AThe process is simple and easy to controlNo environmental pollutionBoron-oxygen compoundsChemical industrySolvent

The invention discloses a method for preparing nuclear power-grade high-purity boracic acid, and belongs to the technical field of chemical industry. The method is characterized by comprising the following steps of: dissolving industrial boracic acid serving as raw materials in a solvent, adding aids, reacting for a certain period of time, and evaporating and crystallizing; mixing the dried intermediate product and reactants, heating and stirring to react for a certain period of time, performing azeotropic distillation, and mixing the obtained distillate and water; and after full reaction, evaporating and crystallizing to obtain products, washing and drying to prepare the nuclear power-grade high-purity boracic acid. The whole process is simple and easily controlled without environmental pollution; and obvious competitive advantages and profit margins in manufacturing cost, product performance and other aspects are shown. The purity of the prepared boracic acid is 99.9999 percent, the impurity content is below 1ppm, the strict requirement of the nuclear industry is met, and special requirements on the boracic acid in the fields of nuclear power industry, optical materials, crystalline materials and other high technology can be met.

Owner:DALIAN UNIV OF TECH

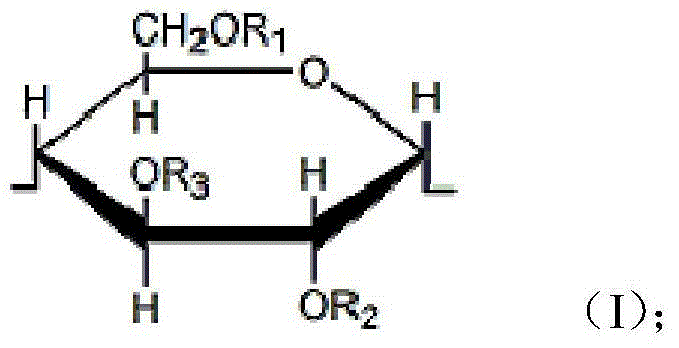

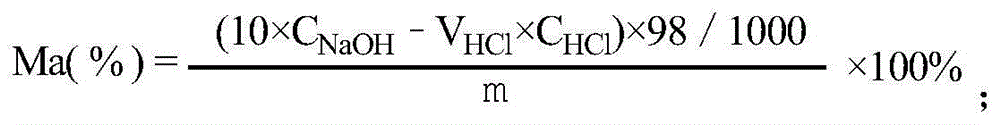

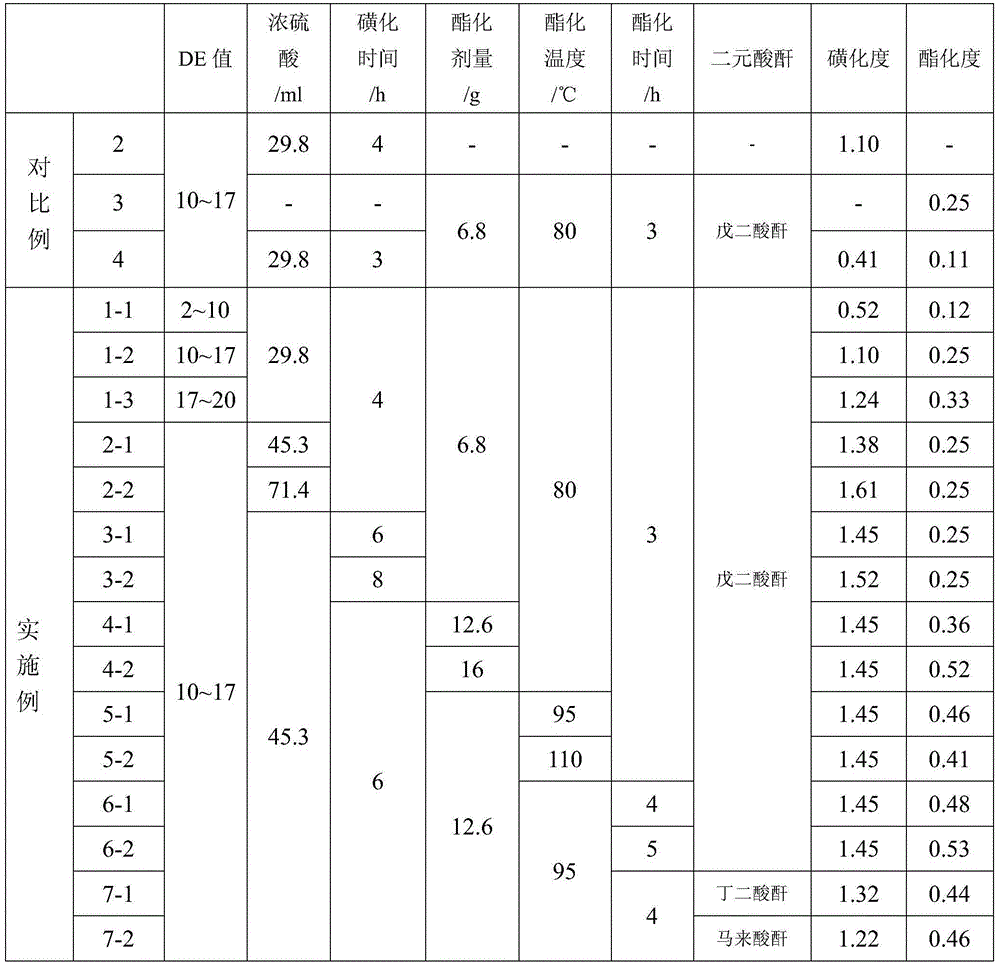

Dual-modified maltodextrin high efficiency water reducing agent and preparation method thereof

The invention provides a dual-modified maltodextrin high efficiency water reducing agent. The structural formula is disclosed as Formula I, wherein R1, R2 and R3 are respectively and independently sulfonate, mono dicarboxylate or hydrogen, and at least comprise one sulfonate (SO<3->) and one mono dicarboxylate. The invention also provides a preparation method of the water reducing agent. The preparation method comprises the following steps: diluting concentrated sulfuric acid with an organic solvent, carrying out sulfonation on maltodextrin at low temperature, carrying out esterification reaction on the sulfonation product by using dibasic acid anhydride, finally, dissolving the product in water, and adding an alkali for neutralization. The dual-modified maltodextrin high efficiency water reducing agent has the advantages of high water solubility and better water reducing performance than most naphthalene high efficiency water reducing agents at present, can be used as a cement water reducing agent, and has the characteristics of recoverability, no environmental pollution and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

Blue-light-cutoff and anti-reflexion dual-function coated glass and preparation method therefor

The invention relates to coated glass with blue-light cutoff and visible light anti-reflexion dual functions and a preparation method therefor. According to the coated glass, a film layer structure consists of a blue-light cutoff film, glass and anti-reflection film sequentially, and coating is carried out by adopting a magnetron sputtering method; the transmittance is increased by 1.5% to 5.5% compared with that of uncoated sheet glass in the spectrum wavelength range of 380nm to 780nm; the blue-light cutoff rate is increased by 40% to 75%, and the ultraviolet ray cutoff rate is 100%; the pencil hardness of a film layer is 8.0H; the obtained coated glass can be applied to the fields of electronic display panels, mobile phone encapsulation glass cover plates, LED (Light Emitting Diode) lighting lampshades, show windows, eyeglass frames, locomotive and steamboat window glass and the like; and through observing through observation window glass, images are free from glare and are clearer, the fatigue of human eyes is reduced, and the injury to the human eyes is prevented.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

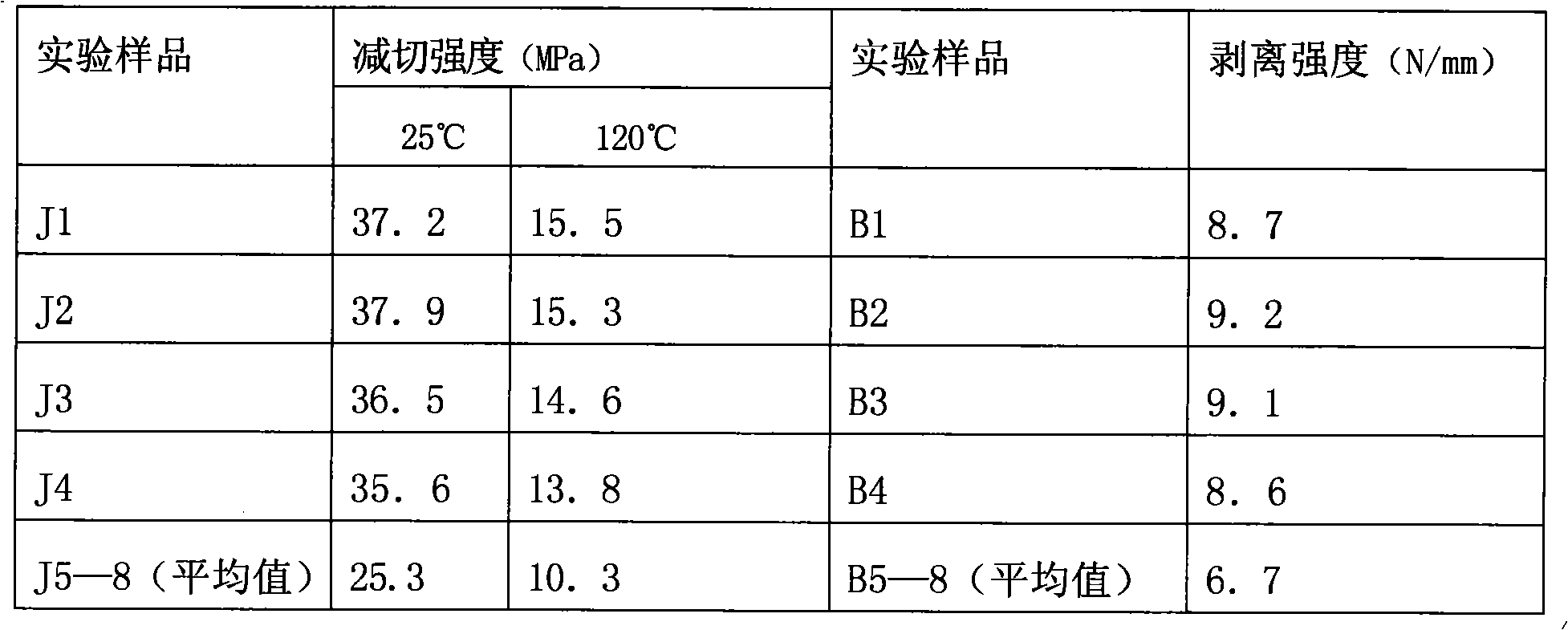

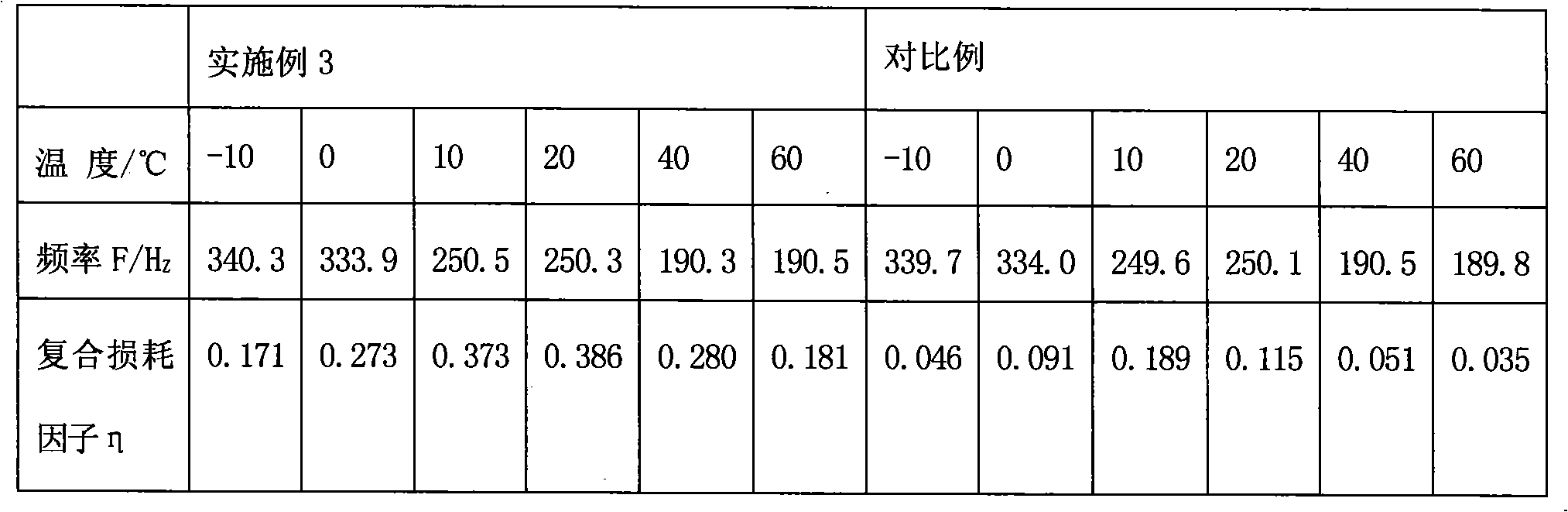

Adhesive gum special for sheet metal and preparation thereof

InactiveCN101343514AImprove heat resistanceReduce permanent deformationLaminationLamination apparatusChemistryEther

The invention relates to an adhesive agent specially used for a metal plate and the preparation method. The formulation is mainly made by the components according to the weight parts: 86 parts to 100 parts of amine terminated liquid nitrile rubber, 40 parts to 50 parts of bisphenol A epoxy resin, 5 parts to 7 parts of nanometer silica, 5 parts to 7 parts of nanometer alumina, 1 part to 2 parts of silane coupling agent, 2.5 parts to 4 parts of dicumyl peroxide, 1 part to 2 parts of triallyl cyanurate, 30 parts to 40 parts of methyl hexahydro phthalic anhydride, 0.5 part to 1 part of benzyl triethyl ammonium chloride and 50 parts to 60 parts of acetic ether. The adhesive agent is used for compounding two layers of the metal plates, and when compared with the traditional adhesive agent, both the shear strength and the peel strength are greatly enhanced. The compounded metal plate bonded by the adhesive agent is particularly suitable for manufacturing a damping and deadening disc, because the damping coefficient of which is high. In addition, the raw material adopted in the adhesive agent belongs to the environmental protection product, and during the large-scale industry application, the problem of the environmental pollution can not be generated.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Method for producing chitin, calcium citrate and protein powder

The invention relates to a method for producing chitin, calcium citrate and albumen powder by using the shells of crustaceans like shrimps and crabs as the materials; the shells of shrimps and crabs are selected and arranged into an oven, and dried and then water with weight of 6 times of the shells are added; then the mixture is heated to be between 50 and 55 DEG C; then a neutral papain with a mass ratio of 1: 0.001 to 0.003 with the shells of shrimps and crabs, is added for carrying out zymohydrolysis and obtaining zymohydrolysis liquid; the zymohydrolysis liquid is filtered for obtaining the shells of shrimps and crabs; 15% to 20% citric acid solution is added for dipping for 24 to 36 hours; then the chitin is obtained through filtering, acid rinsing and drying; cold separation is carried out on the filtered liquid and a cold separation matter which can be named the calcium citrate is obtained through centrifugalizing; vacuum condensing and drying are carried out on the rest liquid obtained through centrifugalizing, thus obtaining the albumen powder. In the invention, the technical method adopts enzymes for removing proteins and citric acid decalcification for leading the separation of the protein and the calcium with the chitin to be more complete; the yield rate of the chitin is high; and the prepared chitin product has the advantages of white color, high purity and good quality.

Owner:RONGCHENG TAIXIANG FOOD

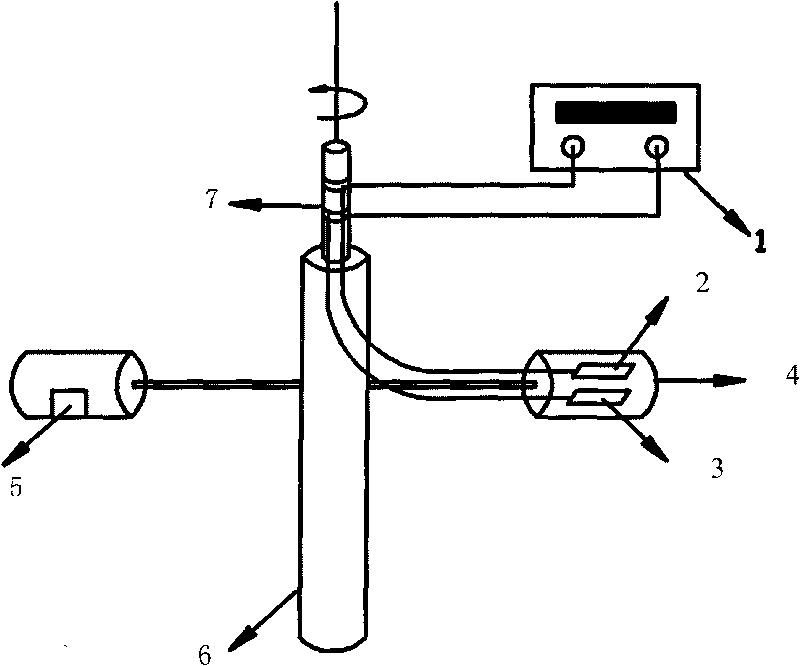

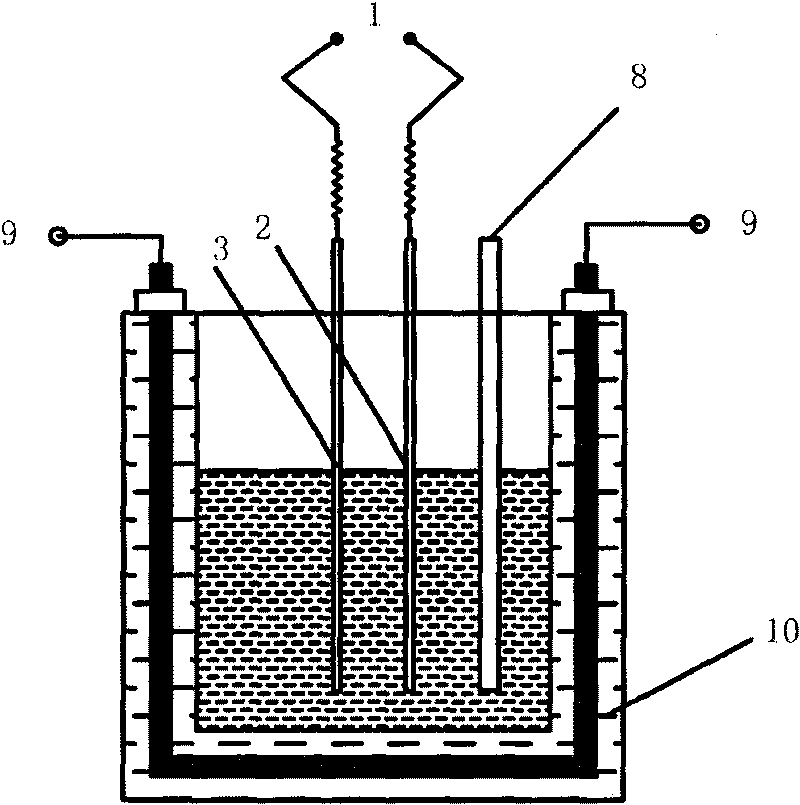

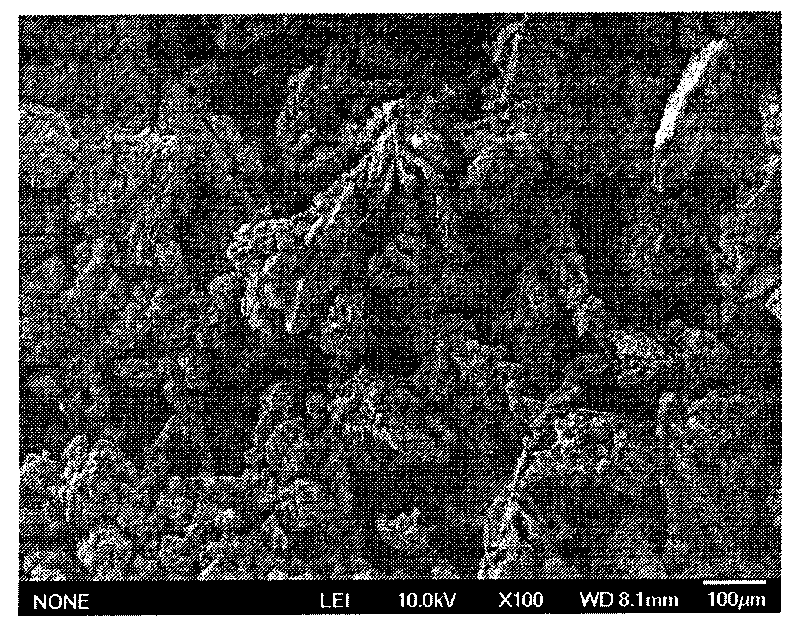

Method for electrolyzing aluminum from ionic liquid on hyper-gravity basis

InactiveCN101760758AEnhance convection and diffusion processesFacilitates ion mass transferPhotography auxillary processesProcess efficiency improvementIonAluminum matrix composites

The invention discloses a method for electrolyzing aluminum from an ionic liquid on a hyper-gravity basis and belongs to the field of metal electrodeposition under special conditions. The method of the invention comprises the following step: electrolyzing aluminum and subjecting an electrolytic tank to centrifugal rotation to generate a hyper-gravity field simultaneously, wherein aluminum sheets or aluminum-based composite material constitute the anode; stainless steel sheets or aluminum sheets constitute the cathode; the ionic liquid of chloroaluminate salt constitutes the electrolyte; and nitrogen or argon constitutes the protective gas. Accordingly, the electrolyzation of aluminum can be achieved in the hyper-gravity field, so as to obtain an aluminum deposition layer. The invention has the following advantages: the hyper-gravity field is capable of enhancing the processes of convection and dispersion, improving the mass transfer of ions, increasing the rate of deposition and reducing the preparation period of aluminum; finer aluminum grains and denser deposition layers can be obtained in the hyper-gravity field; moreover, the adhesion of the aluminum deposition layers can be obviously improved by the contingent mechanical effects, thereby preventing the dendritic crystal aluminum from being generated; the method can solve the problem that the deposition layer is likely to drop off; and no gas is generated at the anode during the refining process, thereby preventing the environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

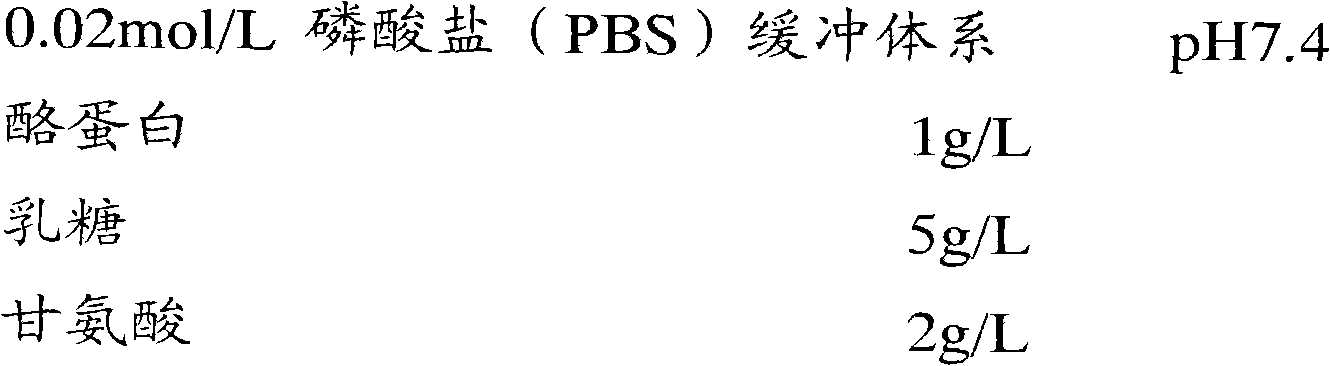

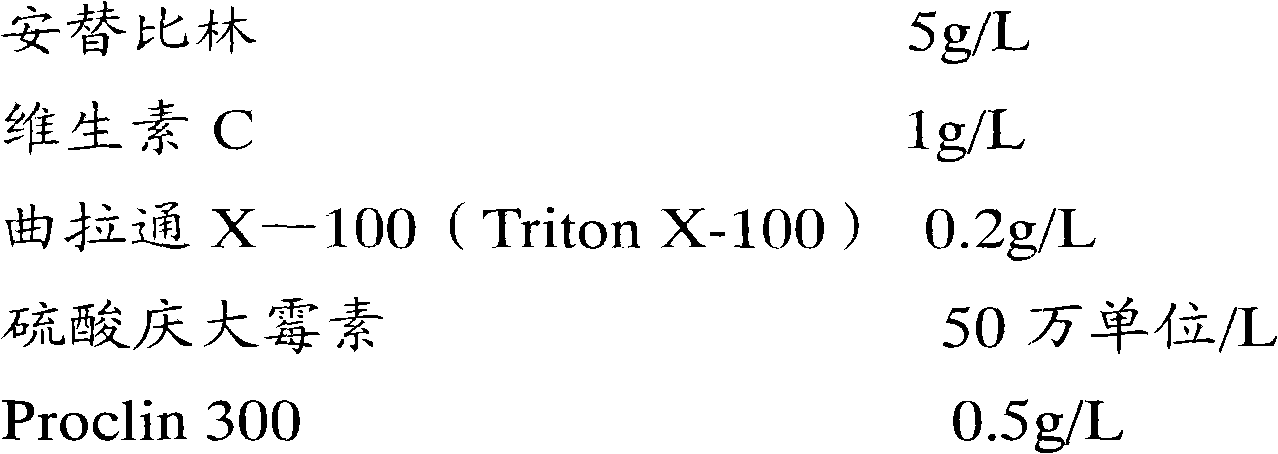

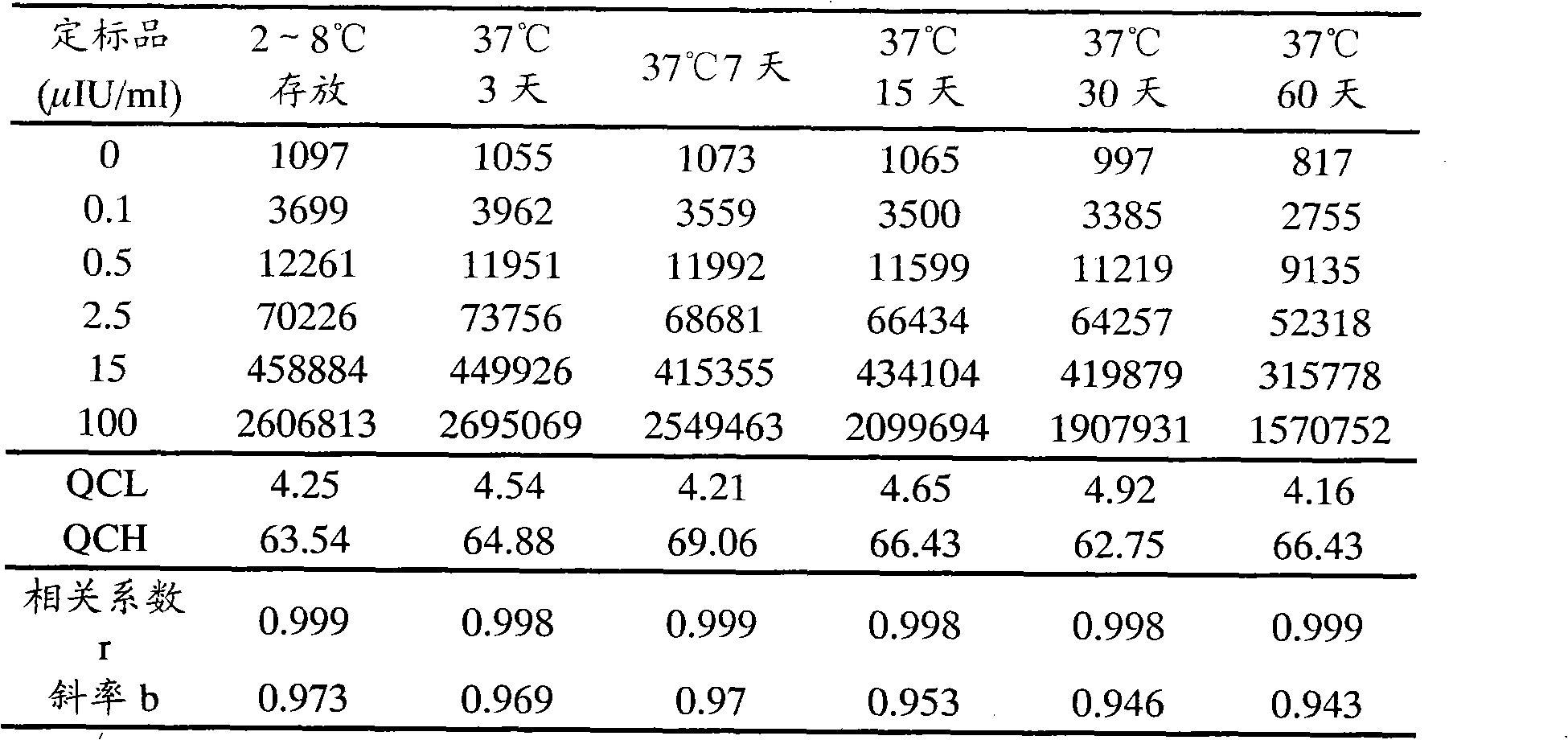

Enzyme conjugate stabilizing solution

ActiveCN102051352AEasy to prepareDoes not affect sensitivityEnzyme stabilisationProtein proteinChemistry

The invention provides an enzyme conjugate stabilizing solution which comprises the following components: 1-7.5g / L protein material, 5-50g / L saccharide material, 2-30g / L amino acid material, 5-50g / L antipyrine, 1-10 g / L vitamin C, 0.2-5g / L surfactant, 0.5-5 million IU / L gentamycin sulfate, 0.5g / L Proclin 300 and 0.02mol / L phosphate buffer solution the pH value of which is 7.4. By using the enzyme conjugate stabilizing solution provided by the invention, after the enzyme conjugate is not in a low temperature environment, the bioactivity of the enzyme conjugate can be maintained for a longer time, thereby solving the problem that the enzyme conjugate is easy to lose activity after the enzyme is not in the low temperature storage environment in the related technology. In addition, the enzyme conjugate stabilizing solution provided by the invention is easy to prepare, the sensitivity is not affected, the cost is low, the operation is simple, environmental pollution can not be caused, the stabilizing solution is nontoxic and harmless to the human body and the like.

Owner:BIOSCIENCE (TIANJIN) DIAGNOSTIC TECH CO LTD

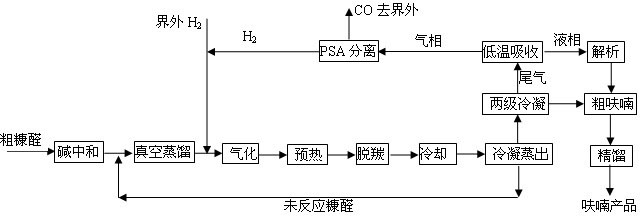

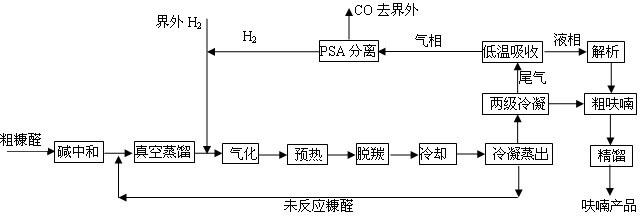

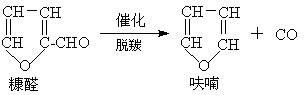

Process for preparing furan through decarbonylation of furfural

ActiveCN101967133AHigh selectivityHigh yieldOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranHigh selectivity

The invention discloses a process for preparing furan through decarbonylation of furfural, which comprises the following steps of: refining furfural, gasifying furfural, decarbonylating, condensing and collecting furan, recovering tail gas and refining furan. The process does not pollute the environment, and the furan has high selectivity, yield and purity.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

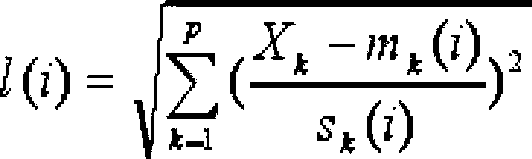

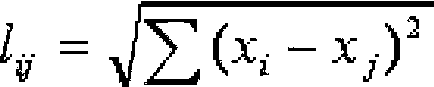

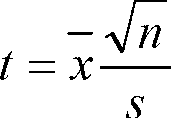

Method for determination of PCTFE content in PBX explosive by near infrared spectrum

ActiveCN103018195AImprove robustnessImprove accuracyColor/spectral properties measurementsPolymer-bonded explosiveRoot mean square

The invention discloses a method for determination of the polychlorotrifluoroethylene (PCTFE) content in a polymer-bonded explosive (PBX) by near infrared spectroscopy. The method includes the steps of: preparing and collecting 260 PBX samples, taking 180 samples of them as a calibration set for establishing a calibration model, taking the remaining 80 samples as a validation set for model validation, and acquiring the near infrared spectrum data of all the samples; using a standard method to determine the PCTFE content in the samples; subjecting the spectrum data of the validation set samples in the wave bands of 6102.0cm<-1>-5697.0cm<-1> and 4680.2cm<-1>-4242.9cm<-1> to a first order derivative treatment, correlating the treated spectrum data with the PCTFE content by a partial least squares method, and establishing the calibration model by cross validation; employing the calibration model to predetermine the PCTFE content of the validation set samples, and selecting an optimal model according to a minimum root mean squared error of prediction (RMSEP) of the validation set; and acquiring the near infrared spectrum data of the samples to be determined, and making use of the optimal model to obtain the PCTFE content directly. Being suitable for determination of the PCTFE content in a PBX explosive, the method has the characteristics of convenient operation, and rapid and accurate analysis.

Owner:XIAN MODERN CHEM RES INST

Treatment process for biological wastes

InactiveCN102794294AUse efficientlyNo environmental pollutionSolid waste disposalPulverizerOil water

The invention discloses a treatment process for biological wastes. The process comprises the following steps of: carrying out dry wet separation of the biological wastes, namely carrying out dry wet separation on household biological wastes to obtain dry wastes and wet wastes; manually sorting the dry wastes, and then sending to recycle; treating the wet wastes, pulverizing, and sending the wet wastes to a pulverizer to pulverize; cooking, namely cooking the pulverized material into a cooking machine so as to achieve the effects of sterilization and fat dissolution; pressing, namely pressing the cooked materials to a presser to obtain residues and oil water; carrying out oil water treatment, namely in an A treatment mode, carrying out anaerobic fermentation on the oil water to obtain methane, and in a B treatment mode, separating oil water by using a separator to obtain oil and water, sending the oil to be used as biological energy sources, such as biodiesel; and carrying out residue treatment, namely adopting the residue as insect feeds, treating the insects obtained by culturing to prepare protein feeds, and utilizing the postbibal feeds of the insects and excrement residues as biofertilizers.

Owner:浙江省长三角循环经济技术研究院

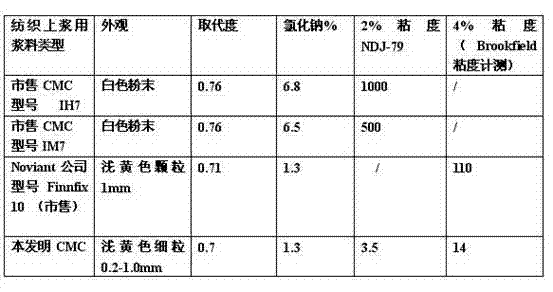

Preparation method of ultralow-viscosity sodium carboxymethyl cellulose

InactiveCN102367279AMedium degree of substitutionHigh viscosityFibre treatmentHigh concentrationCarboxymethyl cellulose

The invention aims at providing a preparation method of ultralow-viscosity sodium carboxymethyl cellulose which is industrially produced by adopting a kneading machine and is suitable for high-count yarn starching. The preparation method comprises the following steps of: adding ethanol and high-concentration caustic soda liquid to cotton fibre, adding a viscosity breaking agent in several times, carrying out viscosity breaking on the cotton fibre at high temperature and alkalizing the cotton fibre at the same time; adding an etherifying agent for etherification, then adding the viscosity breaking agent for viscosity breaking again after etherifying reaction, and adding sodium sulfite to reduce the residual viscosity breaking agent in the ethanol as a reaction medium and in reactants off; and neutralizing and washing, centrifuging, drying and crushing to obtain the ultralow-viscosity sodium carboxymethyl cellulose (CMC) for textile starching. The ultralow-viscosity sodium carboxymethylcellulose prepared by the preparation method disclosed by the invention has moderate substitution degree and low viscosity, wherein a B-type viscometer (Brookfield) 4% is 8-17CPS and has the purity more than 97%. The CMC solution is clear, has stable viscosity and is particularly suitable for a starching process of yarns with high and ultrahigh cotton yarn count.

Owner:HANGZHOU HONGBO NEW MATERIALS

Method for preparing glycol methyl ether acetate

InactiveCN101239907AHigh yieldReduce dosageOrganic compound preparationPreparation by ester-hydroxy reactionAcetic acidMonomethyl ether

The invention discloses a method for preparing glycol monomethyl ether acetate, comprising using ethyl acetate and glycol methyl ether as materials, performing ester changing reaction in the presence of a solid alkali catalyst, distilling by-product ethanol fro a reaction tank through fractionation, filtering and recoverying the catalyst after reaction, fractionating the reaction liquid to obtain glycol monomethyl ether acetate. The invention has the advantages of: (1) high yield of 95.5-99.6%, (2) cheap catalyst and small usage which is 0.1-1.5% of the total weight of reaction materials; (3) gentle reaction condition, reaction under atmosphere pressure; (4) repeatedly-usable catalyst; (5) samll corrosion on the device and no environmental contamination.

Owner:EAST CHINA NORMAL UNIV

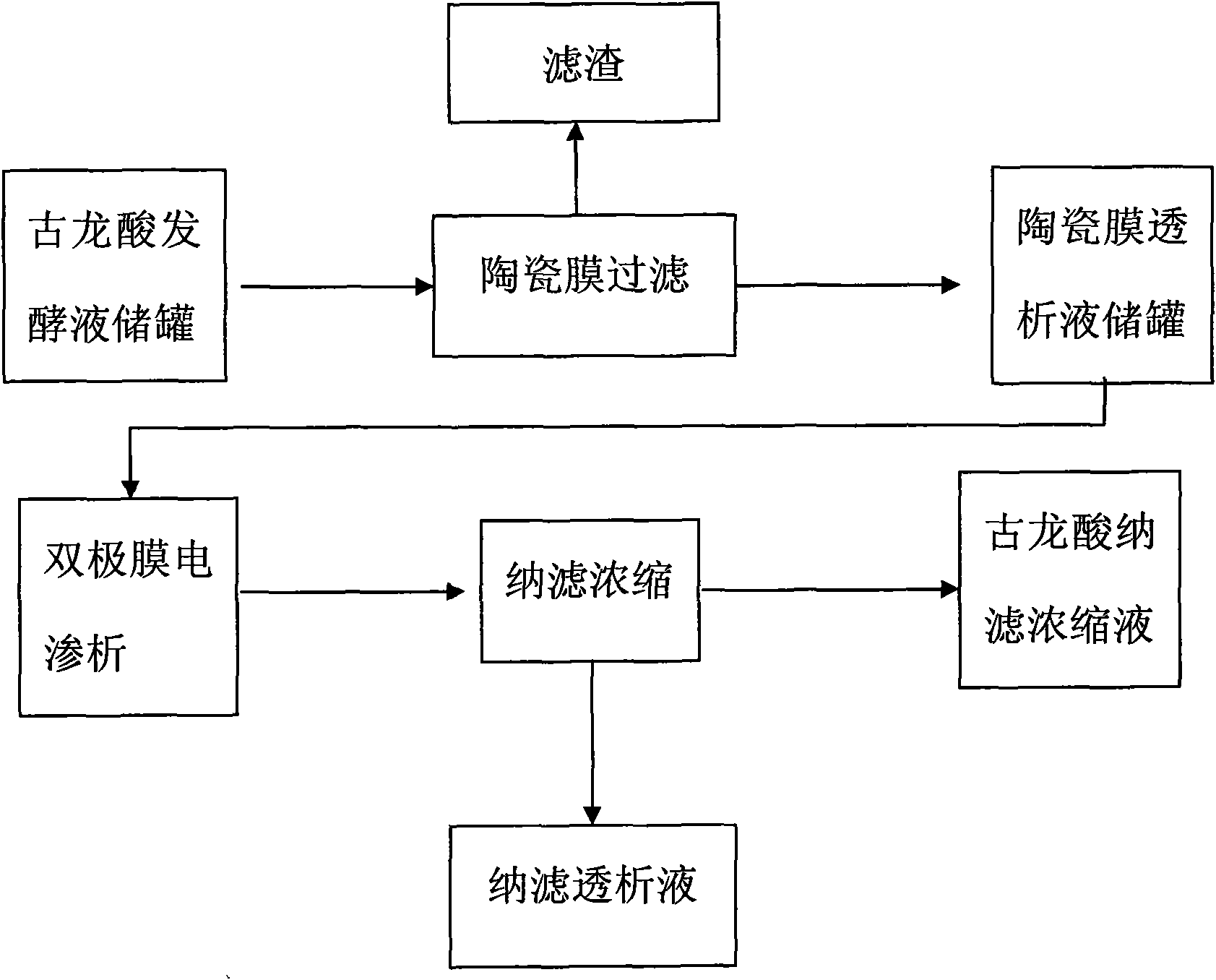

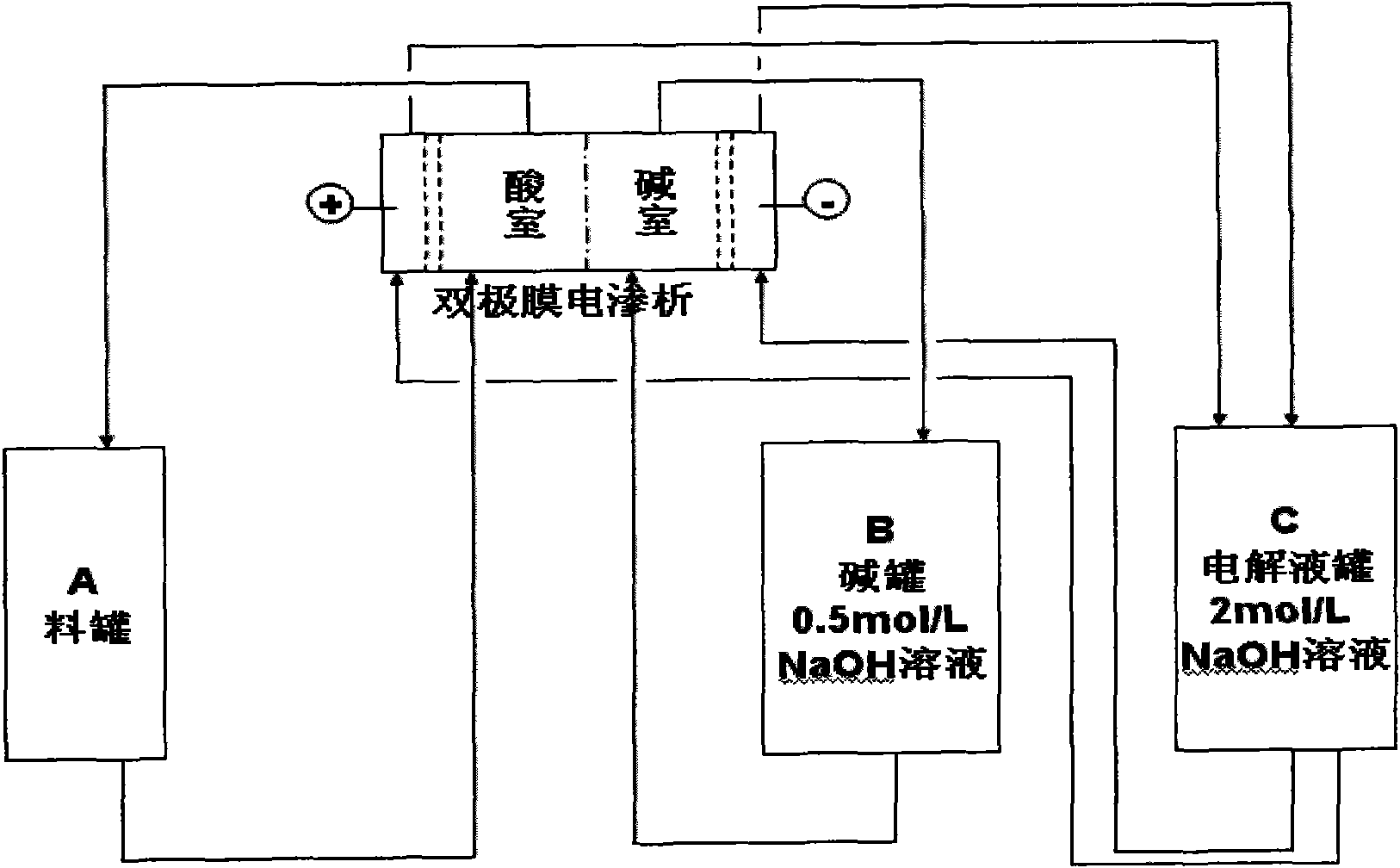

Production method of gulonic acid in production of vitamin C

InactiveCN101643408AReduce pollutionLow costCarboxylic compound separation/purificationVitamin CColloid

The invention provides a production method of gulonic acid in the production of vitamin C, which comprises the following steps: (1) ceramic film filtering: filtering and concentrating a fermentation broth through a ceramic-film filtering apparatus, and removing proteins, hypha, suspended substances, colloid, bacteria and other macromolecular organic substances in filter residues to obtain a gulconic sodium dialysate; (2) double-pole film electrodialysis system: processing the filtrate containing gulconic sodium salts by an electrodialysis system to as to convert the gulconic sodium into the gulconic acid solution; (3) nanofiltration concentration: concentrating the gulconic acid solution in a nanofiltration film apparatus to obtain the concentrated gulconic acid solution. The method can reduce the production cost, increase the total yield, enhance the product quality and achieve the aims of environmental protection and simple apparatus operation.

Owner:XIAMEN STARMEM TECH

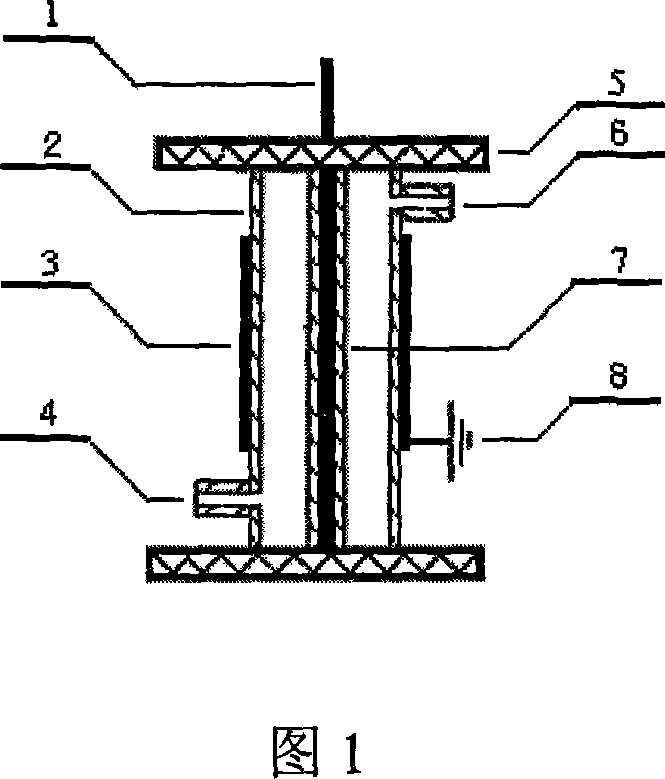

Apparatus for direct oxidization of propane with molecular oxygen to prepare propane epoxide

InactiveCN101020670AInexpensive and clean ingredientsEasy to operateOrganic chemistryChemical synthesisHigh energy

The present invention belongs to the field of low temperature plasma technology and chemical synthesis technology, and is especially apparatus for direct oxidization of propane with molecular oxygen to prepare propane epoxide and with coaxial bilayer glass medium discharge electrode structure. In the annular gap bilayer glass medium constitutes, propane molecule and plasma produce high energy electronic function generating isopropyl free radical and n-propyl free radical, and isopropyl free radical and the active oxygen matter oxygen molecule forms in plasma react mutually to oxidize selectively to produce propane epoxide. The present invention has the advantages of no catalytic condition, cheap clean material, simple operation process, no apparatus corrosion and no environmental pollution.

Owner:DALIAN MARITIME UNIVERSITY

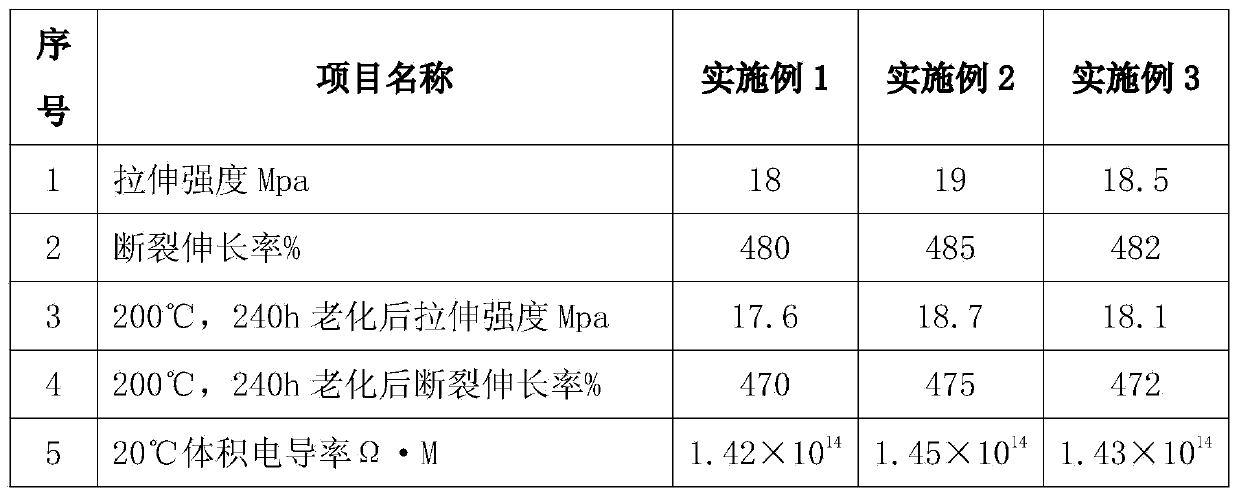

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

Superfine fiber synthetic leather and preparation method thereof

InactiveCN102425070AImprove product qualityWaterproofSynthetic resin layered productsTextiles and paperPolymer scienceEngineering

The invention relates to superfine fiber synthetic leather and a preparation method thereof, and belongs to the technical field of synthetic leather. The superfine fiber synthetic leather consists of a superfine fiber synthetic leather base fabric, a foamed bottom sealing filling layer, a coating top layer, a coating bonding layer and a surface treatment layer, wherein the foamed bottom sealing filling layer comprises the following components in part by weight: 10 to 30 parts of water-borne comprehensive resin, 30 to 40 parts of water-borne foamed resin and 1 to 5 parts of waterproof agent; the coating top layer comprises the following components in part by weight: 70 to 90 parts of water-borne polyurethane, 3 to 10 parts of water-borne color paste, 1 to 5 parts of flatting agent and 1 to5 parts of handfeel agent; the coating bonding layer comprises the following components in part by weight: 70 to 90 parts of water-borne polyurethane bonding agent, 3 to 10 parts of water-borne colorpaste and 1 to 5 parts of flatting agent; and the surface treatment layer comprises the following components in part by weight: 1 to 5 parts of waterproof agent and 1 to 5 parts of handfeel agent. The superfine fiber synthetic leather has good properties of scratch resistance, pollution resistance and water resistance, and has wide application prospect; and by adoption of the superfine fiber synthetic leather, clean production can be realized.

Owner:深圳市天之一科技开发有限公司

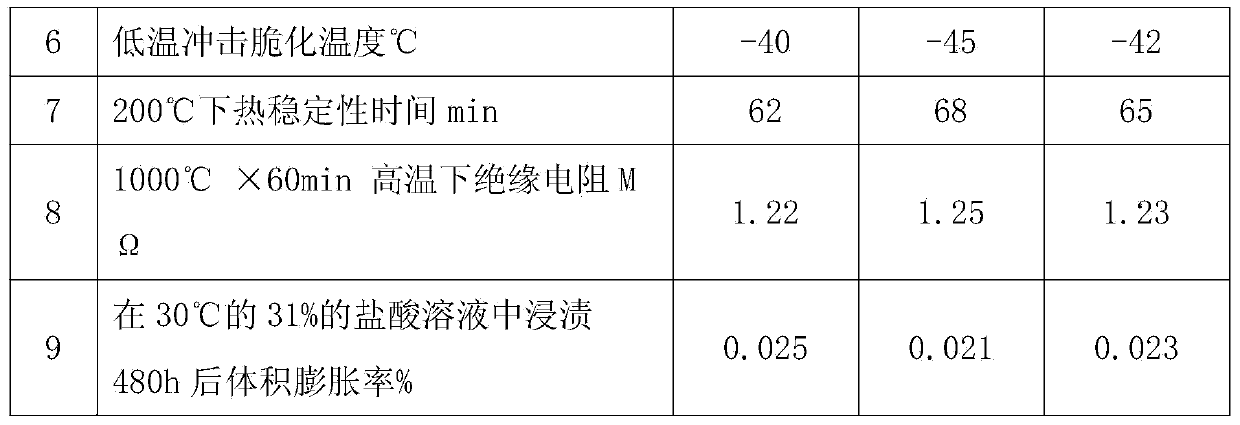

Processing technique for ageing resistance spun-bonded nonwoven fabric

InactiveCN101289785AAvoid generatingTo achieve the purpose of anti-agingNon-woven fabricsArtifical filament manufactureAntioxidantFiltration

The invention discloses a technique for processing ageing resistant spun-bond non-woven fabrics, comprising the following steps of in turn: addition of additives, slice transportation, extrusion, filtration via a fused mass filter, spinning, web forming, hot rolling to form fabric and so on. The technique adds a certain amount of antioxidants and light stabilizers, and can decompound hydroperoxides, prevent generation of free radicals, absorb harmful ultraviolet radiation and consume energy into heat so as not to cause photosensitization, thereby the aim of ageing resistance is achieved. The products can be kept degenerative in the sun for 6 months to the maximum degree, have good ageing resistance and good traction force, and are soft, dry, nontoxic and environment-friendly; the service life of the products is prolonged; moreover, the products can be naturally degraded after use, thereby no environmental pollution is caused. The technique can be widely used for manufacturing various sunshades and beach tents and in the fields such as agricultural harvest cloth, car covers and so on.

Owner:严华荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com